High-precision correcting circuit for band-gap reference voltage source

A reference voltage source, reference source technology, applied in the direction of adjusting electrical variables, control/regulating systems, instruments, etc., can solve the problems of unchangeable output reference, high cost, affecting the accuracy of the reference source, etc., to achieve flexible calibration, high precision, small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, so as to obtain a better understanding.

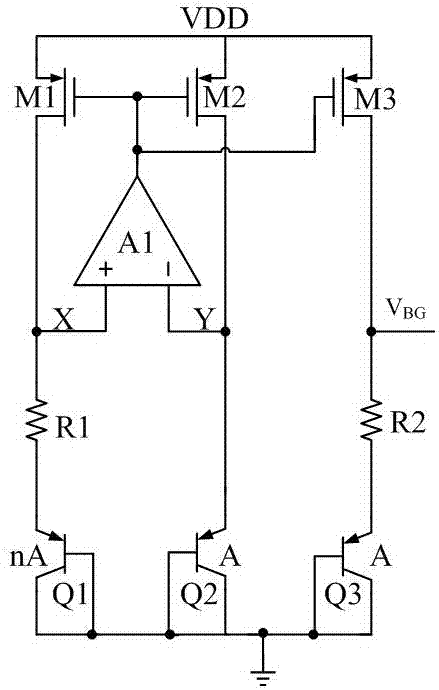

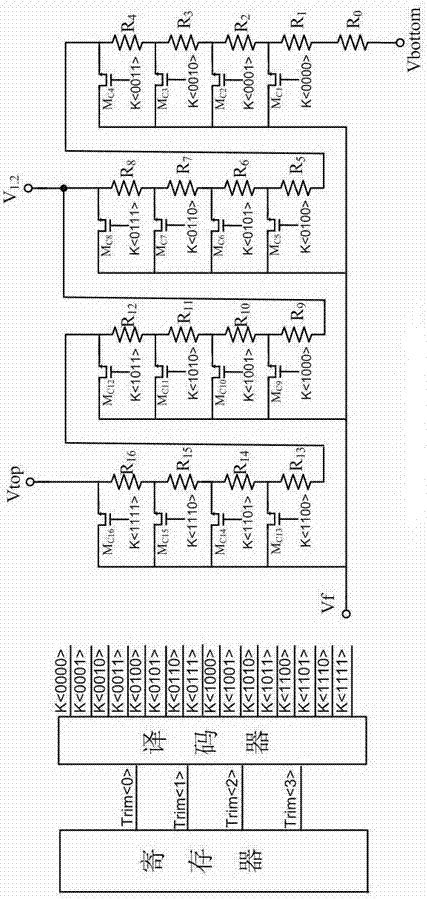

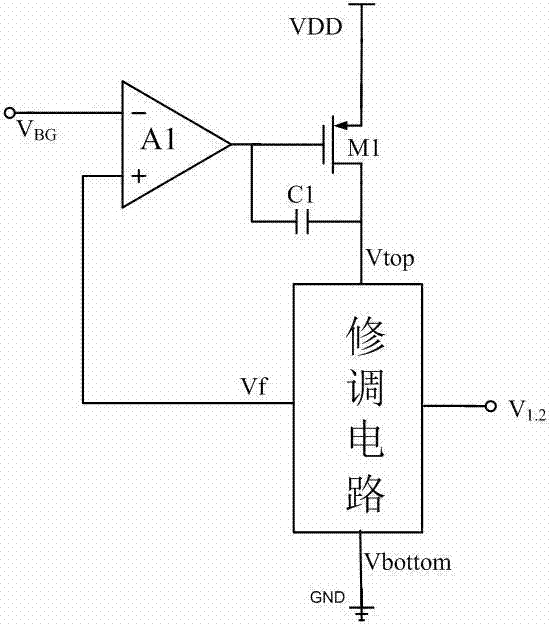

[0014] figure 1 As shown, it is a commonly used bandgap reference voltage source core circuit, which is used to generate a reference voltage V BG , theoretical analysis can draw the reference voltage V when the temperature coefficient is zero BG ≈1.25V, but due to the influence of process angle, offset, temperature and other factors, the reference voltage value will produce errors. In order to eliminate the errors generated by the reference voltage, it is necessary to design a correction circuit to correct the reference voltage to near the ideal value. Through reasonable design and monte carlo simulation of this circuit, the simulation can show that the output reference voltage is between 1.1V-1.3V. The present invention needs to generate a reference voltage of 1.2V, so it is necessary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com