Layered feeding and mixing device for feed production

A mixing device and feeding technology, which is applied to feed, mixers, circuit devices, etc., can solve the problems of uneven feed distribution, short mixing time, uneven mixing, etc., to ensure mixing efficiency and mixing quality, and improve mixing efficiency , to ensure the effect of the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

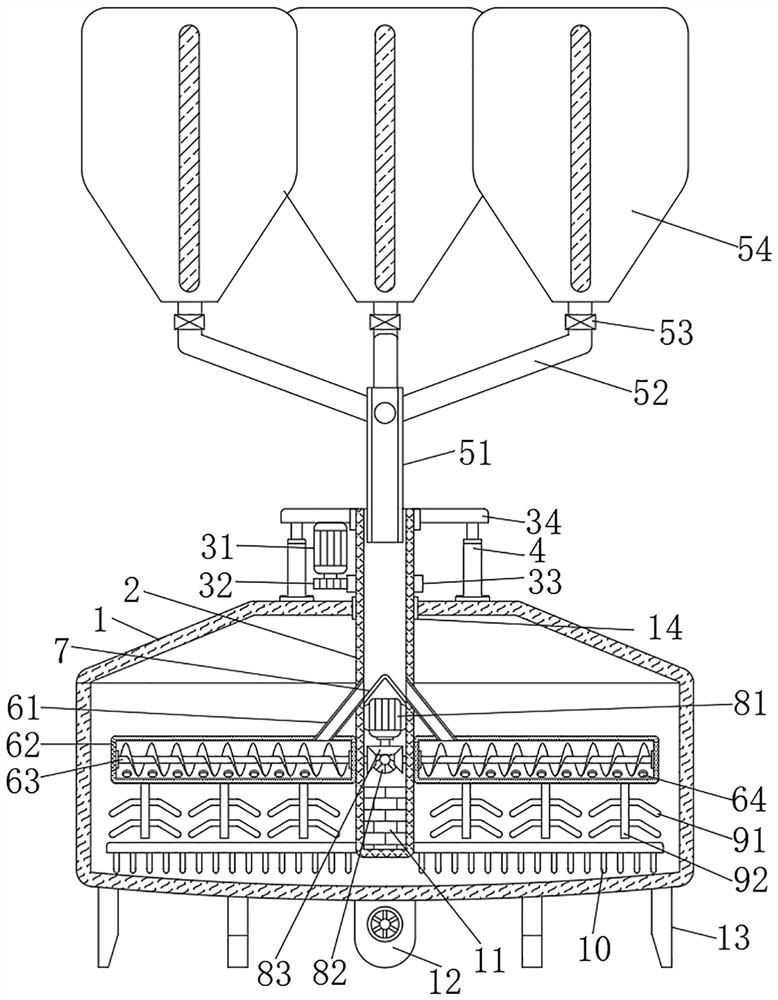

[0041] according to Figure 1-5 As shown, it includes a mixing box 1, a feeding pipe 51 and a discharging pipe 12 arranged at the lower part of the mixing box 1. The discharging pipe 12 is provided with a discharging valve, the bottom of the mixing box 1 is a downward convex arc, and the mixing box The bottom of 1 is provided with a plurality of supporting feet 13 .

[0042]It also includes a layered feeding mechanism and a lifting drive mechanism. The layered feeding mechanism includes a hollow shaft 2, four groups of feeding units, driving components, a battery 11, and the hollow shaft 2 is arranged in the mixing box 1, and its top end passes through the mixing box. 1. The sliding sleeve 14 installed on the top, by setting the sliding sleeve 14, the hollow shaft 2 can slide up and down in the sliding sleeve 14 without affecting the normal rotation of the hollow shaft 2. The bottom end of the hollow shaft 2 is closed and the top is open. The port is provided for feeding, and...

Embodiment 2

[0056] On the basis of Example 1, as figure 1 As shown, four tooth rakes 10 are installed around the outer wall of the lower end of the hollow shaft 2. By arranging the tooth rakes 10, the tooth rakes 10 will open and flatten the raw materials in the mixing box 1 during the rotation process, so as to facilitate the processing of each raw material. Mixing, and the tooth rake 10 can also play a certain role of stirring and mixing the raw materials during the stirring process.

Embodiment 3

[0058] On the basis of the first embodiment, in addition to using the electric push rod 4 to drive the lifting plate 34 to lift and lower in the first embodiment, other lifting methods can also be used, for example, the number of lifting components is two, and the two sets of lifting components are symmetrical It is arranged on both sides of the hollow shaft 2. The lifting assembly includes a lifting motor, a threaded rod and a nut. The lifting motor is installed on the top of the mixing box 1. The bottom end of the threaded rod is fixedly connected with the output shaft of the lifting motor. The nut is installed on the lifting plate 34. Inside, the threaded rod is threadedly connected to the nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com