Automatic cutting device for pocket cloth

A cutting device and automatic technology, which is applied in the cutting, transportation and packaging of textile materials, thin material processing, etc., can solve the problems of inaccurate cutting positioning, inconsistent pressure, wrinkles, etc., to ensure the flattening effect and avoid The effect of stress imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

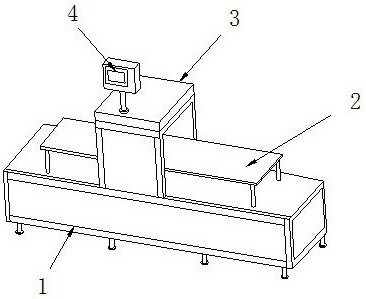

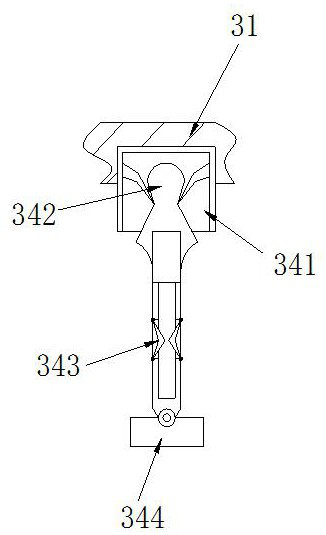

[0029] see Figure 1-Figure 6 , the specific embodiment of the present invention is as follows: a pocket cloth automatic cutting device, its structure includes a base box 1, a conveying table 2, a cutting machine 3, a console 4, the top surface of the base box 1 and the bottom surface of the conveying table 2 are embedded and fixedly connected , the bottom surface of the cutting machine 3 is connected with the top surface of the base box 1 by welding, and the bottom surface of the console 4 is fixedly installed on the top surface of the cutting machine 3; Flat device 34, the bottom surface of the casing 31 is welded to the top surface of the base box 1, the top surface of the lower press 32 is fixedly installed on the inner layer of the casing 31, the bottom surface of the cutter 33 is embedded and fixedly connected to the top surface of the lower press 32, The top surface of the flattener 34 is fixedly installed on the inner layer of the outer casing 31, and two lower pressin...

Embodiment 2

[0036] see Figure 7-Figure 9 , the specific embodiment of the present invention is as follows: the pressure ball B2 includes a rotating shell B21, a sliding groove B22, a pressure frame B23, and an inner core frame B24, and the outer layer of the rotating shell B21 is embedded and connected with the top surface of the guide block B3, so The sliding groove B22 and the inner layer of the rotating shell B21 are integrally formed, and the inner layer of the sliding groove B22 is movably connected with the outer layer of the inner core frame B24 through the pressure frame B23, and the pressure frame B23 is provided with five, five pressure frames The B23 gap is evenly distributed in the inner layer of the sliding groove B22, which is beneficial to generate stronger elastic thrust.

[0037] The inner core frame B24 includes a central ring C1, a vertical frame C2, a moving frame C3, and a sliding head C4. The outer layer of the central ring C1 is embedded and connected to both ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com