Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Efficiently disrupted" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

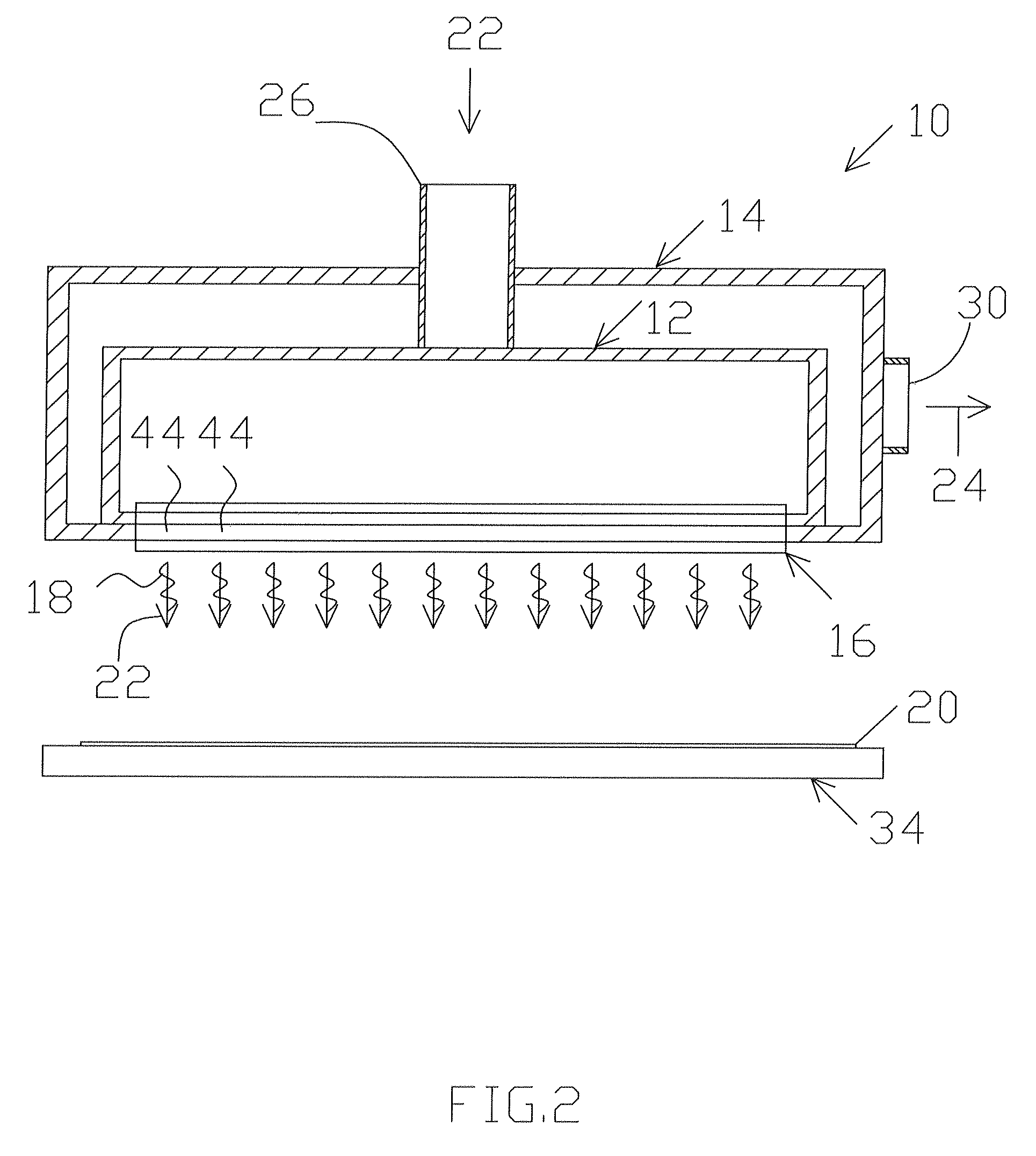

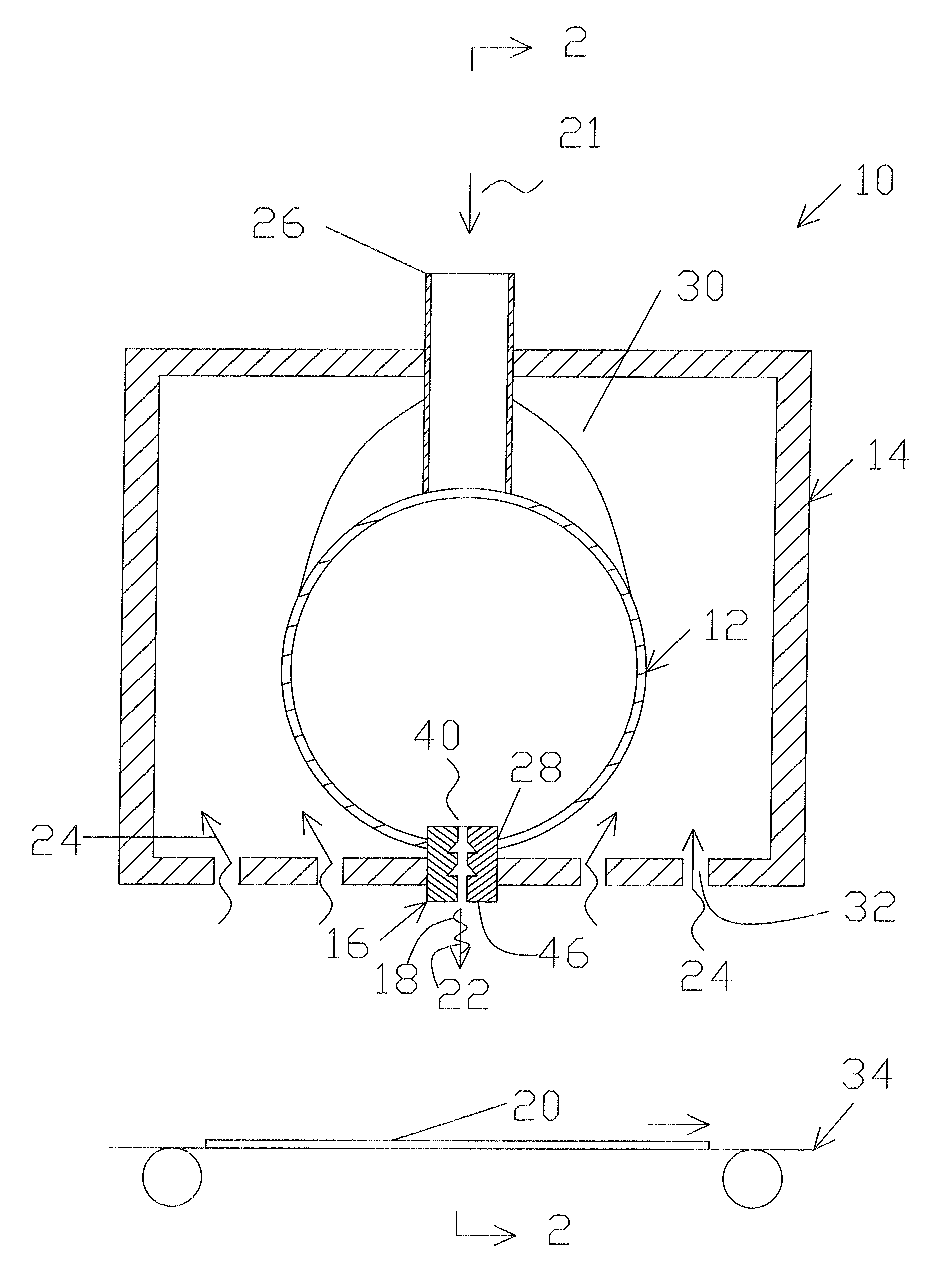

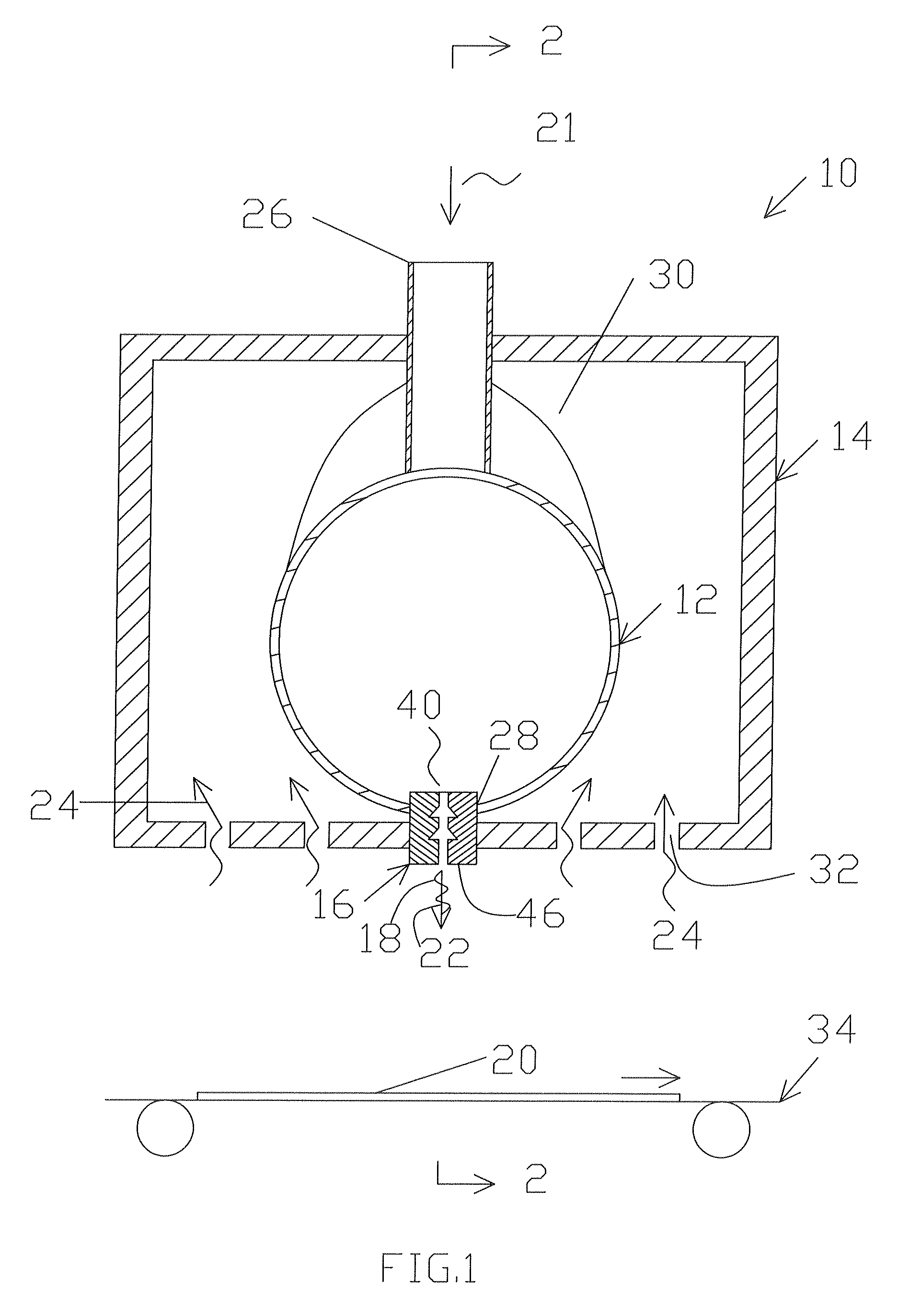

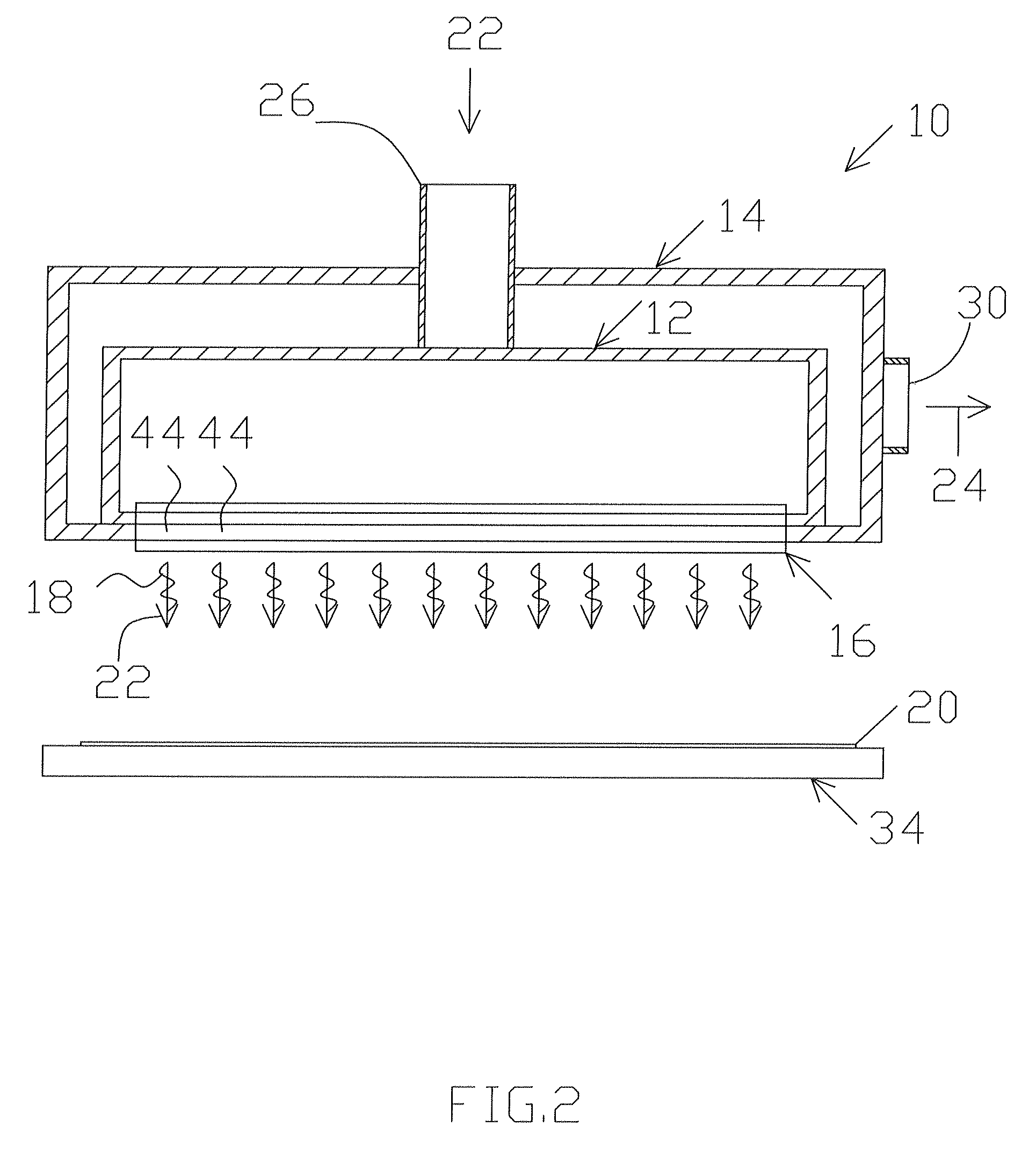

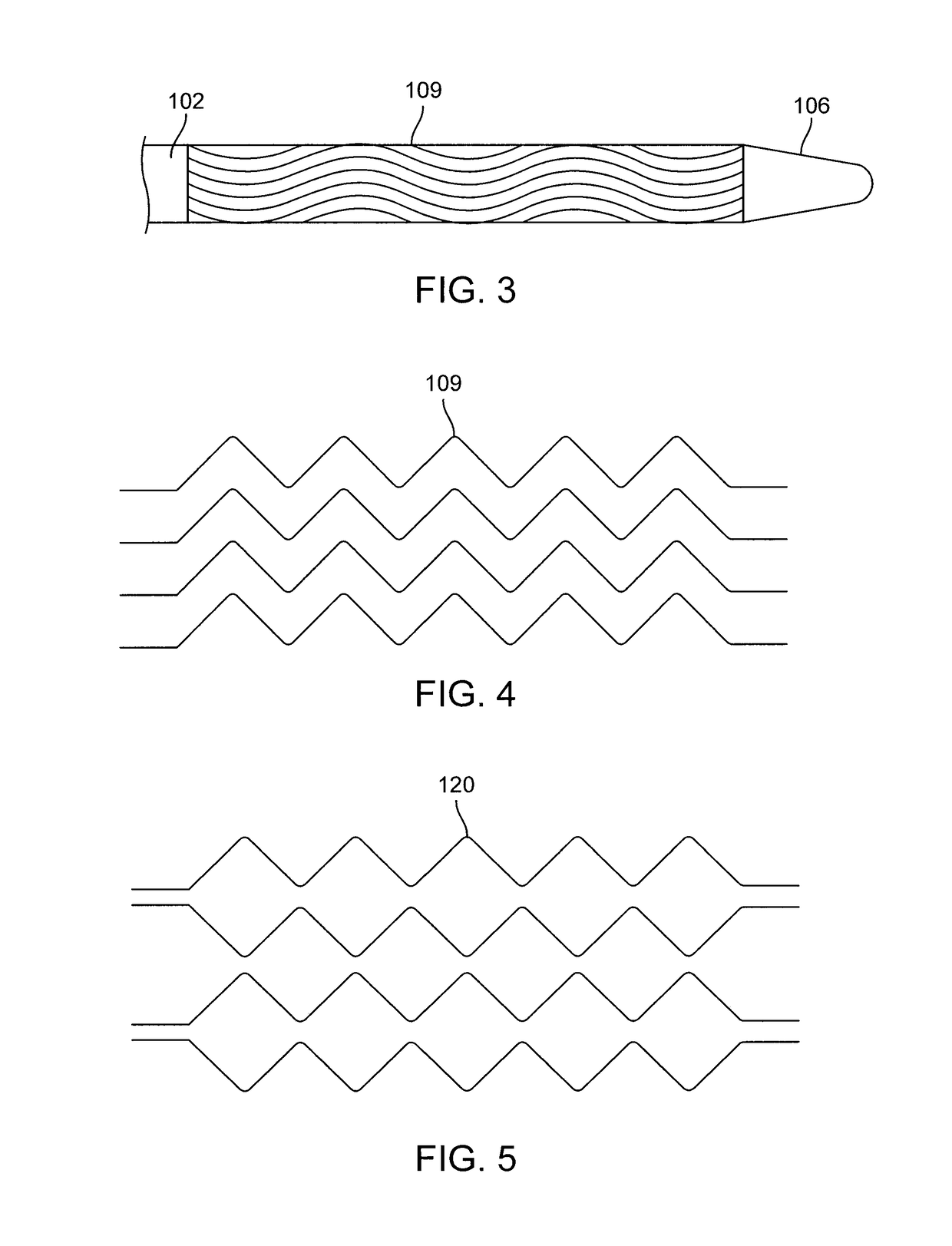

Ultrasonic drying system and method

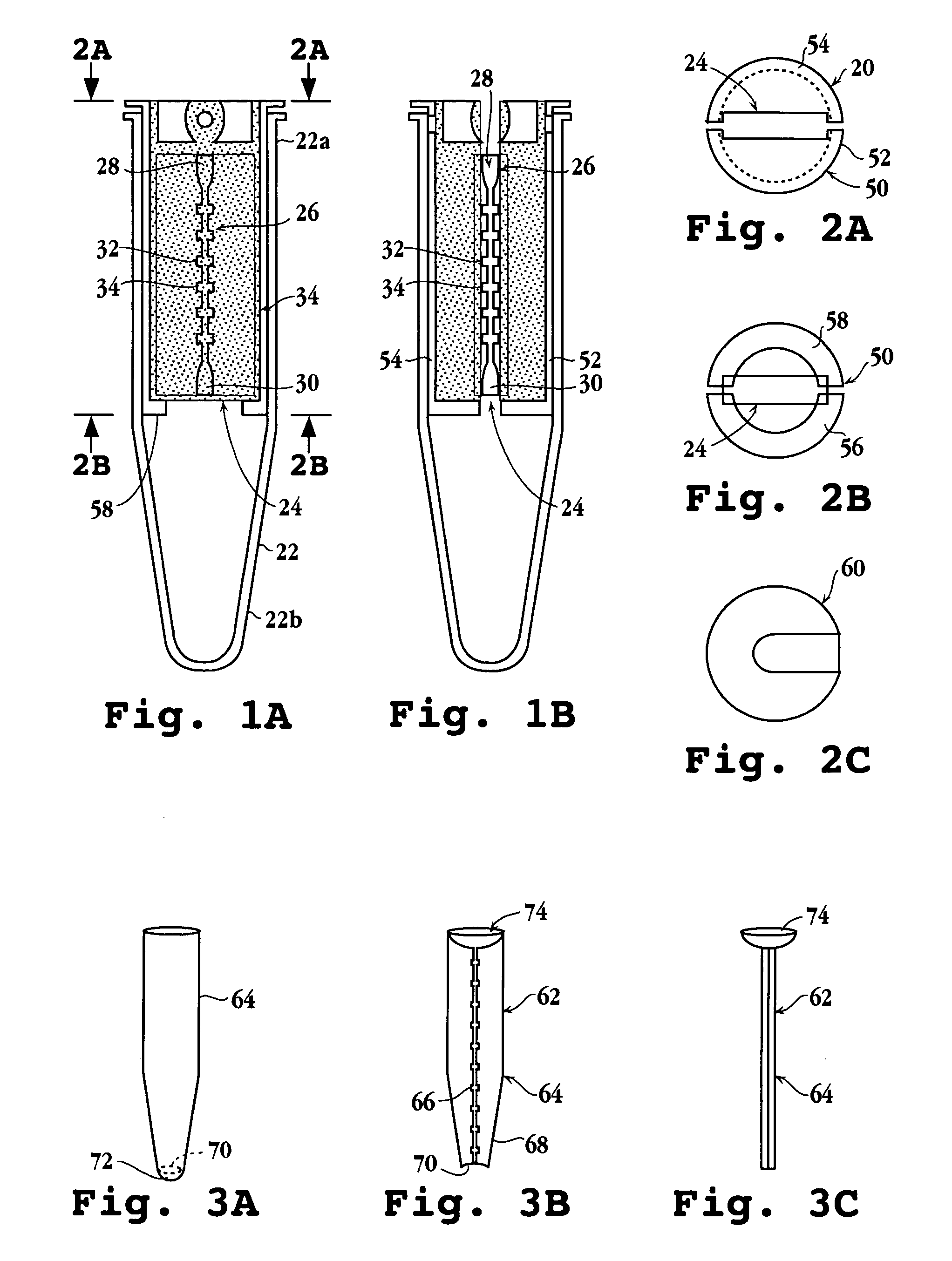

ActiveUS20100199510A1Reduce heat lossEfficiently disruptedDrying using combination processesDrying solid materials with heatSonificationLength wave

A drying apparatus and method including heated airflow and ultrasonic transducers. The ultrasonic transducers are arranged and operated for effectively breaking down the boundary layer to increase the heat transfer rate. The ultrasonic transducers are spaced from the material to be dried a distance of about (λ)(n / 4), where λ is the wavelength of the ultrasonic oscillations and n is an odd integer (i.e., 1, 3, 5, 7, etc.). In this way, the amplitude of the ultrasonic oscillations is maximized to more-effectively agitate the boundary layer. In addition, the ultrasonic transducers are operated to produce about 120-190 dB (preferably, about 160-185 dB) at the interface surface of the material to be dried. In one embodiment, the ultrasonic transducers are of a pneumatic type. In another embodiment, the ultrasonic transducers are of an electric type. And in other embodiments, infrared and / or UV light devices are included for further boundary layer disruption.

Owner:HEAT TECH

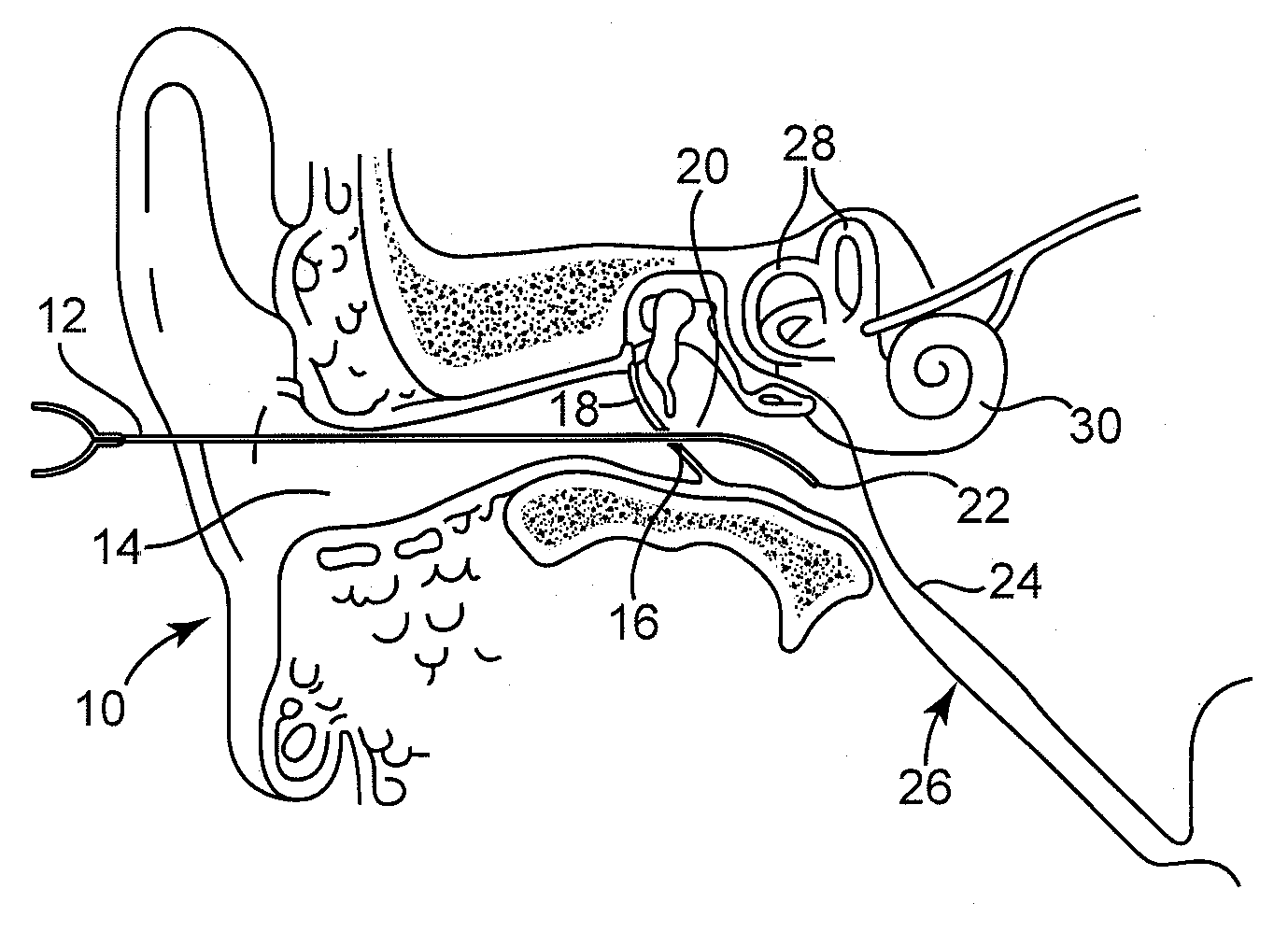

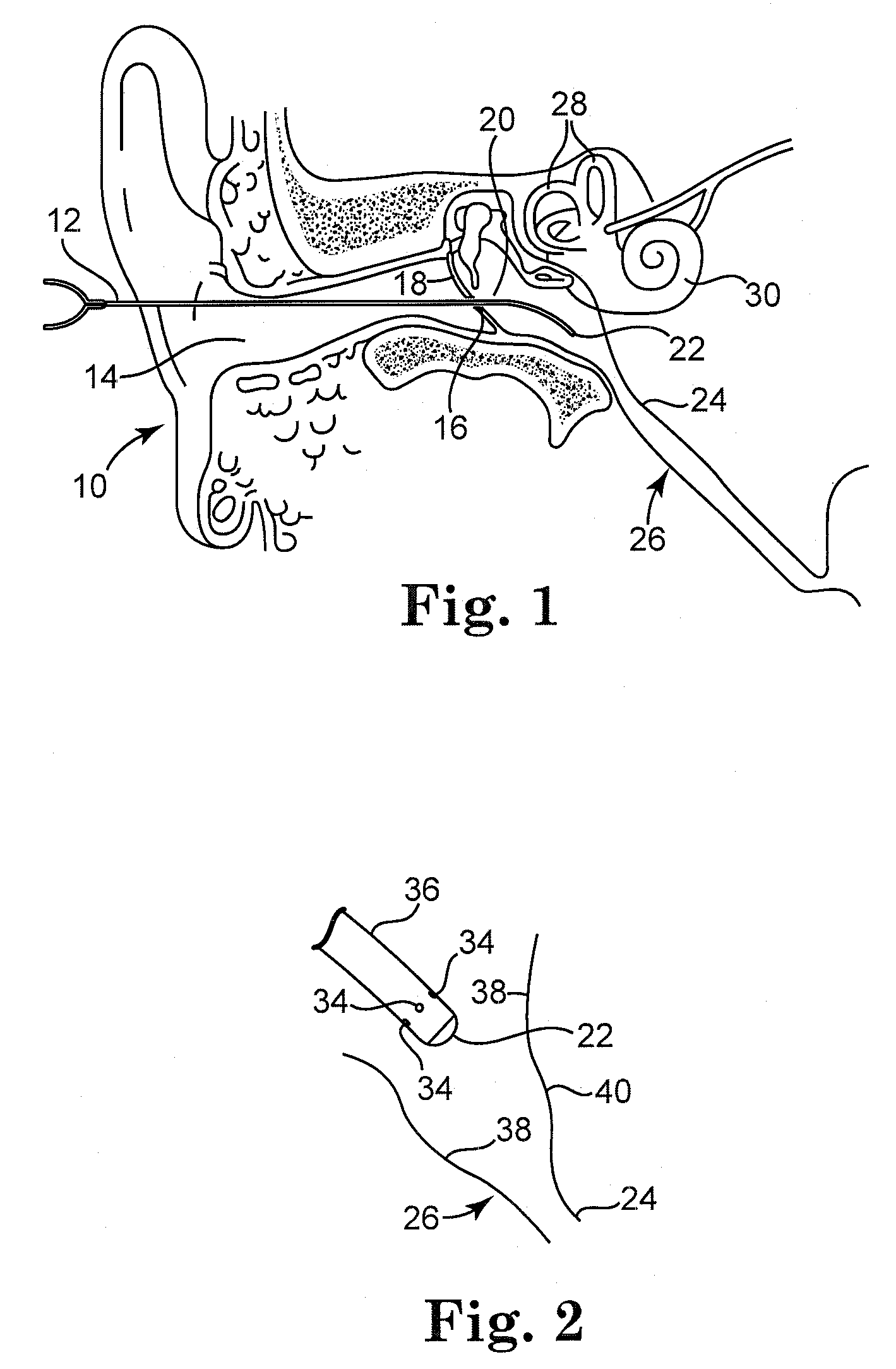

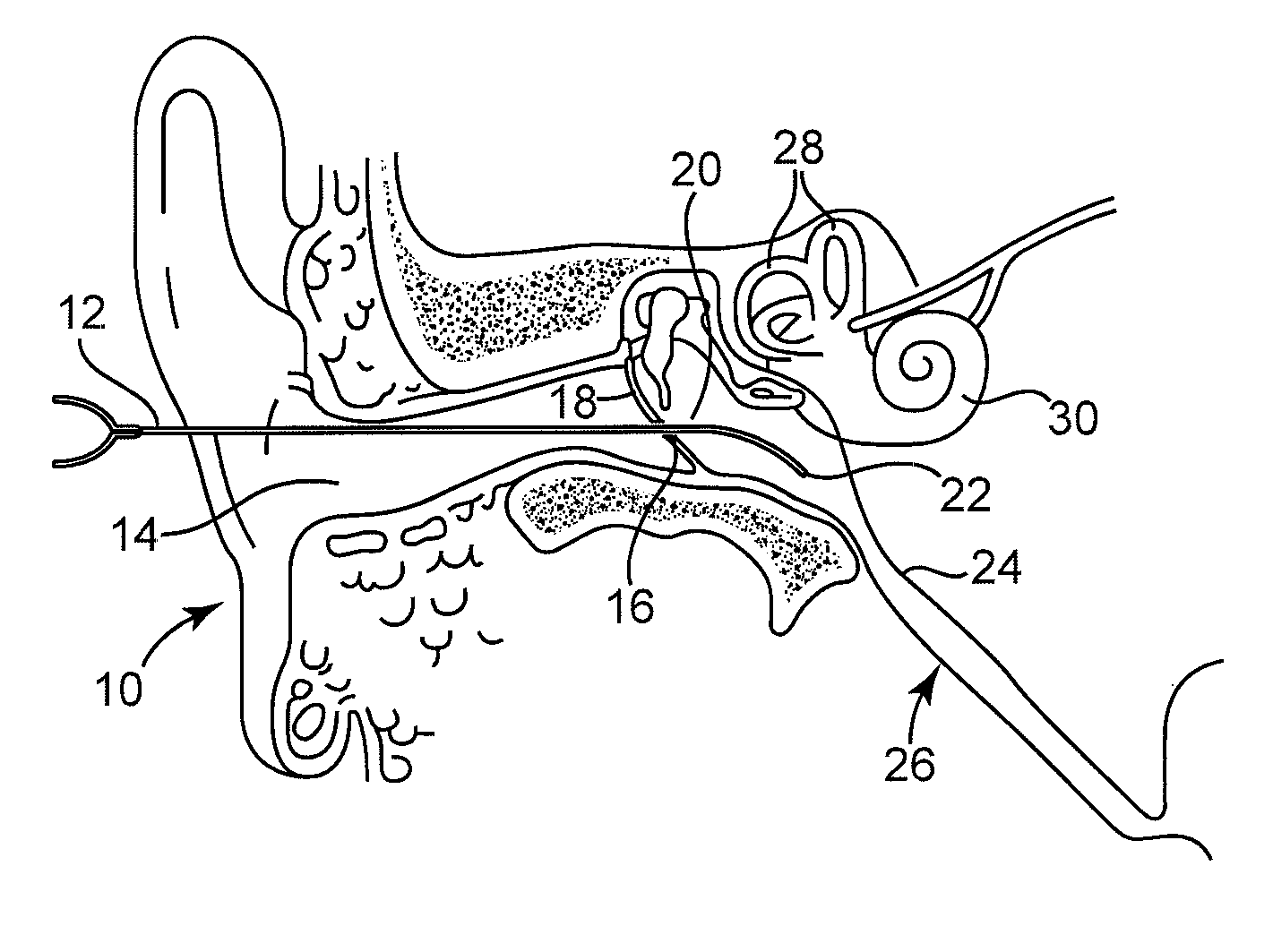

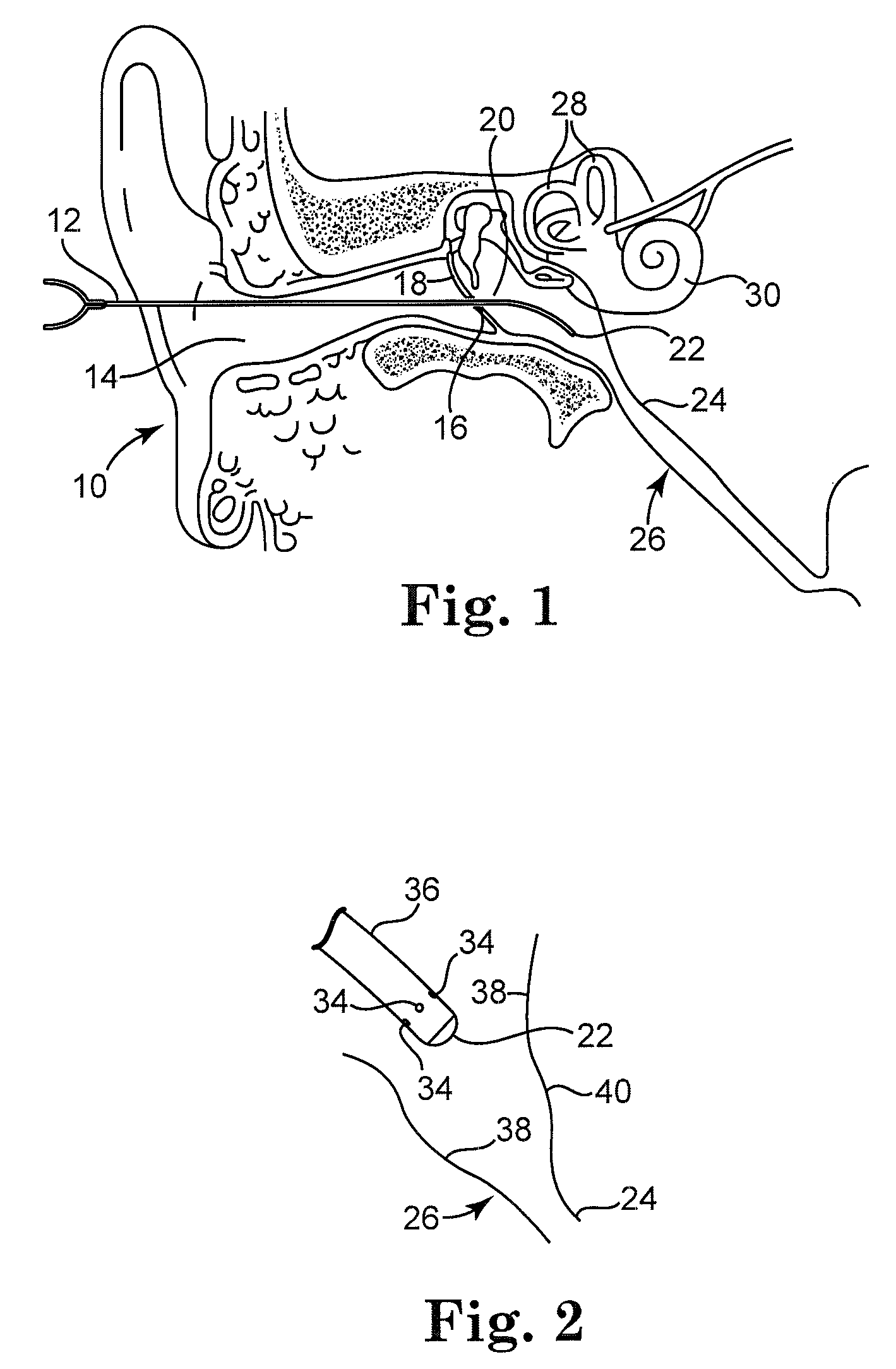

Extracellular polysaccharide solvating system for treatment of bacterial ear conditions

ActiveUS20070264353A1Discourage bacterial recolonization and biofilm reformationEfficiently disruptedAntibacterial agentsHeavy metal active ingredientsBacteroidesBiofilm

Chronic otitis media and other bacterial ear conditions may be treated by applying a solvating system containing a metal ion sequestering agent and surfactant to a bacterial biofilm in the middle or inner ear. The solvating system disrupts the biofilm and aids in its removal.

Owner:MEDTRONIC XOMED INC

Extracellular polysaccharide solvating system for treatment of bacterial ear conditions

ActiveUS7976873B2Discourage bacterial recolonization and biofilm reformationEfficiently disruptedAntibacterial agentsBiocideBacteroidesBiofilm

Chronic otitis media and other bacterial ear conditions may be treated by applying a solvating system containing a metal ion sequestering agent and surfactant to a bacterial biofilm in the middle or inner ear. The solvating system disrupts the biofilm and aids in its removal.

Owner:MEDTRONIC XOMED INC

Methods and compositions for preparation of biological samples

InactiveUS20060240449A1Sufficient volumeIncrease usable surface areaMicrobiological testing/measurementNucleic acid reductionLysisEnzyme

Methods and compositions for preparation of biological samples are disclosed. The methods include a prelysis step and a lysis step to make the cellular DNA available for further processing, amplification or analysis. The prelysis step includes the addition of a prelysis reagent to the cells. The prelysis reagent may include an enzyme to facilitate the disruption of the cells. The lysis step includes the addition of a lysis reagent to at least a portion of the prelysis reagent and cells.

Owner:ACCESS GENETICS

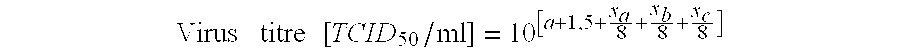

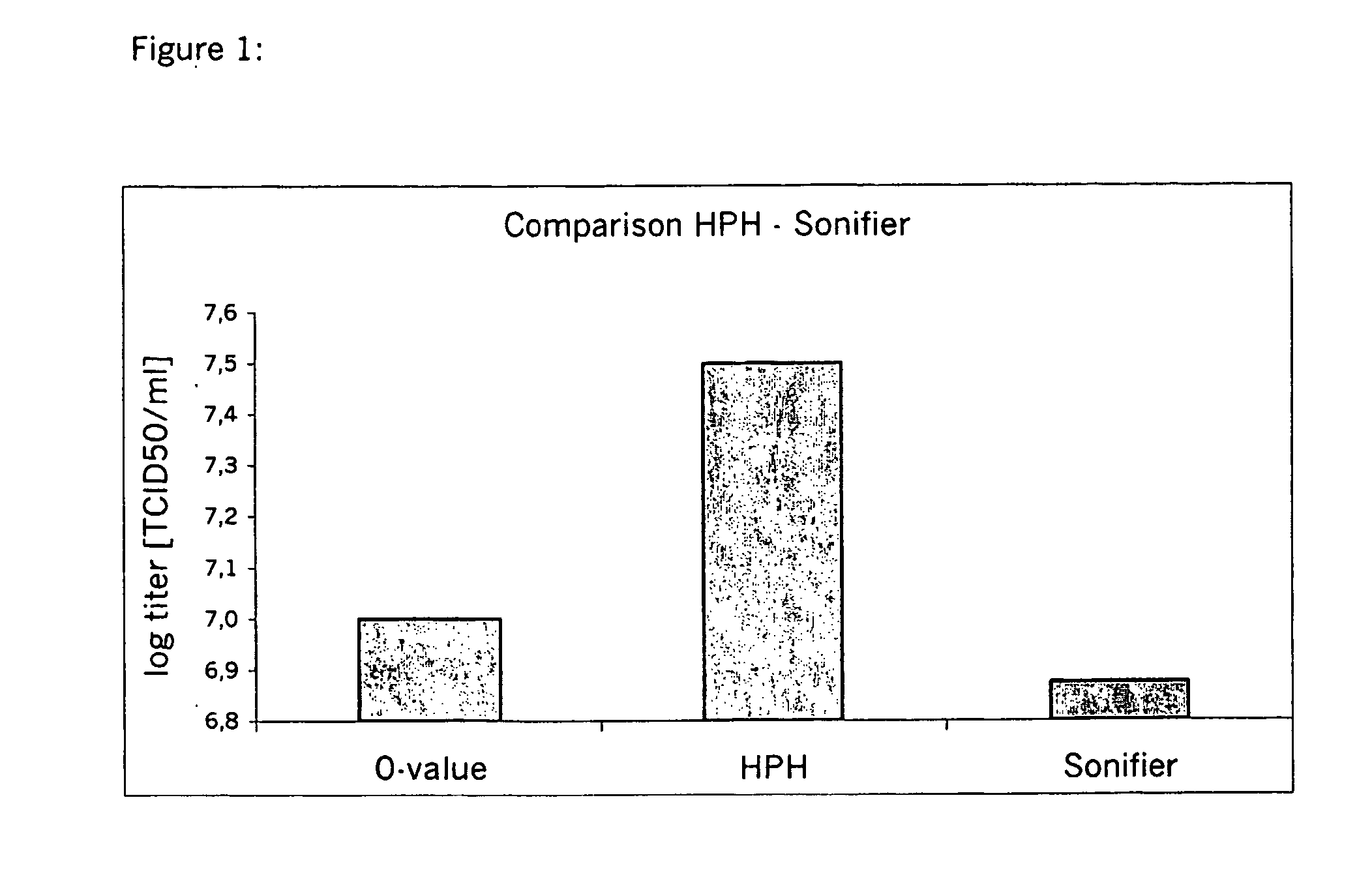

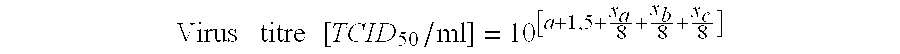

Method for the recovery and purification of poxviruses from infected cells

InactiveUS7056723B2Easy to controlImprove scalabilityViral antigen ingredientsAntiviralsInfected cellVaccinia

Owner:BAVARIAN NORDIC AS

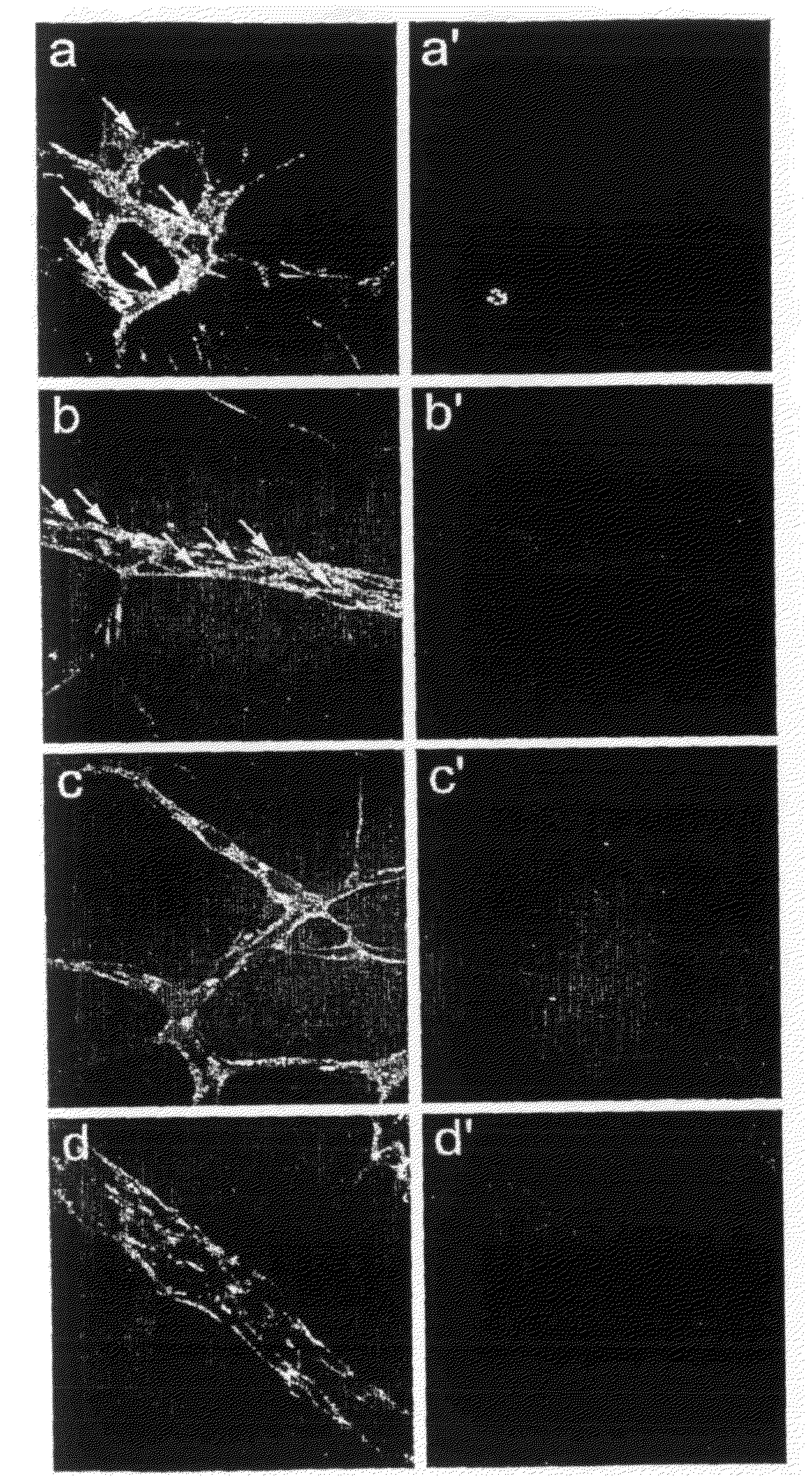

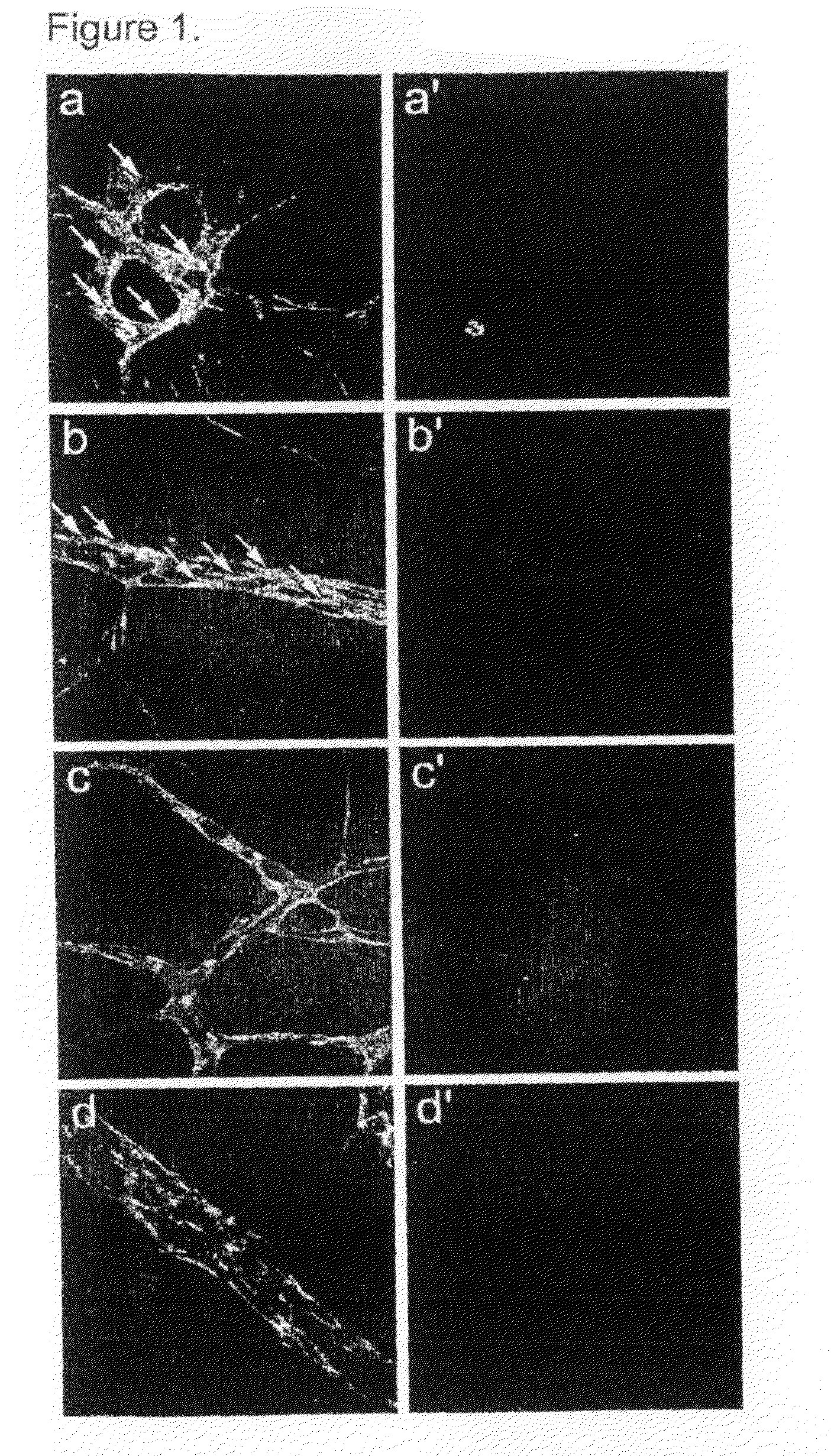

DLL4 Signaling Inhibitors and Uses Thereof

InactiveUS20100119526A1Inhibit tumor growthEfficiently disruptedMicrobiological testing/measurementImmunoglobulins against cell receptors/antigens/surface-determinantsAngiogenesis growth factorAntigen binding

DLL4-binding antibodies, specifically antibodies preventing Notch signaling and internalization of DLL4, can: more efficiently than inhibitors only preventing DLL4-mediated Notch-signaling disrupt angiogenesis and pathological processes including tumor growth.

Owner:BIOINVENT INT AB

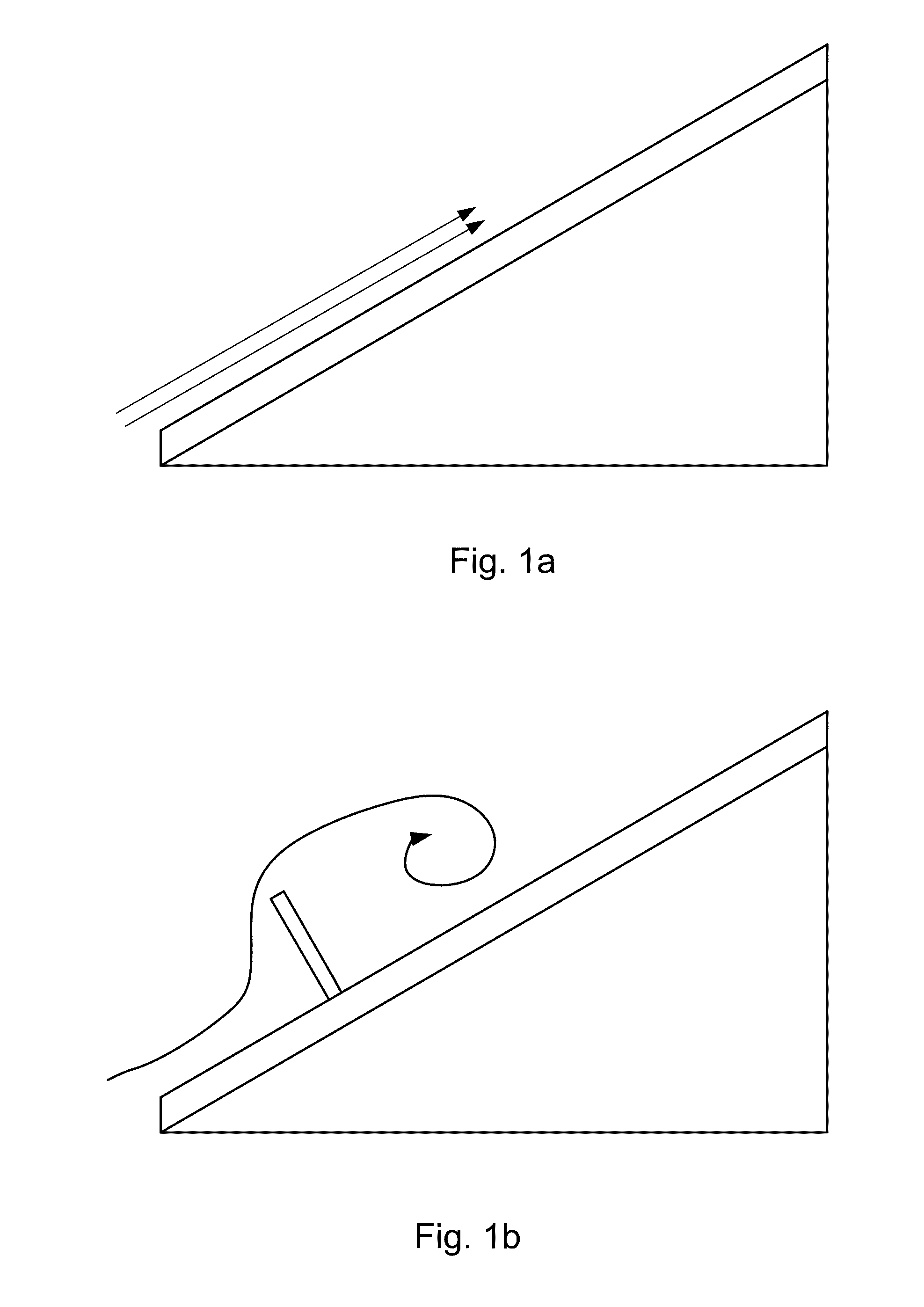

Device and method for fragmenting material by hydrodynamic shear

InactiveUS20060133957A1Increase the number ofEfficiently disruptedAnalysis using chemical indicatorsSamplingCentrifugal forceBiomedical engineering

A device and method for use with a centrifuge for fragmenting solute or particulate material contained in a liquid sample are disclosed. The device includes a substrate adapted to be supported within a centrifuge tube, and providing a microchannel defining a plurality of shear regions. Material contained in a liquid sample applied to the device, with such supported in a centrifuge tube within a centrifuge, is fragmented by shearing as the sample is forced successively through the plurality of shear regions in the microchannel, when the selected centrifugal force applied to the tube.

Owner:SRI INTERNATIONAL +1

Improved insect control strategies utilizing pheromones and rnai

InactiveUS20190343122A1Reducing and preventing plant damageReduces and prevents plant damageBiocideClimate change adaptationSemiochemicalField plot

Systems and methods of preventing or reducing crop damage from pests are provided. In one embodiment, the method comprises: a) applying a mating disruption tactic to a field plot; and b) disrupting expression of one or more target genes in one or more pests, wherein crop damage is reduced in the field plot. In another embodiment, the method comprises applying an attract-and-kill tactic to a field plot, wherein said attract-and-kill tactic comprises: a) applying one or more semiochemicals or factors; and b) disrupting expression of one or more target genes in one or more pests, wherein said disruption is capable of killing the one or more pests, wherein crop damage is reduced in the field plot.

Owner:PROVIVI

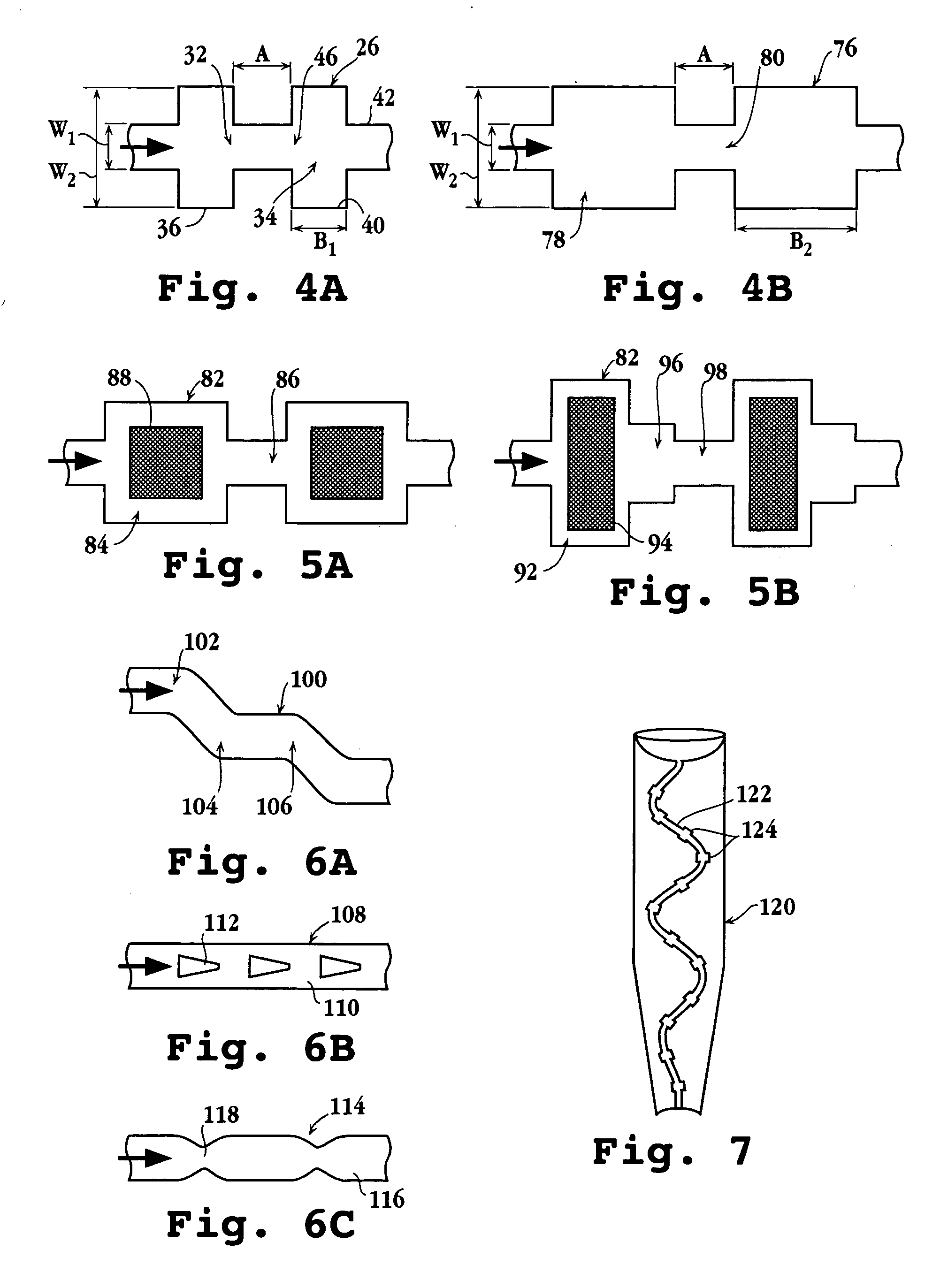

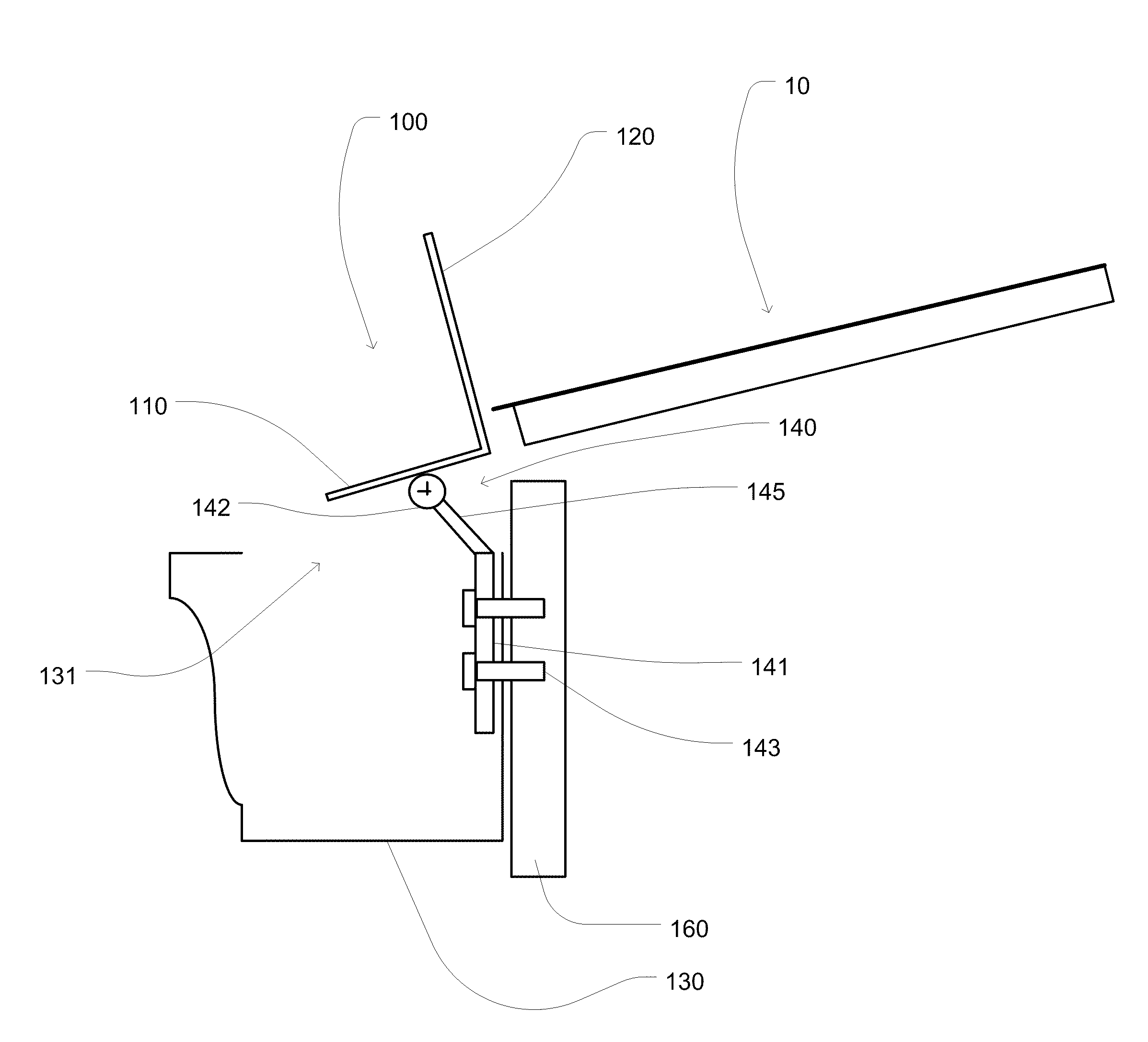

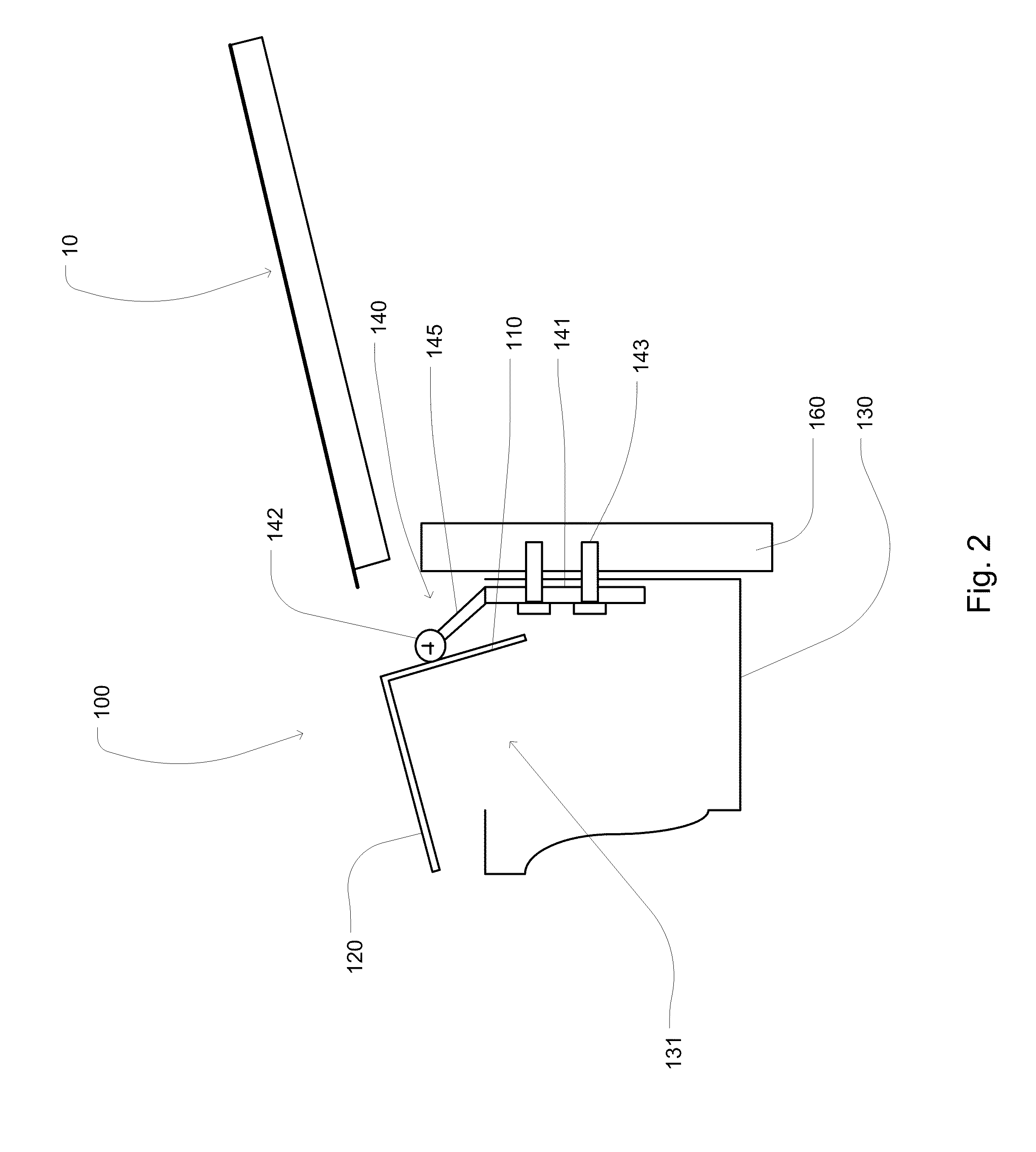

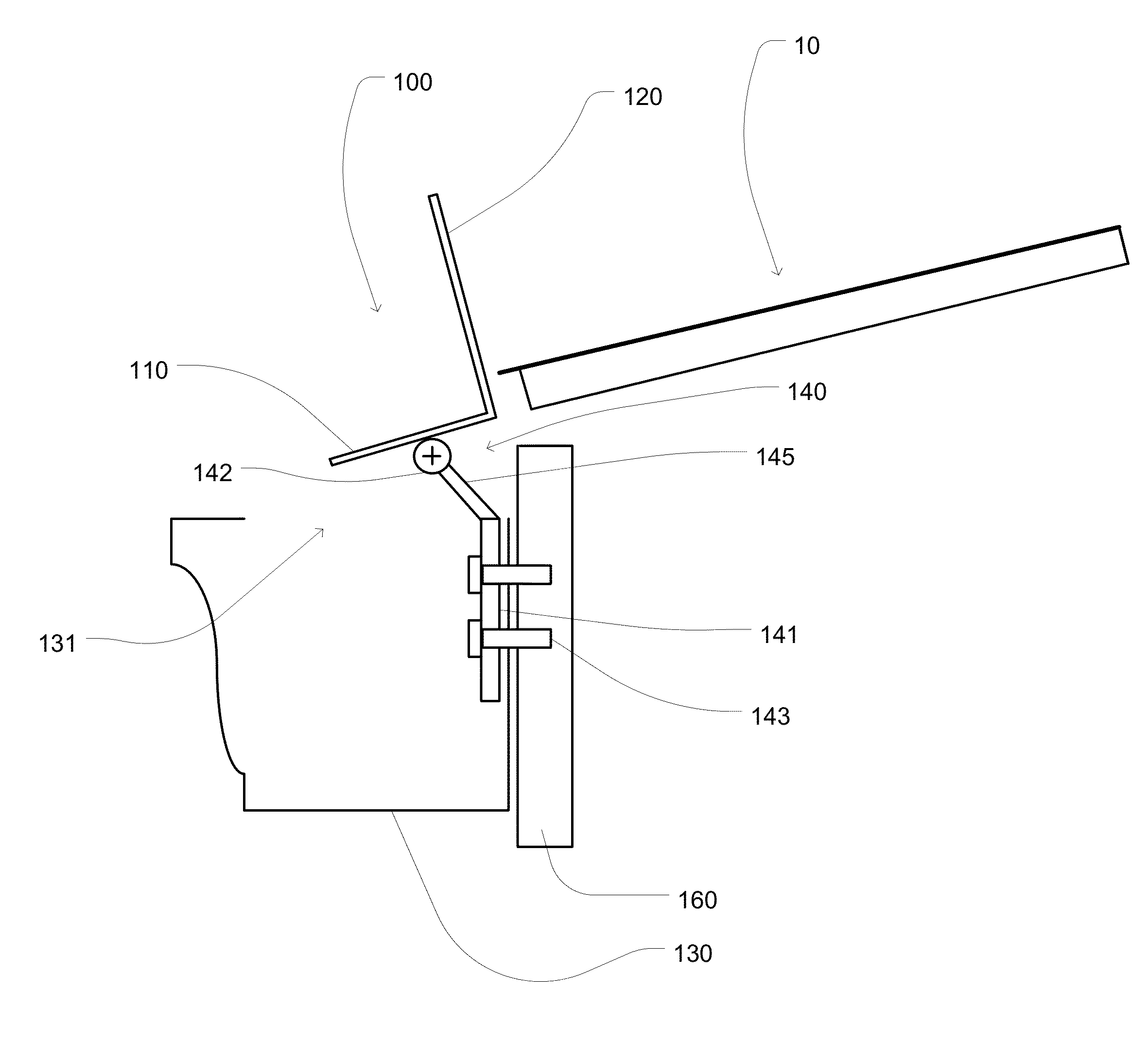

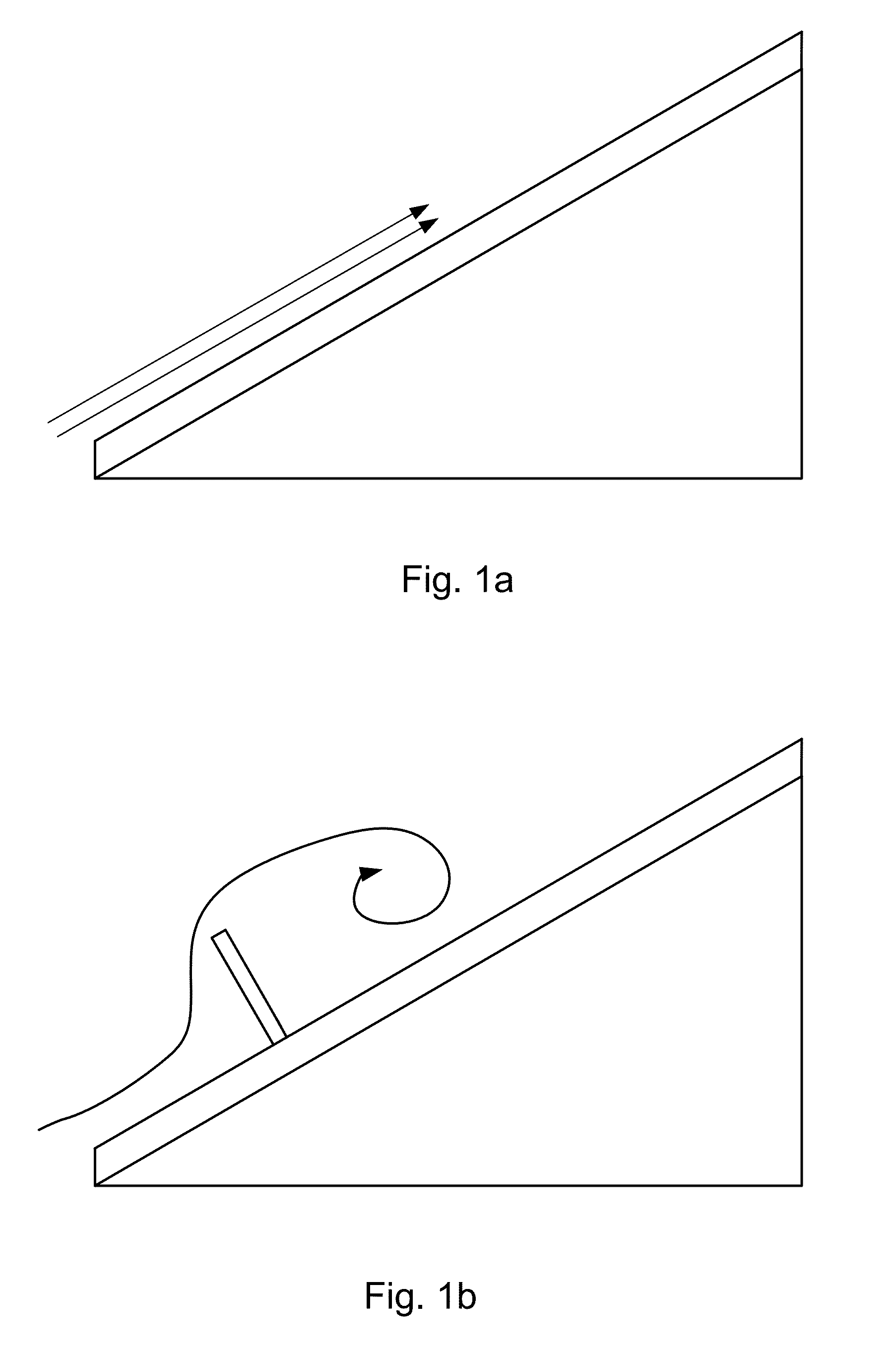

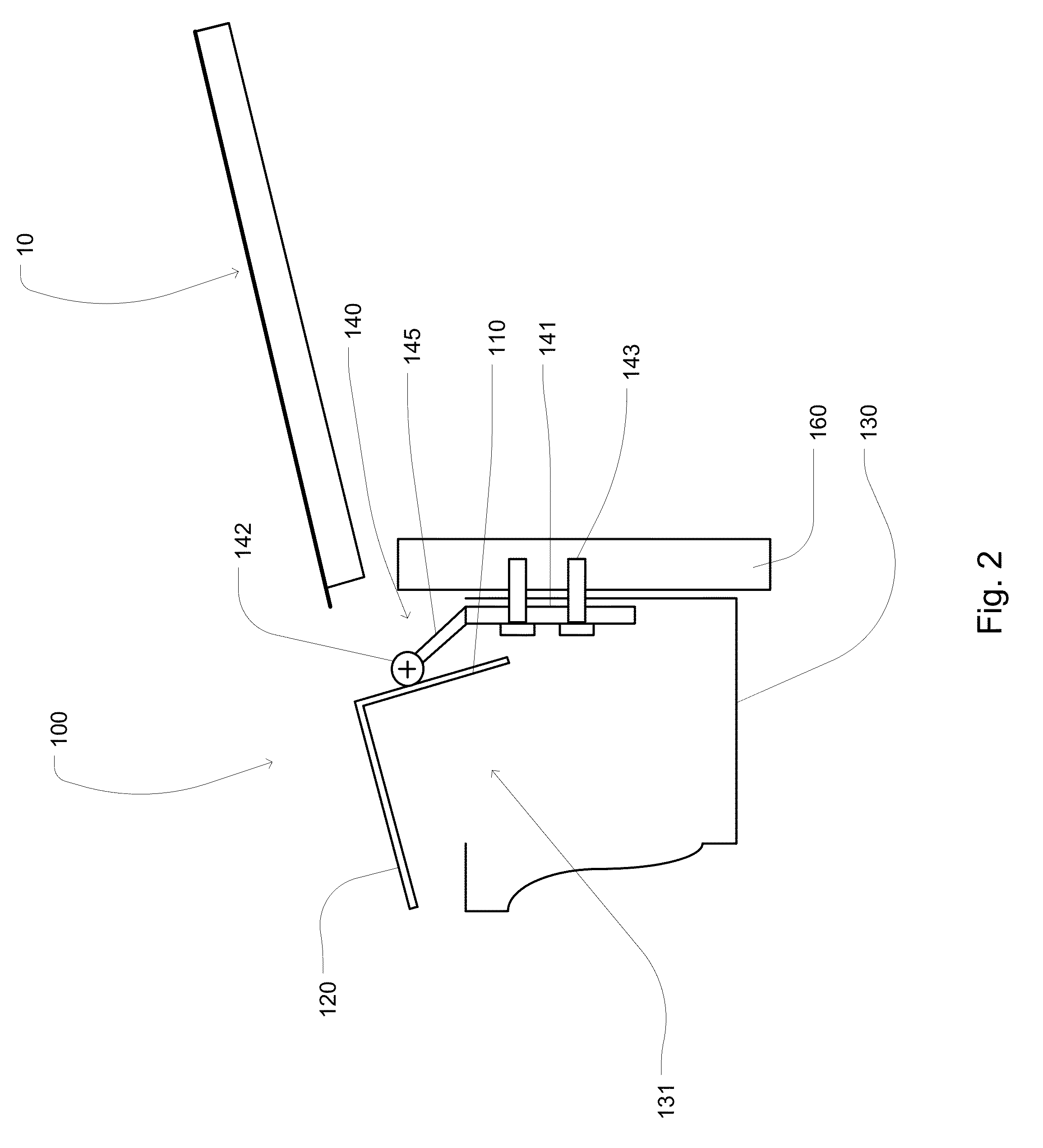

Roof Spoiler

InactiveUS20100281785A1Improve stabilityEfficiently disruptedRoof covering using slabs/sheetsRoof covering using tiles/slatesLeading edge

Disclosed is a roof spoiler that effectively disrupts the attached flow of wind upon a roof surface. This spoiler has a stowed position, whereby it is almost completely out of the view of passersby. It also has a deployed position, wherein a barrier is projected vertically, or substantially vertically, so as to disrupt the flow of air over the roof surface. This spoiler utilizes a hinged design to move between these two positions. The spoiler is specially designed to operate in conjunction with a gutter mounted along the leading edge of the roof. In the stowed position, a portion of the spoiler covers the open gutter. In one embodiment, the spoiler is L-shaped to facilitate its stability in the deployed position.

Owner:WINDTRIPPER CORP

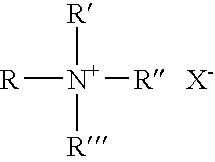

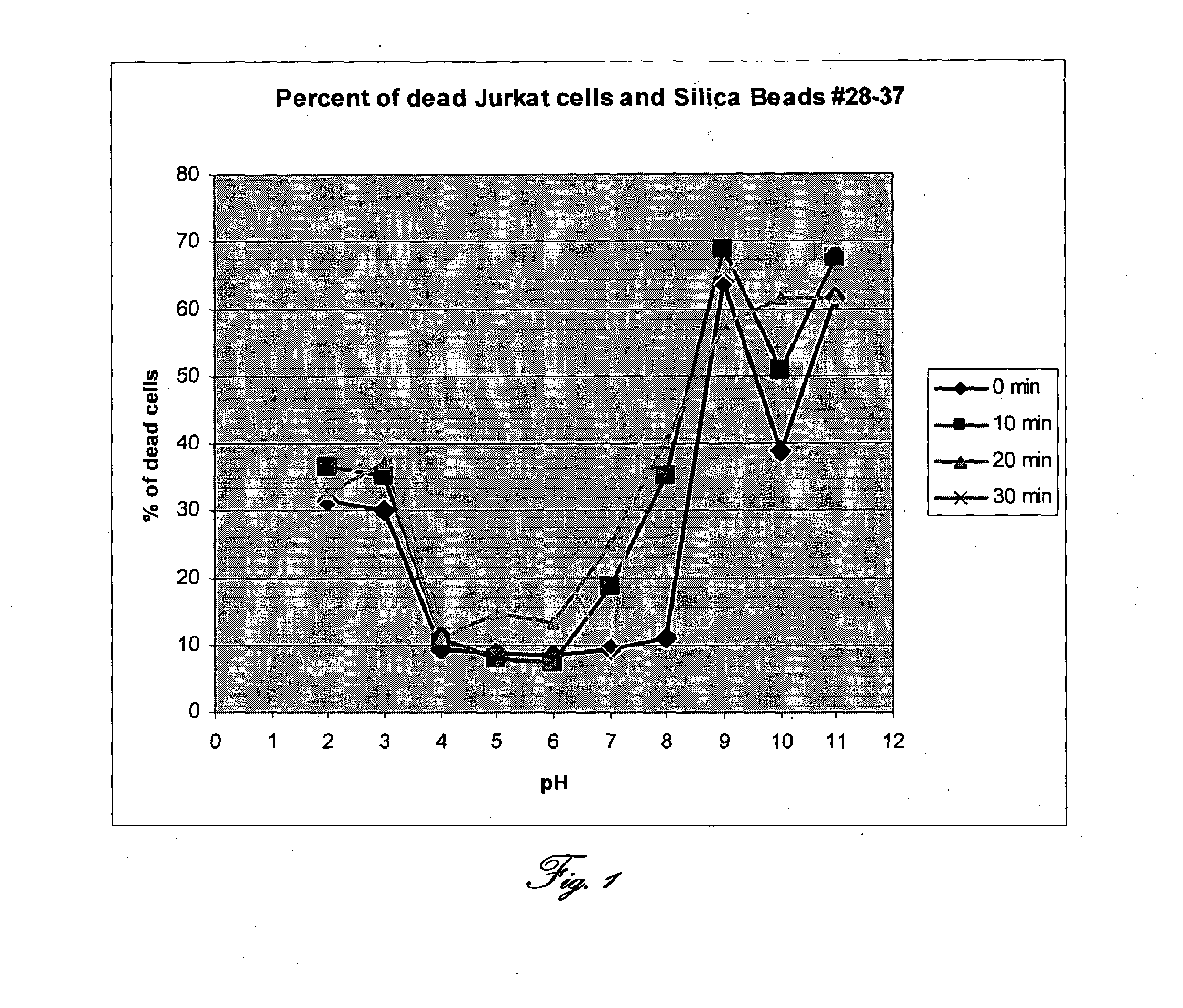

Biocidic household cleansing materials

InactiveUS20100136077A1Effective preservationMinimize changesBiocideWarp knittingElectricityCell–cell interaction

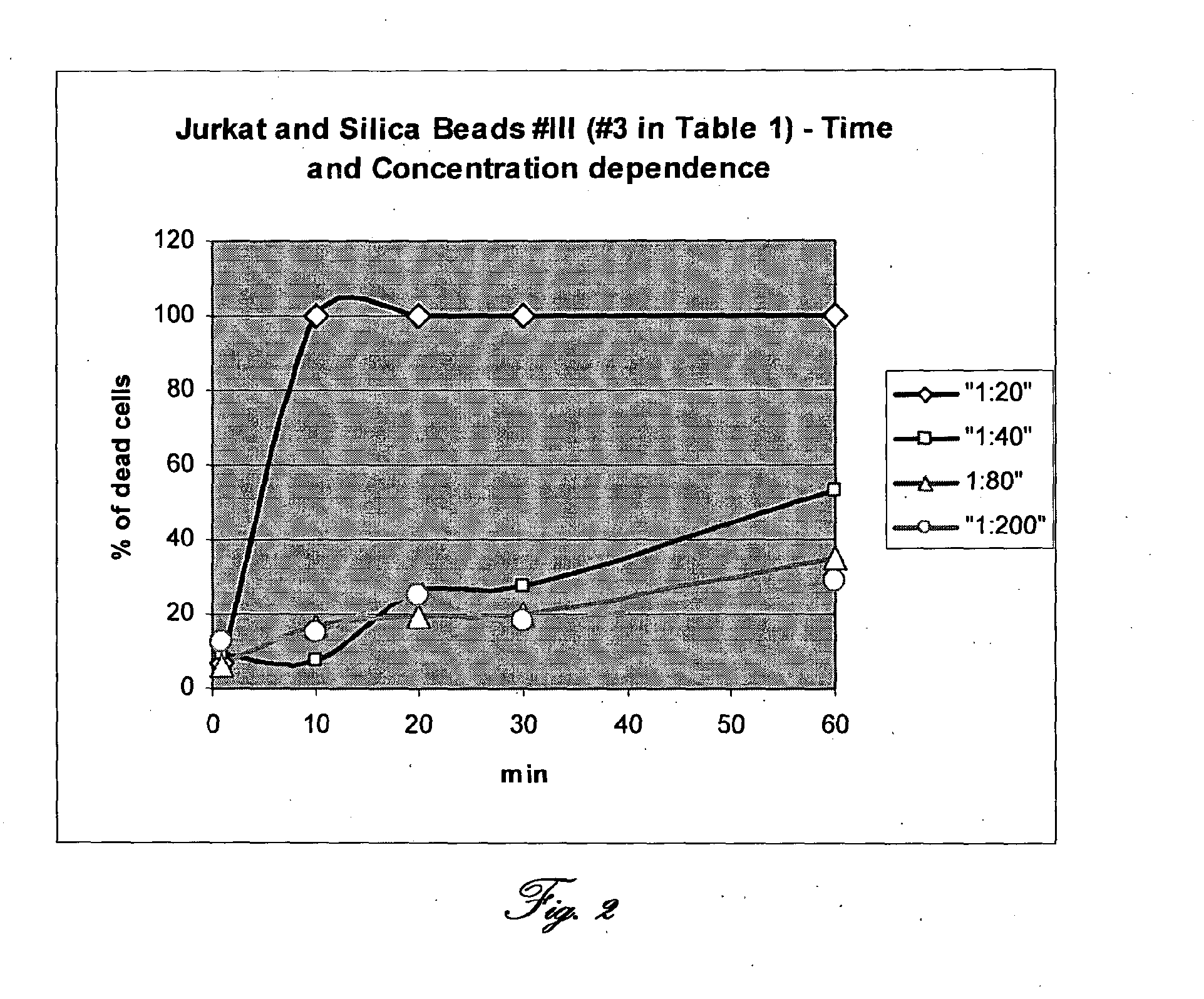

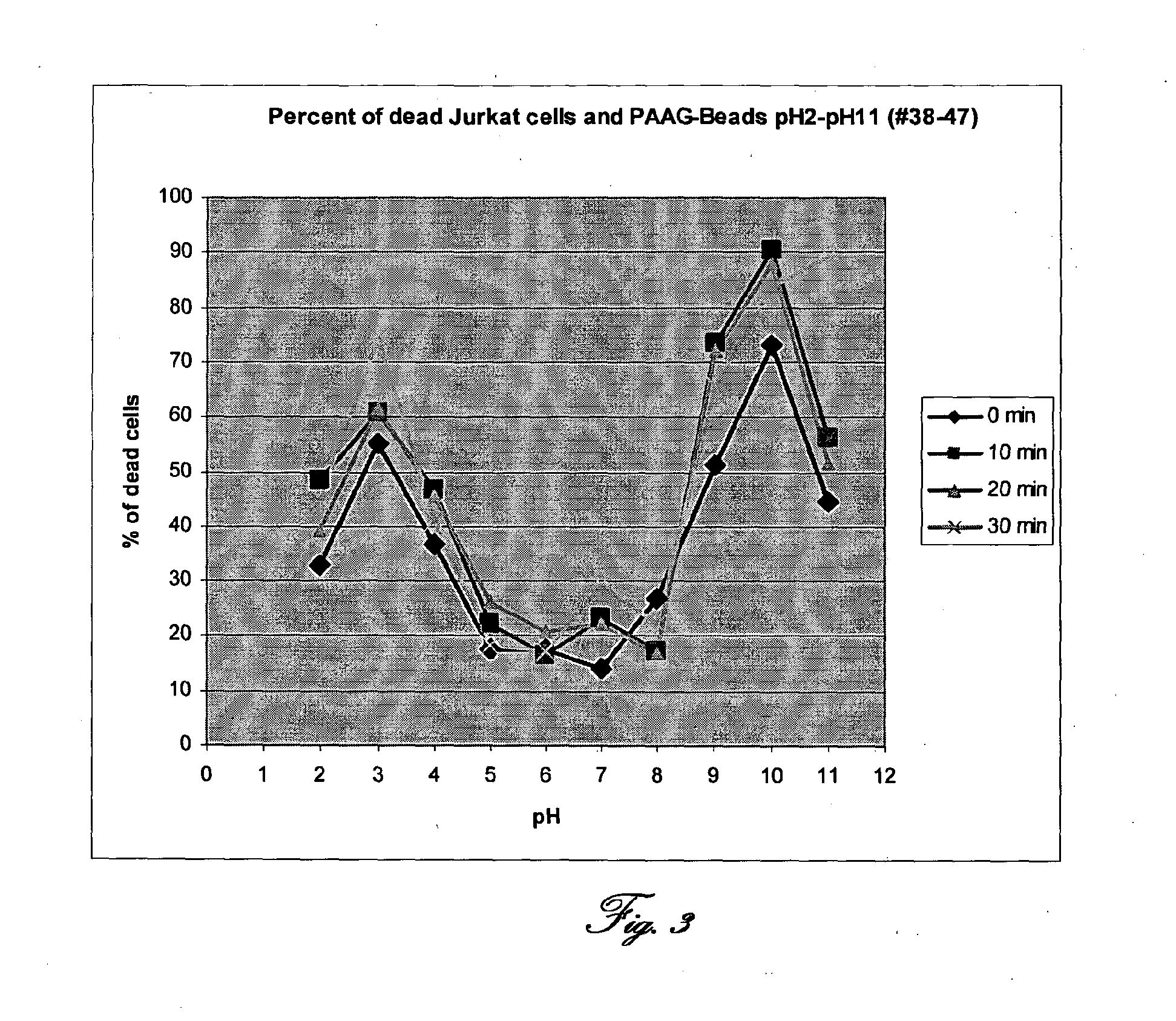

The present invention discloses household cleaning materials comprising at least one insoluble proton sink or source (PSS) and to method for utilizing the PSS as a biocidic agent. The household cleaning materials are provided useful for killing living target cells (LTCs) or otherwise inhibiting LTCs growth, disrupting vital intracellular processes and / or intercellular interactions of the LTC upon contact. The household cleaning materials consisting of at least one PSS, comprises, inter alia, (i) proton source or sink providing a buffering capacity; and (ii) means providing proton conductivity and / or electrical potential. The PSS is effectively disrupting the pH homeostasis and / or electrical balance within the confined volume of said LTC and / or disrupting vital intercellular interactions of said LTCs while efficiently preserving the pH of said LTCs' environment.

Owner:OPLON

Ultrasonic drying system and method

ActiveUS9068775B2Reduce heat lossEfficiently disruptedDrying using combination processesDrying solid materials with heatLength waveUltrasonic oscillation

A drying apparatus and method including heated airflow and ultrasonic transducers. The ultrasonic transducers are arranged and operated for effectively breaking down the boundary layer to increase the heat transfer rate. The ultrasonic transducers are spaced from the material to be dried a distance of about (λ)(n / 4), where λ is the wavelength of the ultrasonic oscillations and n is an odd integer (i.e., 1, 3, 5, 7, etc.). In this way, the amplitude of the ultrasonic oscillations is maximized to more-effectively agitate the boundary layer. In addition, the ultrasonic transducers are operated to produce about 120-190 dB (preferably, about 160-185 dB) at the interface surface of the material to be dried. In one embodiment, the ultrasonic transducers are of a pneumatic type. In another embodiment, the ultrasonic transducers are of an electric type. And in other embodiments, infrared and / or UV light devices are included for further boundary layer disruption.

Owner:HEAT TECH

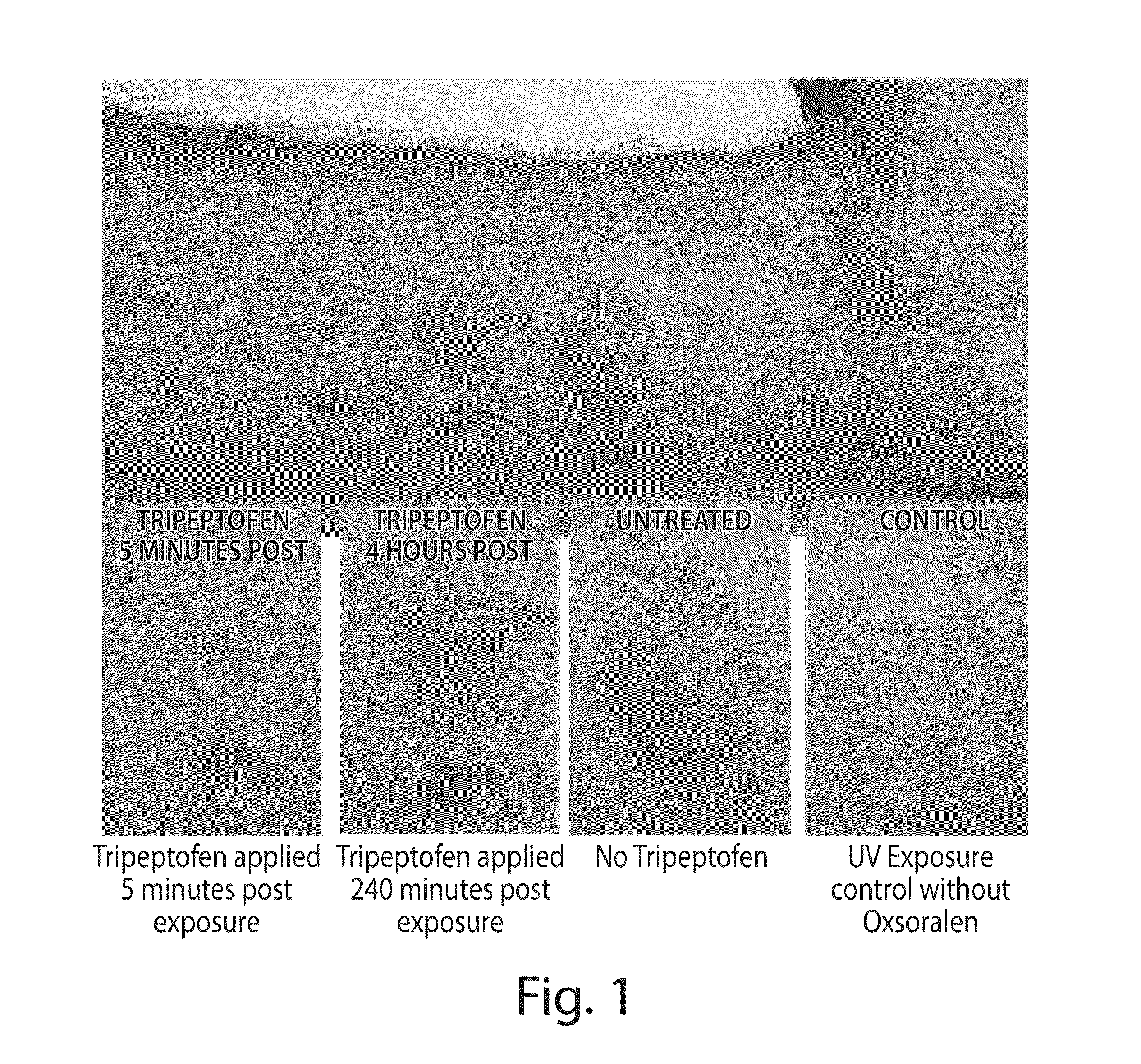

Tissue disruption treatment and composition for use thereof

InactiveUS20150064164A1Efficiently disruptedHeavy metal active ingredientsPeptide/protein ingredientsMedicineTissue healing

The present invention relates to an agent having activity in the treatment of a tissue disruption. In particular the present invention relates to a composition comprising an effective amount of an active fraction having tissue healing properties

Owner:CAMBRIDGE INSTR

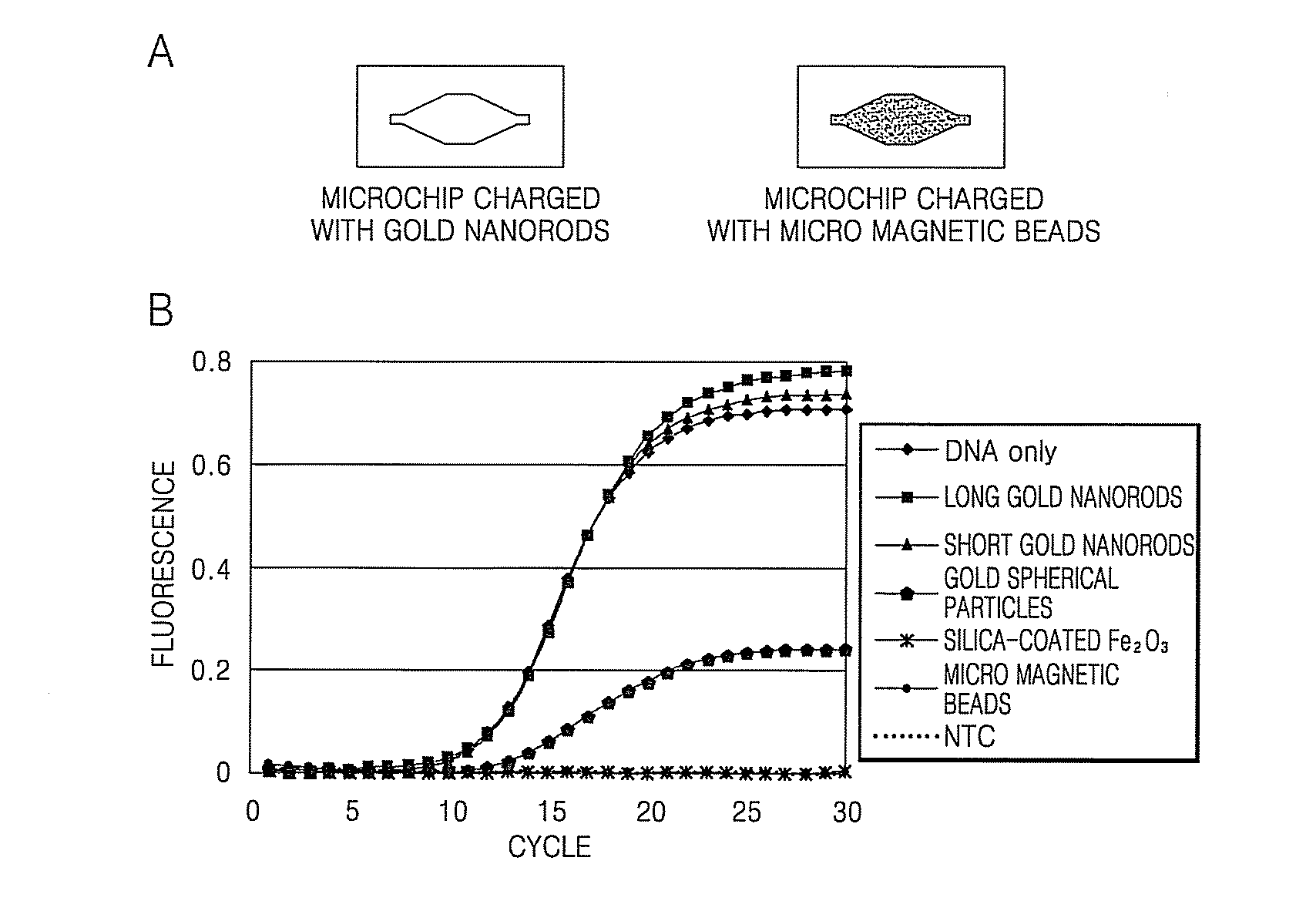

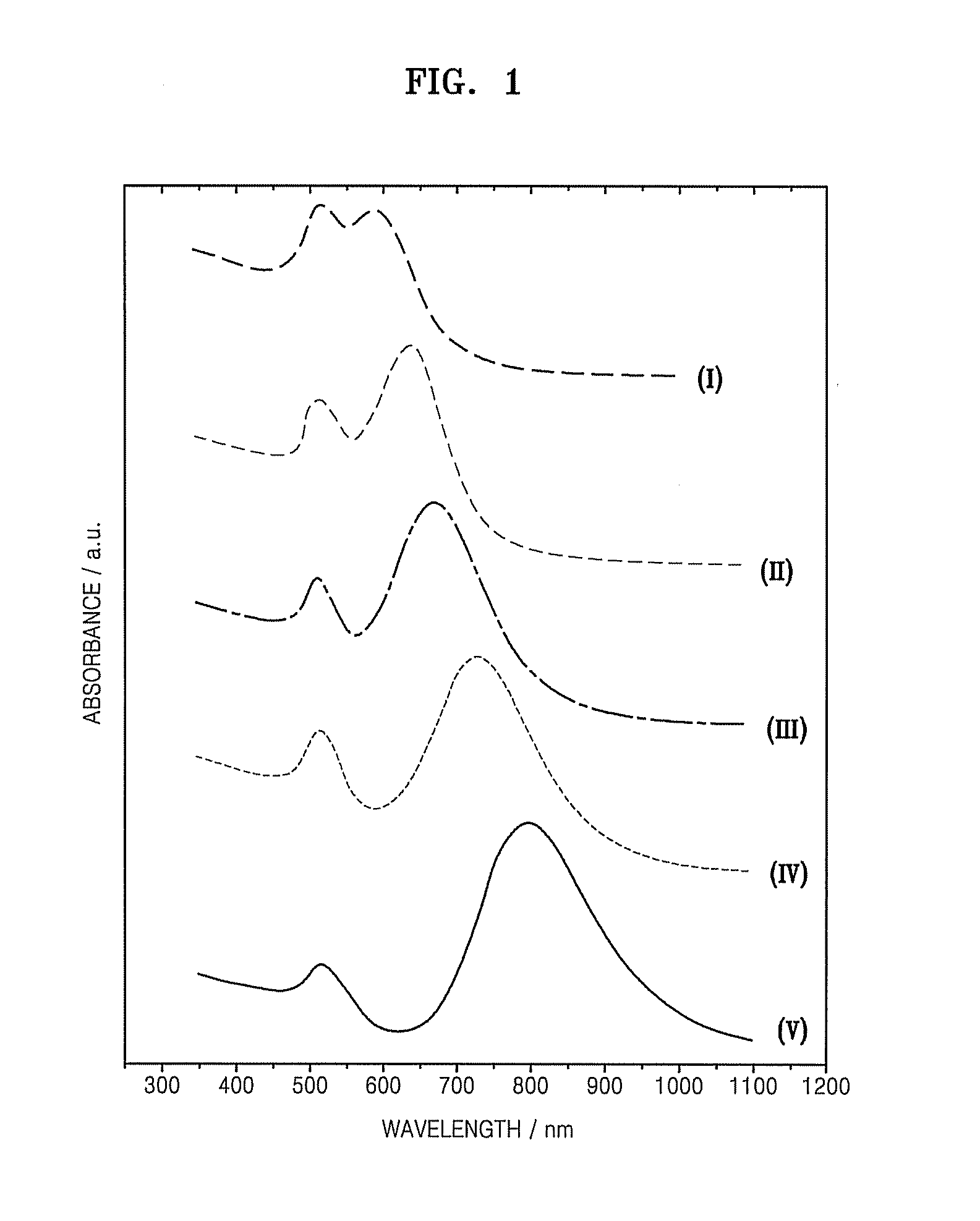

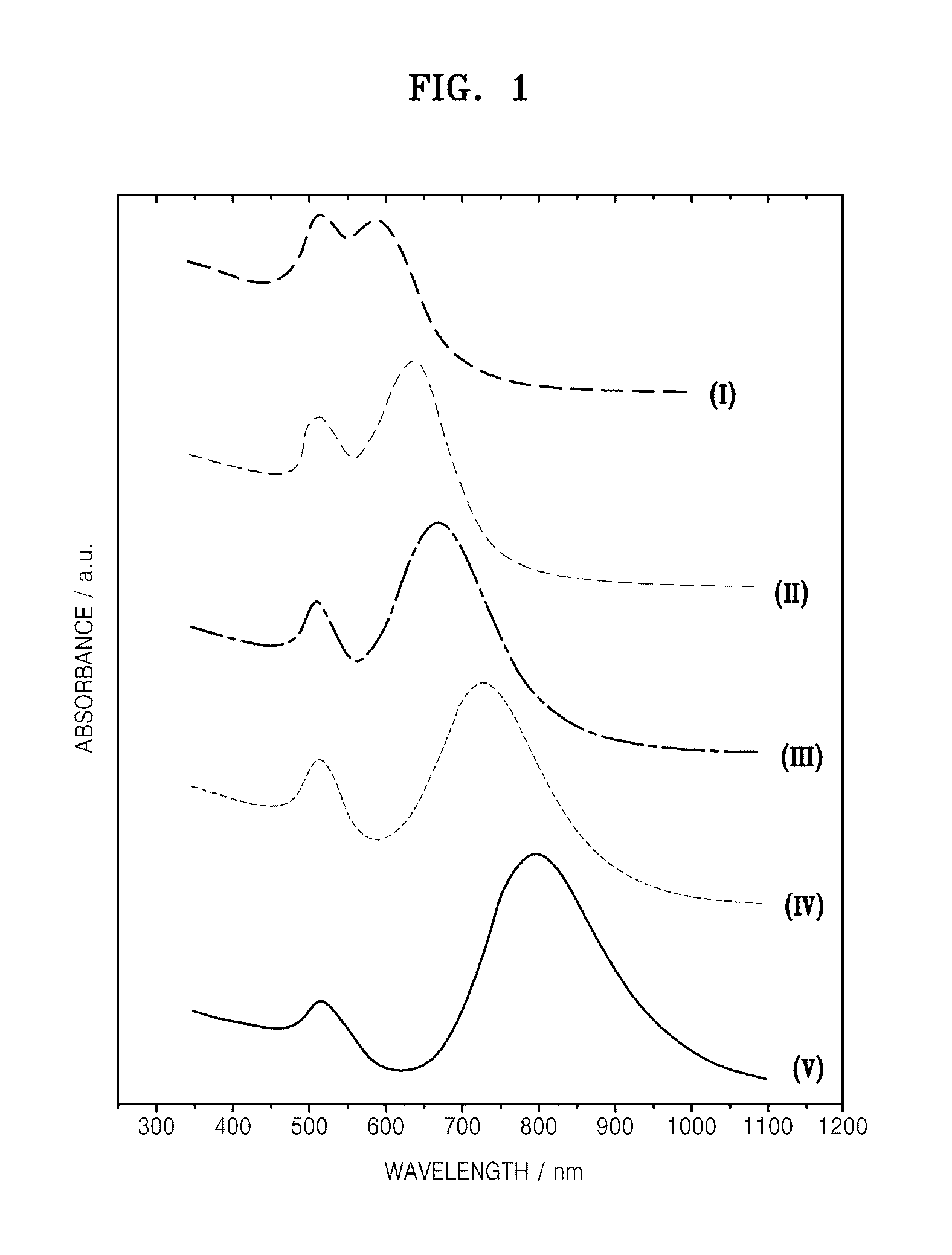

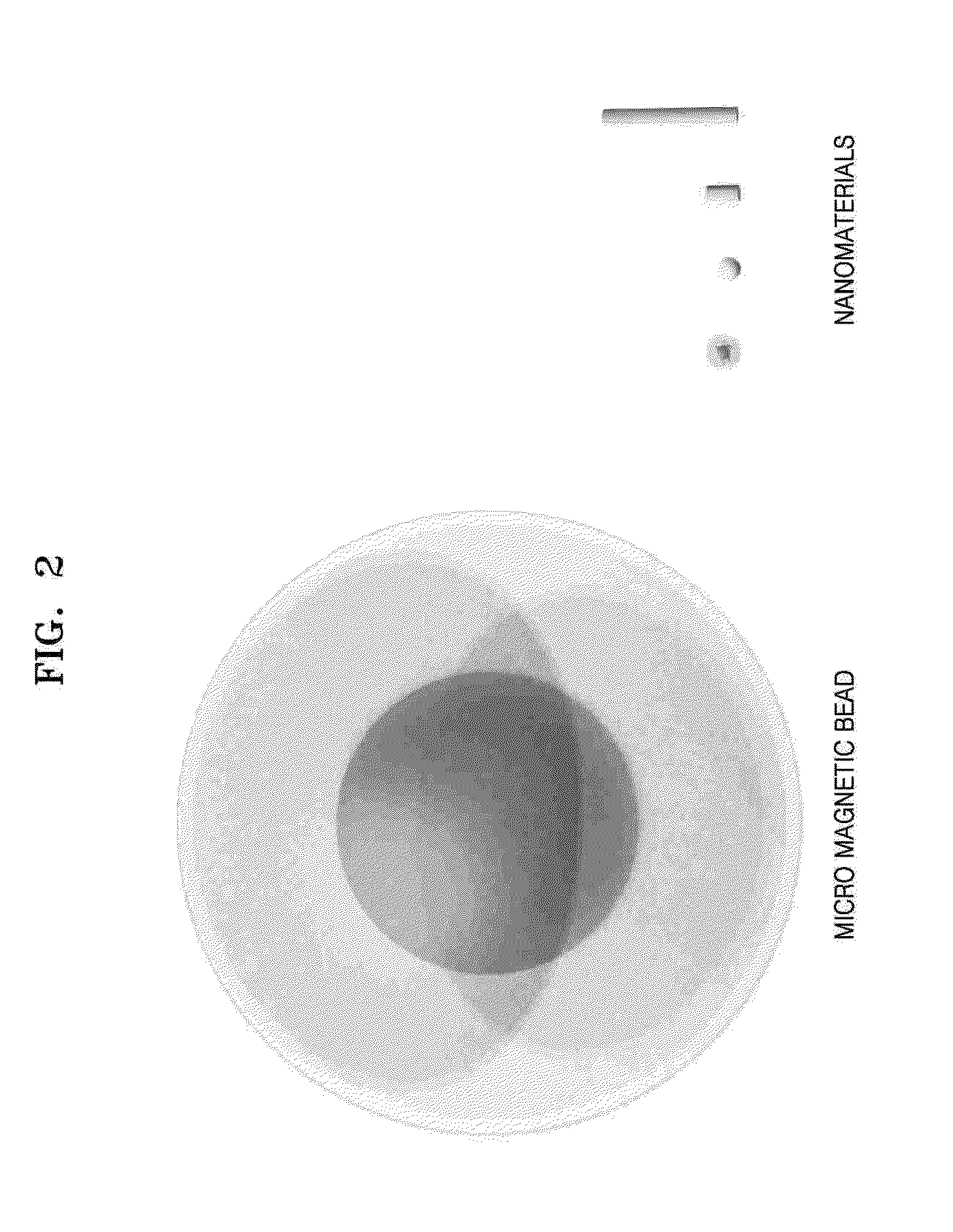

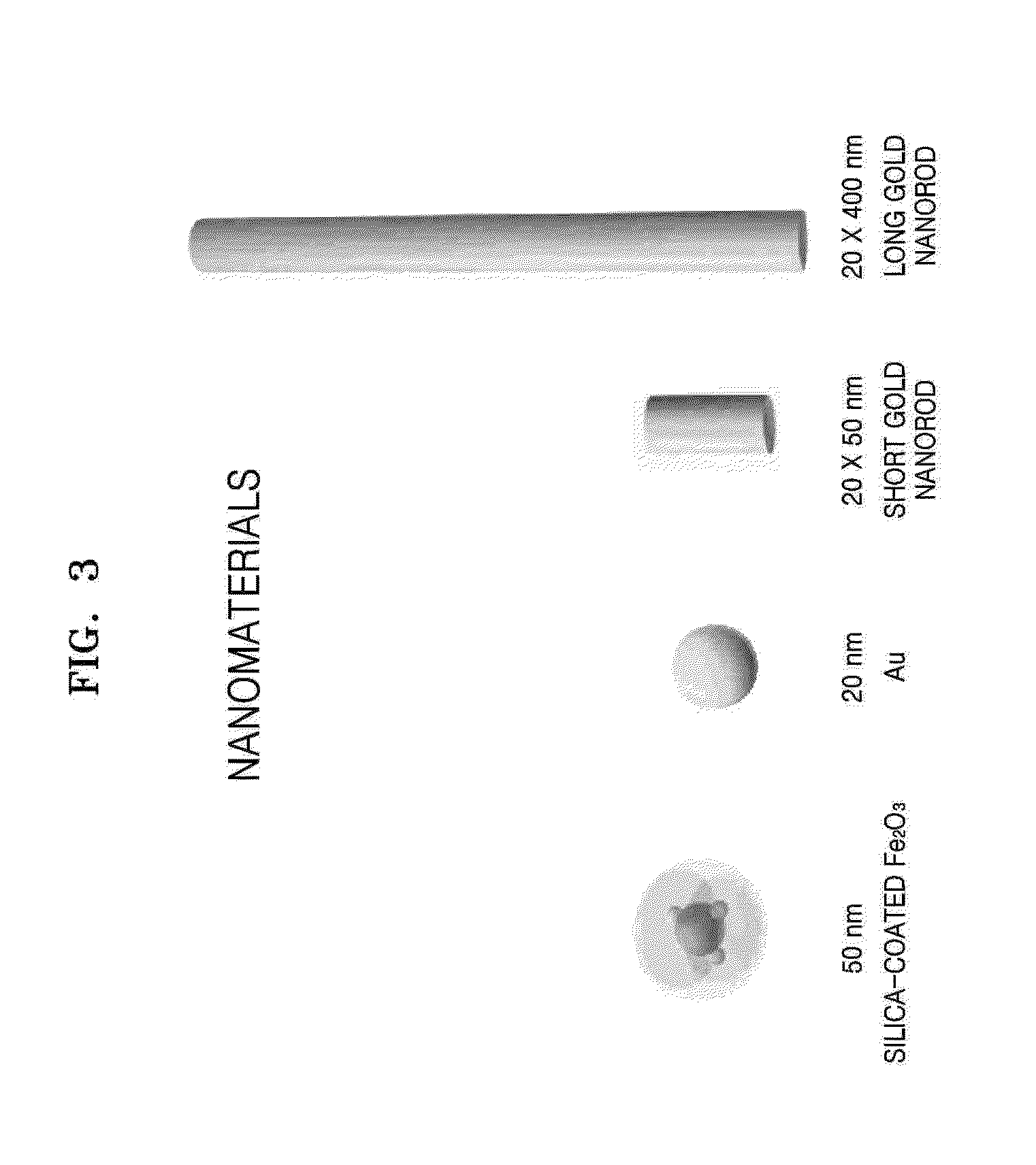

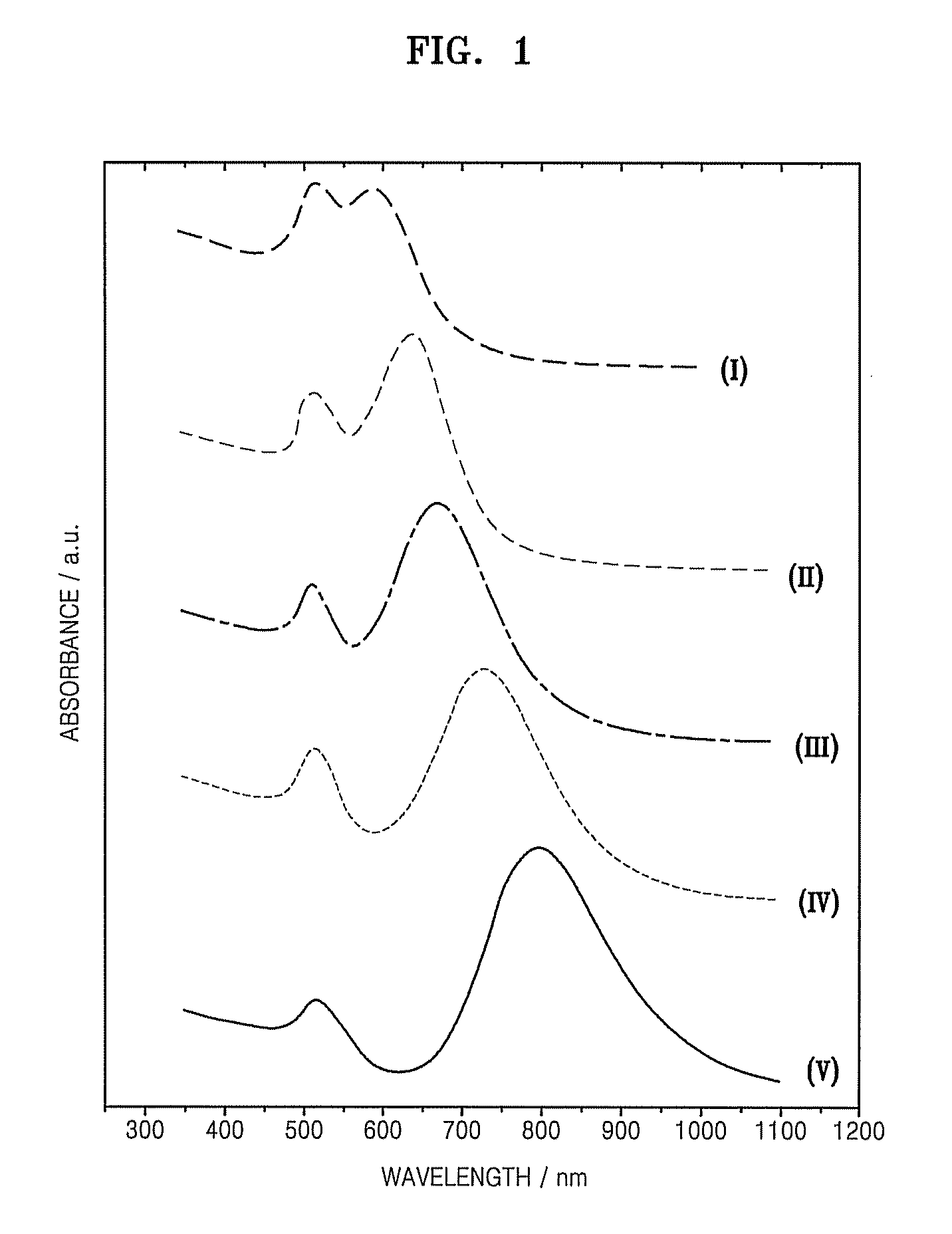

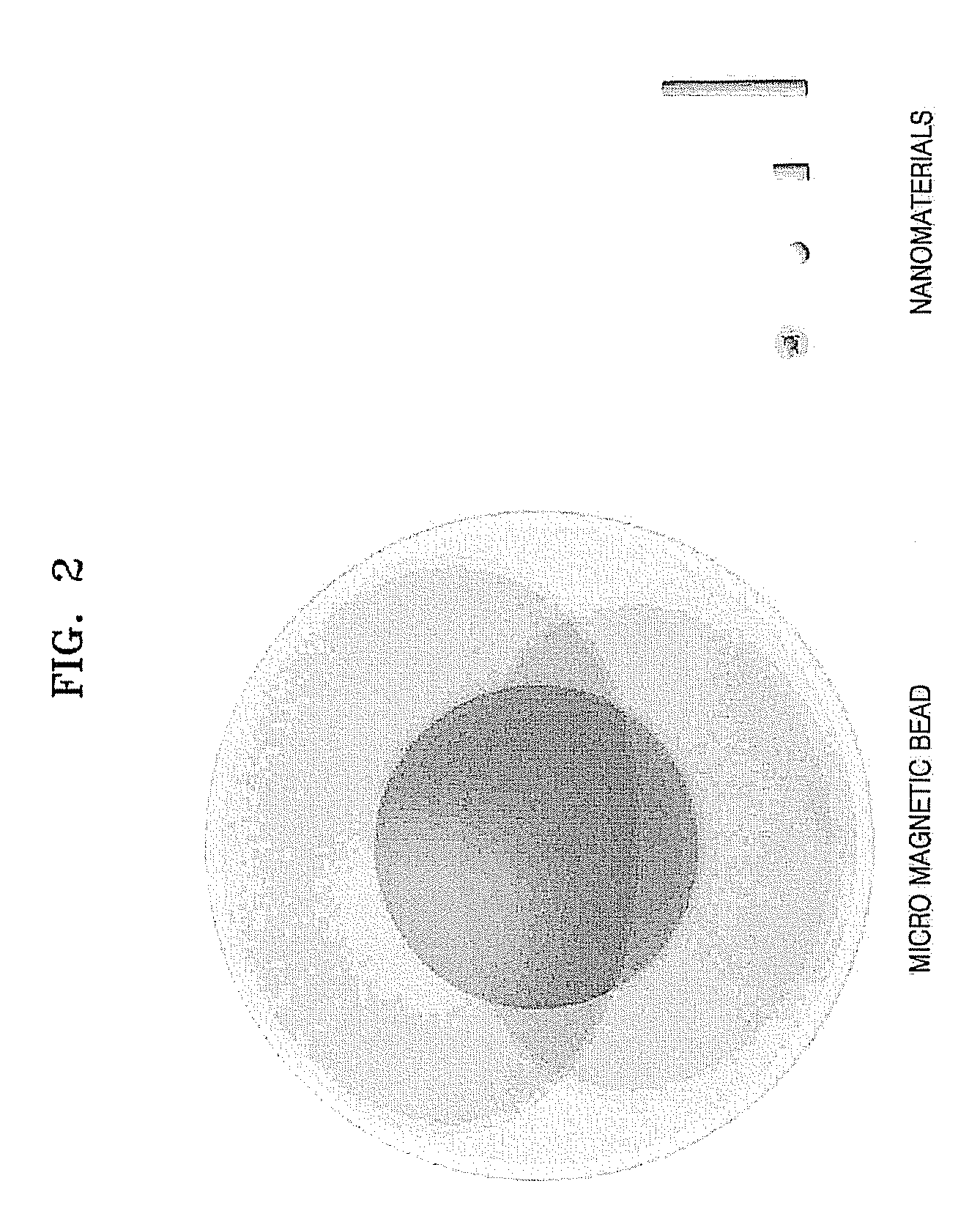

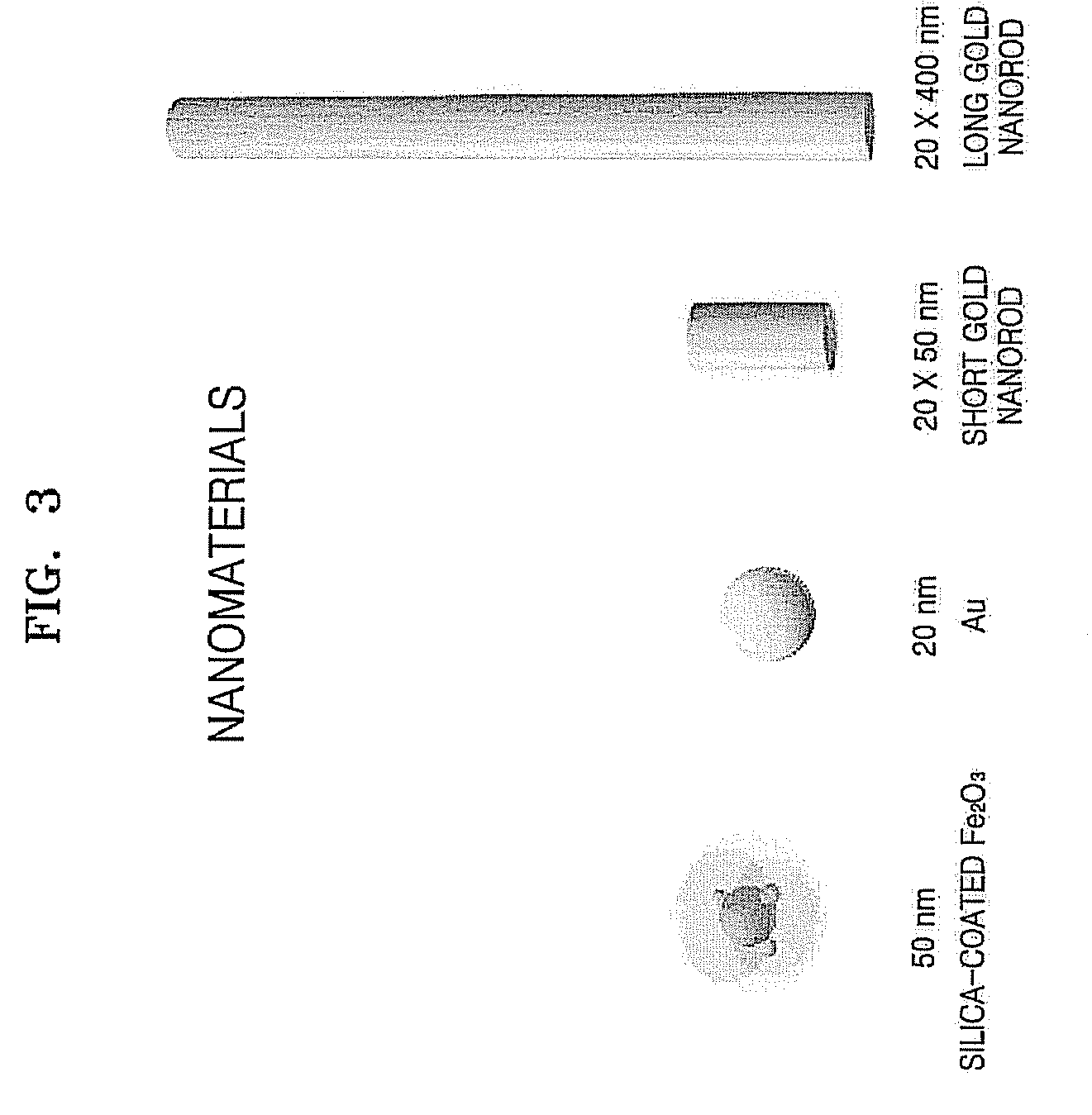

Method and apparatus for disrupting cells and amplifying nucleic acids using gold nanorods

ActiveUS20080171366A1Disrupting cells efficientlyEfficiently disruptedBioreactor/fermenter combinationsBiological substance pretreatmentsGold nanorodBioinformatics

Provided is a method of disrupting cells comprising adding gold nanorods to a solution containing cells and irradiating the gold nanorods with a laser to disrupt the cells. A method and an apparatus for continuously disrupting cells and amplifying nucleic acids in a single microchamber are also provided, wherein the method comprises introducing a solution containing cells and gold nanorods into a microchamber, irradiating a laser onto the gold nanorods to disrupt the cells, and amplifying a nucleic acid from the disrupted cells in the microchamber.

Owner:SAMSUNG ELECTRONICS CO LTD

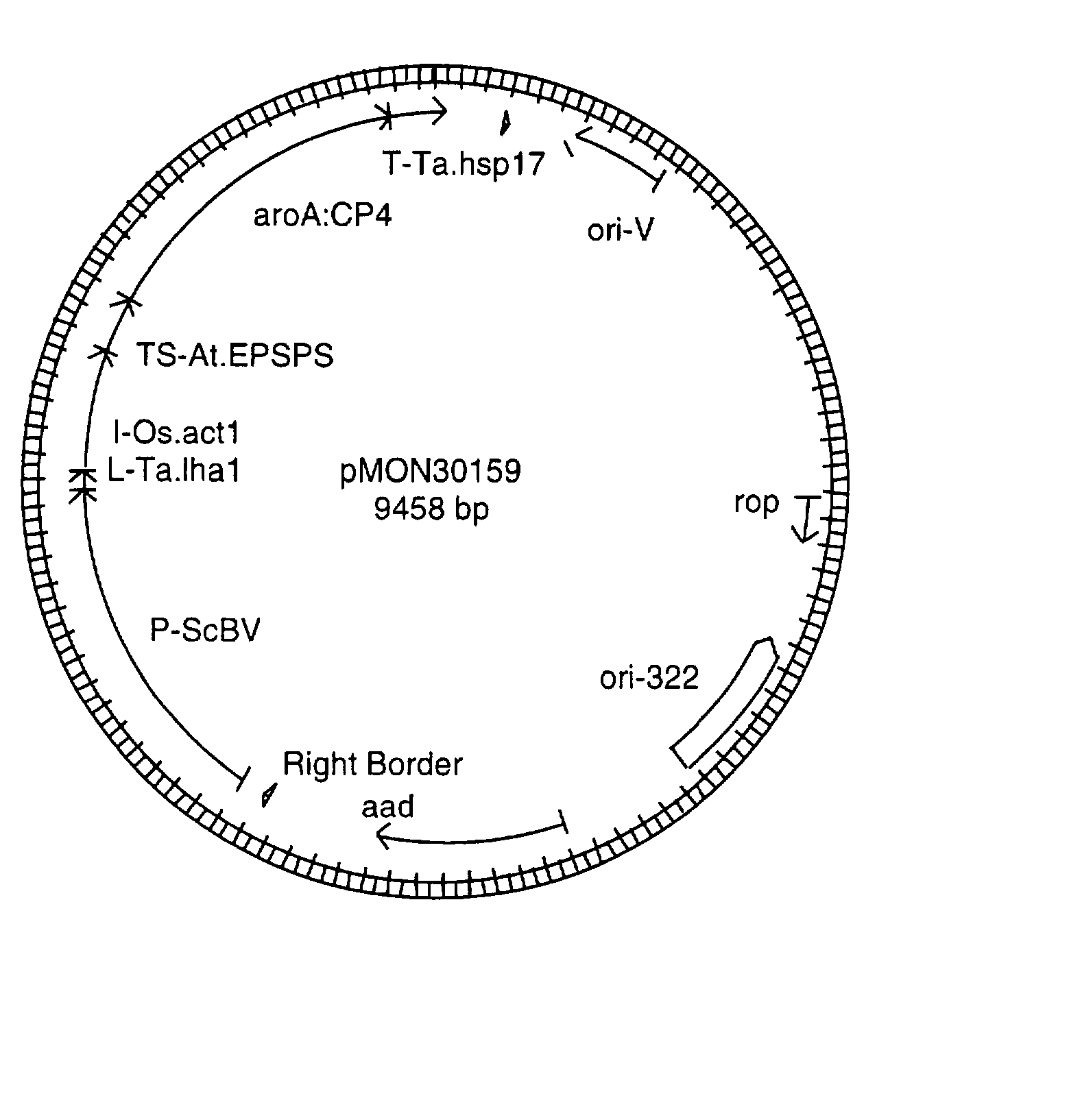

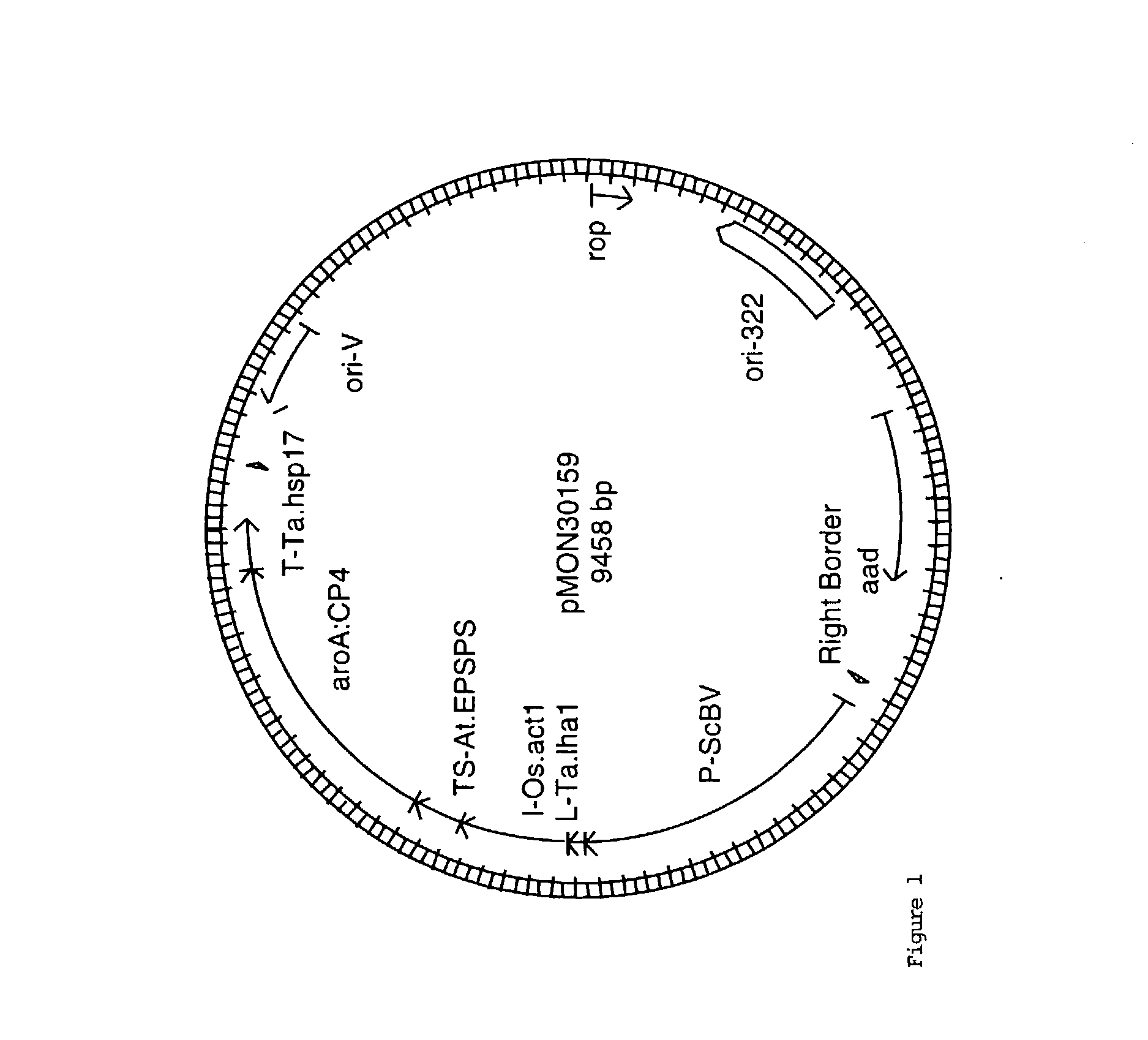

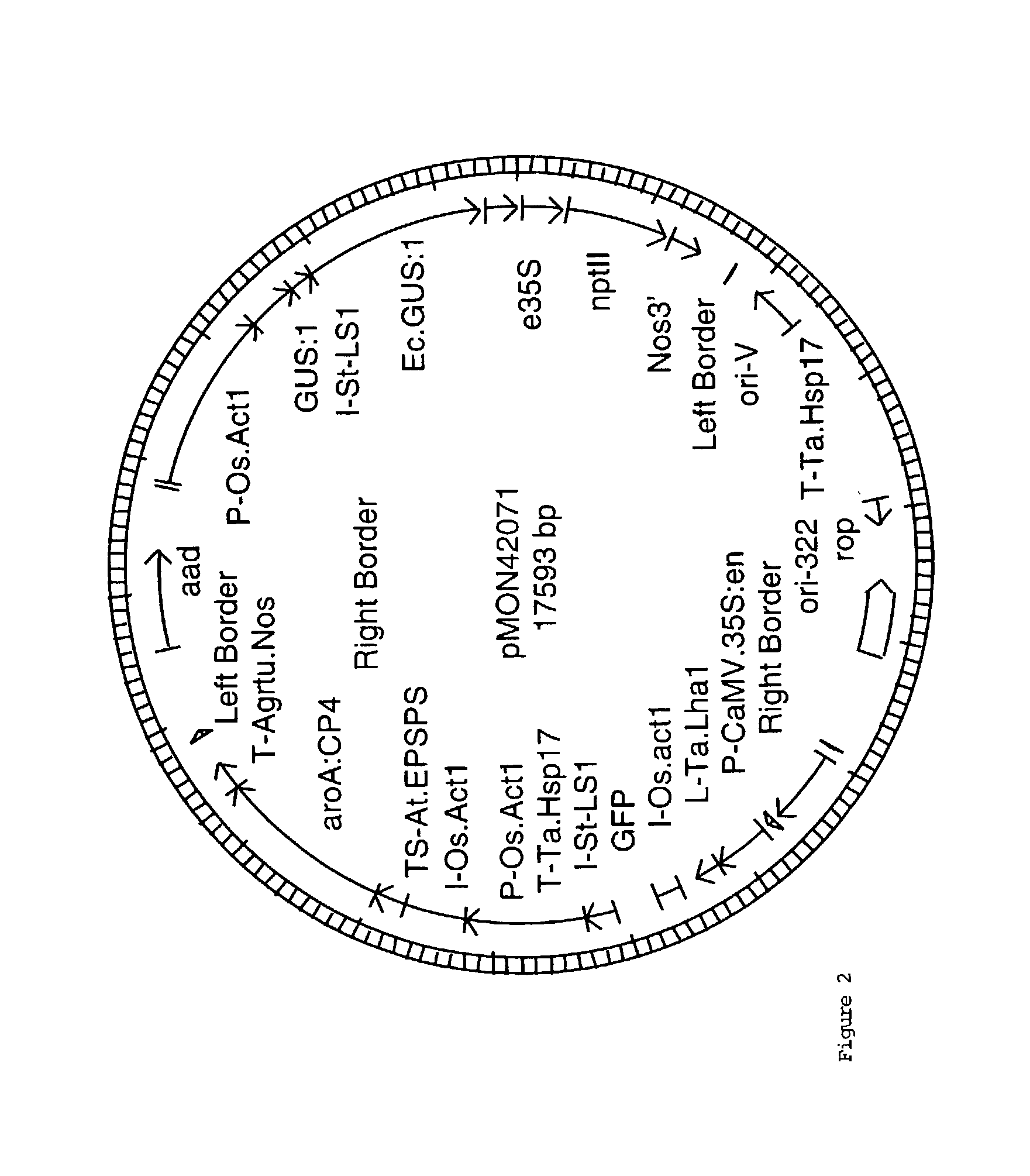

Efficiency agrobacterium-mediated wheat transformation method

ActiveUS20030154517A1Inhibition effectDisruption of biosynthesis of aromatic amino acidsOther foreign material introduction processesTissue cultureGlyphosateSelection system

The present invention relates to an improved transformation and regeneration system for wheat. In particular, the invention relates to enhancements in the glyphosate selection system. The transformation method is efficient and reliable for production of fertile plants with improved agronomic qualities.

Owner:MONSANTO TECH LLC

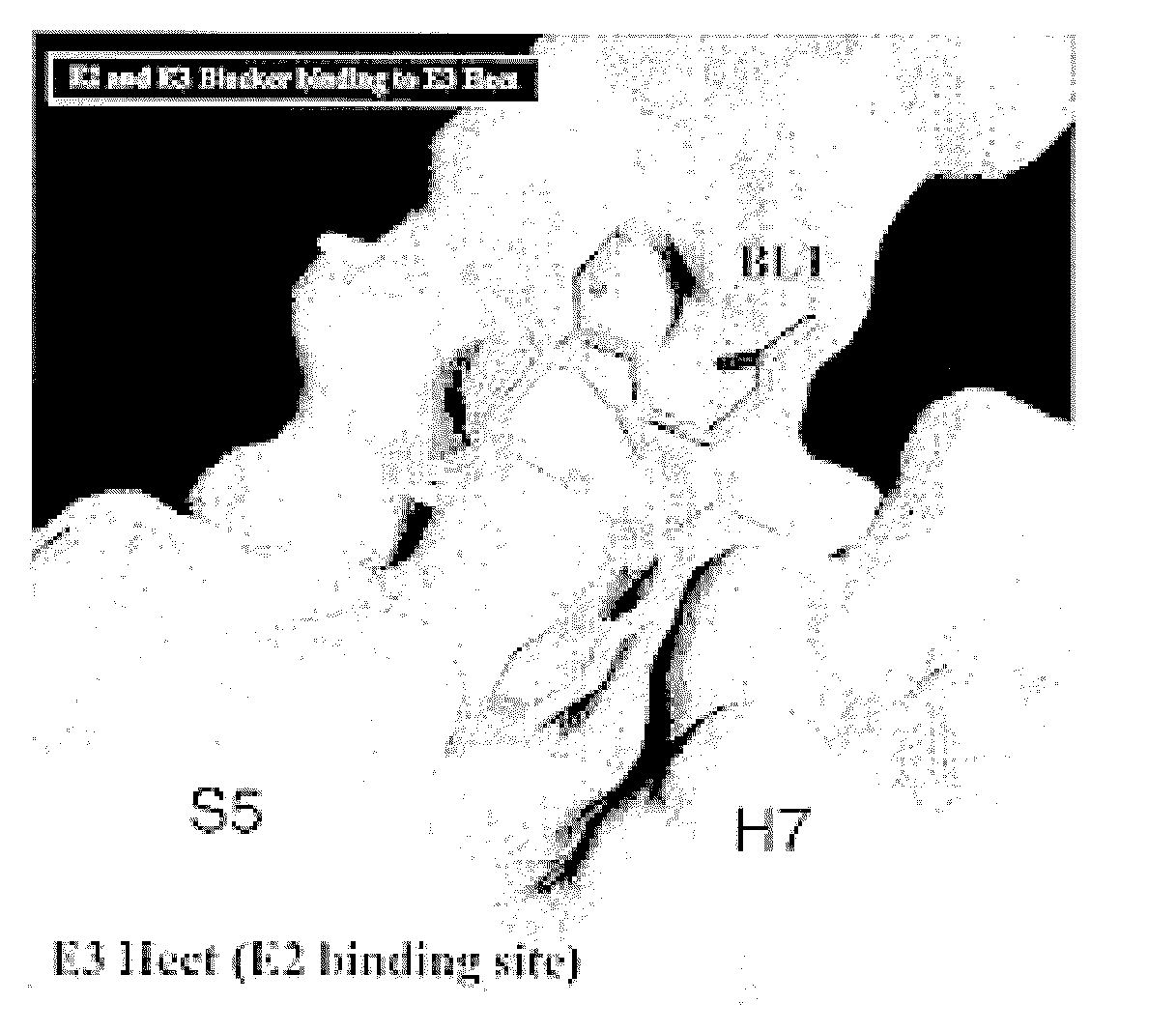

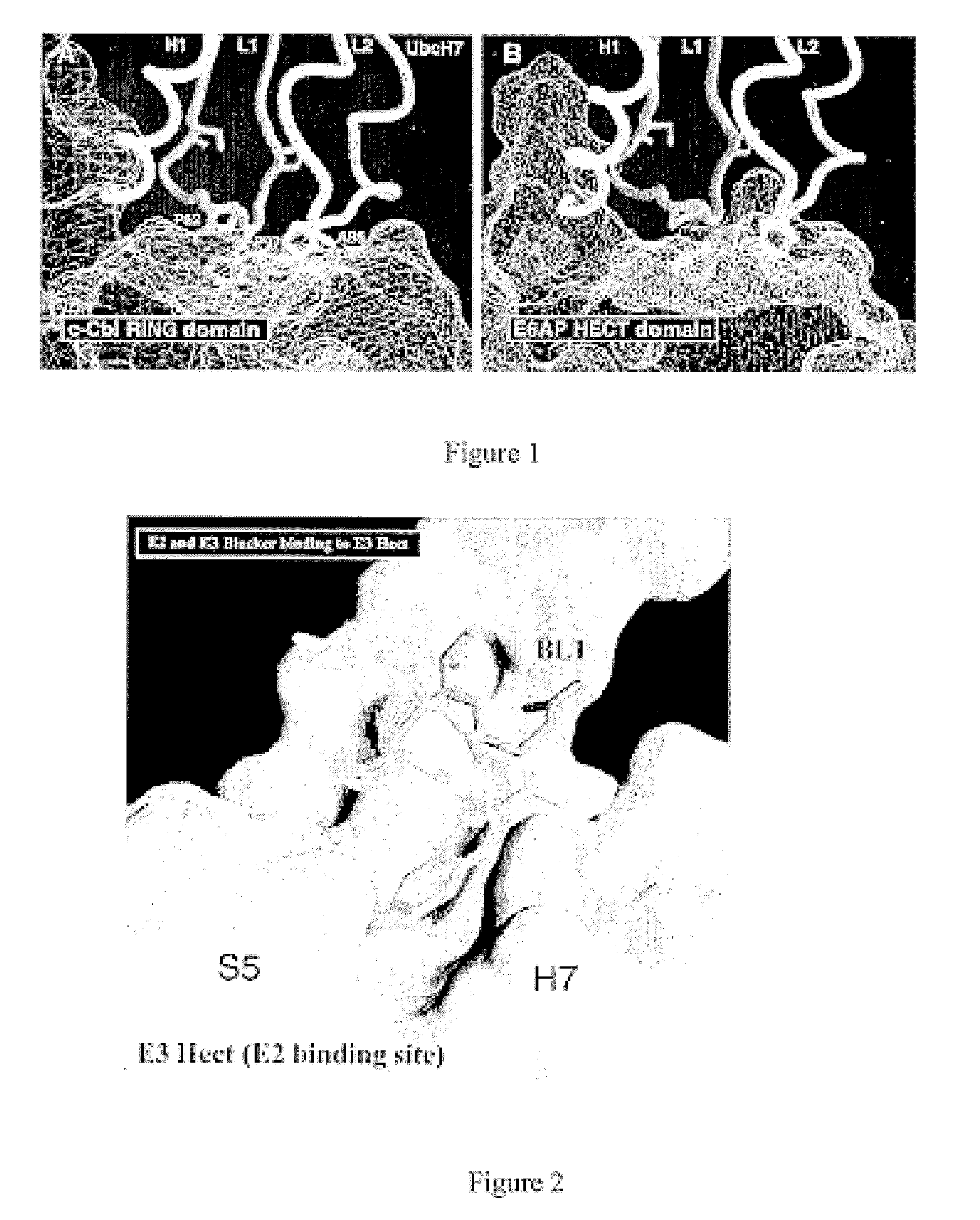

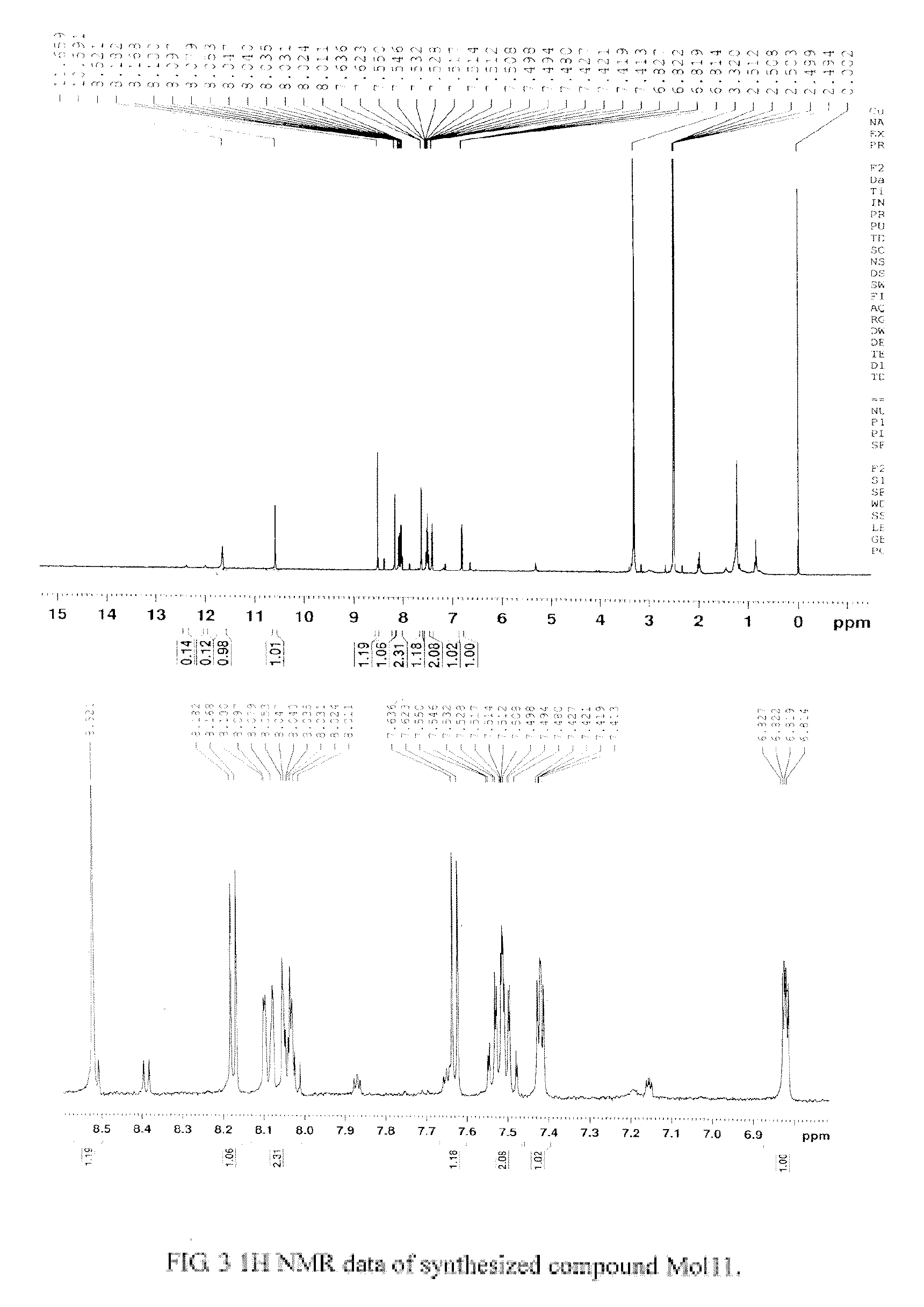

Inhibitors for disrupting the interaction of ubiquitination related enzymes and uses thereof

InactiveUS20100189648A1Efficiently disruptedFormation is complexBiocideOrganic chemistryCrystallographyUbiquitin-Protein Ligases

A hydrophobic binding pocket on ubiquitin-protein ligase E3 is described, and used in designing the inhibitors disrupting ubiquitin conjugating enzyme E2 and E3 interaction. Four types of inhibitors designed by using the binding pocket are provided, which can be used for cancer treatment.

Owner:HUANG LAN +1

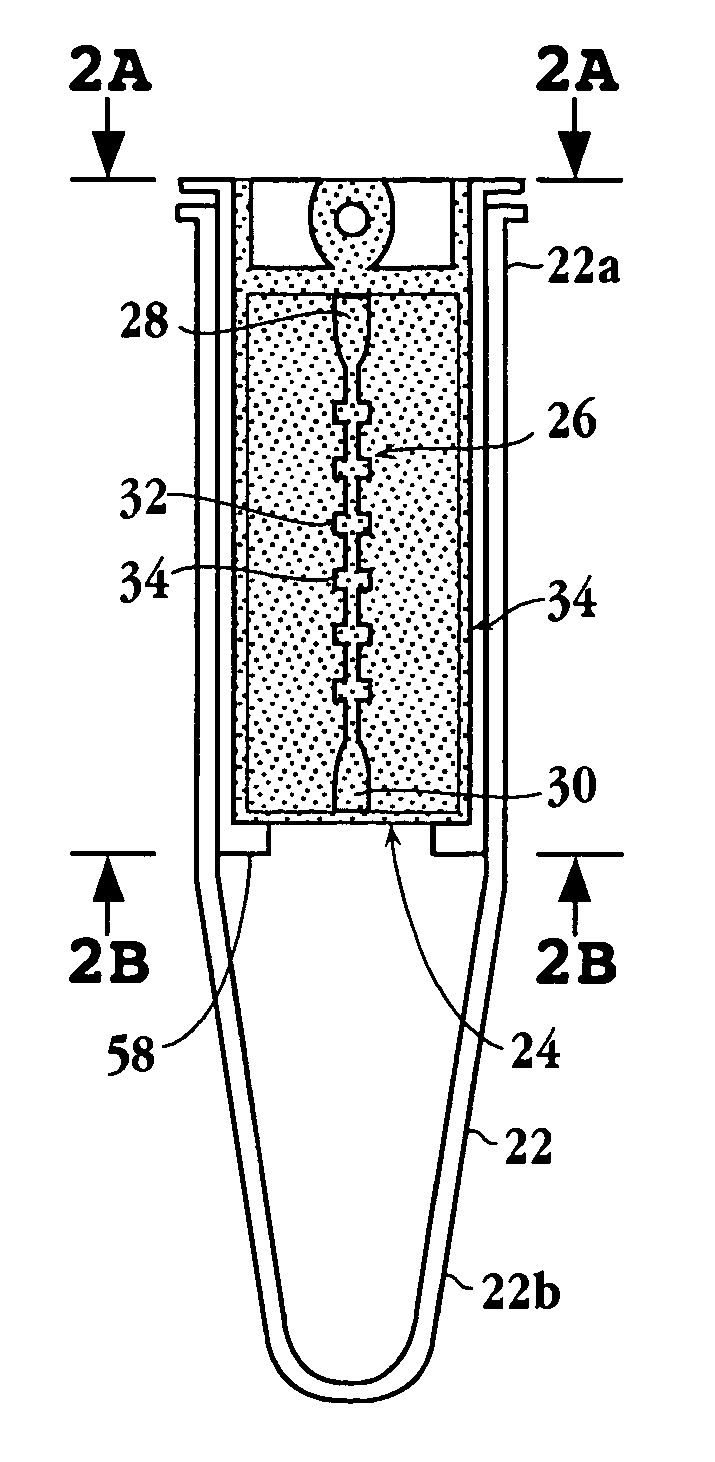

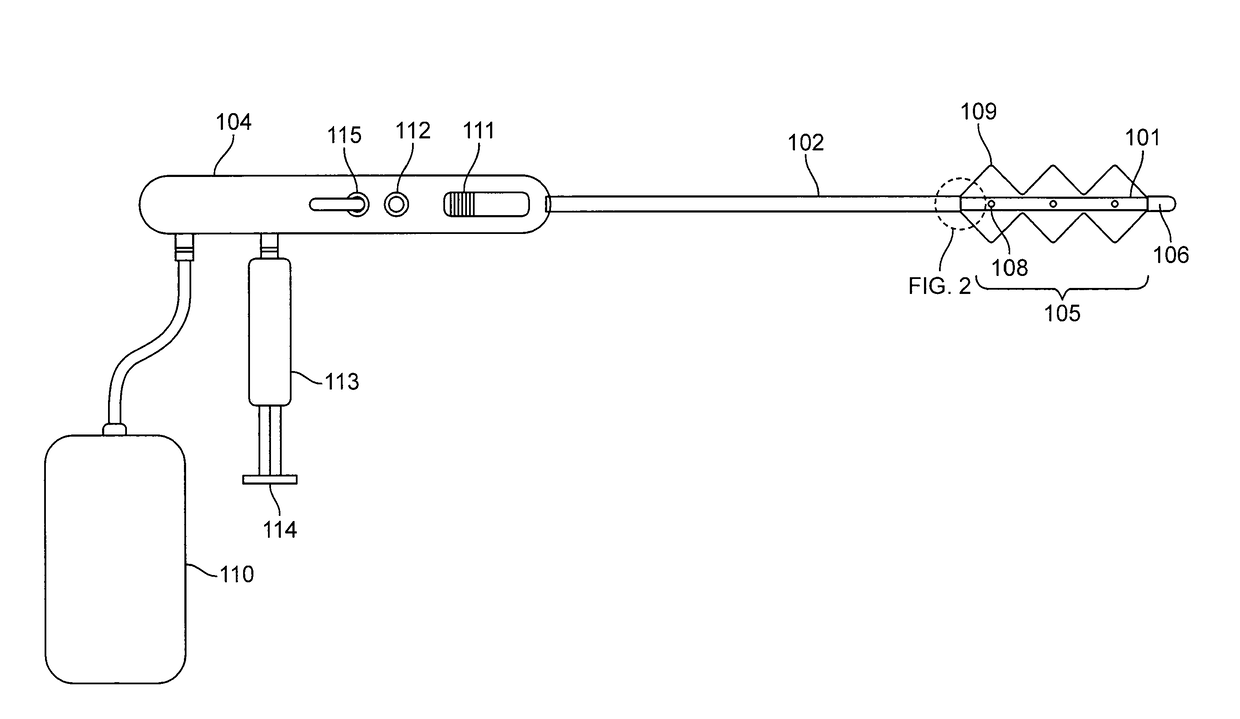

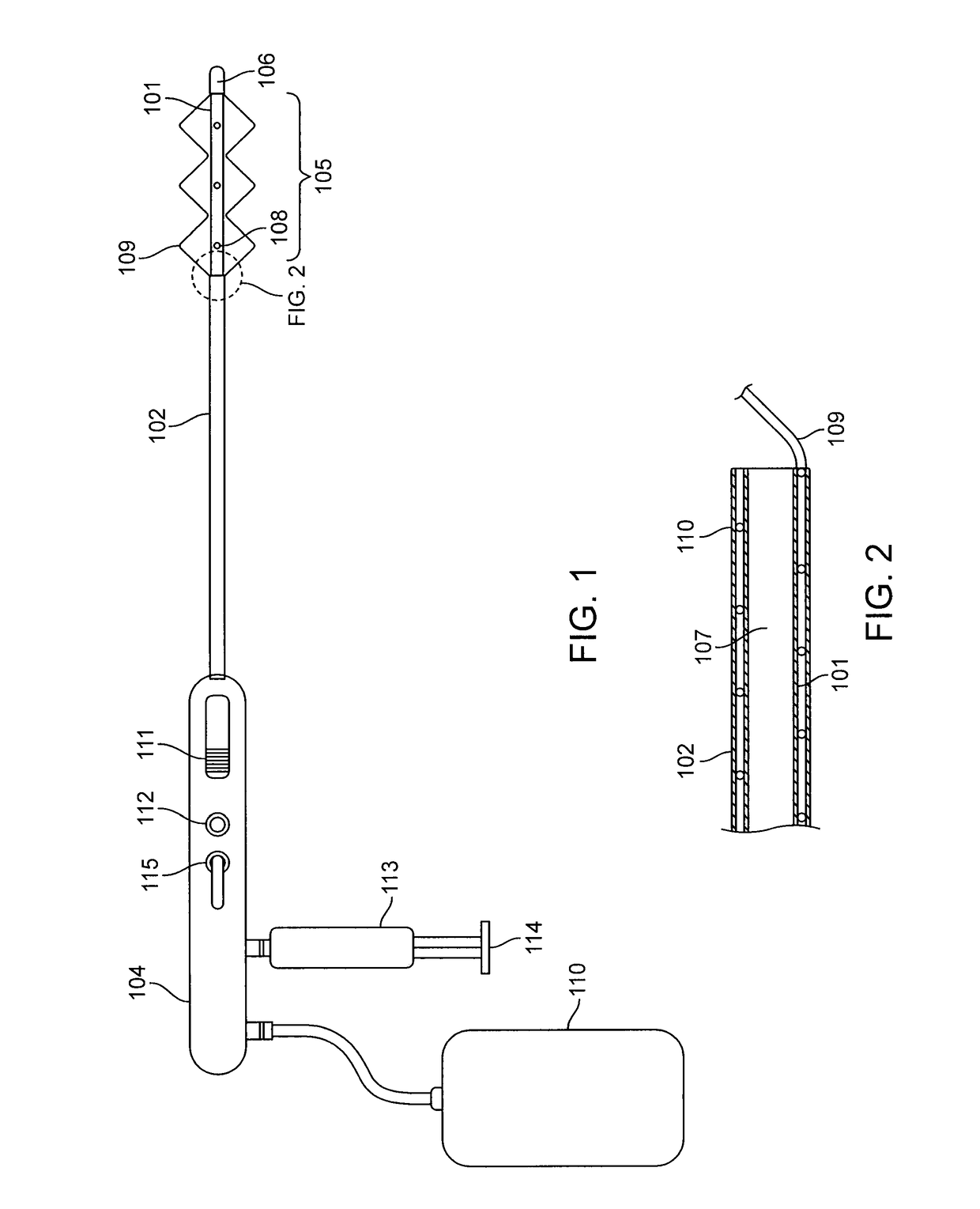

Bone marrow harvesting device

InactiveUS20180078243A1Efficiently disruptedLess traumaSurgical needlesMedical devicesSurgeryBONE MARROW HARVEST

Bone marrow harvesting devices and methods of use for harvesting bone marrow from a biological source of bone marrow are provided that promote ease of use, and reduce patient pain and potential trauma to harvested bone marrow, wherein an exemplary bone marrow harvesting device includes an elongated shaft comprising a distal region, a proximal region, and a lumen extending therebetween, the distal region comprising a plurality of through-wall apertures in fluid communication with the lumen; and an expandable member disposed along the distal region thereof and configured to transition between a collapsed state and an expanded state for vibrating to disrupt the bone marrow. Methods of using the inventive bone marrow harvesting device to provide more efficient bone marrow disruption, improve the efficiency of bone marrow aspiration, and increase the quantity of bone marrow harvested in a single procedure are also provided.

Owner:ROCHA SINGH M D KRISHNA

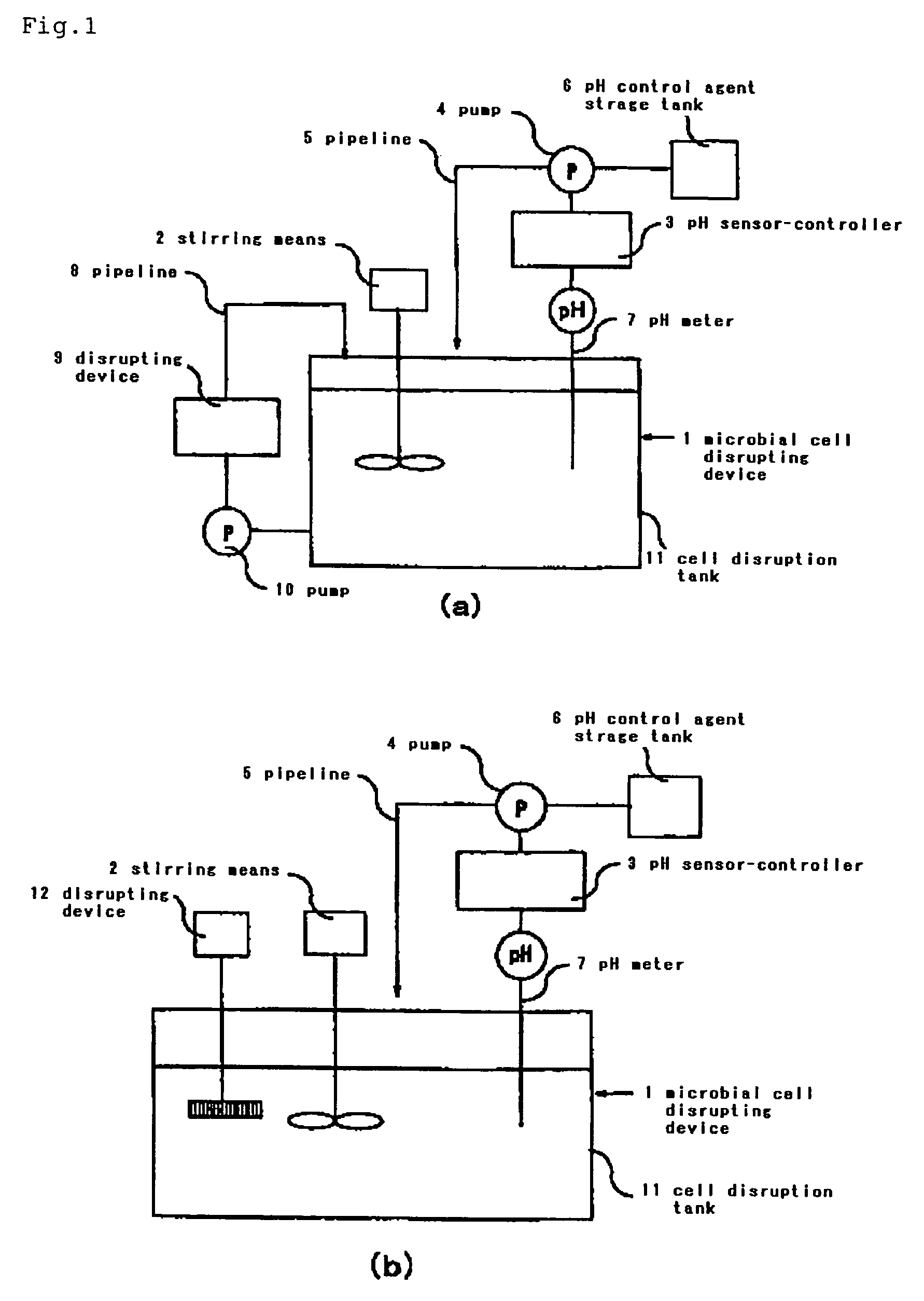

Method of separating poly-3-hydroxyalkanoic acid

Owner:KANEKA CORP

Roof spoiler

InactiveUS8650809B2Efficiently disruptedImprove stabilityRoof covering using slabs/sheetsBuilding roofsLeading edge

Disclosed is a roof spoiler that effectively disrupts the attached flow of wind upon a roof surface. This spoiler has a stowed position, whereby it is almost completely out of the view of passersby. It also has a deployed position, wherein a barrier is projected vertically, or substantially vertically, so as to disrupt the flow of air over the roof surface. This spoiler utilizes a hinged design to move between these two positions. The spoiler is specially designed to operate in conjunction with a gutter mounted along the leading edge of the roof. In the stowed position, a portion of the spoiler covers the open gutter. In one embodiment, the spoiler is L-shaped to facilitate its stability in the deployed position.

Owner:WINDTRIPPER CORP

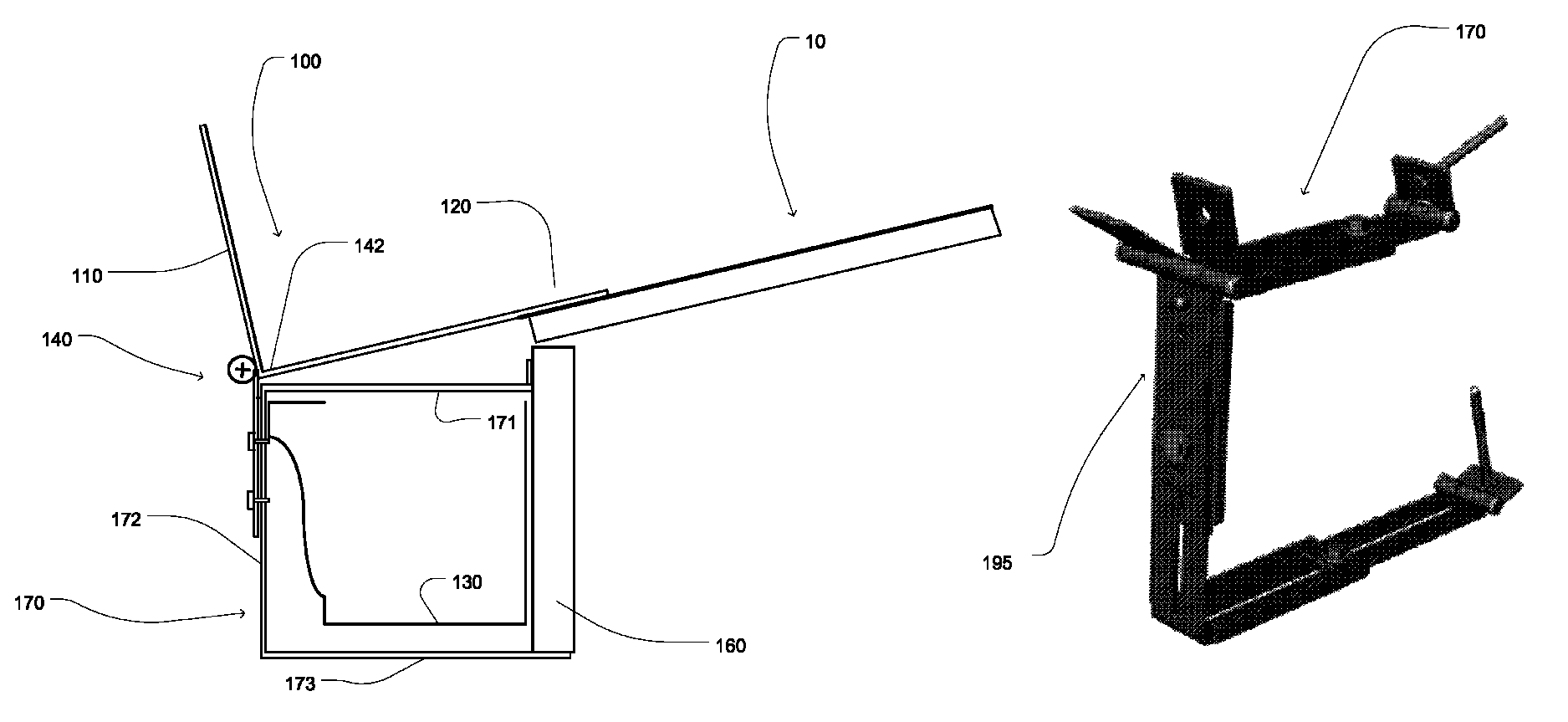

Symmetric roof spoiler

ActiveUS8127503B2Efficiently disruptedBuilding roofsRoof covering using slabs/sheetsLeading edgeMechanical engineering

Disclosed is a roof spoiler that effectively disrupts the attached flow of wind on a roof surface. Preferably, the spoiler is specially designed for installation with a gutter mounted on the roof fascia or along the leading edge of the roof. This spoiler utilizes a hinged design to move between two operating positions. The first position is a stowed position, whereby the spoiler extends beyond the gutter and is designed to be nearly invisible to passersby. In the stowed position, a portion of the spoiler covers the outer edge of the gutter (if present). A second portion of the spoiler may extend outward from the gutter. The second position is a deployed position, wherein a barrier is projected vertically, or substantially vertically, so as to disrupt the flow of air over the roof surface. In one embodiment, the spoiler rests upon the roof covering when in the deployed position. In another embodiment, the spoiler rests near or against the gutter or holding bracket. In one embodiment, a bracketing system, or support structure, is placed around an existing gutter. The roof spoiler is then pivotally attached to this support structure. In another embodiment, the support structure attaches directly to the gutter.

Owner:WINDTRIPPER CORP

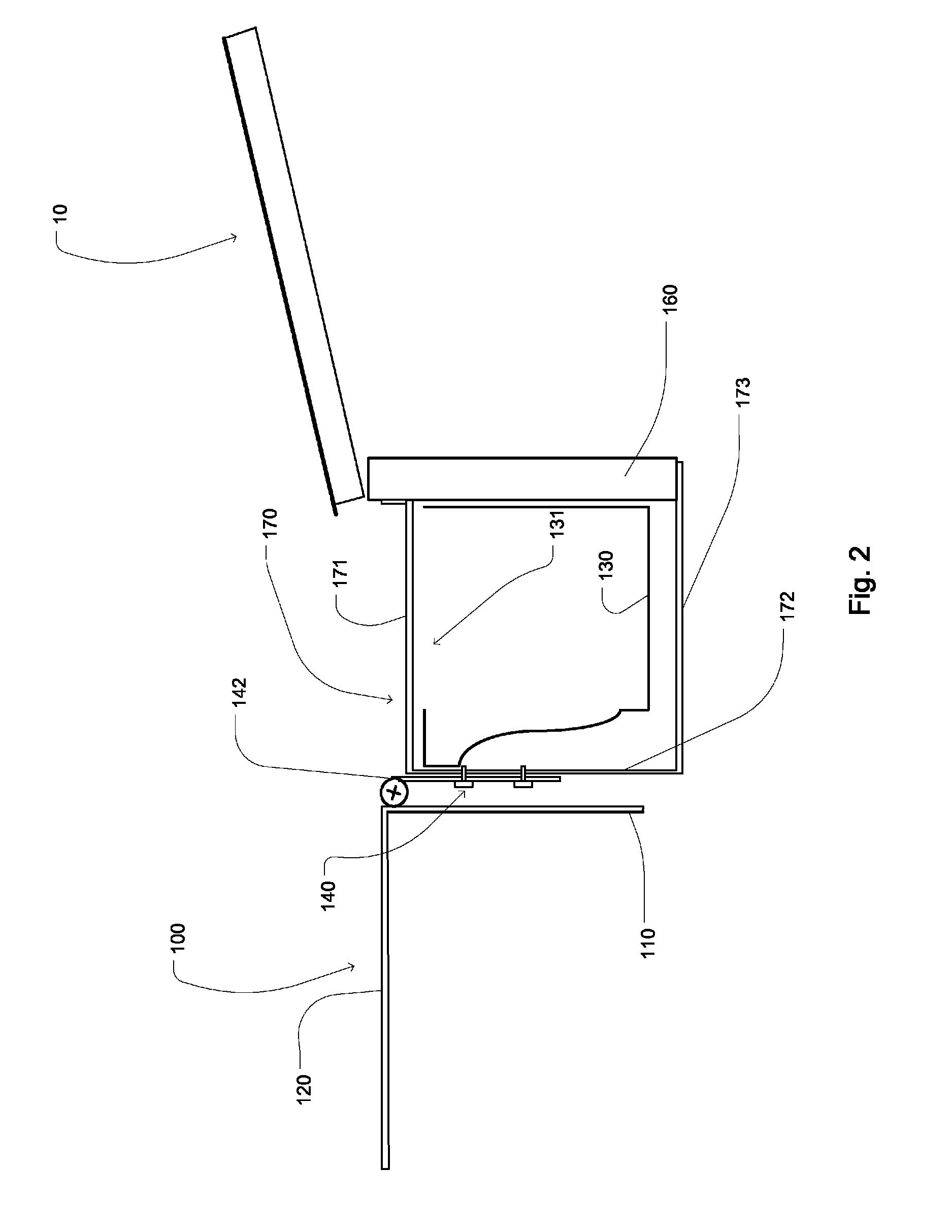

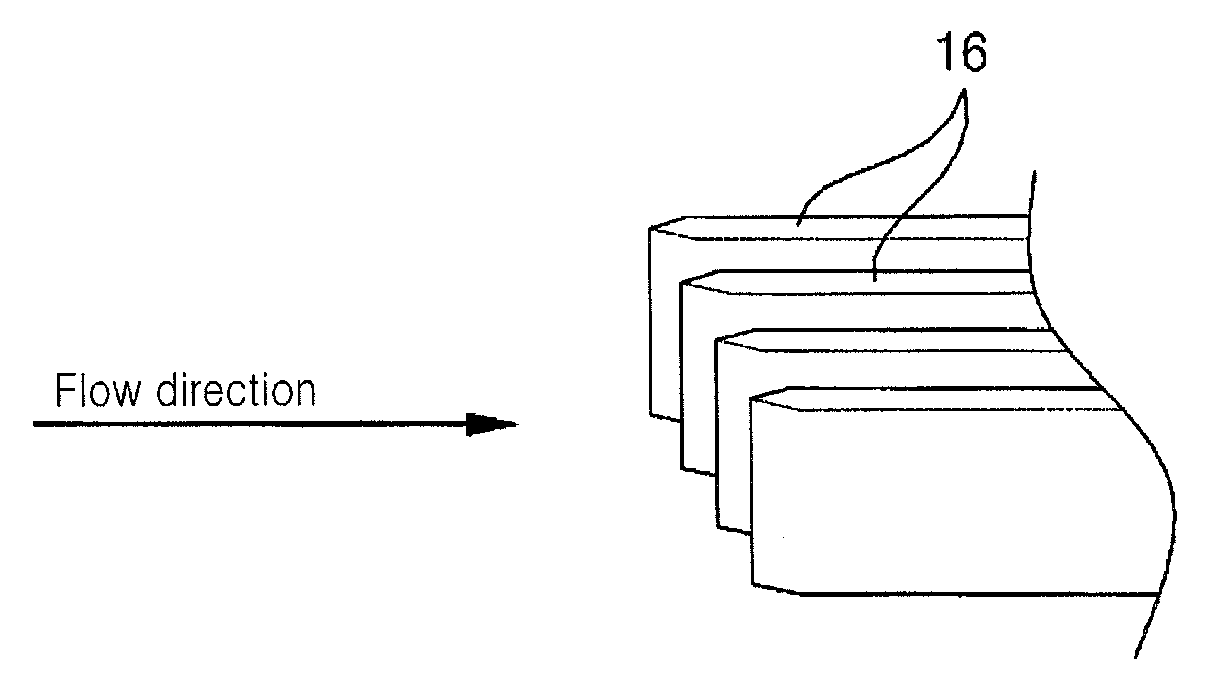

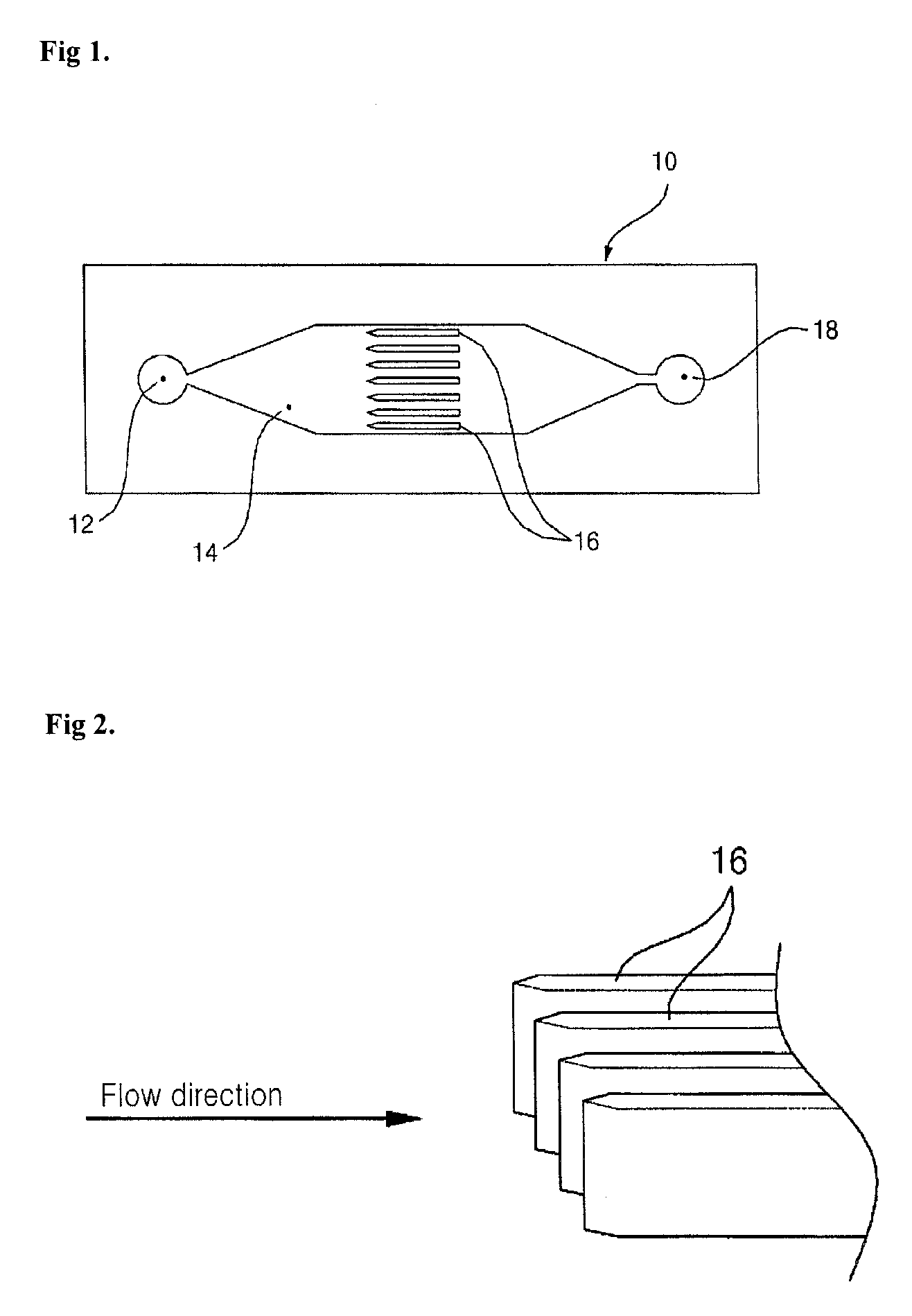

Mechanical cell lysis apparatus

ActiveUS9506028B2Efficiently disruptedQuick analysisBioreactor/fermenter combinationsBiological substance pretreatmentsLysisBiomedical engineering

The present invention relates to a cell lysis apparatus and a manufacturing method thereof, and more particularly, to a cell lysis apparatus, which mechanically performs cell lysis, and a manufacturing method thereof. The cell lysis apparatus includes: an inlet port through which fluid containing cells is supplied; a fluid channel defining a passage through which the cell containing fluid supplied from the inlet port flows; a nano blade array including a plurality of nano blades having pointed leading ends and arranged such that the pointed leading ends of the nano blades are oriented in a direction of the fluid supplied through the inlet port to disrupt the cells passing therethrough; and an outlet port through which the disrupted cells and the fluid are discharged.

Owner:RADIANQBIO CO LTD

Method and apparatus for disrupting cells and amplifying nucleic acids using gold nanorods

ActiveUS20110212514A1Disrupting cells efficientlyEfficiently disruptedBioreactor/fermenter combinationsBiological substance pretreatmentsGold nanorodBioinformatics

Provided is a method of disrupting cells comprising adding gold nanorods to a solution containing cells and irradiating the gold nanorods with a laser to disrupt the cells. A method and an apparatus for continuously disrupting cells and amplifying nucleic acids in a single microchamber are also provided, wherein the method comprises introducing a solution containing cells and gold nanorods into a microchamber, irradiating a laser onto the gold nanorods to disrupt the cells, and amplifying a nucleic acid from the disrupted cells in the microchamber.

Owner:SAMSUNG ELECTRONICS CO LTD

New compositions and methods for cell killing

InactiveUS20100136143A1Effective preservationAvoid developmentBiocideInorganic active ingredientsElectricityCell–cell interaction

The present invention discloses an insoluble proton sink or source (PSS), useful for killing living target cells (LTCs), or otherwise disrupting vital intracellular processes and / or intercellular interactions of the LTC upon contact. The PSS comprises (i) proton source or sink providing a buffering capacity; and (ii) means providing proton conductivity and / or electrical potential. The PSS is effectively disrupting the pH homeostasis and / or electrical balance within the confined volume of the LTC and / or disrupting vital intercellular interactions of the LTCs while efficiently preserving the pH of the LTCs' environment. The invention also provides articles of manufacture comprises the PSS and presents an effective method for killing the LTCs.

Owner:OPLON

Method and apparatus for disrupting cells and amplifying nucleic acids using gold nanorods

ActiveUS7972819B2Disrupting cells efficientlyEfficiently disruptedBioreactor/fermenter combinationsBiological substance pretreatmentsGold nanorodBioinformatics

Provided is a method of disrupting cells comprising adding gold nanorods to a solution containing cells and irradiating the gold nanorods with a laser to disrupt the cells. A method and an apparatus for continuously disrupting cells and amplifying nucleic acids in a single microchamber are also provided, wherein the method comprises introducing a solution containing cells and gold nanorods into a microchamber, irradiating a laser onto the gold nanorods to disrupt the cells, and amplifying a nucleic acid from the disrupted cells in the microchamber.

Owner:SAMSUNG ELECTRONICS CO LTD

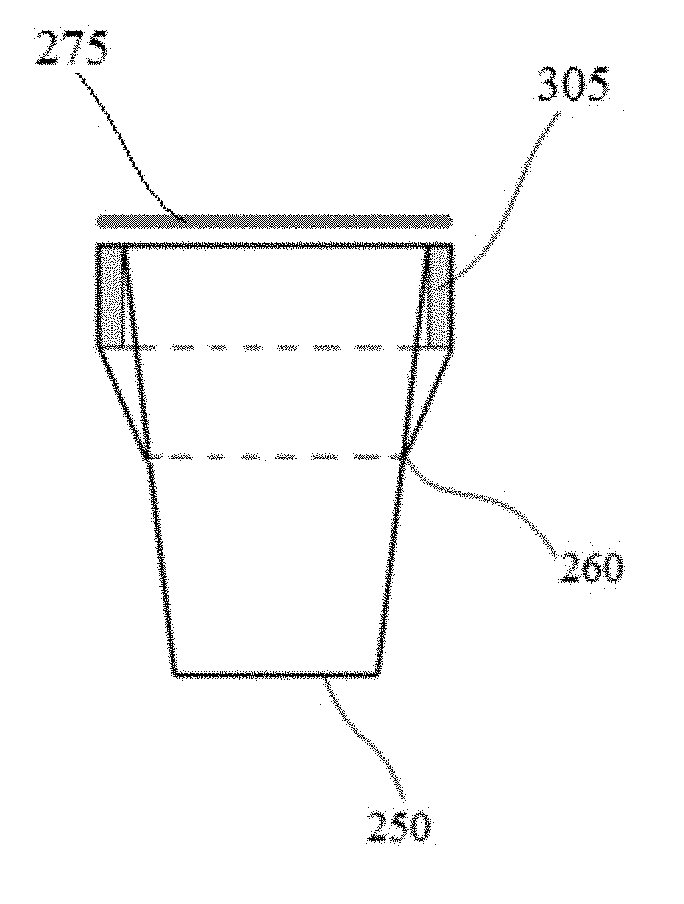

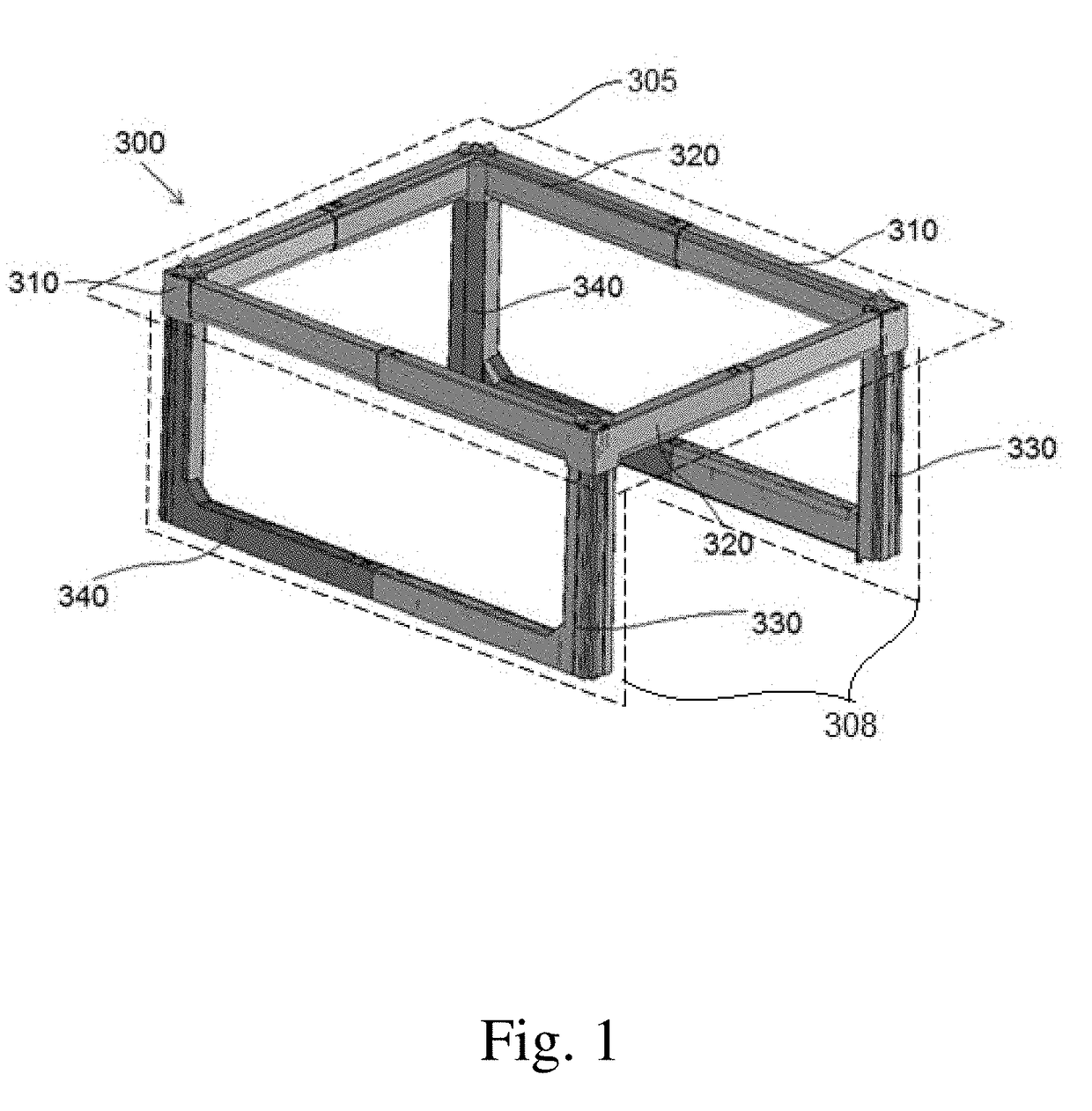

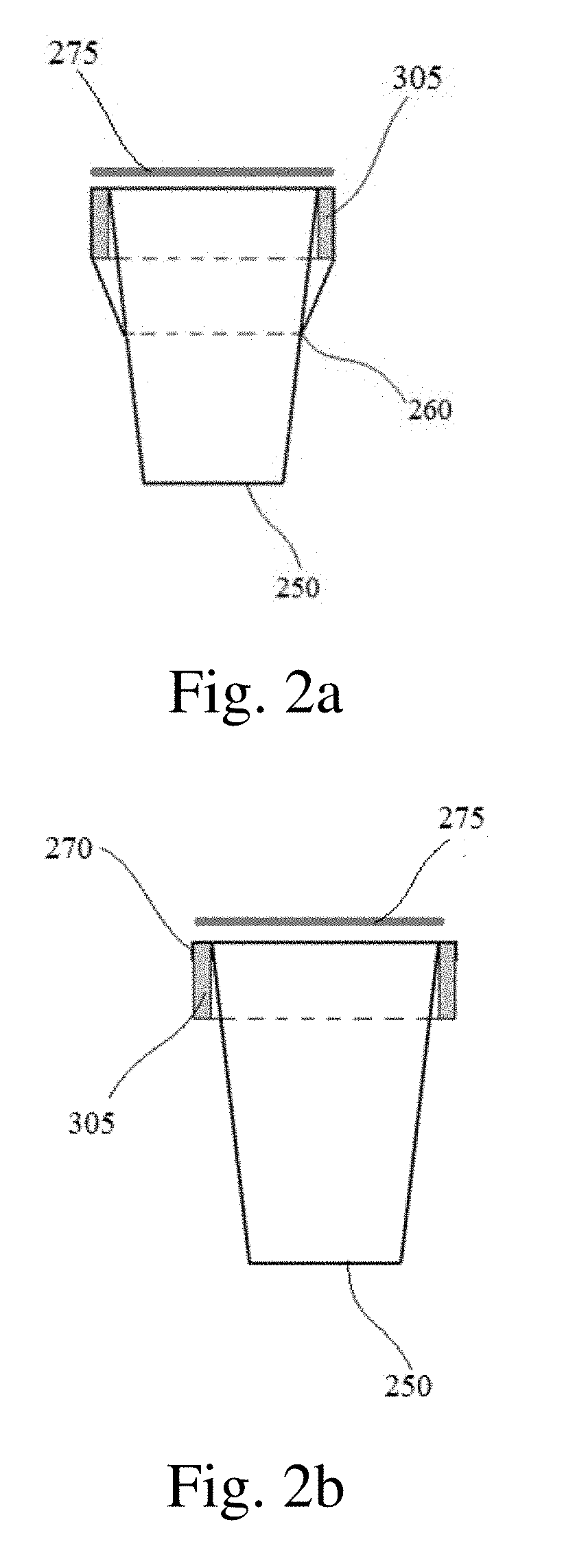

Compactly transportable collapsible container for perrishable goods

InactiveUS20180319579A1Efficiently disruptedFruit and vegetables preservationPackaging by pressurising/gasifyingEngineeringControlled atmosphere

A controllable atmosphere collapsible container for perishable goods comprises a sealable bag accommodating the perishable goods and means for controlling atmosphere therewithin. The bag is mechanically connected to collapsible frame further comprising: (a) a concatenate rectangular carrying sub-frame; (b) concatenate supporting members releasably connectable to the rectangular carrying sub-frame. The bag is downwardly housed into the rectangular carrying sub-frame and configured for accommodating the perishable goods.

Owner:ECO PACK GREEN BOX USA

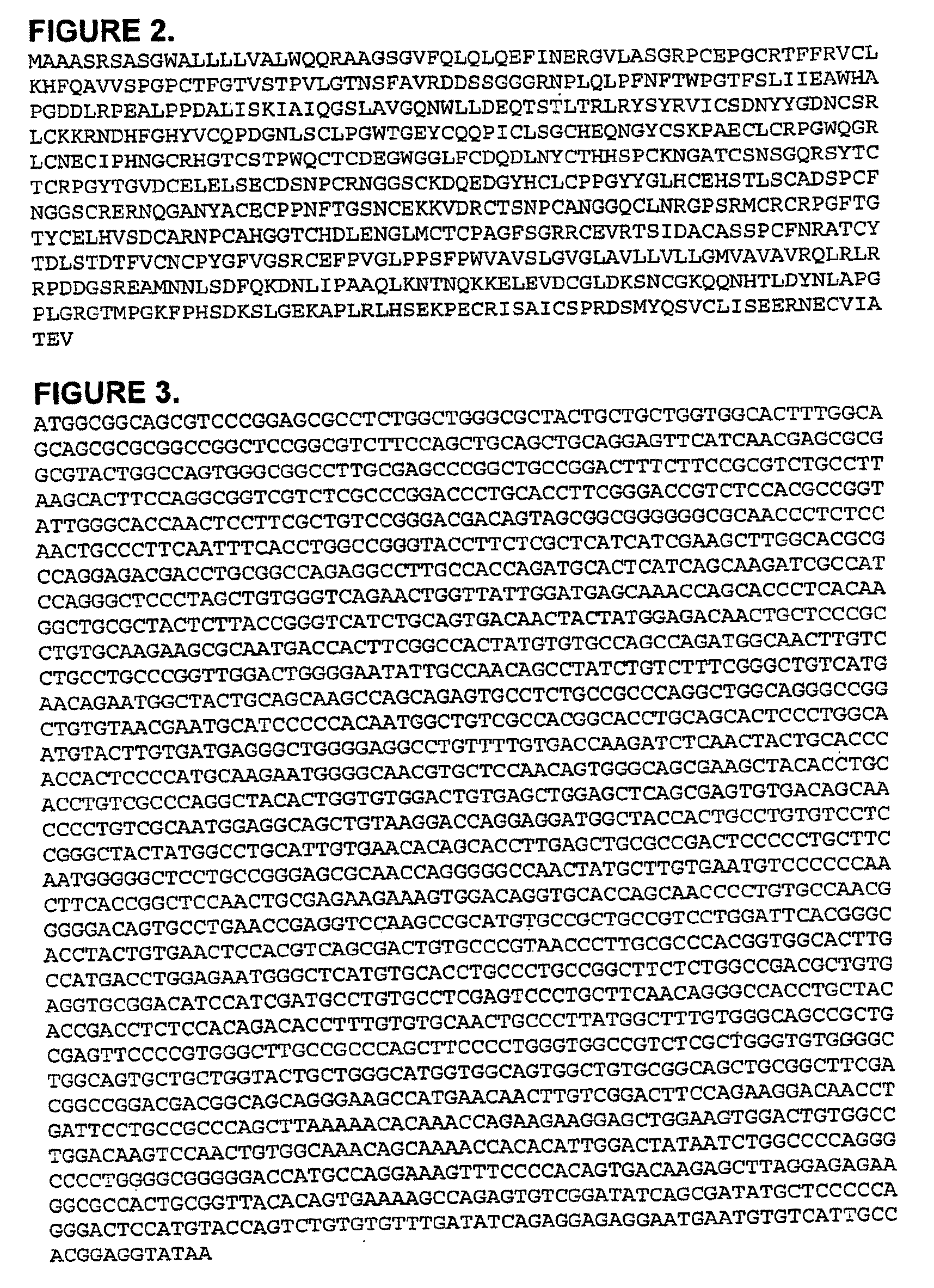

Method for the recovery and purification of poxviruses from infected cells

InactiveUS20040265986A1Easy to controlEasy scaling up to industrial scaleViral antigen ingredientsAntiviralsInfected cellVaccinia

The present invention relates to a method for the recovery of poxviruses, in particular modified Vaccinia virus Ankara (MVA), from infected cells. According to the present invention the virus-infected cells are subjected to a high-pressure homogenization to obtain a virus containing homogenate. The virus containing homogenate can be subjected to at least one purification step to obtain apoxvirus-enriched fraction. The invention further relates to the virus containing fraction and the virus containing homogenate obtained by the method according to the present invention.

Owner:BAVARIAN NORDIC AS

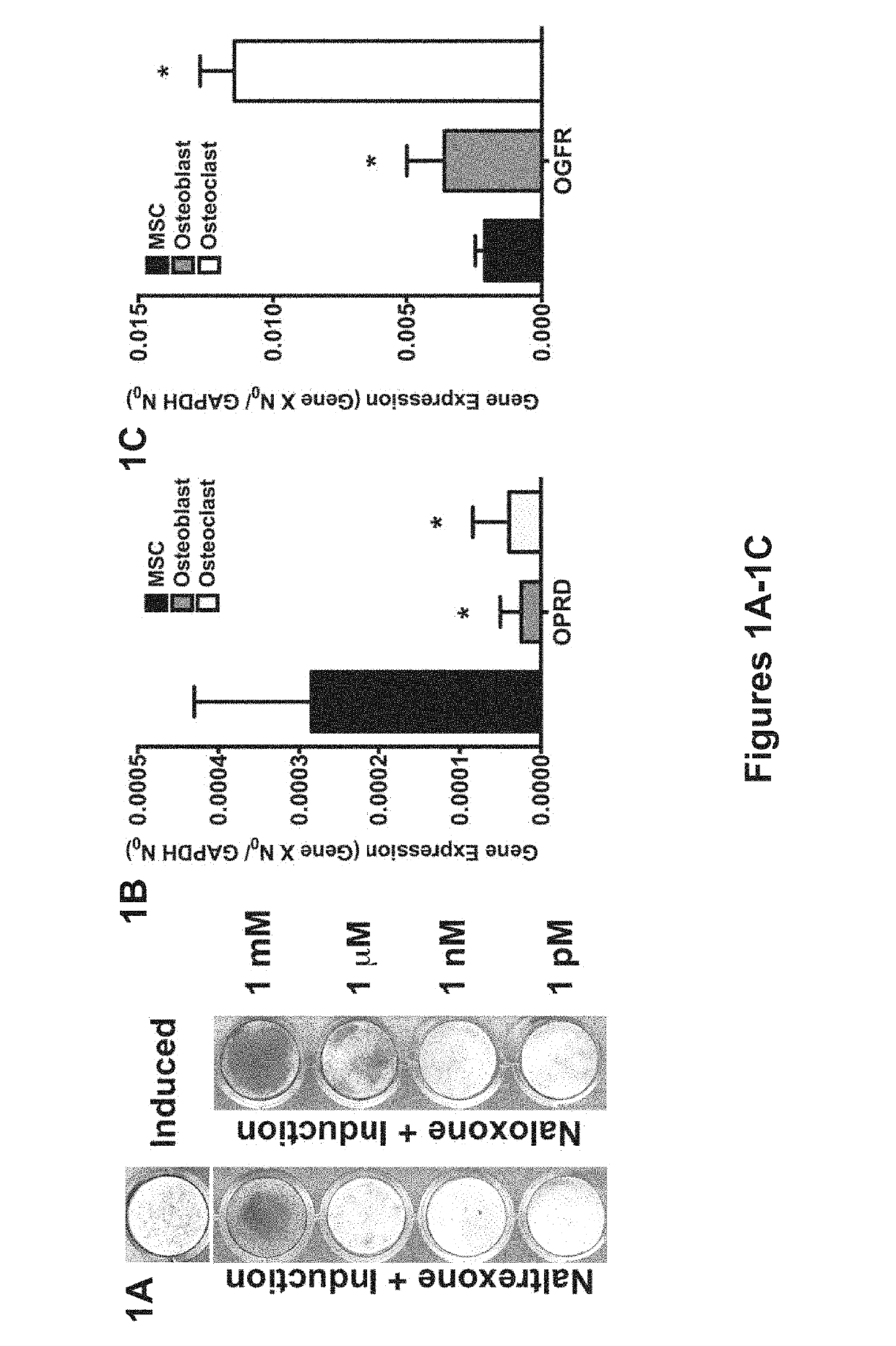

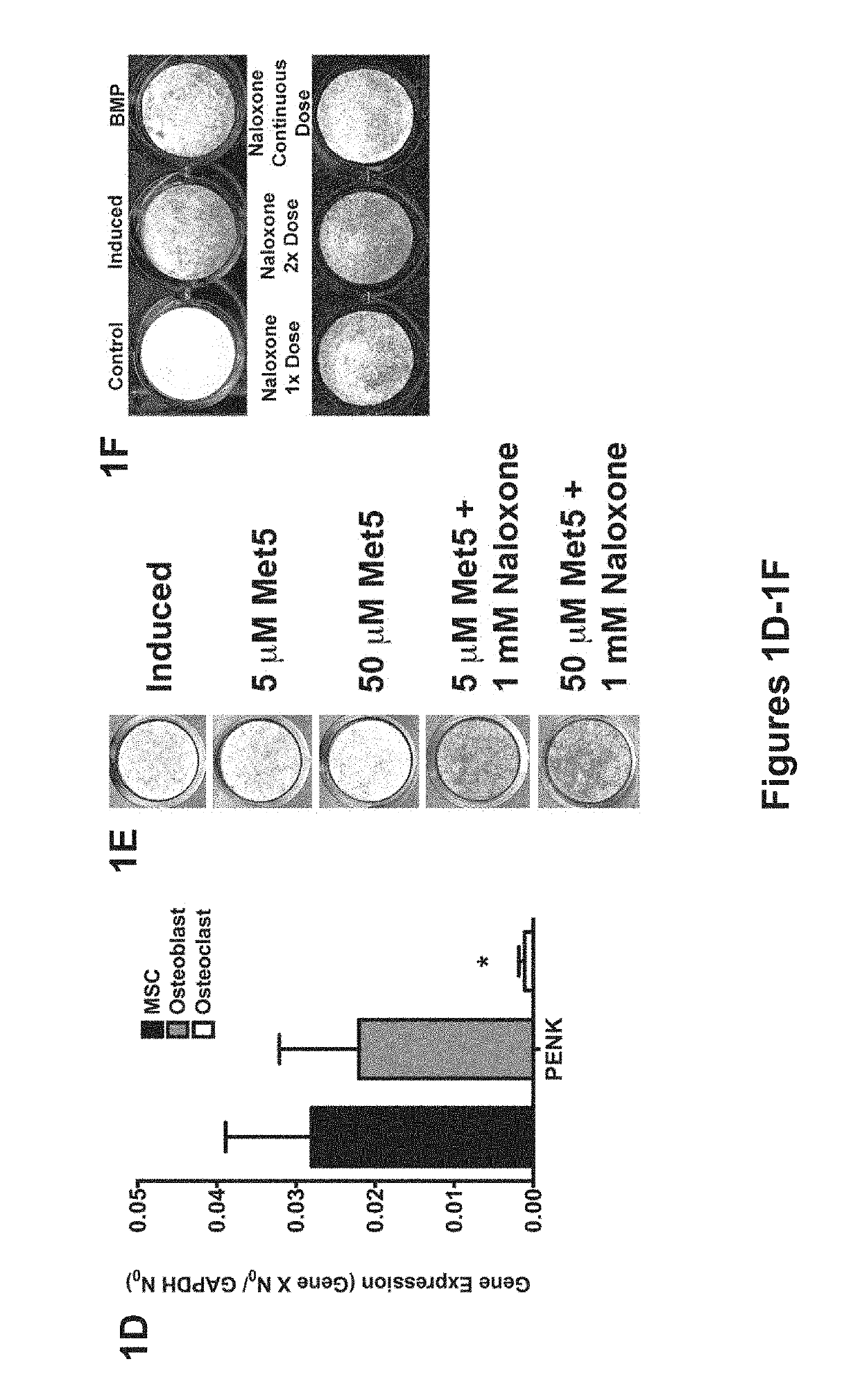

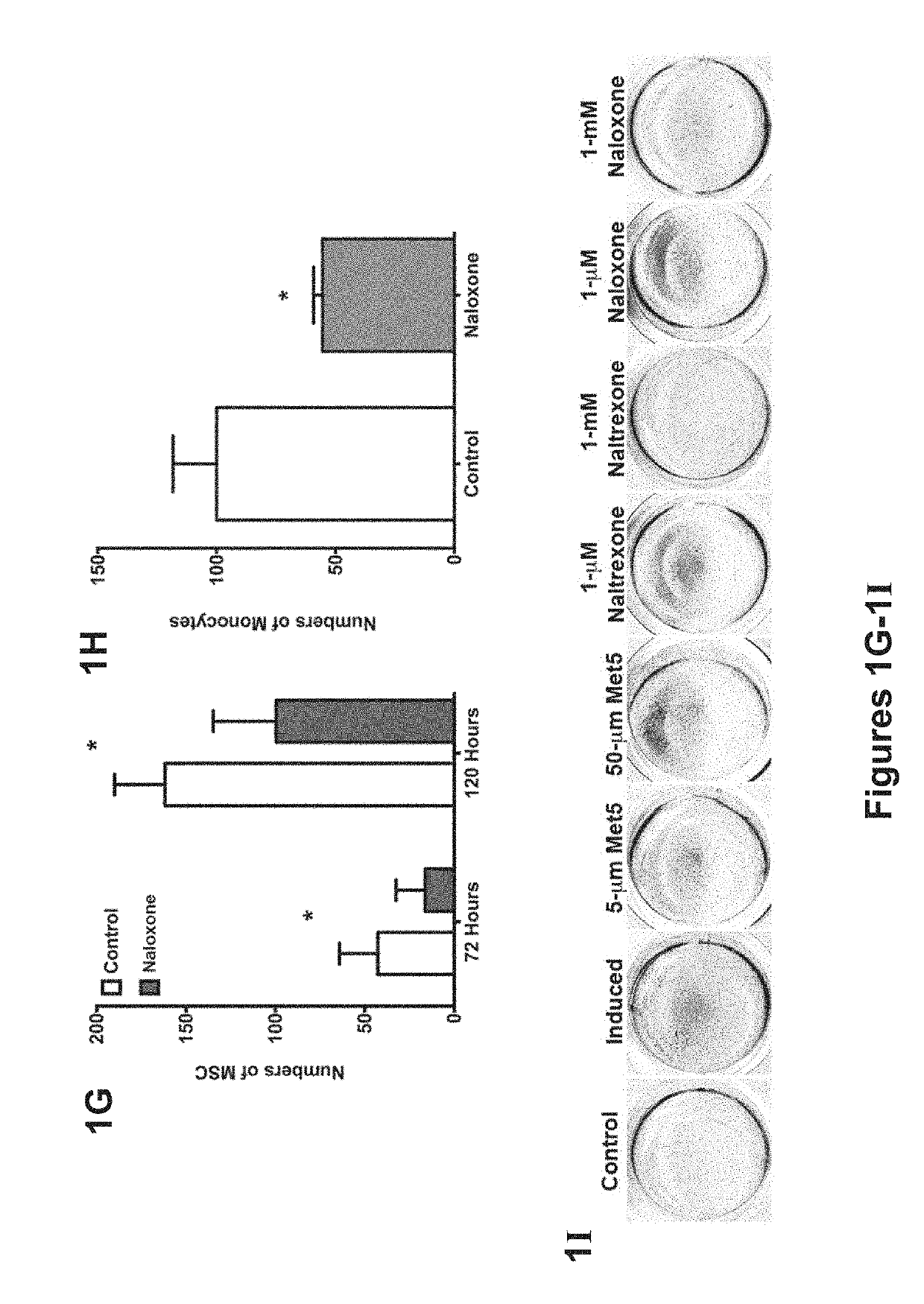

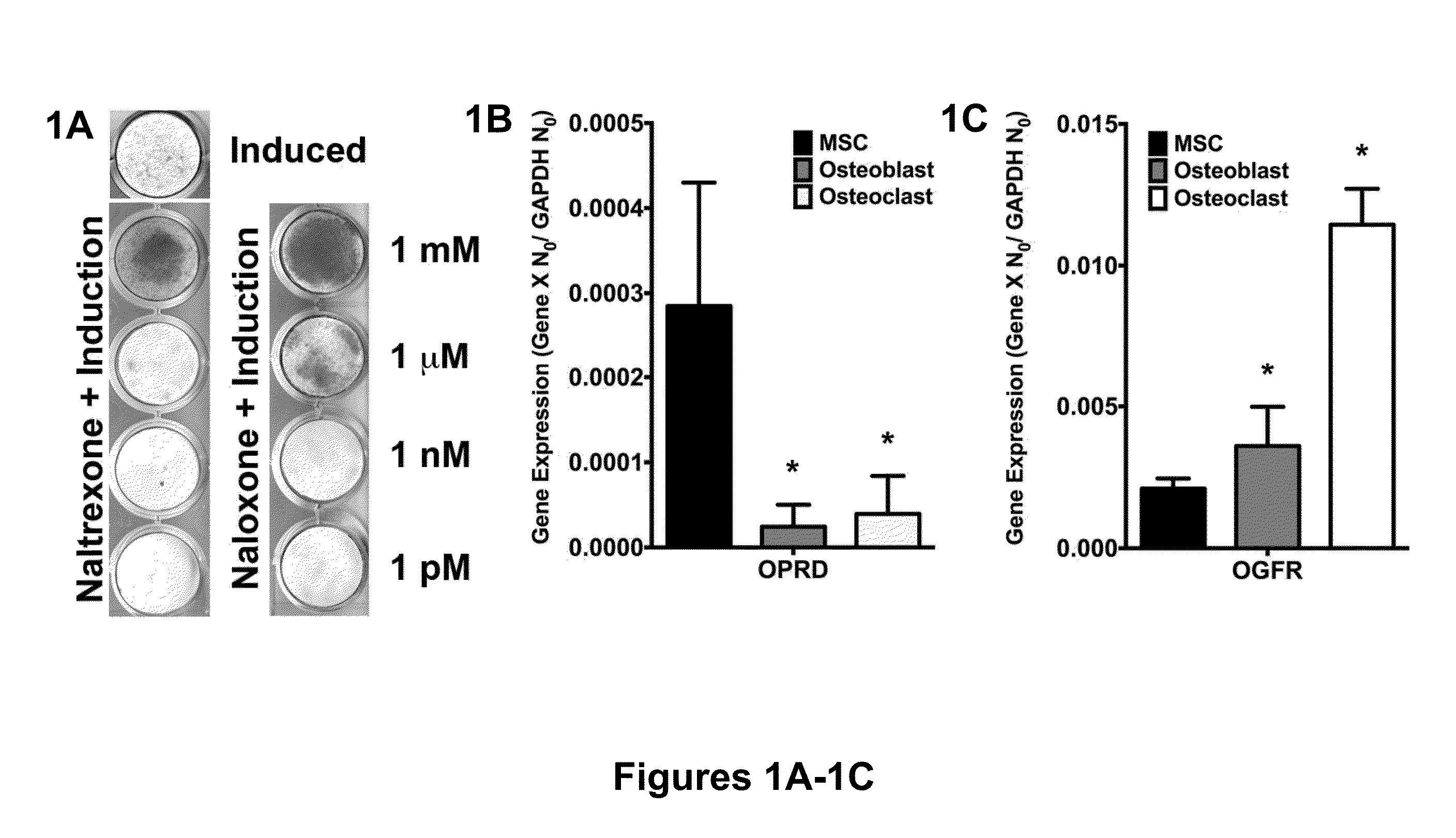

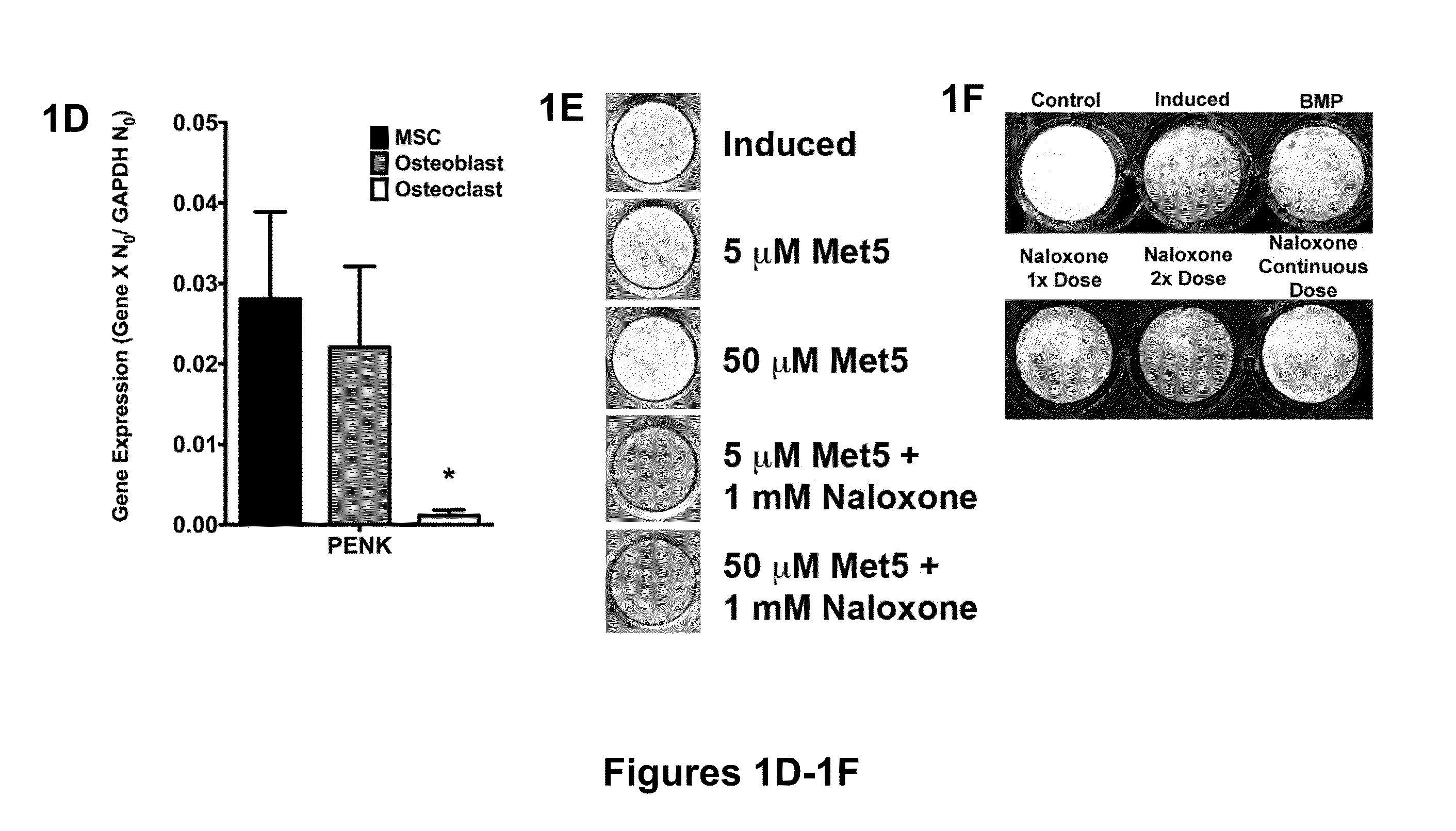

Compositions and methods to promote bone formation

PendingUS20190093109A1Promote differentiationInhibition of differentiationOrganic active ingredientsSkeletal disorderOsteoradionecrosisBone formation

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

Composition and Method for Disrupting Tissue Material

InactiveUS20190376882A1Effectively disrupting and homogenizingSimple sample preparationCell dissociation methodsPreparing sample for investigationEnzymatic digestionLysis

The present invention relates to a composition for disrupting tissue material, the composition comprising solid disrupting particles in combination with at least one enzyme for enzymatic lysis and at least one chaotropic agent , as well as to a method for disrupting tissues material by simultaneously applying mechanical grinding or milling disruption and enzymatic digestion.

Owner:QIAGEN GMBH

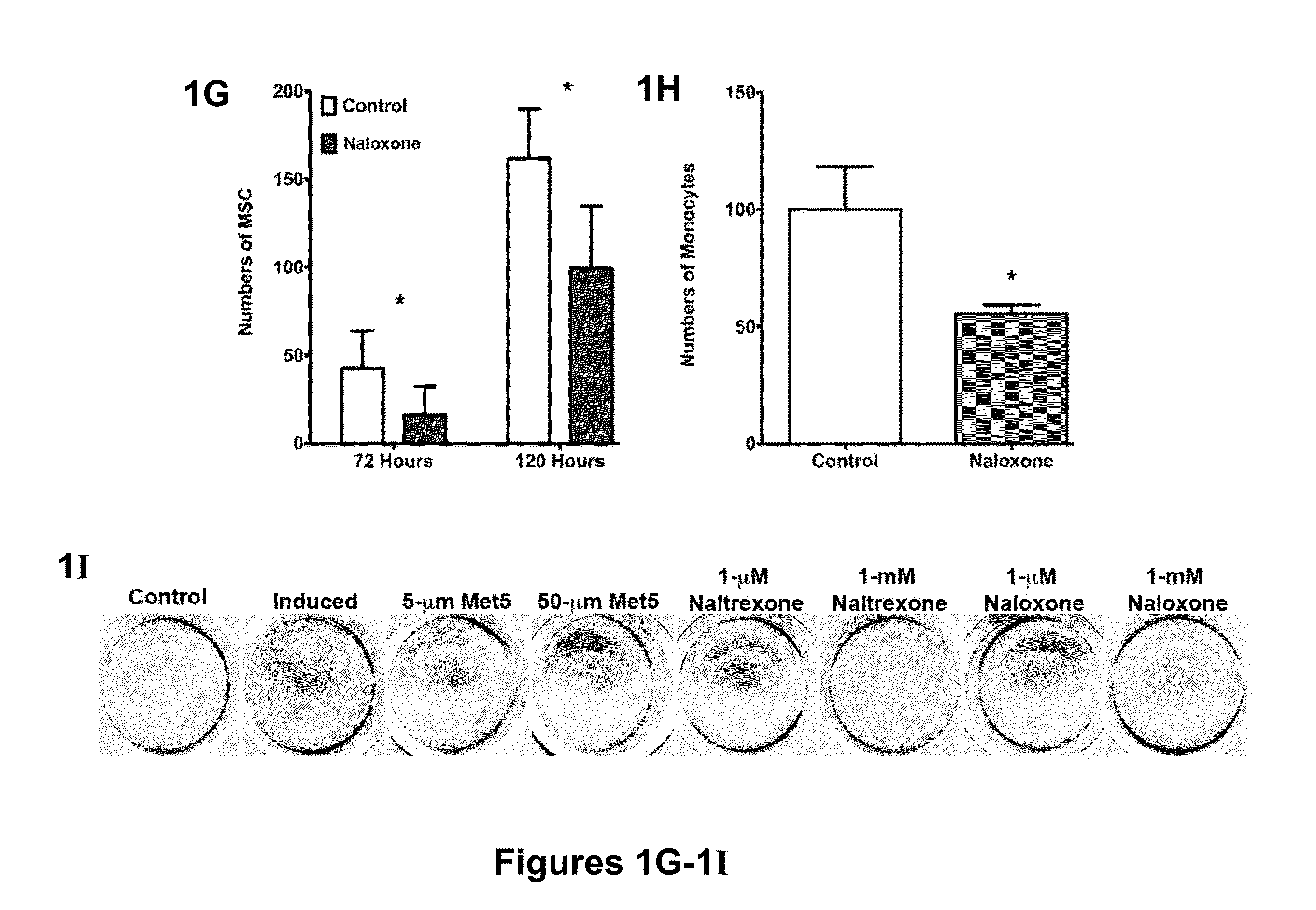

Compositions and methods to promote bone formation

ActiveUS20150344882A1Promotes bone formationReduce bone destructionBiocidePharmaceutical delivery mechanismDysostosisOsteoradionecrosis

This disclosure relates to methods for promoting bone formation or reducing bone destruction. This disclosure also relates to methods for promoting the recruitment of mesenchymal stem cells (MSC) to a local site of injury or surgical intervention in bone to promote healing. In addition, this disclosure relates to methods for reducing or preventing mineral formation or bone growth, or reducing bone mass. The methods disclosed herein are useful for treating conditions such as osteoradionecrosis.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

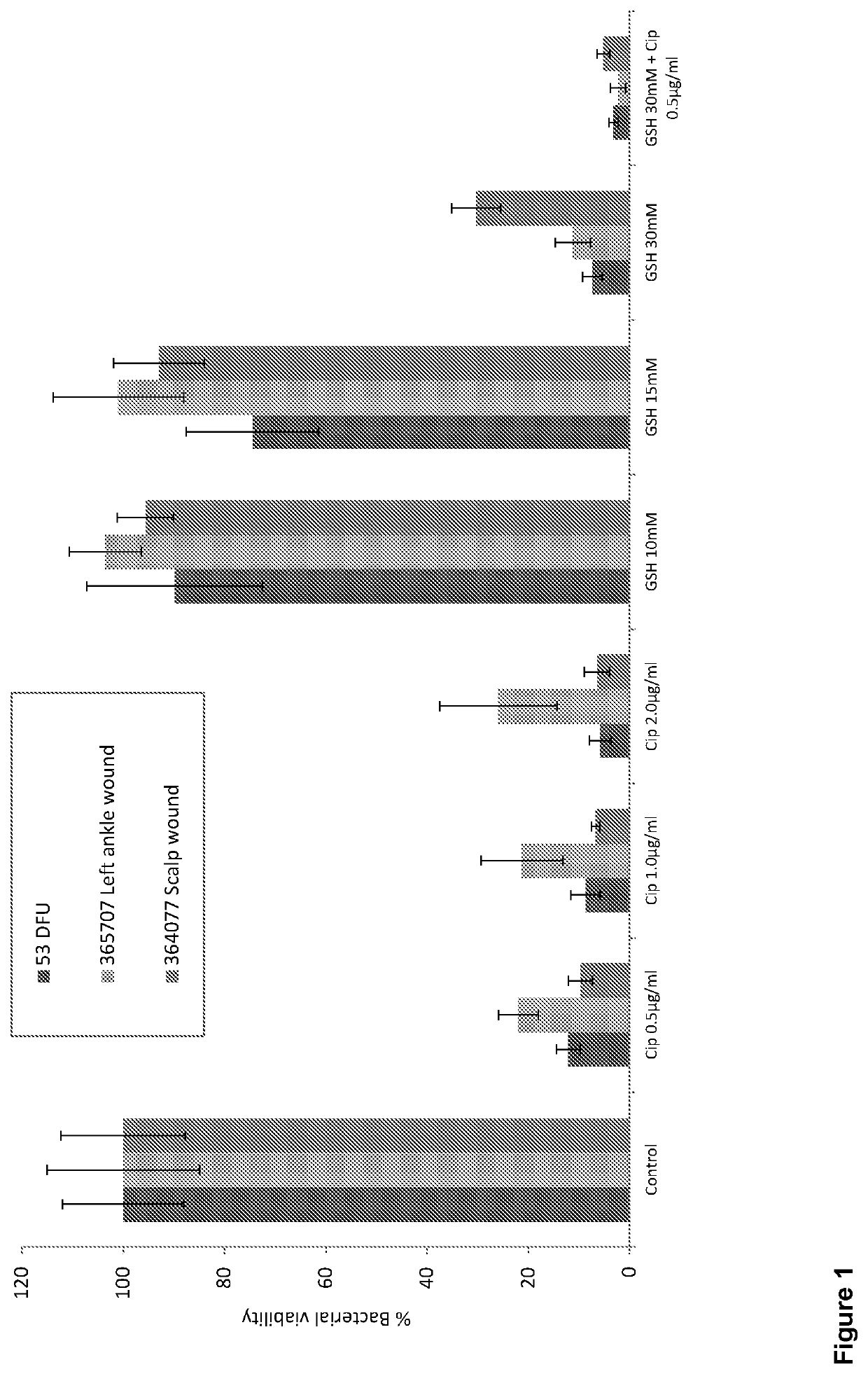

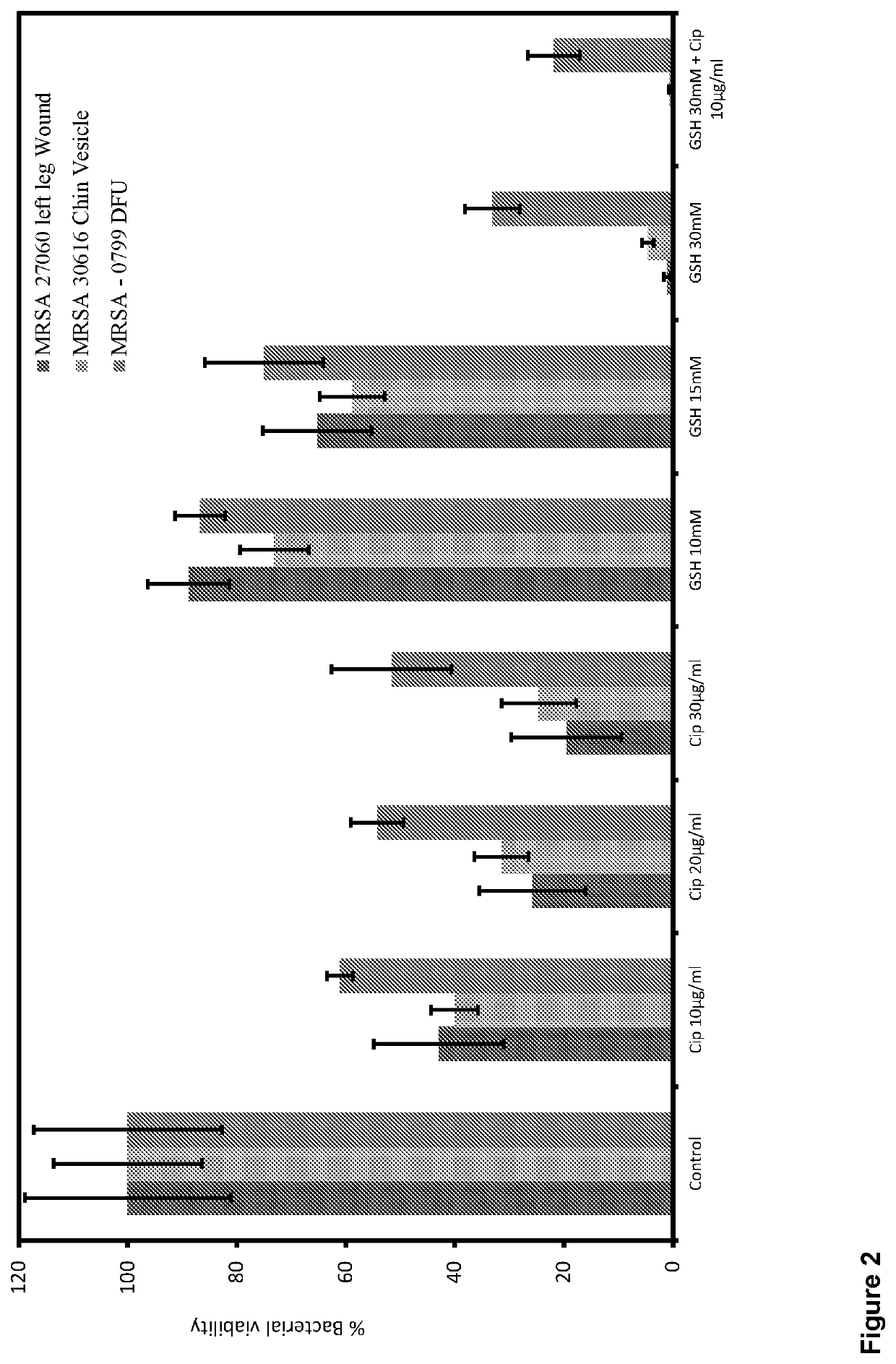

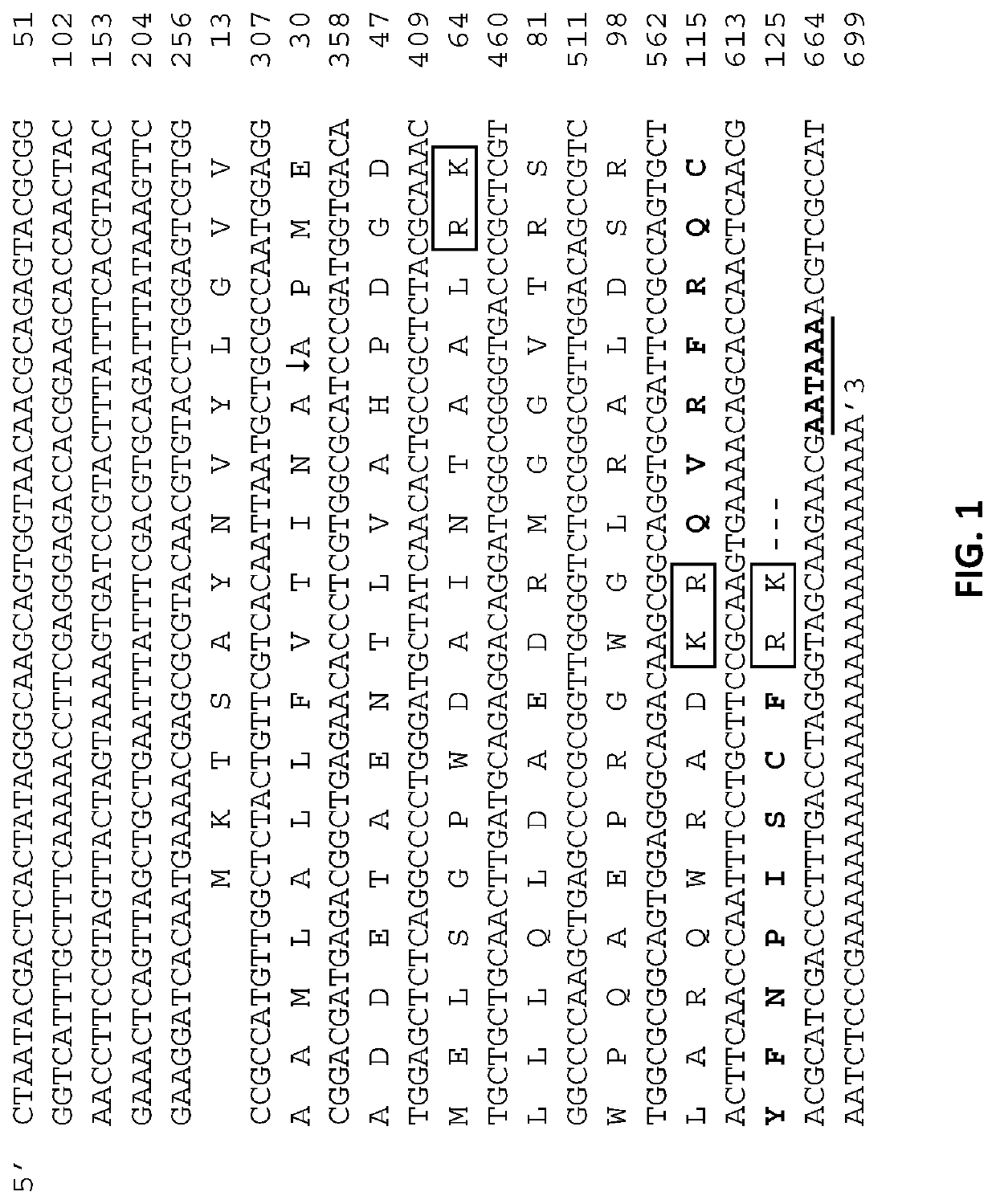

Biofilm disrupting composition

A biofilm disrupting composition for use in treating biofilm-mediated infections due to non-Pseudomonas micro-organisms in the Cystic Fibrosis patient. One embodiment of the composition of the invention comprises at least one biologically acceptable thiol based antioxidant and at least one antibiotic. Another embodiment of the composition of the invention comprises at least one biologically acceptable thiol based antioxidant, at least one enzyme and at least one antibiotic. The invention is also directed to the process of preparing the composition of the invention, the use of the composition for the manufacture of a medicament for disrupting biofilms formed by non-Pseudomonad micro-organisms, and a method of disrupting biofilm formed by non-Pseudomonad micro-organisms in a patient, comprising administering to the patient the composition of the invention.

Owner:WHITELEY +1

Insect control strategies utilitizing pheromones and rnai

InactiveUS20220151237A1Efficiently disruptedBiocideClimate change adaptationBiotechnologySemiochemical

Systems and methods of preventing or reducing crop damage from pests are provided. In one embodiment, the method comprises: a) applying a mating disruption tactic to a field plot; and b) disrupting expression of one or more target genes in one or more pests, wherein crop damage is reduced in the field plot. In another embodiment, the method comprises applying an attract-and-kill tactic to a field plot, wherein said attract-and-kill tactic comprises: a) applying one or more semiochemicals or factors; and b) disrupting expression of one or more target genes in one or more pests, wherein said disruption is capable of killing the one or more pests, wherein crop damage is reduced in the field plot.

Owner:PROVIVI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com