Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Find the exact location" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

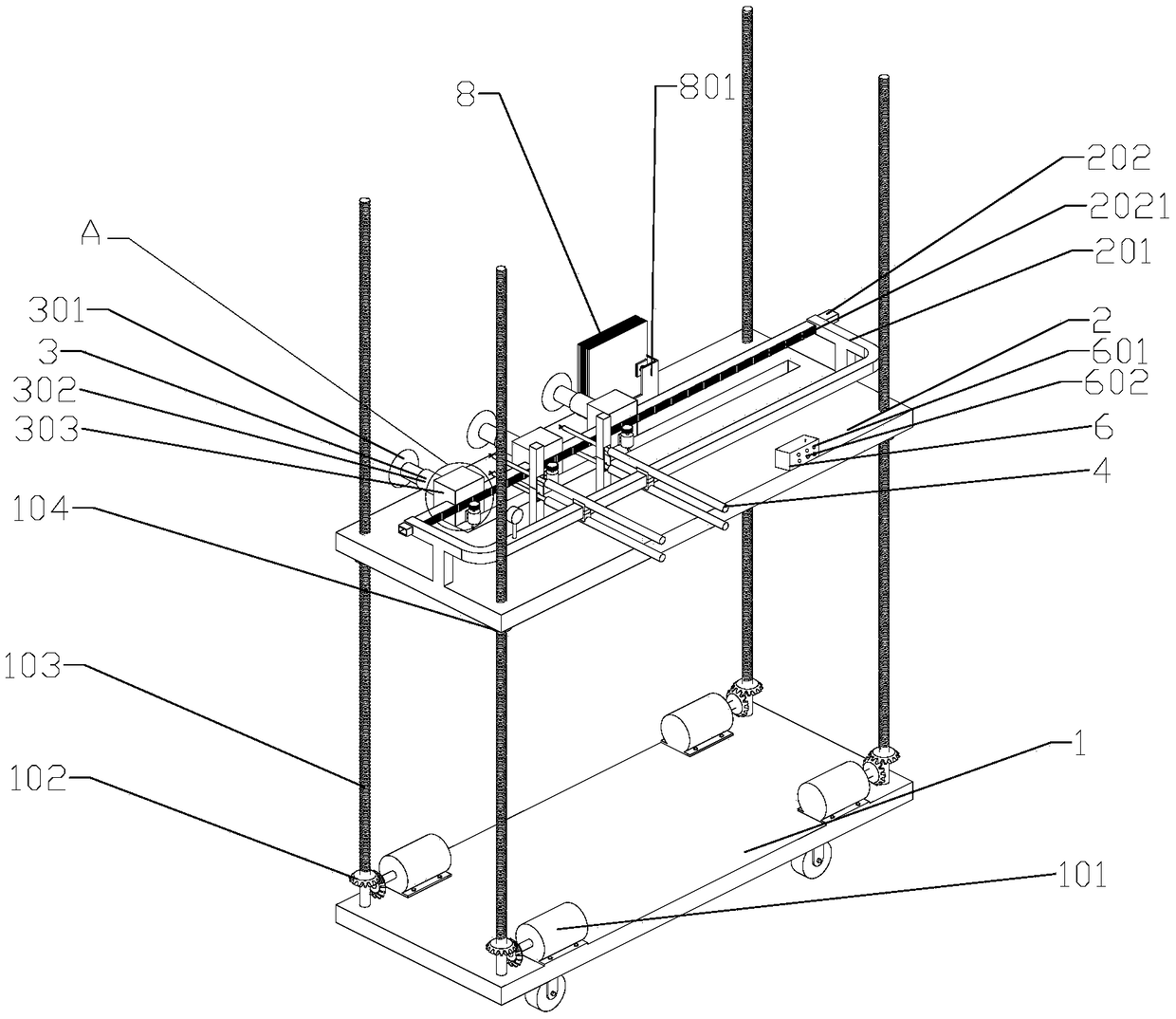

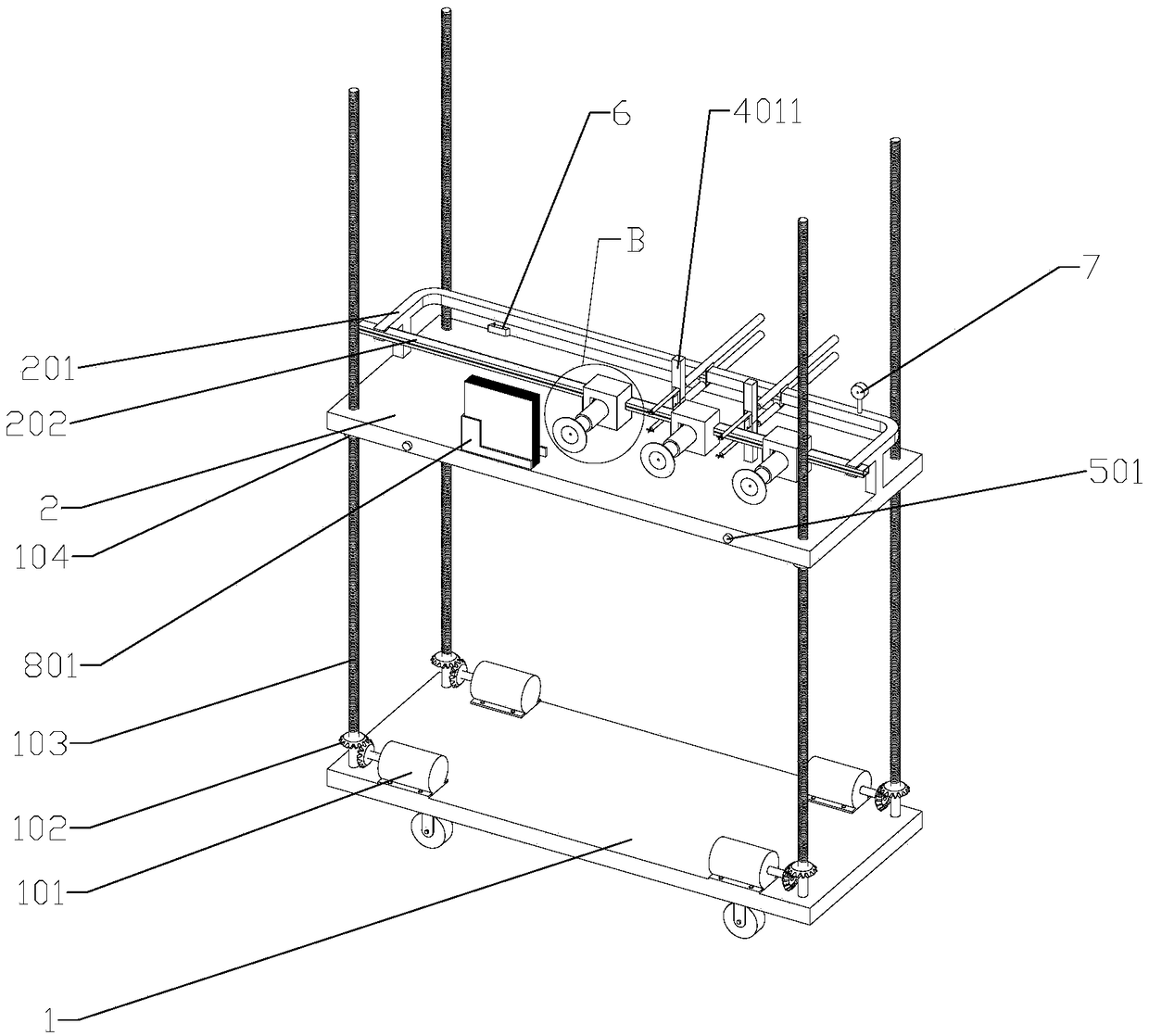

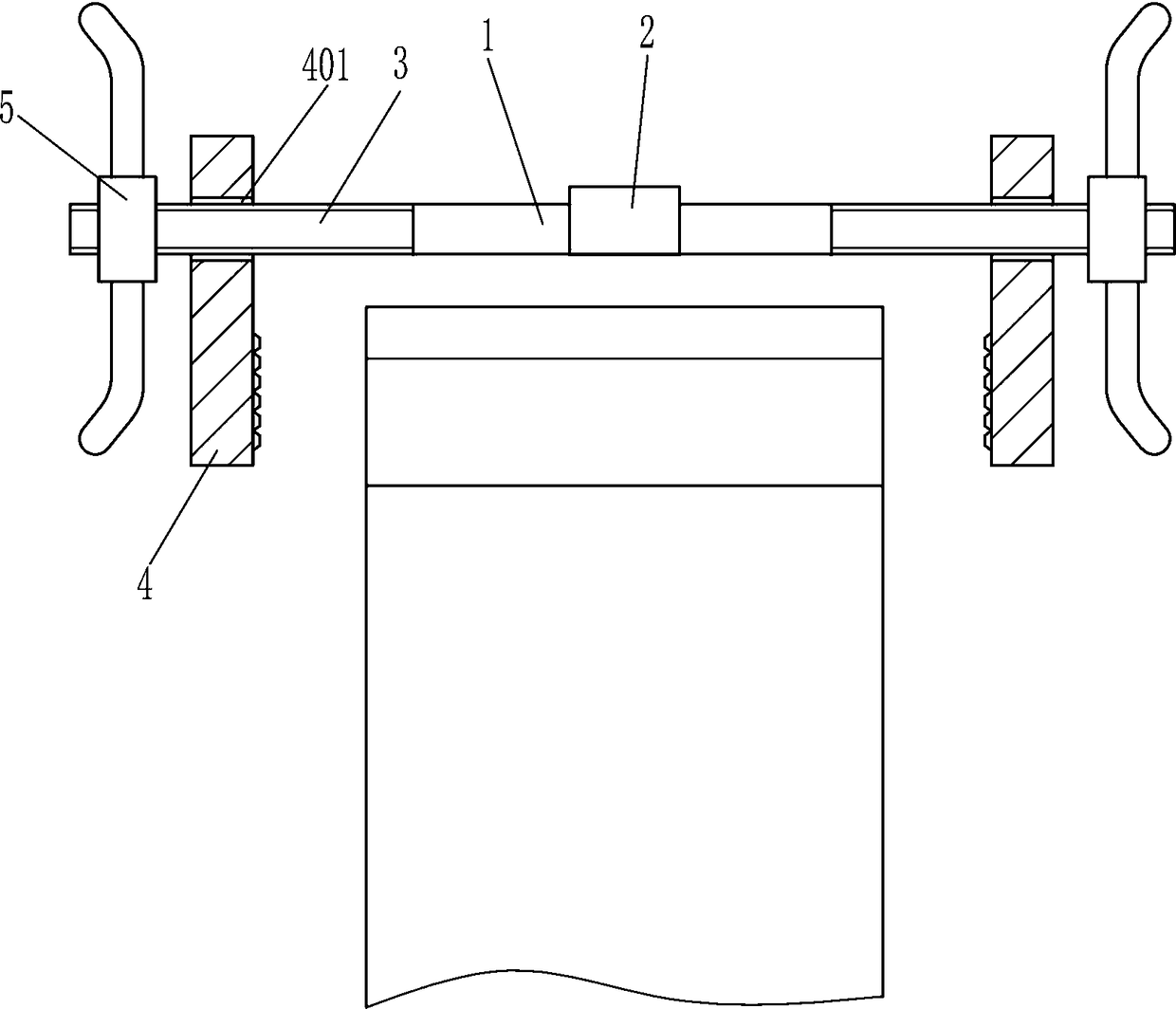

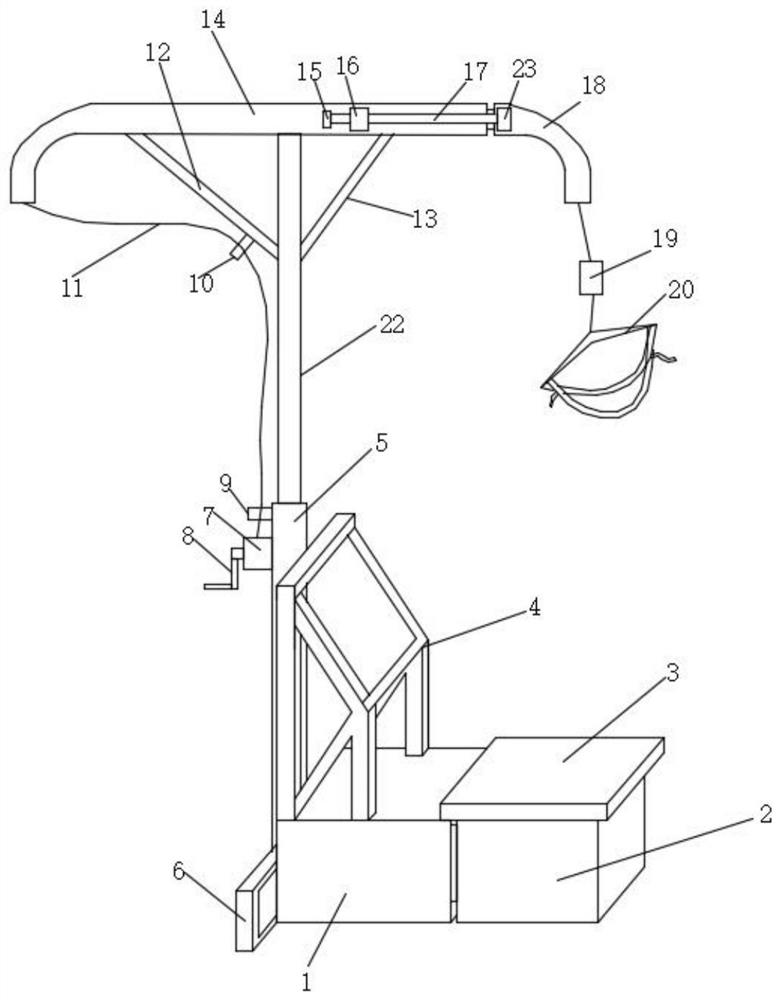

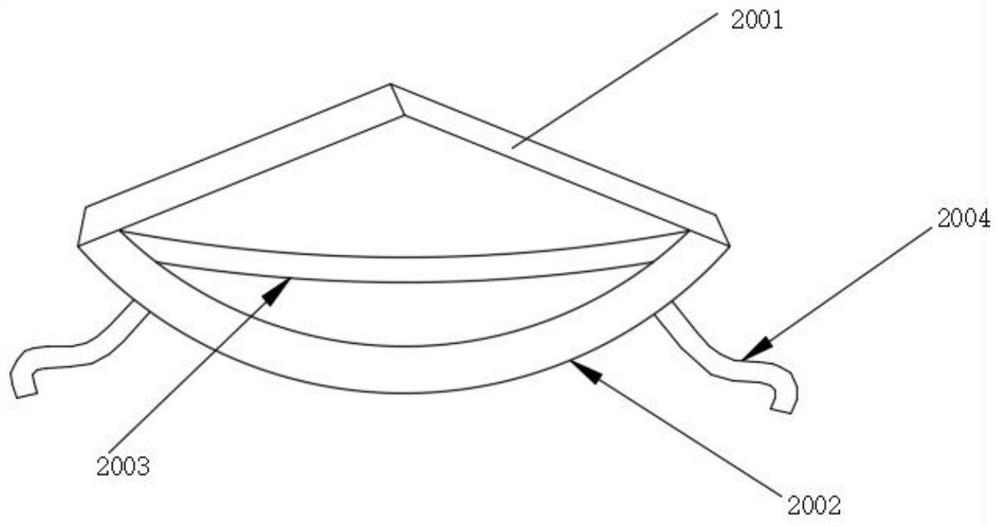

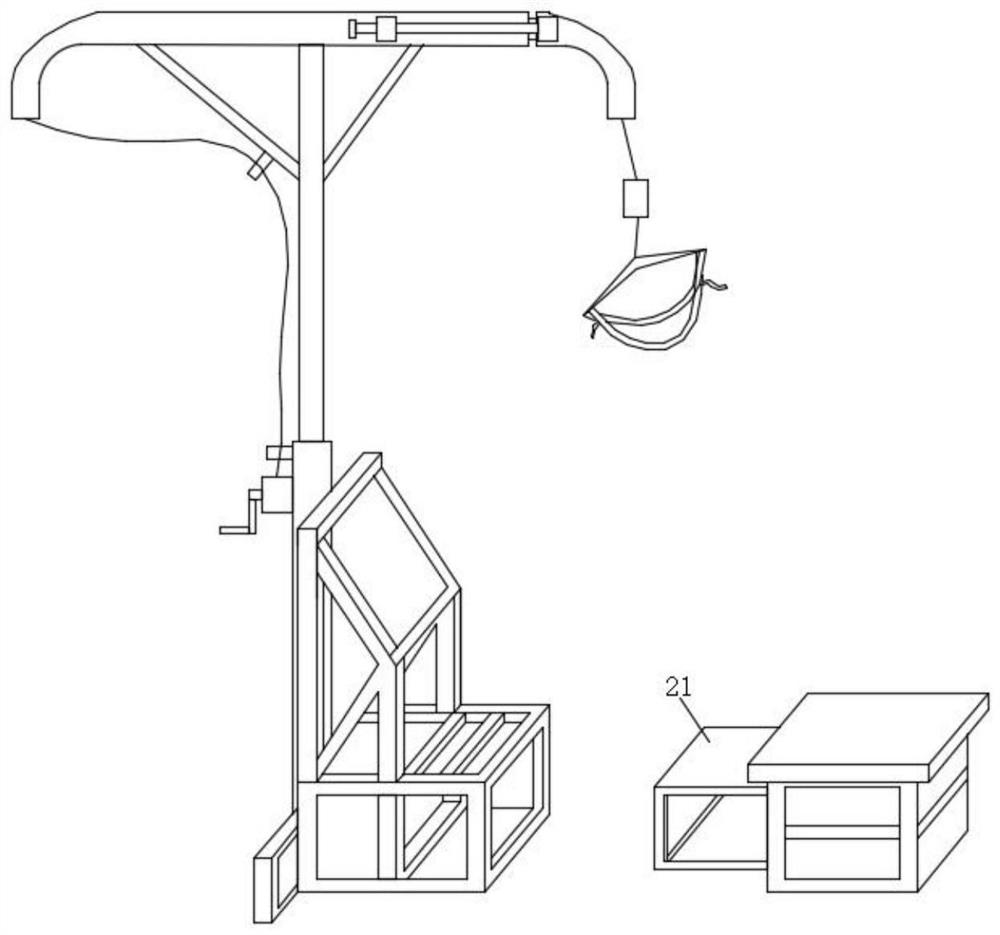

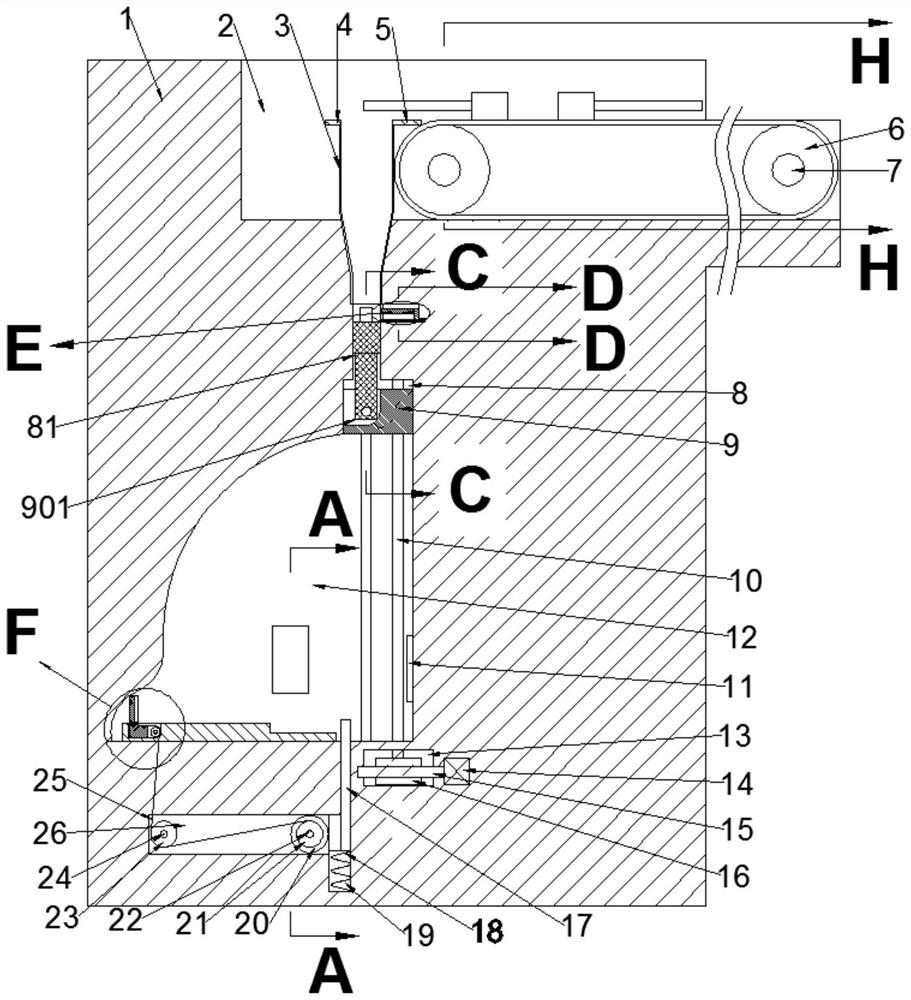

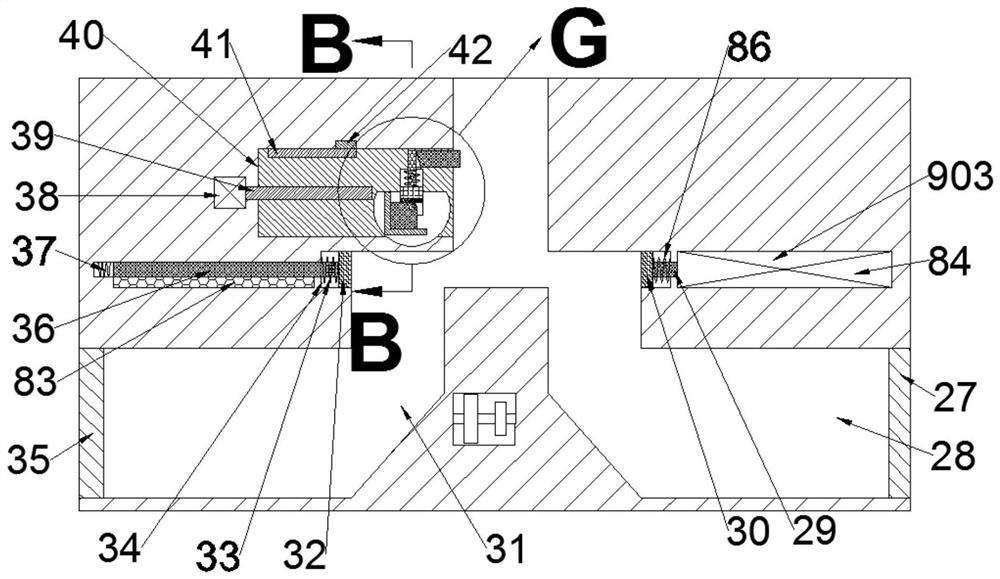

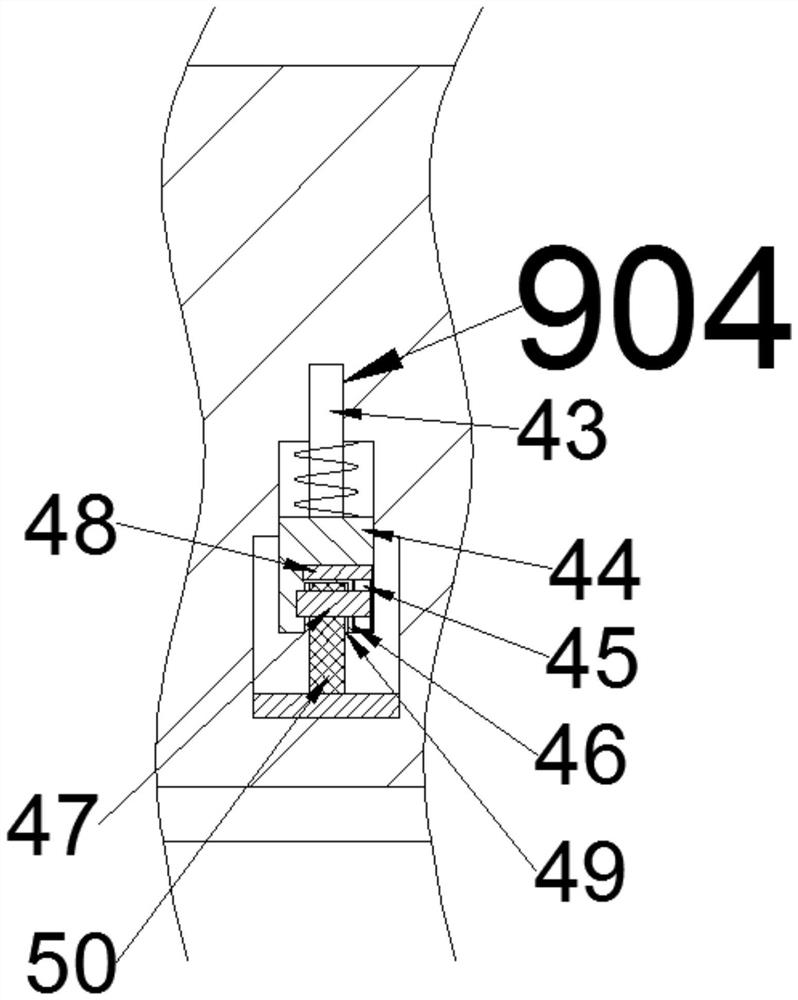

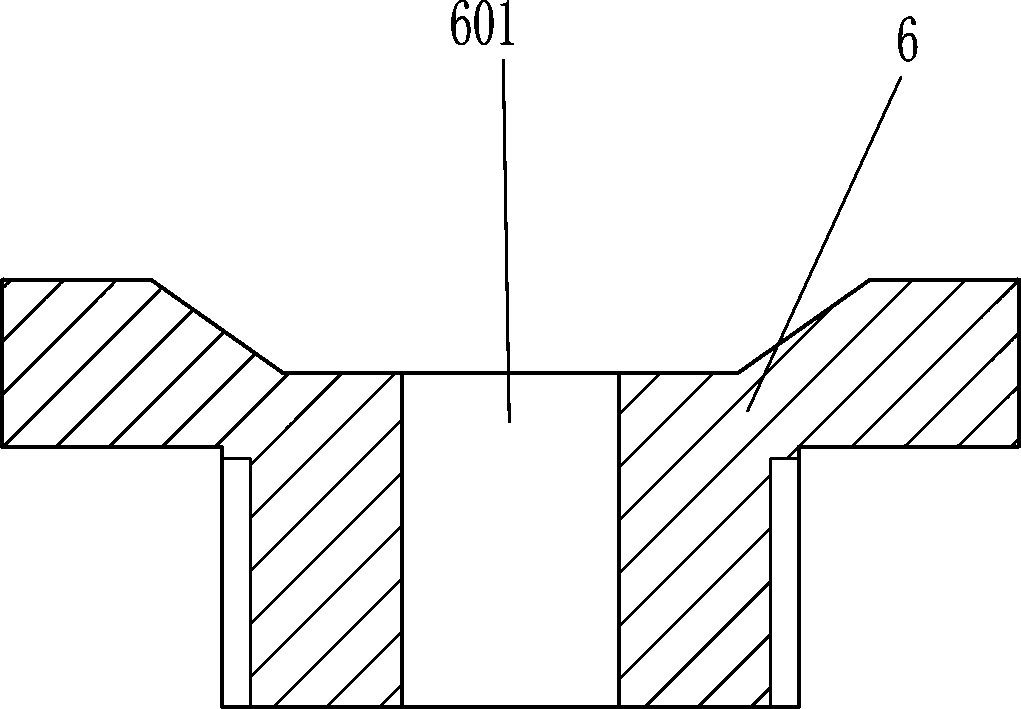

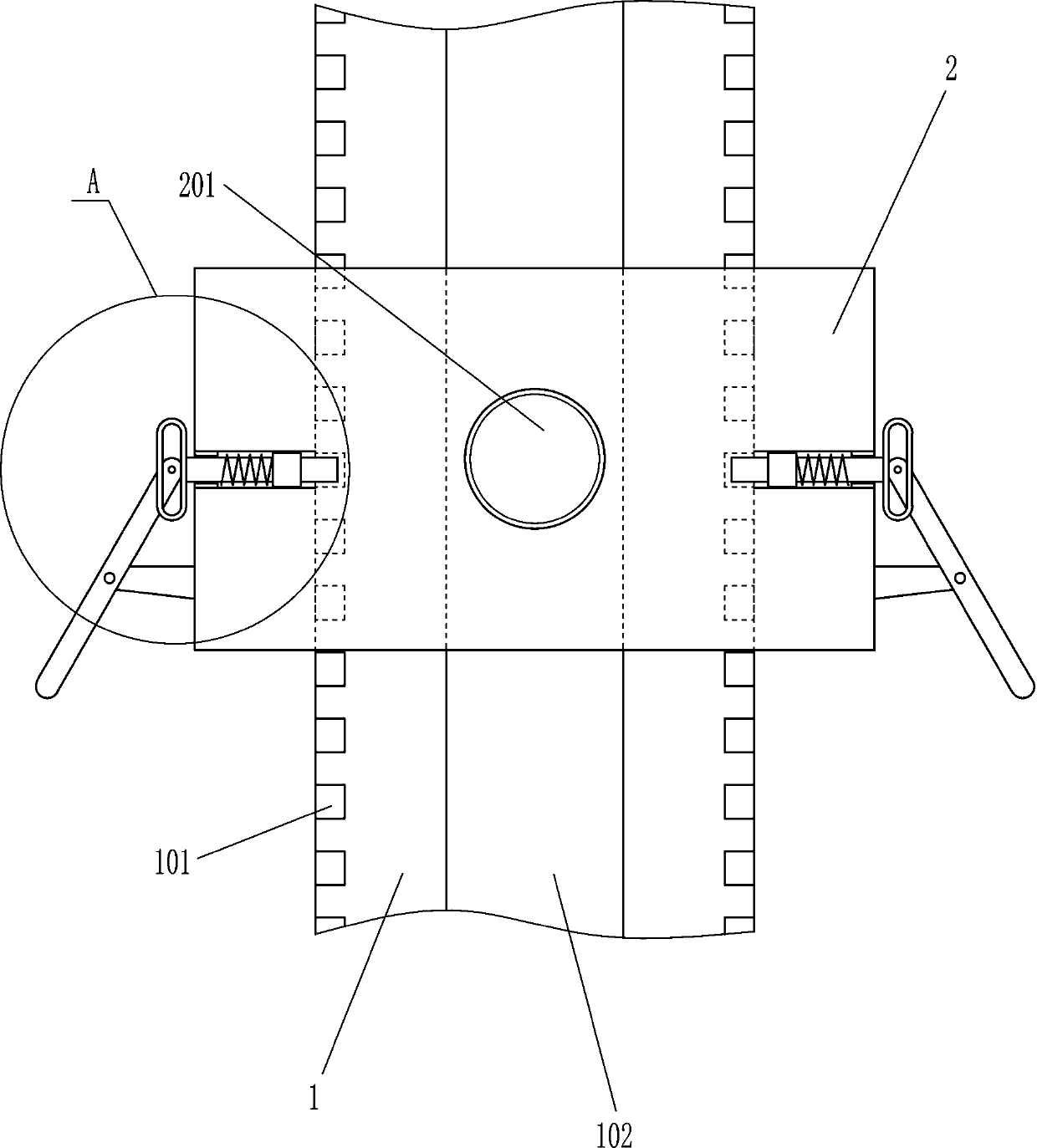

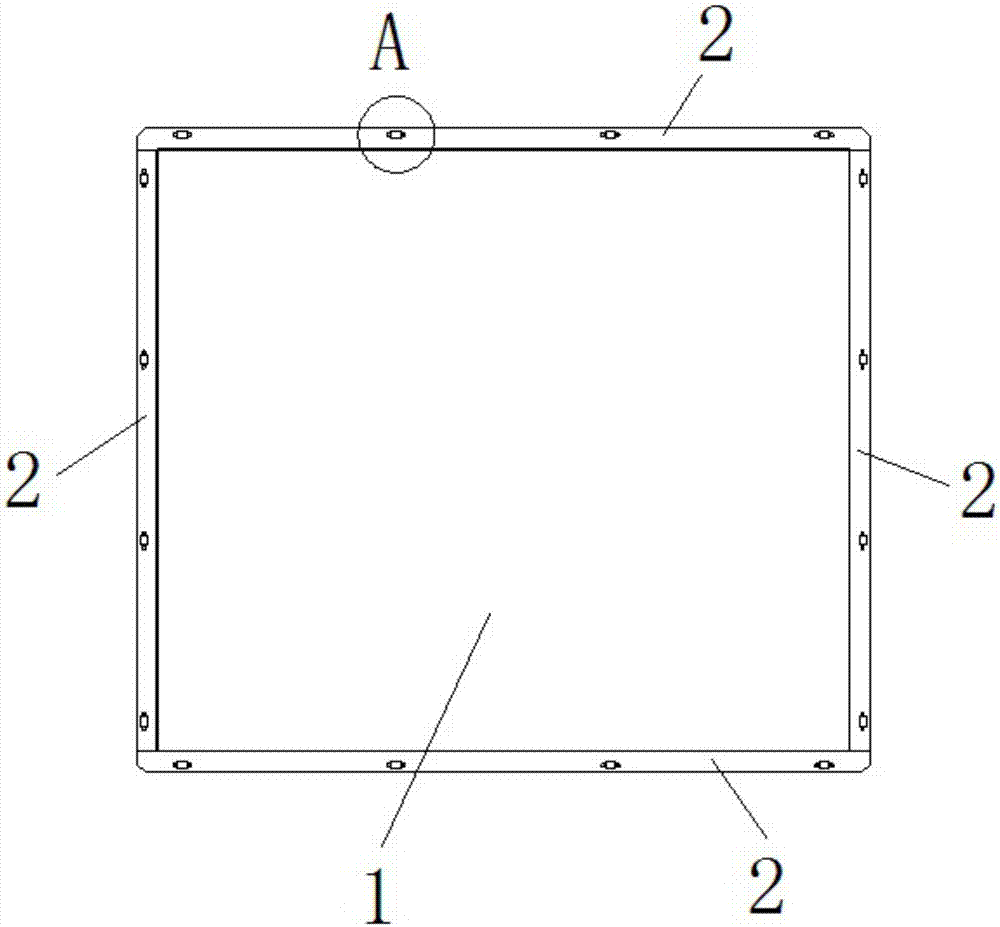

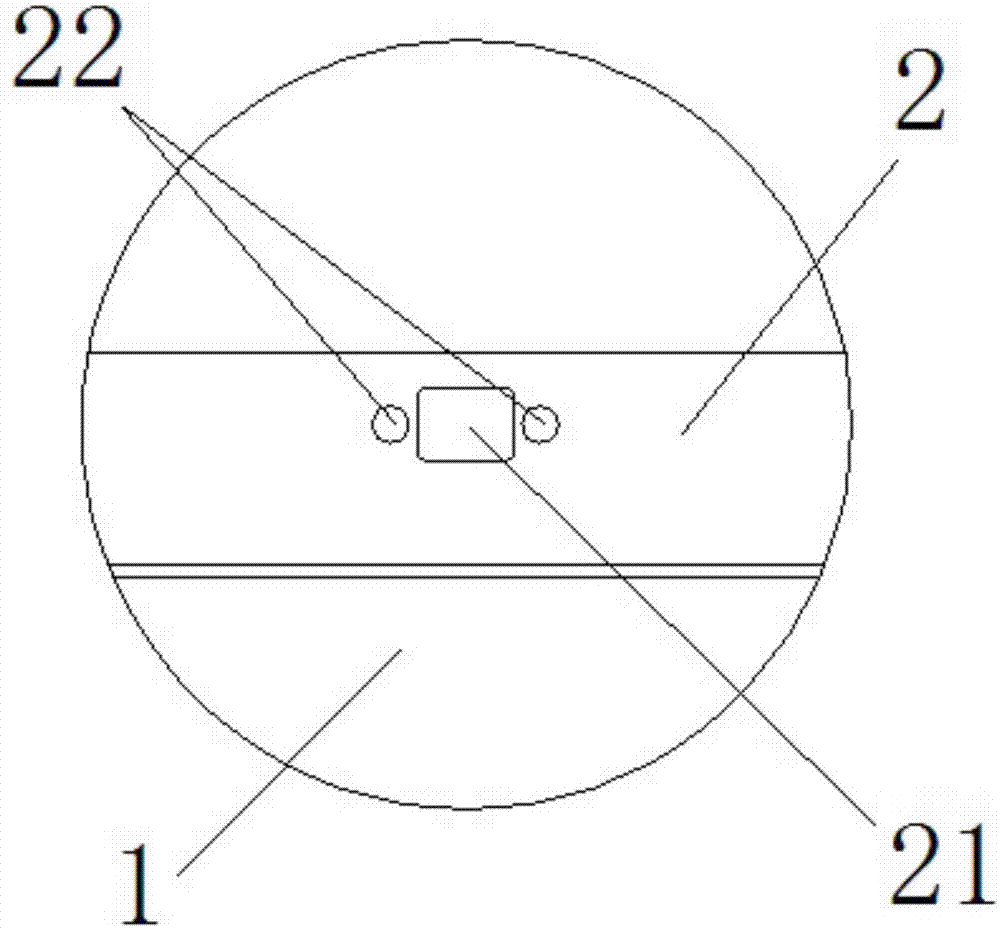

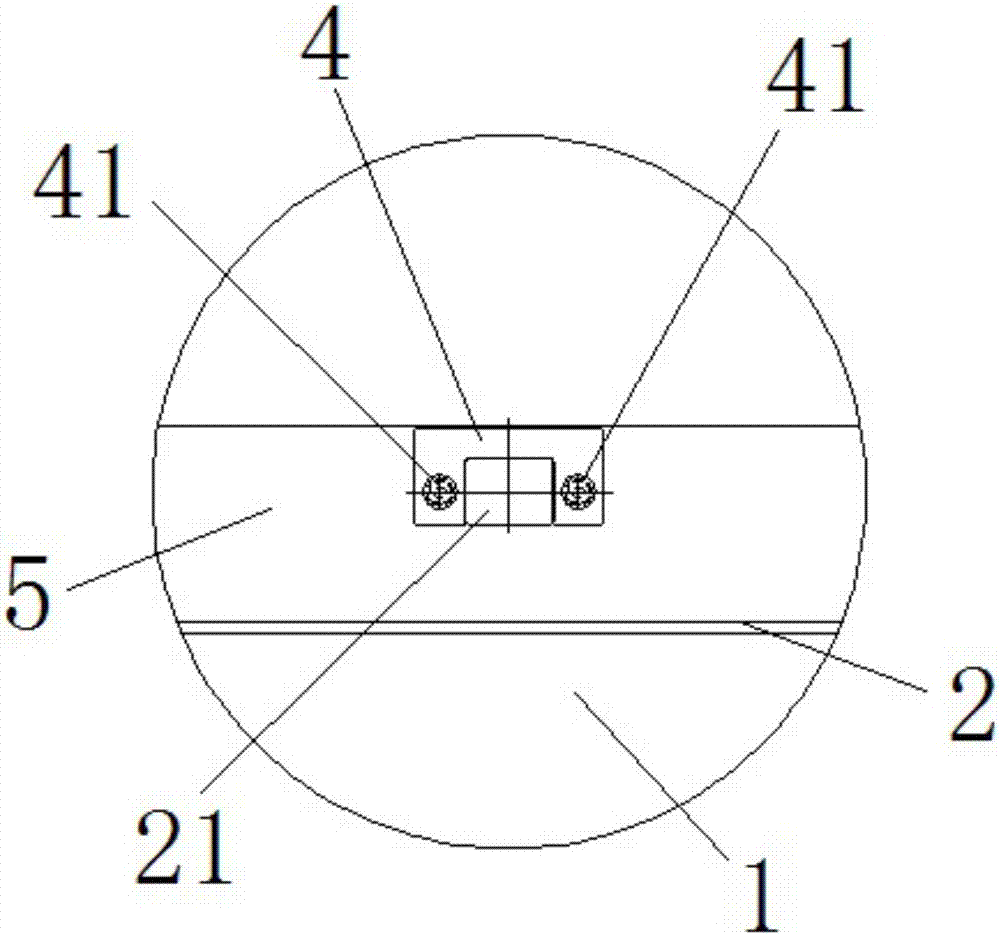

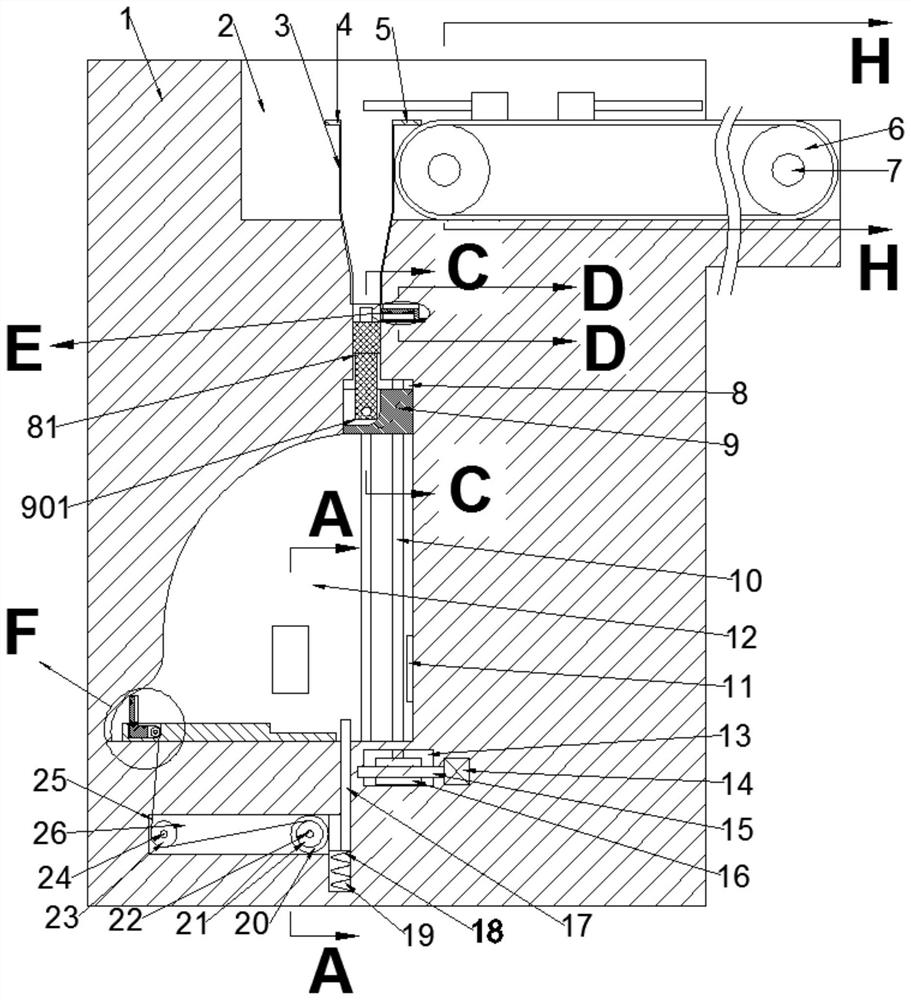

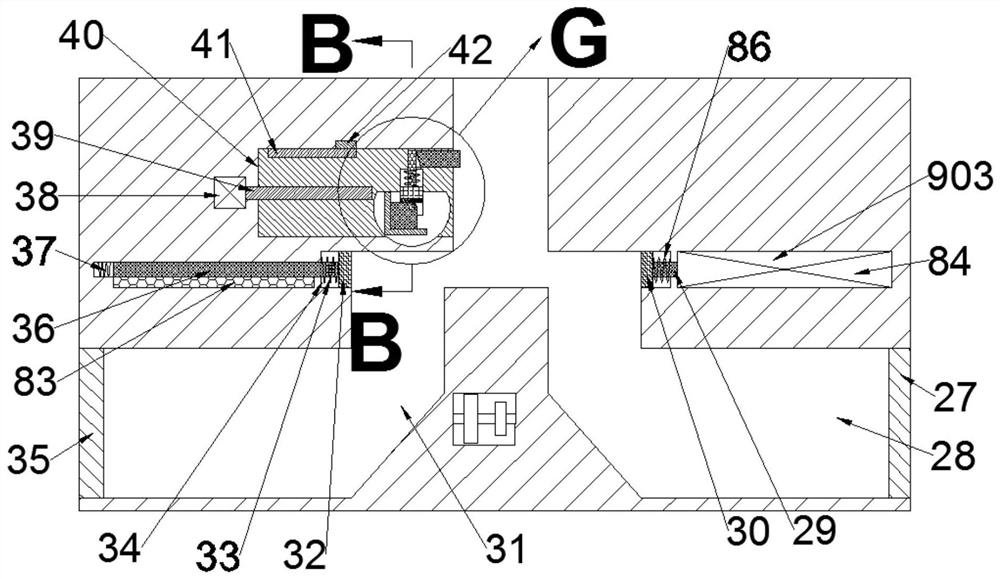

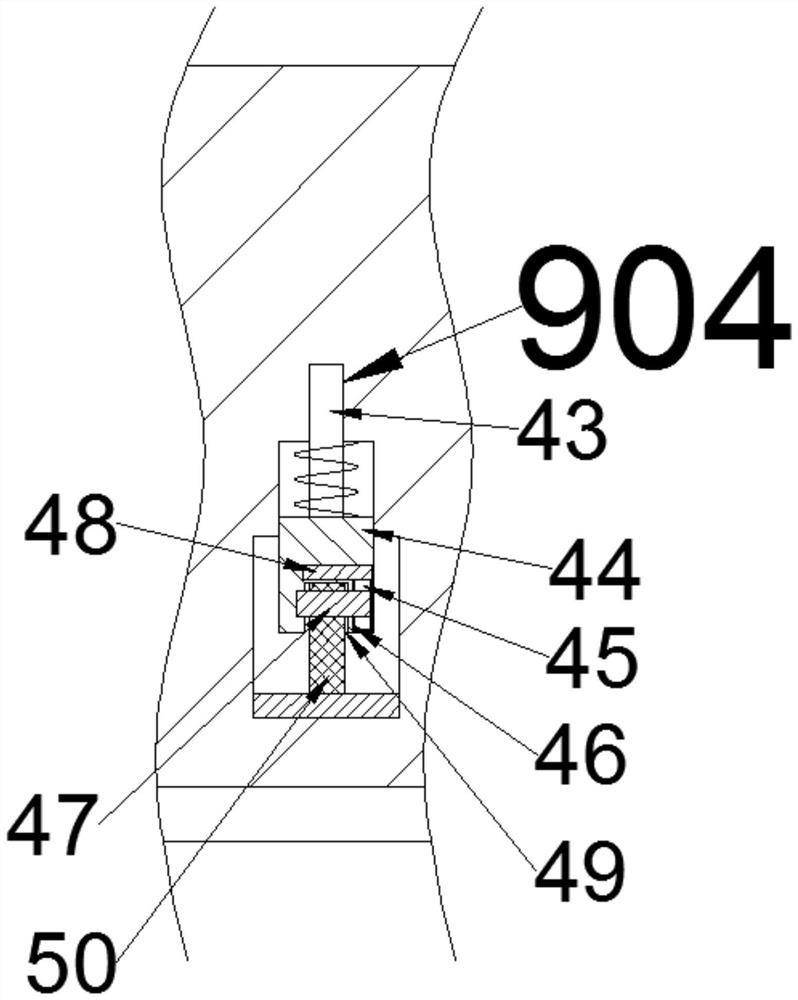

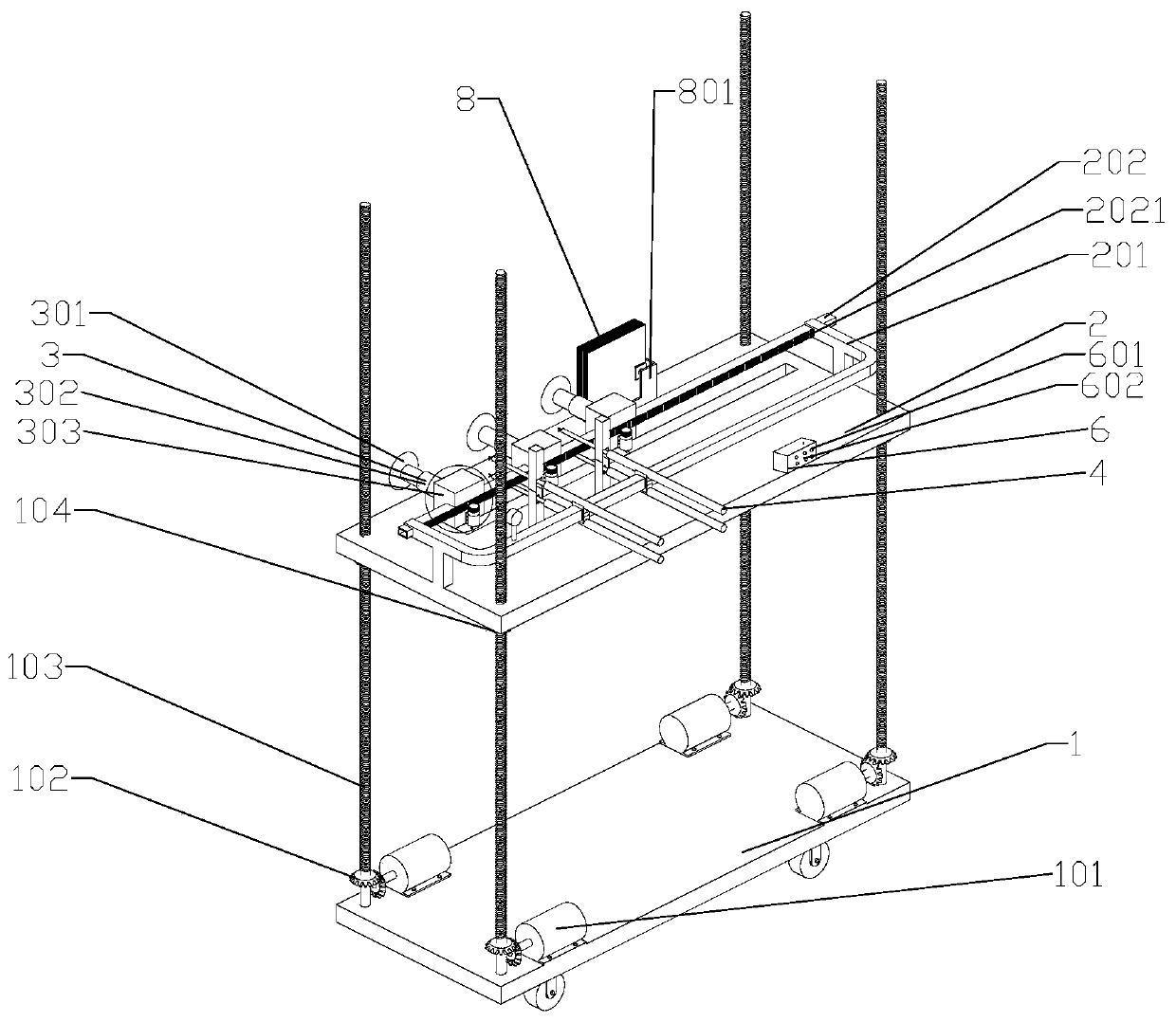

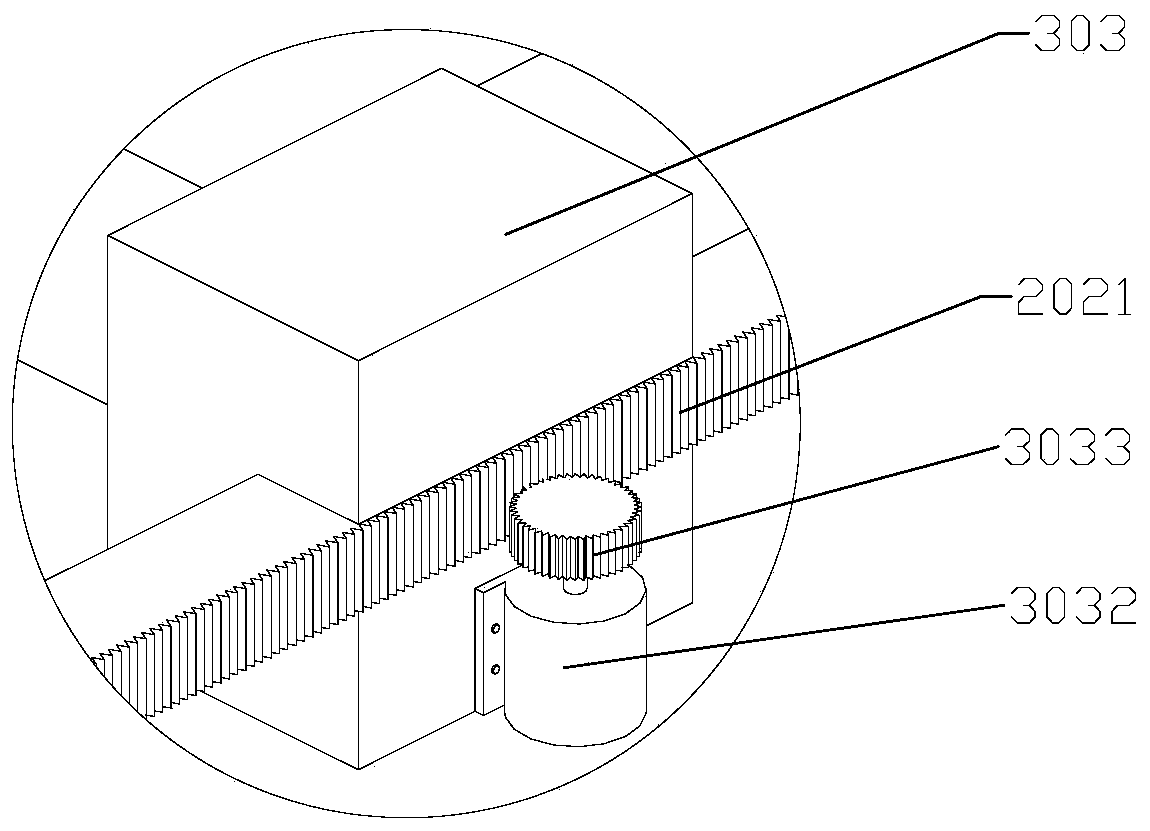

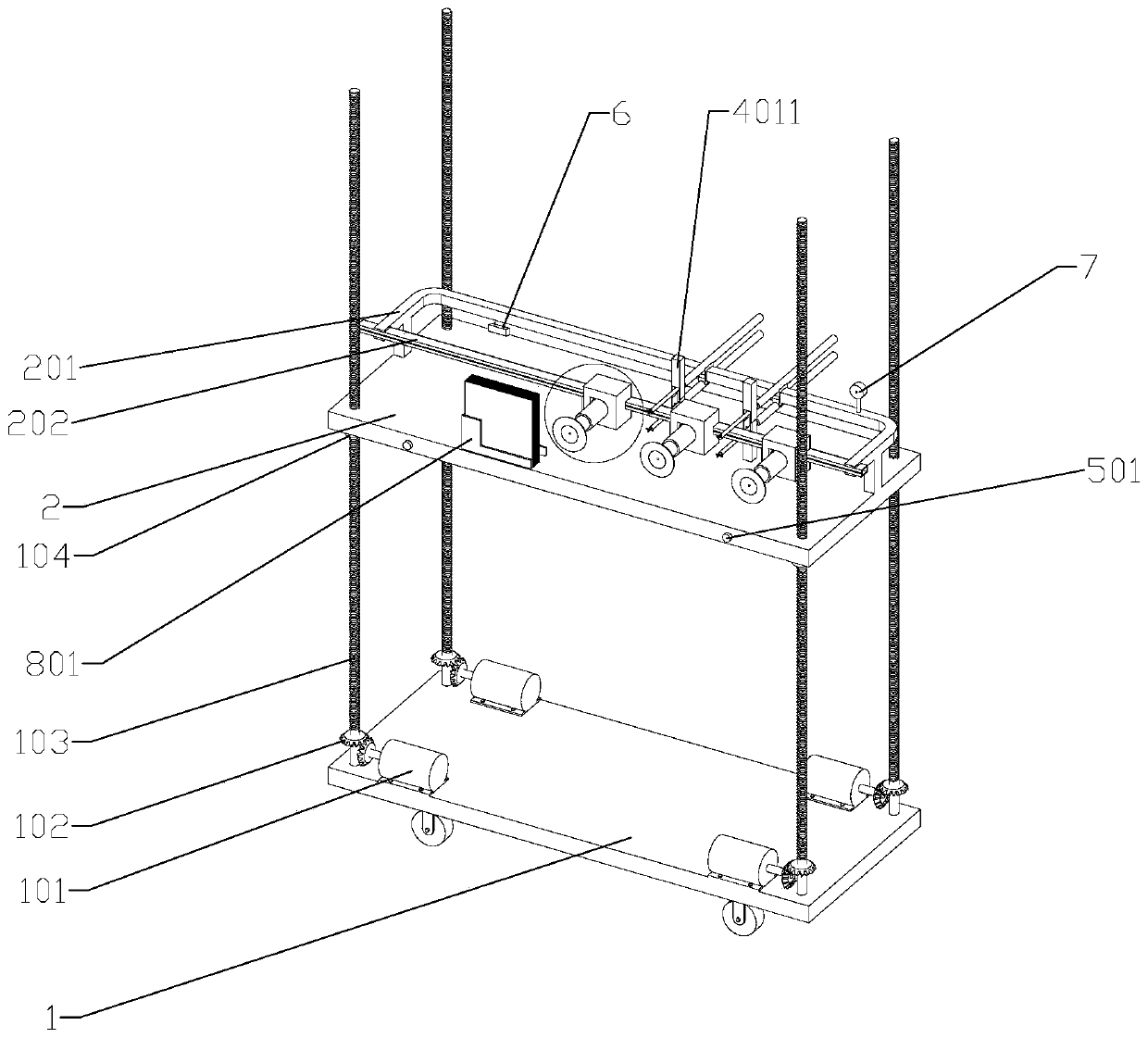

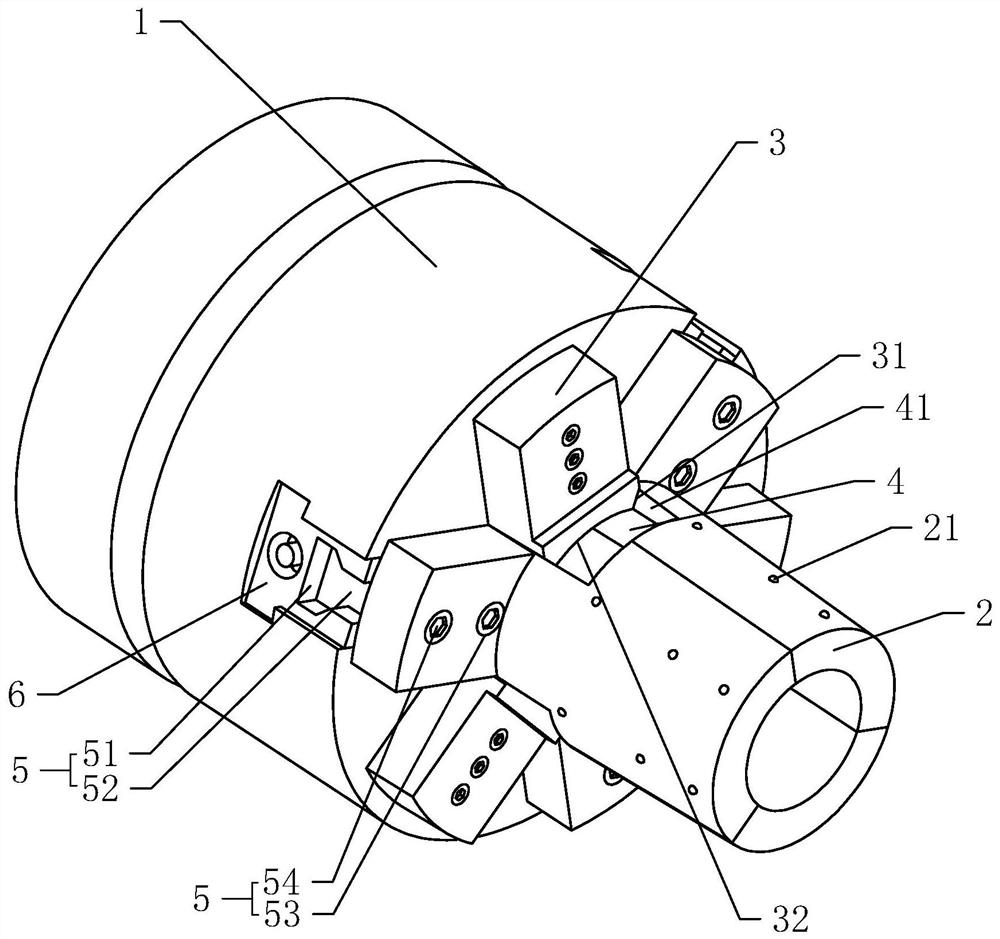

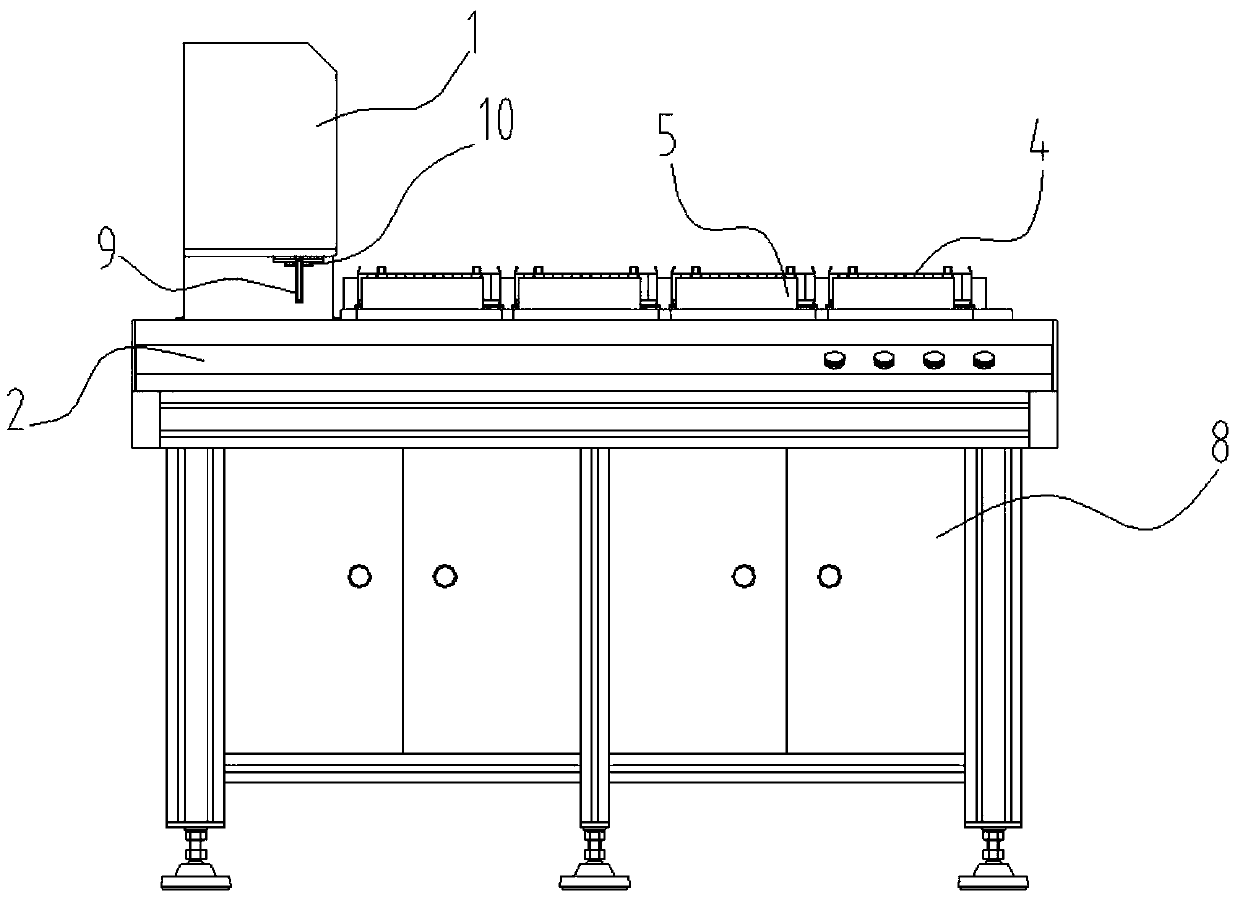

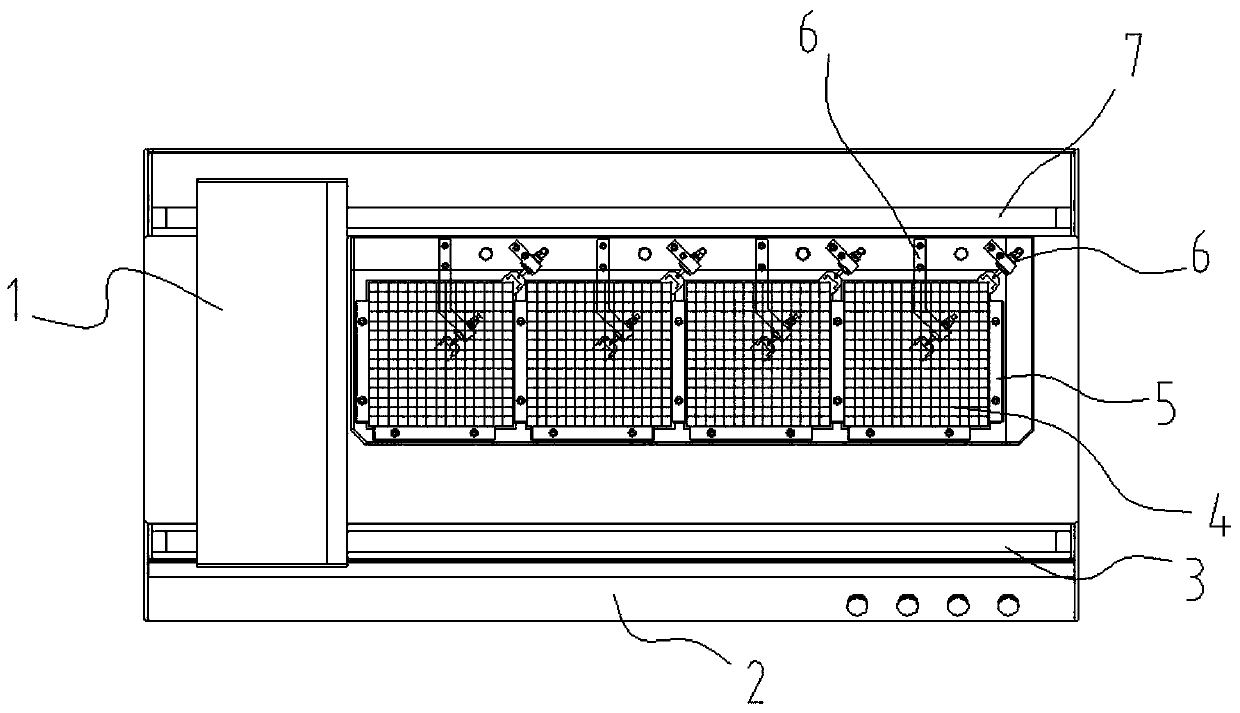

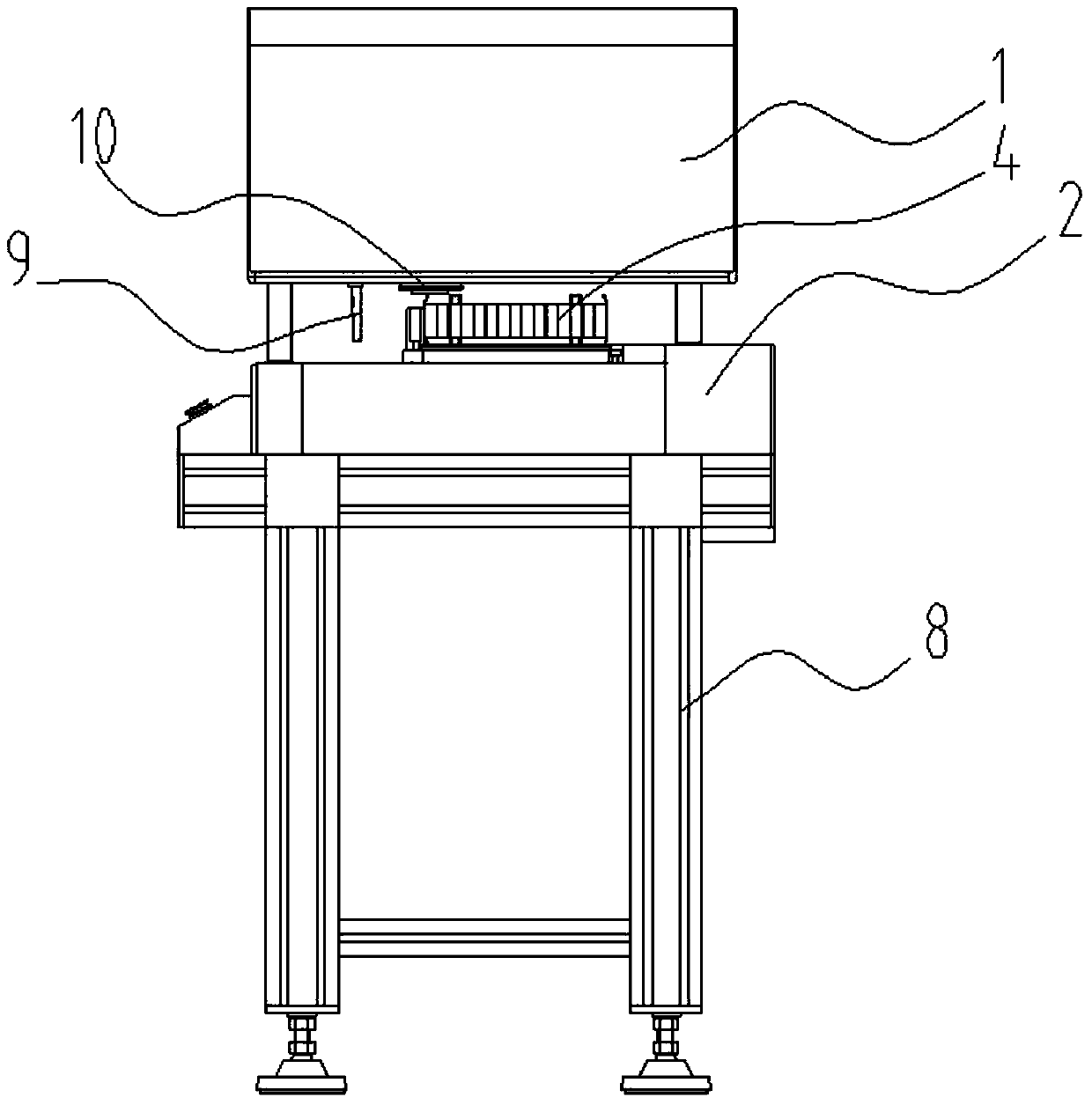

Fast tile attaching machine for building construction

InactiveCN109083381AFast layingAccurate and standard layingBuilding constructionsLaser sensorMechanical engineering

The invention discloses a fast tile attaching machine for building construction. The fast tile attaching machine comprises a vehicle body, an operation platform, a sucker device, multiple seam clamping device conveying mechanisms, a distance setting device and a controller; the seam clamping device conveying mechanisms are arranged at the rear portion of a guide rail, each seam clamping device conveying mechanism comprises a storage clamp and two air cylinders II vertically arranged on a crossbar of a U-shaped support frame, and the front ends of piston rods of the air cylinders II are provided with clamping parts; each storage clamp comprises two identical clamp bodies, each clamp body is internally provided with a cavity, positioning slots are symmetrically formed in both sides of each cavity, positioning plates are disposed above the positioning slots, and gaps are reserved between the positioning plates and the positioning slots and used for seam clamping devices to slide out; thedistance setting device includes two laser sensors arranged in the front of the operation platform and a laser source arranged outside the vehicle body; an infrared emitter, an audible and visual alarm and a tile placement frame are arranged on the operation platform. The fast tile attaching machine can suck multiple tiles at the same time, the laying precision is high, the tiles can be attached automatically, and the seam clamping devices are placed at the same time.

Owner:湖北屹峡峰建设工程有限公司

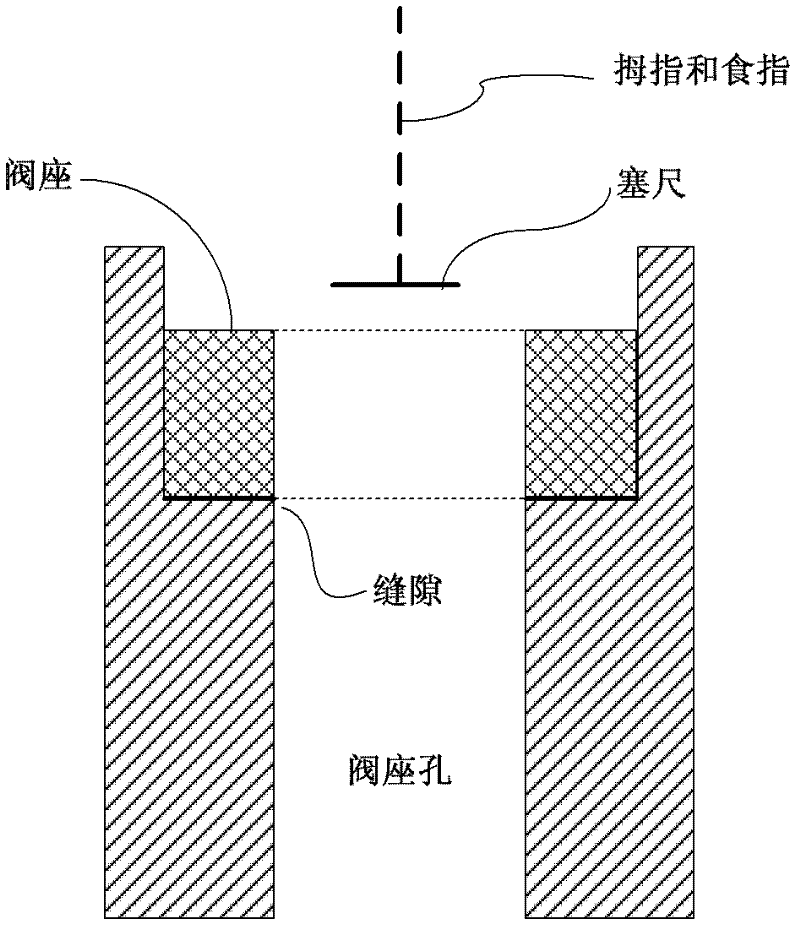

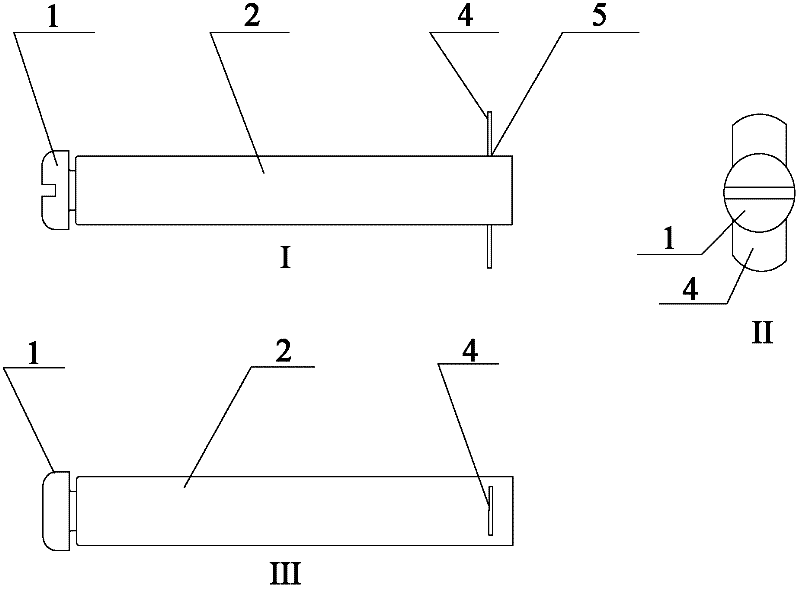

Measuring tool

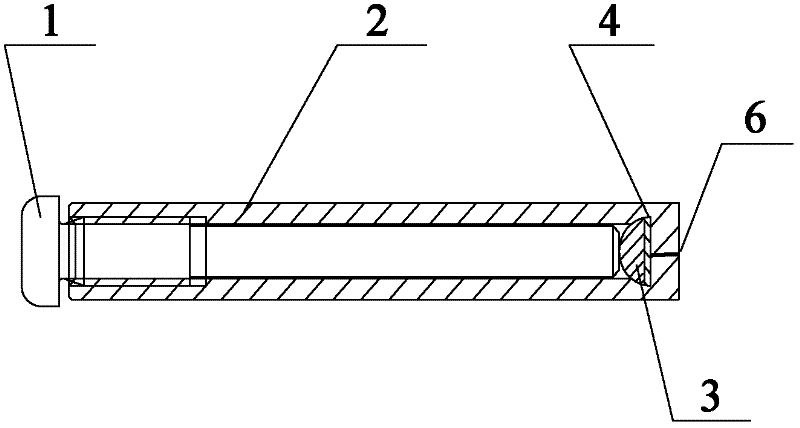

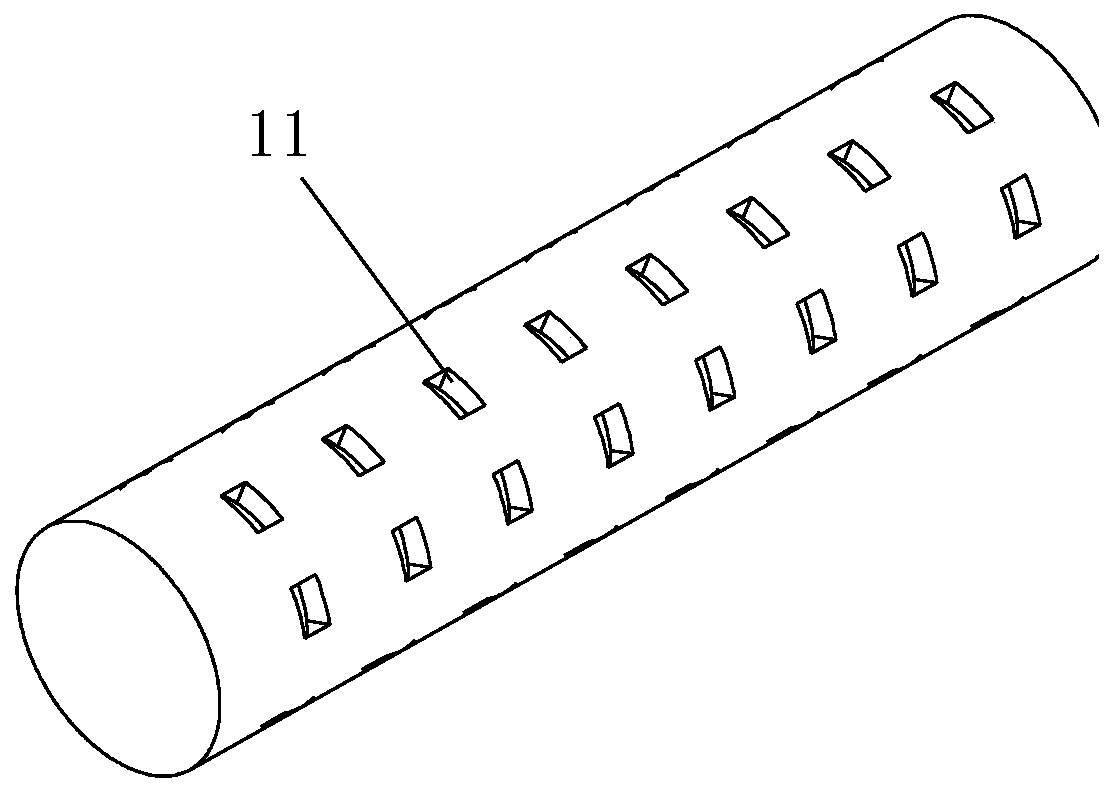

InactiveCN102410801ANot easy to damageFind the exact locationMechanical clearance measurementsEngineeringBlind hole

The invention discloses a measuring tool which comprises a filler gauge, a body, a first pressing part and a second pressing part, wherein the body is a cylinder; a blind hole is formed at one end of the body along an axis direction; a plane which is vertical to an axis of the body is arranged at the bottom of the blind hole; the second pressing part is arranged at the bottom of the blind hole; at least one rectangular hole which passes through the blind hole from the surface of the body is formed on the body; the filler gauge is inserted into the rectangular hole and is locked at the bottom of the blind hole by the first pressing part through the second pressing part; and preferably, the first pressing part is a tightening bolt, the second pressing part is a pressing block, a convex arc-shaped surface is arranged at one end of the pressing block facing to the bolt, and a plane is arranged at one end of the pressing block facing to the bottom of the blind hole. When the measuring tool provided by the invention is used for measuring a gap in an inner cavity, the problems of lower accuracy and efficiency caused by an operation of manually inserting the filler gauge into the inner cavity and the easily blocking problem of the filler gauge caused by inconvenient operation and the like are solved.

Owner:WEICHAI POWER CO LTD

Keyway machining method of same-tangency-point eccentric shaft

The invention discloses a keyway machining method of a same-tangency-point eccentric shaft. A keyway position is confirmed based on a reference part formed by performing end face milling on a cylindrical casting part, a keyway is milled and then an eccentric circle is cut. Compared with the prior art, the keyway machining method can enable the keyway to be accurately positioned and cut, deviation caused by the fact that the eccentric circle is first cut and then the keyway is positioned is avoided, the keyway milling accuracy is greatly improved, workpiece waste is avoided, the time is saved, and the working efficiency is improved.

Owner:ZHENJIANG HENGYU TRANSMISSION MACHINERY

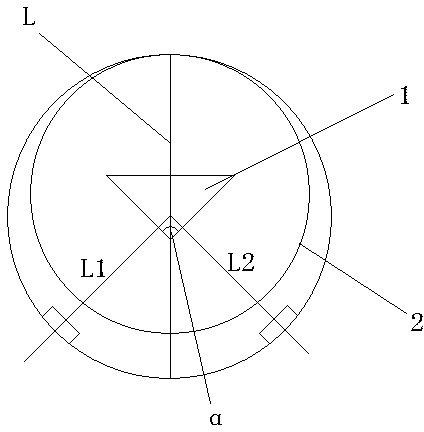

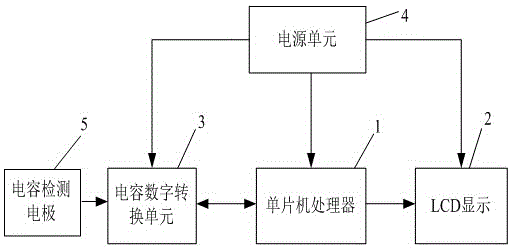

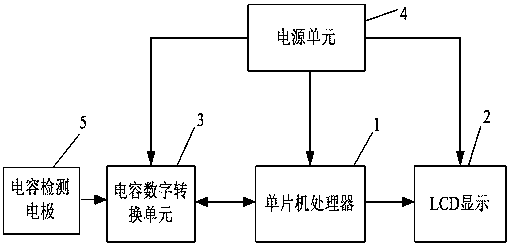

Indicator for measuring oil level inside transformer sleeve through electric field and measurement method thereof

ActiveCN104880235AFind the exact locationFind locationLevel indicators by physical variable measurementDigital conversionElectric field

An indicator for measuring the oil level inside a transformer sleeve through an electric field comprises a power unit which supplies power to a single chip microcomputer processor, an LCD and a capacitance digital conversion unit. A capacitance detection electrode achieves one-way transmission to the capacitance digital conversion unit, mutual transmission is achieved between the capacitance digital conversion unit and the single chip microcomputer processor, and the single chip microcomputer processor achieves one-way transmission to the LCD. By the utilization of different dielectric constants of transformer oil and air, the oil level is judged through different capacitance values of the detection electrode when oil exists, and no oil exists; in the measurement process, through vertical movement, the oil level is gradually found through multi-point measurement; in this way, the purpose of measuring the oil level inside the transformer sleeve in a non-contact multi-point mode without electrification is achieved, and the indicator has the advantages of being high in precision and safety.

Owner:XIAN HUASHUN MEASURING EQUIP

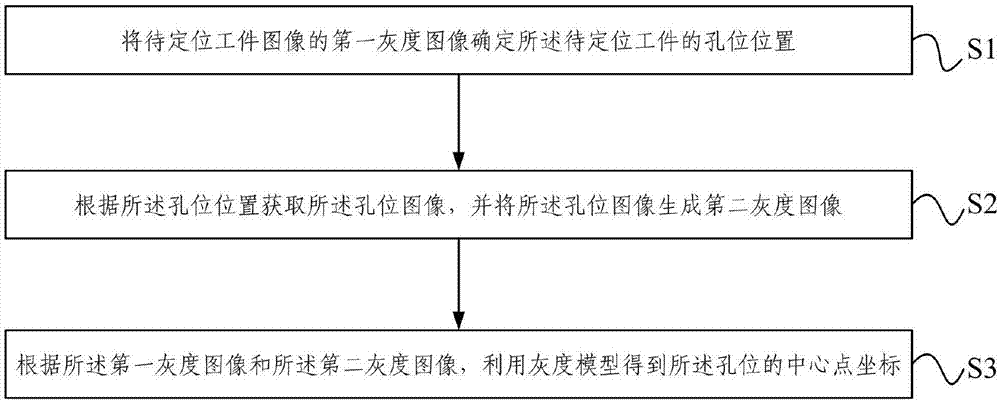

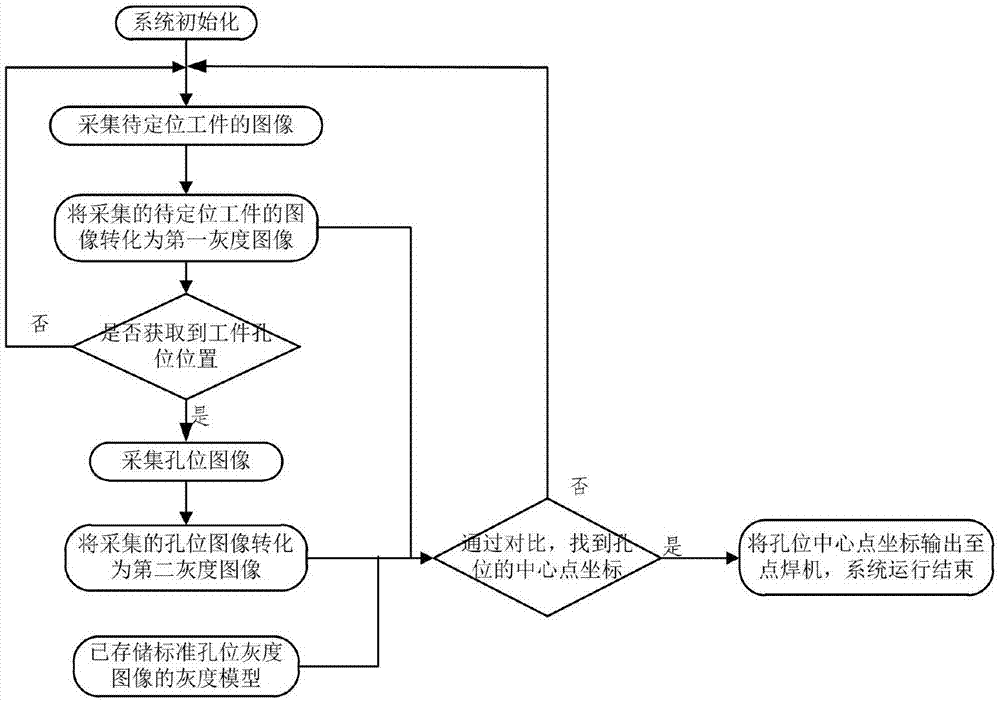

Method and system for positioning welding point

ActiveCN107511576AThe coordinates of the hole center point are accurateAccelerateWelding electric supplySpot weldingProduction line

The invention provides a method and system for positioning a welding point. The method comprises the following steps that 1, the hole position of a workpiece to be positioned is determined according to a first gray image of the workpiece to be positioned; 2, a hole position image is acquired according to the hole position, and the hole position image is generated into a second gray image; and 3, according to the first gray image and the second gray image, the center point coordinates of the hole position is obtained by using a gray model. According to the method and system for positioning the welding point, the center point coordinates of the hole position can be accurately and rapidly obtained, then the speed and accuracy requirements of the whole production line are met, and the exact position is positioned for a next spot welding process.

Owner:HUNAN JUNCHENG TECH

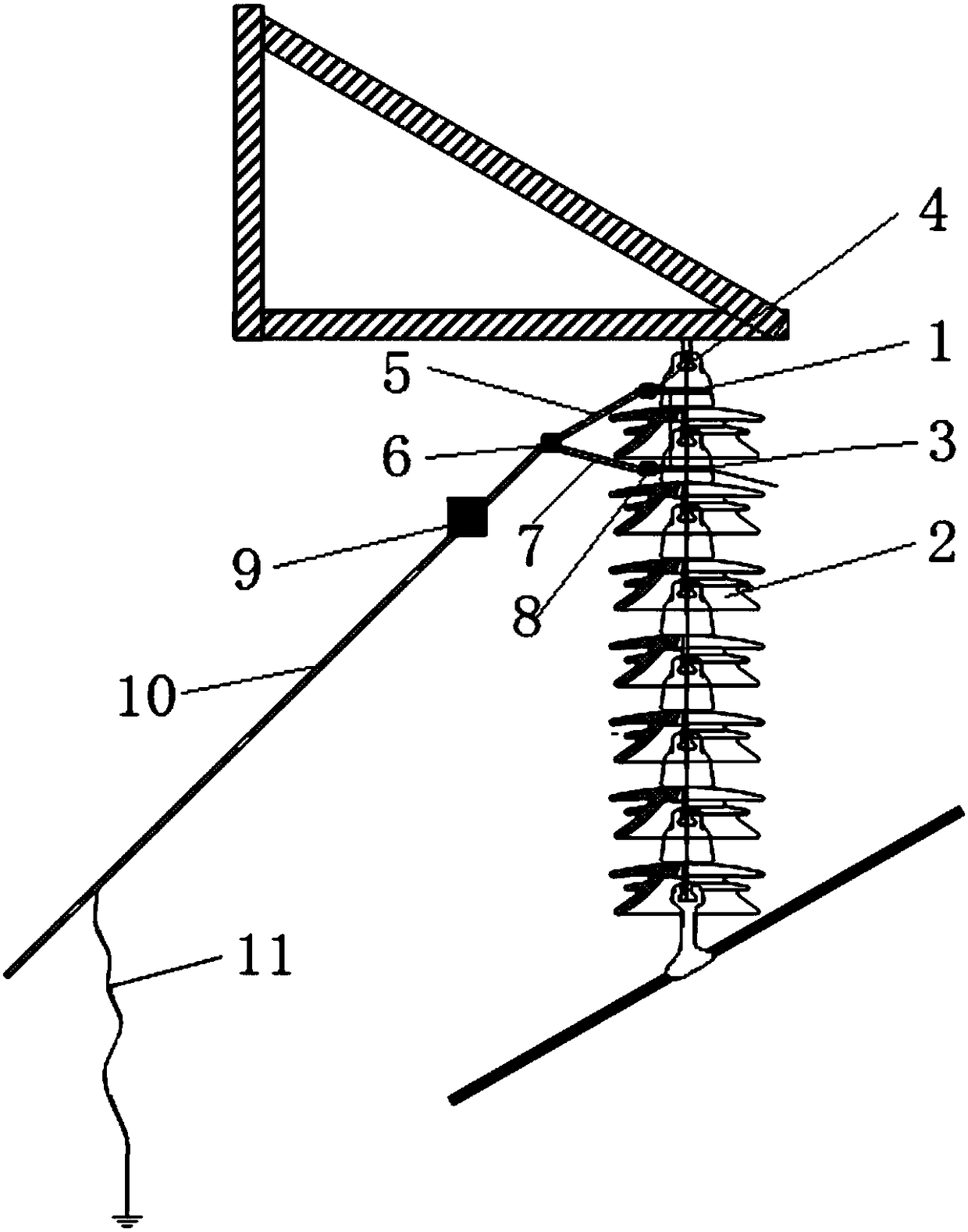

Insulator leakage current and zero value detection device

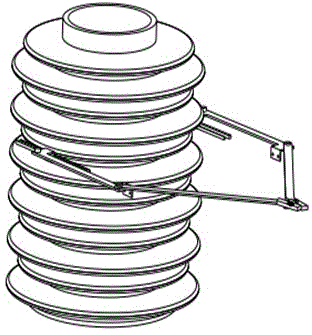

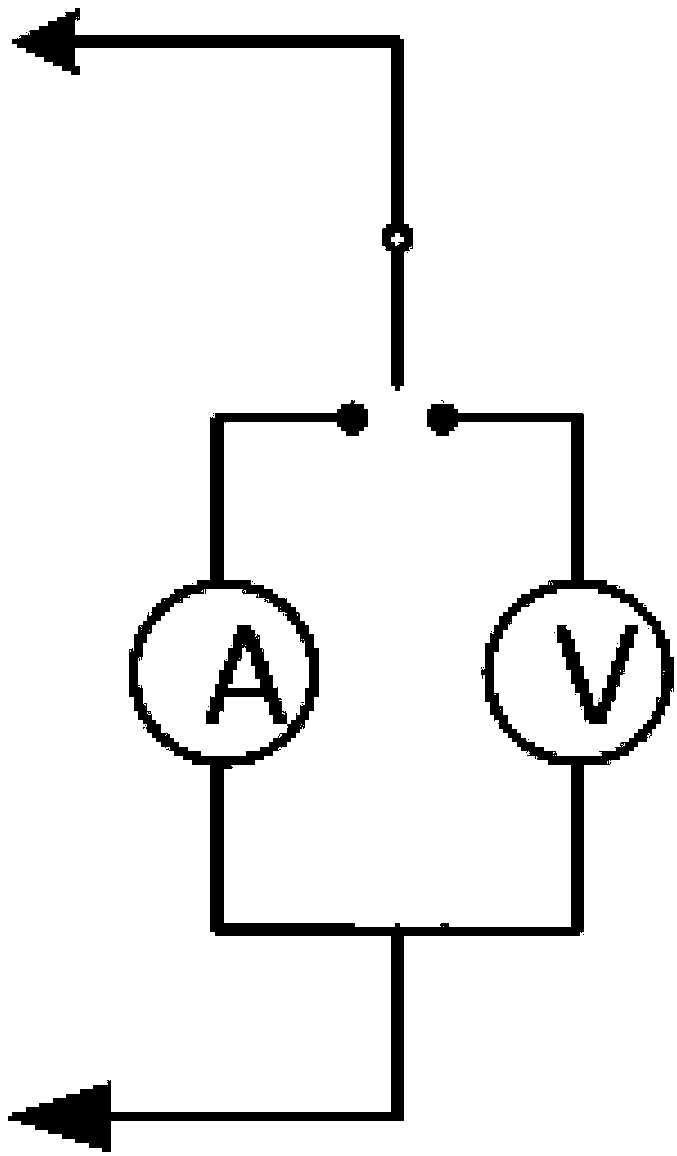

InactiveCN108107330ASimple structureEasy to operateTesting dielectric strengthTransmission systemsWireless transmissionElectric signal

The invention provides an insulator leakage current and zero value detection device comprising an insulation rod. The top of the insulation rod is provided with a clamping assembly for clamping two insulators arranged longitudinally. The insulator leakage current and zero value detection device also comprises a controllable joint assembly disposed between the insulation rod and the clamping assembly and used for adjusting the position of the clamping assembly, and a control assembly disposed on the insulation rod, connected with the controllable joint assembly, and used for controlling the clamping assembly to measure and store the current and the voltage between the two insulators and to mutually convert the current and voltage signals. In addition, a ground controller is installed on theground to send a wireless current signal or a wireless voltage signal to be measured to the control assembly and to receive a measurement result from the control assembly. The detection device is simple in structure and is easy to operate, can detect the insulator zero-value voltage and the insulator string current in an alive state only through the form of wireless transmission, and satisfies the measurement requirements of two different electrical signals.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +2

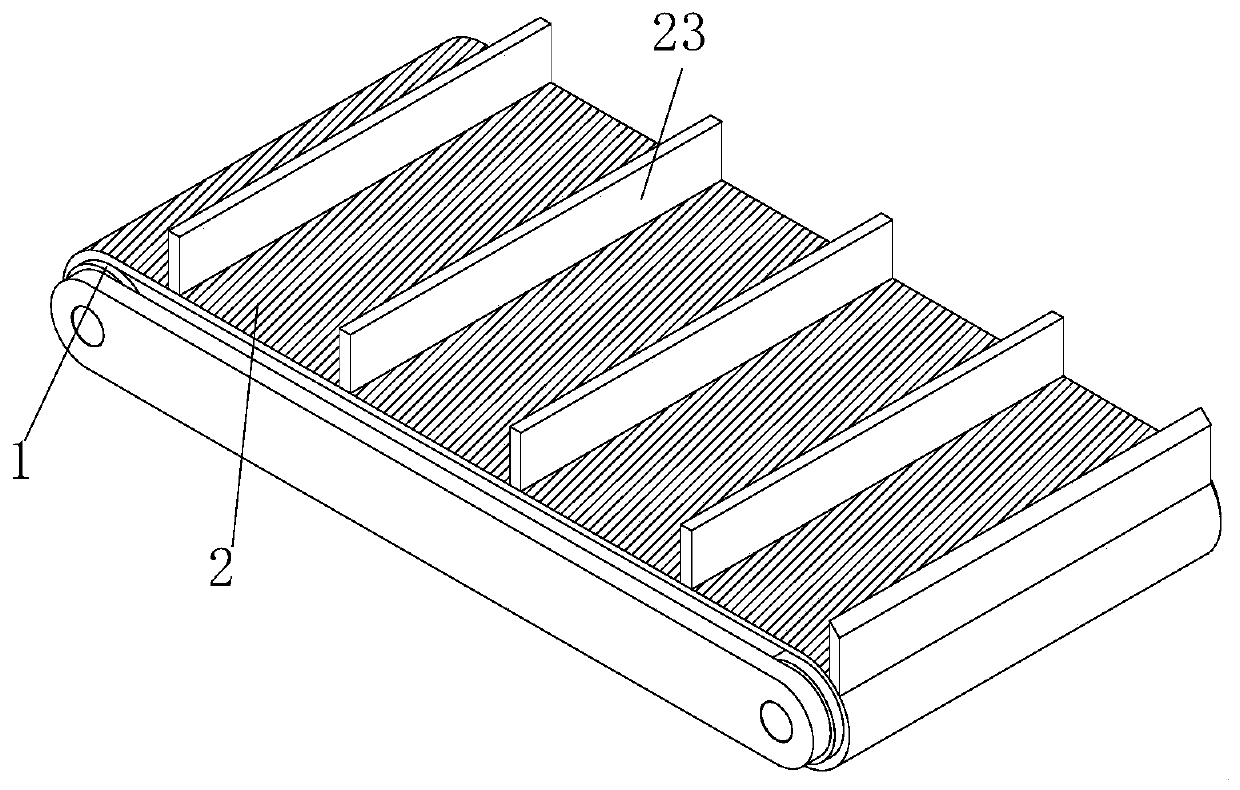

Multistage partition type conveying belt structure used for food processing

ActiveCN110834872AImprove transportation capacityHigh trafficConveyorsRollersNeodymium magnetMechanical engineering

The invention provides a multistage partition type conveying belt structure used for food processing. The multistage partition type conveying belt comprises a conveying roller and a conveying belt. The conveying belt comprises multiple conveying pieces, every two adjacent conveying pieces are connected through an insulation part, and multiple first partition plates are connected to the outer surface of each conveying piece. Each conveying piece comprises four first connecting pieces, wherein the multiple first connecting pieces are arranged at the two ends of a corresponding conveying piece shell correspondingly, and one end of each first connecting piece is provided with a second connecting piece. Two first neodymium magnets are arranged on the inner surface of each second connecting piece, and the top end of each insulation part is connected with a second partition plate. Each insulation part comprises two third connecting pieces, two grooves are formed in the surfaces of the two ends of each third connecting piece, and a second neodymium is stuck in each groove. By means of the multistage partition type conveying belt structure used for food processing, due to the cooperation ofthe conveying pieces and the insulation parts, directional demounting of a conveying belt is achieved.

Owner:湖南福美天食品有限公司

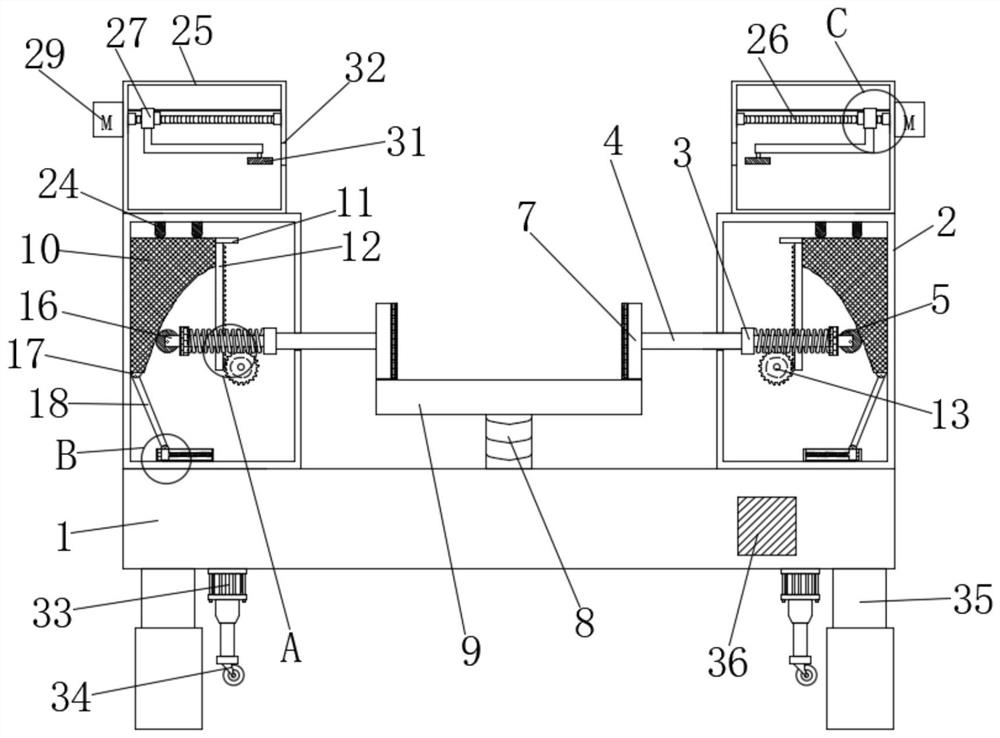

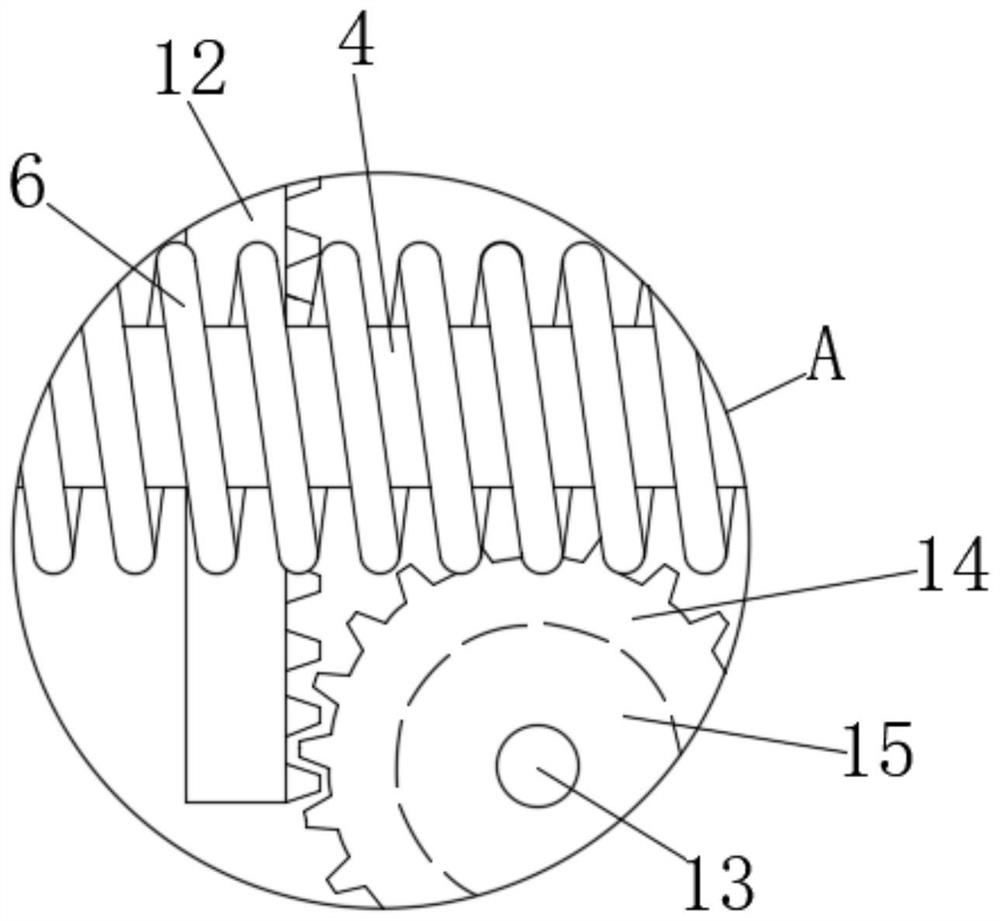

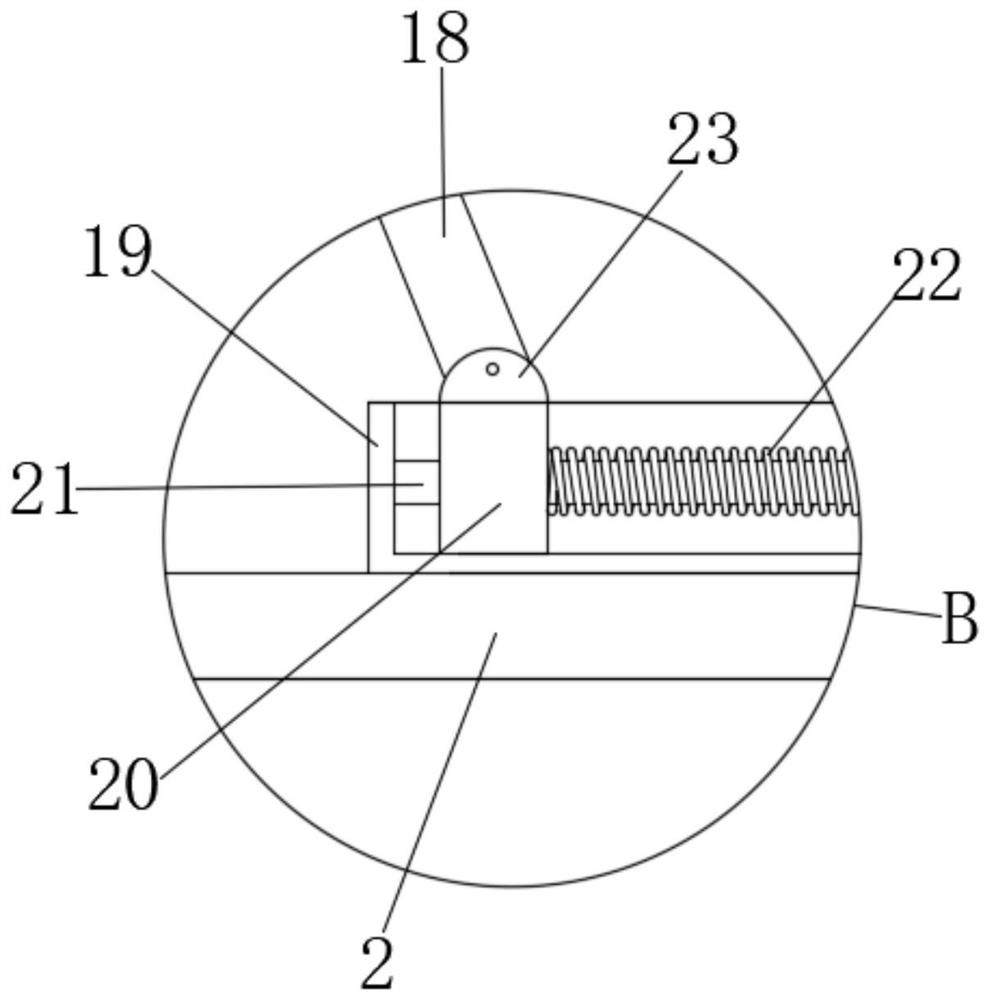

Intelligent hardware installation platform for robot

InactiveCN112476369AIncrease frictionGuaranteed clamping stabilityLighting elementsWork benchesGear wheelControl engineering

The invention discloses an intelligent hardware installation platform for a robot. The intelligent hardware installation platform for the robot comprises an installation base, wherein two clamping boxes are symmetrically and fixedly connected to the top of the installation base; installation cavities are formed in the clamping boxes; and fixing sleeves are fixedly connected into the clamping boxes. The invention relates to the technical field of installation platform devices. A servo motor is started, a rotating shaft drives a gear to rotate, a transmission rack drives a transmission sliding body to vertically move downwards, meanwhile, a rotating plate pushes a sliding block to compress a reset spring B while rotating, the sliding block horizontally moves in an installation frame in the direction of a limiting rod, and in the process, the transmission sliding body slowly abuts against a rolling wheel, the rolling wheel drives a fixing plate to compress a reset spring A to enable a sliding rod to horizontally slide, and two clamping plates slowly get close to tightly clamp the robot, so that installation of intelligent hardware can be facilitated, deviation in the installation process is prevented, the installation speed is increased, and the installation quality is improved.

Owner:汪倩

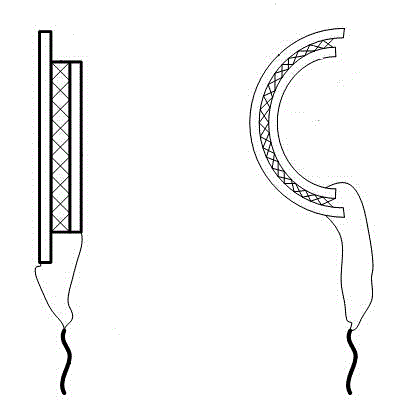

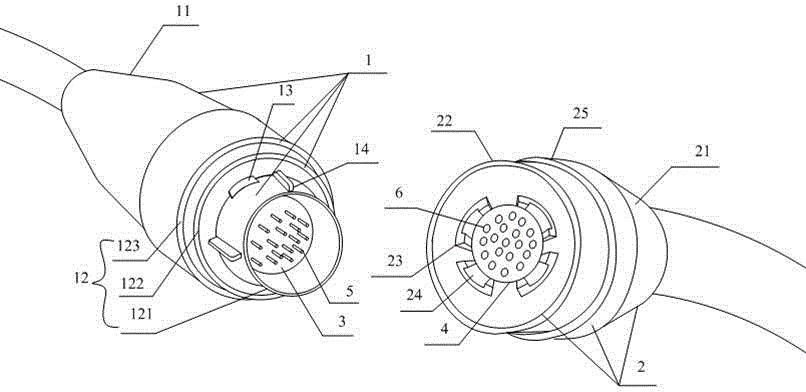

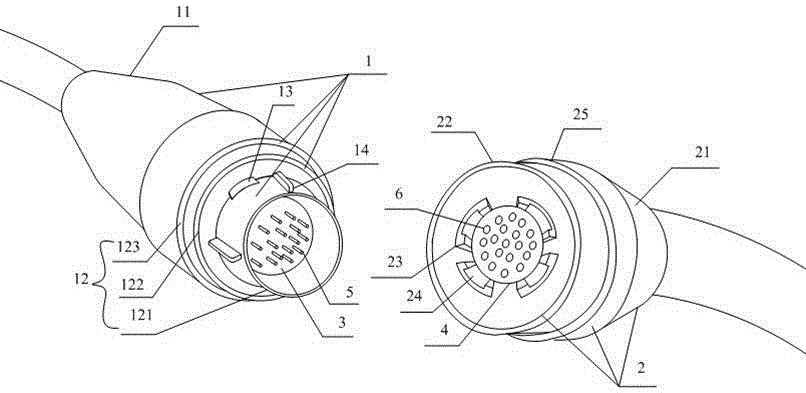

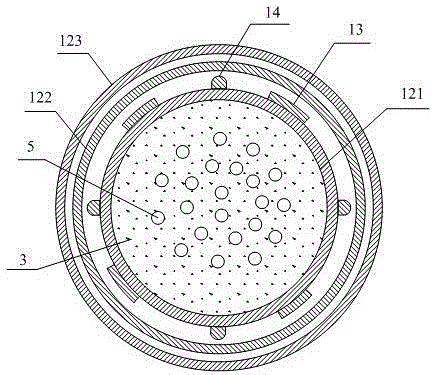

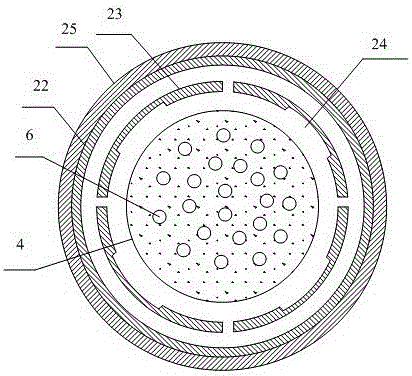

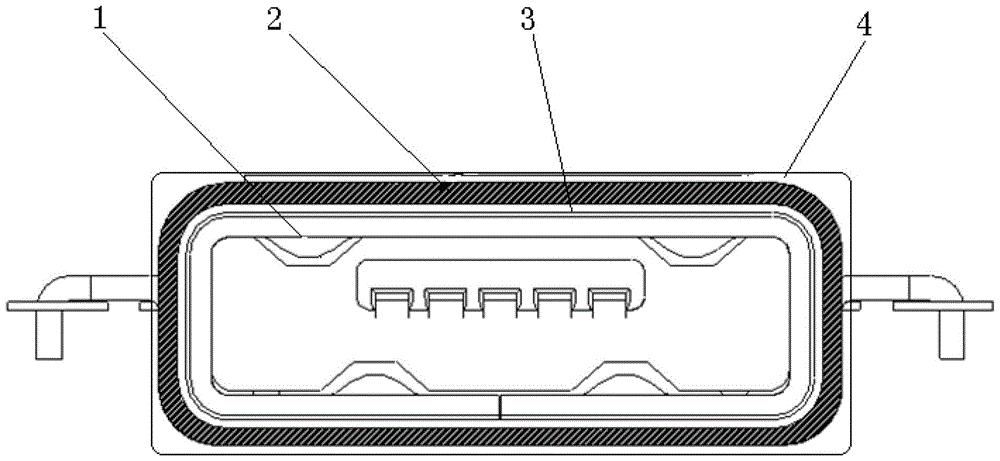

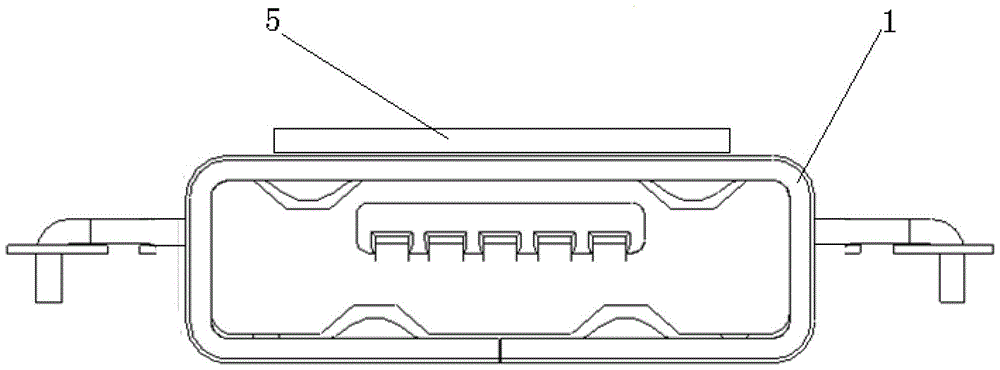

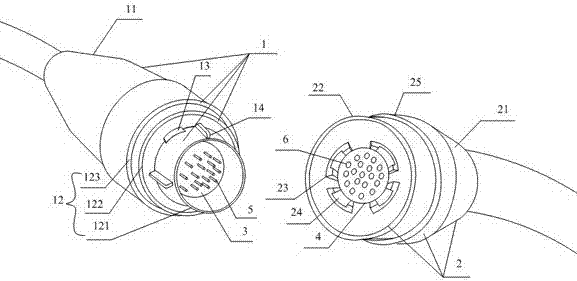

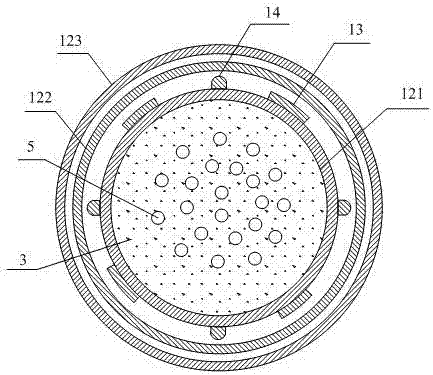

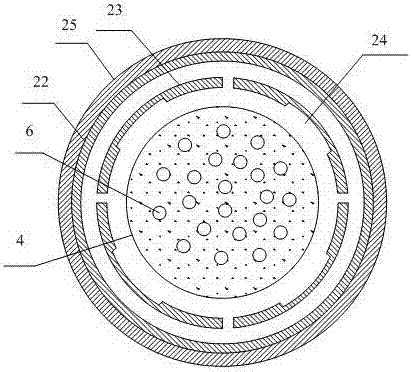

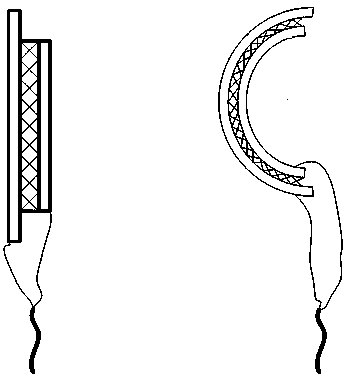

Electrical interface assembly having long service life

InactiveCN104882726AImprove stabilityNot easy to dropCoupling device detailsTwo-part coupling devicesStructural engineeringMechanical engineering

An electrical interface assembly having a long service life includes a plug and a socket, a plug shell includes a first lead connecting part and a socket connecting part, the socket connecting part includes a hollow cylindrical inner barrel and an outer barrel, an outer wall of the inner barrel is provided with a plurality of long-strip-shaped limiting plates, and length directions of the limiting plates is parallel to an axial direction of the inner barrel; the socket shell includes a second lead connecting part and a hollow cylindrical plug connecting part, a check ring is arranged between the plug connecting part and a socket insulator, the check ring is formed by a plurality of baffle plates in a surrounding manner, adjacent baffle plates have gaps, and the limiting plates can be clamped in the gaps. Structures of the plug and the socket are closely matched, so that when inserted in the socket, the plug can rapidly find a position accurately through a clamping position, plugging and unplugging are convenient, and after being inserted in the socket, the plug is good in stability and not easy to fall off. The electrical interface assembly provided by the invention requires relatively low insertion and extraction force and is provided with a protection structure, the plug and the socket are not easy to damage, and the electrical interface assembly has extremely high plugging and unplugging times, and thus has a long service life.

Owner:CHENGDU RUIYI INFORMATION TECH

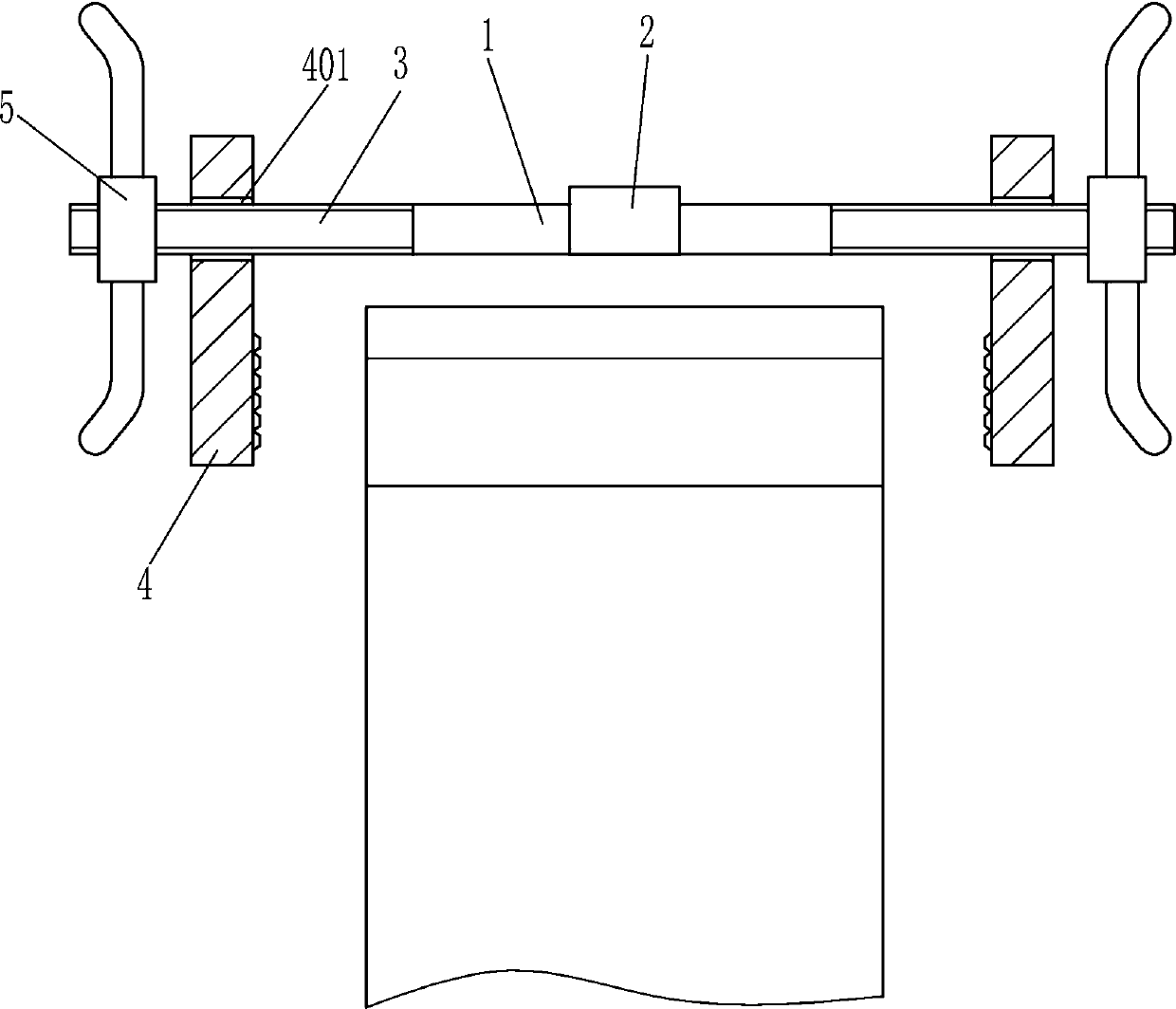

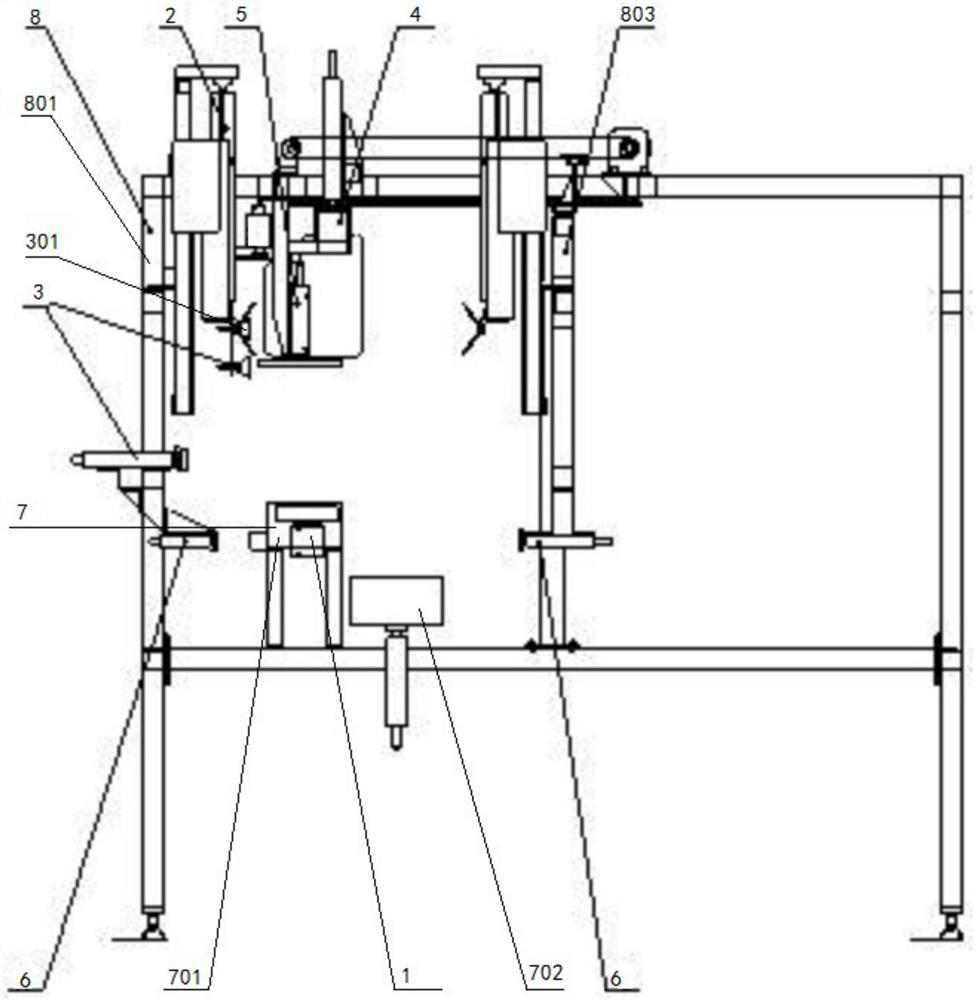

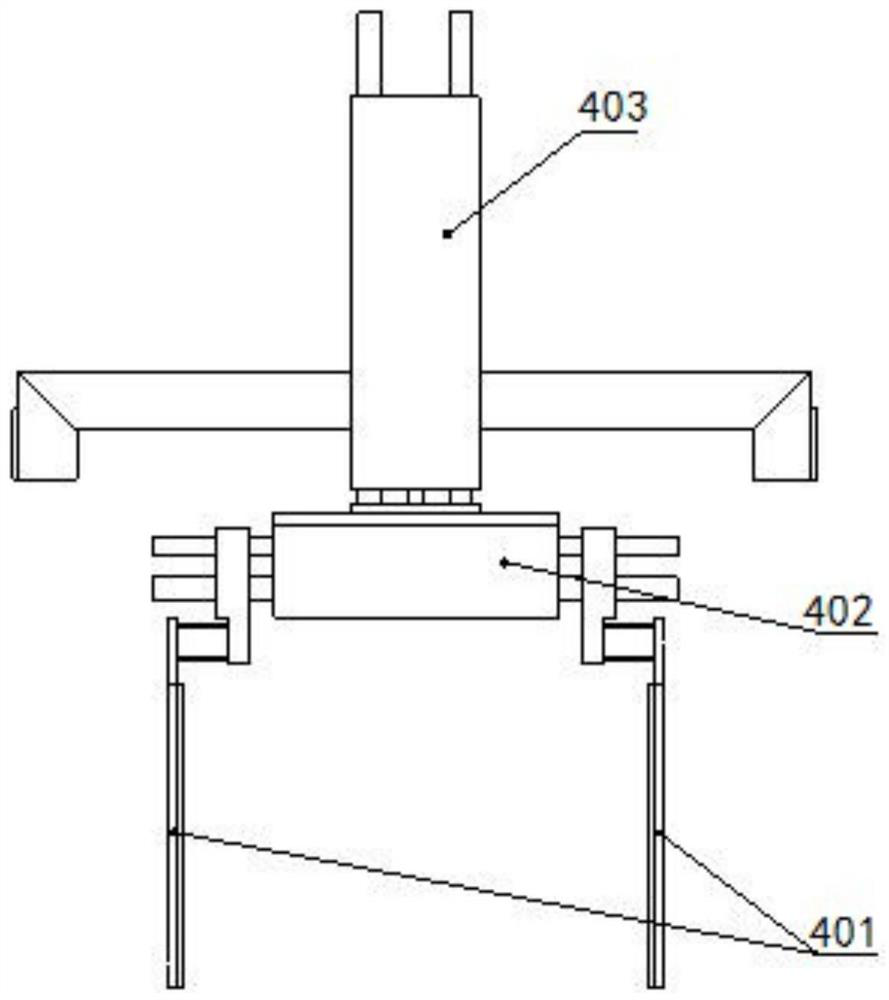

Mechanical gear repairing punching auxiliary mechanism

ActiveCN109396486AReduce damage rateEasy to punchBoring/drilling componentsBoring/drilling machinesPunchingScrew thread

The invention relates to a punching mechanism, in particular to a mechanical gear repairing punching auxiliary mechanism. The technical problem is that the mechanical gear repairing punching auxiliarymechanism which can fix the punching position and reduce the damage rate of a drill bit, and has high safety is provided. The technical scheme is that the mechanical gear repairing punching auxiliarymechanism comprises a guiding rail and the like; and threaded rods are arranged on the left and right sides of the guiding rail, the threaded rods are provided with clamping plates and wing nuts, andleft clamping plate is located at the right parts of left wing nuts, right clamping plates are located at the right parts of left wing nuts, right clamping plates are located at the left parts of right wing nuts, sliding holes are formed in the upper parts of the clamping plates, the outer ends of threaded rods penetrate through the sliding holes, and a straight-through hole is formed in the middle part of the guiding rail. According to the mechanical gear repairing punching auxiliary mechanism, the position of punching is fixed through the straight-through hole in the guiding rail and a threaded hole in a guiding block, a sprigging is inserted into a corresponding groove realizing fixing of the position of the guiding block, and then the punching is carried out in a gear, after the position of the punching is found accurately, the working efficiency can be improved, the damage rate of the drill bit is reduced, and the cost is saved.

Owner:ZHEJIANG ZHENHUA FORGING GEAR CO LTD

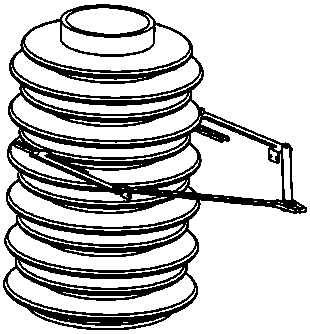

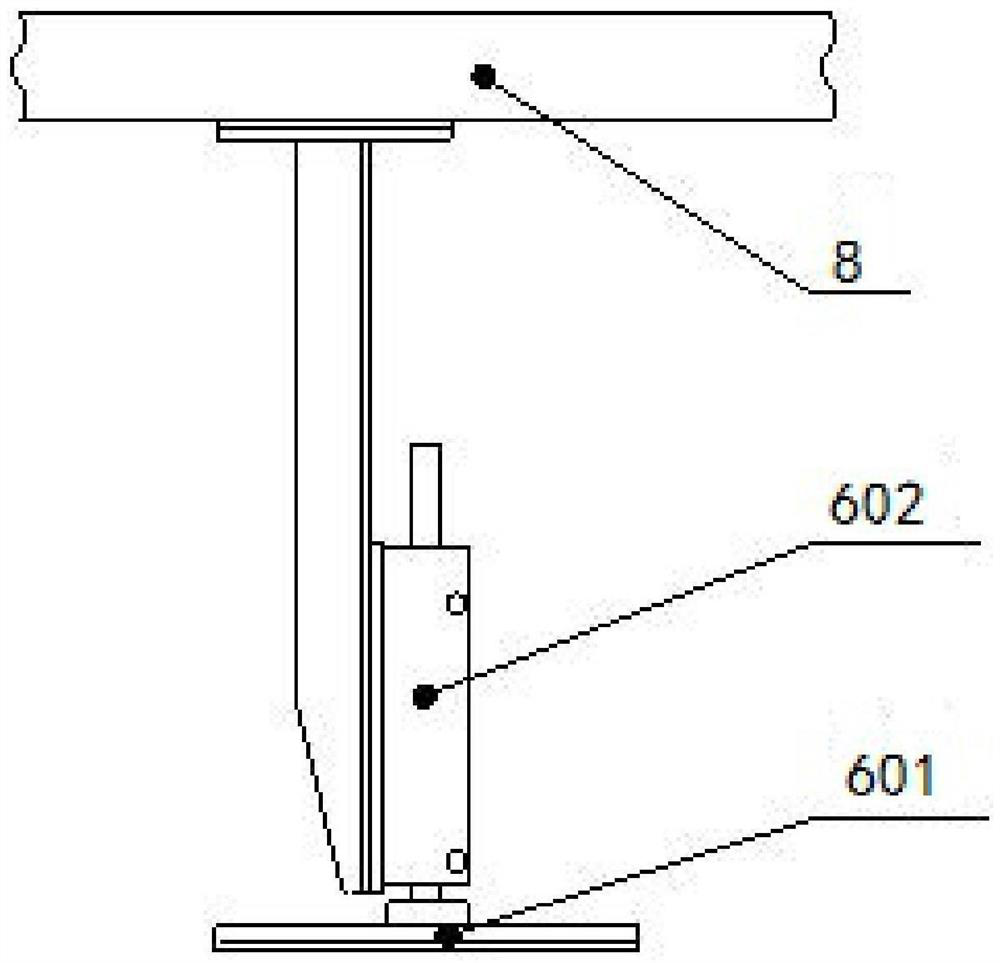

Multifunctional Ma's osteopathic traction stool

PendingCN111772904AAvoid shakingFind the exact locationOperating chairsDiagnosticsPhysical medicine and rehabilitationOsteopathic treatments

The invention discloses a multifunctional Ma's osteopathic traction stool, and relates to the field of traditional Chinese medicine osteopathic treatment devices. The multifunctional Ma's osteopathictraction stool comprises a base and a seat plate, wherein the seat plate is mounted on the base; a drawing mechanism is fixedly arranged at the side part of the base; the drawing mechanism is locatedin a containing cavity; the drawing mechanism is movably connected with the containing cavity; a sleeve rod is arranged in the center of the side, away from the base, of the containing cavity; foot stools are symmetrically arranged on the two sides of the sleeve rod; the foot stools are welded to the side face of the containing cavity; a stretching mechanism is arranged on the top side of the sleeve rod; an extension rod is sleeved with the sleeve rod; a transverse pipe is welded to the top end of the extension rod; a first reinforcing rib and a second reinforcing rib are welded between the two ends of the transverse pipe and the extension rod respectively; the sleeve rod and the first reinforcing rib are provided with a first wire manufacturing groove and a second wire manufacturing groove respectively; a bent pipe is movably arranged at the end, close to the second reinforcing rib, of the transverse pipe; and an adjusting mechanism is arranged between the transverse pipe and the bentpipe. The multifunctional Ma's osteopathic traction stool has the advantages that a patient can be conveniently fixed, positioning treatment can be conducted on a specific part, and the accuracy andsafety of an operation are further improved; the practicability is high, and the occupied space is small.

Owner:马高亮

Long-life electrical interface components

InactiveCN104882726BImprove stabilityNot easy to dropCoupling device detailsTwo-part coupling devicesMechanical engineeringEngineering

An electrical interface assembly having a long service life includes a plug and a socket, a plug shell includes a first lead connecting part and a socket connecting part, the socket connecting part includes a hollow cylindrical inner barrel and an outer barrel, an outer wall of the inner barrel is provided with a plurality of long-strip-shaped limiting plates, and length directions of the limiting plates is parallel to an axial direction of the inner barrel; the socket shell includes a second lead connecting part and a hollow cylindrical plug connecting part, a check ring is arranged between the plug connecting part and a socket insulator, the check ring is formed by a plurality of baffle plates in a surrounding manner, adjacent baffle plates have gaps, and the limiting plates can be clamped in the gaps. Structures of the plug and the socket are closely matched, so that when inserted in the socket, the plug can rapidly find a position accurately through a clamping position, plugging and unplugging are convenient, and after being inserted in the socket, the plug is good in stability and not easy to fall off. The electrical interface assembly provided by the invention requires relatively low insertion and extraction force and is provided with a protection structure, the plug and the socket are not easy to damage, and the electrical interface assembly has extremely high plugging and unplugging times, and thus has a long service life.

Owner:CHENGDU RUIYI INFORMATION TECH

PNP transistor and NPN transistor electrode detection and identification device

ActiveCN112904172AImprove powerFind the exact locationIndividual semiconductor device testingIdentification deviceMechanical engineering

The invention discloses a PNP transistor and NPN transistor electrode detection and identification device which comprises a machine body, a reversing cavity with two openings in the upper right portion is formed in the top wall of the machine body, transmission shafts extending front and back are symmetrically arranged on the left side and the right side of the reversing cavity, and transmission wheels are fixedly arranged on the outer surfaces of the transmission shafts. Due to the fact that thehead gravity of the transistor is greater than that of the electrode part, the direction of the transistor entering the device is adjusted through the two cross rods; then the four rods are inserted between transistor electrodes; the transistor electrodes are combed through the downward moving force of the mechanical arm, and follow-up electrification and accurate position finding are facilitated; after positive electricity is provided for the transistor base electrode, whether the transistor is of a PNP type or an NPN type is judged according to whether the transistor is electrified or not, so that the the purpose of marking the type of thetransistors is achieved by controlling the printing plate with corresponding words to face down to print corresponding words for the transistors; and meanwhile, the purpose of sorting the transistors into different cavities is achieved by controlling an electromagnet or an air cylinder to work through power on or off.

Owner:西安木辛航宇科技电子有限公司

A mechanical gear repairing and punching auxiliary mechanism

ActiveCN109396486BReduce damage rateEasy to punchBoring/drilling componentsBoring/drilling machinesGear wheelScrew thread

Owner:ZHEJIANG ZHENHUA FORGING GEAR CO LTD

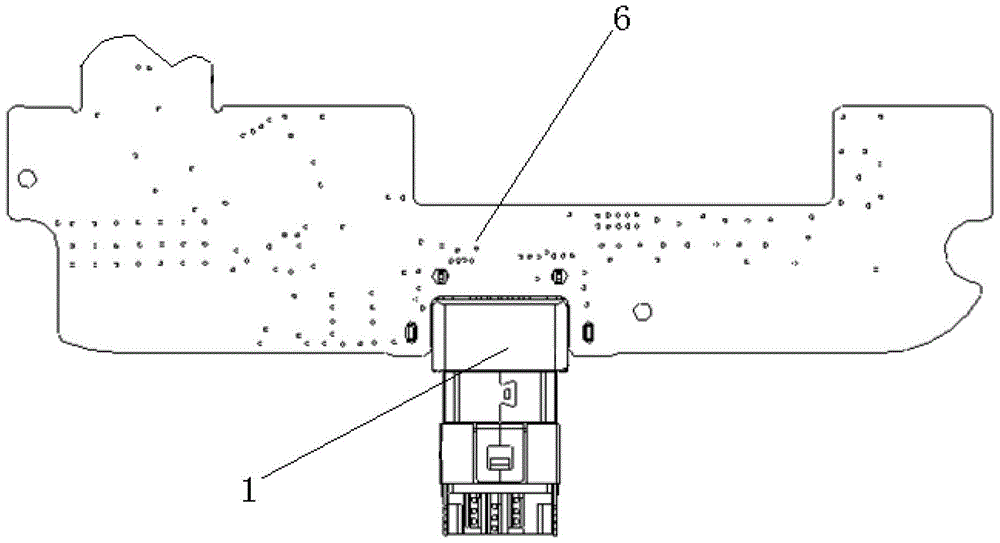

A usb interface component and manufacturing method thereof

ActiveCN103326161BFind the exact locationAccurate locationLine/current collector detailsCouplings bases/casesEngineeringUSB

The invention discloses a USB interface assembly and a manufacturing method thereof. The USB interface assembly comprises a USB connector and a luminescent layer, wherein the USB connector is connected with an electronic product, and the luminescent layer is arranged on the USB connector. The luminescent layer and a luminescent part are arranged on the USB connector, so that the position of a USB interface can shine independently. When the electronic product like a cellphone is in the situation where environmental light is insufficient, the accurate position of the USB connector can be found accurately. Thus, a charging line can be inserted accurately to charge the electronic product, and the USB interface assembly is actually convenient to use.

Owner:XIAOMI INC

FFU installation structure

The invention belongs to the technical field of cleaning equipment, and relates to an FFU installation structure. The FFU installation structure comprises an installation frame arranged on the periphery of a machine case, a plurality of installation holes are formed in the installation frame, the installation frame penetrates screws and nuts of the installation holes to be fixed to a framework, a plurality of rigid limiting gaskets and flexible sealing strips are clamped between the installation support and the framework, the limiting gaskets are located on the peripheries of the installation holes, and the sealing strips are attached to one face of the installation frame and are provided with avoiding grooves avoiding the limiting gaskets. By means of the FFU installation structure, a screw fixation manner is adopted, the FFU machine case is fixedly connected to the framework, sealing is achieved through the limiting gaskets and the sealing strips which are of special structures, installation is facilitated, and the better sealing effect is achieved.

Owner:FUTAI CLEAN TECH KUNSHAN

A device for detecting and identifying electrodes of pnp transistors and npn transistors

ActiveCN112904172BImprove powerFind the exact locationIndividual semiconductor device testingEngineeringIdentification device

Owner:西安木辛航宇科技电子有限公司

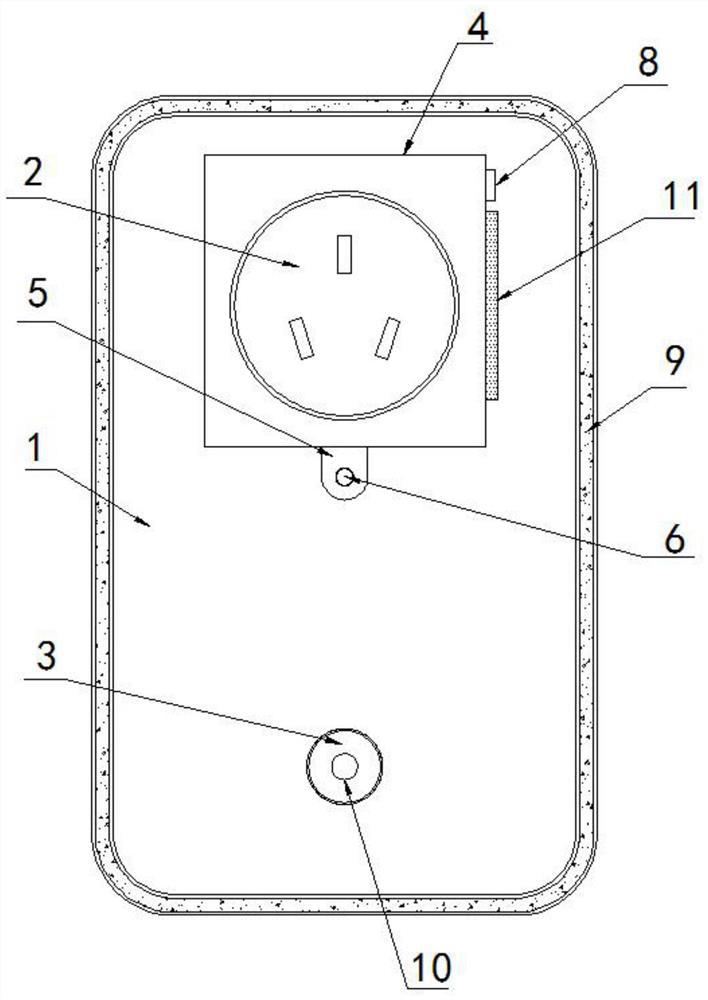

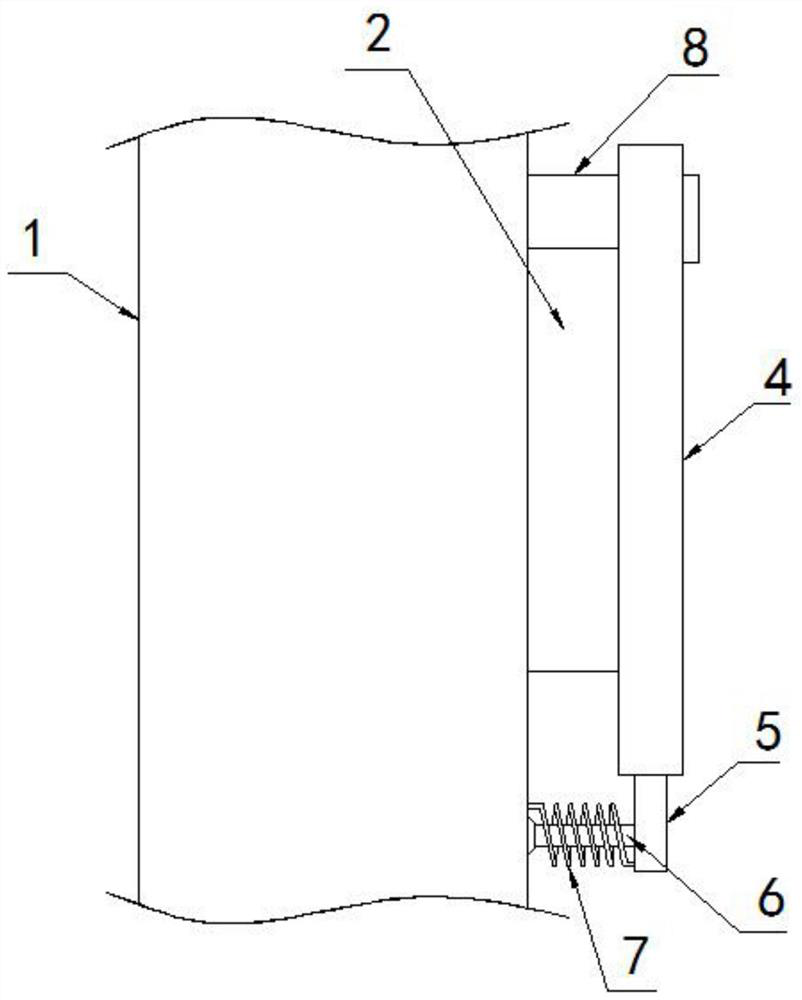

Intelligent socket used in implementation process of network system

InactiveCN112864683APrevent leakageFind the exact locationCouplings bases/casesRolling-element bearingNetworked system

The invention relates to the technical field of sockets, and discloses an intelligent socket used in the implementation process of a network system. The intelligent socket comprises a shell, a jack and a switch button, the jack and the switch button are arranged on the shell, an annular groove is formed in the edge of the front face of the shell in a surrounding mode, a fluorescent strip is fixedly embedded in the annular groove, a baffle is arranged on the front side of the jack, a fixing block is fixedly arranged on the lower side of the baffle, a fixing sleeve hole is formed in the side wall of the fixing block, a rotating shaft is fixedly arranged through the fixing sleeve hole, the end, away from the fixing block, of the rotating shaft is rotationally connected with the front side wall of the shell through a rolling bearing, the shaft wall of the rotating shaft is movably sleeved with a torsion spring, the two ends of the torsion spring are fixedly connected with the fixing block and the side wall of the shell correspondingly, and a limiting check block is fixedly arranged on the front side wall of the shell and located on the right side of the baffle. According to the invention, the socket can be prevented from being blocked by sundries or electric leakage caused by water seepage, people can conveniently find the position of the socket, and the practicability of the socket is improved.

Owner:陕西学考乐信息科技有限公司

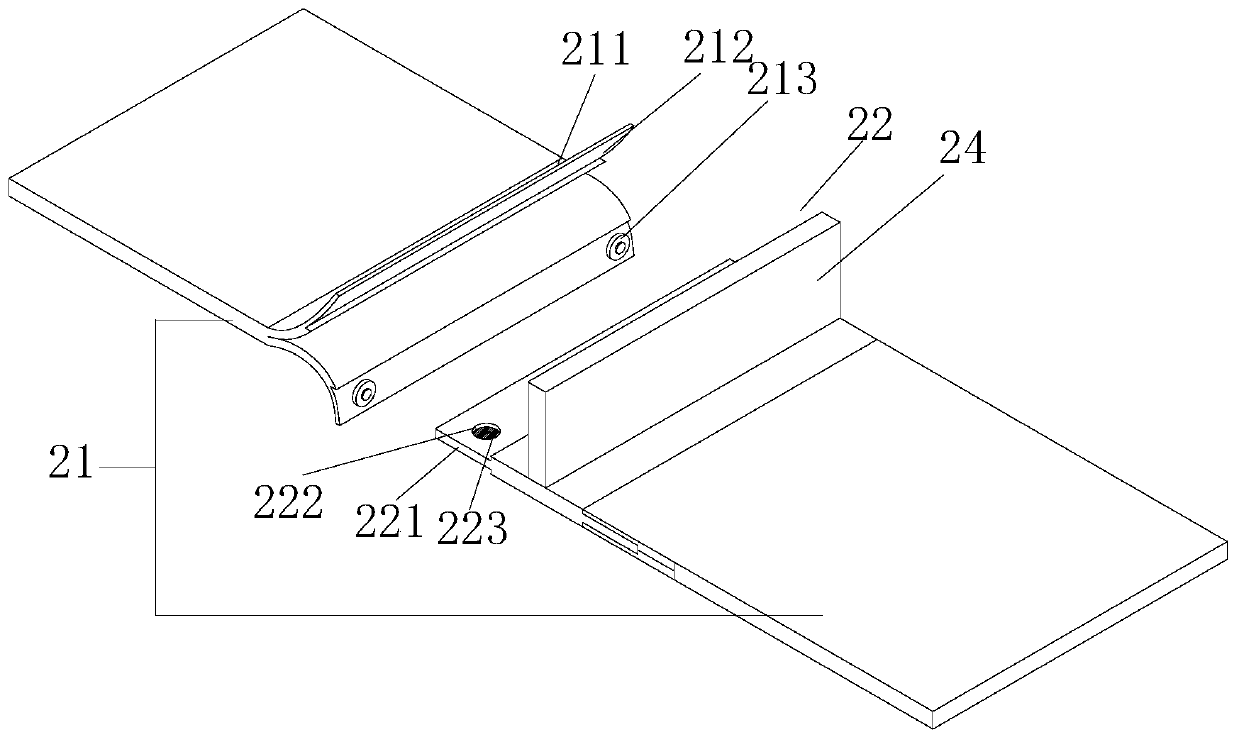

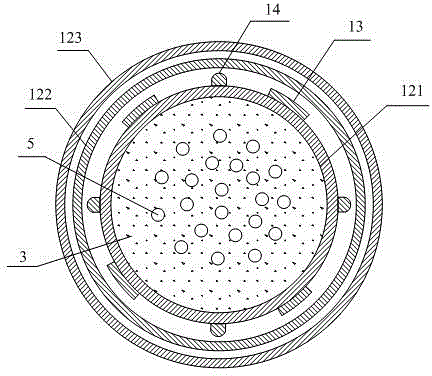

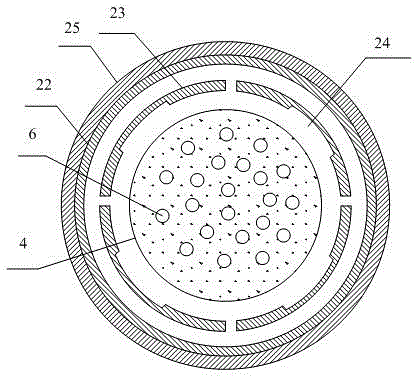

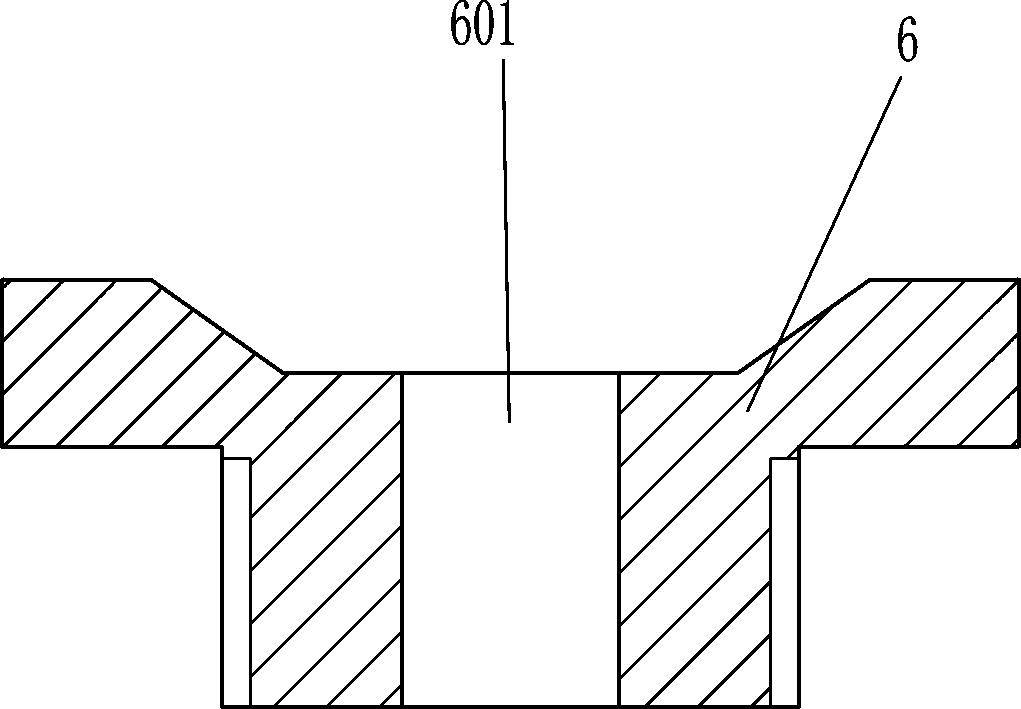

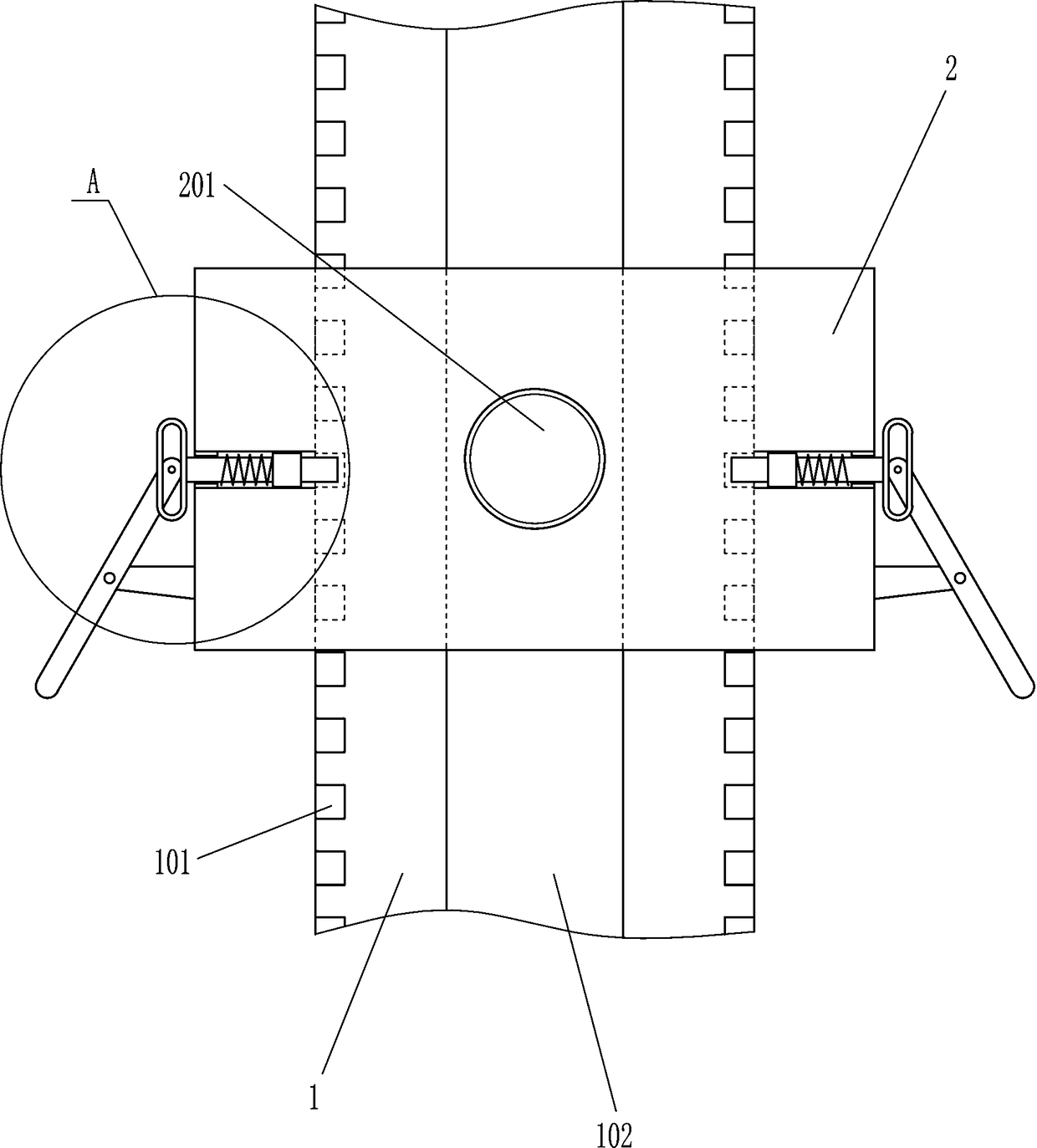

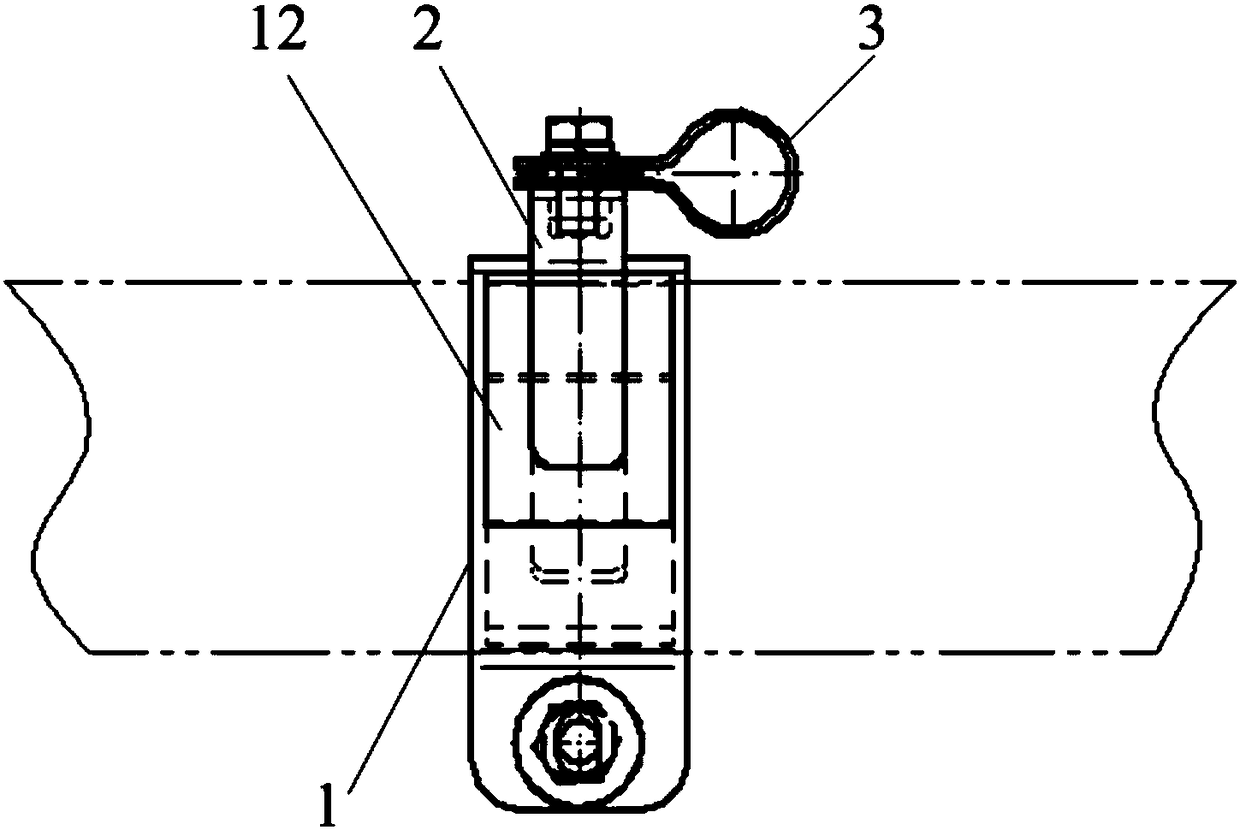

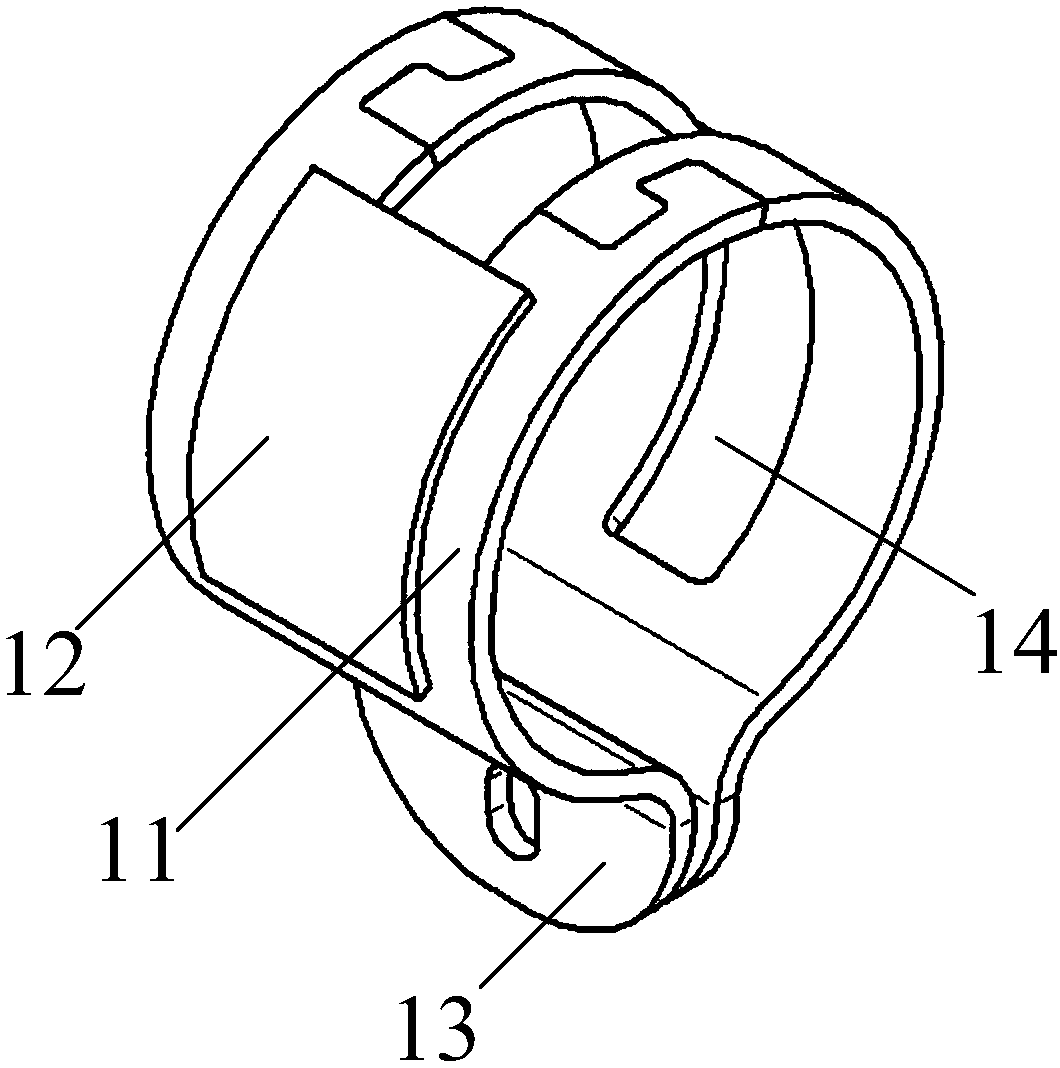

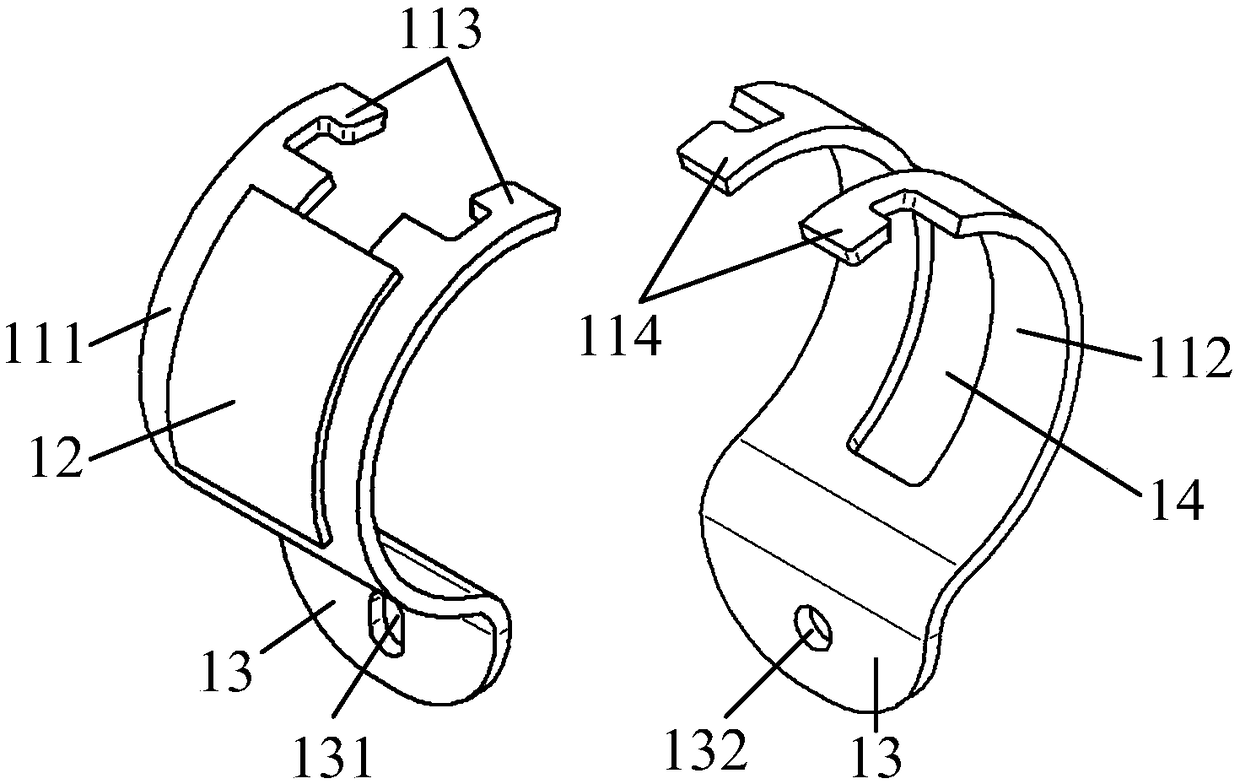

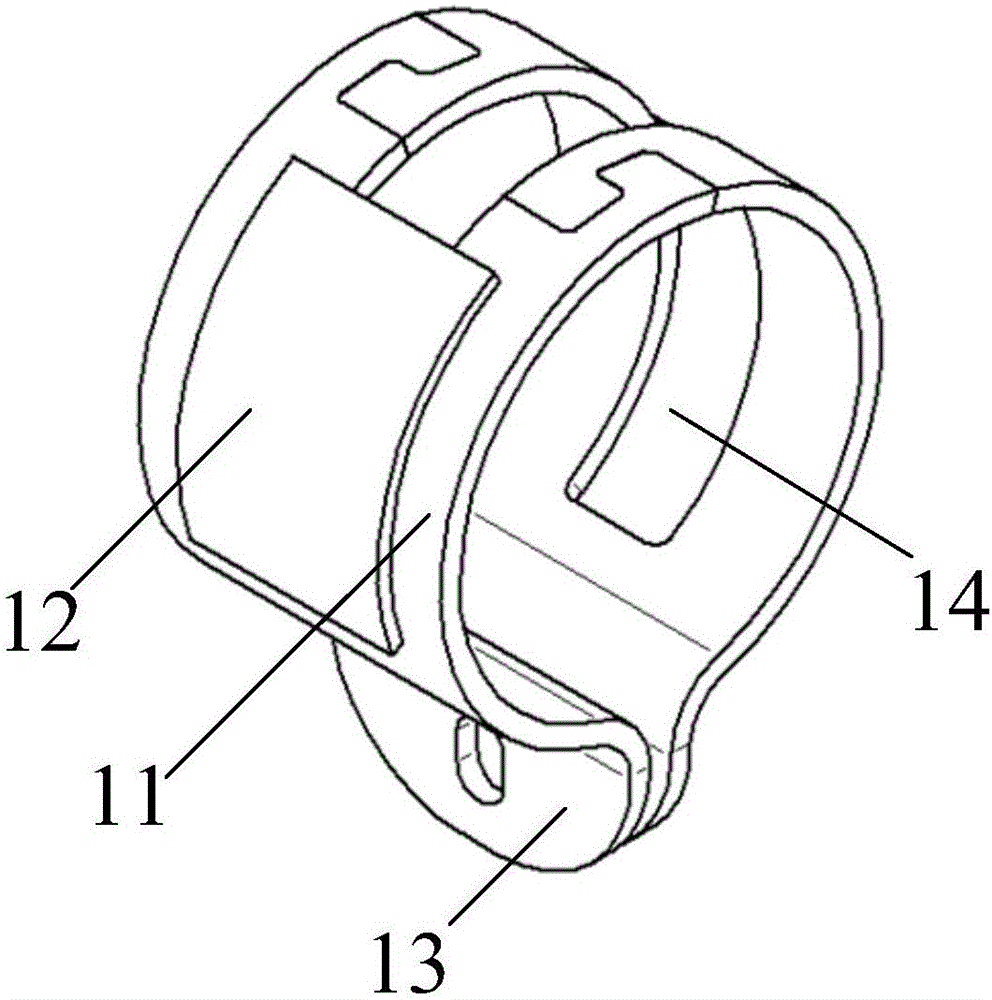

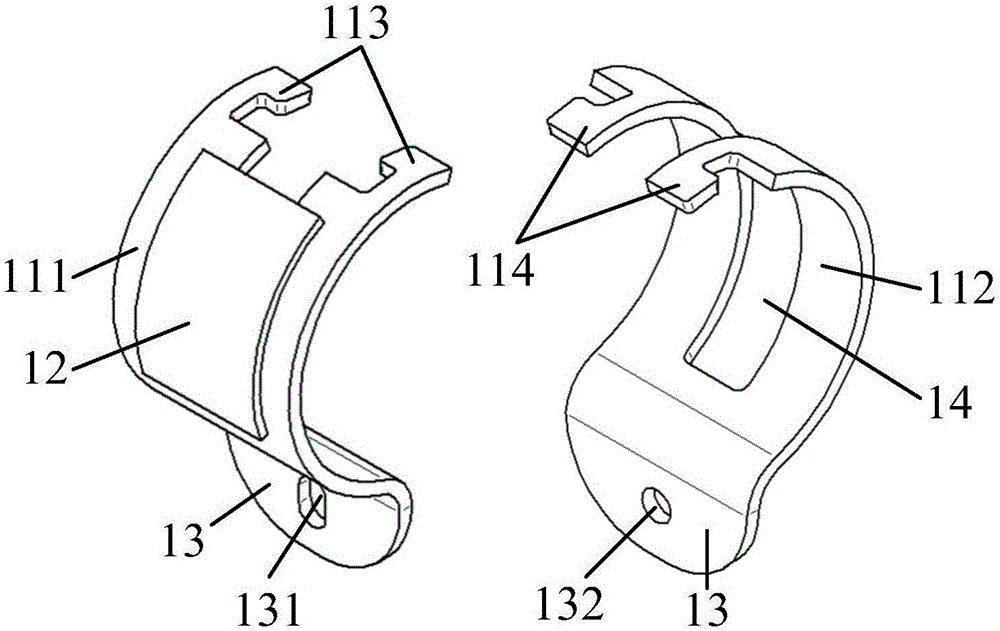

Rotatable fixing bracket assembly

ActiveCN106481620BImprove connection reliabilitySolve the problem of severe wear and tearFriction grip releasable fasteningsEngineeringMechanical engineering

The invention discloses a rotary fixing support assembly. The rotary fixing support assembly comprises a first clamp (1), a connecting support (2) and a second clamp (3). The first clamp (1) comprises an annular clamp body (11) and limiting plates (12). The annular clamp body (11) is provided with an opening, and the two end portions of the annular clamp body (11) are provided with connecting plates (13). The annular clamp body (11) is provided with one adjusting hole (14). The two limiting plates (12) are arranged and symmetrically arranged on the outer walls of the two sides of the annular clamp body (11). The connecting support (2) comprises a guiding part (21) and a connecting part (22). The guiding part (21) is inserted in the adjusting hole (14). The connecting part (22) is fixedly connected with the second clamp (3) through a bolt. By means of the rotary fixing support assembly, reliable connection between two kinds of components moving relative to each other can be achieved, and the rotary fixing support assembly has the beneficial effects that the structure is simple, whole vehicle assembling is facilitated, and the component reliability is high.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

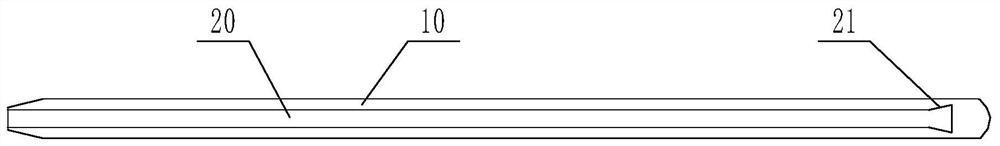

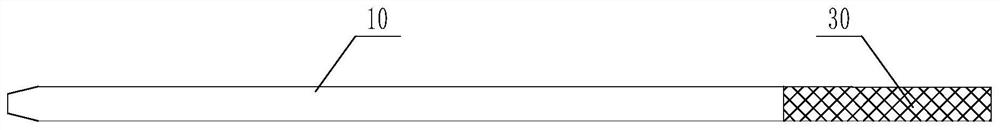

Approach guide rod

PendingCN111658094ASimple structureEasy to useCannulasSurgical needlesArthroscopic procedureArticular cavity

The invention relates to the technical field of arthroscopic surgery, in particular to an approach guide rod. The approach guide rod comprises a rod body, wherein a strip-shaped guide groove is formedin the side wall (peripheral wall) of the rod body, the length direction of the guide groove is consistent with that of the rod body, the tail end of the guide groove penetrates through the tail endof the rod body, and the guide groove is used for sliding arrangement of a puncture needle. The provided approach guide rod can guide the puncture needle to the designated position through the guide groove in the rod body after the position of an articular cavity is found out, so that an approach of the arthroscopic surgery can be established, the perspective link during approach establishment inrelated art can be omitted, and the approach is accurate and efficient to establish. Besides, the guide groove is formed in the side wall of the rod body, that is, the rod body is arranged in a semi-open structure manner, and accordingly, a doctor performing the surgery conveniently puts the puncture needle into the guide groove. The provided approach guide rod is simple in structure and convenient to use.

Owner:GENERAL HOSPITAL OF PLA

Dust-proof electrical interface

InactiveCN104821463BImprove stabilityNot easy to dropCouplings bases/casesEngineeringElectrical and Electronics engineering

Owner:CHENGDU RUIYI INFORMATION TECH

Building Construction Fast Tiling Machine

The invention discloses a fast tile attaching machine for building construction. The fast tile attaching machine comprises a vehicle body, an operation platform, a sucker device, multiple seam clamping device conveying mechanisms, a distance setting device and a controller; the seam clamping device conveying mechanisms are arranged at the rear portion of a guide rail, each seam clamping device conveying mechanism comprises a storage clamp and two air cylinders II vertically arranged on a crossbar of a U-shaped support frame, and the front ends of piston rods of the air cylinders II are provided with clamping parts; each storage clamp comprises two identical clamp bodies, each clamp body is internally provided with a cavity, positioning slots are symmetrically formed in both sides of each cavity, positioning plates are disposed above the positioning slots, and gaps are reserved between the positioning plates and the positioning slots and used for seam clamping devices to slide out; thedistance setting device includes two laser sensors arranged in the front of the operation platform and a laser source arranged outside the vehicle body; an infrared emitter, an audible and visual alarm and a tile placement frame are arranged on the operation platform. The fast tile attaching machine can suck multiple tiles at the same time, the laying precision is high, the tiles can be attached automatically, and the seam clamping devices are placed at the same time.

Owner:湖北屹峡峰建设工程有限公司

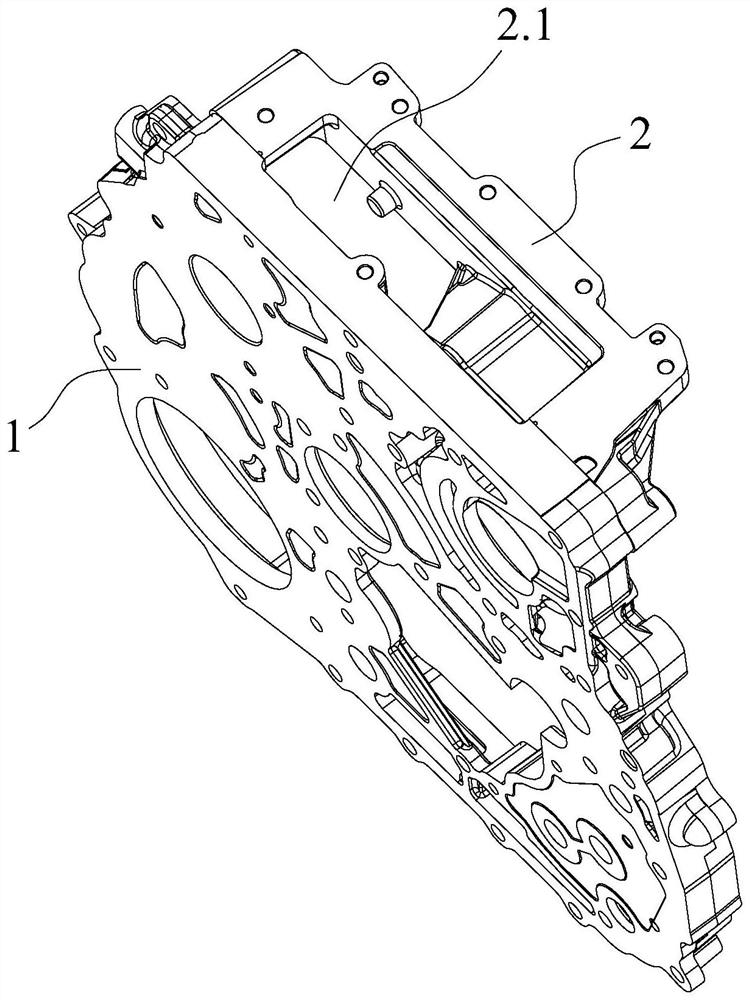

A CNC machine tool fixture for motor shell processing

The invention discloses a numerically controlled machine tool fixture used for machining motor casings, which relates to a fixture and is used to solve the problem that ordinary fixtures easily cause deformation when clamping a casing, including a hydraulic three-grip chuck installed on a machine frame, It also includes a centering support block fixed on the claws of the hydraulic three-grip chuck, the number of the centering support blocks is equal to the number of the claws, and a plurality of centering support blocks are spliced together to form a hollow centering column; the present invention has the following advantages and effects: the centering support block in the form of inner support can correct the casing in the process of supporting the casing, reducing the deviation of the central axis of the casing during the positioning process, so as to facilitate subsequent alignment Find the position of the central axis of the casing when cutting, and improve the coaxiality between the shaft hole on the casing and the inner cavity of the casing, so as to achieve the purpose of reducing the scrap rate of the casing.

Owner:TAIZHOU BAIDA ELECTRICAL APPLIANCE CO LTD

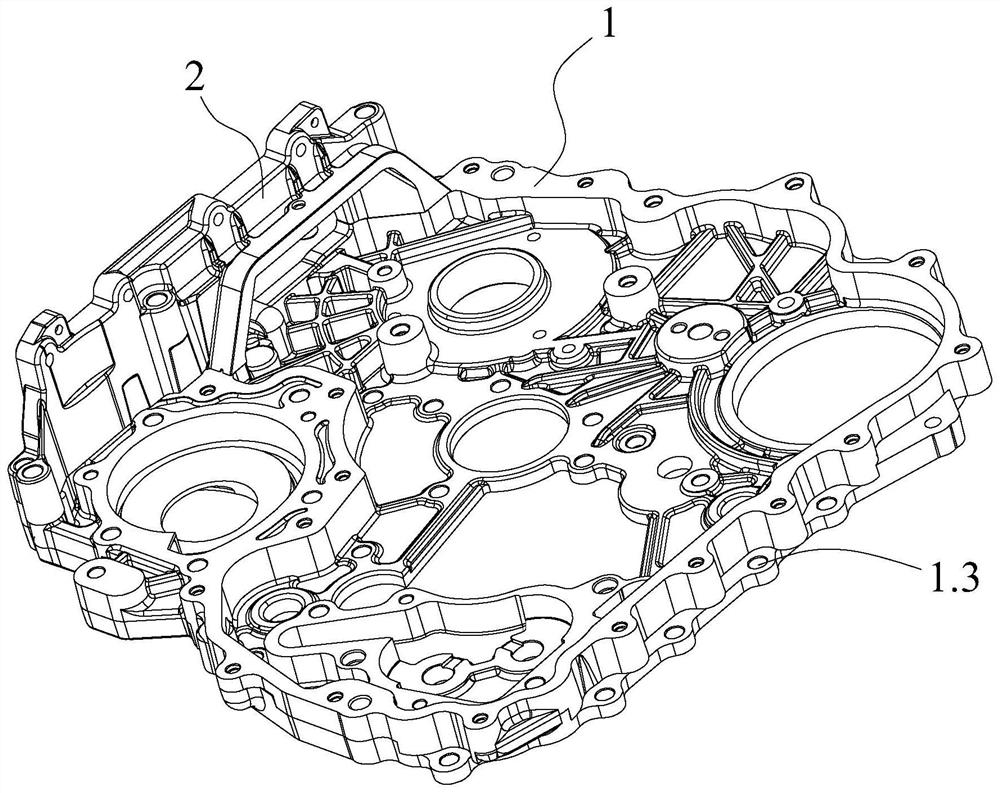

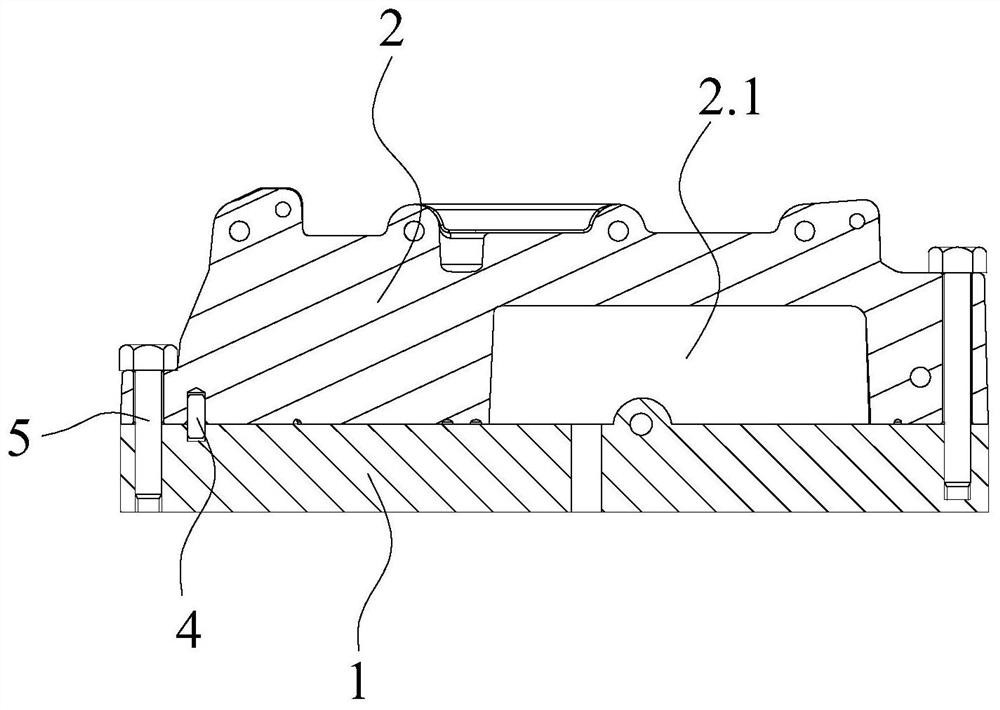

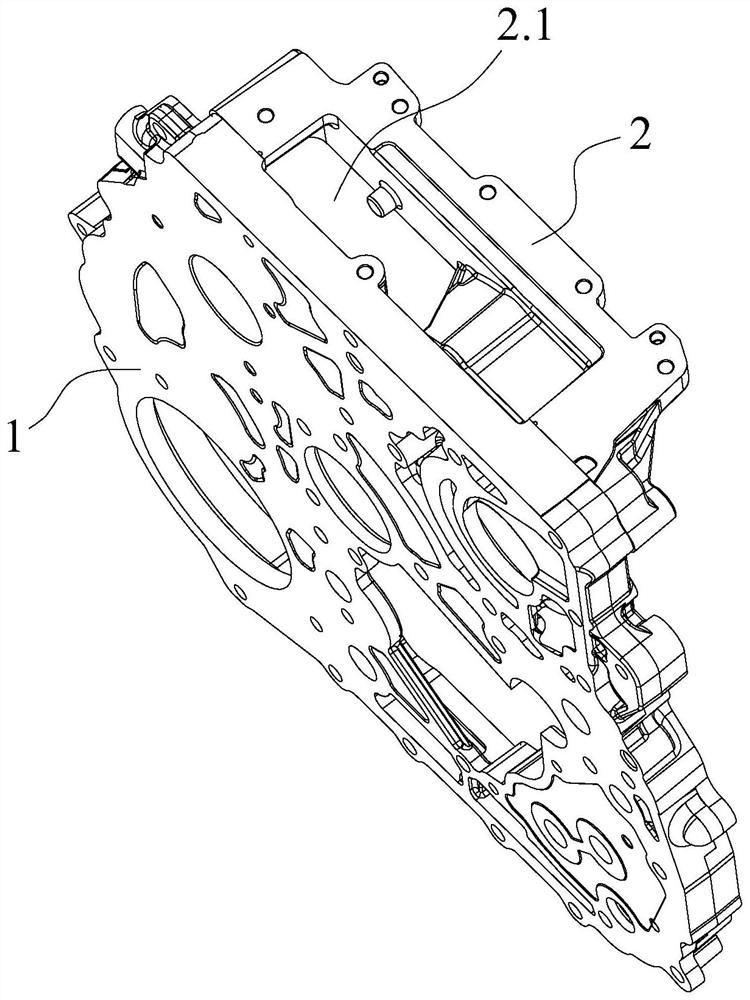

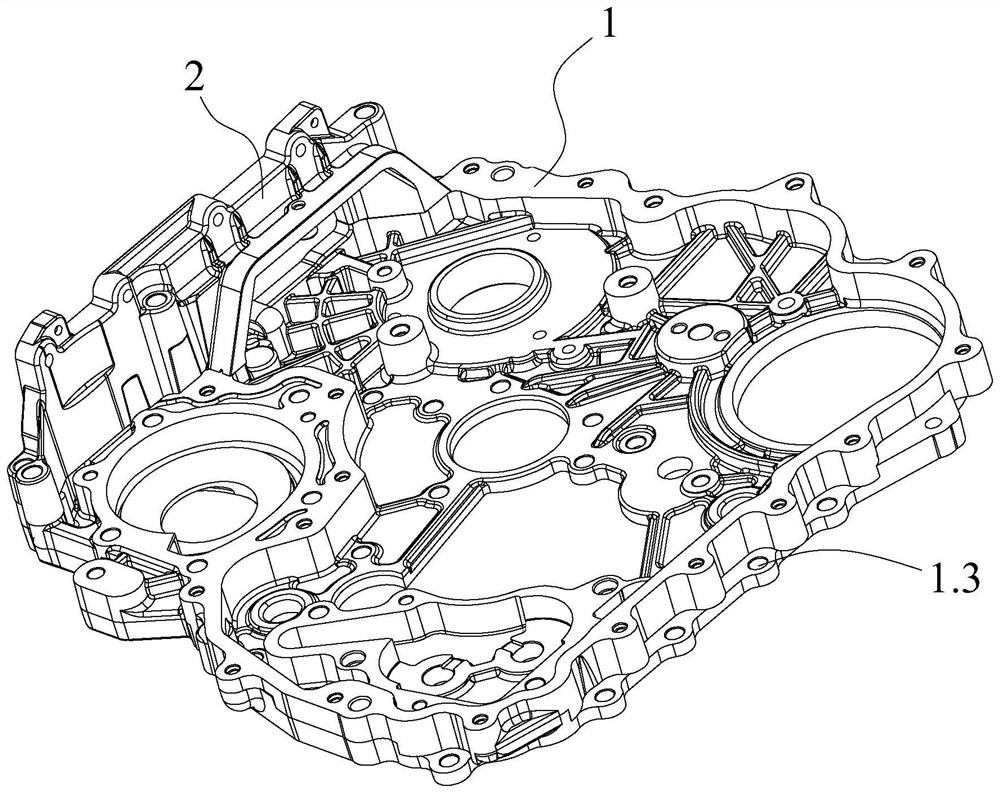

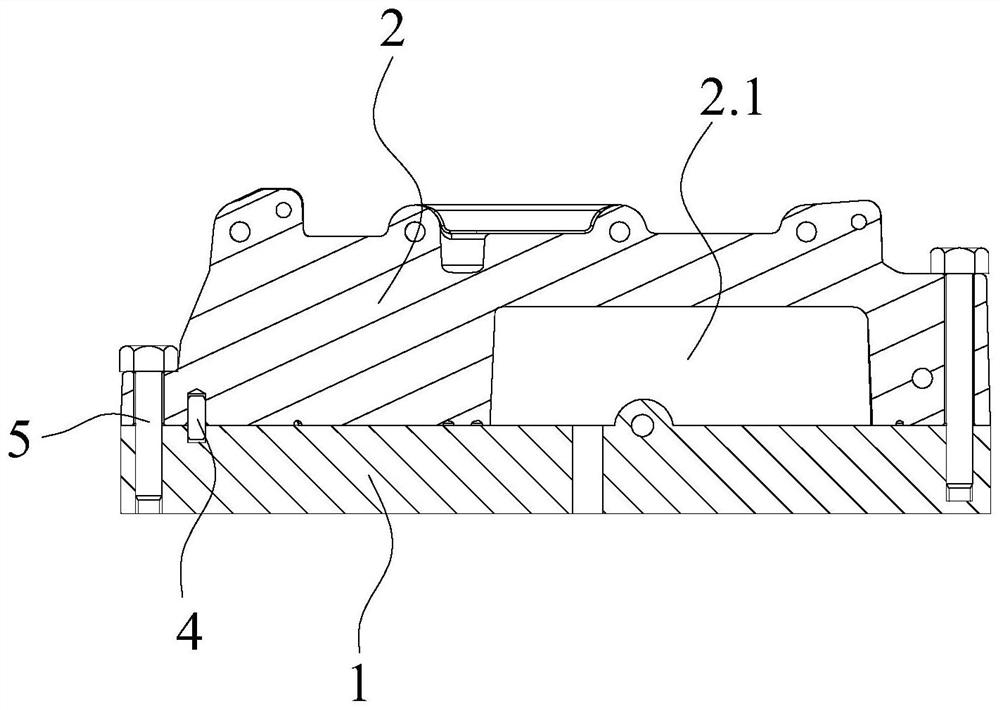

Gear chamber assembly and machining positioning device thereof

ActiveCN112761808AImprove connection strengthFirmly connectedCasingsMachines/enginesGear wheelSprocket

The invention discloses a gear chamber assembly. The gear chamber assembly comprises a gear chamber body and a chain wheel chamber frame, and a mounting part is arranged at one side of the gear chamber body; the chain wheel chamber frame is fixedly connected to the mounting part, and the chain wheel chamber frame and the mounting part are arranged at a vertical angle; a plurality of threaded holes and positioning holes are formed in the mounting part, and bolt through holes and positioning pins matched with positioning holes are correspondingly arranged on the mounting end surface of the chain wheel chamber frame; and first T-shaped grooves are formed in the side wall of the end, close to the mounting portion, of the chain wheel chamber frame, second T-shaped grooves are formed in the side face of one end of the gear chamber body, and when the chain wheel chamber frame and the gear chamber body are matched together, each first T-shaped grooves and the corresponding second T-shaped grooves are combined to form an I-shaped assembling groove, and an I-shaped positioning block is embedded in each I-shaped assembling groove. According to the gear chamber assembly and the machining positioning device thereof, the connecting structure is simple, the stability is high, the machining and clamping process is stable, the machining cost is low, and the precision of machined finished products is high.

Owner:宁波裕隆汽车制泵有限公司

An indicator for measuring the oil level in the bushing of a transformer by an electric field and its measuring method

ActiveCN104880235BFind the exact locationFind locationLevel indicators by physical variable measurementDielectricCapacitance

An indicator for measuring the oil level in the bushing of a transformer by an electric field, including a power supply unit, the power supply unit supplies power to a single-chip processor, an LCD display screen, and a capacitance-to-digital conversion unit, and the capacitance detection electrode transmits unidirectionally to the capacitance-to-digital conversion unit, and the capacitance-to-digital conversion The unit and the single-chip processor communicate with each other, and the single-chip processor transmits one-way to the LCD display screen. Using the difference in dielectric constant between transformer oil and air, the capacitance value between the detection electrodes is different when there is oil and no oil to judge the position of the oil level. , the measurement process moves up and down, multi-point measurement, and gradually finds the oil level position, which realizes the non-contact multi-point measurement of the oil level in the transformer bushing under non-electrical conditions, and has the advantages of high precision and high safety.

Owner:XIAN HUASHUN MEASURING EQUIP

A measuring method using a measuring device

ActiveCN107655608BFind the exact locationAvoid collisionForce measurementPicture taking arrangementsImaging processingEngineering

The invention relates to the technical field of measurement. The invention discloses a measuring device with a measuring head positioning function. The measuring device comprises: a measuring head which is equipped with a strain gauge and a signal conversion device connected with the strain gauge; a worktable for placing lattices and a sliding trolley equipped with the measuring head, wherein theworktable is provided with a track allowing the sliding trolley to walk; a control module for controlling the walking of the trolley, an image processing module, a storage module and a display module.The sliding trolley is also provided with an imaging device, the imaging device is connected with the image processing module, the image processing module is connected with the storage module, the storage module is connected with the control module, and the control module is connected to the display module. The imaging device is used for rapid positioning before measurement, so that collision between the measuring head and lattices is prevented.

Owner:CNNC JIANZHONG NUCLEAR FUEL +1

Box body uncovering method and uncovering device

The invention discloses a box body uncovering method and an uncovering device, and relates to the field of automatic material sorting. According to the box body cover opening method and device, the box cover and the inner sealing cover of the box body can be opened at a single station, the structure is compact, and the efficiency is high; the inner cover opening mechanism is only arranged on one side of the box body, positioning is easier to complete, the structure is simple, and energy consumption can be effectively reduced; and the device can be suitable for various box bodies with different sizes and specifications.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

Gear chamber assembly and its processing and positioning device

ActiveCN112761808BImprove connection strengthFirmly connectedCasingsMachines/enginesGear wheelSprocket

The invention discloses a gear chamber assembly, which comprises a gear chamber body and a sprocket chamber frame, one side of the gear chamber body is provided with a mounting part; the sprocket chamber frame is fixedly connected to the mounting part, and the sprocket chamber frame and The mounting part is set at a vertical angle; the mounting part is provided with a plurality of threaded holes and positioning holes, and the mounting end surface of the sprocket housing frame is respectively provided with bolt through holes and positioning pins matching with the positioning holes; the end of the sprocket housing frame near the mounting part There is a first T-shaped slot on the side wall of the gear chamber body, and a second T-shaped slot is provided on the side of one end of the gear chamber body. The grooves are combined into an "I" font fitting groove, and the "I" font fitting groove is embedded with a "I" font positioning block. The gear chamber assembly and its processing and positioning device provided by the present invention have simple connection structure, high stability, stable processing and clamping process, low processing cost and high processing precision.

Owner:宁波裕隆汽车制泵有限公司

Rotary fixing support assembly

ActiveCN106481620AImprove connection reliabilitySolve the problem of severe wear and tearFriction grip releasable fasteningsEngineeringMechanical engineering

The invention discloses a rotary fixing support assembly. The rotary fixing support assembly comprises a first clamp (1), a connecting support (2) and a second clamp (3). The first clamp (1) comprises an annular clamp body (11) and limiting plates (12). The annular clamp body (11) is provided with an opening, and the two end portions of the annular clamp body (11) are provided with connecting plates (13). The annular clamp body (11) is provided with one adjusting hole (14). The two limiting plates (12) are arranged and symmetrically arranged on the outer walls of the two sides of the annular clamp body (11). The connecting support (2) comprises a guiding part (21) and a connecting part (22). The guiding part (21) is inserted in the adjusting hole (14). The connecting part (22) is fixedly connected with the second clamp (3) through a bolt. By means of the rotary fixing support assembly, reliable connection between two kinds of components moving relative to each other can be achieved, and the rotary fixing support assembly has the beneficial effects that the structure is simple, whole vehicle assembling is facilitated, and the component reliability is high.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

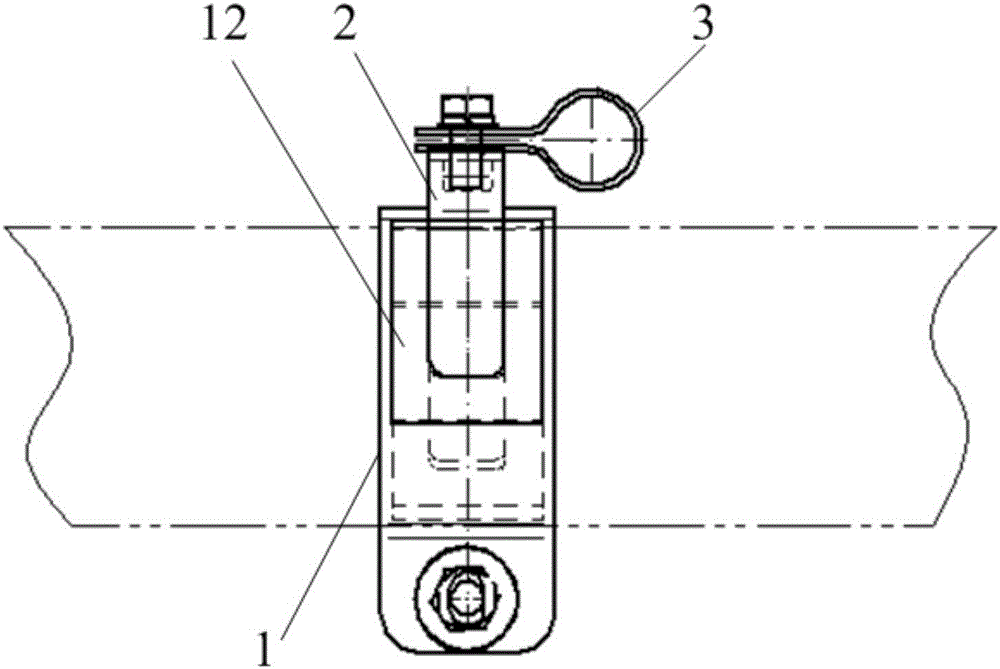

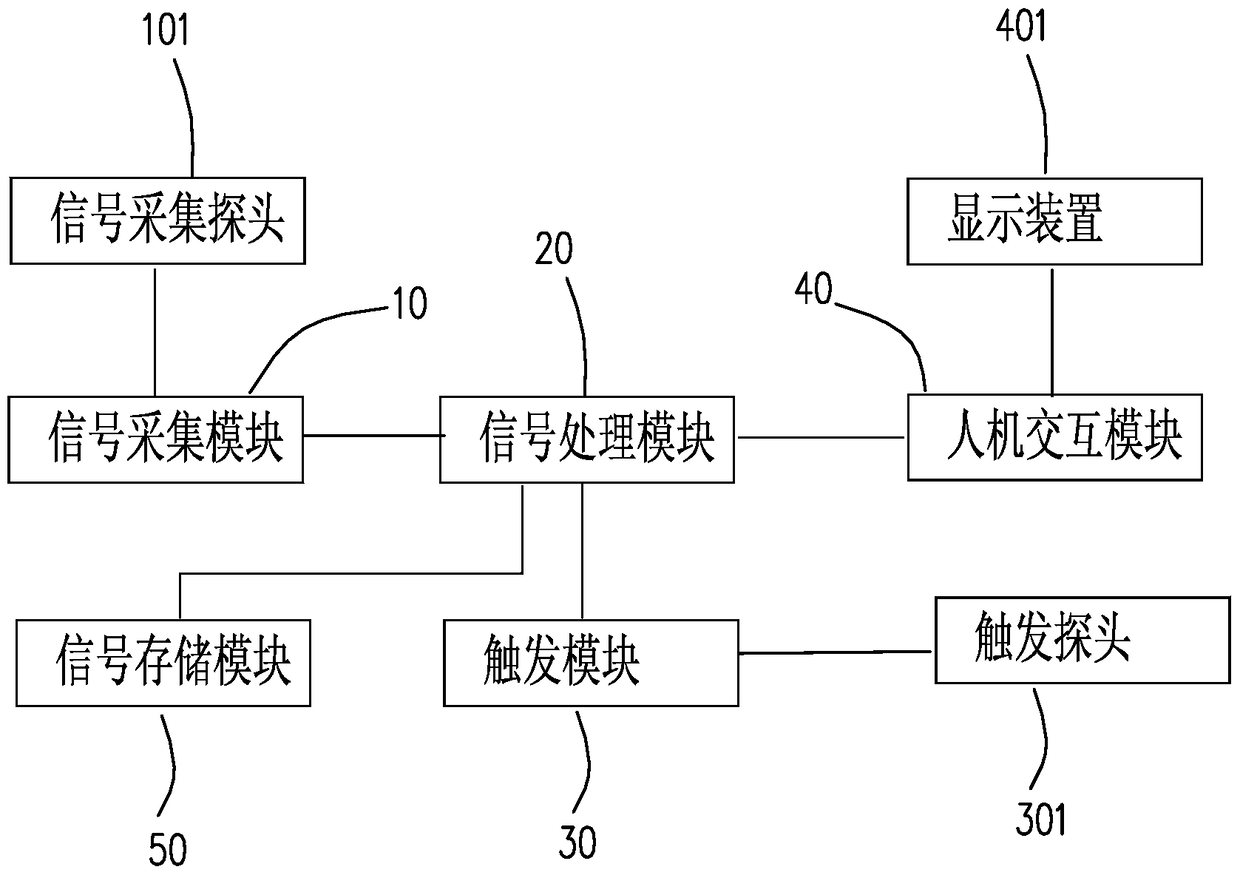

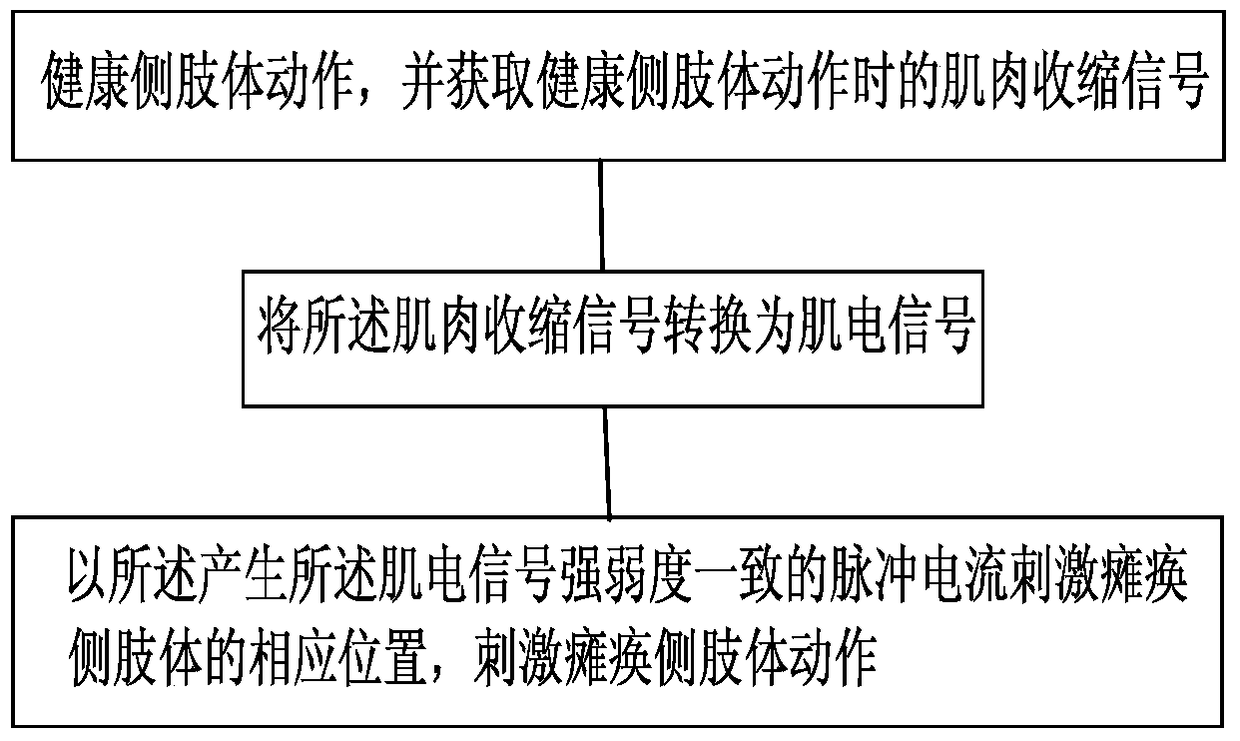

Electrical stimulation training system and training method based on myoelectric signal triggering of uninjured limb

ActiveCN105148404BFind the exact locationGood treatment effectArtificial respirationElectricityTherapeutic effect

The invention discloses an electrical stimulation training system and training method based on the electromyographic signal triggering of the limbs of the healthy side, which collects the electromyographic signal of the healthy side of the hemiplegic patient through the signal acquisition probe, and uses the signal processing module to The myoelectric signal is analyzed and processed, and the trigger probe is controlled to stimulate the same part on the paralyzed side with the same magnitude of pulse current, prompting the same action on the paralyzed side. The electrical stimulation training system and training method based on the electromyographic signals of the healthy limbs can accurately find out the accurate acupuncture points for hemiplegia patients during electrical stimulation therapy, reduce the requirements for the professional knowledge and experience of medical staff, and effectively improve the treatment of hemiplegia. Patient's treatment effect.

Owner:燕铁斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com