Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "High electromechanical coupling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

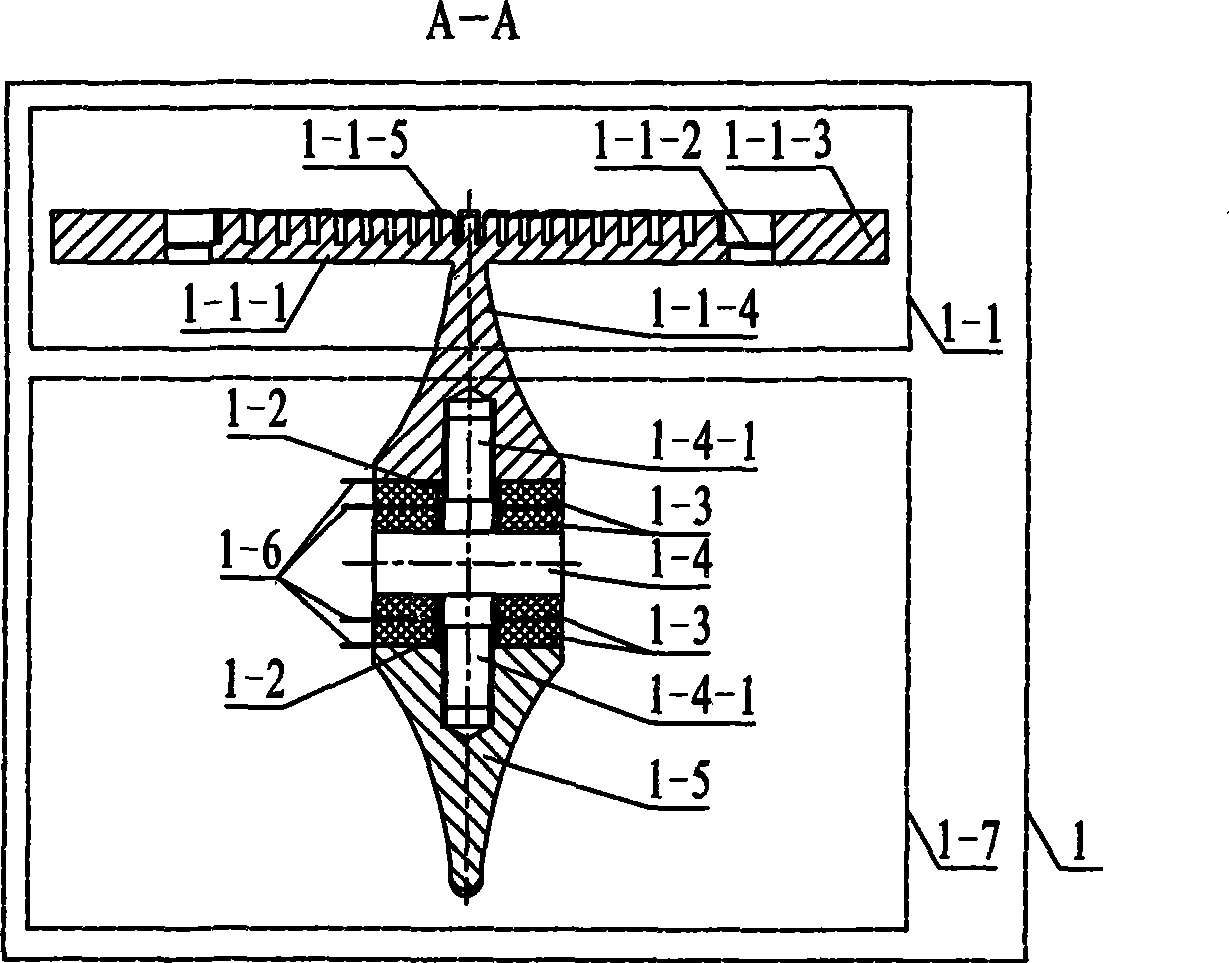

Vibrator of beam type linear ultrasonic motor using bending vibration modes

ActiveCN101626203AImprove mechanical output capabilityImprove performancePiezoelectric/electrostriction/magnetostriction machinesEngineeringControl theory

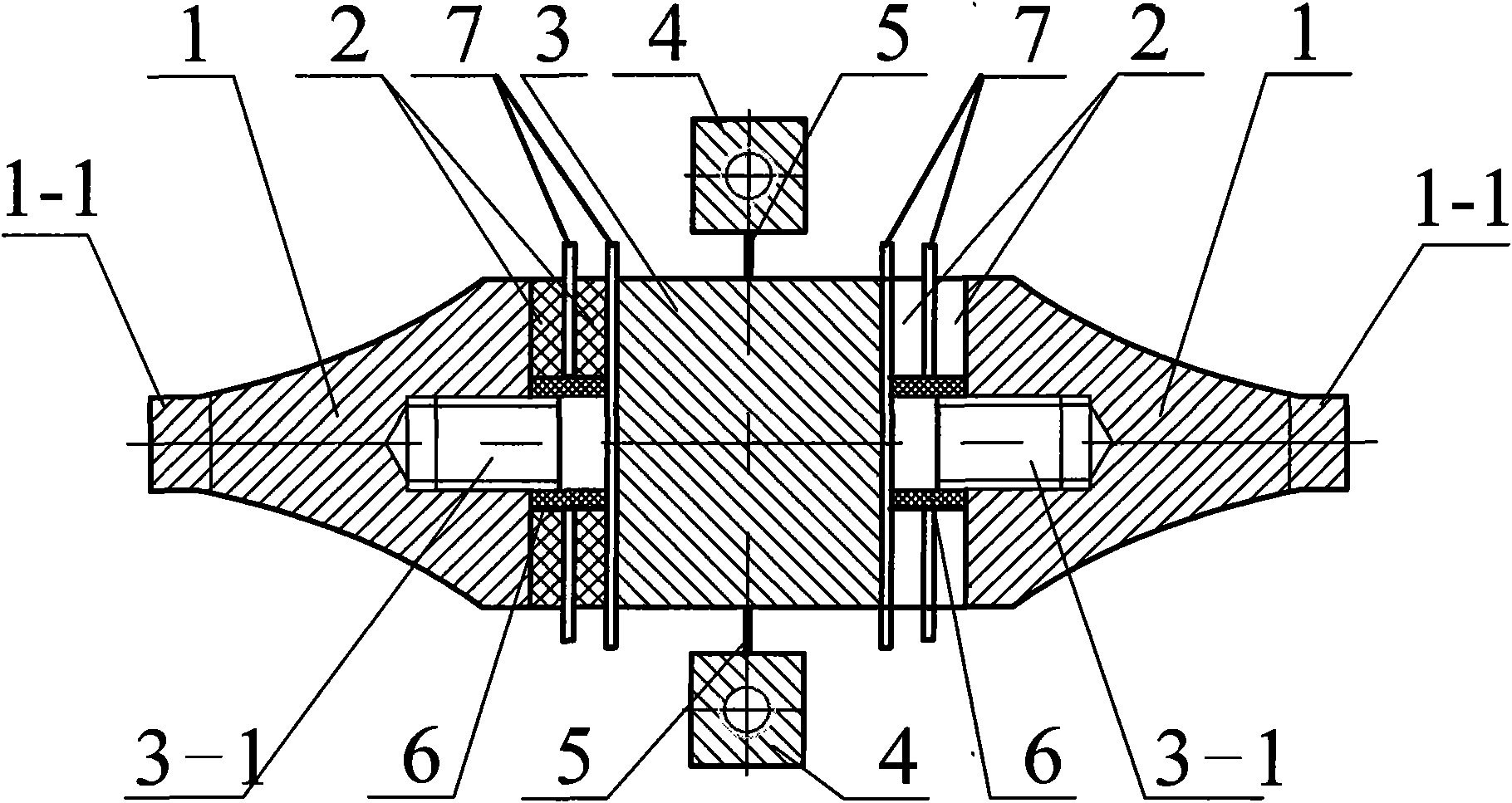

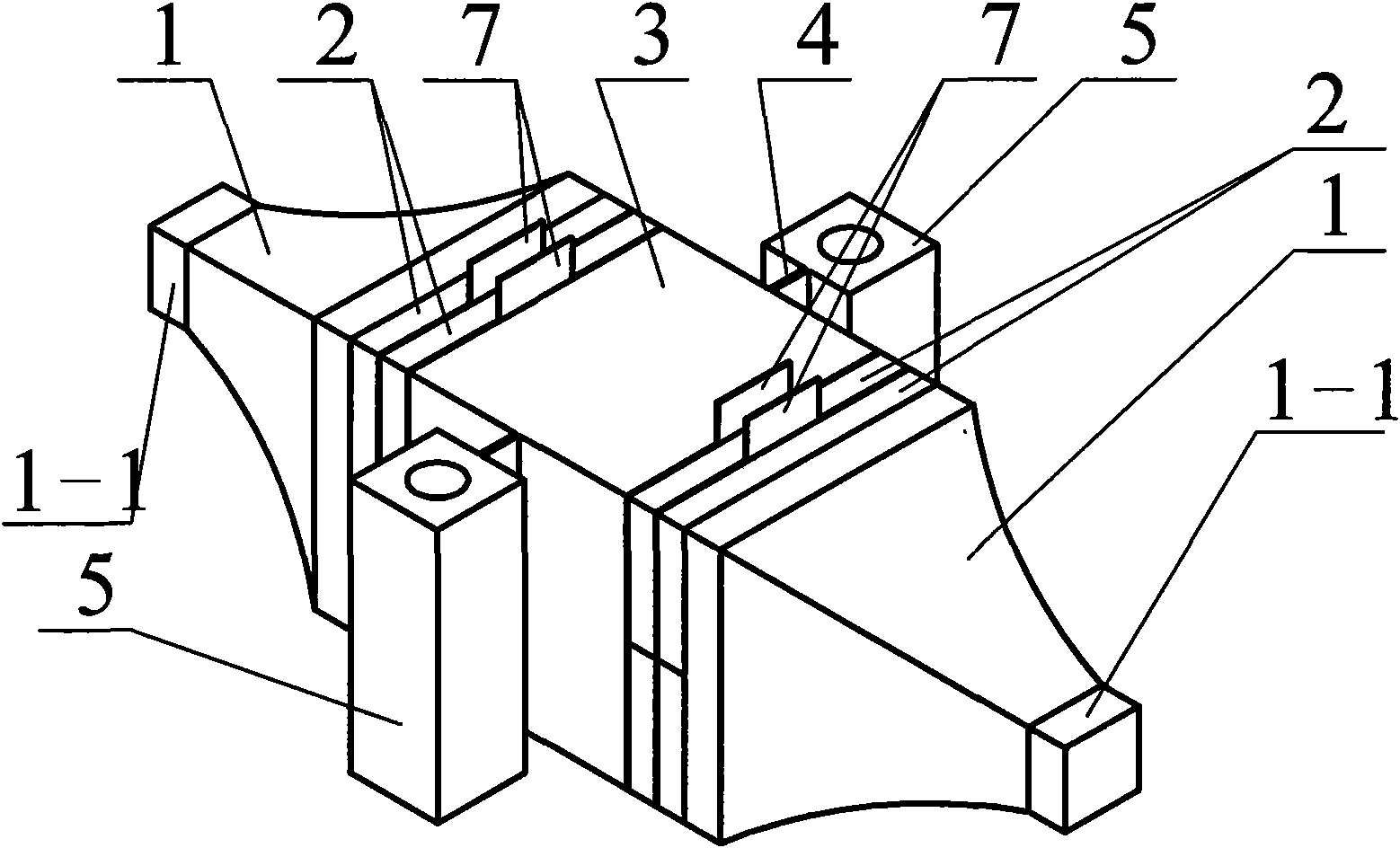

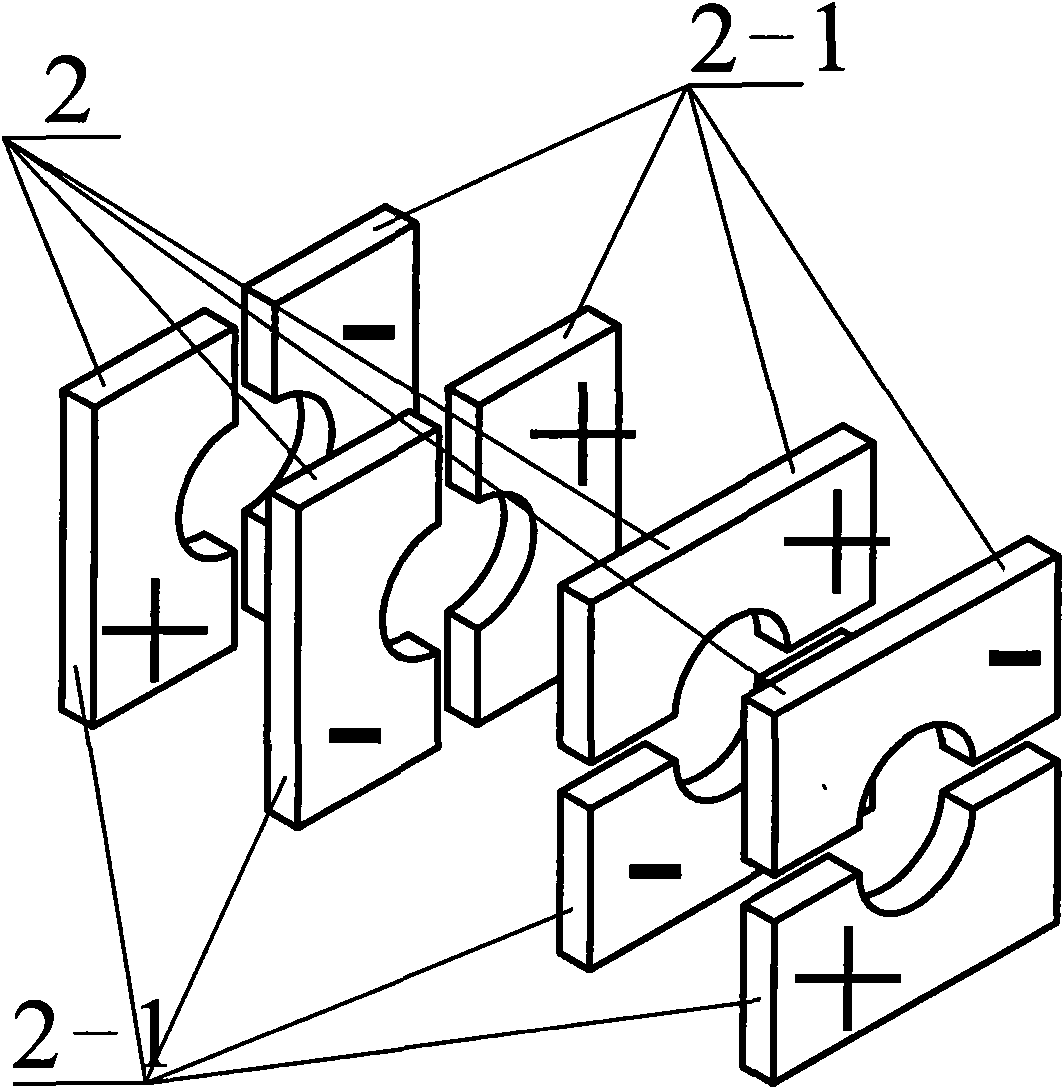

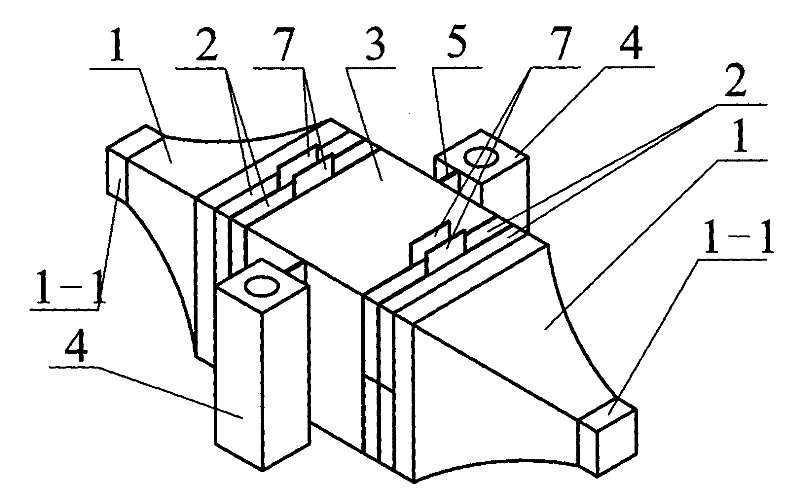

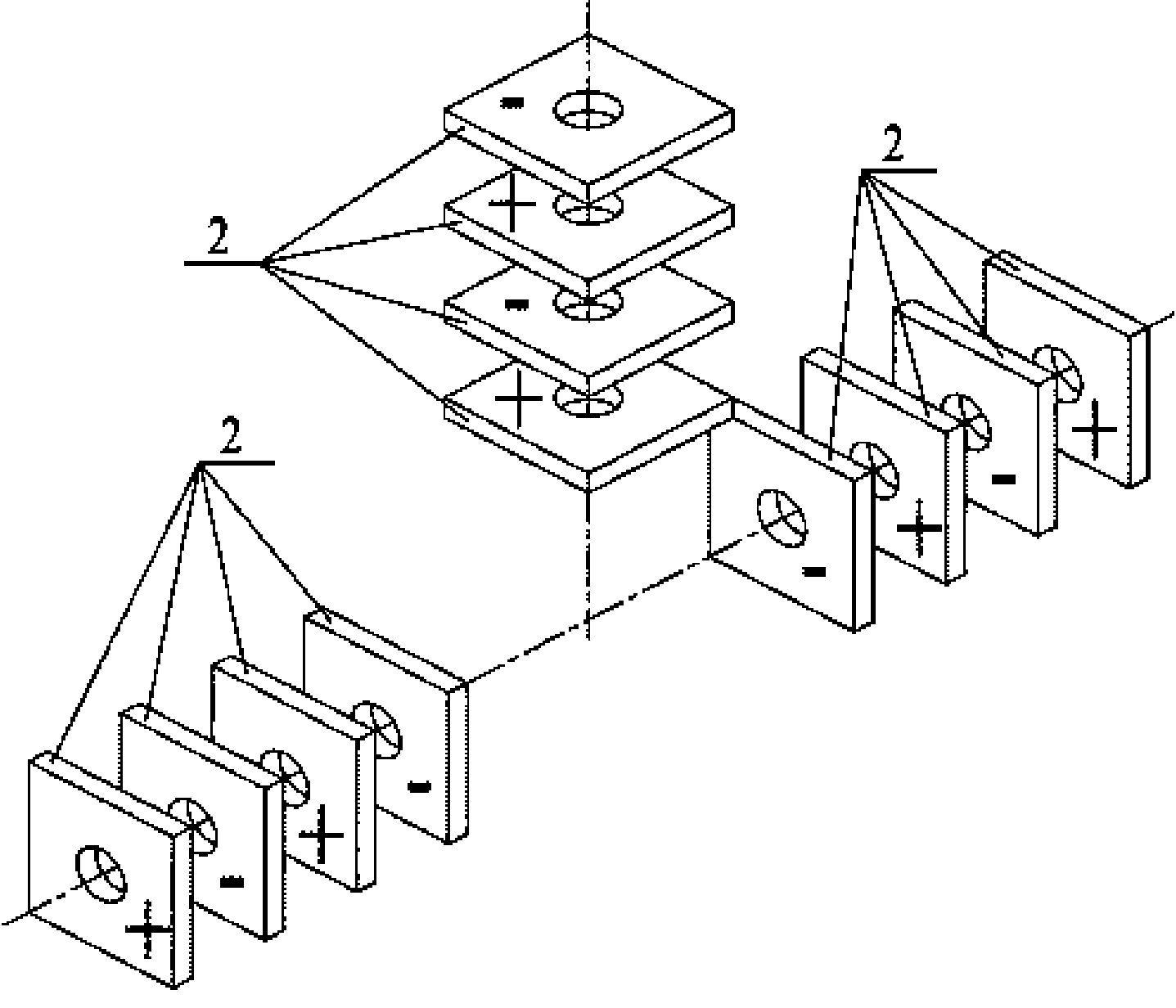

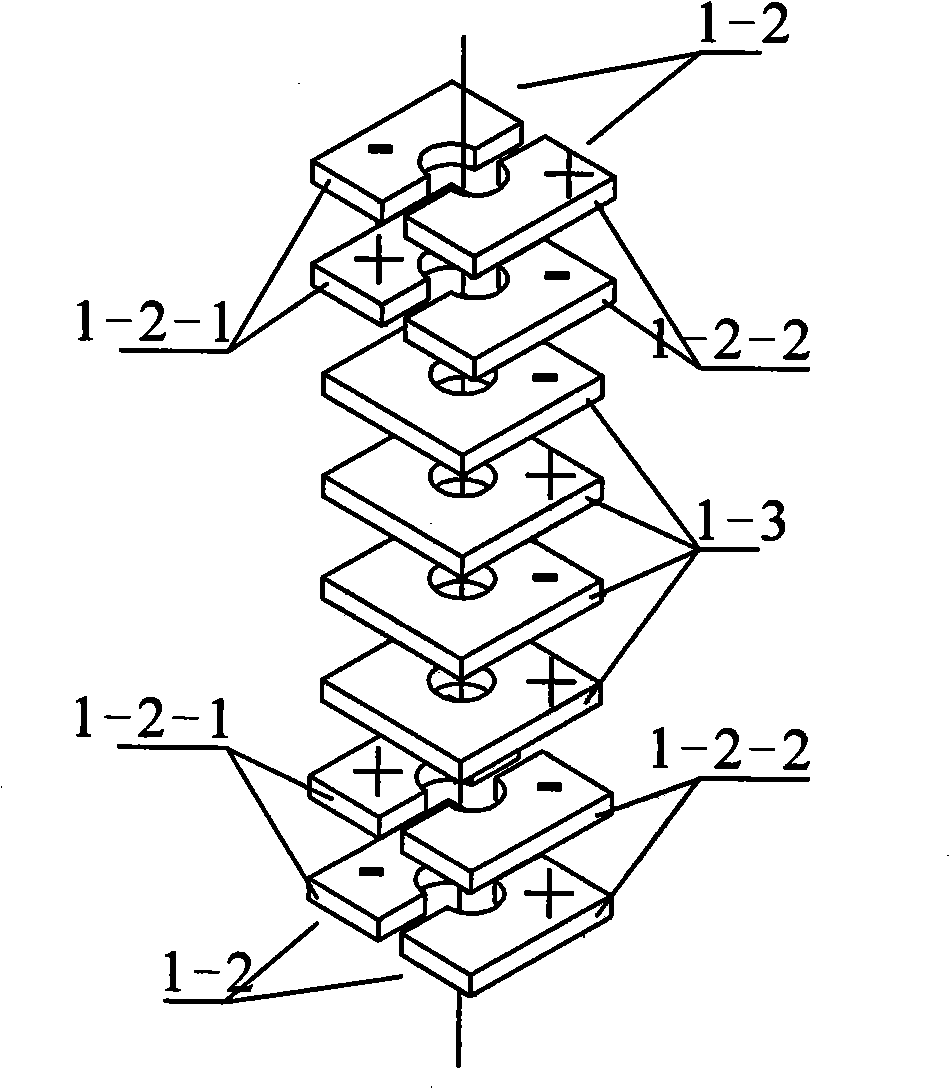

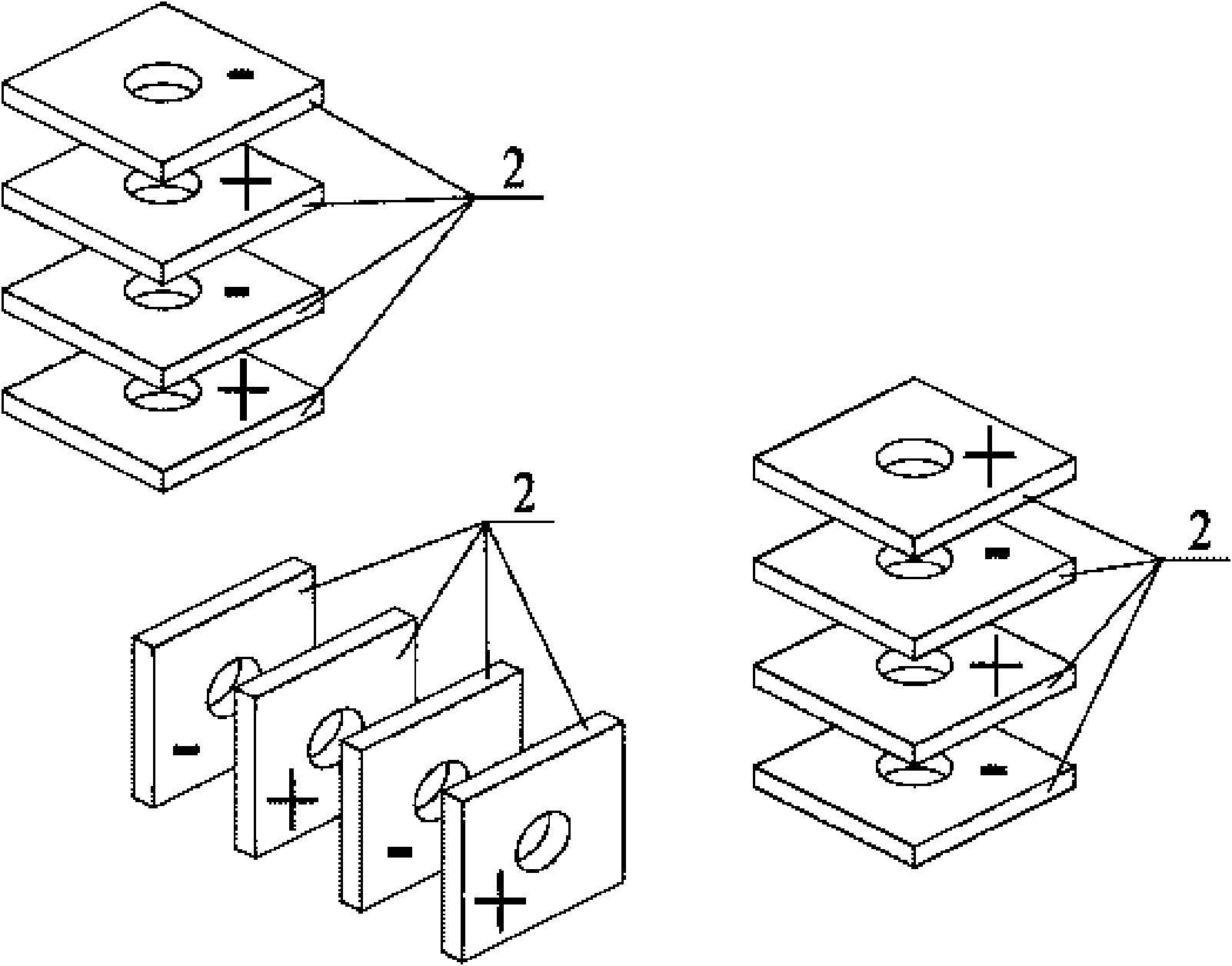

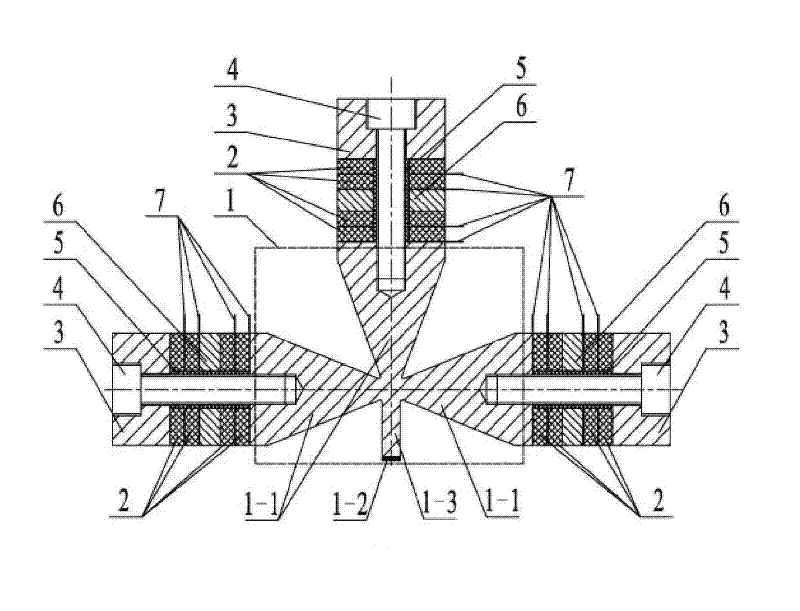

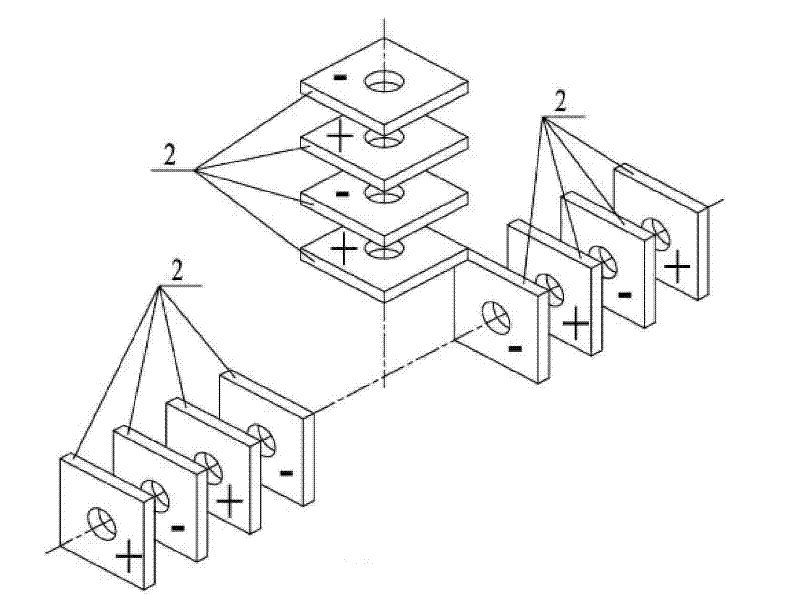

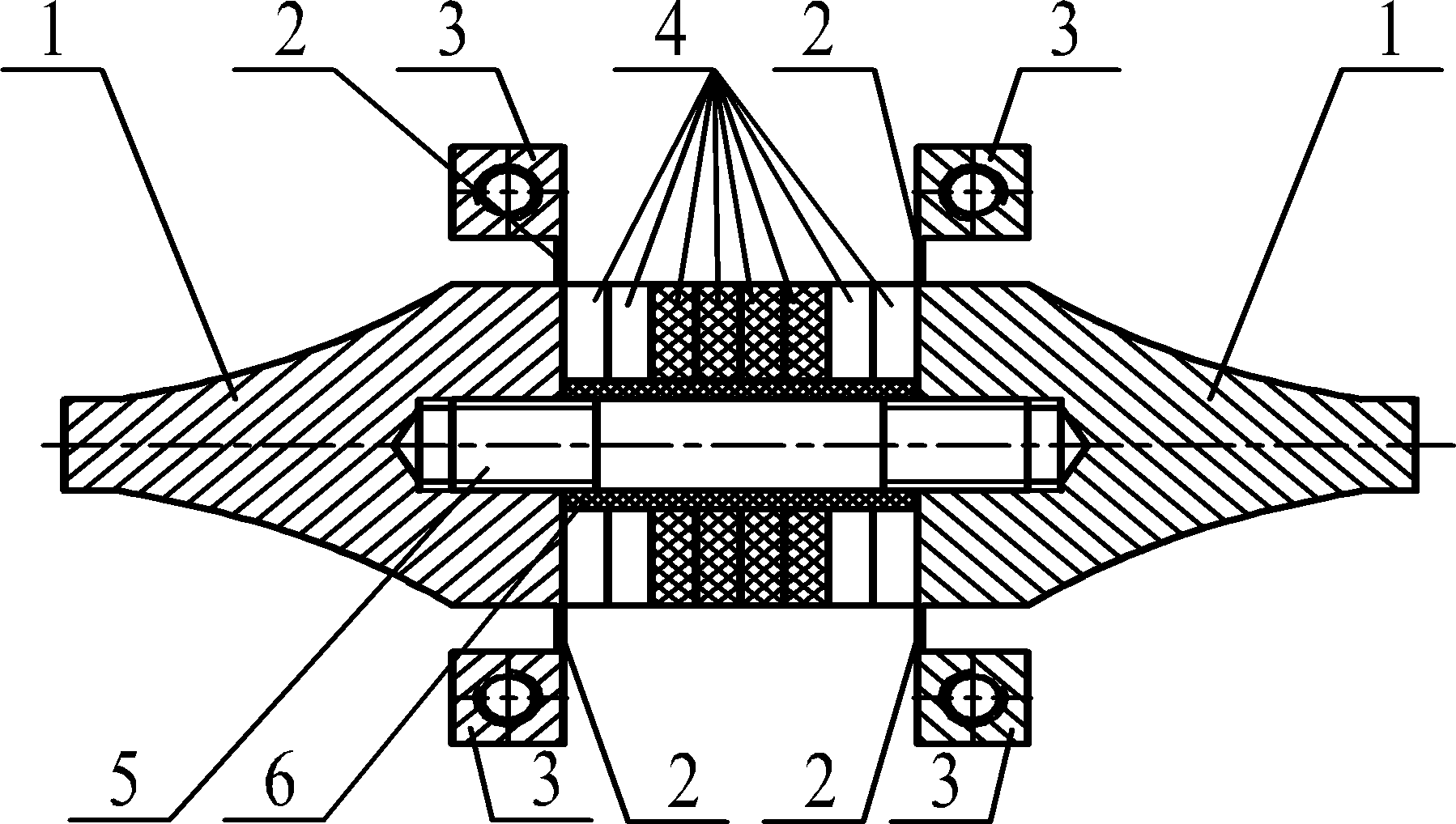

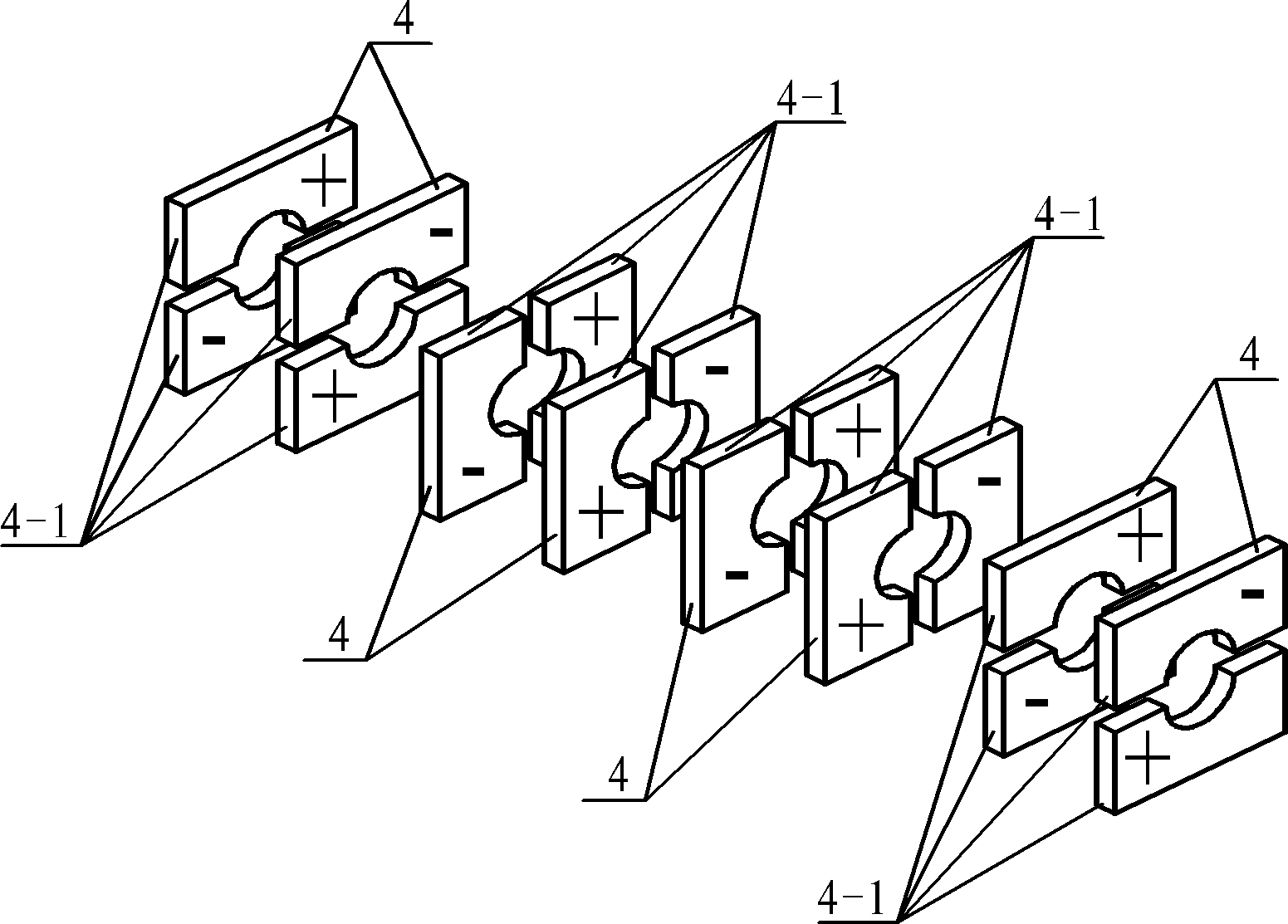

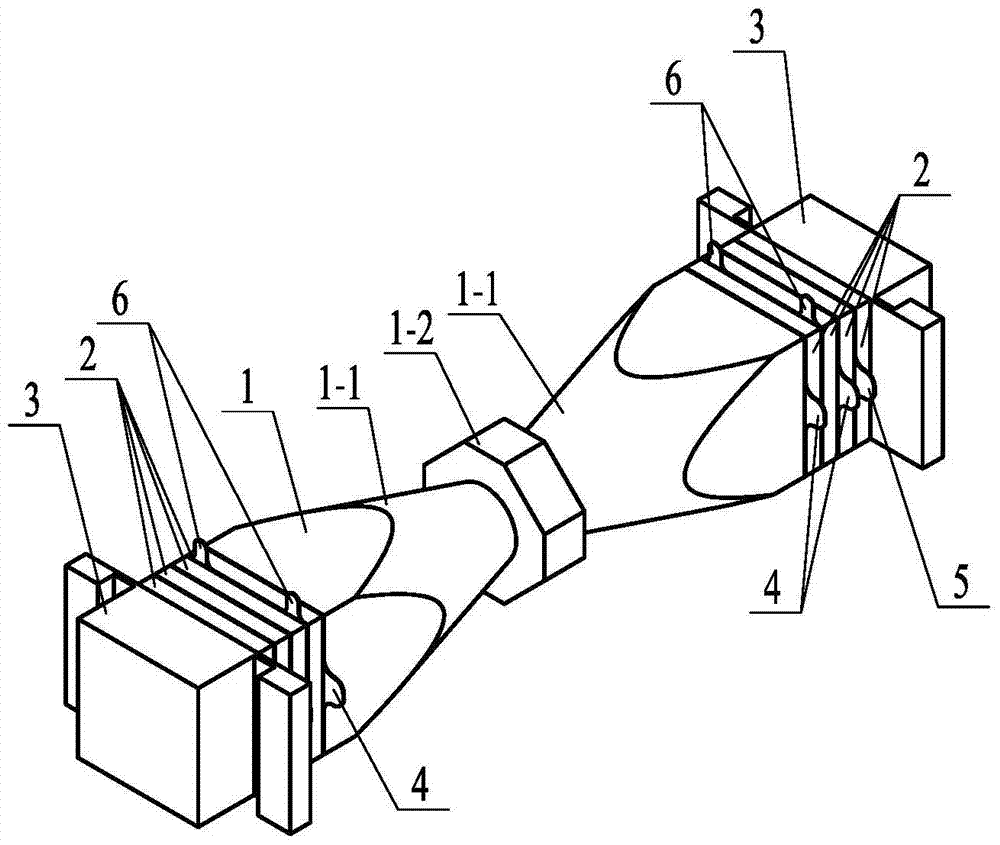

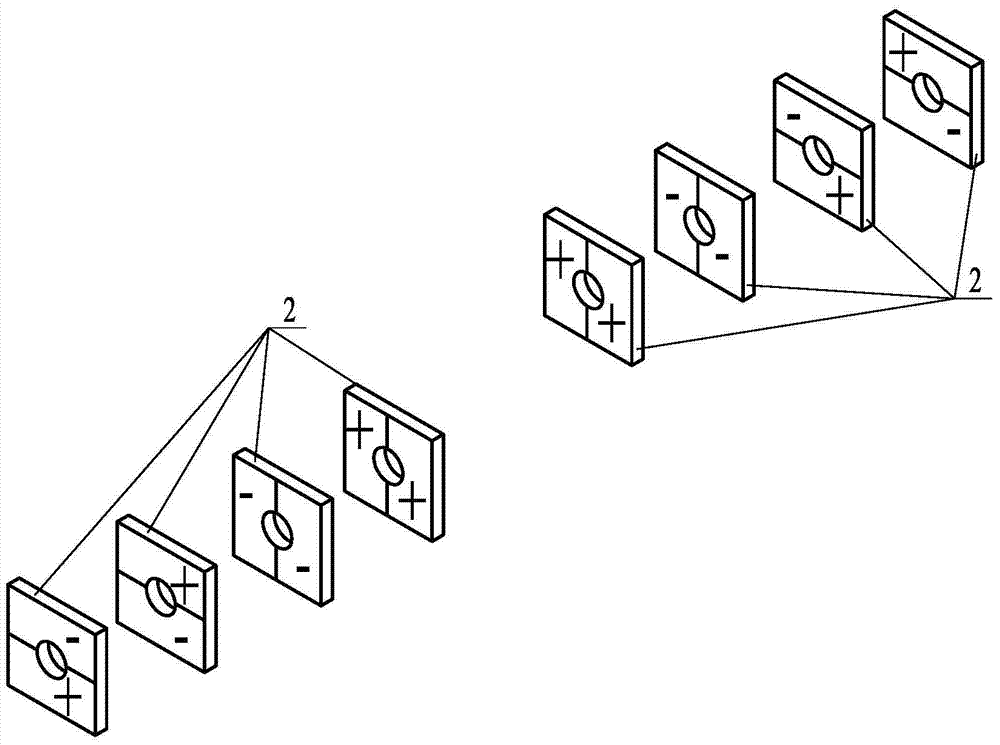

A vibrator of a beam type linear ultrasonic motor using bending vibration modes belongs to the technical field of piezoelectric ultrasonic motors and is used for the piezoelectric ultrasonic motors. The vibrator solves the problem that the mechanical output capabilities of the ultrasonic motors are restricted because of low tensile strength and low electromechanical coupling efficiency of ceramic materials in the prior art. The vibrator comprises two driving pads, two end covers, two insulating sleeves, two pairs of piezoelectric ceramics with polarization directions being thickness directions, a flange, two thin-walled beams and mounting bases; wherein, studs extend out from the end faces of the flange along the axis of the flange; each stud is sleeved with a pair of piezoelectric ceramics; an end cover is screwed at the overhanging end of each stud; the tail end of each end cover is provided with a driving pad; each piezoelectric ceramic is composed of two symmetrical half piezoelectric ceramics which are combined after being split; the polarization directions of the two half piezoelectric ceramics are opposite; the splitting lines of the two pairs of piezoelectric ceramics at both sides of the flange are vertical to each other; the polarization directions of the piezoelectric ceramics in each pair are opposite.

Owner:HARBIN INST OF TECH

Vibrator of beam type linear ultrasonic motor using bending vibration modes

ActiveCN101626203BImprove mechanical output capabilityImprove performancePiezoelectric/electrostriction/magnetostriction machinesElectric machineryEngineering

A vibrator of a beam type linear ultrasonic motor using bending vibration modes belongs to the technical field of piezoelectric ultrasonic motors and is used for the piezoelectric ultrasonic motors. The vibrator solves the problem that the mechanical output capabilities of the ultrasonic motors are restricted because of low tensile strength and low electromechanical coupling efficiency of ceramicmaterials in the prior art. The vibrator comprises two driving pads, two end covers, two insulating sleeves, two pairs of piezoelectric ceramics with polarization directions being thickness directions, a flange, two thin-walled beams and mounting bases; wherein, studs extend out from the end faces of the flange along the axis of the flange; each stud is sleeved with a pair of piezoelectric ceramics; an end cover is screwed at the overhanging end of each stud; the tail end of each end cover is provided with a driving pad; each piezoelectric ceramic is composed of two symmetrical half piezoelectric ceramics which are combined after being split; the polarization directions of the two half piezoelectric ceramics are opposite; the splitting lines of the two pairs of piezoelectric ceramics at both sides of the flange are vertical to each other; the polarization directions of the piezoelectric ceramics in each pair are opposite.

Owner:HARBIN INST OF TECH

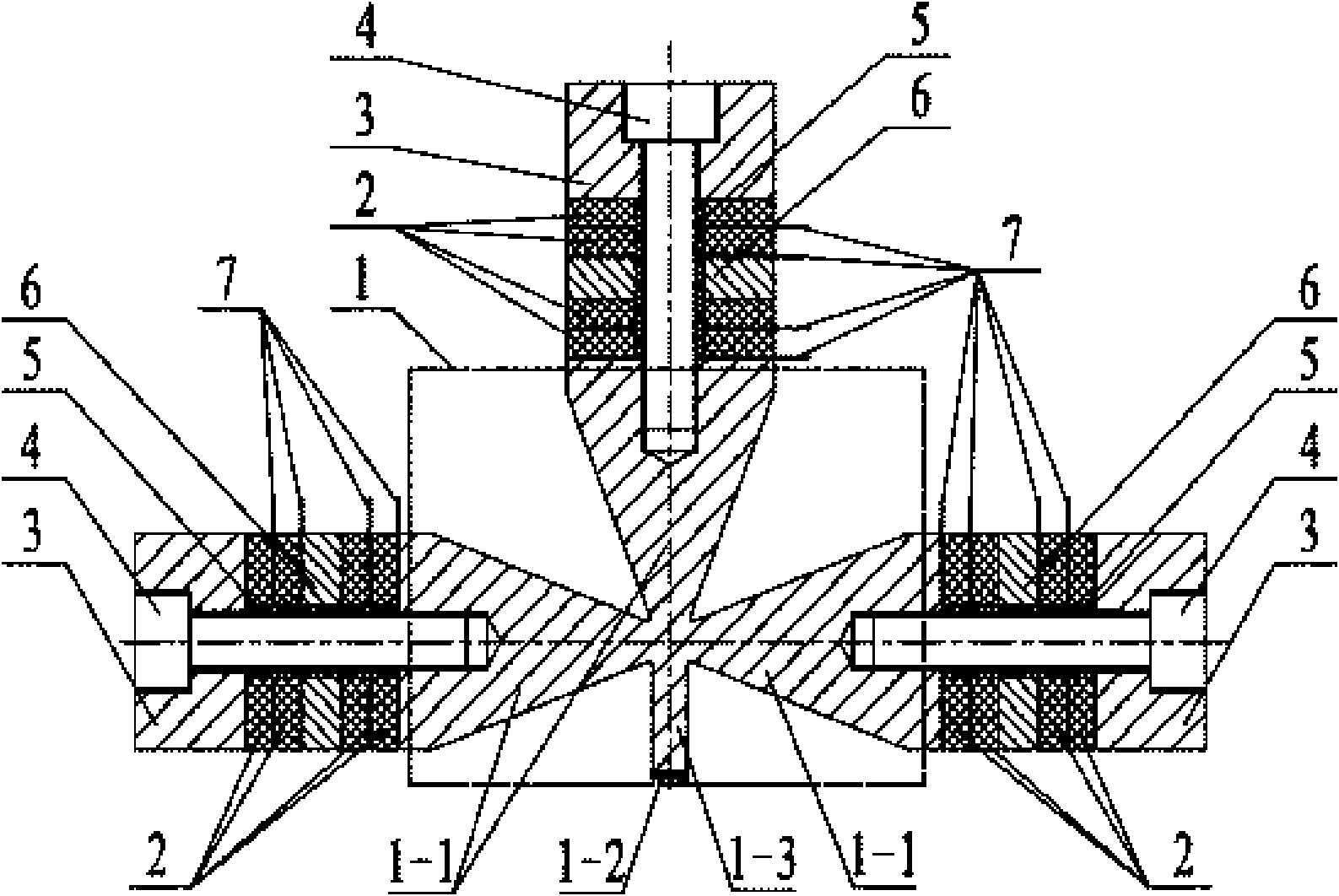

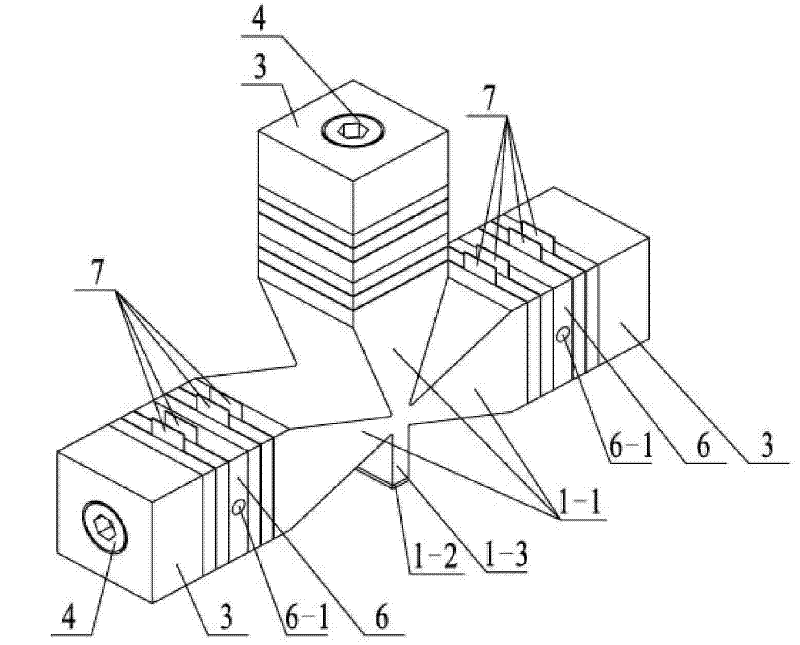

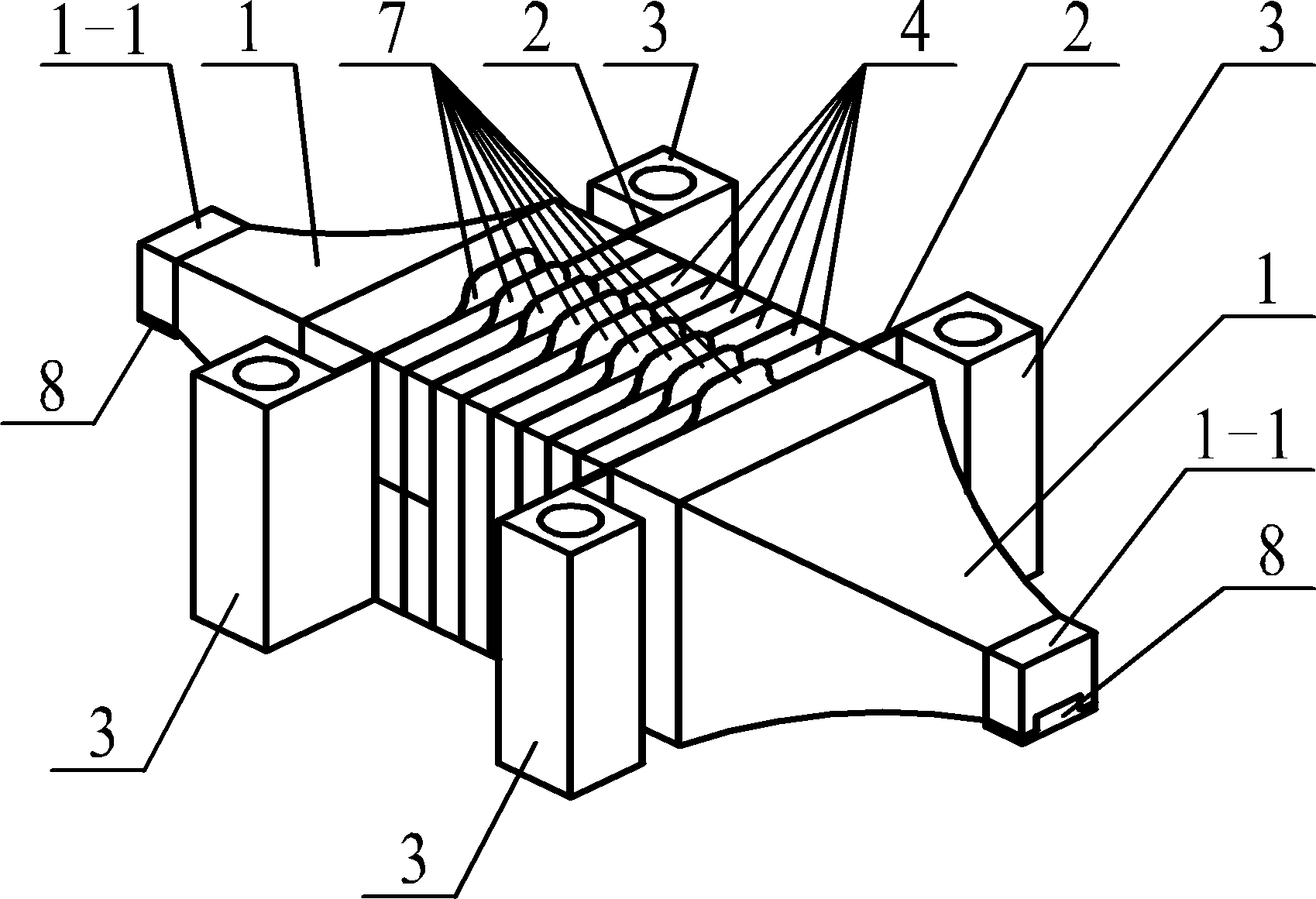

T-shaped linear ultrasonic motor oscillator

InactiveCN101630924ASolve efficiency problemsAddress mechanical propertiesPiezoelectric/electrostriction/magnetostriction machinesUltrasonic motorCeramic

The invention discloses a T-shaped linear ultrasonic motor oscillator, which relates to the technical field of a piezoelectric ultrasonic motor and aims at solving the problem that the mechanical output capacity of the prior ultrasonic motor stator is limited. T-shaped front end covers of the T-shaped linear ultrasonic motor oscillator are combined by small end surfaces of three amplitude rods and are arranged in a T shape, a drive foot is connected with a connection position of the amplitude rods, and the three amplitude rods and the drive foot form an integral member; piezoelectric ceramics are polarized along the thickness direction, and opposite to the polarization direction of every adjacent two pieces of piezoelectric ceramics on the same amplitude rod, the polarization ways of the piezoelectric ceramics of two amplitude rods on the same axial line are opposite, each fastening screw passes through a back end cover, the piezoelectric ceramics and a flange and is connected to a blind hole, and the piezoelectric ceramics and the flange are positioned between the back end cover and the amplitude rod, and a piece of electrode plate is arranged between the piezoelectric ceramics and the flange; and an insulating sleeve is fixed outside the fastening screw. The invention is applied to the manufacture field of the ultrasonic motor.

Owner:HARBIN INST OF TECH

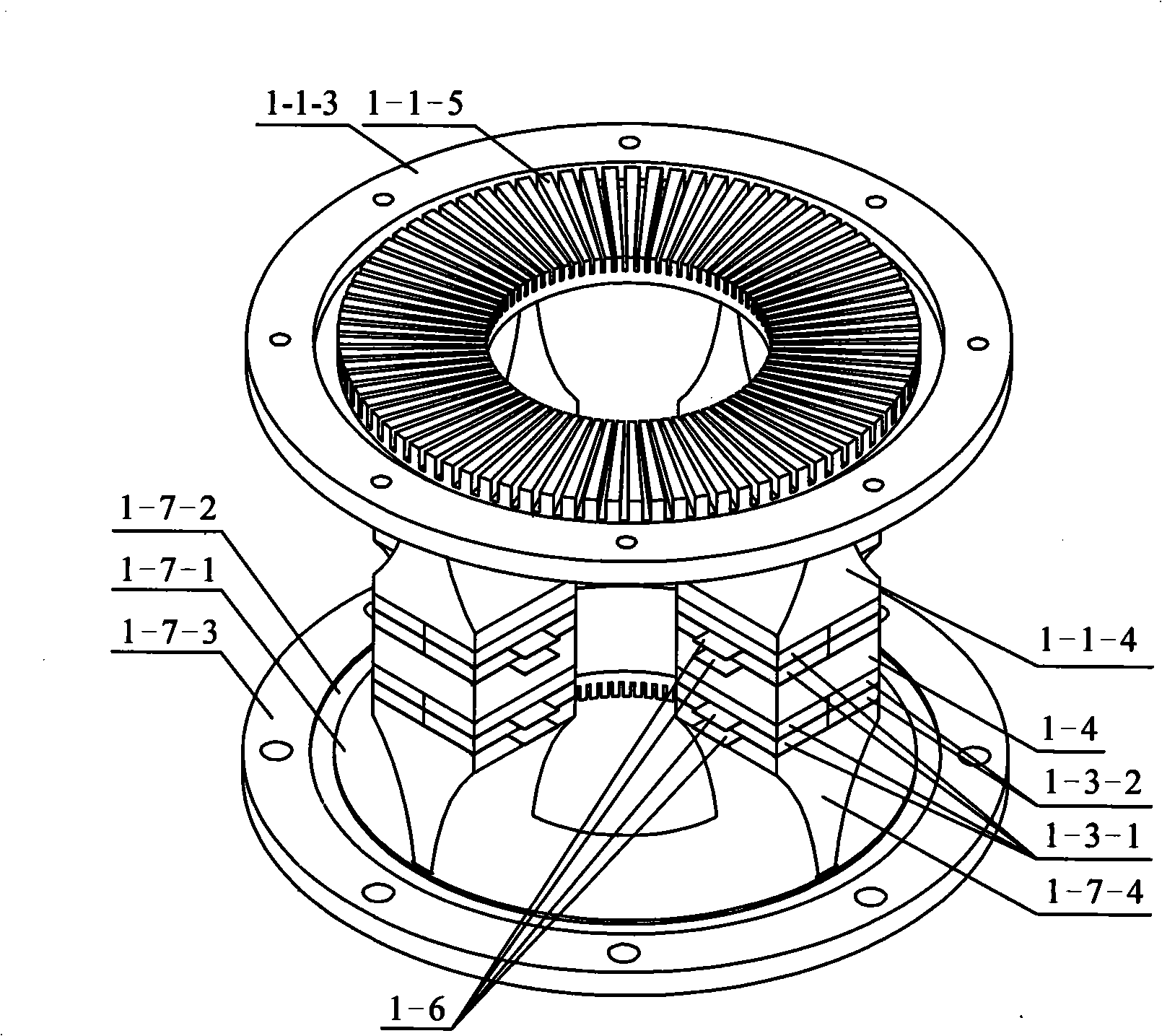

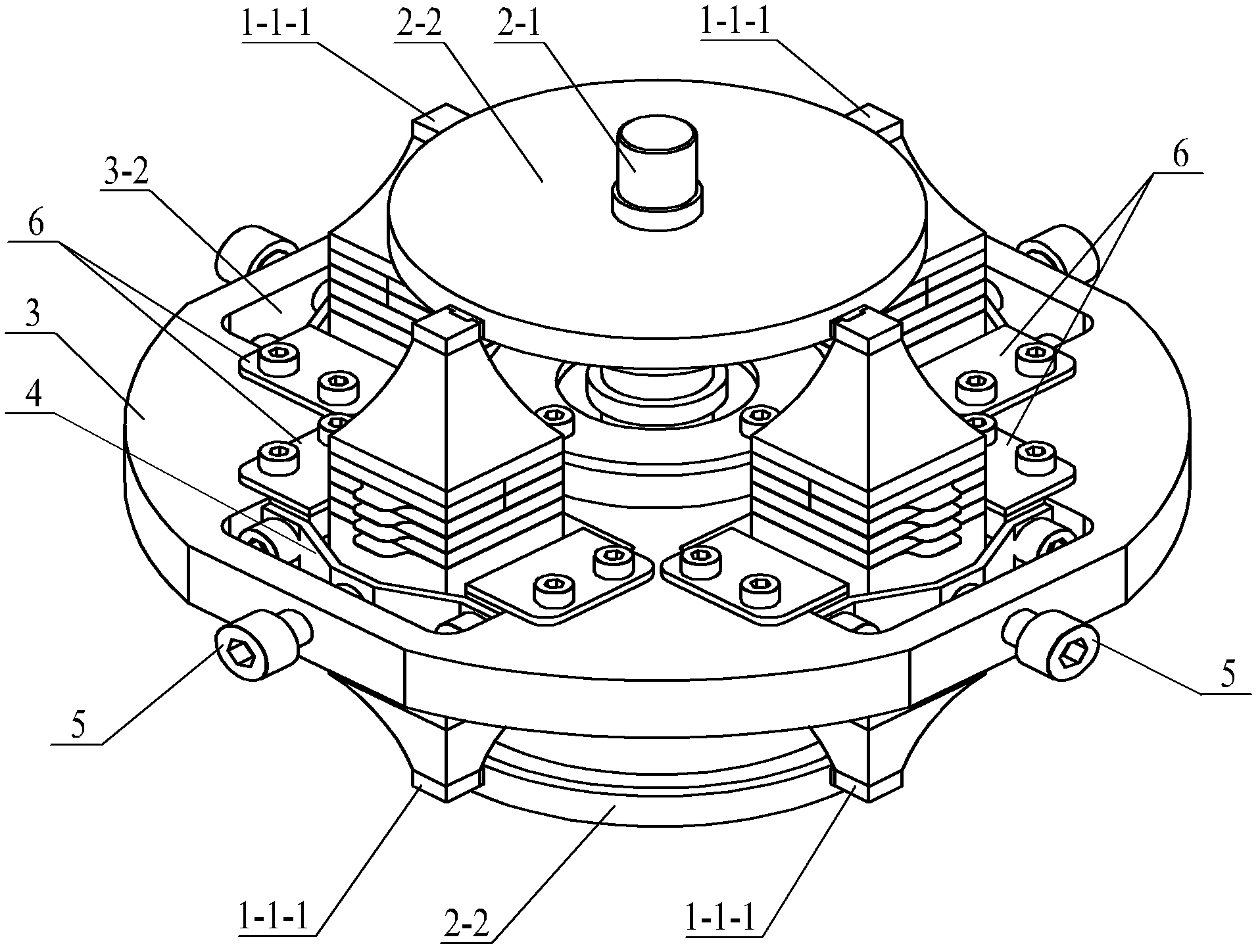

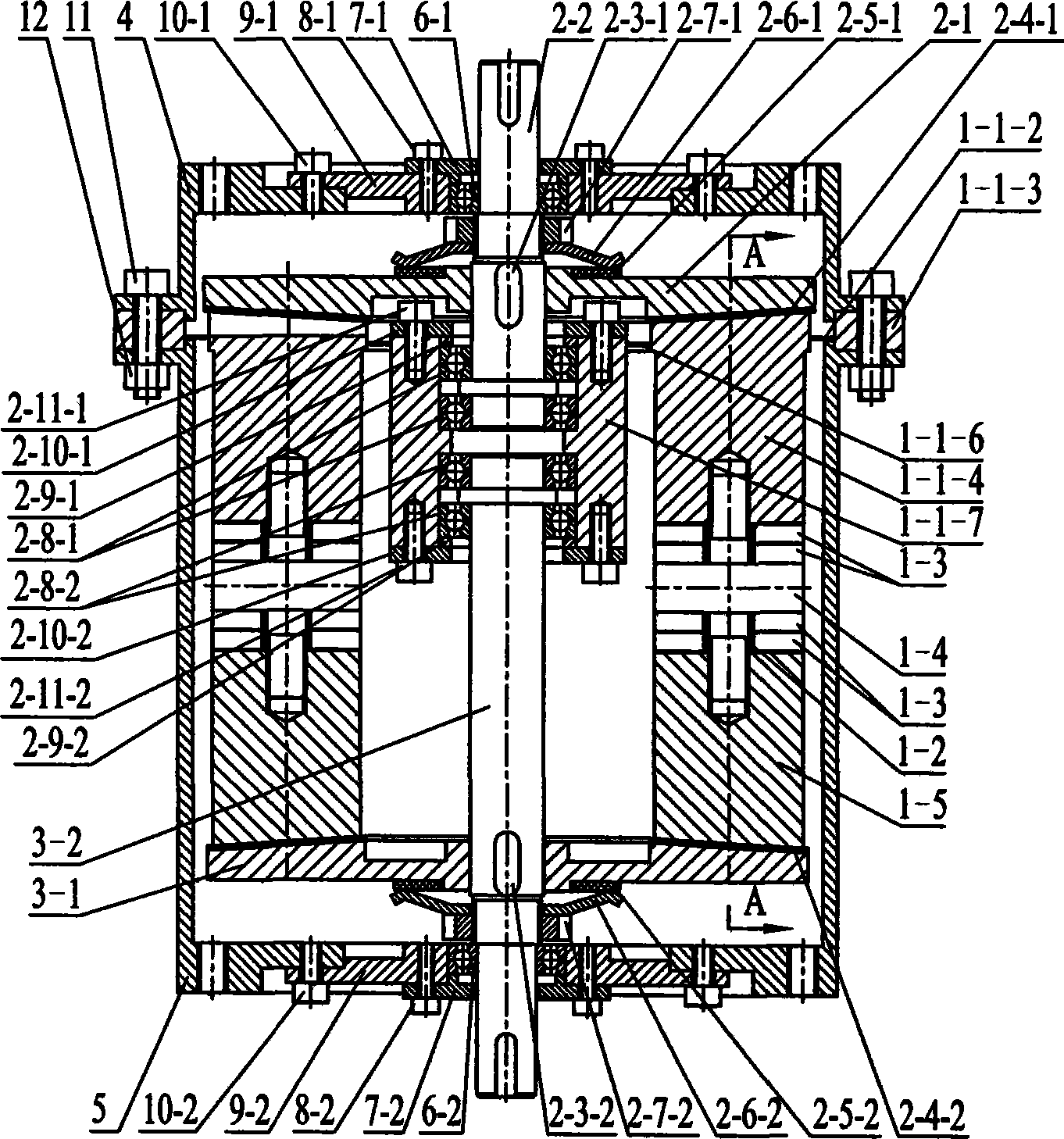

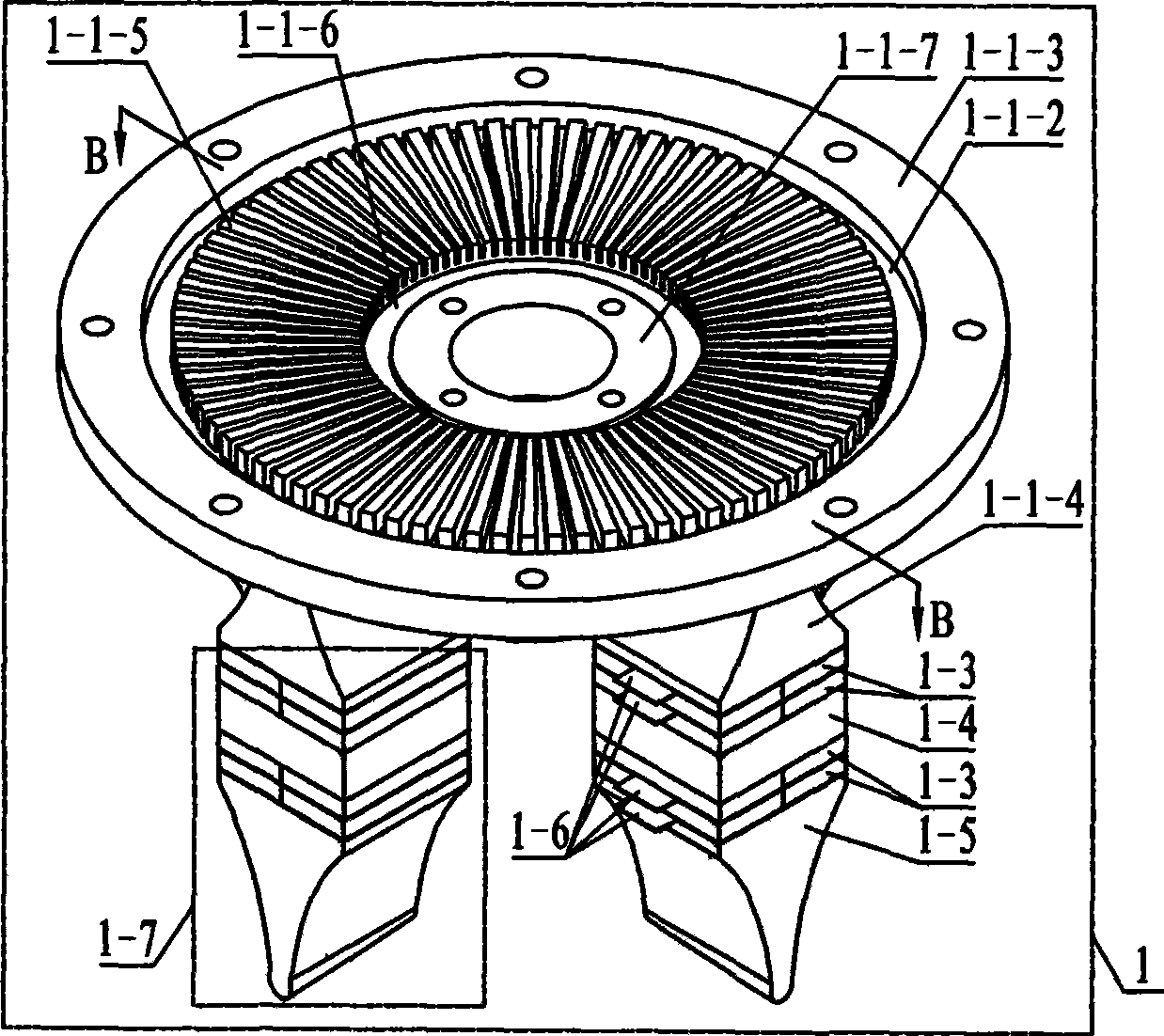

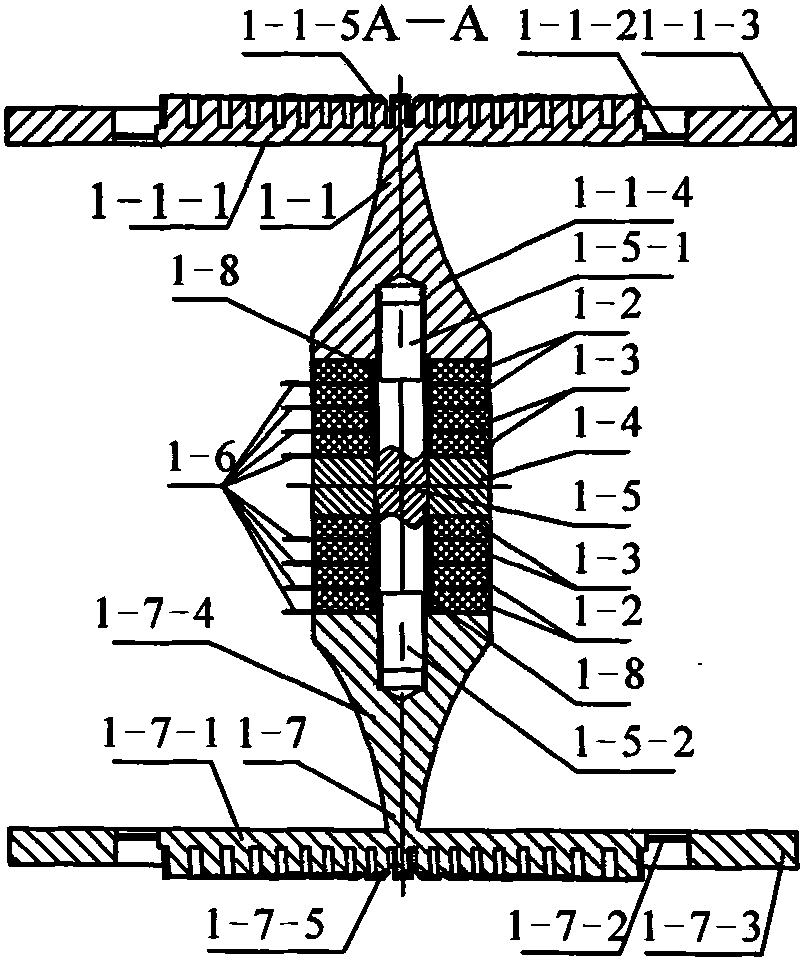

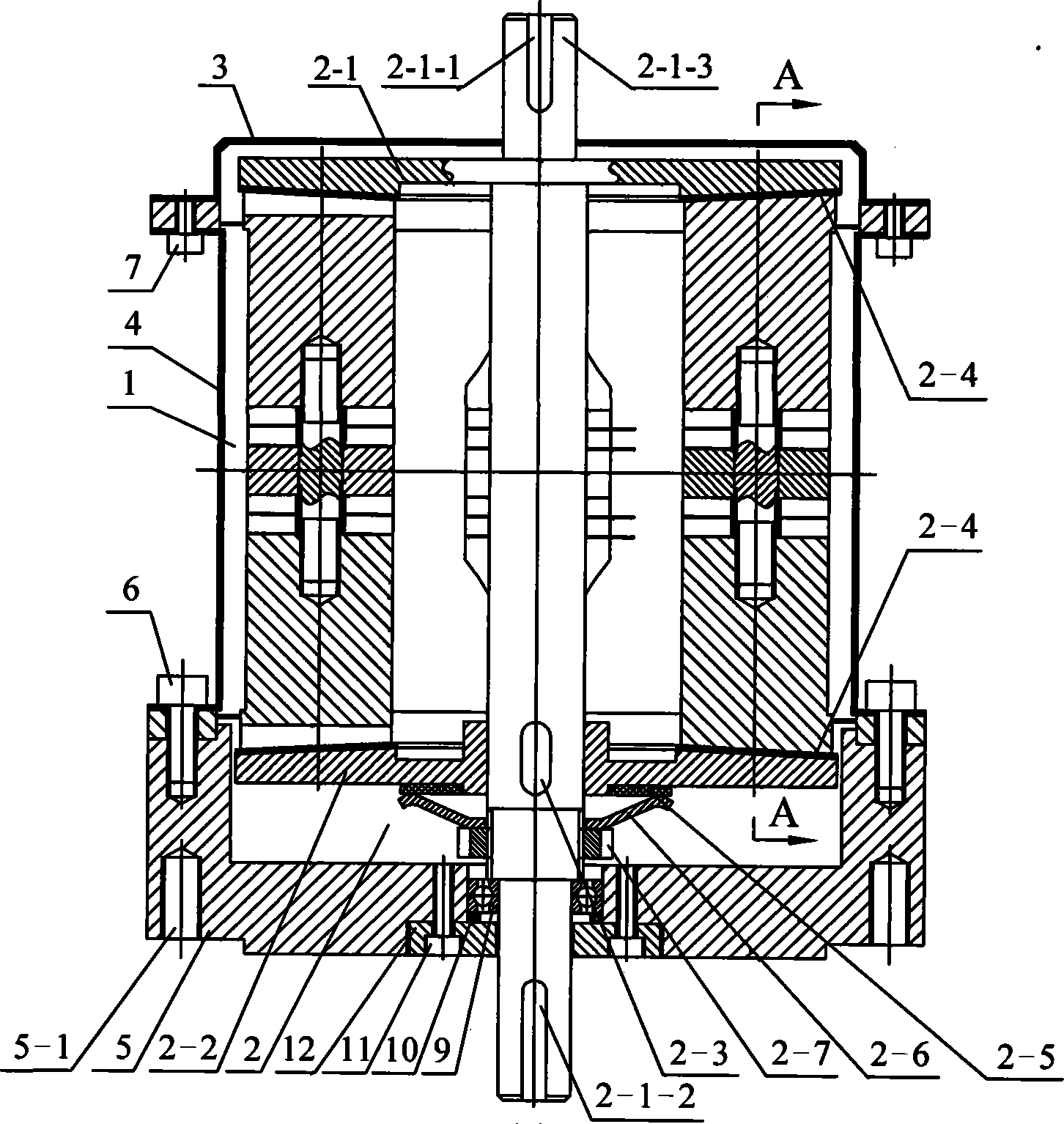

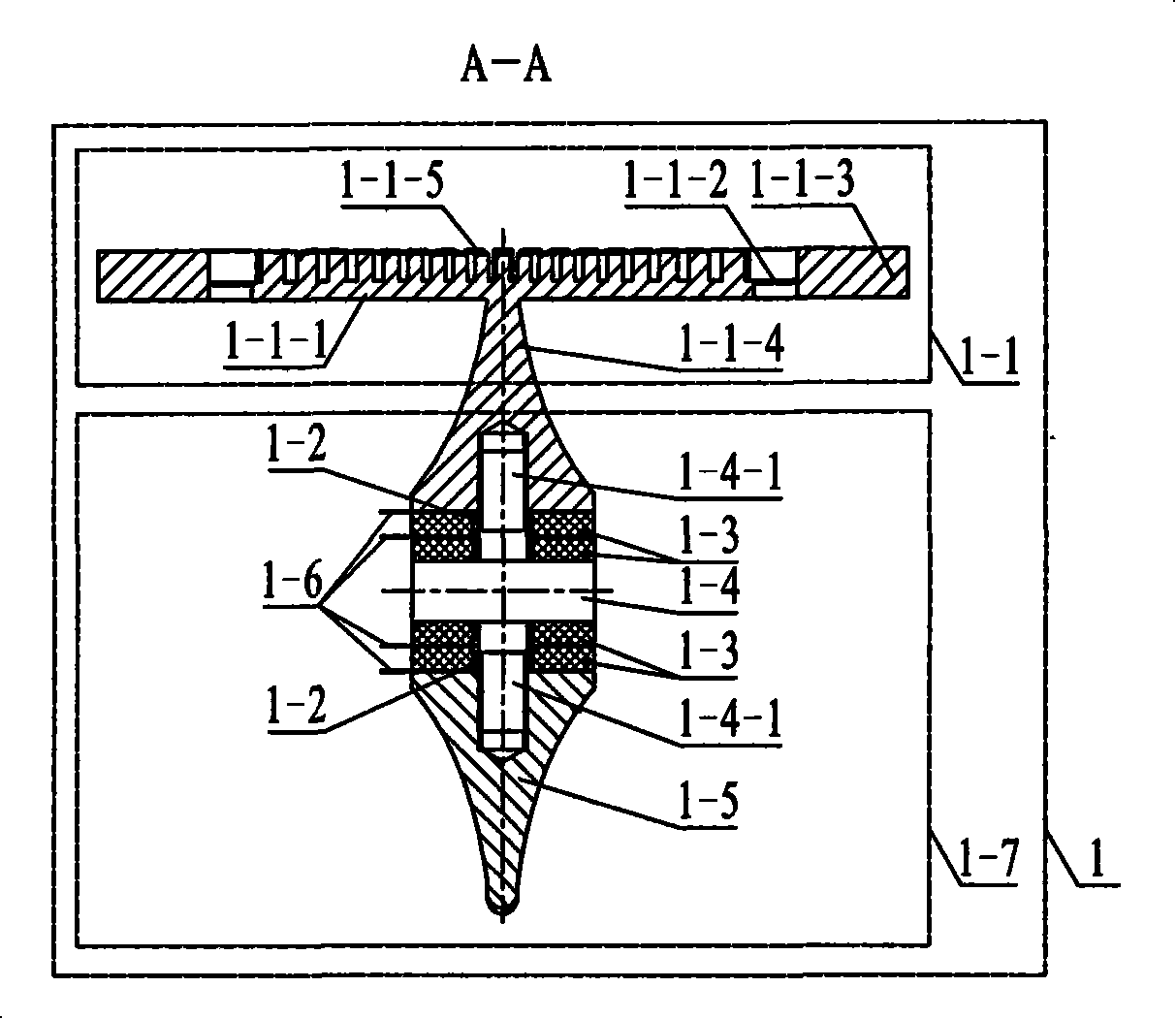

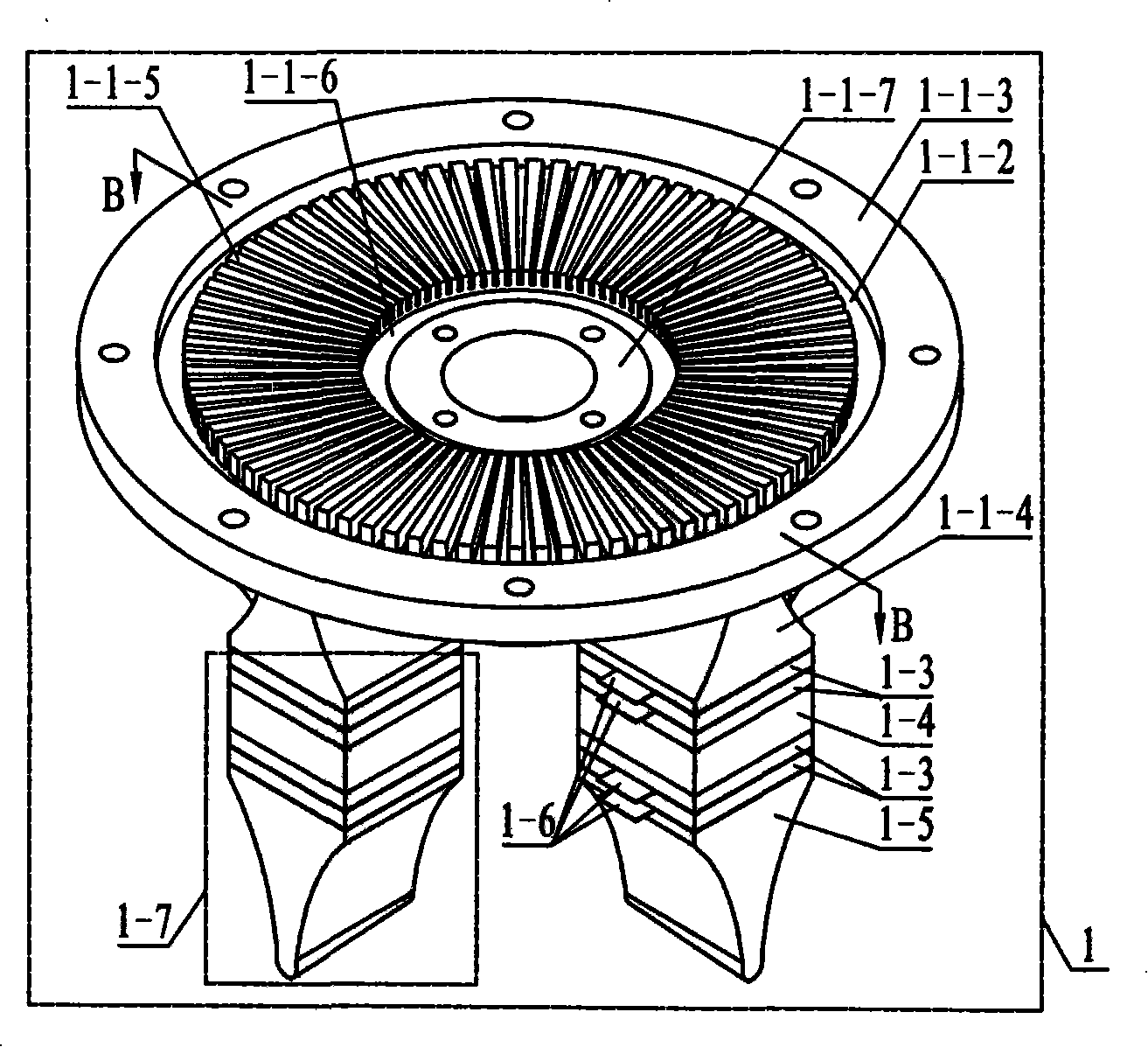

Vertical bending layer energy converter round disk stator and ultrasonic electromotor using this stator

InactiveCN101262184AMake the most of vibrational energyImprove vibration trajectoryPiezoelectric/electrostriction/magnetostriction machinesCircular discEngineering

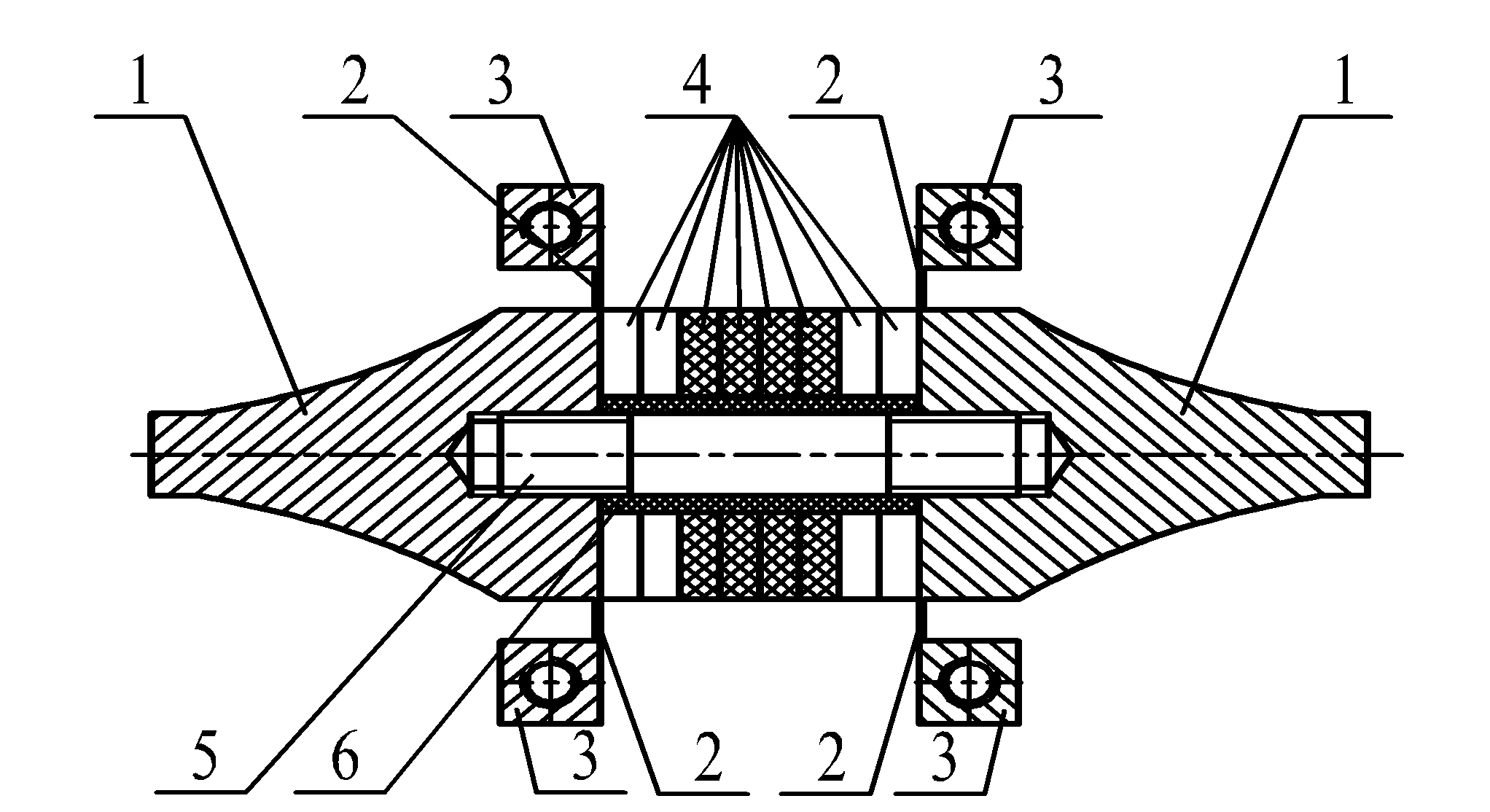

The invention discloses a longitudinal bending sandwiched energy converter-typed round disc stator and an ultrasonic motor to which the stator is applied, which relates to the ultrasonic motor field. The invention solves the problems in the existing ultrasonic motor, of complex processing, difficult assembly, and lower mechanical output capacity and controllability of the ultrasonic motor. The longitudinal bending sandwiched converter of the stator is fixed between a round disc at the upper end and a round disc at the lower end, both the front end cover and the back end cover of the longitudinal bending sandwiched energy converter are a quadrangular with a rectangle cross section narrowing down gradually, the small end faces of the front end cover and the back end cover are fixedly connected with the upper round disc and the lower round disc; each piezoelectric ceramic piece is polarized along the thickness direction and four pairs of piezoelectric ceramic pieces are respectively fixed between the front end cover, the back end cover and the flange. Rotors in the ultrasonic motor take the shape of a round disc and are embedded respectively from the top and the bottom of the stator component, a wearable cushion is fixed at the end face, contacting the round disc, of the rotor and the stator is fixed to a base through the flange on the energy converter. The longitudinal bending sandwiched energy converter-typed round disc stator and the ultrasonic motor of the invention has the advantages of simple structure, flexible design, high electromechanical coupling efficiency, output with large torque, stable performance and easy control.

Owner:HARBIN INST OF TECH

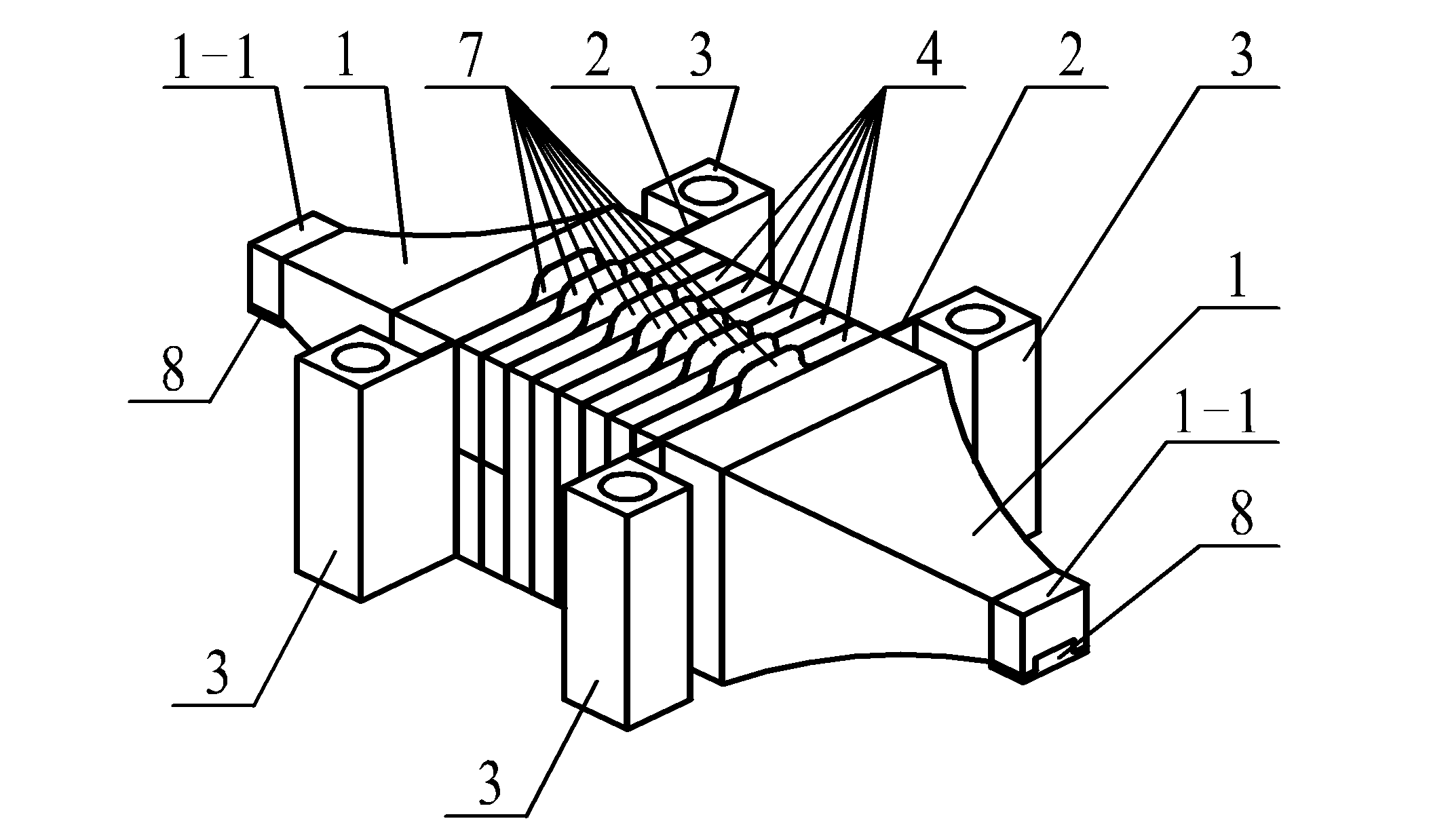

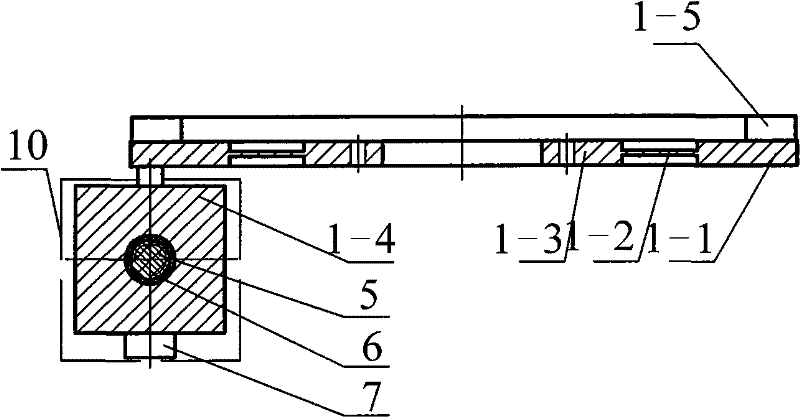

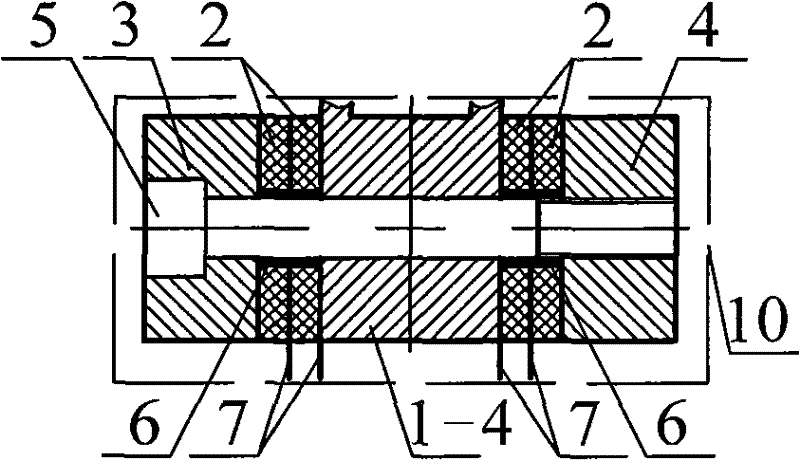

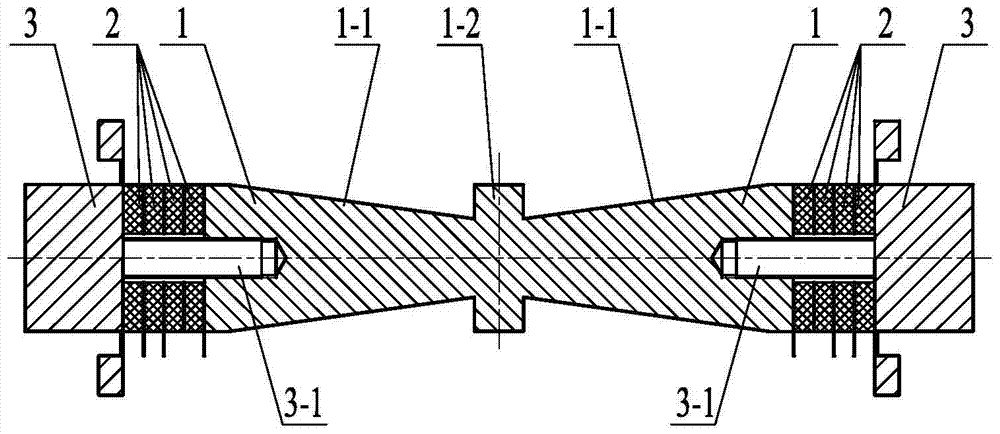

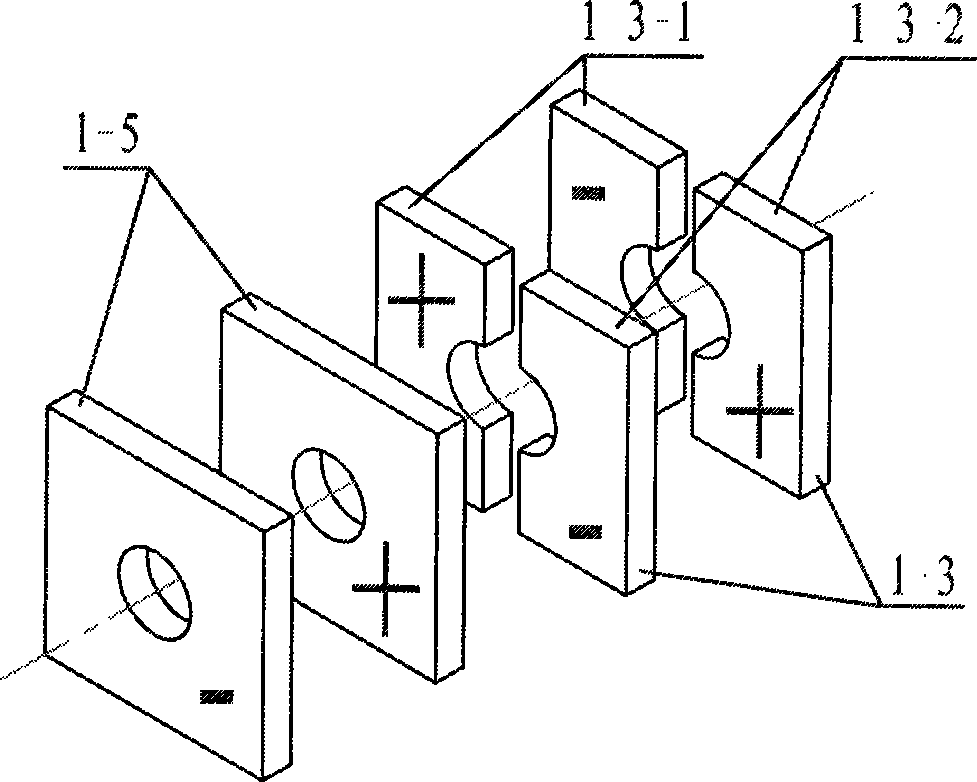

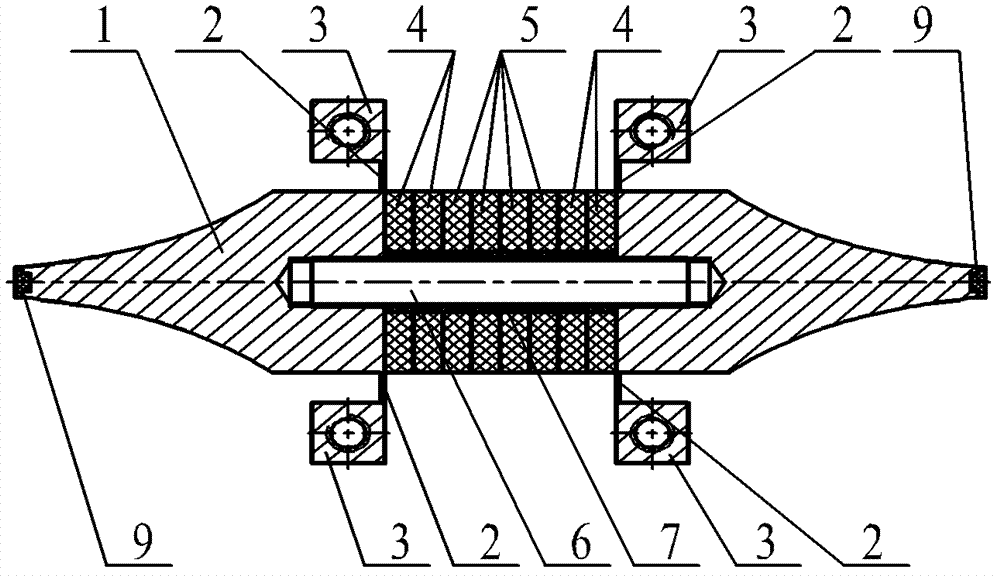

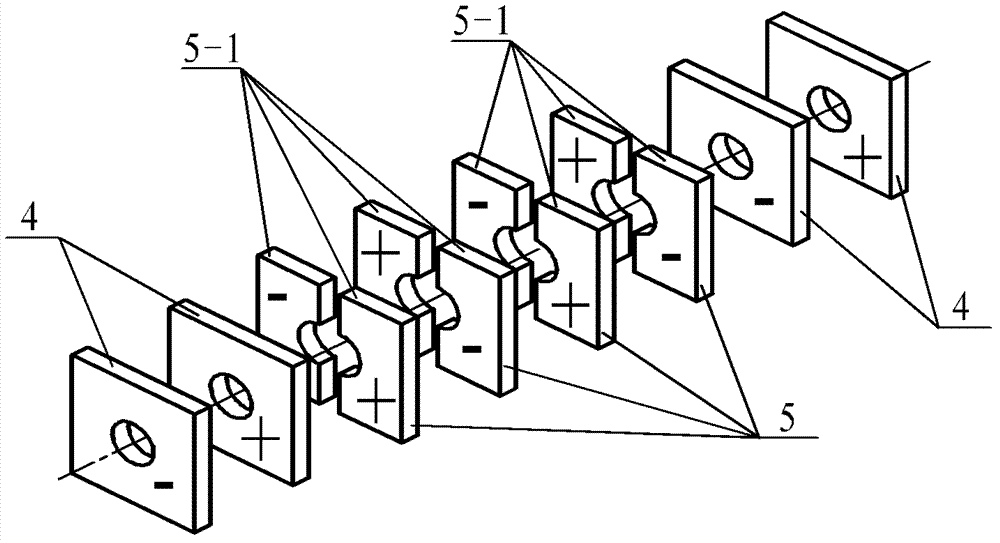

Composite flexural vibration sandwich type double-foot linear ultrasonic motor vibrator

ActiveCN102361413AIncrease flexibilityAchieve macro motion outputPiezoelectric/electrostriction/magnetostriction machinesAcousticsSandwich type

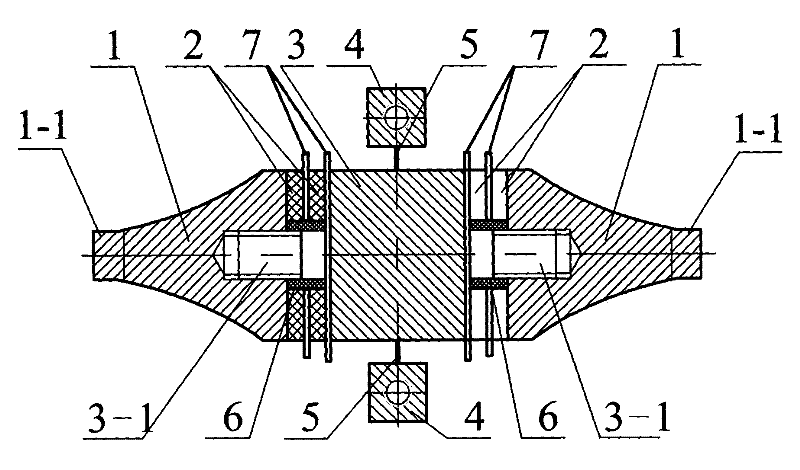

The invention discloses a composite flexural vibration sandwich type double-foot linear ultrasonic motor vibrator, and belongs to the technical field of piezoelectric ultrasonic motors. The vibrator solves the problem that the output thrust of a motor is affected by inconsistent vibration properties of two driving feet of the conventional flexural vibration modal beam type linear ultrasonic motor vibrator. Eight flexural vibration piezoelectric ceramic chips are sleeved on a stud of the vibrator, two end covers are respectively screwed at two ends of the stud to compact the eight flexural vibration piezoelectric ceramic chips, an electrode plate is respectively arranged between the adjacent flexural vibration piezoelectric ceramic chips and between the contact faces of the flexural vibration piezoelectric ceramic chip and the big end face of the end cover, insulating bushes are arranged between the contact faces of all the flexural vibration piezoelectric ceramic chips and the stud and between the contact faces of all the electrode plates and the stud, two thin-wall beams are symmetrically arranged at two sides of the big end face of each end cover, a mounting seat is fixed at the outer side of each thin-wall beam, a driving foot is arranged on the small end face of each end cover, and the driving feet are blocks, the sections of which are in the same shape as the small end faces. The vibrator is suitable for an ultrasonic motor.

Owner:HARBIN INST OF TECH

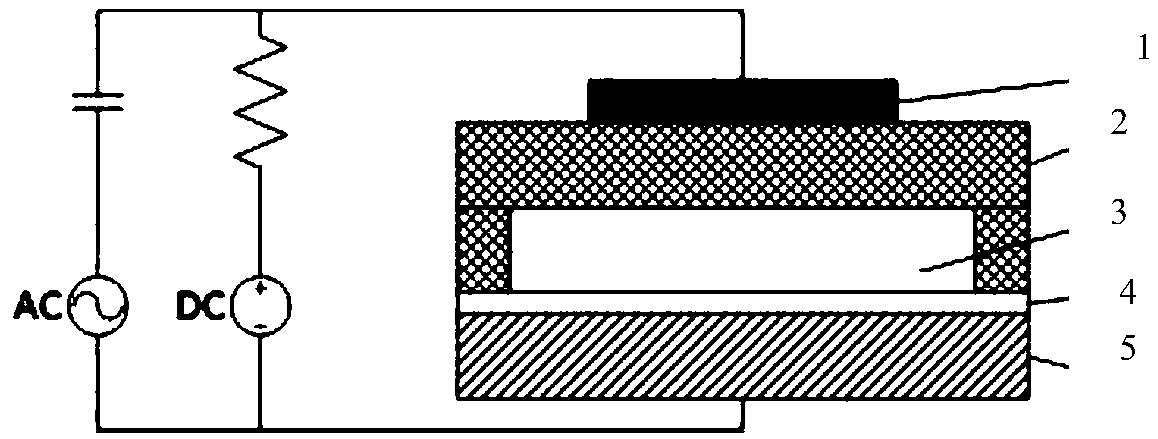

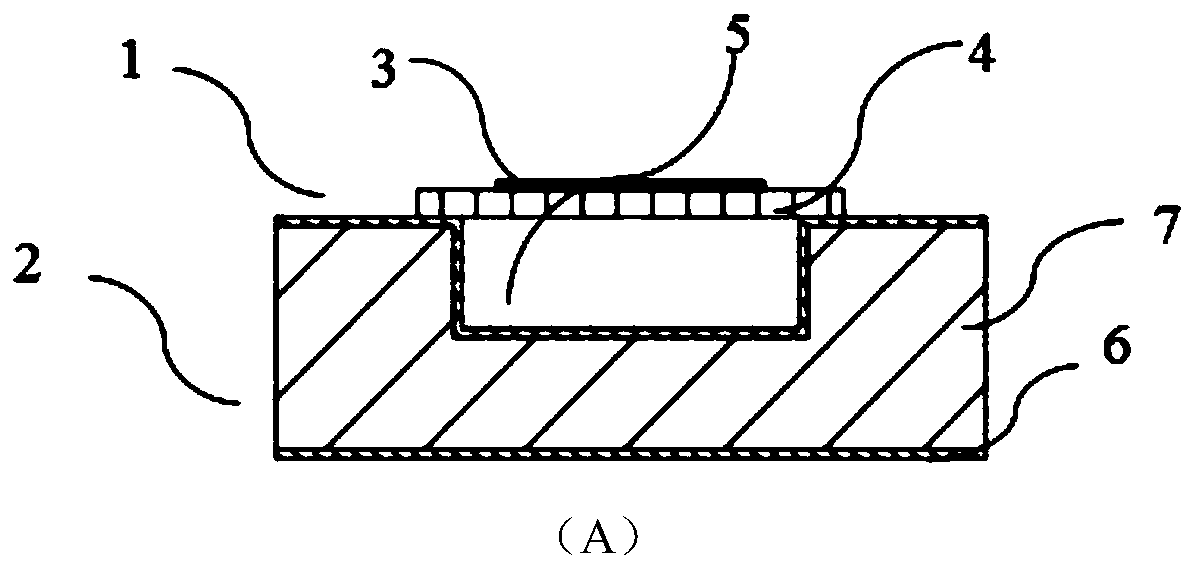

Air-coupled capacitive micromachining ultrasonic transducer, preparation method and application

ActiveCN108704827AHigh electromechanical coupling efficiencyLow acoustic impedanceAfter-treatment detailsVacuum evaporation coatingSilicon nitrideAluminium

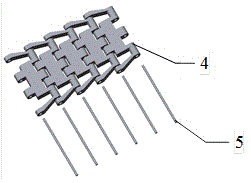

The invention relates to an air-coupled capacitive micromachining ultrasonic transducer, a preparation method and application. A transducer array comprises 16 array elements; each array element is formed by multiple sensing units; each sensing unit is structurally formed by an upper electrode 1, a vibrating diaphragm 2, a cavity 3 and a base 5 sequentially from top to bottom; and each base is usedas a lower electrode. The working frequency of the designed transducer is 100kHz to 2MHz. The transducer array is manufactured based on an SOI bonding process; each vibrating diaphragm is made of monocrystalline silicon; each upper electrode is gold or aluminum; an insulating layer 4 is silicon dioxide or silicon nitride; and the array elements of the transducer are divided through etching the low-resistance-silicon bases to form grooves, so that the array with the multiple array elements is formed. According to the air-coupled ultrasonic transducer, an ultrasonic wave in a metal plate or a composite plate is excited through an air coupling manner and is used for nondestructively detecting internal defects of the plate. The transducer is matched with a phased array system, and pulse drivesignals of the array elements are delay-controlled, so that the phase-controlled deflection and the focusing of an acoustic beam are adjusted, and the freedom degree of detecting is increased.

Owner:TIANJIN UNIV

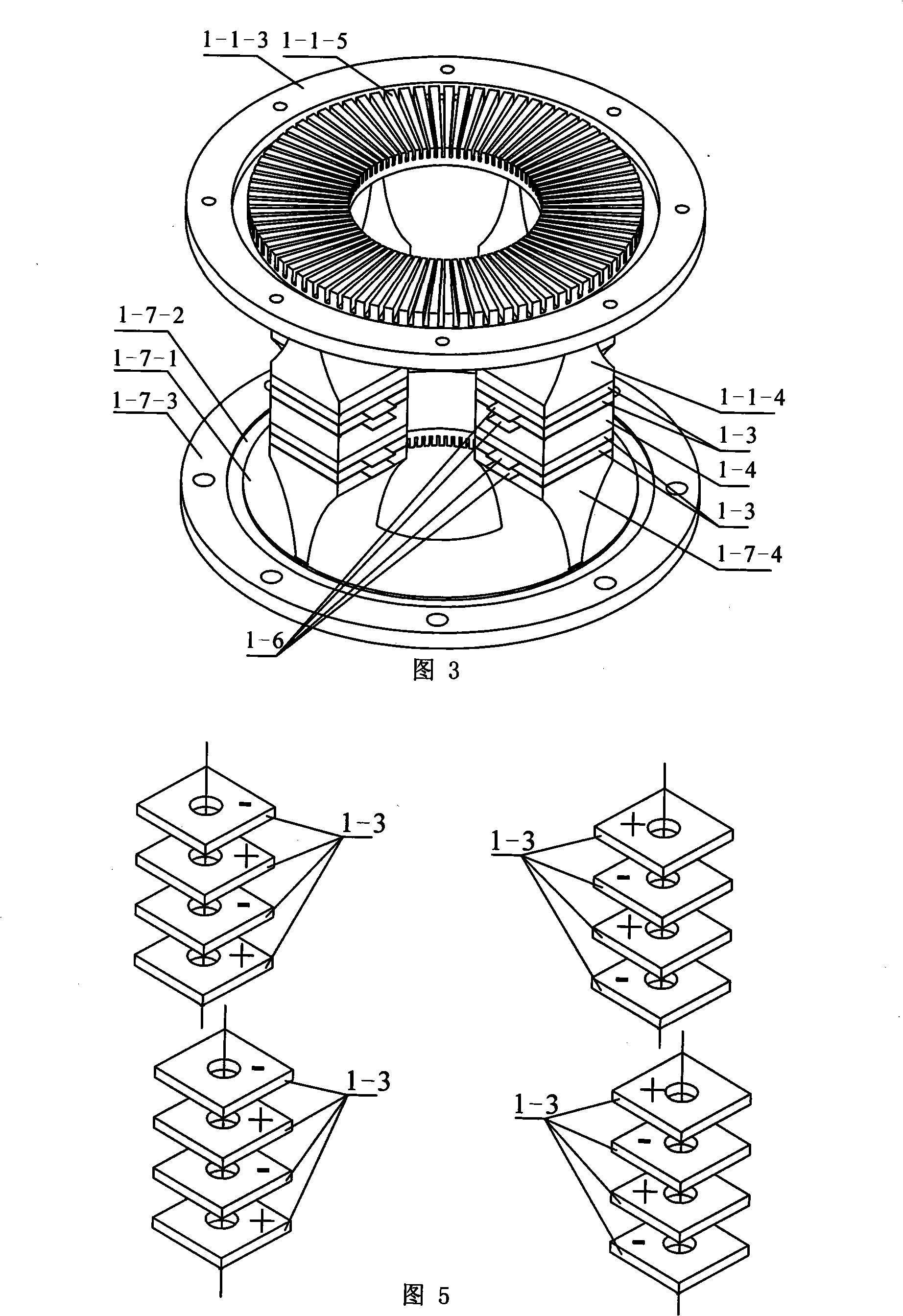

Vertical vibration layer energy converter round disk stator and ultrasonic electromotor using this stator

InactiveCN101262183AIncrease output torqueReduce the influence of output characteristicsPiezoelectric/electrostriction/magnetostriction machinesElastomerVertical vibration

The invention discloses a longitudinal vibration sandwiched energy converter-typed round disc stator and an ultrasonic motor to which the stator is applied, and relates to the ultrasonic motor field. The invention solves the problem in the existing ultrasonic motor that mechanical output capacity is restrained due to the adoption of elastic metal body stuck on piezoelectric ceramic pieces for excitation. Even longitudinal vibration sandwiched energy converters of the stator are symmetrically arrayed and fixed between a round disc at the upper end and a round disc at the lower end; both the front end cover and the back end cover of the sandwiched energy converter are a quadrangular with a rectangle cross section and narrowing down gradually, the small end faces of the front end cover and the back end cover are fixedly connected with the upper round disc and the lower round disc; a flange is arranged at the section where the energy converter vibrates longitudinally and two pairs of piezoelectric ceramic pieces are respectively fixed between the front end cover and the back end cover and the flange. A rotor with a shaft and a rotor without a shaft in the ultrasonic motor both take the shape of a round disc and are embedded respectively from the top and the bottom of a stator cylinder, a wearable cushion is fixed at the end face, contacting the round disc, of the rotor and the stator is fixed to a base through the flange on the energy converter. The longitudinal vibration sandwiched energy converter-typed round disc stator and the ultrasonic motor of the invention are applicable to the manufacturing field of the ultrasonic motor.

Owner:HARBIN INST OF TECH

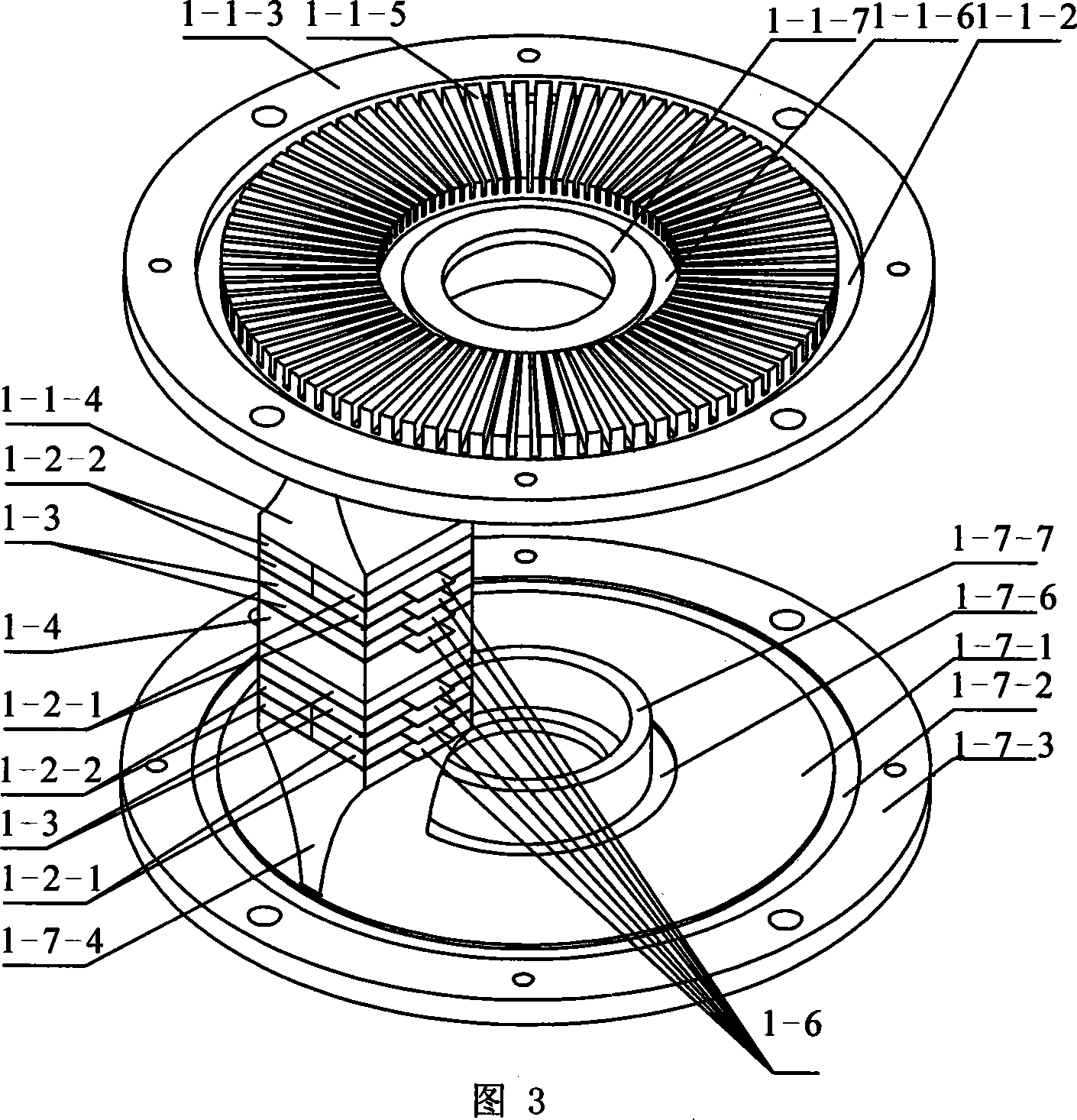

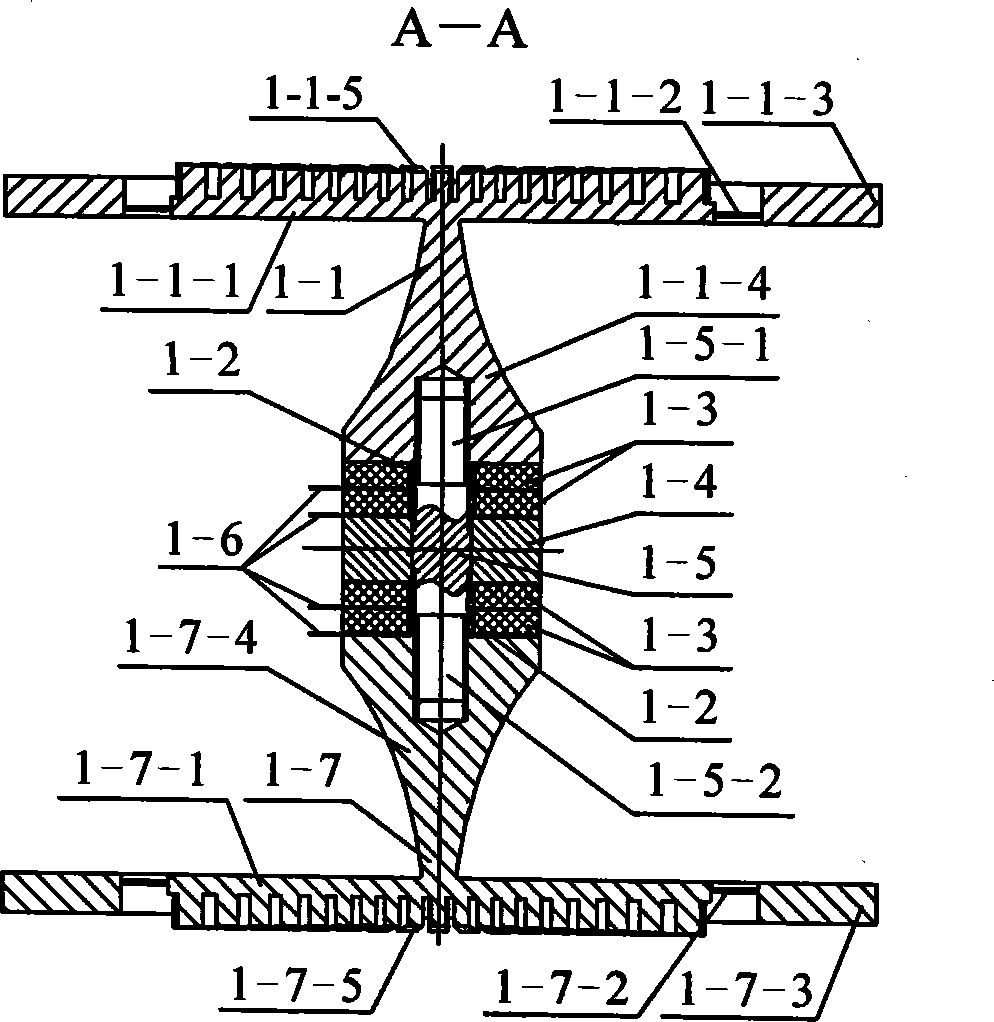

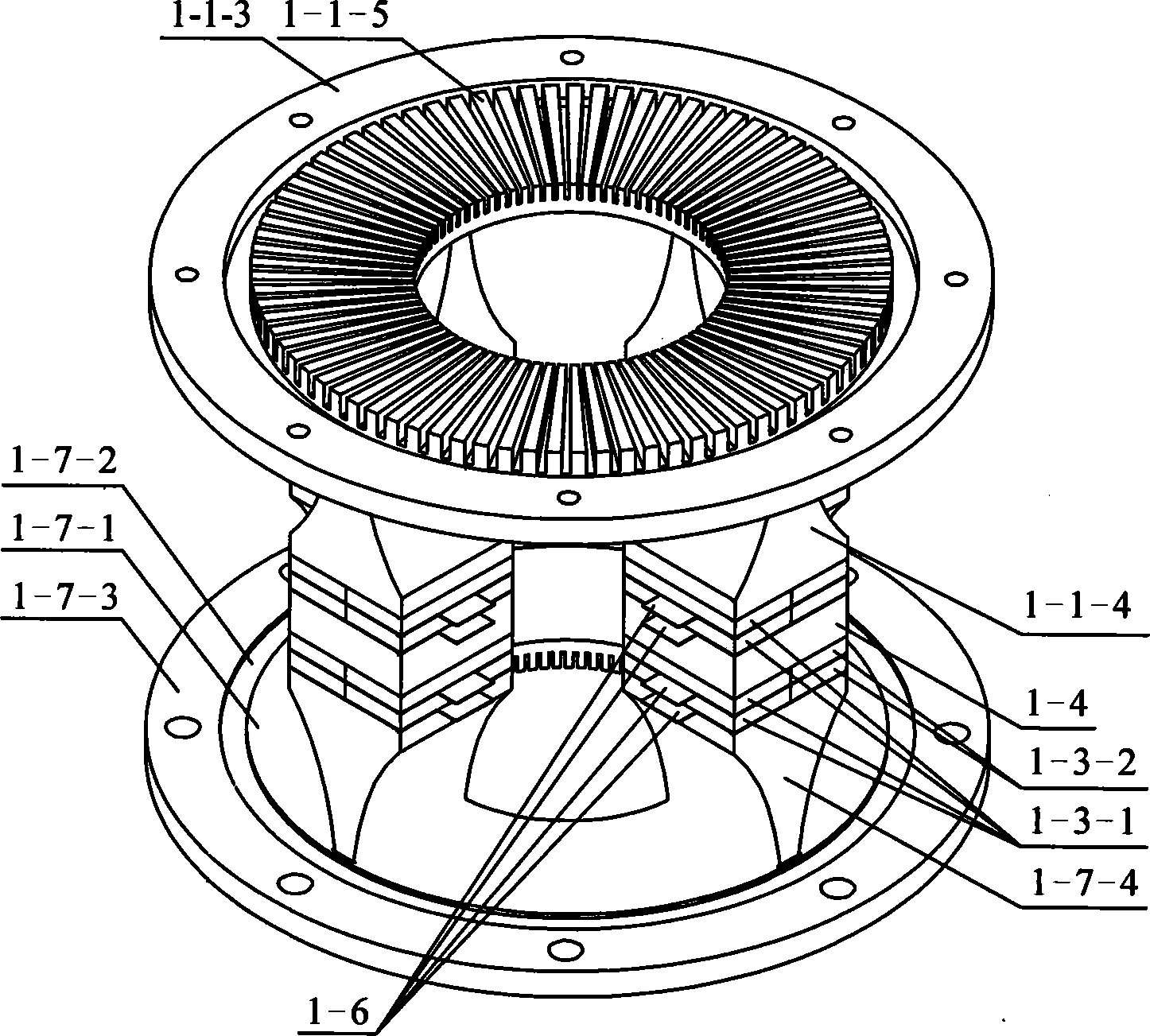

Sandwich type round plate stator and ultrasonic motor using the same

InactiveCN101388621ASolve efficiency problemsAddress mechanical propertiesPiezoelectric/electrostriction/magnetostriction machinesCantilevered beamElastomer

The invention relates to a sandwich disk stator and an ultrasonic motor which uses the stator, which relate to the technical field of piezoelectric ultrasonic motors. The sandwich disk stator and the ultrasonic motor solve the problem in an existing ultrasonic motor that since a mode that a metallic elastomer is pasted with a piezoelectric ceramic slice is adopted to actuate, the mechanical output ability is restricted. Driving elements with even number in the sandwich disk stator are fixed on the upper end surface of a disk, two pairs of piezoelectric ceramic pieces are fixed between each pair of cantilever beams, and a plurality of comb-shaped driving gears are evenly distributed on the lower end surface of the disk. The ultrasonic motor which uses the stator comprises two stators, a rotor component is composed of a rotor and a wear resistance bush ring, wherein the end surface of the wear resistance bush ring is provided with same taper with the upper end surface of the driving gears, two stators are respectively installed on and under the rotor, the pre-tightening between the stator component and the rotor component can be realized through two stator flanges, and the rotor component is connected with bearing blocks of the two stators through output shafts and bearings on two ends of the rotor in a rotary mode. The sandwich disk stator and the ultrasonic motor have simple structure, can realize big force moment output, and have stable performance.

Owner:HARBIN INST OF TECH

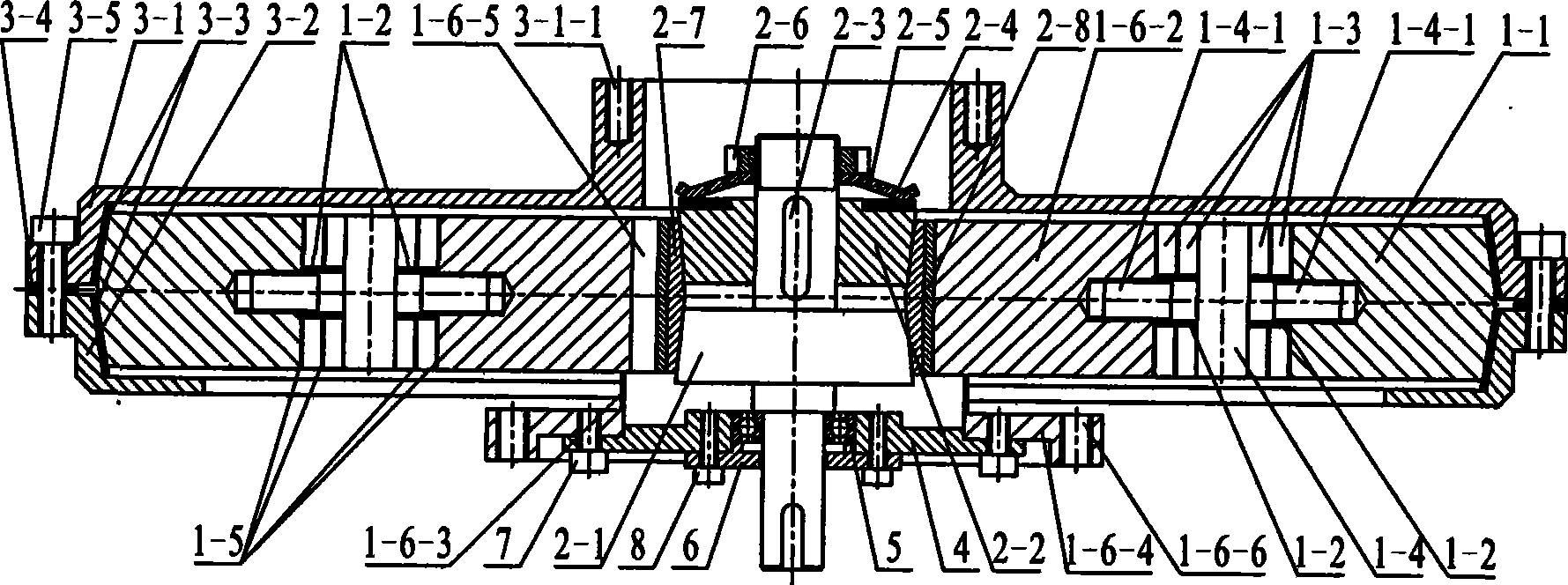

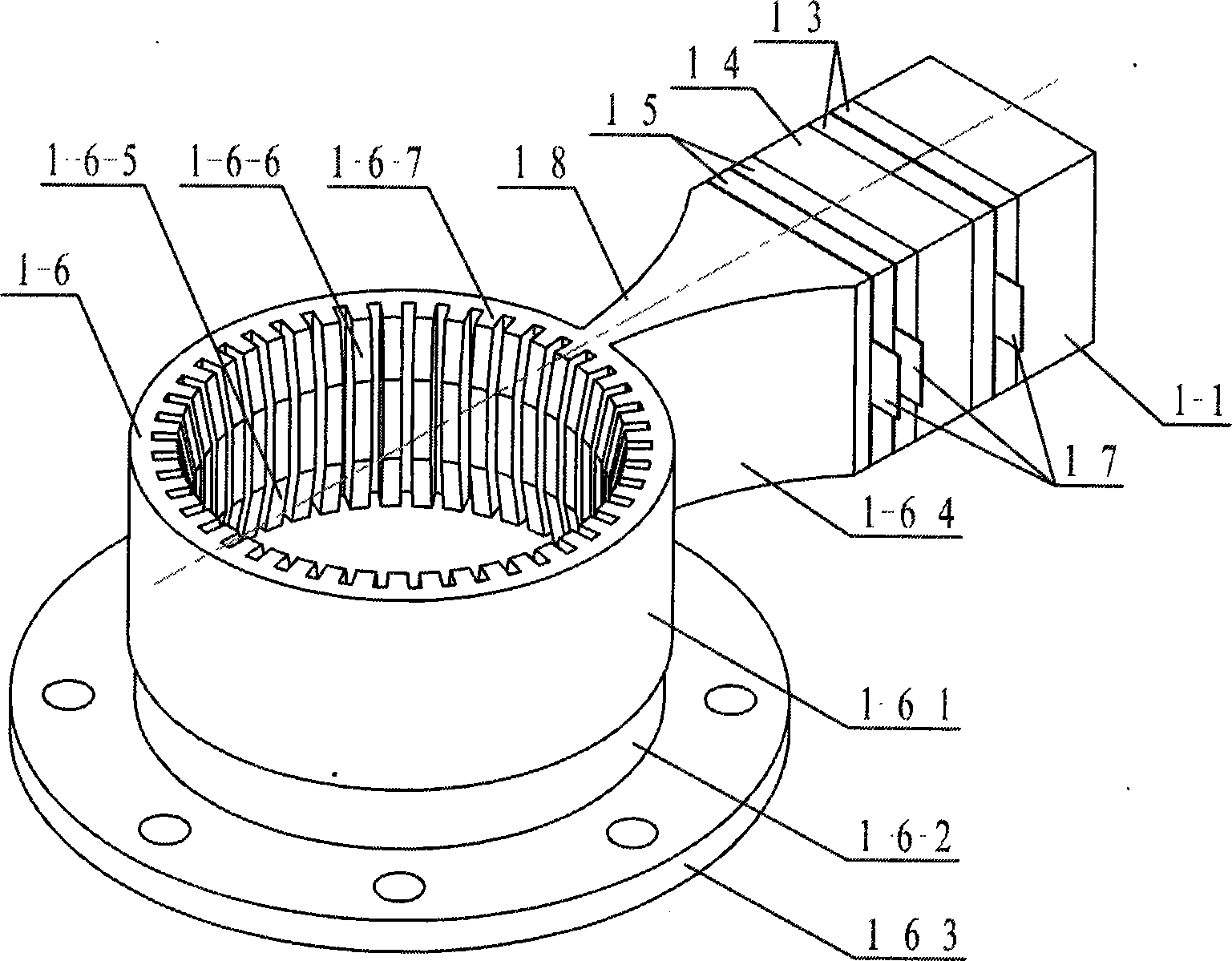

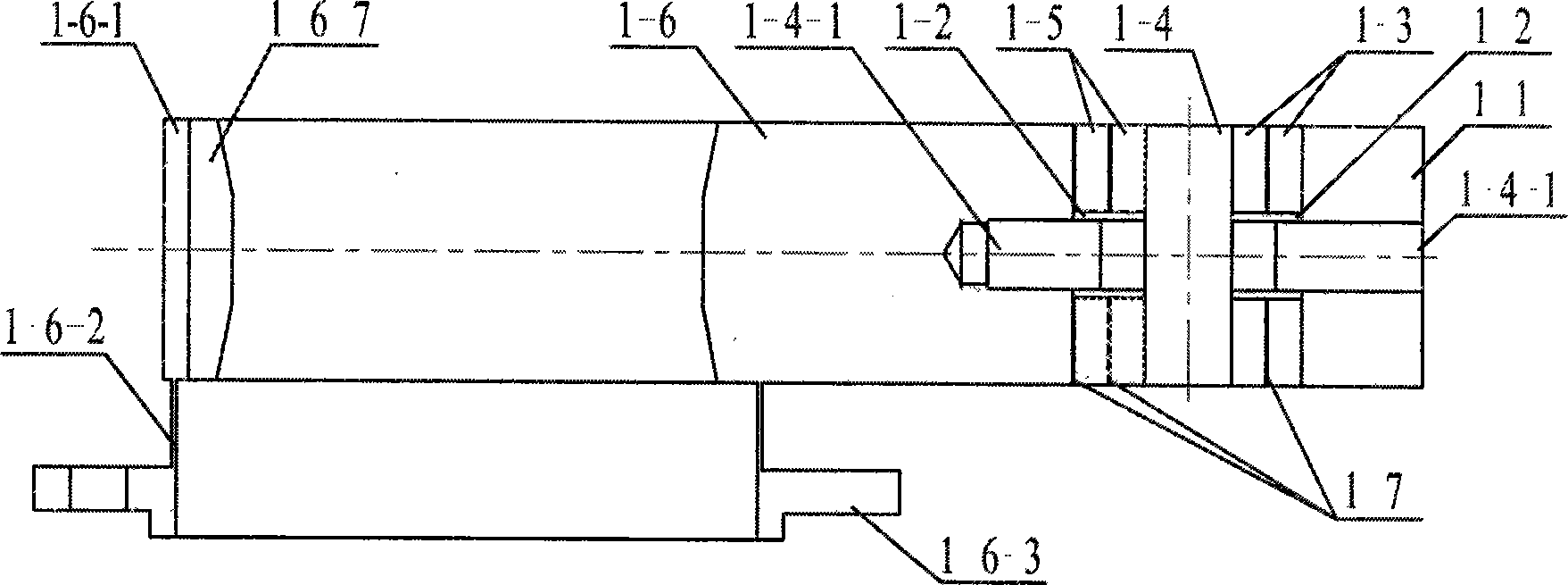

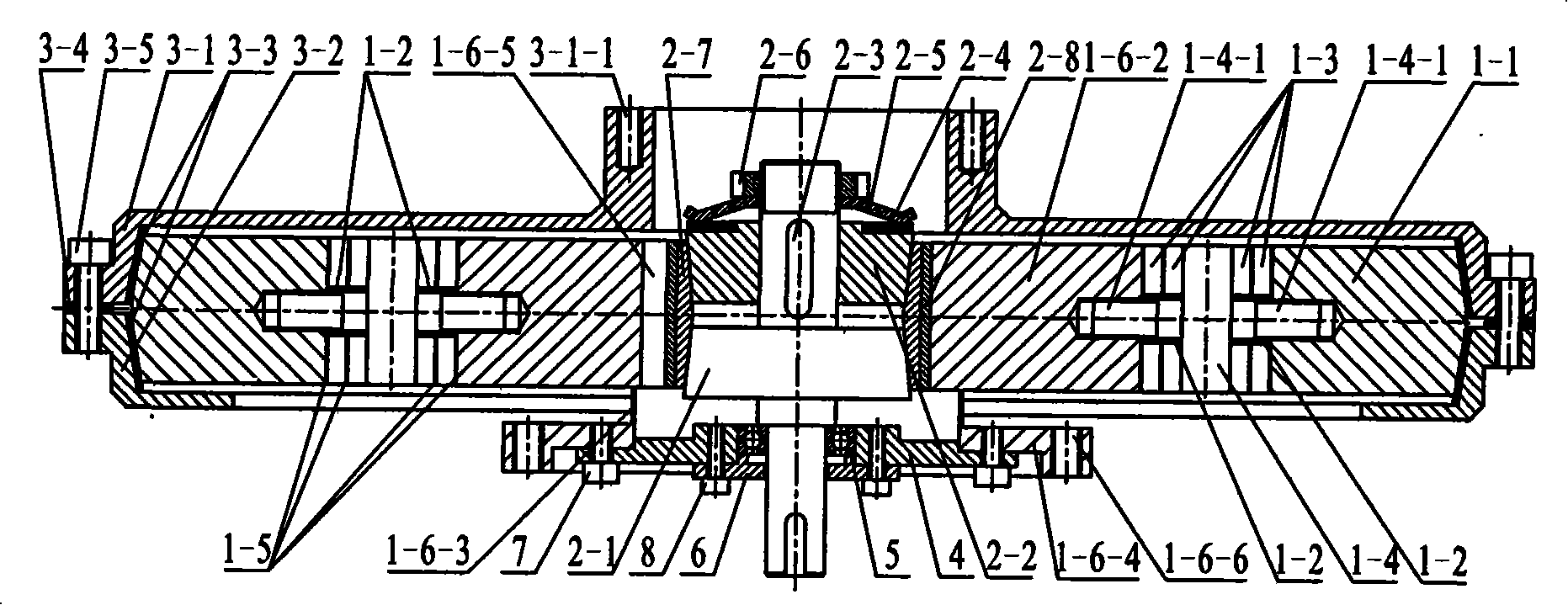

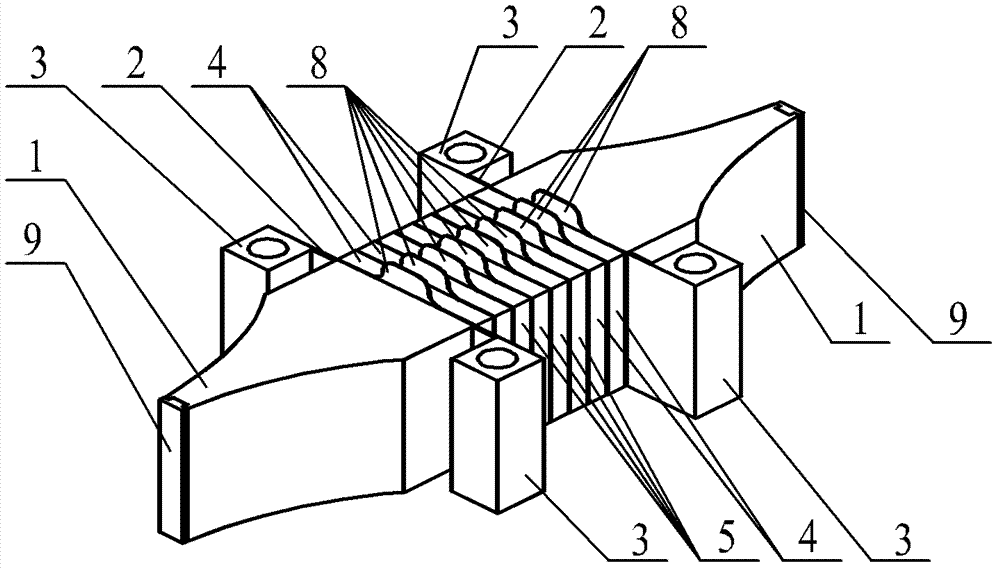

Cantilever longitudinal-bending composite transducer type cylindrical traveling-wave ultrasonic motor vibrator

InactiveCN101651431ASolve efficiency problemsAddress mechanical propertiesPiezoelectric/electrostriction/magnetostriction machinesTransducerLongitudinal vibration

The invention relates to a cantilever longitudinal-bending composite transducer type cylindrical traveling-wave ultrasonic motor vibrator belonging to the technical field of piezoelectric ultrasonic motors and solving the problems that the mechanical output capability of a motor is restricted because the prior ultrasonic motor vibrator adopts a metal elastic body to bond piezoelectric ceramic thinplates to excite, and the mechanical output capability and the controllability of an ultrasonic motor are lowered because a plurality of transducers are simultaneously driven. The cantilever longitudinal-bending composite transducer type cylindrical traveling-wave ultrasonic motor vibrator comprises a cylinder and a cantilever longitudinal-bending composite sandwich transducer which are connectedinto a whole by two cantilevers, a fastening screw is fixedly screwed with a rear end cover after passing through central through holes of a front end cover and the two cantilevers, four longitudinalvibration piezoelectric ceramic plates are arranged between the two cantilevers, two pairs of bending vibration piezoelectric ceramic plates are respectively arranged between the front end cover andthe first cantilever and between the rear end cover and the second cantilever, and the adjacent bending vibration piezoelectric ceramic plates and the adjacent longitudinal vibration piezoelectric ceramic plates have opposite polarization directions. The cantilever longitudinal-bending composite transducer type cylindrical traveling-wave ultrasonic motor vibrator is used for the field of manufacturing ultrasonic motors.

Owner:HARBIN INST OF TECH

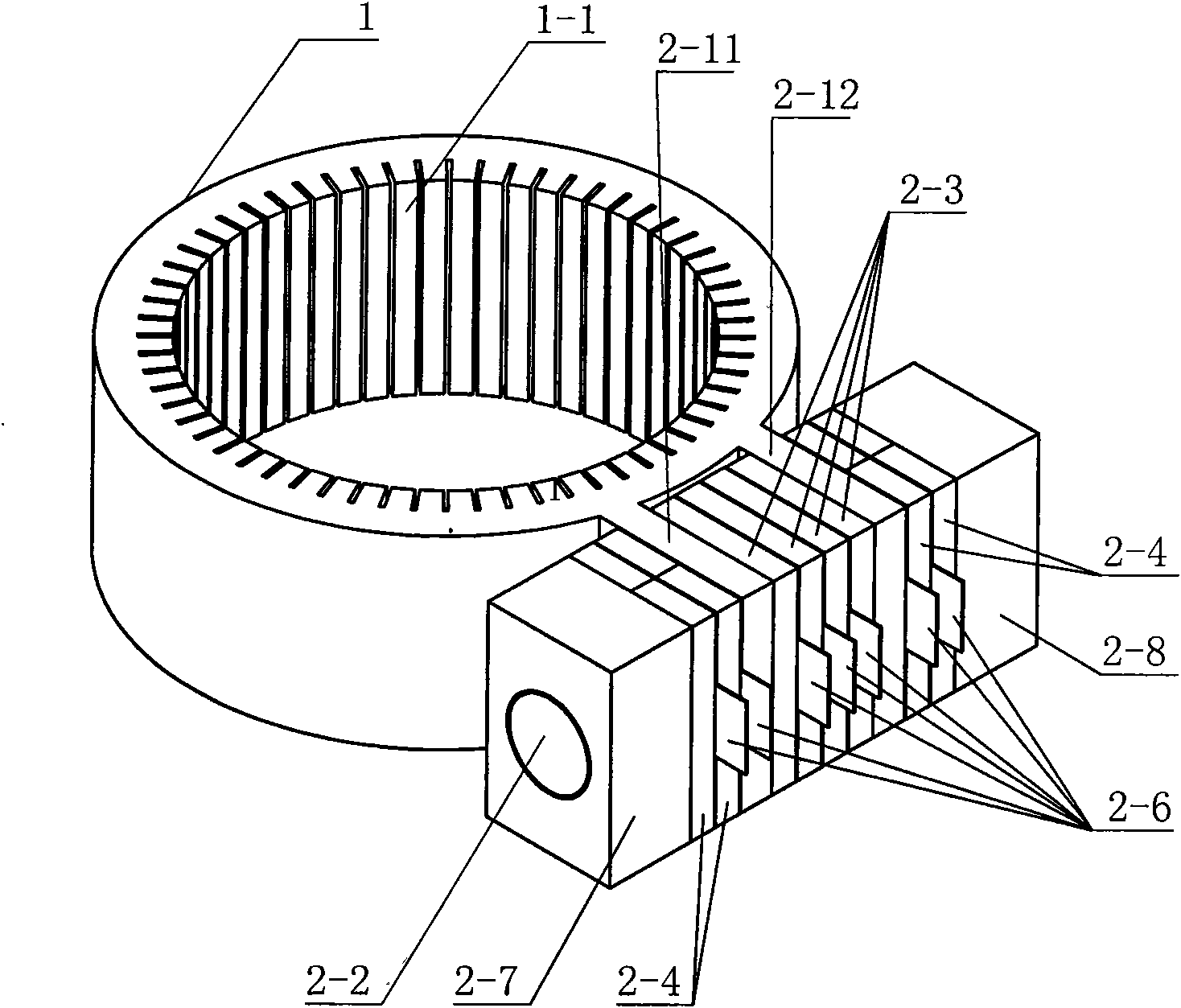

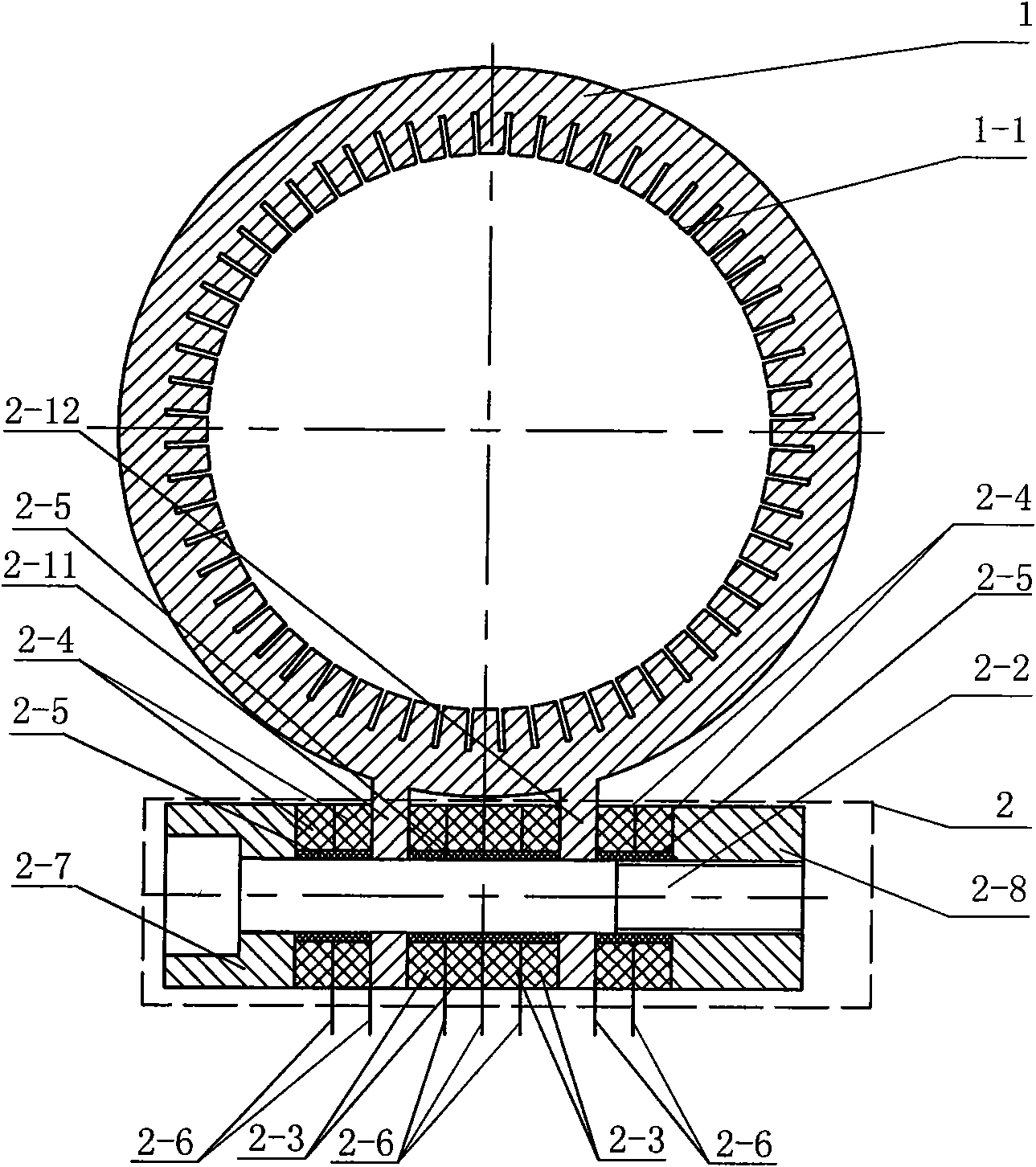

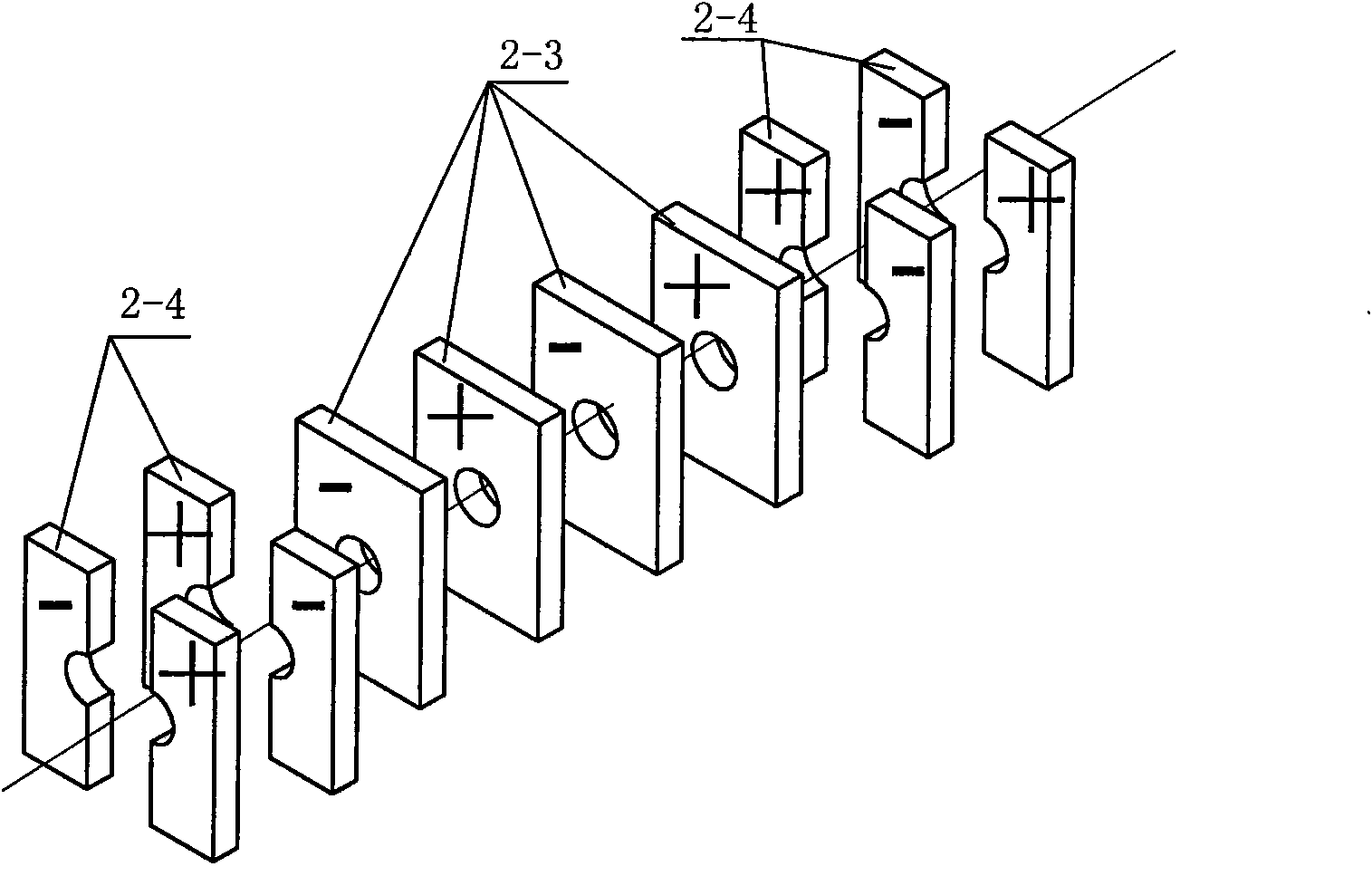

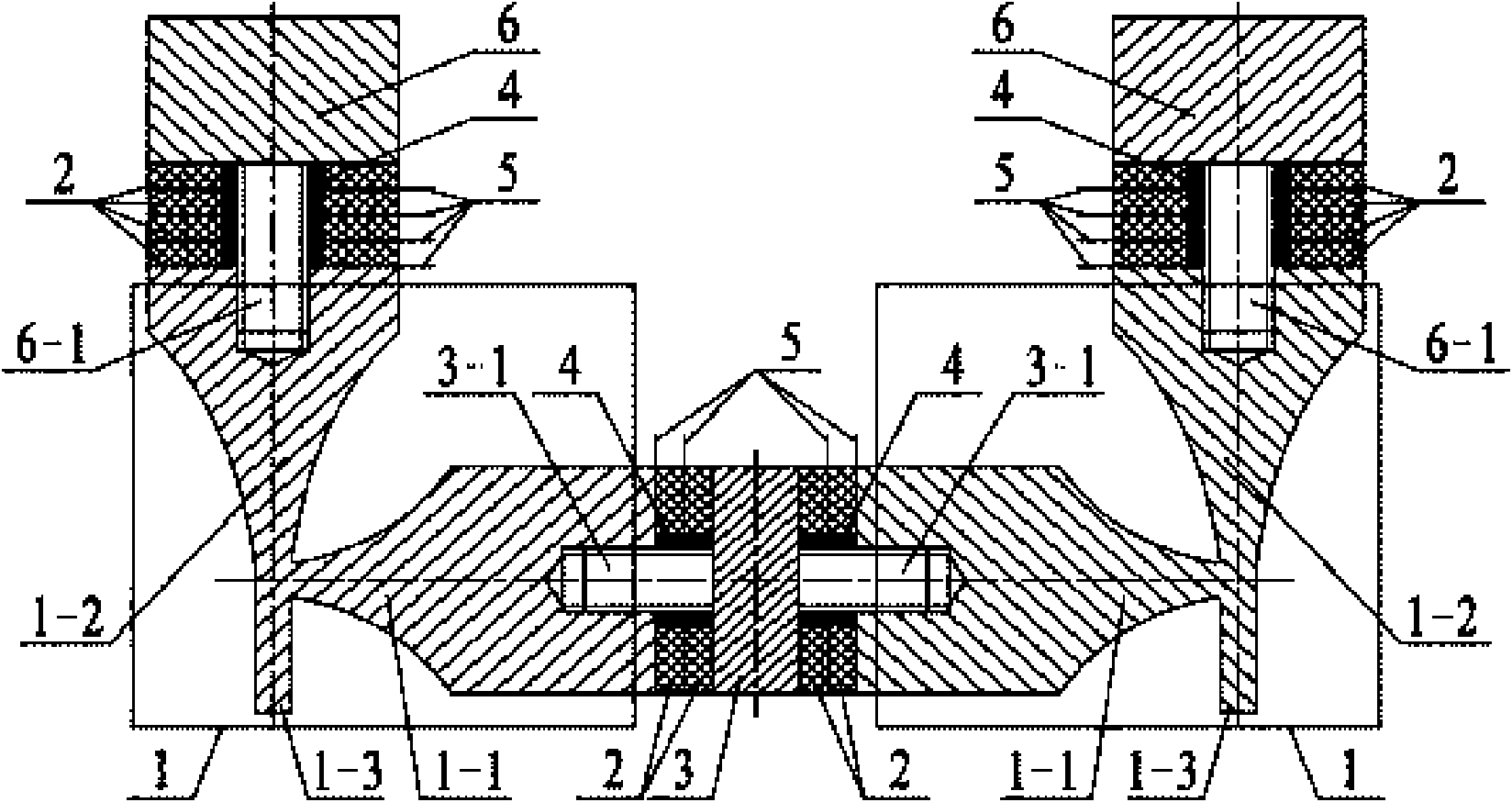

Bending layer energy converter round disk stator and ultrasonic electromotor using this stator

InactiveCN101262185ASolve efficiency problemsAddress mechanical propertiesPiezoelectric/electrostriction/magnetostriction machinesElastomerCircular disc

The invention discloses a flexural vibration sandwiched energy converter-typed round disc stator and an ultrasonic motor to which the stator is applied, and relates to the ultrasonic motor field. The invention solves the problem in the existing ultrasonic motor, that mechanical output capacity is restrained due to the adoption of elastic metal body stuck on piezoelectric ceramic pieces for excitation. Even flexural vibration sandwiched energy converters of the stator are symmetrically arrayed and fixed between a round disc at the upper end and a round disc at the lower end; both the front end cover and the back end cover of the sandwiched energy converter are a quadrangular with a rectangle cross section narrowing down gradually, the small end faces of the front end cover and the back end cover are fixedly connected with the upper round disc and the lower round disc; two pairs of piezoelectric ceramic pieces are respectively and fixed between the front end cover, the back end cover and the flange. A rotor with a shaft and a rotor without a shaft in the ultrasonic motor both take the shape of a round disc and are embedded respectively from the top and the bottom of a stator cylinder, a wearable cushion is fixed at the end face, contacting the round disc, of the rotor and the stator is fixed to a base through the flange on the energy converter. The flexural vibration sandwiched energy converter-typed round disc stator and the ultrasonic motor of the invention are applicable to the manufacturing field of the ultrasonic motors.

Owner:HARBIN INST OF TECH

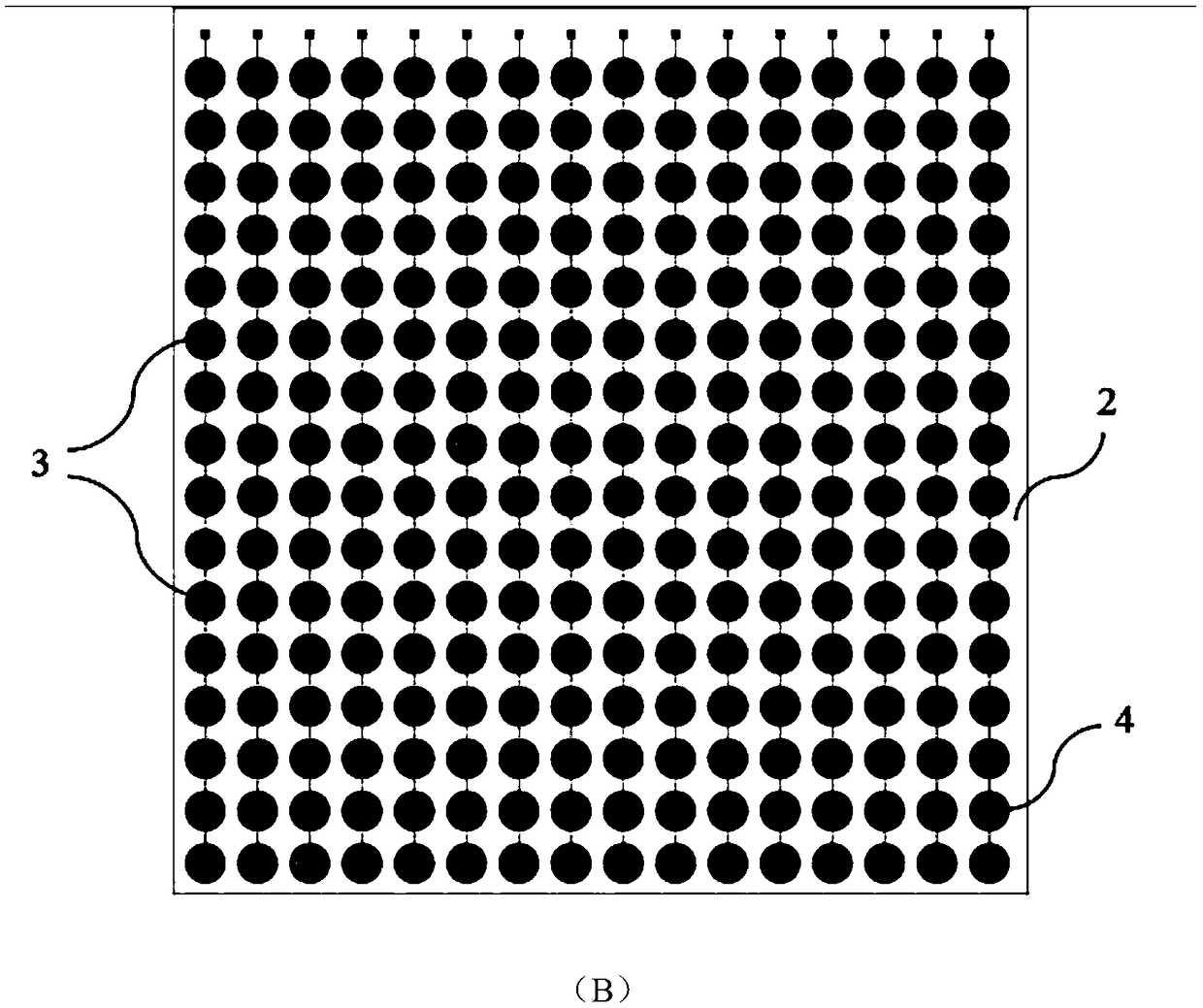

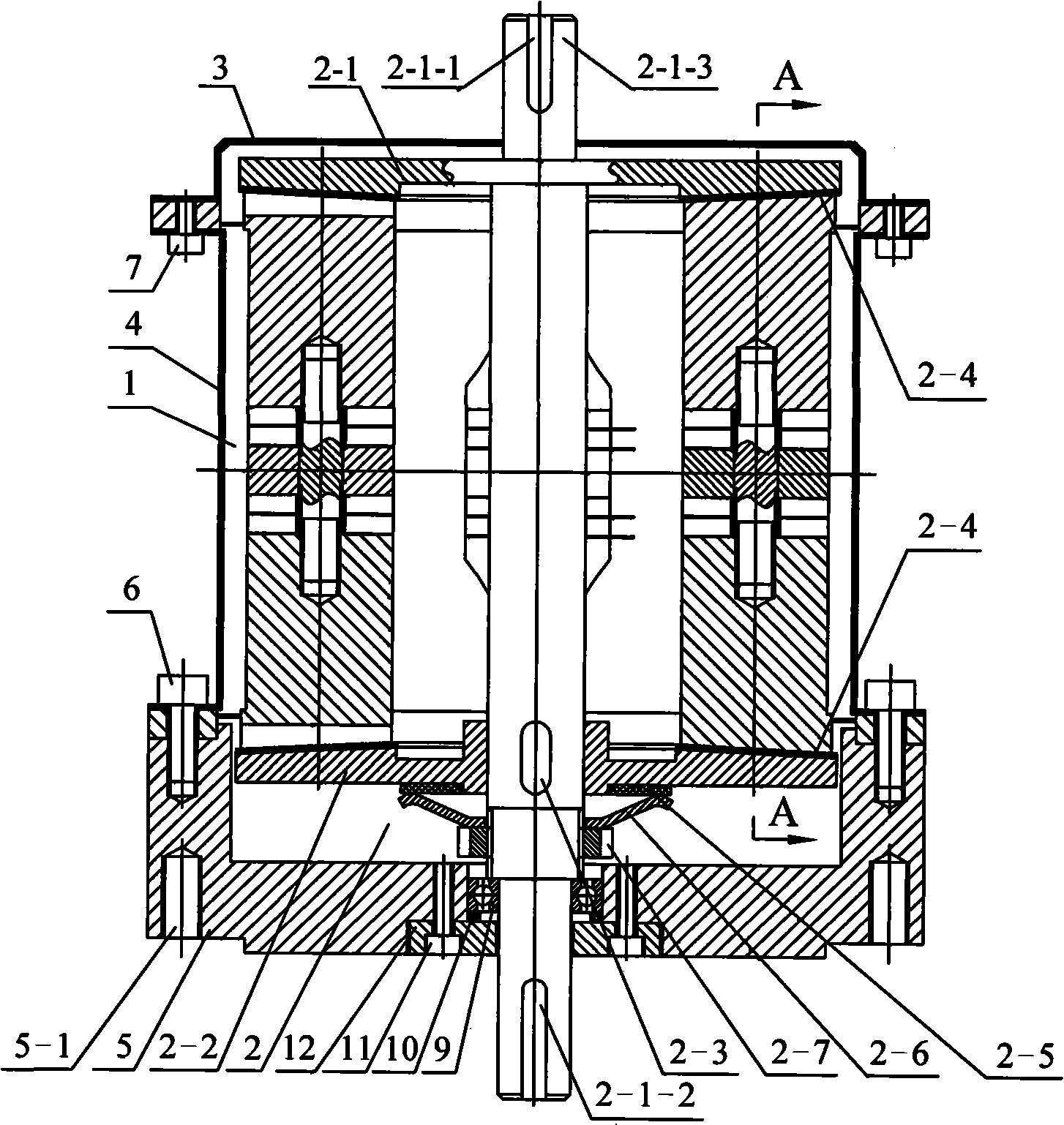

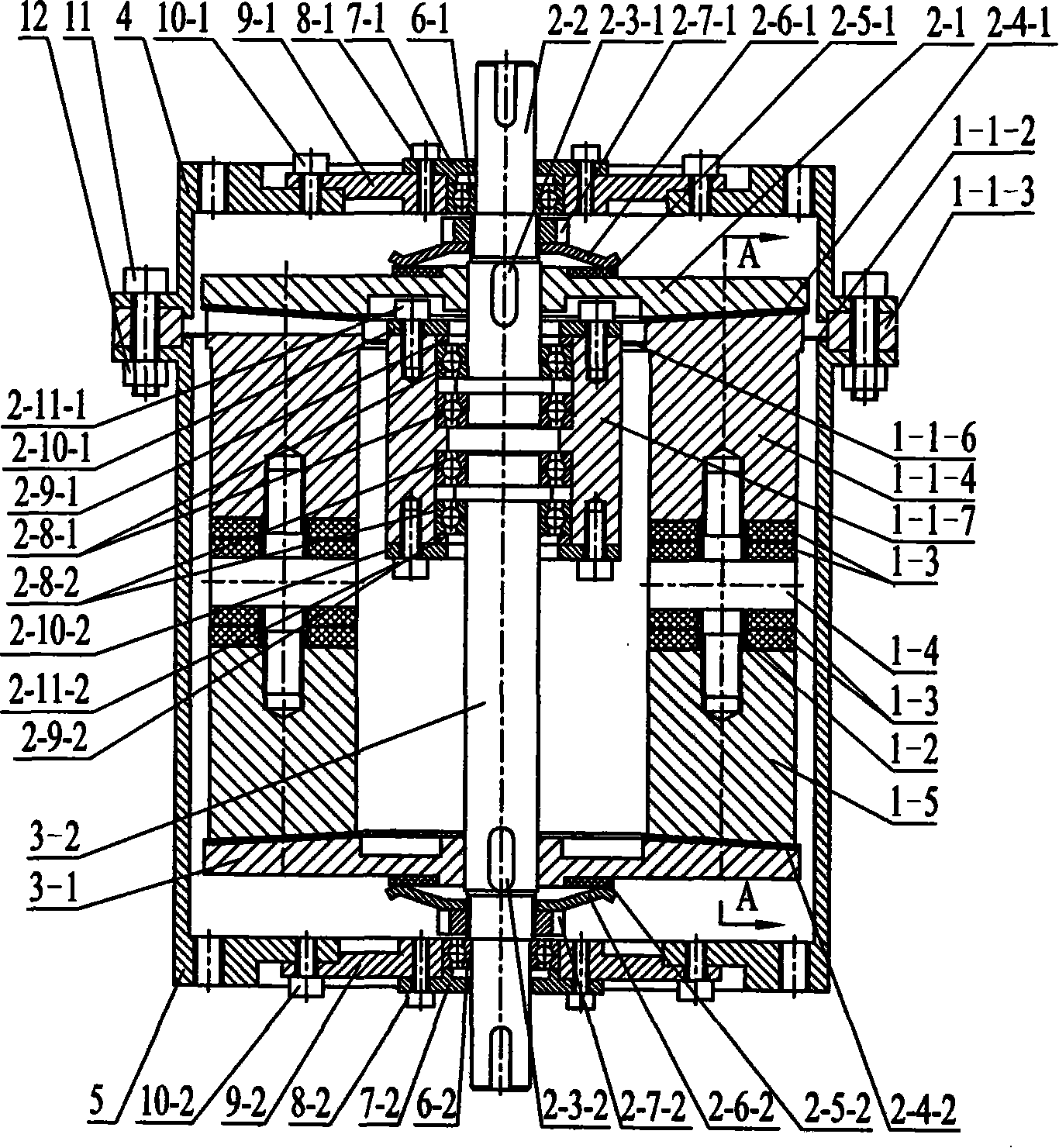

Longitudinal-shaking sandwich energy converter type cylinder type birotor ultrasonic motor

InactiveCN101304223AStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesTransducerLongitudinal vibration

The invention discloses a longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor, which relates to the technical field of an ultrasonic motor and aims at solving the problems that the mechanical output capacity is restricted and a single stator can only realize single moving output existing in present ultrasonic motor. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention comprises a stator component, a medial rotor component, an outer rotor component, a bearing base, a bearing and a bearing pretension cover. The inner surface of a cylinder is manufactured with continuous comb-shaped driving gears; a medial rotor with a shaft and a medial rotor without the shaft are cone-shaped, the thin ends of the medial rotor with the shaft and the medial rotor without the shaft are respectively inserted from the lower part of a stator cylinder and the upper part of the stator cylinder; an outer rotor with the shaft and an outer rotor without the shaft are respectively arranged on the upper part of the stator component and the lower part of the stator component; the lateral surfaces that the outer rotor with the shaft and the outer rotor without the shaft are contacted with the back end cover of the stator are respectively fixed with wear-resistance lining rings; the medial rotor with the shaft is rotatablely connected with the bearing base by the bearing. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention can be applied to the ultrasonic motor manufacturing field.

Owner:HARBIN INST OF TECH

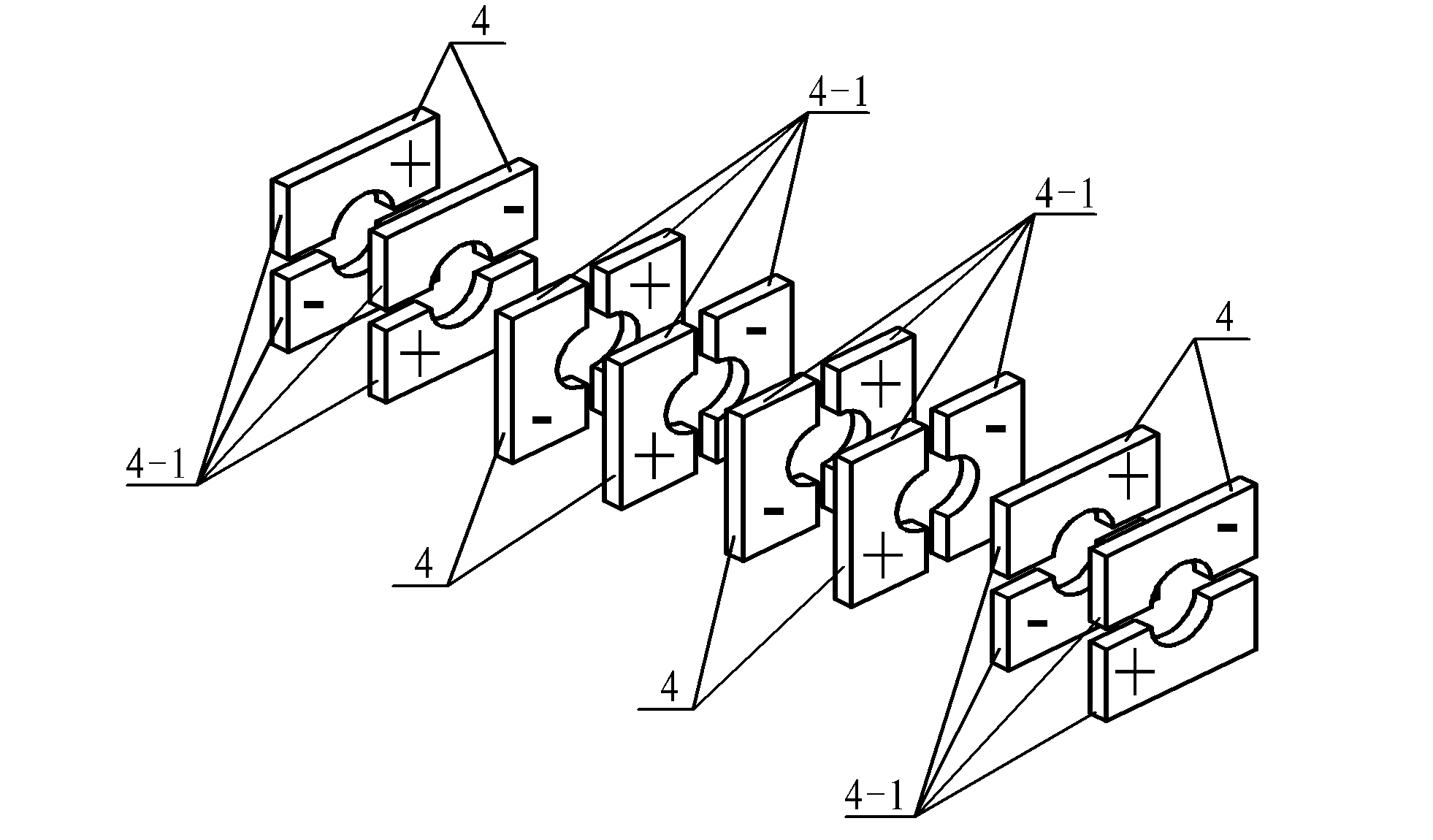

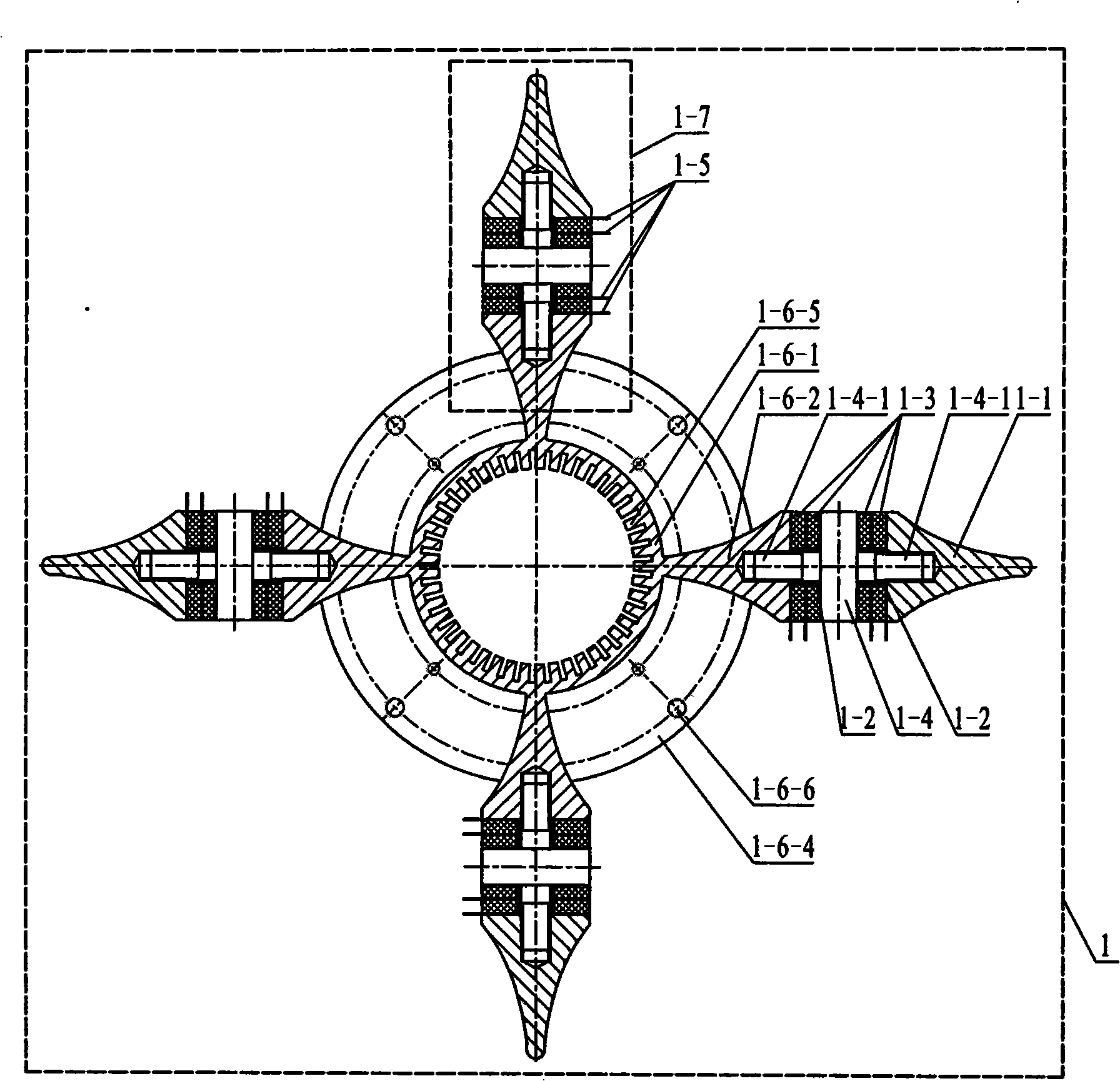

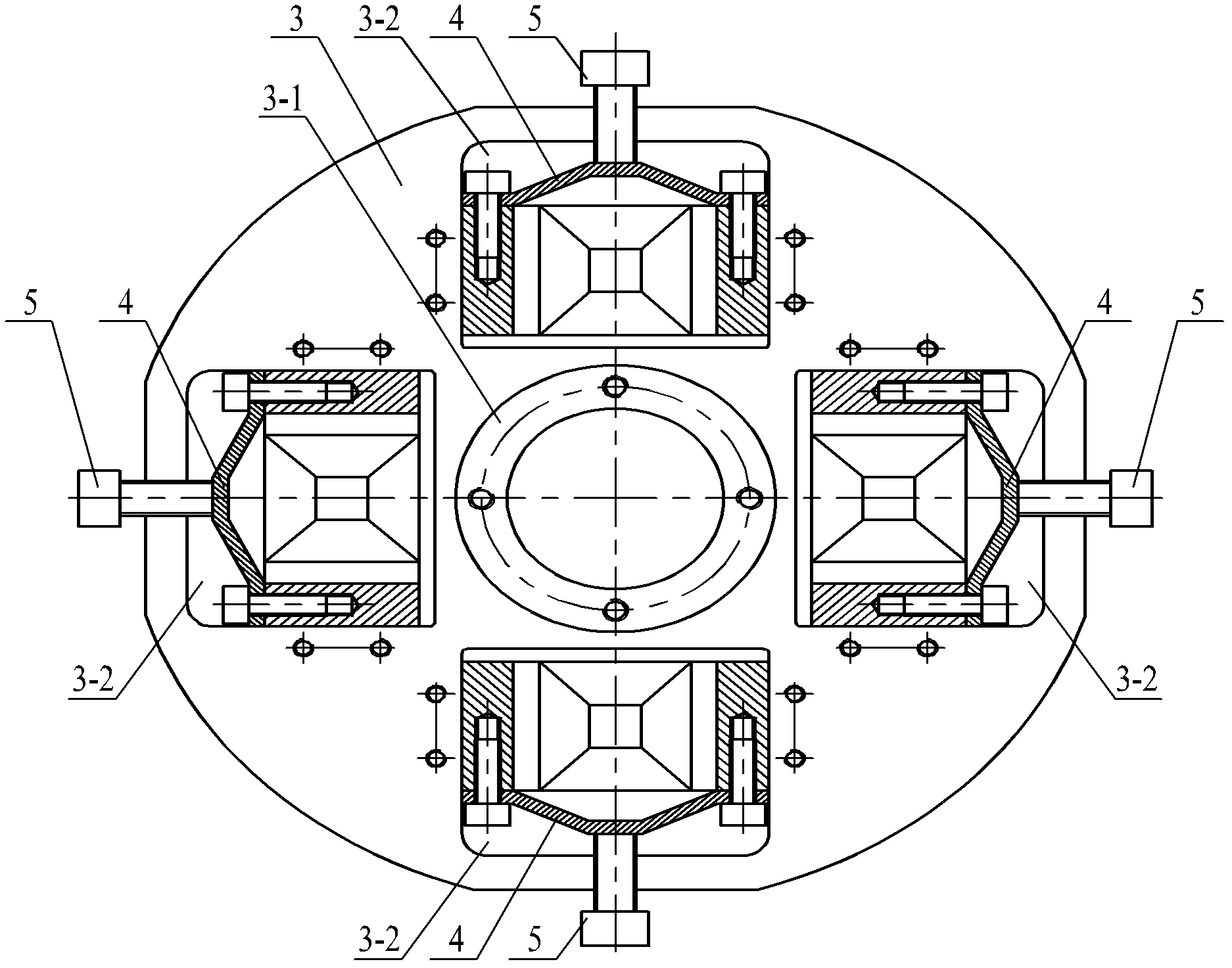

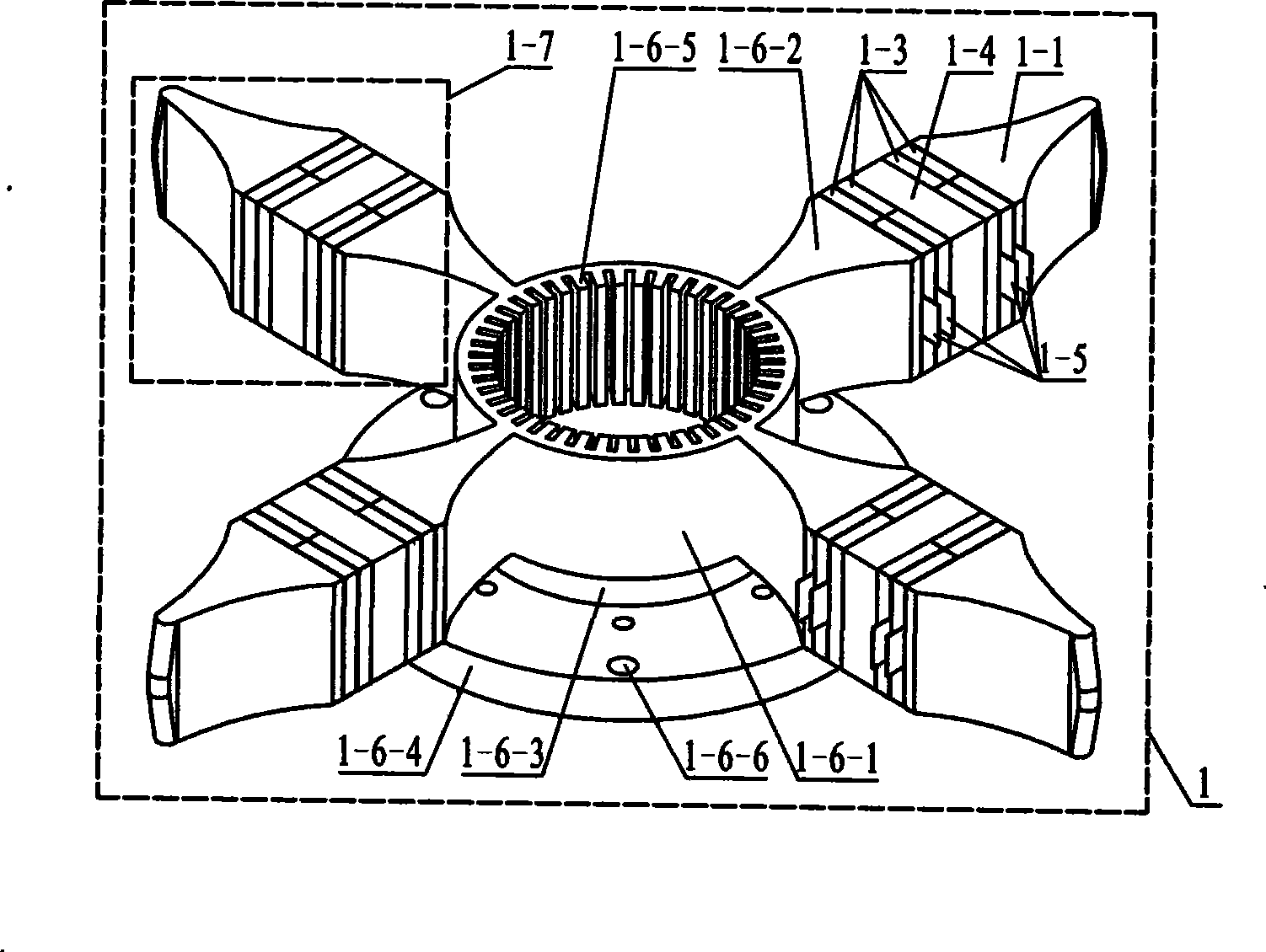

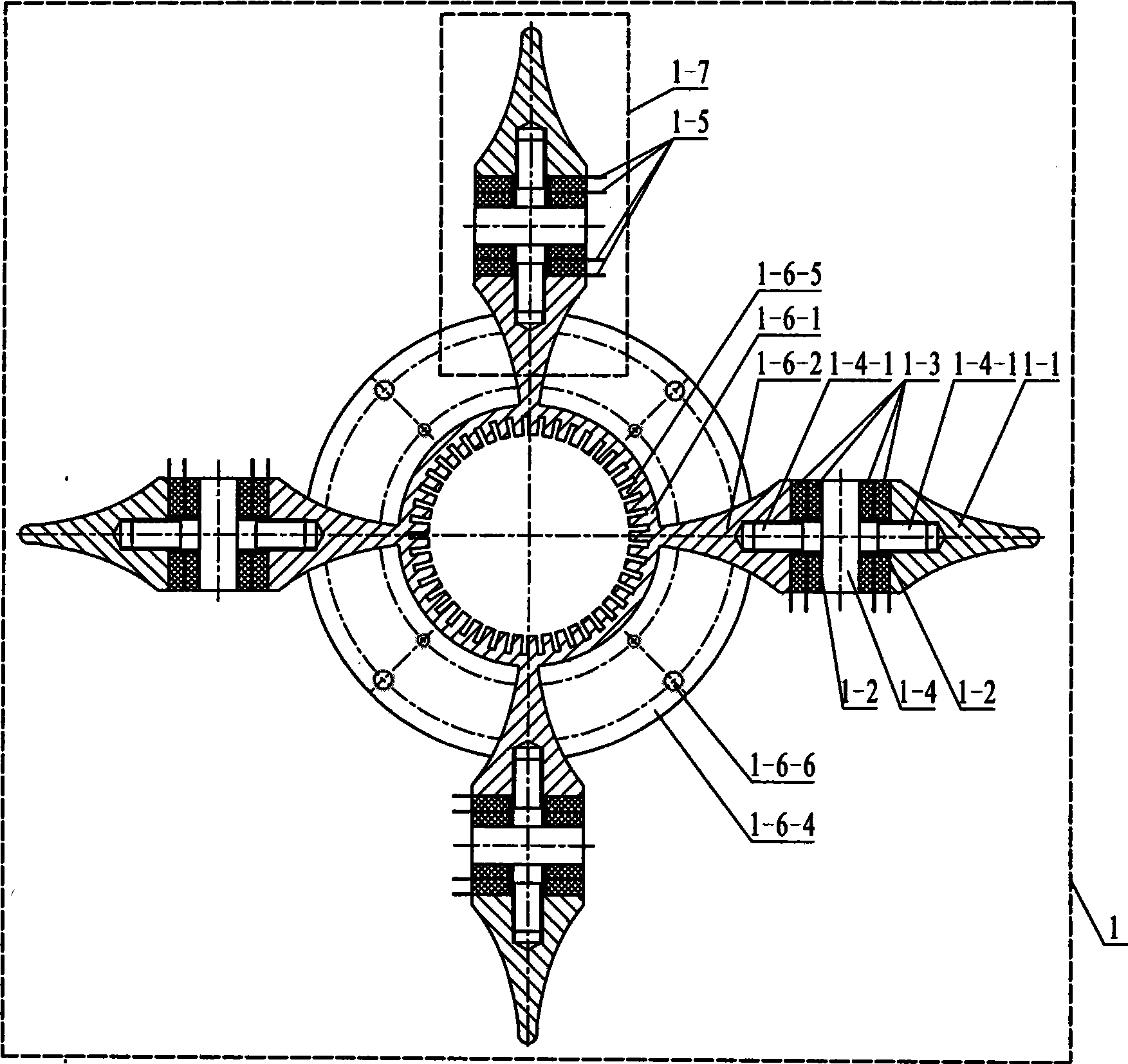

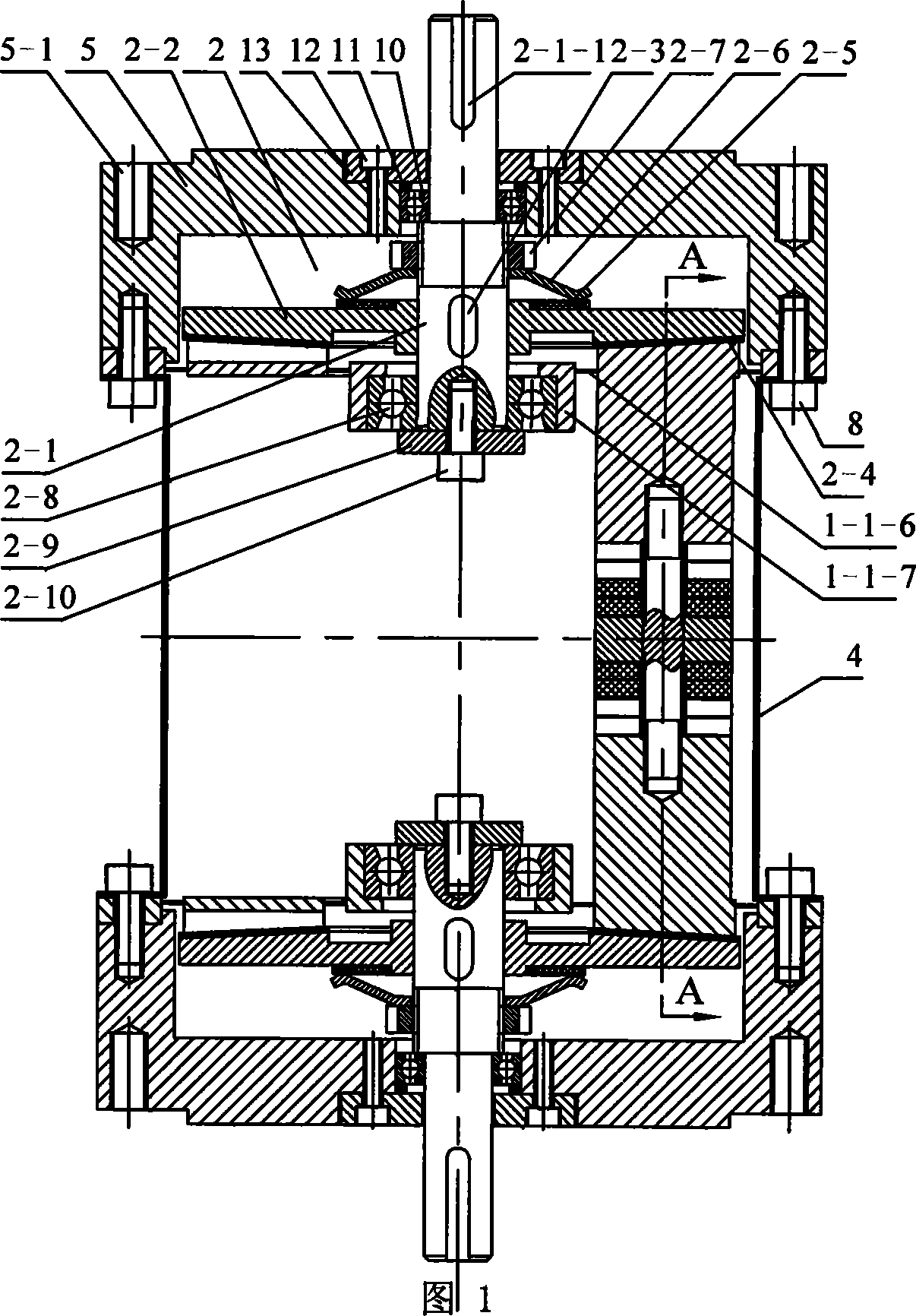

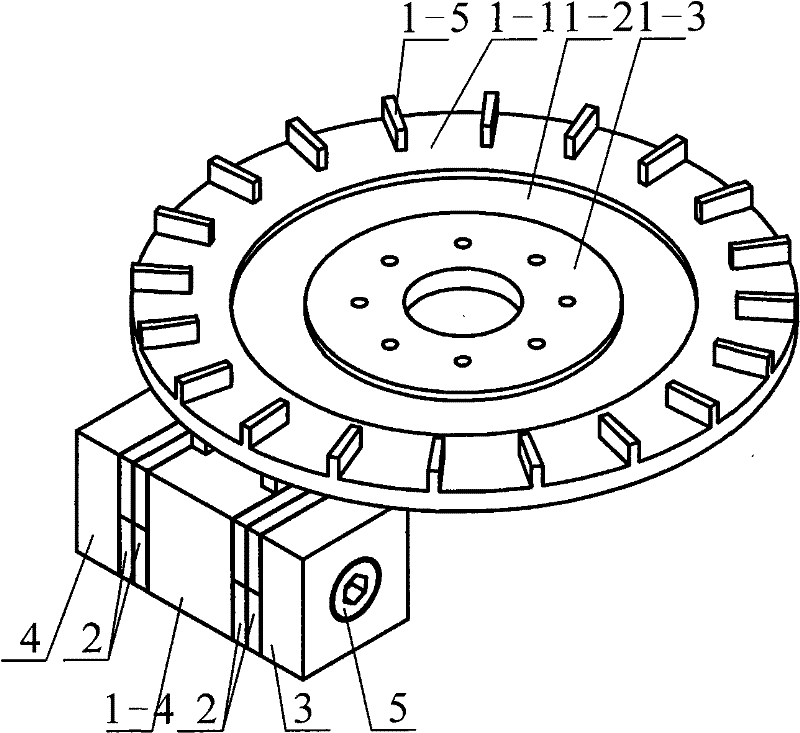

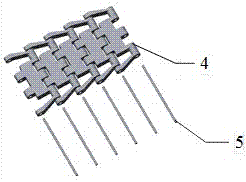

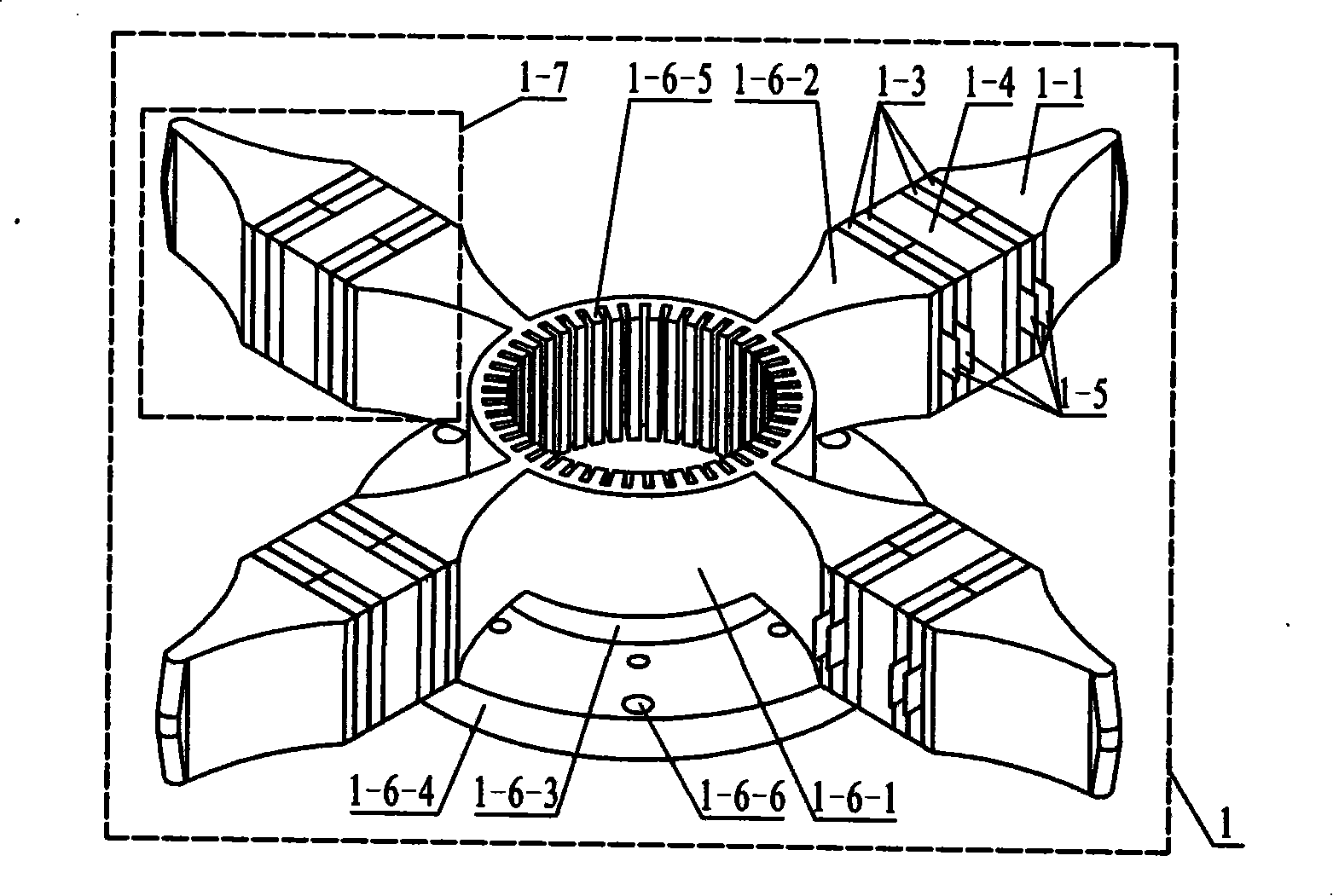

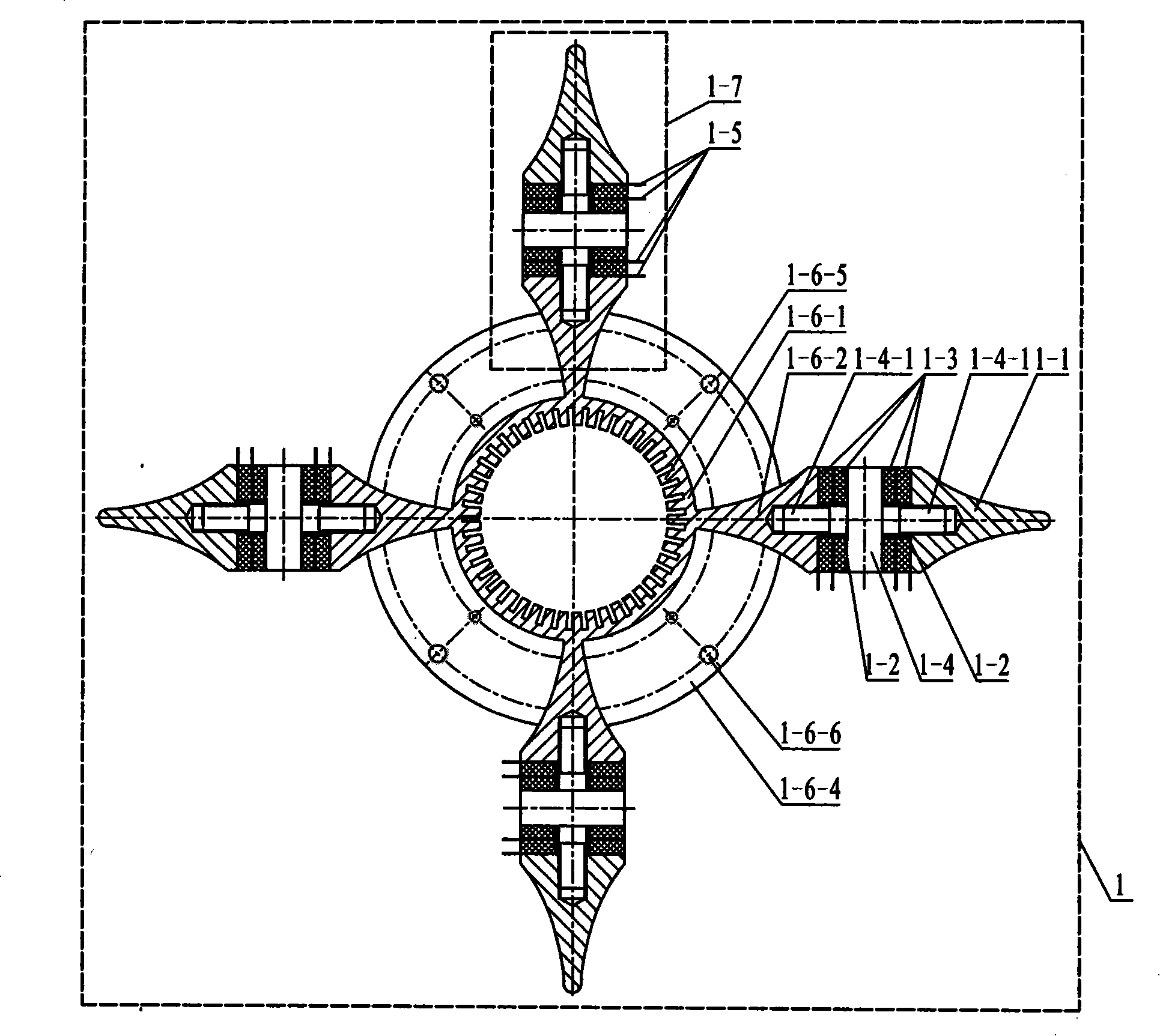

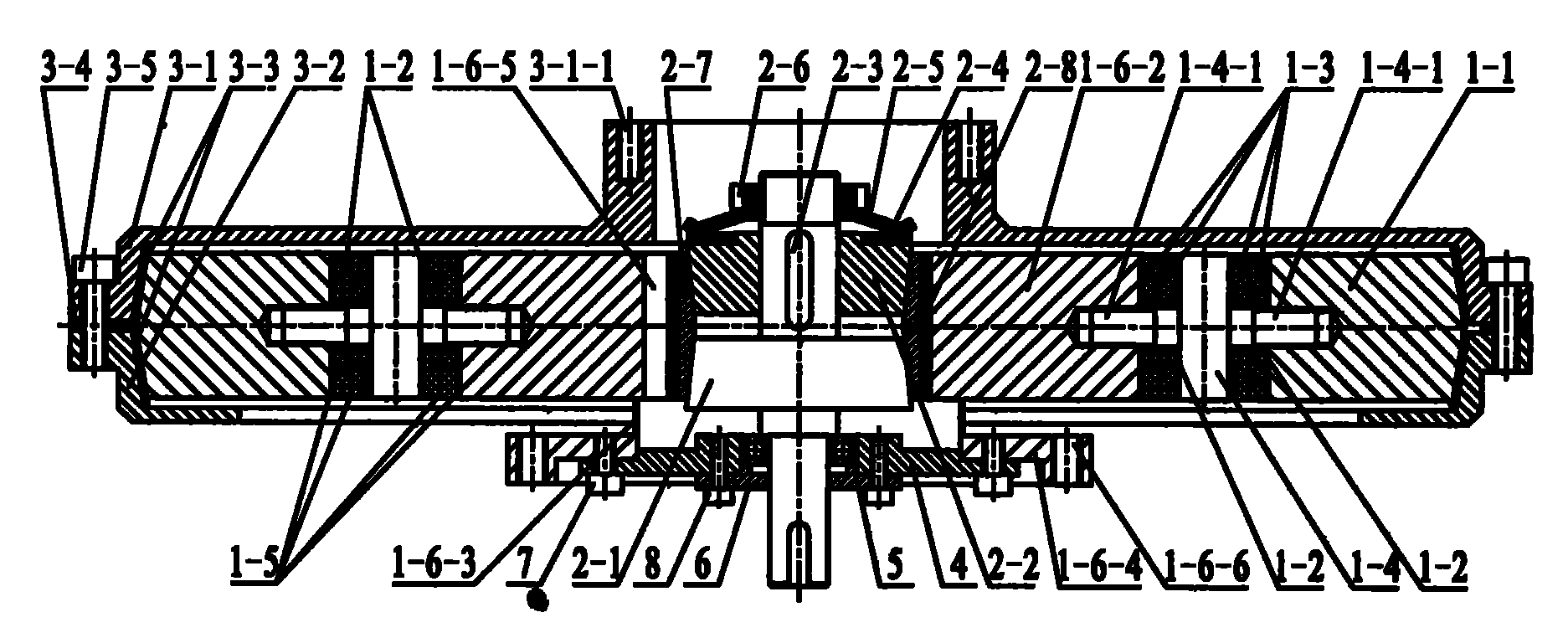

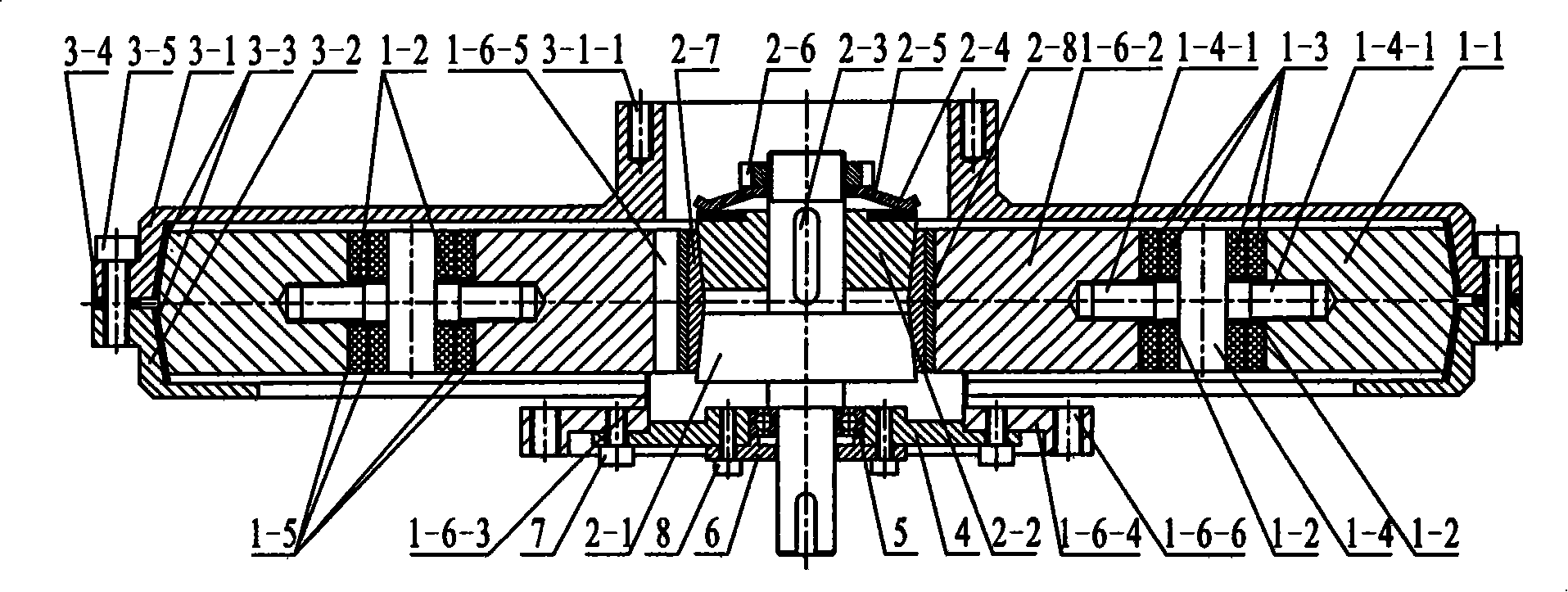

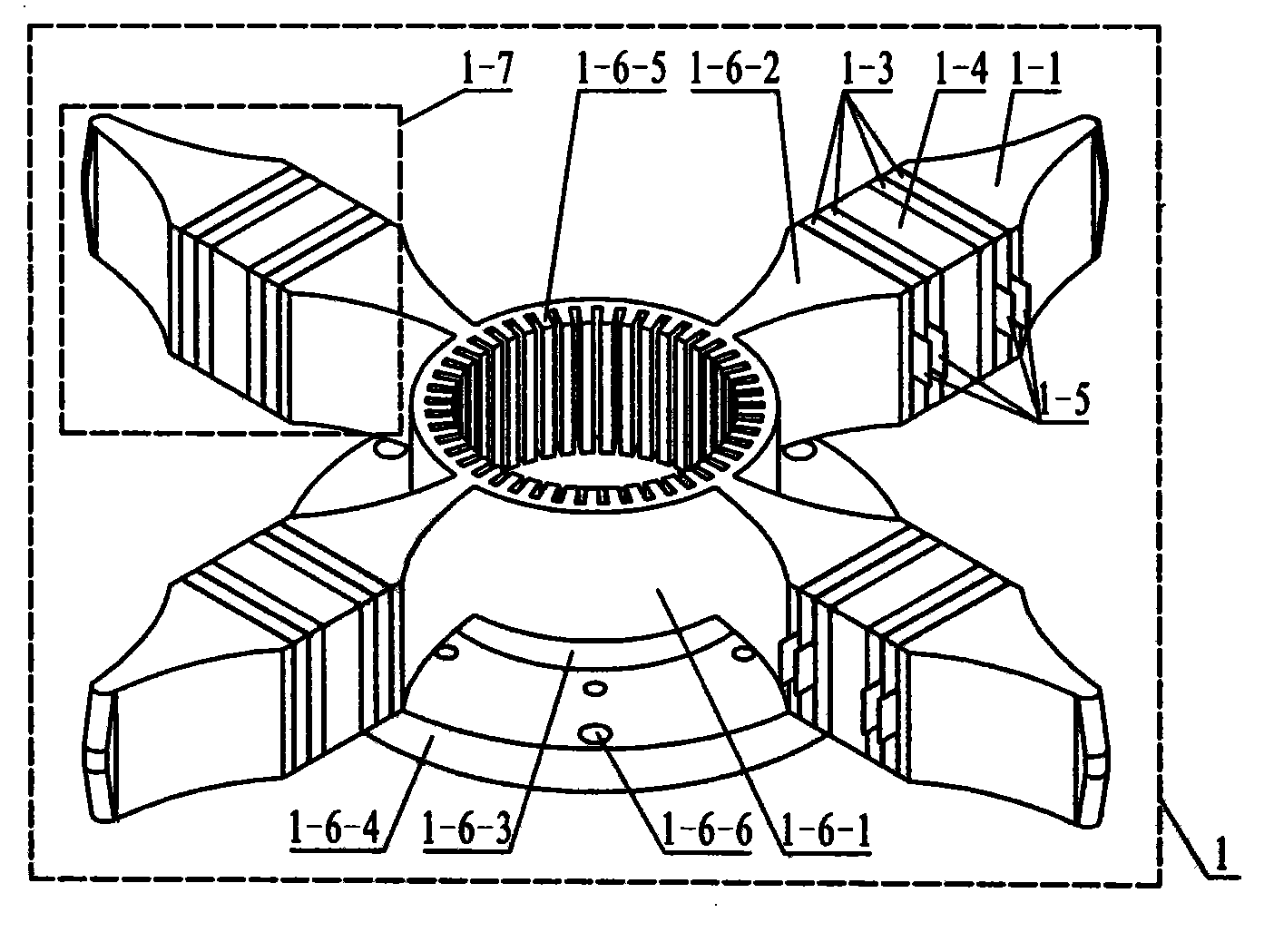

Rotary motor using composite bending vibration biped linear ultrasonic oscillators

ActiveCN102355161AImprove performanceIncrease amplitudePiezoelectric/electrostriction/magnetostriction machinesPatch typeControl theory

The invention provides a rotary motor using composite bending vibration biped linear ultrasonic oscillators, belonging to the technical field of piezoelectric ultrasonic motors. The invention solves the problems that the existing patch type rotary piezoelectric ultrasonic motor has low coupling efficiency, and the mechanical output capability is difficult to improve. The rotary motor provided by the invention comprises n oscillators, a rotor assembly, a base, n plate springs, n pre-pressing screws and 4n baffle plates, wherein n is a positive integer; the center of the base is provided with a central through hole and a bearing seat; the rotor assembly is arranged in the central through hole; n rectangular section slots are uniformly distributed on the base along the outer circumference direction of the bearing seat; one oscillator is arranged in each rectangular section slot; one plate spring is also arranged in each rectangular section slot; and the two ends of each plate spring are respectively connected fixedly with two installing seats of the oscillator positioned in the rectangular section slot. The rotary motor provided by the invention can realize large-torque output.

Owner:HARBIN INST OF TECH

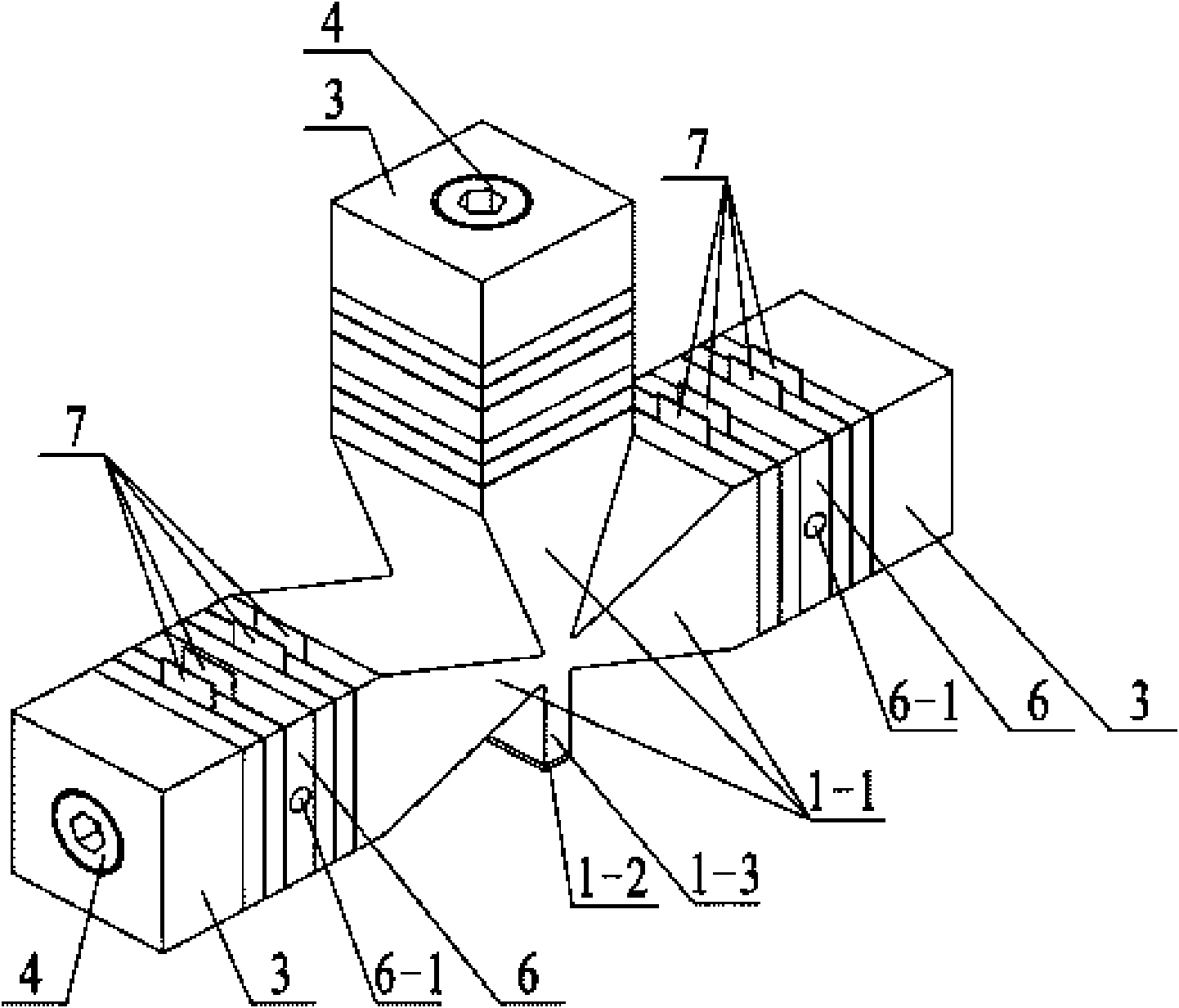

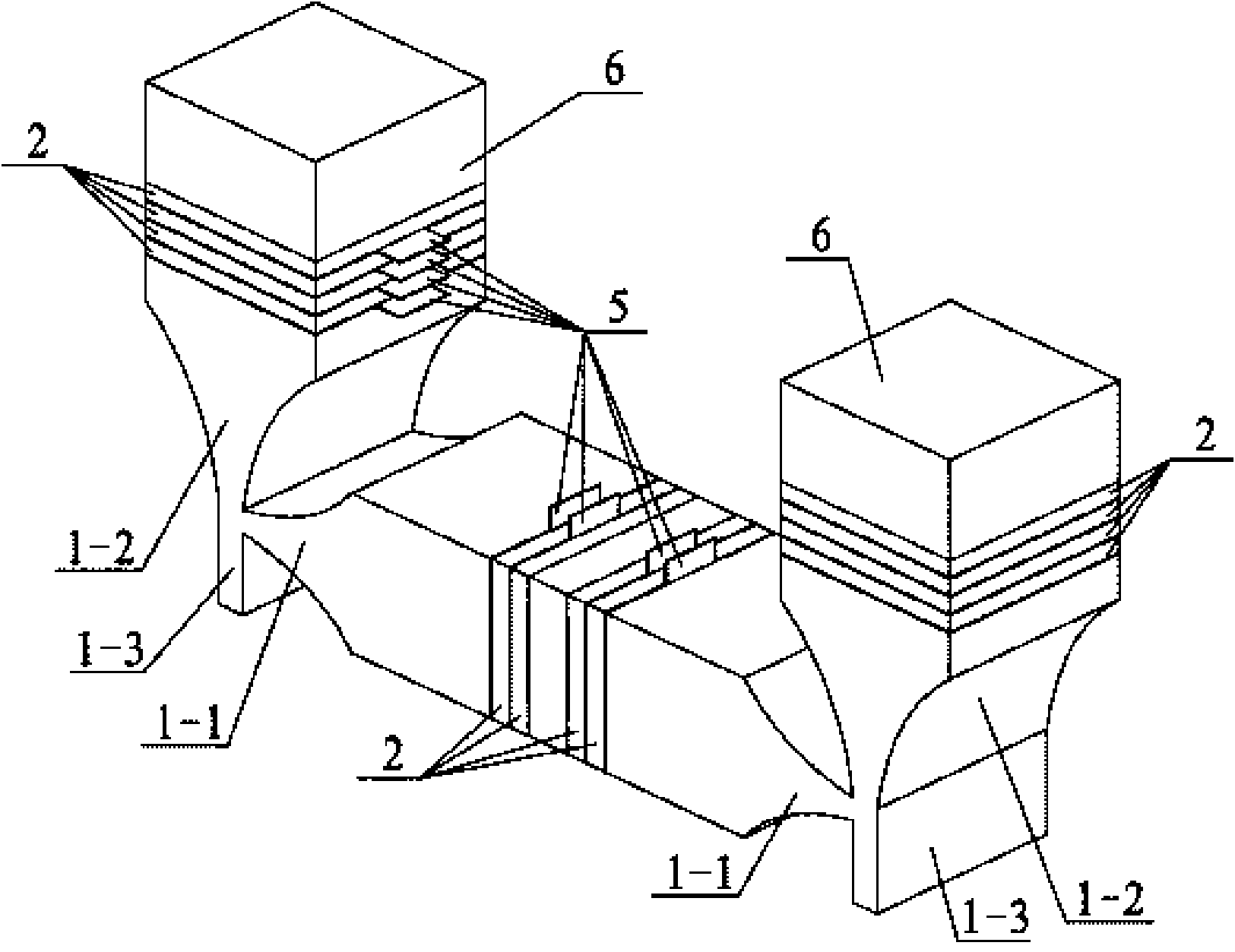

U-type double-pin linear ultrasonic motor vibrator

InactiveCN101626204ASolve efficiency problemsAddress mechanical propertiesPiezoelectric/electrostriction/magnetostriction machinesEngineeringPrism

The invention relates to a U-type double-pin linear ultrasonic motor vibrator, which relates to the field of piezoelectric ultrasonic motors and solves the problem of limited output capability of the prior mechanism. The U-type double-pin linear ultrasonic motor vibrator is characterized in that a vertical horn and a horizontal horn which are connected with end covers are of quadrangular prisms having rectangular sections and gradually thinning; big end faces of the vertical horn and the horizontal horn are provided with blind holes; driving pins are cuboids, the upper end faces of the driving pins are connected with a small end face of the vertical horn, and the upper parts of the side faces of the driving pins are connected with a small end face of the horizontal horn; flanges are provided with double-screw bolts which are fixedly connected with the blind holes and are sleeved with two pieces of piezoelectric ceramic plates; two independent end covers have the same structure and comprise double-screw bolts which are fixedly connected with the blind holes and are sleeved with four pieces of piezoelectric ceramic plates; all the piezoelectric ceramic plates are polarized along the thickness direction, the polarization directions of adjacent piezoelectric ceramic plates are opposite to each other, and electrode slices are arranged on positions applying driving signals; and the double-screw bolts of the flanges and the independent end covers are sleeved with insulation bushes. The invention is applied to the field of motors and has the advantages of high electromechanical coupling efficiency and large momental output.

Owner:HARBIN INST OF TECH

Bend-twist coupling type piezoelectric driving track traveling device and working method thereof

InactiveCN105490582AAvoid weightAvoid complexityPiezoelectric/electrostriction/magnetostriction machinesTransducerTorsional vibration

The invention provides a bend-twist coupling type piezoelectric driving track traveling device and a working method thereof. The device comprises a metal track, two annular components and a variable cross-section piezoelectric transducer, wherein the annular components are arranged at two ends of the variable cross-section piezoelectric transducer; the variable cross-section piezoelectric transducer comprises a plurality of sets of piezoelectric ceramic pieces, two pre-tightening wedge blocks and a variable cross-section beam; and the piezoelectric ceramic pieces are arranged in a certain order and are fixed in a groove of the variable cross-section beam through the pre-tightening wedge blocks. According to the bend-twist coupling type piezoelectric driving track traveling device and the working method thereof, by stimulating the piezoelectric ceramic pieces, a torsional vibration mode and a bending vibration mode are stimulated on the variable cross-section beam, so that a traveling wave, with n (n being greater than or equal to 2) wave crests and wave troughs shown all together, rotating along the peripheral direction is coupled on the annular components, the mass points on the outer surfaces of the annular components carry out micro-amplitude elliptical motions and drive the metal track to move through the action of friction, and the device has the advantages of compact structure, large force (torque) weight ratio, high environmental suitability, structure form flexibility, high speed, high electro-mechanical coupling efficiency and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

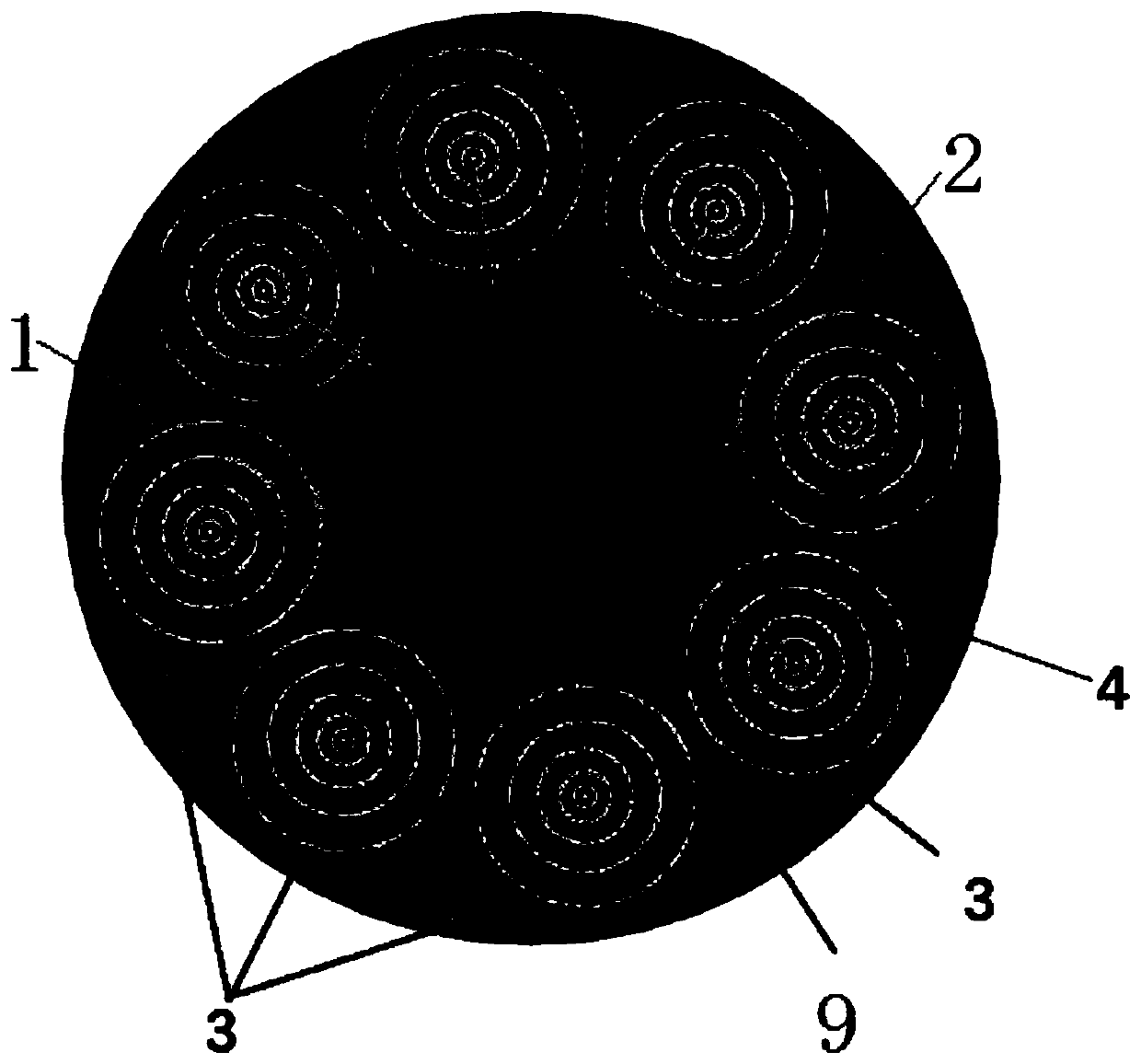

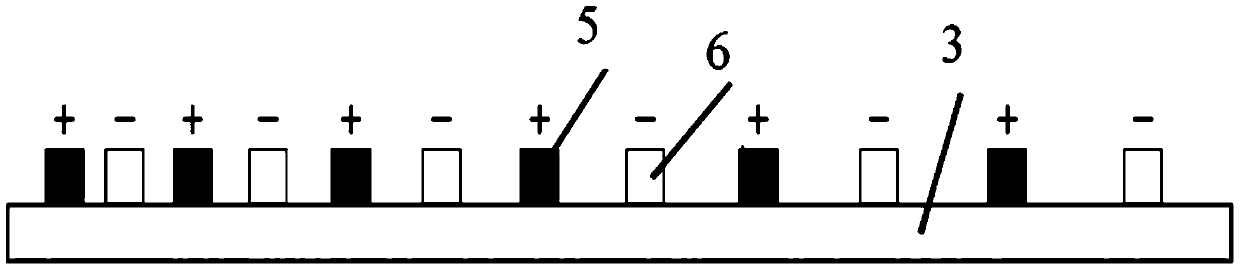

An omnibearing broadband flexible dielectric elastic interdigital transducer and a manufacturing method thereof

The invention provides an omni-directional broadband flexible dielectric elastic interdigital transducer and a manufacturing method thereof. The omni-directional broadband flexible dielectric elasticinterdigital transducer comprises a flexible DE substrate which is disc-shaped; s a flexible annular interdigital electrode arranged on the surface of the flexible DE substrate, wherein flexible annular interdigital electrode includes: a positive electrode interdigital electrode and a negative electrode interdigital electrode, The positive electrode interdigital electrode and the negative electrode interdigital electrode are in a mutually-nested annular interdigital shape, the distance between every two adjacent electrodes in the flexible annular interdigital electrode is gradually increased outwards from the circle center of the flexible annular interdigital electrode in the radial direction, and all-dimensional driving and sensing of ultrasonic signals in a tested component can be achieved; The characteristic of IDT broadband can be realized by changing the electrode spacing, so that the frequency band width has designability, and therefore, guided wave mode selection can be realized, and the recognition rate of effective signals in engineering structure damage detection can be improved.

Owner:JIANGSU UNIV

Longitudinal-shaking sandwich energy converter type cylinder shape dual rotor ultrasonic motor

InactiveCN101388623AStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesTransducerEngineering

The invention relates to a bending vibration sandwich transducer type cylindrical double rotor ultrasonic motor which relates to the technical field of piezoelectric ultrasonic motors. The ultrasonic motor solves the problem in an existing ultrasonic motor that the mechanical output ability is restricted and a single stator only can realize single movement output. The bending vibration sandwich transducer type cylindrical double rotor ultrasonic motor of the invention comprises a stator component, an inside rotor component, an outside rotor component, a bearing block, a bearing and a bearing pre-tightening end cap, wherein continuous comb-shaped driving gears are manufactured on the inner surface of a cylinder, an inside rotor with a shaft and an inside rotor without the shaft are truncated cone-shaped, thin ends of the inside rotor with the shaft and the inside rotor without the shaft are respectively inserted on and under the cylinder, an outside rotor with the shaft and an outside rotor without the shaft are respectively installed on and under the stator component, wear resistance bush rings are respectively fixed on the side surfaces of the outside rotor with the shaft and the outside rotor without the shaft, which are contacted with a stator rear end cap, and the inside rotor with the shaft is connected with the bearing block in a rotary mode through the bearing. The bending vibration sandwich transducer type cylindrical double rotor ultrasonic motor can be applied in the manufacture field of ultrasonic motors.

Owner:HARBIN INST OF TECH

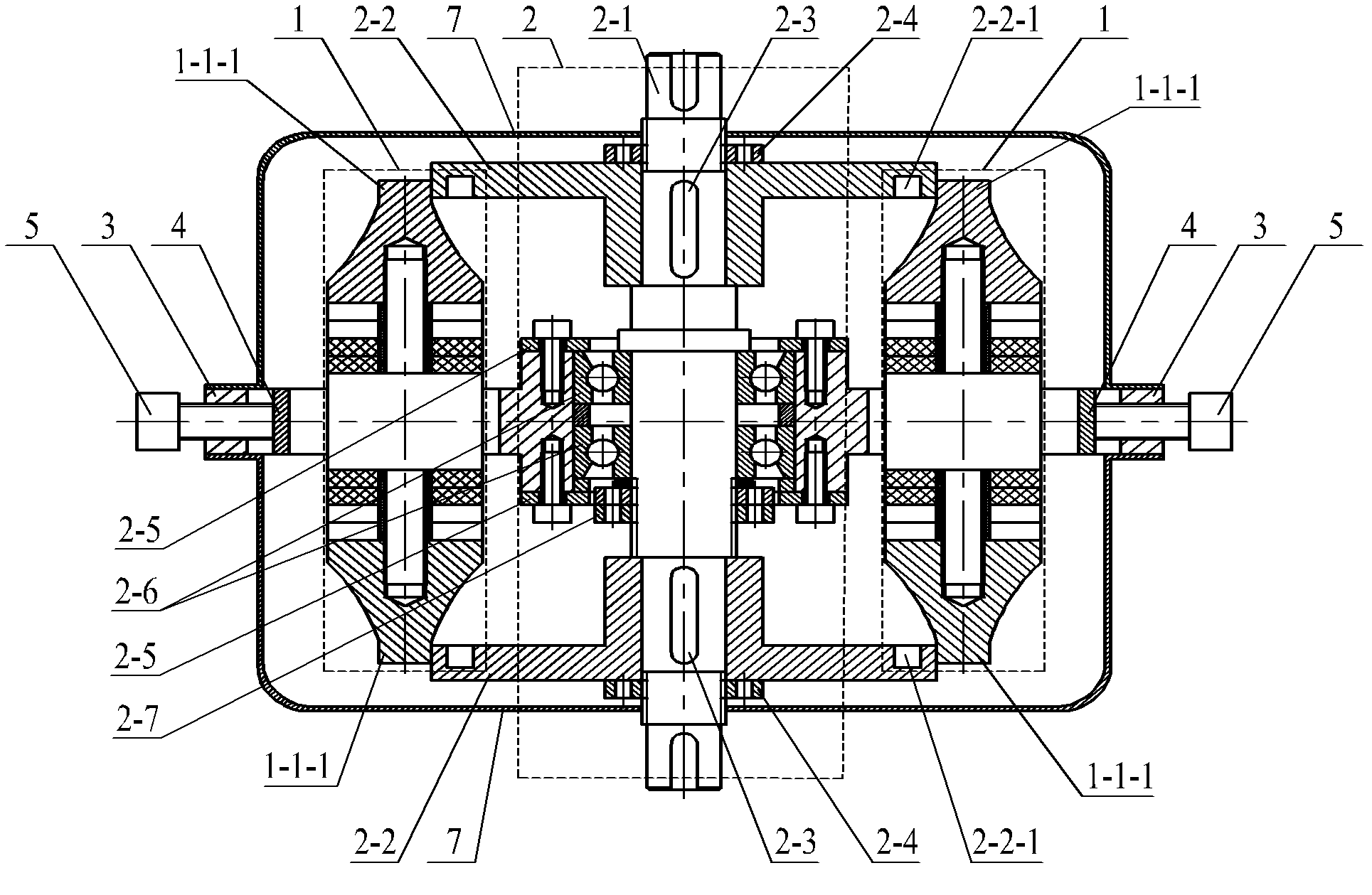

Bent-shaking sandwich energy converter type collar plate shape dual rotor ultrasonic motor

InactiveCN101388622ASimple structureImprove controllabilityPiezoelectric/electrostriction/magnetostriction machinesEnergy converterEngineering

The invention relates to a bending vibration sandwich transducer type disk double rotor ultrasonic motor which relates to the technical field of piezoelectric ultrasonic motors. The ultrasonic motor solves the problem in an existing ultrasonic motor that the mechanical output ability is restricted and a single stator only can realize single movement output. The bending vibration sandwich transducer type disk double rotor ultrasonic motor of the invention comprises a stator component, an upper end rotor component, a lower end rotor component, an upper end outer cover, a lower end outer cover, a rotated bearing, a bearing pre-tightening end cap and a bearing support, wherein continuous comb-shaped driving gears are manufactured on the upper end surface of a disc, a wear resistance bush ring is fixed on the end surface of an upper end disc rotor, which is contacted with the disk, the wear resistance bush ring is fixed on the end surface of a lower end disc rotor, which is contacted with the small end surface of a rear end cap, an upper end output shaft and a lower end output shaft are connected with the bearing block through a bearing in a rotary mode, the upper end outer cover and the lower end outer cover are respectively fixed on the upper end surface and the lower end surface of a cylinder flange, and thereby the upper end outer cover and the lower end outer cover are coaxial with the disk. The bending vibration sandwich transducer type disk double rotor ultrasonic motor can be applied in the manufacture field of ultrasonic motors.

Owner:HARBIN INST OF TECH

T-shaped linear ultrasonic motor oscillator

InactiveCN101630924BIncrease amplitudeImprove performancePiezoelectric/electrostriction/magnetostriction machinesElectricityUltrasonic motor

The invention discloses a T-shaped linear ultrasonic motor oscillator, which relates to the technical field of a piezoelectric ultrasonic motor and aims at solving the problem that the mechanical output capacity of the prior ultrasonic motor stator is limited. T-shaped front end covers of the T-shaped linear ultrasonic motor oscillator are combined by small end surfaces of three amplitude rods and are arranged in a T shape, a drive foot is connected with a connection position of the amplitude rods, and the three amplitude rods and the drive foot form an integral member; piezoelectric ceramicsare polarized along the thickness direction, and opposite to the polarization direction of every adjacent two pieces of piezoelectric ceramics on the same amplitude rod, the polarization ways of the piezoelectric ceramics of two amplitude rods on the same axial line are opposite, each fastening screw passes through a back end cover, the piezoelectric ceramics and a flange and is connected to a blind hole, and the piezoelectric ceramics and the flange are positioned between the back end cover and the amplitude rod, and a piece of electrode plate is arranged between the piezoelectric ceramics and the flange; and an insulating sleeve is fixed outside the fastening screw. The invention is applied to the manufacture field of the ultrasonic motor.

Owner:HARBIN INST OF TECH

Vertical bending layer energy converter round disk stator and ultrasonic electromotor using this stator

InactiveCN101262184BMake the most of vibrational energyImprove vibration trajectoryPiezoelectric/electrostriction/magnetostriction machinesCircular discControllability

The invention discloses a longitudinal bending sandwiched energy converter-typed round disc stator and an ultrasonic motor to which the stator is applied, which relates to the ultrasonic motor field. The invention solves the problems in the existing ultrasonic motor, of complex processing, difficult assembly, and lower mechanical output capacity and controllability of the ultrasonic motor. The longitudinal bending sandwiched converter of the stator is fixed between a round disc at the upper end and a round disc at the lower end, both the front end cover and the back end cover of the longitudinal bending sandwiched energy converter are a quadrangular with a rectangle cross section narrowing down gradually, the small end faces of the front end cover and the back end cover are fixedly connected with the upper round disc and the lower round disc; each piezoelectric ceramic piece is polarized along the thickness direction and four pairs of piezoelectric ceramic pieces are respectively fixed between the front end cover, the back end cover and the flange. Rotors in the ultrasonic motor take the shape of a round disc and are embedded respectively from the top and the bottom of the stator component, a wearable cushion is fixed at the end face, contacting the round disc, of the rotor and the stator is fixed to a base through the flange on the energy converter. The longitudinal bending sandwiched energy converter-typed round disc stator and the ultrasonic motor of the invention has the advantages of simple structure, flexible design, high electromechanical coupling efficiency, outputwith large torque, stable performance and easy control.

Owner:HARBIN INST OF TECH

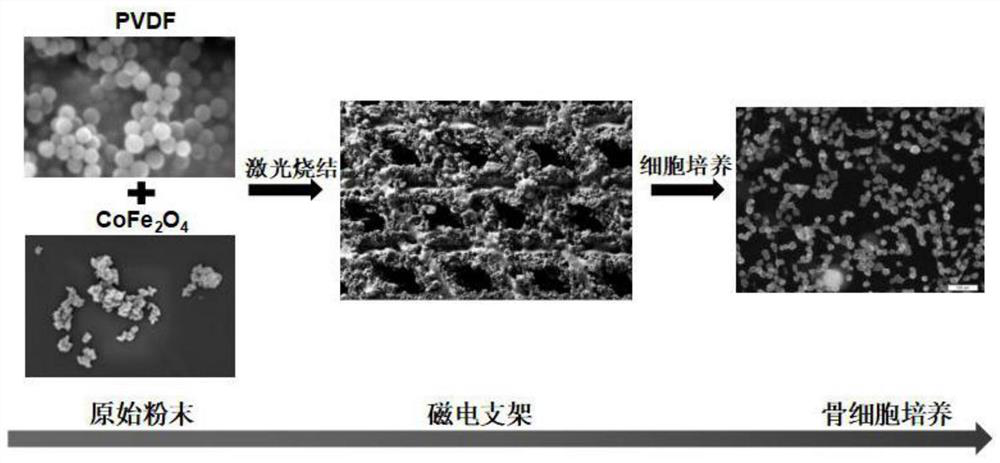

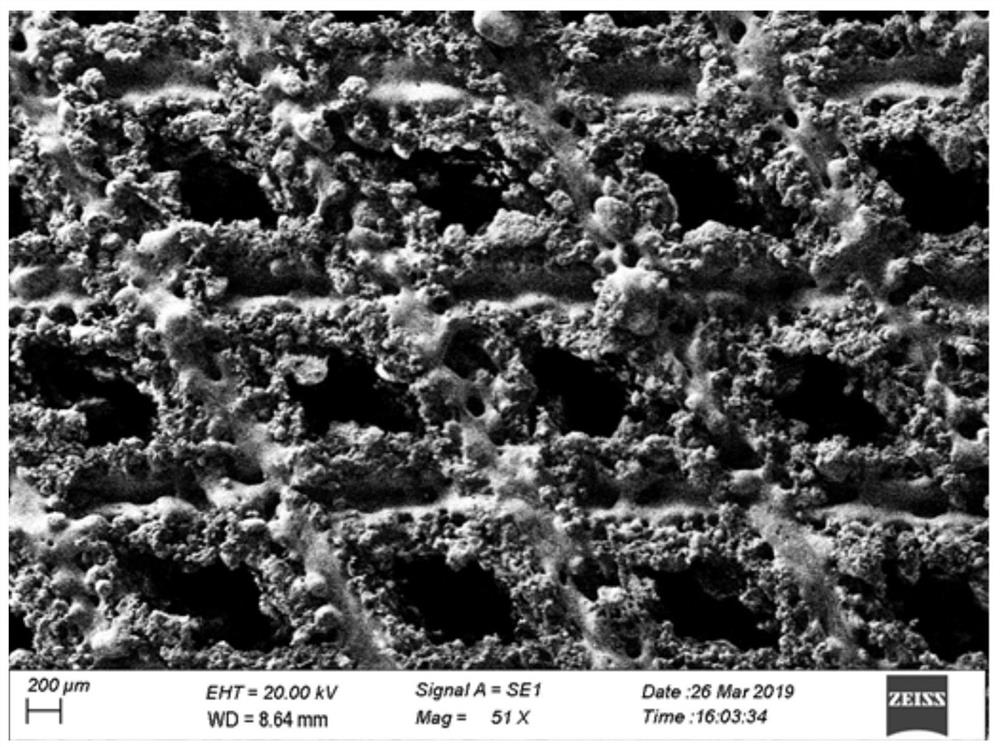

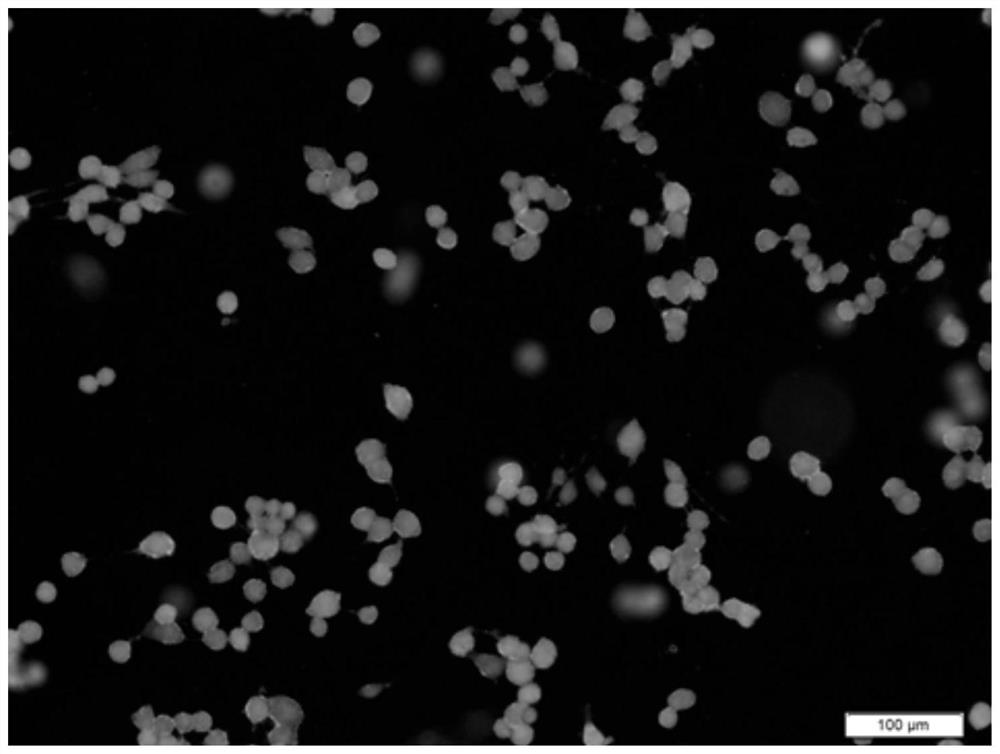

CoFe2O4/PVDF composite bone scaffold and preparation method thereof

ActiveCN112076345AImprove adhesionPromote proliferationTissue regenerationProsthesisSelective laser sinteringFluid phase

The invention relates to a CoFe2O4 / PVDF composite bone scaffold and a preparation method thereof. The CoFe2O4 / PVDF composite bone scaffold is prepared by the following steps: mixing and stirring ethanol suspension of CoFe2O4 and ethanol suspension of PVDF, performing solid-liquid phase separation on the obtained CoFe2O4 / PVDF mixed suspension, drying and ball-milling the obtained solid phase to obtain composite powder, and performing selective laser sintering on the composite powder. According to the CoFe2O4 / PVDF composite bone scaffold provided by the invention, remote non-contact electrical stimulation on bone cells can be realized by externally applying an alternating magnetic field, so that growth of osteoblasts and regeneration and reconstruction of defective tissues are promoted.

Owner:JIANGXI UNIV OF SCI & TECH

Composite flexural vibration sandwich type double-foot linear ultrasonic motor vibrator

ActiveCN102361413BIncrease flexibilityAchieve macro motion outputPiezoelectric/electrostriction/magnetostriction machinesAcousticsSandwich type

The invention discloses a composite flexural vibration sandwich type double-foot linear ultrasonic motor vibrator, and belongs to the technical field of piezoelectric ultrasonic motors. The vibrator solves the problem that the output thrust of a motor is affected by inconsistent vibration properties of two driving feet of the conventional flexural vibration modal beam type linear ultrasonic motor vibrator. Eight flexural vibration piezoelectric ceramic chips are sleeved on a stud of the vibrator, two end covers are respectively screwed at two ends of the stud to compact the eight flexural vibration piezoelectric ceramic chips, an electrode plate is respectively arranged between the adjacent flexural vibration piezoelectric ceramic chips and between the contact faces of the flexural vibration piezoelectric ceramic chip and the big end face of the end cover, insulating bushes are arranged between the contact faces of all the flexural vibration piezoelectric ceramic chips and the stud and between the contact faces of all the electrode plates and the stud, two thin-wall beams are symmetrically arranged at two sides of the big end face of each end cover, a mounting seat is fixed at the outer side of each thin-wall beam, a driving foot is arranged on the small end face of each end cover, and the driving feet are blocks, the sections of which are in the same shape as the small end faces. The vibrator is suitable for an ultrasonic motor.

Owner:HARBIN INST OF TECH

Bending layer energy converter round disk stator and ultrasonic electromotor using this stator

InactiveCN101262185BIncrease output torqueReduce the influence of output characteristicsPiezoelectric/electrostriction/magnetostriction machinesElastomerCircular disc

Owner:HARBIN INST OF TECH

Ring type standing-wave ultrasonic motor vibrator of cantilever bending vibration transducer

InactiveCN101651428BSimple structureFlexible designPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesTransducerUltrasonic motor

The invention provides a ring type standing-wave ultrasonic motor vibrator of a cantilever bending vibration transducer, relating to the technical field of piezoelectric ultrasonic motors and solving the problem that the mechanical output capability of the prior ultrasonic motor stator is restricted. The ring type standing-wave ultrasonic motor vibrator of the cantilever bending vibration transducer comprises a ring and a cantilever bending vibration sandwich transducer, wherein the cantilever bending vibration sandwich transducer comprises a cantilever, a front end cover, a rear end cover, an insulation sleeve, two pairs of bending vibration piezoelectric ceramic plates, fastening screws and electrode plates, wherein the cantilever is fixedly connected with the lower end surface of the ring, a through groove is arranged between the cantilever and the lower end surface of the ring, the front end cover and the rear end cover are fixedly connected with the cantilever are by the fastening screws, and the bending vibration piezoelectric ceramic plates are arranged between the front end cover and the cantilever and between the rear end cover and the cantilever. The ring type standing-wave ultrasonic motor vibrator can be applied to the field of manufacturing ultrasonic motors.

Owner:HARBIN INST OF TECH

Longitudinal-bending compound single-foot two-degree-of-freedom ultrasonic motor vibrator

InactiveCN105406754BIncrease profitHigh electromechanical coupling efficiencyPiezoelectric/electrostriction/magnetostriction machinesElectricitySingle degree of freedom

Owner:HARBIN INST OF TECH

Vertical bending layer energy converter cylinder stator and ultrasonic electromotor using this stator

InactiveCN101262186BSimple structureFlexible designPiezoelectric/electrostriction/magnetostriction machinesTransducerLongitudinal vibration

The invention discloses a longitudinal bending sandwiched energy converter-typed cylindrical stator and an ultrasonic motor to which the stator is applied, which relates to the piezoelectric ultrasonic motor field. The invention solves the problem in the existing ultrasonic motor stator, that mechanical output capacity is restrained with poor controllability and low efficiency due to the adoptionof a plurality of energy converters for driving. The inner side of the stator is evenly provided with a plurality of comb-shaped drive teeth, an upper end conical face and a lower end conical face are symmetrically arrangedl at the upper part and the lower part of the comb-shaped drive teeth; the front end cover of the sandwiched energy converter is a quadrangular with a rectangle cross section narrowing down gradually, the small end face of the front end cover is fixedly connected with the outer face of the cylinder of the stator and the front end cover and the back end cover are fixedly connected through a flange; a longitudinal vibration piezoelectric ceramic pieces and flexural vibration piezoelectric ceramic pieces are respectively fixed between the front end cover and the flange, and the flange and the back end cover. A rotor with a shaft and a rotor without a shaft in the ultrasonic motor are respectively arranged at the upper end conical face and the lower end conical face of the comb-shaped drive teeth in the cylinder of the stator. The longitudinal vibration sandwiched energy converter-typed round disc stator and the ultrasonic motor of the invention are applicable to the manufacturing field of the ultrasonic motors.

Owner:HARBIN INST OF TECH

A bending-torsion coupling piezoelectric drive crawler driving device and its working method

InactiveCN105490582BShort weightCompact structurePiezoelectric/electrostriction/magnetostriction machinesElectricityPiezoelectric actuators

The invention provides a bend-twist coupling type piezoelectric driving track traveling device and a working method thereof. The device comprises a metal track, two annular components and a variable cross-section piezoelectric transducer, wherein the annular components are arranged at two ends of the variable cross-section piezoelectric transducer; the variable cross-section piezoelectric transducer comprises a plurality of sets of piezoelectric ceramic pieces, two pre-tightening wedge blocks and a variable cross-section beam; and the piezoelectric ceramic pieces are arranged in a certain order and are fixed in a groove of the variable cross-section beam through the pre-tightening wedge blocks. According to the bend-twist coupling type piezoelectric driving track traveling device and the working method thereof, by stimulating the piezoelectric ceramic pieces, a torsional vibration mode and a bending vibration mode are stimulated on the variable cross-section beam, so that a traveling wave, with n (n being greater than or equal to 2) wave crests and wave troughs shown all together, rotating along the peripheral direction is coupled on the annular components, the mass points on the outer surfaces of the annular components carry out micro-amplitude elliptical motions and drive the metal track to move through the action of friction, and the device has the advantages of compact structure, large force (torque) weight ratio, high environmental suitability, structure form flexibility, high speed, high electro-mechanical coupling efficiency and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Longitudinal-shaking sandwich energy converter type collar plate shape dual rotor ultrasonic motor

InactiveCN101388624BStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesCircular discTransducer

The invention relates to a longitudinal vibration sandwich transducer type disk double rotor ultrasonic motor which relates to the technical field of piezoelectric ultrasonic motors. The ultrasonic motor solves the problem in an existing ultrasonic motor that the mechanical output ability is restricted and a single stator only can realize single movement output. The longitudinal vibration sandwich transducer type disk double rotor ultrasonic motor of the invention comprises a stator component, an upper end rotor component, a lower end rotor component, an upper end outer cover, a lower end outer cover, a rotated bearing, a bearing pre-tightening end cap and a bearing support, wherein continuous comb-shaped driving gears are manufactured on the upper end surface of a disc, a wear resistancebush ring is fixed on the end surface of an upper end disc rotor, which is contacted with the disk, the wear resistance bush ring is fixed on the end surface of a lower end disc rotor, which is contacted with the small end surface of a rear end cap, an upper end output shaft and a lower end output shaft are connected with the bearing block through a bearing in a rotary mode, the upper end outer cover and the lower end outer cover are respectively fixed on the upper end surface and the lower end surface of a cylinder flange, and thereby the upper end outer cover and the lower end outer cover are coaxial with the disk. The longitudinal vibration sandwich transducer type disk double rotor ultrasonic motor can be applied in the manufacture field of ultrasonic motors.

Owner:HARBIN INST OF TECH

Longitudinal-shaking sandwich energy converter type cylinder shape dual rotor ultrasonic motor

InactiveCN101388623BStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesElectric machineEngineering

Owner:HARBIN INST OF TECH

Longitudinal-shaking sandwich energy converter type cylinder type birotor ultrasonic motor

InactiveCN101304223BStrong process controllabilityReduce adverse effectsPiezoelectric/electrostriction/magnetostriction machinesTransducerLongitudinal vibration

The invention discloses a longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor, which relates to the technical field of an ultrasonic motor and aims at solving the problems that the mechanical output capacity is restricted and a single stator can only realize single moving output existing in present ultrasonic motor. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention comprises a stator component, a medial rotor component, an outer rotor component, a bearing base, a bearing and a bearing pretensioncover. The inner surface of a cylinder is manufactured with continuous comb-shaped driving gears; a medial rotor with a shaft and a medial rotor without the shaft are cone-shaped, the thin ends of the medial rotor with the shaft and the medial rotor without the shaft are respectively inserted from the lower part of a stator cylinder and the upper part of the stator cylinder; an outer rotor with the shaft and an outer rotor without the shaft are respectively arranged on the upper part of the stator component and the lower part of the stator component; the lateral surfaces that the outer rotor with the shaft and the outer rotor without the shaft are contacted with the back end cover of the stator are respectively fixed with wear-resistance lining rings; the medial rotor with the shaft is rotatablely connected with the bearing base by the bearing. The longitudinal vibration sandwiched transducer type cylindrical dual-rotor ultrasonic motor of the invention can be applied to the ultrasonic motor manufacturing field.

Owner:HARBIN INST OF TECH

Longitudinal and bending composite mode sandwich two-foot ultrasonic linear motor oscillator with elastic support

ActiveCN102355160BLongitudinal vibration energy utilization rate is highSimple structurePiezoelectric/electrostriction/magnetostriction machinesUltrasonic linear motorPrism

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com