Fast integrated dismantling wrench

A wrench and fast technology, applied in the direction of wrenches, manufacturing tools, wrenches, etc., can solve the problems of easy rolling of levers, irregular placement, hidden dangers, etc., to achieve good firmness, convenient storage and organization, and safe use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

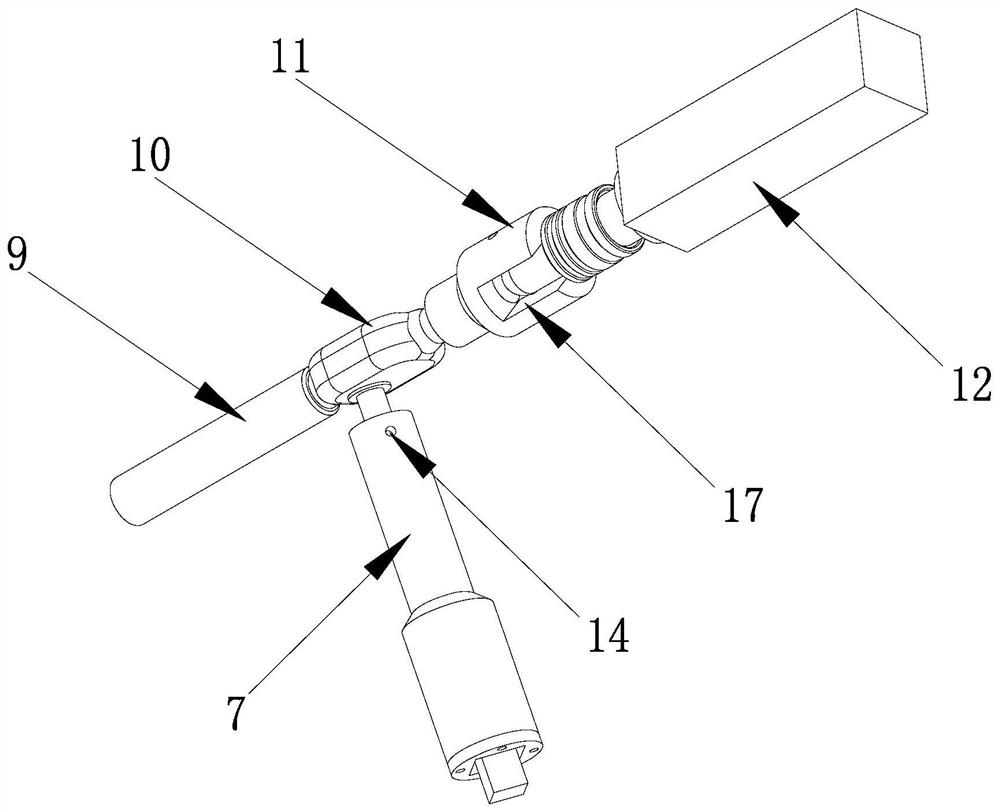

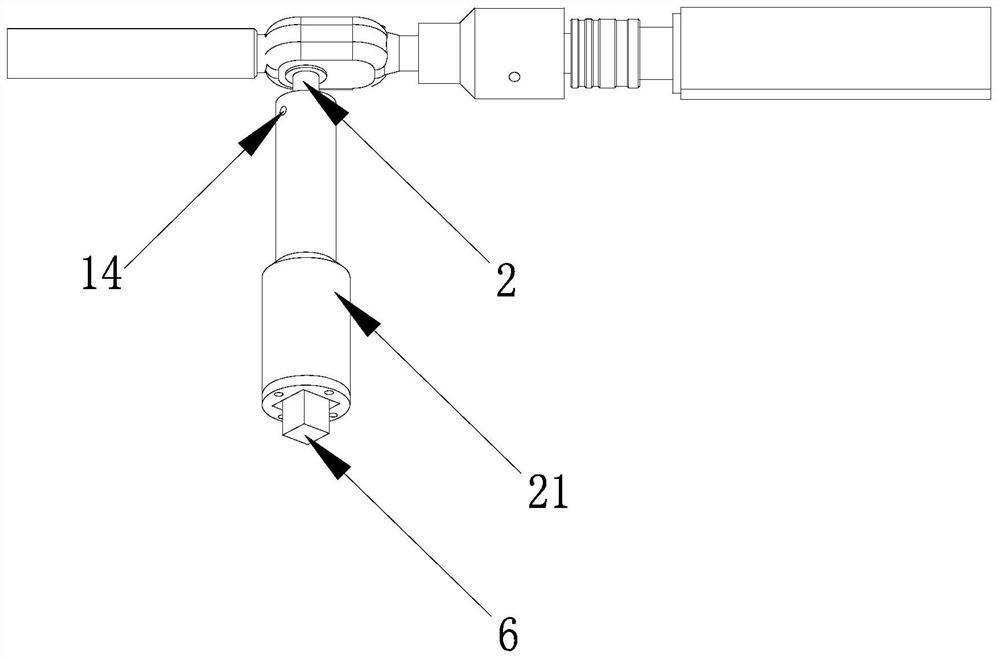

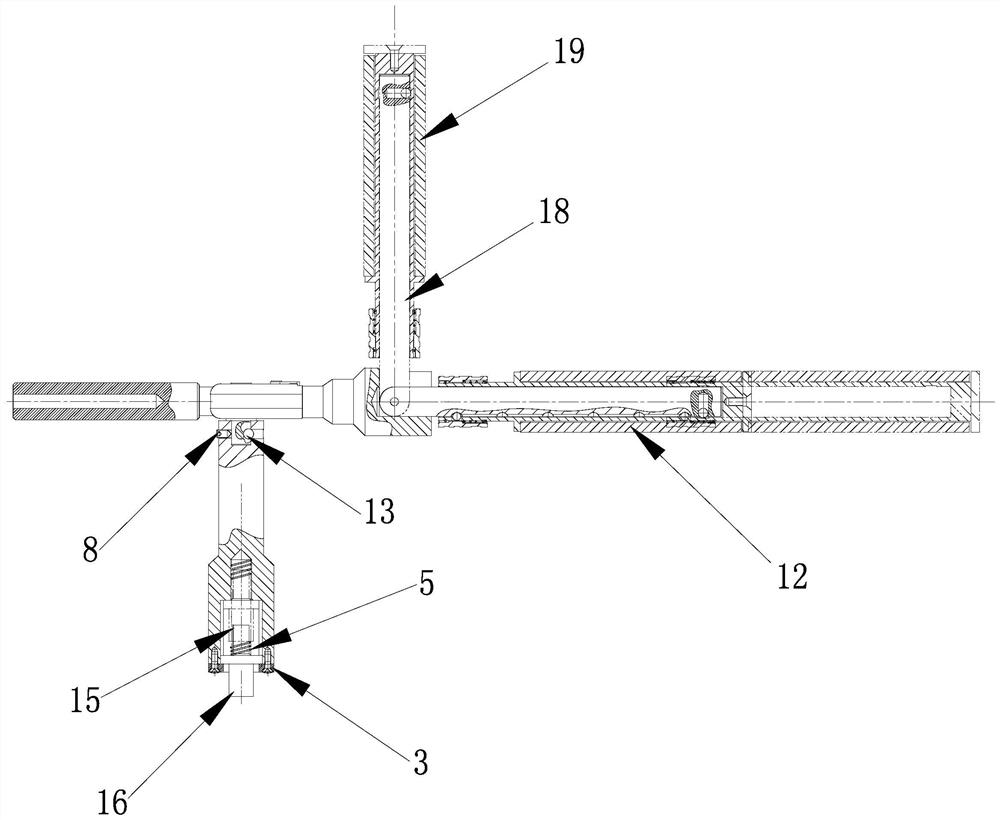

[0034] like Figure 1-4 As shown, a fast integrated disassembly wrench provided in this embodiment includes a connecting rod 9, a ratchet improvement device 10 and a ratchet wrench connection block 11; the connection rod 9 and the ratchet wrench connection block 11 are fixed on both sides of the ratchet improvement device 10 , the other side of the ratchet wrench connecting block 11 is rotatably connected to the telescopic rod device 12; the ratchet wrench connecting block is rotatably connected to the telescopic rod device, wherein the telescopic rod device and the ratchet wrench connecting block are 90 degrees or 180 degrees; Speed at low torque, torque at high torque; the bottom of the ratchet improvement device 10 is vertically arranged with a chuck wrench 7 for dismounting the tool.

[0035] The connecting rod 9 and the ratchet wrench connection block 11 of the present invention are fixed on both sides of the ratchet improvement device 10, and the forward and reverse ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com