Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Fix technical issues with lower accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

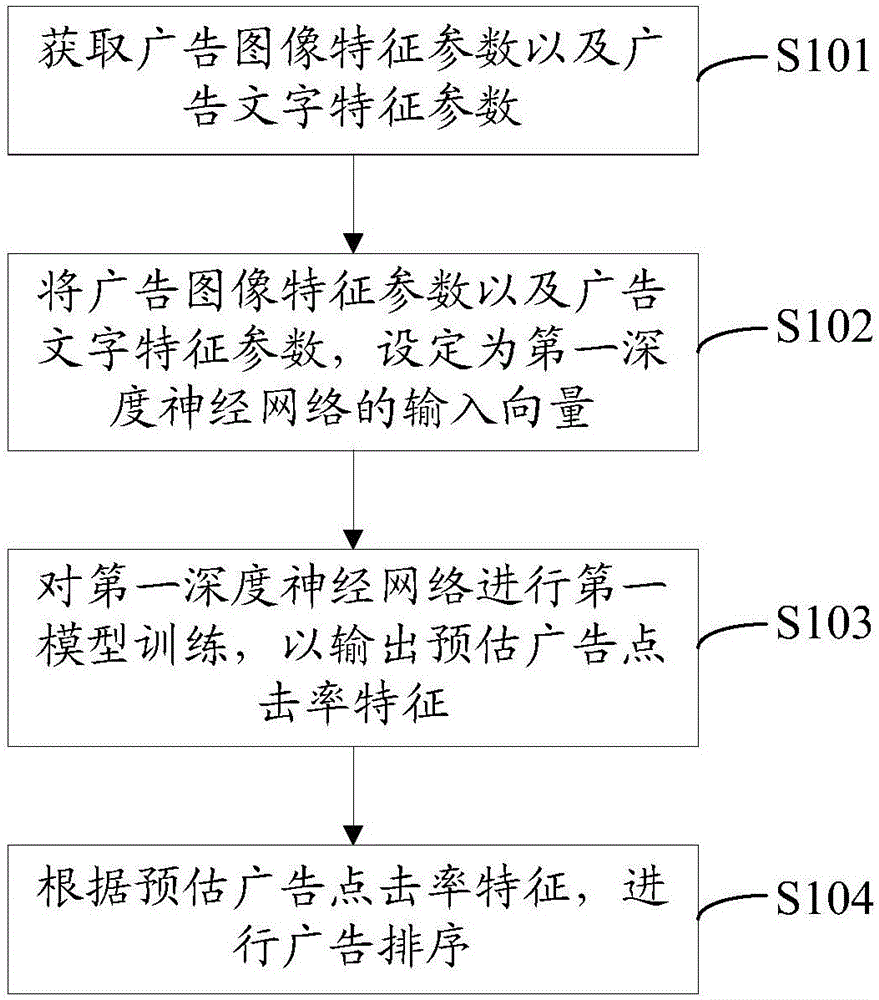

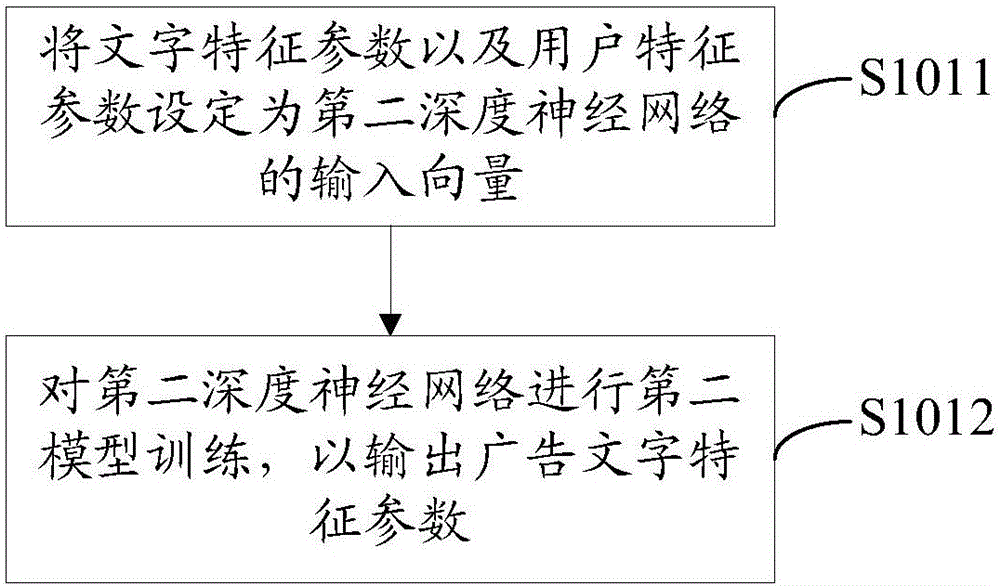

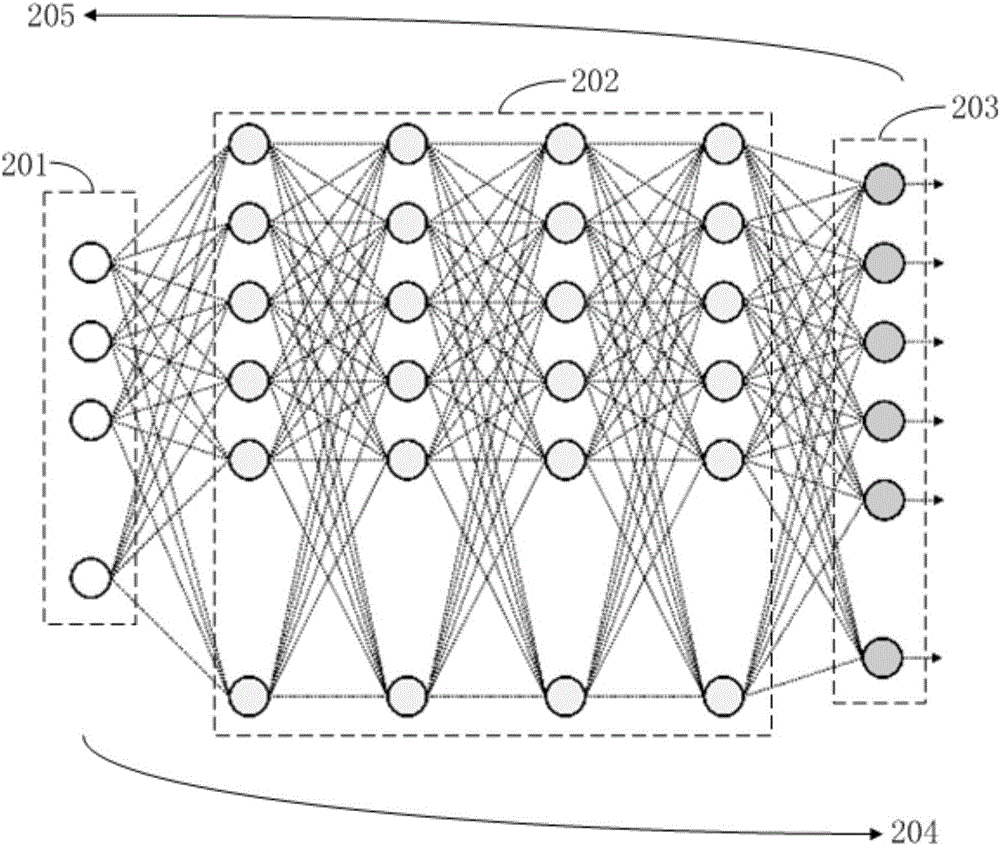

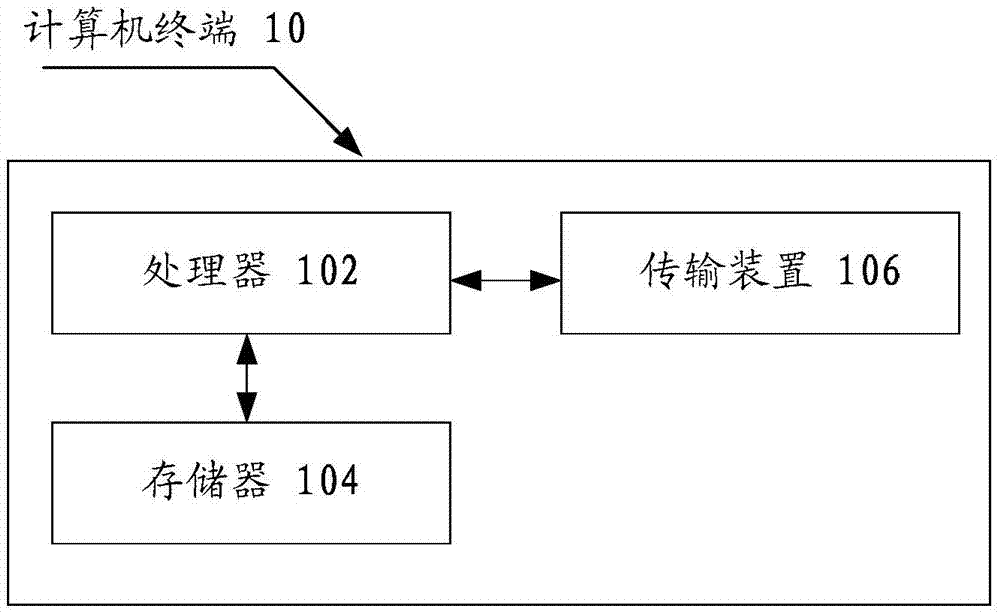

Advertisement ordering method and device

ActiveCN105046515AImprove accuracyFix technical issues with lower accuracyMarketingNeural learning methodsAlgorithmClick-through rate

The invention provides an advertisement ordering method comprising the steps that advertisement image characteristic parameters and advertisement text characteristic parameters are acquired; the advertisement image characteristic parameters and the advertisement text characteristic parameters are set as input vectors of a first depth neural network; first model training is performed on the first depth neural network so that pre-estimated advertisement click-through rate characteristics are outputted; and advertisement ordering is performed according to the pre-estimated advertisement click-through rate characteristics. The invention also provides an advertisement ordering device. According to the advertisement ordering method and device, statistics is performed on the characteristics of advertisement images via the convolutional neural network so that accuracy of advertisement click-through rate pre-estimation is enhanced.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

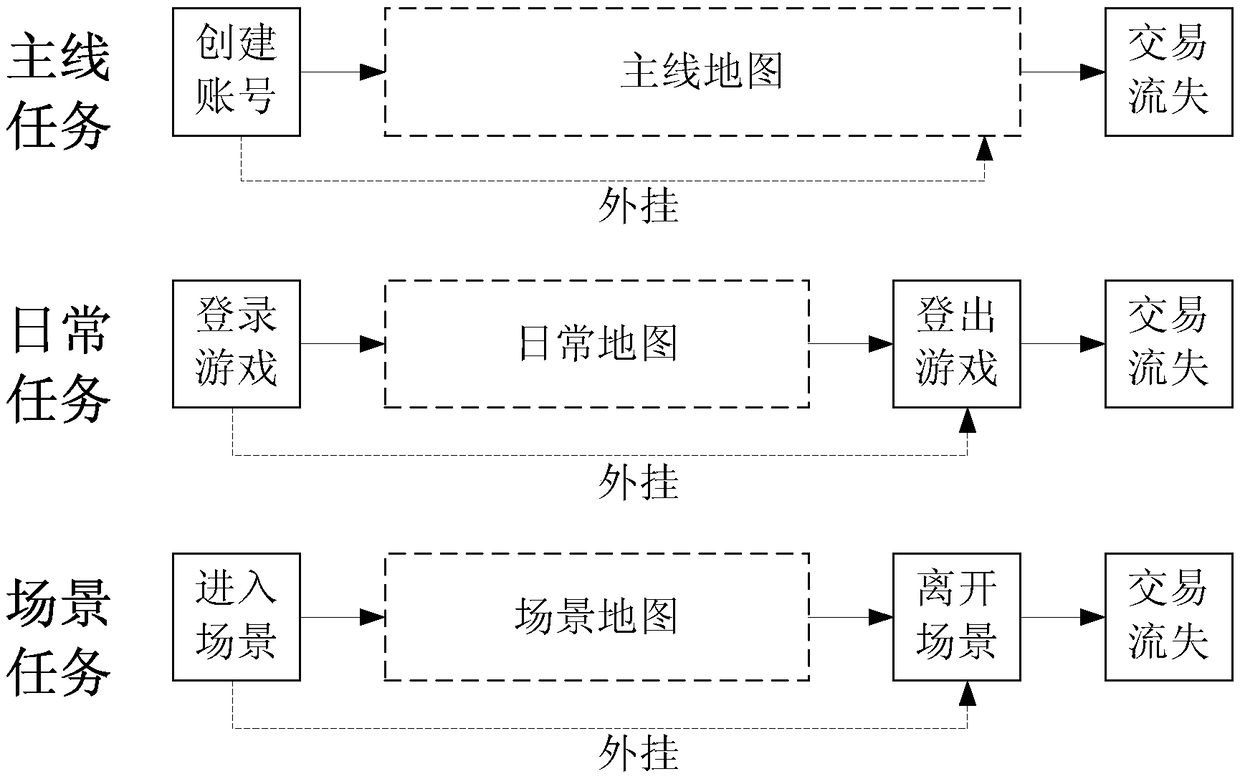

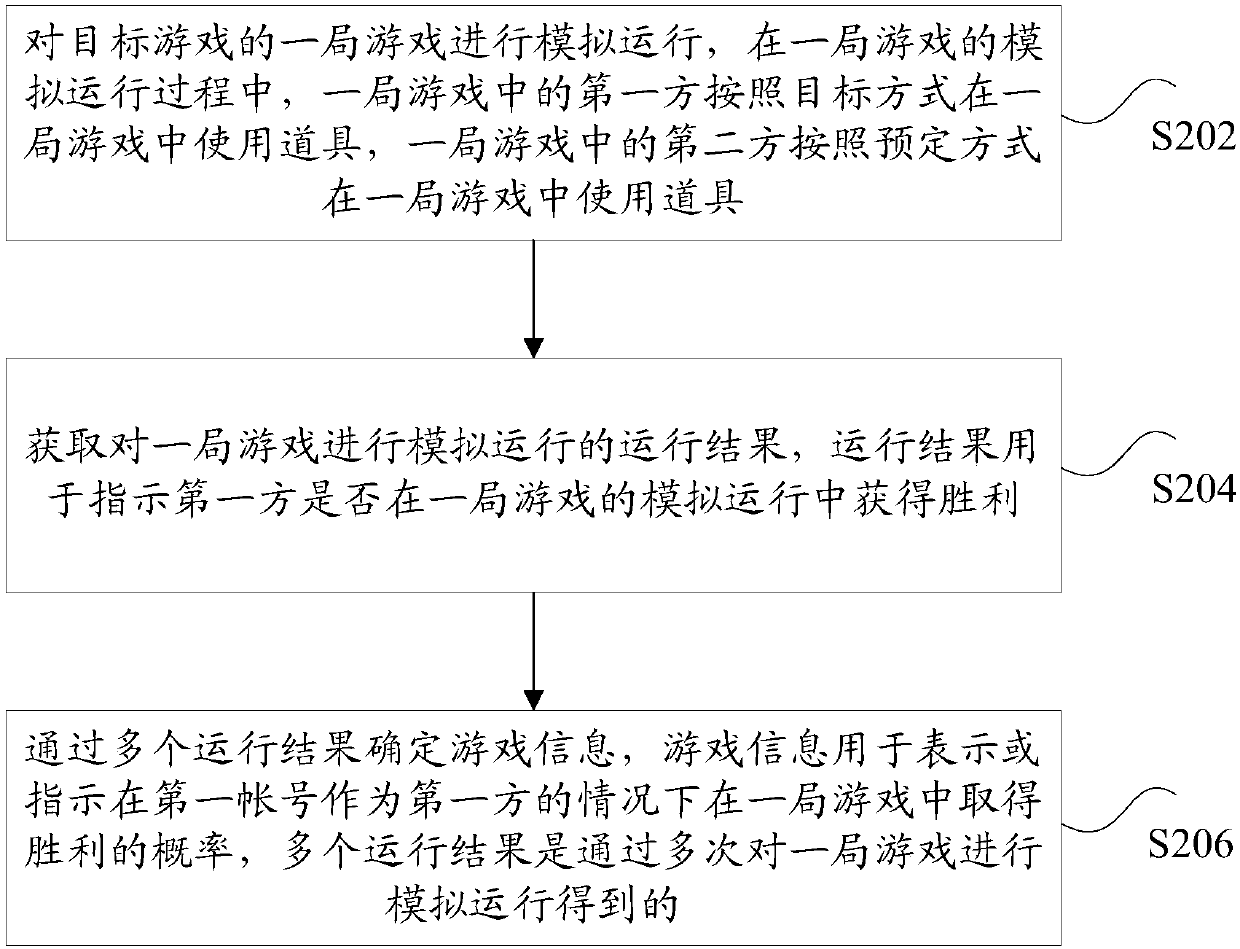

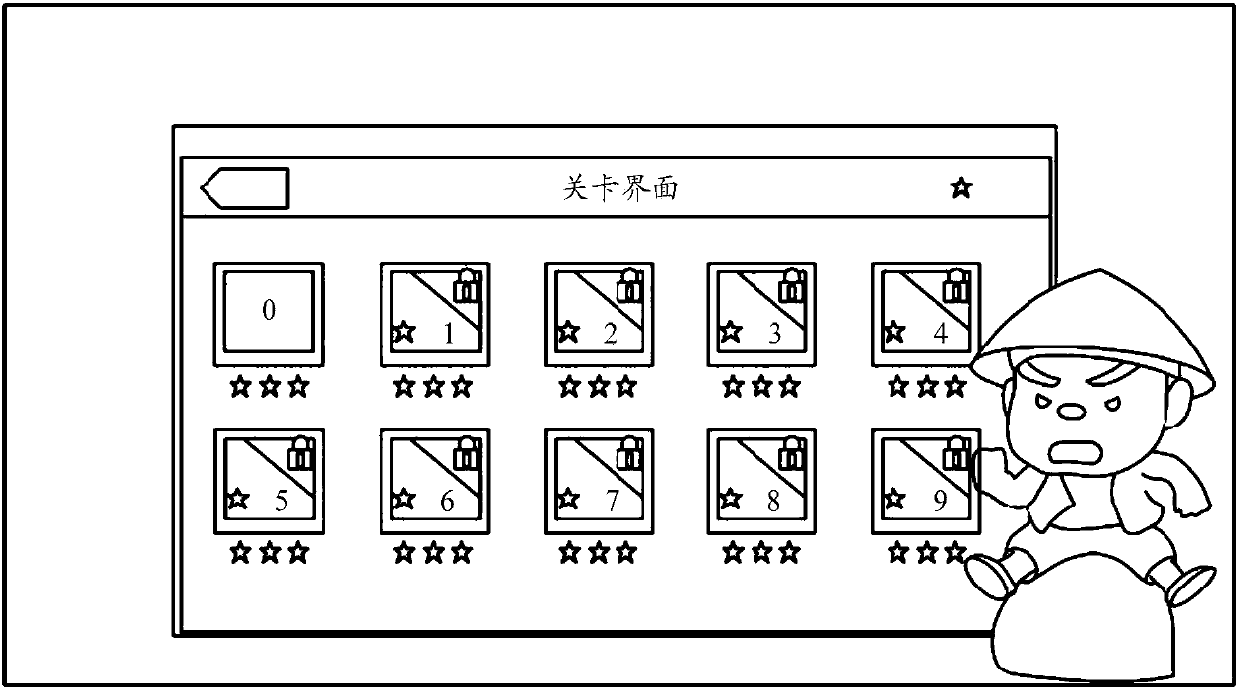

Setting method and device of pass game, storage medium and electronic device

ActiveCN107970608AFix technical issues with lower accuracyAvoid subjective factorsVideo gamesHuman–computer interaction

Owner:TENCENT TECH CHENGDU

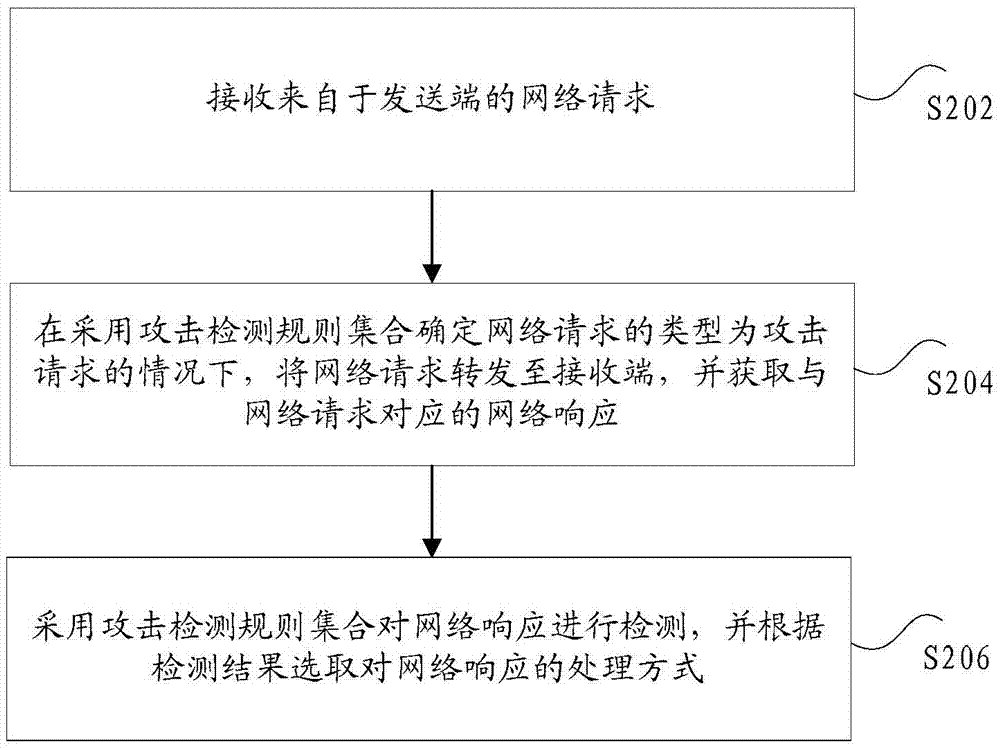

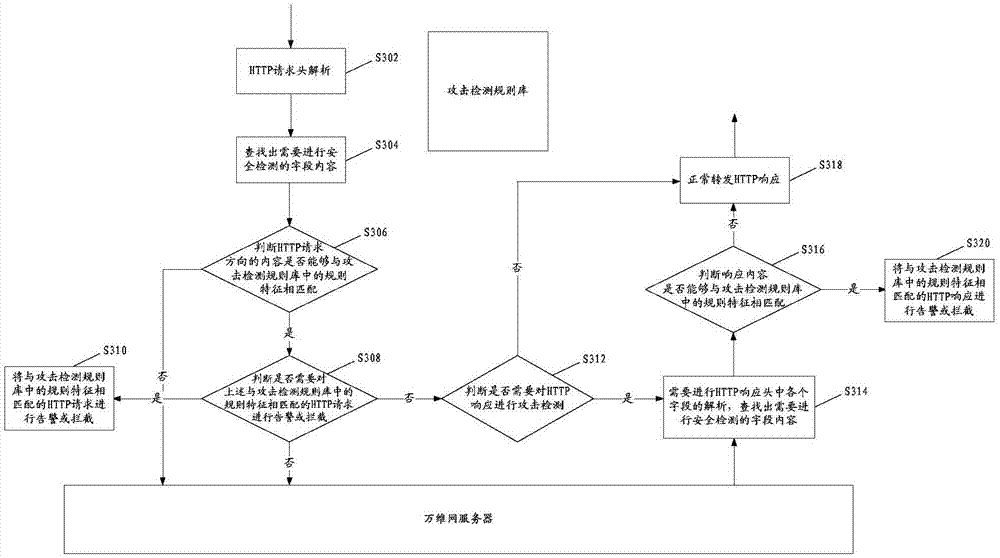

Method and device for detecting network attack

InactiveCN107046518AImprove accuracy and effectivenessLow resolution accuracyTransmissionUnidirectional networkNetwork attack

The invention discloses a method and device for detecting network attacks. The method comprises the following steps: receiving a network request from a sender; when determining that the type of the network request is an attack request by adopting an attack detection rule set, forwarding the network request to a receiver, and acquiring a network response corresponding to the network request; and detecting the network response by adopting the attack detection rule set, and selecting a processing mode of the network response according to a detection result. By adopting the method and device disclosed by the invention, the technical problem that a one-way network attack detection method adopted in related technologies is relatively low in accuracy can be solved.

Owner:ALIBABA GRP HLDG LTD

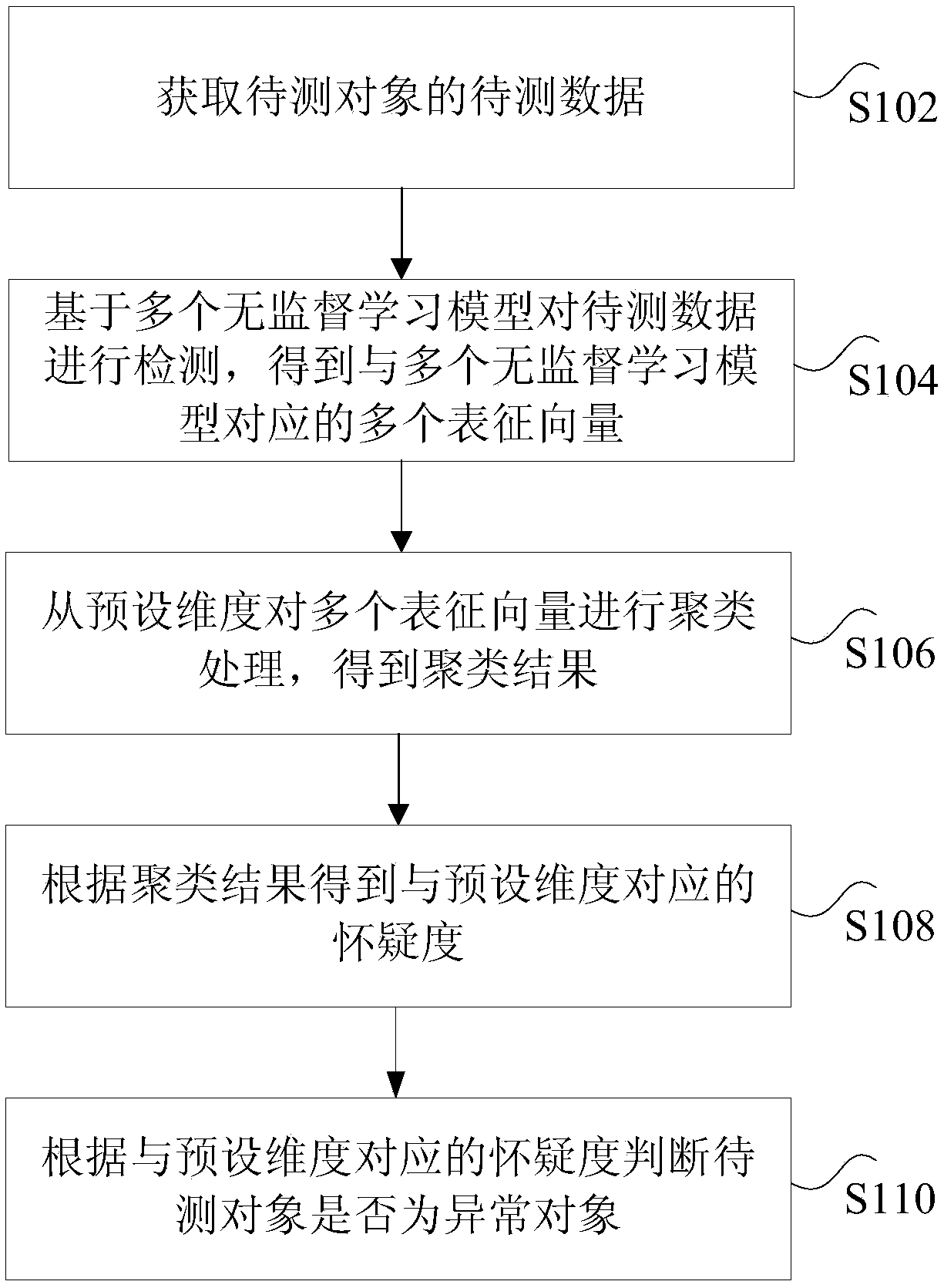

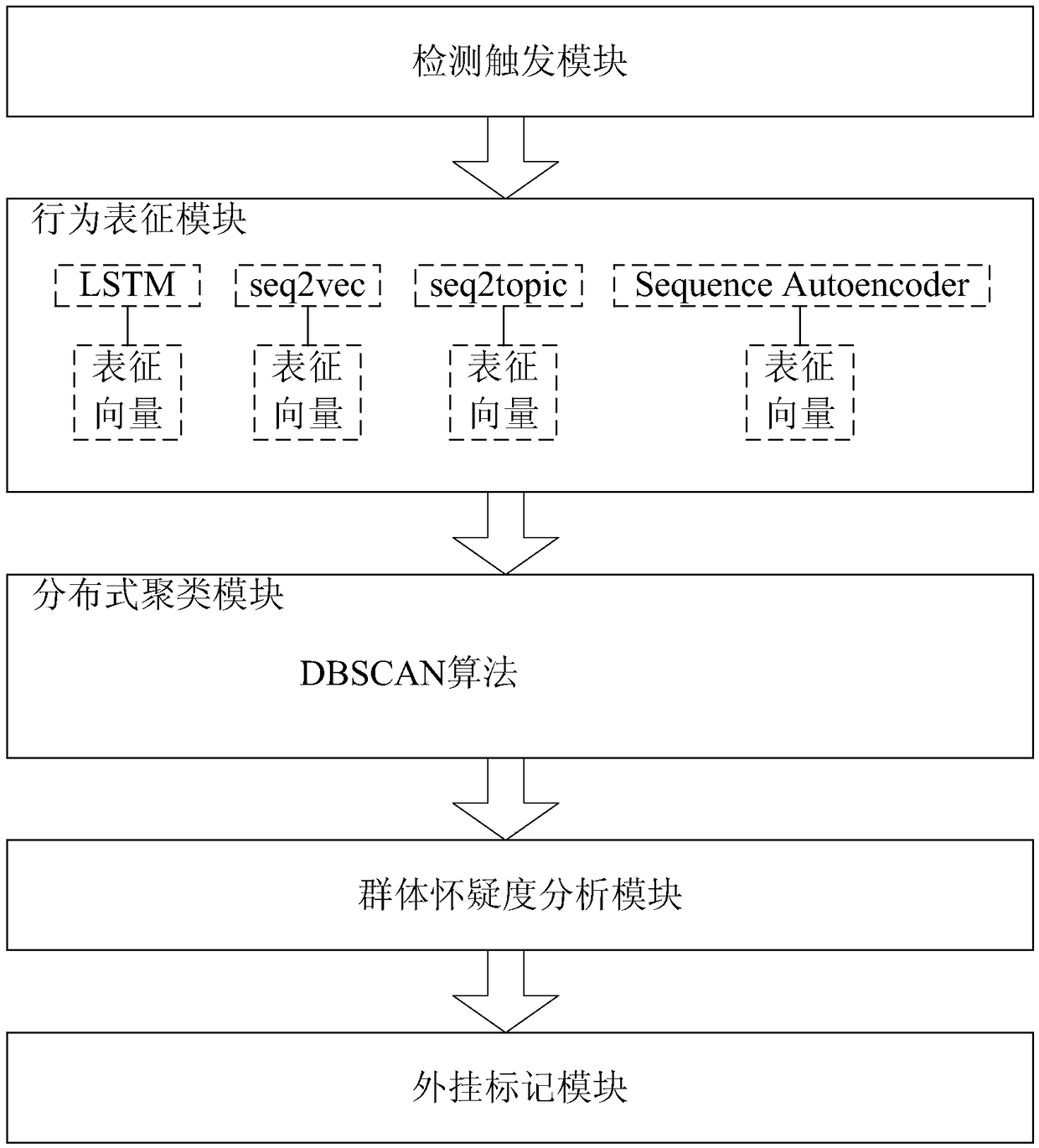

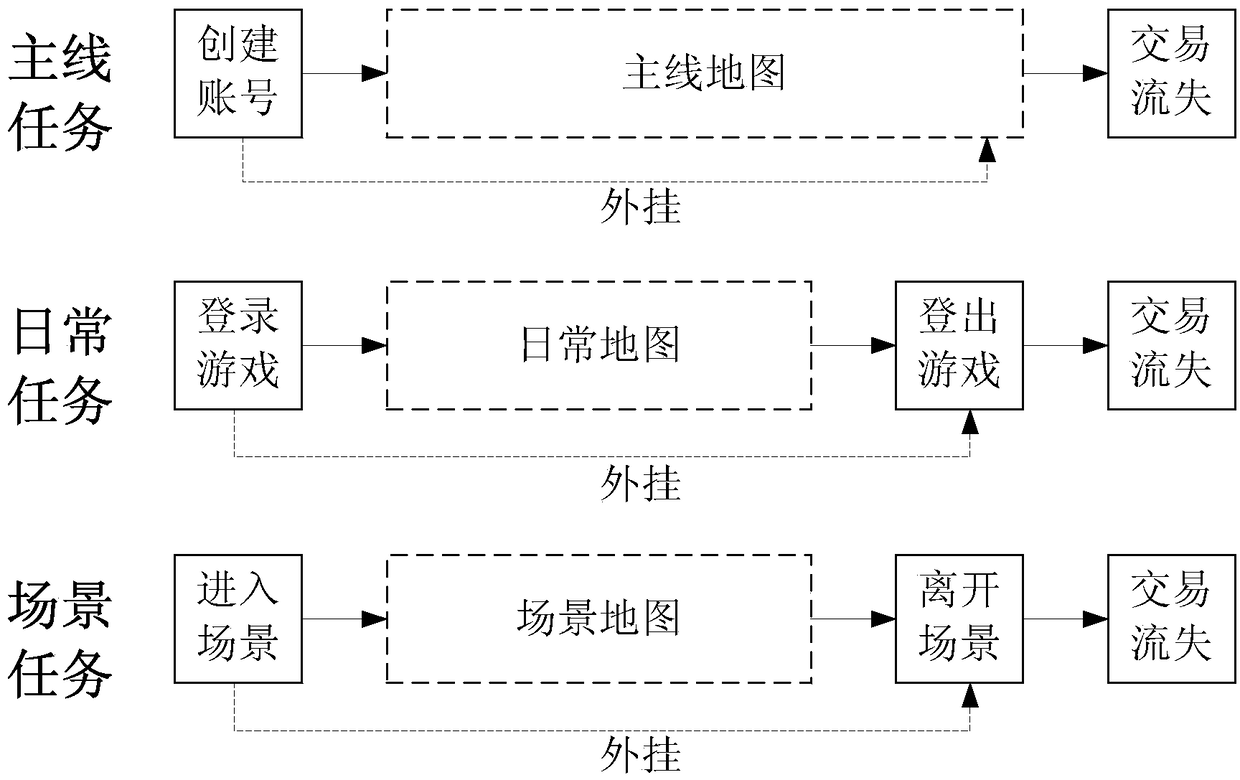

Method, device and terminal for detecting game hanging

The invention discloses a method, device and terminal for detecting game plug-in. The method comprises the following steps of: acquiring data to be detected of an object to be detected; detecting datato be detected based on a plurality of unsupervised learning models to obtain a plurality of characterization vectors corresponding to the plurality of unsupervised learning models, wherein the plurality of unsupervised learning models are used for training data of a plurality of objects to obtain a plurality of characterization vectors; carrying out clustering processing on a plurality of characterization vectors from a preset dimension to obtain a clustering result; obtaining the doubt degree corresponding to the preset dimension according to the clustering result; and judging whether the object to be detected is an abnormal object or not according to the doubt degree corresponding to the preset dimension, wherein the abnormal object has a plug-in behavior. The method, device and terminal for detecting game plug-in solves the technical problem of low accuracy of detecting the game plug-in in the prior art.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

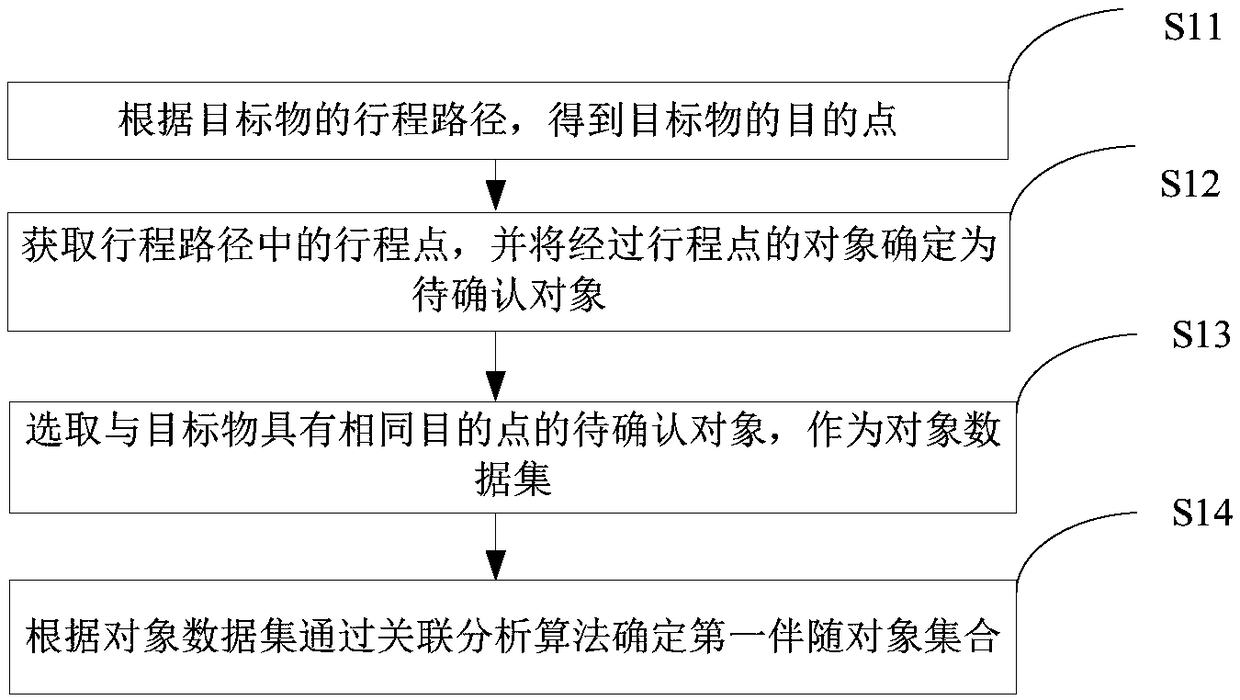

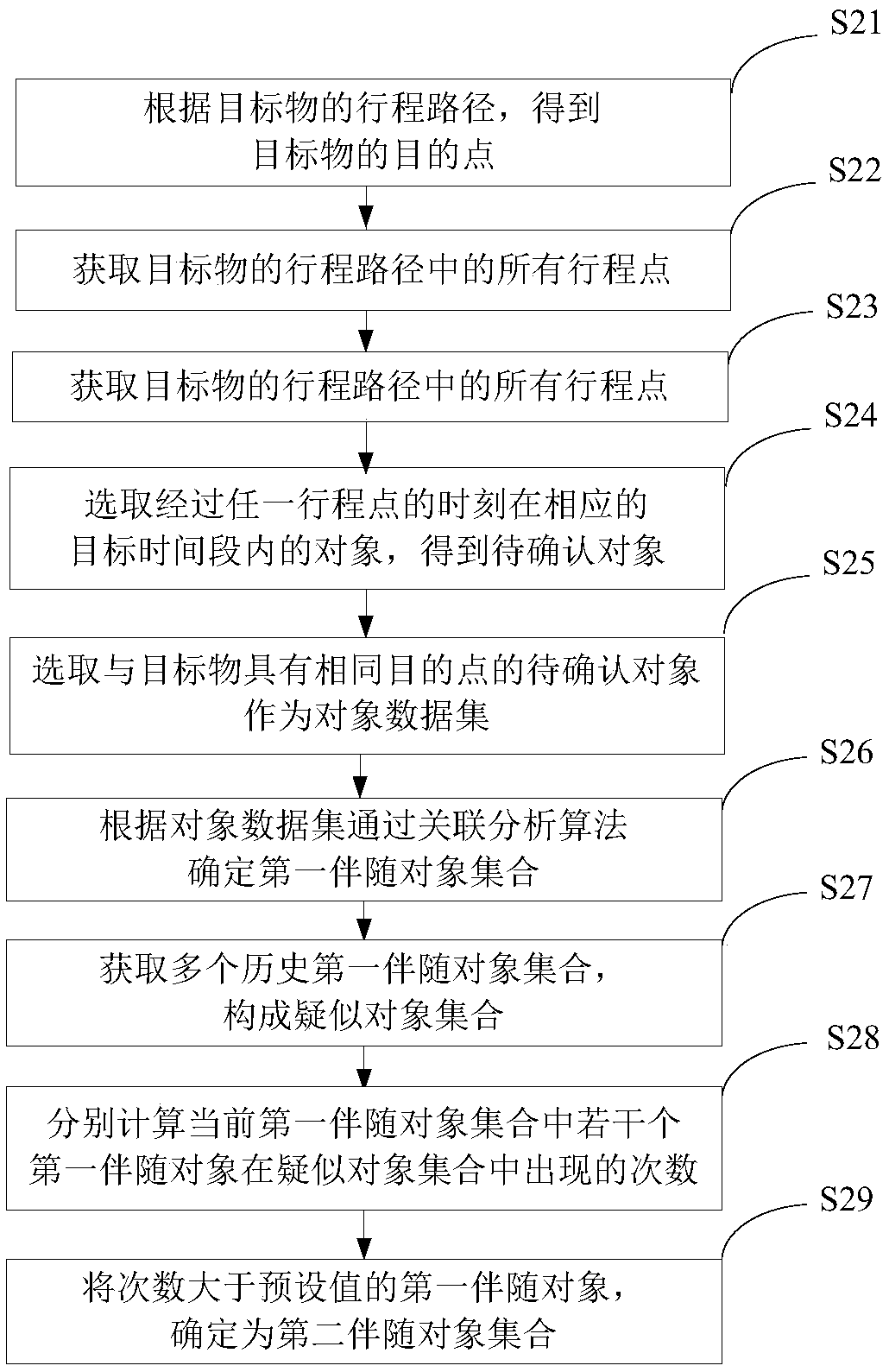

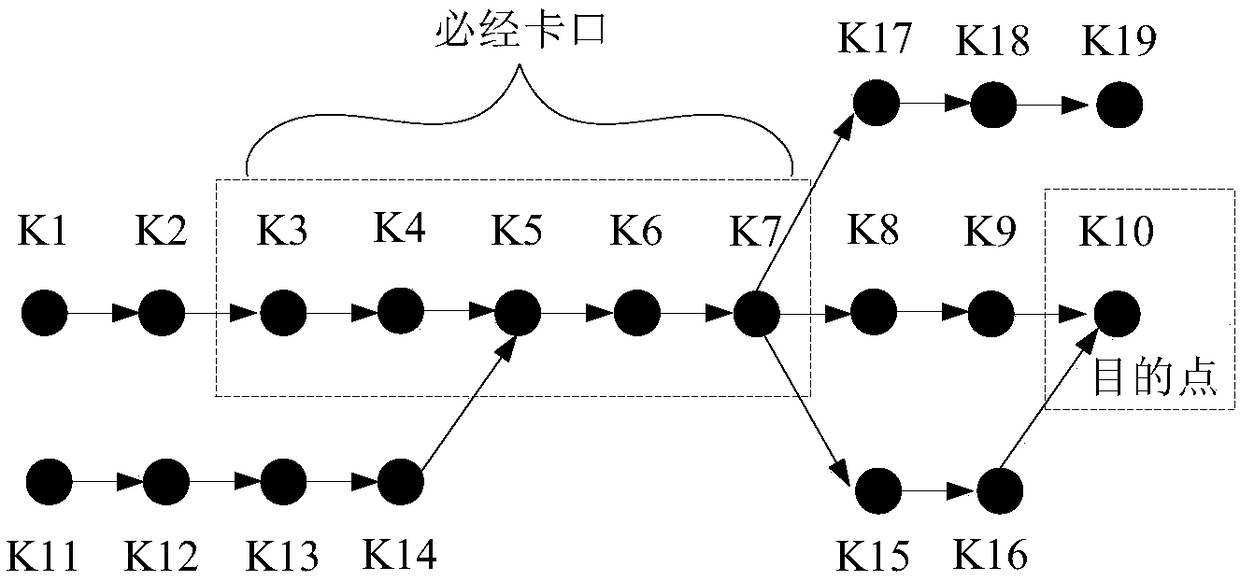

Accompanying object determining method and device, and electronic device

ActiveCN109165237AAvoid misjudgmentReduce false positive rateDigital data information retrievalSpecial data processing applicationsData setComputer vision

The invention provides an accompanying object determining method and device and an electronic device, which relate to the technical field of data mining. The accompanying object determining method comprises the following steps: obtaining a destination point of the target object according to a travel path of the target object; acquiring a travel point in the travel path, and determining an object passing through the travel point as an object to be confirmed; selecting an object to be confirmed having the same destination point as the object as an object data set; according to the object data set, determining a first concomitant object set by an association analysis algorithm, thereby solving the technical problem of low accuracy of current concomitant vehicle discovery methods in the priorart.

Owner:NEW H3C BIG DATA TECH CO LTD

Picture rendering method and device, storage medium, and electronic device

ActiveCN109461199AClear hierarchyThe occlusion relationship is obviousImage analysisVideo gamesComputer graphics (images)Fixed position

The invention discloses a picture rendering method and a device, a storage medium and an electronic device. The method comprises the following steps of: determining a target picture to be rendered ina two-dimensional virtual scene to be rendered by a client, wherein, the target picture comprises a background picture and a character object moving on the background picture, and the background picture comprises a target object located at a fixed position; Determining a first depth value corresponding to pixel points on a target object in a background picture by using a depth offset indicated ina depth map corresponding to the target object, wherein depth maps record depth offsets of pixel points on the target object; Acquiring a second depth value corresponding to a pixel point on the character object moved to the current display position; The target picture is rendered according to the first depth value and the second depth value. The invention solves the technical problem of low accuracy of rendering two-dimensional picture information in the related art.

Owner:TENCENT TECH (SHENZHEN) CO LTD

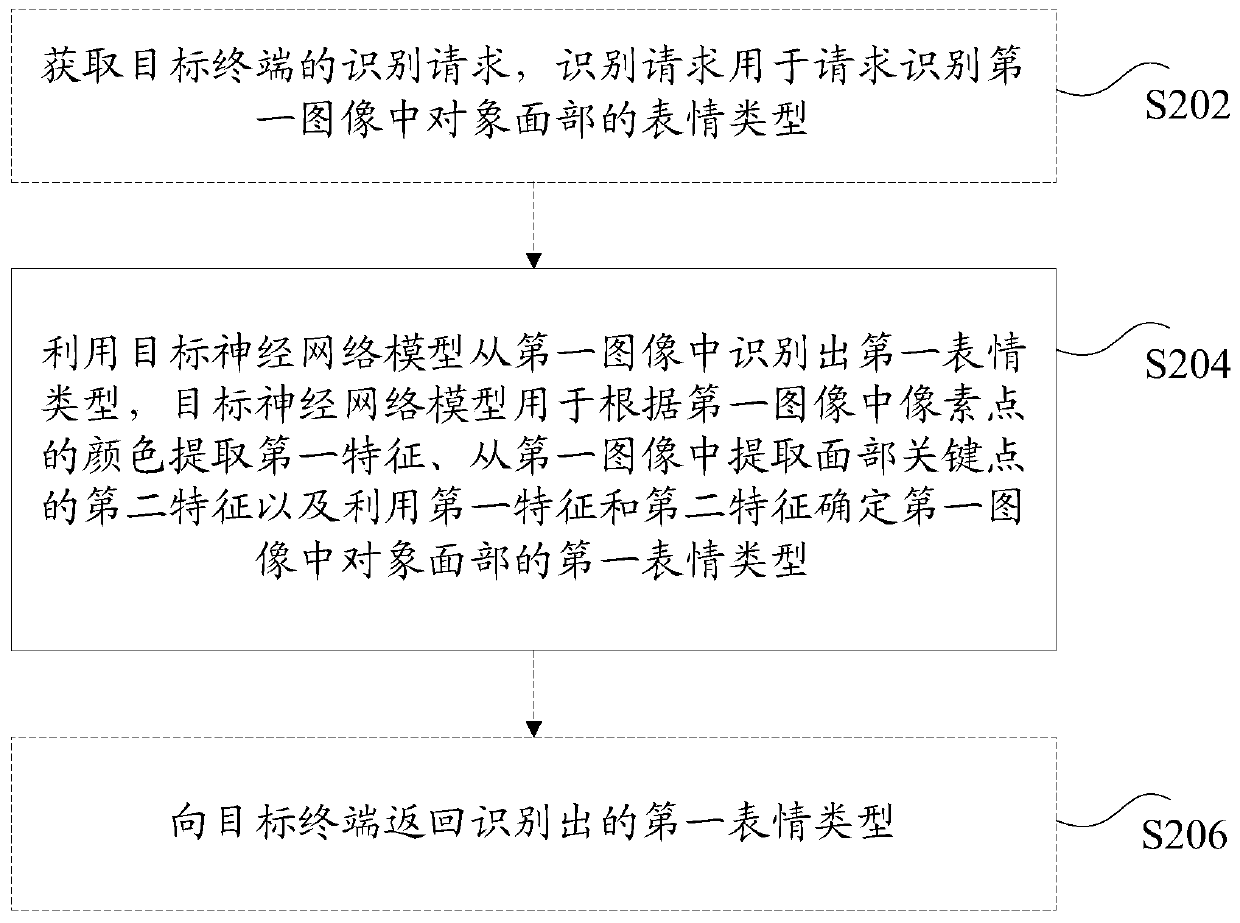

Facial expression recognition method and device, storage medium and electronic device

ActiveCN110263681AAccurate identificationFix technical issues with lower accuracyAcquiring/recognising facial featuresNeural learning methodsPattern recognitionNetwork model

The invention discloses a facial expression recognition method and device, a storage medium and an electronic device. The method comprises the following steps: utilizing the target neural network model to identify a first expression type from the first image, wherein the target neural network model is used for extracting a first feature according to the color of a pixel point in the first image, extracting a second feature of a face key point from the first image, and determining a first expression type of an object face in the first image by using the first feature and the second feature. According to the method, the technical problem of low accuracy of identifying the facial expression type in the prior art is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

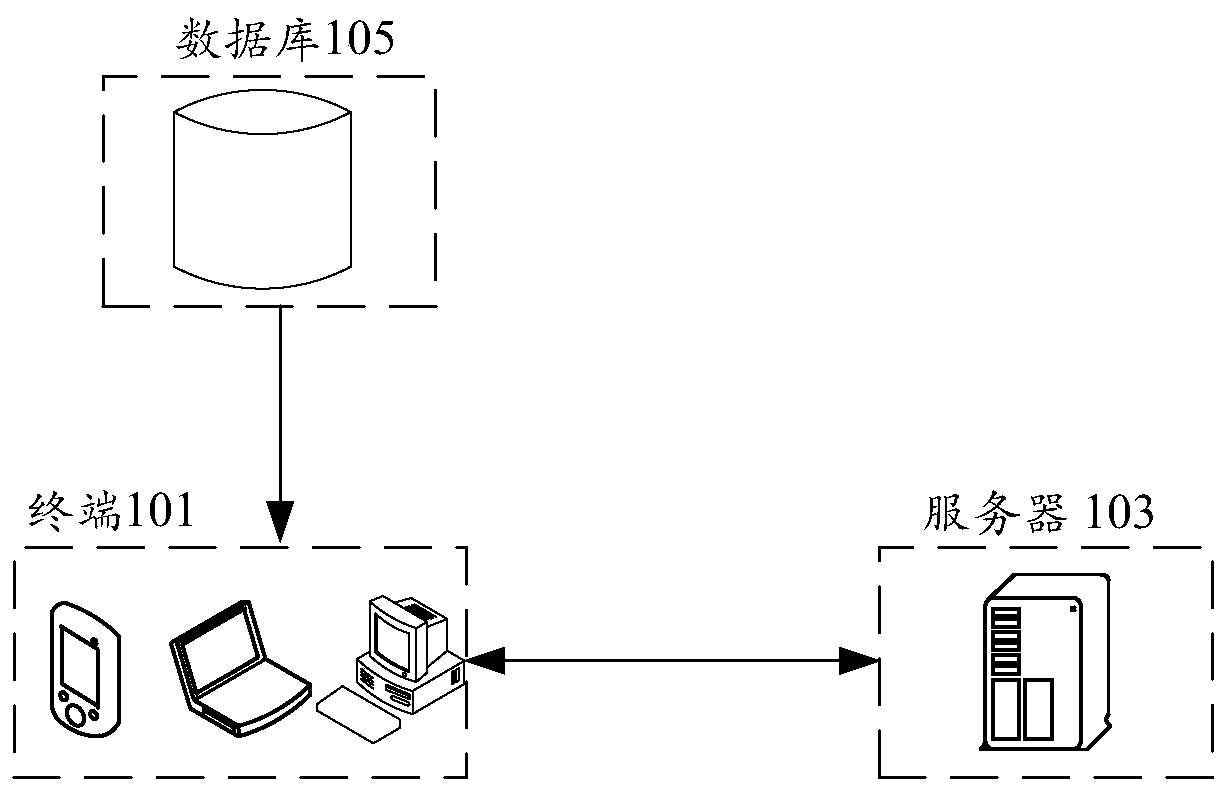

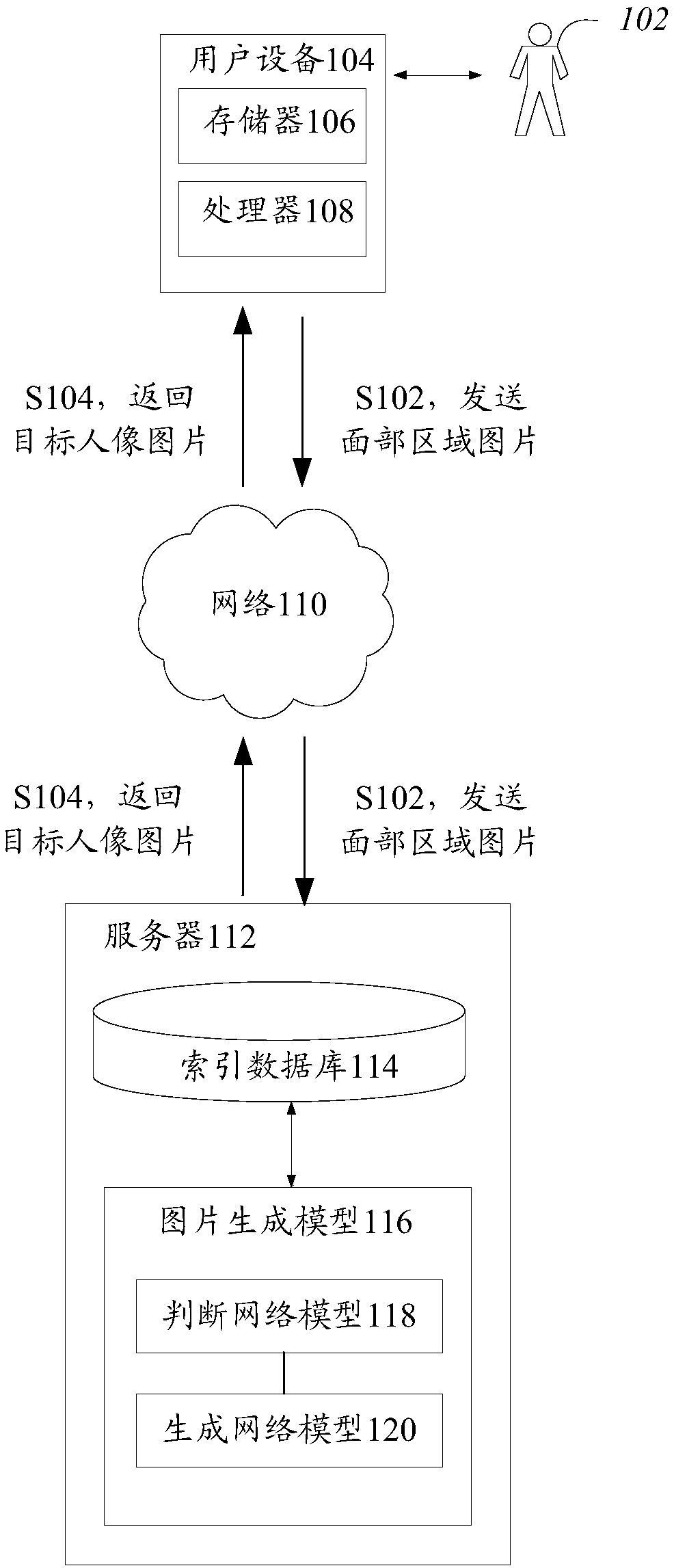

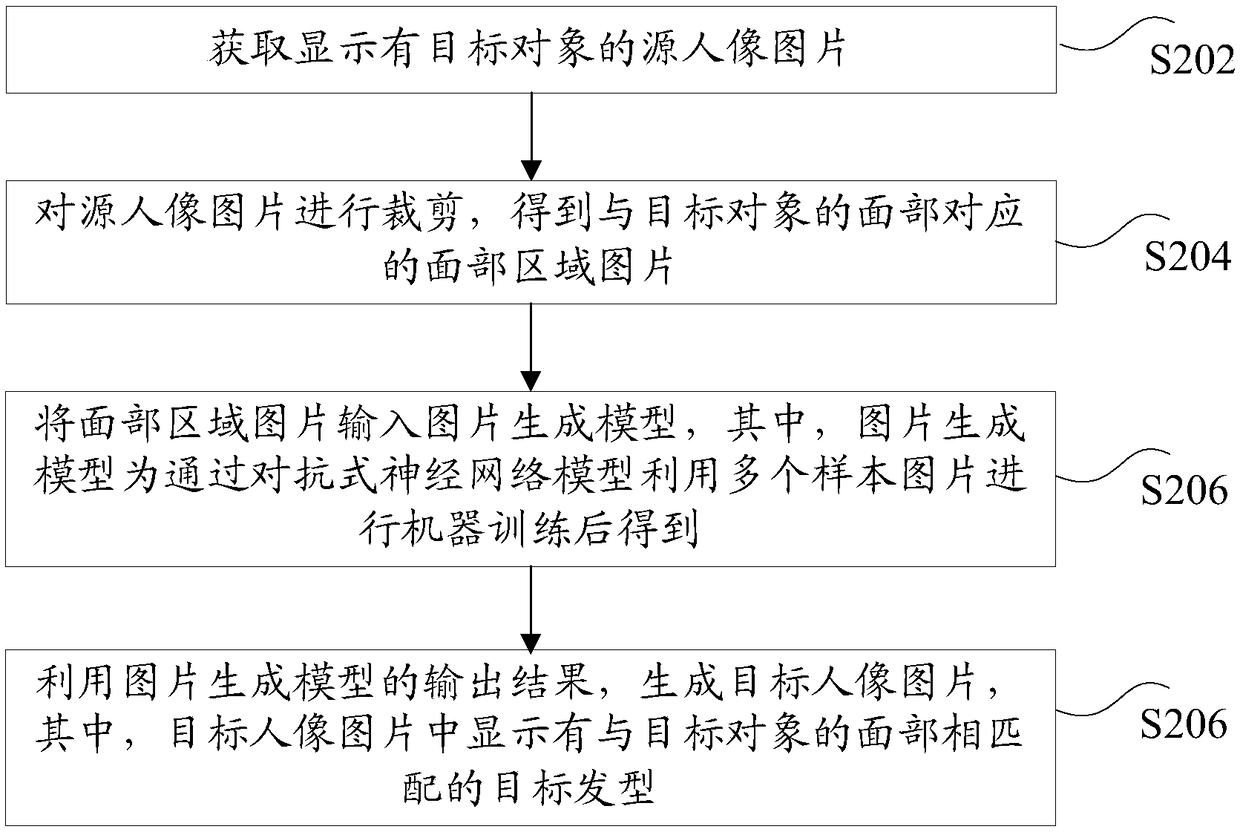

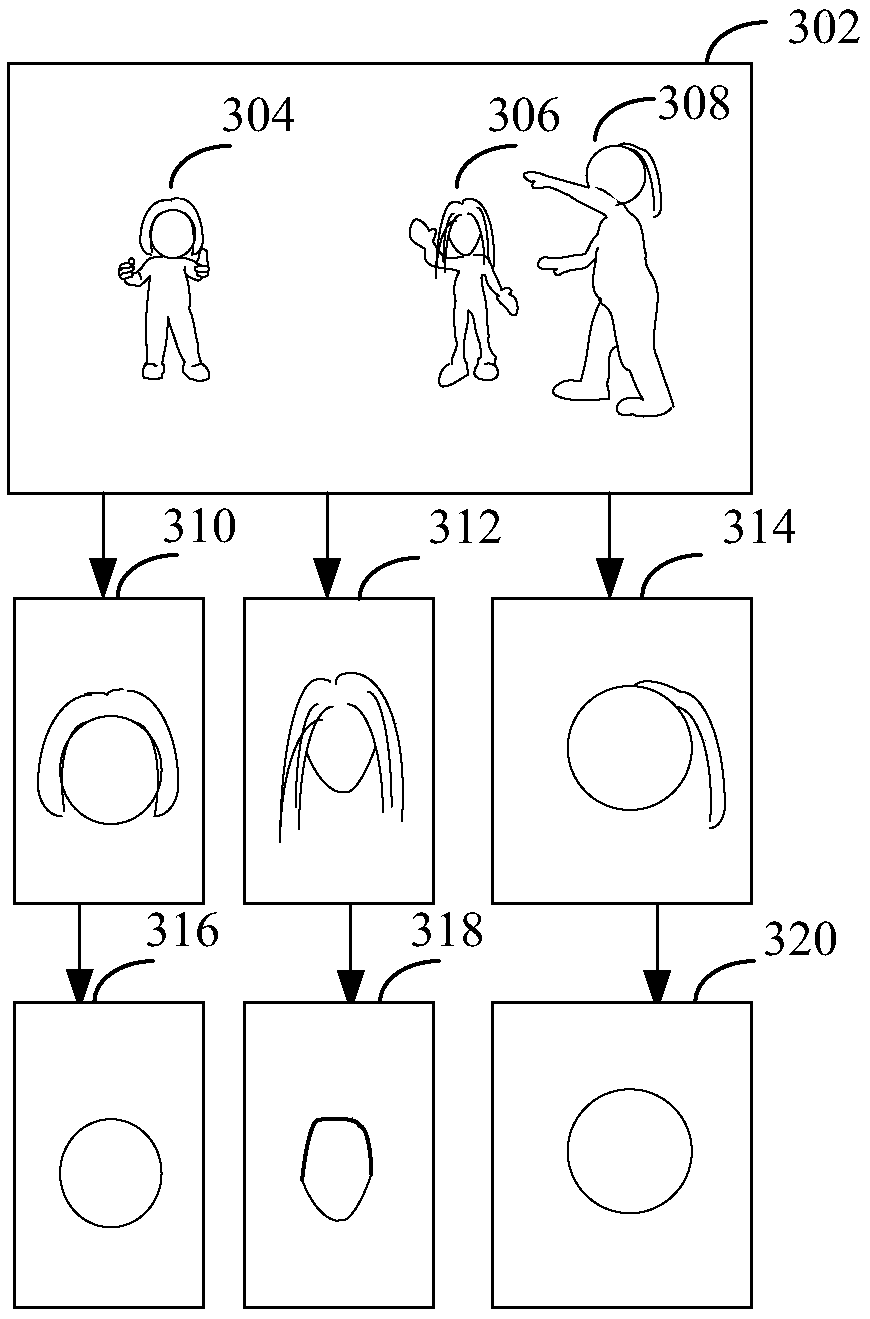

Picture generation method and device, storage medium and electronic device

ActiveCN109447895AImprove production efficiencyImprove accuracyGeometric image transformationCharacter and pattern recognitionFacial regionComputer graphics (images)

Owner:TENCENT TECH WUHAN

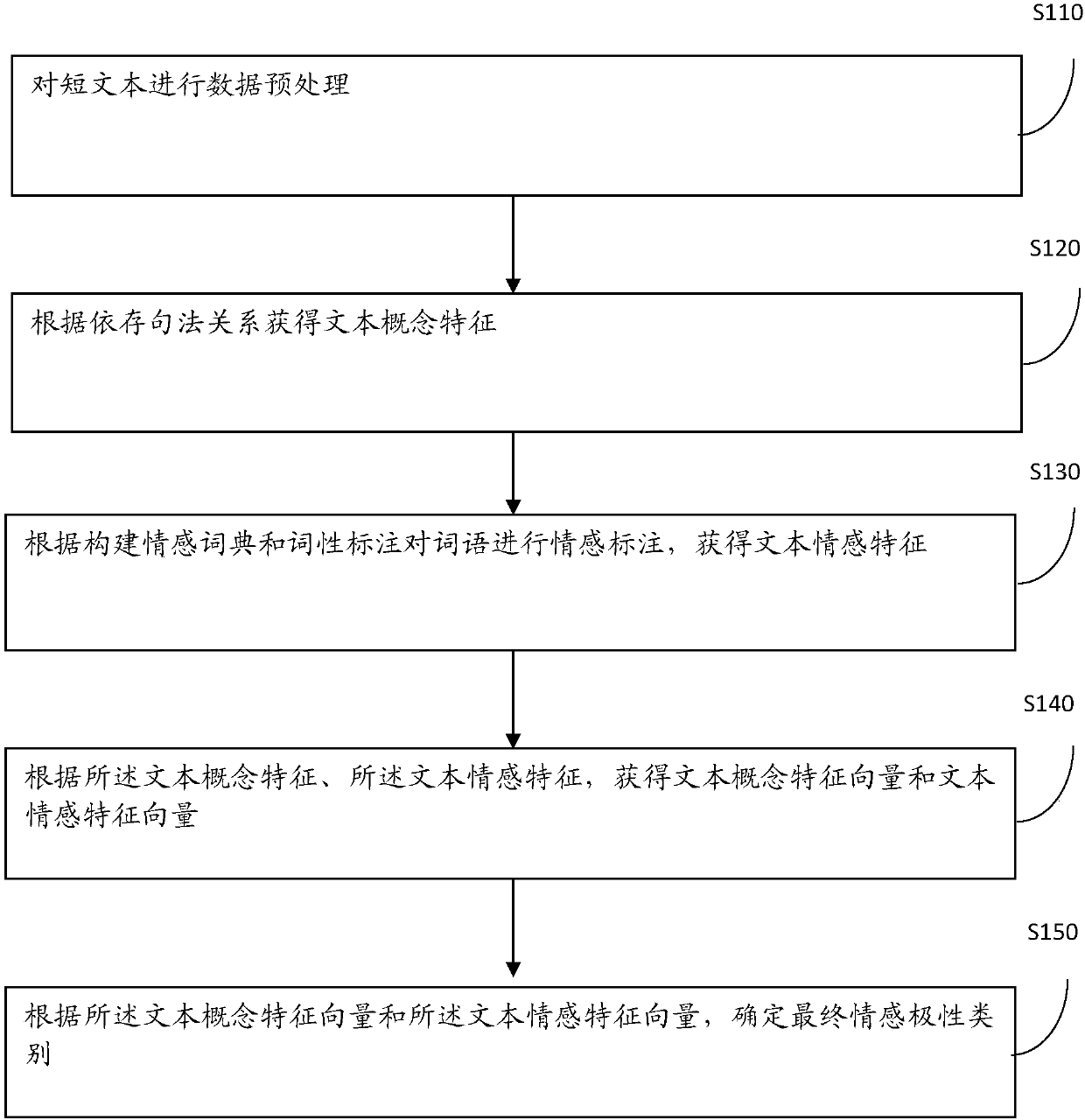

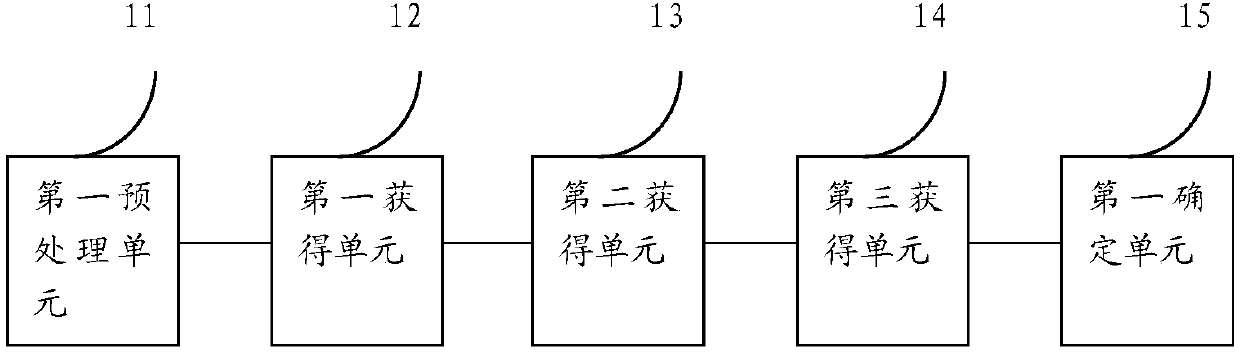

Short-text emotion analysis method and device based on concept based on text emotion

InactiveCN108108468AFix technical issues with lower accuracyImprove accuracySemantic analysisCharacter and pattern recognitionInformation processingPart of speech

The invention provides a short-text emotion analysis method and device based on concept and text emotion, and relates to the technical field of information processing techniques. The method includes the steps of carrying out data preprocessing on a short-text; according to a dependence grammar relation, obtaining text concept features; according to a constructed emotion dictionary and part-of-speech annotations, carrying out emotion annotation and obtaining text emotion features; according to the text concept features and the text emotion features, obtaining text concept feature vectors and text emotion feature vectors; according to the text concept feature vectors and the text emotion feature vectors, determining a final emotion polarity type. The method and device solve the technical problems that since analysis methods in the prior art are influenced by the volume of a corpus and a feature extraction process, the accuracy of emotion analysis is low. The technical effects of fully utilizing valid information of emotion analysis based on the concept features and the text emotion features is achieved, and the technical effect of improving the accuracy of emotion polarity classification is improved.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

Statement-type identification method and device, storage medium and electronic device

ActiveCN108897732AAccurate detectionImprove accuracyNatural language data processingSpecial data processing applicationsFeature vectorCategorical models

Owner:TENCENT TECH (SHENZHEN) CO LTD

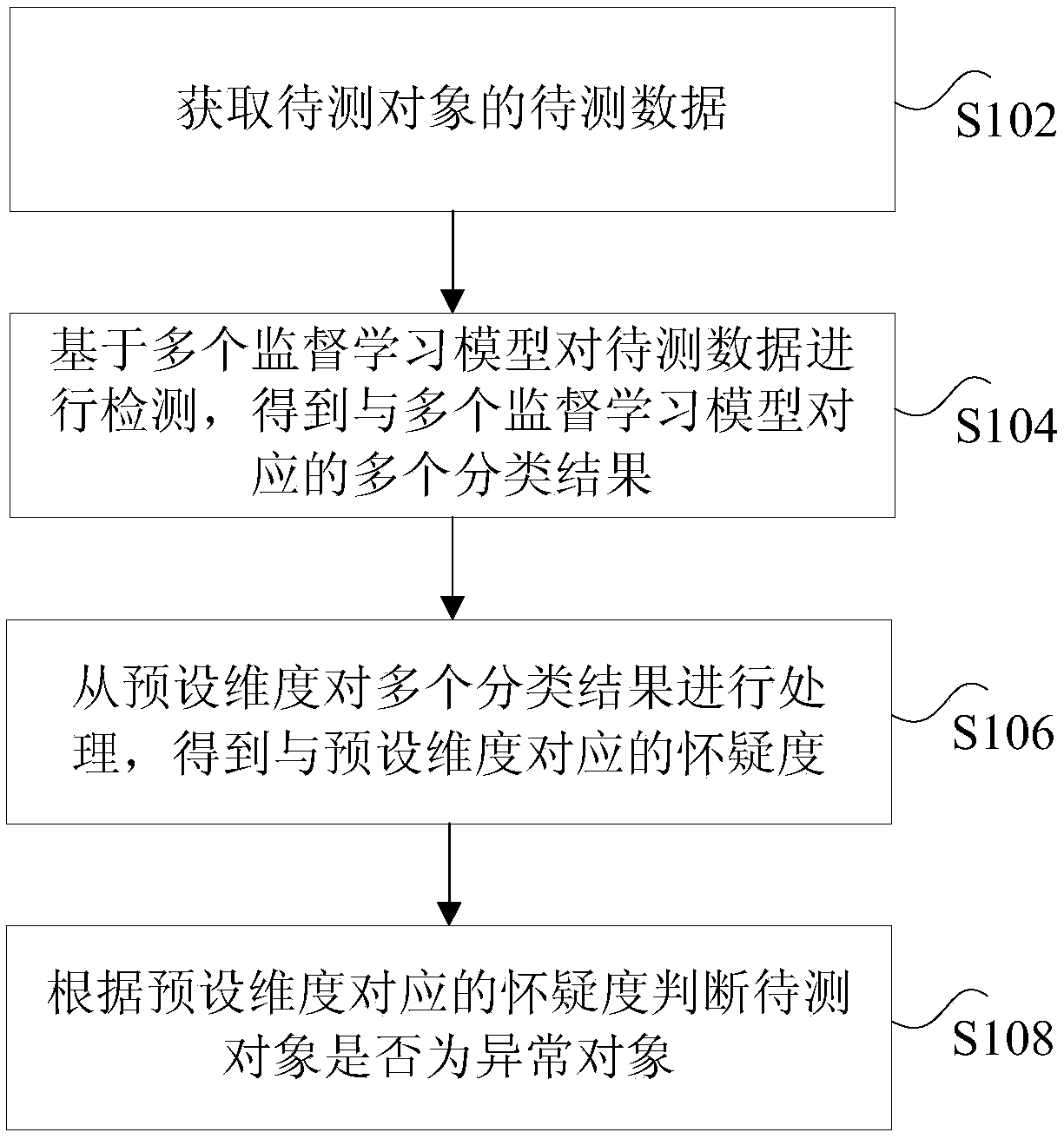

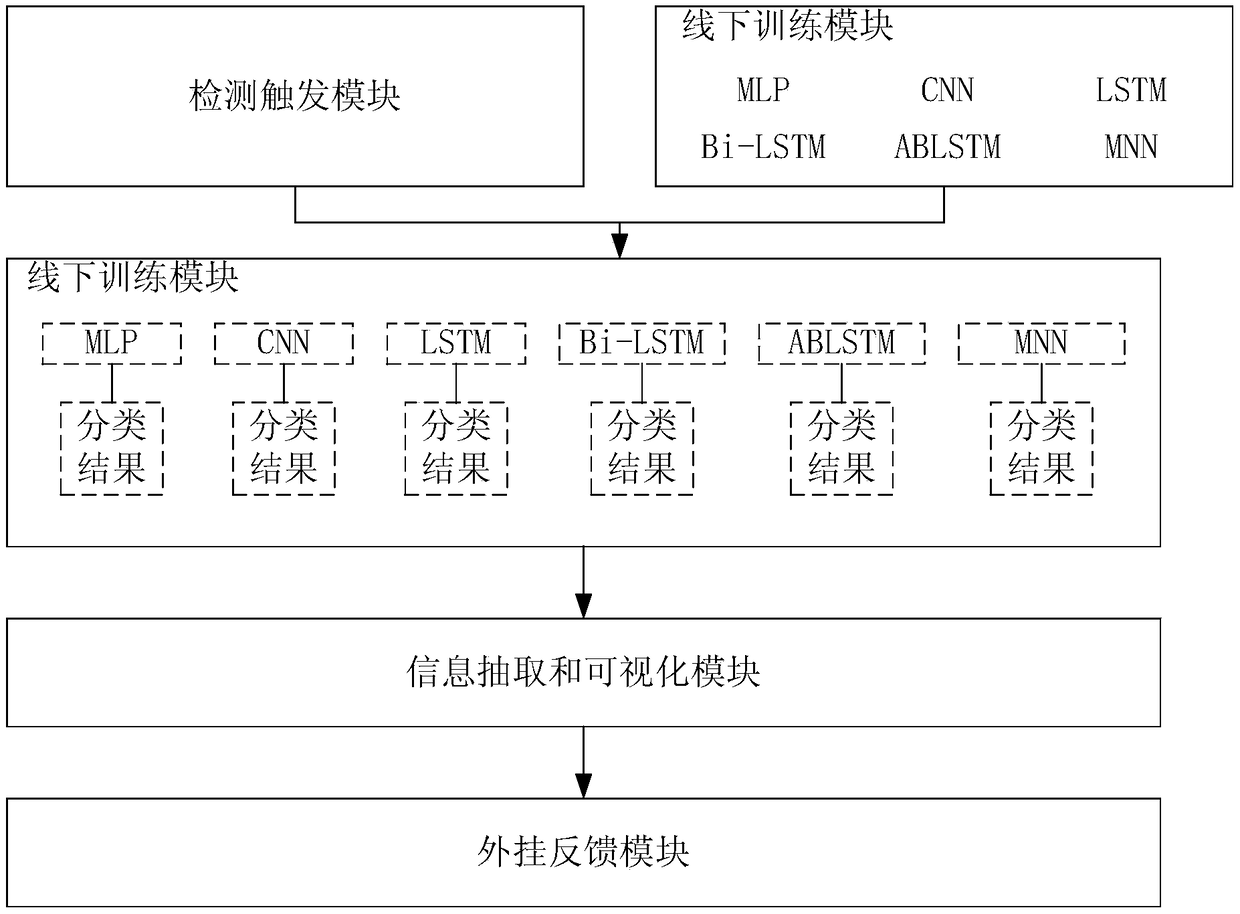

Method, device and terminal for detecting game plug-in

PendingCN109464808AImprove accuracyReduce manual involvementVideo gamesComputer visionClassification result

The invention discloses a method, device and terminal for detecting game plug-in. The method comprises the following steps of: acquiring data to be detected of an object to be detected; detecting datato be detected based on a plurality of supervised learning models to obtain a plurality of classification results corresponding to the plurality of supervised learning models, wherein the plurality of supervised learning models are used for training data of a plurality of objects to obtain a plurality of classification results; processing a plurality of classification results from a preset dimension to obtain a degree of suspicion corresponding to the preset dimension; and judging whether the object to be detected is an abnormal object or not according to the suspicion degree corresponding tothe preset dimension, wherein the abnormal object has a plug-in behavior. The method, device and terminal for detecting game plug-in solves the technical problem of low accuracy of detecting the gameplug-in in the prior art.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

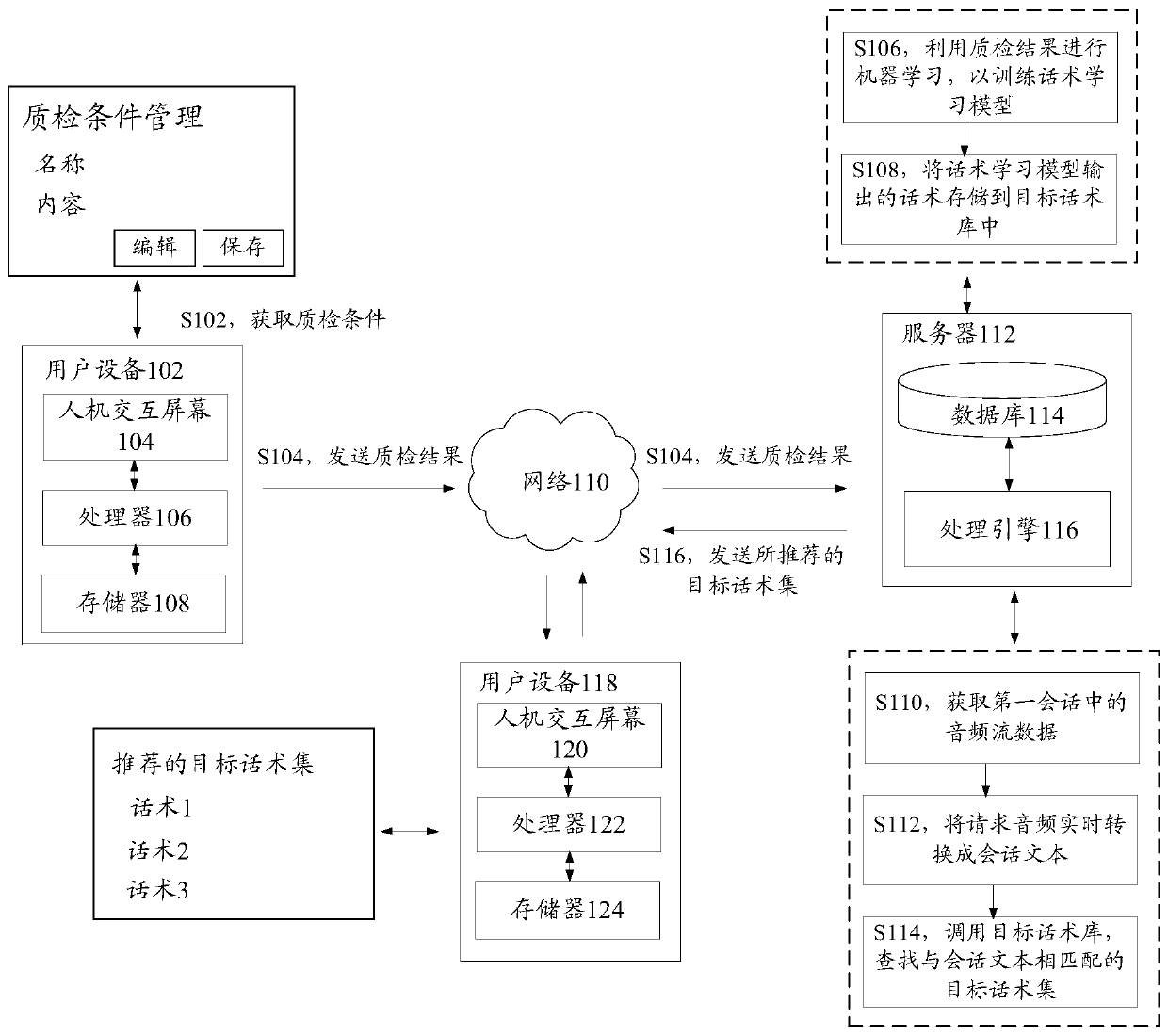

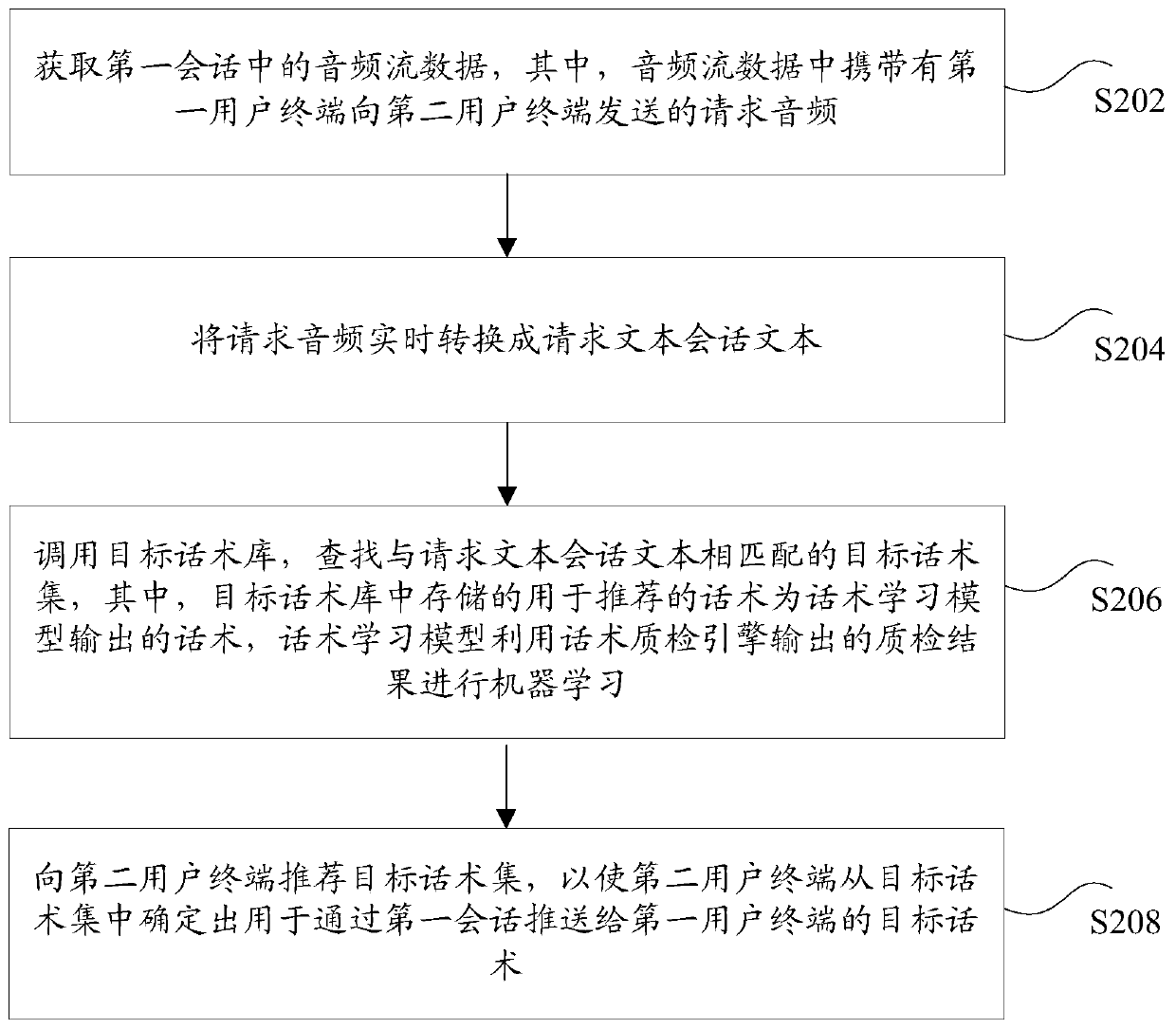

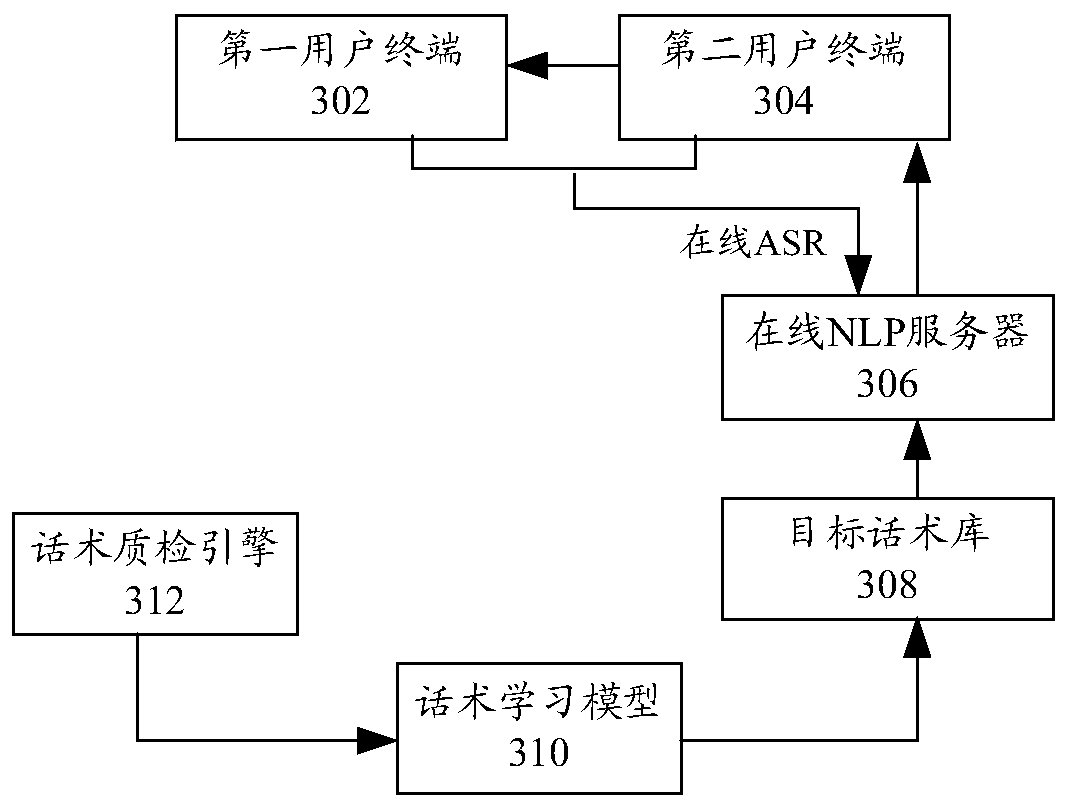

Verbal skill recommendation method and device and storage medium

PendingCN110347863AImprove accuracyImprove matchDigital data information retrievalSpecial data processing applicationsStreaming dataSkill sets

The invention discloses a verbal skill recommendation method and device and a storage medium. The verbal skill recommendation method comprises the following steps: acquiring audio stream data in a first session, the audio stream data carrying request audio sent by a first user terminal to a second user terminal; converting the request audio into a session text in real time; calling a target verbalskill library, searching a target verbal skill set matched with the session text, the verbal skill for recommendation stored in the target verbal skill library being output by a verbal skill learningmodel, and the verbal skill learning model performing machine learning by using a quality inspection result output by a verbal skill quality inspection engine; and recommending the target verbal skill set to the second user terminal, so that the second user terminal determines a target verbal skill used for being pushed to the first user terminal through the first session from the target verbal skill set. The technical problem that a verbal skill recommendation method provided by related technologies is low in accuracy is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

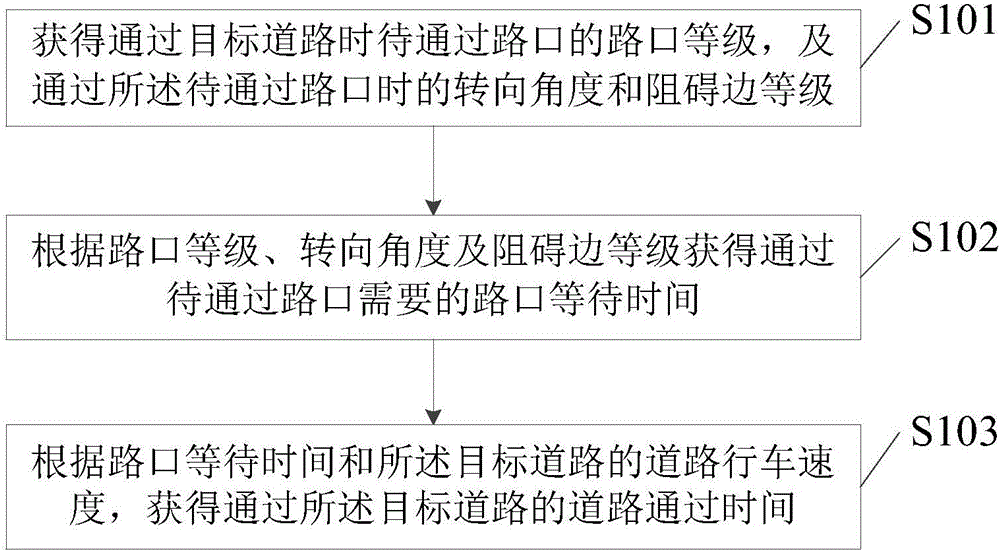

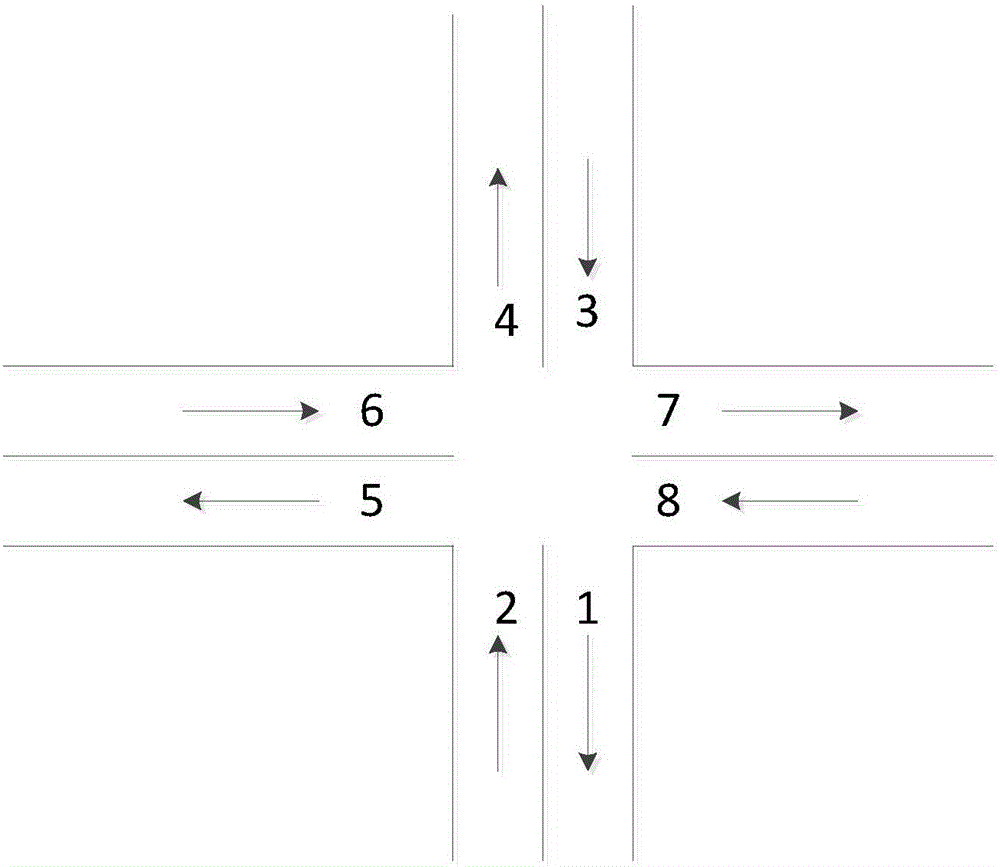

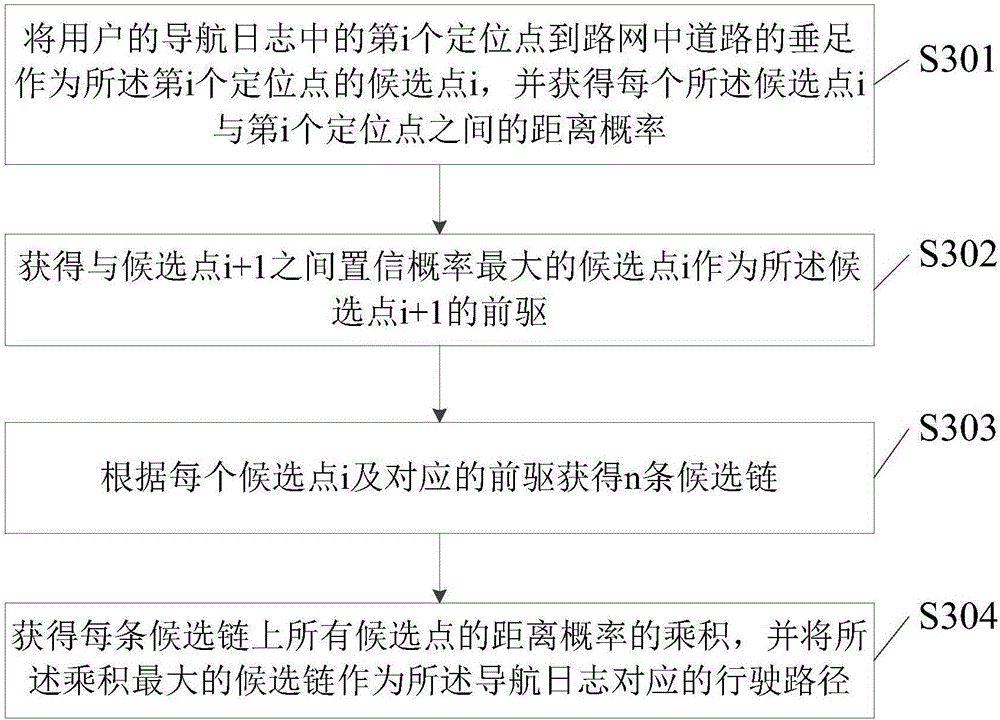

Method for acquiring road passing time and electronic equipment

ActiveCN105737841AFix technical issues with lower accuracyImprove accuracyInstruments for road network navigationSteering angleElectric equipment

The invention discloses a method for acquiring road passing time and electronic equipment. The method comprises the following steps: acquiring an intersection grade of an intersection to be passed when a vehicle passes through a target road, and acquiring a steering angle and a hindering edge grade of the intersection to be passed, wherein the hindering edge grade is a grade of passing through a road corresponding to a traffic light for waiting of the intersection to be passed according to the steering angle; acquiring needed intersection waiting time for passing through the intersection to be passed according to the intersection grade, the steering angle and the hindering edge grade; and acquiring road passing time for passing through the target road according to the intersection waiting time and a road driving speed of the target road. According to the technical scheme, the relatively accurate intersection waiting time can be acquired according to the hindering edge grade so that the road passing time is acquired; and the technical problem in the prior art that the accuracy of acquiring the road passing time is relatively low is solved, and the accuracy of acquiring the road passing time is improved.

Owner:BEIJING SOGOU TECHNOLOGY DEVELOPMENT CO LTD

Determination method and device of game information, storage medium and electronic device

Owner:TENCENT TECH CHENGDU

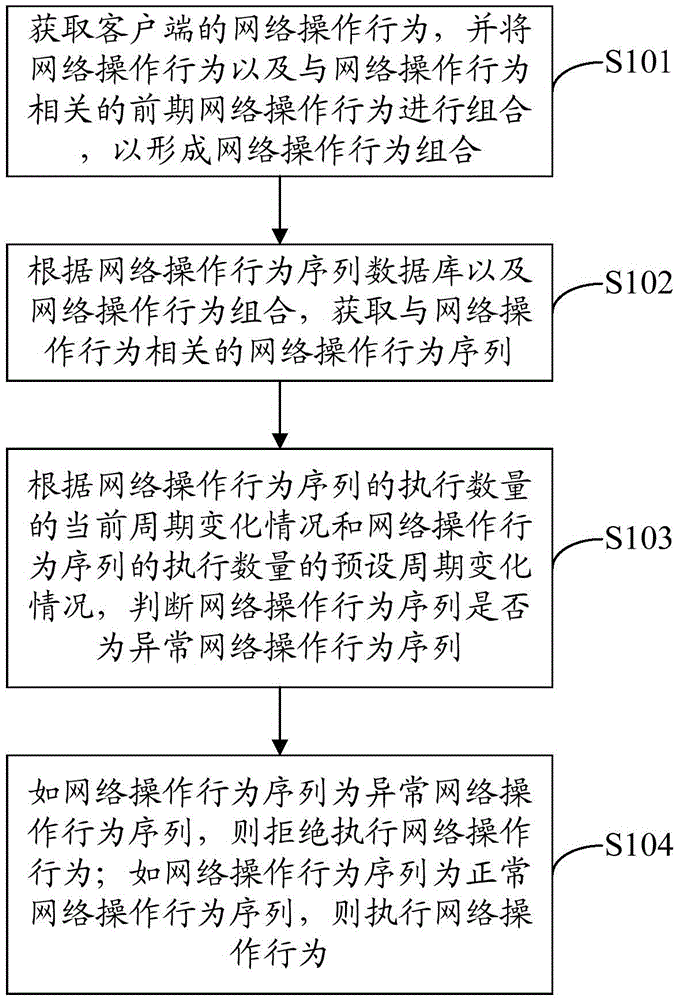

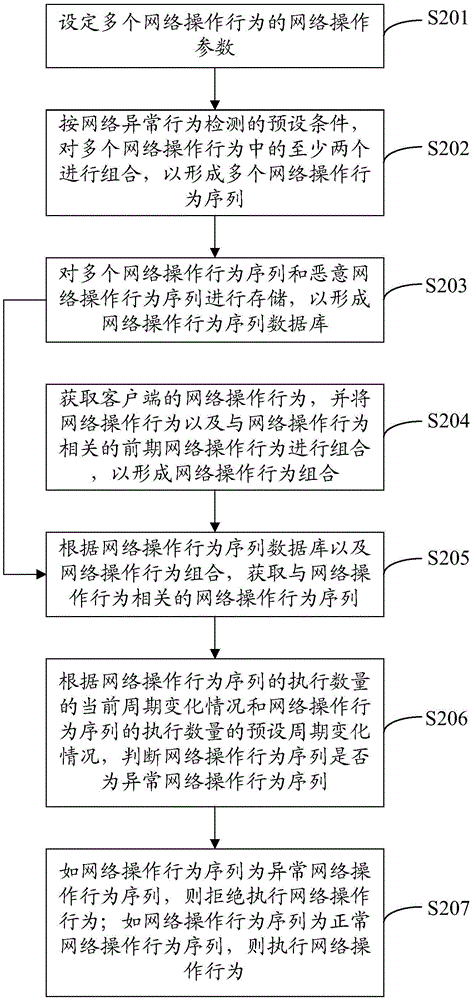

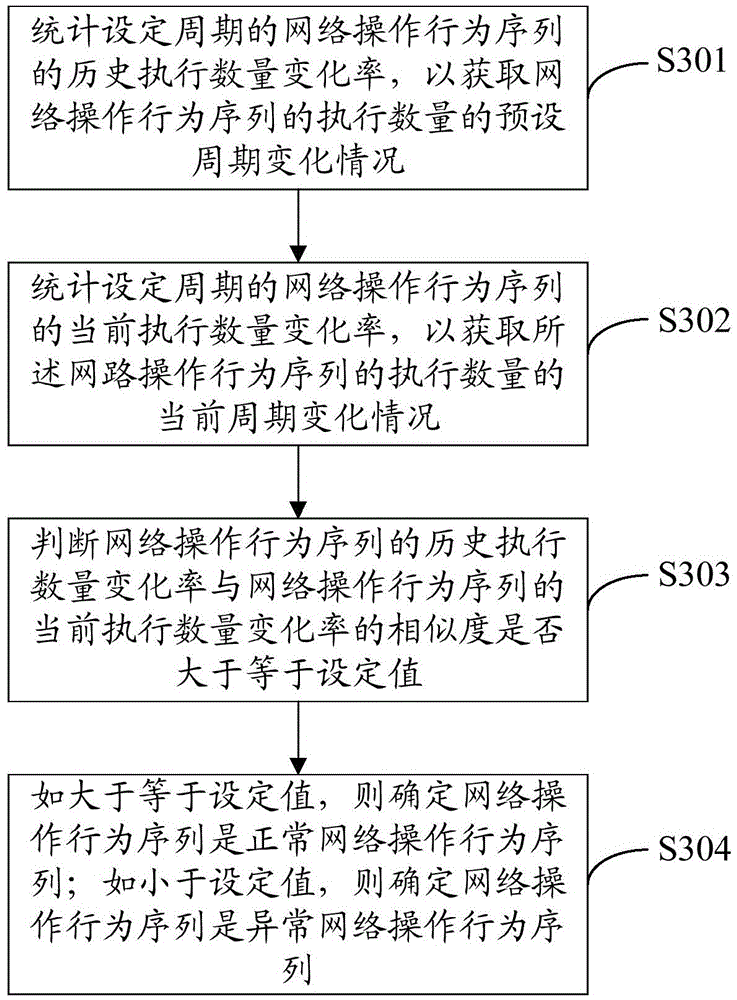

Network abnormal behavior detection method and device

ActiveCN106789837AImprove accuracyGood false detection or missed detectionPlatform integrity maintainanceTransmissionReal-time computingCurrent cycle

The present invention provides a network abnormal behavior detection method and device. The method comprises: obtaining the network operation behavior of a client, combining the early-stage network operation behavior related to the network operation behavior and the network operation behavior to form a network operation behavior combination; according to the network operation behavior sequence database and the network operation behavior combination, obtaining the network operation behavior sequence related to the network operation behavior; determining whether the network operation behavior is an abnormal network operation behavior sequence or not according to the current period changing condition of the execution quantity of the network operation behavior sequence and the preset period changing condition of the execution quantity of the network operation behavior sequence; if the network operation behavior sequence is the abnormal network operation behavior sequence, rejecting the execution of the network operation behavior; and if the network operation behavior sequence is a normal network operation behavior sequence, executing the network operation behavior. The detection accuracy is high, and the network abnormal behavior detection method and device can better avoid checking mistake or checking leakage.

Owner:TENCENT TECH (SHENZHEN) CO LTD

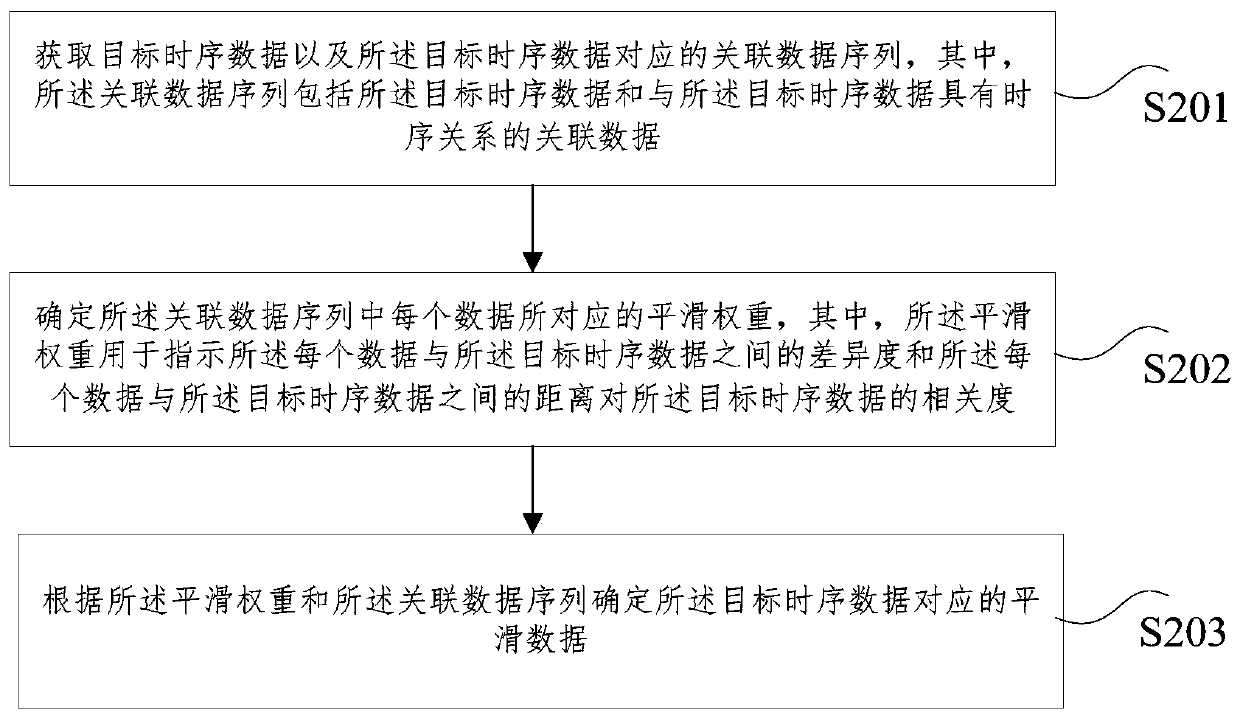

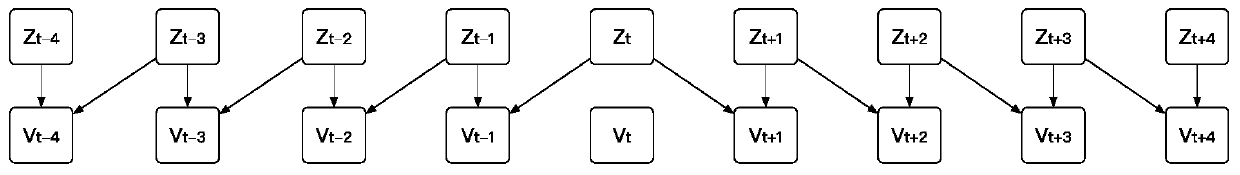

Time series data smoothing method and device

ActiveCN111090688AEliminate jitterImprove accuracyDigital data information retrievalCharacter and pattern recognitionAlgorithmData mining

The invention relates to a time series data smoothing method and device. The method comprises the steps: obtaining target time series data and an associated data sequence corresponding to the target time series data, and enabling the associated data sequence to comprise the target time series data and associated data having a time series relation with the target time series data; determining a smooth weight corresponding to each part of data in the associated data sequence, the smooth weight being used for indicating the degree of difference between each part of data and the target time seriesdata and the relevancy of the distance between each part of data and the target time series data to the target time series data; and determining smooth data corresponding to the target time series data according to the smooth weight and the target time series data. According to the invention, the technical problem of low accuracy of the time series data is solved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

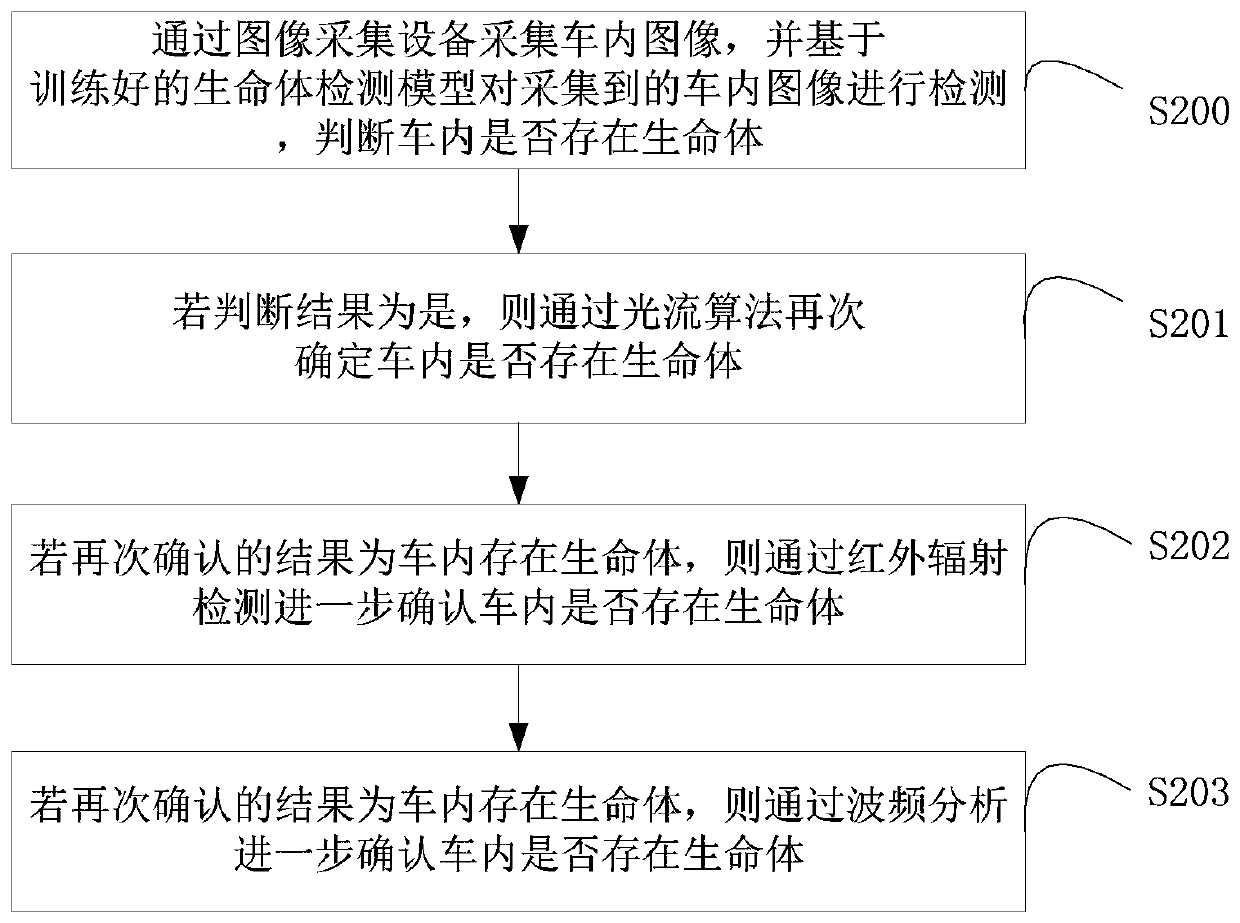

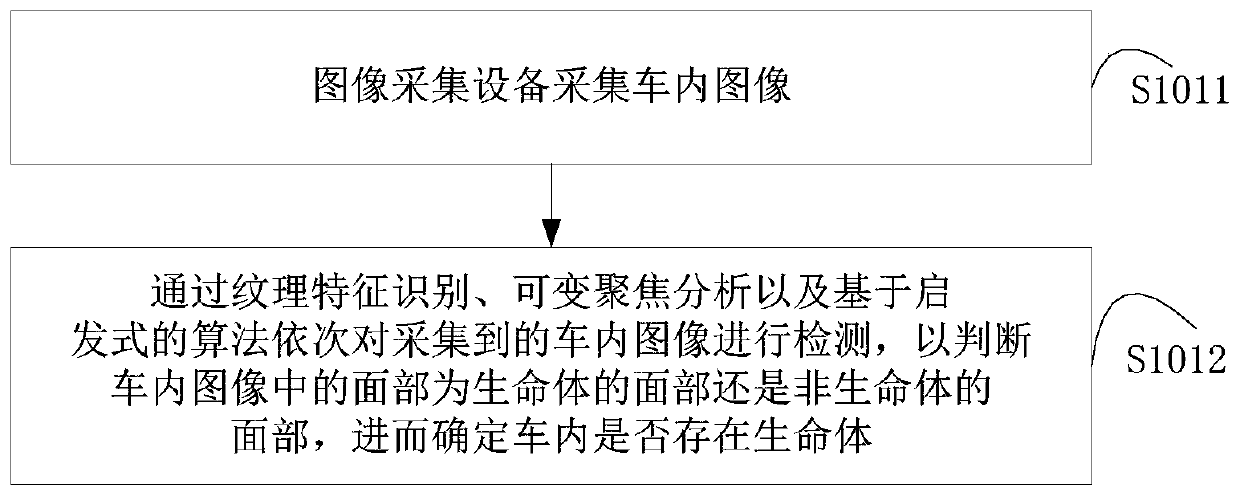

In-vehicle life body detection method, device and system and storage medium

InactiveCN110866451AFix technical issues with lower accuracySolve the technical problem of low detection accuracyImage enhancementImage analysisEngineeringOptical flow

The invention discloses an in-vehicle life body detection method, device and system and a storage medium. The in-vehicle life body detection method comprises the steps: collecting an in-vehicle imagethrough image collection equipment, carrying out the detection of the collected in-vehicle image based on a trained life body detection model, and judging whether a life body exists in a vehicle or not; if the judgment result is yes, determining whether a life body exists in the vehicle or not again through an optical flow algorithm; and if the re-confirmation result is that the life body exists in the vehicle, giving an alarm to prompt. The in-vehicle life body detection method solves the technical problem that in the prior art, the accuracy of detecting the life body in the vehicle is low, accurately and efficiently detects the technical effects that whether the life body exists in the vehicle locked by the vehicle lock or not, gives out an alarm, and avoids misjudgment caused by image matting and mask attacks.

Owner:CHINA FIRST AUTOMOBILE

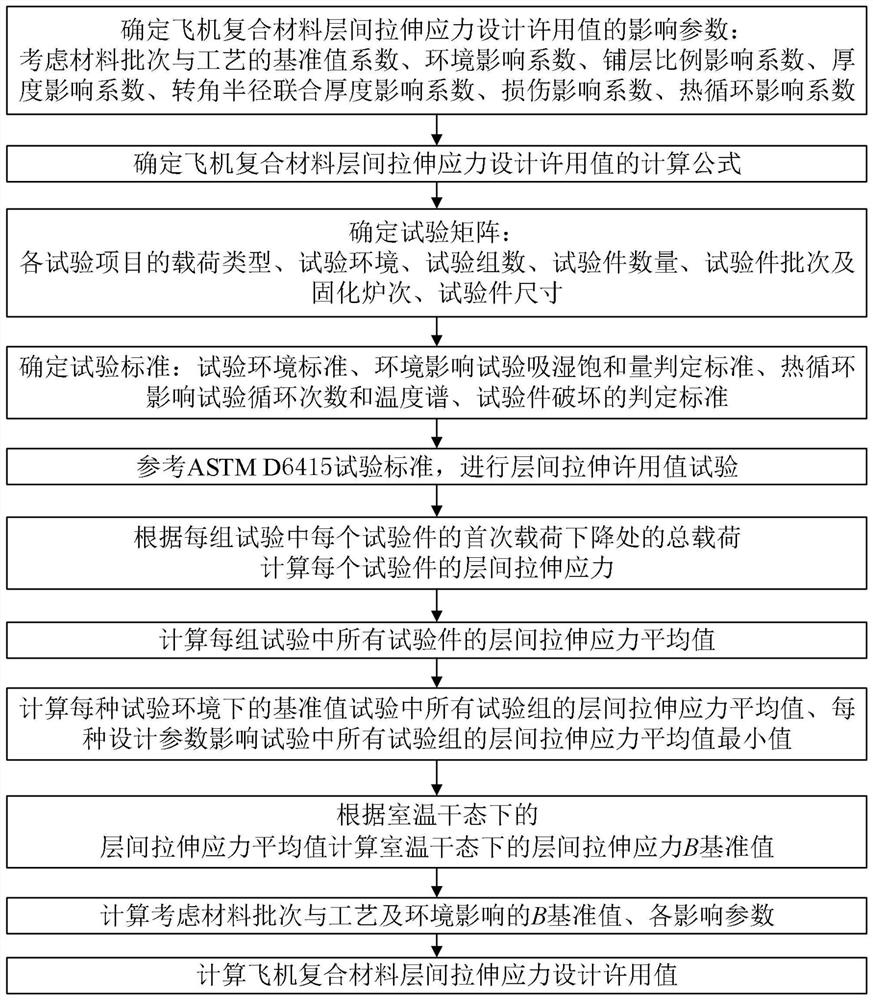

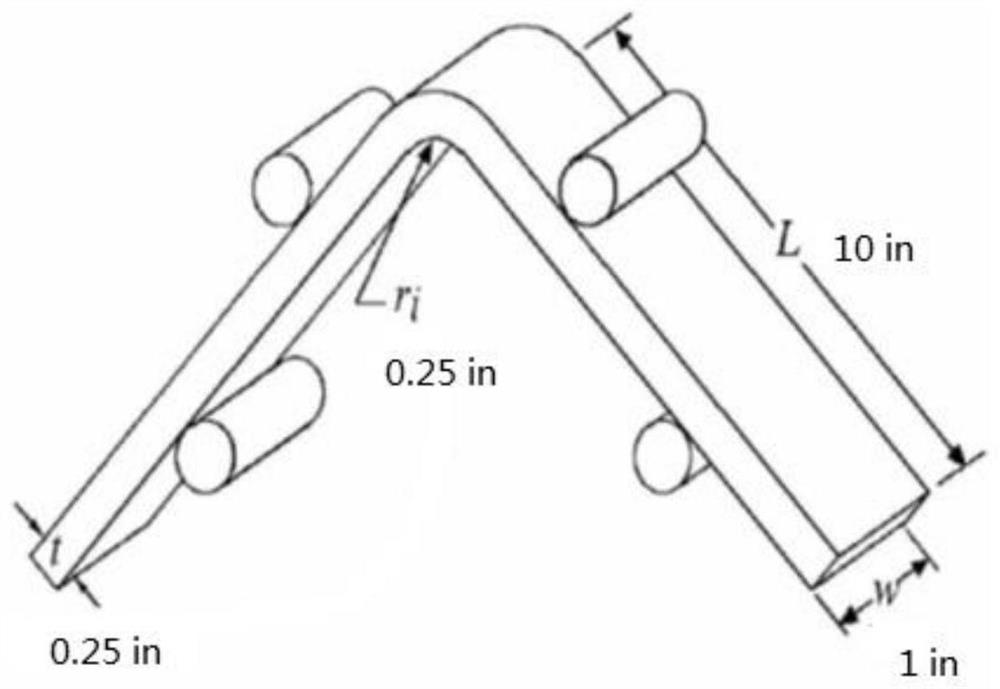

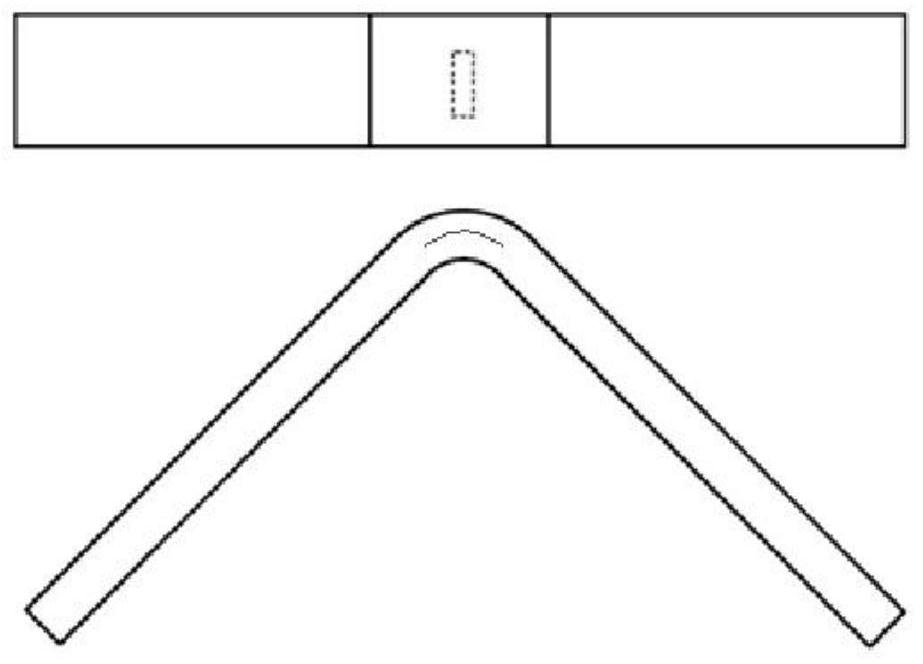

Method for determining allowable value of interlayer tensile stress design of airplane composite material

ActiveCN111695205AImprove accuracyImprove versatilityGeometric CADSustainable transportationStructural engineeringMoisture absorption

The invention relates to the technical field of aircraft composite material interlayer tensile stress design, and provides a method for determining an allowable value of an interlayer tensile stress design of an airplane composite material, which comprises: 1, determining influence parameters including a B reference value coefficient, an environment, a laying proportion, a thickness, a corner radius joint thickness, a damage and a thermal cycle influence coefficient; 2, determining an interlayer tensile stress design allowable value calculation formula based on the B reference value; 3, determining a test matrix; 4, determining a test environment standard, an environmental influence test moisture absorption saturation determination standard, a thermal cycle influence test cycle index and temperature spectrum, and a test piece damage determination standard; 5, performing a test by referring to an ASTM D6415 test standard to obtain an interlayer tensile stress average value and a B reference value initial value; 6, calculating a B reference value and each influence parameter; and 7, calculating an interlayer tensile stress design allowable value. The method is high in accuracy, highin universality, low in test cost and high in test efficiency.

Owner:NORTHEASTERN UNIV

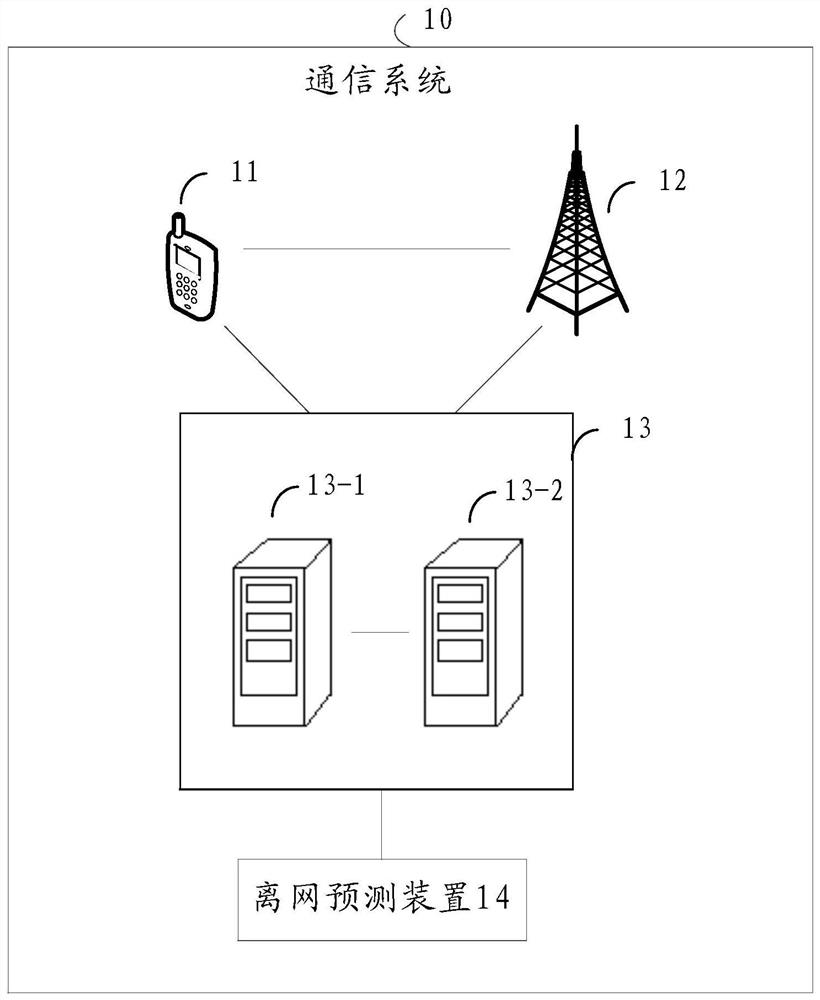

Off-grid prediction method and device

InactiveCN111740866AImprove accuracyFix technical issues with lower accuracyData switching networksOff-the-gridService information

The embodiment of the invention provides an off-network prediction method and device, relates to the technical field of communication, and solves the technical problem that an existing off-network prediction method is relatively low in accuracy. The method comprises the following steps that: an off-network prediction device firstly acquires service information of a terminal at a first moment, andthen predicts off-network information of the terminal according to the service information of the terminal and a pre-constructed decision tree; wherein the service information comprises: service information, wherein the first duration is between the opening moment of the service and the first moment; wherein the second duration is between the termination moment of the service and the first moment,whether the service comprises at least one of an internet protocol television (IPTV) service, the fault frequency of the service in a first preset time period, the total flow of the service in a second preset time period, a third duration in which the transmission flow of the service meets a preset flow threshold, the bandwidth of the service, the regional type of the service or the flow type ofthe service; wherein the off-network information is used for indicating whether the terminal is off-network at the termination moment of the service.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

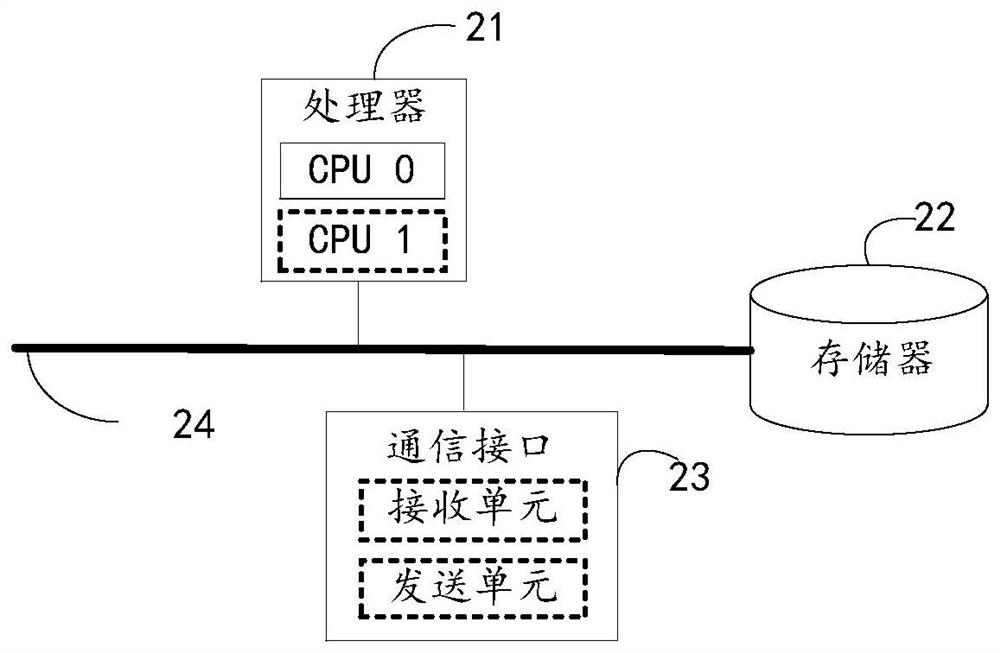

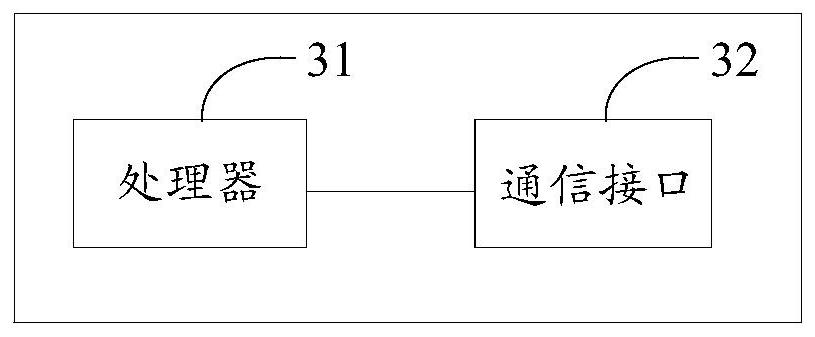

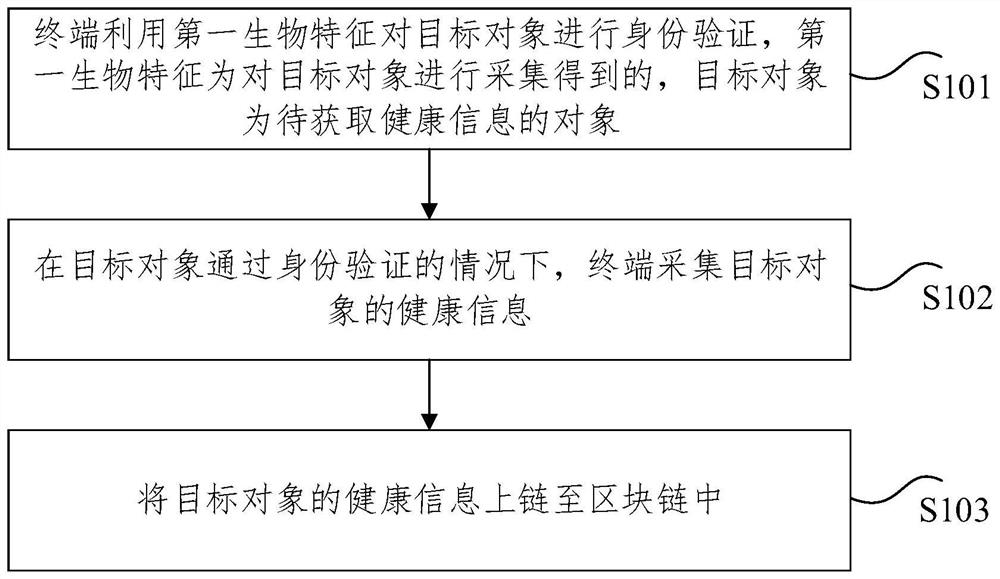

Health information chaining method and device, storage medium and electronic device

PendingCN111815842AFix technical issues with lower accuracyGuaranteed matchUser identity/authority verificationSensing radiation from moving bodiesDatabaseAuthentication

The invention discloses a health information chaining method and device, a storage medium and an electronic device. The method comprises the following steps: carrying out identity verification on a target object through a first biological characteristic, wherein the first biological characteristic is obtained by collecting the target object, and the target object is an object with health information to be obtained; collecting health information of the target object under the condition that the target object passes the identity verification; and uploading the health information of the target object to a block chain. The technical problem of low accuracy of recorded health information in related technologies is solved.

Owner:JD DIGITS HAIYI INFORMATION TECHNOLOGY CO LTD +1

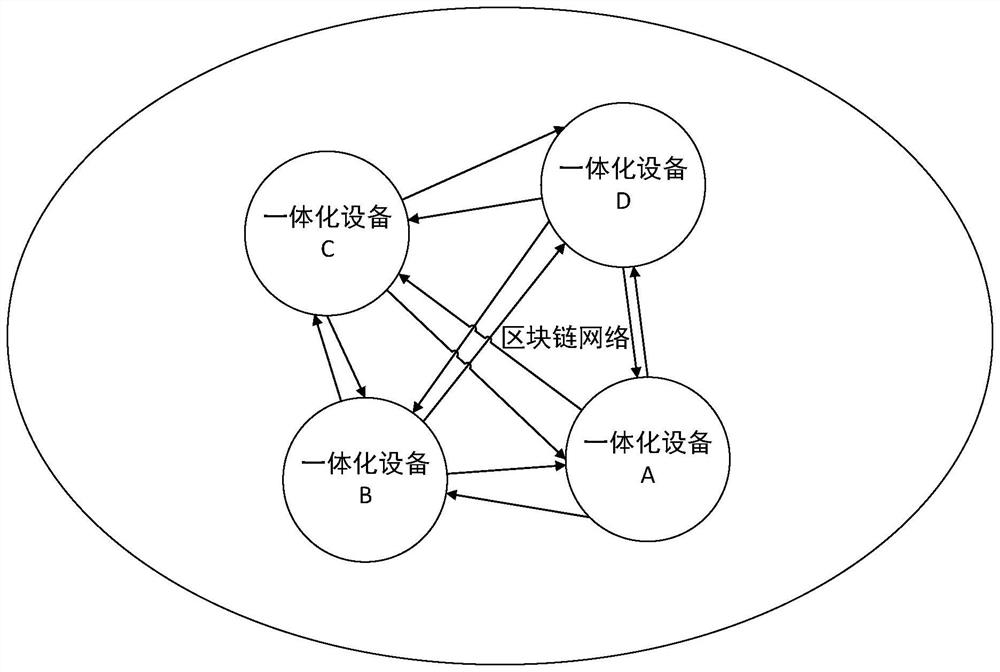

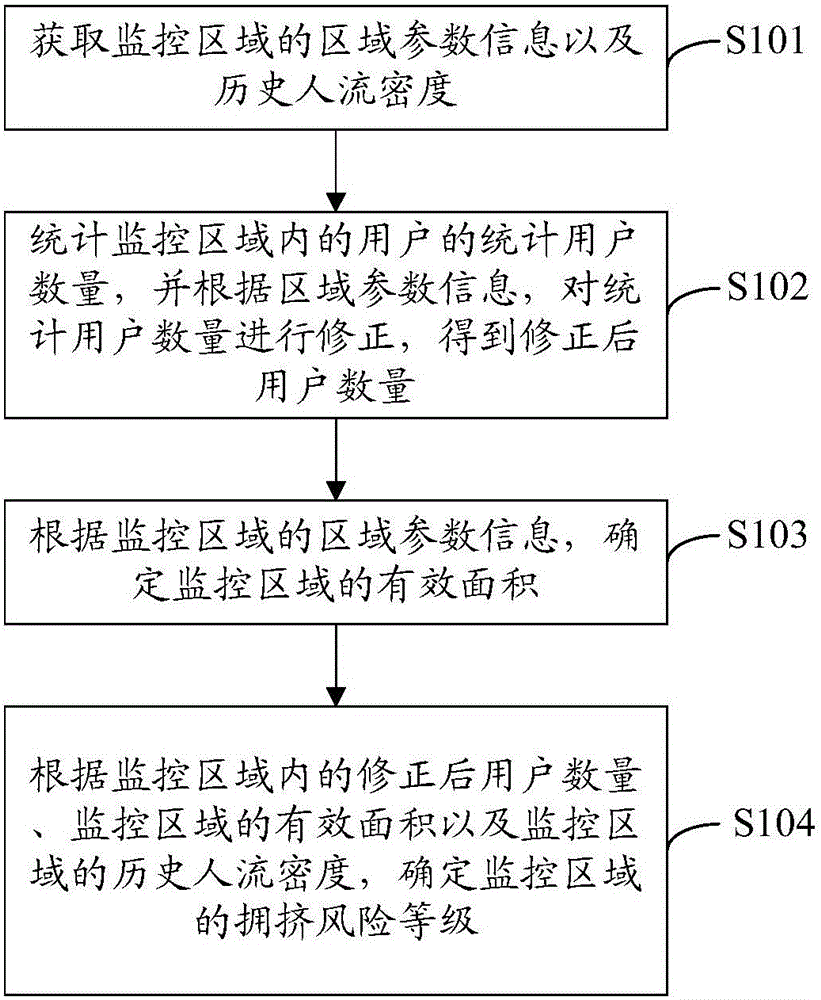

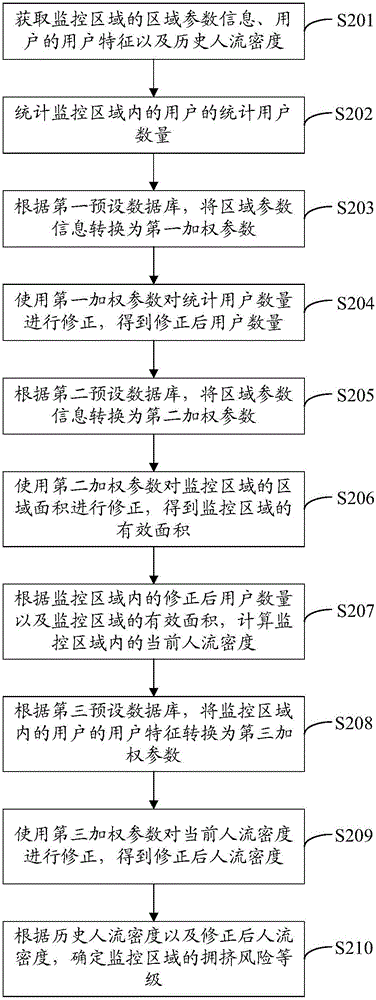

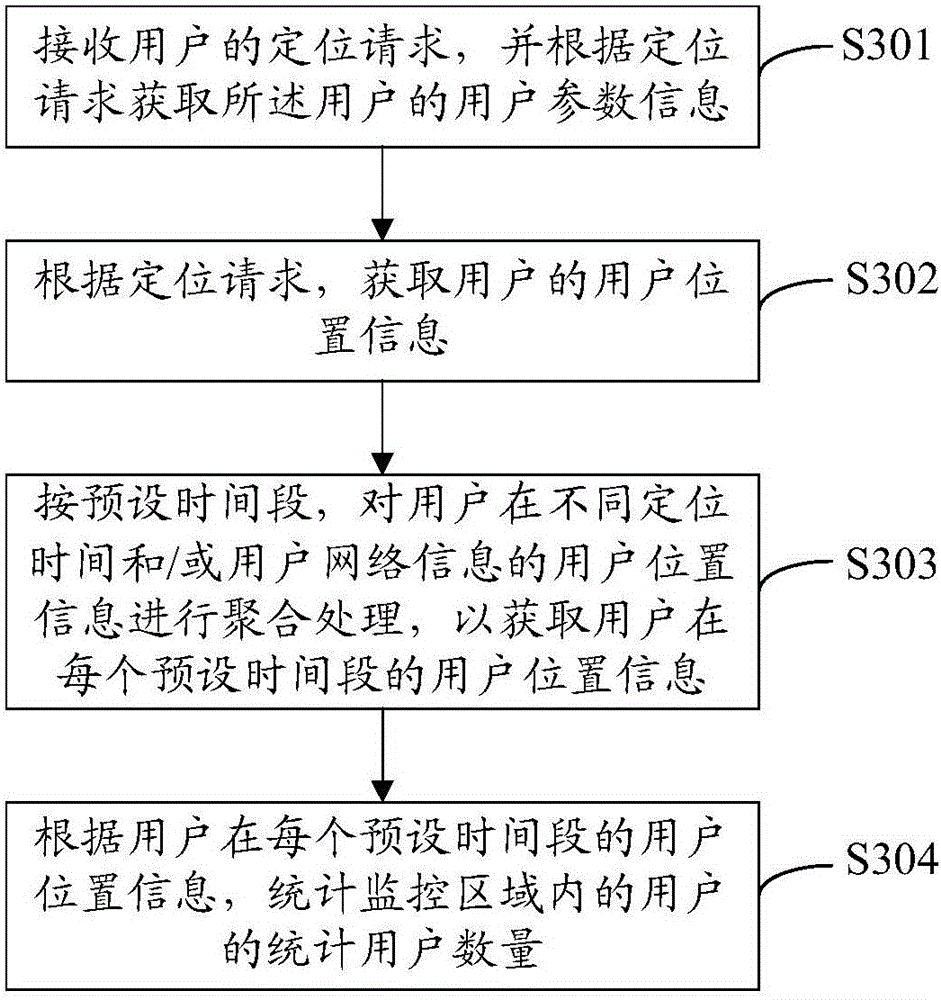

Congestion risk monitoring method and congestion risk monitoring device

ActiveCN105844572AFix technical issues with lower accuracyImprove accuracyData processing applicationsRisk levelComputer science

The invention provides a congestion risk monitoring method which includes the steps of obtaining regional parameter information and historical crowd density of a monitored region, counting the statistics user quantity of users in the monitored region, correcting the statistics user quantity according to the regional parameter information to obtain the corrected user quantity, determining the effective area of the monitored region according to the regional parameter information of the monitored region, and determining the congestion risk level of the monitored region according to the corrected user quantity, the effective area of the monitored region, and the historical crowd density of the monitored region. The invention further provides a congestion risk monitoring device. The congestion risk level in a monitored area is monitored according to the regional parameter information of the monitored region, user characteristics and the historical crowd density of the monitored region, and the monitoring accuracy is high.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Landslide monitoring method and device, electronic equipment and storage medium

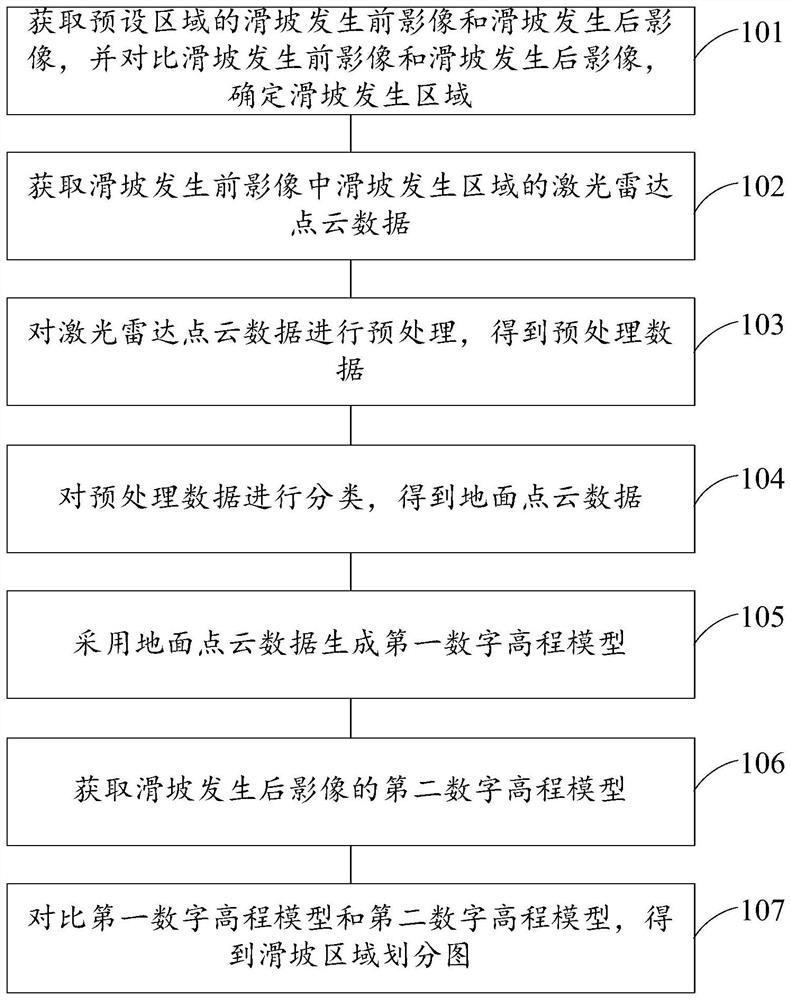

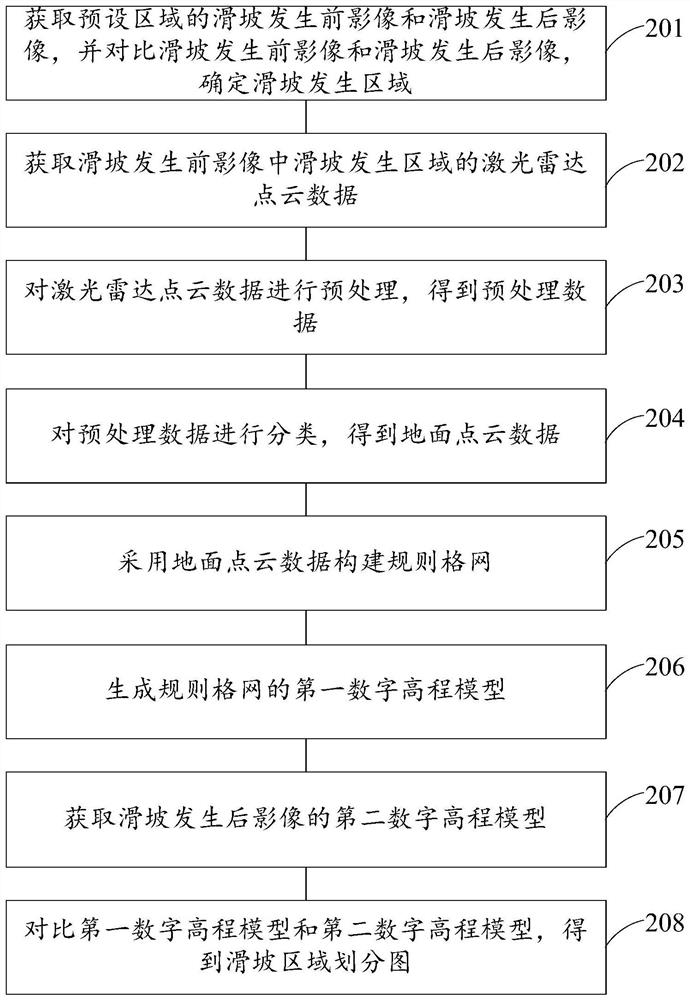

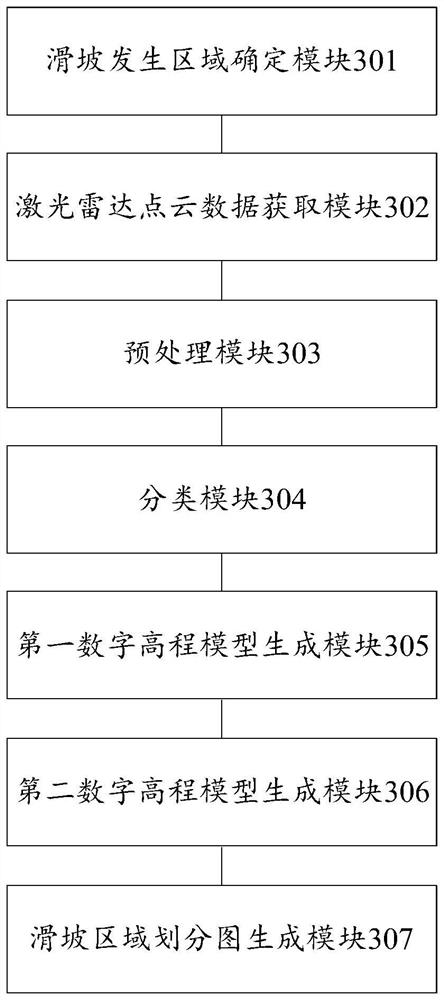

PendingCN113723403AFix technical issues with lower accuracyCharacter and pattern recognitionElectromagnetic wave reradiationSoil sciencePoint cloud

The invention discloses a landslide monitoring method and device, electronic equipment and a storage medium, which are used for solving the technical problem of low accuracy of landslide mass identification and risk evaluation in the existing landslide analysis method. The method comprises the following steps: acquiring an image before landslide and an image after landslide in a preset area, and comparing the image before landslide and the image after landslide to determine a landslide area; acquiring laser radar point cloud data of a landslide occurrence area in the image before landslide occurrence; preprocessing the laser radar point cloud data to obtain preprocessed data; classifying the preprocessed data to obtain ground point cloud data; generating a first digital elevation model by adopting the ground point cloud data; acquiring a second digital elevation model of the image after the occurrence of the landslide; and comparing the first digital elevation model with the second digital elevation model to obtain a landslide region division map.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

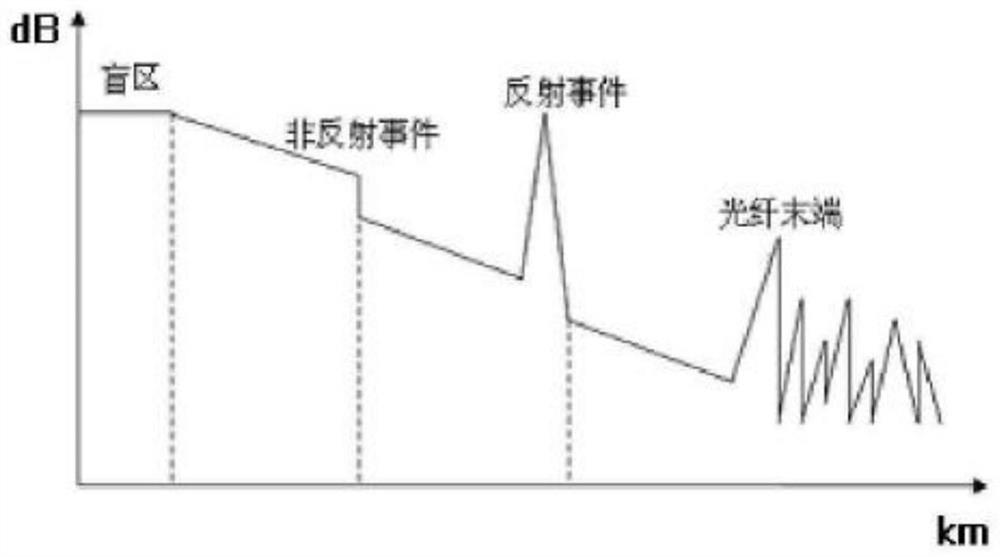

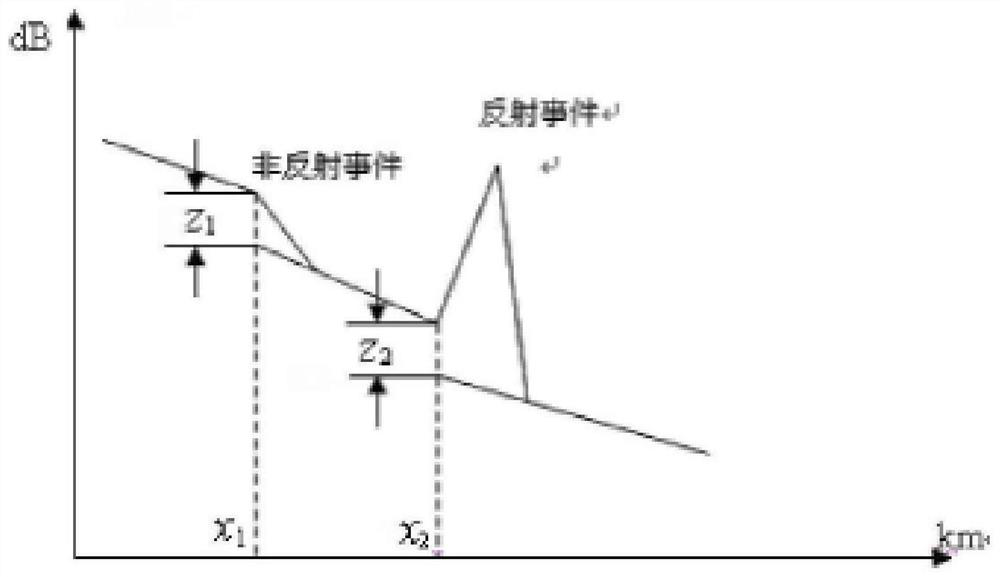

Optical cable anomaly detection method and device

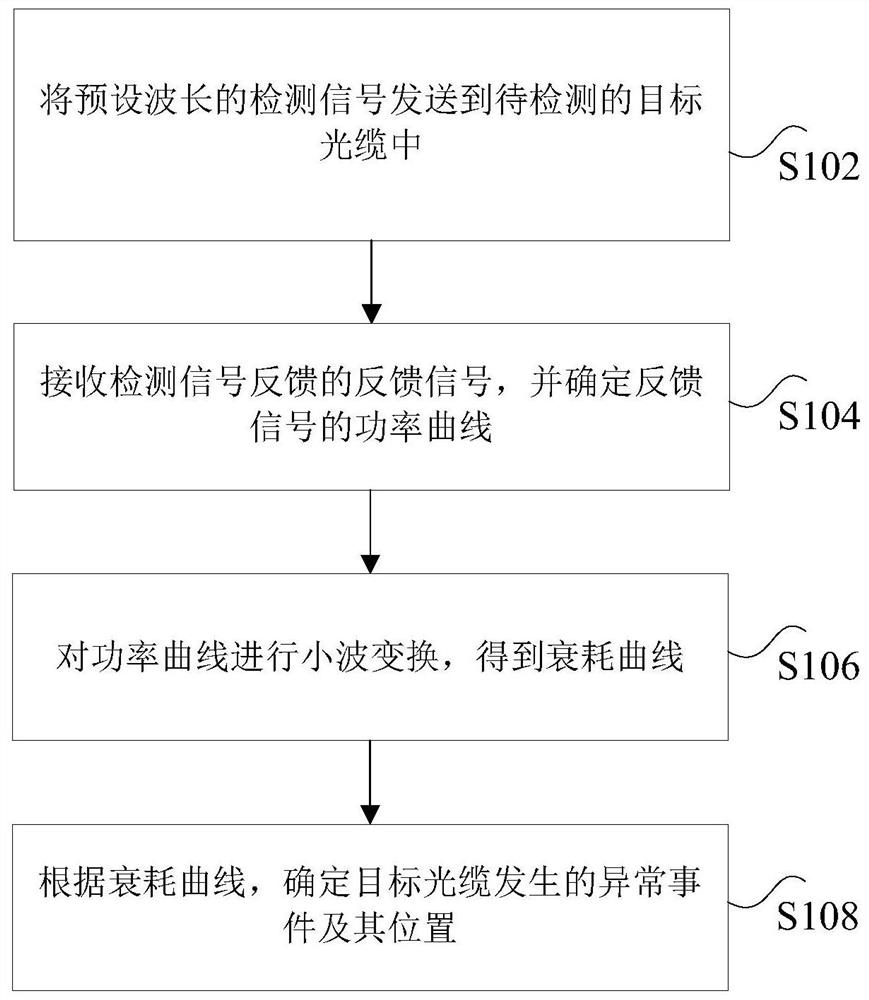

PendingCN113489534AImprove accuracySolve the technical problems of fault detection and low accuracyElectromagnetic transmissionAnomaly detectionWavelength

The invention discloses an optical cable anomaly detection method and device. The method comprises the following steps: sending a detection signal with a preset wavelength to a to-be-detected target optical cable; receiving a feedback signal fed back by the detection signal, and determining a power curve of the feedback signal; performing wavelet transformation on the power curve to obtain an attenuation curve; and according to the attenuation curve, determining the abnormal event of the target optical cable and the position thereof. According to the invention, the technical problem of low accuracy of optical cable fault detection in the prior art is solved.

Owner:INFORMATION & COMM COMPANY OF QINGHAI ELECTRIC POWER +2

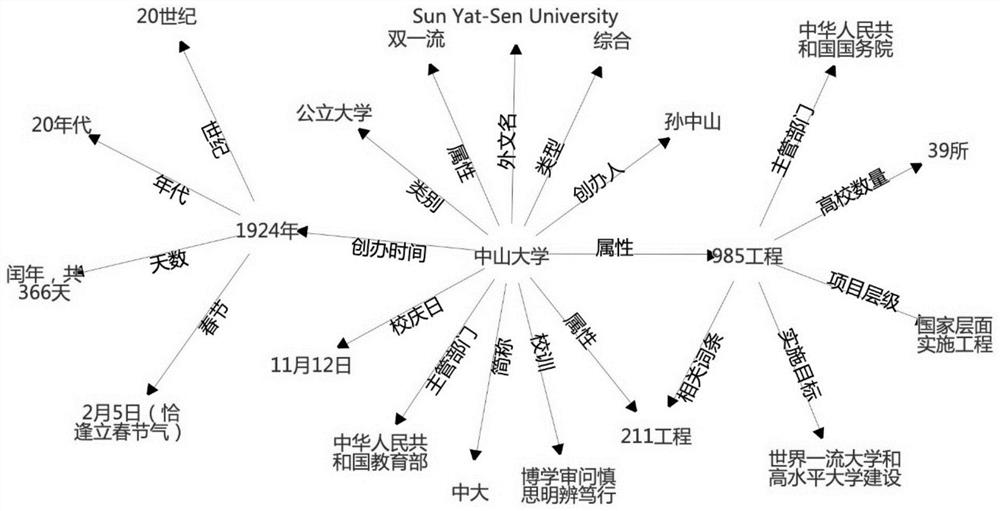

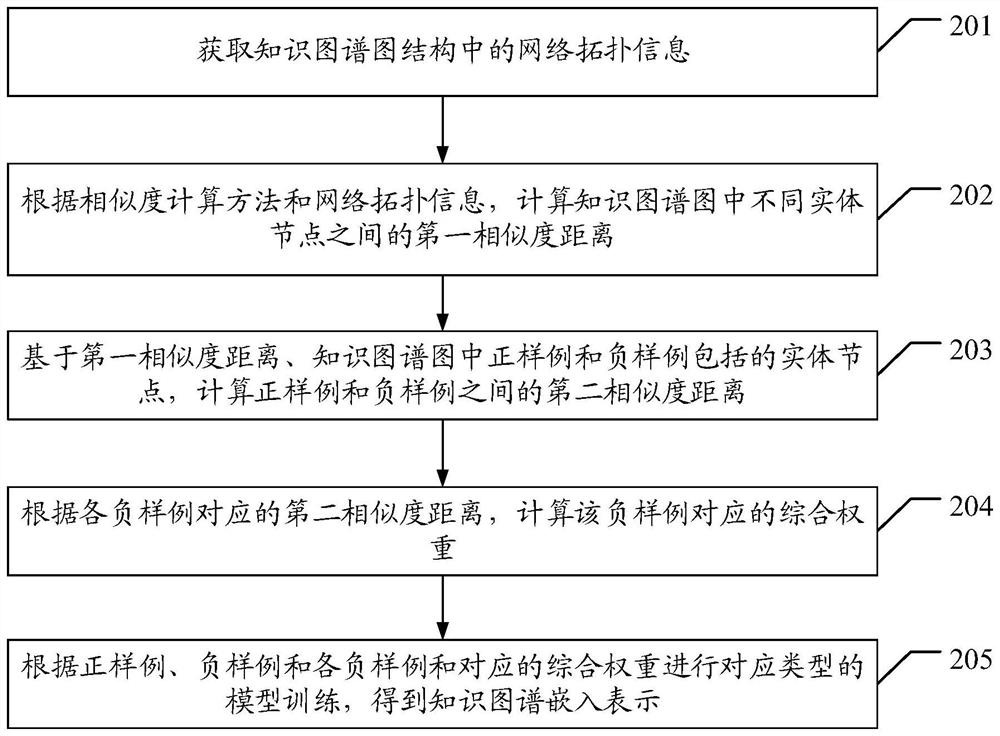

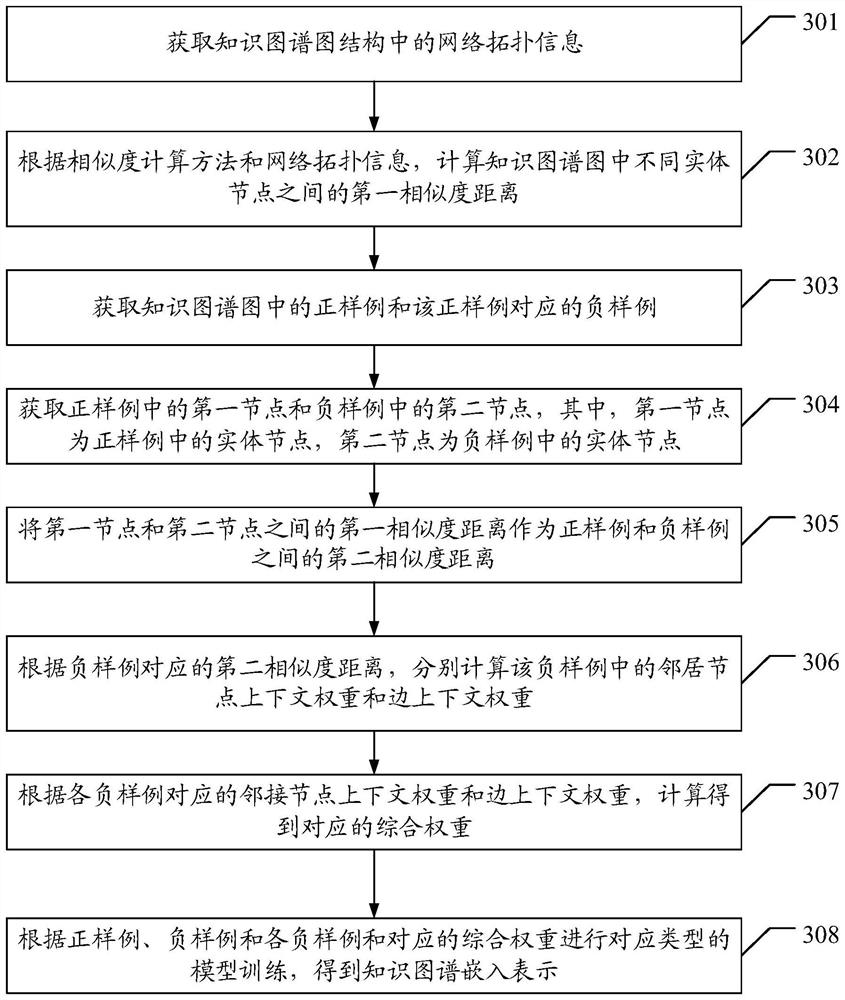

Knowledge graph embedding training method and related device

InactiveCN112685573AGood effectFix technical issues with lower accuracyCharacter and pattern recognitionMachine learningPositive sampleAlgorithm

The invention discloses a knowledge graph embedding training method and a related device. The method comprises the steps of obtaining network topology information in a knowledge graph structure; calculating a first similarity distance between different entity nodes in the knowledge graph according to a similarity calculation method and the network topology information; calculating a second similarity distance between the positive sample and the negative sample based on the first similarity distance and entity nodes included in the positive sample and the negative sample in the knowledge graph; calculating a comprehensive weight corresponding to each negative sample according to the second similarity distance corresponding to each negative sample; and according to the positive sample, the negative sample, each negative sample and the corresponding comprehensive weight, carrying out model training of a corresponding type to obtain knowledge graph embedding representation. The technical problem that in the existing training process of knowledge graph embedding, different negative samples are regarded as the same kernel, and consequently the result accuracy of embedding representation is possibly low is solved.

Owner:SUN YAT SEN UNIV

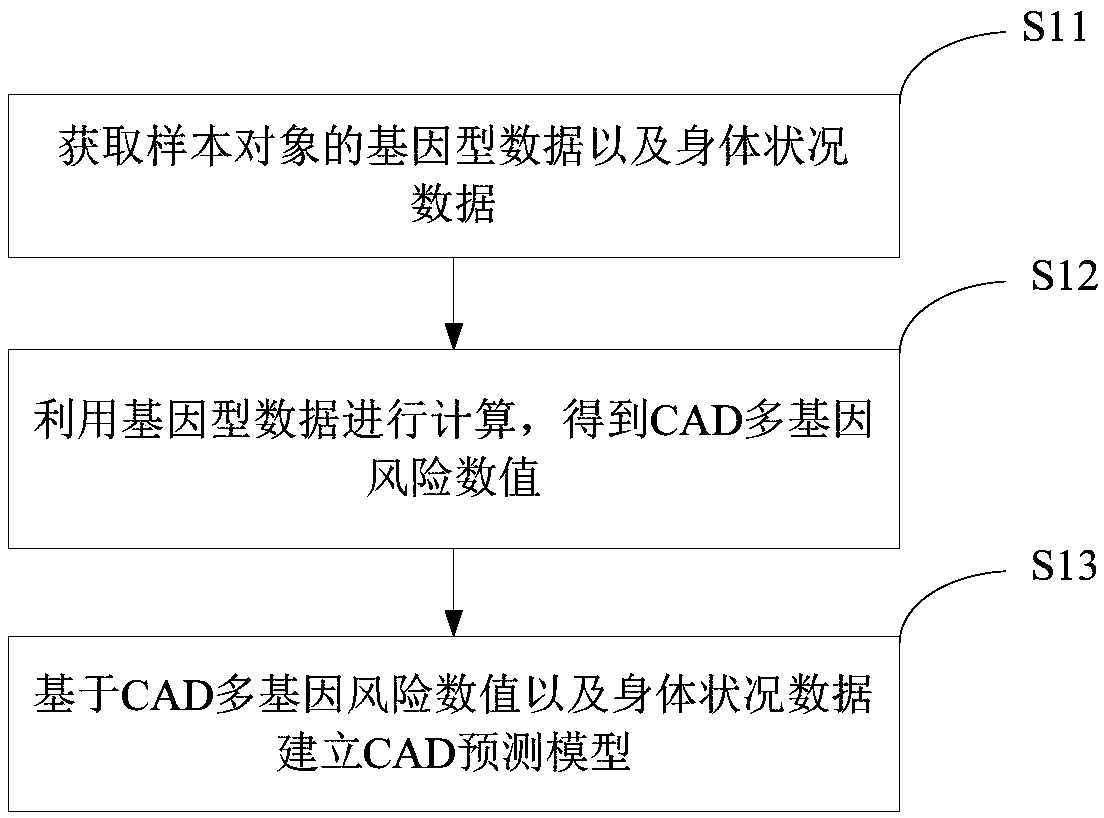

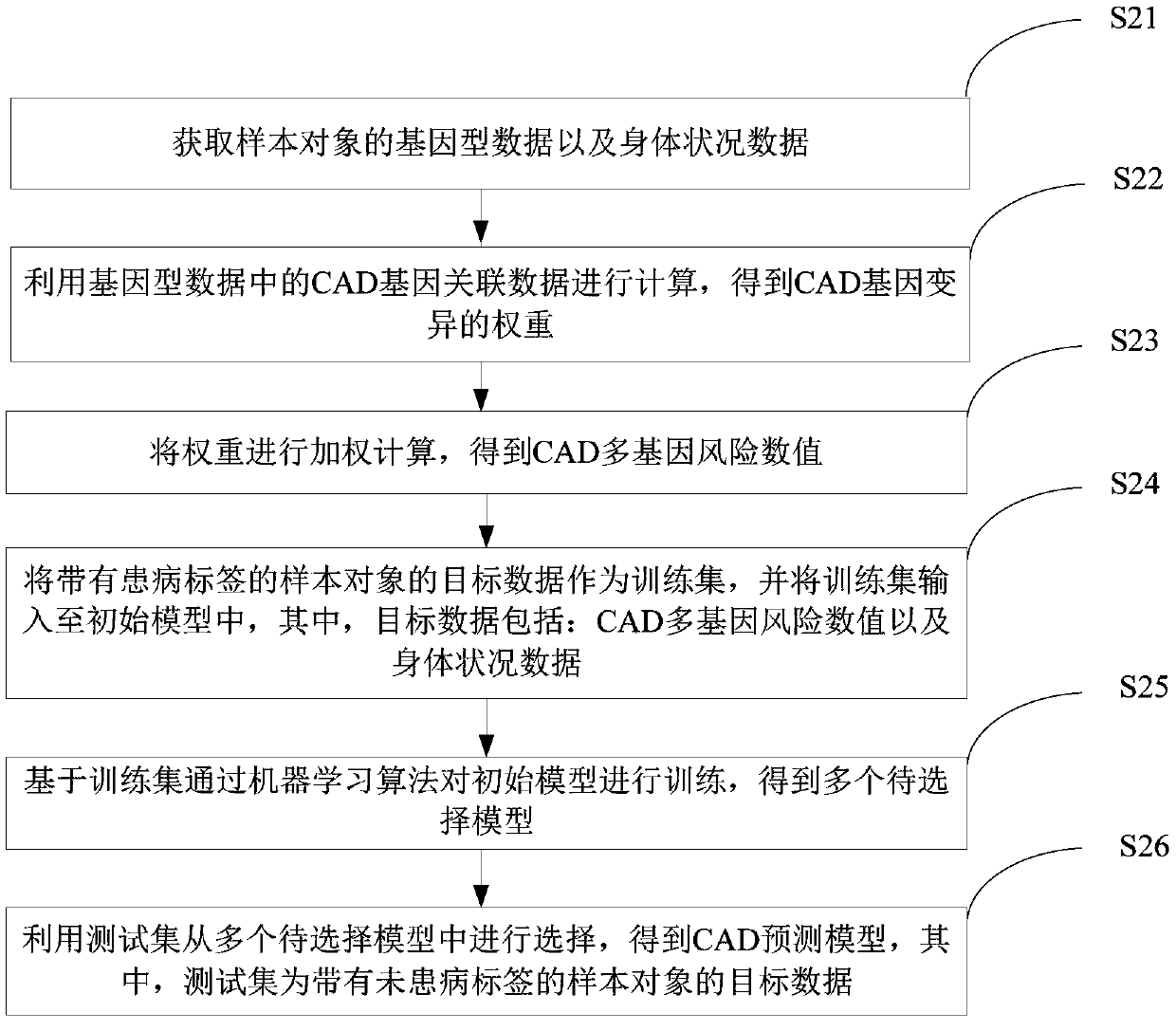

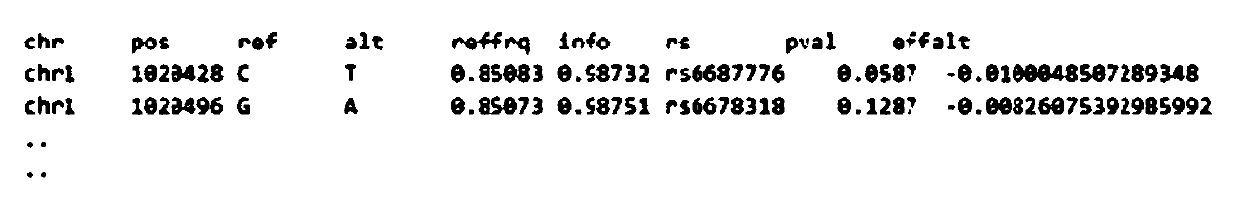

CAD prediction model establishing method and device and electronic equipment

PendingCN111354464AComprehensive prediction resultsAchieving prediction accuracyHealth-index calculationProteomicsData miningData science

The invention provides a CAD prediction model building method and device and electronic equipment, and relates to the technical field of modeling, and the method comprises the steps: obtaining genotype data and physical condition data of a sample object; calculating by utilizing the genotype data to obtain a CAD multi-gene risk value; and establishing a CAD prediction model based on the CAD multi-gene risk value and the physical condition data. The technical problem of relatively low accuracy of data obtained by performing CAD prediction at present in the prior art is solved.

Owner:SHENZHEN INST OF ADVANCED TECH

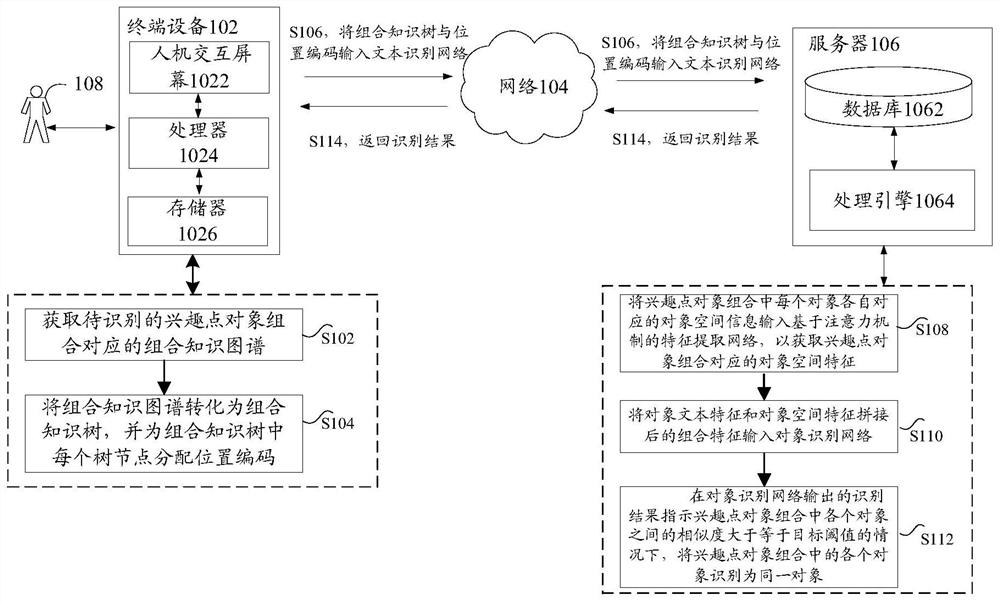

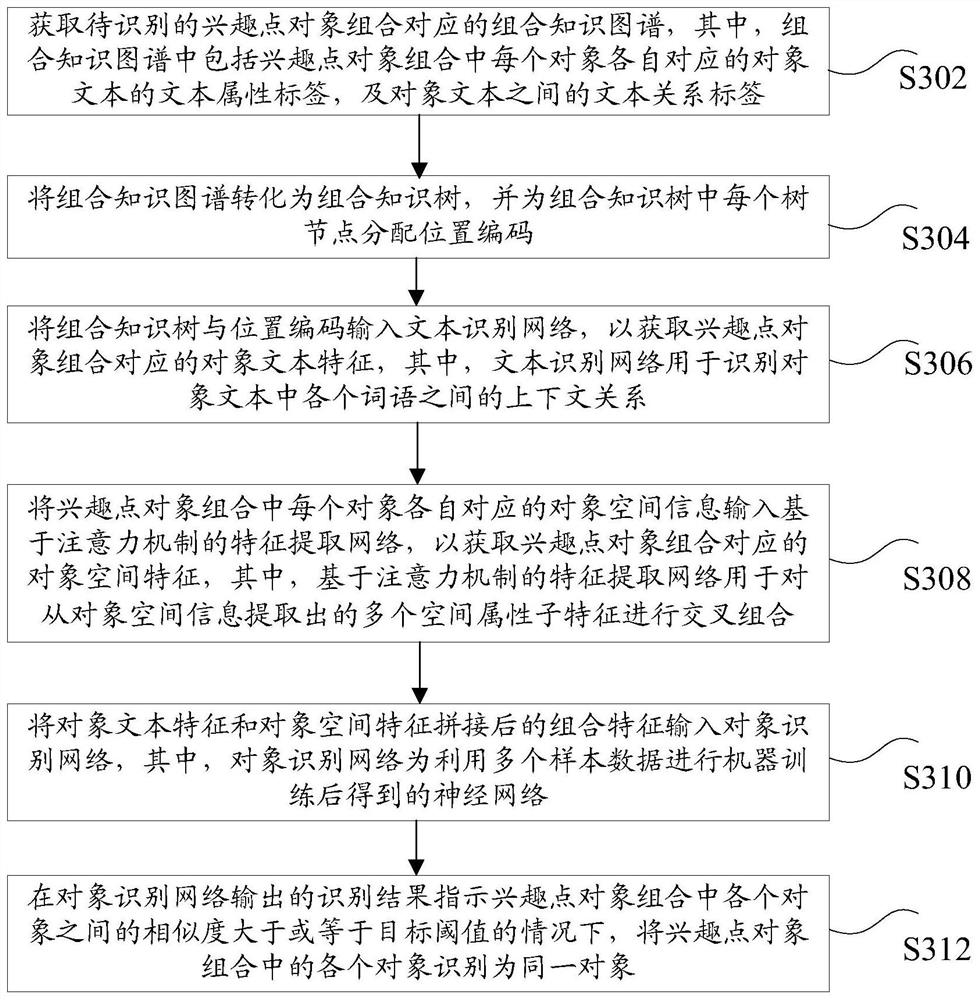

Object recognition method and device, storage medium and electronic equipment

ActiveCN112528639AImprove accuracyAccurate and effective acquisition of combination relationshipsSemantic analysisNeural architecturesText recognitionPoint object

The invention discloses an object recognition method and device, a storage medium and electronic equipment. The method comprises the steps of obtaining a combined knowledge graph corresponding to a to-be-identified interest point object combination, converting the combined knowledge graph into a combined knowledge tree, and allocating a position code to each tree node in the combined knowledge tree; inputting the combined knowledge tree and the position code into a text recognition network to obtain an object text feature corresponding to the interest point object combination; inputting a combined feature formed by splicing the object text feature and the object space feature into an object recognition network; and under the condition that the identification result output by the object identification network indicates that the similarity between the objects in the interest point object combination is greater than or equal to a target threshold, identifying the objects in the interest point object combination as the same object. The invention can be used for map associated scenes. The technical problem of relatively low accuracy of a result of identifying and distinguishing similarPOI entity objects is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

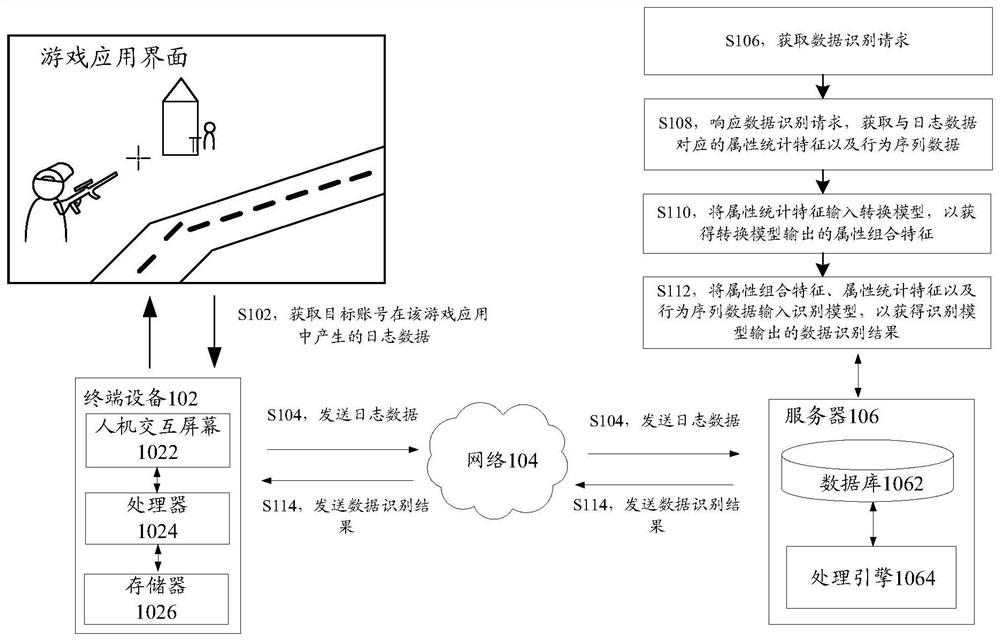

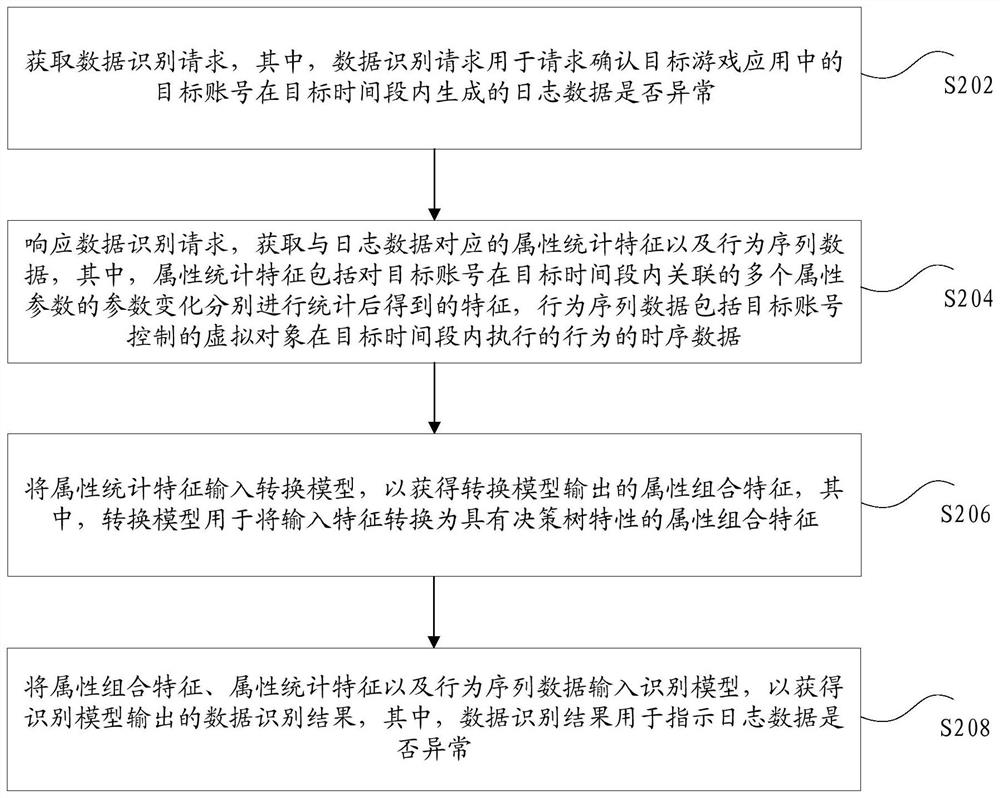

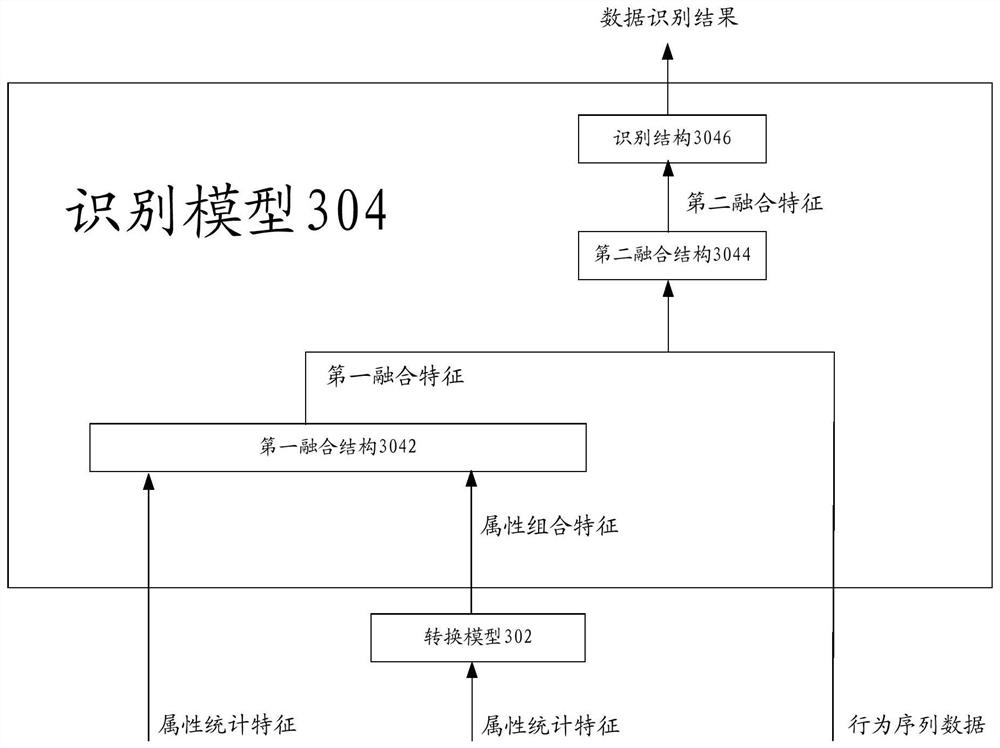

Data exception identification method and device, storage medium and electronic equipment

ActiveCN112221156AAvoid lostImprove accuracyCharacter and pattern recognitionNeural architecturesSequencing dataEngineering

The invention discloses a data exception identification method and device, a storage medium and electronic equipment. The method comprises the steps of obtaining a data identification request; in response to the data identification request, obtaining attribute statistical characteristics and behavior sequence data corresponding to the log data, wherein the attribute statistical characteristics include characteristics obtained by performing statistics on parameter changes of a plurality of attribute parameters associated with a target account in the target time period, and behavior sequence data corresponding to the log data, and the behavior sequence data comprises time sequence data of behaviors executed by a virtual object controlled by the target account in a target time period; inputting the attribute statistical characteristics into a conversion model to obtain attribute combination characteristics output by the conversion model; and inputting the attribute combination features, the attribute statistical characteristics and the behavior sequence data into an identification model to obtain a data identification result output by the identification model. According to the invention, the technical problem of low accuracy of data exception identification is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

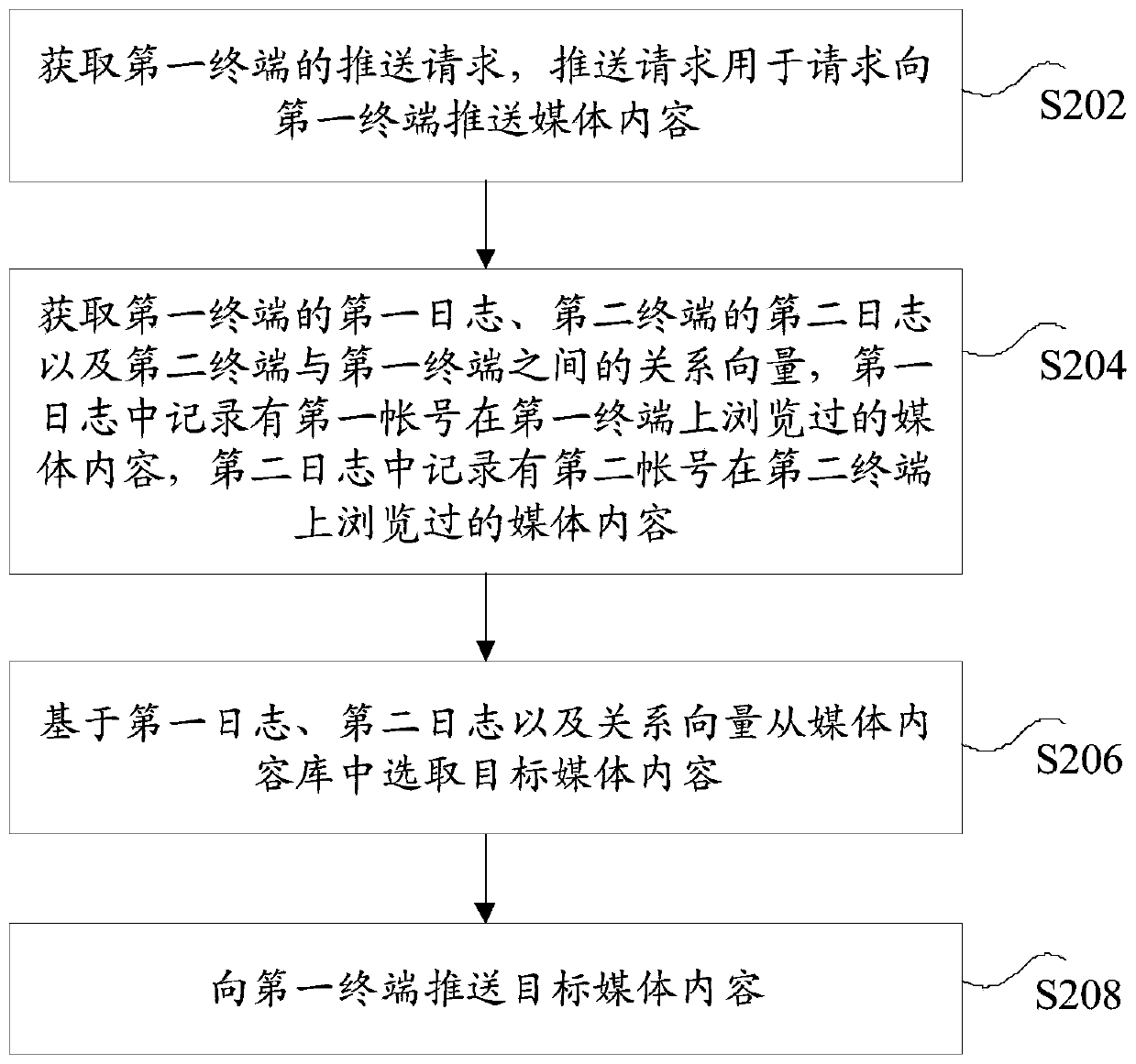

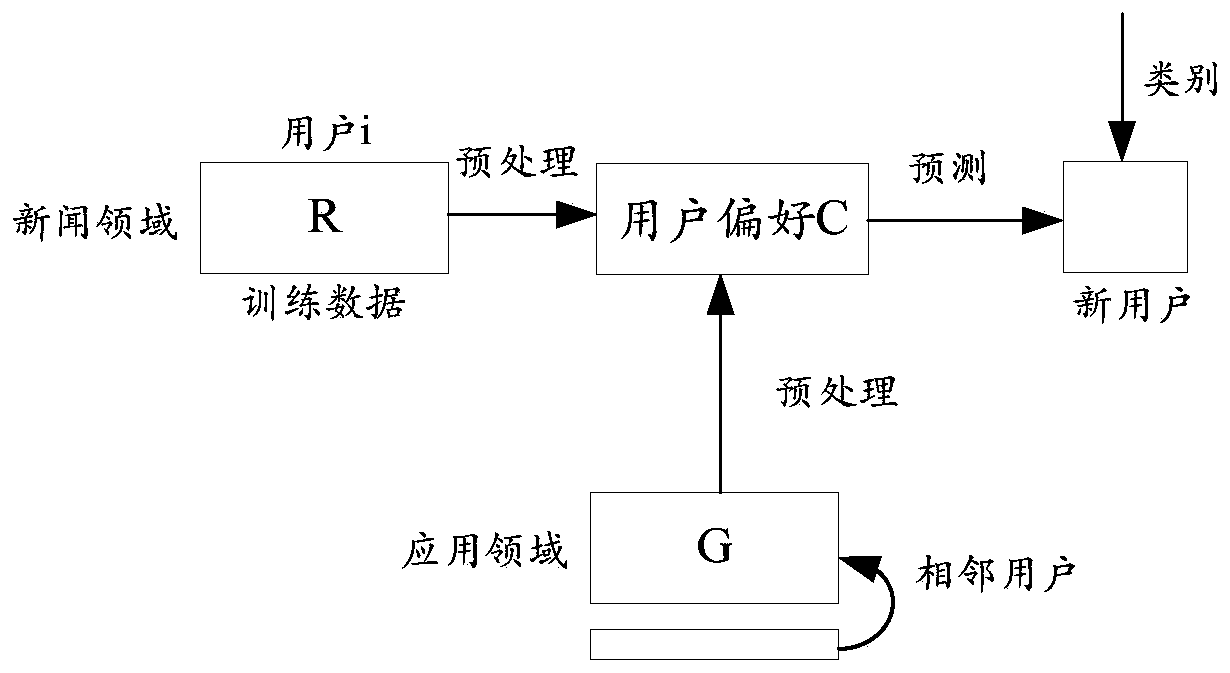

Media content pushing method and device, storage medium and electronic device

ActiveCN110209931AFix technical issues with lower accuracyDigital data information retrievalSpecial data processing applicationsComputer terminalWorld Wide Web

The invention discloses a media content pushing method and device, a storage medium and an electronic device. The media content pushing method comprises the steps: acquiring a push request of a firstterminal, wherein the push request is used for requesting to push media content to the first terminal; obtaining a first log of the first terminal, a second log of the second terminal and a relation vector between the second terminal and the first terminal, wherein media content browsed by the first account on the first terminal is recorded in the first log, and media content browsed by the secondaccount on the second terminal is recorded in the second log, and the relation vector is used for representing the relation between applications installed on the first terminal and the second terminal; selecting target media content from the media content library based on the first log, the second log and the relationship vector; and in response to the push request, pushing the target media content to the first terminal. According to the media content pushing method and device, the technical problem of relatively low accuracy of media content recommended to the user in the related art is solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

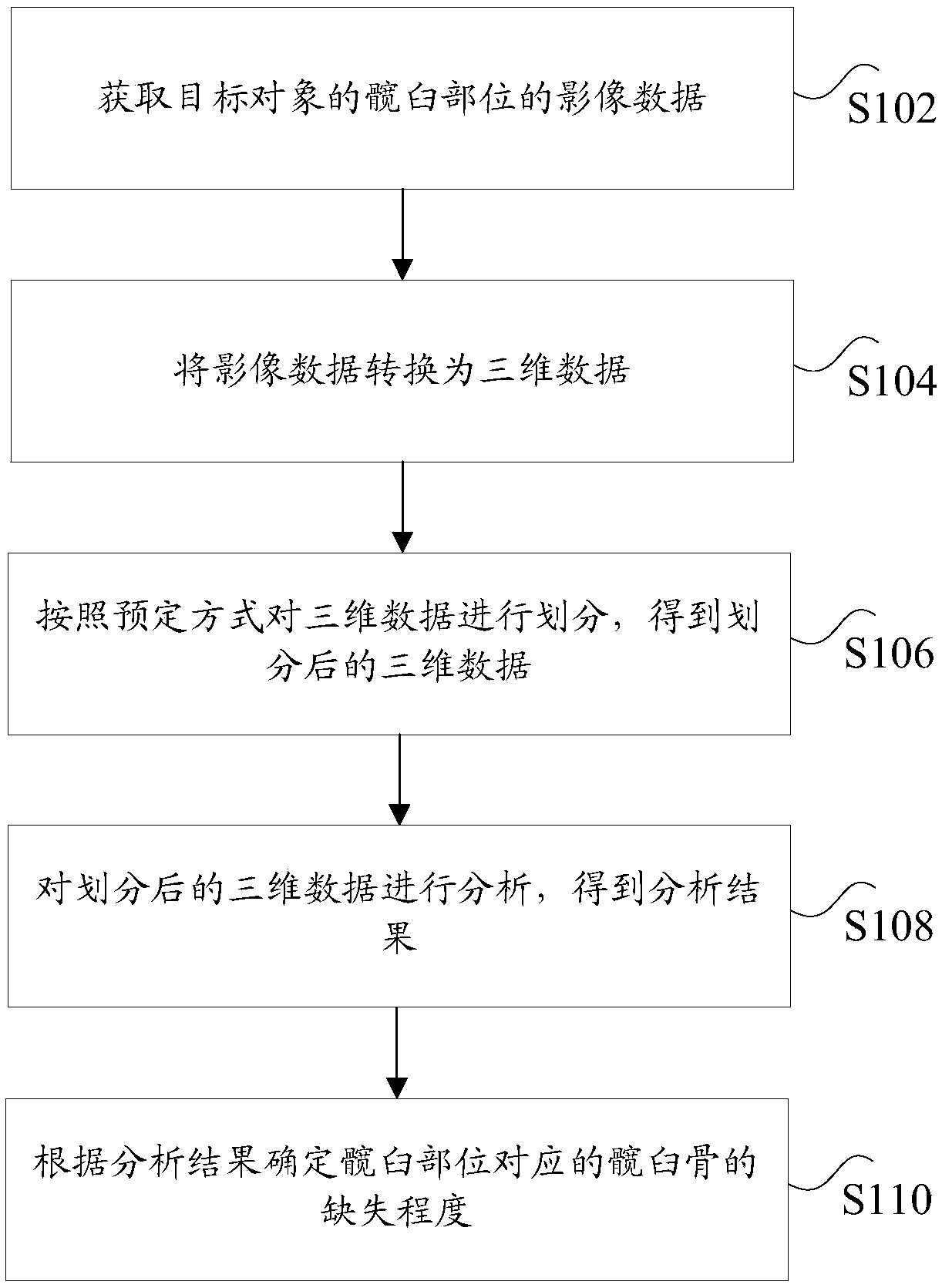

Method and device for determining degree of acetabular bone defect

ActiveCN109106481AFix technical issues with lower accuracyImprove accuracyJoint implantsAcetabular cupsEvaluation resultJoint revision

The invention discloses a method and a device for determining the degree of acetabular bone defect. The method comprises the following steps: obtaining image data of acetabular part of a target object; converting image data into three-dimensional data; dividing the three-dimensional data according to a predetermined mode to obtain the divided three-dimensional data; analyzing the divided three-dimensional data and get the analysis result, and determining the degree of acetabular bone loss corresponding to the acetabular site according to the results of the analysis. The invention solves the technical problem in the related art that the accuracy of the evaluation result obtained by the evaluation method for the acetabular bone defect in the hip joint revision operation is low.

Owner:BEIJING AKEC MEDICAL

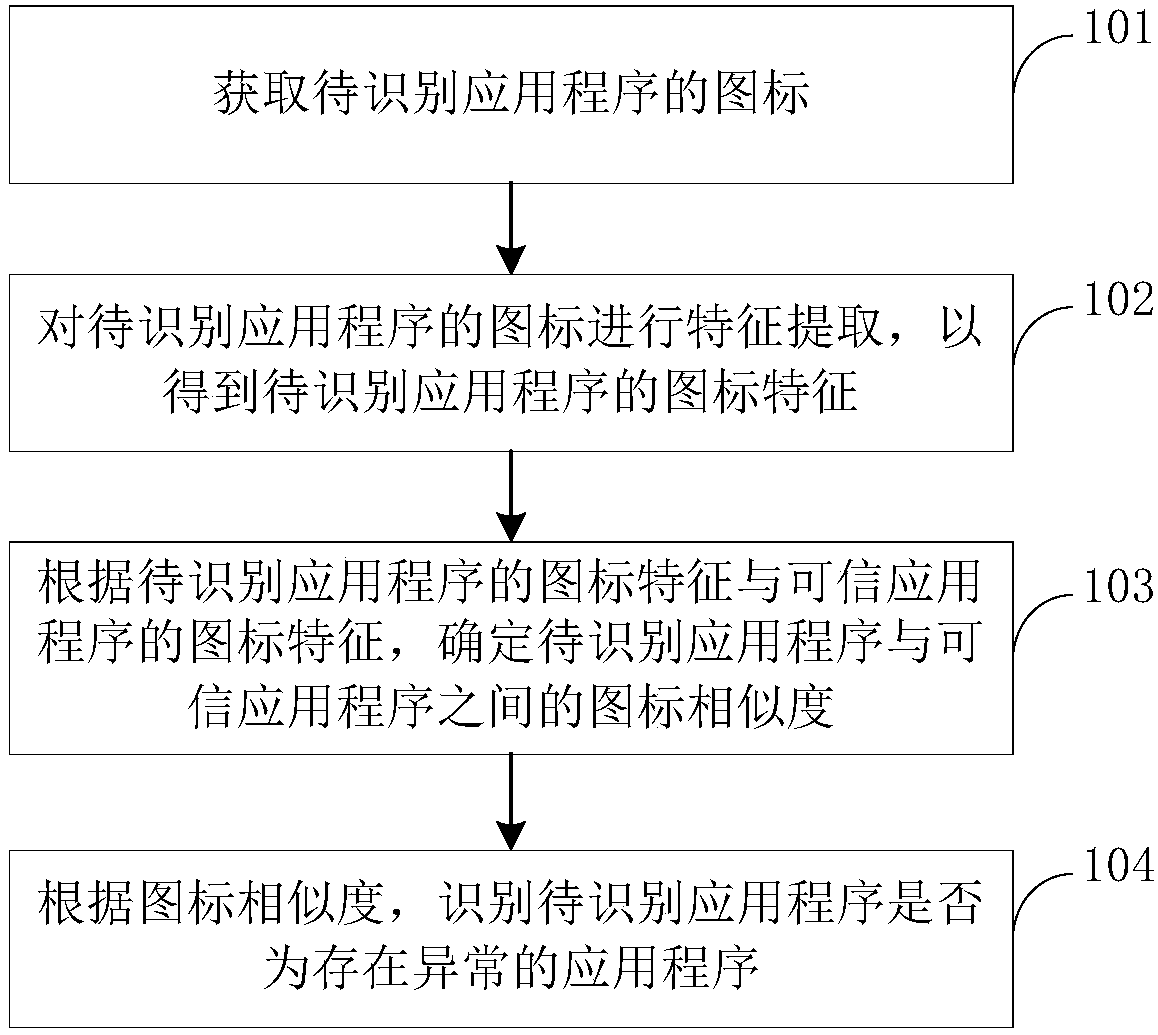

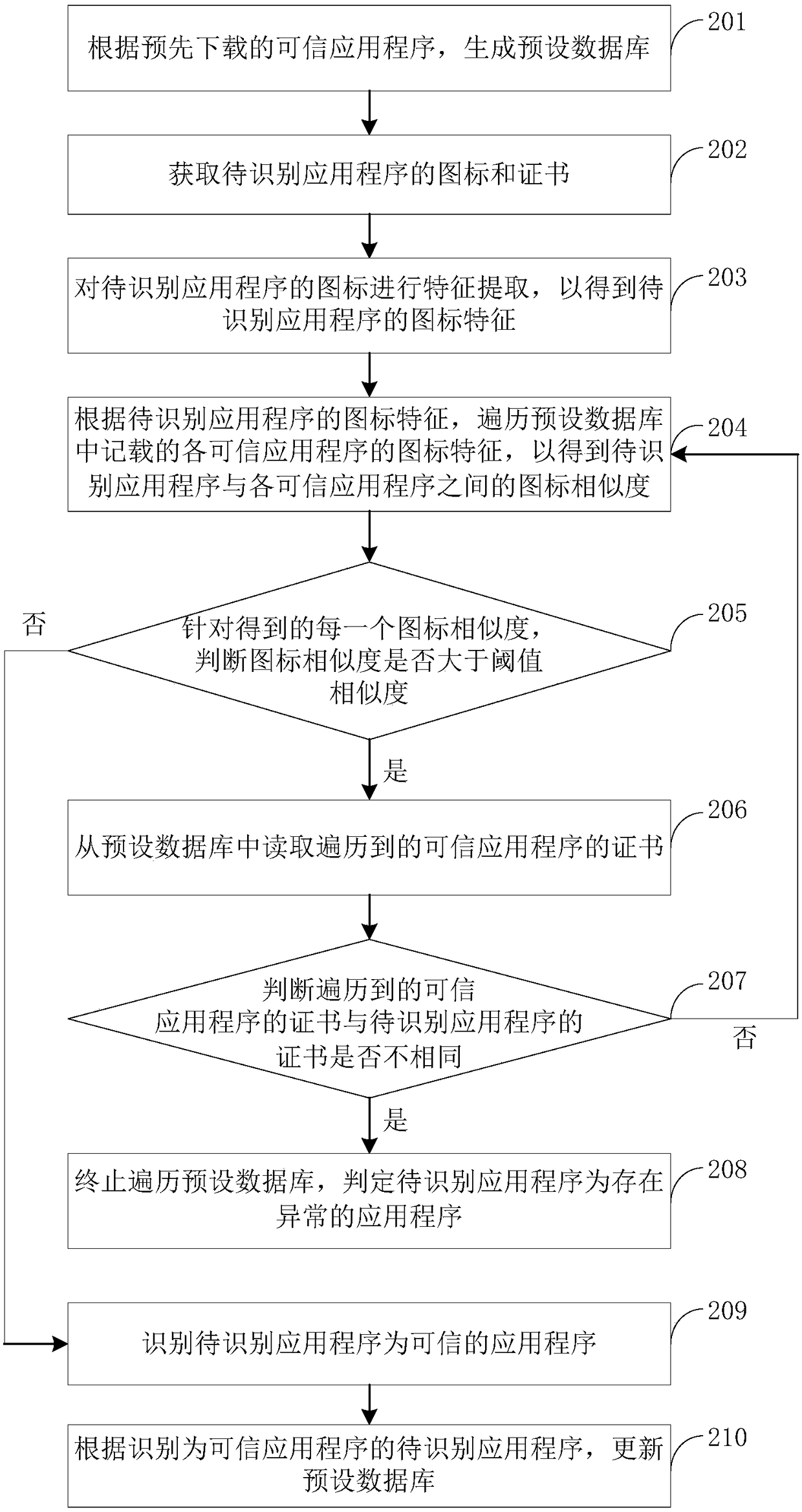

Application program identification method and device

PendingCN108416212AFix technical issues with lower accuracyCharacter and pattern recognitionPlatform integrity maintainanceFeature extractionApplication software

The invention provides an application program identification method and device. The method comprises the steps that icons of to-be-identified application programs are acquired, feature extraction is carried out on the icons of the to-be-identified application programs to obtain icon features of the to-be-identified application programs, according to the icon features of the to-be-identified application programs and reliable application programs, icon similarity between the to-be-identified application programs and the reliable application programs is determined, and according to the icon similarity, it is identified whether or not the to-be-identified application programs are abnormal. According to the icon similarity between the to-be-identified application programs and the reliable application programs, it is identified whether or not the to-be-identified application programs are abnormal, and the problems that application program names are adopted to identify application programs inthe related art, so that the abnormal application programs easily bypass identification, and the identification accuracy is lower are solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com