Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about "Tobacco drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

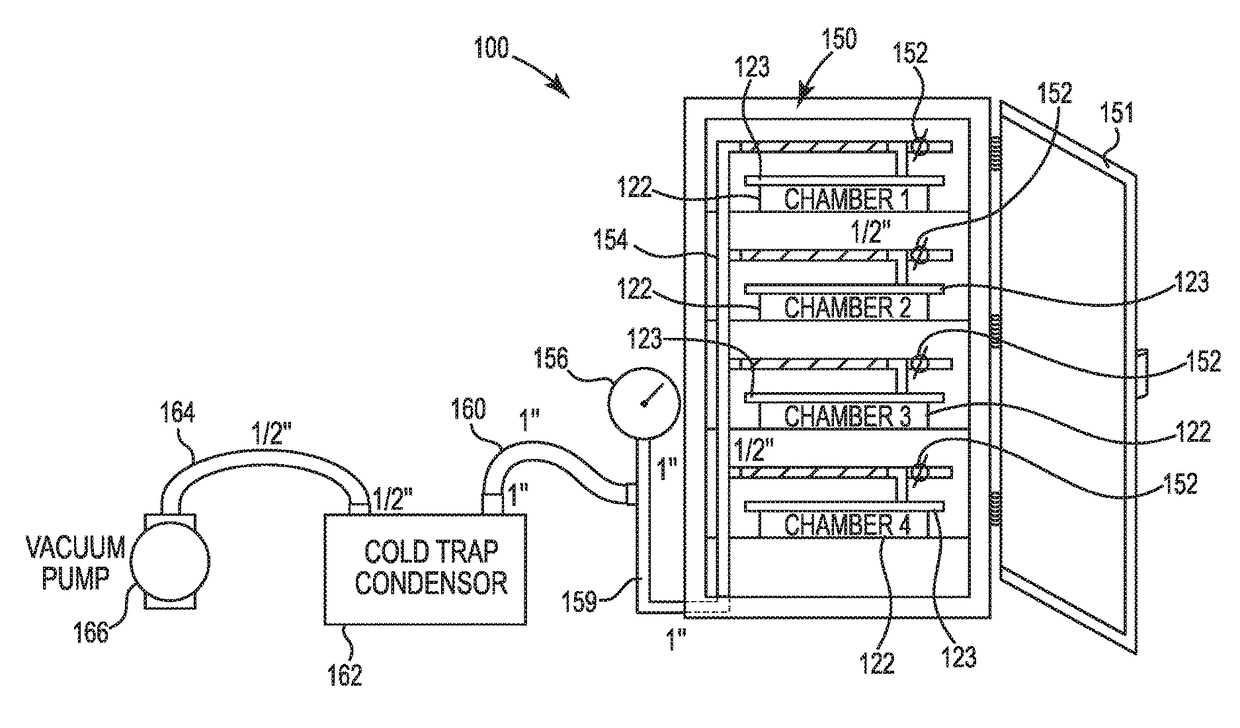

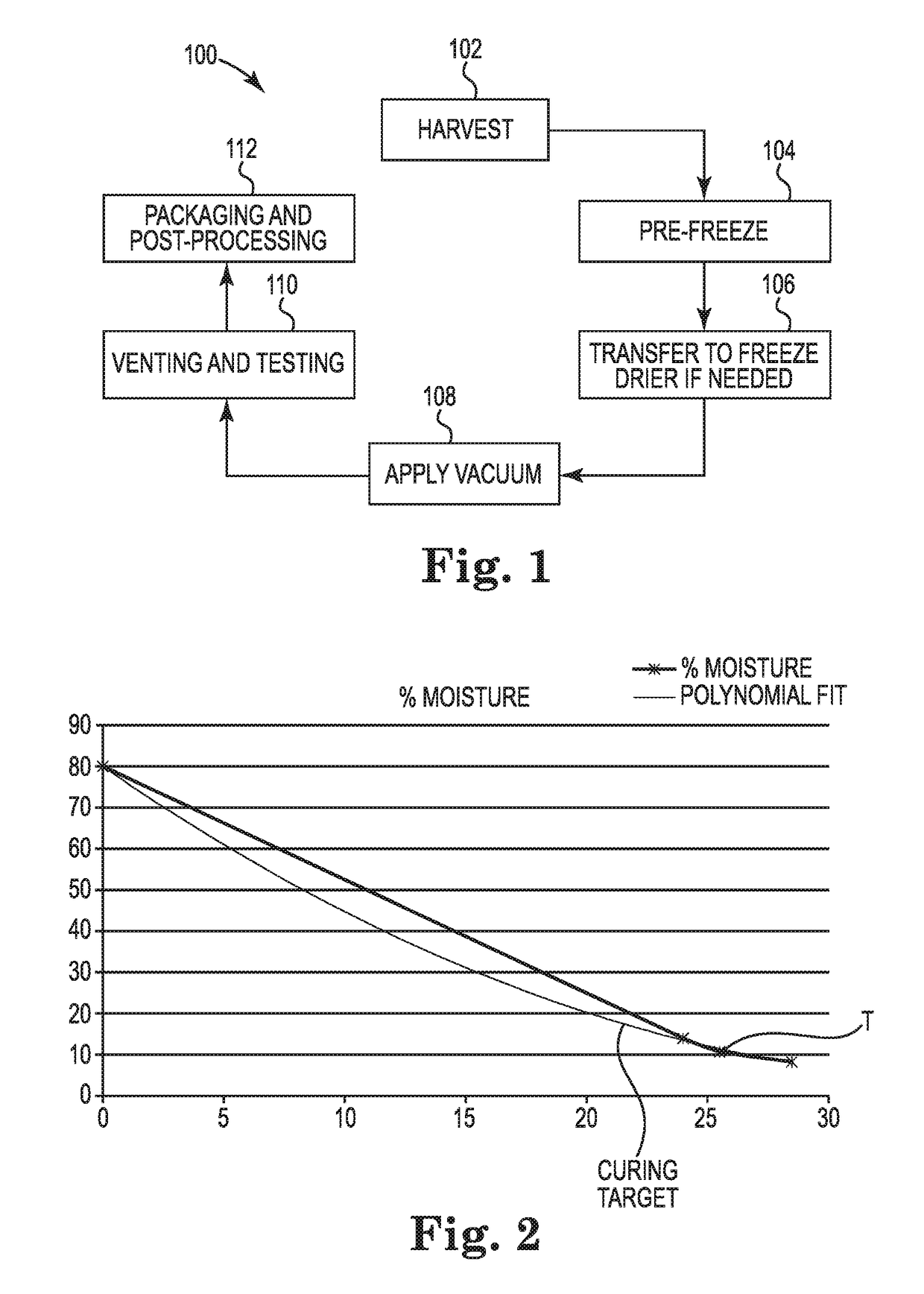

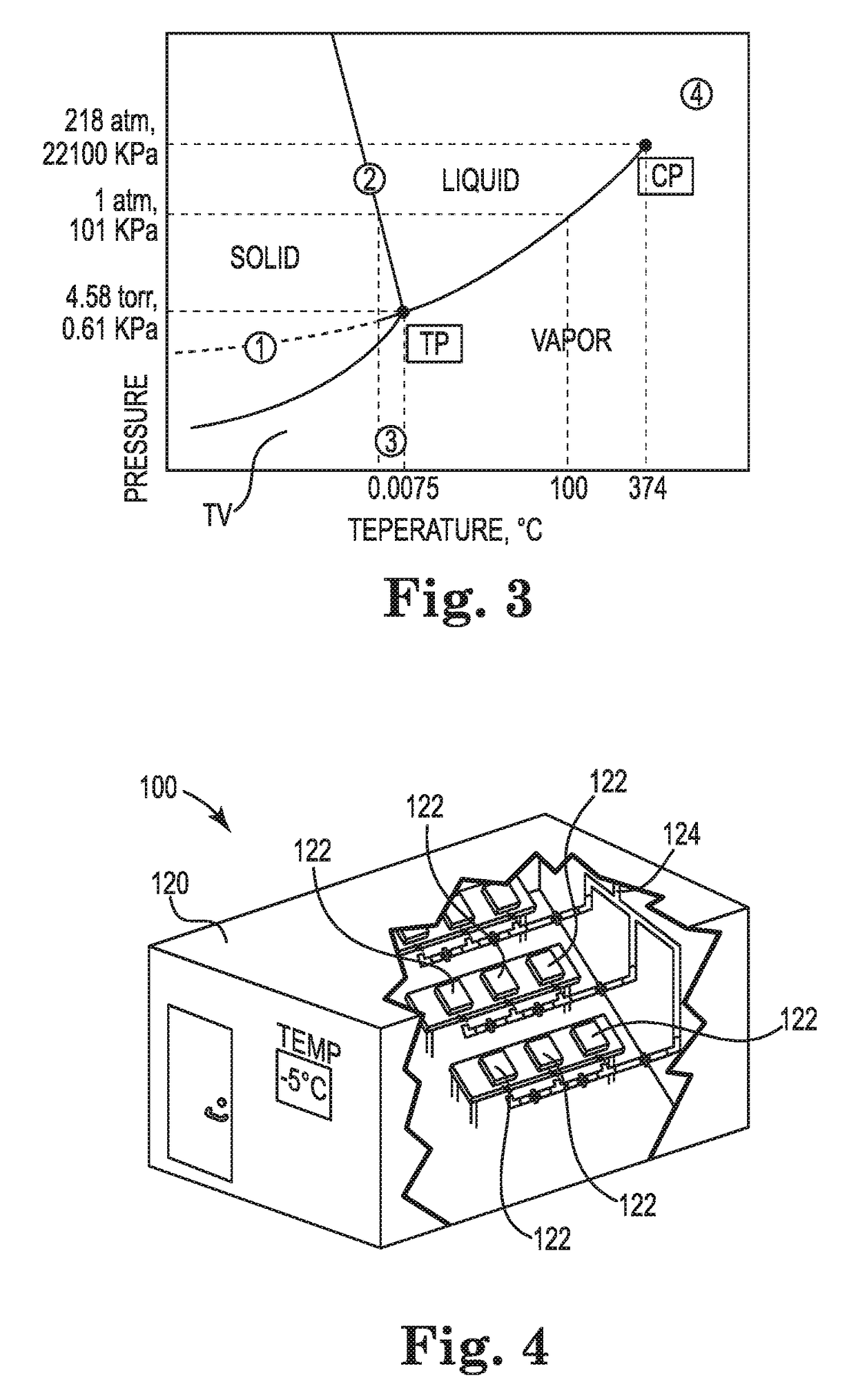

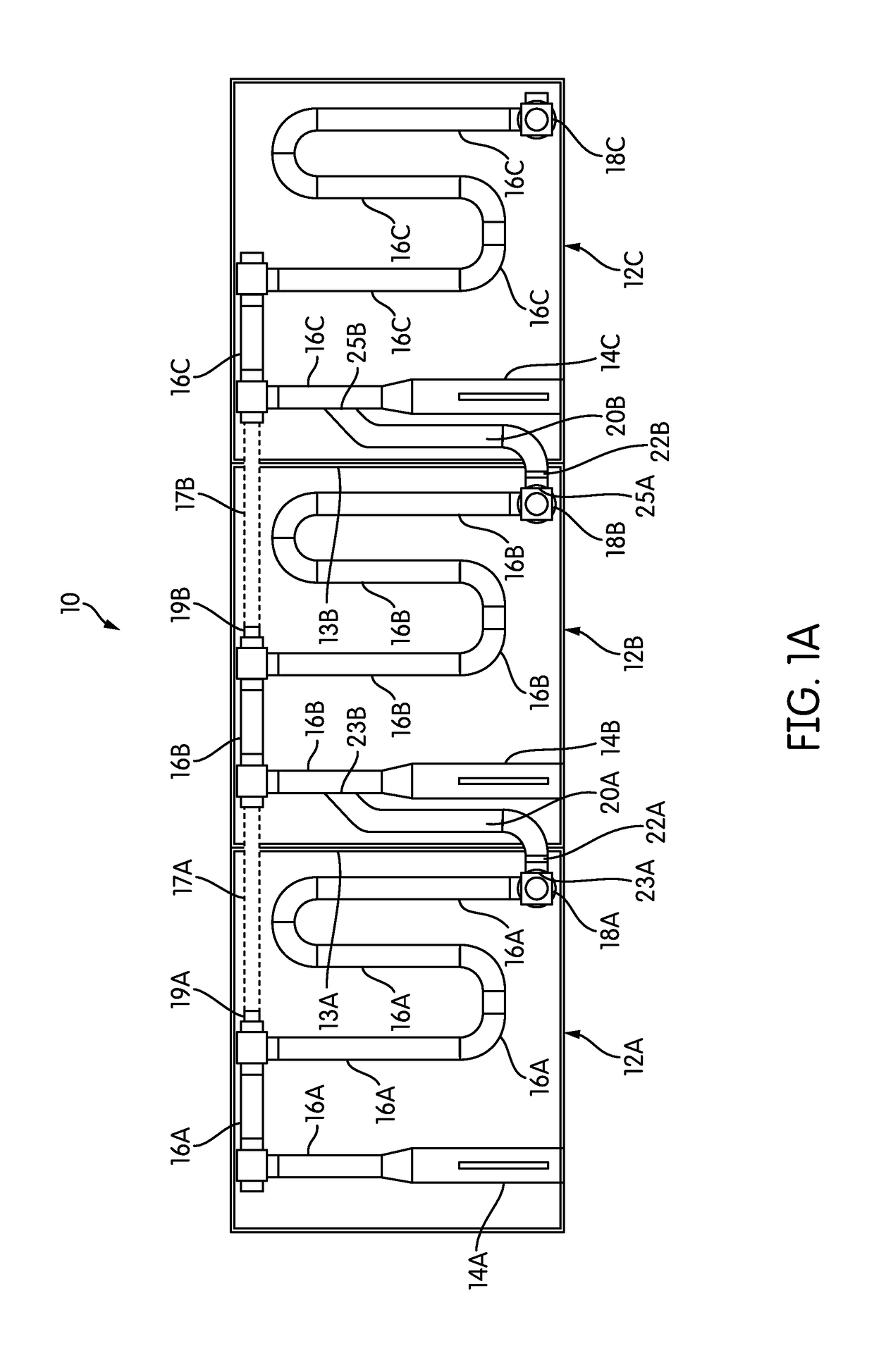

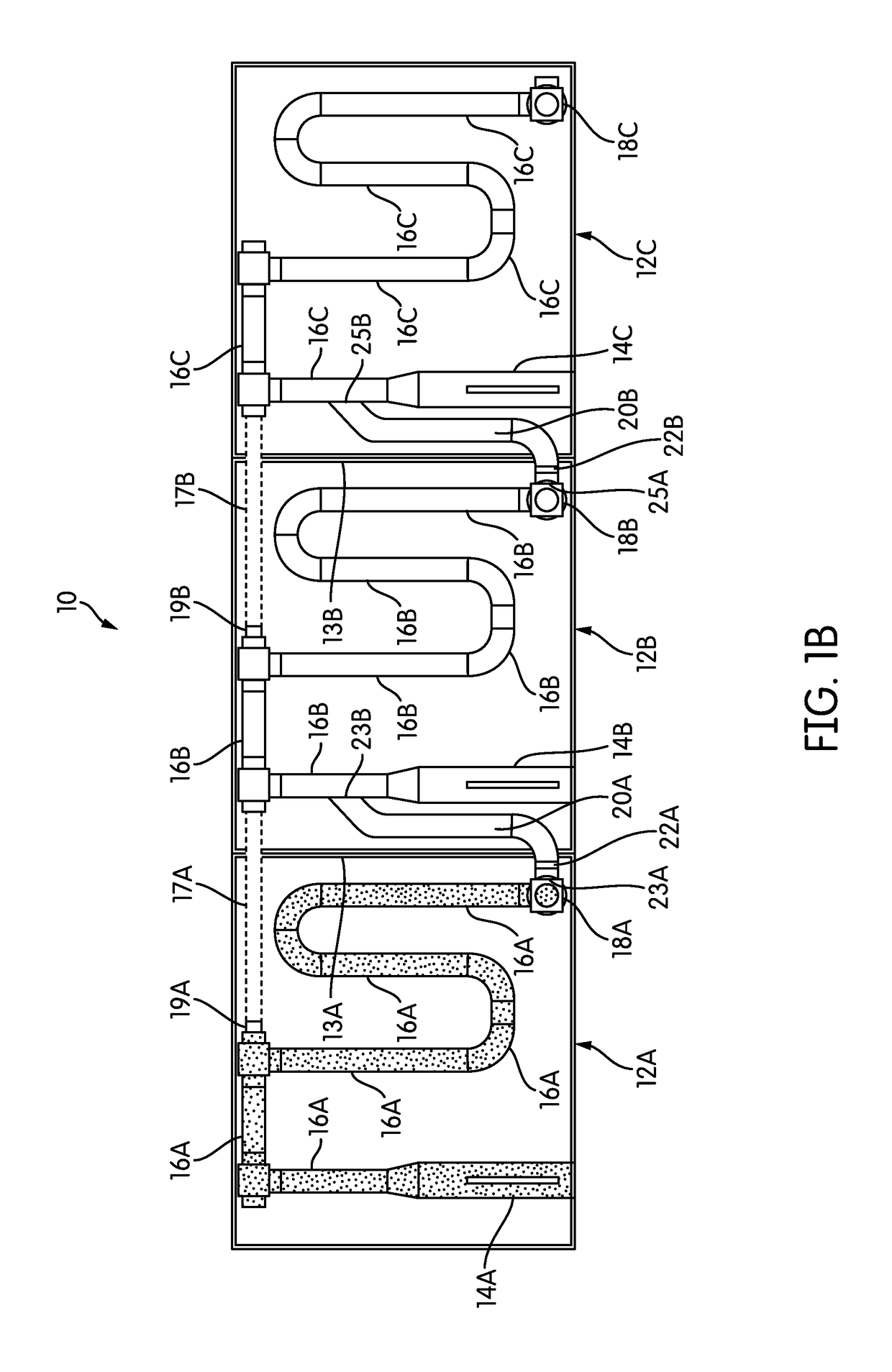

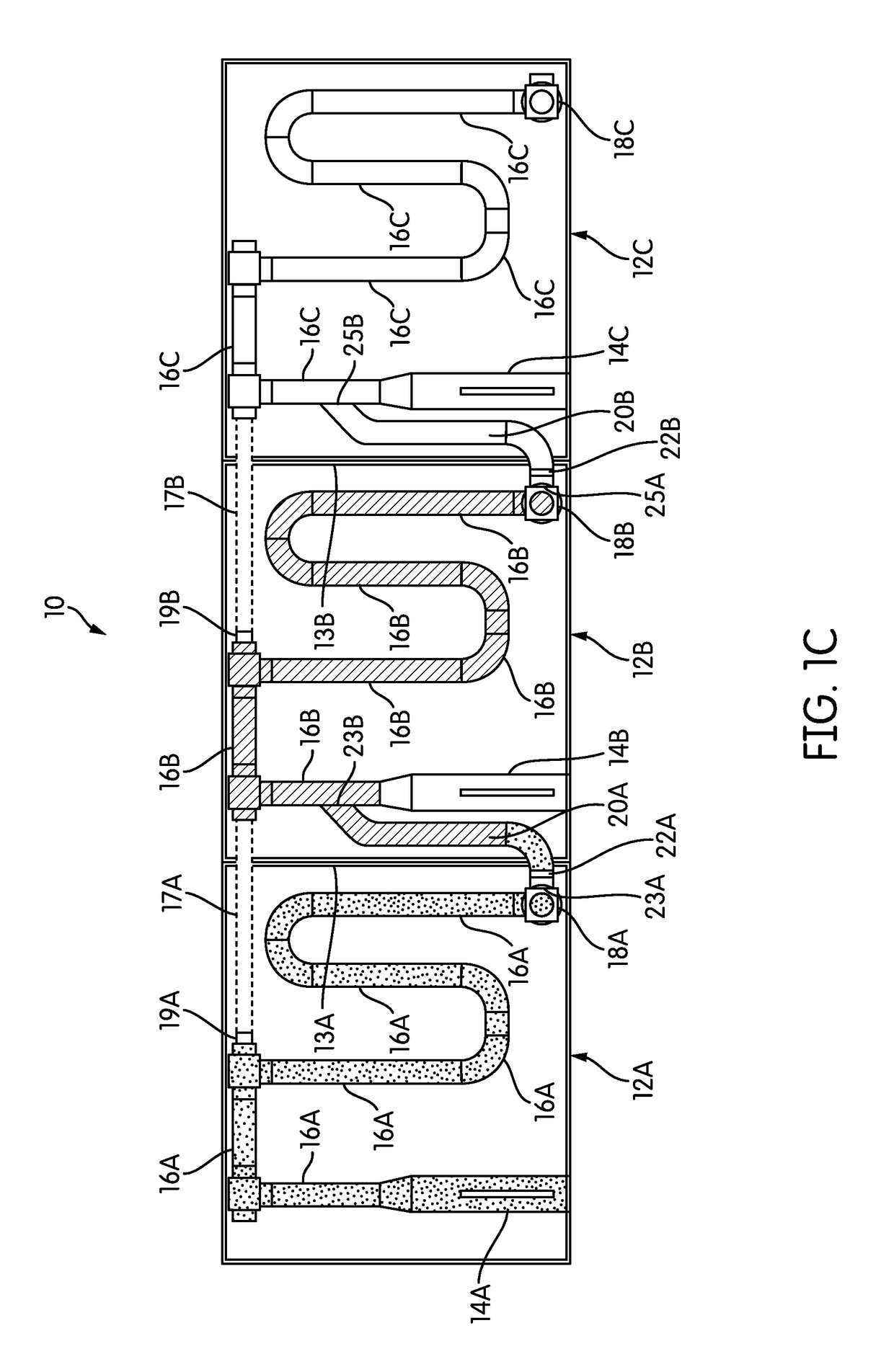

Botanical freeze drying system and method

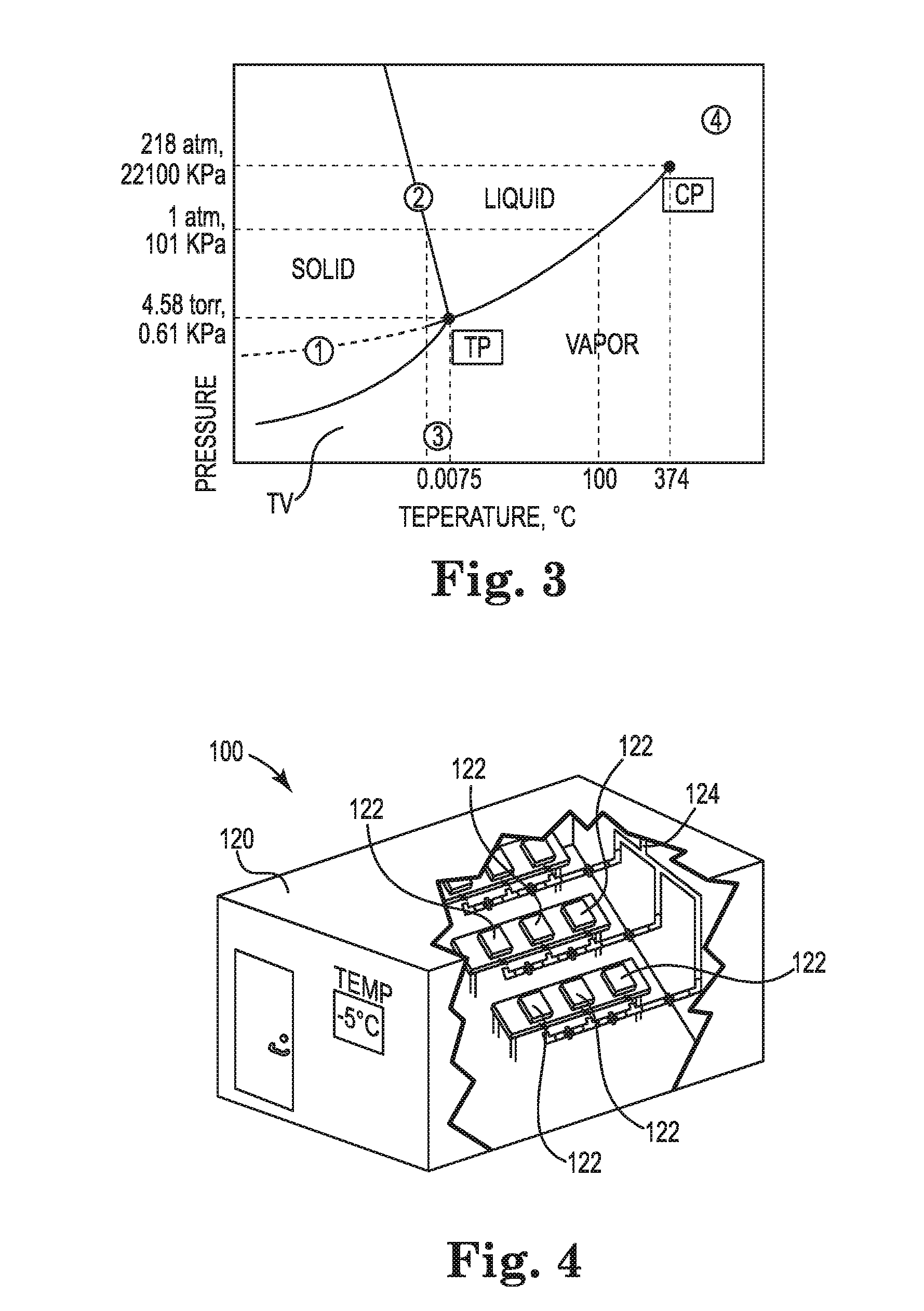

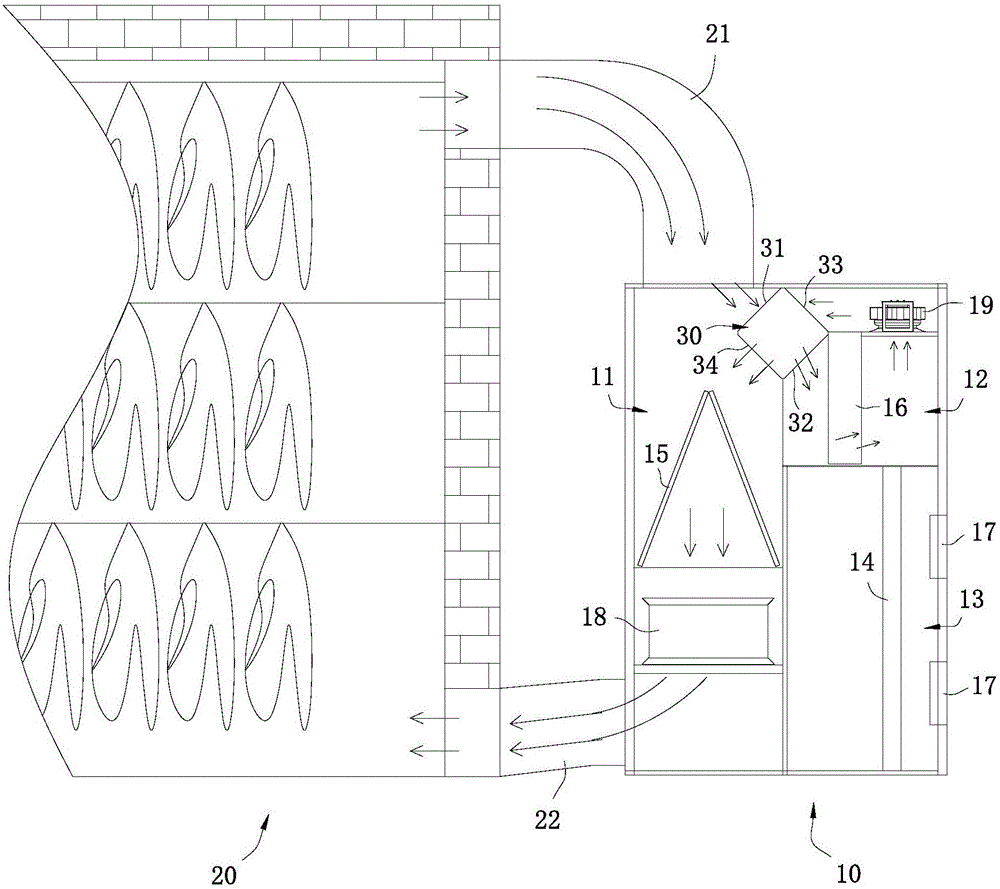

ActiveUS9739532B2Reduce and prevent evaporative lossPromotes sublimationDrying solid materials without heatTea dryingFreeze-dryingPulp and paper industry

Systems and methods for freeze drying botanical or herb items or products using a modular vacuum chamber configuration are provided. Such configurations can reduce or prevent the evaporative loss of volatile compounds while reducing the temperature and removing air to prevent oxidation of the product. The freeze drying systems and methods of the present invention can improve organoleptic characteristics, shelf life, and extractions.

Owner:BAUGH STEVEN F +1

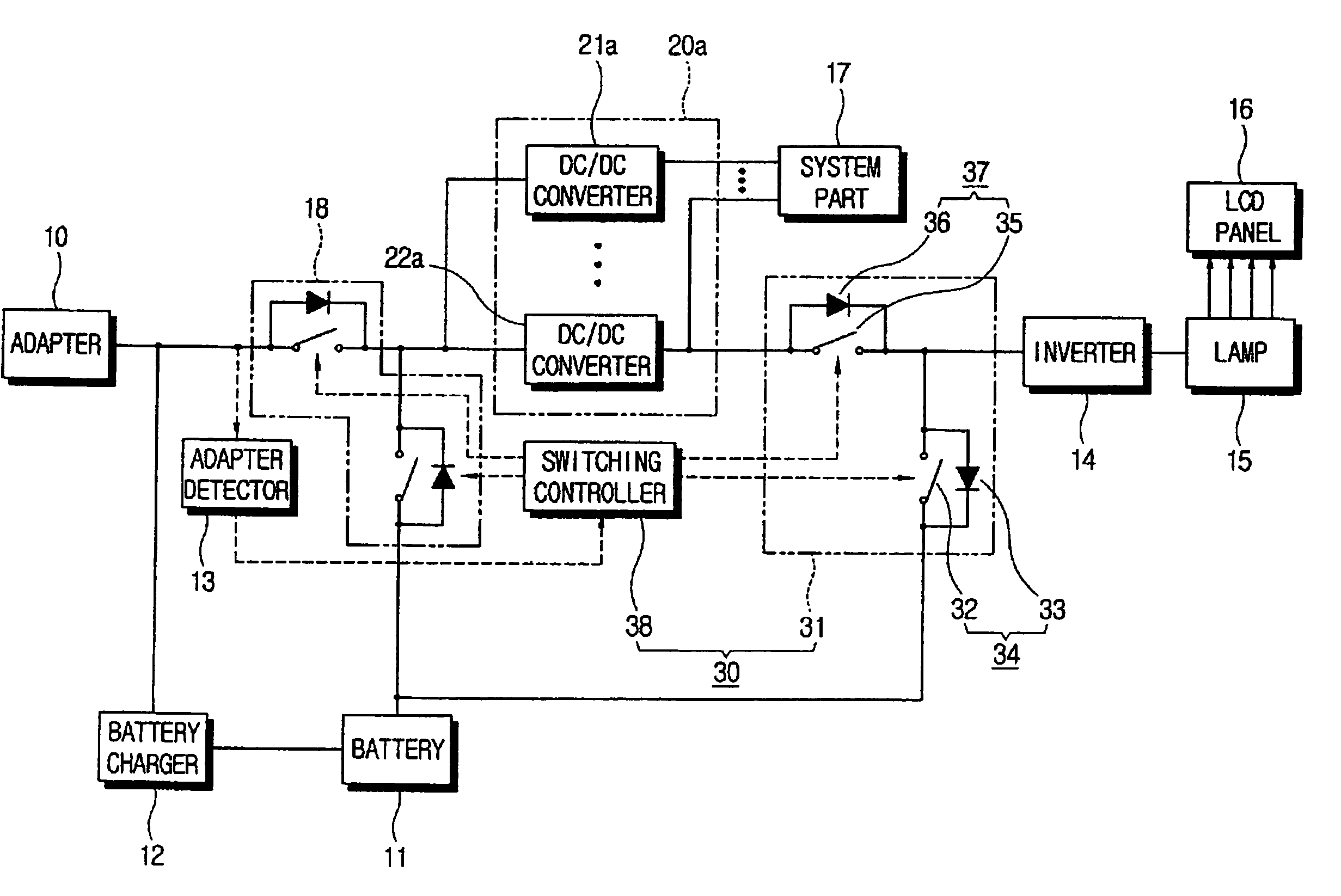

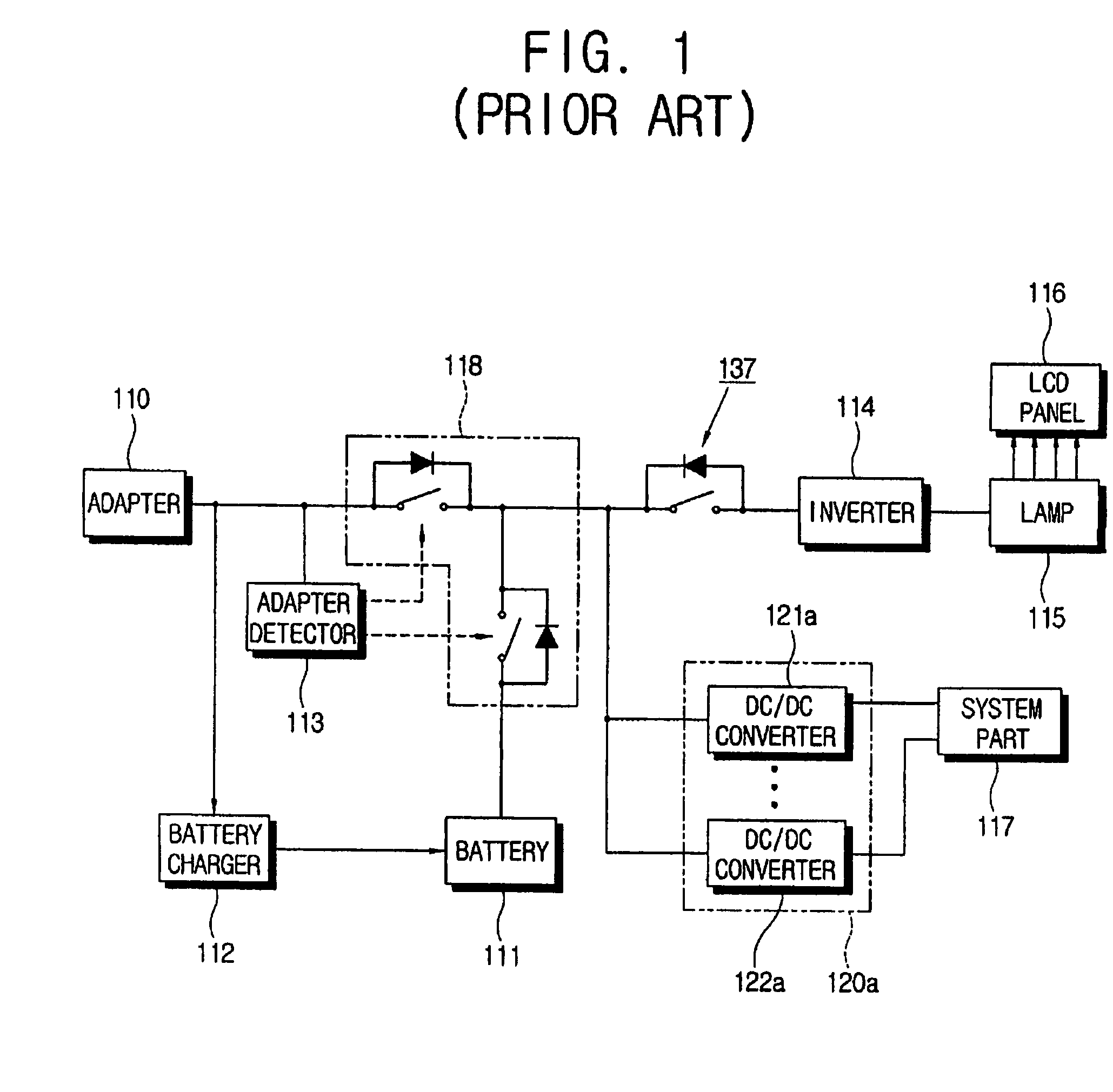

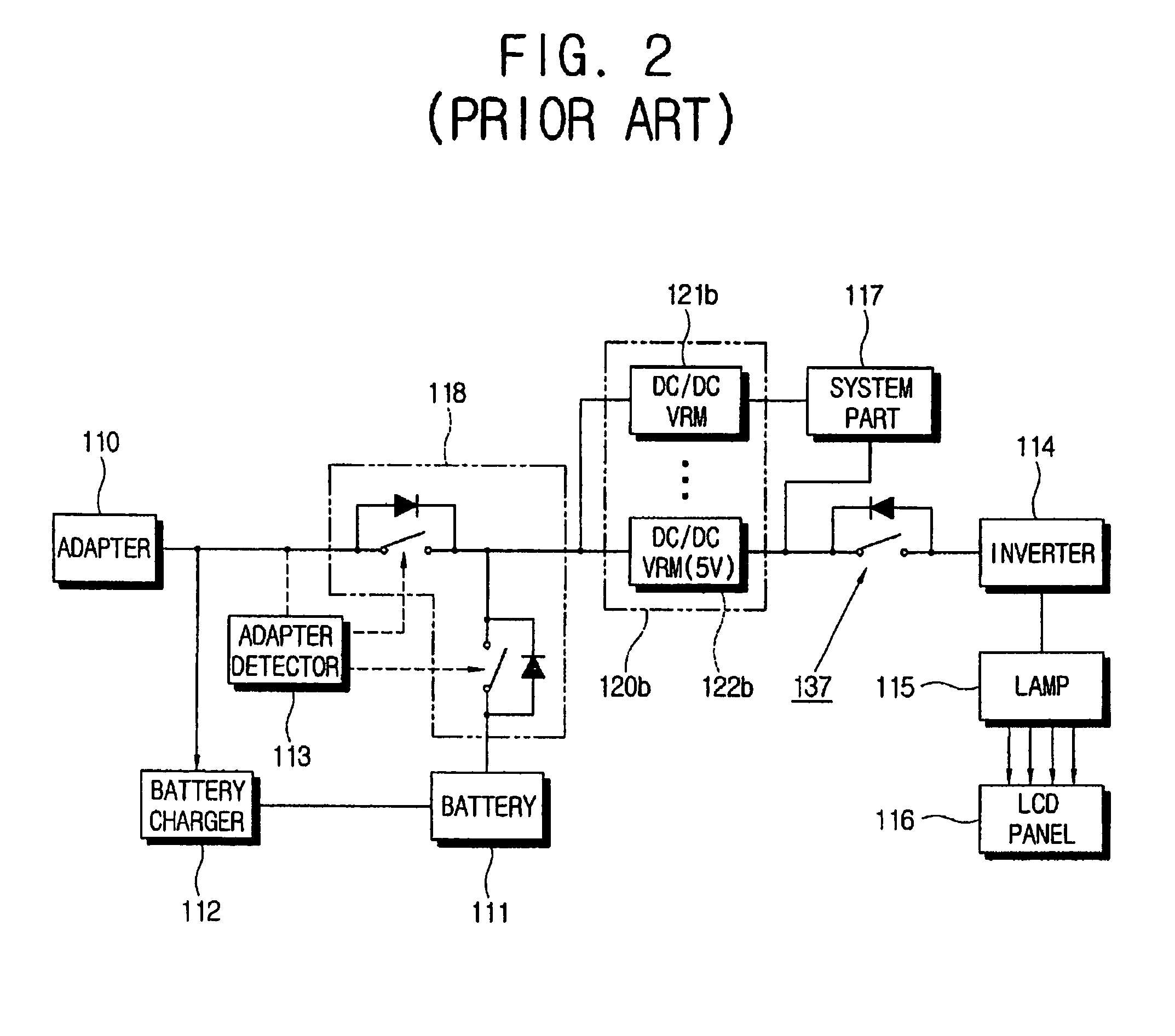

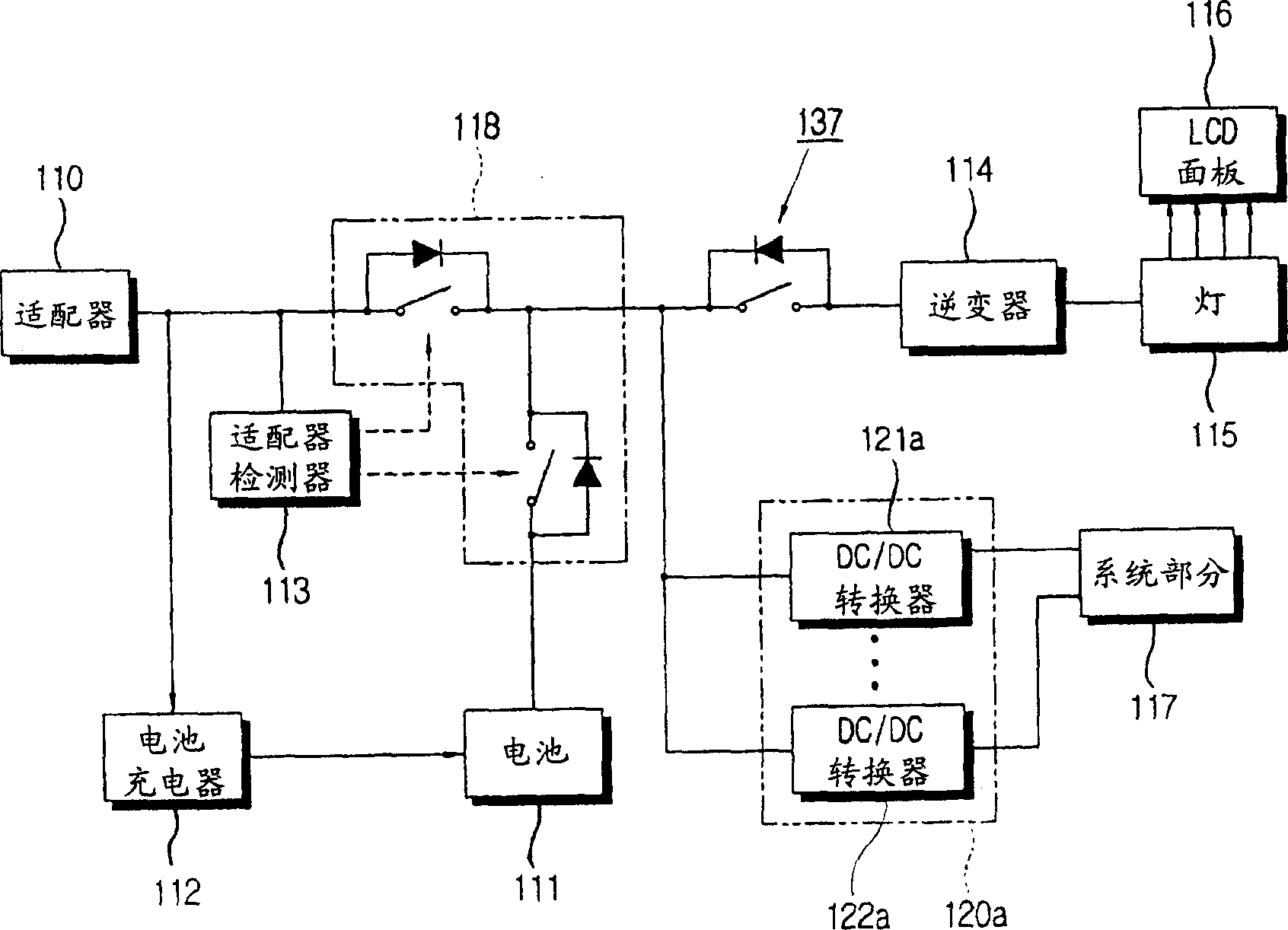

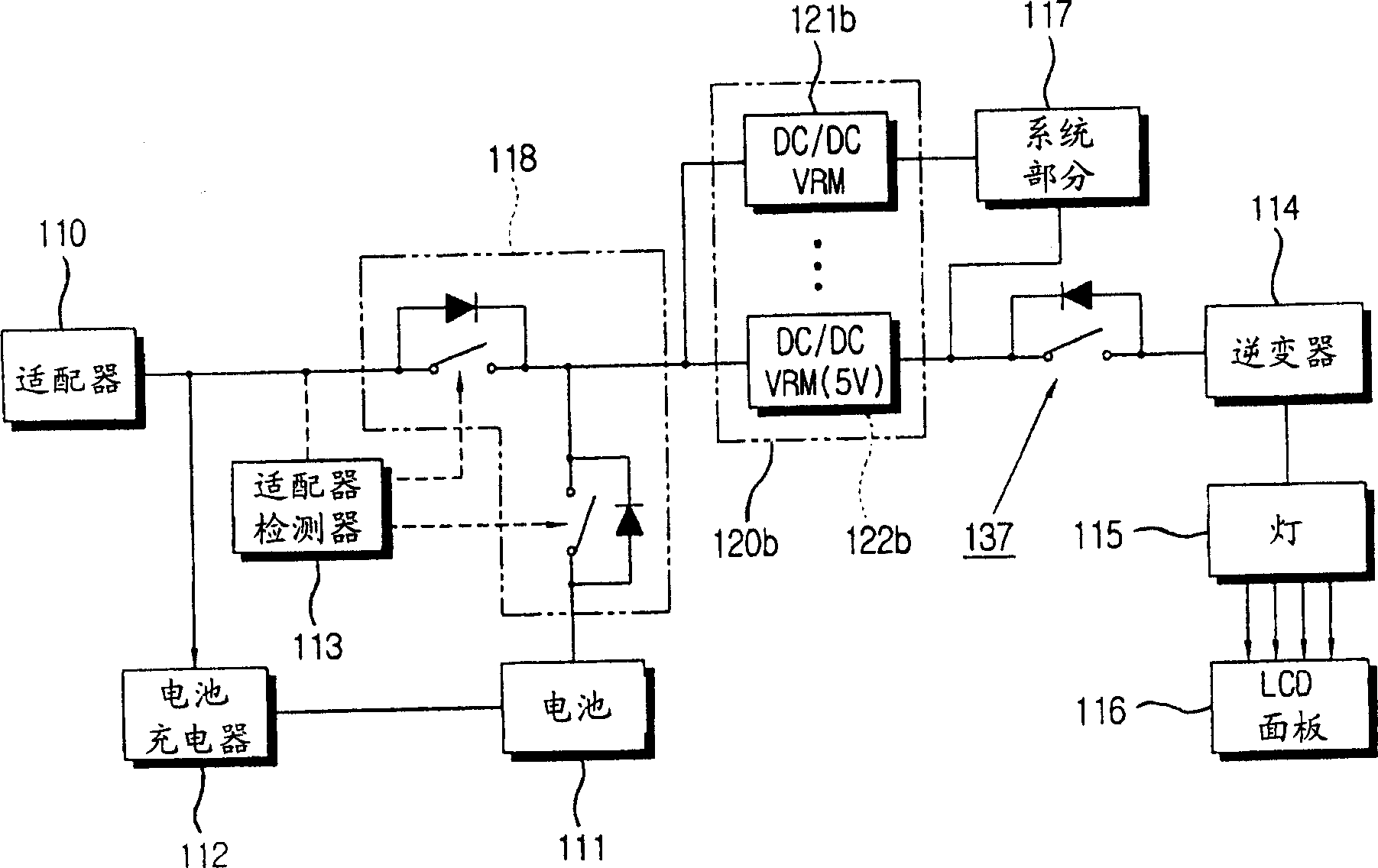

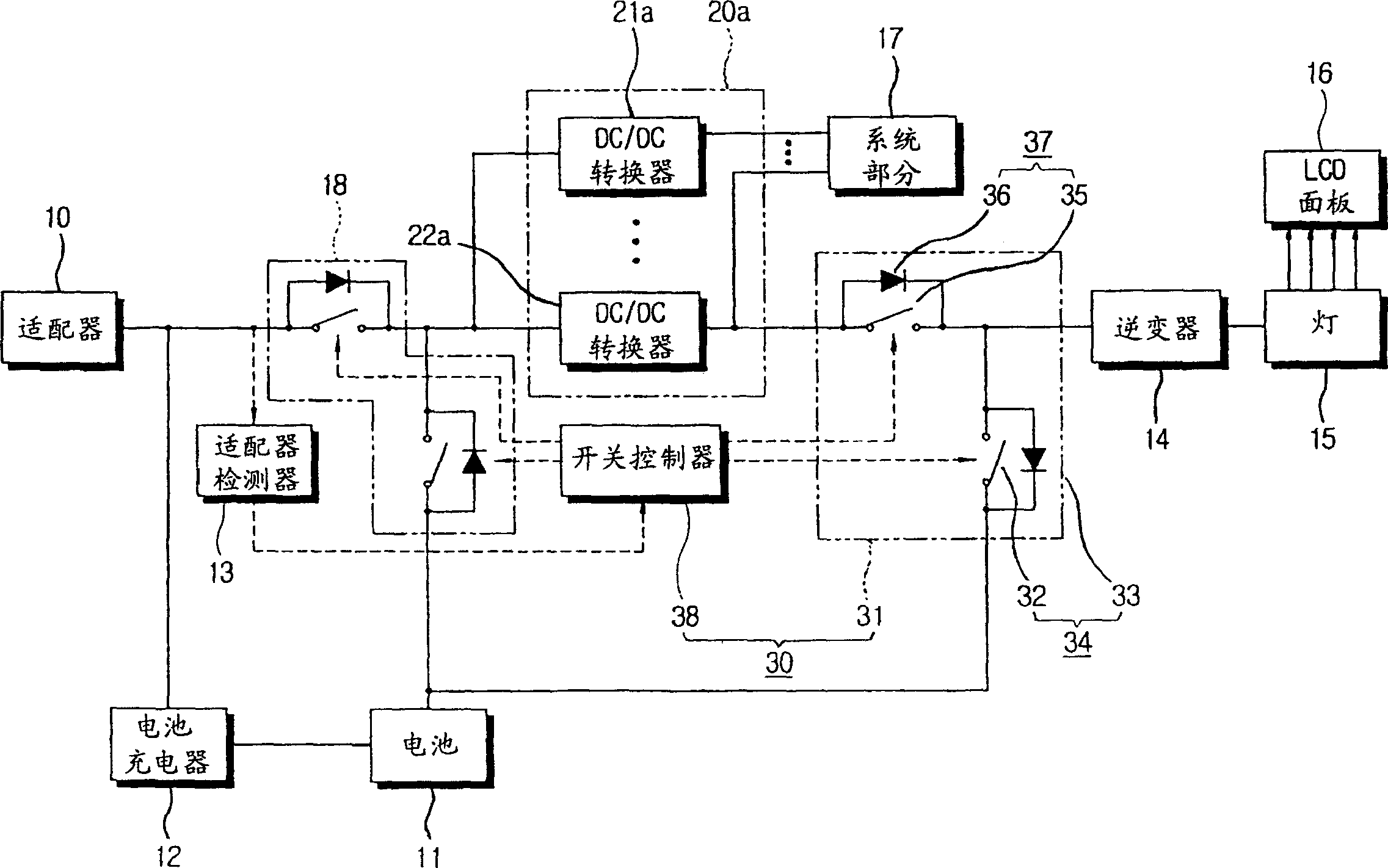

Electronic device having path of power supplied to display part switched according to whether external power is supplied

InactiveUS7446432B2Narrow rangeExtend battery lifeBatteries circuit arrangementsDrying solid materials with heatDisplay devicePower detector

An electronic device operable from one of an external power supply and a battery. The electronic device includes a display part, a power converter, an inverter generating an operating voltage for the display part, a system part generating information to be displayed on the display part and operable from an output of the power converter, a battery, an input power detector, and a switching controller. The switching controller controls power to the inverter so that where the input power detector detects availability of an external power, the switching controller supplies the external power to the power converter and the power converter supplies power to the inverter to generate the operating voltage for the display part; and where the input power detector detects the external power is not available, the switching system supplies battery power to the power converter and the inverter independently.

Owner:SAMSUNG ELECTRONICS CO LTD

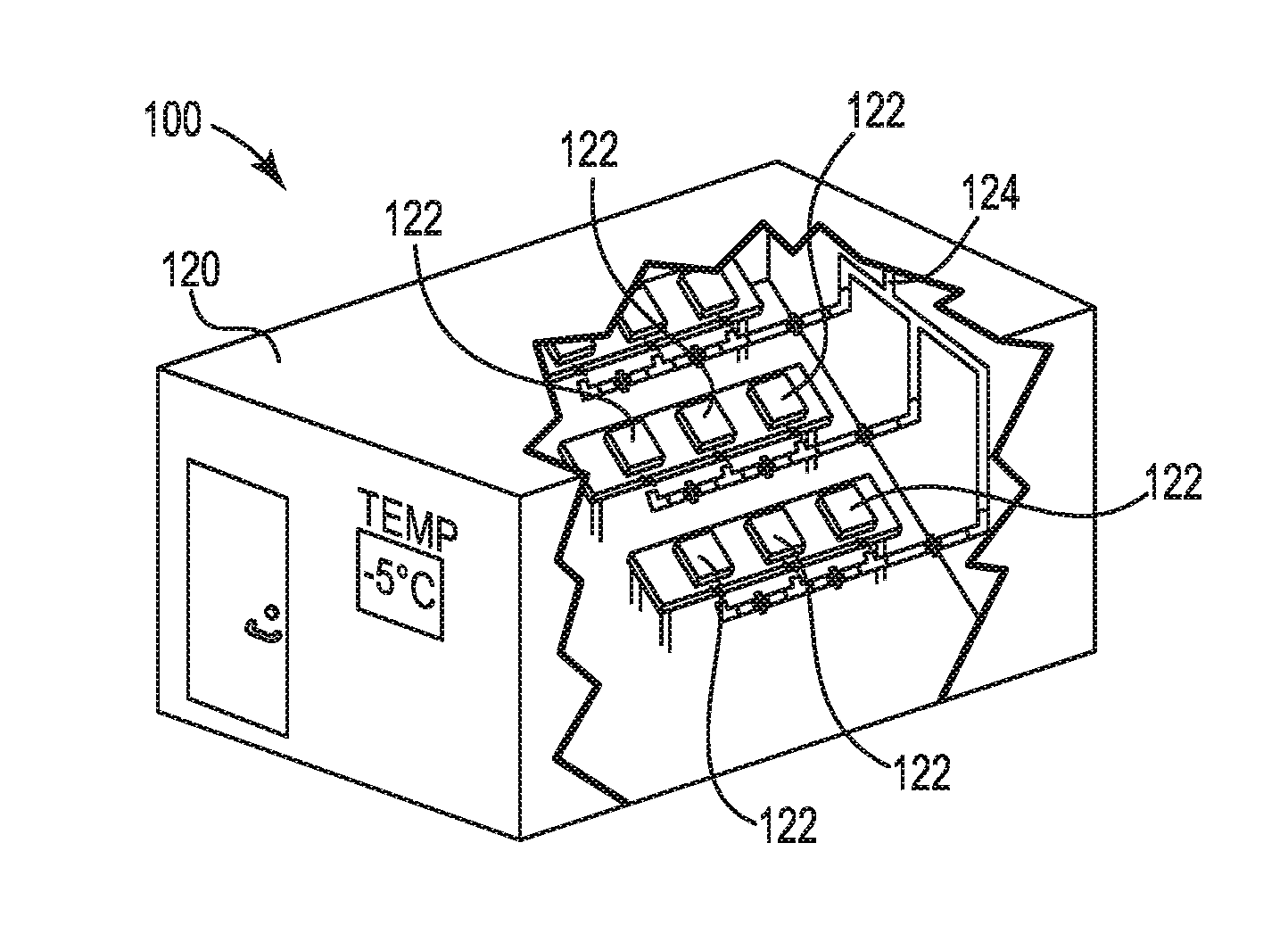

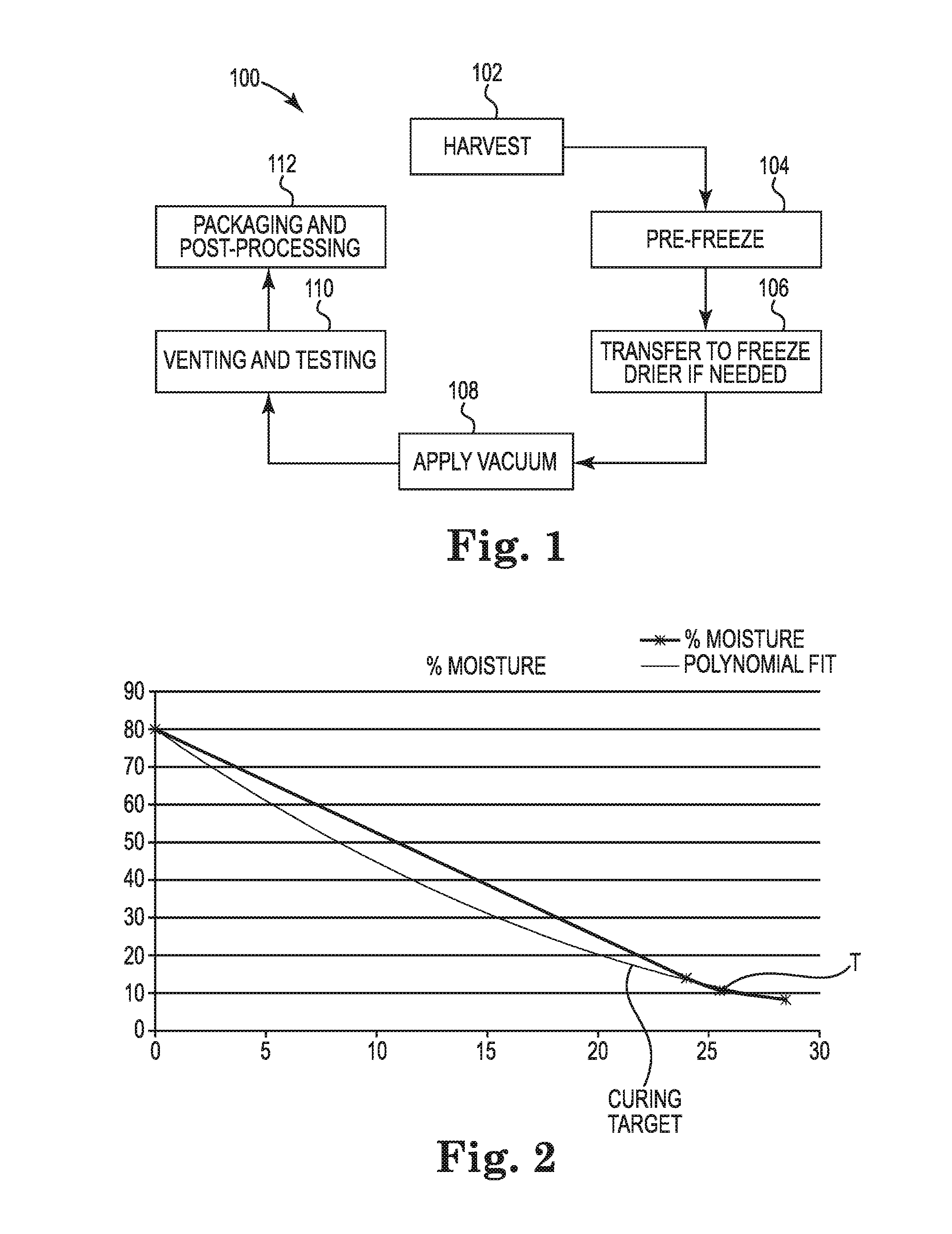

Botanical Freeze Drying System and Method

ActiveUS20160245588A1Reduce and prevent evaporative lossReduce the temperatureDrying solid materials without heatTea dryingFreeze-dryingPulp and paper industry

Systems and methods for freeze drying botanical or herb items or products using a modular vacuum chamber configuration are provided. Such configurations can reduce or prevent the evaporative loss of volatile compounds while reducing the temperature and removing air to prevent oxidation of the product. The freeze drying systems and methods of the present invention can improve organoleptic characteristics, shelf life, and extractions.

Owner:BAUGH STEVEN F +1

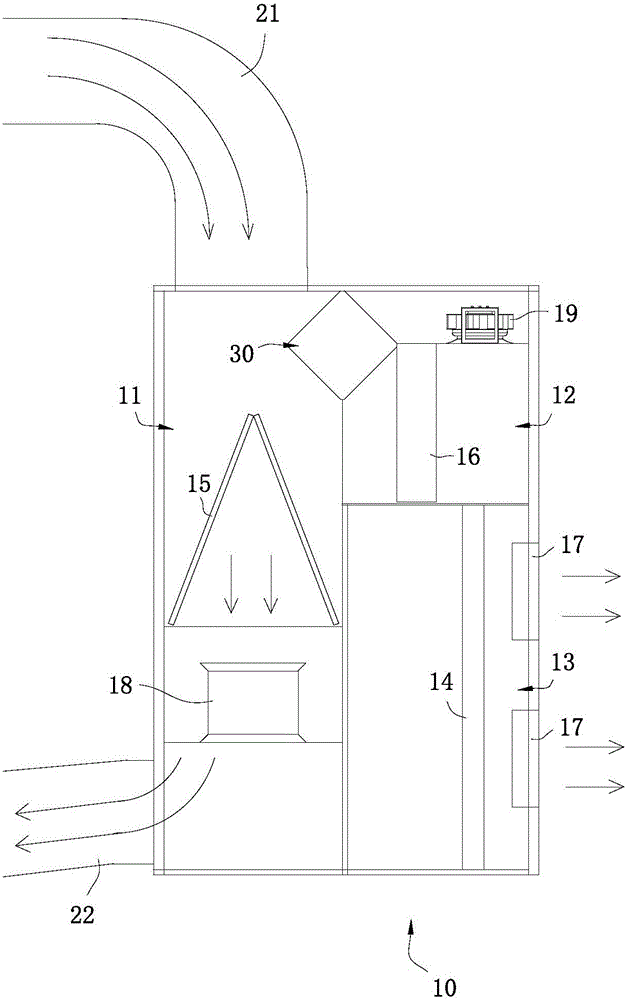

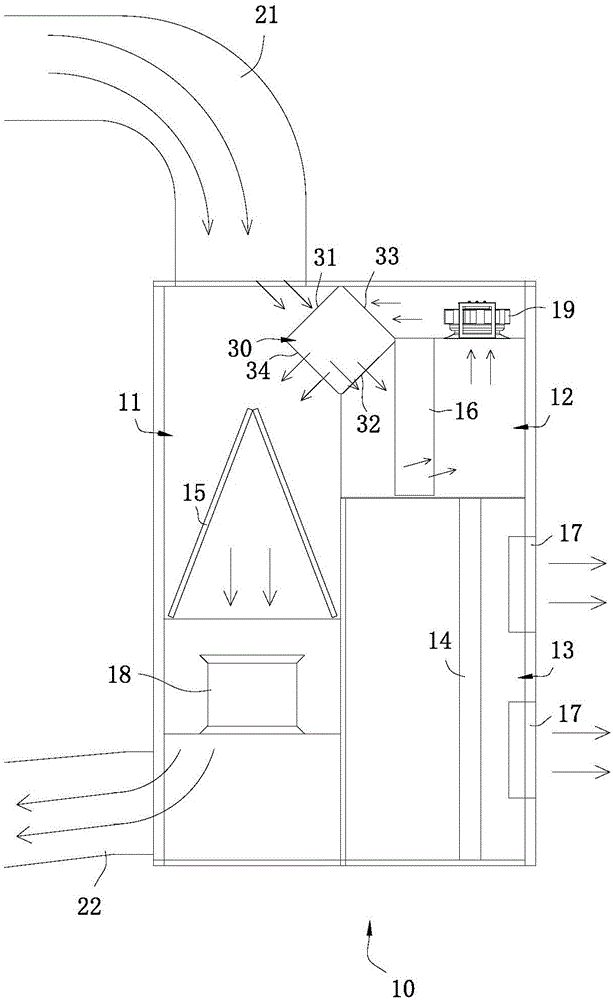

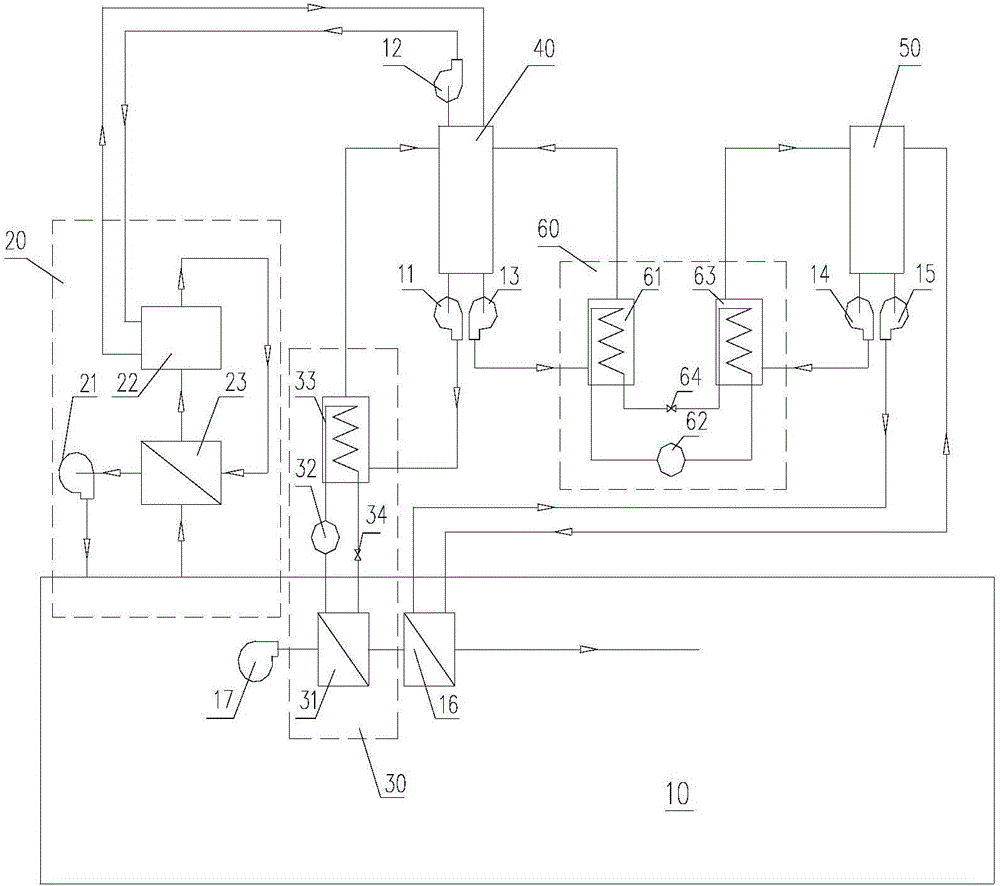

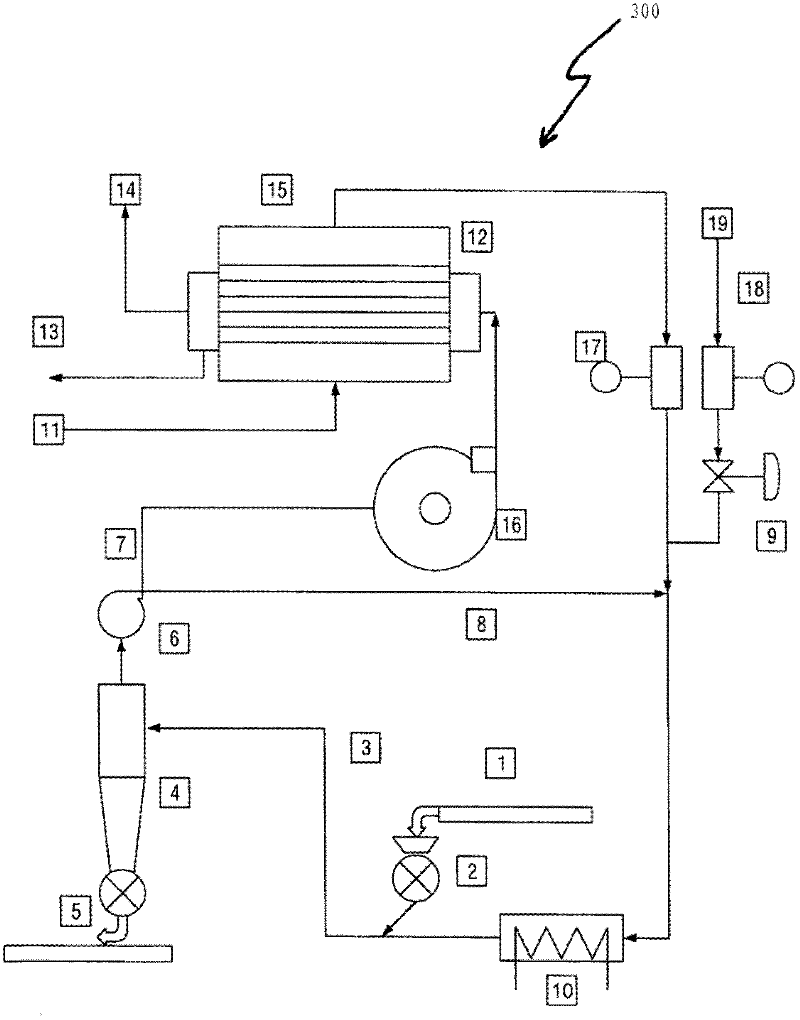

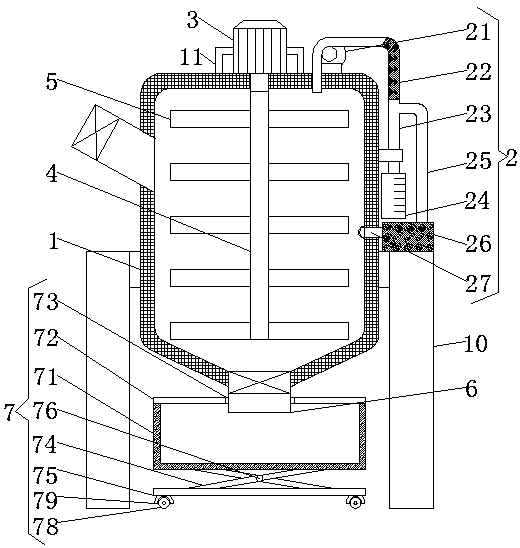

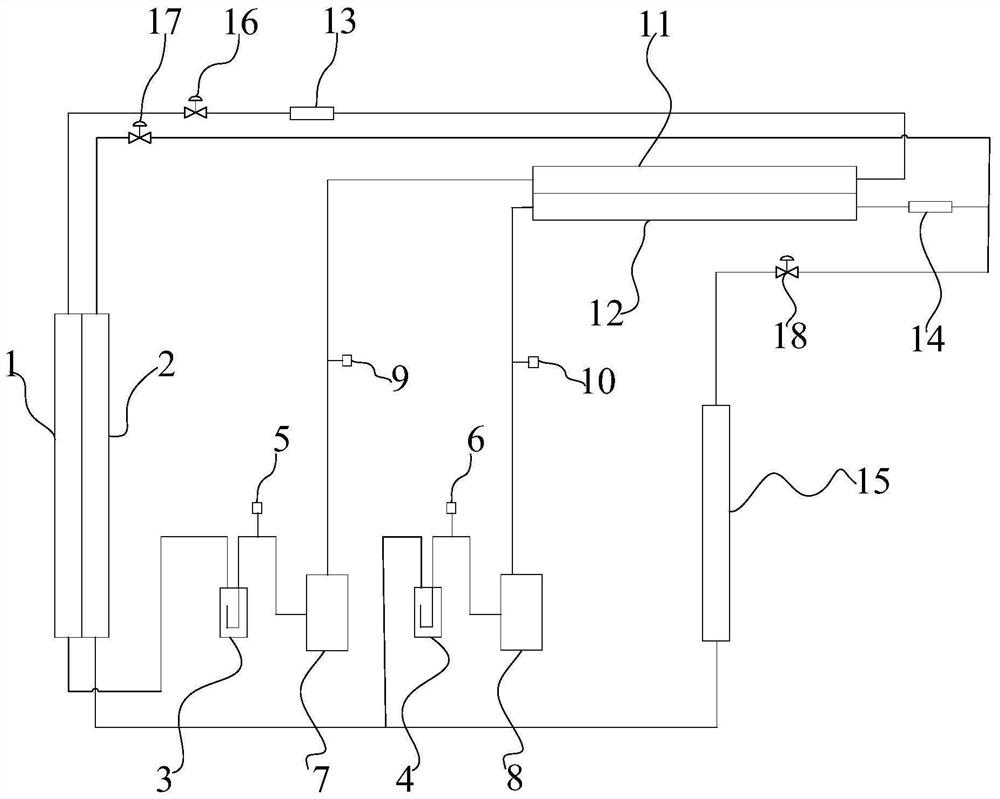

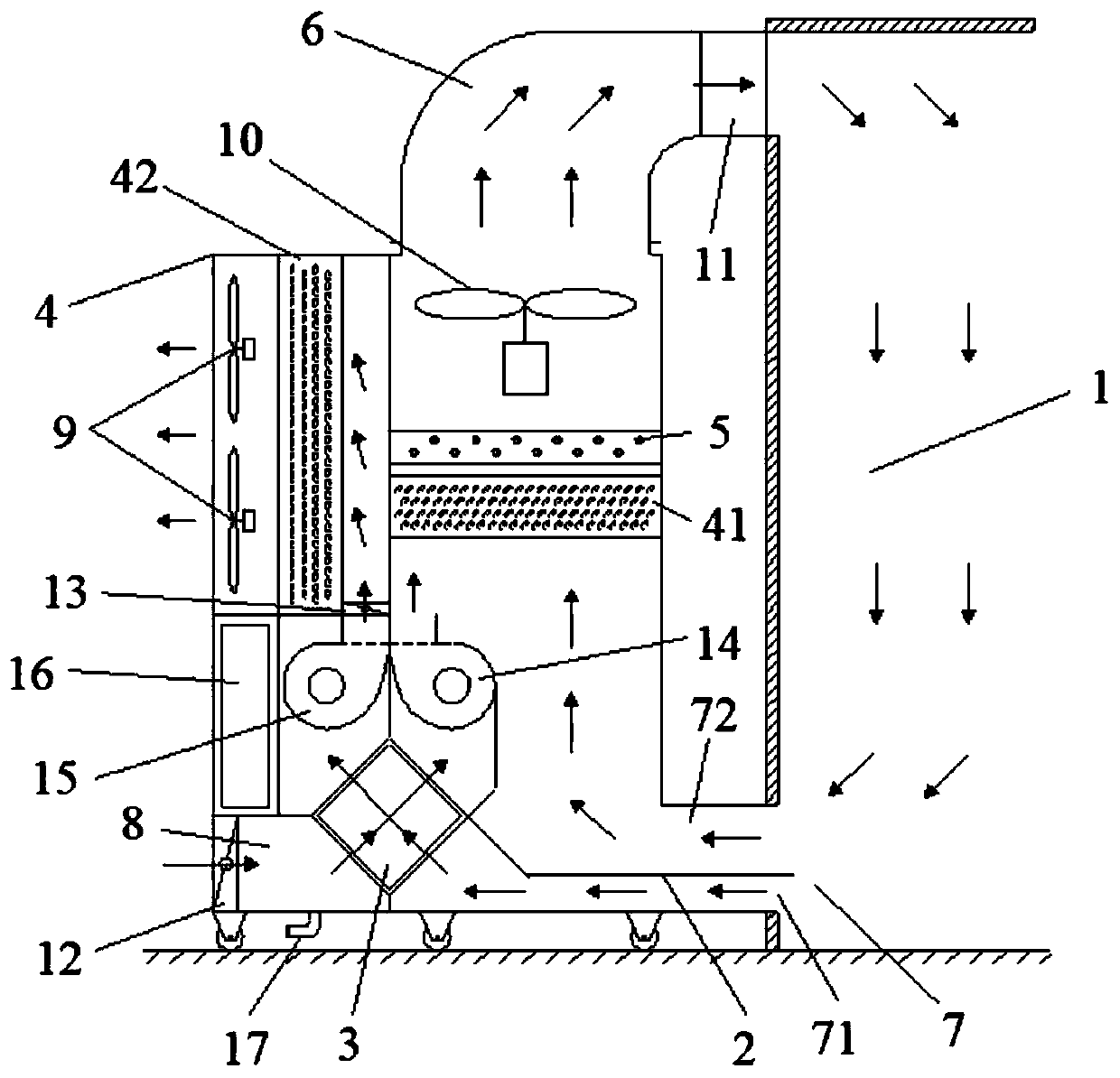

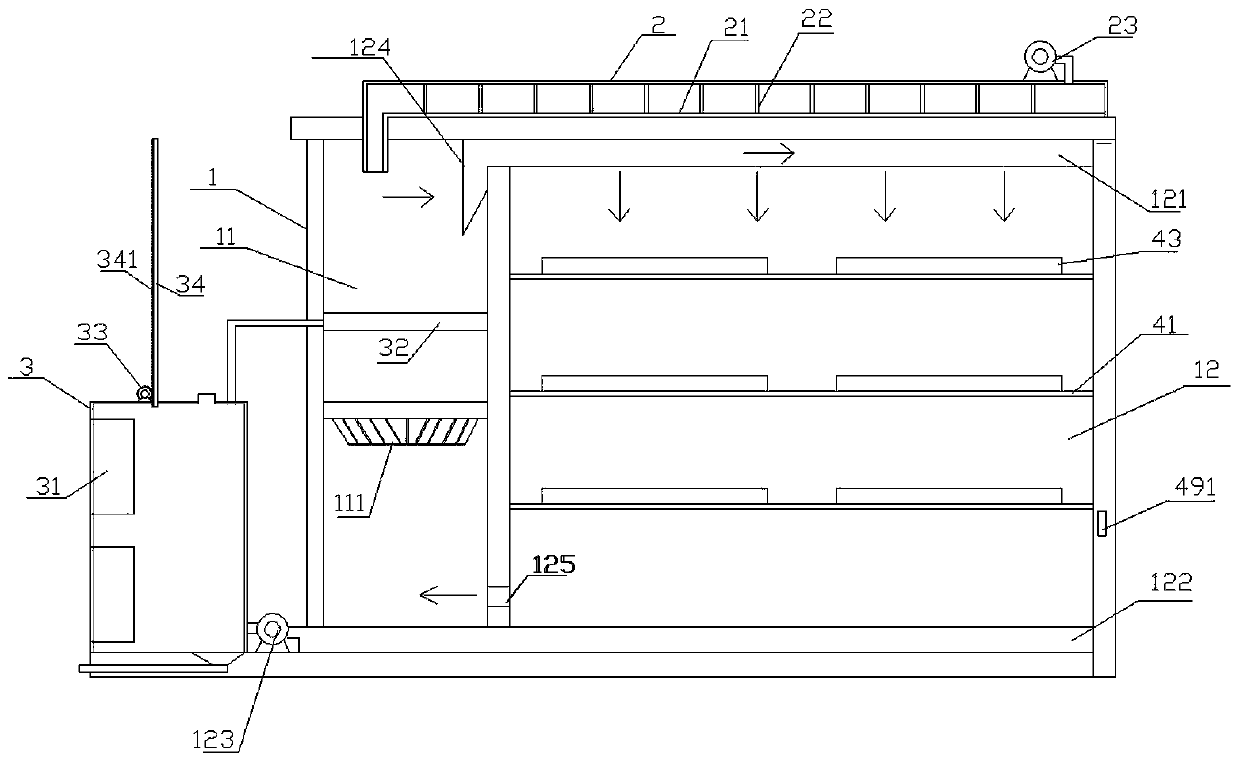

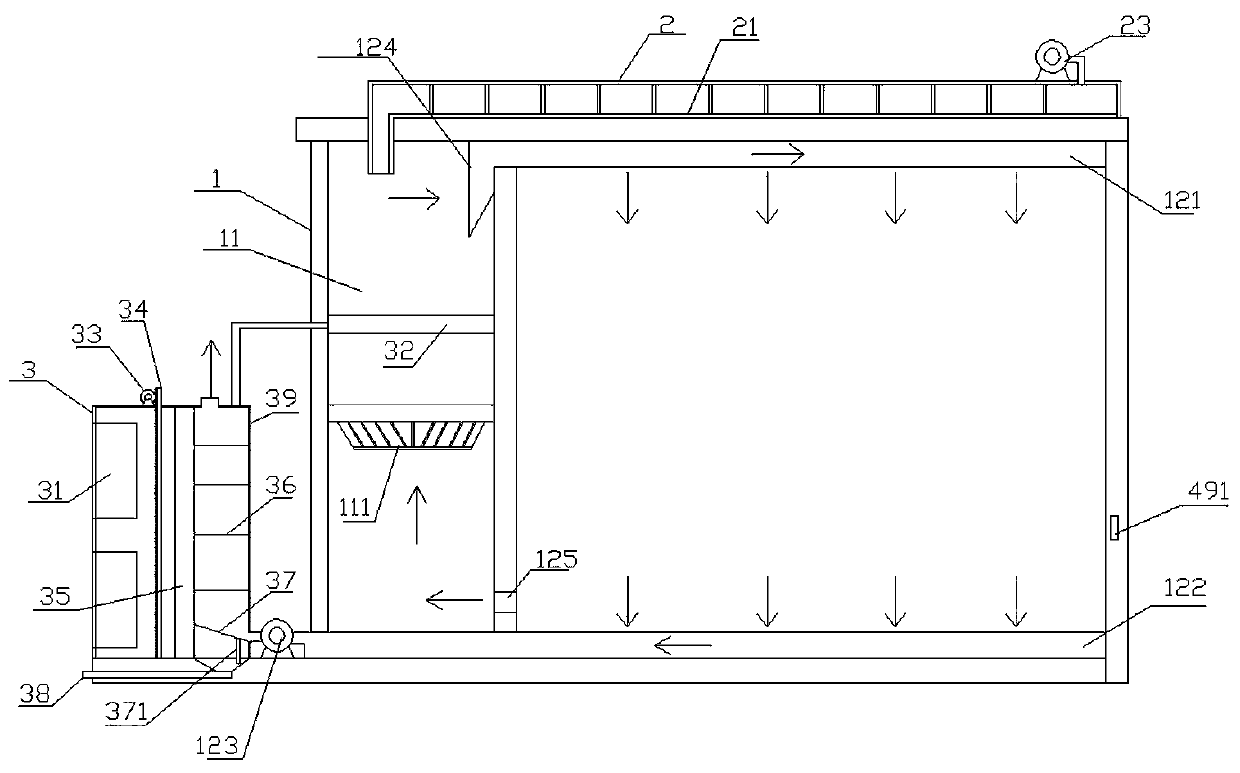

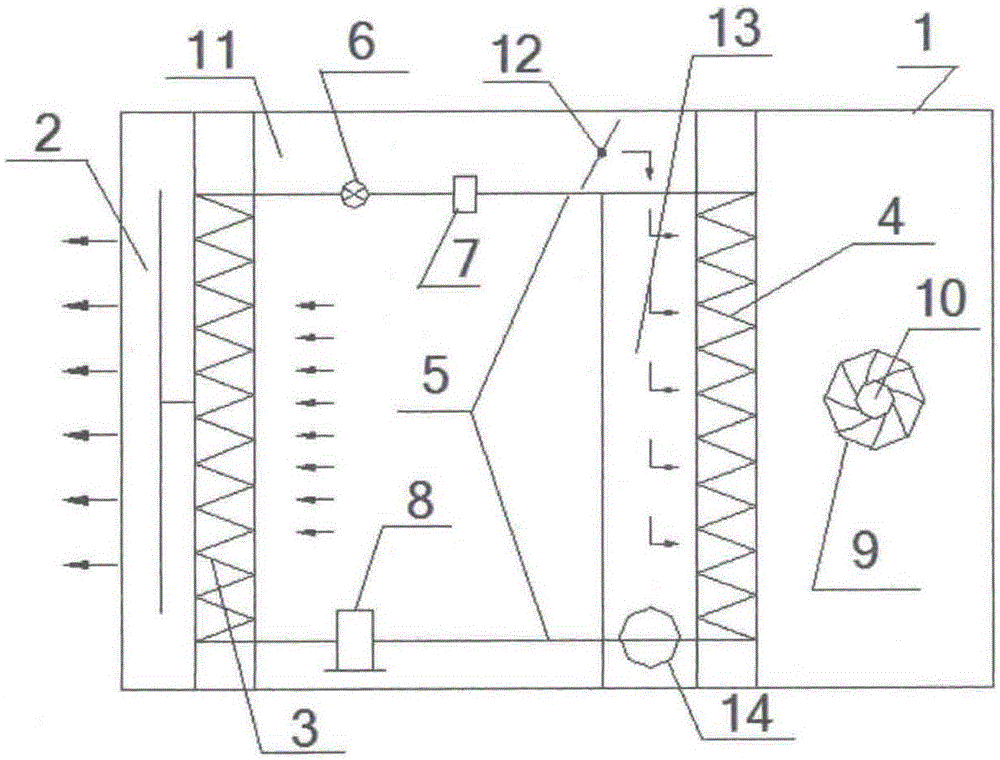

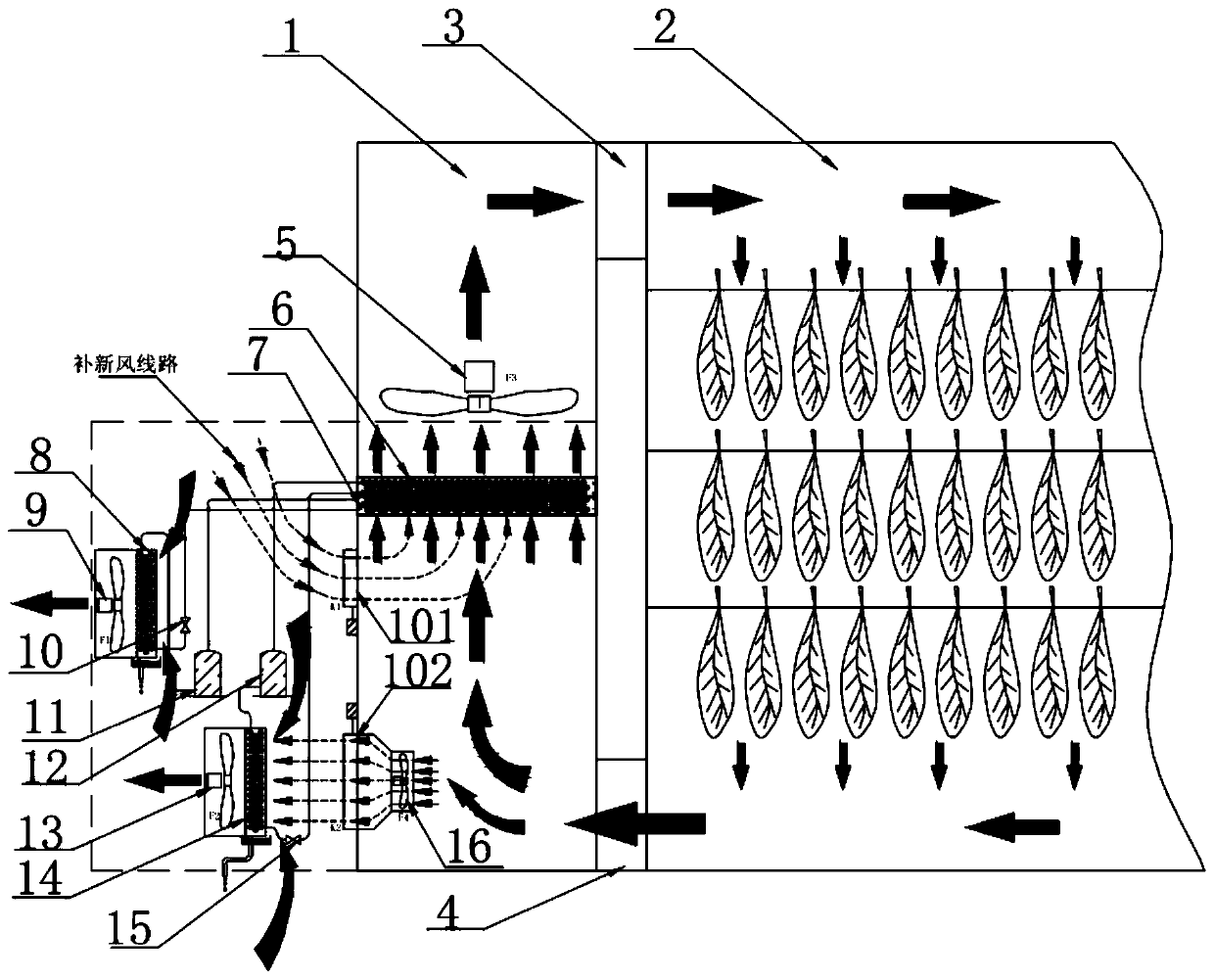

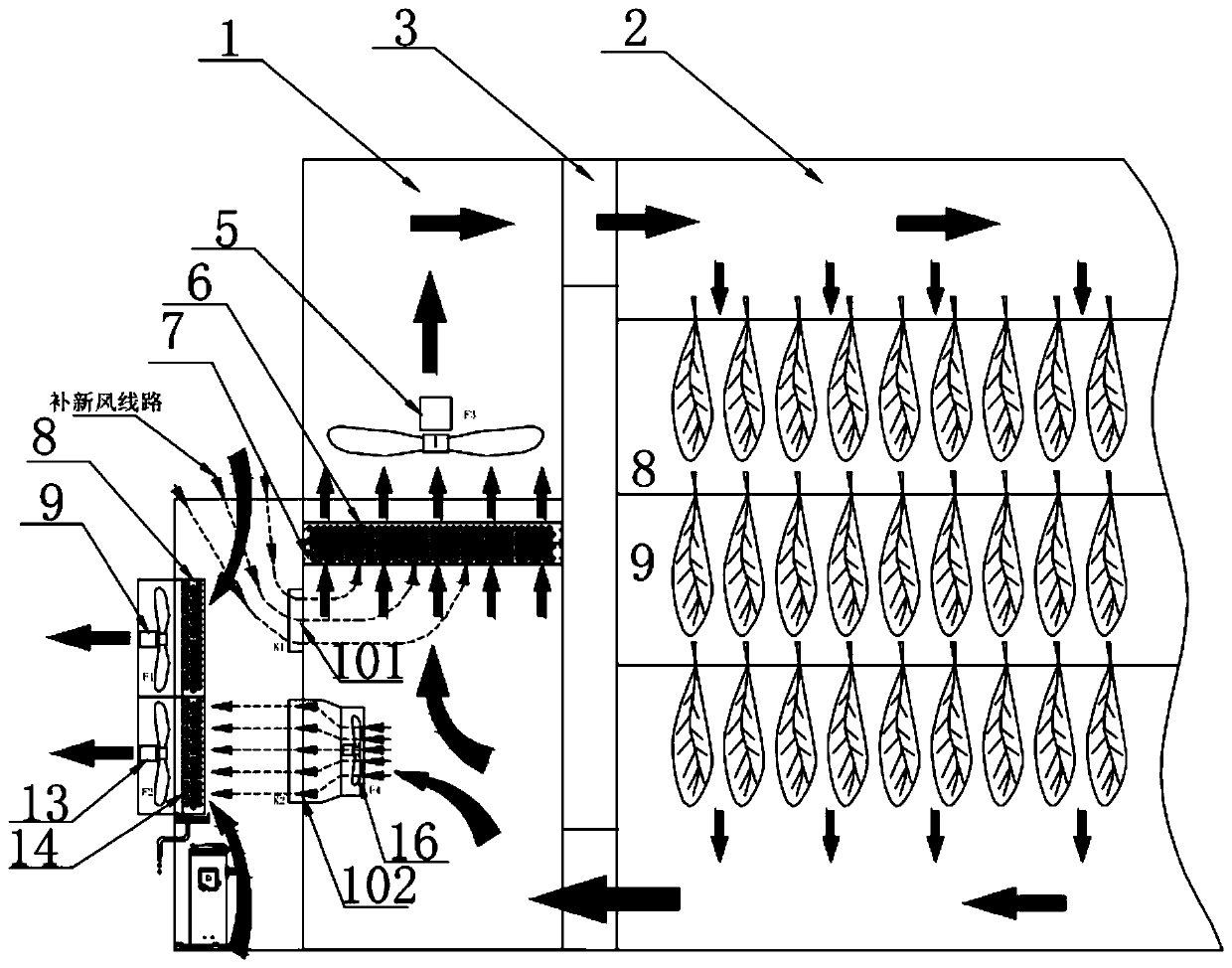

Closed inner circulation type tobacco drying device

InactiveCN105823324AAffect drying qualityPrecise temperature controlTobacco preparationHeat pumpsPlate heat exchangerProcess engineering

The invention discloses a closed inner circulation type tobacco drying device. The closed inner circulation type tobacco drying device comprises a drying chamber and a drying machine body. A closed cavity is formed in the drying machine body and divided by a sensible heat exchanger into a first cavity and a second cavity which communicate with each other. The drying machine body is further provided with a containing cavity communicating with the outside. A first heat exchanger is arranged in the containing cavity. A second heat exchanger is arranged in the middle portion of the first cavity. A third heat exchanger is arranged in the second cavity. The drying machine body is internally provided with a heat pump system controlling the running state of the first heat exchanger, the second heat exchanger and the third heat exchanger. The heat pump system is adopted as a heat source for the drying machine body, closed convection circulation is conducted between the drying chamber and the drying machine body, air exchange with the outside does not exist in the whole convection circulation drying process, and complete closed drying is achieved. The situation that tobacco fragrance leaks in the drying process, and the tobacco drying quality is affected is avoided.

Owner:GUANGZHOU NZY ENERGY SAVING TECH

Tobacco drying device

ActiveCN106016989ASpeed up heat exchangeImprove heating efficiencyDrying gas arrangementsTobacco dryingWater sourceCooling capacity

The invention discloses a tobacco drying device. The tobacco drying device comprises a tobacco drying chamber, a humidity control module, a temperature control module, a cooling capacity storage water tank, a heat storage water tank and a water source hot water heat pump. The humidity control module is used for independently controlling the air humidity of the tobacco drying chamber. The temperature control module is used for independently controlling the air temperature of the tobacco drying chamber. The cooling capacity storage water tank is used for supplying a refrigerant for cooling air to the humidity control module. The heat storage water tank is used for recycling heat in the tobacco drying chamber after tobacco is dried. The water source hot water heat pump achieves heat transmission of water in the cooling capacity storage water tank and the heat storage water tank in a heat pump work manner. According to the tobacco drying device, the temperature and humidity in the drying process can be independently controlled, tobacco drying can be conducted completely according to a traditional temperature and humidity control curve, and the taste of tobacco is kept consistent with traditional taste. Meanwhile, the drying process is conducted under the closing condition, the smell of the tobacco is stored well, energy can be cyclically utilized in the drying process, energy saving and environment friendliness are achieved, and cost is low.

Owner:马军

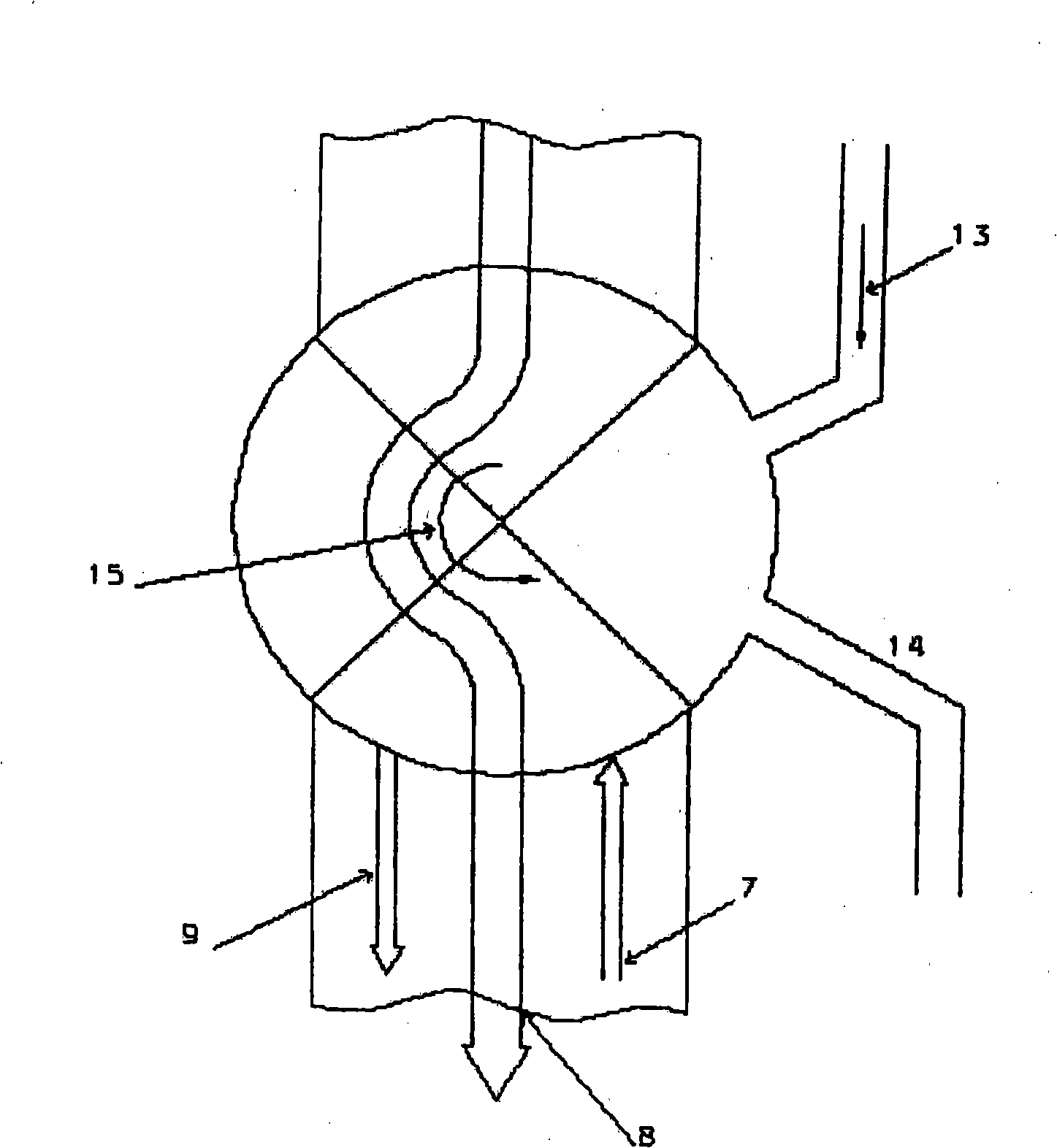

Dehumidification drying unit adopting an air inlet precooling and efficient dehumidification combined module and drying device

PendingCN109442891AIncrease the proportionImprove dehumidification effectMechanical apparatusDrying gas arrangementsEngineeringRefrigerant

The invention discloses a dehumidification drying unit adopting an air inlet precooling and efficient dehumidification combined module and a drying device. At least two sets of heat pump units are included, each heat pump unit includes a compressor, a condenser, a throttling device and an internal dehumidification evaporator which are sequentially connected to form a closed system for refrigerantcirculation, and further includes a cross-flow heat exchanger, each cross-flow heat exchanger is provided with a first heat exchange channel and a second heat exchange channel which are arranged alternately, and air outlets of the first heat exchange channels and air inlets of the second heat exchange channels communicate through circulation channels; the internal dehumidification evaporators of the sets of the heat pump units are sequentially arranged in the circulation channels and located at the air outlets of the first heat exchange channels, and air outlets of the second heat exchange channels are provided with first fans; the condensers of the sets of the heat pump units are sequentially arranged at air outlets of the first fans; and drying airflow is cycled in a closed mode, and part of wet air from the drying device flows through the first heat exchange channels, the multiple internal dehumidification evaporators, the circulation channels, the second heat exchange channels, andthe first fans sequentially, is then mixed with the other part of wet air of the drying device, and passes through the multiple condensers to obtain dry air.

Owner:SHANGHAI BOHAN THERMAL ENERGY TECH CO LTD

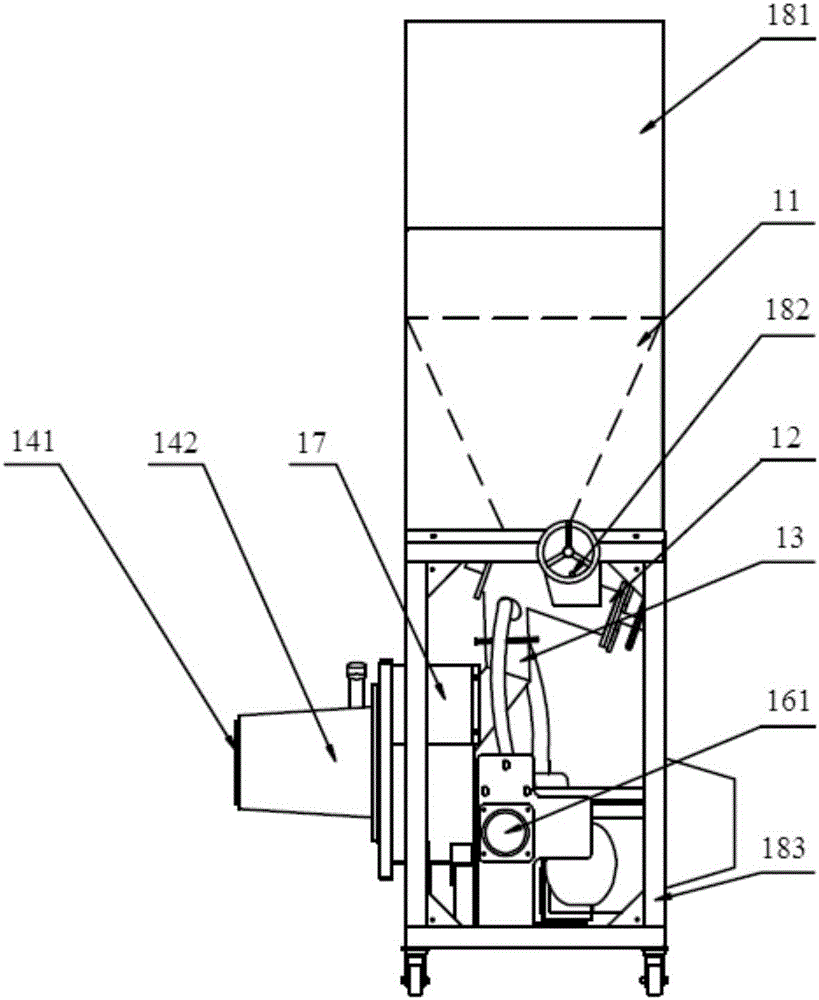

Biomass pellet fuel heating appliance

ActiveCN105942568AEnsure consistencyGuaranteed versatilityTobacco preparationDrying gas arrangementsEconomic benefitsRecuperator

The invention provides a biomass pellet fuel heating appliance, comprising a combustion furnace, a heat exchanger, a central supply system for supplying biomass pellet fuel to the combustion furnace, and a barn; the heat exchanger is used for being connected to one end of a horizontal nozzle of the combustion furnace, the barn includes a heating chamber, the heat exchanger is disposed in the heating chamber, and the combustion furnace and the central supply system are disposed outside the barn; the central supply system is used for providing biomass pellet fuel centrally for more than two combustion furnaces and comprises a suction unit with a vacuum pump, a storage barrel, more than two suction pipes, more than two feed pipes, a screw feeding mechanism, a feeding distribution connector, more than two electromagnetic valves, more than two vacuum buckets and more than two gravity valves. The heating appliance provided herein is reasonable and practical in design, safe and green, and efficient and labor-saving, reduces cost, saves resources, improves work efficiency and enterprise economic benefit, and is suitable for popularization and use.

Owner:HUNAN XINDI NEW ENERGY TECH CO LTD

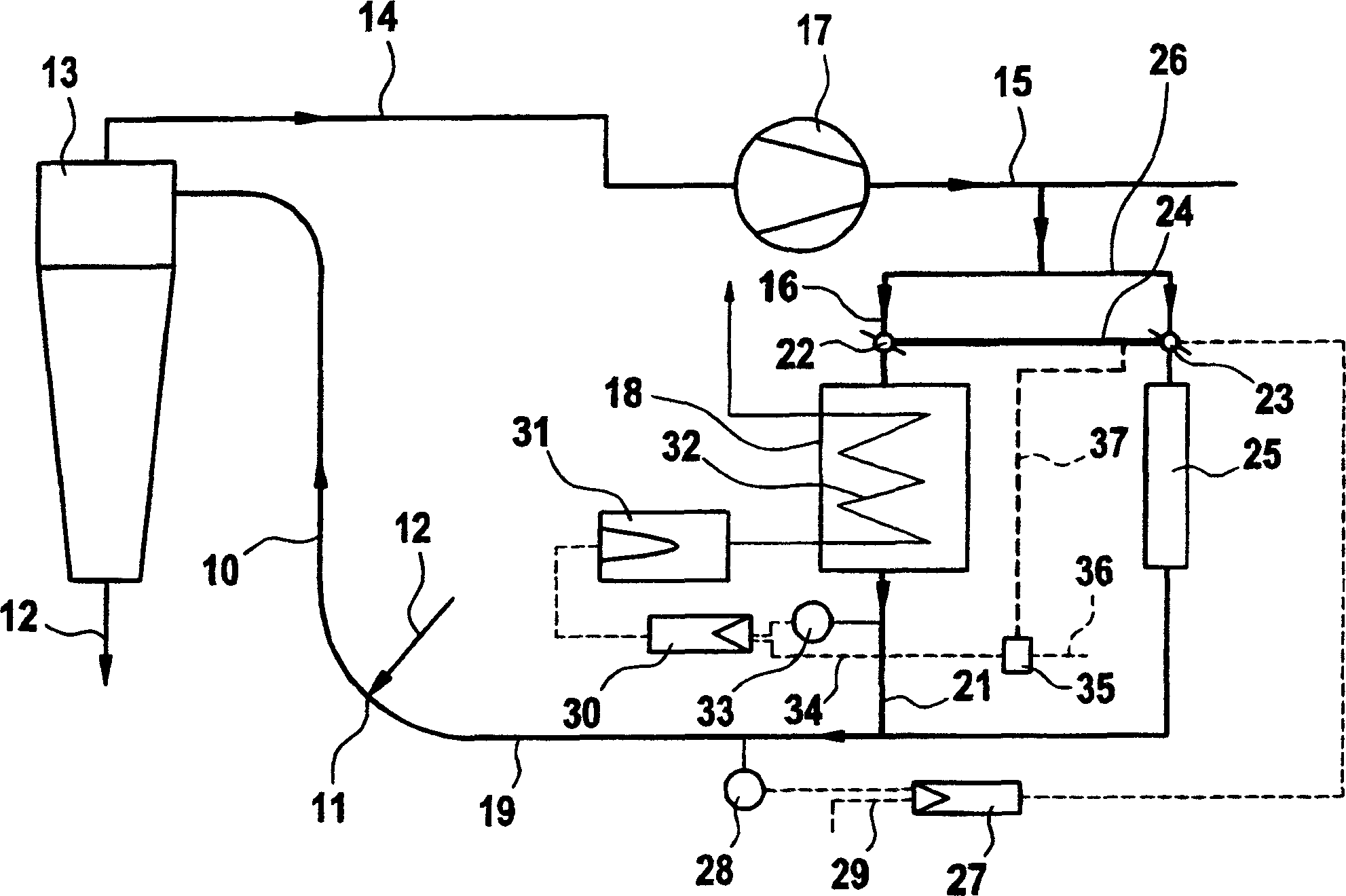

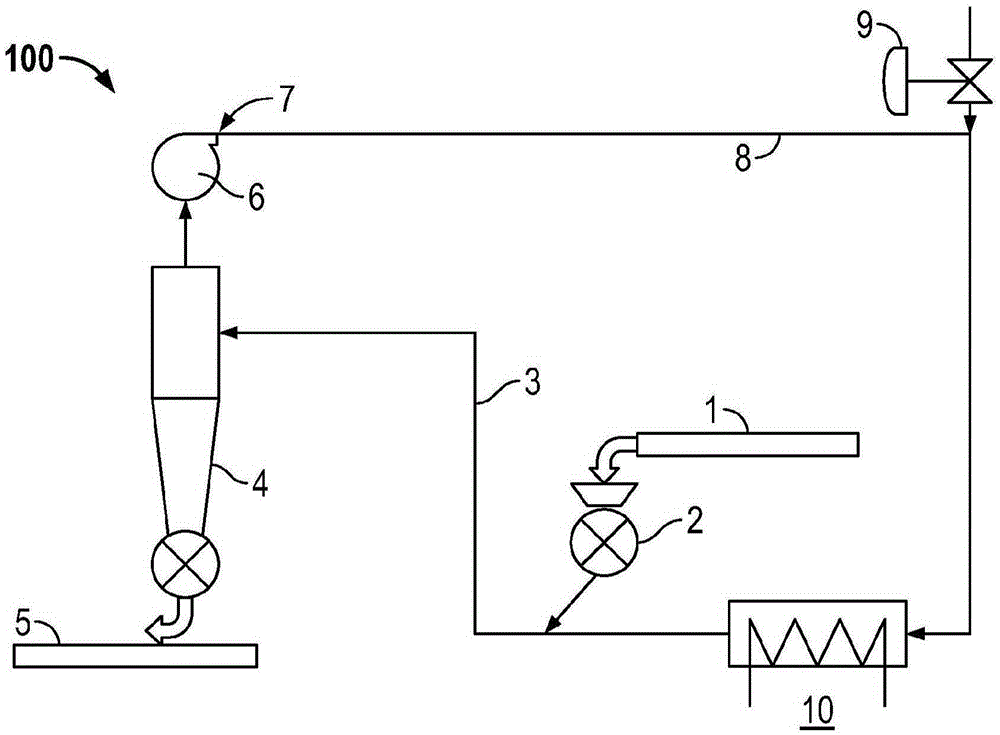

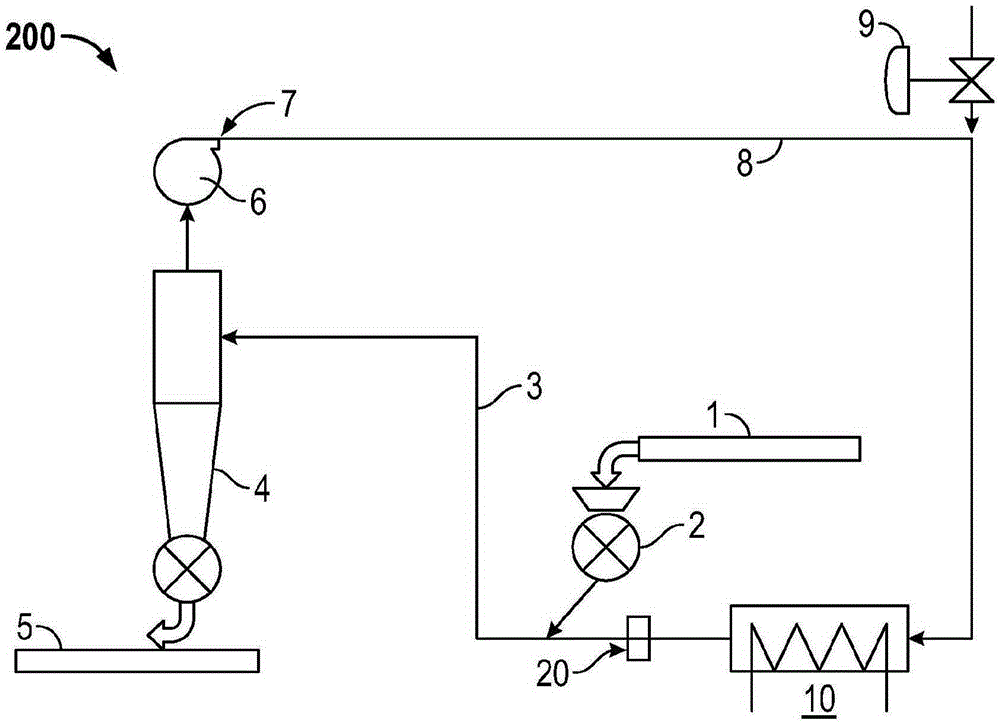

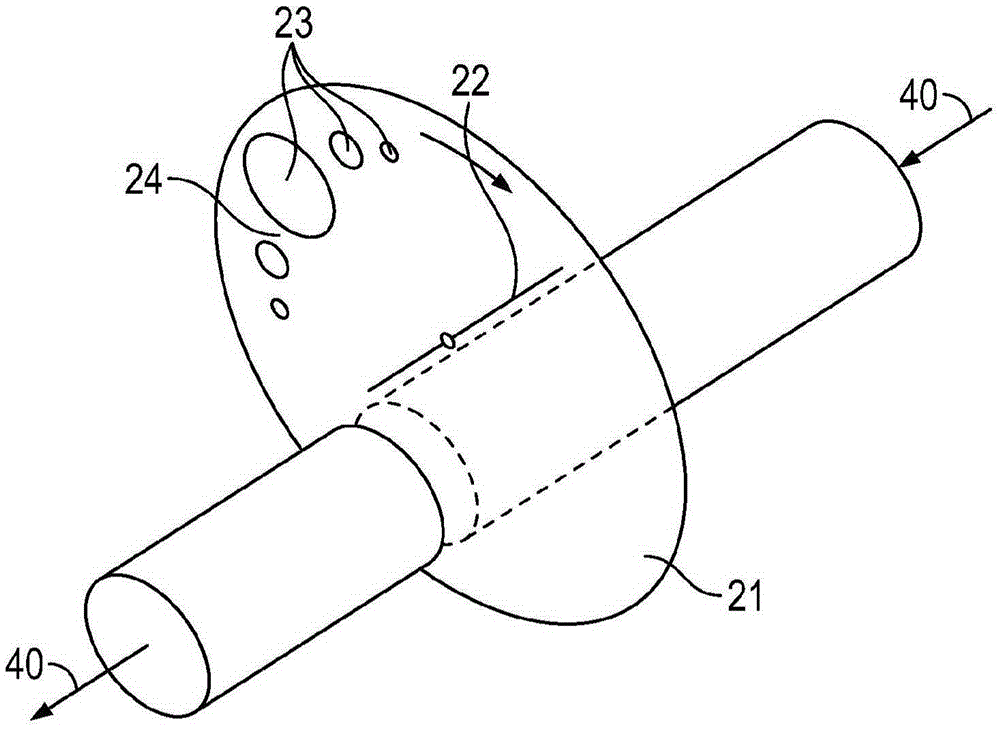

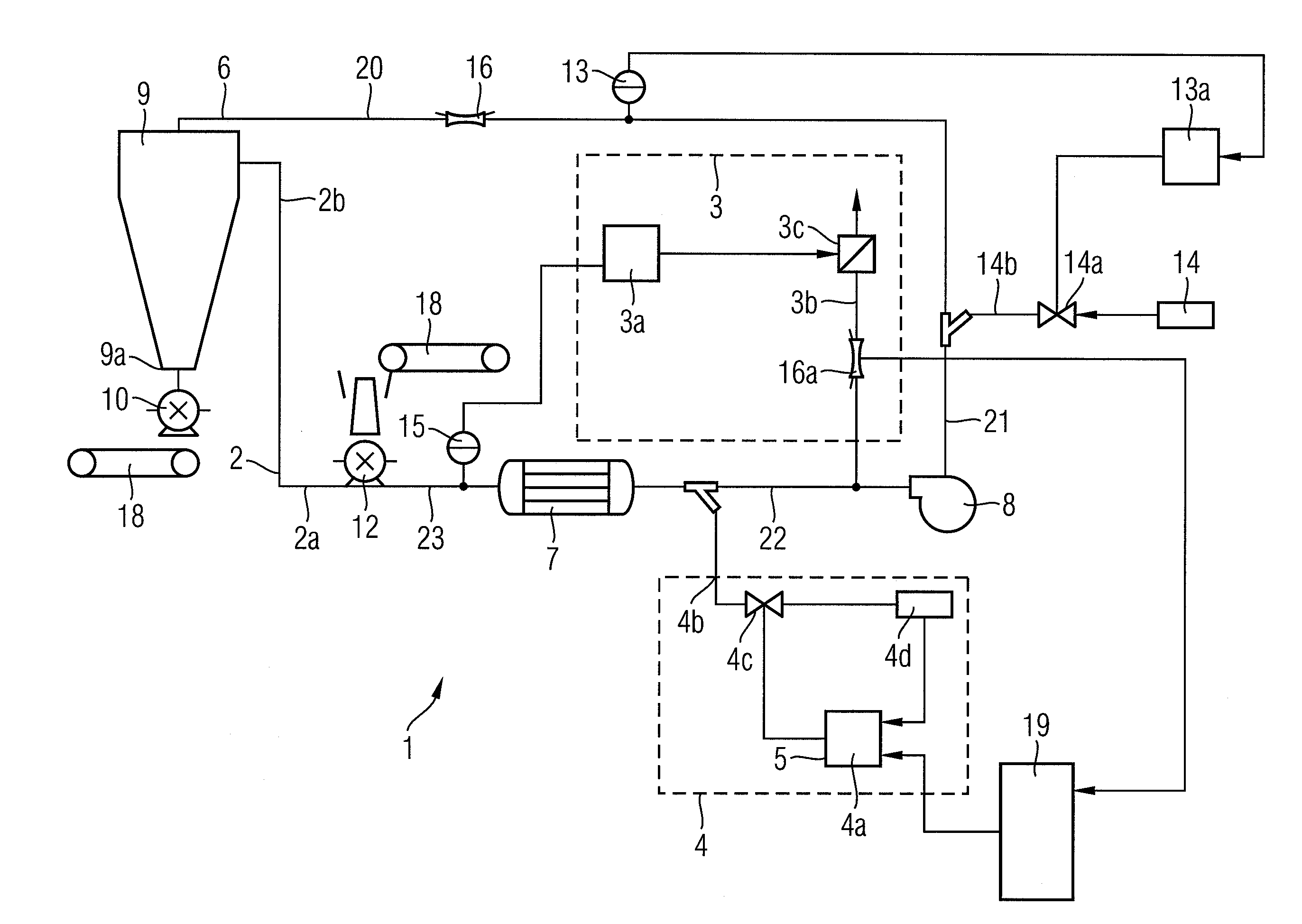

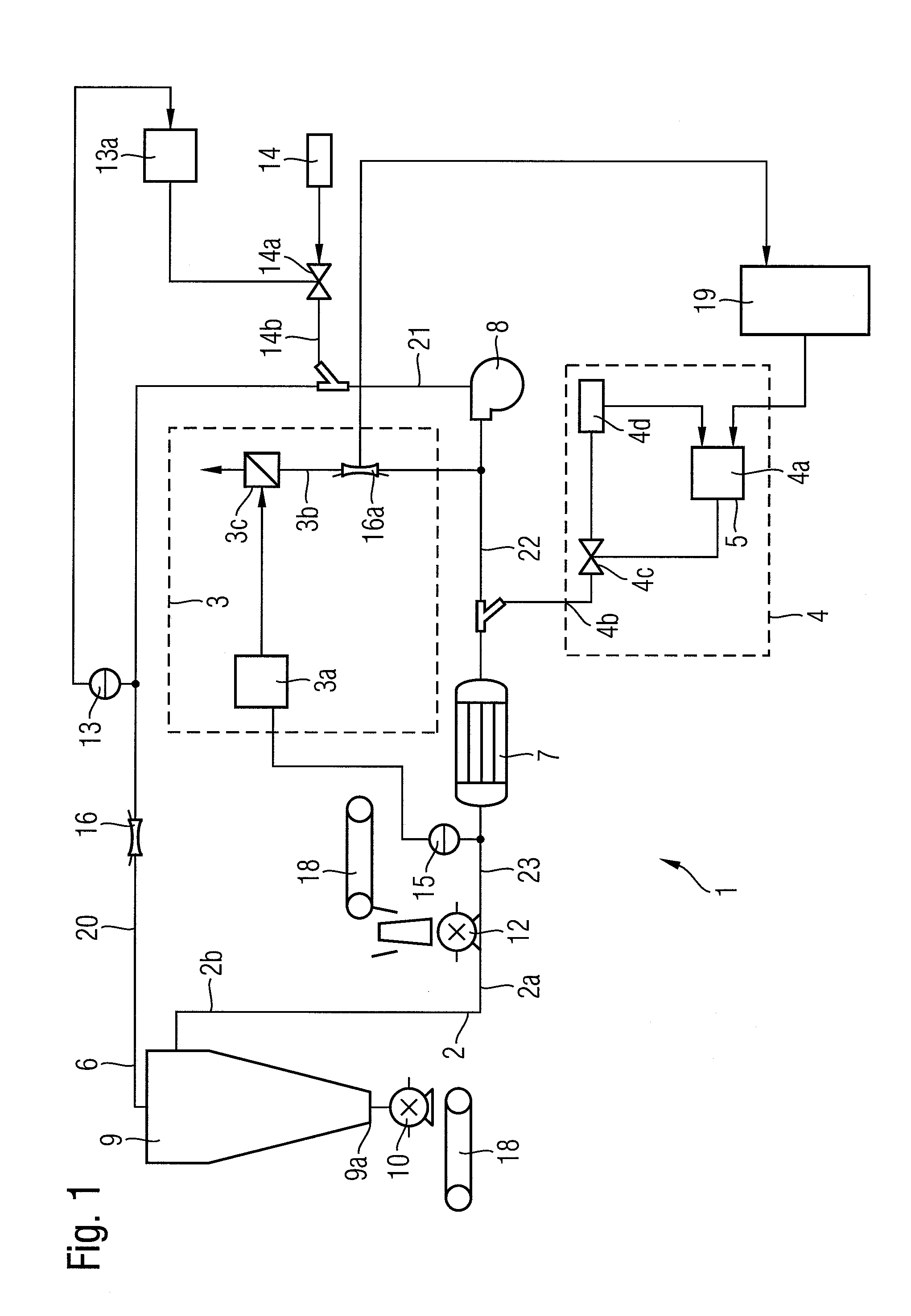

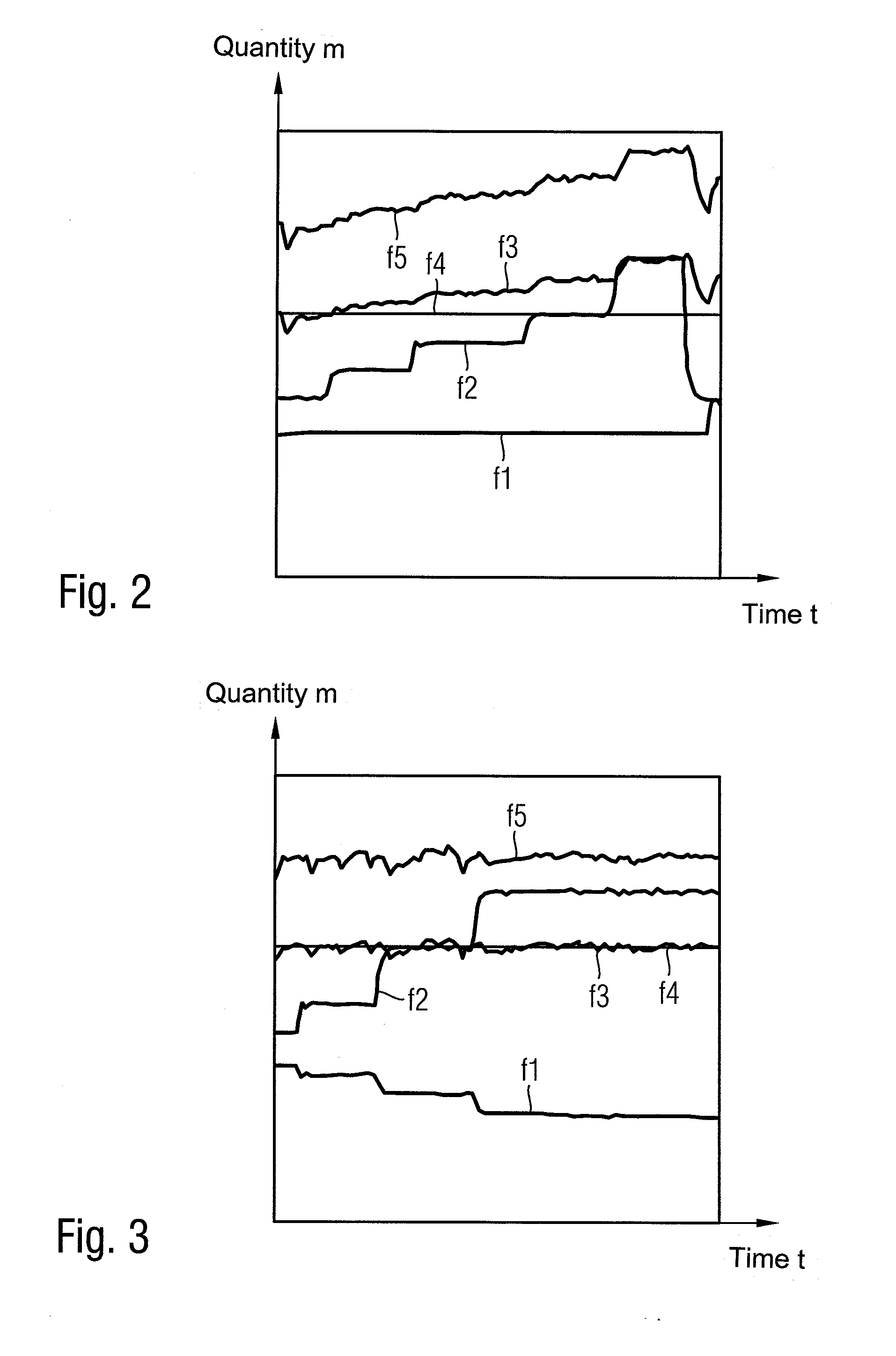

Method and device for drying fiber material

The application concerns a method for drying a fibrous material by means of a process gas stream flowing through a pipe, including heating the process gas flowing through the pipe by means of a heater with controllable heating power, and conducting a portion of the process gas stream through a bypass pipe bypassing the heater, wherein the ratio of mass flows of process gas flowing through the heater and through the bypass pipe is adjustable, and is distinguished by the fact that the heating power of the heater is controlled according to the set ratio of mass flows of process gas through the heater and through the bypass pipe. The application further concerns a corresponding drying apparatus.

Owner:HAUNI MASCHINENBAU AG

System and method for curing tobacco

A system and method for curing or drying tobacco leaves are described herein. The method includes flowing a first combustion gas generated by a first heat source through a first flue pipe provided inside a first barn to heat air inside the first barn to cure a first batch of tobacco leaves disposed inside the first barn; transferring at least a portion of the first combustion gas generated by the first heat source to a second flue pipe provided inside a second barn adjacent the first barn to heat the second barn and start curing a second batch of tobacco leaves disposed inside the second barn; and flowing second combustion gas generated by a second heat source through the second flue pipe to continue curing the second batch of tobacco leaves after the second barn is heated.

Owner:UNIVERSAL LEAF TOBACCO

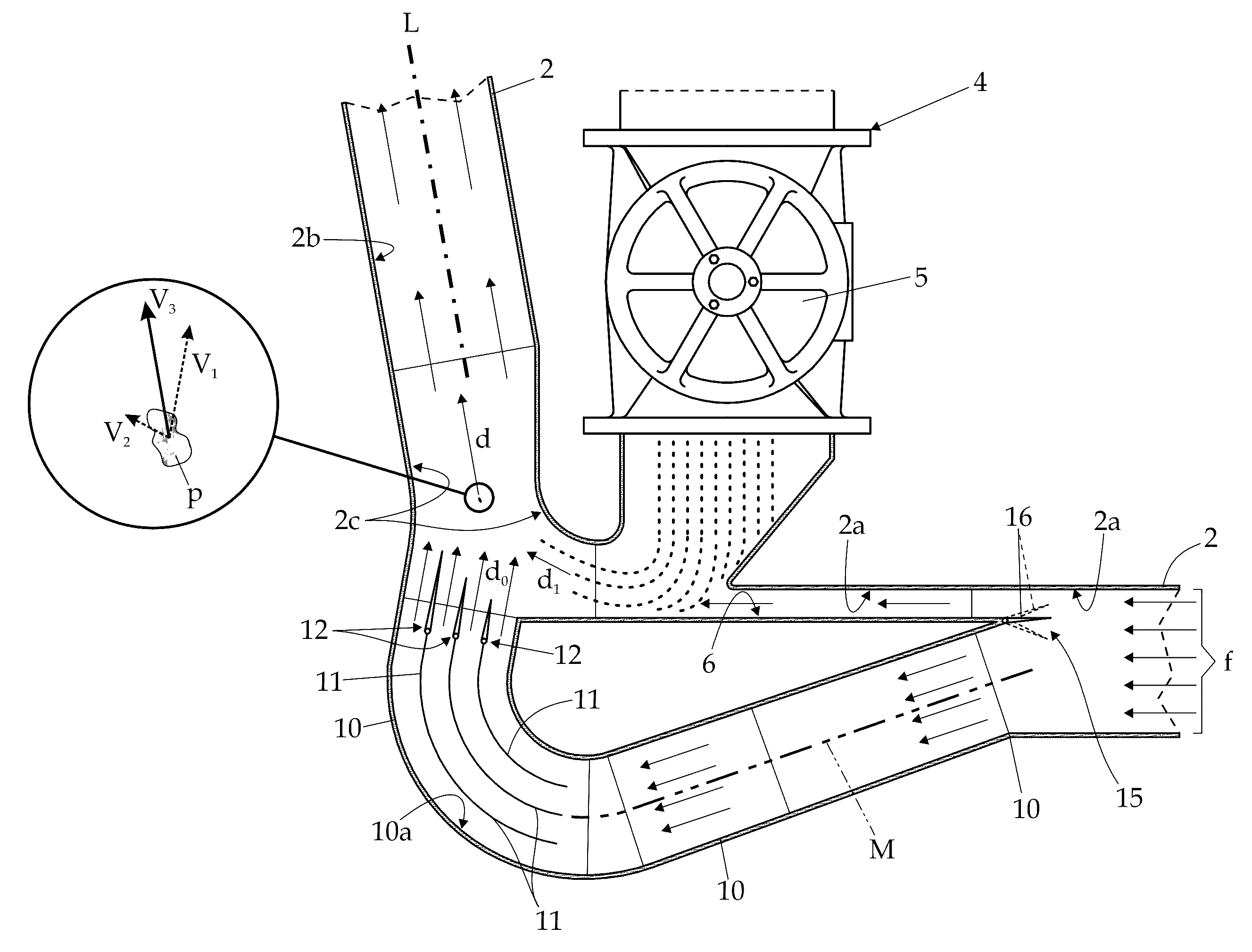

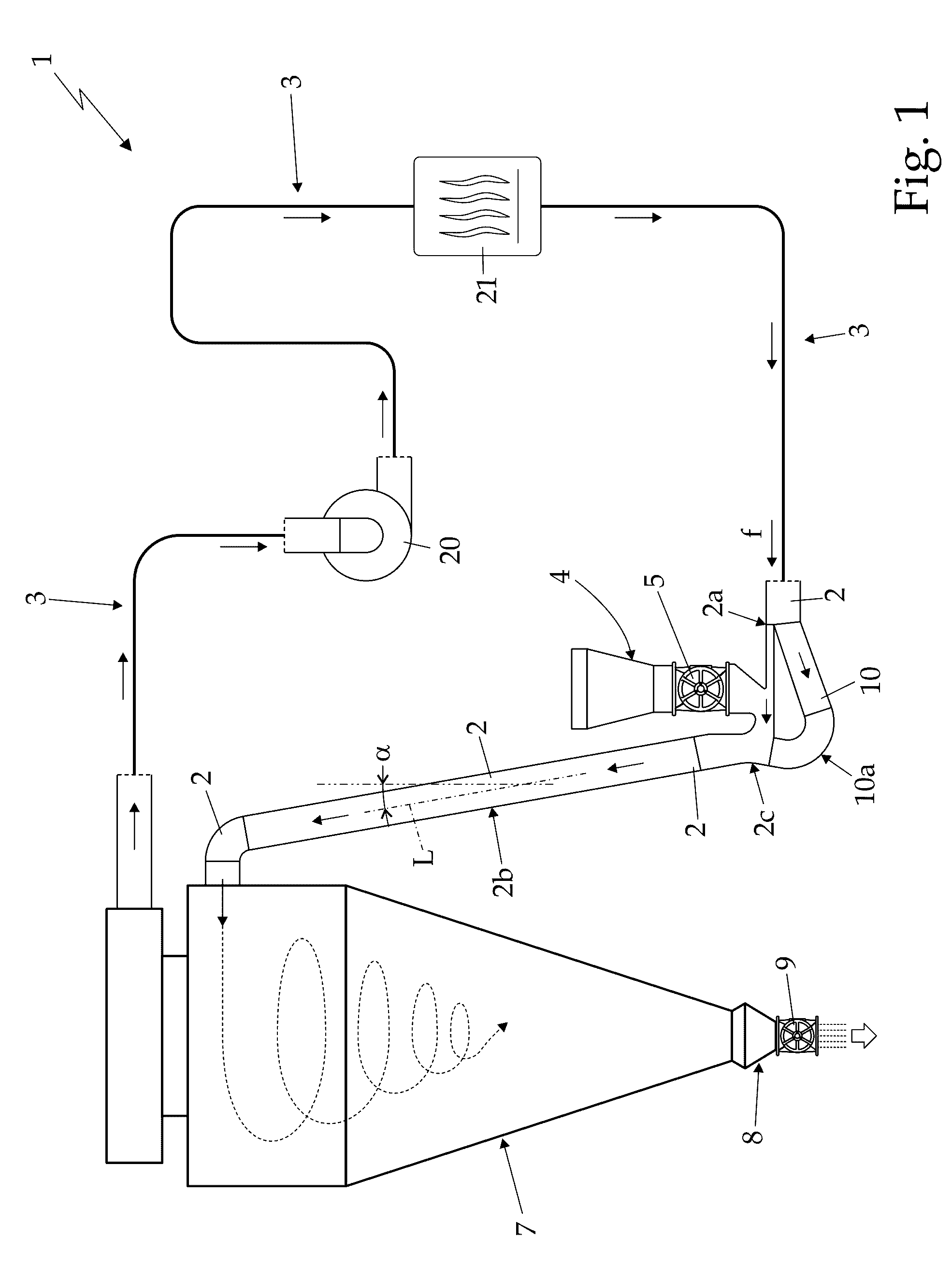

Air flow dryer for granular material

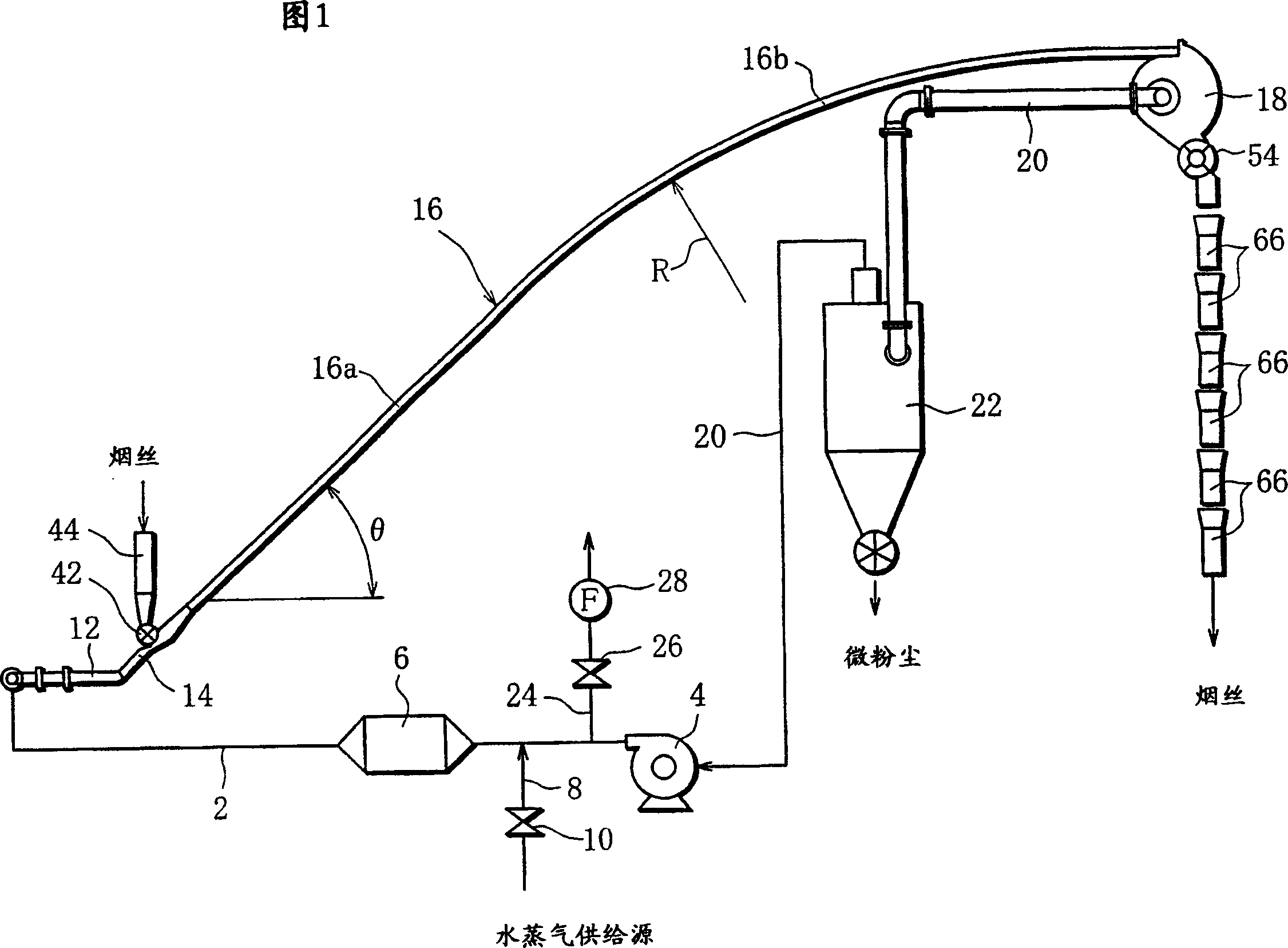

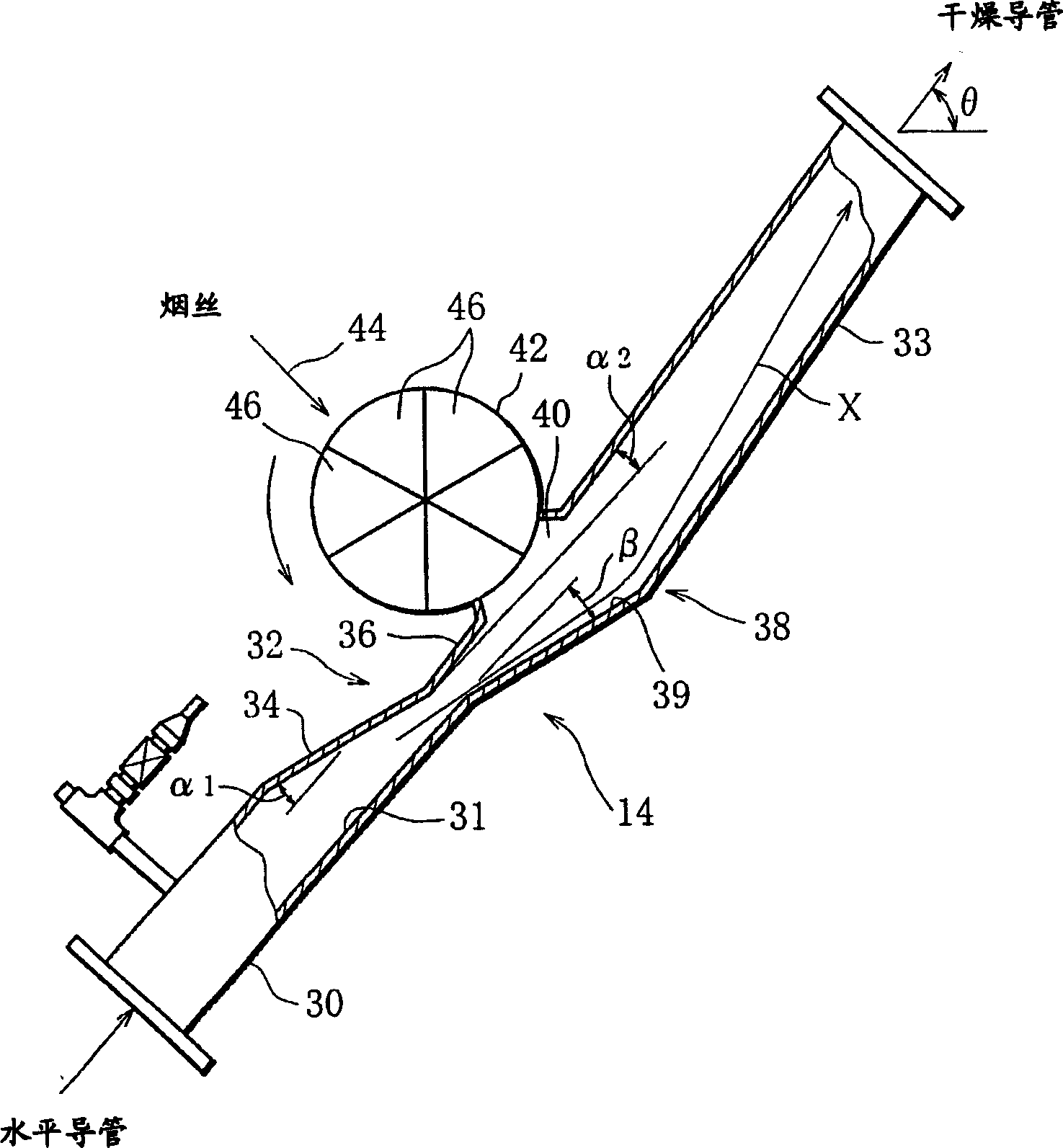

An air flow dryer for cut tobacco, comprising a drying duct (16) connecting a cut tobacco feed section (14) to a tangential separator (18), the drying duct (16) further comprising an upstream side duct portion (16a) linearly extending from the feed section (14) at an elevation of 30 to 60[masculine ordinal] and a downstream side duct portion (16b) projectedly curved upward, wherein drying gas flowing in the drying duct (16) may contain overheated steam.

Owner:JAPAN TOBACCO INC

Electronic device having path of power supplied to display part switched according to whether external power is supplied

InactiveCN1848593ABatteries circuit arrangementsDrying solid materials with heatControl powerPower detector

Owner:SAMSUNG ELECTRONICS CO LTD

Drying apparatus

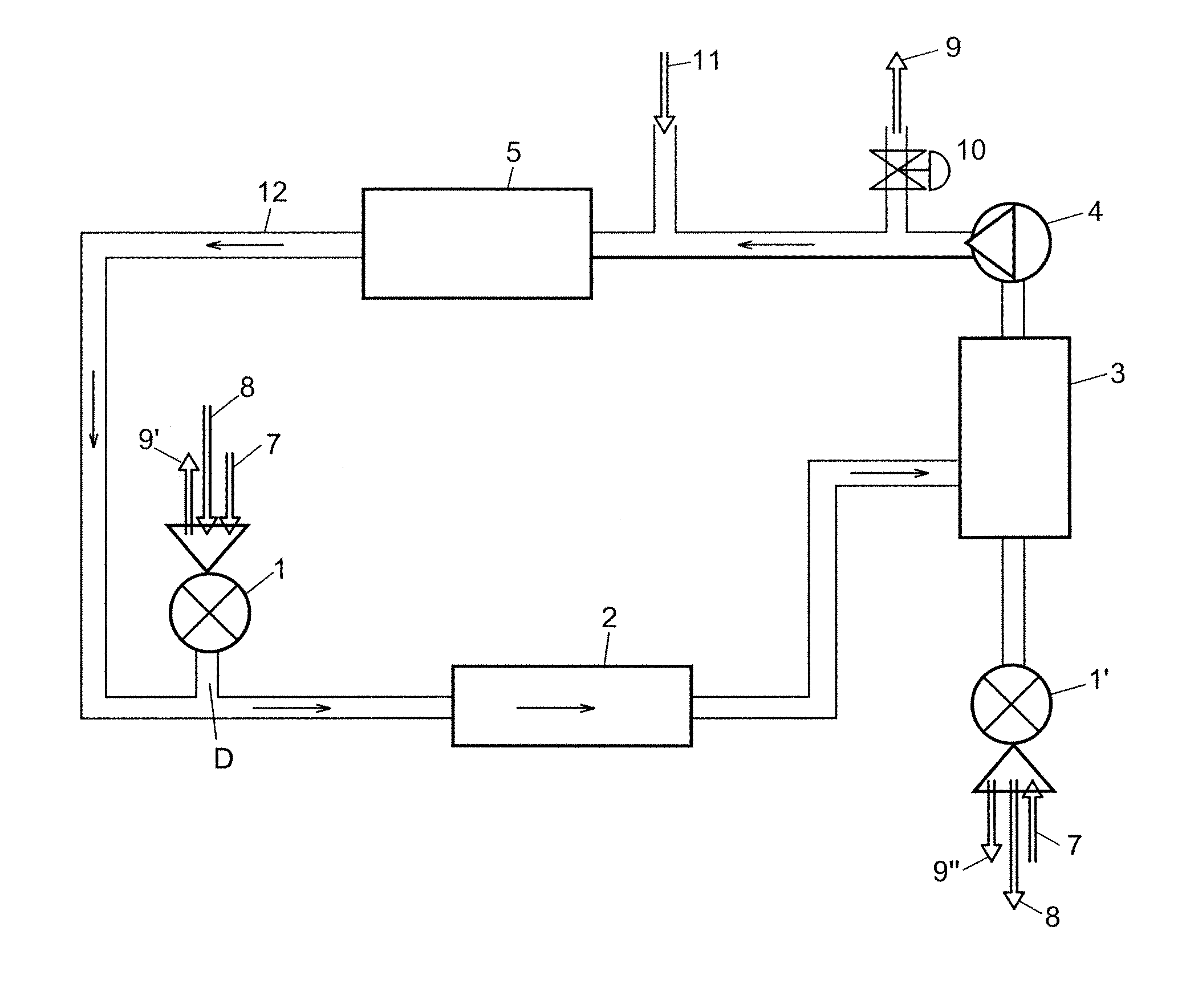

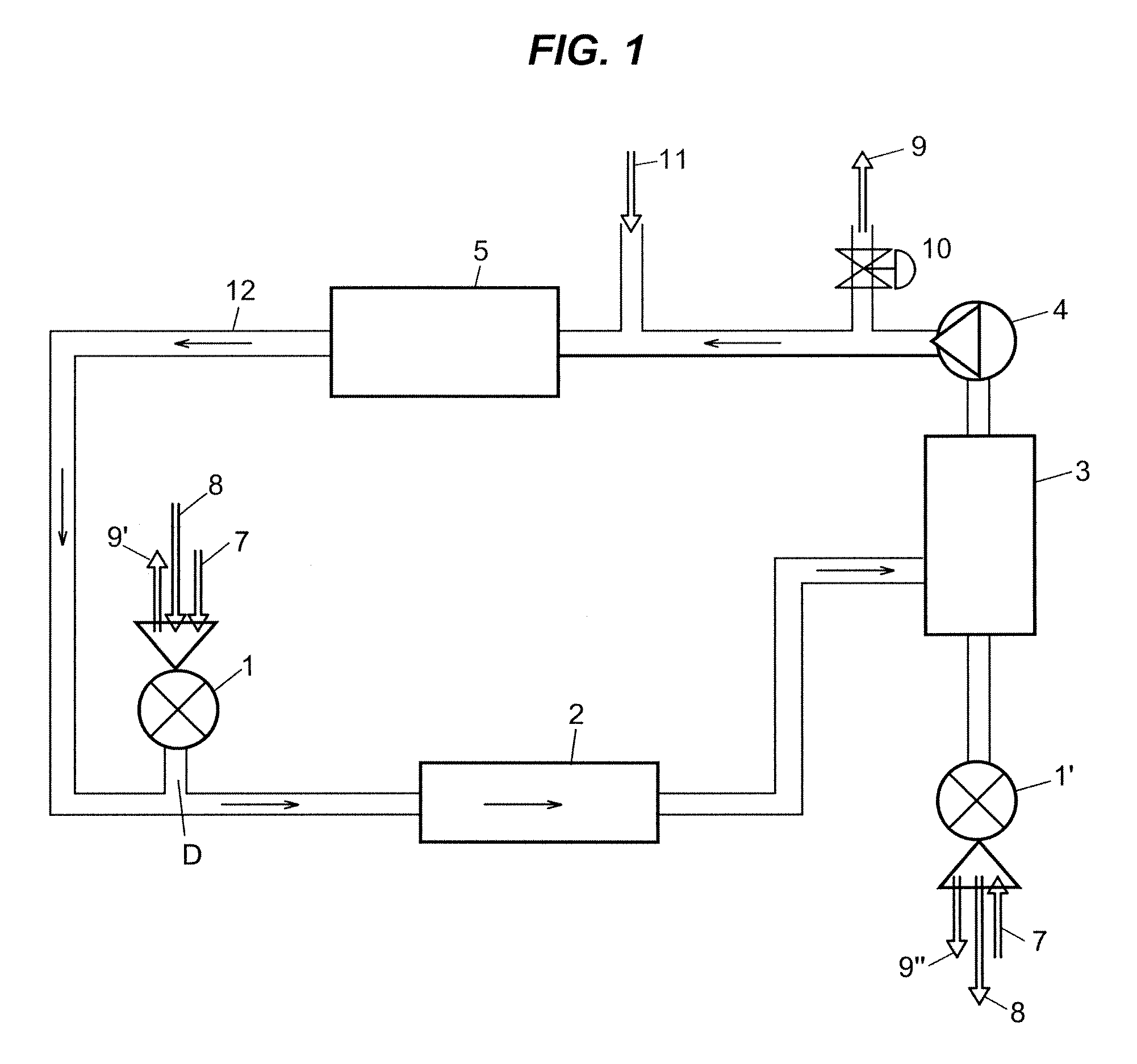

A drying apparatus for drying a fibrous material is described. The drying apparatus comprises a heater arranged to heat a first gas stream and a fibrous material, the first gas stream is arranged to enter the drying apparatus at an inlet, the gas stream including steam, a separator for separating a said fibrous material from the first gas stream to form a second gas stream. The drying apparatus further includes a heat exchanger arranged to condense and separate a steam component and a water component from the second gas stream, and a compressor arranged to compress the steam component and return the steam component to the inlet.; In an alternative the compressor is arranged to compress the second gas stream directly and before the heat exchanger arranged to condense and separate a steam component and a water component from the second gas stream, and return the steam component to the inlet. A method of drying is also described. The invention as disclosed seeks to recover the energy content of the exhaust from the drying apparatus and return this to the dryer for re-use.

Owner:DICKINSON LEGG

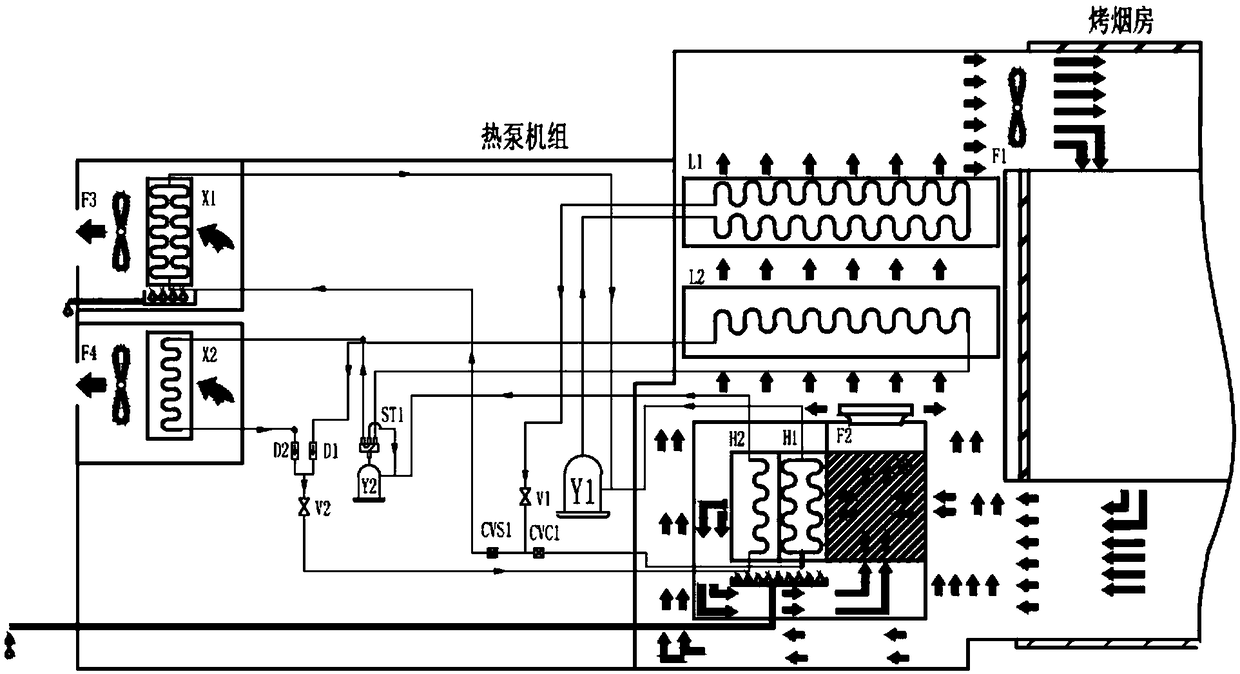

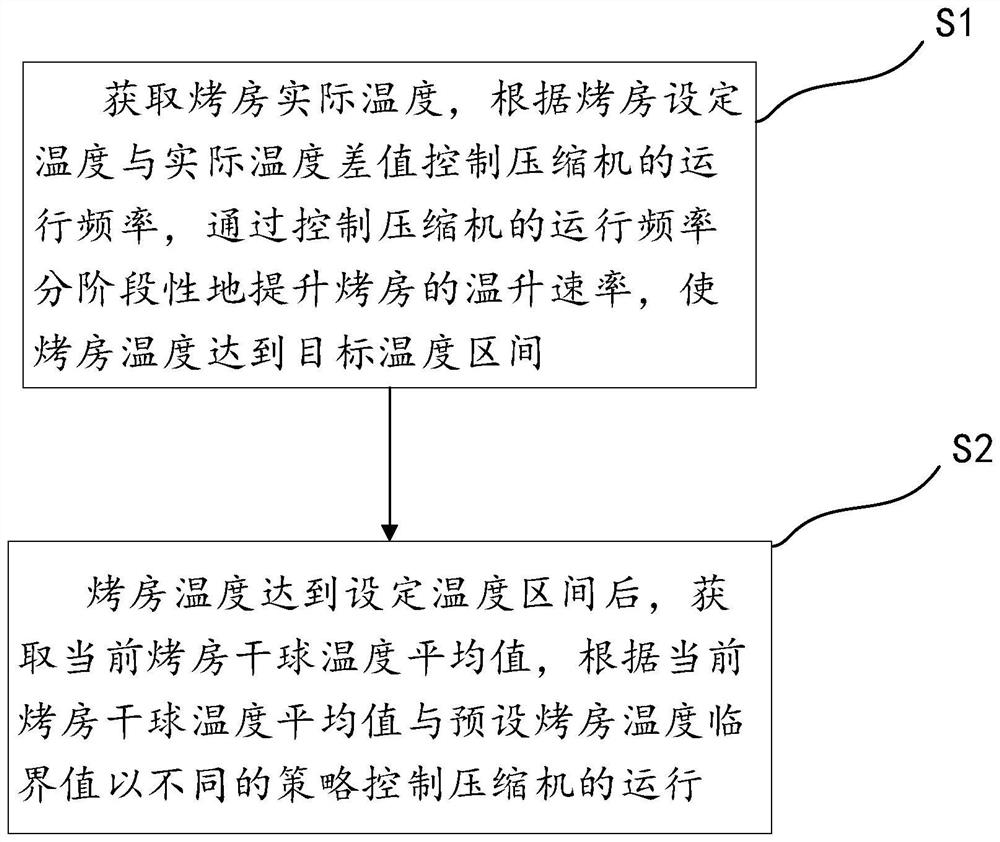

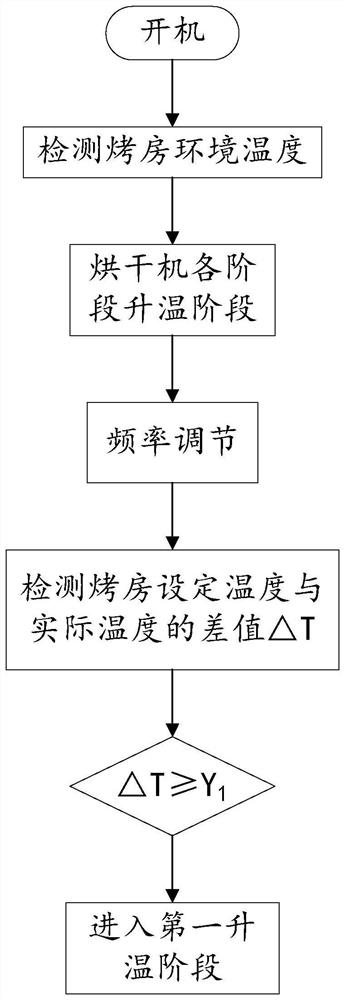

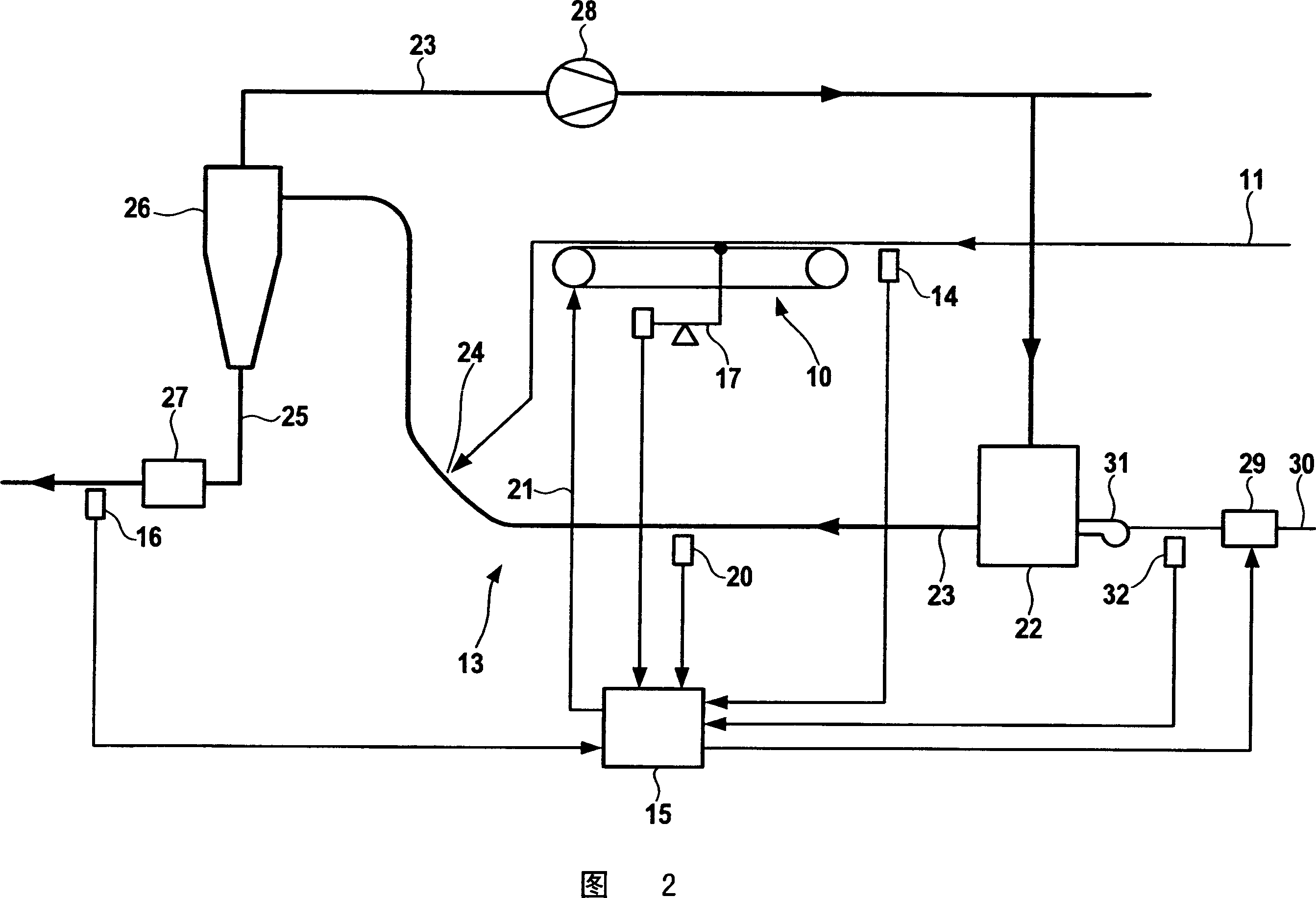

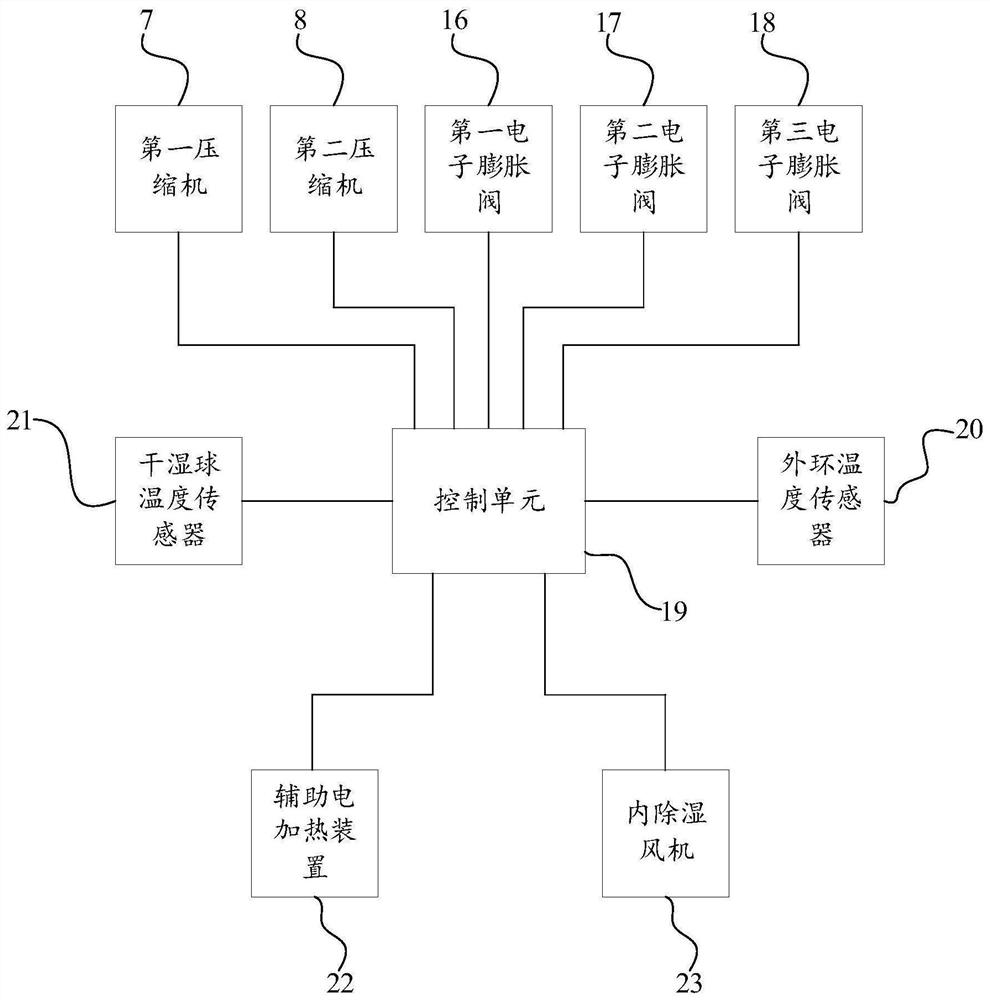

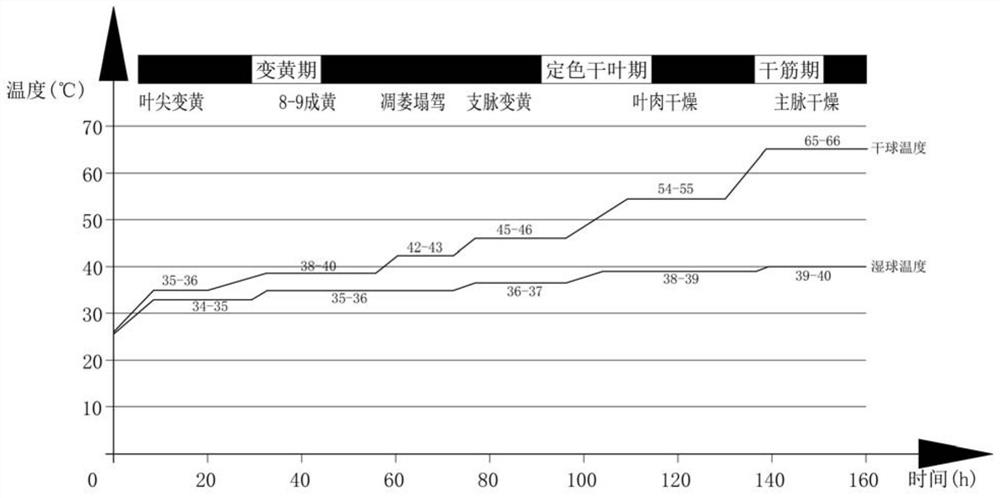

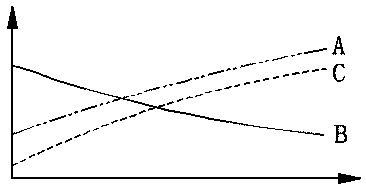

Heat pump type tobacco dryer and control method thereof

ActiveCN114370746AIncrease temperature rise rateFast temperature riseTobacco preparationHeat pumpsThermodynamicsAgricultural science

The invention discloses a heat pump type tobacco dryer and a control method thereof, which are used for solving the problems that tobacco leaves crack and the baking effect is not ideal due to the fact that the temperature rise of the dryer is too fast. The control method of the heat pump type tobacco dryer comprises the steps that the actual temperature of a curing barn is obtained, the operation frequency of a compressor is controlled according to the difference value of the set temperature and the actual temperature of the curing barn, the temperature rise rate of the curing barn is increased in a staged mode by controlling the operation frequency of the compressor, and the temperature of the curing barn reaches a target temperature interval. The temperature rise rate of the curing barn is increased in stages, operation of the compressor is controlled through different strategies according to the current curing barn dry-bulb temperature average value and the preset curing barn temperature critical value, the temperature rise speed of the curing barn can be prevented from being too high, and the curing barn is prevented from being too hot in the temperature drying stage.

Owner:GREE ELECTRIC APPLIANCES INC

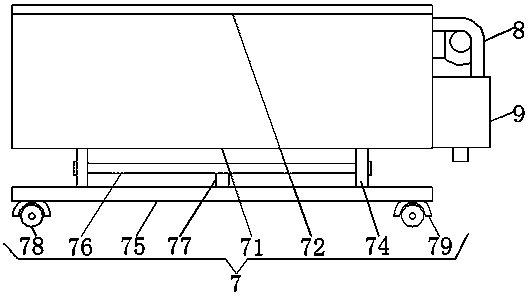

Drying machine for industrial tobacco production

InactiveCN109323555ASolve the problem of not being environmentally friendlyWon't fly awayDrying gas arrangementsTobacco dryingEngineeringIndustrial engineering

The invention discloses a drying machine for industrial tobacco production, and relates to the technical field of industrial tobacco production. The drying machine for industrial tobacco production comprises a drying barrel, a circulating device is arranged on the outer side of the drying barrel, and a motor is arranged at the top of the drying barrel. An output shaft of the motor penetrates through the drying barrel and extends into an inner cavity of the drying barrel, and the output shaft of the motor is fixedly connected with a rotary shaft. Stirring blades are arranged on the outer side of the rotary shaft at equal intervals, and a discharging pipe is formed in the bottom of the drying barrel. The bottom of the discharging pipe is connected with a collecting box in a penetrating manner, and the front face of the collecting box is fixedly connected with an air pump. A suction pipe of the air pump penetrates through the collecting box and extends into an inner cavity of the collecting box. According to the drying machine for industrial tobacco production, by means of the structural design of the discharging pipe, the collecting box, a box body, a box cover, a connector, movablerods, a bottom plate, cross rods, a hydraulic rod, sliding wheels, a braking device, the air pump and a first dust removal box, the problem that a drying machine for industrial tobacco production is not environment-friendly.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

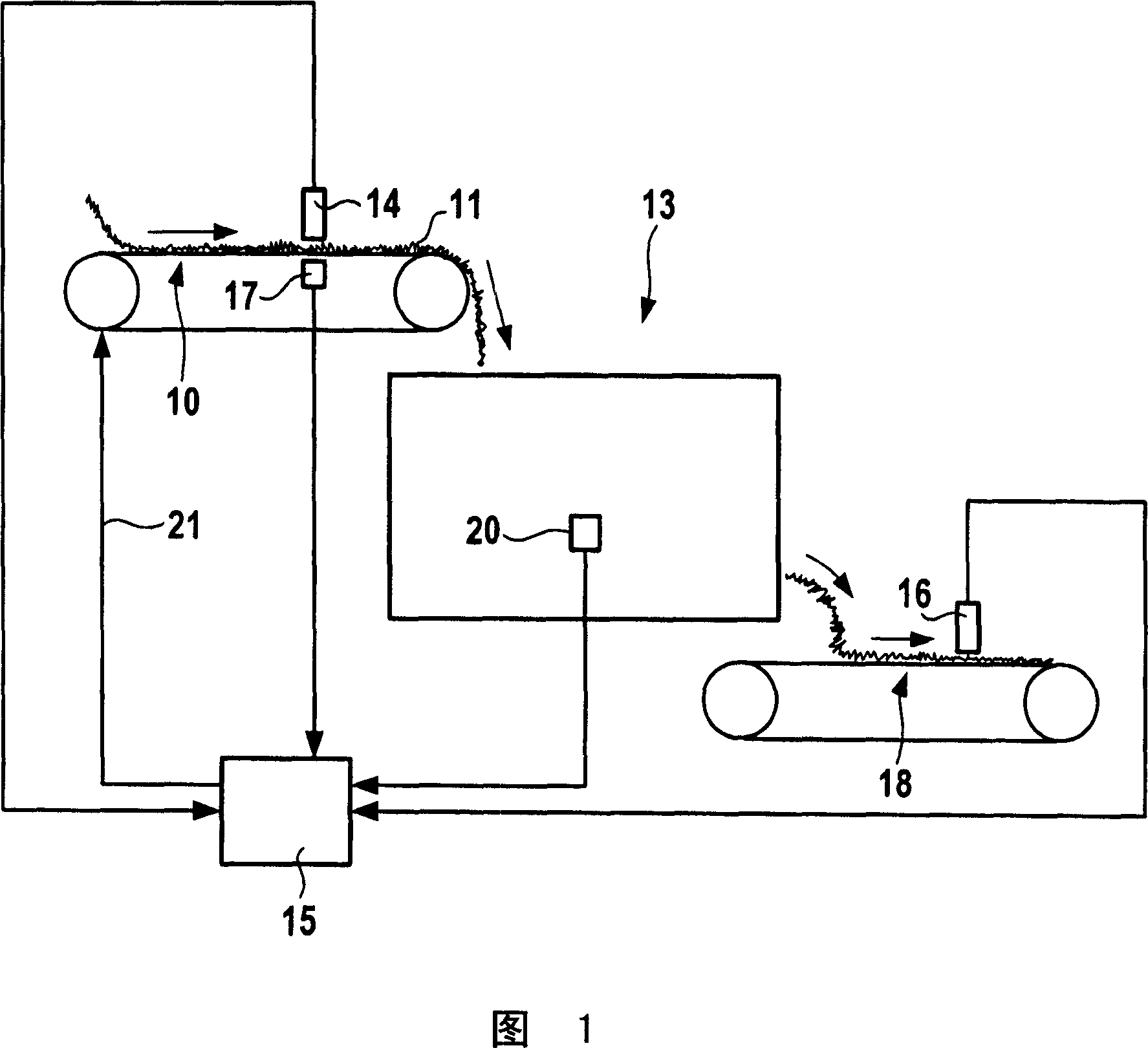

Process and apparatus for drying a fibrous product mass flow

The method involves leading the product mass flow by a dryer and controlling the drying temperature in the dryer. The product mass flow led by the dryer (13) is controlled (20) as a function of the measured drying temperature. During moving the drying temperature, the product mass flow is reduced. That during rising the drying temperature of the product mass flow is increased. An independent claim is included for a drying device for a fibrous product mass flow

Owner:HAUNI MASCHINENBAU AG

Method of increasing the efficiency of drier, particularly a stream drier

InactiveCN101324396AImprove efficiencyTobacco preparationDrying solid materials with heatWorking pressureDesiccant

Owner:INT TOBACCO MACHINERY POLAND

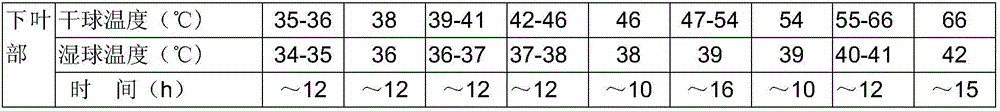

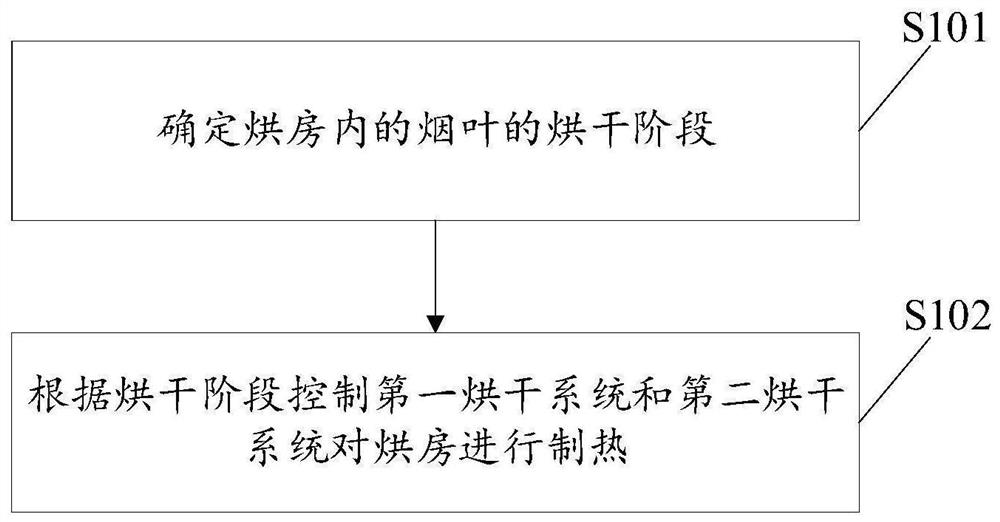

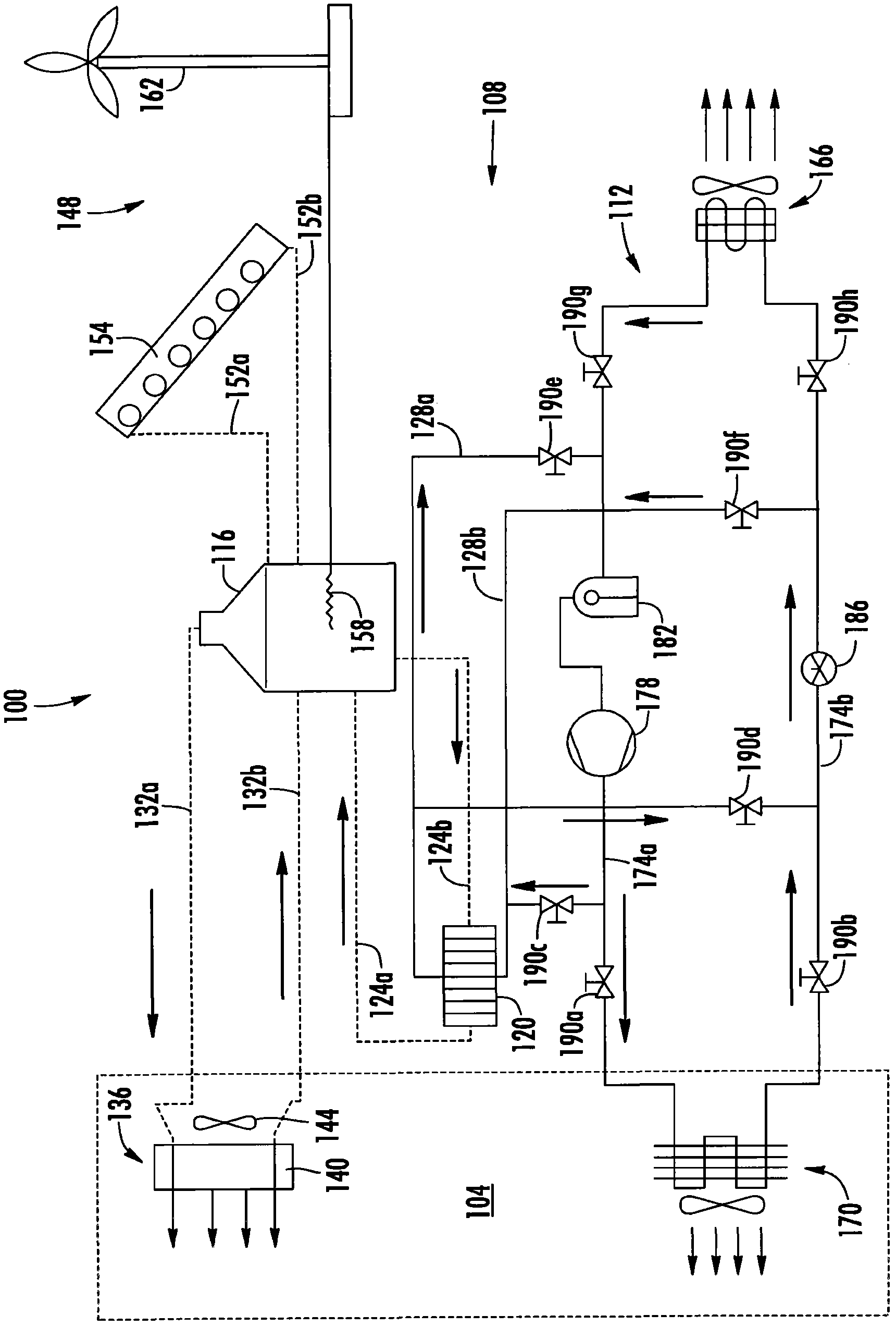

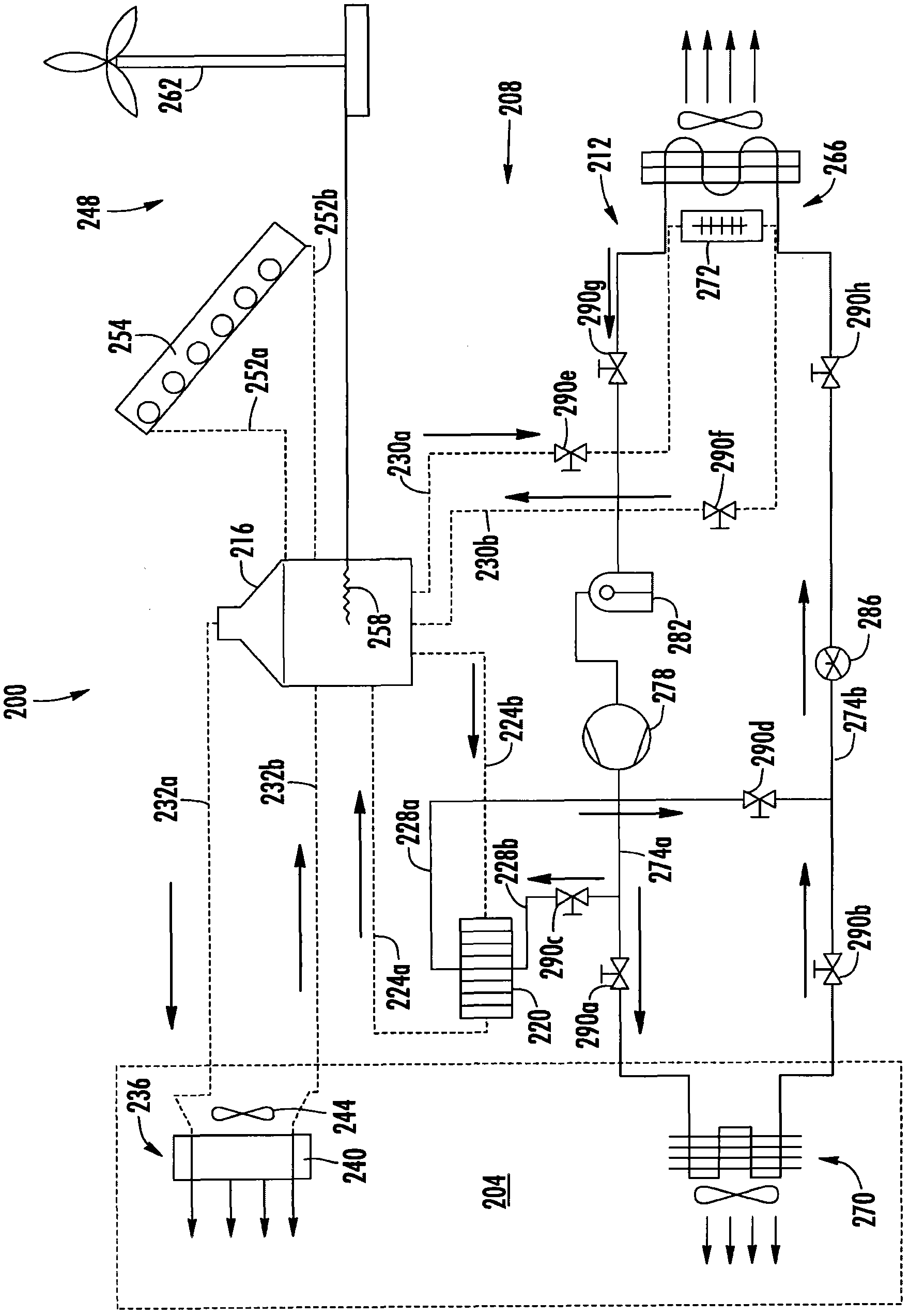

Method and device for adjusting tobacco leaf drying temperature, electronic equipment and storage medium

ActiveCN113959188AAdjust drying temperatureImprove drying effectMechanical apparatusHeat pumpsAgricultural engineeringMechanical engineering

The invention relates to the technical field of drying control, and discloses a method for adjusting the tobacco leaf drying temperature. The method is applied to a heat pump dryer. The heat pump dryer comprises a first drying system and a second drying system, and the first drying system and the second drying system are both used for being controlled to heat a drying room. The method for adjusting the tobacco leaf drying temperature comprises the steps that the drying stage of tobacco leaves in the drying room is determined; and controlling the first drying system and the second drying system to heat the drying room according to the drying stage. Thus, the drying room is heated by controlling the first drying system and the second drying system, the drying temperature of the tobacco leaves in different drying stages can be adjusted, accurate control over the drying systems in the different drying stages is implemented, and the drying effect on the tobacco leaves is improved. The invention further discloses a device for adjusting the tobacco leaf drying temperature, electronic equipment and a storage medium.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD +3

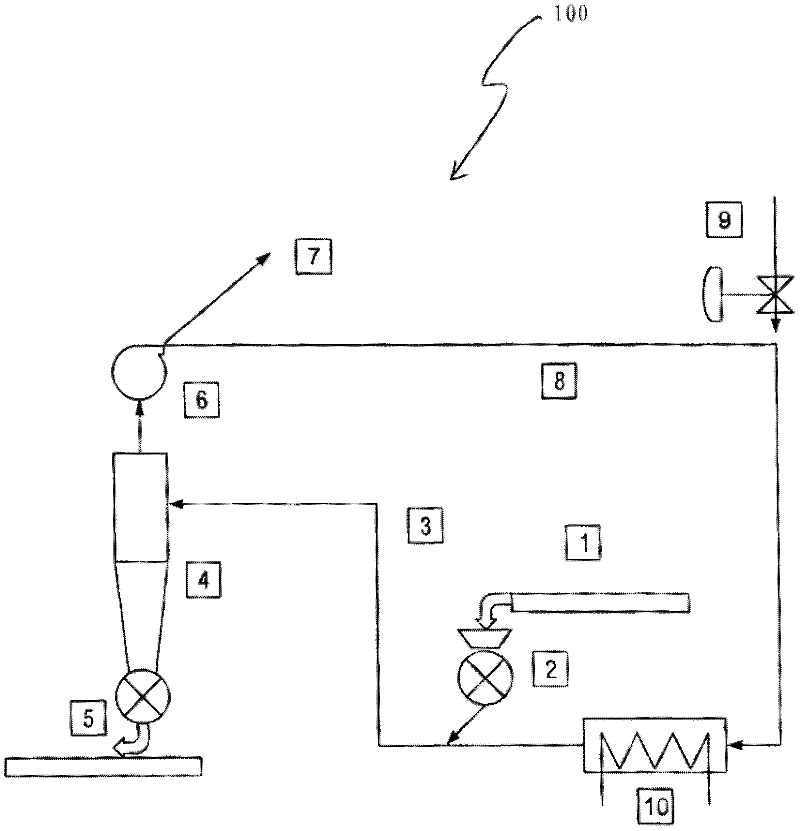

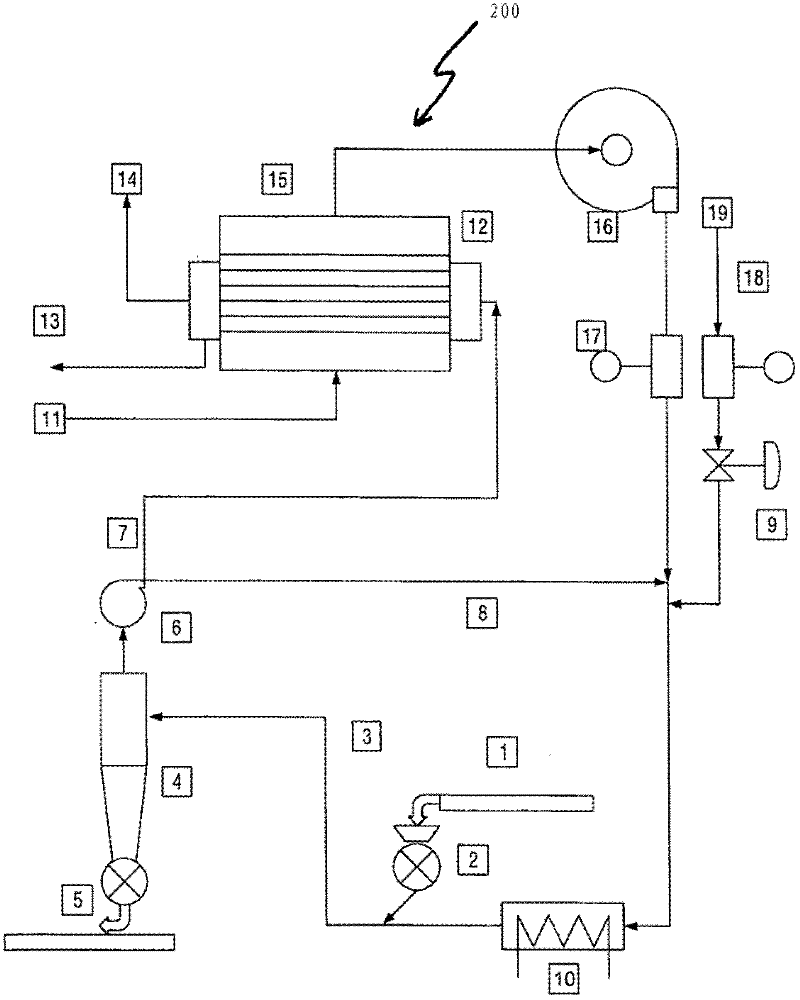

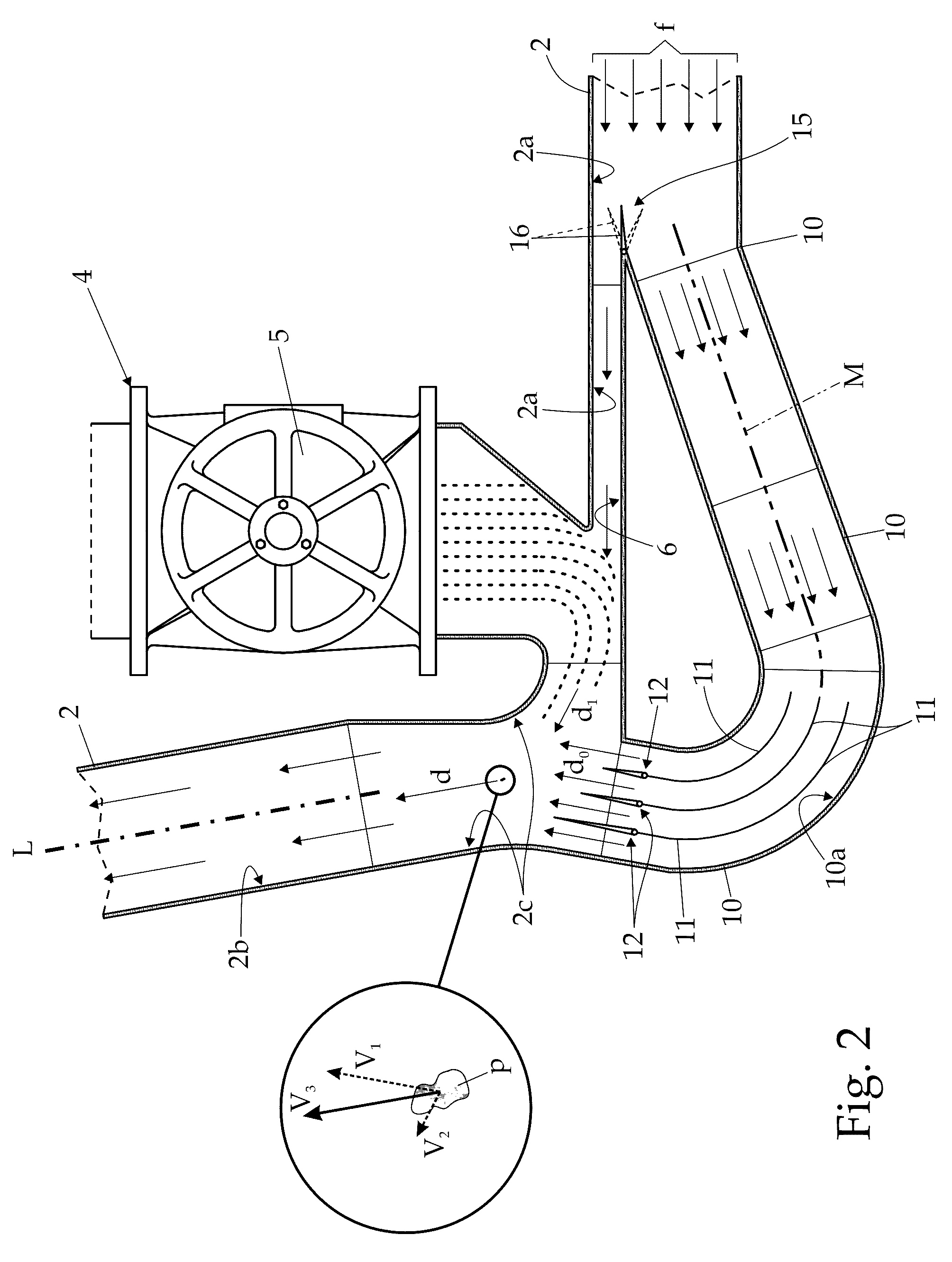

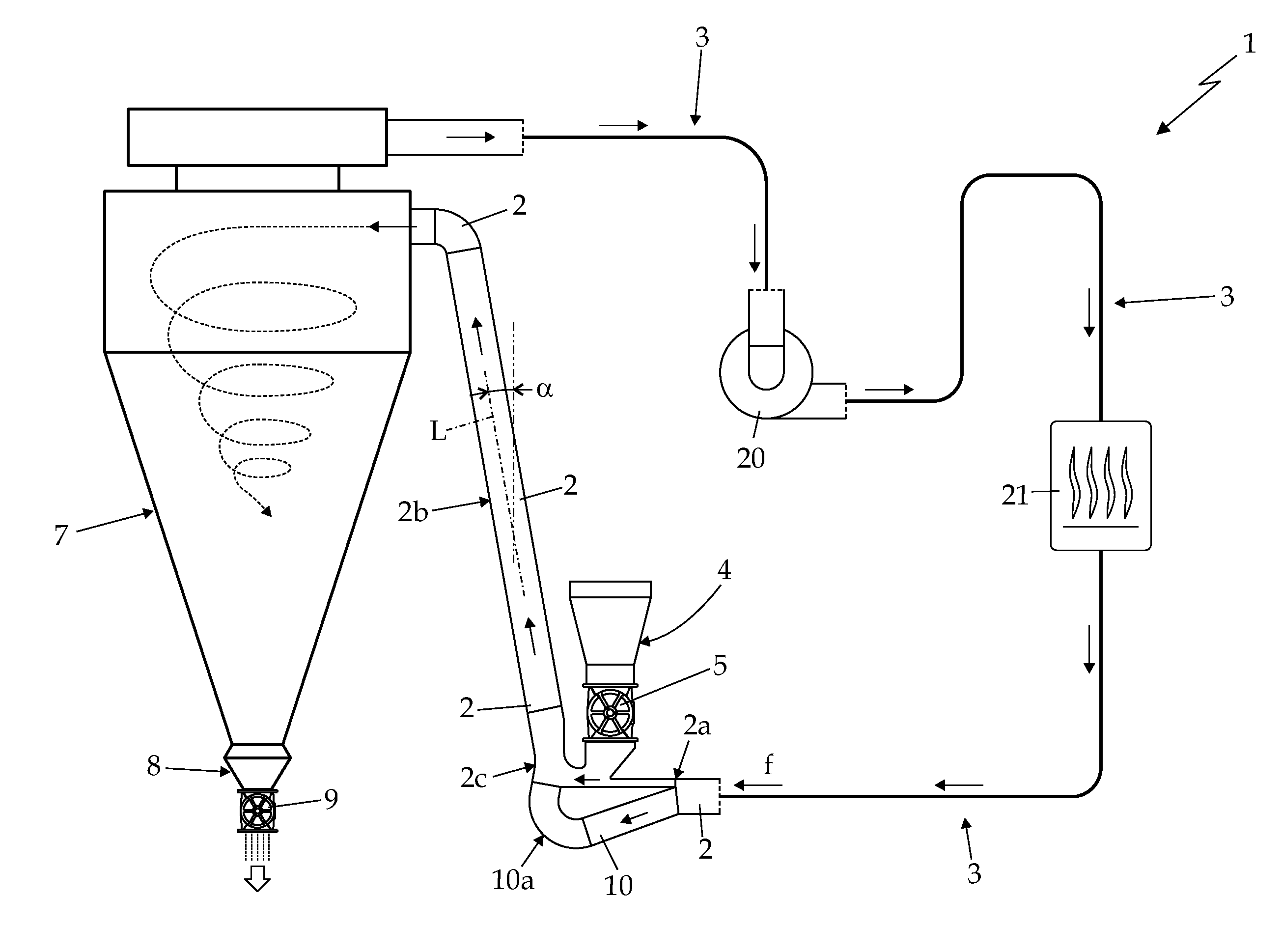

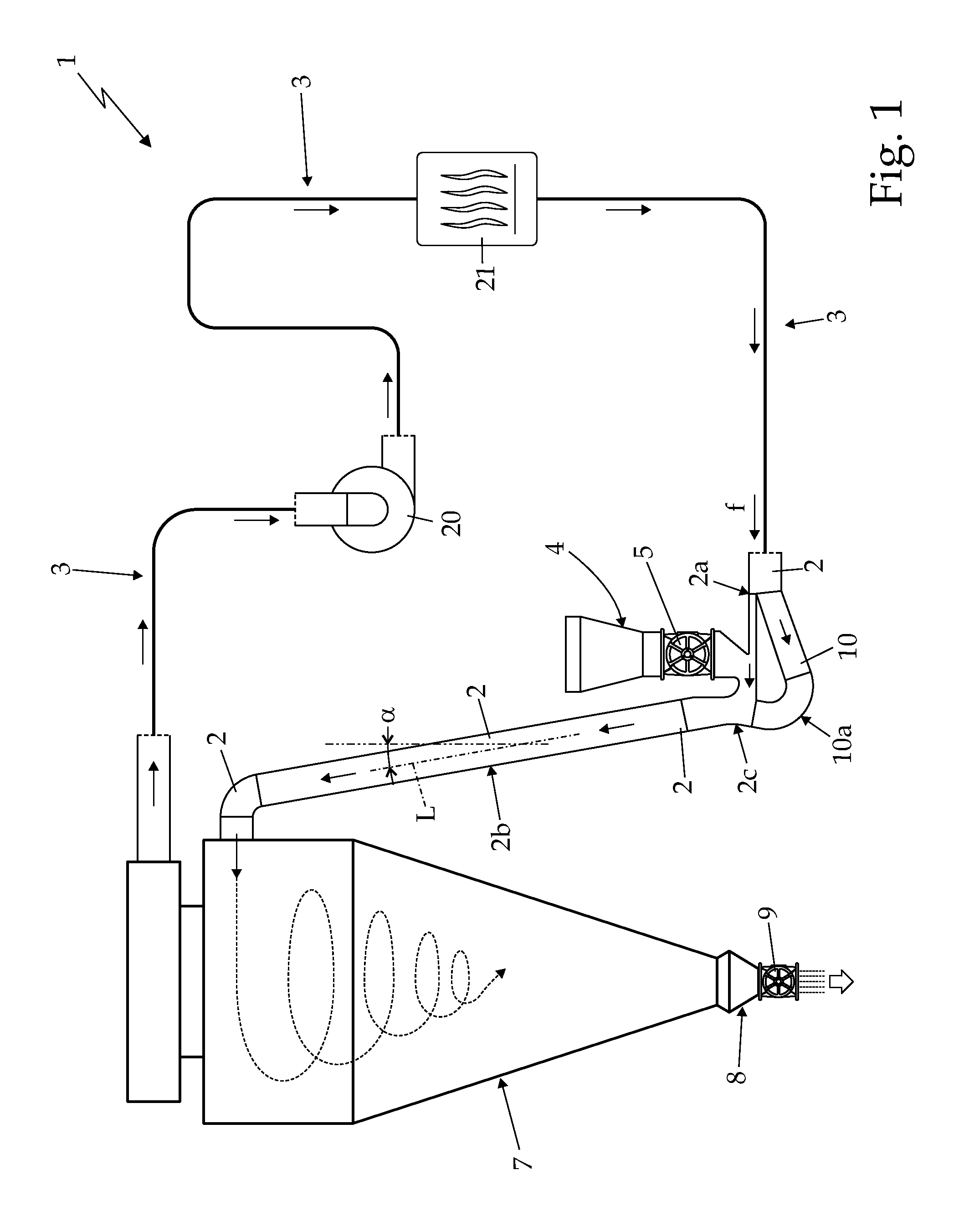

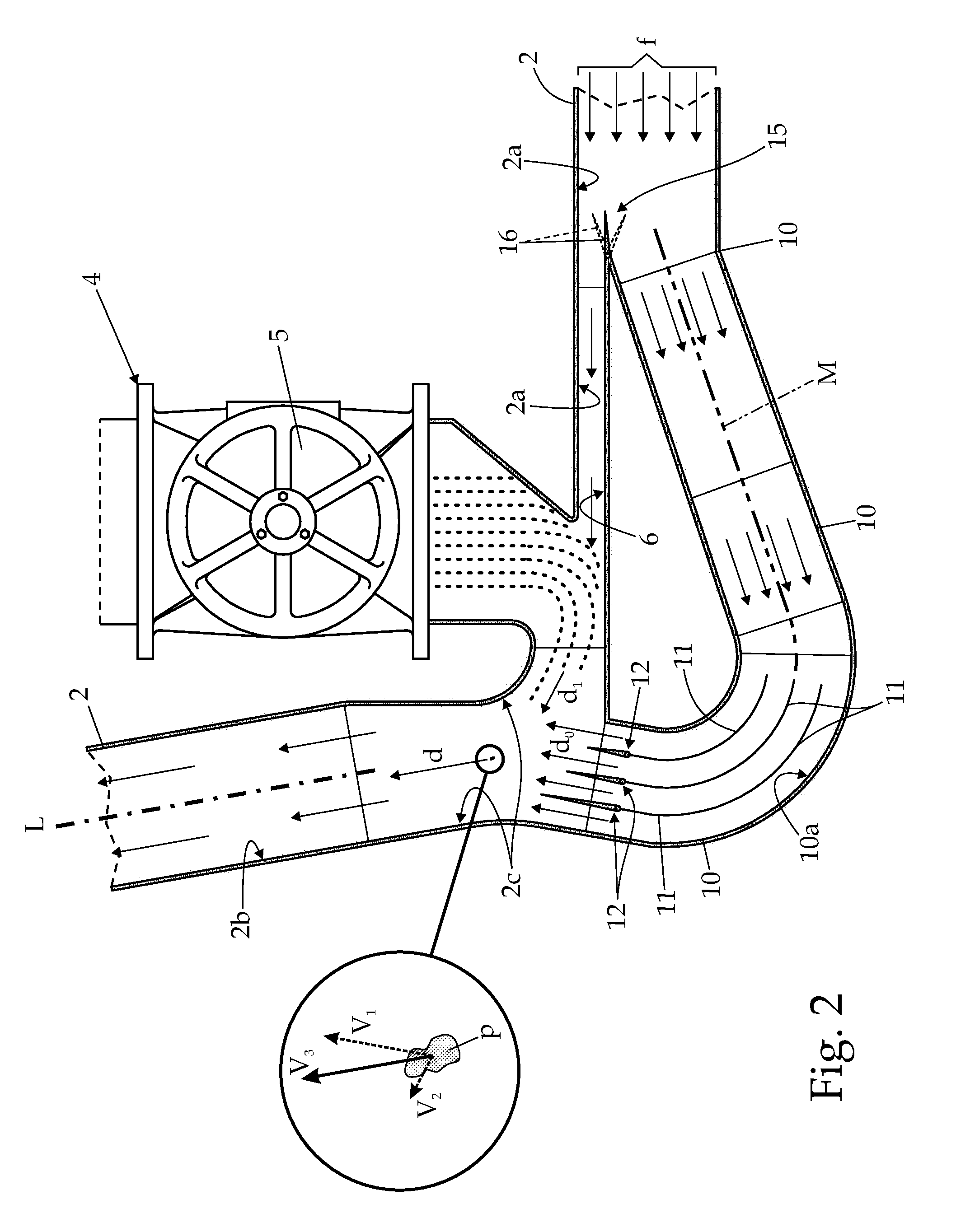

Drying plant for particulate materials

ActiveUS9518779B2Drawback can be obviatedTobacco preparationDrying solid materials with heatParticulatesProcess engineering

Drying plant for particulate materials comprising: a drying duct which is provided with a substantially horizontal rectilinear starting section, a rectilinear ascending final section which extends upwards with a predetermined angle of inclination with respect to the vertical, and a curved intermediate section which connects the rectilinear starting section to the rectilinear final section; a hot gas generator designed for supplying to the inlet of the rectilinear starting section of the drying duct a flow of process gas at high temperature; a particulate feeding device which is structured so as to be able to feed / introduce into the rectilinear starting section of the drying duct a flow of particulate material to be dried substantially without relevant leaks of process gas from the drying duct; and a bypass duct which branches from the rectilinear starting section of the drying duct upstream of the particulate feeding device, and then re-joins the drying duct at the curved intermediate section, so as to feed back into the drying duct the process gas diverted inside it.

Owner:GARBUIO

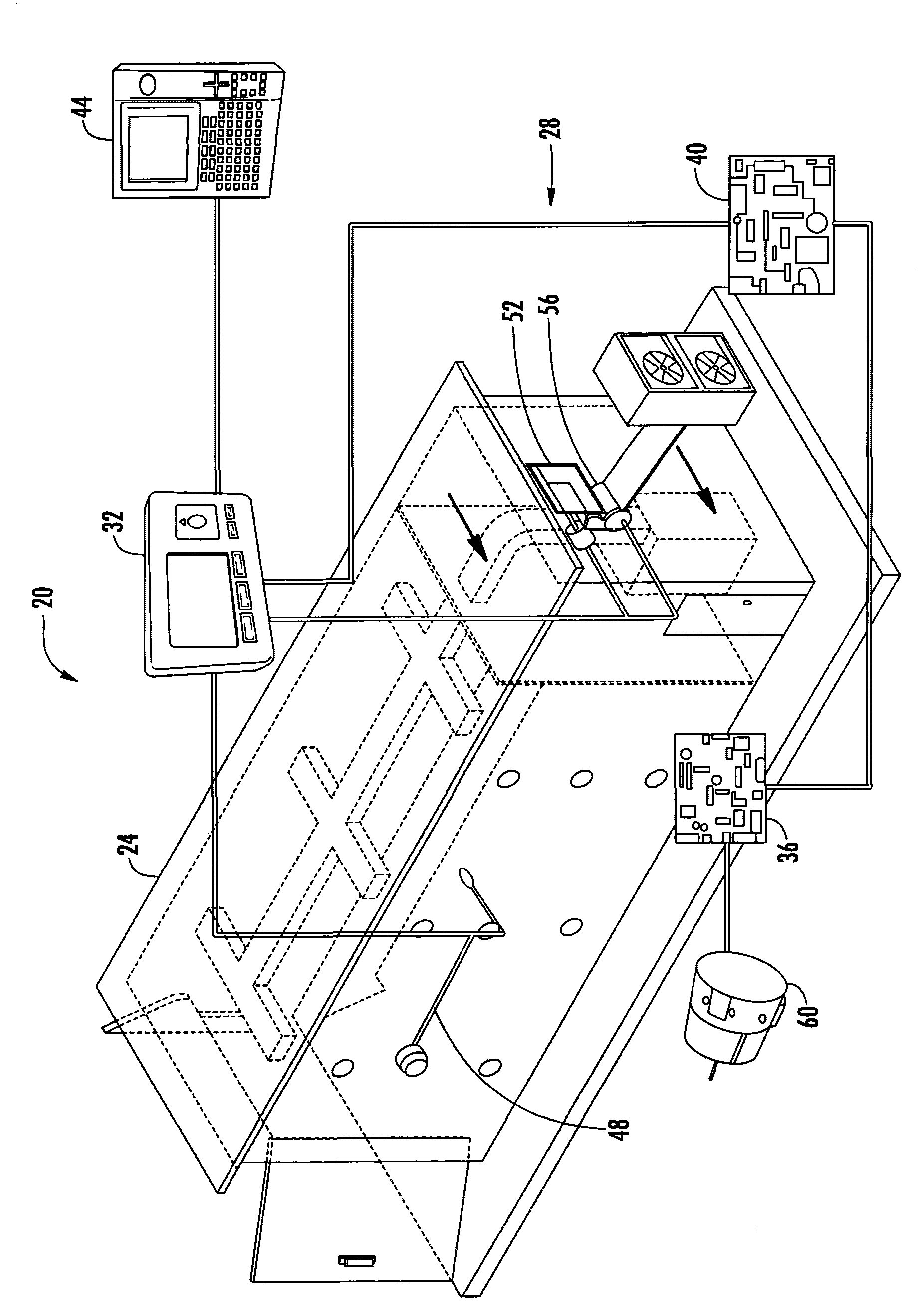

Device and method used for drying materials

InactiveCN103256806AReduce installation costsReduce maintenance costsTobacco preparationTobacco dryingProcess engineeringAuxiliary heating

The invention discloses a device and a method used for drying materials, and provides a relevant controlling device. In an embodiment, the controlling device used for a material drying system is arranged to select one or more heat sources from a plurality of different kinds of heat sources to dry materials. The selection is executed based on inputs of one or more sensors. The selected heat sources are controlled by the controlling device to provide heat for drying the materials. In some arrangements, the material drying system is used as a typical heat pump to operate only when more cost-efficient auxiliary heating schemes cannot be provided to keep a drying temperature.

Owner:EMERSON ELECTRIC CO

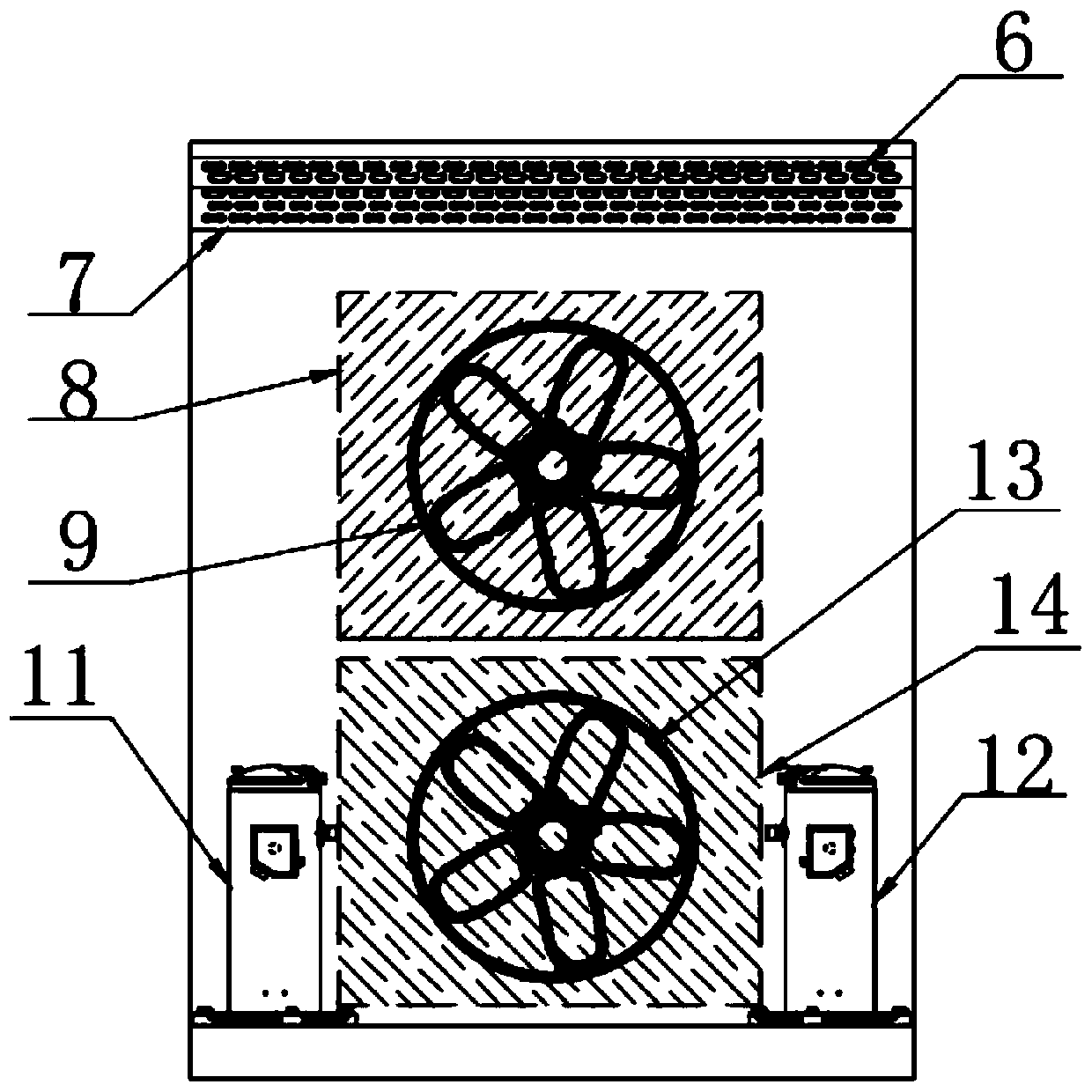

Heat pump drying device

PendingCN109520282AImprove moisture removalIncrease profitHeat recovery systemsDrying gas arrangementsFresh airEngineering

The invention provides a heat pump drying device, and relates to the technical field of drying devices. The heat pump drying device comprises a material chamber, a separation partition, a heat recoverer, a heat pump, an auxiliary electric heater and a fresh air duct, wherein an air inlet of the material chamber is provided with an air supply duct; an air outlet of the material chamber is providedwith an air return duct; the separation partition is arranged in the air return duct and divides the air return duct into a first air duct and a second air duct; the fresh air duct communicates with the second air duct through the heat recoverer; the first air duct is connected with the heat pump through the heat recoverer; the auxiliary electric heater is mounted on the heat pump; and the secondair duct and the air supply duct are connected with the auxiliary electric heater through the heat pump. According to the heat pump drying device provided by the invention, the heat pump is a main heat supply element, the auxiliary electric heater helps supply heat, the separation partition divides the air return duct into the first air duct and the second air duct, air in the material chamber isdivided into two parts to be separately treated, and the utilization rate of heat and the moisture exhaust quantity in the material chamber are increased.

Owner:北京达特集成技术有限责任公司

Air path opening and closing combined drying device

PendingCN112352993ASolve the problem of effluxFluorine circuit structure is simplifiedTobacco preparationDrying gas arrangementsThermodynamicsFresh air

The invention relates to an air path opening and closing combined drying device, and the device comprises a heating and dehumidifying room, wherein the interior of the heating and dehumidifying room is divided into at least one inner cavity and at least one outer cavity through a partition plate; the outer cavity is communicated with ambient air, and the inner cavity is communicated with a curingbarn to form a circulating channel of drying airflow; the side wall of the inner cavity or the partition plate is further provided with a fresh air opening and a moisture discharging opening. When thedrying airflow is in closed circulation, the fresh air opening and the moisture discharging opening are closed at the same time, and the drying airflow circularly moves in a closed circulation channel formed by the inner cavity and the curing barn; when the drying airflow is partially circulated in an open circuit mode, the fresh air opening and the moisture discharging opening are opened at thesame time, warm and wet return air in the curing barn enters the inner cavity, part of the warm and wet return air entering the inner cavity is discharged out of the inner cavity through the moisturedischarging opening, and meanwhile environment fresh air is supplemented into the inner cavity through the fresh air opening. The method solves the problems that in the yellowing period, cells such asfresh tobacco leaves are still in the aerobic respiration and living body metabolism stages, and the autologous heat productivity of the tobacco leaves is large, so that more heat is generated in thecuring barn, and the dry-bulb temperature exceeds the target value.

Owner:SHANGHAI BOHAN THERMAL ENERGY TECH CO LTD

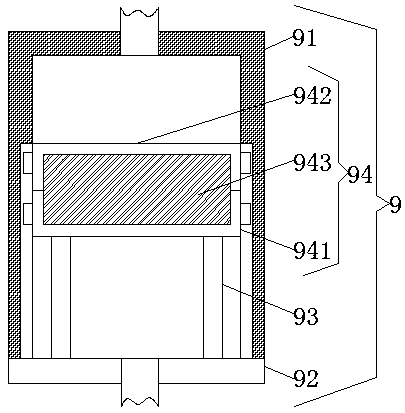

Drying apparatus

InactiveCN105264319AThe flow changes periodicallyImprove heat transfer performanceTobacco preparationDrying solid materials with heatFiberProduct gas

A drying apparatus for drying a fibrous material is described. The apparatus provides a drying apparatus for drying a fibrous or granular material comprising, a heater arranged to heat a first gas stream and a fibrous material, the first gas stream arranged to enter the drying apparatus at an inlet, the gas stream including steam. A separator is provided for separating a said fibrous material from the first gas stream to form a second gas stream, and a fan and a duct are arranged to recirculate the second gas stream to the process heater steam injection apparatus. A flow variation apparatus is arranged to vary the flow of gas in a first gas stream and improve the drying function due to increased heat and mass transfer between the gas stream and the tobacco product.

Owner:DICKINSON LEGG

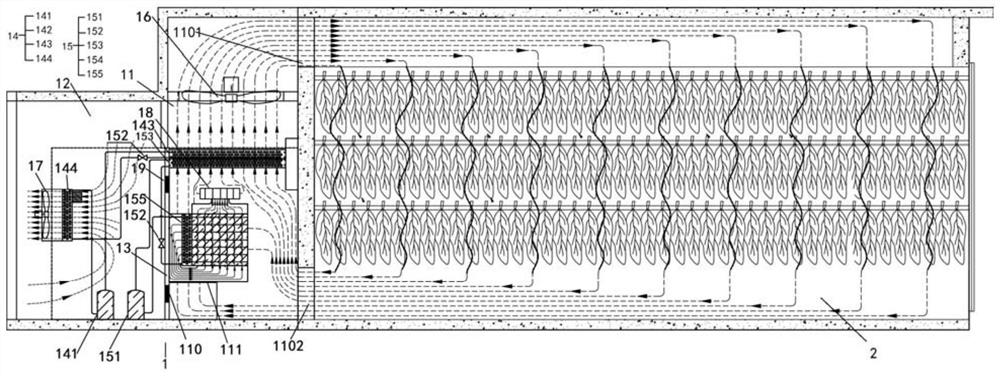

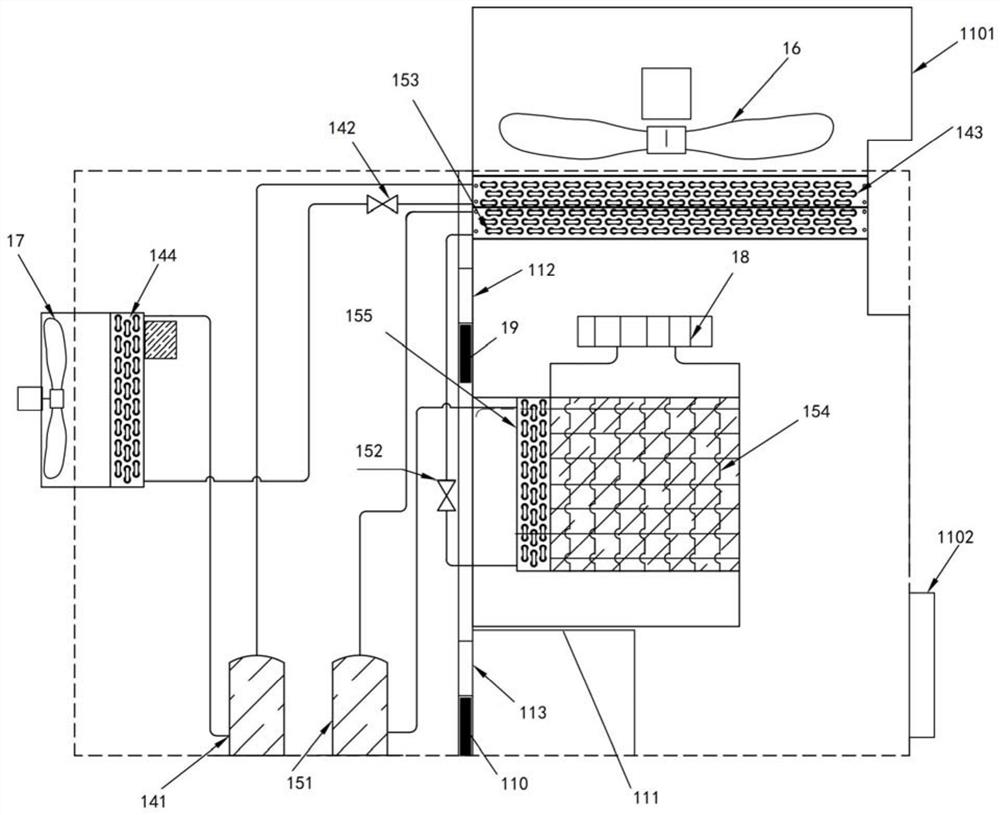

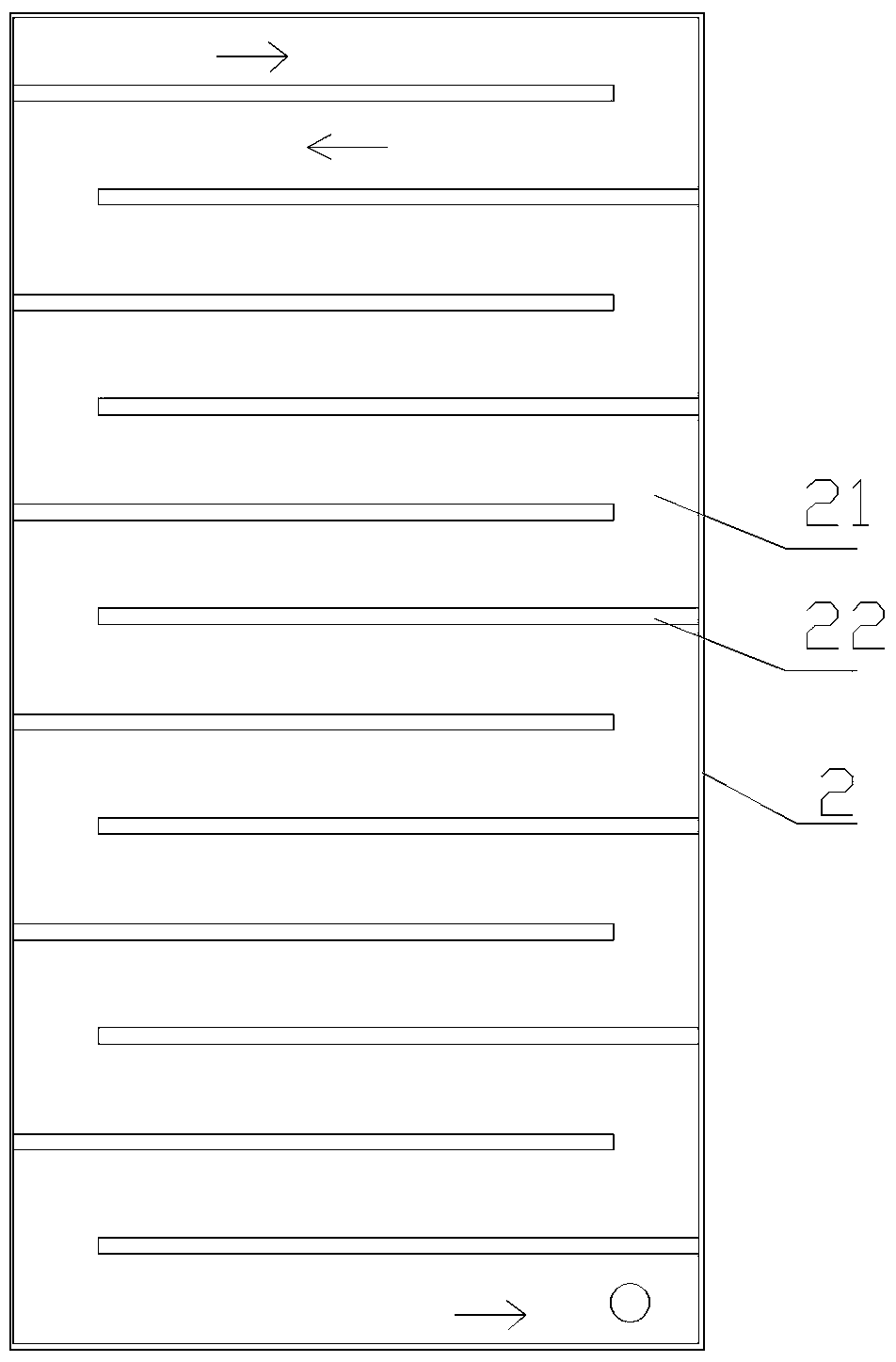

Multipurpose heat pump curing barn

PendingCN110108098AIncrease the flow distanceExtended dwell timeTobacco preparationDrying gas arrangementsProduct gasEngineering

The invention relates to a multipurpose heat pump curing barn. The curing barn comprises an air energy heat pump and a barn body, wherein the interior of the barn body is separated into a unit chamberand a hot air chamber; an evaporator case of the air energy heat pump is located outdoors, a condenser is located in the unit chamber, a circulating fan is arranged below the condenser, an air guidefan and a residual hot air box are arranged on the two sides of an evaporator in the evaporator case correspondingly, and a movable heat insulation plate is arranged between the air guide fan and theevaporator; and an air supply cavity and a moisture discharge cavity are formed in the top and the bottom of the hot air chamber respectively, the air inlet of the air supply cavity is located in theunit chamber, a circulating air port is formed in the bottom of the side wall, close to the unit chamber, of the hot air chamber, and an air outlet of the moisture discharge cavity is connected with the residual hot air box through a moisture discharge fan. The curing barn is suitable for drying various crops, and can effectively protect moisture removal gas against invalid heat dissipation in thedischarge process at the same time, so that the heat of the moisture removal gas can be sufficiently absorbed by the evaporator of the air energy heat pump to a maximum extent, and the heat energy utilization rate is improved.

Owner:HENAN AGRICULTURAL UNIVERSITY +2

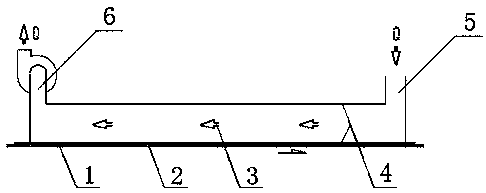

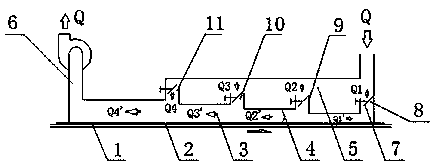

Incremental hot air countercurrent drying device and method

PendingCN109405506AConsistent wind speedIncrease temperatureDrying gas arrangementsTobacco dryingSurface moistureAir volume

The invention relates to an incremental hot air countercurrent drying device and method. The incremental hot air countercurrent drying device comprises a conveying belt, a ventilation tunnel is arranged above the conveying belt, the air direction of the ventilation tunnel is opposite to the direction of the conveying belt, a plurality of ventilation holes are formed in the ventilation tunnel, eachventilation opening is not located on the same horizontal plane, so that the sectional area of the ventilation tunnel is different or changes along the wind direction in a certain rule, the hot air enters the ventilation tunnel from each ventilation opening at the same time, and the air volume in the ventilation tunnel is gradually increased relative to the material countercurrent direction. According to the incremental hot air countercurrent drying device, the surface moisture of the material can be accelerated to diffuse into hot air, so that the drying and dewatering energy efficiency of the device is improved.

Owner:昆明烟机集团三机有限公司

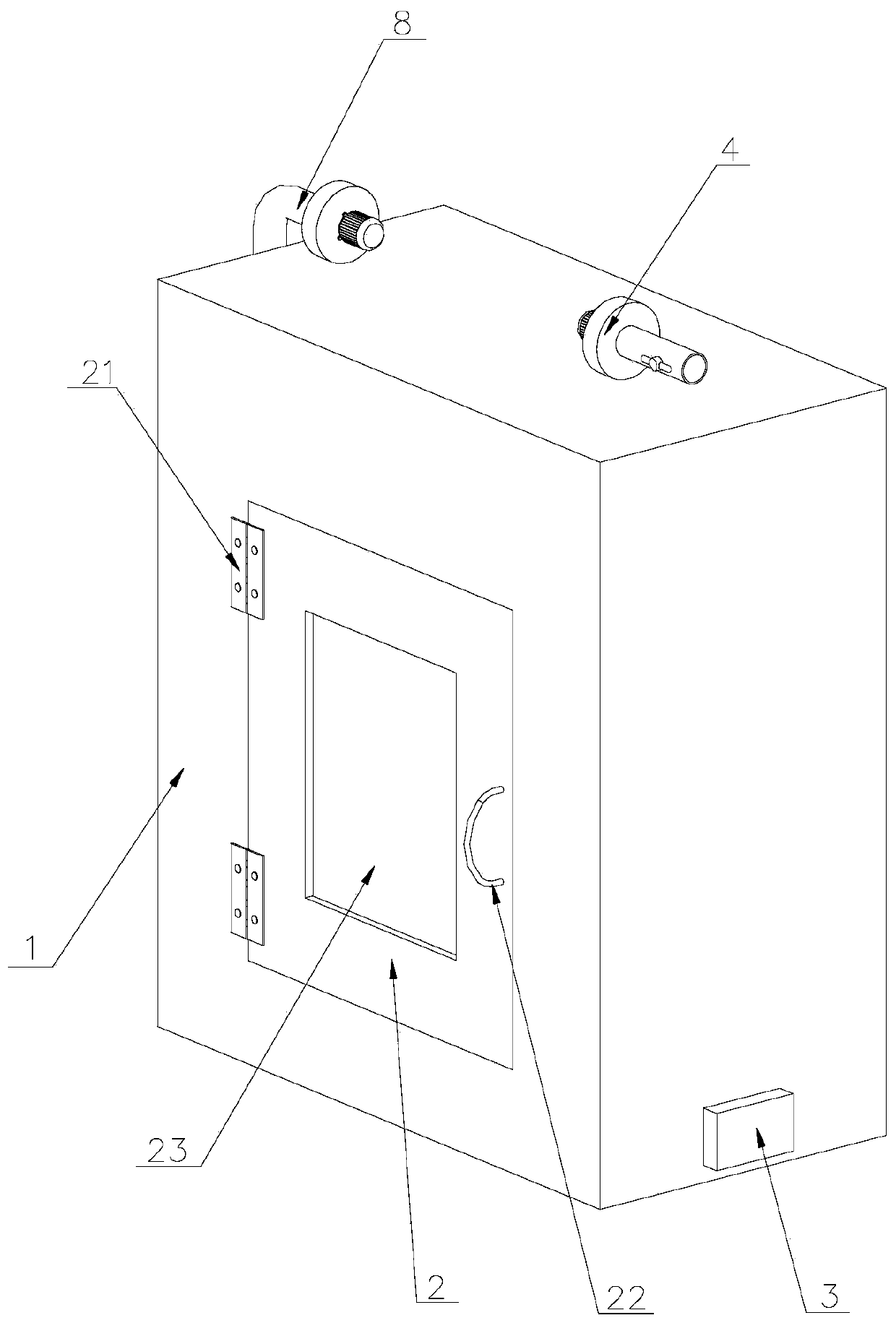

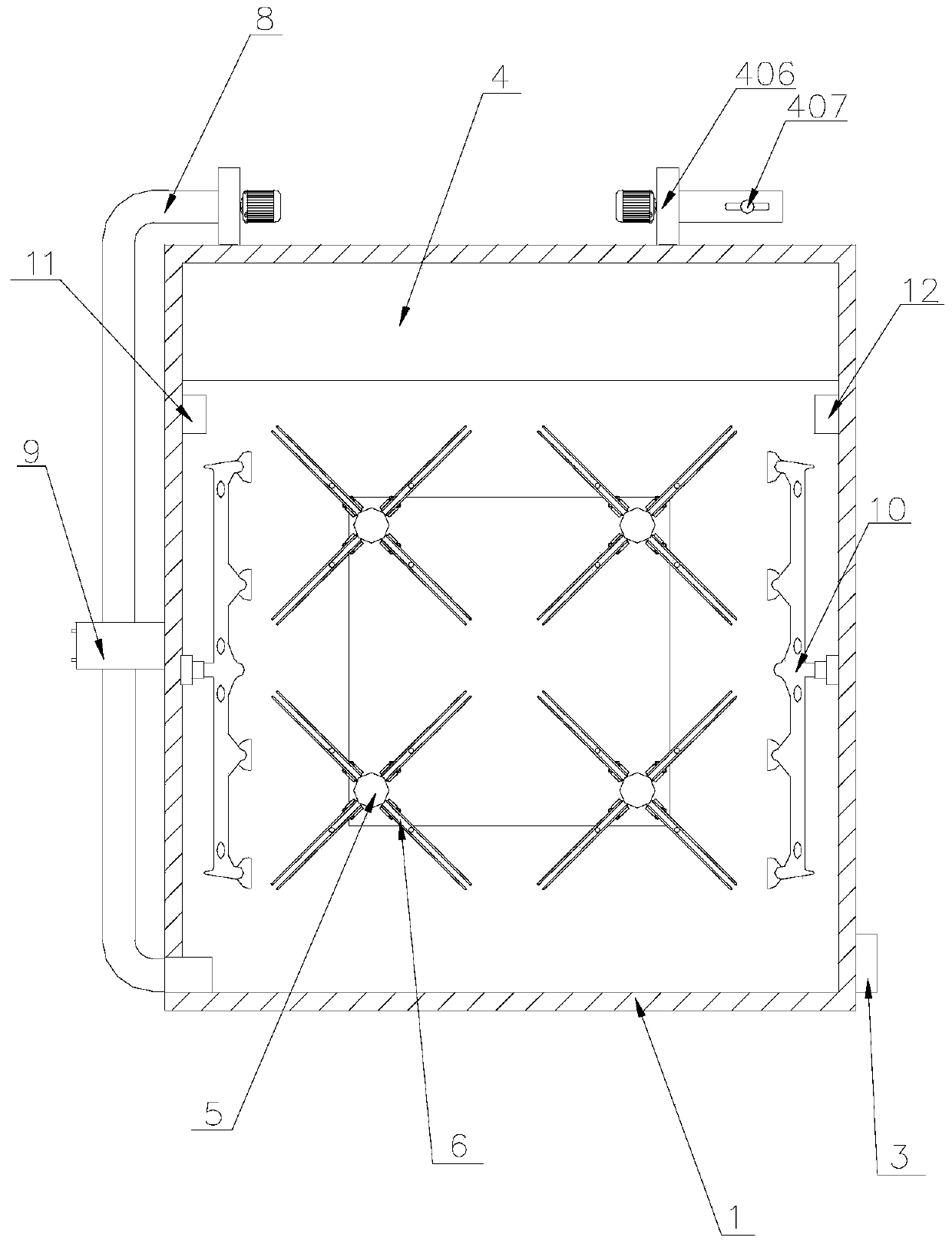

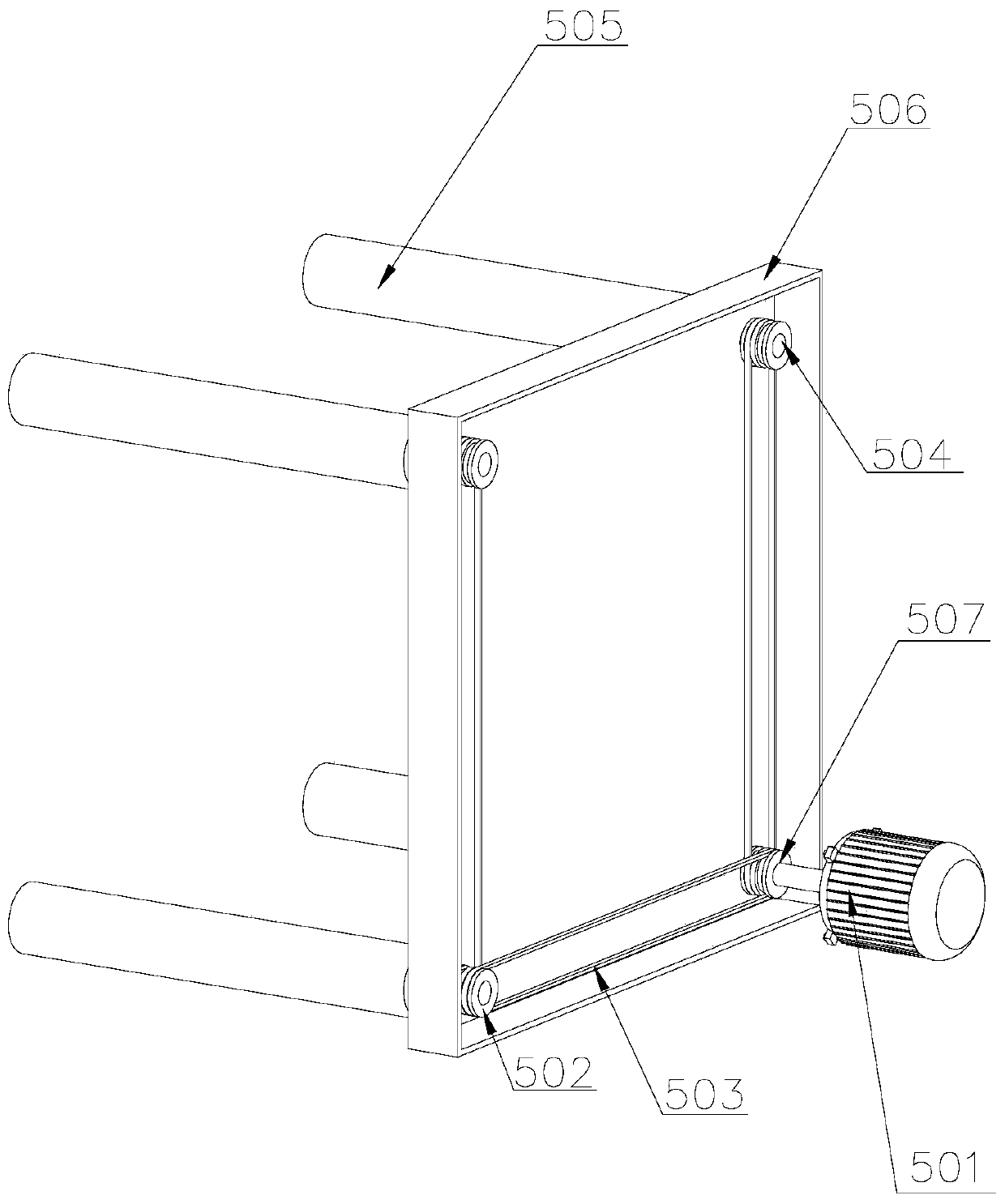

Drying device used in tobacco industry

ActiveCN110285648AEvenly heatedQuality assuranceDrying solid materials with heatDrying gas arrangementsPulp and paper industryEngineering

The invention discloses a drying device used in tobacco industry. The drying device comprises a working box body, a movable door, a heating device and a drying frame, wherein the movable door is arranged on the working box body, a handle is arranged on the movable door, the movable door is hinged to the working box body through a hinge, the heating device is arranged at the upper part inside the working box body, and the drying frame is arranged below the heating device. The drying device provided by the invention can be used for full drying to cigarettes and tobacco, so that cigarettes and tobacco is heated uniformly, the quality of the finished cigarettes and tobacco is ensured, gas produced after tobacco drying can be recycled, energy waste is reduced, and environment protection is facilitated.

Owner:SHANDONG QINGDAO TOBACCO

Direct-heat and constant-temperature circulating heat pump drying machine

InactiveCN105546967AHeating fastImprove work efficiencyTobacco preparationMechanical apparatusAir volumeLiquid storage tank

The invention relates to a direct-heat and constant-temperature circulating heat pump drying machine. The direct-heat and constant-temperature circulating heat pump drying machine comprises a machine case, a draught fan arranged in the machine case, an evaporator arranged on the right side of the draught fan, a condenser arranged on the right side of the evaporator, a circulating loop connected with the evaporator and the condenser, a throttling device, a liquid storage tank, a compressor, an air inlet pipe arranged on the throttling device, an electric adjusting valve arranged at the tail end of the air inlet pipe, an air supply pipe arranged on the left side of the condenser, an air returning port formed in the tail end of the air supply pipe, an air outlet formed in the right side of the condenser, and a centrifugal fan arranged in the air outlet, wherein the throttling device, the liquid storage tank and the compressor are arranged on the circulating loop. According to the direct-heat and constant-temperature circulating heat pump drying machine, the air volume can be adjusted through the electric adjusting valve and the centrifugal fan, and the constant-temperature air discharging is achieved; a circulating air flue is formed through the air outlet and the air returning port, exhausted waste heat can be recycled, and the drying efficiency is high. Heat is absorbed through the evaporator, heating of the evaporator is improved, the effect of energy saving is achieved, the work efficiency ratio of a main machine is increased, meanwhile, the structure is simple, and using is convenient.

Owner:HUBEI KEYANG ENERGY SAVING EQUIP

Drying plant for particulate materials

ActiveUS20150285554A1Drawback can be obviatedTobacco preparationDrying solid materials with heatParticulatesProcess engineering

Drying plant for particulate materials comprising: a drying duct which is provided with a substantially horizontal rectilinear starting section, a rectilinear ascending final section which extends upwards with a predetermined angle of inclination with respect to the vertical, and a curved intermediate section which connects the rectilinear starting section to the rectilinear final section; a hot gas generator designed for supplying to the inlet of the rectilinear starting section of the drying duct a flow of process gas at high temperature; a particulate feeding device which is structured so as to be able to feed / introduce into the rectilinear starting section of the drying duct a flow of particulate material to be dried substantially without relevant leaks of process gas from the drying duct; and a bypass duct which branches from the rectilinear starting section of the drying duct upstream of the particulate feeding device, and then re-joins the drying duct at the curved intermediate section, so as to feed back into the drying duct the process gas diverted inside it.

Owner:GARBUIO

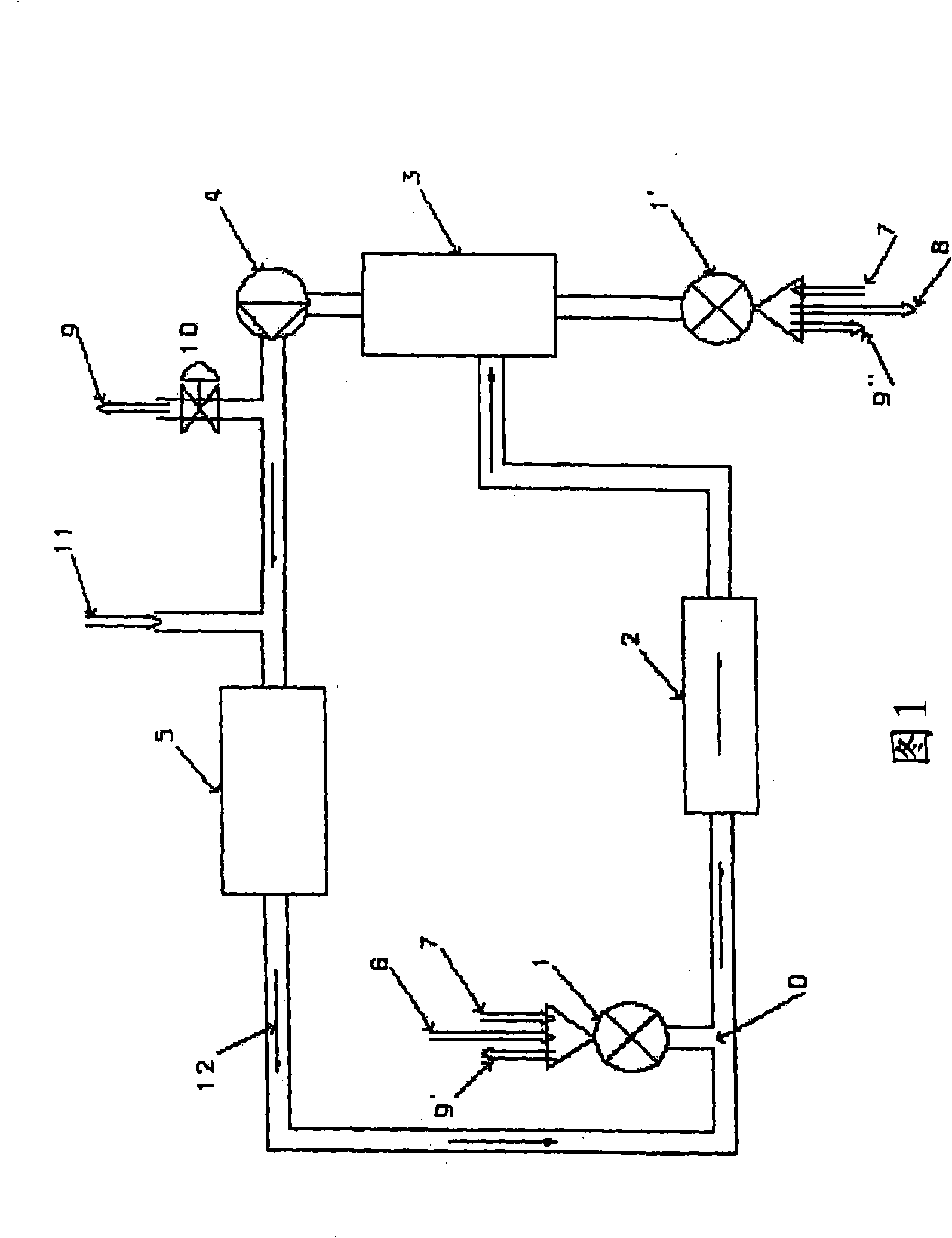

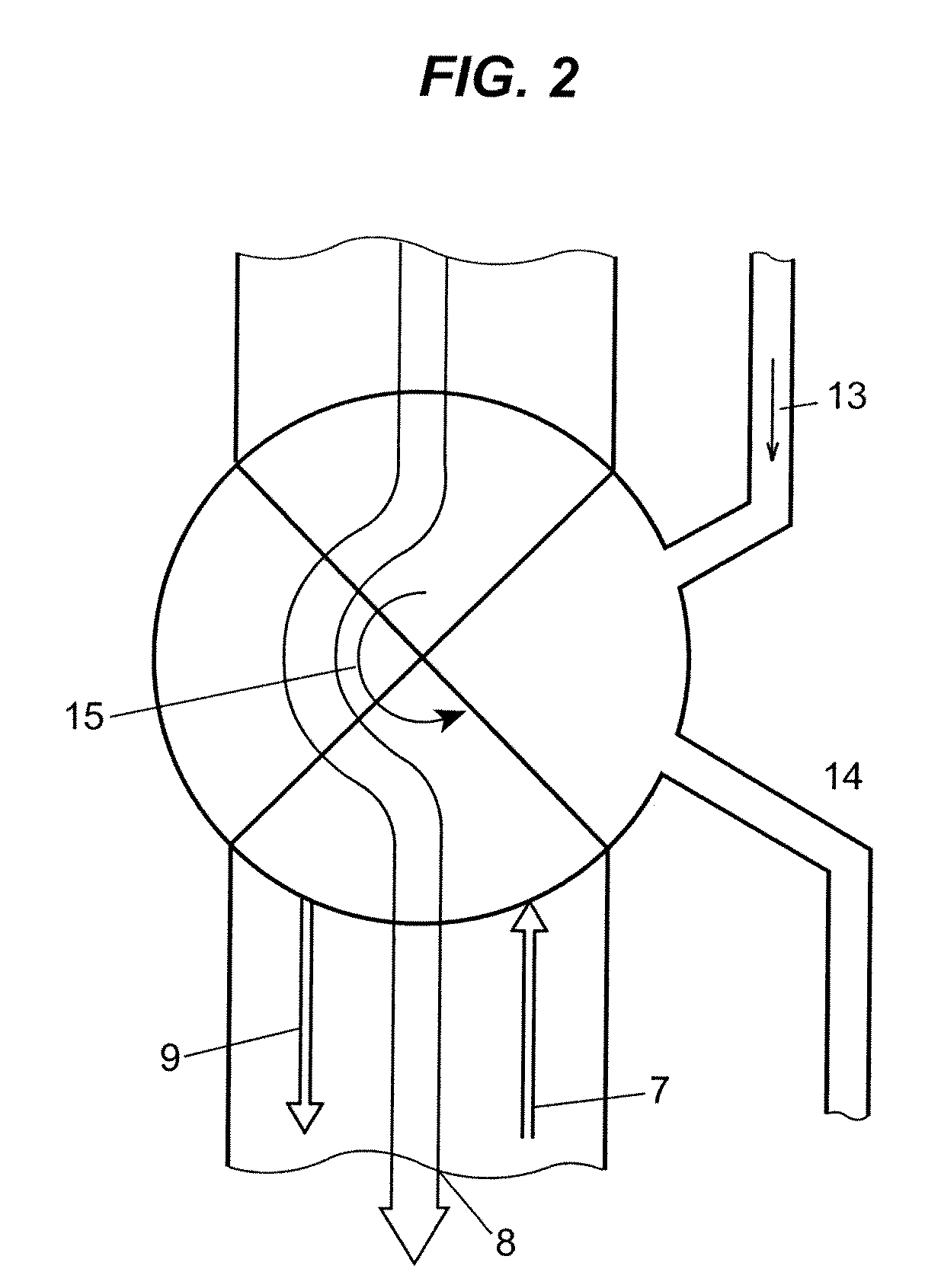

Method of increasing the efficiency of a drier, particularly a stream drier

InactiveUS20080295355A1Improve efficiencyTobacco preparationDrying solid materials with heatWorking pressureWaste product

A method of increasing the efficiency of a drier, particularly a stream drier for loose and flammable materials, particularly cut tobacco, working with a gaseous drying agent under a working pressure from 5 kpa to 10 MPa, measured as an absolute pressure, preferably the drying agent being superheated steam. A pressurized process gas, preferably waste steam, particularly coming from the interior of the drier, is passed through a dosing-separating valve, preferably a rotary vane feeder (1′) mounted behind the stream drier (2), particularly through its movable section with the dried material being emptied therefrom, the steam being returned from a release valve (10) for reusing it in the process of diluting the air, the steam being regarded as a technology waste product.

Owner:SIEREDZINSKI MAREK

Device and method for processing tobacco

InactiveUS20120279081A1Quantity minimizationEnhances qualitative propertyTobacco preparationDrying solid materials with heatProduct gasProcess engineering

The present invention provides a device and a method, wherein the process conditions can be kept constant in a device for processing tobacco. The device comprises a combining device for combining the tobacco to be processed and a process gas and which is connected to a discharge device for discharging a first quantity of the process gas and a supply device for supplying a second quantity of the process gas; the device having at least one control device for controlling the first quantity of the discharged process gas and / or the second quantity of the supplied process gas.

Owner:JT INT SA

Outward discharging wet type two-effect drying heat pump unit

PendingCN111219955AForm a positive feedback loopRaise the evaporation temperatureTobacco preparationHeat pumpsFresh airEngineering

The invention discloses an outward discharging wet type two-effect drying heat pump unit which comprises an air flow circulation channel provided with an air inlet and an air outlet and further comprises at least two heat pump units. Each heat pump unit comprises a compressor, a condenser, a throttling device and an evaporator which are connected in sequence, wherein the evaporator is located in environment air outside the air flow circulation channel, and the condenser is located in the air flow circulation channel. The air flow circulation channel is provided with a wet discharging opening and a fresh air opening, and the evaporator of at least one heat pump unit is arranged at the wet discharging opening. The wet discharging opening and an air suction opening are provided with hole plate structures with adjustable hole opening degrees. Part of warm and wet air flows out from the wet discharging opening and then flows through the evaporators at the wet discharging opening, the otherpart of warm and wet air is mixed with fresh air supplied from the fresh air opening, the mixed air then flows through all the condensers to be heated into high-temperature dry air, and the high-temperature dry air is sent by into a drying chamber to be subjected to the new round of drying work.

Owner:SHANGHAI BOHAN THERMAL ENERGY TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com