Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Close together" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

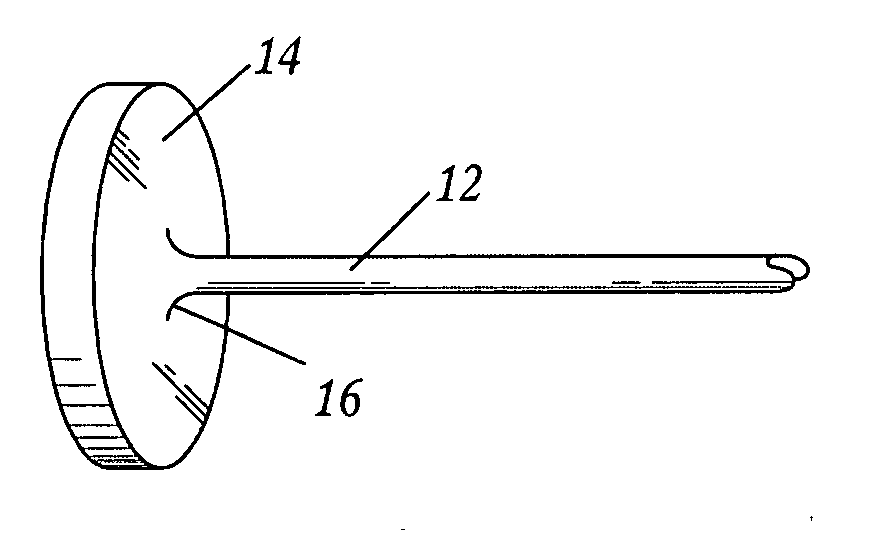

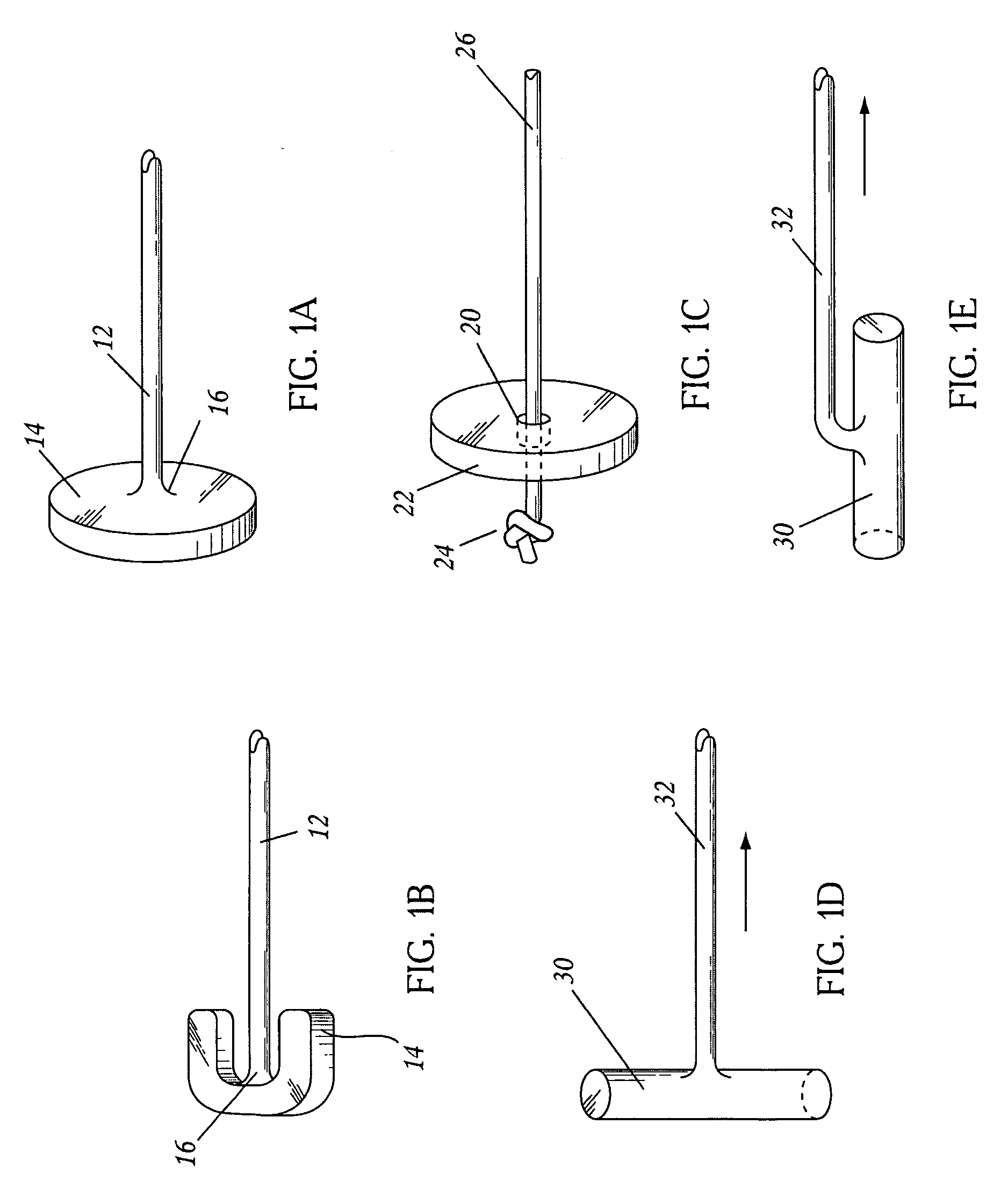

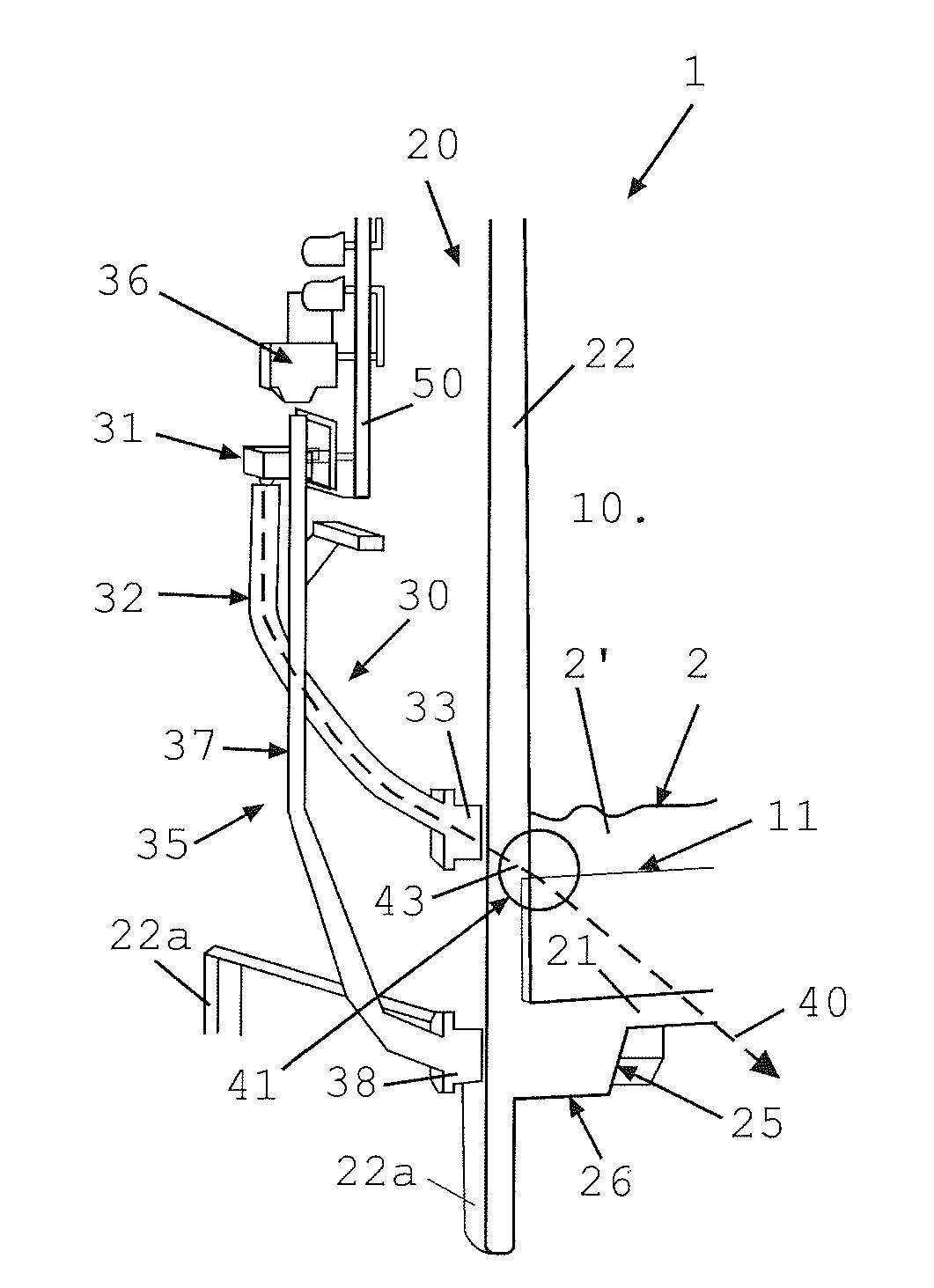

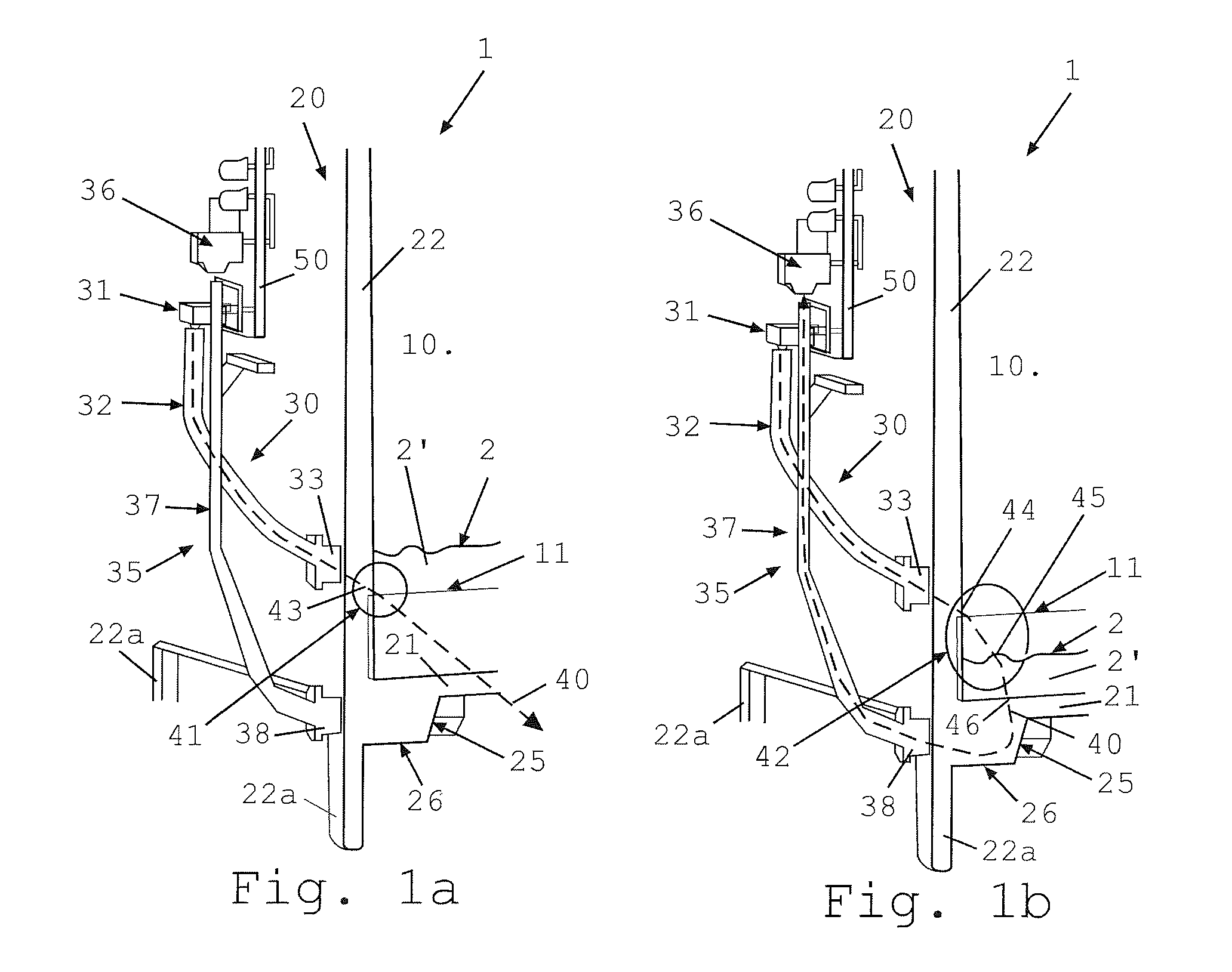

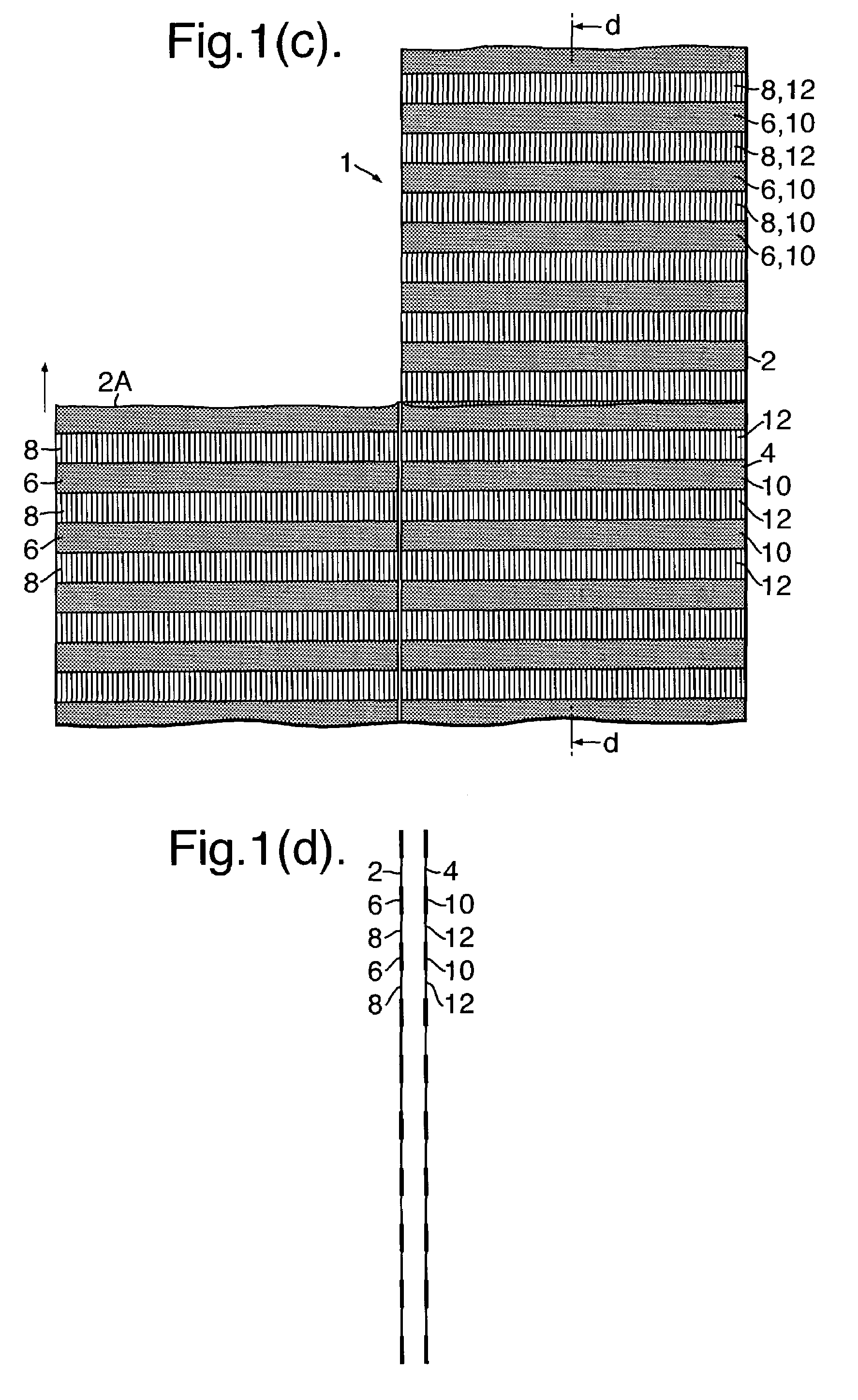

Methods and devices for combined gastric restriction and electrical stimulation

InactiveUS20060074473A1Reduce internal volumeReduction procedureSuture equipmentsSurgical needlesDevice implantGastric restriction

Disclosed are methods and apparatus for implantation into the walls of an organ such as the stomach. Deformable or inflatable anchors with a connector between are used to pull the walls of the organ together, or to implant devices in the wall of the organ. Also disclosed are surgical instruments useful in practicing the disclosed methods.

Owner:GERTNER MICHAEL

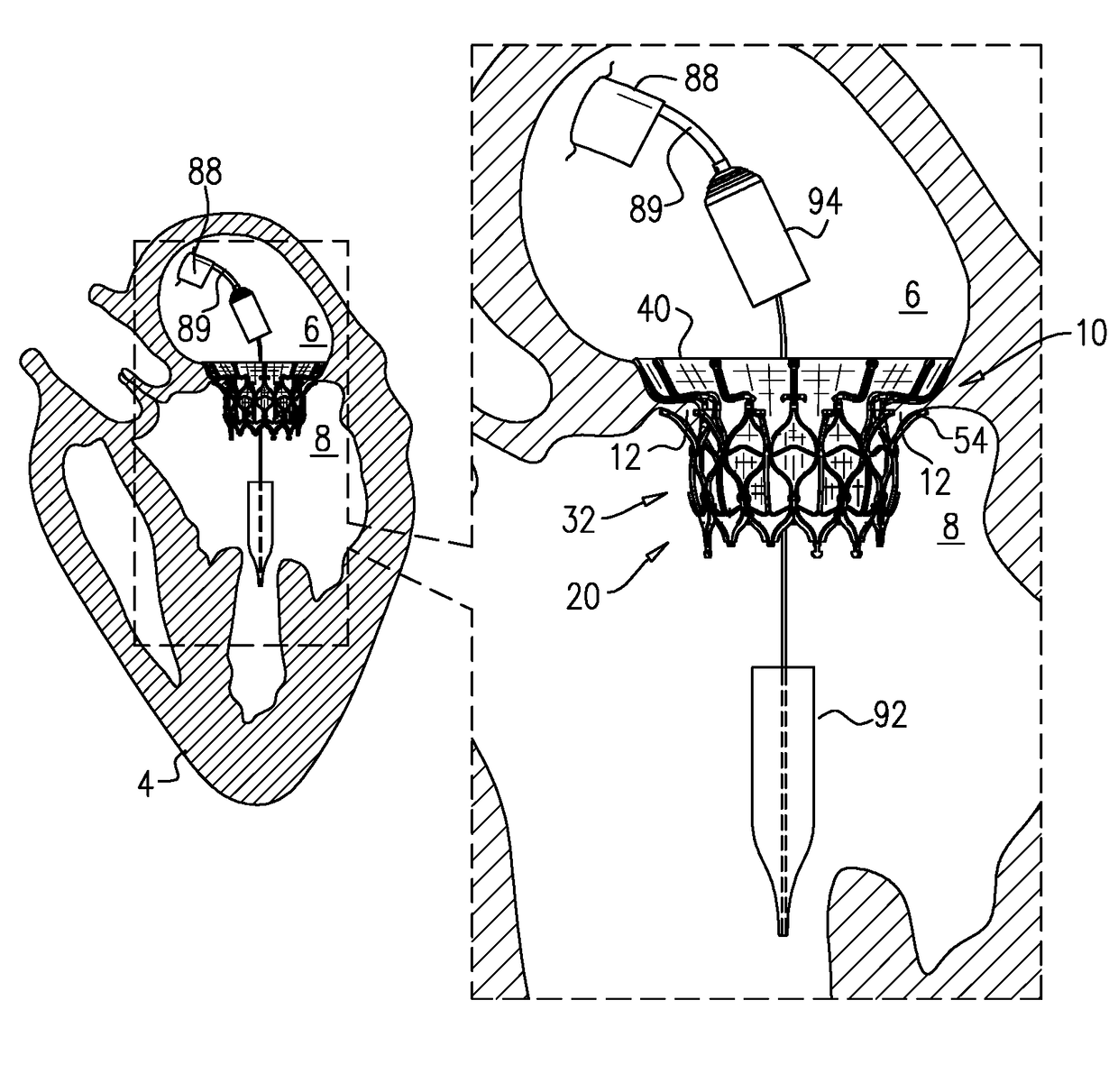

Prosthetic Heart Valve with Compressible Frames

A tubular portion of a valve frame circumscribes a longitudinal axis, and defines a lumen along the axis and a plurality of valve-frame coupling elements disposed circumferentially around the axis. An outer frame: (a) comprises a ring defined by a pattern of alternating peaks and troughs, the pattern having an amplitude, (b) comprises a plurality of legs, coupled to the ring at respective troughs, and (c) is shaped to define a plurality of outer-frame coupling elements, each coupled to the ring, and fixed with respect to a respective valve-frame coupling element. Compression of the tubular portion from an expanded state toward a compressed state reduces a circumferential distance between each of the outer-frame coupling elements and its adjacent outer-frame coupling elements, and increases the amplitude of the pattern of the ring.

Owner:CARDIOVALVE LTD

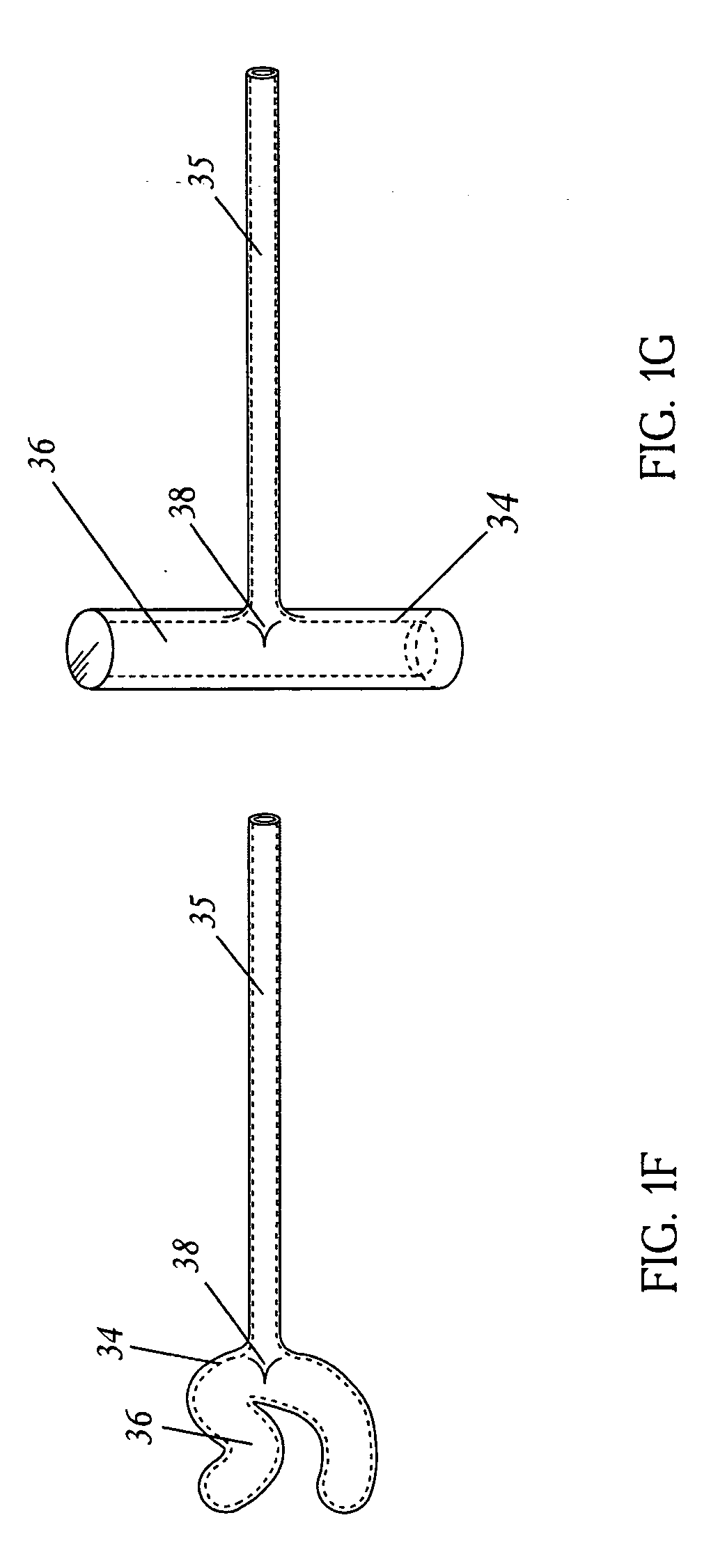

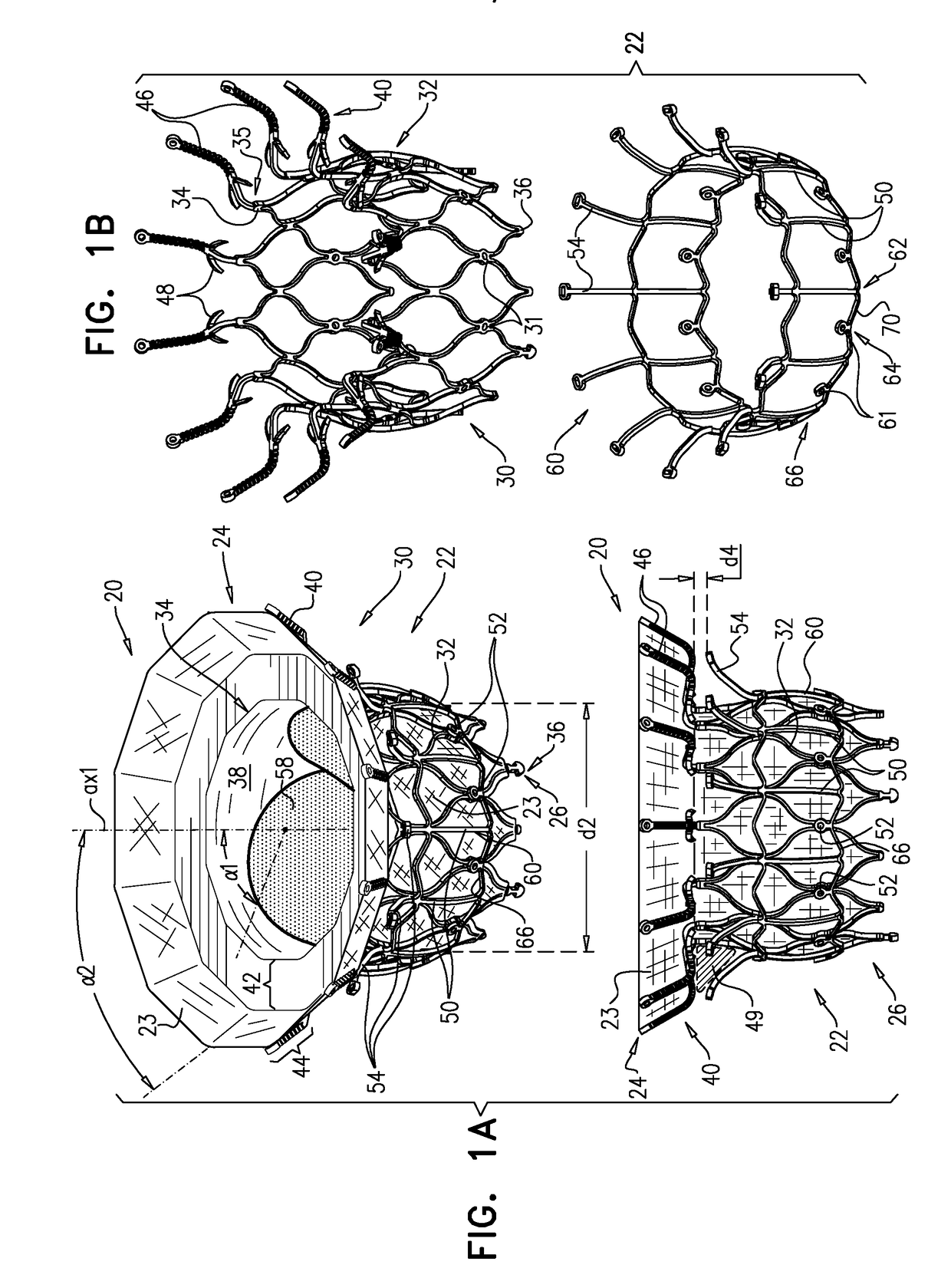

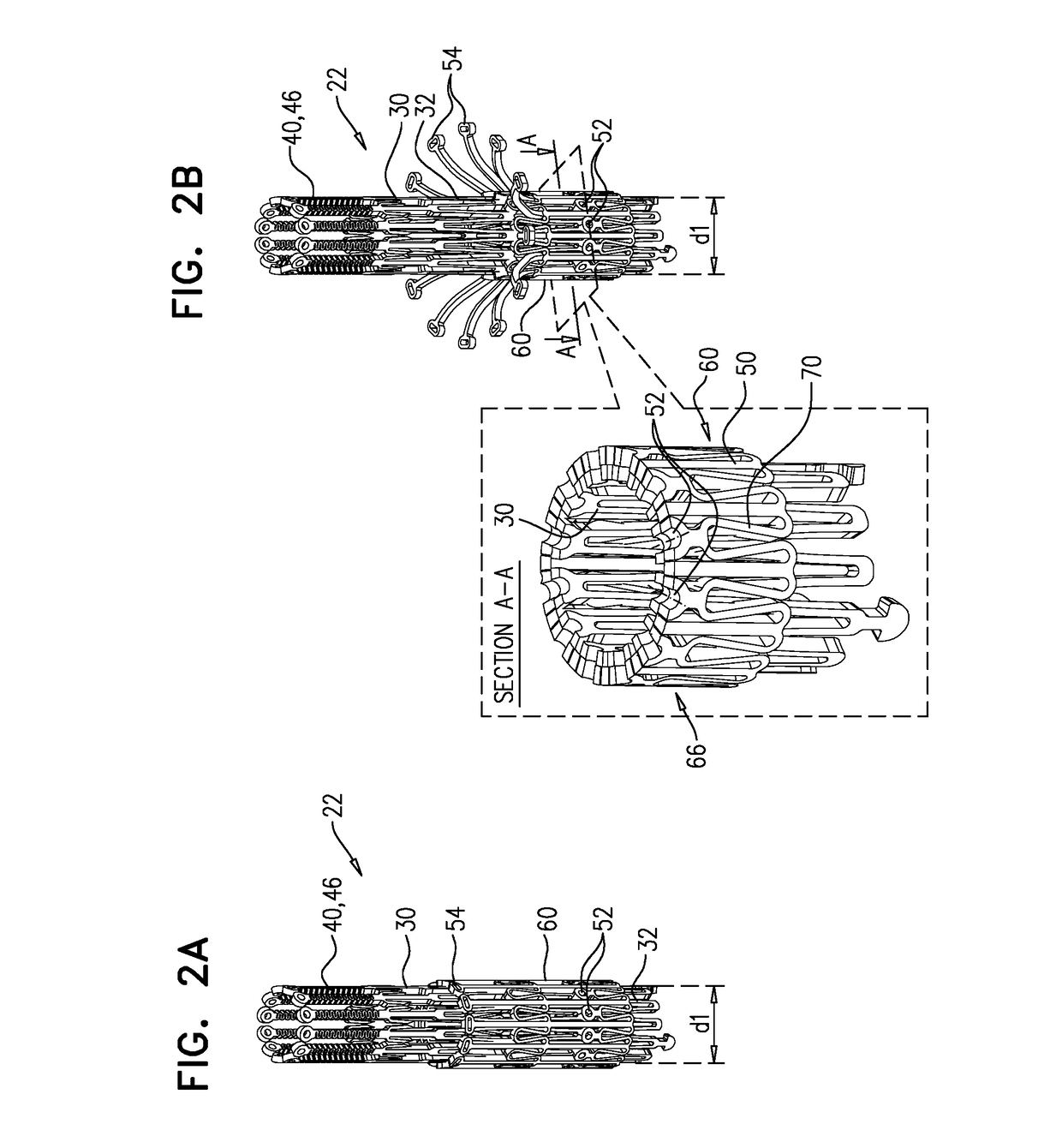

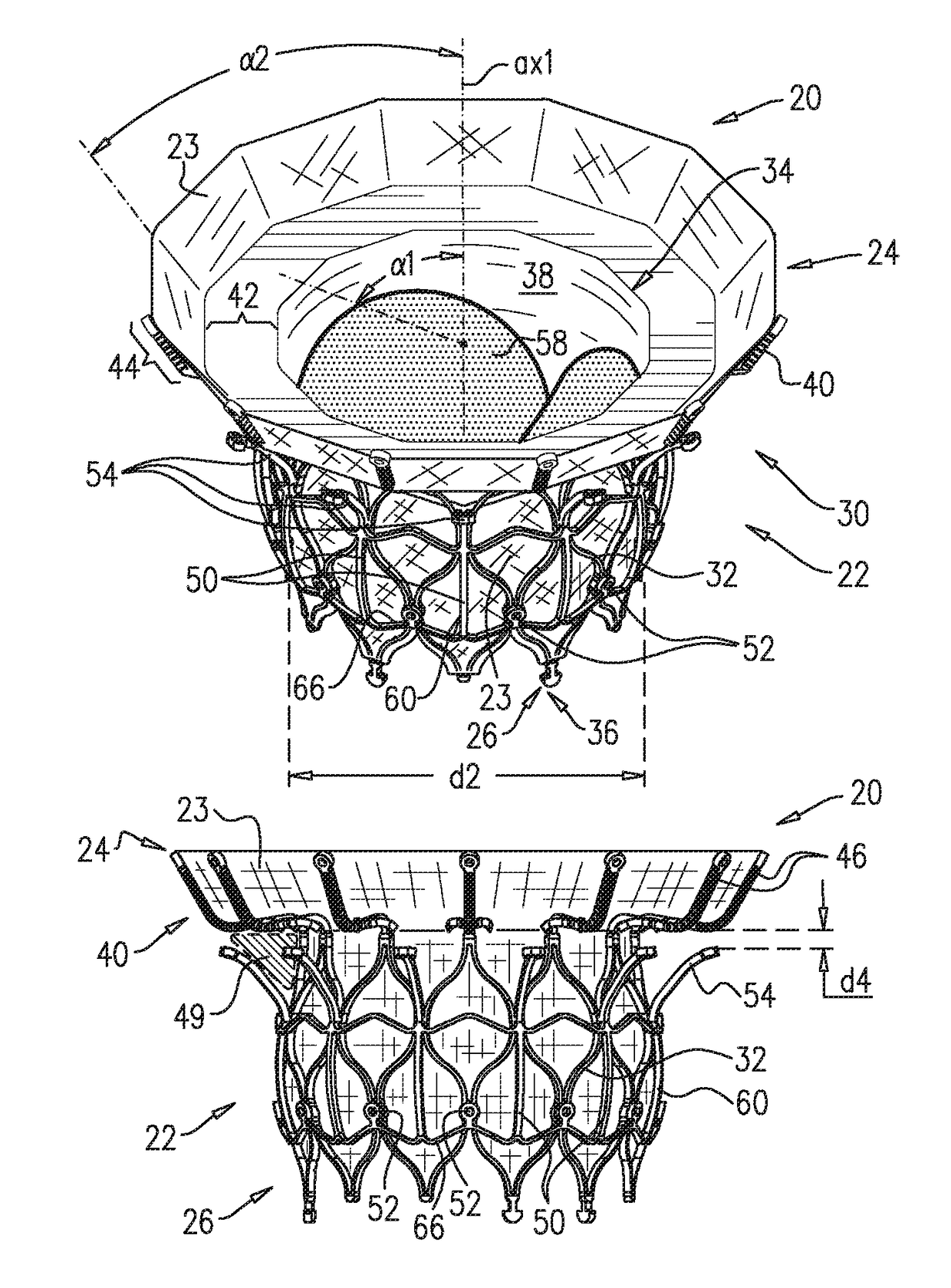

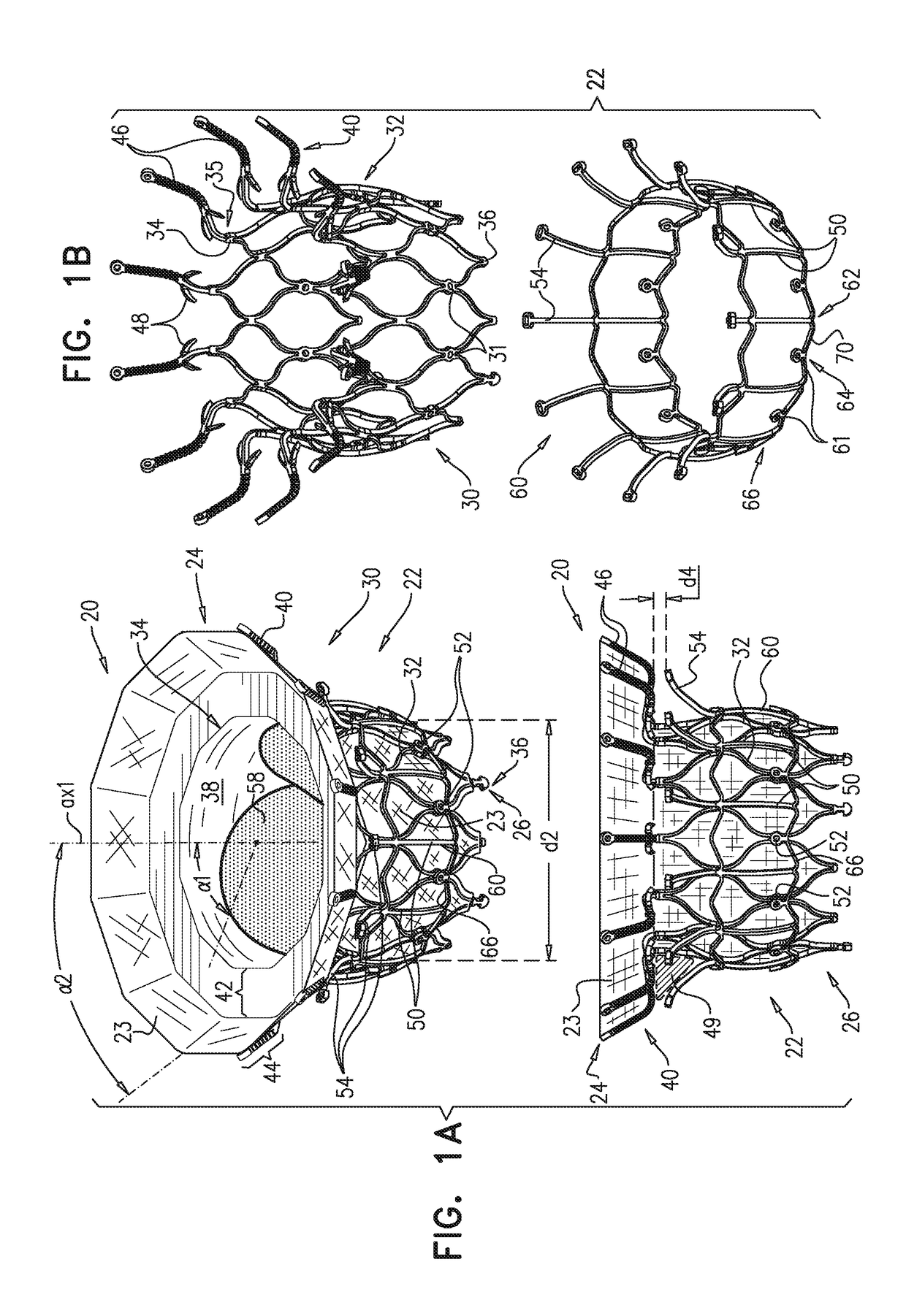

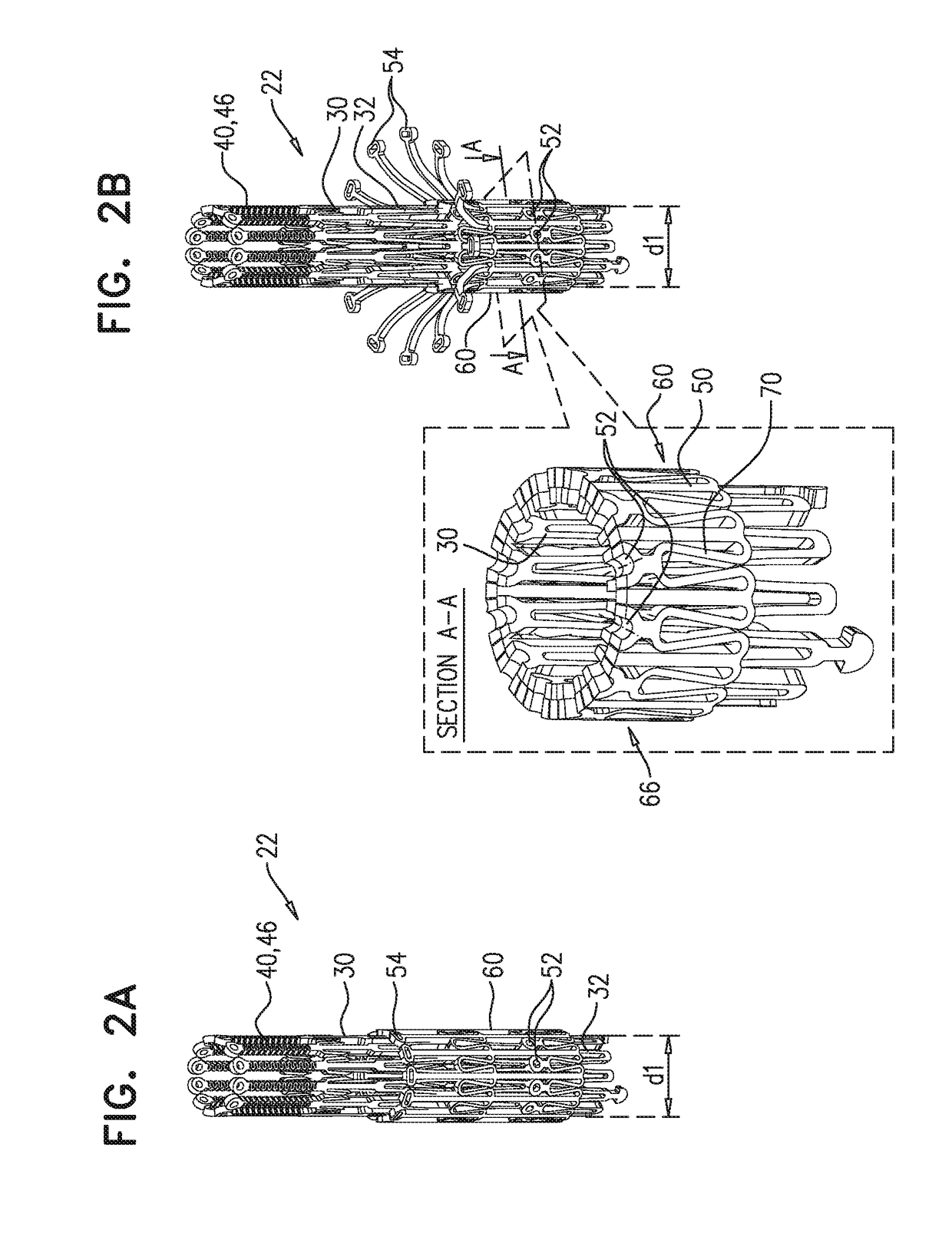

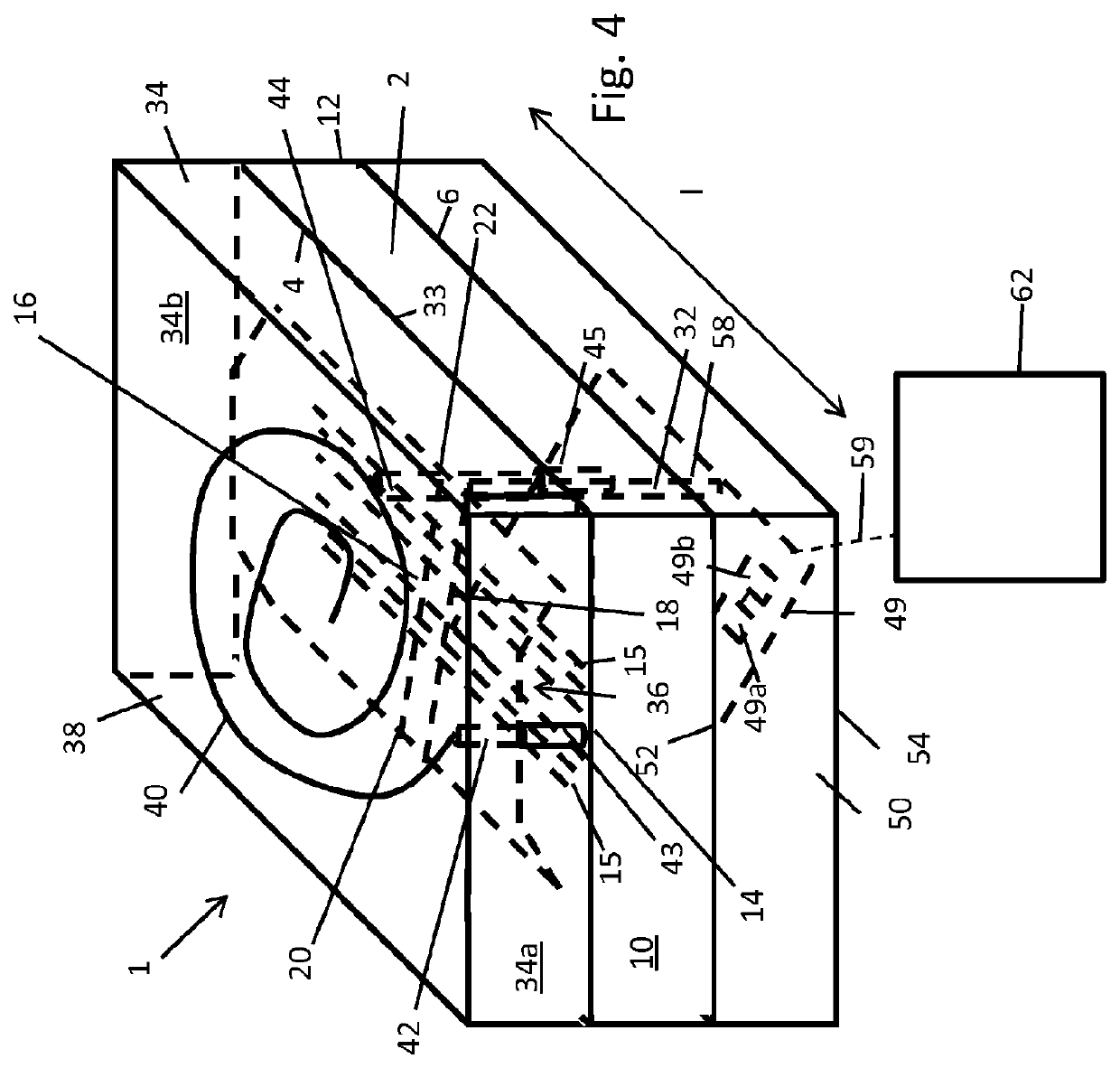

Prosthetic valve with axially-sliding frames

A tubular portion (32) of a valve frame (30) circumscribes a longitudinal axis, and defines a lumen along the axis and a plurality of valve-frame coupling elements (31) disposed circumferentially around the axis. An outer frame (60): (a) comprises a ring (66) defined by a pattern of alternating peaks and troughs, the pattern having an amplitude, (b) comprises a plurality of legs (50), coupled to the ring at respective troughs, and (c) is shaped to define a plurality of outer-frame coupling elements (61), each coupled to the ring at a respective peak, and fixed with respect to a respective valve-frame coupling element. Compression of the tubular portion from an expanded state toward a compressed state reduces a circumferential distance between each of the outer-frame coupling elements and its adjacent outer-frame coupling elements, and increases the amplitude of the pattern of the ring.

Owner:CARDIOVALVE LTD

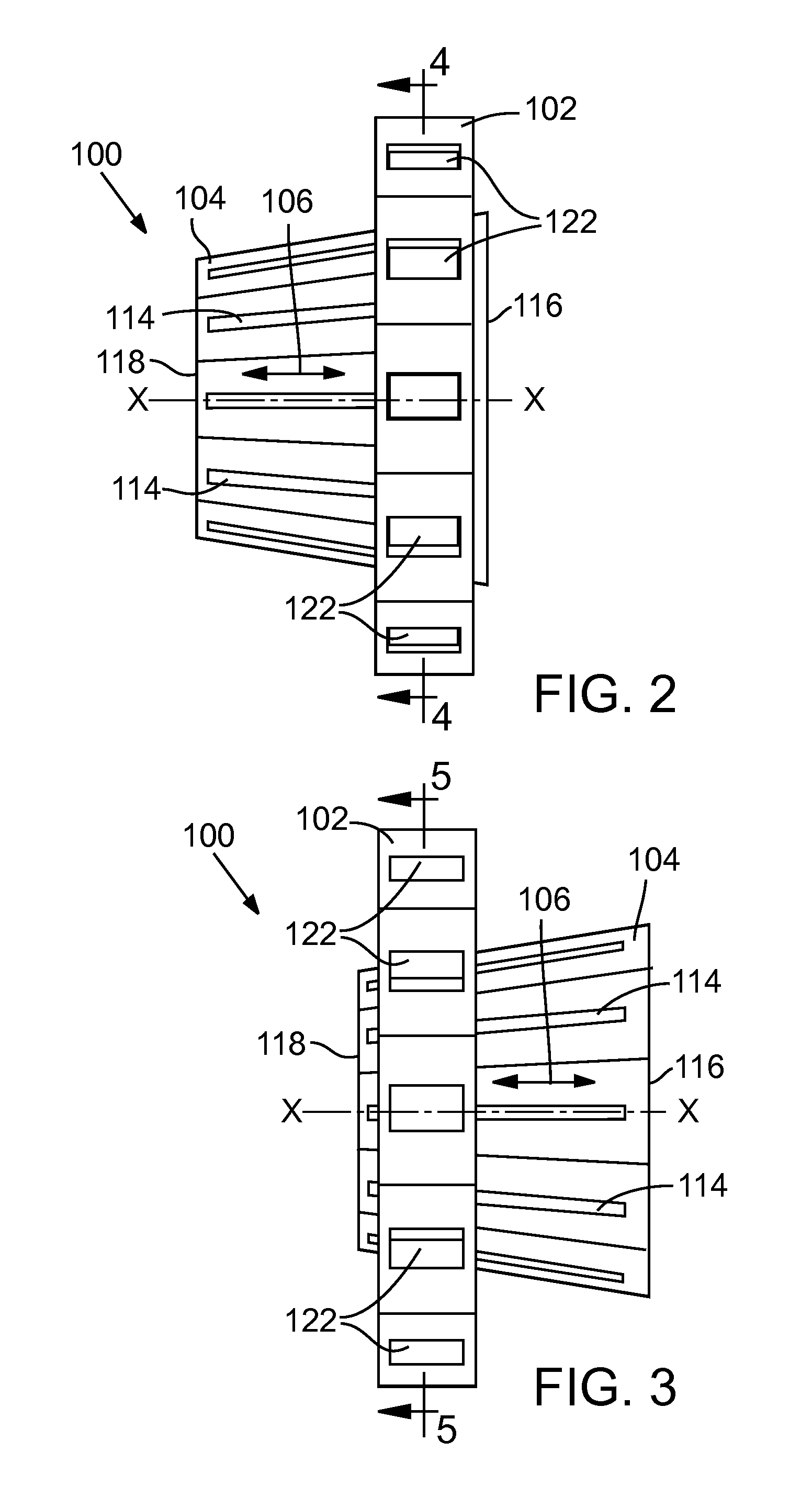

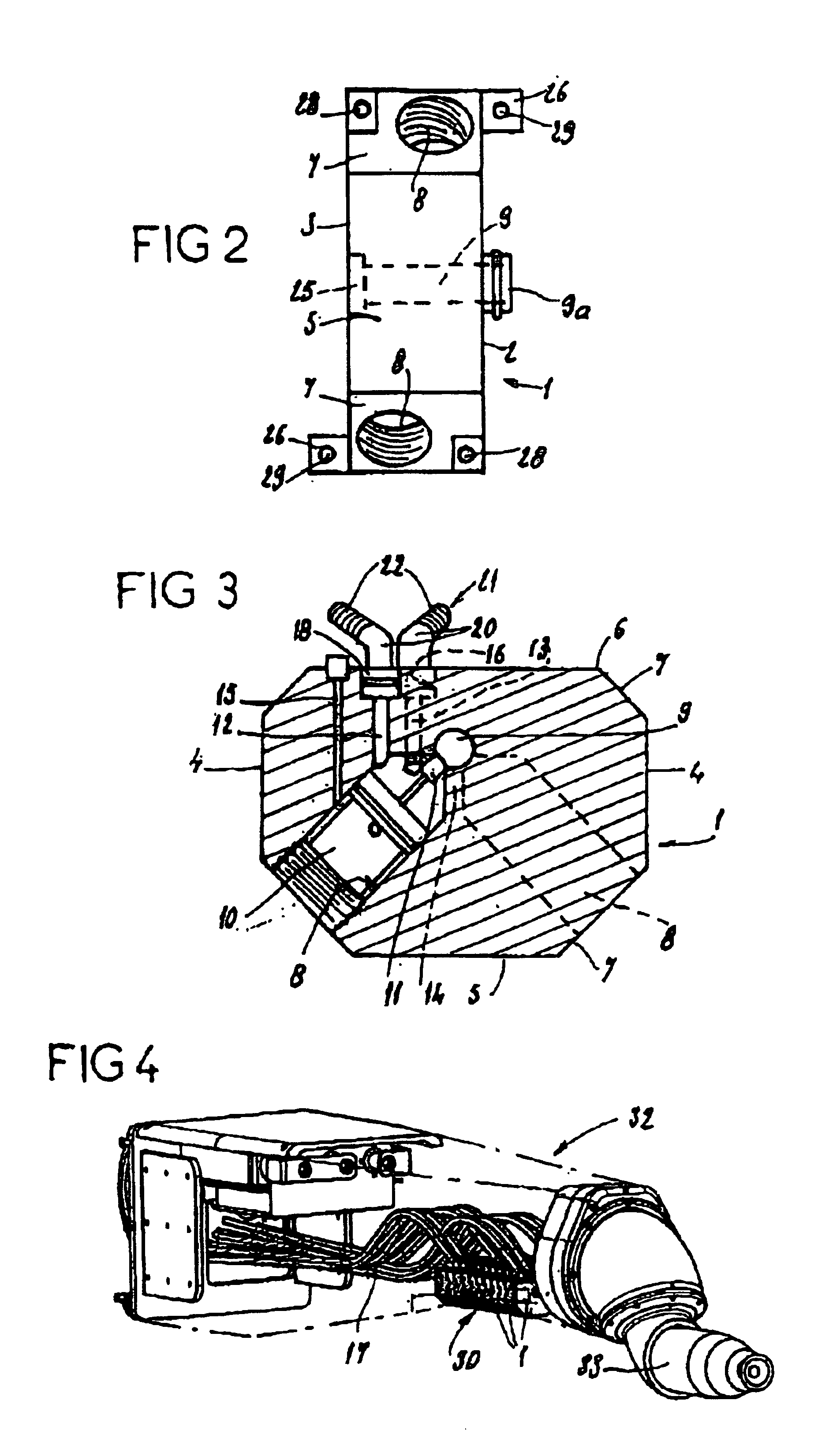

Conical crimper

ActiveUS20130030418A1Reduce the overall diameterClose movementStentsBalloon catheterIn planeProsthetic valve

Embodiments of crimping devices for crimping stented prosthetic valves and other medical devices from a larger, expanded diameter to a smaller, crimped diameter are disclosed. Some crimping devices utilize a conical surface extending out-of-plane from the direction of crimping, where motion of the conical surface in the out-of-plane direction causes in-plane radially crimping. Other crimping devices comprise a funnel-shaped rigid body having a tapered inner lumen that compresses a medical device moving therethrough. Some funnel-shaped embodiments have slotted sides that allow portions of the medical device to project therethrough. Other funnel-shaped embodiments are used with a tubular sock to pull the medical device through the tapered lumen. Other crimping devices utilize rotating rollers that compress a medical device while the medical device spins between the rollers.

Owner:EDWARDS LIFESCIENCES CORP

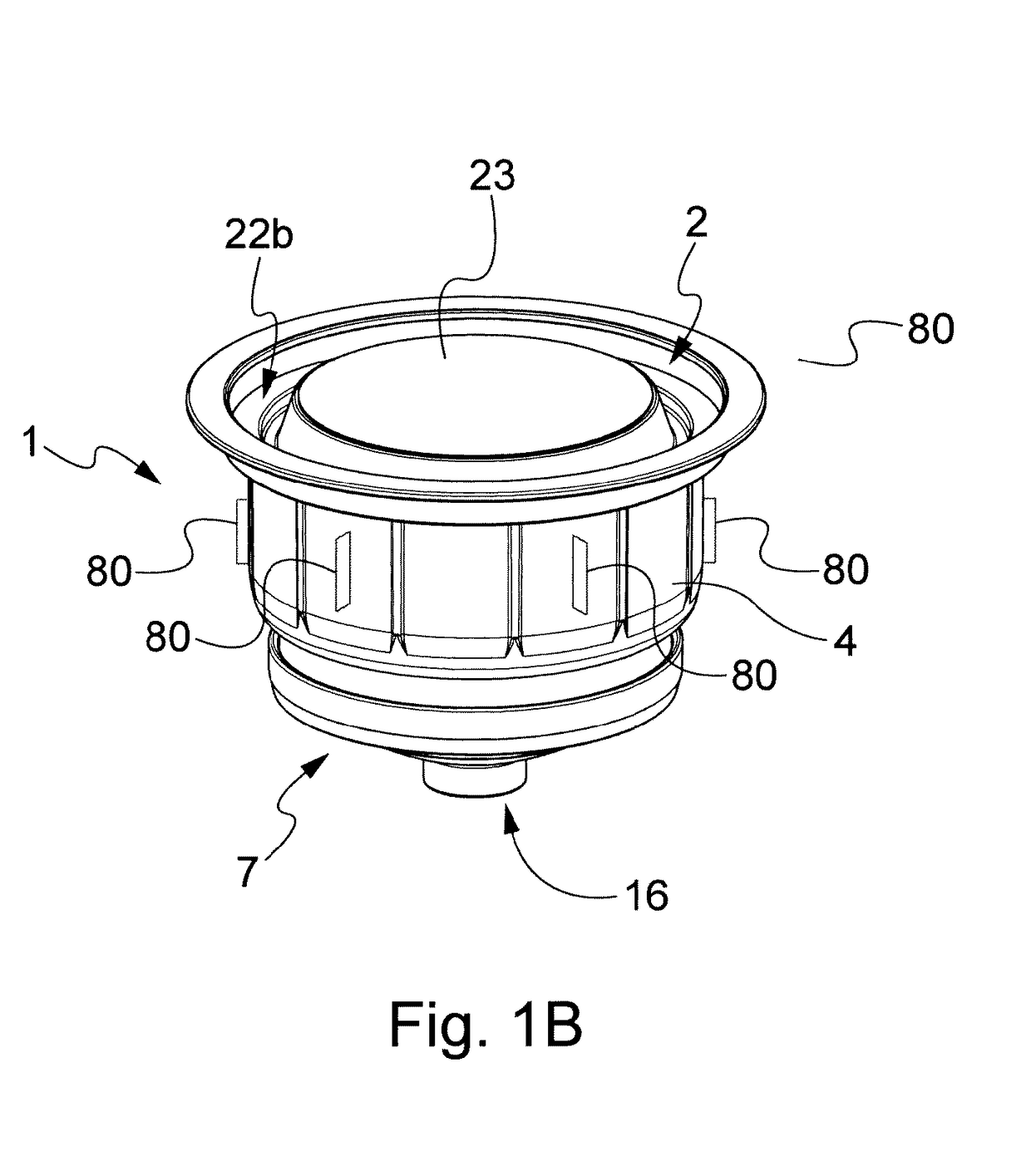

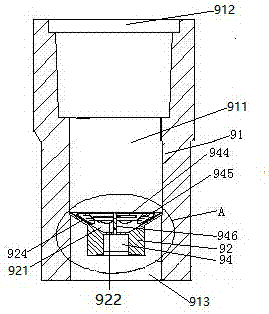

Optical level detector for a beverage machine

ActiveUS8338811B2Mitigate such drawbackClose togetherInvestigating moving fluids/granular solidsScattering properties measurementsLight beamLight emitter

A level detection device for detecting an upper surface of a liquid at a reference level. The device includes a reservoir having a bottom wall and one or more side walls that delimit a cavity for containing the liquid; a light emitter for emitting a light beam towards this cavity; at least one reflection surface for reflecting the light beam; and a light detector for detecting the emitted light beam upon reflection. The emitter and detector are so arranged that, when the surface of the liquid passes the reference level, a state of detection of the light beam by the detector is changed. The emitter, detector and reflection surface(s) are so located and oriented relative to the cavity that the emitted light beam is: detectable by the detector upon travelling through the liquid in the cavity; and refractable at the surface of the liquid towards or away from the detector so that the state of detection is a function of such refraction.

Owner:SOC DES PROD NESTLE SA

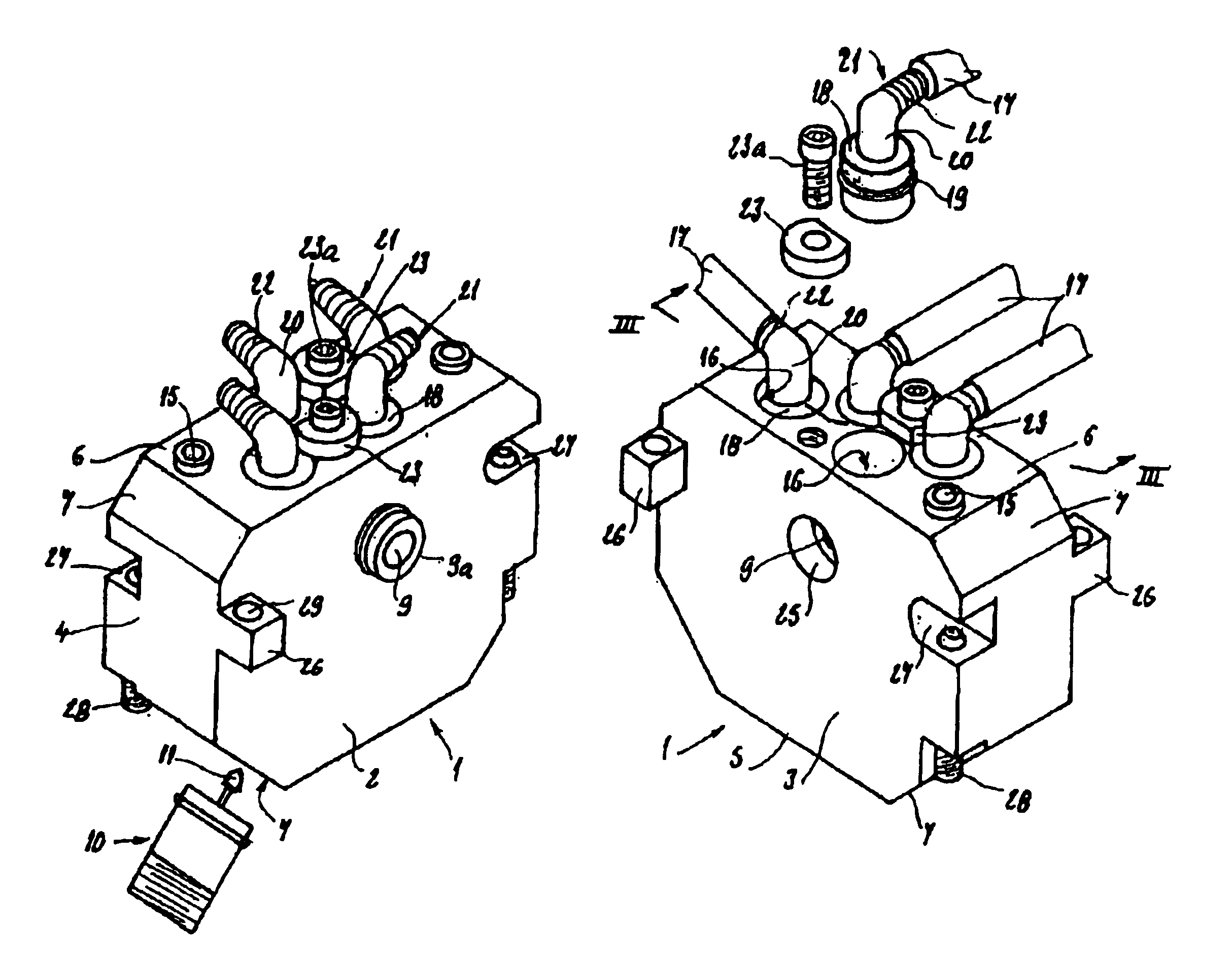

Color shade changing unit module for painting installation

InactiveUS6892764B2Convenient ArrangementSimple structureServomotor componentsMultiple way valvesEngineeringReturn channel

A color shade changing unit module for a painting installation is provided including a generally parallelepiped-shaped part, a bore formed in the part, a central channel into which the bore converges, the channel being perpendicular to end faces of the module, a valve housed in the bore, the valve including a closing element, a chamber formed in the part, a paint feed channel and a paint return channel leading into the chamber and leading out onto a side face of the module generally opposite from a wall in which the bore is formed, the closing element of the valve being designed, depending on a position of the closing element, to isolate, or to connect the central channel and the paint feed and paint return channels, and also including external pipes, connectors which connect the paint feed and paint return channels to the external pipes, each such connector having an externally threaded first, smaller-diameter part designed to screw into the external pipe, and a second, larger-diameter part surrounded by at least one seal and designed to fit leaktightly into a well formed in the module, the bottom of which leads into the respective paint feed and paint return channels.

Owner:EISENMANN FRANCE

Overload indicator for a load supporting apparatus

ActiveUS7363875B2Second distanceReduce distanceAnalysis using chemical indicatorsMeasurement apparatus componentsEngineeringMechanical engineering

Owner:D B IND

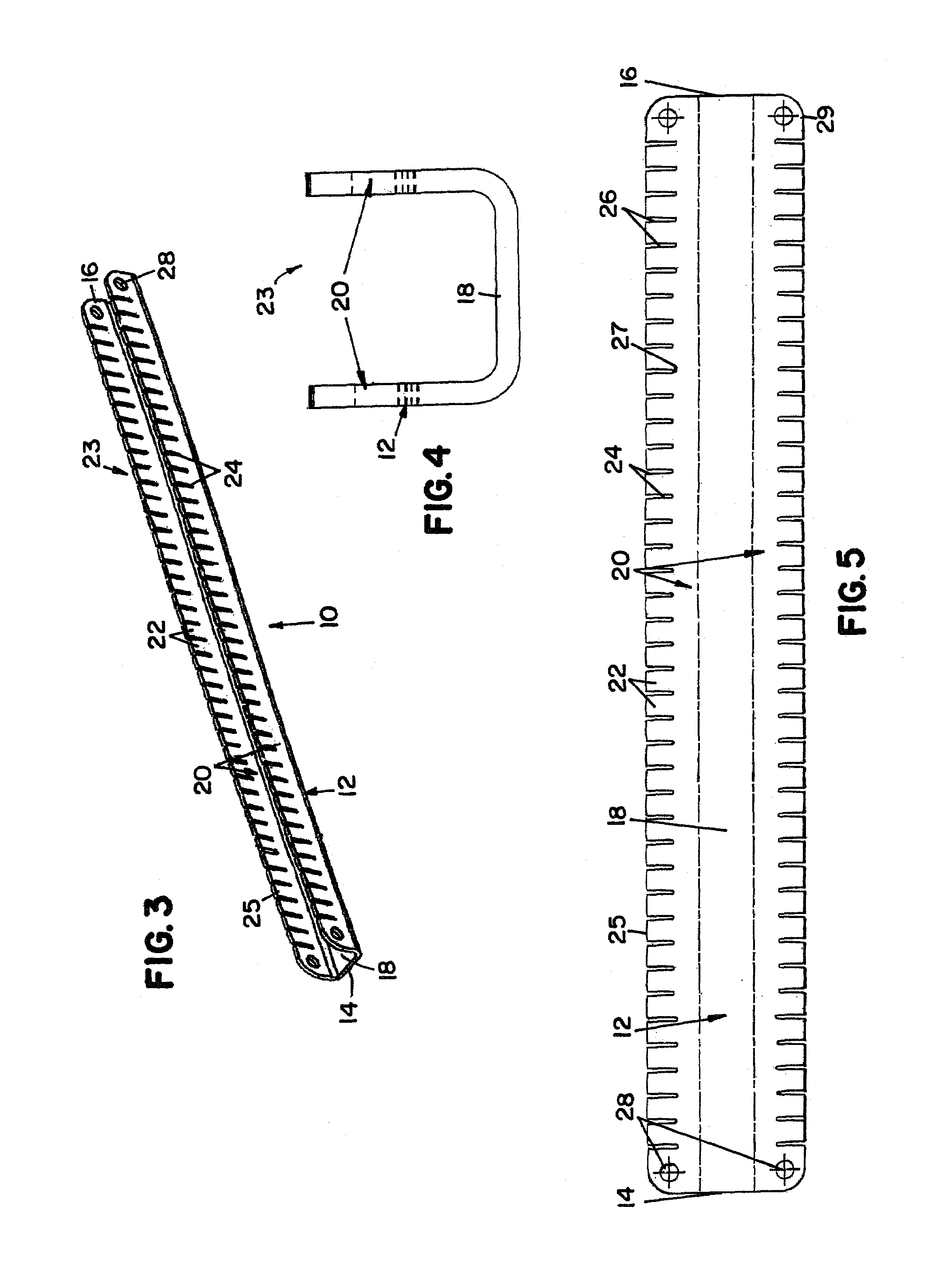

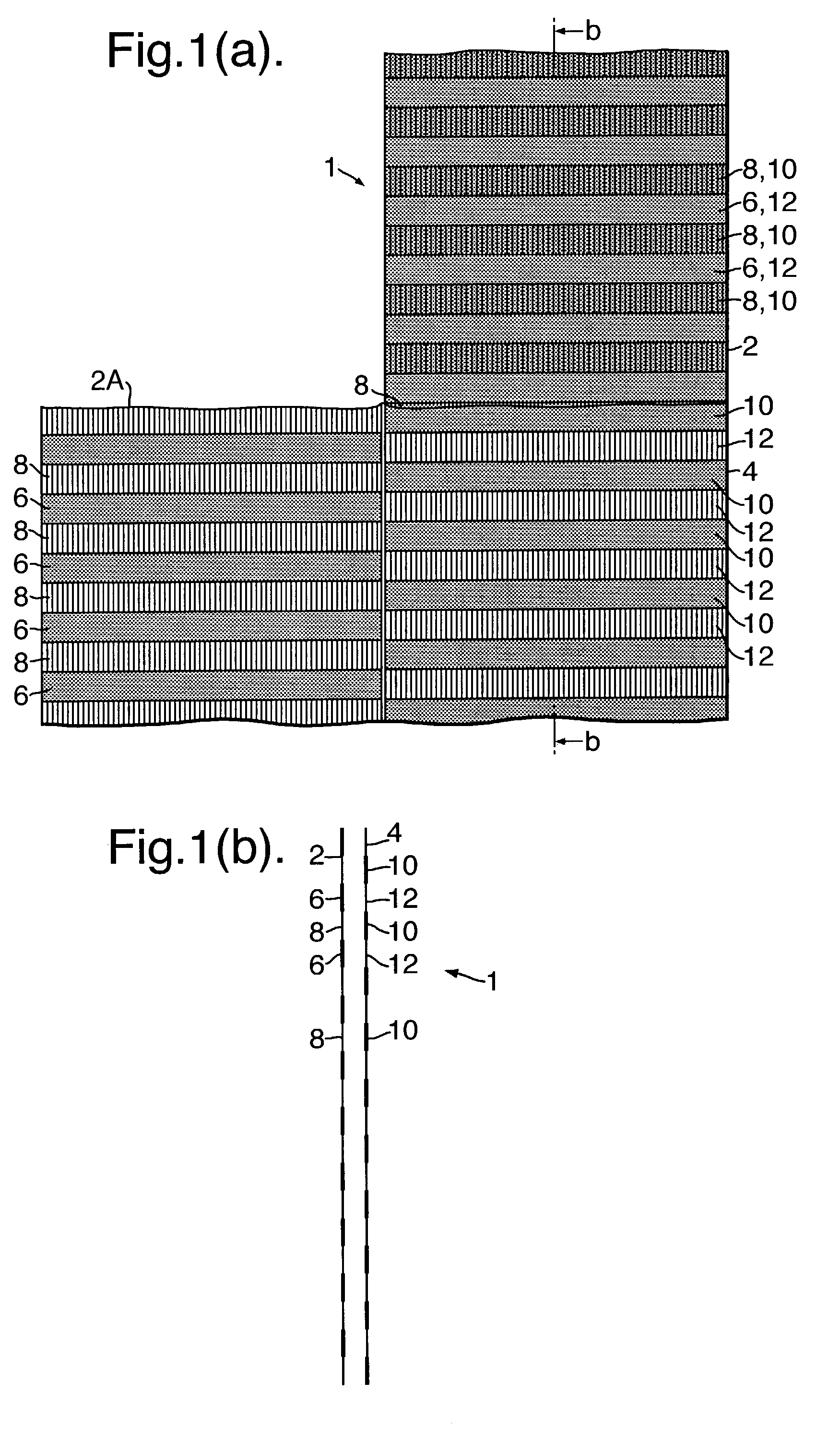

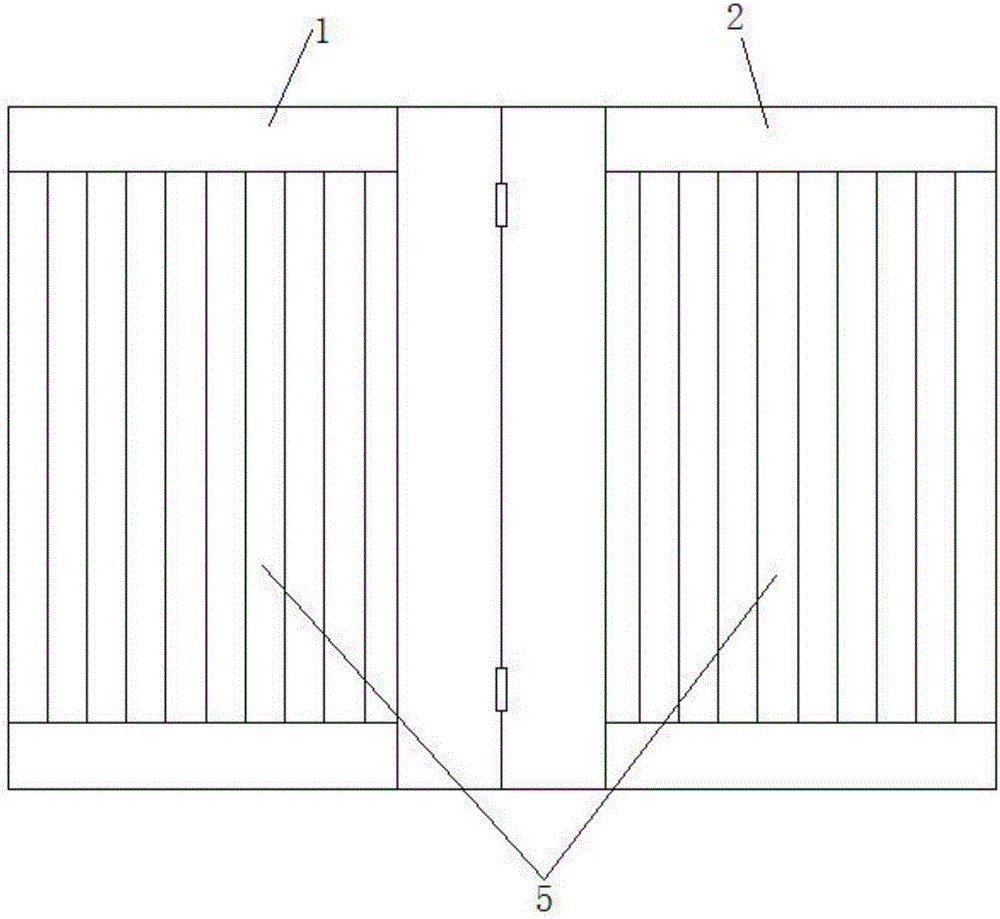

Architectural covering

InactiveUS7192633B2Close togetherExtensible doors/windowsShutters/ movable grillesEngineeringSecondary layer

A covering for an architectural opening, having a first layer with alternating relatively opaque stripes and relatively translucent stripes, and a second layer with alternating relatively opaque stripes and relatively translucent stripes. The first and second layers are positioned one behind the other, with the stripes substantially parallel. The first and second layers are movable relative to one another in a direction substantially perpendicular to the stripes. The covering also includes a series of parallel binder threads for attaching the first layer to the second layer. The binder threads run substantially perpendicular to the stripes, and thereby, one of the layers can be slid along the binder threads when moved relative to the other. The blind is preferred to be woven as a double-layer fabric.

Owner:HUNTER DOUGLAS IND BV

Antenna apparatus

ActiveUS20190372199A1Reduce signal lossDecreased signal propagationMultiple-port networksDecorative surface effectsElectrical conductorEngineering

The invention relates to antenna apparatus comprising: an antenna, a signal conductor and one or more RF MEMS switches, the antenna being conductively connected to the signal conductor, the MEMS switches and at least a portion of the signal conductor being supported by a crystalline MEMS substrate; and a capping substrate comprising a capping portion, wherein an enclosed volume is formed around the said MEMS switches between the capping portion and at least a portion of the crystalline MEMS substrate, and wherein the capping substrate comprises the said antenna.

Owner:SOFANT TECH

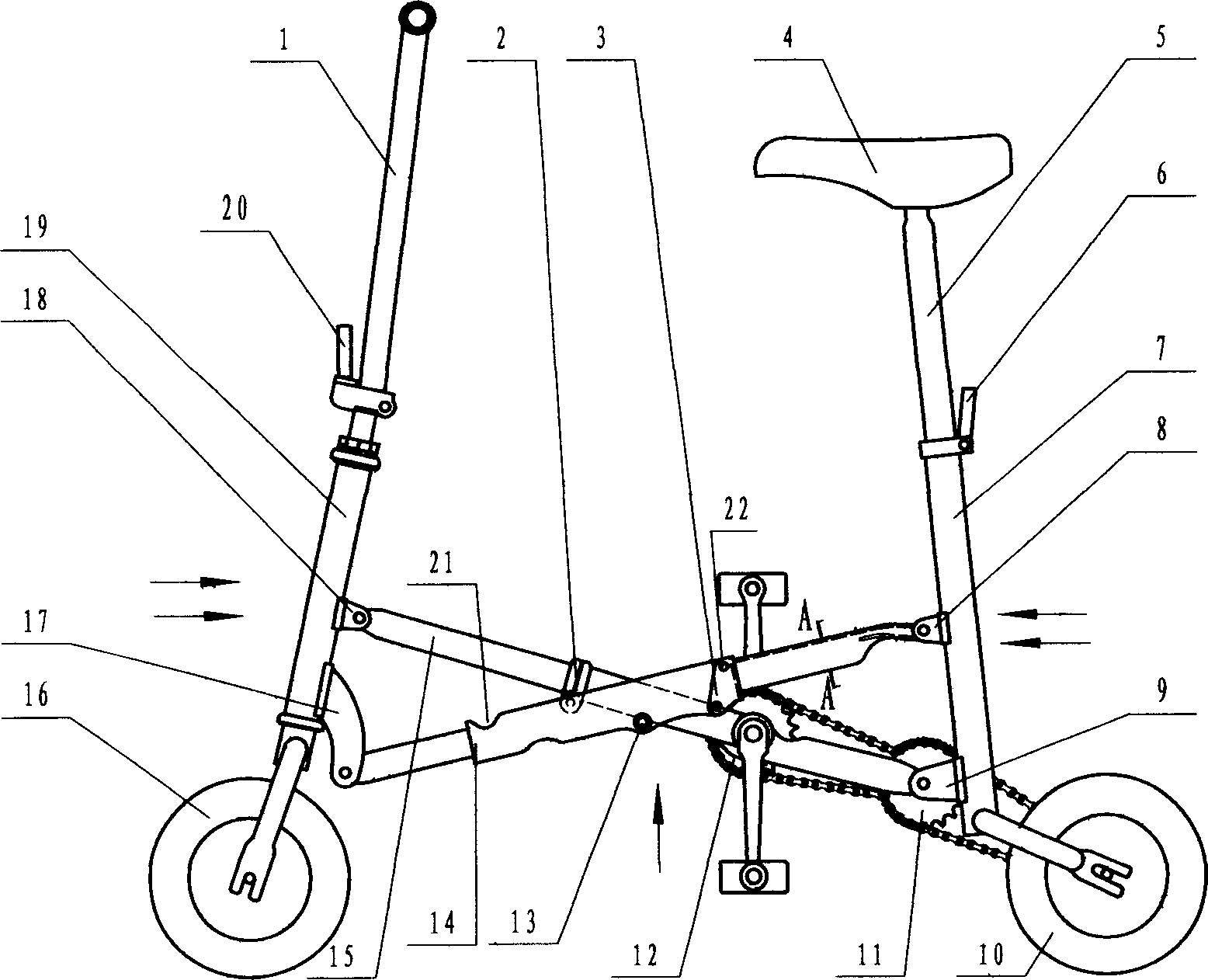

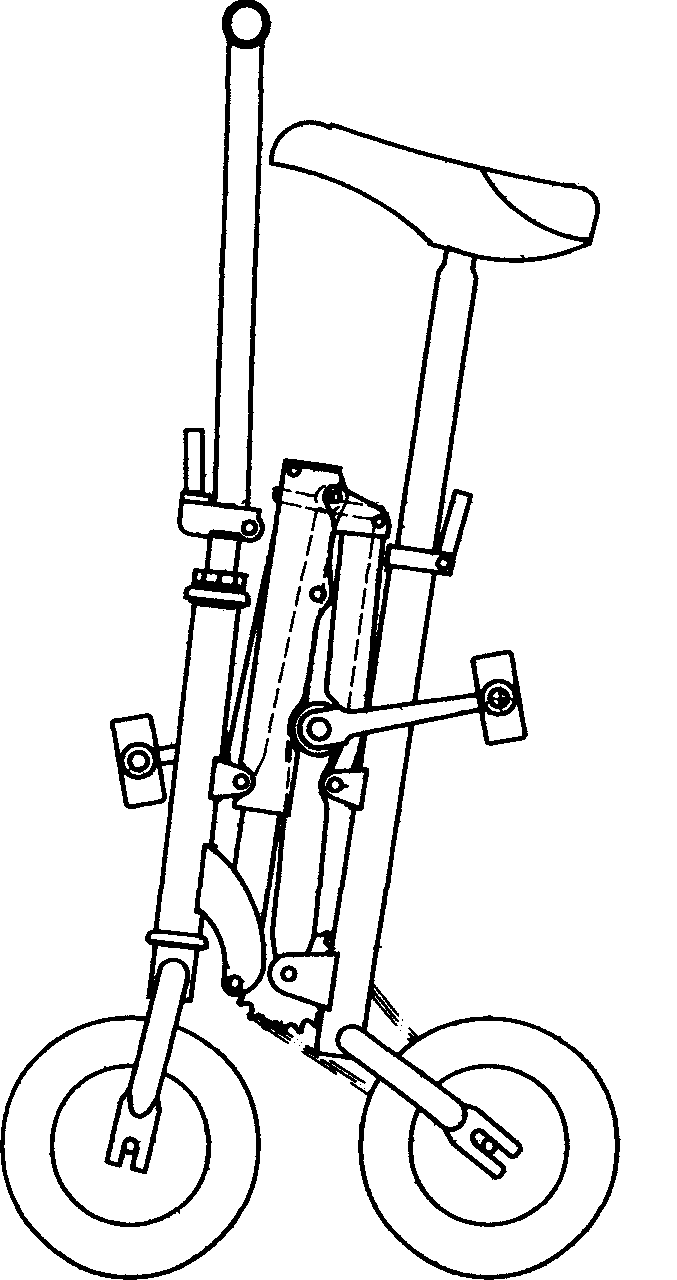

Compact type folding bicycle

A foldable compact bicycle is composed of frame with front tube, vertical tube and main tube unit consisting of two tubes A and B which are pinned at their middles, handle-bar, saddle and its supporting tube, front and back wheels, and a two-stage driver consisting of crank chain wheel and acceleration wheel for high speed.

Owner:詹富生

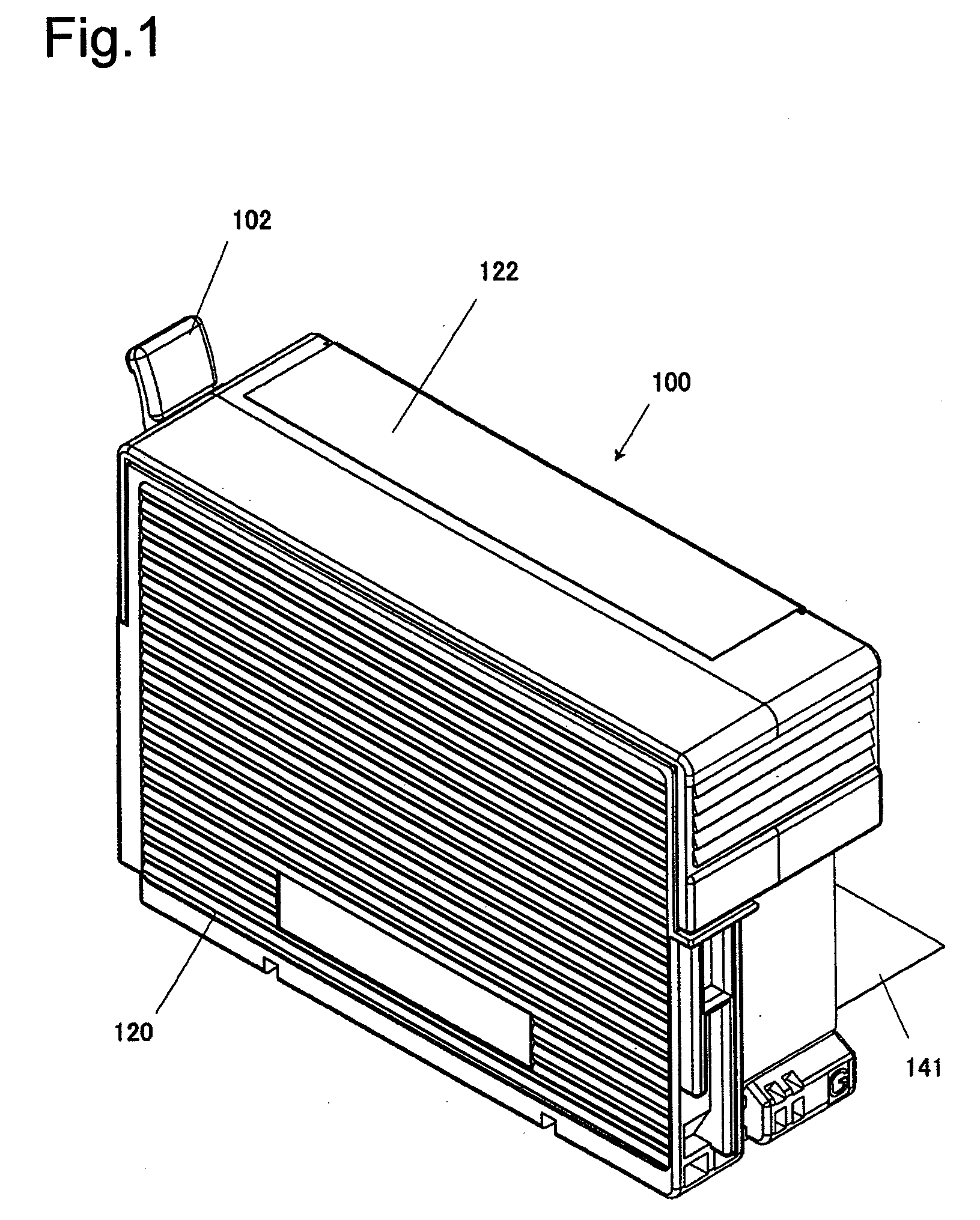

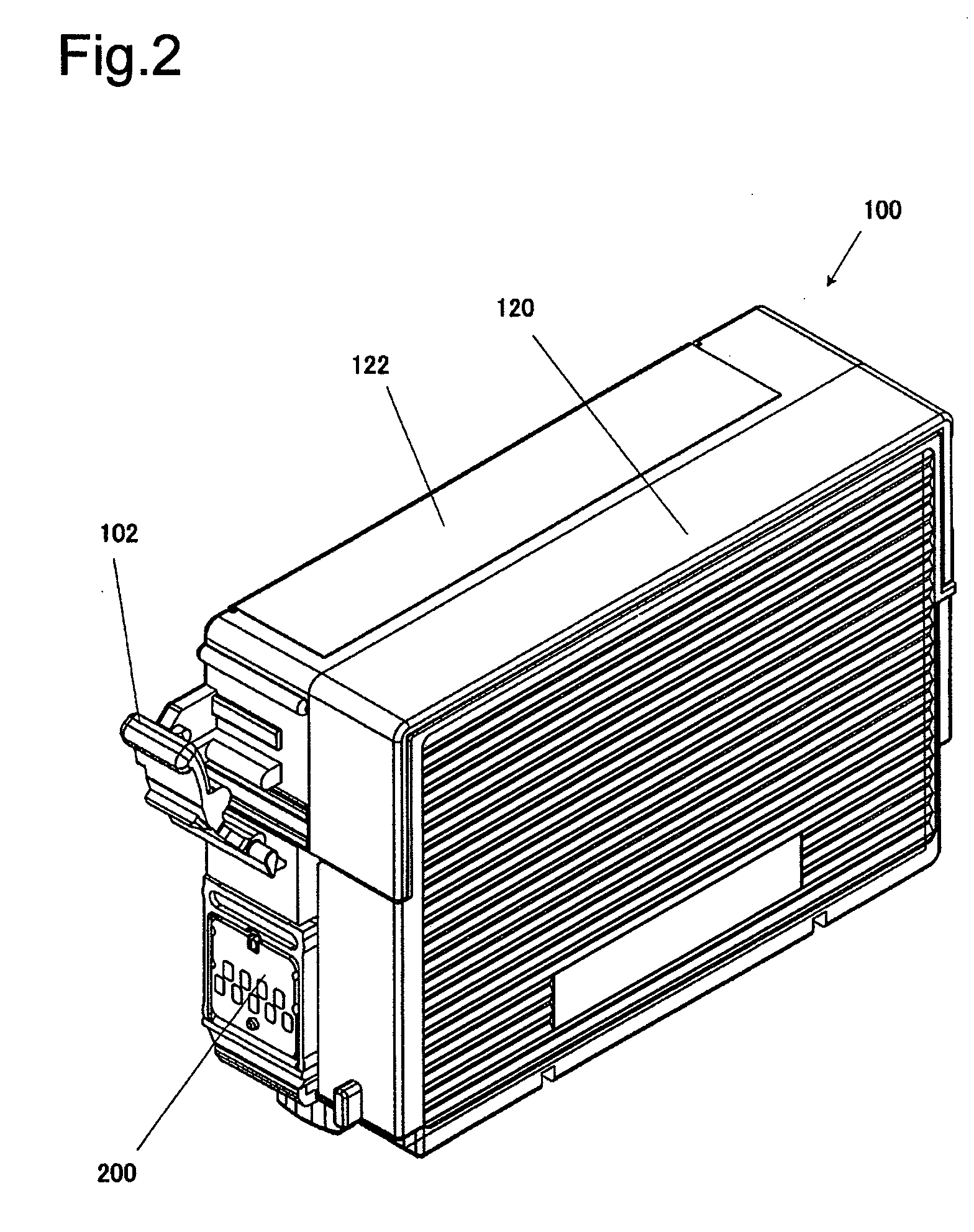

Liquid container and method of manufacturing the same

ActiveUS20090237475A1Fast chargingAvoid breakingWriting implementsMetal-working apparatusEngineeringLiquid storage

The liquid container has substantially rectangular parallelepiped shape having a bottom face that is situated at bottom when the liquid container is attached to the liquid consuming apparatus, and a first side face that is substantially orthogonal to the bottom face. The liquid container pertaining the second mode comprises a liquid storage portion that stores a liquid, a liquid feed portion that is situated downstream from the liquid storage portion and that feeds the liquid to the liquid consuming apparatus, and an air introduction portion that is situated upstream from the liquid storage portion and that introduces air into the liquid storage portion from an upstream side in association with feed of the liquid to the liquid consuming apparatus. The liquid storage portion includes a first liquid storage chamber having a first storage chamber bottom face situated at bottom, a first upstream opening situated along the first storage chamber bottom face, and a first downstream opening situated along the first storage chamber bottom face, a second liquid storage chamber that is situated further downstream from the first liquid storage chamber and that includes a second storage chamber bottom face situated at bottom, a second upstream opening situated along the second storage chamber bottom face, and a first downstream opening situated along the second storage chamber bottom face, and a connecting flow channel disposed between the first downstream opening and the second upstream opening so as to connect the first liquid storage chamber with the second liquid storage chamber. The first upstream opening, the first downstream opening, the second upstream opening, and the second downstream opening are juxtaposed in proximity to the bottom face of the liquid container. The first storage chamber bottom face slopes so as to be lower towards the juxtaposed first upstream opening and first downstream opening with the container attached to the liquid consuming apparatus. The second storage chamber bottom face slopes so as to be lower towards the juxtaposed second upstream opening and second downstream opening with the container attached to the liquid consuming apparatus.

Owner:SEIKO EPSON CORP

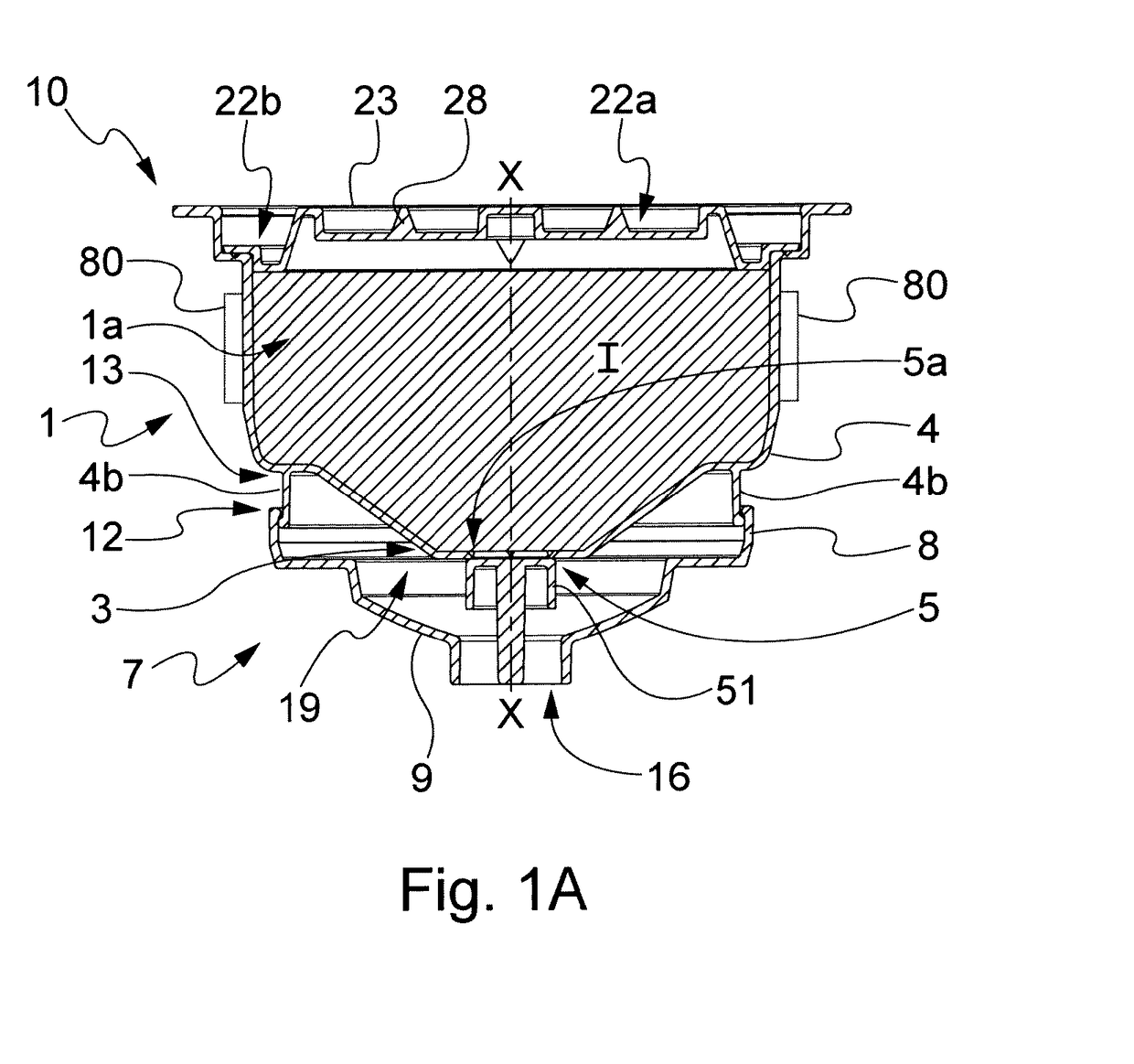

A capsule assembly comprising a capsule and a conveyor cap configured to open said capsule

ActiveUS20190016527A1Fully protectedConvenient amountBeverage vesselsPackagingBiomedical engineering

A capsule assembly including a capsule for preparation of beverages and a conveyor cap mounted on the capsule for conveying the beverage exiting the capsule. The capsule includes an inlet wall, an outlet wall, and a lateral wall defining an internal volume inside which at least one beverage ingredient is housed. The outlet wall includes one or more capsule beverage outlets. The conveyor cap is mounted on the capsule to define an enclosure space between the outlet wall and an inner surface of the conveyor cap. The conveyor cap includes one or more beverage delivery openings and is movably mounted on the capsule. The capsule beverage outlets and the conveyor cap are configured to interact so that the capsule beverage outlets are opened by the conveyor cap due to a relative movement between the capsule and the conveyor cap.

Owner:TUTTOESPRESSO SRL

Cam accessible portable bow press

InactiveUS8733333B2Ease and transportabilityClose togetherBows/crossbowsLaunching weaponsEngineeringCam

A cam accessible portable bow press is comprised of a pair of press arm, each press arm further comprising a pair of press levers, each press lever comprising a limb lever adapted to be adjustably disposed between a bow's riser and one of the bow's cams and a cam lever adapted to substantially enclosed the outer circumference of a cam without obstructing access to the side of each cam. The press arms are tensioned using a combination of straps and buckles, allowing the user to compress the bow's limbs to aid in stringing or unstringing the bow or to perform maintenance on the bow's cams without to unstringing the bow.

Owner:BARRIOS ANTHONY

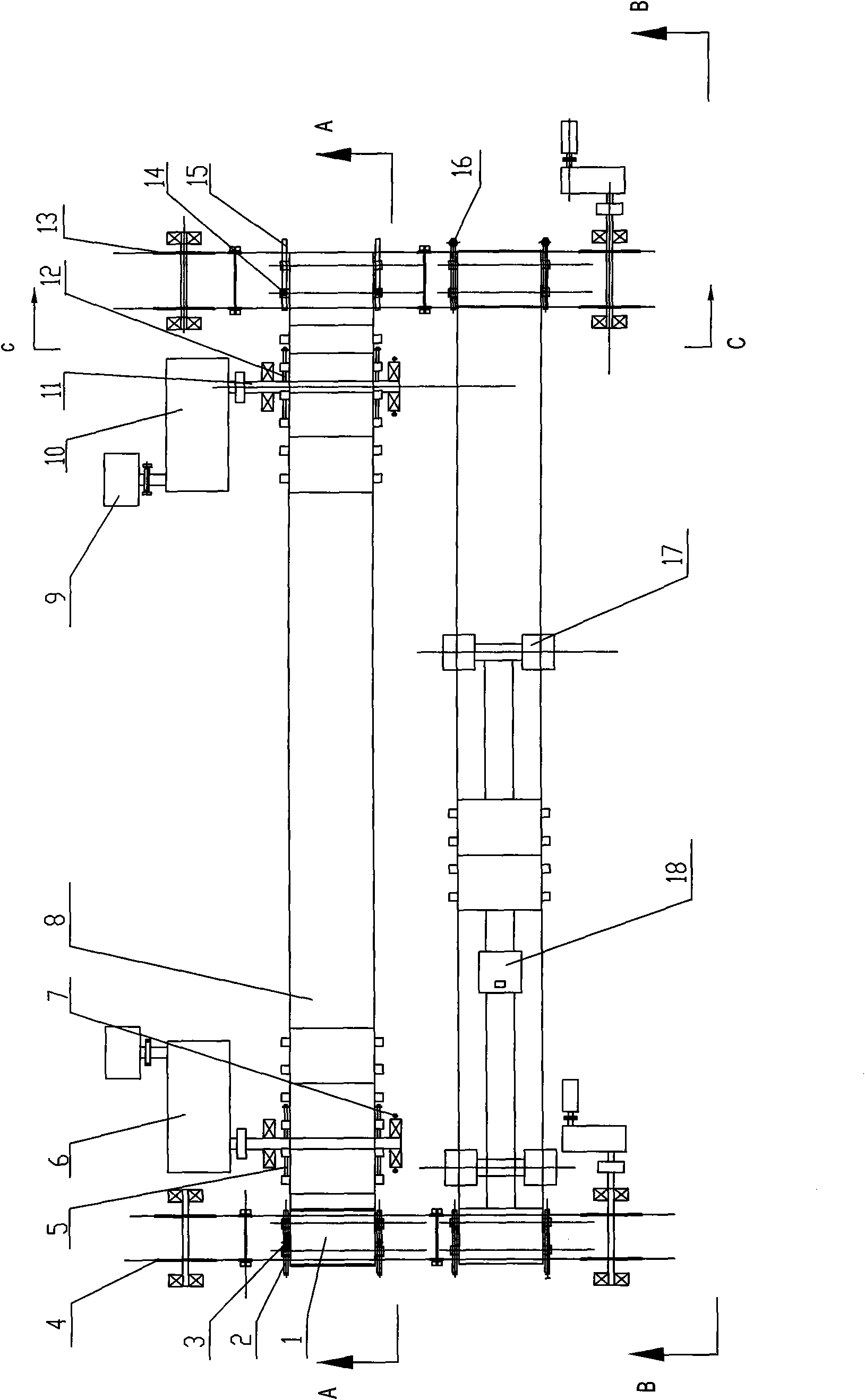

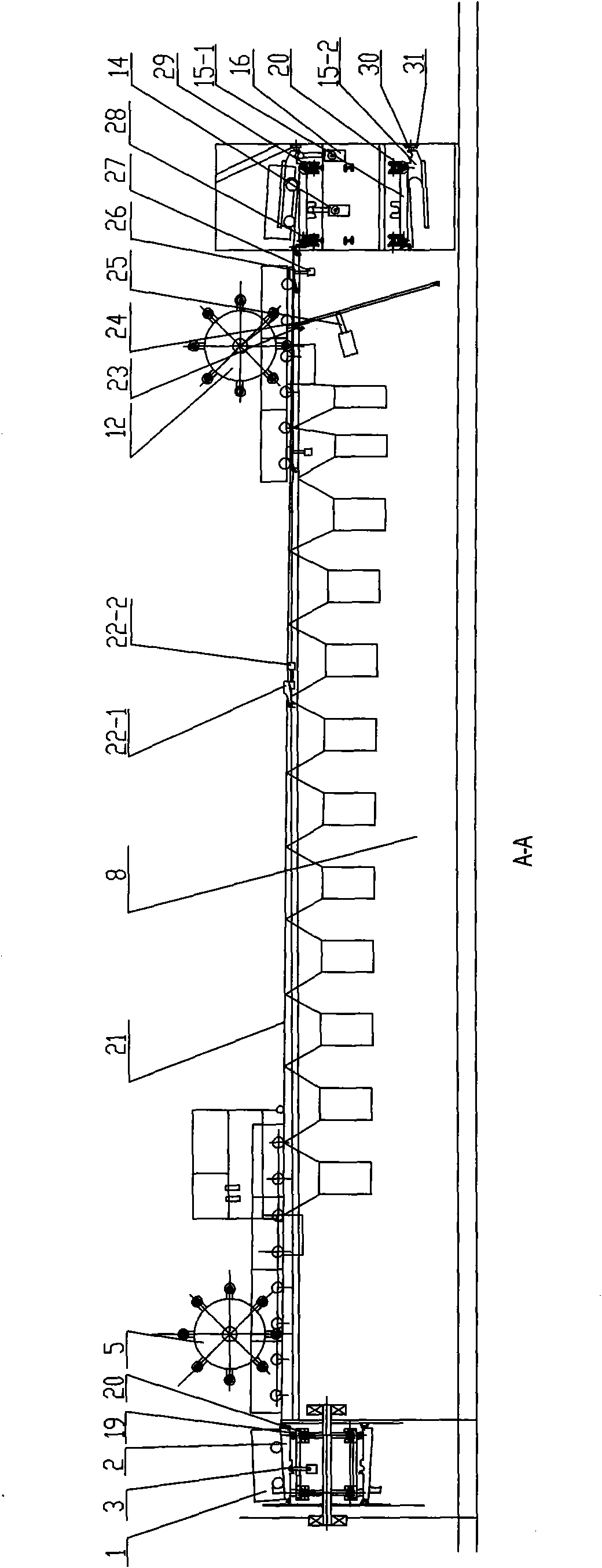

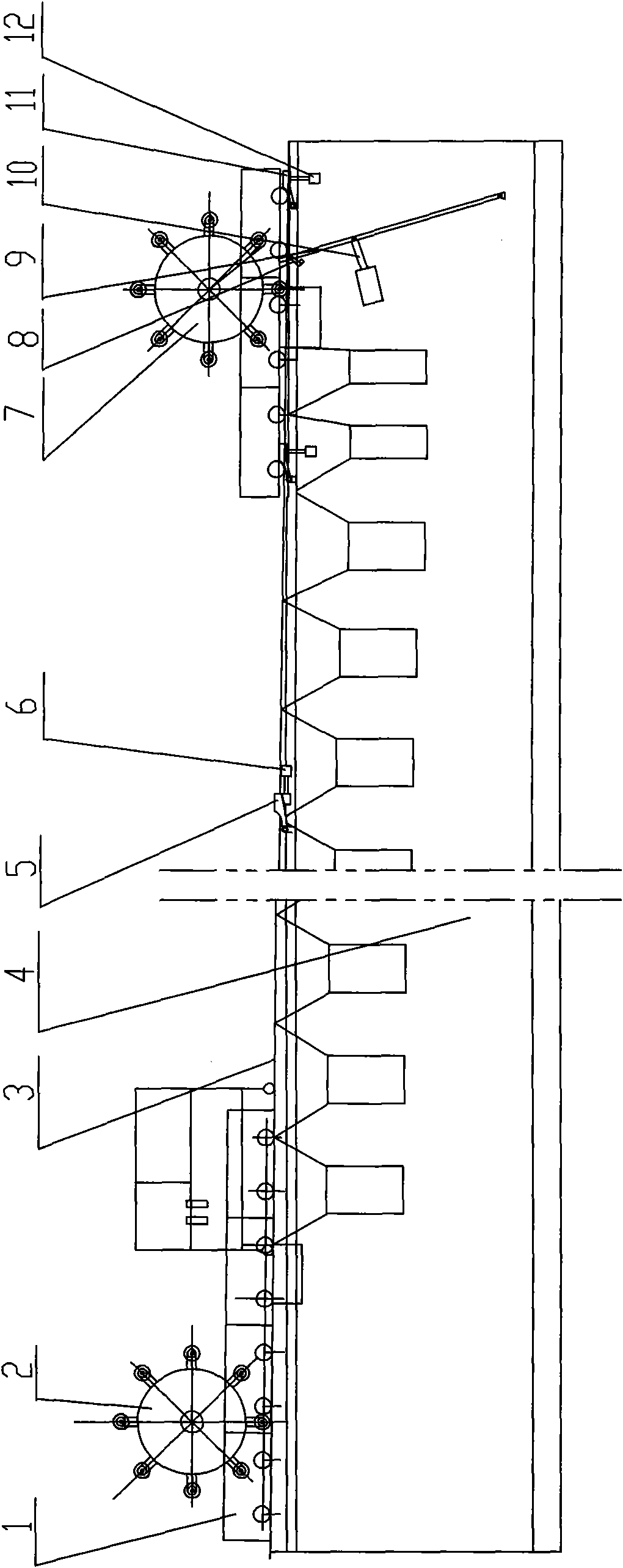

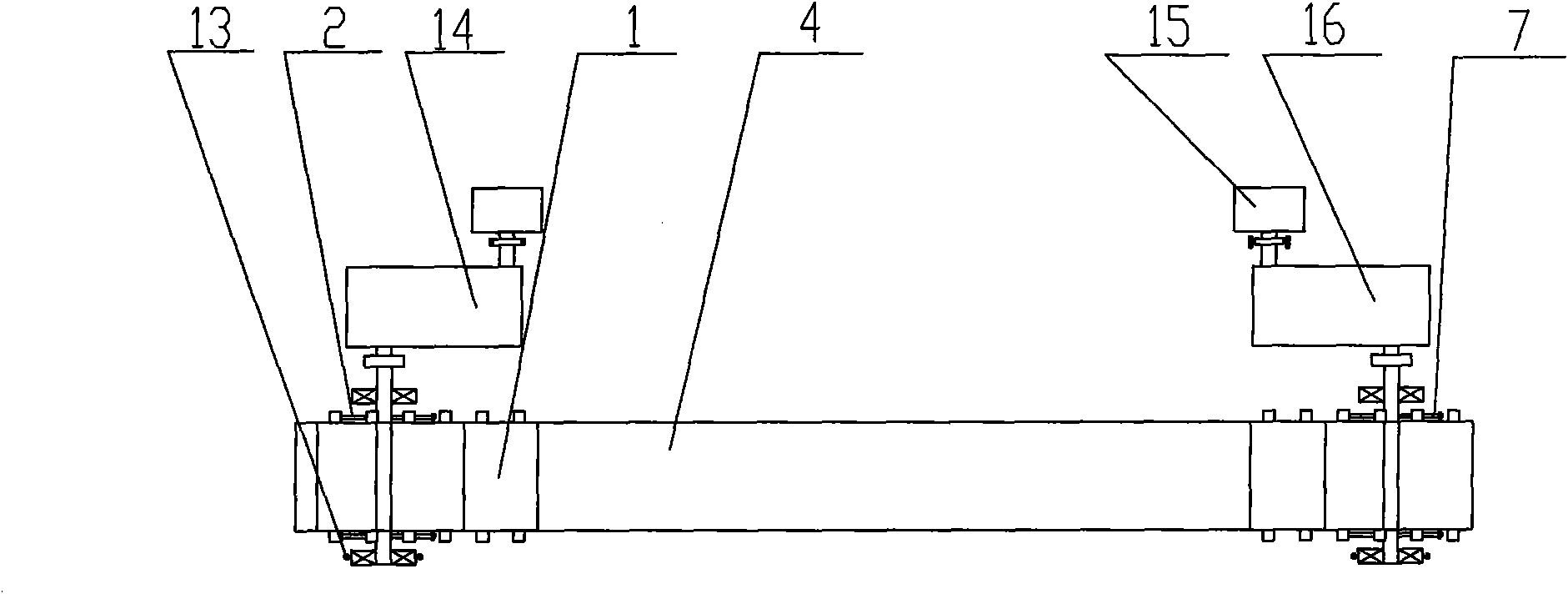

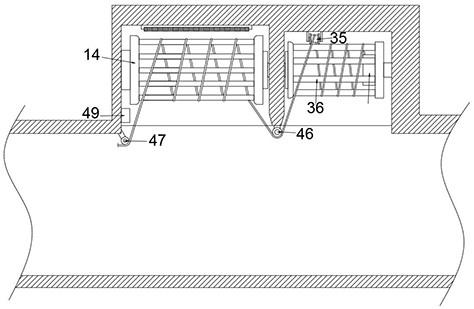

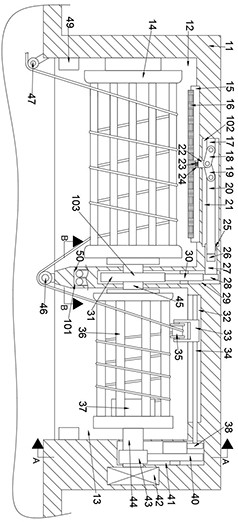

Energy-saving continuous operation inclined plane sintering machine

The invention relates to an energy-saving continuous operation inclined plane sintering machine, which is characterized in that: a trolley track is obliquely arranged in a mode of a high feed end and a low discharge end; a tail of a sintering machine main body is provided with a damping mechanism and a rapid feeding mechanism; a trolley limiting mechanism is arranged between a head and the tail of the trolley track and on the tail of the trolley track; supports below two chain wheel groups of a head chain conveying device and a tail chain conveying device are provided with guide grooves respectively, a head board turning mechanism is transversely arranged discontinuously between left and right chains of the head chain conveying device, and a tail board turning mechanism is transversely arranged discontinuously between left and right chains of the tail chain conveying device; the trolley return track consists of a low-front high-back trolley rolling section, a high-front low-back climbing section and a low-front high-back conveying section; and a winding gear is arranged below the climbing section of the trolley return track, and the supports below the climbing section are uniformly provided with backward stoppers. The energy-saving continuous operation inclined plane sintering machine has the advantages of good energy-saving effect, low air leakage ratio of a device and easy implementation of the large-scale device.

Owner:张健

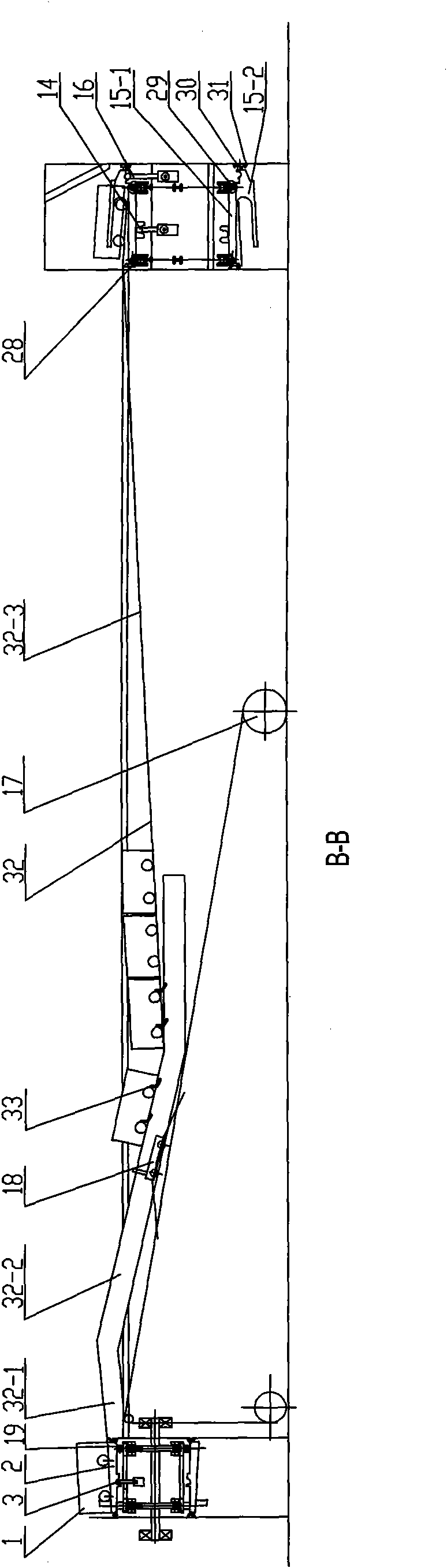

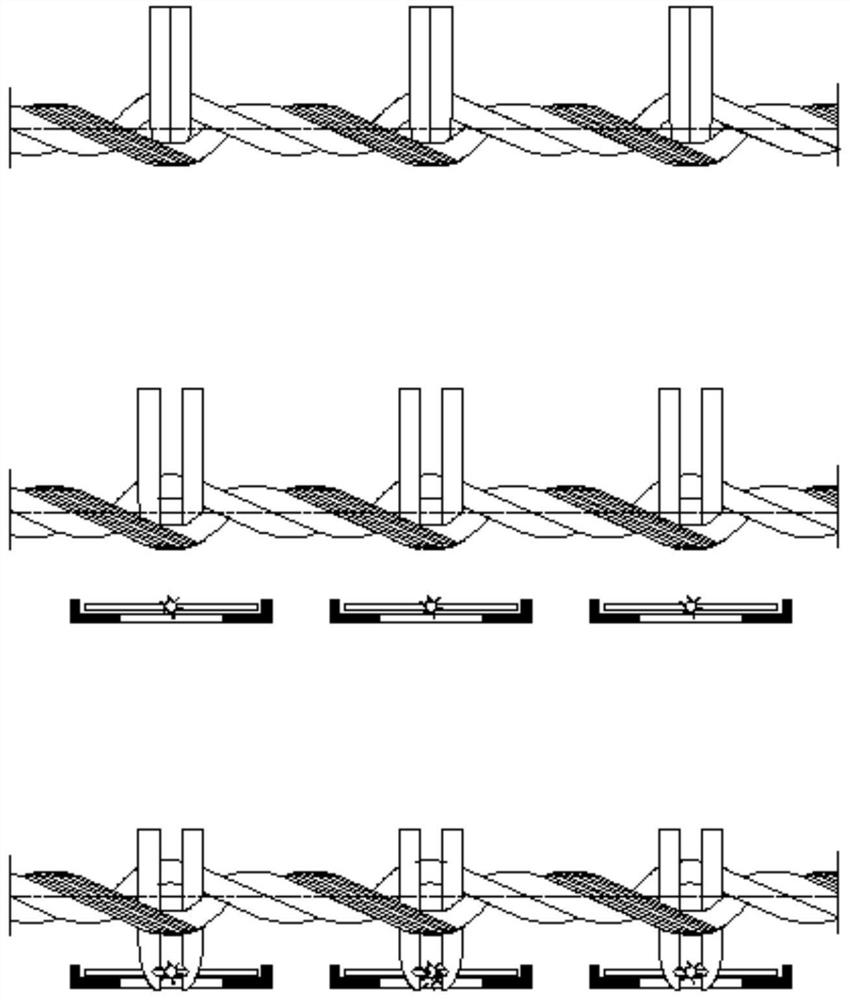

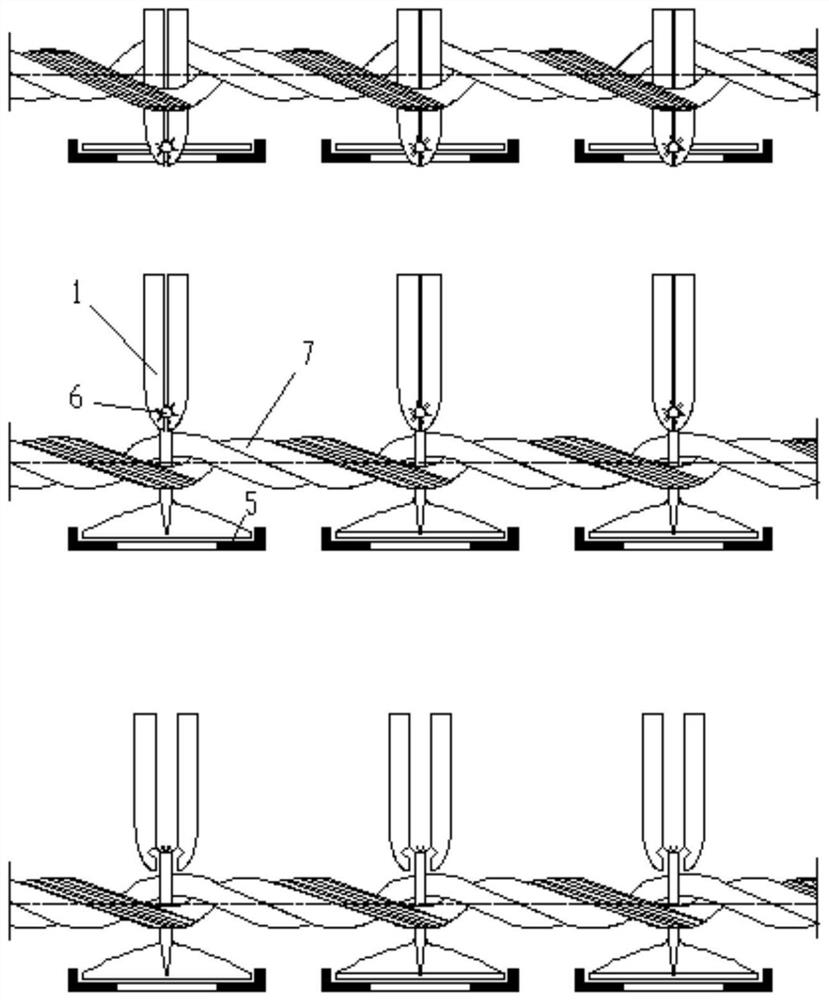

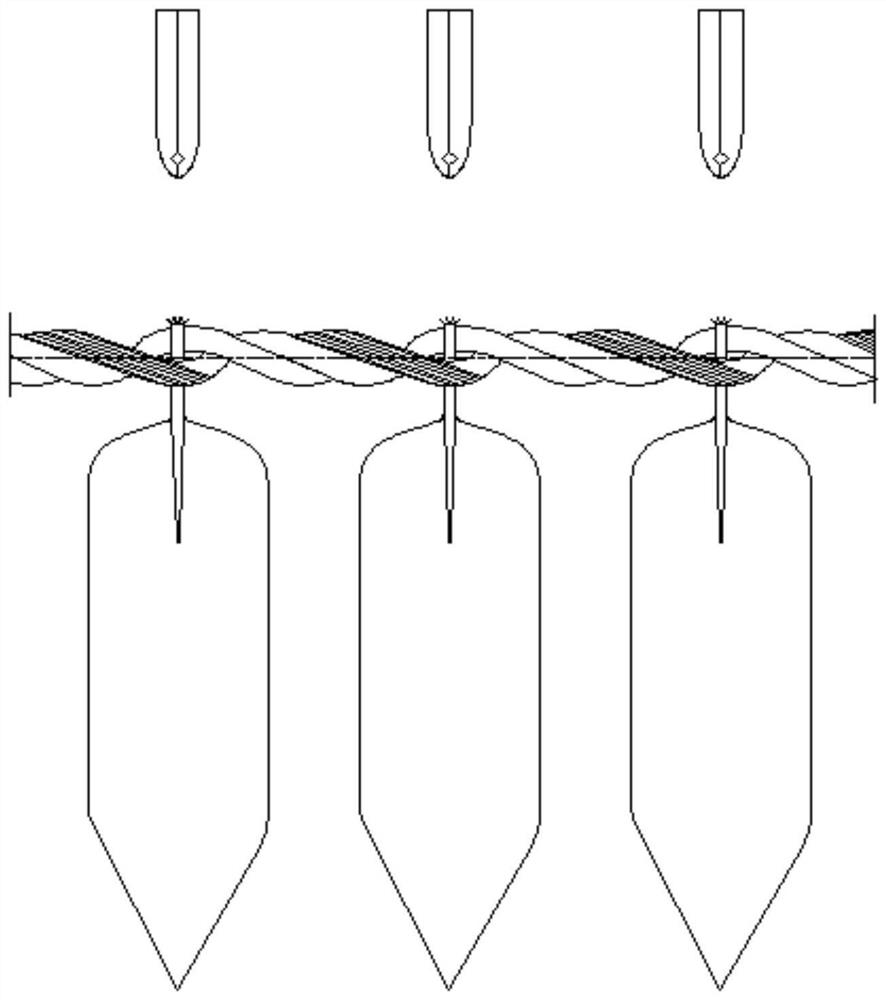

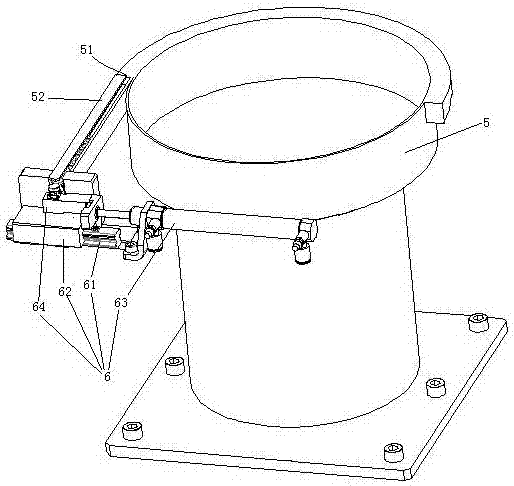

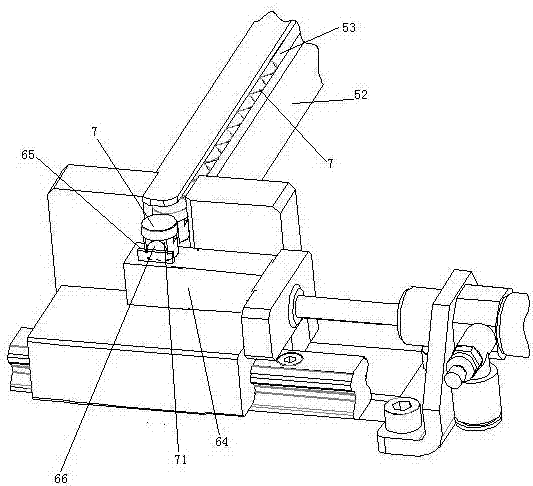

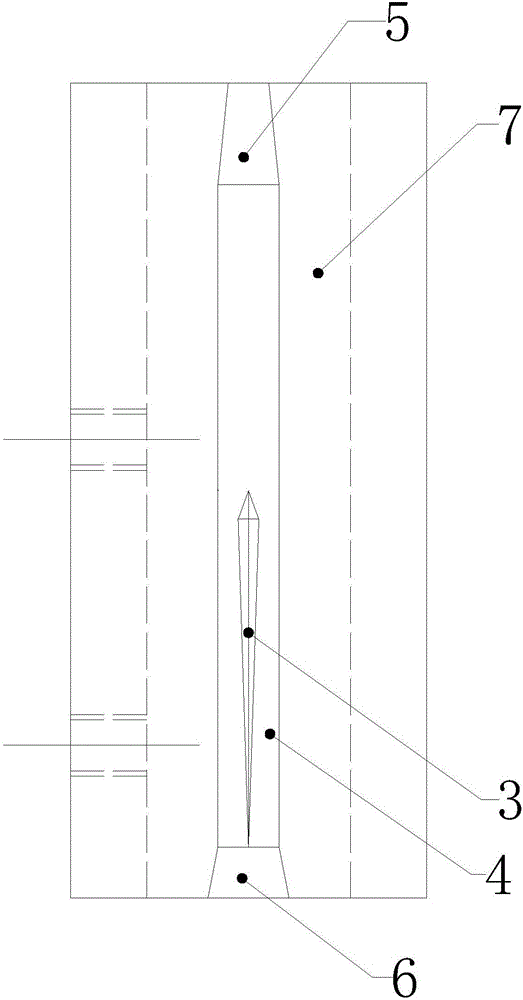

Device and method for vertically clamping seedlings of kelp in rows

ActiveCN112205289ASolve the problem of top deathResolve the breakCultivating equipmentsSeaweed cultivationBiologySeedling

The invention relates to a device for vertically clamping seedlings of kelp in rows. The direction of seedling ropes is in the left-right direction, the direction horizontally perpendicular to the direction of the seedling ropes is in the front-back direction, and the device comprises seedling clamping devices and a seedling boxes. The seedling clamping devices comprise left seedling clamping fingers and right seedling clamping fingers, the ends of the left seedling clamping fingers and the right seedling clamping fingers are downward to be ellipsoidal when the left seedling clamping fingers and the right seedling clamping fingers are folded, a groove is formed in each seedling clamping finger in the front-back direction, and the cross section generated when the pair of grooves of each seedling clamping device is folded is square or polygonal when the pair of grooves is folded to be used for containing kelp roots and stems. The seedling boxes are located below the corresponding seedling clamping devices, kelp seedlings are horizontally placed in the seedling boxes in the front-back direction, and when the left seedling clamping fingers and the right seedling clamping fingers of theseedling clamping devices clamp the kelp seedlings and upwards penetrate through gaps of one strand of seedling ropes, the kelp seedlings are in a Z shape in the left-right view angle. Due to the fact that kelp seedlings are horizontally placed in the seedling boxes, the seedling clamping direction is horizontal, a root system protector can be omitted, the overall structure of the device is simplified, and meanwhile the problem that due to the root system protector, the needed gap opening degree among three strands of seedling ropes is too large, and consequently equipment arrangement is difficult is solved.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Sintering stage of slope sintering machine

InactiveCN101806543ACapable of continuous productionReduce loadFurnace typesHydraulic cylinderAutomatic control

The invention relates to the technical field of sintering equipment, in particular to a sintering stage of a slope sintering machine. The sintering stage is characterized in that a trolley track is inclined with a higher feed end and a lower ore removal end, a damping mechanism is arranged on the tail of the machine body of the sintering machine, two fine-adjustment mechanisms are separately arranged on the bearing seats of the driven ends of the transmission shafts of a driving mechanism and the damping mechanism, a fast feeding mechanism is arranged on the tail of the machine body of the sintering machine, two trolley spacing mechanisms are separately arranged on the tail of the trolley track and between the head and the tail of the trolley track, and the driving wheel of the driving mechanism and the damping wheel of the damping mechanism are both next to and connected with the shaft sleeve which is arranged on the axle of the trolley and near the wheels of the trolley; and the fast feeding hydraulic cylinder of the fast feeding mechanism and the spacing hydraulic cylinders of the trolley spacing mechanisms are connected with an automatic control system. The invention has good energy-saving effect and low air leakage ratio of equipment, and the enlargement of equipment is easy to realize by using the invention.

Owner:张健

Cryosurgery compositions and methods

InactiveUS20060122588A1Easy to implementEffectively causingSurgical instruments for heatingSurgical instruments for coolingBiochemistryBULK ACTIVE INGREDIENT

A eutectic changing composition, including a system and method of its use. The eutectic changing composition can be used in a localized area of a biological material, such as in a mammal, where the eutectic changing composition includes as an active ingredient at least one solute effective to change a tissue eutectic freezing point at the localized area of biological material. The solute can be effective to increase the tissue eutectic freezing point of the biological material.

Owner:RGT UNIV OF MINNESOTA

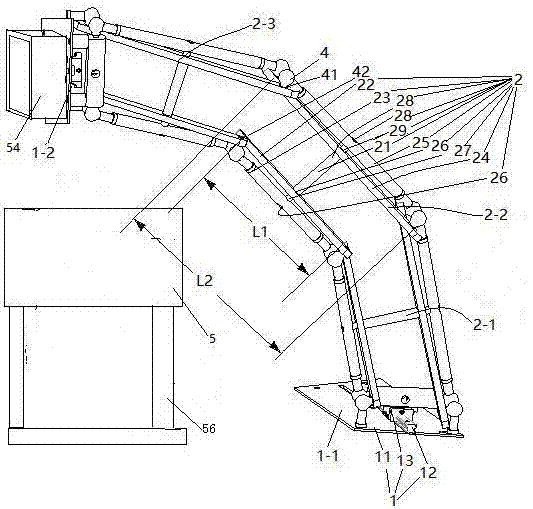

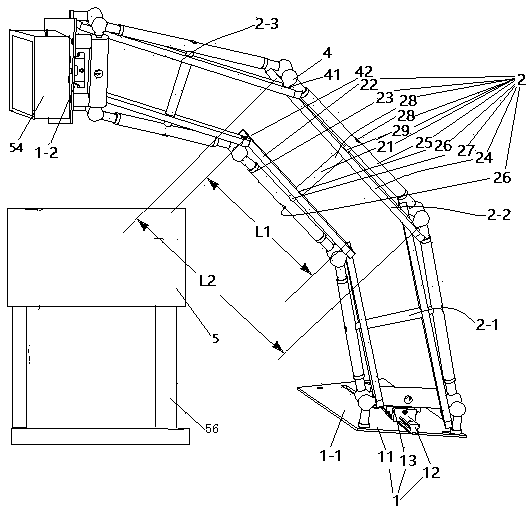

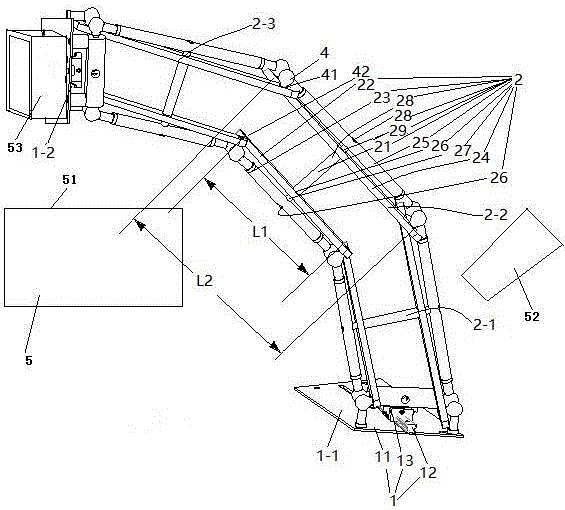

Material conveying manipulator for pharmacy

ActiveCN106976078AClose togetherReduce in quantityProgramme-controlled manipulatorPharmacyEngineering

The invention relates to equipment for steel production. A material conveying manipulator for pharmacy comprises a plurality of arms comprising an outer first rod, an inner first rod, an inner second rod and an outer second rod which are arranged in turn in the axial direction of a center shaft; the inner first rod, the inner second rod, the outer first rod and the outer second rod of one arm section are hinged with the spherical surfaces of the outer first rod, the outer second rod, the inner first rod and the inner second rod of another arm section correspondingly, and the distance between two hinge points of the inner first rod is smaller than that of the inner second rod; the first arm section is connected to the first connecting base assembly section, and the last arm section is connected to the last connecting base assembly section; and an end connecting base support is connected to a charging basket through screws fit to nuts. The material conveying manipulator for pharmacy provided by the invention has the advantages that the charging basket is easy to install and remove, and all arm sections can be driven to extend and retract through only one driving mechanism, and the material conveying manipulator is used for solving the problem that raw materials are hard to manually convey to the charging basket in the pharmaceutical process.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD +1

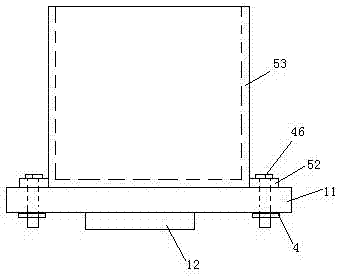

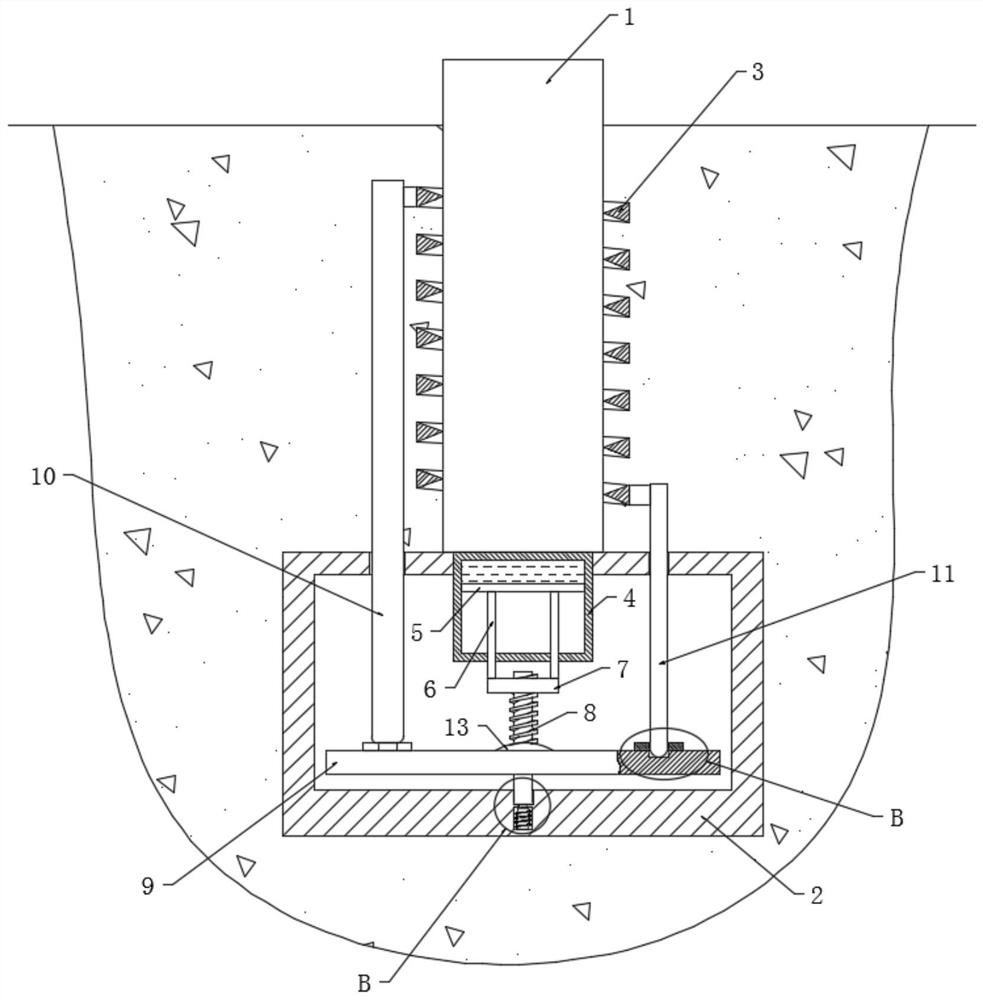

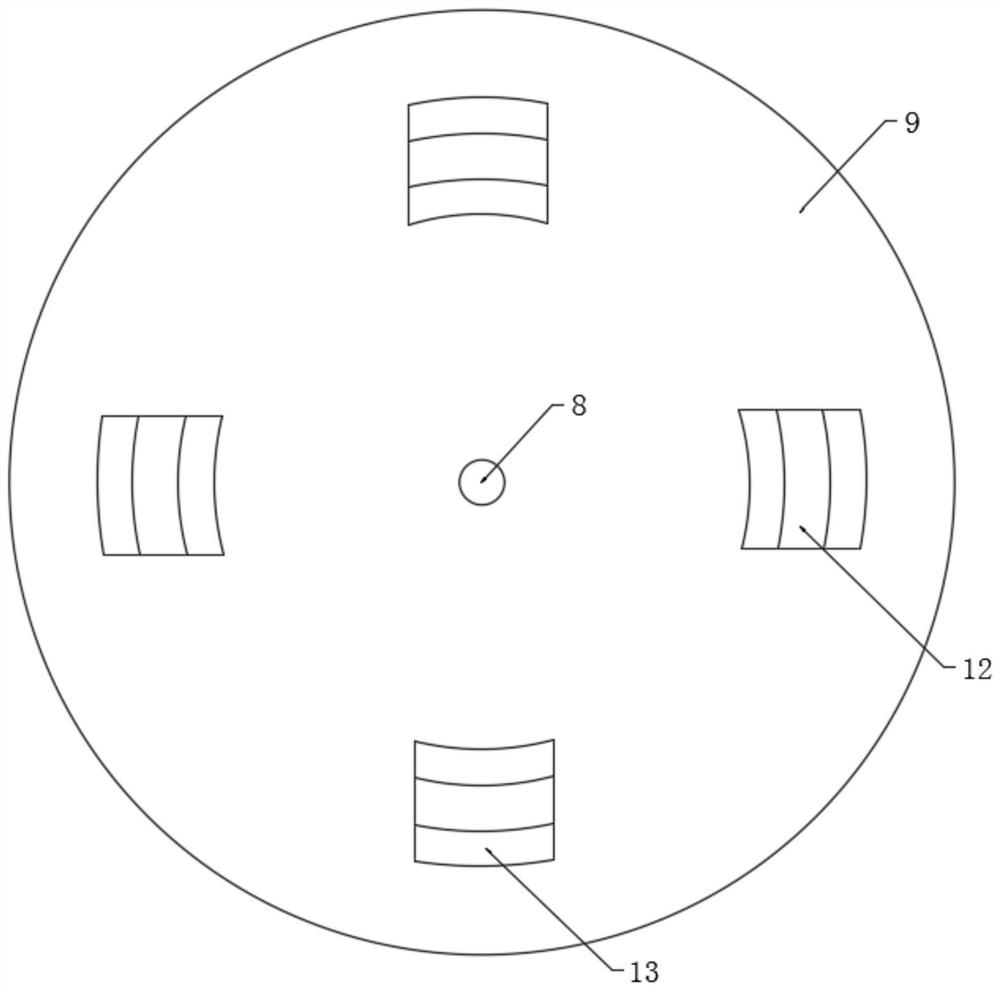

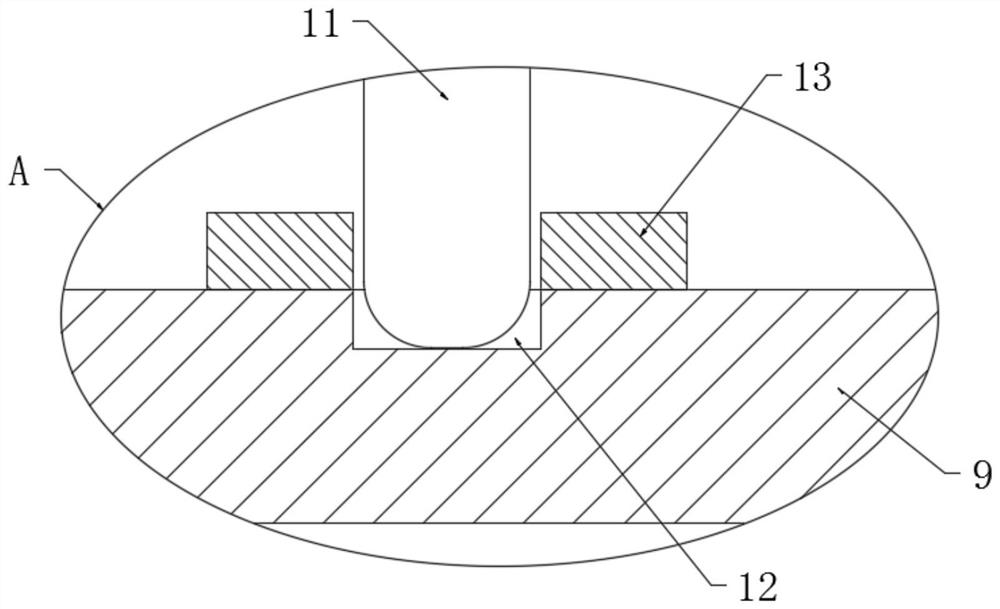

Lightning arrester grounding device convenient to maintain

InactiveCN111834763AWith self-maintenance functionPlay a tensioning effectCoupling device detailsConnection contact member materialCircular discStructural engineering

The invention discloses a lightning arrester grounding device convenient to maintain. The grounding device comprises a grounding rod, and the lower end of the grounding rod is welded with an insulatedcase. The grounding rod and the case are buried in the ground together; a scraper ring is arranged on the portion, buried in the ground, of the grounding rod around a shaft, a cylindrical box is welded to the box wall of the top of the case, the box wall of the upper portion of the cylindrical box penetrates through the box wall of the case to make contact with the bottom end of the grounding rod, and a piston plate is connected to the inner wall of the cylindrical box in a sealed and sliding mode. Evaporated liquid on the piston plate in the device is heated and vaporized to push the pressing plate to slide downwards to drive a threaded shaft disc to rotate; due to the fact that the disc is provided with the groove and the protruding block, when the lower end of the thick rod and the lower end of the thin rod make contact with the groove and the protruding block, the whole thick rod and the whole thin rod vibrate, the scraper ring is driven to vibrate to scrape off an oxide layer onthe grounding rod, and the grounding device has the self-maintenance function.

Owner:湖州浪佩智能科技有限公司

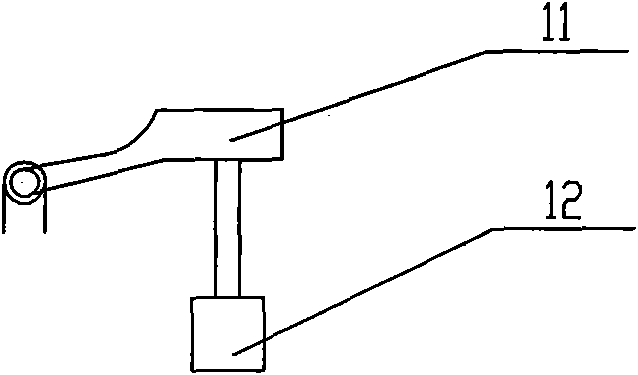

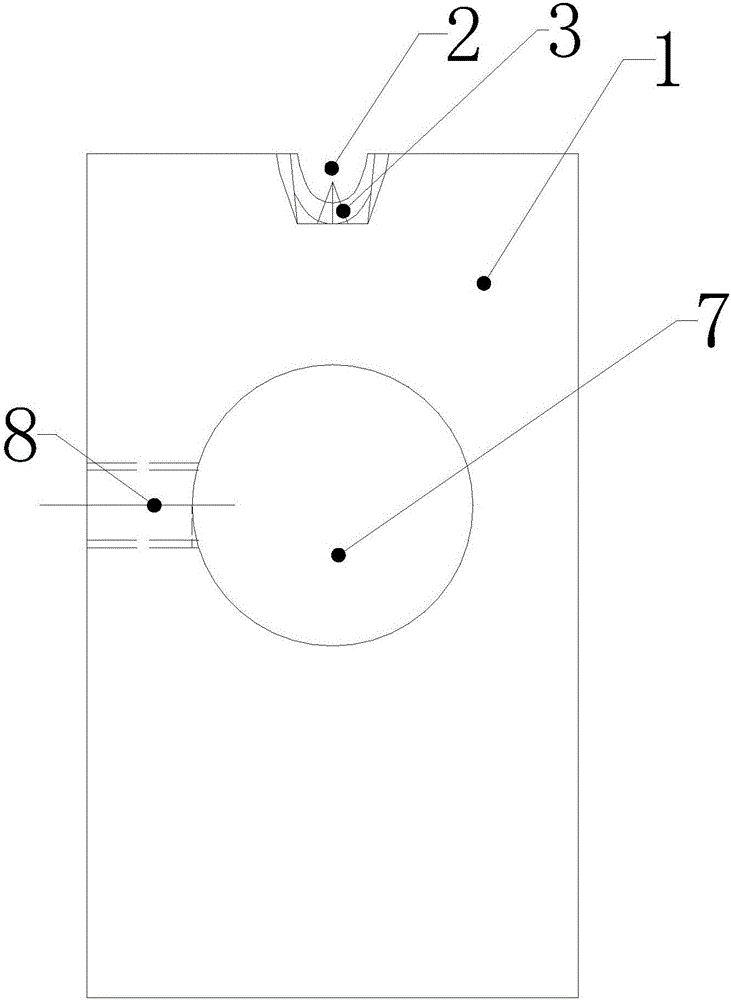

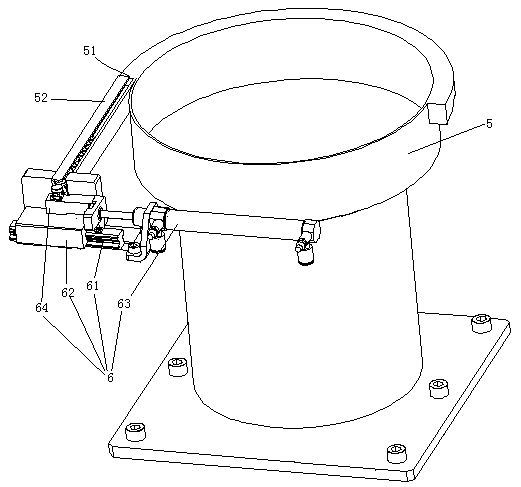

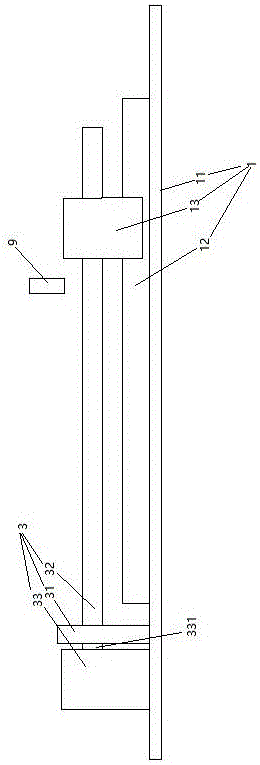

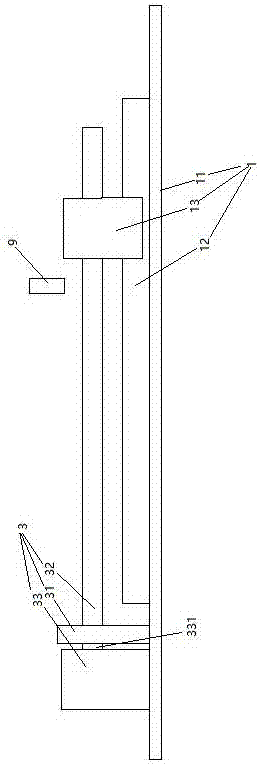

Lead seal feeding line-up mechanism for ammeter lead seal machine

The invention relates to equipment for lead seal installation of an ammeter, in particular to a lead seal feeding line-up mechanism for an ammeter lead seal machine. The lead seal feeding line-up mechanism comprises a vibrating disc, wherein the vibrating disc is provided with a material outlet; the material outlet is butted with a line-up chute; a guide bar which can be arranged in a through groove in the end surface of each lead seal in a penetrating manner is arranged on the bottom wall of the line-up chute; a lead seal one-by-one transfer mechanism is arranged at the lower end of the line-up chute and comprises a slide rail extending in the direction perpendicular to the line-up chute, a slider connected to the slide rail in a sliding manner, and a driving cylinder used for driving the slider to slide on the slide rail; a lead seal accommodating notch which can only accommodate one of the lead seals and can be aligned with the line-up chute is formed in the edge of the slider; and a rotation stop block which can be inserted into the through groove in the end surface of each lead seal is arranged on the bottom wall of the lead seal accommodating notch. The lead seal feeding line-up mechanism has the advantage that the through grooves of the lead seals can perform lining-up and transferring in the directions the same as that of the through grooves, and the problem of inconvenient lead seal installation caused by the reason that a conventional vibrating disc cannot guarantee the lining-up and transferring directions of the lead seals is solved.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

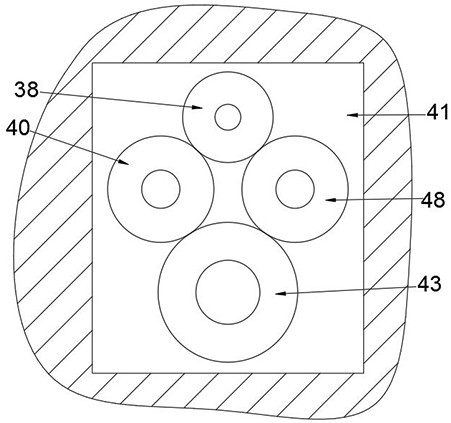

A communication cable mounting frame for a tunnel

ActiveCN113562537BClose togetherEfficient recyclingFilament handlingFire rescueElectric machineryEngineering

The invention discloses a communication cable installation frame for a tunnel, which comprises a casing, and a first cavity is arranged inside the casing; the invention can drive the rotation of the installation frame by starting a motor, and at the same time allow the wire take-up device to move leftward on the installation frame , so that the cables can be tightly packed together, so that the space utilization when taking up the wires is more efficient, and the wire take-up device can move to the right when the first round is finished, and the cables can be folded in the second round, so that the cables are in the installation frame Efficient recycling, and the second installation frame can be quickly removed through the quick release plate, which is convenient for disassembly and replacement operations, and the cleaning block is lowered when the cable is taken up to clean the cables on the first installation frame In addition, when smoke is detected after a fire, the cable is sprayed with dry powder at the first time, so that the cable can be extinguished by dry powder at the first time, and the greater danger caused by the cable after encountering a fire is avoided.

Owner:江苏南瓯物联网科技有限公司

Zipper type edge sealing mold

Owner:JIANGSU YUANXIANG INTERNET OF THINGS SCI & TECH

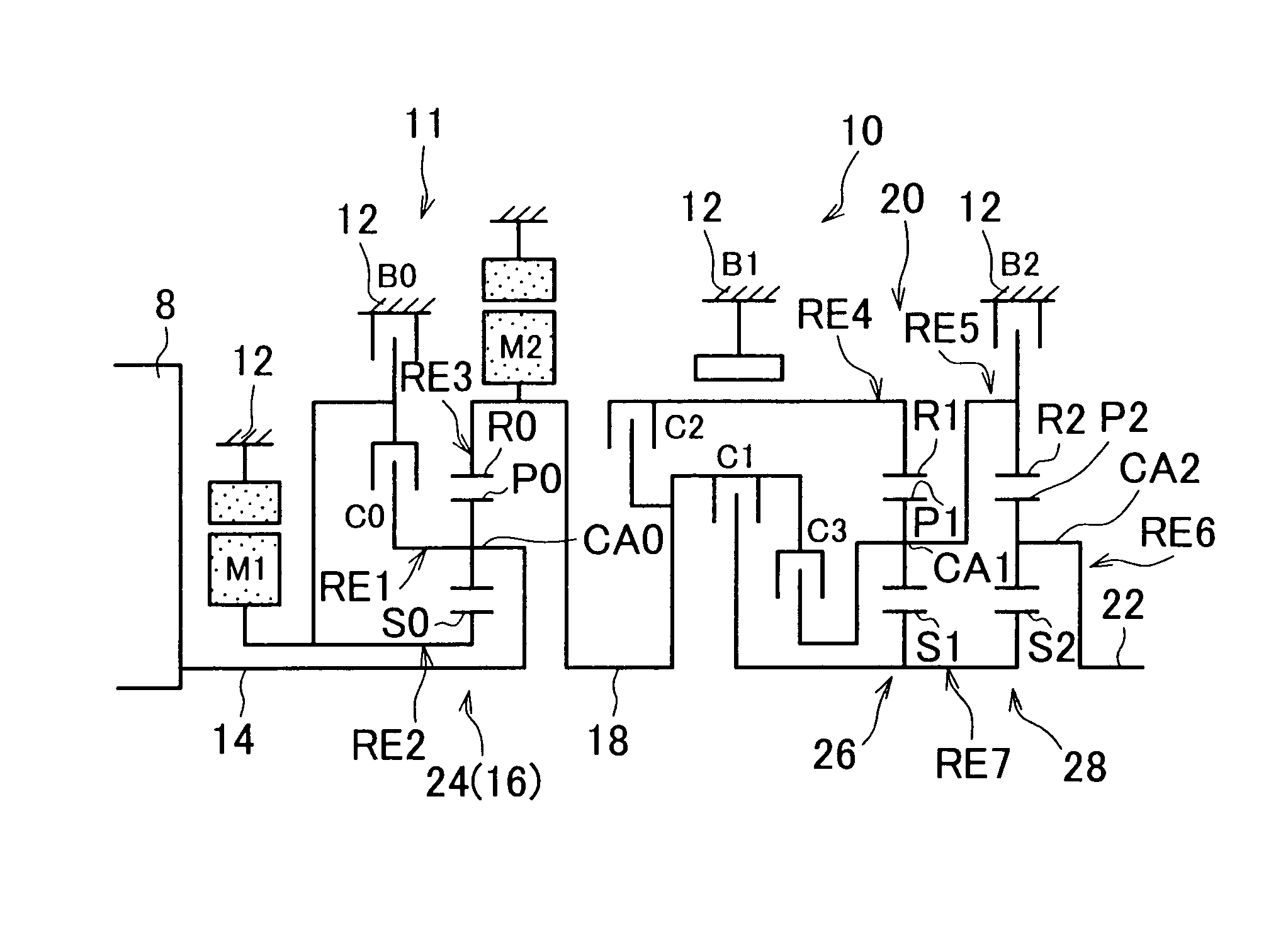

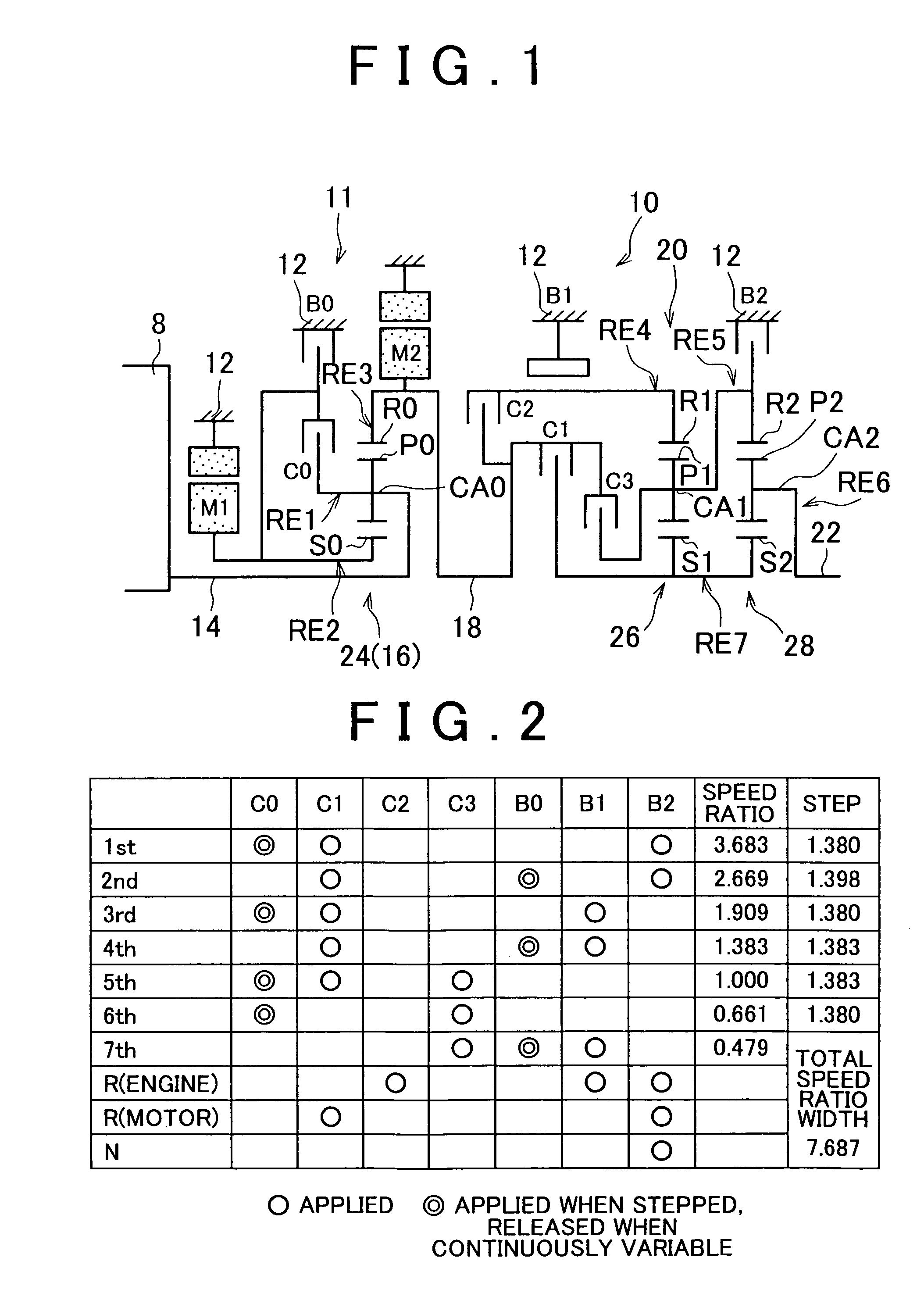

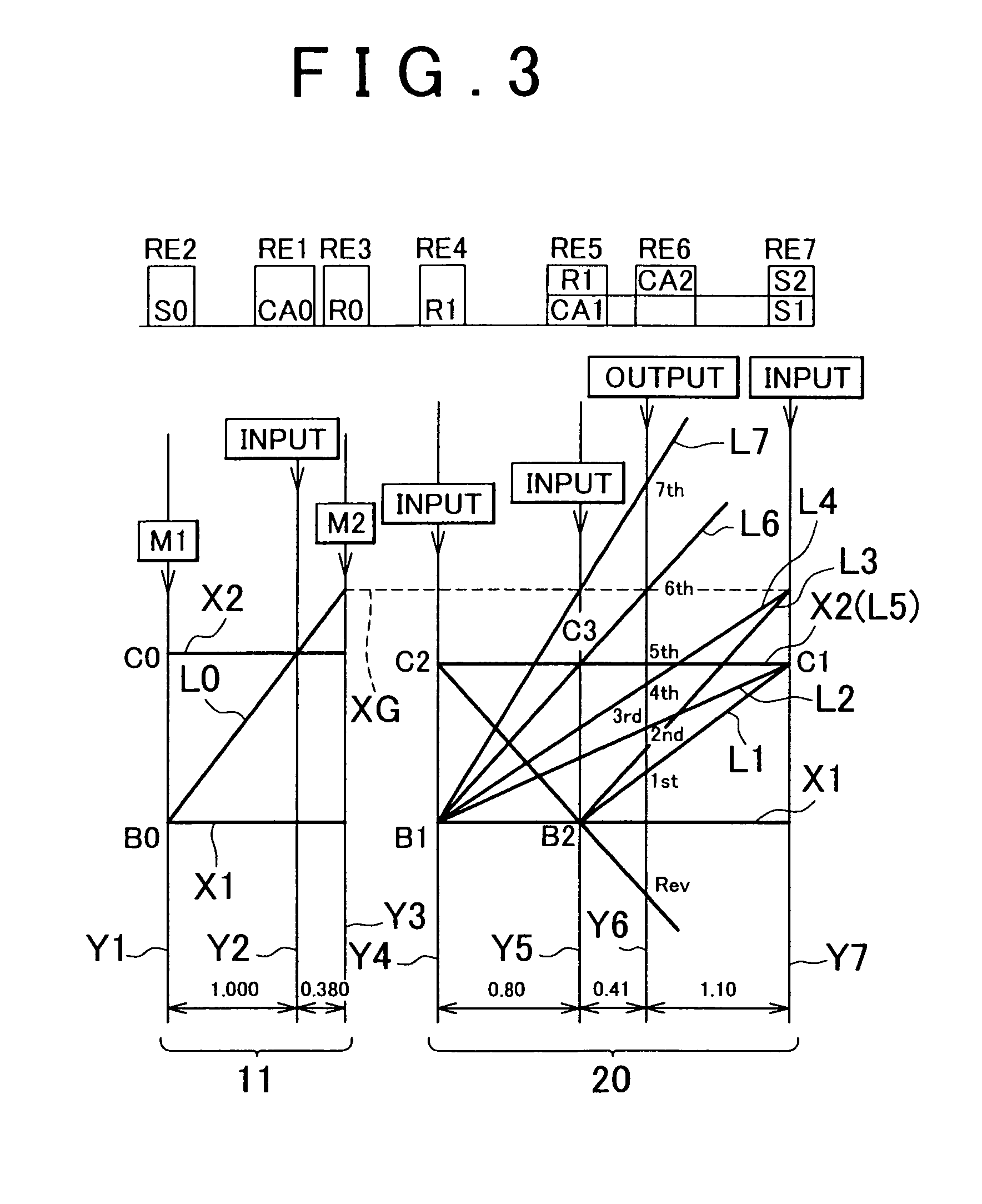

Control apparatus and control method for vehicular power transmitting apparatus

ActiveUS8224535B2Increase in sizeClose togetherHybrid vehiclesInternal combustion piston enginesDifferential functionEngineering

A control apparatus for a vehicular power transmitting apparatus includes, in series, i) a differential portion which is provided with a differential mechanism having a differential function with respect to an input shaft and an output shaft, in which the differential mechanism is switched between a differential state and a non-differential state, and ii) a stepped shifting portion that shifts between a plurality of gears in a stepped manner. During a shift with a switch between the differential state and the non-differential state in the differential portion, the control apparatus either maintains the gear at that time or shifts into a gear that is adjacent to that gear.

Owner:TOYOTA JIDOSHA KK

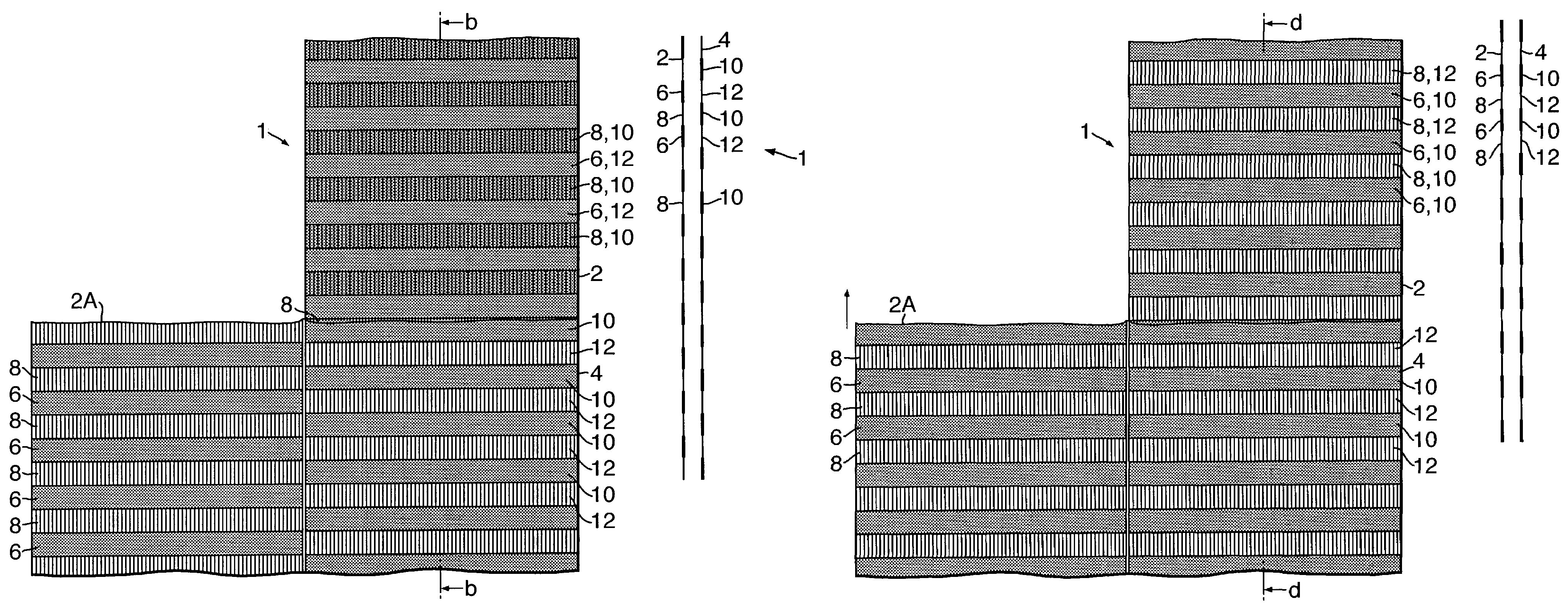

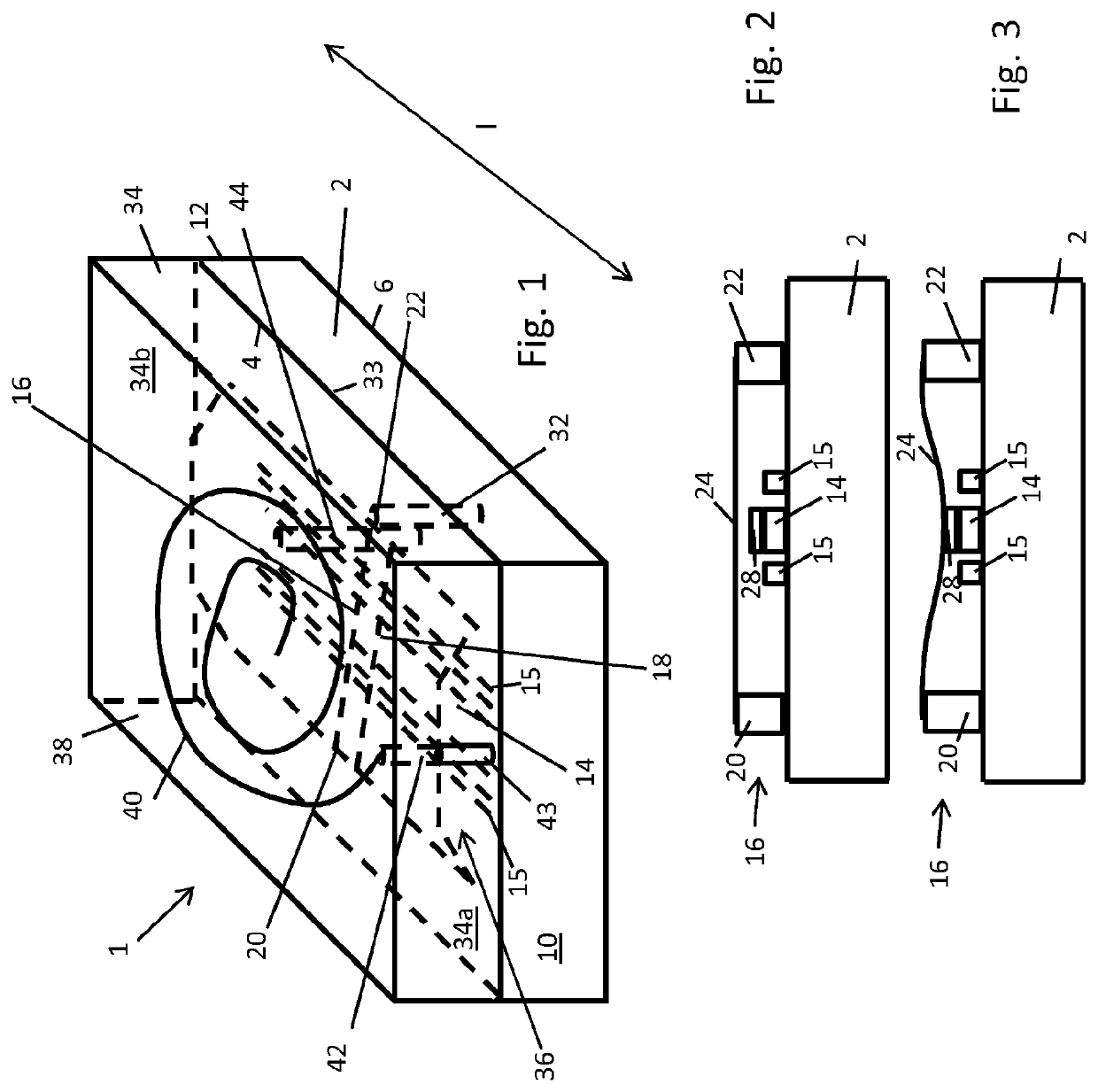

Arrangement having at least one long-stator linear motor, for operating magnetically levitated vehicles

ActiveUS7173387B2Convenient ArrangementClose togetherMotor/generator/converter stoppersDC motor speed/torque controlLinear motorOperating frequency

The invention relates to an arrangement for operating a magnetically levitated vehicle by means of an arrangement having at least one long-stator linear motor. The linear motors are sub-divided, longitudinally of a track, into individual motor regions (A) in each of which only one vehicle (7) is able to travel at a time. To make possible different frequencies of service for the vehicles (7), i.e. different intervals between the vehicles (7), the region boundaries (B) between at least two motor regions (A1, A2) which follow one another in the direction of travel are arranged to be variable.

Owner:SIEMENS AG

Electric meter lead sealing machine lead seal feeding queuing mechanism

The invention relates to equipment for lead seal installation of an ammeter, in particular to a lead seal feeding line-up mechanism for an ammeter lead seal machine. The lead seal feeding line-up mechanism comprises a vibrating disc, wherein the vibrating disc is provided with a material outlet; the material outlet is butted with a line-up chute; a guide bar which can be arranged in a through groove in the end surface of each lead seal in a penetrating manner is arranged on the bottom wall of the line-up chute; a lead seal one-by-one transfer mechanism is arranged at the lower end of the line-up chute and comprises a slide rail extending in the direction perpendicular to the line-up chute, a slider connected to the slide rail in a sliding manner, and a driving cylinder used for driving the slider to slide on the slide rail; a lead seal accommodating notch which can only accommodate one of the lead seals and can be aligned with the line-up chute is formed in the edge of the slider; and a rotation stop block which can be inserted into the through groove in the end surface of each lead seal is arranged on the bottom wall of the lead seal accommodating notch. The lead seal feeding line-up mechanism has the advantage that the through grooves of the lead seals can perform lining-up and transferring in the directions the same as that of the through grooves, and the problem of inconvenient lead seal installation caused by the reason that a conventional vibrating disc cannot guarantee the lining-up and transferring directions of the lead seals is solved.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

Single-force-source tipper for steel production

ActiveCN106839782AReduce in quantitySolve the shortage of manual feedingCharge manipulationEngineeringMechanical engineering

The invention relates to equipment for steel production, and provides a single-force-source tipper for steel production. The single-force-source tipper for steel production comprises two connecting seat assemblies and a plurality of arms, wherein each arm comprises a first external rod, a first internal rod, a second internal rod and a second external rod which are successively arranged in the axial direction of a central shaft; the first internal rod, the second internal rod, the first external rod and the second external rod of one arm are spherically hinged to the first external rod, the second external rod, the first internal rod and the second internal rod of the other arm in a one-to-one correspondence manner; the distance between two hinged points of each first internal rod is smaller than the distance between two hinged points of the corresponding second internal rod; and the first arm is connected with one connecting seat assembly while the last arm is connected with the other connecting seat assembly. The single-force-source tipper for steel production has the advantage that the various arms can be driven to stretch and retract by only one driving structure. The problem that labor is wasted when raw materials are manually conveyed to a raw material inlet in a steel production process is solved.

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

Process for making aluminum-plastic ceiling board

InactiveCN1320237CReduce weightEasy to disassemble and scrubCovering/liningsTemperature controlHeating time

The aluminum-plastic ceiling board making process includes the following steps: cutting, eliminating four corners, punching holes, forming, trimming, packing, etc. The present invention features the aluminum-plastic material for making ceiling board; the male and female molds with interval less than 0.03 mm and female mold with chromium plated and polished surface; and the heating treatment of the board inside one constant temperature stoving channel, with the stoving channel being 8 m long and complex circulative heat dissipated, the conveying belt being made of 1 mm-mesh stainless steel net for homogeneous and stable temperature and having speed proportional directly with temperature raising, the heating time being 380 sec and temperature being 180 deg.c. The aluminum-plastic ceiling board is light, easy in detaching and cleaning and low in cost.

Owner:王明昌

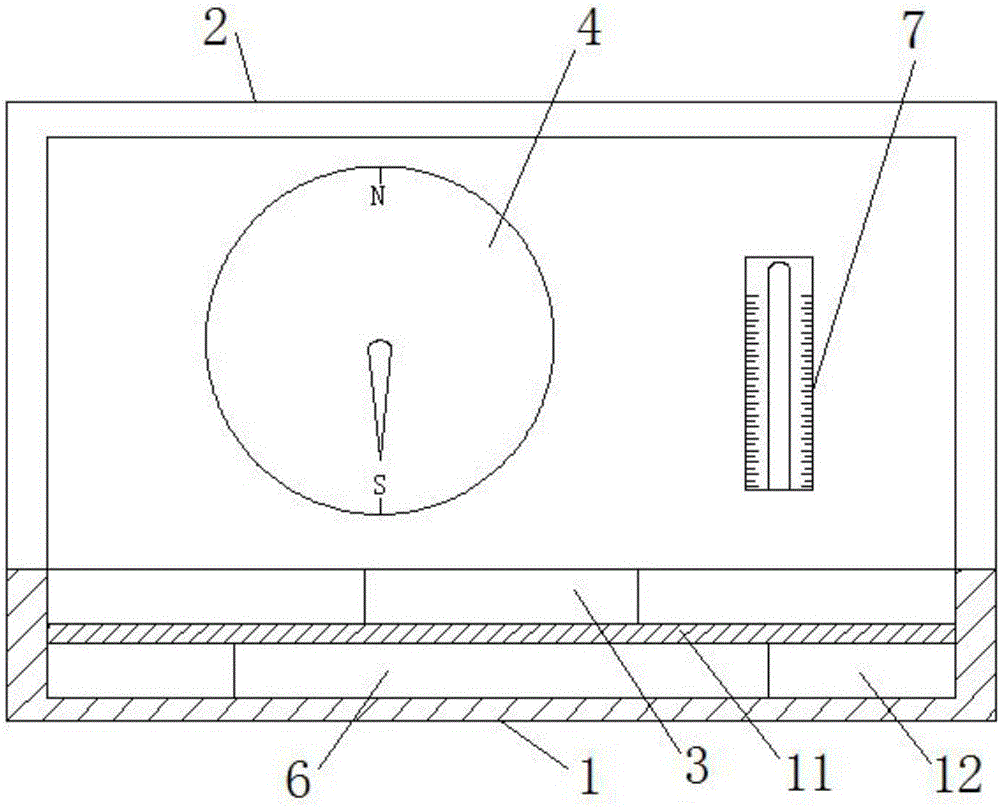

Multifunctional solar illuminating lamp box

InactiveCN105782763ASimple structureEasy to useLighting elementsWith electric batteriesLED lampCompass

The invention relates to the technical field of illumination, in particular to a multifunctional solar illuminating lamp box. The multifunctional solar illuminating lamp box comprises an upper box body and a lower box body, wherein the upper box body is arranged at the edge of one side of the top of the lower box body in a hinged way and can cover on the top of the upper box body, an LED lamp is embedded to the lower box body, a storage battery is arranged in the lower box body, a compass is arranged in the upper box body, solar panels are embedded to the outer surfaces of the lower box body and the upper box body, and the solar panels and the LED lamp are respectively in electric connection to the storage battery. The multifunctional solar illuminating lamp box has the advantages of being simple in structure, convenient to use, convenient to carry, and diversified in functions, being capable of illuminating and indicating direction and temperature and humidify in the field, and having strong practicability.

Owner:武汉美格科技股份有限公司

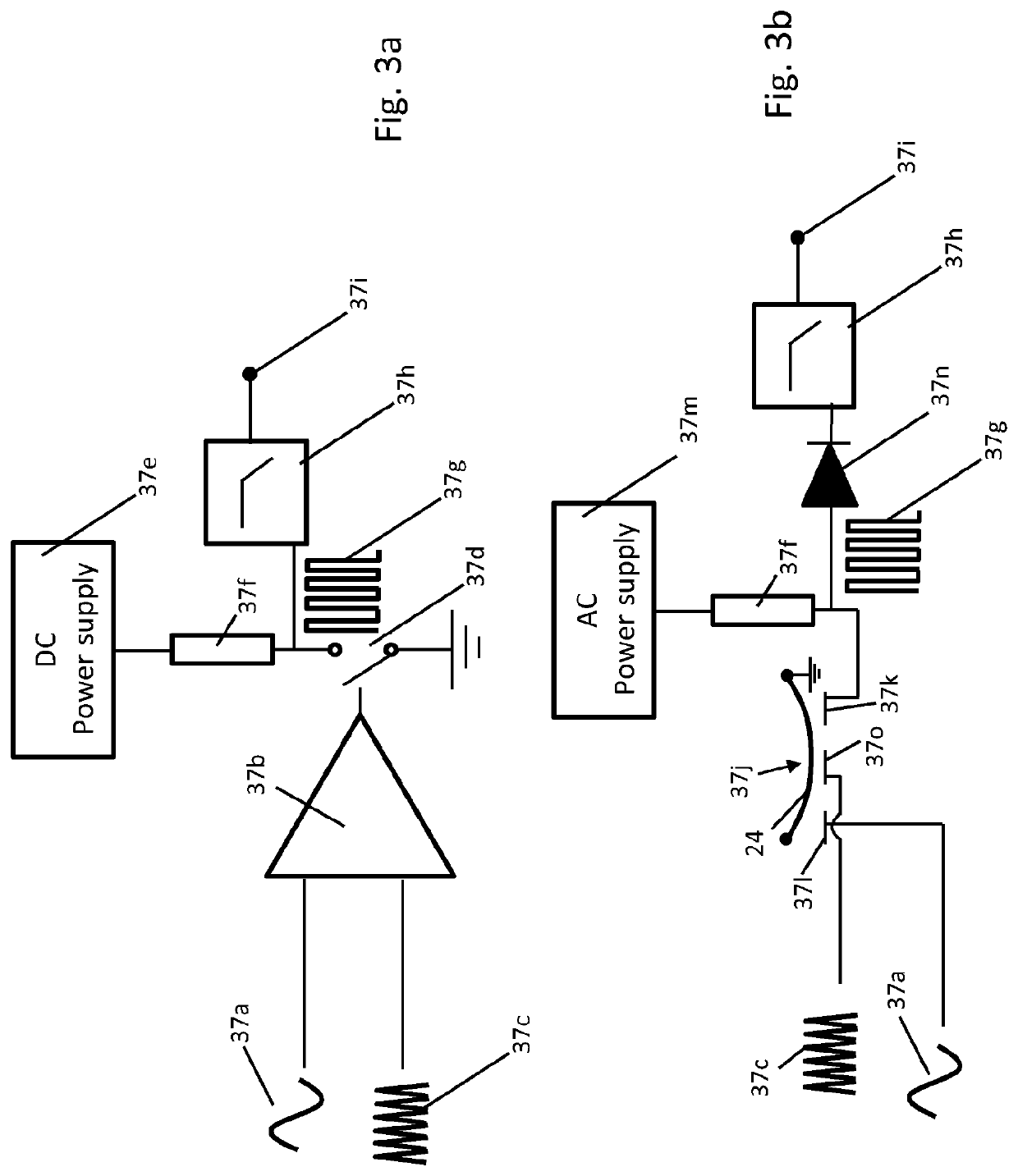

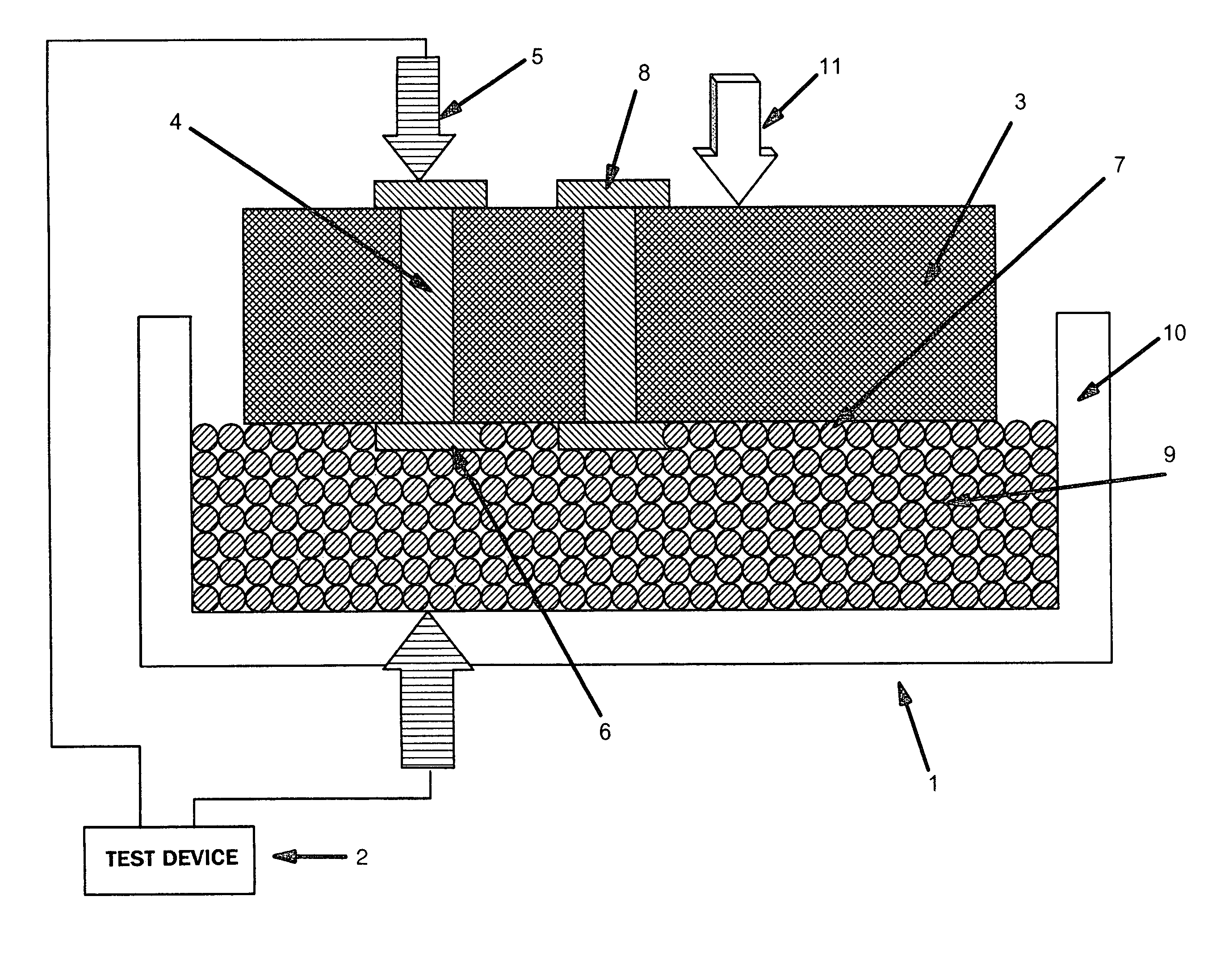

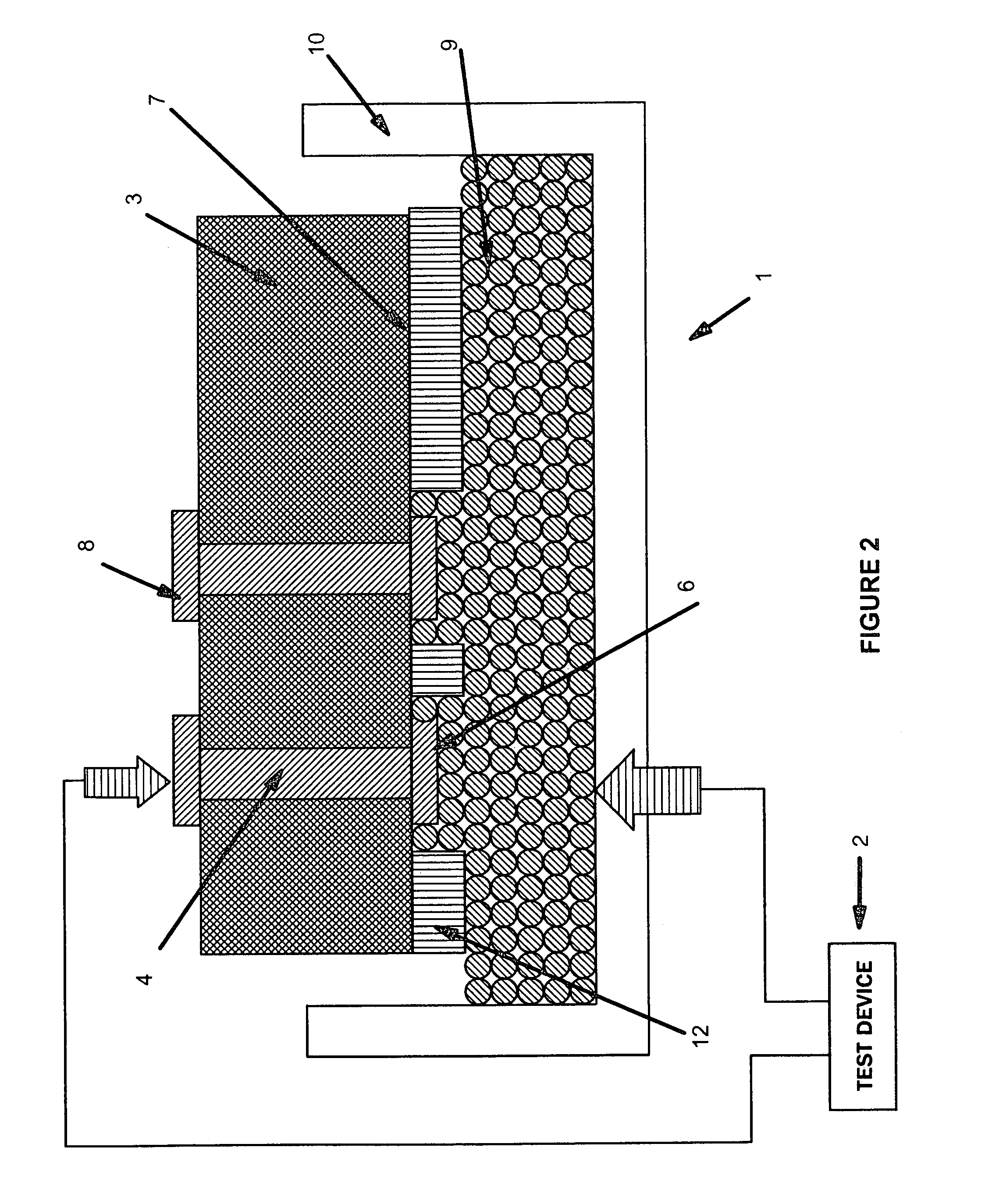

Method and apparatus for electrical commoning of circuits

ActiveUS7038462B2Reduce wasteReduce customer complaintsPrinted circuit testingFault locationElectricityContact pad

Improved methods and apparatus is disclosed for electrical testing of electronic circuits such as those existing in microcircuit devices including chip carriers, printed circuit boards and substrates. The invention provides for the testing of the continuity of electronic circuits in progressively smaller devices having increased density of circuits and having pads closely spaced. A quasi-fluidized bed of conductive particles is provided for effectively contacting pads on a first side of a substrate. Pads on another side of the substrate which are connected to the pads on the first side are then contacted by a test device. The circuit interconnecting respective pads on the two sides of the substrate can then be assessed for electrical continuity.

Owner:TWITTER INC

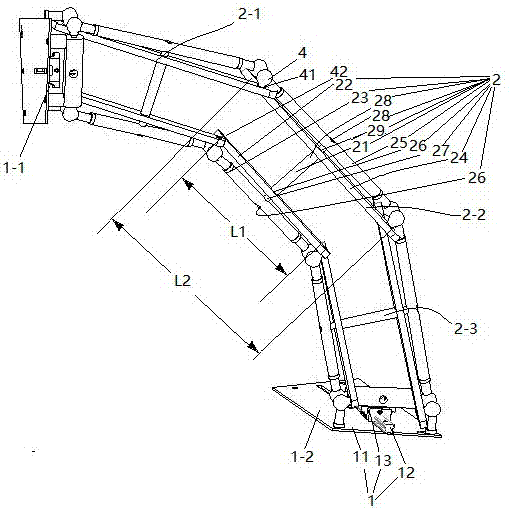

Curve telescopic mechanical arm

ActiveCN106903716AReduce in quantitySimple structureProgramme-controlled manipulatorArmsEngineeringManipulator

Owner:ZHEJIANG HOUDAR INTELIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com