Injectors for cylinder lubricating oil distribution systems for large diesel engine cylinders

A diesel engine and fuel injector technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problems of unsuitable needle valves, different oil volumes, large gaps, etc., and achieve the effect of less maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

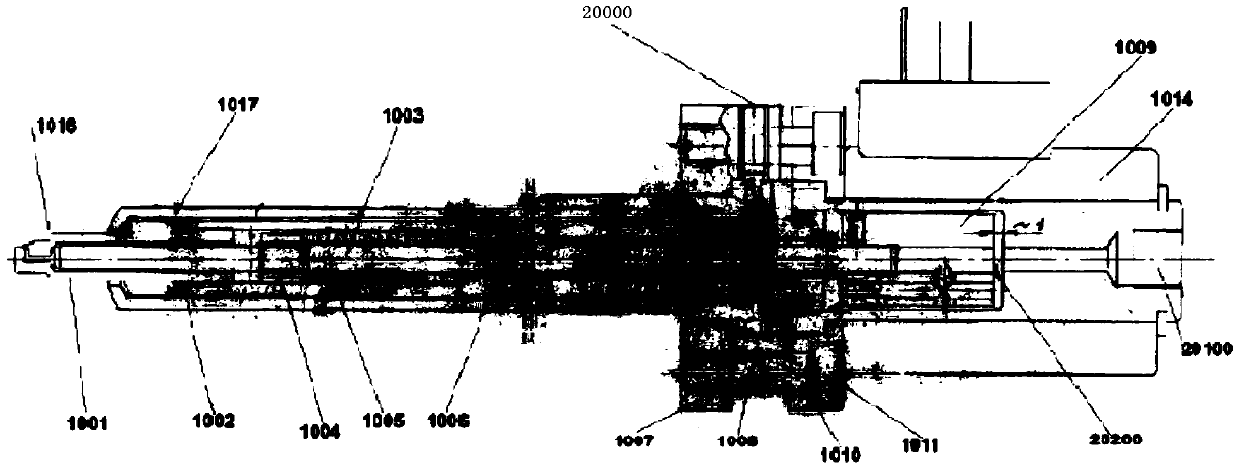

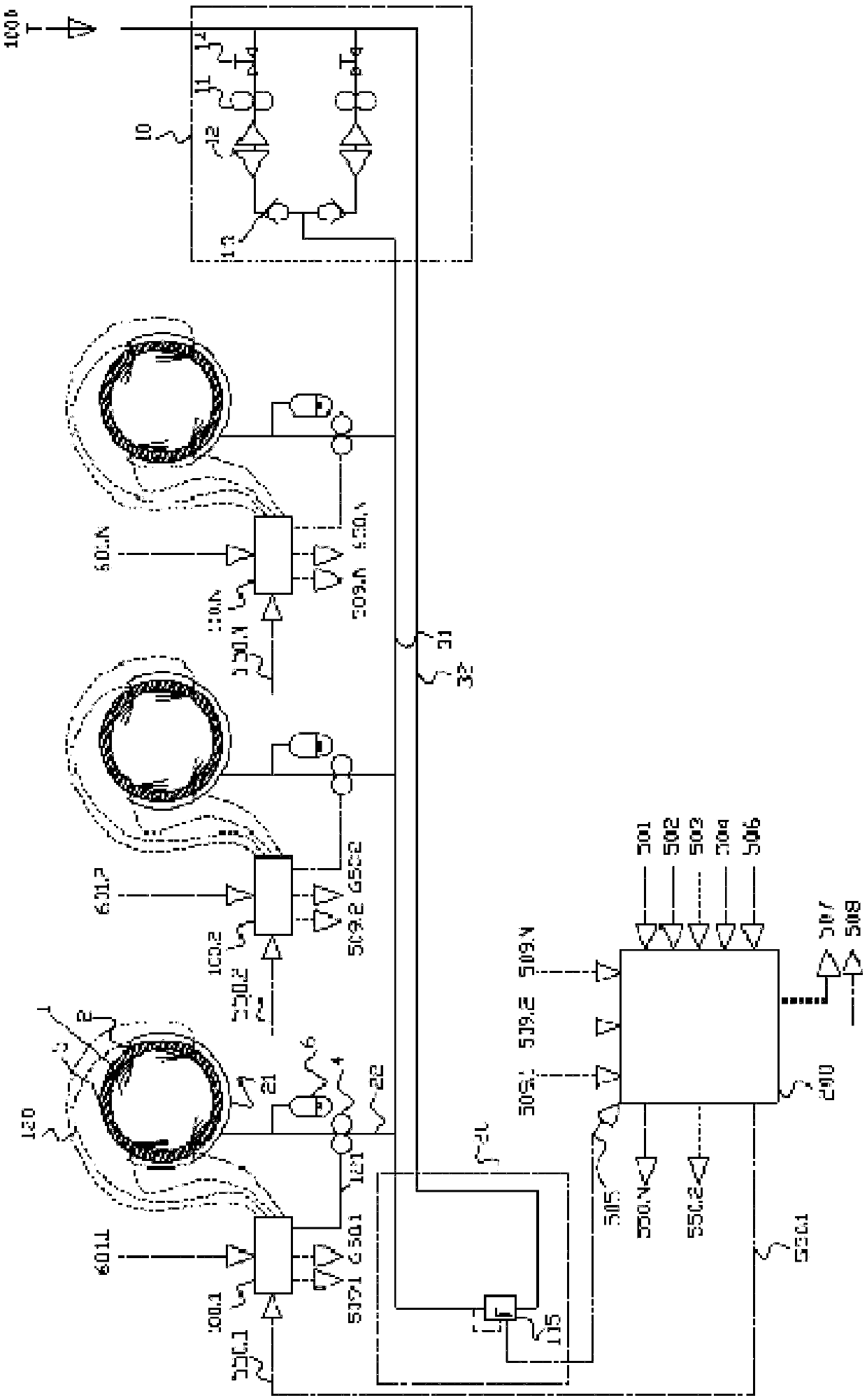

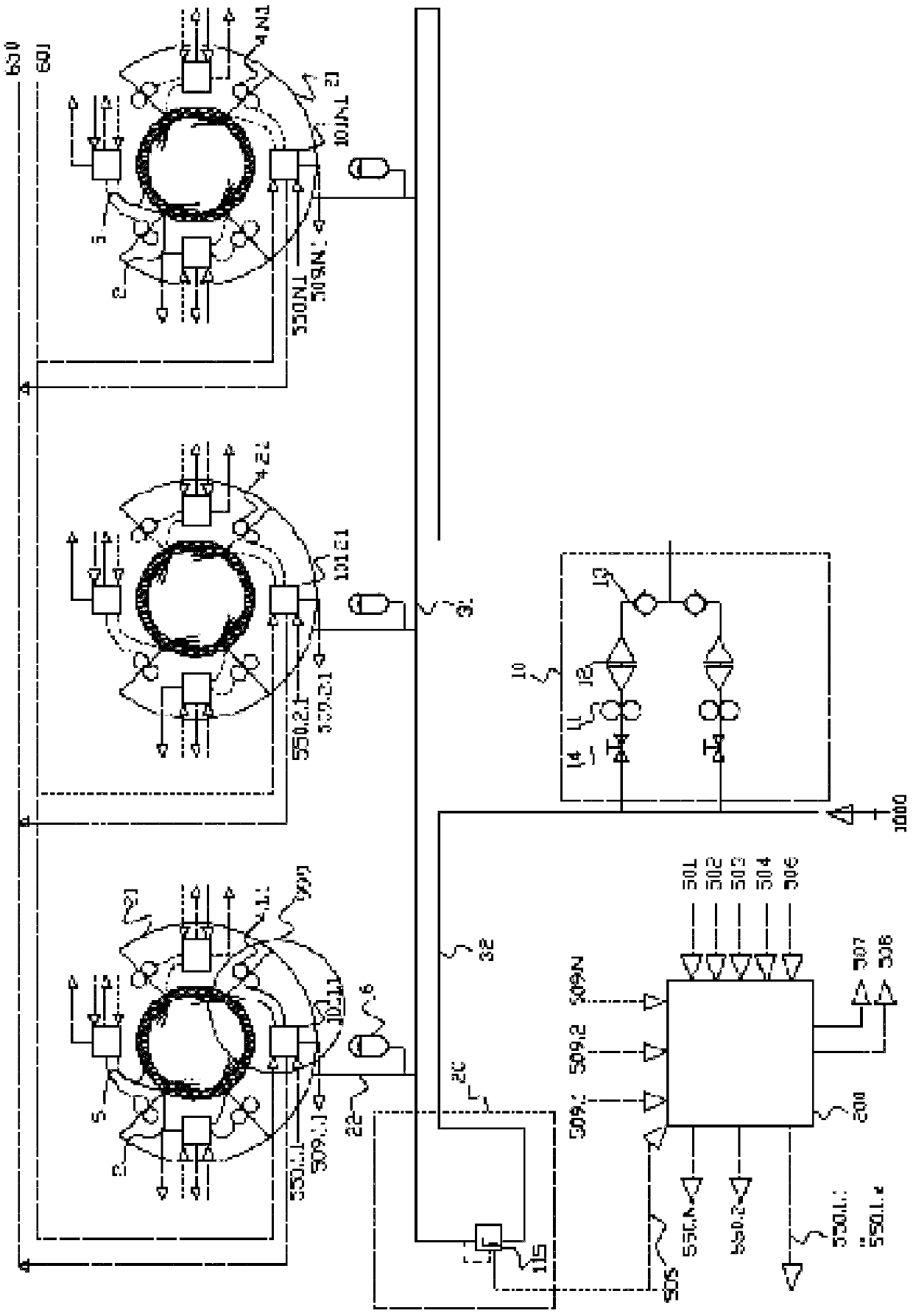

[0127] figure 1 A complete lubrication system with N cylinders 1 is shown. Each cylinder is equipped with several X injectors 2 connected to a common lubricating oil supply line 31 with a constant supply pressure, for example 30 to 100 bar in size. Oil supply pressure is supplied from the daily oil tank 1000 and transmitted through the hydraulic pump unit 10 .

[0128]The pumping station 10 comprises two pumps 11 , two filters 12 and two non-return valves 13 which prevent the return flow of lubricating oil through the stationary pumps 11 . The pump station also includes two shut-off valves 14 inserted into the oil supply pipe 34 so that the filter 12 can be cleaned during operation. Both pumps 11 back up each other and are automatically activated in the event of a drop in oil pressure.

[0129] The end of the fuel supply pipe 31 is provided with a boost valve 20 or a stepless electronically controlled boost valve 115 (the latter is shown in principle). Usually, the oil pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com