Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Improve cutting and crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

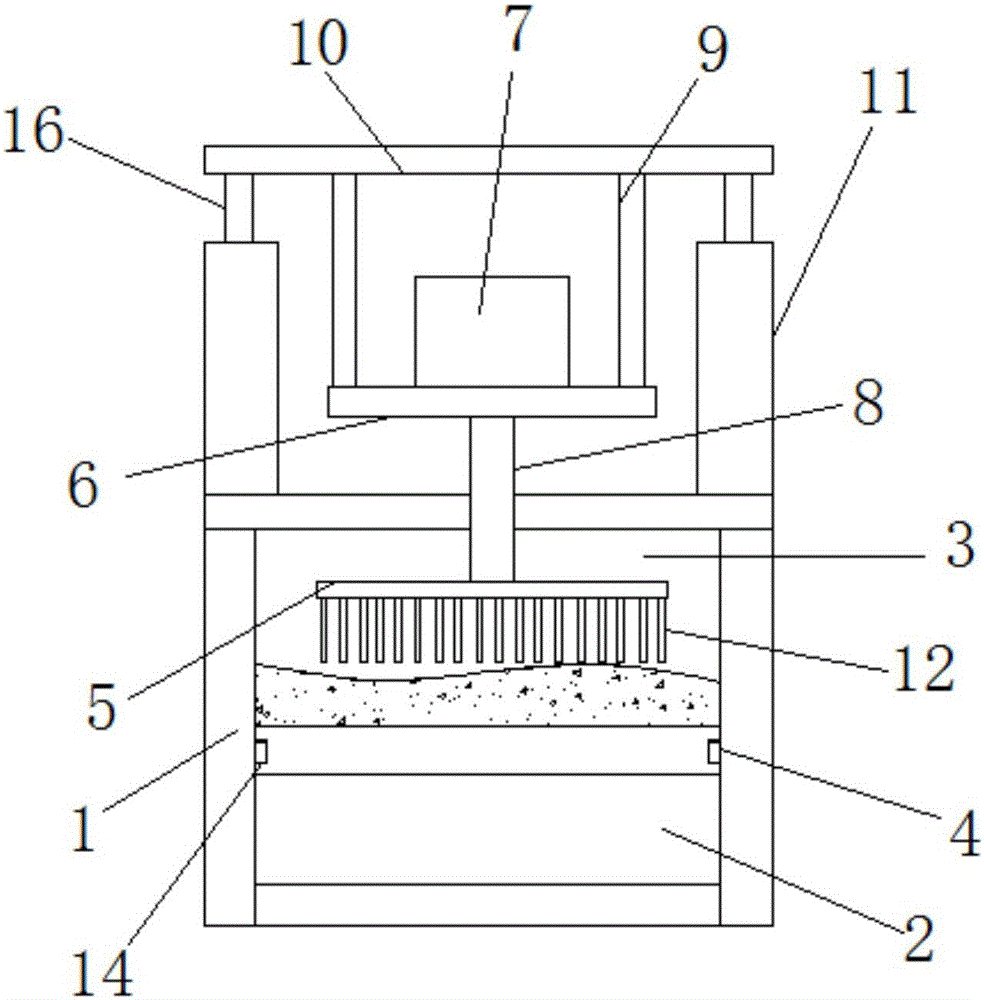

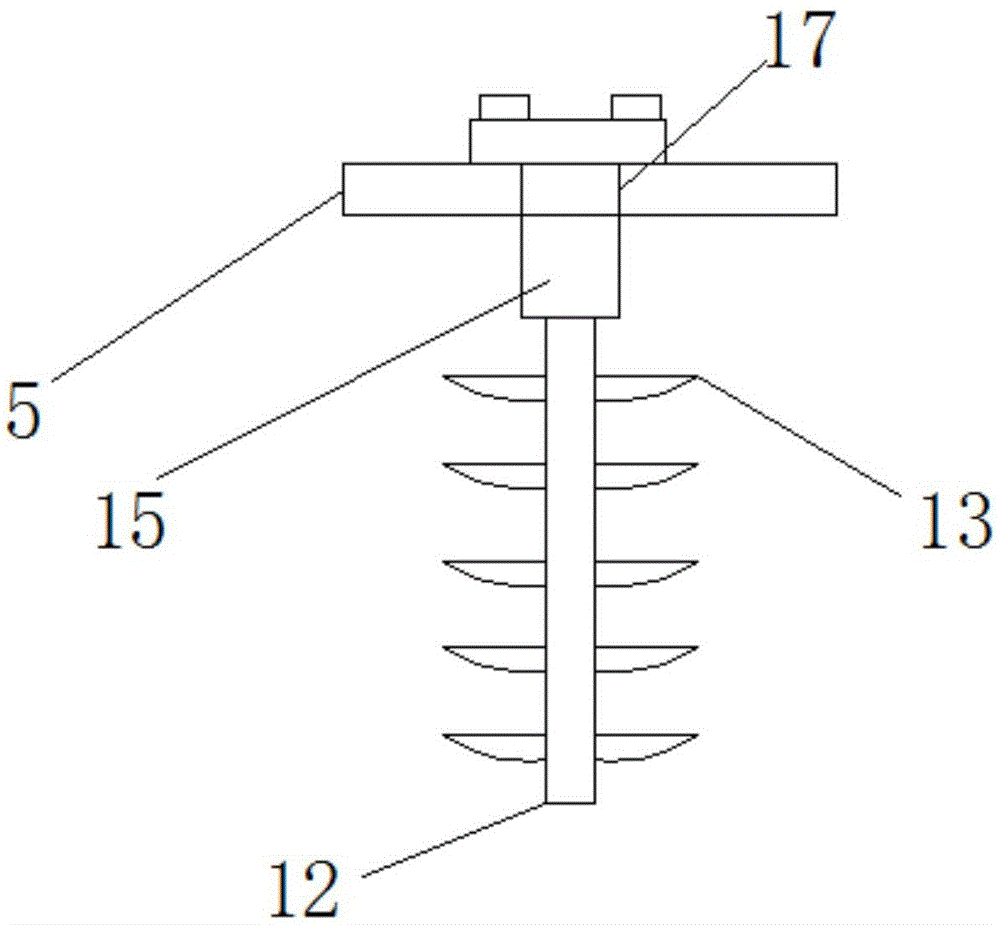

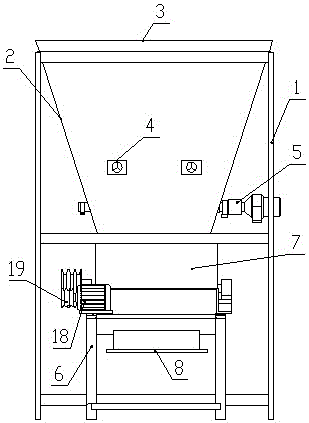

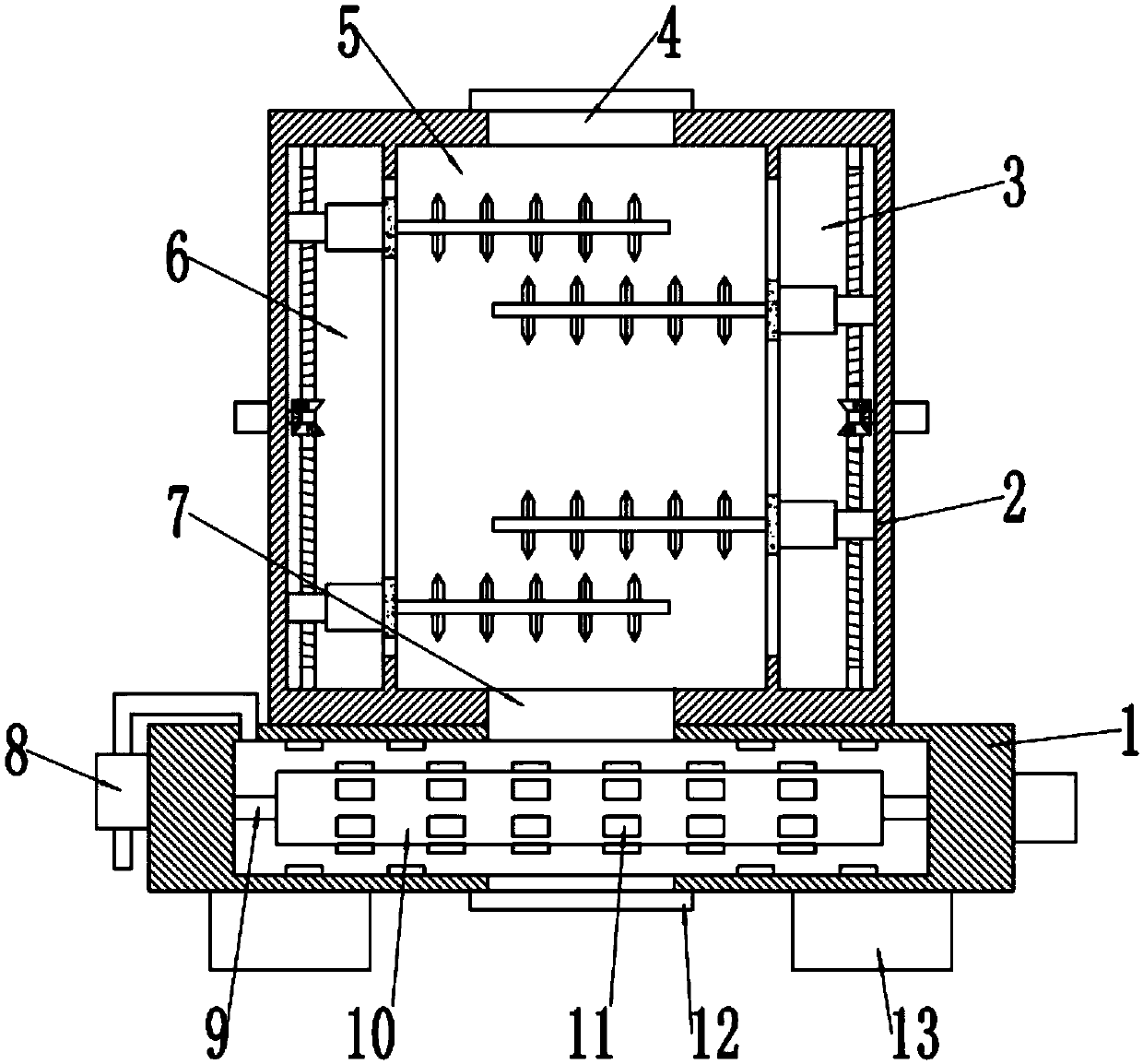

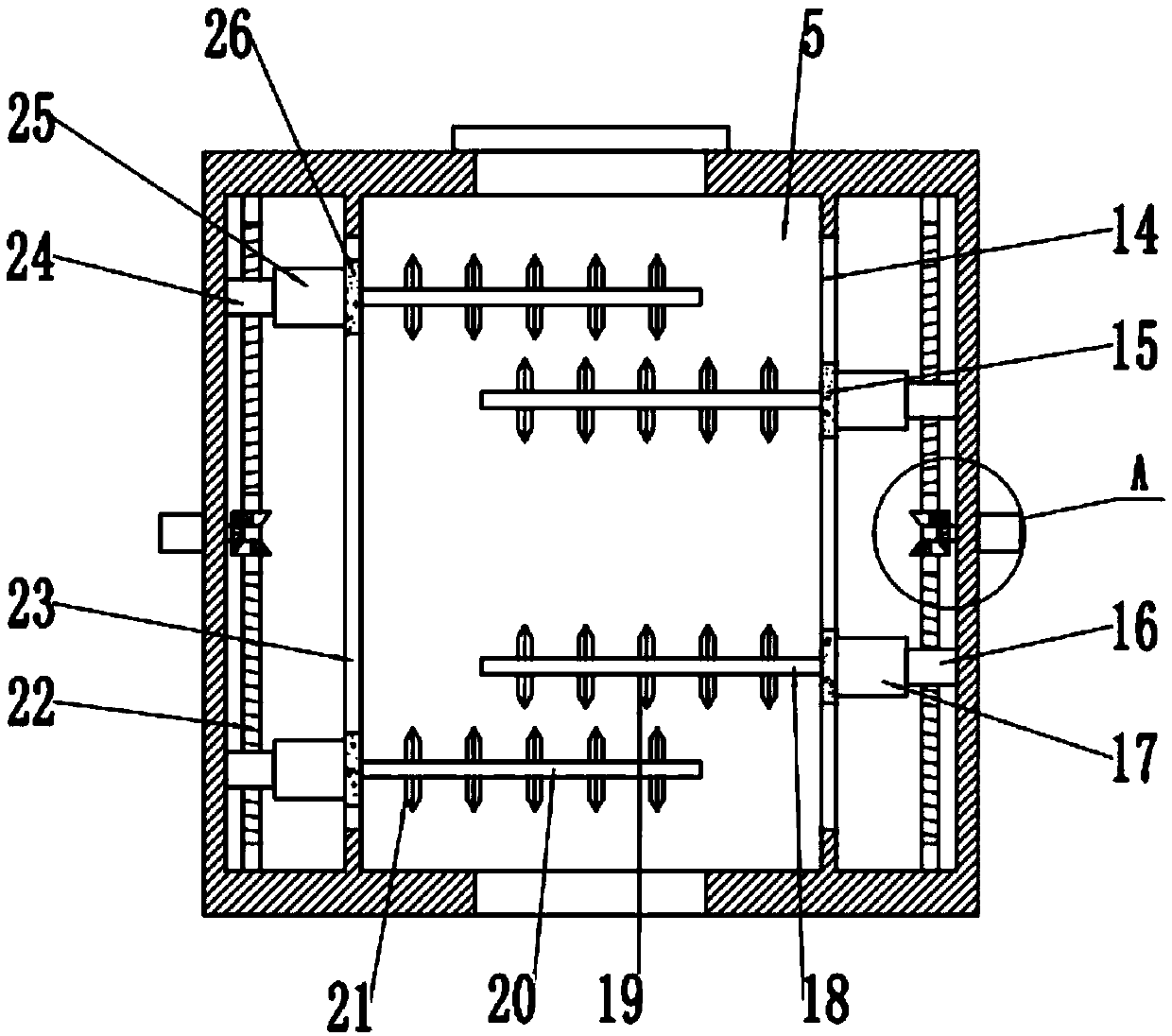

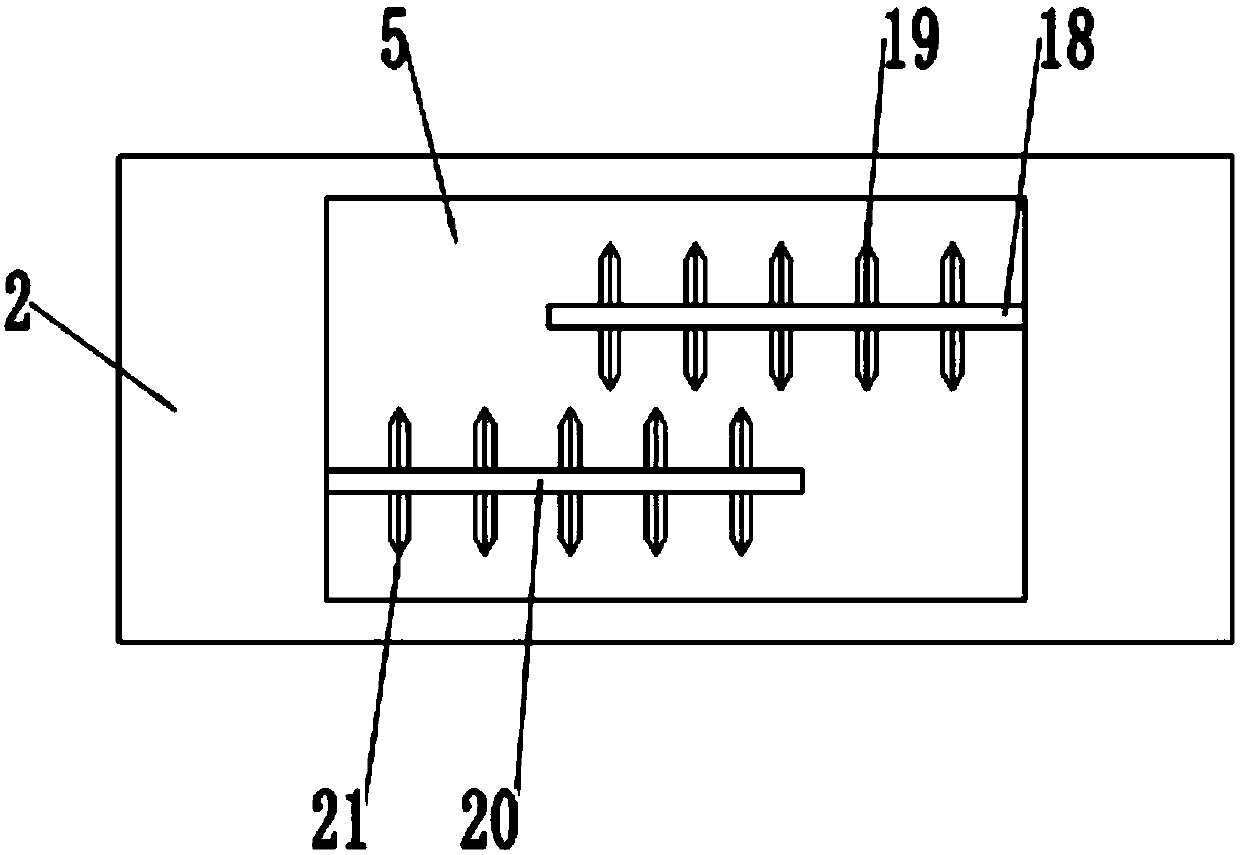

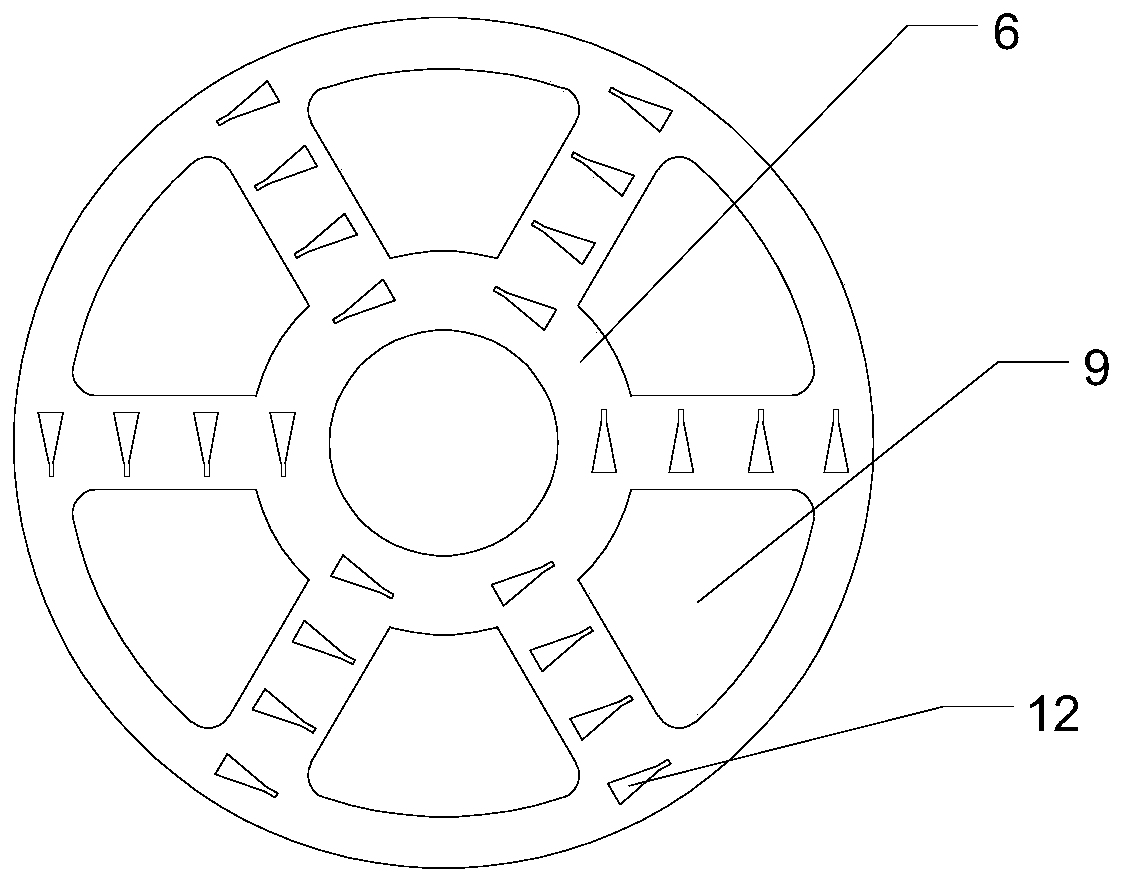

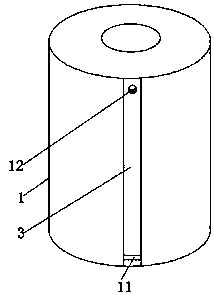

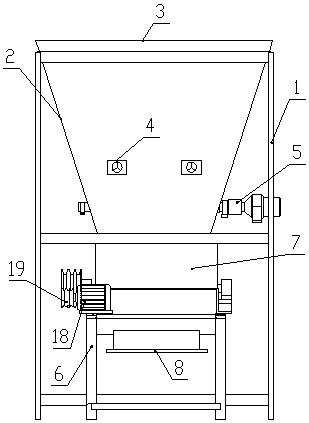

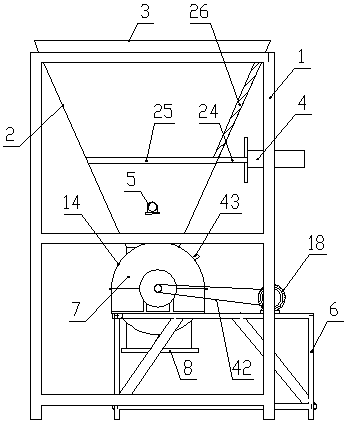

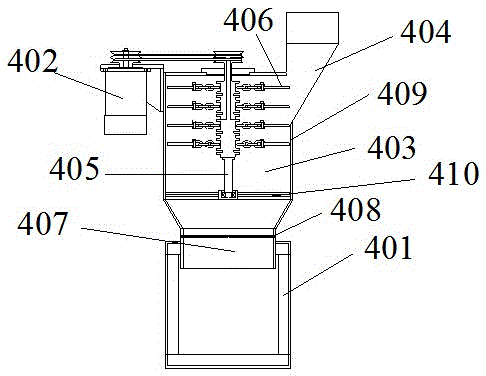

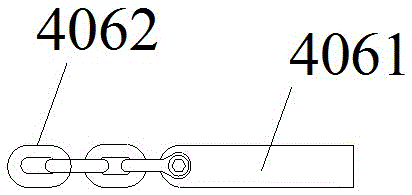

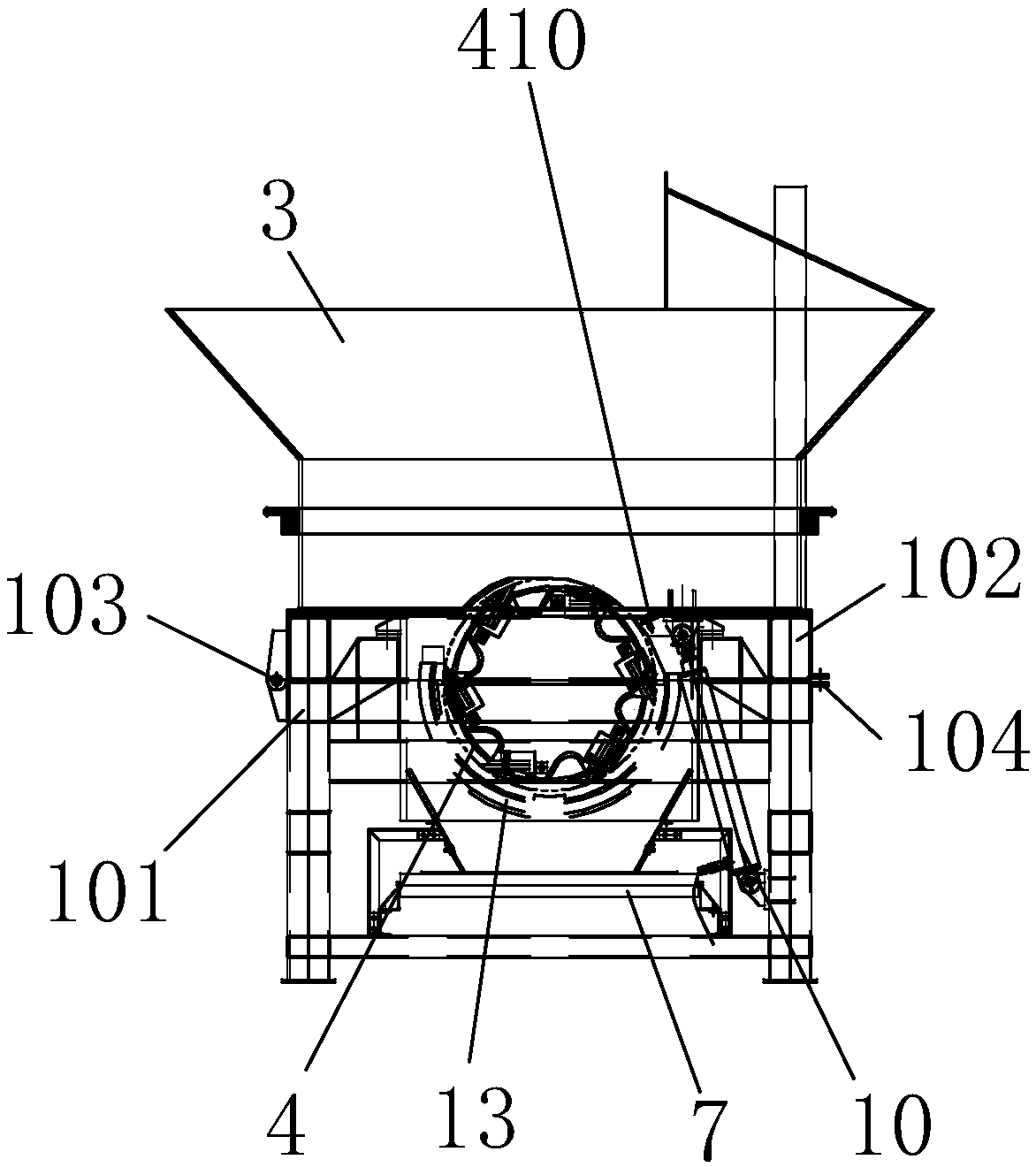

Dandelion rhizome smashing device

InactiveCN106694161AGood cutting and crushing effectImprove cutting and crushing effectGrain treatmentsEngineeringDandelion

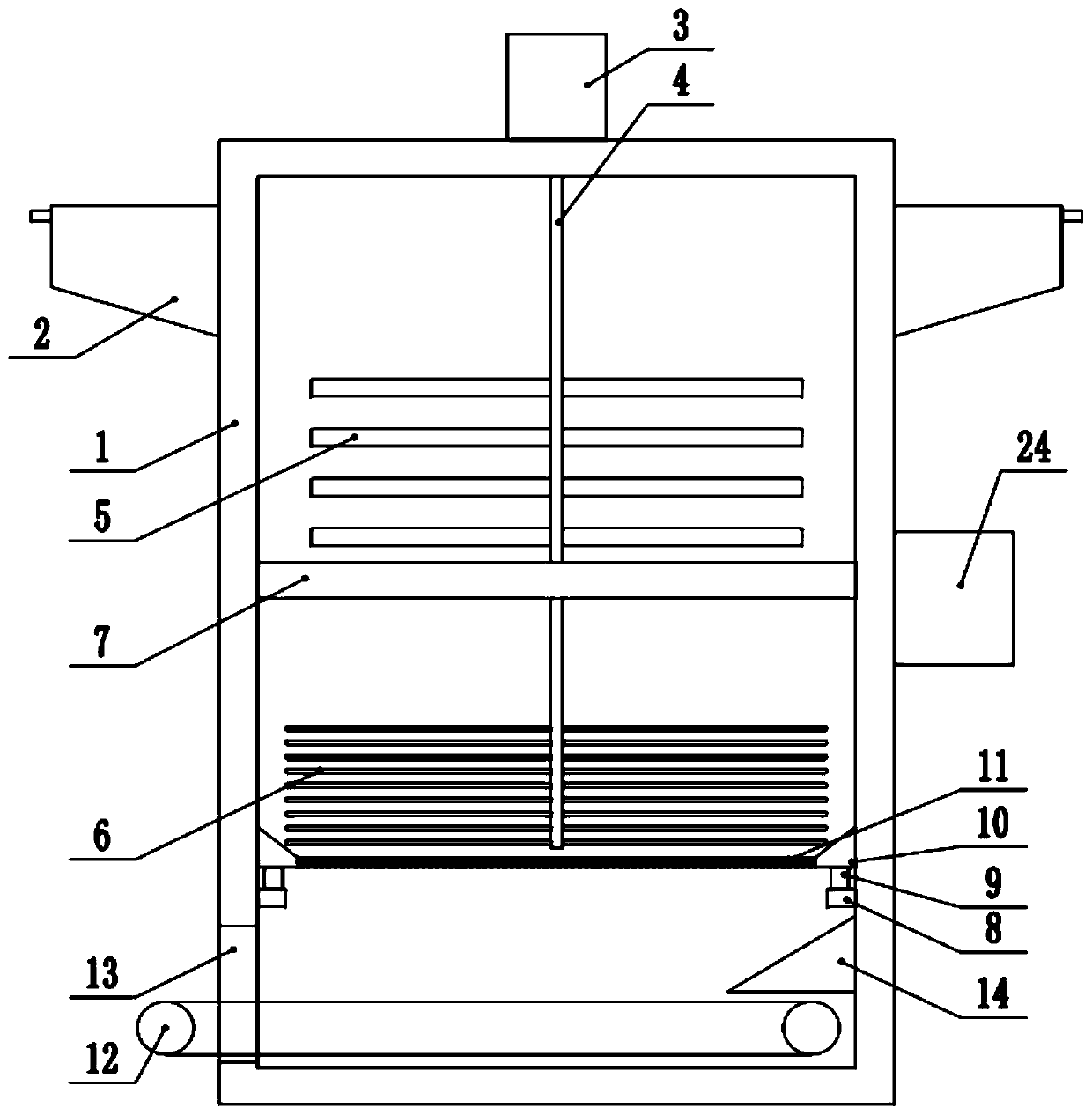

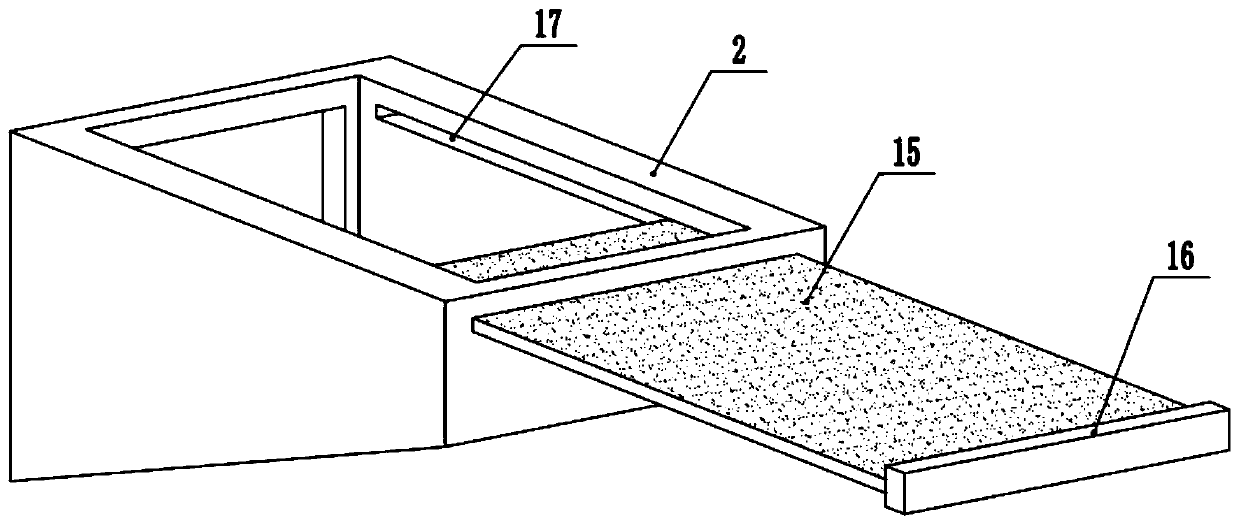

The invention relates to the technical field of smashing machines, in particular to a dandelion rhizome smashing device, which comprises a machine body, wherein a storage chamber is arranged on the bottom part in the machine body; a working table is parallelly arranged on the top part of the storage chamber; a sliding device is arranged between the working table and an inner wall of the machine body; a smashing chamber is arranged above the working table; a motor platform is arranged above the machine body, and is connected with a pushing device; a motor is arranged on the motor platform; the tail end of an output shaft of the motor is connected with a connecting rod; the other end of the connecting rod penetrates through a shell of the top part of the machine body, and is located in the smashing chamber; a working plate is connected to the other end of the connecting rod; matrix-arranged through holes are formed in the working plate. The invention provides the dandelion rhizome smashing device, which has the beneficial effects that matrix-arranged cutters are arranged, auxiliary cutting teeth are arranged on one sides of the cutters, and the cutters can move up and down and can rotate at the same time, so that a cutting and smashing effect is more ideal.

Owner:冯宗伟

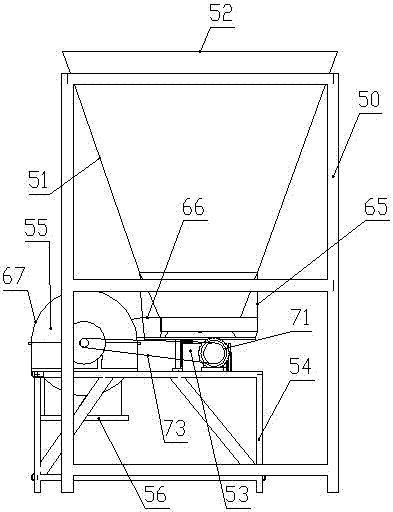

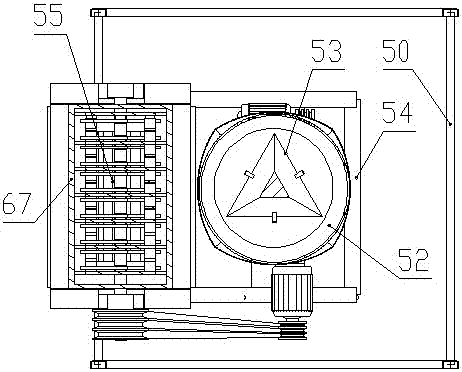

Automatic feeding and crushing device

The invention discloses an automatic feeding and crushing device which comprises a rack, a crushing device, a feeding device and a crushed powder collecting device. The feeding device is composed of a feed bin, an anti-winding feed drum, an upper feed inlet baffle and a horizontal feed tray; the crushing device comprises a crushing bin and a crushing blade installed in the crushing bin, the crushing blade comprises a center shaft sleeve and three blade bodies evenly arranged on the outer side face of the center shaft sleeve, and the three blade bodies and the center shaft sleeve are combined into a Y-shaped moving blade body; V-shaped rubber material pushing plates are evenly distributed on the anti-winding feed drum; the crushed power collecting device is composed of a draught fan, a reversing device which is composed of a three-way pipe and a reversing plate arranged in the three-way pipe and a pair of powder accumulators connected through the reversing device. The automatic feeding and crushing device is simple, practical and easy to popularize, and therefore obvious economical benefit and social benefit can be generated; the crushing blade adopts the Y-shaped moving blade body, and therefore the crushing cutting efficiency can be effectively improved.

Owner:姚旺东

On-site and ex-situ polluted soil restoring device

ActiveCN104174644AImprove work efficiencyReduce manual laborContaminated soil reclamationGrain treatmentsSoil scienceEnvironmental engineering

The invention discloses an on-site and ex-situ polluted soil restoring device. The restoring device comprises a soil supply tank, a reagent supply tank and a pulverizer, wherein the soil supply tank and the reagent supply tank are respectively connected with the pulverizer. The restoring device is simple in structure, simple and convenient to operate, applicable to restoration engineering of polluted soil, and capable of fully pulverizing and mixing soil to be restored and a restoring regent.

Owner:SOUTHEAST UNIV +1

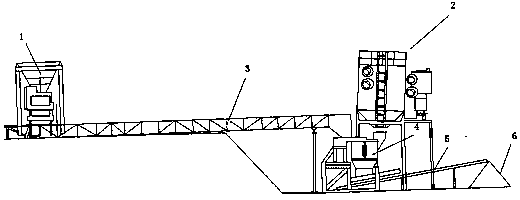

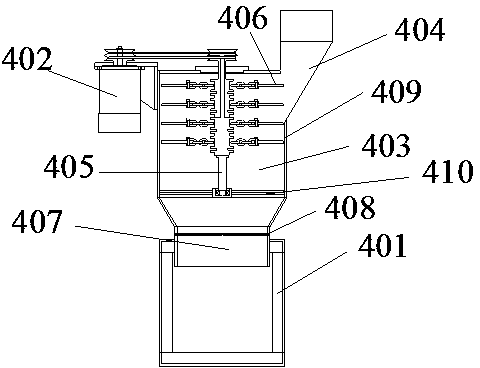

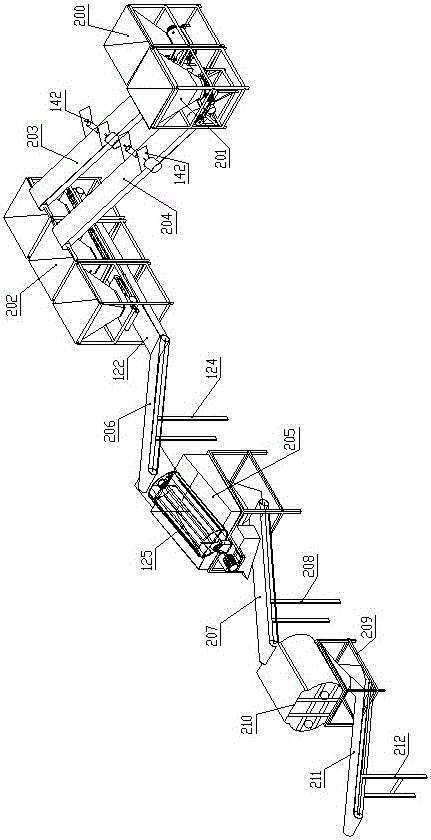

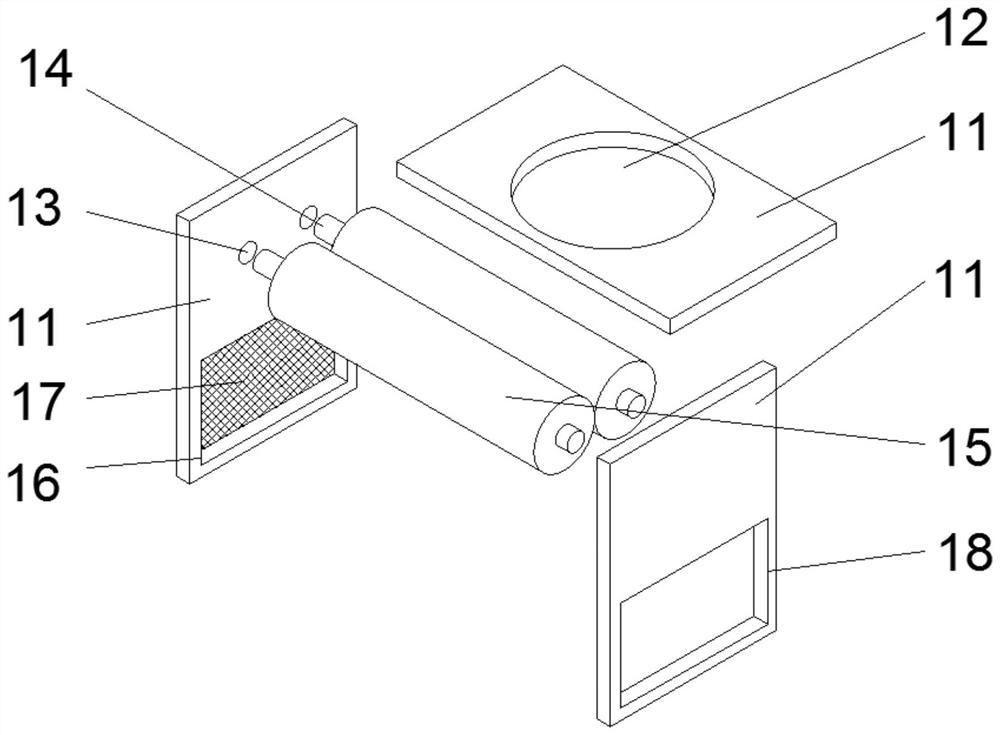

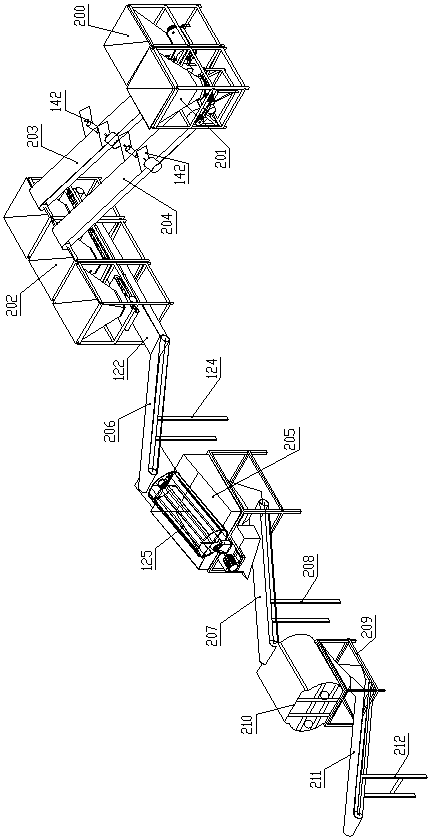

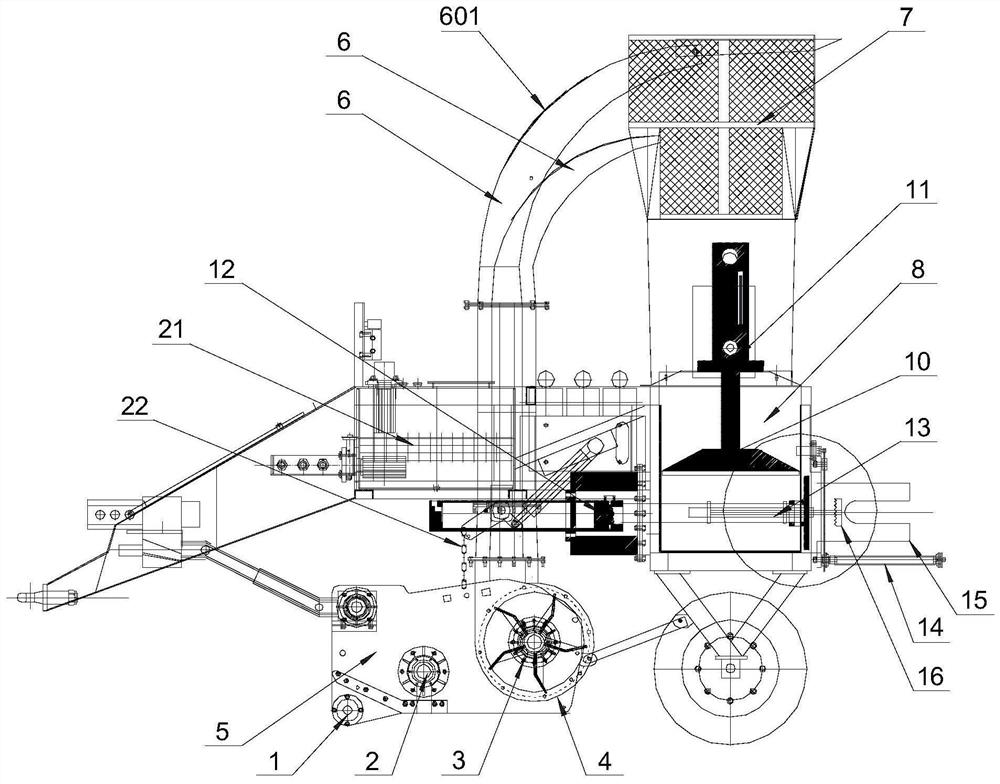

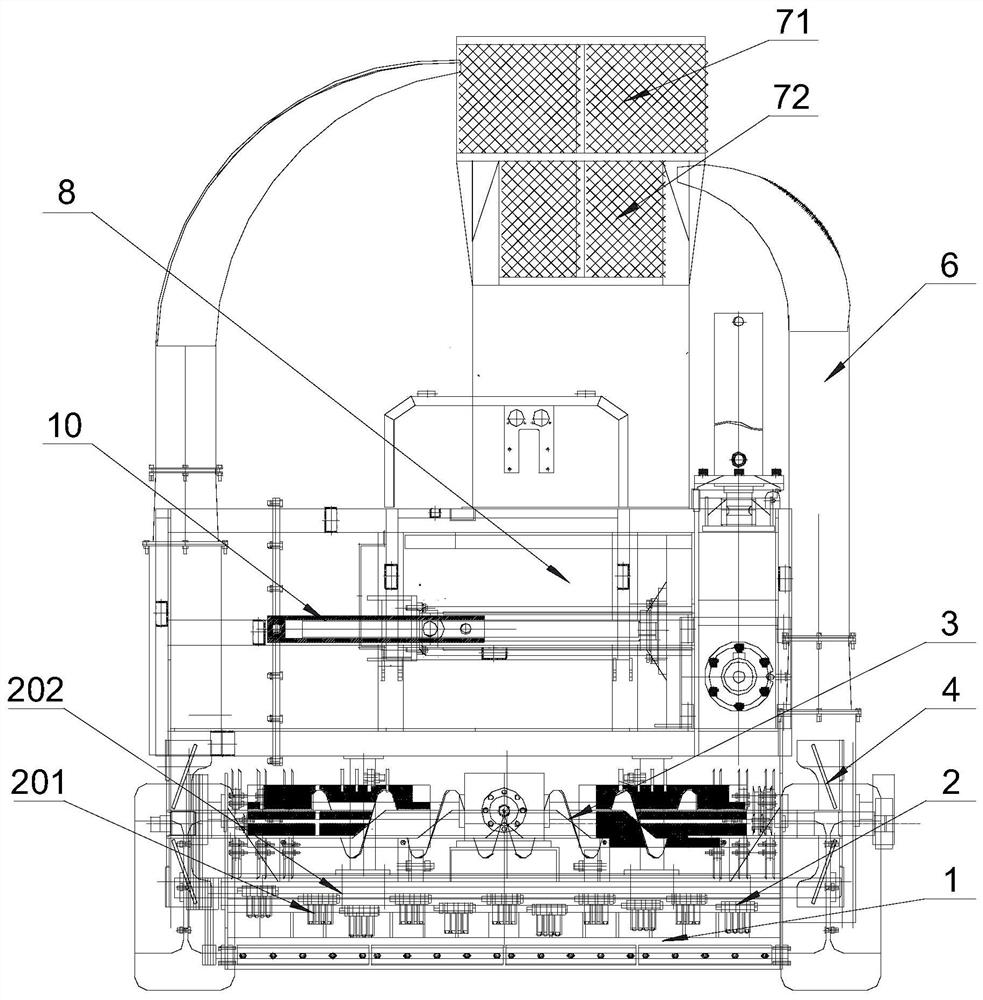

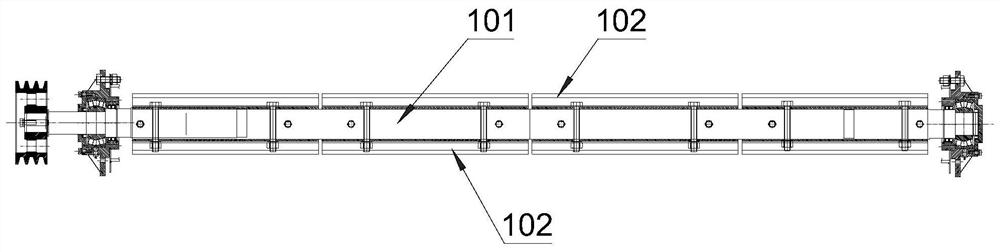

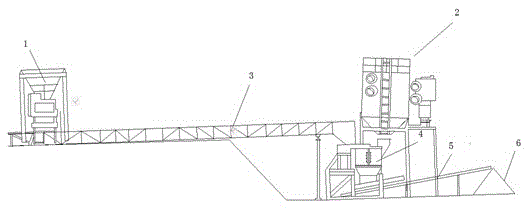

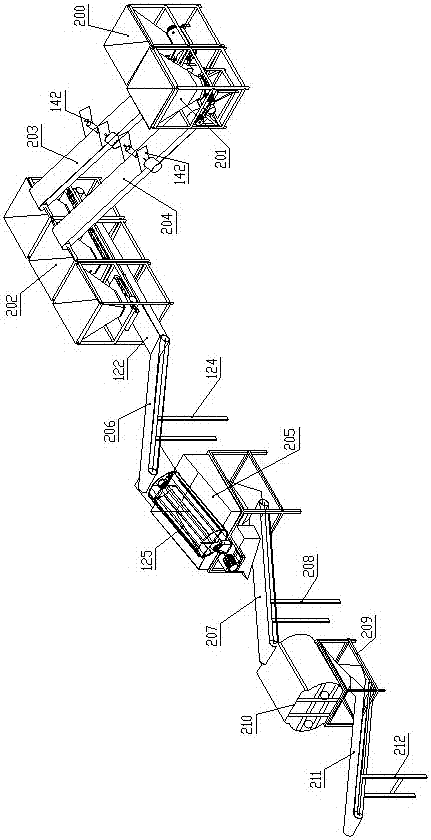

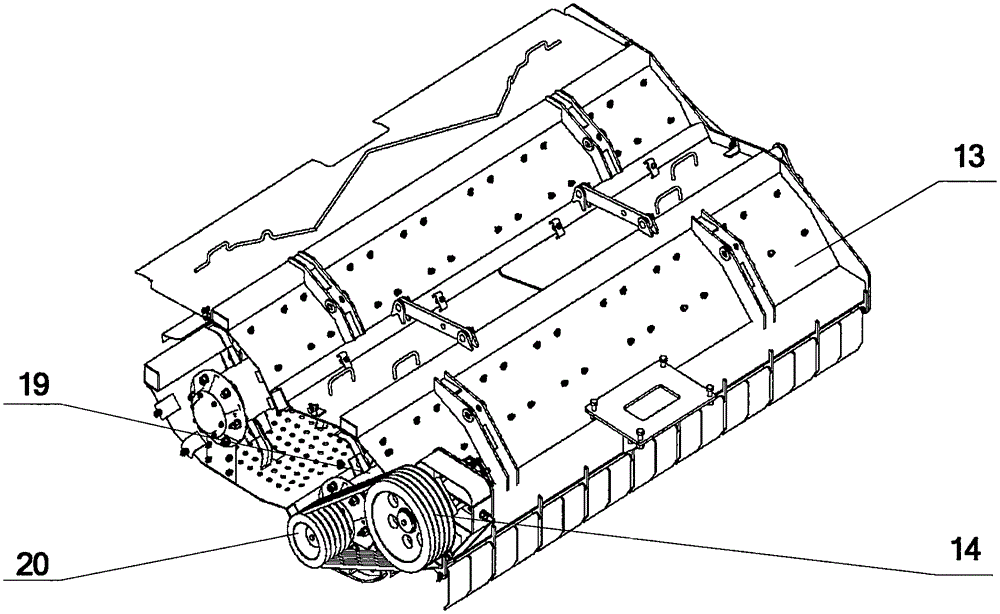

Material mixing station for LID soil changing and filling engineering

ActiveCN105689080AImprove cutting and crushing effectPrevent overflowSievingScreeningScreening effectEngineering

A material mixing station for LID soil changing and filling engineering comprises a coir block pulverizing system, a soil block pulverizing system, a proportioning system and a screening system. The material mixing station is high in automation degree and reliable in work. Coir blocks and soil blocks are respectively cut and pulverized by the coir block pulverizing system and the soil block pulverizing system, so that the material pulverizing effect is good, pulverizing efficiency is high, feeding amount is adjusted through a feeding amount adjusting device, material blockage is avoided, through the proportioning system, the materials are mixed and proportioned evenly, by a scrap iron adsorption device, scrap iron mixed in the materials can be adsorbed, by a third shifting device, accumulation of the coir blocks is avoided, therefore, the material mixing station works stably, the materials of which grain sizes meet requirements are screened from a screening discharge hole in a screening process, and large granular materials are discharged via a guiding box and is reused. By an anti-blockage device, the screening effect is good, and work efficiency is improved.

Owner:河南省交通建设工程有限公司

Energy-saving and environment-friendly plastic residual film recovery machine

InactiveCN109591221AImprove cutting and crushing effectIncrease the probability of collisionPlastic recyclingMechanical material recoveryEngineeringPlastic film

The invention relates to the technical field of plastic film recovery, in particular to an energy-saving and environment-friendly plastic residual film recovery machine. The energy-saving and environment-friendly plastic residual film recovery machine comprises a cleaning box and a crushing box. The crushing box is fixedly mounted on the cleaning box, a feed inlet is formed in the top of the crushing box, the bottom of the crushing box communicates to the cleaning box through a discharge port, and the discharge port is formed in the bottom of the cleaning box; a left partition plate and a right partition plate are symmetrically and fixedly mounted in the crushing box to divide the crushing box into a left cavity, a crushing cavity and a right cavity successively from left to right; screwsare rotatably mounted in the left cavity and the right cavity; and two external threads opposite in rotating directions are symmetrically arranged on the upper and lower sides of each screw. Shearingis formed between first crushing blades, second crushing blades and the first and second crushing blades, the cutting and crushing effect of the plastic residual film is improved greatly.

Owner:吴英姿

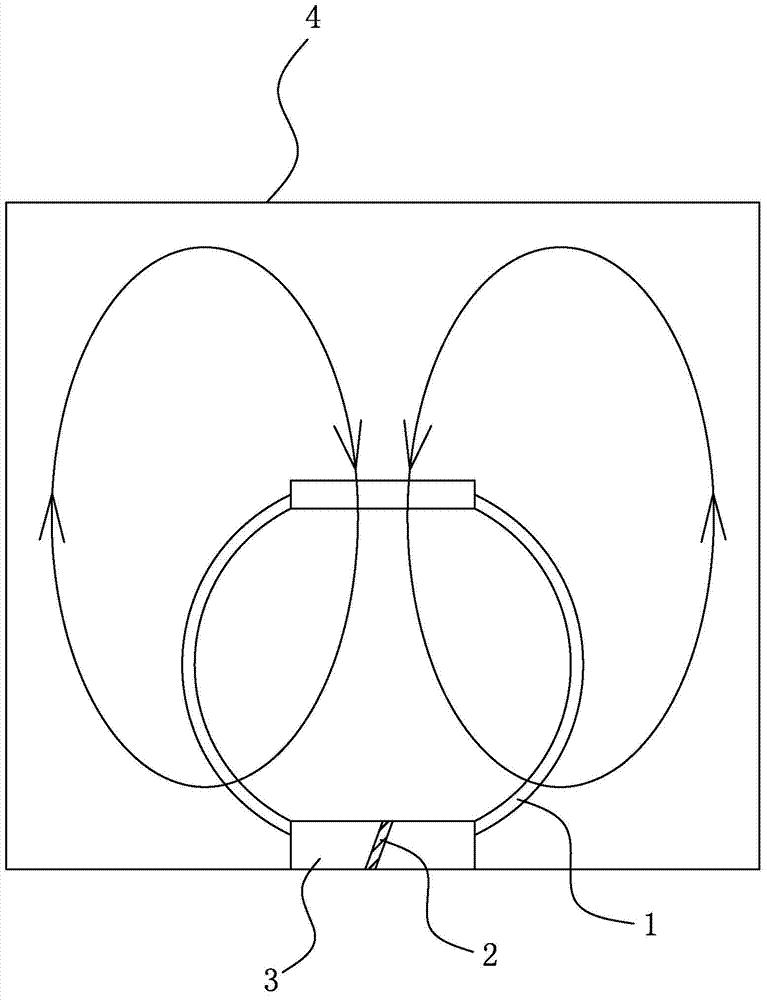

Liquid-phase mechanical stripper

PendingCN109701700AExtended service lifeImprove device stabilityGrain treatmentsEngineeringShort life

The invention belongs to the technical field of liquid-phase mechanical strippers, and provides a liquid-phase mechanical stripper. The liquid-phase mechanical stripper comprises a shell, a rotating shaft, a plurality of movable discs, a plurality of static discs, a plurality of cutting teeth, a feeding inlet and a discharging outlet, wherein the rotating shaft is arranged in the shell in a penetrating mode and rotationally arranged in the shell, the multiple movable discs are arranged in the shell, the movable discs and the rotating shaft are fixed, the multiple static discs are arranged on the shell, the static discs and the movable discs are arranged sequentially and alternately along the rotating shaft, the multiple cutting teeth are arranged on the movable discs and the static discs correspondingly, and in the rotating process of the movable discs, the cutting teeth on the movable discs pass through gaps between the adjacent cutting teeth on the static discs. Through the technicalscheme, the problems of low output rate, short life of equipment accessories and large operation noise in the prior art are solved.

Owner:赵宁

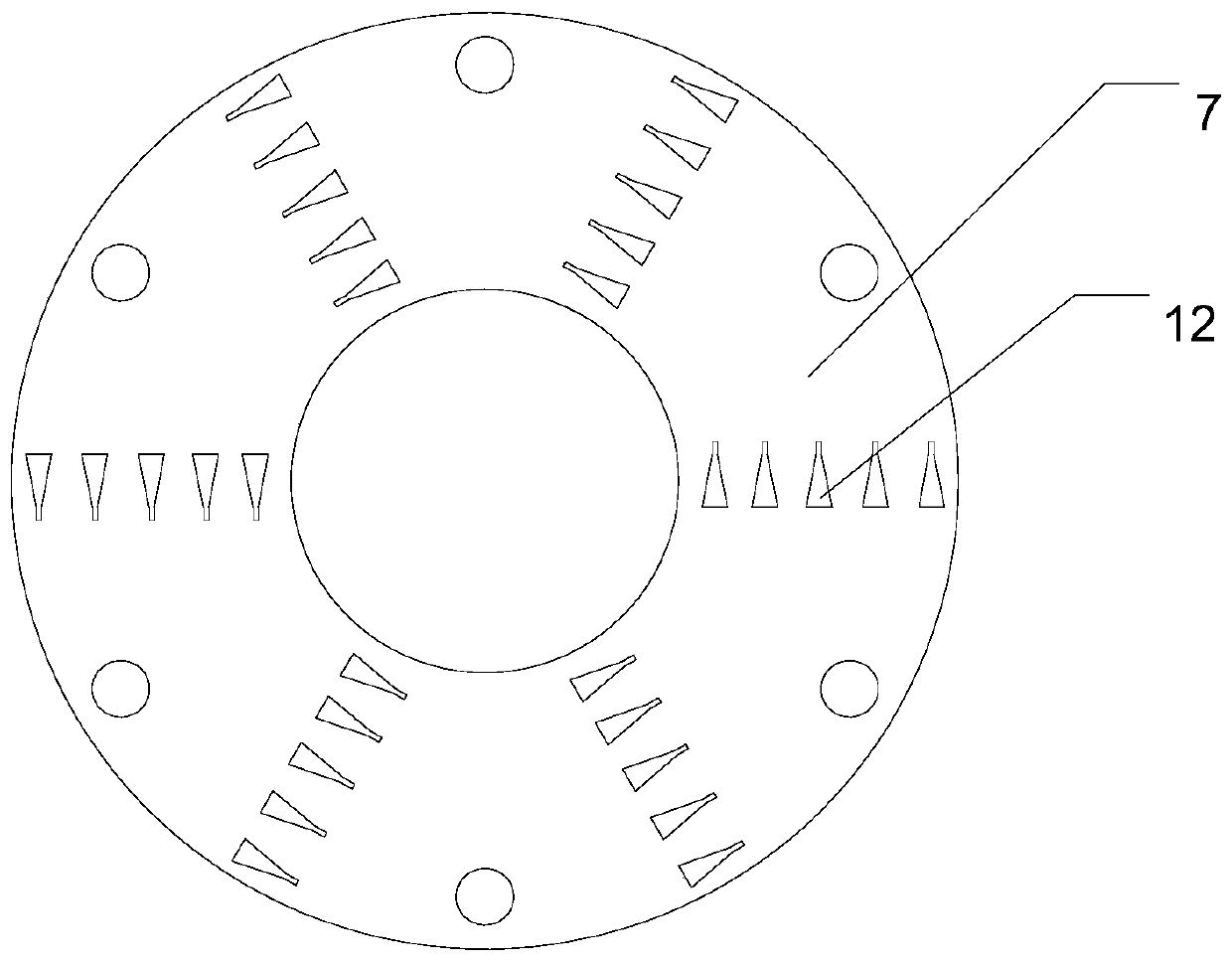

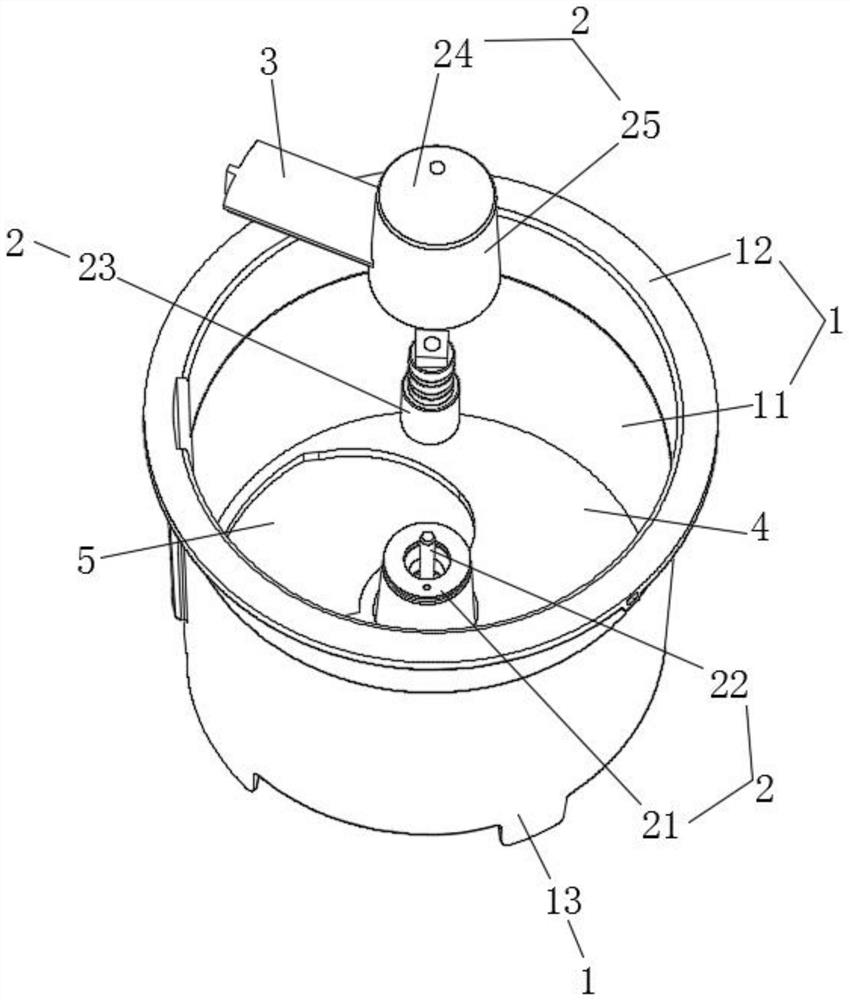

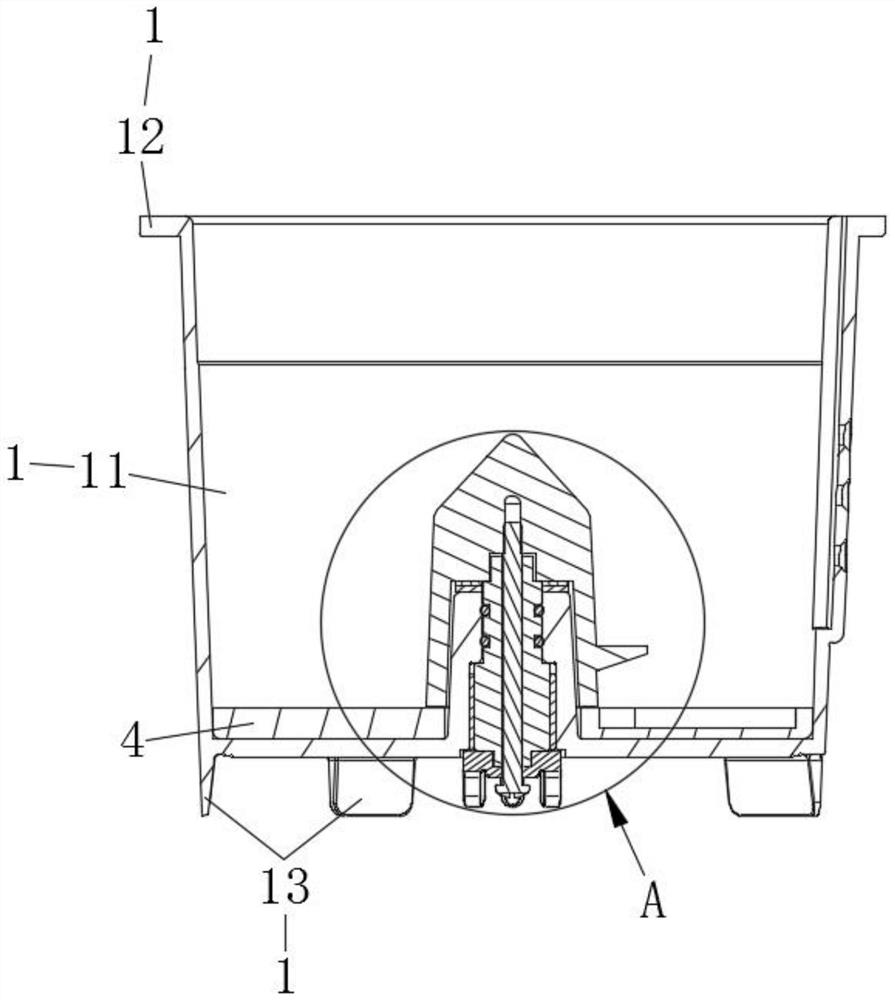

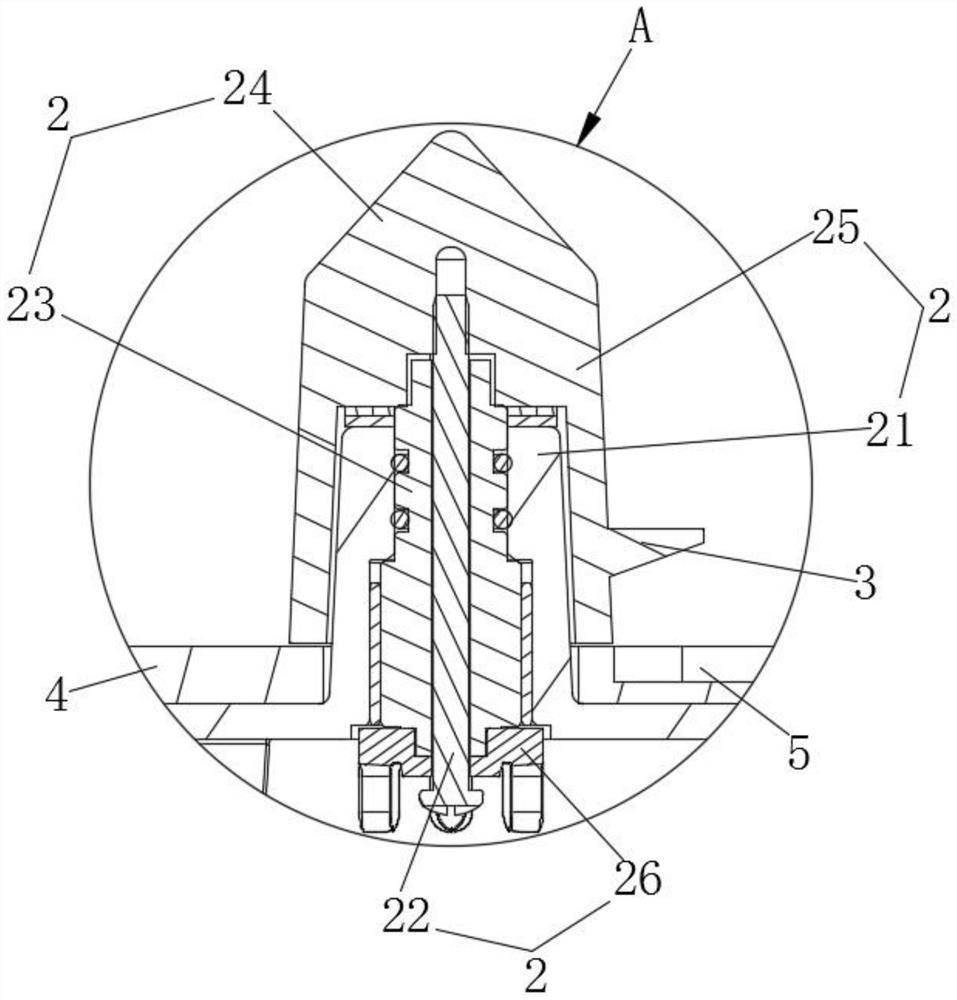

Kitchen garbage crushing combined cutter

The invention discloses a kitchen garbage crushing combined cutter. The kitchen garbage crushing combined cutter comprises a material barrel, a cutting assembly, a fixed blade and a bottom notch, wherein, the fixed blade is fixed at the bottom in the material barrel; the cutting assembly comprises a movable blade; a rotating assembly capable of rotating is mounted at the bottom inside the material barrel; the rotating assembly rotates with the axis of the material barrel as the center; the movable blade is fixed on the lower half section of the rotating assembly; the movable blade is arranged above the fixed blade; at least one side of the fixed blade is provided with the bottom notch which is provided with an edge part and faces the cutting edge of the movable blade; and one ends of the bottom notches extend towards the center of the bottom of the material barrel. According to the kitchen garbage crushing combined cutter, harder garbage blocks can be cut through self-adaptive adjustment of a shearing force arm and shearing force, and the use performance is obviously improved; frequent cutter clamping and cutter damage in the cutting process are effectively avoided, manual intervention is reduced, the treatment process is smoother, and the effect is better; and the length of the cutting working section is increased, so that more garbage is cut at the same time, and the cutting and crushing efficiency is improved.

Owner:ANHUI JIANGHANG ENVITEK ENVIRONMENTAL TECH CO LTD

Multi-stage crushing device for Chinese medicinal material production

InactiveCN110075979AGuaranteed uniformityComprehensive treatment effectGrain treatmentsEngineeringDrive motor

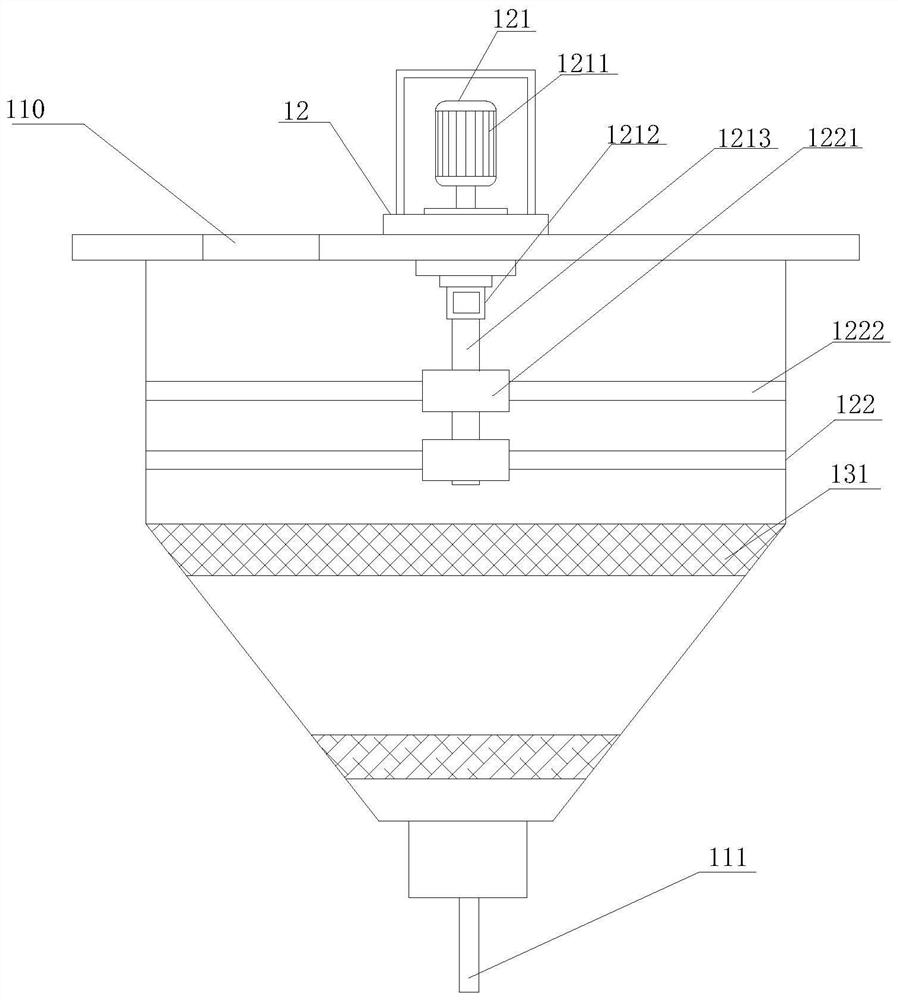

The invention discloses a multi-stage crushing device for Chinese medicinal material production and relates to the field of Chinese medicinal material processing. The multi-stage crushing device comprises a crushing box. The two sides of the top of the crushing box are both fixedly connected with feed hoppers. A first driving motor is fixedly connected to the center of the top of the crushing box.An output shaft of the first driving motor penetrates through the crushing box to be fixedly connected with a rotary shaft. A first crushing knife set and a second crushing knife set are arranged onthe rotary shaft. A material distribution device and a screen net are arranged in the crushing box from top to bottom in sequence. The multi-stage crushing device can conduct two-stage separated crushing on Chinese medicinal materials through the first crushing knife set and the second crushing knife set, ensures the uniformity of the crushed Chinese medicinal materials, can conduct cutting on Chinese medicinal material fragments clamped discharge holes through the material distribution device, can screen out the Chinese medicinal material fragments meeting the size requirement through the screen net and vibration motors, can prevent the situation that mesh holes of the screen net is blocked by the Chinese medicinal material fragments and is perfect in Chinese medicinal material processingeffect and good in cutting and crushing effect.

Owner:张德书

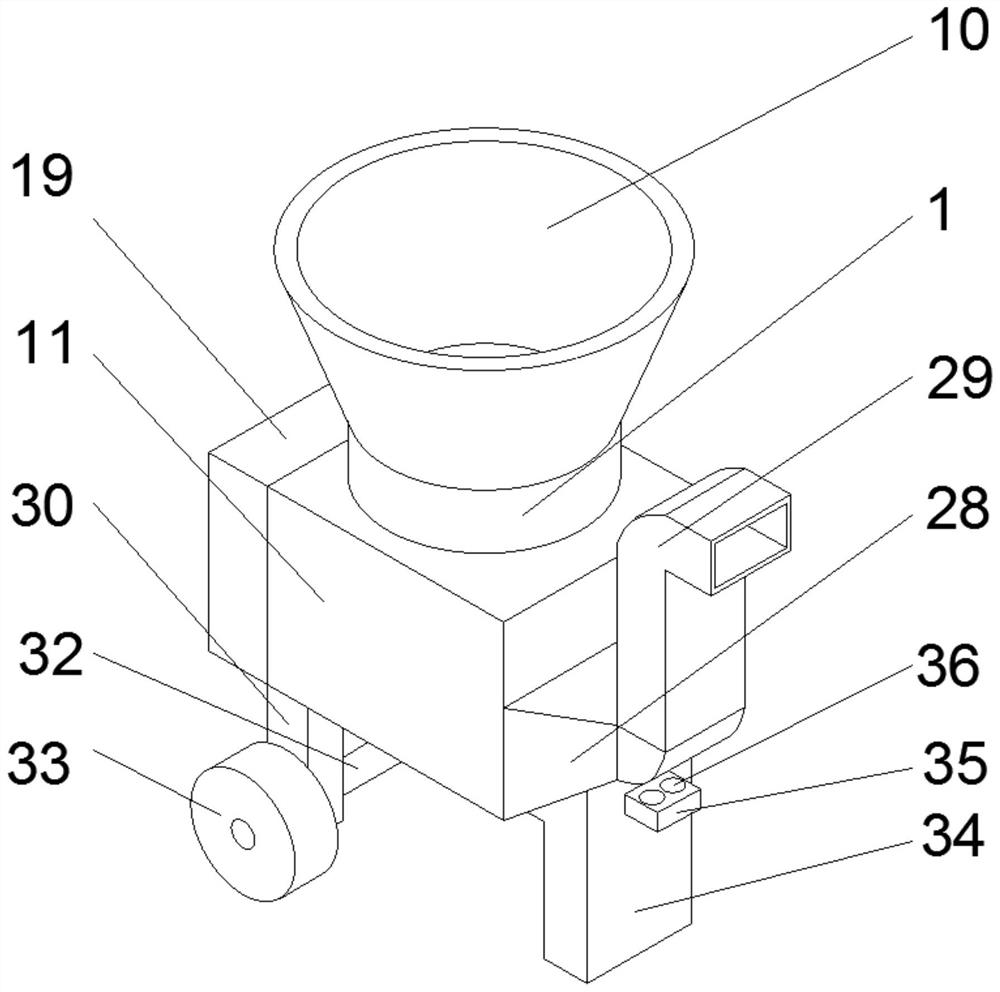

Feed scattering device for aquaculture

PendingCN112806296AReach the mobile functionEasy to feedClimate change adaptationPisciculture and aquariaEngineeringMechanical engineering

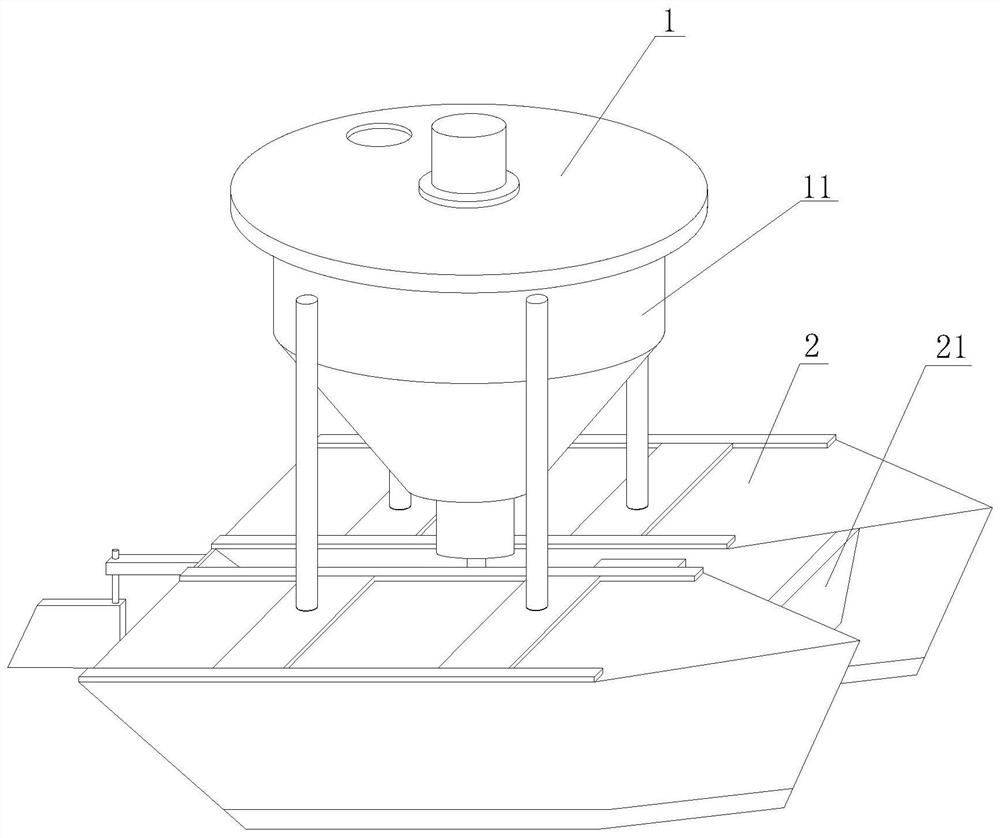

The invention discloses a feed scattering device for aquaculture, and relates to the technical field of feed scattering devices. The feed scattering device comprises a feed scattering equipment main body and a movable ship body; a feeding box is fixedly installed at the top of the feed scattering equipment main body; a feeding opening is formed in the top of the feeding box; a discharging pipe is fixedly connected to the bottom of the feeding box; the movable ship body is fixedly connected to the bottom of the feed scattering equipment main body; a movable device is fixedly installed on the side face of the movable ship body; and a stirring device is fixedly installed in the feeding box. Feed is put into the feeding box, the stirring device conducts internal stirring and smashing, the feed is better fed and filtered and sterilized, then the feed is discharged through the discharging pipe, and then the moving device moves in the whole area, so that the automatic feed scattering function is achieved, the feeding efficiency is high, the feeding effect is good, and the feeding efficiency is high, time is saved, and labor intensity is reduced.

Owner:王军

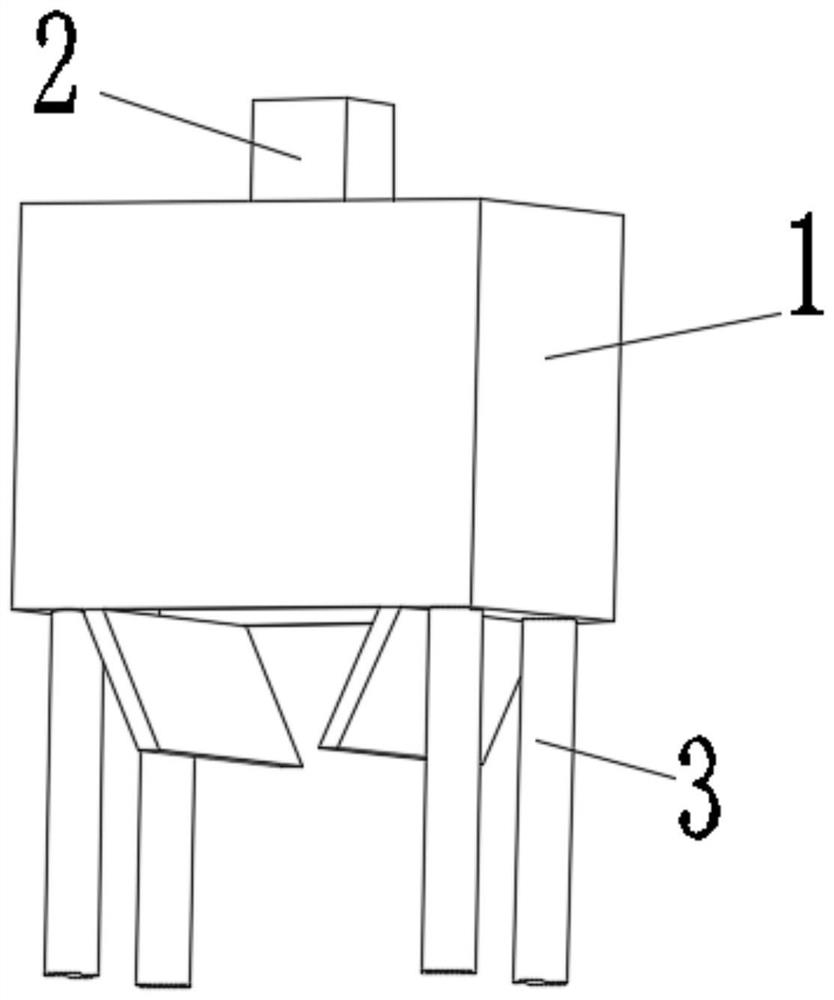

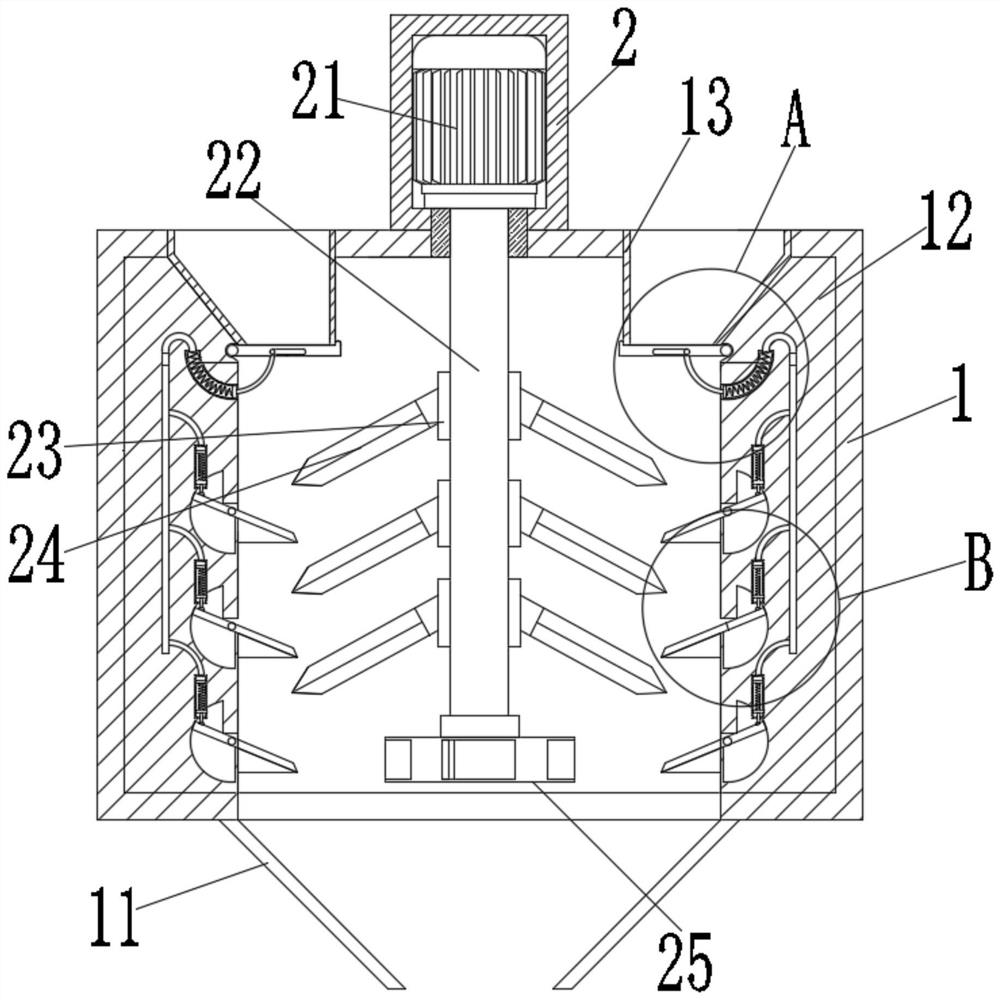

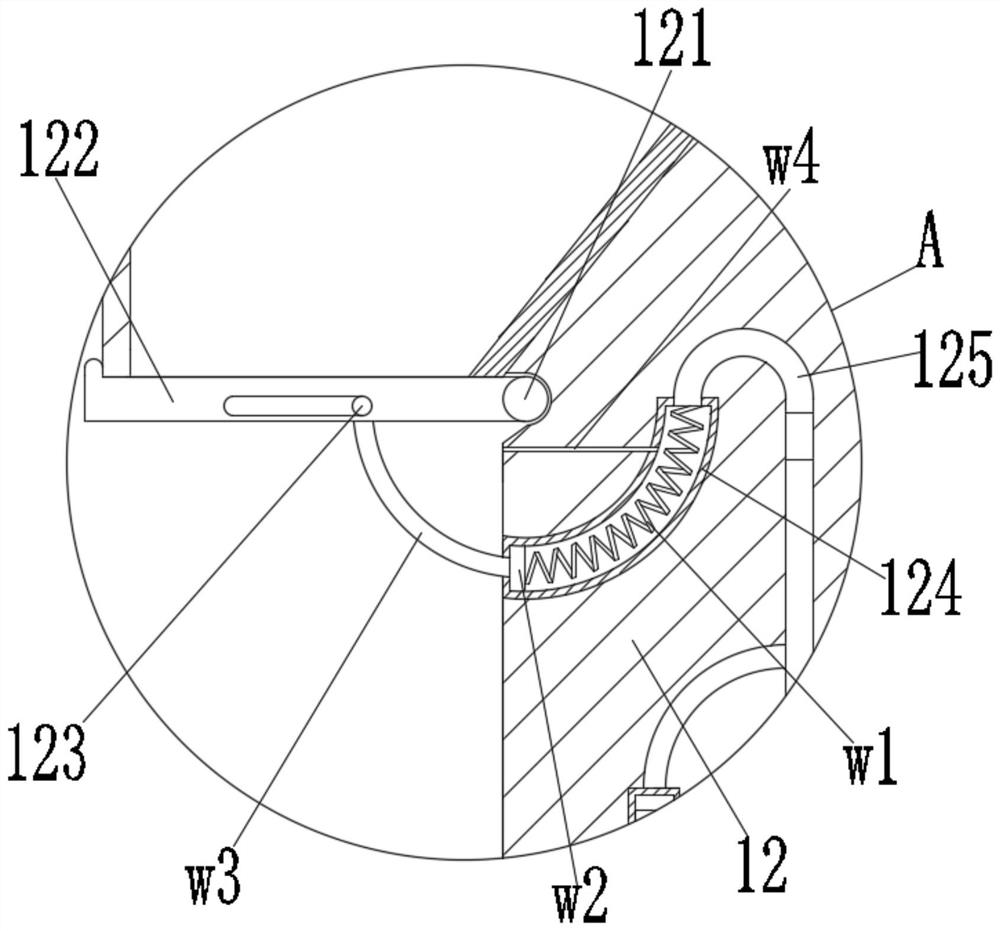

Efficient biomass energy straw smashing device

InactiveCN113439551AImprove cutting and crushing effectImprove practicalityCuttersSuction forceElectric machine

The invention discloses an efficient biomass energy straw smashing device. The efficient biomass energy straw smashing device comprises a box body, a motor protection box is fixedly installed at the top of the box body, supporting legs are arranged at the bottom of the box body, and a motor is fixedly installed in the motor protection box. A first fixing block is arranged, straw enters the interior of the box body to impact a first fixing plate, air in an arc-shaped block is pushed through a first clamping block, a second fixing plate is pushed through a first fixing rod, the effect that the left side of the second fixing plate is pushed upwards is achieved, so that the effect that straw on the left side and the right side of the inner wall of the box body is pushed inwards is achieved, the cutting and smashing effects are improved to a certain degree, and the practical degree is greatly improved; and a first air pipe is arranged, and when the air in the first arc-shaped block flows into a second air pipe and no air exists in the first arc-shaped block, the air in the first arc-shaped block can be rapidly supplemented through the first air pipe through suction force generated when the first clamping block is pushed to return by a spring.

Owner:王清勤

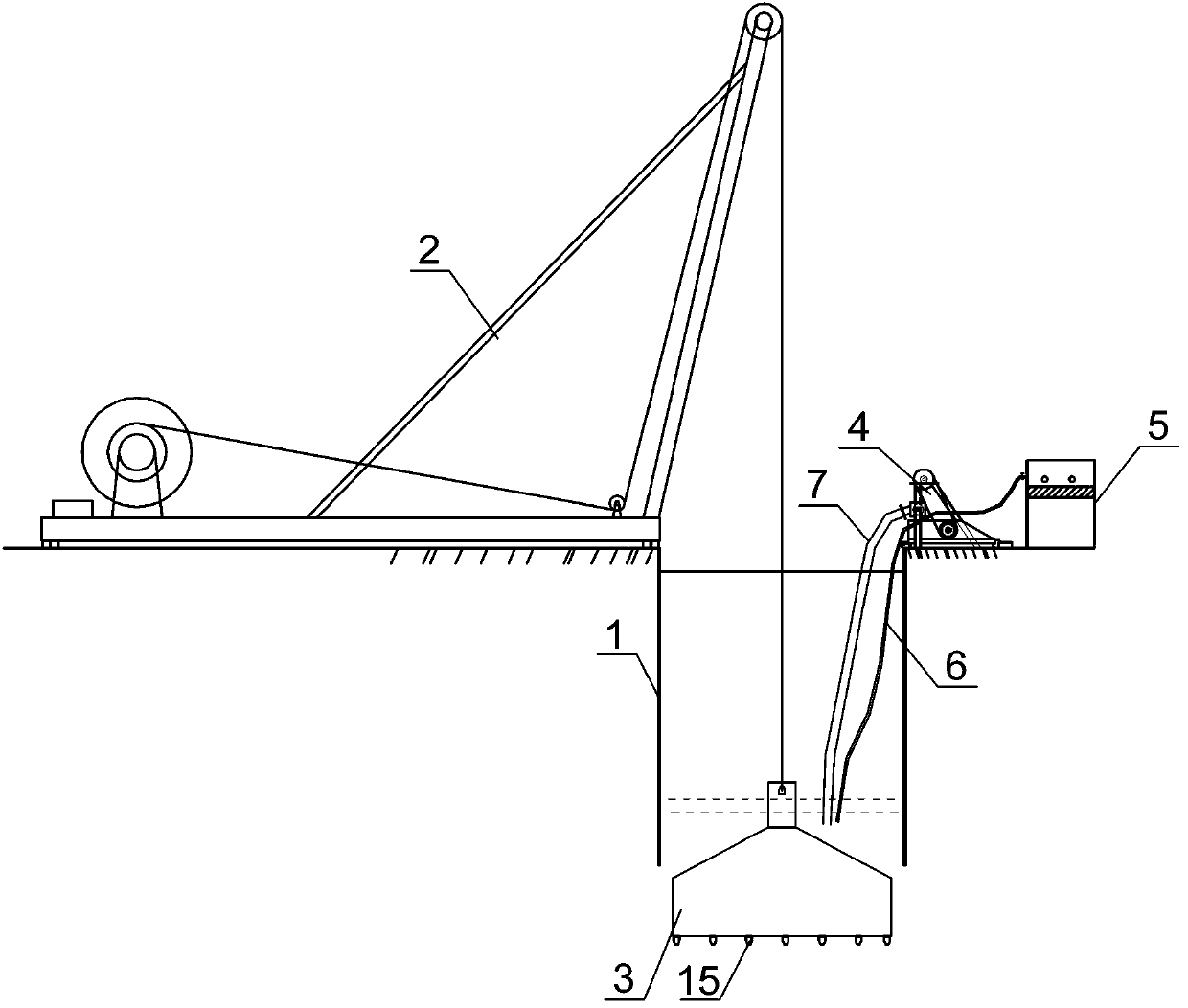

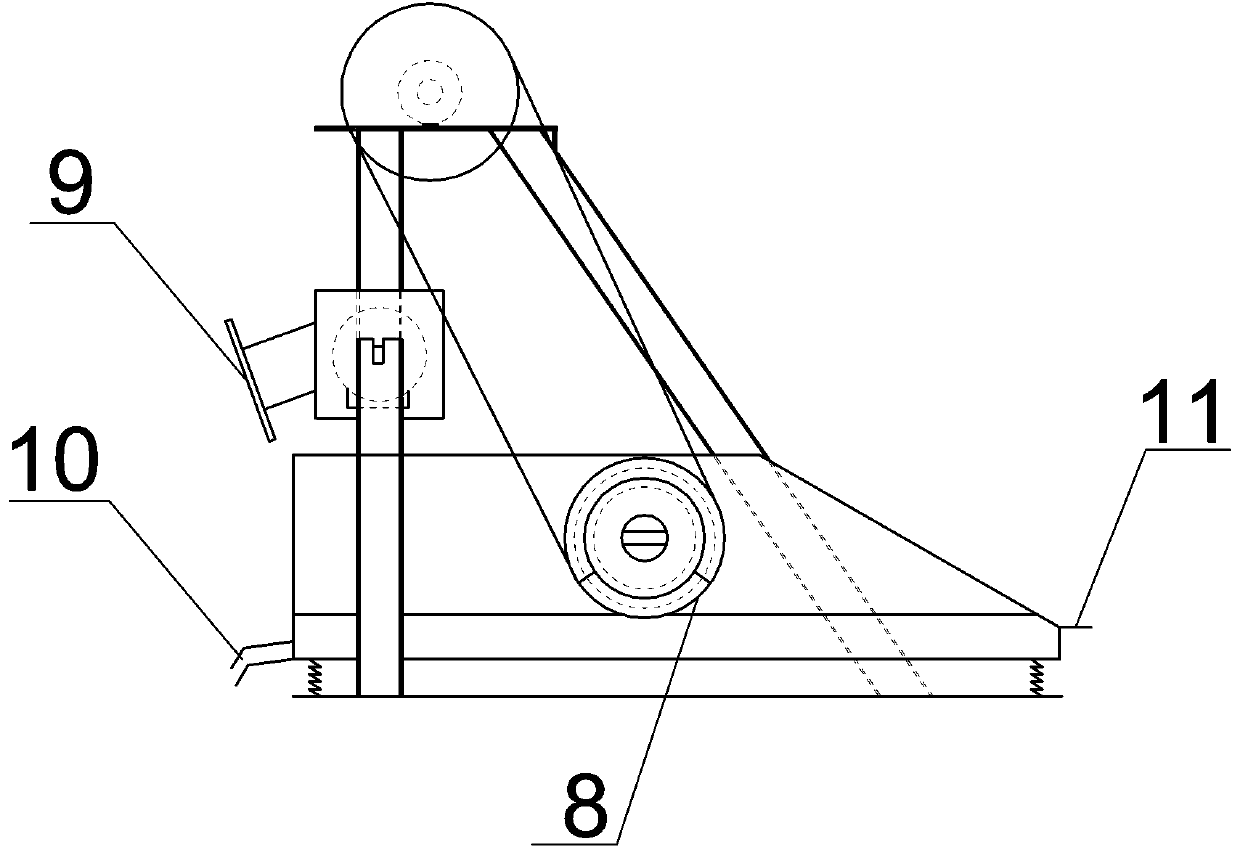

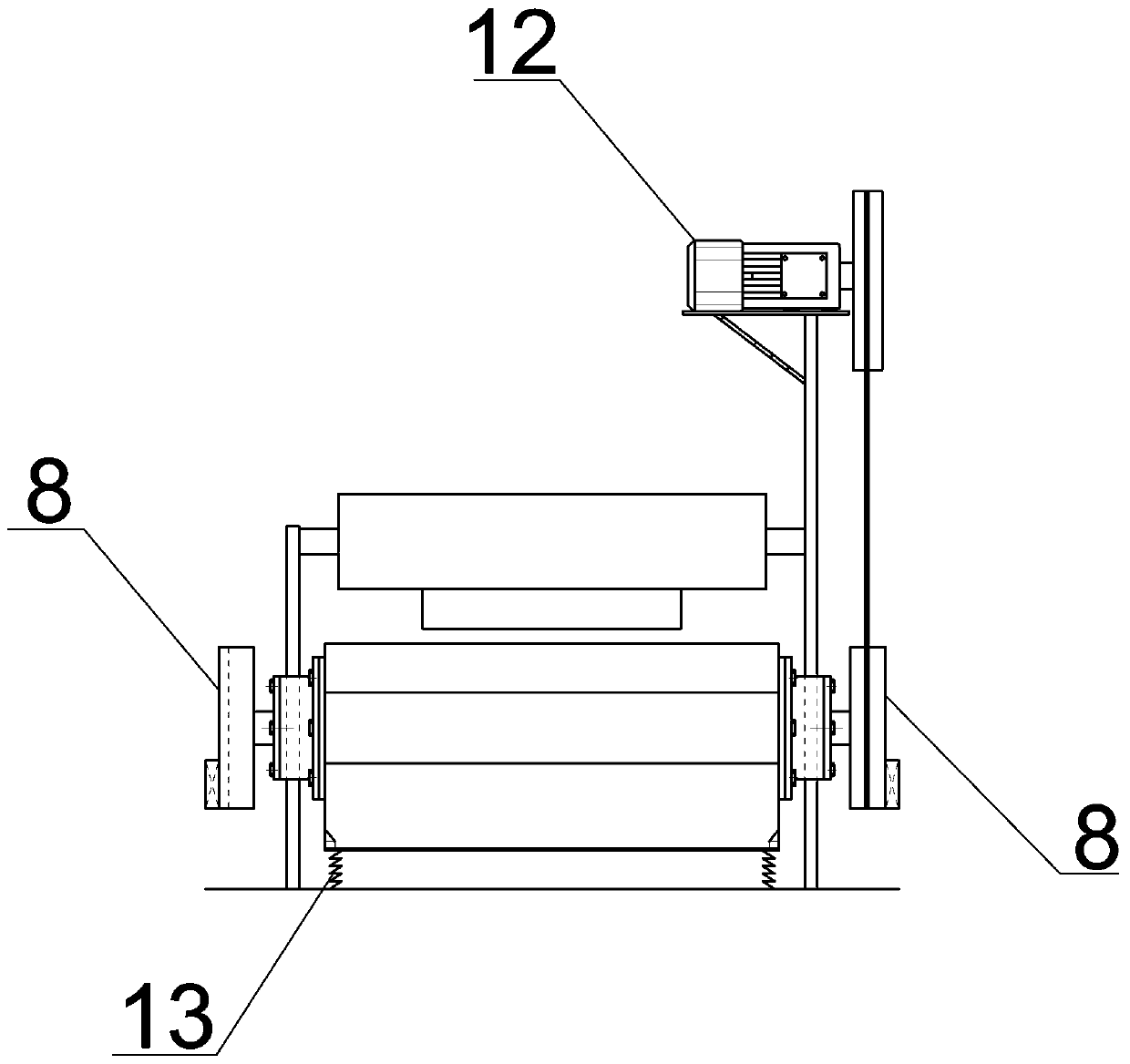

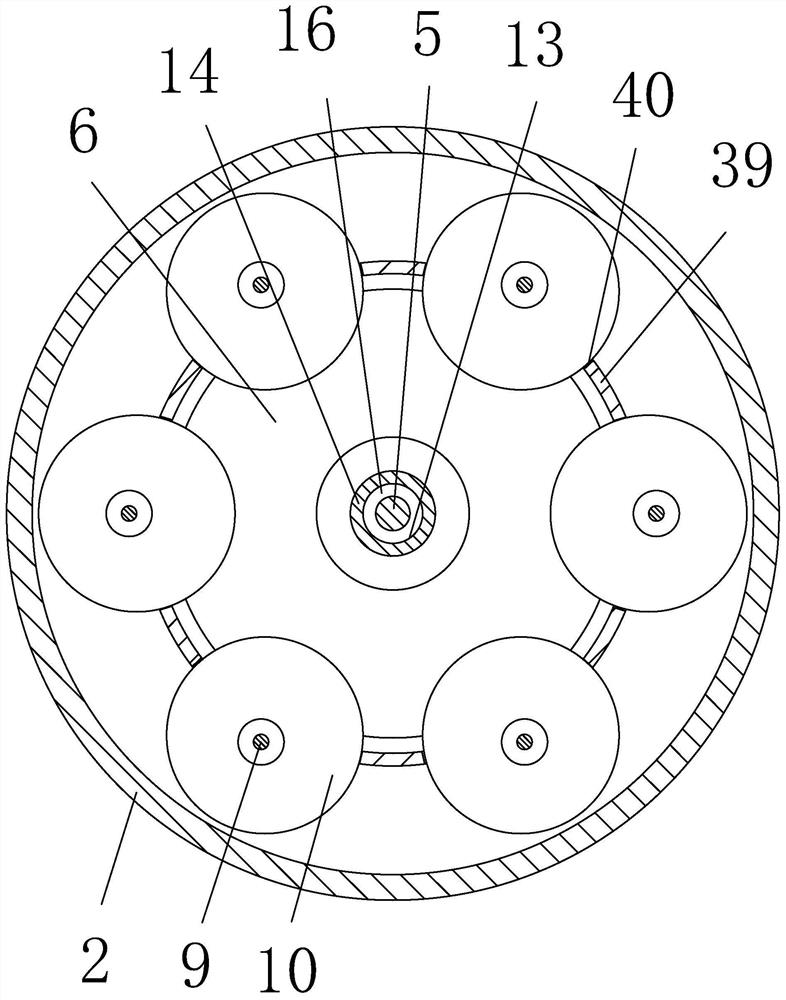

Novel percussion drill reverse circulation pile foundation drilling device and construction method

PendingCN109989703AImprove cutting and crushing effectSpeed up drilling footageConstructionsReciprocating drilling machinesSlagAir compressor

The invention provides a novel percussion drill reverse circulation pile foundation drilling device and a construction method. The novel percussion drill reverse circulation pile foundation drilling device comprises a percussion drill, and a percussion drill bit of the percussion drill is arranged in a steel casing; a mud pipe and an air pipe communicate with the positions, below a mud liquid level, in the steel casing, the other end of the mud pipe is connected with a slag removal and separation device, and the other end of the air pipe is connected with an air compressor and ventilates the interior of pile hole mud; a slurry outlet of the slag removal and separation device is arranged right above the steel casing, and the slurry flows back to a pile hole. The drilling device is a novel percussion drill reverse circulation slag removal drilling device aiming at solving the problems that a traditional percussion drill positive circulation slag removal drilling technology is low in efficiency, a whole set of import equipment is high in cost and the like in the prior art, and solves the problem that a traditional percussion drill is low in drilling efficiency of a large-diameter pilefoundation in the hard rock stratum geology by simple transformation on traditional common percussion drill drilling equipment.

Owner:CHINA GEZHOUBA GROUP NO 5 ENG

Contaminated soil remediation machine and contaminated soil remediation method

ActiveCN109127710BImprove repair effectImprove repair efficiencyRotary stirring mixersTransportation and packagingSoil remediationEngineering

The invention relates to a polluted soil remediation machine and a polluted soil remediation method. A contaminated soil remediation machine, comprising: a body with a discharge pipe at the lower end, a connecting block at the upper end of the body and several feed hoppers distributed along the circumference of the connecting block, and a pivot shaft at the upper end that is pivotally connected with the connecting block, and is located at the Several main crushing knives outside the intermediate shaft, the number of which is the same as the number of main crushing knives and one-to-one correspond to the upper stirring rod group located on the lower side of the main crushing knife, several lower stirring rods located in the discharge pipe and connected to the intermediate shaft Rod group, a number of side shafts pivotally connected to the upper and lower ends of the machine body one by one, the number of side shafts is the same as the number of main pulverizers and one-to-one corresponds to the side pulverizers located above the main pulverizer, Rotary shaft driving device, restoration agent feeding device, vibrating sieving device located at the lower side of the discharge pipe. The polluted soil remediation machine has good remediation effect and high remediation efficiency on contaminated soil.

Owner:杭州鸿明市政工程有限公司

Cutting and crushing mechanism

The invention provides a cutting and crushing mechanism. Synchronous wheels are used for driving a screw to crush materials which are then discharged through a pore plate. A through hole formed in the pore plate is arranged according to actual needs. The cutting and crushing mechanism is simple in structure, stable in performance and easy to operate, has a quite good cutting and crushing effect for chemical goods and food materials which do not need quite high processing precision and reduces production cost.

Owner:ZHENJIANG SINOWA POLYURETHANE EQUIP

Wood smashing device for building construction

InactiveCN111437948AImprove the effect of post-processingImprove cleaning efficiencyWood working apparatusCleaning using liquidsDrive shaftArchitectural engineering

The invention discloses a wood smashing device for building construction, and relates to the technical field of building machinery. The wood smashing device comprises a box, a cover plate and supporting legs, the cover plate is connected to the upper end of the box in a buckling mode, the multiple supporting legs are fixedly connected to the bottom end of the box, a feeding opening is formed in the surface of the box, an electric push rod is installed on the upper surface of the cover plate, and a push plate is arranged in the box. The output end of the electric push rod penetrates through thecover plate to stretch into the box to be connected with the push plate, a drive motor is installed at the bottom end of the box, a drive shaft is connected to the output end of the drive motor, anda smashing rod is arranged at the bottom end of the interior of the box. A first telescopic shaft is connected to one end of the drive shaft, the smashing rod is connected with the first telescopic shaft, an undertake slot is formed in the lower part of the box, a filter screen is arranged on the inner surface of the bottom end of the box, and the filter screen is located below the smashing rod. According to the wood smashing device for the building construction, the smashing rod is used for transversely cutting and smashing woods, the push plate in the box is used for longitudinal extrusion,so that the woods are more concentrated, the fineness is high during smashing, and later further processing is facilitated.

Owner:陈元定

Novel environment-friendly mechanical device for removing plastic garbages

InactiveCN110883991AWith adjustment functionPractical to usePlastic recyclingMechanical material recoveryStructural engineeringKnife blades

Owner:苏州吉玛自动化科技有限公司

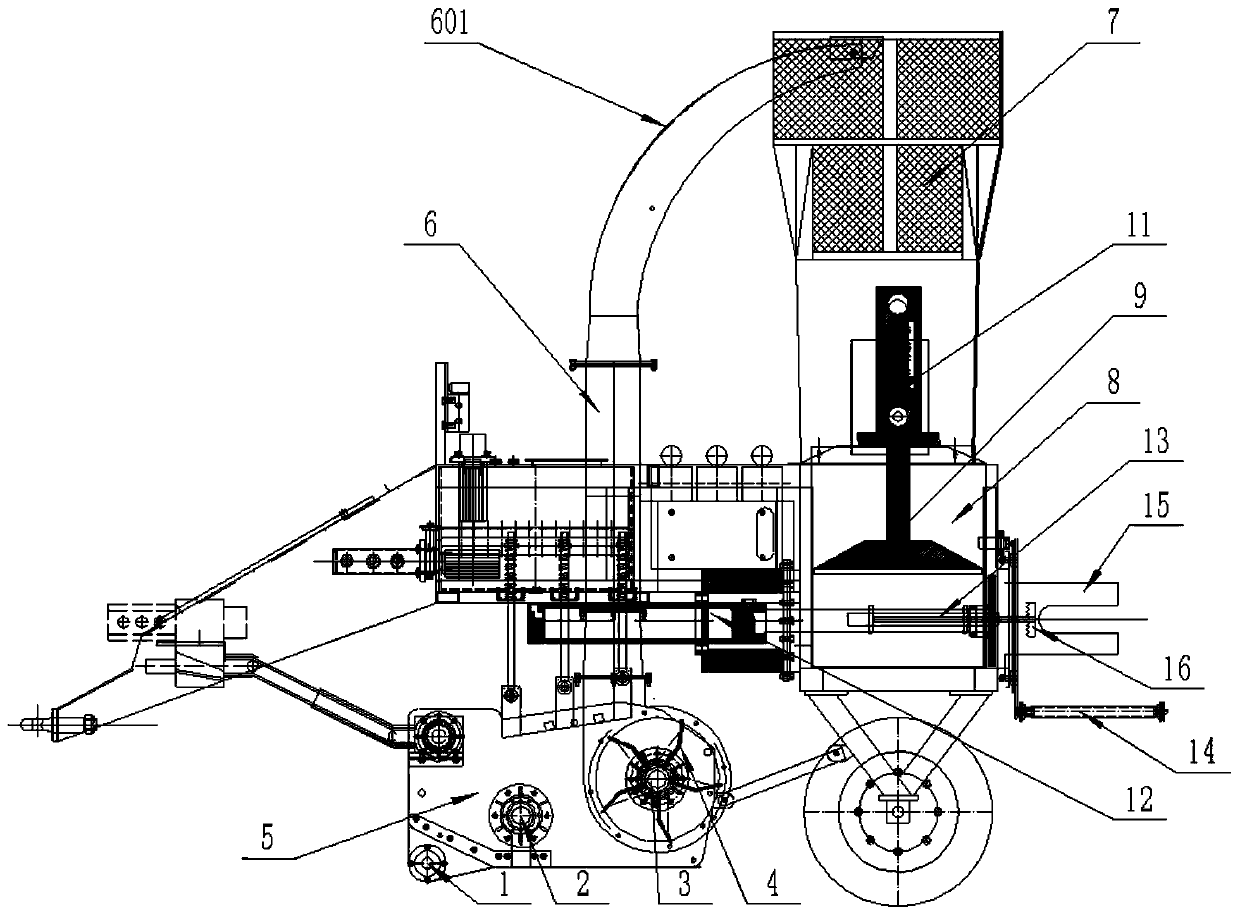

Straw picking and bundling machine

PendingCN111528501AQuick cutQuality improvementWrapping material feeding apparatusFeeding-stuffRotational axisBrick

The invention discloses a straw picking and bundling machine. The straw picking and bundling machine comprises a traction frame, a pickup device, a feeding bin, a discharging bin, a compression chamber and a compression assembly located in the compression chamber, wherein the pickup device comprises a pickup bin, a rotary knife assembly, a hammer claw assembly, an auger assembly and a fan; the rotary knife assembly comprises a rotating shaft and a rotary knife which extend in the length direction of an opening of the pickup bin, and the rotary knife is in a long sheet shape; the fan communicates with the pickup bin; one end of the feeding bin is connected with the fan, the other end of the feeding bin faces the discharging bin, and the compression chamber communicates with the dischargingbin; the compression assembly comprises three pressing plates connected with the compression chamber in a sliding mode and three compression powers connected with the pressing plates in a one-to-one correspondence mode, the compression directions of the three pressing plates are perpendicular in pairs, a feeding port of the compression chamber is located in the compression stroke of the first horizontal compression direction, and a discharging port of the compression chamber is located on the downstream of the second horizontal compression direction. Straw can be cut and picked up, meanwhile,picking-up of bricks, stones, tiles and the like is reduced, and picking-up, cutting and smashing, sundry removing and bundling are integrated.

Owner:吉林省凯迪农业机械制造有限公司

Straw pulverizer capable of removing worm eggs and comprehensive pest and disease control system

PendingCN113366980AImprove cutting and crushing effectLimit shakingCrop conditionersMowersAgricultural scienceAgricultural engineering

The invention relates to the technical field of pulverizers, and discloses a straw pulverizer capable of removing worm eggs and a comprehensive pest and disease control system. The system comprises a cutting box, a working hole is formed in the center of the top face of the cutting box, feeding ports are formed in one end and the other end of the top face of the cutting box correspondingly, a first motor is fixedly installed in the working hole, and a fixing shaft is fixedly installed on a rotating shaft of the first motor; and a plurality of rotating cutters are fixedly installed at the top and the middle of the side wall of the fixing shaft, fixing blocks are movably installed at the middle and the bottom of the side wall of the fixing shaft correspondingly, and a plurality of fixing cutters are fixedly installed on the outer side walls of the fixing blocks. The first motor drives the rotating cutters to rotate and work, straw cutting work is completed through interaction of the rotating cutters and the fixing cutters, a second motor is started, a rolling cylinder rotates oppositely to conduct rolling treatment, worm eggs and the like in straw are damaged through rolling, the worm eggs in the straw are killed, diseases and insect pests are prevented from occurring when cultivation is conducted again, and the growth of crops is protected.

Owner:田军

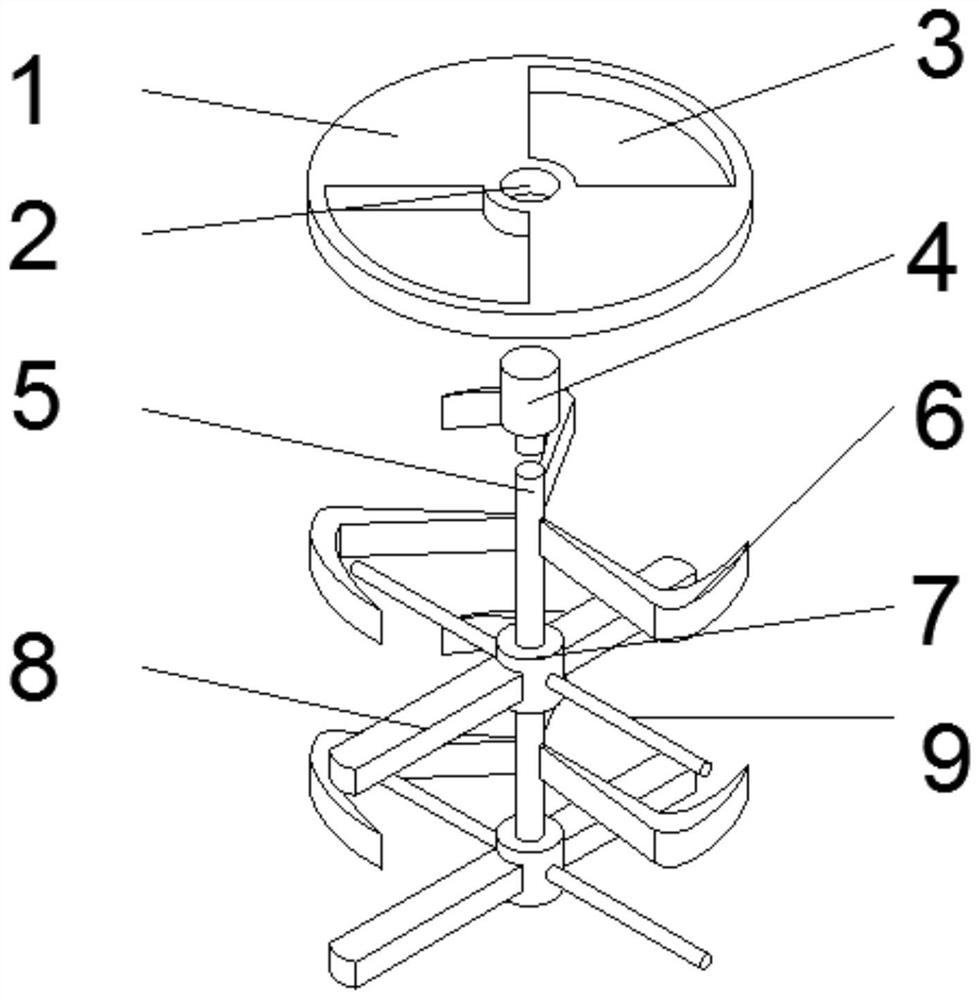

Claw cutter used for crusher

InactiveCN105381850AImprove cutting and crushing effectImprove crushing effectPlastic recyclingGrain treatmentsPlastic materialsEngineering

The invention discloses a claw cutter used for a crusher. The claw cutter used for the crusher comprises a rotating shaft and a plurality of cutter bodies, wherein the multiple cutter bodies are installed on the rotating shaft, and a plurality of cutter blades are fixedly installed on the cutter bodies. Each cutter blade comprises a base cutter blade body and a movable cutter blade body, and each movable cutter blade body is located between the corresponding base cutter blade body and the corresponding cutter body. Due to the facts that the base cutter blade bodies are arranged on the movable cutter blade bodies and can assist the movable cutter blade bodies in cutting and crushing plastics, the cutting capability and the crushing capability of the movable cutter blade bodies are further improved under the combined actions of the movable cutter blade bodies and the base cutter blade bodies, and the crushing effect on hard and thick plastic materials by the crusher is improved.

Owner:JIANGMEN XIECHENG MACHINERY

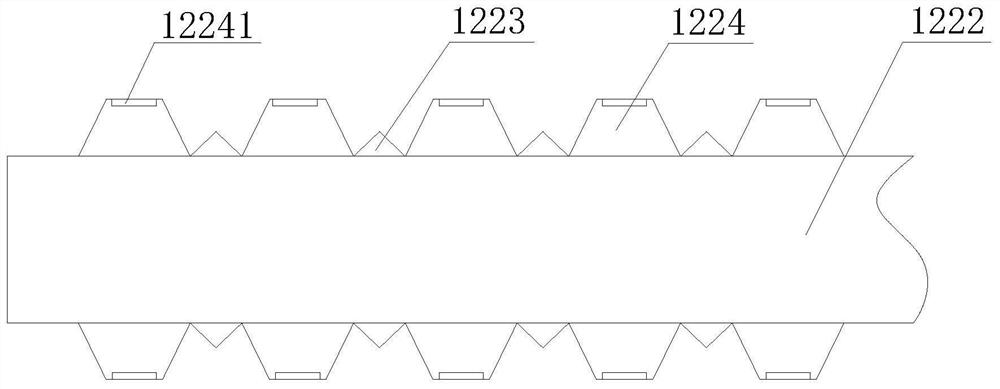

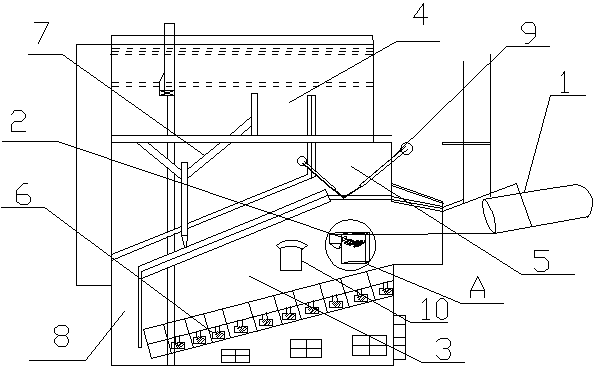

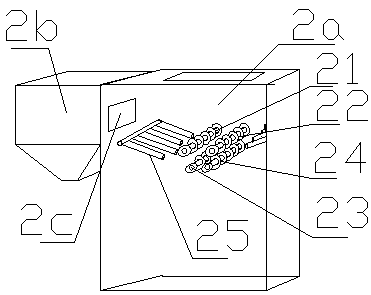

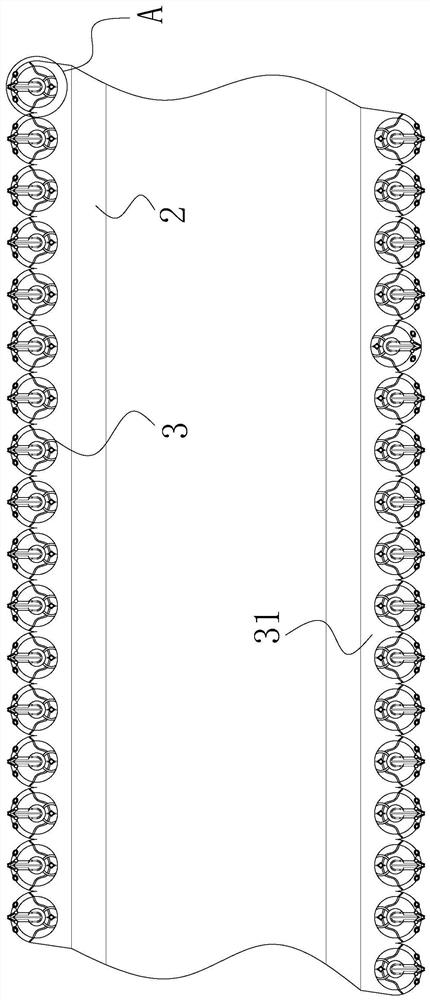

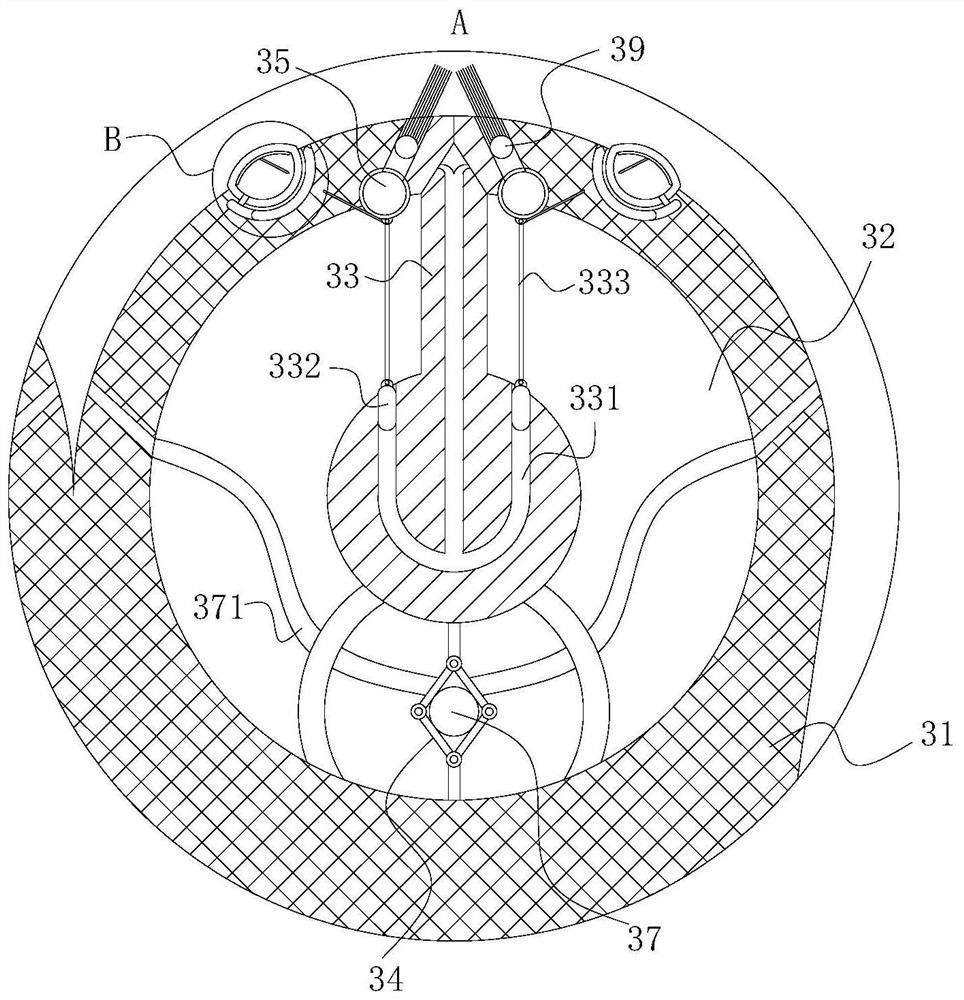

lid replacement soil engineering material mixing station

ActiveCN105689080BImprove cutting and crushing effectPrevent overflowSievingScreeningScreening effectCoir

LID soil replacement project material mixing station, including coconut peat block crushing system, soil block crushing system, batching system and screening system. The invention has high degree of automation and reliable operation. Coconut chaff block and soil block are respectively cut and crushed by coconut chaff block crushing system and soil block crushing system, so that the material crushing effect is good, and the crushing efficiency is high. Make adjustments to avoid material blockage, make the material mixing ratio even through the proportioning system, adopt the iron filings adsorption device, which can absorb the iron filings mixed in the material, and use the third feeding device to avoid the accumulation of coconut peat blocks, making the work more stable. During the screening process, the materials with the required particle size are screened out through the screening outlet, and the materials with large particles are discharged through the material guide box for reuse. The anti-blocking device is used to make the screening effect better and improve the work efficiency. efficiency.

Owner:河南省交通建设工程有限公司

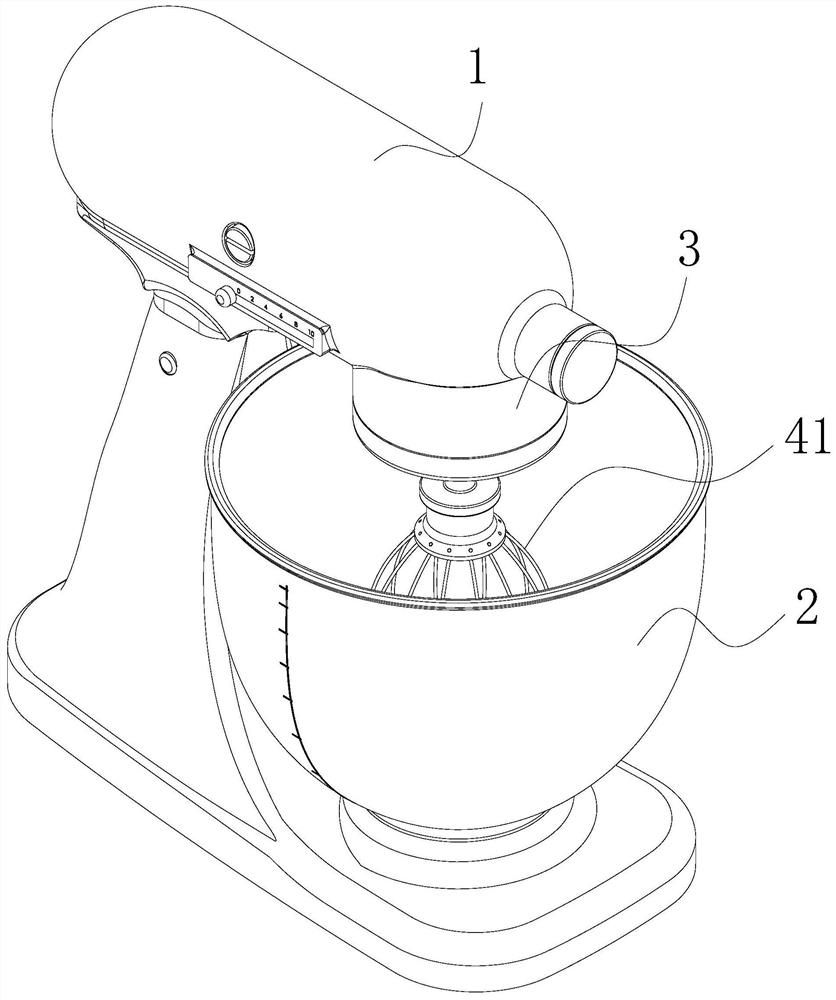

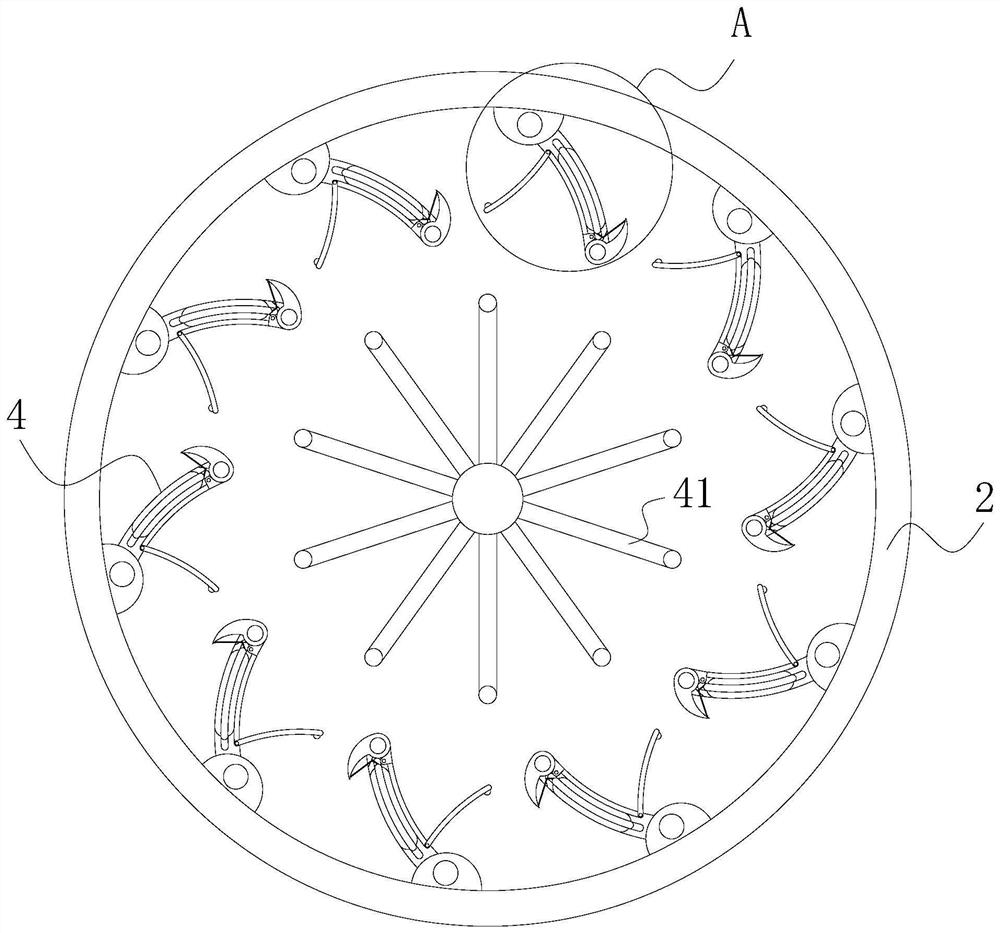

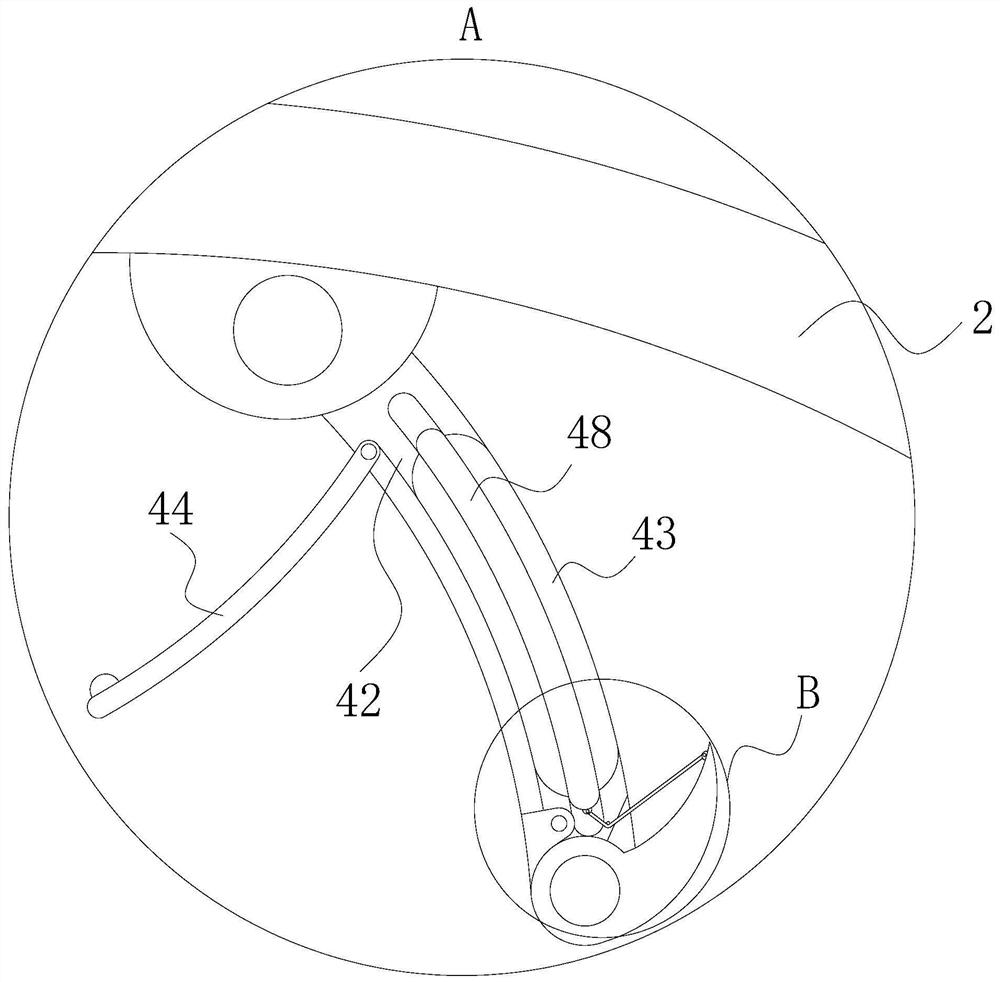

Cake material-mixing apparatus

InactiveCN103931688AImprove cutting and crushing abilityImprove mixing solubilityMixing/kneading with vertically-mounted toolsMechanical engineeringMetal strips

A disclosed cake material-mixing apparatus comprises a charging basket and a motor base arranged below the charging basket, the motor base is inside provided with a motor, the output shaft of the motor is connected with a material-mixing device arranged in the charging basket, and the material-mixing apparatus is characterized in that the material-mixing device comprises blade-type stirring heads at the bottom and a spherical stirring head arranged above the blade-type stirring head; the blade-type stirring head is formed by arranging at least two blades in a centrosymmetric manner, and the spherical stirring head is a hollow ball formed by a circle of a plurality of metal strips in a longitude arrangement manner; and the top of the spherical stirring head is provided with an inflow port communicated with the interior of the hollow ball. Through the cooperation of the hollow spherical stirring head and the blade-type stirring head, the product quality is effectively improved and the production cost is reduced.

Owner:DING HAI MACHINERY DA FENG

Automatic picking and bundling machine capable of achieving double feeding and discharging

PendingCN111727746AReduce pick upReduce the problem of easy retention and blockageLoadersBalingRotational axisAuger

The invention discloses an automatic picking and bundling machine capable of achieving double feeding and discharging. The automatic picking and bundling machine comprises a traction frame, a pickup device, an auger assembly, two feeding fans, two feeding bins, a blanking bin, a compression chamber and a net winding assembly, wherein the pickup device is connected with the traction frame through aheight adjusting mechanism and comprises a pickup bin, a rotating cutter assembly, a hammer claw assembly and the auger assembly; the rotating cutter assembly located at an opening of the pickup bincomprises a rotating shaft and a plurality of rotating cutters distributed on the rotating shaft in the circumferential direction; each rotating cutter is in a long sheet shape and extends in the samedirection as the rotating shaft; the auger assembly comprises an auger shaft, two auger blades with opposite rotating directions and two groups of movable cutters; the two feeding fans both communicate with the pickup bin; the two feeding bins are connected to air outlets of the two feeding fans in a one-to-one correspondence manner; the compression chamber is provided with a feed port, a compression assembly and a discharge port; and the net winding assembly is provided with net winding power, a rotating roller and a net breaking device; the rotating roller rotates in the circumferential direction of the discharge port; and the net breaking device is located on a rotating path of the rotating roller. The problems that the amount of picked dust is high, blockage and lagging are easy in feeding and the dust removal effect is not ideal are solved.

Owner:吉林省凯迪农业机械制造有限公司

An in-situ heterogeneous contaminated soil remediation device

ActiveCN104174644BImprove work efficiencyReduce manual laborContaminated soil reclamationGrain treatmentsSoil sciencePollution soil

Owner:SOUTHEAST UNIV +1

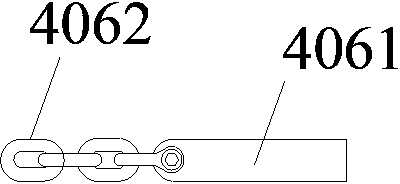

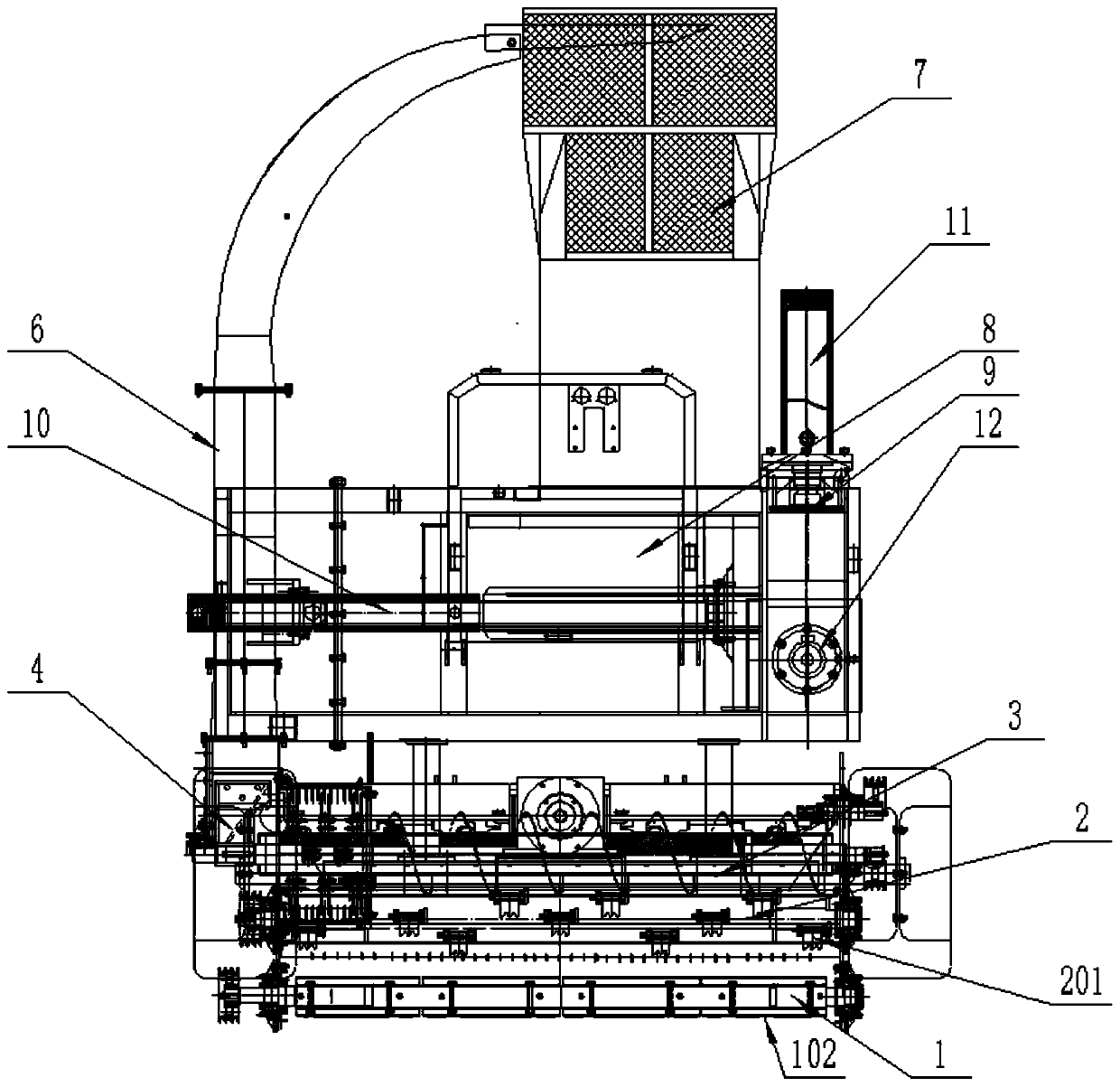

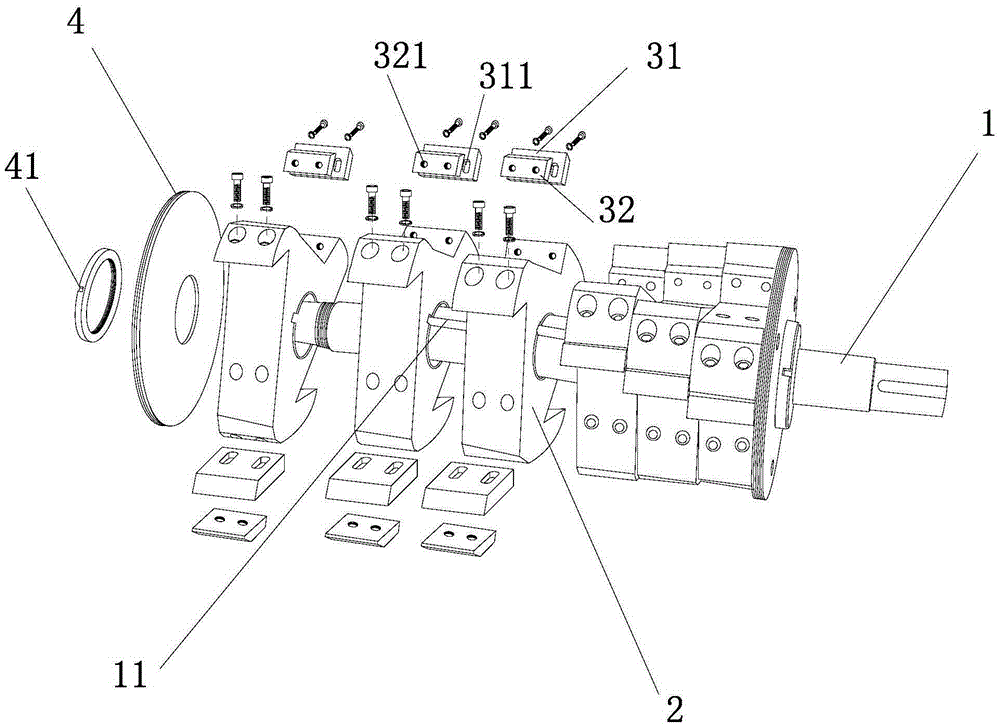

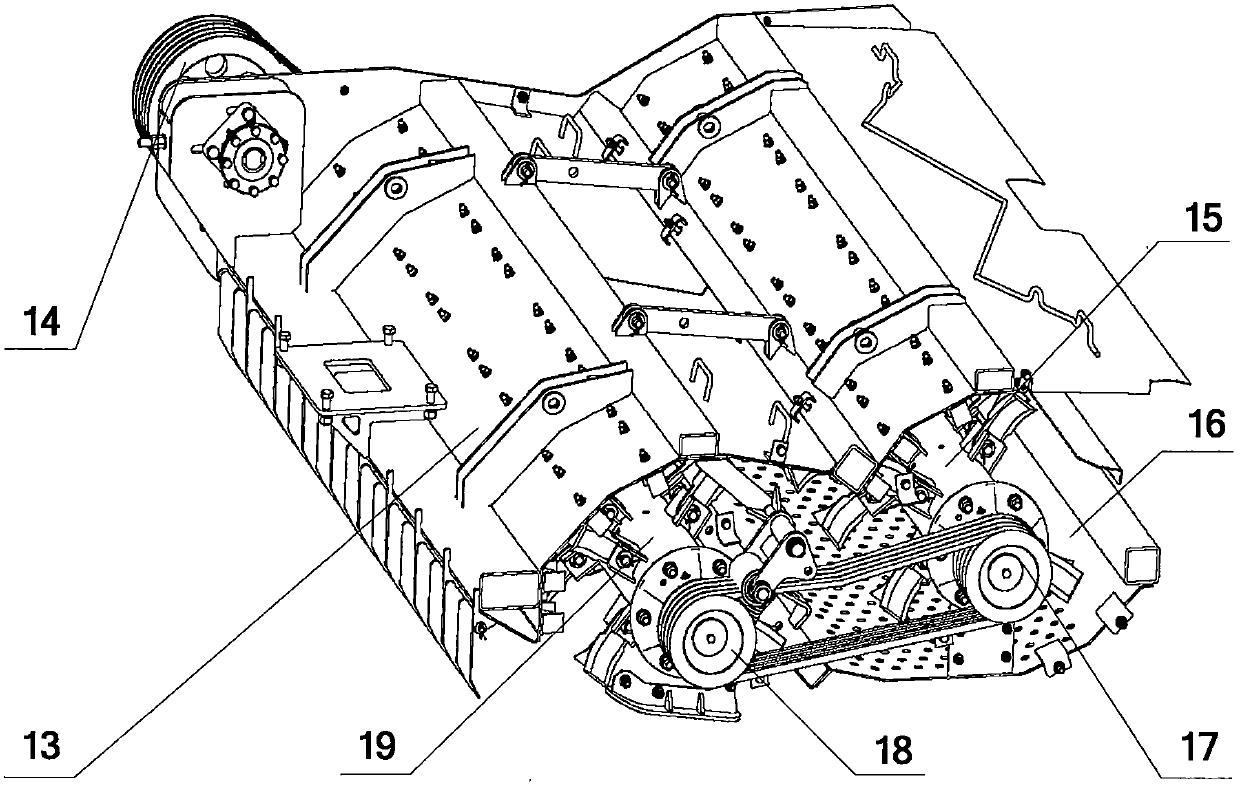

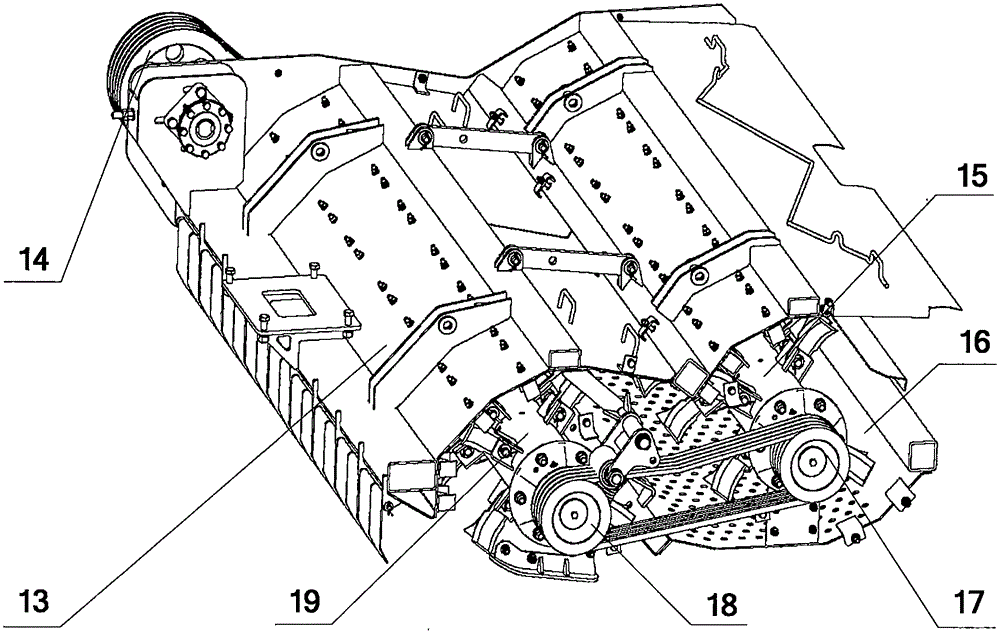

Double cutter shaft cutting and crushing device

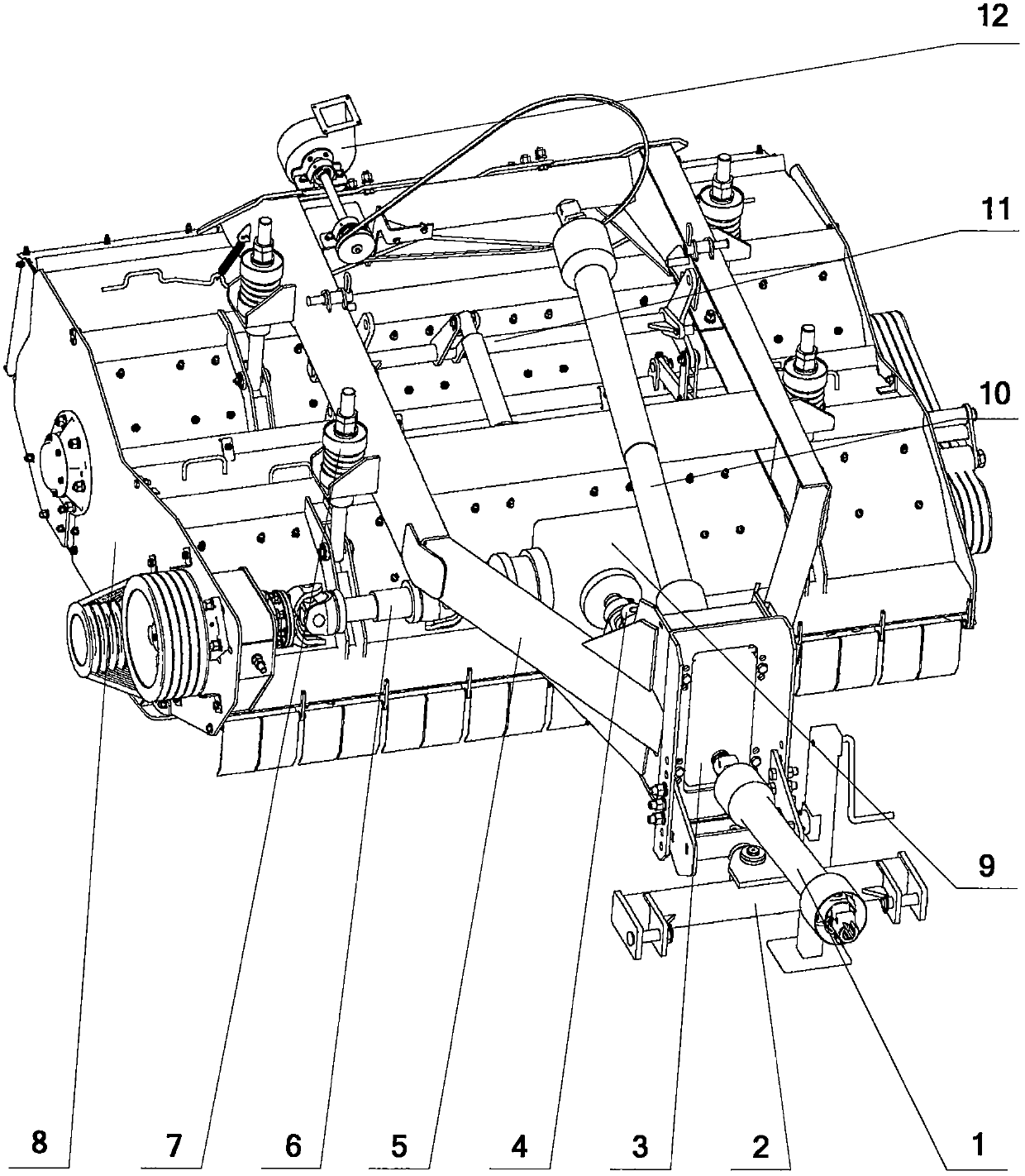

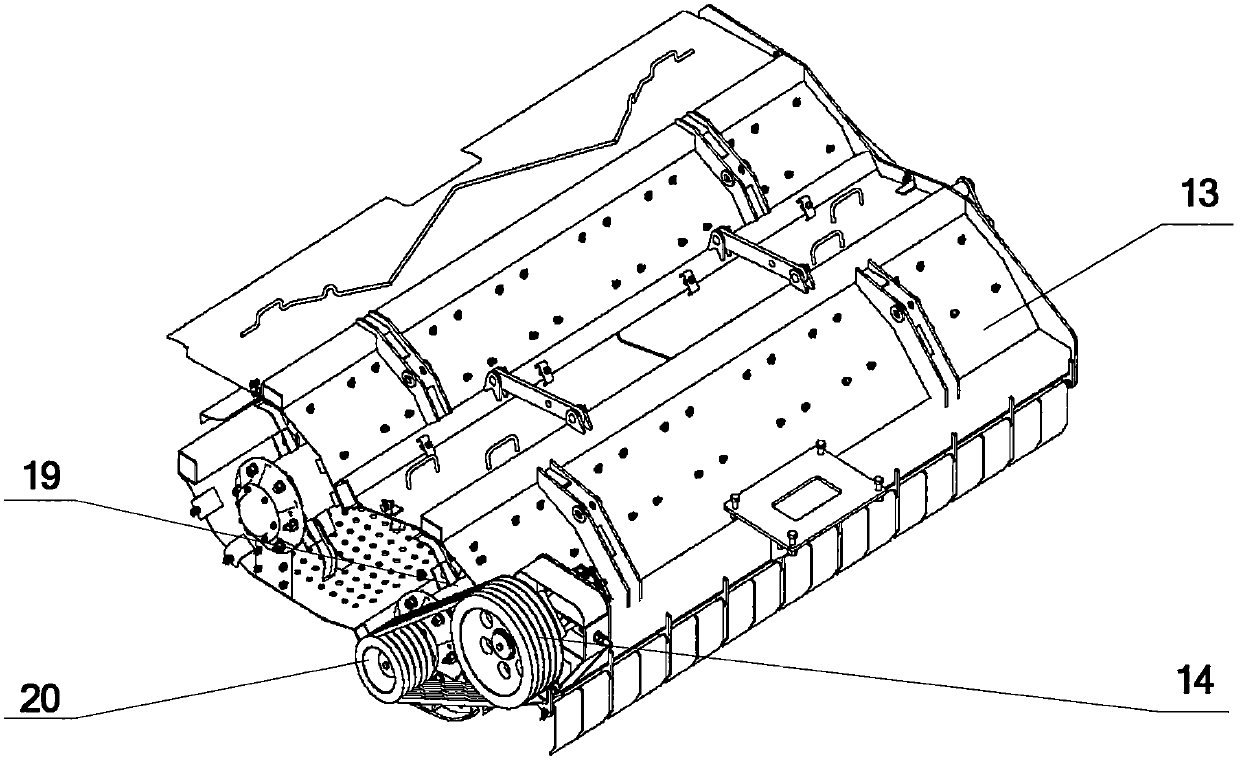

ActiveCN106508314BImprove cutting and crushing effectTo promote floatingCuttersEngineeringAnimal husbandry

The invention is a cutting and crumbling device with double knife shaft for replacing a binder pickup, which belongs to the technical field of agriculture and animal husbandry machinery and is mainly used in cutting and harvesting work of corn straws and other crop straws which stand and scatter in the farm. The device finishes cutting, crumbling collecting and other work of crop straws through a transmission part, a double knife shaft, a rack and a floating device working.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI

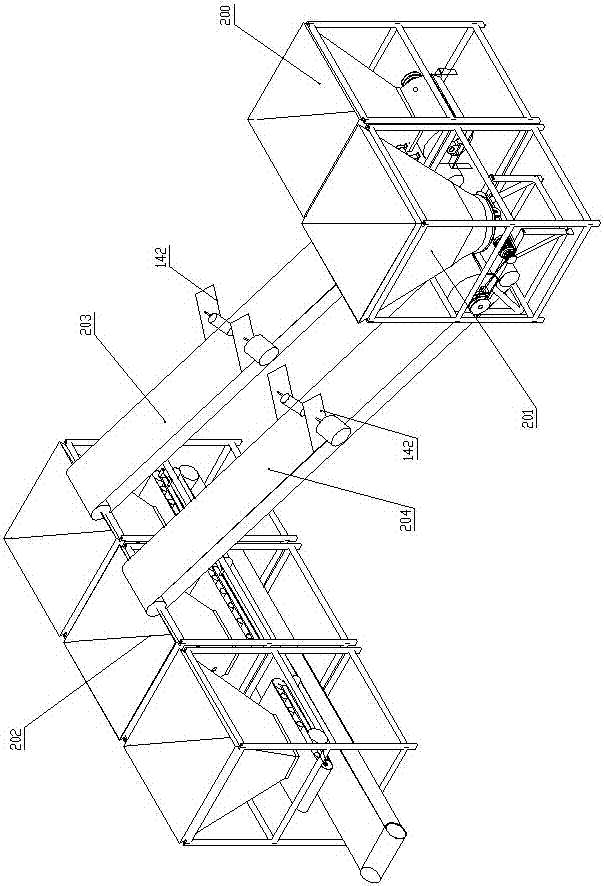

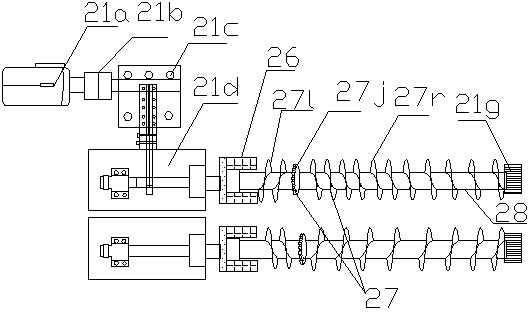

Material crushing and conveying mixing and proportioning device for lid replacement and filling engineering

ActiveCN105709892BImprove cutting and crushing effectPrevent overflowMagnetic separationGrain treatmentsEngineeringCoir

Material crushing and conveying mixing and proportioning device for LID soil replacement project, including coconut peat block crushing system, soil block crushing system and batching system. machine, the soil block crushing system includes a second feeding device and a soil block crushing machine, and the batching system includes a third feeding device and a material volume control device. The invention has high degree of automation and reliable operation. Coconut chaff block and soil block are respectively cut and crushed by coconut chaff block crushing system and soil block crushing system, so that the material crushing effect is good, and the crushing efficiency is high. Make adjustments to avoid material blockage, make the material mixing ratio even through the proportioning system, adopt the iron filings adsorption device, which can absorb the iron filings mixed in the material, and use the third feeding device to avoid the accumulation of coconut peat blocks, making the work more stable. Improved work efficiency.

Owner:河南省交通建设工程有限公司

High-temperature four-axis spiral crushing device for animal hazard-free treatment

PendingCN108592036AAvoid affecting cutting efficiencyImprove cutting and crushing effectIncinerator apparatusCombustion chamberPull force

The invention discloses a high-temperature four-axis spiral crushing device for animal hazard-free treatment. The high-temperature four-axis spiral crushing device comprises an inclined feeding device, a crushing device, a primary combustion chamber, a secondary combustion chamber flame channel, an inclined fire grate, and an ash discharge funnel, wherein the crushing device is arranged above theinclined fire gate in the primary combustion chamber; the primary combustion chamber is connected with a secondary combustion chamber through a flame channel; the ash discharge funnel is arranged at the lower end of the secondary combustion chamber; the crushing device comprises a primary crushing room and a side room; the primary crushing room is connected with the side door through a ventilatingduct; the side room provides sufficient oxygen gas to the primary room through the ventilating duct; an upper helix I, an upper helix II, a lower helix I and a lower helix II are arranged in the maincrushing room; a distance between the upper helix I and the upper helix II is greater than that between the lower helix I and the lower helix II; and a plurality of combustion guns are arranged on the side wall. In a cutting process, dead animal bodies bear transverse shearing force and longitudinal pulling force, so that the cutting process is a secondary cutting process for cutting coarse deadanimal bodies into fine dead animal bodies; and moreover, combusting and heating are performed while cutting is performed, so that cutting and crushing effects are good, and efficiency is good.

Owner:山东世纪阳光科技有限公司

Extrusion cutting device

PendingCN112549100AAvoid big discountsIncrease brushing powerSevering textilesMetal working apparatusElectric machineryEngineering

The invention belongs to the technical field of mechanical cutting devices, and particularly relates to an extrusion cutting device. The extrusion cutting device comprises a main body, rotating pipesand cutting mechanisms, wherein the rotating pipes are rotationally connected into the upper end wall of the main body; the two rotating pipes are arranged in parallel; the left ends of the rotating pipes are rotationally connected with a motor in the left side of the main body; and the cutting mechanisms are arranged at the outer ends of the rotating pipes. When cutting is completed and cutting knives return into rubber pipes, No. 1 air bags lose the negative pressure state, namely the No. 1 air bags extrude brushes outwards, the brushes make contact with the two side wall faces of the cutting knives to rub and scrap away cotton wool adhering to the outer surfaces of the brushes, meanwhile the cutting knives rub the wall faces of the rubber pipes when the cutting knives return into the rubber pipes, and the outer walls of the rubber pipes are slightly sunken inwards when the cutting knives return into the rubber pipes, so that the radians of the brushes and the surfaces of the cuttingknives can be changed into vertical angles gradually, the brushing strength of the brushes is indirectly improved, and the cleaning effect is further improved.

Owner:王俊

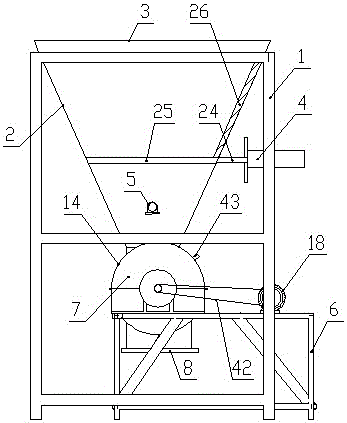

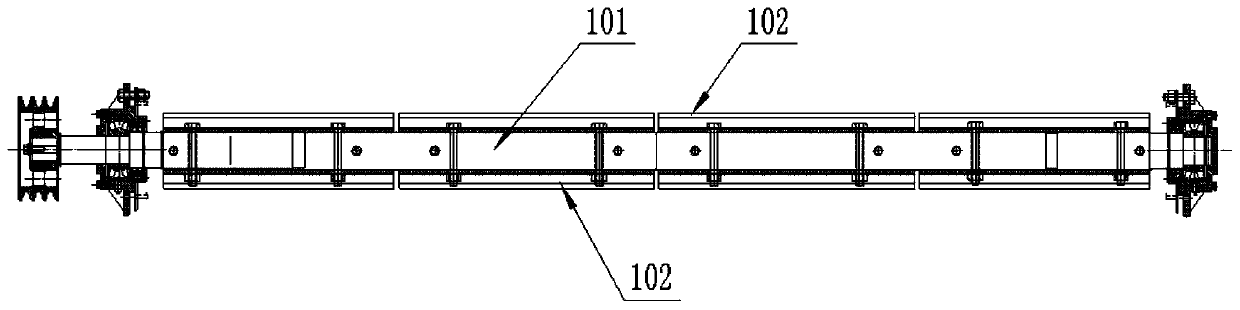

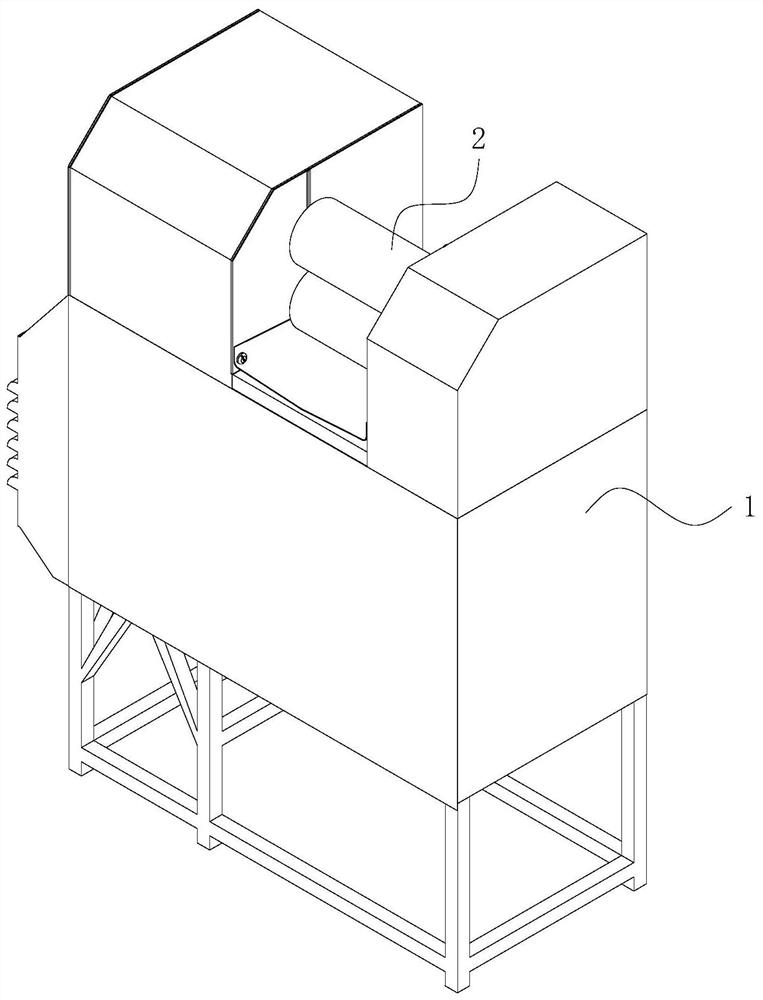

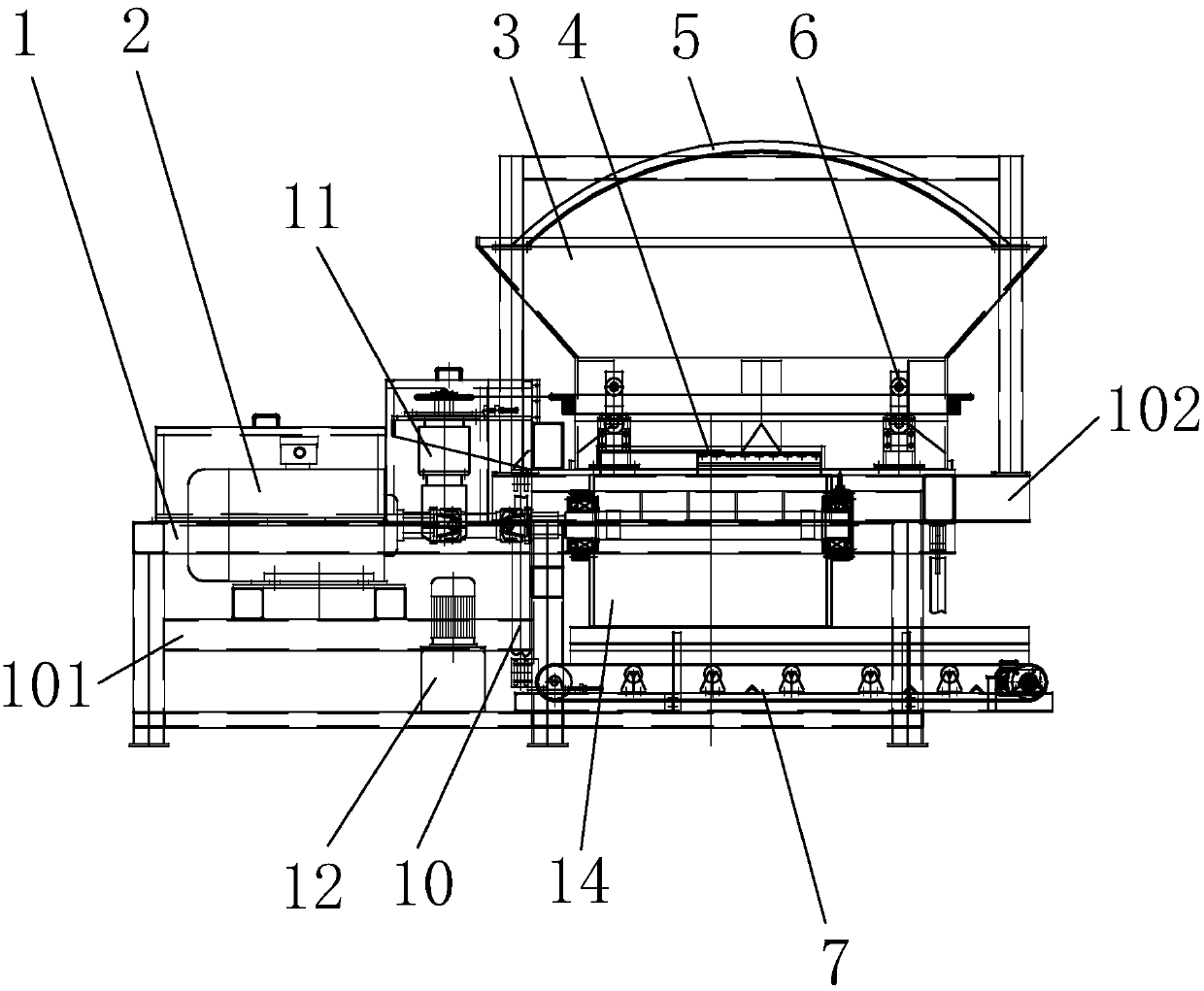

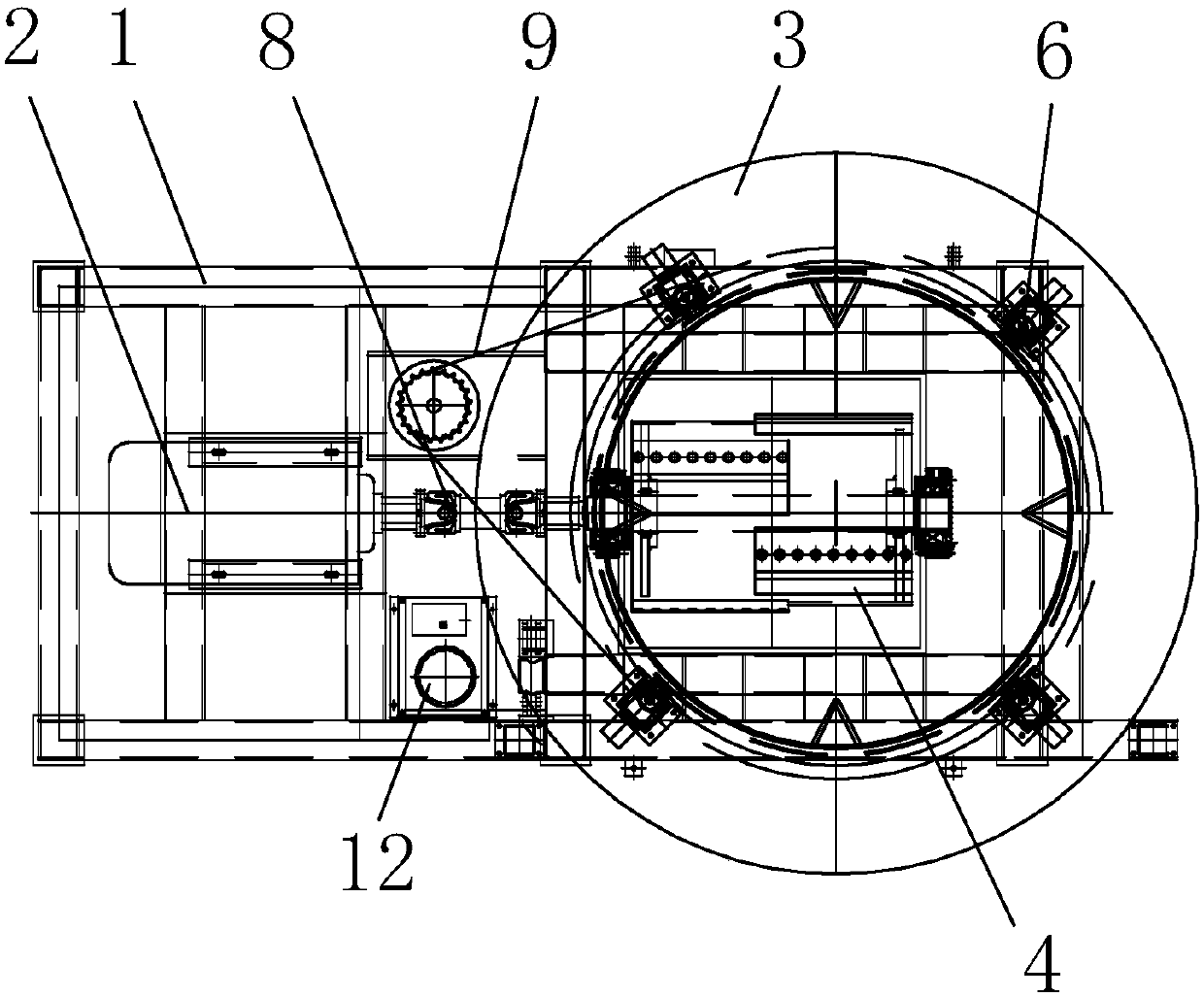

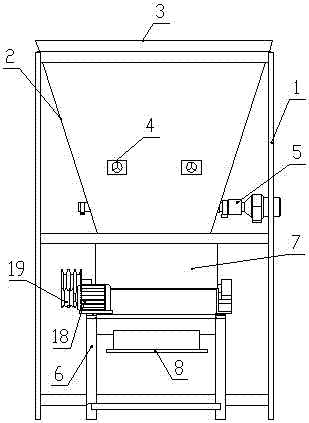

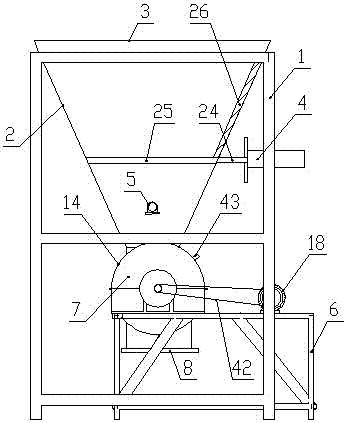

Pulverizer

PendingCN110523492AConvenient chip crushingReliable chip crushingWood working apparatusGrain treatmentsSpeed reductionPulverizer

The invention relates to a pulverizer which is mainly used for pulverizing the materials, such as the stumps, etc., through a rotating knife roll assembly. The technical scheme is that the pulverizercomprises a rack (1), a speed reduction main motor (2), a feeding assembly (3), the knife roll assembly (4) and a speed reduction auxiliary motor (11), and the speed reduction main motor (2) drives the knife roll assembly (4) to rotate. The pulverizer is characterized in that the feeding assembly (3) comprises a conical cylinder (301), a cylinder (302) and a material guide plate (303), the conicalcylinder (301) is fixedly connected with the cylinder (302), and the inner side of the cylinder (302) is fixedly connected with the material guide plate (303), and the speed reduction auxiliary motor(11) drives the feeding assembly (3) to rotate. After the technical scheme is adopted, the pulverizing effect is improved.

Owner:江苏保龙机电制造有限公司

Homogeneous mixing equipment for lid soil replacement engineering materials

ActiveCN105709893BImprove cutting and crushing effectPrevent overflowMagnetic separationGrain treatmentsScreening effectAutomation

LID soil replacement engineering material uniform mixing equipment, including coconut peat block crushing system, soil block crushing system, batching system and screening system. The invention has high degree of automation and reliable operation. Coconut chaff block and soil block are respectively cut and crushed by coconut chaff block crushing system and soil block crushing system, so that the material crushing effect is good, and the crushing efficiency is high. Make adjustments to avoid material blockage, make the material mixing ratio even through the proportioning system, adopt the iron filings adsorption device, which can absorb the iron filings mixed in the material, and use the third feeding device to avoid the accumulation of coconut peat blocks, making the work more stable. During the screening process, the materials with the required particle size are screened out through the screening outlet, and the materials with large particles are discharged through the material guide box for reuse. The screening effect is good and the work efficiency is improved.

Owner:河南省交通建设工程有限公司

Dessert processing device

ActiveCN112656251AIncrease finenessImprove cutting and crushing effectKitchen equipmentCheese manufactureMetallic materialsEngineering

The invention belongs to the technical field of dessert processing devices, and particularly relates to a dessert processing device which comprises a machine body, a processing cavity, a motor and a stirring mechanism. The processing cavity is fixedly formed in the upper surface of the front end of the machine body; the cross section of the processing cavity is U-shaped, and the stirring mechanism is arranged in the processing cavity; the stirring mechanism comprises stirring rods, a hinge plate, a filter screen, a rotating plate, a cutting block, a pushing block, a pull rope and a dislocation plate; the stirring rods are arranged to be in an arc shape at the beginning, the multiple stirring rods are arranged circumferentially, and the stirring rods are made of elastic memory metal materials; and when the hinge plate is reset, a part of cheese is driven to pass through gaps between the cutting block and the stirring rods, and the outer end of the cutting block instantly cuts the cheese passing through the gaps under the reset effect of the hinge plate, so that particles mixed in the cheese can be cut, the particles are crushed, and a better stirring effect is achieved.

Owner:安徽京创食品有限公司

Cutting and crumbling device with double knife shaft

ActiveCN106508314AImprove cutting and crushing effectTo promote floatingCuttersEngineeringAnimal husbandry

The invention is a cutting and crumbling device with double knife shaft for replacing a binder pickup, which belongs to the technical field of agriculture and animal husbandry machinery and is mainly used in cutting and harvesting work of corn straws and other crop straws which stand and scatter in the farm. The device finishes cutting, crumbling collecting and other work of crop straws through a transmission part, a double knife shaft, a rack and a floating device working.

Owner:HUHHOT BRANCH OF CHINESE ACAD OF AGRI MECHANIZATION SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com