Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Good product selection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

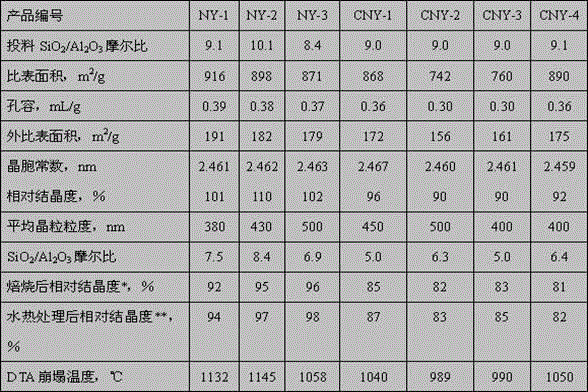

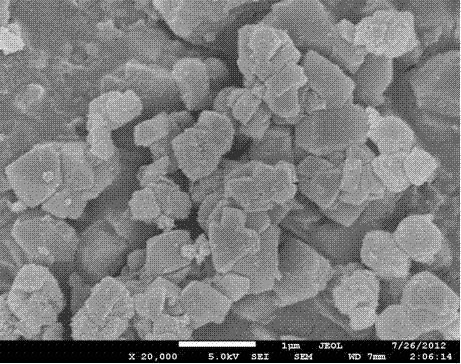

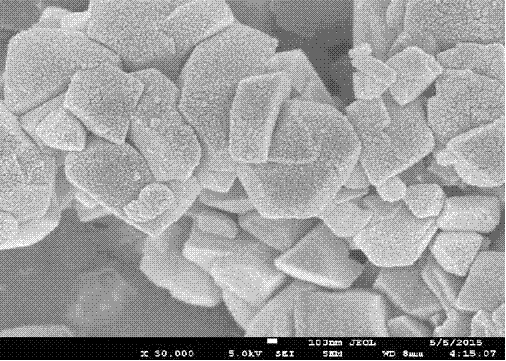

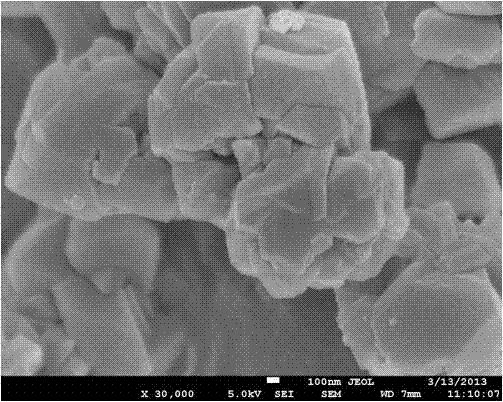

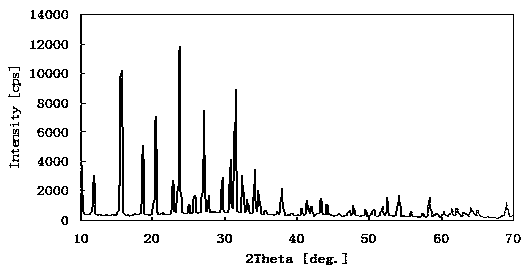

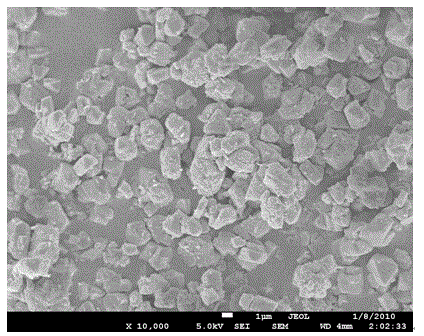

NaY-type molecular sieves and preparation method thereof

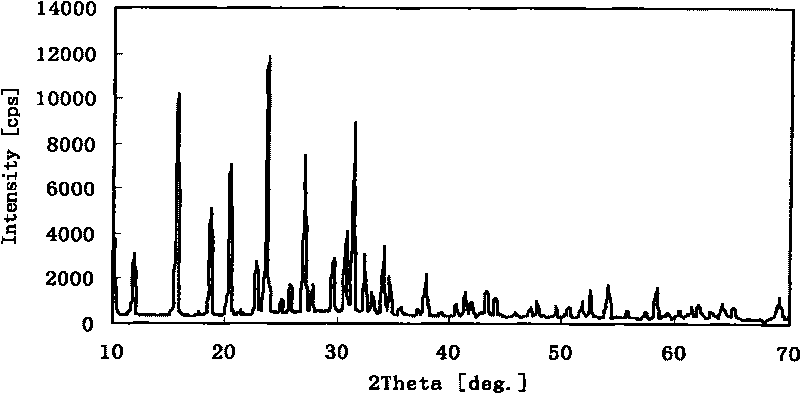

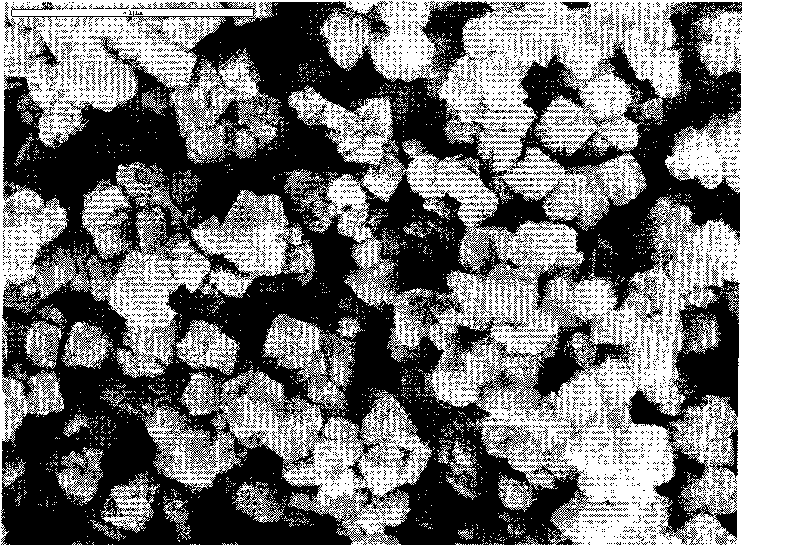

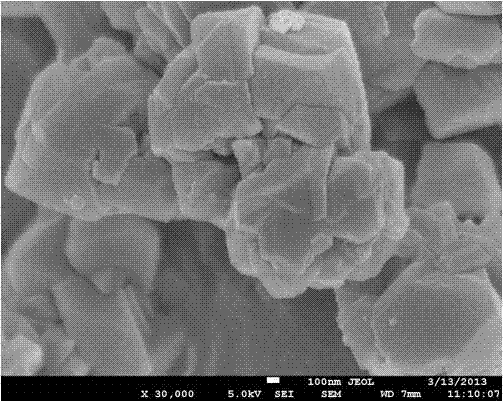

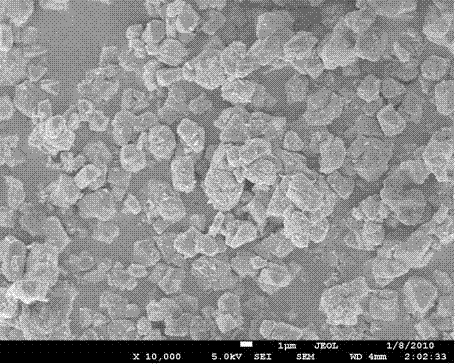

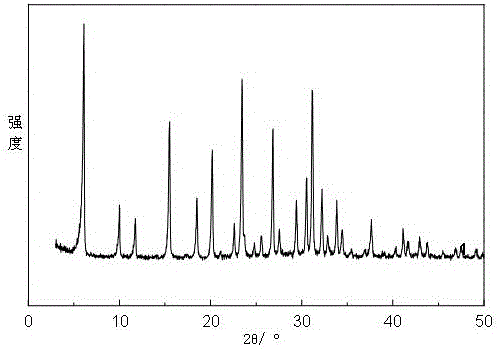

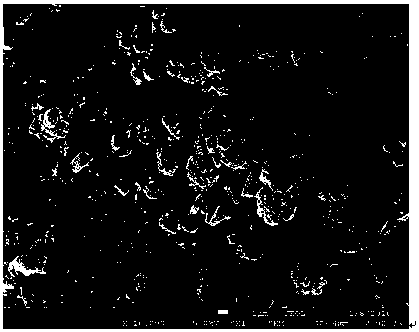

ActiveCN101722023AOrderly formationOrderly and stableMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveThermal stability

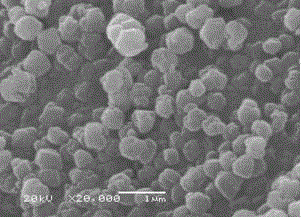

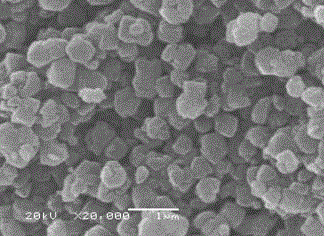

The invention discloses microcrystal NaY-type molecular sieves and a preparation method thereof. In the microcrystal NaY-type molecular sieves, the molar ratio of SiO2 to Al2O3 is 4.0 to 6.0, and the average particle size is 100 to 700 nanometers. The microcrystal NaY-type molecular sieves are prepared by a method combining low-temperature synthesis directing agent, low-temperature synthesis gel and two-stage variable-temperature dynamic crystallization. The NaY-type molecular sieves have a relative crystallinity of over 80 percent after being roasted in the air at 600 DEG C for 3 hours or after undergoing hydrothermal treatment with vapor at 650 DEG C for 1 hour, as well as high thermostability and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

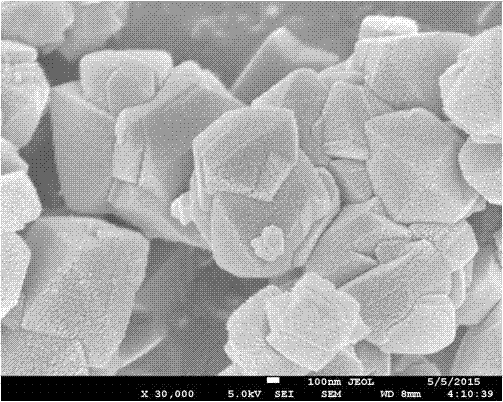

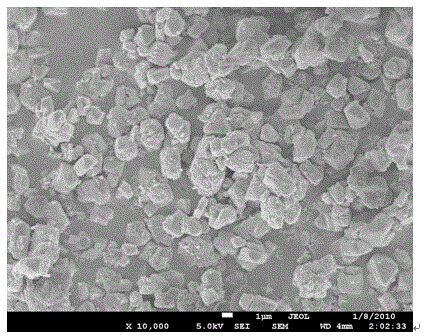

Small crystal grain Y-shaped molecular sieve and preparation method thereof

ActiveCN101723400AGuaranteed skeleton continuityReduce collapseFaujasite aluminosilicate zeoliteOxygenFluosilicates

The invention discloses a small crystal grain Y-shaped molecular sieve and a preparation method thereof. The small crystal grain Y-shaped molecular sieve has the following properties that: the molar ratio of SiO2 / Al2O3 is 5.0-20.0; the average diameter of crystal grains is 100 to 700nm; the crystallization reservation degree is over 95 percent; and the weight percentage of sodium oxide is less than or equal to 0.1 percent. The small crystal grain Y-shaped molecular sieve takes a small crystal grain NaY molecular sieve with good thermal stability and hydrothermal stability as a raw material, has a high silicon-aluminum ratio, good stability and a uniform framework, namely a silicon-aluminum structure, can uniformly remove aluminum and supplement silica in an ammonium exchanging and ammonium fluosilicate dealuminizing and silica-supplementing process, guarantees the framework continuity of the molecular sieve product, decreases the probability of framework structure collapse, and furthest reserves the integrity of the product, namely the silicon-aluminum-oxygen structure so that the product has very high crystallization reservation degree.

Owner:CHINA PETROLEUM & CHEM CORP +1

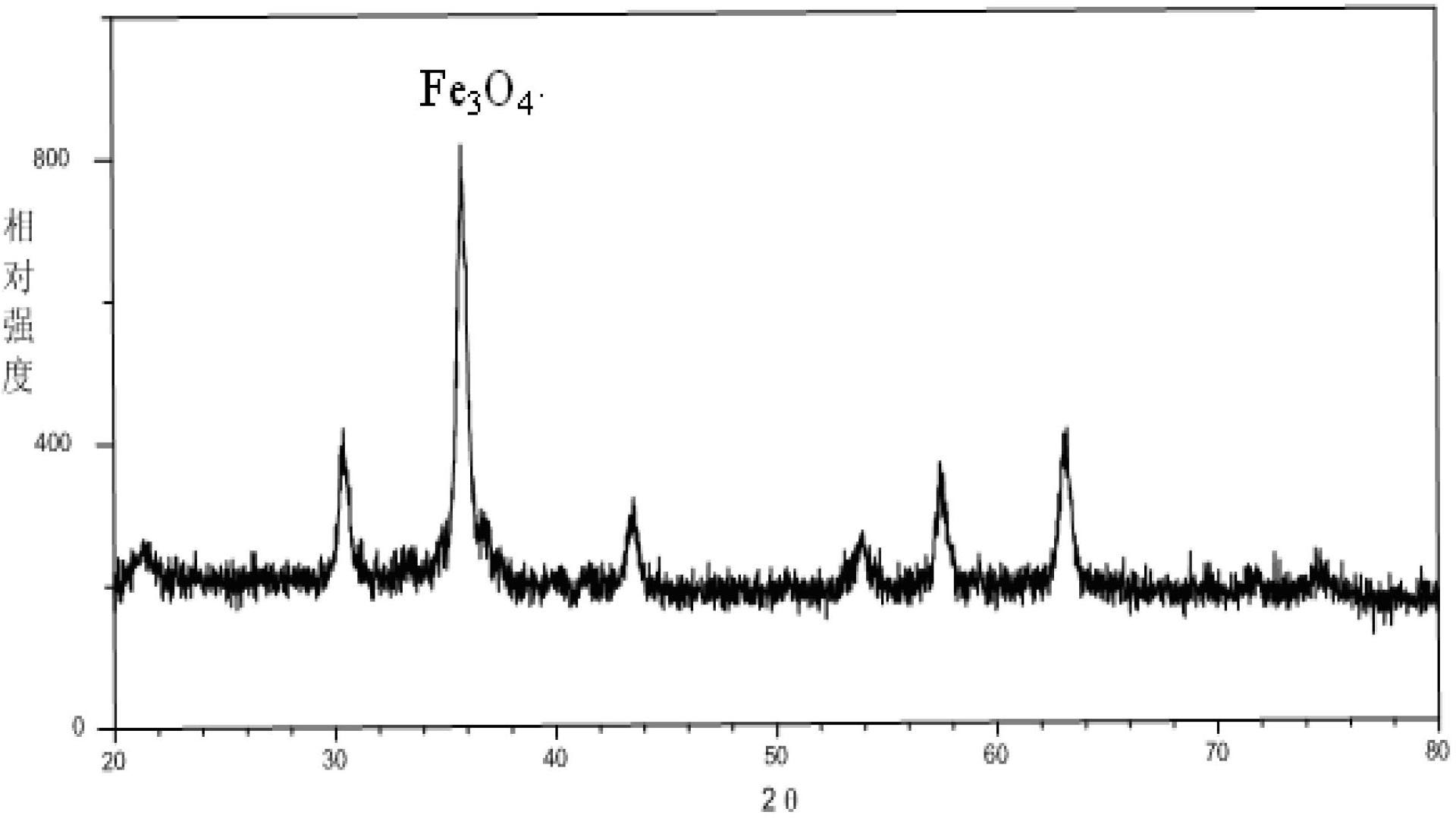

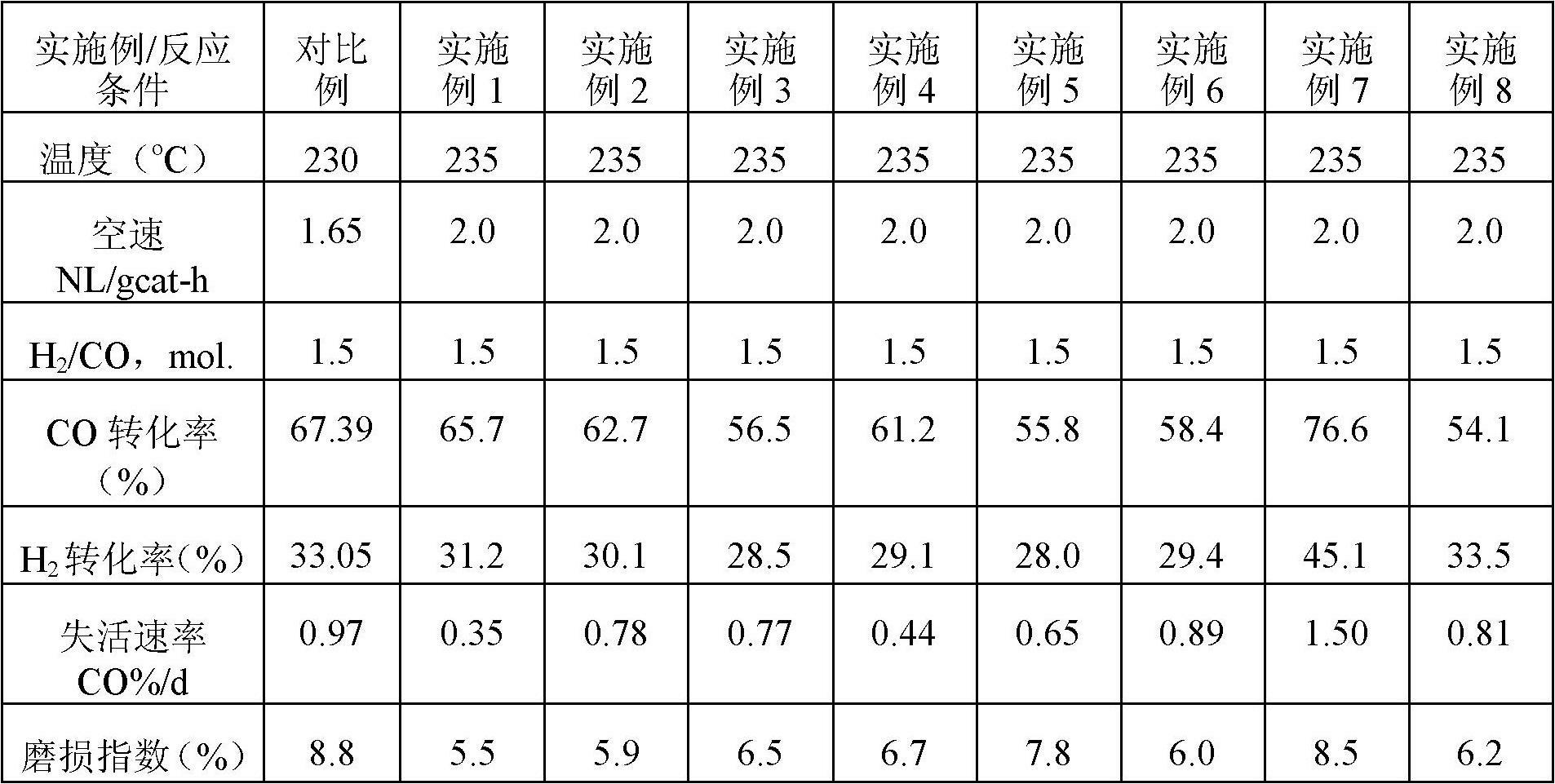

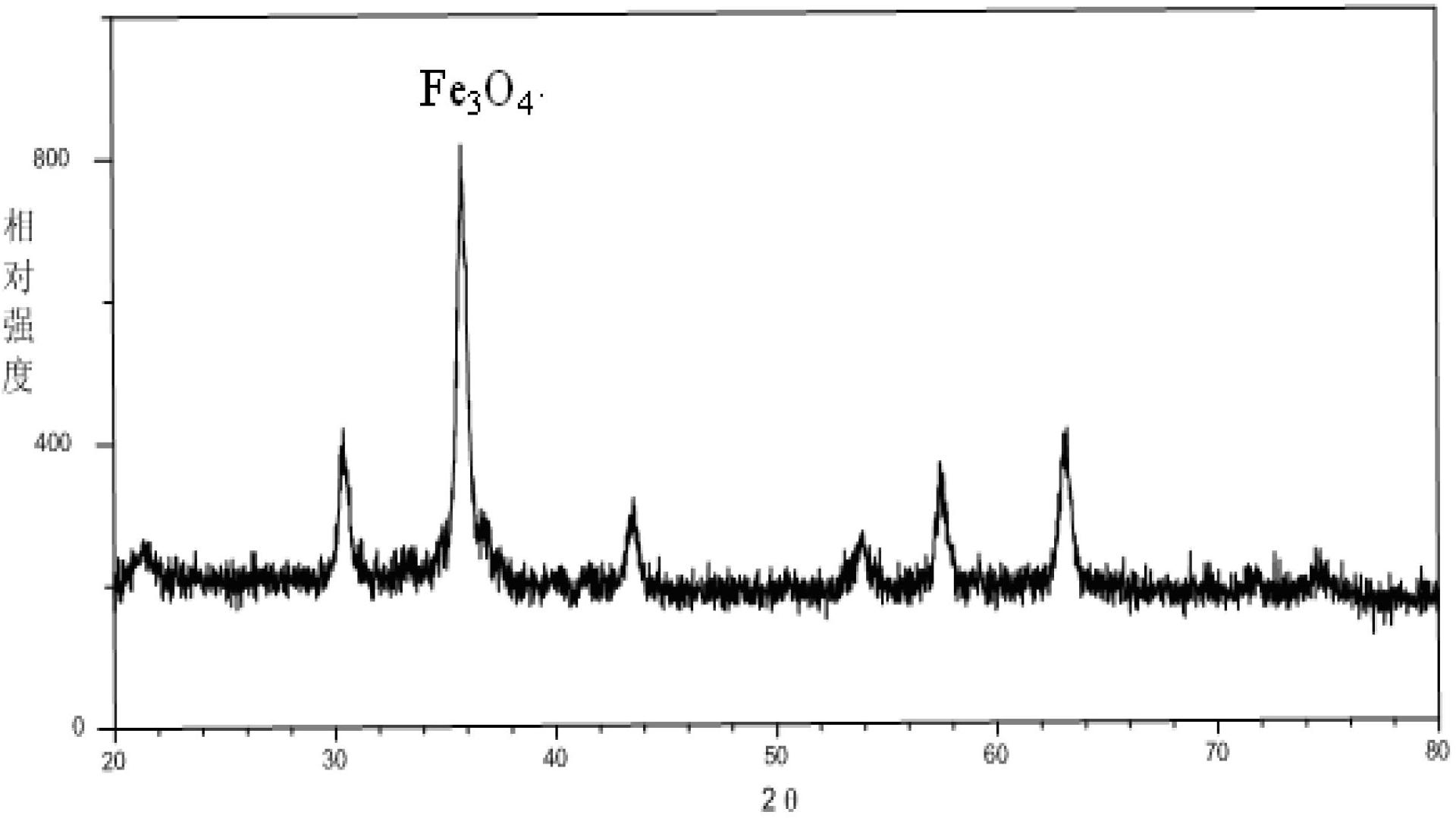

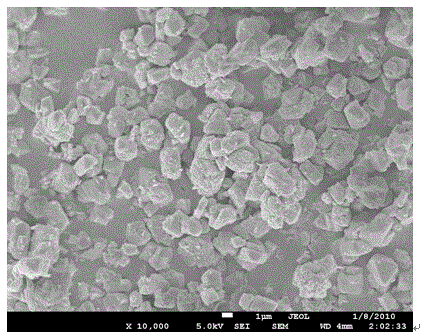

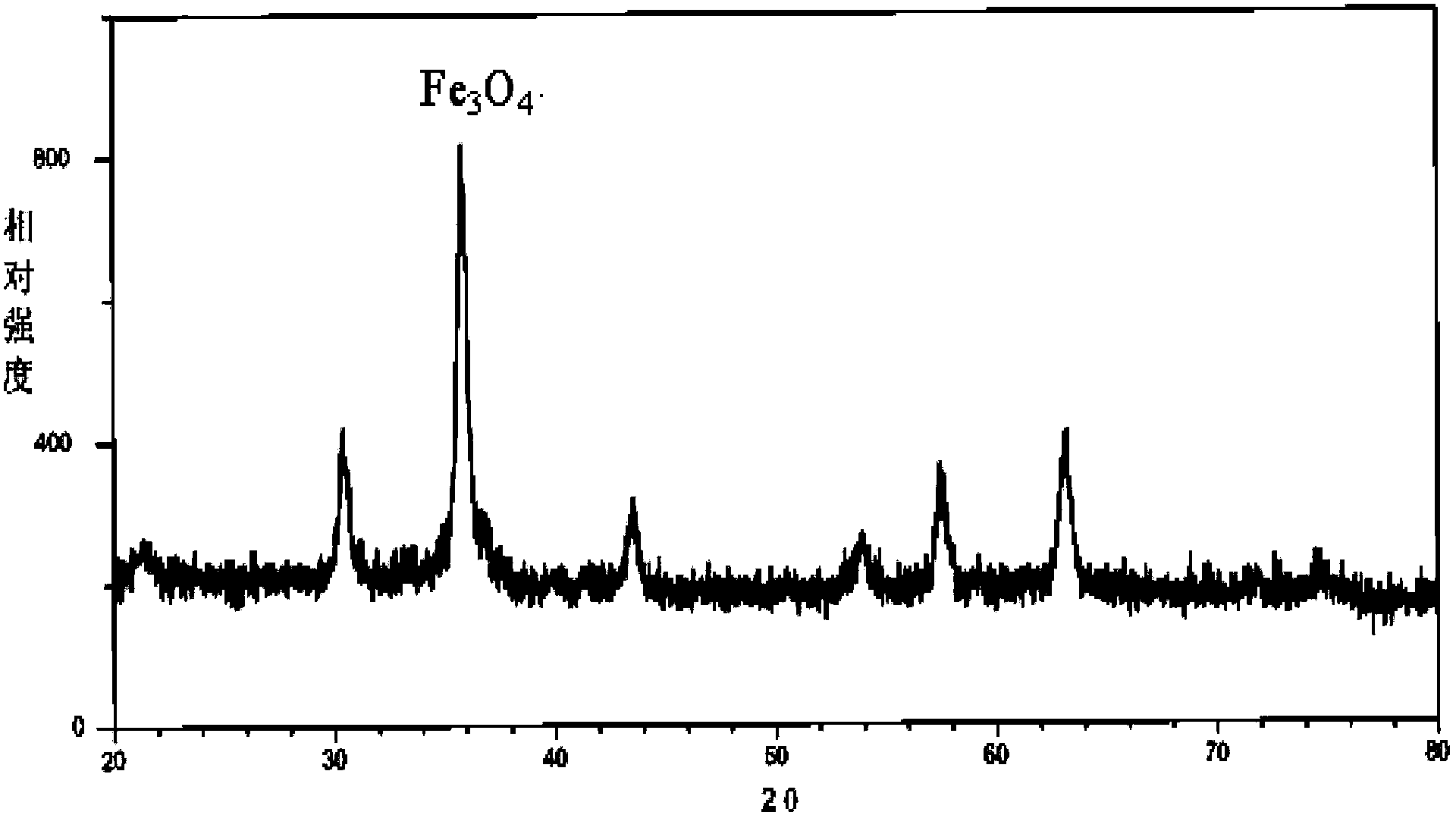

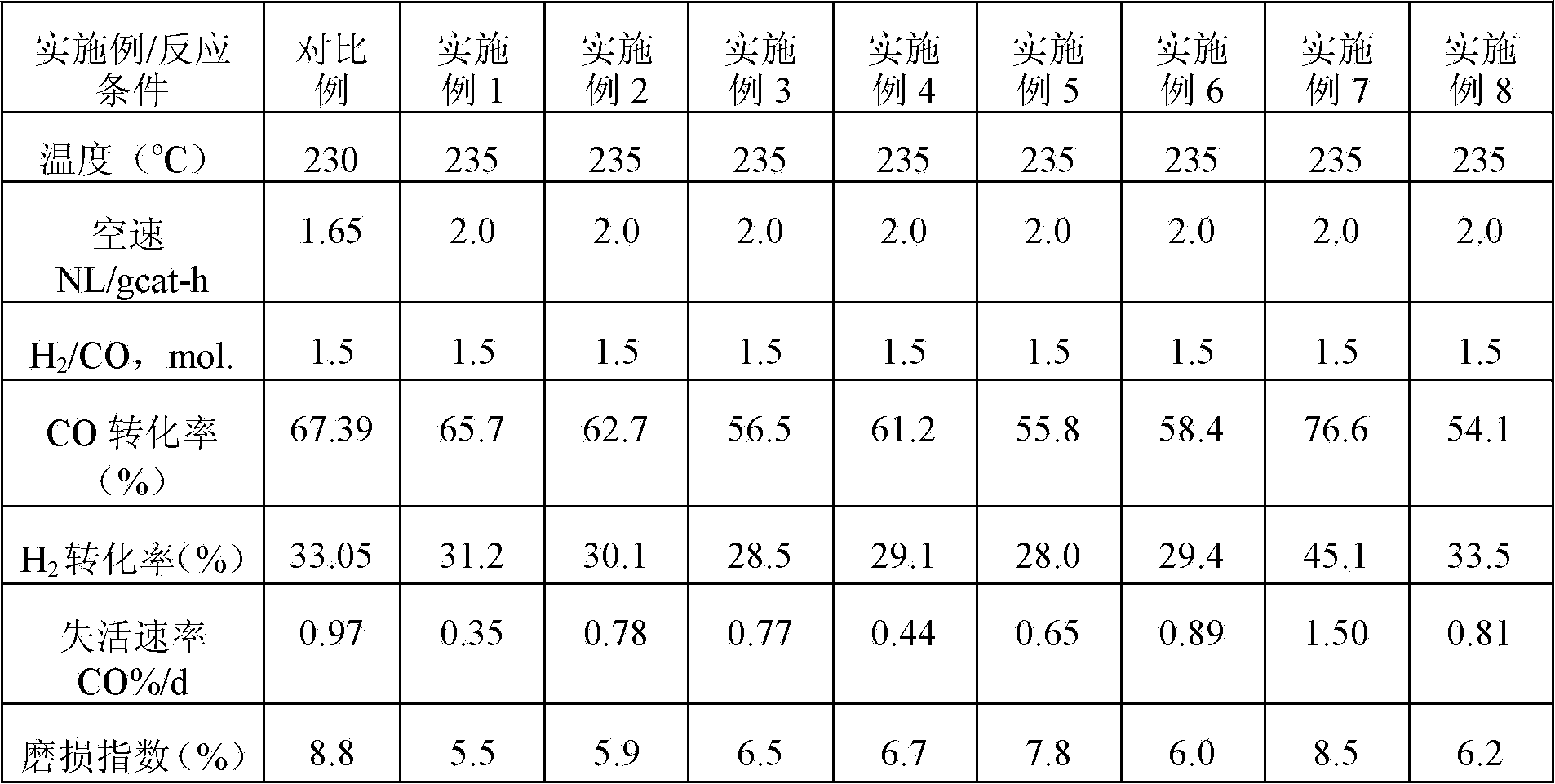

Precipitated iron catalyst for catalyzing Fischer-Tropsch synthetic reaction and preparation method thereof

ActiveCN102688761AImprove physical stabilityHigh mechanical strengthLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsUltimate tensile strengthPhysical stability

The invention discloses a precipitated iron catalyst for catalyzing Fischer-Tropsch synthetic reaction and a preparation method thereof. The catalyst comprises the following components in part by weight: 100 parts of Fe, 0.1 to 10 parts of Cu, 0.1 to 10 parts of K, 0.1 to 10 parts of Mg, 0.1 to 10 parts of Al, and 1 to 20 parts of SiO2, wherein the elements Cu, K and Si exist in a form of oxides, Fe exists in a mixed form of Fe2O3 and Fe3O4, and Mg and Al exist in a form of composite oxide MgAl2O4. Reorganization and cracking of the catalyst in the Fischer-Tropsch synthetic reduction reaction are weakened, long-term running stability of the catalyst is improved, and the main body structure of the catalyst plays a role of a carrier and plays a role in activity balance; and in the presence of the MgAl2O4, the stability of the stable core of the catalyst is improved, and the physical stability and the mechanical strength of the precipitated iron catalyst are improved.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

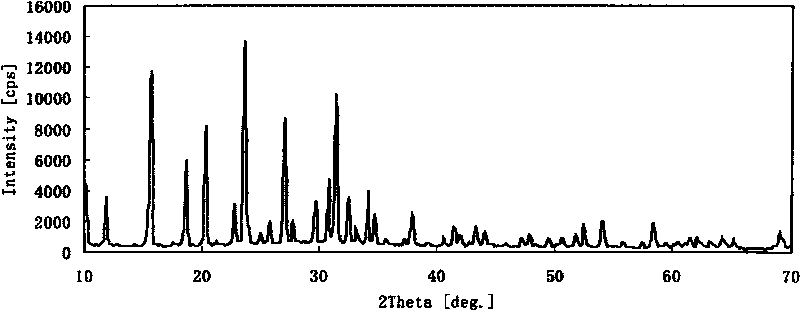

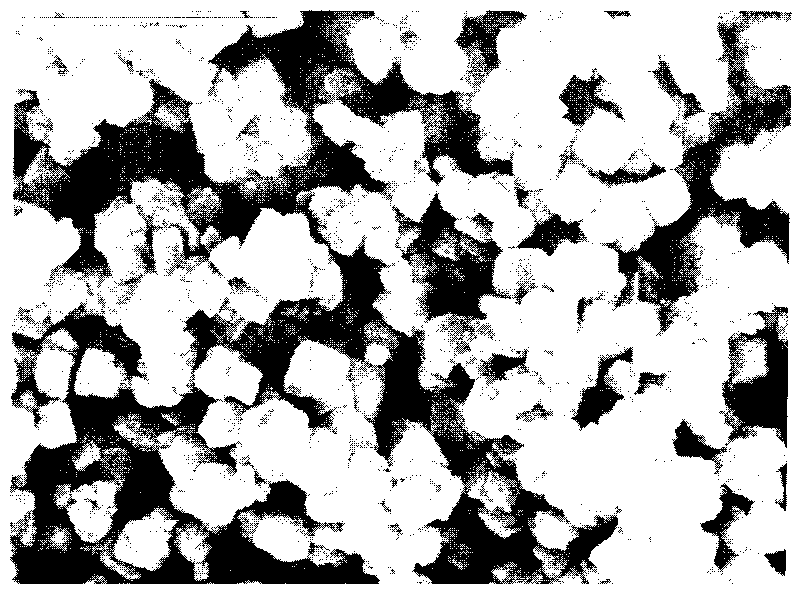

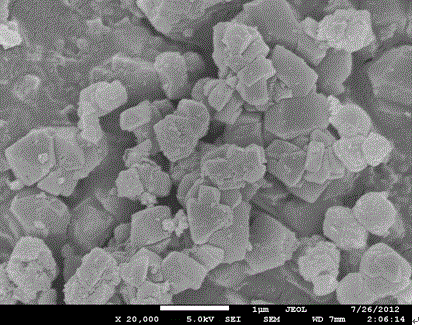

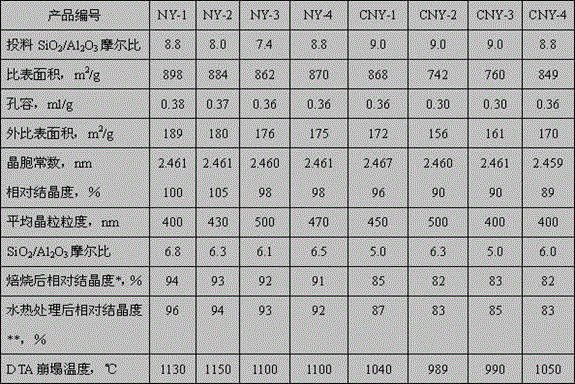

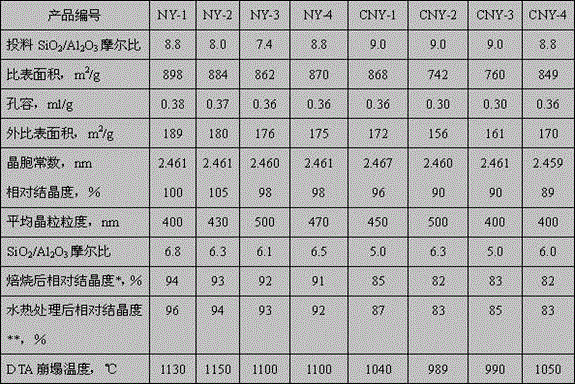

Small-grain NaY-type molecular sieve and preparation method thereof

ActiveCN104591207AImprove stabilityHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-AMolecular sieveWater vapor

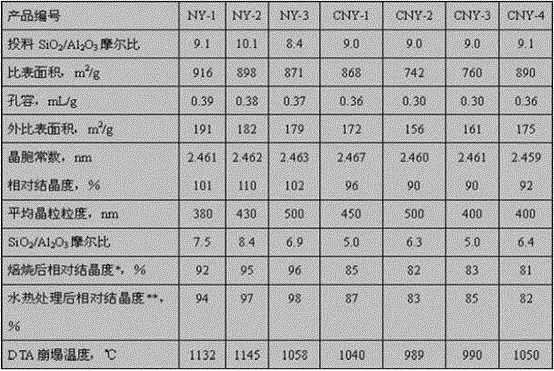

The invention discloses a small-grain NaY-type molecular sieve and a preparation method thereof. The small-grain aY-type molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is higher than 6.0 and no higher than 9.0; the grain average diameter is 200-700nm; the specific surface area is 800-1000m<2> / g; the pore volume is 0.30-0.45mL / g; the relative crystallinity degree is 90-130%; the lattice parameter is 2.460-2.470nm; the relative crystallinity degree after roasting for 3h under a temperature of 650 DEG C in air is higher than 90%; and the relative crystallinity degree after a water vapor hydrothermal treatment for 2h under a temperature of 700 DEG C is higher than 90%. The preparation method comprises the following steps: an amorphous silica-alumina precursor prepared with a specific carbonization method, a directing agent synthesized under low temperature, part of a silicon source, and the like are mixed under a low temperature, such that silica-alumina gel is prepared; and crystallization is carried out, such that the small-grain NaY-type molecular sieve is obtained. The small-grain NaY-type molecular sieve can be applied in a hydrocracking reaction, has has good cracking activity and product selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method

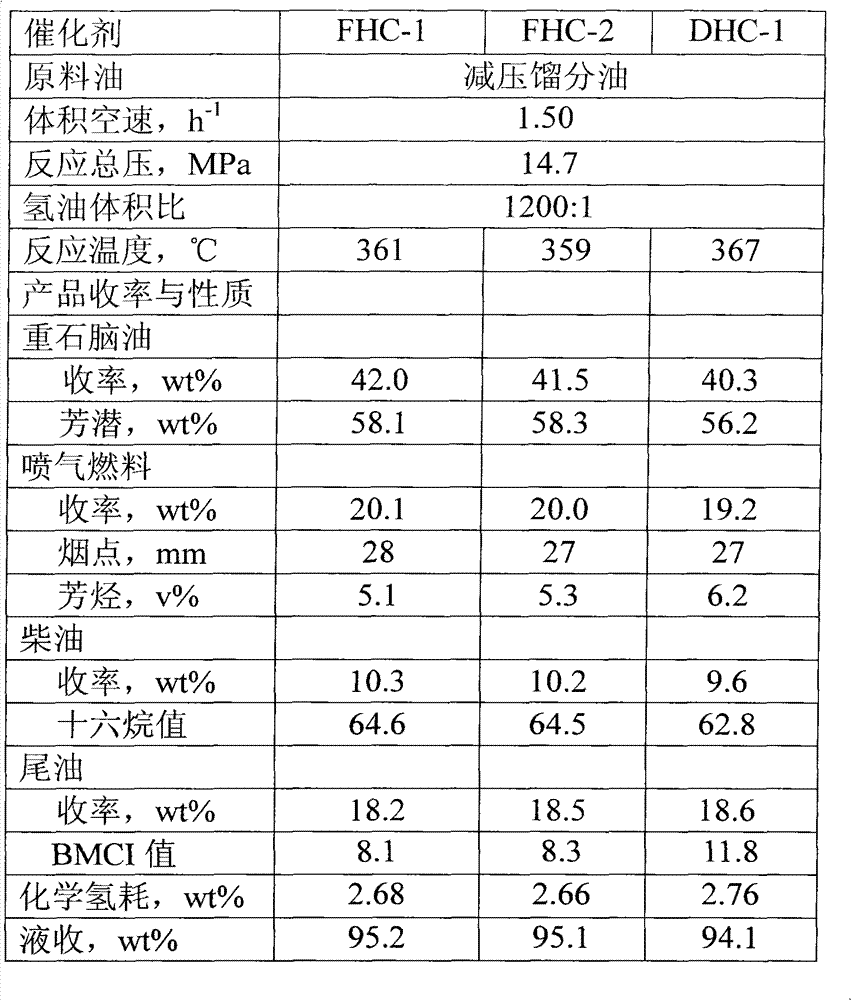

ActiveCN107345155AThe skeleton structure is stable and perfectElimination of non-skeletal structuresMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking method which comprises the following steps that a straight-run diesel oil raw material is in contact with a hydrocracking catalyst to carry out hydrocracking reaction, and an obtained hydrocracking product is separated to obtain heavy naphtha, diesel oil, a jet fuel and hydrogenation tail oil, wherein the used hydrocracking catalyst adopts a modified Y-shaped molecular sieve, amorphous silica-alumina and aluminum oxide as carriers, and the modified Y-shaped molecular sieve is an Y-shaped molecular sieve which is rich in meso pores and is concentrated in effective pore size distribution. The hydrocracking method is particularly suitable for a hydrocracking technology for carrying out hydro-conversion on straight-run diesel oil to produce the jet fuel, and has very high catalytic activity and aviation fuel product yield and the quality of a product is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN105709845AGood product selectionHigh activityCatalyst carriersMolecular sieve catalystsMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier adopts a large-grained and high-silicon modified Y type molecular sieve with centralized effective aperture distribution as the main cracking component, and takes amorphous silica-alumina as a second cracking component. The prepared hydrocracking catalyst has high activity and medium oil selectivity, and the produced middle distillate oil has good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN105709848AGood product selectionHigh activityCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier adopts a large-grained and high silicon modified Y type molecular sieve with concentrated effective pore size distribution as the main cracking component, the hydrocracking catalyst prepared from the carrier is suitable to serve as the hydrocracking catalyst for flexible production of high quality heavy naphtha, aviation kerosene and diesel, and has very high activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

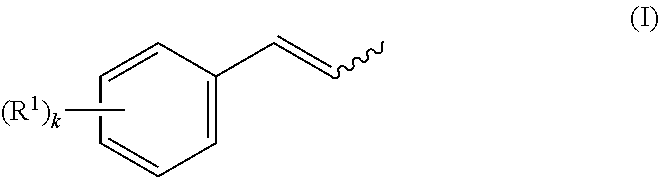

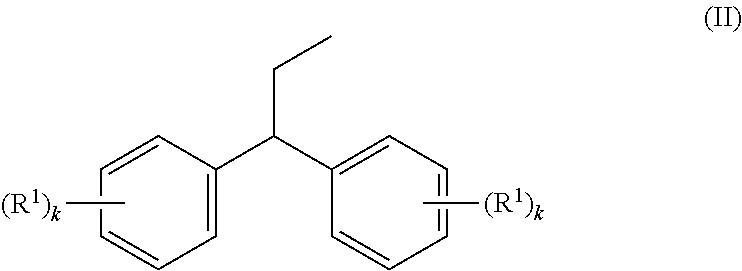

Method for producing arylpropenes

InactiveUS20160332944A1Good product selectionReduce formationOrganic compound preparationCarboxylic acid esters preparationBenzenePropenyl

Owner:BASF AG

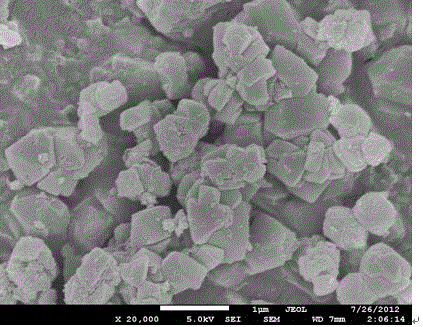

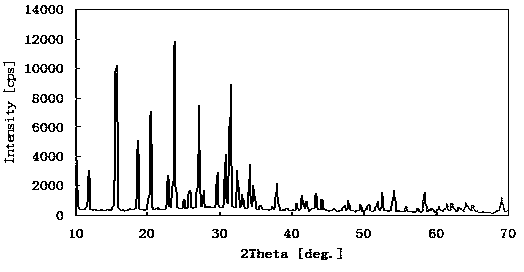

Modified Y type molecular sieve as well as preparation method and application thereof

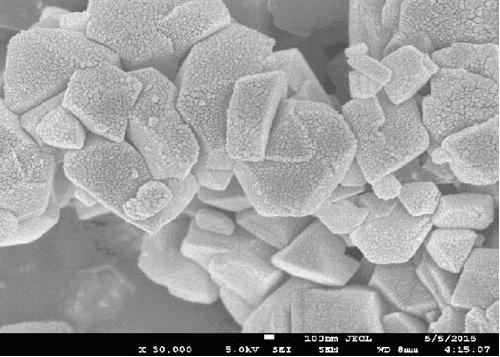

ActiveCN107344721AImprove utilization efficiencyHigh ratio of silicon to aluminumMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveStrong acids

The invention discloses a modified Y type molecular sieve as well as a preparation method and application thereof. The Y type molecular sieve has the following properties: the crystal particle average diameter is 2.0 to 5.0 mu m, the relative crystallinity is 100 percent to 140 percent, the molar ratio of SiO2 / Al2O3 is 30 to 100 and is preferably 40 to 100, the crystal cell parameter is 2.428 to 2.445nm, and the pore volume of a hole with the hole diameter being 2nm to 8nm accounts for 80 percent to 95 percent, preferably 80 percent to 90 percent of the total pore volume. The total acid content of NH3-TPD is 0.2 to 1.0mmol / g, wherein, the strong acid accounts for 75 percent or more of the total acid amount at the temperature larger than 250 DEG C, the pore volume of the Y type molecular sieve is 0.55cm<3> / g to 0.70cm<3> / g, and the specific surface area is 700m<2> / g to 1000m<2> / g. The molecular sieve has the advantages of large crystal particle, high crystalline, high silicon, more concentrated effective hole diameter distribution, favorable heat stability and hydrothermal stability and the like, and is suitable to be used for preparing a hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

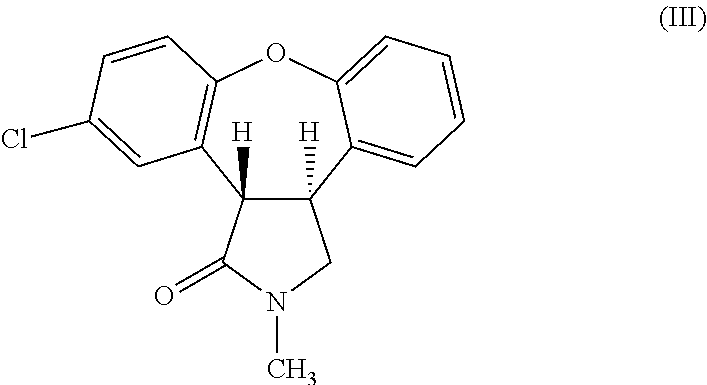

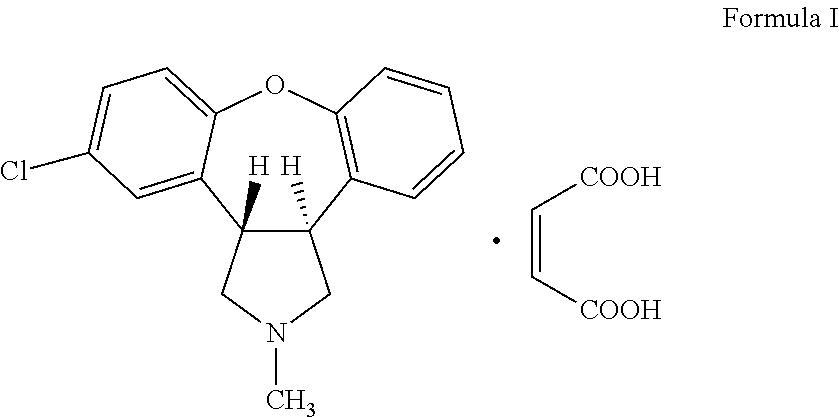

Process for the preparation of asenapine intermediate

InactiveUS20140336391A1Good product selectionSpeed up the processOrganic chemistryAsenapineMagnesium

The present invention provides a process for the preparation of the asenapine intermediate of Formula (III) using a magnesium-methanol-acetic acid mixture.

Owner:RANBAXY LAB LTD

Preparation method of small-grain NaY-type molecular sieve

ActiveCN104591213AEvenly distributedAvoid easy to cause silicon agglomerationFaujasite aluminosilicate zeoliteMolecular sieveAmorphous silica-alumina

The invention discloses a preparation method of a small-grain NaY-type molecular sieve. According to the invention, an amorphous silica-alumina precursor, a directing agent synthesized under a low temperature, part of a silicon source, and the like are mixed under a low temperature, such that silica-alumina gel is prepared; and crystallization is carried out, such that the small-grain NaY-type molecular sieve is obtained. According to the amorphous silica-alumina precursor, a part of a silicon-containing material is added in an aluminum-containing material before and / or during a gelling process; and the rest of the silicon-containing material is added after gelling and before aging, such that silica-alumina forms a stable structure, and can cooperate with subsequent steps. With the method, a phenomenon of silicon agglomeration or loss caused by the addition of a large amount of the silicon source in prior arts is avoided. The addition amount of silicon is reduced; silicon effective utilization rate is improved; the silica-to-alumina ratio is improved; and the obtained small-grain molecular sieve has good stability. The small-grain NaY-type molecular sieve provided by the invention can be used in a hydrocracking reaction, and has good cracking activity and product selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for one-step synthesis of diamino decalin by catalytic hydrogenation of dinitro naphthalene

InactiveCN103172522AGood dispersionHigh reuse rateMolecular sieve catalystsOrganic compound preparationReaction temperatureSolvent

The invention relates to a method for one-step synthesis of diamino decalin by catalytic hydrogenation of dinitro naphthalene. The method is characterized in that a non-noble transition metal, namely nickel with catalytic activity is impregnated to different oxides and zeolite molecular sieve frameworks with different bore diameters and different structures in a certain loading ratio through an impregnation method under the situation of ultrasonic assisted vibration to prepare a nickel-loaded oxide or zeolite molecular sieve hydrogenation catalyst; and in a pressure reaction kettle, the load type nickel-based hydrogenation catalyst, dinitro naphthalene and a solvent are added, hydrogen is charged and heated to a certain reaction temperature, and the reaction is performed for a certain period of time for performing catalytic hydrogenation on dinitro naphthalene so as to realize the one-step synthesis of diamino decalin. According to the method disclosed by the invention, the conversion rate of dinitro naphthalene can be significantly improved; and simultaneously, the catalyst has the advantages of low cost, simplicity and convenience in preparation and long service life, and further shows great application prospects.

Owner:HUBEI UNIV

Precipitated iron catalyst for catalyzing Fischer-Tropsch synthetic reaction and preparation method thereof

ActiveCN102688761BImprove physical stabilityHigh mechanical strengthLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsUltimate tensile strengthPhysical stability

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Hydrocracking catalyst and preparation method thereof

ActiveCN107344102AThe skeleton structure is stable and perfectElimination of non-skeletal structuresMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst and a preparation method thereof. The hydrocracking catalyst takes a modified Y-type molecular sieve which contains rich mesopores and has intensive effective pore diameter distribution as an acidic component; the modified Y-type molecular sieve has the following characteristics: the relative crystallization degree is 110 percent to 150 percent, the mol ratio of SiO2 / Al2O3 is 10 to 50, the lattice parameter is 2.436nm to 2.445nm, the total pore volume is 0.55mL / g to 1.0mL / g and the mesopore pore volume accounts for 70 percent of the total pore volume or more. The hydrocracking catalyst disclosed by the invention is suitable for being used in a hydrocracking process of increasing the yield of high-quality heavy naphtha and has relatively high catalytic activity and product selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

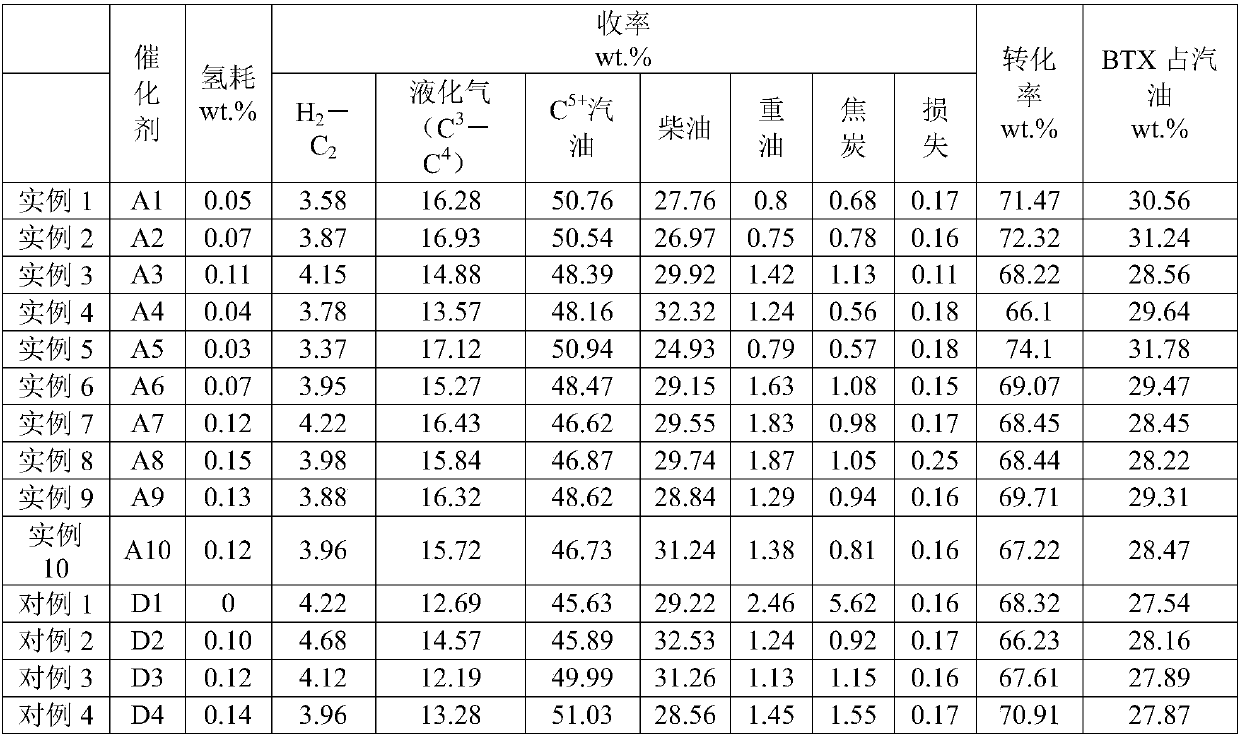

Hydrocracking catalyst and preparation method thereof and heavy raw oil hydrocracking method

ActiveCN109701624AHigh product conversion rateGood product selectionMolecular sieve catalystsCatalyst activation/preparationMolecular sieveOxide

The invention relates to the field of hydrocracking, and particularly relates to a hydrocracking catalyst and a preparation method thereof and a heavy raw material oil hydrocracking method. The catalyst comprises a carrier and a supported metal accelerator, wherein the carrier is composed of a binder, a silicon-aluminum molecular sieve and an alkaline metal oxide; the total weight of the catalystis taken as a reference, the content of the silicon-aluminum molecular sieve is 10-65 wt %, the content of the metal accelerator is 1-30% by weight, the content of the alkaline metal oxide is 0.5-30 wt %, and the content of the binder is 5-50 wt %; the silicon-aluminum molecular sieve is a combination of a silicon-aluminum molecular sieve with a twelve-membered ring pore structure and a silicon-aluminum molecular sieve with an MFI structure. The hydrocracking catalyst disclosed by the invention is suitable for increased yield production of high-octane gasoline, the high-octane gasoline contains higher BTX, the product conversion rate is high, the product selectivity is good, the coke yield is relatively low, and the method is suitable for producing low-sulfur high-octane-value gasoline andliquefied gas for a long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking method of inferior diesel oil

ActiveCN107345154BGood product selectionSuitable for acidityMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveGasoline

The invention discloses a hydrocracking method for inferior diesel oil. The method comprises the steps of subjecting inferior diesel oil feedstock and a hydrocracking catalyst to contact, carrying out a hydrocracking reaction, and subjecting the obtained hydrocracking product to separation, thereby obtaining a gasoline fraction and a diesel fuel fraction, wherein modified Y molecular sieves serve as the hydrocracking catalyst and have the following properties: the relative crystallinity is 110% to 150%, the SiO2 / Al2O3 mole ratio is 10 to 50, the unit cell parameter is 2.436nm to 2.445nm, the total pore volume is 0.55mL / g to 1.0mL / g, and the pore volume of mesopores accounts for 70% or more of the total pore volume. The method can be used for effectively converting fractions of the inferior diesel oil to produce superior-quality gasoline and high-quality diesel fuel products.

Owner:CHINA PETROLEUM & CHEM CORP +1

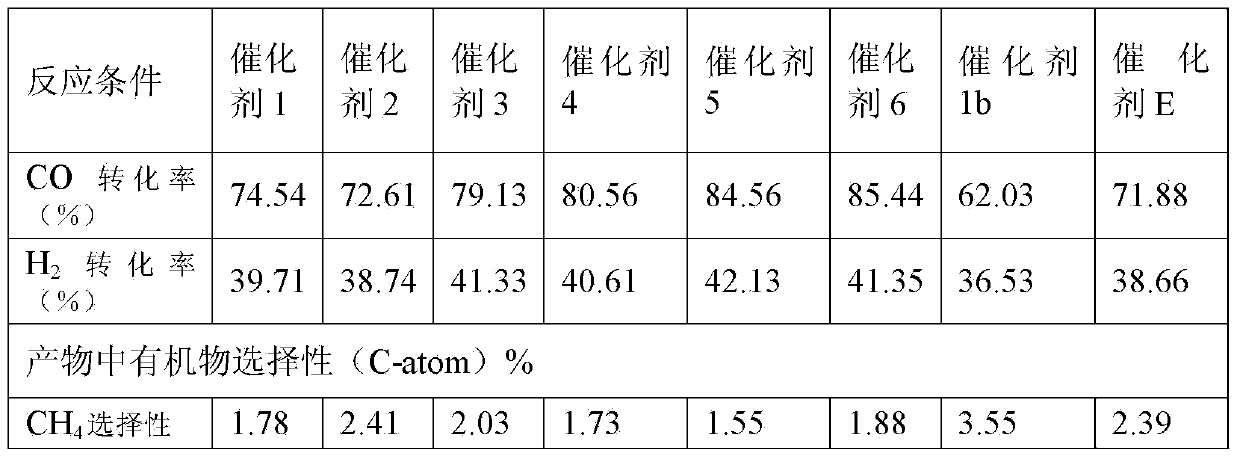

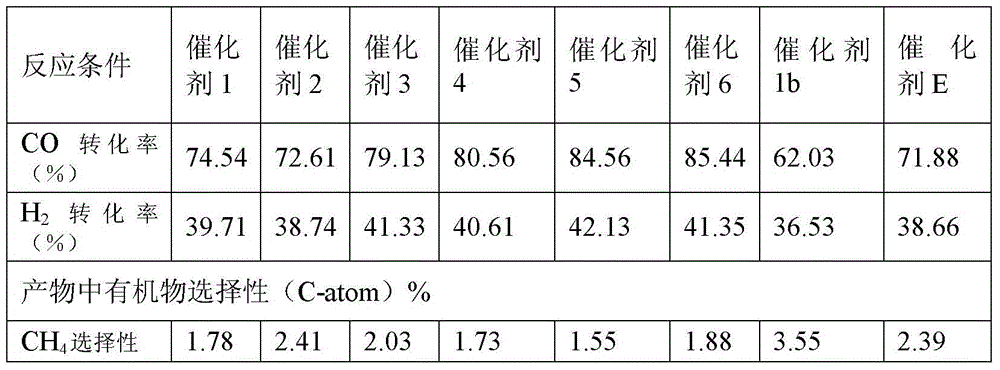

Precipitated iron catalyst for Fischer-Tropsch synthesis and preparation method thereof

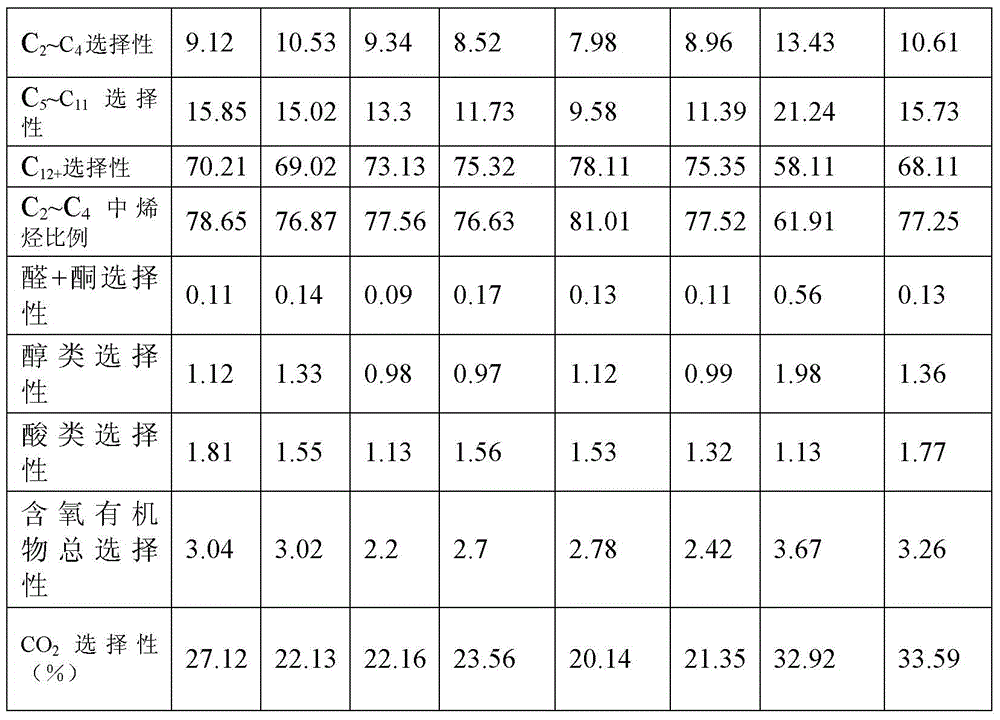

ActiveCN103801308ALow selectivityReduce pollutionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsGasolineFixed bed

The invention discloses a precipitated iron catalyst for Fischer-Tropsch synthesis and a preparation method thereof. The weight ratio of the components including Fe, Y, Ti, Cu, K and SiO2 in the catalyst is 100:(0.5-7.5):(0.4-11.2):(1.0-8.5):(1.0-7.0):(5-30), wherein Y, Ti and K exist in the form of oxide; Fe exists in the form of Fe2O3; Cu exists in the form of CuO. The catalyst provided by the invention has good activity and product selectivity, is capable of achieving high CO conversion rate and low CH4 and CO2 selectivity, increasing the main product, reducing the byproducts and reducing the environmental pollution on the premise of ensuring the raw material conversion rate and the effective product selectivity when being applied to Fischer-Tropsch synthesis for preparing oil products and paraffin, and is suitable for joint production of gasoline, diesel and high-quality paraffin in the large-scale fixed bed Fischer-Tropsch synthesis industry.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Method for preparing 1,5-diamino-decahydronaphthalene by catalytic hydrogenation of 1,5-diaminonaphthalene

InactiveCN103319351ALarge specific surface areaHigh reuse rateMolecular sieve catalystsOrganic compound preparationPtru catalystDisplacement reactions

The invention relates to a method for preparing 1,5-diamino-decahydronaphthalene (H10NDA) by catalytic hydrogenation of 1,5-diaminonaphthalene (NDA), and is characterized in that: adding NDA and a solvent in a pressure reaction kettle, adding a load type nickel hydrogenation catalyst in an amount of 2.5 to 10% by mass, based on the addition amount of the reaction substrate NDA, replacing air in the reaction kettle with hydrogen for three times, then inletting hydrogen to make the reaction pressure of the reaction kettle reach 4.0 MPa, starting to stir, heating the reaction kettle to make the temperature reach 190 to 230 DEG C, replenishing hydrogen and maintaining the reaction pressure of the reaction kettle of 6 to 8 MPa, undergoing a thermostatic reaction for 5 to 8 h, and filtering out the catalyst after cooling to obtain H10NDA. The method can significantly improve the NDA conversion rate; and at the same time, the catalyst has low cost, simple preparation and long service life, and shows a good application prospect.

Owner:武汉椿岭科技有限公司

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN105709845BGood product selectionHigh activityCatalyst carriersMolecular sieve catalystsMolecular sieveHigh activity

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking catalyst carrier and its preparation method

ActiveCN105709848BGood product selectionHigh activityCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The catalyst carrier adopts a large-grained and high silicon modified Y type molecular sieve with concentrated effective pore size distribution as the main cracking component, the hydrocracking catalyst prepared from the carrier is suitable to serve as the hydrocracking catalyst for flexible production of high quality heavy naphtha, aviation kerosene and diesel, and has very high activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of small grain nay type molecular sieve and preparation method thereof

ActiveCN104591207BImprove stabilityHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-AWater vaporCarbonization

The invention discloses a small-grain NaY-type molecular sieve and a preparation method thereof. The small-grain aY-type molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is higher than 6.0 and no higher than 9.0; the grain average diameter is 200-700nm; the specific surface area is 800-1000m<2> / g; the pore volume is 0.30-0.45mL / g; the relative crystallinity degree is 90-130%; the lattice parameter is 2.460-2.470nm; the relative crystallinity degree after roasting for 3h under a temperature of 650 DEG C in air is higher than 90%; and the relative crystallinity degree after a water vapor hydrothermal treatment for 2h under a temperature of 700 DEG C is higher than 90%. The preparation method comprises the following steps: an amorphous silica-alumina precursor prepared with a specific carbonization method, a directing agent synthesized under low temperature, part of a silicon source, and the like are mixed under a low temperature, such that silica-alumina gel is prepared; and crystallization is carried out, such that the small-grain NaY-type molecular sieve is obtained. The small-grain NaY-type molecular sieve can be applied in a hydrocracking reaction, has has good cracking activity and product selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst and preparation method thereof

ActiveCN102049282BGuaranteed continuityReduce collapseMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst and a preparation method thereof. The catalyst comprises hydrogenation activity metals and a carrier consisting of a modified small crystal particle Y-shaped molecular sieve and alumina, wherein the small crystal particle Y-shaped molecular sieve has the following properties: the SiO2 / Al2O3 molar ratio is 10.0-120.0, the average diameter of the crystal particles is 100-700nm, the cell parameter is 2.436-2.445nm, sodium oxide is less than or equal to 0.1 weight percent, and the crystal retention rate is over 95 percent. The hydrocracking catalyst has the characteristics of high catalytic activity, high heavy naphtha selectivity, high potential aromatic hydrocarbon content, low bureau of mines correlation index (BMCI) value of hydrocracking tail oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

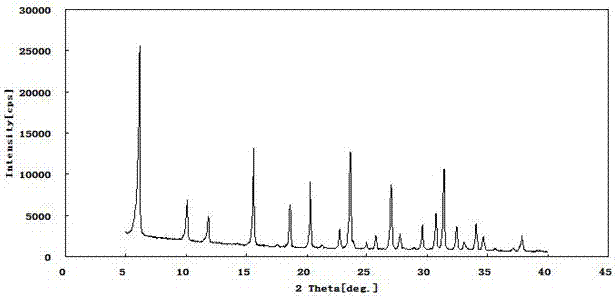

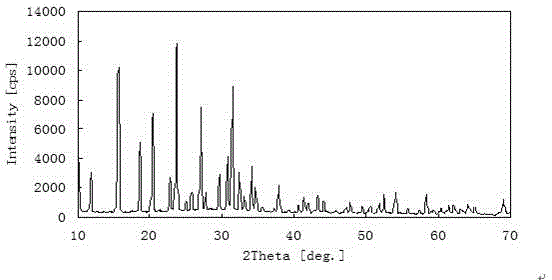

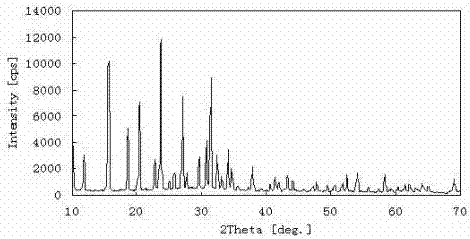

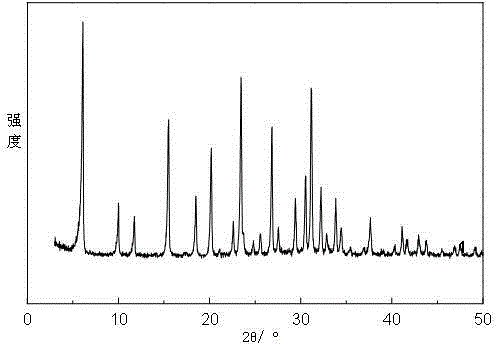

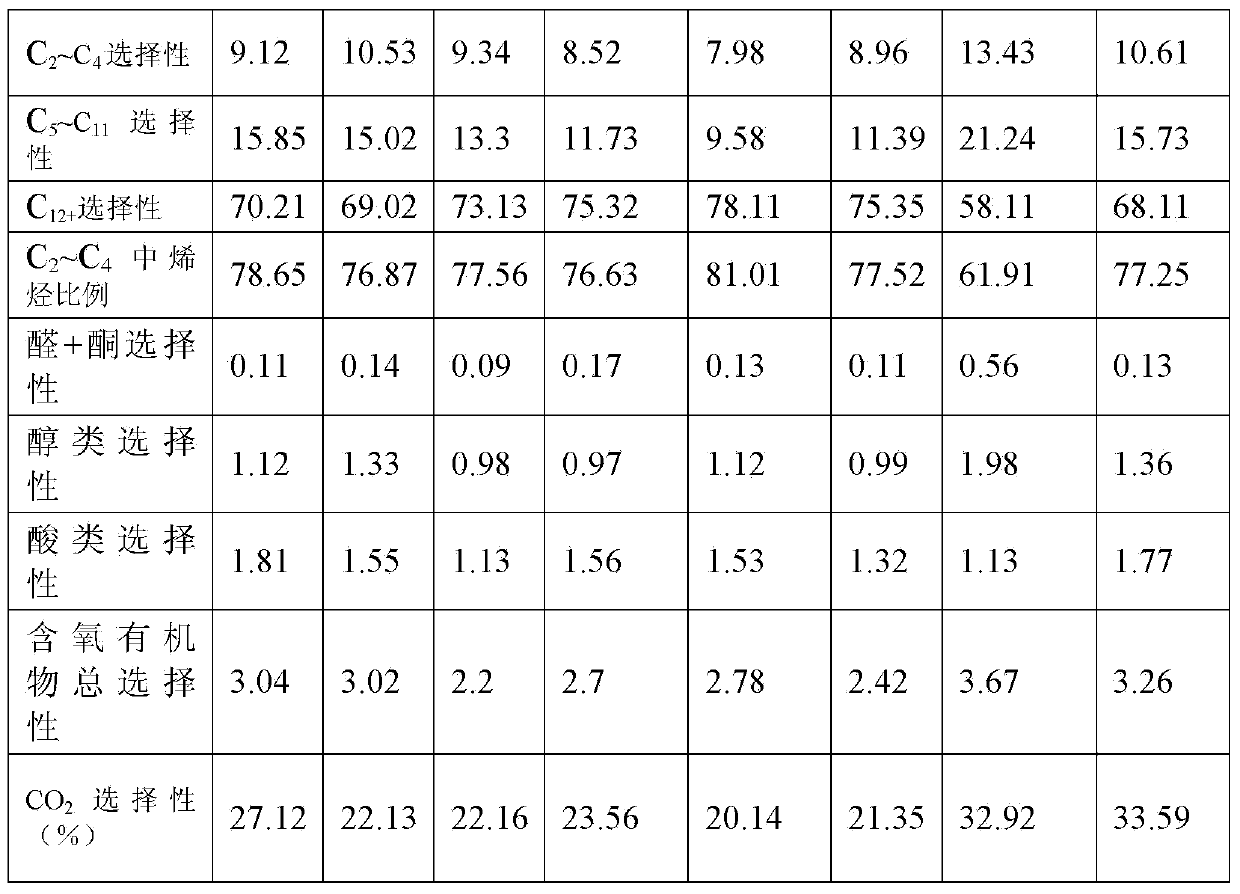

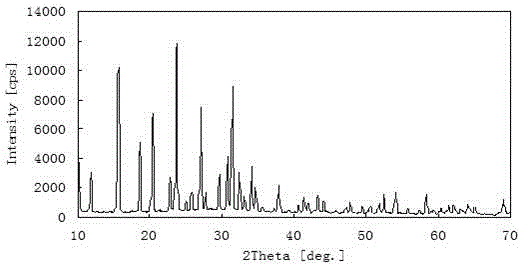

Production method of linear alkylbenzene

PendingCN113912472AHigh reactivityHigh product selectivityMolecular sieve catalystsMolecular sieve catalystPtru catalystSolid acid

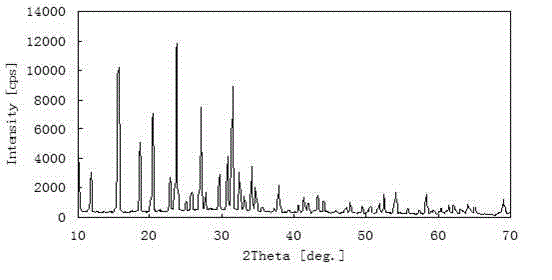

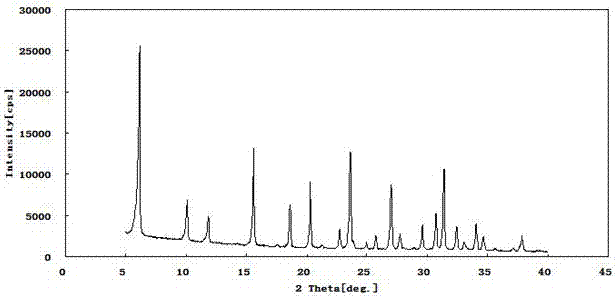

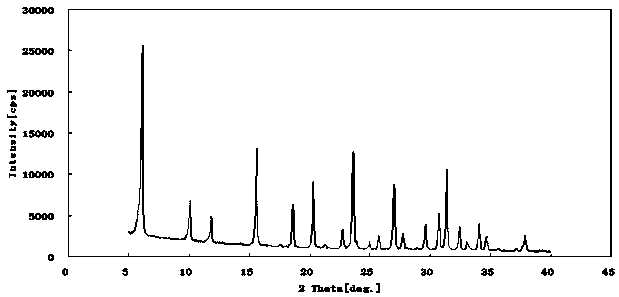

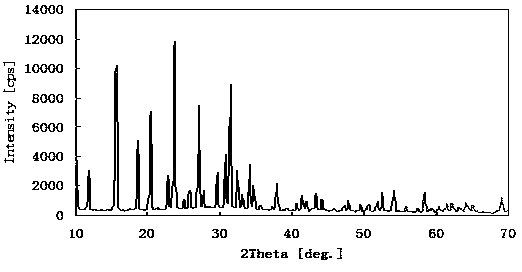

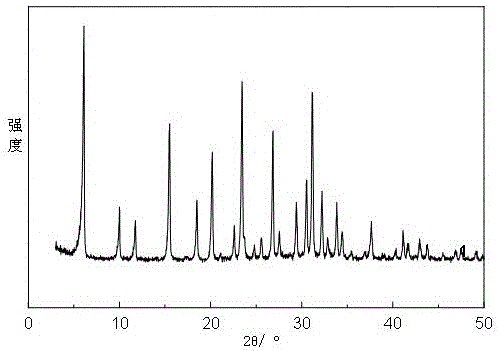

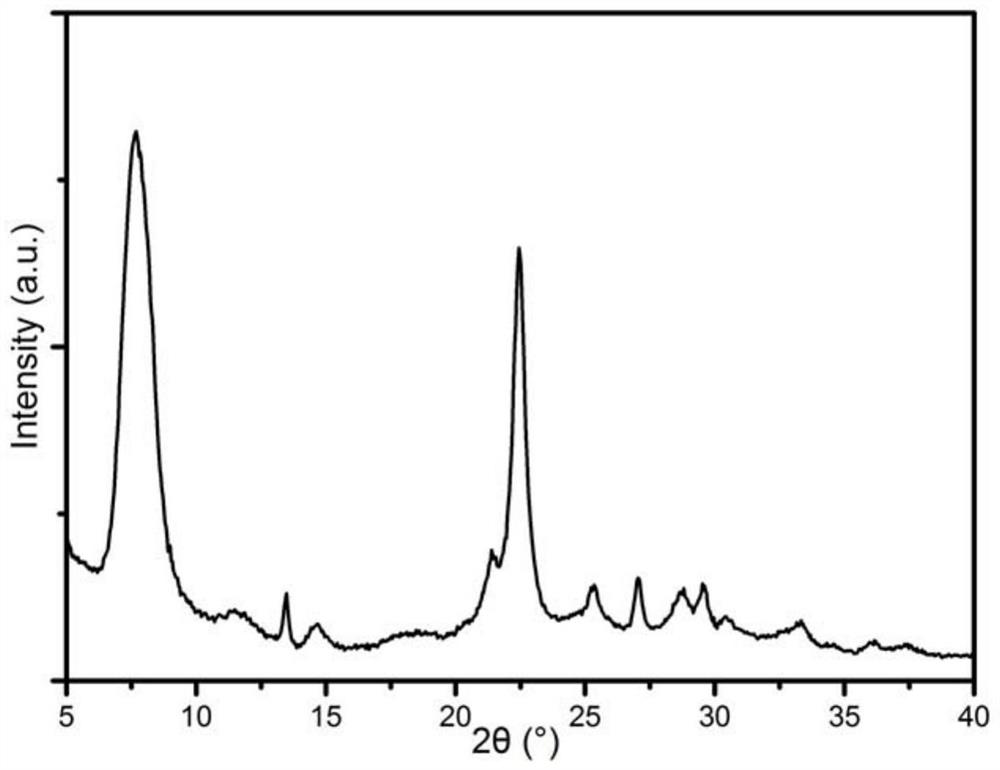

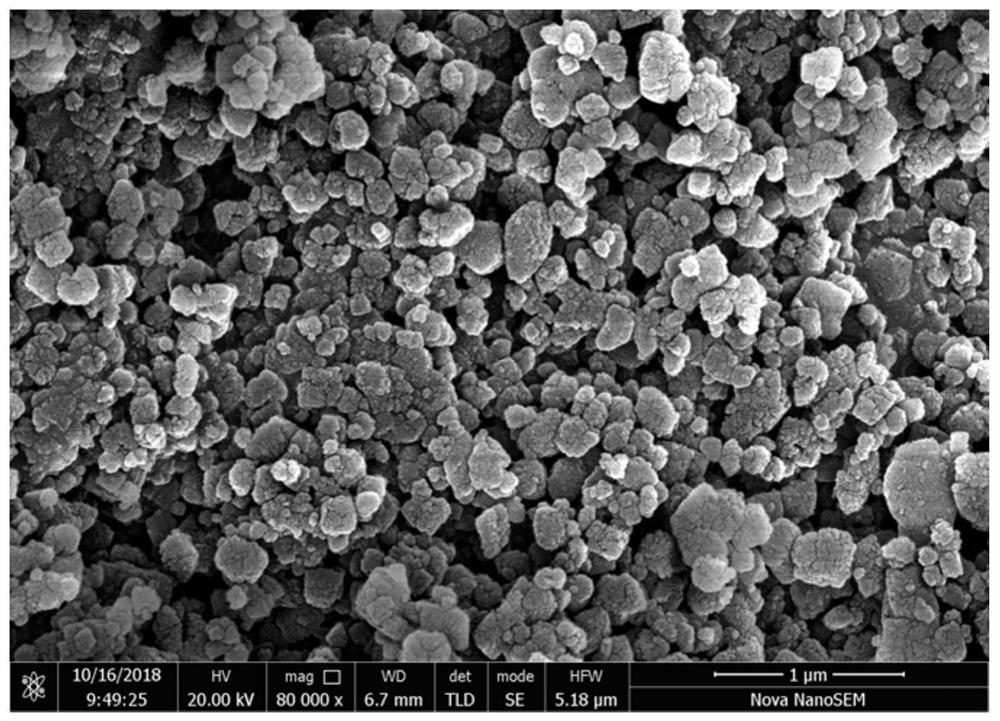

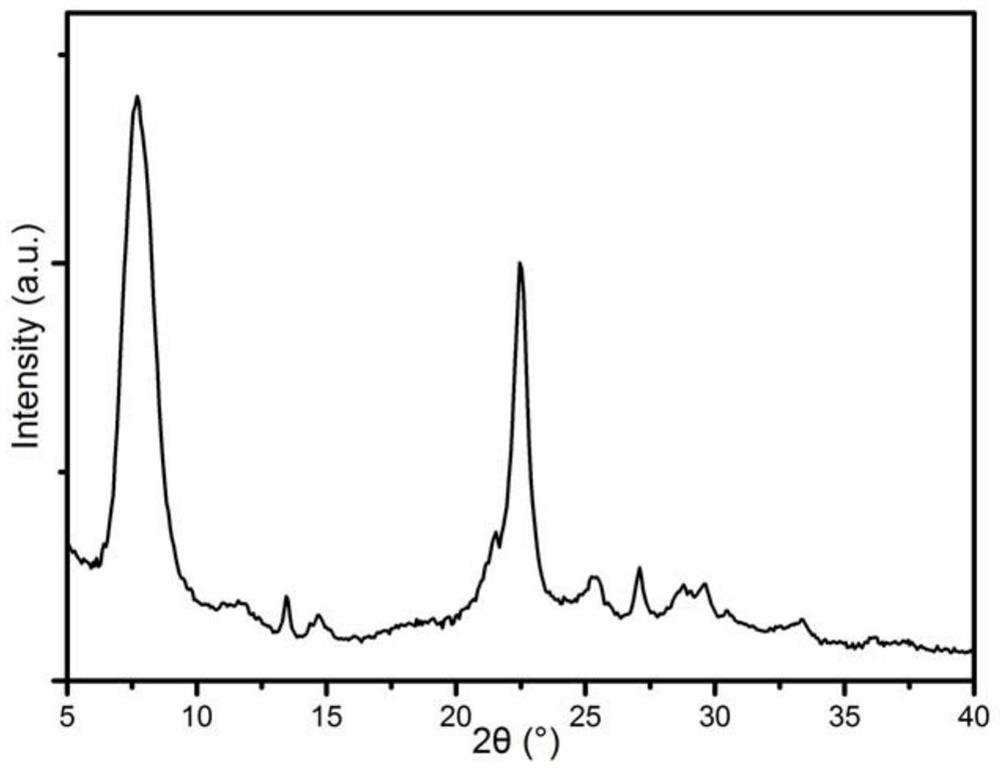

The invention relates to a production method of linear alkylbenzene. In the method, benzene and long-chain olefin are subjected to an alkylation reaction under the catalysis of a solid acid catalyst, and the solid acid catalyst comprises the following components in percentage by mass: 10-95% of a low-agglomeration-degree microcrystalline zeolite molecular sieve with a BEA topological structure and 5-90% of an inorganic oxide binder. The low-agglomeration-degree microcrystalline zeolite molecular sieve with the BEA topological structure is a beta zeolite molecular sieve, an XRD spectrogram of the low-agglomeration-degree microcrystalline zeolite molecular sieve has strong diffraction peaks at 2theta angles of 6.98 + / -0.5, 7.74 + / -0.5, 21.92 + / -0.5 and 22.11 + / -0.4 which are obviously widened, and the full width at half maximum is (0.60-0.71) degrees, (0.20-0.24) degrees, (0.33-0.41) degrees and (0.34-0.45) degrees respectively; the structure crystallite size is 10-50 nm, and the agglomerated particle size is 50-300 nm.

Owner:PETROCHINA CO LTD

Precipitated iron catalyst for Fischer-Tropsch synthesis and preparation method thereof

ActiveCN103801308BLow selectivityReduce pollutionLiquid hydrocarbon mixture productionMetal/metal-oxides/metal-hydroxide catalystsParaffin waxFixed bed

The invention discloses a precipitated iron catalyst for Fischer-Tropsch synthesis and a preparation method thereof. The weight ratio of the components including Fe, Y, Ti, Cu, K and SiO2 in the catalyst is 100:(0.5-7.5):(0.4-11.2):(1.0-8.5):(1.0-7.0):(5-30), wherein Y, Ti and K exist in the form of oxide; Fe exists in the form of Fe2O3; Cu exists in the form of CuO. The catalyst provided by the invention has good activity and product selectivity, is capable of achieving high CO conversion rate and low CH4 and CO2 selectivity, increasing the main product, reducing the byproducts and reducing the environmental pollution on the premise of ensuring the raw material conversion rate and the effective product selectivity when being applied to Fischer-Tropsch synthesis for preparing oil products and paraffin, and is suitable for joint production of gasoline, diesel and high-quality paraffin in the large-scale fixed bed Fischer-Tropsch synthesis industry.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

NaY-type molecular sieves and preparation method thereof

ActiveCN101722023BHigh reactivityHigh surface energyMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention discloses microcrystal NaY-type molecular sieves and a preparation method thereof. In the microcrystal NaY-type molecular sieves, the molar ratio of SiO2 to Al2O3 is 4.0 to 6.0, and the average particle size is 100 to 700 nanometers. The microcrystal NaY-type molecular sieves are prepared by a method combining low-temperature synthesis directing agent, low-temperature synthesis gel and two-stage variable-temperature dynamic crystallization. The NaY-type molecular sieves have a relative crystallinity of over 80 percent after being roasted in the air at 600 DEG C for 3 hours or after undergoing hydrothermal treatment with vapor at 650 DEG C for 1 hour, as well as high thermostability and hydrothermal stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst carrier and preparation method thereof

ActiveCN105709847AImprove utilization efficiencyLow costCatalyst carriersMolecular sieve catalystsMolecular sieveNaphtha

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The hydrocracking catalyst carrier adopts a large-grained Y type molecular sieve with concentrated effective pore size distribution as the acidic component, is suitable for a hydrocracking catalyst for increase production of high quality heavy naphtha, and has very high catalytic activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of small grain nay type molecular sieve

ActiveCN104591213BImprove stabilityHigh ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveAmorphous silica-alumina

The invention discloses a preparation method of a small-grain NaY-type molecular sieve. According to the invention, an amorphous silica-alumina precursor, a directing agent synthesized under a low temperature, part of a silicon source, and the like are mixed under a low temperature, such that silica-alumina gel is prepared; and crystallization is carried out, such that the small-grain NaY-type molecular sieve is obtained. According to the amorphous silica-alumina precursor, a part of a silicon-containing material is added in an aluminum-containing material before and / or during a gelling process; and the rest of the silicon-containing material is added after gelling and before aging, such that silica-alumina forms a stable structure, and can cooperate with subsequent steps. With the method, a phenomenon of silicon agglomeration or loss caused by the addition of a large amount of the silicon source in prior arts is avoided. The addition amount of silicon is reduced; silicon effective utilization rate is improved; the silica-to-alumina ratio is improved; and the obtained small-grain molecular sieve has good stability. The small-grain NaY-type molecular sieve provided by the invention can be used in a hydrocracking reaction, and has good cracking activity and product selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking catalyst carrier and its preparation method

ActiveCN105709847BGood product selectionHigh activityCatalyst carriersMolecular sieve catalystsNaphthaCatalyst support

The invention discloses a hydrocracking catalyst carrier and a preparation method thereof. The hydrocracking catalyst carrier of the invention adopts a Y-type molecular sieve with large grain size and concentrated effective pore size distribution as the acid component, is suitable for the hydrocracking catalyst for increasing the production of high-quality heavy naphtha, and has high catalytic activity and selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

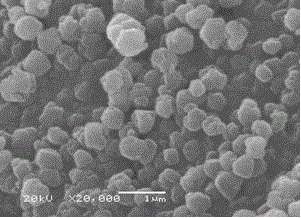

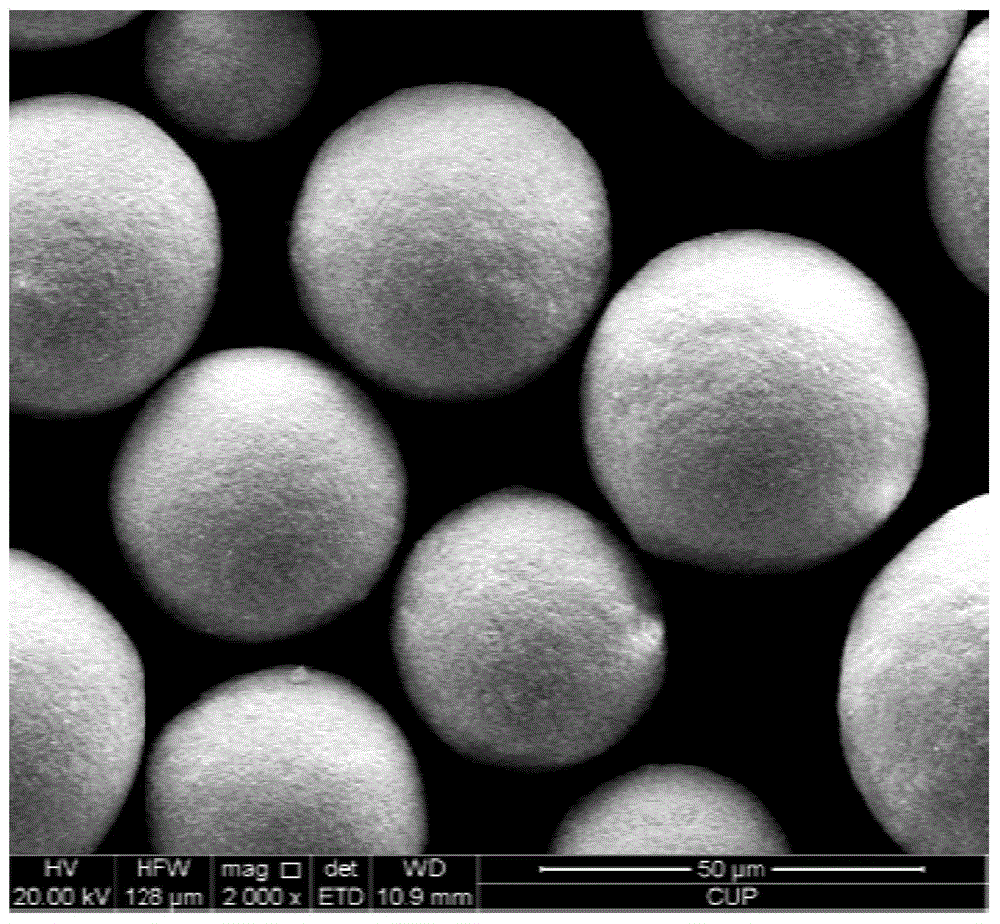

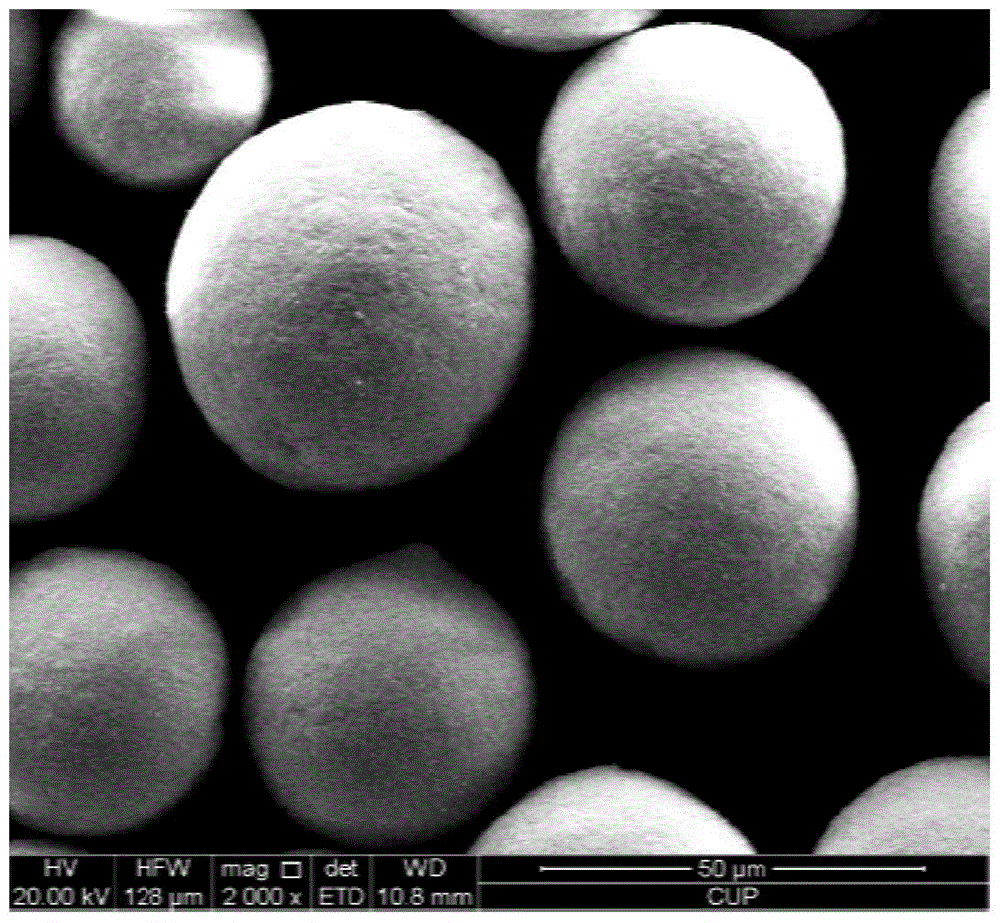

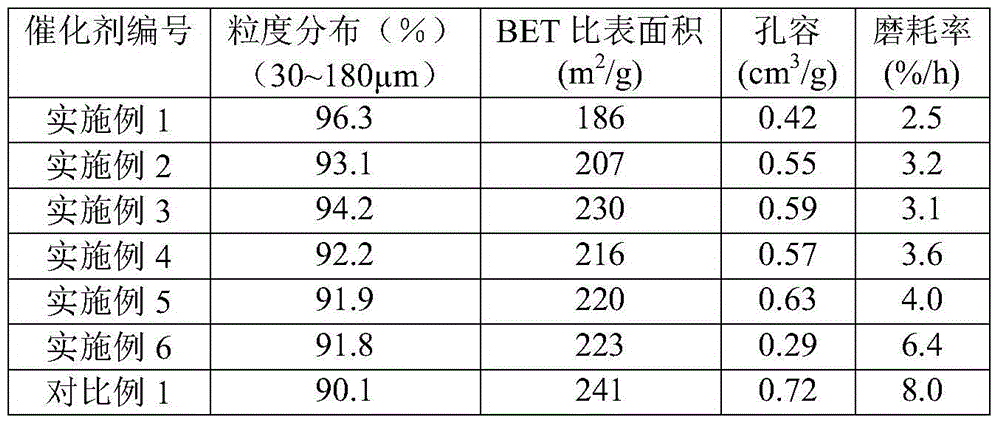

Microspherical catalyst for preparing oil and paraffin from syngas and preparation method thereof

ActiveCN103801329BGood sphericityLarge specific surface areaLiquid hydrocarbon mixture productionMineral wax recovery/refiningParaffin waxGasoline

The invention discloses a microspheric catalyst for preparing oils and paraffin from synthesis gas and a preparation method thereof. The catalyst comprises the following components of Fe, V, Cu, K, Ag and SiO2 according to the weight ratio of 100:(0.1-1.4):(0.8-7):(1.0-8):(0.1-2.5):(5-35), wherein the elements Cu, K and Ag exist in the form of oxide, Fe exists in the form of Fe2O3, and V exists in the form of V2O5. The catalyst has the good degree of sphericity, large specific surface area, high strength, and good activity and product selectivity, is applicable to joint production of gasoline, diesel and high quality paraffin in large-scale fischer-tropsch synthesis of a slurry bed, and has the advantages of high CO conversion rate, low CH4 selectivity and reasonable HC product distribution when being used in fischer-tropsch synthesis. The preparation method has continuous technological processes, and is applicable to large-scale industrial production.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

A kind of method for preparing 1,5-diaminodecalin by catalytic hydrogenation of 1,5-diaminonaphthalene

InactiveCN103319351BGood dispersionHigh reuse rateMolecular sieve catalystsOrganic compound preparationPtru catalystPhysical chemistry

The invention relates to a method for preparing 1,5-diaminodecalin by catalytic hydrogenation of 1,5-diaminonaphthalene, which is characterized in that: adding 1,5-diaminonaphthalene and a solvent into a pressure reactor, adding Type nickel-based hydrogenation catalyst, the amount of the catalyst is 2.5-10% of the added amount of the reaction substrate 1,5-diaminonaphthalene in terms of mass, and the air in the reactor is replaced with hydrogen for three times, and then filled with hydrogen to make the reactor When the reaction pressure reaches 4.0MPa, start stirring, and heat the reactor to make the temperature 190-230°C. Supplement hydrogen and maintain the reaction pressure of the reactor to 6-8MPa. React at constant temperature for 5-8 hours. After cooling, filter out the catalyst to obtain 1 ,5-Diaminodecalin. The invention can significantly improve the conversion rate of 1,5-diaminonaphthalene, and at the same time, the catalyst has low cost, simple preparation and long service life, and exhibits good application prospects.

Owner:武汉椿岭科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com