Rotor punching sheet of high-speed permanent magnet motor

A technology for punching permanent magnet motors and rotors, which is applied to the rotating parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., and can solve the problems of complete machine scrapping and motor jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

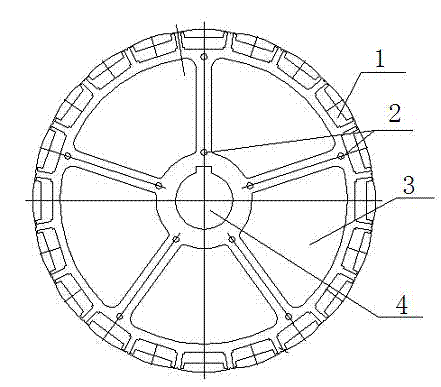

[0009] Such as figure 1 As shown, the high-speed permanent magnet motor rotor punching sheet includes punching sheet inner slot 1, punching sheet combined hole 2, weight reducing hole 3 and rotor shaft hole 4. The punching sheet inner slot 1 is distributed on the outer circumferential surface of the punching sheet to reduce The heavy holes 3 are distributed around the rotor shaft holes 4, the punching piece combination holes 2 are arranged between the weight-reducing holes 3, the rotor shaft hole 4 is arranged at the center of the punching piece, and the weight-reducing holes 3 are sector-shaped. The high-speed permanent magnet of the present invention The motor rotor punching piece, the permanent magnet block is inserted in the inner slot of the punching piece, which can prevent the permanent magnet block from falling off at high speed. The overall punching piece structure makes the magnetic flux form a closed circuit to prevent the permanent magnet block from losing its magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com