Preparation method of high-sphericity ternary precursor seed crystal and method for preparing high-sphericity ternary precursor by using seed crystal

A high sphericity, precursor technology, applied in chemical instruments and methods, electrical components, inorganic chemistry, etc., can solve the problems of uneven tap density, obtain the desired product, and long product production cycle, and avoid major discounts. , The effect of ensuring early delivery and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

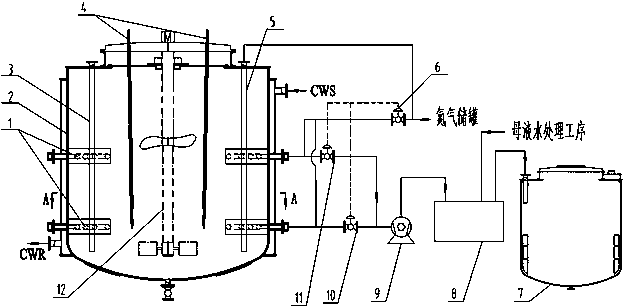

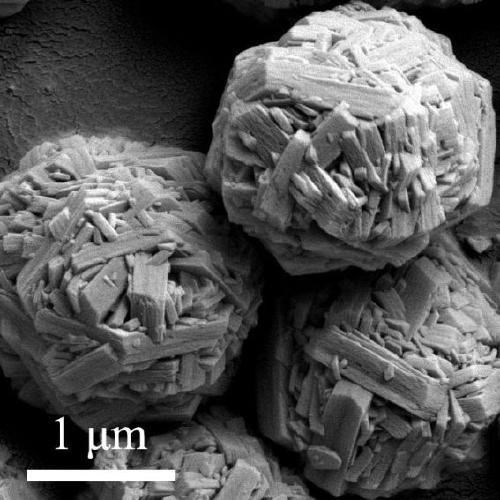

[0049] The chemical formula is Ni 0.8 co 0.1 mn 0.1 (OH) 2 1. A method for preparing a high-sphericity ternary precursor crystal seed with a particle size less than 2.5 μm, the steps are as follows:

[0050] Step 1, according to the molar ratio of nickel, cobalt and manganese in the required high sphericity ternary precursor crystal seed 8:1:1, select nickel, cobalt, manganese sulfate as raw material and pure water to prepare the total concentration of metal ions as 2.0mol / L mixed salt solution;

[0051] Step 2, preparation concentration is the sodium hydroxide solution of 6.0mol / L;

[0052] Step 3, preparation concentration is the ammoniacal liquor of 10.0mol / L as complexing agent;

[0053] Step 4, open the jacket of the seed crystal reactor to feed water and return water, and pass nitrogen into the seed crystal reactor for atmosphere protection, and maintain nitrogen protection during the entire reaction process;

[0054] Step 5, add pure water to the seed crystal reac...

Embodiment 2

[0074] The chemical formula is Ni 0.6 co 0.2 mn 0.2 (OH) 2 1. A method for preparing a high-sphericity ternary precursor crystal seed with a particle size less than 1.6 μm, the steps are as follows:

[0075] Step 1, according to the molar ratio of nickel, cobalt and manganese in the required high sphericity ternary precursor crystal seed 6:2:2, select nickel, cobalt, manganese sulfate as raw material and pure water to prepare the total concentration of metal ions as 2.0mol / L mixed salt solution;

[0076] Step 2, preparation concentration is the sodium hydroxide solution of 10.0mol / L;

[0077] Step 3, preparation concentration is the ammoniacal liquor of 10.0mol / L as complexing agent;

[0078] Step 4, open the jacket of the seed crystal reactor to feed water and return water, and pass nitrogen into the seed crystal reactor for atmosphere protection, and maintain nitrogen protection during the entire reaction process;

[0079]Step 5, add pure water to the seed crystal reac...

Embodiment 3

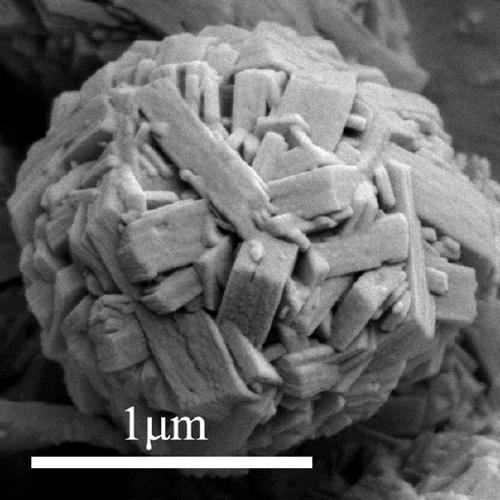

[0099] The chemical formula is Ni 0.9 co 0.05 mn 0.05 (OH) 2 1. A method for preparing a high-sphericity ternary precursor crystal seed with a particle size less than 1.2 μm, the steps are as follows:

[0100] Step 1, according to the molar ratio of nickel, cobalt and manganese in the required high sphericity ternary precursor crystal seed 9:0.5:0.5, select nickel, cobalt, manganese sulfate as raw material and pure water to prepare the total concentration of metal ions as 2.0mol / L mixed salt solution;

[0101] Step 2, preparation concentration is the sodium hydroxide solution of 5.0mol / L;

[0102] Step 3, preparation concentration is the ammoniacal liquor of 7.0mol / L as complexing agent;

[0103] Step 4, open the jacket of the seed crystal reactor to feed water and return water, and pass nitrogen into the seed crystal reactor for atmosphere protection, and maintain nitrogen protection during the entire reaction process;

[0104] Step 5, add pure water to the seed crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com