Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Achieve torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

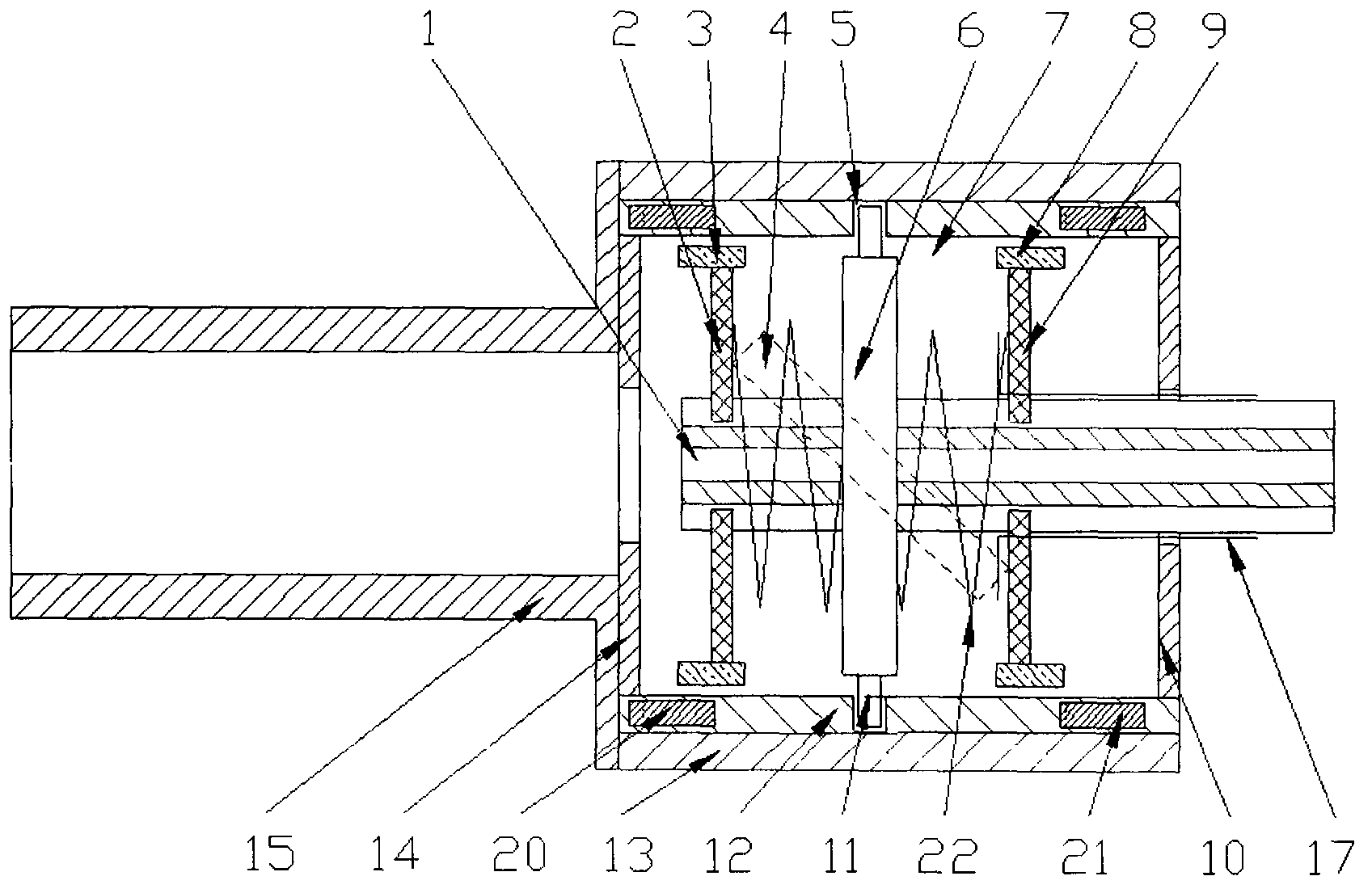

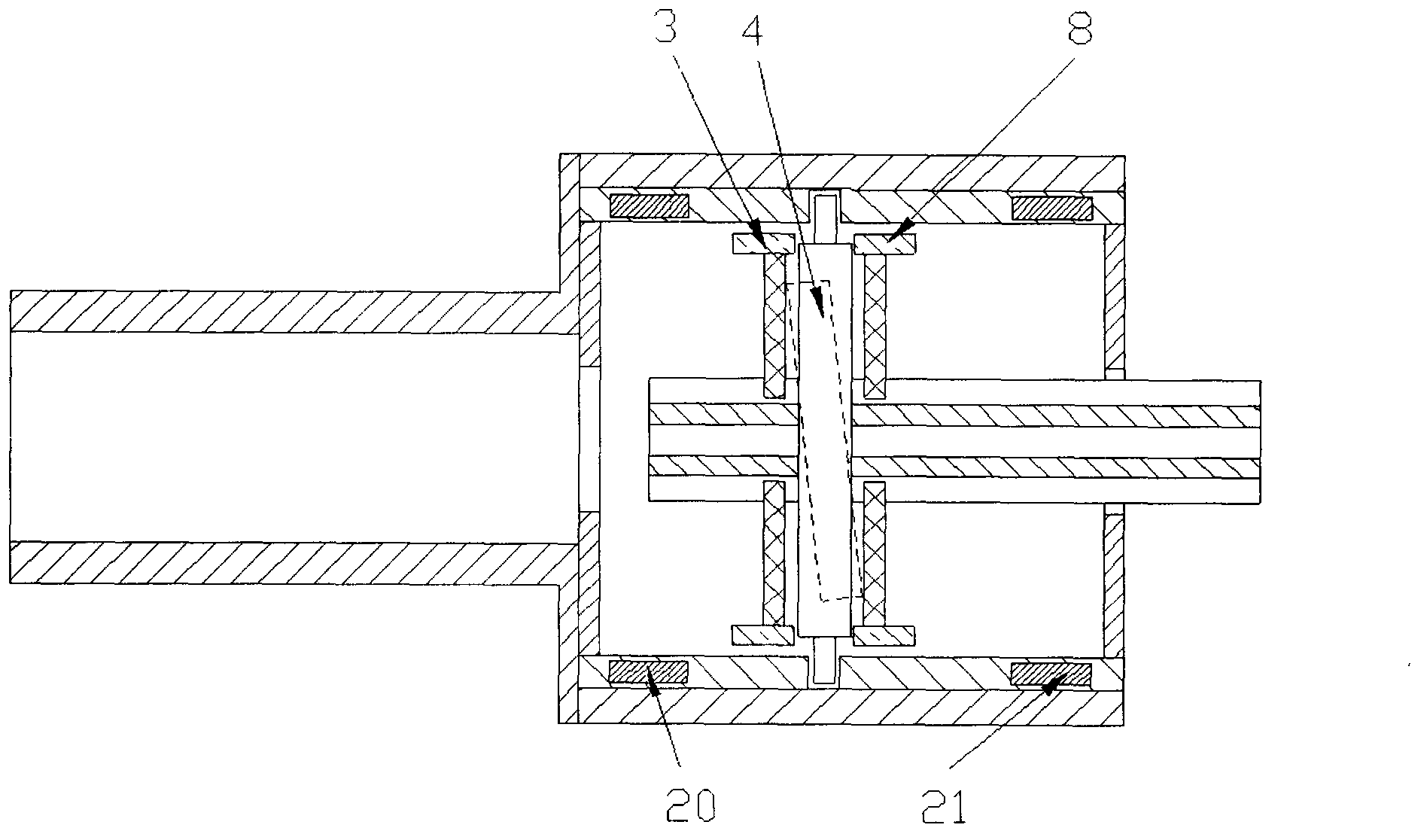

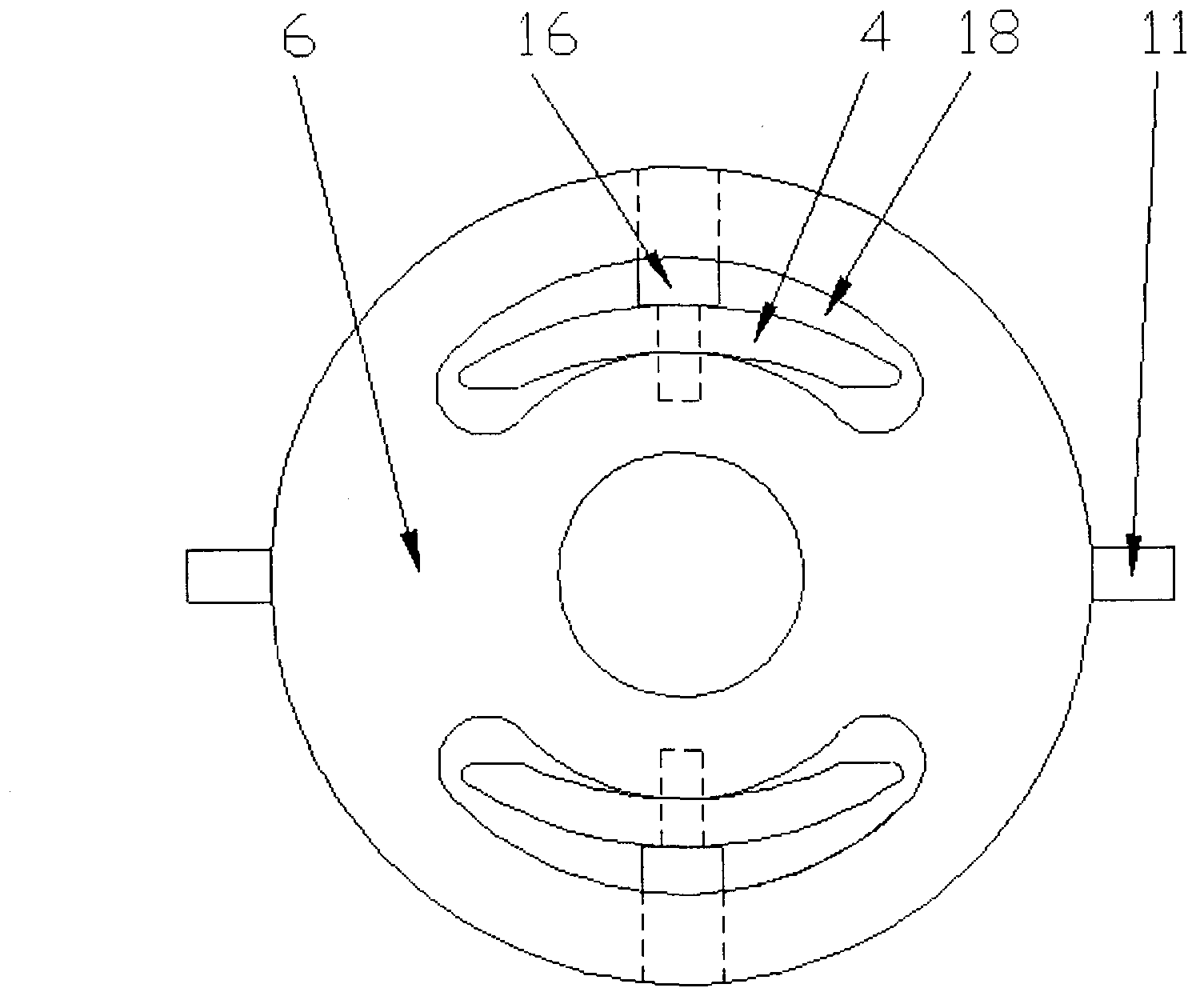

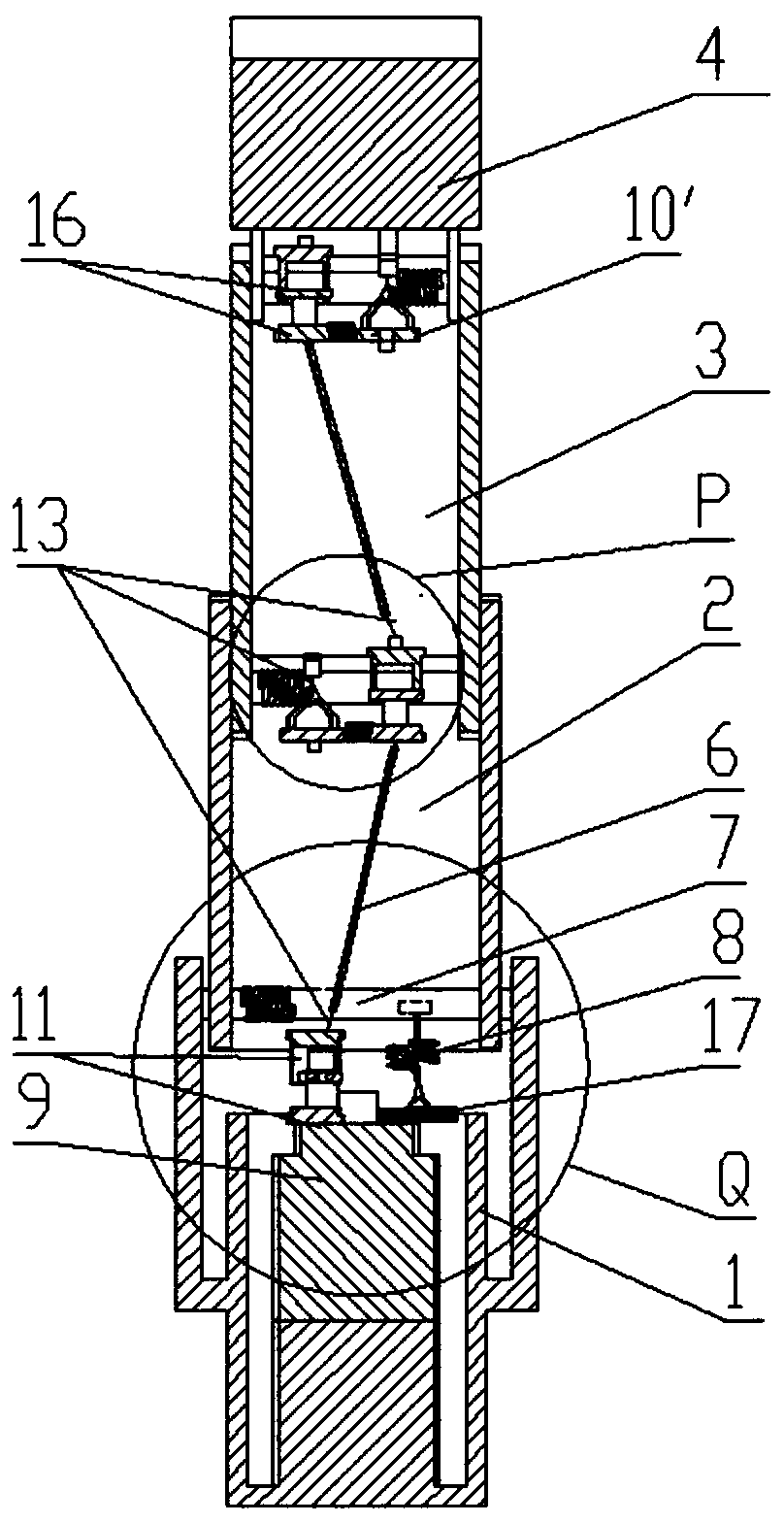

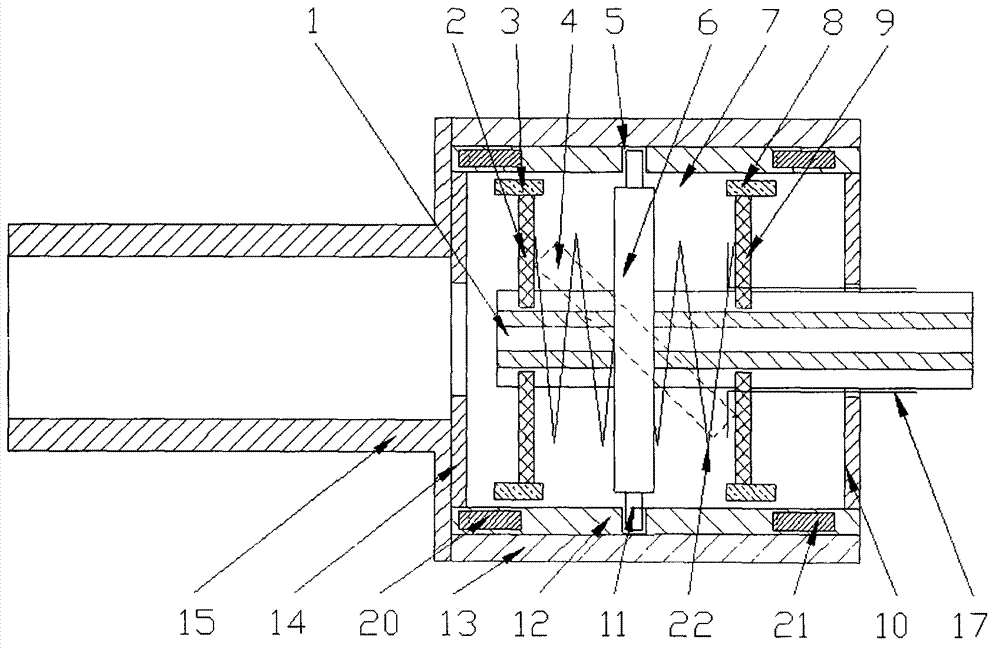

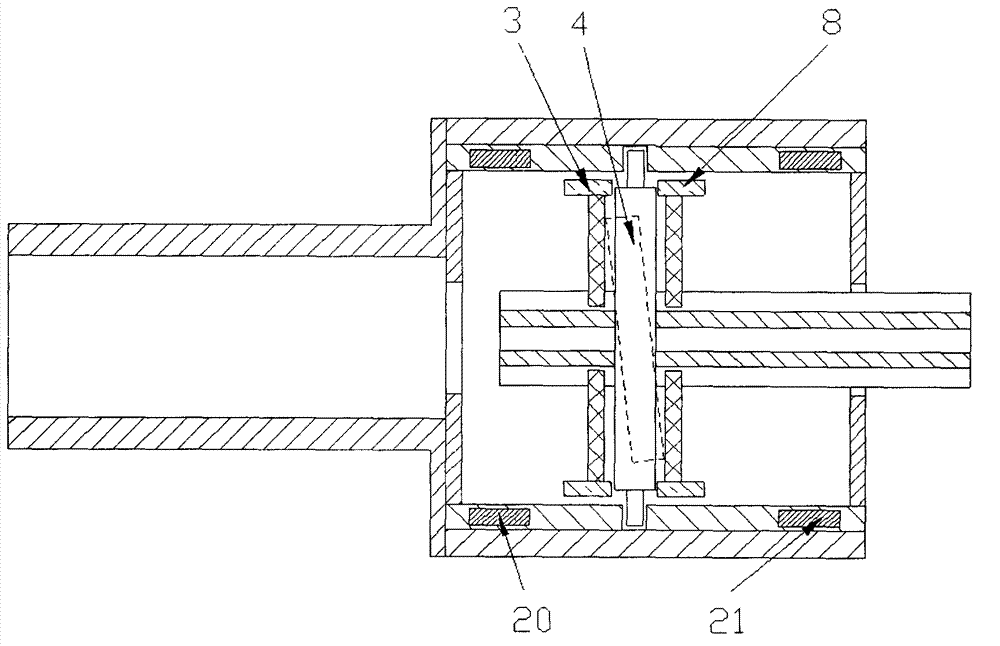

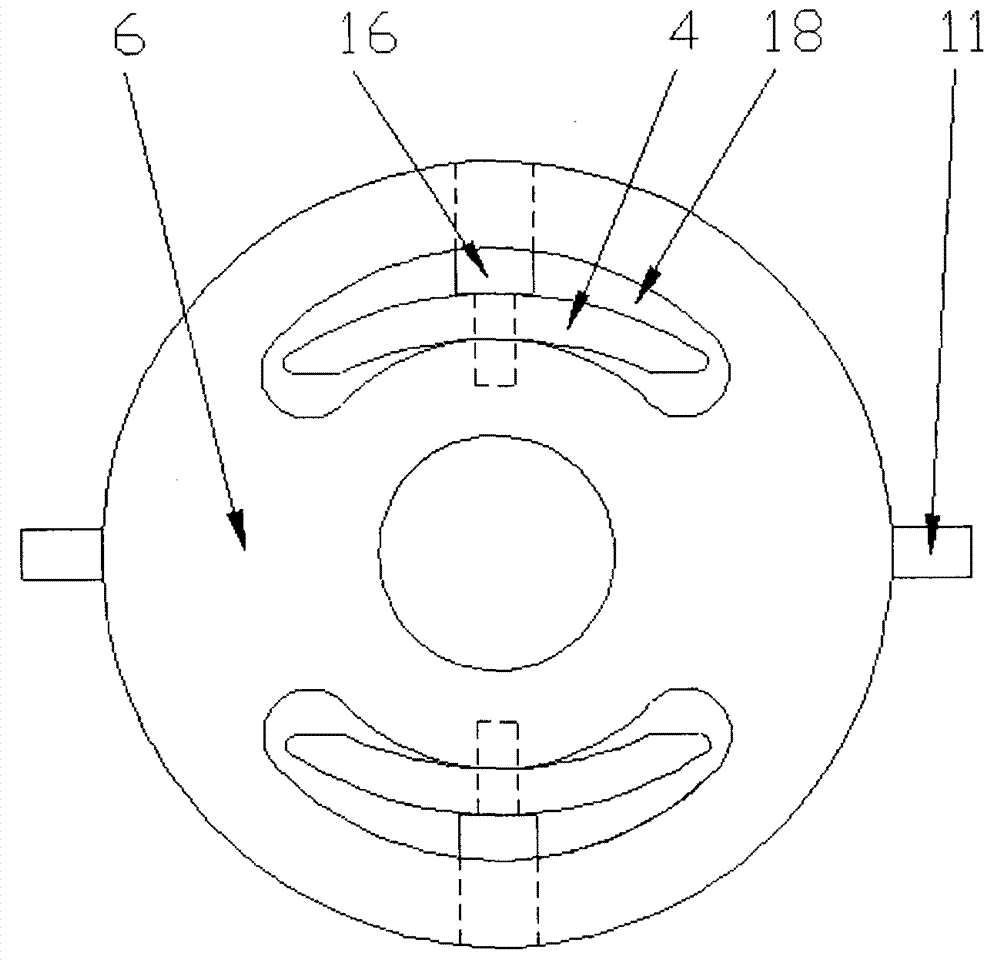

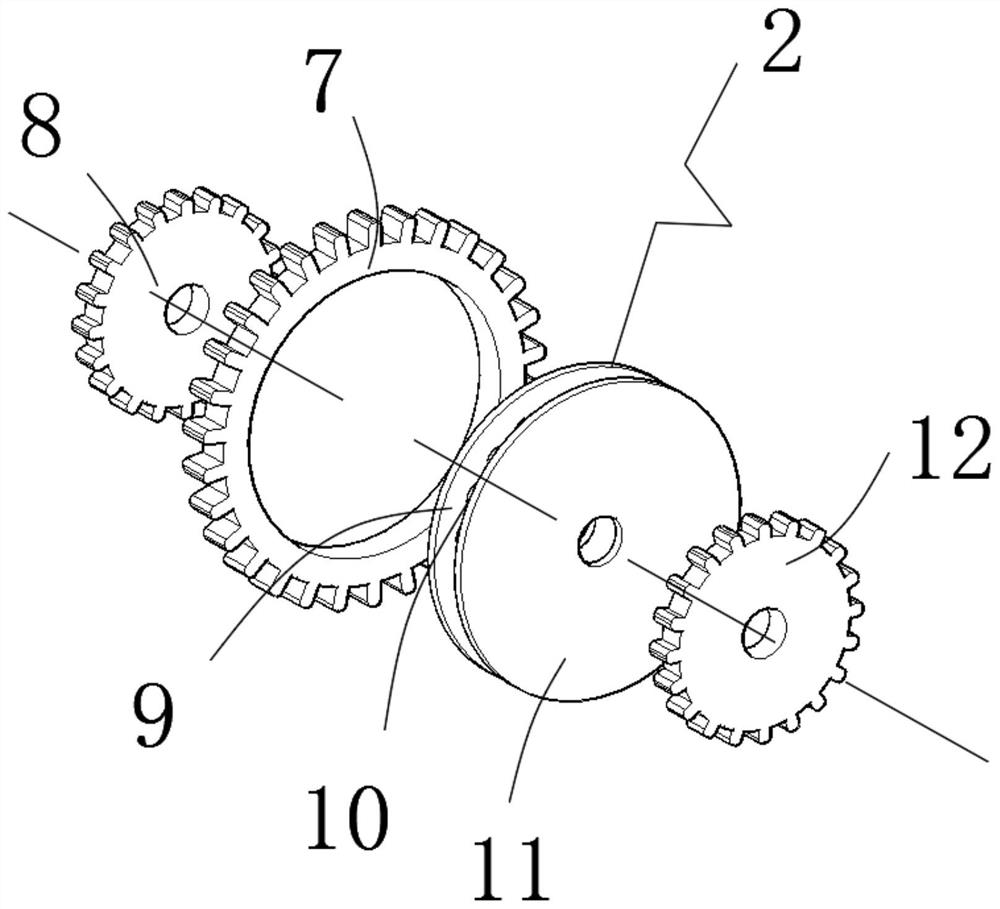

Permanent-magnet slip transmission mechanism

InactiveCN103236775AReduce volumeSimple structureDynamo-electric gearsGenerators/motorsMachine toolWind power generation

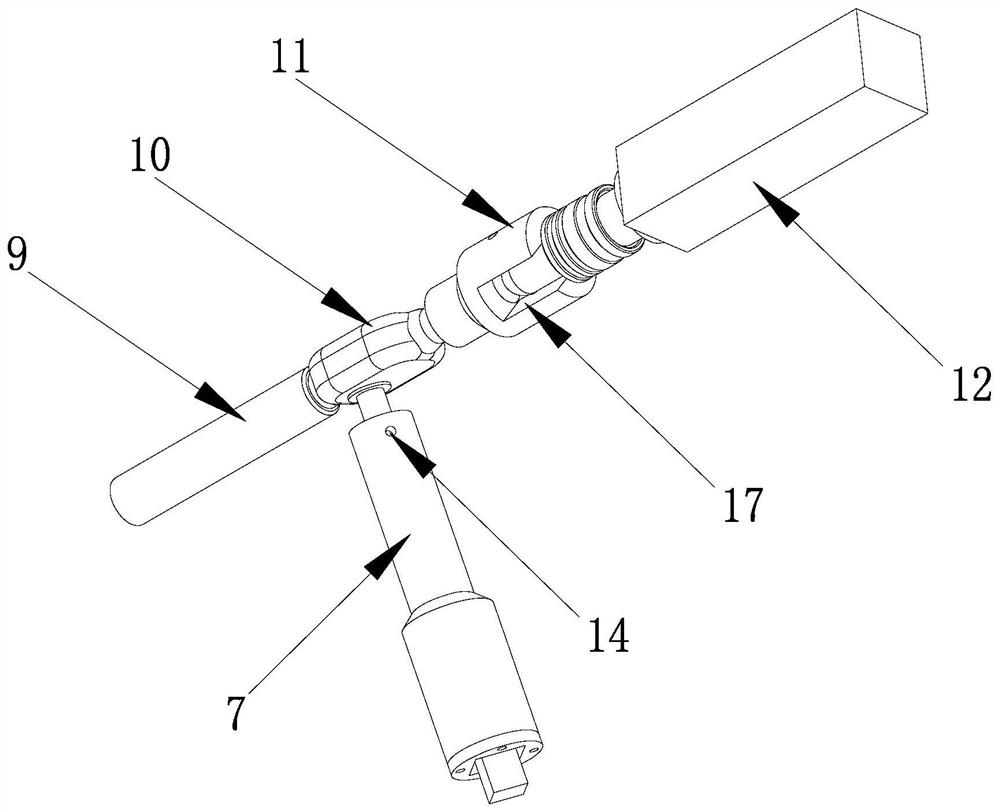

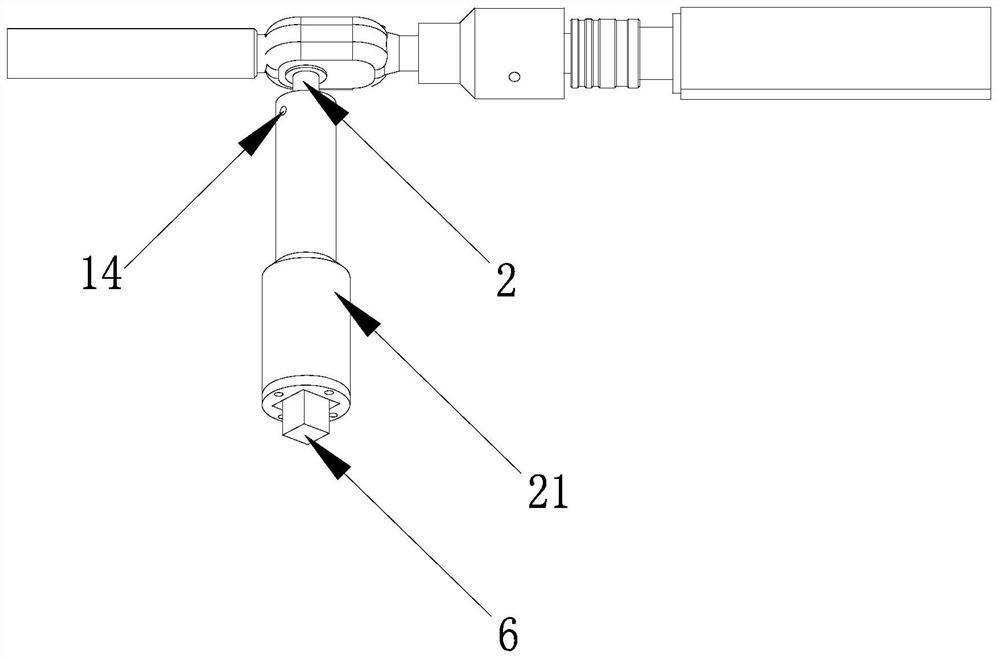

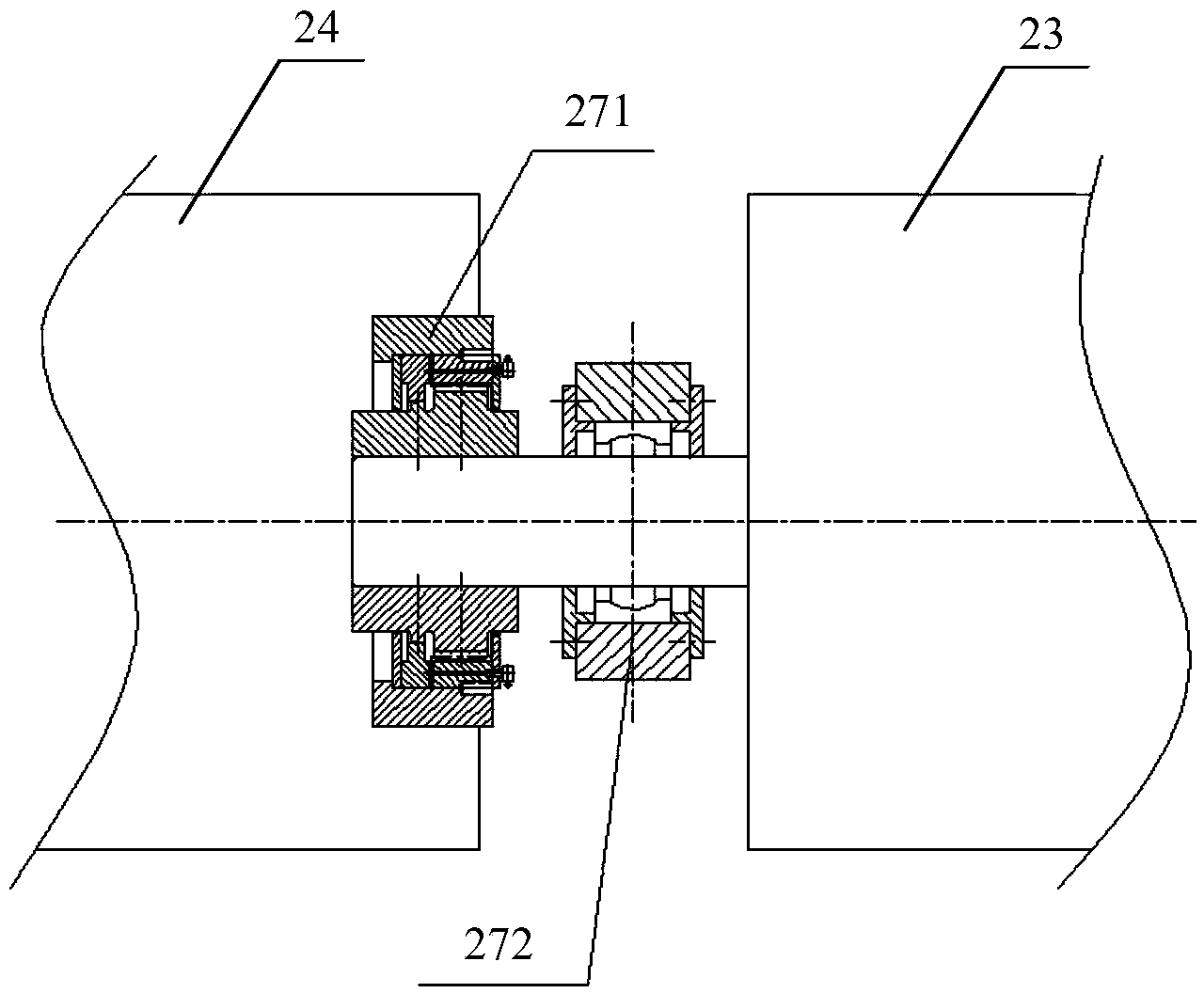

The invention relates to a permanent-magnet slip transmission mechanism with a slip transmission function. The permanent-magnet slip transmission mechanism structurally comprises a grooved drum provided with two magnetic disks and a groove, a base disk connected with the two magnetic disks through a spring, two pairs of radial-flux magnets, an operating lever and two levers; a torque can be reliably and stably transferred during slip transmission; and the value of the transferred torque can be changed in a stepless manner. The permanent-magnet slip transmission mechanism comprises the base disk 6, the grooved drum 13, the magnetic disk 14, the magnetic disk 10, the magnetic disk 2, the magnetic disk 9, the levers 4, the operating lever 17, and the like, and is suitable for the fields of vehicles, wind power generation systems, air vehicles, machine tools, general machinery, industrial and mineral machinery, engineering machinery, and the like.

Owner:NANJING INST OF TECH

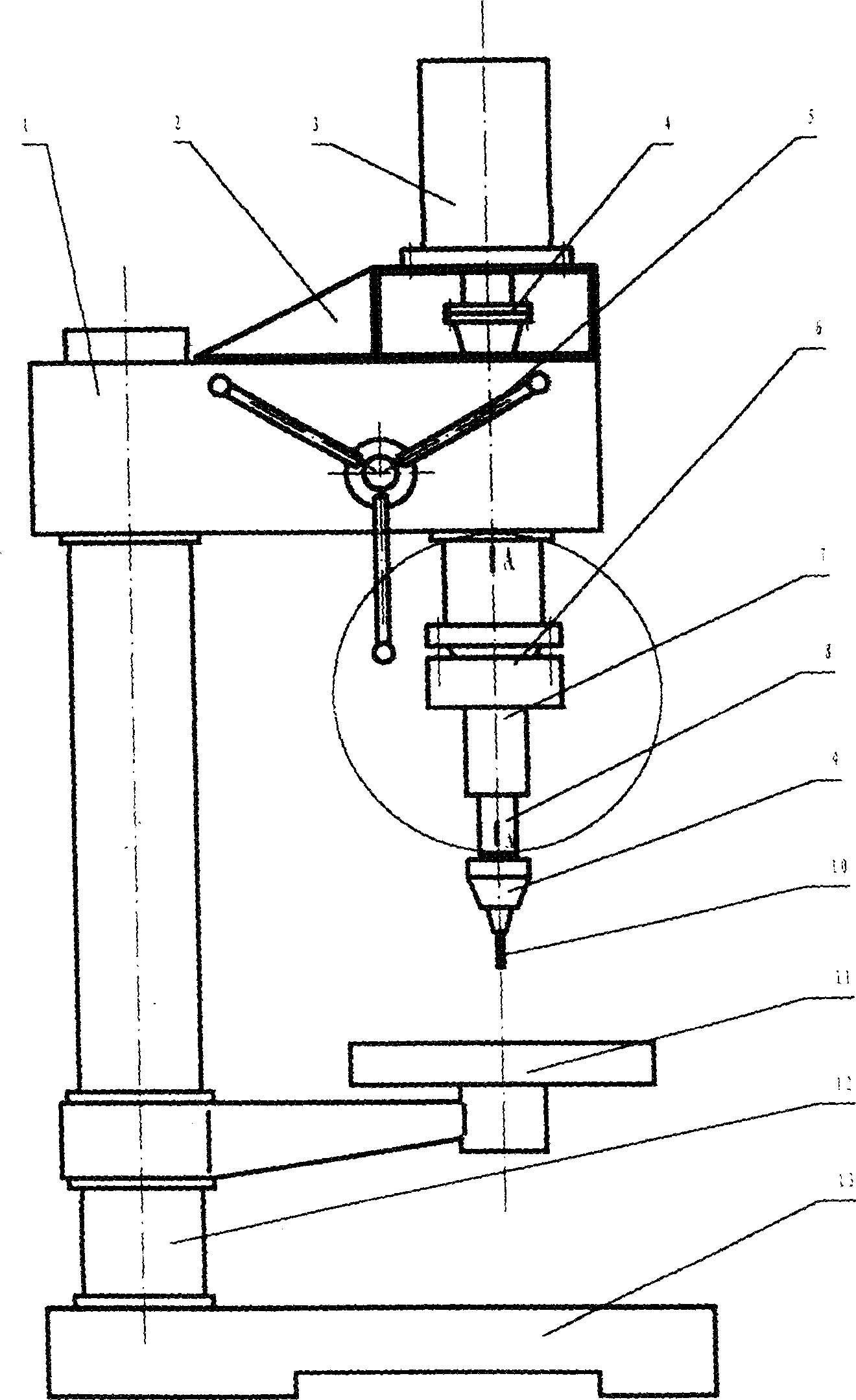

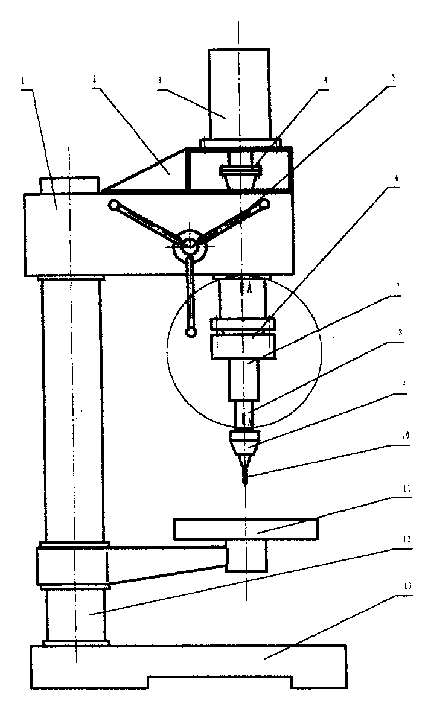

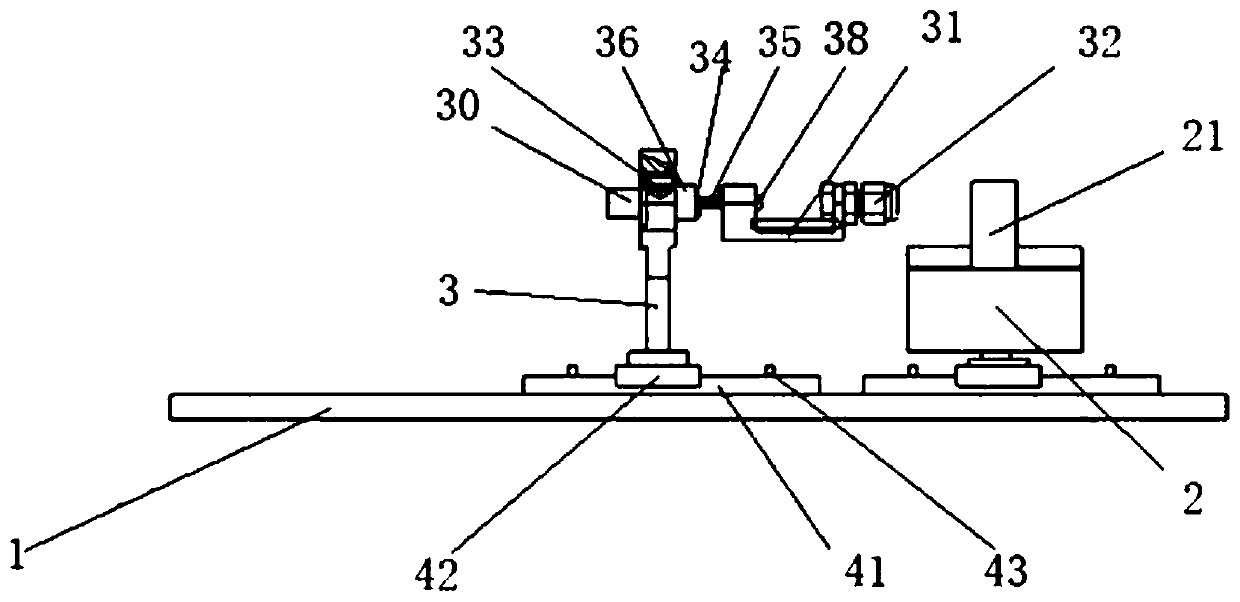

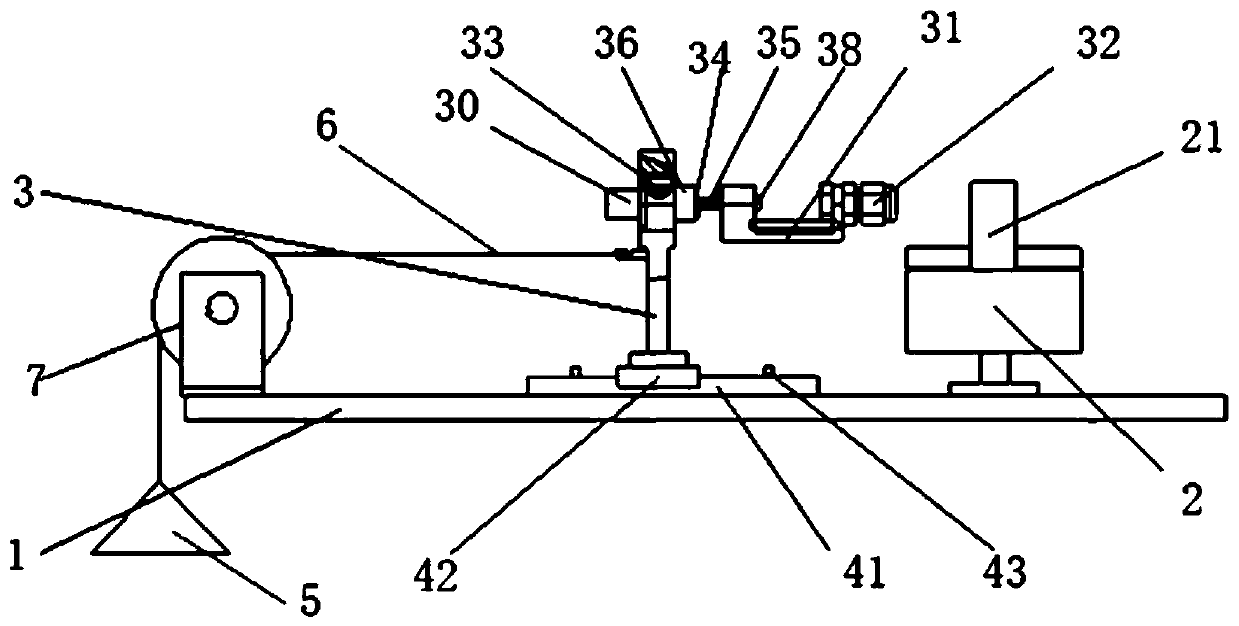

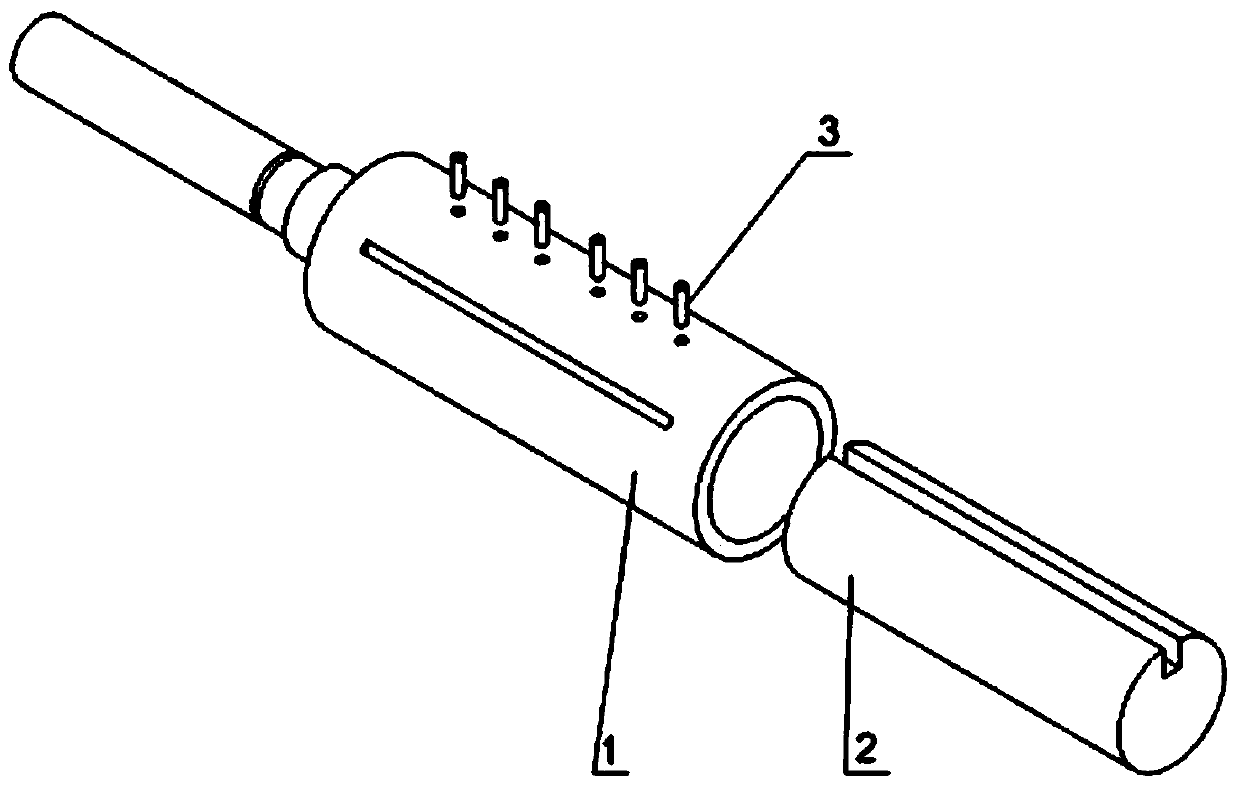

Method for on-line fault diagnosis of vibration threading and its equipment

InactiveCN1394712AEasy to installFirmly connectedAutomatic control devicesThread cutting machinesTorque analysisDiagnosis methods

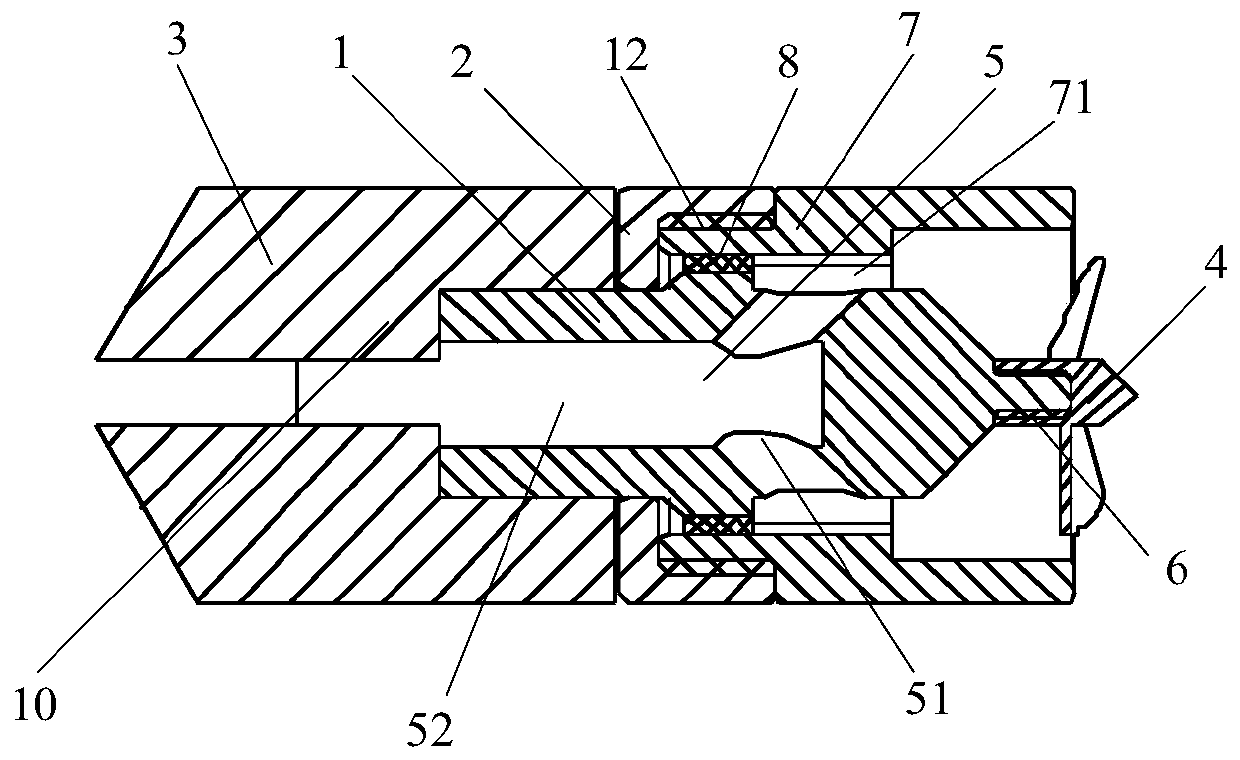

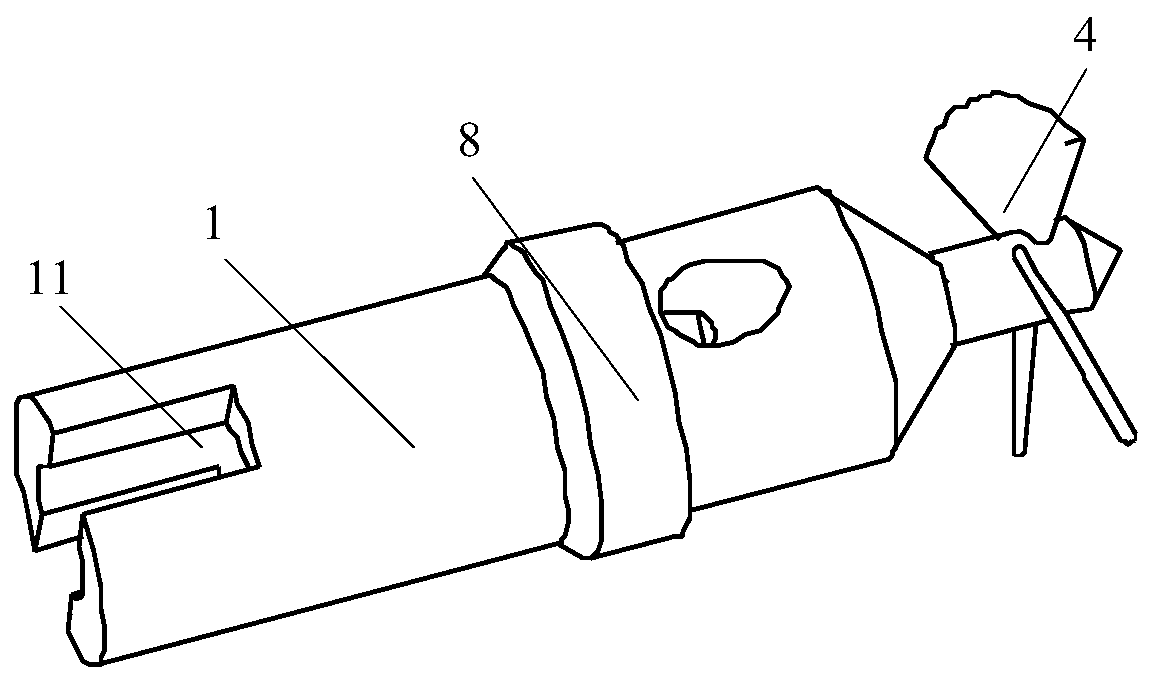

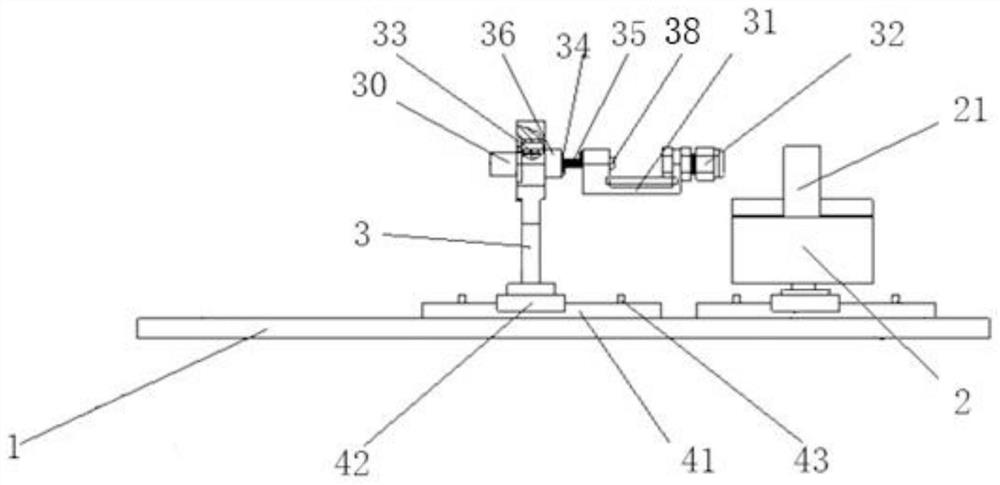

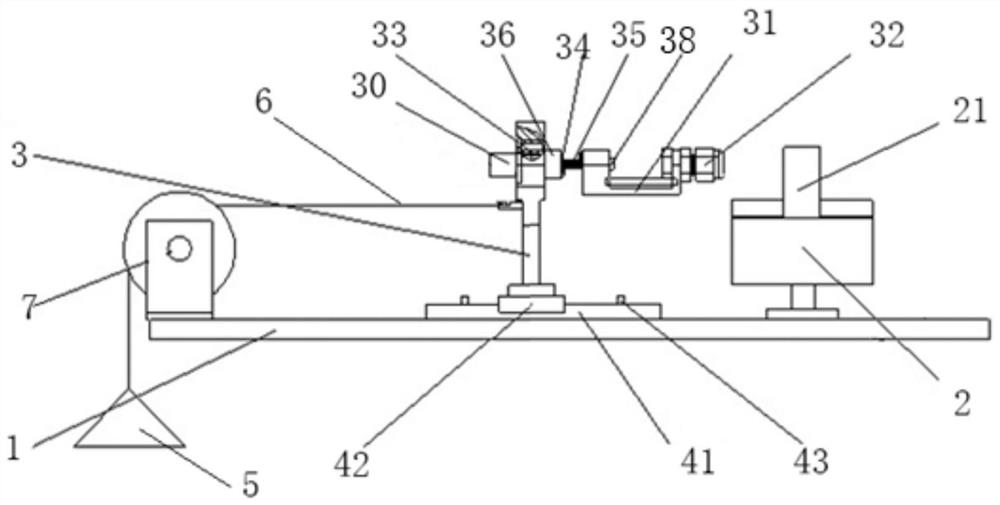

The present invention relates to a vibration threading on-line fault diagnosis method and its equipment, including vibration threading machine unit, drive and control unit of stepper motor and torque measuring unit, a torque sensor and a threading torque analysis and storage system are series-connected between its main sahft input end and threading grip holder, and said torque sensor is fixedly connected with main shaft of threading machine by means of elastic holding mechanism formed from elastic holder base cover, locking cover and locking screw. Said invention adopts the stepper motor as vibration source and threaidng force source, utilzies torque sensor to receive moving force and vibration source signal transferred by main shaft of machine tool of machine unit, and unilizes the signal amplification.

Owner:JIANGSU UNIV

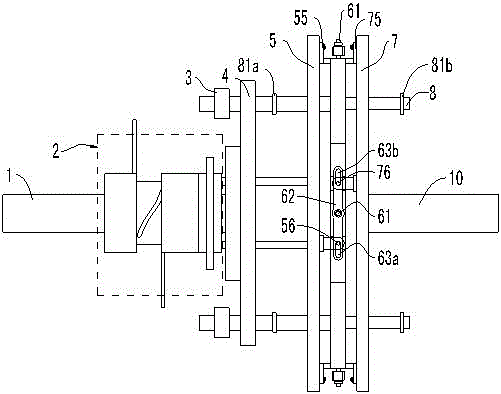

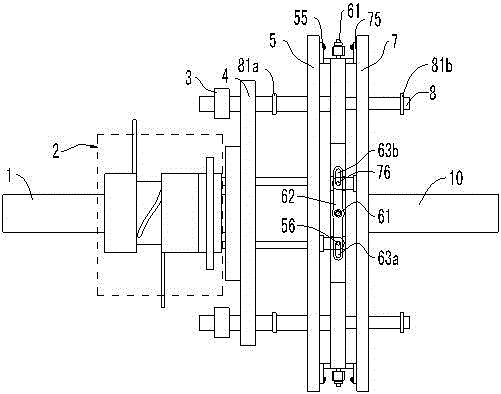

Outer rotor regulation type eddy current speed controller

InactiveCN104682662ASimple structureReduce processing difficultyDynamo-electric gearsMagnetic polesEddy current

The invention discloses an outer rotor regulation type eddy current speed controller. The outer rotor regulation type eddy current speed controller comprises an inner rotor and an outer rotor, wherein the inner rotor comprises an inner rotor rotation disc in which a plurality of groups of permanent magnets are embedded; the outer rotor comprises two outer rotor motion discs which are symmetrically arranged at two sides of the inner rotor rotation disc, and a rotation liner regulating mechanism; each outer rotor motion disc is provided with a conducting metal disc; a variable gas gap is formed between each conducting metal disc and the corresponding inner rotor rotation disc; the rotation linear regulating mechanism, on one hand, enables each conducting metal disc to rotate synchronously together with the outer rotor, and on the other hand, enables the two variable gas gaps to change axially at the opposite directions or the same direction. After the structure is adopted, only one inner rotor rotation disc comprising the permanent magnets is required, so that the magnetic connection of the inner rotor and the outer rotor can be realized; the inner rotor is simple in structure, is low in processing difficulty, and is convenient for assembling and overhauling; two magnetic poles of each permanent magnet in the inner rotor rotation disc can be used at the same time, so that the permanent magnetic utilization ratio is high, the cost is reduced, and the product is economic.

Owner:HOHAI UNIV

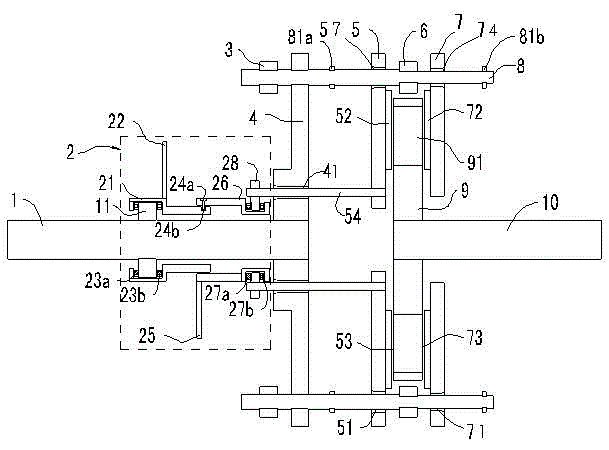

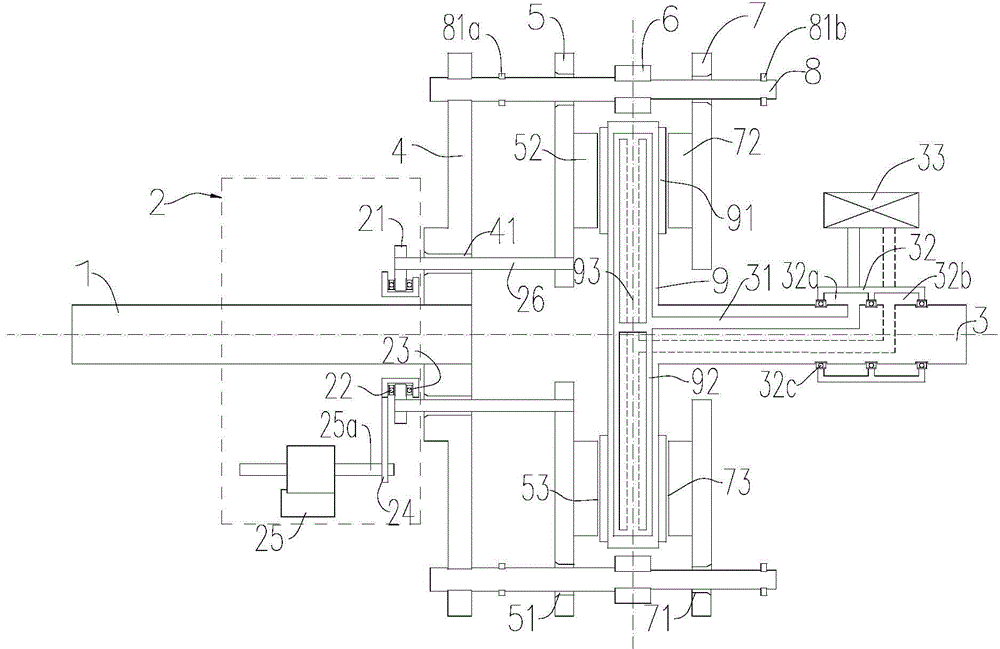

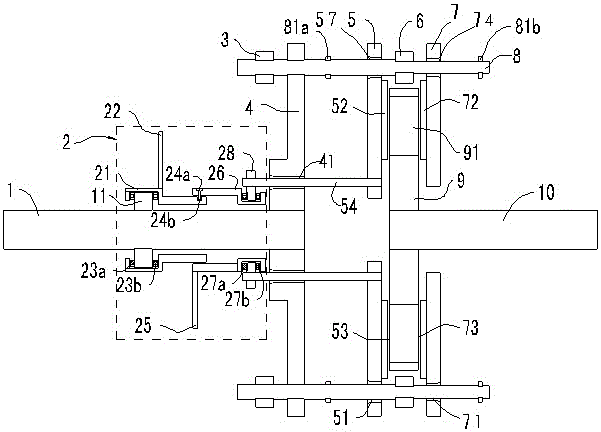

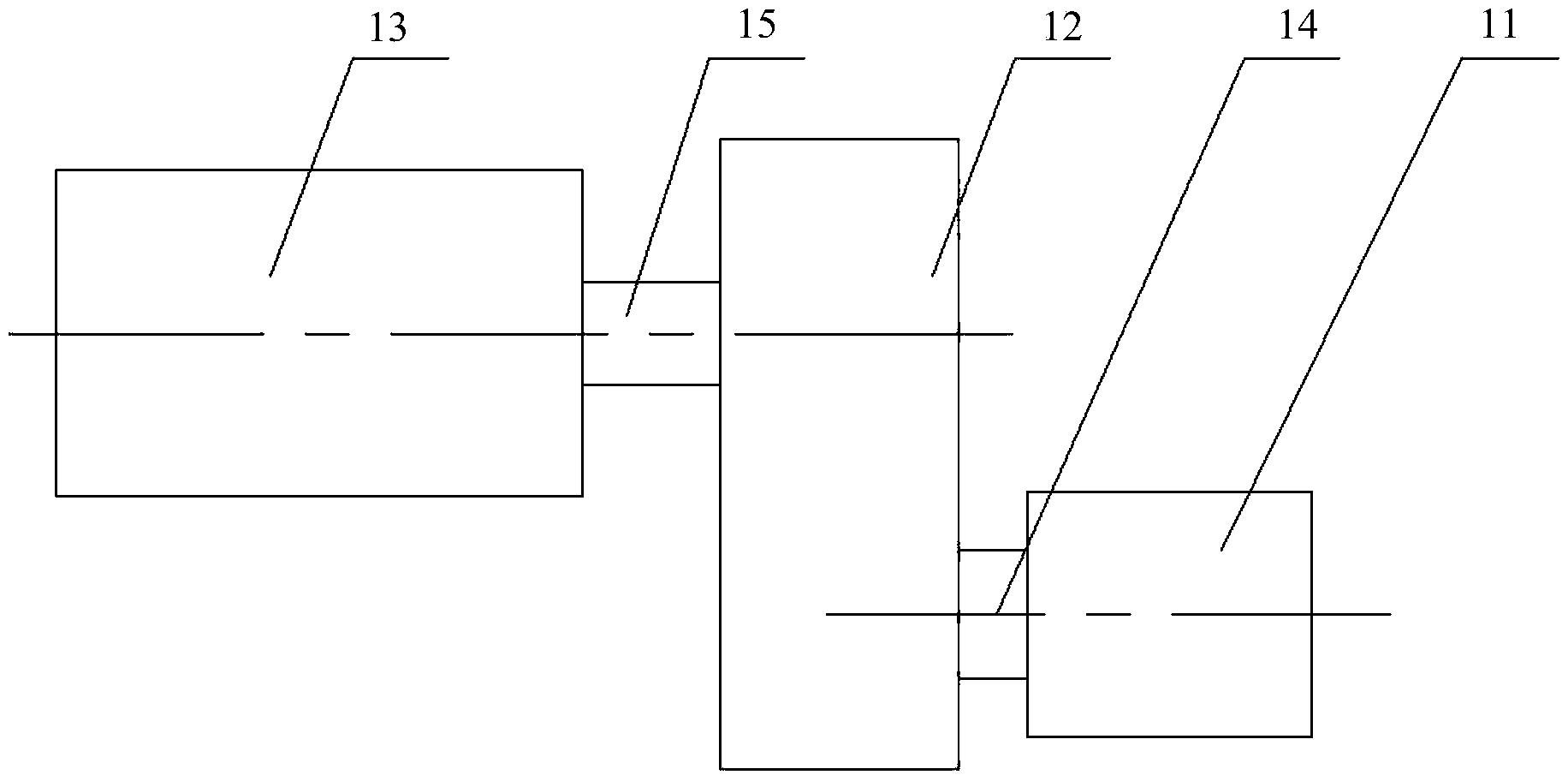

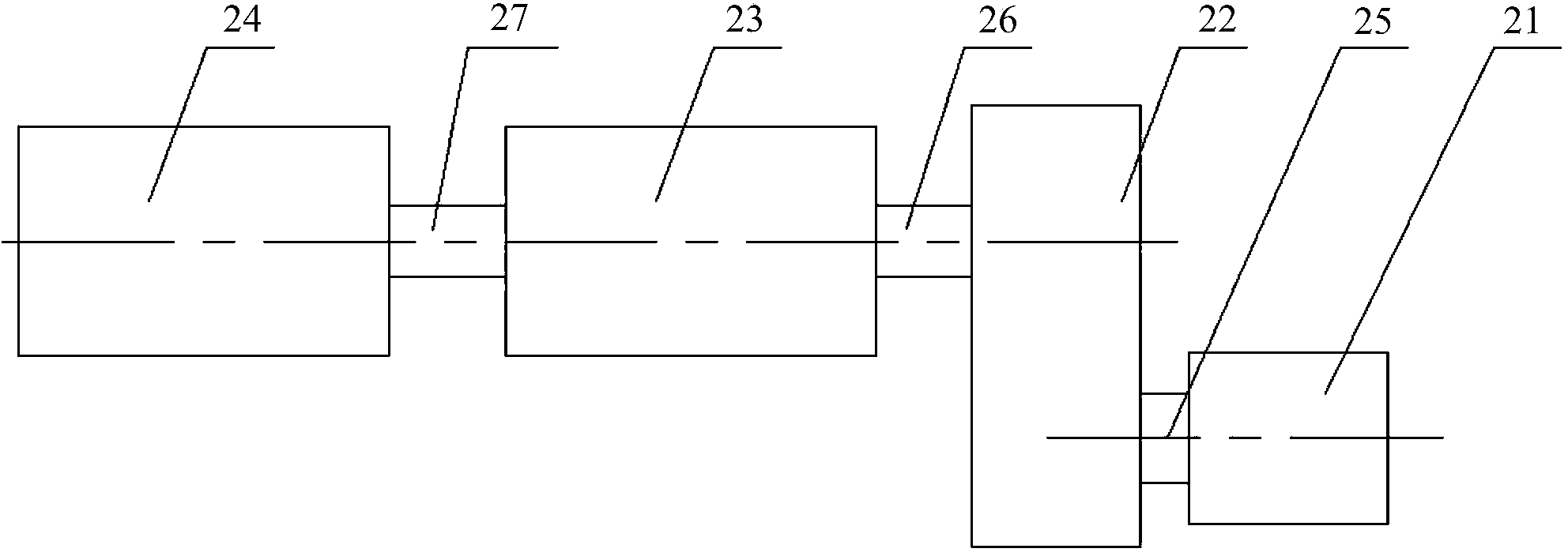

Dynamic load sensing device for three-point-suspension space of tractor and working method of dynamic load sensing device

ActiveCN108489657AAchieve tractionAchieving liftMeasurement of force componentsTransverse forceLoad sensing

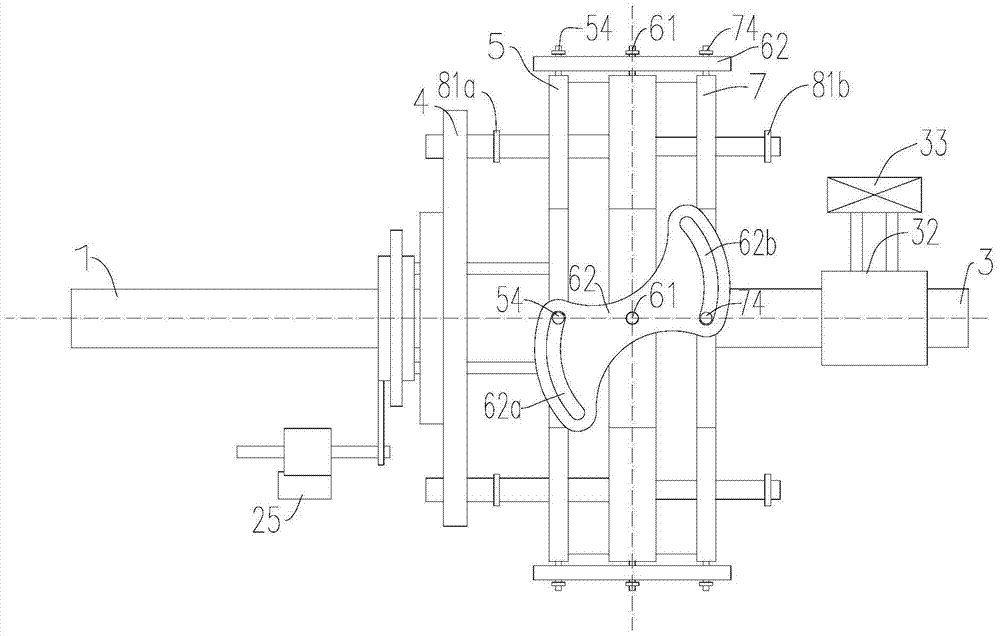

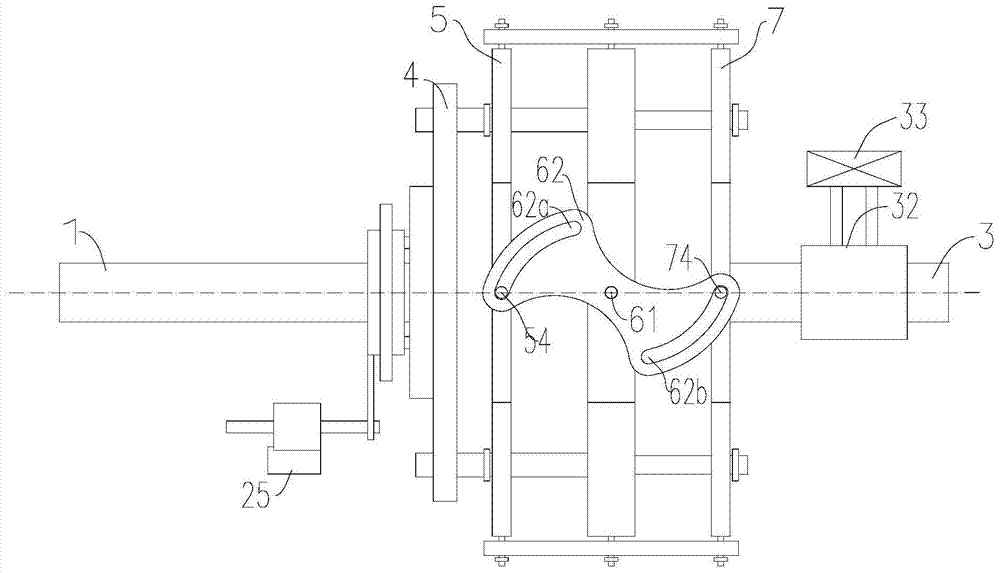

The invention discloses a dynamic load sensing device for a three-point-suspension space of a tractor and a working method of the dynamic load sensing device. The dynamic load sensing device comprisesa cross beam, two longitudinal beams and three-component force sensors, wherein the cross beam and the two longitudinal beams are connected to form a n-shaped framework, the three-component force sensors are arranged in the middle of the cross beam and the bottoms of the two longitudinal beams, linkage components are respectively arranged on the front and rear sides of the three-component force sensors, the front-side linkage components are used for being connected with the tractor, and the rear-side linkage components are used for being connected with an agricultural implement; the three-component force sensors can be used for measuring the sizes of stresses in the three rectangular coordinate axes X, Y and Z and are arrayed to form a measurement array; and a first angle sensor and a second angle sensor are respectively used for measuring the pitch angles, transverse roll angles and azimuth angles of the sensing device and the tractor and converting measurement results from a coordinate system of the sensing device to a coordinate system of the tractor. According to the sensing device, the component forces of three suspension points in three directions can be simultaneously tested, so that the test of the traction force, lifting force, transverse force and moment of the agricultural implement can be realized.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

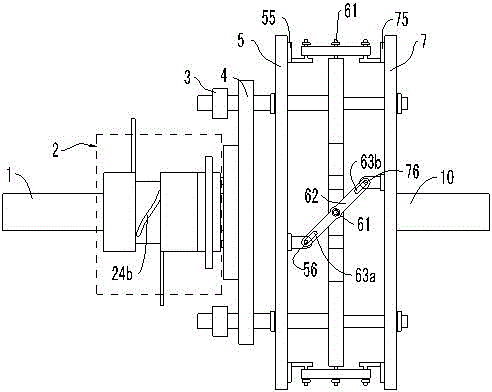

Inner rotor cooling type high-power eddy speed regulator

InactiveCN104811012ASimple structureReduce processing difficultyMagnetic circuit rotating partsDynamo-electric gearsMagnetSpeed regulator

The invention discloses an inner rotor cooling type high-power eddy speed regulator. The inner rotor cooling type high-power eddy speed regulator comprises an inner rotor, an outer rotor and a cooling liquid feeding and discharging system, wherein the inner rotor comprises an inner rotor shaft, an inner rotor rotating disk and two symmetric electroconductive metal disks, the cooling liquid feeding and discharging system comprises a cooling liquid feeding and discharging pipeline, a cooling liquid collector and an outer heat exchange mechanism, and the outer rotor comprises an outer rotor shaft, two symmetric magnetic outer rotor moving disks and a rotary linear adjusting mechanism. The cooling liquid feeding and discharging pipeline is arranged inside the inner rotor shaft and the inner rotor rotating disk. A changeable air gap is reserved between each outer rotor moving disk and the electroconductive metal disk which are arranged on the same side. After the structure is adopted, the inner rotor is in flexible (magnetic) connection with the outer rotor and is simple in structure, low in processing difficulty and beneficial to assembly and maintenance. The cooling liquid feeding and discharging system is capable of cooling the inner rotor rotating disk maximally and subjecting the outer rotor permanent magnet disks to air convection cooling, so that high-power eddy speed regulation is achieved.

Owner:HOHAI UNIV

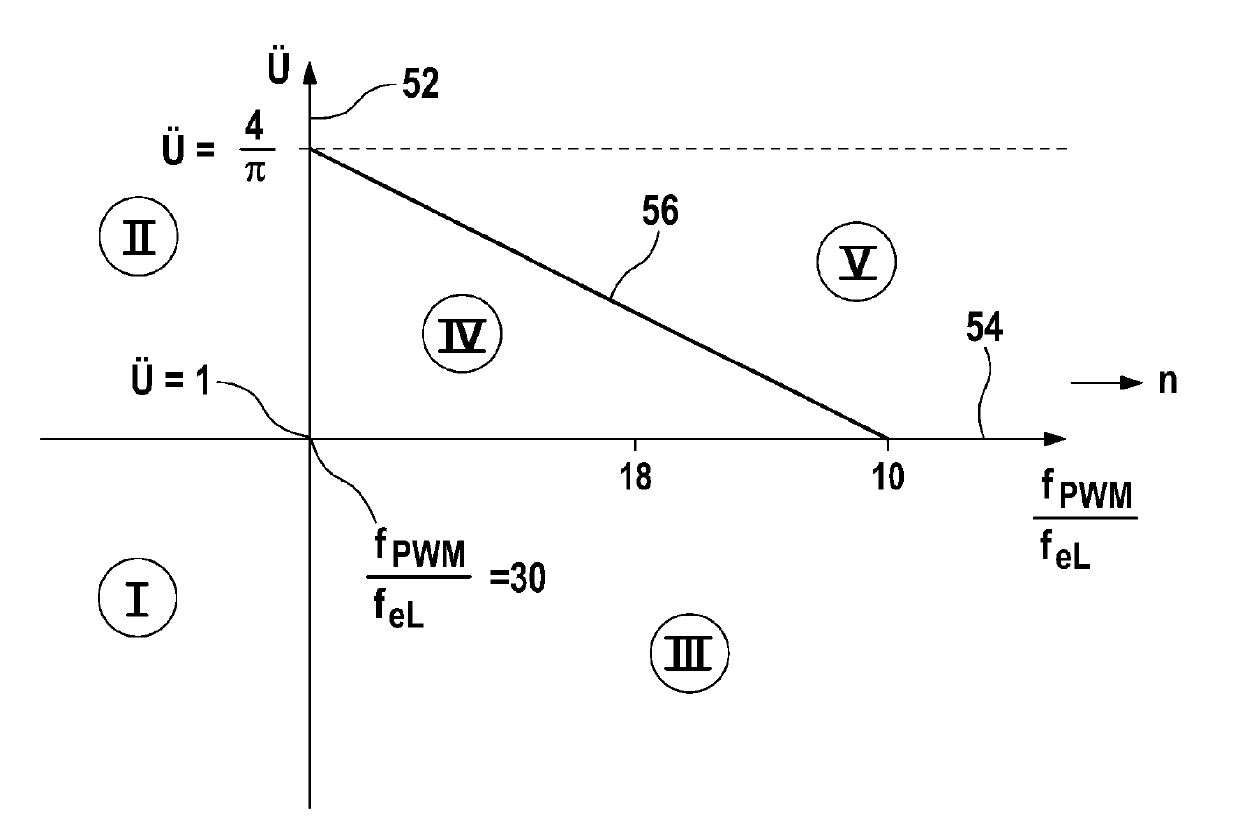

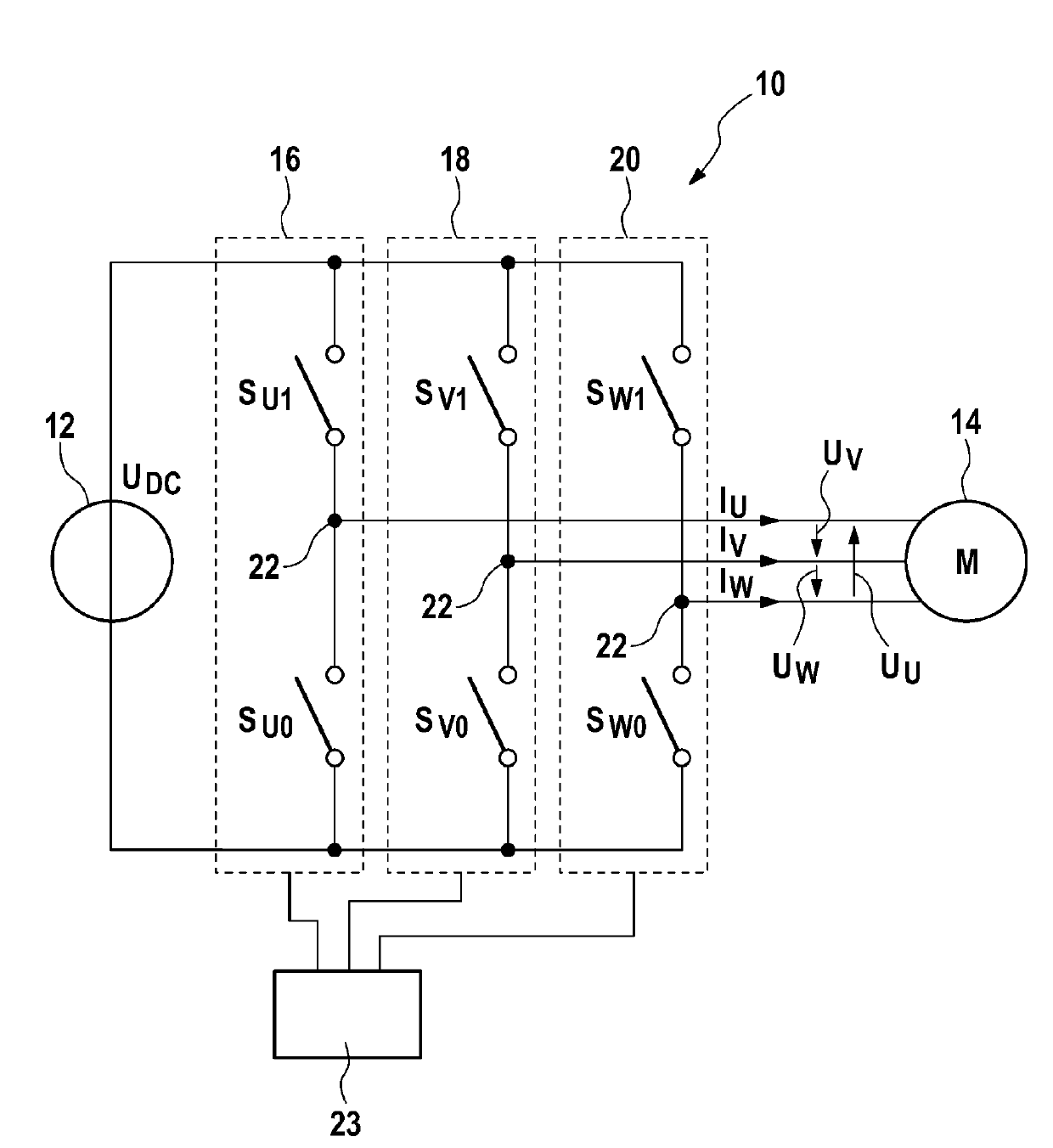

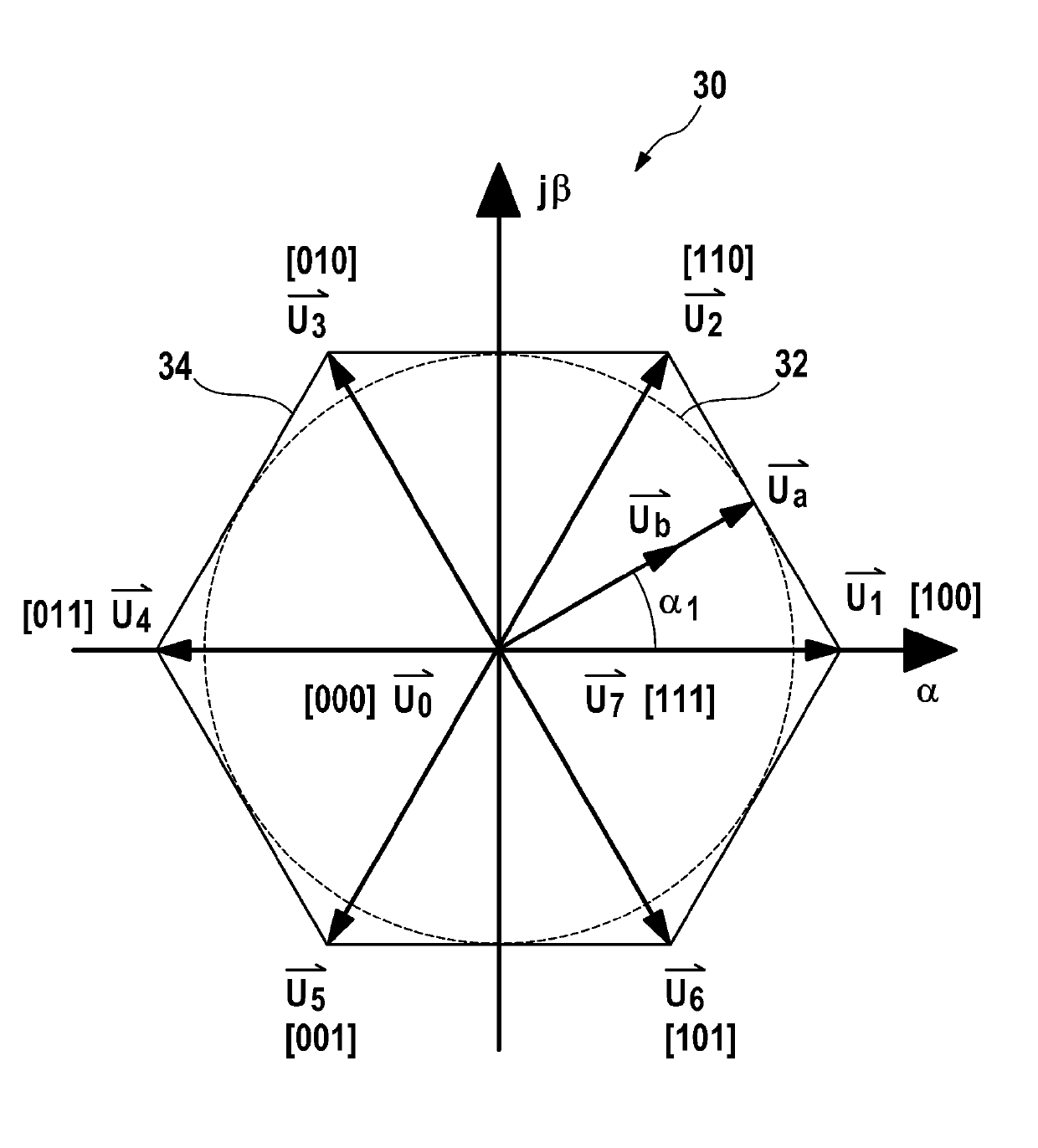

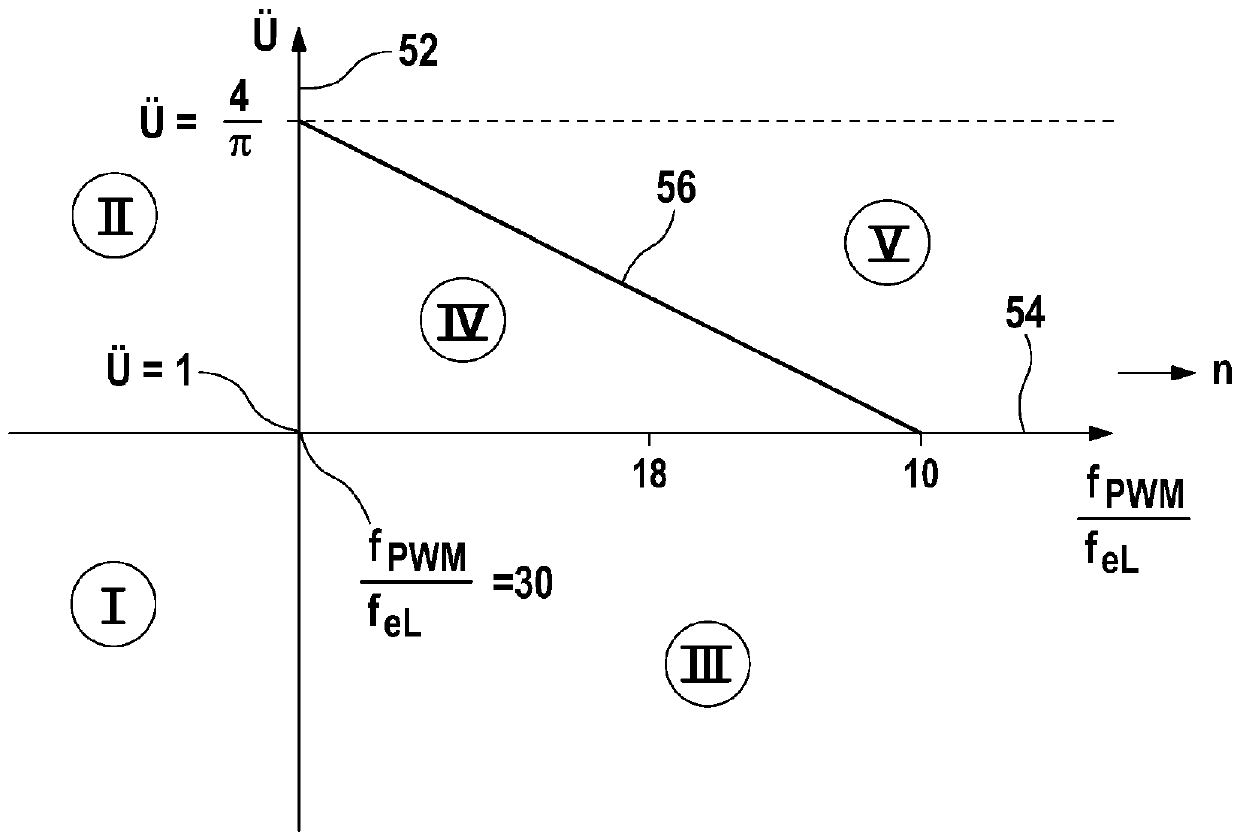

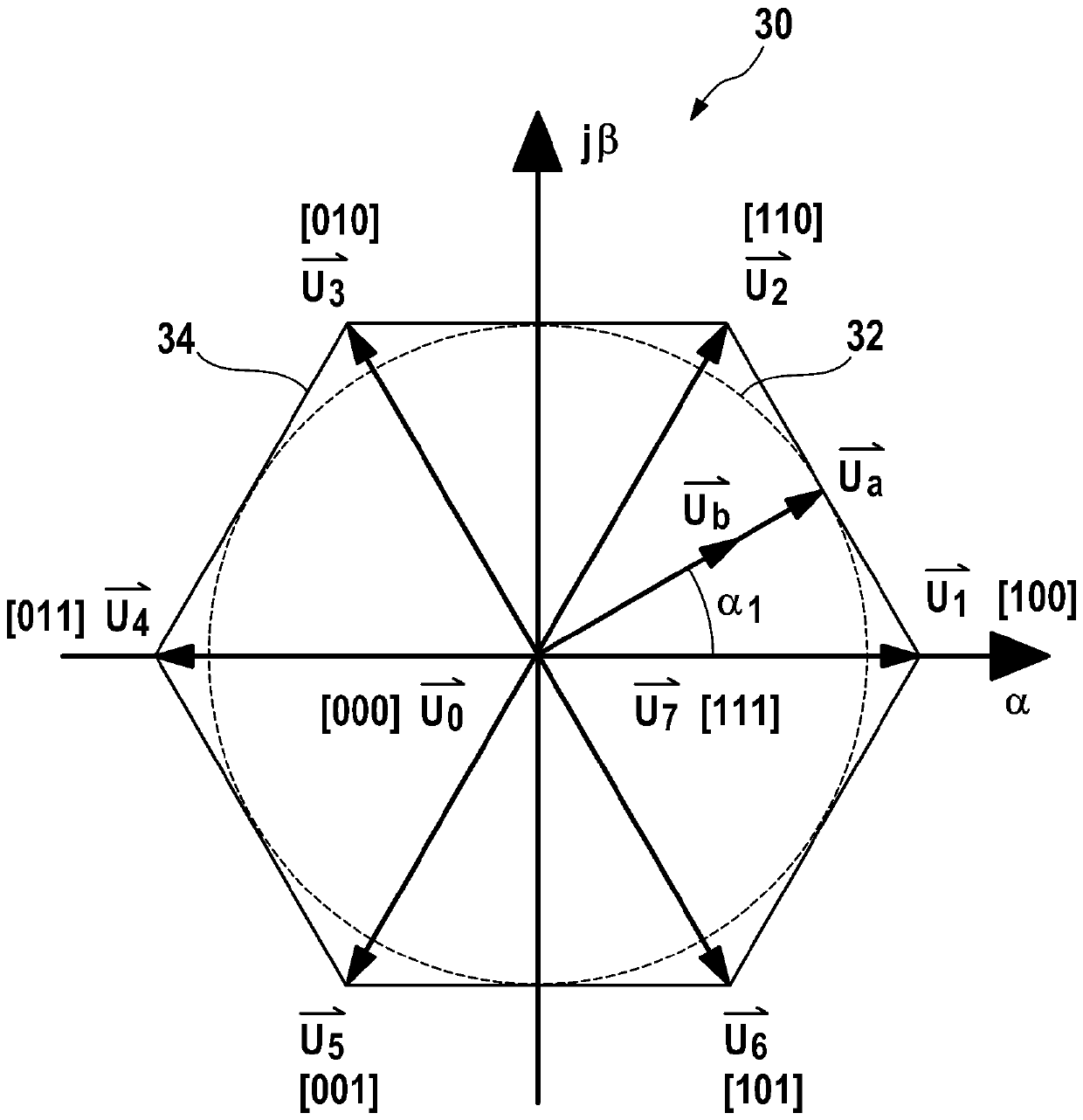

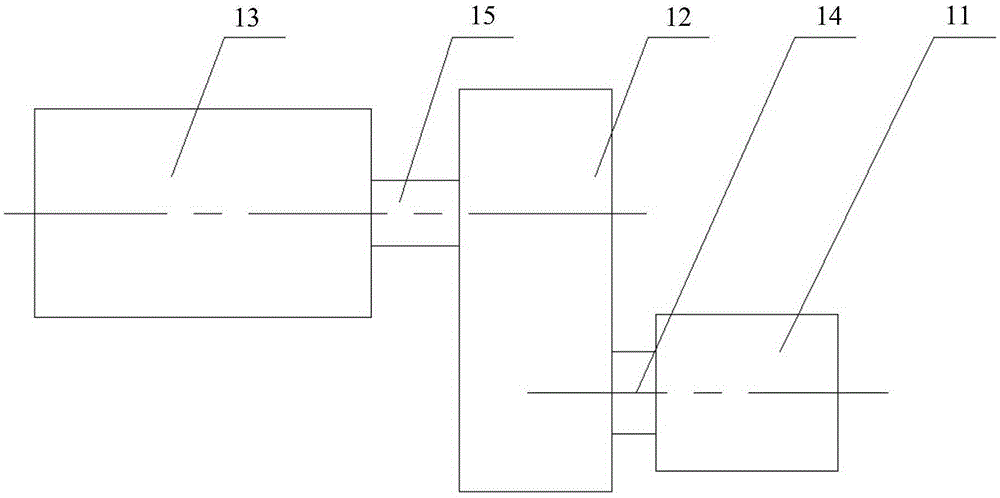

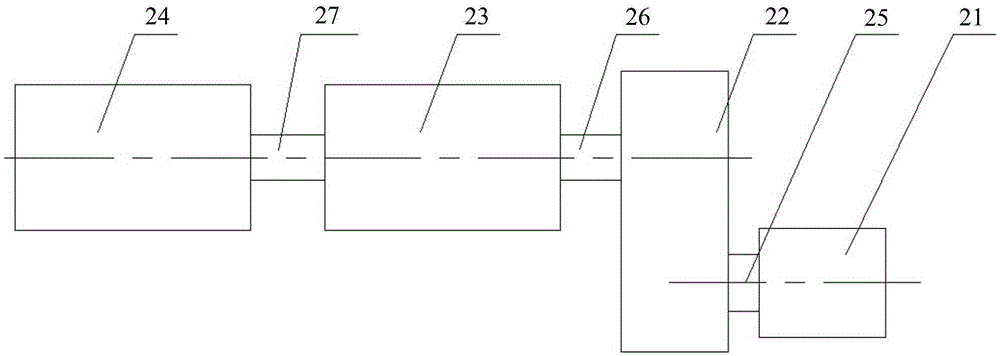

Actuation method for three-phase current machine and actuation device

The present invention relates to a method for actuating an electric three-phase current machine, in particular a synchronous machine (14), which is supplied with current by means of an inverter, the inverter having a plurality of circuit breakers that are provided to supply the electric machine with electricity in multiphase manner, it being possible to actuate the inverter in different actuation modes (I, II, III, IV, V), the actuation modes (I, II, III, IV, V) being formed by space vector modulation (I), overmodulation (II, III, IV) or block commutation (V), and the corresponding actuation mode (I-V) being selected according to a rotational speed (n) or an electric frequency (FEL) of the three-phase current machine and according to a power or torque requirement.

Owner:ROBERT BOSCH GMBH

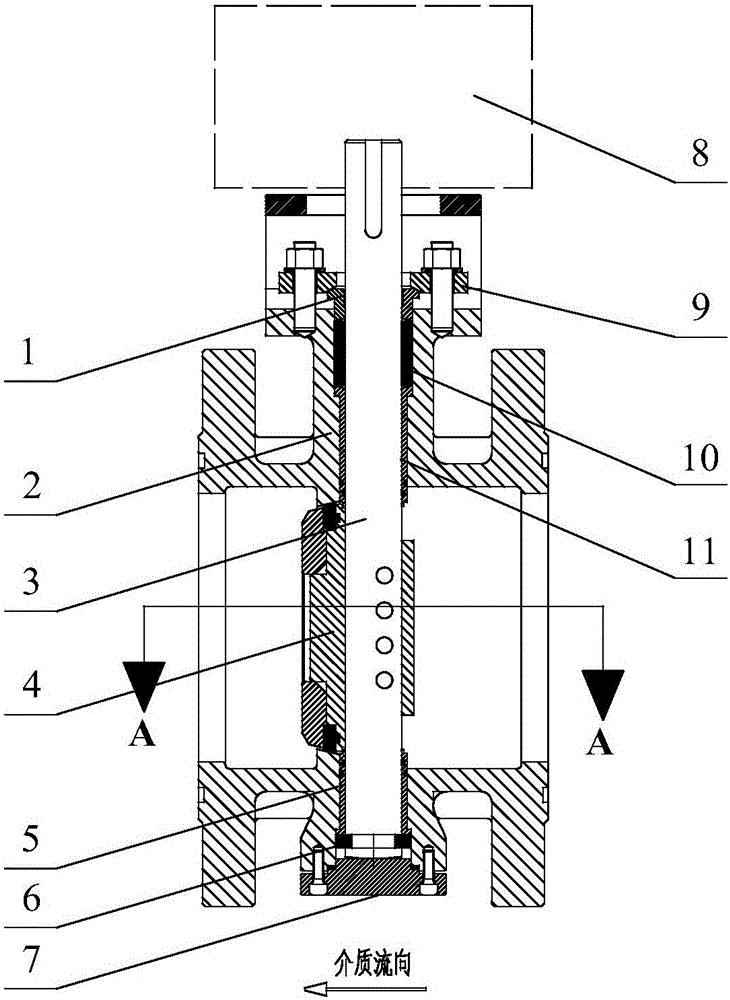

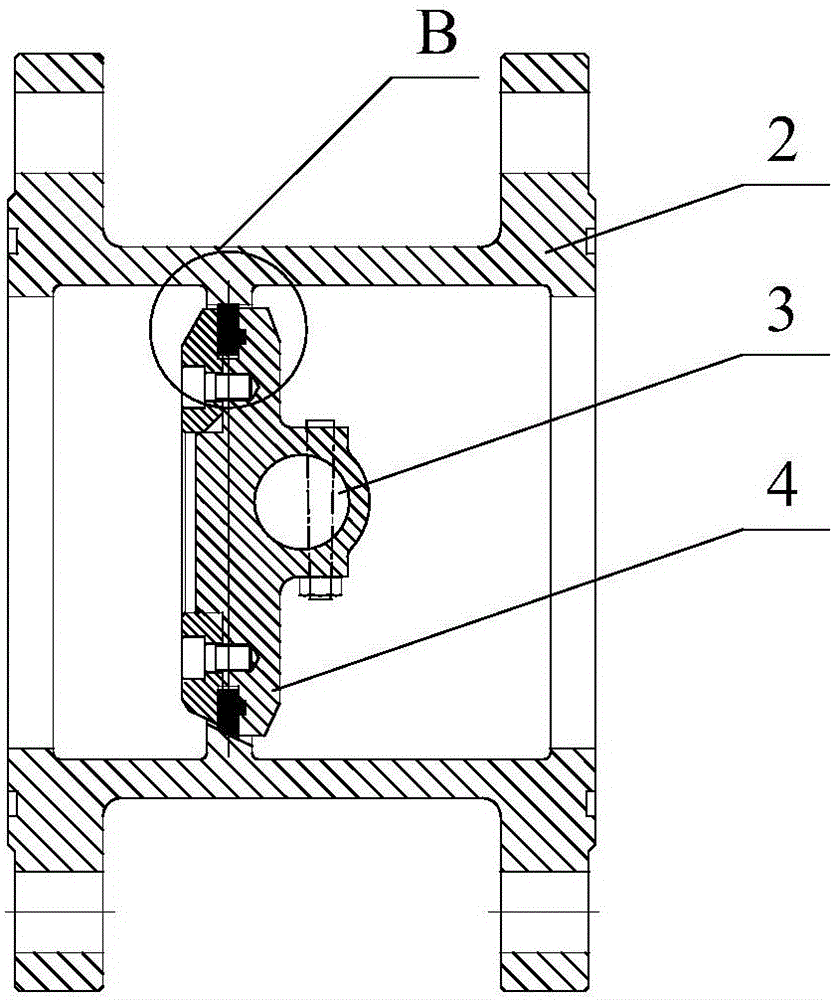

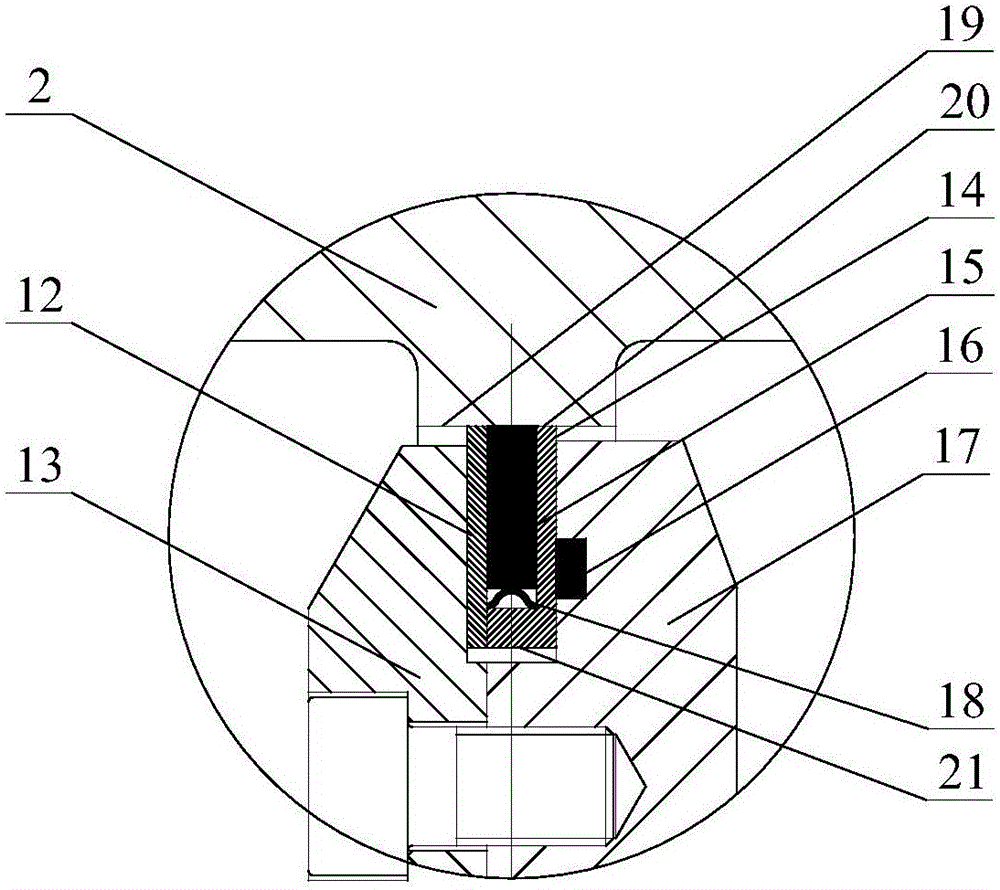

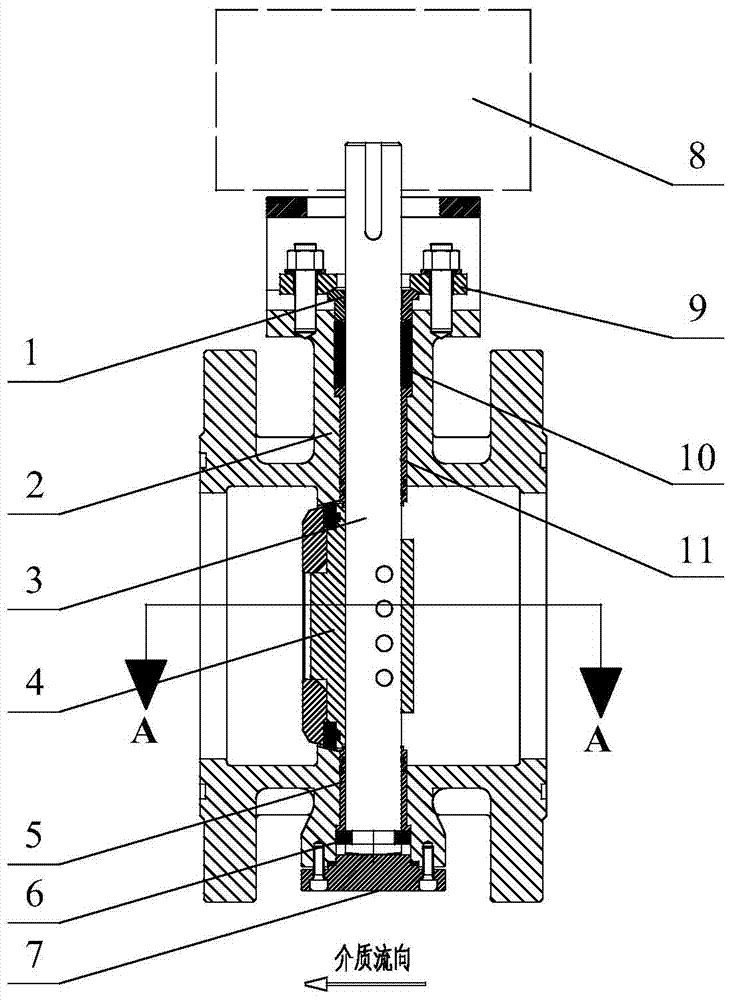

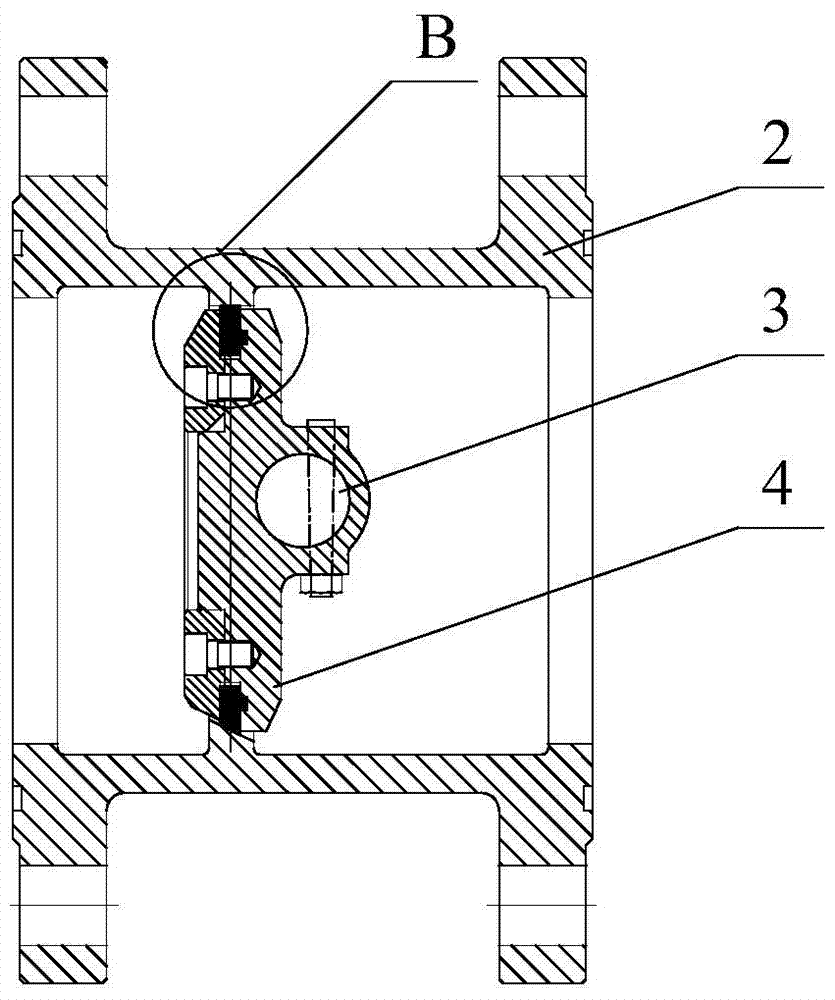

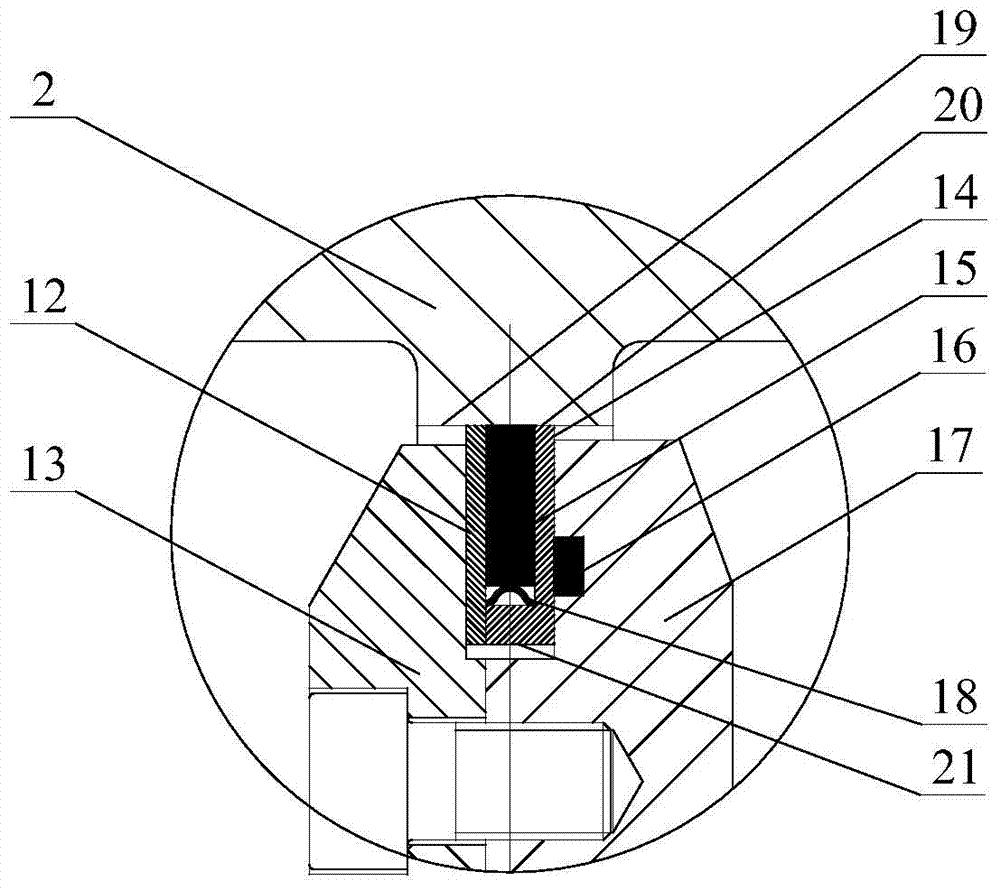

Seal-ring-bearing three-eccentric seal butterfly valve

ActiveCN105156699AAchieving Zero LeakageAchieve unbalanced momentSpindle sealingsLift valveButterfly valveValve stem

The invention discloses a seal-ring-bearing three-eccentric seal butterfly valve, relating to the field of valves. The seal-ring-bearing three-eccentric seal butterfly valve comprises a valve body, an operating mechanism, a disk plate assembly and a valve stem, wherein the operating mechanism is positioned outside the valve body; one end of the valve stem is positioned outside the valve body and connected with the operating mechanism, and the other end is positioned inside the valve body and connected with the disk plate assembly; a valve body sealing surface used for matching with the disk plate assembly is arranged inside the valve body; the disk plate assembly comprises a disk plate, a pressure plate and a seal ring; the seal ring comprises a seal end and a fixed end; the fixed end is positioned between the disk plate and pressure plate; the seal end is positioned outside the disk plate, and used for matching with the valve body sealing surface; and the cross-section area of the seal end is smaller than that of the disk plate. The seal-ring-bearing three-eccentric seal butterfly valve can implement zero medium leakage, well improve the opening and reversing sealing properties, and widen the application range of the three-eccentric seal butterfly valve.

Owner:CSIC SPECIAL EQUIP CO LTD

Underactuated robot finger device based on rope winding

The invention discloses an underactuated robot finger device based on rope winding. The problem that in the prior art, an anthropomorphic robot finger still needs to be improved is solved. The underactuated robot finger device comprises a base outer shell, a first finger middle shell, a second finger middle shell and a finger tail shell which are hinged in sequence, and loosening reset springs arearranged at hinged positions; one end of the base outer shell is connected with a mechanical arm, and the other end of the base outer shell is provided with a gripping control motor, a first universal joint, a gripping adjustment driving wheel, a gripping adjustment spring, a pull rope, a pull rope winding device, a pull rope straight sleeve and an arc-shaped pull rope positioning sleeve; a second universal joint and a first gripping adjustment driven wheel are arranged at the hinged position of the first finger middle shell and the second finger middle shell; and a third universal joint anda second gripping adjustment driven wheel are arranged at the hinged position of the second finger middle shell and the finger tail shell. According to the technology, the effect of muscle stretchingis simulated by producing tensile force by winding two pull ropes to shorten the length in a vertical direction.

Owner:郑州蓝智枫智能科技有限公司

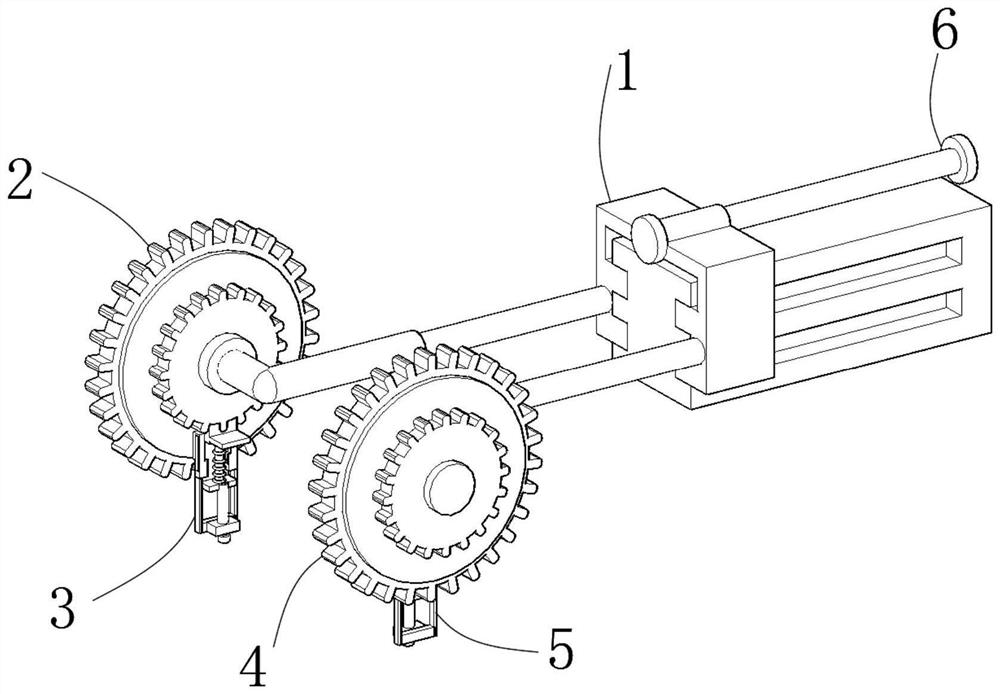

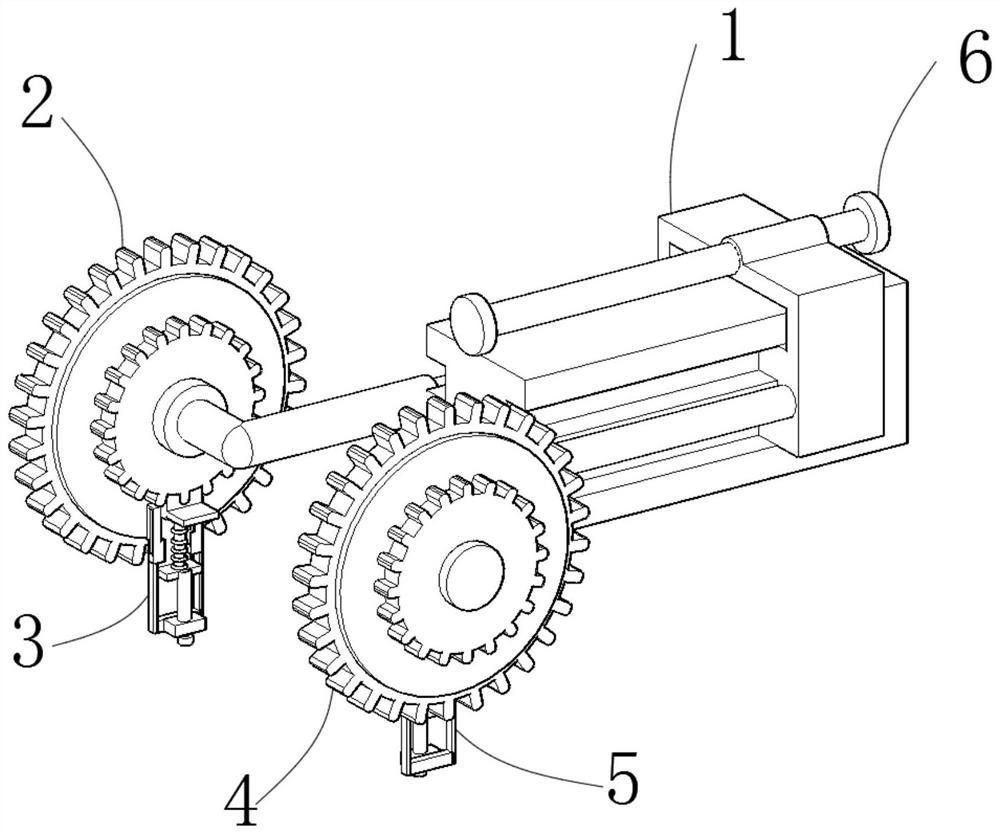

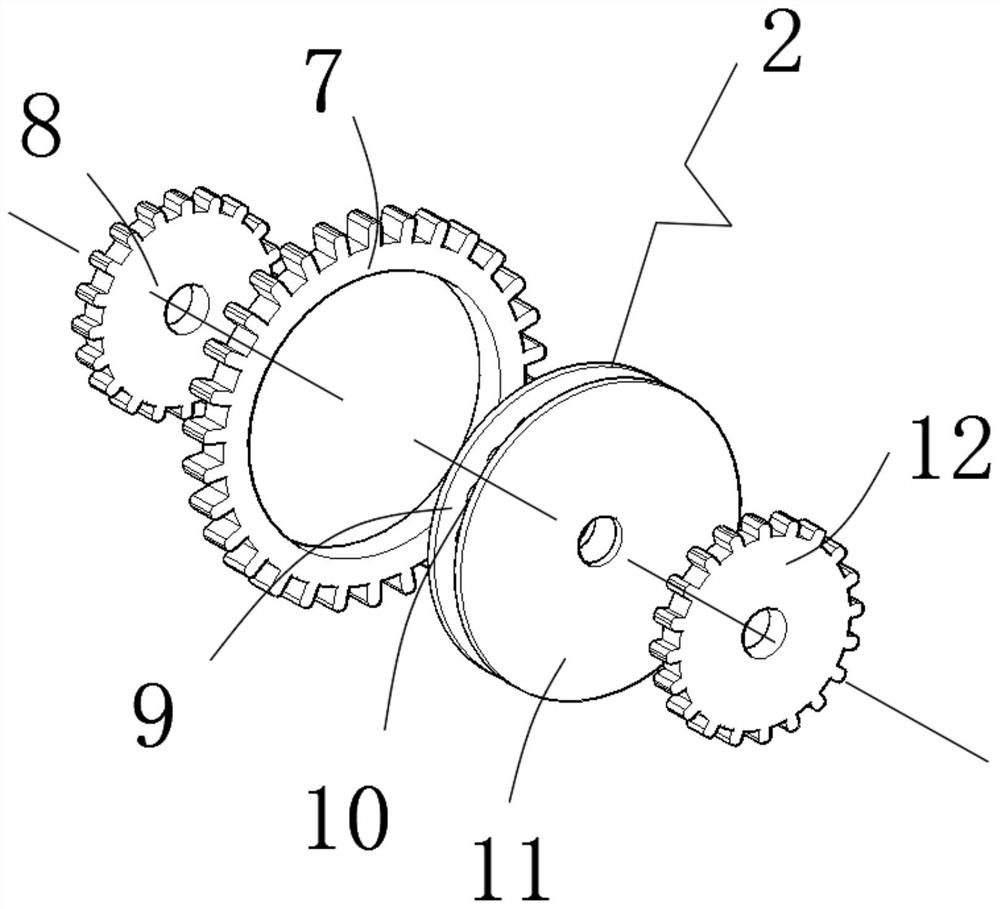

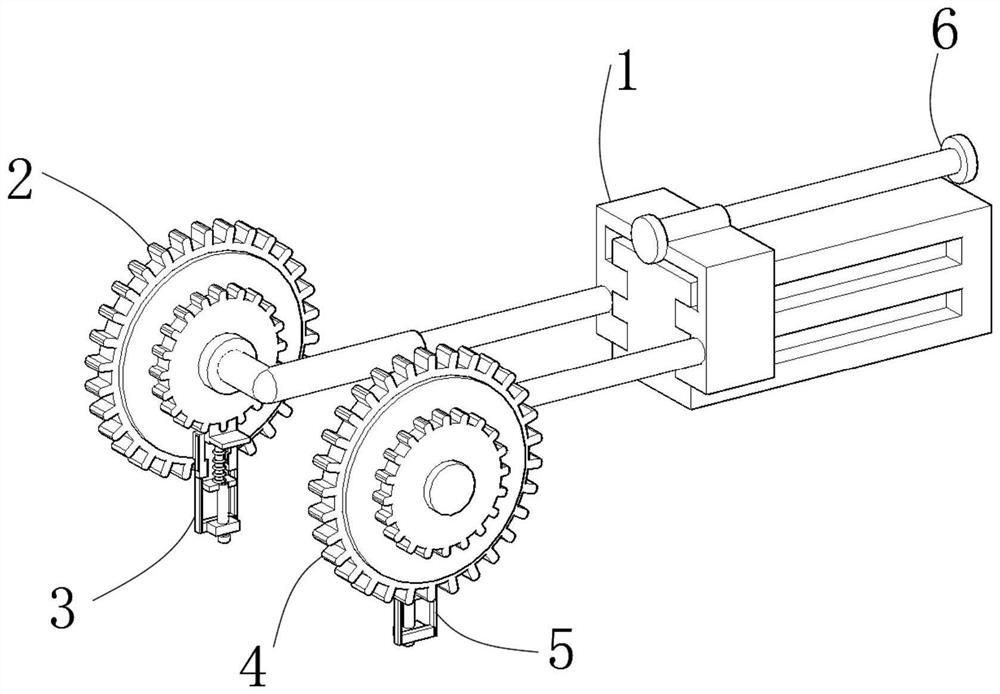

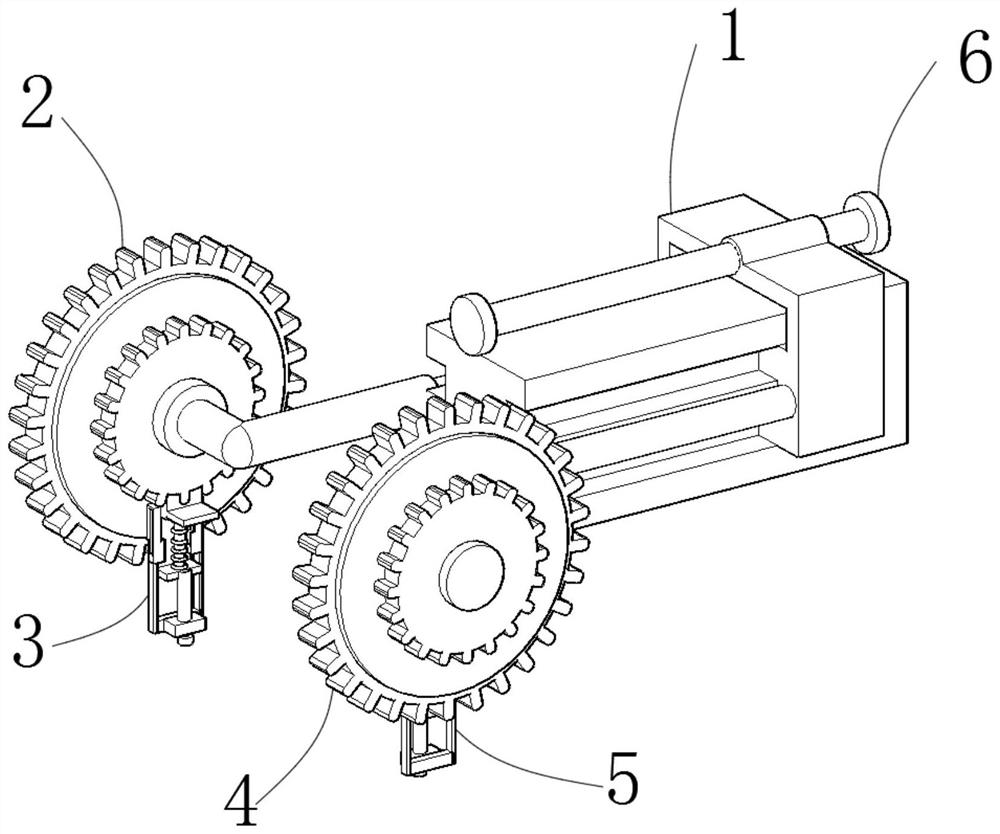

Double-gear type linkage speed change device

ActiveCN111692297AAchieve connectionAchieve lockingToothed gearingsGearing controlEngineeringMechanical engineering

Owner:绍兴柯桥皓悦纺织科技有限公司

Three-phase AC motor trigger method and trigger device

ActiveCN103733507BAchieve torqueOptimum Voltage UtilizationAC motor controlPhase currentsElectric machine

The present invention relates to a method for actuating an electric three-phase current machine, in particular a synchronous machine (14), which is supplied with current by means of an inverter, the inverter having a plurality of circuit breakers that are provided to supply the electric machine with electricity in multiphase manner, it being possible to actuate the inverter in different actuation modes (I, II, III, IV, V), the actuation modes (I, II, III, IV, V) being formed by space vector modulation (I), overmodulation (II, III, IV) or block commutation (V), and the corresponding actuation mode (I-V) being selected according to a rotational speed (n) or an electric frequency (FEL) of the three-phase current machine and according to a power or torque requirement.

Owner:ROBERT BOSCH GMBH

Fast integrated dismantling wrench

The invention relates to a fast integrated dismantling wrench which comprises a connecting rod, a ratchet wheel improved device and a ratchet wheel wrench connecting block; the connecting rod and theratchet wheel wrench connecting block are fixedly arranged on the two sides of the ratchet wheel improved device; a telescopic rod device is rotatably connected with the other side of the ratchet wheel wrench connecting block; and a chuck wrench for dismantling a cutter is perpendicularly arranged at the bottom of the ratchet wheel improved device. The fast integrated dismantling wrench is simplein structure, reasonable in design and convenient to mount; and compared with three auxiliary tools ( a chuck key, a knife rest key and a lever) of traditional lathe operation, the fast integrated dismantling wrench integrates the traditional three pieces, improves the dismantling efficiency and reduces the potential safety hazard.

Owner:浙江省平湖技师学院

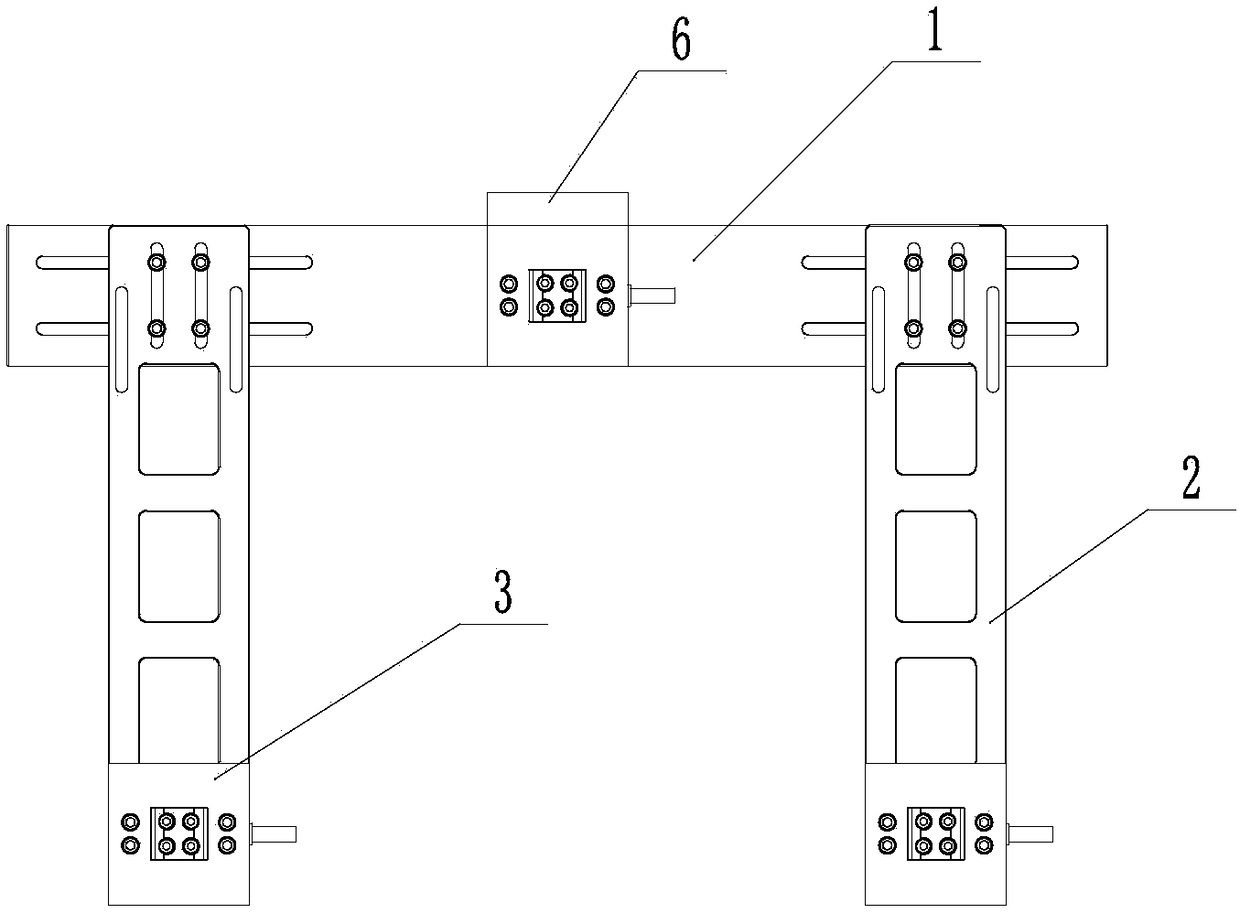

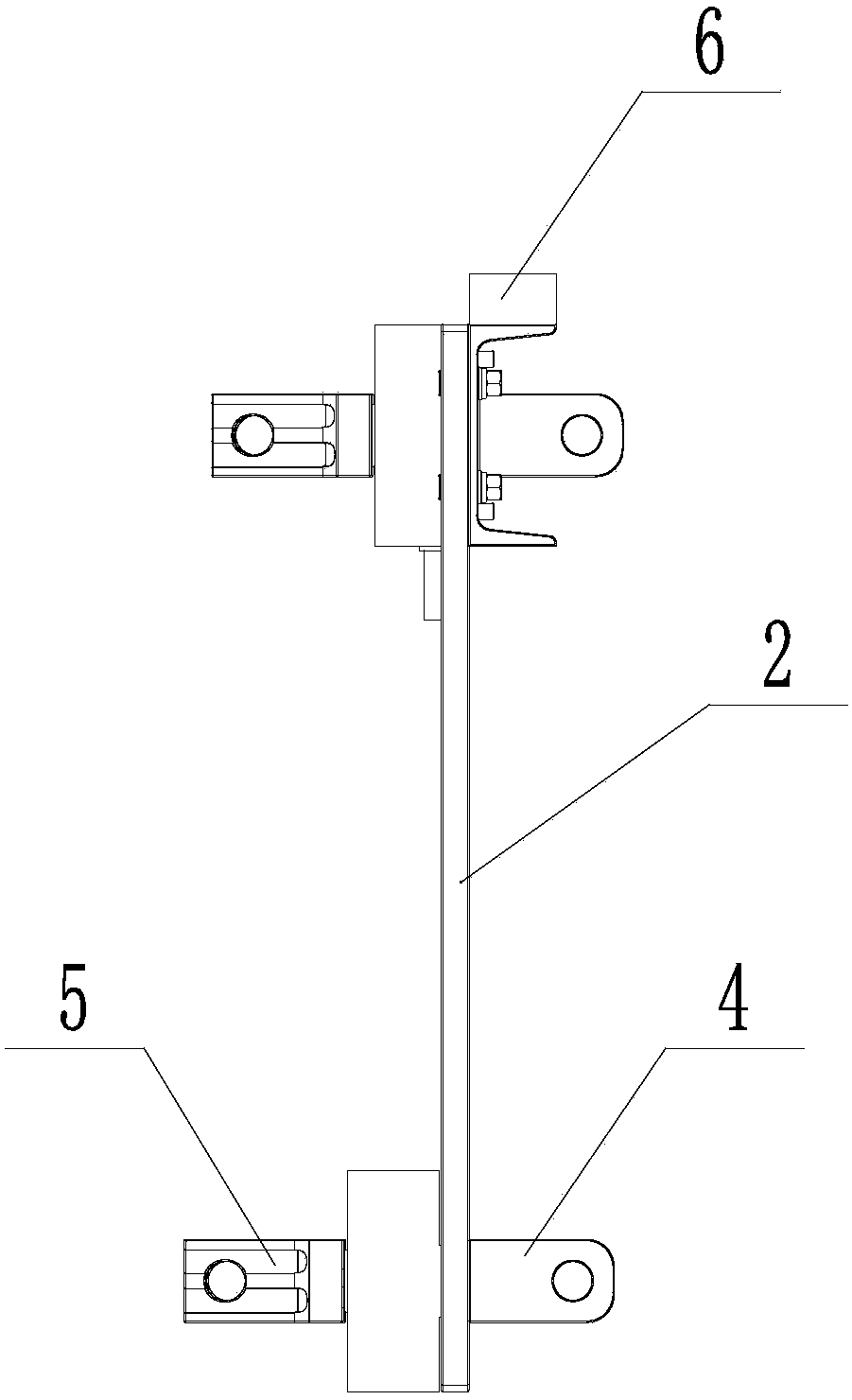

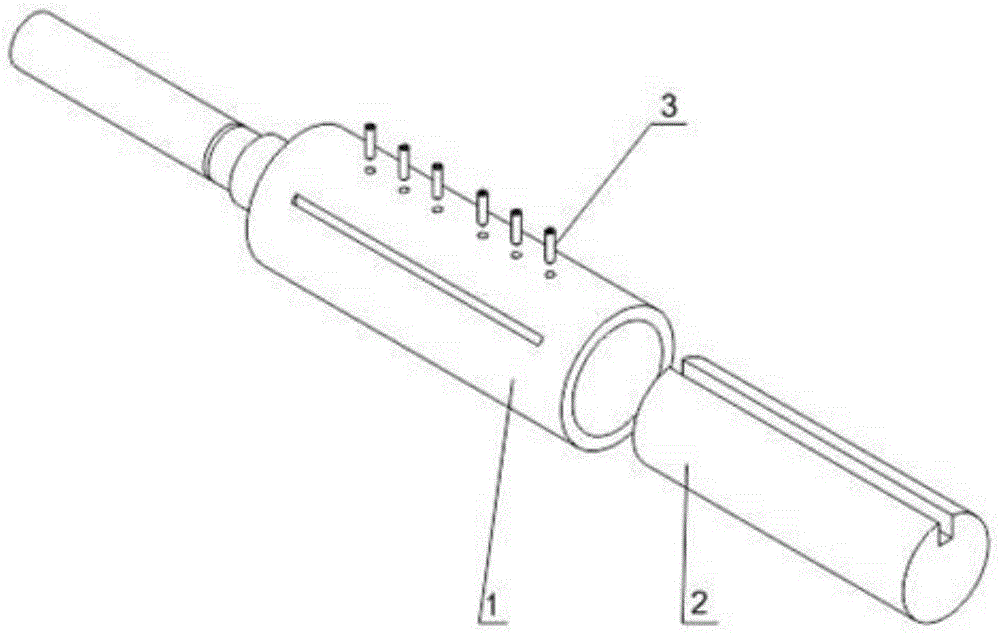

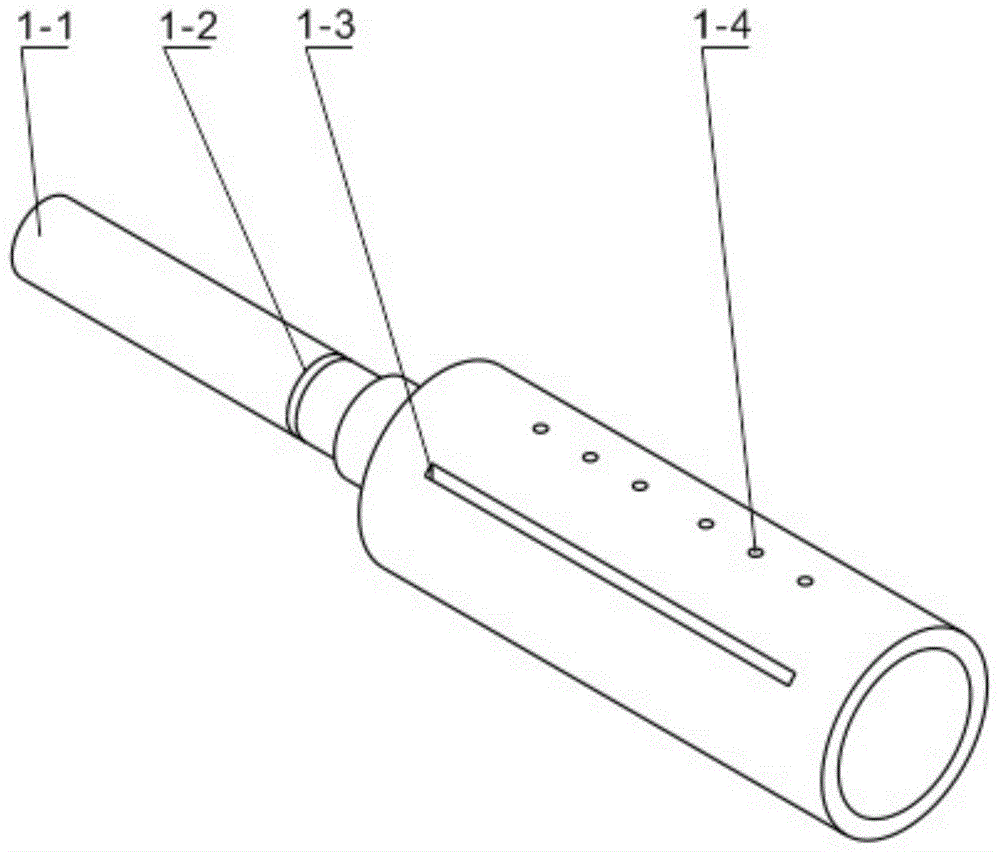

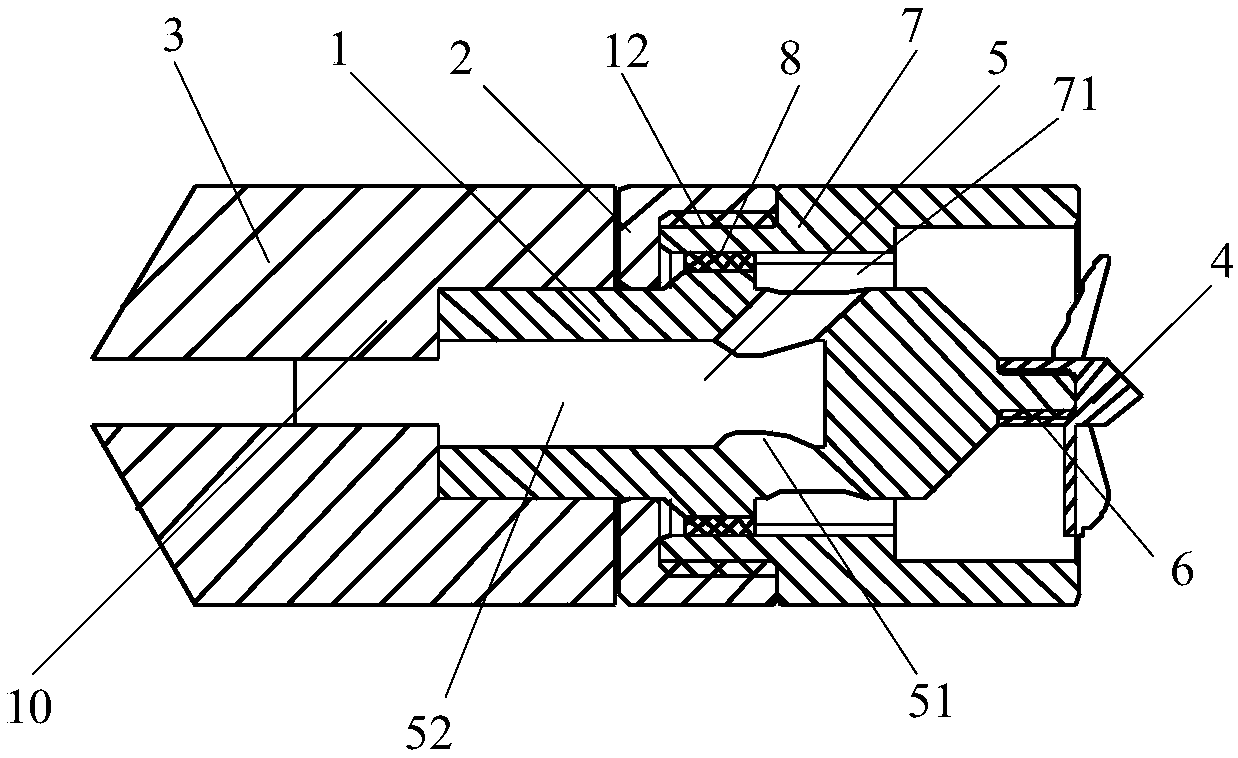

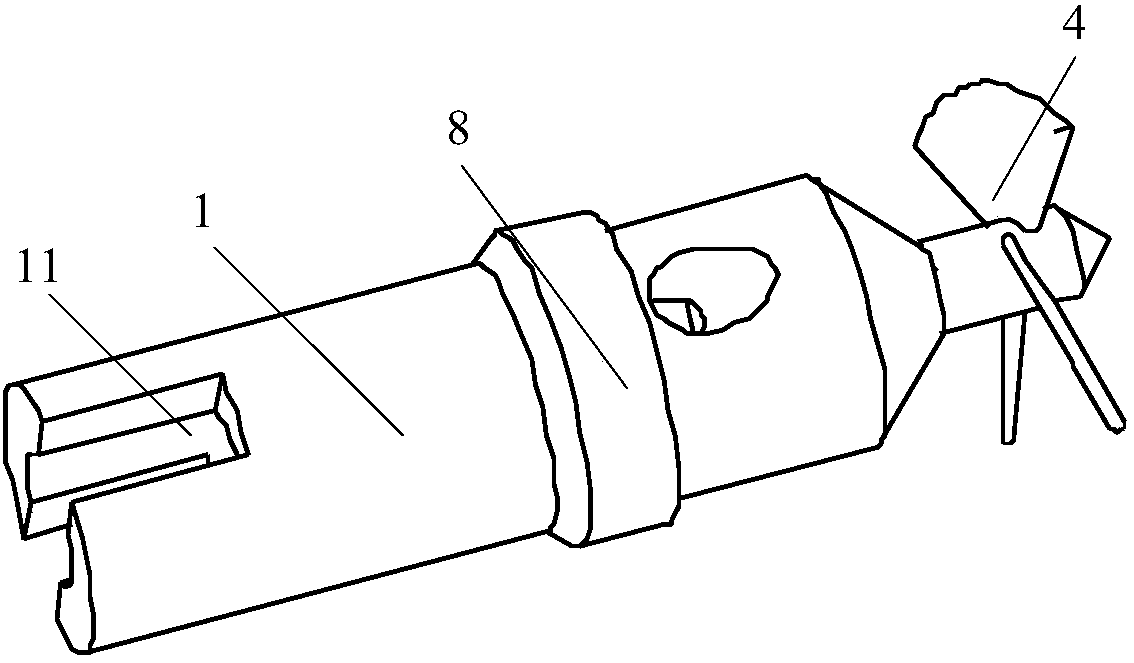

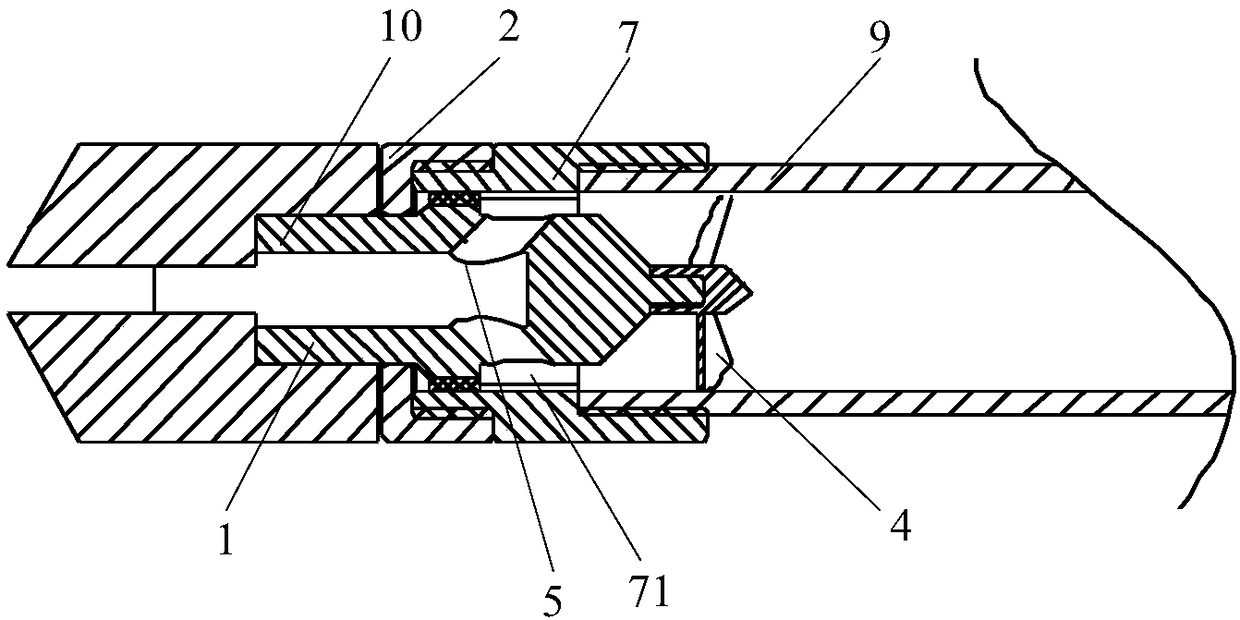

Flexible substrate winding and clamping device

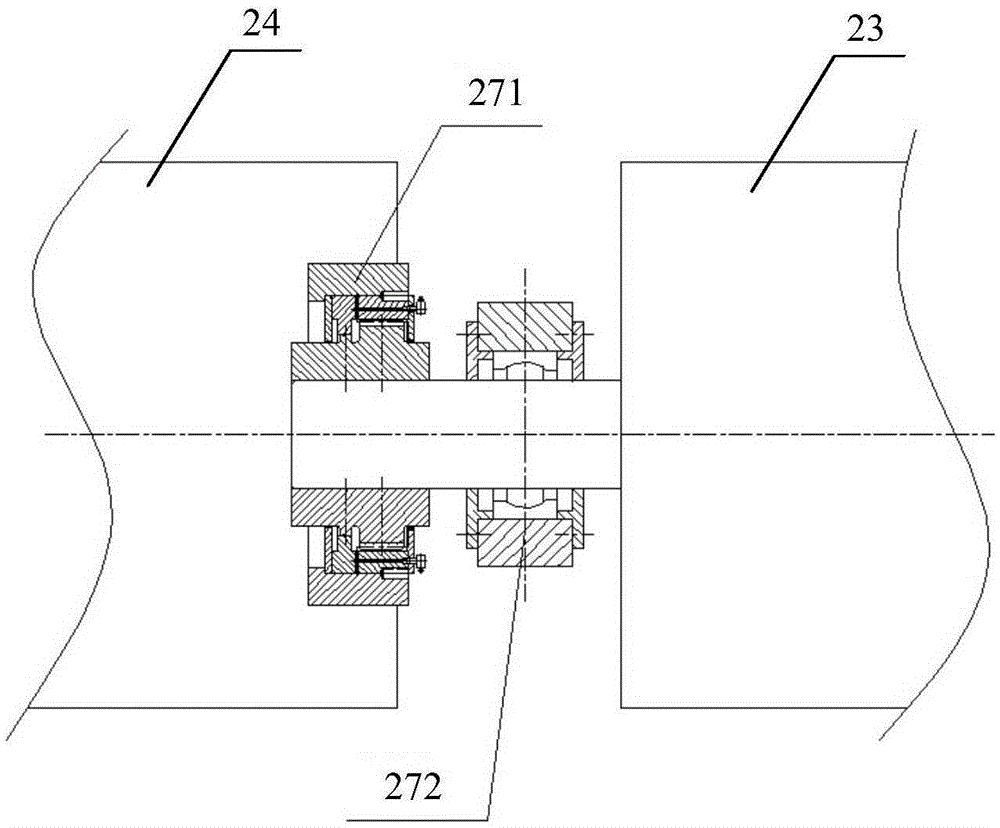

ActiveCN104087907BSimple structureEasy to operateVacuum evaporation coatingSputtering coatingEngineeringConductor Coil

The invention relates to a flexible substrate winding and clamping device, comprising: a clamping sleeve, a clamping core and a clamping device; the clamping sleeve is provided with a feeding groove for the flexible substrate to pass through; the clamping sleeve is covered on the clamping core In addition, the clamping device passes through the clamping sleeve and clamps the clamping core against the inner wall of the clamping sleeve. The jacking device is a plurality of parallel fastening screws; the clamping sleeve is provided with the same number of screw holes as the fastening screws, and the fastening screws pass through the screw holes to clamp one side of the clamping core. The invention has the advantages of simple structure, convenient operation, and uniform clamping of flexible substrates, and belongs to the technical field of mechanical winding processing.

Owner:SOUTH CHINA UNIV OF TECH

Permanent-magnet slip transmission mechanism

InactiveCN103236775BReduce volumeSimple structureDynamo-electric gearsGenerators/motorsMachine toolWind power generation

The invention relates to a permanent-magnet slip transmission mechanism with a slip transmission function. The permanent-magnet slip transmission mechanism structurally comprises a grooved drum provided with two magnetic disks and a groove, a base disk connected with the two magnetic disks through a spring, two pairs of radial-flux magnets, an operating lever and two levers; a torque can be reliably and stably transferred during slip transmission; and the value of the transferred torque can be changed in a stepless manner. The permanent-magnet slip transmission mechanism comprises the base disk 6, the grooved drum 13, the magnetic disk 14, the magnetic disk 10, the magnetic disk 2, the magnetic disk 9, the levers 4, the operating lever 17, and the like, and is suitable for the fields of vehicles, wind power generation systems, air vehicles, machine tools, general machinery, industrial and mineral machinery, engineering machinery, and the like.

Owner:NANJING INST OF TECH

Drill bit used for petroleum well-drilling

ActiveCN109322617AAchieve torqueTo achieve the purpose of cutting and breaking rockConstructionsBorehole drivesImpellerWell drilling

The invention provides a drill bit used for petroleum well-drilling. The drill bit comprises a drill bit body and a buckling-connection ring used for being connected with a well-drilling pipe, and cutting blades and an impeller are arranged at the two ends of the drill bit body correspondingly. The buckling-connection ring sleeves the drill bit body. The drill bit body is internally provided witha first flow-passing channel communicating with an inner cavity of the well-drilling pipe and the ends of the cutting blades arranged on the drill bit body, and the cross section area of the first flow-passing channel is smaller than that of the inner cavity of the well-drilling pipe. The mode of transmitting the torque and the bit pressure through a drill column can be discarded, the torque is transmitted through a drill bit autorotation mode, the throttling pressure difference is generated in the drill bit body, under the effect of the throttling pressure difference, the drill bit generatesthe drill pressure to formation rock in contact with the cutting blades, the purpose of cutting for rock breaking is achieved, and thus the purpose of producing a micro petroleum borehole is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

An Outer Rotor Adjustable Eddy Current Speed Governor

InactiveCN104682662BSimple structureReduce processing difficultyDynamo-electric gearsMagnetic polesEddy current

The invention discloses an outer rotor regulation type eddy current speed controller. The outer rotor regulation type eddy current speed controller comprises an inner rotor and an outer rotor, wherein the inner rotor comprises an inner rotor rotation disc in which a plurality of groups of permanent magnets are embedded; the outer rotor comprises two outer rotor motion discs which are symmetrically arranged at two sides of the inner rotor rotation disc, and a rotation liner regulating mechanism; each outer rotor motion disc is provided with a conducting metal disc; a variable gas gap is formed between each conducting metal disc and the corresponding inner rotor rotation disc; the rotation linear regulating mechanism, on one hand, enables each conducting metal disc to rotate synchronously together with the outer rotor, and on the other hand, enables the two variable gas gaps to change axially at the opposite directions or the same direction. After the structure is adopted, only one inner rotor rotation disc comprising the permanent magnets is required, so that the magnetic connection of the inner rotor and the outer rotor can be realized; the inner rotor is simple in structure, is low in processing difficulty, and is convenient for assembling and overhauling; two magnetic poles of each permanent magnet in the inner rotor rotation disc can be used at the same time, so that the permanent magnetic utilization ratio is high, the cost is reduced, and the product is economic.

Owner:HOHAI UNIV

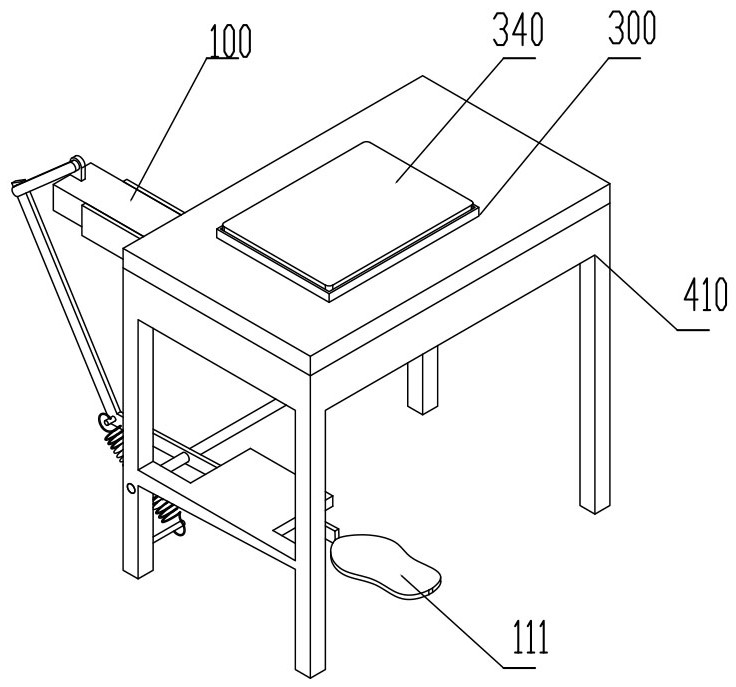

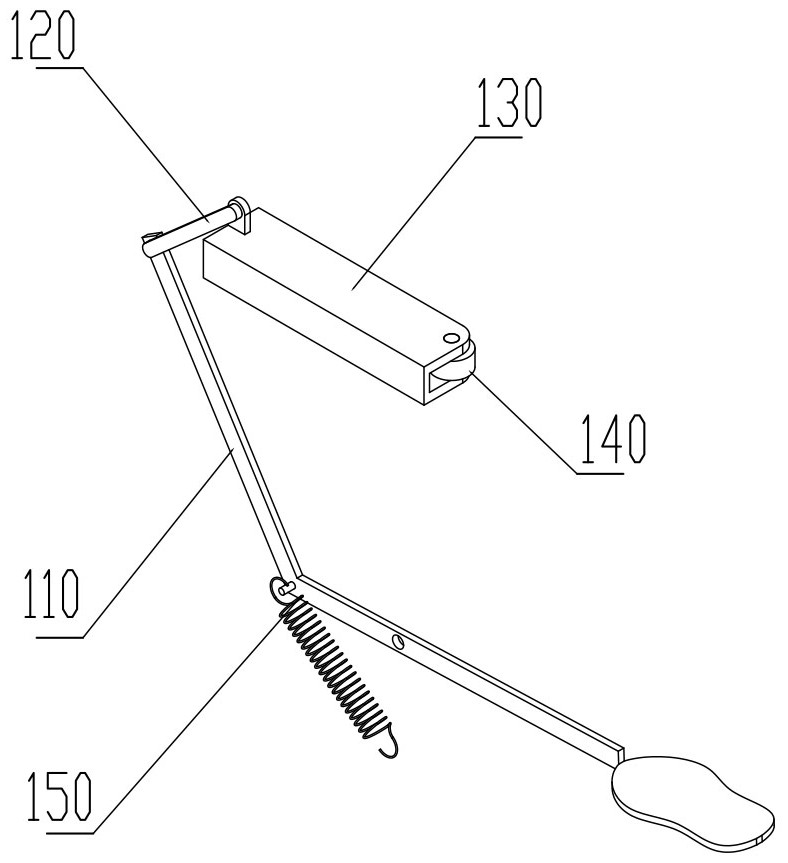

Computer machining and assembling device

A computer machining and assembling device comprises a driving device, a positioning device, a rotating device and an operation table, the driving device comprises a driving rod, a connecting rod, a sliding block, a rolling wheel and a tension spring, the positioning device comprises a positioning cap, a pin and a spring, the rotating device comprises the positioning device, a hopper, an operation face and a rotating table, an inner cavity is formed in the middle of the operation table, and a rotating shaft hole is formed in the middle of the inner cavity. A sliding groove is formed in the left side of the operation table, four supporting legs are arranged on the lower portion of the operation table, shafts for connecting the two supporting legs are arranged on the lower portions of the two supporting legs on the rear side, a spring shaft is arranged on the lower portion of each supporting leg on the rear side, and a positioning face is arranged between the two supporting legs on the left side.

Owner:洪世勇

A drill bit for oil drilling

ActiveCN109322617BAchieve torqueTo achieve the purpose of cutting and breaking rockConstructionsBorehole drivesImpellerWell drilling

Owner:CHINA PETROLEUM & CHEM CORP +1

An Inner Rotor Cooling Type High Power Eddy Current Governor

InactiveCN104811012BSimple structureReduce processing difficultyMagnetic circuit rotating partsDynamo-electric gearsEddy currentEngineering

The invention discloses an inner rotor cooling type high-power vortex governor, which comprises an inner rotor, an outer rotor and a coolant supply and discharge system. The inner rotor includes the inner rotor shaft, the inner rotor rotating disk and two symmetrical conductive metal disks. The coolant supply and discharge system includes the coolant supply and discharge pipelines, the coolant collector and the inner rotor shaft and the inner rotor rotating disk. External heat exchange mechanism. The outer rotor includes an outer rotor shaft, two symmetrical outer rotor moving discs with magnetism and a rotary linear adjustment mechanism. There is a variable air gap between each outer rotor moving disc and the conductive metal disc on the same side. After adopting the above structure, the inner rotor and the outer rotor are connected softly (magnetically), the inner rotor has a simple structure, low processing difficulty, and is convenient for assembly and maintenance. The above-mentioned coolant supply and discharge system can reduce the temperature of the rotating disk of the inner rotor to the maximum extent, and at the same time realize air convection cooling of the permanent disk of the outer rotor, and realize high-power eddy current speed regulation.

Owner:HOHAI UNIV

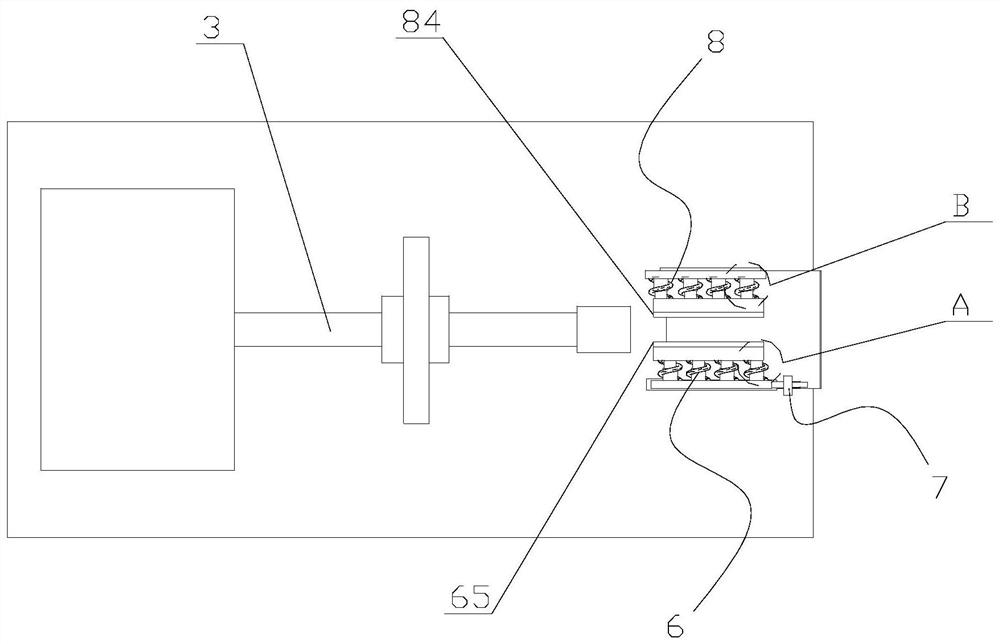

Torque test device and torque and tension test device

ActiveCN110361123AAchieve torqueEasy to detectApparatus for force/torque/work measurementPull forceEngineering

Owner:CHANGZHOU RUISHENAN MEDICAL DEVICES

Grab dredger and lifting mechanism of grab machine thereof

ActiveCN103835327ASave installation spaceImplement a single driveMechanical machines/dredgersDrive shaftEngineering

The invention provides a grab dredger and a lifting mechanism of a grab machine of the grab dredger. The lifting mechanism of the grab machine comprises one or more sets of driving units, wherein each driving unit comprises a motor, a transmission, a first coiling block and a second coiling block, the input end of the transmission is connected with a transmission shaft of the motor, a rotating shaft of the first coiling block is connected with the output end of the transmission, the block body of the second coiling block is connected with the rotating shaft of the first coiling block, and the first coiling block and the second coiling block are coaxially driven by the motor through the transmission. The mounting space of the whole lifting mechanism can be reduced, and single-drive, large-span and large-torque requirements can be met.

Owner:SHANGHAI ZHENHUA HEAVY IND

A torque and torque and tension detection device

ActiveCN110361123BAchieve torqueEasy to detectApparatus for force/torque/work measurementPull forceMedicine

Owner:CHANGZHOU RUISHENAN MEDICAL DEVICES

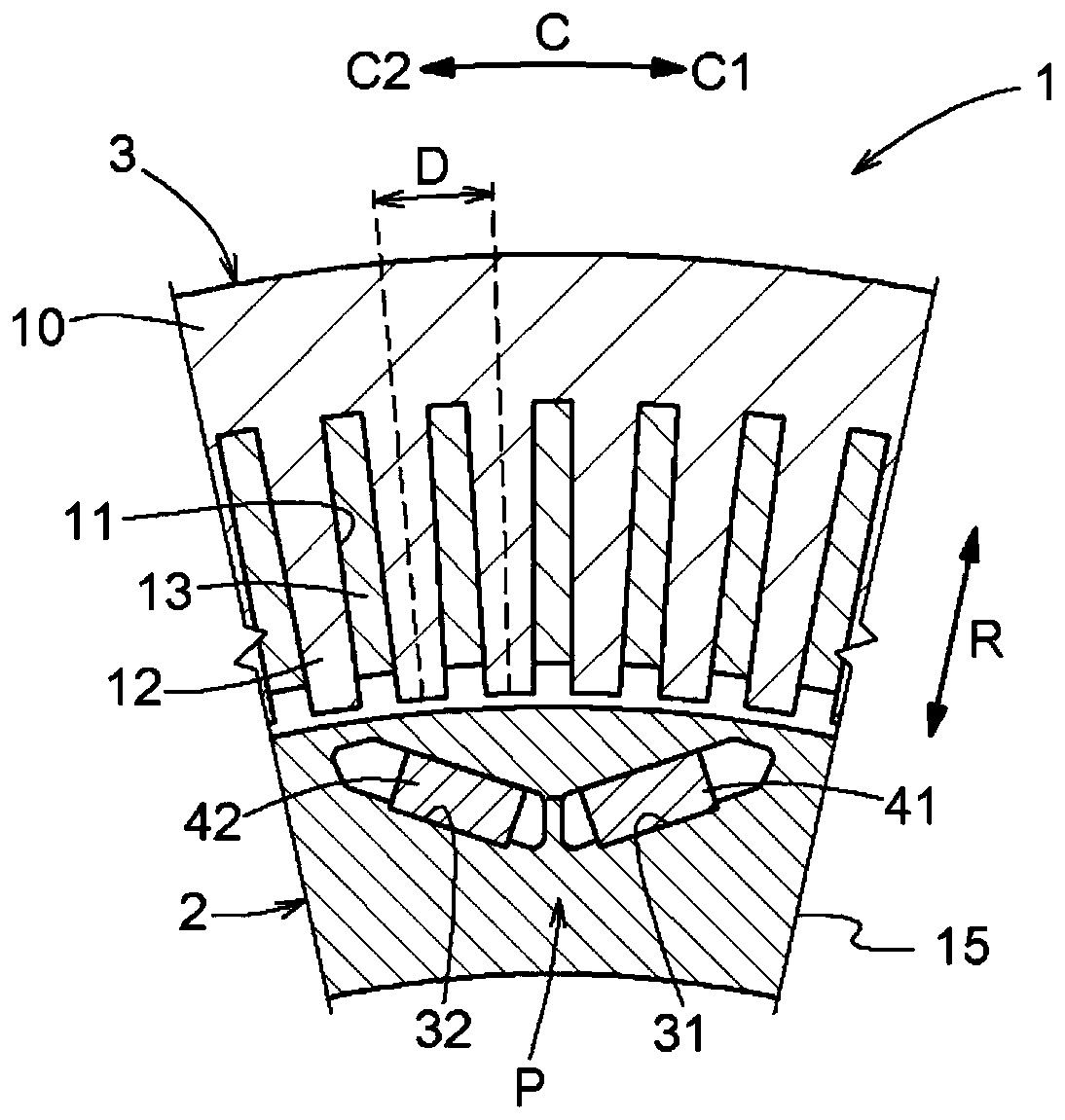

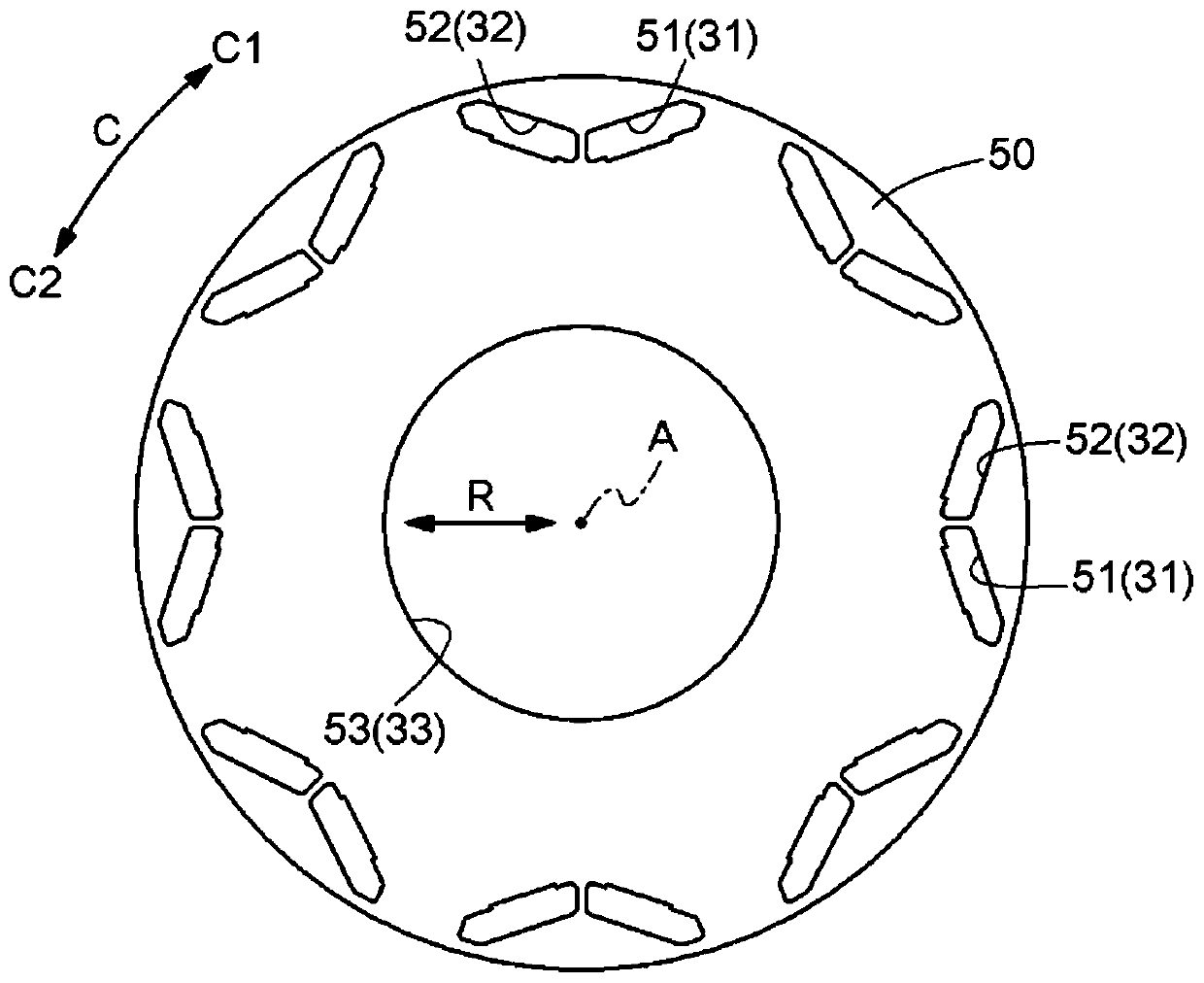

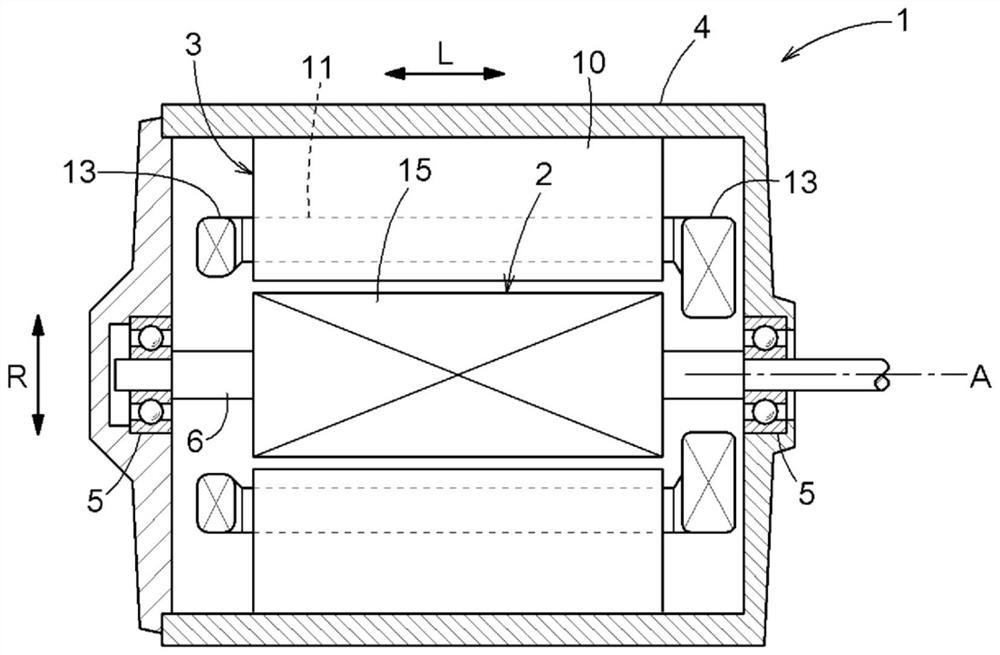

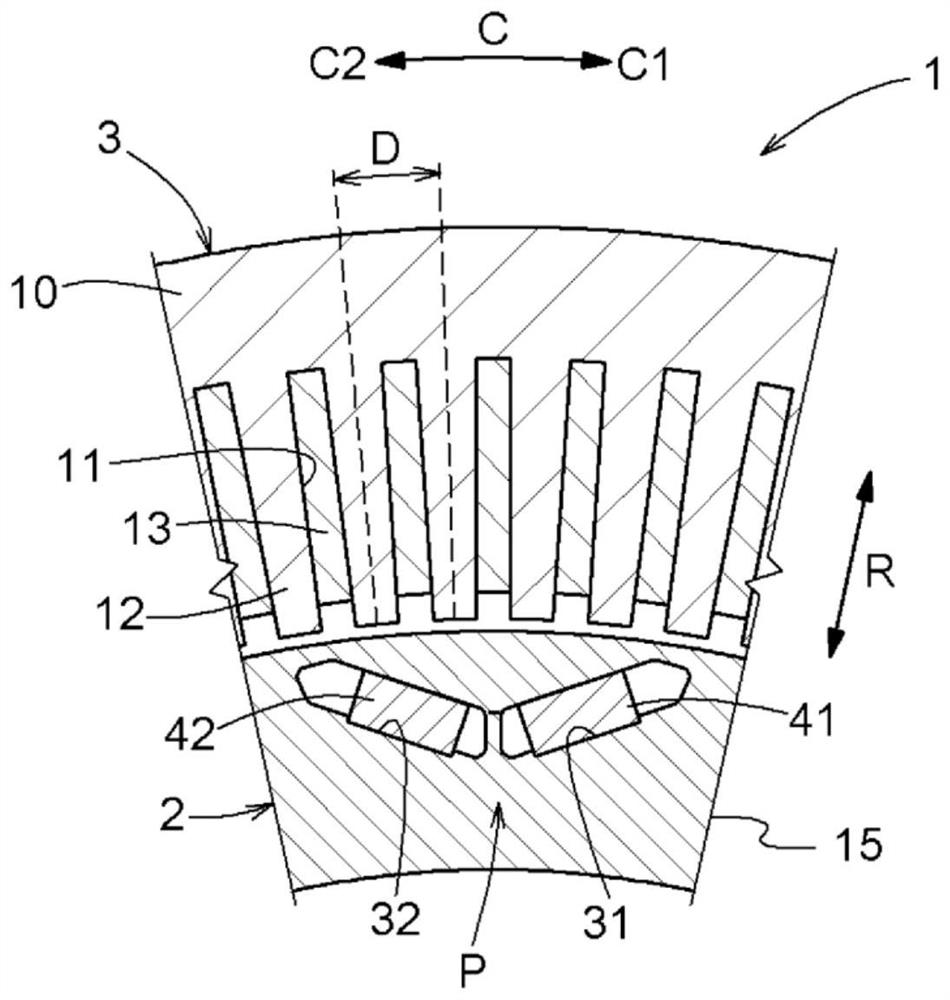

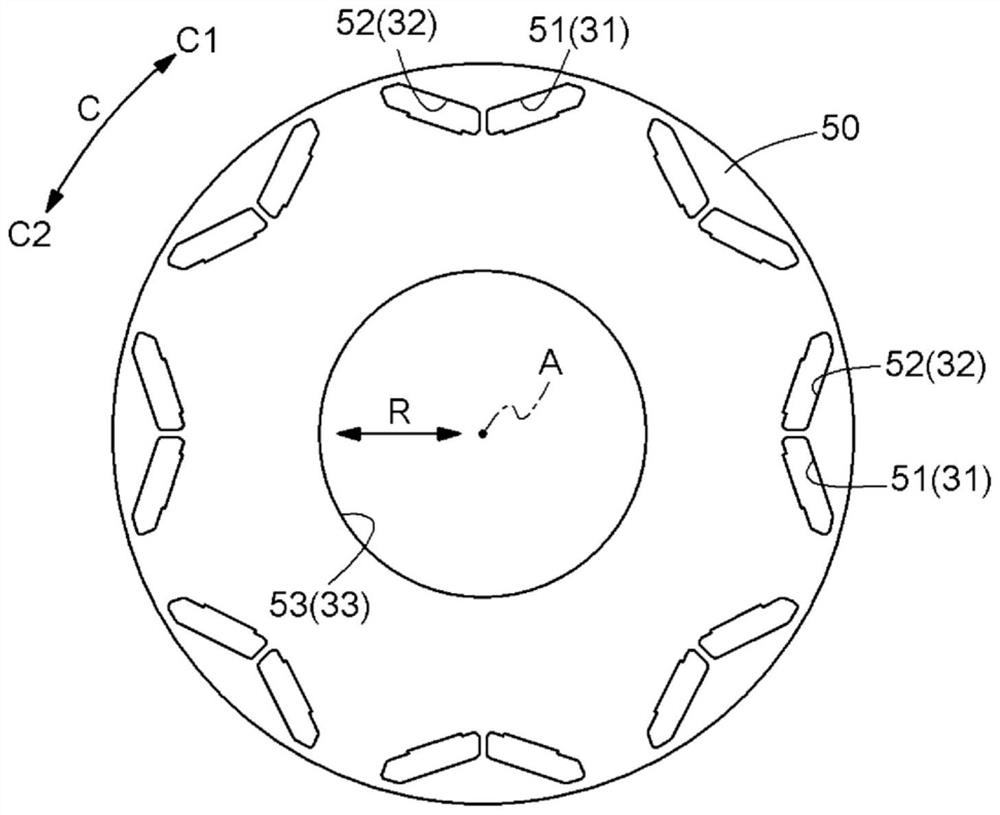

Rotor for rotating electrical machine, and method of manufacturing rotor for rotating electrical machine

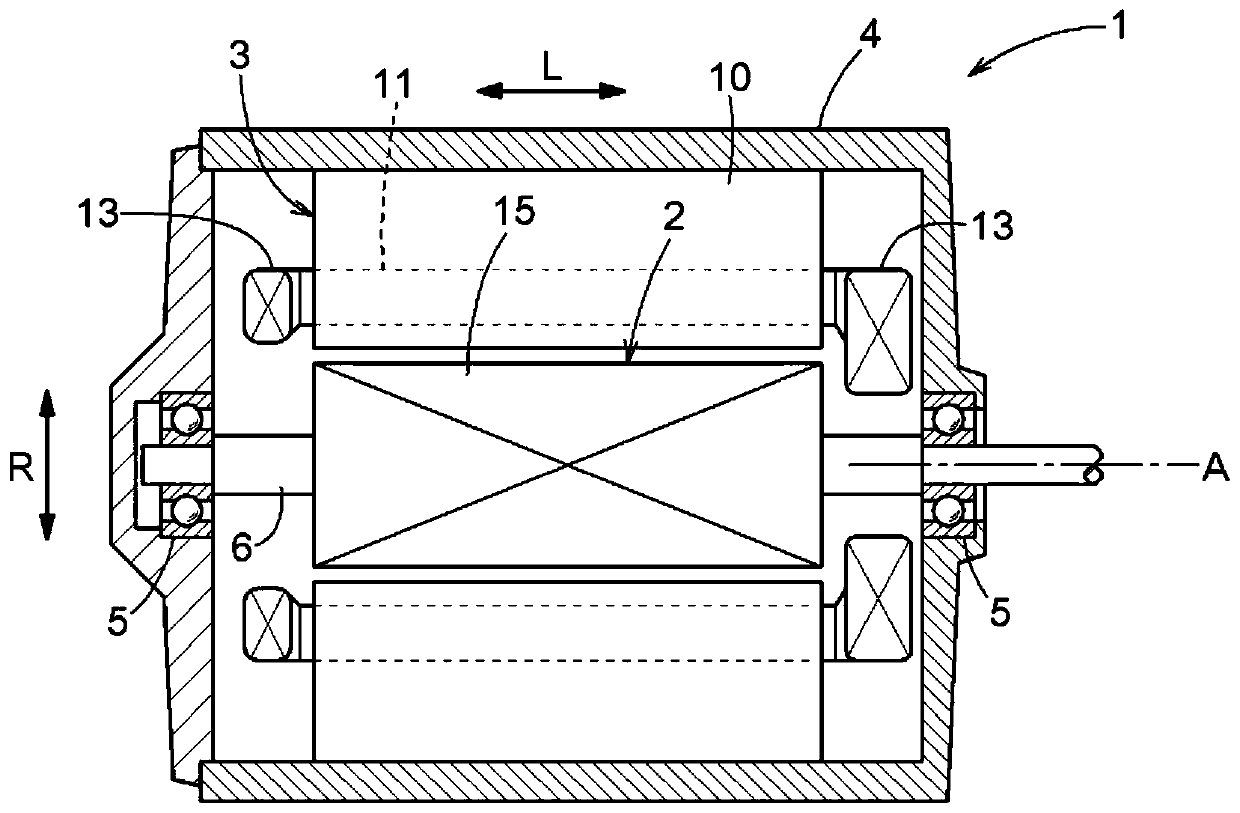

ActiveCN109964388AAchieve torqueAchieving Torque RippleMagnetic circuit rotating partsManufacturing dynamo-electric machinesElectric machineEngineering

A rotor core 15 is provided with a stacked structure 20 in which a plurality of magnetic plates 50 are stacked in an axial direction L. In the stacked structure 20, the plurality of magnetic plates 50are arranged in such a way that the positions thereof are offset from one another to one side in a circumferential direction C by a fixed angle with increasing distance towards one side in the axialdirection L. Magnet insertion holes 31, 32 are formed by means of a plurality of through-holes which penetrate in the axial direction L through all the plurality of magnetic plates 50. Permanent magnets 41, 42 have a shape that is twisted about an axis A such that the permanent magnets 41, 42 are accommodated into the magnet insertion holes 31, 32 from the outside in the axial direction L.

Owner:AISIN AW CO LTD +1

Grab Dredger and Grab Hoisting Mechanism

ActiveCN103835327BSave installation spaceImplement a single driveMechanical machines/dredgersDrive shaftEngineering

The invention provides a grab dredger and a lifting mechanism of a grab machine of the grab dredger. The lifting mechanism of the grab machine comprises one or more sets of driving units, wherein each driving unit comprises a motor, a transmission, a first coiling block and a second coiling block, the input end of the transmission is connected with a transmission shaft of the motor, a rotating shaft of the first coiling block is connected with the output end of the transmission, the block body of the second coiling block is connected with the rotating shaft of the first coiling block, and the first coiling block and the second coiling block are coaxially driven by the motor through the transmission. The mounting space of the whole lifting mechanism can be reduced, and single-drive, large-span and large-torque requirements can be met.

Owner:SHANGHAI ZHENHUA HEAVY IND

A double-tooth linkage transmission device

ActiveCN111692297BAchieve connectionAchieve lockingToothed gearingsGearing controlDouble teethEngineering

Owner:常州市嘉盾机械制造有限公司

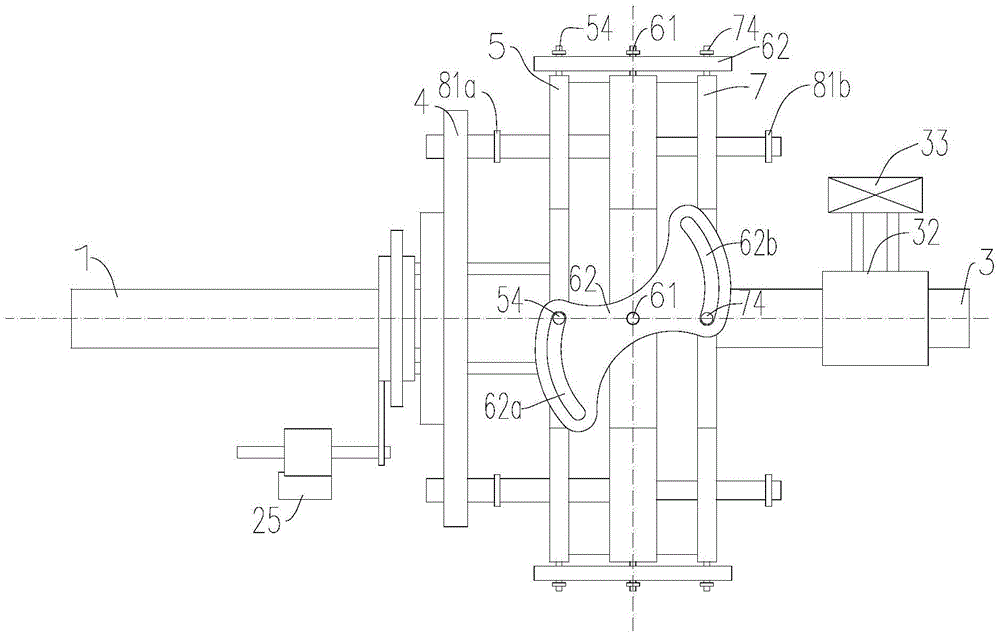

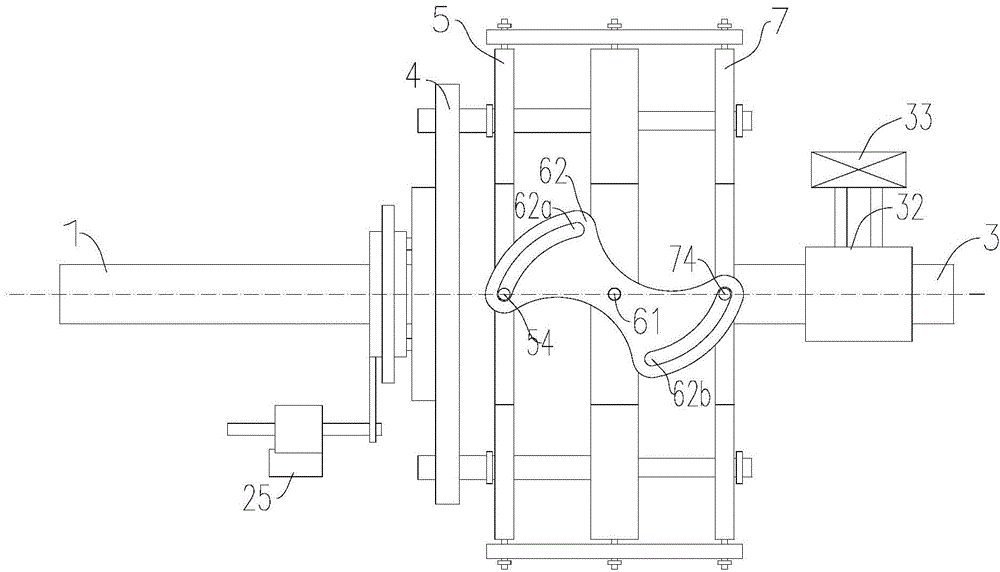

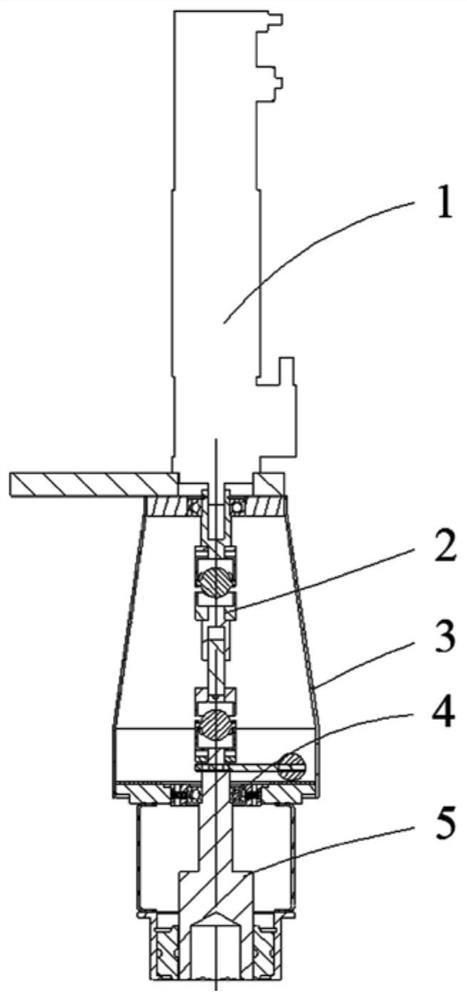

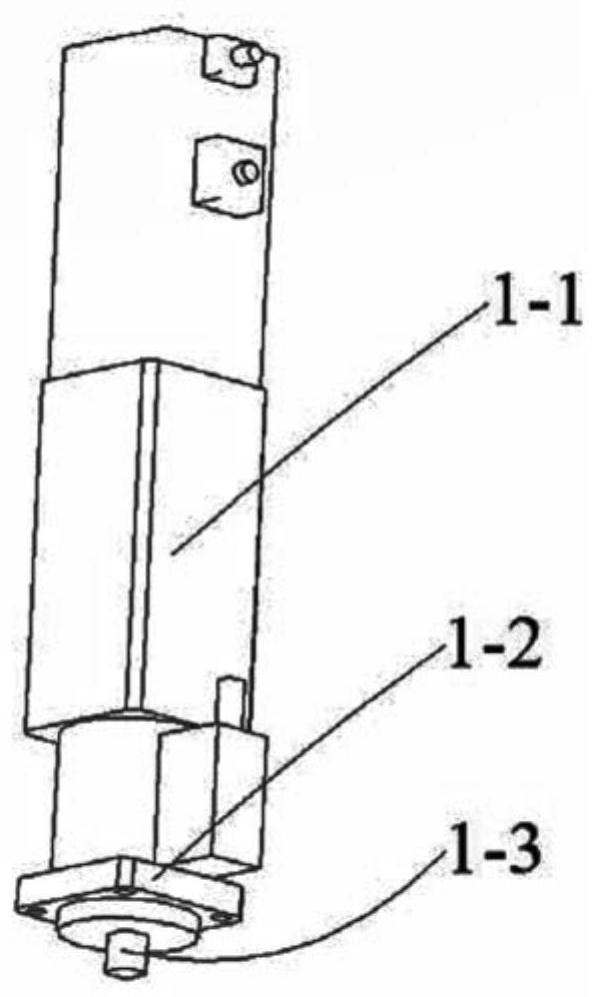

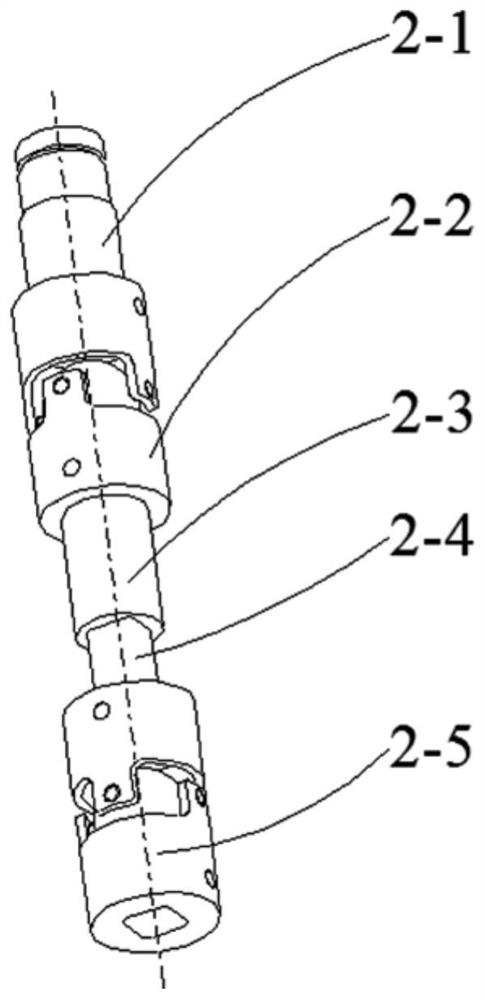

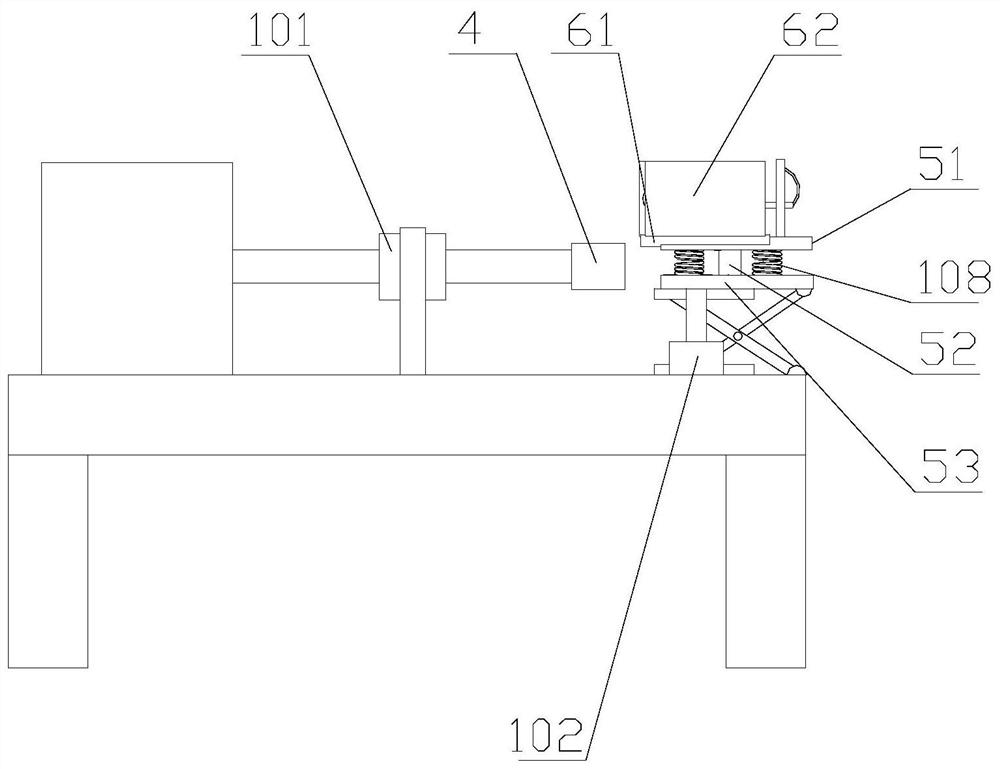

Inclination angle alignment controllable thread tightening mechanism and operation method

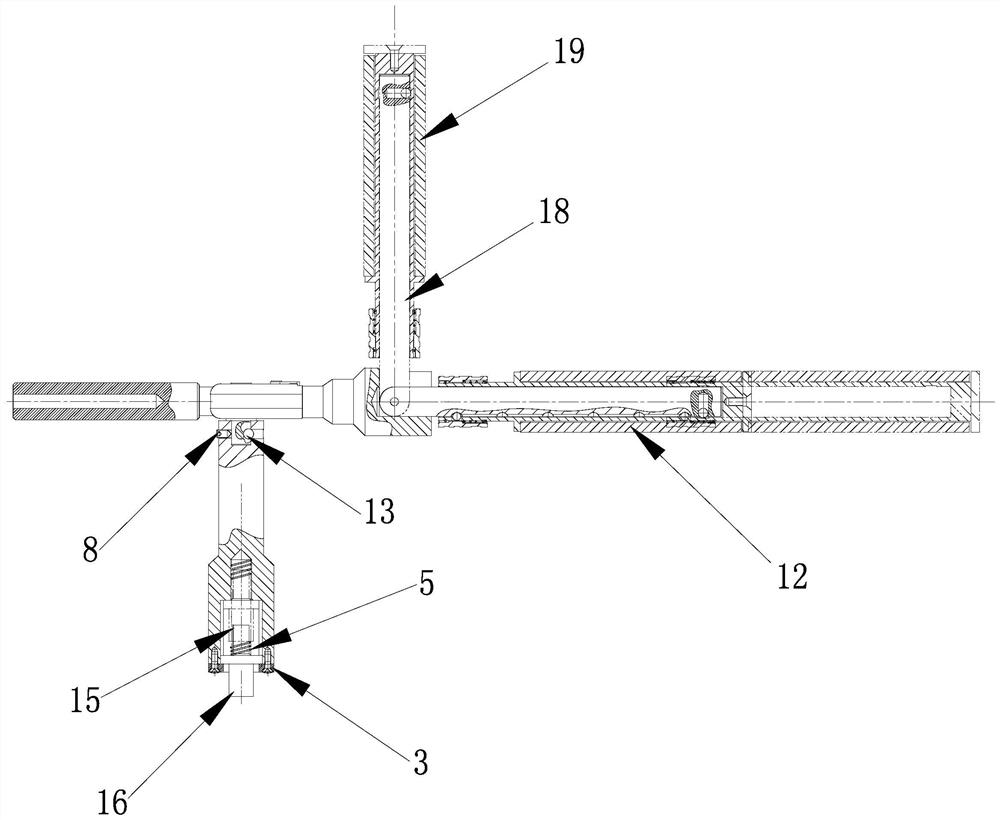

PendingCN112388565AAchieve deflectionControl deflection angleMetal-working hand toolsUniversal jointRotation - action

The invention relates to an inclination angle alignment controllable thread tightening mechanism and an operation method. The inclination angle alignment controllable thread tightening mechanism comprises a tightening mechanism (1), a connecting bracket (3) and a swing wrench (5), wherein the tightening mechanism (1) is connected with the swing wrench (5) through a telescopic two-stage universal joint connecting shaft (2) and transmits torque and rotation action; and an elastic assembly (4) is arranged between the swing wrench (5) and the connecting bracket (3) and provides elastic support forthe swing wrench (5). During thread installation, the tightening mechanism (1) drives the swing wrench (5) to rotate, a centrifugal mechanism on the swing wrench (5) can provide centrifugal force ina rotating process, and the swing wrench (5) deflects under the combined action of centrifugal force, elastic force of the elastic assembly and internal resistance of the mechanism. Under the condition that a certain included angle exists between central shafts of two parts in threaded fit, inclination angle deflection alignment can be achieved, threads can be screwed in, in the working conditionof mechanically aligning and installing the threads, after the central points of two matched parts are aligned, inclination angle alignment and thread assembly tightening can be carried out.

Owner:CRCC HIGH TECH EQUIP CORP LTD

A triple eccentric sealing butterfly valve with a sealing ring

ActiveCN105156699BAchieving Zero LeakageAchieve unbalanced momentSpindle sealingsLift valveEngineeringButterfly valve

The invention discloses a seal-ring-bearing three-eccentric seal butterfly valve, relating to the field of valves. The seal-ring-bearing three-eccentric seal butterfly valve comprises a valve body, an operating mechanism, a disk plate assembly and a valve stem, wherein the operating mechanism is positioned outside the valve body; one end of the valve stem is positioned outside the valve body and connected with the operating mechanism, and the other end is positioned inside the valve body and connected with the disk plate assembly; a valve body sealing surface used for matching with the disk plate assembly is arranged inside the valve body; the disk plate assembly comprises a disk plate, a pressure plate and a seal ring; the seal ring comprises a seal end and a fixed end; the fixed end is positioned between the disk plate and pressure plate; the seal end is positioned outside the disk plate, and used for matching with the valve body sealing surface; and the cross-section area of the seal end is smaller than that of the disk plate. The seal-ring-bearing three-eccentric seal butterfly valve can implement zero medium leakage, well improve the opening and reversing sealing properties, and widen the application range of the three-eccentric seal butterfly valve.

Owner:CSIC SPECIAL EQUIP CO LTD

Rotor for rotating electrical machine and method for manufacturing rotor for rotating electrical machine

ActiveCN109964388BAchieve torqueAchieving Torque RippleMagnetic circuit rotating partsManufacturing dynamo-electric machinesElectric machineMachine

The present invention relates to a rotor for a rotating electrical machine and a method for manufacturing the same. A rotor core (15) includes a laminated structure (20) formed by laminating a plurality of magnetic plates (50) in an axial direction L. In the laminated structure (20), a plurality of magnetic plates (50) are arranged so that their positions are shifted to one side in the circumferential direction C by a certain angle each time as they go to one side in the axial direction L. The magnet insertion holes (31, 32) are formed by a plurality of through holes communicating in the axial direction L over all of the plurality of magnetic plates (50). The permanent magnets (41, 42) are twisted around the axis A so as to be accommodated in the magnet insertion holes (31, 32) from the outside in the axial direction L.

Owner:AISIN AW CO LTD +1

Winding and clamping device of flexible substrate

ActiveCN104087907AEven force clampingEffective protectionVacuum evaporation coatingSputtering coatingClassical mechanicsEngineering

Owner:SOUTH CHINA UNIV OF TECH

Dynamic torque detection system

PendingCN114323384AImprove stabilityAchieve torqueInternal-combustion engine testingWork measurementPhysicsEngineering

The invention relates to the technical field of torque detection equipment, in particular to a dynamic torque detection system. Comprising a base, a torque detector body, a bearing, a coupler, a placing plate, a first clamping assembly, a fixing assembly and a second clamping assembly, the fixing assembly is fixedly connected with the placing plate, and the second clamping assembly is fixedly connected with the placing plate. The first clamping assembly comprises a rotating shaft, a first fixing plate, first adjusting springs, a first clamping plate, a first buffer pad, a first outer cylinder and a first inner rod, the rotating shaft is rotationally connected with the placing plate, one end of each first adjusting spring is fixedly connected with the first fixing plate, and the other end of each first adjusting spring is fixedly connected with the first clamping plate; compression adjustment is carried out through the first adjusting spring according to a shell of the engine, the first clamping plate and the second clamping assembly clamp the engine, and torque detection of engines of different specifications is achieved.

Owner:阿米检测技术有限公司

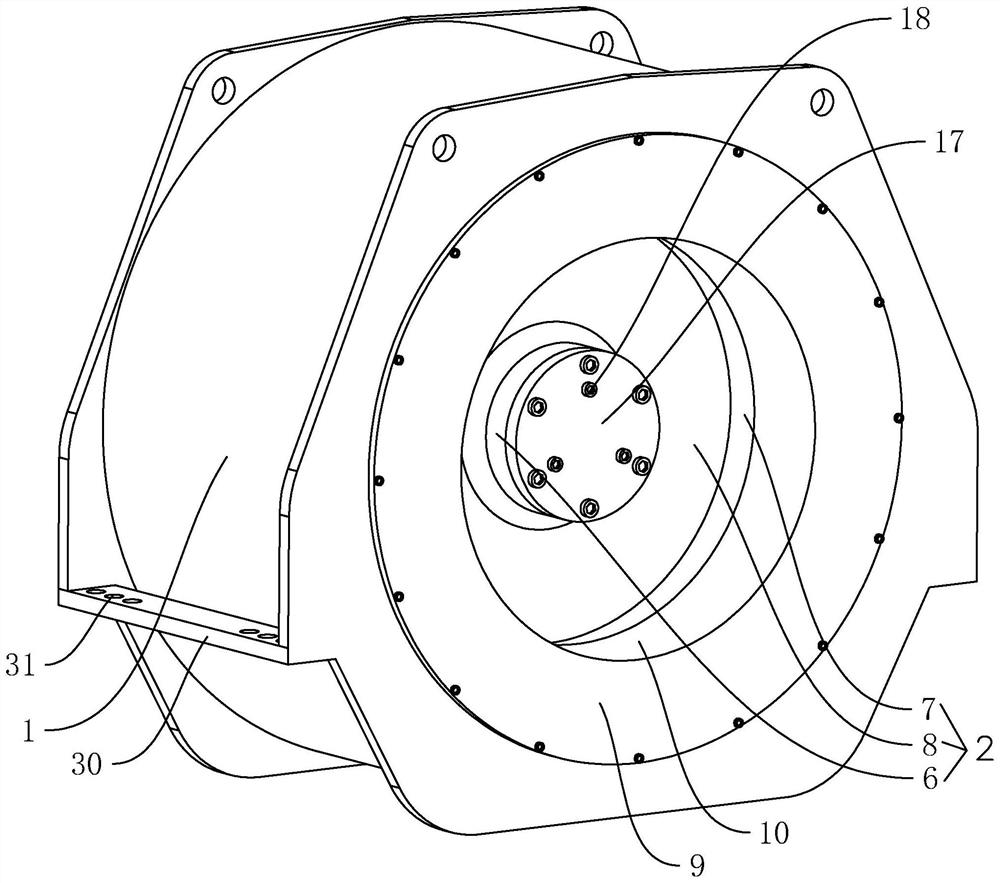

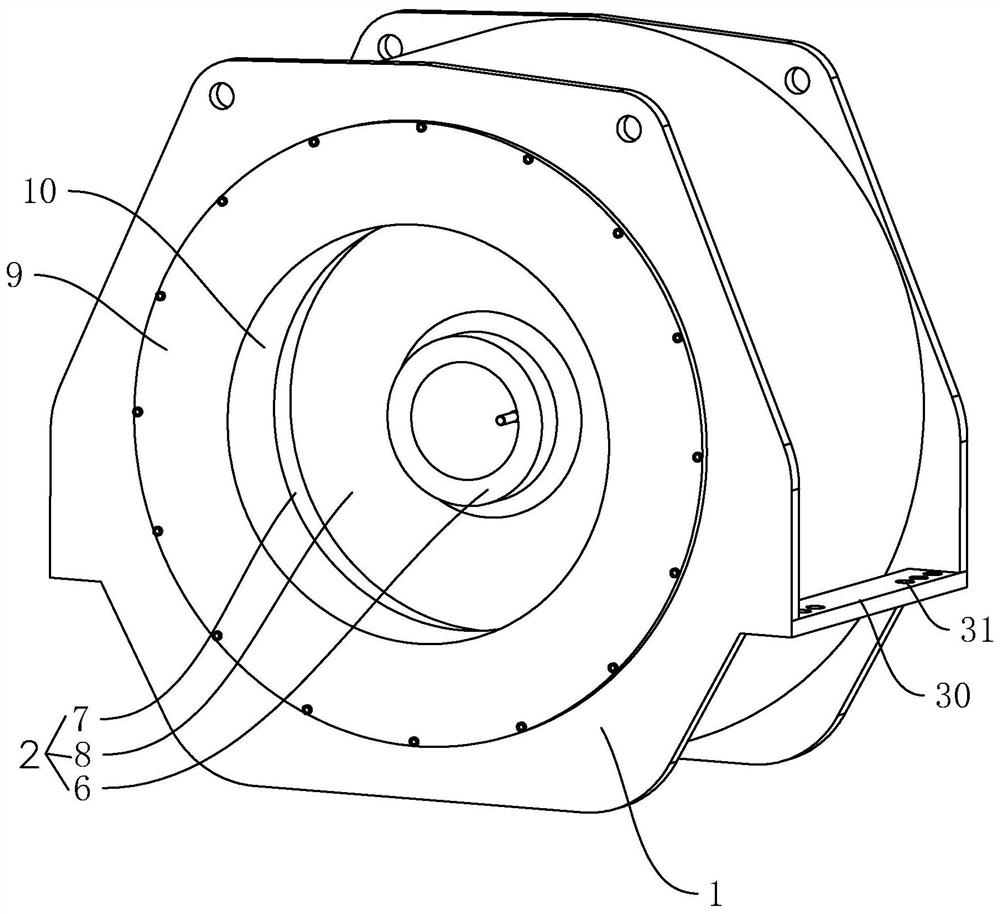

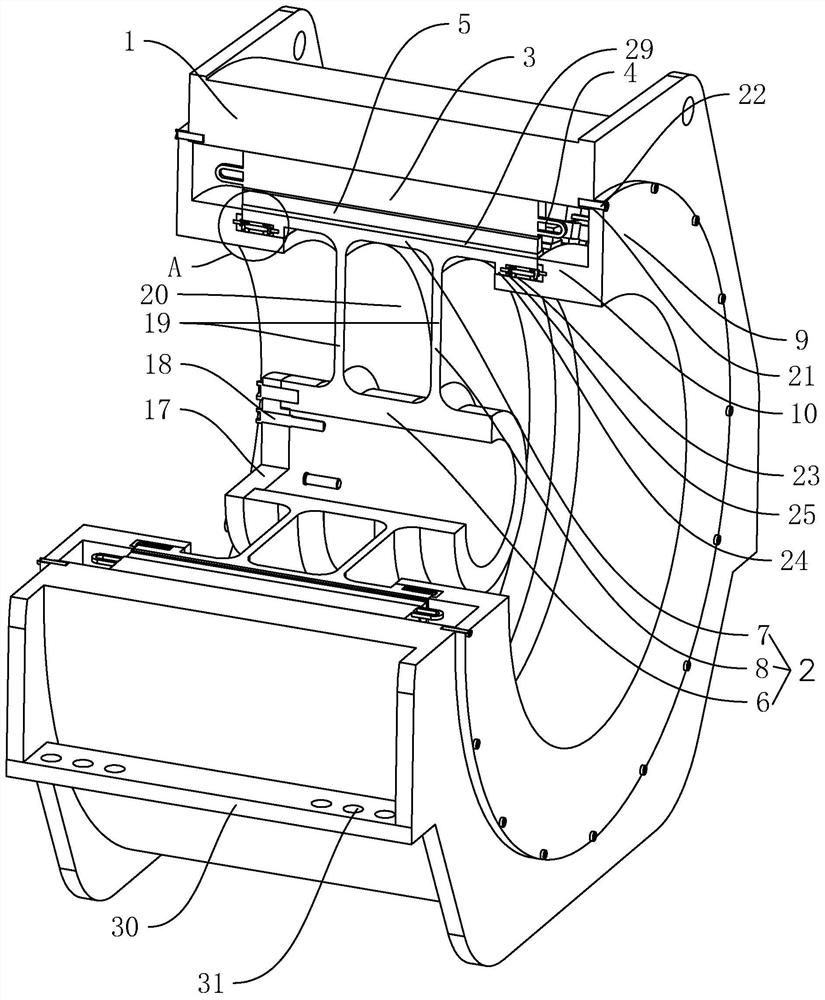

High-power suspension type permanent magnet direct drive motor

PendingCN113497535AAchieve torqueImprove the convenience of loading and unloadingSupports/enclosures/casingsSynchronous machines with stationary armatures and rotating magnetsElectric machineryMagnetic poles

The invention discloses a high-power suspension type permanent magnet direct drive motor, relates to the field of motors, and aims to solve the problem of difficulty in assembly and disassembly. The high-power suspension type permanent magnet direct drive motor is characterized by comprising a stator base and a driving rotor support, wherein a plurality of stator iron cores are mounted on the inner circumferential surface of the stator base at equal angles, each stator core is provided with a motor winding, and a plurality of permanent magnet poles are installed on the outer circumferential face of the driving rotor support at equal angles; the driving rotor support comprises a center sleeve, a connecting ring sleeve and a connecting part, the stator base is of a two-end-penetrating structure, and supporting end covers are arranged at the two ends of the stator base respectively; the supporting end covers are provided with inward turning parts, the inward turning parts are located in the connecting ring sleeve, and a rotary supporting mechanism is arranged between the inward turning parts and the connecting ring sleeve. According to the high-power suspension type permanent magnet direct drive motor, the assembly and disassembly convenience is effectively improved.

Owner:JINGJI TECH JIAXING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com