Inclination angle alignment controllable thread tightening mechanism and operation method

A kind of thread and operation technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of difficulty in fixing and inability to screw in the thread.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the following briefly introduces the drawings required for the description of the embodiments or the prior art. Apparently, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other embodiments according to these drawings without creative efforts.

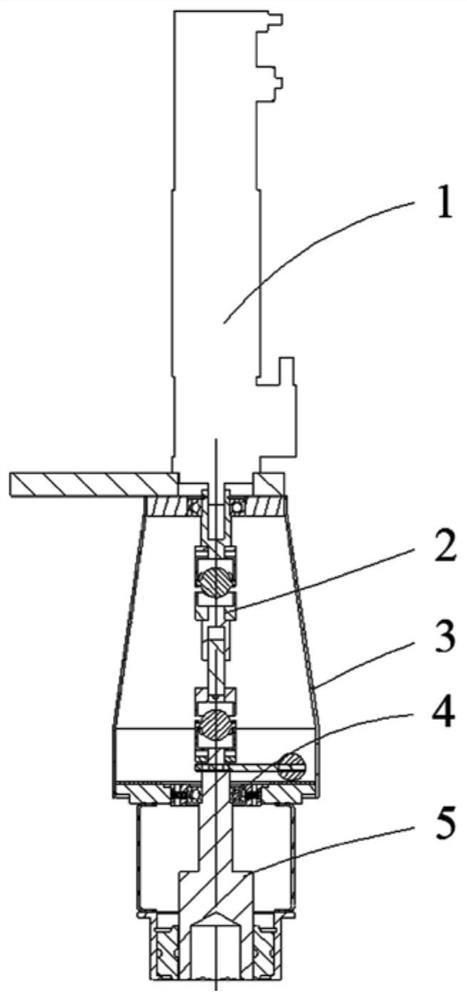

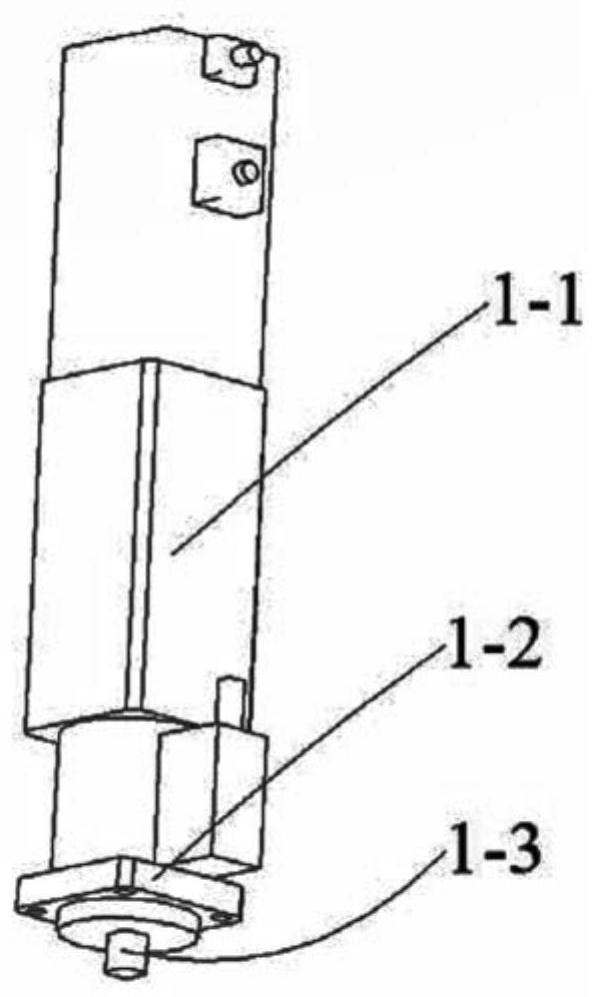

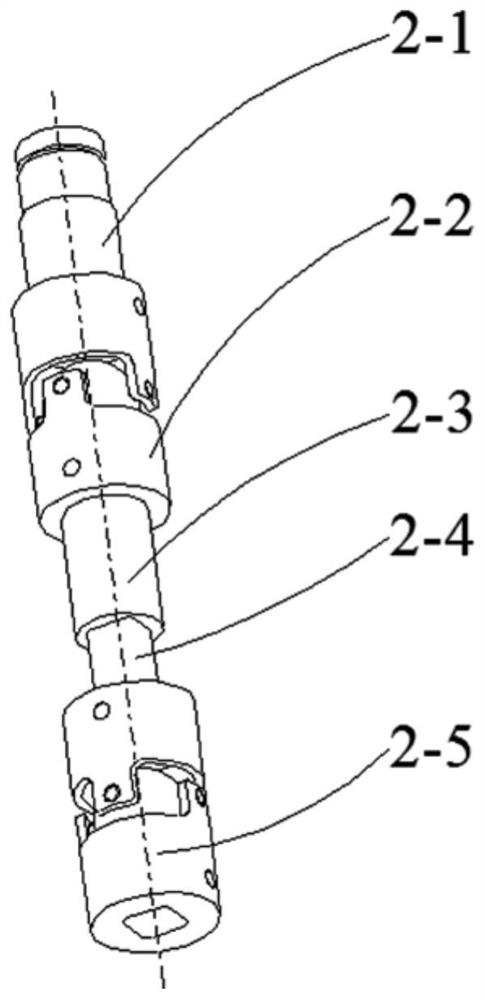

[0070] Such as figure 1 Shown is a schematic structural view of a preferred embodiment of the screw tightening mechanism with controllable inclination angle alignment according to the present invention. The tightening mechanism and working method of the screw tightening machine with controllable inclination angle alignment of the present invention include a tightening mechanism 1, a connecting bracket 3 and a swing wrench 5, and the connecting bracket 3 is detachably connected between the tightening mechanism 1 and the swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com