Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62results about How to "Guaranteed mixing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

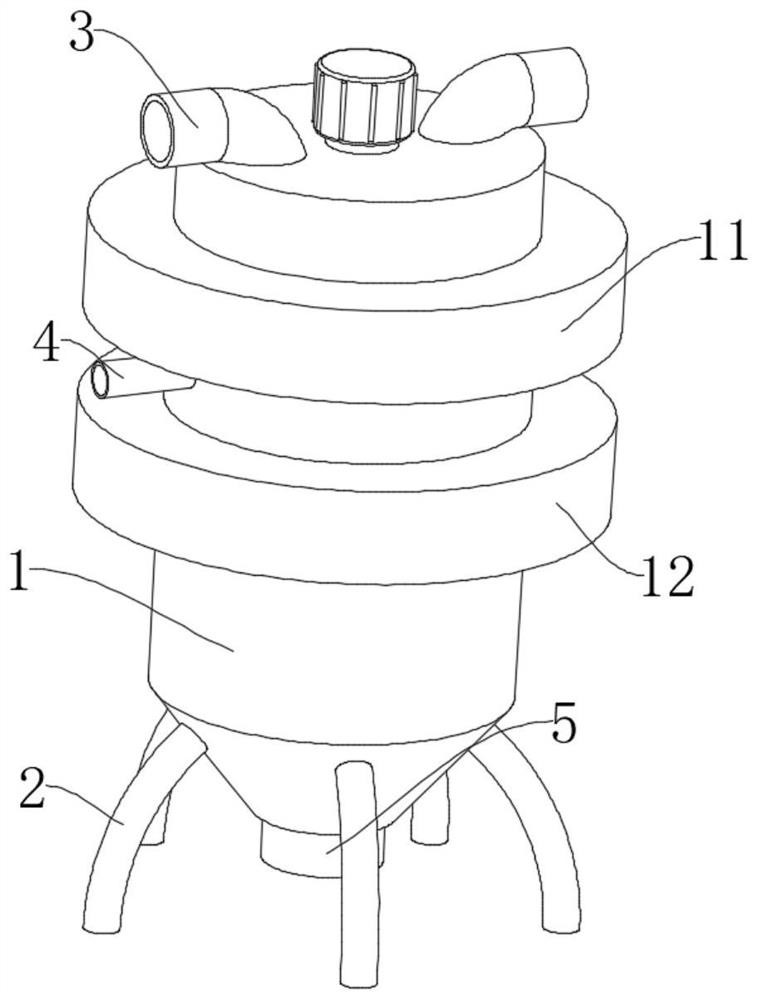

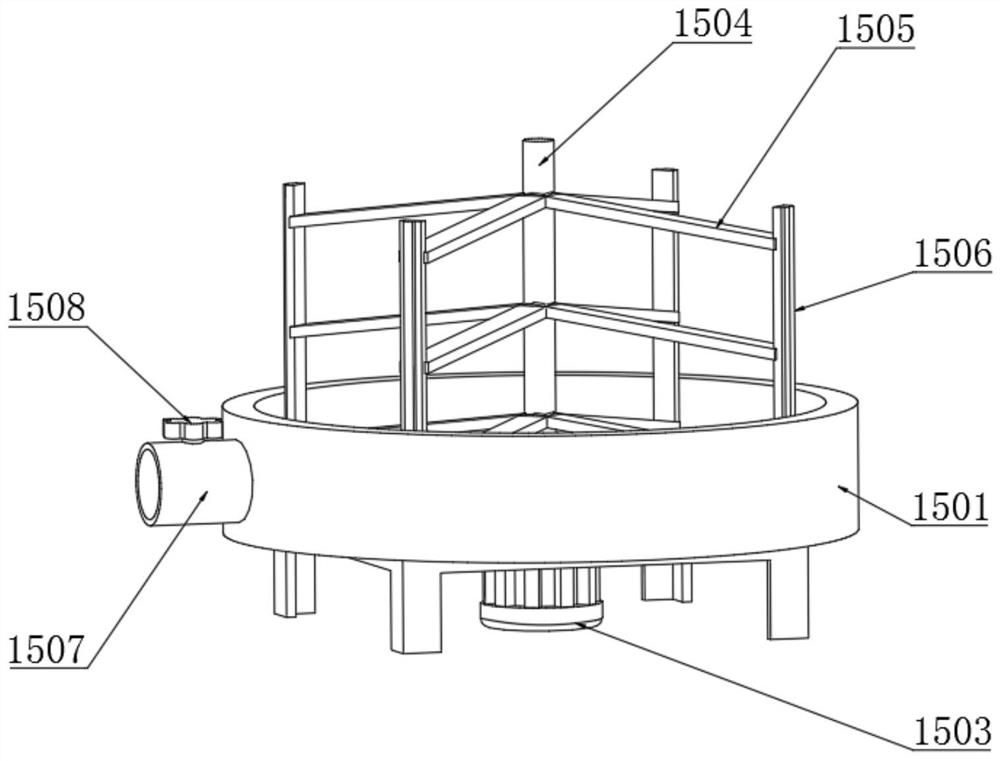

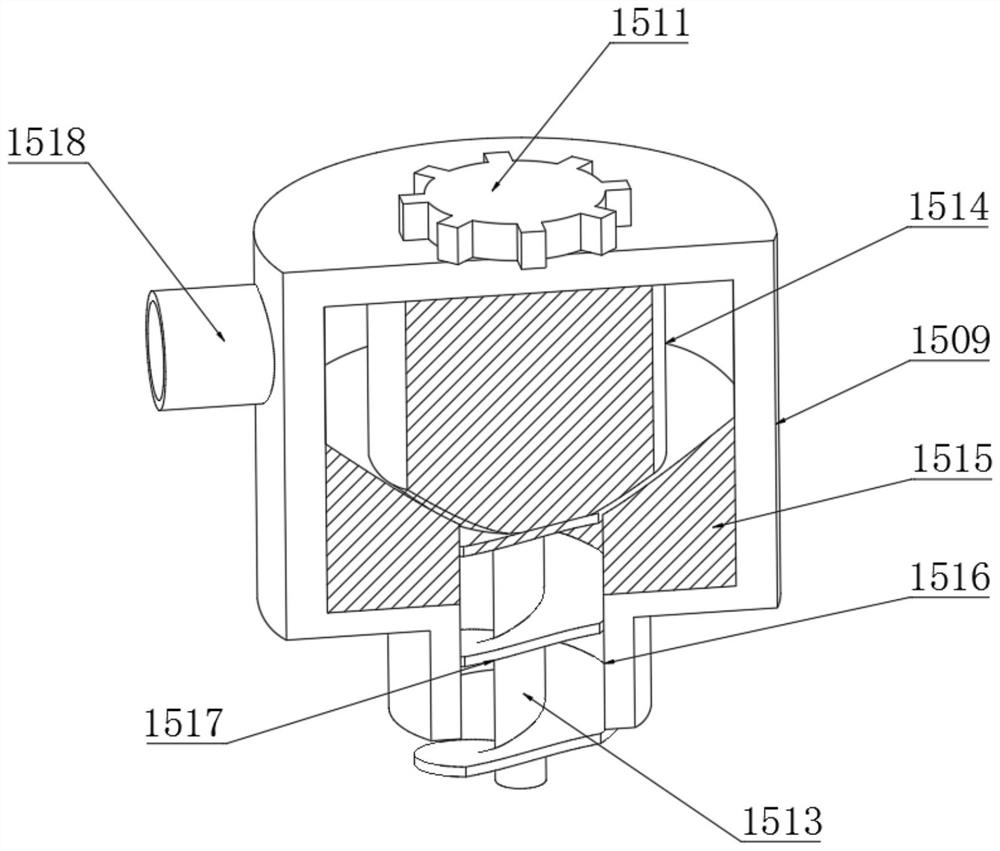

Soil remediation ecological moisturizing method based on efficient stirring

ActiveCN111804724AScientific and reasonable structureEasy to useSievingDispersed particle filtrationSoil remediationElectric machine

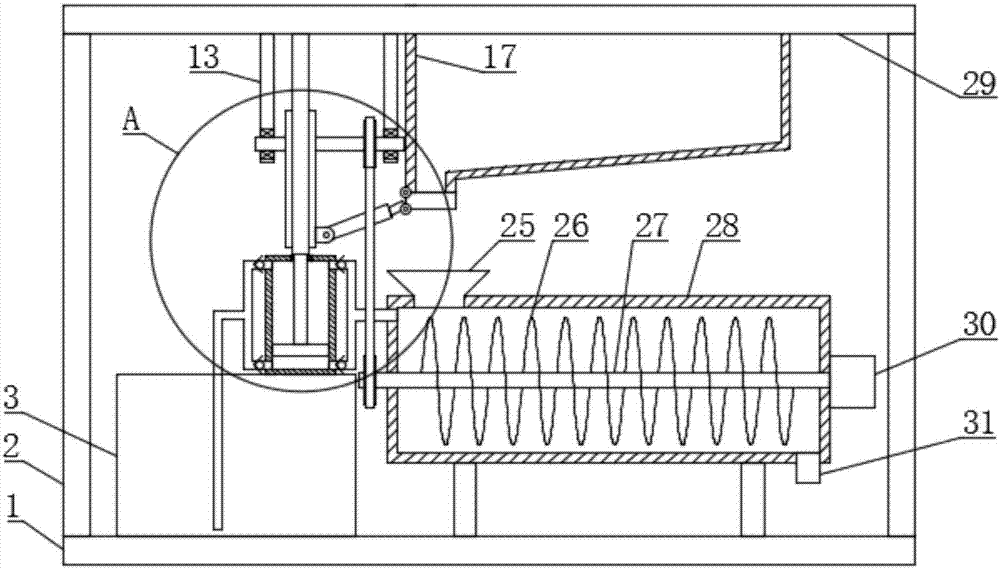

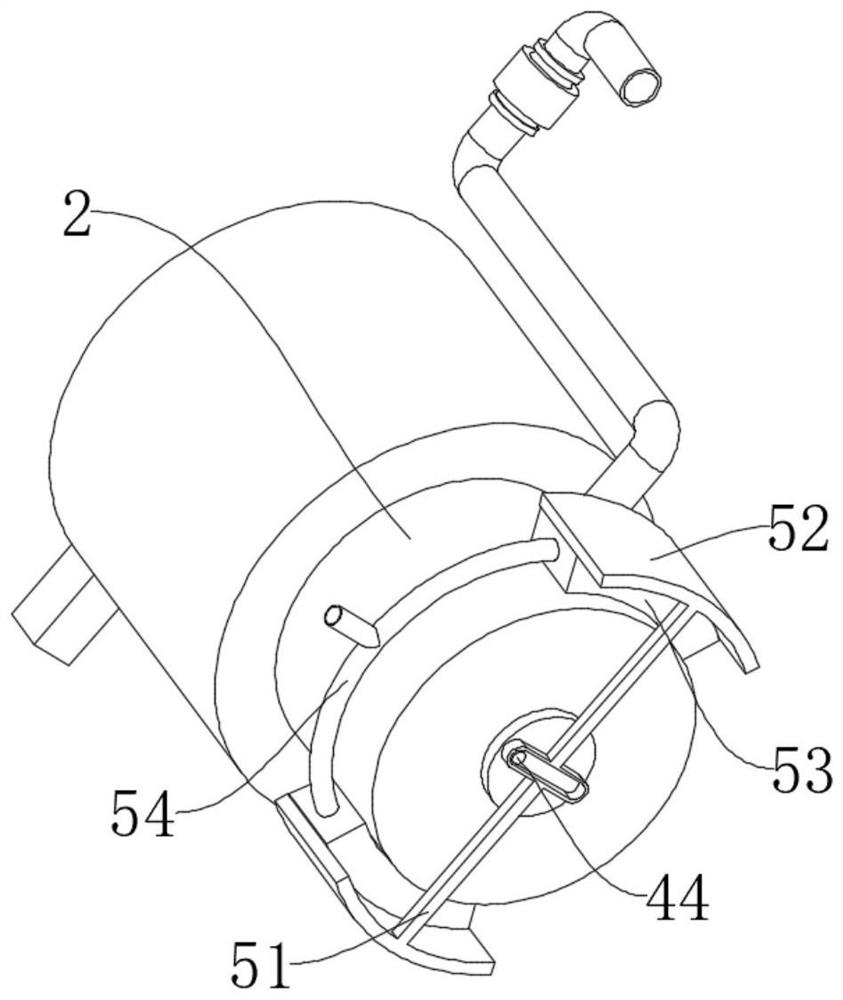

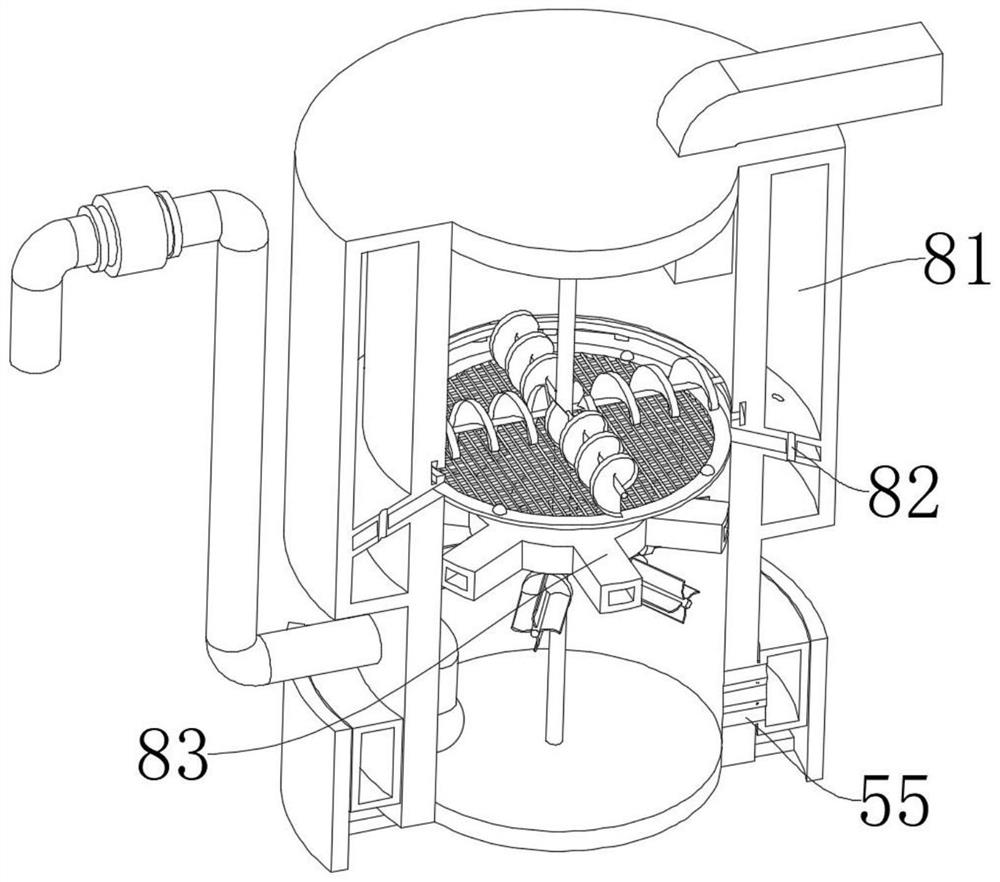

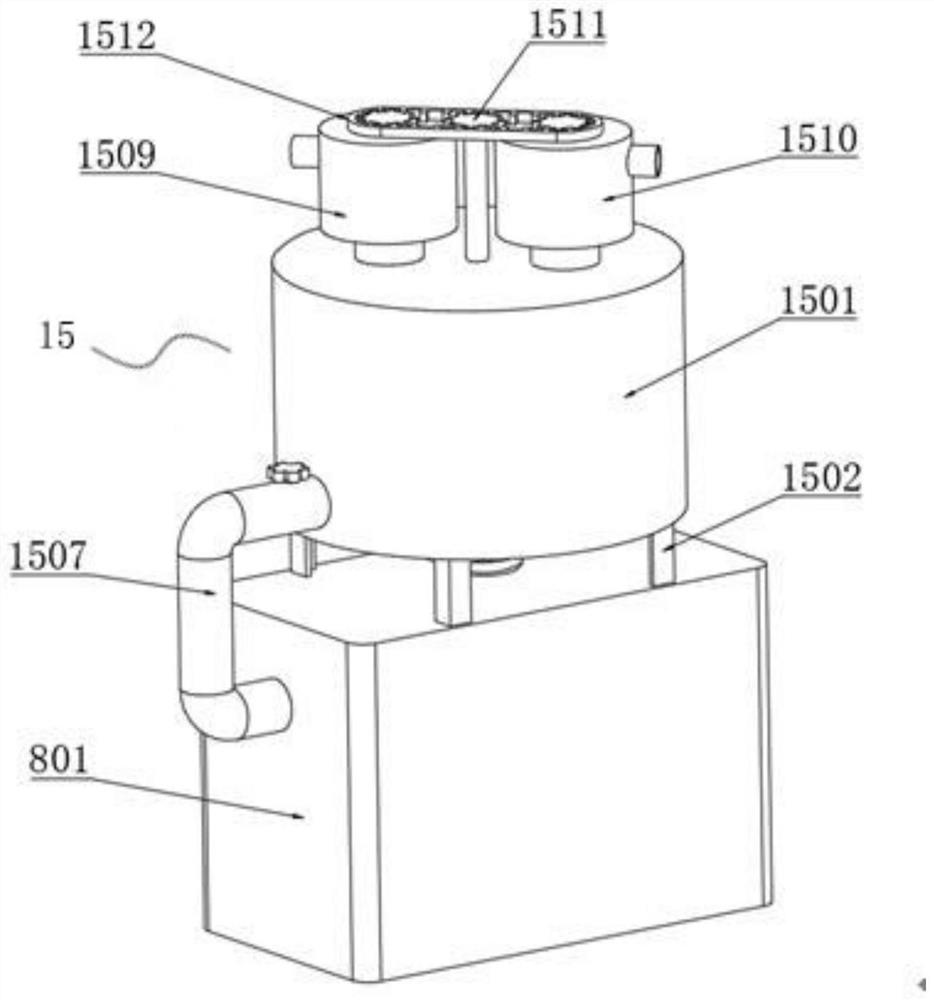

The invention discloses a soil remediation ecological moisturizing method based on efficient stirring. A solution mixing and effect-improving mechanism comprises a mixing cylinder, a bracket, a secondrotating motor, a stirring rod, a stirring frame, a shovel plate, a discharge pipe, a water stop valve, a charging barrel, a filtering barrel, a chain wheel, a chain, a rotating rod, an upper grinding block, a lower grinding block, a channel, a spiral feeding plate, a feeding pipe, a rotary vane, a filtering barrel, a water outlet and a water inlet pipe, the bottom end of the mixing cylinder is fixedly connected with a bracket, safe and convenient use is realized, a solution mixing and efficiency improving mechanism is arranged, the second rotating motor drives the stirring rod to rotate, andthe two rotating rods are driven to move and rotate through transmission of the chain wheels and the chains, so that the repairing agent is crushed through cooperation of the upper grinding block andthe lower grinding block, the repairing agent can be rapidly mixed with water, meanwhile, the rotary vane and the filtering barrel are matched to filter the water, impurities in the water are reduced, and the effect of the mixed repairing liquid is prevented from being affected by too many impurities.

Owner:合肥润田规划设计有限公司

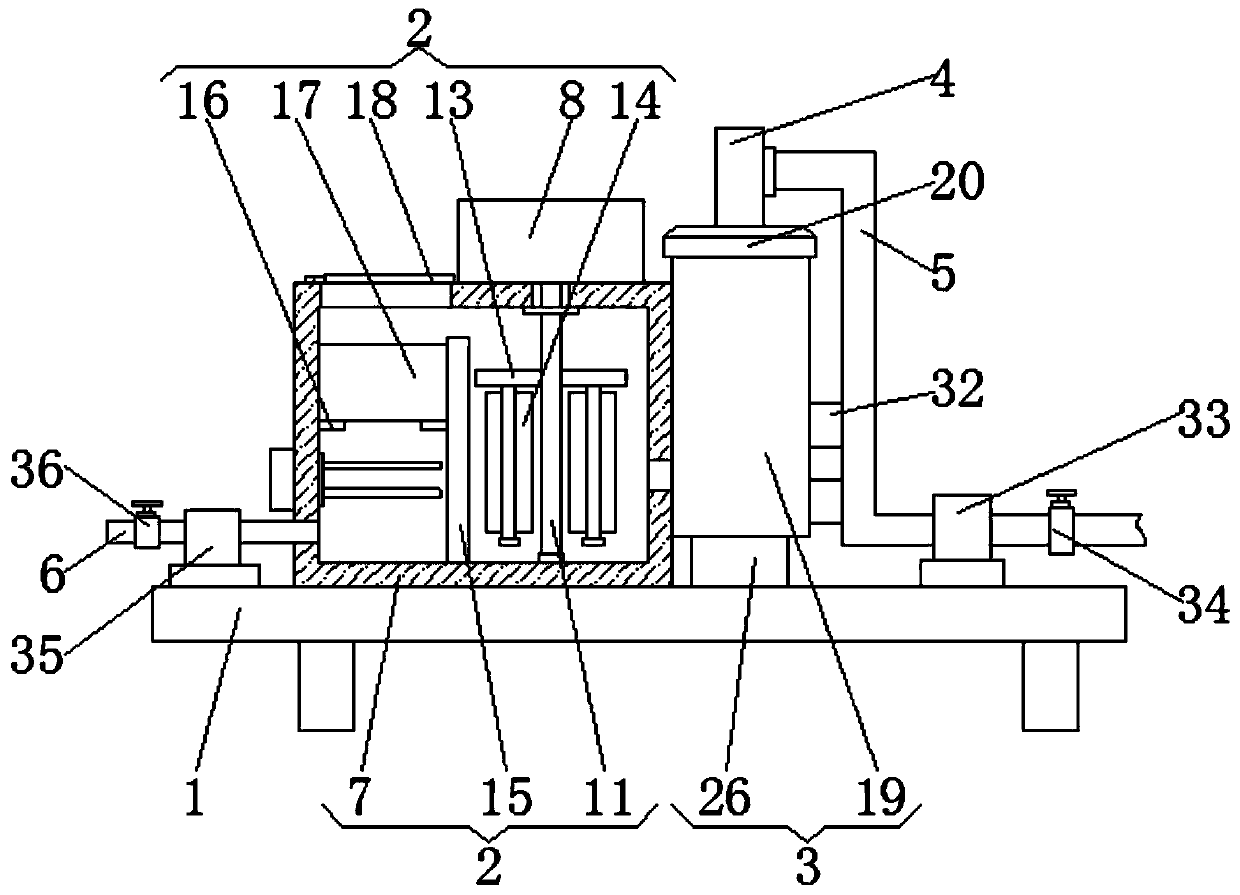

Ingredient stirring device for brake pad production and use method of ingredient stirring device

InactiveCN111974276AImprove fluencyImprove the mixing effectTransportation and packagingRotary stirring mixersElectric machineCoupling

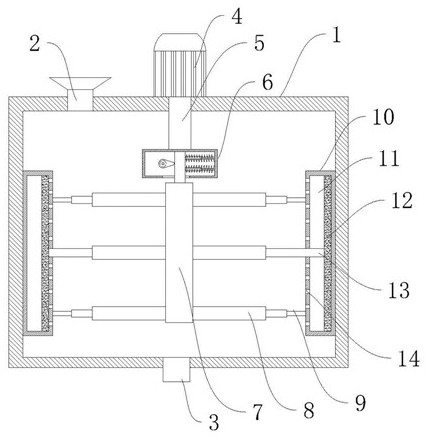

The invention discloses an ingredient stirring device for brake pad production and a use method of the ingredient stirring device, relates to the technical field of ingredient stirring devices for brake pad production and aims to improve the stirring effect. The device comprises a main body, wherein a stirring motor is fixed on the outer wall of the top of the main body through screws, a feeding hopper is welded on the outer wall of the top of the main body, a discharging port is formed in the outer wall of the bottom of the main body, an output end of the stirring motor is rotationally connected with a stirring spindle through a coupling, and the same annular support frame is welded on the circumferential outer wall of the stirring spindle through four support rods. The use method of thedevice comprises the following steps: a user puts a to-be-stirred material into the main body from the feeding hopper, and the height of the material is lower than that of a first guide seat. Multi-directional stirring is realized, the device is different from a common central rotating mechanism, the stirring effect of a second discharge hole is better, and the stirring efficiency is higher; and besides, by means of structures such as balls and the like, the rotating smoothness of a stirring countershaft is improved.

Owner:HENGYANG MAITE BRAKE SYST CO LTD

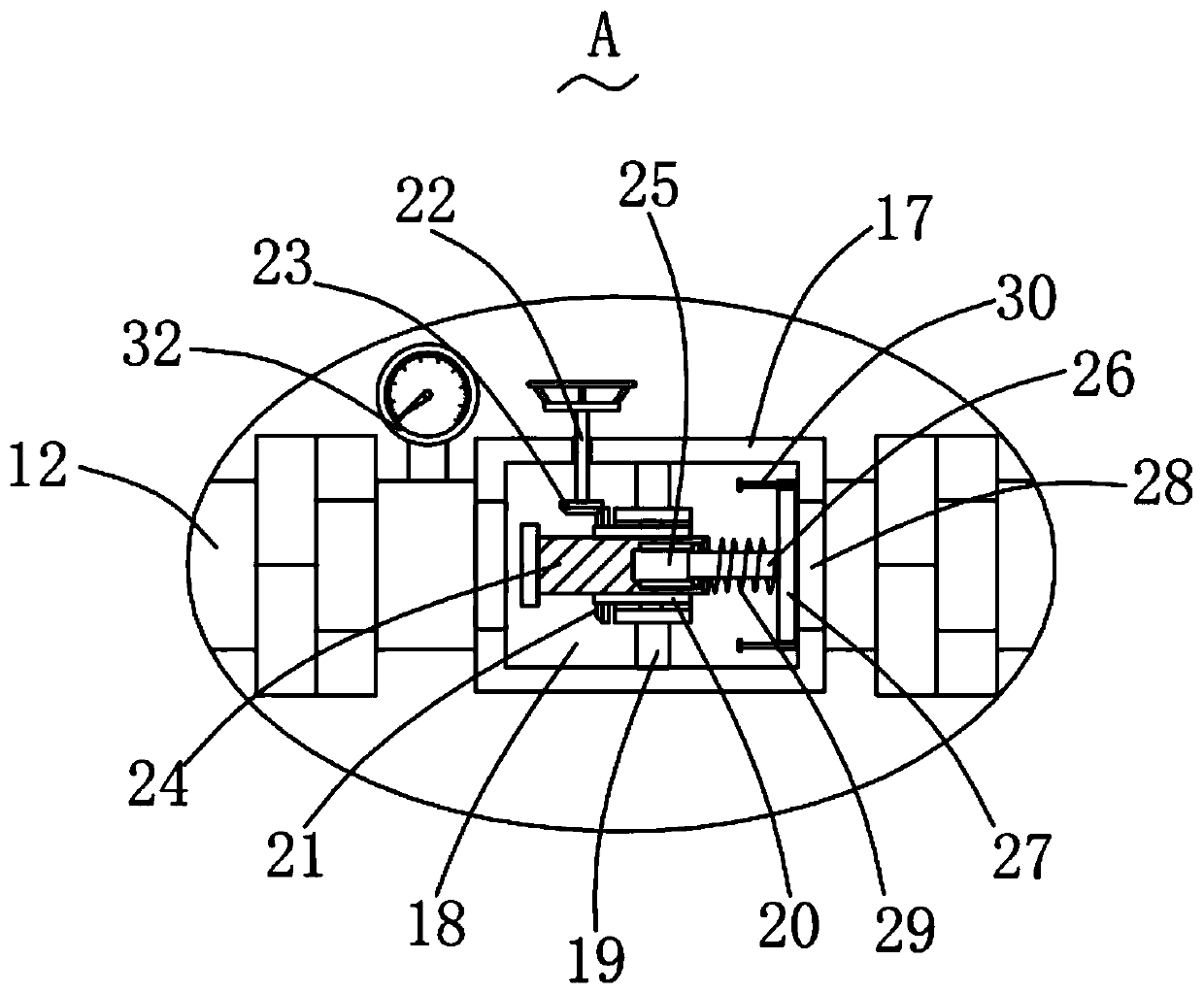

High-precision combustible gas mixer

ActiveCN110898693AGuaranteed mixing efficiencyGuaranteed mixed precisionTransportation and packagingMixer accessoriesElectric machineCombustible gas

Belonging to the technical field of combustible gas mixing, the invention particularly relates to a high-precision combustible gas mixer. The high-precision combustible gas mixer comprises a support seat, a mixing tank is fixedly mounted at the top of the support seat, a first threaded rod is rotatably mounted in the mixing tank, a speed reducing motor is fixedly mounted on one side of the mixingtank, one end of the first threaded rod extends out of the mixing tank and is fixedly connected to an output shaft of the speed reducing motor, a piston is slidably and airtightly installed in the mixing tank, the piston is in threaded connection with the first threaded rod, a sliding rod is fixedly installed in the mixing tank, and the sliding rod runs through the piston and is slidably and airtightly connected to the piston. The high-precision combustible gas mixer provided by the invention is easy to operate, high in practicability and adjustable in volume, can guarantee the mixing efficiency and precision in mixing gas of any volume, at the same time can change the pressure and flow of different raw material gases during entering, can balance the pressure difference when different rawmaterial gases enter, and improves the mixing precision.

Owner:苏州浦煦流体控制系统有限公司

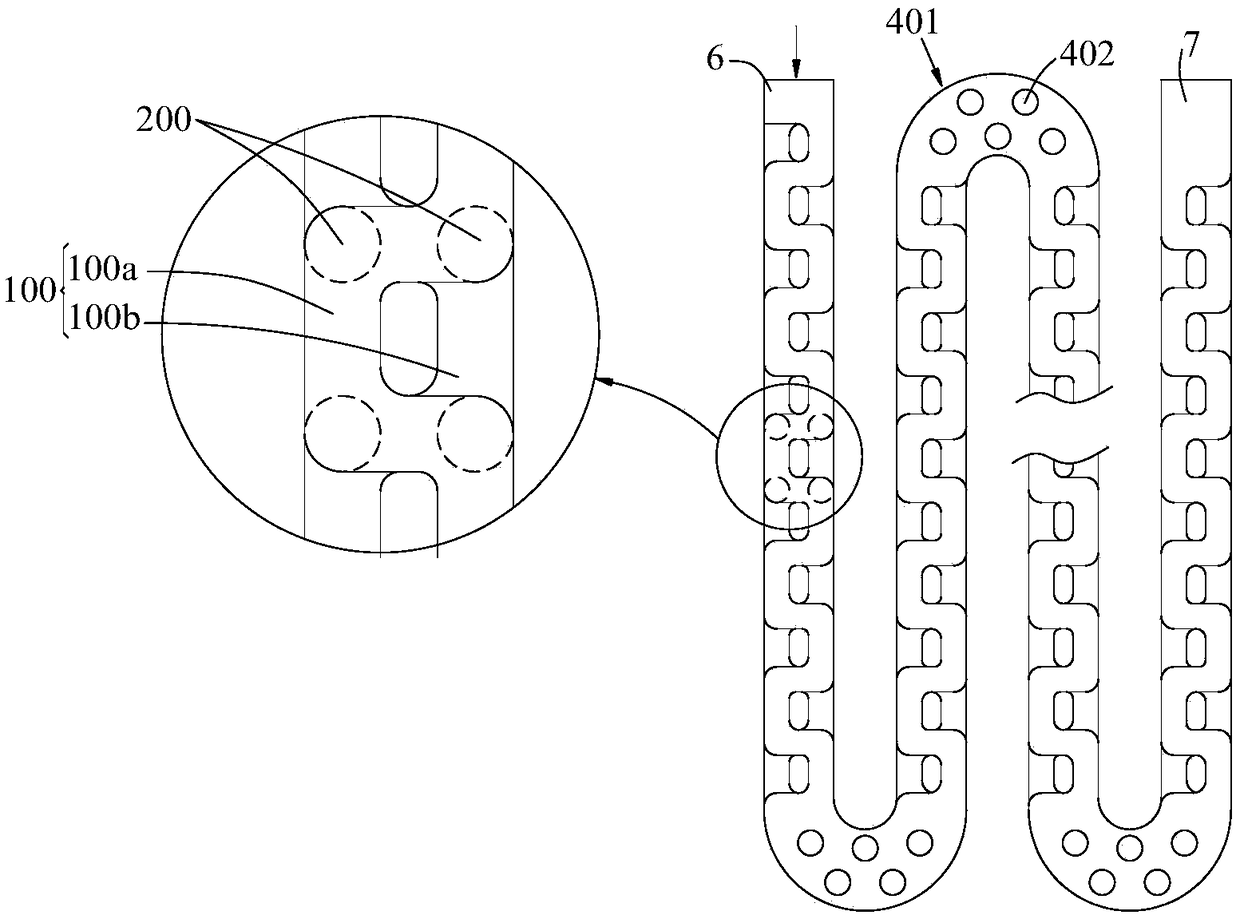

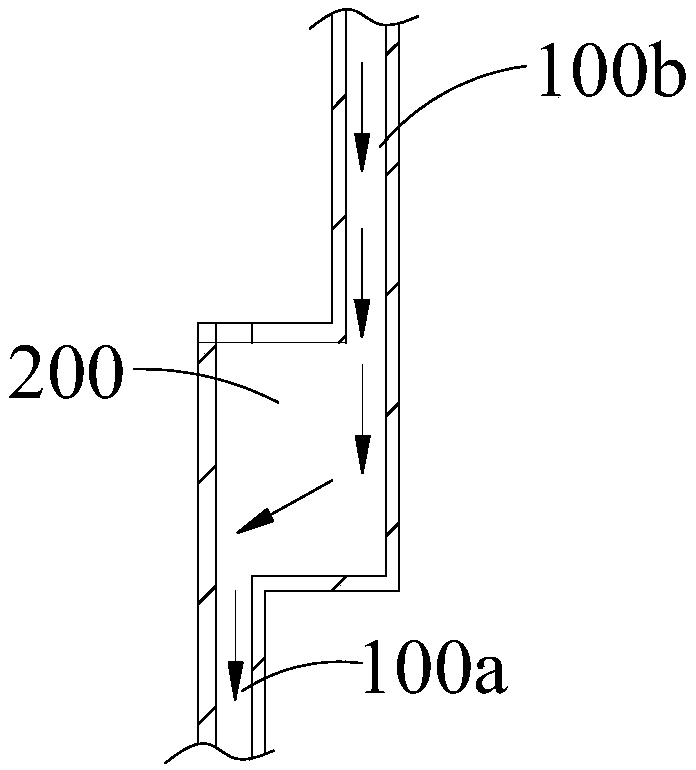

Microreaction chip, microfluidic mixing method and preparation method thereof

ActiveCN108854891AReduce occupancyReasonable useTransportation and packagingChemical/physical/physico-chemical microreactorsThree-dimensional spaceEngineering

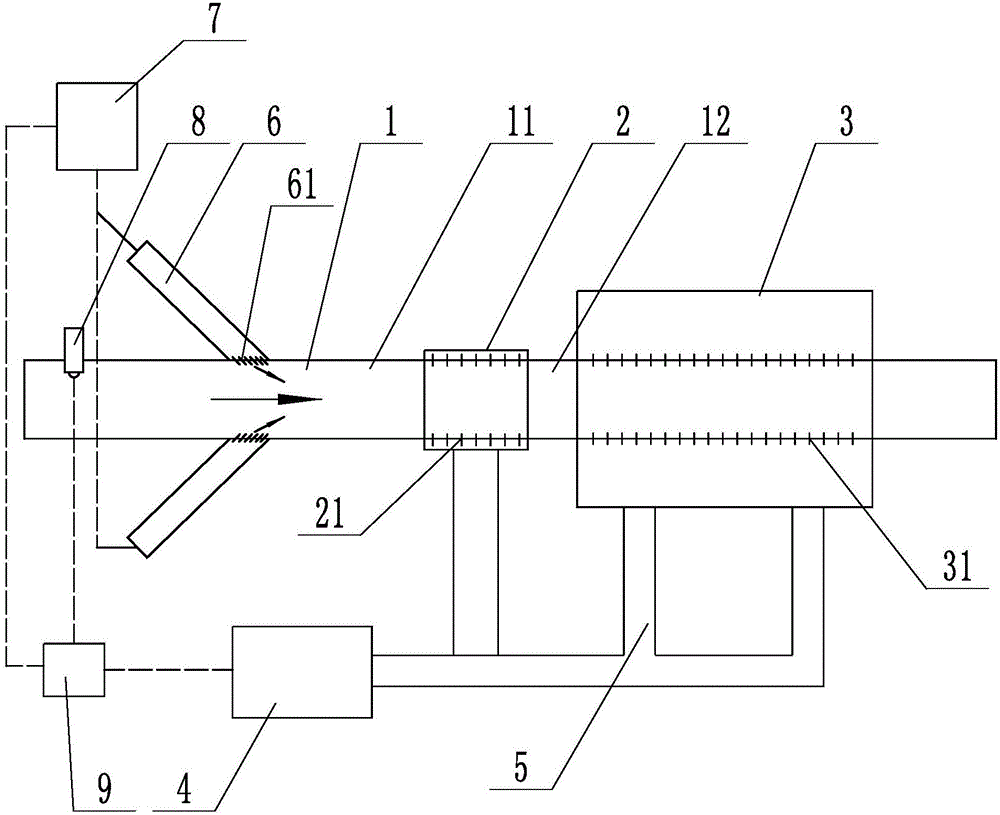

The invention provides a microreaction chip, a microfluidic mixing method and a preparation method thereof. The microreaction chip comprises a microreaction channel unit, wherein the microreaction channel unit comprises two micro channels which are stacked up and down; furthermore, the two micro channels are mutually communicated to enable fluid in the two micro channels to mutually mixed. According to the microreaction chip, firstly, the two micro channels are stacked, so that occupancy of plane space is reduced, and three-dimensional space is reasonably utilized; then, three-dimensional cross mixing of the fluid is achieved through communication between the stacked micro channels, so that the microreaction channels are lengthened, and the reaction efficiency is improved; furthermore, a narrowed outlet designed at the finished position of each microreaction channel unit is avoided; in addition, pressure drop of the fluid is reduced, the high flow speed of the fluid is ensured, the mixing efficiency is ensured, and the yield is simultaneously improved.

Owner:CHANGZHOU NAYANG BIOTECHNOLOGY CO LTD

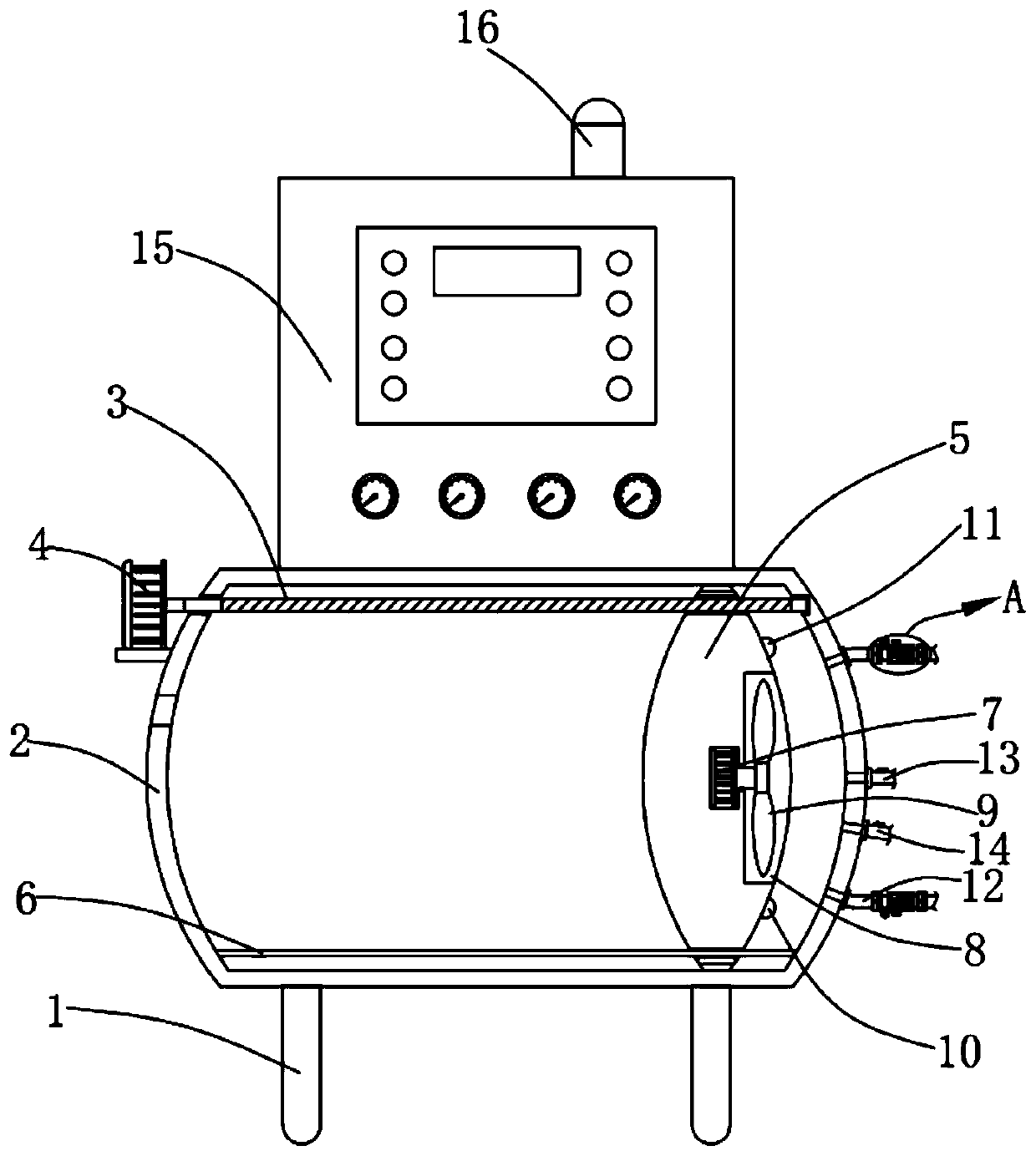

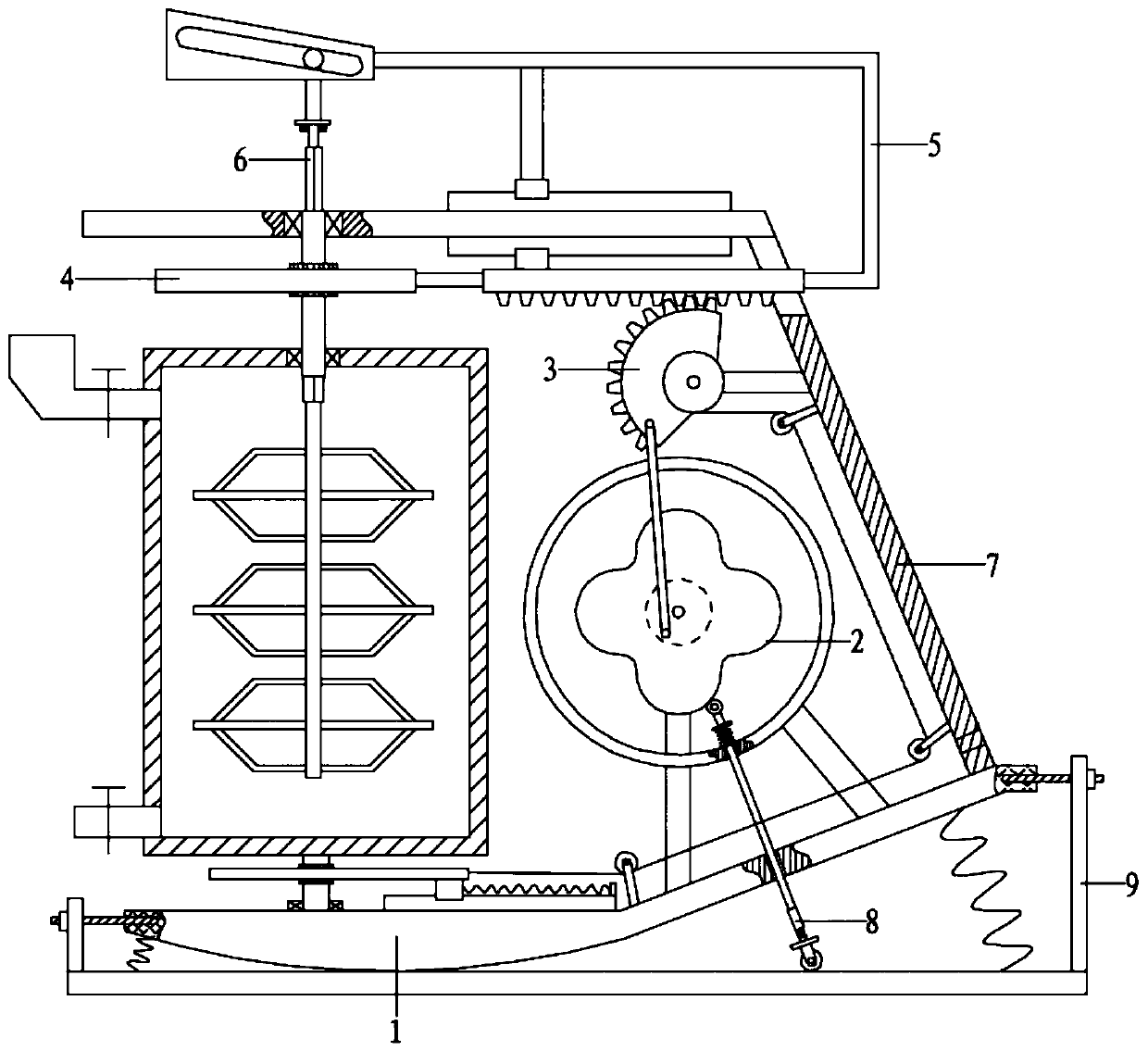

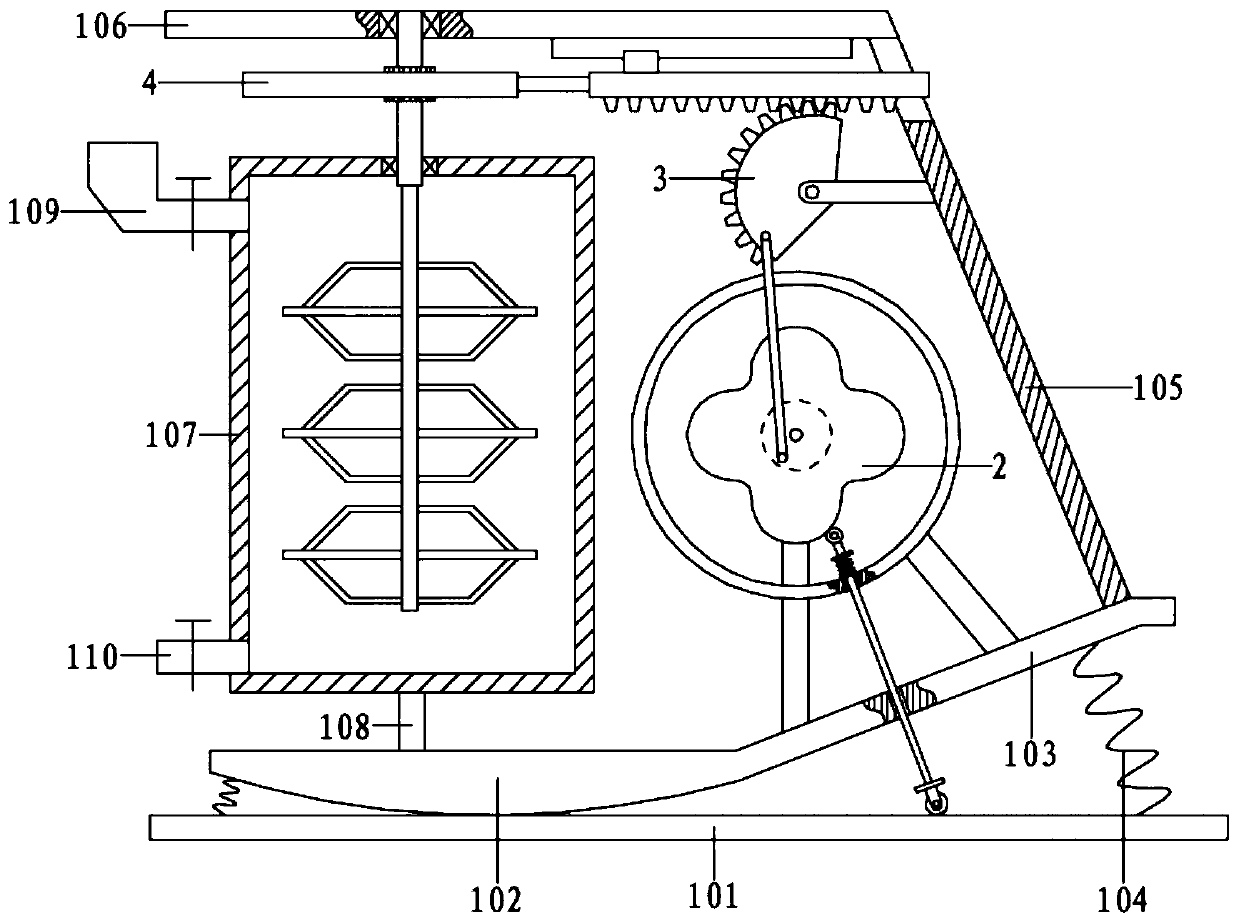

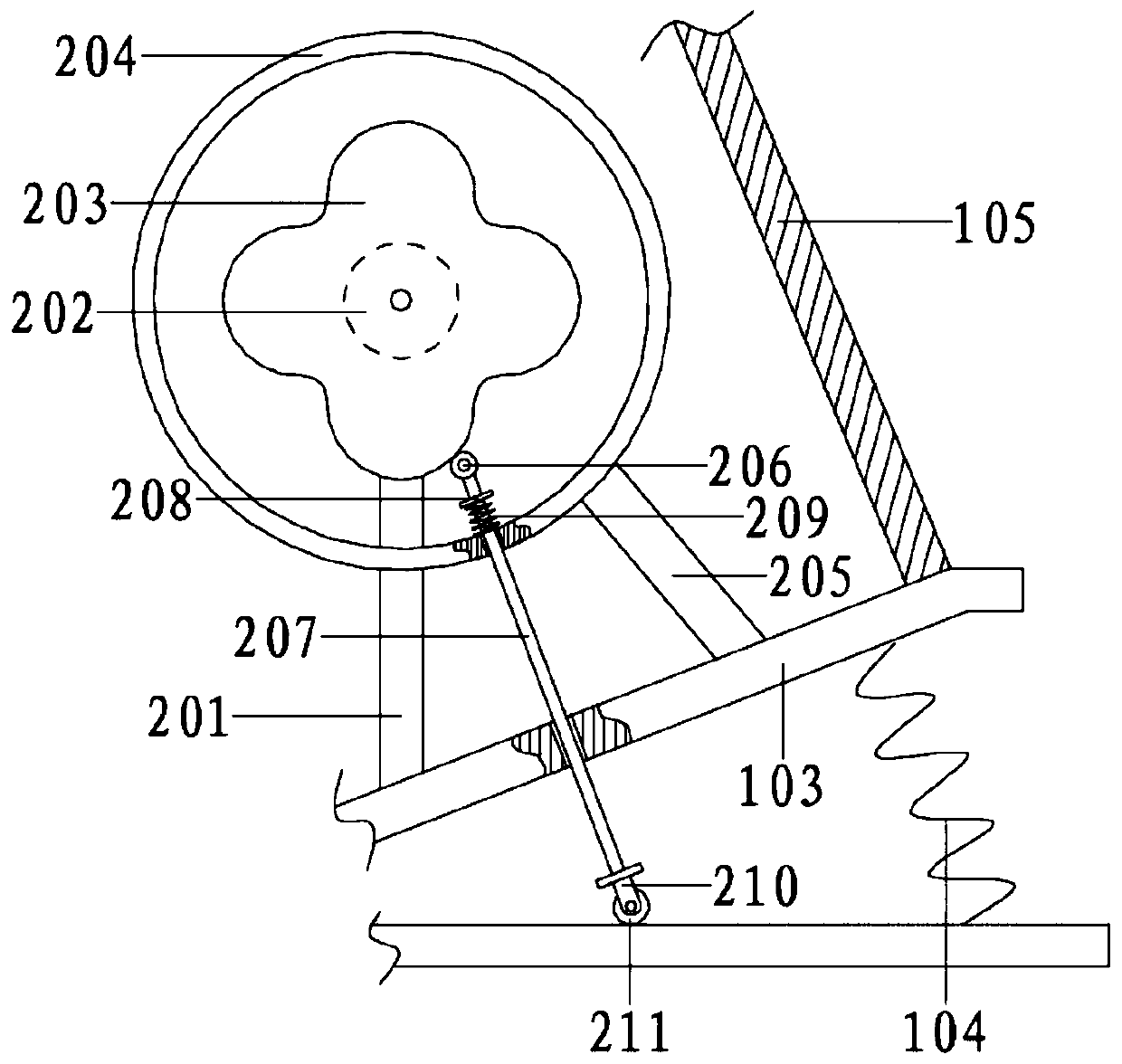

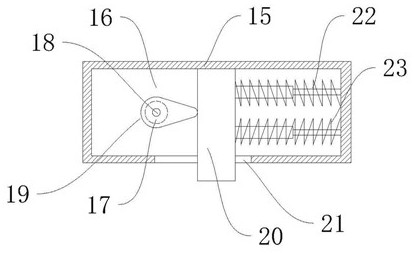

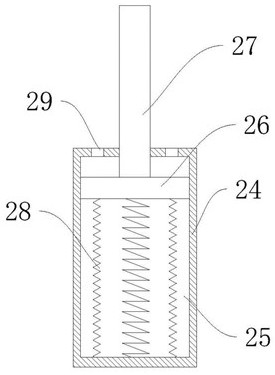

Shaking type machine tool cooling liquid efficient production equipment

PendingCN111359501AGuaranteed mixing efficiencyEnsure mixing uniformityShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringServo

The invention relates to the technical field of machine tool cooling liquid production, in particular to shaking type machine tool cooling liquid efficient production equipment. A servo motor is adopted to drive a cam to rotate, a roller acts with the cam under the matching action of a first spring, so that a force application rod reciprocates, a force application rod drives the roller to press abottom plate and apply a force to the bottom plate, a supporting plate is lifted or falls down through cooperation with a reset spring, a shaking base synchronously swings and drives a mixing tank above the shaking base to shake along with the shaking base, raw materials in the mixing tank are automatically mixed, when the cam rotates, a first connecting rod drives a half gear to swing back and forth, so that the first rack moves back and forth in the direction of a first sliding rail, a second connecting rod drives a second rack to move synchronously, the second rack drives a first driven gear to drive a rotating part to rotate, so that the stirring shaft rotates along with the first driven gear, the stirring part is driven to stir and mix the raw materials in the mixing tank, and the mixing efficiency and uniformity are guaranteed in cooperation with shaking of the mixing tank.

Owner:李明军

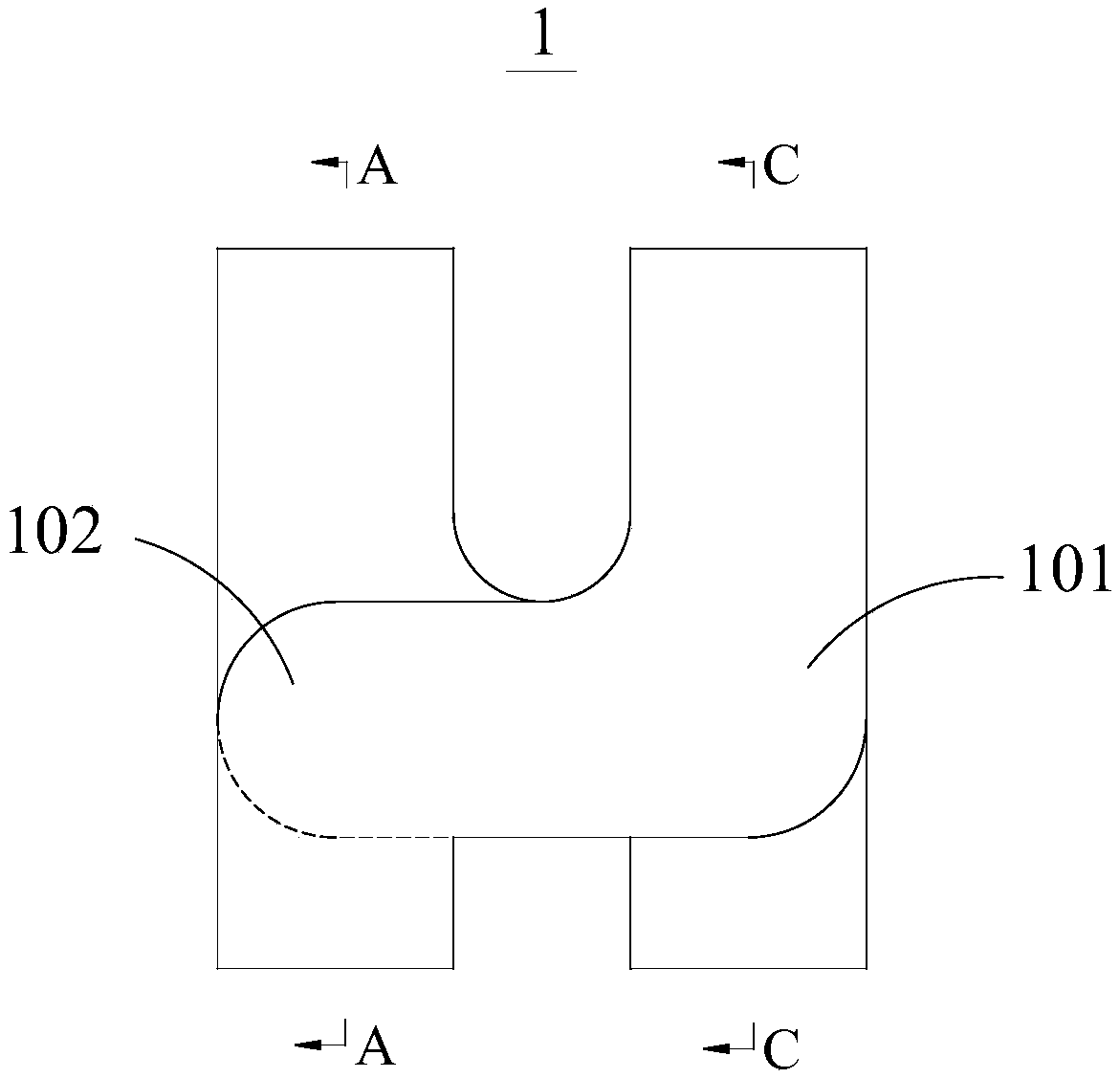

Multi-stage polymerization method for polylactic acid preparation by ring-opening polymerization of lactide

The present invention discloses a multi-stage polymerization method for polylactic acid preparation by ring-opening polymerization of lactide, the method is as follows: molten L-lactide and a composite catalyst system are fully mixed in a ring-type static mixing reaction device comprising a corrugated plate type static mixer, the reaction device temperature is raised for initial ring-opening polymerization, then the reaction device temperature is further raised for L-polylactic acid preparation. According to the multi-stage polymerization method, by adjusting of temperature and reaction time of different stages and adjusting of reaction system flow rate and shear rate, high optical purity and molecular weight polylactic acid with the distribution meeting the requirements of spinning can be obtained. Compared with the conventional polymerization method, the multi-stage polymerization method has the advantages of simple polymerization equipment, low energy consumption, low investment, short reaction time, controllable product properties, high production magnification degree and the like.

Owner:杭州聚丰新材料有限公司

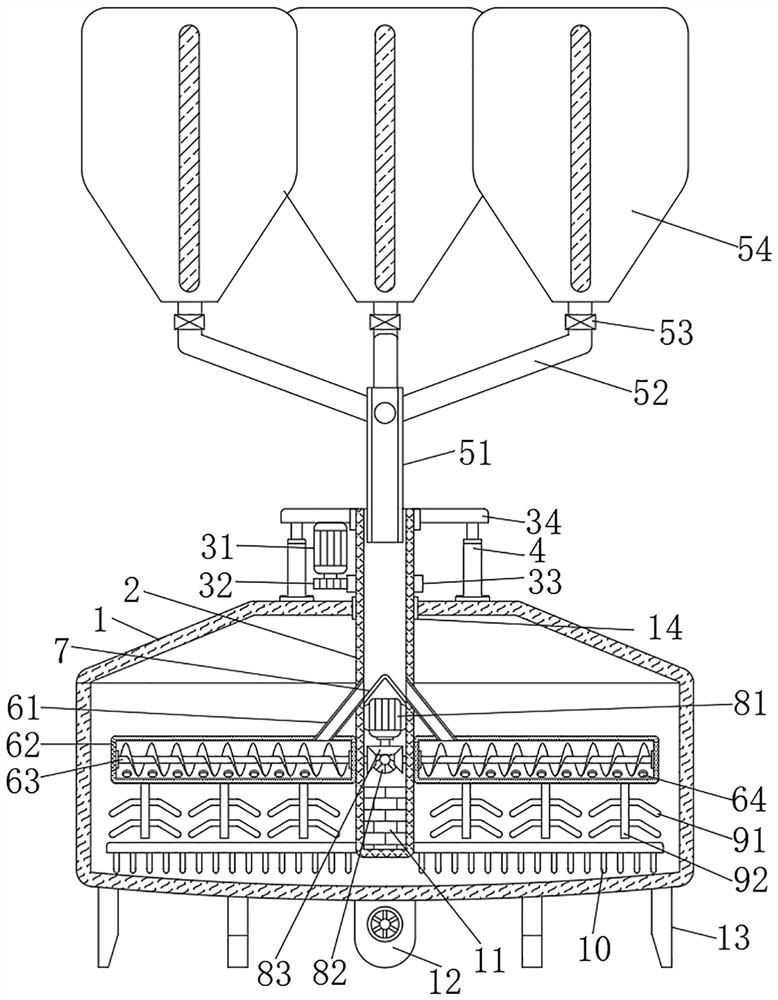

Layered feeding and mixing device for feed production

PendingCN114713125AWell mixedSpread evenlyBatteries circuit arrangementsFeeding-stuffGear wheelElectric machinery

The invention discloses a layered feeding and mixing device for feed production, and relates to the field of feed production.The layered feeding and mixing device comprises a mixing box, a discharging pipe and a discharging pipe arranged on the lower portion of the mixing box and further comprises a layered feeding mechanism and a lifting driving mechanism. Then through cooperation of a driving motor, a first bevel gear and a second bevel gear, a spiral conveying wheel conveys raw materials in feeding barrels from inside to outside, in the conveying process, feed falls into a mixing box through feeding holes, meanwhile, a stirring motor rotates, and through cooperation of a driving gear and a driven gear, a hollow shaft and the multiple feeding barrels rotate at the same time; the raw materials are uniformly spread in the mixing box in the rotating process of the feeding cylinder, the raw materials are poured into the mixing box one by one through the discharging pipe, so that the raw materials are spread layer by layer and are uniformly spread, accumulation of the raw materials is avoided, the raw materials are conveniently mixed, the mixing efficiency of the raw materials is improved, and meanwhile, the mixing effect of the raw materials is ensured.

Owner:河南海大九州生物科技有限公司

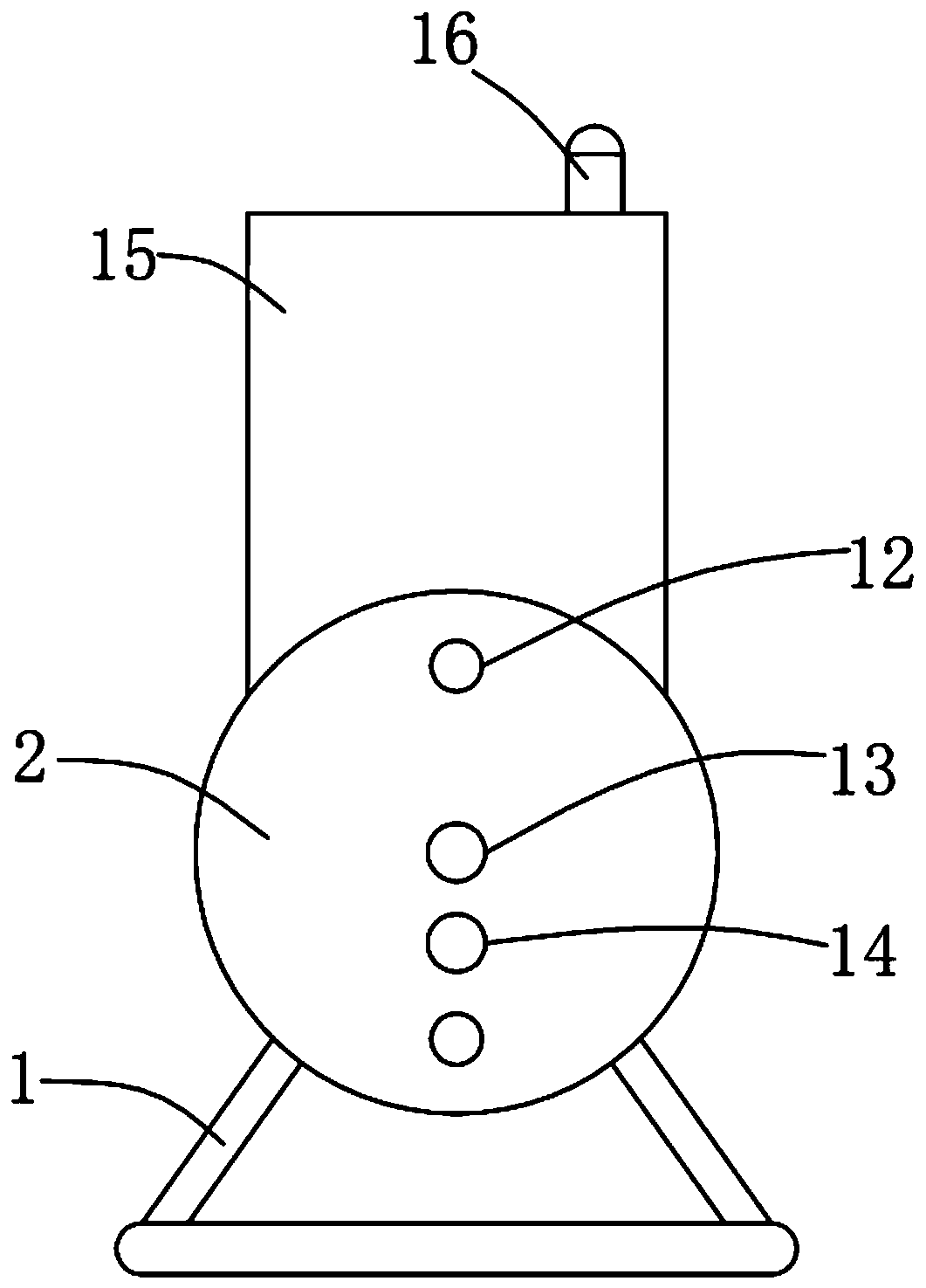

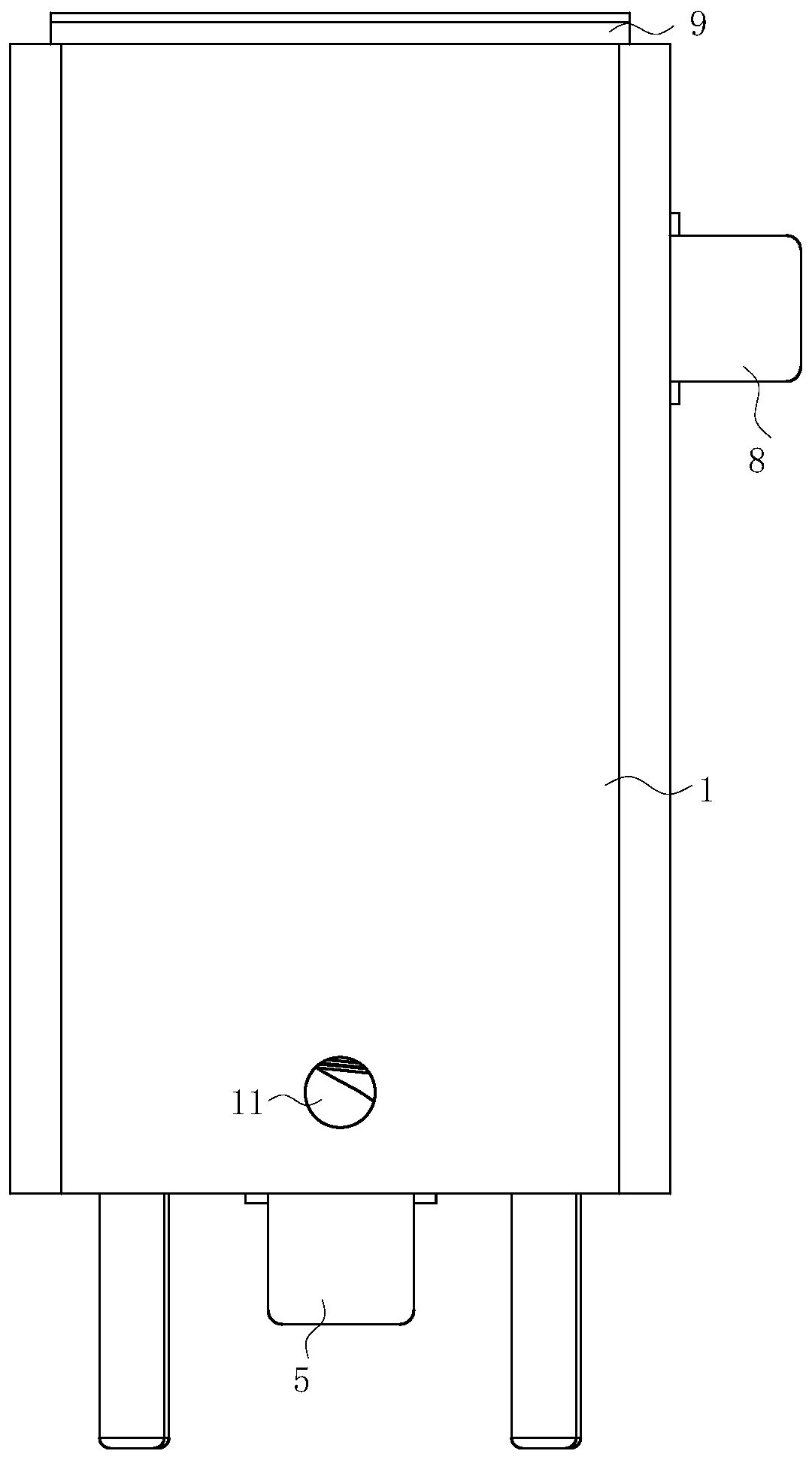

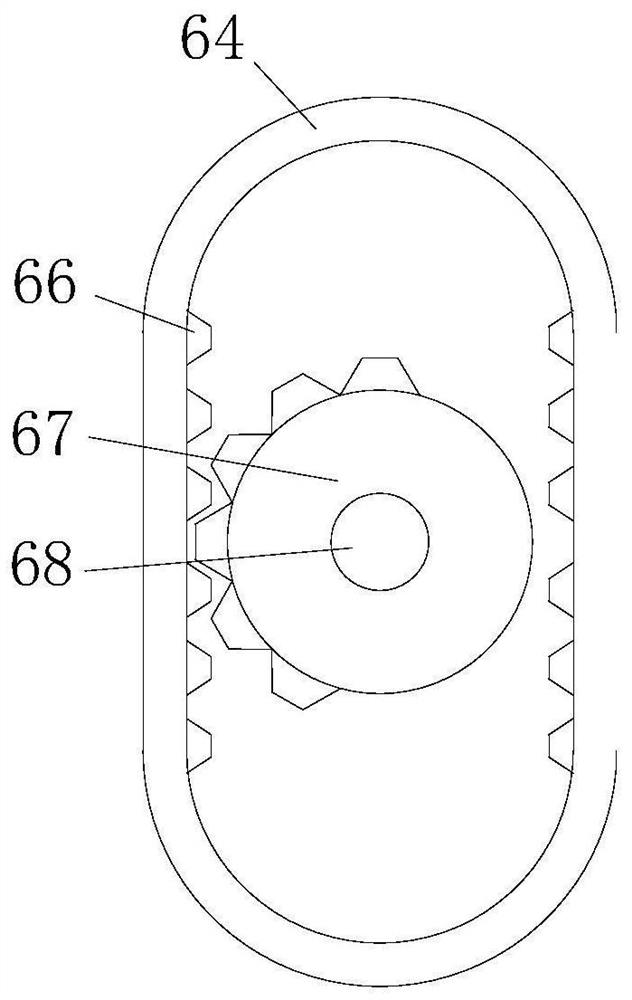

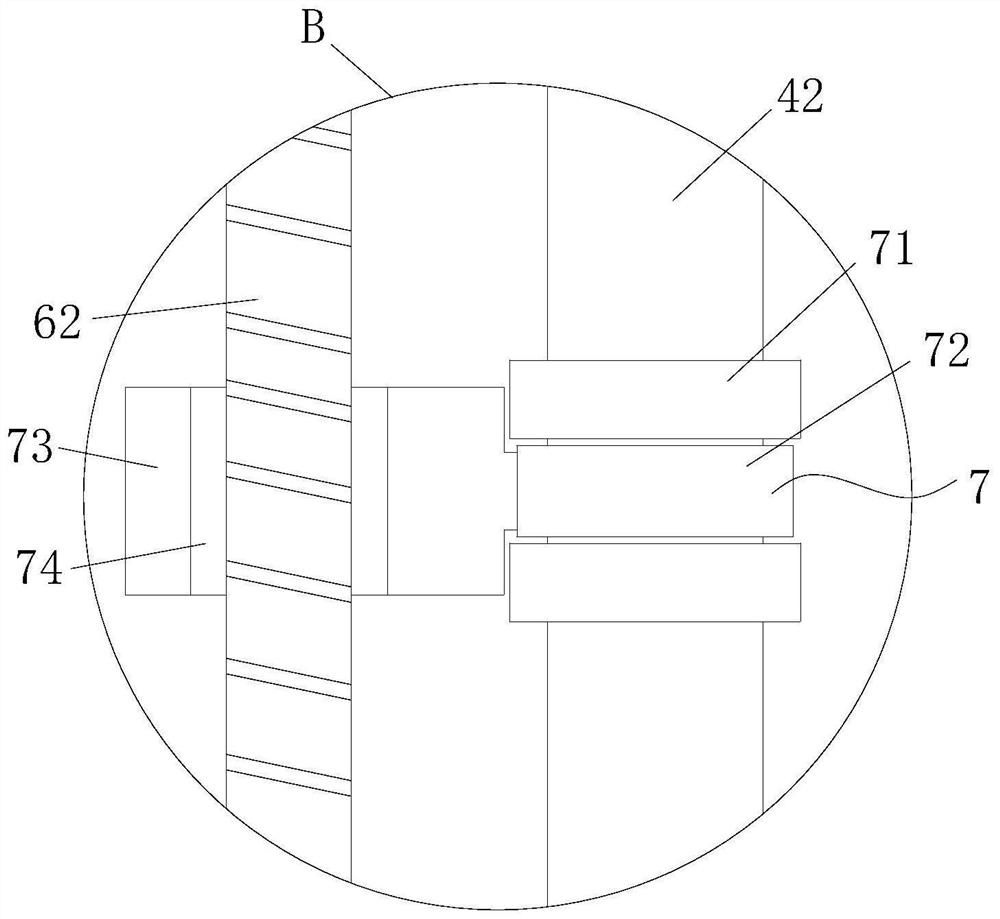

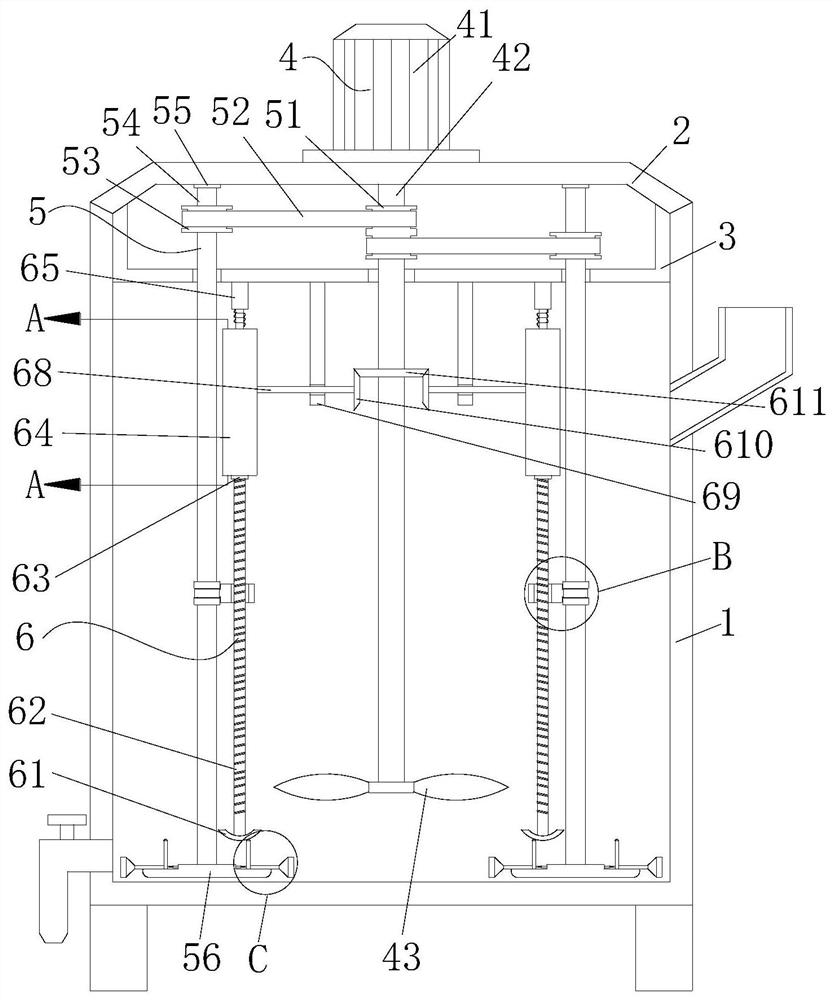

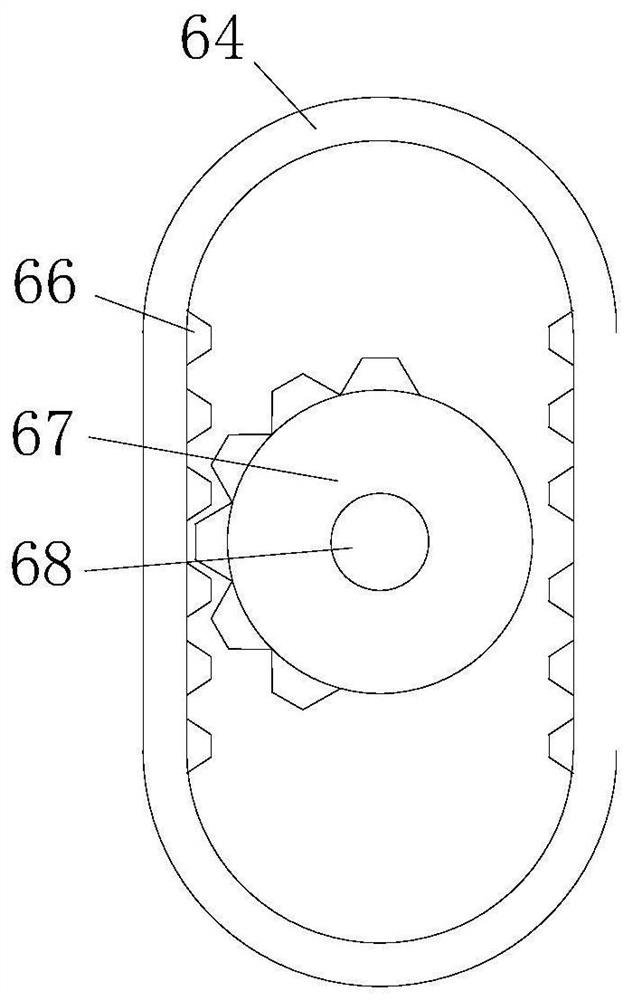

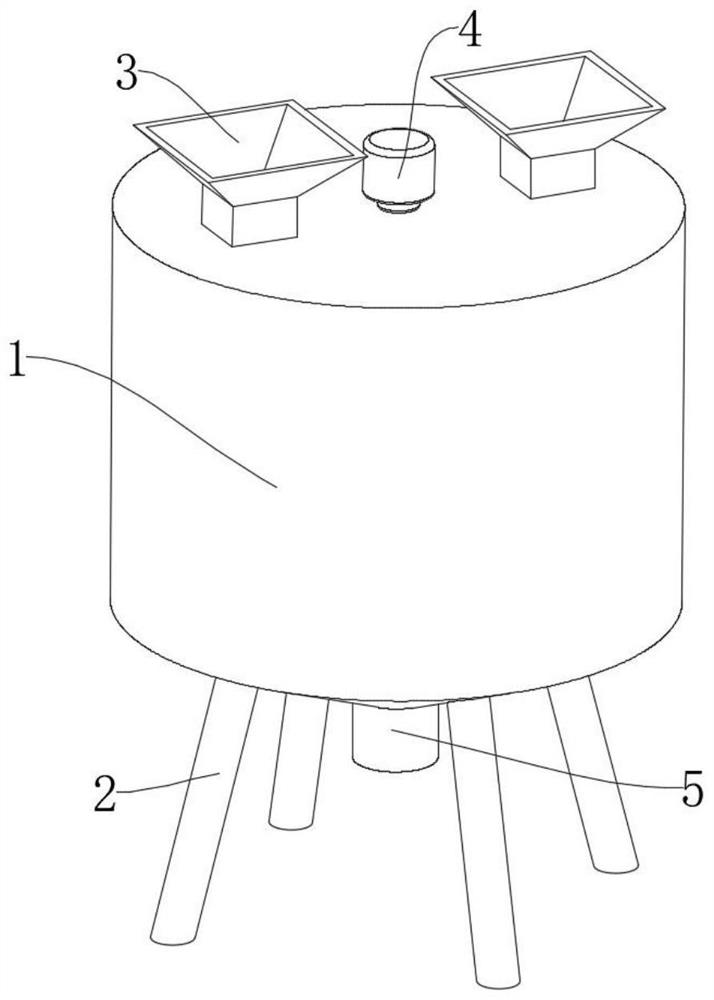

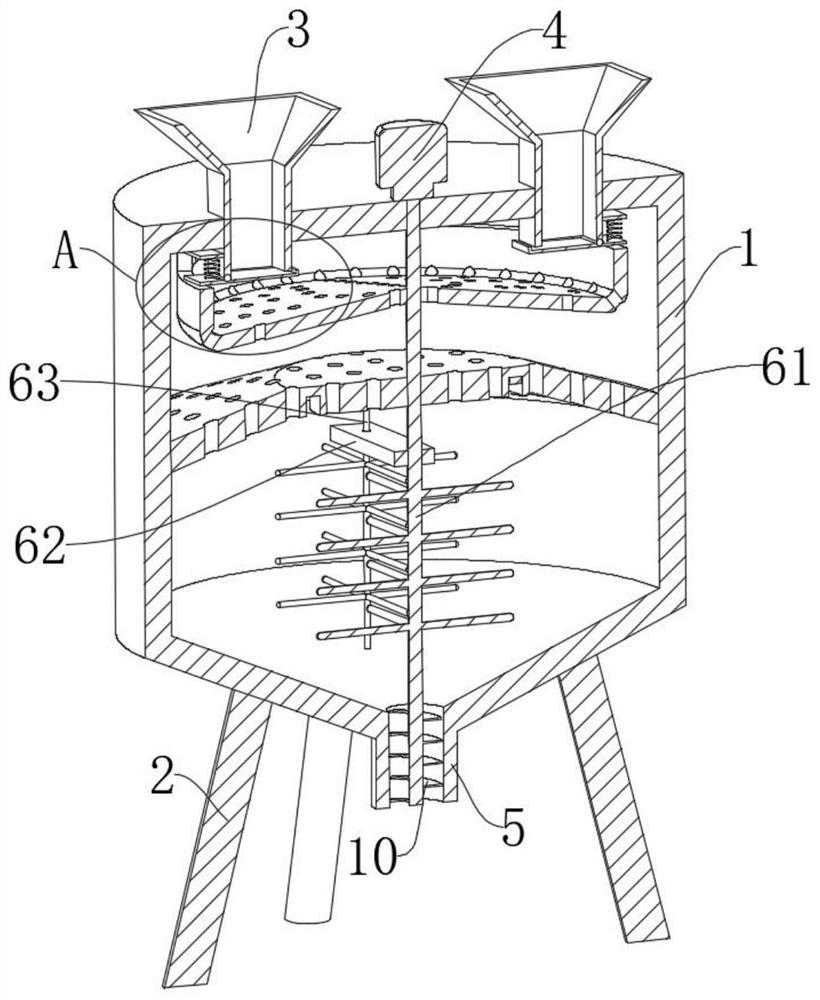

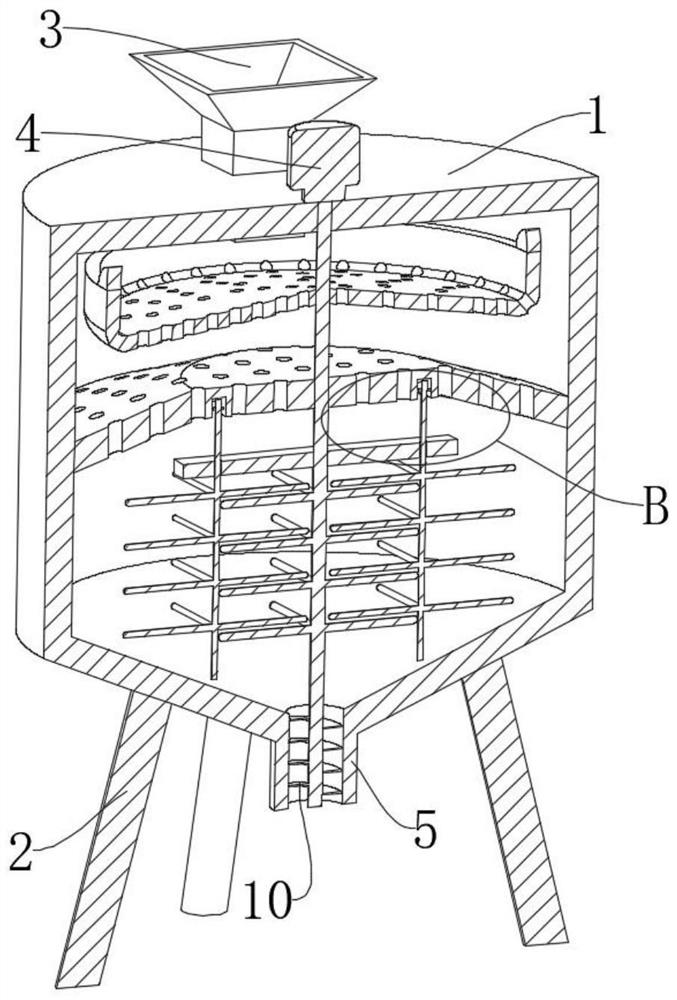

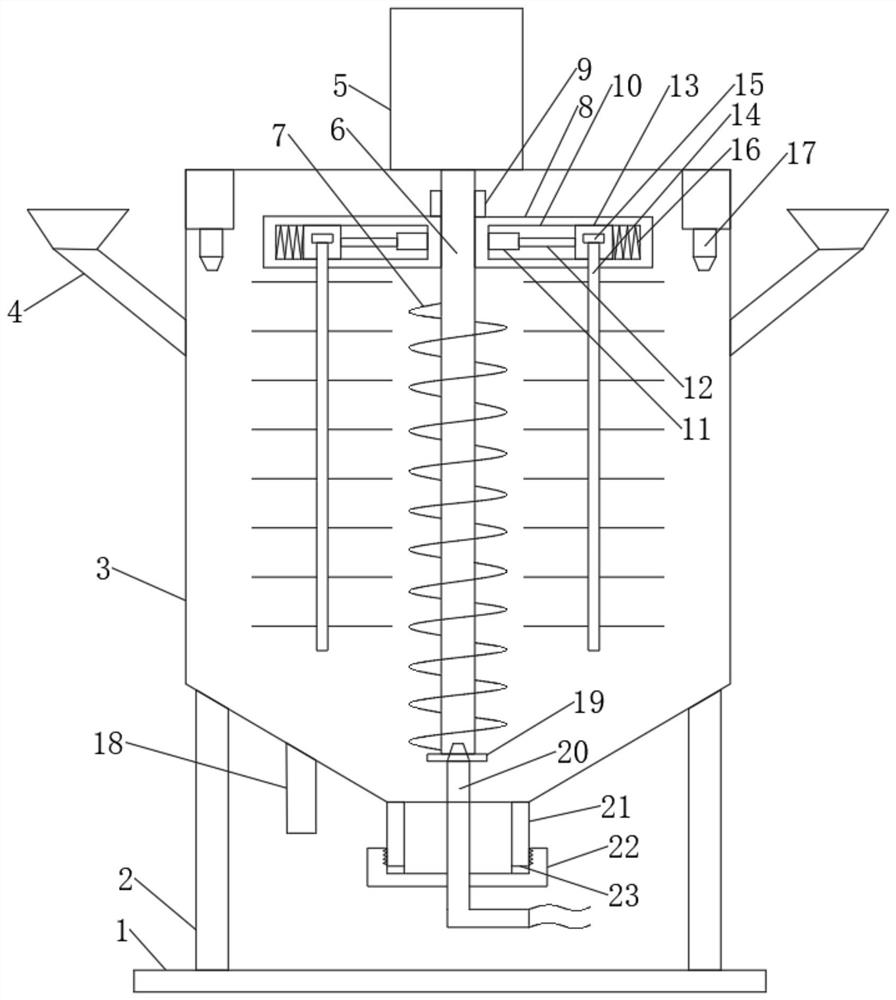

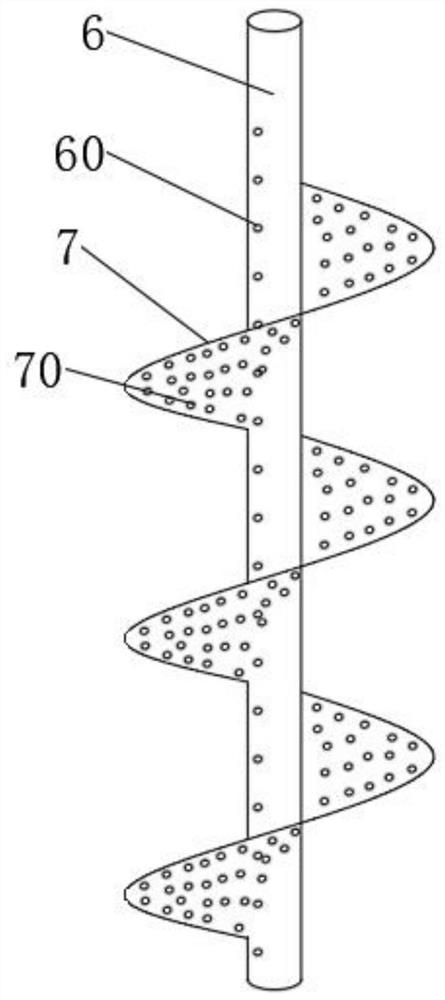

Automatic production device for concentration-adjustable ore pulp

InactiveCN107376704AChange production concentrationEasy to operateTransportation and packagingRotary stirring mixersMotor driveSpiral blade

The invention discloses an automatic production device for concentration-adjustable ore pulp. The automatic production device comprises a base, wherein a mixing box is fixedly arranged on the base through a bracket; the left side of the top of the mixing box is equipped with a feeding funnel; the right side wall of the mixing box is equipped with a variable-frequency motor; a motor shaft at the left end of the variable-frequency motor is connected with a first rotary shaft; a spiral blade is mounted on the first rotary shaft; the right side of the bottom of the mixing box is further connected with a discharge hole; a water tank is further arranged on the base; a pressurizing cylinder is arranged on the top of the water tank; the top and the bottom of the left side wall of the pressurizing cylinder are separately connected with branch water inlet tubes; the branch water inlet tubes are connected to the bottom in the water tank through a head water inlet tube; the top and the bottom of the right side wall of the pressurizing cylinder are separately connected with branch water outlet tubes; and the branch water outlet tubes are connected to the left upper corner in the mixing box through a head water outlet tube. One variable-frequency motor drives the automatic production device, so that three functions of adding water, charging and mixing can be realized. The automatic production device is convenient to operate, is simple to use, does not need manual control, is convenient to use, and reduces labor cost.

Owner:六安市金安区一元通包装设计中心(普通合伙)

Dry-type mixing tank

InactiveCN111420603AShorten mixing timeImprove efficiencyRotary stirring mixersTransportation and packagingPhysicsEngineering

The invention belongs to the technical field of mixing equipment, and particularly relates to a dry-type mixing tank which comprises a tank body, a main mixing chamber is downwards formed in the tankbody along the middle part, a main rotating shaft is arranged in the main mixing chamber, spiral blades are arranged on the surface of the main rotating shaft, the bottom of the main rotating shaft isconnected with a main motor, and the main motor is mounted at the bottom of the tank body; an auxiliary mixing chamber is arranged at the top of the main mixing chamber; in the rotating process of the auxiliary motor, when shifting plates rotate, the dry materials between the two adjacent shifting plates are enable to enter the space between other two shifting plates through the leakage holes; initial mixing on the dry materials is carried out; meanwhile, when the shifting plates rotate to the bottom of the auxiliary mixing chamber, one part of the dry materials are enable to enter the mainmixing chamber from the position where the bottom of the auxiliary mixing chamber is communicated with the main mixing chamber, and due to the fact that the dry materials are initially mixed, when thespiral blades are used for stirring, the stirring time is greatly shortened, and then the stirring efficiency is improved.

Owner:马慧慧

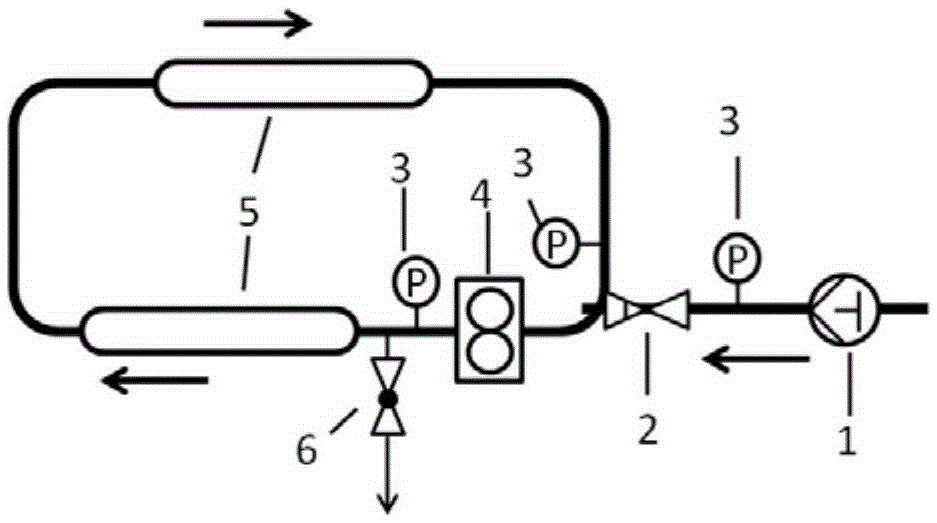

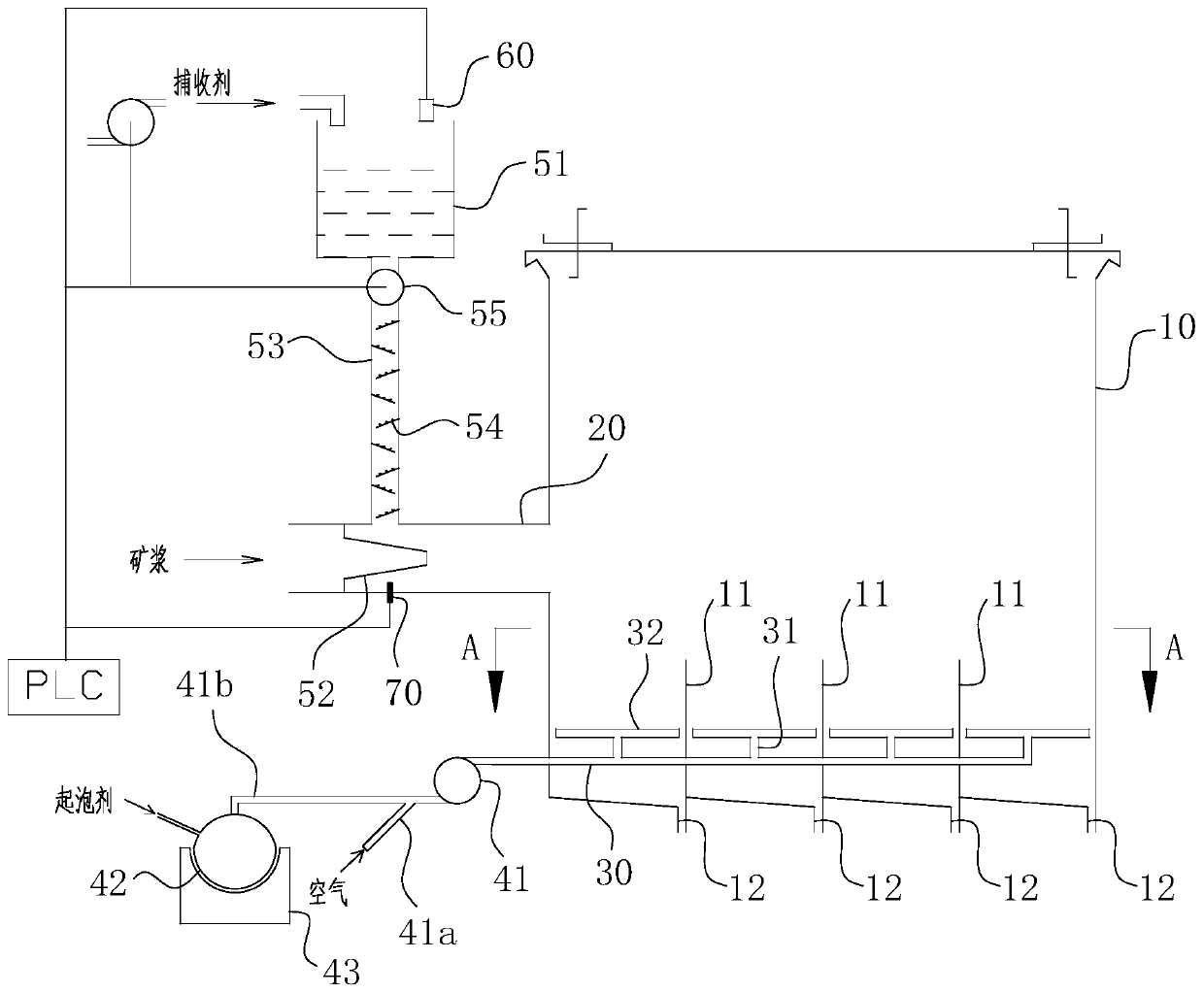

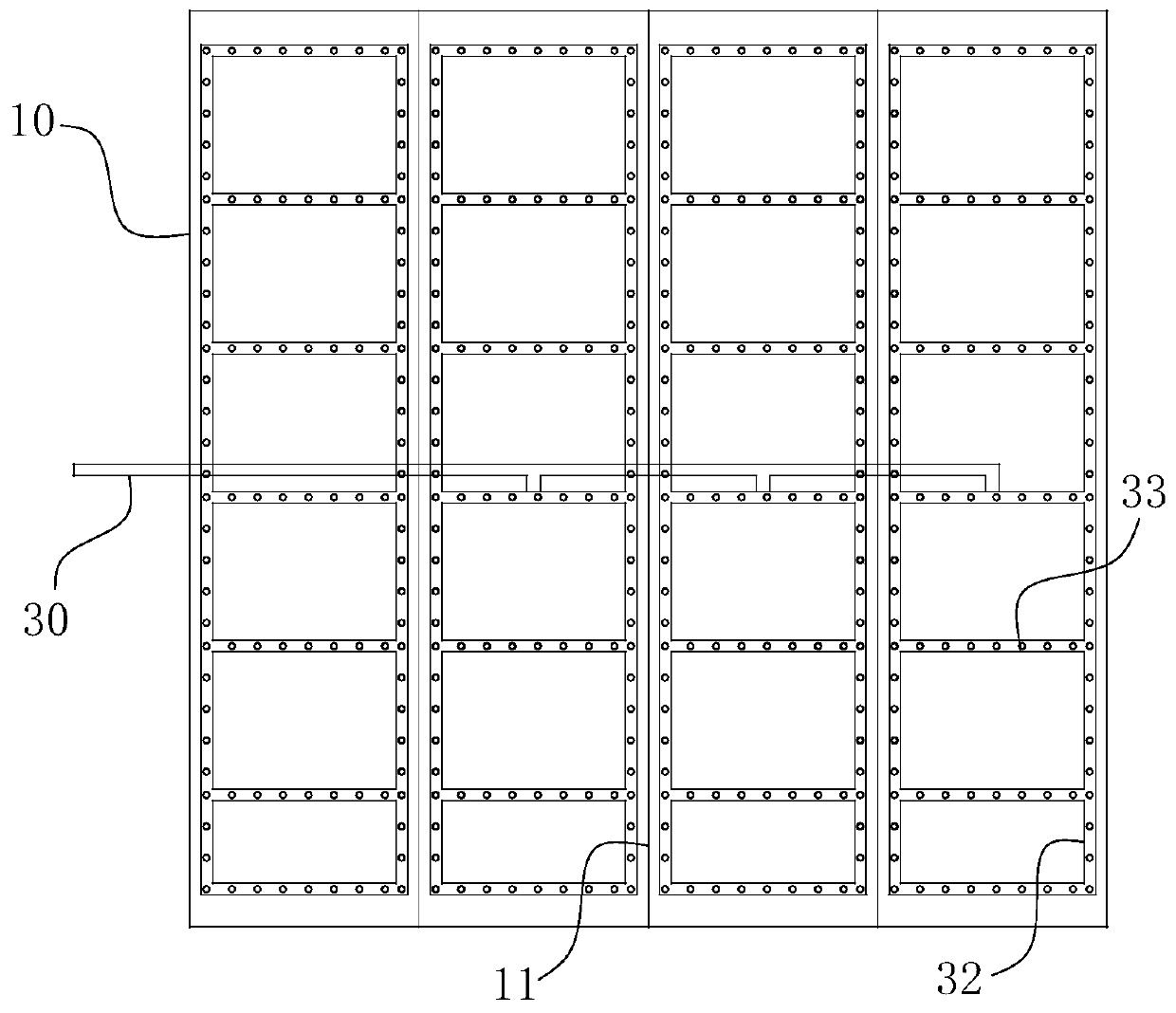

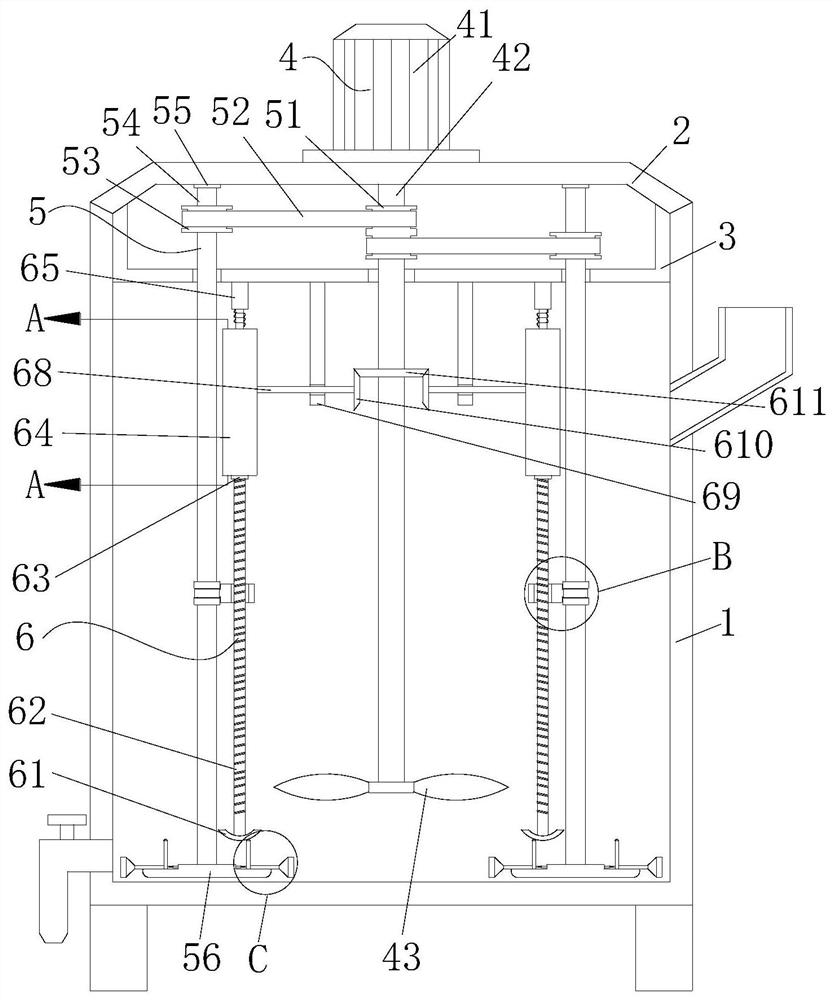

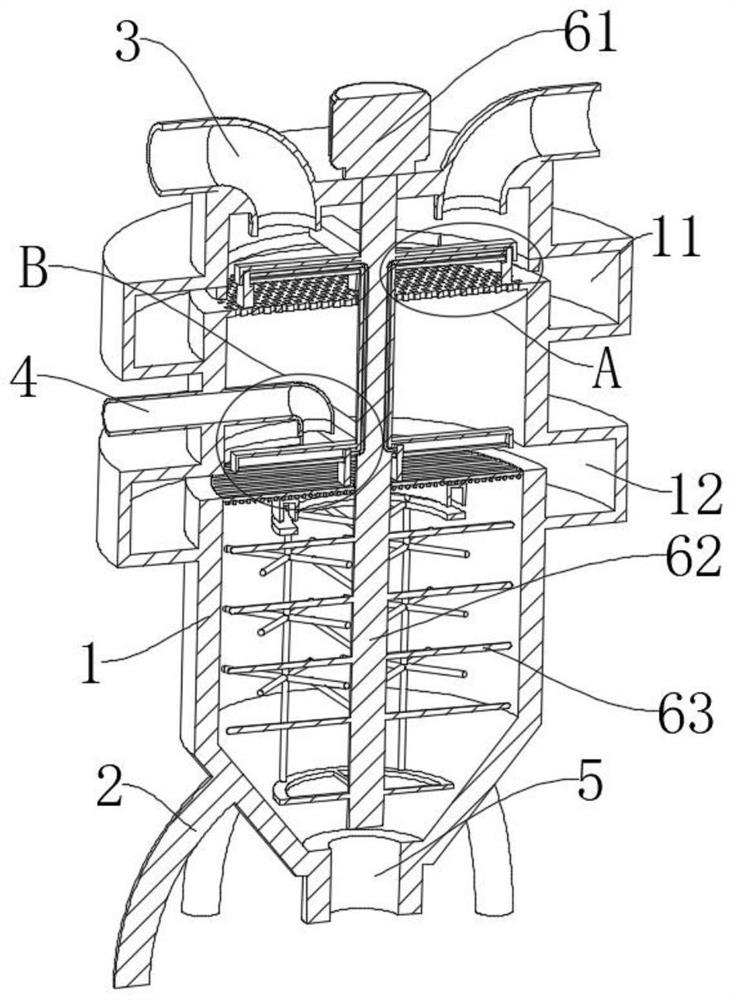

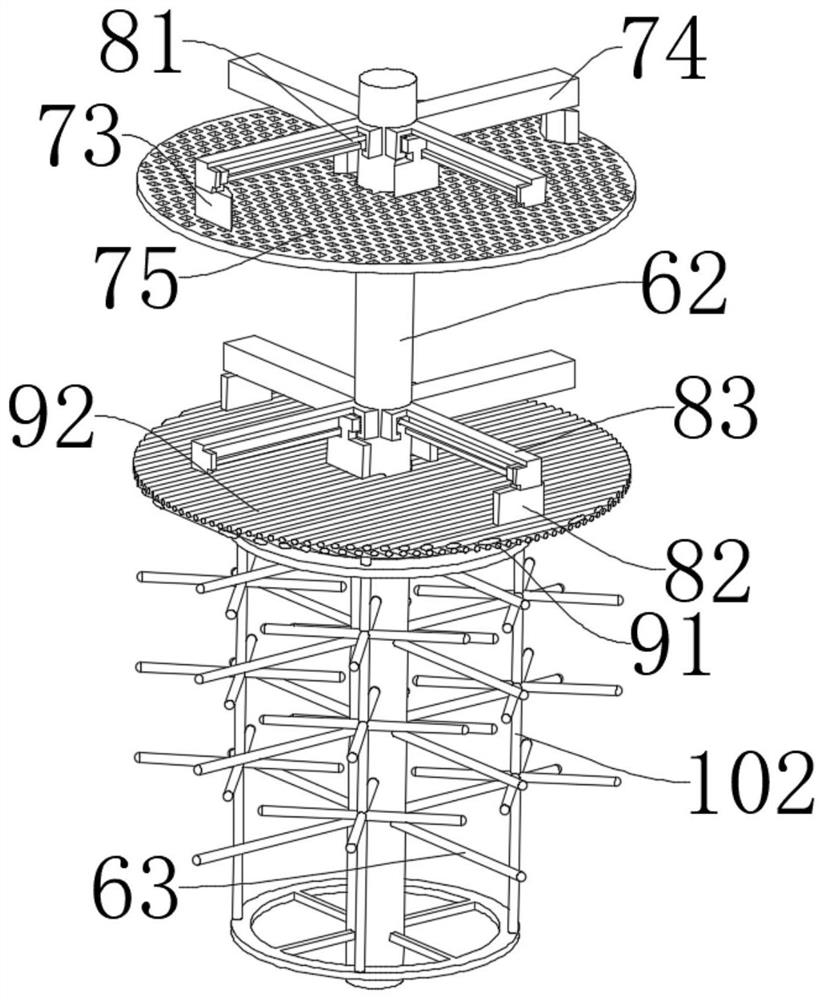

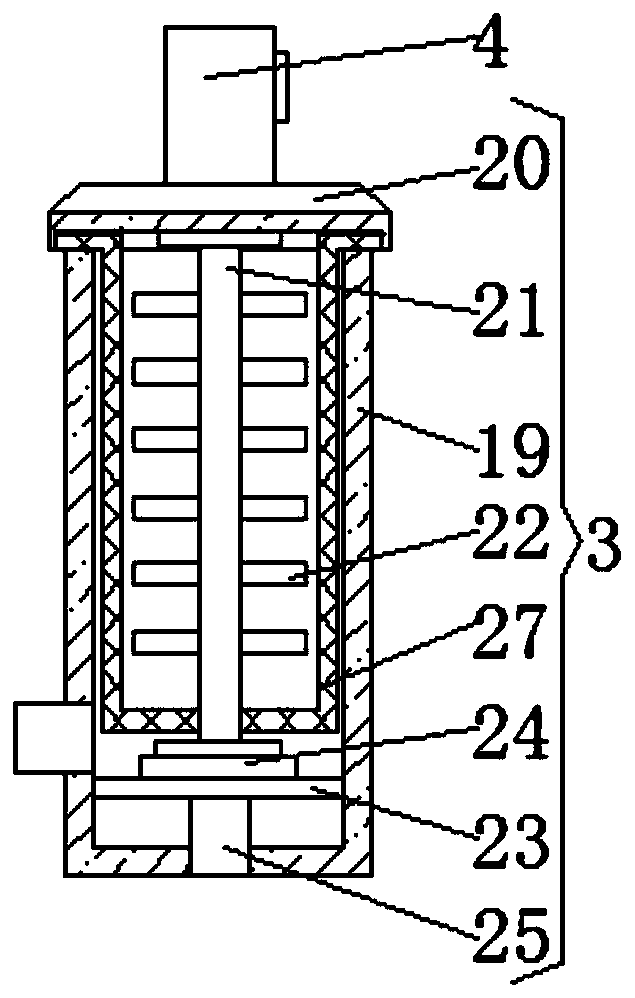

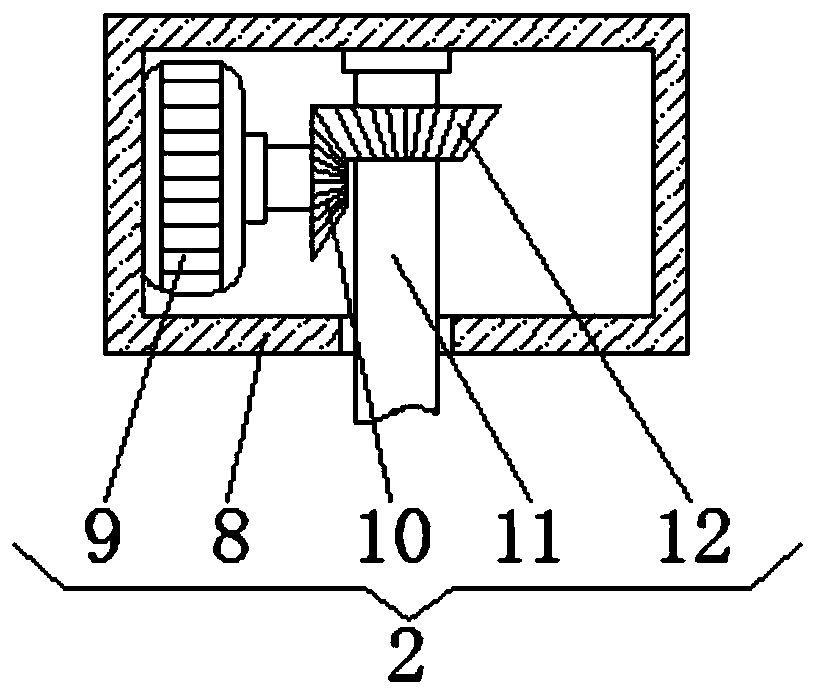

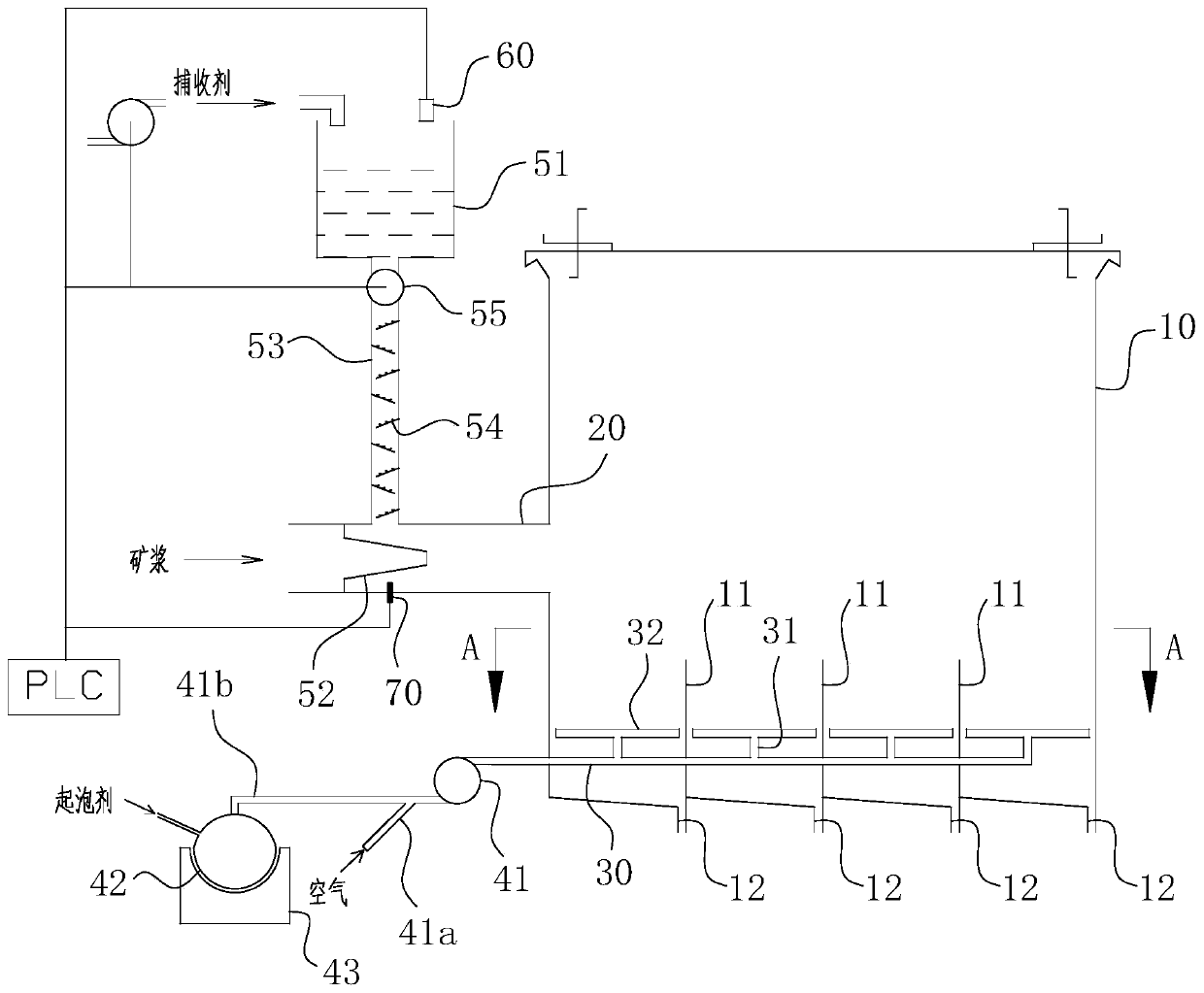

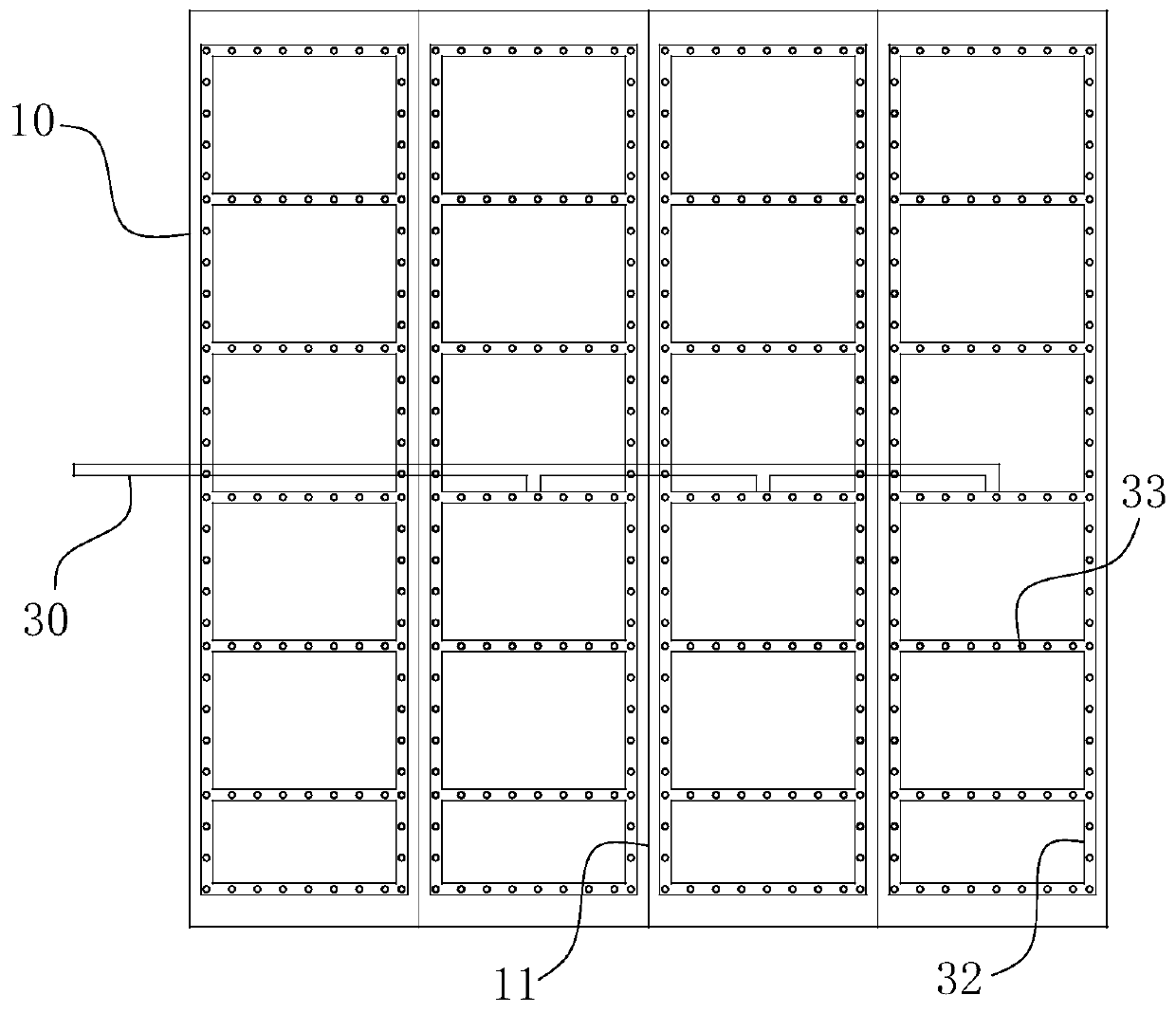

Partition flotation system

ActiveCN109772595AFacilitated zonal flotationTo achieve the collision effectFlotationVertical mixingMineral particles

The invention relates to the technical field of mineral flotation technology, specifically to a partition flotation system. The system comprises a flotation cell and a mixed slurry injection pipe. Anoutput port of the mixed slurry injection pipe horizontally penetrates through the cell wall of the flotation cell; more than one vertical partition is arranged at the bottom of the flotation cell, and the arrangement height of the vertical partition is lower than the height of the output port of the mixed slurry injection pipe; the board of the vertical partition is vertical to the spraying direction of the mixed slurry; a bubble generator tube used for inputting bubbles into corresponding sedimentation zone is arranged at the bottom of each sedimentation zone, and the aperture of an air outlet at each bubble generator tube is gradually reduced; and a discharge port used for outputting settled mineral particles of the current sedimentation zone is arranged at the bottom of the flotation cell of each sedimentation zone. The system of the invention has the advantages of compact structure, high flotation efficiency and good flotation effect, can increase flotation output while guaranteeing flotation quality, and is suitable for industrial operation.

Owner:ANHUI UNIV OF SCI & TECH

Mixing equipment for animal husbandry feed

InactiveCN112439343AWell mixedPlay a role in mixingShaking/oscillating/vibrating mixersFeeding-stuffControl theoryAnimal husbandry

The invention relates to mixing equipment for animal husbandry feed. The mixing equipment comprises a mixing tank and a tank cover, the tank cover is buckled on an opening in the upper end of the mixing tank, and a first mixing mechanism is arranged on the tank cover; a rotating mechanism is arranged in the mixing tank and comprises two fixed limiting rings, a rotating ring, a connecting plate anda threaded hole, the two fixed limiting rings are fixedly arranged outside a first rotating rod in a sleeving mode, the rotating ring is arranged between the two fixed limiting rings, and the rotating ring is movably arranged outside the first rotating rod in a sleeving mode; and the connecting plate is fixedly connected to the outer side wall of the rotating ring, and the threaded hole is formedin the connecting plate and is in threaded connection with a threaded rod. By additionally arranging multiple stirring mechanisms and turning mechanisms, when the feed is mixed, the feed at differentparts in the mixing tank can be stirred and mixed through the multiple stirring mechanisms, so that the effect of rapid stirring and mixing can be achieved, and the effect of uniform mixing can alsobe achieved.

Owner:成善华

High-efficiency livestock feed mixing device

ActiveCN112452194AWell mixedPlay a role in mixingShaking/oscillating/vibrating mixersFeeding-stuffCrop livestockEngineering

The invention relates to a high-efficiency livestock feed mixing device, which comprises a mixing tank and a tank cover, the tank cover is buckled on an opening in the upper end of the mixing tank, and a first mixing mechanism is arranged on the tank cover; by additionally arranging the multiple stirring mechanisms and a turning mechanism, when a feed is mixed, the feed at different parts in the mixing tank can be stirred and mixed through the multiple stirring mechanisms, so that the effect of rapid stirring and mixing can be achieved, the effect of uniform mixing can be achieved, and meanwhile, due to the arrangement of the turning mechanism, the mixing device can be used for stirring the feed, the feed at the bottom of the mixing tank and the feed at the upper part of the mixing tank can be mixed, so that the feed is mixed more uniformly, and in the use process, the mixing device can achieve the effect of efficiently mixing the feed and the effect of uniformly mixing the feed; and therefore, the use value is higher.

Owner:辽宁明瑞农牧科技有限公司

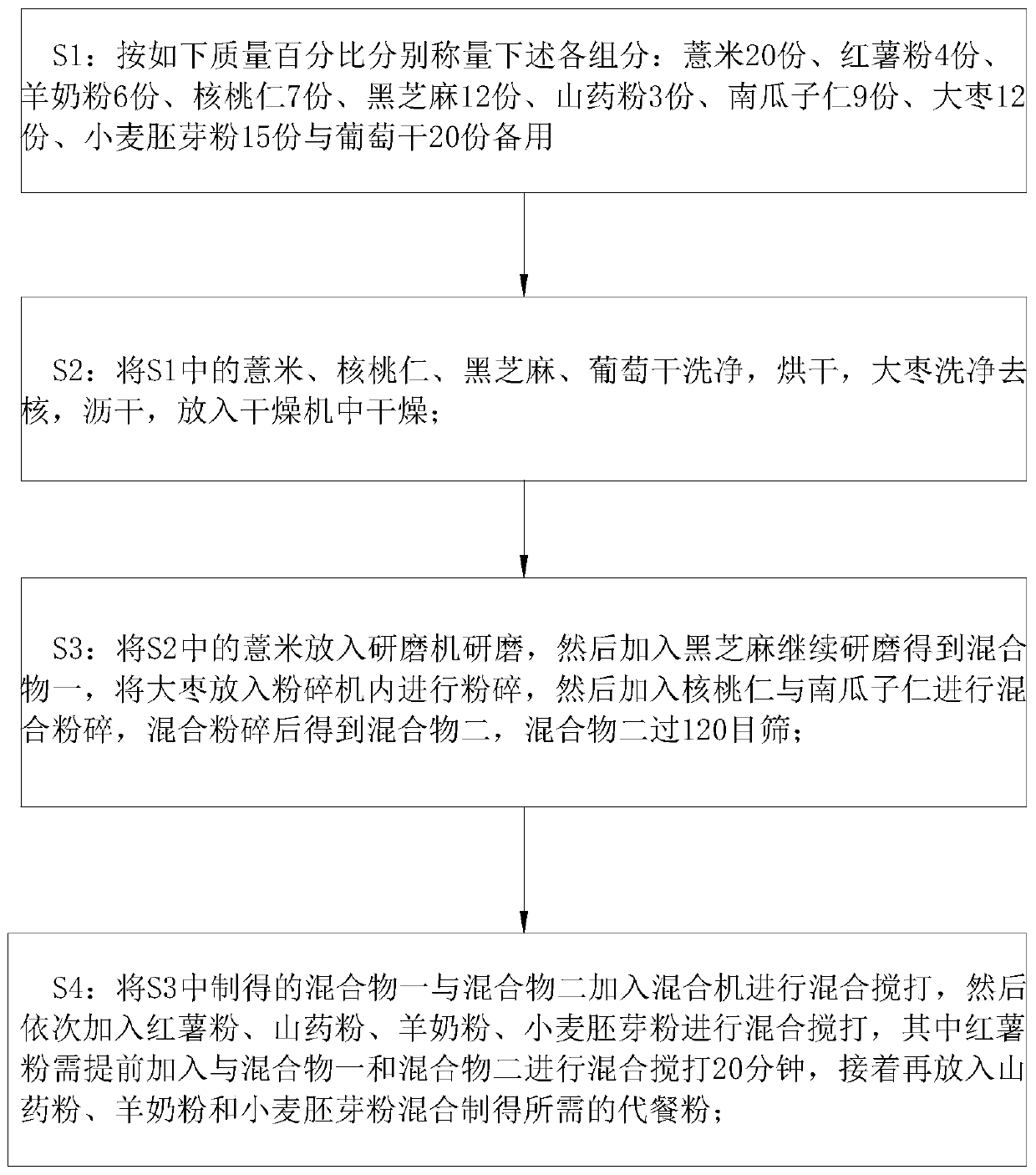

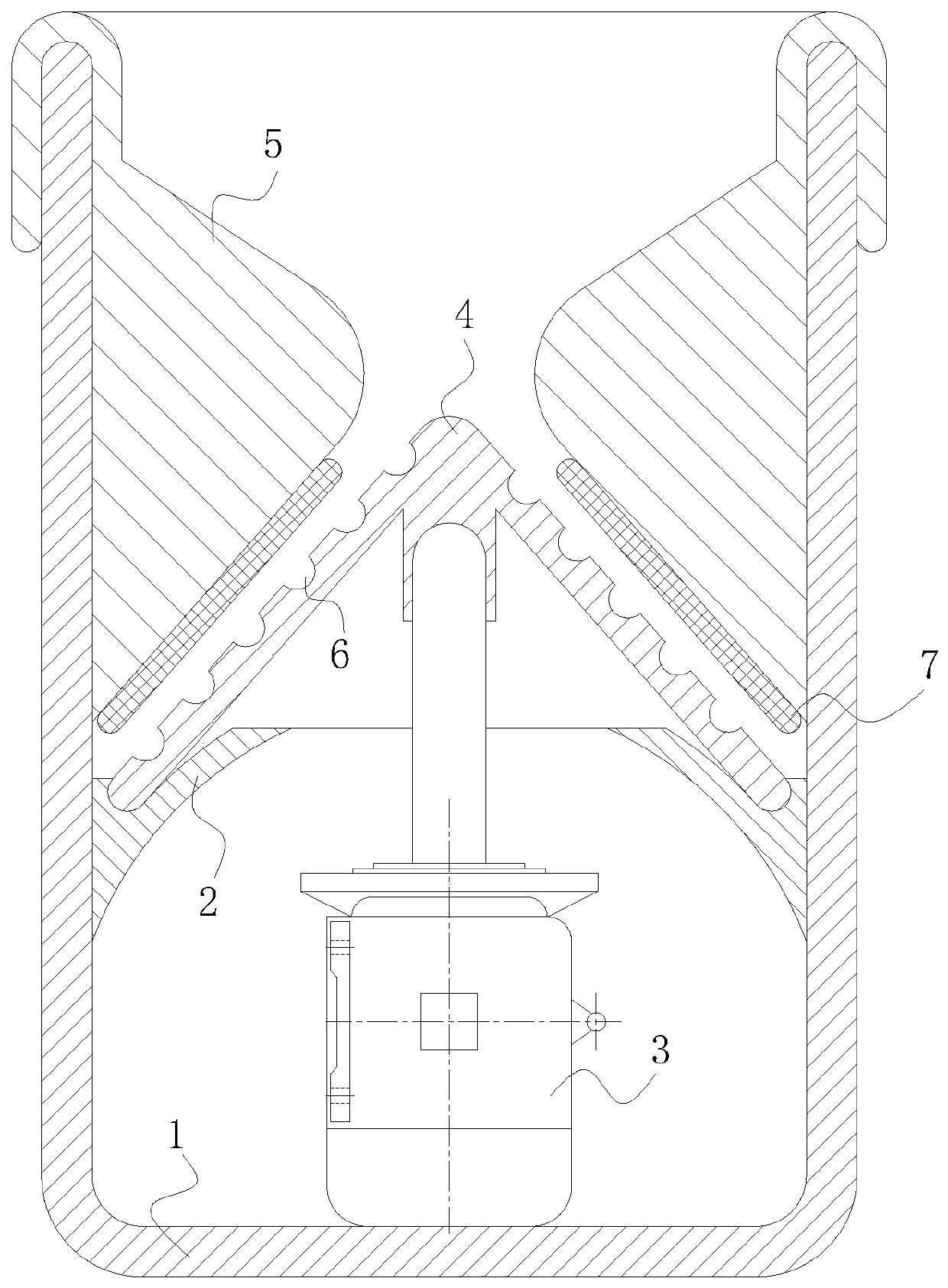

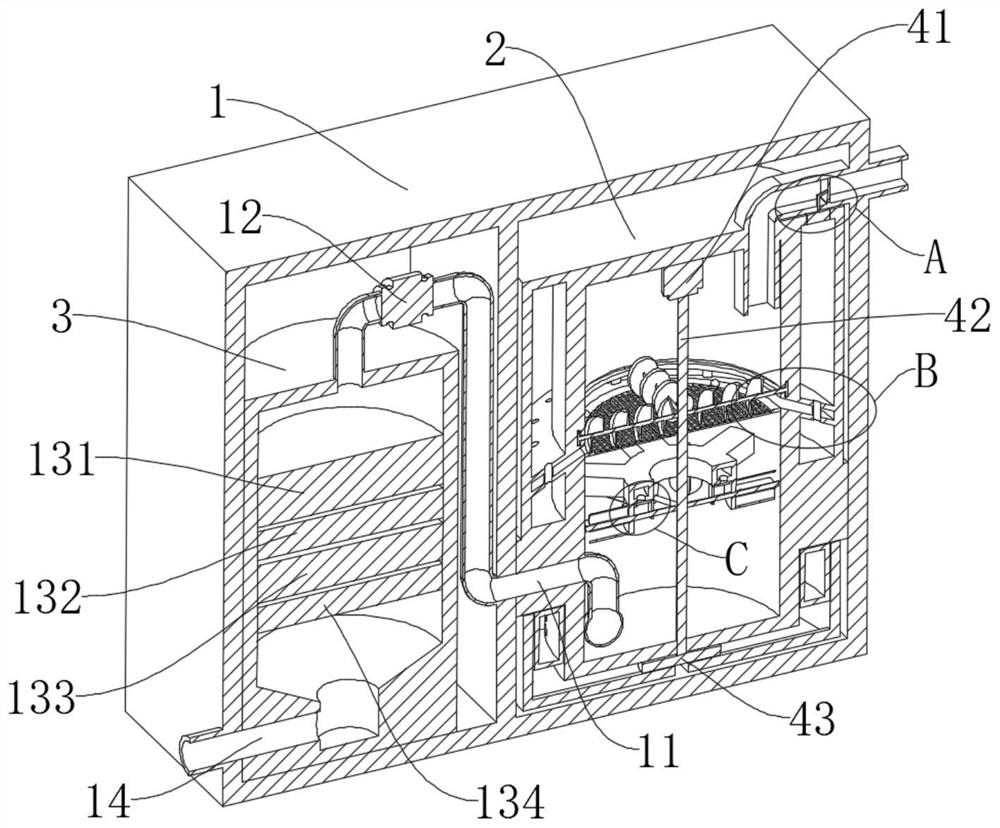

Meal replacement powder and preparation method thereof

InactiveCN111053240APromotes grinding mixing efficiency and effectivenessKeep healthyMilk preparationGrain treatmentsPumpkin seedFunctional food

The invention belongs to the technical field of health-care functional food and specifically relates to meal replacement powder and a preparation method thereof. The preparation method comprises the following steps: respectively weighing, in parts by mass, 20 parts of coix seeds, 4 parts of sweet potato powder, 6 parts of goat milk powder, 7 parts of walnut kernels, 12 parts of black sesame, 3 parts of Chinese yam powder, 9 parts of pumpkin seed kernel, 12 parts of Chinese dates, 15 parts of wheat germ powder and 20 parts of raisin for later use; and cleaning and drying the coix seeds, the walnut kernels and the black sesame, cleaning and denucleating the Chinese dates, carrying out draining, and performing drying in a drying machine. The meal replacement powder is mainly used for solvingthe problems that conventional meal replacement powder contains a large number of substances which cannot be eaten by pregnant women and easily affects the health of the pregnant women, and the conventional meal replacement powder cannot be used for solving a series of reactions such as inappetence, nausea and emesis.

Owner:广州高馨能生物科技有限公司

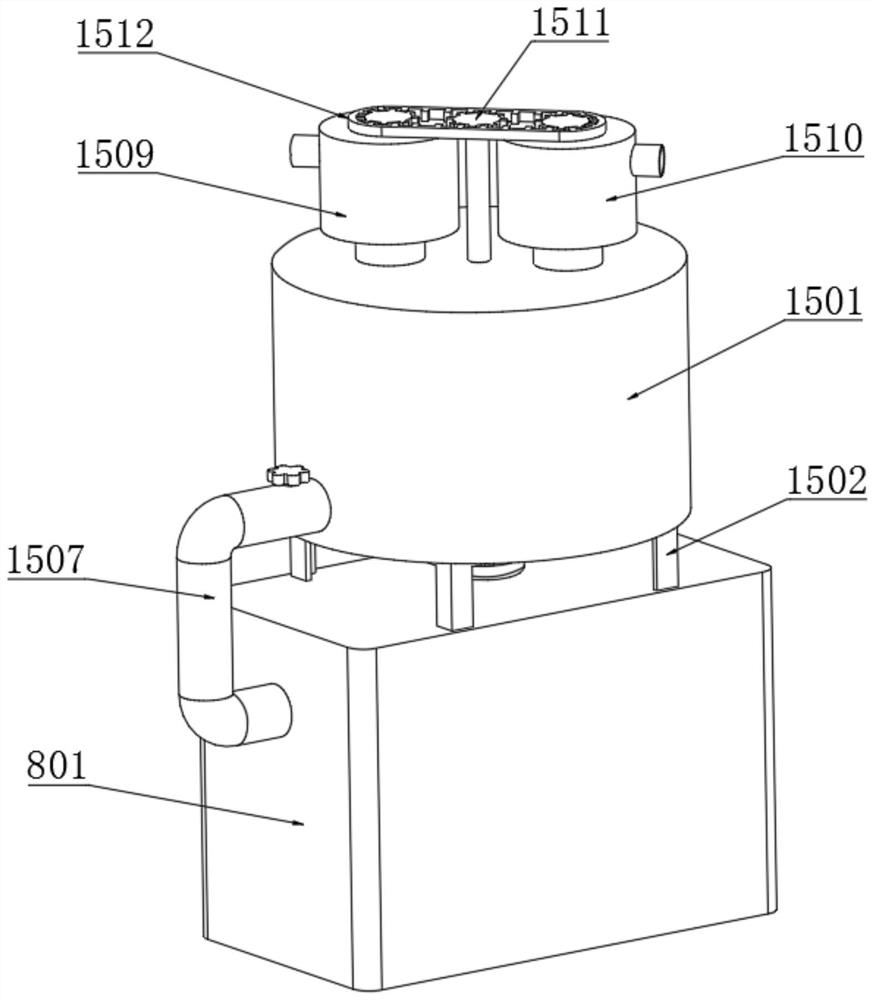

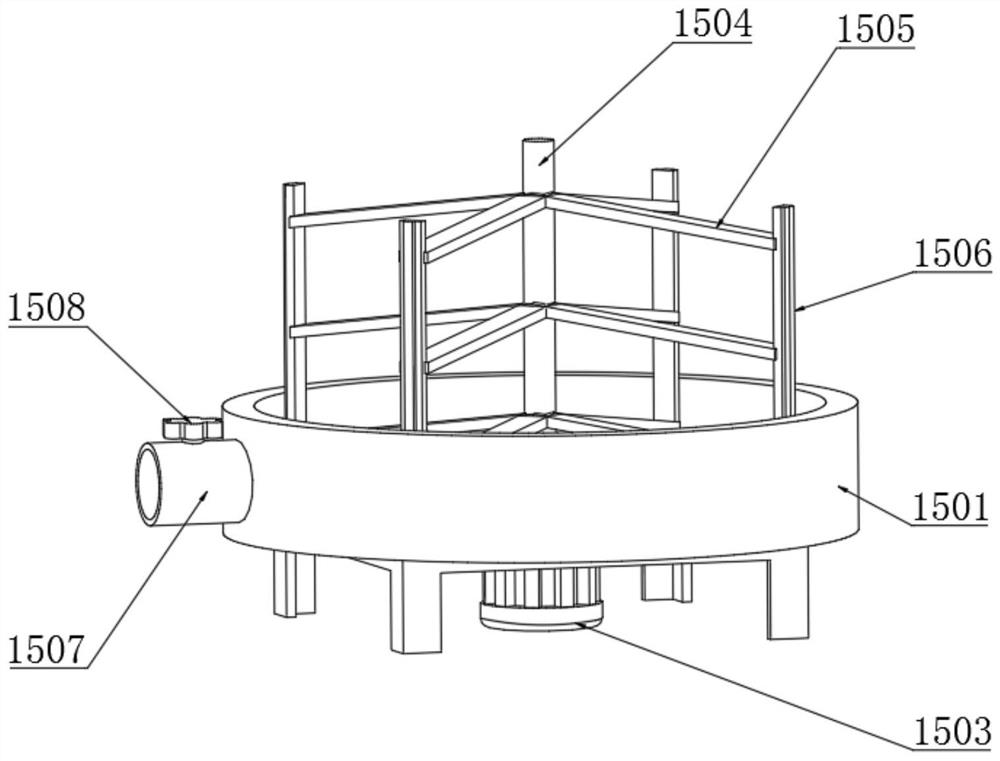

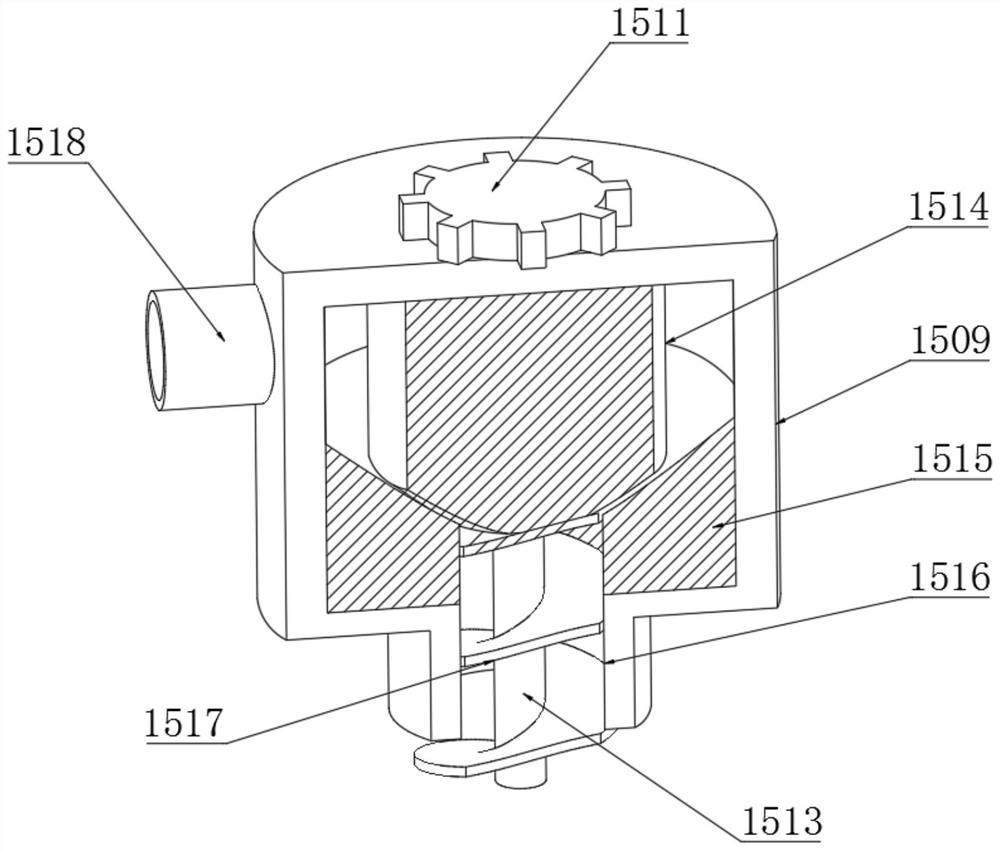

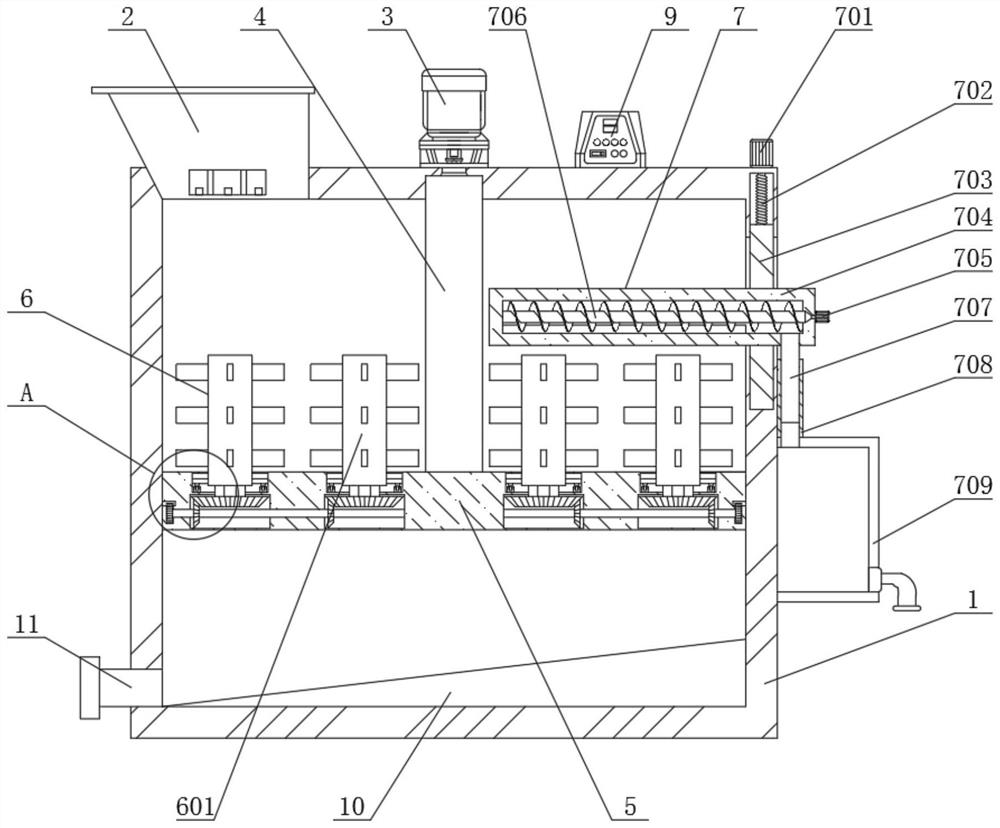

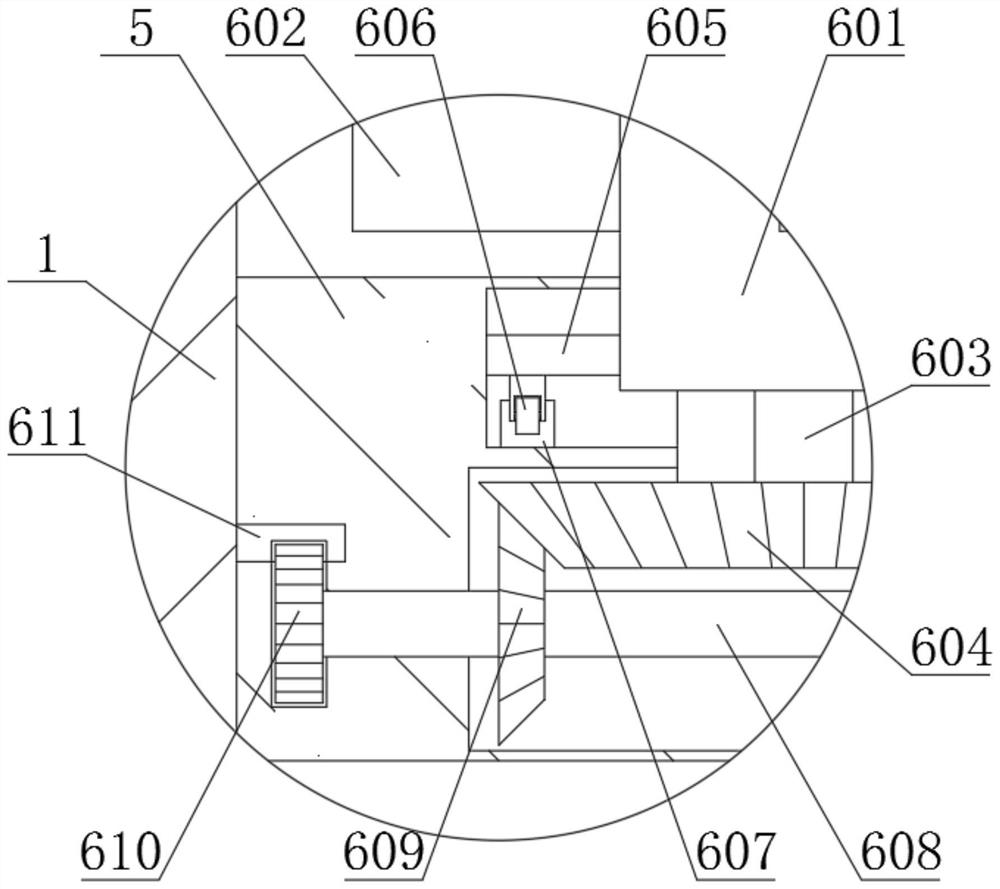

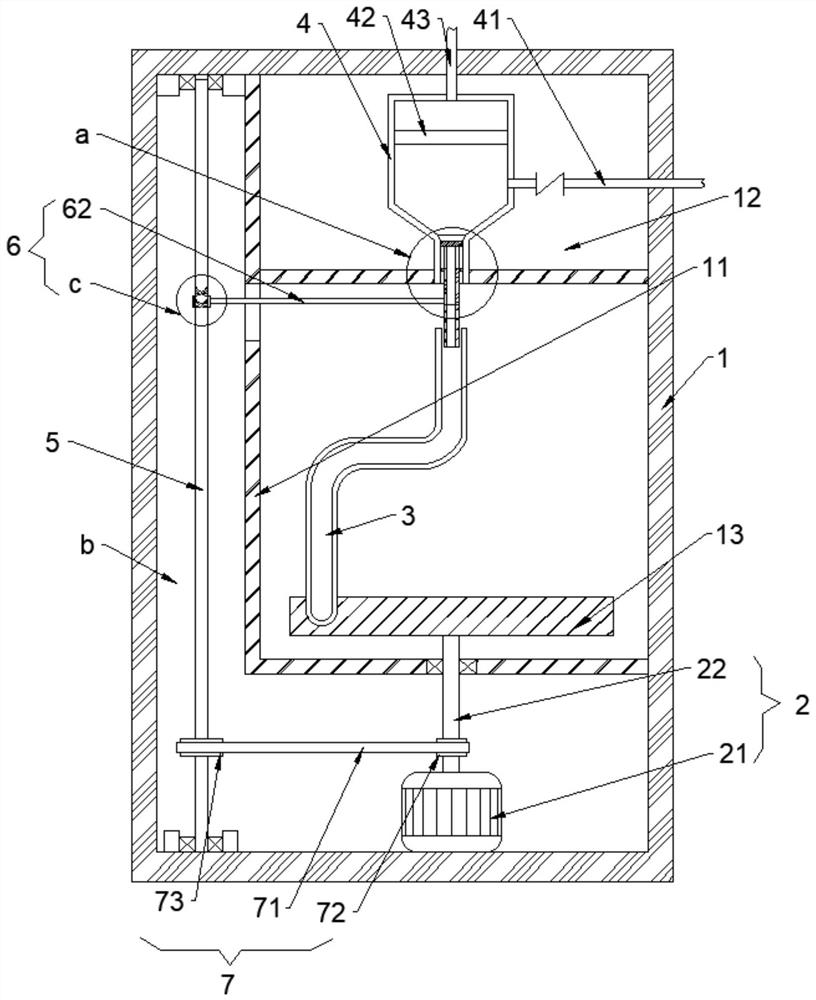

Full-automatic multifunctional multipurpose energy-saving environment-friendly water purification equipment

InactiveCN114105408AEffective adsorption treatmentGuaranteed processing efficiencySpecific water treatment objectivesTreatment involving filtrationStructural engineeringSewage treatment

The invention discloses full-automatic multifunctional multi-purpose energy-saving environment-friendly water purification equipment, and relates to the technical field of water purification, the full-automatic multifunctional multi-purpose energy-saving environment-friendly water purification equipment comprises a box body, when the full-automatic multifunctional multi-purpose energy-saving environment-friendly water purification equipment works, through revolution of a conveying roller, a transmission gear is driven to move along the inner side wall of a tooth groove, and due to the fact that the transmission gear is meshed with the tooth groove, the transmission gear is driven to rotate; the conveying rollers rotate, the conveying rollers rotate, the magnetic blocks arranged on the outer side walls of the conveying rollers and the cross rods of the filter screen are intermittently and magnetically arranged, so that the elastic cross rods are driven to shake while the conveying rollers rotate, impurities accumulated on the surface and in the filter screen are effectively extruded, and in the process, the impurities in the filter screen are effectively removed. Due to the autorotation of the conveying roller, the conveying roller intermittently pushes the push block, so that the filter screen is shaken, the filter screen is prevented from being blocked, impurities accumulated at the top of the filter screen are effectively conveyed, the filter screen is ensured to have a good filtering effect, and the sewage treatment efficiency is further ensured.

Owner:黄茜

Alkyd resin production device

PendingCN112387185AAchieve hybridGuaranteed mixing efficiencyTransportation and packagingMixersPolymer scienceEngineering

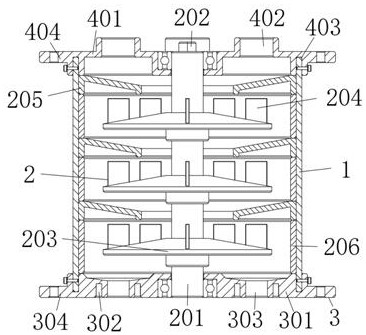

The invention discloses an alkyd resin production device which comprises a sleeve shell, a mixing mechanism is installed in the sleeve shell, plug blocks are machined at the top ends of first rotatingshafts, the multiple first rotating shafts are connected in a sleeving mode through the plug blocks, and the outer walls of the first rotating shafts are evenly and fixedly connected with multiple rotating discs. A plurality of vertical plates are evenly and fixedly connected to the upper surfaces of the rotating discs, baffle rings are arranged above the rotating discs, sleeves are attached to the lower surfaces of the baffle rings, the lower surfaces of the sleeves are attached to the upper surfaces of the baffle rings below the sleeves, and the outer walls of the baffle rings and the outerwalls of the sleeves are connected with the inner wall of the sleeve shell in a sleeving mode. The alkyd resin production device can effectively realize mixing of various materials, can realize multi-stage mixing according to actual requirements so as to ensure the mixing efficiency, does not stop in the material mixing process, can ensure the completion of mixing operation when materials are output, saves the working time, and is simple in use method, high in practicability and convenient to popularize.

Owner:曾维权

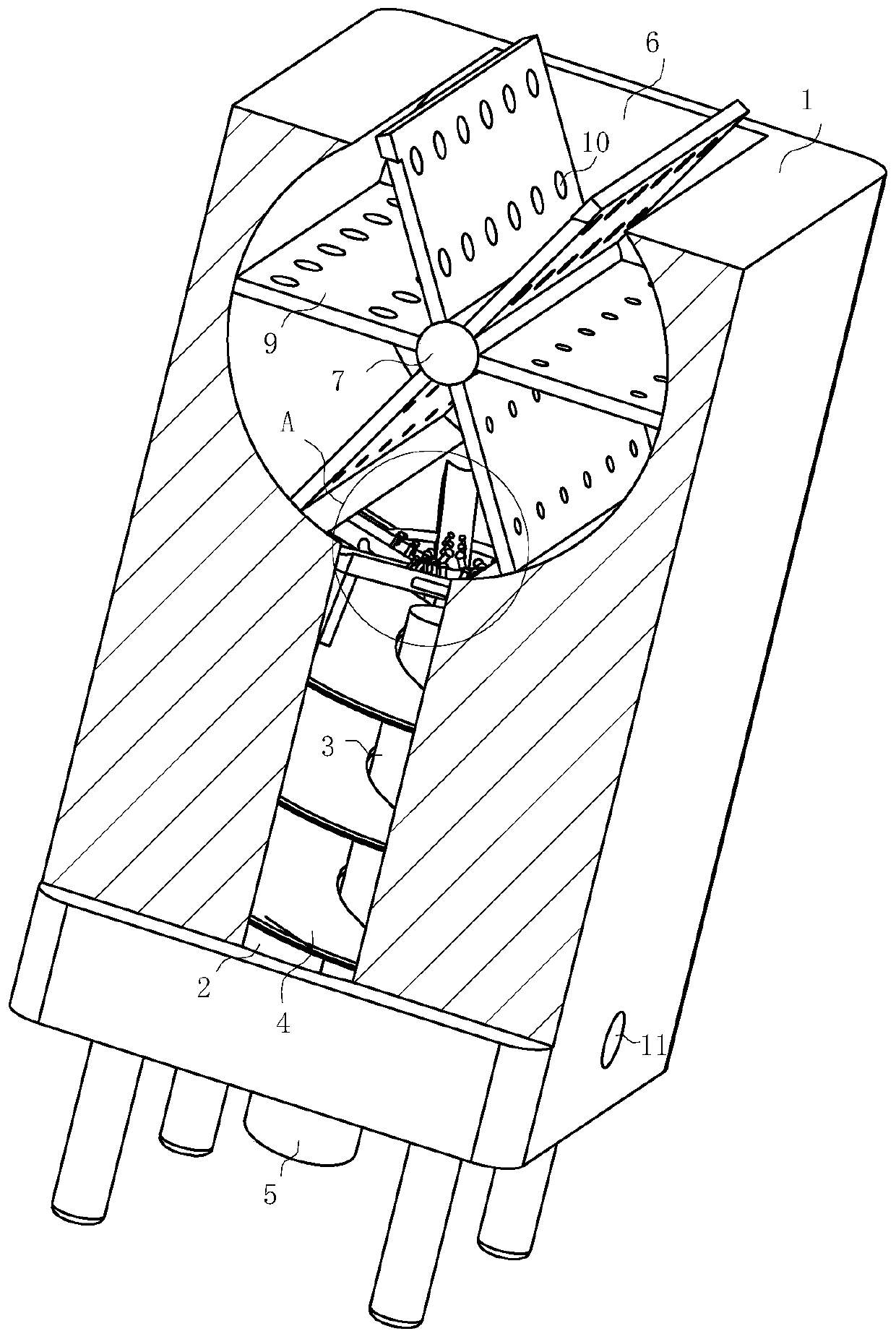

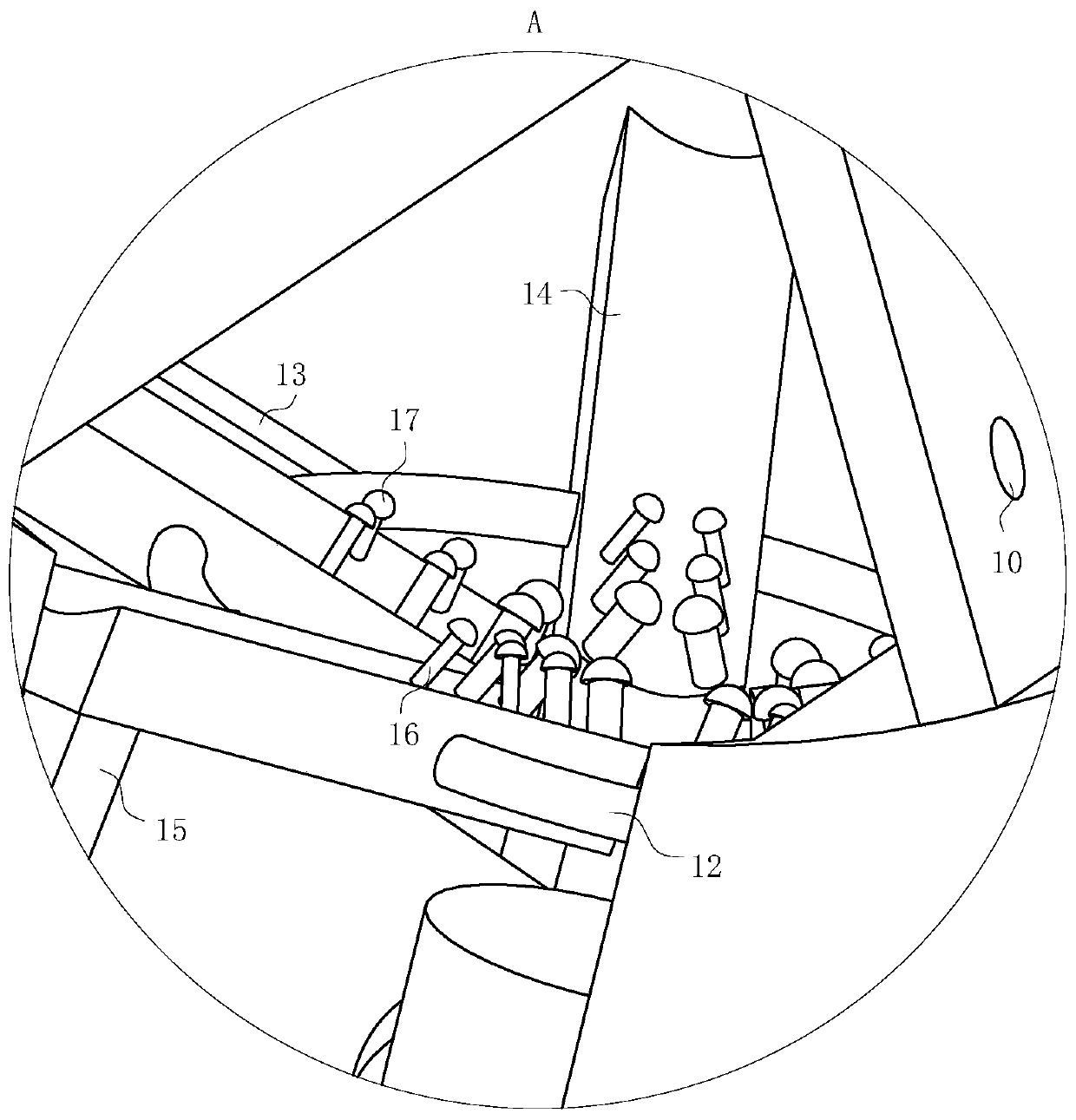

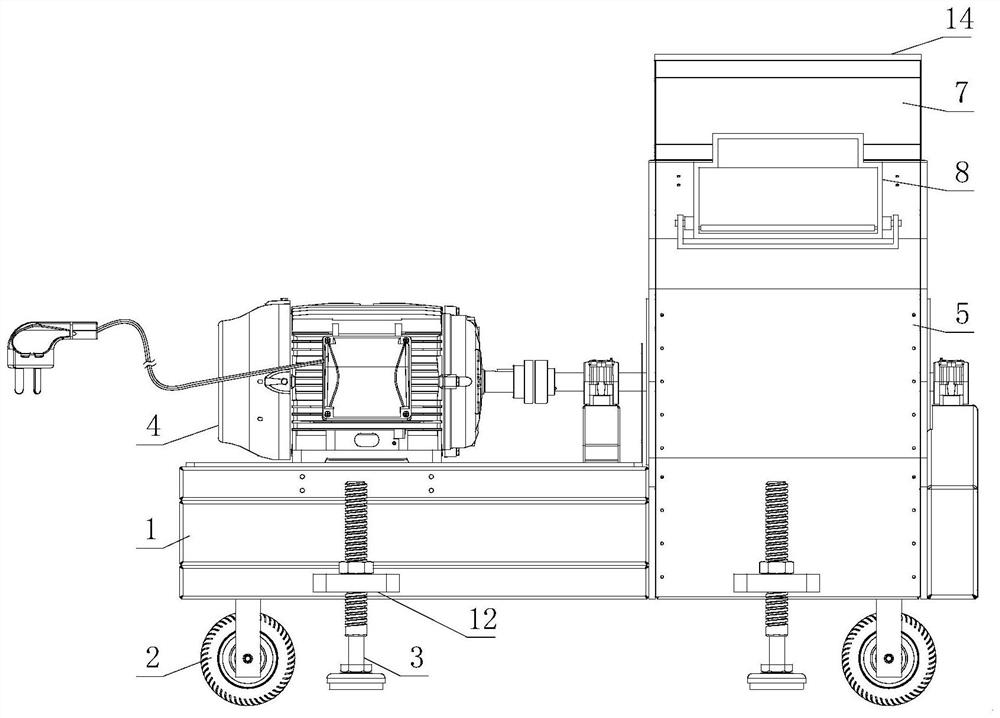

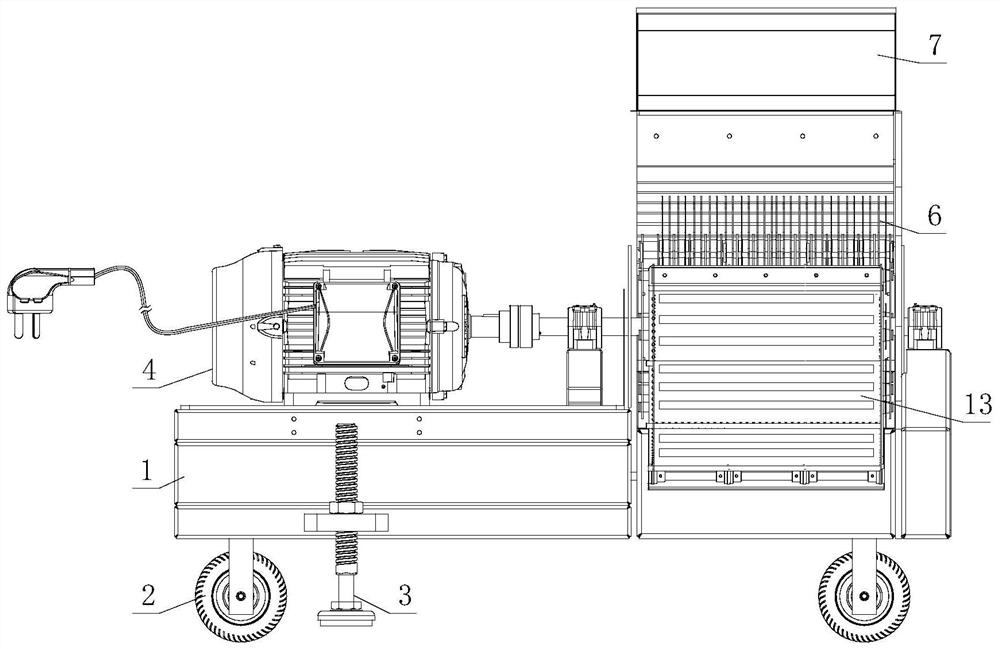

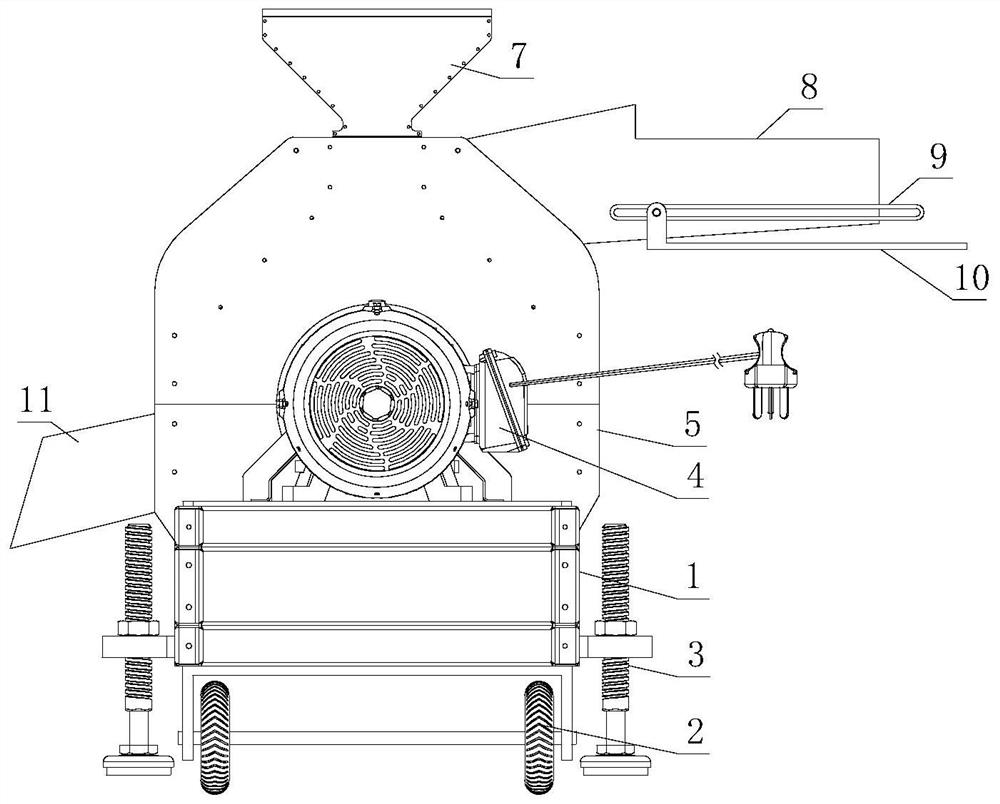

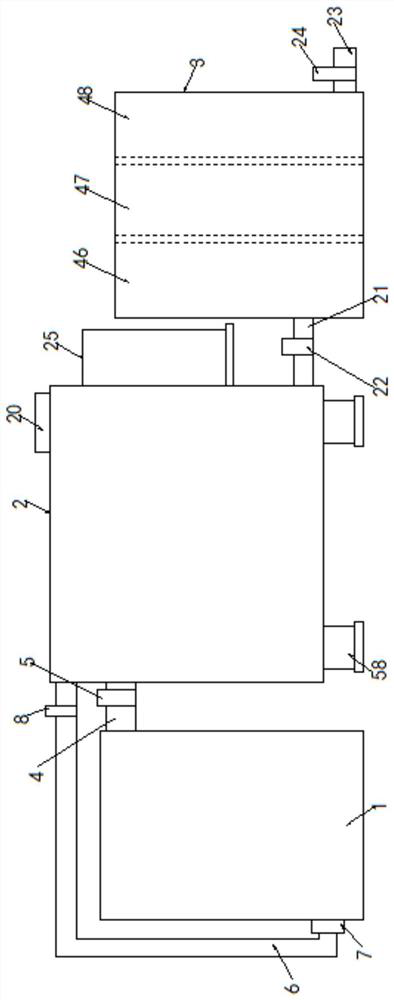

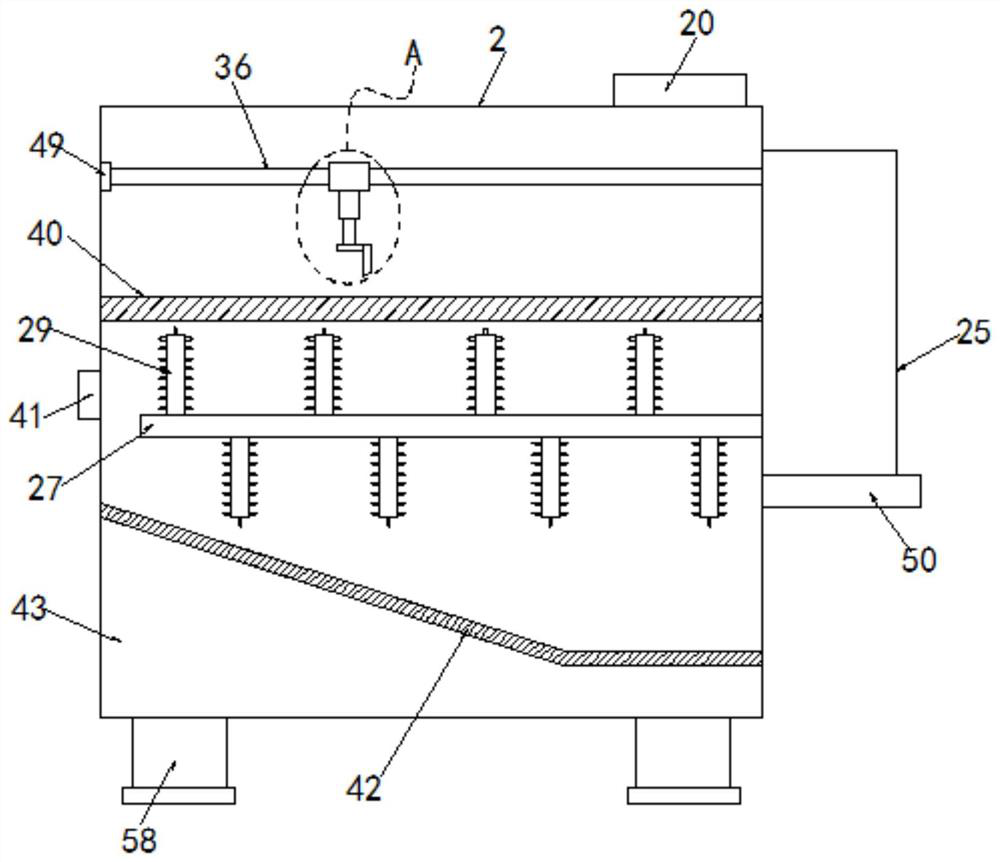

Novel biomass pellet production and processing equipment in field of new energy

InactiveCN109225005AEasy to mix and handleFully and effectively mixed treatmentShaking/oscillating/vibrating mixersTransportation and packagingNew energyEngineering

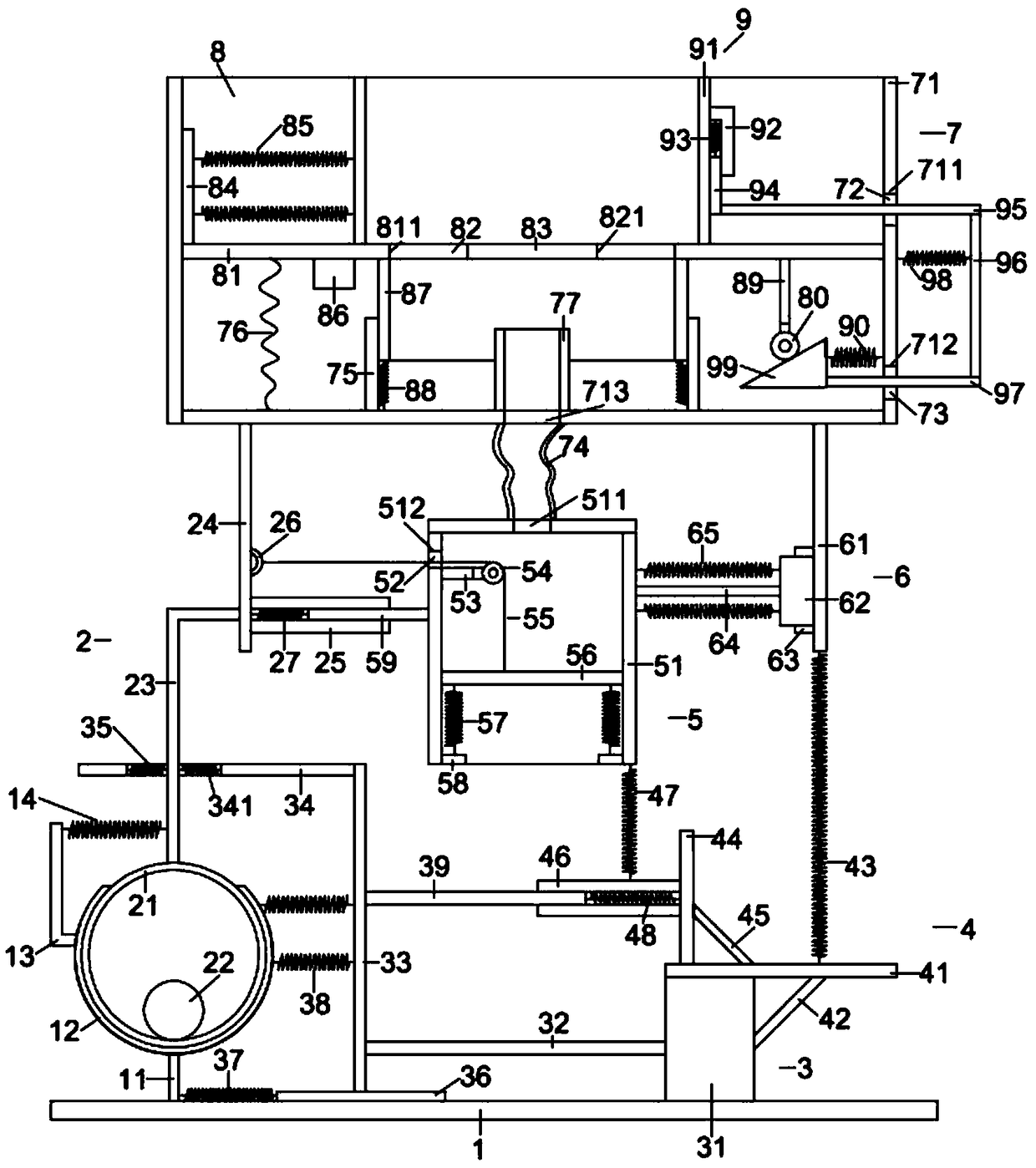

The invention relates to novel biomass pellet production and processing equipment in the field of new energy. The novel biomass pellet production and processing equipment comprises a bottom plate, a connecting device positioned above the bottom plate, a push device arranged on the bottom plate, a locating device arranged on the push device, a piston device arranged on the locating device, a driving device arranged at the right side of the piston device, a frame body device located above the piston device, a lifting device contained in the frame body device, and a mixing frame device arranged on the frame body device. The novel biomass pellet production and processing equipment can realize the sufficient and effective mixing treatment of biomass pellets, and is sufficient in mixing; furthermore, the biomass pellets can be driven to fully roll, so that the biomass pellets are comprehensively mixed, and the mixing efficiency of the biomass pellets is increased; a mixing frame is driven tomove left and right by means of the up and down movement of a lifting plate, and the air ejected upwards can be sprayed onto the biomass pellets through filter holes of a filter screen, so that the mixing of the biomass pellets is promoted.

Owner:SHENZHEN ANSIKE ELECTRONICS TECH CO LTD

Ecological antibiotic-free black goat breeding method based on agricultural product leftovers

ActiveCN113508781ANutritional balanceImprove immunityFeeding-stuffFood processingAnimal scienceNutrition

The invention relates to an ecological antibiotic-free black goat breeding method based on agricultural product leftovers. A TMR mode is adopted for the feeding, and the weight ratio of concentrated feed to coarse feed of TMR is 3-5 to 5-7; the coarse feed is a mixture of sugarcane tail leaves, jasmine flower residues and honeysuckle flower residues; and the coarse feed is put into a small-sized simple TMR production device, stirring is conducted for 10-15 minutes, then the concentrated feed is put into the small-sized simple TMR production device, continuously stirring is conducted for 5-10 minutes, the stirring is stopped, and the black goats is fed with the feed. According to the ecological antibiotic-free black goat breeding method, the sugarcane tail leaves are cut and crushed in advance and then mixed with the jasmine flower residues, the honeysuckle flower residues and the concentrated feed, kneaded and ground into the total mixed ration for feeding the goats, so that the nutrition balance of the goats is ensured, the immunity of the goats is improved, and the goats are bred by combining improved variety breeding, environmental control and health and epidemic prevention, and the disease incidence rate of the goats is obviously reduced, so that green and antibiotic-free ecological breeding is realized.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION INST OF ANIMAL HUSBANDRY

Waste liquid treatment device for ecological environment construction

ActiveCN114163008AGuaranteed processing efficiencyAvoid cloggingSpecific water treatment objectivesTreatment involving filtrationEcological environmentFiltration

The invention discloses a waste liquid treatment device for ecological environment construction, and relates to the technical field of ecological environment, the waste liquid treatment device comprises a shell, and a driving device is mounted on the shell; due to the fact that the bottom of a cleaning plate is attracted to the top of an elastic rod, when the cleaning plate slides, the elastic rod deforms upwards, a second S-pole magnet pushes large impurities filtered at the top of a filter plate into a first collecting box, and when the second S-pole magnet rotates to the first S-pole magnet from the N-pole magnet, the second S-pole magnet rotates to the first S-pole magnet from the N-pole magnet. When the filter screen is filtered, a second S-pole magnet is pushed to slide inwards, so that a pull rope is loosened, and then impurities at the top of the filter screen are pushed into a second collecting box by a cleaning plate, so that the impurities are effectively cleaned, the top of the filter screen and filter holes of the filter screen are prevented from being blocked by the impurities subjected to secondary filtration, and the filtering effect of the filter screen is prevented from being influenced; and impurities generated after filtration are cleaned, the burden of personnel is relieved, the waste liquid treatment efficiency is guaranteed, and the device is convenient to use by the personnel.

Owner:广东粤海水务检测技术有限公司

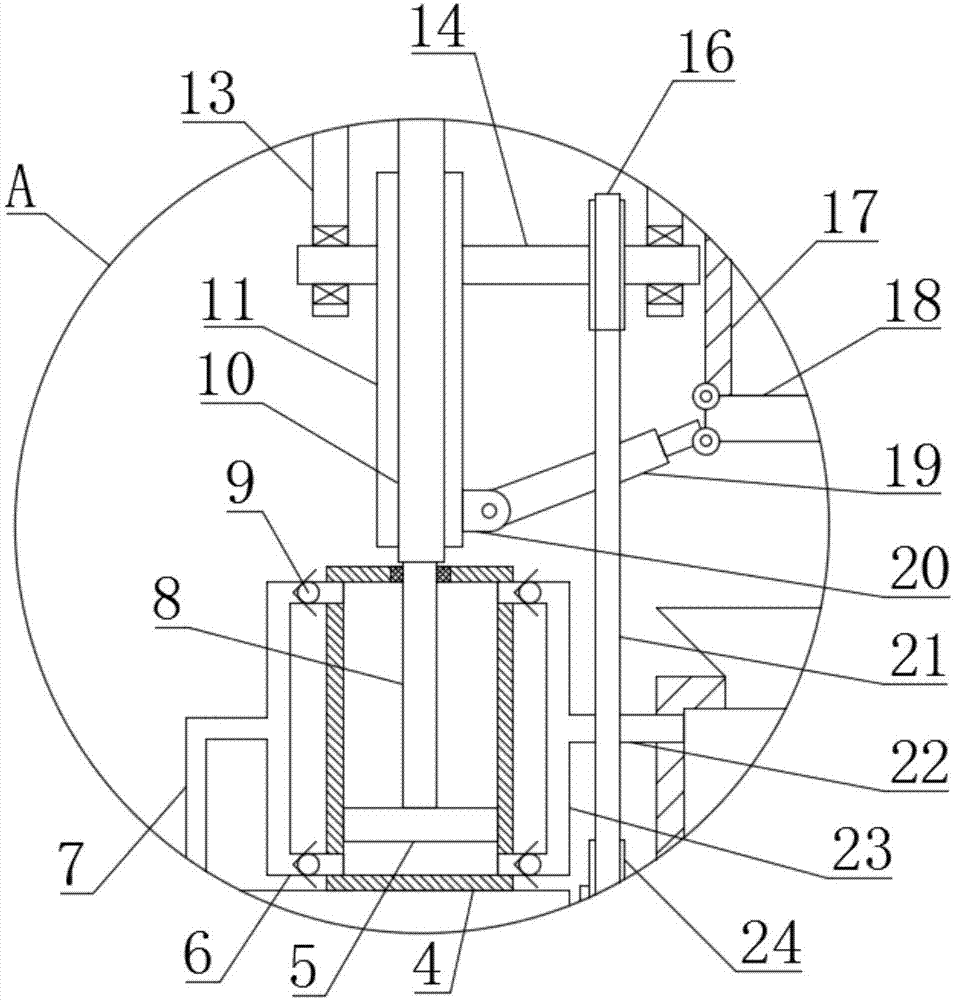

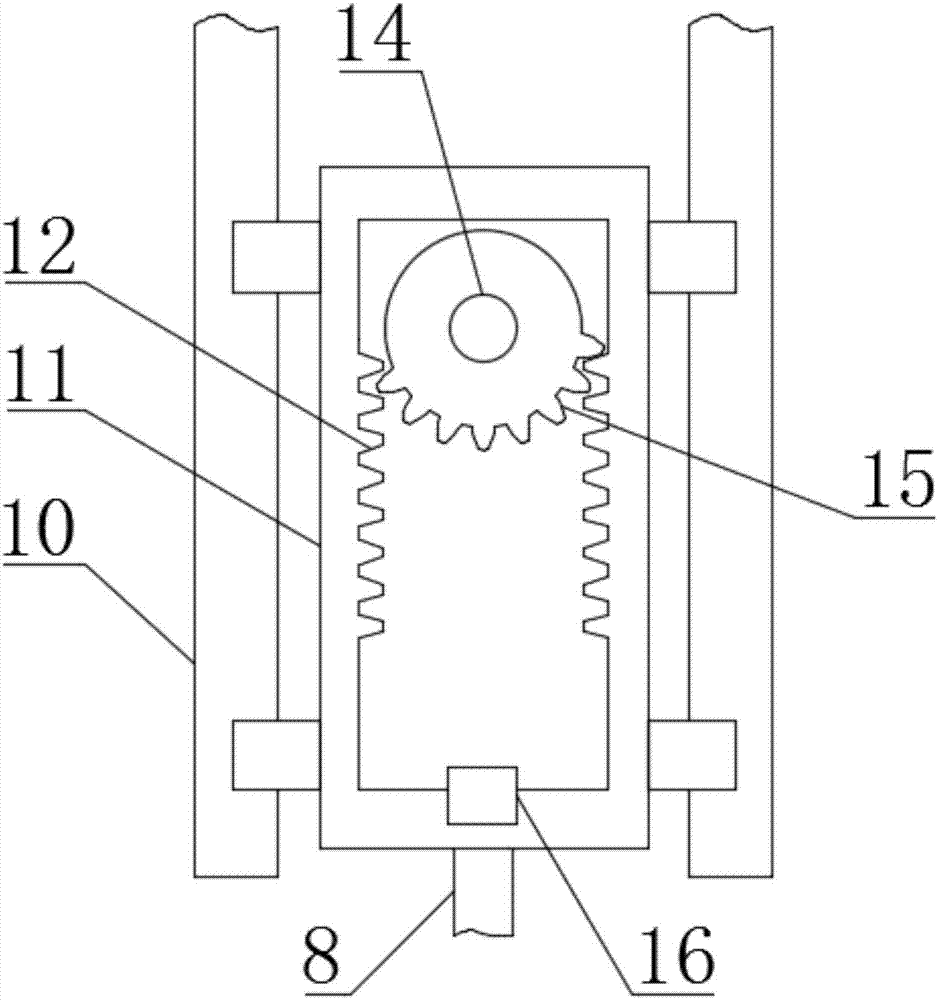

Seed pesticide mixing device with stirring mechanism for agricultural machinery and using method thereof

InactiveCN112675746ARealize up and down movementDrug mixing to achieveShaking/oscillating/vibrating mixersRotary stirring mixersAgricultural engineeringMechanical engineering

The invention relates to the technical field of pesticide mixing devices, in particular to a seed pesticide mixing device with a stirring mechanism for agricultural machinery and a using method thereof. The seed pesticide mixing device comprises a pesticide mixing box, the top end of the pesticide mixing box communicates with a feeding hopper, a first motor is fixedly connected to the center of the top end of the pesticide mixing box, and a transmission shaft is fixedly connected to the tail end of a main shaft of the first motor; the bottom end of the transmission shaft is fixedly connected with a rotary discharging disc, a rotary pesticide stirring mechanism is arranged on the inner side of the rotary discharging disc, the rotary pesticide stirring mechanism comprises a pesticide stirring rod, pesticide stirring blades, a polygonal shaft rod, a first bevel gear, a connecting rod, a second bevel gear, a spur gear and a gear ring, and the outer end face of the pesticide stirring rod is fixedly connected with the pesticide stirring blades. By arranging the rotary pesticide stirring mechanism, in the rotating process of the rotary discharging disc, a pesticide stirring rod can drive pesticide stirring blades to stir seeds, pesticide stirring of the seeds is achieved, the pesticide stirring efficiency of the seeds is guaranteed, and therefore the yield of crops is increased.

Owner:沈慧红

Dust monitoring type moving dust removal mixing system for workshop

InactiveCN106310845AImprove the mixing effectIncrease the ash feeding speedUsing liquid separation agentAerospace engineeringEngineering

The invention relates to a dust monitoring type moving dust removal mixing system for a workshop. The mixing system comprises a dust removal mixing tube mounted in the workshop, wherein the dust removal mixing tube comprises a front-mounted dust removal section and a rear-mounted mixing section; the dust removal section is connected with a dust remover; a plurality of acceleration jet tubes are obliquely mounted on the outer wall of the dust removal section; the jet direction of jet holes at the inner ends of the jet tubes inclines to the dust entering direction and faces to the center of the dust removal section; the jet tubes are connected with a gas pump; a water spraying device is mounted on the mixing section; the water spraying device comprises a front-mounted water spraying cavity and a rear-mounted water spraying cavity which are mounted on the outer wall of the mixing section; the front-mounted water spraying cavity and the rear-mounted water spraying cavity are connected with a high pressure water pump through pipelines; a front-mounted spray hole communicated with the mixing section is formed in the inner wall of the front-mounted water spraying cavity; a rear-mounted spray hole communicated with the mixing section is formed in the inner wall of the rear-mounted water spraying cavity; the mixing system also comprises a detection control device; and the detection control device comprises a controller and a dust sensor mounted at the front end of the dust removal section.

Owner:无锡派乐科技有限公司

Glue solution raw material mixing machine for bottle body production

InactiveCN113244825AAchieve spoilerImprove mixing efficiencyShaking/oscillating/vibrating mixersFlow mixersBLENDER/MIXEREngineering

The invention relates to the field of bottle production, and especially relates to a glue solution raw material mixing machine for bottle body production. The mixing machine comprises a stirring mechanism mounted on a mixing box and comprising a driving assembly, an oscillating assembly, a stirring assembly and a spraying assembly; and the oscillating assembly is connected with the driving assembly, the stirring assembly is connected with the oscillating assembly, and the spraying assembly is connected with the stirring assembly. According to the structural arrangement of the device, when the device works, the stirring assembly is driven to rotate through the driving assembly to stir raw materials, meanwhile, the oscillating assembly is started, the stirring assembly is driven to oscillate at a high speed in a small range under the action of the oscillating assembly, and turbulent flow of the raw materials is achieved, so the stirring and mixing efficiency and quality are improved; the spraying assembly is arranged, under the action of the oscillating assembly, the spraying assembly is driven by vibration of the stirring assembly to absorb and spray raw materials, the raw materials are further disturbed while the positions of the raw materials are changed, and the mixing efficiency and quality are greatly guaranteed.

Owner:山东奥扬新能源科技股份有限公司

Wastewater treatment device

InactiveCN111925030AImprove purification efficiencySimple structureWater/sewage treatment by irradiationSpecific water treatment objectivesElectric machineryStructural engineering

The invention discloses a wastewater treatment device. The wastewater treatment device comprises a storage box, a reaction box and a purification box; one side edge of the top end of the storage box is fixed with one side edge of the top of the reaction box through a connecting pipe II; a valve II is fixed on the connecting pipe II; the bottom of one side, away from the connecting pipe II, of thestorage box is connected with the top end of the reaction box through a connecting pipe I; the connecting pipe I is connected with the storage box through a water pump; a valve I is fixed at one end,close to the reaction box, of the connecting pipe I; and a sliding groove I is fixed to the top end in the storage box. A sliding plate matched with the sliding groove I is connected into the first sliding groove in a sliding mode. An electric telescopic rod II is fixed at the bottom end of the sliding plate; an extrusion plate is fixed at the bottom end of the electric telescopic rod II; and a filter plate II is connected to the position, located below the extrusion plate, in the storage box, a sliding sleeve II is fixed to one side of the middle of the bottom end of the filter plate II and slidably connected to the outer side of a threaded rod II, and one end of the threaded rod II penetrates through the storage box, extends to the outer side of the storage box, and is connected with theoutput shaft of a motor II.

Owner:吴科文

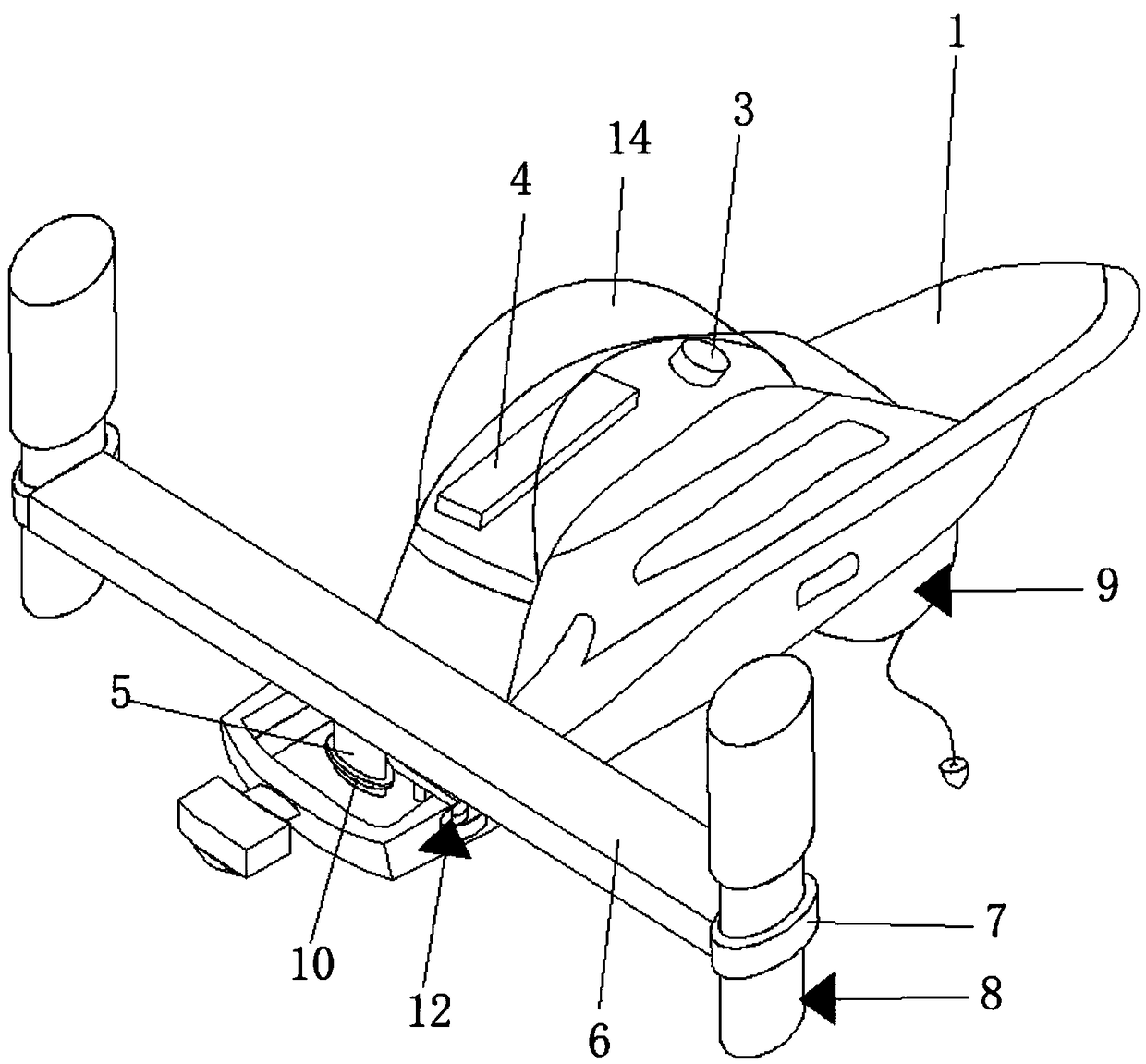

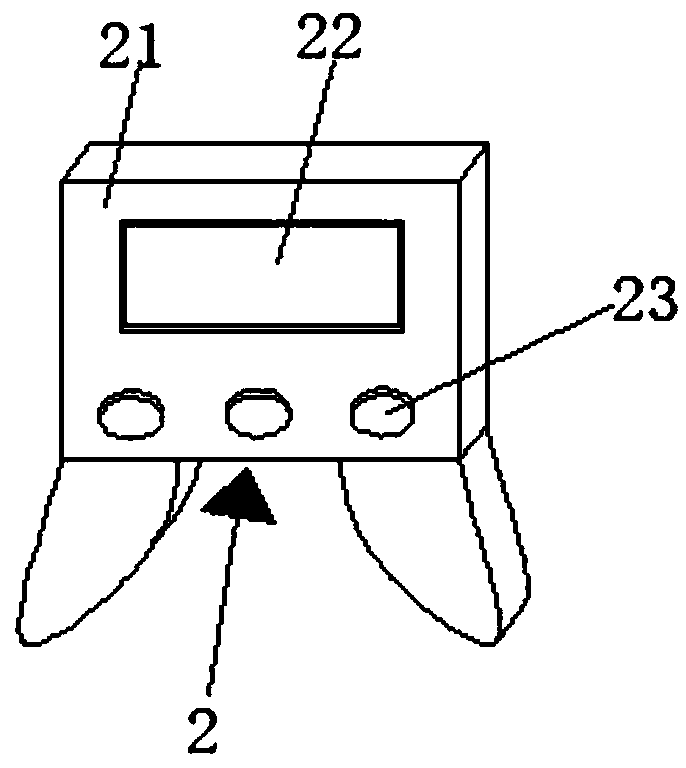

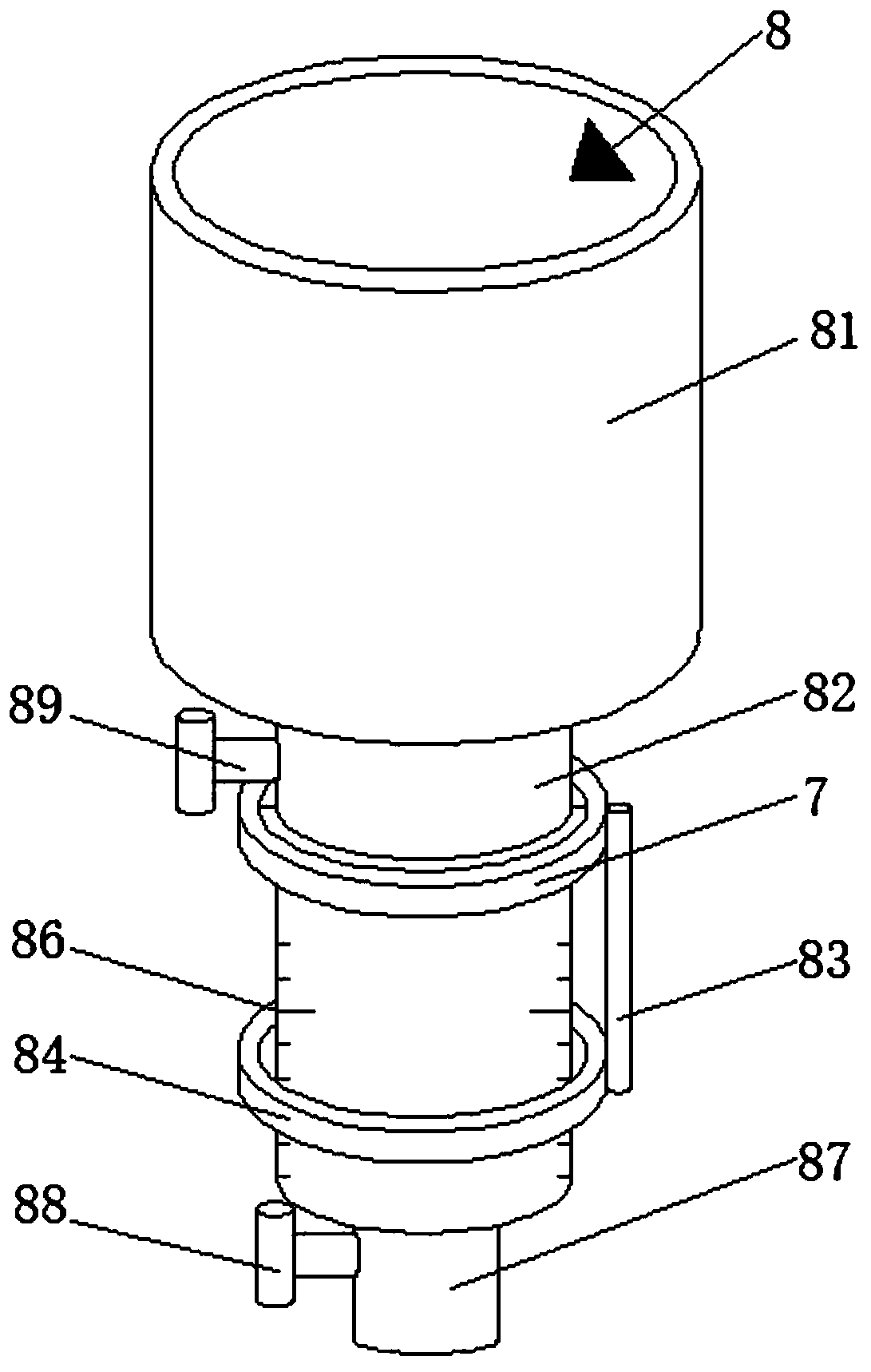

Coagulant feeding device for swimming pools

InactiveCN109384296AImprove mixing efficiencyImprove uniformityWater/sewage treatment by flocculation/precipitationGratingRemote control

The invention discloses a coagulant feeding device for swimming pools, and belongs to the technical field of water treatment equipment. The coagulant feeding device for the swimming pools comprises aremote control boat main body, a remote control, a central processing unit and a grating sensor, wherein the central processing unit and the grating sensor are both connected to the remote control boat main body, a horizontal cross plate is connected with the tail end of the remote control boat main body through a rotating shaft, quantitative feeding assemblies are connected to two ends of the cross plate through bushings, and a turbidity measuring assembly is connected to the bottom of the remote control boat main body. The feeding quantity of a coagulant can be determined according to turbidity of pool water, so that the coagulant is moderately fed, feeding uniformity is excellent, the mixing rate of the coagulant is stable, and the stable coagulation effect is further ensured.

Owner:大连识汇岛科技服务有限公司

Waste-heat-available mixing device based on rare earth waste and processing technology of waste-heat-available mixing device

ActiveCN113908735AAvoid affecting processingEnsure the efficiency of follow-up processingRotary stirring mixersTransportation and packagingThermodynamicsFiltration

The invention discloses a waste heat available mixing device based on rare earth waste and a processing technology of the waste heat available mixing device, and relates to the technical field of rare earth. The device comprises a tank body and a mixing mechanism. During use, rare earth waste and materials needing to be mixed are added through the feeding hopper, and then the servo motor is started; the servo motor rotates to drive the rotating shaft to rotate, so that the centrifugal hopper rotates, the centrifugal hopper rotates to drive the push block to rotate, and the push block intermittently pushes the baffle to rotate upwards; therefore, the bottom of the feeding hopper is intermittently opened, so that the rare earth waste and materials needing to be mixed are added into the centrifugal hopper; and then preliminary mixing of the materials needing to be mixed and the rare earth waste is achieved through rotation of the centrifugal hopper, large impurities in the rare earth waste are filtered under the action of centrifugal force, and the rare earth waste enters the filter plate for secondary filtration after being filtered; in this way, the impurities in the rare earth waste are prevented from being mixed with materials needing to be mixed to affect subsequent processing, so that the subsequent processing efficiency is guaranteed.

Owner:赣州中凯稀土材料有限公司

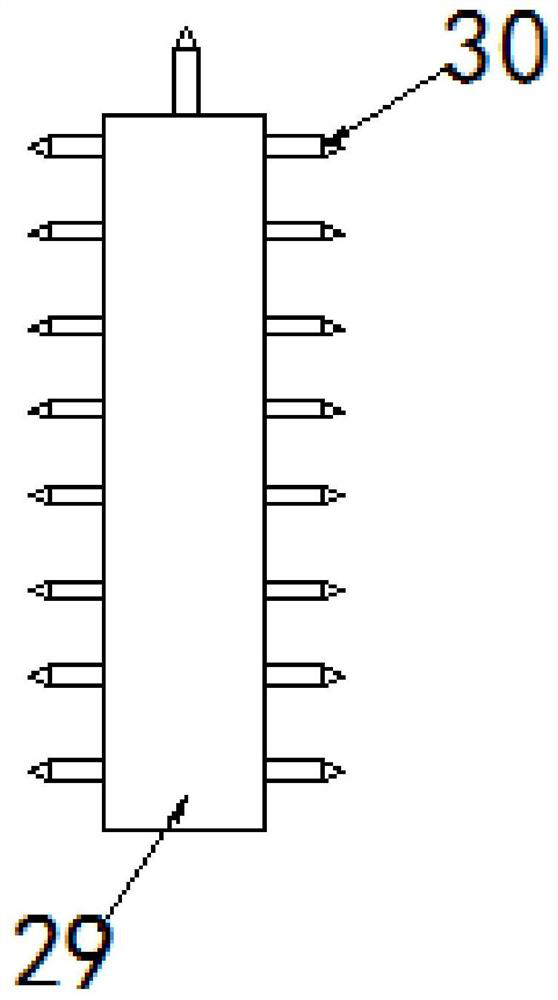

Preparation method and preparation device of exosome

PendingCN114250135AGuaranteed mixing efficiencyAvoid uneven mixingBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringExosome

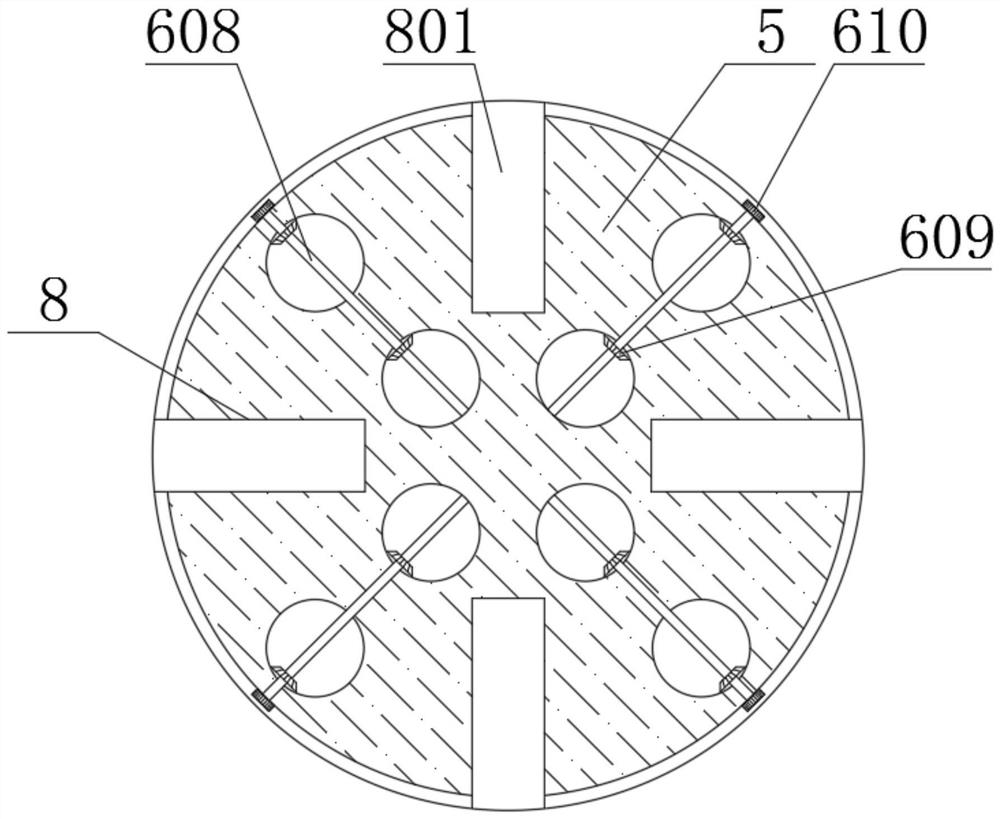

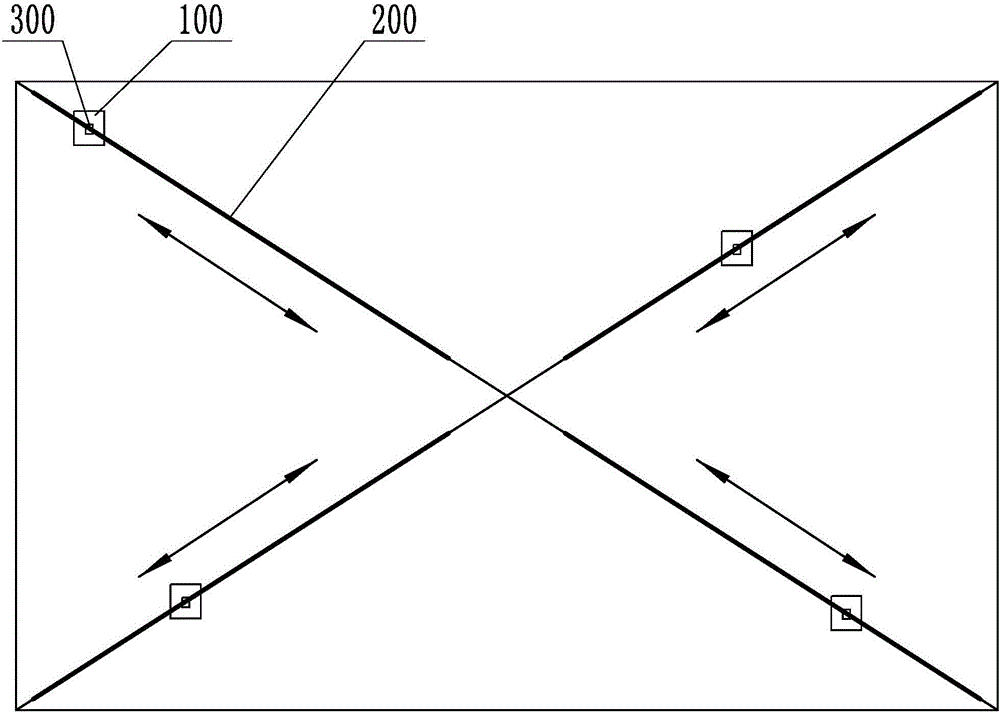

The invention provides an exosome preparation method and device, and relates to the technical field of exosome preparation.The preparation device comprises a box body and a partition frame arranged in the box body, the partition frame divides the interior of the box body into a preparation cavity and a power cavity, a rotating disc is arranged at the bottom in the preparation cavity, and a rotating mechanism is arranged in the power cavity; the rotating mechanism is used for driving the rotating disc to rotate, a treatment test tube is detachably inserted into one side of the top face of the rotating disc, a storage box is arranged at the top opening end of the treatment test tube, a bottom opening of the storage box is located over a top opening of the treatment test tube, and the storage box transfers raw materials stored in the storage box into the treatment test tube. The top opening rotation axis of the treatment test tube coincides with the rotation axis of the turntable; the intermittent feeding mechanism is arranged in the discharging pipe, so that preparation raw materials in the storage box are intermittently injected into the treatment test tube, the mixing efficiency of the preparation raw materials in the treatment test tube is guaranteed, and the preparation efficiency of the exosome is improved.

Owner:南京国青血液净化科技有限公司

Household kitchen and bath disinfection device and control method thereof

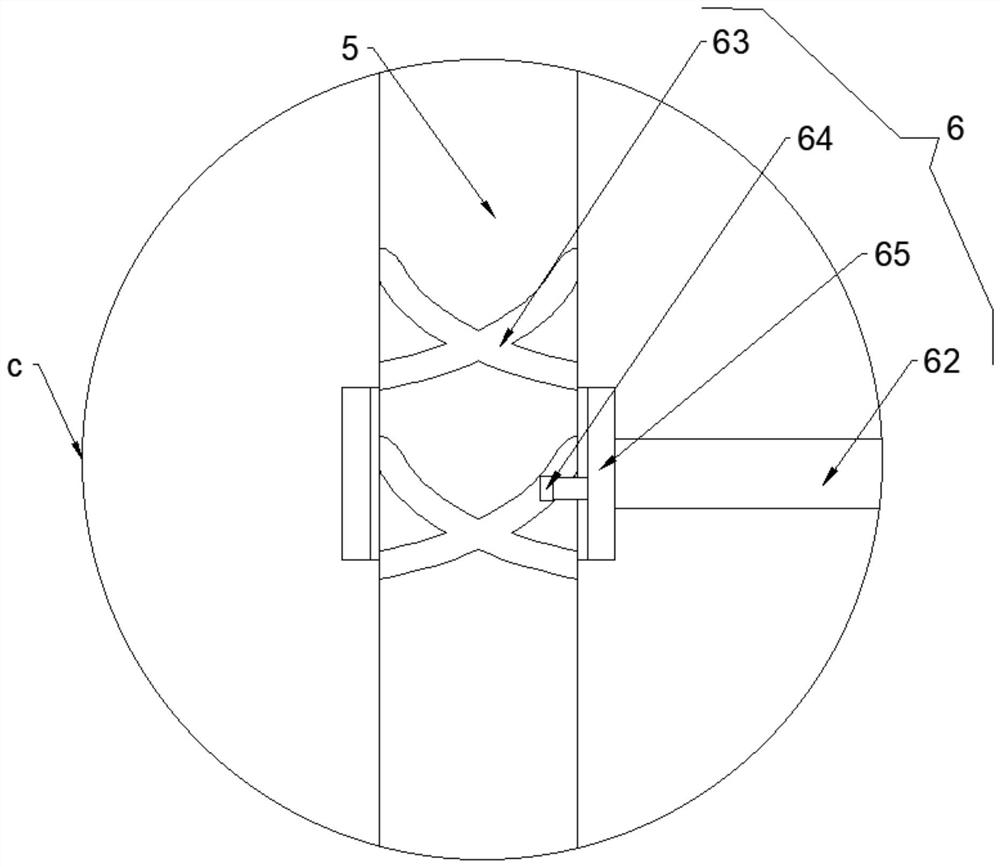

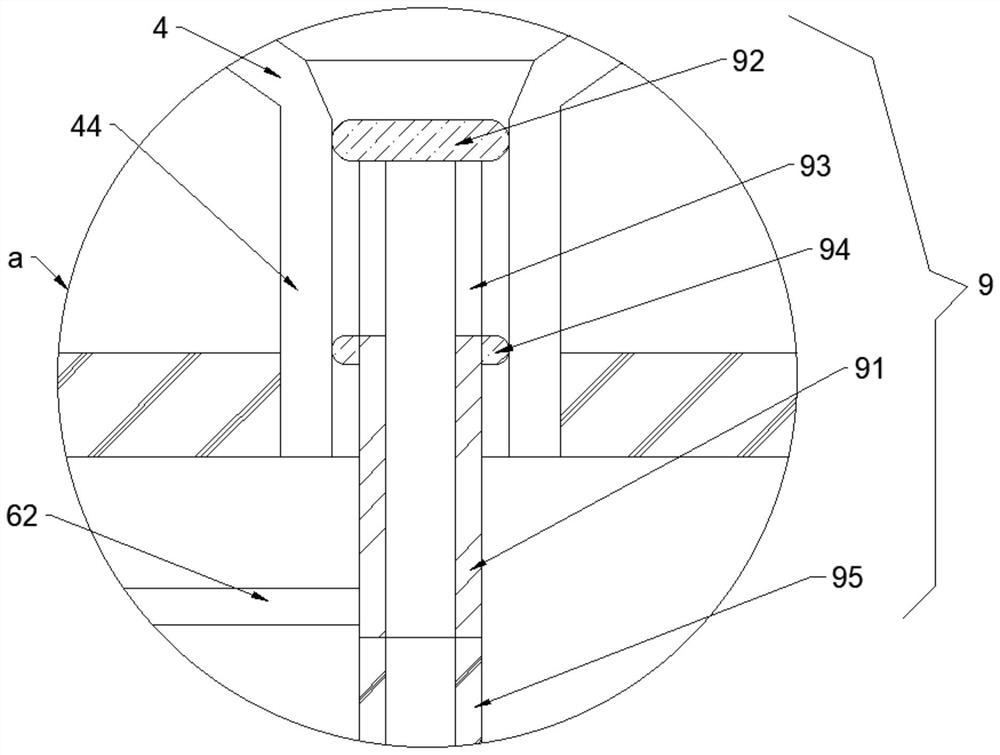

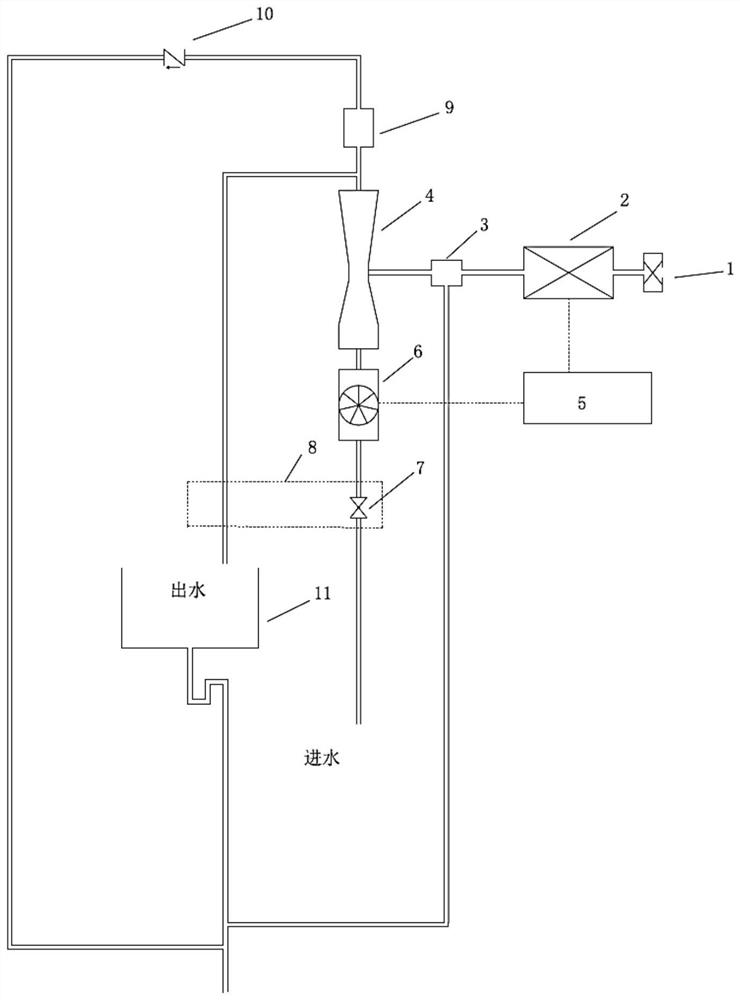

InactiveCN113083146APrevent water splashImprove gas-liquid mixing efficiencyFlow mixersMixing methodsIntegrated circuitOzone generators

The invention discloses a household kitchen and bath disinfection device and a control method thereof. The household kitchen and bath disinfection device comprises a peristaltic air pump, a low-temperature plasma ozone generator, a valve assembly, a Venturi tube, an integrated circuit control board, a turbine flowmeter, a low-resistance-loss water inlet and outlet system, an exhaust valve and a water tank. The peristaltic air pump is connected with an air inlet pipe of the low-temperature plasma ozone generator. A water inlet and a gas inlet of the Venturi tube are respectively connected with a water inlet pipe and a gas outlet pipe of the low-temperature plasma ozone generator, and the exhaust valve is arranged at an outlet of the Venturi tube. The low-resistance-loss water inlet and outlet system is characterized in that a low-resistance water inlet valve is mounted at a water inlet, a valve is not mounted at a water outlet, and water flow is controlled through the low-resistance water inlet valve during operation. The low-temperature plasma ozone generator receives signals of the turbine flowmeter through the integrated circuit control board. The device is scientific and reasonable in structure, safe and convenient to use and capable of effectively killing various bacteria.

Owner:杭州启臻科技有限公司

Industrial wastewater filtering device

InactiveCN110316846AImprove filtering effectImprove purification effectTreatment involving filtrationMultistage water/sewage treatmentIndustrial waste waterFiltration

The invention discloses an industrial wastewater filtering device. The industrial wastewater filtering device comprises a fixing frame. A purifying mechanism is fixedly connected to the top of the fixing frame, a filtering mechanism is fixedly connected to the right side of the purifying mechanism, and a connection pipe is communicated to the top of the filtering mechanism. A water inlet pipe is connected to the right side of the connection pipe in a threaded mode, and a water outlet pipe is communicated to the left bottom of the purifying mechanism. The purifying mechanism comprises a casing.The industrial wastewater filtering device has the advantages that through cooperative use of the fixing frame, the purifying mechanism, the filtering mechanism, the connection pipe, the water inletpipe and the water outlet pipe, the problem that filter screens or filter plates of conventional industrial wastewater filtering devices are inconvenient to replace can be effectively solved; the device can solve the clogging problem caused during wastewater treatment, the effect of conveniently replacing the filter screens is achieved, the wastewater filtration and purification effect can be further improved, the wastewater stirring and mixing efficiency can be sufficiently ensured, and the wastewater treatment efficiency can be guaranteed.

Owner:徐顺球

A partition flotation system

ActiveCN109772595BFacilitated zonal flotationTo achieve the collision effectFlotationMineral flotationMineral particles

Owner:ANHUI UNIV OF SCI & TECH

Raw material mixing device for coating production

InactiveCN111773967AAvoid accumulationReduce pillingRotary stirring mixersTransportation and packagingElectric machineStructural engineering

The invention discloses a raw material mixing device for coating production, relates to the technical field of coating mixing, and mainly solves the problems that in the existing coating mixing process, mixing is not uniform, and raw materials are easily attached to the inner wall. The device comprises a base, a stand column is arranged on the base. The stand column is connected with the shell, wherein a feeding hopper is arranged on the shell; a first motor is arranged at the top of the shell; the first motor is connected with an output shaft; the output shaft and the center of the shell arerotationally installed. Stirring blades are arranged on the output shaft; a mounting frame is arranged on the output shaft; a mounting groove is formed in the mounting frame, a second motor is arranged in the mounting groove, the second motor is connected with an ejector rod, the ejector rod is connected with a sliding block, a stirring rod is connected to the sliding block, stirring brushes are evenly arranged on the stirring rod, spray heads are arranged on the two sides of the shell, and a discharging pipe is arranged at the bottom of the shell.

Owner:马恒

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com