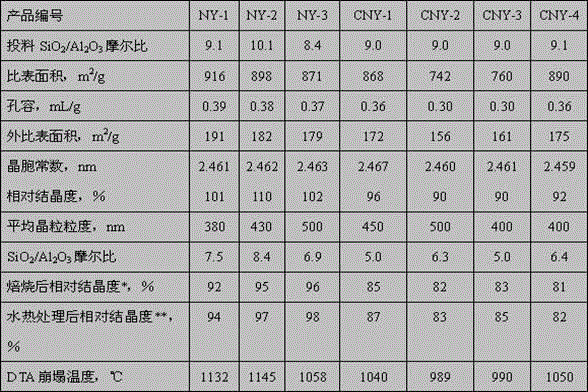

Small-grain NaY-type molecular sieve and preparation method thereof

A small-grain, molecular sieve technology, which is applied in the direction of crystalline aluminosilicate zeolite, A-type crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problem of poor hydrothermal stability of fine-grained Y-type molecular sieve, Solve problems such as uneven distribution of silicon and aluminum, complex process steps, etc., achieve good cracking activity and product selectivity, reduce coke yield, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of guiding agent: Dissolve 10 g of sodium hydroxide solid in 80 g of water, add 2 g of sodium metaaluminate (Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%), then add 36g water glass (SiO 2 Content is 28wt%, Na 2 O content is 8 wt%), mixed evenly and aged at 15°C for 4 hours to prepare the directing agent.

[0037] (2) Preparation of amorphous silicon-aluminum precursor

[0038] Prepare solid sodium aluminate to a concentration of 40gAl 2 o 3 / L sodium aluminate working solution, take SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 100g SiO 2 / L sodium silicate working solution. Take 1L of sodium aluminate working solution and place it in a gel-forming tank, then add 0.2L of sodium silicate working solution, control the reaction temperature at 20°C, and feed CO with a concentration of 50v%. 2 gas, stop passing CO when the pH reaches 10.0 2 , and then add 0.4L sodium silicate working solution, and then ventilate and...

Embodiment 2

[0044] (1) Preparation of directing agent: Dissolve 8 g of sodium hydroxide solid in 80 g of water, add 2.5 g of sodium metaaluminate (Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%). Then add 40g of water glass (SiO 2 Content is 28wt%, Na 2 The O content is 8 wt%), mixed evenly and aged at 18°C for 4 hours to prepare the directing agent.

[0045] (2) Preparation of amorphous silicon-aluminum precursor

[0046] Prepare solid sodium aluminate to a concentration of 30gAl 2 o 3 / L sodium aluminate working solution, take SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 70g SiO 2 / L sodium silicate working solution. Take 1L of sodium aluminate working solution and place it in a gel-forming tank, then add 0.4L of sodium silicate working solution, control the reaction temperature at 18°C, and feed CO with a concentration of 50v%. 2 gas, stop passing CO when the pH reaches 10.2 2 , and then add 0.6L sodium silicate working solution, and then v...

Embodiment 3

[0052] (1) Preparation of guiding agent: Dissolve 10 g of sodium hydroxide solid in 90 g of water, add 3 g of sodium metaaluminate (Al 2 o 3 Content is 45wt%, Na 2 O content is 41wt%). Then add 50g of water glass (SiO 2 Content is 28wt%, Na 2 O content is 8 wt%), mixed evenly and then aged at 20°C for 4 hours to prepare the directing agent.

[0053] (2) Preparation of amorphous silicon-aluminum precursor

[0054] Prepare solid sodium aluminate to a concentration of 50gAl 2 o 3 / L sodium aluminate working solution, take SiO 2 28wt% sodium silicate solution, then diluted to a concentration of 120g SiO 2 / L sodium silicate working solution. Take 1L of sodium aluminate working solution and place it in a gel-forming tank, then add 0.2L of sodium silicate working solution, control the reaction temperature at 20°C, and feed CO with a concentration of 50v%. 2 gas, stop passing CO when the pH reaches 10.0 2 , and then add 0.22L sodium silicate working solution, and then ven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com