Longitudinal-bending compound single-foot two-degree-of-freedom ultrasonic motor vibrator

A technology of ultrasonic motors and degrees of freedom, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve problems such as difficult planar two-degree-of-freedom drives, and achieve a series of and commercialization, ease of serialization and commercialization, and the effect of overcoming the serious problem of fever

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

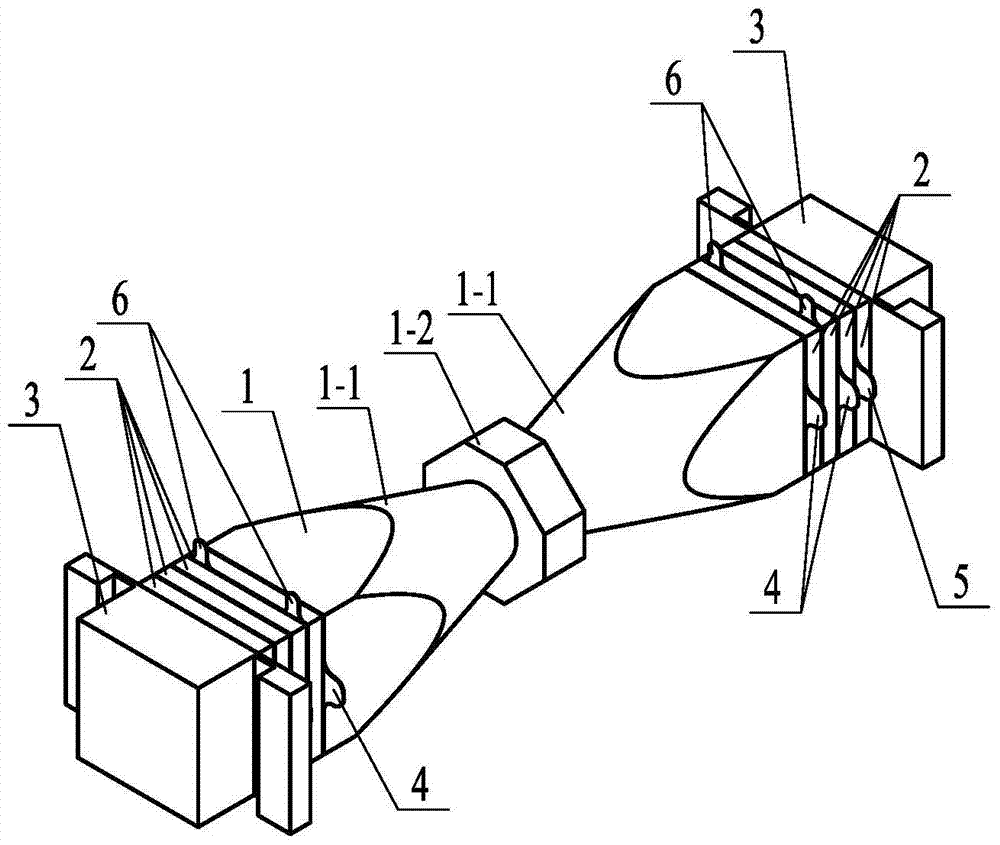

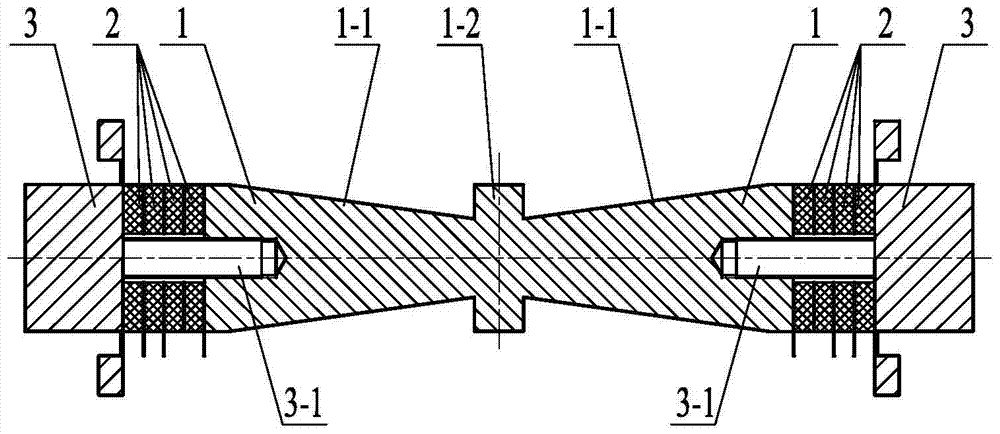

[0037] Specific implementation mode one: see Figure 1 to Figure 4 Describe this embodiment, the longitudinal bending composite single-legged two-degree-of-freedom ultrasonic motor vibrator described in this embodiment includes a middle beam 1, eight piezoelectric ceramic sheets 2 and two rear end covers 3, and is characterized in that the The middle beam 1 includes two horns 1-1 and a driving foot 1-2, and the two sides of the driving foot 1-2 are respectively fixedly connected with the end surfaces of the two horns 1-1; the rear end cover 3 A stud 3-1 is provided at the center of one side, and each stud 3-1 is fitted with four piezoelectric ceramic sheets 2, and the rear end cover 3 is screwed on the horn through the stud 3-1. 1-1, and realize the compression of the piezoelectric ceramic sheet 2;

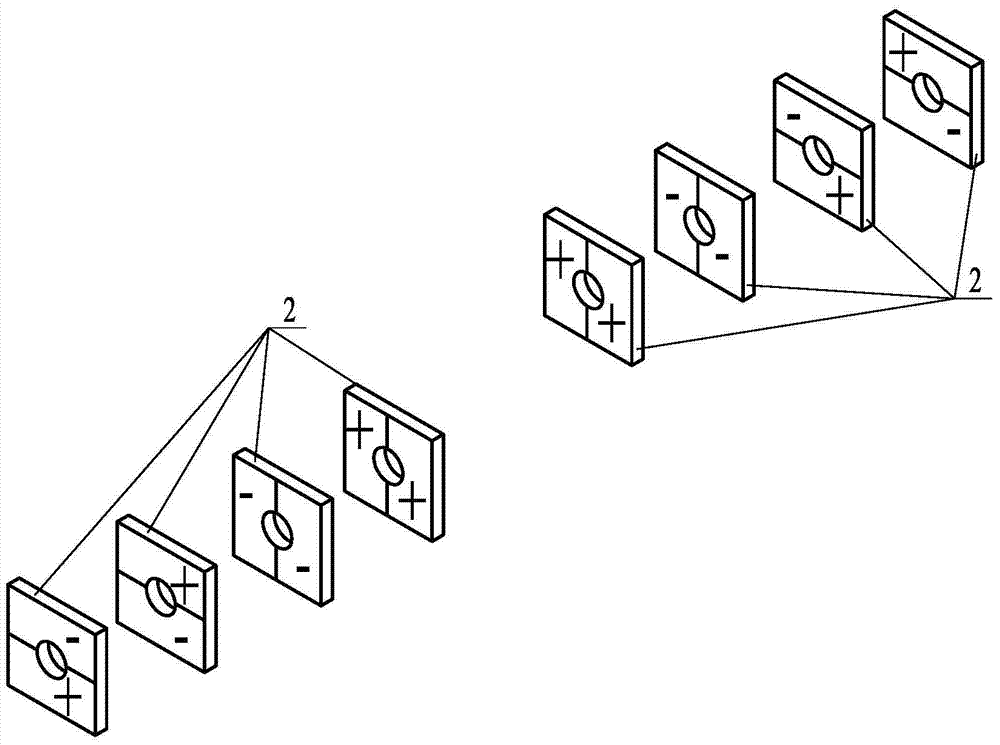

[0038] The eight piezoelectric ceramic sheets 2 are all polarized along the thickness direction, and in the direction from one rear end cover 3 to the other rear end cover 3, the...

specific Embodiment approach 2

[0045] Specific Embodiment 2: The difference of the longitudinal-bending compound single-foot two-degree-of-freedom ultrasonic motor vibrator described in this embodiment is that all the ground electrode sheets 4 are connected to the common end of the excitation signal, and all the bending vibration electrode sheets 5 are connected to the first The phase driving signals are connected, and all the longitudinal bending multiplexing electrode sheets 6 are connected to the second phase driving signal, and the first phase driving signal and the second phase driving signal have a phase difference of 90 degrees in time.

[0046] In this embodiment, the first-phase drive signal and the second-phase drive signal have a phase difference of 90 degrees in time. Under various drive modes, the longitudinal bending compound single-leg two-degree-of-freedom ultrasonic motor vibrator will pass through the longitudinal vibration (see Figure 5 ) and bending vibration in the vertical direction (s...

specific Embodiment approach 3

[0047] Embodiment 3: The difference between this embodiment and the longitudinal bending compound single-leg two-degree-of-freedom ultrasonic motor vibrator described in Embodiment 1 is that all the ground electrode sheets 4 are connected to the common end of the excitation signal, and all the bending vibration electrodes Sheet 5 is connected to the first phase drive signal, the longitudinal bending multiple electrode sheet 6 on the left side between the third and fourth piezoelectric ceramic sheets 2 is connected to the second phase drive signal, the fifth and sixth piezoelectric ceramic sheets 2 are connected to the second phase drive signal, The longitudinal bending multiplexing electrode sheet 6 on the right side between the electric ceramic sheets 2 is connected to the second phase drive signal;

[0048] The longitudinal bending multiple electrode sheet 6 on the right side between the third and the fourth piezoelectric ceramic sheet 2 is connected to the third-phase drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com