Raw material mixing device for coating production

A mixing device and raw material technology, applied in mixers, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of difficult cleaning of raw materials, influence of coating performance, easy pilling of raw materials, etc., to reduce pilling of raw materials , Improve the quality, improve the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

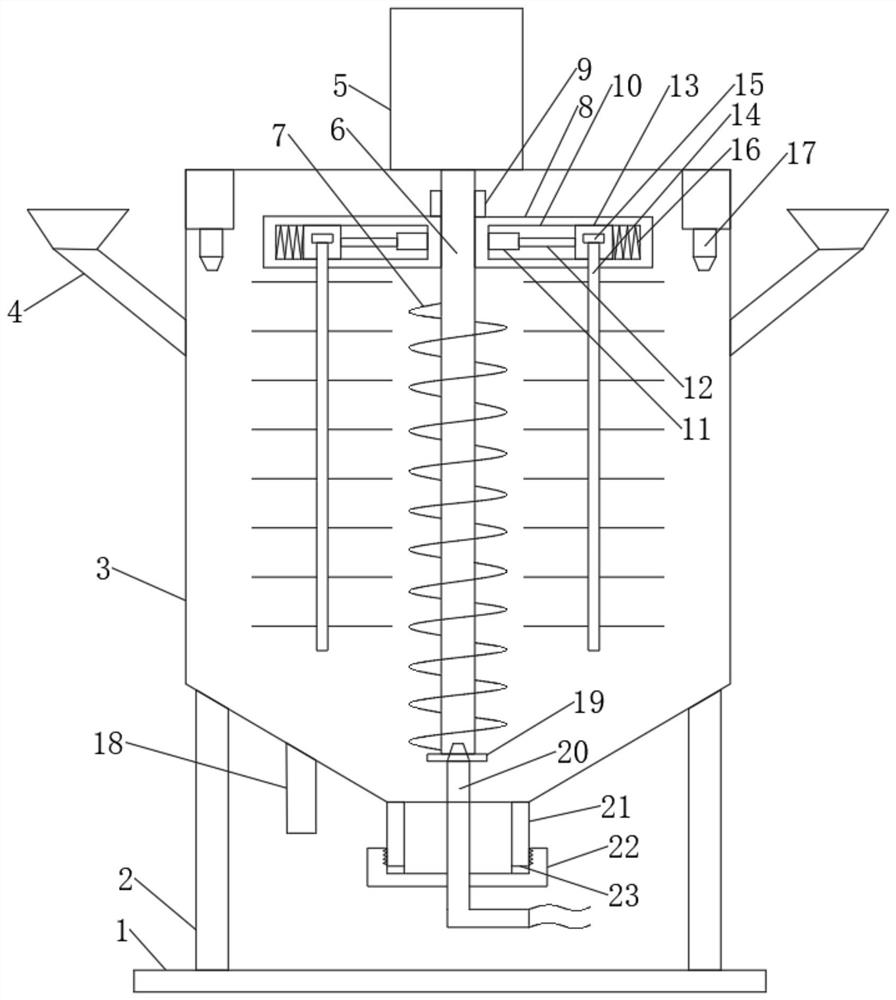

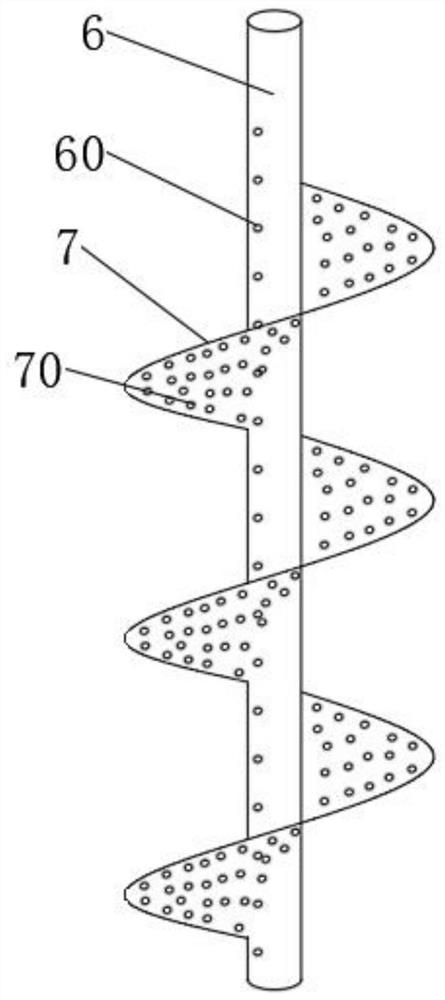

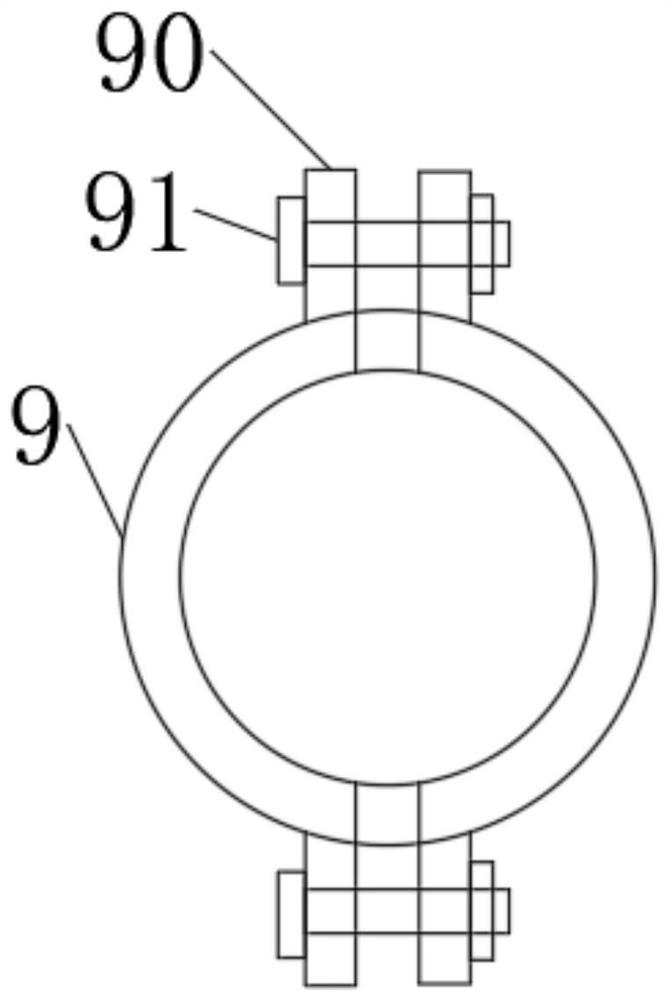

[0025] Such as Figure 1-4 As shown, a raw material mixing device for paint production includes a base 1, a column 2 is arranged on the base 1, the column 2 is connected with a housing 3, and two feeding hoppers are symmetrically arranged on the housing 3 4. The top of the housing 3 is provided with a first motor 5, the first motor 5 is connected to the output shaft 6, the output shaft 6 is rotatably installed in the center of the housing 3, and the output shaft 6 is set Stirring blade 7 is arranged, and described output shaft 6 is provided with installation frame 8, and described installation frame 8 is connected with output shaft 6 through fixed block 9, and described fixed block 9 is symmetrically distributed on both sides of output shaft 6, and described fixed block 9 The block 9 is provided with fixing flanges 90, and fixing bolts 91 are arranged between the fixing flanges 90, and a mounting groove 10 is arranged in the mounting bracket 8, and a second motor 11 is arrange...

Embodiment 2

[0040] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0041] A raw material mixing device for coating production, including all parts in embodiment 1, also includes:

[0042] Further, the bottom of the housing 3 is provided with a connecting sleeve 21, the connecting sleeve 21 is connected with a threaded sleeve 22, and the threaded sleeve 22 is provided with a water pipe 20, and the water pipe 20 passes through the first rubber The pad 19 is connected with the bottom of the output shaft 6 , the output shaft 6 is hollow, and the output shaft 6 is uniformly provided with water outlet holes 60 .

[0043] Specifically, since the water at the output shaft 6 is not easy to reach, by connecting the water pipe 20 at the bottom of the output shaft 6 and evenly setting the water outlet holes 60 on the output shaft 6, the water is introduced into the raw materials to improve the stirring effect and reduce the stirring effect. tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com