Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Flexible correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

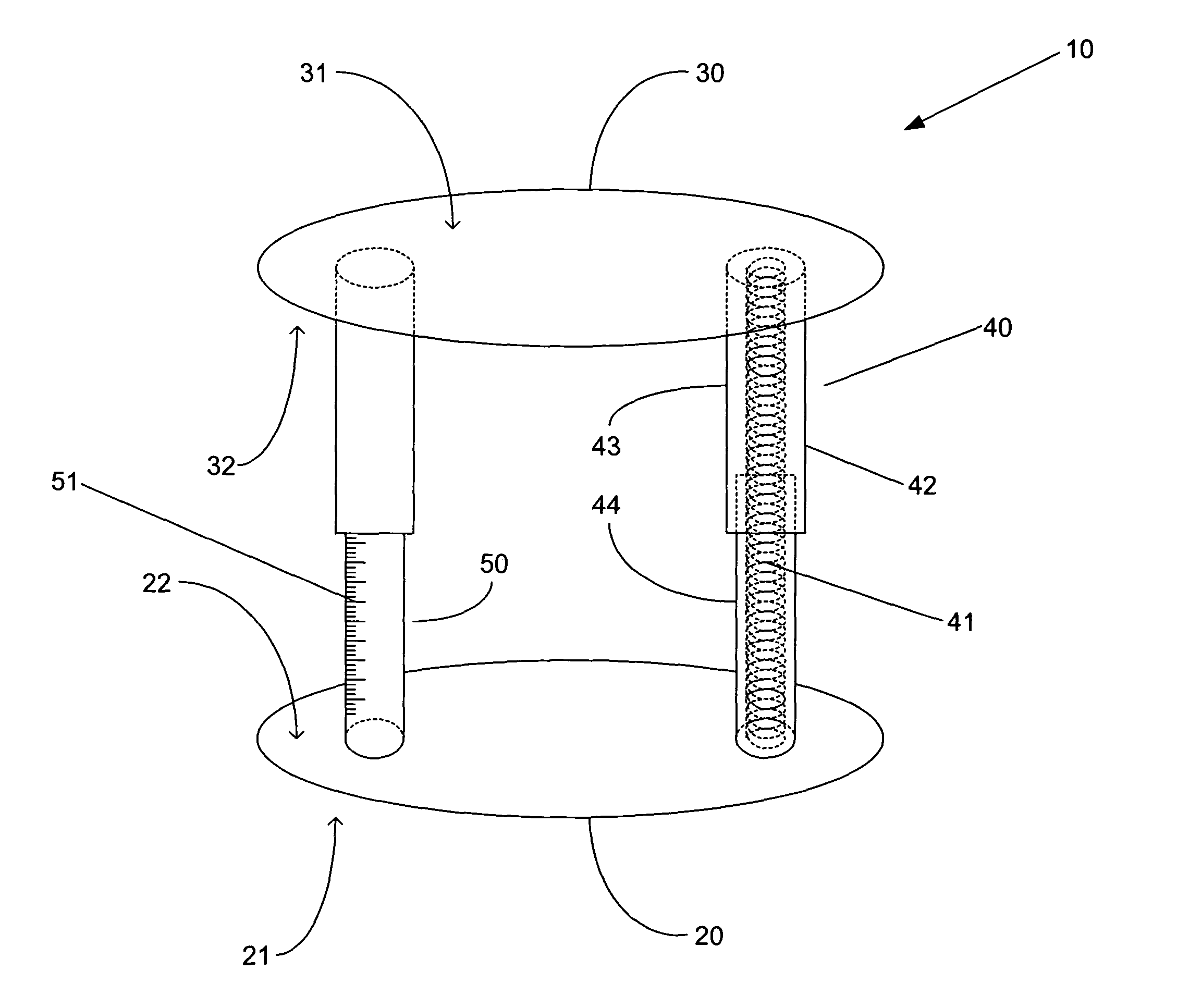

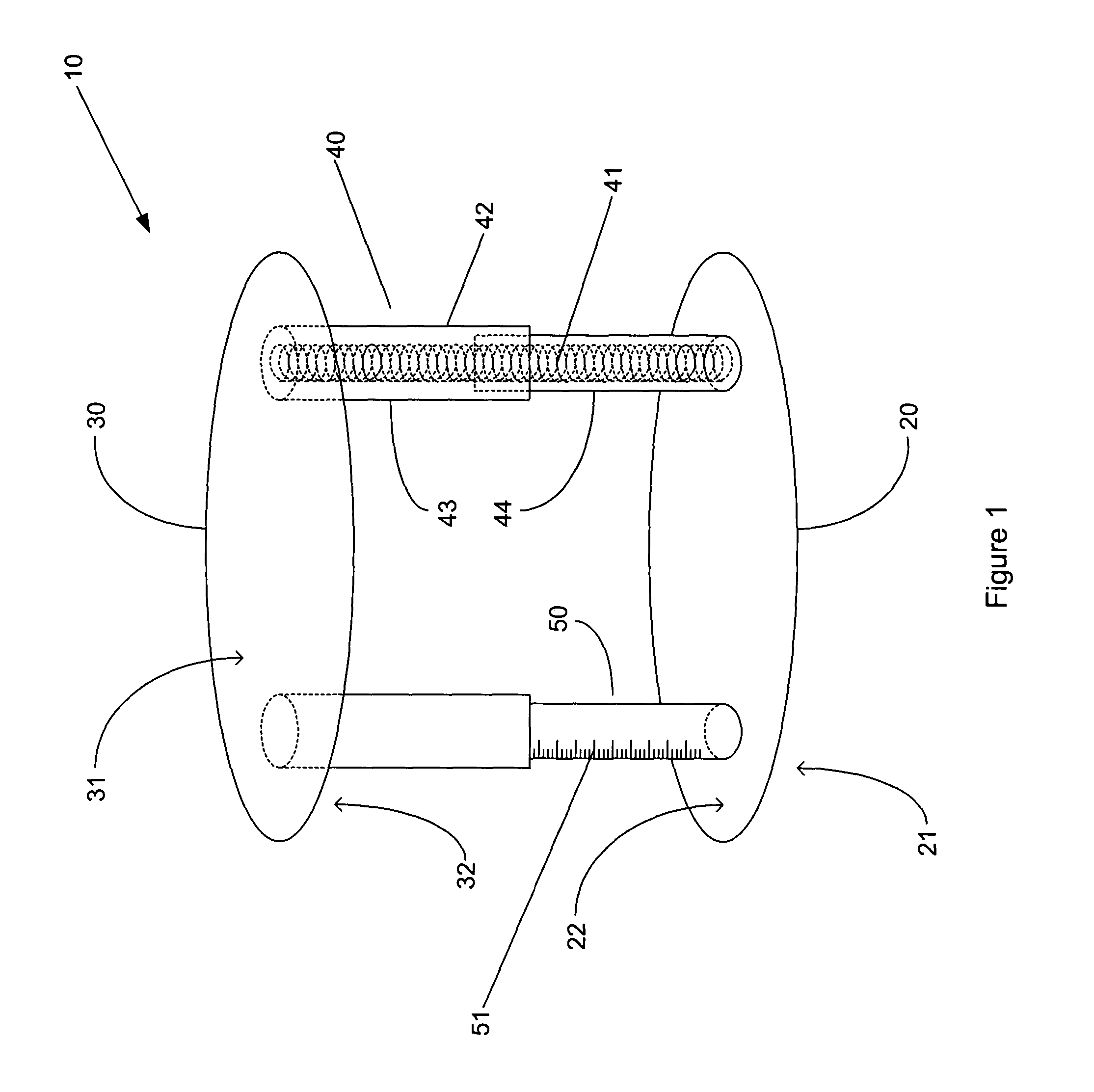

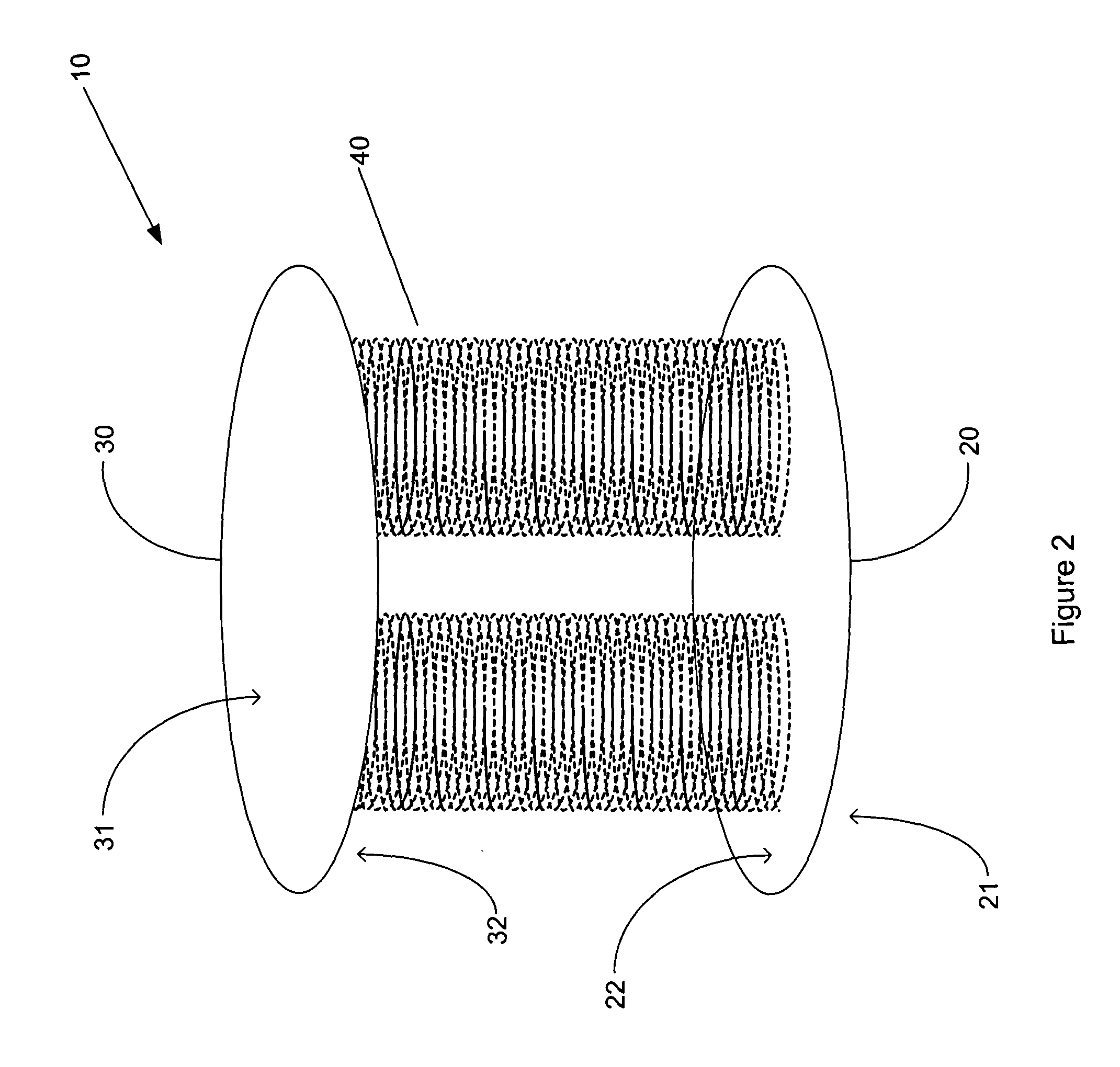

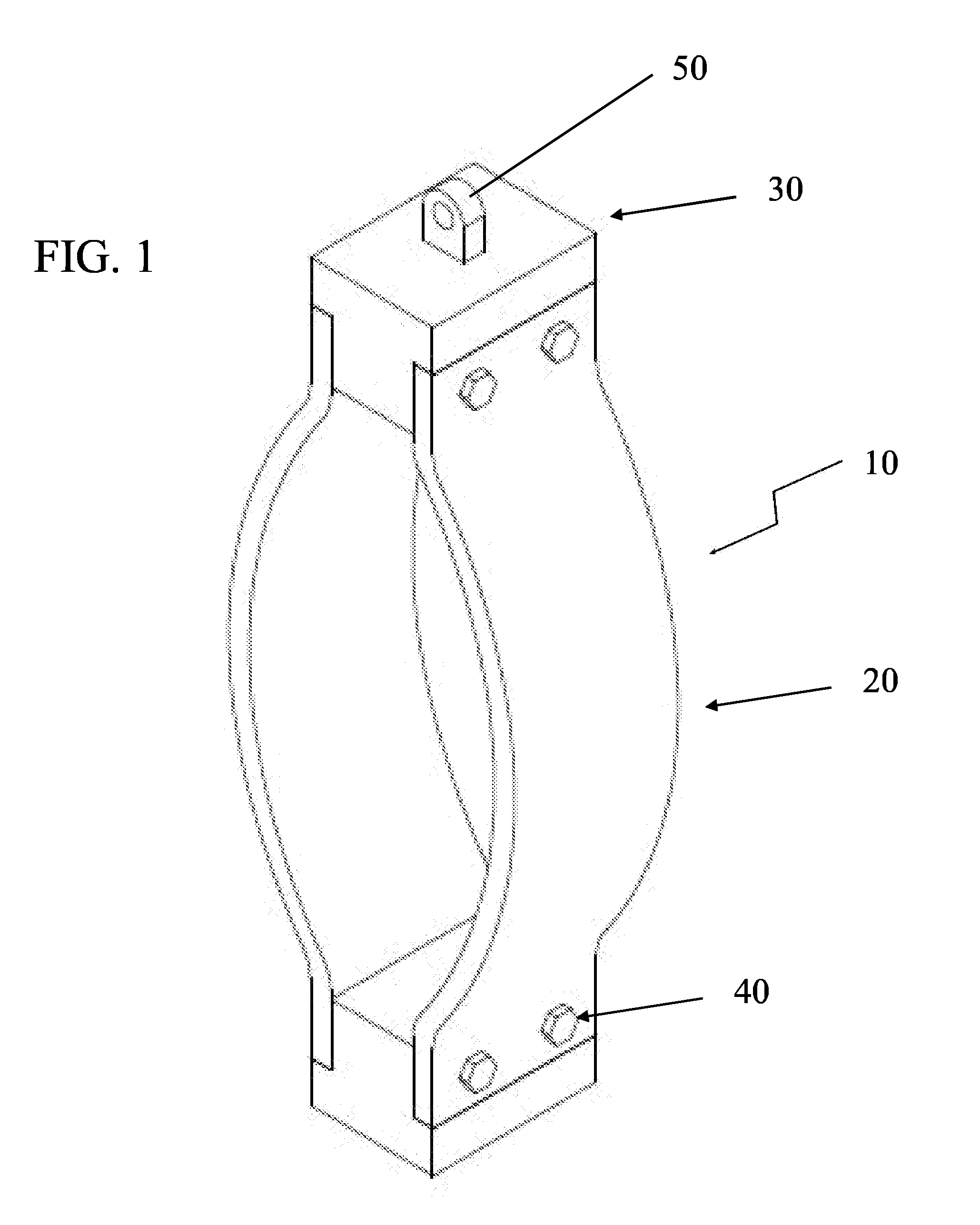

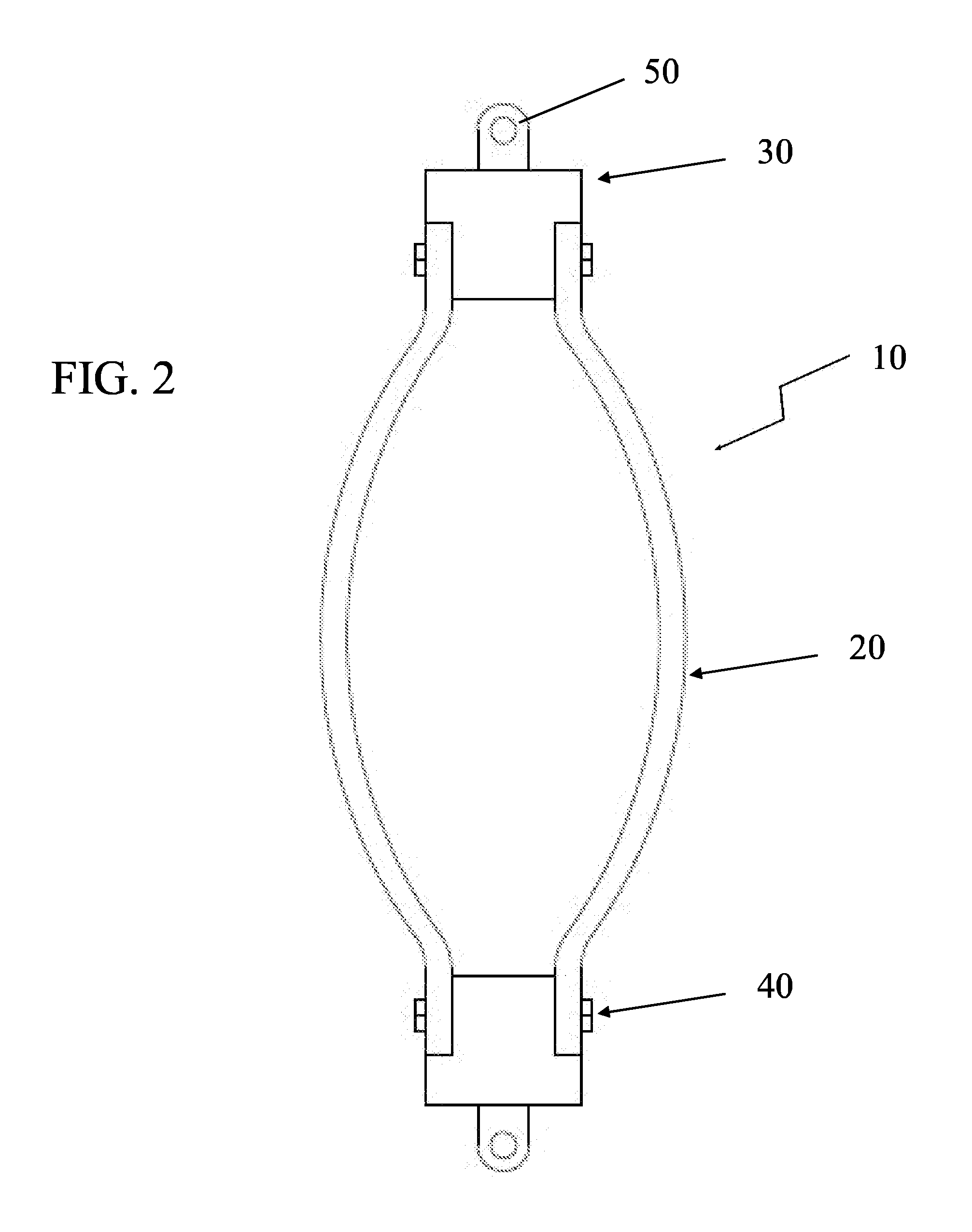

Dynamic spacer for total knee arthroplasty

InactiveUS20050020941A1Easy to useEasy constructionSurgeryPerson identificationPhysical medicine and rehabilitationSurgical instrumentation

A dynamic spacer is provided for measuring flexion-extension gap during total knee arthroplasty. The dynamic spacer is an improved surgical instrumentation system that it easy to use, simple in construction, and accurately measures flexion-extension gaps under repeatable soft tissue tension. The dynamic spacer generally comprises a first planar member having a lower tissue engaging surface, a second planar member having an upper tissue engaging surface. A tensioner is disposed between the first planar member and the second planar member for applying a tensile force acting upon the first and second planar members. The tensioner is fixedly attached to the first and second planar members, such that the first planar member is held substantially parallel to the second planar member in the absence of compressive load. The dynamic spacer allows for accurately measuring flexion-extension gaps and angular deviation in flexion indicating the appropriateness of femoral rotation.

Owner:TARABICHI SAMIH

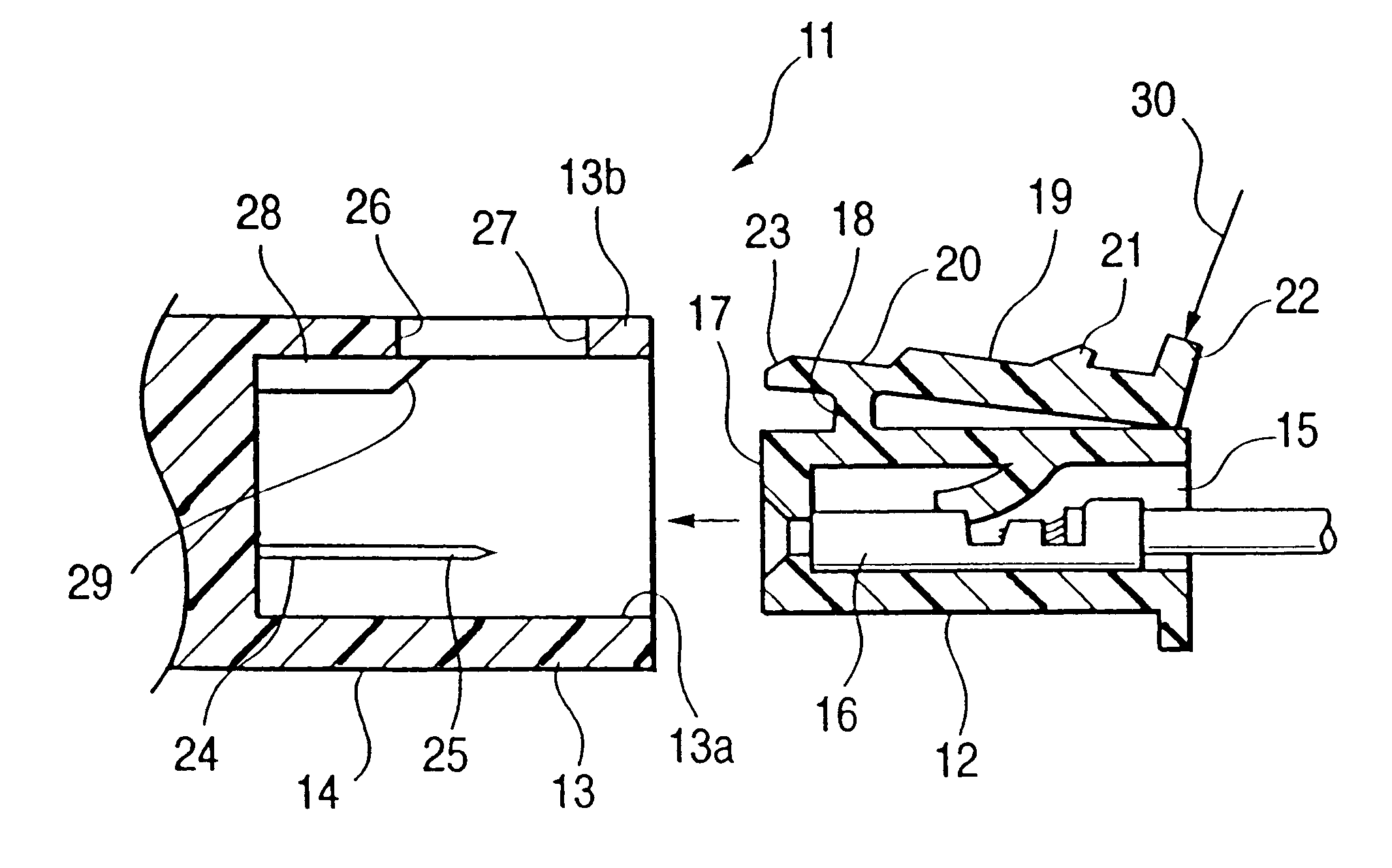

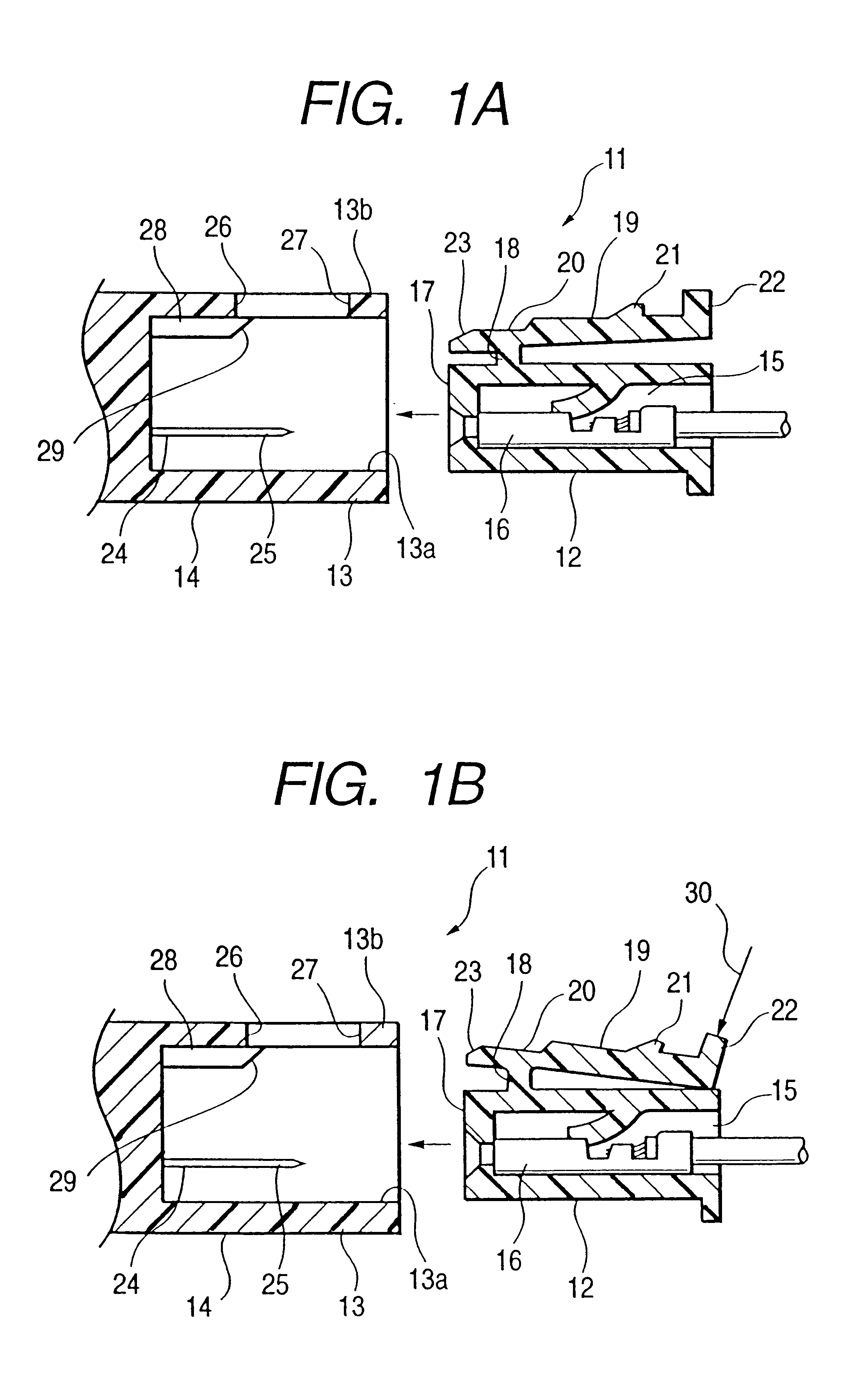

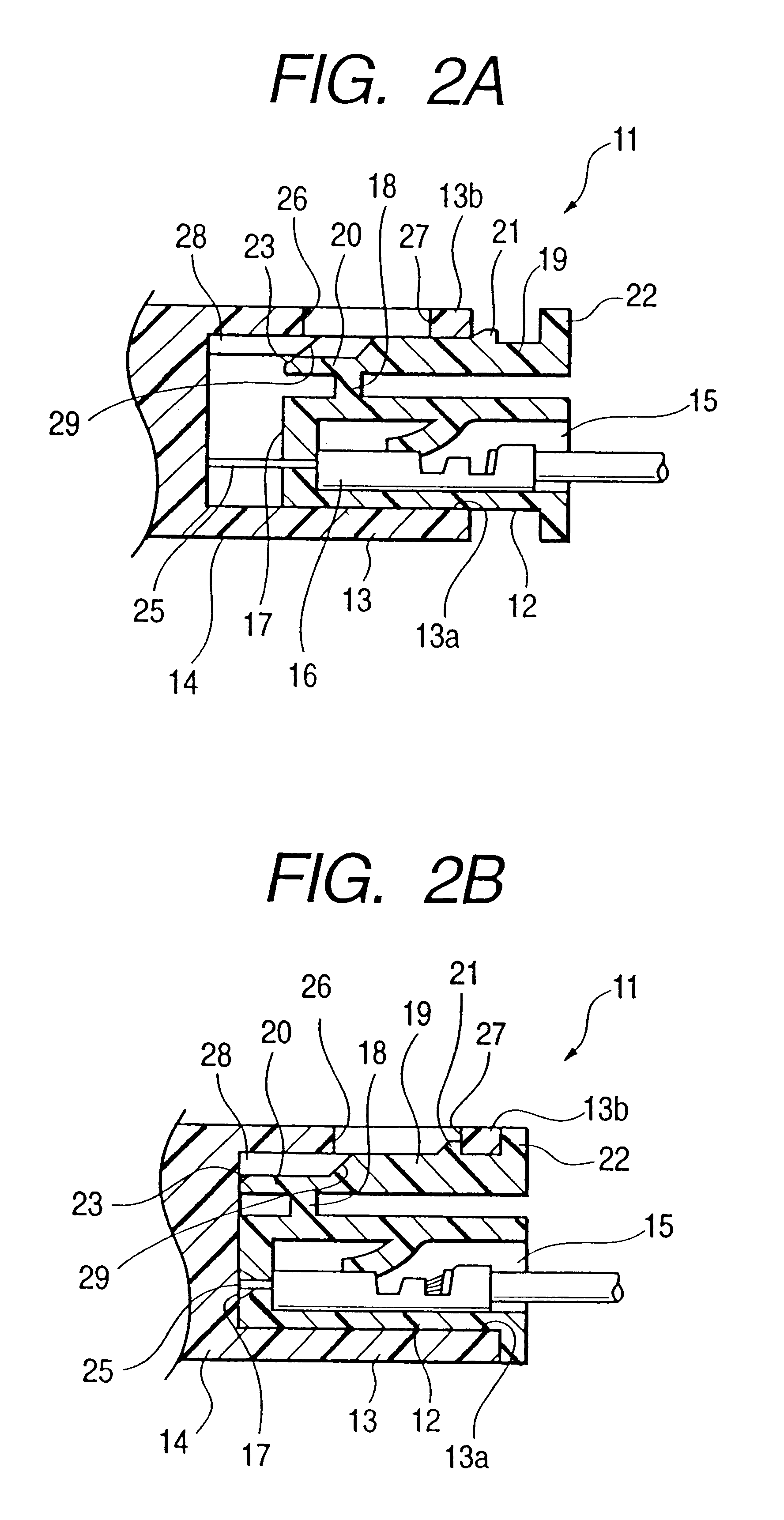

Lock structure for locking male and female connector housings together

InactiveUS6325656B1Easy to operateLocking can be effected positivelyCoupling device detailsEngineeringMechanical engineering

Owner:YAZAKI CORP

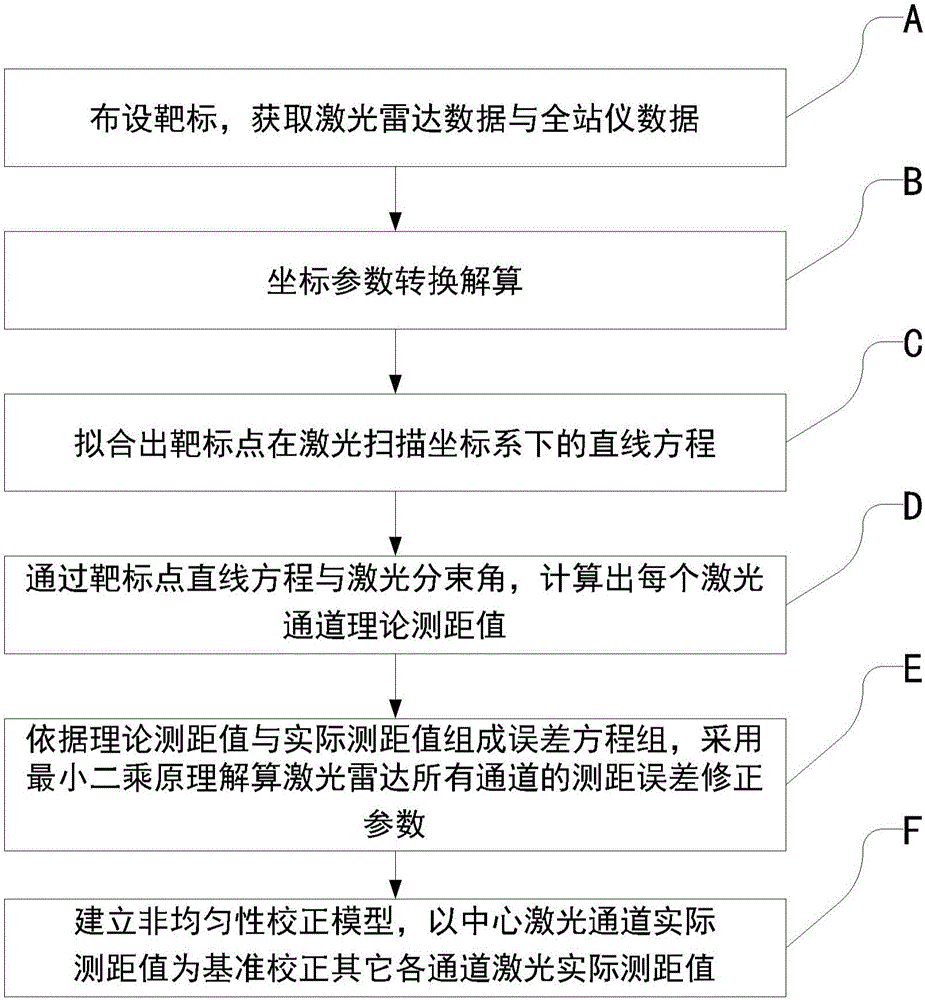

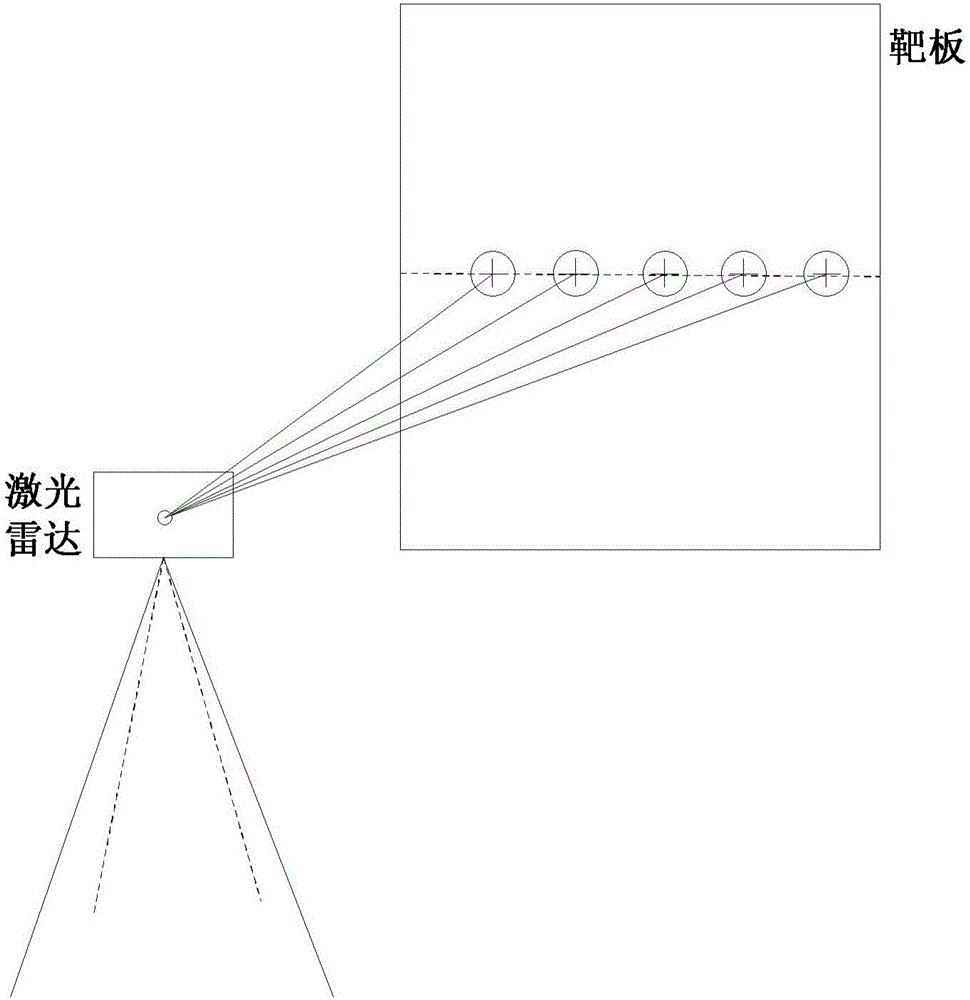

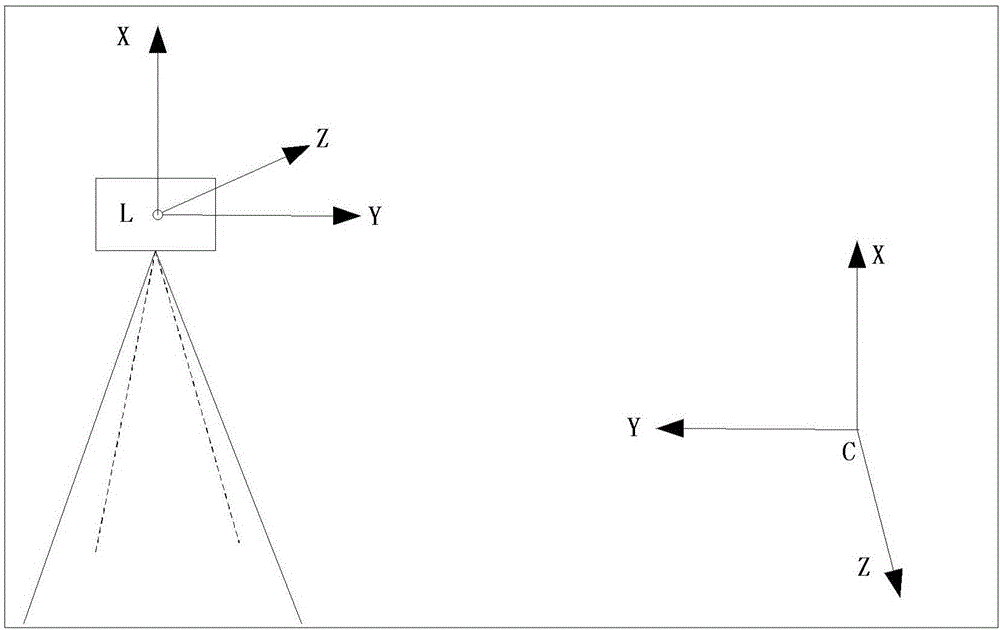

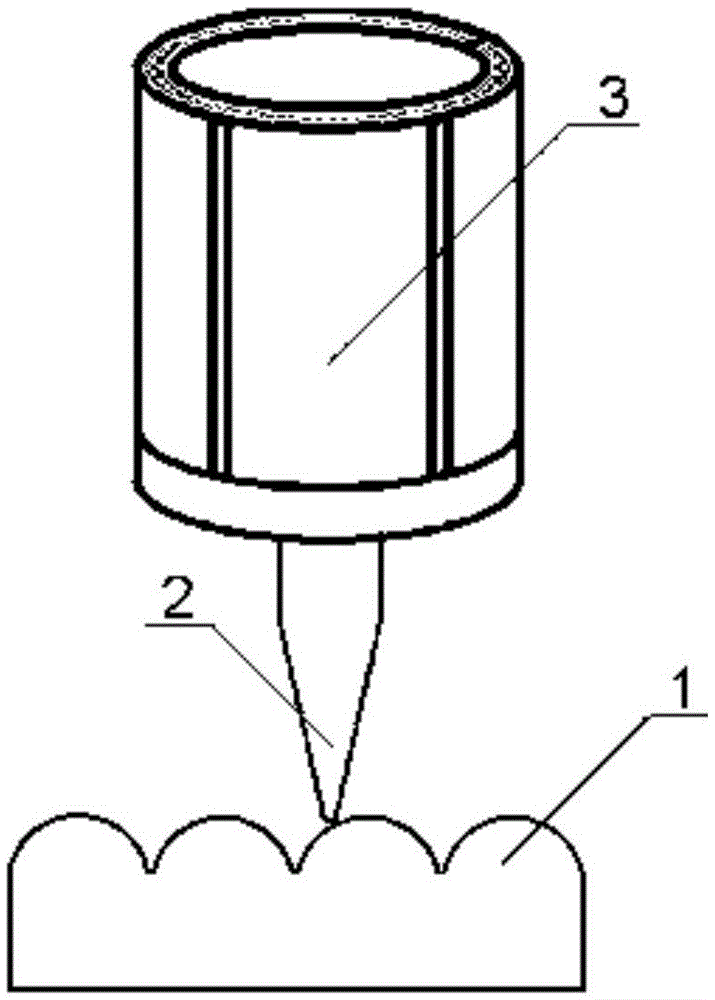

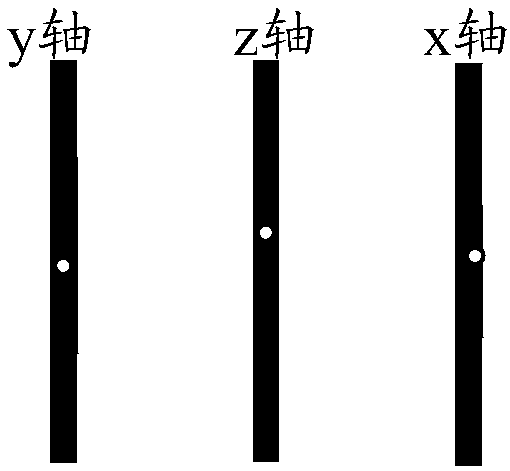

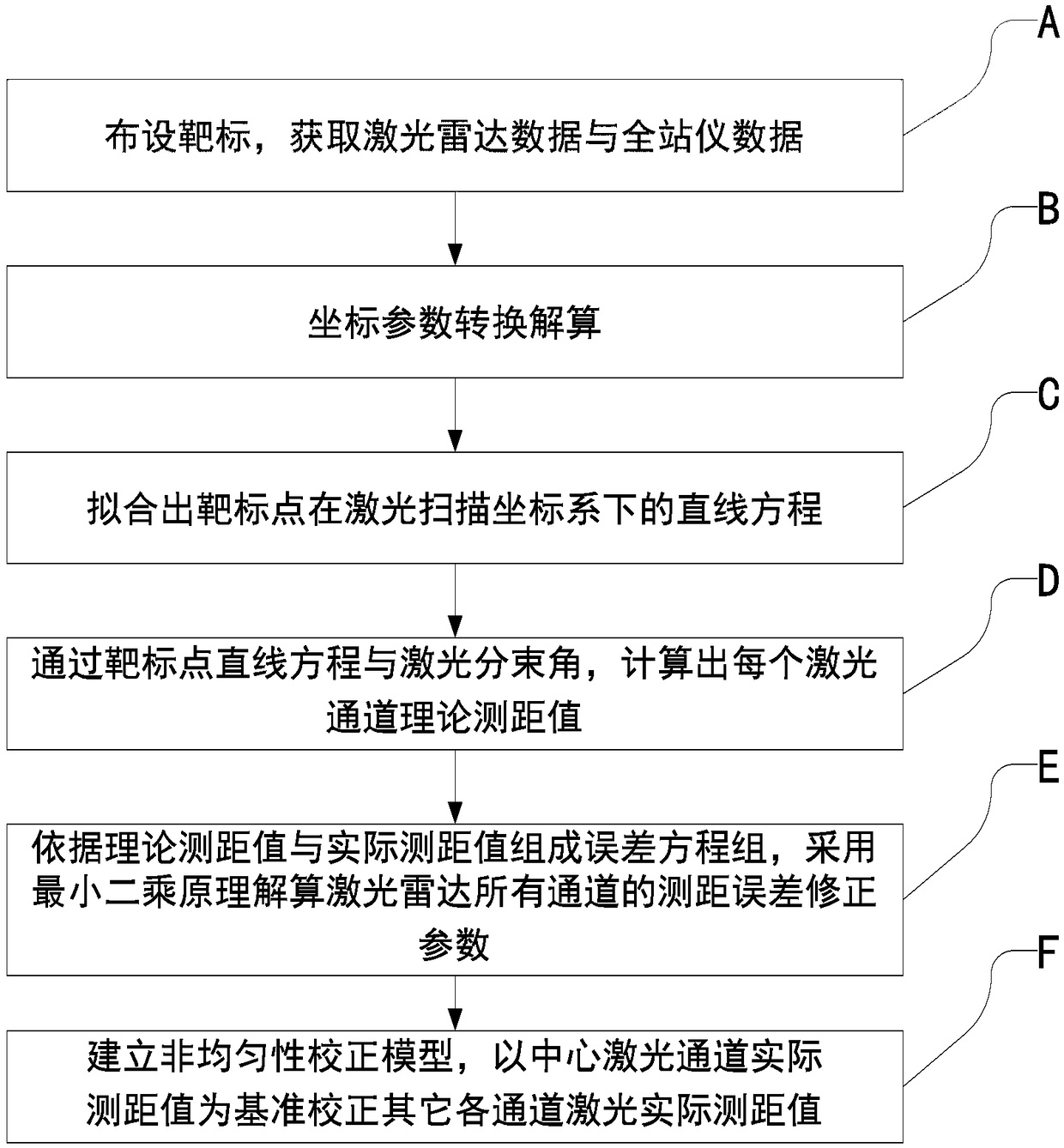

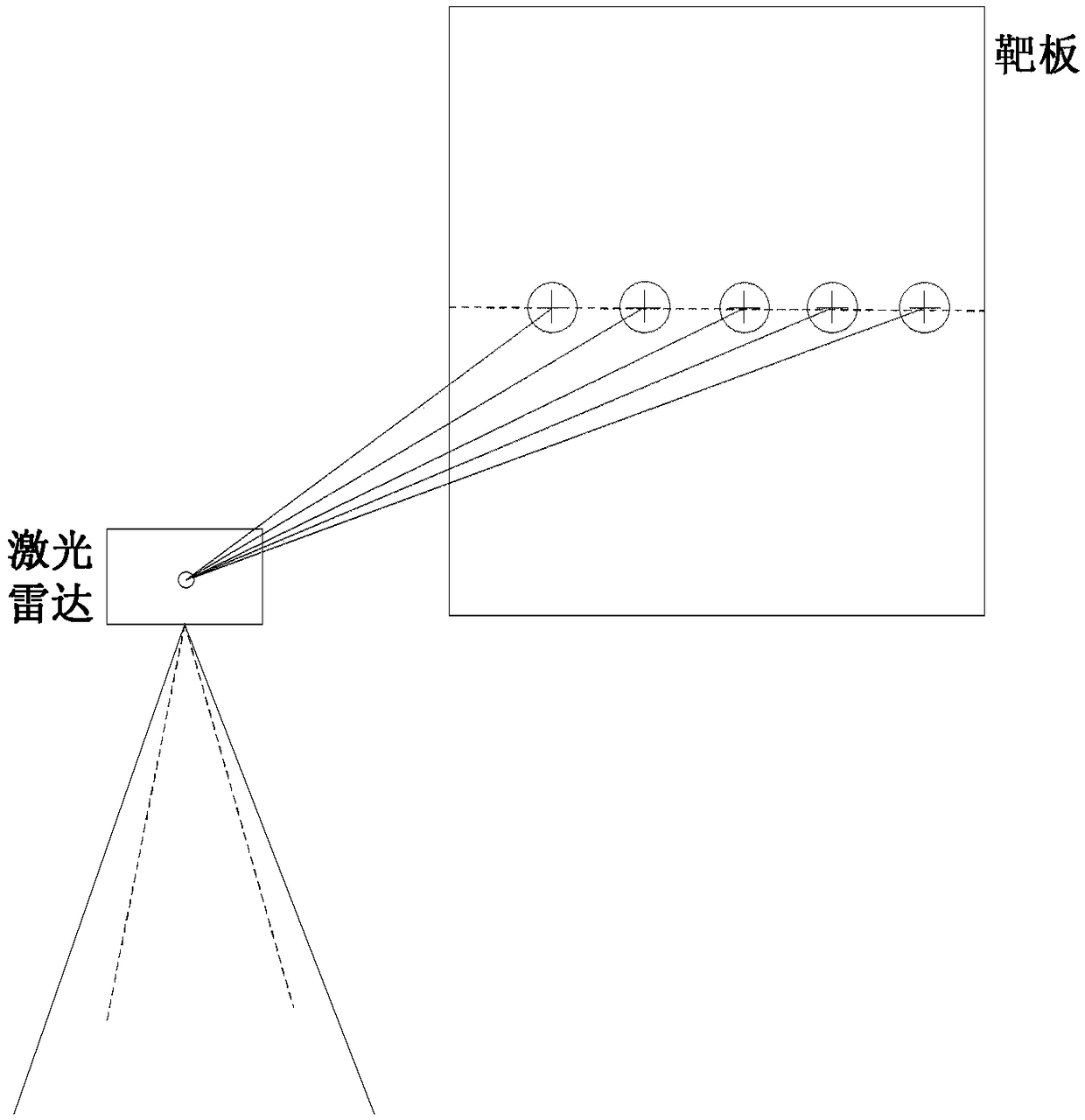

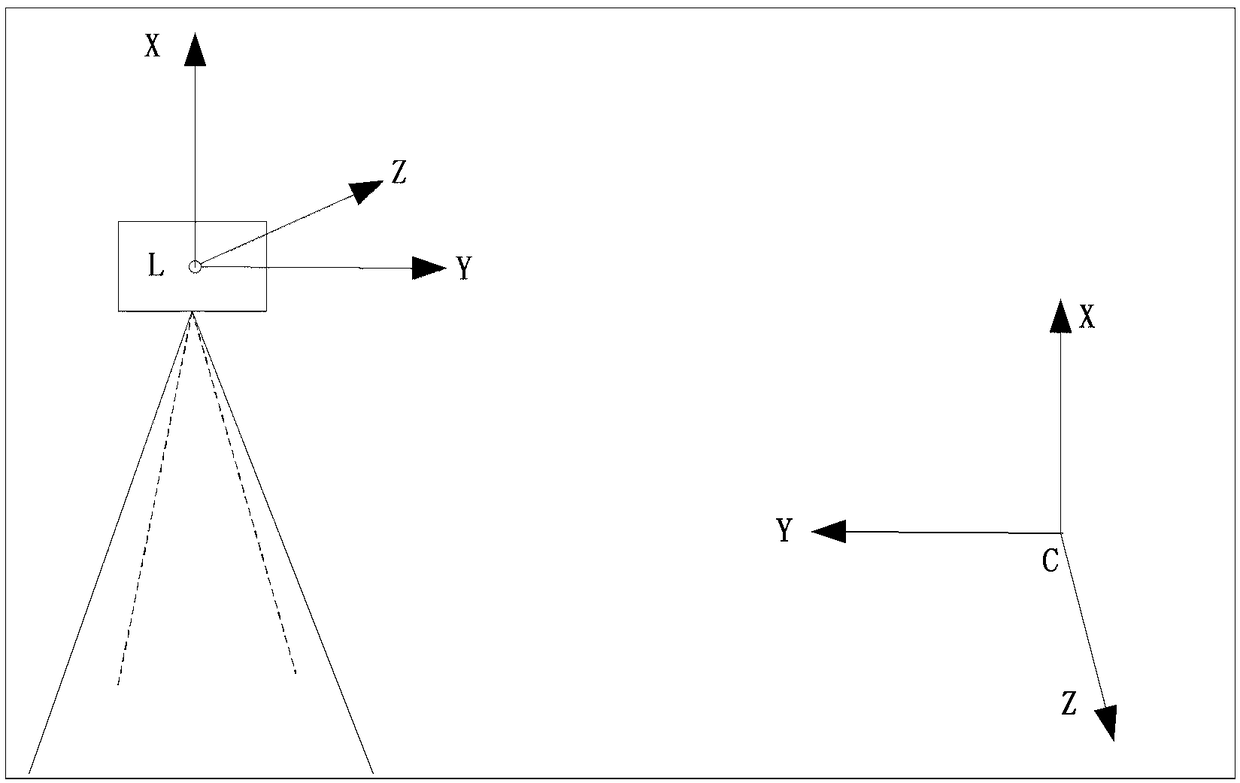

Method for non uniformity correction of range finding of array push-scan type laser radar

ActiveCN106291512AEliminate ranging differencesImprove applicabilityElectromagnetic wave reradiationRadarOptoelectronics

The invention provides a method for non uniformity correction of range finding of an array push-scan type laser radar. An array push-scan type laser radar with N laser channels are used for detecting a target plate, the relative position of the array push-scan type laser radar and the target plate is changed, and the target plate is detected for M times, so laser radar data and total station data corresponding to each laser channel are obtained. By carrying out operation like coordinate transformation, a non uniformity correction model is established, and an actual range finding value of any one laser channel is used as a reference correction value to correct actual range finding values of other laser channels.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

Pipe jacking construction method

ActiveCN104455725AControl level deviationControl high-level deviationPipe laying and repairComing outArchitectural engineering

The invention discloses a pipe jacking construction method. The pipe jacking construction method is characterized by comprising the steps that firstly, surveying and setting out are carried out; secondly, working well construction is carried out; thirdly, assembling type back wall installation is carried out; fourthly, a guide rail is installed; fifthly, a main jacking jack is installed; sixthly, a pipe jacking auxiliary device is installed; seventhly, a pipeline is jacked; eighthly, deviation is rectified, and mould weights are stacked at the front end of a water draining pipe to increase the weight of a pipe section; ninthly, coming out of a hole is carried out. According to the pipe jacking construction method, the horizontal deviation and high-level deviation of a pipe jacking axis are effectively controlled, the stability of an excavation face can be effectively kept, the disturbance on the soil body around a pipe body is small, and the pipeline floating is avoided.

Owner:鸿昊建设集团有限公司

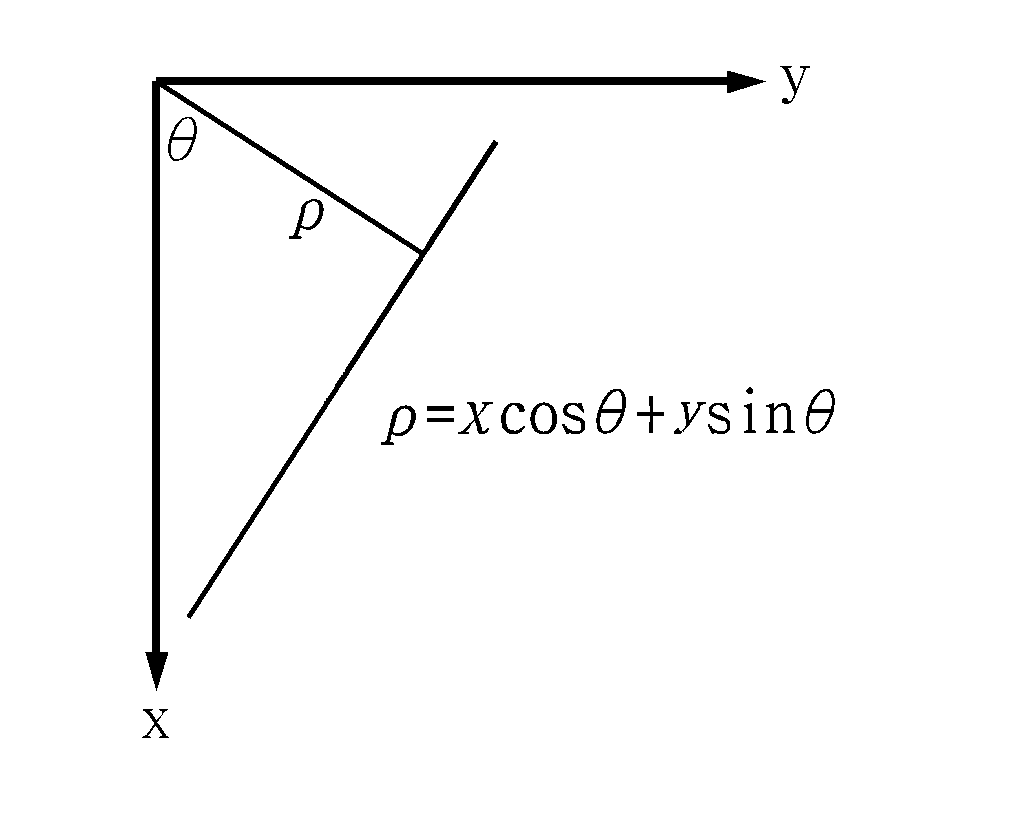

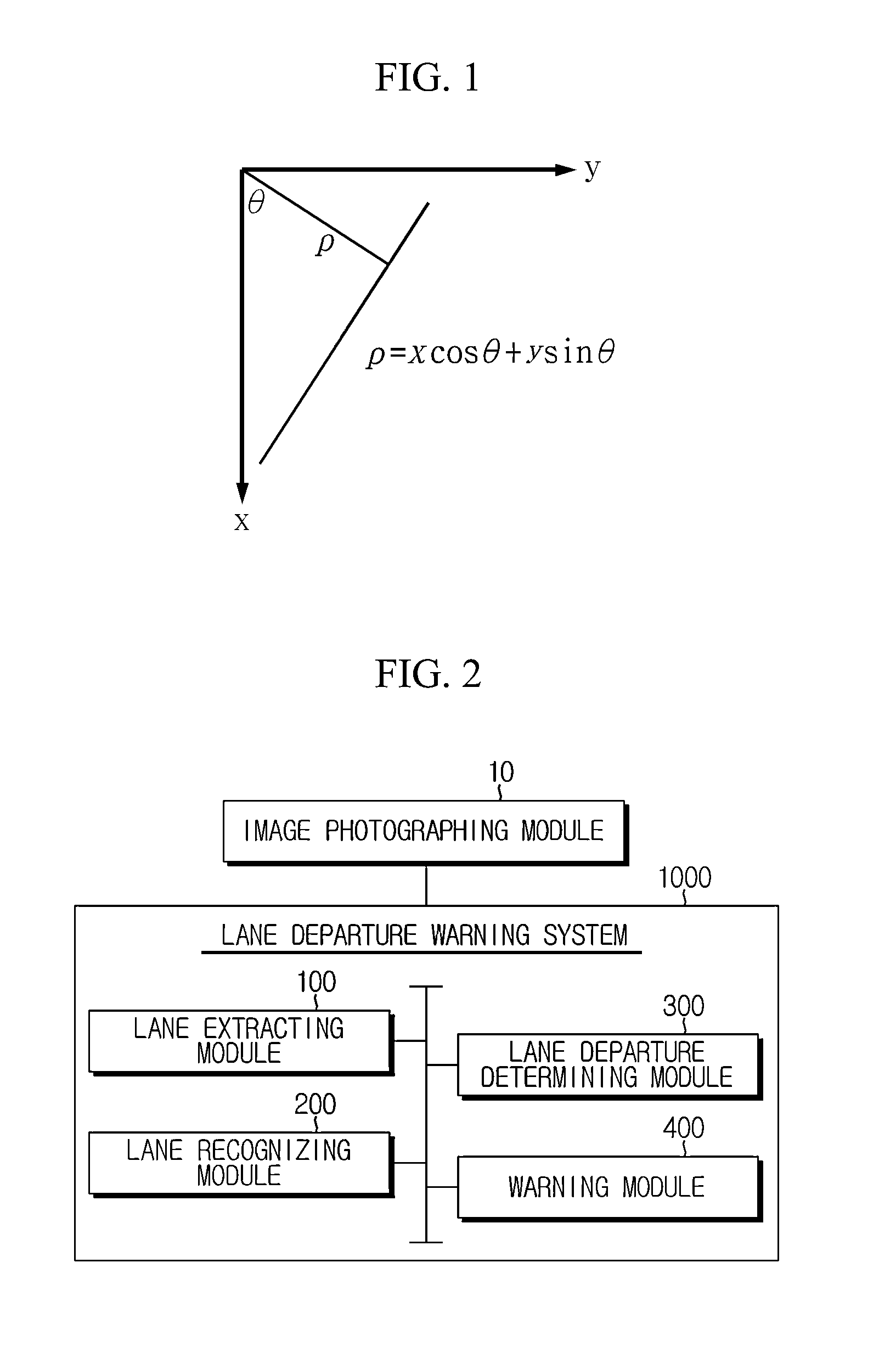

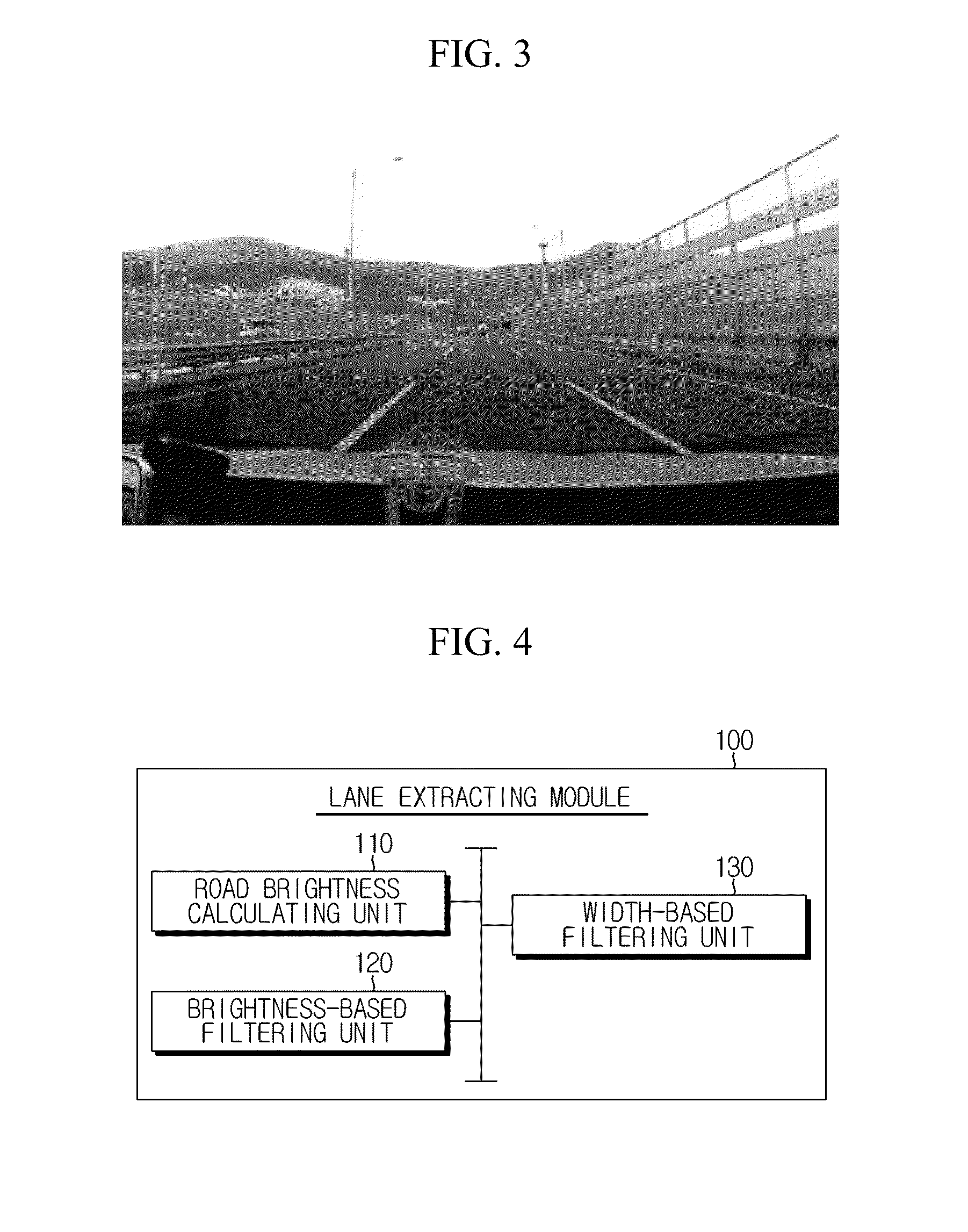

System and Method for Warning Lane Departure

InactiveUS20150248837A1Improve accuracyReduce the amount of calculationImage enhancementImage analysisComputer graphics (images)Computer vision

A system for warning lane departure includes a lane extracting module configured to receive a driving image of a vehicle from an image photographing module and generate an extracted lane image by removing an image other than a lane from the input image at least partially to extract a lane, a lane recognizing module configured to draw a linear functional formula corresponding to the extracted lane from the extracted lane image generated by the lane extracting module, and a lane departure determining module configured to determine lane departure of a vehicle by using the linear functional formula drawn by the lane recognizing module.

Owner:CORELOGIC

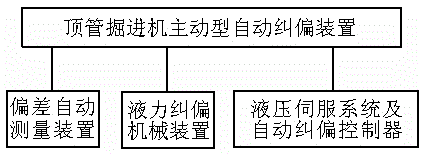

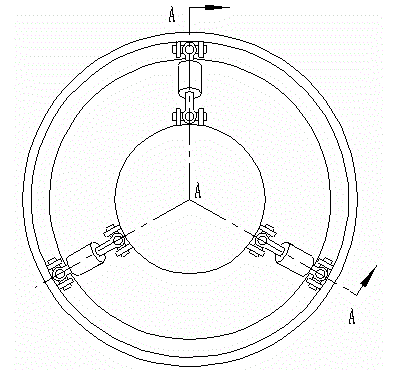

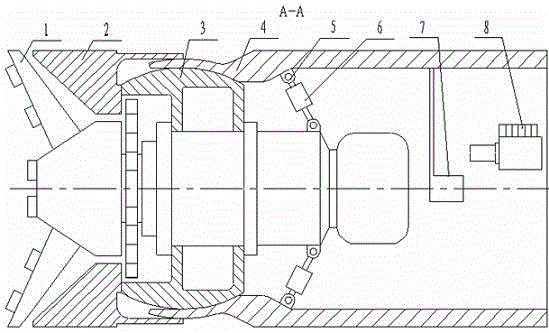

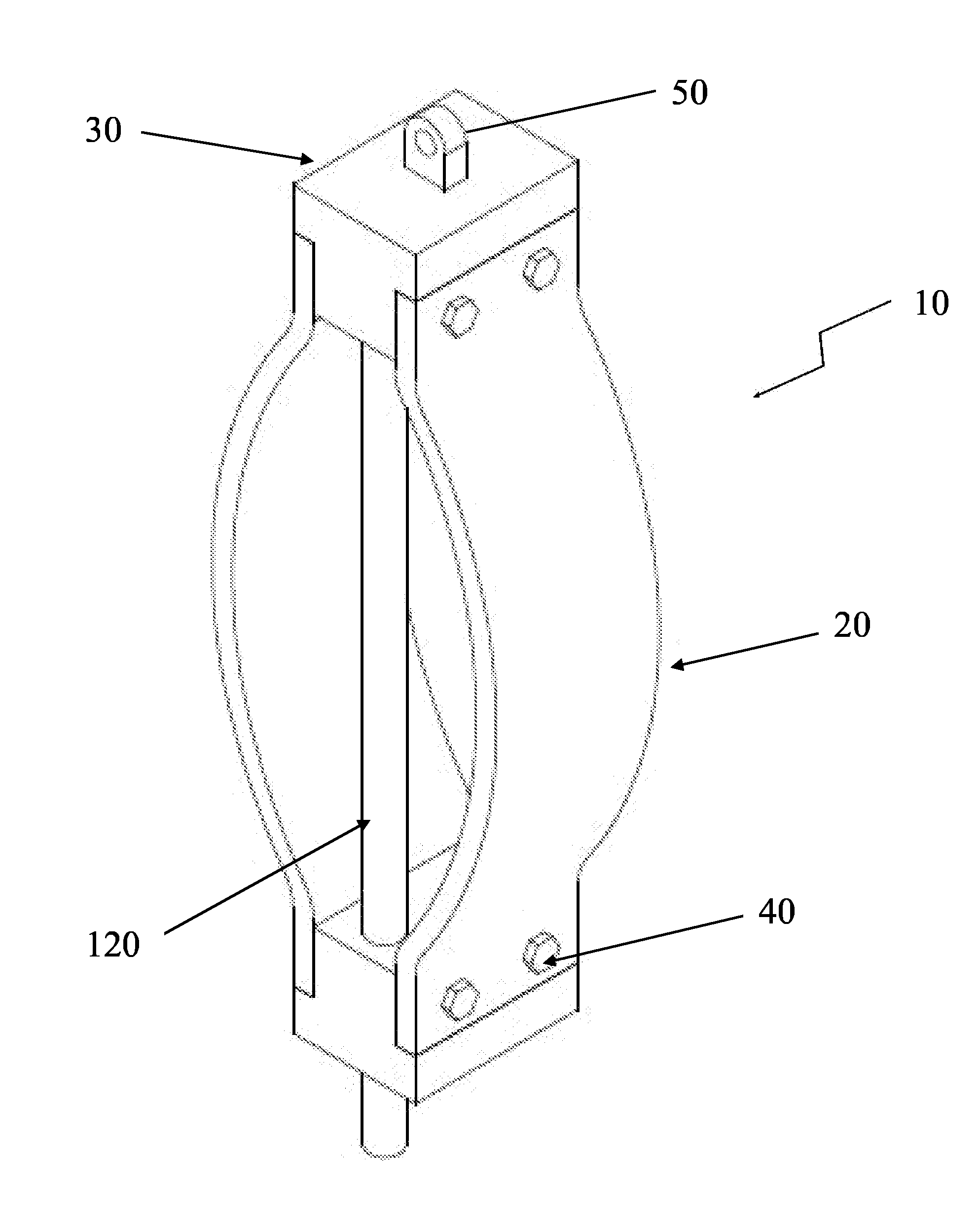

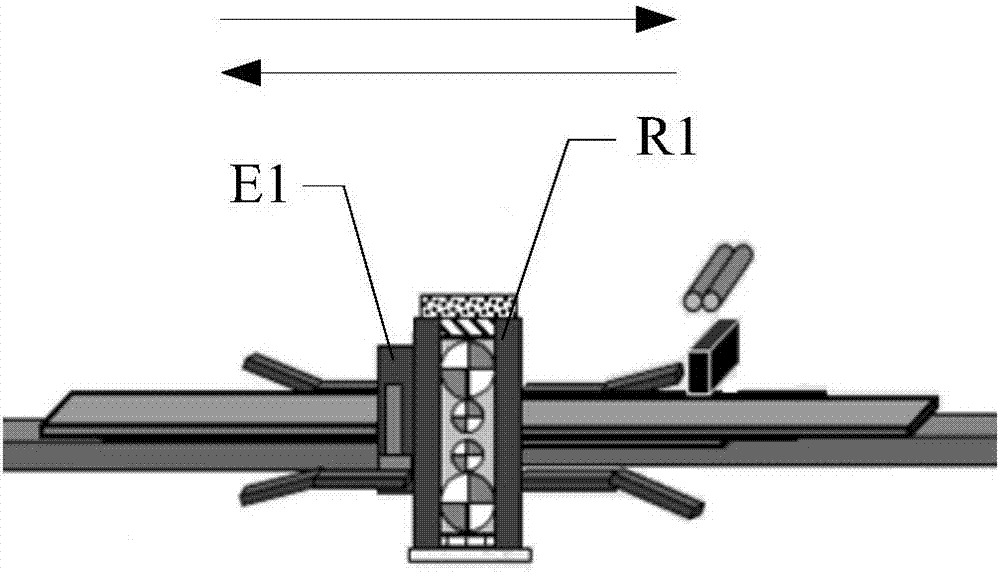

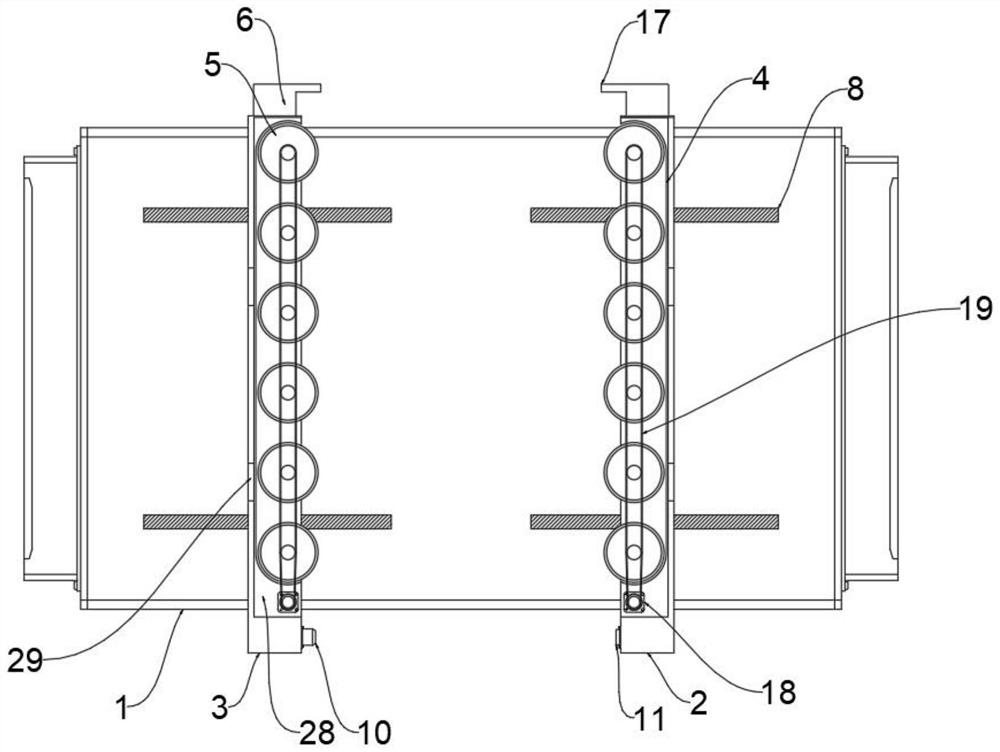

Active-type automatic deviation rectification device of pipe-jacking tunneling machine

InactiveCN102720503AGravitational moment minimizationReduce the numberTunnelsHydraulic cylinderOperating instruction

The present invention relates to a pipe-jacking tunnelling machine, in particular to an active-type automatic deviation rectification device of the pipe-jacking tunnelling machine. The device can realize automatic, highly efficient, safe and reliable deviation rectification according to deviations of proceeding direction of the pipe-jacking tunnelling machine with respect to a pipeline designed axis. Deviation rectification output force of a hydraulic cylinder is weak; the active-type automatic deviation rectification device of the pipe-jacking tunnelling machine is capable of being used for curve pipe-jacking tunneling; technical basis for automation pipe-jacking tunnelling of the pipe-jacking tunnelling machine is provided; and problems of unsuccessful deviation rectification and low deviation rectification efficiency caused by misjudgments of operators or operating instruction input errors which are caused by influences of factors such as ever-changing construction conditions, extremely high labor intensity and insufficiency in operating experience or negligence of operation personnel are avoided; and therefore, pipe-jacking tunnelling efficiency is raised and quality of pipe-jacking construction is improved.

Owner:JIANGSU UNIV

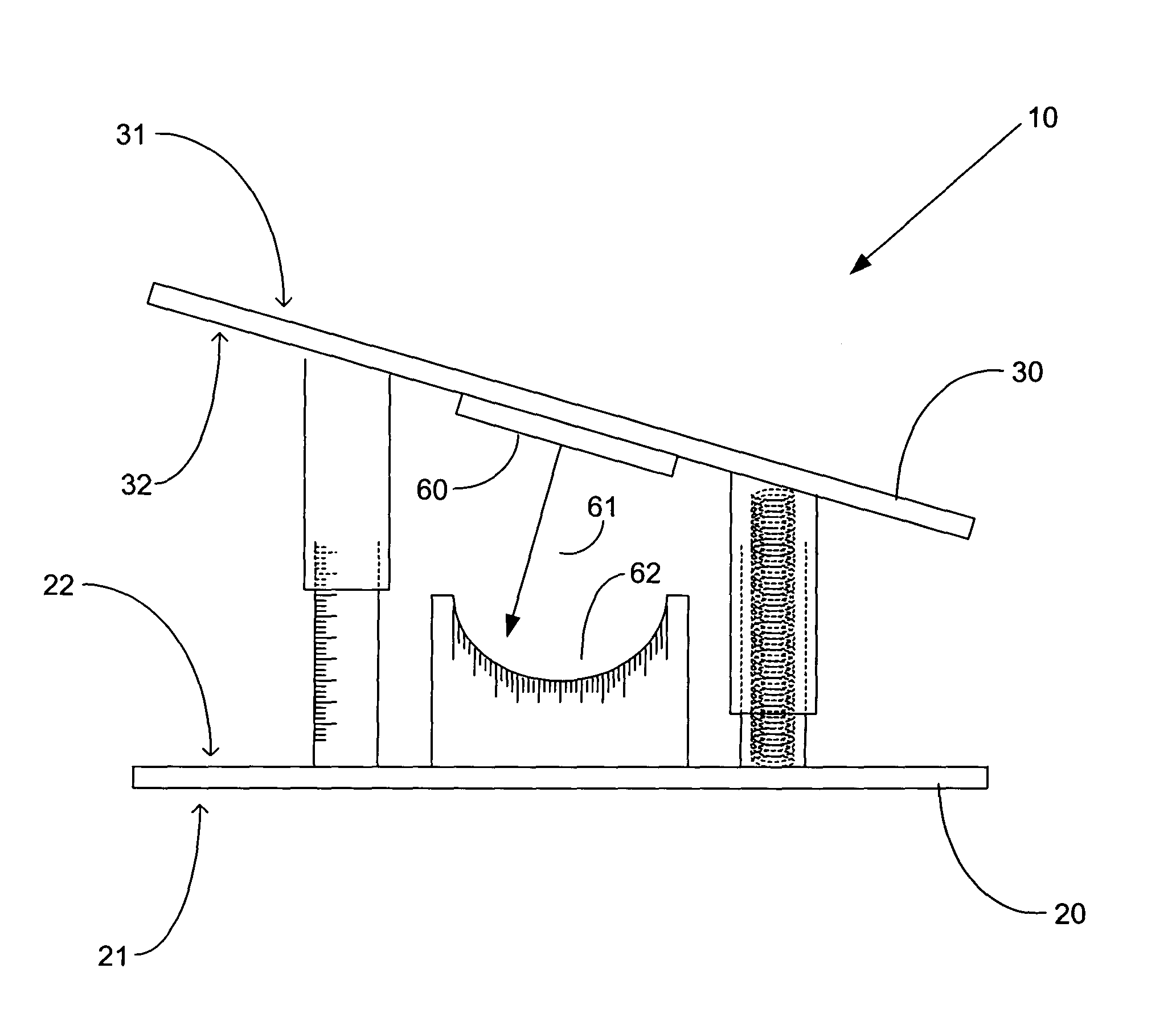

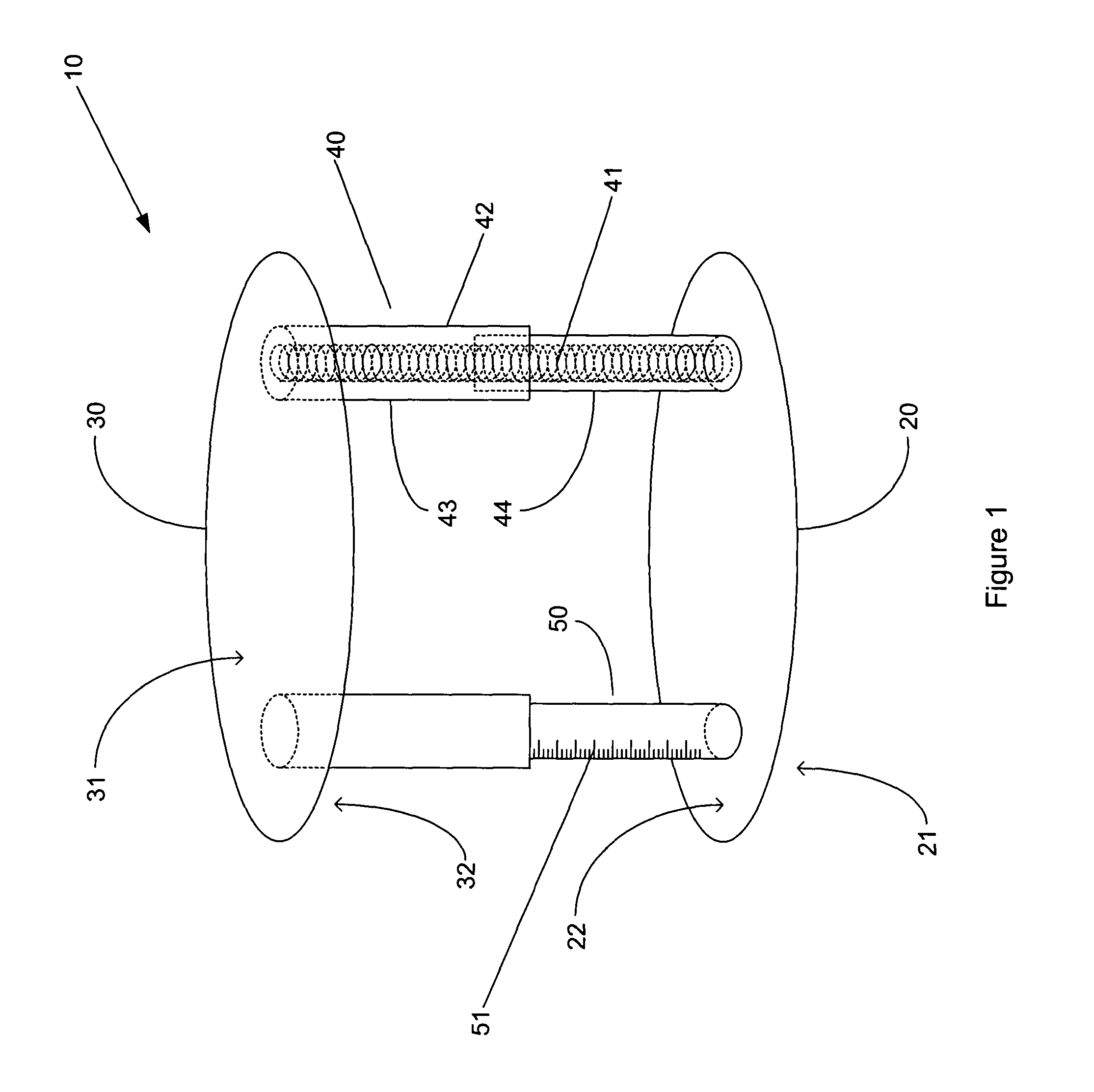

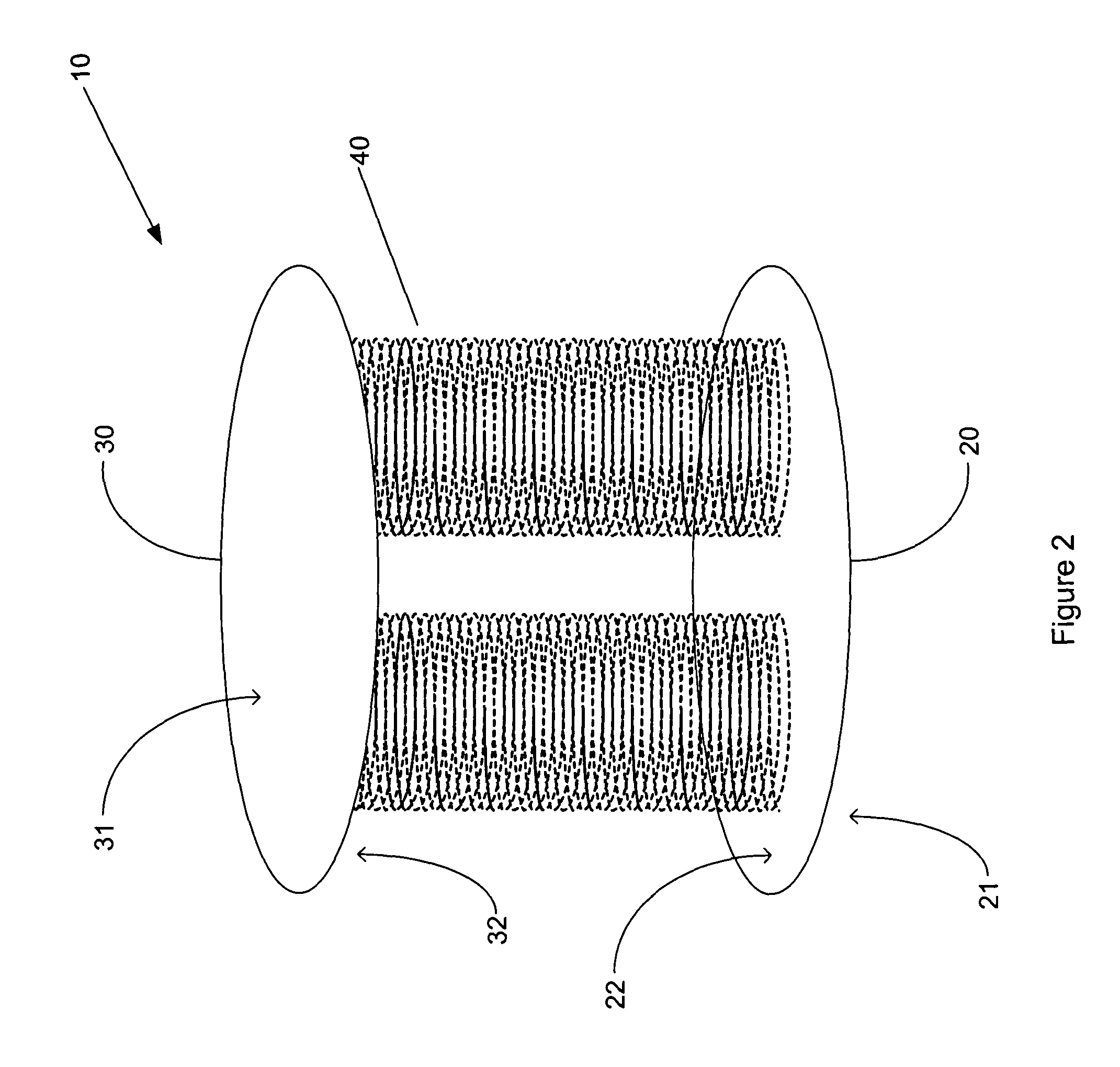

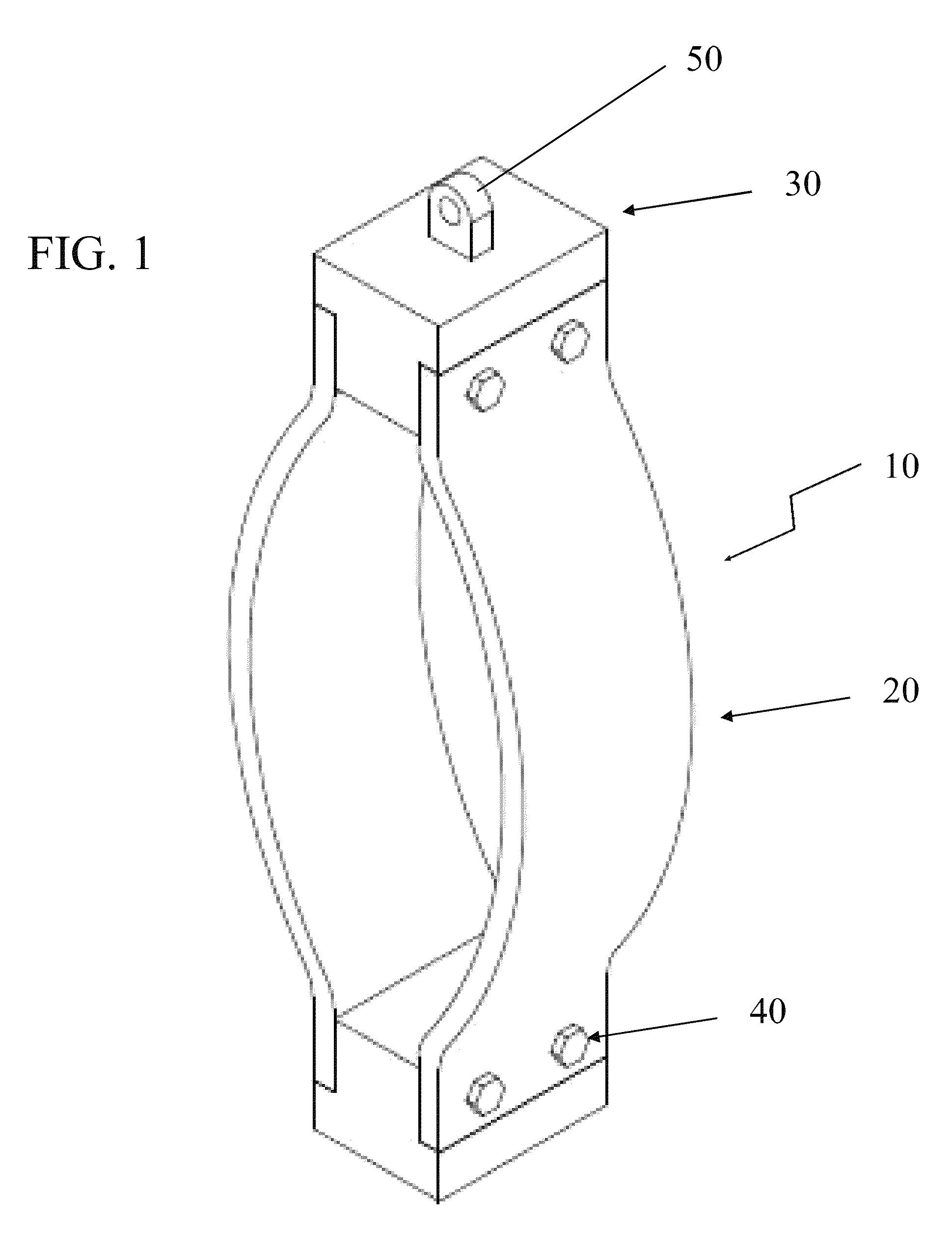

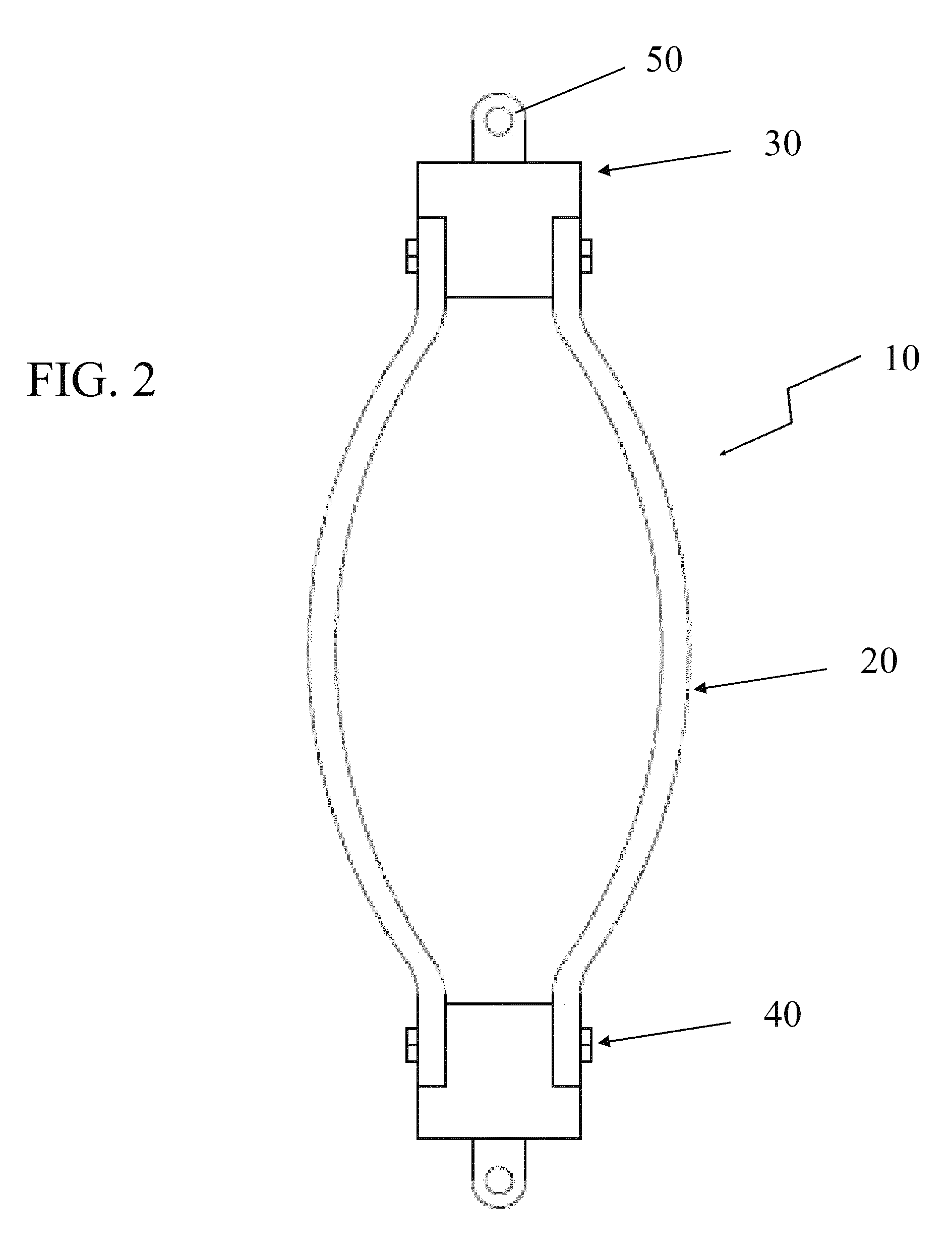

Shock Absorber with Compliant Members

InactiveUS20120146311A1Simple designFew movable jointPortable framesWheel based transmissionEngineeringShock absorber

The present invention provides a shock absorber with compliant members. Shock absorption is provided by the bending and rebound of curved, flexible arms. The deflection and the damping capabilities of the shock absorber are determined by the dimensions, curvature, and material modulus of elasticity of these compliant members. The shock absorber with compliant members technology may be applied to a bicycle front fork shock absorber and a rear shock absorber, both described herein. The benefits of a shock absorber with compliant members are that it is light-weight, it is simple in design, it has few movable joints, it can be designed to have precise flexion and damping characteristics, and it is resilient in harsh conditions.

Owner:WILLIAMS DAVID DELON

Dynamic spacer for total knee arthroplasty

InactiveUS7455647B2Easy to useEasy constructionSurgeryPerson identificationTotal hip arthroplastyPhysical medicine and rehabilitation

A dynamic spacer is provided for measuring flexion-extension gap during total knee arthroplasty. The dynamic spacer includes a first planar member having a lower tissue engaging surface, and a second planar member having an upper tissue engaging surface. A tensioner is disposed between the first planar member and the second planar member for applying a tensile force acting upon the first and second planar members. The tensioner is attached to the first and second planar members, such that the first planar member is held substantially parallel to the second planar member in the absence of compressive load. The dynamic spacer allows for accurately measuring flexion-extension gaps and angular deviation in flexion indicating the appropriateness of femoral rotation.

Owner:TARABICHI SAMIH

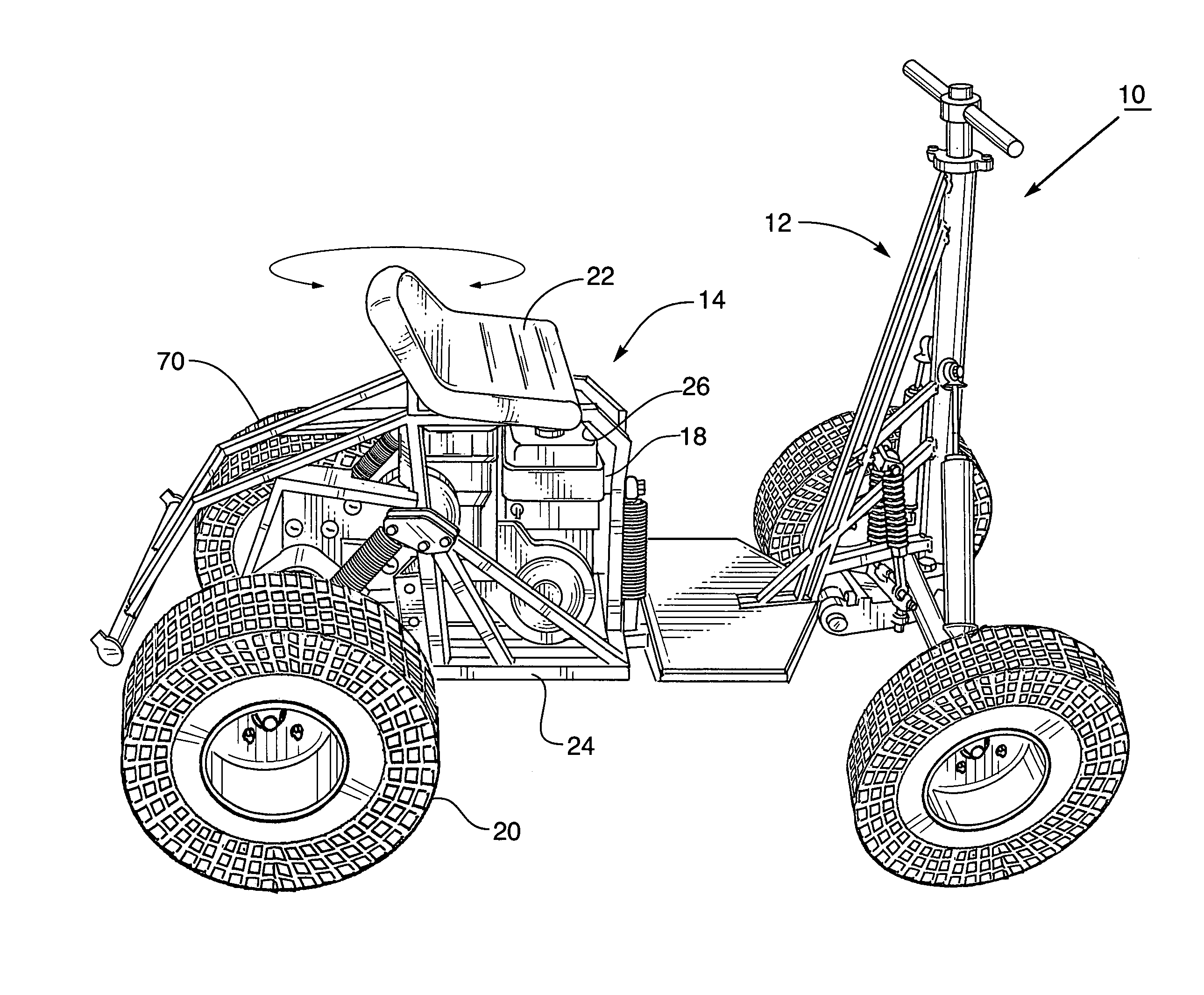

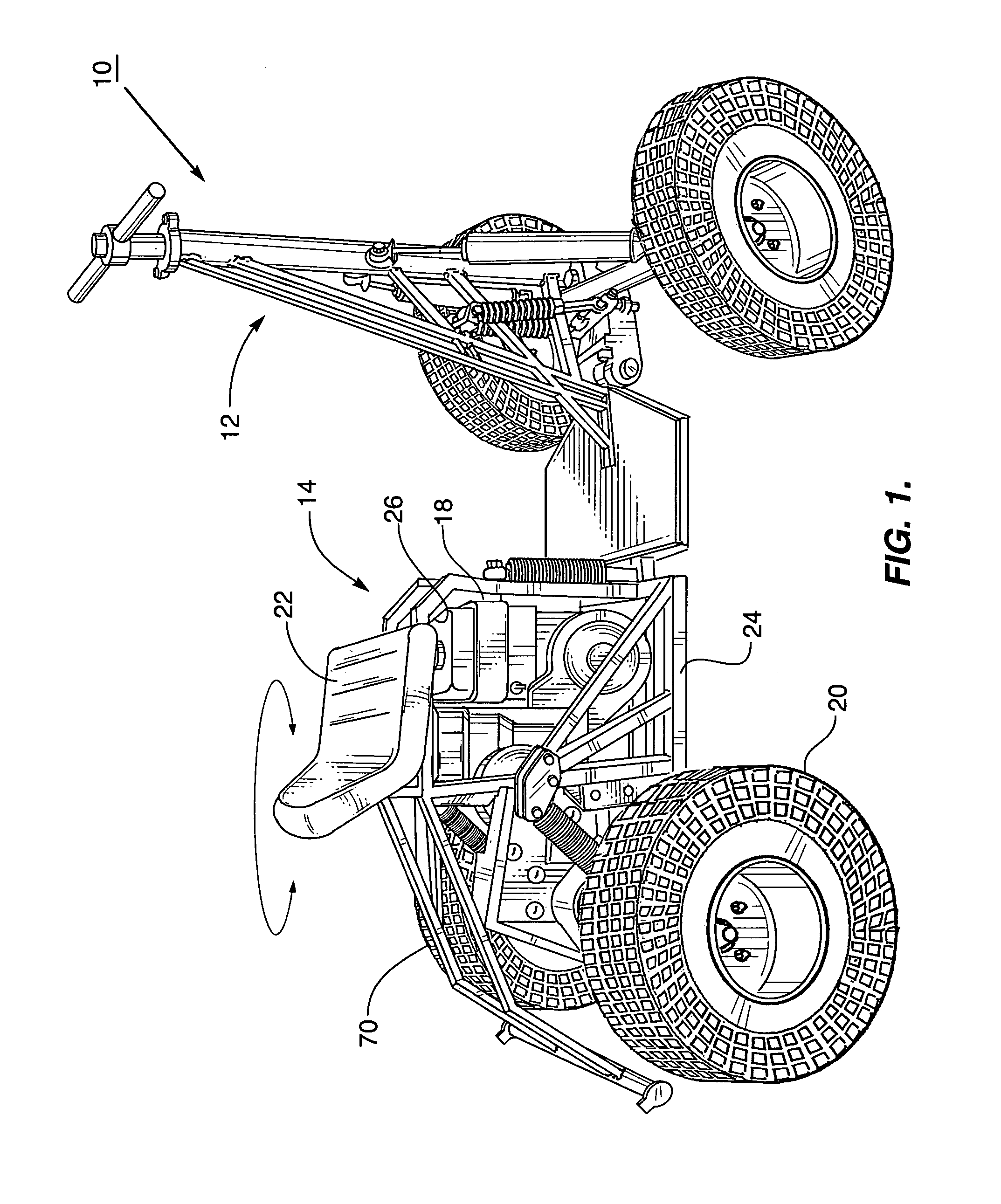

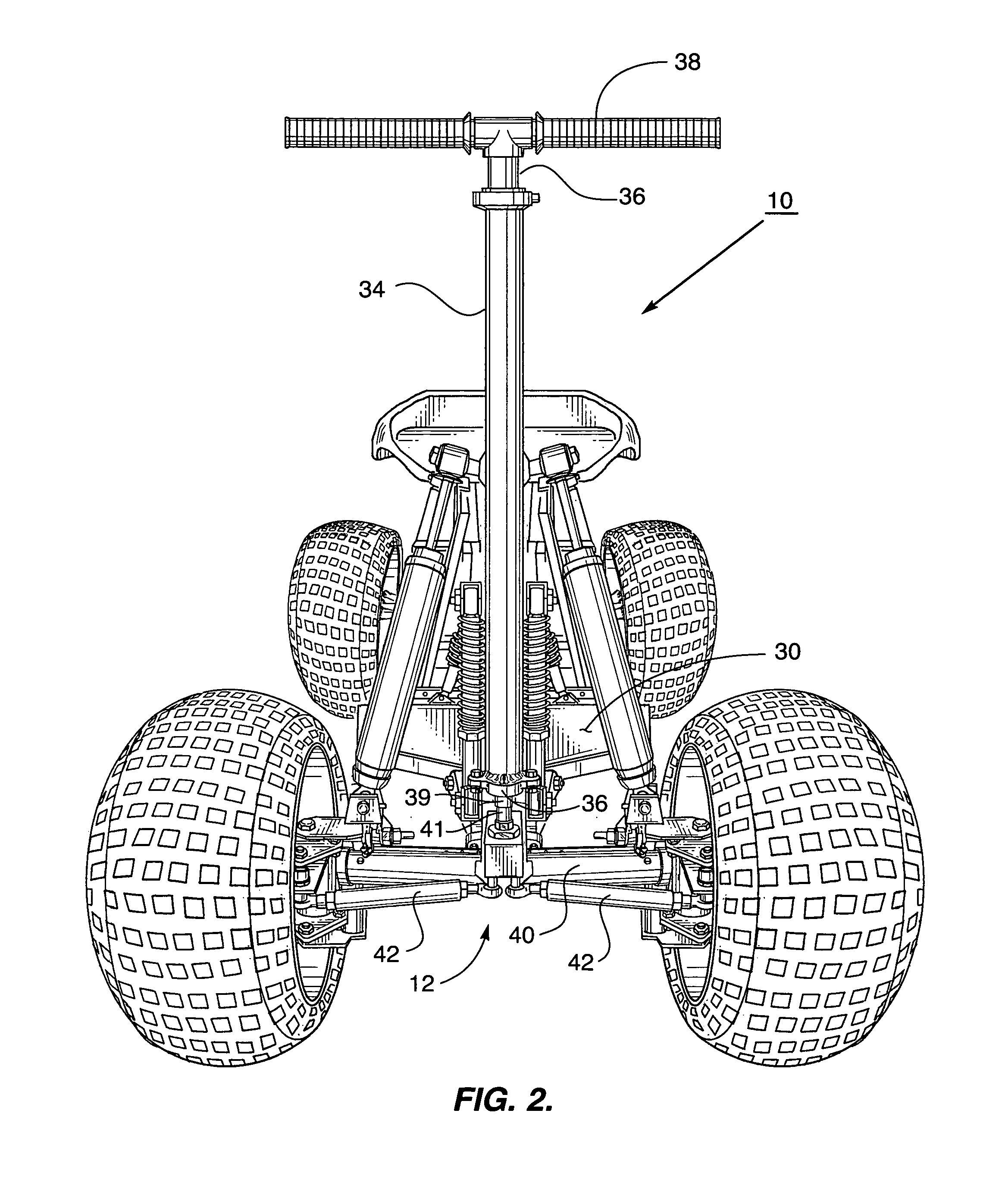

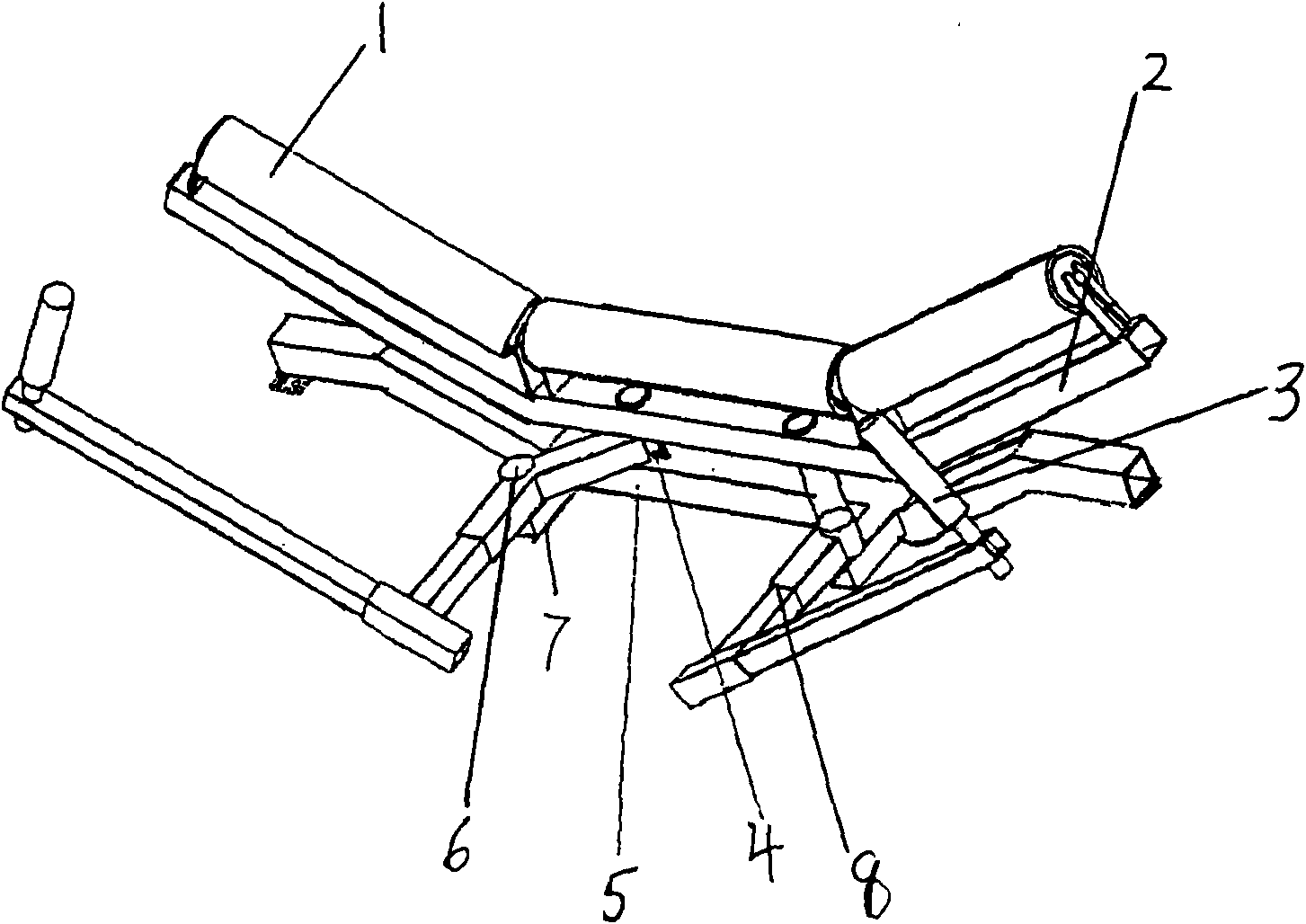

Four wheel off-road vehicle

ActiveUS7309081B1Flexible correctionCyclesVehicle body-frame connectionsSteering columnShock absorber

An off road vehicle comprises a front frame joined to a rear frame by a swivel rotates about a longitudinal axis. Springs are mounted to a horizontal planar structure and to the rear frame. The springs maintain the front frame to rear frame alignment but allows rotation between the front frame and the rear frame. A steering column extends upwardly and forwardly from a front axle having two wheels mounted laterally therefrom. The is connected to the two front wheels to turn in a desired direction. Front springs connect the axle to the steering column. A pair of shock absorbers connect the axle proximate to the wheels and the steering column. The pair of front springs and the pair of shock absorbers, in combination, maintain the front frame alignment to the axle but allow rotation between the front frame and the axle.

Owner:ZUHLSDORF DAVID A

Fisheye image correction method and device and computer equipment

ActiveCN107749050ASimple correctionFlexible correctionImage enhancementImage correctionComputer vision

The invention relates to a fisheye image correction method and device. The fisheye image correction method comprises the steps of acquiring an optical imaging center of an initial fisheye image to becorrected, and converting image coordinates of the initial fisheye image into image physical coordinates; performing correction on the initial fisheye image according to a preset mapping relation to obtain a longitudinal repair image of the initial fisheye image; performing a primary rotation operation on the longitudinal repair image to obtain a rotated image, wherein the rotating angle of the primary rotation operation is odd times of 90 degrees; performing correction of the rotated image according to the mapping relation to obtain a preliminary repair image of the initial fisheye image; andperforming a secondary rotation operation on the preliminary repair image to obtain a target corrected image of the initial fisheye image, wherein the secondary rotation operation and the primary rotation operation are identical in angle and opposite in direction. According to the invention, the reading and writing efficiency of a memory in the image correcting process is improved, and the correcting process is simple and flexible.

Owner:ZHUHAI JIELI TECH

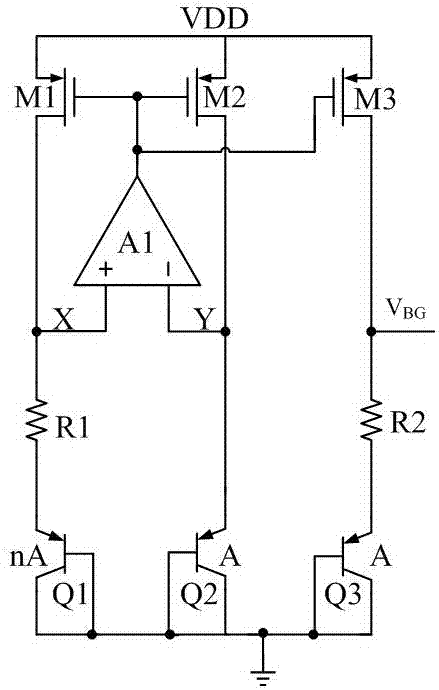

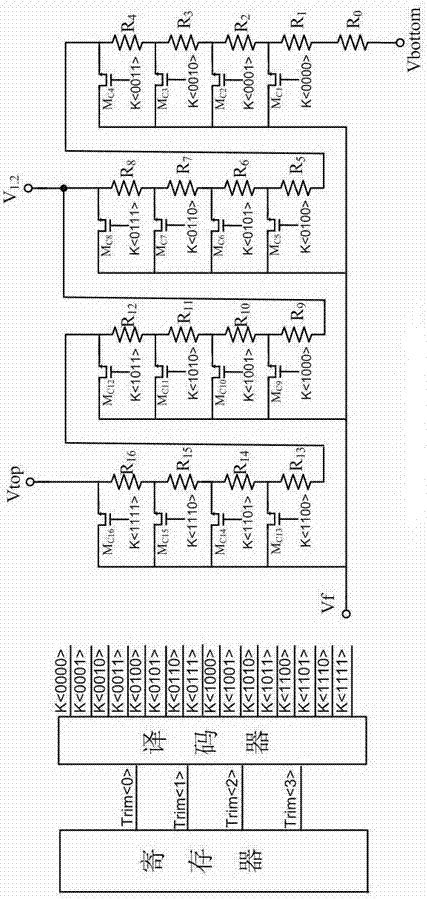

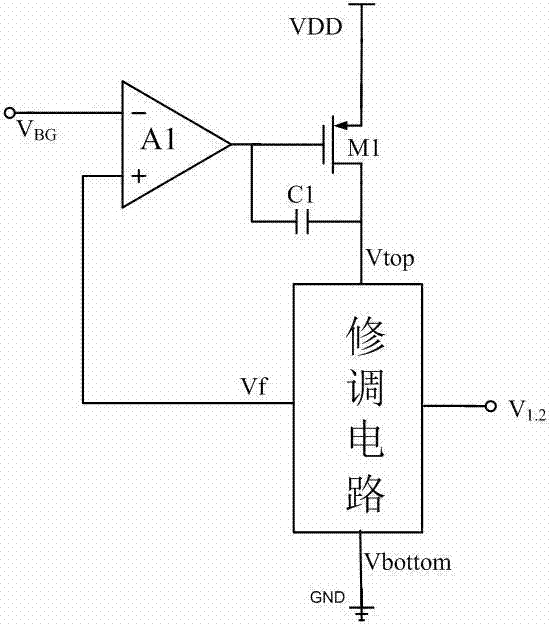

High-precision correcting circuit for band-gap reference voltage source

ActiveCN107479617AEliminate temperature characteristicsIncrease load carrying capacityEfficient power electronics conversionElectric variable regulationCapacitanceHemt circuits

The invention discloses a high-precision correcting circuit for a band-gap reference voltage source. The circuit includes an operational amplifier, a capacitor, a PMOS tube and a trimming circuit. The opposite phase end of the operational amplifier is connected with reference voltage VBG generated by the band-gap reference voltage source, the in-phase end of the operational amplifier is connected with a first terminal Vf of the trimming circuit, and the output end of the operational amplifier is connected with a first terminal of the capacitor and a grid electrode of the PMOS tube; a source electrode of the PMOS tube is connected with an electric source VDD, a drain electrode of the PMOS tube is connected with a second terminal of the capacitor and a second terminal Vtop of the trimming circuit, a third terminal V1.2 of the trimming circuit is output voltage after correcting, and a fourth terminal Vbottom of the trimming circuit is connected with the ground. According to the high-precision correcting circuit for the band-gap reference voltage source, a snubber circuit in the band-gap reference voltage source is integrated with the correcting circuit, errors caused by influences of process corners, imbalance, temperature and other factors in the reference voltage can be corrected, the influences caused by fine adjustment on the temperature features of the reference voltage can be eliminated and the load carrying capacity of the output voltage is improved. By adopting a digital trimming mode, the high-precision correcting circuit has the advantages of being flexible in correcting, high in precision, low in power consumption and small in area.

Owner:GUANGXI NORMAL UNIV

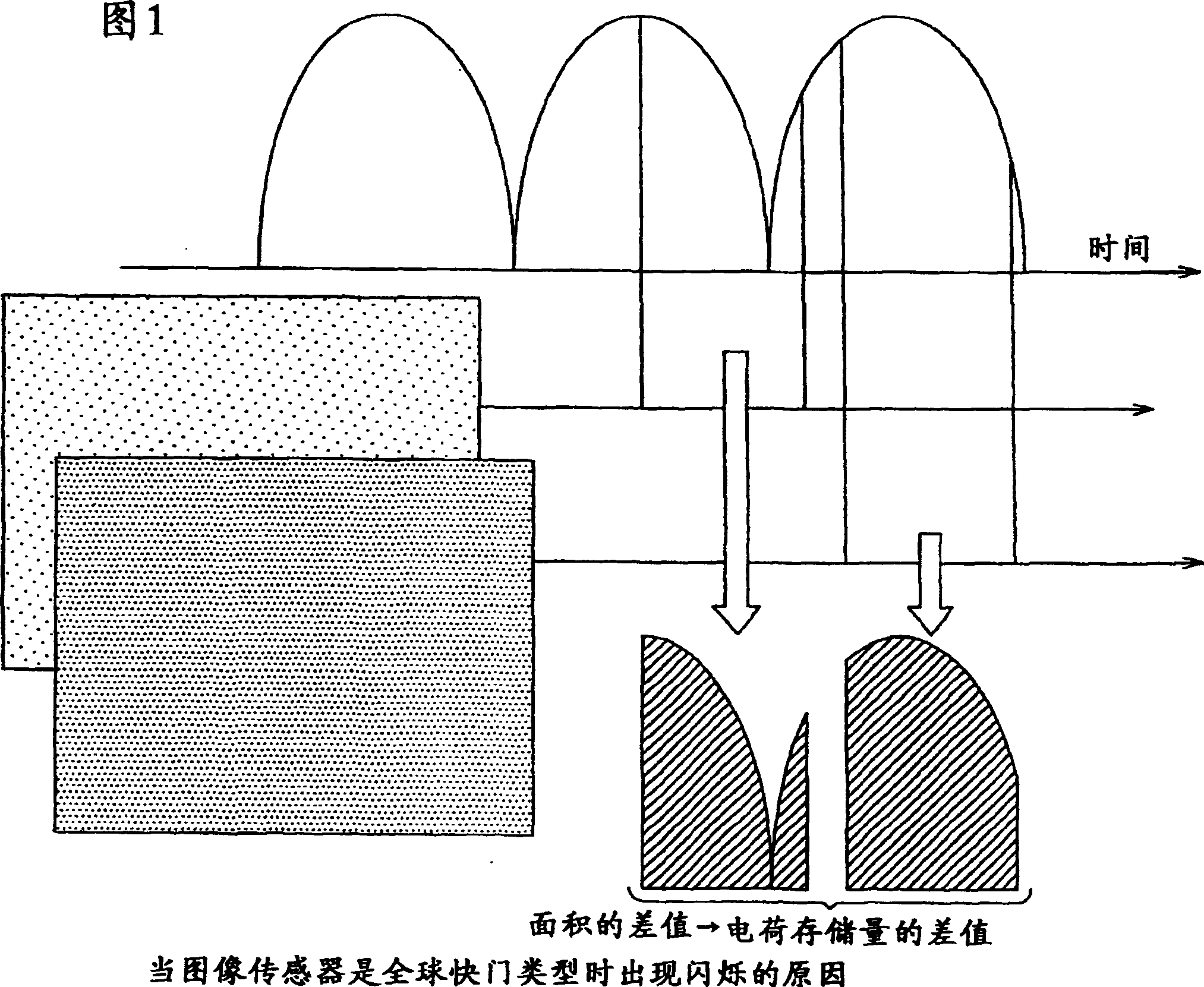

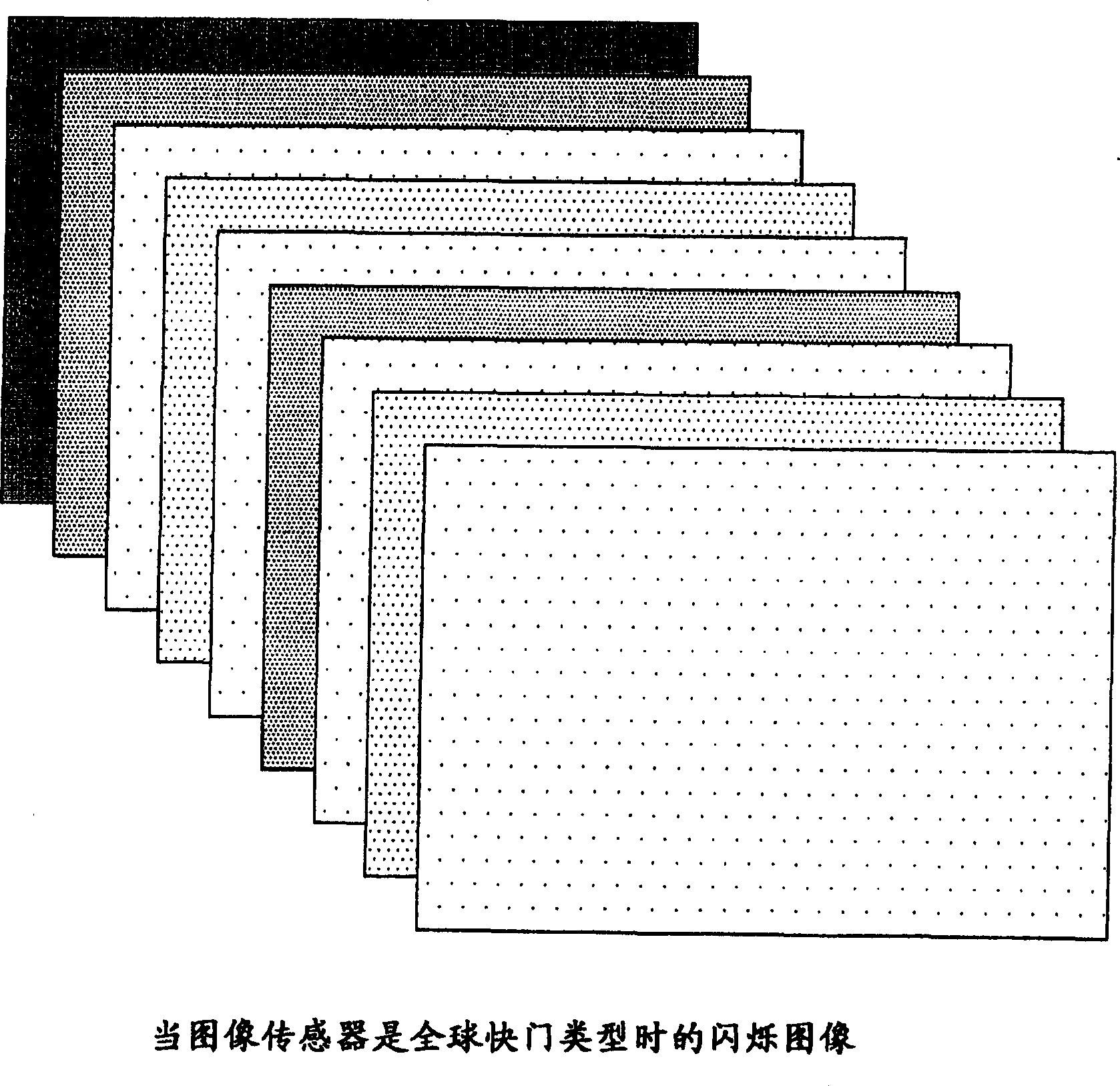

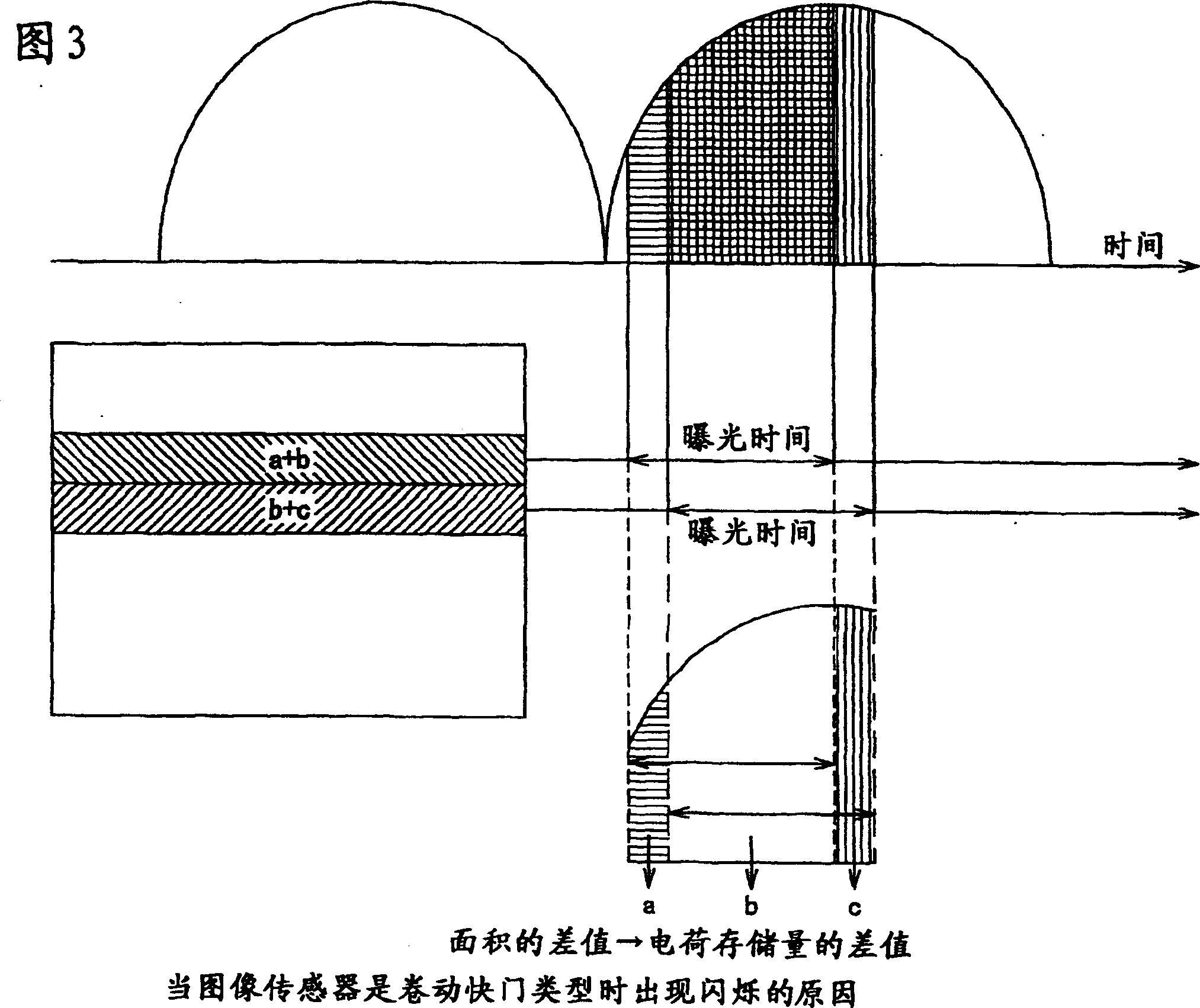

Flicker correction method and device, and imaging device

InactiveCN1856029AAccurate correctionCorrection values can be used for multiple flicker-accurateTelevision system detailsColor signal processing circuitsShutter speedImage signal

Even in case the shutter speed is high, a flicker can be corrected accurately. The present invention provides a flicker correction method in which a flicker is corrected by predicting, from a present input frame image, a flicker component in an image of a next frame and adding a correction value to the next frame image on the basis of the predicted flicker component, the method including the steps of holding a plurality of flicker data, calculating the correction value by combining a plurality of flicker data together at a ratio set correspondingly to a shutter speed and frame rate, and adding the calculated correction value to the input image signal.

Owner:SONY GRP CORP

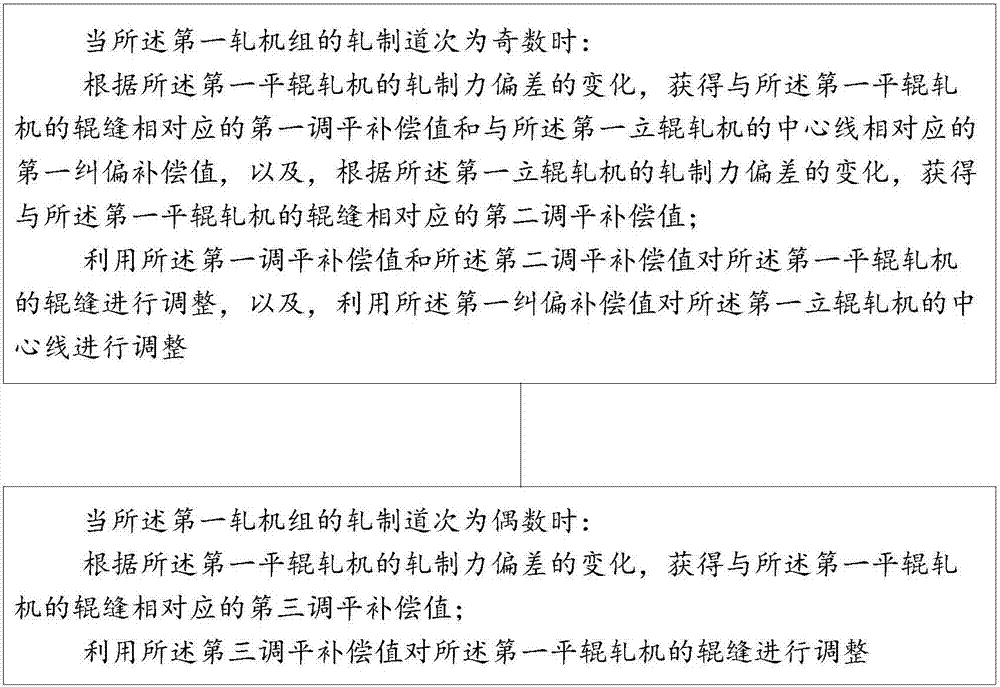

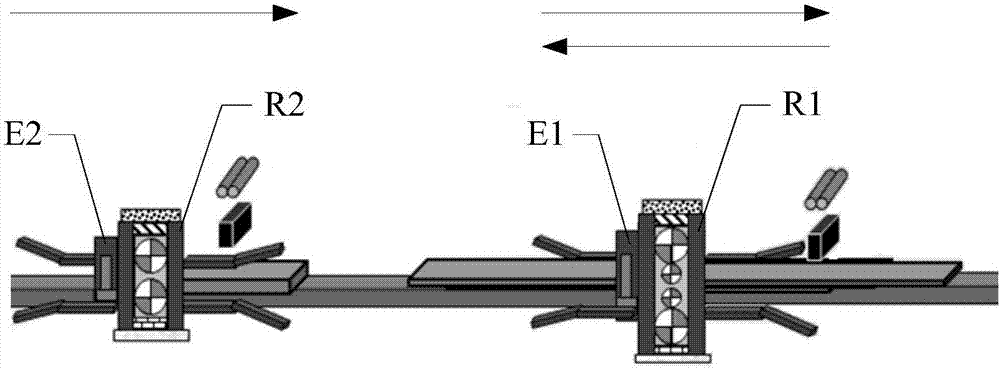

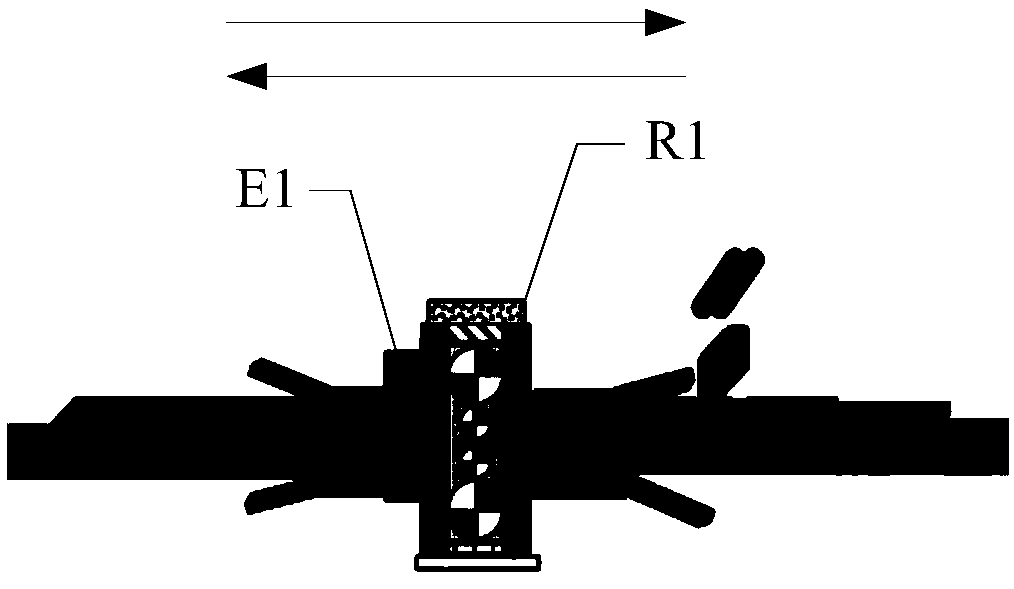

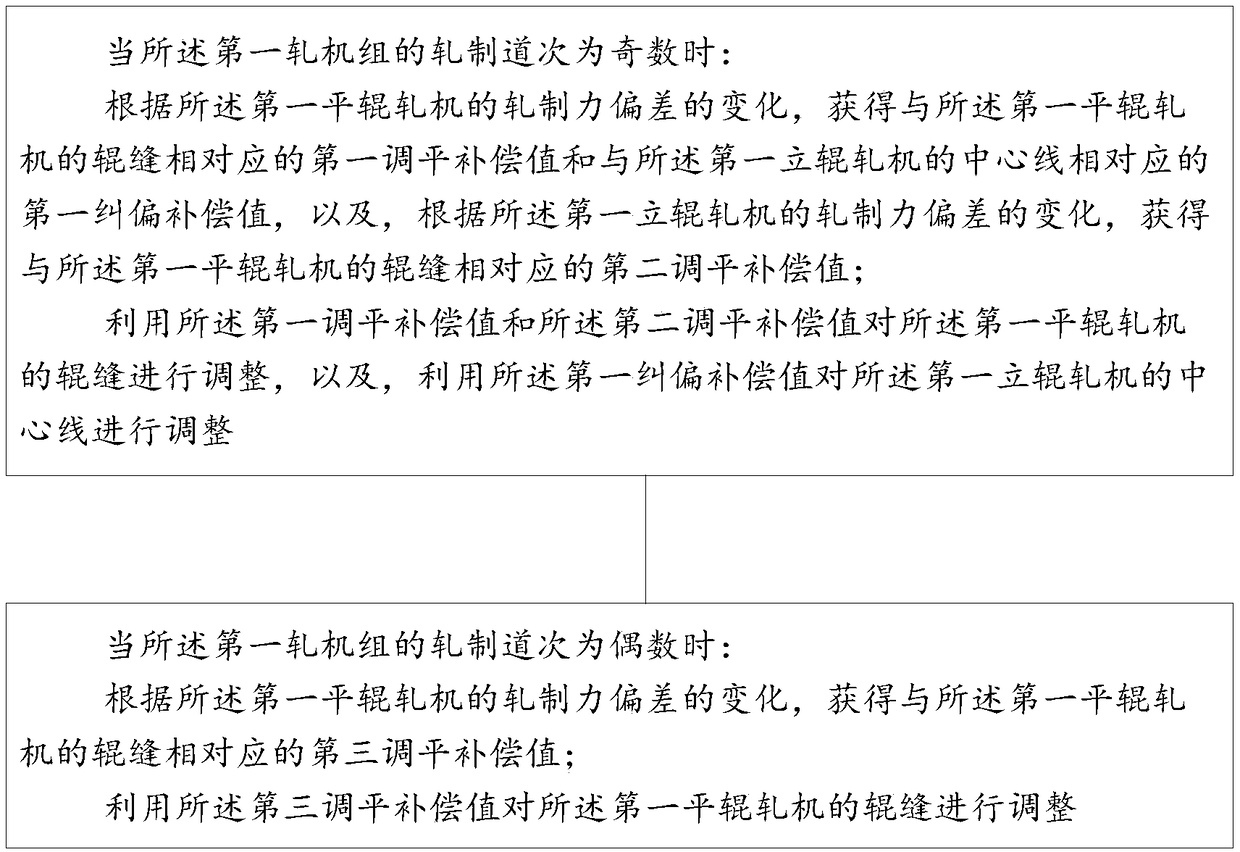

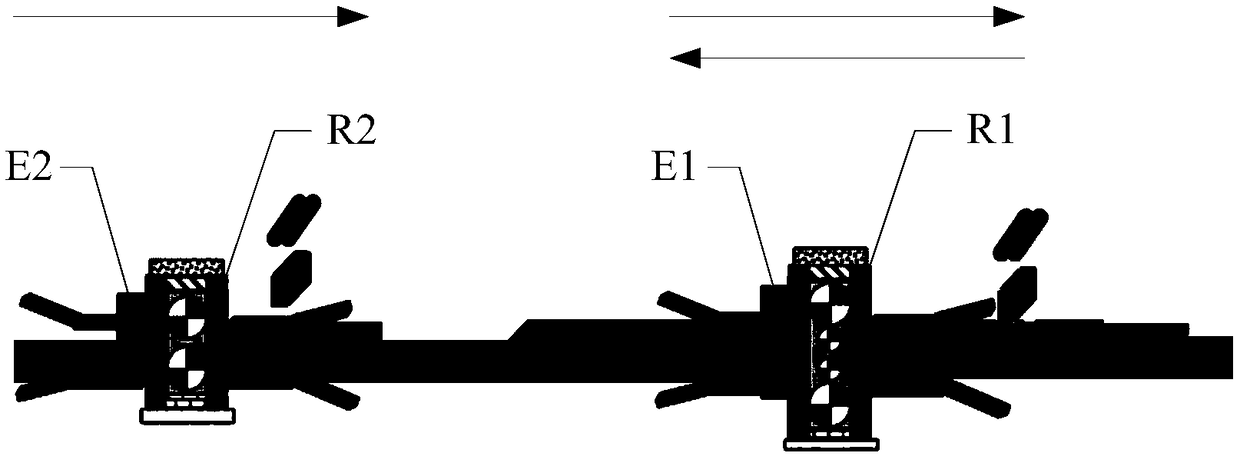

Rolling mill unit deviation rectification control method and device

ActiveCN107008759ARealize cross three-dimensional deviation correctionEasy to shapeProfile control deviceStrip steelControl theory

The invention relates to the technical field of hot continuous rough rolling, in particular to a rolling mill unit deviation rectification control method and device. The rolling mill unit deviation rectification control method comprises the steps that for a first rolling mill unit comprising a first vertical rolling mill and a first horizontal rolling mill, in the process of reciprocating rolling of band steel through the first rolling mill unit, at an odd rolling pass, according to the change of rolling force deviation of the first horizontal rolling mill, a first levelling compensation value is obtained, a roll gap of the first horizontal rolling mill is adjusted, a first deviation rectification compensation value is obtained, the center line of the first vertical rolling mill is adjusted, according to the change of the rolling force deviation of the first vertical rolling mill, a second levelling compensation value is obtained, and the roll gap of the first horizontal rolling mill is adjusted; during an even rolling pass, according to the change of the rolling force deviation of the first horizontal rolling mill, a third levelling compensation value is obtained, and the roll gap of the first horizontal rolling mill is adjusted. By the adoption of the rolling mill unit deviation rectification control method and device, crossing stereoscopic deviation is conducted on the band steel in the longitudinal direction and the transverse direction, and the deviation rectification accuracy is improved.

Owner:BEIJING SHOUGANG CO LTD

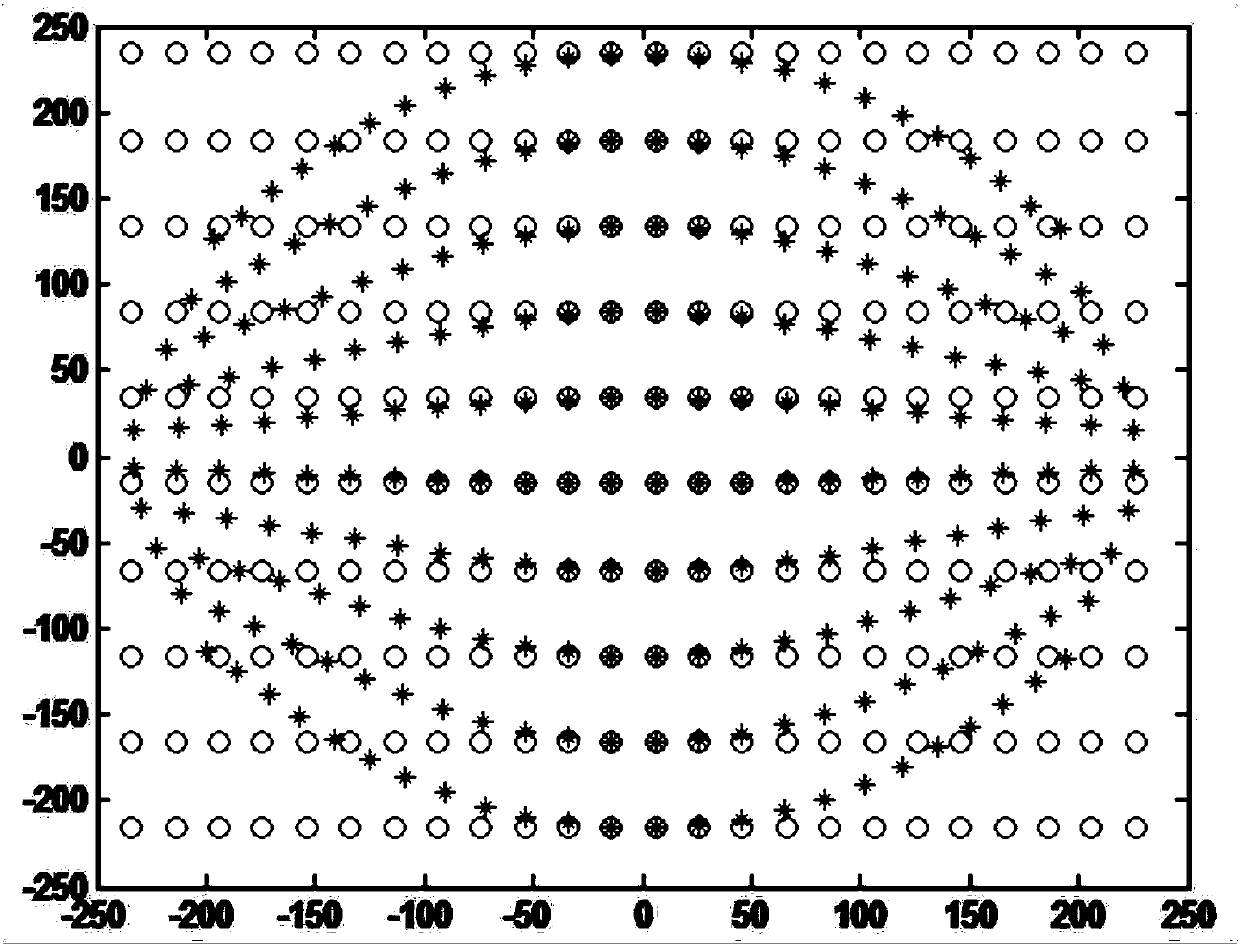

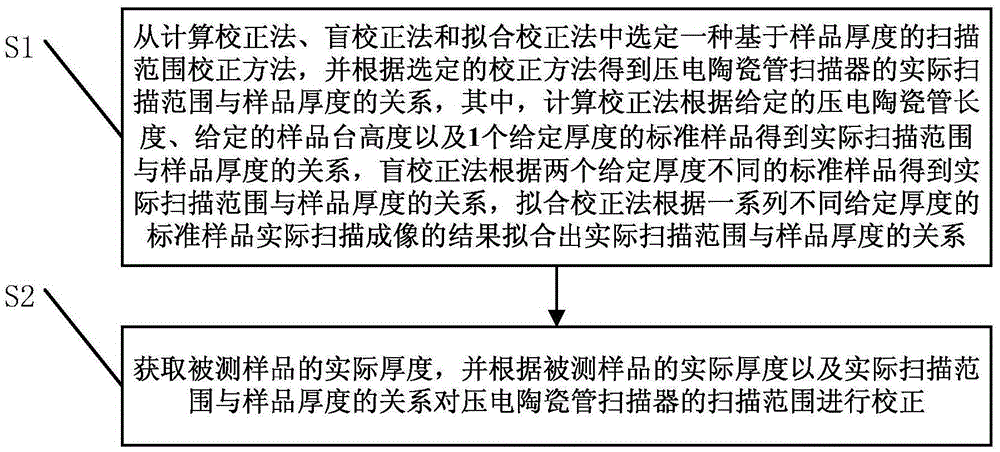

Method and system for correcting scanning range of piezoelectric ceramic tube scanner

ActiveCN105675922AEffective correctionFlexible correctionScanning probe techniquesTest sampleCorrection method

The invention discloses a method and system for correcting the scanning range of a piezoelectric ceramic tube scanner, and the method comprises the steps: selecting one scanning range correction method based on sample thickness from a calculation correction method, a blind correction method and a fitting correction method, and obtaining the relation between the actual scanning range of the piezoelectric ceramic tube scanner and the sample thickness; obtaining the actual thickness of a tested sample, and correcting the scanning range of the piezoelectric ceramic tube scanner according to the actual thickness of the tested sample and the relation between the actual scanning range and the sample thickness. According to the invention, the calculation correction method, the blind correction method and the fitting correction method are added, and the method can obtain the relation between the actual scanning range and the sample thickness, corrects the scanning range according to the actual thickness of the sample, effectively corrects the change, caused by the change of the sample thickness, of the scanning range of the piezoelectric ceramic tube scanner, and is more accurate and reliable. The method can be widely used in the technical field of microscopes.

Owner:BEING NANO INSTR LTD

Shock absorber with compliant members

InactiveUS8973937B2Simple designFew movable jointPortable framesWheel based transmissionEngineeringShock absorber

The present invention provides a shock absorber with compliant members. Shock absorption is provided by the bending and rebound of curved, flexible arms. The deflection and the damping capabilities of the shock absorber are determined by the dimensions, curvature, and material modulus of elasticity of these compliant members. The shock absorber with compliant members technology may be applied to a bicycle front fork shock absorber and a rear shock absorber, both described herein. The benefits of a shock absorber with compliant members are that it is light-weight, it is simple in design, it has few movable joints, it can be designed to have precise flexion and damping characteristics, and it is resilient in harsh conditions.

Owner:WILLIAMS DAVID DELON

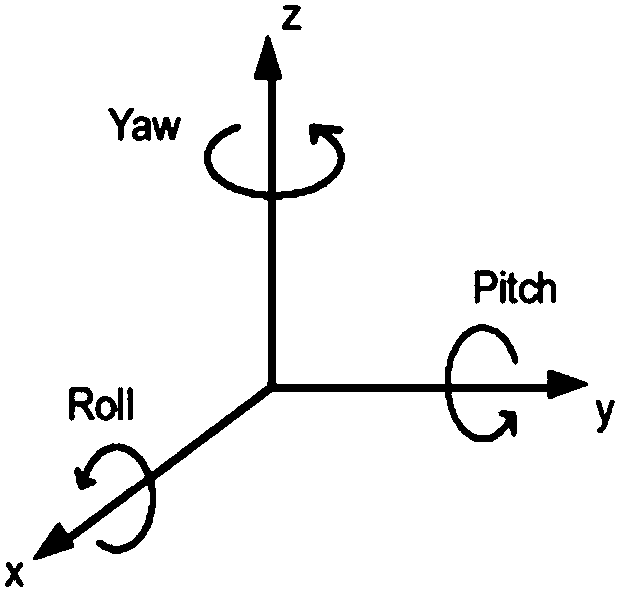

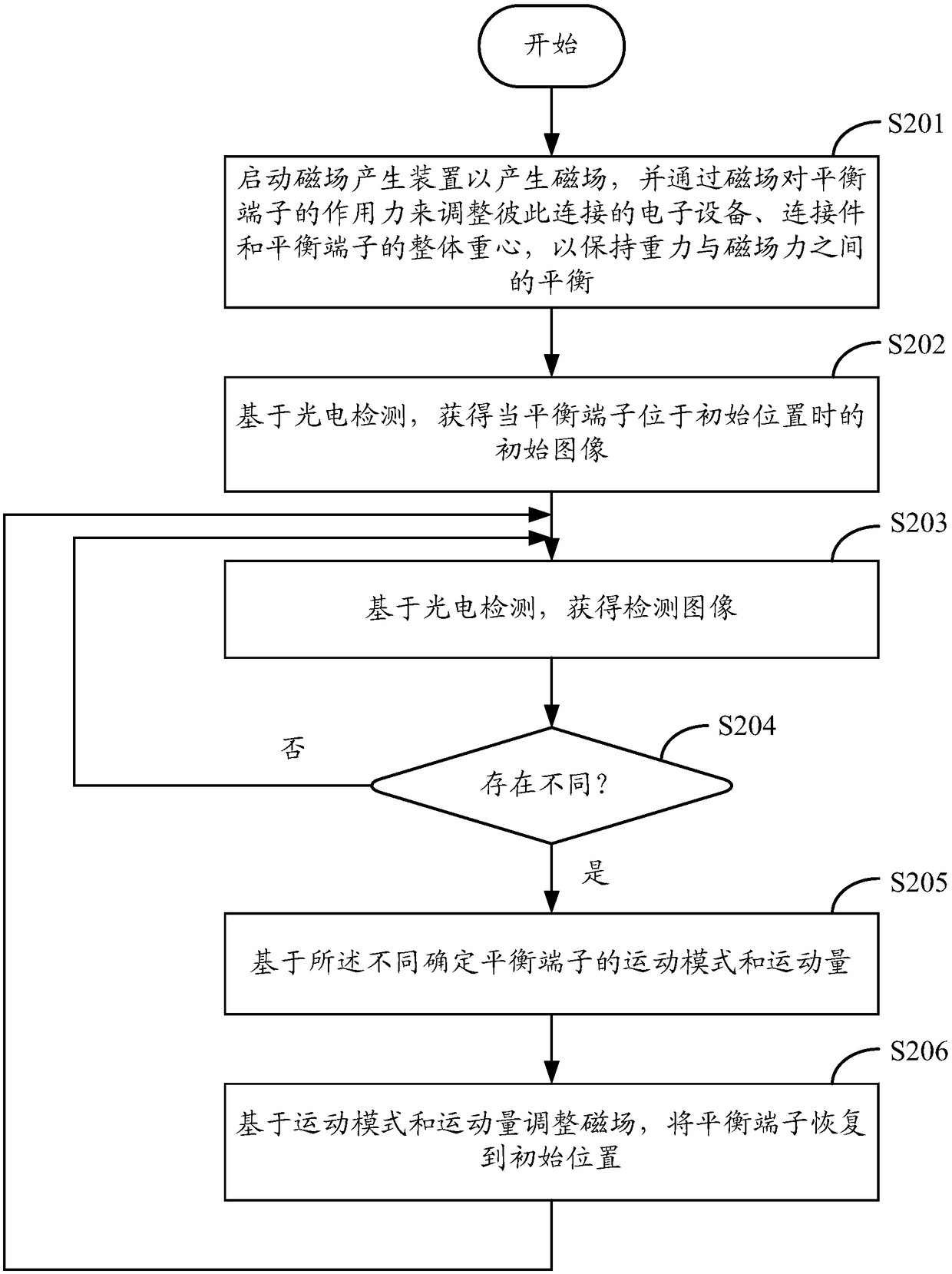

Jitter correction method and jitter correction apparatus

ActiveCN109040573AHigh precisionFlexible Jitter CorrectionTelevision system detailsColor television detailsCorrection methodMotion Mode

A jitter correction method and a jitter correction apparatus are disclosed. The jitter correction method comprises: after the electronic device is connected to the jitter correction device, starting the magnetic field generating means to generate a magnetic field, and adjusting the integral center of gravity of the electronic device, the connecting member and the balance terminal connected to eachother by the force of the magnetic field on the balance terminal to maintain a balance between gravity and magnetic field force; obtaining an initial image when the balance terminal is at an initialposition and a detection image thereafter based on photoelectric detection; determining a motion mode and a motion amount of the balance terminal based on the difference when the initial image is different from the detection image; and adjusting a magnetic field based on the motion mode and the motion amount to restore the balance terminal to an initial position.

Owner:RICOH KK

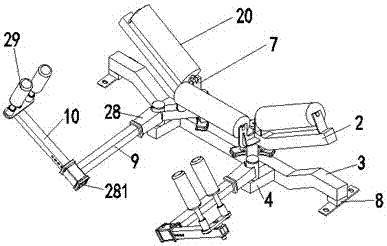

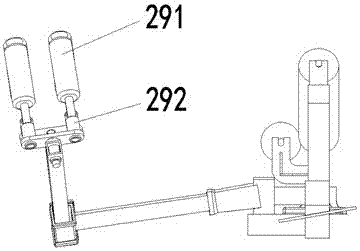

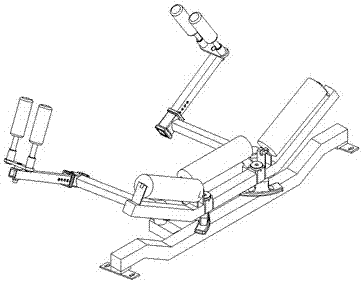

Automatic correction device of heavy-duty conveyor belt

The invention discloses an automatic correction device of a heavy-duty conveyor belt, comprising a beam and a carrier roller bracket, wherein the carrier roller bracket is provided with a carrier roller, a supporting wheel is respectively and fixedly arranged on the left side and the right side of the lower end of the carrier roller bracket, and the supporting wheels are arranged on the beam; oneside of the beam is fixedly connected with an extended connecting rod; the same side of the two supporting rods is respectively provided with a crankarm in a rotating mode; the middle of the crankarmis connected with the connecting rod in a rotating mode; and the outer end of the crankarm is provided with a vertical roll. The invention has the advantages of simple structure, small volume, flexible correction, high efficiency, favourable stability, safety, reliability, low cost, convenient maintenance and long service life, not only can be used under the harsh conditions of dustiness, moist, high temperature and the like, but also can be used in dangerous places of inflammable places and explosive places.

Owner:淮北高罗输送装备有限公司

Method for adjusting plane reference of parts

InactiveCN102873589AAccurate correctionQuick correctionMeasurement/indication equipmentsWorkbenchEnvironmental geology

The invention discloses a method for adjusting a plane reference of parts. The method comprises the following steps of: putting a plane adjusting jig on a workbench; putting workpieces on the plane adjusting jig; measuring the parallelism of the workpieces by using a dial indicator; and adjusting the height of the plane adjusting jig. By the method, the reference plane of the workpieces is corrected accurately, quickly and flexibly.

Owner:大连艺才精密模具有限公司

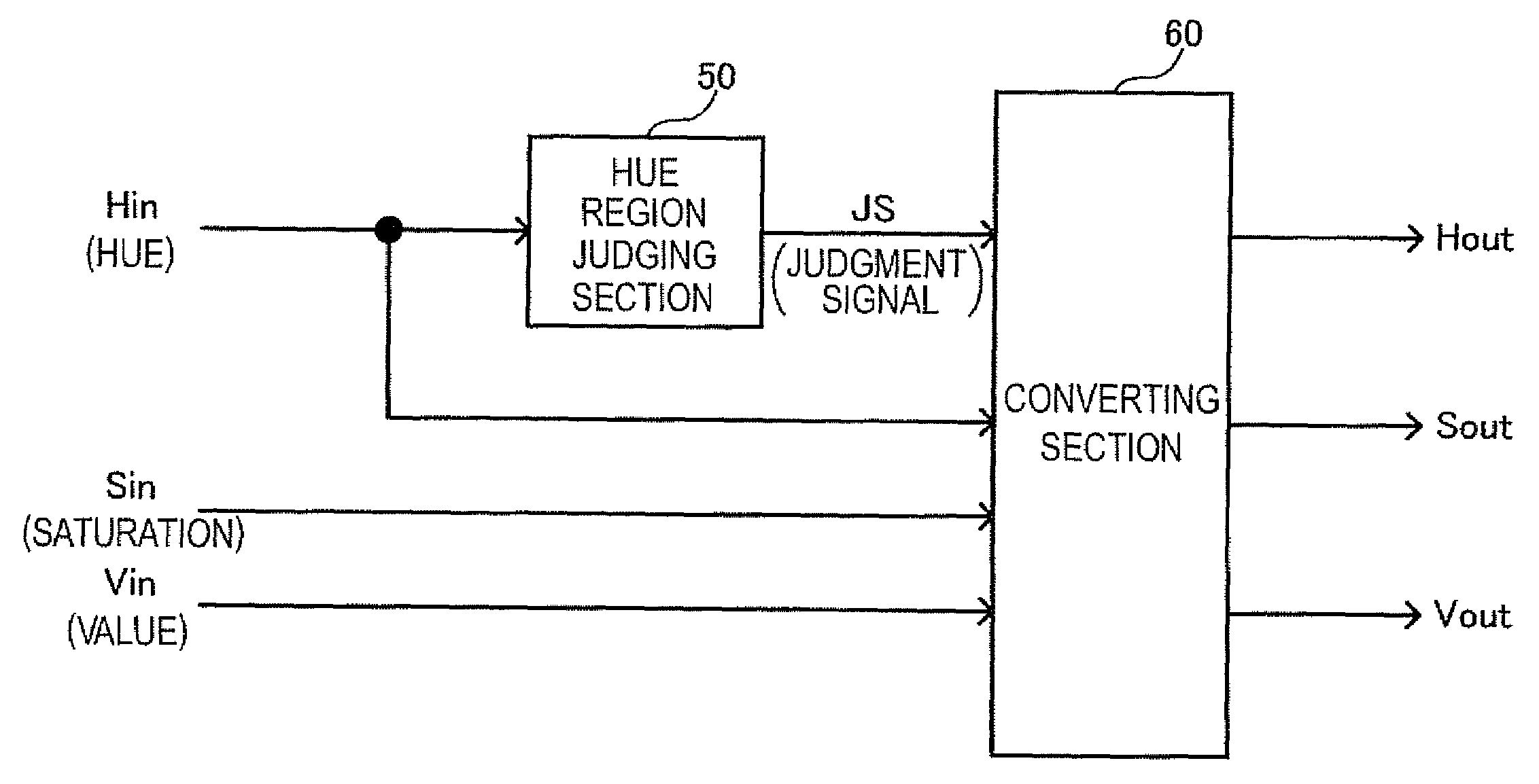

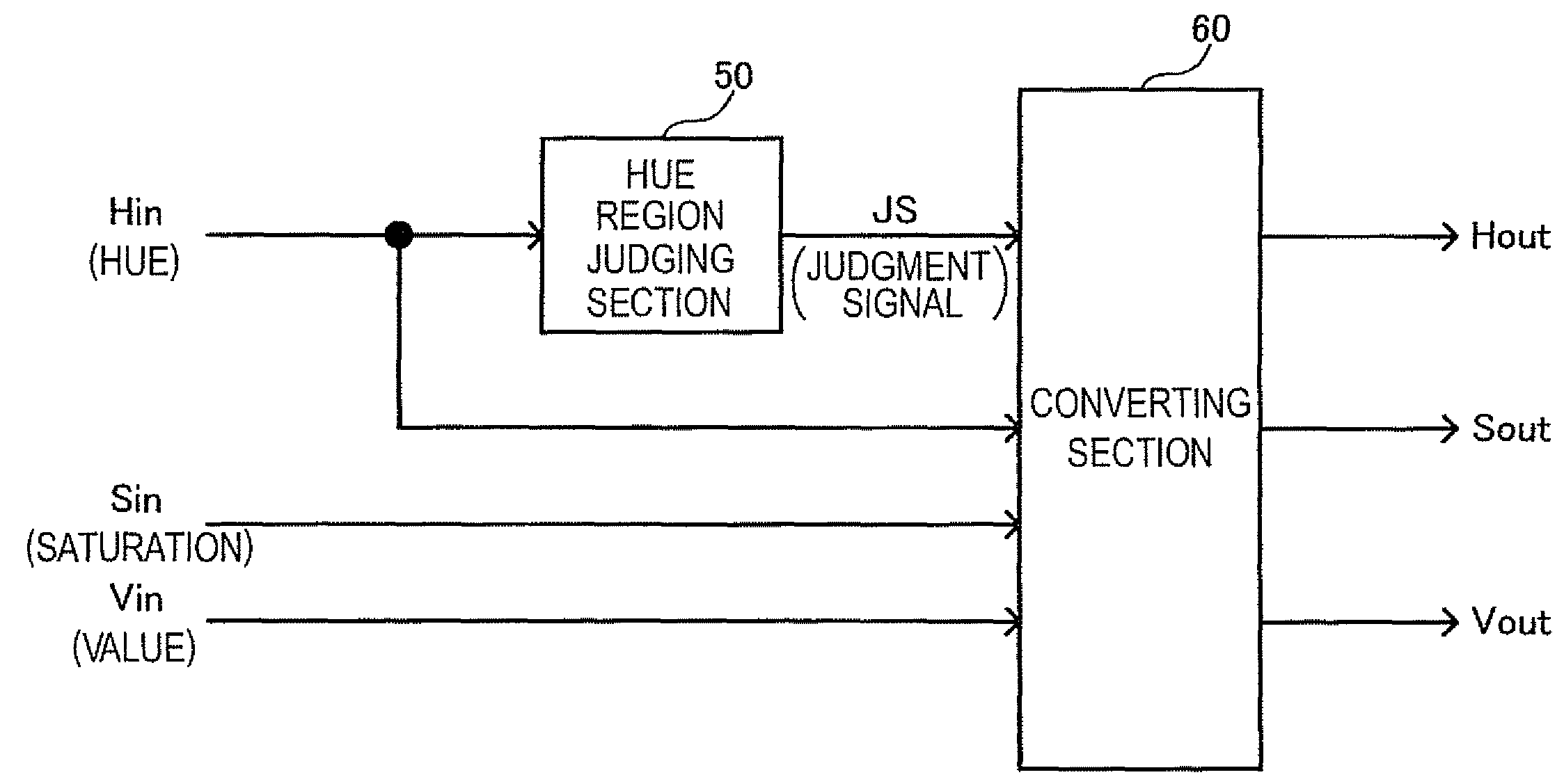

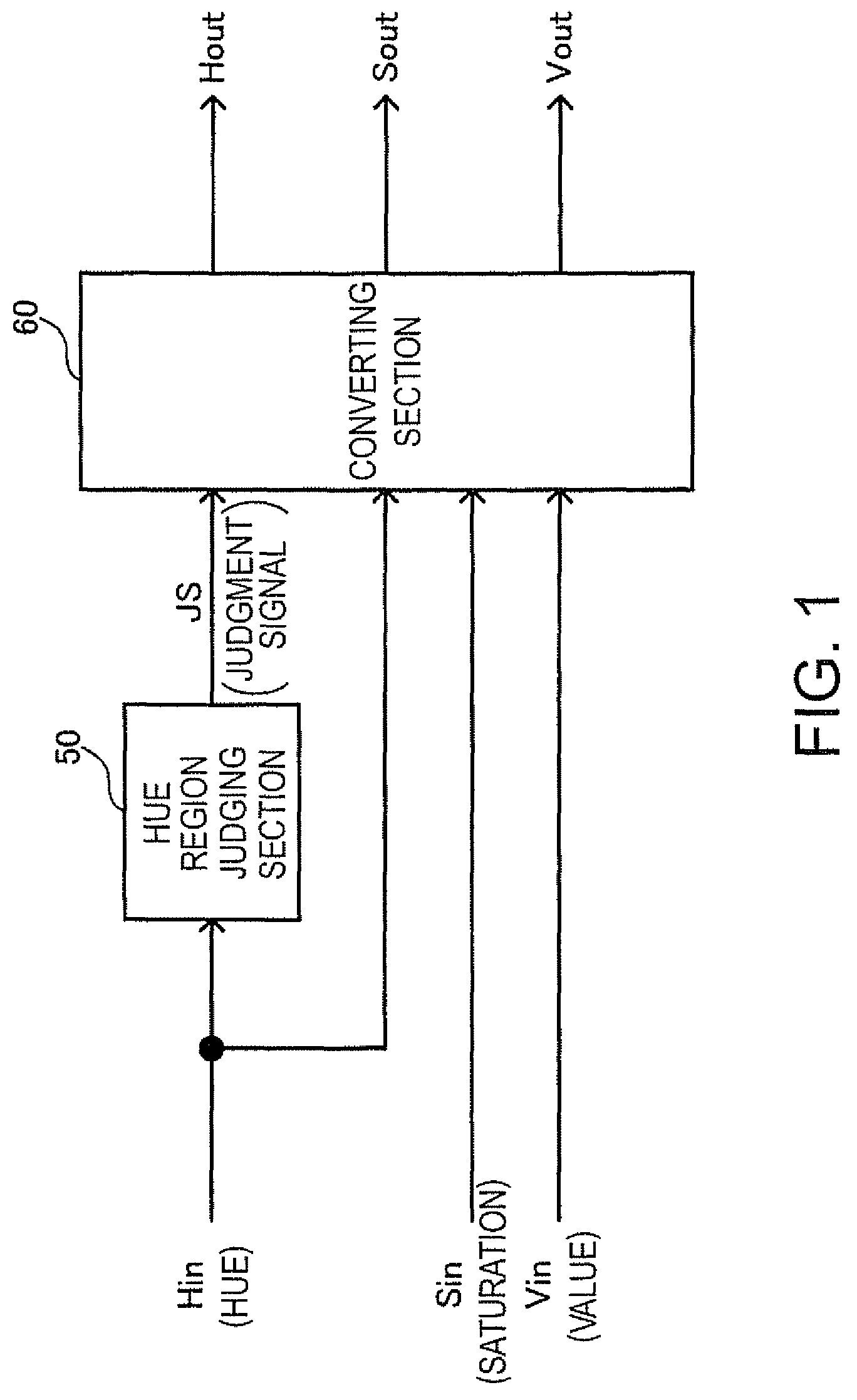

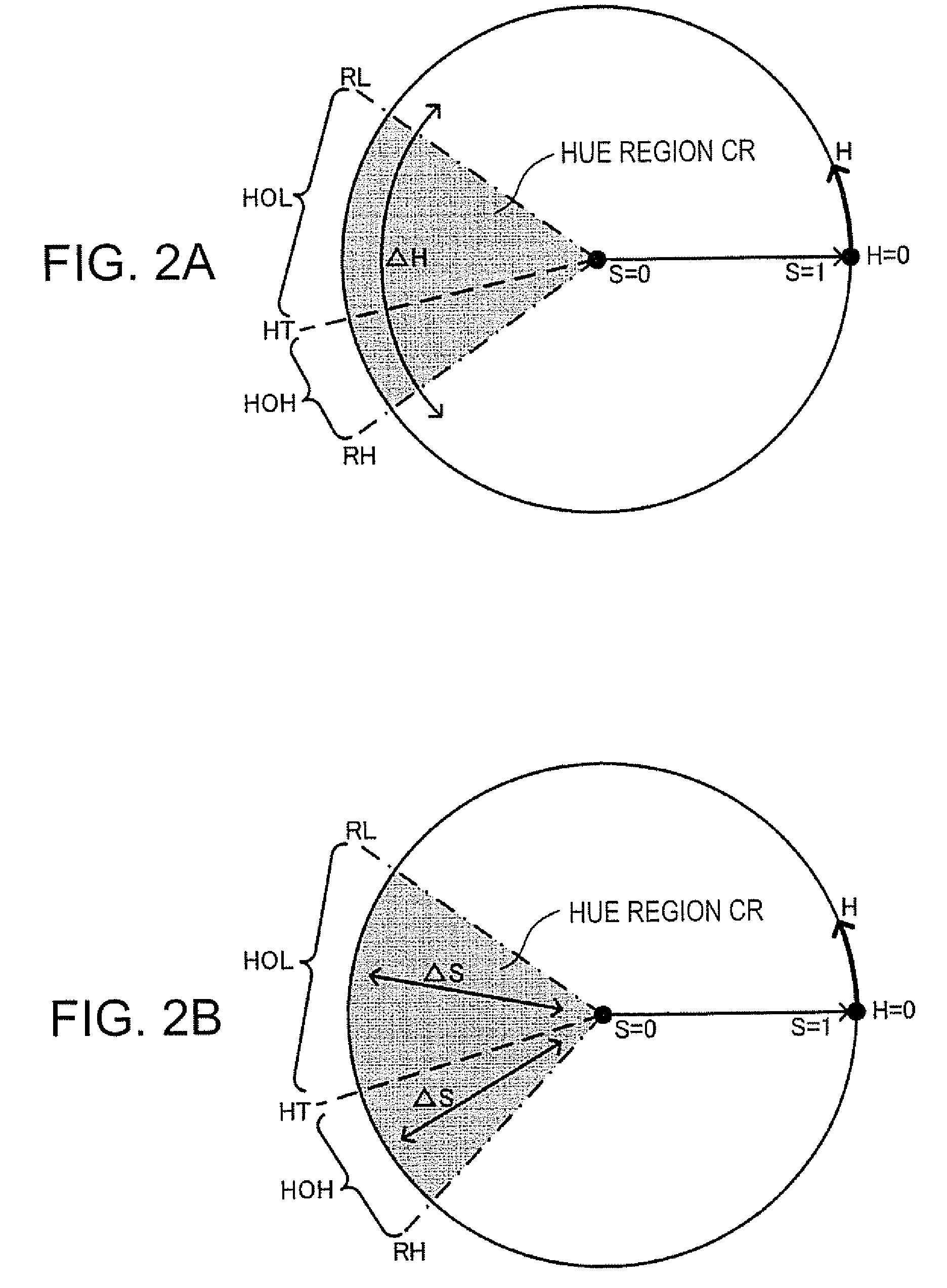

Image processor, integrated circuit device, and electronic apparatus

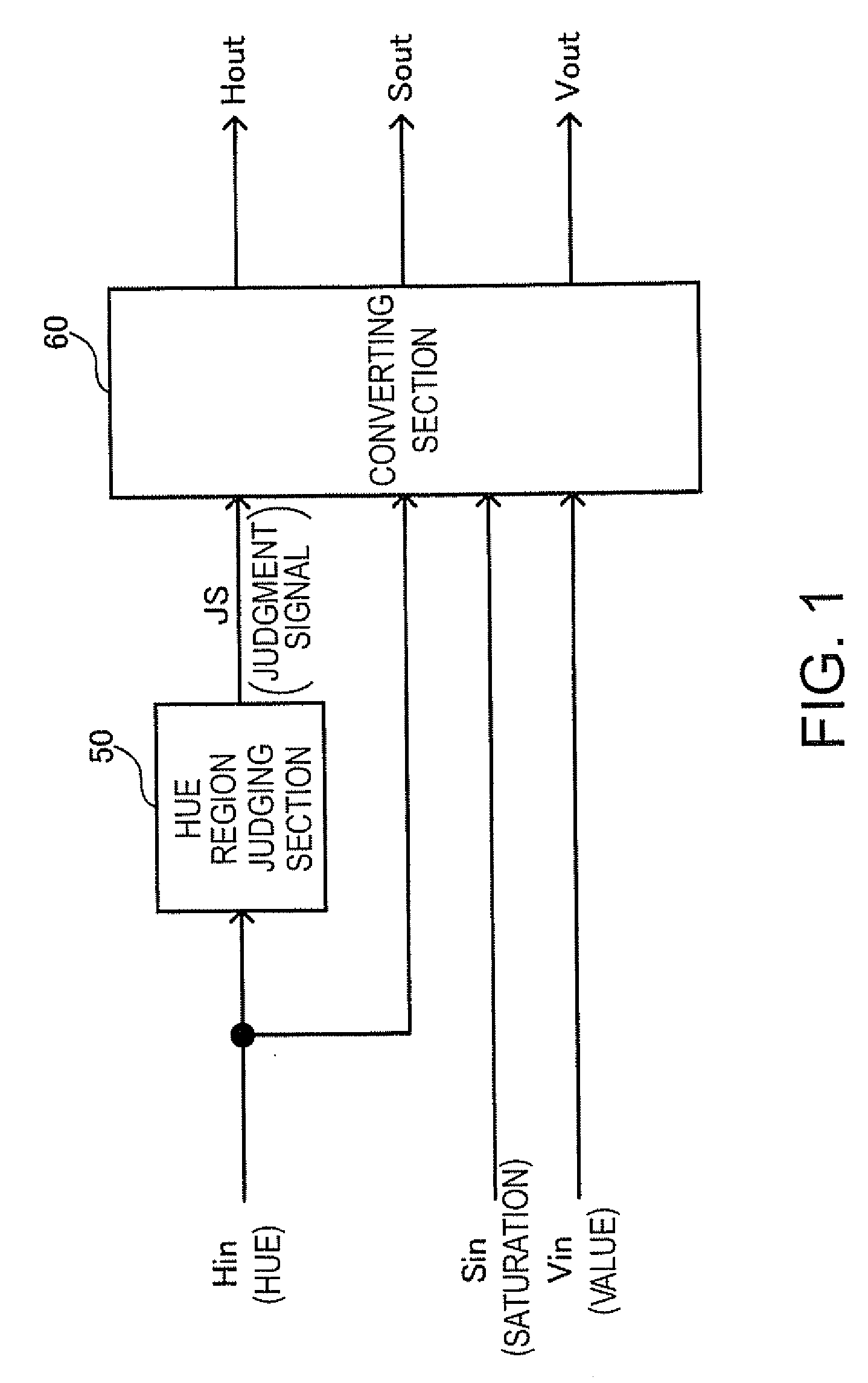

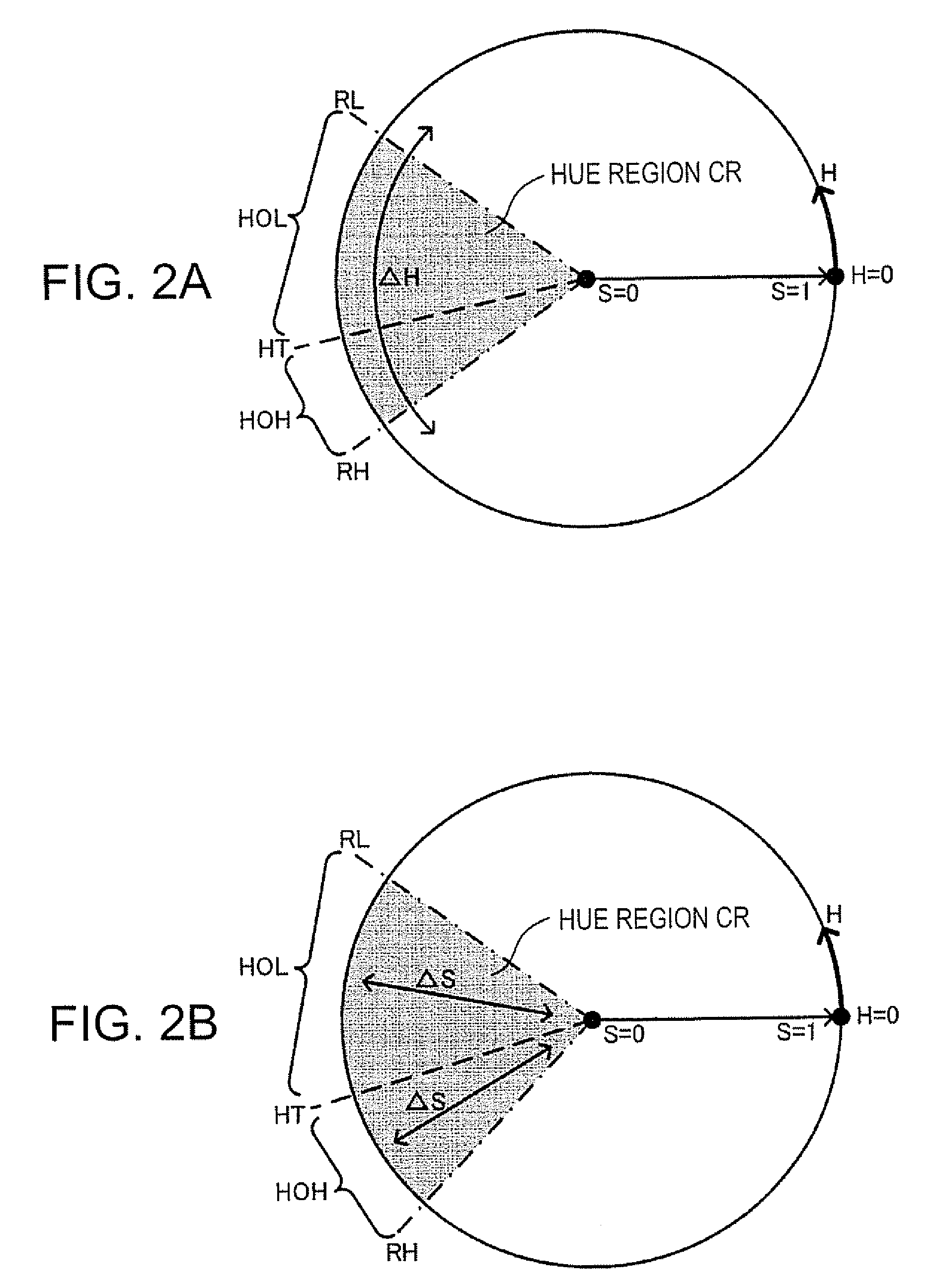

ActiveUS20090310860A1Flexible correctionImage enhancementCharacter and pattern recognitionAlgorithmHue

An image processor includes a hue region judging section judging which one of a plurality of hue regions corresponds to a hue and a converting section obtaining a correction value by using the hue to correct the hue based on the correction value. The converting section obtains a first difference value by using a difference between the hue and a first reference value, obtains a second difference value by using a difference between a second reference value and the first difference value, and obtains the correction value by using the second difference value. The hue is corrected based on the correction value.

Owner:SEIKO EPSON CORP

Method and device for deviation correction control of rolling mill

ActiveCN107008759BRealize cross three-dimensional deviation correctionEasy to shapeProfile control deviceStrip steelControl theory

The invention relates to the technical field of hot continuous rough rolling, in particular to a rolling mill unit deviation rectification control method and device. The rolling mill unit deviation rectification control method comprises the steps that for a first rolling mill unit comprising a first vertical rolling mill and a first horizontal rolling mill, in the process of reciprocating rolling of band steel through the first rolling mill unit, at an odd rolling pass, according to the change of rolling force deviation of the first horizontal rolling mill, a first levelling compensation value is obtained, a roll gap of the first horizontal rolling mill is adjusted, a first deviation rectification compensation value is obtained, the center line of the first vertical rolling mill is adjusted, according to the change of the rolling force deviation of the first vertical rolling mill, a second levelling compensation value is obtained, and the roll gap of the first horizontal rolling mill is adjusted; during an even rolling pass, according to the change of the rolling force deviation of the first horizontal rolling mill, a third levelling compensation value is obtained, and the roll gap of the first horizontal rolling mill is adjusted. By the adoption of the rolling mill unit deviation rectification control method and device, crossing stereoscopic deviation is conducted on the band steel in the longitudinal direction and the transverse direction, and the deviation rectification accuracy is improved.

Owner:BEIJING SHOUGANG CO LTD

A load-bearing four-link automatic correction device

The invention discloses a load-bearing type four-bar linkage automatic deviation correction device. The device comprises a runway mechanism. The runway mechanism comprises rotary assemblies I, rotary assemblies II, carrier roller cross beams and a load-bearing cross beam. The carrier roller cross beams and the load-bearing cross beam are connected through a pair of the rotary assemblies I. Front-extending square tubes are disposed on the load-bearing cross beams and provided with the rotary assemblies II. The rotary assemblies II are provided with parallel extending sleeves. Supports are welded to the carrier roller cross beams, and carrier rollers are arranged on the supports. One end of each of parallel extending tubes is inserted into the corresponding parallel extending sleeve of the runway mechanism. Adjustable vertical roller linkage bars are inserted into an installation cavity where the other end of each of the parallel extending sleeves is welded. Dual vertical roller sleeve assemblies and detection vertical rollers are movably installed on the adjustable vertical roller linkage bars. The deviation correction device can conduct effective deviation correction on high-speed, large-capacity, long-distance and high-strength belt conveyers in the severe work environment, especially on large wide belts.

Owner:淮北合众机械设备有限公司

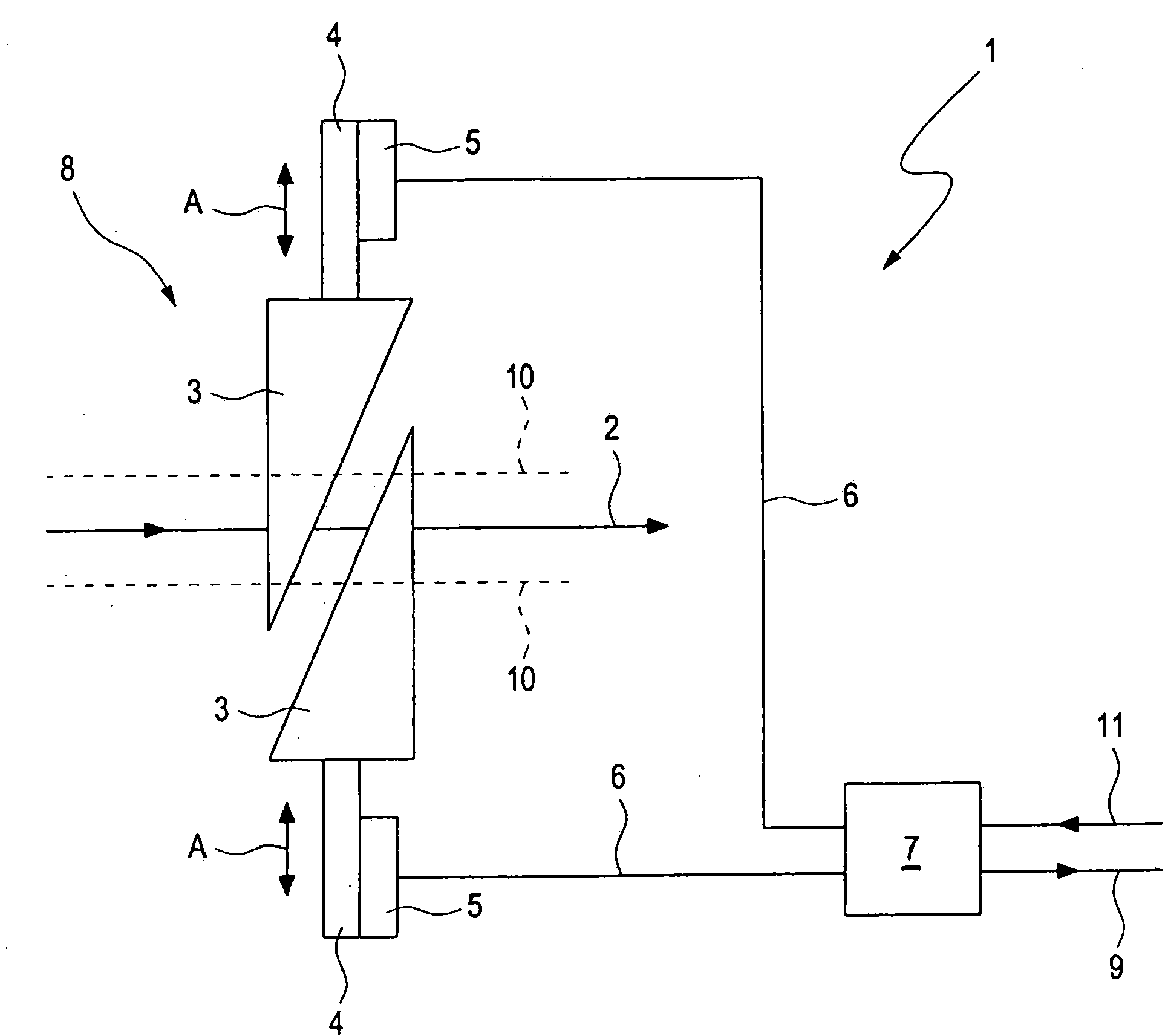

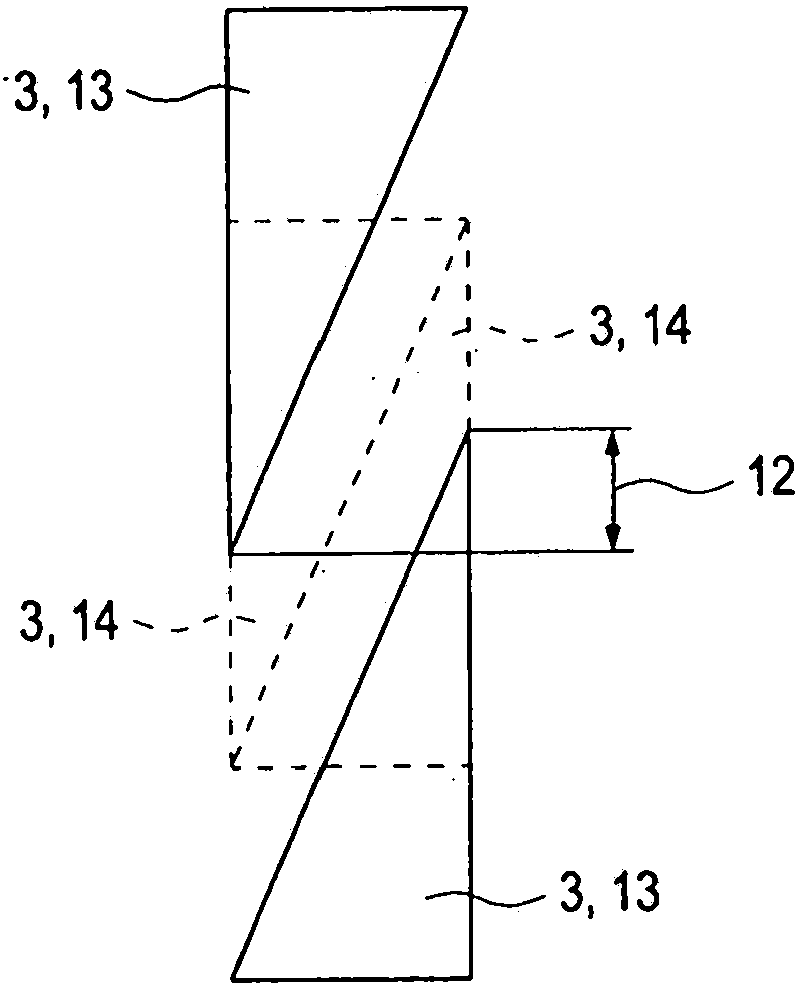

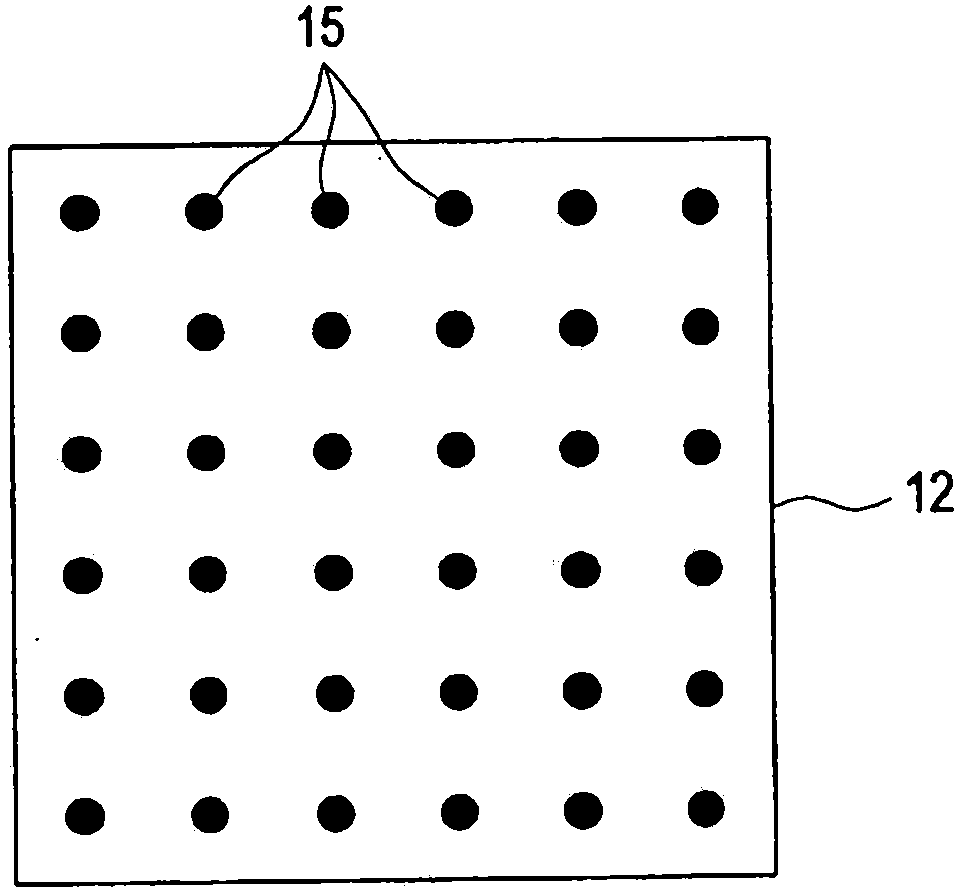

Improved energy modulator

ActiveCN103732290AAccurate adjustmentAvoid influenceRadiation/particle handlingX-ray/gamma-ray/particle-irradiation therapyEnergy variationParticle beam

The invention relates to a particle energy adjustment system (1) for variably changing the energy of a particle beam (2, 10). The particle energy adjustment system (1) is provided with a variable energy variation device (8) having a control value correction unit (7) for correcting a supplied control value (11). The control value correction unit (7) corrects the supplied control values (11) using previously determined calibration data (15).

Owner:GSI重离子研究亥姆霍茨中心有限公司

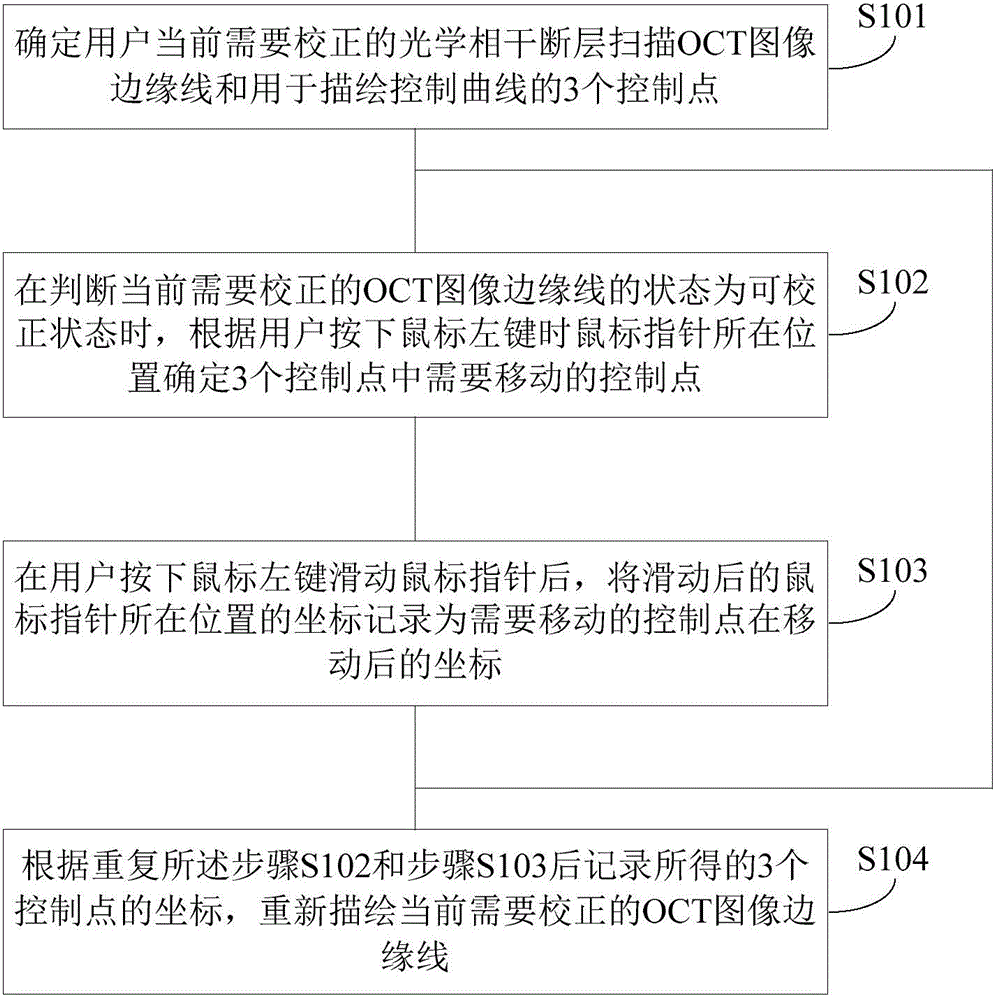

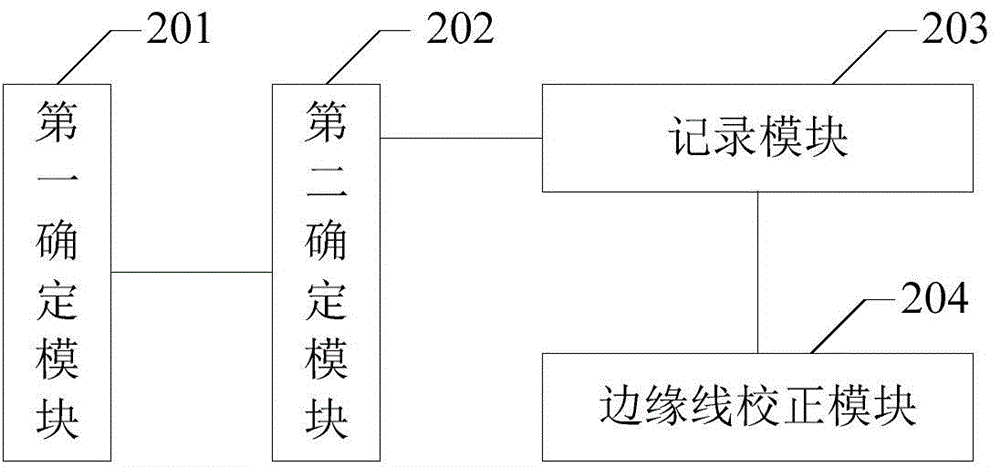

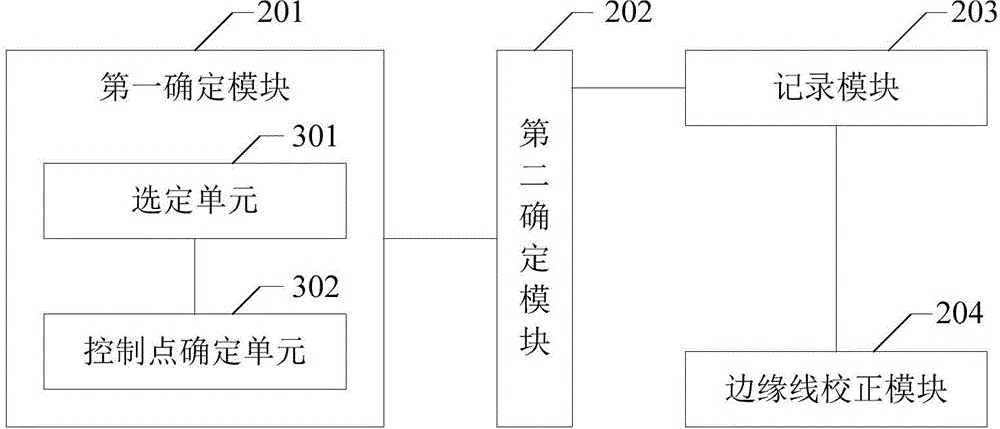

Method for correcting optical coherent tomography scanning image edge line and device thereof

InactiveCN104463789AAvoid the problem of unsmooth curves and large errorsEasy to operateImage enhancementComputer visionTomography

The invention discloses a method for correcting an optical coherent tomography scanning image edge line and a device thereof. The method comprises the steps that S101, an OCT image edge line currently needed to be corrected by a user and three control points used for describing a control curve are confirmed; S102, when the state of the OCT image edge line currently needed to be corrected is a correctable state through judgment, the control points needed to be moved of the three control points are confirmed according to location of a mouse pointer when the user presses a left mouse button; S103, after the user presses the left mouse button and slides the mouse pointer, the coordinates of location of the mouse pointer after sliding are recorded to be the coordinates of the control points needed to be moved after movement; the step S102 and the step S103 are repeated until the coordinates of the three control points are recorded completely; and S104 the OCT image edge line currently needed to be corrected is described again according to the recorded coordinates of the three control points. A smooth OCT image edge line can be obtained via the method. The correction process is convenient, flexible, accurate and highly-efficient so that the accurate OCT image edge line can be rapidly and conveniently obtained.

Owner:GUANGDONG FORTUNE NEWVISION TECH

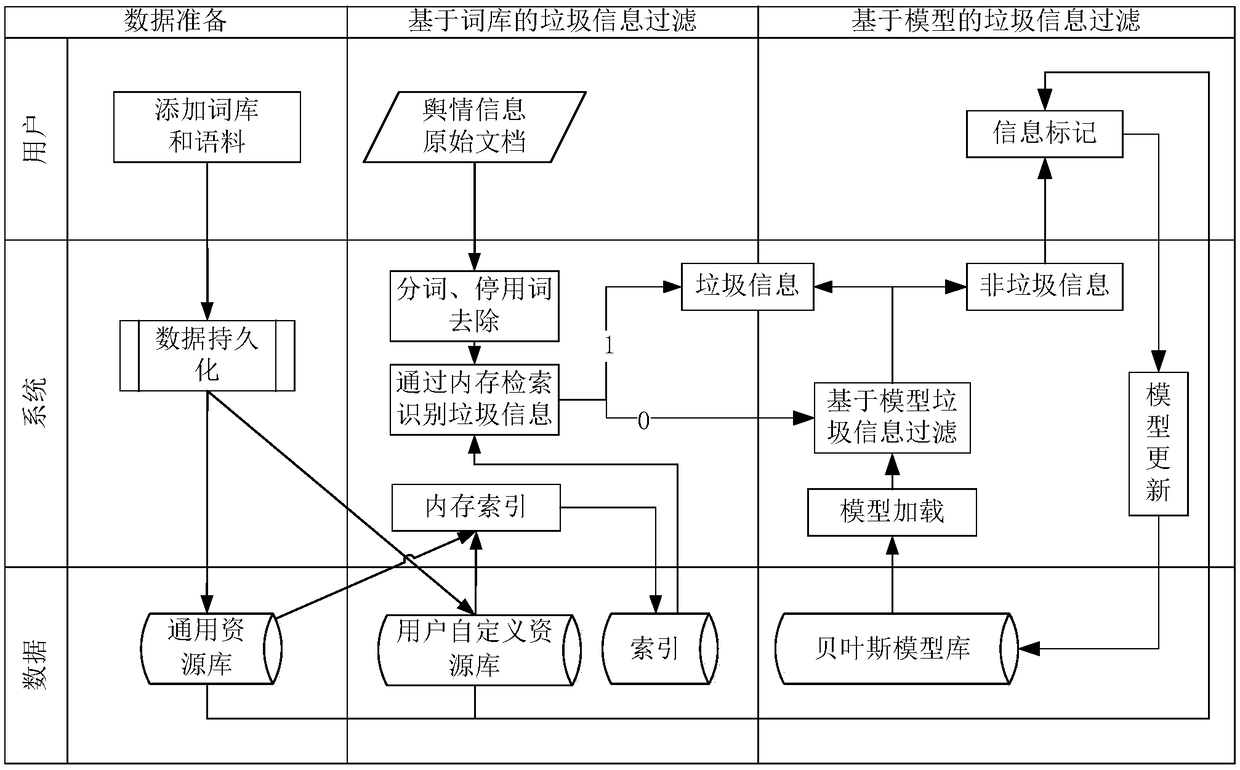

Method and system of personalized junk information filtering in public-sentiment information

InactiveCN108874852AImprove filtering effectFlexible correctionCharacter and pattern recognitionNatural language data processingPersonalizationDocumentation

The invention provides a method and a system of personalized junk information filtering in public-sentiment information. The steps of the method include: constructing a memory index library on the basis of a general word library and a user-personalized word library; carrying out word segmentation on an original document containing the public-sentiment information, and removing stop words; identifying the document after the above processing according to the memory index library, and obtaining junk information and non-junk information by identification; inputting the above non-junk information into an updateable information classification model to further identify junk information and non-junk information; and carrying out labeling of the junk information and the non-junk information on thenon-junk information identified by the information classification model on the basis of a general junk identification labeling corpus and a user-personalized junk identification labeling corpus to generate a training set, and using the same to update the information classification model.

Owner:INST OF INFORMATION ENG CHINESE ACAD OF SCI

Image processor, integrated circuit device, and electronic apparatus

An image processor includes a hue region judging section judging which one of a plurality of hue regions corresponds to a hue and a converting section obtaining a correction value by using the hue to correct the hue based on the correction value. The converting section obtains a first difference value by using a difference between the hue and a first reference value, obtains a second difference value by using a difference between a second reference value and the first difference value, and obtains the correction value by using the second difference value. The hue is corrected based on the correction value.

Owner:SEIKO EPSON CORP

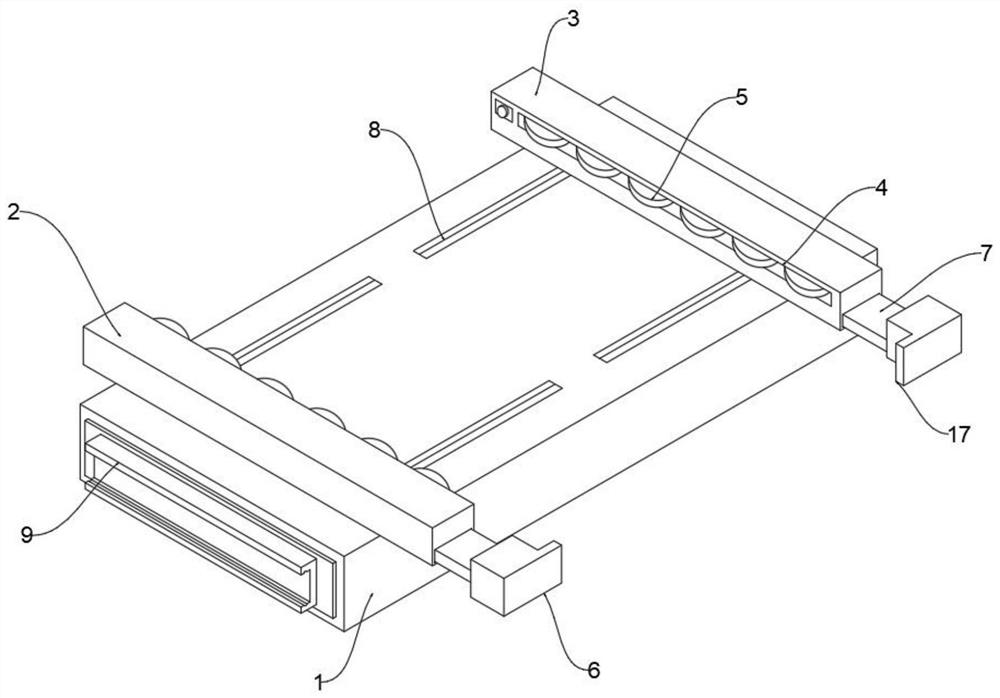

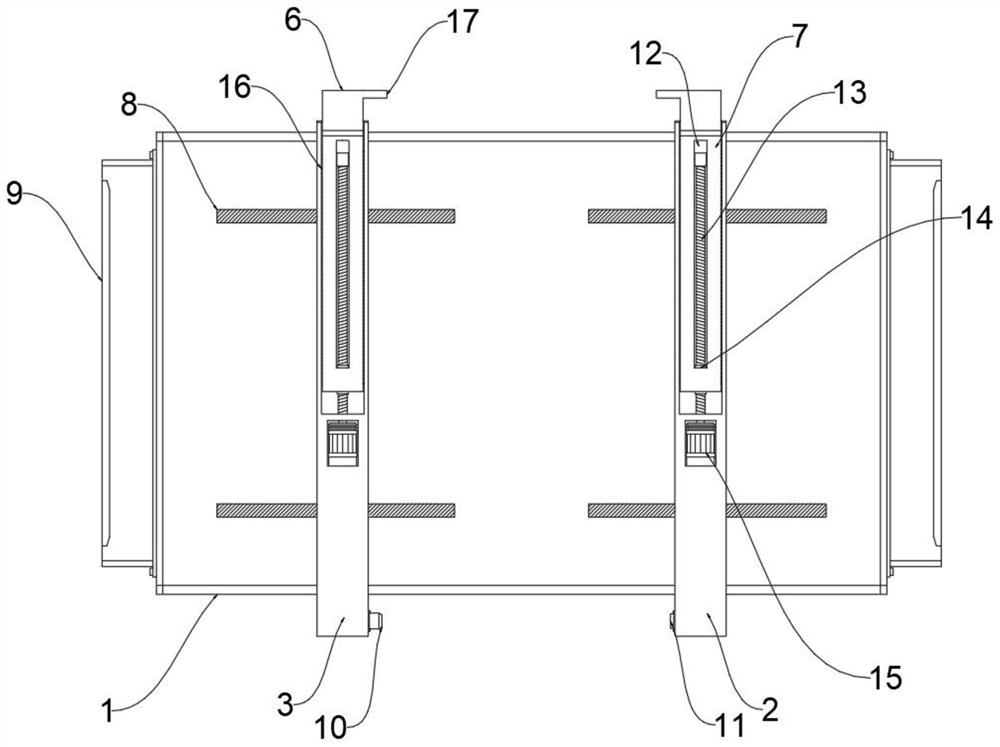

Position correction device for machining and feeding of aluminum template and correction method thereof

PendingCN113927357AReduce workloadQuick move adjustmentMeasurement/indication equipmentsMetal working apparatusEngineeringStructural engineering

The invention discloses a position correction device for machining and feeding of an aluminum template and a correction method thereof, relates to the technical field of machining auxiliary devices of aluminum templates, and aims to solve the problems that according to a conventional correction device, the aluminum template is easily damaged in the adjusting process and the adjusting accuracy is poor. A first position correction block is mounted at one side of the upper end surface of a movable base, a second position correction block is mounted at the other side of the upper end surface of the movable base, mounting blocks are arranged in the first position correction block and the second position correction block, wheel body mounting grooves are formed in the mounting blocks, six adjusting wheels mounted at equal intervals are arranged in the wheel body mounting grooves, second sliding grooves are formed in the lower ends of the interiors of the first position correction block and the second position correction block, extension plates are mounted in the second sliding grooves in a sliding mode, and clamping fixing blocks are integrally arranged at one ends of the extension plates.

Owner:安徽源升新型材料有限公司

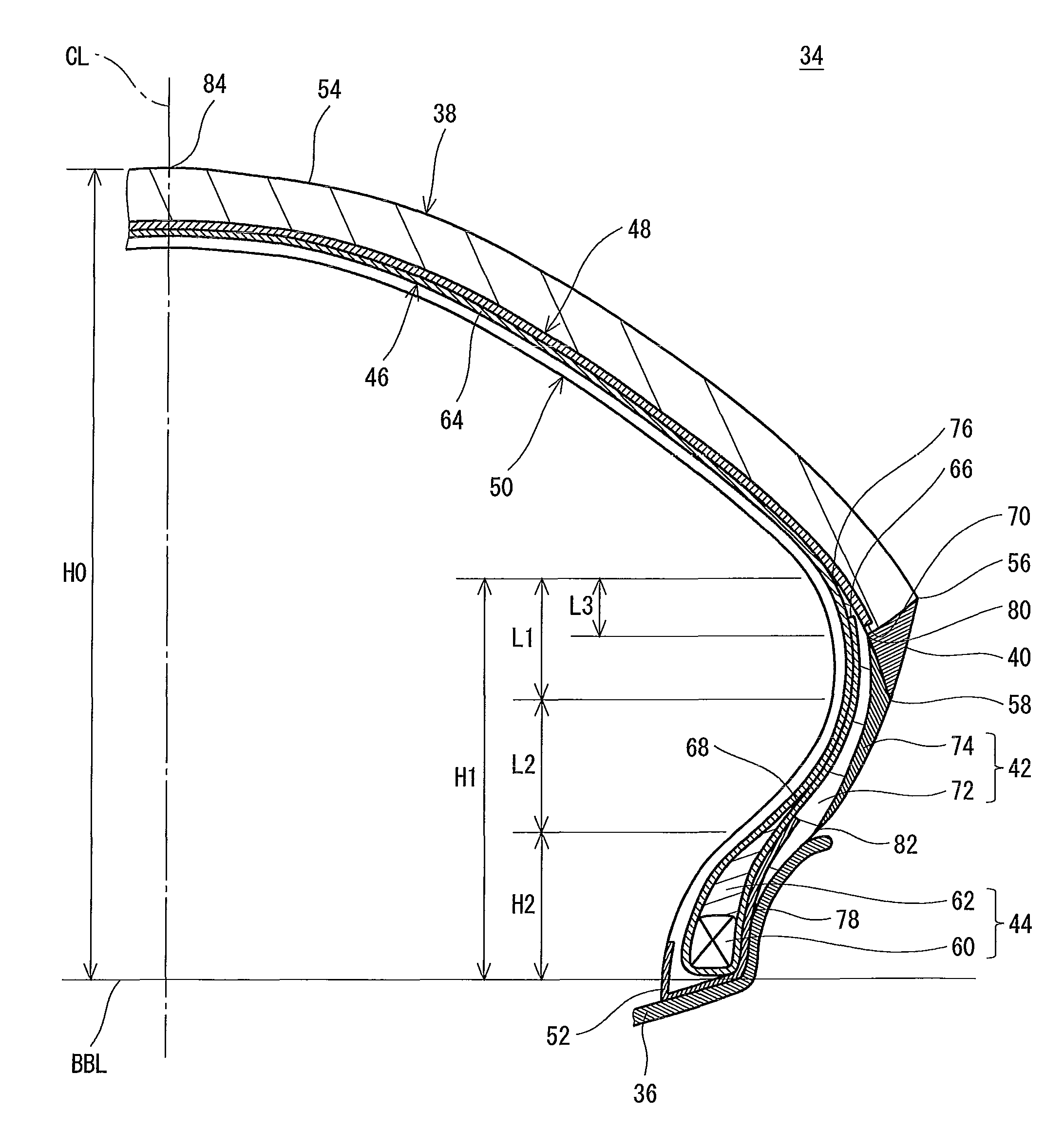

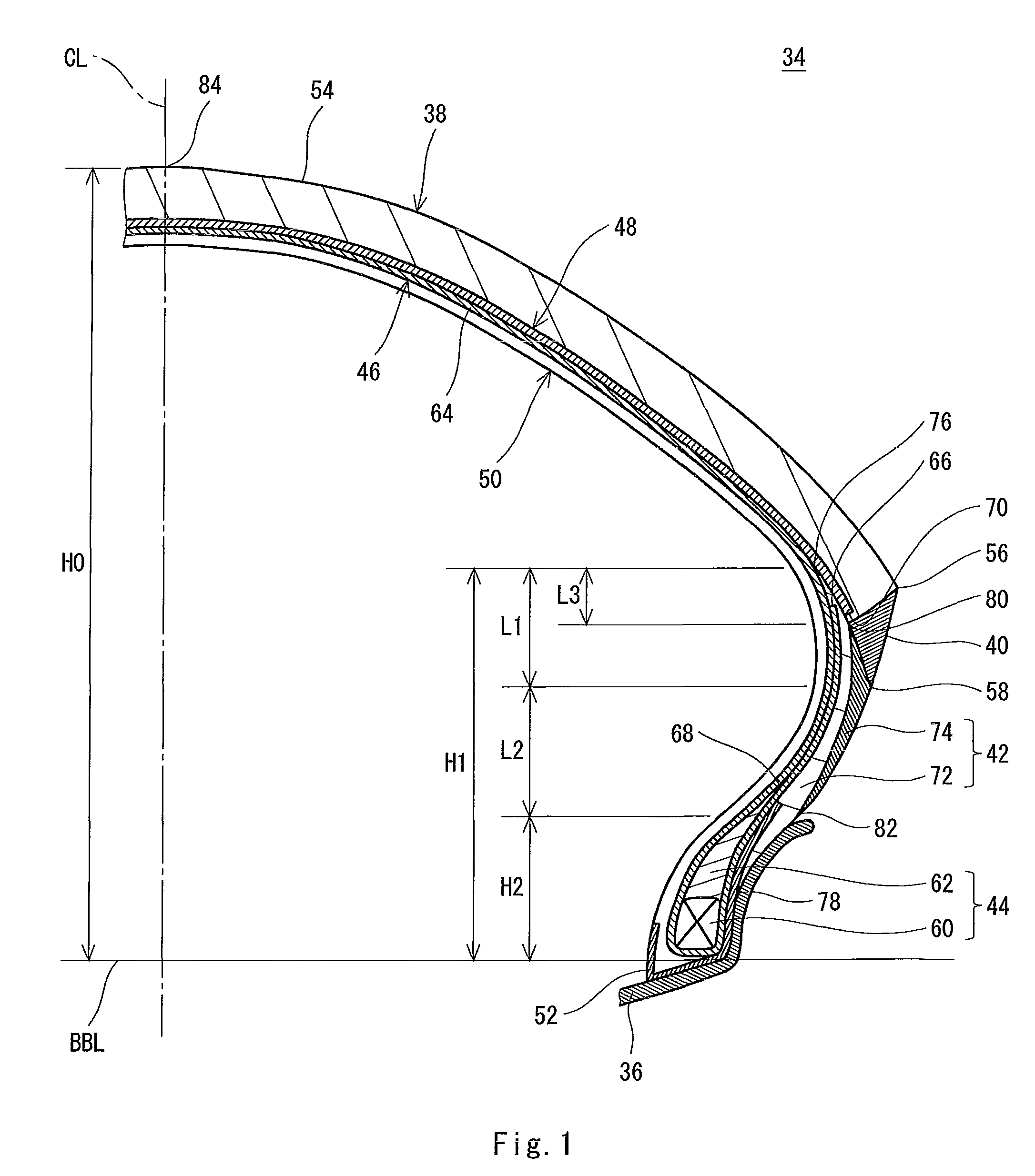

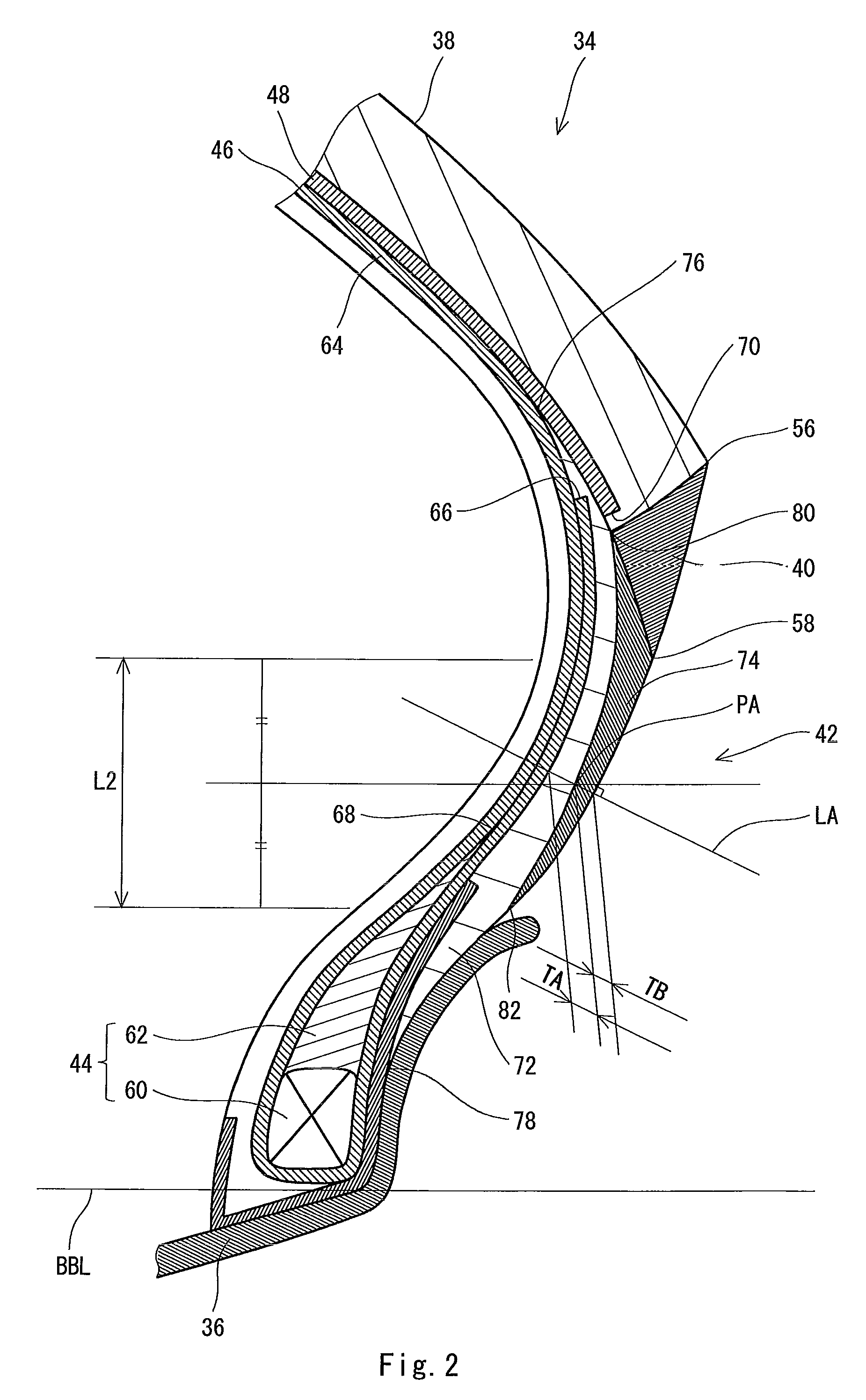

Pneumatic tire for motorcycle with tread wings and with sidewalls each having inner layer and outer layer

InactiveUS8602074B2Feel goodGuaranteed uptimePneumatic tyre reinforcementsMotorcycle tyresEngineeringMechanical engineering

A tire (34) includes a tread (38), a pair of sidewalls (42), a pair of beads (44), a carcass (46) laid between both of the beads (44) along an inside of the tread (38) and the sidewalls (42), and a pair of wings (40) positioned on an outside in an axial direction of the sidewalls (42) respectively. Each of the sidewalls (42) includes an inner layer (72) positioned on an outside of the carcass (46) in the axial direction and extended in a radial direction along the carcass (46) and an outer layer (74) positioned on a further outside of the inner layer (72) and extended in the radial direction along the inner layer (72). An inner end (82) of the outer layer (74) is positioned on an inside of an inner end (58) of each of the wings (40) in the radial direction. The inner layer (72) has a higher hardness than a hardness of the outer layer (74).

Owner:SUMITOMO RUBBER IND LTD

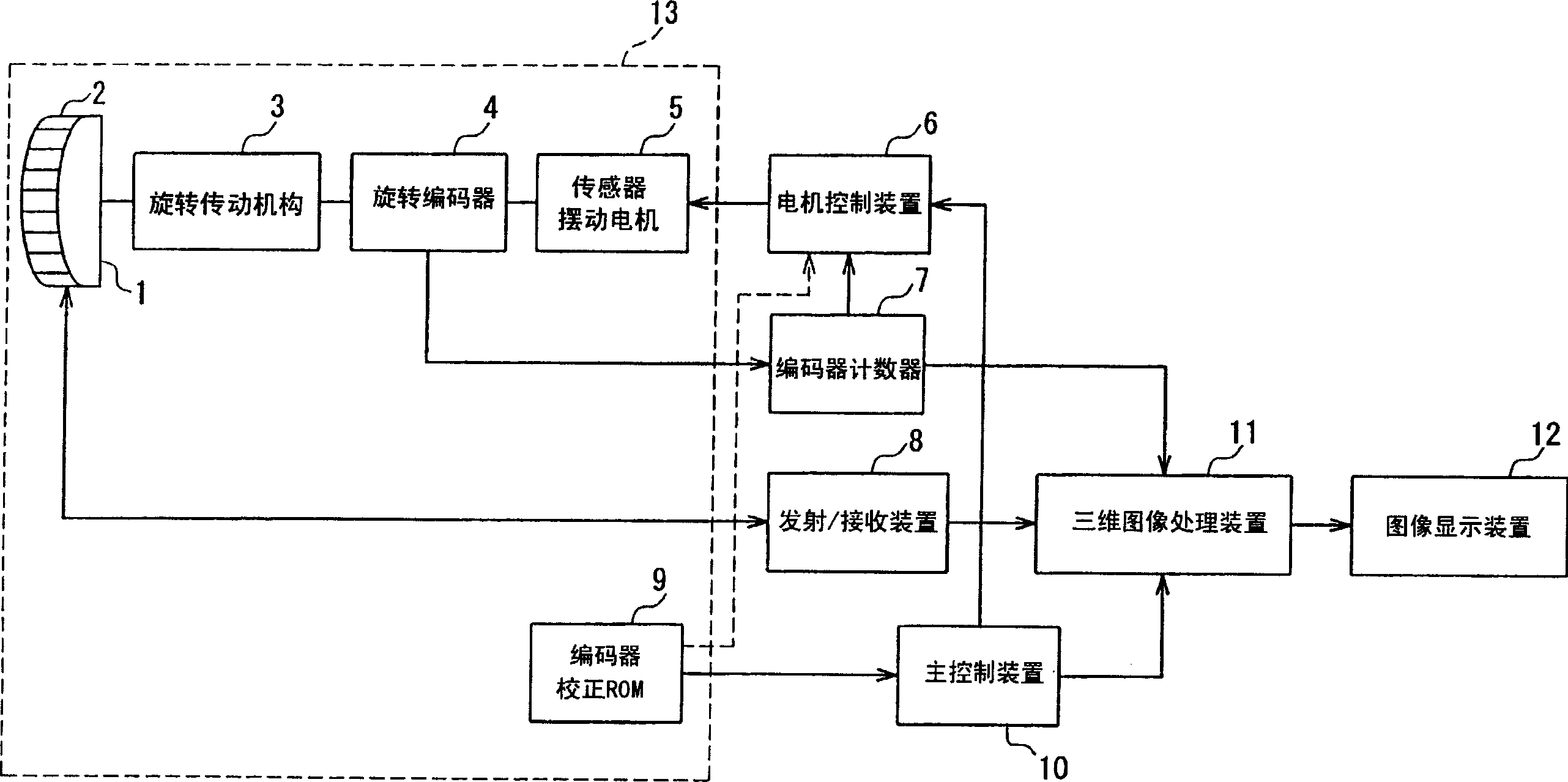

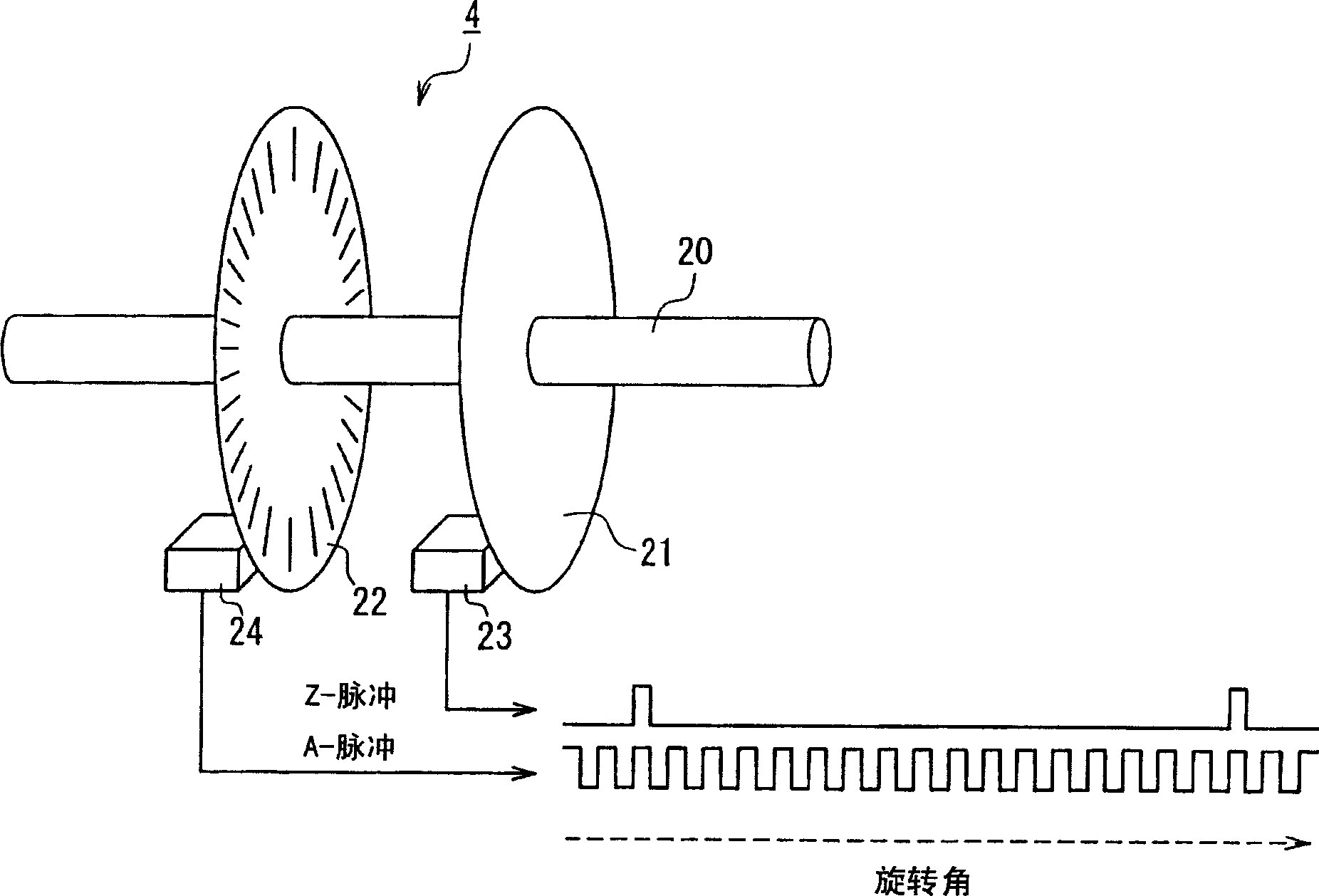

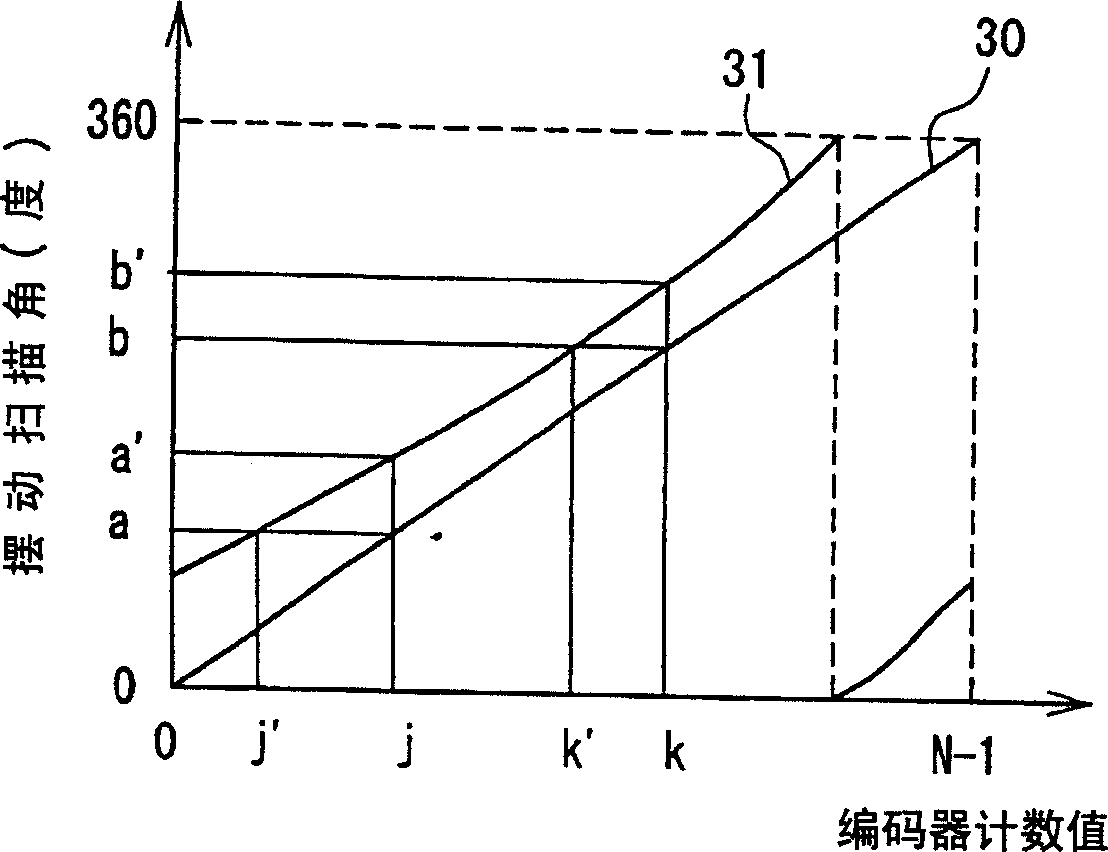

Ultrasonic probe and ultrasonographic device

InactiveCN1761428AFlexible correctionUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsImaging processingScan angle

There is provided an excellent ultrasonographic device capable of building a three-dimensional image at a spatially correct position not affected by an ultrasonic probe used and realizing it without lowering the treatment productivity. The ultrasonic probe includes an ultrasonic oscillator, a rotation transmission mechanism, a rotary encoder, an oscillator swivel motor, and an encoder correction ROM which are built in the probe The encoder correction ROM stores in advance a swivel scan angle of the actual ultrasonic oscillator for each count value obtained by counting the pulses from the rotary encoder. Three-dimensional image processing means builds a three-dimensional image of the main cross section scan surface in the actual swivel scan angle direction while correcting the encoder count value from an encoder counter according to the content of the encoder correction ROM read out via main control means.

Owner:PANASONIC CORP

A method for non-uniformity correction of array push-broom laser radar ranging

ActiveCN106291512BEliminate ranging differencesImprove applicabilityElectromagnetic wave reradiationRadarOptoelectronics

The invention provides a method for non uniformity correction of range finding of an array push-scan type laser radar. An array push-scan type laser radar with N laser channels are used for detecting a target plate, the relative position of the array push-scan type laser radar and the target plate is changed, and the target plate is detected for M times, so laser radar data and total station data corresponding to each laser channel are obtained. By carrying out operation like coordinate transformation, a non uniformity correction model is established, and an actual range finding value of any one laser channel is used as a reference correction value to correct actual range finding values of other laser channels.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

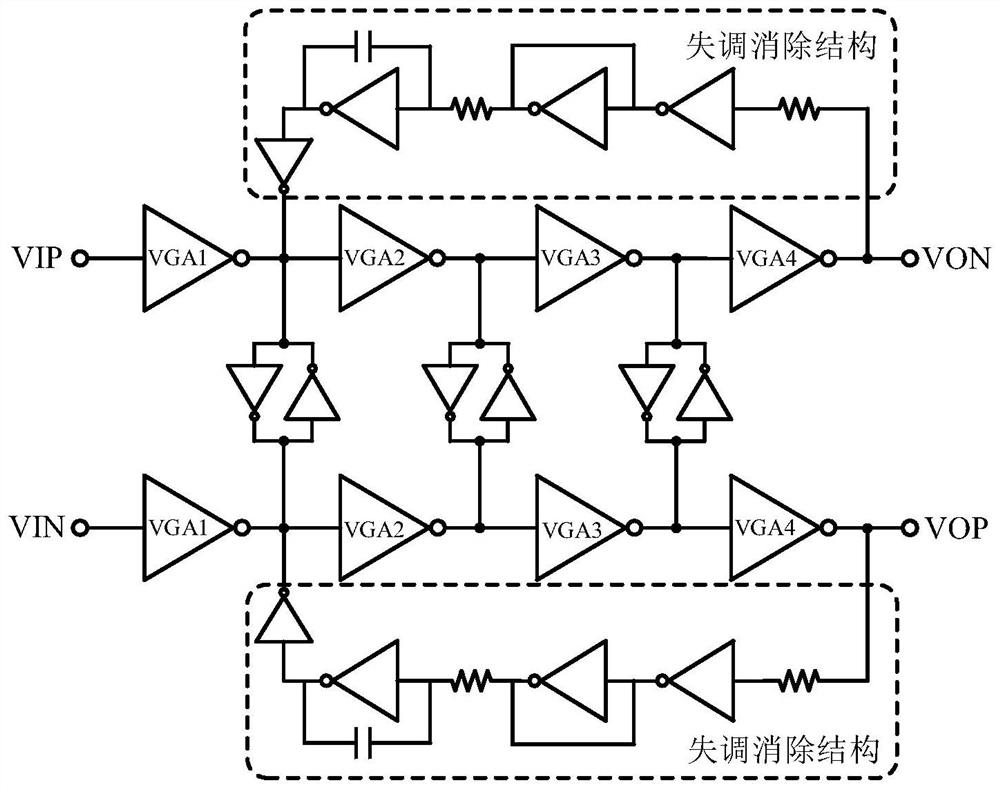

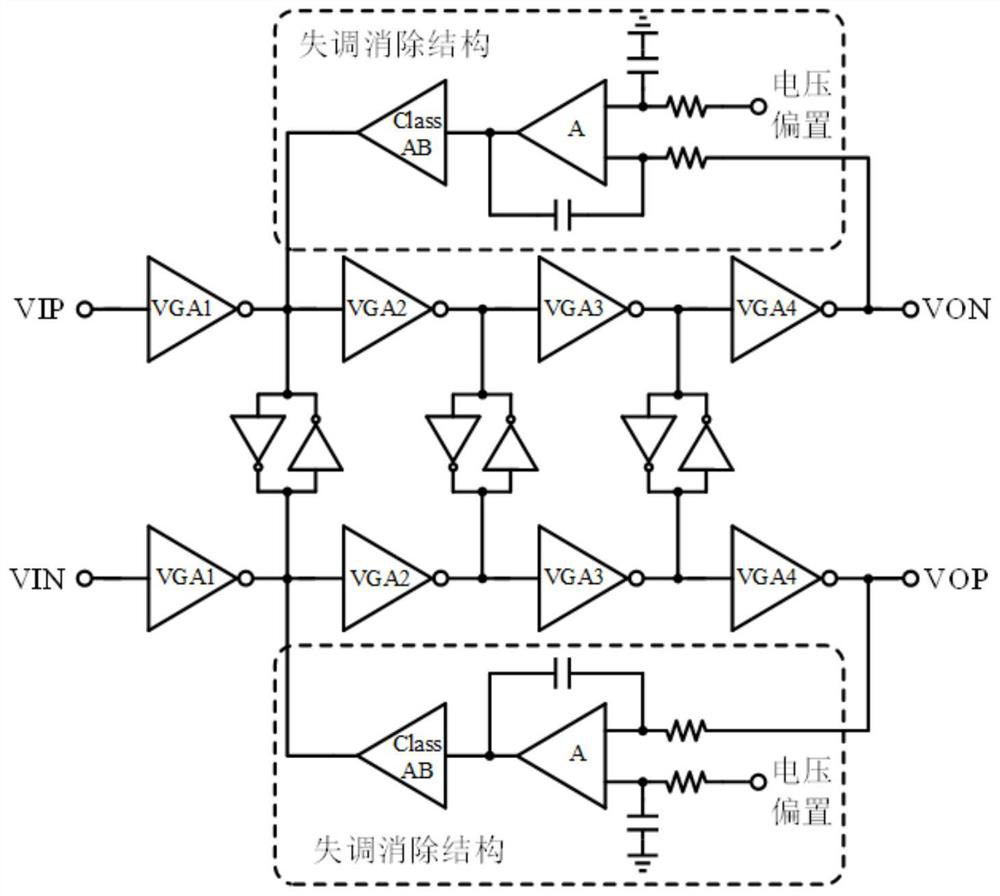

DC offset cancellation circuit and method

PendingCN114866041AMeet the requirements of linearityImprove reliabilityAmplifier modifications to reduce non-linear distortionAmplifier modifications to reduce temperature/voltage variationOffset cancellationControl engineering

The invention discloses a DC offset cancellation circuit and method. The DC offset cancellation circuit comprises an offset cancellation module, an amplifier group and a phase inverter structure, the inverter structures are connected between the two amplifier groups, one end of each amplifier group is connected with a signal input end, and the other end of each amplifier group is connected with a signal output end; an offset elimination module is arranged between the input end and the output end of each amplifier group; the structure of the circuit is different from an existing offset elimination circuit structure, common-mode voltage can be corrected, differential-mode offset can be corrected, and the working reliability of the circuit is improved. An output DC point is stabilized at an optimal bias point in a single-end bias mode, and for an amplifier with an inverter structure, it can be ensured that the amplifier works in a state with the best linearity, and then the requirement for the linearity of a whole circuit is met. Static power consumption can be greatly reduced by the Class AB output stage, waste of current on a transconductance tube is avoided, and the driving capability is much stronger than that of a single transconductance tube.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com