Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Avoid loss of magnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stator electro-magnetic vernier motor

ActiveCN105391202ASolve the problem of loss of magnetismAvoid loss of magnetismMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineConductive materials

The invention discloses a stator electro-magnetic vernier motor. The stator electro-magnetic vernier motor is characterized in that the stator electro-magnetic vernier motor comprises a stator, wherein the stator is in a circular ring shape, a plurality of grooves are formed in the circumferential direction the wall of the ring body, an armature winding or an excitation winding is embedded in each groove, and projection parts among the grooves form stator teeth; a rotor, wherein the rotor is in a circular ring shape, a plurality of magnetic regulating blocks made of a magnetic conductive material are uniformly arranged in the circumferential direction of the ring body at intervals, the stator and the rotor are coaxially assembled in a sleeving manner, and an interval exists between the stator and the rotor. According to the invention, the armature windings and the excitation windings are embedded in the stator grooves, and the rotor magnetic regulating blocks are utilized, so that low-speed large torque is not provided by a vernier effect of a permanent magnet, the magnetic loss problem of a permanent magnet vernier motor in a specific operation environment is solved, the efficiency is improved, and the cost is saved.

Owner:WUHAN UNIV OF TECH

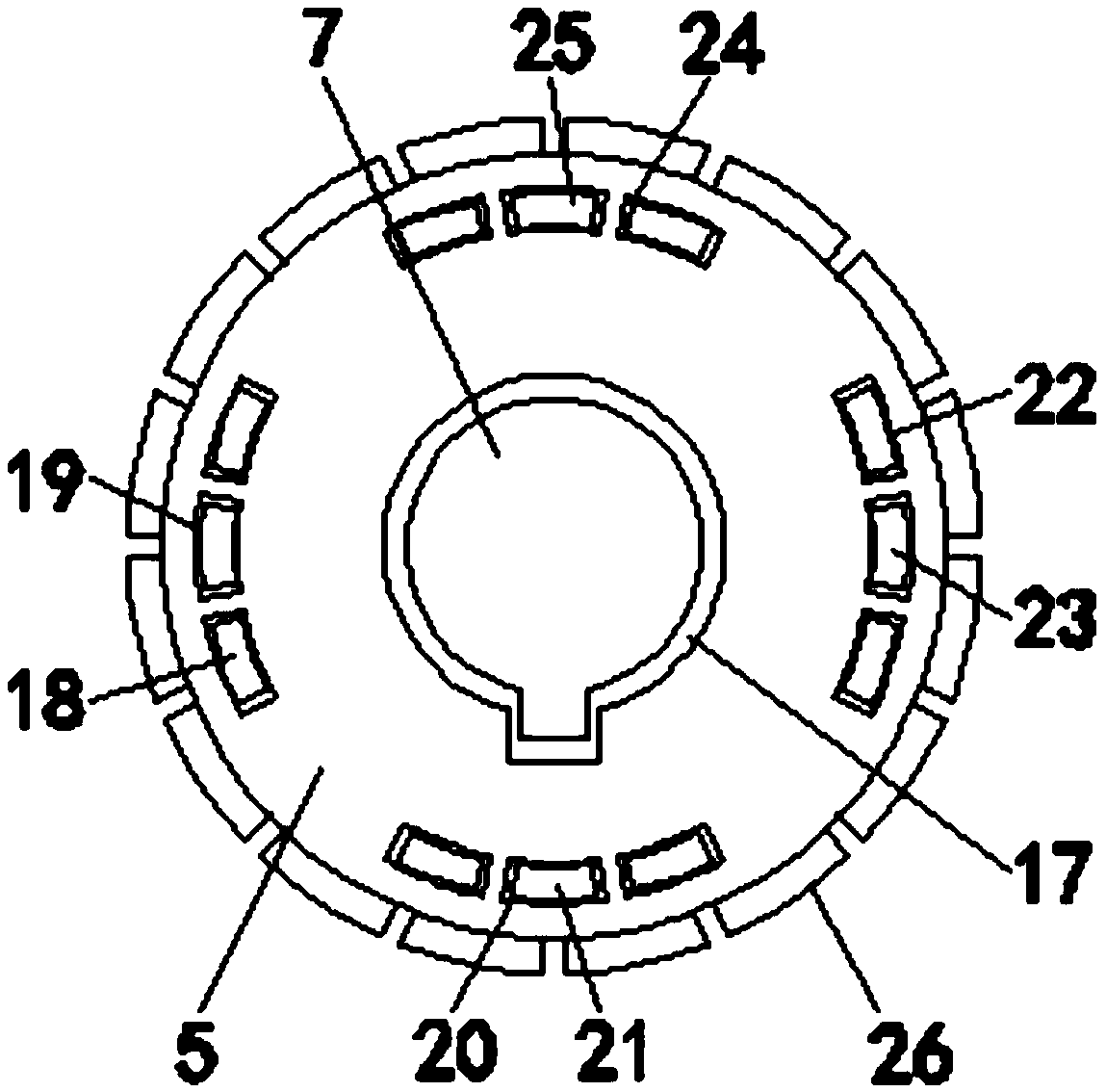

Wave energy power generation device

ActiveCN106050537ANo dynamic sealing problemEasy to operateMachines/enginesEngine componentsMagnetic polesEngineering

The invention provides a wave energy power generation device. A floater and a conical end cover of the wave energy power generation device are located at the two ends of a machine shell, and the floater, the conical end cover and the machine shell form a sealed cavity. A stator, a rotor, springs and a rotor sliding rail are sealed in the machine shell. The stator is cylindrical, located on the inner side of the machine shell and formed by alternately stacking a plurality of stator units which are the same in thickness and a plurality of stator magnetism isolating rings which are the same in thickness in the axial direction. Stator teeth are uniformly distributed on the inner side of each stator unit. A coil is wound on each stator tooth. A square hole is formed in the top of each stator tooth. A square radially magnetized permanent magnet is embedded in each square hole. The magnetic poles of the permanent magnets are alternately arranged in the circumferential direction. The rotor is cylindrical, located on the inner side of the stator and formed by alternately stacking a plurality of rotor magnetism conducting rings which are the same in thickness and a plurality of rotor magnetism isolating rings which are the same in thickness in the axial direction. The rotor and the springs are installed on the rotor sliding rail. The rotor can slide up and down along the rotor sliding rail. The rotor sliding rail and the machine shell are concentric and coaxial, and the two ends of the rotor sliding rail are fixed to the floater and the conical end cover correspondingly. The springs are located on the two sides of the rotor and connected with the floater and the conical end cover correspondingly.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

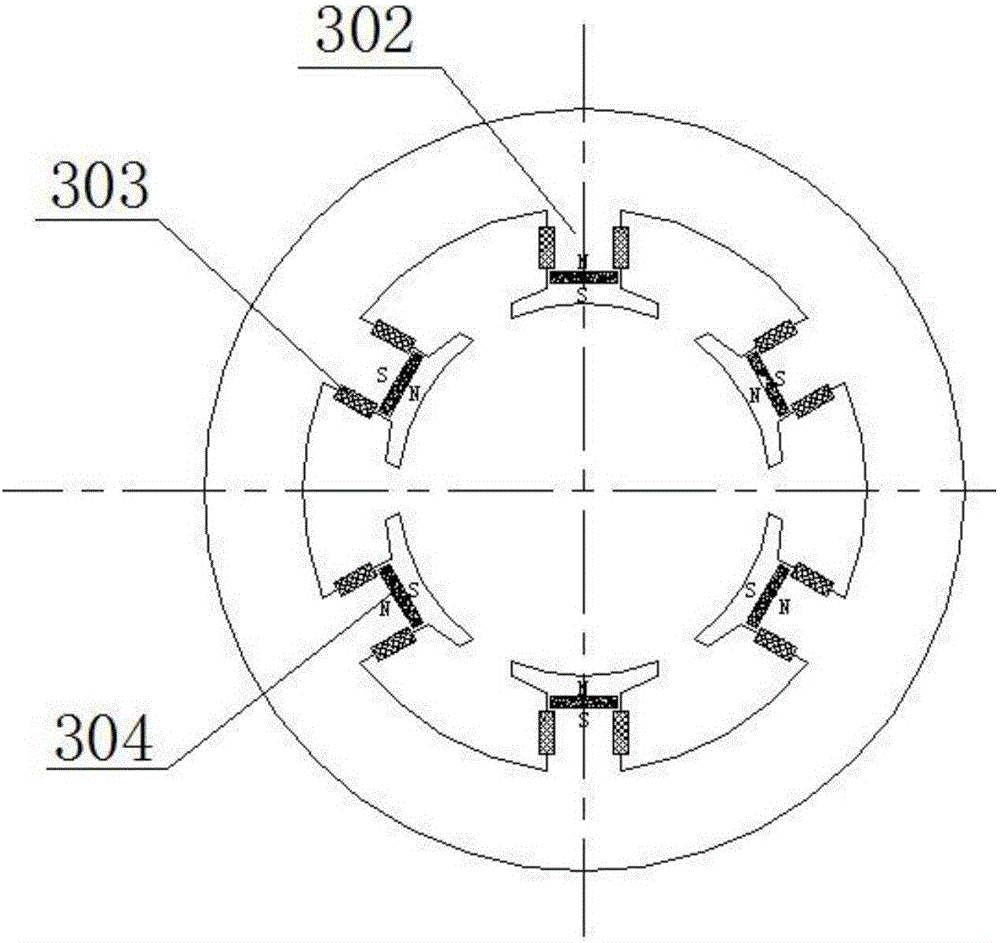

Mixed excitation type composite double-rotor motor

InactiveCN107026544ALow torque densityEnhanced air gap magnetic field adjustment capabilityMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineThree-phase

The invention discloses a hybrid excitation type compound double-rotor motor, which comprises a stator, an outer rotor and an inner rotor assembled from the outside to the inside. The stator is a salient pole structure assembled from six E-shaped arc iron cores. A permanent magnet magnetized in the circumferential direction is clamped between two adjacent E-shaped arc iron cores. The magnetization directions of the two adjacent permanent magnets are opposite. The DC excitation winding is wound on the middle tooth of the E-shaped arc-shaped iron core. Three-phase centralized AC excitation windings are wound on the salient poles formed by two E-shaped arc iron cores and permanent magnets. The DC excitation windings and the three-phase centralized AC excitation windings share a stator slot and are separated from each other. The technical effect of the invention is that the structure is simple, the heat dissipation is easy, the motor performance can be improved, the output force can be increased, the starting torque is large, the speed regulation range is wide, and the motor is suitable for high-speed operation of the motor.

Owner:CHONGQING UNIV

Excitation adjustable type permanent magnet synchronous motor

InactiveCN104767339AImprove efficiencyAvoid loss of magnetismSynchronous machine detailsElectric machinesPhysicsMagnetic flux

The invention discloses an excitation adjustable type permanent magnet synchronous motor. The excitation adjustable type permanent magnet synchronous motor comprises a rotor, the rotor comprises a plurality of paired permanent magnet assemblies, and each permanent magnet assembly comprises a cylindrical permanent magnet, a cover plate and a rotary driving mechanism. Parallel magnetization is adopted in the cylindrical permanent magnets, and the cylindrical permanent magnets are closely arranged in parallel. The appearances of the cover plates are of a cuboid structure, the cover plates are made of permeability magnetic materials, and the cylindrical permanent magnets are arranged in the cover plates to form the cuboid-shaped permanent magnets. The rotary driving mechanisms are connected with the cylindrical permanent magnets, and when the rotor rotates, the cylindrical permanent magnets are driven to rotate around the axes of themselves so that the magnetic flux of the permanent magnet assemblies can be reduced. The rotor structure of a traditional permanent magnet synchronous motor is changed, magnetic poles of the permanent magnets are pulled by an electromagnet in the motor to rotate, the excitation magnetic flux can be adjusted by itself, and therefore large demagnetizing current components do not need to be applied at high speed, and motor efficiency is improved.

Owner:JILIN UNIV

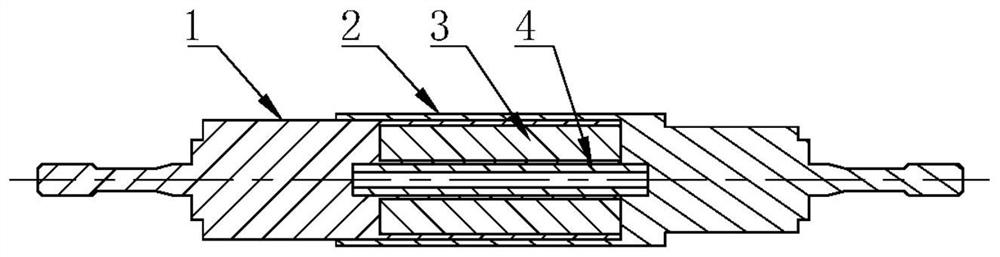

Monostable permanent magnet control mechanism with multiple force output air gaps

InactiveCN101320634ASave electricityImprove reliabilitySwitch power arrangementsHigh-tension/heavy-dress switchesEngineeringElectric power

The invention provides a multi-strength gap monostable permanent magnet driven mechanism. A permanent magnet of the driven mechanism is mounted between a fourth silicon-steel sheet group and a third silicon-steel sheet group of a fixed core, while B permanent magnet is mounted between the third silicon-steel sheet group and a second silicon-steel sheet group of the fixed core. Lower end surface of the fixed core is mounted on a connection board. The fixed core is put relatively to a moving core, and an on and off coil is sleeved on a lower central post of the fixed core. An on and off spring, which is sleeved on upper central post of the moving core, is located above the on and off coil. Upper end of a transmission rod orderly runs through a central hole of the connection board, a second central through hole of the fixed core and a first central through hole of the moving core, then runs through A pin hole, B pin hole, D pin hole and C pin hole by pins, and connection with one end of the transmission rod by the moving core is implemented. The multi-strength gap monostable permanent magnet driven mechanism of the invention is able to coordinate with power electronic device to perform millisecond movement, meet disconnection time demand of mechanical contact and implement quick on and off movement of an operation mechanism.

Owner:BEIHANG UNIV +1

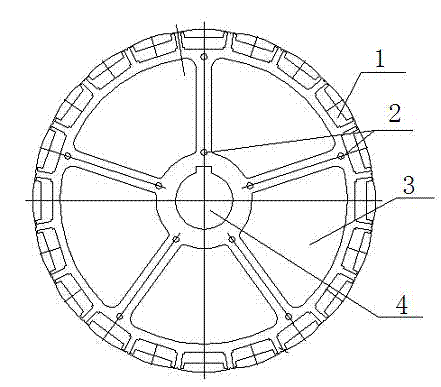

Rotor punching sheet of high-speed permanent magnet motor

InactiveCN102522839AExtended service lifePrevent reverse installationMagnetic circuit rotating partsPunchingPermanent magnet motor

The invention discloses a rotor punching sheet of a high-speed permanent magnet motor. The rotor punching sheet comprises punching sheet inner slots (1), punching sheet combined holes (2), lightening holes (3) and a rotor shaft hole (4), wherein the punching sheet inner slots (1) are distributed on an outer circumferential surface of the punching sheet, the lightening holes (3) are arranged around the rotor shaft hole (4) in a surrounding manner, the punching sheet combined holes (2) are arranged among the lightening holes (3), and the rotor shaft hole (4) is arranged at the center of the punching sheet. According to the rotor punching sheet of the high-speed permanent magnet motor disclosed by the invention, a permanent magnet block is embedded in the punching sheet inner slot so that the permanent magnet block can be prevented from falling off during a high-speed operation; due to an integrated punching sheet structure, a magnetic flux forms closed circulation so as to prevent the permanent magnet block from loss of excitation, and the service life of the permanent magnet motor is prolonged; and reverse installation of the punching sheet is avoided by utilizing asymmetrical webs in the punching sheet.

Owner:DALIAN YULIN ELECTRIC MOTOR

Rotor permanent magnet series distribution-linked high-voltage permanent-magnet synchronous motor

InactiveCN108667252AAvoid loss of magnetismLarge intersection areaMagnetic circuit rotating partsMagnetic circuit stationary partsPunchingSynchronous motor

The invention relates to the technical field of high-voltage permanent magnet synchronous motors, and discloses a rotor permanent magnet series distribution-linked high-voltage permanent magnet synchronous motor, which comprises a motor shell, a stopper is fixedly connected with the motor shell, a first fixing seat is fixedly connected with stopper, a second fixing seat is fixedly arranged on theinner wall on the right side of the motor shell. The rotor permanent magnet series distribution-linked high-voltage permanent magnet synchronous motor can make the waveform of the counter electromotive force achieve the best effect as long as the design of each segment length is appropriate, the useless harmonic generated by the stator is minimized, the harmonic loss is minimized, the motor achieves high efficiency, the manufacturability is good, the rotor punching die is most simple, and each magnetic steel is easy to install due to small volume, and the design level and the process level ofthe high-voltage permanent magnet motor become reliable and efficient, so that the design of this type of motor becomes feasible, and meanwhile, the motor can be applied to various complex occasions.

Owner:武汉麦迪嘉机电科技有限公司

Melt spinning technology

ActiveCN108085774AHigh strengthImprove toughnessArtificial thread manufacturing machinesInorganic material artificial filamentsPolymer scienceMaterials science

The invention relates to a melt spinning technology and belongs to the field of spinning. According to the melt spinning technology, magnetic force parallel to the direction of the ground is applied to a melt in a wire drawing process, and the melt is prepared with a method comprising steps as follows: step 1, a-Al2O3 coated magnetic material particles are prepared; step 2, the a-Al2O3 coated magnetic material particles obtained in step 1 are mixed with other fiber raw materials, and a mixture is molten. With adoption of the technology and a device, magnetic fibers with consistent magnetic orientation can be obtained.

Owner:无锡佳成纤维有限公司

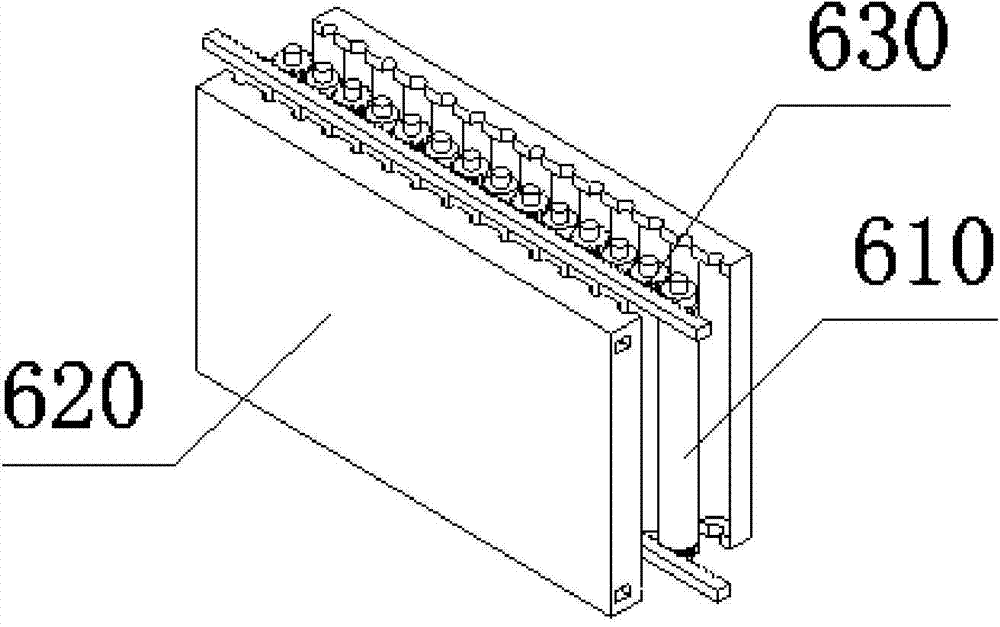

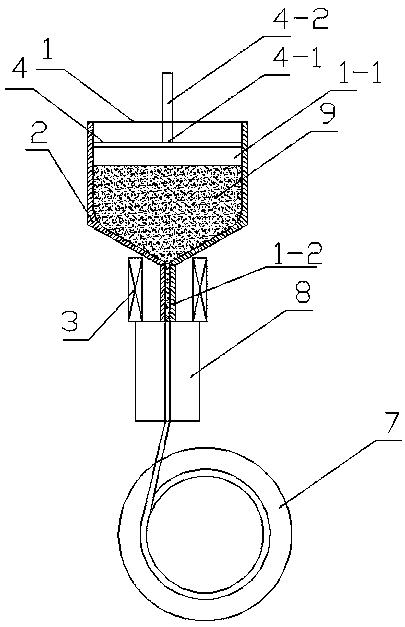

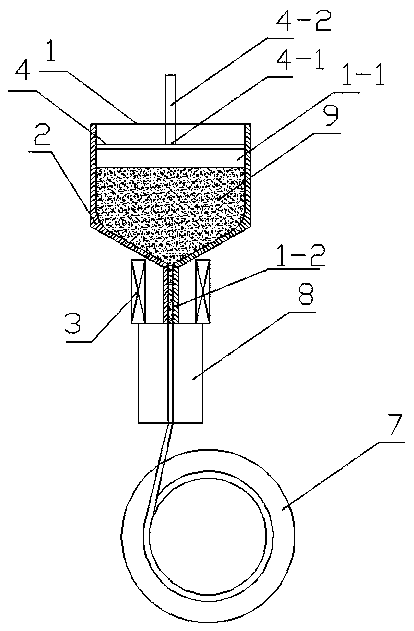

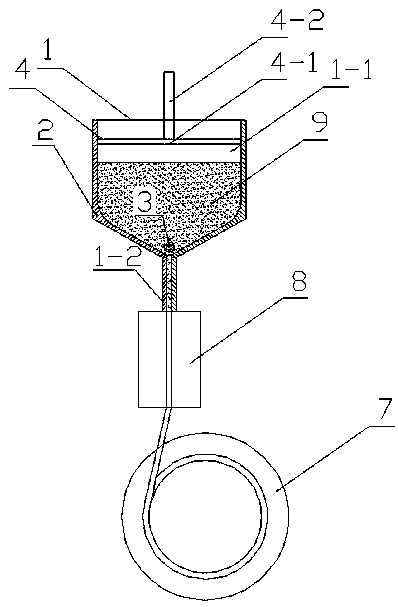

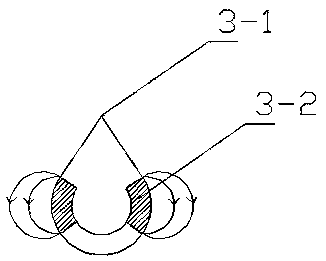

Melt spinning device

InactiveCN111394807AHigh strengthImprove toughnessSpinnerette packsArtificial thread manufacturing machinesPolymer scienceMelt spinning

The invention relates to a melt spinning device, and belongs to the field of spinning. The melt spinning device comprises a funnel-shaped material containing device, wherein the material containing device consists of a material containing part and a fiber forming part; a magnetic field generating device capable of generating a magnetic field direction parallel to the ground is arranged outside thematerial containing device; and the magnetic field generated by the magnetic field generating device acts on the whole fiber forming part and the part, close to the joint of the material containing part and the fiber forming part, of the material containing part. The melt spinning device is provided with the magnetic field generating device, and the magnetic field generating device is a device capable of generating the magnetic field direction parallel to the ground. When a melt raw material containing magnetic material particles flows through the magnetic field generating device, the melt raw material is arranged according to the direction of a magnetic line of force, the magnetic particles are arranged according to the same magnetic domain orientation to a certain degree, and fibers formed subsequently have consistency of magnetic orientation. The device is simple in structure, easy to operate and high in spinning efficiency.

Owner:蒋秋菊

A Stator Electric Excitation Vernier Motor

ActiveCN105391202BSolve the problem of loss of magnetismAvoid loss of magnetismMagnetic circuit rotating partsMagnetic circuit stationary partsConductive materialsConductor Coil

The invention discloses a stator electro-magnetic vernier motor. The stator electro-magnetic vernier motor is characterized in that the stator electro-magnetic vernier motor comprises a stator, wherein the stator is in a circular ring shape, a plurality of grooves are formed in the circumferential direction the wall of the ring body, an armature winding or an excitation winding is embedded in each groove, and projection parts among the grooves form stator teeth; a rotor, wherein the rotor is in a circular ring shape, a plurality of magnetic regulating blocks made of a magnetic conductive material are uniformly arranged in the circumferential direction of the ring body at intervals, the stator and the rotor are coaxially assembled in a sleeving manner, and an interval exists between the stator and the rotor. According to the invention, the armature windings and the excitation windings are embedded in the stator grooves, and the rotor magnetic regulating blocks are utilized, so that low-speed large torque is not provided by a vernier effect of a permanent magnet, the magnetic loss problem of a permanent magnet vernier motor in a specific operation environment is solved, the efficiency is improved, and the cost is saved.

Owner:WUHAN UNIV OF TECH

A thermoplastic resin composite sheet production device and process

ActiveCN108045065BHigh strengthImprove toughnessLamination ancillary operationsSpinning head liquid feederFiberEngineering

The invention belongs to the field of sheet preparation and relates to a thermoplastic resin composite sheet production device and process. The thermoplastic resin composite sheet production device comprises a substrate forming mechanism and at least one composite layer forming mechanism. Each composite layer forming mechanism is integrally positioned above a conveying belt (202) and comprises a magnetic fiber laying device, a magnetic field generating unit (402) and a cooling roller (303) from one side close to a die head I (101), wherein the magnetic fiber laying device is used for laying fibers on substrate slurry (501), the magnetic field generating unit (402) is capable of generating a magnetic field perpendicular to the ground, and the cooling roller (303) is used for receiving composite layer slurry (502) from a die head II (102) to enable cooling of the composite layer slurry (502) on the cooling roller (303). The thermoplastic resin composite sheet production device is simplein structure and easy in operation.

Owner:江苏维尔克汽车内饰件有限公司

Magnetization method and magnetization component of permanent magnet motor

ActiveCN102158019BSolve assembly problemsEasy to assembleMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePermanent magnet motor

The invention discloses a magnetization method of a permanent magnet motor, which comprises the following steps of: firstly winding a magnetization coil on the surface of an unmagnetized permanent magnet, then placing the unmagnetized permanent magnet where the magnetization coil is wound in a motor rotor or stator, and then assembling the motor rotor or stator of the permanent magnet motor, charging the magnetization coil after assembling, wherein the direction of the magnetic field generated by the coil is the same with the magnetization direction of the unmagnetized permanent magnet, and the unmagnetized permanent magnet is magnetized to a permanent magnet to realize magnetization purpose of the permanent magnet motor. The invention further provides a magnetization component for carrying out the magnetization method. The magnetization method and magnetization component of a permanent magnet motor provided by the invention have the advantages that the problem of difficult assembly of a permanent magnet motor is solved, the re-magnetization purpose of a permanent magnet unbuilt can be realized conveniently, the cost for assembling and maintaining a permanent magnet motor is reduced, and the capacity and volume of the power supply to be magnetized are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

A kind of melt spinning device and process

ActiveCN108085773BHigh strengthImprove toughnessInorganic material artificial filamentsArtificial thread manufacturing machinesPolymer scienceMelt spinning

The invention relates to a melt spinning device and technology and belongs to the field of spinning. According to the melt spinning technology, magnetic force parallel to the direction of the ground is applied to a melt in a wire drawing process, and the melt is prepared with a method comprising steps as follows: step 1, a-Al2O3 coated magnetic material particles are prepared; step 2, the a-Al2O3coated magnetic material particles obtained in step 1 are mixed with other fiber raw materials, and a mixture is molten. With adoption of the technology and the device, magnetic fibers with consistentmagnetic orientation can be obtained.

Owner:QINGDAO ST MEER FIBER TECH CO LTD

Electromagnetic force driving mechanism of an SF6 high voltage circuit breaker

InactiveCN101447364ALight in massSmall inertiaHigh-tension/heavy-dress switchesAir-break switchesMagnetic tension forceElectricity

An electromagnetic force driving mechanism of an SF6 high voltage circuit breaker belongs to the technical field of power transmission and transformation equipment. The mechanism comprises the SF6 high voltage circuit breaker, a connecting rod and the electromagnetic force driving mechanism, wherein, a transmission rod of the electromagnetic force driving mechanism is connected with the connecting rod; the electromagnetic force driving mechanism comprises a primary core, a secondary core, a main permanent magnet, an auxiliary permanent magnet, a magnetism isolating material, a winding coil and the transmission rod; the secondary core of the electromagnetic force driving mechanism is subjected to effects of electromagnetic force in a magnetic field, so as to drive the moving contact of the SF6 high voltage circuit breaker to conduct a switching / closing movement; and the auxiliary permanent magnet of the electromagnetic force driving mechanism causes a switching / closing position of the high voltage circuit breaker to be kept fixed. The mechanism has the advantages that by adopting the auxiliary permanent magnet, the switching / closing position of the high voltage circuit breaker is caused to be kept fixed; the mechanism has a small mass and a small inertia, and is easy to control; the winding coil is arranged in the secondary core; and the secondary core moves to drive the winding core to move, thereby preventing loss of excitation of the mechanism.

Owner:SHENYANG POLYTECHNIC UNIV +1

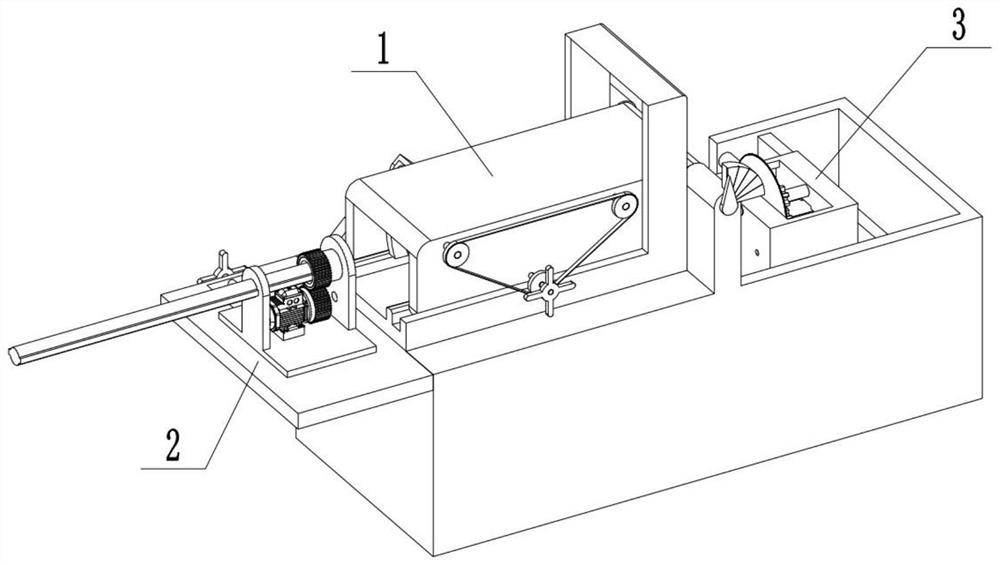

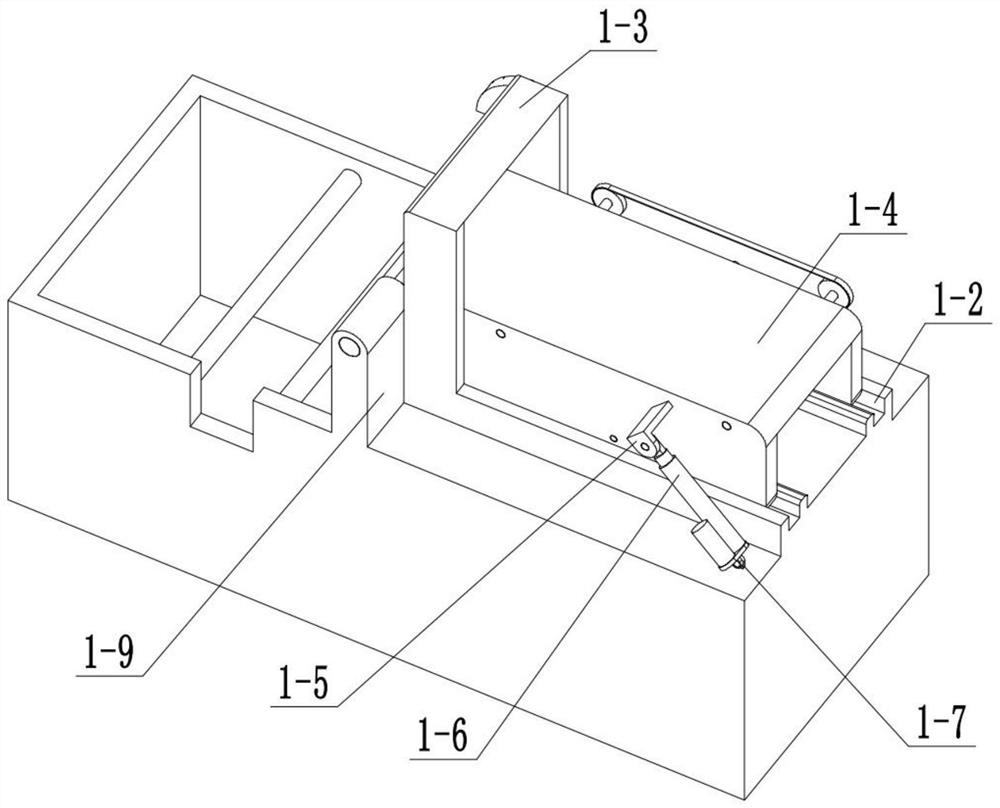

Permanent magnet material cutting equipment

ActiveCN113172774APrevent overheating and demagnetizationEasy to cutInductances/transformers/magnets manufactureWorking accessoriesCooling effectEngineering

The invention relates to the field of novel materials, in particular to permanent magnet material cutting equipment. During production of permanent magnet materials, the materials may be demagnetized by adverse factors such as vibrations and high temperature generated by a conventional cutting way for modification of processed materials. To solve the problems, the permanent magnet materials are put into a clamping assembly; the clamping assembly clamp circular rod materials of different diameters at different angles, so that cutting under various conditions is convenient; vibrations are not generated when the clamping assembly cuts, so that demagnetization is effectively prevented; the assembly can be pushed and pulled to adjust the cutting length, and a cutting assembly can cut the materials at a uniform speed and a low speed, so that vibrations are reduced to be the smallest; and saw blades are cooled by cooling liquid all the time during cutting, and the sprayed-out cooling liquid is re-added into a cooling liquid box after being filtered and cooled to a proper temperature, so that the materials are prevented from being demagnetized due to loss of cooling effect at a high temperature of the cooling liquid while resources are saved.

Owner:东阳市盛邦磁业有限公司

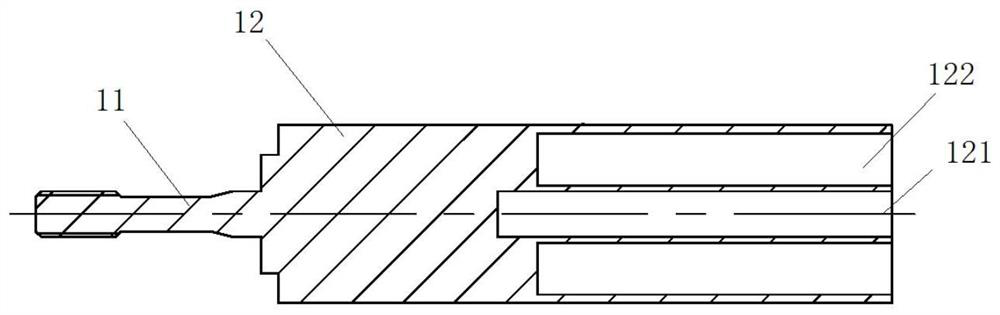

Rotor structure of a double-layer sheathed permanent magnet motor

ActiveCN112994292BHigh strengthIncrease profitMagnetic circuit rotating partsElectric machinesElectric machineryPermanent magnet motor

The present invention relates to the technical field of motors, in particular to a double-sheathed permanent magnet motor rotor structure, which includes a first mandrel, a second mandrel, a third mandrel and a plurality of permanent magnet units. One end of the first mandrel is opened There are a first tank body and a second tank body, the second tank body is located on the outside of the first tank body, a plurality of reinforcing ribs are evenly distributed in the second tank body along the axial direction, and the multiple reinforcing ribs divide the second tank body into multiple A sub-slot body, the permanent magnet unit is embedded in the sub-slot body; at least a part of the second mandrel is sheathed on the outer wall of the first mandrel, and a third slot is opened on the end of the second mandrel close to the first mandrel; The two ends of the three mandrels respectively abut against the bottoms of the first tank body and the third tank body. The double-sheathed permanent magnet motor rotor structure proposed by the invention solves the problems of low strength and low utilization rate of permanent magnet materials in the existing rotor structure.

Owner:XI AN JIAOTONG UNIV +1

Hybrid Excitation Turbo Generator with Multi-stage Axial-Centrifugal Ventilation and Cooling System

ActiveCN113346678BImprove power densityChange different working statusMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineCooling effect

The invention discloses a hybrid excitation turbogenerator with a multistage axial flow-centrifugal ventilation and cooling system, which relates to the field of motors. In order to solve the problems of low power density and high component temperature of the existing turbogenerators, the present invention installs stator core sections with different thicknesses along the axial direction, and radial ventilation grooves are left between the stator core sections. There are axial ventilation holes on the stator yoke and axial ventilation holes on the stator teeth. The multi-stage axial flow-centrifugal hybrid fan is installed on one side of the turbogenerator. The outer surface of the rotor core is provided with fan-shaped grooves and rectangular deep holes. Slots, high-coercivity permanent magnets and low-coercivity permanent magnets are installed in fan-shaped grooves, rotor excitation windings are installed in rectangular deep grooves, rotor internal cooling ventilation channels are opened in rotor excitation windings, and rotor excitation windings are opened below There is a ventilation channel at the bottom of the rotor groove, and an axial ventilation hole of the rotor core is opened under the fan-shaped groove. The invention improves the power density and cooling effect of the generator, has a simple structure and is easy to realize.

Owner:HARBIN UNIV OF SCI & TECH +2

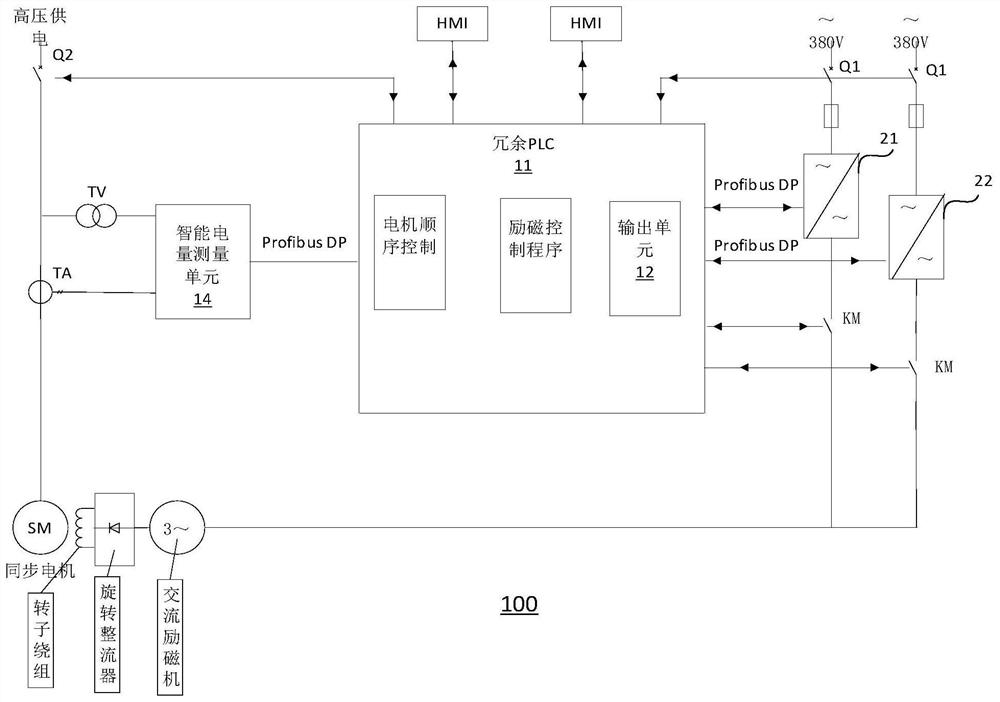

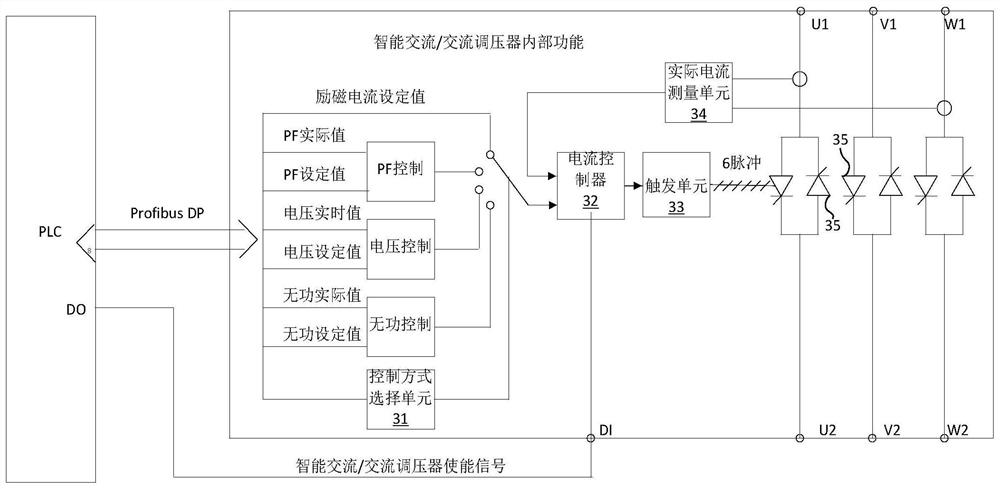

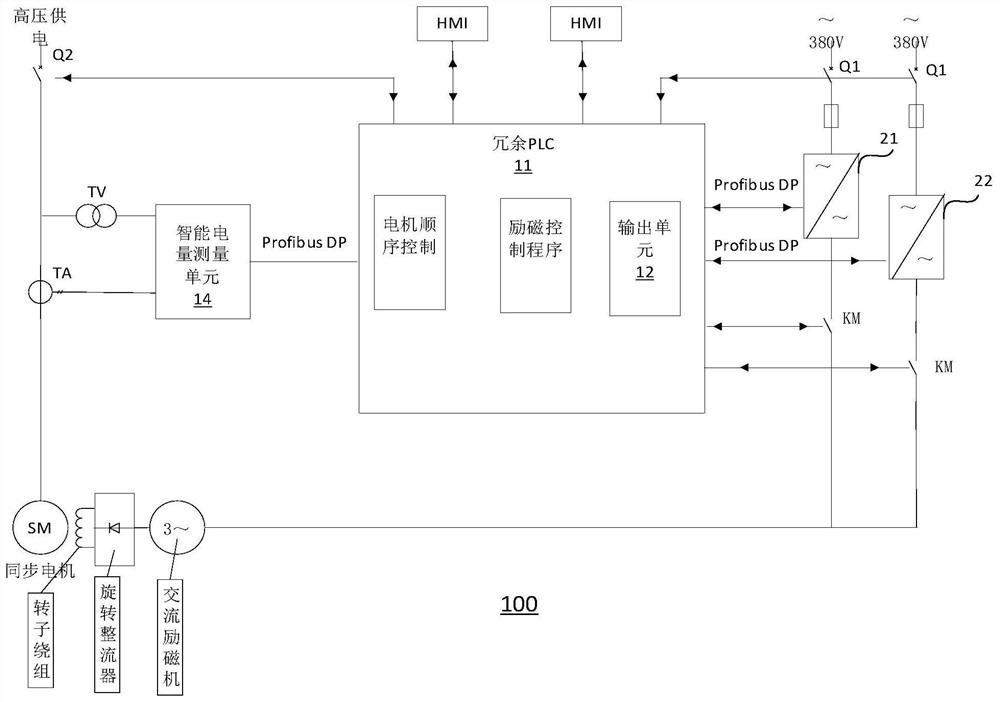

A Synchronous Motor Excitation System

ActiveCN112821846BAvoid loss of magnetismImprove stabilityAC motor controlElectric motor controlSynchronous motorControl engineering

Owner:武汉钢铁有限公司

A permanent magnet synchronous motor rotor with gas circulation function

ActiveCN106451856BSpeed up circulationSmall temperature differenceMagnetic circuit rotating partsSpiral bladePermanent magnet synchronous motor

The invention discloses a permanent magnet synchronous motor rotor with a gas circulating function. A spiral blade is arranged on a rotating shaft of the rotor; a rotor iron core and a permanent magnet are arranged at the outer edge of the spiral blade; the rotor comprises the rotating shaft, the spiral blade, external spline discs, the rotor iron core and a permanent magnet sleeve; the inner edge of the spiral blade is fixed on the rotating shaft; the external spline discs are coaxially fixed on the rotating shaft at two ends of the spiral blade; internal splines matched with the corresponding external spline discs are arranged on the rotor iron core and at two ends of an inner cavity of the permanent magnet sleeve; ventilation holes are formed in the external spline discs. According to the permanent magnet synchronous motor rotor disclosed by the invention, air circulation inside the motor can be accelerated, temperature differences among all parts of a whole permanent magnet synchronous motor are enabled to be reduced, magnetic loss of a permanent magnet caused by local overheat is avoided, and the aim of reducing the temperature of a motor rotor is indirectly achieved.

Owner:GUANGXI UNIV

A force component anti-compression type cable trench

ActiveCN112117731BImprove stress resistanceNo need to increase the thicknessCable installations on groundMagnetic/electric field screeningInterior spaceElectrical connection

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

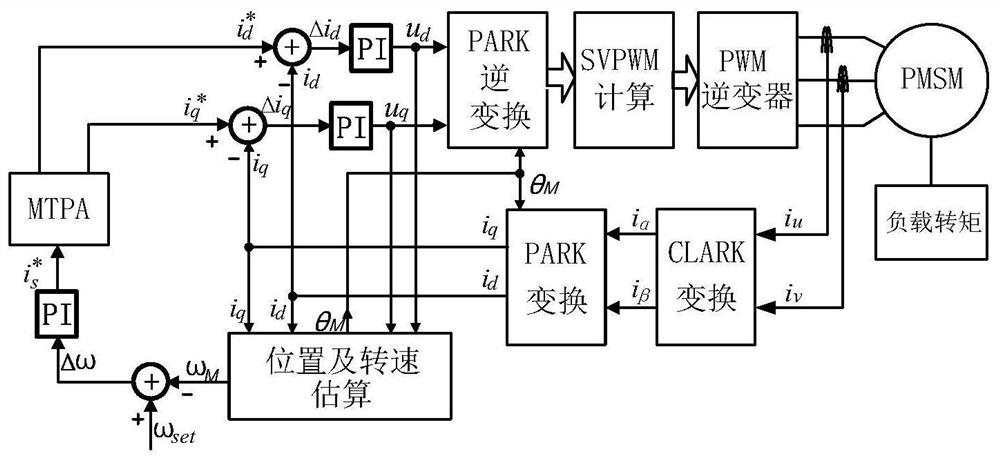

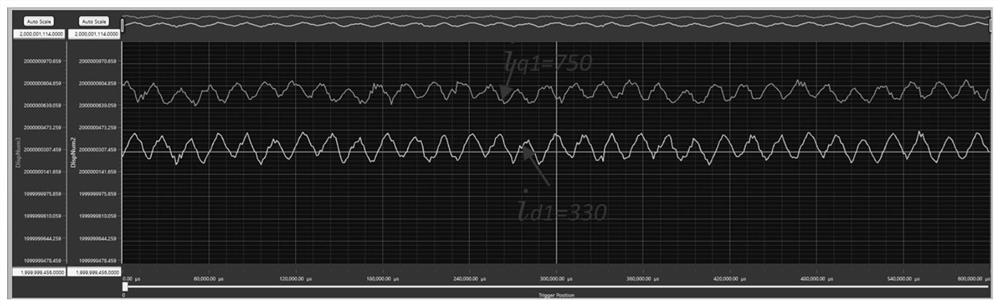

Judgment method for position sensorless control starting stalling of permanent magnet synchronous motor

PendingCN113746405AAvoid loss of magnetismAvoid powerElectric motor controlStarter arrangementsSine waveShaft voltage

The invention discloses a judgment method for position sensorless control starting stalling of a permanent magnet synchronous motor. The judgment method comprises the following steps: establishing a voltage equation of the permanent magnet synchronous motor under an actual rotation dq coordinate system; based on a voltage equation, under a preset consistent operation frequency, generating a three-phase sine wave current to form an active rotating magnetic field in two modes of taking a d-axis voltage as 0 and a q-axis voltage as a preset voltage and taking the d-axis voltage as the preset voltage and the q-axis voltage as 0, so as to make the motor normally operate in an open loop under the condition of no locked-rotor, and respectively calculating d-axis current and q-axis current of the motor in the two modes; and according to the relationship between the dq-axis current and the current preset value of the motor in the two modes, judging whether locked-rotor occurs at the starting stage of the motor. Whether the motor is in the locked-rotor state or not in the starting stage is judged by applying two groups of dq-axis voltage and analyzing the magnitude of the obtained current, and the problems of motor excitation loss, power module damage and the like caused by motor locked-rotor and current overshoot can be avoided.

Owner:GUANGDONG UNIV OF TECH

Double-layer sheath permanent magnet motor rotor structure

ActiveCN112994292AHigh strengthIncrease profitMagnetic circuit rotating partsElectric machinesElectric machineryEngineering

The invention relates to the technical field of motors, and in particular relates to a double-layer sheath permanent magnet motor rotor structure which comprises a first core shaft, a second core shaft, a third core shaft and a plurality of permanent magnet units, a first groove body and a second groove body are formed in one end of the first core shaft, the second groove body is located on the outer side of the first groove body, a plurality of reinforcing ribs are uniformly distributed in the second groove body along the axial direction, the second groove body is equally divided into a plurality of sub-groove bodies by the plurality of reinforcing ribs, and the permanent magnet units are embedded into the sub-groove bodies; the outer wall of the first core shaft is sleeved with at least one part of the second core shaft, and a third groove body is formed in the end, close to the first core shaft, of the second core shaft; the two ends of the third core shaft abut against the groove bottoms of the first groove body and the third groove body respectively. According to the double-layer sheath permanent magnet motor rotor structure provided by the invention, the problems of low strength and relatively low utilization rate of a permanent magnet material of an existing rotor structure are solved.

Owner:XI AN JIAOTONG UNIV +1

A permanent magnet material cutting equipment

ActiveCN113172774BPrevent overheating and demagnetizationEasy to cutInductances/transformers/magnets manufactureWorking accessoriesCooling effectEngineering

The invention relates to the field of new materials, and more particularly to a permanent magnet material cutting device. During the production of permanent magnet materials, there are always material modifications that have been processed. Cutting with traditional cutting methods will undoubtedly produce Vibration, high temperature, these unfavorable factors will demagnetize the material. The present invention solves the above problems. The permanent magnet material is placed in the clamping assembly, and the clamping assembly can clamp the round bar materials of different diameters at different angles, which is convenient for In various cutting situations, the clamping assembly will not generate vibration when cutting, which can effectively prevent loss of magnetism. The push-pull assembly can adjust the cutting length. The cutting assembly can cut the material at a uniform and slow speed, and minimize the vibration. The saw blade is always cooled by the cooling liquid, the sprayed cooling liquid is filtered and cooled to a suitable temperature and then added to the cooling liquid tank, which saves resources and prevents the material from overheating and demagnetizing because the temperature of the cooling liquid is too high and the cooling effect is lost.

Owner:东阳市盛邦磁业有限公司

Motor cooling device and motor

ActiveCN109787381BAxial temperature difference is smallUniform axial temperature distributionMagnetic circuit stationary partsWindings conductor shape/form/constructionElectric machineMechanical engineering

The invention provides a motor cooling device and a motor. The motor cooling device comprises the following parts of a plurality of stator vent holes formed in a stator core along an axial direction of the stator core; a first mounting member and a second mounting member respectively coupled to the both axial sides of the stator core and respectively formed with a plurality of first vent holes anda plurality of second vent holes along the axial direction; and a bracket comprising a main body and first and second support portions protruding radially outward from both sides of the main body, wherein the main body is formed with a plurality of bracket vent holes, the first mounting member and the second mounting member are respectively supported on the first support portion and the second support portion, the first vent hole and the second vent hole respectively form a first vent passage and a second vent passage that are independent of each other with the corresponding stator vent holes, and the flows of the air flowing through the first vent passage and the second vent passage are reciprocal and flow out to the outside through the bracket vent holes. According to the motor coolingdevice provided by the invention, the axial temperature difference of the motor can be reduced.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

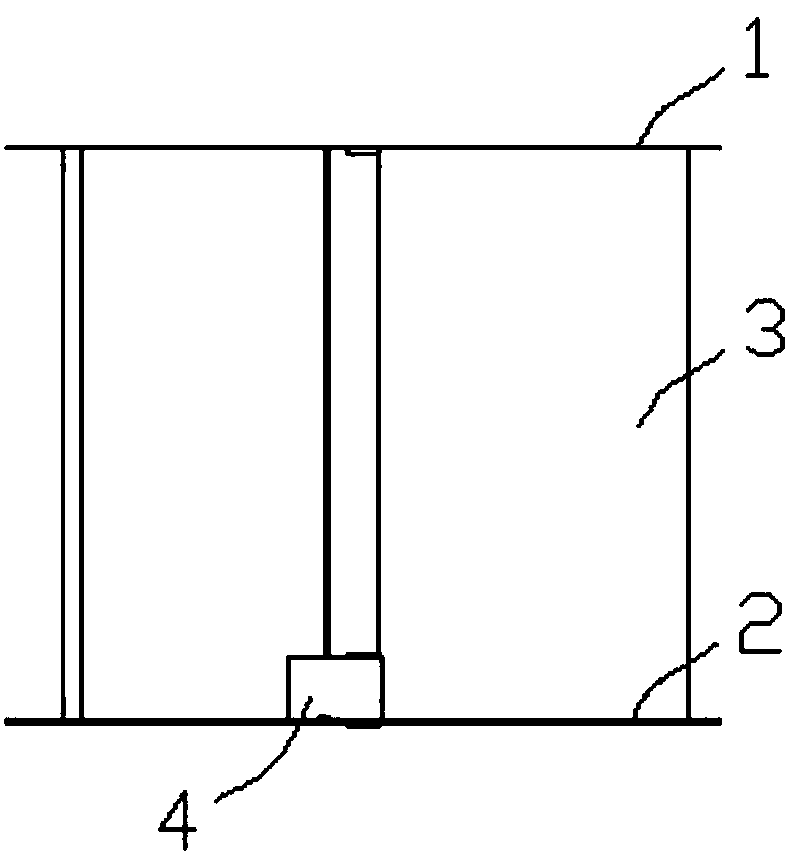

Integrated vertical-axis wind turbine

PendingCN108050017AAvoid wear and tearIncrease profitRenewable energy generationMachines/enginesElectricityIntegrated design

The invention relates to an integrated vertical-axis wind turbine which comprises an upper cover, a lower cover, blades, a power generator and a shaft body, wherein the lower cover is arranged below the upper cover; the blades are arranged between the upper cover and the lower cover; two ends of each blade are fixedly connected with the upper cover and the lower cover correspondingly; the power generator is arranged at the center of the upper end of the lower cover; the lower part of the power generator is fixedly connected with the lower cover through a bolt; the shaft sequentially penetratesthrough the upper cover, the power generator and the lower cover from top to bottom, and is connected with the upper cover, the power generator and the lower cover through a plurality of bearings; and the bearings all sleeve the shaft body. Compared with the prior art, the integrated vertical-axis wind turbine provided by the invention achieves the integrated design of a wind wheel and a permanent magnet power generator of a conventional wind turbine. Accordingly, the structure of the integrated vertical-axis wind turbine can be simplified, the integrated vertical-axis wind turbine can rotateand produce electricity energy as long as the internal cogging torque of a motor is overcome, the mechanical abrasion caused by a transmission device and the consumption of wind energy can be reduced, and the wind energy utilization ratio can be effectively improved.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Thermoplastic resin composite sheet production device and process

ActiveCN108045065AHigh strengthImprove toughnessLamination ancillary operationsInorganic material artificial filamentsFiberSlurry

The invention belongs to the field of sheet preparation and relates to a thermoplastic resin composite sheet production device and process. The thermoplastic resin composite sheet production device comprises a substrate forming mechanism and at least one composite layer forming mechanism. Each composite layer forming mechanism is integrally positioned above a conveying belt (202) and comprises a magnetic fiber laying device, a magnetic field generating unit (402) and a cooling roller (303) from one side close to a die head I (101), wherein the magnetic fiber laying device is used for laying fibers on substrate slurry (501), the magnetic field generating unit (402) is capable of generating a magnetic field perpendicular to the ground, and the cooling roller (303) is used for receiving composite layer slurry (502) from a die head II (102) to enable cooling of the composite layer slurry (502) on the cooling roller (303). The thermoplastic resin composite sheet production device is simplein structure and easy in operation.

Owner:江苏维尔克汽车内饰件有限公司

A fiber manufacturing process

ActiveCN107904677BImproves Strength and ToughnessSimple equipment structureGlass making apparatusArtificial thread manufacturing machinesMelt spinningFiber fabrication

The invention relates to a fiber manufacturing process, and belongs to the field of fiber manufacturing. The fiber manufacturing process is a melt spinning process. A melt is prepared by the followingsteps of firstly, preparing a-Al203 wrapping magnetic material particles; secondly, mixing the a-Al203 wrapping magnetic material particles obtained in the first step with other fiber materials, andthen melting. The melt comprises magnetic particles, and the magnetic particles are the a-Al203 wrapping magnetic material particles; the a-Al203 with high intensity is wrapped outside the magnetic material, on one hand the intensity and tenacity of the fiber can be improved, on the other hand, the a-Al203 has high melting point, the magnetic particles are wrapped inside the a-Al203, the magnetismloss of magnetic substances inside the a-Al203 caused by acting with other fibers can be avoided.

Owner:上海沙驰服饰有限公司

A fiber manufacturing device and process

ActiveCN107988633BHigh strengthImprove toughnessSpinnerette packsHollow filament manufactureFiber fabricationMelt spinning

The invention belongs to the field of fiber manufacturing and relates to a fiber manufacturing device and process. The fiber manufacturing process refers to a melt spinning process, and melt is prepared by steps: step one, preparing a-Al2O3 coated magnetic material particles; step two, mixing the a-Al2O3 coated magnetic material particles obtained at the step one with other fiber materials, and melting to obtain the melt. The magnetic particles which are a-Al2O3 coated magnetic material particles are included in the melt prepared according to the process. By external coating of a magnetic material with high-strength a-Al2O3, on the one hand, strength and toughness of obtained fibers can be improved, and on the other hand, due to high melting point of a-Al2O3, wrapping the magnetic materialinside avoids magnetism loss of inner magnetic substances due to reaction with other fibers.

Owner:PUNING XINSHENG PRINTING & PACKAGING CO LTD

A melt spinning process

ActiveCN108085774BHigh strengthImprove toughnessArtificial thread manufacturing machinesInorganic material artificial filamentsPolymer scienceMelt spinning

The invention relates to a melt spinning technology and belongs to the field of spinning. According to the melt spinning technology, magnetic force parallel to the direction of the ground is applied to a melt in a wire drawing process, and the melt is prepared with a method comprising steps as follows: step 1, a-Al2O3 coated magnetic material particles are prepared; step 2, the a-Al2O3 coated magnetic material particles obtained in step 1 are mixed with other fiber raw materials, and a mixture is molten. With adoption of the technology and a device, magnetic fibers with consistent magnetic orientation can be obtained.

Owner:无锡佳成纤维有限公司

Synchronous motor excitation system

ActiveCN112821846AAvoid loss of magnetismImprove stabilityAC motor controlElectric motor controlSynchronous motorElectrical and Electronics engineering

The invention discloses a synchronous motor excitation system which comprises a redundant PLC, a first intelligent voltage regulator, a second intelligent voltage regulator and a synchronous motor. The first intelligent voltage regulator and the second intelligent voltage regulator are connected in parallel and then are connected with the synchronous motor, and the first intelligent voltage regulator and the second intelligent voltage regulator are both connected with the redundant PLC; the first intelligent voltage regulator is used for stopping working when a fault occurs and sending a fault signal to the redundant PLC; and the redundant PLC is used for starting the second intelligent voltage regulator to work when the fault signal is received. The stability of the excitation system of the synchronous motor can be improved, and excitation loss of the synchronous motor caused by faults of the voltage regulator is avoided.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com