Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Guaranteed flattening effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

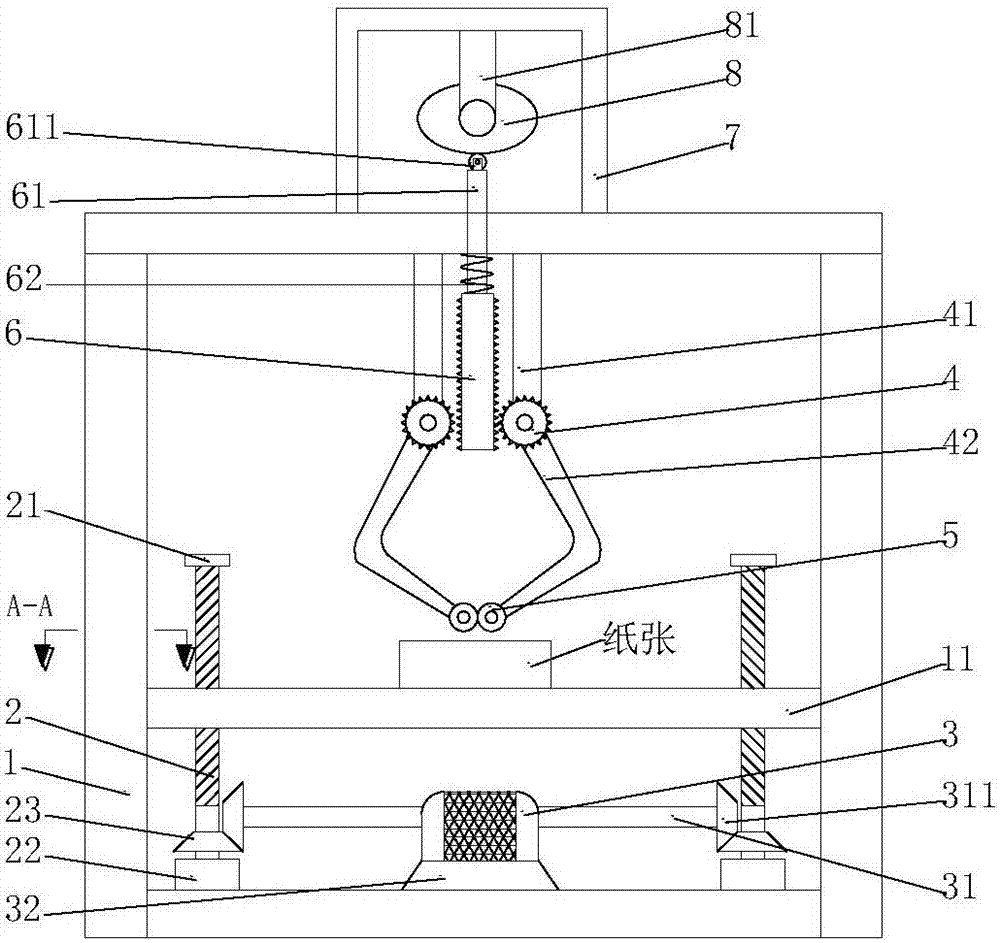

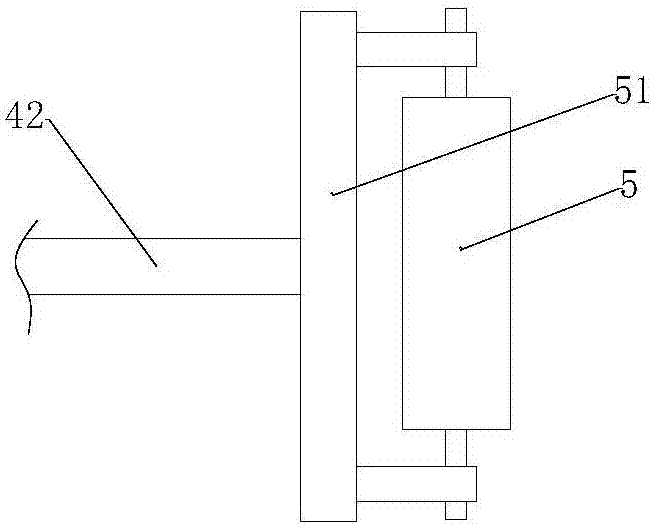

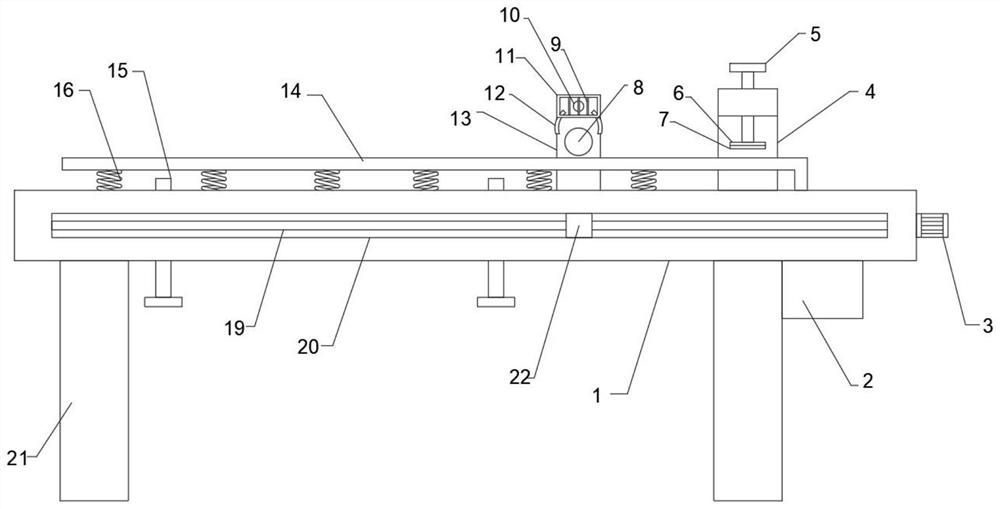

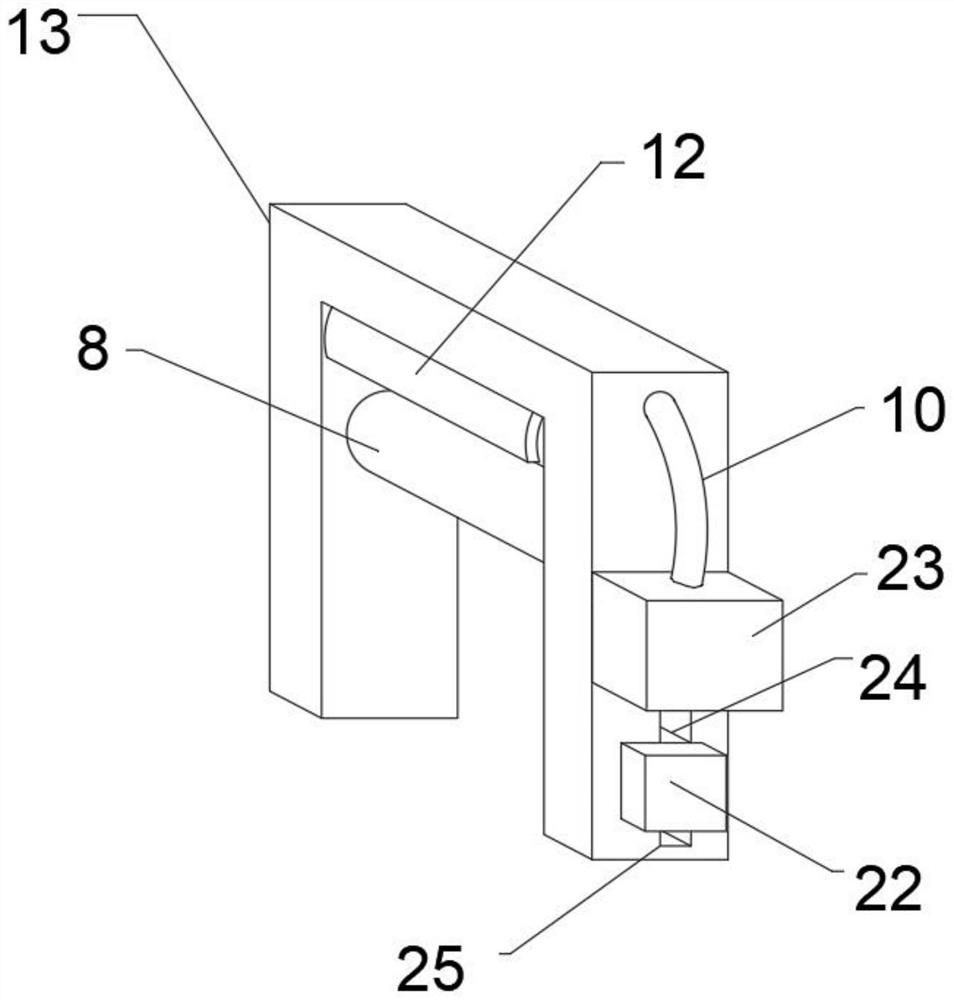

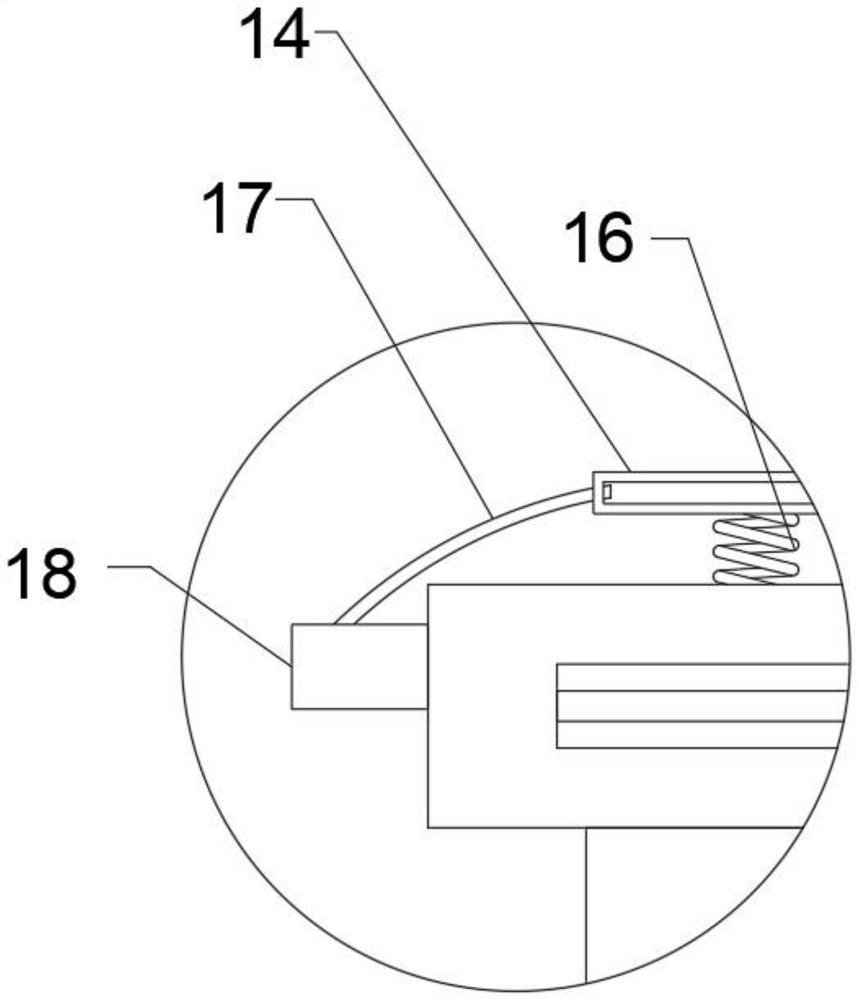

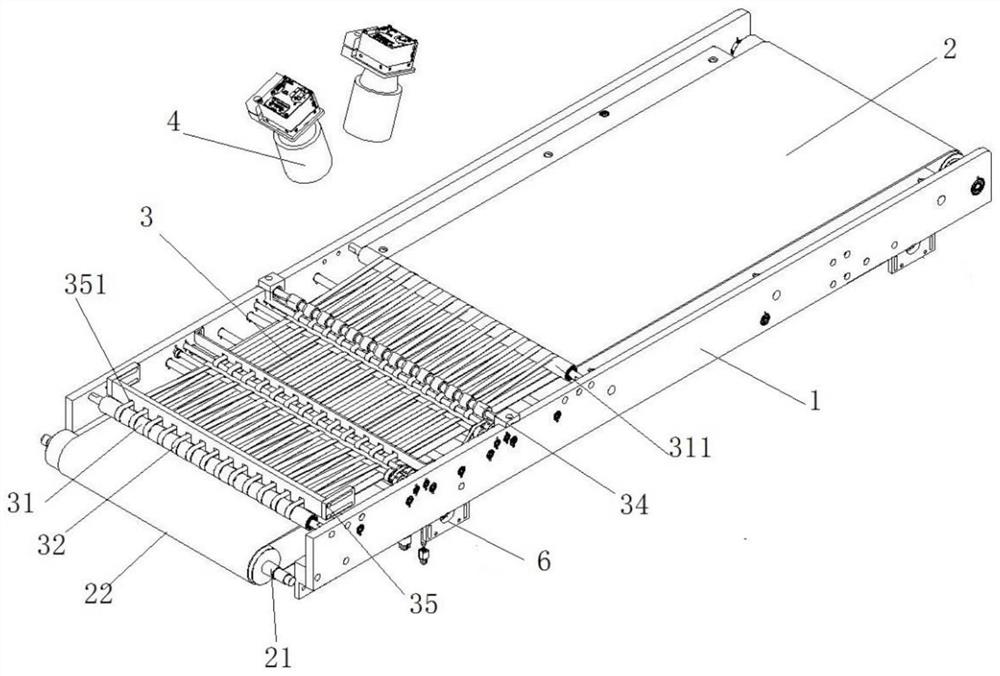

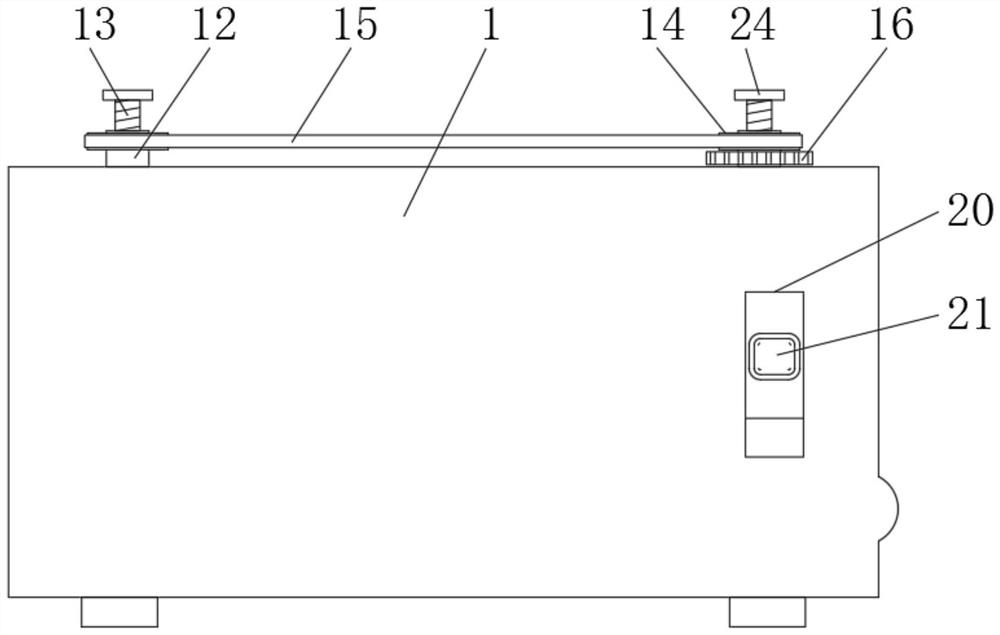

High-efficiency paper pressing device used for paper printing machine

ActiveCN107297778AEasy to operateGuaranteed flattening effectMechanical working/deformationMetal working apparatusEngineeringPrinting press

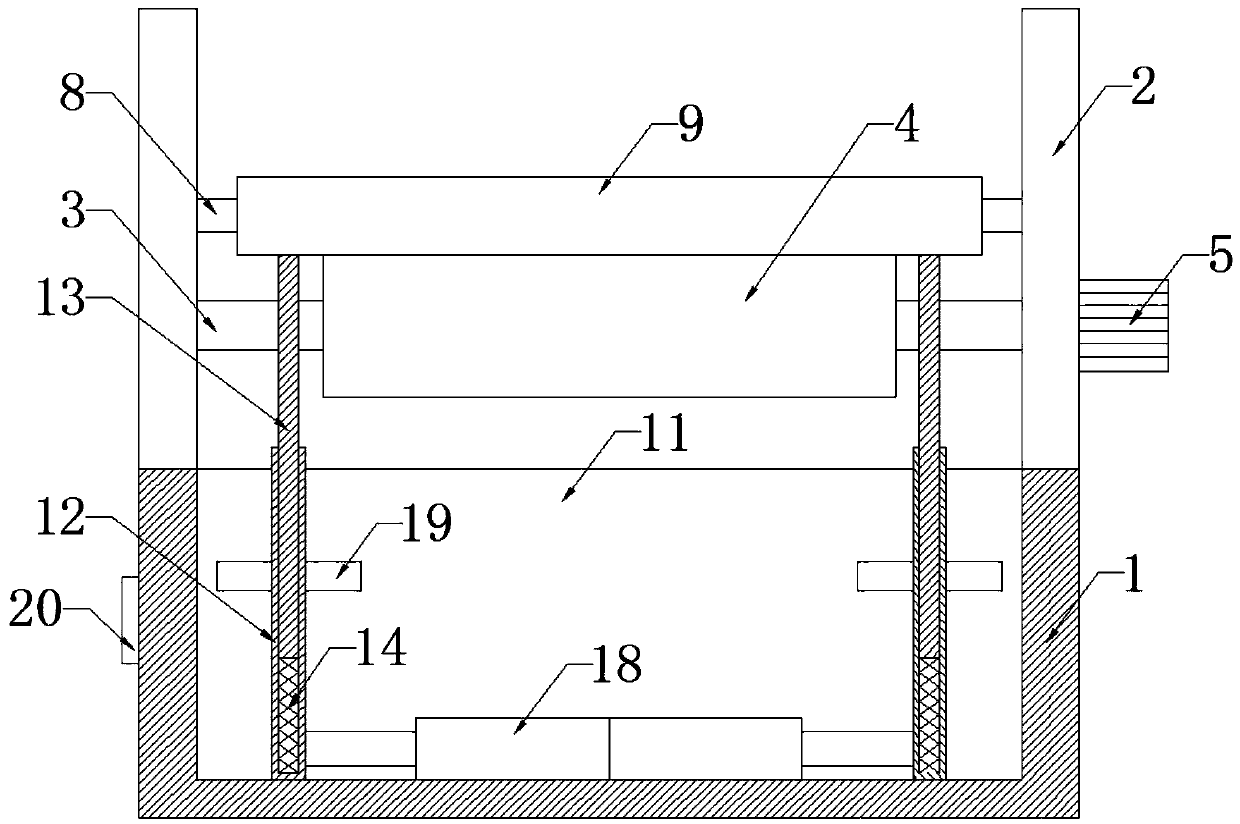

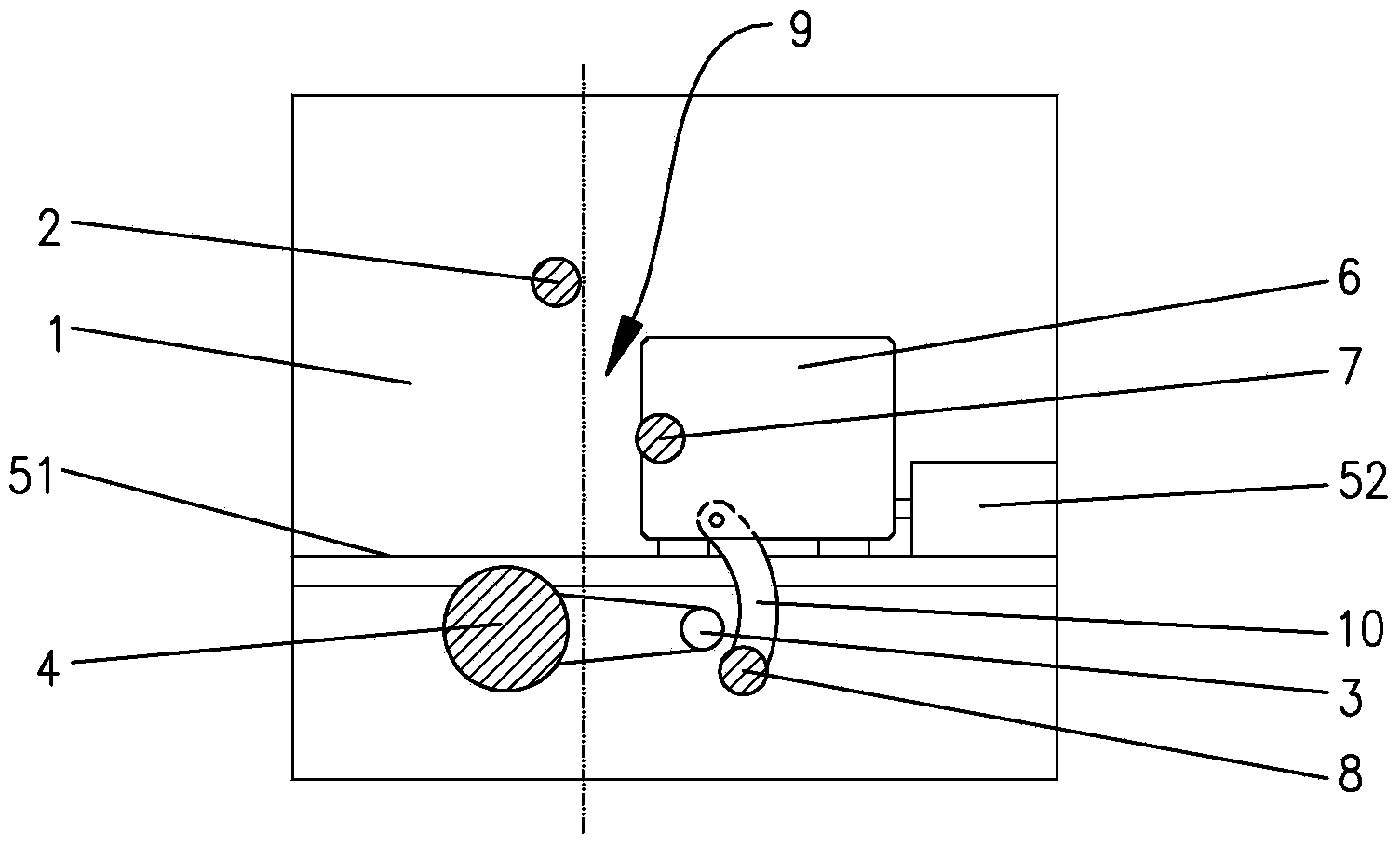

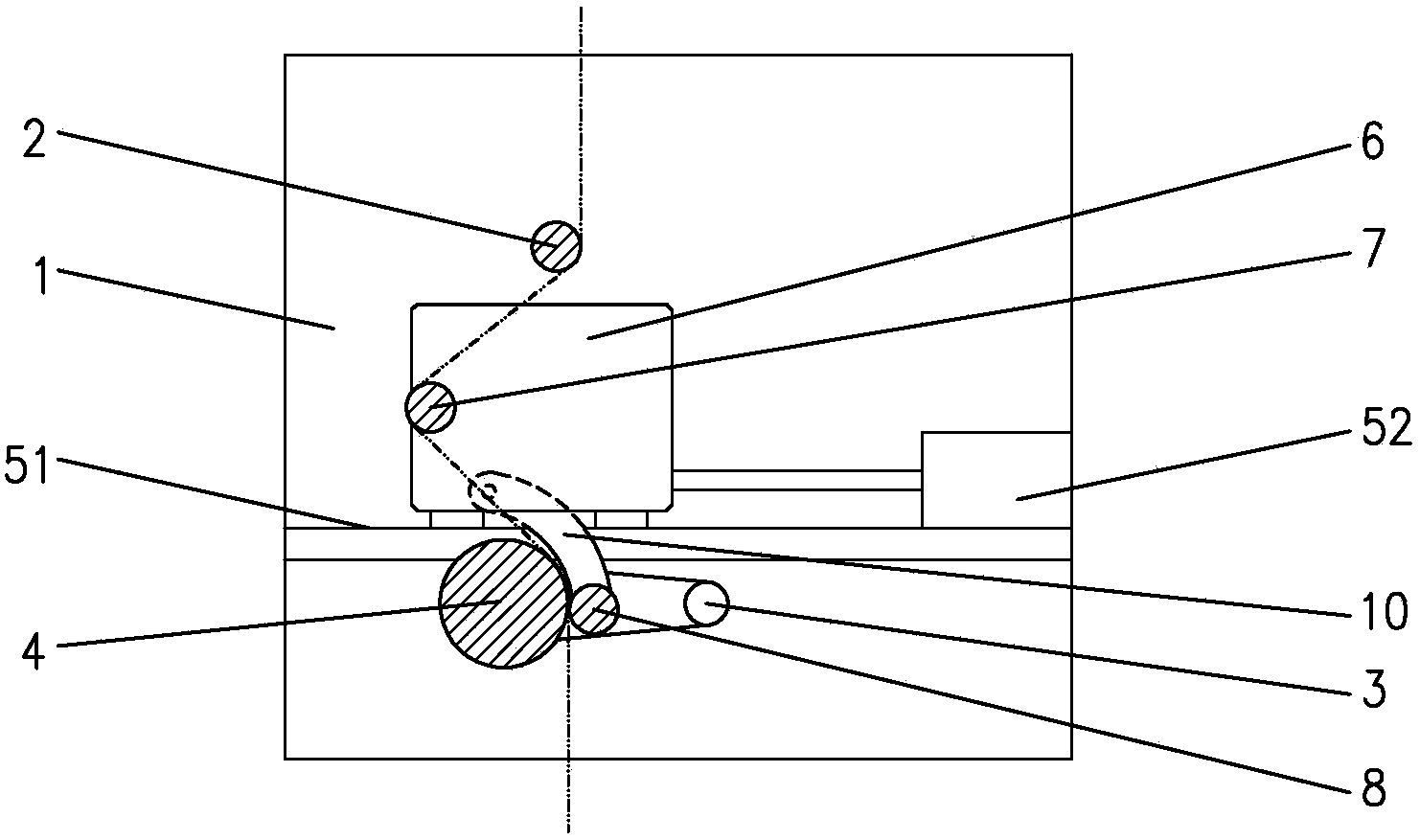

The invention discloses a high-efficiency paper pressing device used for a paper printing machine. The device includes a frame, the frame is internally provided with a bearing plate used for placing paper, the two sides of the bearing plate are fixedly provided with sliding blocks, the side wall of an inner cavity of the frame is provided with sliding grooves matched with the sliding blocks, and the sliding blocks are clamped into the sliding grooves in a sliding mode; the bearing pate is provided with a height adjusting mechanism, the upper portion of the frame is provided with gears in a bilaterally symmetrical mode, the bottoms of the gears are connected with cranks, the other end of each crank is connected with a press roller support, and press rollers are arranged on the press roller support; the center of the inner cavity of the upper portion of the frame is provided with a double-sided rack meshed with the gears on the two sides, the top of the frame is provided with drive mechanism used for driving the double-sided rack to move. When the device is used for pressing paper, winkles on the paper can be effectively eliminated, at the same time, operation is simple, and the paper pressing effect is good.

Owner:浙江夏王纸业有限公司

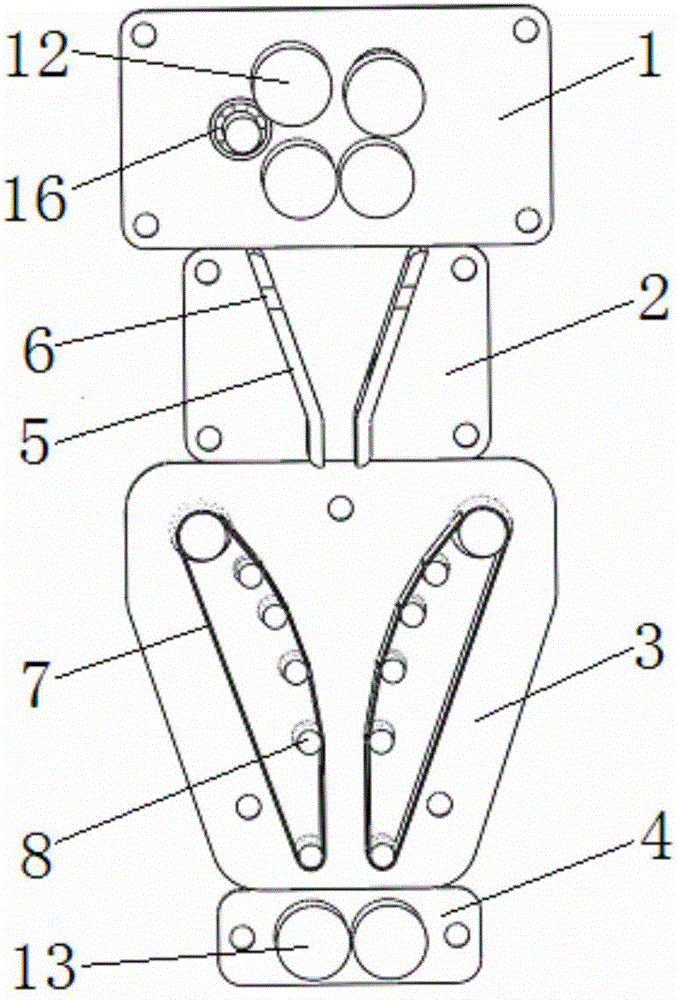

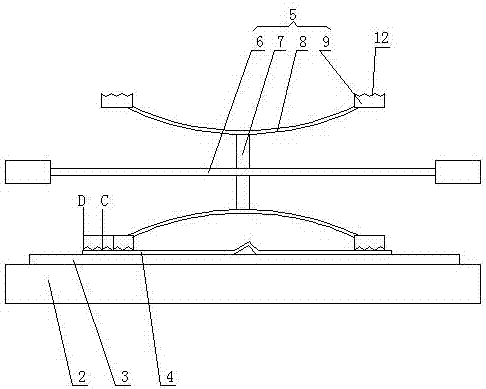

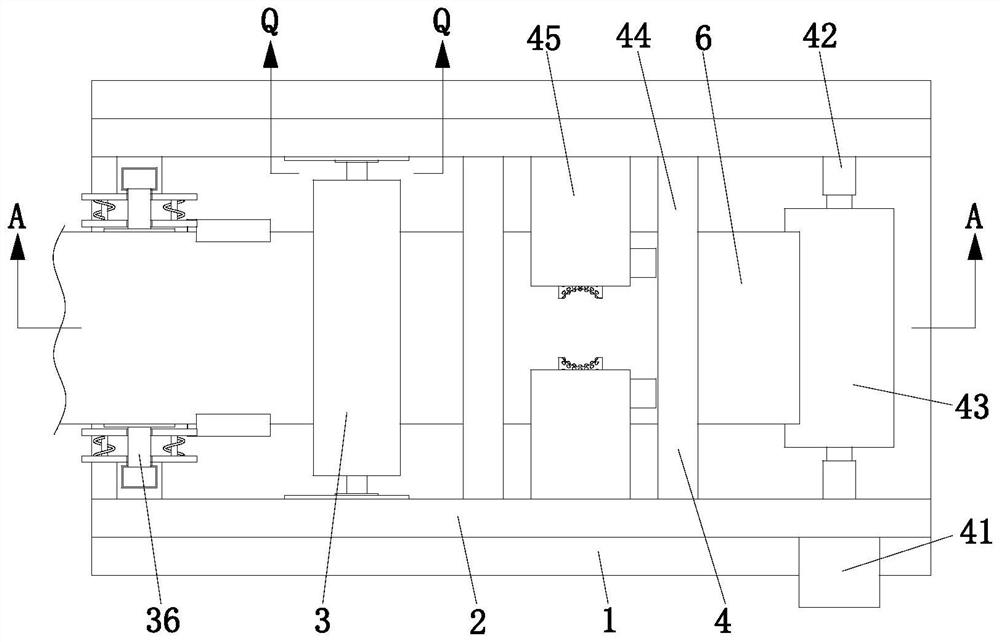

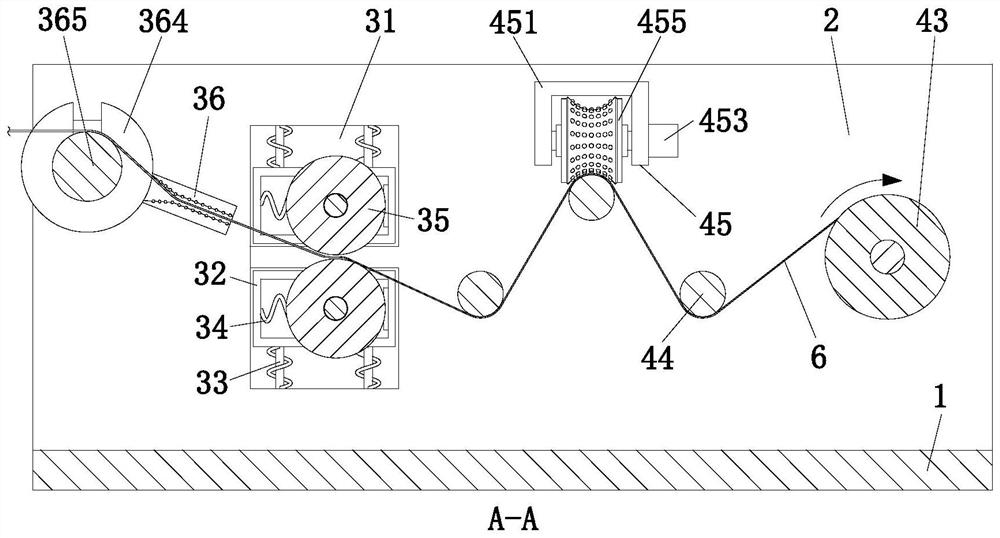

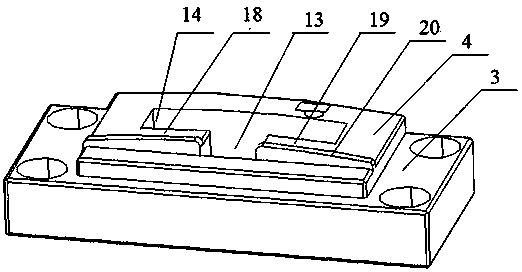

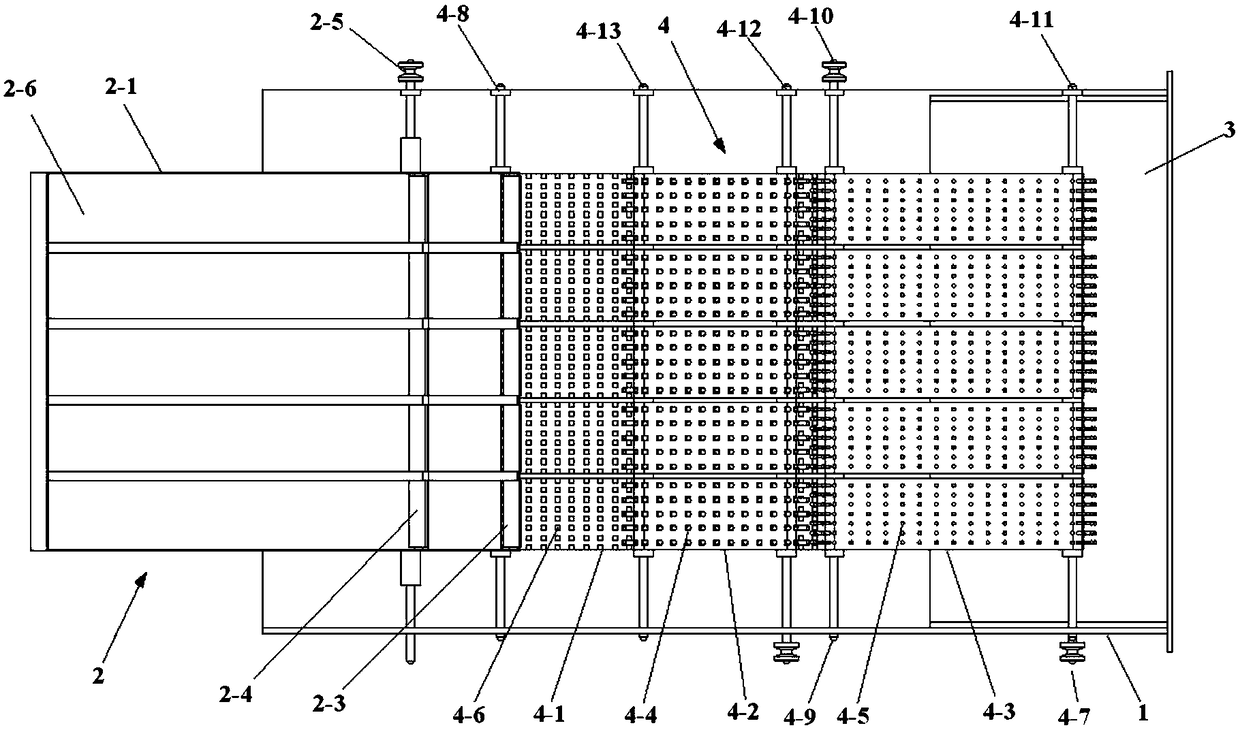

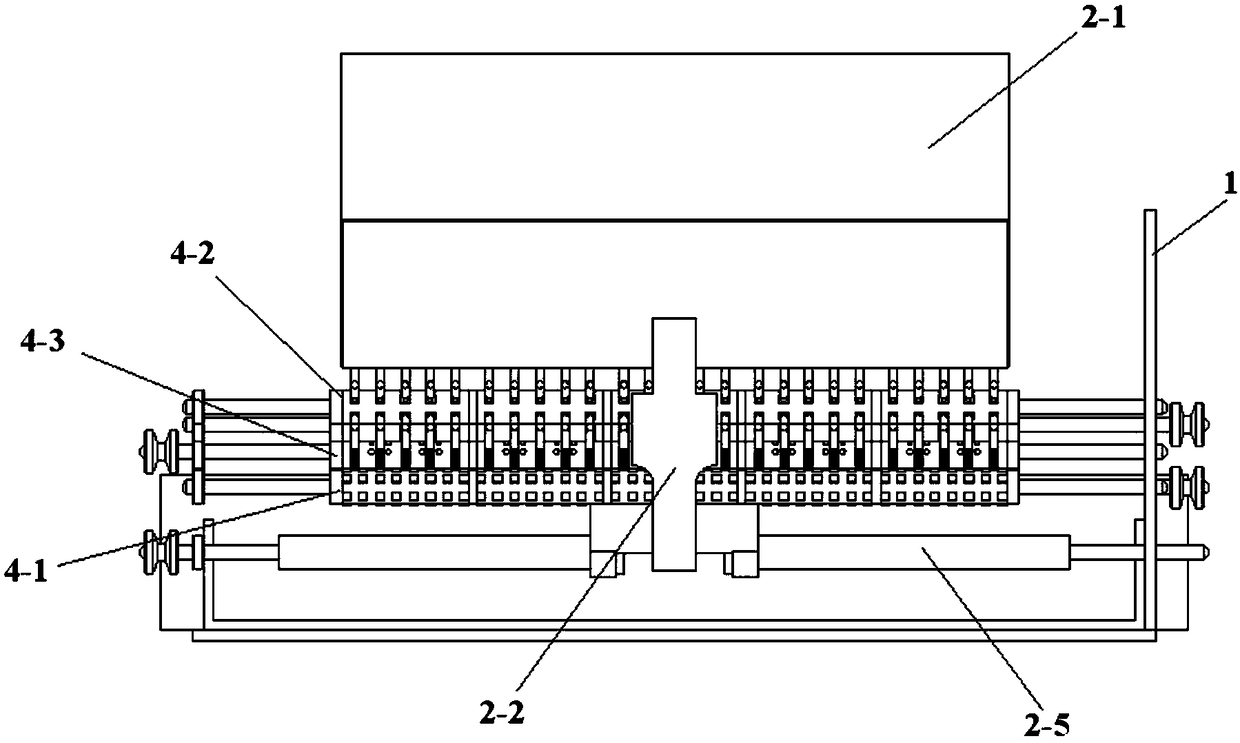

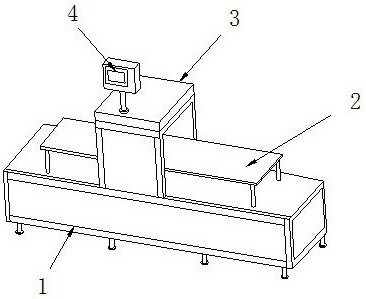

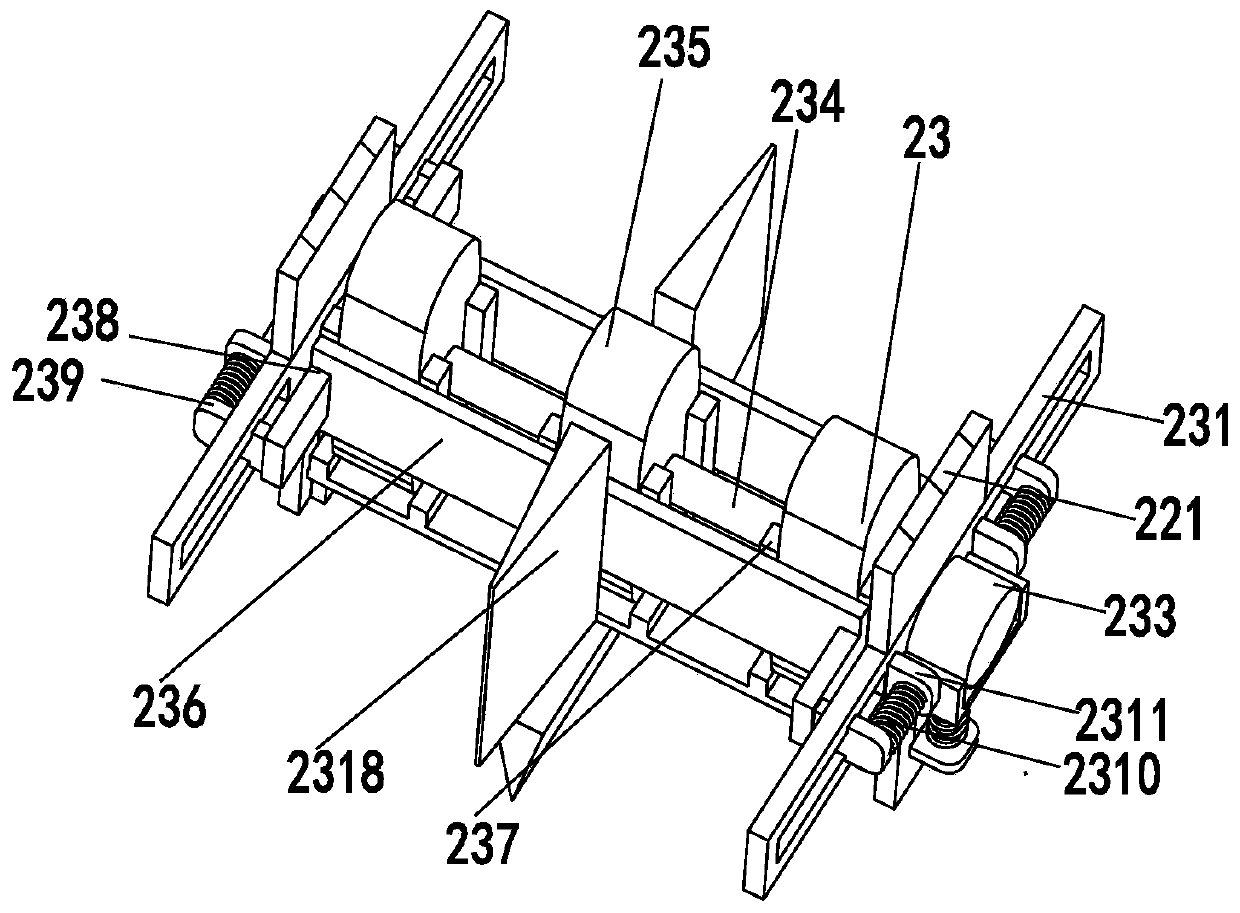

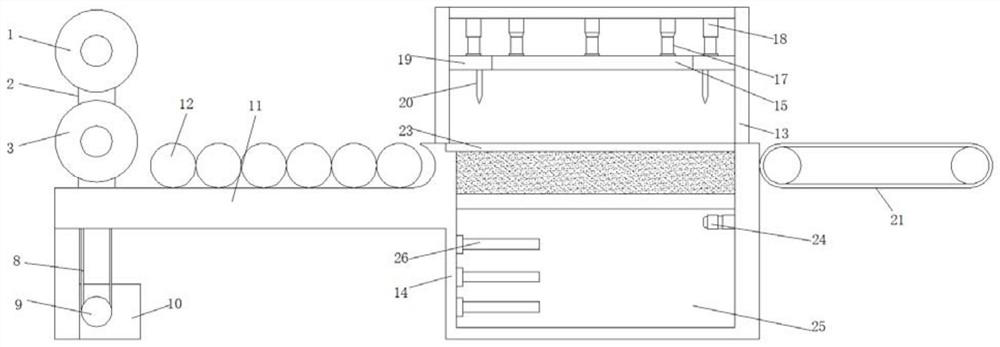

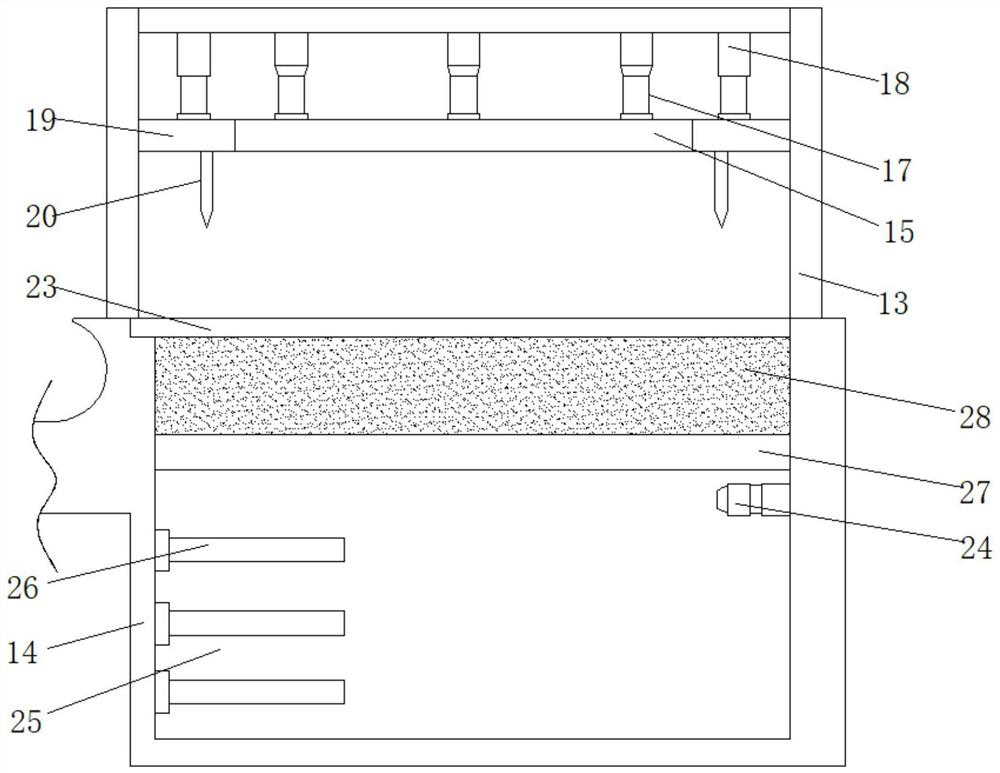

Paper currency unfolding arrangement device

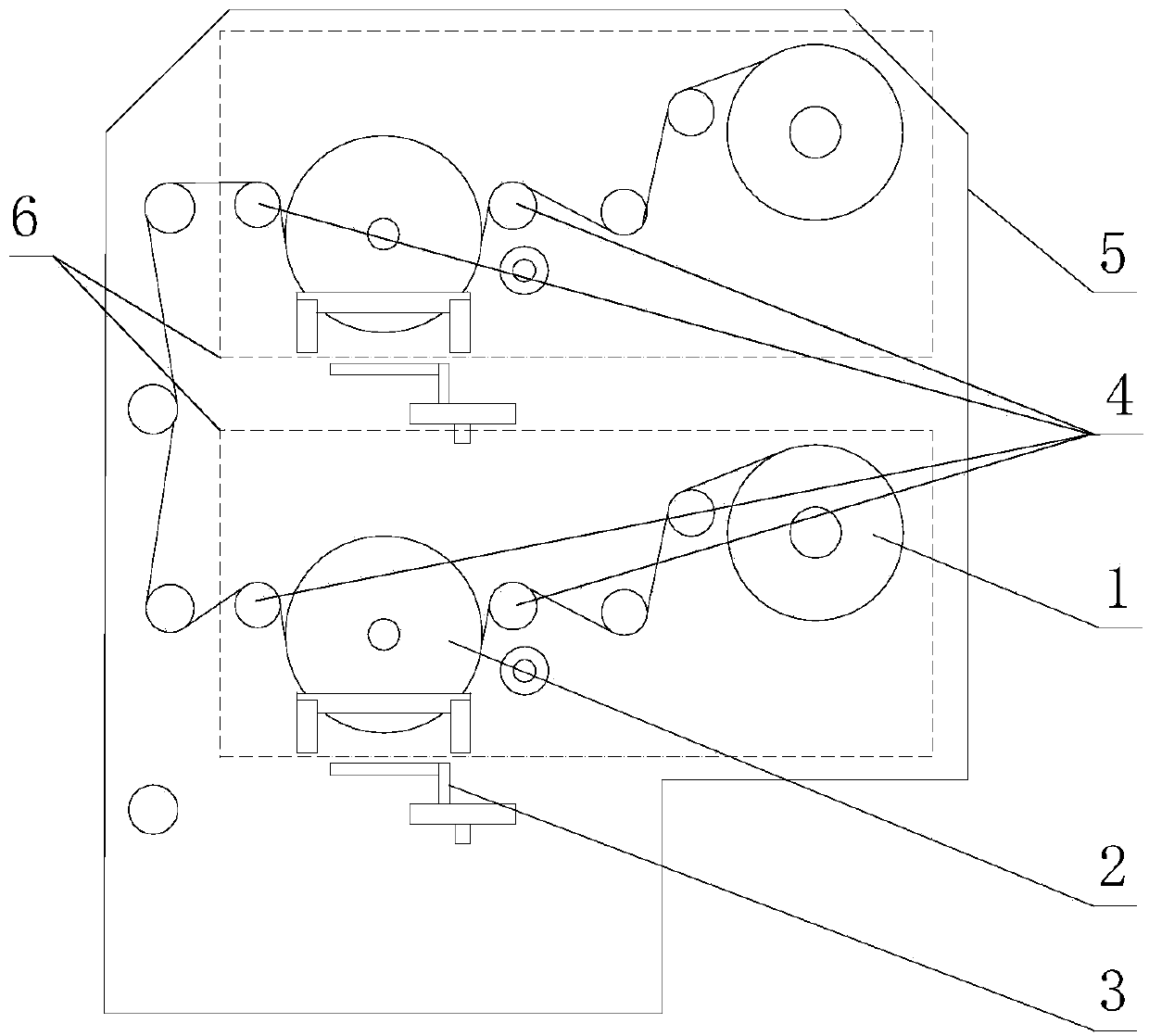

The invention provides a paper currency unfolding arrangement device. The paper currency unfolding arrangement device comprises a first conveying unit, a wetting unit, an unfolding unit and a second conveying unit which are sequentially mounted in the paper currency conveying direction. The size of the wetting unit in the paper currency conveying direction is smaller than the length of paper currency, and the wetting unit comprises wetting side plates, mounting plates and ultrasonic atomizers; the unfolding unit comprises unfolding side plates and two sets of unfolding assemblies which are symmetrically arranged with the paper currency conveying direction as the axis; each unfolding assembly is composed of an unfolding motor, a coupler, a rolling shaft set and a track with brushes, wherein each track with the brushes is arranged on the corresponding rolling shaft set in a sleeving manner, and the distance between two rolling shafts, with the opposite positions, in each rolling shaft set is gradually decreased in the paper currency conveying direction; and each track with the brushes is composed of a rubber track body and the brushes. The brushes are perpendicular to the paper currency conveying direction to be fixed to the outer surfaces of the rubber track bodies, and the rotating speed of the unfolding motors is larger than the rotating speed of a first motor and smaller than the rotating speed of a second motor; and according to the device, paper currency with folded corners or in the wrinkling state can be subject to wetting-flat brushing treatment, and in the treatment process, the paper current is not damaged.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

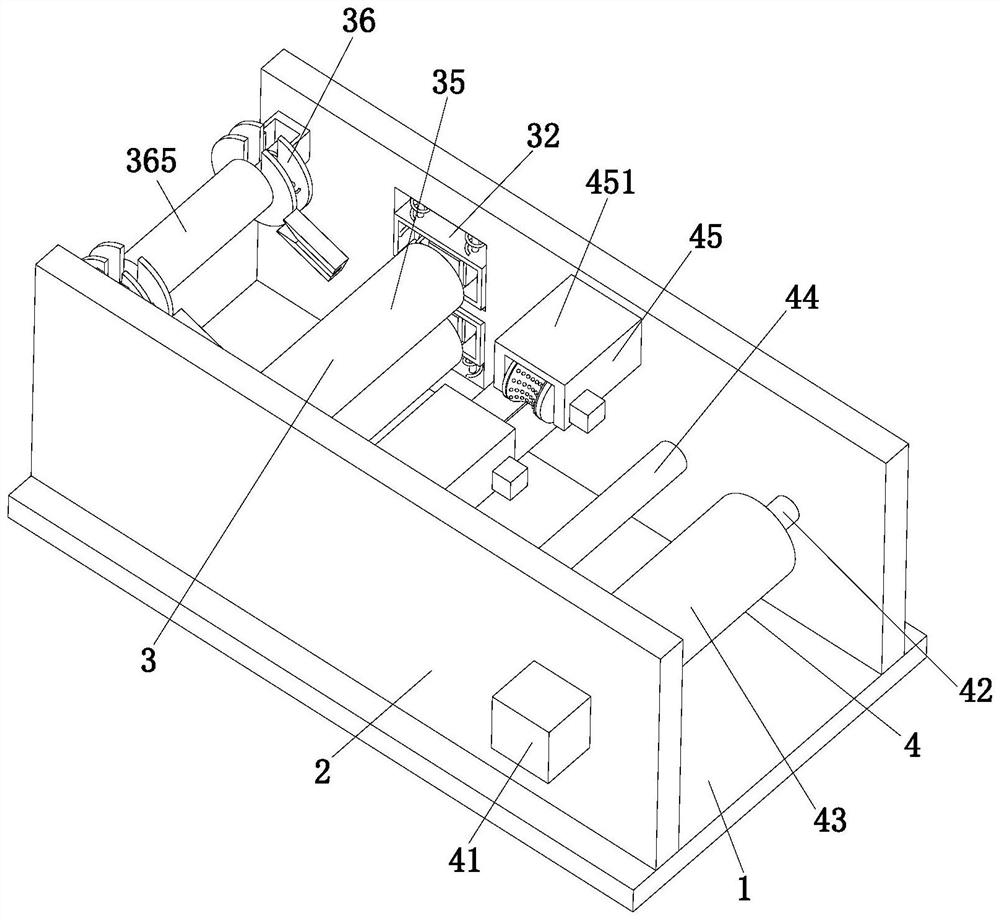

Flattening treatment device for copper foil production

ActiveCN114054544AImprove flattening effectIncrease contact areaMetal-working feeding devicesPositioning devicesMetallurgyEngineering

The invention relates to the technical field of copper foil production, in particular to a flattening treatment device for copper foil production. The device comprises a worktable, bearing plates, a rolling unit and a winding unit, wherein the two bearing plates are symmetrically arranged at the front and back of the upper end of the worktable, and the rolling unit and the winding unit are sequentially arranged on the opposite sides of the bearing plates from left to right. An existing flattening device has the following problems that: when the existing device is used for flattening copper foil with different thicknesses, the device needs to be correspondingly adjusted, and the operation is tedious; and the device cannot perform all-directional flattening treatment on the copper foil, and flattening dead angles exist, so that the flattening effect on the copper foil cannot be ensured. The flattening treatment device can be used for flattening the copper foil with different thicknesses, and does not need to be frequently adjusted, so that the workload can be reduced; and the copper foil can be subjected to all-directional flattening treatment through flattening elastic pieces, so that the flatness of the copper foil can be ensured, and the flattening effect on the copper foil is ensured.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

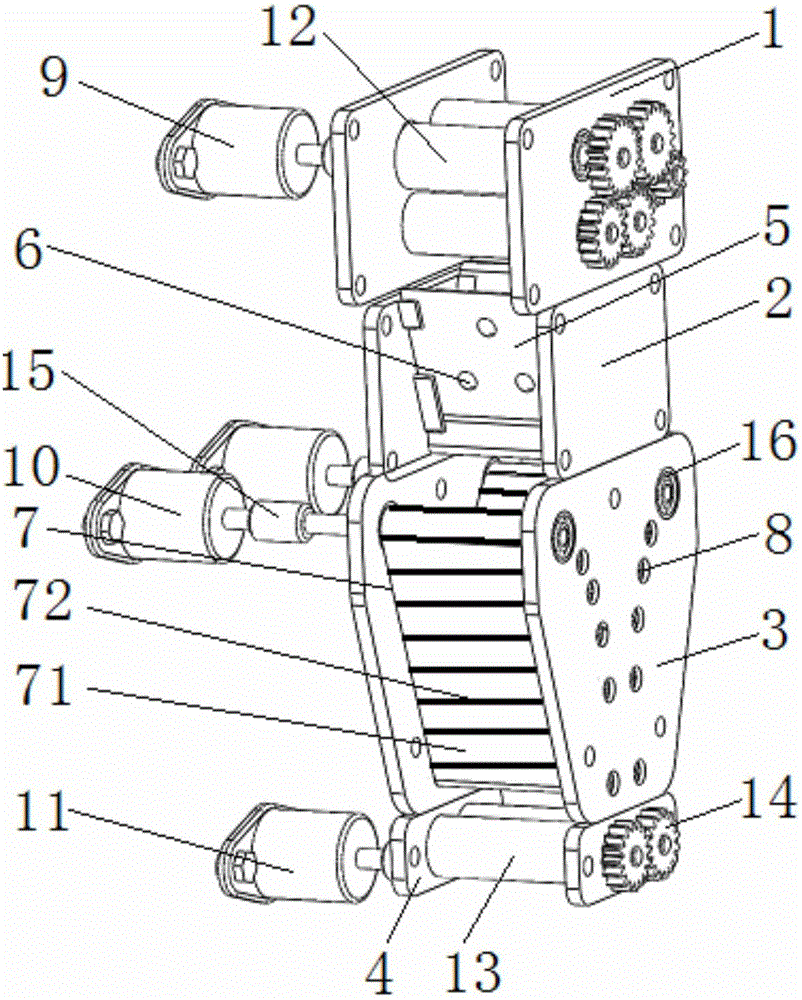

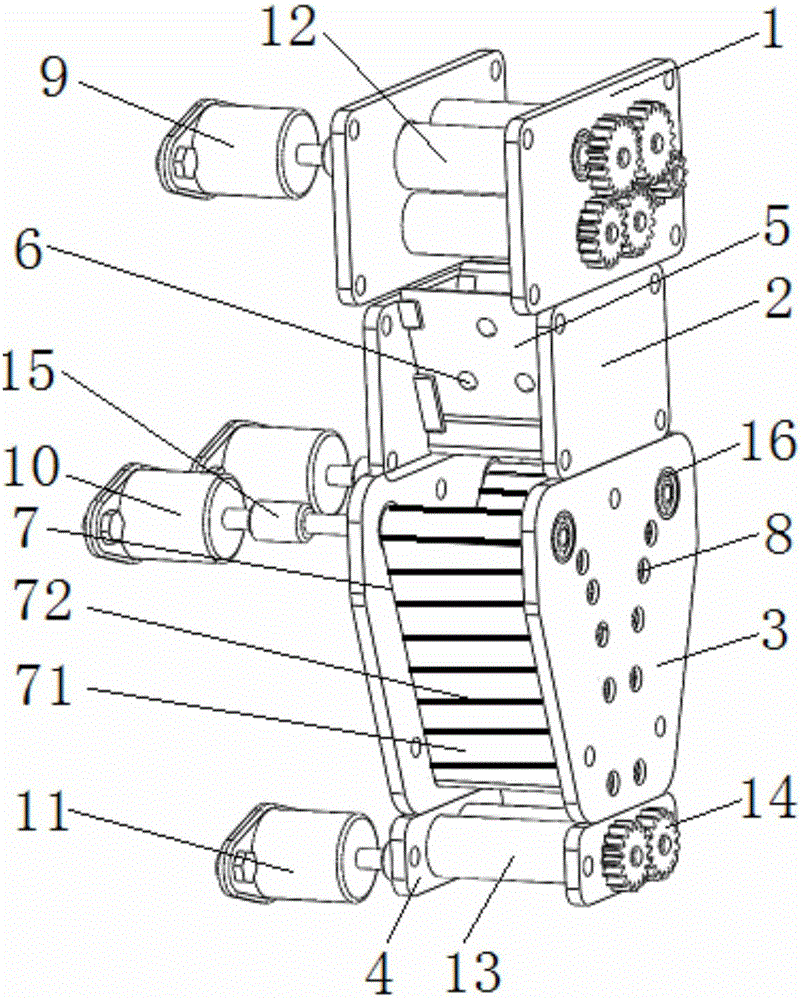

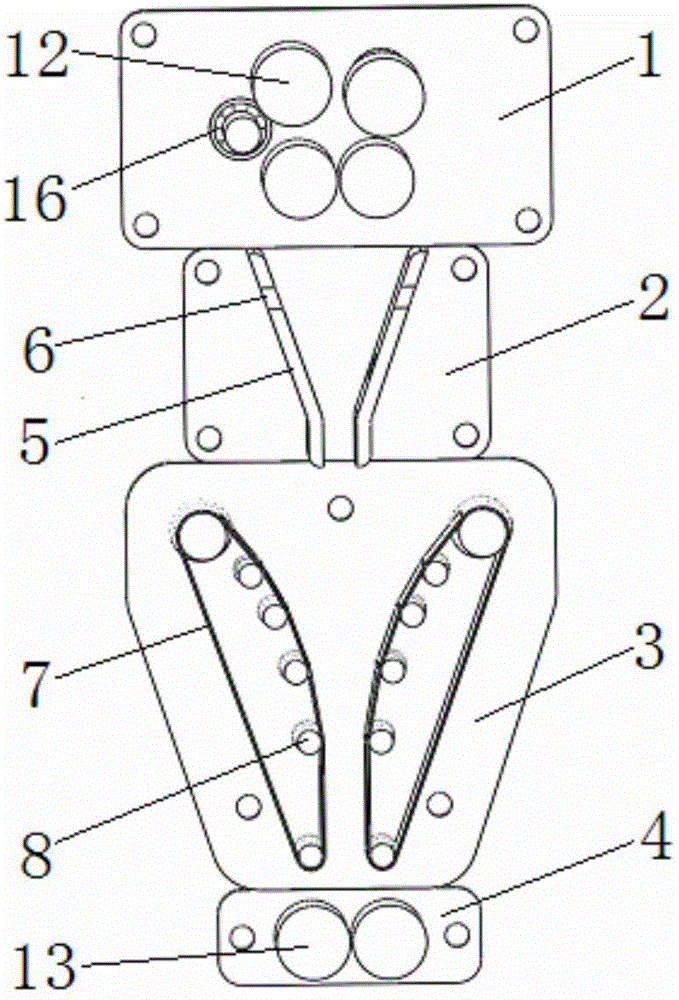

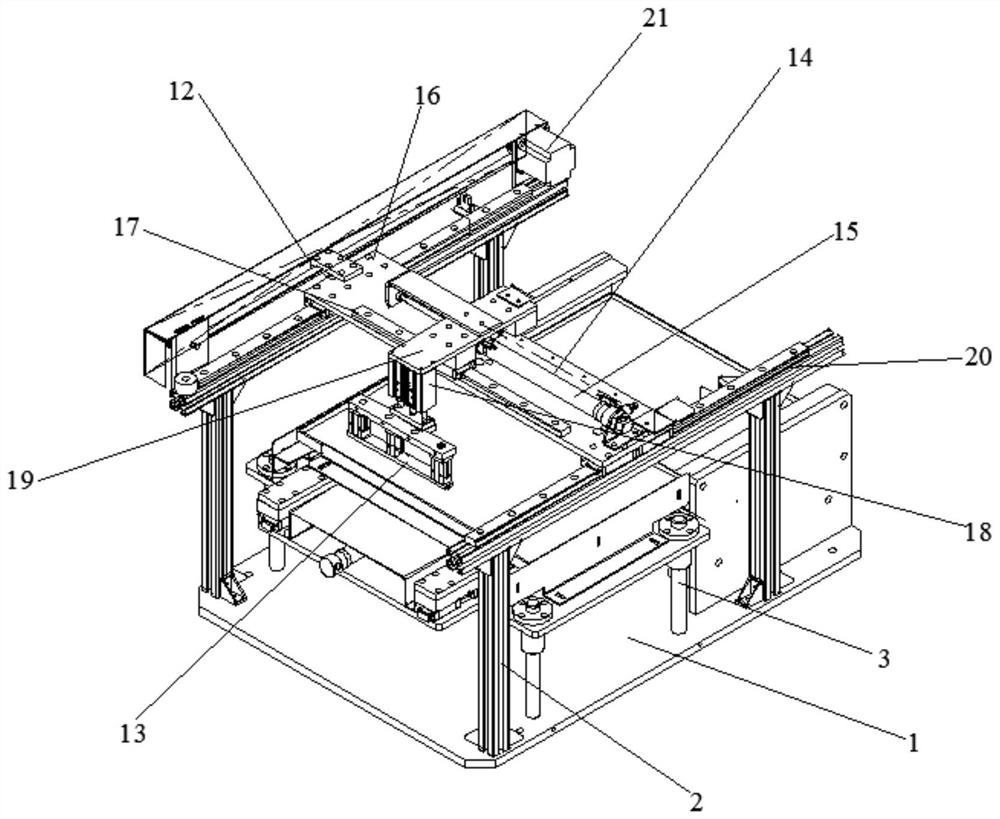

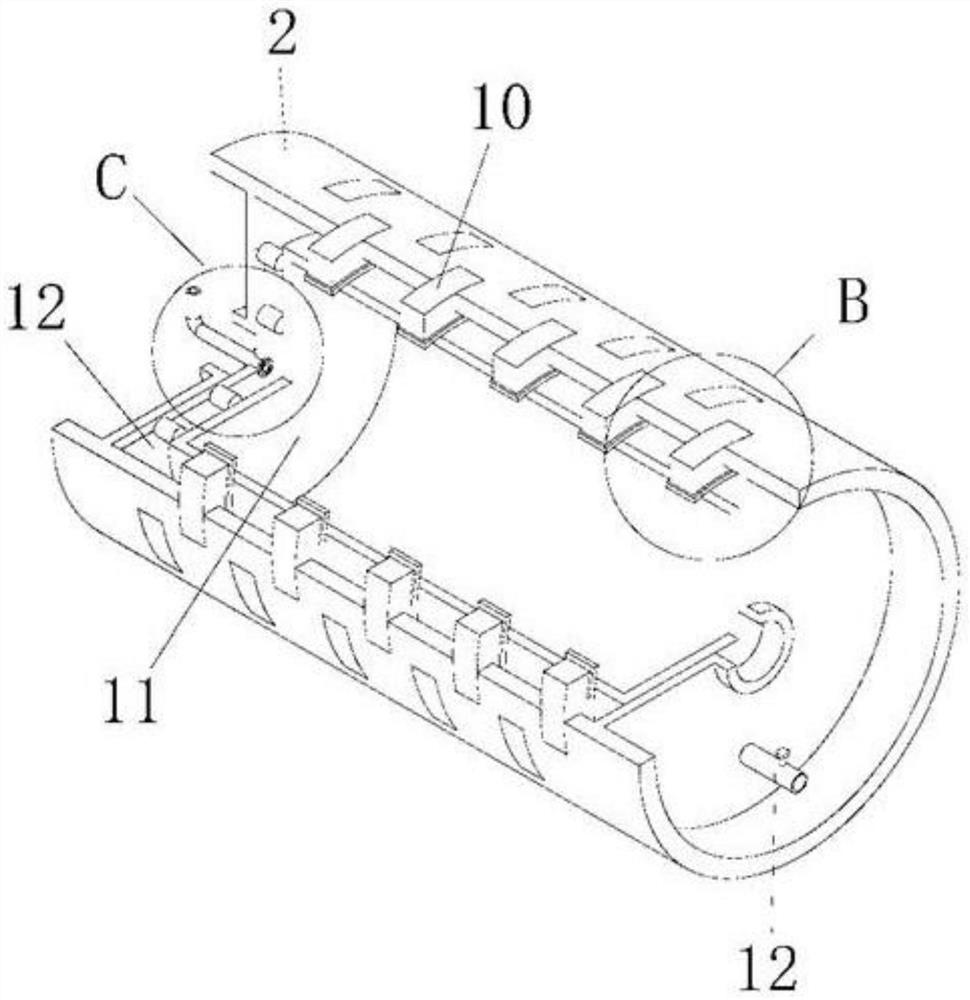

A banknote unfolding and sorting device

InactiveCN105692267BGuaranteed flattening effectAct as a squeezeArticle feedersCouplingPulp and paper industry

The invention provides a paper currency unfolding arrangement device. The paper currency unfolding arrangement device comprises a first conveying unit, a wetting unit, an unfolding unit and a second conveying unit which are sequentially mounted in the paper currency conveying direction. The size of the wetting unit in the paper currency conveying direction is smaller than the length of paper currency, and the wetting unit comprises wetting side plates, mounting plates and ultrasonic atomizers; the unfolding unit comprises unfolding side plates and two sets of unfolding assemblies which are symmetrically arranged with the paper currency conveying direction as the axis; each unfolding assembly is composed of an unfolding motor, a coupler, a rolling shaft set and a track with brushes, wherein each track with the brushes is arranged on the corresponding rolling shaft set in a sleeving manner, and the distance between two rolling shafts, with the opposite positions, in each rolling shaft set is gradually decreased in the paper currency conveying direction; and each track with the brushes is composed of a rubber track body and the brushes. The brushes are perpendicular to the paper currency conveying direction to be fixed to the outer surfaces of the rubber track bodies, and the rotating speed of the unfolding motors is larger than the rotating speed of a first motor and smaller than the rotating speed of a second motor; and according to the device, paper currency with folded corners or in the wrinkling state can be subject to wetting-flat brushing treatment, and in the treatment process, the paper current is not damaged.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Fully automatic table skirt machine

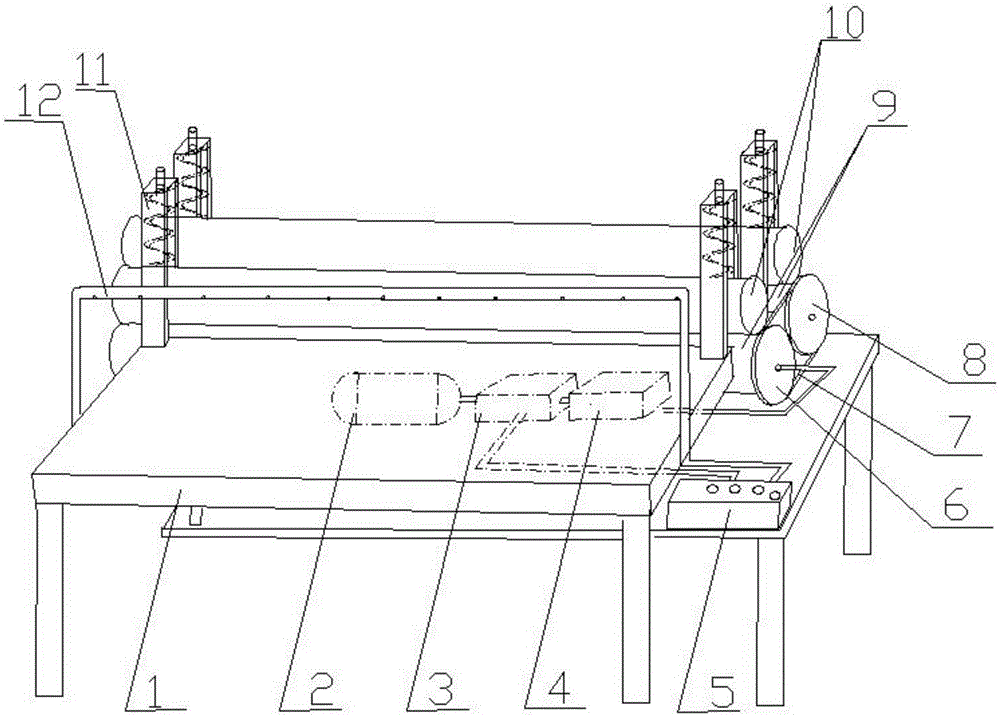

The invention provides a fully automatic table skirt machine, and relates to the field of table skirt machines. The machine comprises a working table, a side of the working table is provided with a bracket, the inside of the bracket is movably provided with a feeding roller, side plates are clamped to the two ends of one side, near the bracket, of the top of the working table, and a fixing shaft is movably mounted between the two side plates. According to the fully automatic table skirt machine, a motor drives a reciprocating plate to rotate through a belt, the reciprocating plate rotates to drive an interlocking shaft to swing in a reciprocating manner through a movable shaft, the principle of a crank arm connecting rod is formed, so that a rotating rod drives a rubber pleated shovel to swing back and forth, a material is shoveled into a plated shape to formed a skirt, the rubber pleated shovel is used, thereby avoiding the hard contact between the pleated shovel and the material, theexcessive contact is prevented from damaging the material, and a set pressure bar can be expanded and contracted inside a pressure cylinder to prevent the excessive contact from damaging the materialand affecting the processing quality.

Owner:廖其明

Printing medium flattening device of printer and printer

PendingCN113619295AReduce areaPlay a supporting roleTypewritersOther printing apparatusComputer printingMechanical engineering

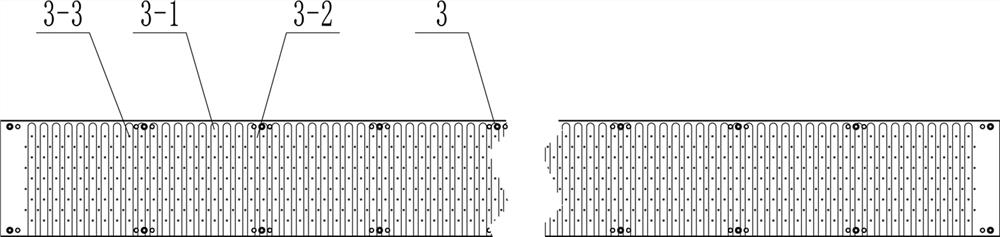

The invention provides a printing medium flattening device of a printer. The printing medium flattening device comprises a rack, a paper feeding end brush roller, a printing panel and a paper discharging end brush roller, and the paper feeding end brush roller, the printing panel and the paper discharging end brush roller are arranged on the rack; the paper feeding end brush roller and the paper discharging end brush roller both comprise roller bodies and brushes densely distributed on the surfaces of the roller bodies, the paper feeding end brush roller is arranged on the paper feeding side of the printing panel, and the paper discharging end brush roller is arranged on the paper discharging side of the printing panel; and a plurality of parallel grooves are formed in the printing panel, a boss is formed between every two adjacent grooves, the upper surfaces of the bosses are located on the same horizontal plane, and ventilation holes are densely distributed in the printing panel. The printing medium flattening device of the printer has the advantages that a good flattening effect on a thin medium is achieved, and excessive deformation of the thin medium after printing is avoided.

Owner:NEW CENTURY DIGITAL PRINT TECH

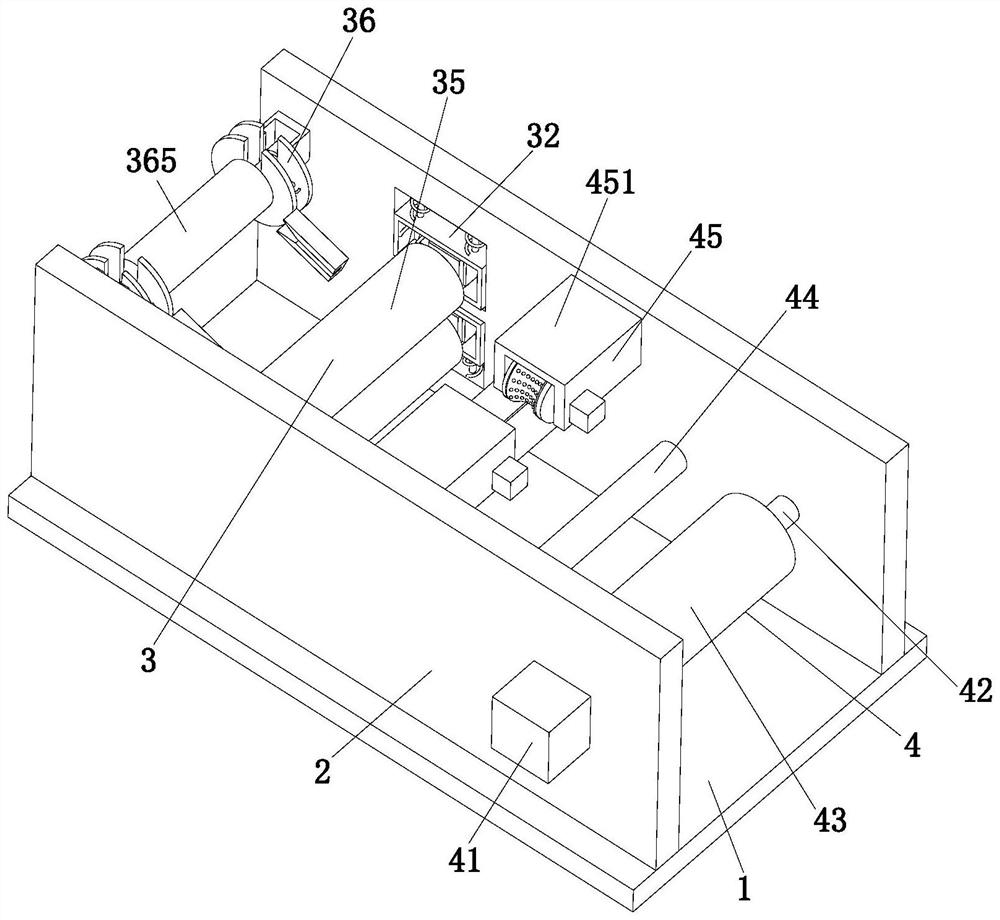

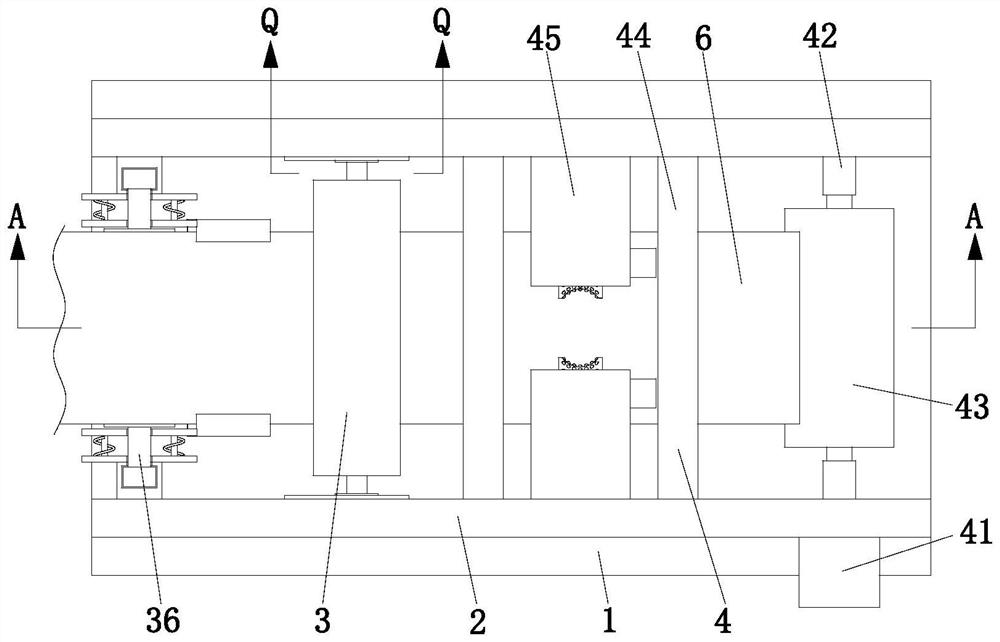

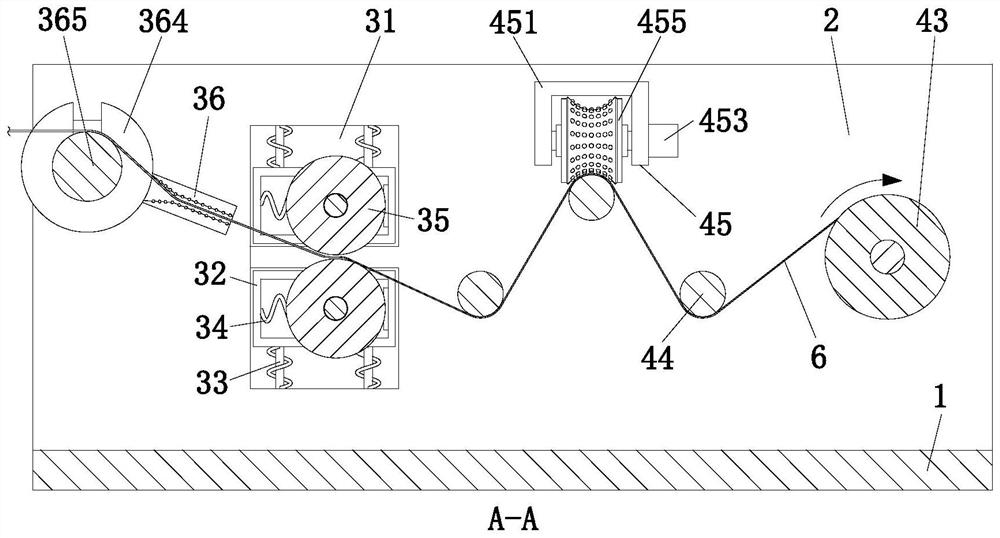

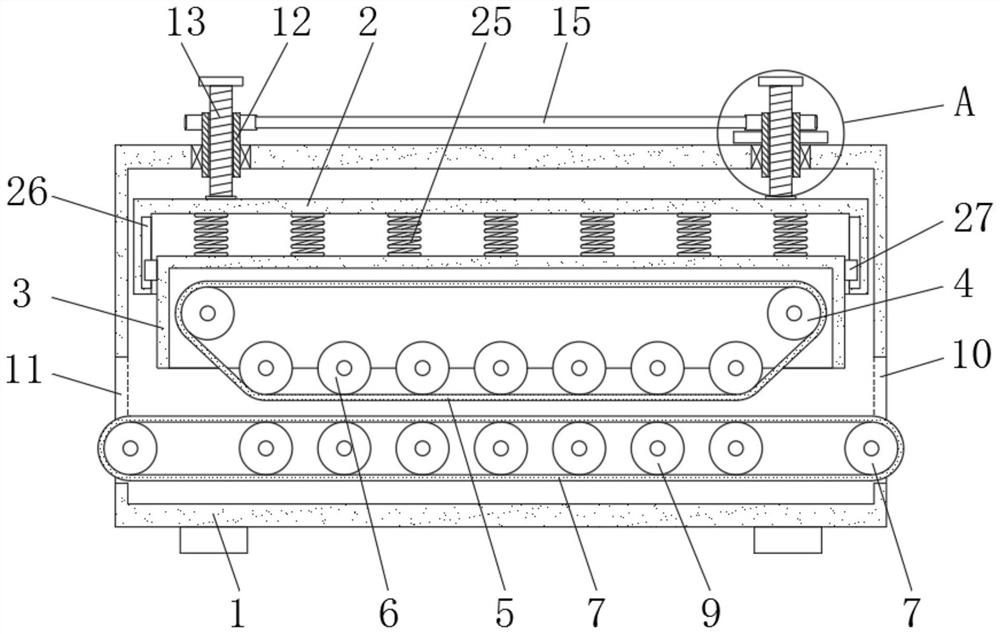

Pole piece winding equipment for lithium battery manufacturing

PendingCN111320009AGuaranteed flattening effectEnsure that the pressure roller can continue to play the role of flatteningWebs handlingEngineeringPole piece

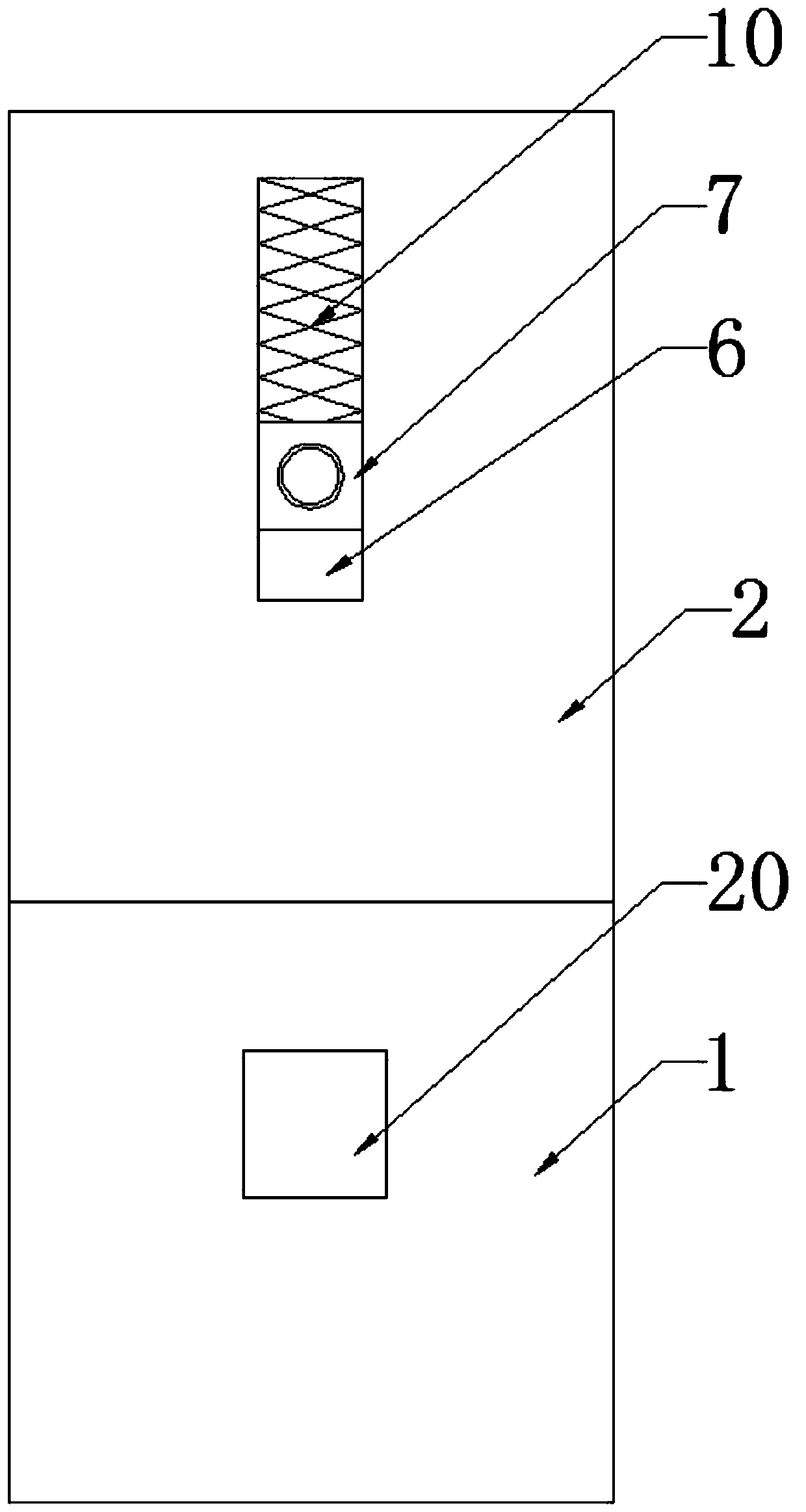

The invention discloses pole piece winding equipment for lithium battery manufacturing. The equipment comprises a base, wherein two supporting plates are fixedly arranged on the two sides of the top end of the base correspondingly, the bottoms of the two supporting plates are connected with the two ends of a first rotating shaft in an inserted mode through bearings correspondingly, sliding groovesare formed in the tops of the two supporting plates correspondingly, two sliding blocks are slidably arranged in the two sliding grooves correspondingly, the middles of the two sliding blocks are connected with the two ends of a second rotating shaft in an inserted mode through bearings correspondingly, and the top ends of the two sliding blocks are fixedly connected with the top ends of the inner walls of the two sliding grooves through two first springs correspondingly. According to the pole piece winding equipment for lithium battery manufacturing, a pole piece can be pressed to be flattened through a pressing roller in the winding process, wrinkles are avoided, and meanwhile, the position of the pressing roller can be changed along with the change of the thickness of a pole piece rollthrough the first springs, so that the pressing roller can continuously play a pressing flattening role, the winding efficiency is improved, manual pressing flattening is avoided, and the safety of workers is guaranteed.

Owner:广东省秦田科技有限公司

Film coating machine flattening roller layout structure and film coating machine using the same

PendingCN109536896AGuaranteed flattening effectQuality improvementVacuum evaporation coatingSputtering coatingGas phaseTransfer system

The invention discloses a film coating machine flattening roller layout structure. The structure includes a vacuum chamber and film coating components arranged in the vacuum chamber. The film coatingcomponents include a strip transfer system and evaporation sources. The strip transfer system includes two reeling wheels, two main rollers and the two evaporation sources. When the equipment works, one of the two reeling wheels is used as a winding wheel and the other is used as an unwinding wheel. In a strip transfer path, the two main rollers are located between the two reeling wheels, one of the two main rollers acts on one side of a strip, and the other main roller acts on the other side of the strip. The two evaporation sources are both used for vaporizing a material to be coated, and one of the evaporation sources and one of the main rollers form a film coating station. At any film coating station, gas phase obtained by heating through the evaporation sources acts on a strip sectionthat is bonded to the main rollers. The equipment can realize double-sided film coating of materials and help to obtain thicker film coating thickness.

Owner:四川海格锐特科技有限公司

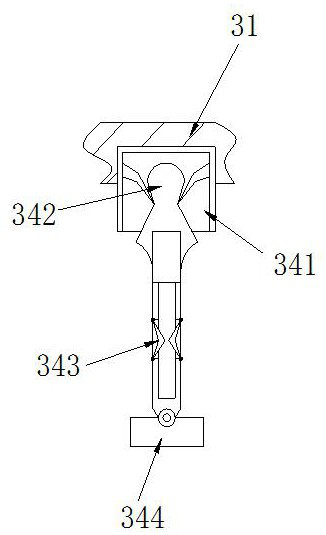

Efficient intelligent planting all-in-one machine for camphor tree dwarf forest planting in mountainous and hilly areas

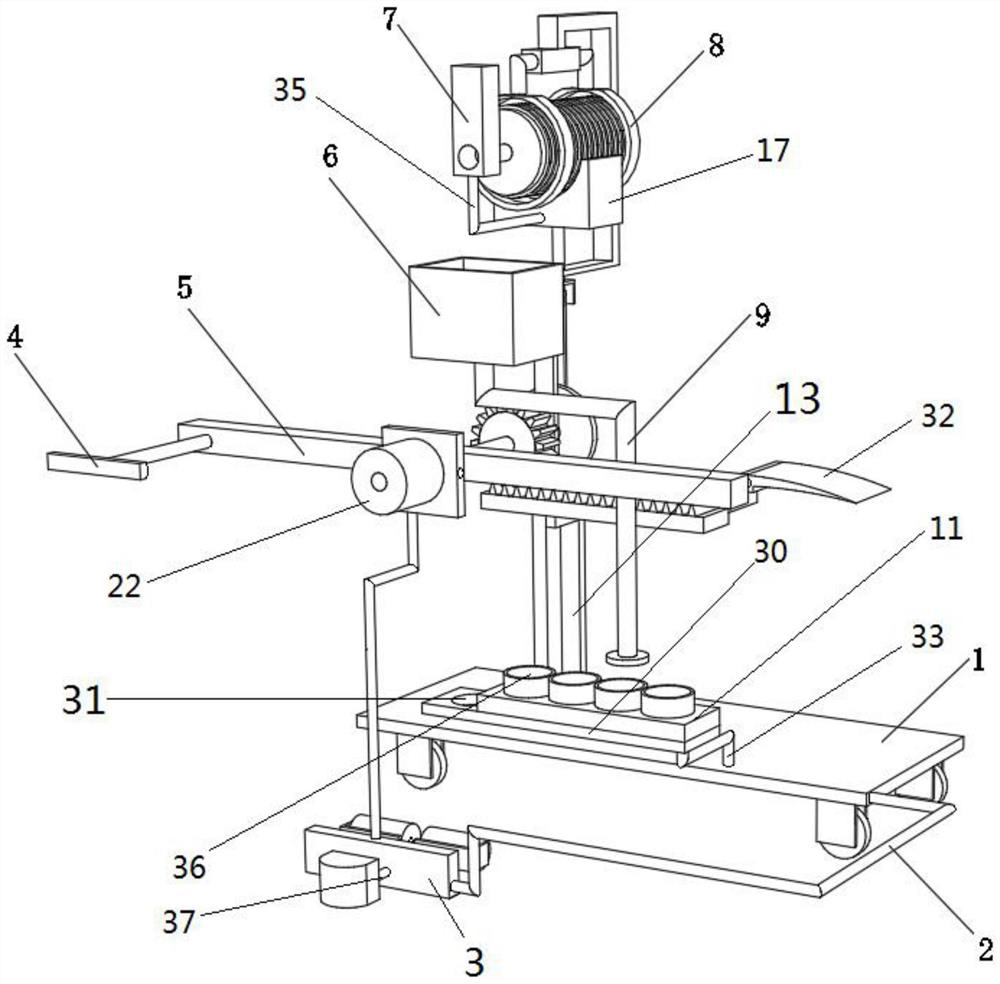

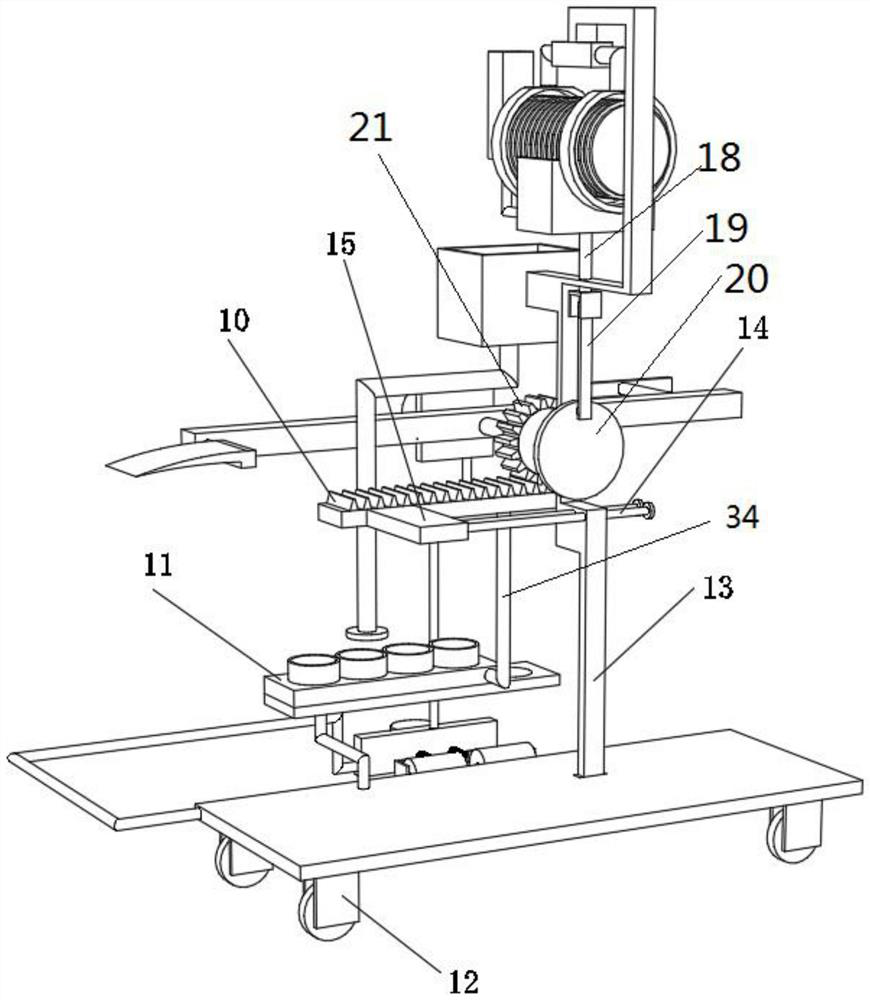

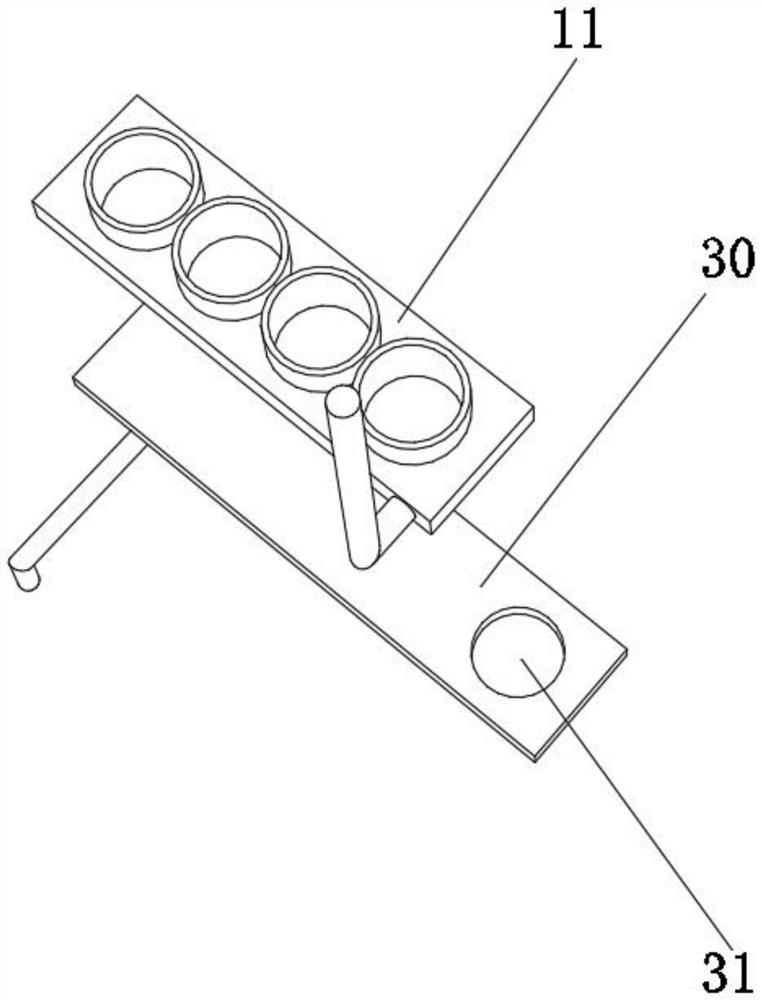

PendingCN114467672APrevent outflowPrevent disengagementTransplantingForestryCinnamomum camphoraPygmy forest

The invention relates to an efficient intelligent planting all-in-one machine for camphor tree dwarf forest planting in mountainous and hilly areas. A mounting frame is fixed on a base; the flattening mechanism is slidably connected to the bottom end of the mounting frame; a transplanting fixing frame is fixed to the base, the seedling transplanting mechanism comprises a bearing plate, a transplanting plate located on the bearing plate and a transmission mechanism driving the transplanting plate to slide, the bearing plate is fixed to the transplanting fixing frame, a seedling pit falling hole is formed in one end of the bearing plate, and a seedling transplanting hole is formed in the transplanting plate; a watering mechanism mounting rack is fixed on the base, and the watering mechanism is mounted on the watering mechanism mounting rack; the earth cutting mechanism is located above the base and provided with an earth cutting shovel at one end and a flattening mechanism driving part at the other end; the driving mechanism is mounted at the top end of the mounting frame, and the output end of the driving mechanism is in transmission connection with the earth cutting mechanism, the transmission mechanism and the watering mechanism so as to drive the device to complete the functions of rotary earth cutting, earthing flattening, transplanting and irrigation; the device is complete in function, simple in operation step, labor-saving and high in planting efficiency.

Owner:NANCHANG INST OF TECH

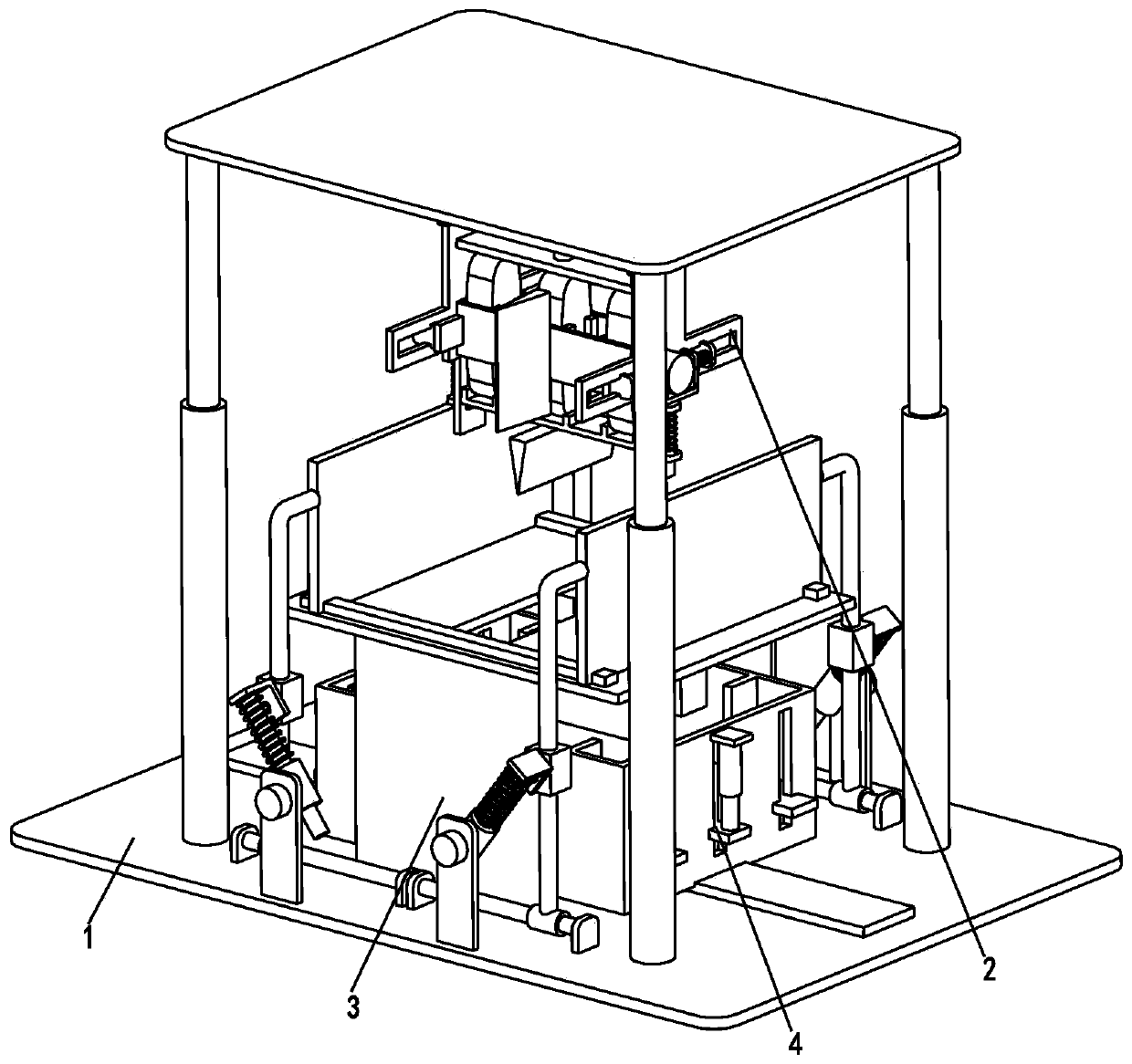

Positioning and clamping device for garment processing

InactiveCN114098199AGuaranteed flattening effectEasy to flattenClothes making applicancesEngineeringElectric control

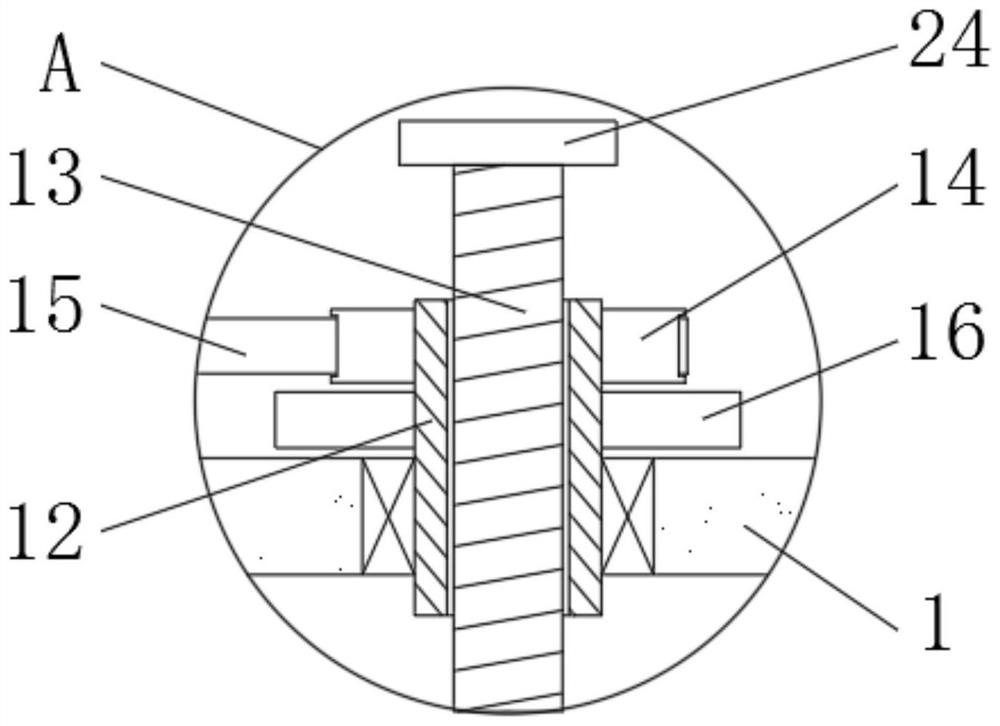

The positioning and clamping device comprises a workbench, supporting legs are fixedly connected to the four corners of the outer wall of the bottom of the workbench, an electric control box is fixedly connected to the outer wall of the bottom of the workbench, a fixing frame is fixedly connected to one end of the outer wall of the top of the workbench, and a clamping mechanism is arranged on the outer wall of the fixing frame; sliding grooves are formed in the outer walls of the two sides of the workbench, and transverse adjusting mechanisms are arranged on the inner walls of the sliding grooves. Cloth can be borne by arranging the bearing plate, one end of the cloth is clamped and fixedly connected through the clamping mechanism arranged on the outer wall of the fixing frame, the transverse adjusting mechanism is arranged to control the moving frame to slide along the sliding groove, and therefore rolling flattening treatment can be conducted on the cloth through a pressing roller in the moving frame; by arranging the height adjusting mechanism, the height of the moving frame can be controlled, the cloth can be flattened under different pressures, and the flattening effect of the clothes is further guaranteed.

Owner:天门悦姿服饰有限公司

Printing paper conveying device

The invention relates to the technical field of paper printing, and discloses a printing paper conveying device. The printing paper conveying device comprises a machine frame, wherein the machine frame is provided with conveying rollers, a conveying belt is wound around the conveying rollers, paper is conveyed on the conveying belt, and the printing paper is required to be smooth; and the machine frame is further provided with a flattening roller, the flattening roller is provided with a power linkage shaft core, a plurality of radial connecting rods are arranged in the middle of the shaft core, arc reeds are connected outside the connecting rods, the middle parts of the arc reeds are arranged at the outer ends of the connecting rods, the arc reeds are arranged on the periphery of the shaft core in an arrayed mode, the two ends of the arc reeds are provided with rubber blocks, and the flattening roller is arranged above the conveying rollers. When the rubber blocks at the two ends of the arc reeds make contact with the conveying belt, the arc reeds are in compressed states, and the conveying belt and the flattening roller run forward synchronously. The printing paper conveying device has the advantages that the printing paper can be flattened, the flaws are reduced, and the product quality is improved.

Owner:HENAN HUAGANG PRINTING

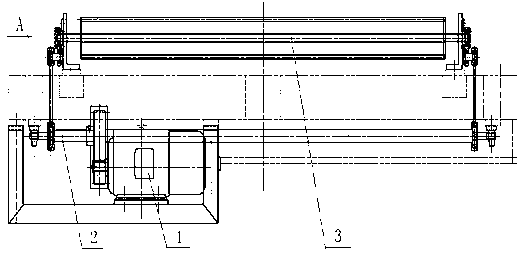

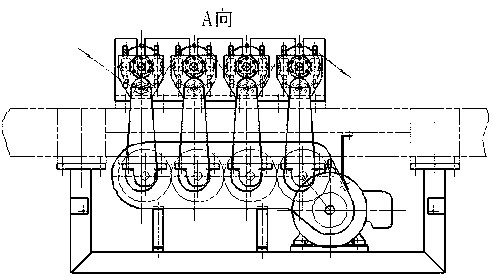

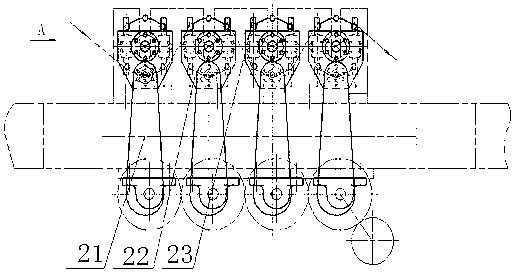

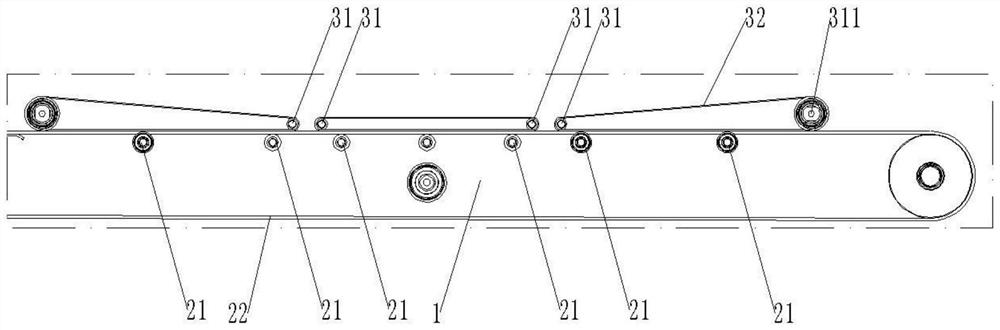

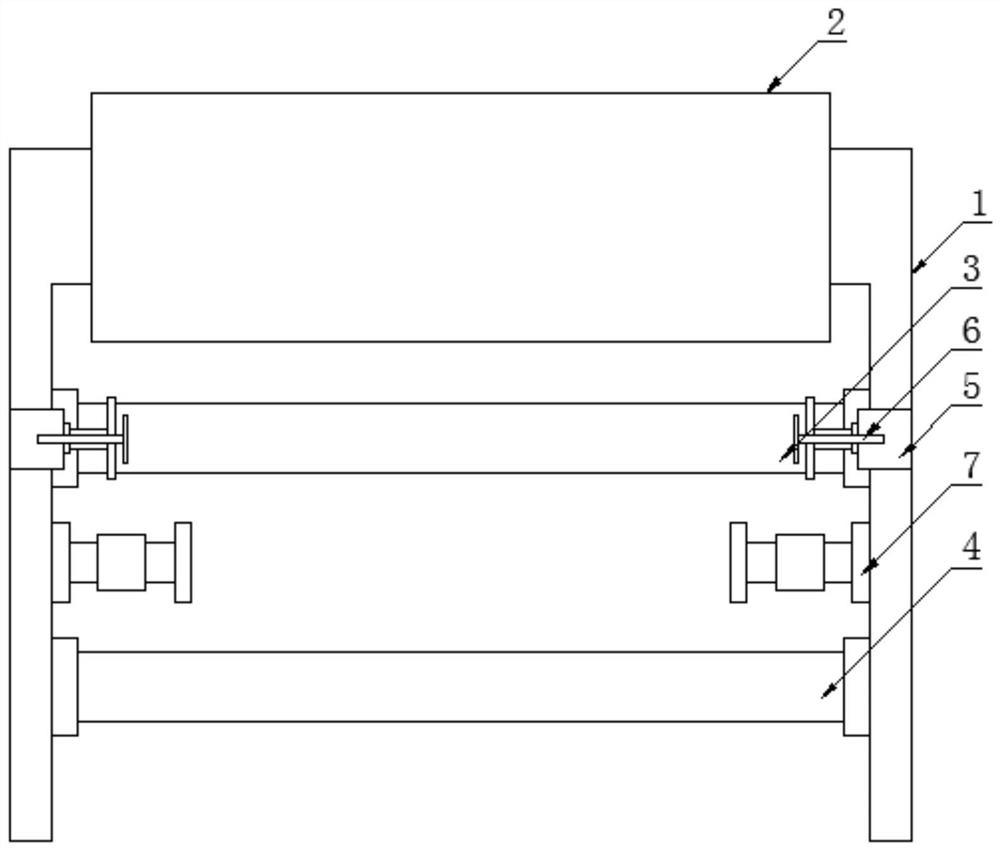

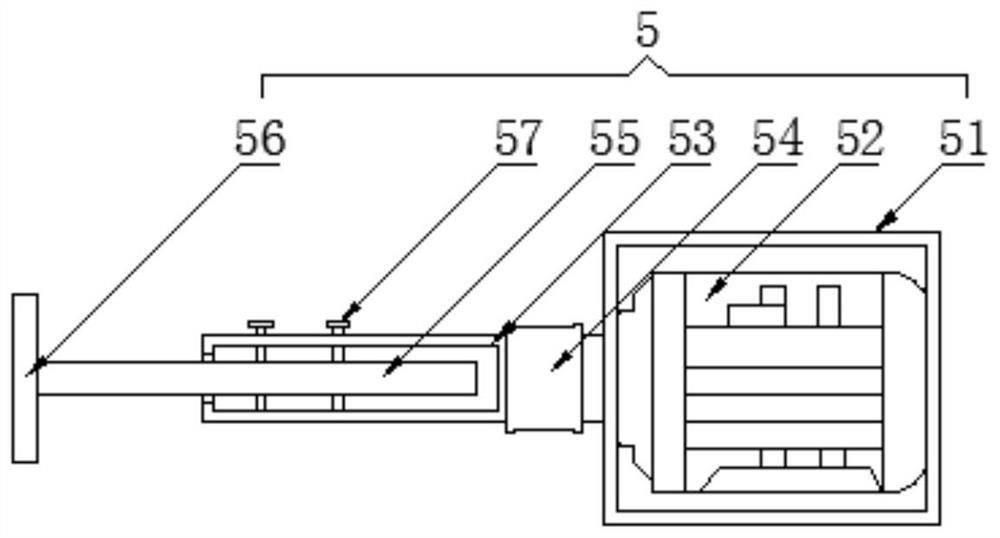

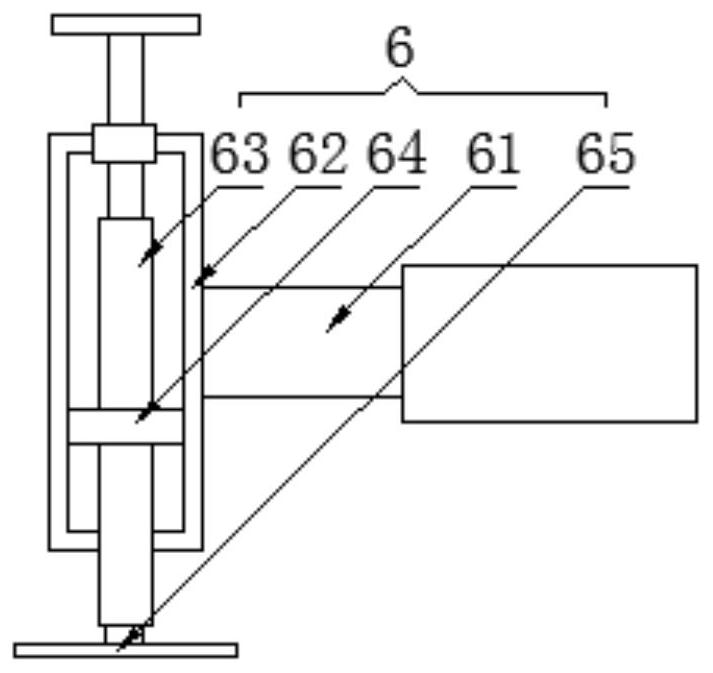

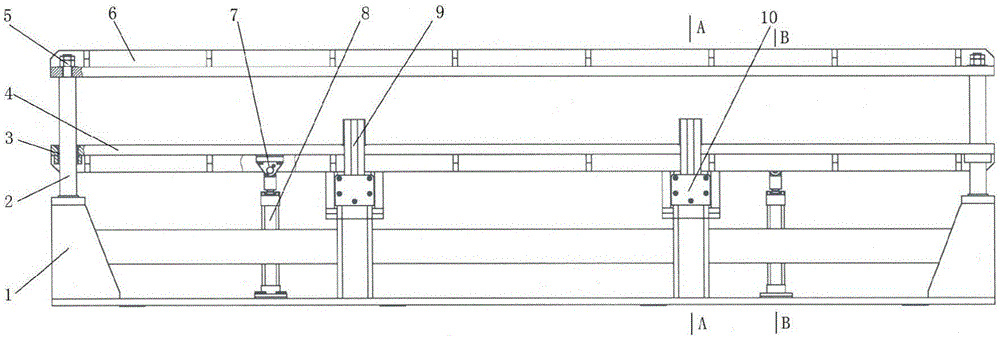

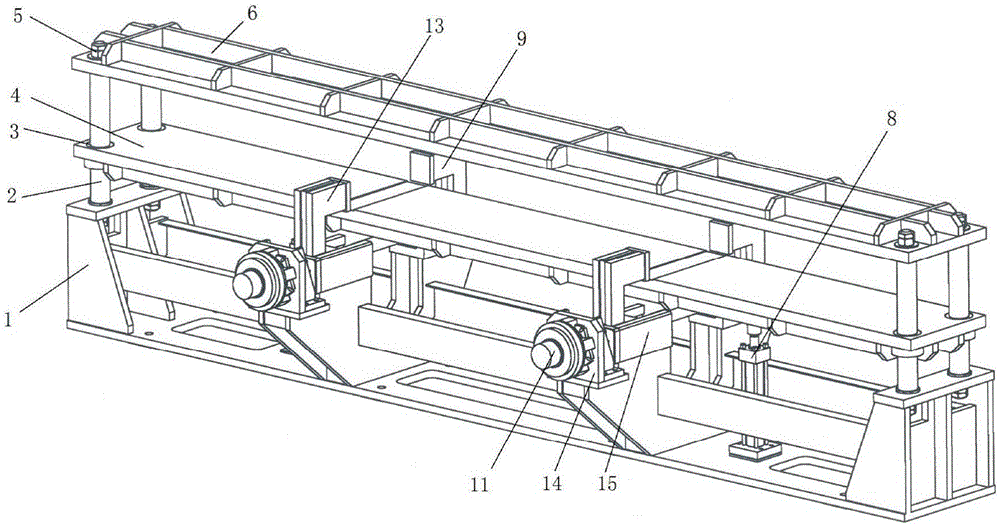

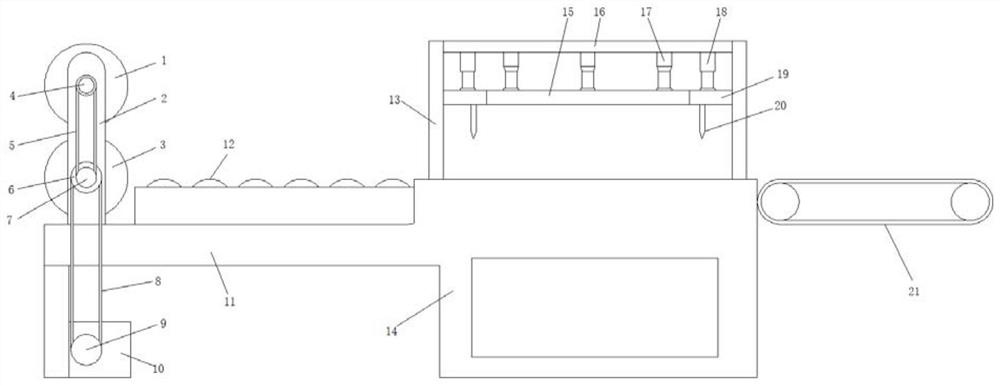

Up-down vibration flattening device

ActiveCN102517691BGuaranteed flattening effectNovel structureTextile/flexible product manufactureFibre chemical featuresMoving partsCarbon filaments

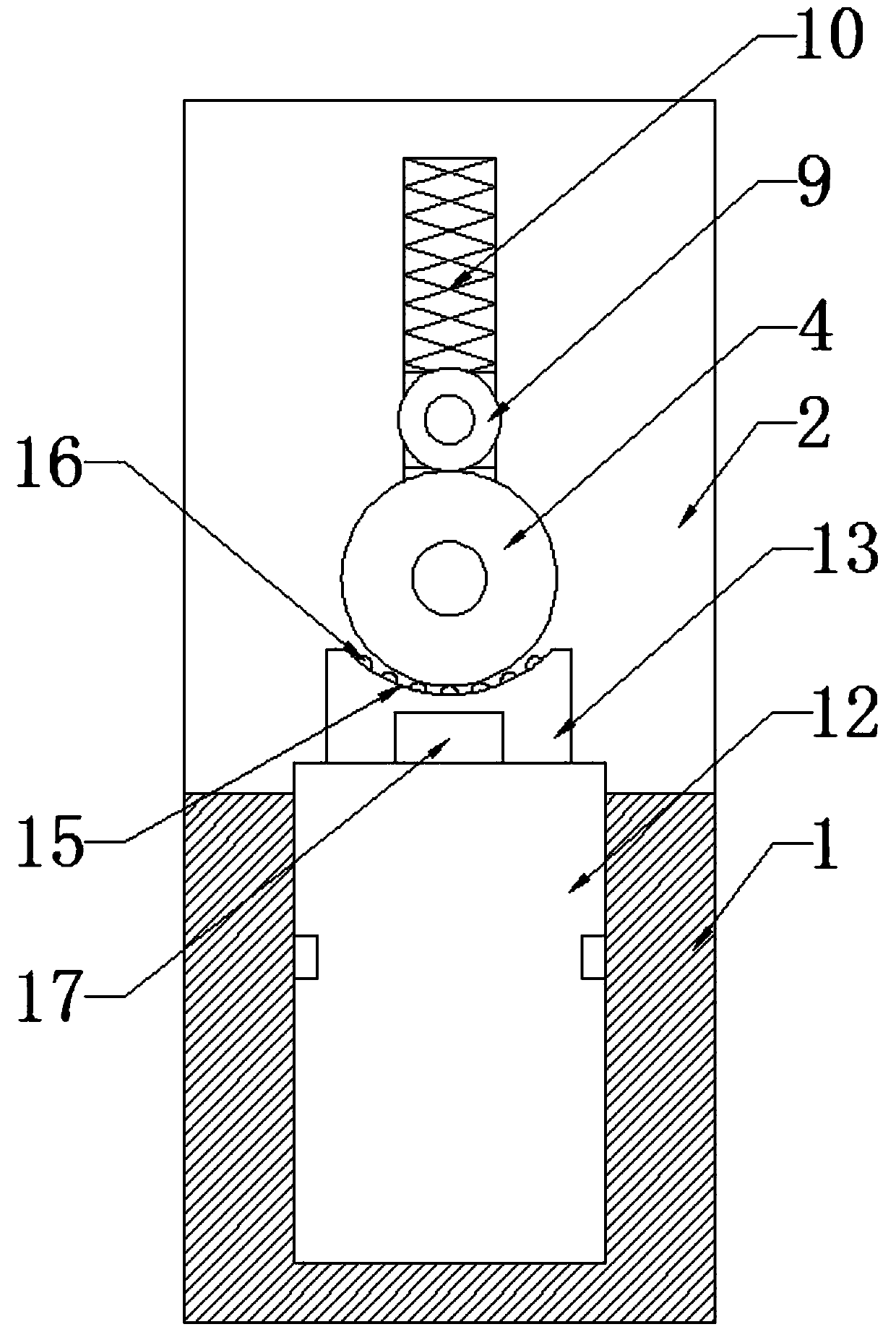

The invention discloses an up-down vibration flattening device which mainly consists of a transmission part (1), a moving part (2) and a vibration roller part (3), wherein the transmission part (1) is mounted at the bottom of a frame body of the flattening device; the moving part (2) is mounted on the frame body; the vibration roller part (3) is arranged at the upper part of the frame body and connected with the moving part (2); the vibration roller part (3) consists of four groups of vibration rollers; and every two adjacent groups of vibration rollers move relatively up and down in the axial direction under the effect of an eccentric wheel of the moving part (2). The up-down vibration flattening device disclosed by the invention has a novel, compact and reasonable structure; the transmission part adopts a variable-frequency motor which directly drives a rotation shaft with the eccentric wheel to rotate to realize up-down vibration, and can realize online adjustment of the vibration frequency according to the production process; the moving part adopts a precise linear guide rail to ensure vibration stability; and the vibration roller adopts a rachis structure so that the carbon filament is in linear contact and the carbon filament flattening effect is ensured.

Owner:大连橡胶塑料机械有限公司

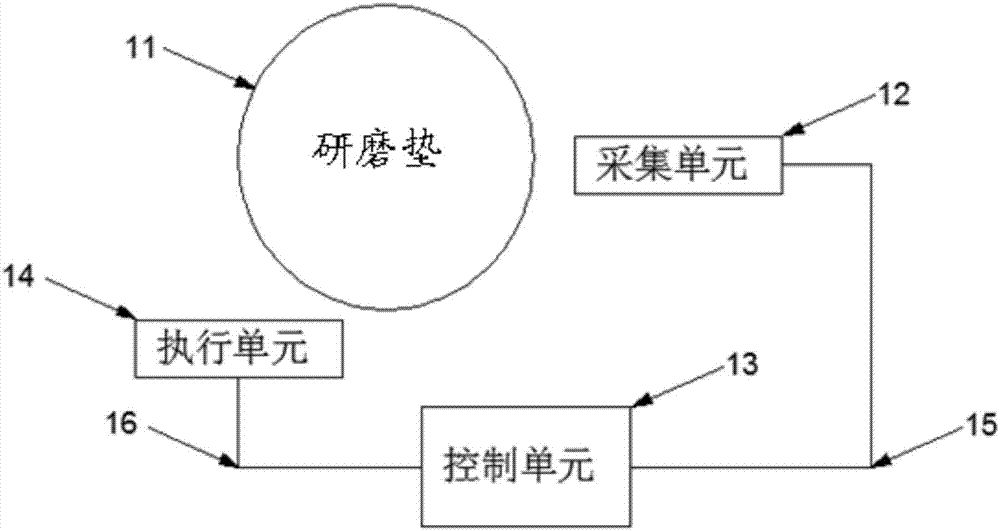

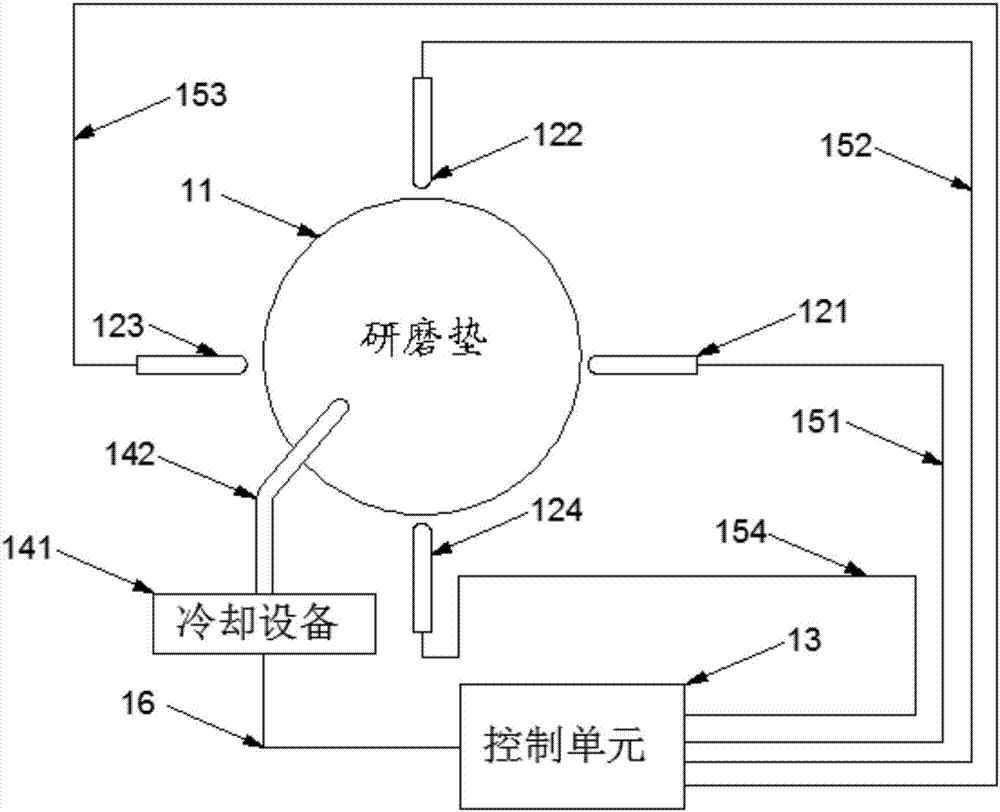

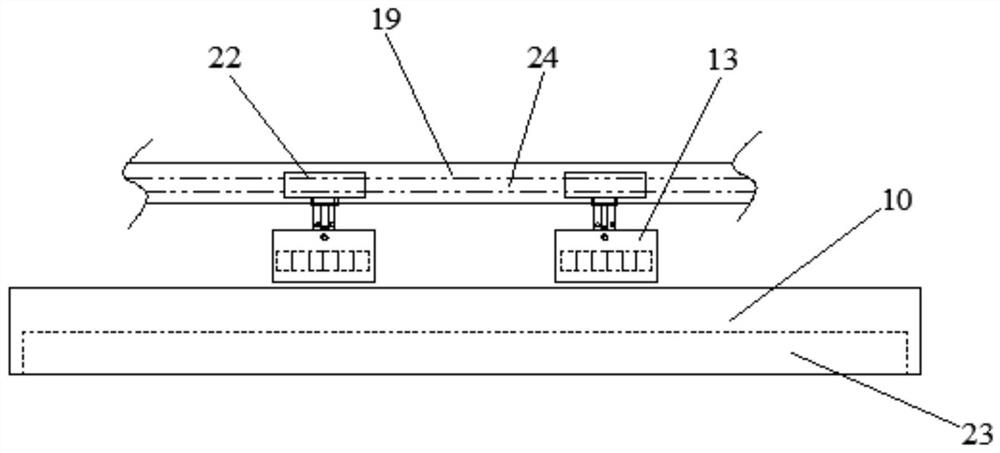

Chemical-mechanical grinding machine table, temperature control system and temperature control method of temperature control system

InactiveCN107088825AEnsuring chemical reactivity propertiesGuaranteed flattening effectLapping machinesEngineeringTemperature control

The invention provides a chemical-mechanical grinding machine table, a temperature control system and a temperature control method of the temperature control system. The temperature control system comprises a collecting unit, a control unit and an executing unit which are sequentially in communication connection. The temperature control method comprises the steps that the collecting unit collects the temperature information of a grinding pad in the chemical-mechanical grinding process; and the control unit controls the executing unit to cool the grinding pad according to the temperature information of the grinding pad so that the temperature of the grinding pad can be kept within the preset range. The chemical-mechanical grinding machine table comprises the grinding pad and the temperature control system. The collecting unit is used for obtaining the temperature information of the grinding pad in the grinding process, the control unit controls the executing unit to cool the grinding pad according to the temperature information, accordingly, the temperature of the grinding pad is controlled, the temperature of the grinding pad in the chemical-chemical grinding process can be stabilized within a certain value range, and accordingly the wafer grinding effect is ensured.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

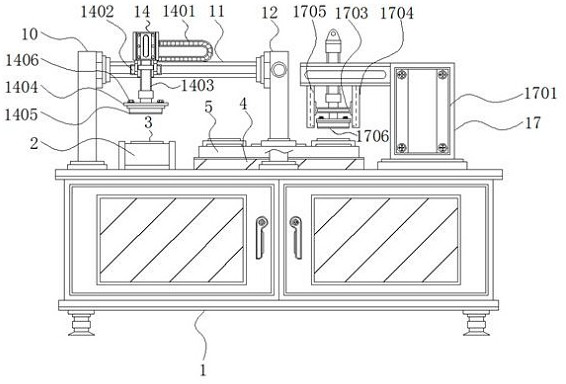

Flatness detection equipment with clamping structure for detecting metal pendants of bags and suitcases

InactiveCN112254684AGuaranteed accuracyAvoid tiltingUsing optical meansMechanical measuring arrangementsPhysicsEngineering

The invention discloses flatness detection equipment with a clamping structure for detecting metal pendants of bags and suitcases, and relates to the technical field of luggage metal pendant detection. The flatness detection equipment comprises a base, a first clamping mechanism and a detection mechanism, and a feeding conveying belt is arranged on the left side of the upper end of the base. According to the invention, a connecting plate and a driving cylinder are vertically distributed, and thus the position accuracy is ensured. The driving cylinder drives a connecting plate to enable a magnetic attraction clamping block to ascend or descend to complete clamping and attraction work on the metal pendant body, and a shallow groove which is uniform with the metal pendant body in shape and size is formed in the inner side of the lower end of the magnetic attraction clamping block; the stability of the metal pendant main body in the transferring process is guaranteed by completing adsorption clamping work on the metal pendant main body through the electromagnet in the shallow groove, and the corresponding model can be conveniently replaced according to the actually detected model of the metal pendant main body through the magnetic clamping block and the connecting plate which are in threaded connection through the fastening bolt, so that the metal pendant is convenient to use.

Owner:东莞市优伟机电科技有限公司

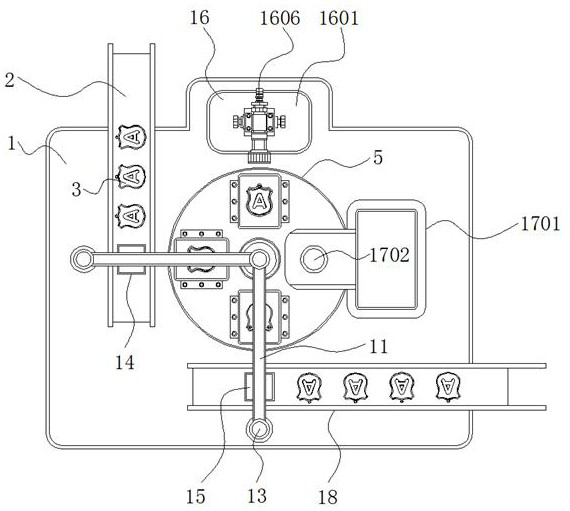

Synchronous flattening structure for flaky materials

The invention discloses a sheet material synchronous flattening structure which is characterized by comprising a rack, a conveying assembly installed on the rack, a flattening assembly used for flattening materials, a driving assembly used for driving the conveying assembly and the flattening assembly to operate and a detection element used for detecting the quality of the sheet materials. The conveying assembly comprises a lower conveying roller rotationally connected to the rack and a lower conveying belt wrapping the lower conveying roller, and the flattening assembly comprises an upper conveying roller rotationally connected to the rack and an upper conveying belt installed on the upper conveying roller in a matched mode. A conveying channel for allowing materials to pass through is arranged between the upper conveying belt and the lower conveying belt; the driving assembly and the detection element are mounted on the rack; and through the arrangement of the flattening structure, the upper conveying belt can press the sheet-shaped materials and flatten the sheet-shaped materials, the flattening effect is guaranteed, and the accuracy of subsequent detection is facilitated.

Owner:HANGZHOU ZHANTUO INTELLIGENT TECH

A multi-angle flattening device for processing decorative panels

InactiveCN111570562BGuaranteed flatnessAccurately control the size of the forceEngineeringMechanical engineering

The invention discloses a multi-angle flattening device for processing decorative boards. The invention uses electromagnetic attraction force to realize the control of the flattening force, effectively guarantees the smoothness of the flattening, and can accurately control the size of the force; The flattening transverse drive mechanism of the present invention can drive two flattening blocks to move at the same speed in opposite directions, so as to realize the flattening movement of the decorative panel at various positions and angles, and the electromagnetic controller can control the electromagnetic disk to move up and down during the flattening. Electromagnetic attraction pressure between the lower electromagnet disc; the electromagnetic controller is configured so that when the flattening operation is forwarded, the electromagnetic attraction pressure at the front end of each flattened block in the forward direction is smaller than its The size of the electromagnetic suction pressure at the rear end. This design of electromagnetic suction pressure ensures the accuracy of the forward movement of the flattening block and the smooth forward performance, thereby ensuring the flattening ability of the flattening. The large pressure at the rear can further ensure the flattening block. Flattening effect, to achieve step-by-step flattening.

Owner:CHONGQING WATER RESOURCES & ELECTRIC ENG COLLEGE

A flattening treatment device for copper foil production

ActiveCN114054544BImprove flattening effectIncrease contact areaMetal-working feeding devicesPositioning devicesCopper foilMechanical engineering

The invention relates to the technical field of copper foil production, in particular to a flattening treatment device for copper foil production, comprising a worktable, a support plate, a rolling unit and a winding unit. The upper end of the worktable is symmetrically arranged with two supporting The support plate, the opposite side of the support plate is provided with a rolling unit and a winding unit in sequence from left to right; the existing flattening device has the following problems: when the existing device is flattening copper foils of different thicknesses, The device needs to be adjusted accordingly, and the operation is complicated; the device cannot perform all-round flattening treatment on the copper foil, and there is a flattening dead angle, so that the flattening effect of the copper foil cannot be guaranteed; The flattening treatment does not require frequent adjustment of the device, thereby saving the workload; the present invention can flatten the copper foil in all directions by flattening the elastic sheet, so the flatness of the copper foil can be ensured, thereby ensuring that the copper foil is flattened. Flattening effect of foil.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

Efficient roadbed flattening device for highway engineering construction

InactiveCN114775369AAchieving a flattening and compacting effectReduce work intensityRoads maintainenceAir pumpRolling sliding

The invention relates to the technical field of highway engineering flattening devices, and discloses an efficient roadbed flattening device for highway engineering construction.The efficient roadbed flattening device comprises a pressing wheel fixing frame and a pressing wheel roller body, and the left end and the right end of the pressing wheel roller body are connected to the left inner wall and the right inner wall of the pressing wheel fixing frame through rotating shafts correspondingly; holes are evenly distributed in the outer side wall of the pressing wheel roller body in the circumferential direction, a rolling sliding block is arranged in each hole, a weight adjusting inner cylinder is arranged in the pressing wheel roller body, supports are fixedly connected to the top faces of the left end and the right end of the pressing wheel fixing frame, and air pumps are fixedly connected to the top faces of the left ends of the supports. The left side and the right side of the bottom end of the pressing wheel fixing frame are each provided with two supporting connecting rods, the top face of each supporting connecting rod is provided with a hydraulic telescopic rod, operation is easy, use is convenient, and the claw rolling effect can be achieved without carrying, disassembling and installing a claw roller; and the working intensity of constructors is effectively reduced, and the construction efficiency of highway engineering is effectively improved.

Owner:浙江广通环境建设有限公司

Printing process of a haircut scissors sign board

ActiveCN107020648BHigh impactImprove heat resistancePattern printingMetal working apparatusRubber materialAlcohol

Owner:JIANGSU BETTER CO LTD

Tab flattening device with simple and convenient operation for lithium ion battery production

ActiveCN112670675AEven by forceNot easy to damageFinal product manufactureCell component detailsStructural engineeringLithium-ion battery

The invention discloses a tab flattening device with simple and convenient operation for lithium ion battery production, which comprises a box body, wherein a buffer frame is arranged on the upper portion of an inner cavity of the box body, a pressing frame is embedded in the buffer frame, first transmission rollers are movably installed at the left end and the right end of the inner cavity of the pressing frame correspondingly, the surfaces of the two first transmission rollers are jointly sleeved with a lower pressing belt, lower pressing rollers are embedded in the lower pressing belt at equal intervals, a conveying belt is arranged below the lower pressing belt, supporting rollers are embedded in the middle of the conveying belt at equal intervals, and a sleeve is embedded in the top of the box body through a bearing. According to the invention, the lower pressing belt is used for extruding and flattening the whole tab so as to enable the whole tab to be stressed uniformly and not easy to damage, the probability that the edges of the tab tilt is reduced, the whole flattening effect on the tab is good, and the distance between the lower pressing belt and the conveying belt can be adjusted by rotating the handle, so that the pressure on the whole tab is adjusted, and the tab flattening effect is effectively improved.

Owner:湖南久森新能源有限公司

Tensioning mechanism

The invention discloses a tensioning mechanism, which comprises a rack; the rack is provided with at least one fixed roll and a pull roll which is driven by a first power unit; the pull roll is located below the at least one fixed roll; the rack is also provided with a moving rack driven by a straight-line motion mechanism; the moving rack is provided with at least one moving roll; the at least one fixed roll and the at least one moving roll are arranged in a staggering manner in the vertical direction; the moving rack is also provided with a press roll used for tightly pressing a flexible material to the pull roll; at an initial position, a vertical gap used for the flexible material to pass is formed between the at least one moving roll and the at least one fixed roll. According to the tensioning mechanism disclosed by the invention, by twining the flexible material for multiple times, the tension requirement and the flattening effect of the flexible material in feeding and receiving states can be ensured; manual insertion is not needed during a flexible material twining process, so that the labor strength of an operator is reduced, and the potential safety hazard that the operator is crushed is eliminated.

Owner:GOERTEK INC

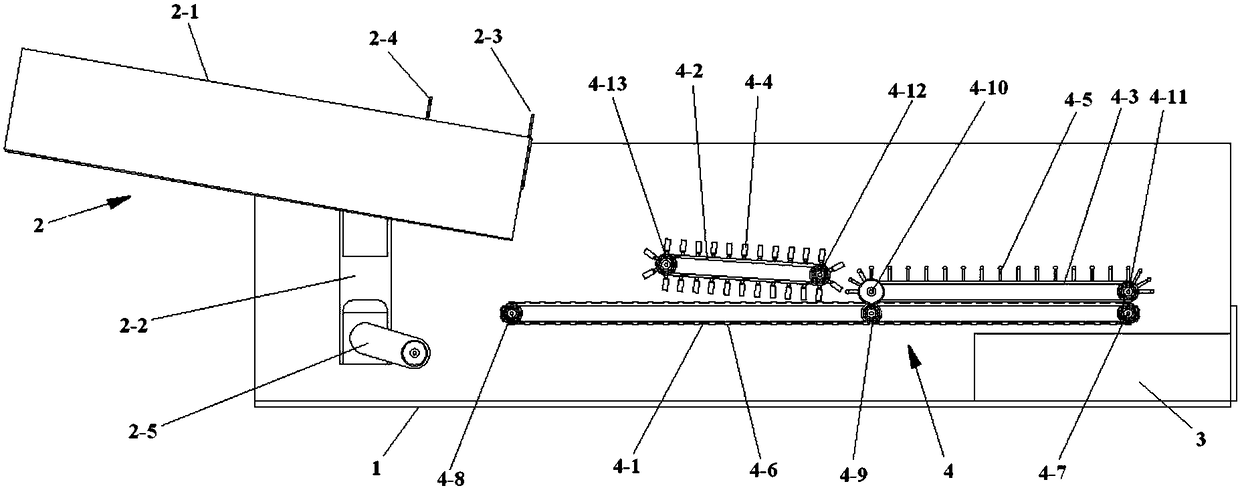

A high-density felt shrinking machine

InactiveCN103820961BGuaranteed flattening effectImprove productivityTextile treatment machine partsTextile treatment by spraying/projectingProduction rateHigh density

The invention provides a high-density felt flat shrinking machine, comprising a rack, a motor, a transmission, a coupler, a driving chain wheel, a driven chain wheel, a chain, upper press shafts, lower press shafts, pressure springs, a steam water pipe and a control box; the motor is connected with the transmission and the coupler in sequence; the coupler is connected with the main chain wheel connected with the driven chain wheel by the chain; the lower press shafts are respectively arranged on the shafts of the driving chain wheel and the driven chain wheel; an upper press shaft is arranged above each lower press shaft in parallel; the pressure springs are arranged at two ends of each upper press shaft; the control box is connected with a steam water pipe and a gearbox; the upper press shafts, the pressure springs and the steam water pipe are all arranged above the rack; an air outlet is formed in the steam water pipe parallel with the press shafts. The upper press shafts, the lower press shafts and the pressure springs are adopted for controlling the friction of a felt in the flat shrinking process, multiple times of fat shrinking can be realized at one step, the flat shrinking effect is ensured, and the productivity is improved; the steam water pipe is parallel with the press shafts, so the felt can uniformly suck water content before flat shrinking, and the flat shrinking processing demands can be met.

Owner:NANJING HONGSHENG FELT PRODION

A device for collecting copper foil ear material of a raw foil machine

ActiveCN111438749BAdjustable widthEasy to fixMetal working apparatusWebs handlingEngineeringCopper foil

The invention discloses a device for collecting copper foil ear material of a raw foil machine in the technical field of copper foil processing. A first transmission shaft and a second transmission shaft are arranged on the opposite end faces of the fixed brackets, and both the first transmission shaft and the second transmission shaft are arranged under the container, and the outer walls of the front ends of the two sets of fixed brackets are all provided with cutting device, the front side outer wall of the fixed end of the slitting device is provided with a flat pressing device, and the opposite end faces of the two sets of fixed brackets are provided with a collecting device, and the collecting device is arranged in the interlayer between the first transmission shaft and the second transmission shaft. The width of the copper foil needs to be adjusted to ensure a certain flattening effect on the copper foil, to prevent it from tearing, and to ensure that it will not hinder the transmission of the copper foil. The copper foil is collected to ensure its tightness , there will be no scattered phenomenon, and the collection efficiency will be improved.

Owner:TAIXING SHENGDA COPPER IND CO LTD

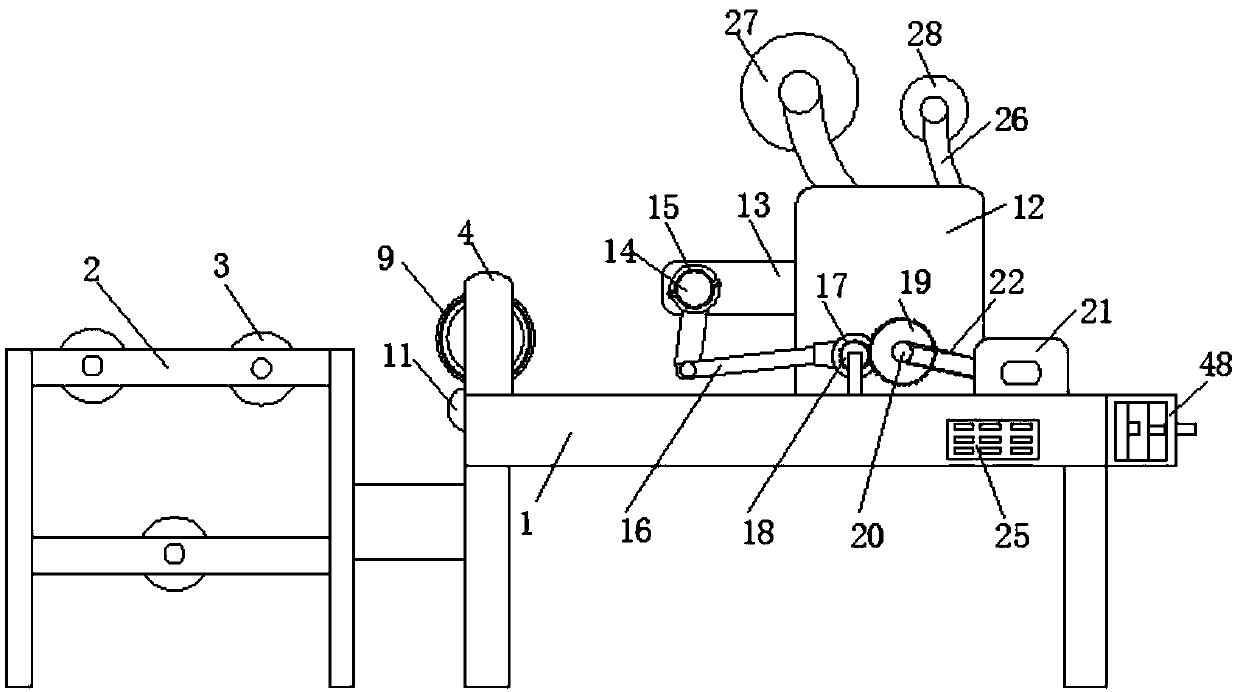

A friction type banknote flattening device

InactiveCN105844787BSolve processing problemsFlattening and finishingCoin/currency accepting devicesSmall toothSmall teeth

The invention provides a friction bank note flattening sorting device. The device comprises a frame, wherein the frame is internally equipped with a bank note spreading flattening mechanism, the bank note spreading flattening mechanism comprises a lower conveying belt horizontally mounted in the frame, the lower conveying belt is equipped with a spreading conveying belt and an upper conveying belt, the spreading conveying belt is close to a hopper mechanism, the upper conveying belt is close to a collection hopper, the spreading conveying belt is obliquely arranged, height of one end of the spreading conveying belt close to the upper conveying belt is smaller than height of one end of the spreading conveying belt away from the upper conveying belt, the spreading conveying belt and the lower conveying belt have an included angle, the upper conveying belt and the lower conveying belt are vertically mounted in a parallel contact mode, the outer surface of the spreading conveying belt is hinged with multiple uniformly-distributed hanging teeth, and the outer surface of the upper conveying belt is provided with multiple uniformly-distributed flexible small teeth. According to the device, a processing problem of wrinkled bank notes is solved, so bank note sorting mechanization is realized, functions are practical, and the wrinkled bank notes are flattened and sorted and are easy for market development and popularization.

Owner:CHANGAN UNIV

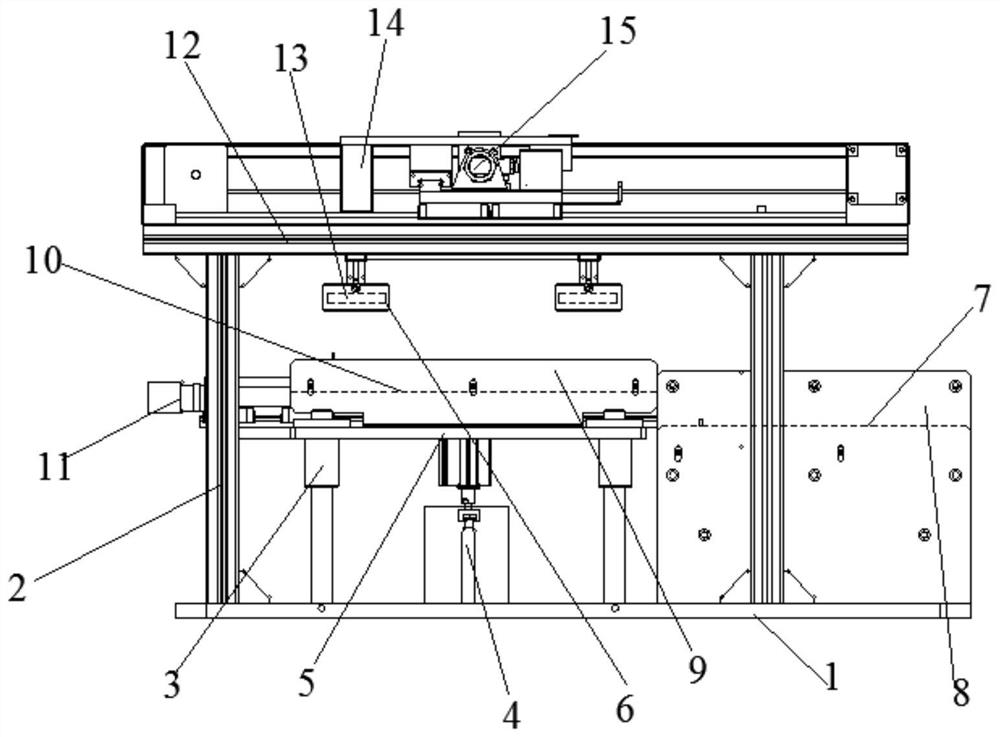

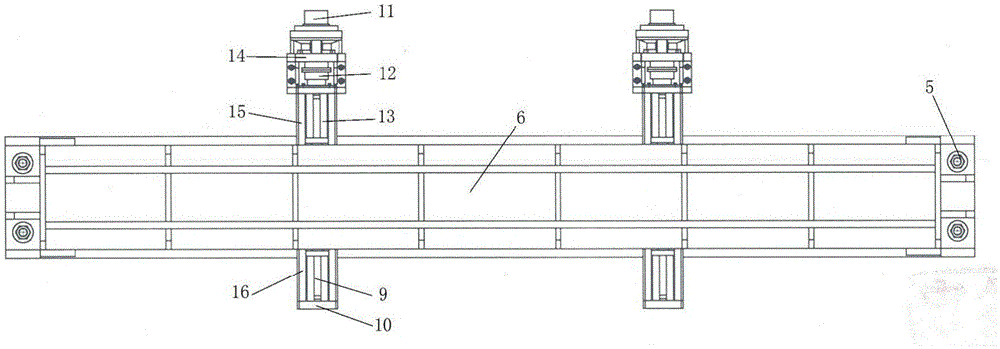

Metal sheet stacking and flattening device

ActiveCN104998925AIncrease productivityGood lift synchronizationMetal rolling arrangementsProduction lineMetal sheet

The invention provides a metal sheet stacking and flattening device. The metal sheet stacking and flattening device comprises a frame. A pressure bearing device is arranged above the frame. The pressure bearing device comprises a fixing pressing plate at the topmost end, a lifting pressing plate below the fixing pressing plate and a lifting power system. Centering and aligning devices are arranged on the two sides of the frame. Each centering and aligning device comprises a left centering plate, a right centering plate, a horizontally-moving power system and a guiding device, wherein the left centering plate and the right centering plate are located at the left side and the right side of the lifting pressing plate respectively; the horizontally-moving power system provides left-and-right motion power for the left centering plate and the right centering plate; the guiding device provides a left-and-right motion guiding function. A plurality of sheets can be treated at the same time; the production efficiency is high, the lifting synchronism is good, centering is reliable, and the flattening effect can be guaranteed; the metal sheet stacking and flattening device can be additionally arranged beside a roller way of an existing production line, so that upgrading and reconstruction are convenient.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Automatic cutting device for pocket cloth

InactiveCN114772361AGuaranteed flattening effectGuaranteed fitSevering textilesArticle deliveryMechanical engineeringCotton material

The invention discloses an automatic pocket cloth cutting device which structurally comprises a base box, a conveying table, a cutting machine and a control console, cloth is conveyed into the cutting machine through the conveying table, a cutter is matched with a pressing machine to cut the cloth, during pressing, firstly, a tension spring generates pushing force, a wrapping block is pushed downwards, and then the cutting machine cuts the cloth; meanwhile, the center block is driven to move downwards, the downward conveying frame rotates by a certain angle, pressure is applied to the cloth through the pressure head, the cloth is flattened, and when the downward conveying frame cannot continue to rotate, the center block starts to continue to work at the moment; pressure is output downwards through a pressure ball in a pressure block arranged on a center block, vertical output force is kept through a vertical frame, overlarge counter-acting force is absorbed through a suspension ball, and if a pressure head is abraded, the pressure head can be kept in contact with cloth through continuous downward pressure, so that the cloth is prevented from being damaged, and the service life of the cloth is prolonged. Pressure unbalance of the two sides caused by excessive abrasion of one side is avoided, and the flattening effect of the fed cloth is guaranteed.

Owner:ANQING VOCATIONAL & TECHN COLLEGE

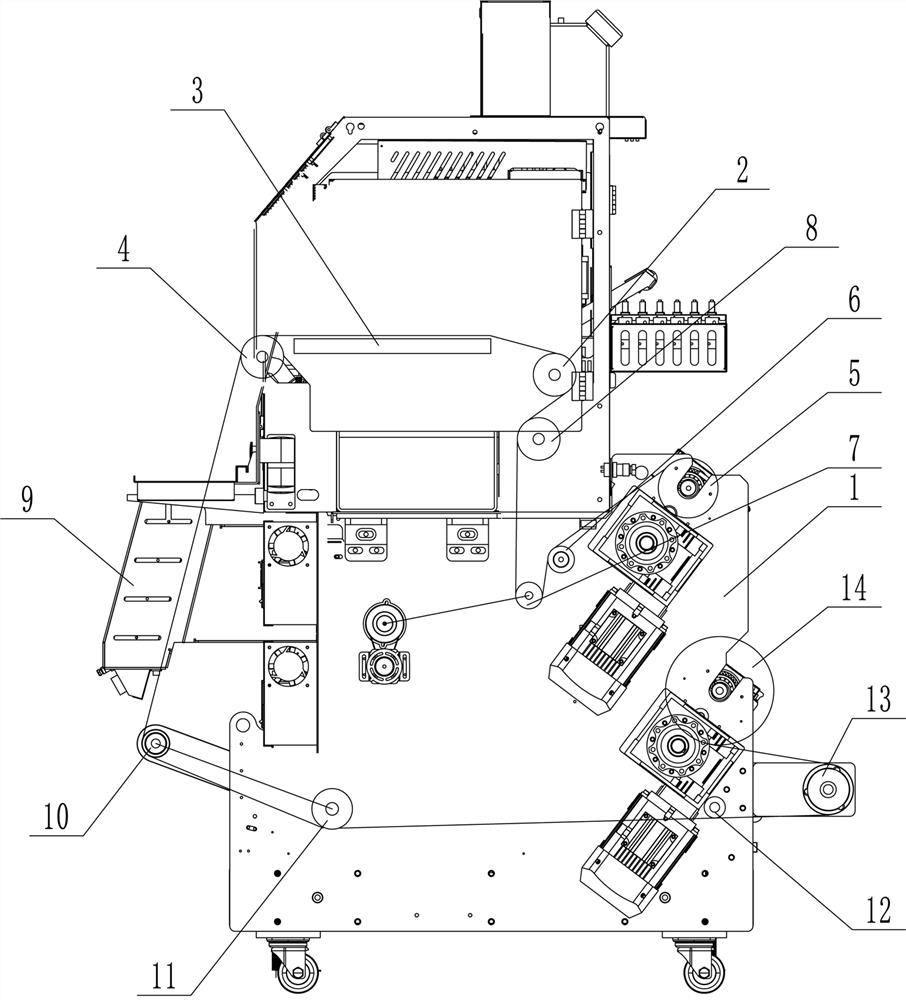

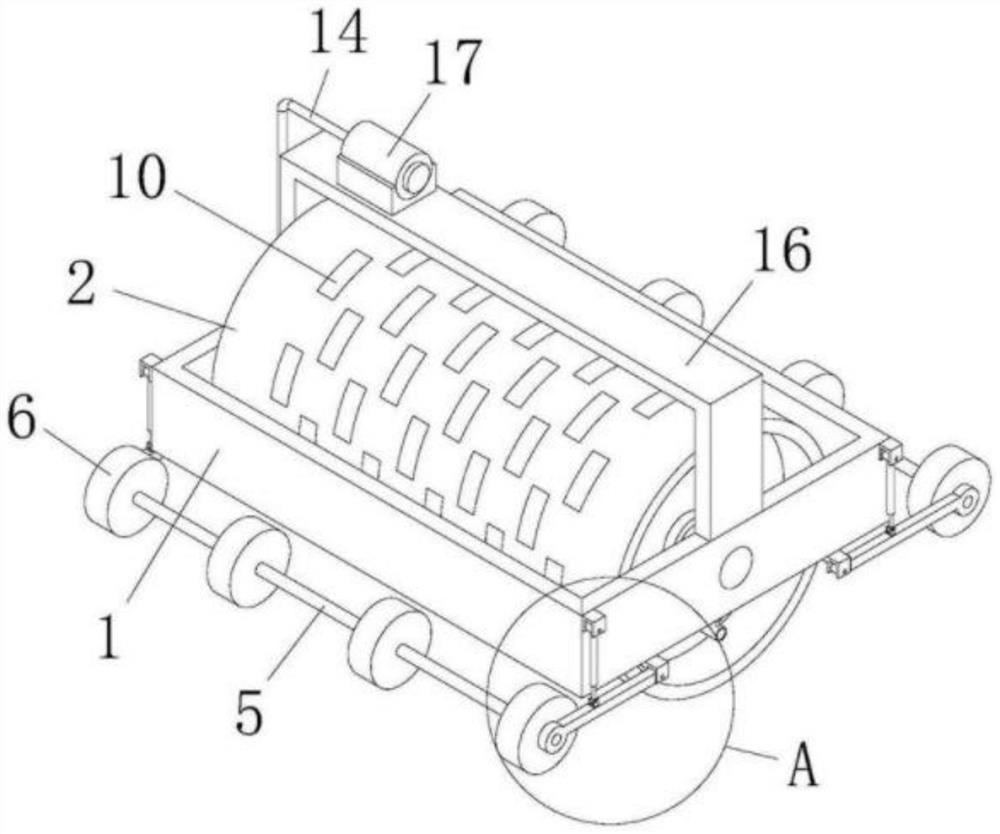

A corrugated carton automatic environmental protection recycling robot

ActiveCN108688214BImprove work efficiencyDecrease productivityManipulatorPressesCartonElectrical and Electronics engineering

Owner:安徽兆隆纸业有限公司

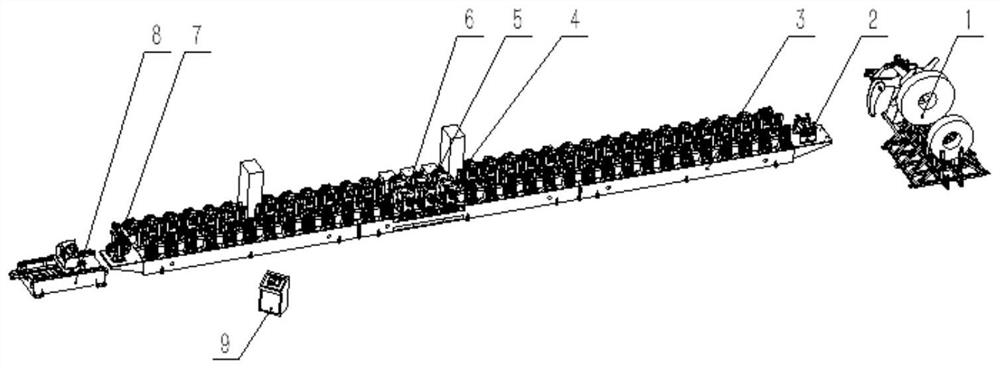

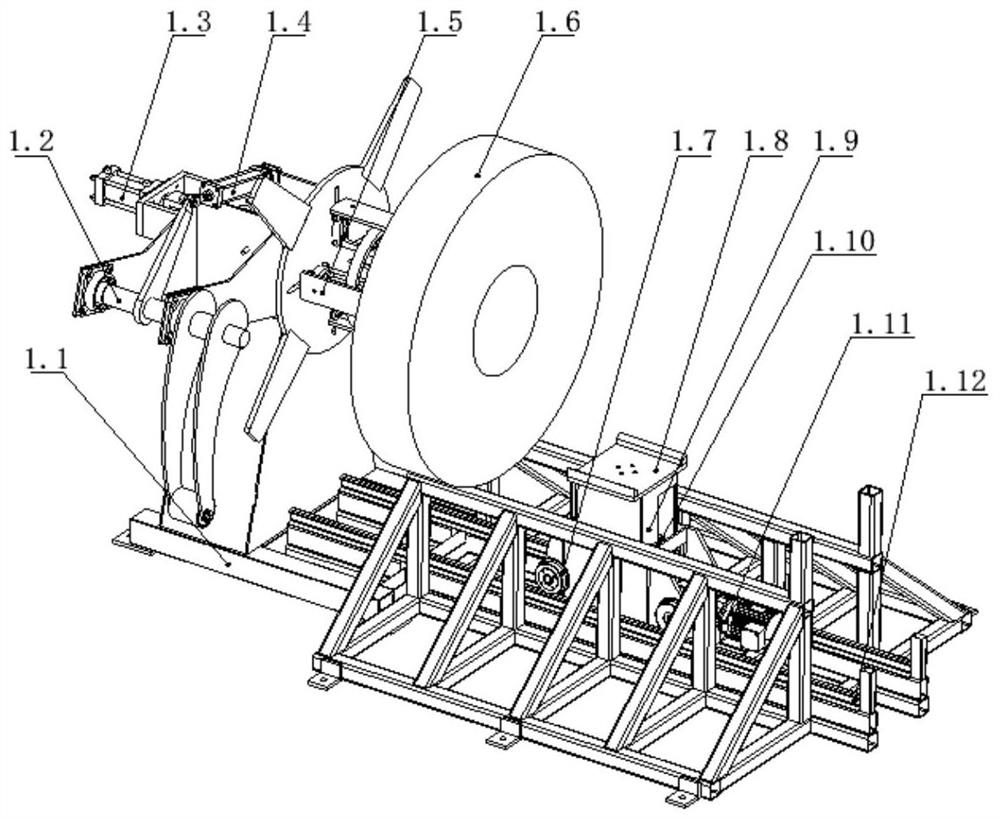

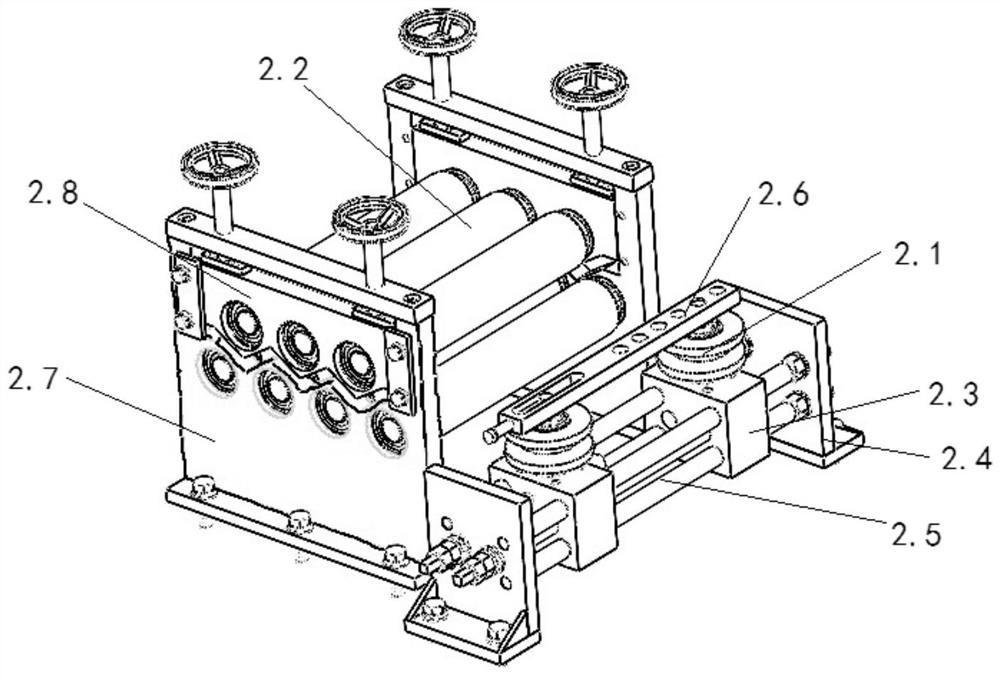

Light steel profile rolling punching forming production line

PendingCN114683053ARealize automatic feeding processGuaranteed flattening effectPerforating toolsMetal-working feeding devicesProduction linePunching

The invention discloses a light steel profile rolling and punching forming production line, relates to the technical field of strip steel cold roll forming and punching, solves the problem that the existing light steel profile forming and punching process is complex, and improves the working efficiency, and adopts the specific scheme that the light steel profile rolling and punching forming production line comprises a forming main machine, and a tensioning and uncoiling mechanism is arranged at one end of the forming main machine; one end of the forming main machine is provided with a tensioning uncoiling mechanism, the other end of the forming main machine is provided with a tracking filing mechanism, a flattening mechanism is fixedly arranged between the forming main machine and the tensioning uncoiling mechanism, and a correcting mechanism is movably arranged between the forming main machine and the tracking filing mechanism and can rotate and move in the vertical direction and the transverse direction; a rolling punching unit is fixedly arranged in the middle of the forming main machine and used for conducting punching work on a web plate and a waist plate of the light steel profile at the same time. The tensioning uncoiling mechanism, the flattening mechanism, the forming main machine, the rolling punching unit, the correcting mechanism and the tracking filing mechanism are all connected with the control center.

Owner:SHANDONG JINBOLIDA PRECISION MASCH CO LTD +1

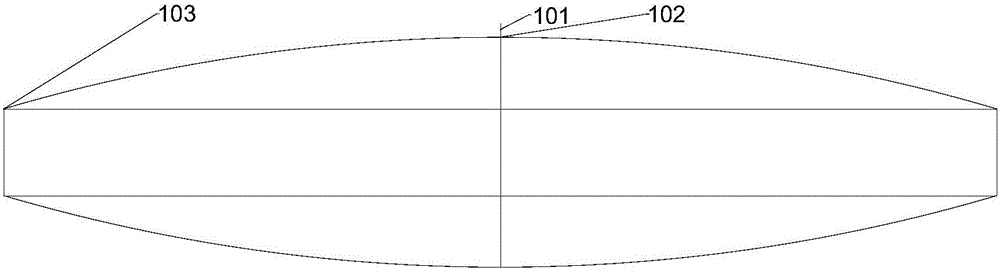

Method for flattening original film base belt for magnetron sputtering coating

InactiveCN106048554AOvercome static frictionStrong enoughVacuum evaporation coatingSputtering coatingFilm baseEngineering

The invention provides a method for flattening an original film base belt for magnetron sputtering coating. The method is used for winding a base material in the operation process of flexible or winding type or continuous magnetron sputtering coating and flattening the base belt in the fabric width direction in the base material winding process. According to the method, a rotary flattening roller is used for flattening the original film base belt. The flattening roller comprises a roller shaft which is made of hard materials. The roller shaft is in the shape of a drum with the two ends thin and the middle thick. The diameter of the middle section circle of the outer surface of the roller shaft is larger than the diameter of end face circles of the outer surface of the roller shaft. The outer surface of the roller shaft is further provided with spiral grooves symmetrical with respect to the middle section of the roller shaft. The rotating direction of the flattening roller meets the requirements that the point where the spiral grooves in the outer surface of the roller shaft make contact with the original film base belt at the later moment is farther from the middle section of the roller shaft than the point where the spiral grooves in the outer surface of the roller shaft make contact with the original film base belt at the former moment.

Owner:南京汇金锦元光电材料有限公司

A rapid prototyping device and method of operation thereof

The invention discloses a die sheet rapid prototyping device and its operation method, which comprises a frame, on which a pressing roller mechanism, a conveying roller and a flattening and cutting mechanism are arranged, and the pressing roller mechanism is arranged at the head of the frame. end, the conveying roller is installed at the position where the frame is located at the rear side of the pressing roller mechanism, and the conveying roller is located between the pressing roller mechanism and the flattening and cutting mechanism, and the flattening and cutting mechanism is installed at the tail end of the frame, the The frame is located on the rear side of the flattening and cutting mechanism, and a conveyor belt is provided. The present invention arranges the pressing roller mechanism, the conveying roller and the flattening and cutting mechanism, and directly arranges the frame at the output end of the extruder, so that the extruded mold The flattened die is transported to the flattening and cutting mechanism, squeezed and flattened by the extrusion plate in the flattening and cutting mechanism, and then cut by a cutting knife. The whole process is continuous, replacing the The situation of relying on manual operation in the traditional production process has greatly improved production efficiency and saved costs.

Owner:广东利辉电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com