Device for lubricating cylinders

A cylinder block and lubricant technology, applied in the field of cylinder block lubrication devices, can solve problems such as increasing lubricant volume and pollutant accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

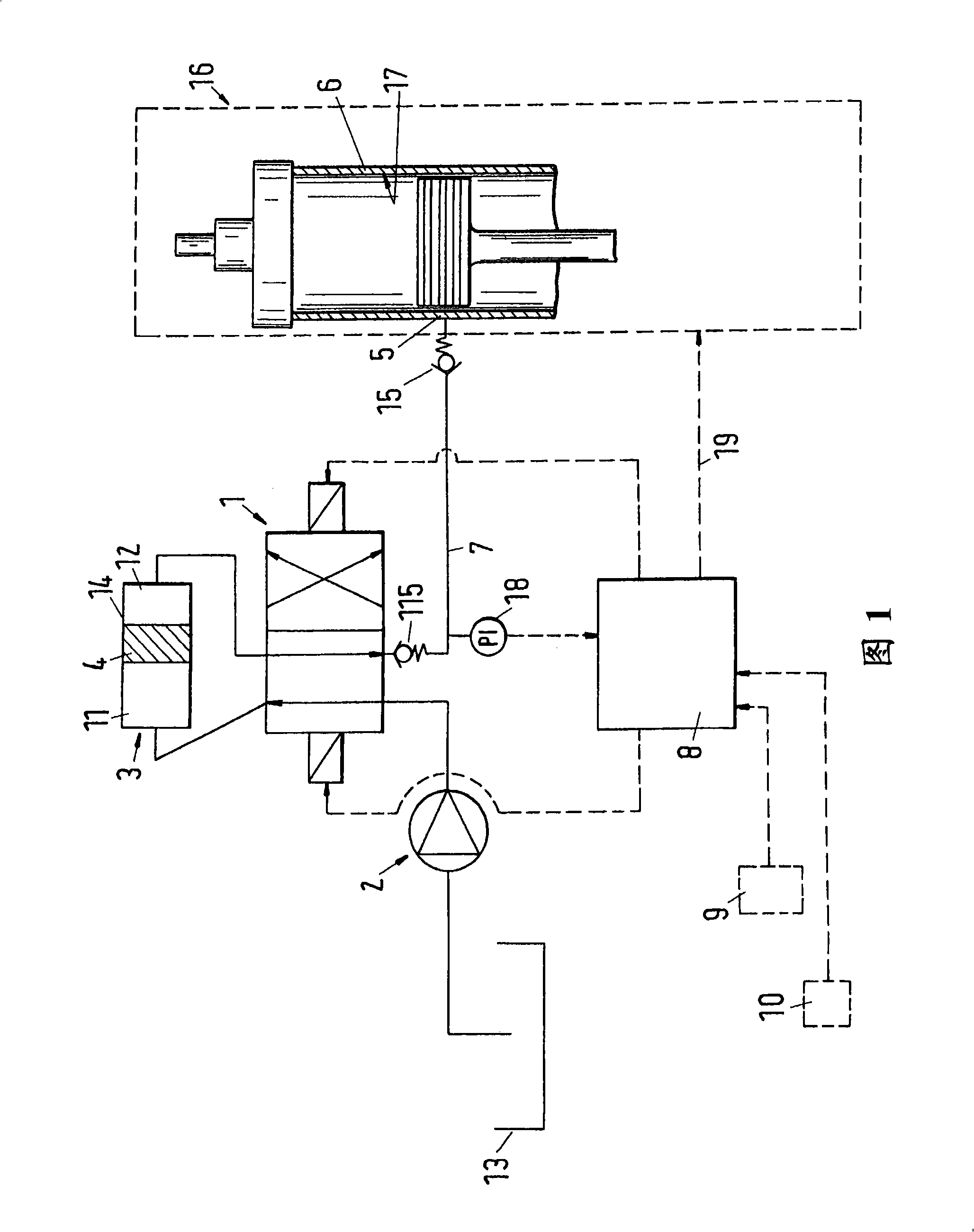

[0036] according to figure 1 The device according to the invention comprises a lubricant source 13 which can be formed as a lubricant reservoir and through which lubricant can be supplied. The supply device 2 is connected to a lubricant source 13 via which lubricant can be supplied from the lubricant source to the consumption mechanism. The lubricant outlet 5 is shown as a consumption mechanism, which may for example comprise a lubricant nozzle through which the lubricant is conveyed to the system to be lubricated, which in the shown case is the cylinder block 6 of the internal combustion engine 16 work surface. As an alternative to the supply means, a common rail reservoir can be provided which already contains lubricant under sufficient pressure so that lubricant can be supplied to the relevant consumer if necessary. Pressurized lubricant is delivered to the first chamber 1 of the piston unit 3 by the pump 2 or from a common rail reservoir. The pressure of the lubricant a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com