Outer rotor regulation type eddy current speed controller

An outer rotor and speed governor technology, which is applied to electrical components, electromechanical devices, electromechanical transmission devices, etc., can solve the problems of complex structure of the inner rotor adjustment mechanism, increase the difficulty and difficulty of processing, etc. The effect of maintenance and product economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

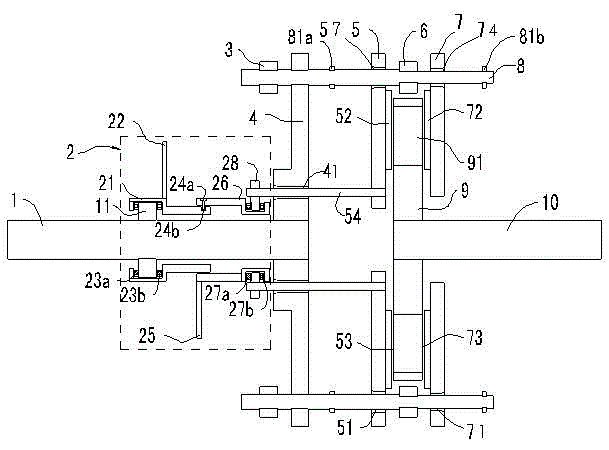

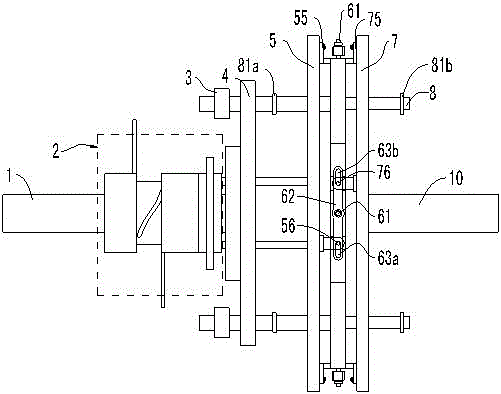

[0041] Such as figure 1 As shown, a vortex speed governor with external rotor adjustment includes an inner rotor and an outer rotor coaxially arranged.

[0042] The inner rotor includes an inner rotor shaft 10 and an inner rotor rotating disk 9 . Wherein, the inner rotor rotating disk 9 is coaxially and fixedly fitted on the outer periphery of the inner rotor shaft 10 .

[0043] Such as Figure 9 As shown, the inner rotor rotating disk 9 is uniformly provided with several through holes 93 along the circumferential direction, preferably eight through holes 93 . The shape of each through hole 93 is preferably a small rectangle, and a group of square permanent magnets 91 are nested in each through hole 93 .

[0044] The outer rotor includes an outer rotor shaft 1, two outer rotor moving discs and a rotary linear adjustment mechanism. Wherein, the outer rotor shaft 1 and the two outer rotor moving disks are coaxially arranged with the inner rotor shaft 10 .

[0045] The t...

Embodiment 2

[0090] The structure and principle of embodiment 2 are basically the same as embodiment 1, the difference is: as Figure 10 As shown, the inner surface of the fixing sleeve 21 is connected with the axial fixing disk 11 through the first bevel bearing 29a. The linear rotation sleeve 26 and the connection plate 28 are connected through a second angled bearing 29b.

[0091] Additionally, if Figure 11 As shown, the inner rotor rotating disk 9 is uniformly provided with several through holes 93 along the circumferential direction, preferably eight through holes 93 . The shape of each through hole 93 is trapezoidal, and a group of trapezoidal disc planar windings 92 are nested in each through hole 93 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com