Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Ultrasonic linear motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

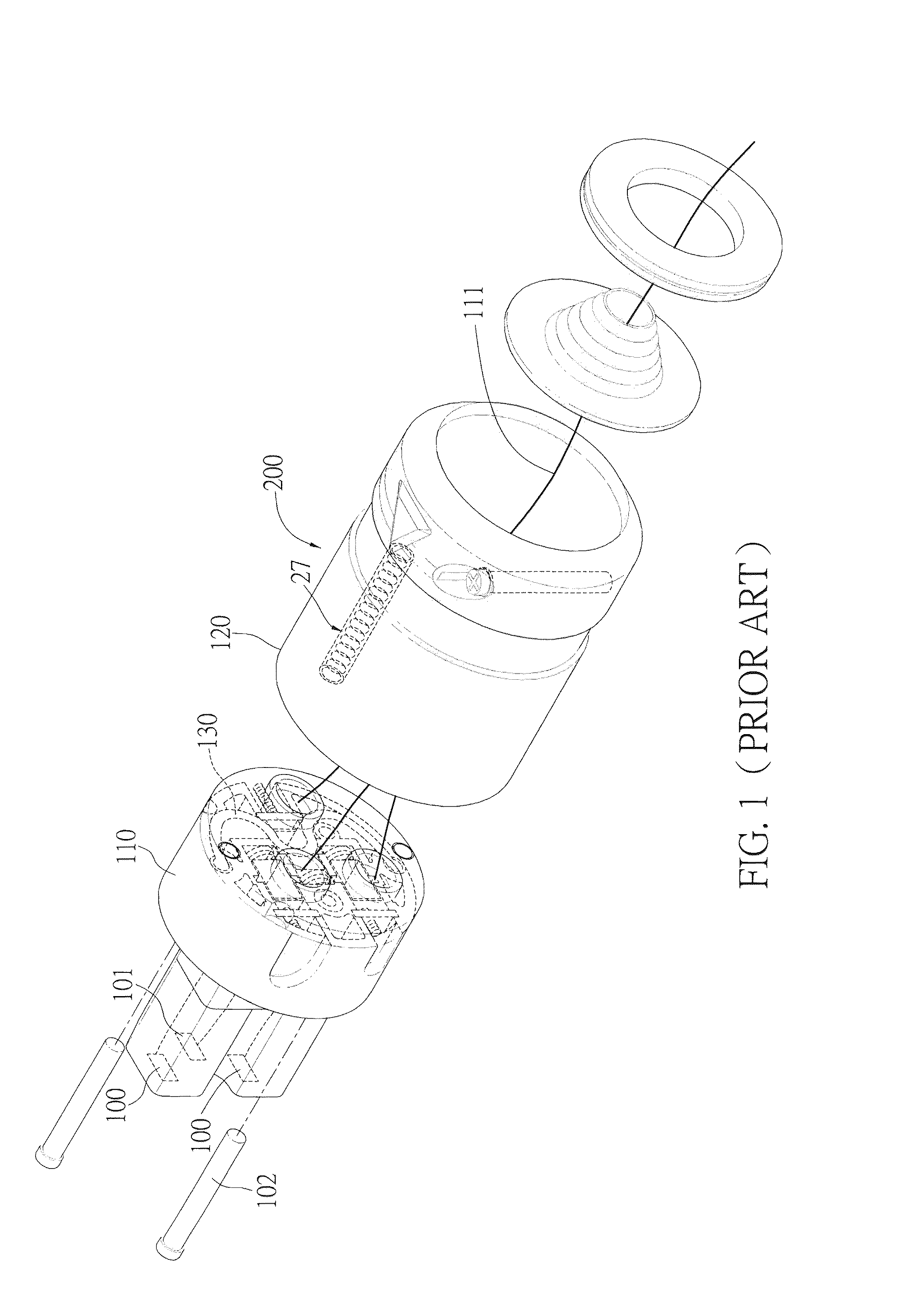

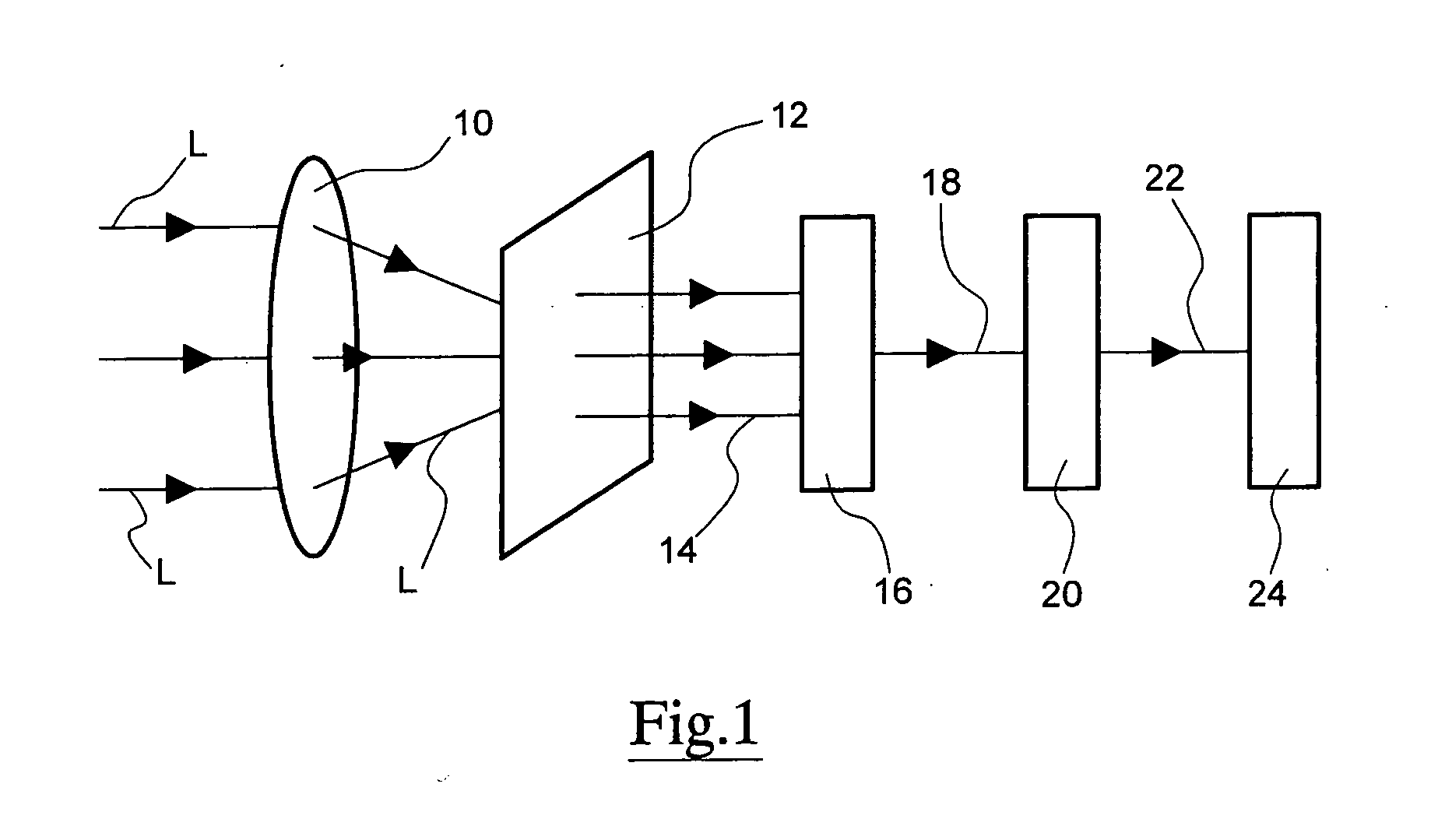

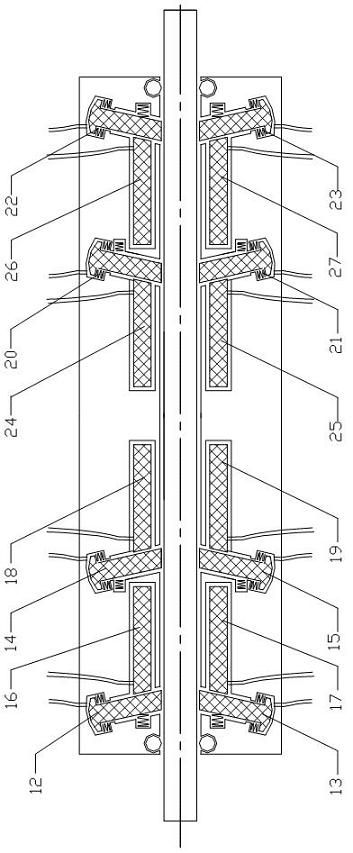

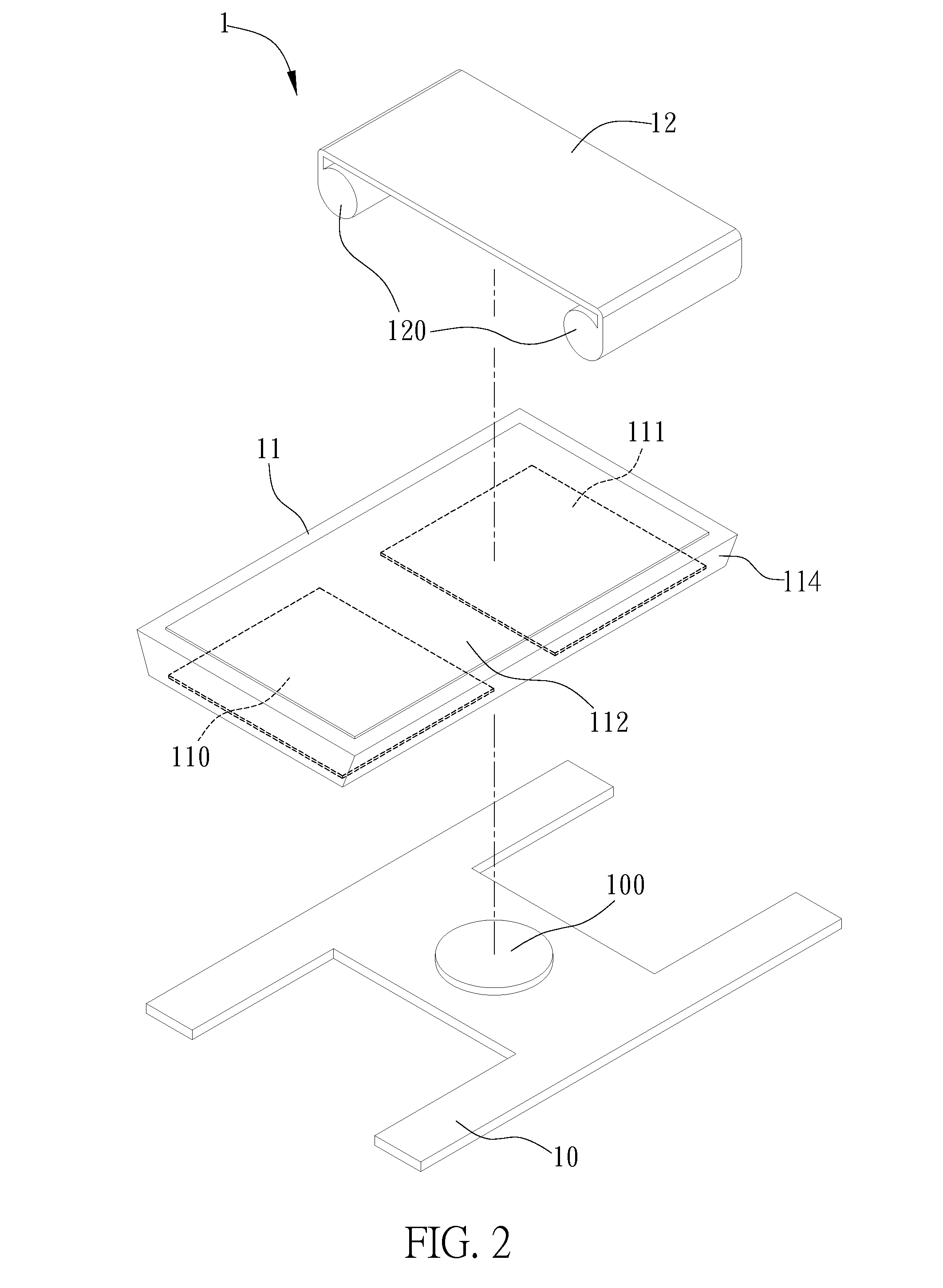

Ultrasonic straight line motor and automatic focusing/zooming system driven thereby

InactiveCN101425762APiezoelectric/electrostriction/magnetostriction machinesProjector focusing arrangementCamera lensLinear motion

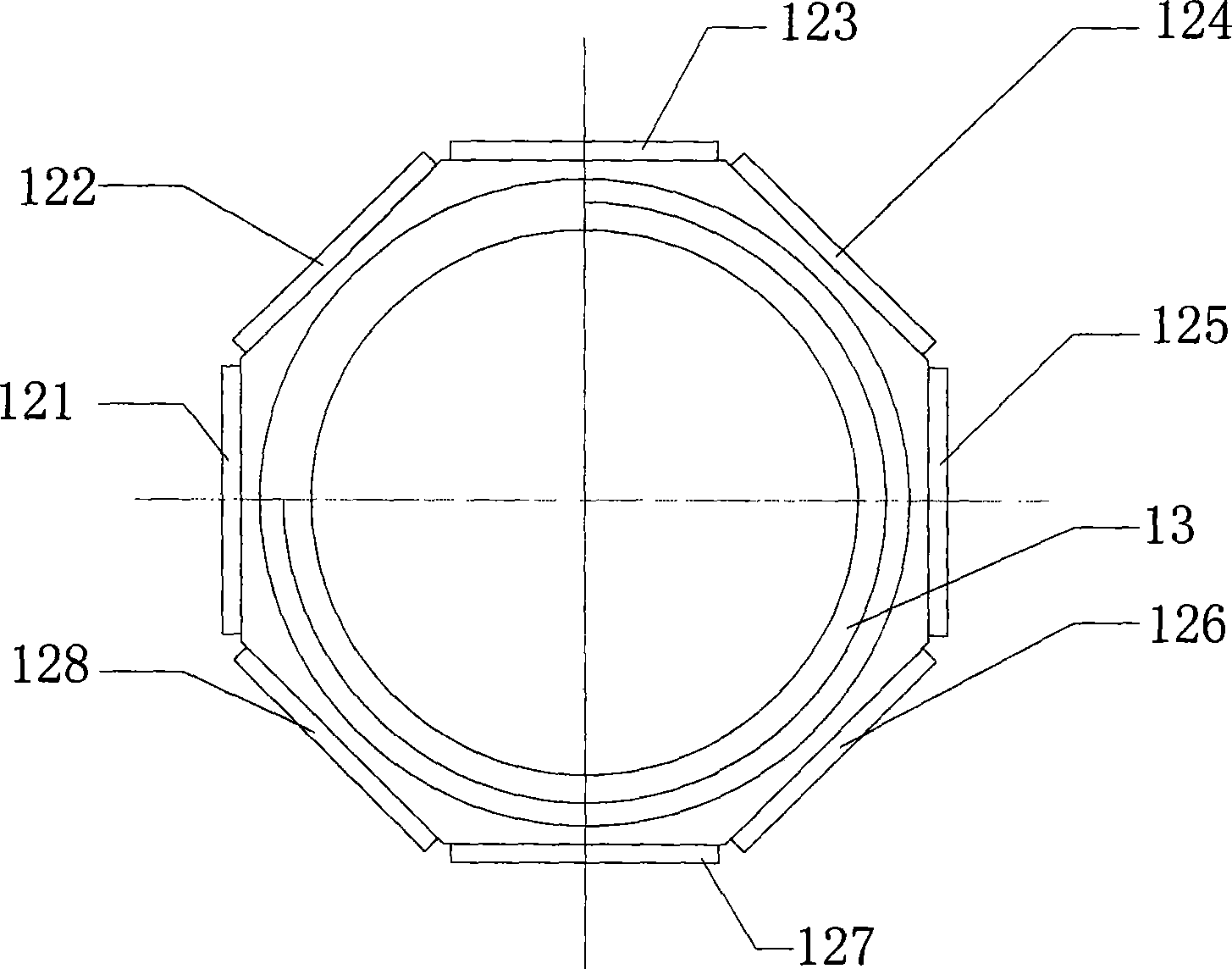

The invention discloses an ultrasonic linear motor which comprises an outer tube stator, a middle tube rotor, an inner tube, a guide mechanism and a piezoelectric piece, wherein the piezoelectric piece is fixed on the outer side surface of the stator, the stator drives the middle tube rotor to rotate, the inner tube is connected with the stator through the guide mechanism, and the middle tube rotor drives the inner tube to make linear motion. The invention also discloses an automatic focusing / zooming system driven by the ultrasonic linear motor, an optical lens is inserted inside the inner tube, and a light sensing chip is fixed on a plane at the bottom part of the stator. The invention has the advantages that two-stage drive motor structure is provided, the helical motion generated by the rotor in the first-stage drive is restored to be the only linear motion of the inner tube through the second-stage drive, only the linear displacement without rotation is generated during the working process of the automatic focusing / zooming lens module, so as to meet the requirements of high pixel, and high-precision automatic focusing or zooming, and the invention still has simple and compact structure, is suitable for the miniaturization, and has high precision of the linear displacement.

Owner:BOLY MEDIA COMM SHENZHEN

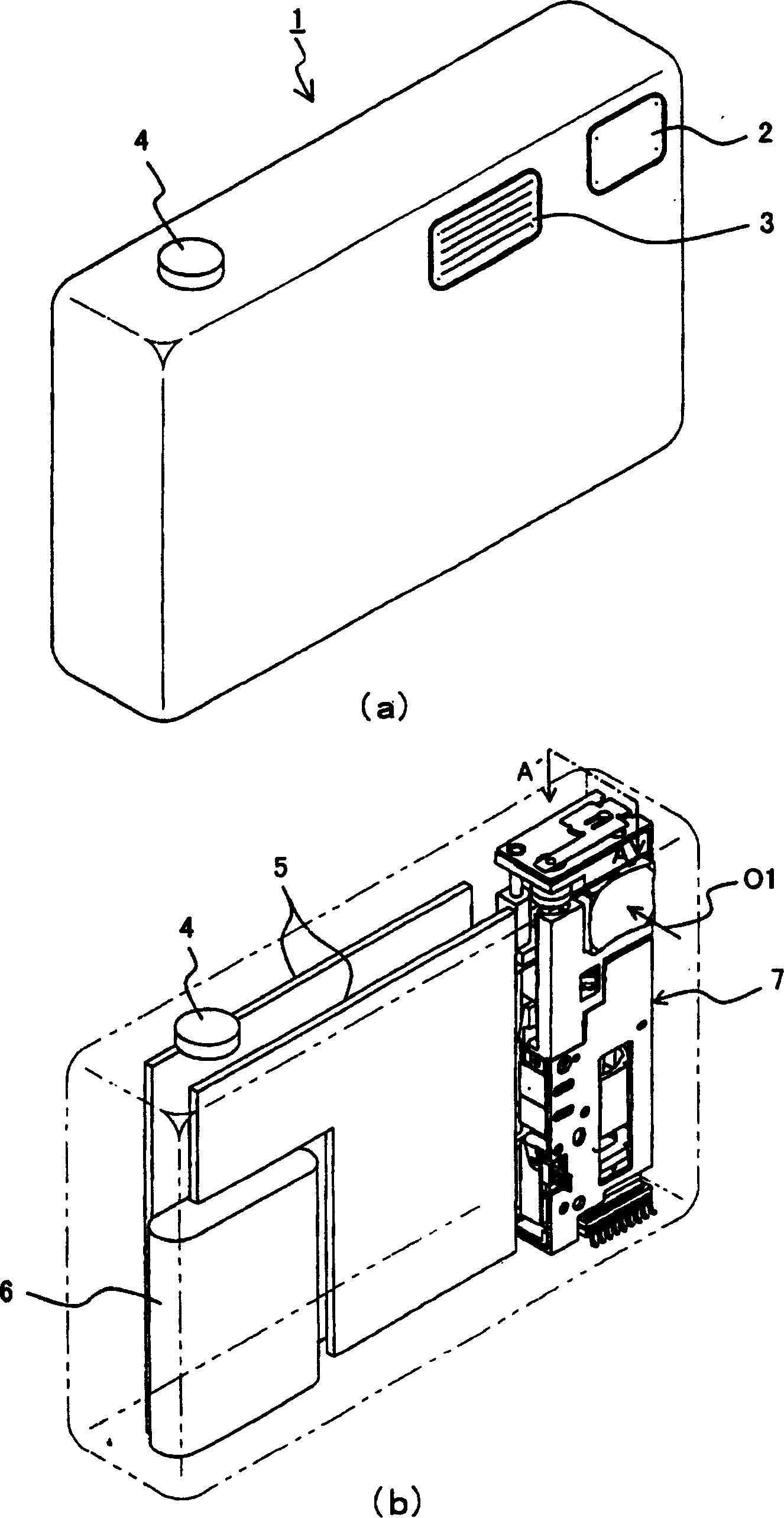

Encoder, lens-implement and digital camera

InactiveUS20050036056A1Television system detailsColor television detailsUltrasonic linear motorPrism

All members of a lens-implement are arranged in a rectangular space of a main lens frame. A lens prism is fixed, three movable lens frames for zoom and focusing inserted the two guide shafts are arranged, and a image capturing lens is fixed top-to-bottom seriatim occupying the horizontal ⅔ portion of the rectangular space, and the image capturing device is arranged at foot portion. A zoom motor is arranged at the back of the lens prism, and a zoom shaft cam, a diaphragm / shutter, a focusing ultrasonic linear motor, and a magnetic sensor are arranged along the lens frames.

Owner:OLYMPUS CORP

Inertia type piezoelectric linear motor

InactiveCN103023374ALarge outputQuick responsePiezoelectric/electrostriction/magnetostriction machinesUltrasonic linear motorDiagonal

The invention discloses an inertia type piezoelectric linear motor which comprises a displacement amplifying mechanism, a rotor and a stator shaft. The displacement amplifying mechanism is in a diamond symmetrical structure, two diagonals of the diamond are mutually perpendicular and unequal in length, laminated piezoelectric ceramic is arranged along the long diagonal of the diamond, and a fixed face and a translation face are arranged at two corners in the short diagonal direction of the diamond and parallel to the laminated piezoelectric ceramic which is externally connected with a power source. The stator shaft is directly mounted on the translation face of the displacement amplifying mechanism, and the rotor is sleeved on the stator shaft. Compared with general coil type linear motors and other ultrasonic linear motors, the inertia type piezoelectric linear motor has the advantages of large output force, quickness in response, simple structure, easiness in processing, convenience in use, avoidance of electromagnetic interference and the like.

Owner:SOUTHEAST UNIV

Encoder, lens-implement and digital camera

InactiveUS7567284B2Television system detailsColor television detailsCamera lensUltrasonic linear motor

All members of a lens-implement are arranged in a rectangular space of a main lens frame. A lens prism is fixed, three movable lens frames for zoom and focusing inserted the two guide shafts are arranged, and a image capturing lens is fixed top-to-bottom seriatim occupying the horizontal ⅔ portion of the rectangular space, and the image capturing device is arranged at foot portion. A zoom motor is arranged at the back of the lens prism, and a zoom shaft cam, a diaphragm / shutter, a focusing ultrasonic linear motor, and a magnetic sensor are arranged along the lens frames.

Owner:OLYMPUS CORP

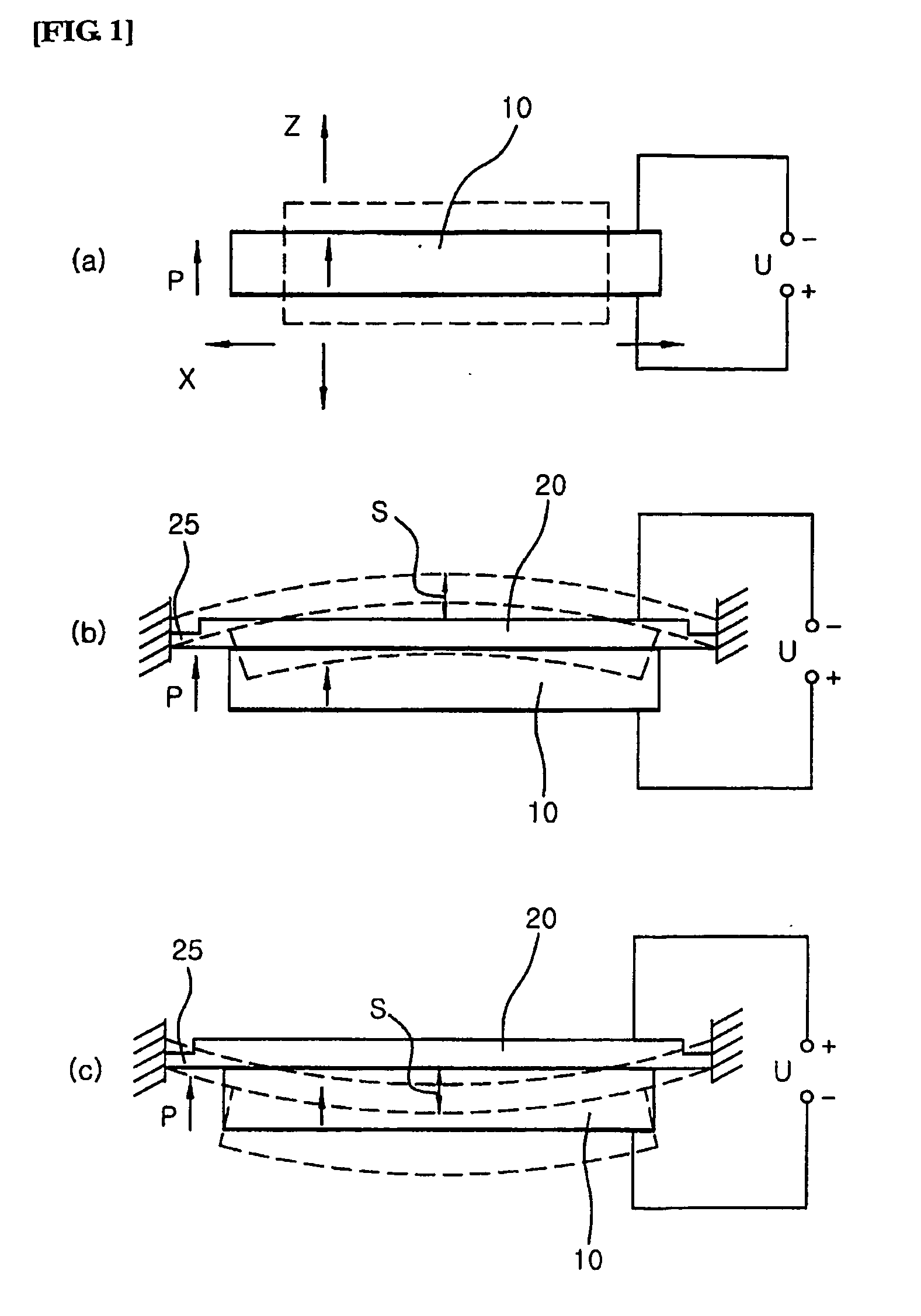

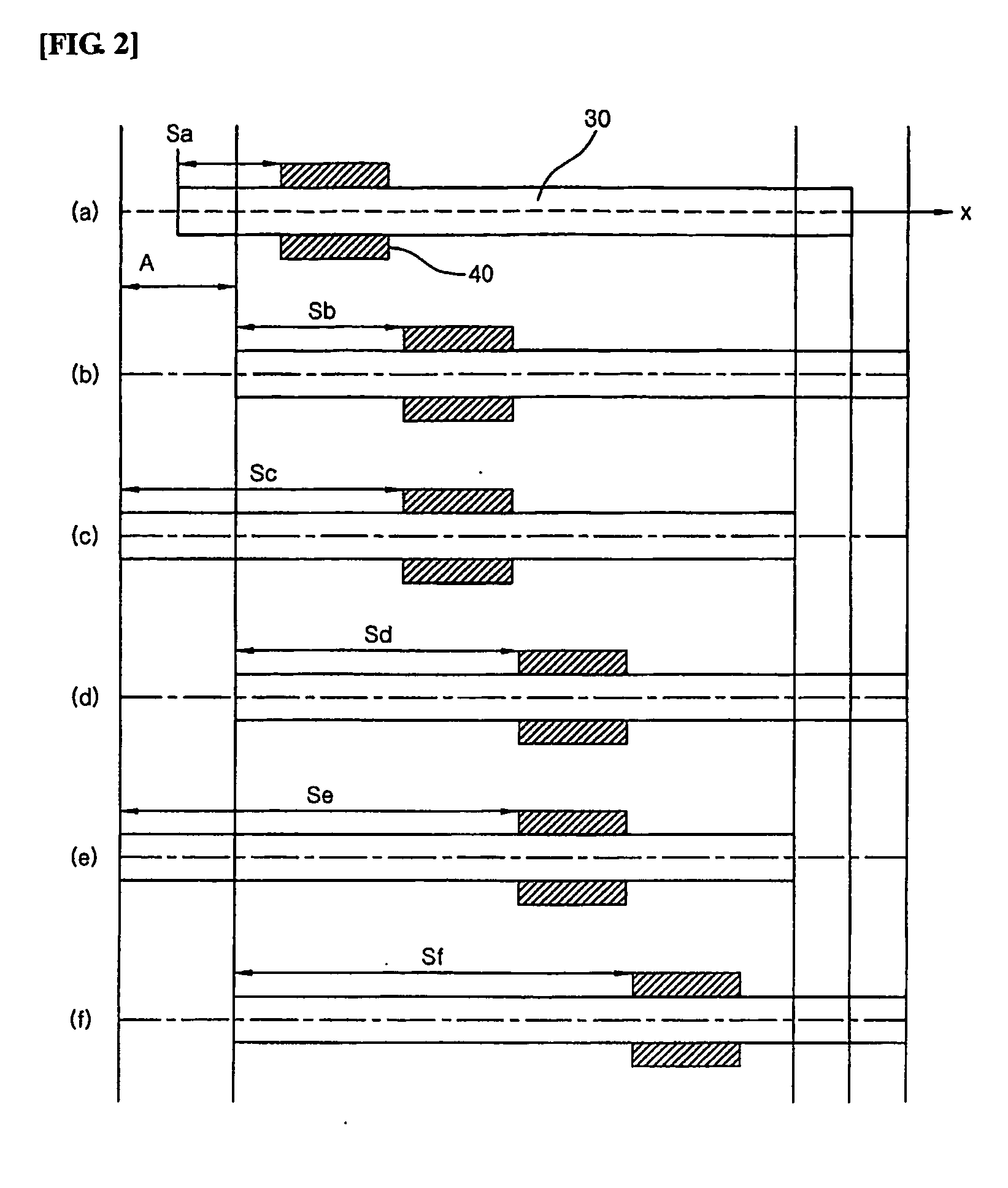

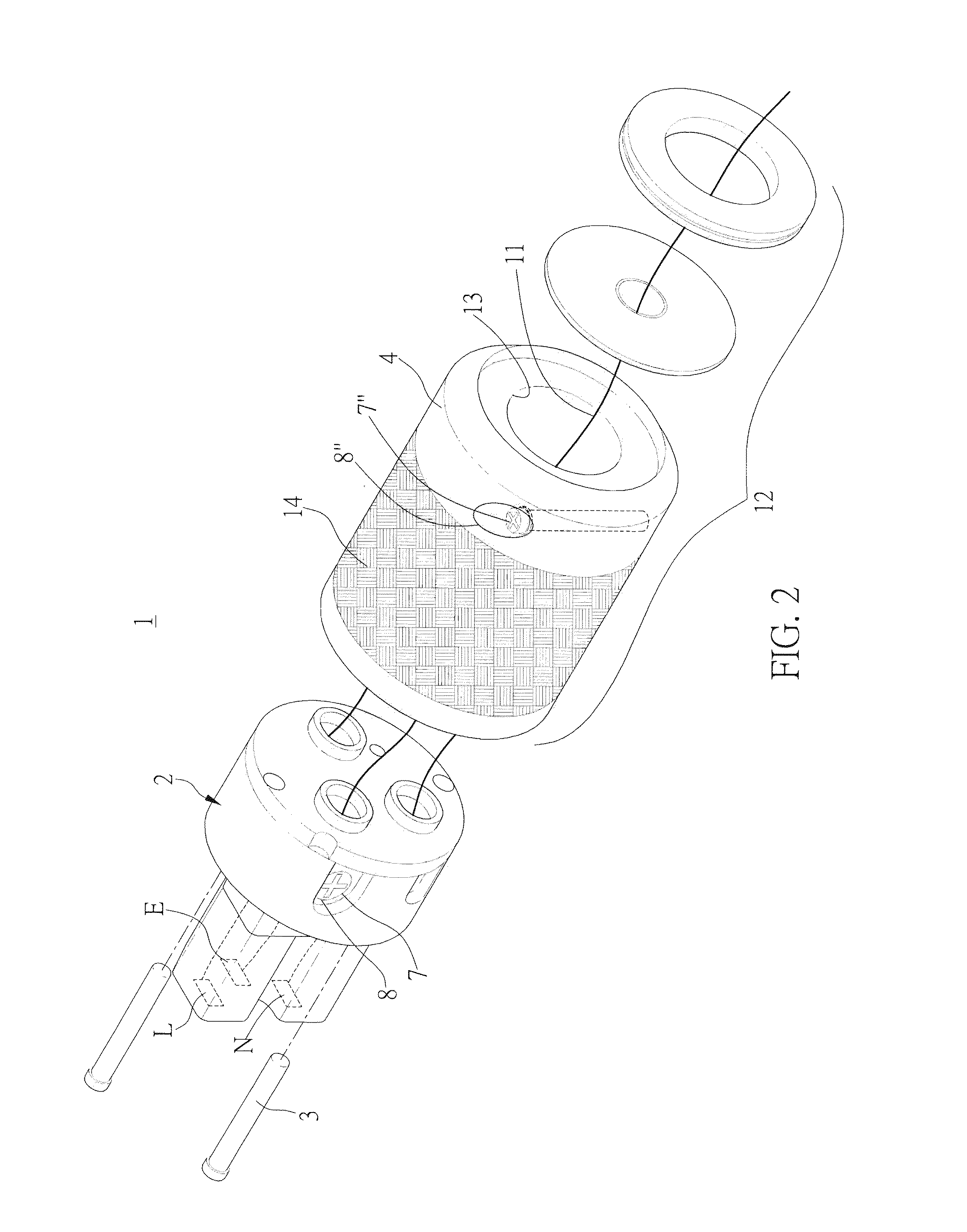

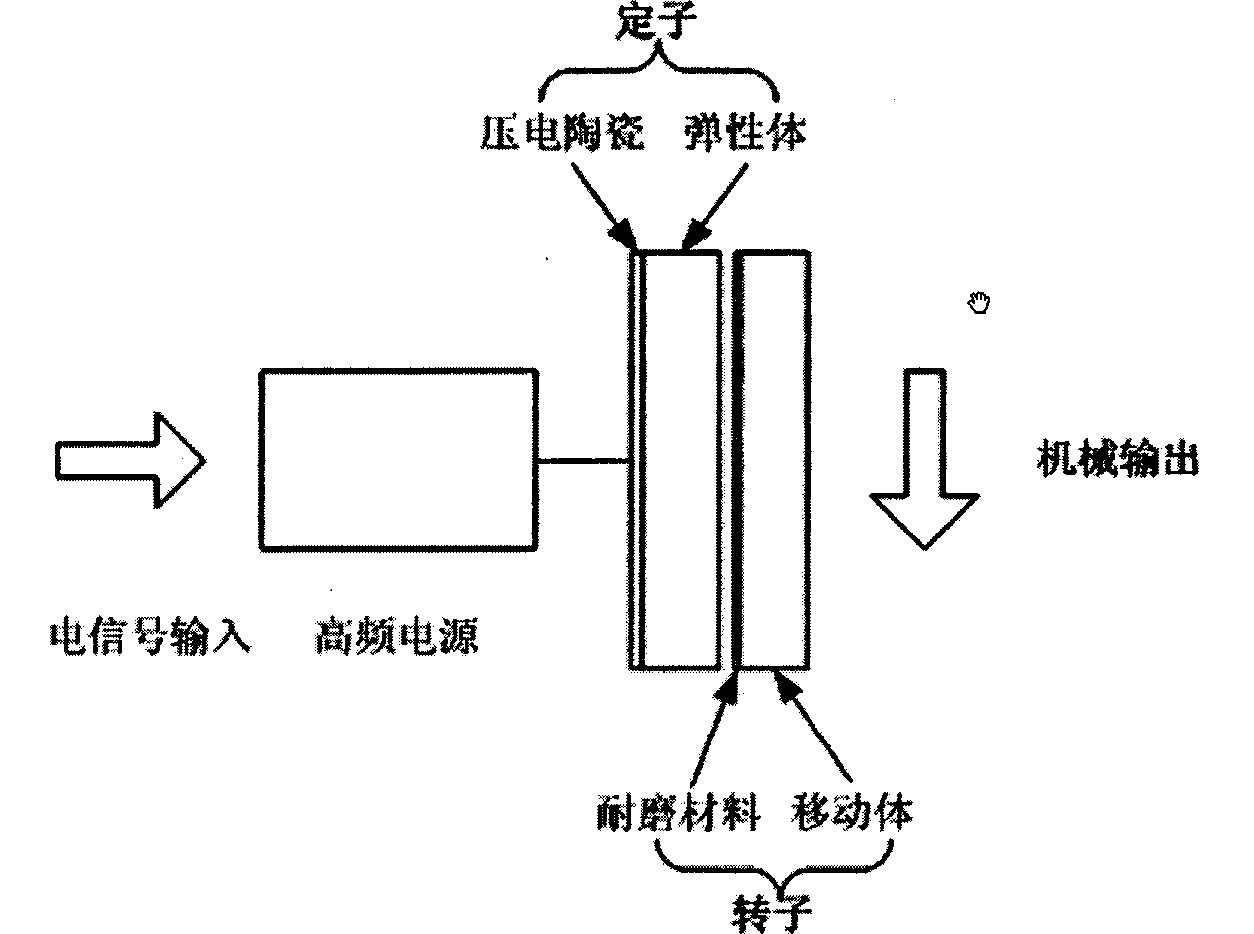

Small piezoelectric or electrostrictive linear motor

ActiveUS20070120442A1Simple manufacturing processEasy to implementPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesUltrasonic linear motorElectric machine

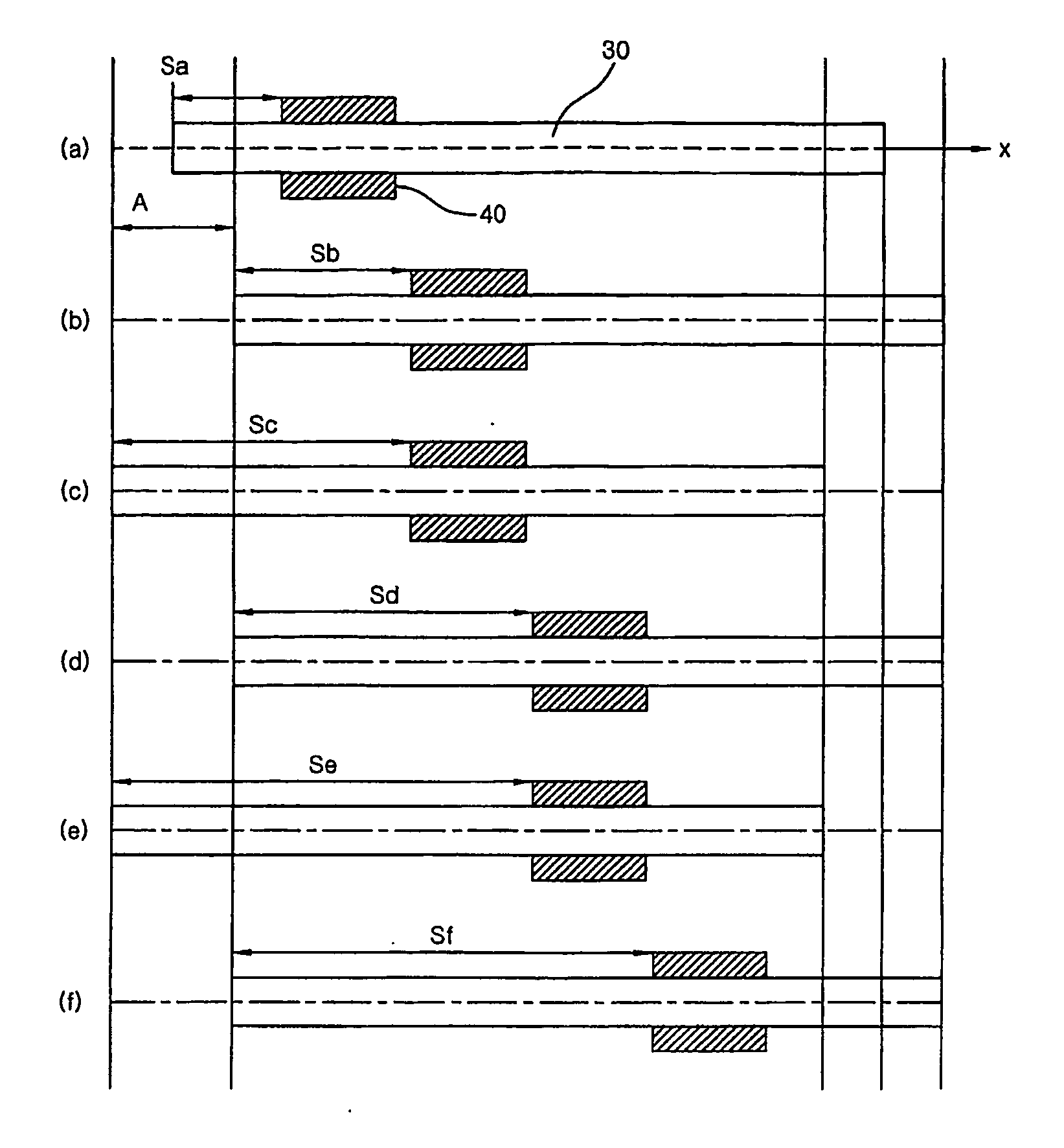

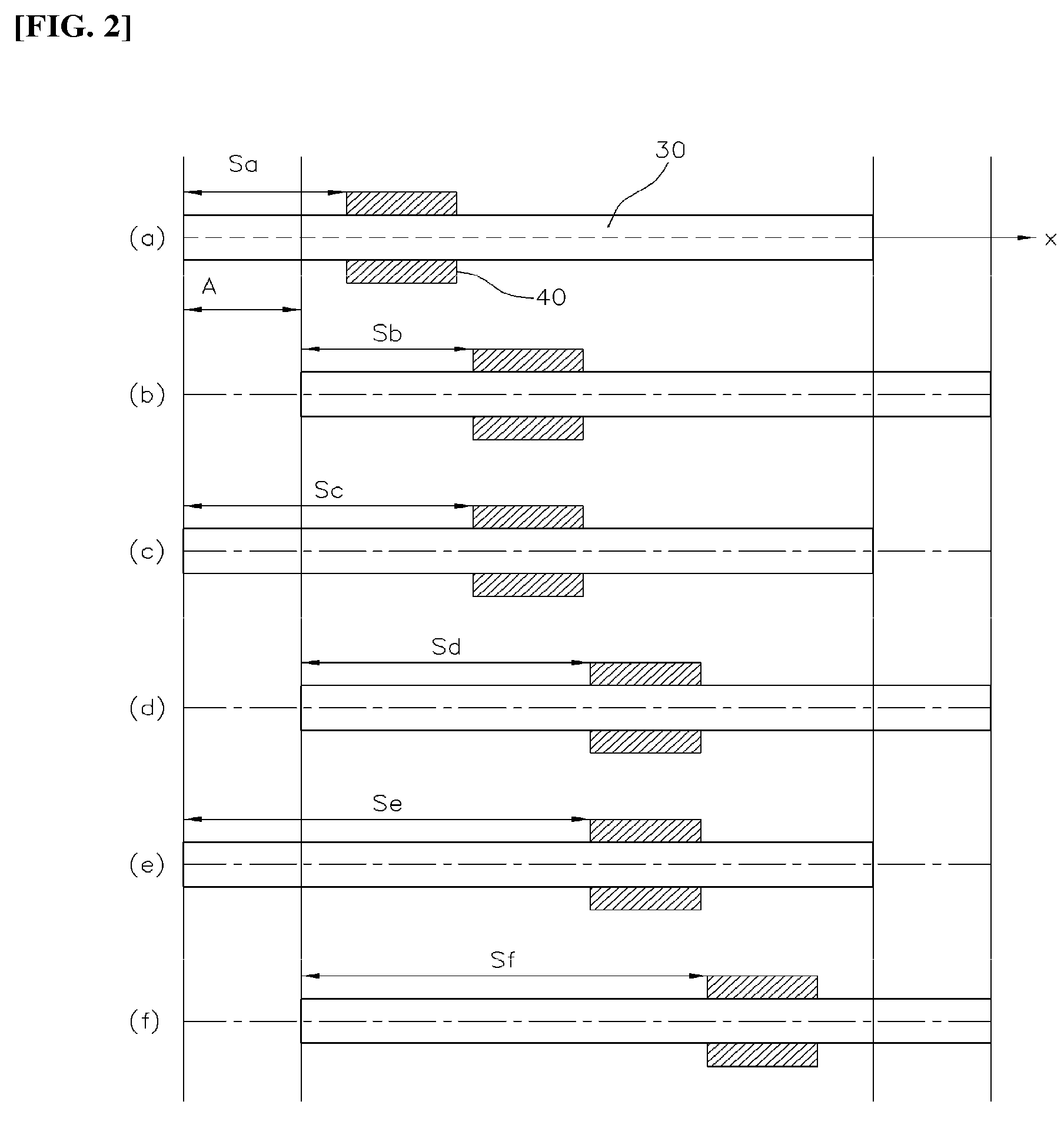

The present invention provides a small piezoelectric / electrostrictive ultrasonic linear motors which are installed in cell phones or PDAs, etc. to drive their camera lenses. In the present invention, a movable shaft (30) is coupled to a unimorph or bimorph, which is made by attaching a piezoelectric or electrostrictive substrate to an elastic body (20) (metal), so that a movable body (40) fitted over the movable shaft (30) is linearly moved along the movable shaft (30) by vibration of the piezoelectric or electrostrictive substrate, thus simplifying a manufacturing process, being easily practicable according to a basic principle, and having superior characteristics.

Owner:PIEZOELECTRIC TECH

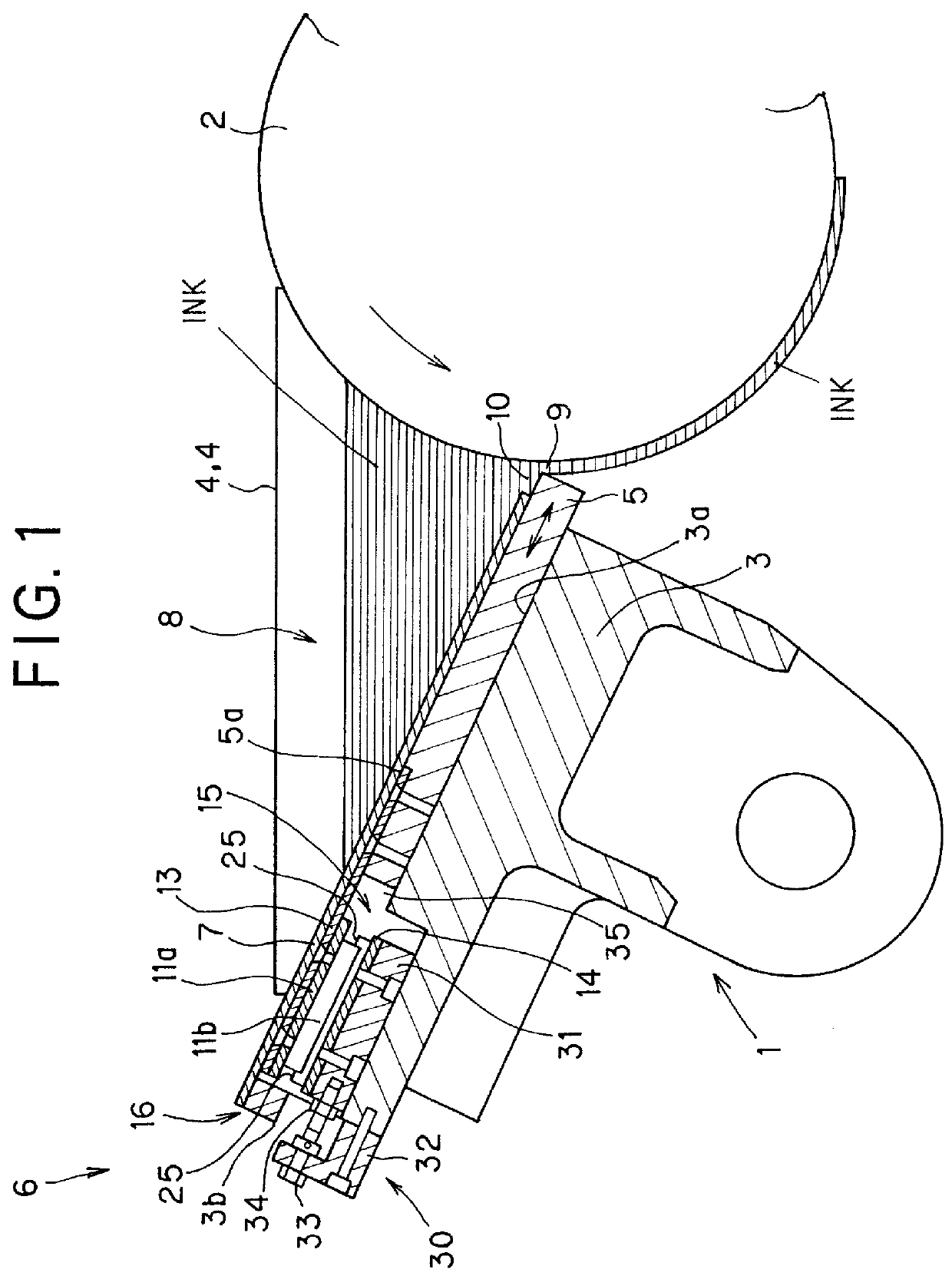

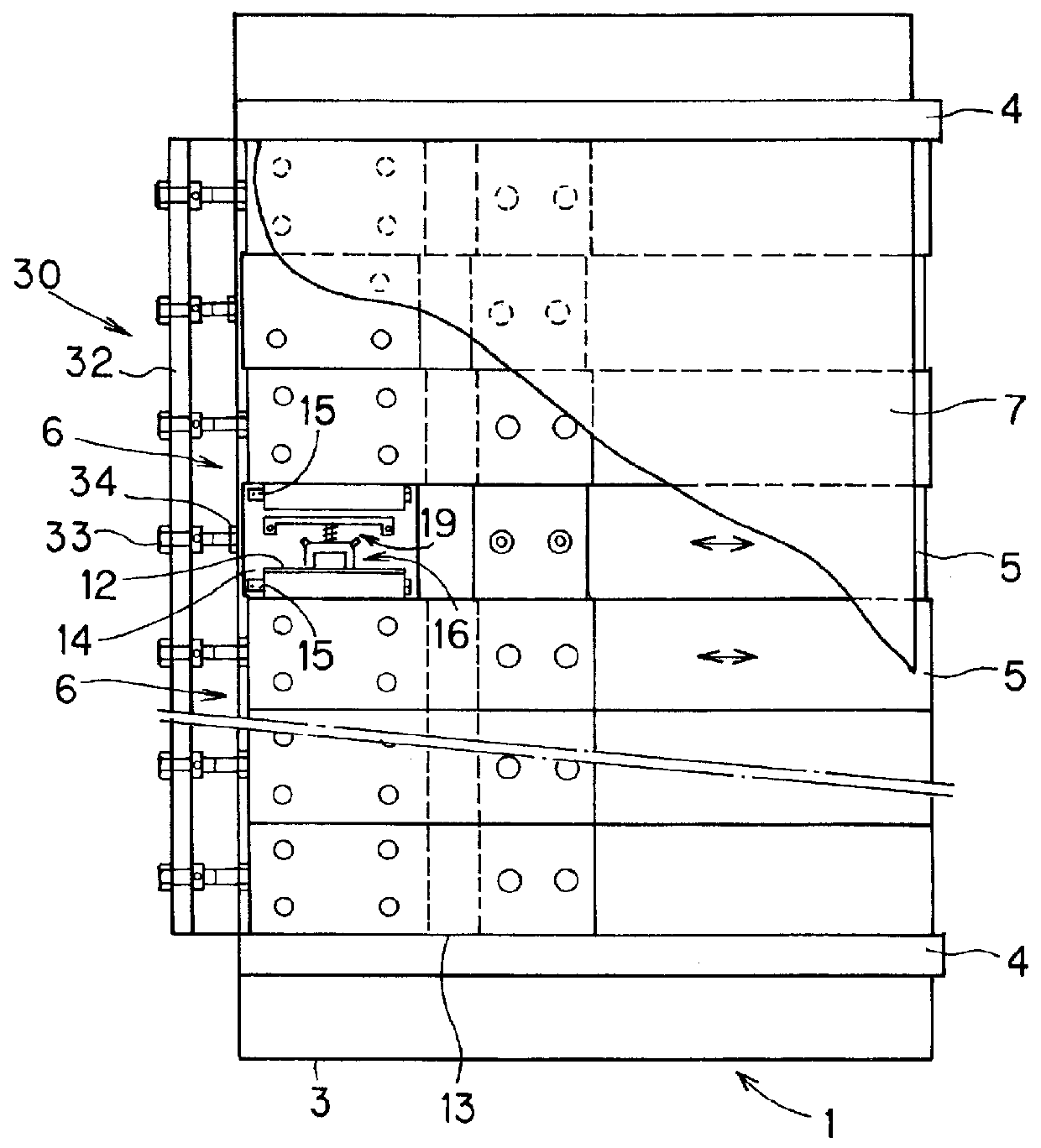

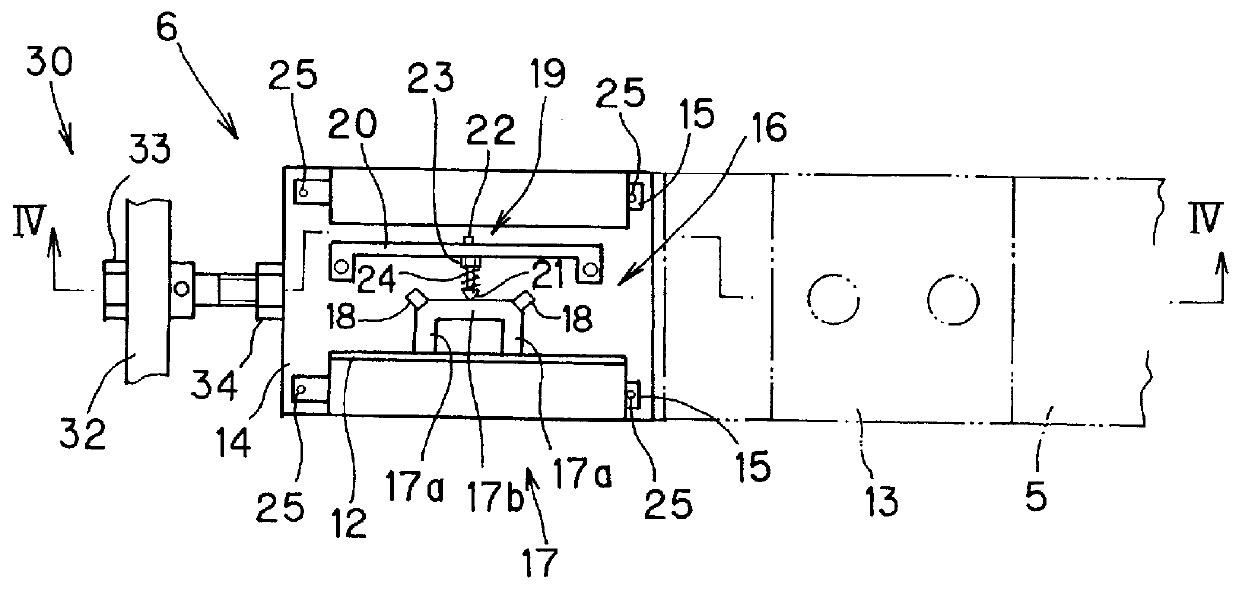

Device for adjusting ink supply gap for ink fountain apparatus

InactiveUS6062139AHigh precisionPrecise maintenancePrinting press partsUltrasonic linear motorMechanical engineering

A device for adjusting an ink supply gap is employed in an ink fountain apparatus in which the bottom portion of the ink fountain apparatus forms a space for storing ink in cooperation with a peripheral surface of an ink fountain roller while a forward edge of the bottom portion faces the peripheral surface of the ink fountain roller in order to form a gap serving as an ink supply port. The device for adjusting an ink supply gap includes a plurality of blade segments and a plurality of ultrasonic linear motors corresponding to the blade segments. The blade segments are disposed on a base in a row extending in the axial direction of the ink fountain roller and are adapted to individually advance toward or retract from the ink fountain roller so as to adjust the opening of the ink supply port. The ultrasonic linear motors are adapted to individually advance or retract the corresponding blade segments.

Owner:TOKYO KIKAI SEISAKUCHI LTD

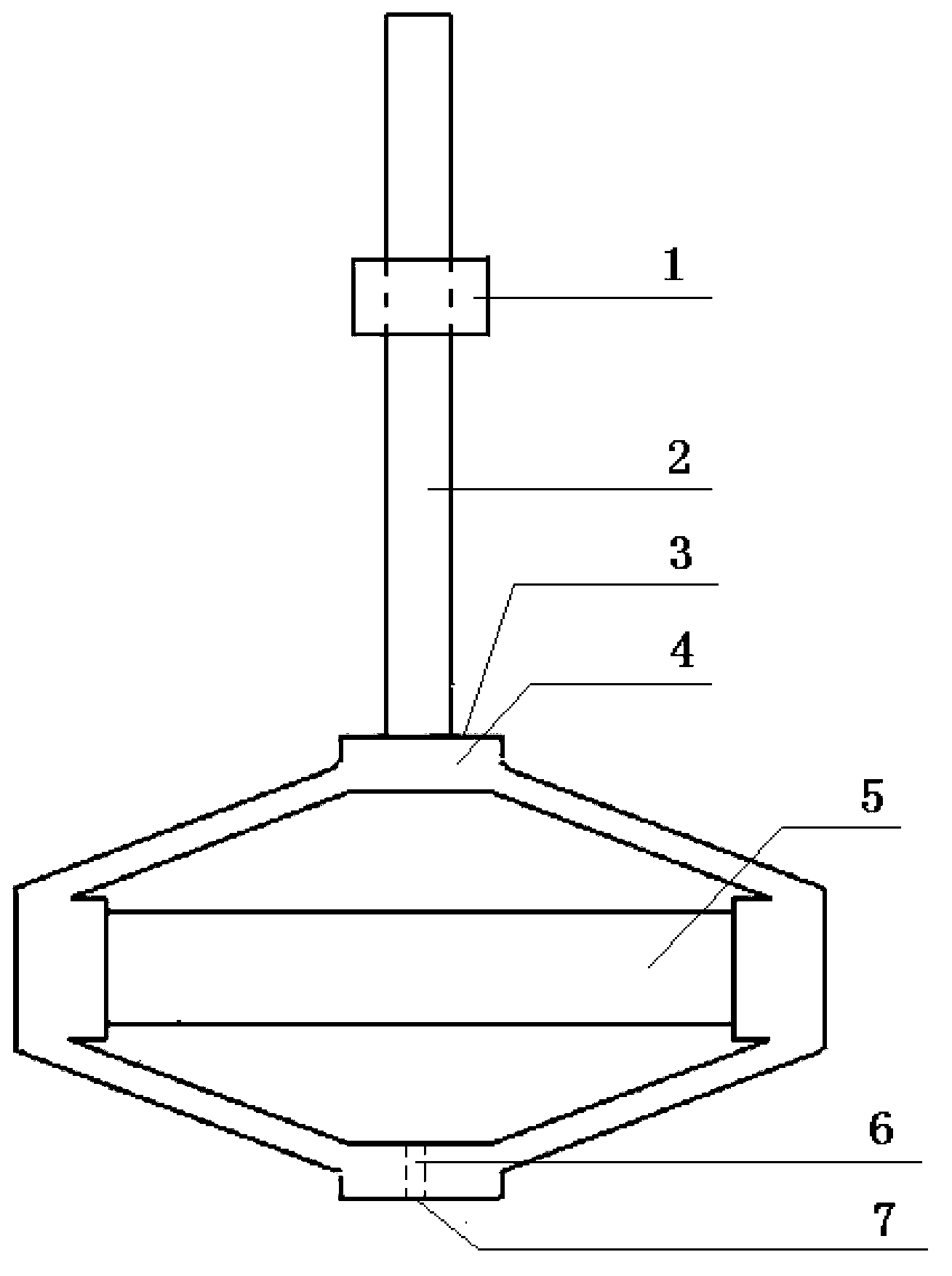

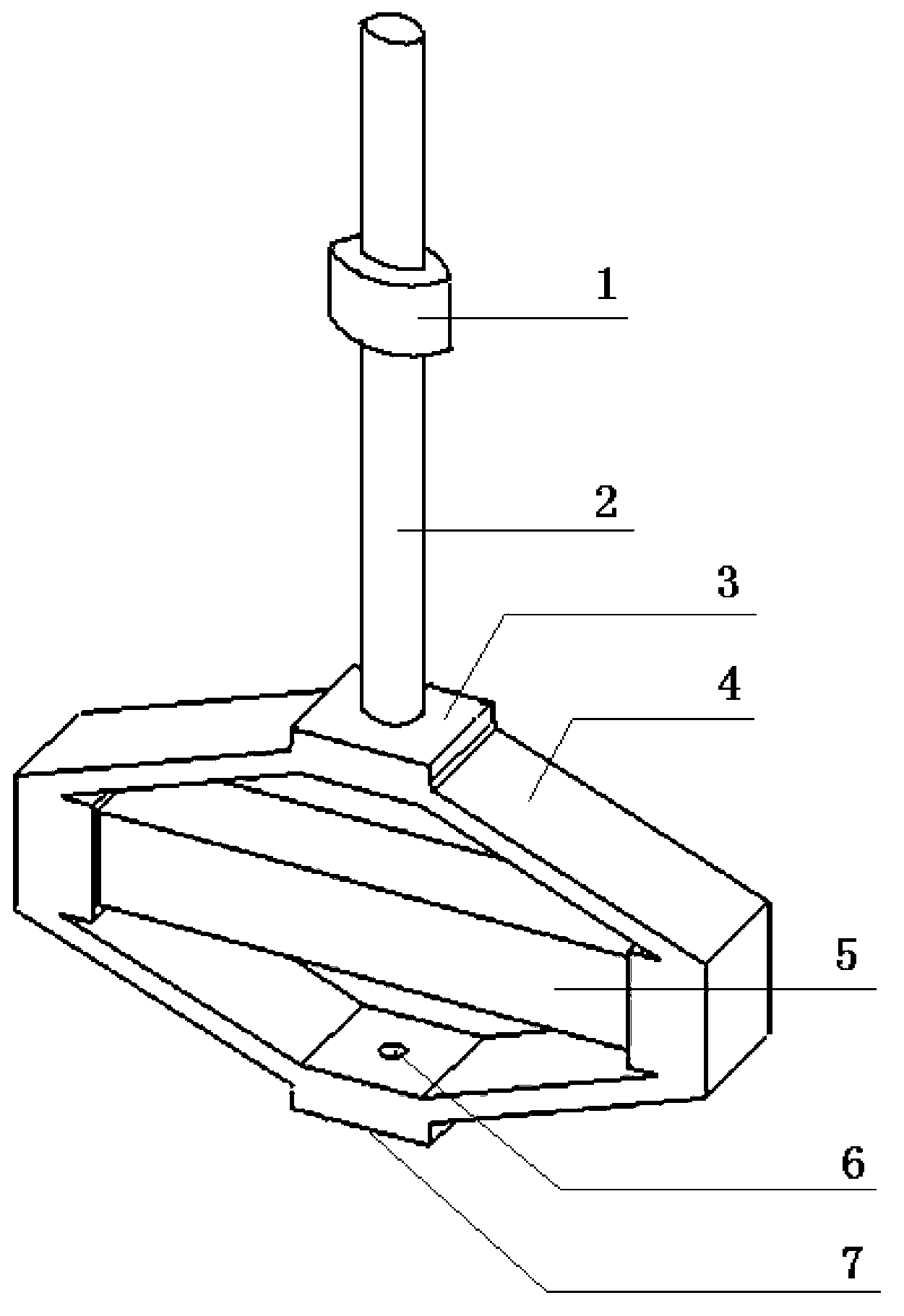

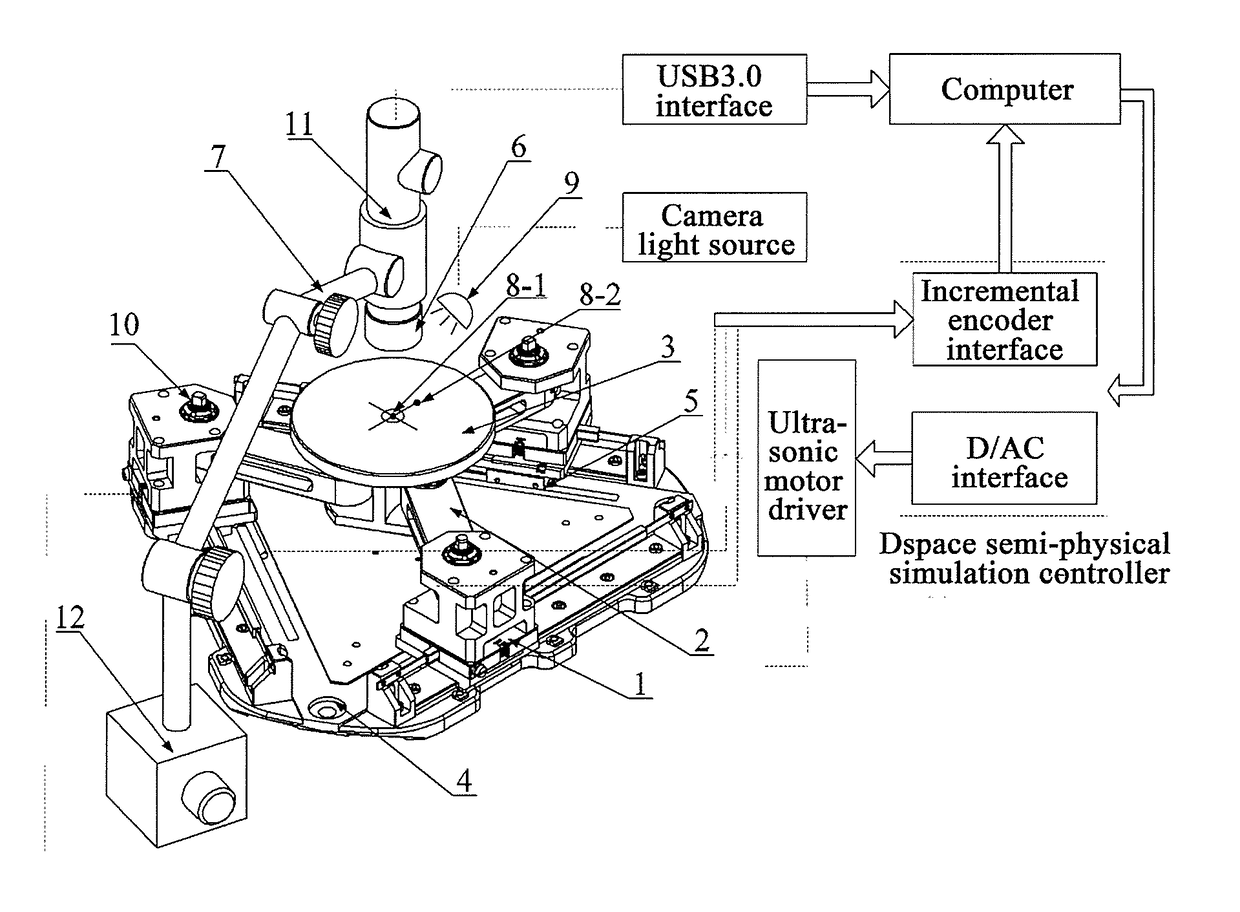

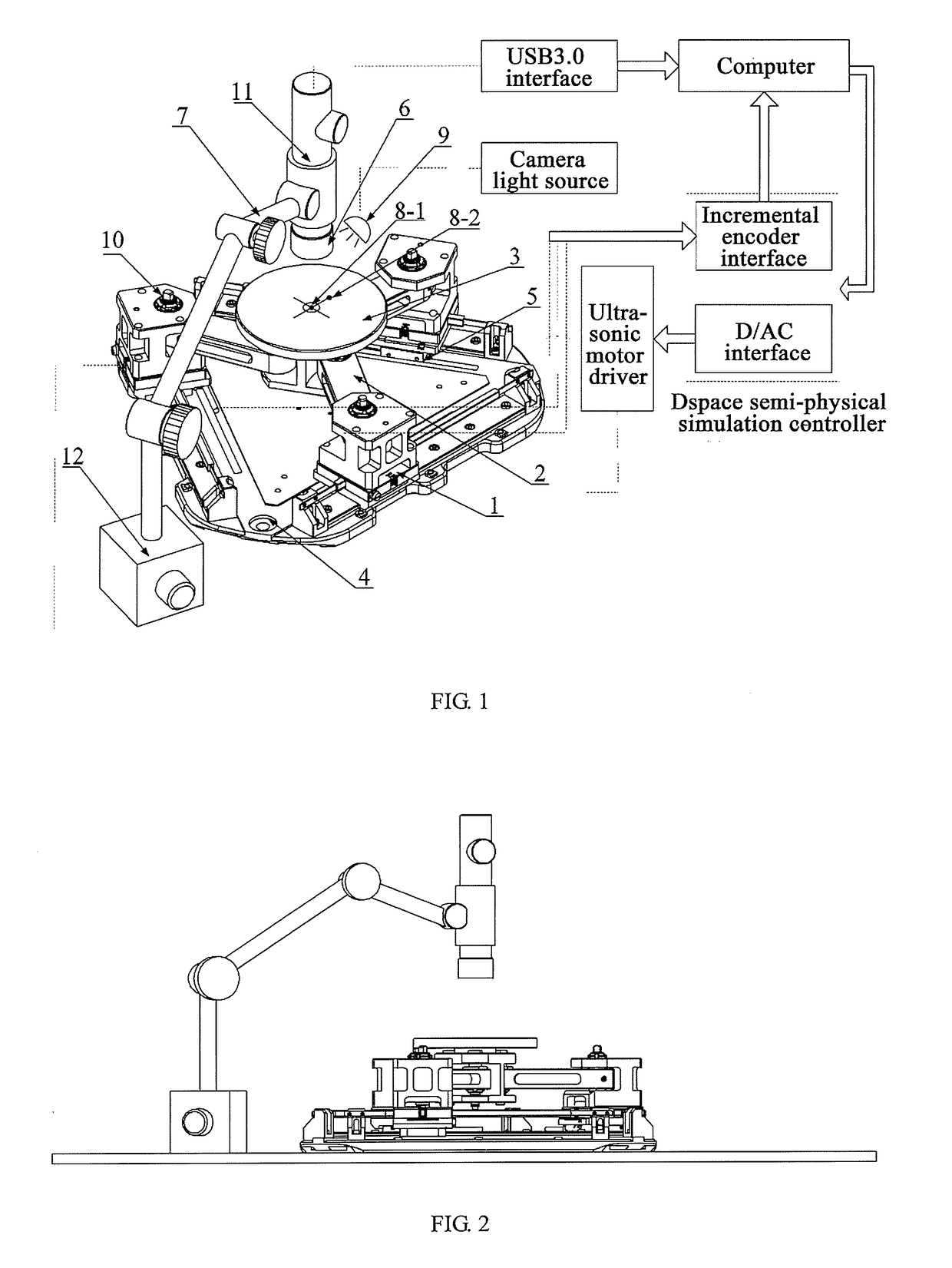

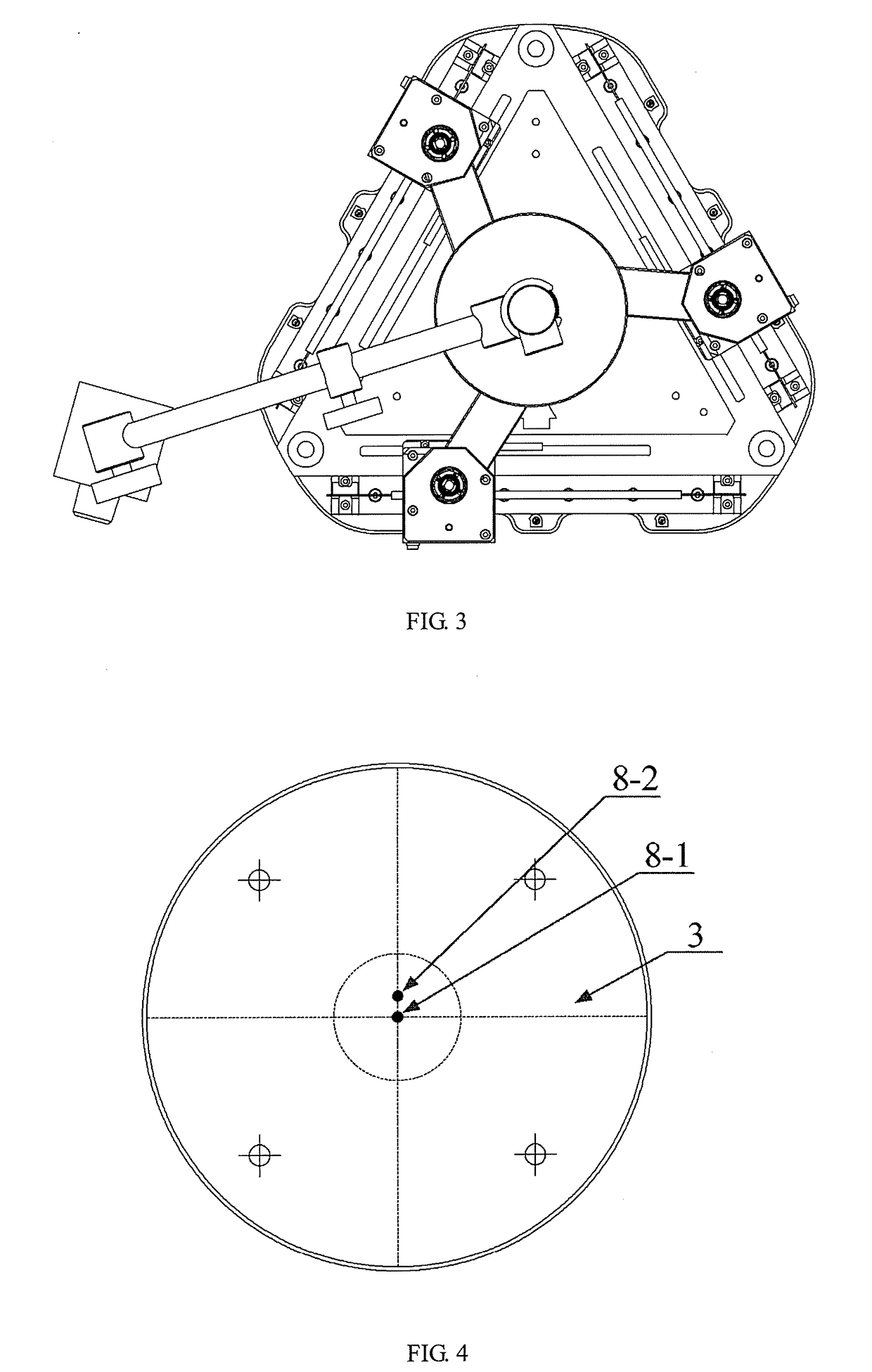

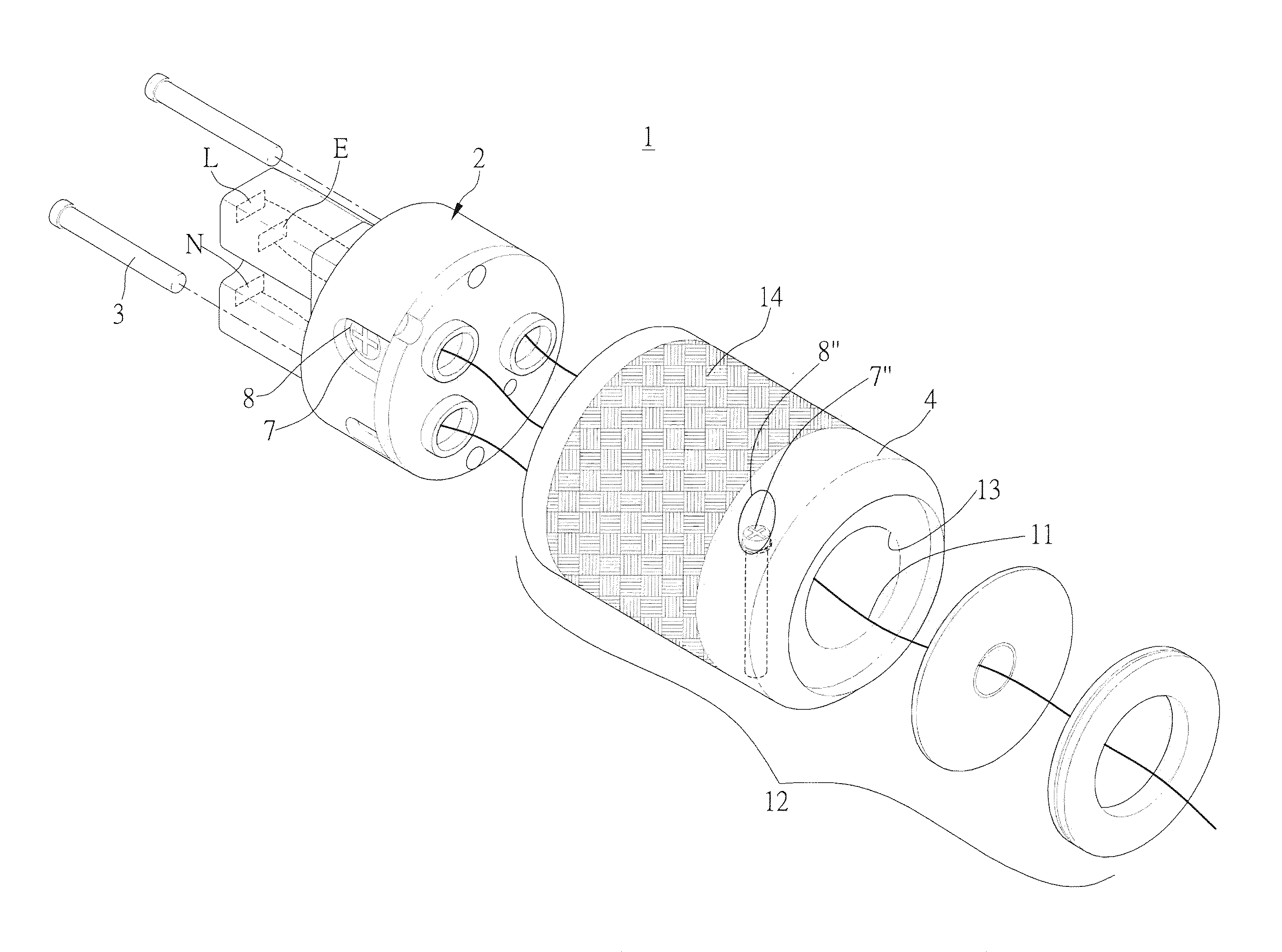

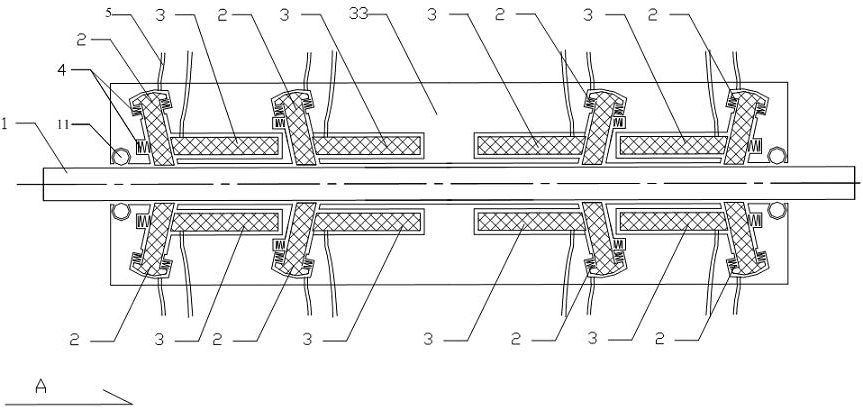

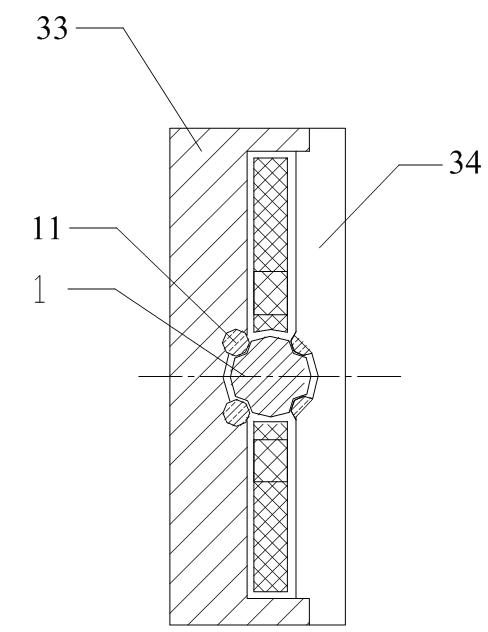

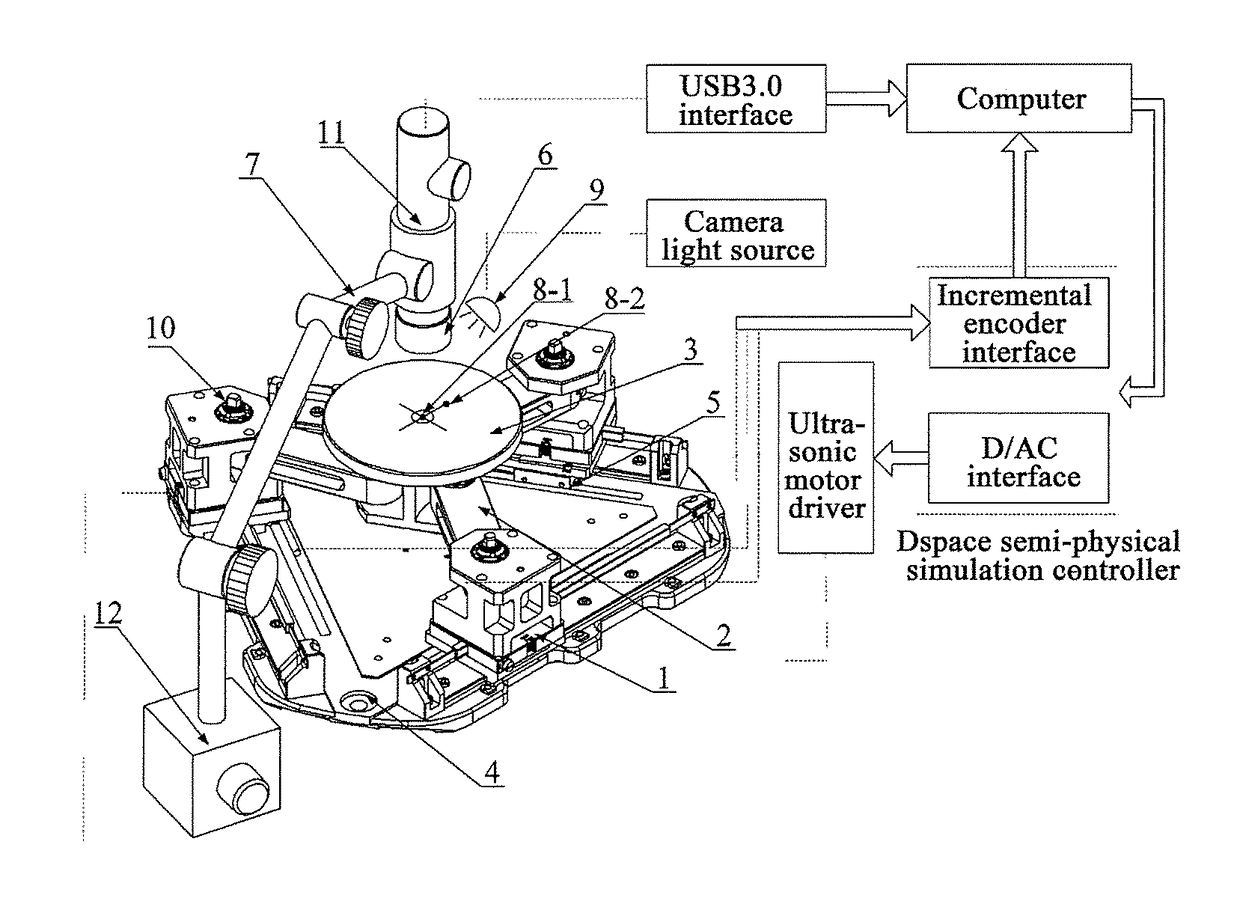

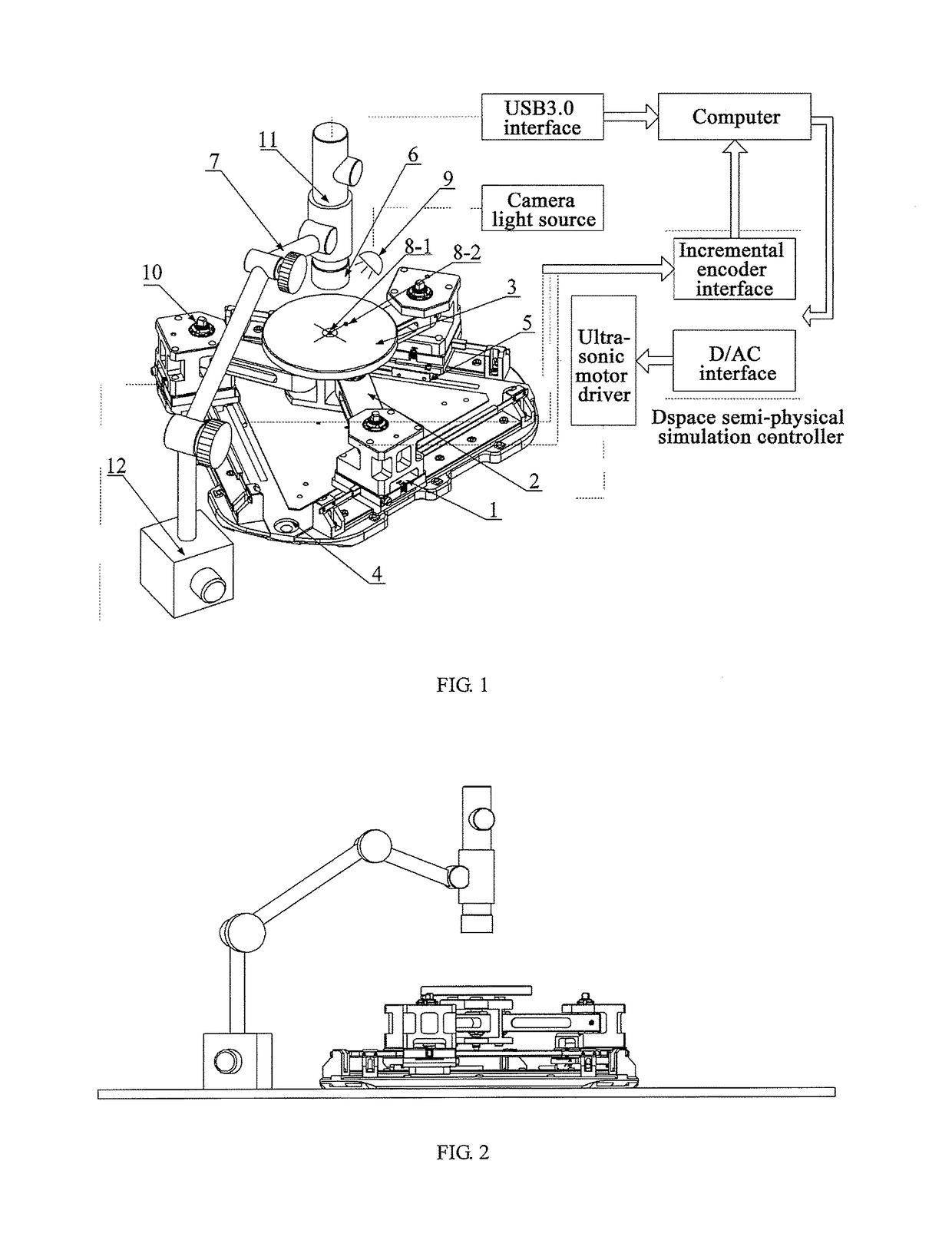

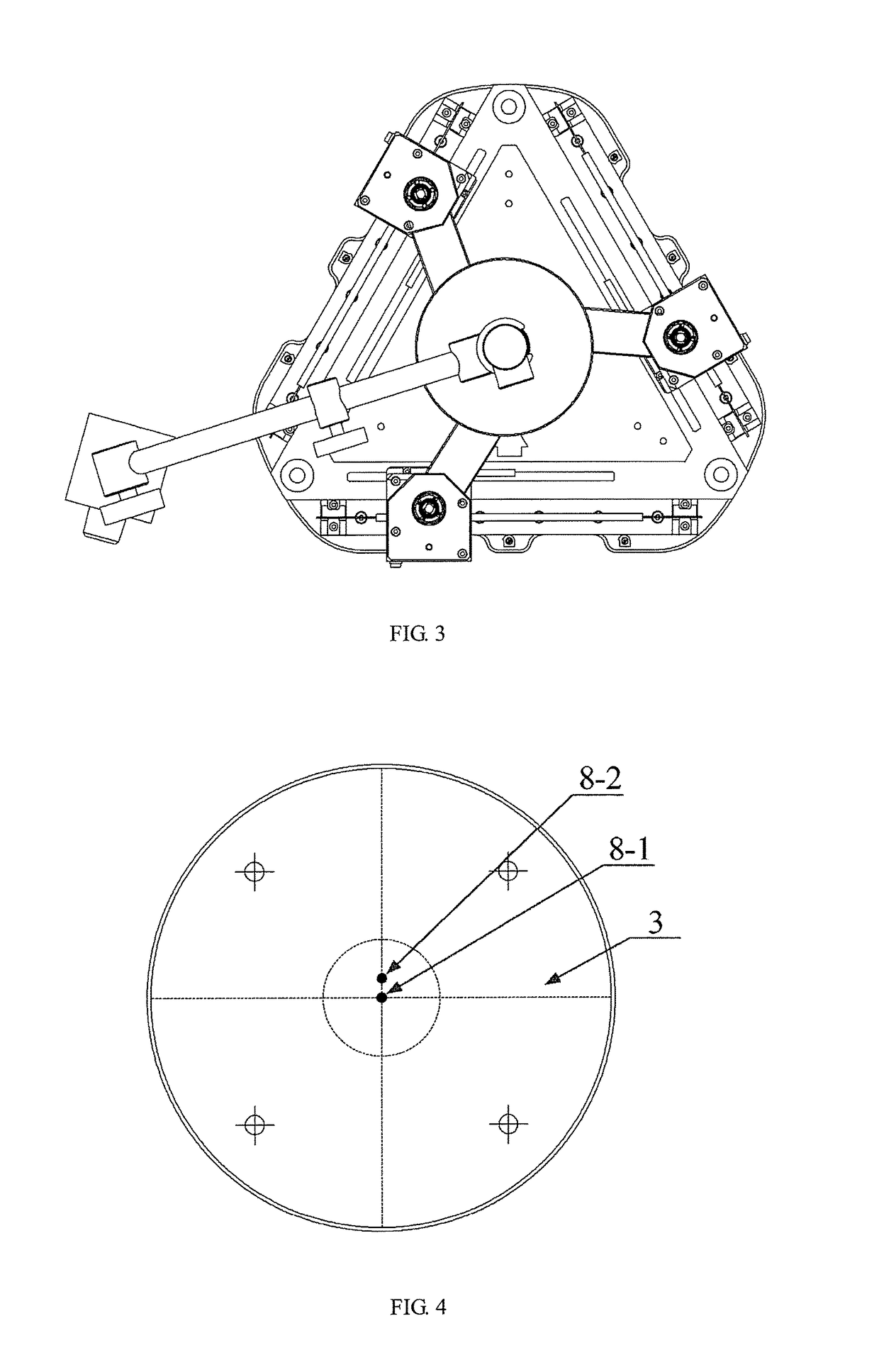

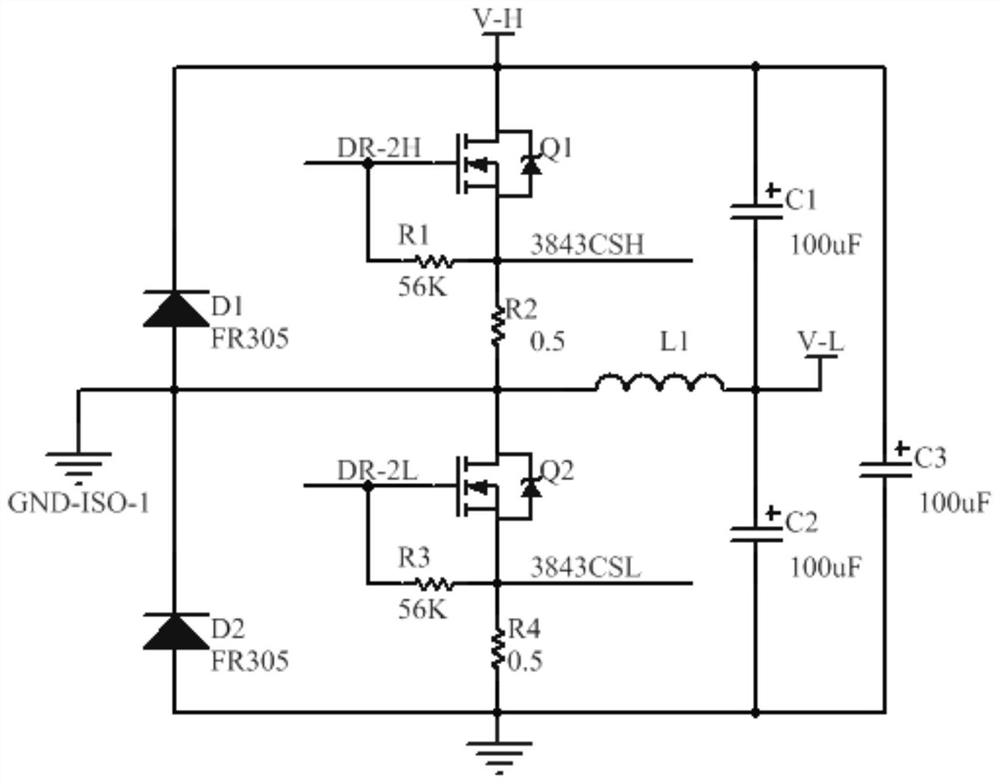

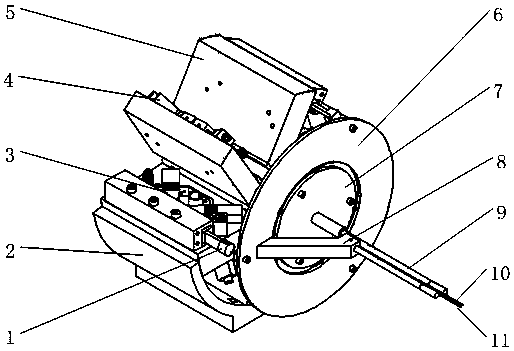

Parallel platform tracking control apparatus using visual device as sensor and control method thereof

ActiveUS20180081376A1Simplifies image processing difficultyImage processing speed can be increasedProgramme controlProgramme-controlled manipulatorGratingImaging processing

A parallel platform tracking control apparatus and method using a visual device as a sensor are disclosed. The apparatus comprises a parallel platform body, a CCD camera (11), a lens (6), a camera light source (9), a computer (11), a Dspace semi-physical simulation controller, an ultrasonic motor driver and the like. The parallel platform comprises an ultrasonic linear motor (1), a linear grating encoder (5), a driven rod (2), a moving platform (3), a stationary platform (4) and the like. The CCD camera photographs the moving platform in a perpendicular and opposite manner, and the photographed images are subjected to an image processing algorithm to measure the position of the corresponding marker on the moving platform, which is not only applicable to measurement, but also implements real-time feedback of the termination position of the moving platform, such that a full closed-loop system is constituted. In this way, the parallel platform is precisely positioned.

Owner:SOUTH CHINA UNIV OF TECH

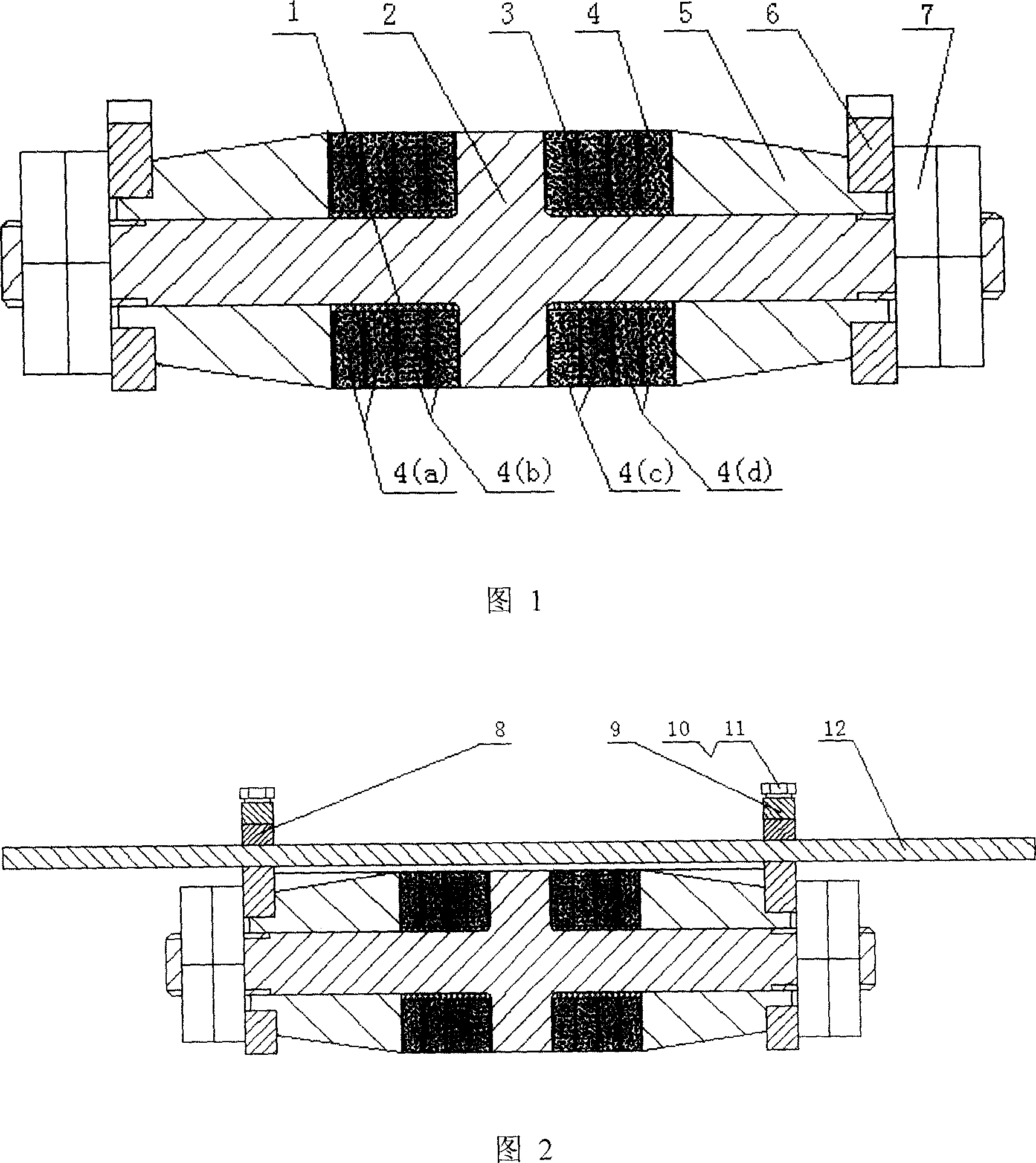

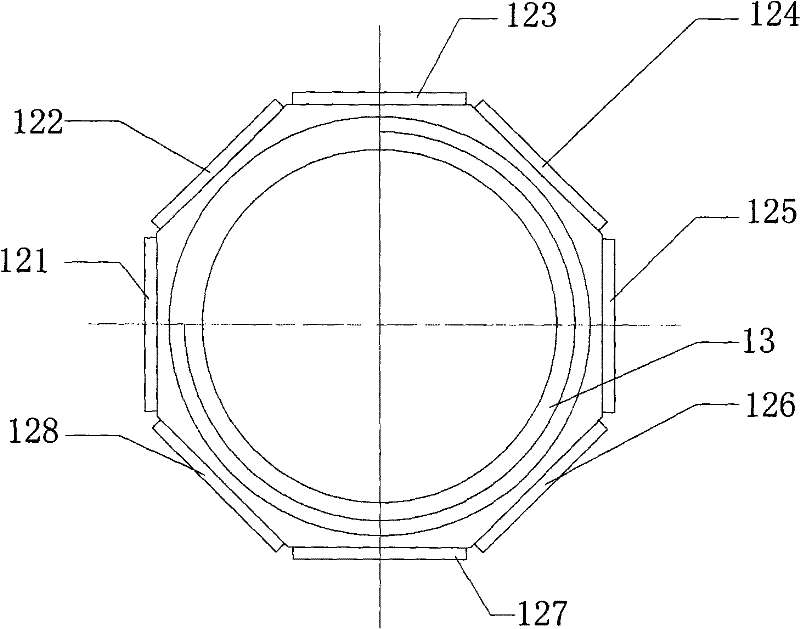

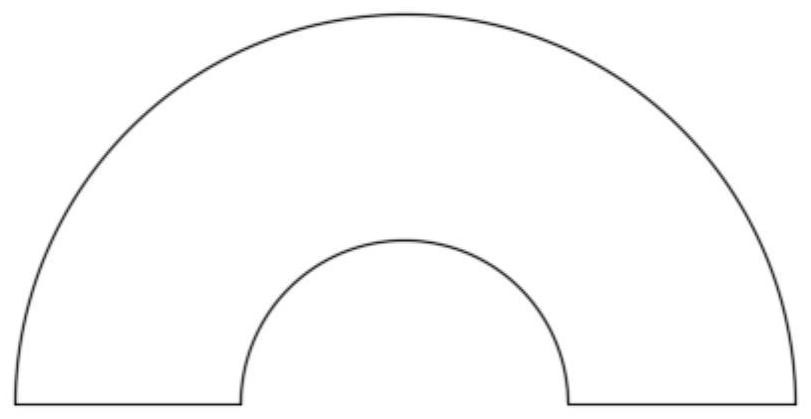

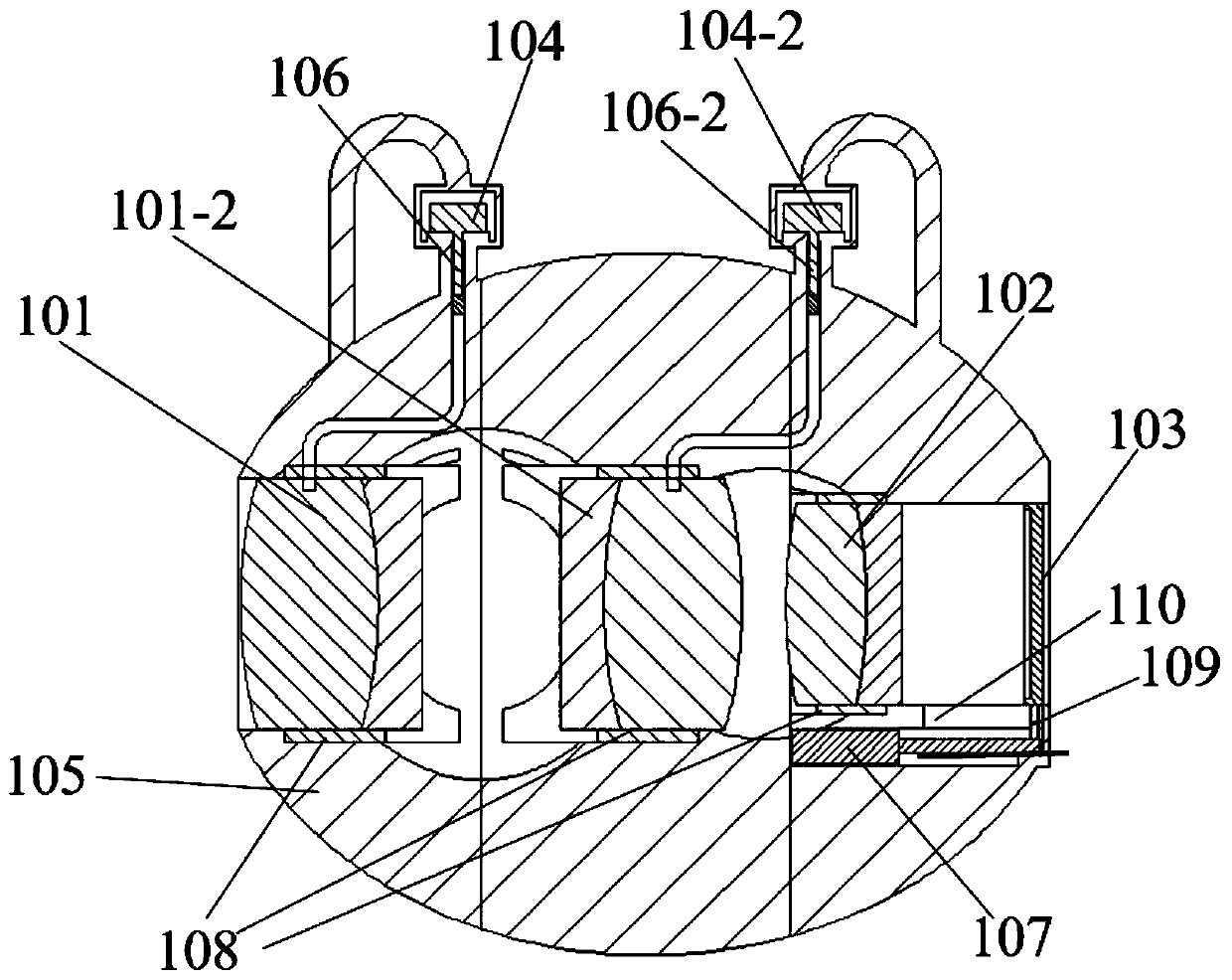

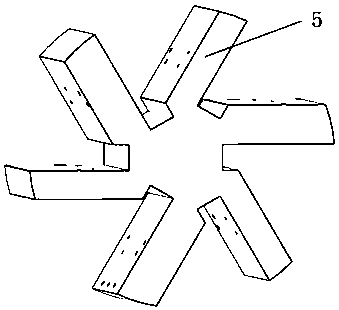

Conoid stator longitudinal and bending combination ultrasonic linear motor

InactiveCN101013862AMake up for the problem that the performance cannot be completely consistentConsistent performancePiezoelectric/electrostriction/magnetostriction machinesSet screwUltrasonic linear motor

The invention relates to one tamper stator longitude compound supersonic line motor, which adopts tamper stator and dial tooth adopt the middle structure with protruding benches for rotor fixing, sliding and guiding; the stator acts on dial tooth through symmetric distributed eight piezoelectricity pads through pressure axis cover to tighten the pads into spiral middle axis; the stator two ends adopt double screw loose to adjust stator pre-pressure and sets screw bolt through pressure board to press rotor for positive pressure.

Owner:JIANGSU UNIV

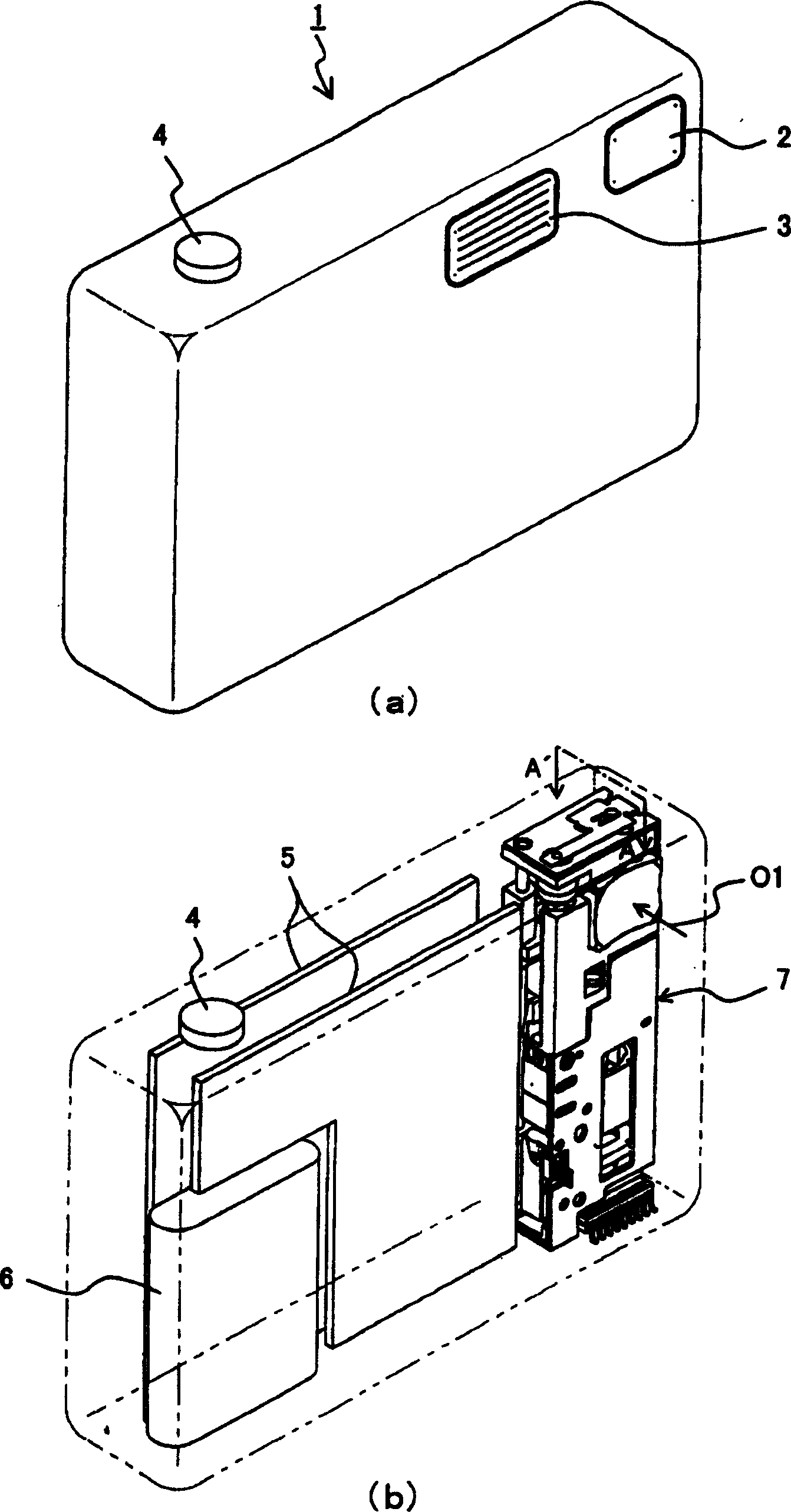

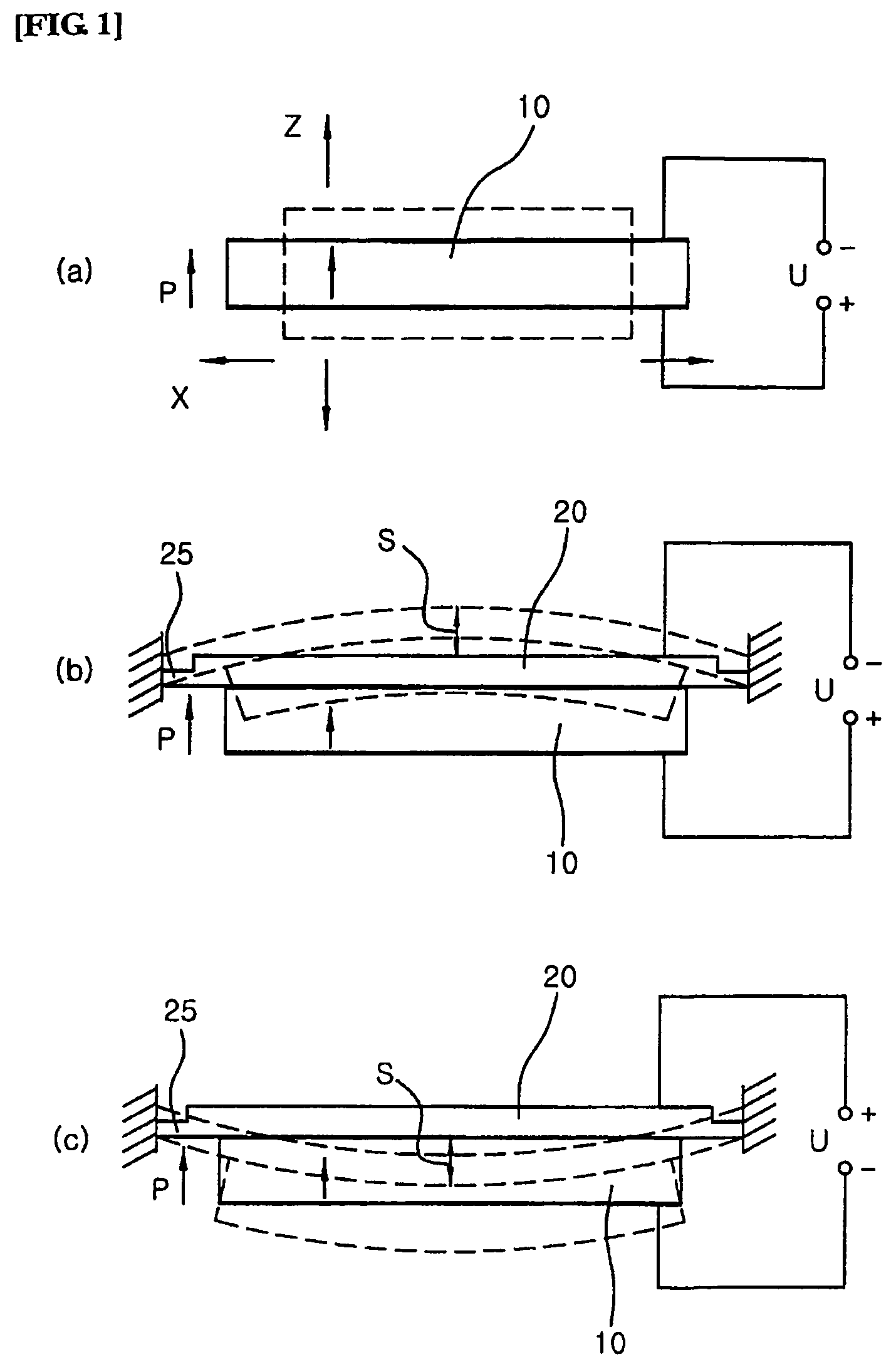

Small piezoelectric or electrostrictive linear motor

ActiveCN1898856ADrive stabilitySimplify the manufacturing processPiezoelectric/electrostriction/magnetostriction machinesMountingsElastomerUltrasonic linear motor

The present invention provides a small piezoelectric / electrostrictive ultrasonic linear motors which are installed in cell phones or PDAs, etc. to drive their camera lenses. In the present invention, a movable shaft (30) is coupled to a unimorph or bimorph, which is made by attaching a piezoelectric or electrostrictive substrate to an elastic body (20) (metal), so that a movable body (40) fitted over the movable shaft (30) is linearly moved along the movable shaft (30) by vibration of the piezoelectric or electrostrictive substrate, thus simplifying a manufacturing process, being easily practicable according to a basic principle, and having superior characteristics.

Owner:PIEZOELECTRIC TECH

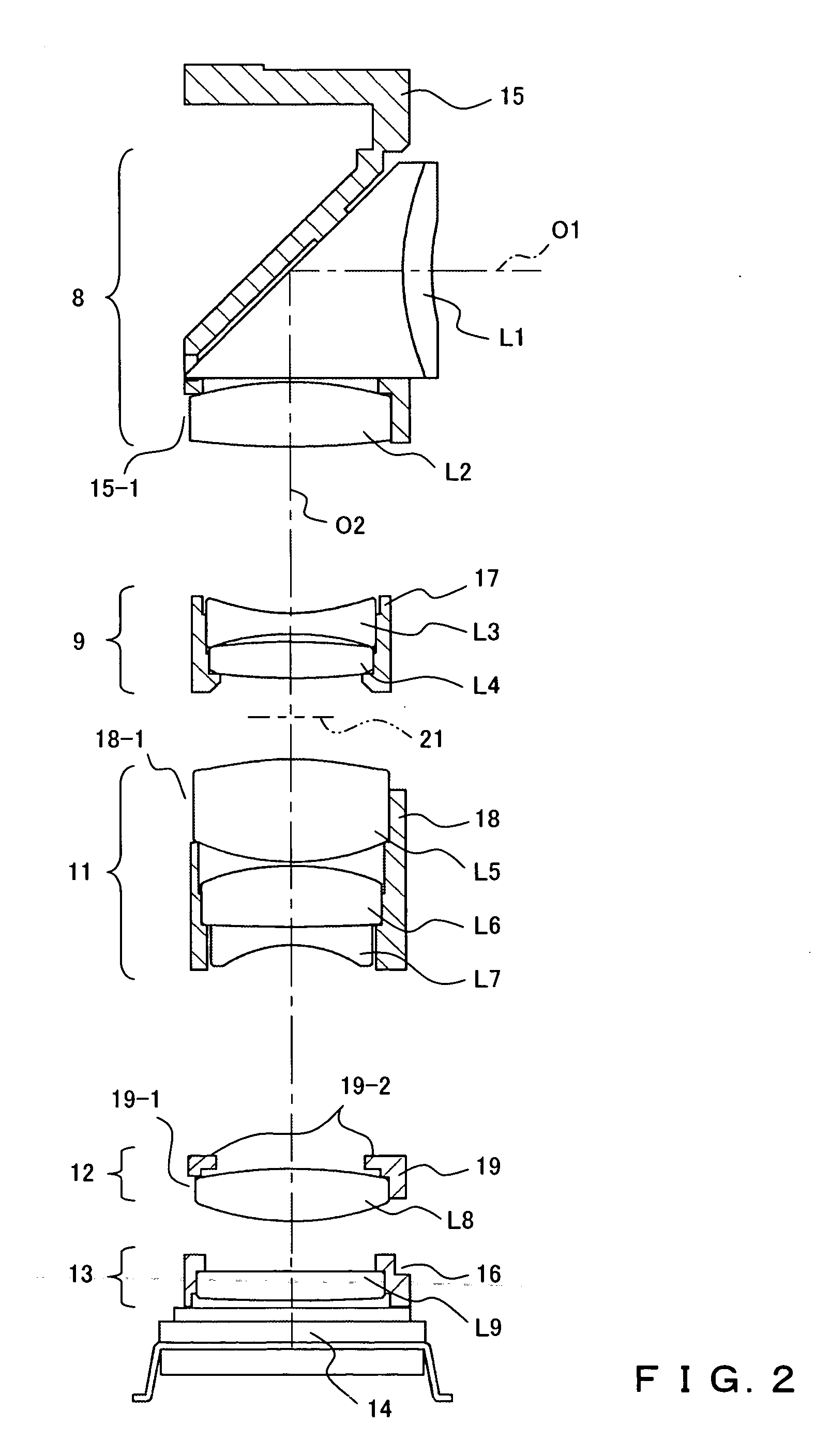

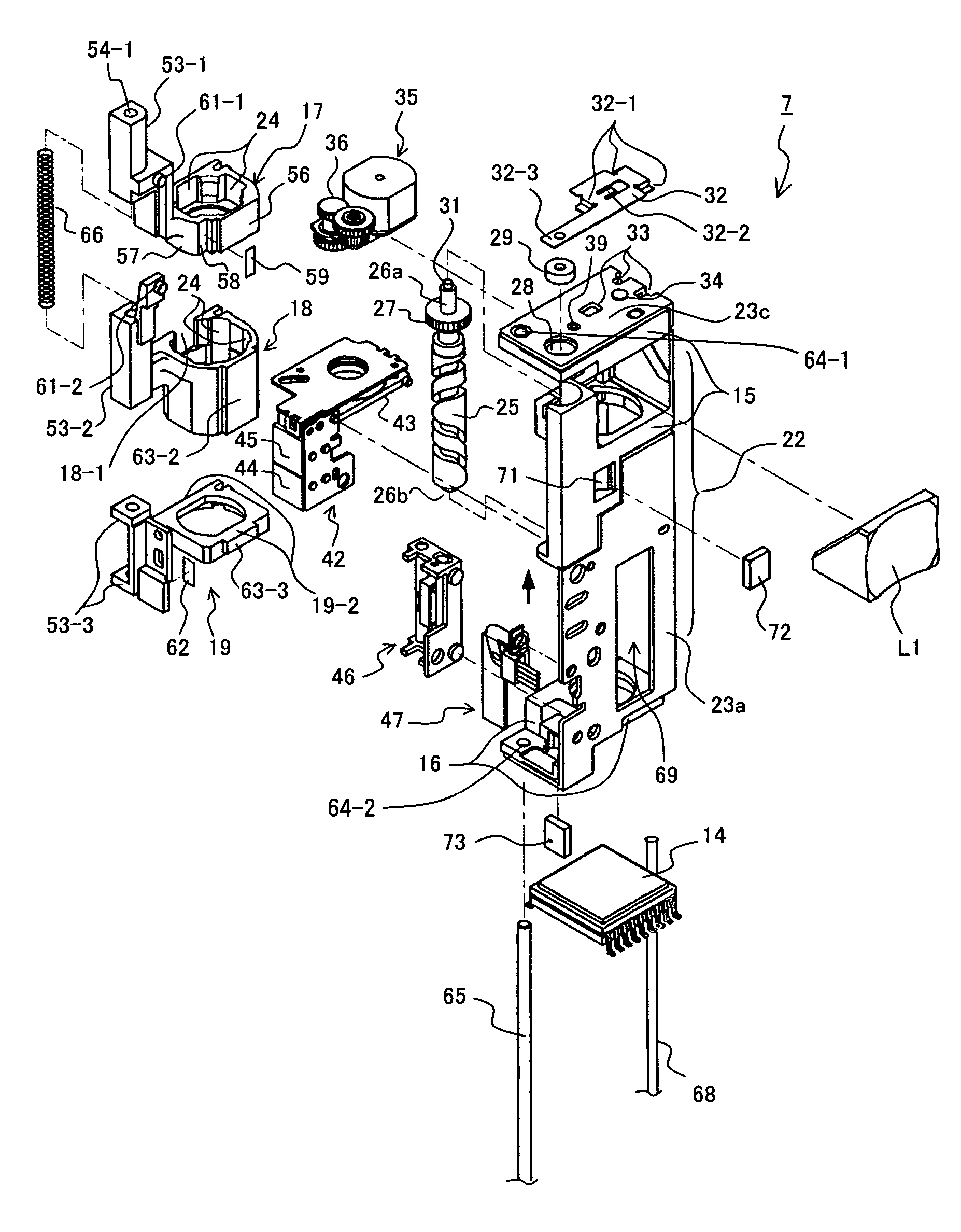

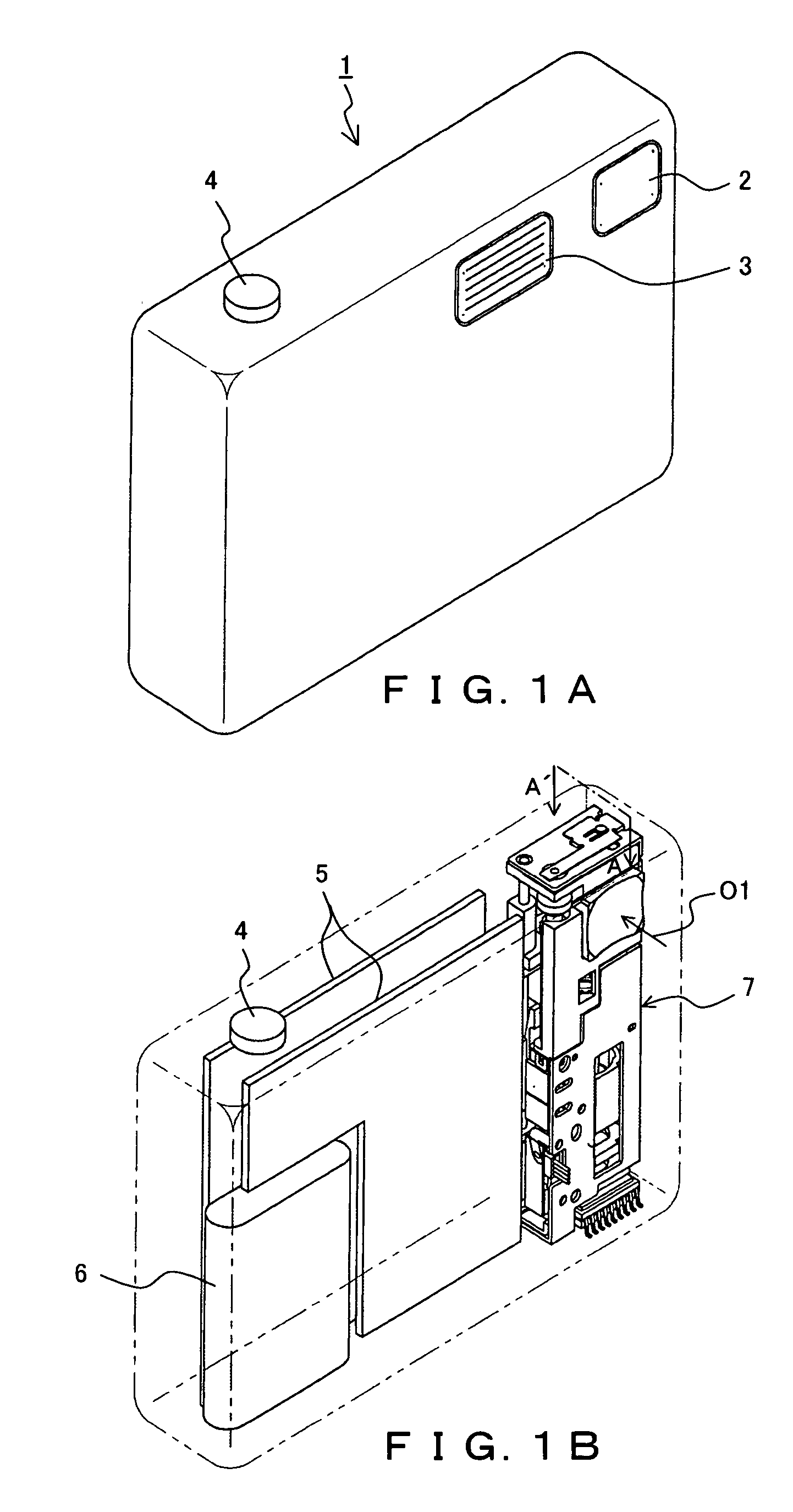

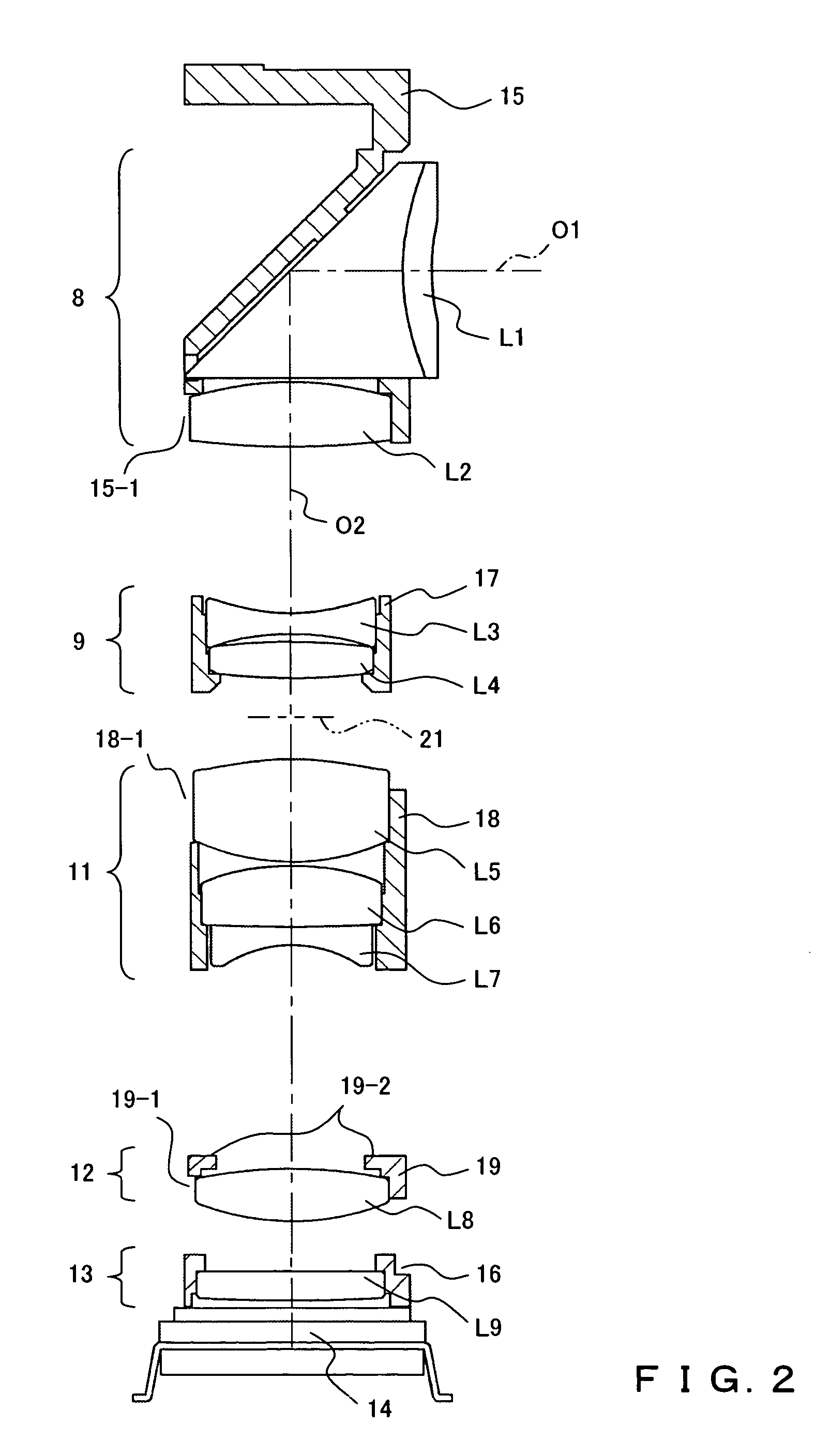

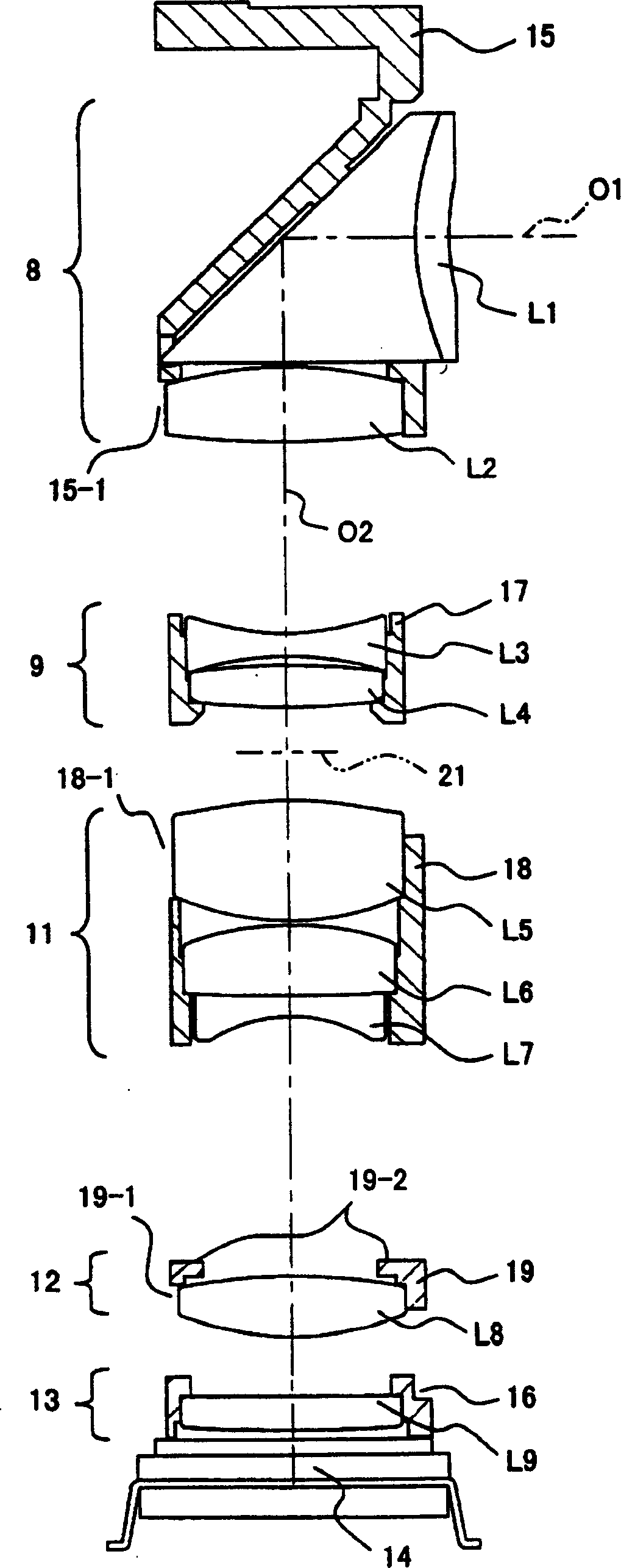

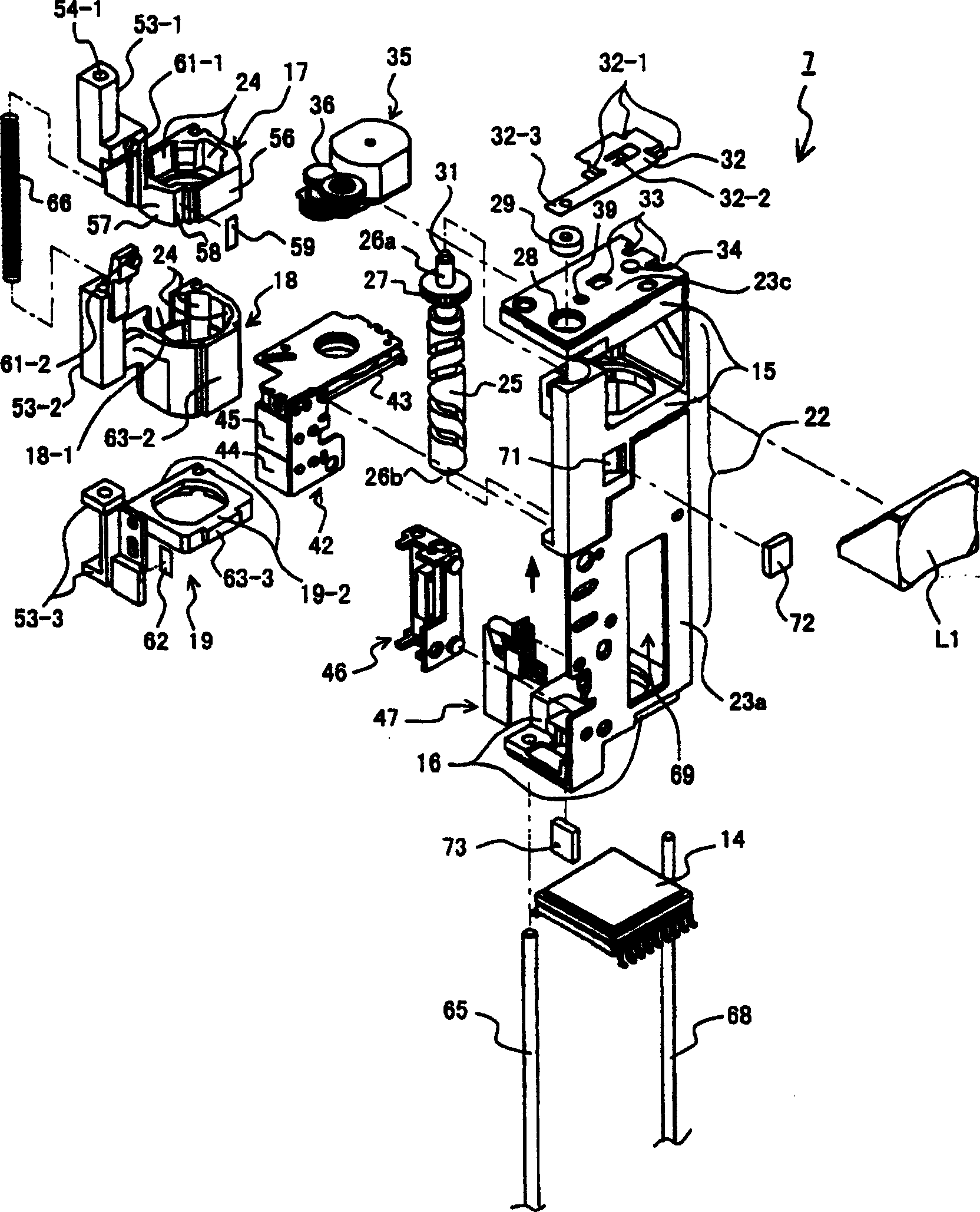

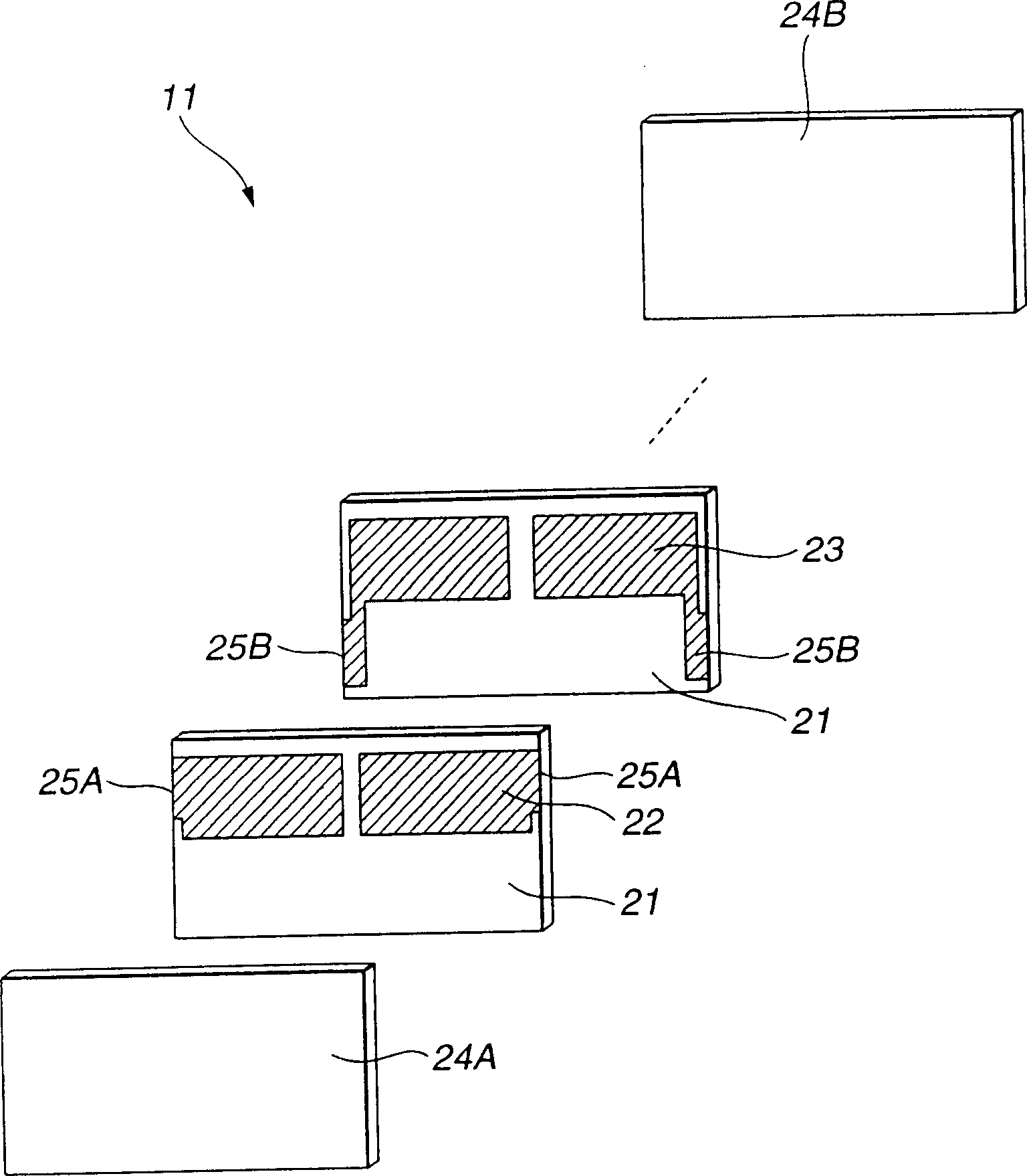

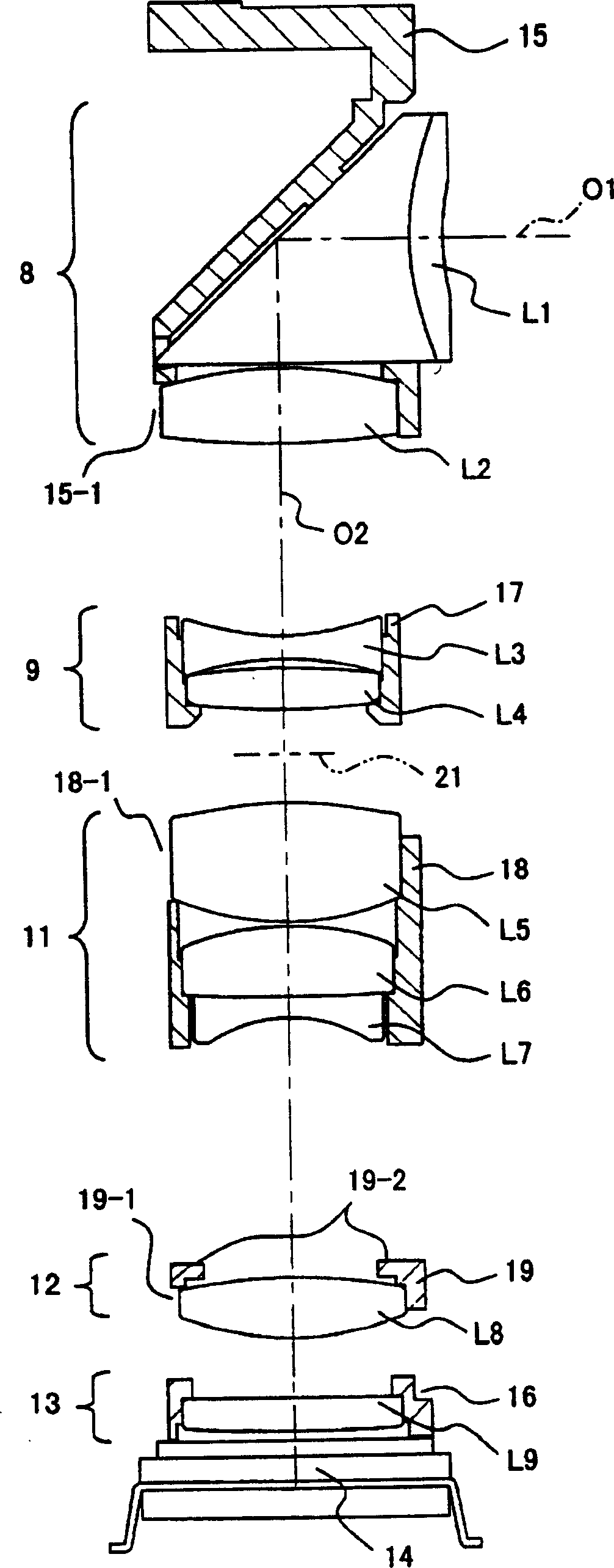

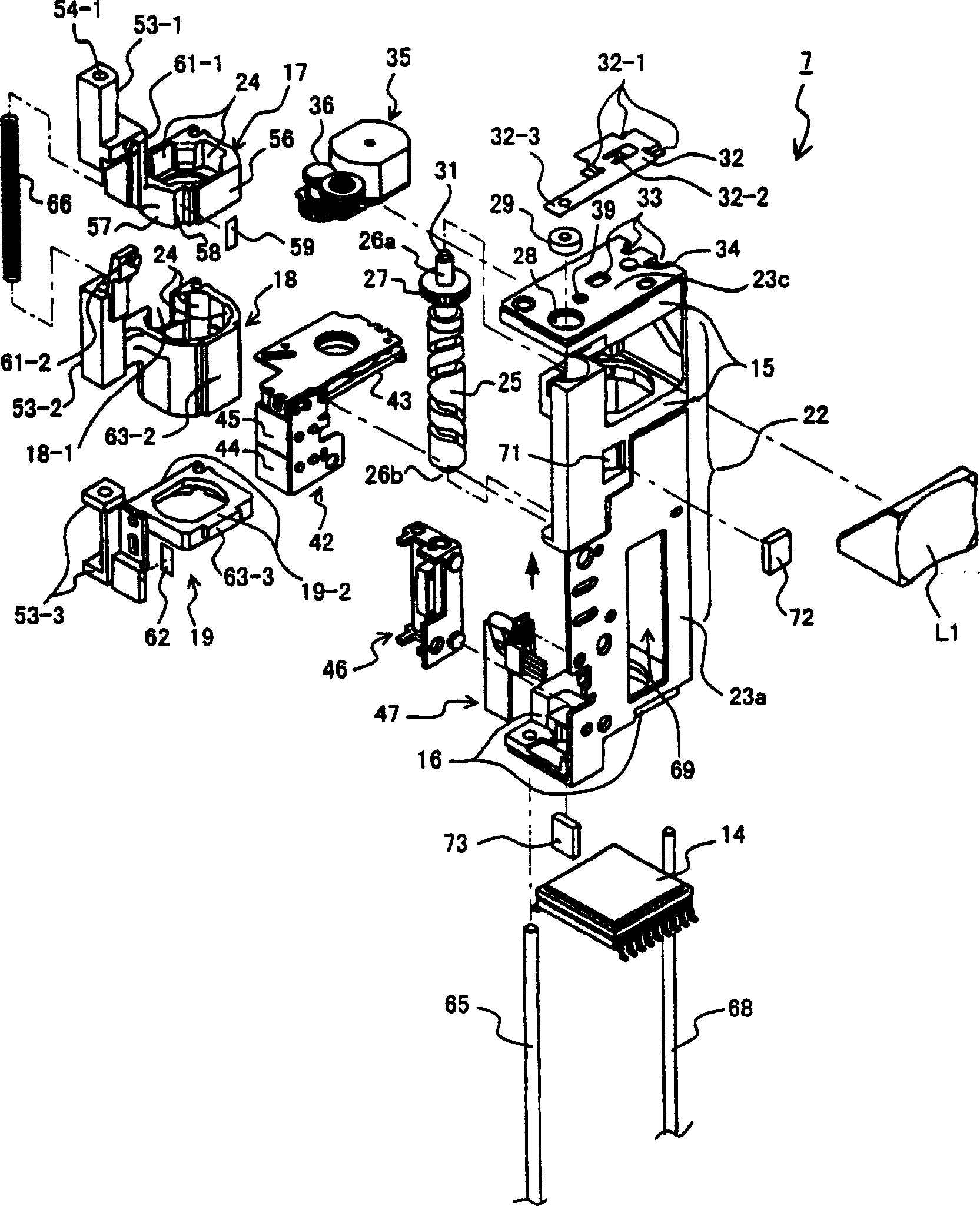

Lens device and digital camera using same

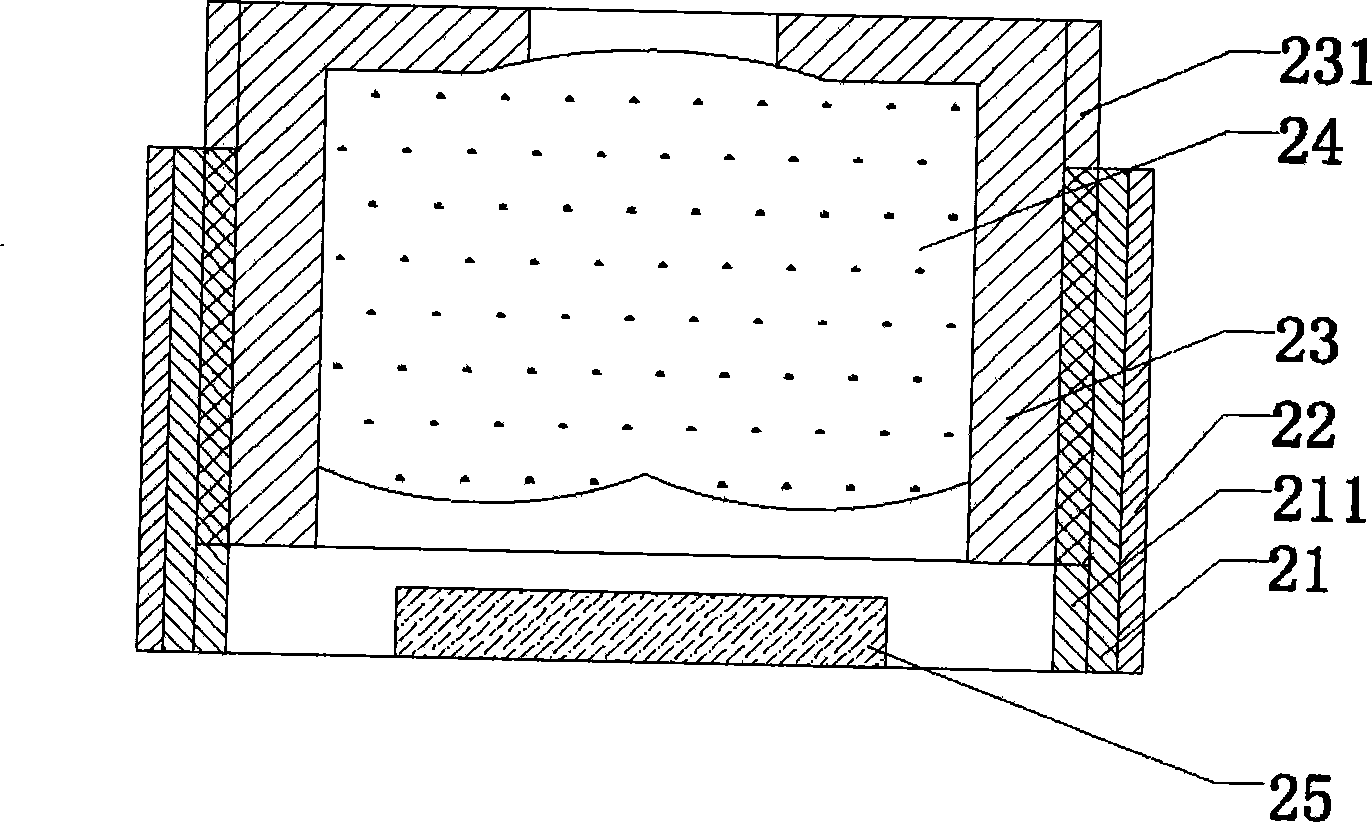

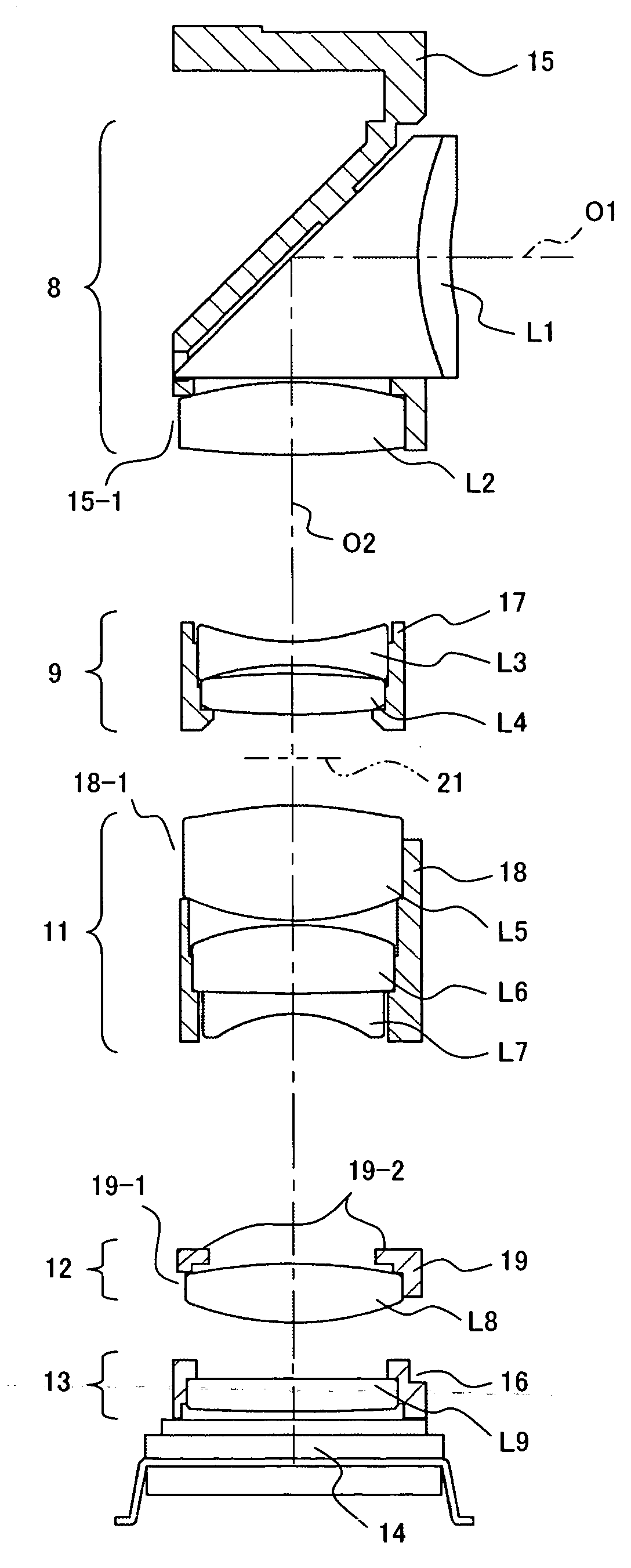

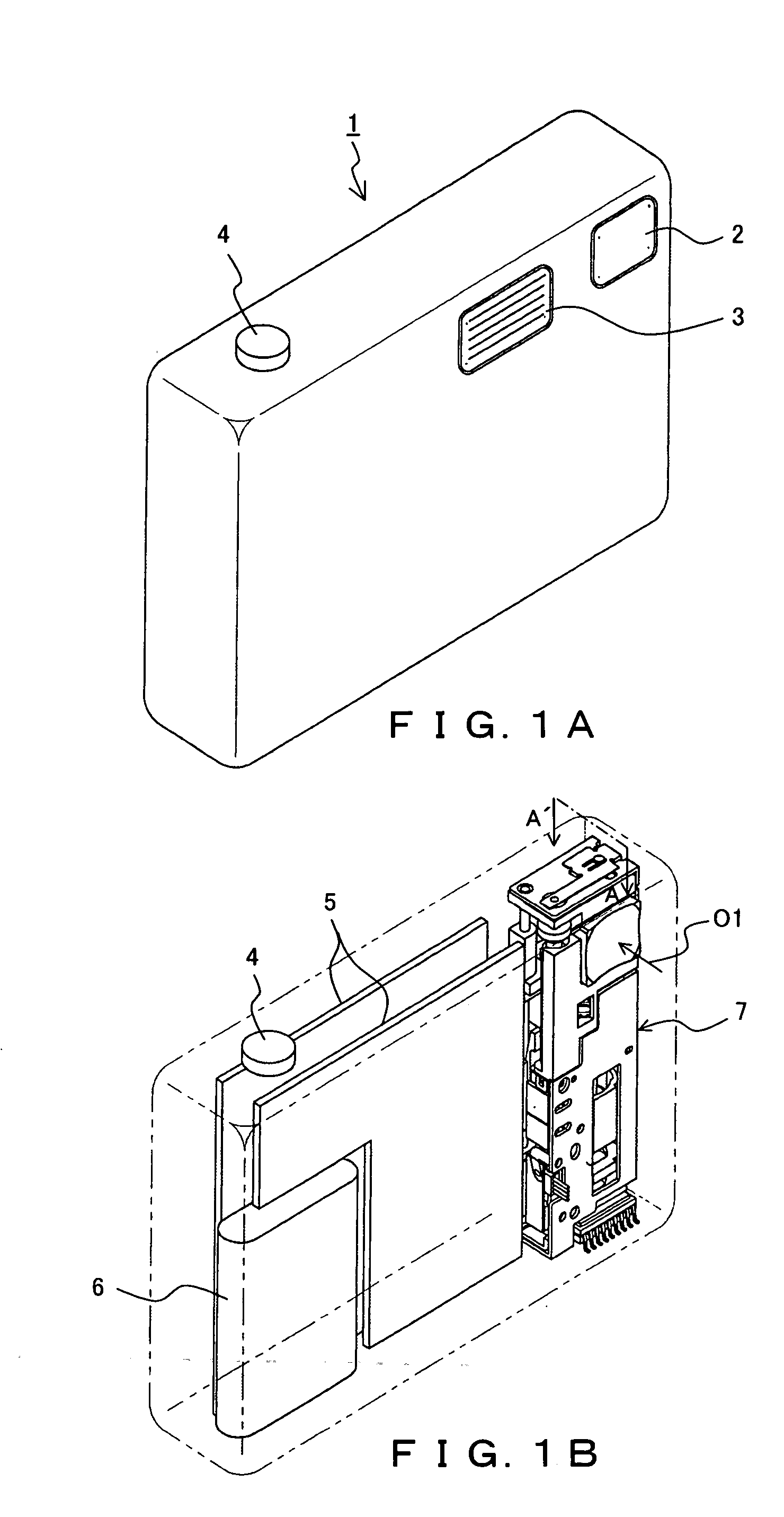

InactiveCN1573399AIncreased functional reliabilityTelevision system detailsColor television detailsUltrasonic linear motorMetal framework

Provided is a lens device realizing further thinning and the reduction of cost, and a digital camera using the lens device. As to a lens device 7, all the members are arranged in a rectangular paralelepipedic space which is flat in a front-and-rear direction and long lengthwise and is formed by a main fixed lens frame 22. In the rectangular paralelepipedic space, the opposite surface to the metallic frame 23a of the main surface and opposite surface to the metallic frame 23b of one side surface in a longitudinal direction are open surfaces, and the fixed lens frame parts 15 and 16 made of resin are integrally formed with the metallic frames 23a, 23b and 23c. A lens prism L1 is fixed, three moving lens frames 17, 18 and 19 for zooming and for focusing through which guide shafts 65 and 68 are inserted are arranged, an imaging lens is fixed, and an imaging device 14 is arranged at the lowermost part successively from the top to the bottom so as to occupy 2 / 3 of the width of the rectangular paralelepipedic space. A motor unit for zooming 35 is arranged behind the lens prism L1, and a shaft cam for zooming 25, a diaphragm / shutter unit 42, an ultrasonic linear motor for focusing 46 and a magnetic sensor unit 47 are arranged along a lens frame group.

Owner:OLYMPUS CORP

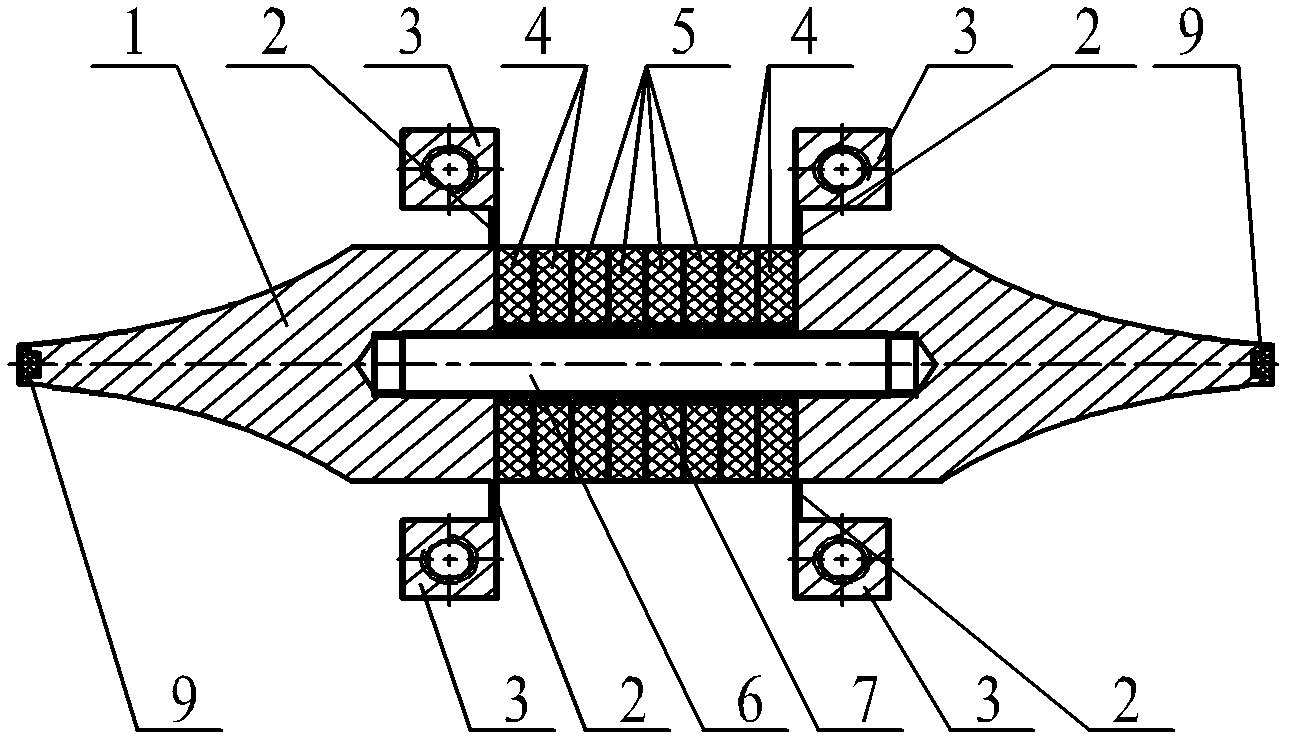

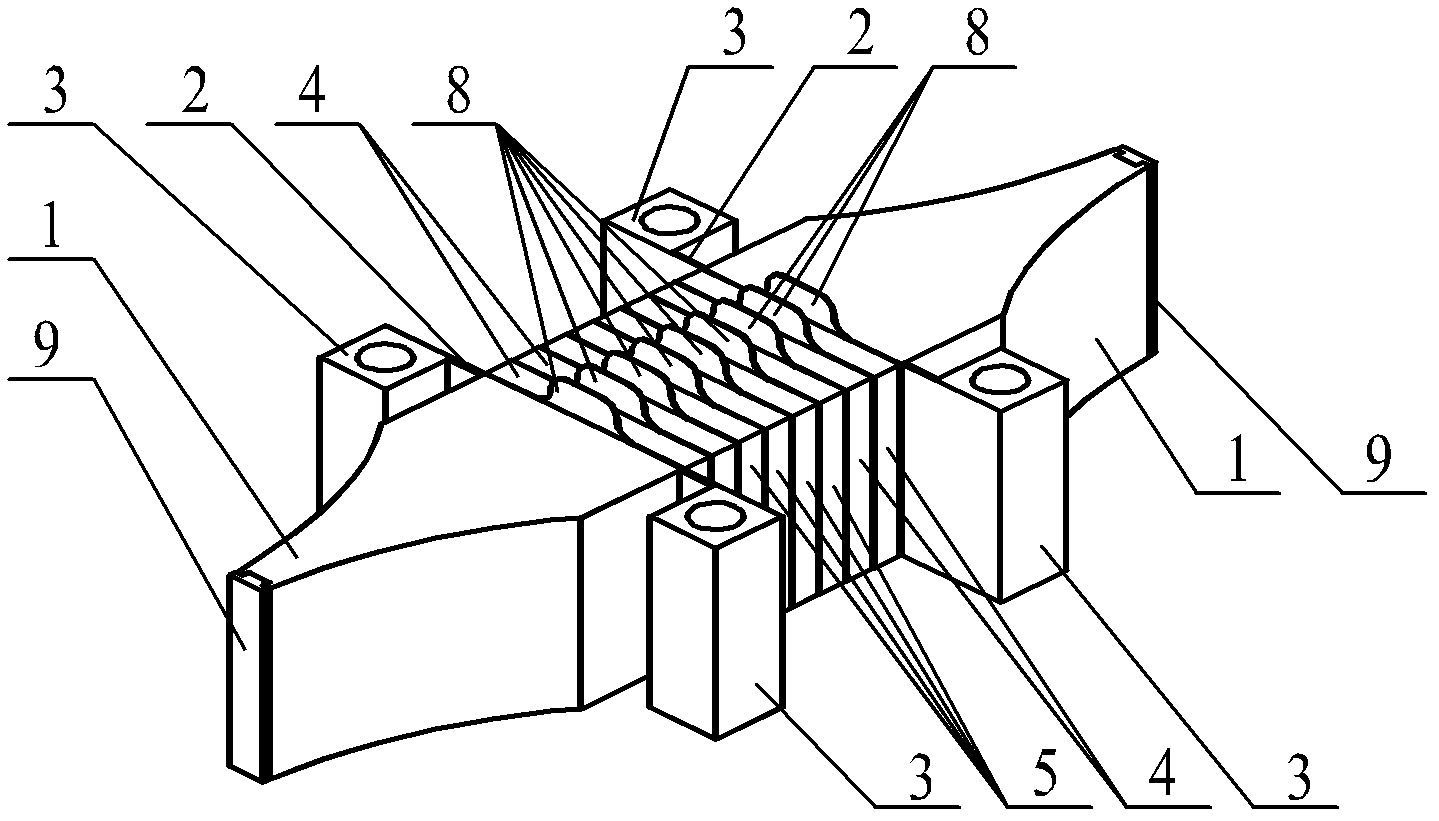

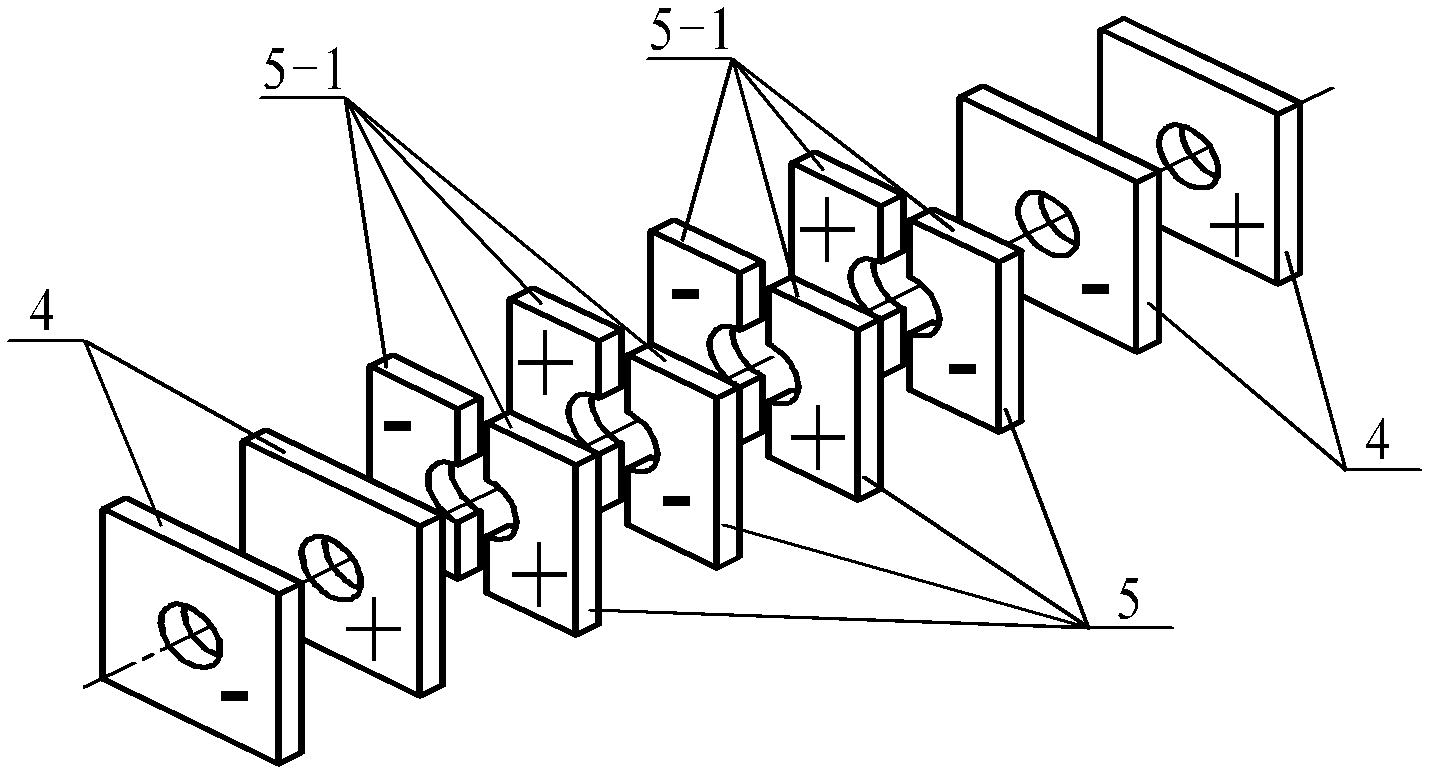

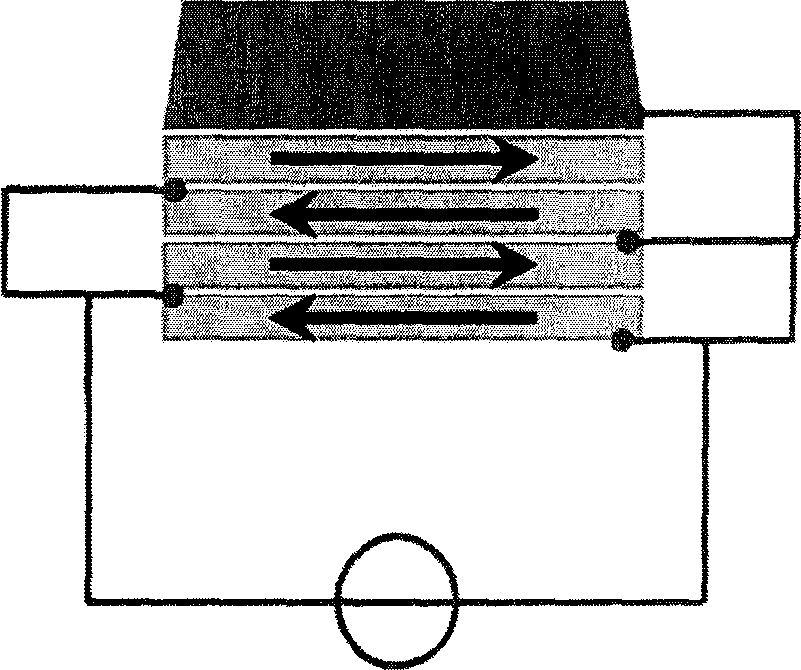

Longitudinal and bending composite mode sandwich two-foot ultrasonic linear motor oscillator with elastic support

ActiveCN102355160AImprove performanceSolve efficiency problemsPiezoelectric/electrostriction/magnetostriction machinesUltrasonic linear motorPrism

The invention relates to a longitudinal and bending composite mode sandwich two-foot ultrasonic linear motor oscillator with an elastic support, and relates to the technical field of piezoelectric ultrasonic motors. The problems that the traditional ultrasonic motor oscillator has insufficient vibrational energy utilization and restricted mechanical output capability are solved. The oscillator comprises two end covers, two pairs of longitudinal vibration piezoelectric ceramic chips, two pairs of bending vibration piezoelectric ceramic chips, a stud, four mounting seats, four thin-walled beams, an insulating sleeve, nine electrode chips and two friction plates, wherein the end cover is a tapered quadrangular prism body with a rectangular section, the small end surface of the end cover is used as a driving foot, the friction plates are fixed in through grooves of the small end surfaces of the end covers, and the end covers are respectively screwed on the two end parts of the studs through threaded holes on the large end surfaces of the end covers, so that the bending vibration piezoelectric ceramic chips and the longitudinal vibration piezoelectric ceramic chips are tightly pressed between the two end covers. The invention can be applied to the field of ultrasonic motor production.

Owner:HARBIN INST OF TECH

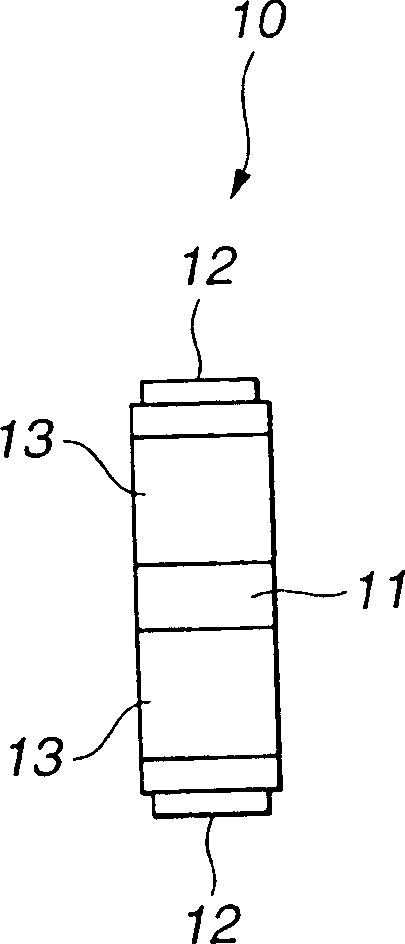

Ultrasonic linear motor

InactiveCN1449103AStable outputPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesUltrasonic linear motorMiniaturization

The ultrasonic linear motor (30) of the present invention constitutes the ultrasonic vibrator (10) by bonding the driver (12) on the opposite face of the ultrasonic vibrator (10) and at a position opposite to the rotation direction of the elliptical vibration, and a pair of The guide device (31) contacted by the driver (12) is provided with an ultrasonic vibrator (10) therebetween, and a plate spring (34) as a pressing device for mutual traction is arranged between the pair of guide devices (31), A self-propelled ultrasonic linear motor constituting the self-propelled ultrasonic vibrator. Thereby, not only the running performance of the ultrasonic vibrator itself can be improved, but also the miniaturization of the ultrasonic linear motor can be realized.

Owner:OLYMPUS CORP

Ultrasonic linear motor

ActiveUS20100035448A1Reduce in quantityEffective shieldingRelieving strain on wire connectionTwo pole connectionsElectric power transmissionPower cable

A power plug is proposed, comprising: an electrode terminal base having a pair of electrically conductive terminals and a ground terminal; a power cable having insulated wires respectively connected to the conductive terminals and the ground terminal; a conductive casing comprised of a casing body covering and connecting with the electrode terminal, an isolating portion disposed on the outer layer of the casing body for isolating outside electrical noise or electromagnetic interference, an insulating layer disposed on the inner layer of the casing body, a cable fastener disposed in the casing body for holding the cable in position and a conductive fixture electrically connecting with the electrode terminal base, thereby ensuring the quality of electric power transmission.

Owner:FURUTECH CO LTD

Small piezoelectric or electrostrictive linear motor

ActiveUS7498719B2Simple manufacturing processEasy to implementPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive device detailsElastomerUltrasonic linear motor

The present invention provides a small piezoelectric / electrostrictive ultrasonic linear motors which are installed in cell phones or PDAs, etc. to drive their camera lenses. In the present invention, a movable shaft (30) is coupled to a unimorph or bimorph, which is made by attaching a piezoelectric or electrostrictive substrate to an elastic body (20) (metal), so that a movable body (40) fitted over the movable shaft (30) is linearly moved along the movable shaft (30) by vibration of the piezoelectric or electrostrictive substrate, thus simplifying a manufacturing process, being easily practicable according to a basic principle, and having superior characteristics.

Owner:PIEZOELECTRIC TECH

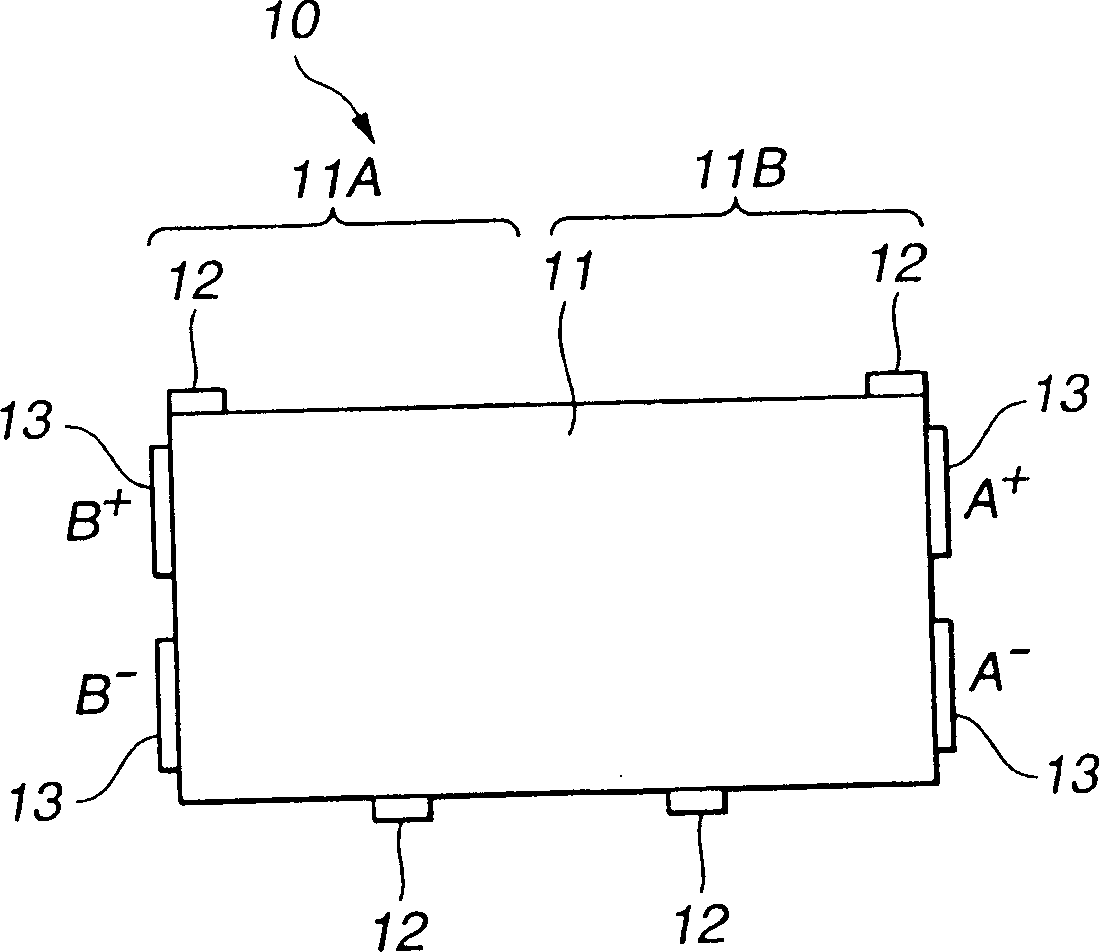

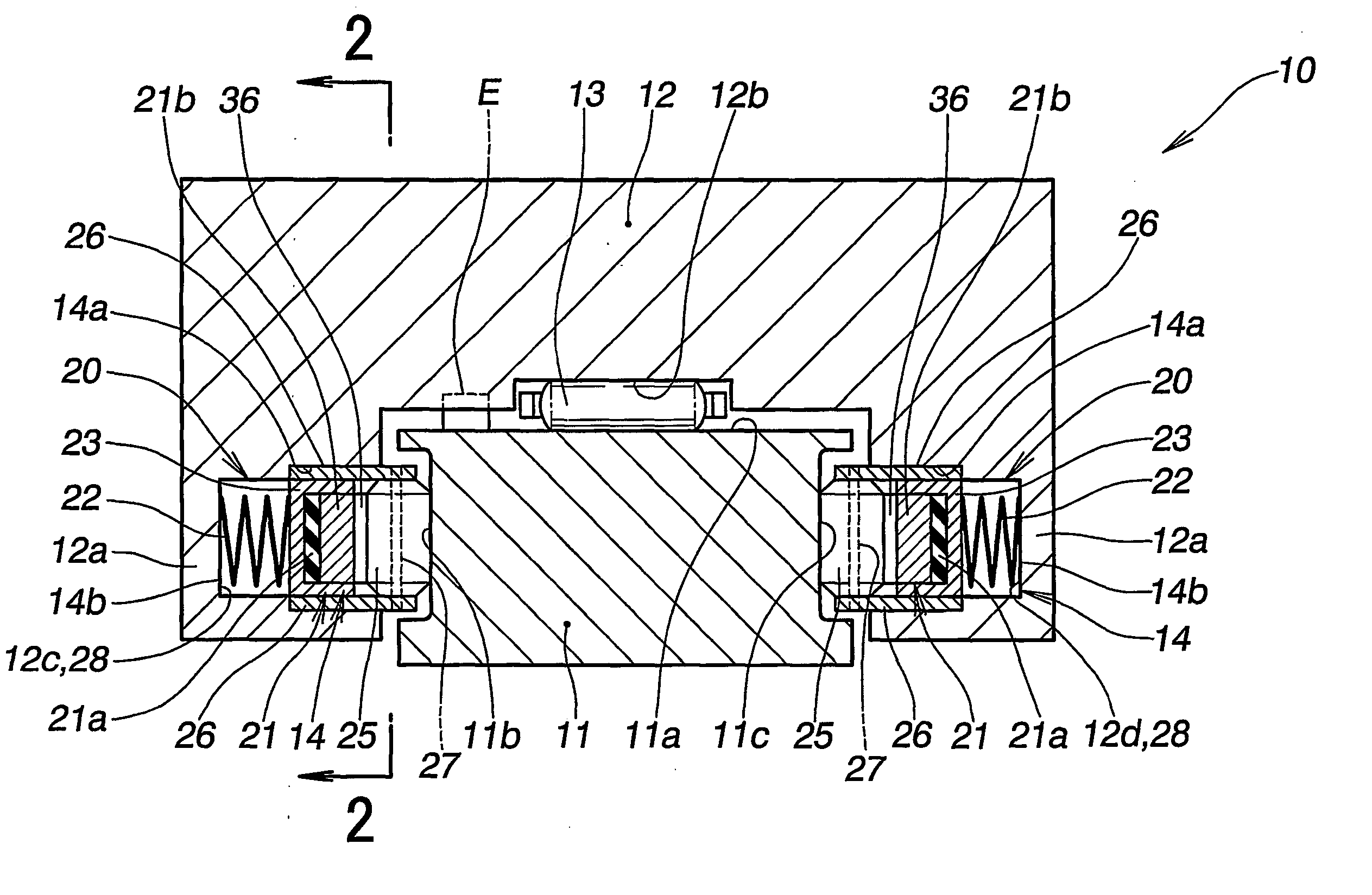

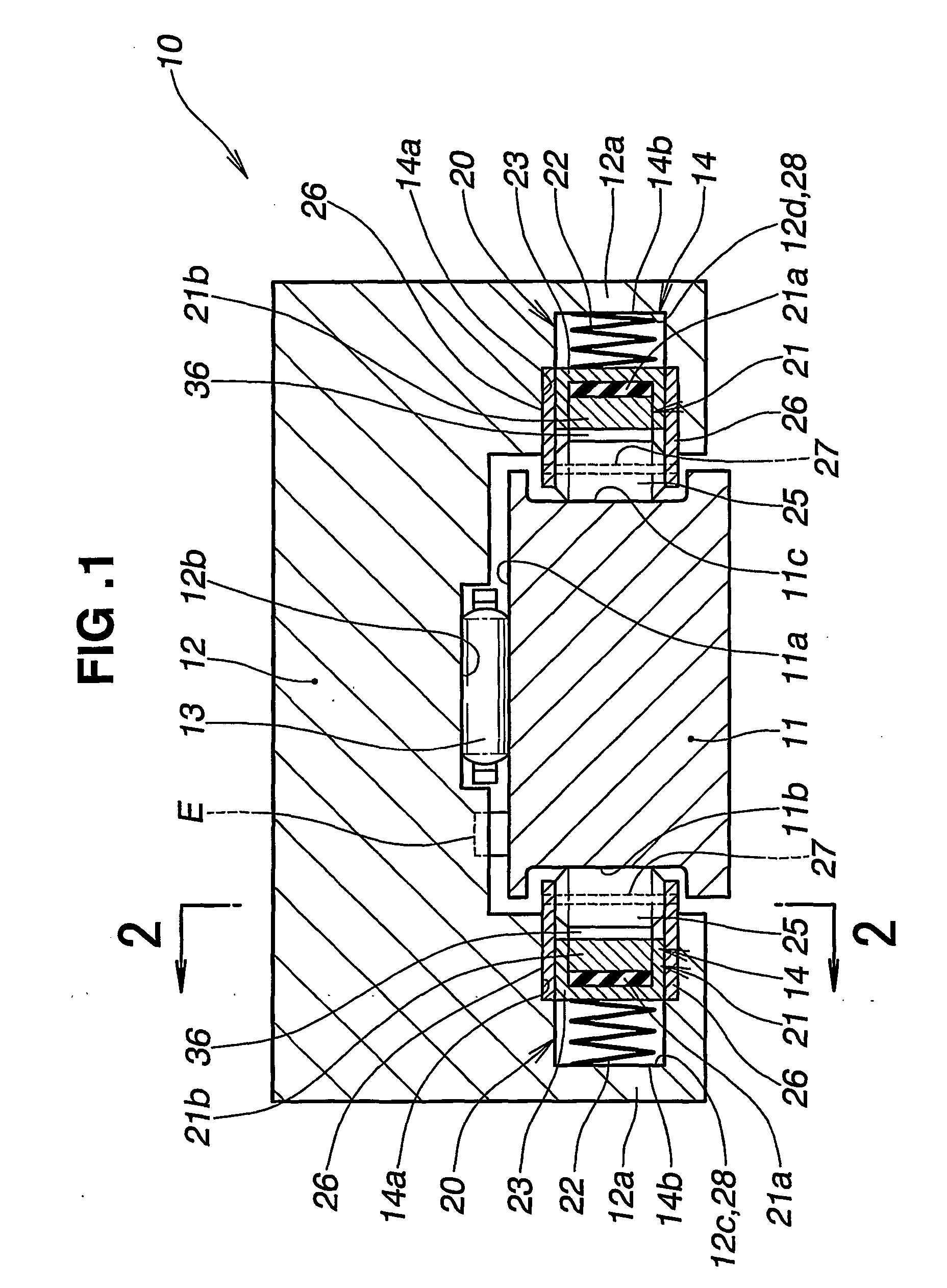

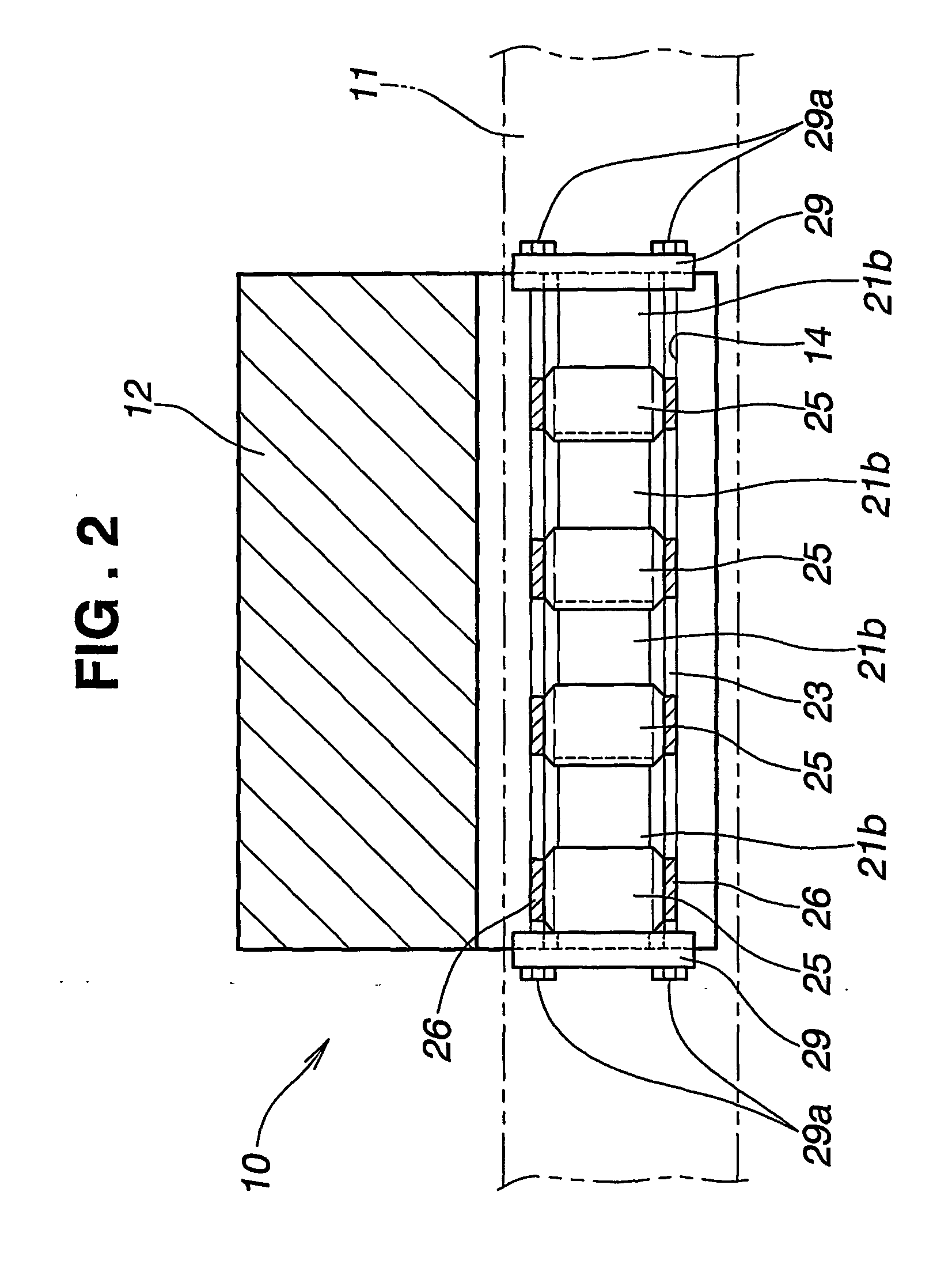

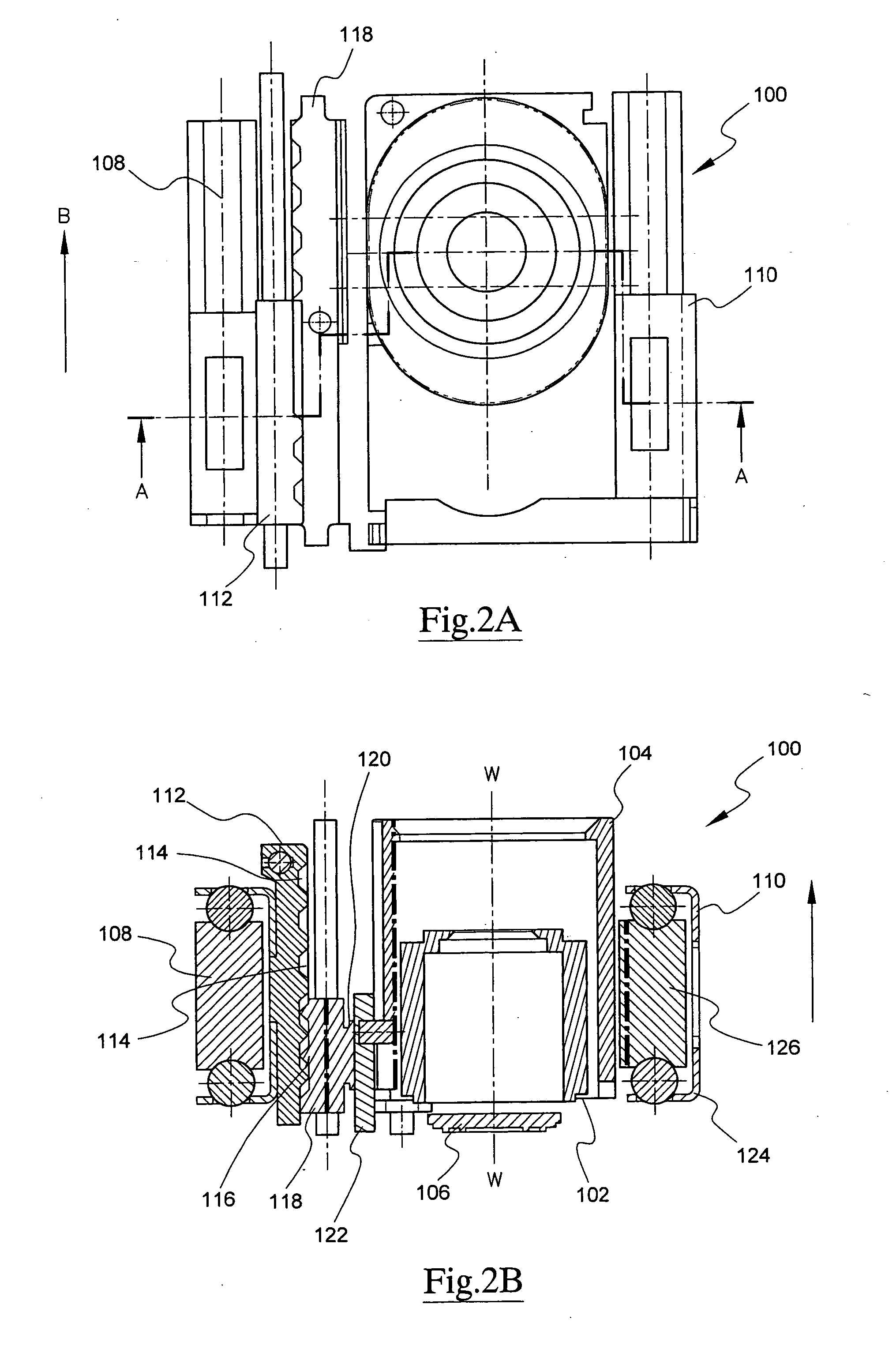

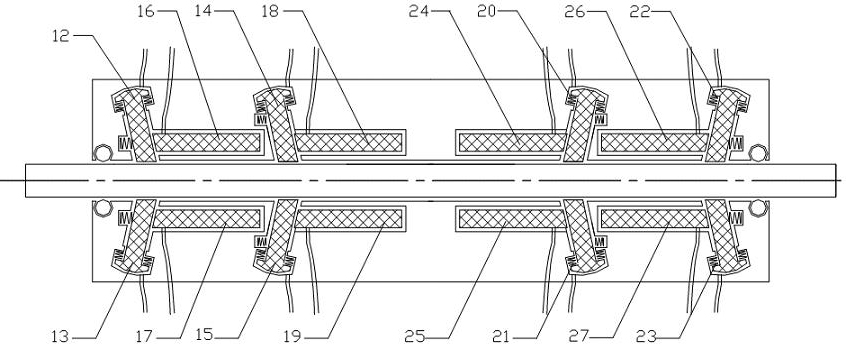

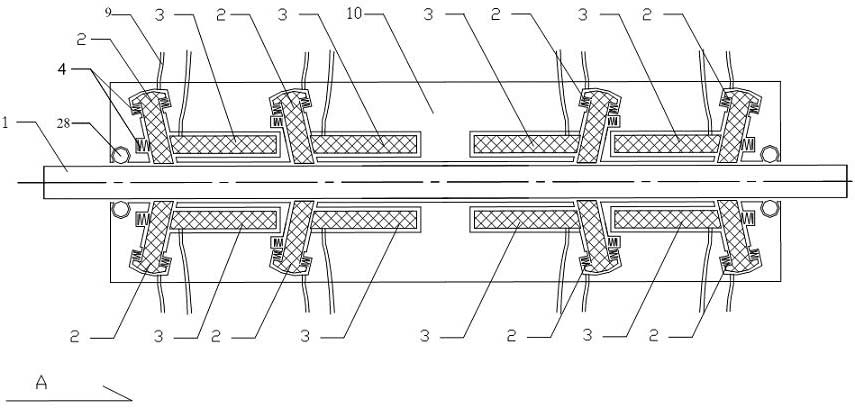

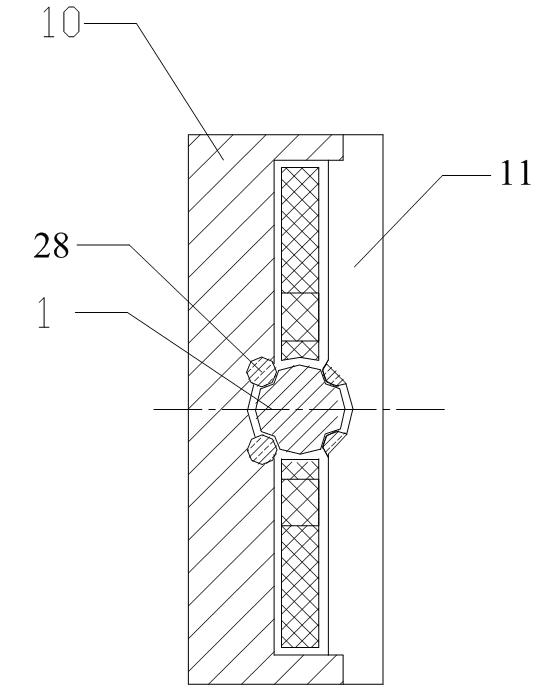

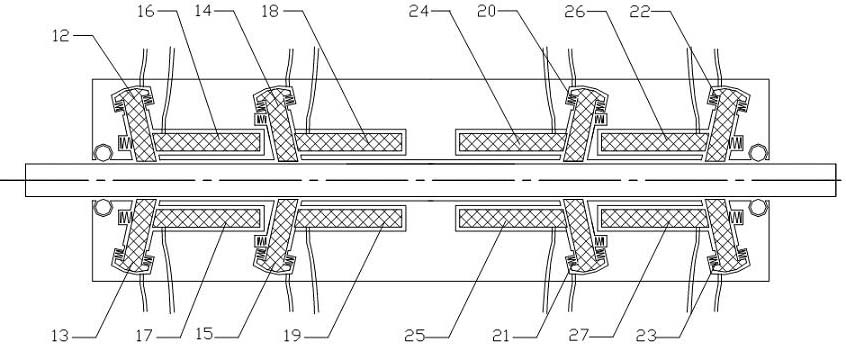

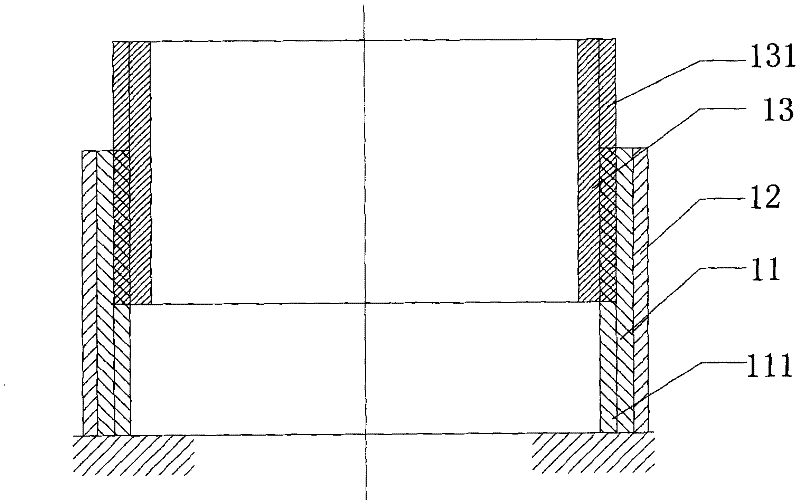

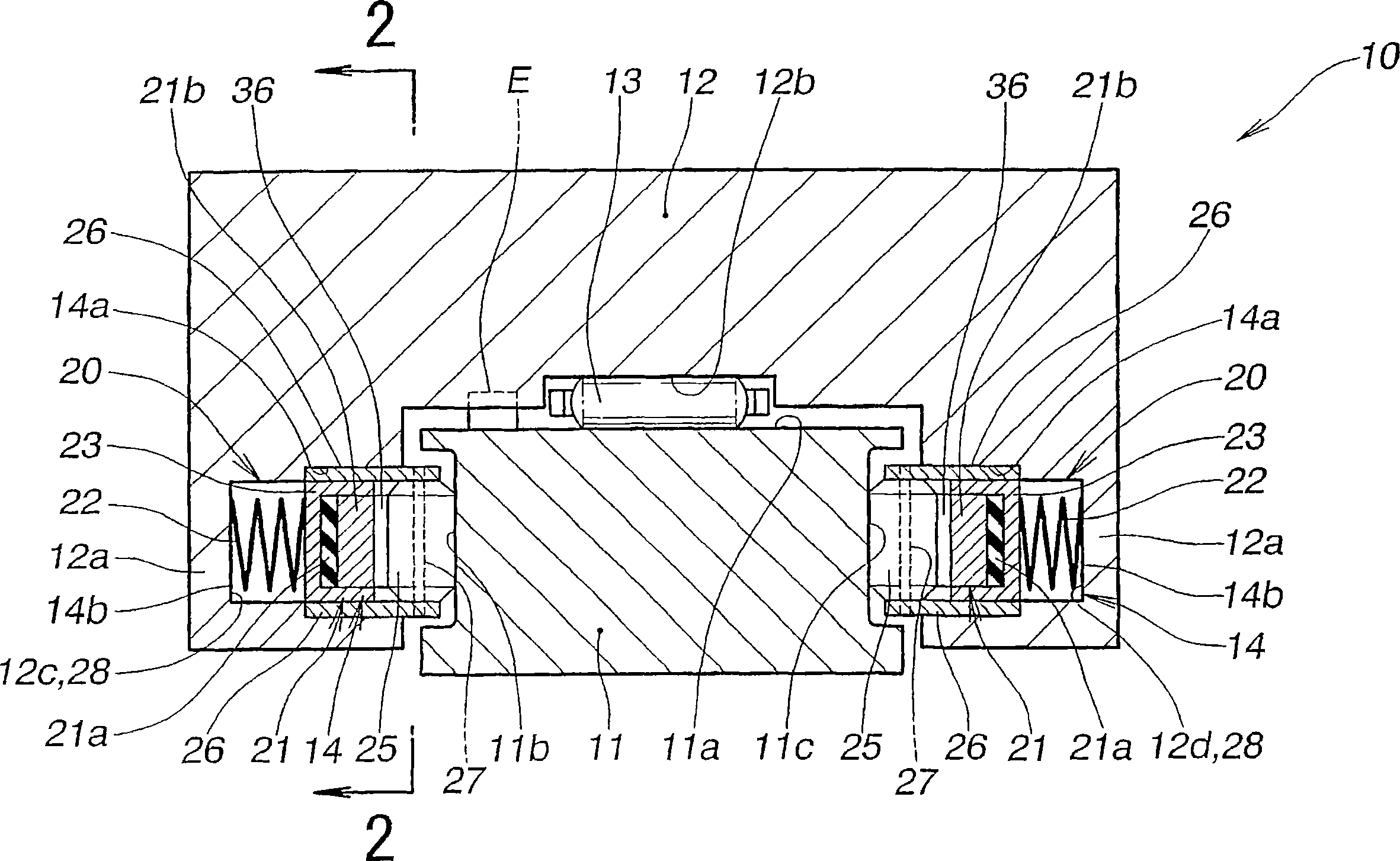

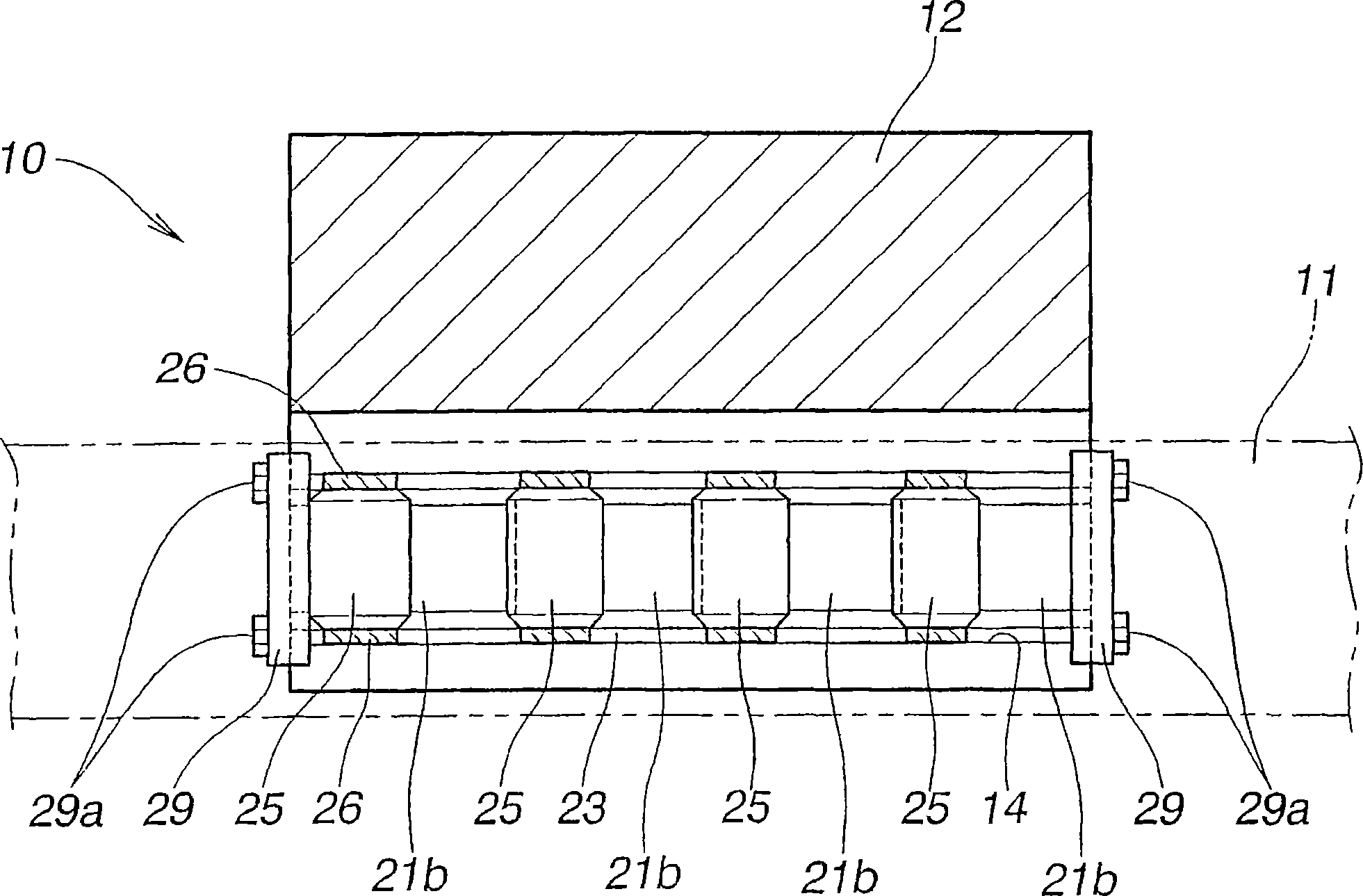

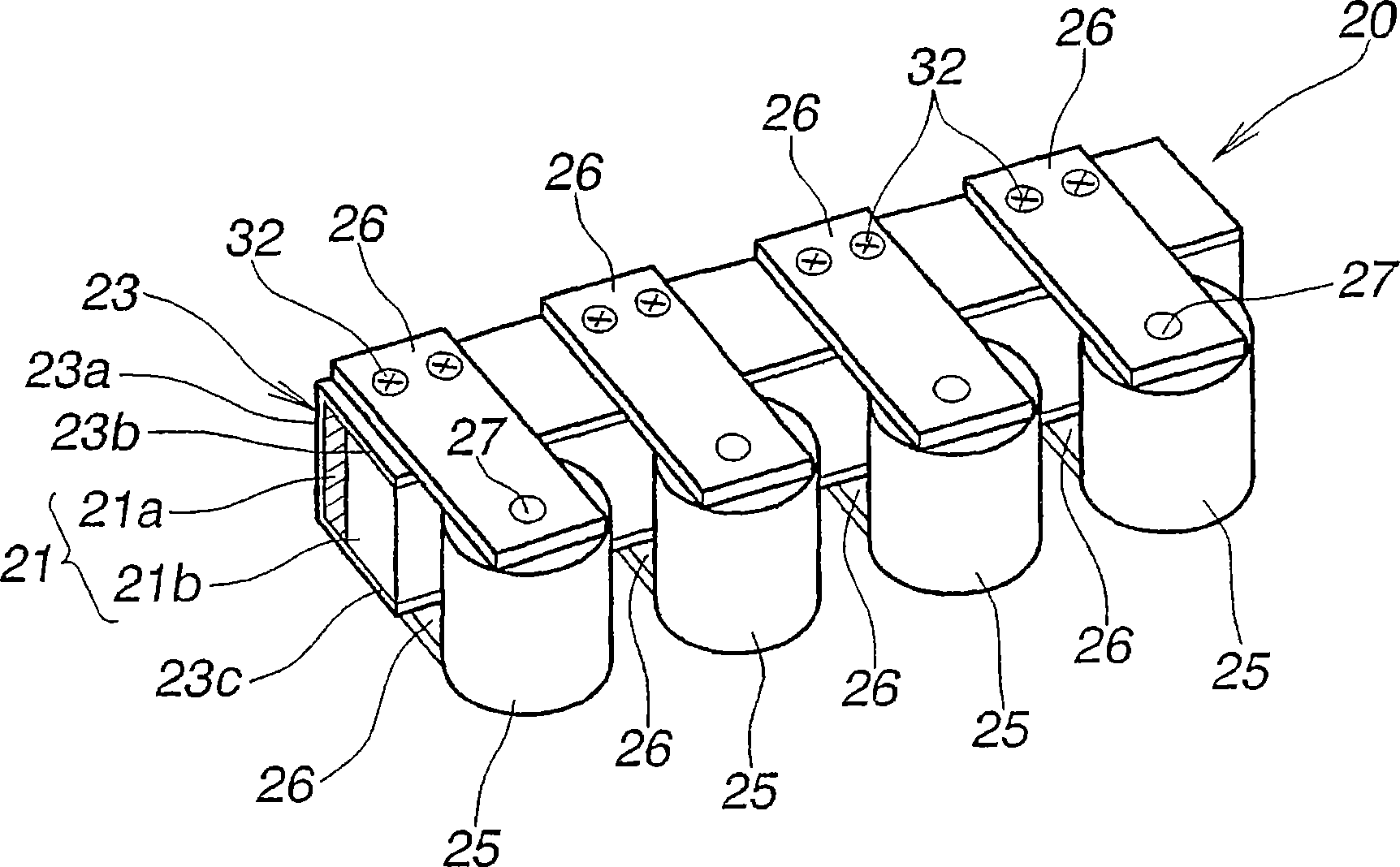

Drive device for ultrasonic linear motor

InactiveUS20070096598A1Good left and right balanceMoved strongly and smoothlyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesEngineeringUltrasonic linear motor

This invention relates to a drive device of an ultrasonic linear motor having a rail (11, 42) and a base body (12, 44) and driving parts (20, 50) interposed between rail and base body. The base body is moved in a straight line with respect to the length direction of the rail by the driving parts. The driving parts are provided on left and right leg parts (12a, 44a) of the base body, and the load of the base body acts almost not at all on the driving part. The driving parts have ultrasonic vibrators (21,52) and rollers (25, 51) rotationally driven by the ultrasonic vibrators. The rollers are urged by urging means (22, 53) toward and into contact with guiding side faces (11b, 11c, 42b, 42c) of the rail, driving forces generated by the driving parts act on the guiding side faces of the rail, and the base body moves in the length direction of the rail.

Owner:HONDA MOTOR CO LTD

Ultrasonic linear motor

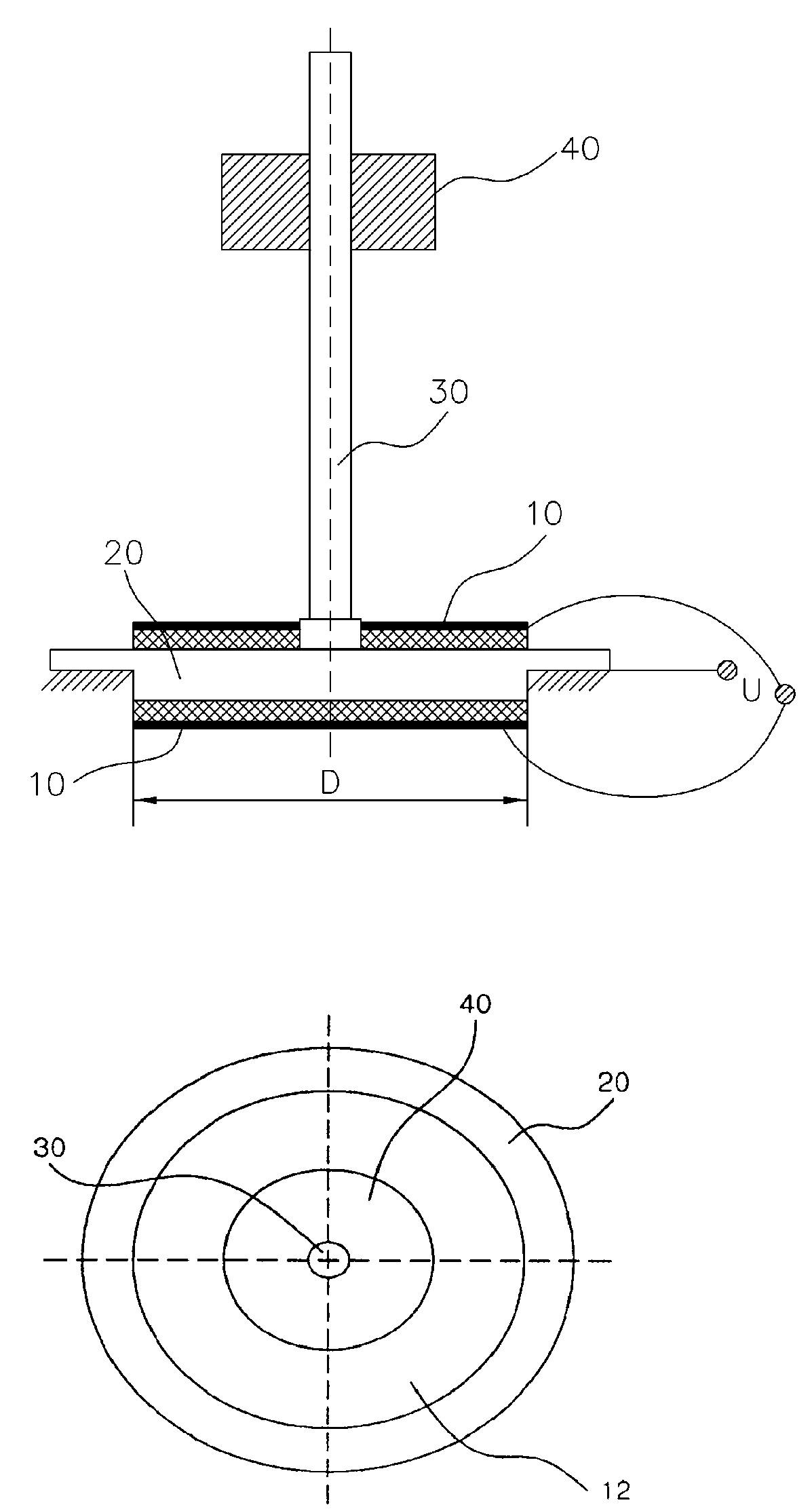

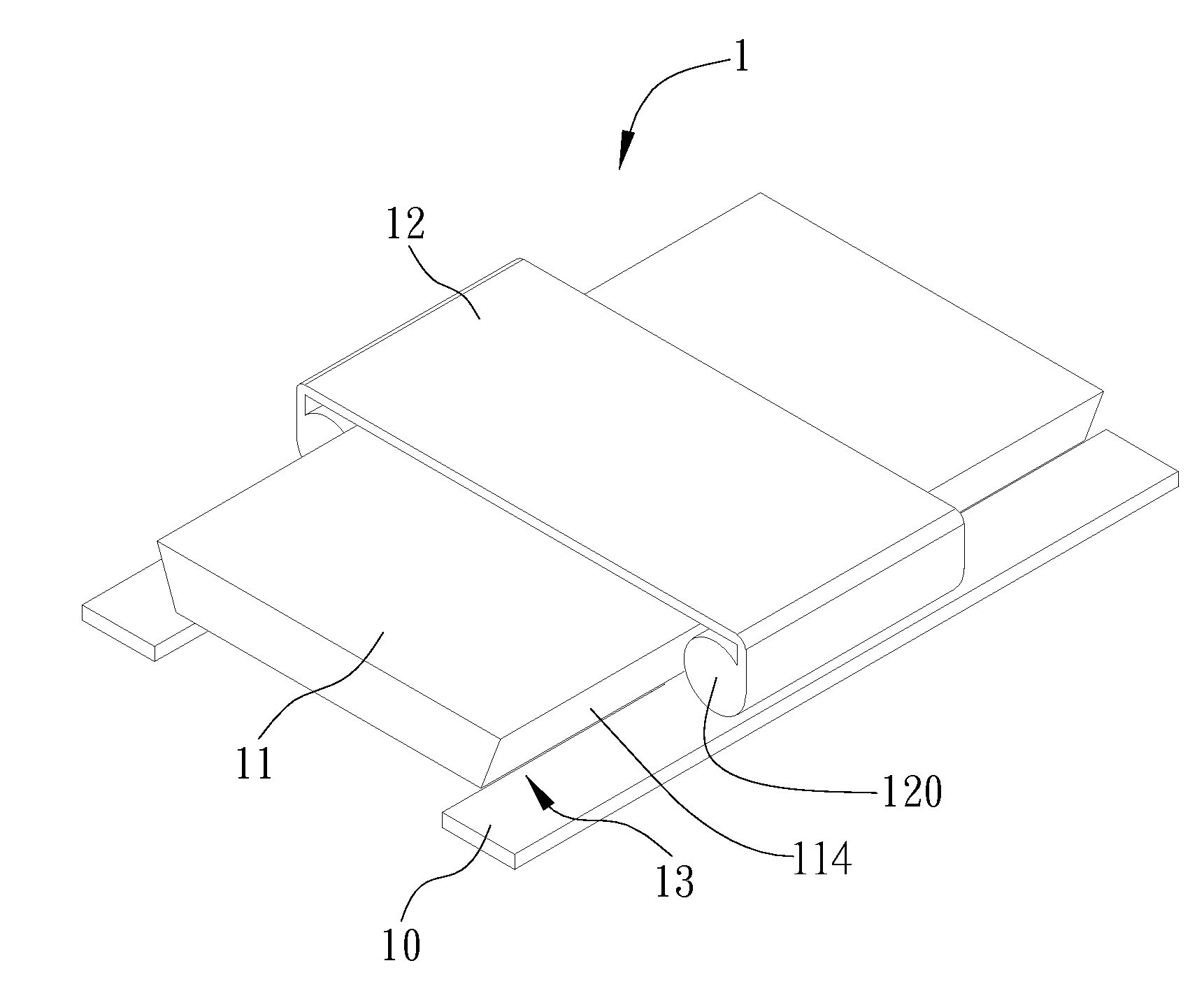

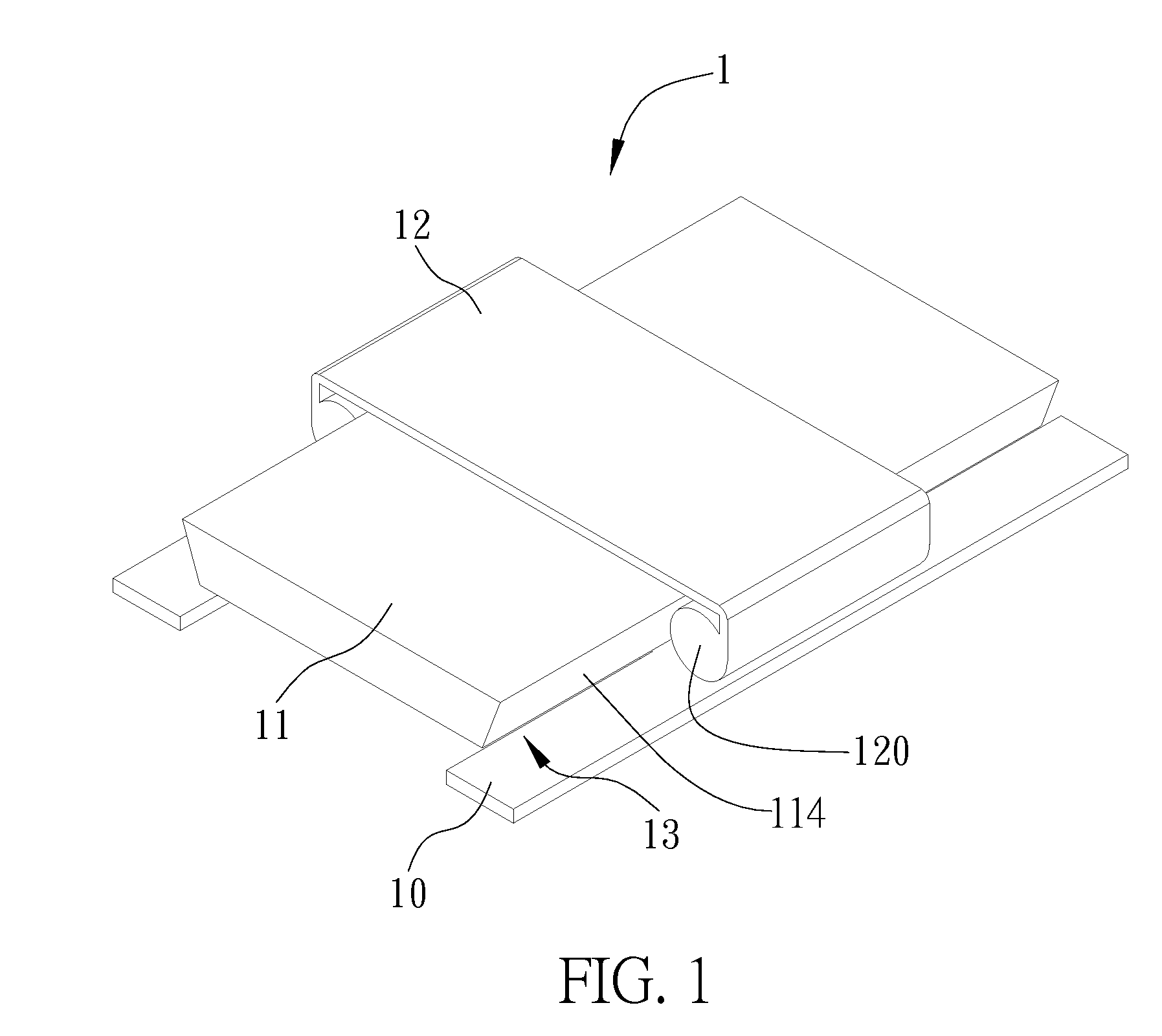

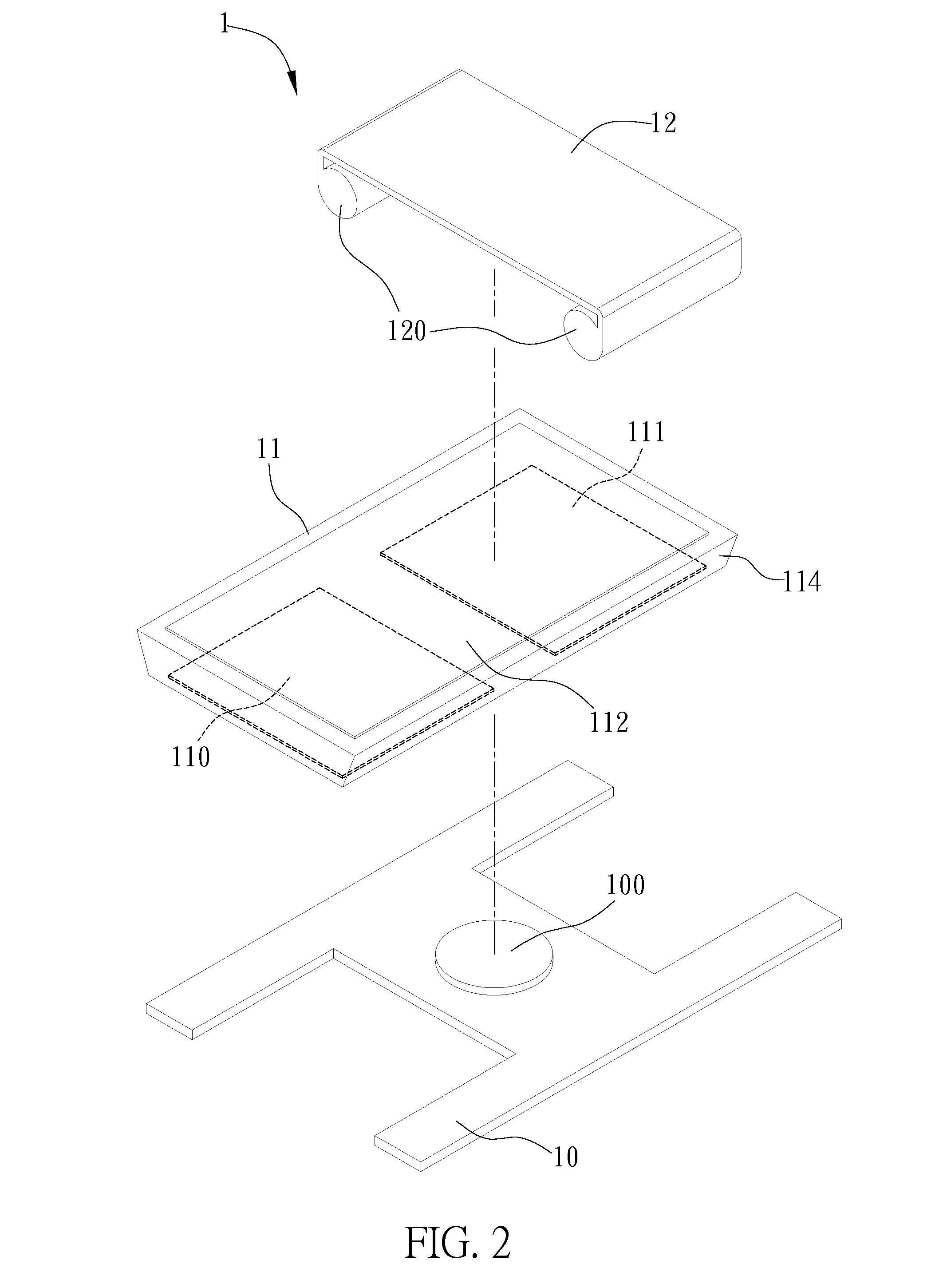

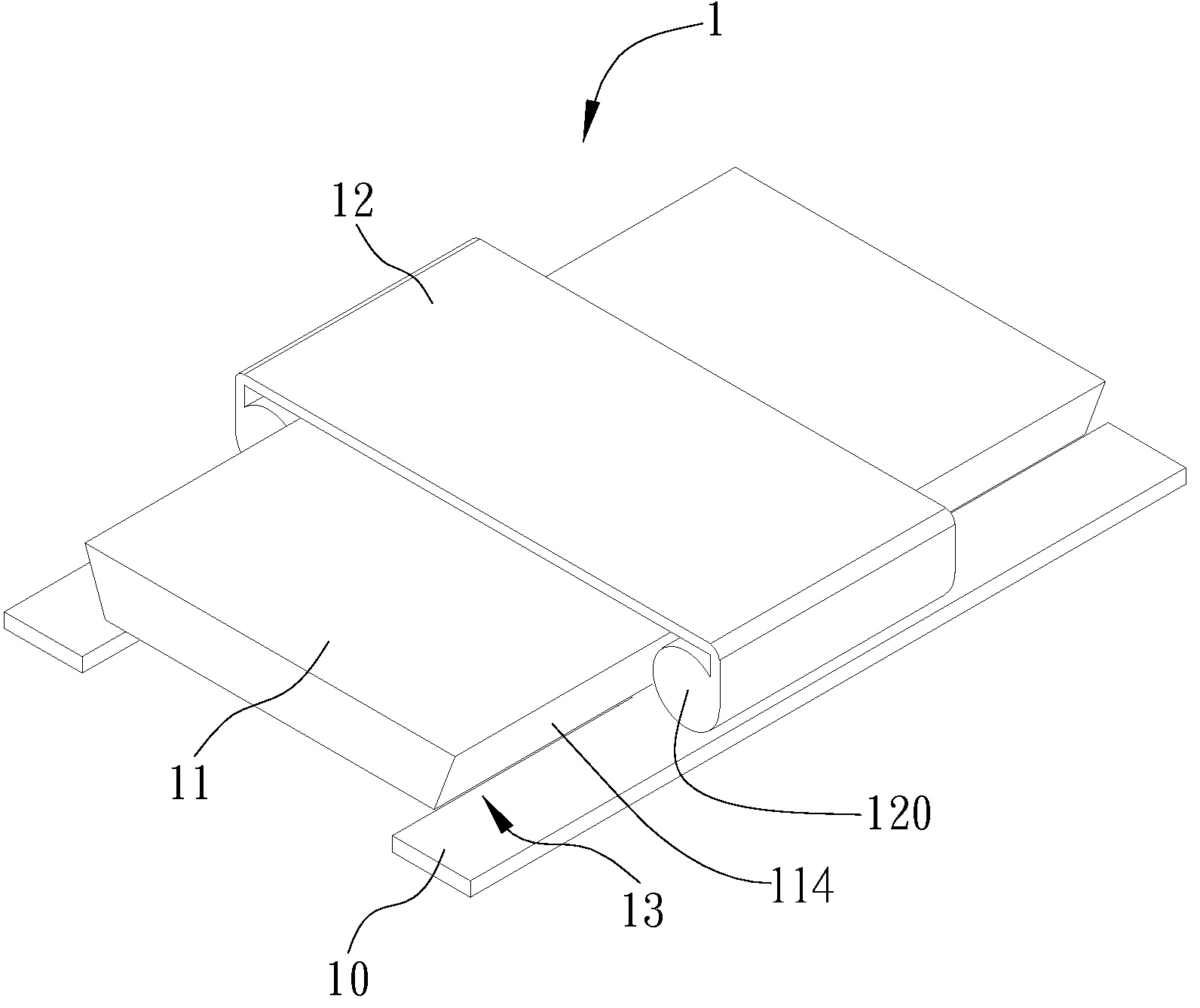

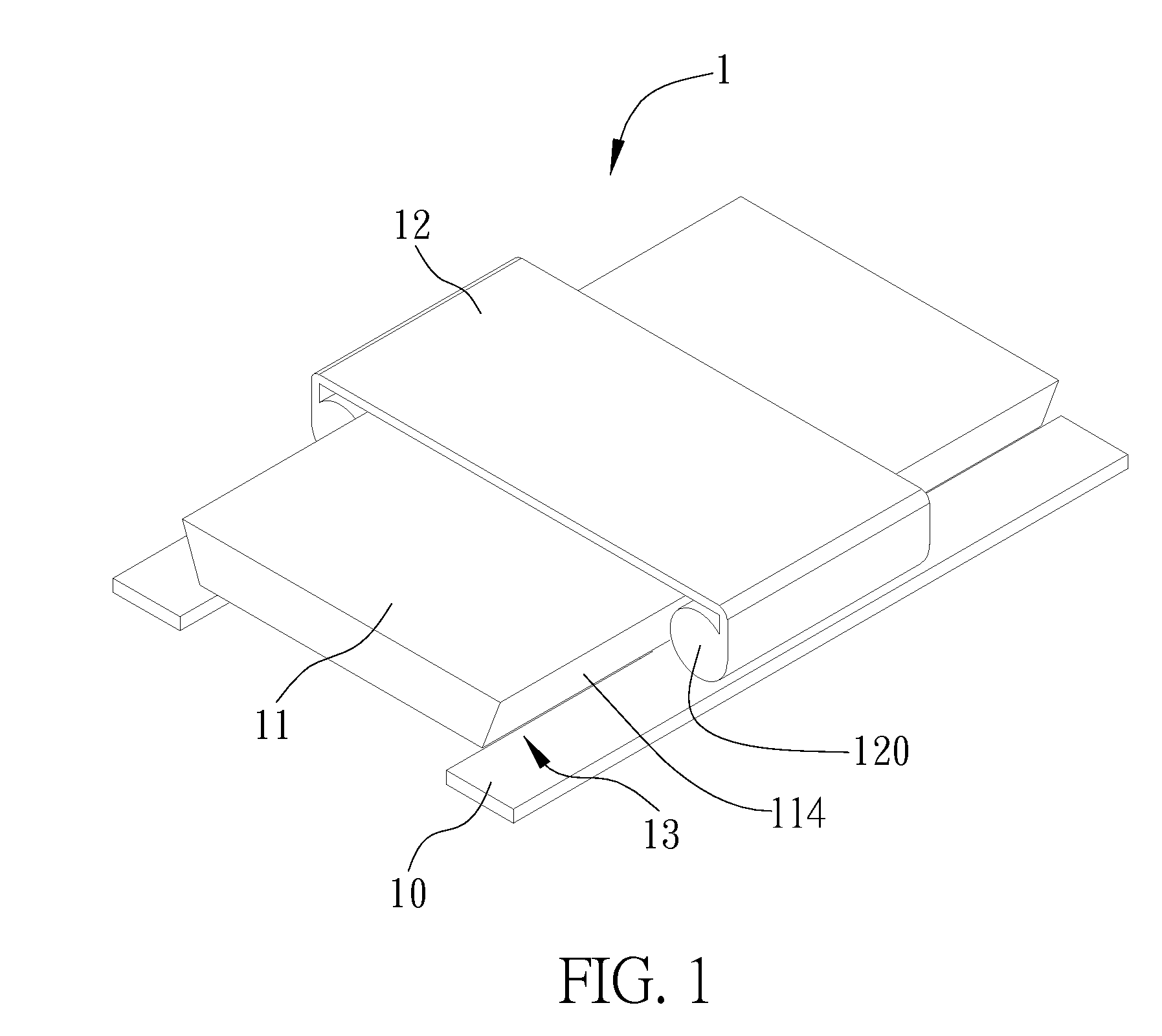

ActiveUS20100033057A1Simple structureReduce manufacturing costPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesUltrasonic linear motorEngineering

An ultrasonic linear motor includes a substrate; a vibrator disposed on the substrate having an oblique or curved face at two sides thereof forming concave receiving portions with the surfaces of the substrate; and a slider having clamping portions at two sides thereof for correspondingly clamping to the receiving portions, wherein the vibrator is for generating a driving force to the slider while connecting with a power supply, such that the clamping portions of the slider move within the receiving portions, thereby generating a linear translation. The present invention adopts a simple structure having few elements that enables easy manufacturing and integration with other elements, thus reducing manufacturing cost.

Owner:IND TECH RES INST

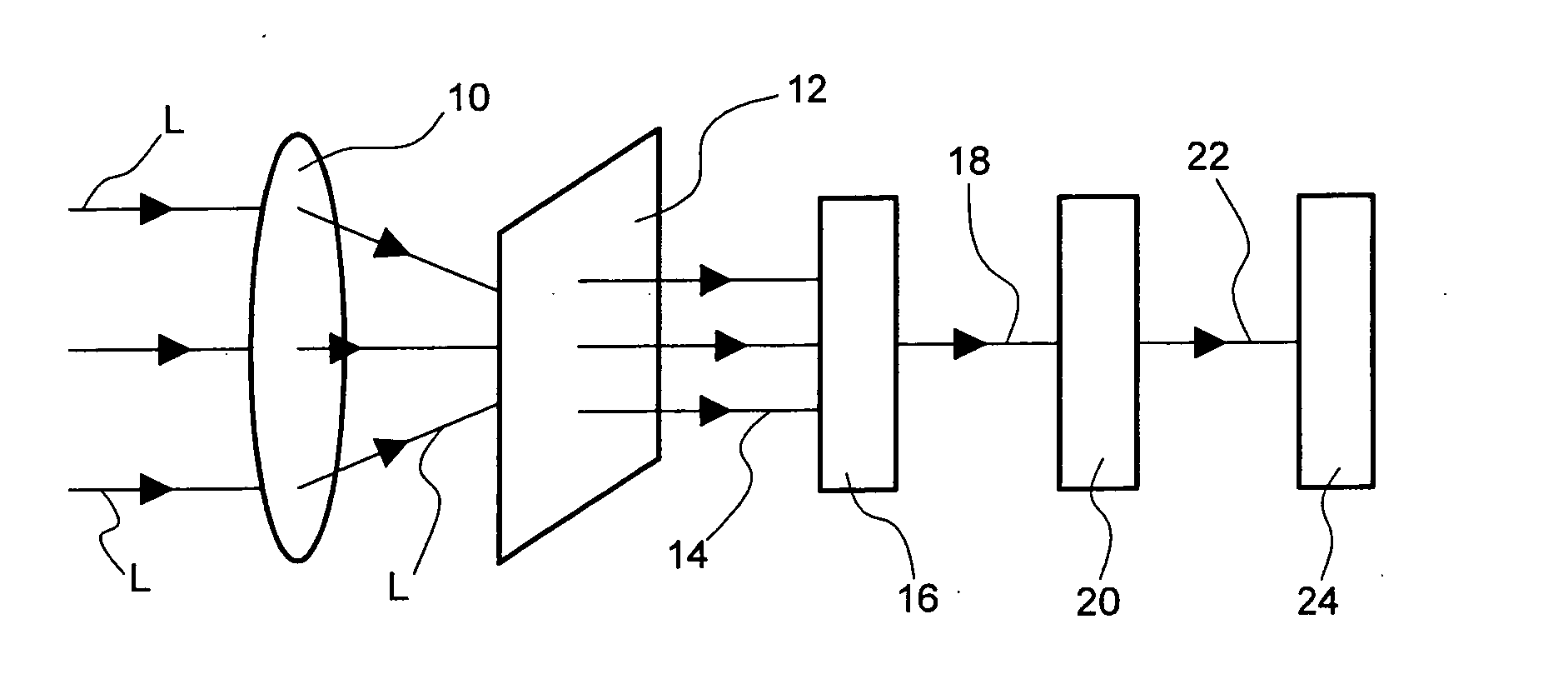

Optical lens assembly for a handheld electronic device

An optical lens assembly is disclosed as including a light-sensitive member; first and second lenses / lens groups with their respective optical axis aligned with each other along a common optical axis; and first and second piezo electric ultrasonic linear motors; in which the first motor is operable to move the first and second lenses / lens groups relative to each other to vary their distance; and the second motor is operable to move the light-sensitive member or at least one of the first and second lenses / lens groups to vary the distance between the light-sensitive member and the lens / lens group. A handheld electronic device, e.g. a mobile phone or a personal digital assistant, with digital camera function, and including such an optical lens assembly is also disclosed. There is further disclosed an optical lens system including an optical system, a light-sensitive component, an auto-focus judge for determining if an image captured by the light-sensitive component is in focus, and a driving IC for driving a piezo electric ultrasonic linear motor in response to the result arrived at by the auto-focus judge.

Owner:MAXFORD TECH LTD

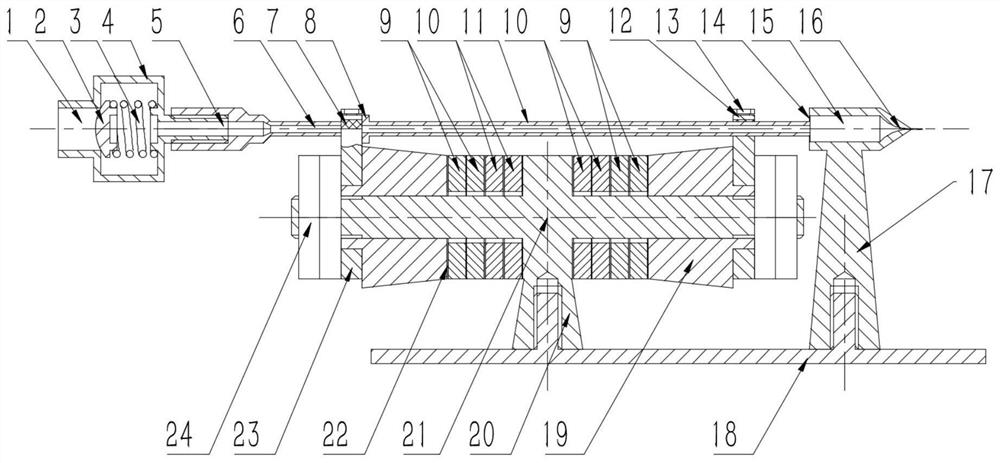

Ultrasonic linear motor with hydraulic displacement amplification mechanism and operating method thereof

InactiveCN102158121ALarge thrustRun fastPiezoelectric/electrostriction/magnetostriction machinesUltrasonic linear motorControl theory

The invention discloses an ultrasonic linear motor with a hydraulic displacement amplification mechanism, which comprises a motor stator with a centre hole and a motor rotor penetrated in the centre hole; the motor stator mainly consists of a stator shell, and a radial groove and an axial groove installed on the stator shell, the radial groove and the axial groove are respectively radially and axially arranged along the centre hole; one end of the radial groove is communicated with the centre hole, and the left side or the right side of the radial groove is provided with a spring groove communicated therewith; the axial groove is positioned at the right side or the left side of the radial groove and communicated with the radial groove; the radial groove is provided with a radial piezoelectric stripe, the axial groove is provided with an axial piezoelectric stripe therein; and a spring is installed in the spring groove. The invention further discloses an operating method of the ultrasonic linear motor with hydraulic displacement amplification mechanism. The ultrasonic linear motor with hydraulic displacement amplification mechanism has the advantages of large thrust, high efficiency, small loss, fast speed and long service life.

Owner:刘勤

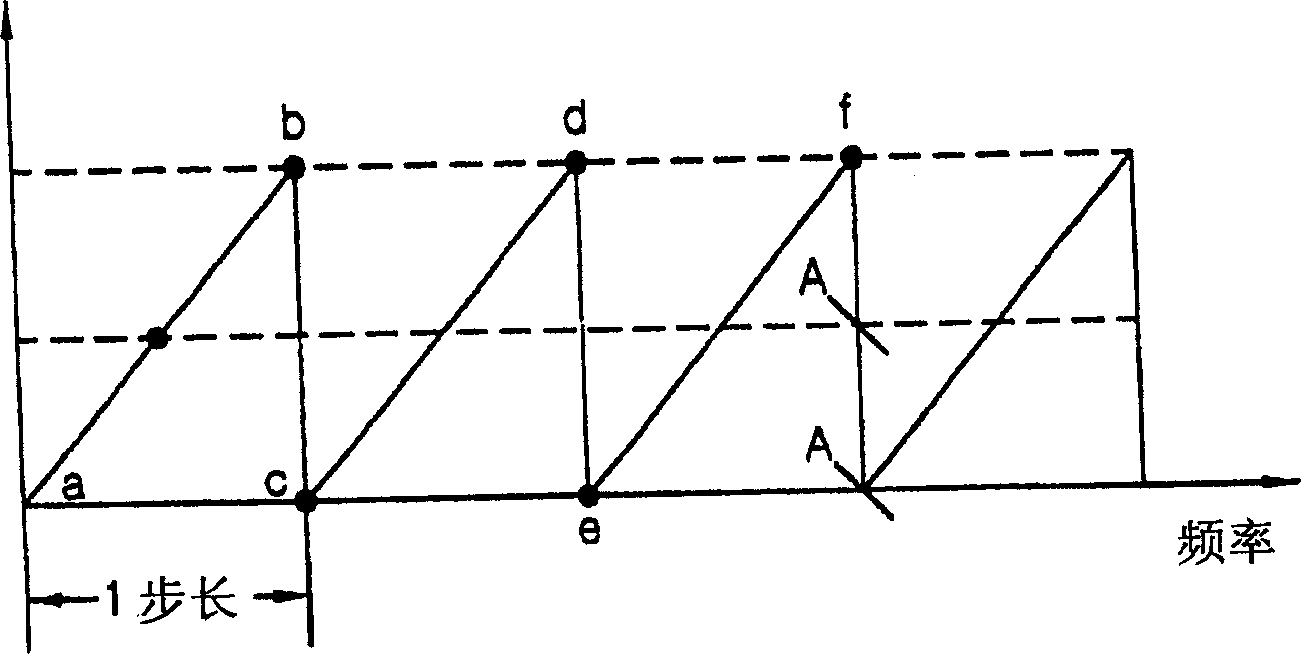

Dual-mode ultrasonic linear motor with high speed, high resolution ratio and high driving force

InactiveCN103516252APiezoelectric/electrostriction/magnetostriction machinesUltrasonic linear motorDual mode

The invention aims at providing a dual-mode ultrasonic linear motor with a high speed, a high resolution ratio and a high driving force. A basic principle is characterized in that inertia is used to realize linear movement under vibration and friction of a piezoelectric ceramic driver; and ultrasonic vibration energy is converted into translational kinetic energy of an object. An innovation point of the dual-mode ultrasonic linear motor provided in the invention is that two indexes of the high speed and high precision which can not be compatible traditionally are realized on same equipment. The motor can operate in an mm / s high speed mode and can operate in a high precision mode in which the resolution ratio is a nanometer scale. Simultaneously, the motor can work at an extreme low temperature, in an ultrahigh vacuum, in a high-intensity magnetic field and in other extreme conditions and possesses advantages that a stroke is large and a load is high.

Owner:SOURCES SHANGHAI OPTOELECTRONICS TECH CO LTD

Displacement amplification ultrasonic linear motor and working method thereof

InactiveCN102142789ALarge thrustRun fastPiezoelectric/electrostriction/magnetostriction machinesUltrasonic linear motorEngineering

The invention discloses a displacement amplification ultrasonic linear motor which mainly comprises a motor stator with a centre hole and a motor rotor penetrating in the center hole, wherein the motor stator mainly comprises a stator shell as well as a radial groove and an axial groove which are arranged on the stator shell; the radial groove and the axial groove are radially arranged and axially arranged along the center hole respectively; one end of the radial groove is communicated with the center hole; the left side or right side of the radial groove is provided with a spring groove communicated with the radial groove; the axial groove is positioned on the right side or left side of the radial groove and communicated with the radial groove; a radial piezoelectric strip is arranged inthe radial groove; an axial piezoelectric strip is arranged in the axial groove; and a spring is arranged in the spring groove. The invention also discloses a working method of the displacement amplification ultrasonic linear motor. The displacement amplification ultrasonic linear motor disclosed by the invention has the advantages of large thrust, high efficiency, low loss, high speed and long service life.

Owner:刘勤

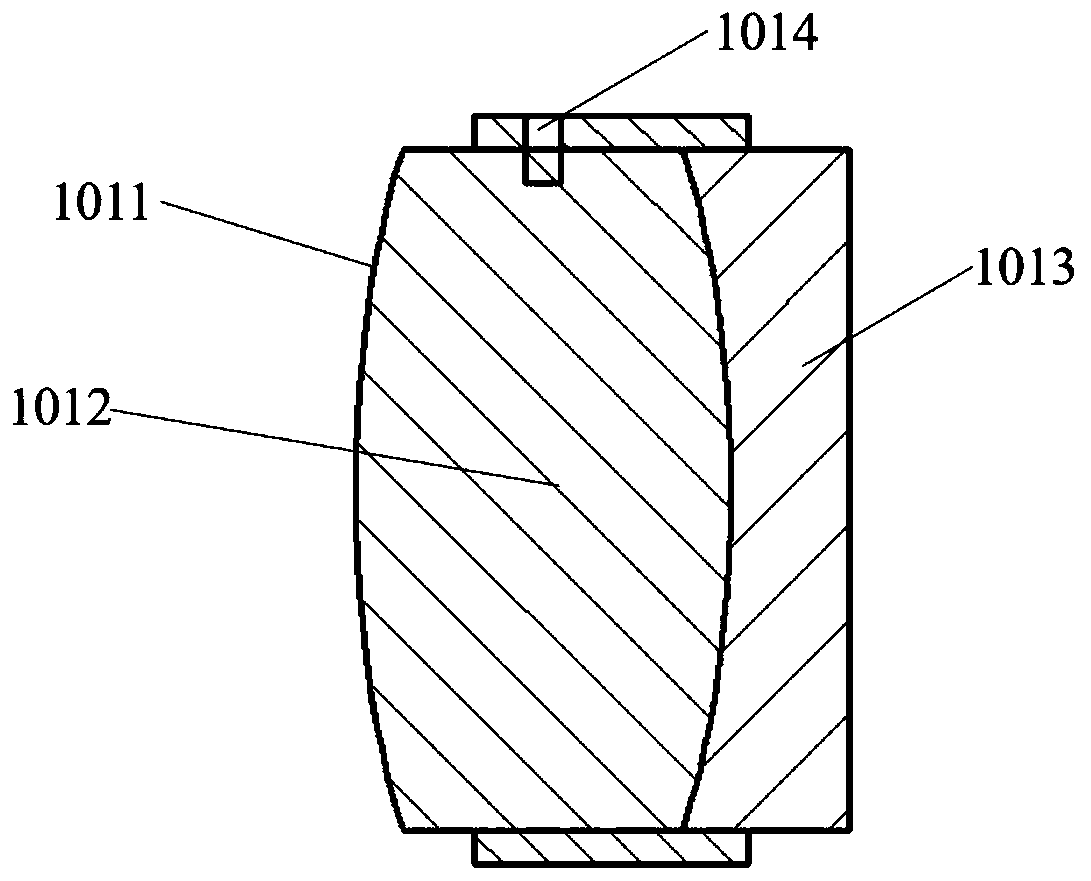

Ultrasonic straight line motor and automatic focusing/zooming system driven thereby

InactiveCN101425762BPiezoelectric/electrostriction/magnetostriction machinesProjector focusing arrangementLinear motionCamera lens

The invention discloses an ultrasonic linear motor which comprises an outer tube stator, a middle tube rotor, an inner tube, a guide mechanism and a piezoelectric piece, wherein the piezoelectric piece is fixed on the outer side surface of the stator, the stator drives the middle tube rotor to rotate, the inner tube is connected with the stator through the guide mechanism, and the middle tube rotor drives the inner tube to make linear motion. The invention also discloses an automatic focusing / zooming system driven by the ultrasonic linear motor, an optical lens is inserted inside the inner tube, and a light sensing chip is fixed on a plane at the bottom part of the stator. The invention has the advantages that two-stage drive motor structure is provided, the helical motion generated by the rotor in the first-stage drive is restored to be the only linear motion of the inner tube through the second-stage drive, only the linear displacement without rotation is generated during the working process of the automatic focusing / zooming lens module, so as to meet the requirements of high pixel, and high-precision automatic focusing or zooming, and the invention still has simple and compact structure, is suitable for the miniaturization, and has high precision of the linear displacement.

Owner:BOLY MEDIA COMM SHENZHEN

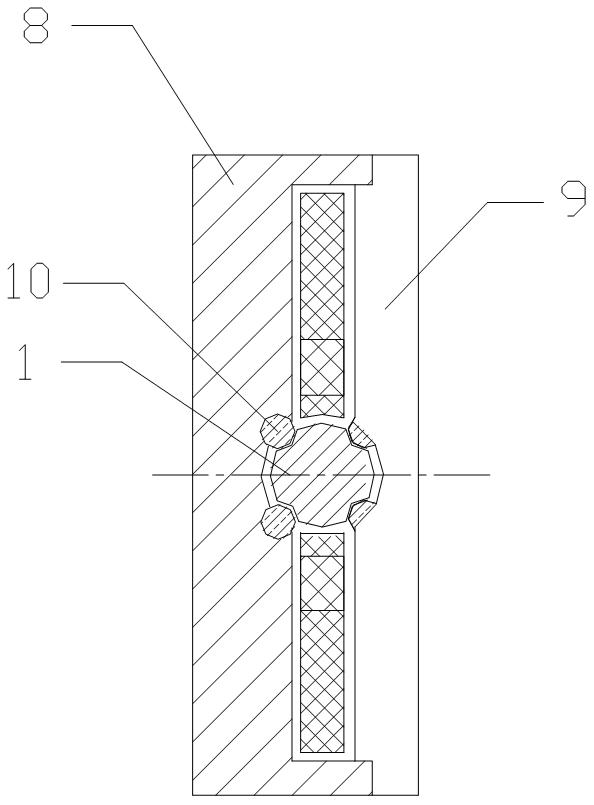

Radial and axial multi-vibrator ultrasonic linear motor and operating method thereof

InactiveCN102158120ALarge thrustRun fastPiezoelectric/electrostriction/magnetostriction machinesUltrasonic linear motorEngineering

The invention discloses a radial and axial multi-vibrator ultrasonic linear motor, which mainly comprises a motor stator with a central hole and a motor rotor which penetrates through the central hole, wherein the motor stator mainly comprises a stator shell as well as a radial vibrator groove and an axial vibrator groove on the stator shell; the radial vibrator groove and the axial vibrator groove are arranged in a radial direction and an axial direction respectively along the central hole; one end of the radial vibrator groove is communicated with the central hole, and the left side or right side of the radial vibrator groove is provided with a spring groove which is communicated with the radial vibrator groove; the axial vibrator groove is arranged at the right side or left side of the radial vibrator groove, and communicated with the radial vibrator groove; and the radial vibrator groove is internally provided with radial vibrators, the axial vibrator groove is internally provided with axial vibrators, and the spring groove is internally provided with springs. The invention also discloses an operating method based on the radial and axial multi-vibrator ultrasonic linear motor. The invention has the advantages that the thrust is high, the efficiency is high, the loss is low, the speed is quick, and the service life is long.

Owner:刘勤

Drive device for ultrasonic linear motor

InactiveCN1906776AReduce wearIncreased durabilityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive devicesUltrasonic linear motorMechanical engineering

This invention relates to a drive device of an ultrasonic linear motor having a rail (11, 42) and a base body (12, 44) and driving parts (20, 50) interposed between rail and base body. The base body is moved in a straight line with respect to the length direction of the rail by the driving parts. The driving parts are provided on left and right leg parts (12a, 44a) of the base body, and the load of the base body acts almost not at all on the driving part. The driving parts have ultrasonic vibrators (21,52) and rollers (25, 51) rotationally driven by the ultrasonic vibrators. The rollers are urged by urging means (22, 53) toward and into contact with guiding side faces (llb, 11c, 42b, 42c) of the rail, driving forces generated by the driving parts act on the guiding side faces of the rail, and the base body moves in the length direction of the rail.

Owner:HONDA MOTOR CO LTD

Ultrasonic stepping superfine single droplet generator

ActiveCN112701954ASatisfies the requirements for generating tiny dropletsSlow down the feed ratePiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationLinear motionUltrasonic linear motor

The invention provides an ultrasonic stepping superfine single droplet generator. A one-way valve is composed of a valve body, a valve core and a spring, the valve body is connected with a nozzle through a guide pipe, and the guide pipe is driven to do linear motion by utilizing an inverse piezoelectric effect of piezoelectric ceramics through an ultrasonic direct-current motor composed of the piezoelectric ceramics. And liquid in a spraying cavity is extruded out of the nozzle by utilizing the nanoscale feeding amount of an ultrasonic linear motor, so that tiny and quantitative liquid drops are obtained. Due to the fact that the piezoelectric vibrator drives the guide pipe to generate the nanoscale feeding amount, the volume of liquid drops overflowing each time can reach the micron scale, and the requirement for generating tiny liquid drops is met.

Owner:JIANGSU UNIV

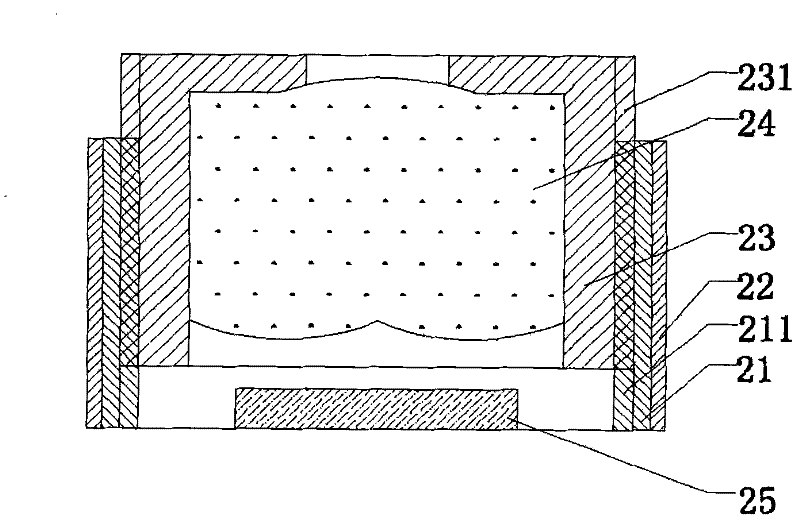

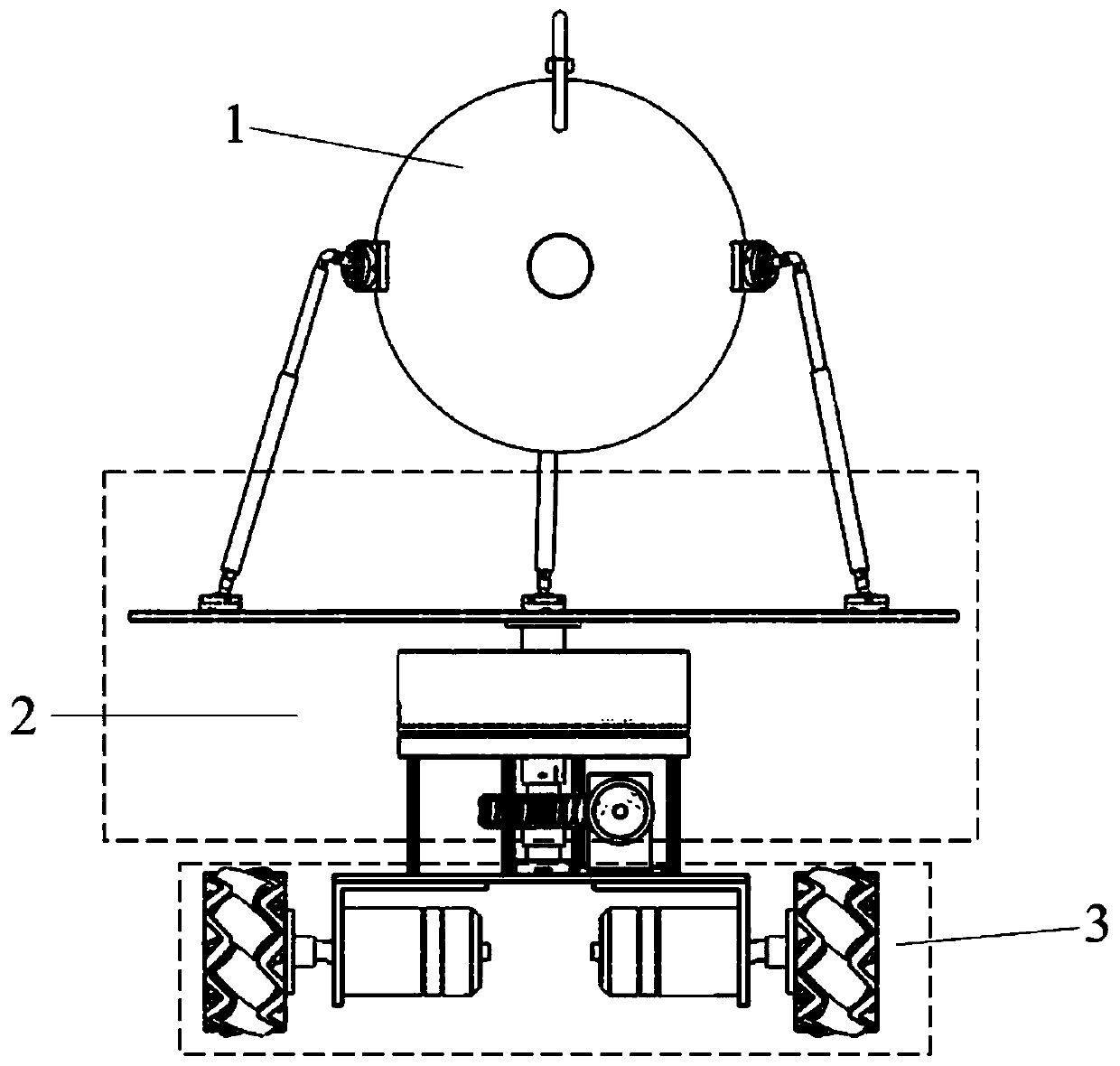

Bionic flexible mobile optical imaging device

ActiveCN111552070APrecise control of surface deformationClear focusMountingsLensUltrasonic linear motorOptical axis

The invention discloses a bionic flexible mobile optical imaging device. The bionic flexible mobile optical imaging device comprises a bionic flexible optical device, a rotating mechanism and a mobilechassis. According to the bionic flexible optical device, a flexible lens, optical liquid and a glass lens are used as main refractive media; in the imaging process, an ultrasonic linear motor extrudes liquid through a piston to enable the outer surfaces of the flexible lenses to deform, then the focal lengths of the flexible lenses are changed, and continuous focusing adjustment of the device can be achieved by cooperatively adjusting the focal lengths of the two flexible lenses. The rotating mechanism and the moving chassis have camera attitude control and motion control functions, and multi-azimuth and multi-angle observation of the whole device can be realized. The device has the characteristics of compact and small structure, stable optical axis, large observation range and double-axis rotary movement, and can be applied to various modern optical imaging devices.

Owner:宁波奇镜科技有限公司

Ultrasonic linear motor

ActiveUS7816839B2Less elementSimple structurePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesUltrasonic linear motorEngineering

An ultrasonic linear motor includes a substrate; a vibrator disposed on the substrate having an oblique or curved face at two sides thereof forming concave receiving portions with the surfaces of the substrate; and a slider having clamping portions at two sides thereof for correspondingly clamping to the receiving portions, wherein the vibrator is for generating a driving force to the slider while connecting with a power supply, such that the clamping portions of the slider move within the receiving portions, thereby generating a linear translation. The present invention adopts a simple structure having few elements that enables easy manufacturing and integration with other elements, thus reducing manufacturing cost.

Owner:IND TECH RES INST

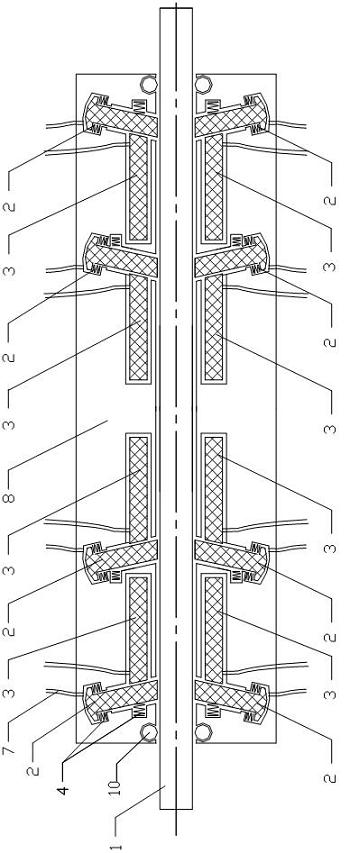

Parallel platform tracking control apparatus using visual device as sensor and control method thereof

ActiveUS9971357B2Easy to measureHigh sampling frequencyImage enhancementProgramme-controlled manipulatorGratingImaging processing

A parallel platform tracking control apparatus and method using a visual device as a sensor are disclosed. The apparatus comprises a parallel platform body, a CCD camera (11), a lens (6), a camera light source (9), a computer (11), a Dspace semi-physical simulation controller, an ultrasonic motor driver and the like. The parallel platform comprises an ultrasonic linear motor (1), a linear grating encoder (5), a driven rod (2), a moving platform (3), a stationary platform (4) and the like. The CCD camera photographs the moving platform in a perpendicular and opposite manner, and the photographed images are subjected to an image processing algorithm to measure the position of the corresponding marker on the moving platform, which is not only applicable to measurement, but also implements real-time feedback of the termination position of the moving platform, such that a full closed-loop system is constituted. In this way, the parallel platform is precisely positioned.

Owner:SOUTH CHINA UNIV OF TECH

Lens device and digital camera using same

InactiveCN1573396ATelevision system detailsColor television detailsUltrasonic linear motorOptical axis

Provided is a lens device which is equipped with an ultrasonic linear motor and a coupling mechanism with a moving lens frame which is suitable for the linear motor, and a digital camera equipped with the lens device. The moving lens frame for focusing is constituted of a lens frame main body holding a moving lens, a bearing part and an engaging protrusive part, and the ultrasonic linear motor is arranged between the side surface of the main body and the protrusive part. A slot which is parallel with the moving direction along the optical axis of the main body is bored at the central part of the protrusive part, and a leaf spring engages in the slot from the opposite side. A pin member fixed and protrusively provided in the center of the motor is inserted through a gap formed between the energizing part of the spring and the left end of the slot, and its movement in the direction of an optical axis O2 in the slot is inhibited and its play in the vertical direction is allowed. Thus, the direction and the force of the movement of an oscillator in the direction of the optical axis O2 are accurately transmitted to the 3rd moving lens frame, and the vertical movement by the elliptical oscillation of the oscillator is absorbed and is not transmitted to the 3rd moving lens frame.

Owner:OM DIGITAL SOLUTIONS CORP

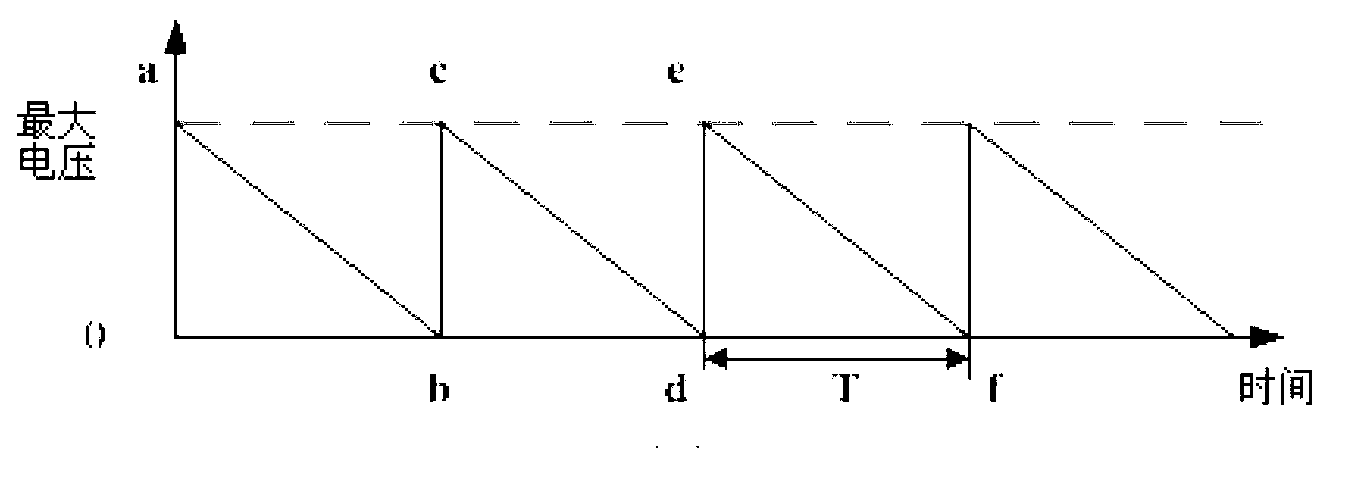

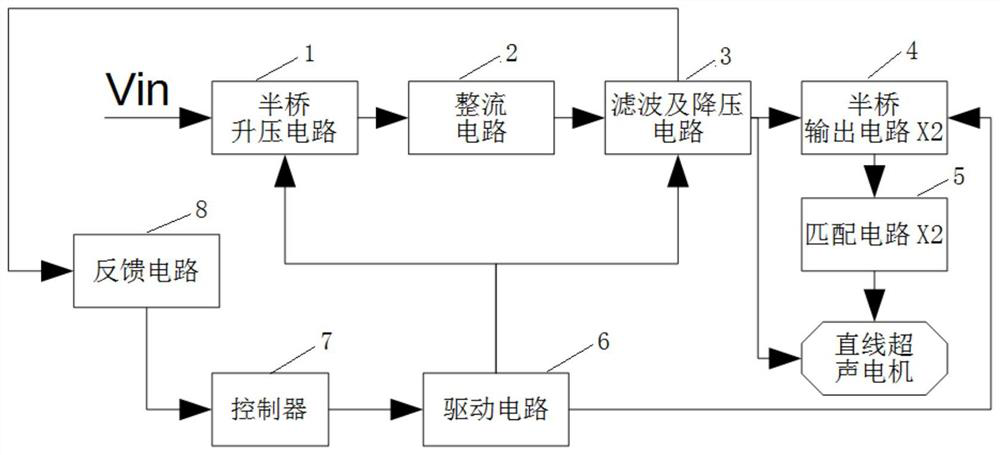

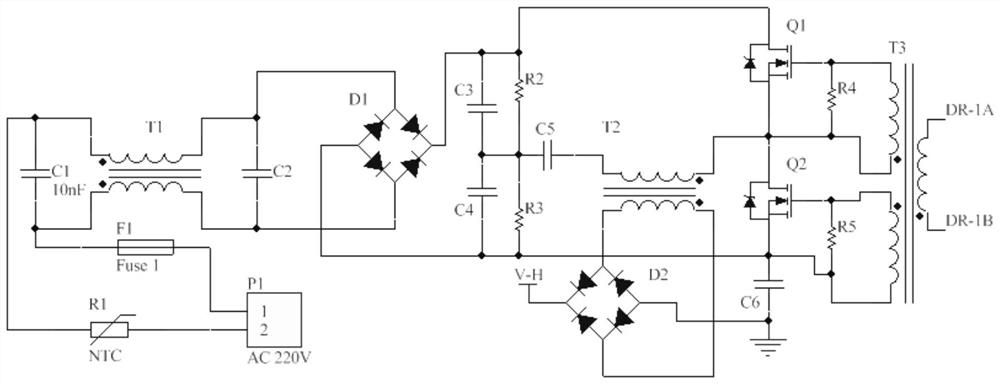

V-shaped ultrasonic linear motor driving power supply and driving method thereof

ActiveCN112104260ARealize fine-tuning of preloadHigh control precisionPiezoelectric/electrostriction/magnetostriction machinesDc-dc conversionCapacitanceHigh-voltage direct current

The invention provides a V-shaped ultrasonic linear motor driving power supply. Commercial power is boosted by a half-bridge boost circuit and then rectified by a rectifying circuit to obtain high-voltage direct current isolated from the commercial power, a filtering and voltage reducing circuit filters the high-voltage direct current, the filtering and voltage reducing circuit comprises two capacitors which are connected in series, a voltage division is formed by series points, and the voltage division is adjustable in size. An adjustable direct-current voltage stabilizing source is obtainedand used for driving the voltage through static deformation of the piezoelectric ceramic in the micro-displacement movement process; the filtered high-voltage direct current and the adjustable directcurrent voltage stabilizing source are connected to a half-bridge output circuit; a controller adjusts the half-bridge boost circuit, the filtering and voltage reducing circuit and the half-bridge output circuit through a drive circuit, and provides stable direct current bias adjustable alternating current pulse voltage or adjustable direct current voltage for an ultrasonic linear motor. Accordingto the invention, two motion states of rapid stepping motion and micro-displacement motion in the field of precision positioning can be realized, a motor control system is simplified, and the stability is improved.

Owner:SOUTH CHINA AGRI UNIV

Six-degree of freedom dual-finger parallel micro/nano operation device and operation method thereof

PendingCN107720691AMeet operational requirementsAchieving cross-scale operationsMicrostructural devicesUltrasonic linear motorBall joint

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com