Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Guaranteed moving distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

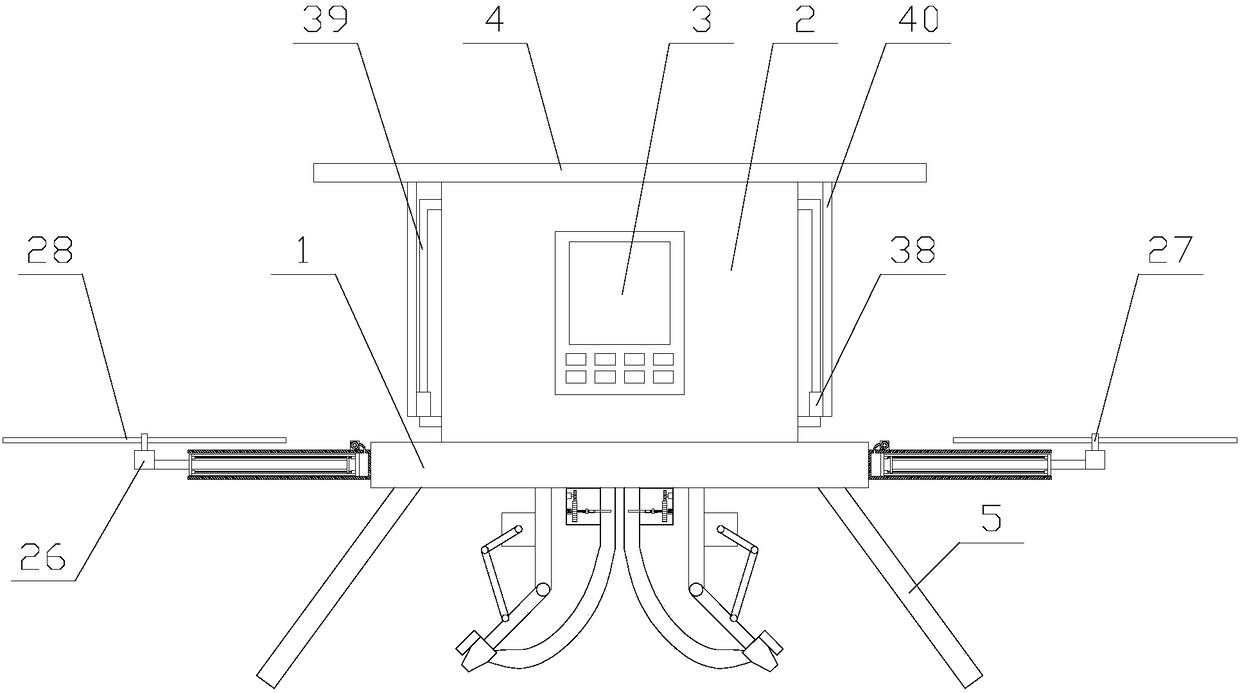

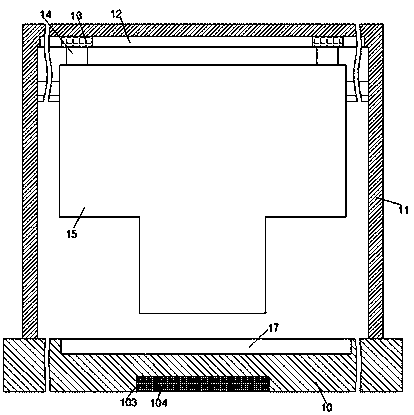

Accurately-spraying intelligent plant protection unmanned aerial vehicle with adjusting function

InactiveCN108438229ASpraying with adjustable function Precise sprayingSpraying precision pesticide dosage control with adjustment functionAircraft componentsInsect catchers and killersPistonHelicopter rotor

The invention relates to an accurately-spraying intelligent plant protection unmanned aerial vehicle with an adjusting function. The unmanned aerial vehicle comprises a main body, a pesticide tank, atop board, two pesticide spaying mechanisms, multiple flight mechanisms and multiple supporting feet. Each flight mechanism comprises a flight component, an air pump, an air cylinder, a piston board and a telescopic component. Each telescopic component comprises a horizontal motion board, a horizontal motion rod and two horizontal motion units. Each pesticide spraying mechanism comprises a nozzle,a direction adjusting component, a liquid conveying component and a connecting pipe. Each adjusting component is arranged in a corresponding adjusting room. Each adjusting component comprises a firstmotor, a first gear, a second gear, a lead screw, a casing pipe and an adjusting board. By the adoption of the accurately-spraying intelligent plant protection unmanned aerial vehicle with the adjusting function, through the air pumps and the telescopic components in the flight mechanisms, the flight components are away from the main body, crops affected by airflow generated by rotors is avoided,pesticide is sprayed more accurately, furthermore, in the pesticide spaying mechanisms, the spraying amount of the pesticide is flexibly adjusted according to the pest amount around the crops, it isguaranteed that the crops grow healthily, and the practicability of equipment is improved.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

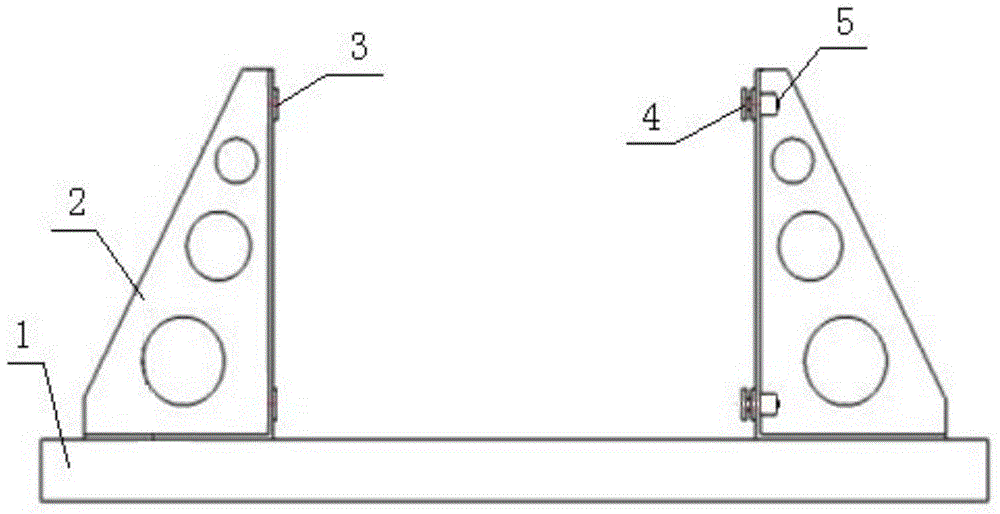

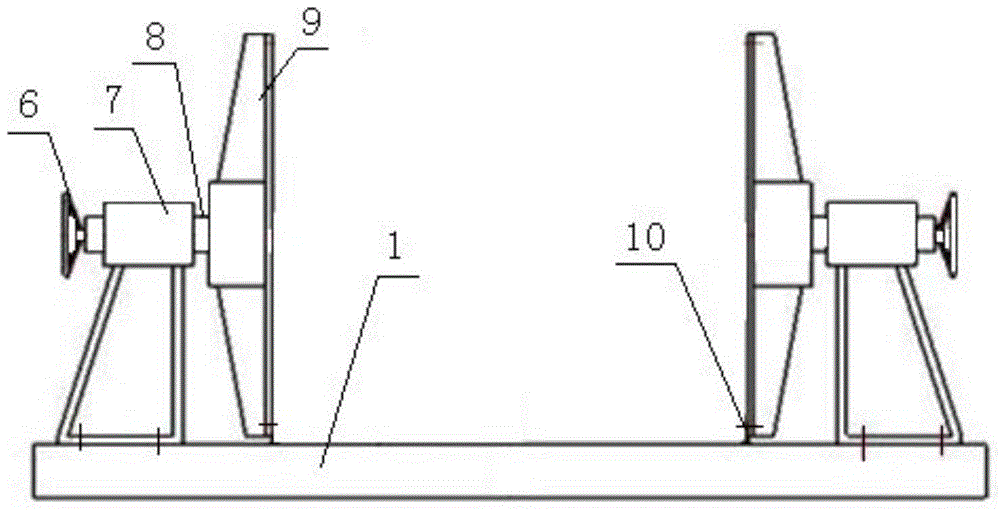

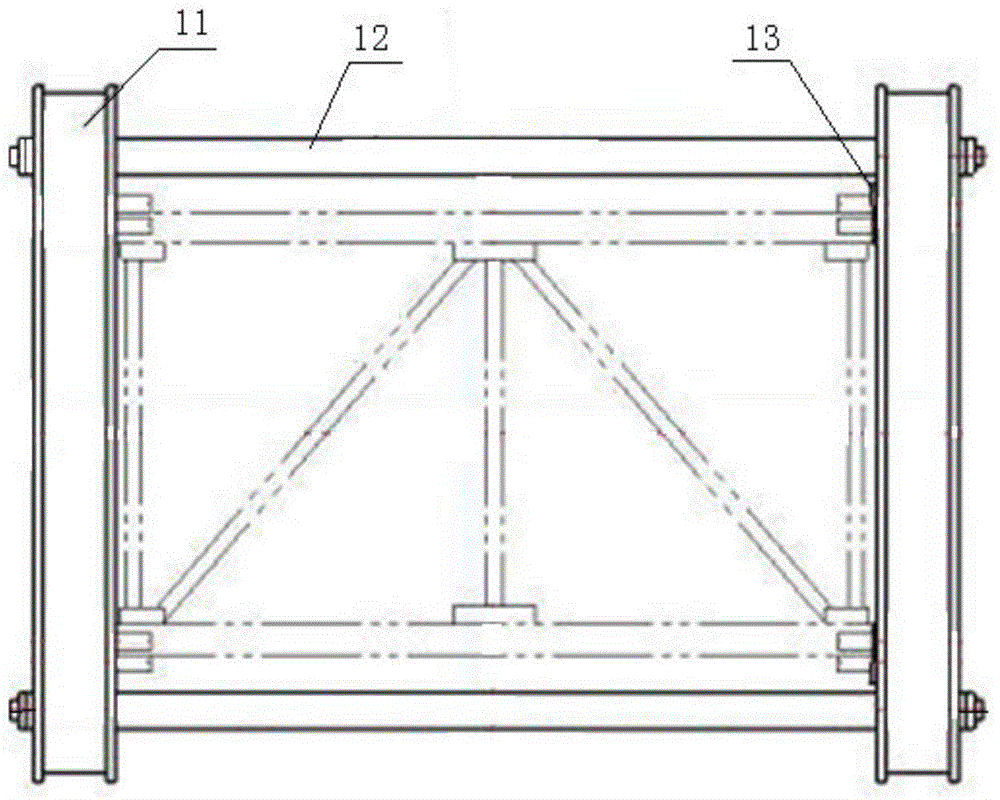

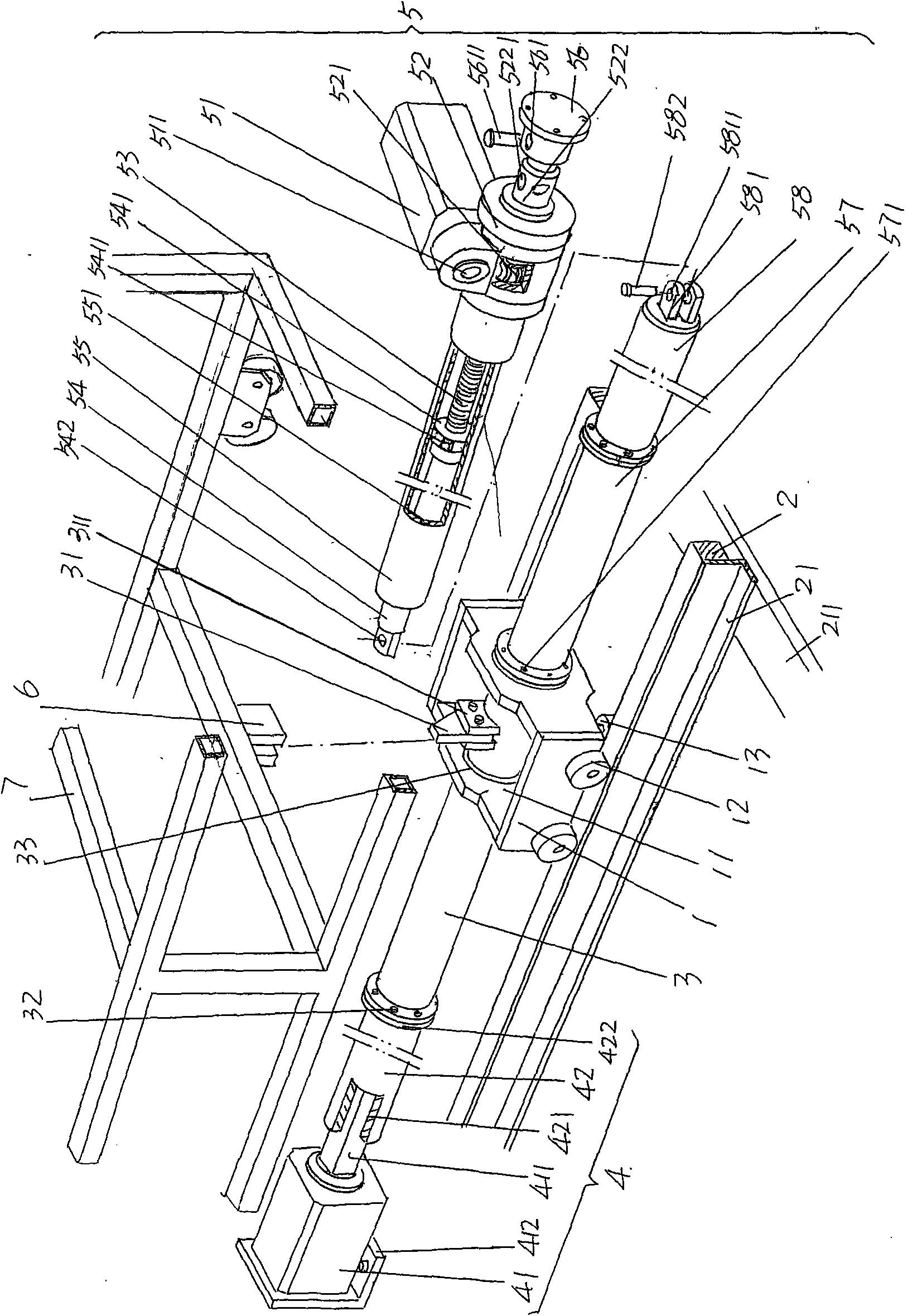

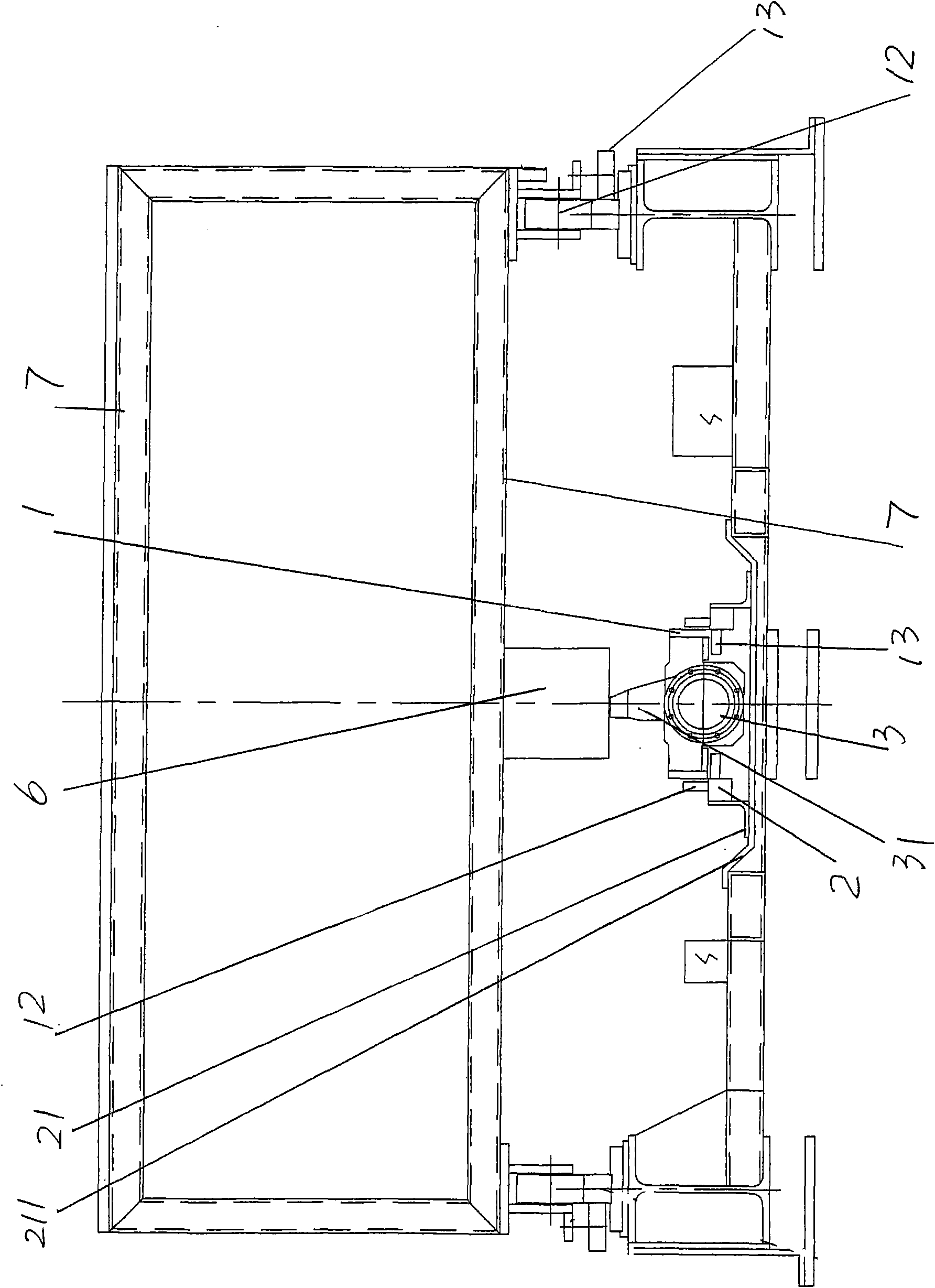

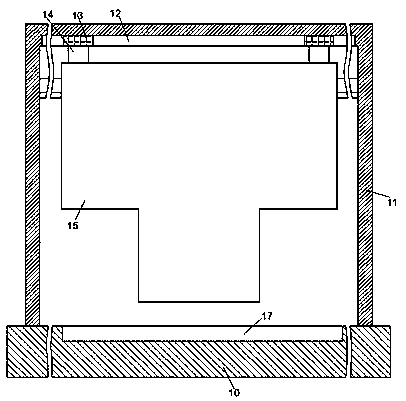

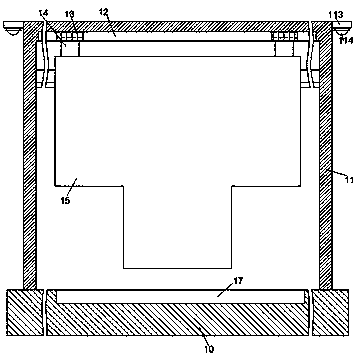

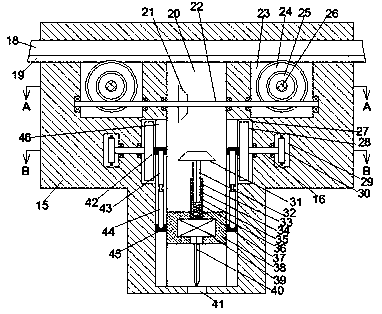

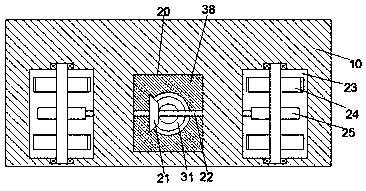

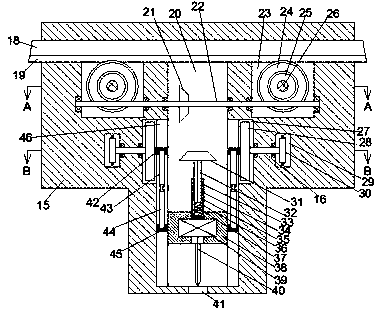

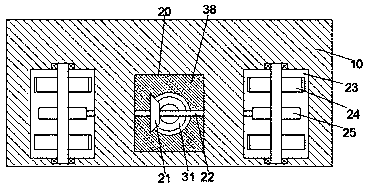

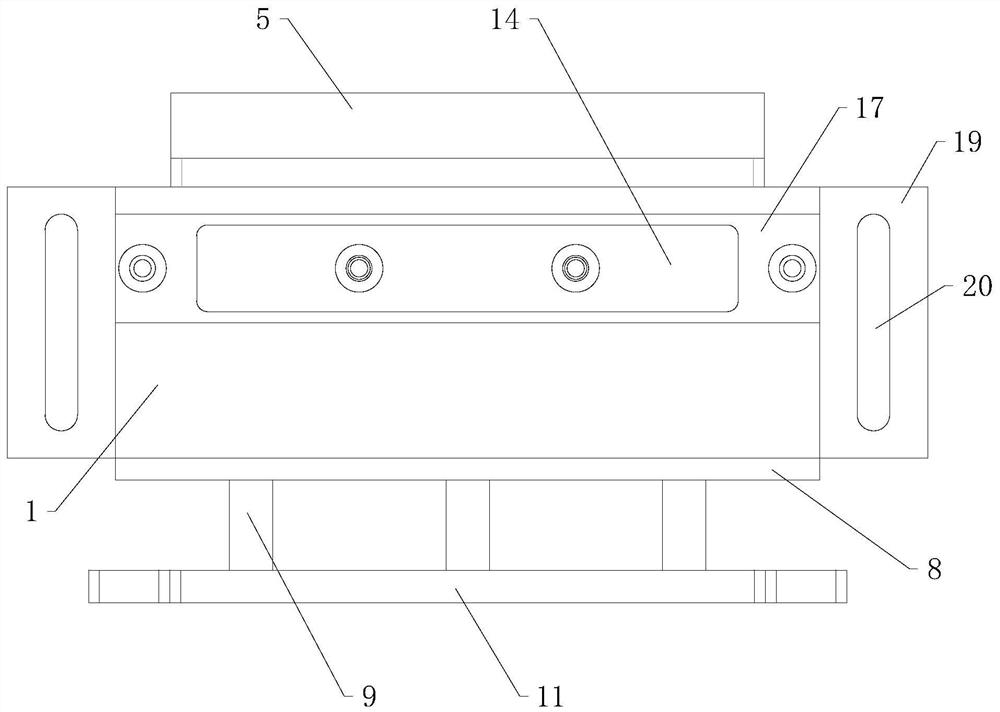

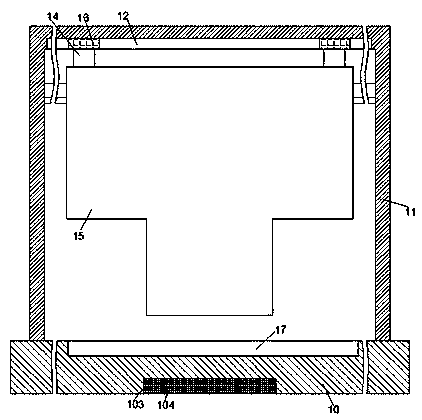

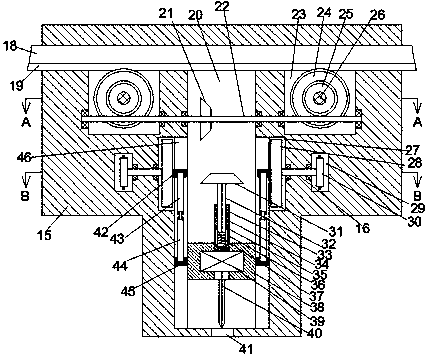

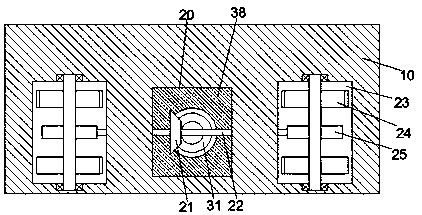

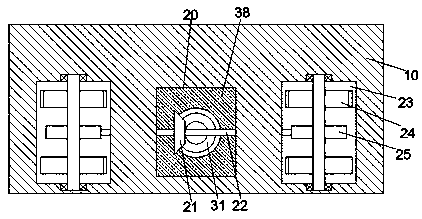

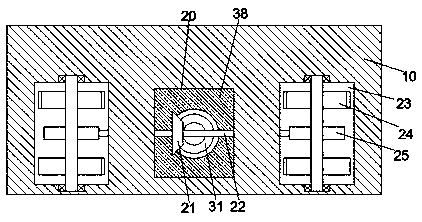

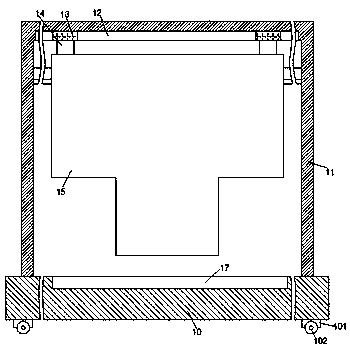

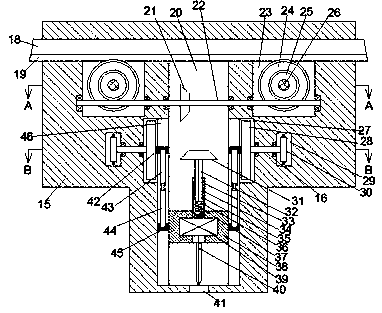

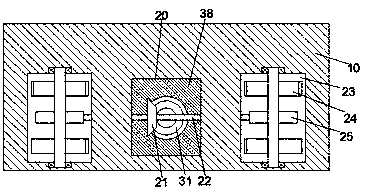

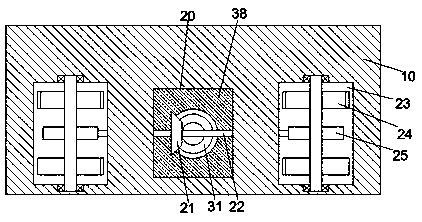

Steel structure numerical control assembly center

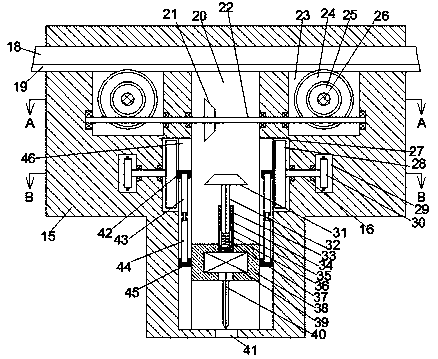

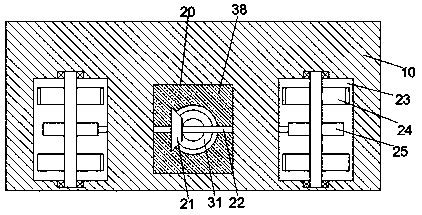

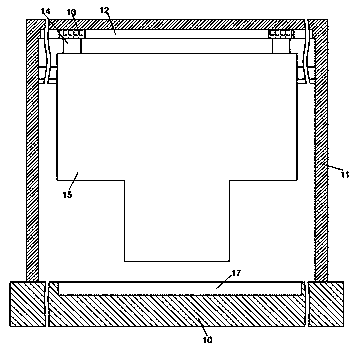

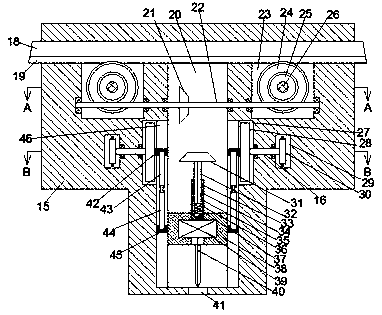

InactiveCN105312798AEase of workImprove mobile stabilityWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlPipe fitting

The invention discloses a steel structure numerical control assembly center. The steel structure numerical control assembly center comprises a fixed device, a moving device, a T-shaped fixing seat and a long framework formed by splicing multiple sections of a steel structure framework. The T-shaped fixing seat is located in the middle of the long framework; the fixed device and the moving device are installed at the two ends of the long framework respectively; the fixed device is fastened to the steel structure framework through the T-shaped fixing seat to serve as a positioning reference; the moving device is installed on the steel structure framework through sliding blocks and sliding ways; the moving device is provided with a gear set, a servo motor and a speed reducer which are connected in sequence; a magnetic railing ruler and a gear rack connected with the gear set are installed on the two sides of the T-shaped fixing seat respectively; the magnetic railing ruler is composed of a ruler body and an inductor arranged on the ruler body; the inductor is connected with a control panel disposed on the fixed device through a data line. By means of the steel structure numerical control assembly center, a steel structure pipe fitting can be welded in an omni-directional and shifting mode, necessary work and work difficulty are reduced for workers, and the work efficiency and the equipment operation safety are improved.

Owner:GUIZHOU TIPTOP NUMERICAL CONTROL EQUIP CO LTD

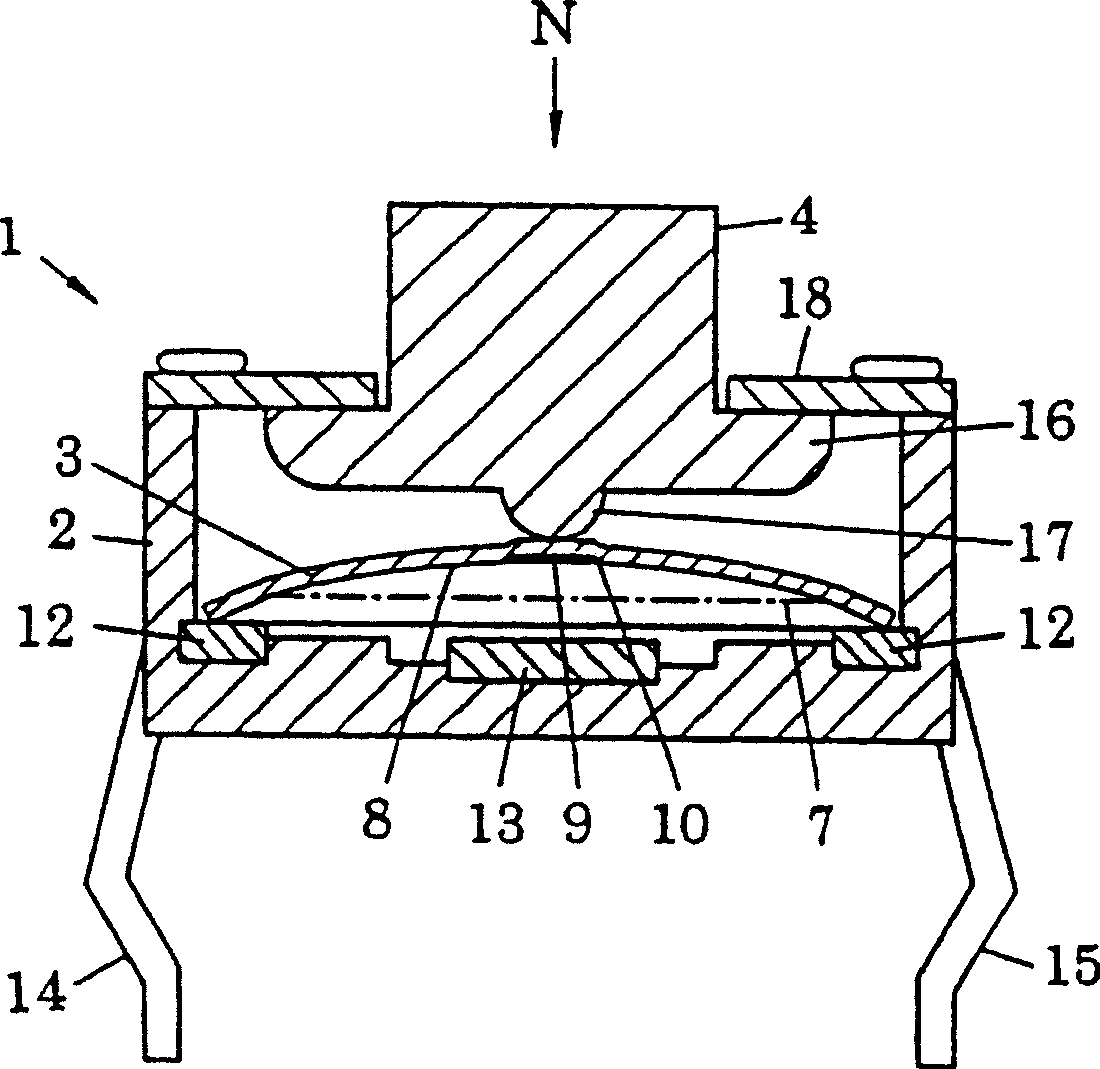

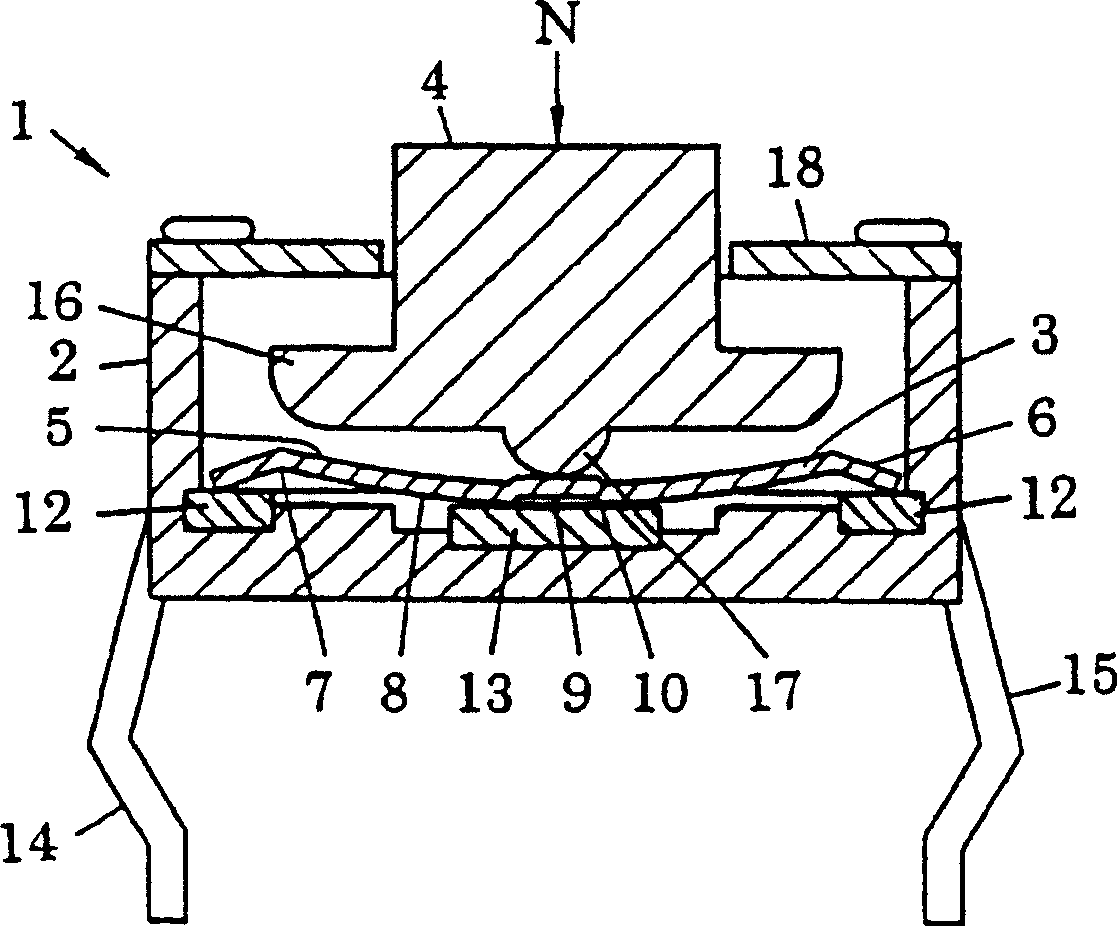

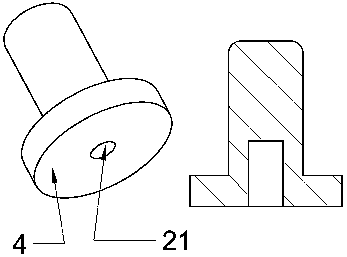

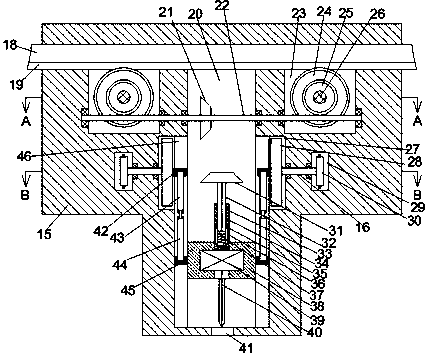

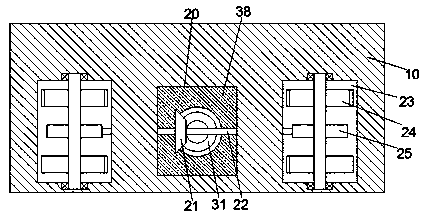

Switch for inputting signal

InactiveCN100490036CGuaranteed moving distanceEmergency actuatorsSnap-action arrangementsEngineeringElectric contact

There is provided a switch which is excellent in stability in electric contact between an edge part of a contact spring and a fixed contact part, ensures a stroke required for an eccentric load which is imposed on the contact spring and reduces variations in clicking feeling without shortening a life of the dome-shaped contact spring which can be clicked. A depression is formed on an inner central part of the contact spring, namely, on a movable contact part and the edge part formed on the periphery of the depression is allowed to contact the surface of the fixed contact part by a line contact, thereby ensuring electric stability of contact between the edge part and the fixed contact part. Since the movable contact part has no hole, no dust enters the switch, thereby preventing a life of the contact spring from being shortened. Further, since the central part of the contact spring is formed in a dome part by a spherical surface and a skirt part is formed of a conical surface on the outer peripheral edge part of the dome part, a required stroke is ensured and variations in clicking feeling are reduced.

Owner:FEI控股株式会社

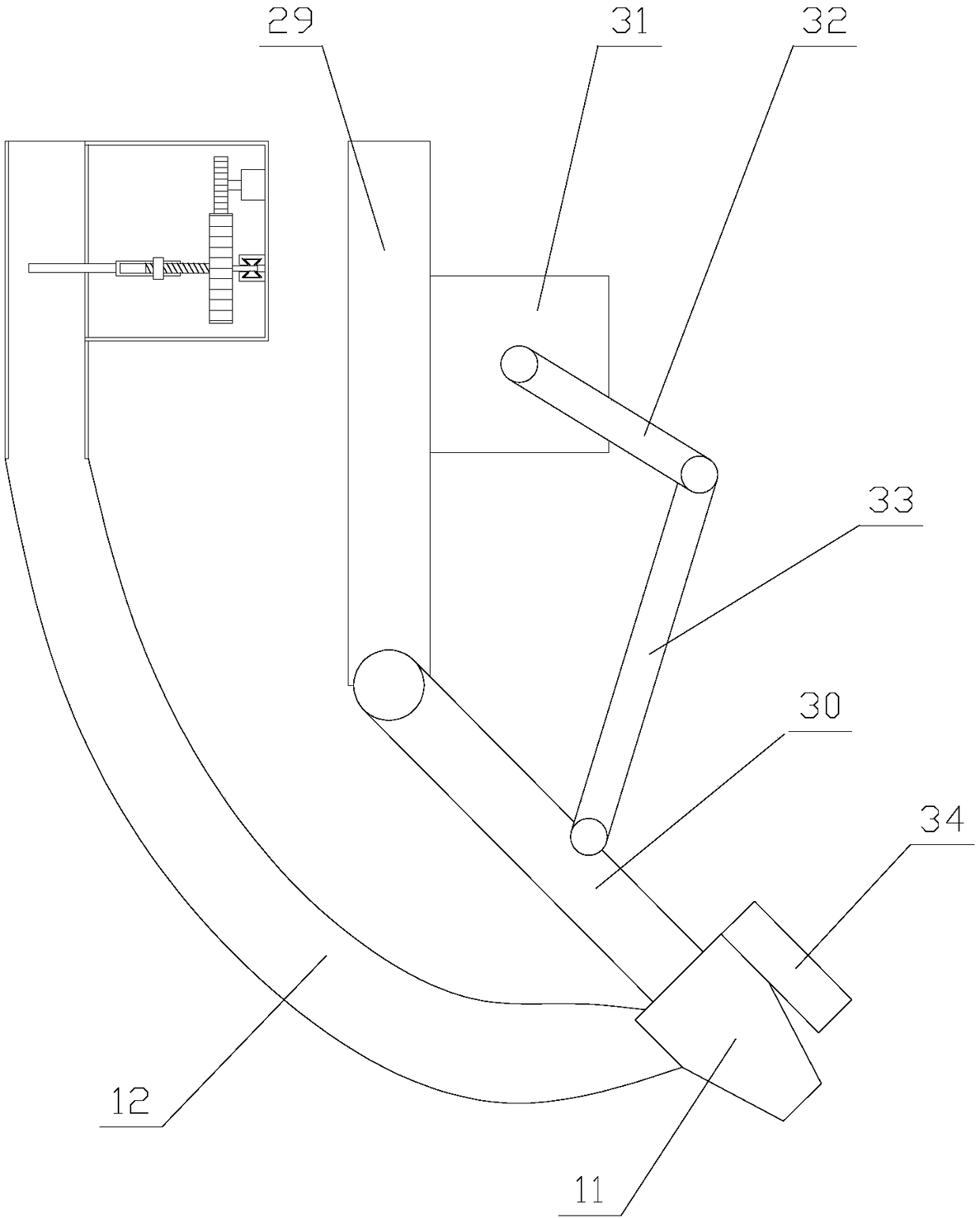

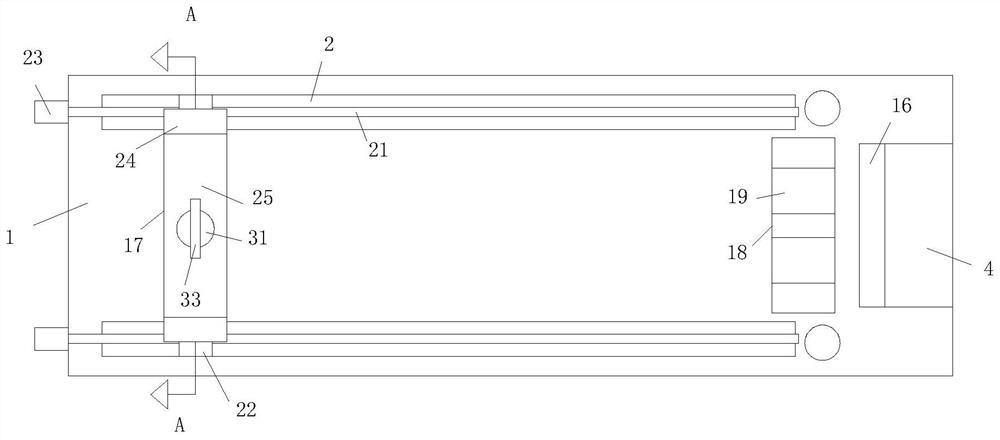

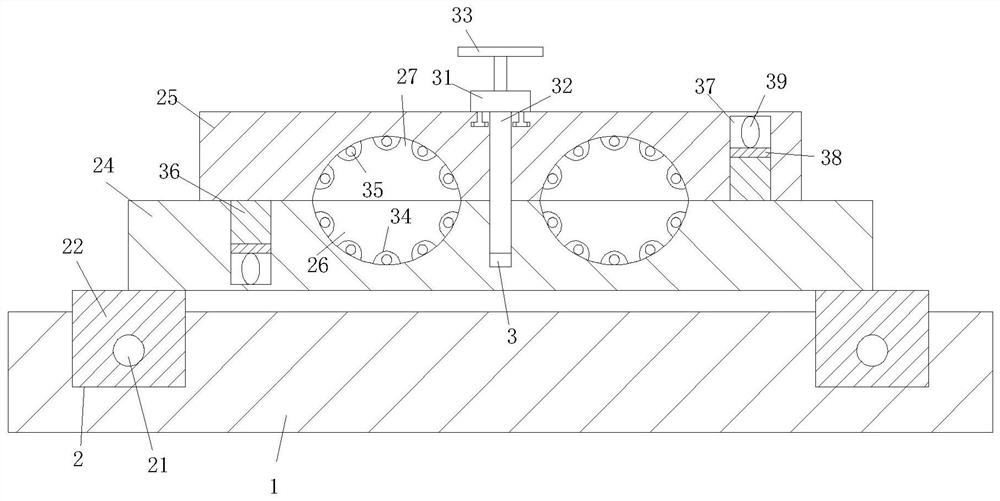

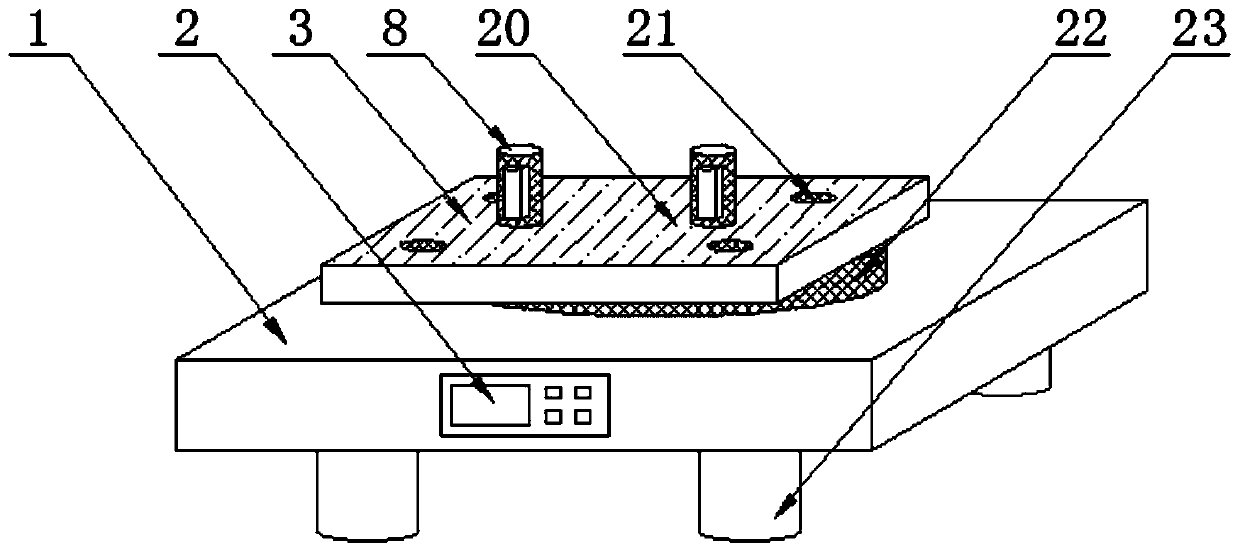

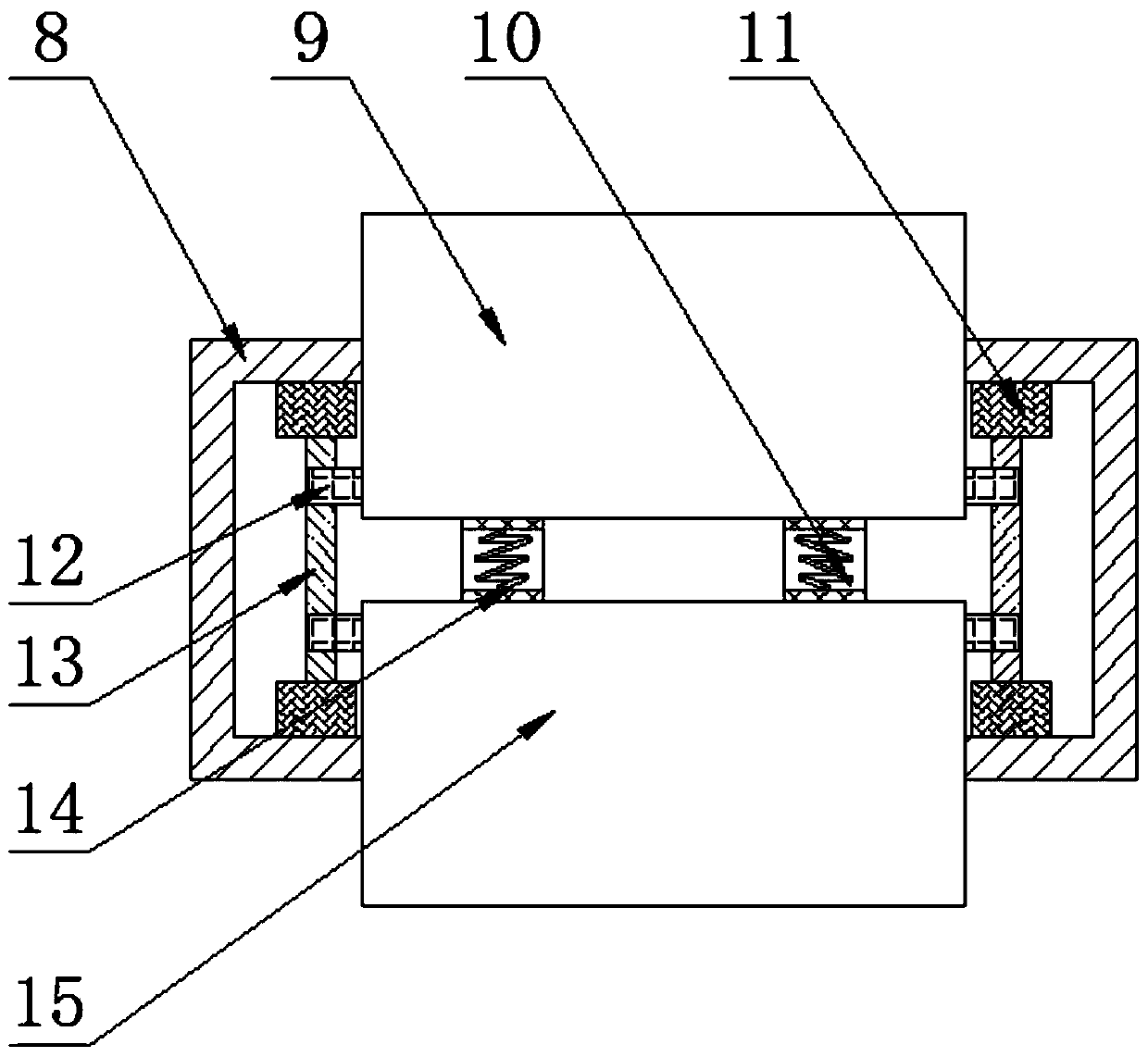

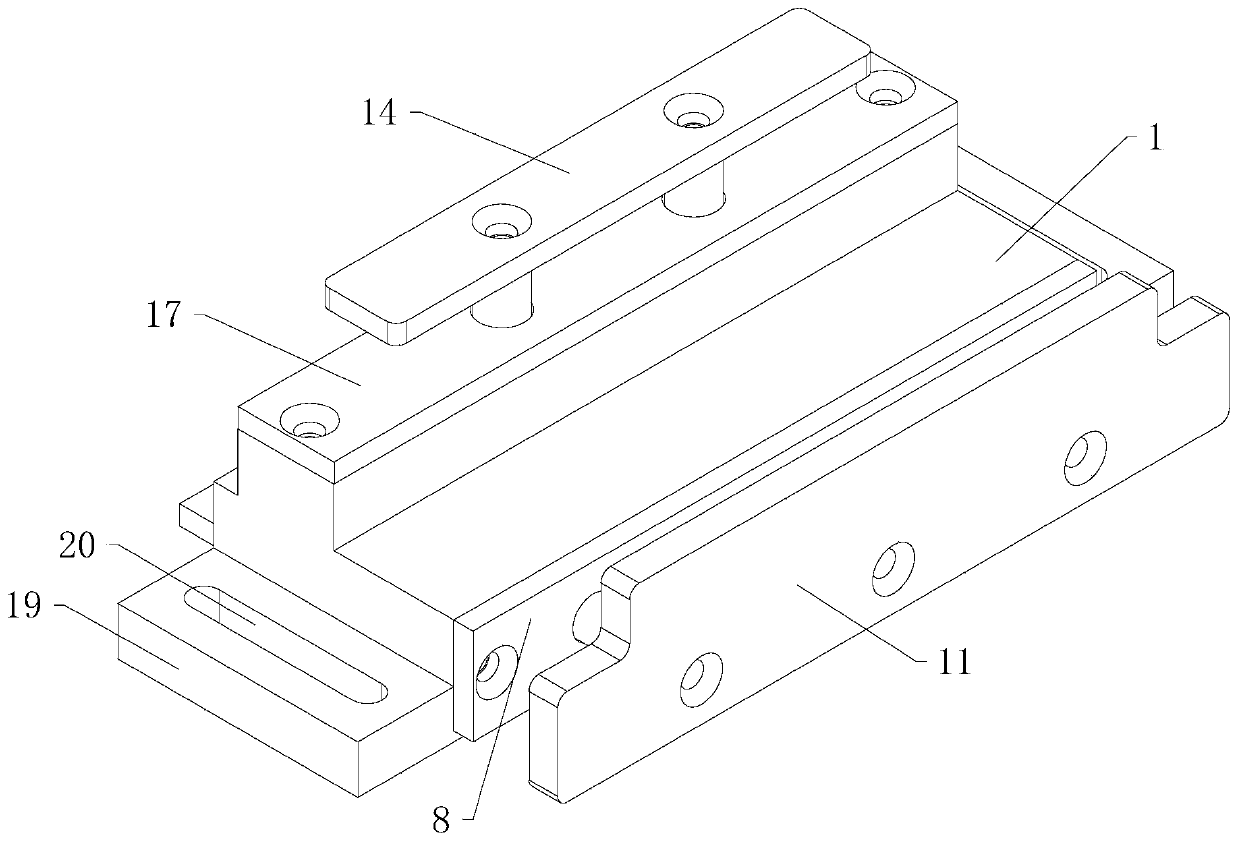

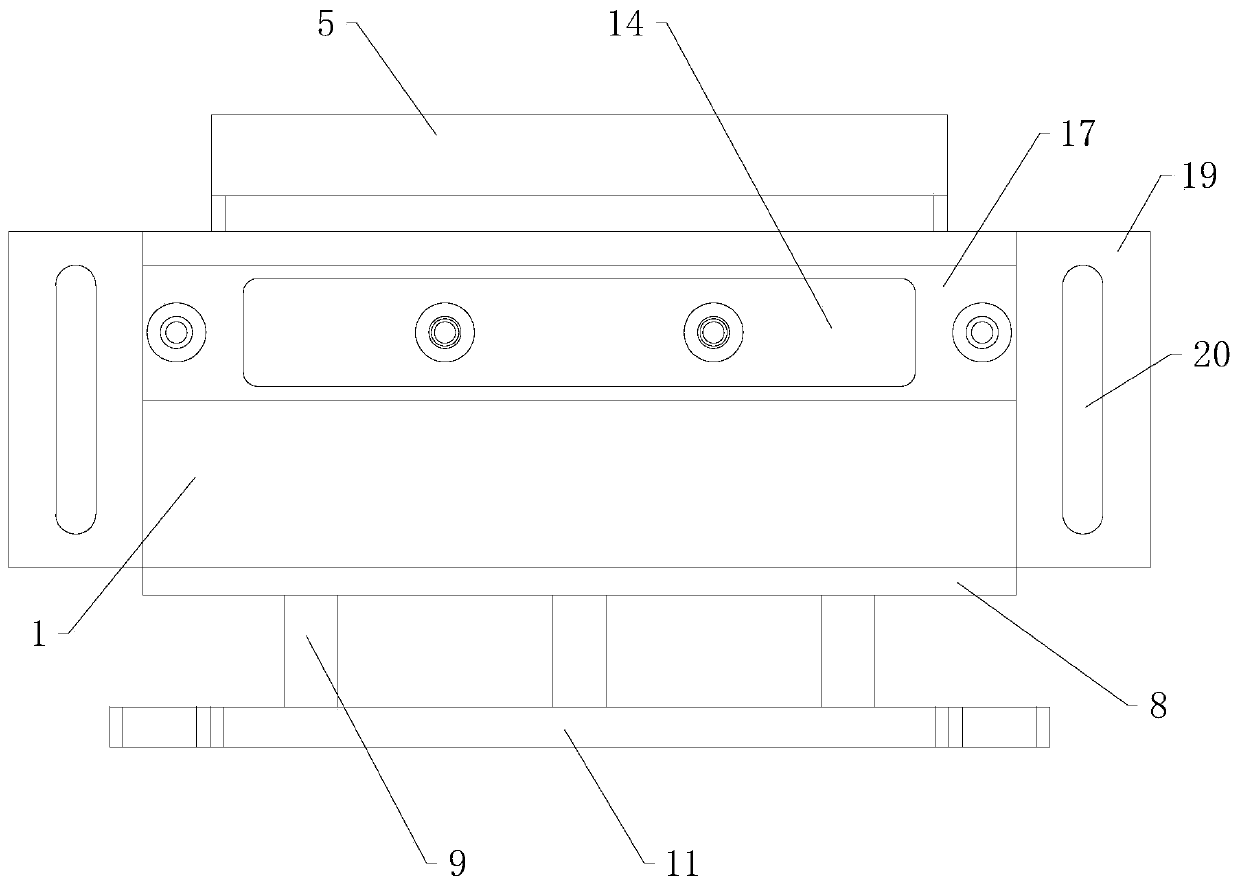

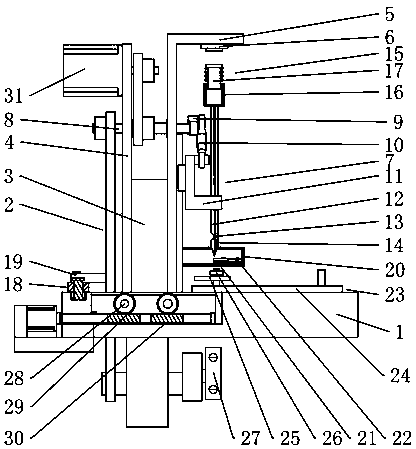

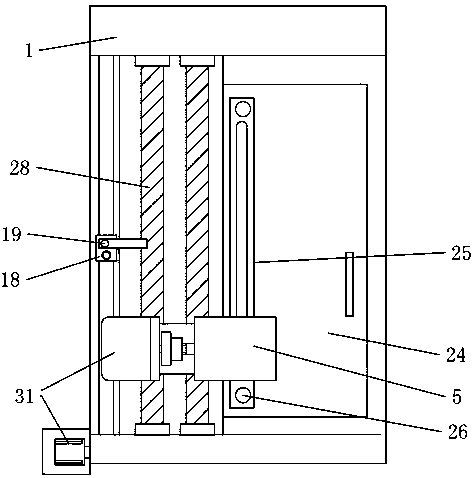

Feeding mechanism for metal machining and manufacturing

ActiveCN114260505AGuaranteed moving distanceGuaranteed uniformityMetal sawing devicesMetal working apparatusHydraulic cylinderMetal machining

The invention belongs to the technical field of machining and manufacturing, and particularly relates to a feeding mechanism for metal machining and manufacturing. The workbench is fixedly connected with a fixing plate through a fixing column. The top end of the fixed plate is fixedly connected with a hydraulic cylinder; a hydraulic rod is arranged at the output end of the bottom end of the hydraulic cylinder; the bottom end of the hydraulic rod is fixedly connected with a first motor; the first motor is fixedly connected with a cutting wheel through a first rotating shaft; a first through groove is formed in the position, opposite to the cutting wheel, of the workbench. A placing seat is fixedly connected to the position, close to the first through groove, of the workbench. A group of first grooves are formed in the placing seat; according to the feeding mechanism for metal machining and manufacturing, the problems that steel pipes need to be cut in a uniform segmentation mode for use, but when the steel pipes are cut in a segmentation mode and manually pushed to move and cut, the segmentation lengths of the steel pipes are different, and the cutting quality is affected are solved.

Owner:常德市鼎城区正荣机械制造有限公司

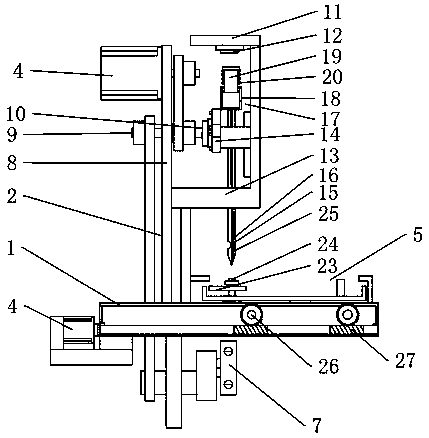

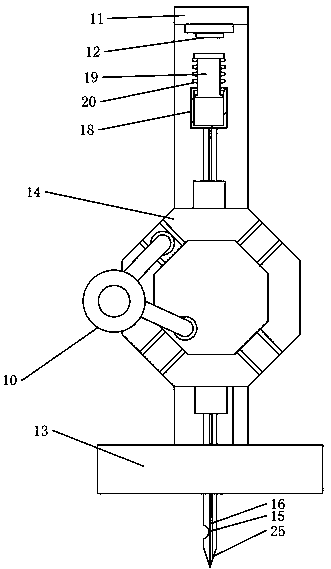

Special three-hole and double-thread punching and threading all-in-one machine for archives room

The invention discloses a special three-hole and double-thread punching and threading all-in-one machine for an archives room. The special three-hole and double-thread punching and threading all-in-one machine comprises a rack, and a stand column is arranged on the rack. A punching mechanism moving up and down is movably arranged on the stand column, and a driving device dynamically connected withthe punching mechanism is arranged on the stand column. A movable positioning clamping plate moving back and forth is correspondingly arranged at the lower part of the punching mechanism, and a powermechanism dynamically connected with the movable positioning clamping plate is arranged on a rack. A switch of the power mechanism is arranged at the upper part of the punching mechanism, and the switch is turned on along with the rising of the punching mechanism and is turned off along with the falling of the punching mechanism. A rotating shuttle forming a lock stitch with the punching mechanism is arranged at the lower part of the rack, and the rotating shuttle is dynamically connected with the driving device. The special three-hole and double-thread punching and threading all-in-one machine is convenient in use, reduces the difficulty of operation, and achieves the technical effects of realizing punching and threading at one time and improving the binding quality.

Owner:LINQU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

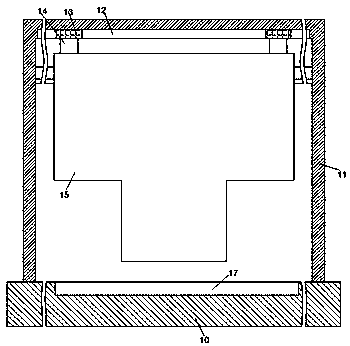

Material loading trolley moving mechanism of electronic product annealing or sintering furnace

InactiveCN101603779APrecise positioningAvoid out-of-sync situationsToothed gearingsCharge manipulationEngineeringMechanical engineering

The invention discloses a material loading trolley moving mechanism of an electronic product annealing or sintering furnace, and belongs to the technical field of industrial stoves. The material loading trolley moving mechanism comprises a moving seat, a sliding sleeve, a sliding sleeve rotating device, a moving seat driving device and a push head; two sides of the moving seat are matched on a rail in a sliding way; one end of the sliding sleeve is arranged on the moving seat and extends into a seat cavity of the moving seat, while the other end is connected with the sliding sleeve rotating device; the sliding sleeve rotating device is fixed on a terrace or a support additionally arranged; the sleeve body of the sliding sleeve extending into the seat cavity of the moving seat is provided with a propelling head; the moving seat driving device is fixed on the terrace or a support additionally arranged and is connected with the sliding sleeve; and the push head is fixed on the bottom of a material loading trolley and is matched with the propelling head. The material loading trolley moving mechanism has the advantages of enabling the material loading trolley accurately positioned and not move about, and avoiding asynchrony between material loading trolleys.

Owner:SUZHOU HUIKE EQUIP CO LTD

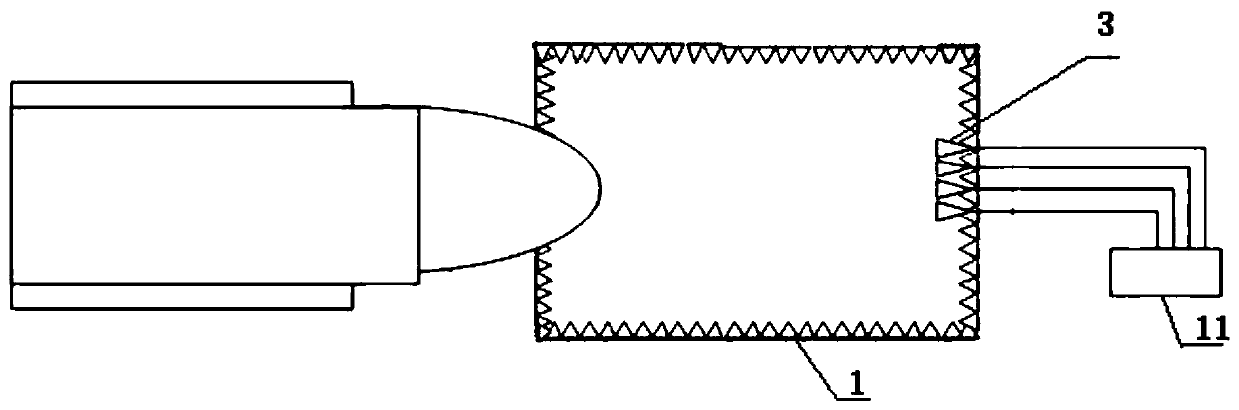

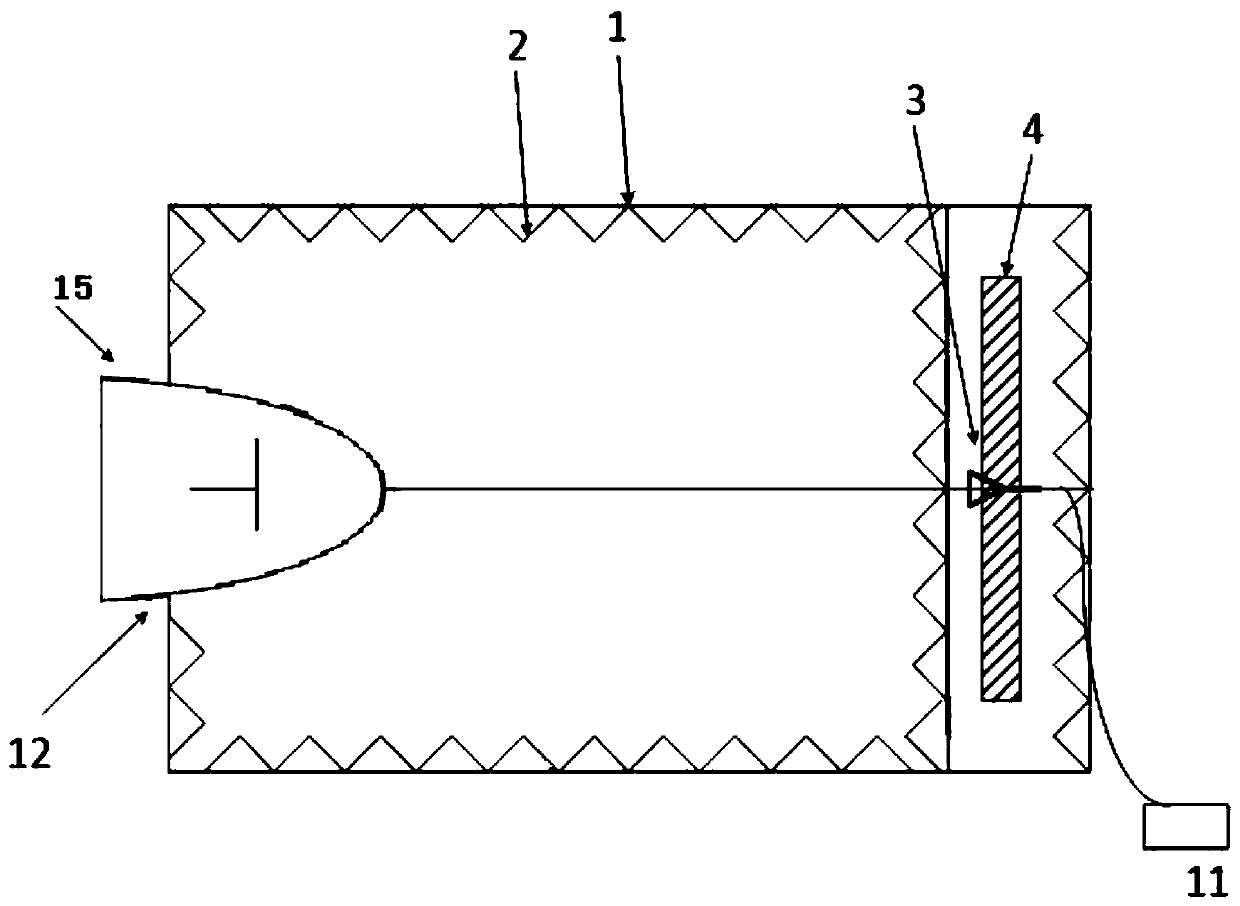

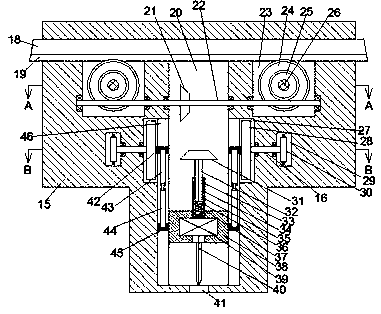

Active radar seeker general assembly testing device

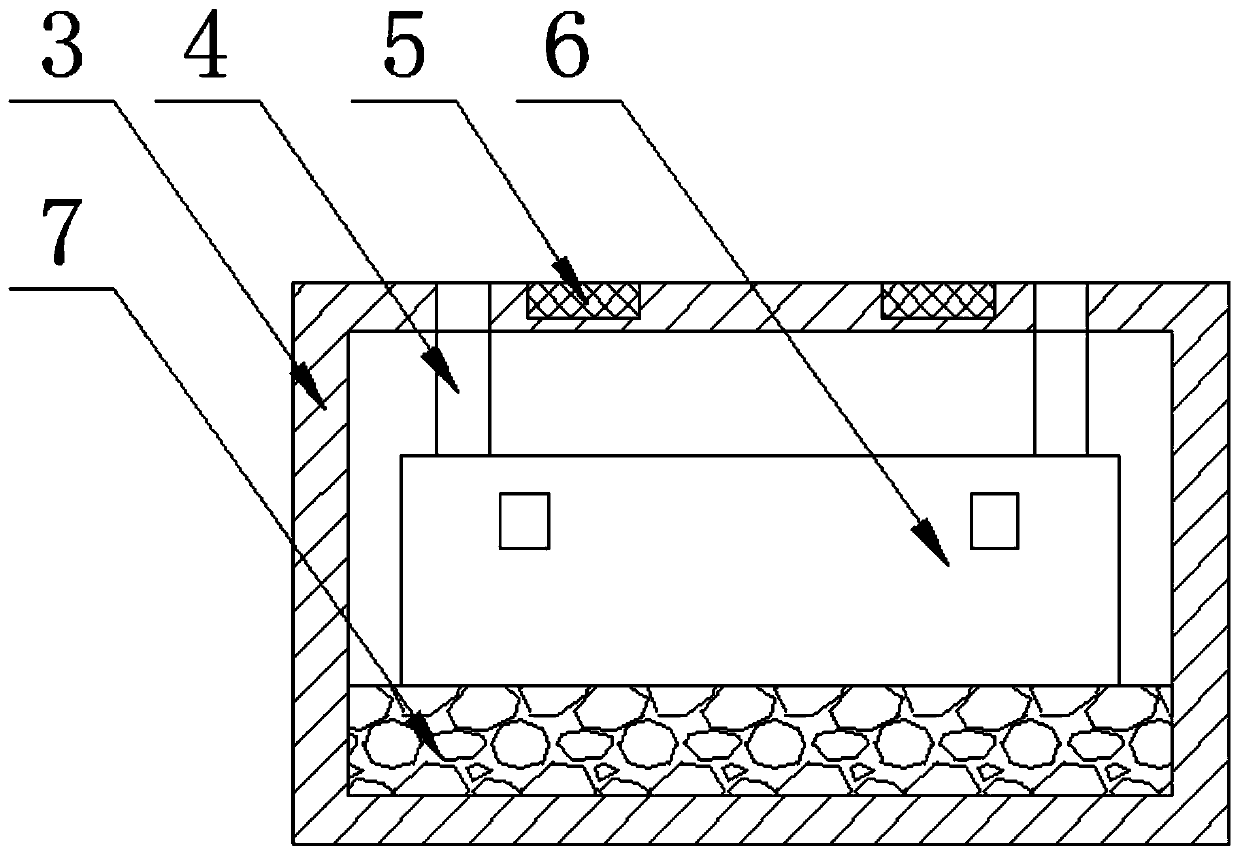

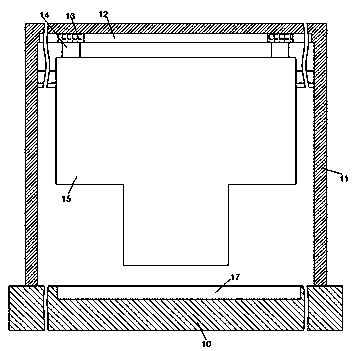

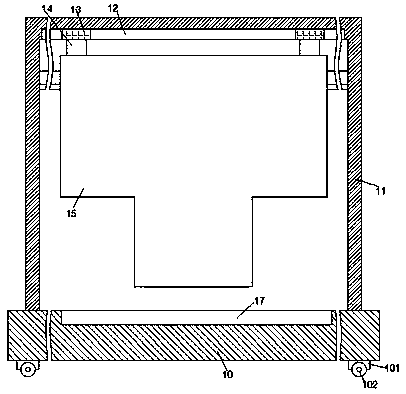

PendingCN110850379AThere is no problem of difficulty in reinstallingAvoid outside interferenceWave based measurement systemsScreening casingsRadarEngineering

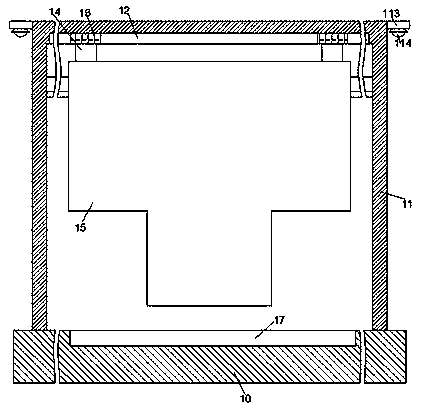

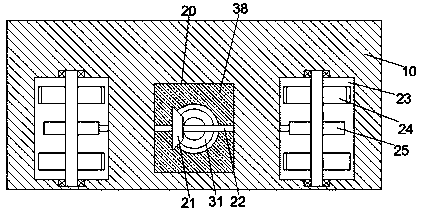

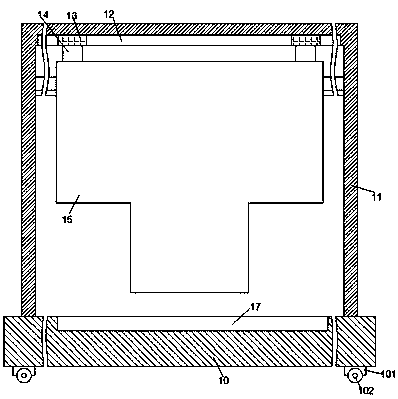

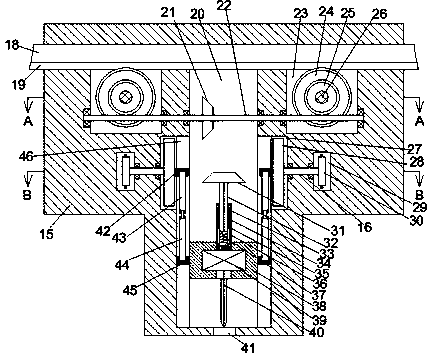

The invention discloses an active radar seeker general assembly testing device. The active radar seeker general assembly testing device comprises a testing camera obscura, a shielding interlayer is arranged on one inner side face of a shell of the testing camera obscura, an antenna housing is embedded in the other side face of the testing camera obscura, and an antenna is arranged in the antenna housing; a target simulator is placed in the shielding interlayer, and a receiving / sending loudspeaker is installed on the target simulator; the target simulator drives the receiving / sending loudspeaker to lift and translate, and a manual adjusting end hermetically penetrates through a shell of the testing camera obscura; the shielding interlayer is provided with a window; a wave-absorbing materialis adhered to the inner side surface of the shell; a signal source is placed outside the testing camera obscura, and the signal source is connected with the receiving / sending loudspeaker through a radio frequency cable which penetrates through the shell of the testing camera obscura in a sealed mode. The closed testing camera obscura is adopted, and disassembly and assembly are not needed; the wave-absorbing material and the shielding interlayer are arranged, so that external interference is avoided; and the target simulator is manually adjusted, so that the complexity of the system is reduced, and the maintainability is good.

Owner:SICHUAN AEROSPACE SYST ENG INST

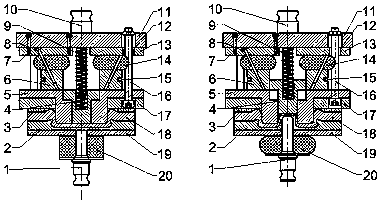

Bidirectional internal lock pressure riveting connecting device

ActiveCN111001716AGuaranteed moving distanceWon't separateShaping toolsStampingIndustrial engineering

The invention discloses a bidirectional internal lock pressure riveting connecting device which is used for forming a double-internal-lock mechanical structure in two stages; main components comprisea first pressure riveting mechanism, a second pressure riveting mechanism, a side sliding mechanism, a power mechanism and other components; the power mechanism and the other components are connected,and the first pressure riveting mechanism comprises a first stamping die, elastic rubber and the like; the second rivet pressing mechanism comprises a second stamping die, a third stamping die and the like; the second stamping die, the third stamping die and a lower die plate are connected with an upper die base and an upper die plate through bolt guide columns; the side sliding mechanism comprises a side sliding core, a semicircular sliding block, elastic rubber and the like, and the side sliding mechanism can ensure that the second stamping die and the third stamping die form a composite stamping die to be pressed into a plate together in the first stage and the second stamping die is separated from the third stamping die to move upwards without being hindered in the second stage; the first pressure riveting mechanism is arranged below a connected material, the second pressure riveting mechanism and the side sliding mechanism are arranged at the upper end, the connected material isarranged in the middle, and all the mechanisms are coaxial, connected with one another and cooperate with one another to ensure that a pressure riveting joint is good in formability. According to thedevice, a bidirectional internal locking structure of the pressure riveting connecting point can be formed in a single device, compared with an existing single-internal-locking pressure riveting joint, the appearance is more attractive, the joint strength and the production efficiency are improved to a large extent, and the application range is flexible and wide.

Owner:XIANGTAN UNIV

Novel carton customizing machine

InactiveCN108909014AGuaranteed moving distanceExtended mesh timeBox making operationsPaper-makingCartonEngineering

The invention discloses a novel carton customizing machine comprising a base, a support frame fixedly arranged on the top end face of the base, and a rack slidably installed on the support frame. Therack is provided with a first sliding chute extending up and down, and the left and right end walls of the first sliding chute are internally provided with straight slots symmetrically; the first sliding chute is internally provided with a sliding table slidably, and the sliding table is internally provided with a first motor fixedly; the bottom end face of the first motor is dynamically providedwith a drilling head extending downwards, and the top end face of the first motor is dynamically provided with a rotating sleeve extending upwards; the rotating sleeve is internally provided with a spline slot of which an opening is upward, and a spline shaft is matched with a spline in the spline slot; the top of the spline shaft is fixedly provided with a first bevel gear, and the end faces of the left and right sides of the sliding table are symmetrically provided with first connecting blocks which extend into the straight slots and are connected in a sliding fit manner.

Owner:佛山金颖科技有限公司

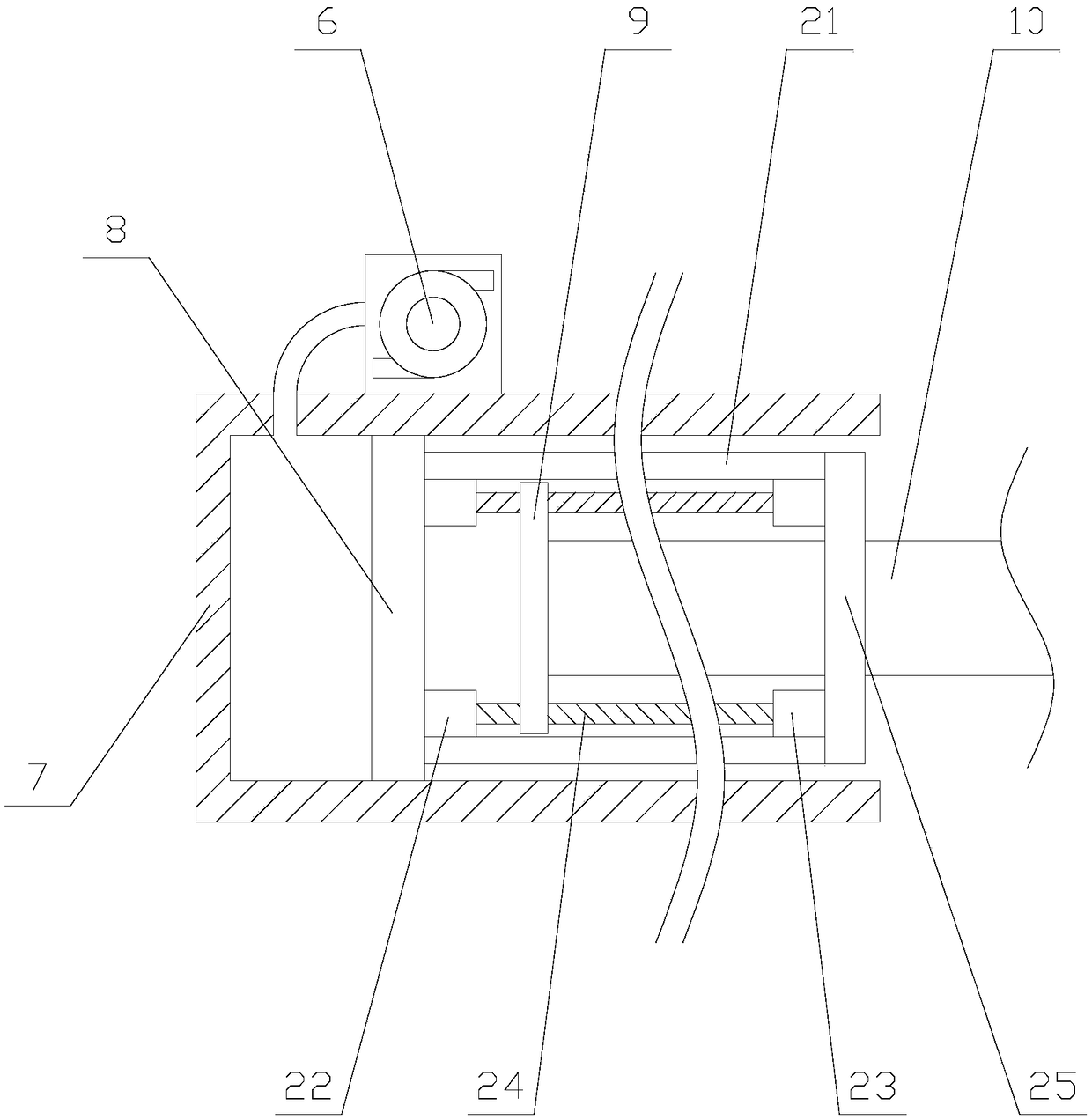

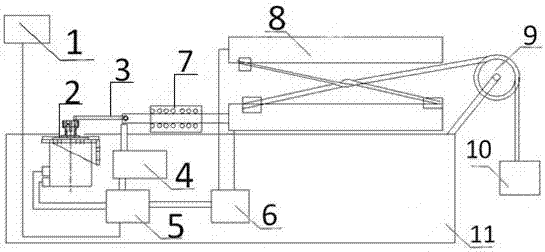

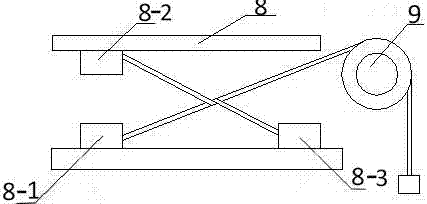

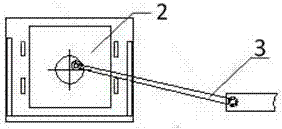

Method and device for testing abrasive resistance of optical cable

PendingCN107238544ALow calorific valueReduce coefficient of frictionInvestigating abrasion/wear resistanceElectric machineryNeedle roller bearing

The invention discloses a device for testing abrasive resistance of an optical cable. The device comprises a clamp device, a crankshaft connecting rod mechanism, a needle bearing, a human-computer interface operation screen and an electric cabinet; the device is characterized in that the clamp device comprises a clamp I, a clamp II, a clamp III and a fixed guide wheel; the clamp I, the clamp II and the clamp III are respectively arranged along upper, lower and left directions of the clamp device; the fixed guide wheel is located above the electric cabinet; the clamp device is arranged above the electric cabinet; the electric cabinet comprises a servo motor, a counter, a PLC (Programmable Logic Controller) and a conducting control switch; the counter is arranged on the crankshaft connecting rod mechanism; the crankshaft connecting rod mechanism is arranged between the servo motor and the clamp device; the servo motor is connected with the PLC; the PLC is connected with the human-computer interface operation screen; the human-computer interface operation screen is arranged above the exterior of the electric cabinet. The device can keep long-term stable running, is not changed following the change of the external environment factors, such as temperature and humidity, is characterized by being convenient in operation, high in precision, and long in service life and is economical and reliable.

Owner:江苏通光电子线缆股份有限公司

High-practicability fixing clamp for polishing connection rod of engine

InactiveCN110948389AEasy to fixEffective lubrication and maintenanceGrinding machinesGrinding work supportsSpray nozzleFuel tank

The invention discloses a high-practicability fixing clamp for polishing a connection rod of an engine. The fixing clamp comprises a base, a control plate, a clamping plate, a dedusting pipe, reinforcement ribs, a dusting machine, a base plate, mounting bases, a first fixing plate, spiral springs, limit blocks, slide blocks, slide rails, spring plates, a second fixing plate, atomization spray nozzles, oil conveying pipes, oil storage tanks, micro oil pumps, a wear-resistance spacer, dedusting ports, a rotation base and supporting columns. The bottom of the base is provided with the supportingcolumns through bolts, one side of the base is provided with the control plate through bolts, and the top of the base is provided with the rotation base through bolts. The top of the rotation base isprovided with the clamping plate through bolts, the top of the clamping plate is provided with the wear-resistance spacer through a connector, and the base plate is installed in the clamping plate through bolts. The fixing clamp is simple in structure and convenient to operate, can stably fix the connection rod of the engine, and has dusting and lubrication functions, and the practicability duringapplication is greatly improved.

Owner:何瑞荣

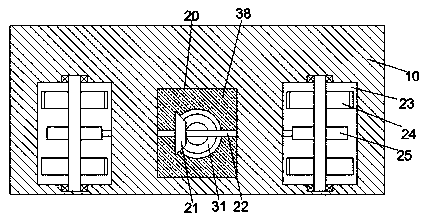

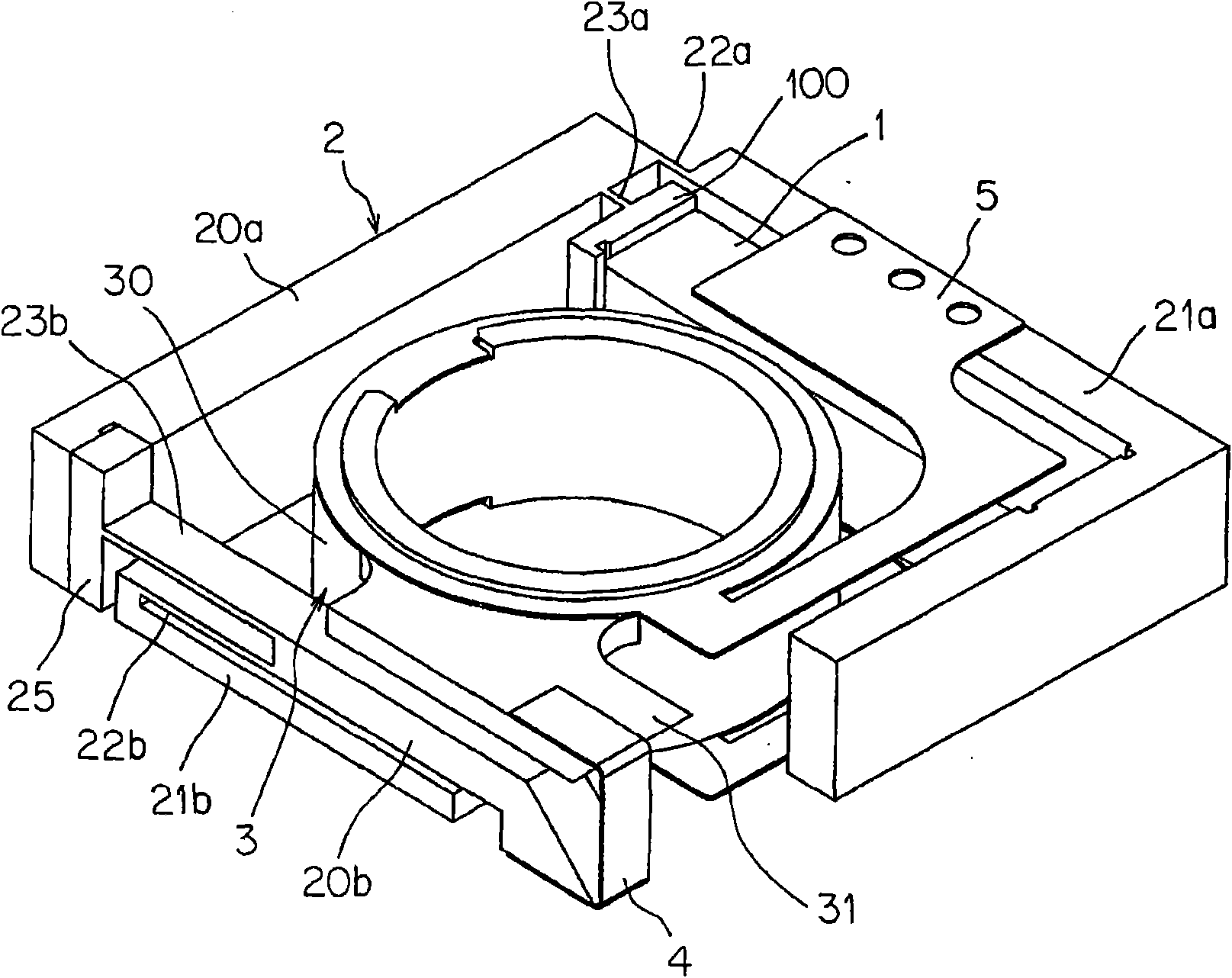

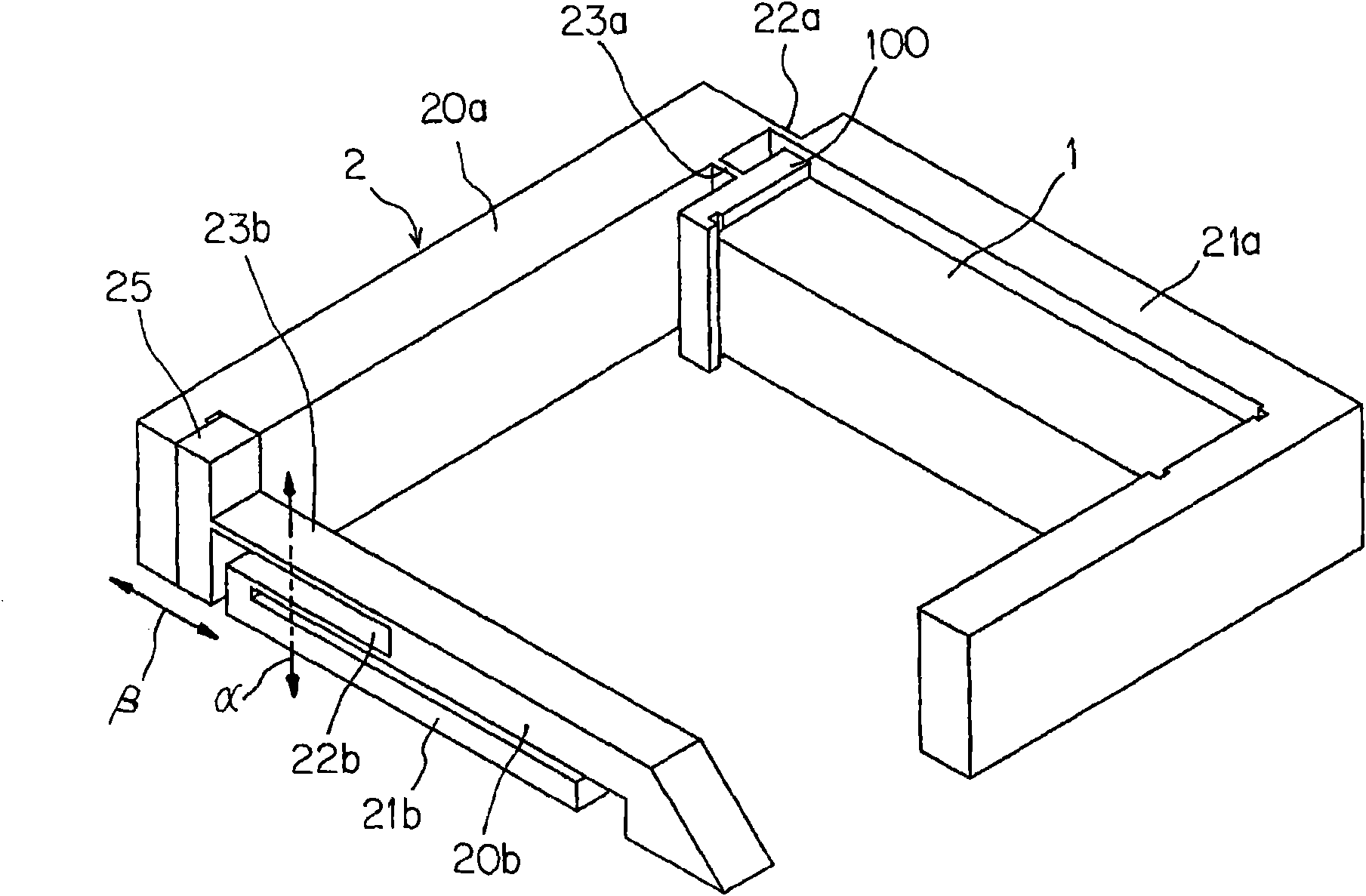

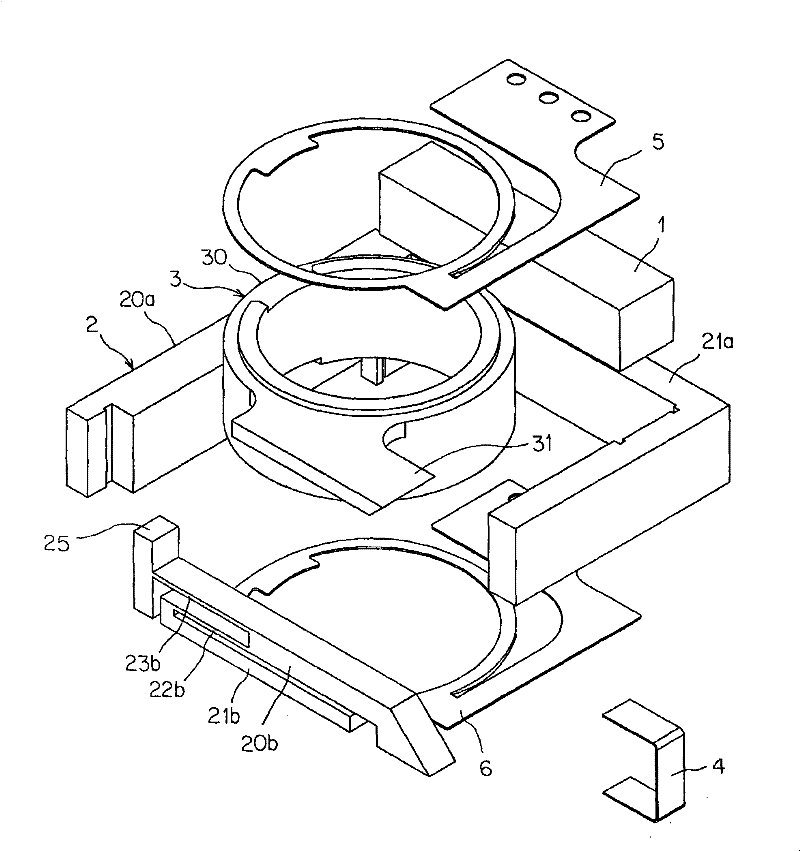

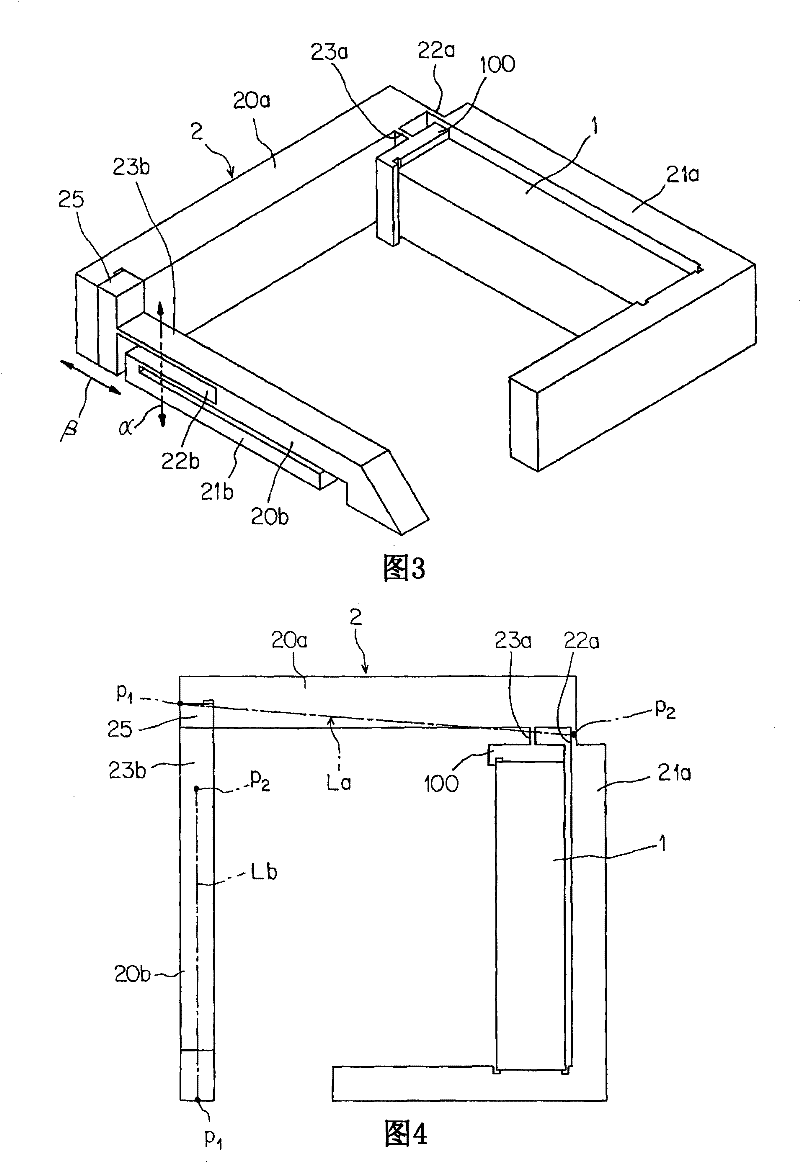

Actuator

InactiveCN101563540AGuaranteed moving distanceMiniaturizationPiezoelectric/electrostriction/magnetostriction machinesMachines/enginesEngineeringActuator

Provided is an actuator which can be reduced in size and thickness while keeping the moving distance of a mechanical element or an optical element sufficient. The unidirectional displacement, as outputted from a drive member (1) such as a piezoelectric element, is transmitted, while being enlarged in displacement, to a movable member (3) by a displacement enlarging mechanism (2) of a specific constitution, which includes a plurality levers (20a and 20b) arranged along the displacement transmitting direction, stationary portions (21a and 21b) for supporting those levers (20a and 20b), fulcrum joint portions (22a and 22b) made elastically deformable for forming the fulcrums of the levers, and elastically deformable joint portions (23a and 23b) for establishing the points of force of the levers. Although the size and thickness are reduced, the actuator can retain a large extent of movement for the movable member (3).

Owner:АДАМАНТ НАМИКИ ПРЕСИЖН ДЖУЭЛ КО ЛТД +1

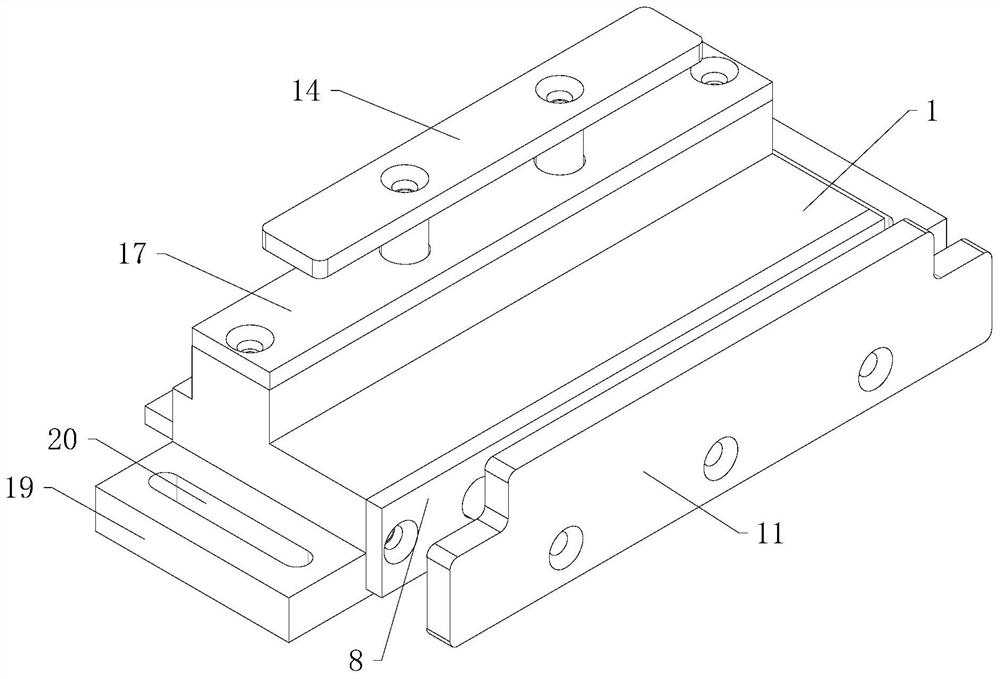

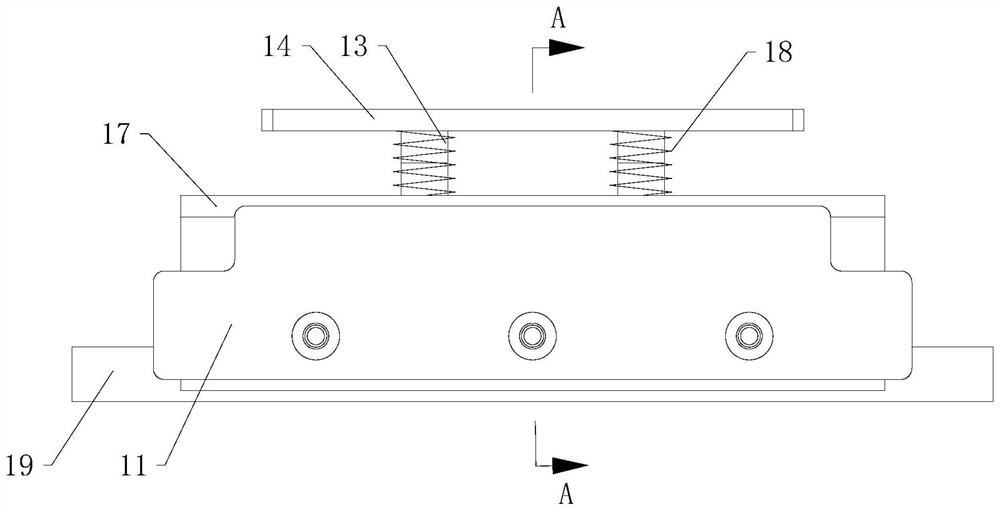

Buckle clamp and clamping tool

ActiveCN111152145AGuaranteed moving distanceWill not affect product qualityWork holdersStructural engineeringMechanical engineering

The invention provides a buckle clamp, and belongs to the technical field of tool clamps. The buckle clamp comprises a base, a first sliding part and a second sliding part, wherein a first slideway isarranged inside the base in a penetrating manner, a second slideway communicating with the first slideway is arranged on the base, the first sliding part is arranged along the first slideway in a sliding mode, a pressing block used for pressing a product is arranged at one end of the first sliding part, an elastic assembly used for pressing the pressing block is arranged at the other end of the first sliding part, a clamping groove is formed in the first sliding part, a second sliding part is slidably arranged along the second slideway, and the end of the second sliding part cooperates with the clamping groove in a clamped mode and used for limiting the first sliding part in the first slideway. The invention further provides a clamping tool using the buckle clamp. The buckle clamp can besuitable for clamping products of different sizes, manual application of external force is not needed, operation is easy and convenient, and the product quality of a precise electronic product is notaffected.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Threading and perforating integrated machine for archiving materials of files

PendingCN109397917AGuaranteed moving distanceEasy to useSheet bindingEngineeringMaterial Perforation

The invention discloses a threading and perforating integrated machine for archiving materials of files. A stand column reciprocating forwards and backwards is arranged on a rack; a power mechanism inpower connection with the stand column is mounted on the rack; a perforating mechanism reciprocating up and down is movably mounted on the stand column; a driving device is further mounted on the stand column; a positioning clamping plate is correspondingly arranged at the lower part of the perforating mechanism; a switch of the power mechanism is arranged at the upper part of the perforating mechanism; a rotating shuttle which is mounted on the stand column is mounted at the lower part of the rack; the rotating shuttle and the perforating mechanism form a lock stitch; the rotating shuttle isin power connection with the driving device; a thread shearing mechanism matched with the perforating mechanism is mounted on the stand column; a triggering mechanism arranged on the relatively leftside of the stand column is mounted on the rack; and the action of the triggering mechanism can be used for controlling the thread shearing action of the thread shearing mechanism. The integrated machine is convenient to use, the operation difficulty is reduced, and the technical effects that perforation and threading are completed at a time, the binding quality is improved, the integrated machineadapts to paper materials in different specifications and multiple paper materials can be bound simultaneously are achieved.

Owner:LINQU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Climbing frame equipment for building construction

InactiveCN109175448ARealize mobile punching operationGuaranteed moving distanceBoring/drilling componentsBoring/drilling machinesEngineeringDrill bit

The invention discloses climbing frame equipment for building construction. The equipment comprises a base body, a supporting plate fixedly arranged on the end face of the top of the base body, and amain case body installed on the supporting plate smoothly. A first smooth groove extending vertically is formed in the main case body. Thorough grooves are symmetrically formed in the left end wall and the right end wall of the first smooth groove. A sliding table is installed in the first smooth groove smoothly. A first motor is fixedly installed in the sliding table. A drill bit extending downwards is installed on the end face of the bottom of the first motor in a power manner. A steering sleeve extending upwards is installed on the end face of the top of the first motor in a power manner. Aspline groove with the upward opening portion is formed in the steering sleeve. A spline shaft is installed in the spline groove in a spline fitting manner. A first cone oblique wheel is fixedly arranged on the top of the spline shaft. First connecting bases are symmetrically arranged on the end face of the left side and the end face of the right side of the sliding table, extend into the thorough grooves, and are connected in a smooth fitting manner.

Owner:广州吉和电子商务有限公司

Hard alloy pipe fitting

InactiveCN109128268ASimple structureHigh degree of automationFeeding apparatusBoring/drilling componentsPipe fittingAlloy

The invention discloses a hard alloy pipe fitting which comprises a base, a bearing frame fixedly arranged on the end face of the top of the base, and an installation frame installed on the bearing frame in a sliding manner. A first sliding groove extending vertically is formed in the installation frame. Communication grooves are symmetrically formed in the left end wall and the right end wall ofthe first sliding groove. A sliding table is installed in the first sliding groove in a sliding manner. A first driving machine is fixedly installed in the sliding table, and a drill bit extending downwards is installed on the end face of the bottom of the first driving machine in a power manner. A rotating sleeve extending upwards is installed on the end face of the top of the first driving machine in a power manner. A spline groove with an upward end opening is formed in the rotating sleeve, a spline shaft is installed in the spline groove in a spline fit manner, and a first conical wheel isfixedly arranged on the top of the spline shaft. First connecting blocks stretching in the communication grooves and are connected with the communication grooves in a sliding fit manner are symmetrically formed in the left side end face and the right side end face of the sliding table.

Owner:佛山常百乐机械设计有限公司

Efficient super-wear-resistant plastic runway material device

InactiveCN109291132AGuaranteed moving distanceExtended mesh timeMetal working apparatusPower modeElectric machine

The invention discloses an efficient super-wear-resistant plastic runway material device. The device comprises a frame base, supporting columns and a machine body, wherein the supporting columns are fixedly arranged on the top end surface of the frame base, and the machine body is installed on the supporting columns in a sliding mode; a first sliding connection groove which extends up and down isformed in the machine body, through connection grooves are symmetrically formed in the left end wall and the right end wall of the first sliding connection groove, and a sliding connection platform isinstalled in the first sliding connection groove in a sliding mode; a first electric machine is fixedly installed in the sliding connection platform, a downwards-extending drill bit is installed on the bottom end surface of the first electric machine in a power mode, and an upward-extending adapter sleeve is installed on the top end surface of the first electric machine in a power mode; a splinegroove with an upward through hole is formed in the adapter sleeve, a spline shaft is installed on a spline in the spline groove in a matched mode, and the top of the spline shaft is fixedly providedwith a first conical edge wheel; and the left side and the right side of the sliding platform are symmetrically provided with first connection platforms which extend into the through connection grooves and are connected to the sliding platform in a sliding mode.

Owner:广州佶兔工业设计有限公司

Storage rack

InactiveCN109128265ARealize mobile punching operationGuaranteed moving distanceBoring/drilling componentsBoring/drilling machinesEngineeringMechanical engineering

The invention discloses a storage rack. The storage rack comprises a base body, a support plate fixedly arranged on the top end surface of the base body and a machine shell arranged on the support plate in a horizontal sliding manner. A first horizontal sliding groove extending up and down is formed in the machine shell. Through grooves are symmetrically formed in the left end wall and the right end wall of the first horizontal sliding groove. A sliding table is arranged in the first horizontal sliding groove in a horizontal sliding manner. A first motor is fixedly arranged in the sliding table. A drilling bit extending downwards is arranged on the bottom end surface of the first motor in a power manner. An upward extending steering sleeve is arranged on the top end surface of the first motor in a power manner. A spline groove with an upward opening is formed in the steering sleeve. A spline shaft is arranged in the spline groove in a spline fit manner. A first tapered wheel is fixedlyarranged at the top of the spline shaft. First connecting seats which extend into the through grooves and are in horizontal sliding fit connection are symmetrically arranged on the left end surface and the right end surface of the sliding table.

Owner:广州吉和电子商务有限公司

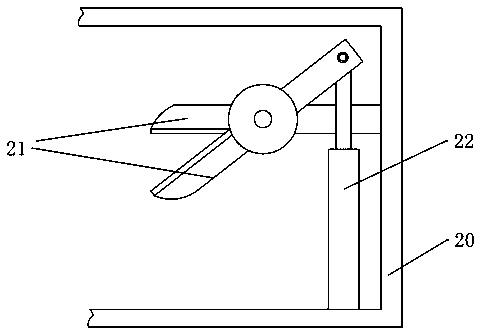

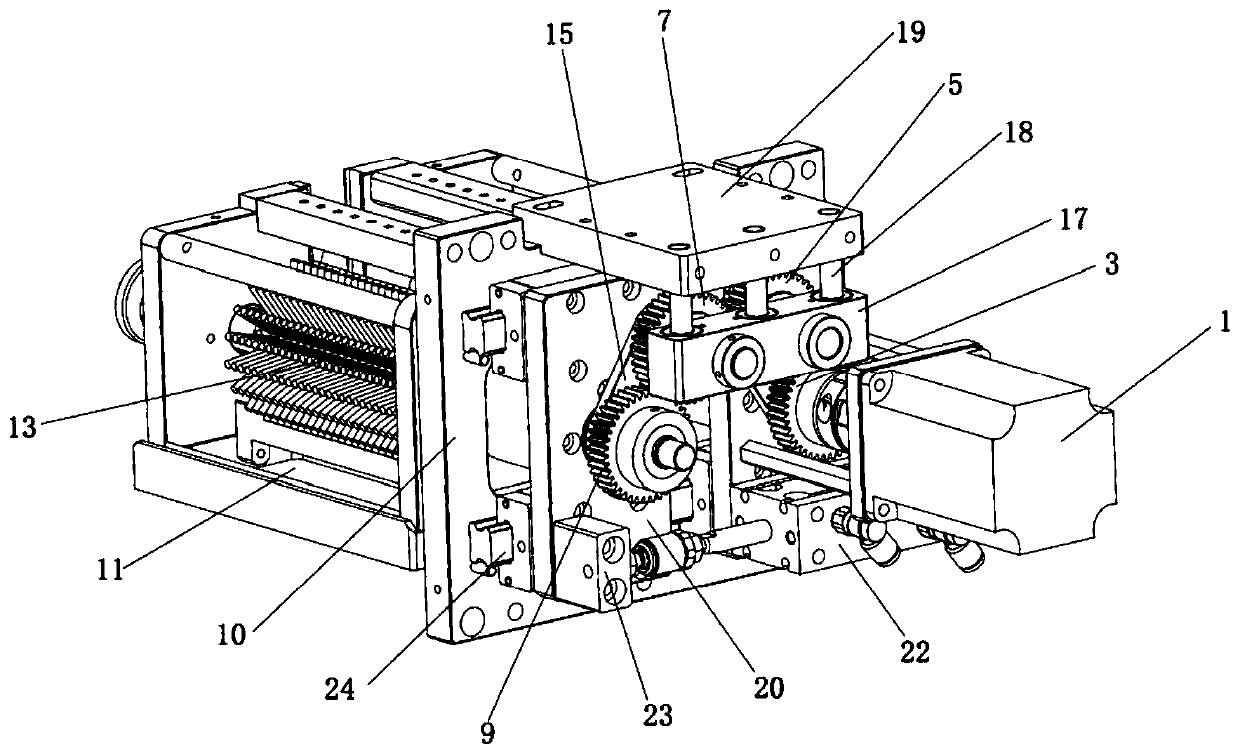

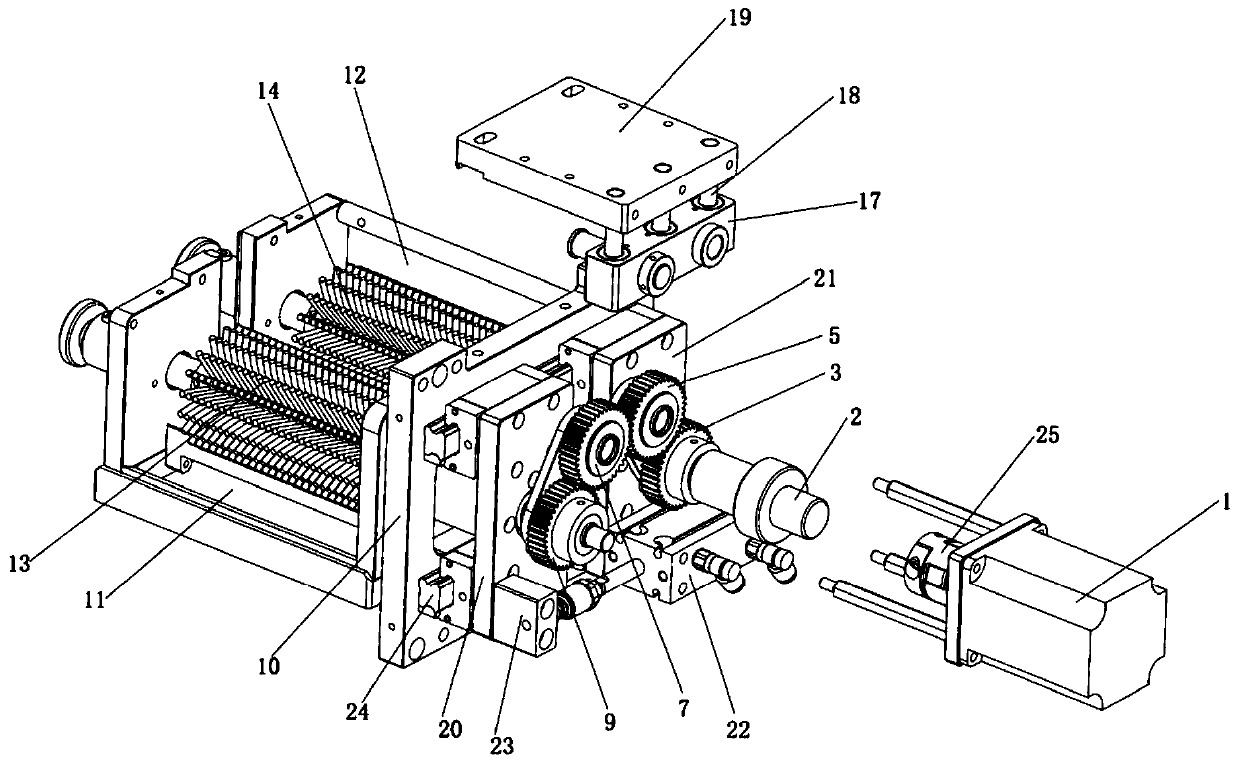

A pole piece dust brushing mechanism

The invention relates to a pole piece dust brushing mechanism, which includes a motor, a first gear shaft, a first gear, a second gear shaft, a second gear, a third gear shaft, a third gear, a fourth gear shaft, a fourth gear, Support plate, left brush ash box, right brush ash box, left brush wheel, right brush wheel, left connecting block, right connecting block, sliding block, guide rod, adjusting plate, left sliding plate, right sliding plate, cylinder, cylinder connection The overall structure of the head, slide rail, and pole piece dust brushing mechanism is reasonably designed. When the cylinder drives the left and right skateboards to move to the left and right outer or inner sides along the slide rail, the corresponding sliding block moves down or up along the guide rod to ensure that the left and right brushes The moving distance of the wheel system is equal and is always symmetrical about the center line of the two brush wheel axes, which improves the quality of dust brushing, has a stable structure, and fast dust brushing speed. In addition, the addition of a handle mechanism makes it easy to replace the brush wheels without dismantling the entire mechanism, saving manpower and time. , strong practicality.

Owner:东莞泓宇智能装备有限公司

Actuator

Owner:NAMIKI PRECISION JEWEL CO LTD +1

Light guide plate assembling device

InactiveCN109047842ASimple structureHigh degree of automationBoring/drilling machinesLight guideEngineering

The invention discloses a light guide plate assembling device which comprises a bottom plate, a supporting arm fixedly arranged on the end face of the top of the bottom plate and a case movably installed on the supporting arm. A first movable groove extending vertically is formed in the case, and communication grooves are symmetrically formed in the left end wall and the right end wall of the first movable groove. A sliding seat is movably installed in the first movable groove, and a first motor is fixedly installed in the sliding seat. A drill bit extending downwards is installed on the end face of the bottom of the first motor through power. A rotating shell extending upwards is installed on the end face of the top of the first motor through power. A spline groove with an upward openingend is formed in the rotating shell, a spline shaft is installed in the spline groove in a spline fit manner, and a first cone pulley is fixedly arranged on the top of the spline shaft. First jointingblocks which stretch in the communication grooves and are movably connected in a matched manner are symmetrically arranged on the end faces of the left side and the right side of the sliding seat.

Owner:广州酬建电器有限公司

A buckle fixture and clamping tooling

ActiveCN111152145BGuaranteed moving distanceWill not affect product qualityWork holdersElastic componentEngineering

The invention provides a snap clamp, belonging to the technical field of tooling clamps, comprising a base, a first sliding member and a second sliding member. A first slideway runs through the base, and the base is provided with a second slideway for communicating with the first slideway; the first slide piece is slidably arranged along the first slideway, one end is provided with a pressing block for pressing the product, and the other is provided with a pressing block for pressing the product. One end is provided with an elastic component for pressing the pressing block, the first sliding member is provided with a clamping groove; the second sliding member is slidably arranged along the second sliding path, and the end of the second sliding member is engaged with the clamping groove, and is used for The first sliding member is limited in the first slideway. The invention also provides a clamping tool using the snap clamp. The snap clamp provided by the invention can be suitable for clamping products of different sizes, does not need to manually apply external force, is easy to operate, and does not affect the product quality of precision electronic products.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

Safe light guide plate assembling device

InactiveCN109047840AGuaranteed moving distanceExtended mesh timeBoring/drilling machinesPower modeLight guide

The invention discloses a safe light guide plate assembling device. The device comprises a bottom plate, supporting arms fixedly arranged on the top end surface of the bottom plate, and a case movablyinstalled on the supporting arms, a first movable groove which extends up and down is arranged in the case, through fit grooves are symmetrically formed in the left end wall and the right end wall ofthe first movable groove, a sliding seat is movably installed in the first movable groove, a first motor is fixedly installed in the sliding seat, a drill bit extending downwards is installed on thebottom end surface of the first motor in a power mode, a rotating shell extending upwardly is arranged on the top end surface of the first motor in a power mode, a spline groove with an upward openingend is formed in the rotating shell, a spline shaft is arranged in the spline groove in a spline fit mode, a first bevel wheel is fixedly arranged at the top of the spline shaft, and the left side end surface and the right side end surface of the sliding seat are symmetrically provided with first connecting blocks which extend into the through combining grooves and are connected with the throughcombining grooves in a movable fit mode.

Owner:广州酬建电器有限公司

Environment-friendly plastic new material equipment

InactiveCN109278108ASimple structureHigh degree of automationMetal working apparatusPower modeFrame based

The invention discloses environment-friendly plastic new material equipment. The equipment comprises a frame base, a supporting column fixed to the top end face of the frame base, and a machine body installed on the supporting column in a sliding connection mode, a first sliding connection groove which extends up and down is formed in the machine body, through connection grooves are symmetricallyformed in the left end wall and the right end wall of the first sliding connection groove, a sliding connection table is arranged in the first sliding connection groove in a sliding connection mode, afirst electric rotating machine is fixedly installed in the sliding connection table, a downwards-extending drill bit is arranged at the bottom end face of the first electric rotating machine in a power mode, an upward-extending rotating connection sleeve is arranged on the top end face of the first electric rotating machine in a power mode, a spline groove with an upward through hole is formed in the rotating connection sleeve, a spline shaft is arranged in the spline groove in a spline cooperative mode, the top of the spline shaft is fixedly provided with a first conical edge wheel, and theleft side end face and the right side end face of the sliding connection table are symmetrically provided with first connecting tables which extend into the through connection grooves and are cooperatively connected with the through connection grooves in a sliding connection mode.

Owner:广州佶兔工业设计有限公司

Novel hard alloy pipe

InactiveCN109079193ASimple structureHigh degree of automationFeeding apparatusBoring/drilling componentsEngineeringAlloy

The invention discloses a novel hard alloy pipe. The novel hard alloy pipe comprises a base, a support frame fixedly arranged at the end surface of the top of the base, and a mounting frame slidably mounted on the support frame; the mounting frame is internally provided with a first sliding groove extending up and down; connecting grooves are symmetrically formed in the left end wall and the rightend wall of the first sliding groove; a sliding table is slidably mounted in the first sliding groove; a first driving machine is fixedly mounted in the sliding table; the end surface of the bottom of the first driving machine is dynamically provided with a drill bit extending downwards; the end surface of the top of the first driving machine is dynamically provided with a rotating sleeve extending upwards; the rotating sleeve is internally provided with a spline groove with an end port facing upwards; a spline shaft is mounted in the spline groove in a matched mode; a first conical wheel isfixedly arranged at the top of the spline shaft; and first connecting blocks which extend into the connecting grooves and are sliably connected with the connecting grooves are symmetrically arranged on the end faces of the left side and the right side of the sliding table.

Owner:广州常佰机械设计有限公司

Automatic aluminum machining technical equipment

InactiveCN109014340ASimple structureHigh degree of automationFeeding apparatusBoring/drilling componentsEngineeringMechanical engineering

The invention discloses automatic aluminum machining technical equipment. The automatic aluminum machining technical equipment comprises a machine base, a support fixedly arranged on the top end faceof the machine base, and an arranging frame arranged on the support in a sliding manner. An up-down-extending first sliding groove is formed in the arranging frame. Communication grooves are symmetrically formed in the left end wall and the right end wall of the first sliding groove. The first sliding groove is internally provided with a sliding table in a sliding manner. A first motor is fixedlyarranged in the first sliding table. A downward-extending drill bit is arranged on the bottom end face of the first motor in a power manner. An upward-extending rotation barrel is arranged on the topend face of the first motor in a power manner. A spline groove with an upward notch is formed in the rotation barrel. A spline shaft is arranged in the spline groove in a spline fit manner. A first bevel gear is fixedly arranged on the top of the spline shaft. First connection blocks which stretch into the communication grooves and are in sliding fit connection are symmetrically arranged on the end faces of the left side and the right side of the sliding table.

Owner:广州酷汇电子科技有限公司

Safe super-wear-resistant plastic runway material device

InactiveCN109262734ASimple structureHigh degree of automationMetal working apparatusPower modeWear resistant

The invention discloses a safe super-wear-resistant plastic runway material device. The device comprises a frame base, a supporting column and a machine body, wherein the supporting column is fixedlyarranged on the top end face of the frame base, and the machine body is slidingly arranged on the supporting column; a first sliding connection groove which extends up and down is formed in the machine body, through connection grooves are symmetrically formed in the left end wall and the right end wall of the first sliding connection groove, and a sliding connection platform is slidingly arrangedin the first sliding connection groove; a first electric machine is fixedly installed in the sliding connection platform, and a downwards-extending drill bit is arranged on the bottom end face of thefirst electric machine in a power mode; an upward-extending adapter sleeve is arranged on the top end face of the first electric machine in a power mode, and a spline groove with an upward through hole is formed in the adapter sleeve; a spline shaft is cooperatively arranged on a spline in the spline groove, the top of the spline shaft is fixedly provided with a first conical edge wheel, and leftand right end faces of the sliding connection platform are symmetrically provided with first connecting tables which extend into the through connection grooves and are slidingly and cooperatively connected.

Owner:广州佶兔工业设计有限公司

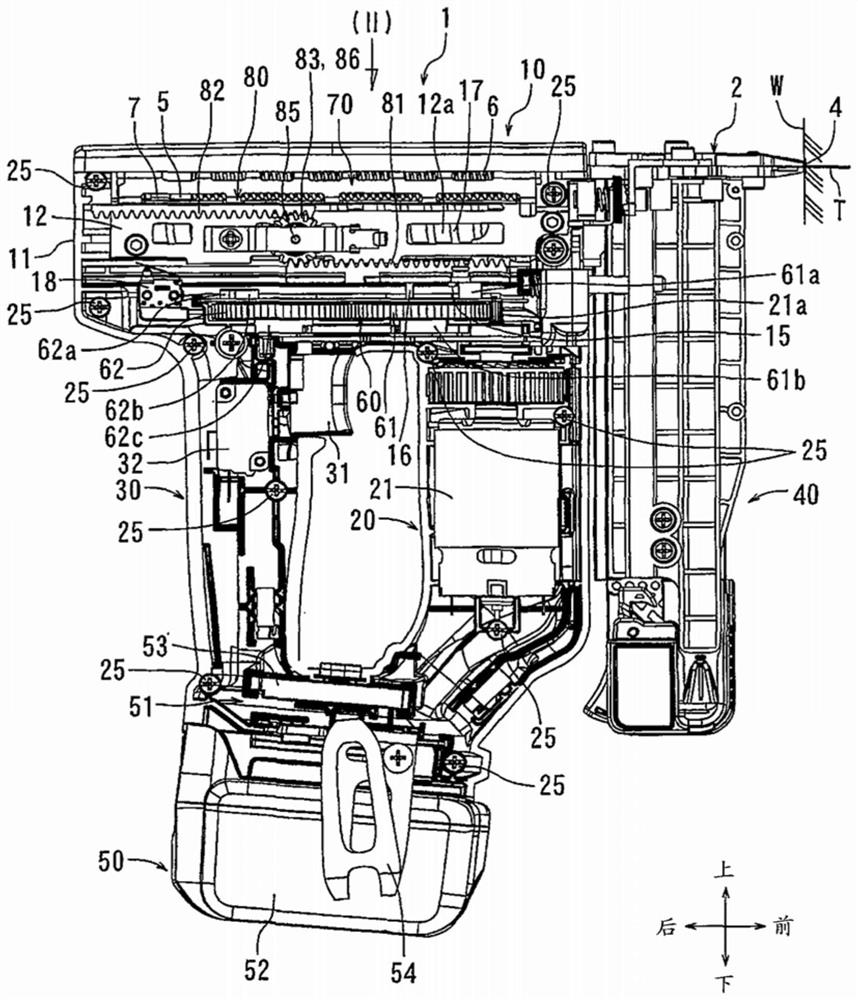

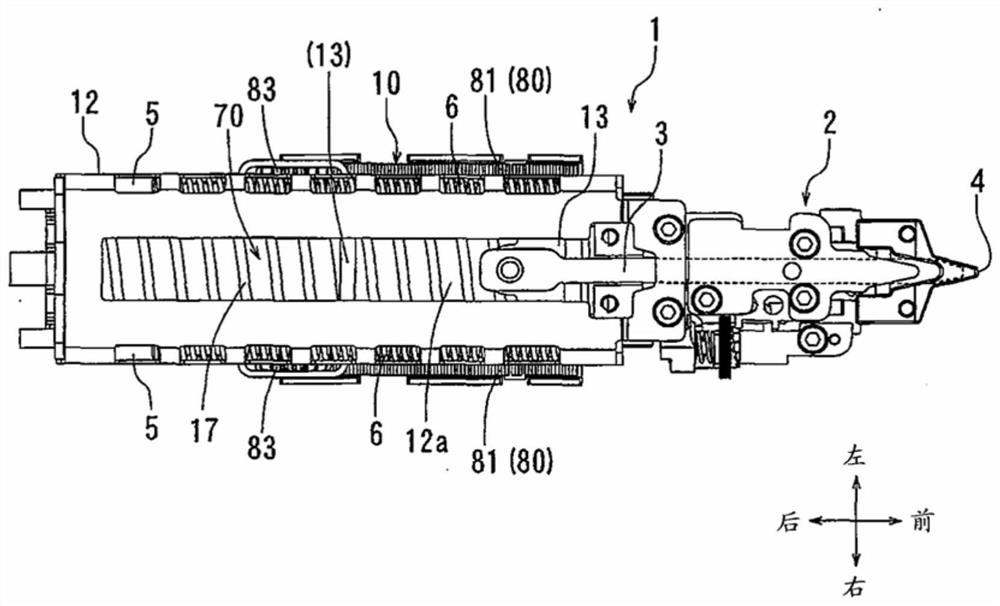

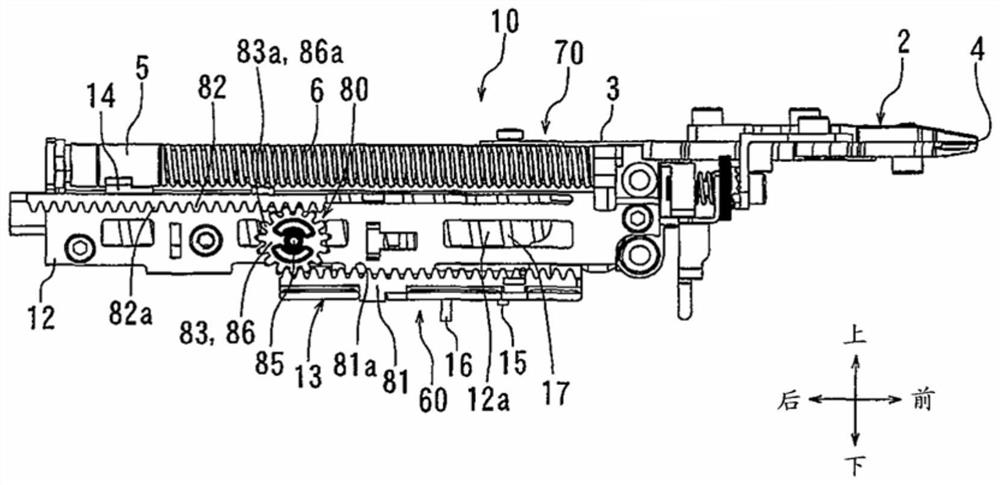

drive tool

In the rack and pinion mechanism (80), a driving side gear (83) and a driven side gear (86) are provided so as to be coaxially rotatable relative to each other within a predetermined angular range. Due to this structure, the moment when the driver (3) reaches the forward end position and contacts the forward end damper (19) deviates from the moment when the counterweight device (5) reaches the retracted end position and contacts the moving end damper (7) In the case of the case, through the relative rotation of the gear (83) and the gear (86), no excessive external force will be applied to the meshing teeth (81a) and the meshing teeth (82a). Therefore, due to this structure, the durability of the rack and pinion mechanism (80) absorbing the end impact by elastic deformation is improved.

Owner:MAKITA CORP

Efficient carton box customizing machine

InactiveCN109109370ASimple structureHigh degree of automationPaper-makingBox making operationsPower modeCarton

The invention discloses an efficient carton box customizing machine. The efficient carton box customizing machine comprises a base, a supporting frame and a machine frame, wherein the supporting frameis fixedly arranged on the top end face of the base, the machine frame is installed on the supporting frame in a sliding mode, a first sliding groove which extends up and down is formed in the machine frame, through grooves are symmetrically formed in the left end wall and the right end wall of the first sliding groove, a sliding table is installed in the first sliding groove in a sliding mode, afirst motor is fixedly installed in the sliding table, a drilling head which extends downwards is installed on the bottom end face of the first motor in a power mode, a rotating sleeve which extendsupwards is installed on the top end face of the first motor in a power mode, a spline groove with an upward opening is formed in the rotating sleeve, a spline shaft is installed in the spline groove in a spline fit mode, a first bevel gear is fixedly arranged at the top of the spline shaft, and first connecting blocks which extend into the through grooves and are connected with the through groovesin a sliding fit mode are symmetrically arranged on the end faces of the left side and the right side of the sliding table.

Owner:佛山金颖科技有限公司

Transparent daylighting panel equipment

InactiveCN109203072ASimple structureHigh degree of automationMetal working apparatusPower modeEngineering

The invention discloses transparent daylighting panel equipment, which comprises a bottom plate, a supporting arm fixedly arranged on the top end face of the bottom plate, and a case movably mounted on the supporting arm. A first movable groove extending up and down is formed in the case; through grooves are symmetrically formed in the left and right end walls of the first movable groove; a sliding seat is movably mounted in the first movable groove; a first motor is fixedly mounted in the sliding seat; a drill bit extending downwards is mounted on the bottom end face of the first motor in a power mode; a rotating shell extending upwards is mounted on the top end face of the first motor in a power mode; a spline groove with the upward open end is formed in the rotating shell, and a splineshaft is mounted in the spline groove in a spline fit mode; a first cone pulley is fixedly arranged at the top of the spline shaft; and first connecting blocks are symmetrically arranged on the end faces of the left and right sides of the sliding seat, wherein the first connecting blocks extend into the through grooves and are connected with the through grooves in a movable fit mode.

Owner:广州酬建电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com