Extrusion cutting device

A cutting device, cutting knife technology, applied in textile and papermaking, metal processing, cutting of textile materials, etc., can solve the problems of cutting efficiency discount, increased frequency of blade replacement, rust and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

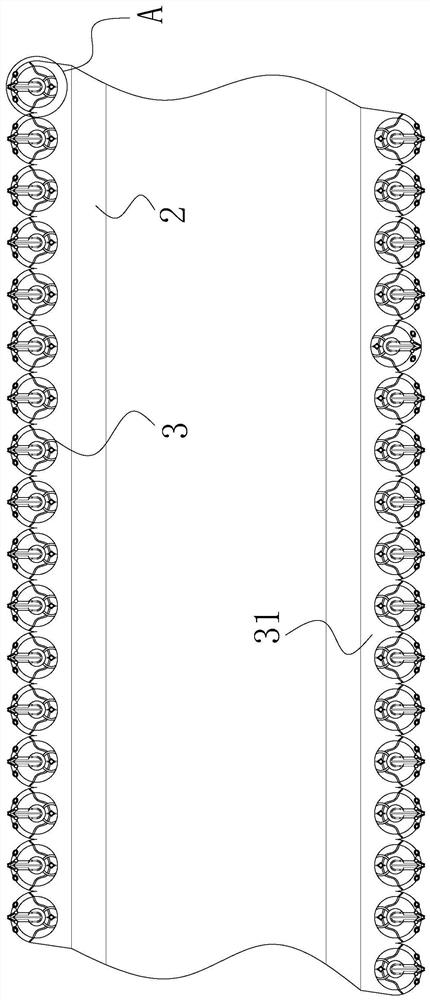

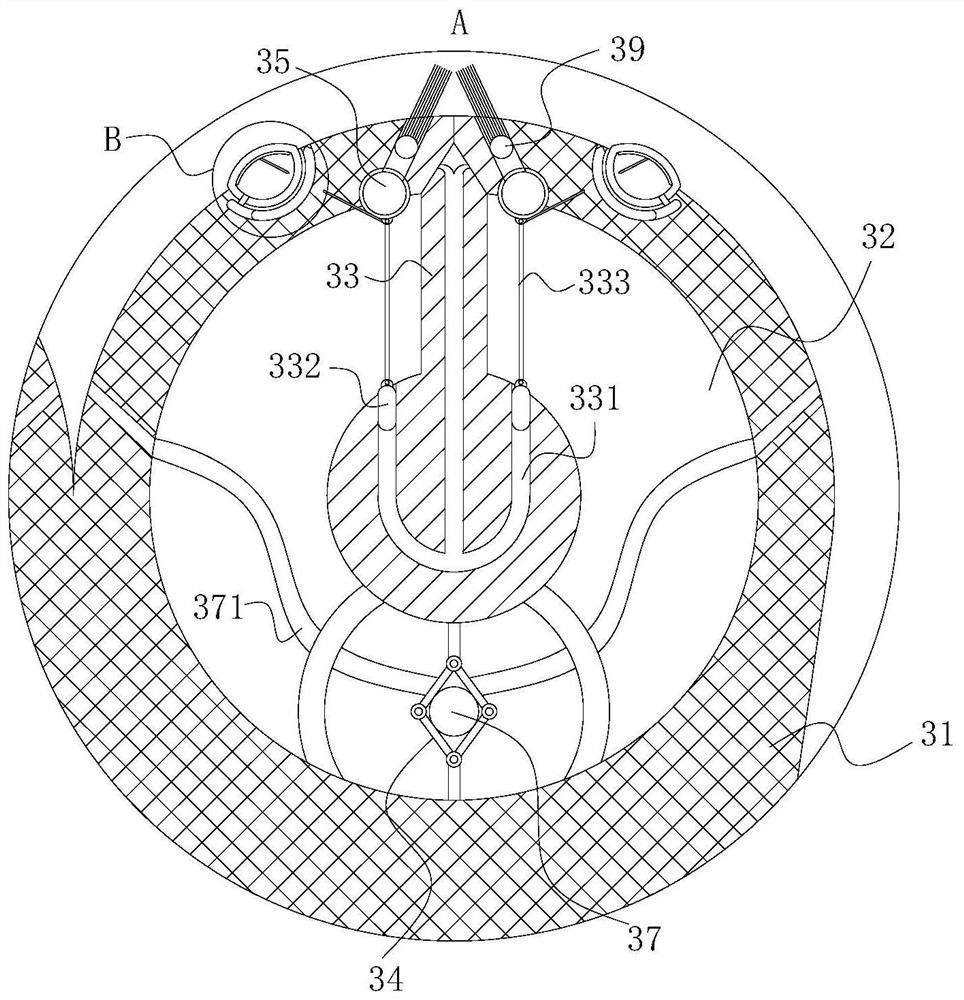

[0018] use Figure 1-Figure 4 An extrusion cutting device according to one embodiment of the present invention will be described below.

[0019] Such as Figure 1-Figure 4 As shown, an extrusion cutting device according to the present invention includes a main body 1, a rotating tube 2 and a cutting mechanism 3; the upper end wall of the main body 1 is rotatably connected with a rotating tube 2; the rotating tube 2 is provided with two Two rotating tubes 2 are arranged in parallel, the left end of the rotating tube 2 is connected to the left internal motor of the main body 1, and the outer end of the rotating tube 2 is provided with a cutting mechanism 3; the cutting mechanism 3 includes a rubber tube 31 , installation cavity 32, cutting knife 33, articulated frame 34, No. 1 airbag 35, No. 2 airbag 36, No. 3 airbag 37, curved needle 38 and hairbrush 39; , the outer surface of the rubber tube 31 is set in a spiral shape, and an installation cavity 32 is provided in the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com