A rapid prototyping device and method of operation thereof

A molding equipment and die technology, applied in thin material processing, sending objects, transportation and packaging, etc., can solve problems such as low processing efficiency, save costs, avoid uneven heating, and uniform heat conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

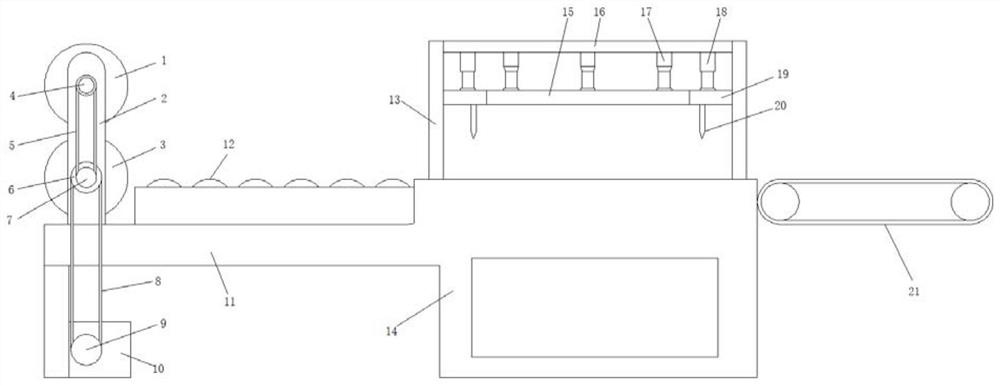

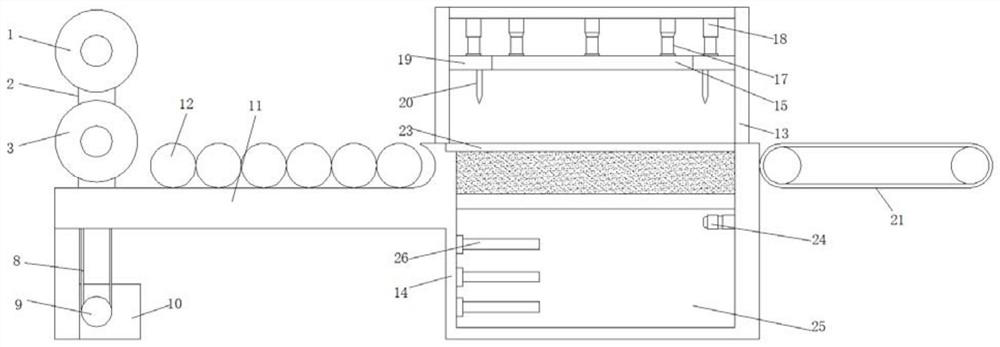

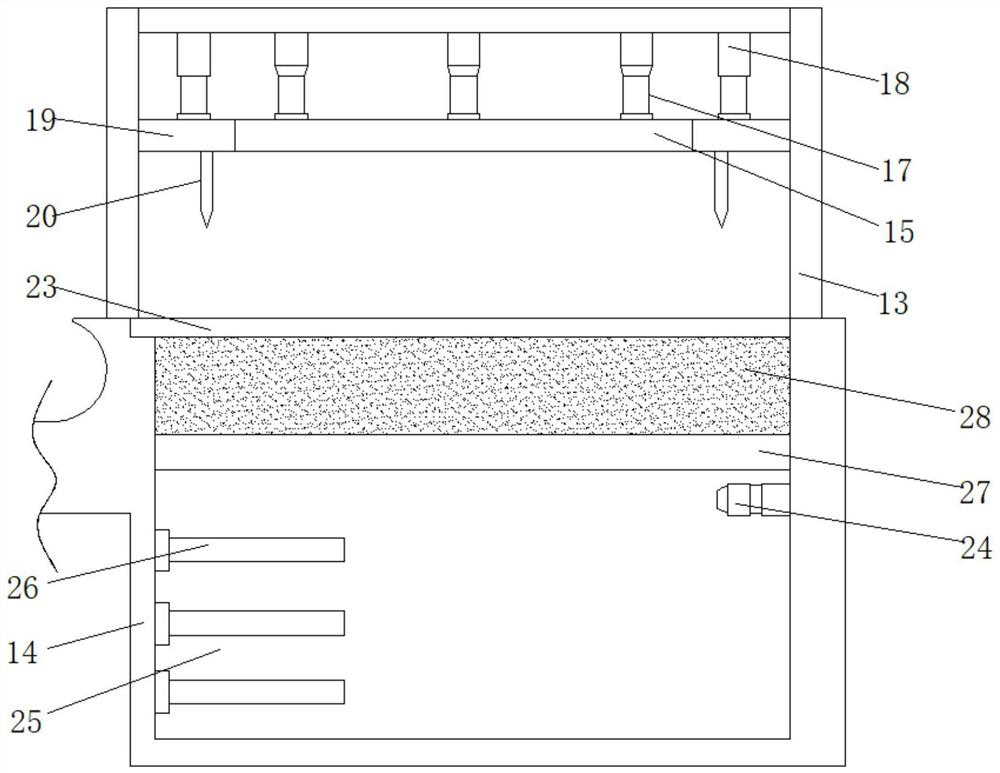

[0028] like Figure 1-5 As shown, the present invention provides a technical solution: a die rapid prototyping equipment and an operation method thereof, including a frame 11, and the frame 11 is provided with a pressing roller mechanism, a conveying roller 12 and a flattening and cutting mechanism, so The pressing roller mechanism is arranged at the head end of the frame 11, the conveying roller 12 is installed at the position where the frame 11 is located at the rear side of the pressing roller mechanism, and the conveying roller 12 is located between the pressing roller mechanism and the flattening and cutting mechanism. The flattening and cutting mechanism is installed at the rear end of the frame 11. The frame 11 is provided with a conveyor belt 21 at the rear side of the flattening and cutting mechanism. The frame 11 is positioned below the flattening and cutting mechanism with a base 14, and the base A constant temperature structure is installed in 14.

[0029] Further...

Embodiment 2

[0037] like Figure 1-5 As shown, the present invention provides a technical solution: an operation method of a die rapid prototyping device, comprising the following steps:

[0038] S1. Set the rapid prototyping equipment at the output end of the extruder, place the extruded die sheet between the upper pressing roller 1 and the lower pressing roller 3 of the pressing roller mechanism, and use the upper pressing roller 1 and the lower pressing roller 3 Flatten the extruded die;

[0039] S2, the flattened die is transported to the lower part of the flattening and cutting mechanism through the conveying roller 12, and according to the value set by the controller, the electric heater 26 in the constant temperature structure is activated, so that the extrusion bottom plate 23 is in a constant temperature state;

[0040] S3. In a constant temperature state, use the pressing plate 15 in the flattening and cutting mechanism to press and shape, and then use the cutting knife 20 to cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com