Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about "Timed pressure lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

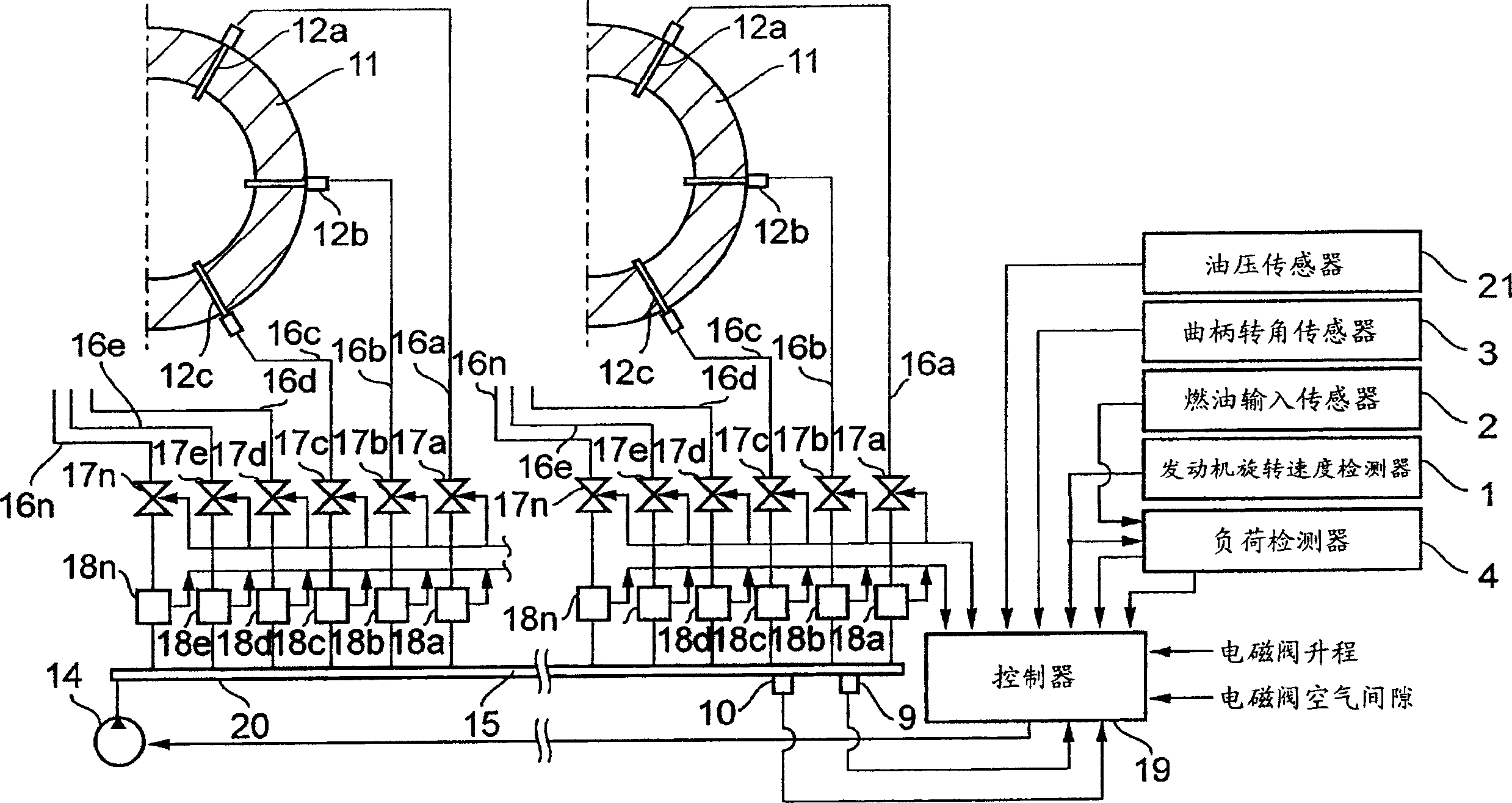

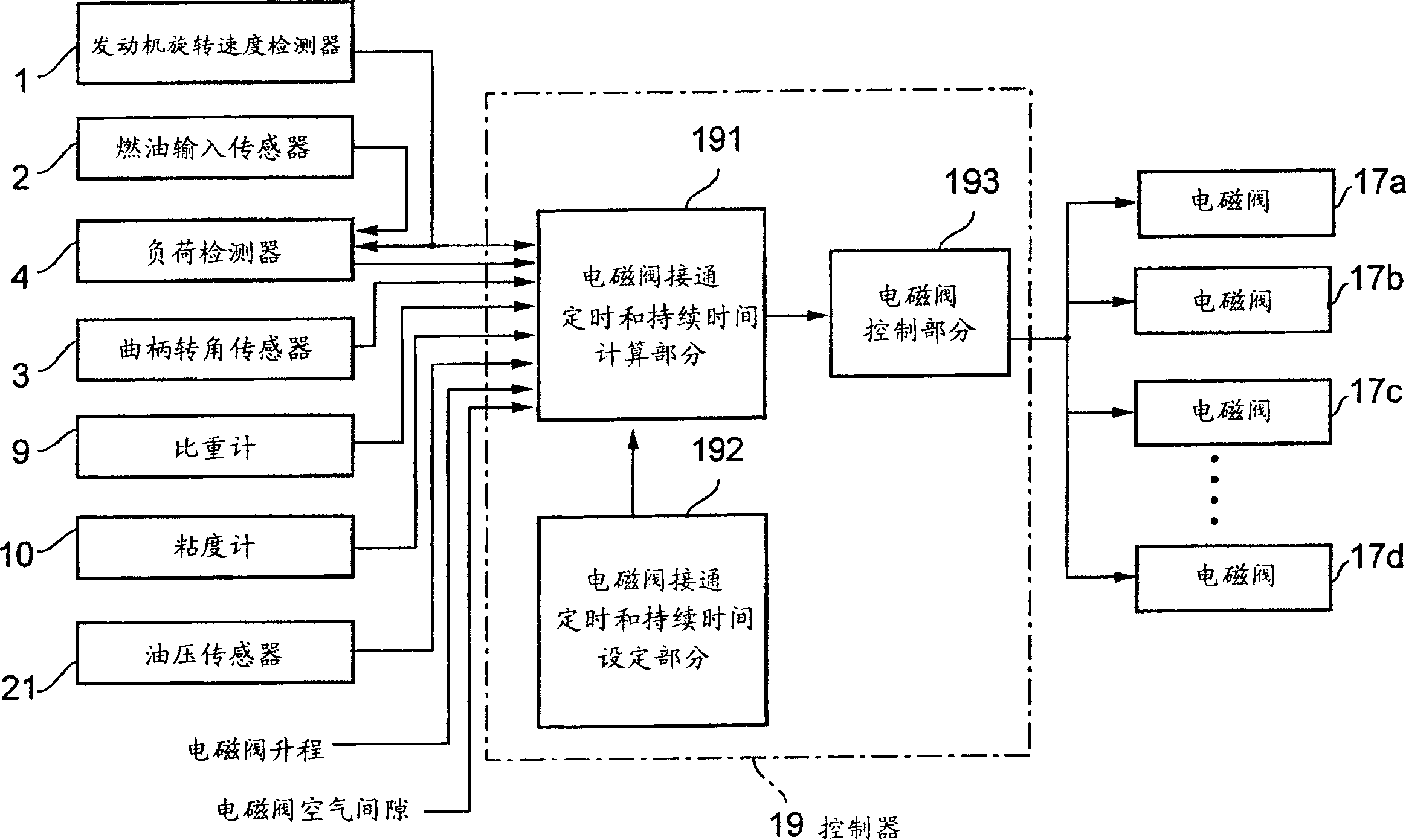

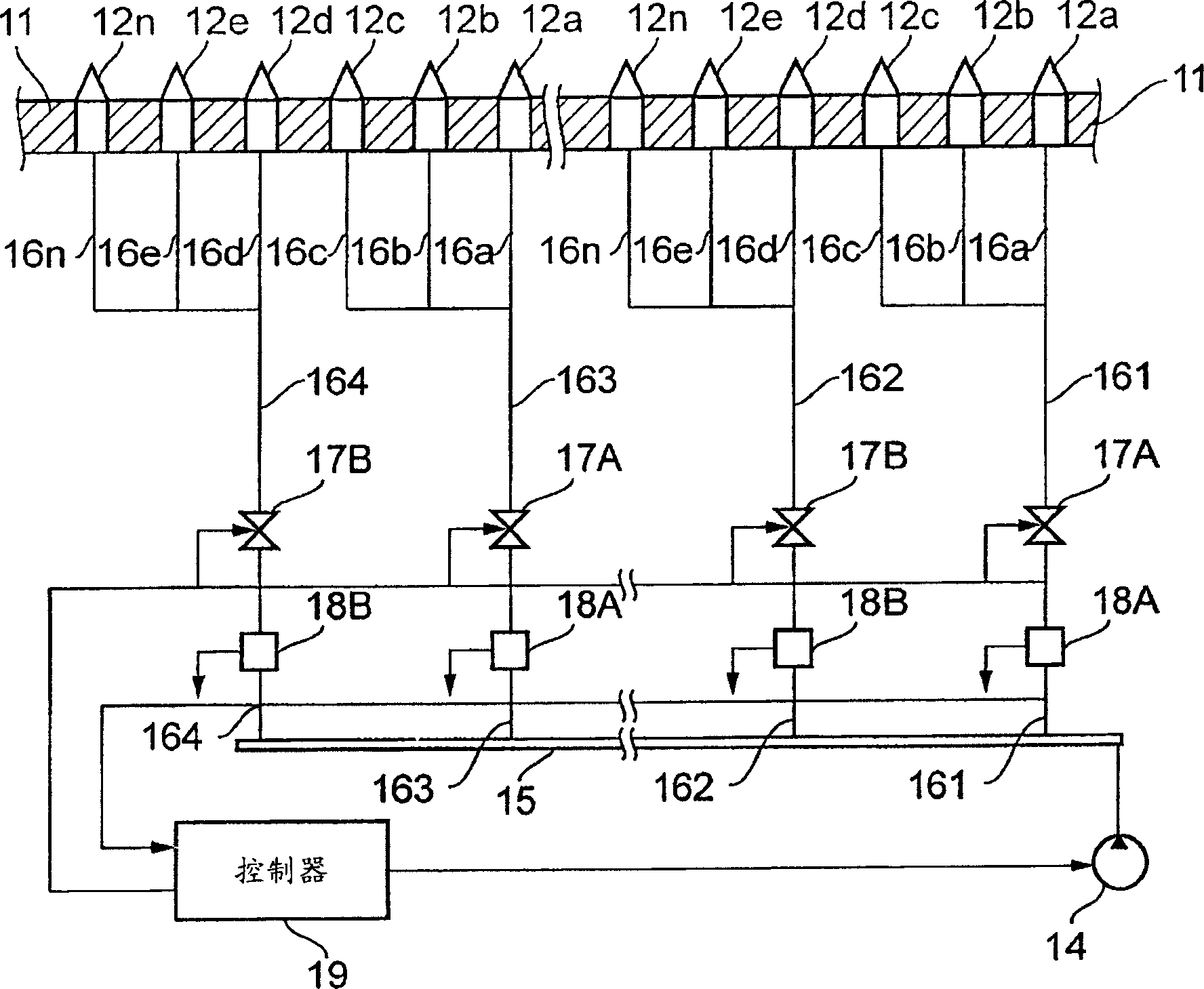

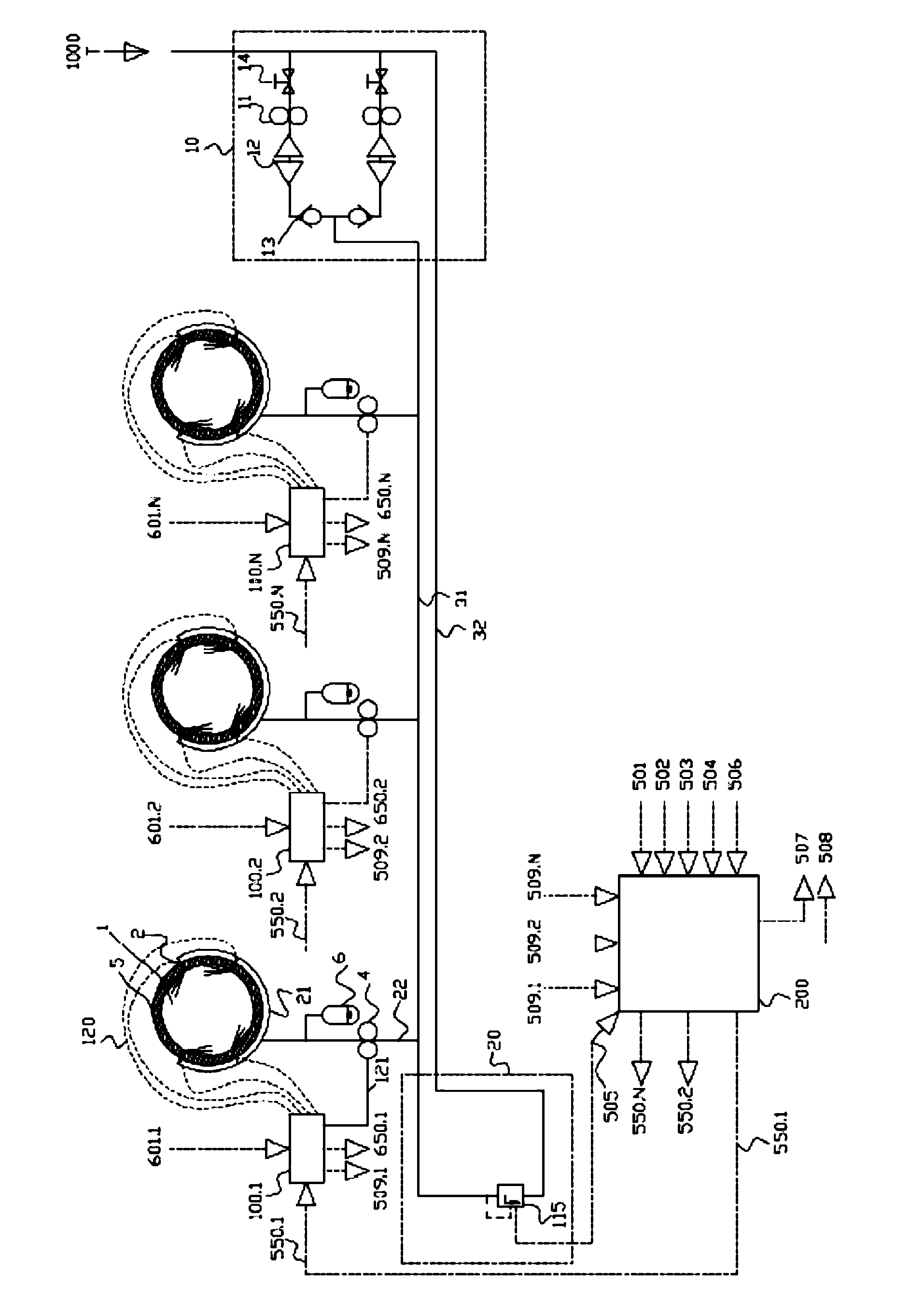

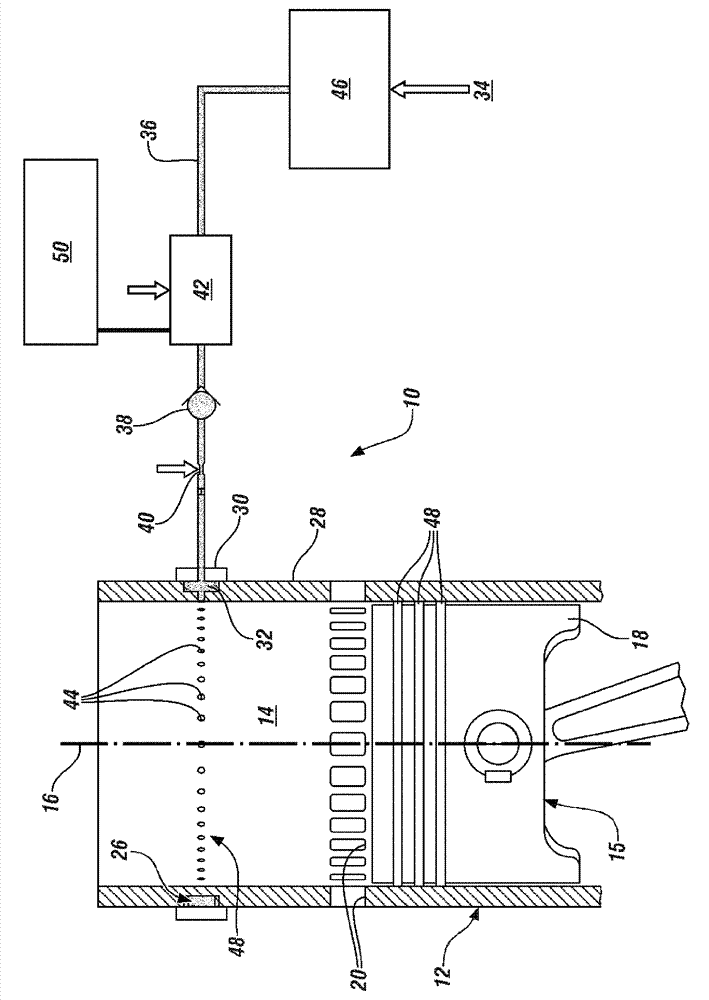

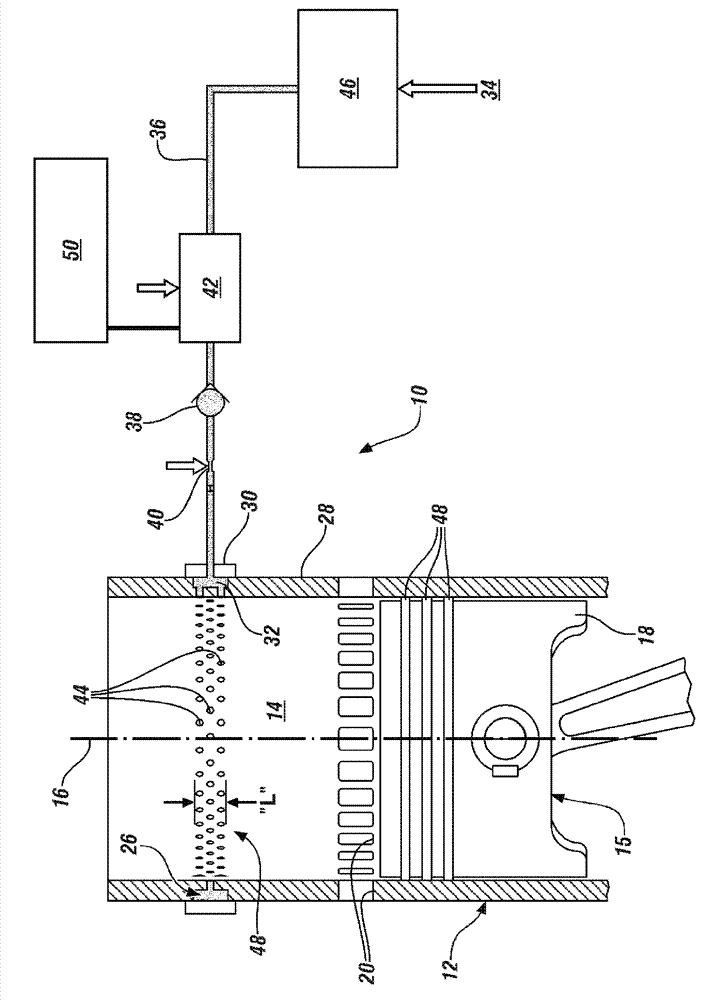

Internal combustion engine with cylinder lubricating system

InactiveCN1676888AReduce supplySupply impactElectrical controlCylinder headsExternal combustion enginePiston ring

An internal combustion engine with a cylinder lubricating system is proposed; with the system it becomes possible to supply lube oil of required amount at required timing to each of lubricators, and normal supply of lube oil is possible even when malfunction occurs in some of the lubricators or magnetic valves, and further the timing and amount of lube oil supply can be adjusted even in engine operation in accordance with varying factors such as properties of lube oil, lube oil pressure, etc., resulting in a reduction of lube oil consumption. Lubricating oil pressure-fed by a lubricating oil pump is accommodated in a common lube oil feeding section, the lubricating oil accumulated in said common lube oil feeding section is supplied to a plurality of lubricators (injectors) through oil passages connecting said common lube oil feeding section to said lubricators and injected to the inner surfaces of cylinders of the engine by said lubricators, a plurality of electromagnetic valves are provided for opening or closing the oil passages and the timing and period of opening of each of the valves are controlled independently so that lube oil is injected from the lubricators to spaces between piston rings once per one reciprocation of piston.

Owner:MITSUBISHI HEAVY IND LTD +1

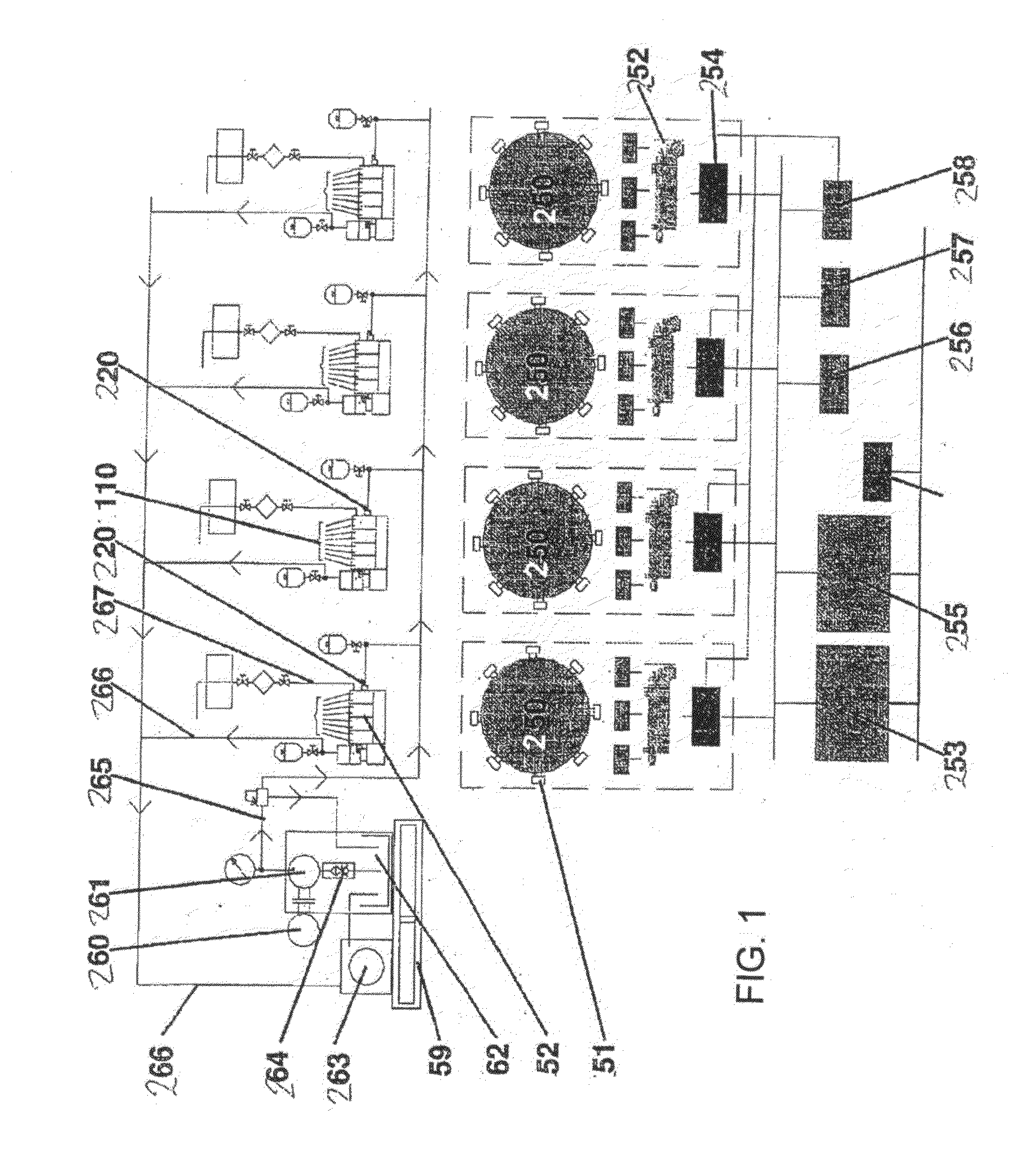

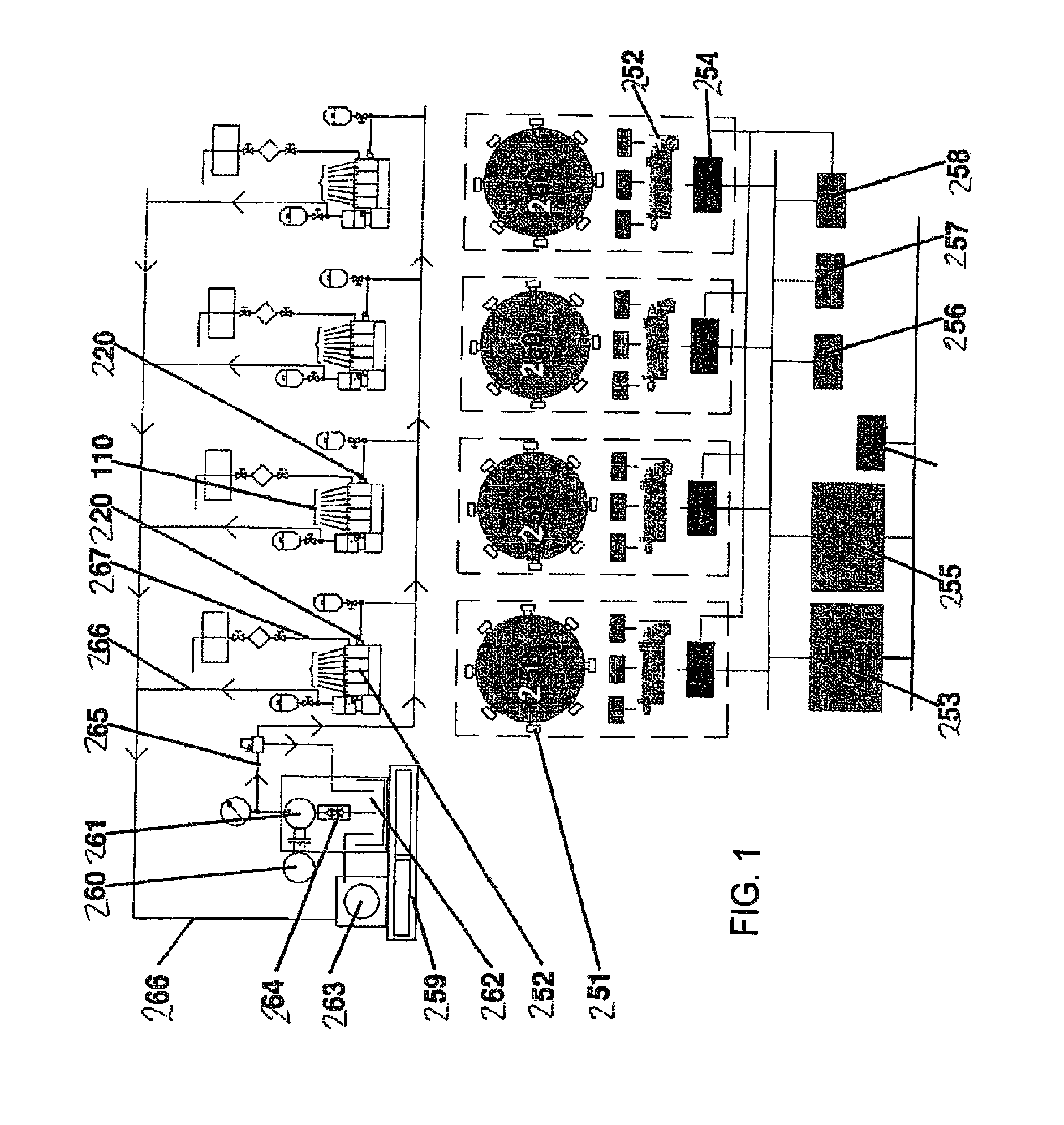

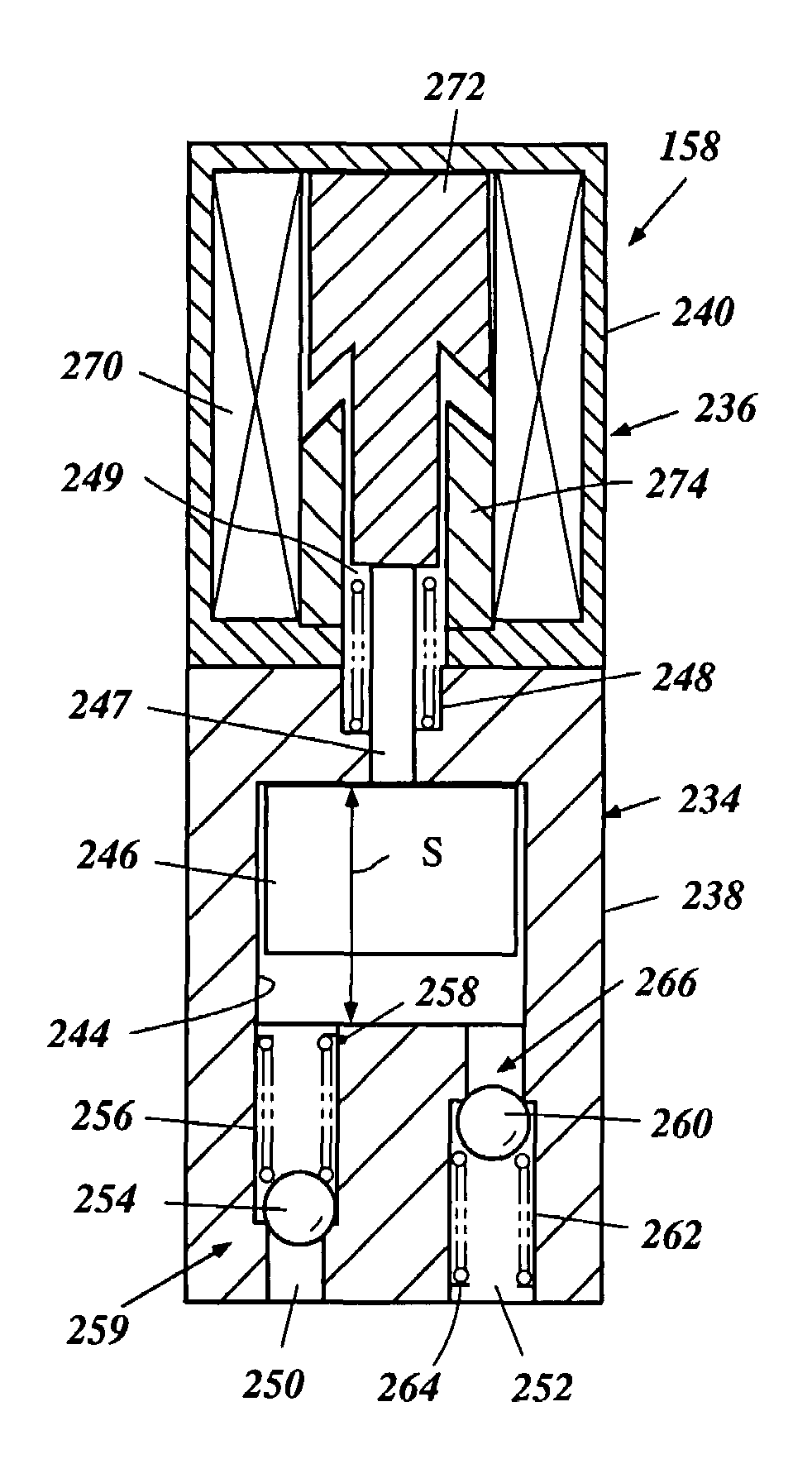

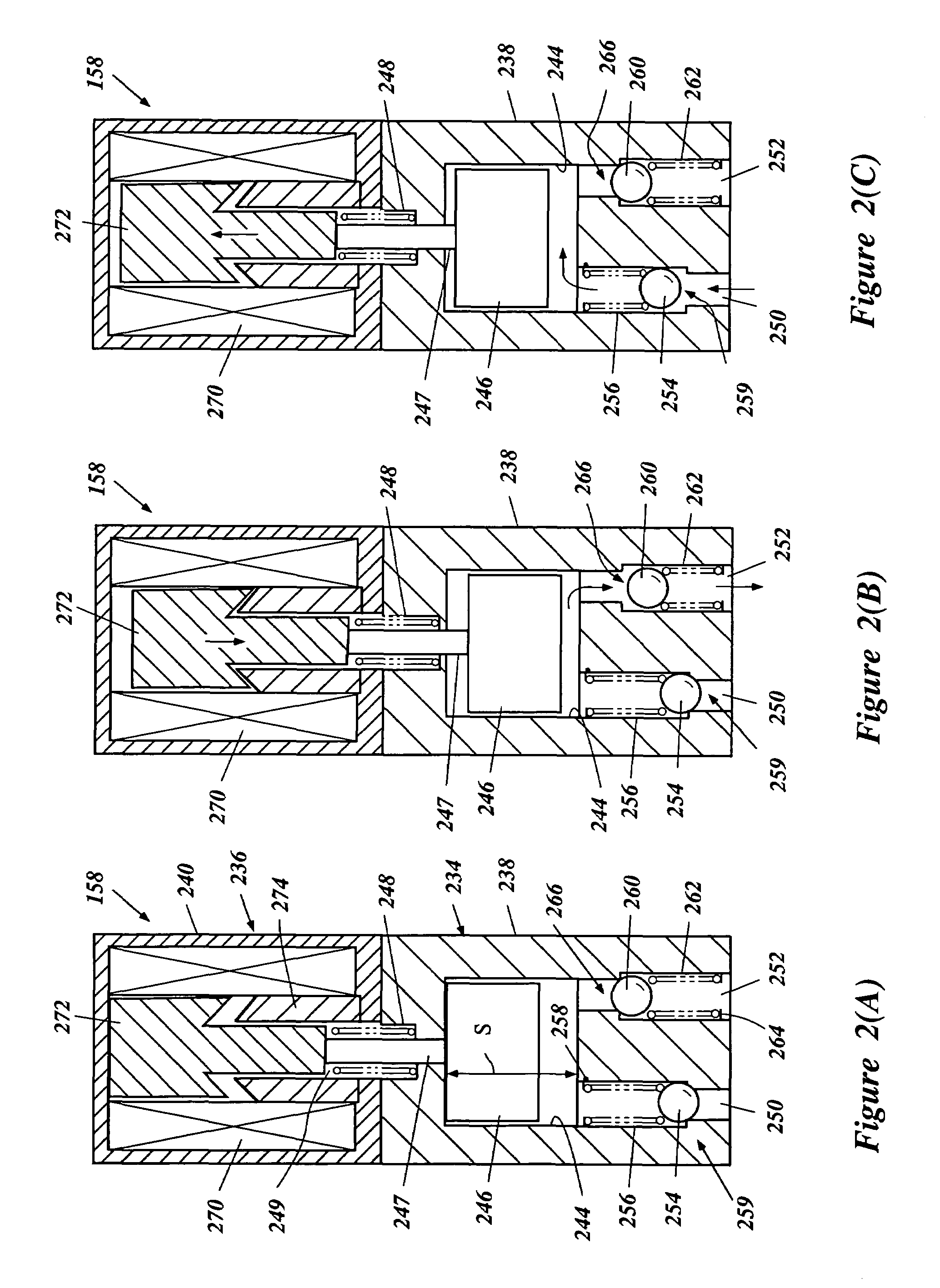

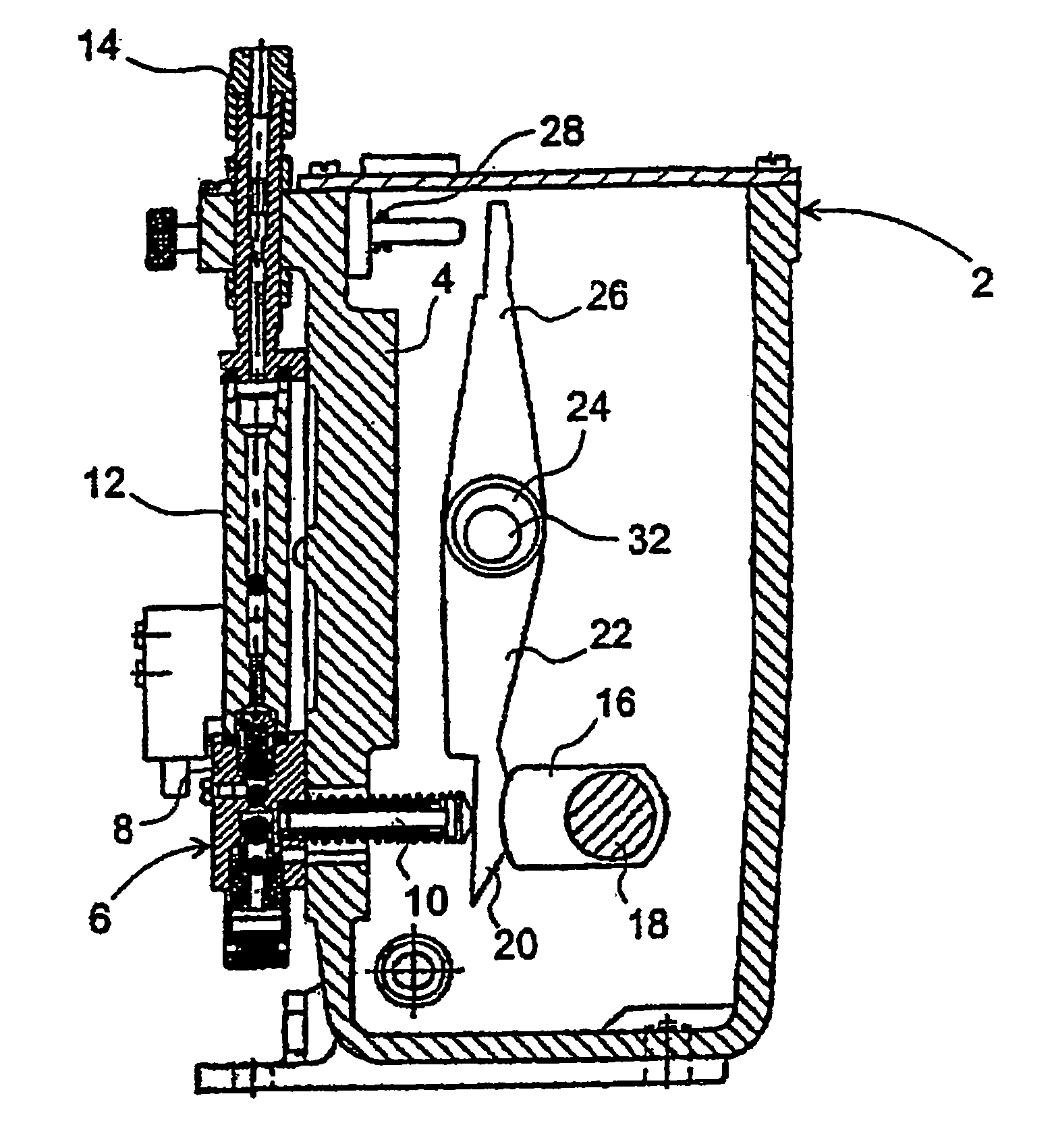

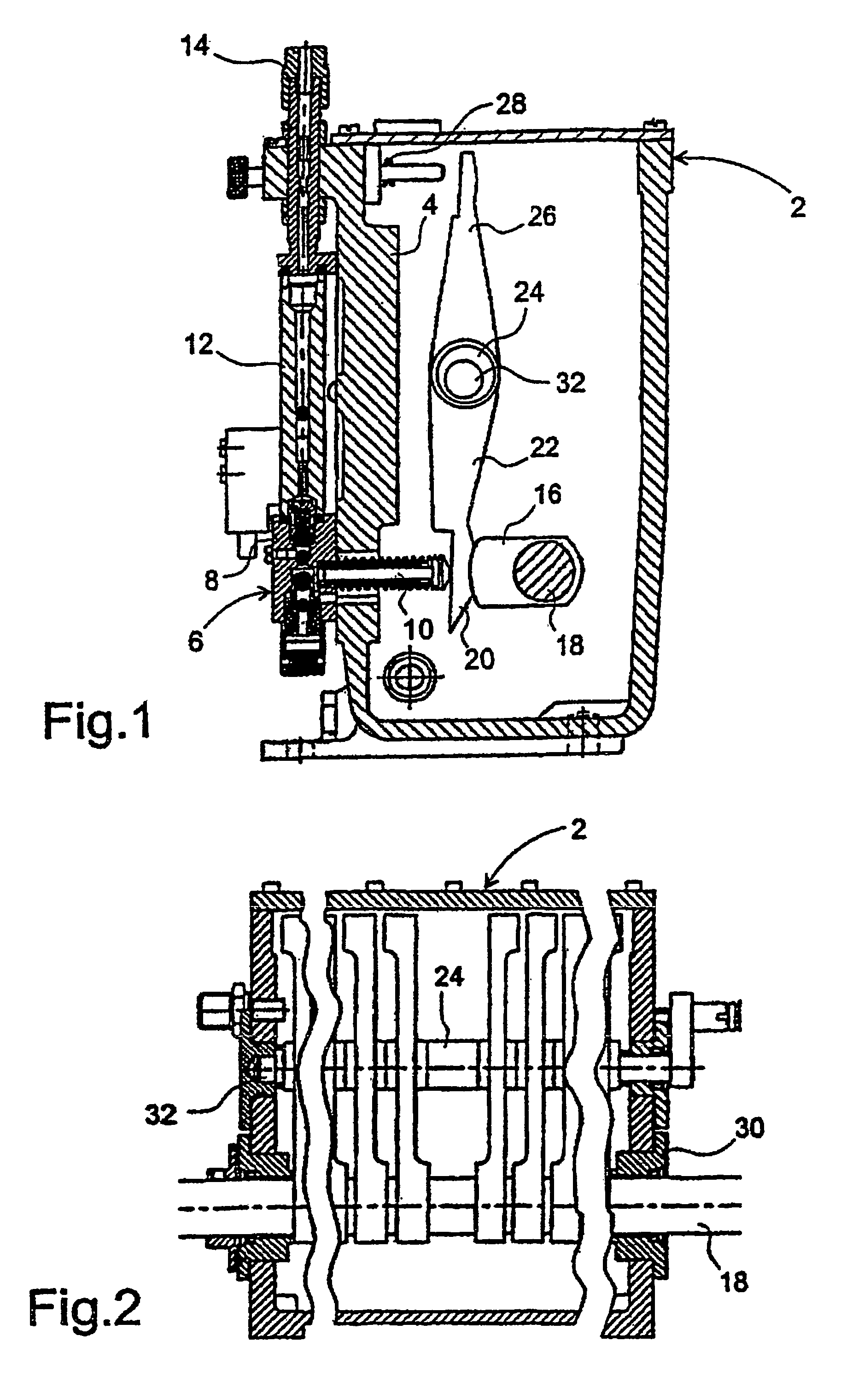

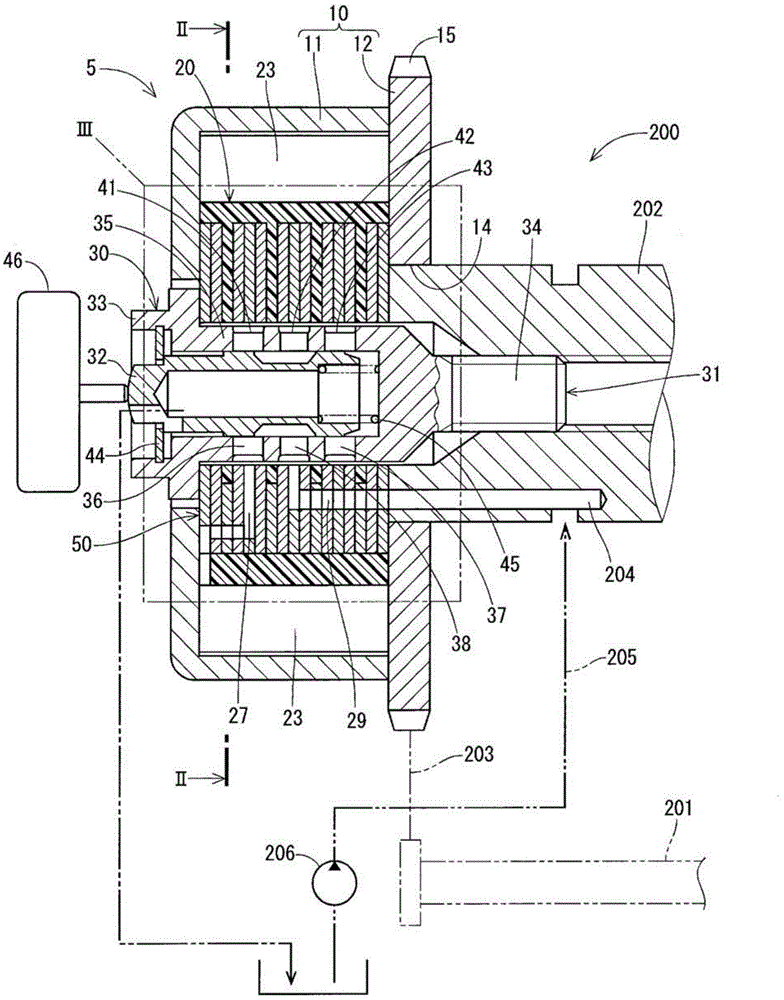

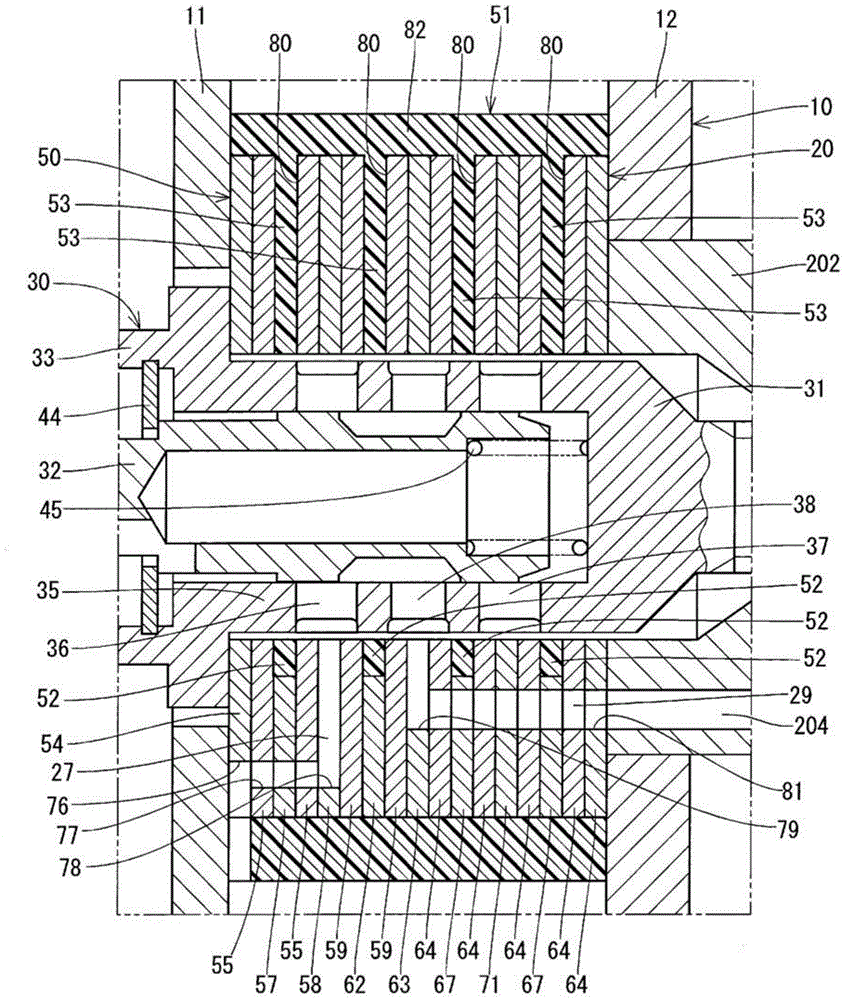

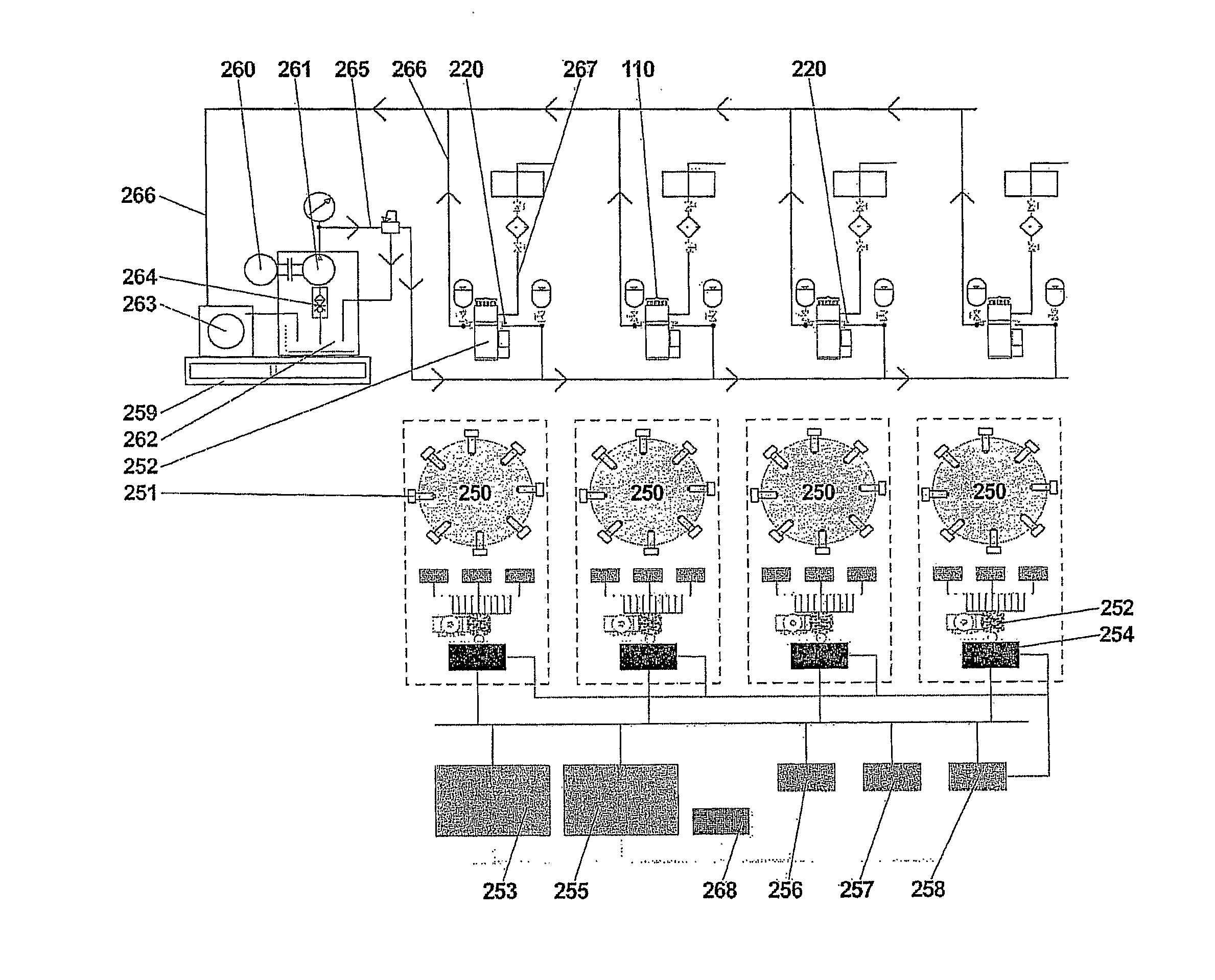

Lubricating apparatus and method for dosing cylinder lubrication oil

ActiveUS20100162989A1Prevent movementSimple and compact designLubrication of auxillariesLubricant conduit arrangementsHydraulic cylinderEngineering

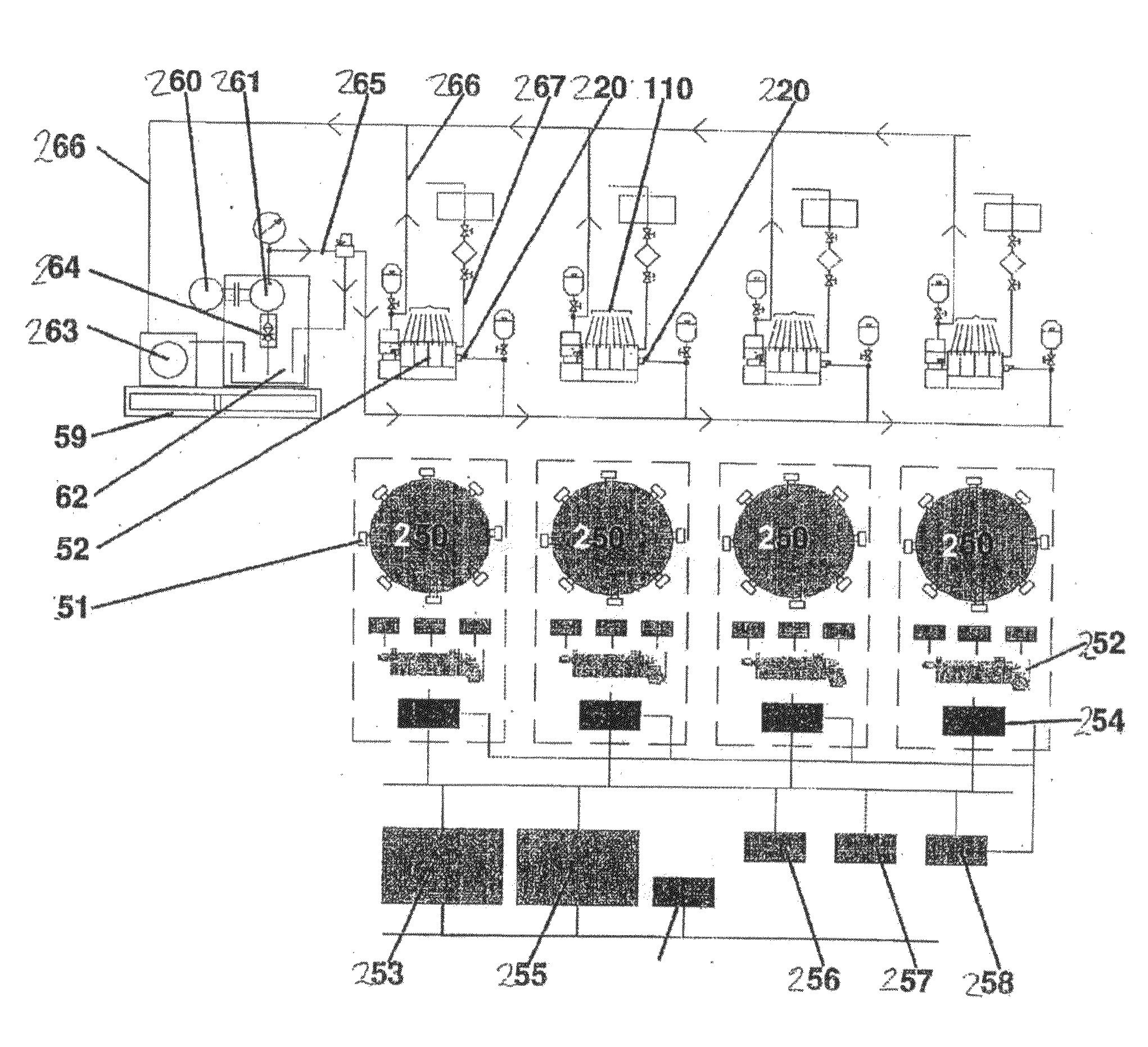

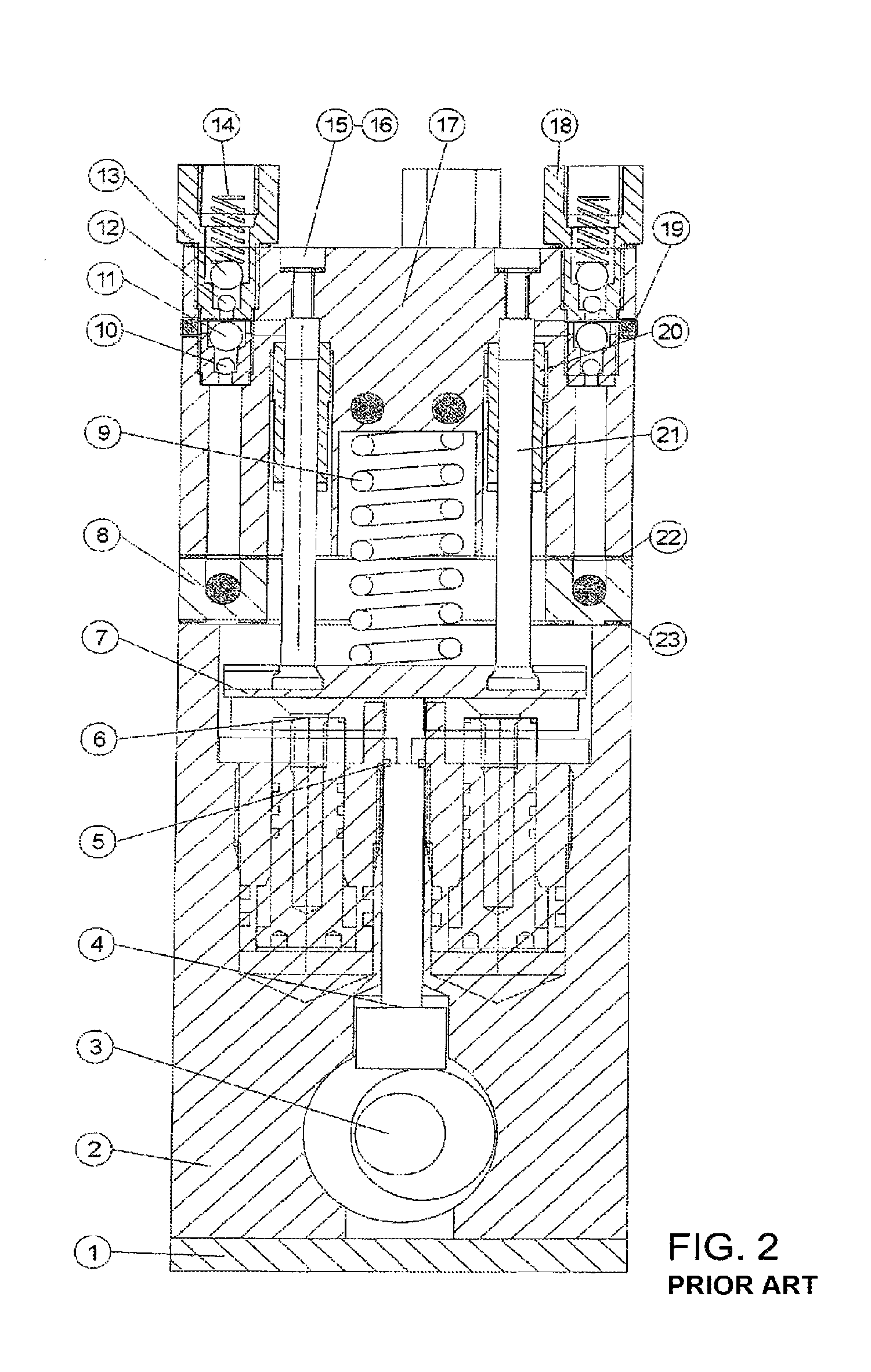

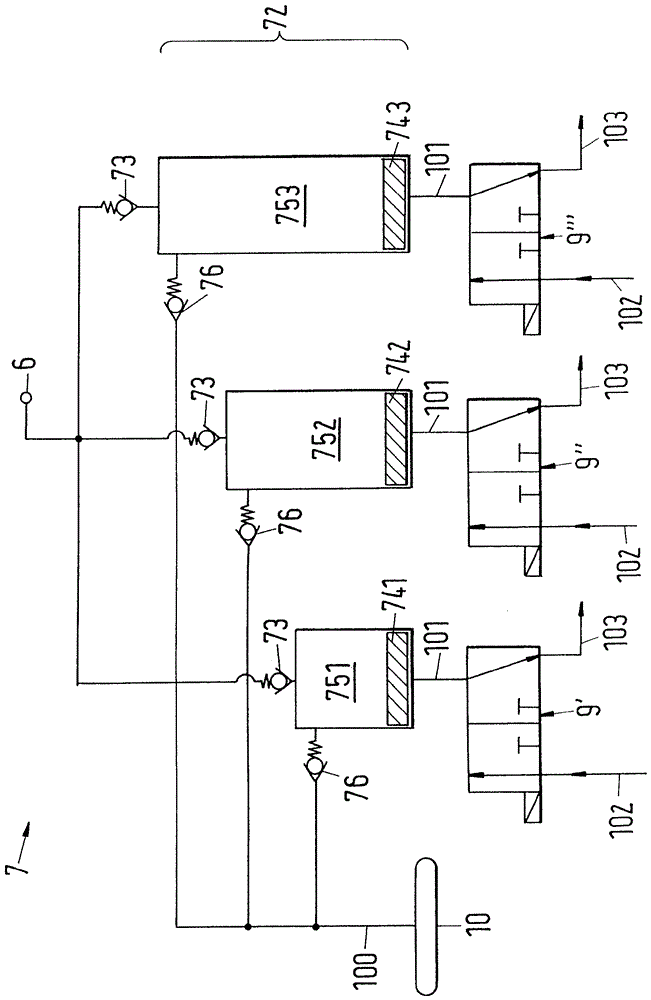

There is described a hydraulic lubricating apparatus (252) for dosing cylinder lubricating oil, including a housing which via one or more valves (220) is connected to a source for supplying hydraulic oil (262) and cylinder lubricating oil (not shown), a number of hydraulic cylinders each having a hydraulic piston (6) and which may be pressurised by hydraulic oil. Furthermore, there are a number of injection units (251) corresponding to a multiple of the cylinder (250) number in the engine, and which are connected with each their dosing cylinder by a dosing piston (21). Also, there is provided a distributor plate (7) which at one side is in contact with the dosing pistons (21) and which at its other side is in contact with the hydraulic pistons (6) for displacing the distributor plate for actuating the dosing pistons. The hydraulic pistons (6) are provided in groups, where each group is adapted for independent displacement of the distributor plate (7) for actuating the dosing pistons, and where each group of hydraulic pistons have each their individual stroke. In that way there may be achieved an individual quantity adjustment of lubricating oil, depending on the group of hydraulic pistons that is activated.

Owner:HANS JENSEN LUBRICATORS

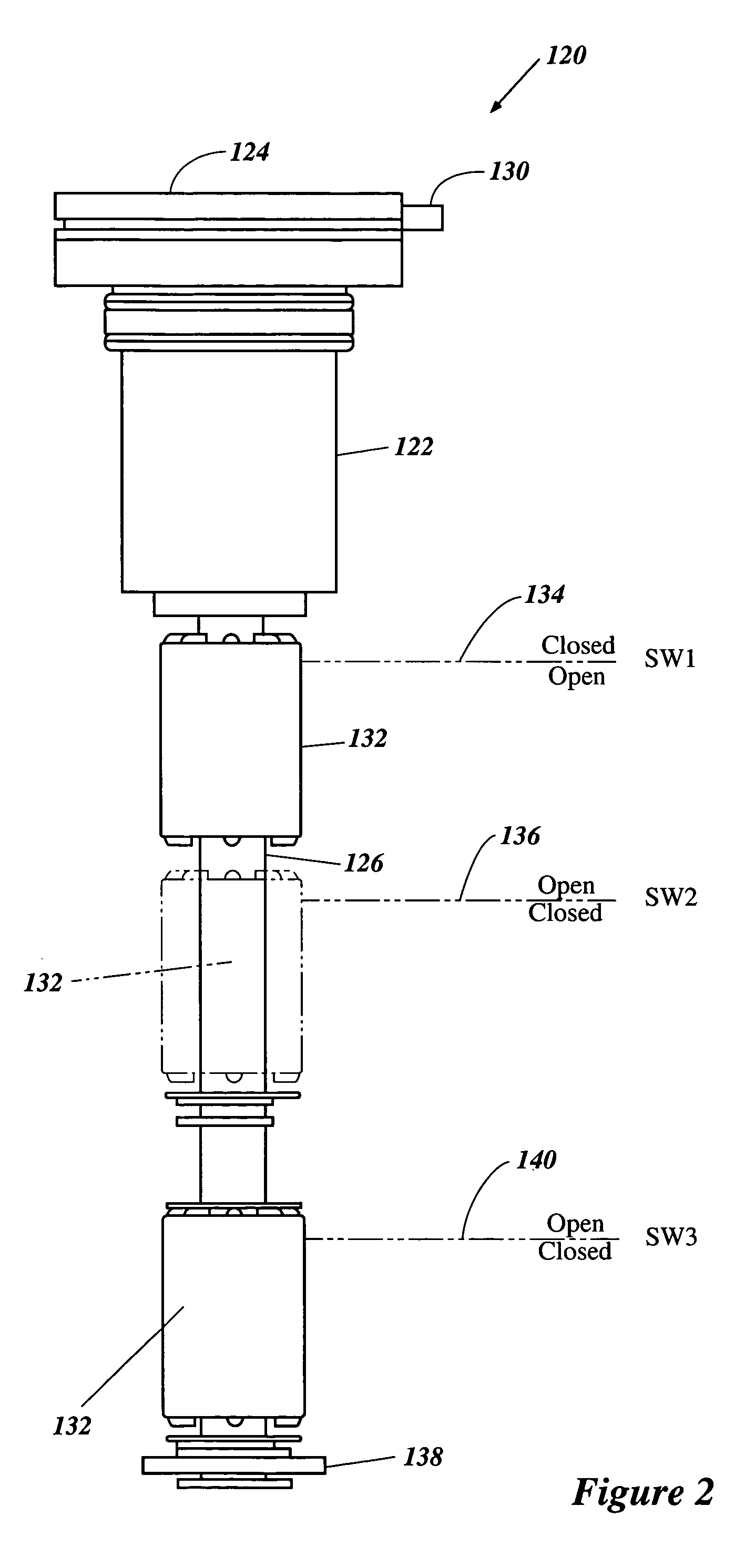

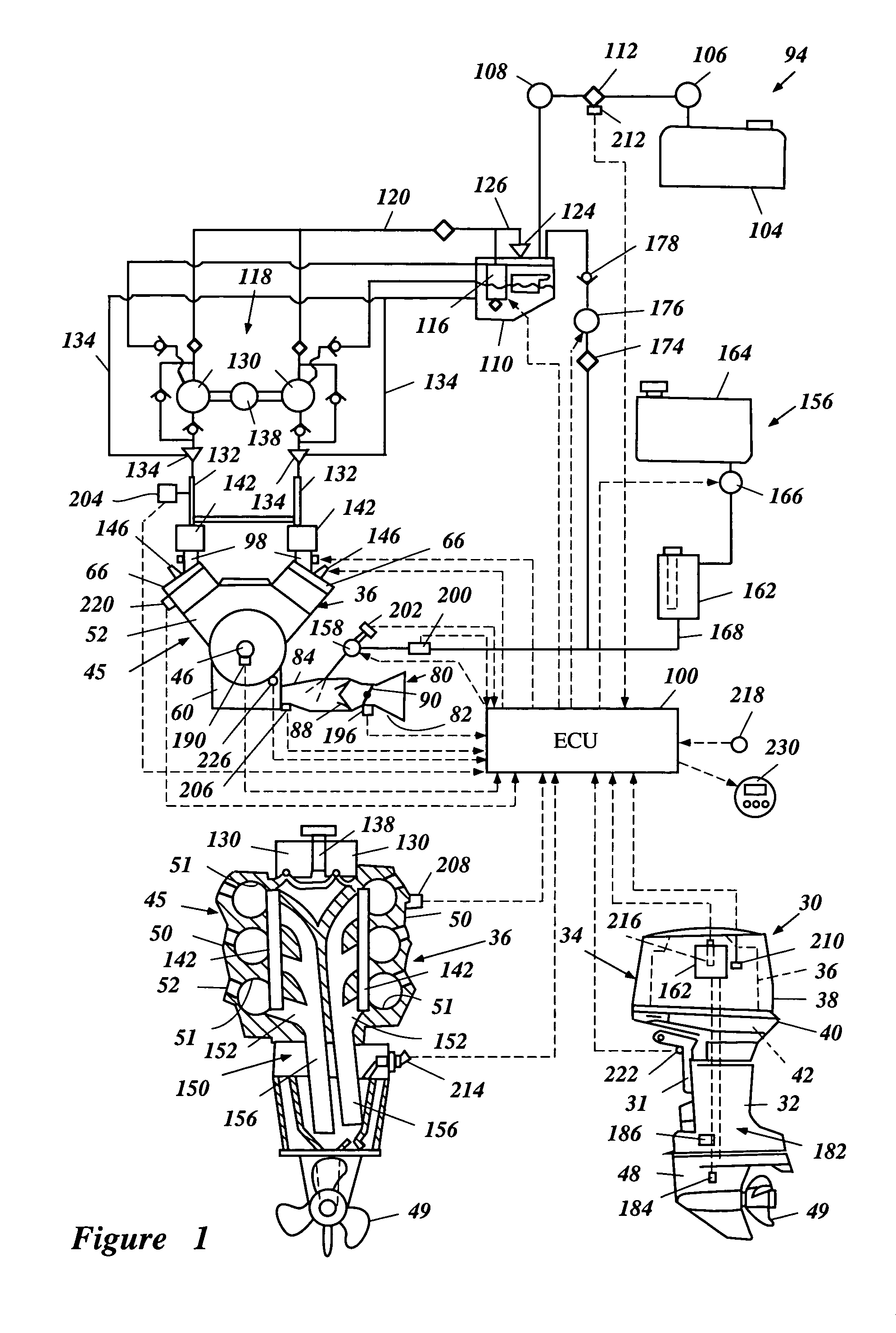

Lubrication supply control system

An engine has a lubrication system to lubricate at least a portion of the engine with lubricant. The lubrication system has a lubrication pump that periodically pressurizes the lubricant toward the portion of the engine. A first sensor senses an engine speed. A second sensor senses an engine load. A third sensor senses a temperature of the lubricant or the engine. A control device controls the lubrication pump. The control device determines a frequency of periodic pressurization by the lubrication pump based upon outputs from the first and second sensors. The control device determines a pressurization time of the lubrication pump based upon at least one of outputs from the first sensor, second sensor, third sensor, and a battery voltage.

Owner:YAMAHA MARINE KK

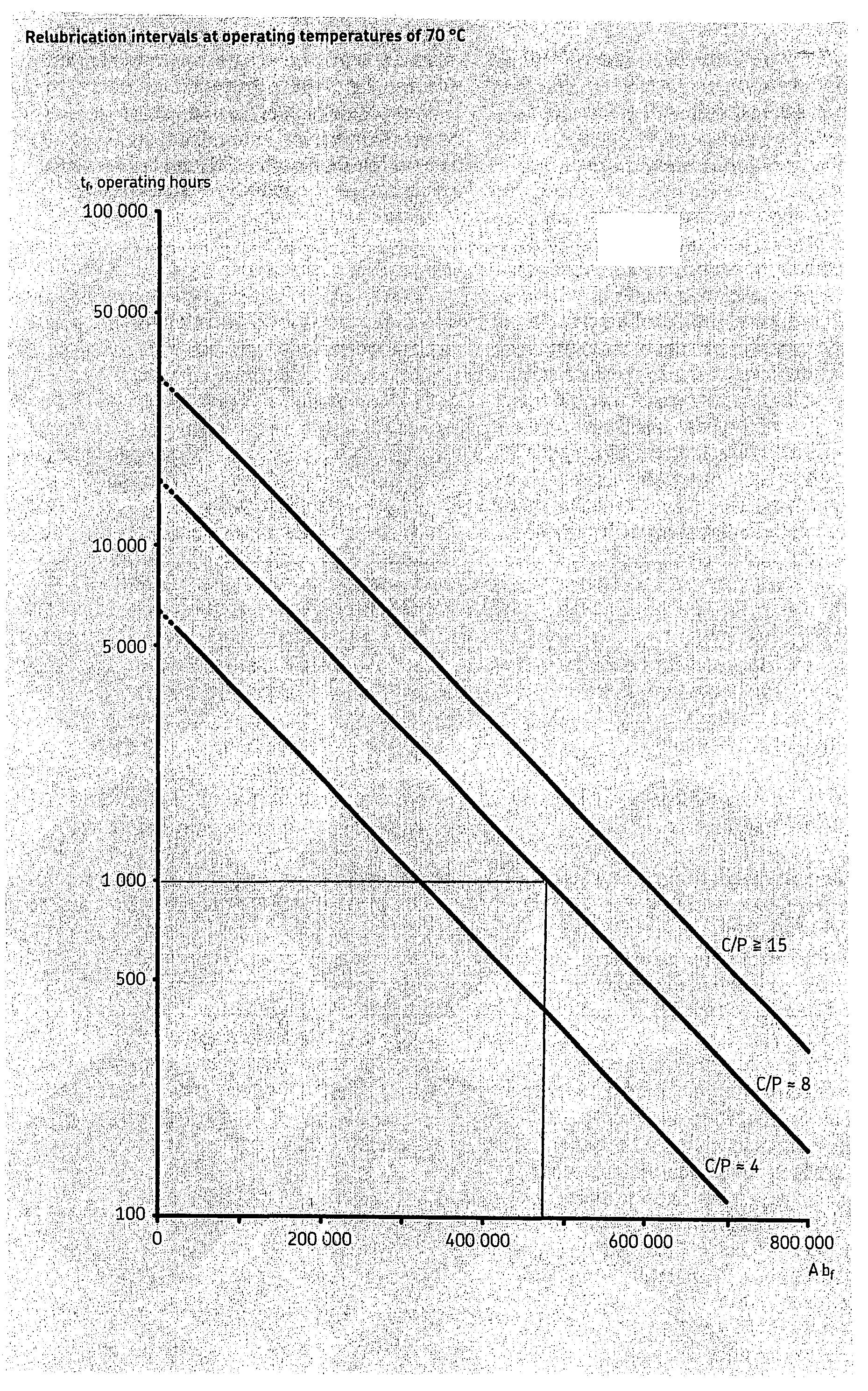

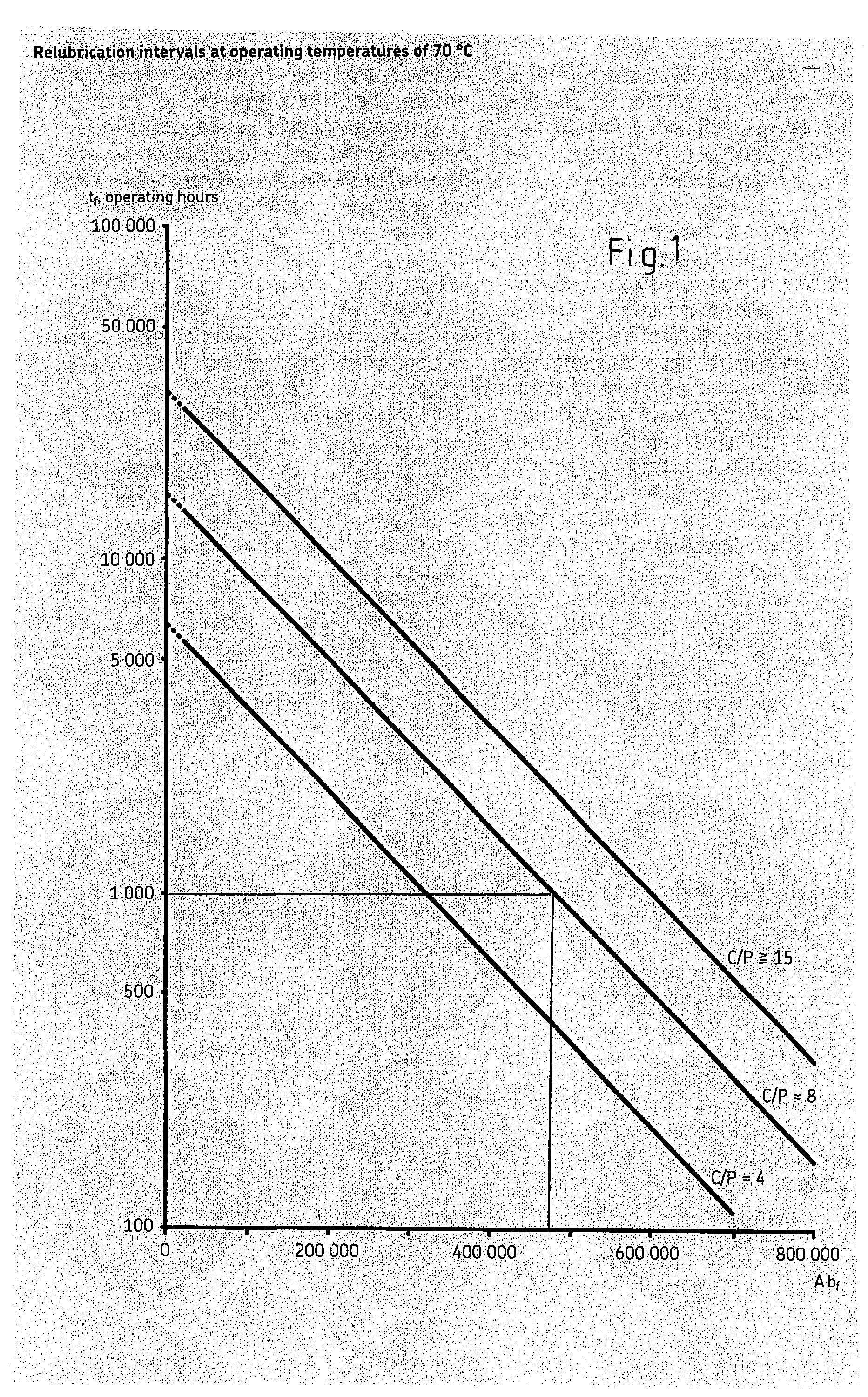

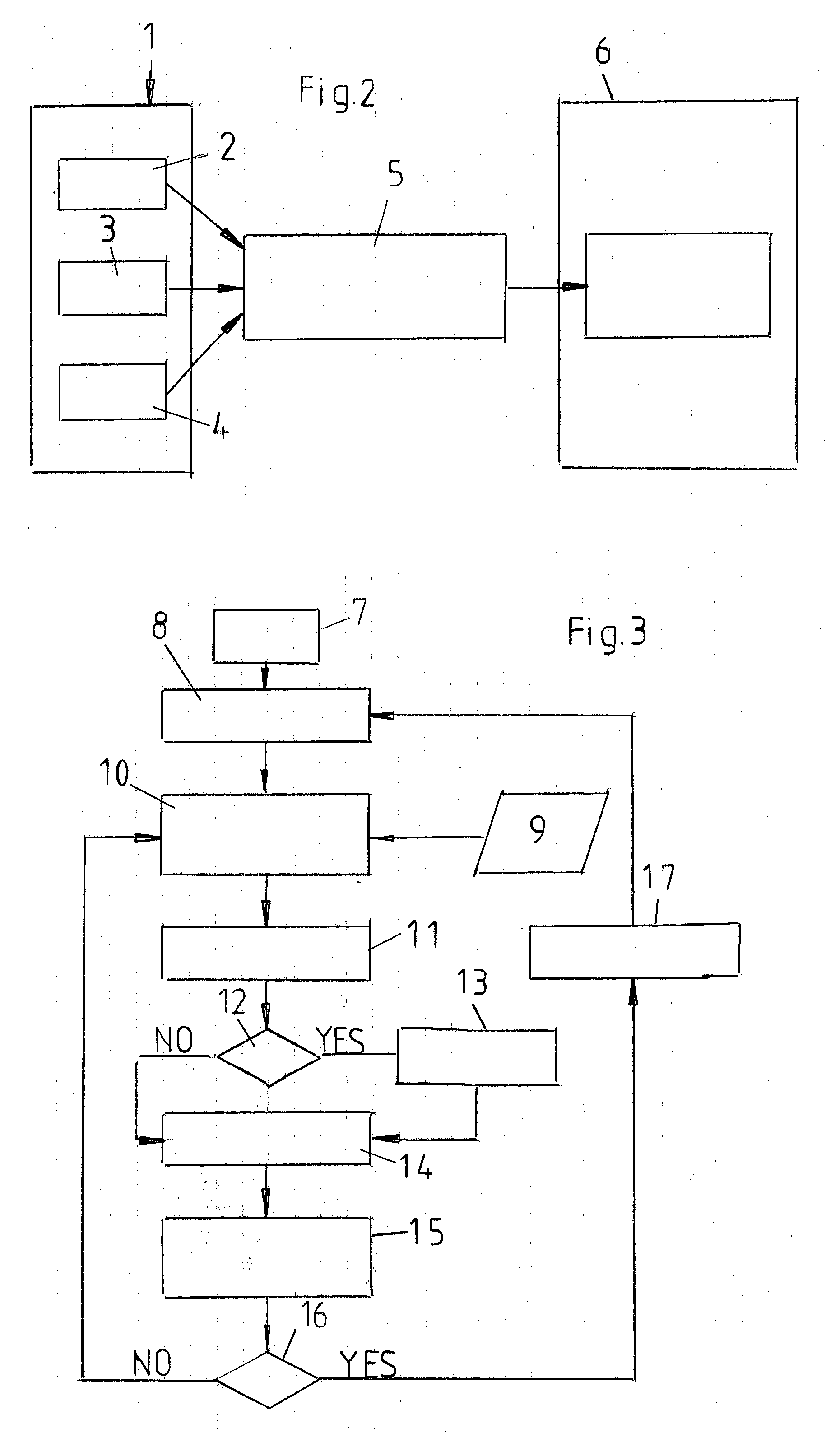

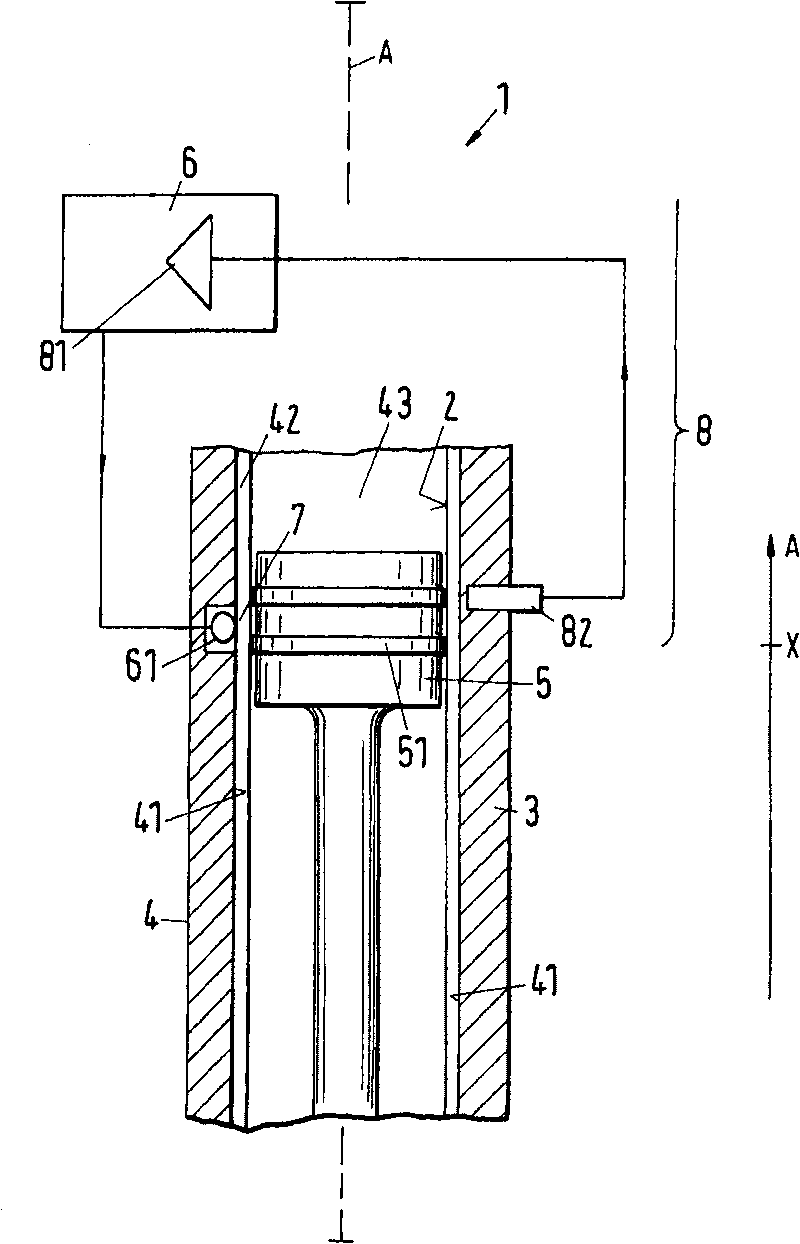

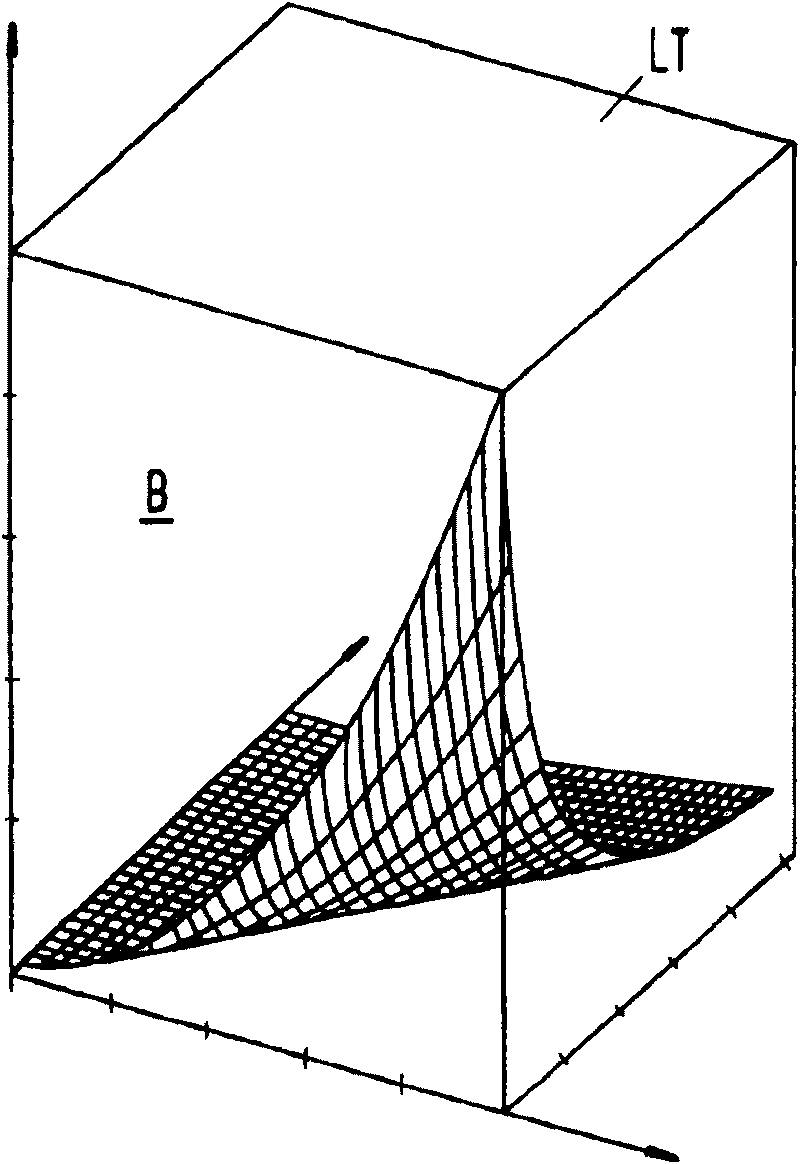

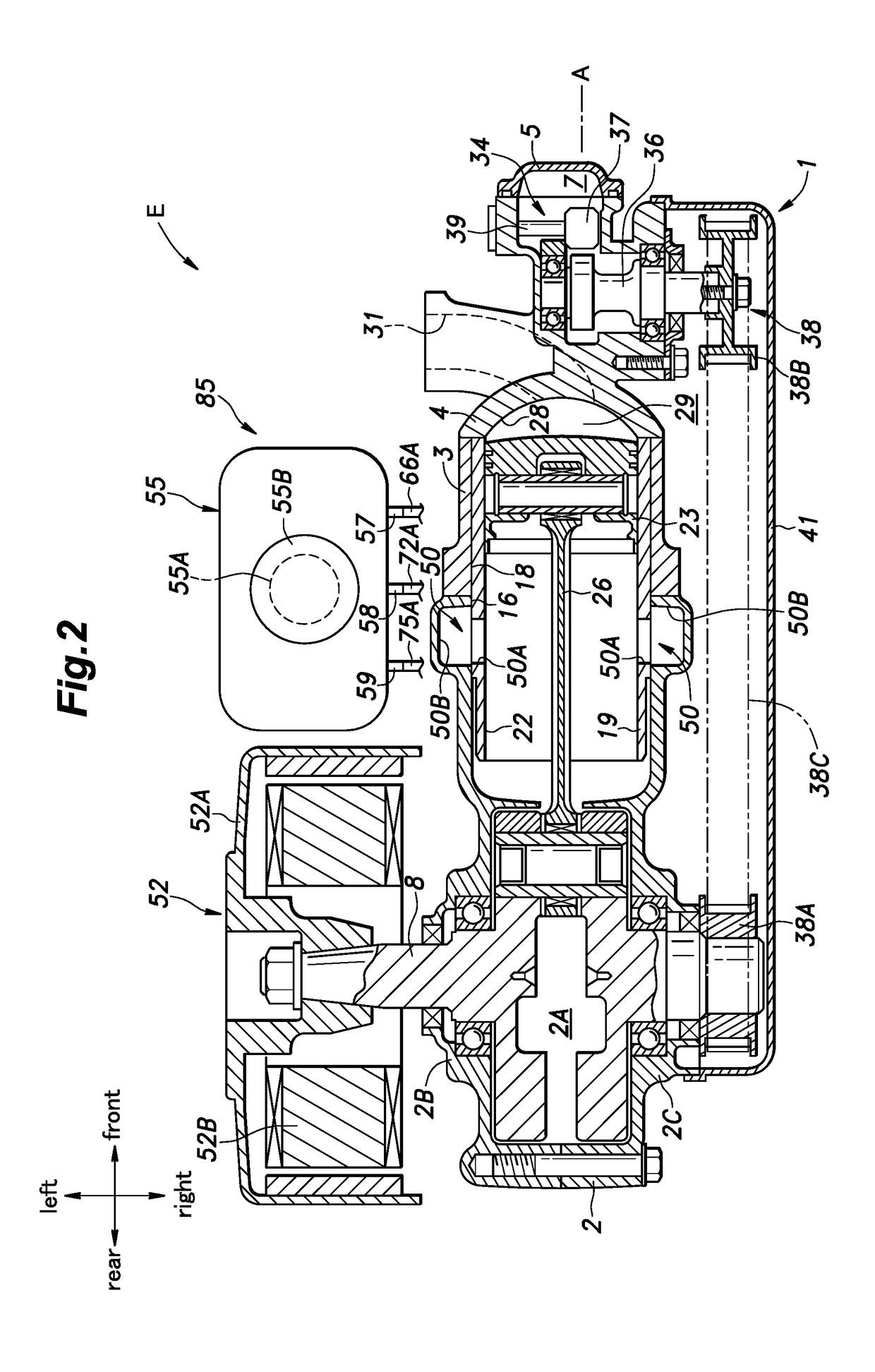

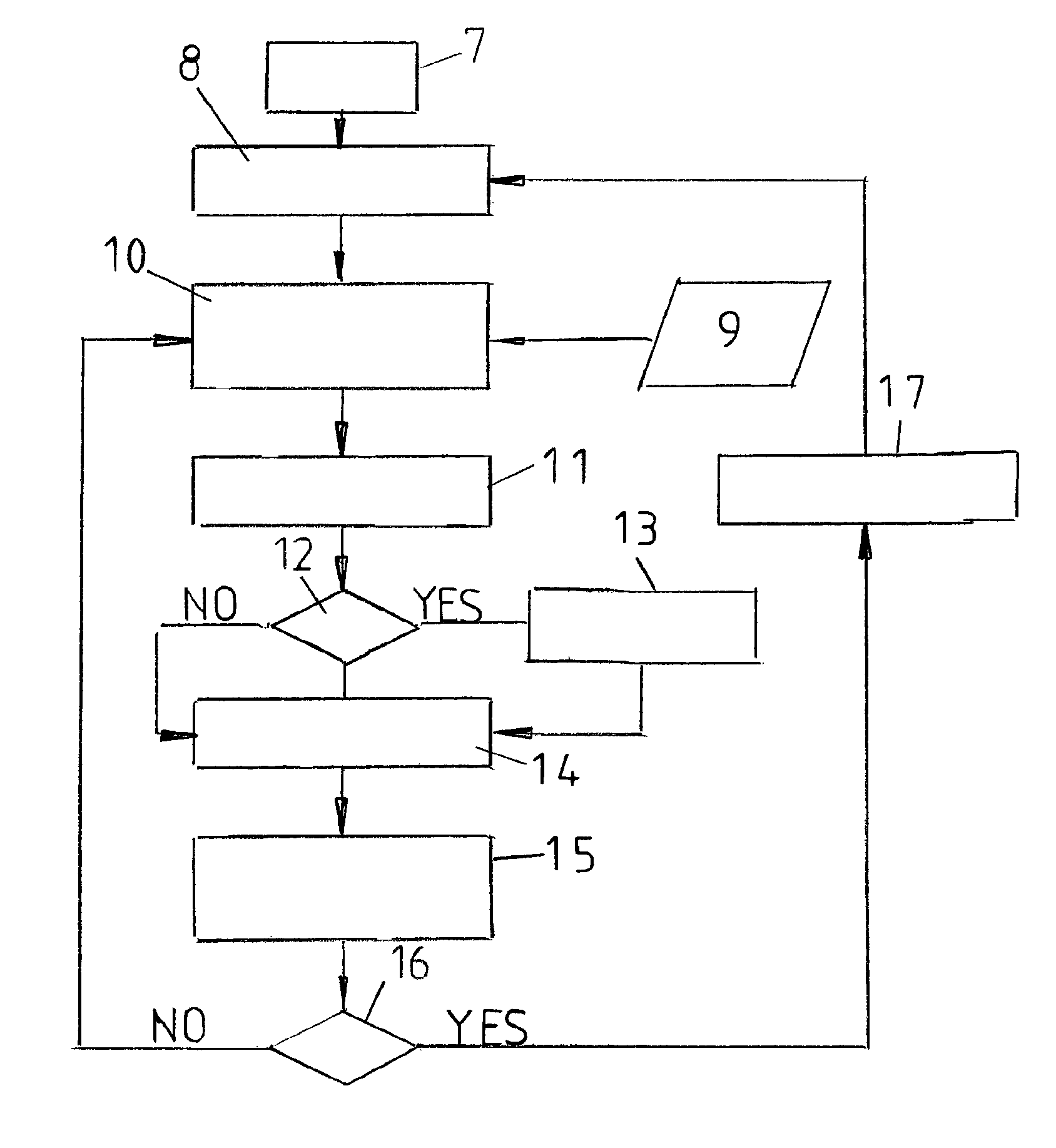

Method and a system for establishing and executing correct automatic relubrication for a number of bearings

A method and a system for establishing and executing correct automatic relubrication for a number of bearings incorporated in a grease lubrication system. The system determines initial values for the relubrication interval tf and / or lubricant volume utilizing data collected from the different bearing assemblies during operation. The data includes bearing load, bearing temperature and bearing rotational speed. A processor calculates a correct lubricant volume and a value for current lubrication interval tf by comparing an initial value with a current value. The calculated correct lubricant volume and current lubrication interval tf are supplying to an automatic lubricating apparatus, which functions in accordance with the determined values. The data collection and calculation procedures are repeated after each application of lubricant to the bearings.

Owner:AB SKF

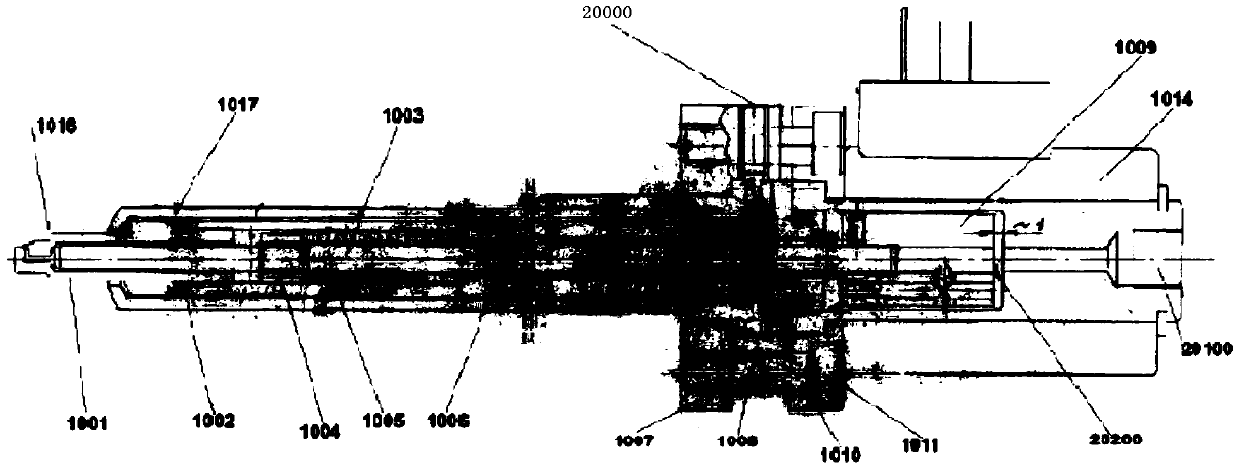

Detection device, method for operating stroke piston internal combustion engine, and stroke piston internal combustion engine

InactiveCN101749072AAdvantageous implementationOK to introduceElectrical controlMachines/enginesInterior spaceReciprocating motion

The invention relates to a detection device, a method for operating a stroke piston internal combustion engine, and a stroke piston internal combustion engine. The detection device is arranged for the stroke piston internal combustion engine which has a cylinder, particularly for a slow-running double-stroke large size diesel motor. In the cylinder, a piston can perform reciprocating motion between a lower dead point and an upper dead point along a working face, wherein a cylinder wall of the cylinder is provided with a lubricant nozzle which is supplied with lubricants by a dosing device so the lubricant can be guided into the cylinder under the action of the lubricant nozzle in a working mode. According to the invention, the detection device comprises a sensor device having a trigger unit which is connected with the dosing device and is signal-connected with a position sensor which is communicated with the interior of the cylinder in an operating condition based on a detection technique so a position of the piston is detected by the position sensor with respect to an axial direction of the cylinder in the operating condition and a reciprocating piston internal-combustion engine is controllable and / or adjustable according to the position of the piston.

Owner:WAERTSILAE SCHWEIZ AG

Lubricating apparatus and method for dosing cylinder lubrication oil

ActiveUS8602167B2Prevent movementSimple and compact designOutboard propulsion unitsLubricant conduit arrangementsHydraulic cylinderEngineering

There is described a hydraulic lubricating apparatus (252) for dosing cylinder lubricating oil, including a housing which via one or more valves (220) is connected to a source for supplying hydraulic oil (262) and cylinder lubricating oil (not shown), a number of hydraulic cylinders each having a hydraulic piston (6) and which may be pressurized by hydraulic oil. Furthermore, there are a number of injection units (251) corresponding to a multiple of the cylinder (250) number in the engine, and which are connected with each their dosing cylinder by a dosing piston (21). Also, there is provided a distributor plate (7) which at one side is in contact with the dosing pistons (21) and which at its other side is in contact with the hydraulic pistons (6) for displacing the distributor plate for actuating the dosing pistons. The hydraulic pistons (6) are provided in groups, where each group is adapted for independent displacement of the distributor plate (7) for actuating the dosing pistons, and where each group of hydraulic pistons have each their individual stroke. In that way there may be achieved an individual quantity adjustment of lubricating oil, depending on the group of hydraulic pistons that is activated.

Owner:HANS JENSEN LUBRICATORS

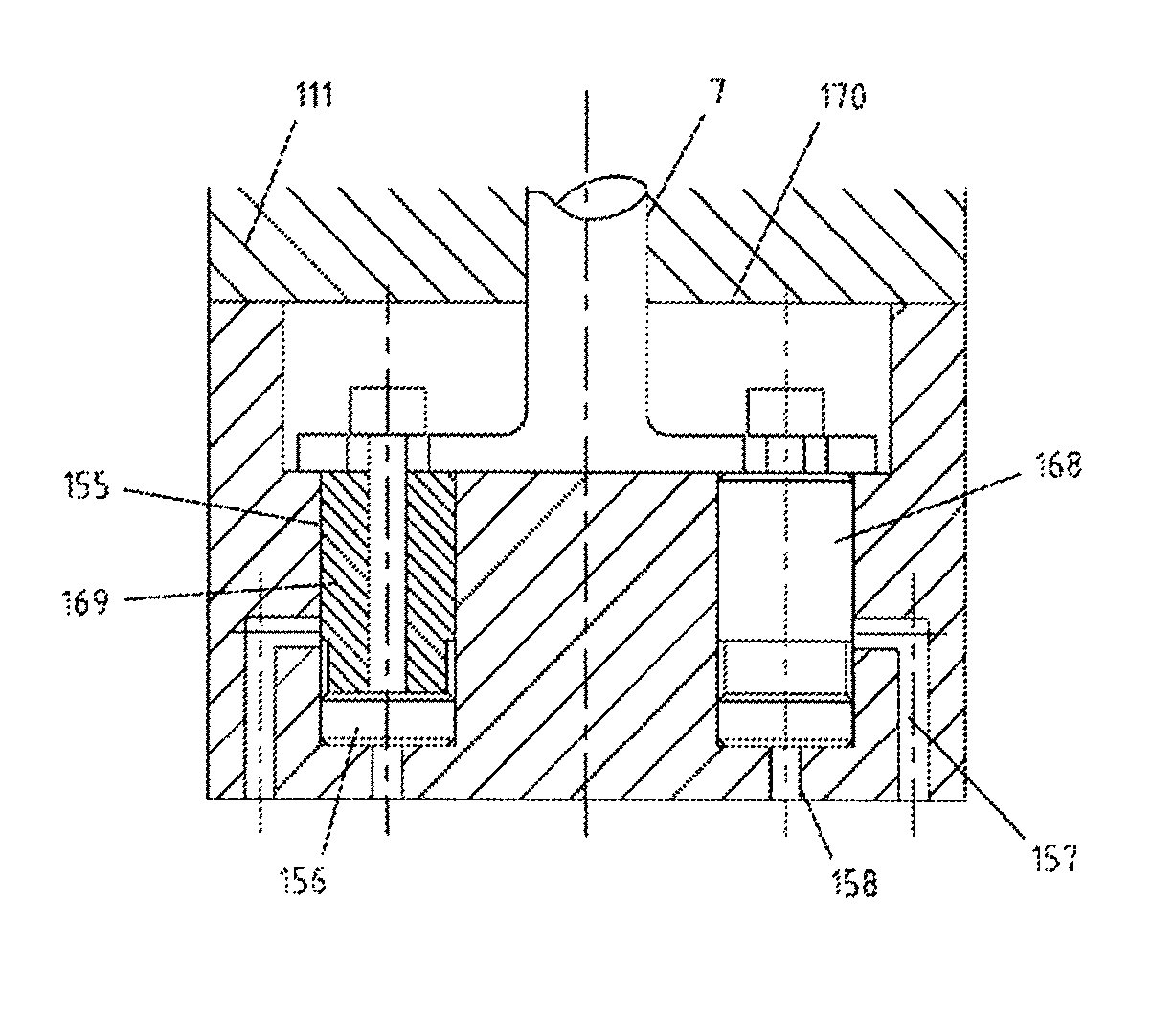

Device for lubricating cylinders

InactiveCN101514646ALess quantityAvoid mixingCylinder headsCylindersEngineeringInternal combustion engine

The invention relates to a device for lubricating cylinders. A device for lubricating a contact surface of the cylinder body of an internal combustion engine comprises a lubricant source making the lubricant available and a lubricant outlet by which the lubricant is applied on the contact surface, wherein the lubricant is conveyed from the lubricant source to the lubricant outlet. A switching element and a piston element are arranged between the lubricant source and the lubricant outlet. The piston unit includes a first chamber and a second chamber separated by a movable piston. The switching element positioned between the lubricant source and the lubricant outlet connects the first chamber or the second chamber with the lubricant outlet.

Owner:WAERTSILAE SCHWEIZ AG

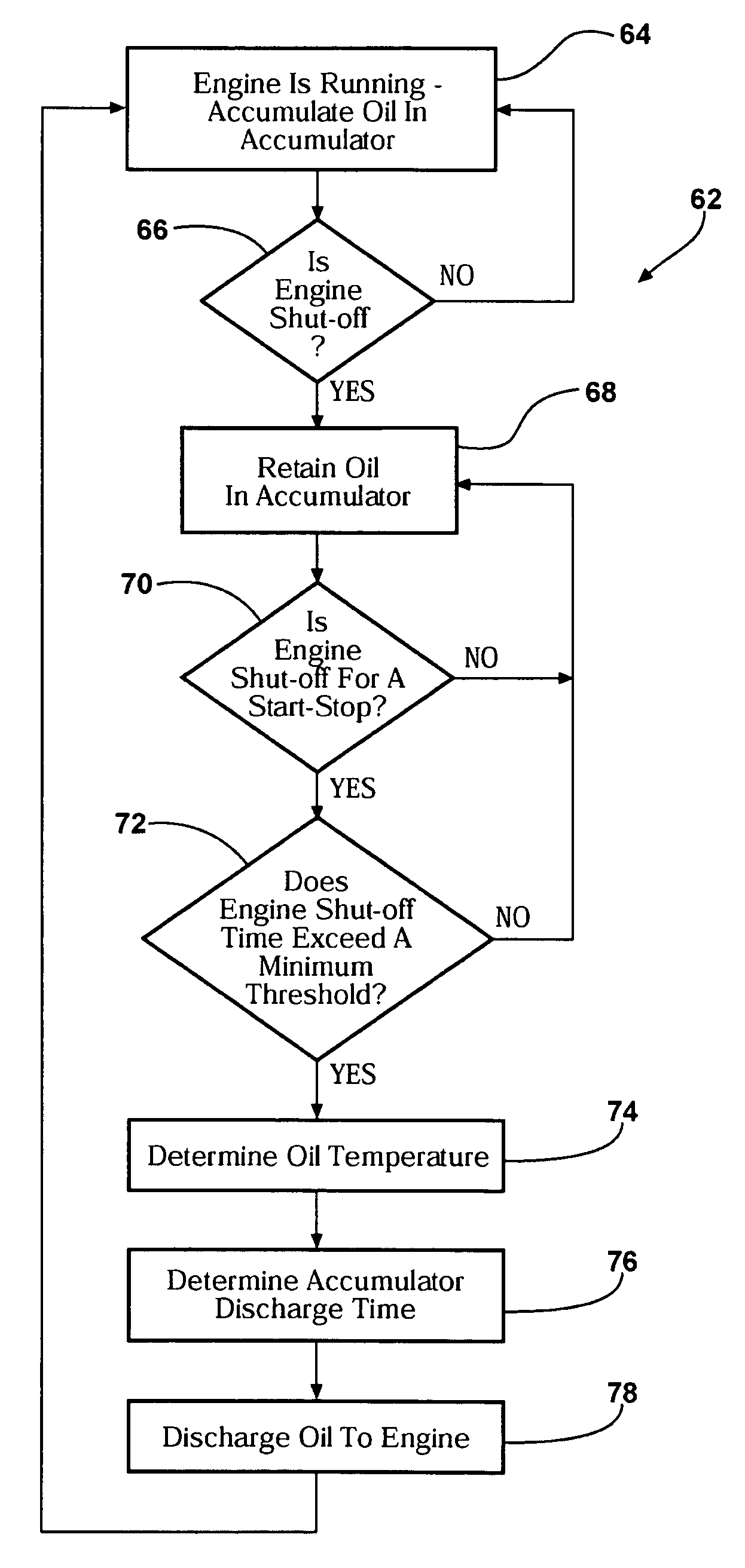

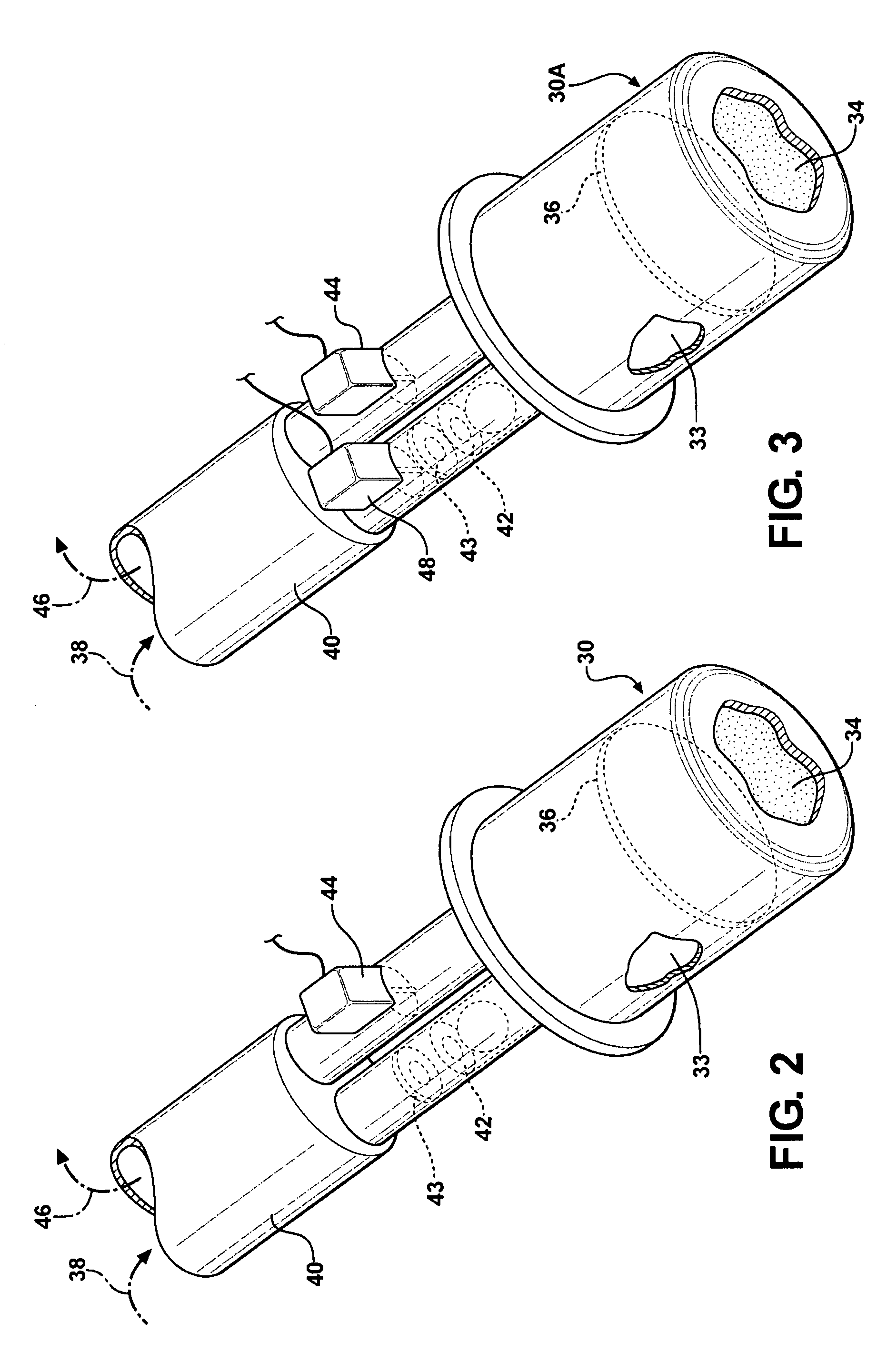

Method of oil pressure control in an engine

ActiveUS8245684B2Lubrication of auxillariesLubricant conduit arrangementsControl systemControl theory

An engine having a fluid lubrication and control system is provided. The engine also includes a pump configured to maintain fluid pressure in the lubrication and control system when the engine is running. The engine additionally includes an accumulator in fluid communication with the lubrication and control system. The accumulator is configured to accumulate and retain fluid when the engine is running, and to discharge the fluid when the engine is not running in order to maintain fluid pressure in the lubrication and control system. A method for controlling oil pressure in the engine is also provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

Lubrication system for two-cycle engine

InactiveUS7150249B2Optimize volumeHigh viscosity of lubricantLubrication of auxillariesLubricant conduit arrangementsThrottle position sensorControl theory

An engine has a lubrication system that lubricates the engine with lubricant. The lubrication system incorporates a lubrication pump that periodically pressurizes the lubricant toward the engine. An engine speed sensor and a throttle valve position sensor are provided to sense an engine speed and a throttle valve position (i.e., engine load), respectively. A control device controls the lubrication pump. The control device determines a frequency of the periodic pressurization based upon signals from the sensors. The control device sets a pressurizing time of the lubrication pump to a period of time shorter than the maximum period of time that can be set for the lubrication pump at the determined frequency, when the signals from the sensors indicate that the engine speed is less than a preset engine speed and the engine load is less than a preset engine load.

Owner:YAMAHA MARINE KK

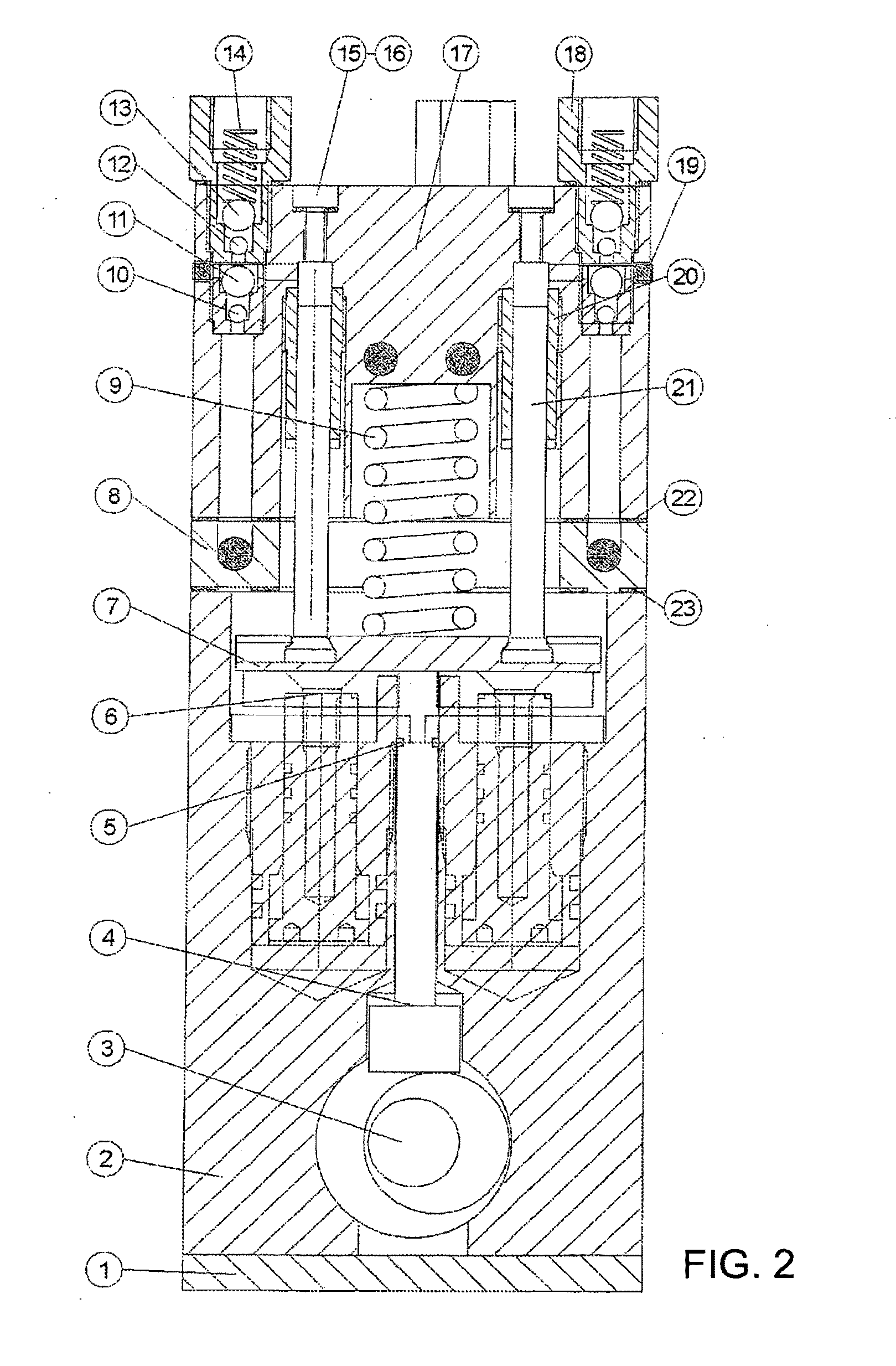

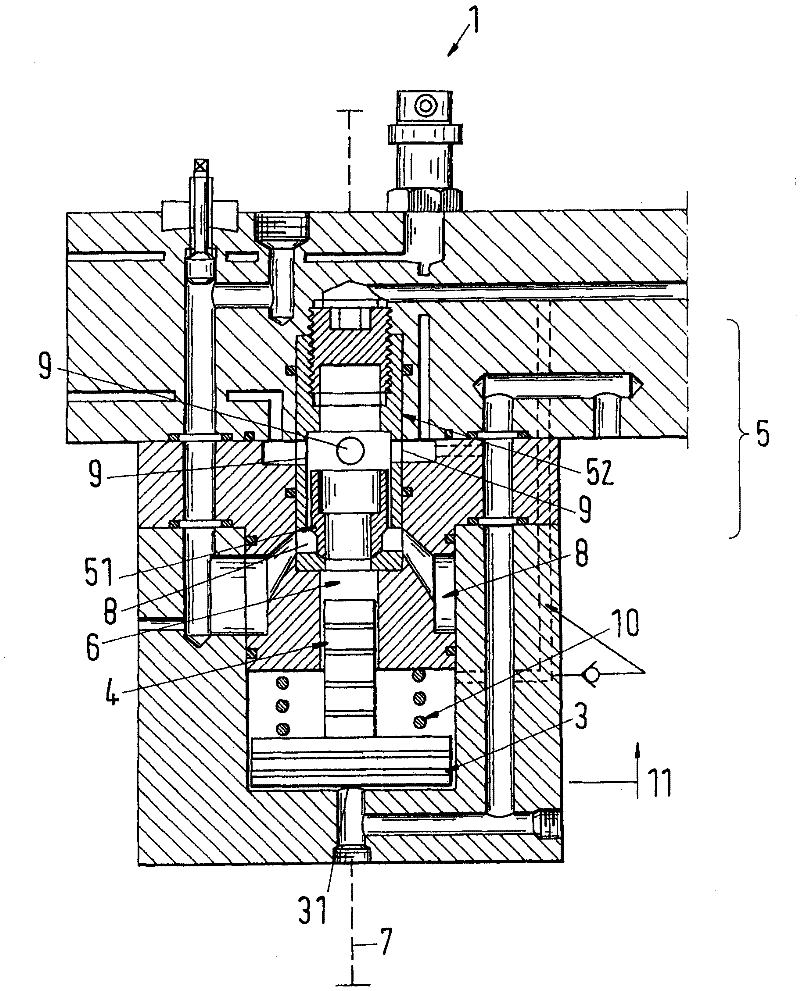

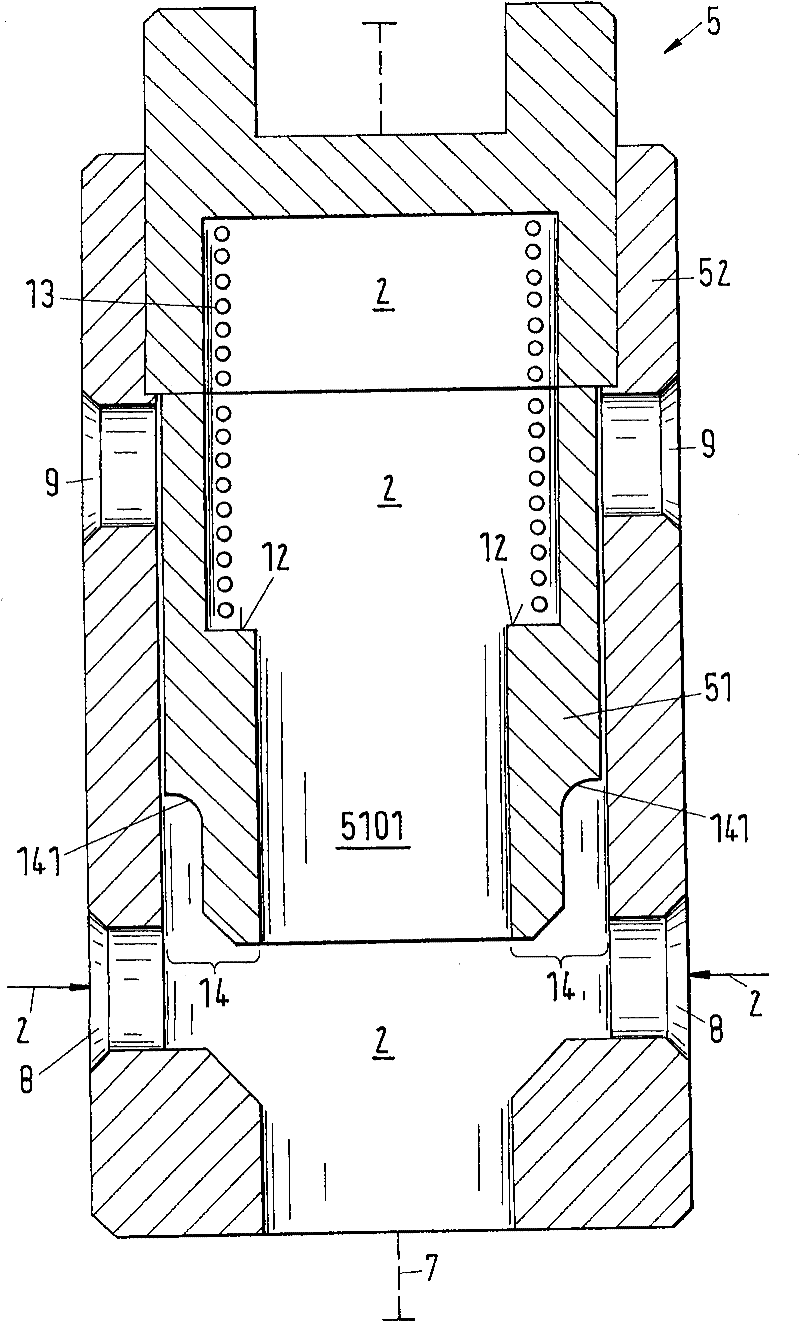

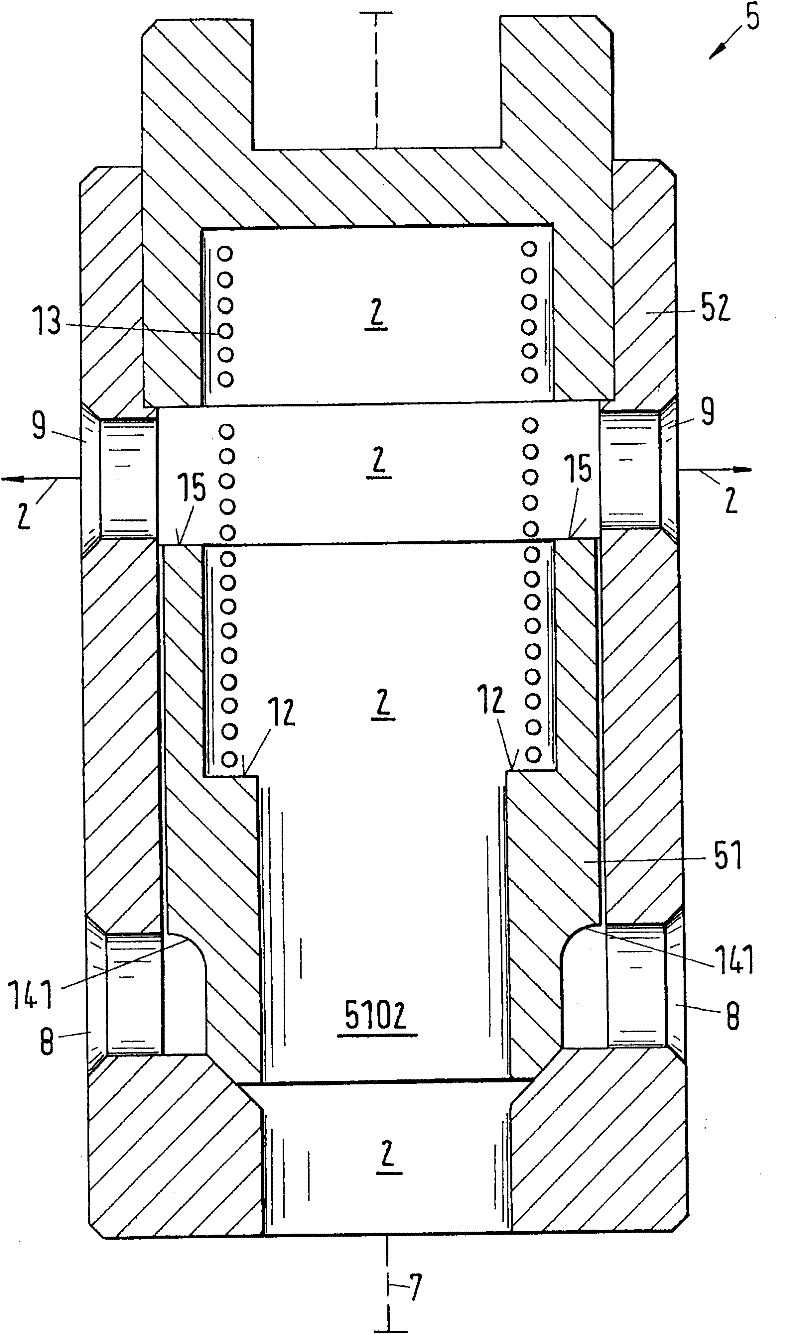

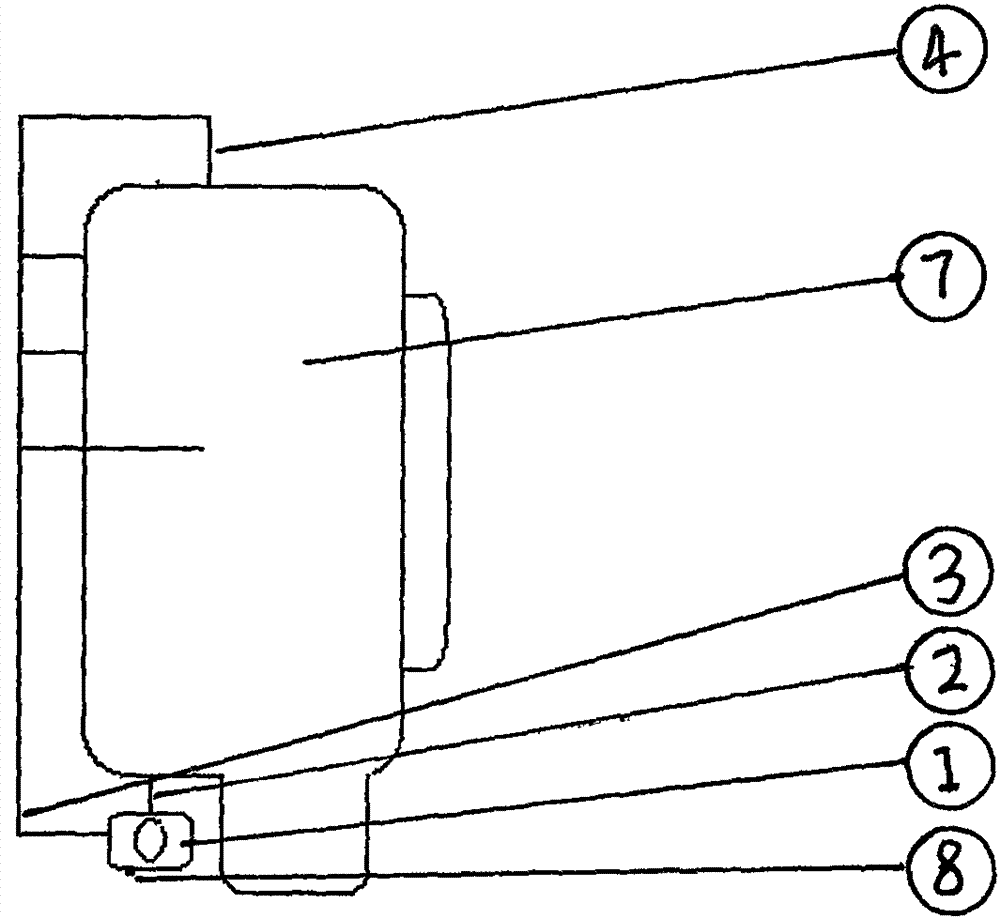

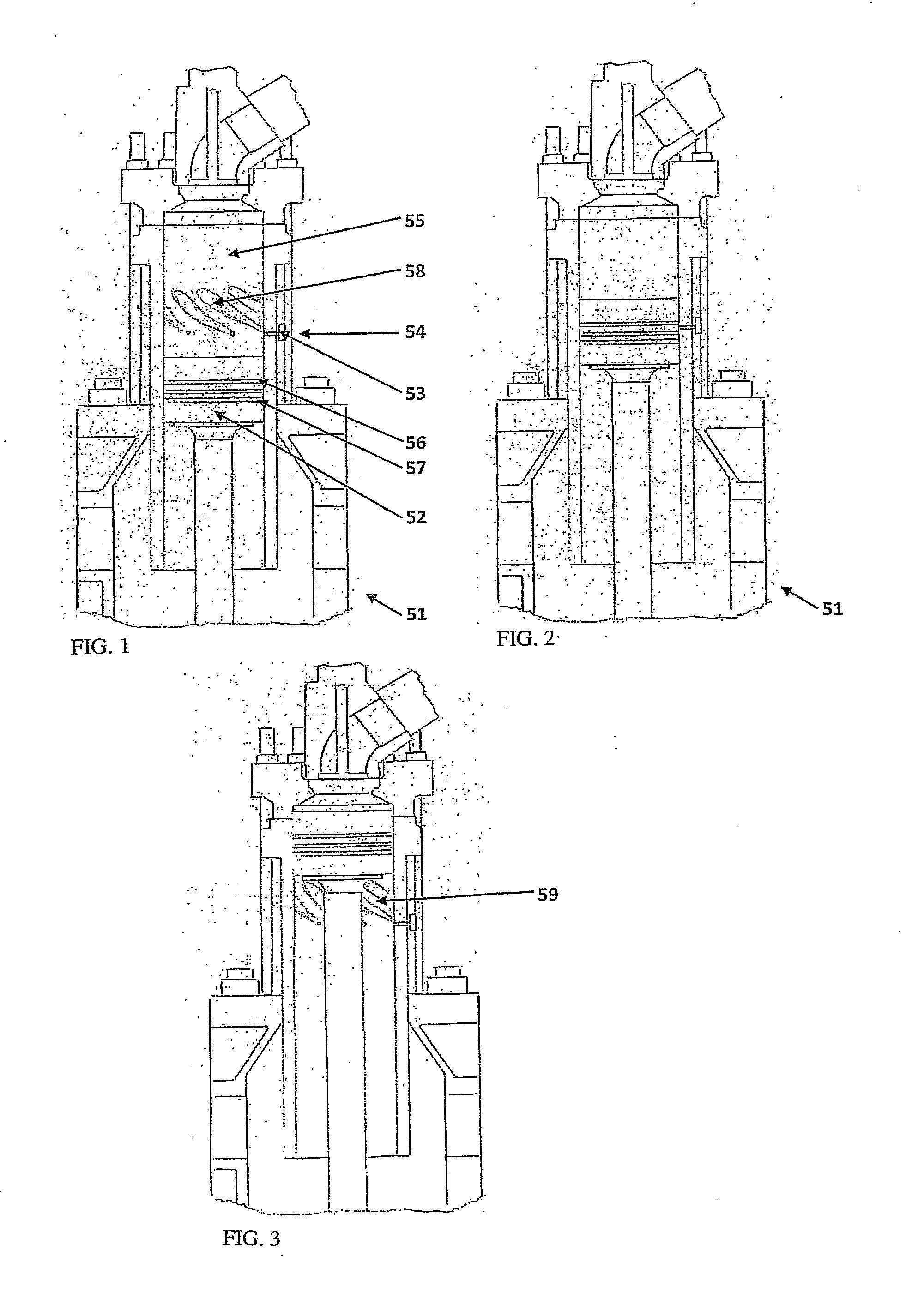

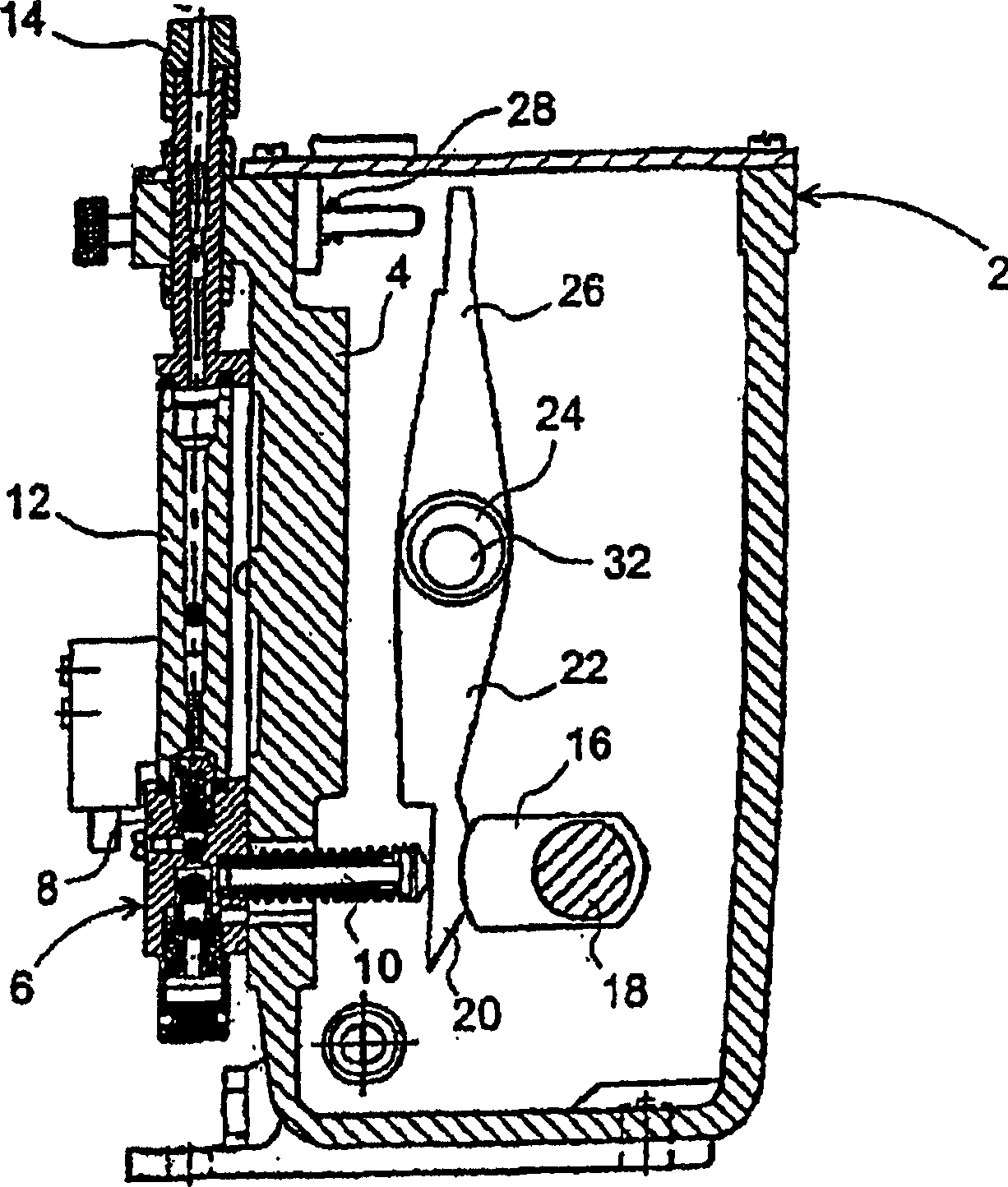

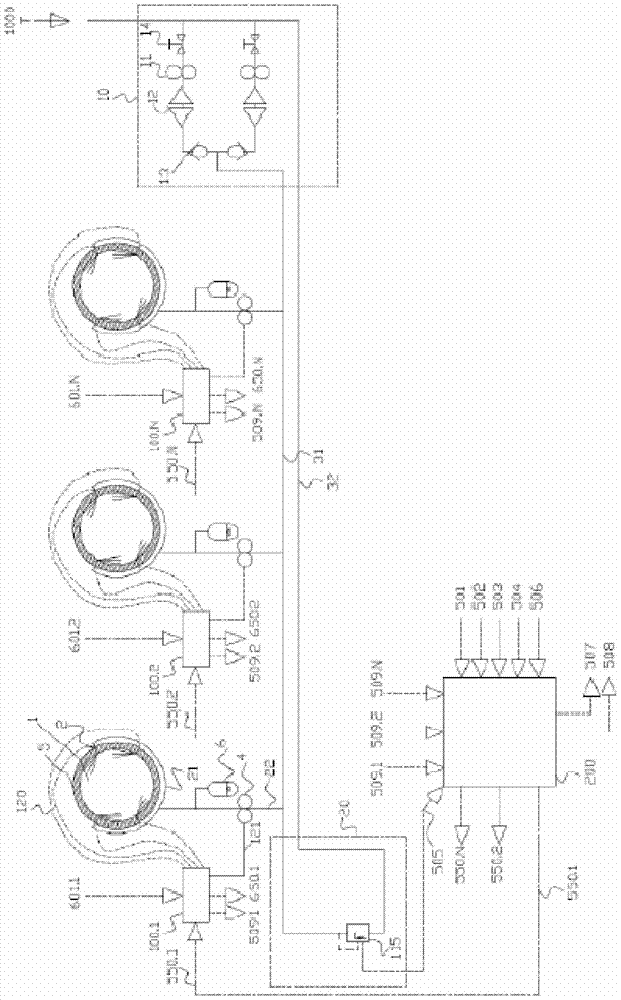

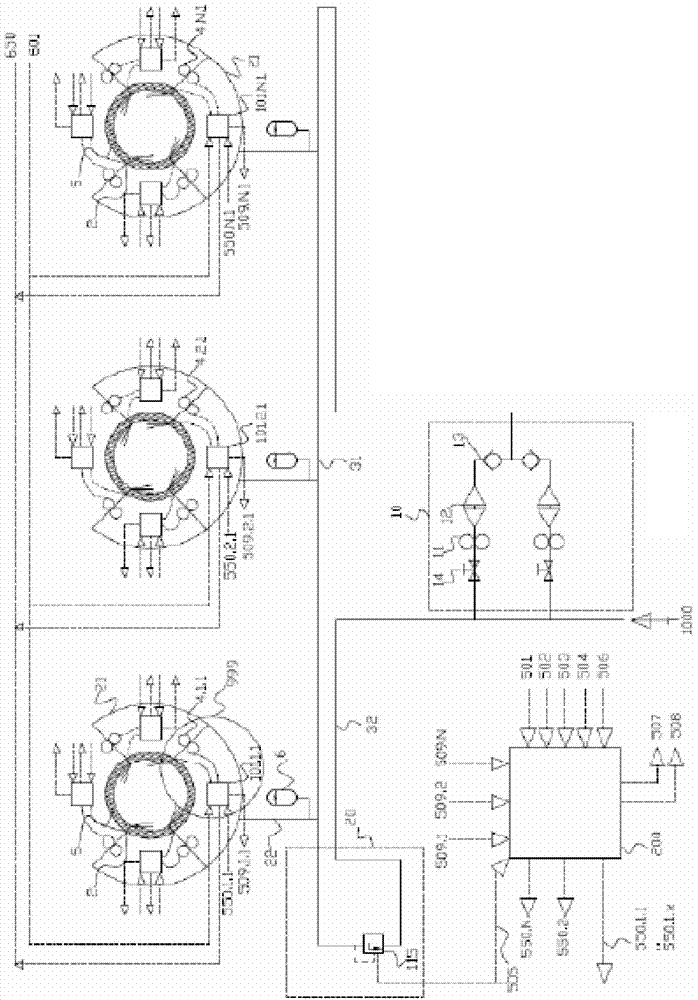

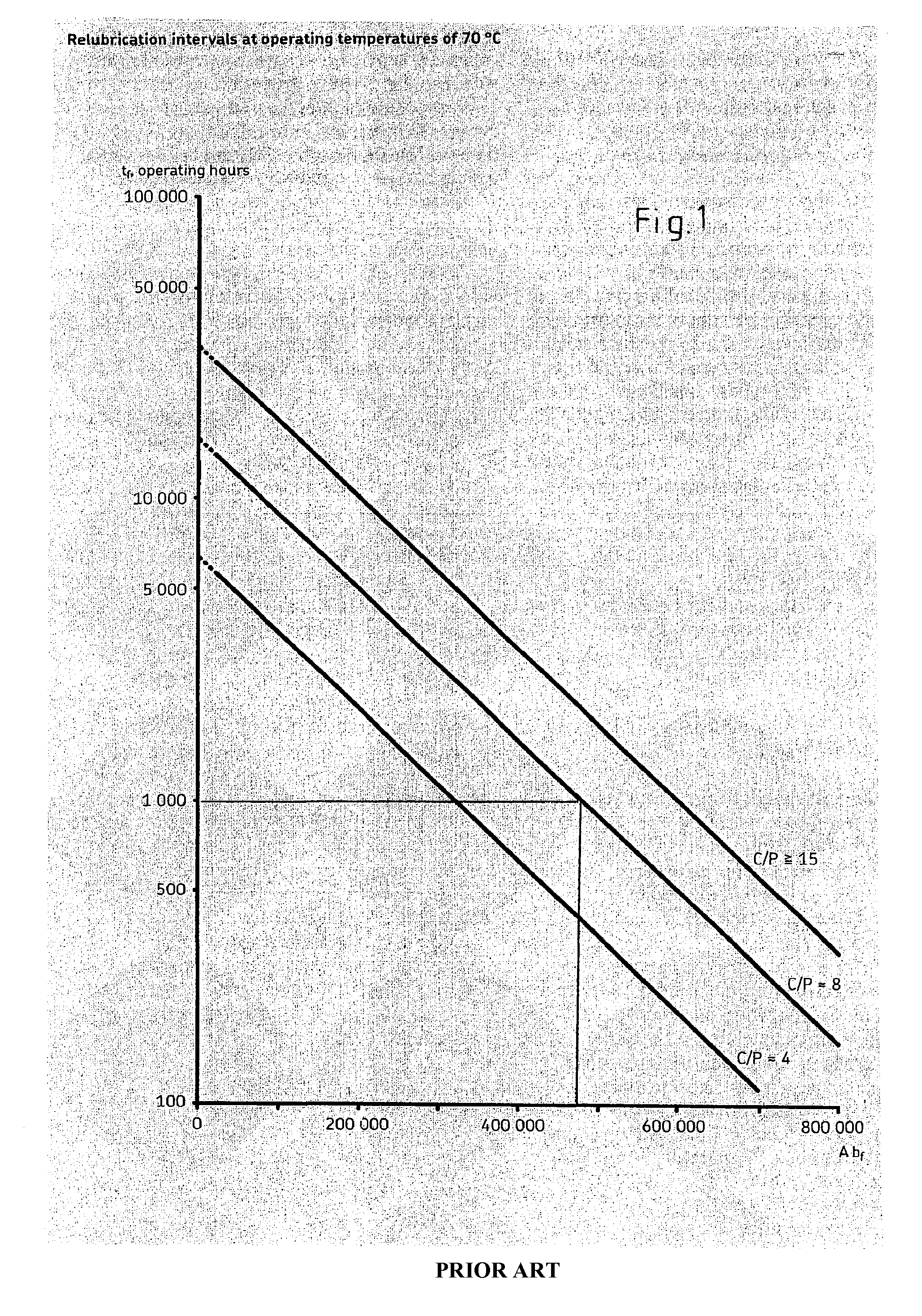

A cylinder oil dosage pump, a cylinder lubricating system, and an internal combustion engine

InactiveCN101749069ASimple structureLow costLubricating pumpsMachines/enginesReciprocating motionExternal combustion engine

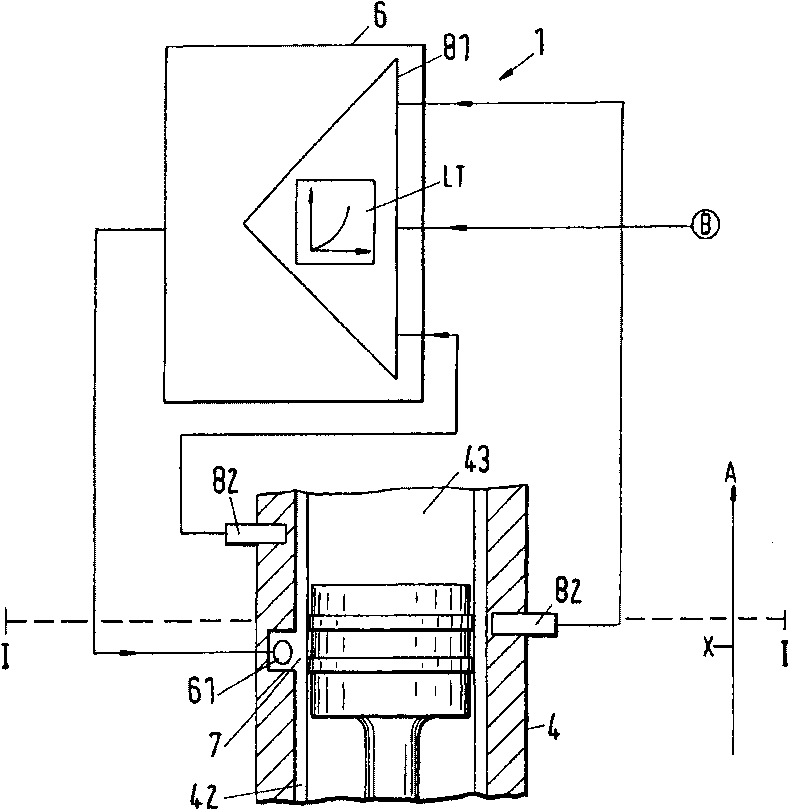

The invention relates to a cylinder oil dosage pump (1) for dosing a presettable amount of a cylinder lubricating oil (2) to a lubricating quill of a cylinder of an internal combustion engine, in particular a two stroke large diesel engine. The cylinder oil dosage pump (1) comprises an actuating piston (3), a dosage plunger (4) and a delivery means (5). According to the invention, the delivery means (5) is a hollow delivery means (5) of a two-part design, including a switching member (51) and a delivery member (52). The switching member (51) is movable arranged within the delivery member (52) so as to reciprocate between a filling position (5101) and a delivery position (5102), wherein in the filling position (5101) the dosing space (6) is refillable with lubrication oil (2) via a lubricating oil supply-opening (8) and in the delivery position (5102) the lubricating oil (2) is deliverable by means of the dosage plunger (4) via a quill-opening (9) to the lubricating quill. In addition, the invention relates to a cylinder lubricating arrangement and an internal combustion engine with a lubricating arrangement according to the invention.

Owner:WAERTSILAE SCHWEIZ AG

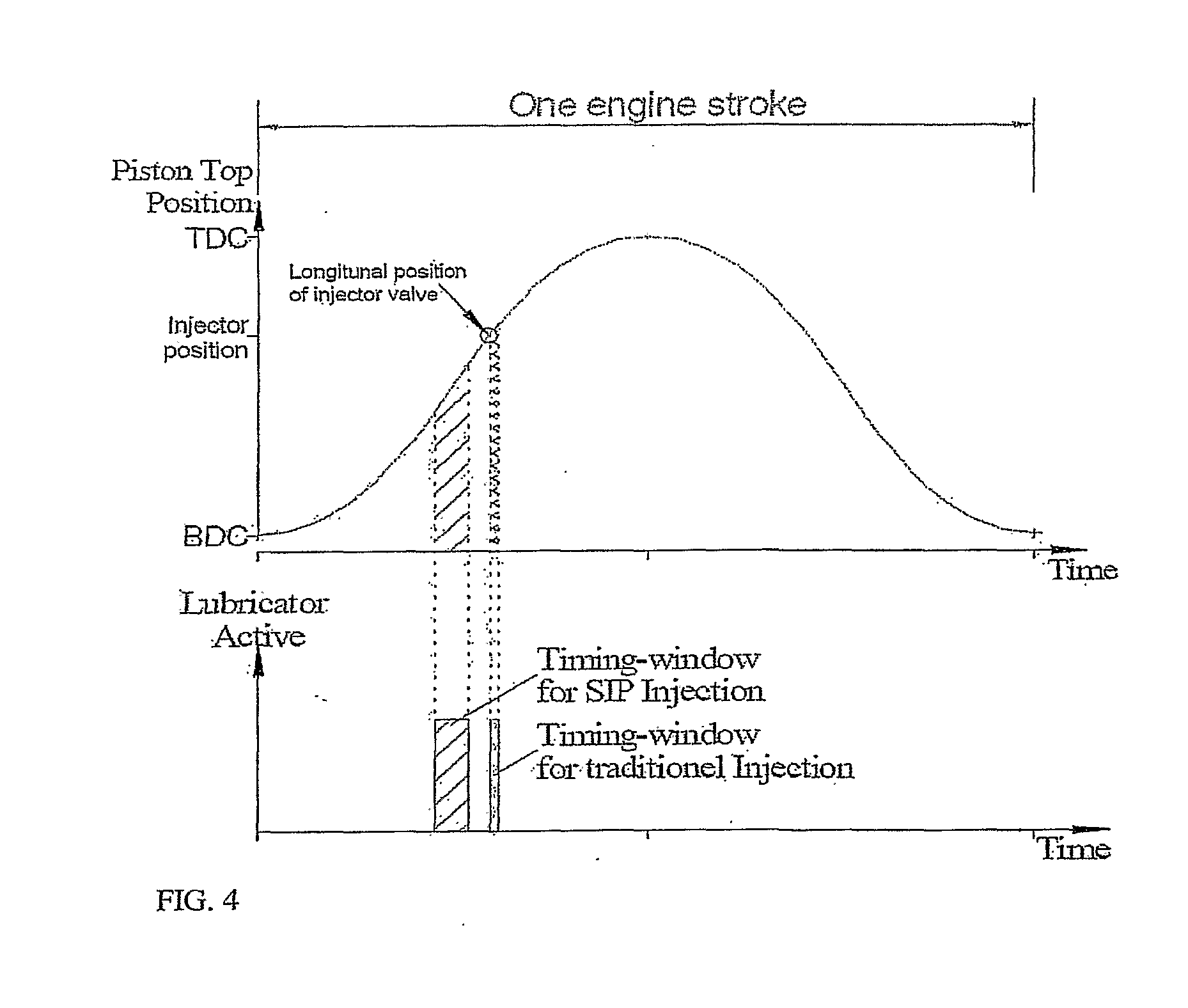

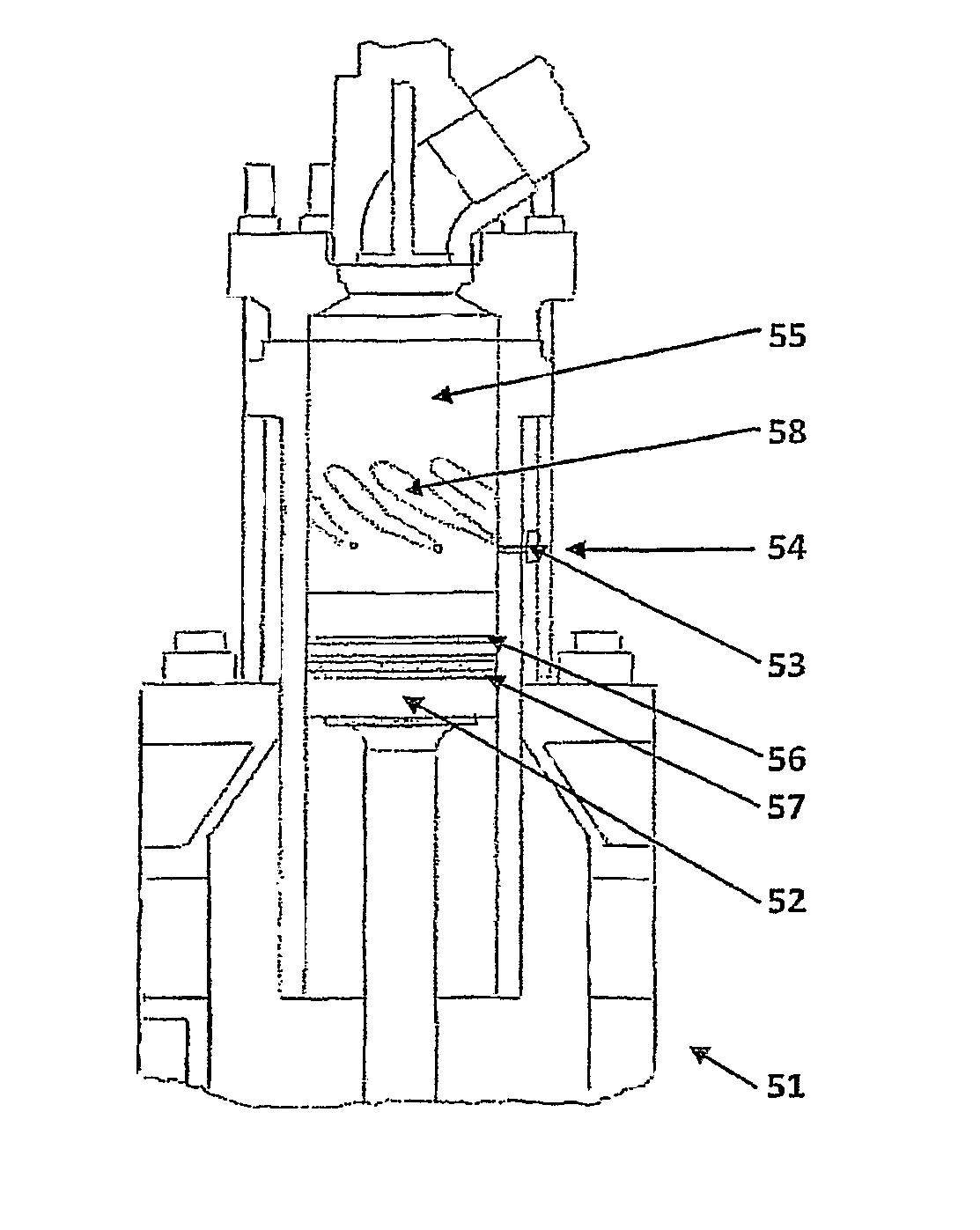

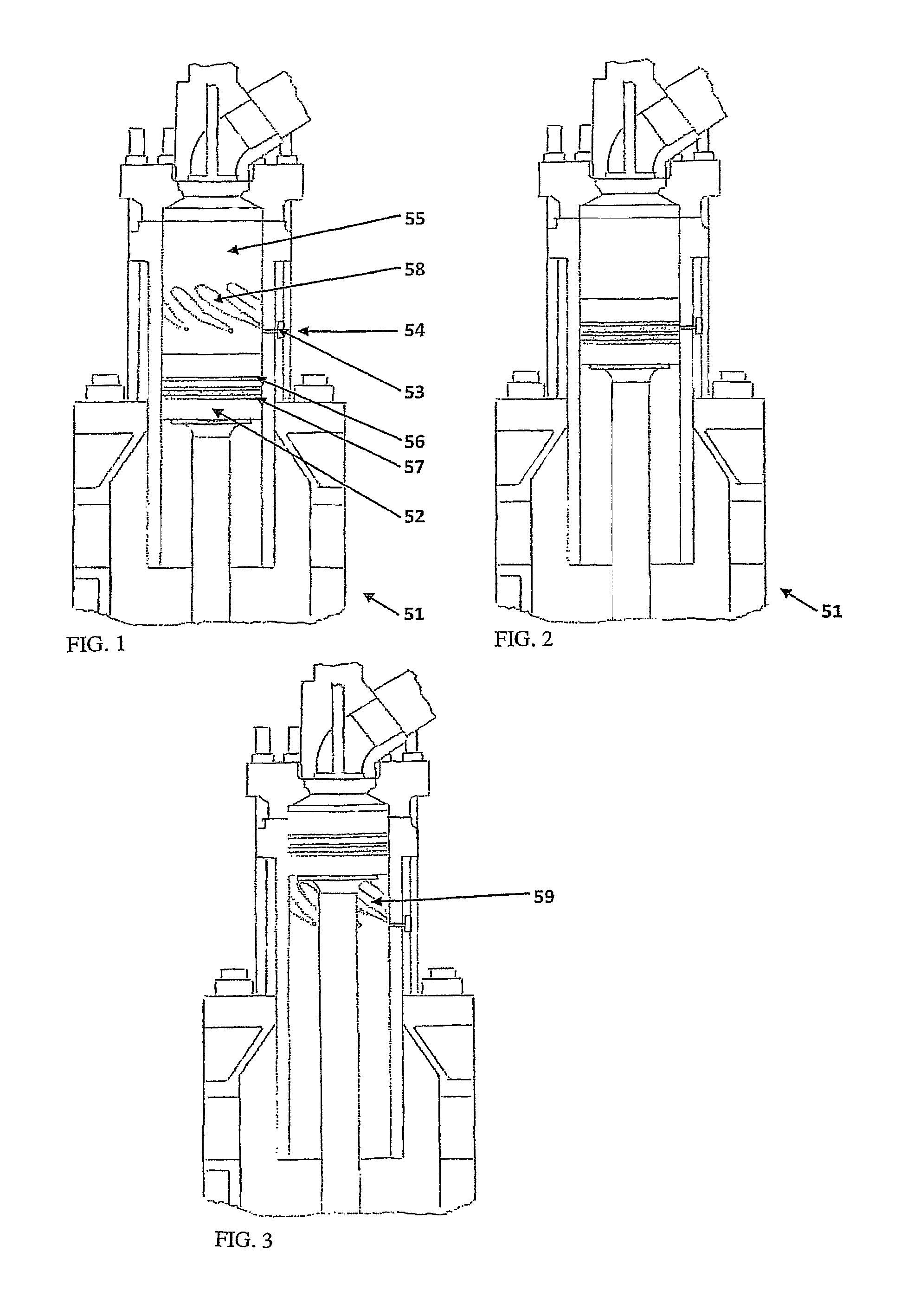

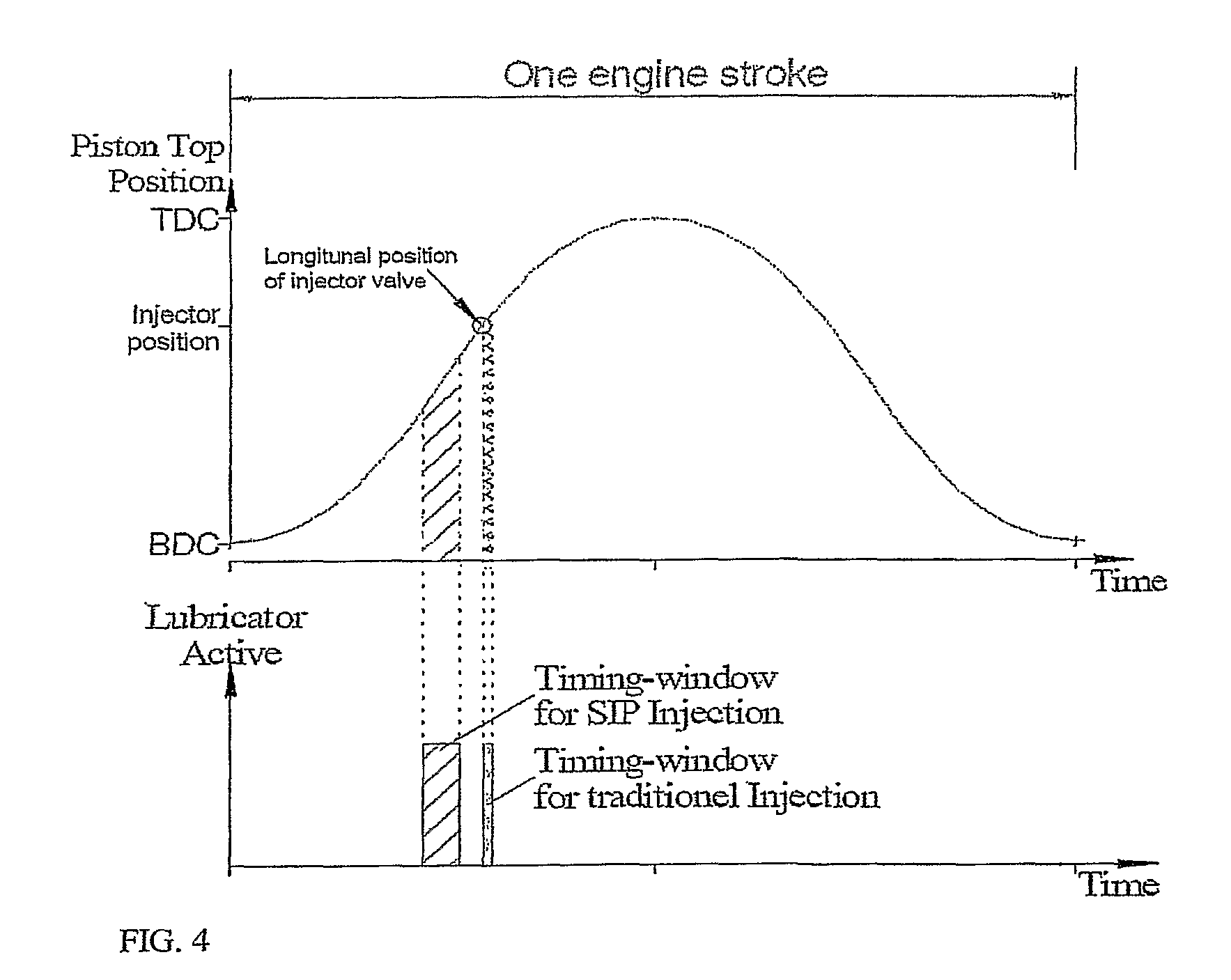

Dosing of cylinder lubricating oil into large cylinders

ActiveCN103534447AAccurate measurementReduce maintenanceMachines/enginesLubrication pressure controlSpray nozzleLubrication

There is disclosed dosing system and a method for cylinder lubrication oil in large diesel engine cylinders, e.g. in marine engines, including: - a lubricating oil supply that may be constituted by a pump station or an accumulator; - a supply line from the lubricating oil supply; - a number of injectors having an inlet, an opening / closing valve unit and one or more nozzle apertures for injecting cylinder lubricating oil into an associated cylinder, and which are connected with the supply line and corresponding to the number of cylinders in the engine or a multiple thereof; and - a control unit controlling each opening / closing valve unit. Furthermore, there is disclosed an injector for use in the system.; In order to overcome the drawback of dependence on flow and viscosity in the supply pipes, the system is peculiar in that the dosing system includes a flow measuring unit for each injector and / or for each cylinder, and that the flow measuring units are connected with the control unit for use in a closed circuit regulation.

Owner:HANS JENSEN LUBRICATORS

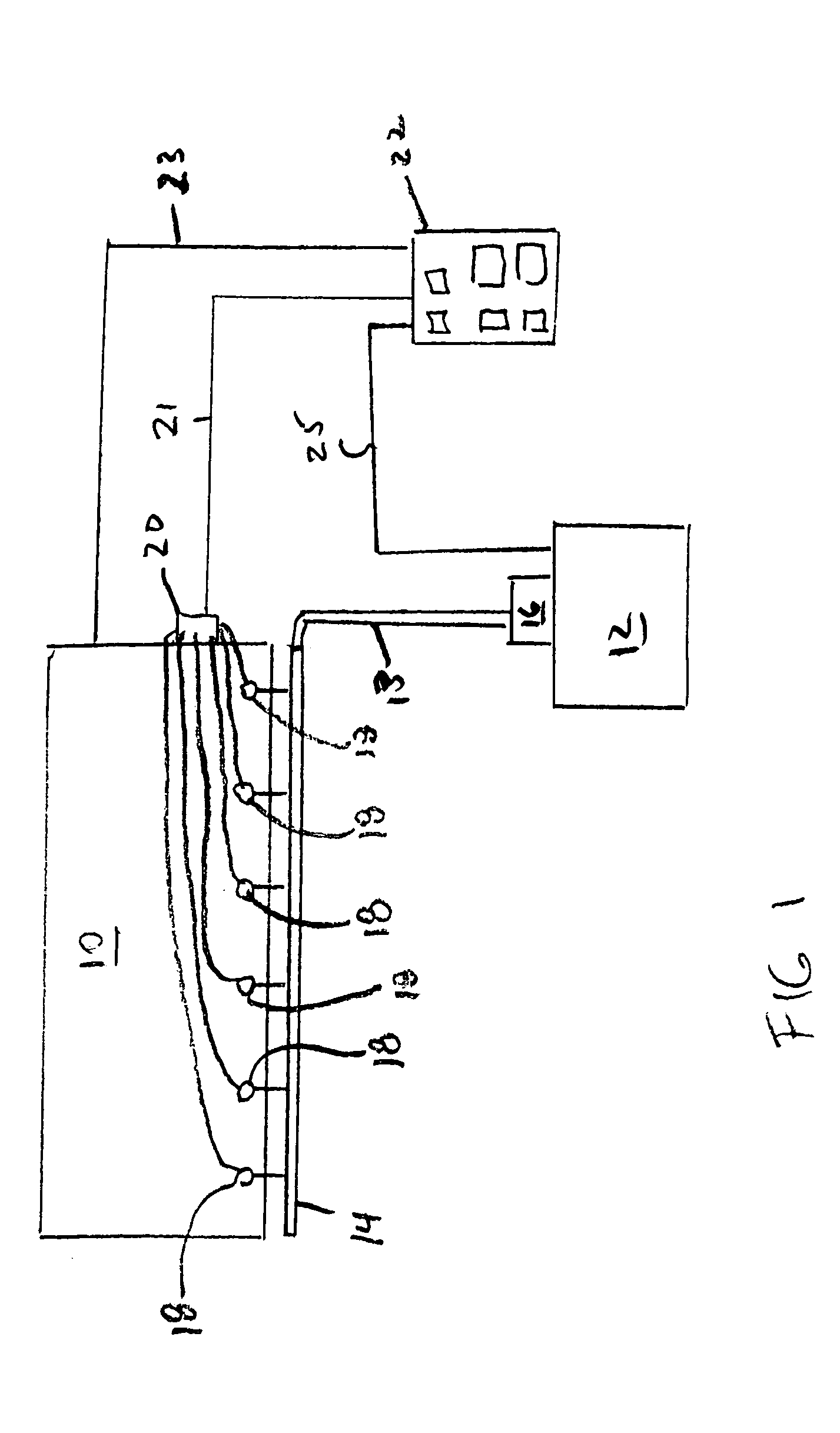

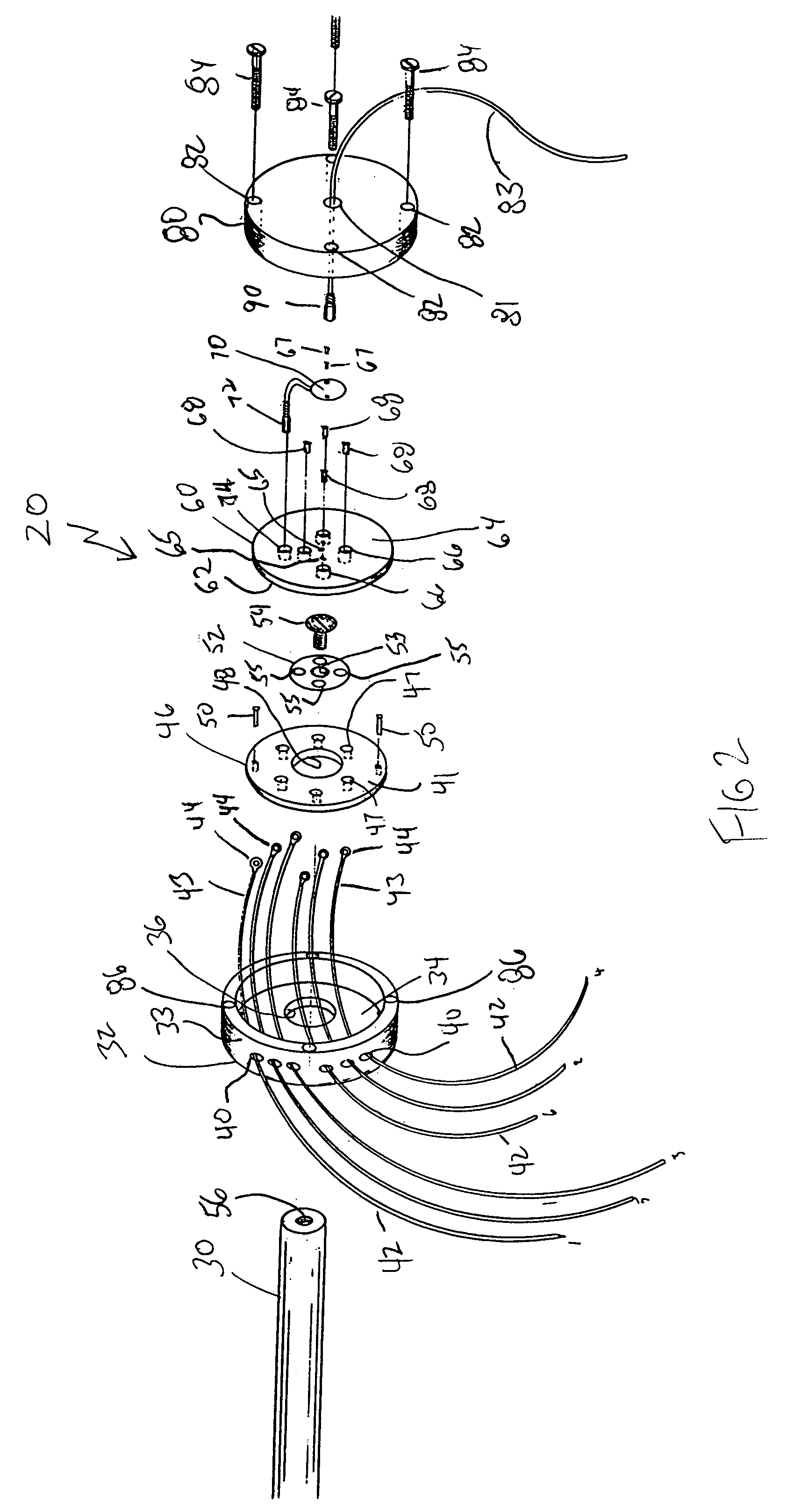

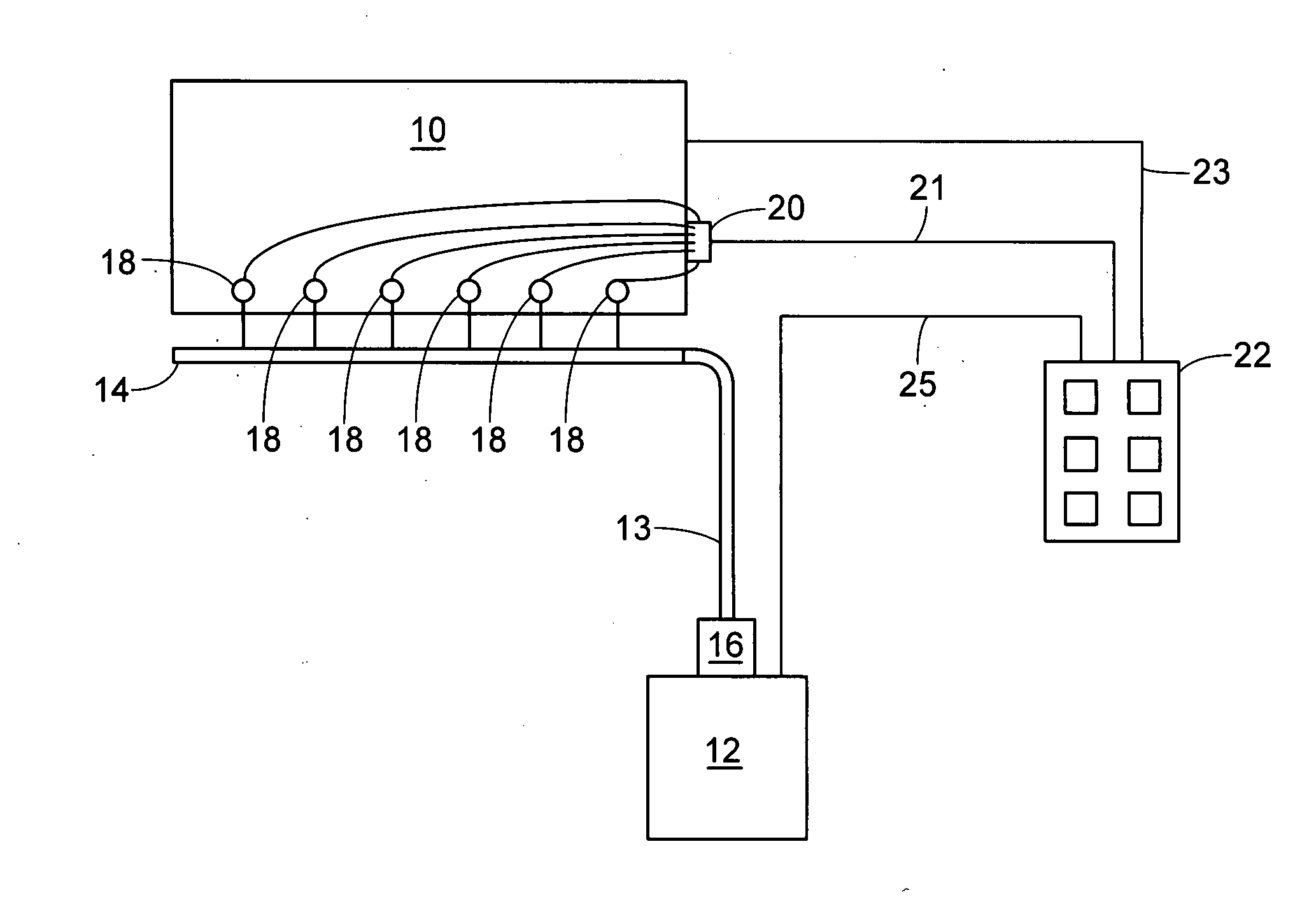

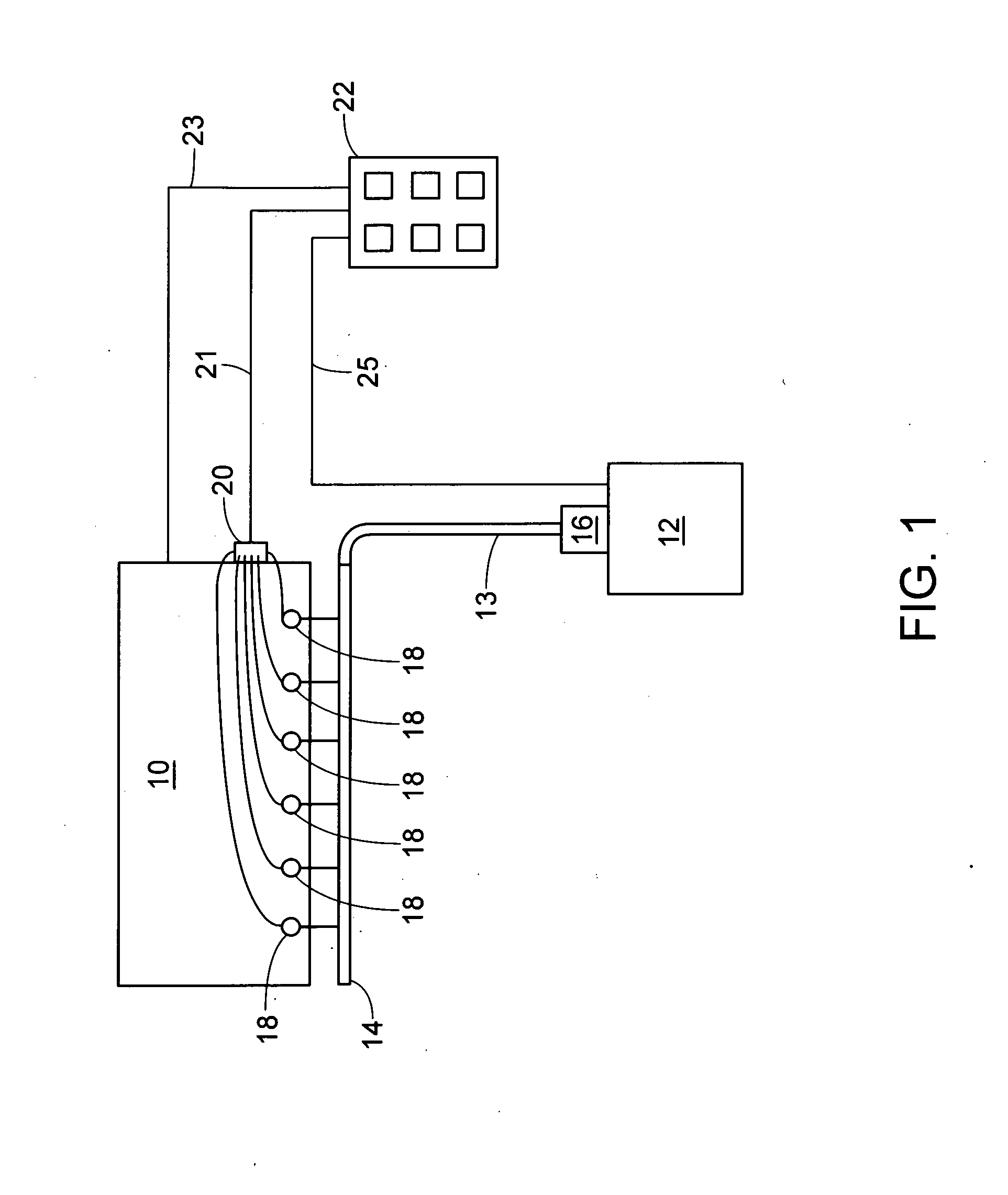

Sequential injection lubrication system for a spherical rotary valve internal combustion engine operating on natural gas or alternative fuels

A sequential injection lubrication system for a spherical rotary valve internal combustion engine operating on natural gas or alternative fuels, the lubrication system having a plurality of injectors, one for each cylinder, the injectors and communication with a lubricant reservoir and with a control unit which sequentially opens and closes the injectors for the introduction of lubricant into the cylinder, the control unit in communication with a control panel allowing the selective setting of the duration of the pulse injection and the frequency thereof.

Owner:COATES GREGORY

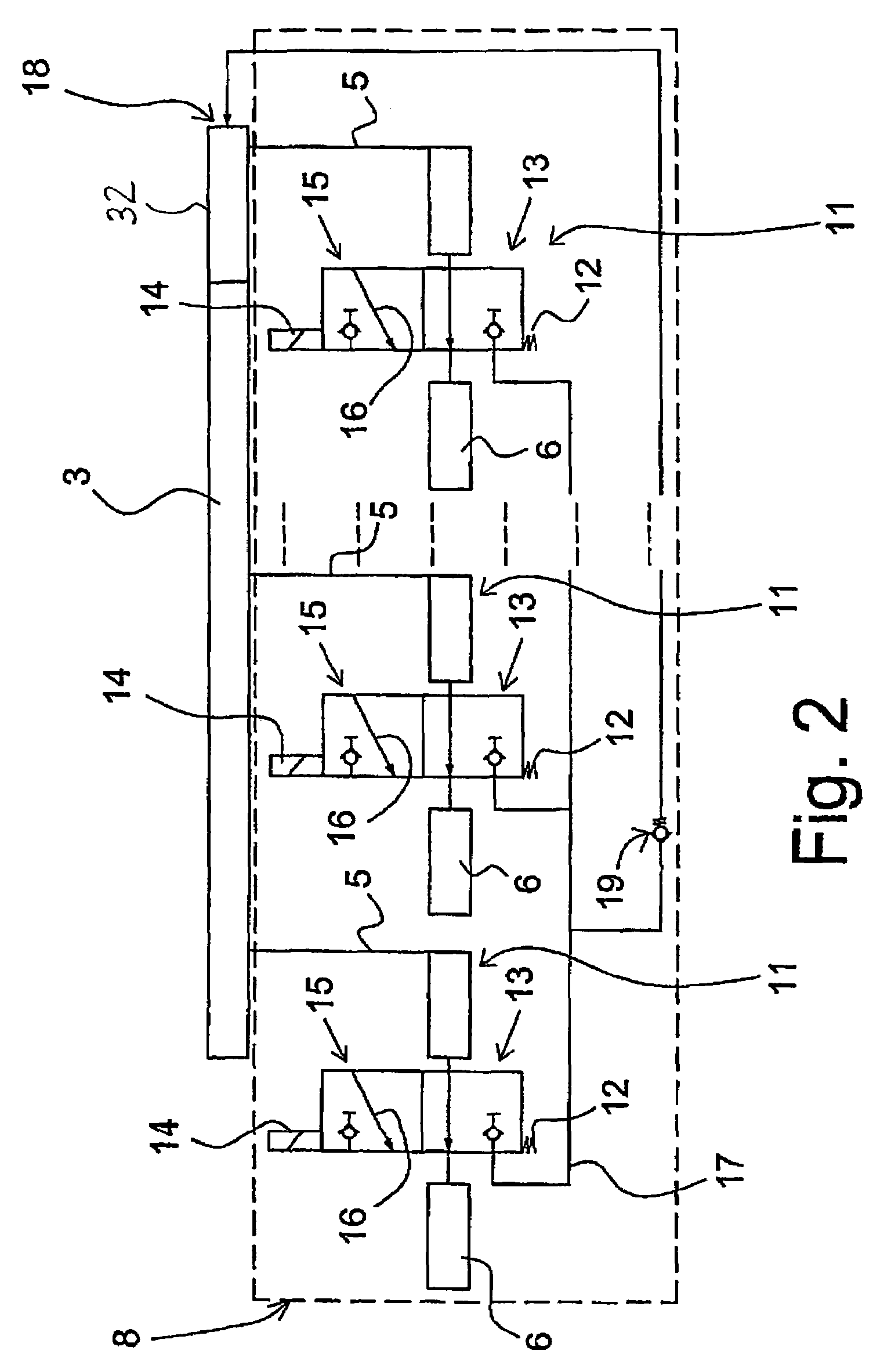

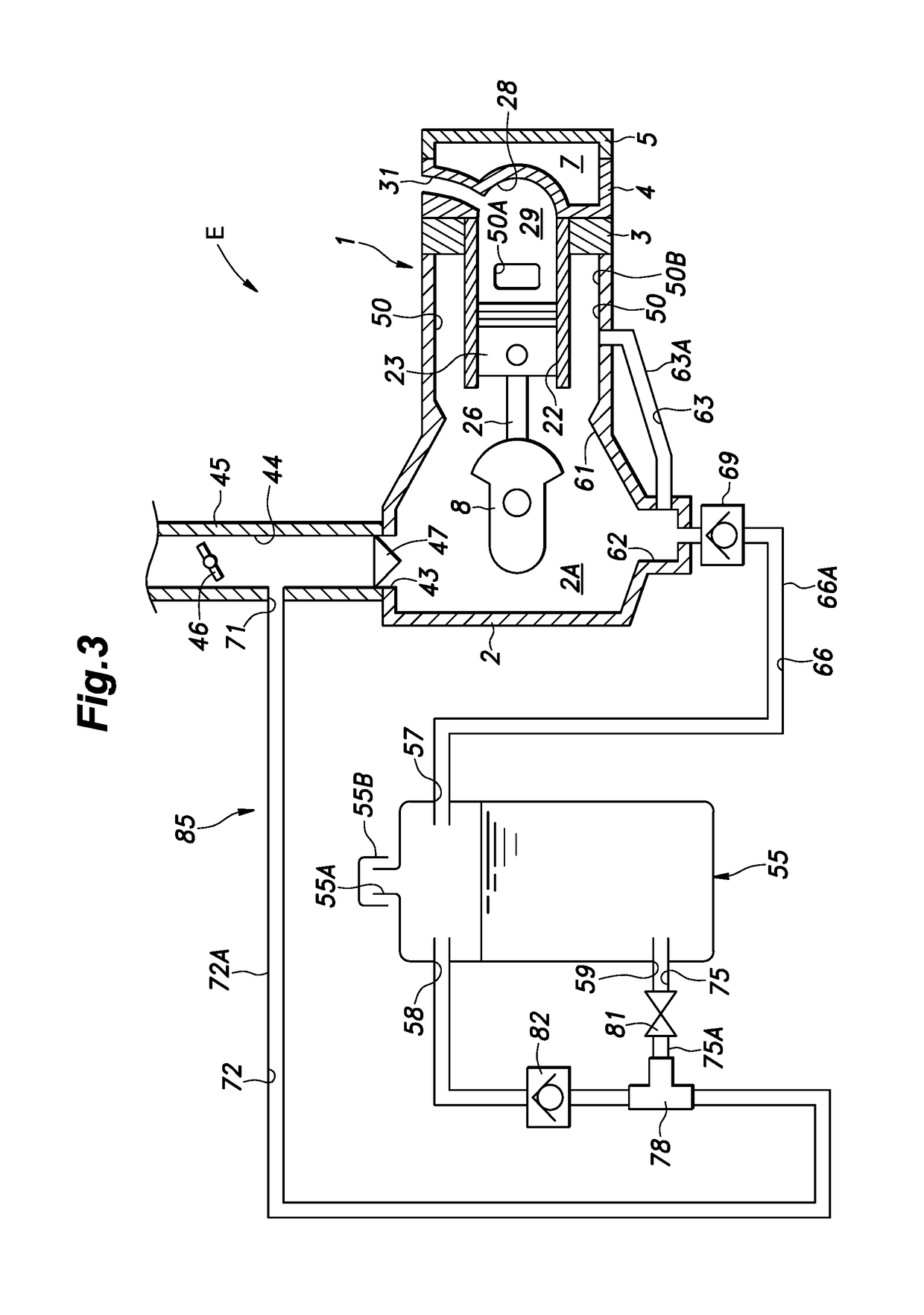

Centralised lubrication of large diesel engines

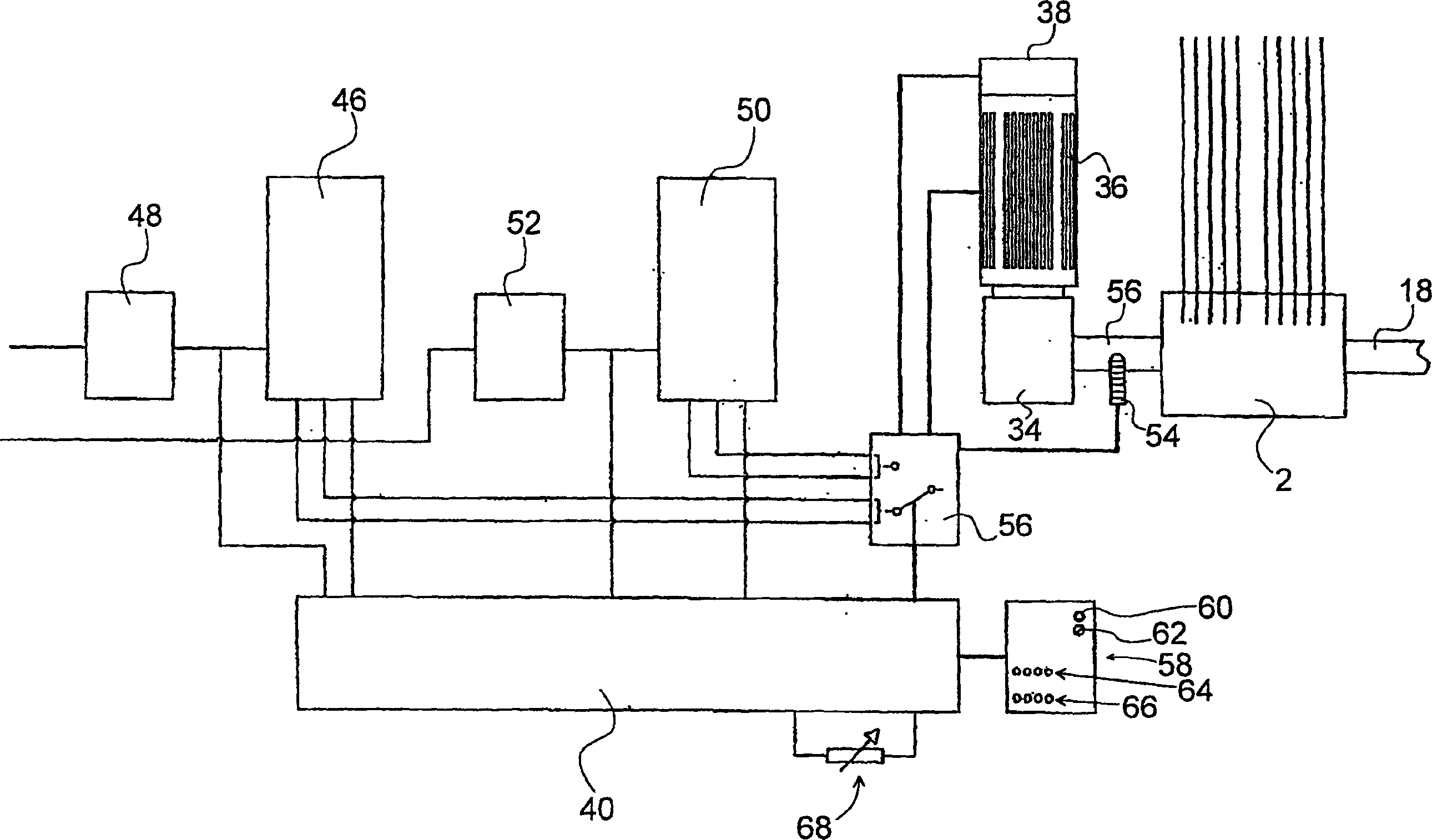

A centralised lubrication system and method lubricates cylinder faces in large diesel engines, particularly marine engines. At least one lubricating apparatus has a rotating control shaft preferably running synchronously with the engine main shaft. To make a system that does not have a mechanical drive between the lubricating apparatus and the main shaft, the system is constructed with an AC motor driving the control shaft. Reference means are provided in association with the main shaft, indicating the angular position of the main shaft, and sensor means detect the position of the reference means. The system includes a control unit receiving signals from the sensor and detecting angular position as well as angular speed of the reference means and the main shaft. The control unit is connected with and controls the AC motor (36) for regulating the rotation of the control shaft (18) and thereby actuation of reciprocating pumps providing the cylinder lubrication.

Owner:HANS JENSEN LUBRICATORS

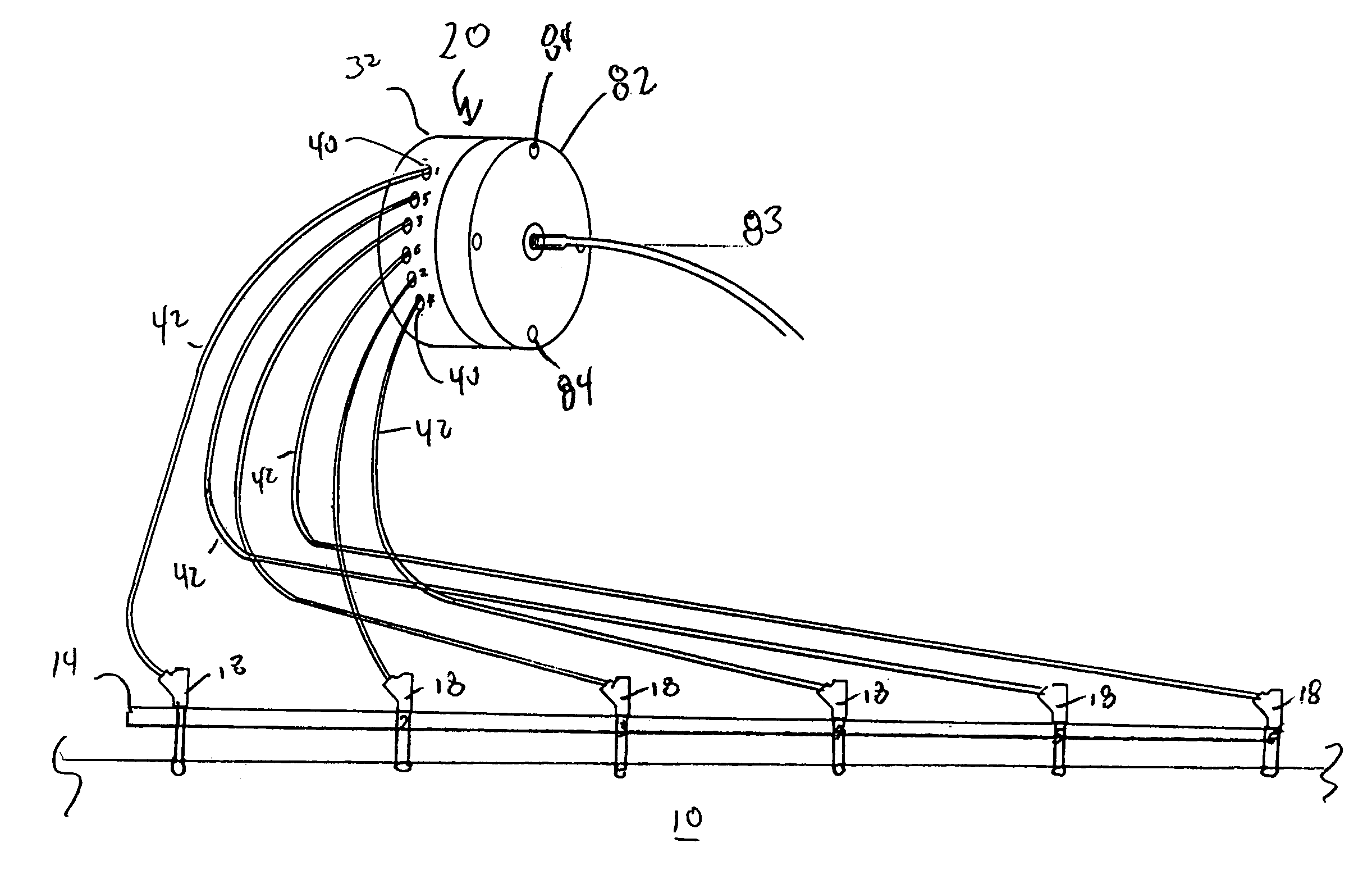

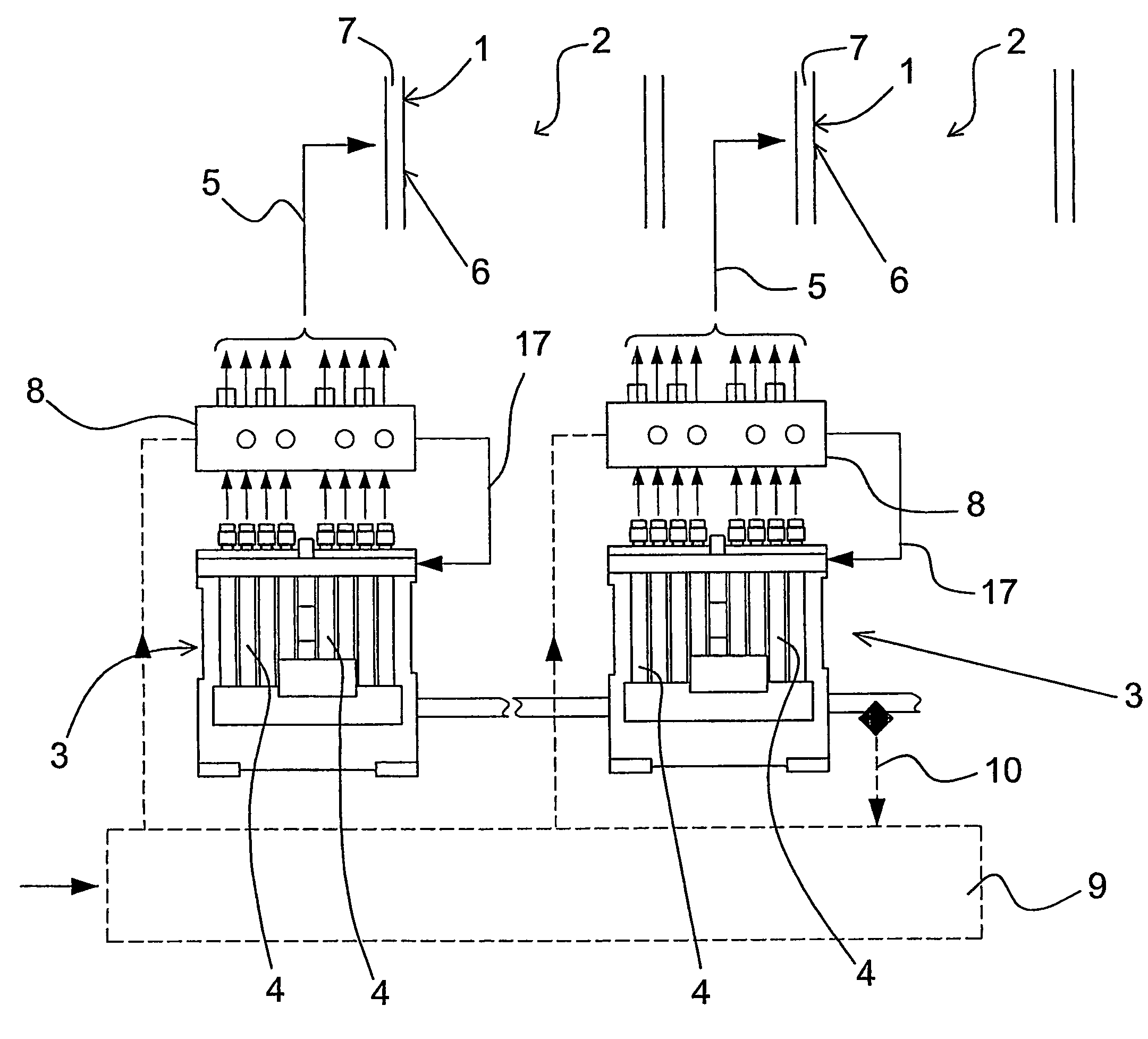

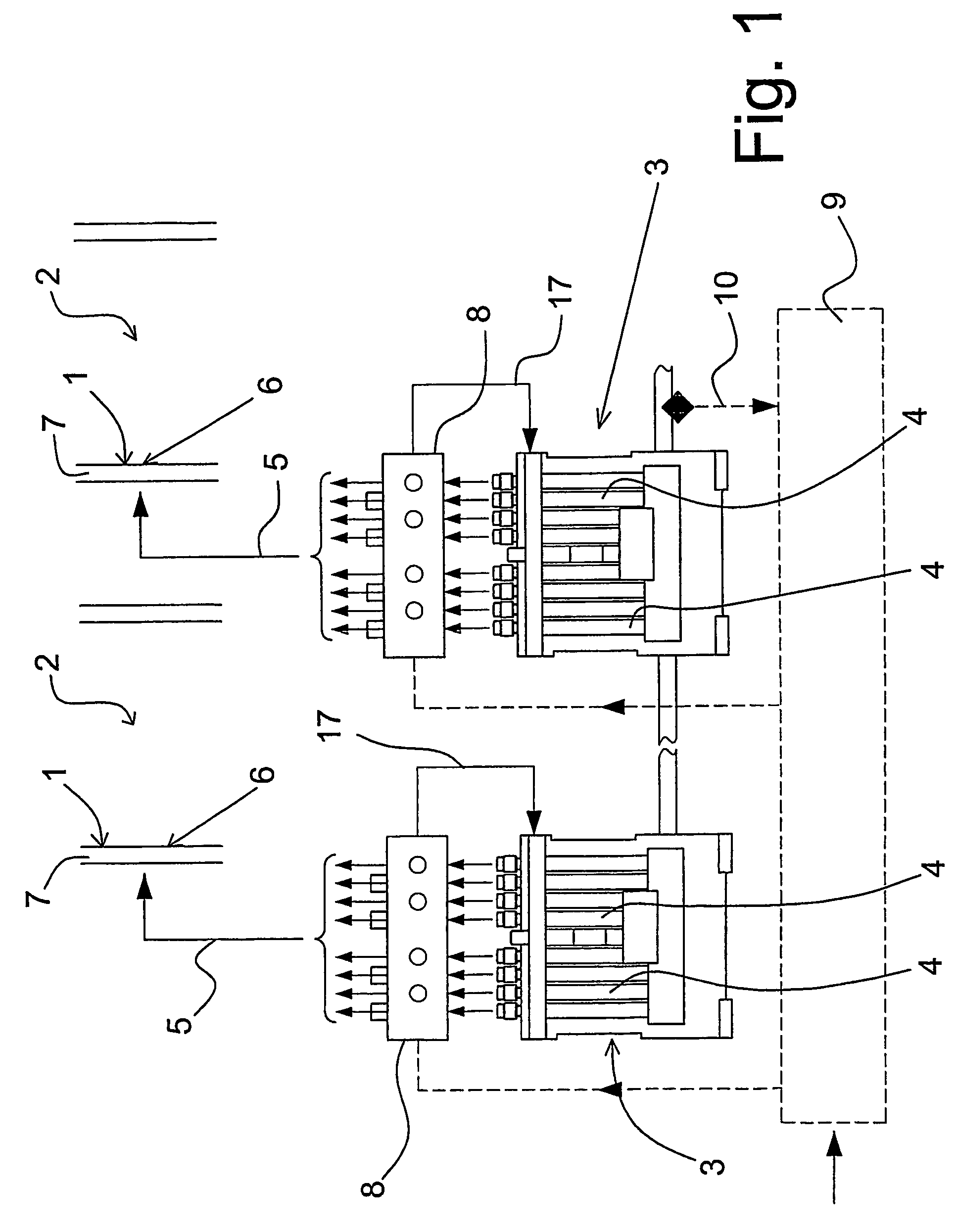

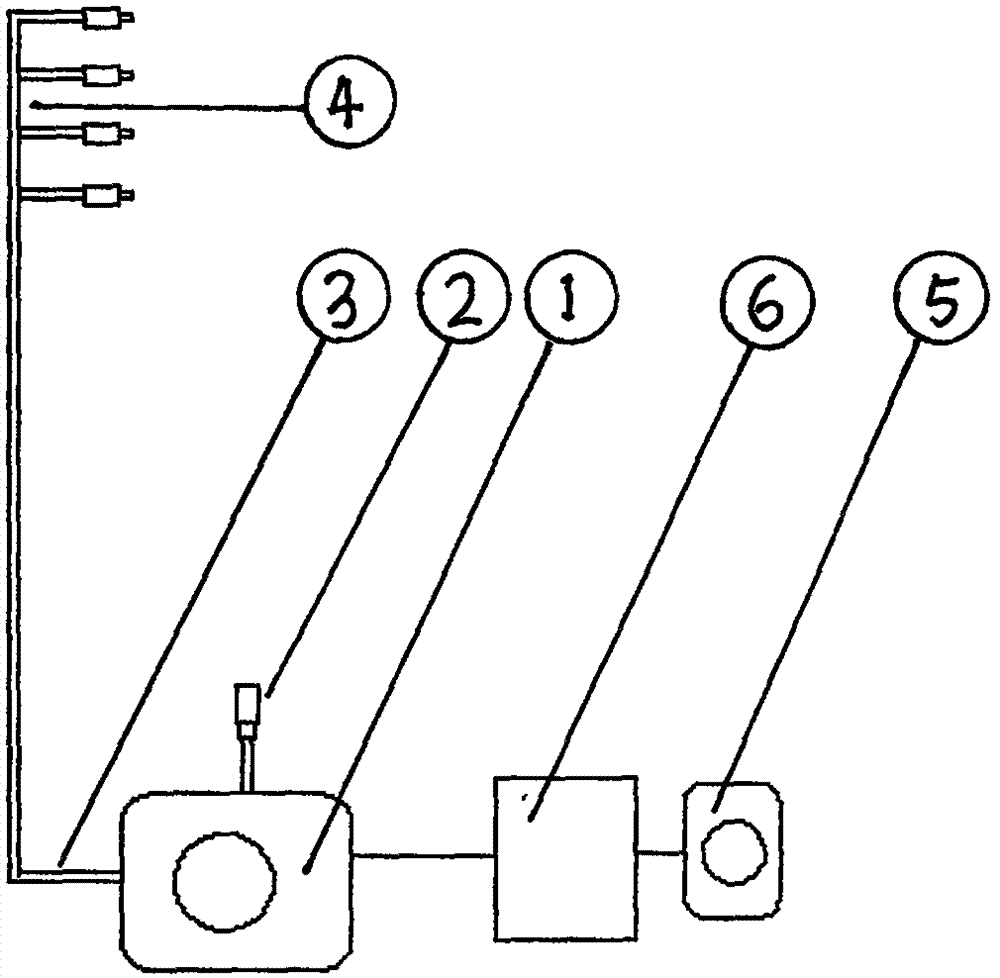

Method and apparatus for lubricating cylinder surface in large diesel engines

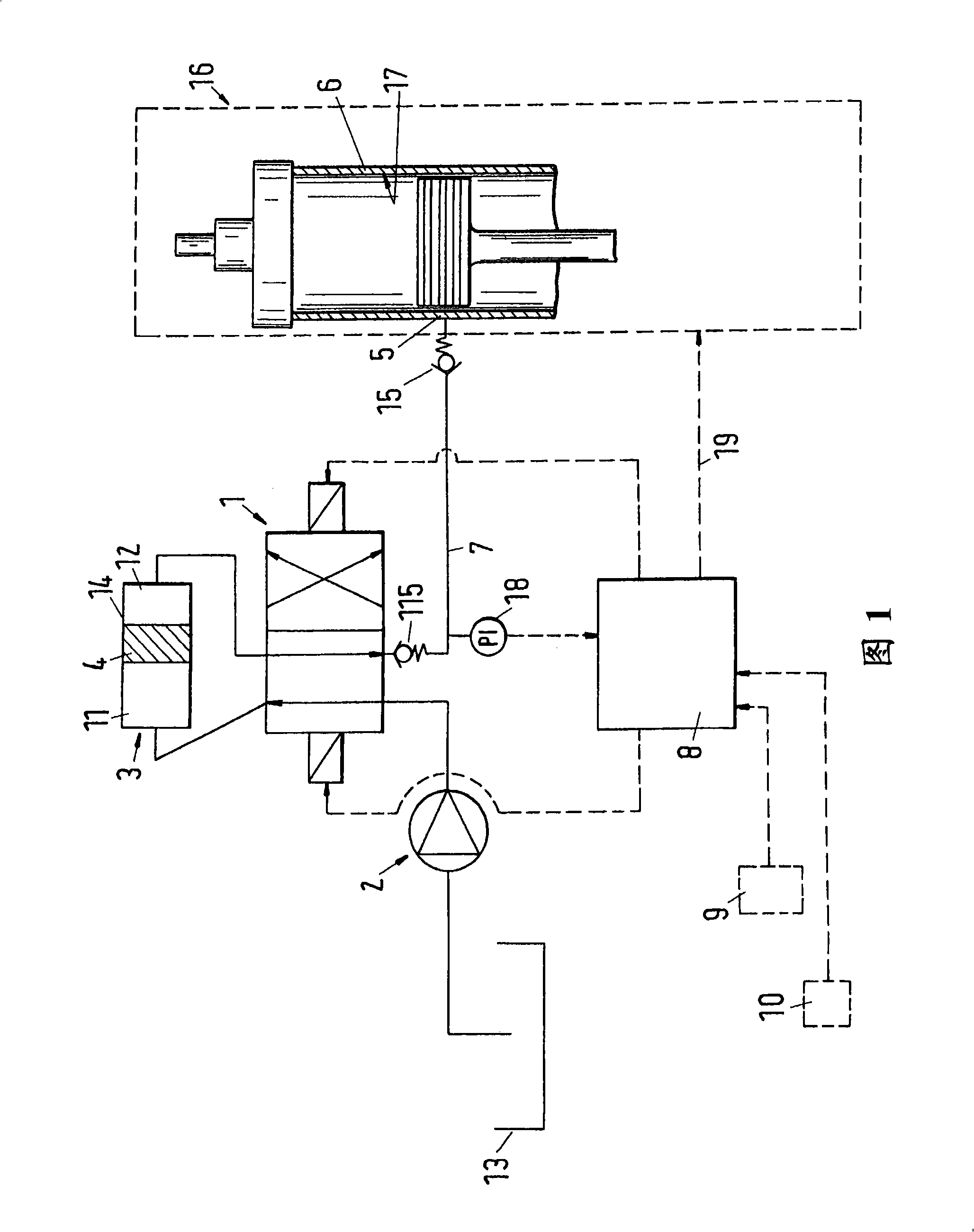

InactiveUS7681548B2Simple systemLubrication of auxillariesLubricant conduit arrangementsEngineeringMechanical engineering

There is described a method and an installation for lubricating cylinder surfaces 6 in large diesel engines. The installation includes a lubricating apparatus 3 with a number of piston pumps 4 which via connecting lines 5 are connected with lubricating points 6 in the cylinder walls 7. In order to enable electronically controlled regulation of the lubricating oil portion, there is provided an electronic control unit 9 which is connected with a flow regulator 8. The flow regulator includes redirecting valves 12 which are inserted in connecting lines 5 between the lubricating apparatus 3 and the lubricating points 6.

Owner:HANS JENSEN LUBRICATORS

Sequential injection lubrication system for internal combustion engine operating on natural gas or alternative fuels

InactiveUS20160290187A1Fuel injection apparatusMachines/enginesAlternative fuelsExternal combustion engine

A sequential injection lubrication system for an internal combustion engine operating on natural gas or alternative fuels, the lubrication system having a plurality of injectors, one for each cylinder, the injectors and communication with a lubricant reservoir and with a control unit which sequentially opens and closes the injectors for the introduction of lubricant into the cylinder, the control unit in communication with a control panel allowing the selective setting of the duration of the pulse injection and the frequency thereof.

Owner:COATES GREGORY

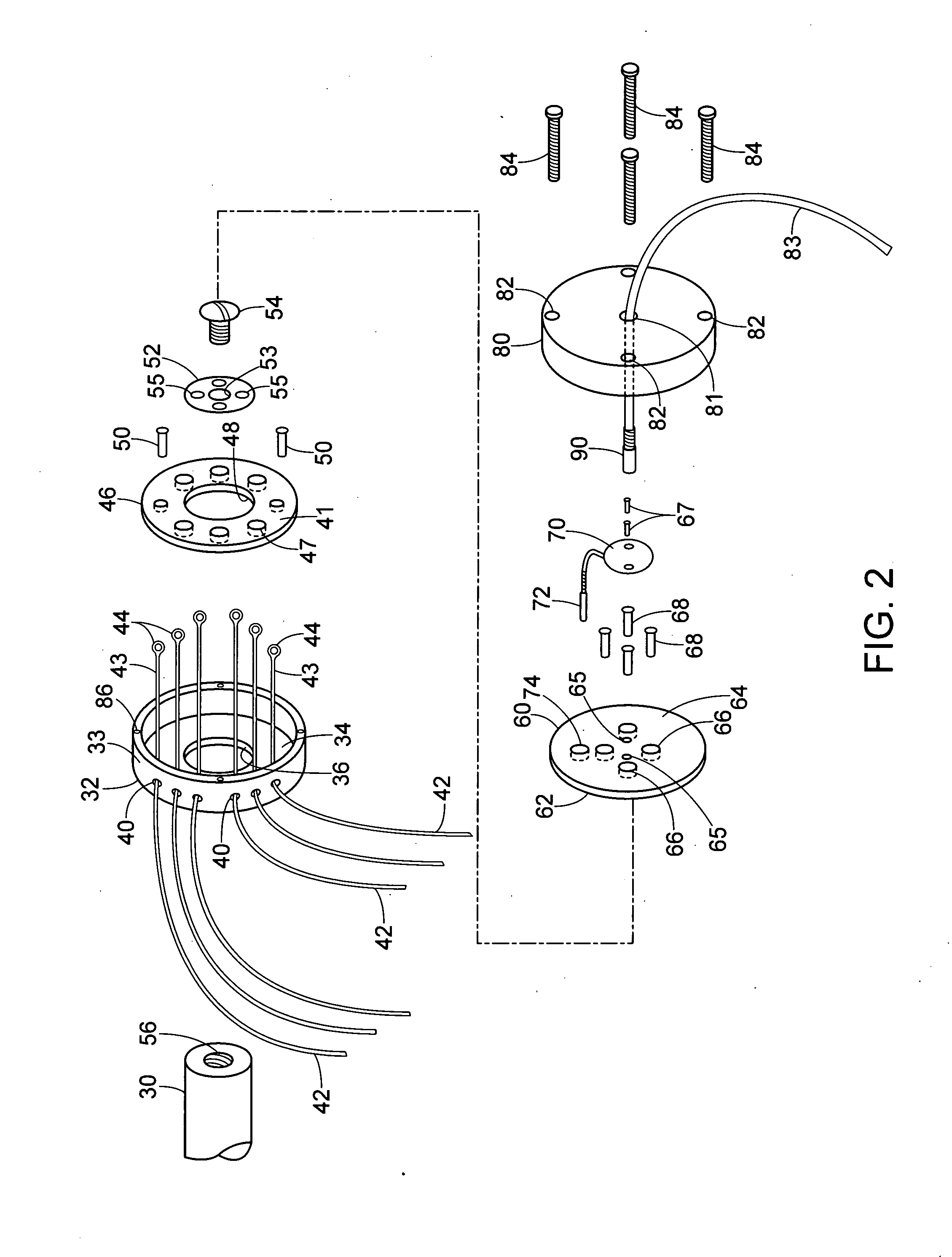

Engine oil pre-supply control method

InactiveCN110671167AAvoid scuffingAvoid Phenomena Like LavaLubrication pressure controlTimed pressure lubricationControl theoryOil temperature

The invention discloses an engine oil pre-supply control method. The method comprises the steps that before an engine is started, an ECU controls a pre-supply oil pump at the first time to pre-supplyengine oil to all movement pairs for first preset time; according to the current engine oil temperature monitored by an engine oil temperature sensor, the ECU judges a current pre-supplied oil threshold value; and when the oil pressure of the pre-supplied oil is larger than or equal to the pre-supplied oil threshold value, the pre-supply oil pump stops working, and the engine is normally started.Accordingly, by means of the engine oil pre-supply control method, engine oil pressure before starting of the large-power engine is ensured, and the phenomena such as scuffing and bearing score of thelarge-power engine are avoided.

Owner:GUANGXI YUCHAI MASCH CO LTD

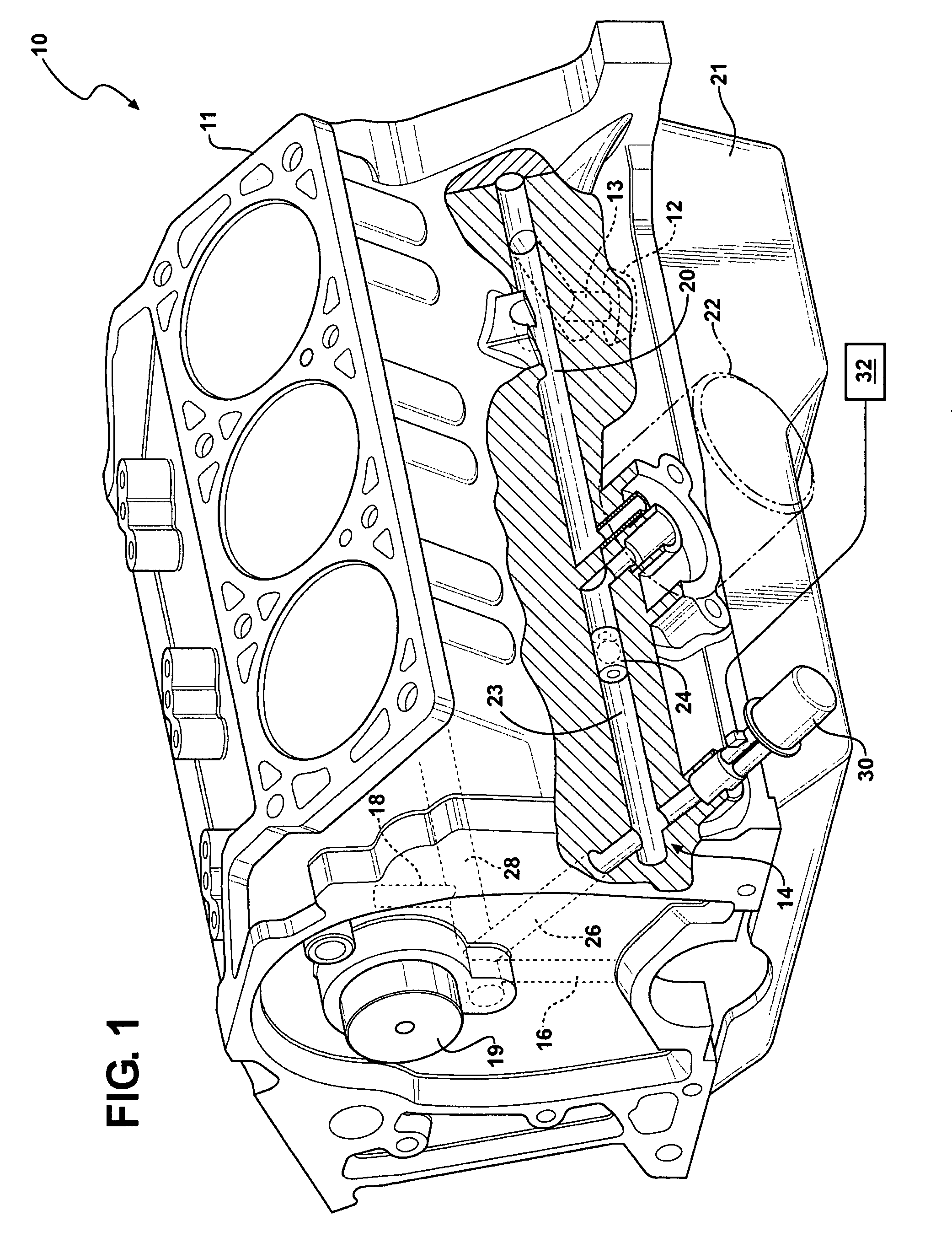

Cylinder lubrication system

The invention relates to a cylinder lubrication system, comprising a cylinder liner defining a cylinder, a piston reciprocally mounted in the cylinder for axial travel along a cylinder axis and having a piston skirt that moves in close proximity with the cylinder, an oil supply passage extending substantially circumferentially about an outer surface of the cylinder liner, an oil supply line fluidly connecting the oil supply passage to an oil supply, a series of small holes extending radially through the cylinder liner, from the cylinder to the oil supply passage, and operable as oil passages for lubricating oil from the oil supply to flow to the upper portion of the cylinder.

Owner:GM GLOBAL TECH OPERATIONS LLC

Pre-lubricating system of engine

InactiveCN107476843AAvoid lubricationAvoid wear and tearPressure lubrication with lubrication pumpTimed pressure lubricationPumpjackPetroleum engineering

The invention relates to a lubricating system of an engine. The pre-lubricating system of the engine is composed of an oil pump, an oil distribution pipeline, a start controller, and a start switch. The oil pipe is connected to the oil distribution pipe and connected to the main wear-resistant parts of the engine respectively. The start controller is used for the control of the whole system, and the start switch is used for the start detection of the system. When the human body is sitting on the seat of the cab, the start switch can sense After the existence of the human body, the signal is input to the start controller. At this time, the start controller will start the oil well pump immediately. After work, the controller delays the oil pump for 5 to 20 seconds to turn off the pump. When the driver finishes all the preparations and starts the engine, the system has lubricated the engine, so as to avoid the wear caused by the engine starting without effective lubrication.

Owner:王明中

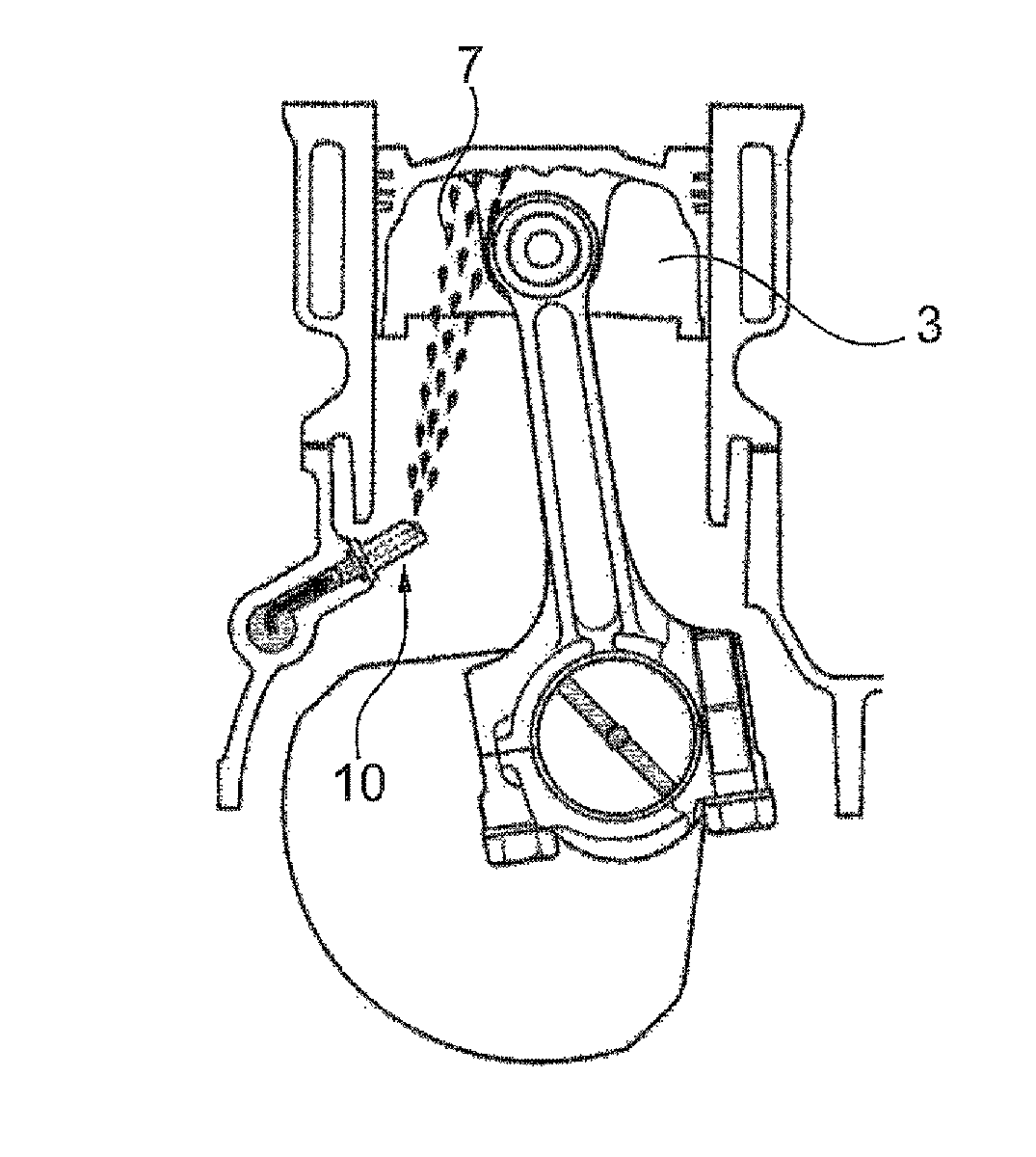

Method for controlling a piston cooling circuit of an internal combustion engine of an industrial vehicle

ActiveUS9803521B2Reduce energy consumptionImprove efficiencyLiquid coolingMachines/enginesTop dead centerExternal combustion engine

The present invention refers to a method for controlling a piston cooling circuit of an internal combustion engine wherein said circuit comprises at least a circulation pump and means for emitting cooling oil connected to the delivery of the pump. According to the method, said pistons are cooled by a jet generated by said emitting means only during the upward stroke of said pistons from the bottom dead center to the top dead center.

Owner:FPT IND

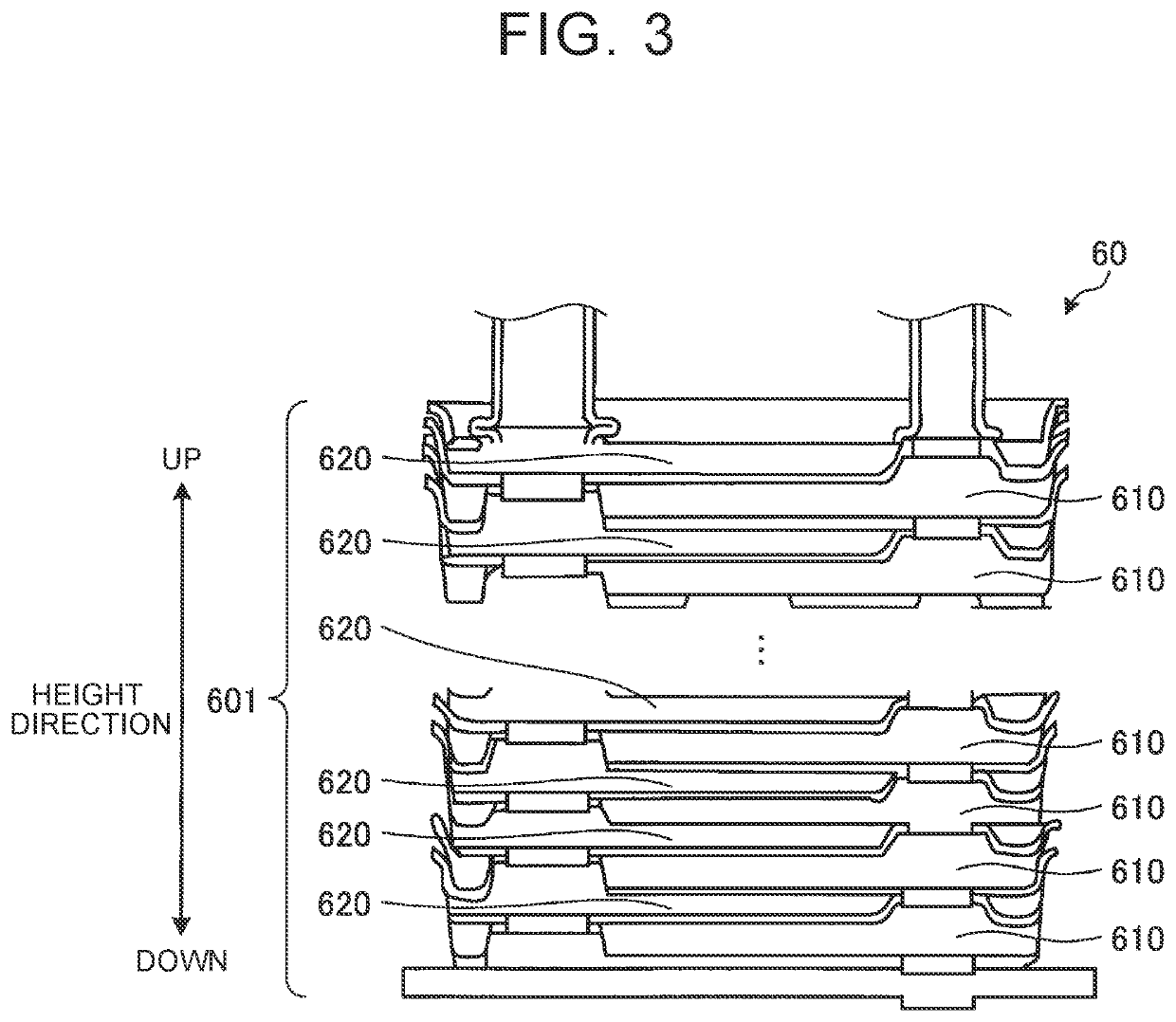

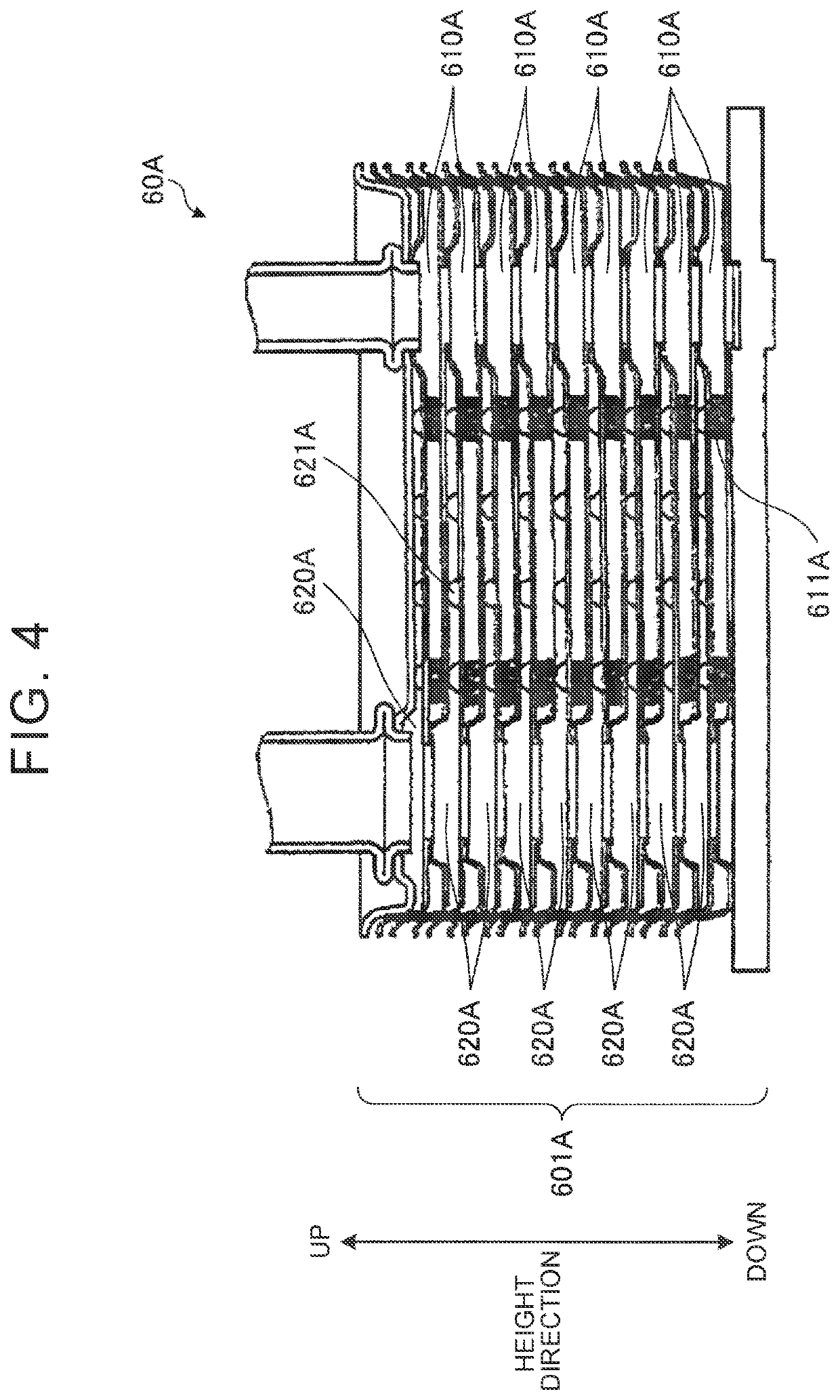

Valve Timing Adjusting Apparatus

A vane rotor includes a laminated portion and seal portions. The laminated portion includes a plurality of metal plates, which are stacked in an axial direction. The seal portions are placed on two axially opposite sides of each of an advancing port, a retarding port, and a supply port. Each seal portion is configured into an annular form to extend along an outer peripheral surface of a sleeve in a circumferential direction and is engaged with the laminated portion to limit deformation of the seal portion toward a radially outer side. The seal portion is made of a material that has a thermal expansion coefficient, which is larger than a thermal expansion coefficient of a material of each metal plate.

Owner:DENSO CORP

Lubrication Of Cylinders Of Large Diesel Engines, Such As Marine Engines

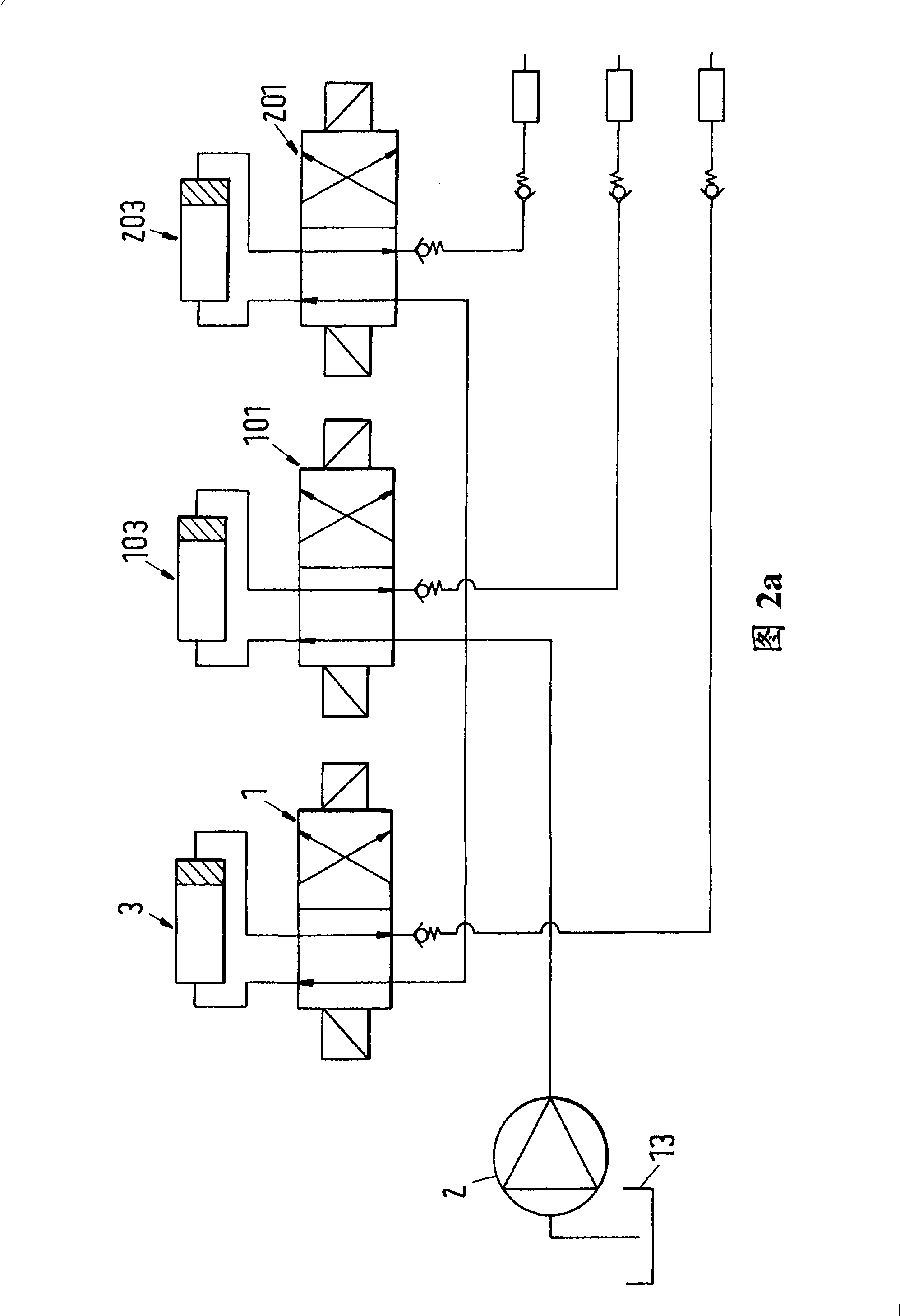

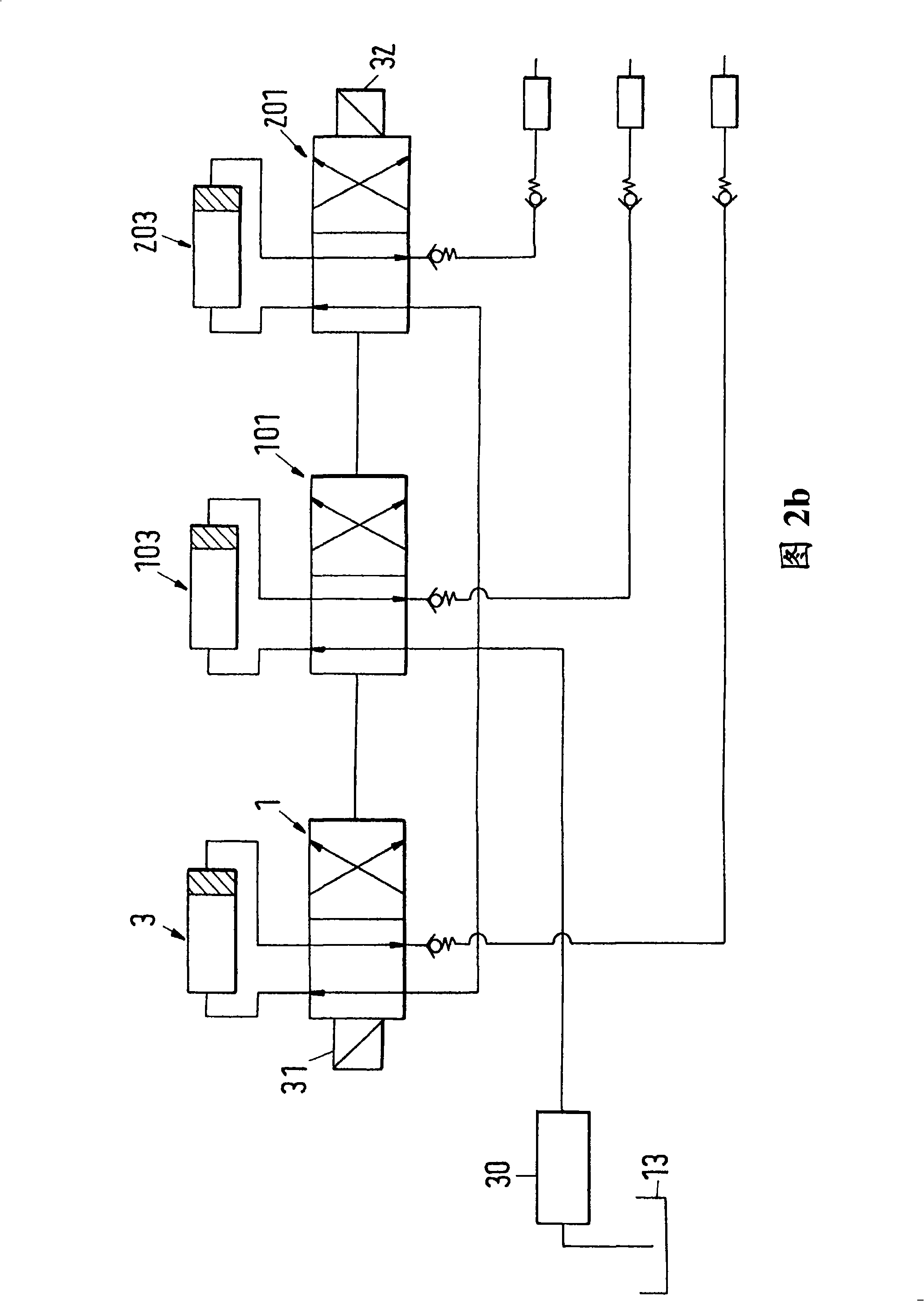

ActiveUS20120118260A1Reduce fuel consumptionEffective distributionLubrication of auxillariesLubricant conduit arrangementsEngineeringDiesel engine

There is disclosed a method for cylinder lubrication of large diesel engines, such as marine engines. Injection of lubricating oil is performed via a number of injection units that correspond to a multiple of the cylinder number in the engine. There is desired an efficient distribution of the lubricating oil, not only across the periphery of the cylinder, but also across the travel of the piston in the cylinder in order thereby to reduce the consumption of lubricating oil. This is achieved in that lubricating oil is supplied by a combination of injection of a first part of the lubricating oil directly on a ring area of the cylinder wall before the passage of the piston and an injection of a second part of the lubricating oil directly onto the piston during its passage.

Owner:HANS JENSEN LUBRICATORS

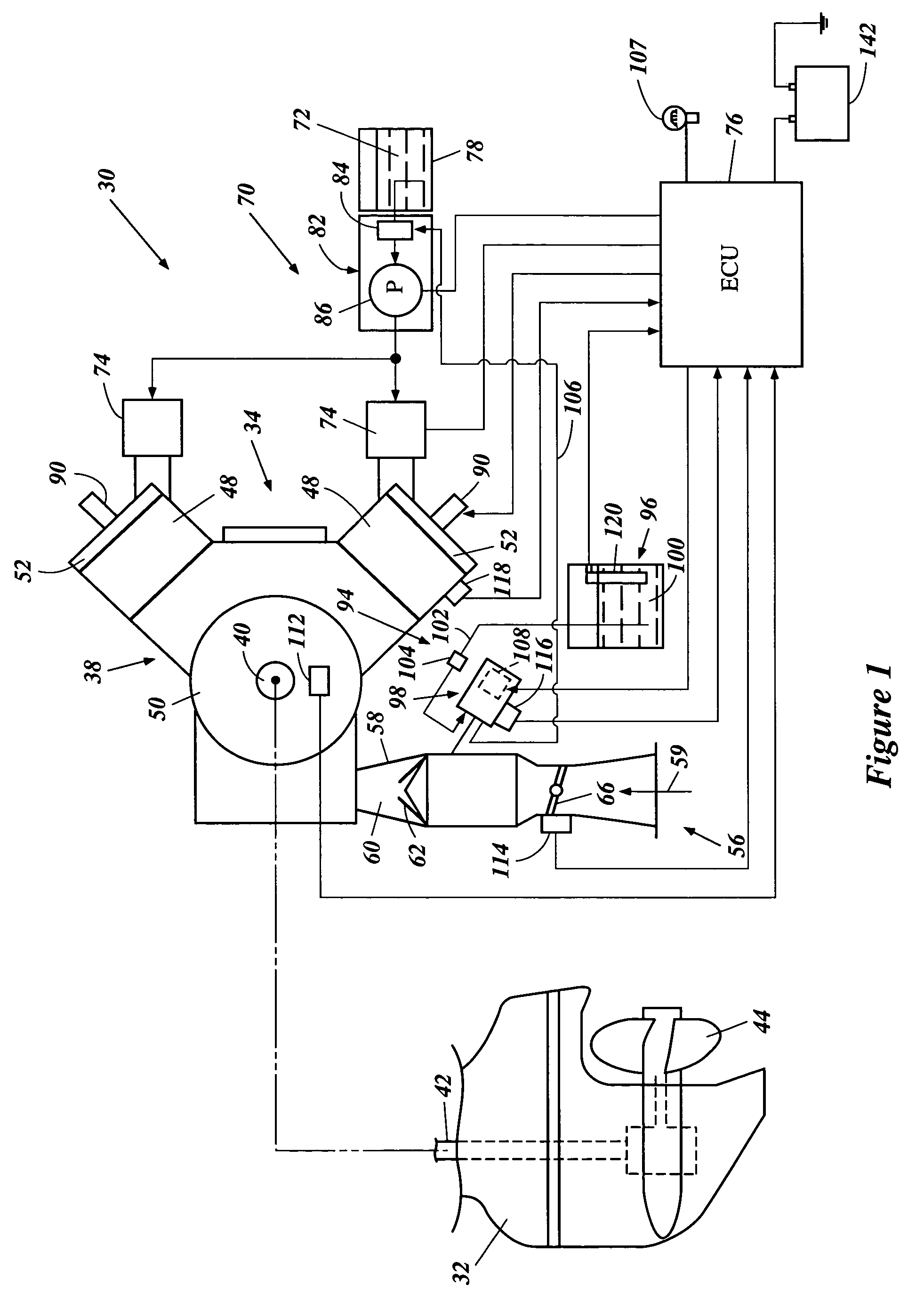

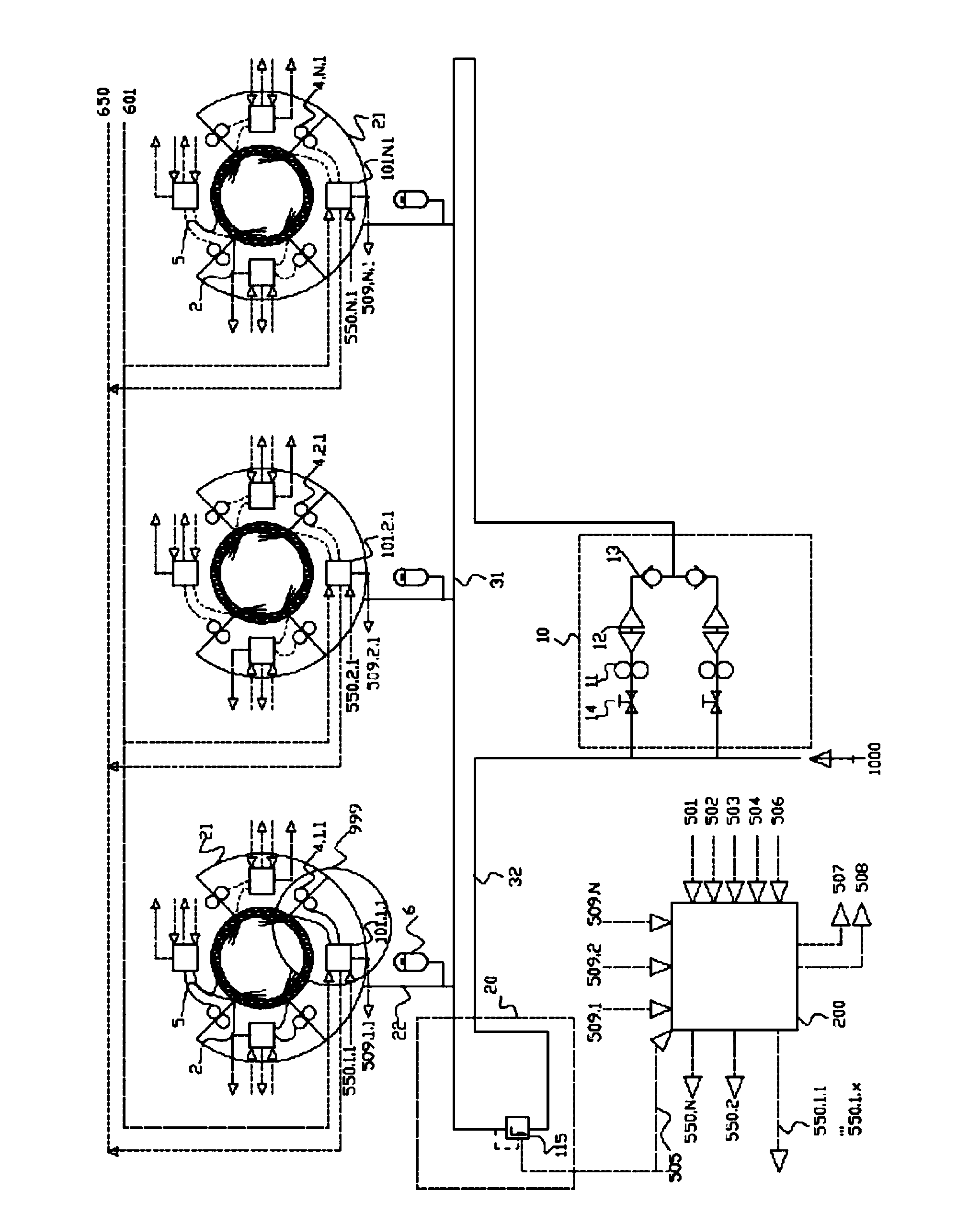

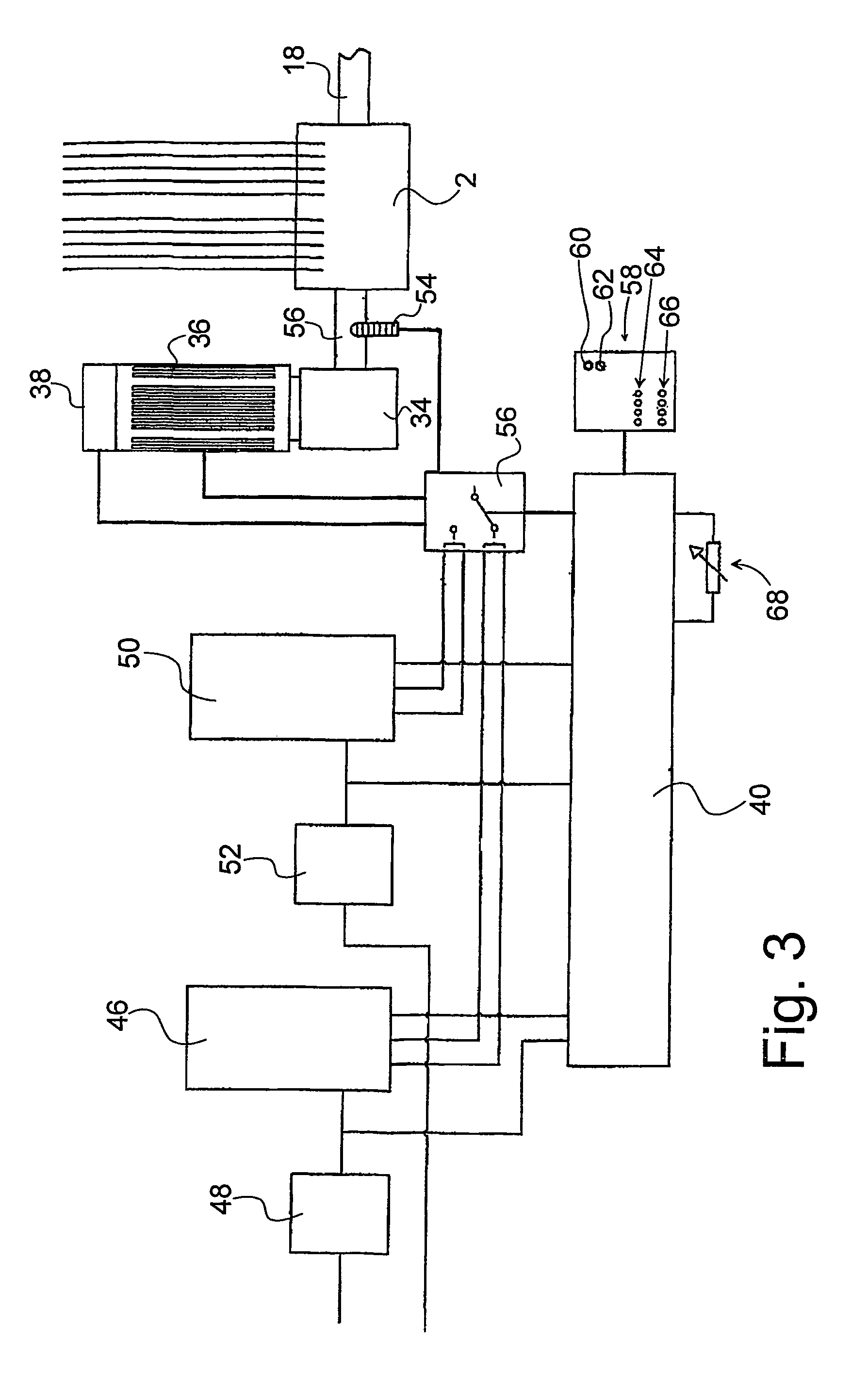

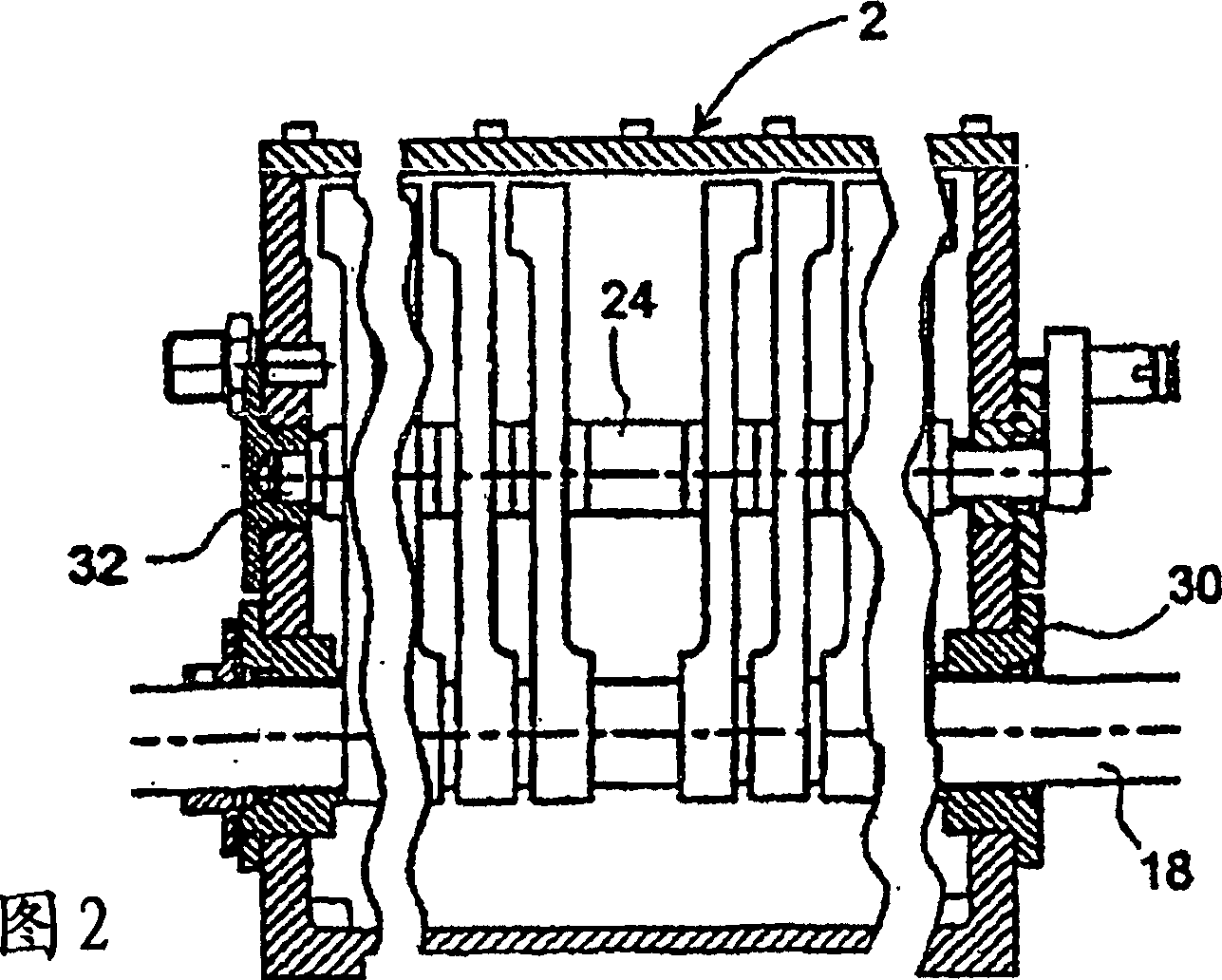

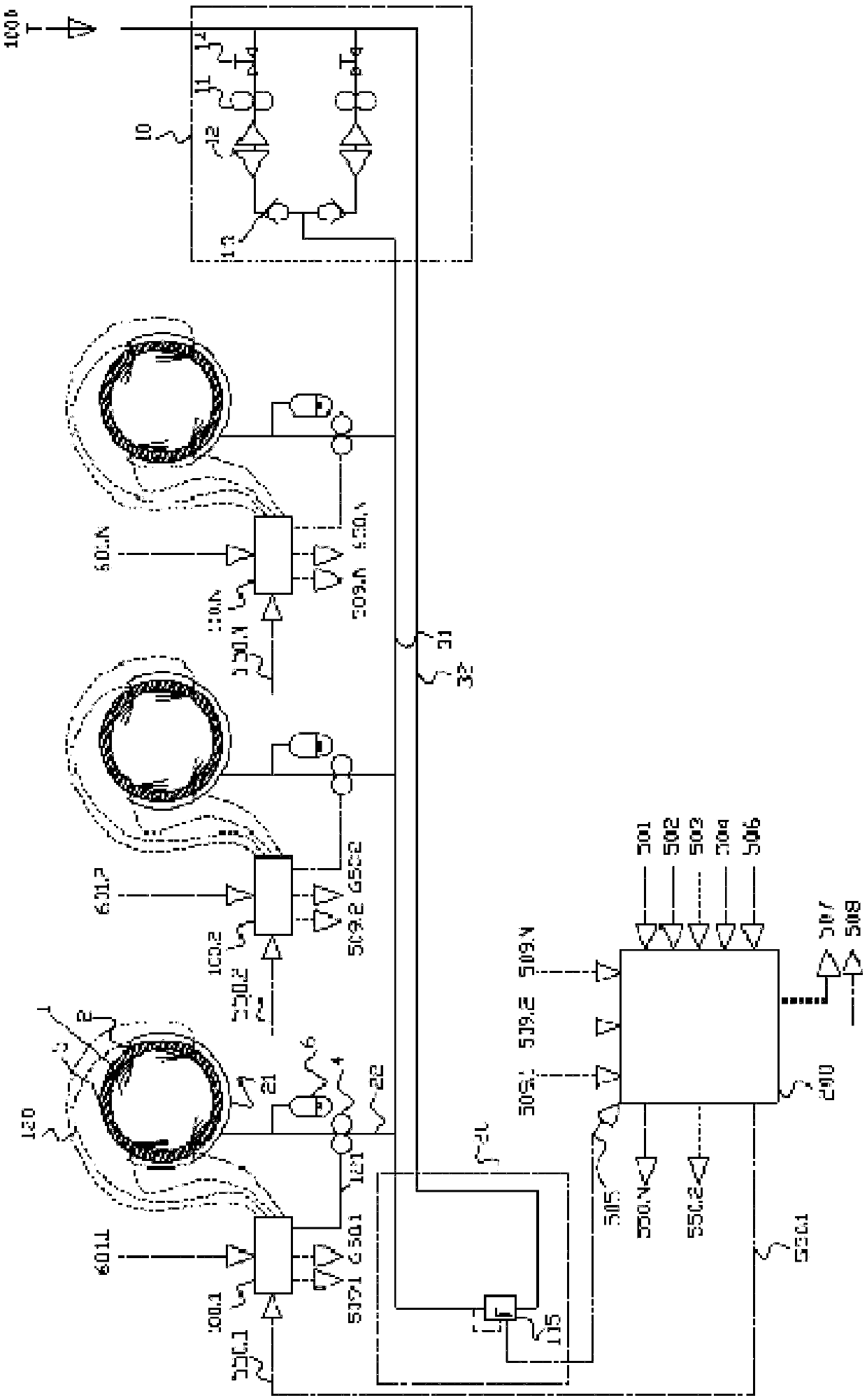

Centralised lubrication of large diesel engines

There is described a centralised lubrication system and a method for lubricating the cylinder faces in large diesel engines, in particular marine engines. The system includes at least one lubricating apparatus (2) having a rotating control shaft (18) for preferably running synchronously with the main shaft (44) of the diesel engine. In order to make a system that does not have a mechanical drive between the lubricating apparatus (2) and the main shaft (44), the system is constructed with an AC motor (36) driving the control shaft (18). Reference means (72, 78) are provided in association with the main shaft (44), indicating the angular position of the main shaft, and sensor means (74, 76, 80) detecting the position of the reference means. Furthermore, the system includes a control unit (40) receiving signals from the sensor means and which includes means for detecting angular position as well as angular speed of the reference means and thereby of the main shaft (44). The control unit (40) is connected with and controls the AC motor (36) for regulating the rotation of the control shaft (18) and thereby actuation of reciprocating pumps providing the cylinder lubrication.

Owner:HANS JENSEN LUBRICATORS

System and method for dosing cylinder lubrication oil into large diesel engine cylinders

ActiveCN103939174AAvoid blockingEasy to makeMachines/enginesLubrication pressure controlViscosityLubrication

There is disclosed dosing system and a method for cylinder lubrication oil in large diesel engine cylinders, e.g. in marine engines, including: - a lubricating oil supply that may be constituted by a pump station or an accumulator; - a supply line from the lubricating oil supply; - a number of injectors having an inlet, an opening / closing valve unit and one or more nozzle apertures for injecting cylinder lubricating oil into an associated cylinder, and which are connected with the supply line and corresponding to the number of cylinders in the engine or a multiple thereof; and - a control unit controlling each opening / closing valve unit. In order to overcome the drawback of dependence on flow and viscosity in the supply pipes, the system is peculiar in that the dosing system includes a flow measuring unit for each injector and / or for each cylinder, and that the flow measuring units are connected with the control unit for use in a closed circuit regulation.

Owner:HANS JENSEN LUBRICATORS

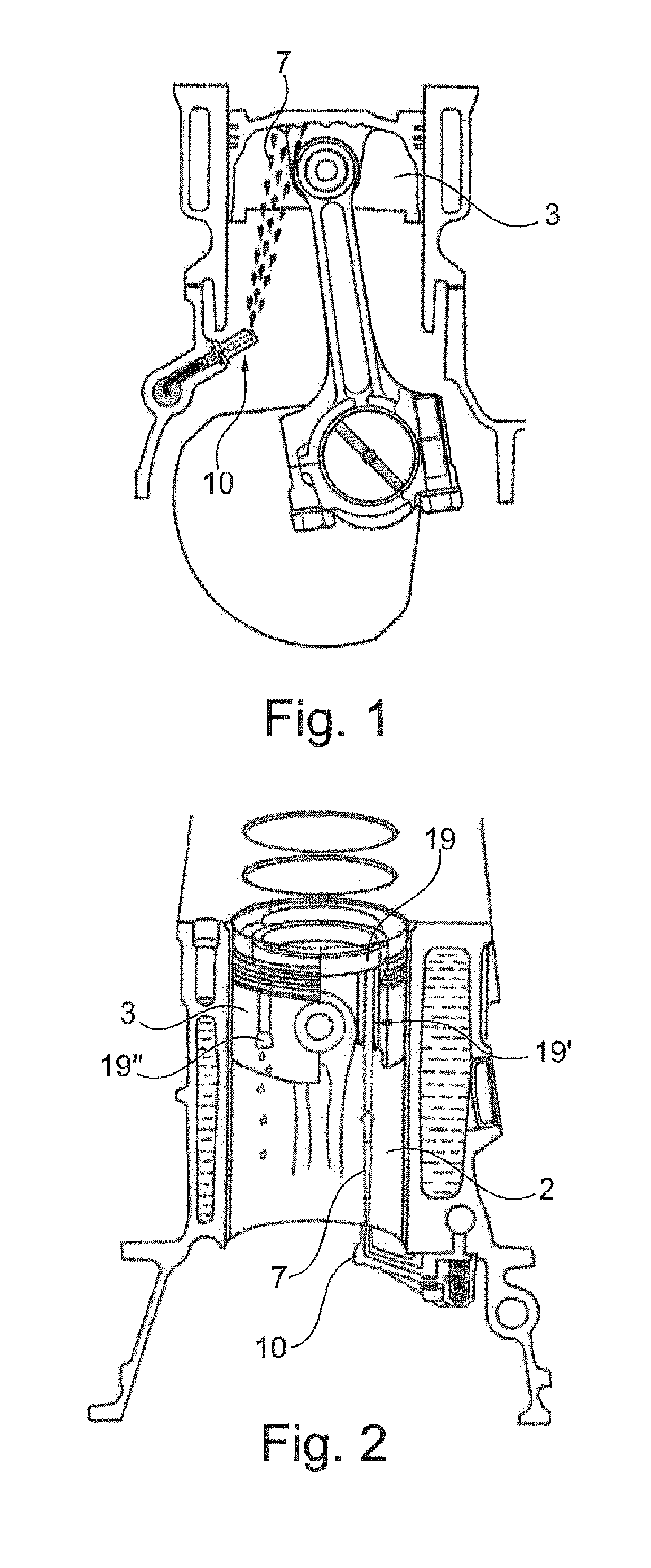

Large diesel engine

InactiveCN105888766AMachines/enginesPressure lubrication with lubrication pumpEngineeringLubrication

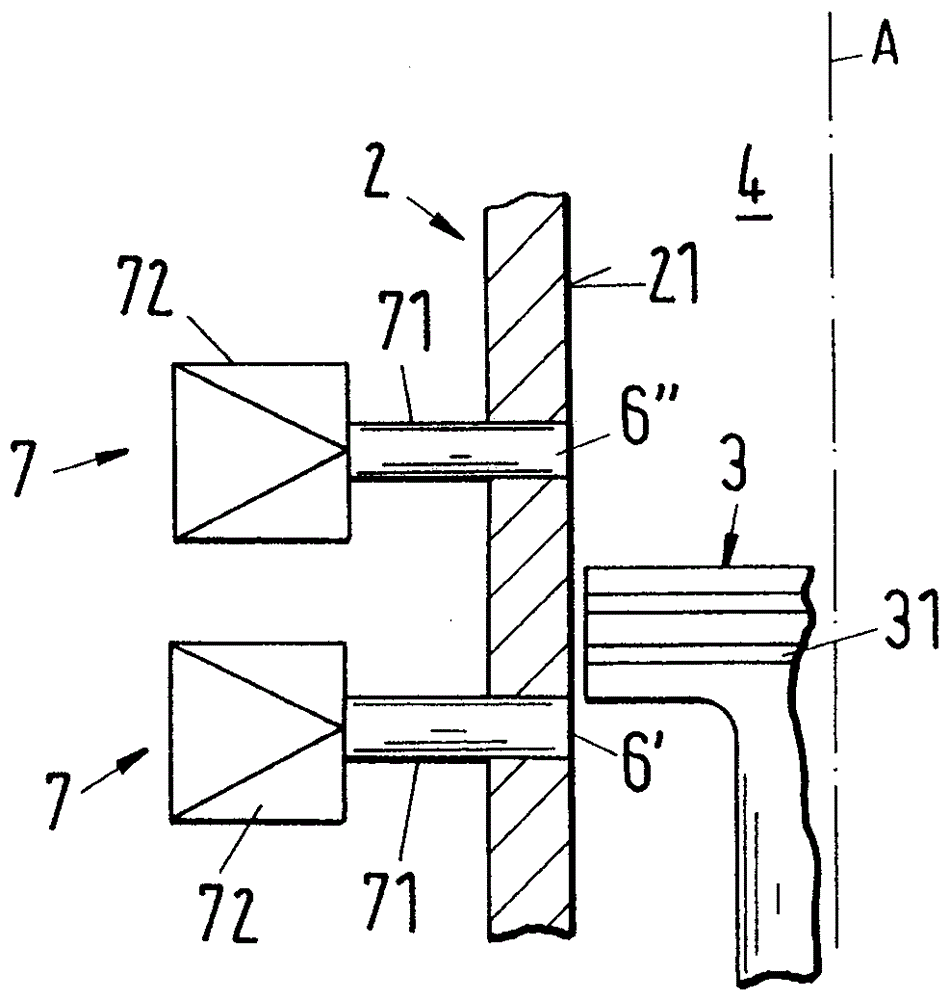

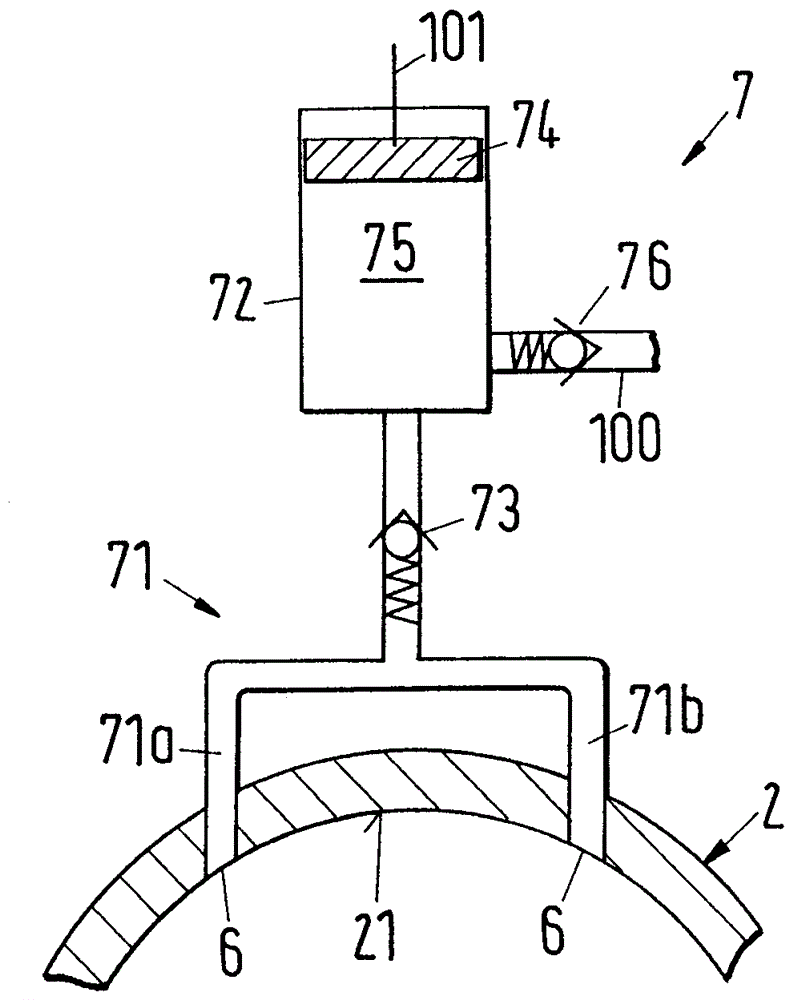

The invention provides a large diesel engine comprising at least one cylinder (2), the cylinder (2) having a cylinder bore (B) and a longitudinal axis (A) and the piston (3) therein being arranged capable of moving along a running surface (21), and a lubricating system (5) provided for cylinder lubrication. The lubricating system (5) includes at least two lubricating points (6) through which the lubricant is applied to the running surface (21) and a lubricant supply device (8) for delivering the lubricant from the lubricant storage (10) to the lubricating points (6). The lubricant supply device (8) includes at least one pump nozzle unit (7) provided at the lubricating points (6), and each pump nozzle unit (7) includes a pump (72) connected to at most two lubricating points (6), so that each pump nozzle unit (7) supplies lubricant to at most two lubricating points (6).

Owner:丰泰天然气及柴油有限公司

Lubrication of cylinders of large diesel engines, such as marine engines

ActiveUS8813714B2Reduce fuel consumptionEffective distributionLubricant conduit arrangementsMachines/enginesEngineeringMechanical engineering

There is disclosed a method for cylinder lubrication of large diesel engines, such as marine engines. Injection of lubricating oil is performed via a number of injection units that correspond to a multiple of the cylinder number in the engine. There is desired an efficient distribution of the lubricating oil, not only across the periphery of the cylinder, but also across the travel of the piston in the cylinder in order thereby to reduce the consumption of lubricating oil. This is achieved in that lubricating oil is supplied by a combination of injection of a first part of the lubricating oil directly on a ring area of the cylinder wall before the passage of the piston and an injection of a second part of the lubricating oil directly onto the piston during its passage.

Owner:HANS JENSEN LUBRICATORS

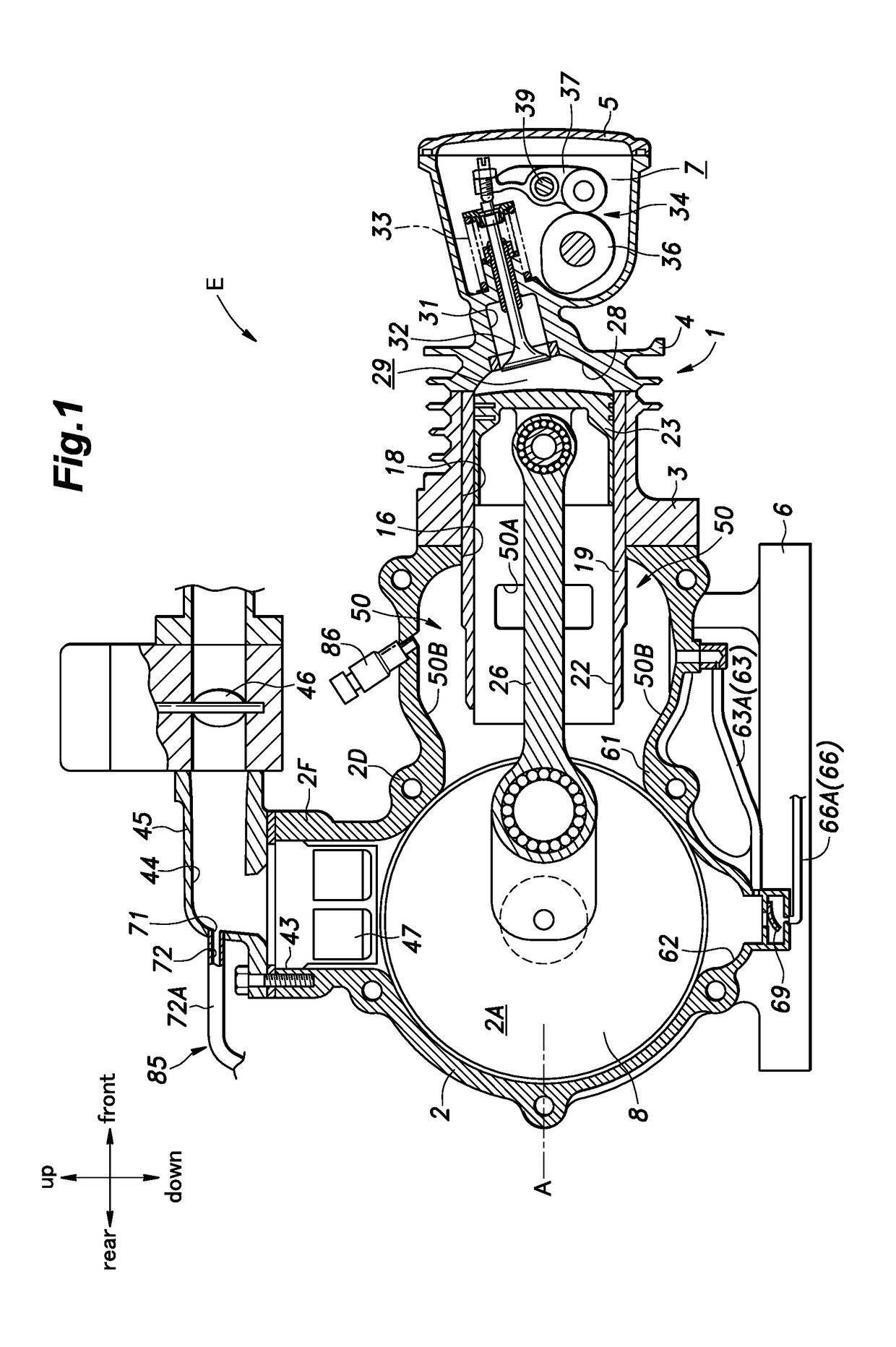

Lubrication system for internal combustion engine

ActiveUS10221732B2Simple structureLubricant conduit arrangementsMachines/enginesExternal combustion engineFuel tank

A lubrication system for an engine is provided which includes an oil tank, a first passage communicating a bottom part of the crankcase chamber with an upper part of the oil tank, a first check valve provided in the first passage to permit a flow from the crankcase chamber to the oil tank but not in a reverse direction, a second passage communicating an upper part of the oil tank with an upper part of the crankcase chamber, a second check valve provided in the second passage to permit a flow from the oil tank to the crankcase chamber but not in a reserve direction and a third passage communicating a lower part of the oil tank with the second passage.

Owner:HONDA MOTOR CO LTD

Method and a system for establishing and executing correct automatic relubrication for a number of bearings

A method and a system for establishing and executing correct automatic relubrication for a number of bearings incorporated in a grease lubrication system. The system determines initial values for the relubrication interval tf and / or lubricant volume utilizing data collected from the different bearing assemblies during operation. The data includes bearing load, bearing temperature and bearing rotational speed. A processor calculates a correct lubricant volume and a value for current lubrication interval tf by comparing an initial value with a current value. The calculated correct lubricant volume and current lubrication interval tf are supplying to an automatic lubricating apparatus, which functions in accordance with the determined values. The data collection and calculation procedures are repeated after each application of lubricant to the bearings.

Owner:AB SKF

Vehicle lubrication structure and vehicle lubrication control method

InactiveUS20200292053A1Reduce lossesReduce oil resistanceGear lubrication/coolingLubricant conduit arrangementsElectric machineLubrication

A vehicle lubrication structure includes a rotating electrical machine, a driving force transmission apparatus, a first reservoir, a second reservoir, a first oil path, a second oil path, and an electric oil pump. The second reservoir has a capacity smaller than that of the first reservoir. The first oil path connects the first reservoir to the second reservoir. The second oil path connects the second reservoir to the driving force transmission apparatus and the rotating electrical machine. The electric oil pump is configured to supply oil stored in the first reservoir to the driving force transmission apparatus and the rotating electrical machine. The electric oil pump is provided in the first oil path or the second oil path.

Owner:TOYOTA JIDOSHA KK

Injectors for cylinder lubricating oil distribution systems for large diesel engine cylinders

ActiveCN103534447BEasy to installImprove reliabilityMachines/enginesLubrication pressure controlDistribution systemOil distribution

The invention discloses a fuel injector for a cylinder lubricating oil distribution system in a cylinder of a large diesel engine, such as a marine engine. The fuel injector comprises: an inlet connected to an oil supply pipe, a switching valve unit and one or more The nozzle holes are used to inject the cylinder lubricating oil into the associated cylinders, and the oil supply pipe is led out from the lubricating oil supply equipment of the distribution system. The injector is characterized in that its on-off valve unit consists of a ball valve body and interacting valve seats, and that there is a gap with a width of more than 10 microns between the valve body stem and the valve guide wall of the on-off valve.

Owner:HANS JENSEN LUBRICATORS

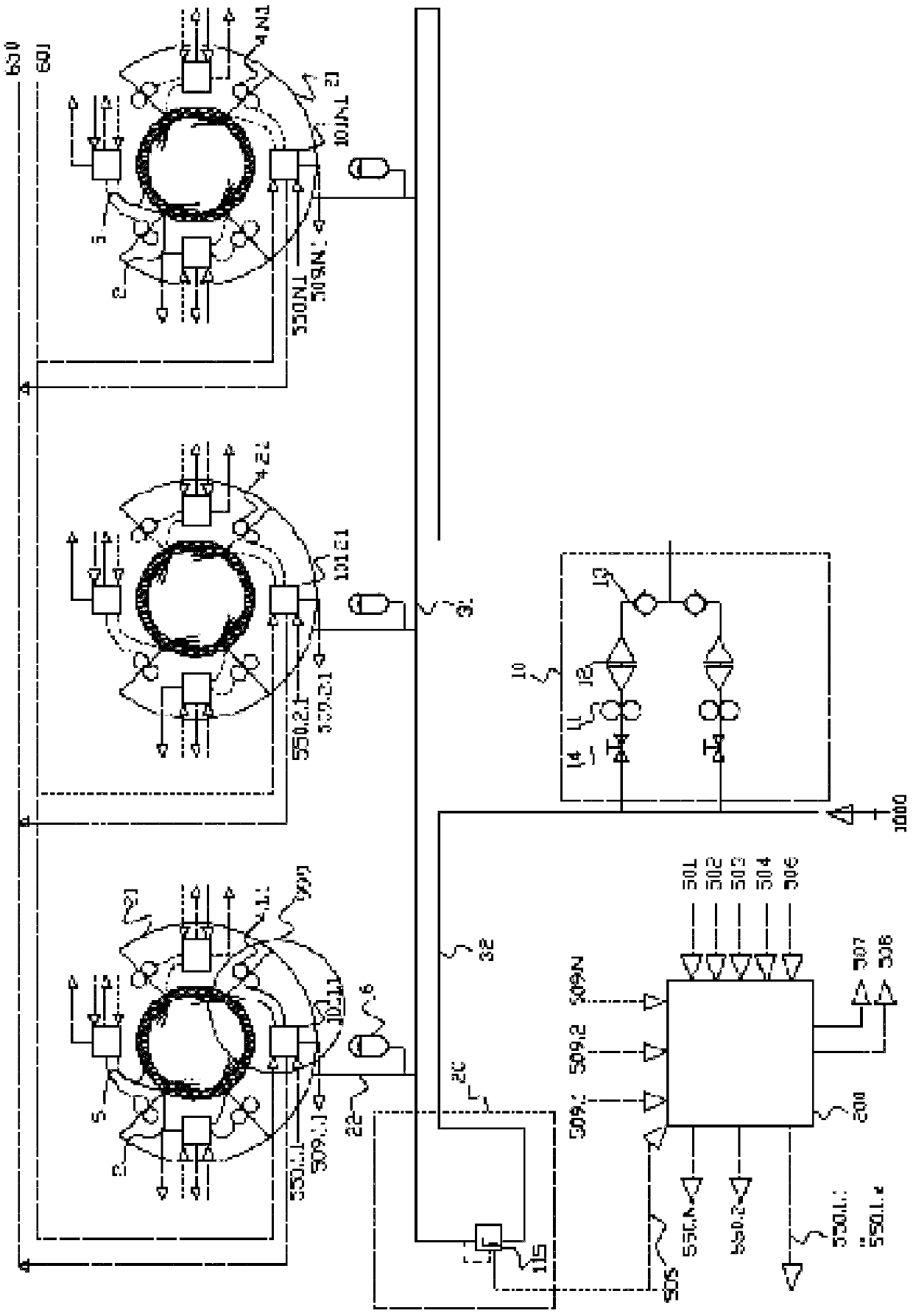

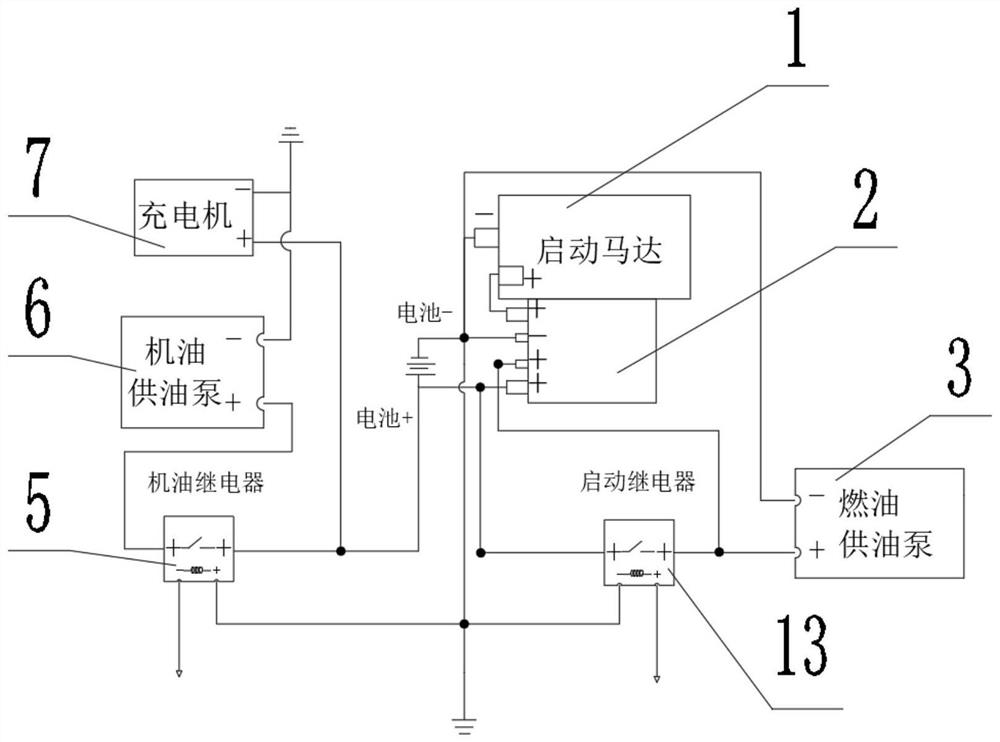

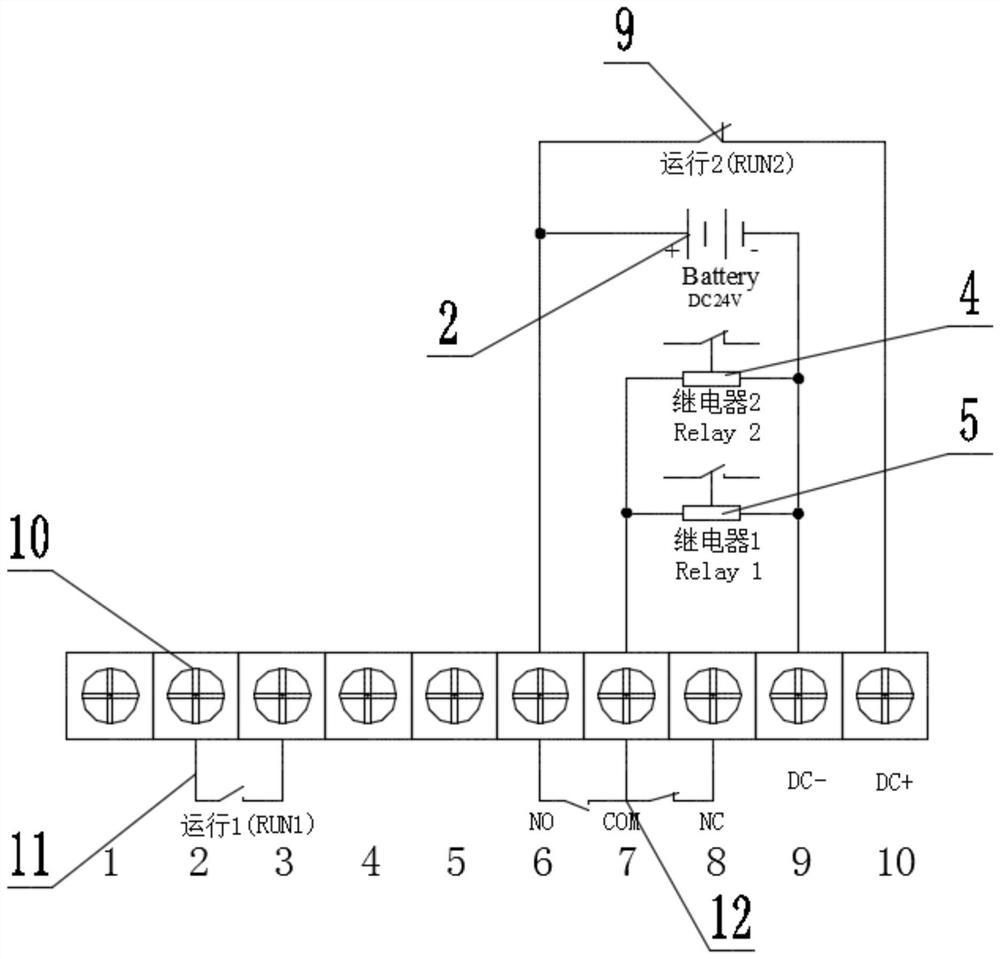

Engine lubricating oil circulation control system for engine of motor set

PendingCN114483295ARapid Response Power GenerationElectric motor startersMachines/enginesOil sludgeFuel oil

The invention discloses a motor set engine lubricating oil circulation control system which comprises a starting motor, a battery, a fuel oil supply pump, a starting relay, an engine oil relay, an engine oil supply pump, a charger, a generator set operation switch, a wiring terminal, a circulation timer operation switch, a micro-control switch and an engine. The engine oil supply pump is controlled to work in a circulating and timing mode through the circulating timer operation switch, engine oil is conveyed into the engine through the output end of the engine oil supply pump, the engine is kept lubricated in the idle state, it is guaranteed that the engine can be started at any time, and engine lubricating time is not consumed any more; when the engine runs, the engine pumps engine oil through the kinetic energy of the engine so that the engine oil with the high temperature in the engine and carbides, oil sludge and abraded metal particles on engine parts can be circularly brought out of the engine, cooling of the engine and cleaning of the interior of the engine are achieved, and the service life of the engine can be prolonged.

Owner:CHONGQING GOOGOL ENGINE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com