Feed scattering device for aquaculture

A material spreading device and aquaculture technology, applied in the field of material spreading device, can solve the problems of long time consumption, lower survival rate of aquaculture, increased cost and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

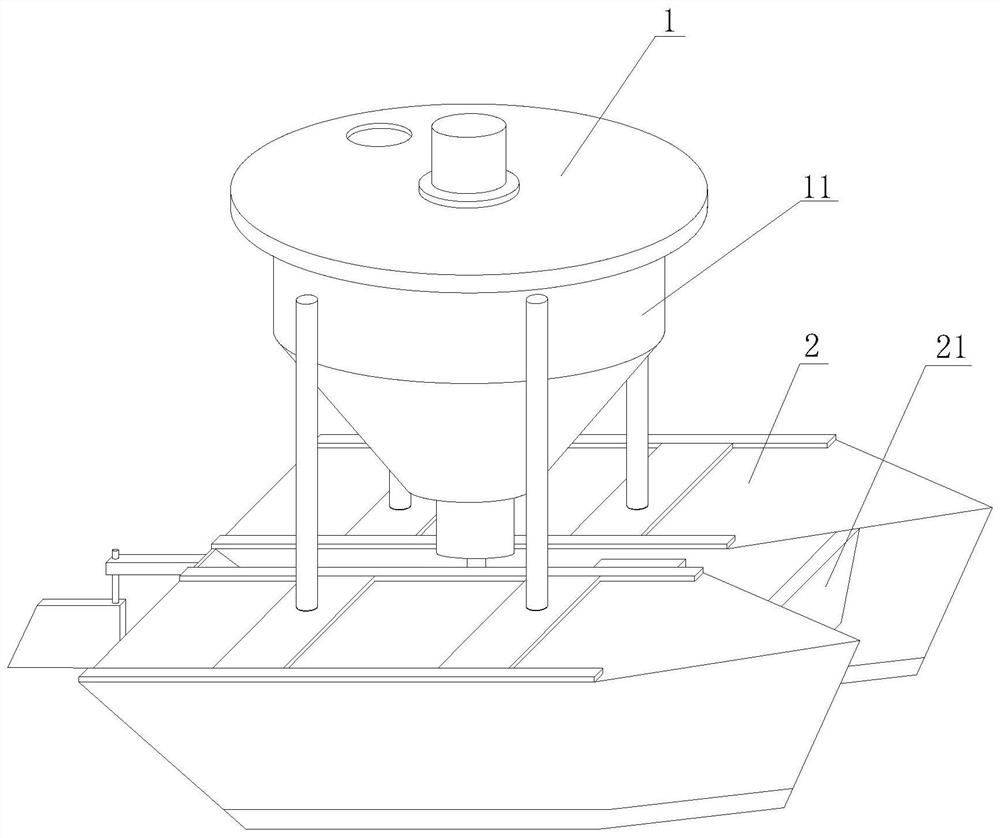

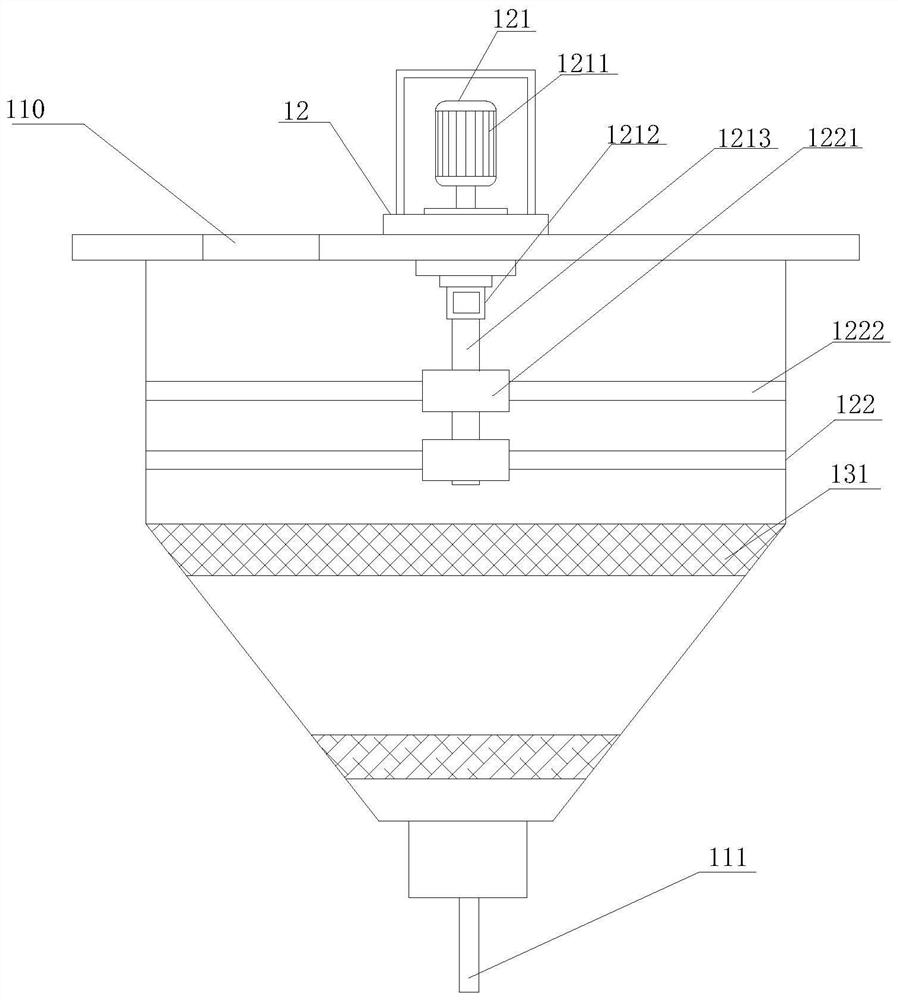

[0044] Such as Figure 1-8As shown, the present invention provides a feed spreading device for aquaculture, comprising a spreading equipment main body 1 and a moving hull 2, a feeding box 11 is fixedly installed on the top of the feeding equipment main body 1, and a feeding box 11 is provided on the top of the feeding box 11. Port 110, the bottom of the feed box 11 is fixedly connected with a discharge pipe 111, the bottom of the material spreading equipment main body 1 is fixedly connected with a mobile hull 2, the side of the mobile hull 2 is fixedly equipped with a mobile device 21, and the inside of the feed box 11 is fixedly installed with Stirring device 12, the bottom of stirring device 12 is fixedly installed with sterilizing device 13, the top of stirring device 12 is fixedly installed with rotating device 121, the bottom of rotating device 121 is fixedly installed with cutting device 122, and the top of sterilizing device 13 is fixedly installed with filtering devic...

Embodiment 2

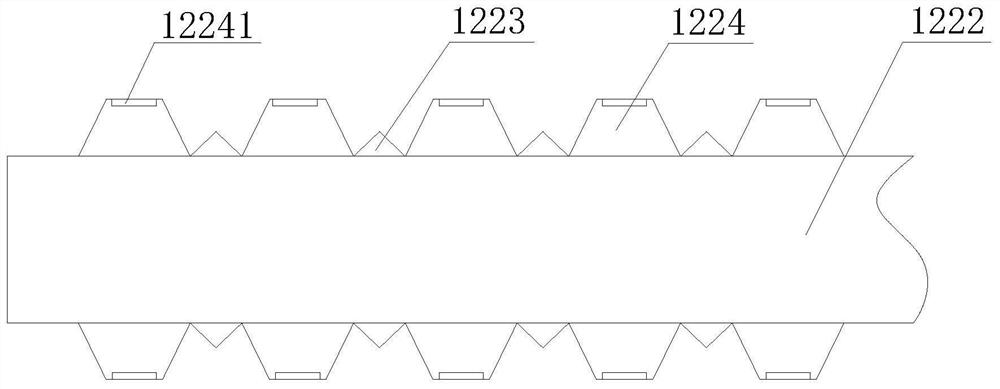

[0047] Such as Figure 1-8 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: preferably, the surface of stirring blade 1222 is fixedly installed with cutting blade 1223, and the side of cutting blade 1223 is fixedly installed with elastic blade 1224, and elastic blade 1224- The top of the side is fixedly equipped with a sheet 12241, the bottom of the sheet 12241 is fixedly installed with a push block 12242, the bottom of the push block 12242 is fixedly installed with a fixed plate 122421, the bottom of the fixed plate 122421 is provided with a fixed groove 122422, and the inner wall of the fixed groove 122422 is movable. Connected with telescopic column 12243, the bottom of telescopic column 12243 is fixedly sleeved with elastic spring 12244, and the bottom of elastic spring 12244 is fixedly connected with fixed base plate 12245, and the bottom of fixed base plate 12245 is fixedly connected on the inner wall of elastic blade 1224, a...

Embodiment 3

[0050] Such as Figure 1-8 Shown, on the basis of embodiment 1, the present invention provides a kind of technical proposal: preferably, the outer side of filtering device 131 is fixedly installed with filter casing 1311, and the inner wall of filter casing 1311 is fixedly installed with filter screen 1312, and filter screen 1312 A filter iron sheet 13121 is fixedly installed inside, and a filter hole 13122 is provided on the surface of the filter iron sheet 13121. An ultraviolet lamp 1321 is fixedly installed inside the sterilization device 132, and a reflective lens 1322 is fixedly installed on the outside of the ultraviolet lamp 1321. Both sides of the tube 1321 are fixedly equipped with a power box 1323, and the side of the power box 1323 away from the ultraviolet lamp 1321 is fixedly connected with a plasma generator 1324, and the inside of the plasma generator 1324 is fixedly equipped with a release electronic network 1325.

[0051] In this embodiment, the larger feed is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com