Energy-saving and environment-friendly plastic residual film recovery machine

An energy-saving and environmental-friendly recycling machine technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems such as low efficiency, failure to achieve separation, labor and time-consuming, etc., to improve recycling efficiency, increase collision rate, The effect of improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

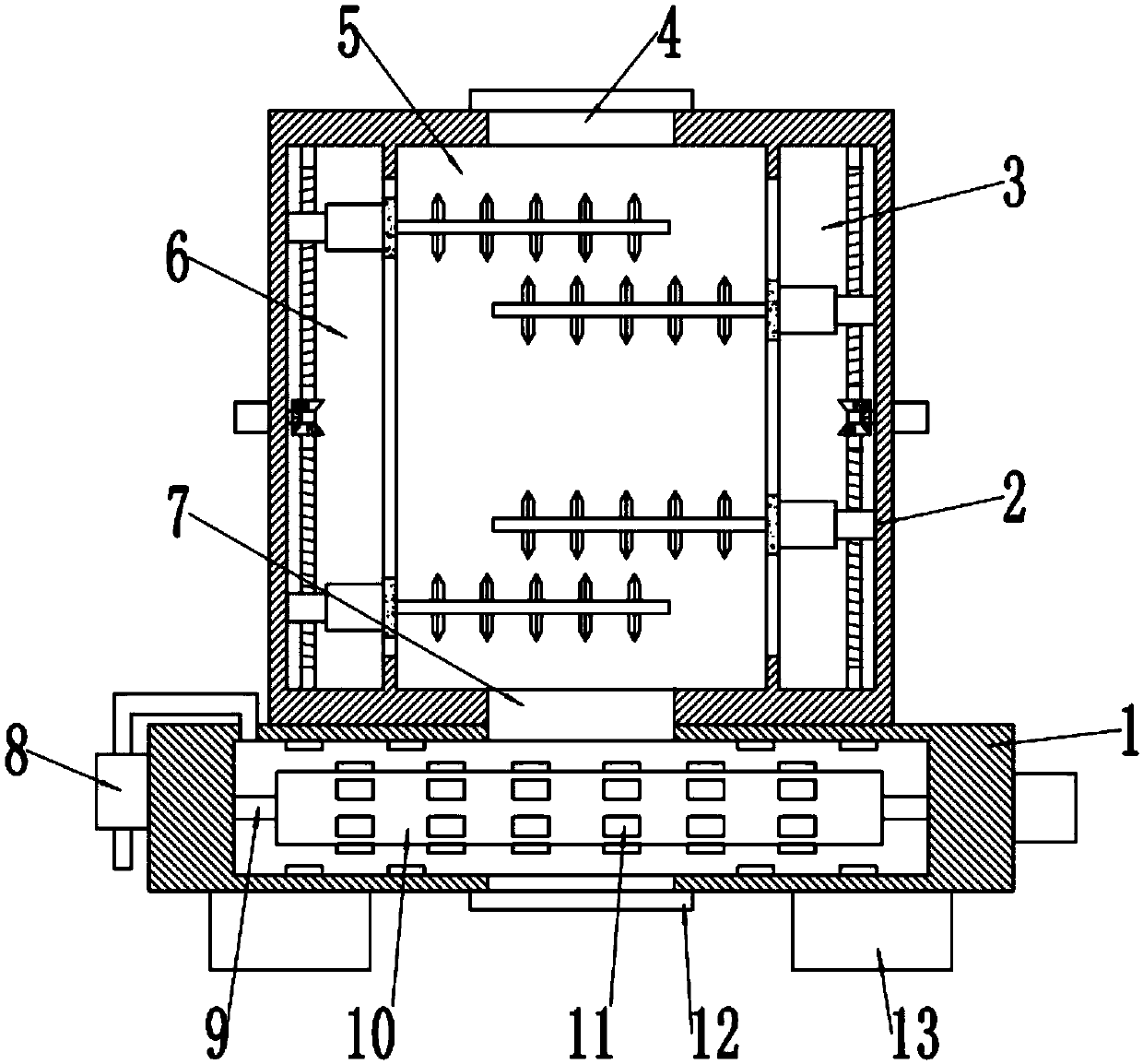

[0027] see Figure 1~4 , in the embodiment of the present invention, an energy-saving and environment-friendly plastic residual film recycling machine includes a cleaning box 1 and a crushing box 2; legs 13 are fixedly installed at the four corners of the bottom of the cleaning box 1, and the crushing box 2 is fixed Installed on the cleaning box 1, the top of the crushing box 2 is provided with a feed port 4 for the addition of materials to be recycled, and the bottom of the crushing box 2 is connected to the cleaning box 1 through the feeding port 7, so that the crushed materials can be added to the cleaning box 1 The inside of the cleaning box 1 is cleaned, and the bottom of the cleaning box 1 is provided with a discharge port 12 for the discharge of the cleaned material;

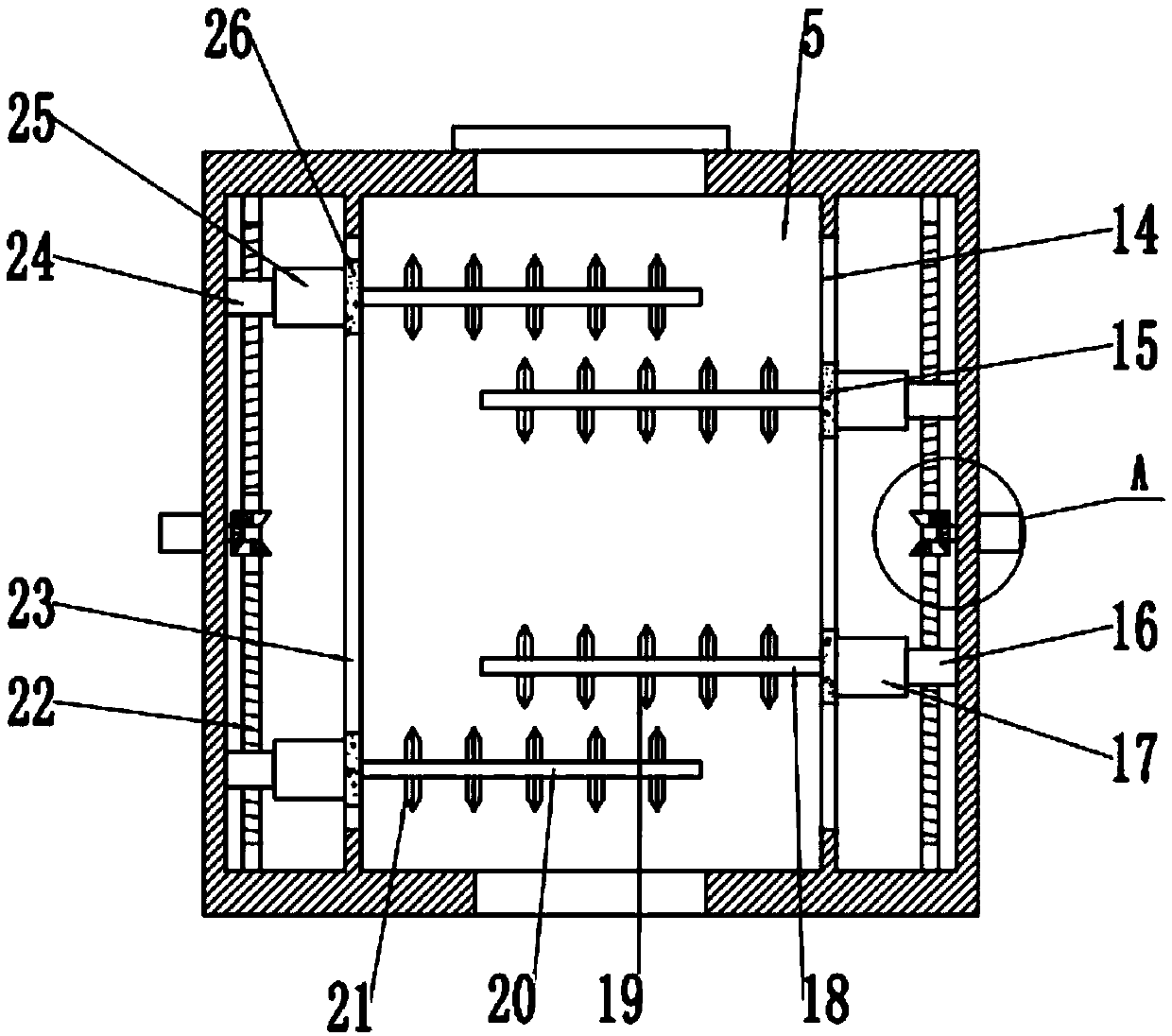

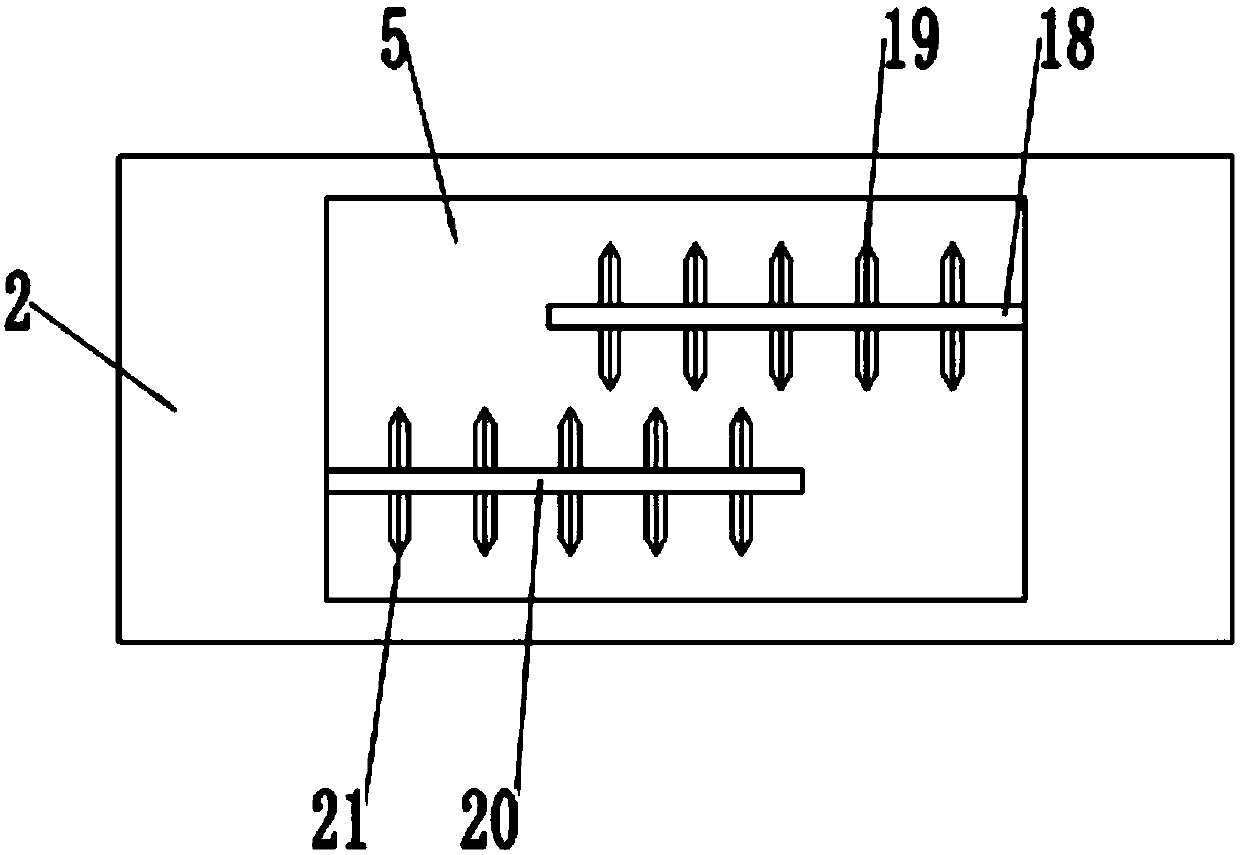

[0028] The inside of described crushing box 2 is left and right symmetrically fixedly installed with left dividing plate 23 and right dividing plate 14, and left dividing plate 23 and right dividing plate...

Embodiment 2

[0032] see Figure 1~4, in the embodiment of the present invention, an energy-saving and environment-friendly plastic residual film recycling machine includes a cleaning box 1 and a crushing box 2; legs 13 are fixedly installed at the four corners of the bottom of the cleaning box 1, and the crushing box 2 is fixed Installed on the cleaning box 1, the top of the crushing box 2 is provided with a feed port 4 for the addition of materials to be recycled, and the bottom of the crushing box 2 is connected to the cleaning box 1 through the feeding port 7, so that the crushed materials can be added to the cleaning box 1 The inside of the cleaning box 1 is cleaned, and the bottom of the cleaning box 1 is provided with a discharge port 12 for the discharge of the cleaned material;

[0033] The inside of described crushing box 2 is left and right symmetrically fixedly installed with left dividing plate 23 and right dividing plate 14, and left dividing plate 23 and right dividing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com