Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

870results about "Provision for safeguarding apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

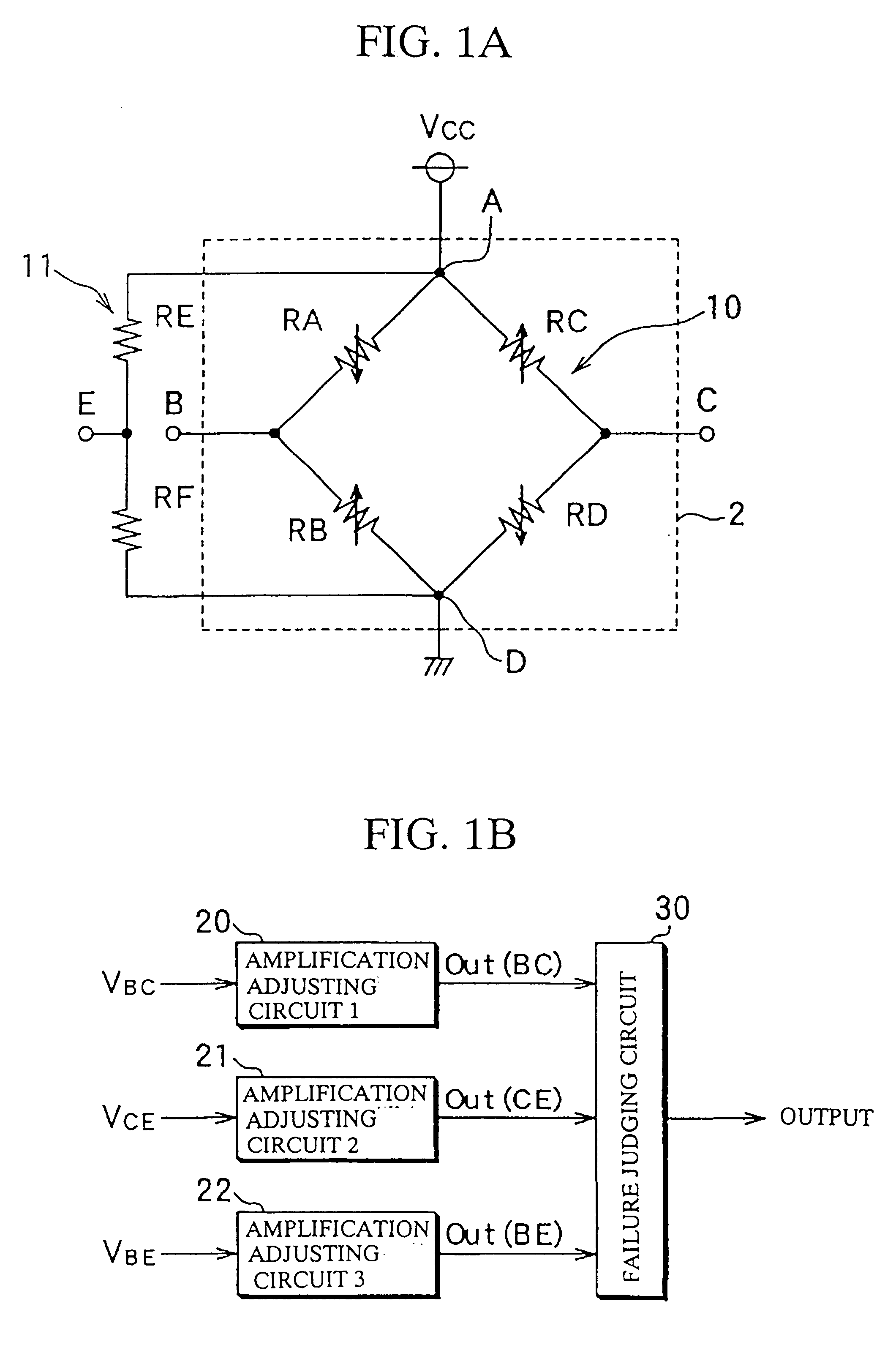

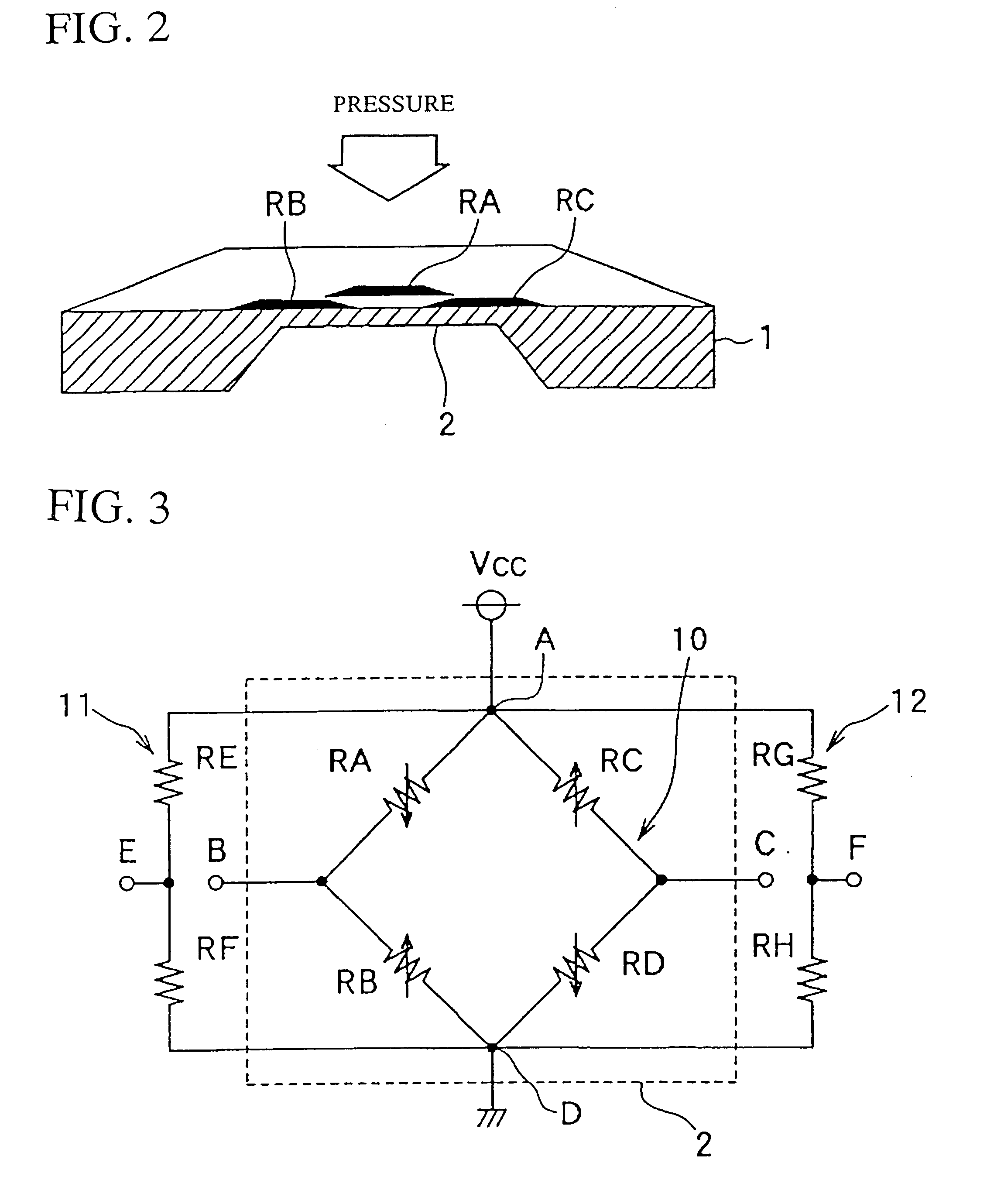

Sensor failure or abnormality detecting system incorporated in a physical or dynamic quantity detecting apparatus

InactiveUS6422088B1Detect failureFluid pressure measurement using ohmic-resistance variationForce measurementElectrical resistance and conductanceAnomaly detection

A reference voltage generating circuit is constituted by resistors RE and RF each having a resistance not influenced by an application of pressure. The reference voltage generating circuit is connected between one and the other ends of a bridge circuit. A failure judgement of the bridge circuit is performed based on a comparison of a voltage difference VBC between two midpoints B and C of the bridge circuit and voltage differences VCE and VBE between a reference voltage level of the reference voltage generating circuit and the voltage levels of two midpoints B and C.

Owner:DENSO CORP

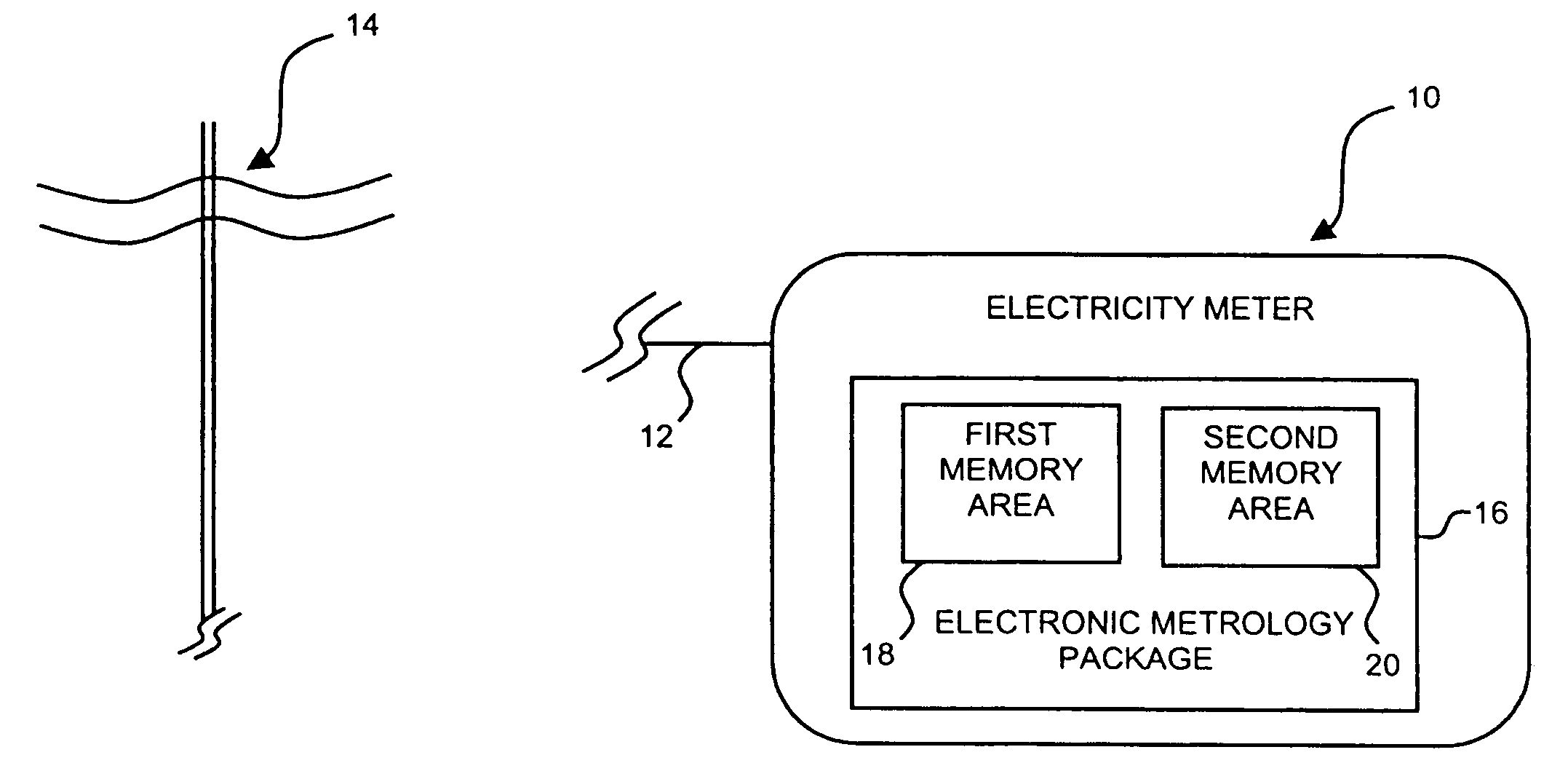

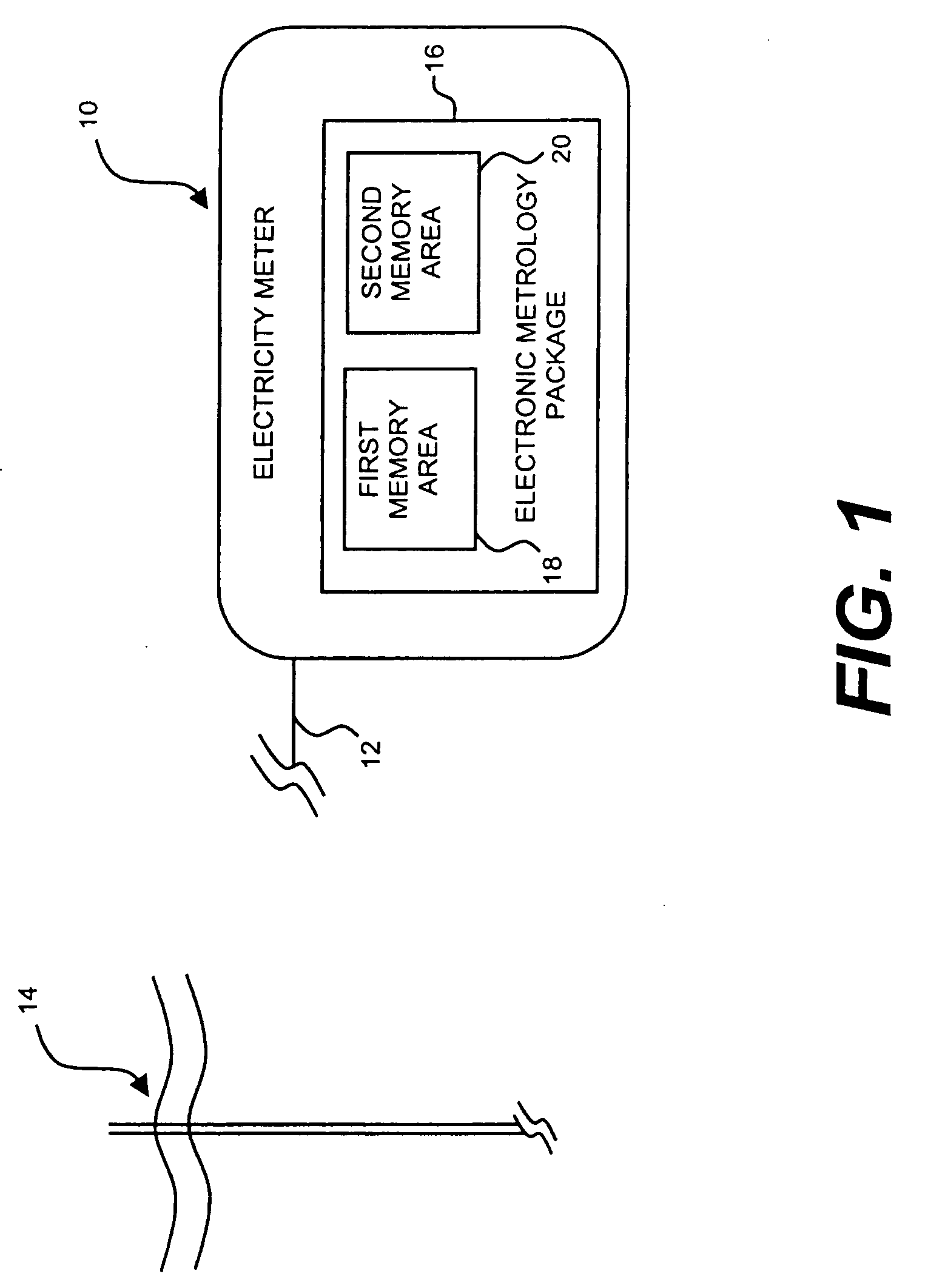

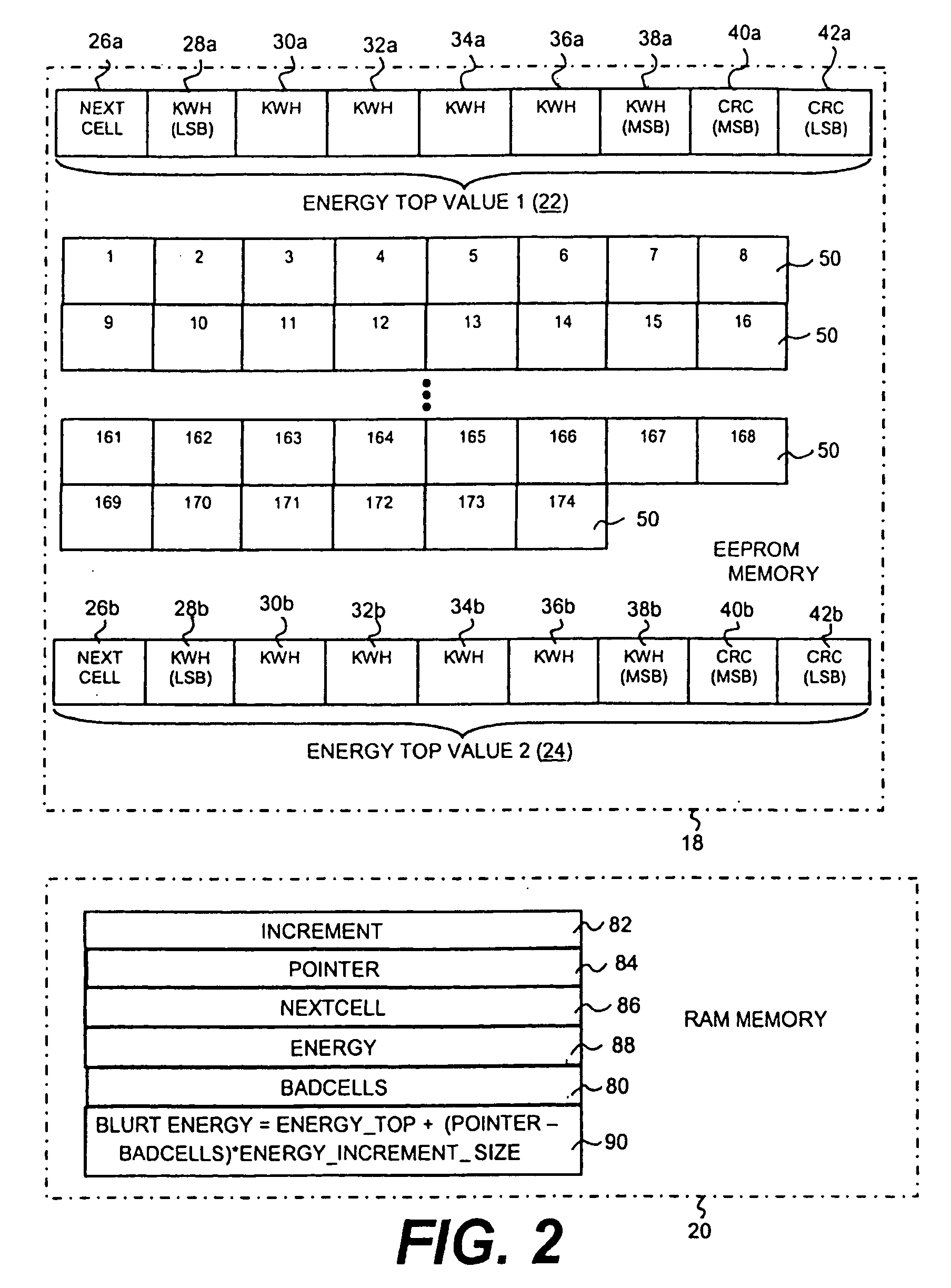

System and method for storing metering data while increasing memory endurance

ActiveUS20080010212A1Simple structureImprove integrityTariff metering apparatusRead-only memoriesNew energyEngineering

Methodology and corresponding apparatus ensure the integrity of utility metering data during power outages while providing improved memory integrity. An initial step includes determining and storing an energy top value that is representative of metered energy, and also includes establishing an update pattern. Accumulated energy is then monitored until a predetermined energy threshold is crossed, at which point a selected state in the update pattern is stored into one of a plurality of energy increment cells. Such stored value can be validated at some point after the data read. The steps of monitoring accumulated energy and storing a selected value / state of the update pattern into additional energy increment cells continue until each of the plurality of energy increment cells is updated with a new value. Upon completion, the energy top value is updated with a new energy total and the process of cycling through each energy increment cell is repeated.

Owner:ITRON

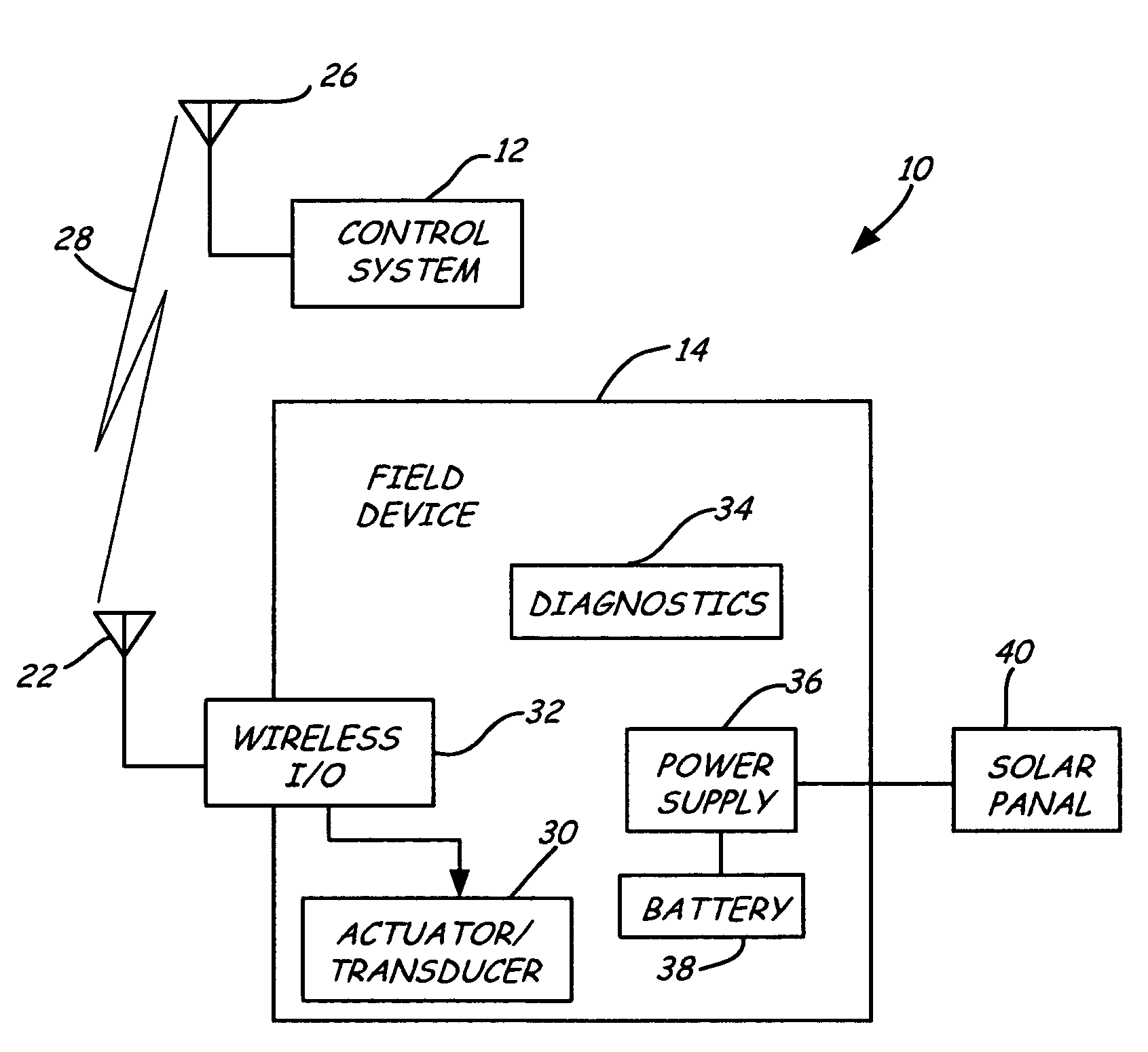

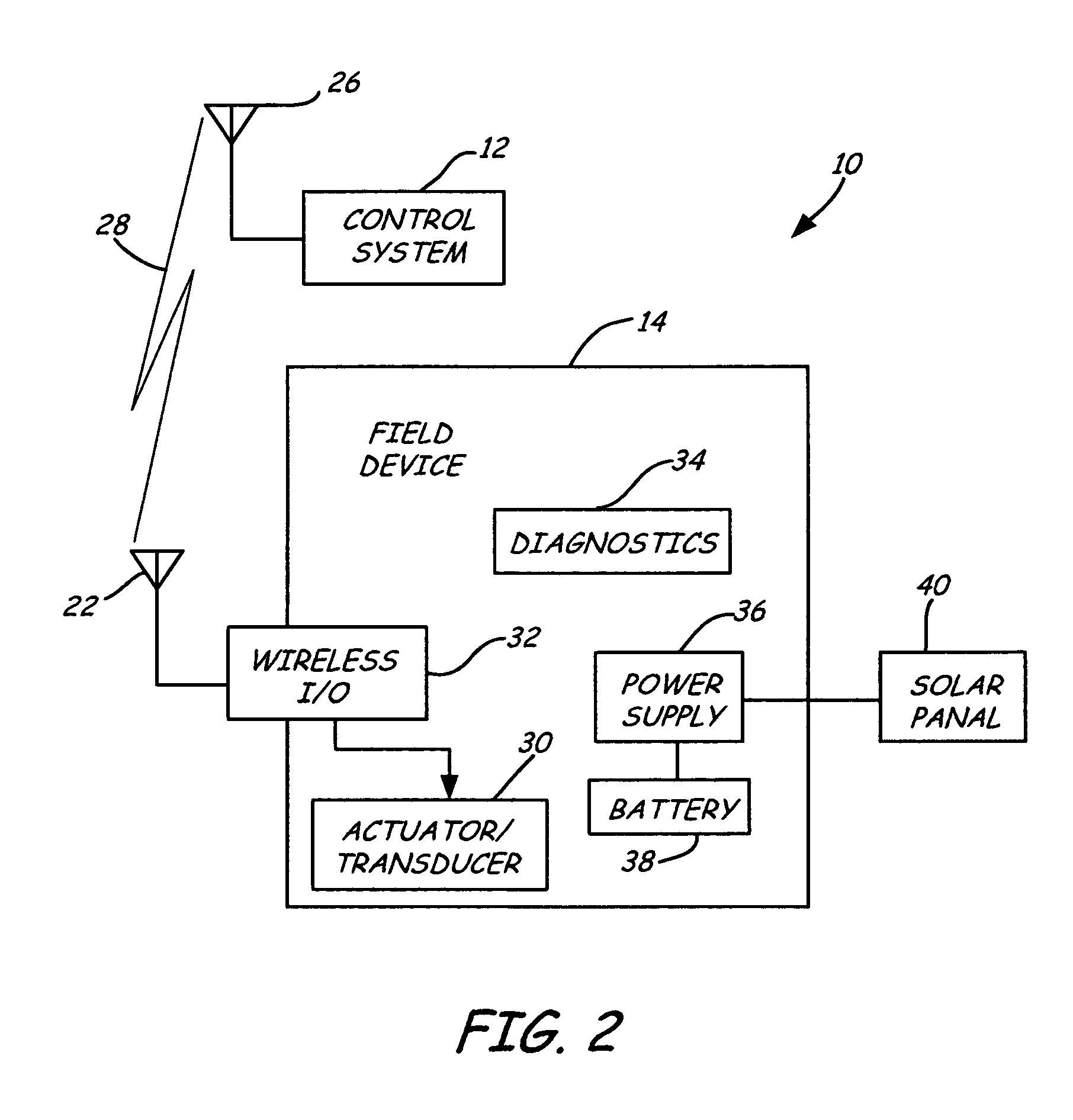

Wireless process field device diagnostics

ActiveUS20060148410A1Electric signal transmission systemsSubstation equipmentTelecommunications linkMonitoring system

A wireless process device for use in an industrial process control or monitoring system comprising includes a power source configured to power the process device. Diagnostic circuitry is configured to diagnose operation of process device and provides a diagnostic output. Wireless communication circuitry transmits information over a wireless communication link.

Owner:ROSEMOUNT INC

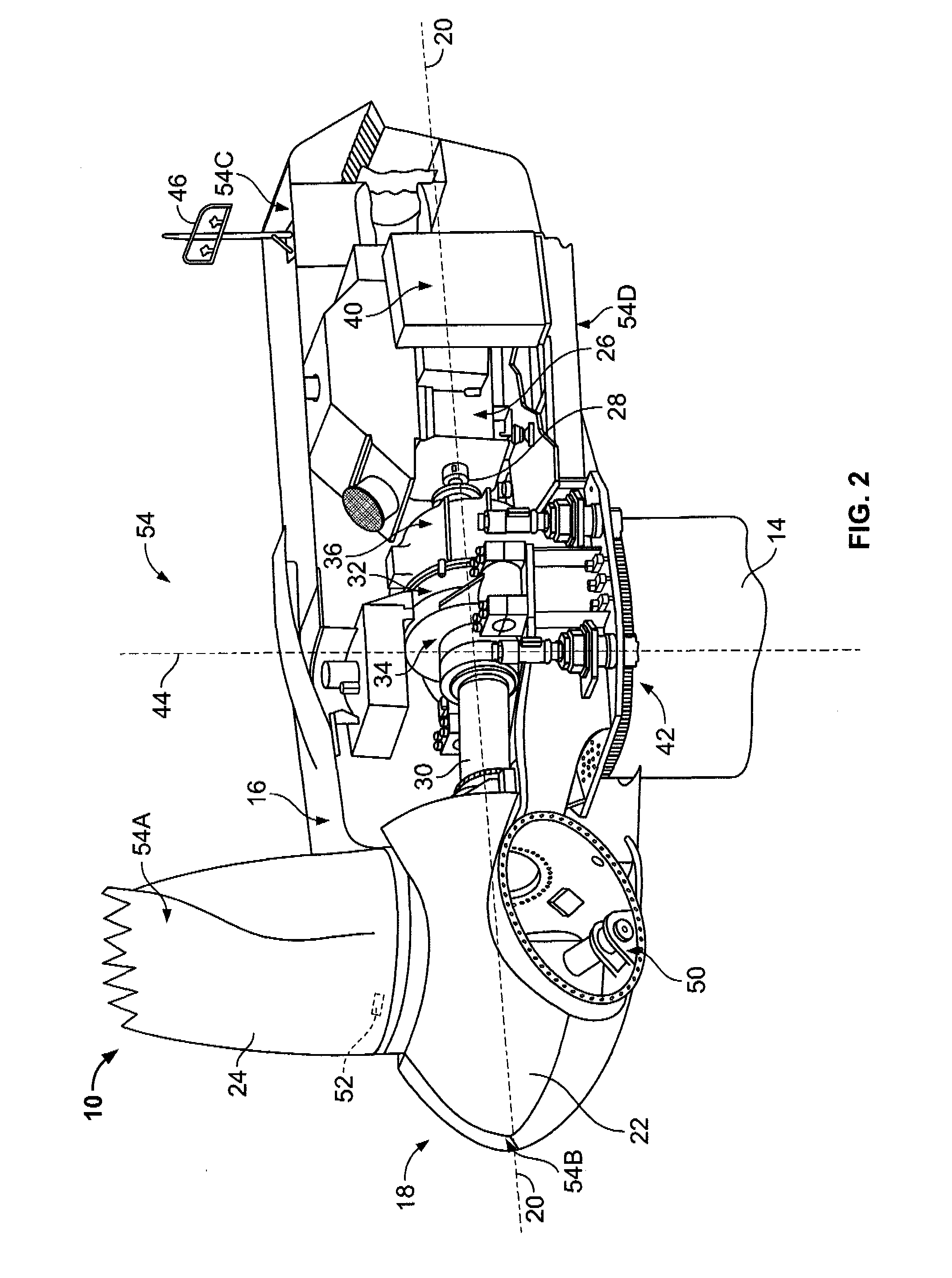

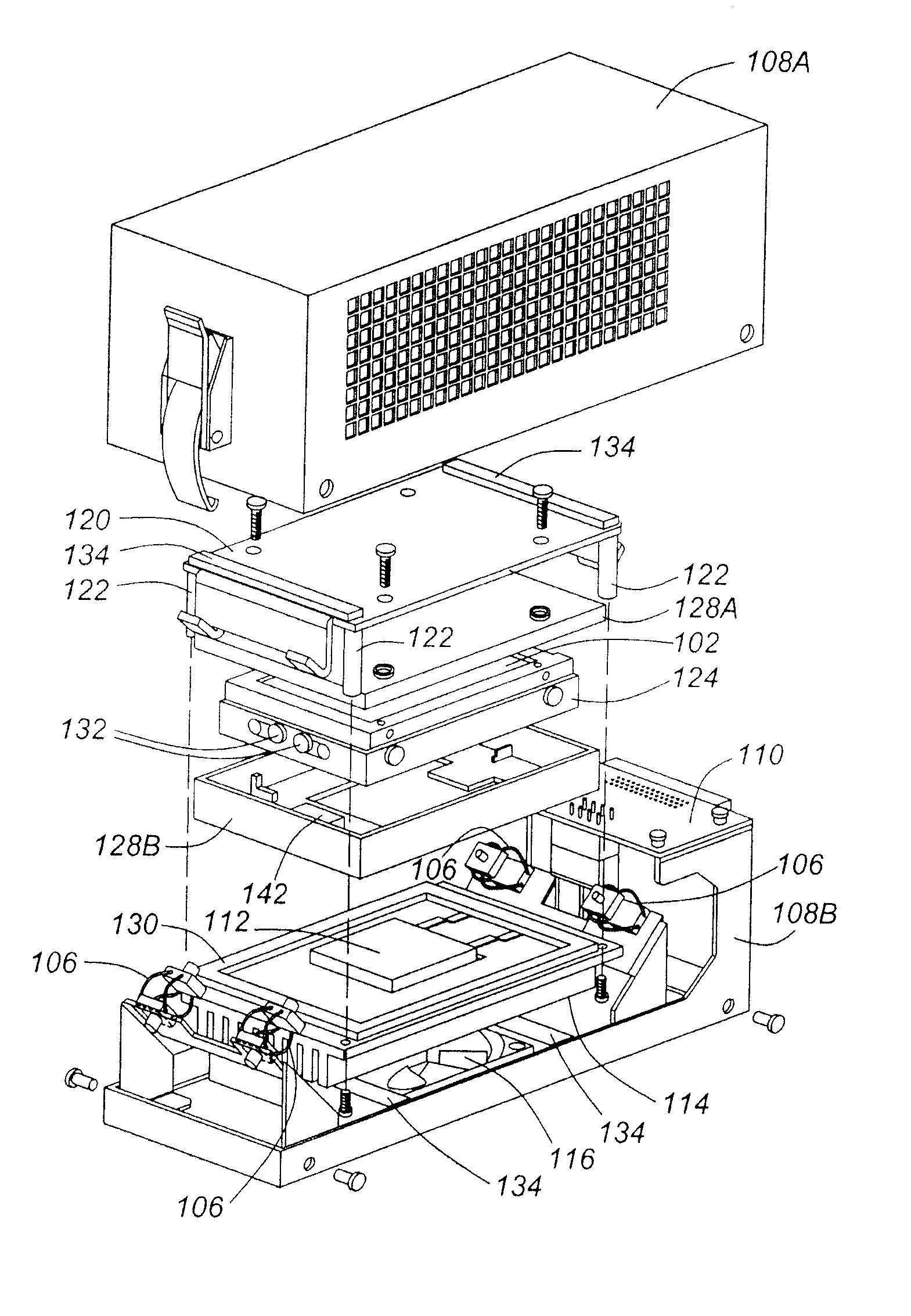

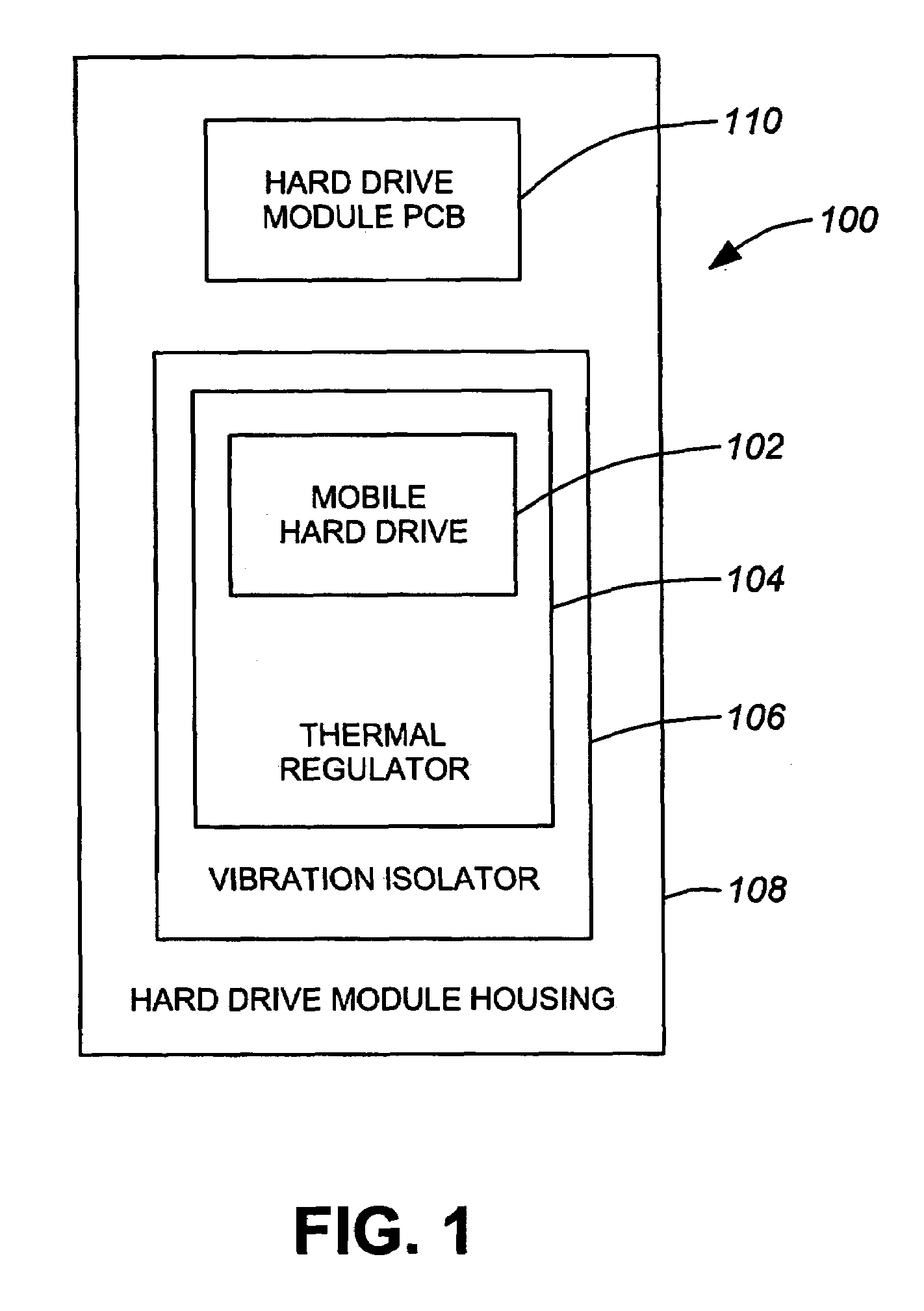

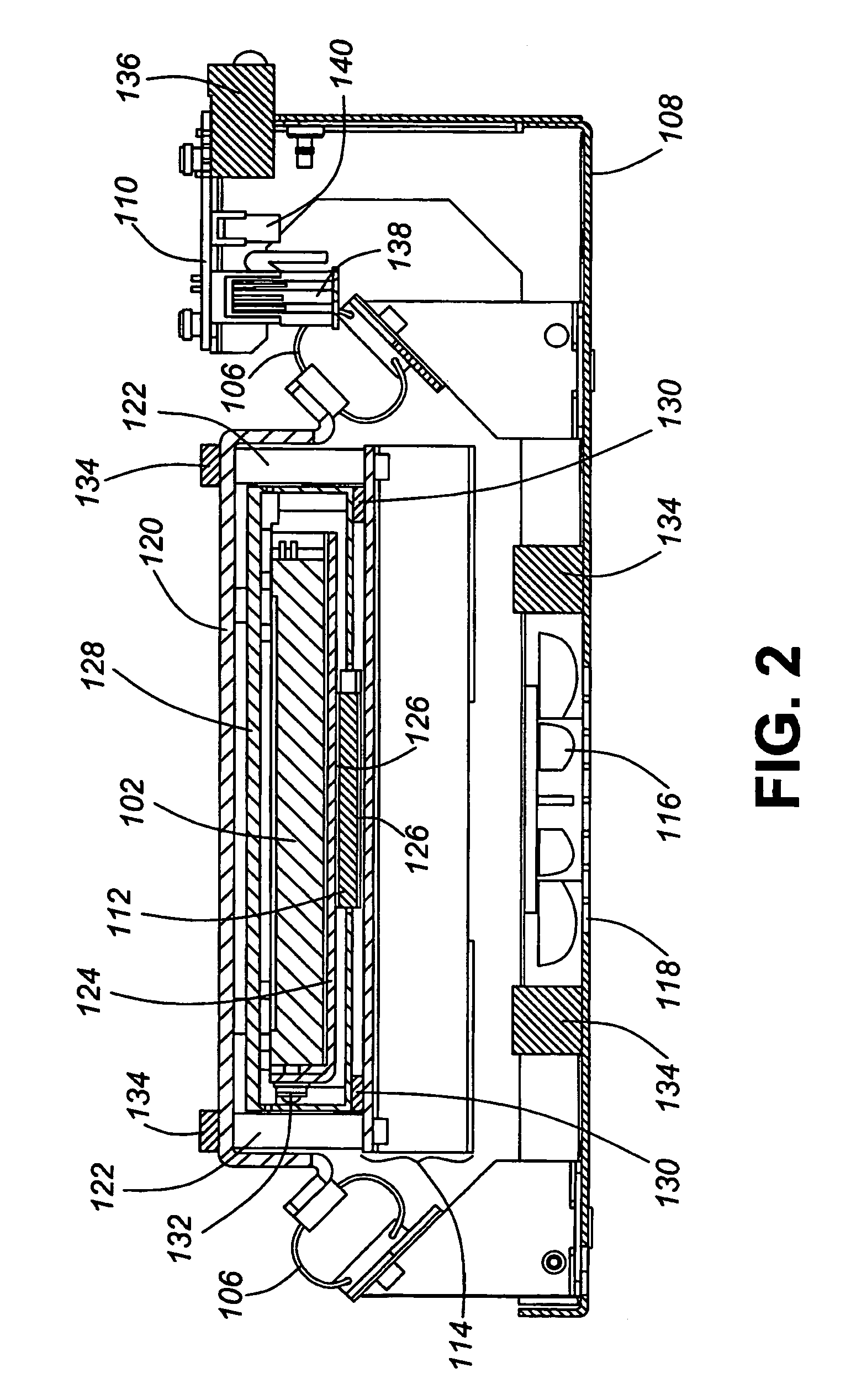

Contained environmental control system for mobile event data recorder

ActiveUS20060232891A1Reduce vibration effectsFast heat conductionReducing temperature influence on carrierDisposition/mounting of recording headsData packHard disc drive

An environmental control system, or data pack, is provided in accordance with embodiments of the present invention. The system allows for audio and video recording on hard drive media in situations where temperature, vibration and humidity would otherwise have prevented the use of such technology. The system can be used in conjunction with an event recorder for use in motor vehicles, trains and the like. The environmental control system includes a thermoelectric module connected to the hard drive and to a housing. The thermoelectric module is for transferring heat between the hard drive and the housing in response to an applied voltage in order to maintain a hard drive temperature within a hard drive operable temperature range. The vehicle operating temperature range includes temperatures outside the hard drive operable temperature range.

Owner:MARCH NETWORKS

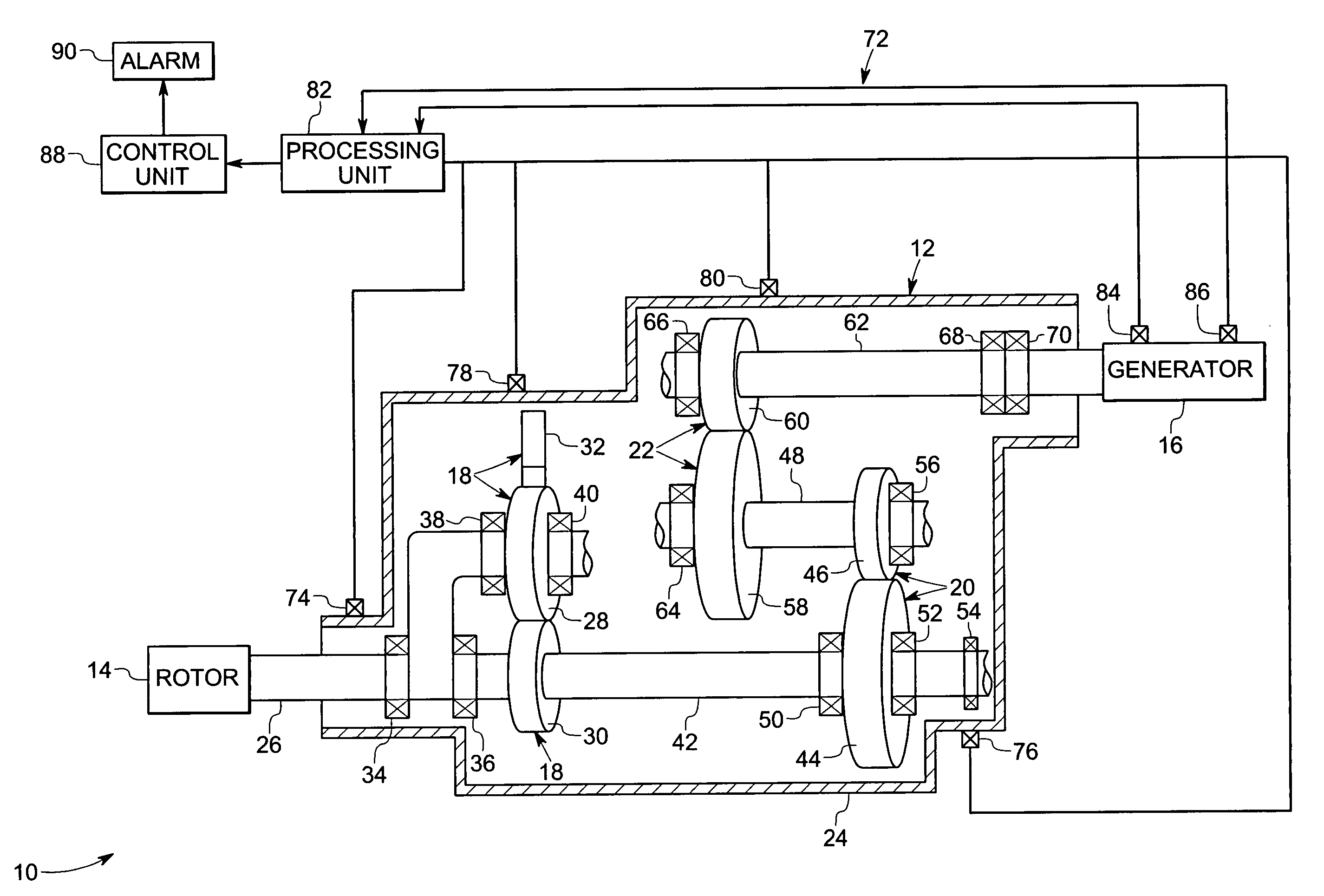

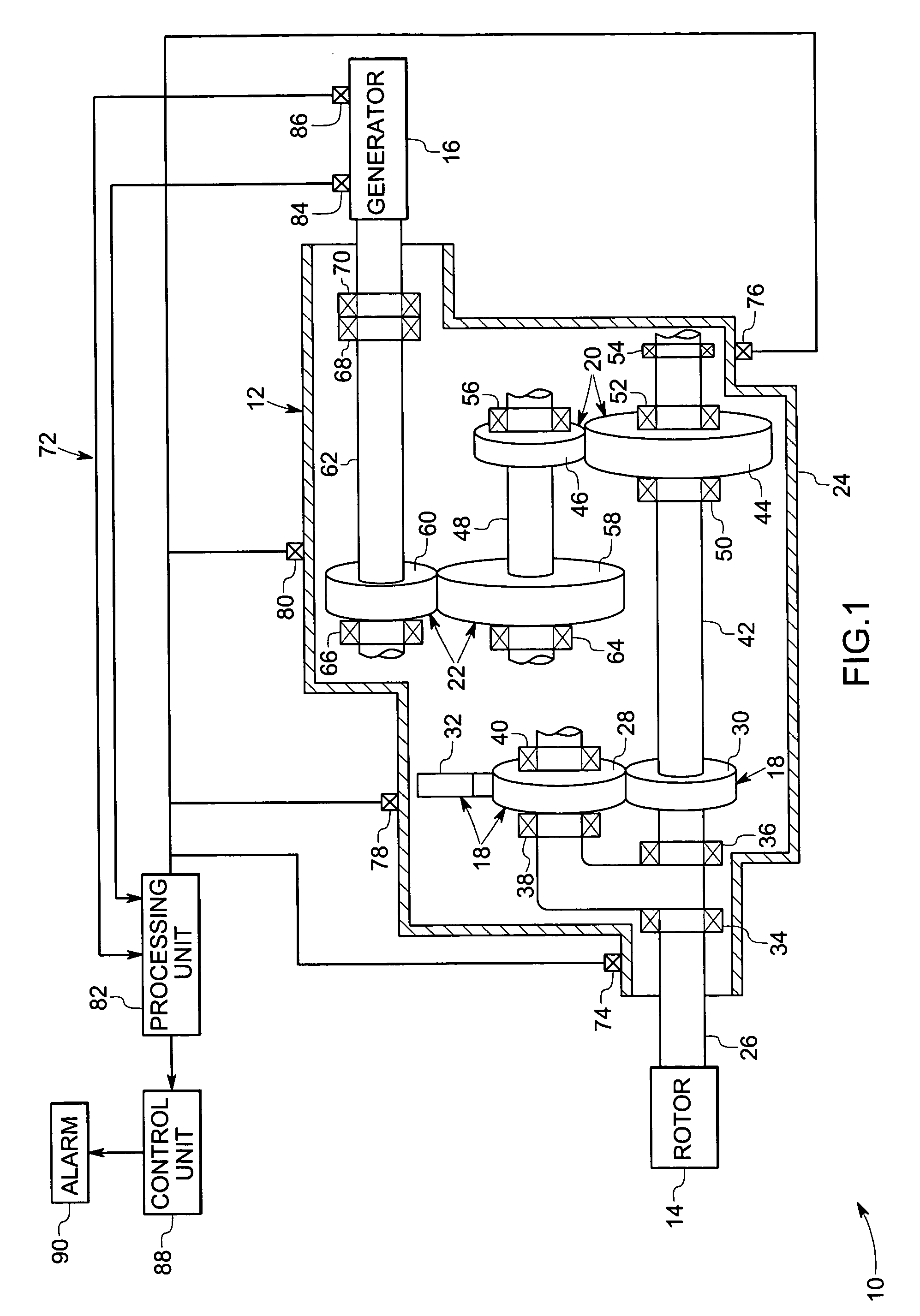

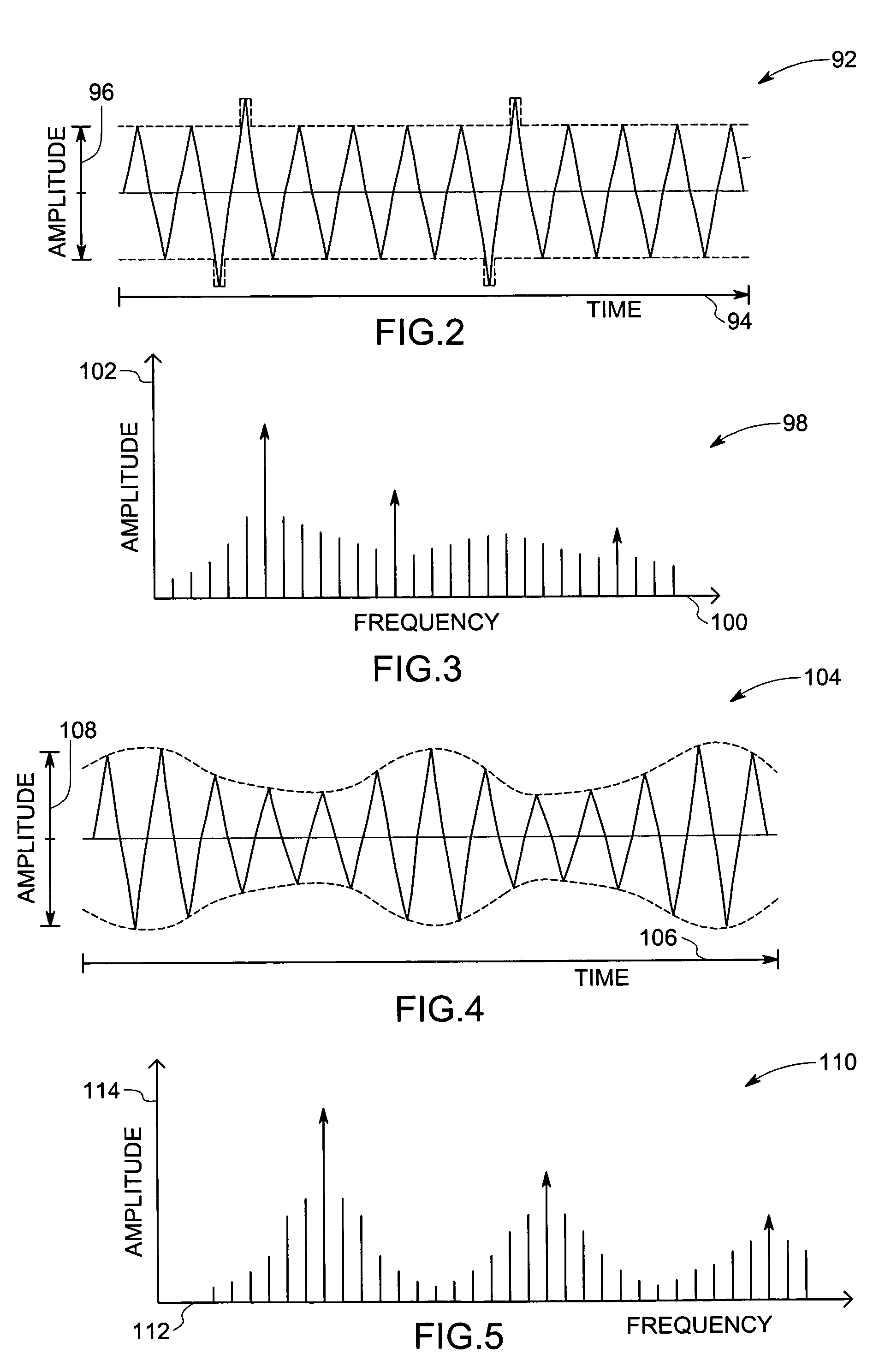

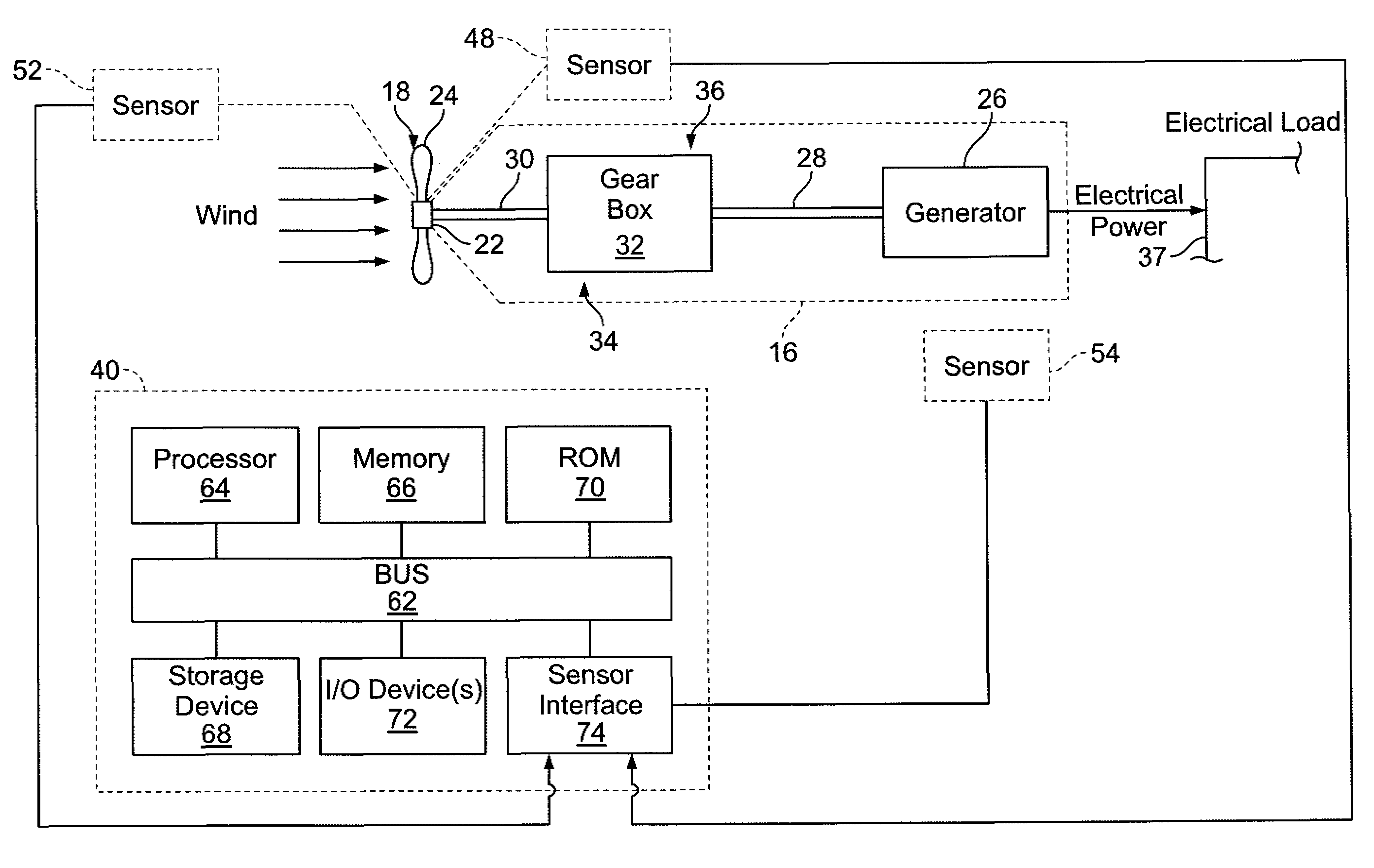

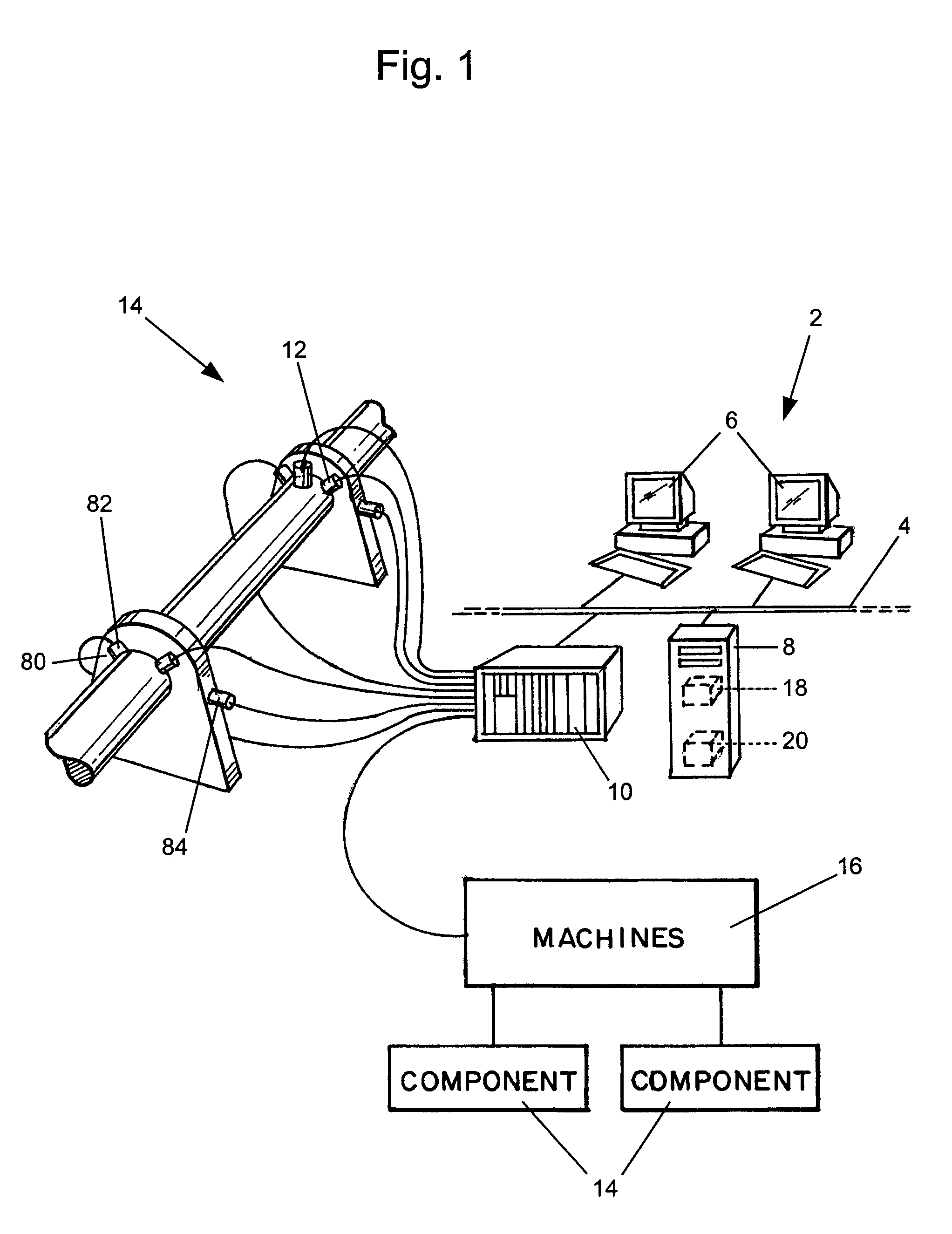

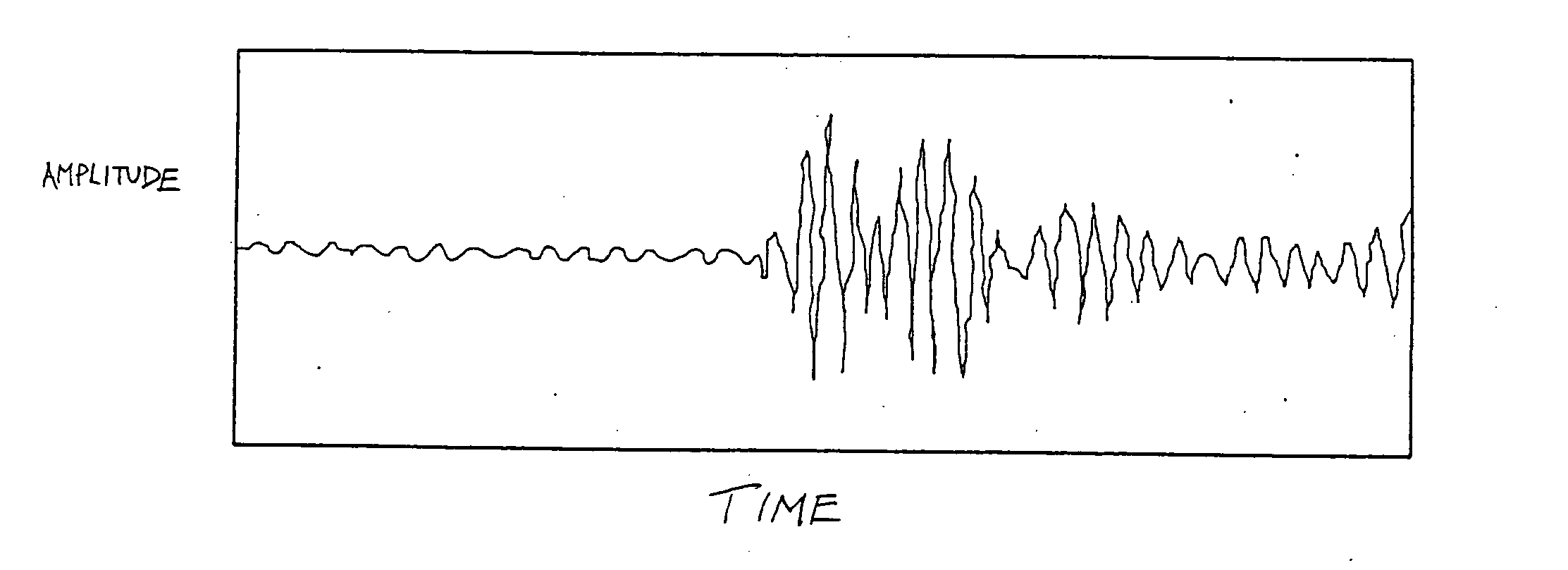

System and method for monitoring the condition of a drive train

ActiveUS20050284225A1Vibration measurement in solidsMachine part testingEngineeringCondition monitoring

A gearbox condition monitoring system comprises at least one vibration sensor located on a gearbox casing. A processing unit is coupled to the vibration sensor and is configured to receive signals representative of the detected vibrations from the vibration sensor. The processing unit may be operable to process the signals representative of detected vibrations of gears and bearings and to compute at least one dynamic energy index or location of fault.

Owner:GENERAL ELECTRIC CO

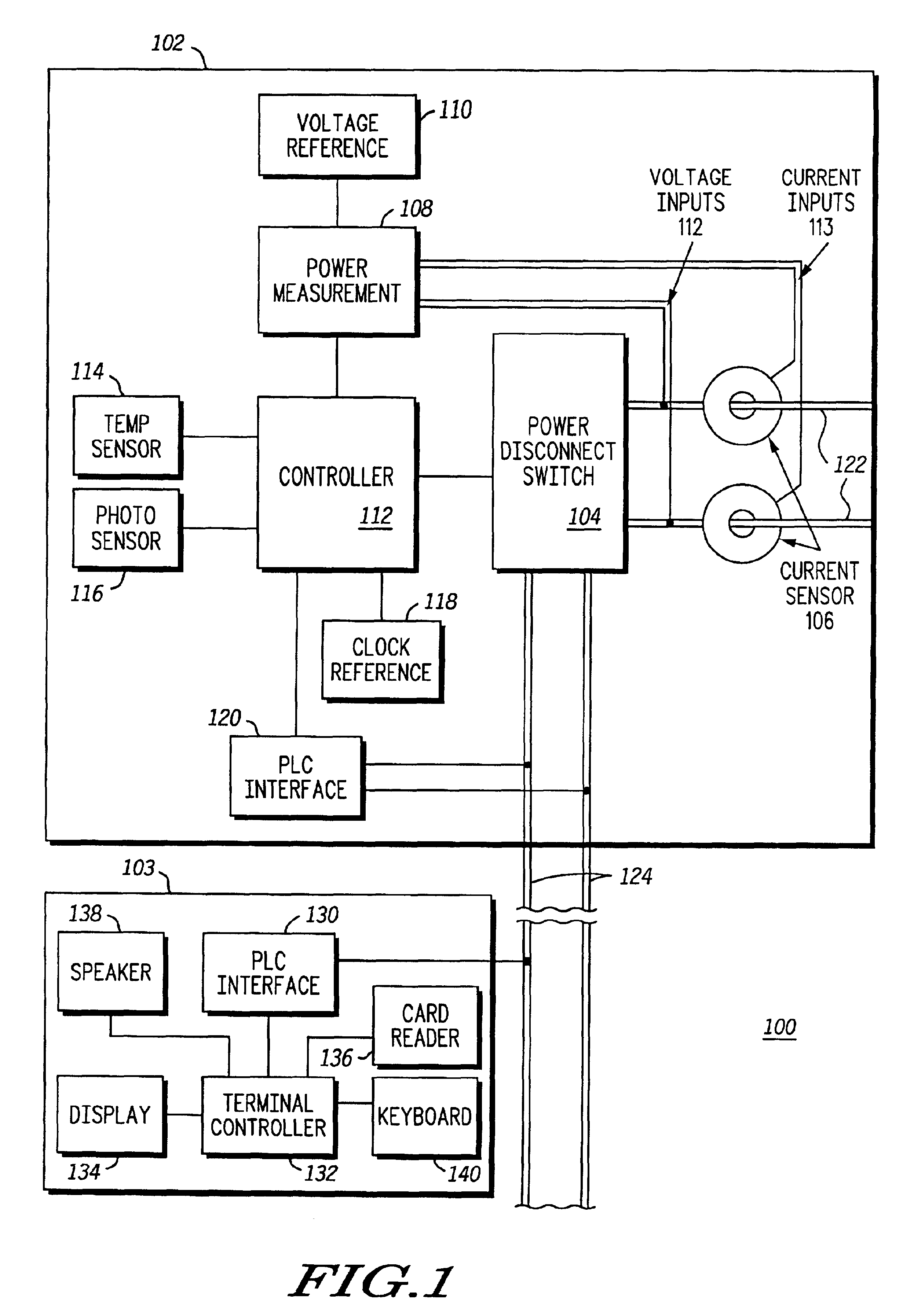

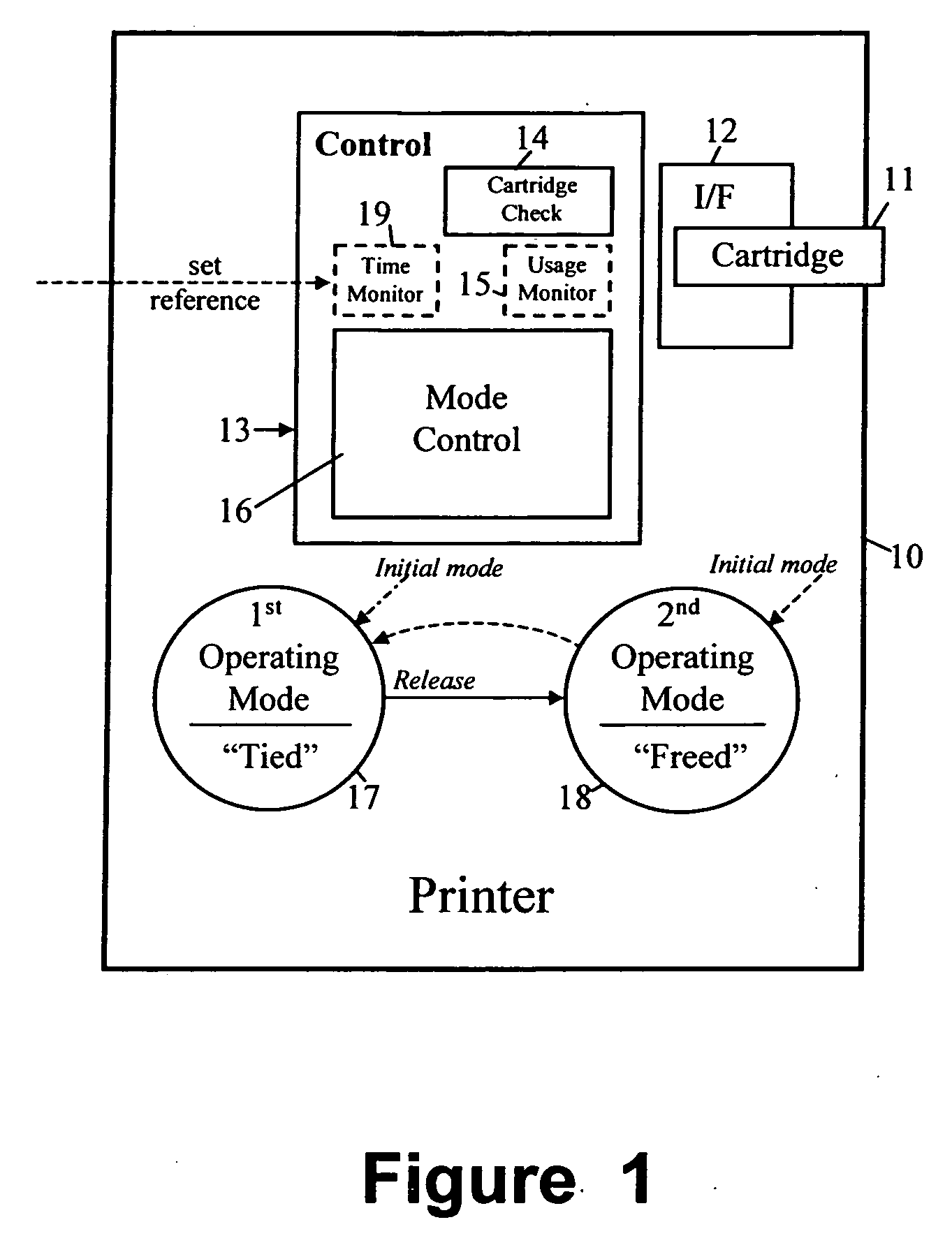

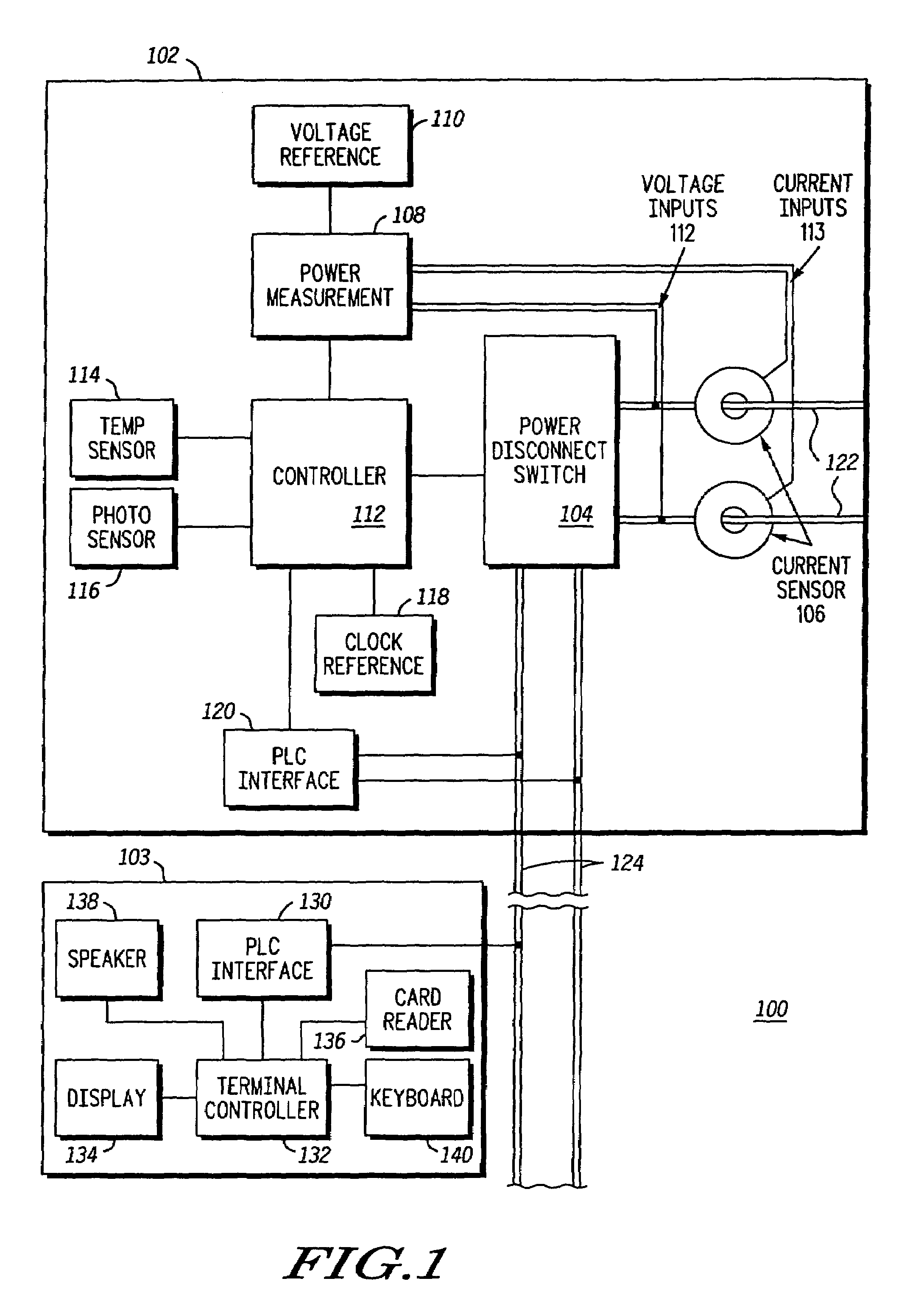

Electric power meter including a temperature sensor and controller

InactiveUS6847300B2Electric signal transmission systemsBoards/switchyards circuit arrangementsElectric power systemEngineering

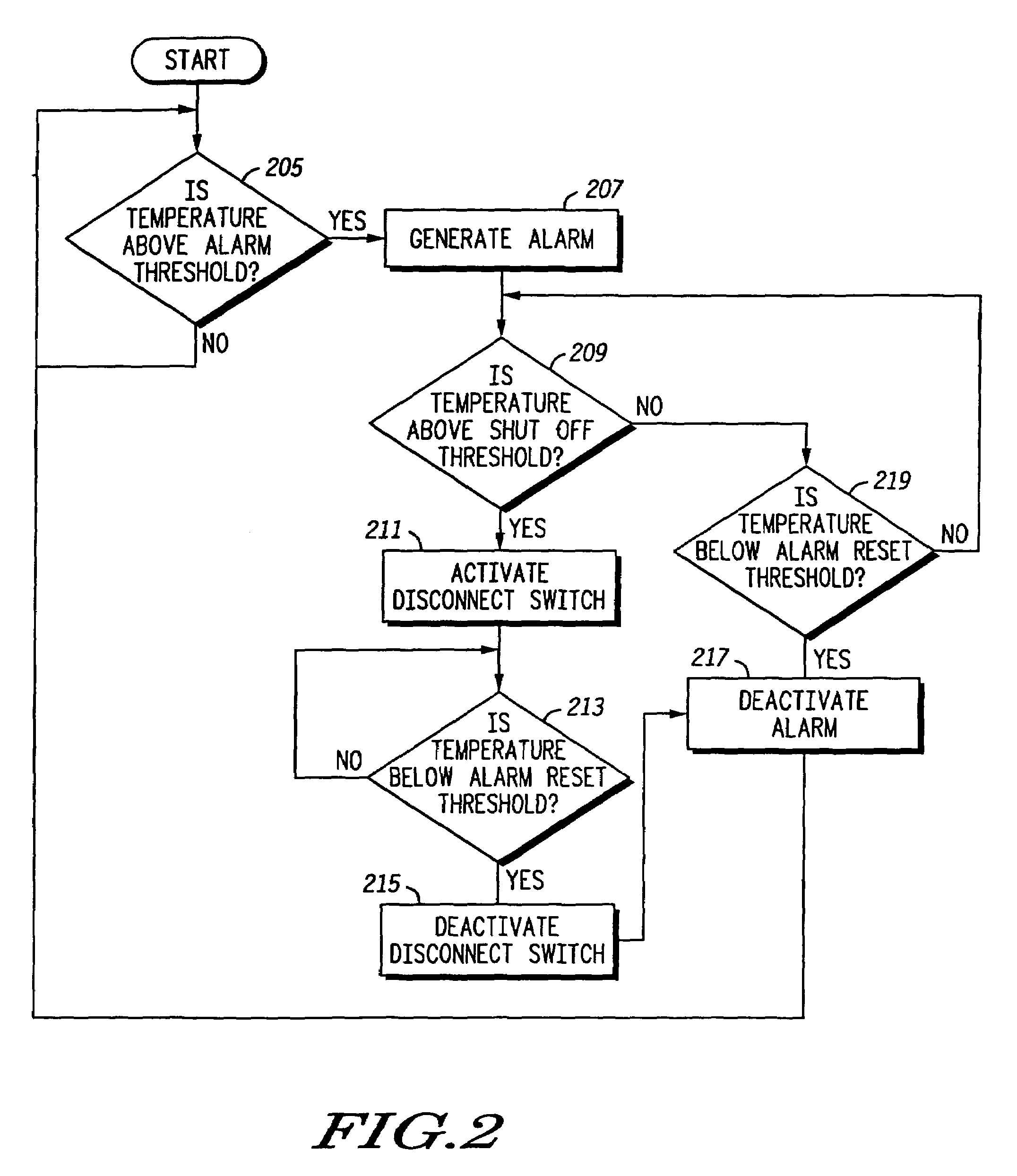

An electric power meter (102) includes a temperature sensor (114) and a controller (112). The controller (112) is operable, based on the temperature reported from the temperature sensor (114), to generate alarm(s) when the temperature exceeds certain alarm threshold(s) (307, 507, 508) and to activate a power disconnect switch (104), thereby shutting off power to a customer premises, when the temperature exceeds a shut off threshold (309, 509). The controller (112) is operable to activate the power disconnect switch (104) for non-payment of electricity cost, subject to secondary criteria based on regulatory requirements. A customer terminal (103) may be used to notify a customer of an alarm condition, to provide information regarding electrical power usage or to provide information regarding disconnection of electrical power.

Owner:MOTOROLA SOLUTIONS INC

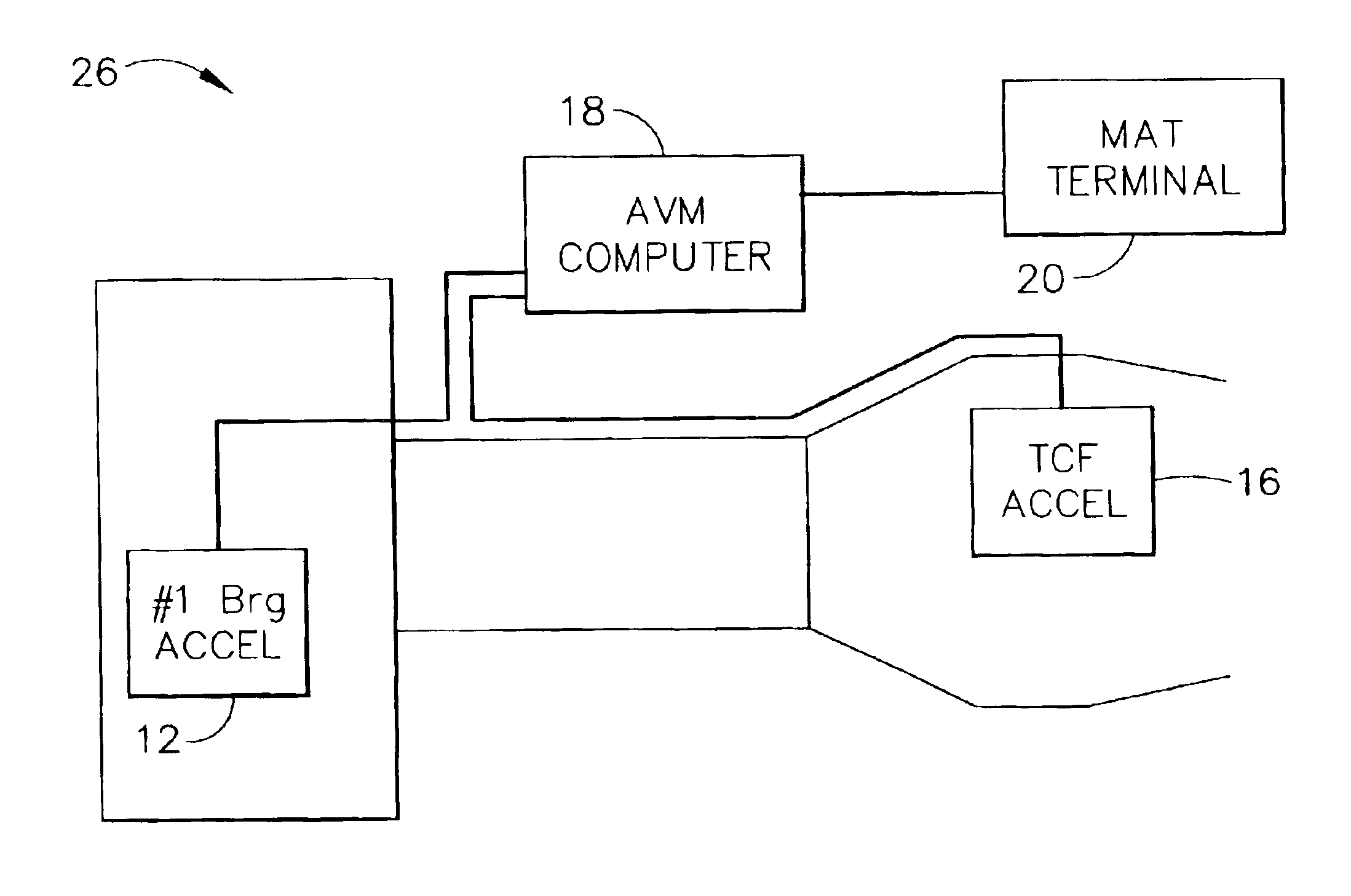

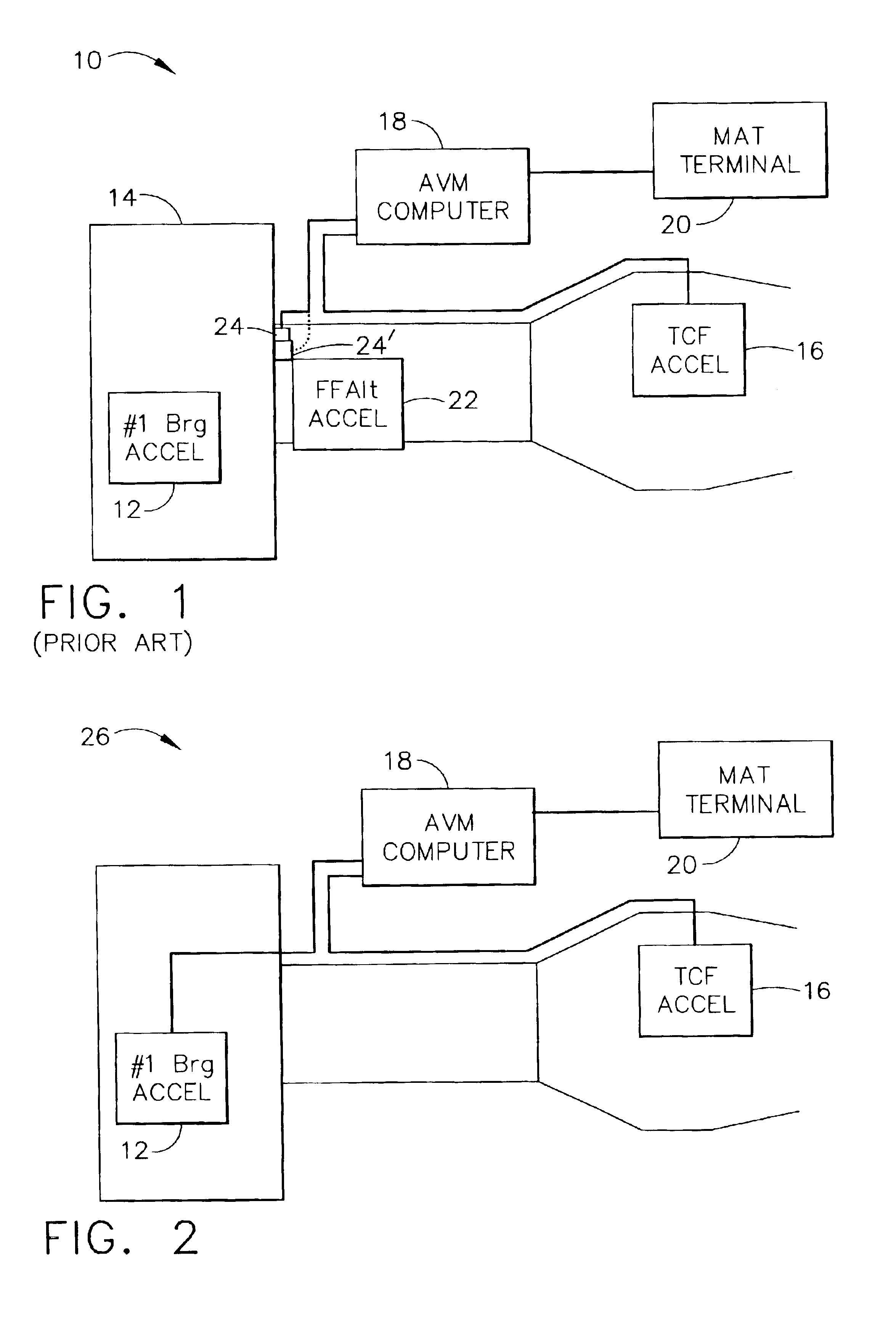

Accelerometer configuration

InactiveUS6909948B2Eliminate needVehicle testingRegistering/indicating working of vehiclesAccelerometerSignal conditioning

The present invention provides a system and method for using the external accelerometer in an aircraft engine configuration as a backup accelerometer, in the event the internally located production accelerometer fails. The sensor location of the external accelerometer has an acceptable sensitivity to fan imbalance, similar to the location of the former alternate accelerometer. The signal from this external accelerometer is duplicated using software in the signal conditioning hardware, creating the second, alternate signal. As an alternative embodiment, the signal may be duplicated by simply teeing or branching the original signal, using hardware rather than software.

Owner:GENERAL ELECTRIC CO

Methods and apparatus for evaluating sensors and/or for controlling operation of an apparatus that includes a sensor

A method for evaluating sensors includes receiving a first measurement signal from a first sensor configured to measure a parameter relating to a first apparatus, receiving a second measurement signal from a second sensor configured to measure the parameter as the parameter relates to a second apparatus, comparing the first measurement signal with the second measurement signal, and determining at least one of, whether the first measurement signal is inaccurate or the first sensor has failed based, at least in part, on the comparison between the first and second measurement signals.

Owner:GENERAL ELECTRIC CO

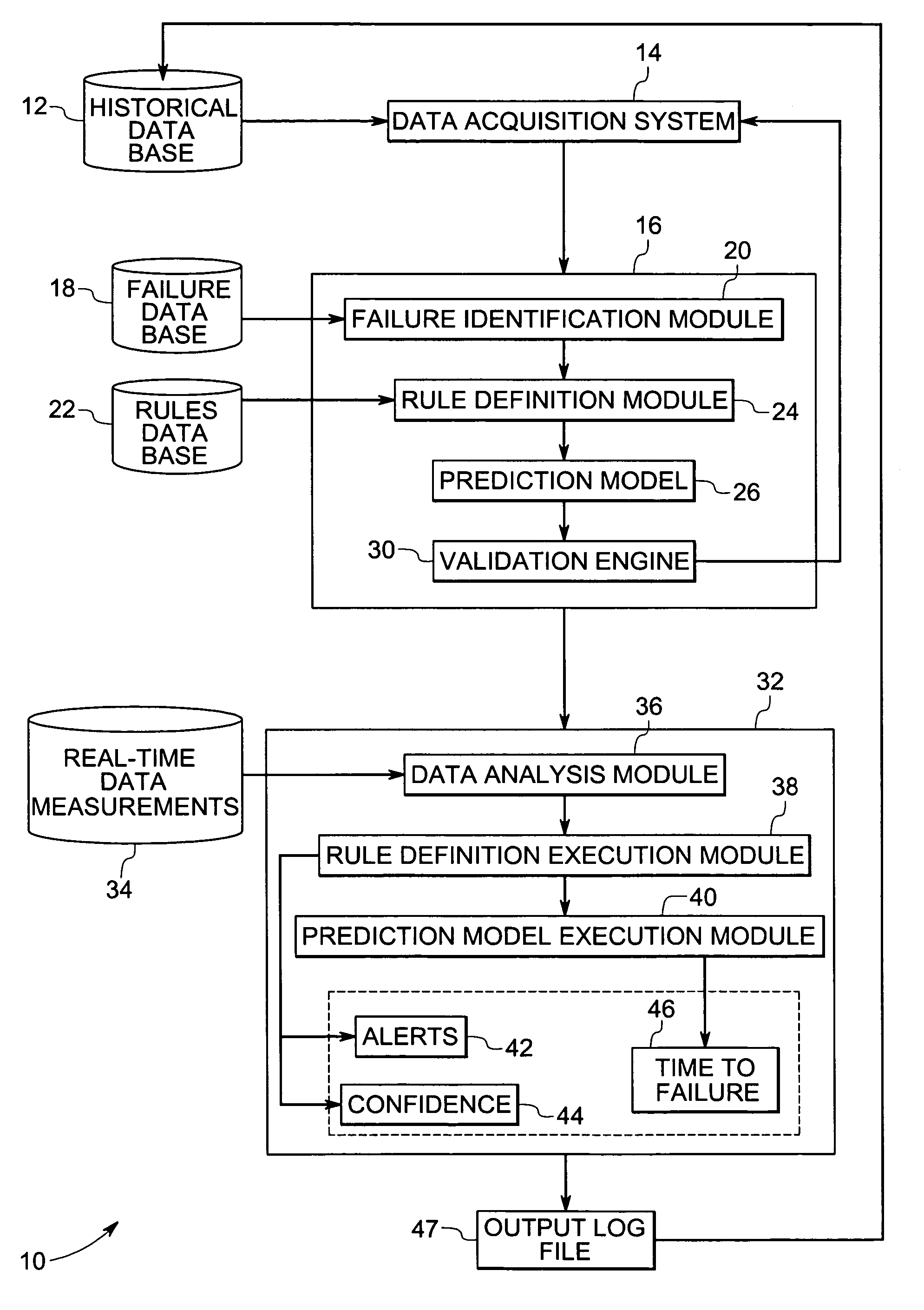

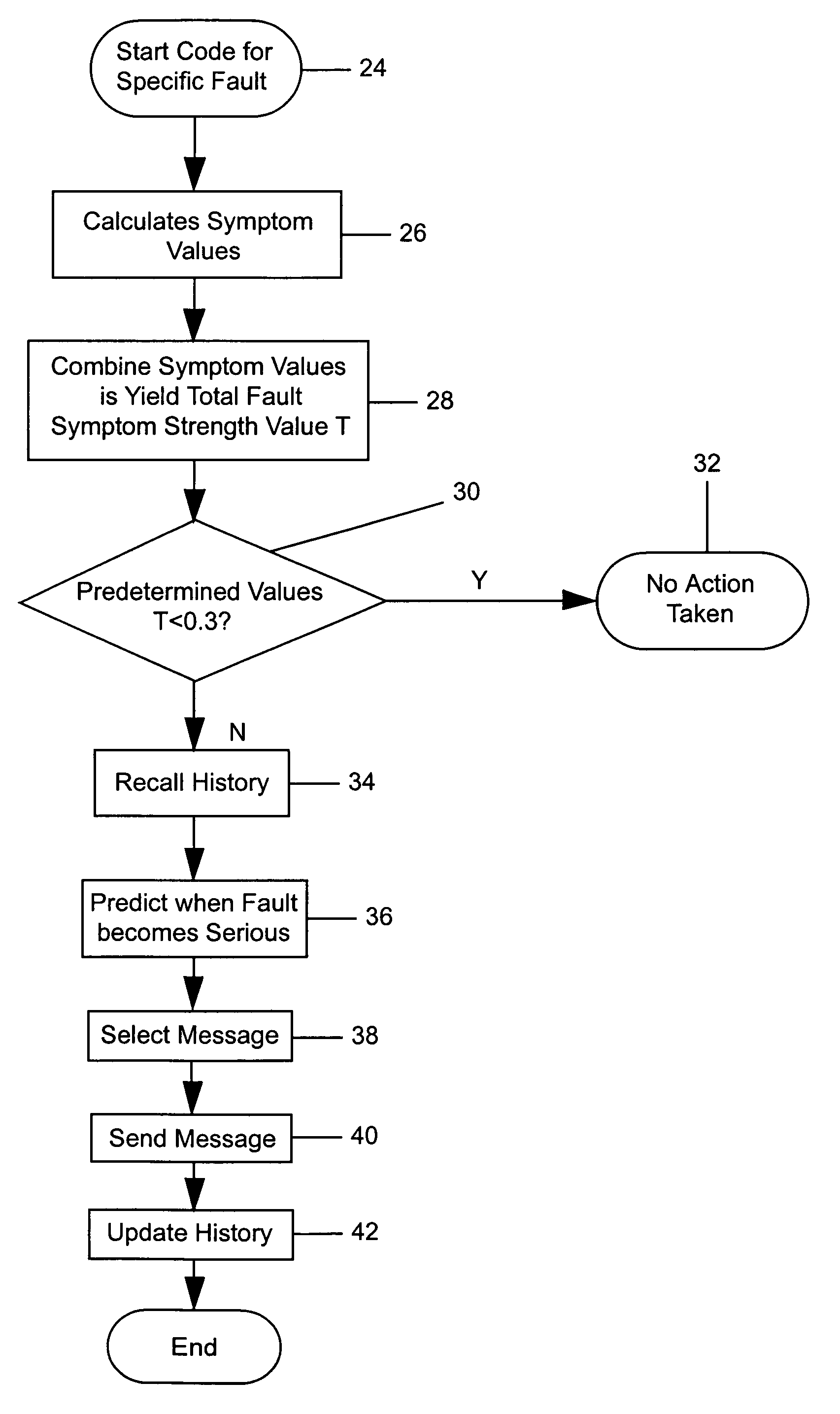

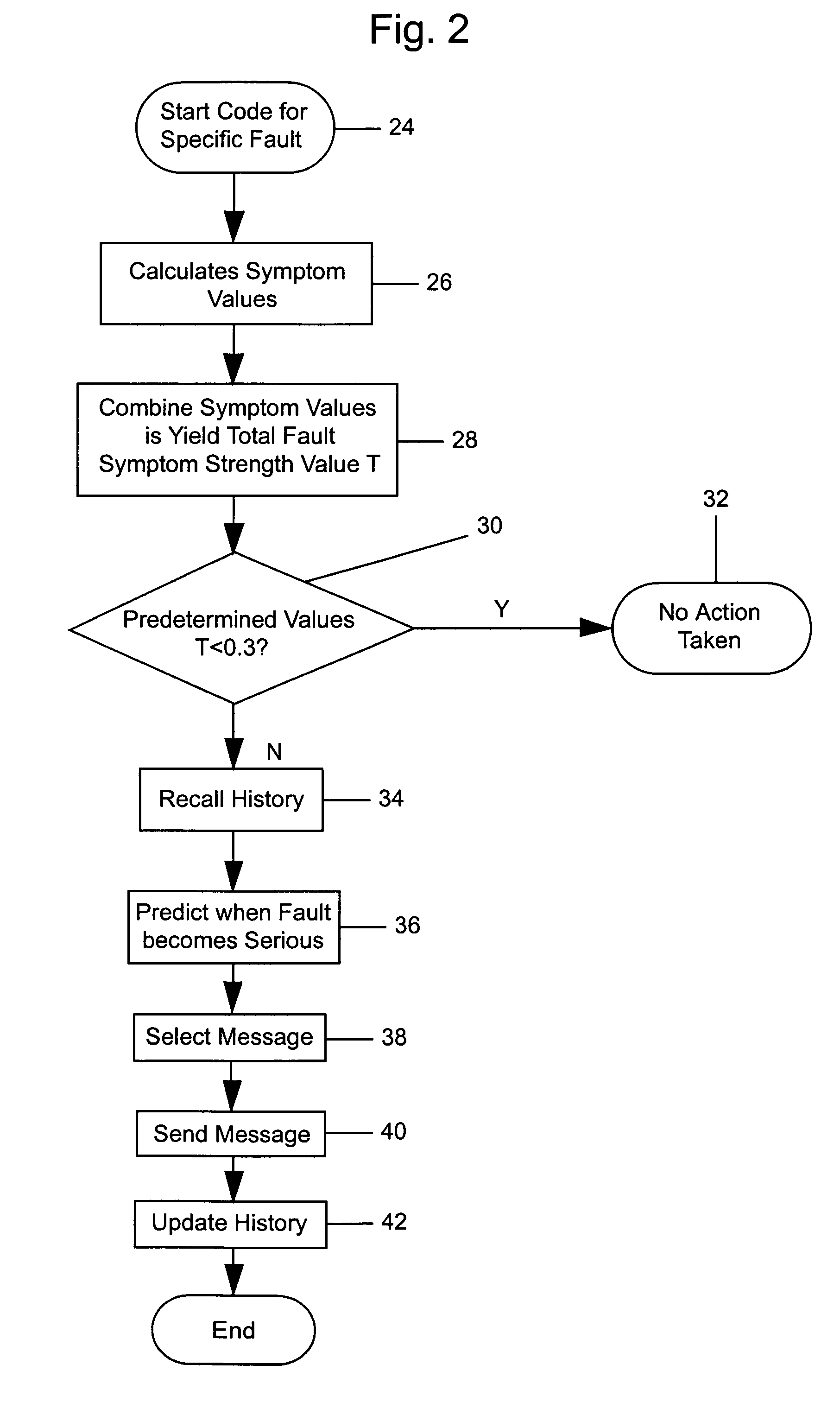

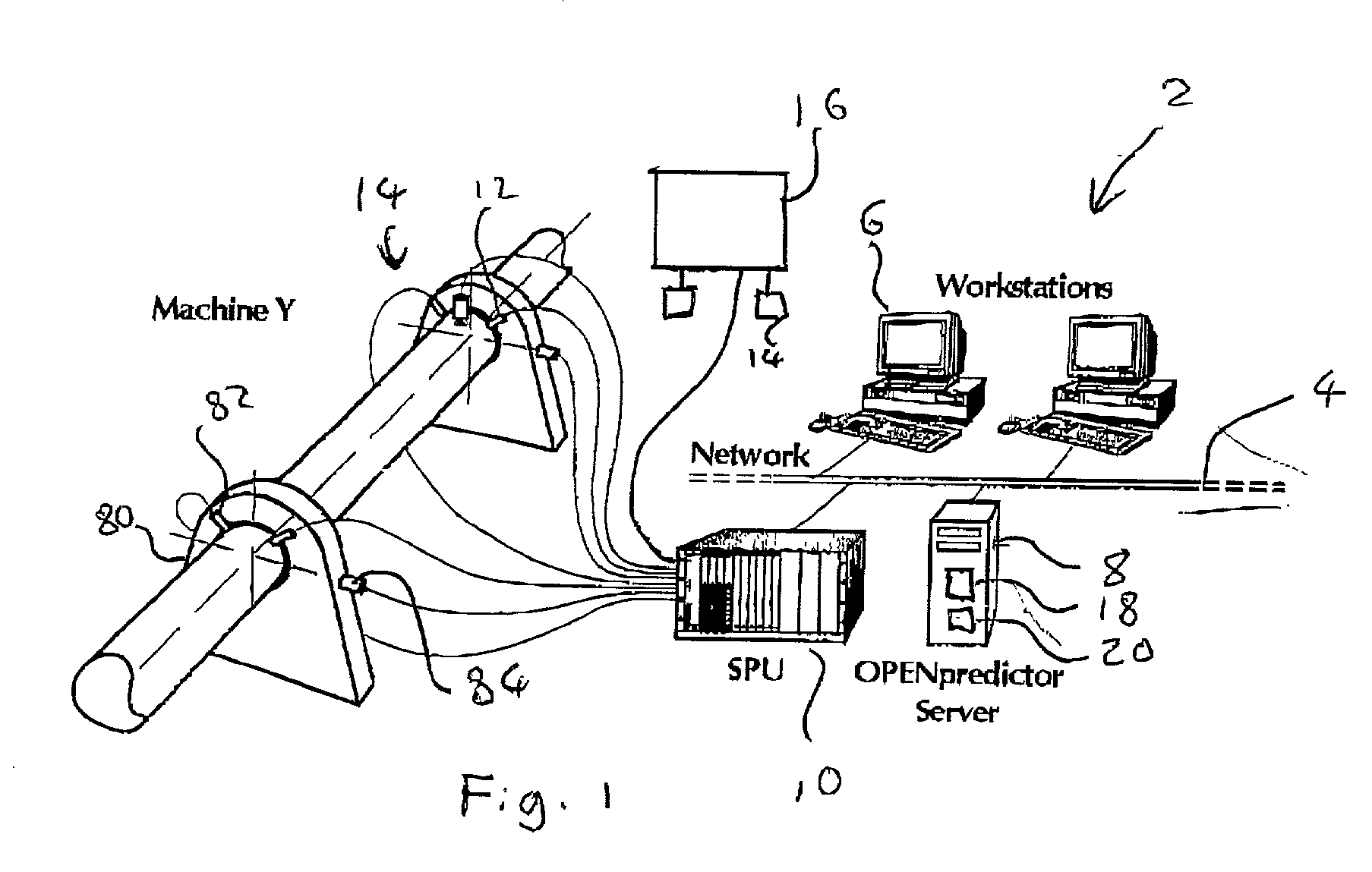

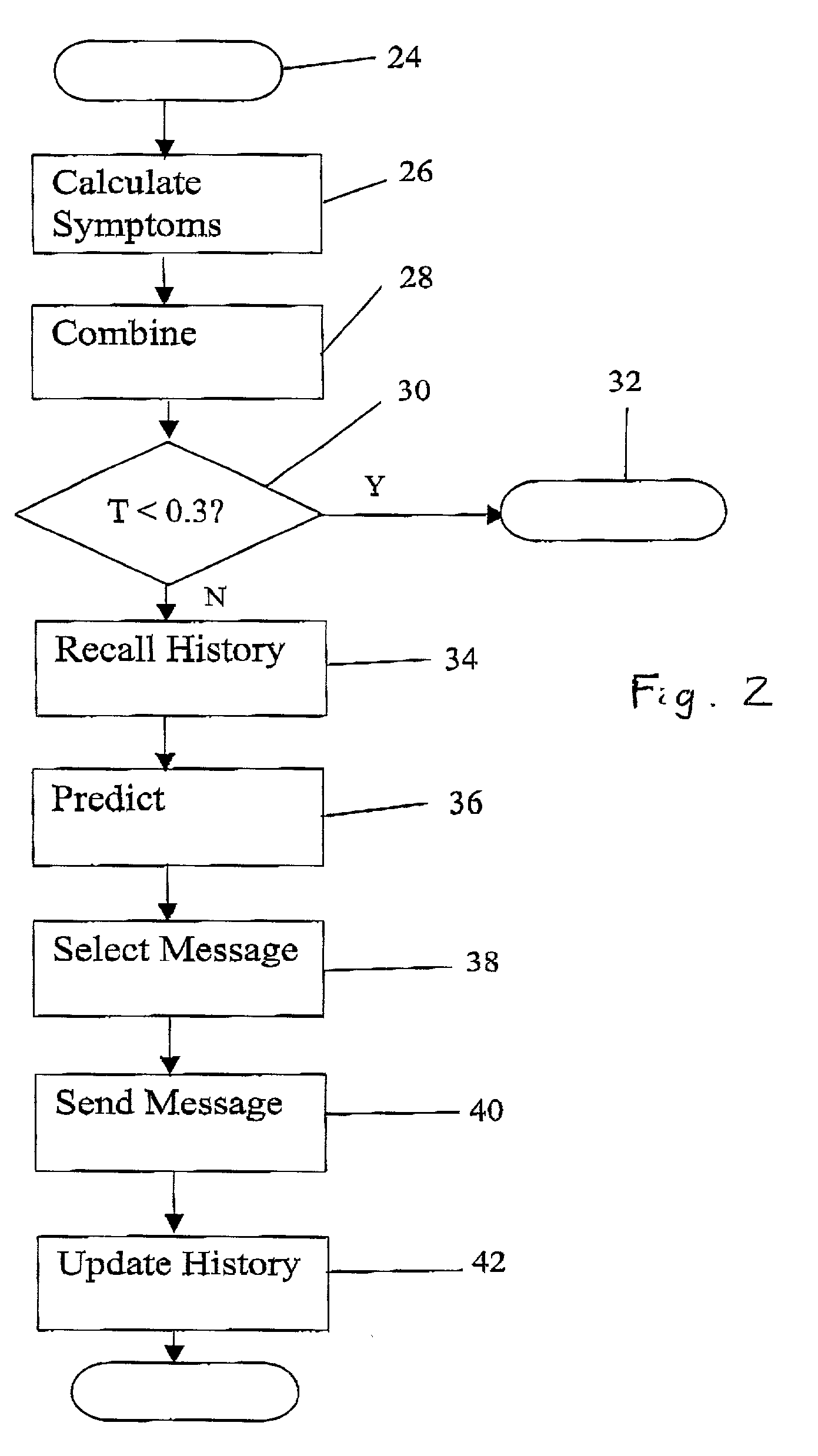

System and method for predicting component failures in large systems

ActiveUS7103509B2Computing modelsMeasurement arrangements for variablePrediction systemComputer science

A method for predicting a time to failure of a component in a system is presented. The method comprises obtaining a set of data measurements related to the component. The set of data measurements are representative of a plurality of parameters including a plurality of leading parameters. The method comprises generating a prediction model based upon the leading parameters considered in combination. The prediction model is then used to predict the time to failure of the component based on a set of real-time measurements, wherein the plurality of parameters are processed to predict the time to failure for the component. Finally, a confidence level for the predicted time to failure is determined based upon the plurality of parameters.

Owner:GENERAL ELECTRIC CO

Automatic machinery fault diagnostic method and apparatus

InactiveUS7089154B2Reduce the amount requiredShorten the timeMachine part testingDigital computer detailsUltimate tensile strengthDiagnostic methods

Owner:GP ROVSING DYNAMICS APS

Contained environmental control system for mobile event data recorder

ActiveUS7703291B2Reduce vibration effectsFast heat conductionReducing temperature influence on carrierDisposition/mounting of recording headsHard disc driveMobile vehicle

An environmental control system, or data pack, is provided in accordance with embodiments of the present invention. The system allows for audio and video recording on hard drive media in situations where temperature, vibration and humidity would otherwise have prevented the use of such technology. The system can be used in conjunction with an event recorder for use in motor vehicles, trains and the like. The environmental control system includes a thermoelectric module connected to the hard drive and to a housing. The thermoelectric module is for transferring heat between the hard drive and the housing in response to an applied voltage in order to maintain a hard drive temperature within a hard drive operable temperature range. The vehicle operating temperature range includes temperatures outside the hard drive operable temperature range.

Owner:MARCH NETWORKS

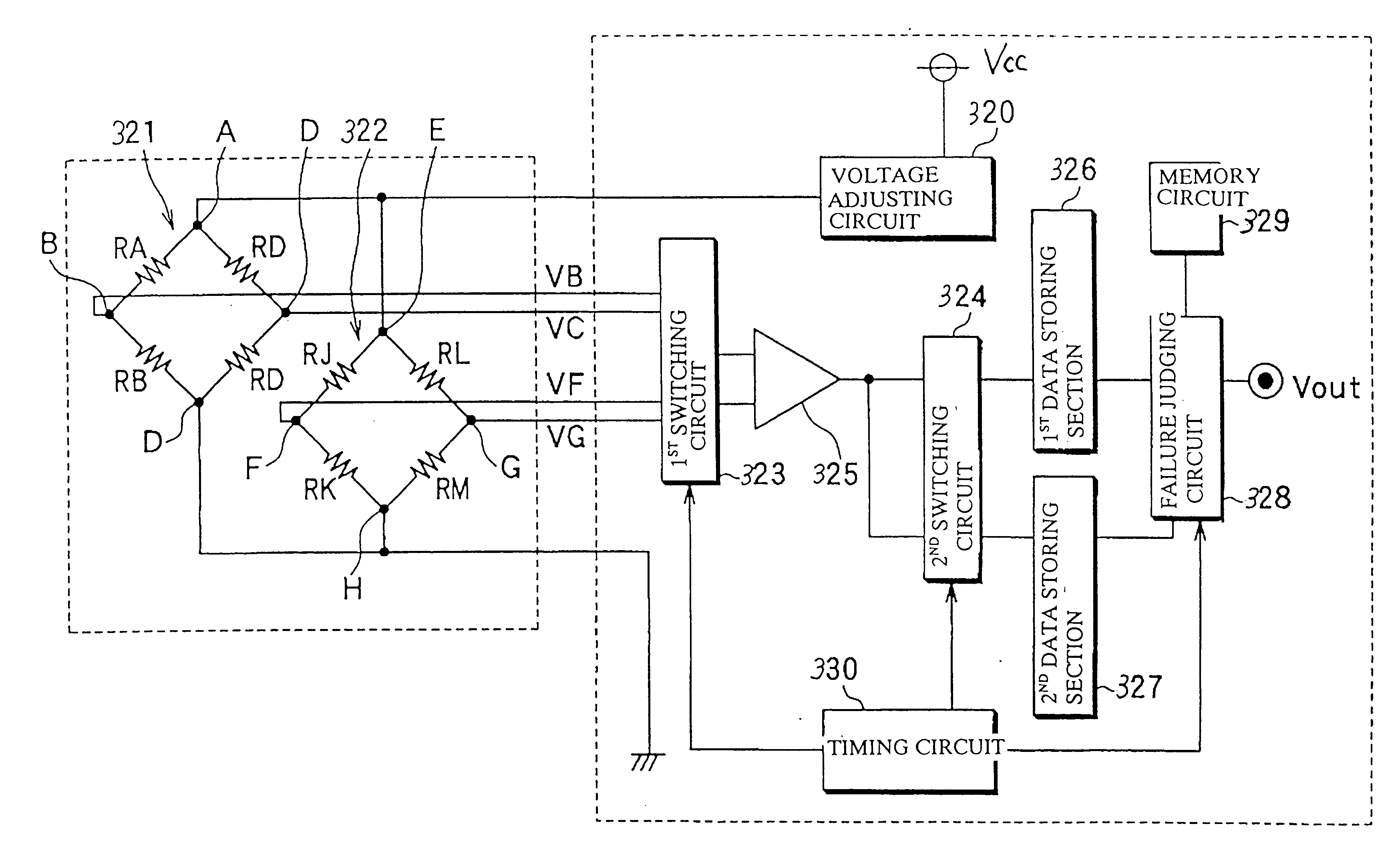

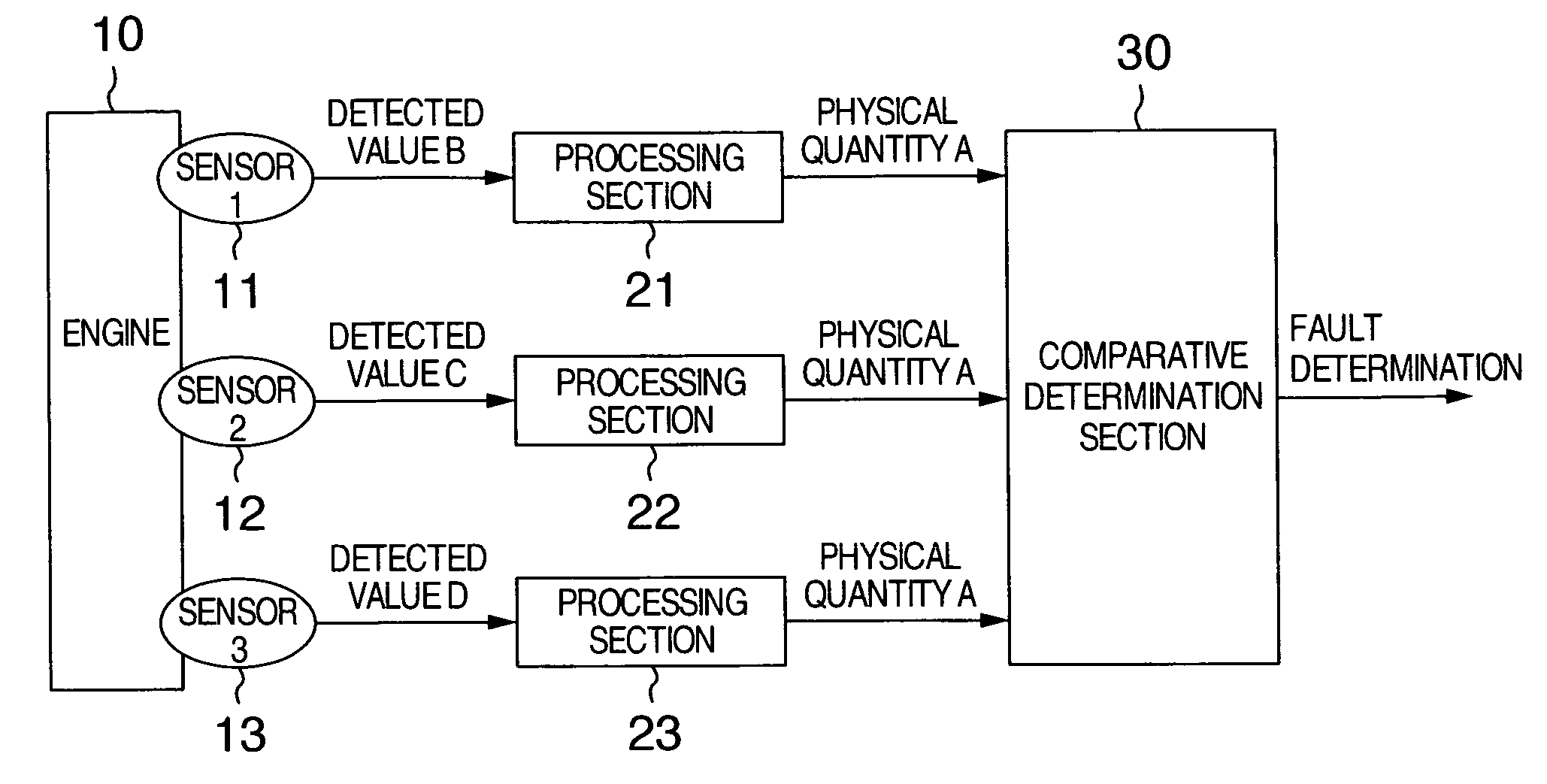

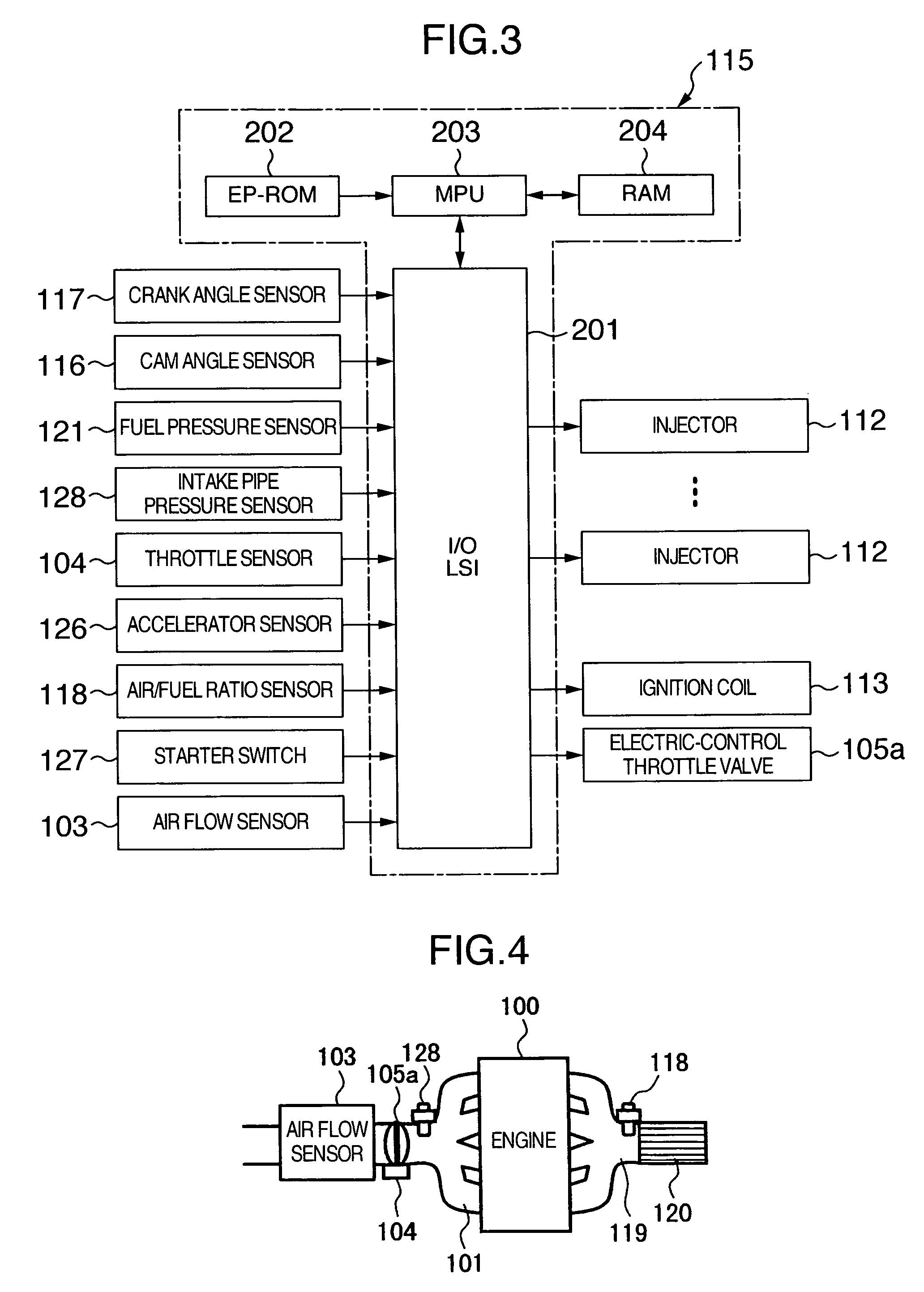

Fault diagnosis apparatus for sensors used in a system

InactiveUS20060287806A1Increase costReduce probabilityAnalogue computers for vehiclesElectrical controlEngineeringPhysical quantity

A fault diagnosis apparatus for sensors in an apparatus system has at least three sensors which detect different physical quantities for one physical phenomenon which vary in correlation with one another, the sensors outputting signals indicating the detected physical quantities, wherein outputs from the at least three sensors are converted into one identical physical quantity in accordance with the correlations so that the resulting identical physical quantity can be used to determine whether or not each of the sensors is defective.

Owner:HITACHI LTD

Automatic machinery fault diagnostic method and apparatus

InactiveUS20030040878A1Easy to updateLittle can be alteredMachine part testingDigital computer detailsUltimate tensile strengthDiagnostic methods

Owner:GP ROVSING DYNAMICS APS

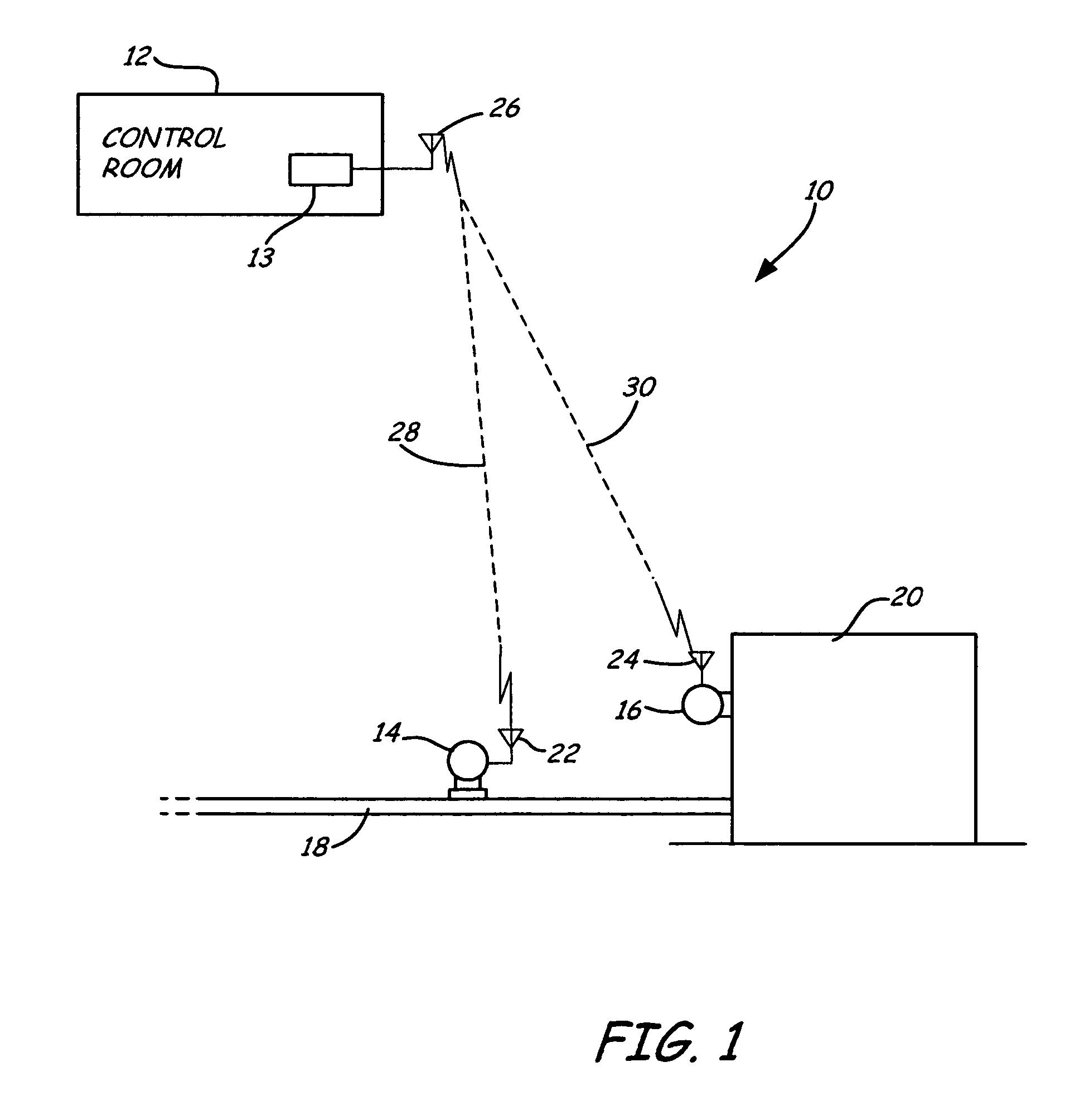

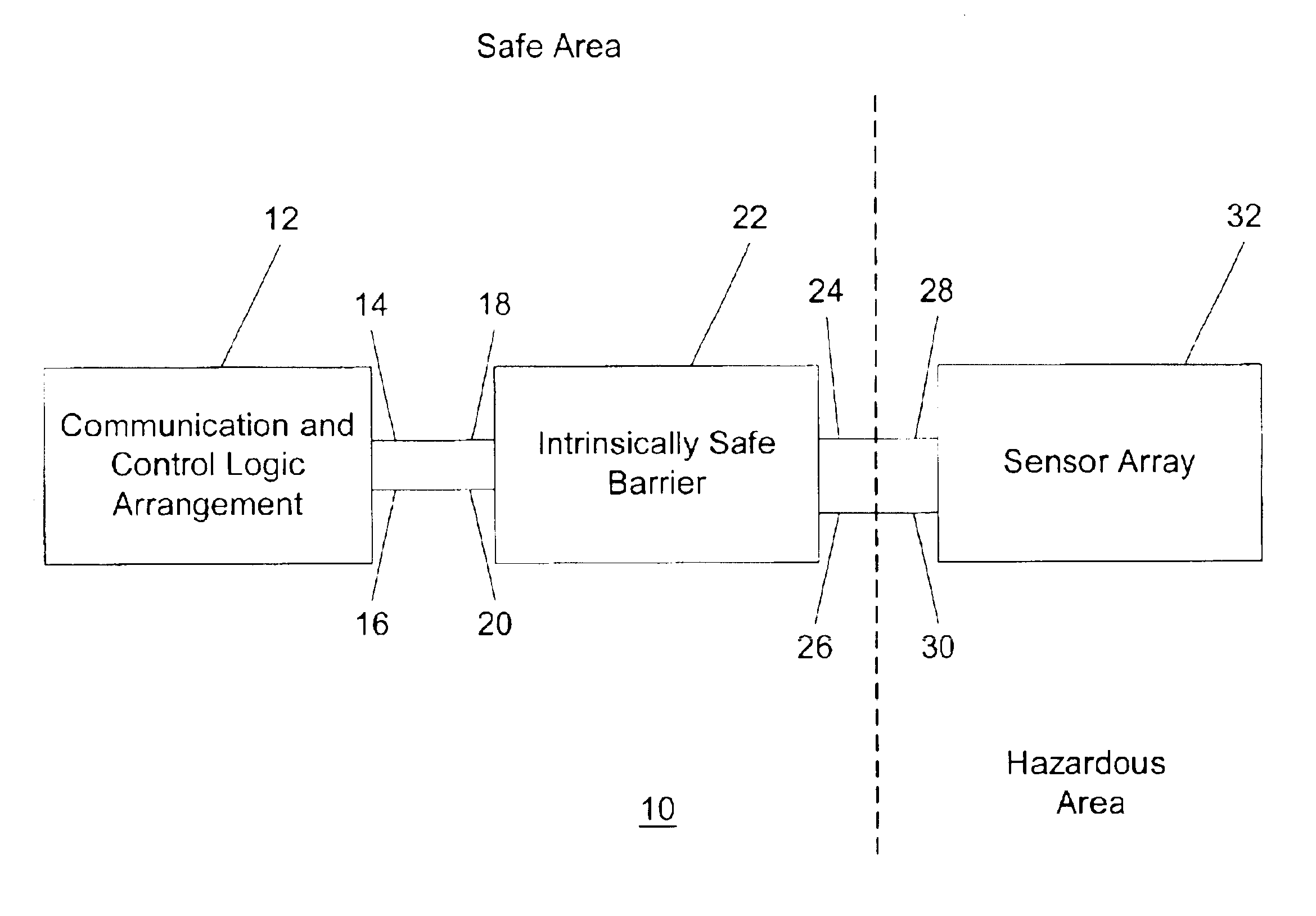

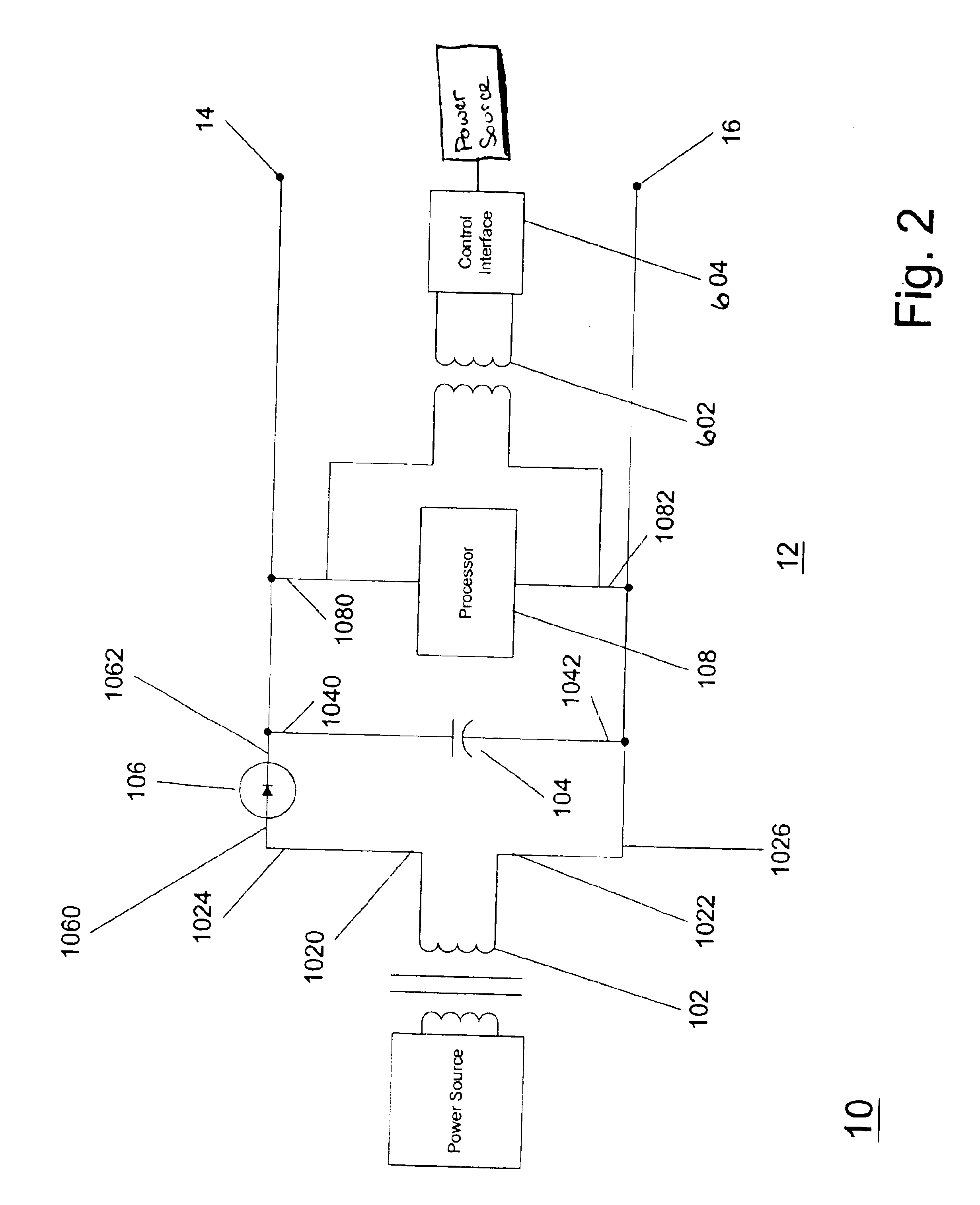

System and method for measuring system parameters and process variables using multiple sensors which are isolated by an intrinsically safe barrier

InactiveUS6885949B2Current be limitedSafety arrangmentsConverting sensor ouput using wave/particle radiationIntrinsic safetyMultiple sensor

A system for measuring at least one parameter is provided. The system includes a control logic arrangement powered by a power source, and an intrinsically safe barrier operatively connected to the control logic arrangement, and also powered by the same power source. The intrinsically safe barrier is adapted to be operatively connected to at least one sensor which is also powered by the same power source. The sensor is configured to communicate data representing a parameter to the control logic arrangement via the intrinsically safe barrier. In one embodiment, the control logic arrangement, the intrinsically safe barrier and the sensor are galvonically isolated from external components and / or provided in one enclosure.

Owner:SMAR RES CORP

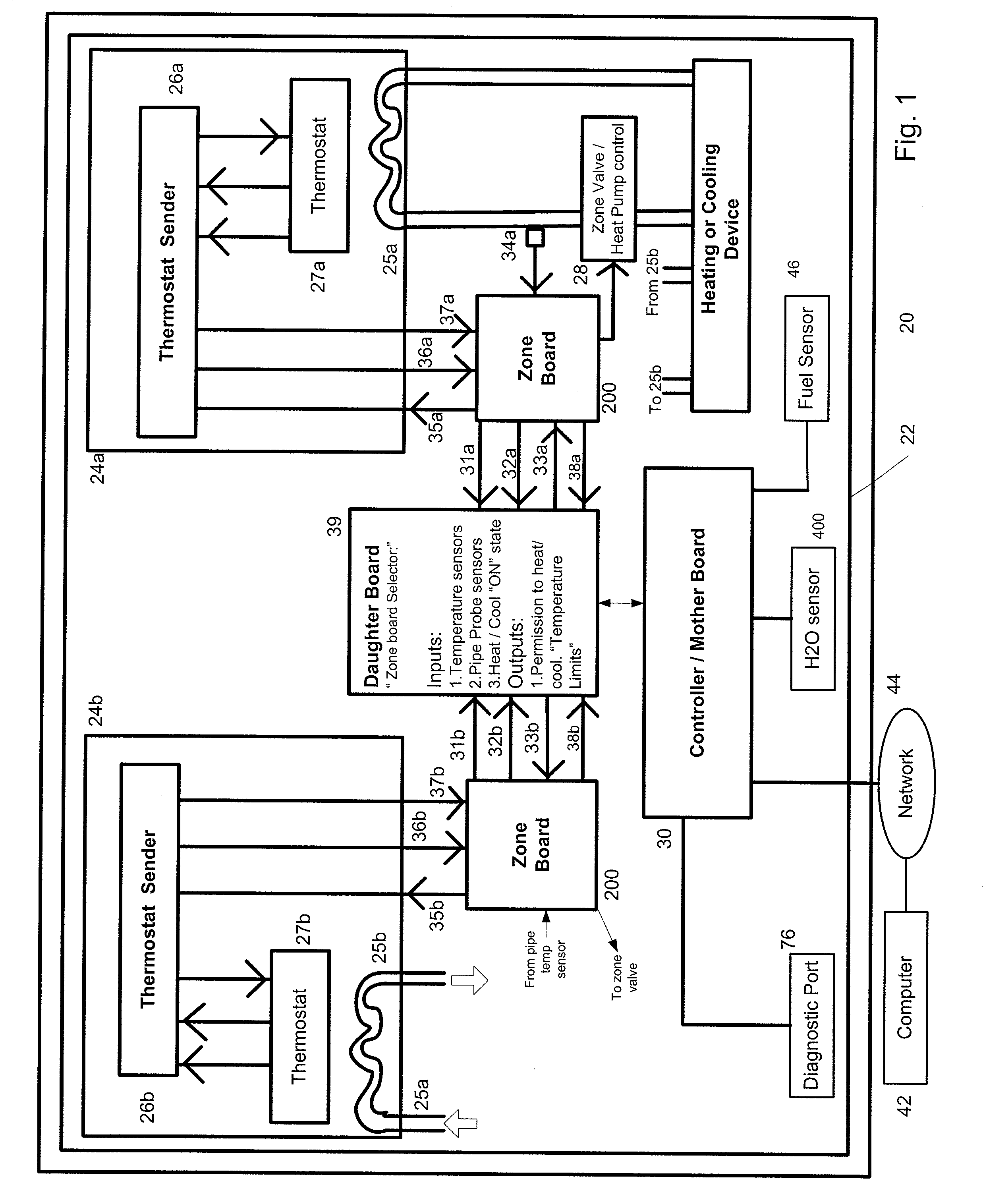

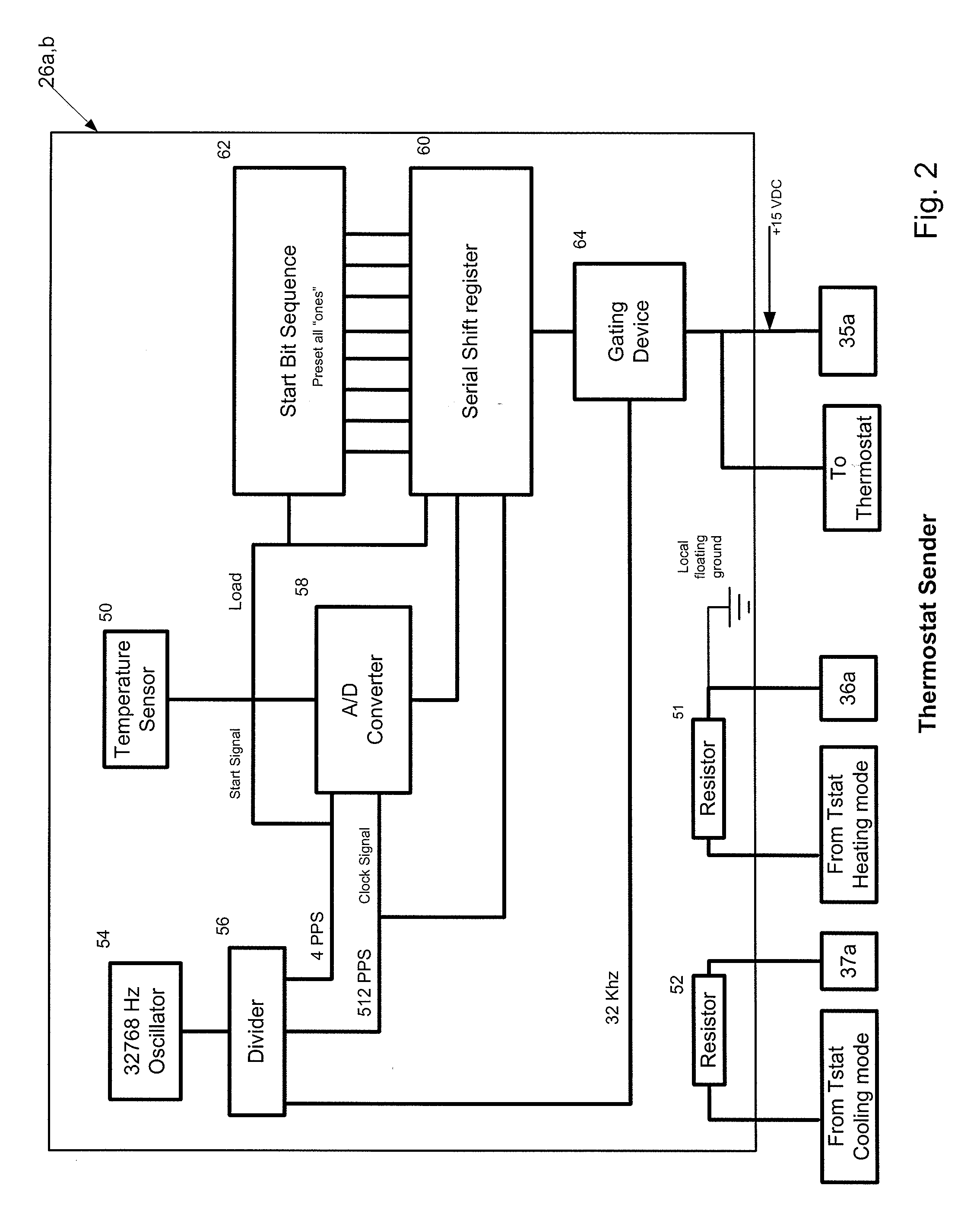

Systems and methods for monitoring, controlling and limiting usage of utilities

InactiveUS20100163634A1Easy to installMechanical apparatusLighting and heating apparatusThermostatEngineering

Systems and methods for monitoring, controlling and limiting utility usage for a plurality of units in a building. An example system includes a controller and one or more sensing devices in signal communication with the controller using a buildings existing thermostat wiring. The system senses the state of a thermostat, the air temperature near each thermostat and the pipe / ducting temperature in each of a plurality of units. The pipe / ducting sensor monitors the temperature of piping or ducting leading from a thermostatically controlled supply valve to the unit requesting heating or cooling. Being able to use existing building thermostat wiring allows for installation into older buildings. The controller records utility usage information for each of the plurality of units based on information received from the one or more sensing devices and communicates with a website.

Owner:KLEIN MICHAEL J +1

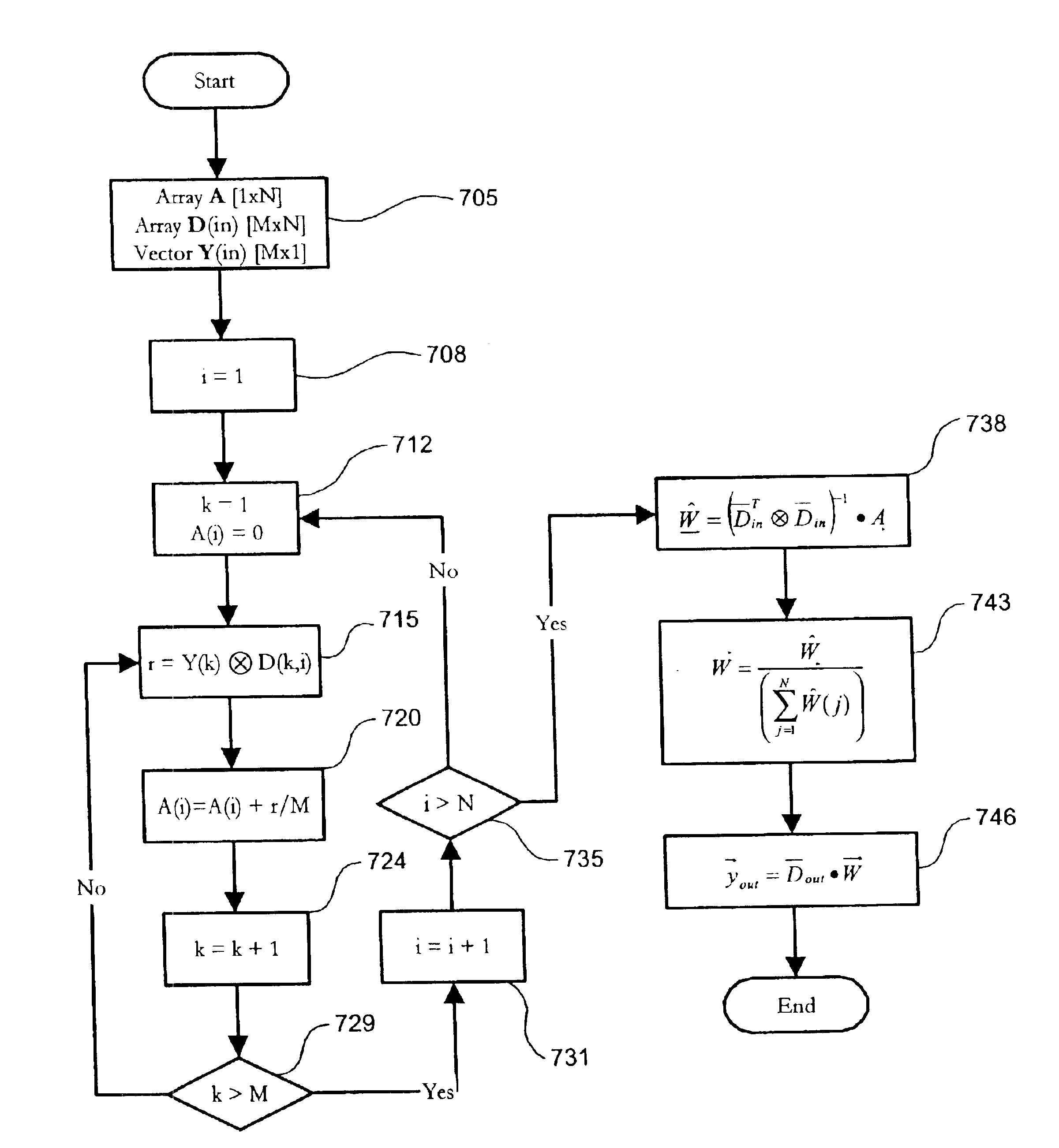

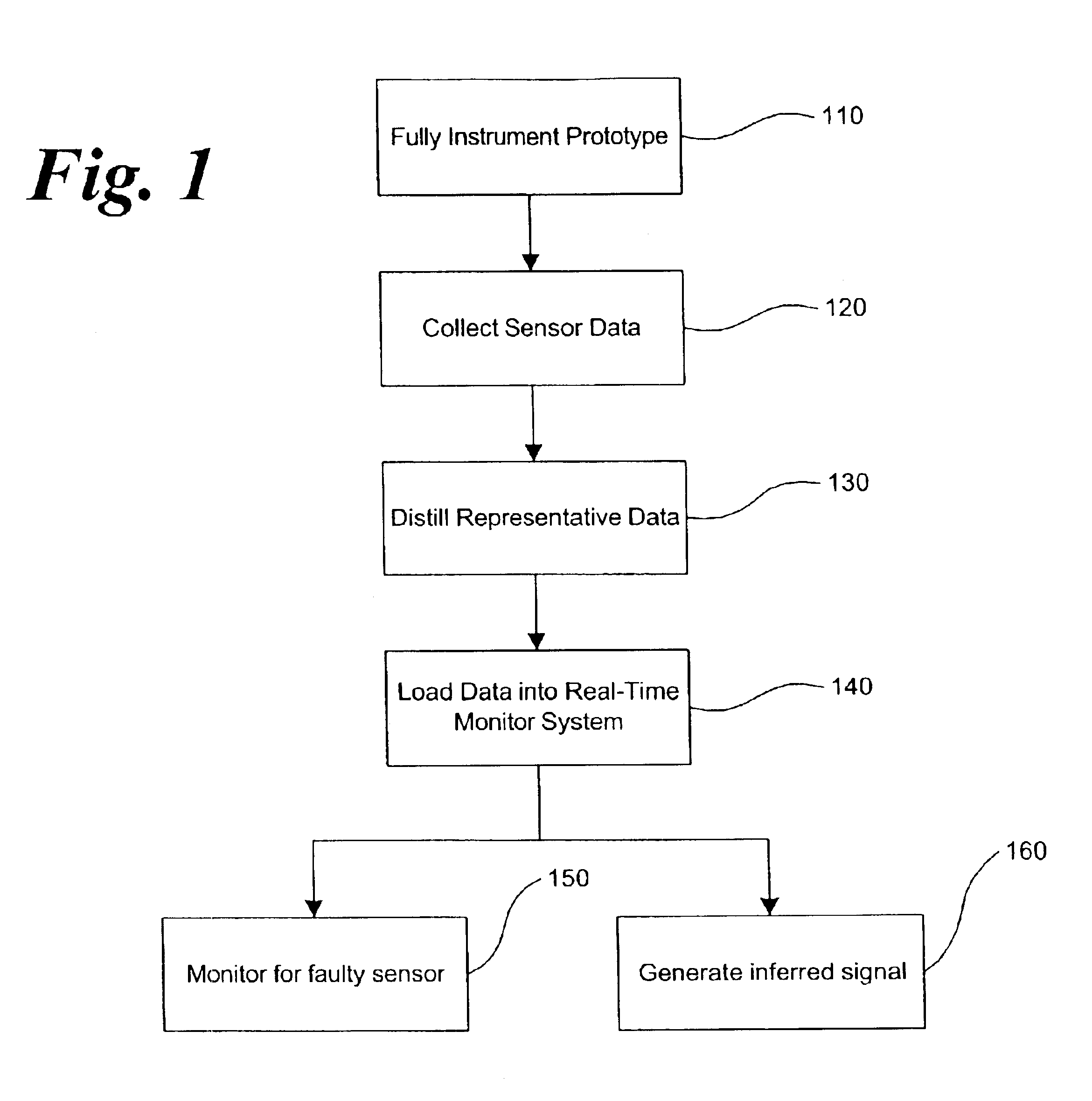

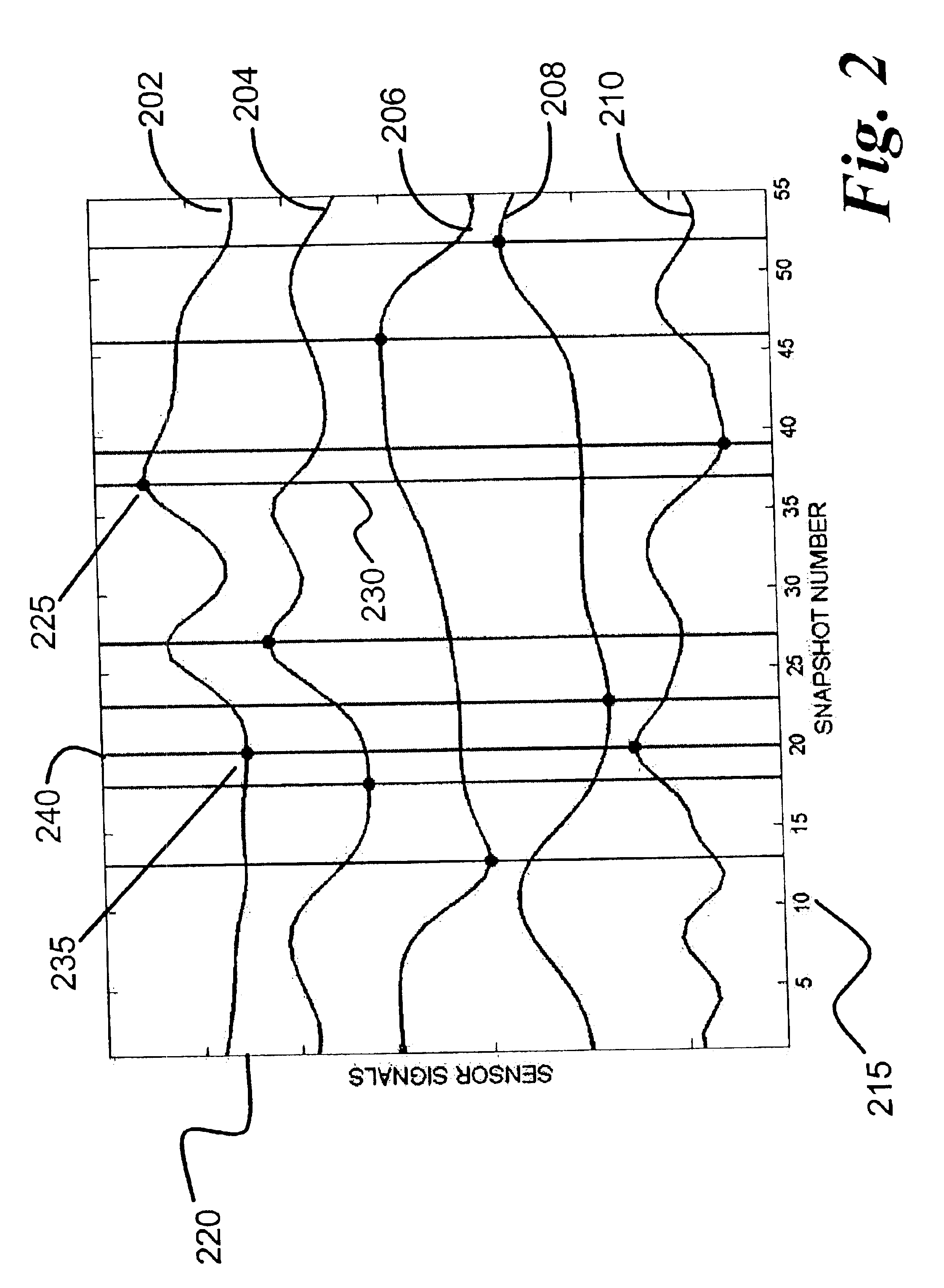

Inferential signal generator for instrumented equipment and processes

InactiveUS6876943B2Low production costReduce in quantitySubsonic/sonic/ultrasonic wave measurementSimulator controlData setComputer module

An improved system and method for producing replacement sensor signals for failed sensors, and inferred sensor signals for non-instrumented physical parameters, in processes and equipment having one or more sensors in place for monitoring physical parameters. A data history from a fully-instrumented prototype provides a representative data set of anticipated operating parameters for forming an empirical model in a computer module for generating “virtual” signals for a process or machine in real-time. Replacement or inferential sensor signals can be advantageously used in downstream control processing or analysis. A memory for storing the representative training set, or a transformation thereof, is coupled to a processor. The processor receives from an input data signals embodying real values from sensors actually on the process or machine, and may receive these in real-time. The processor is disposed to take a set of readings of the actual sensors from the input, mid generate an estimate of one or more desired inferred sensors, using a linear combination of the representative training set sensor data, as weighted by the result of a measure of similarity of the input sensor data to the representative training set sensor data.

Owner:SMARTSIGNAL CORP

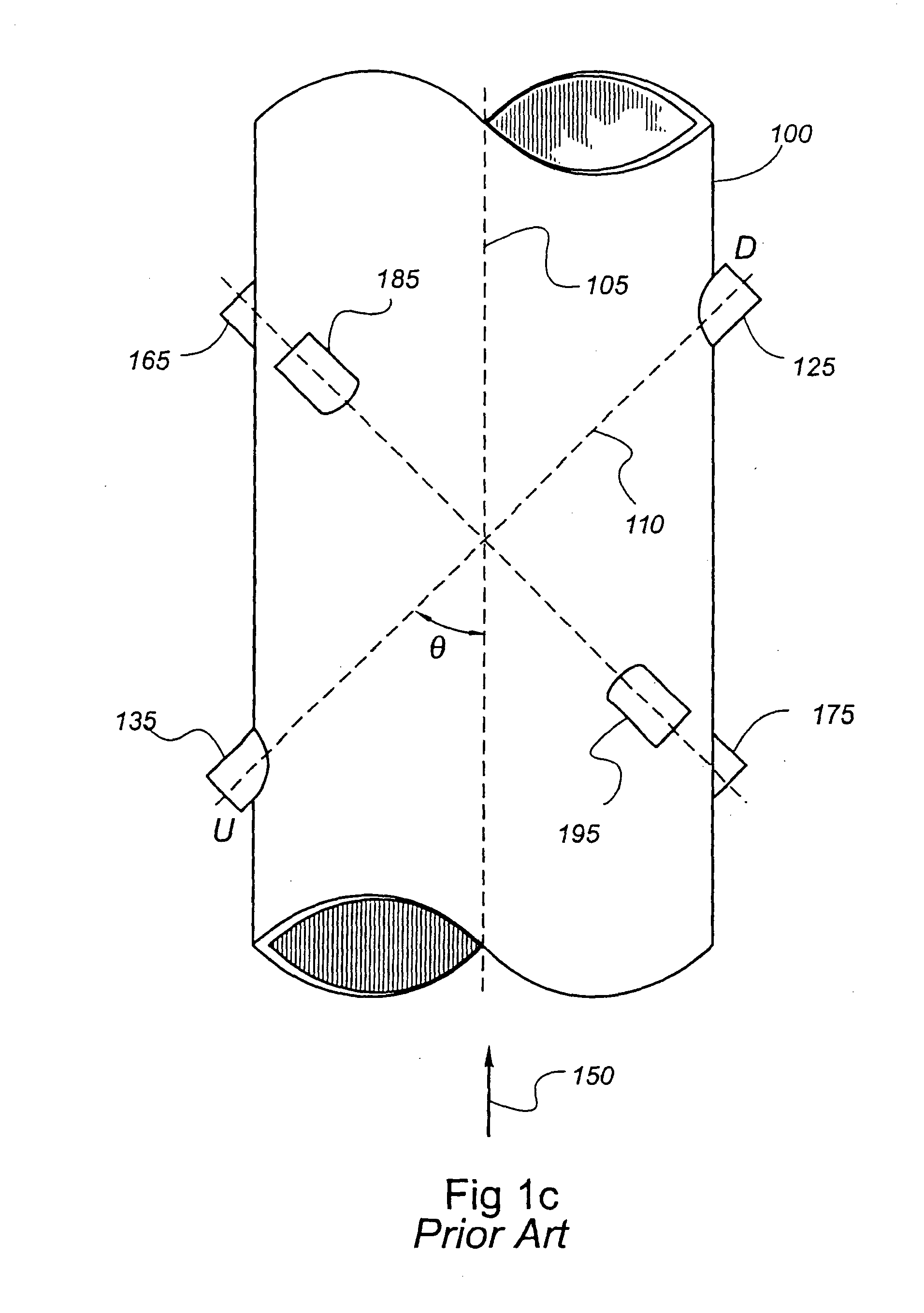

Self-tuning ultrasonic meter

InactiveUS20050055171A1Correction errorWide applicabilityVolume/mass flow measurementElectrical measurementsSelf-tuningTemperature stratification

A method and related ultrasonic meter identify and correct for transit time errors such as peak switch errors. The method includes calculating values for a set of diagnostics from measurements of the fluid flow, including transit time measurements. Based on the values for the diagnostics, and whether and how they fall outside of their respective ranges, the meter can identify a variety of problems with the meter or fluid flow, such as whether there has been an intermittent peak switch, a permanent peak switch, or the presence of noise, velocity pulsation in the fluid flow, temperature stratification, or other problem. In the event there is a problem with the meter, the meter self-tunes in order to minimize the chances of the problem happening again.

Owner:MICRO MOTION INC

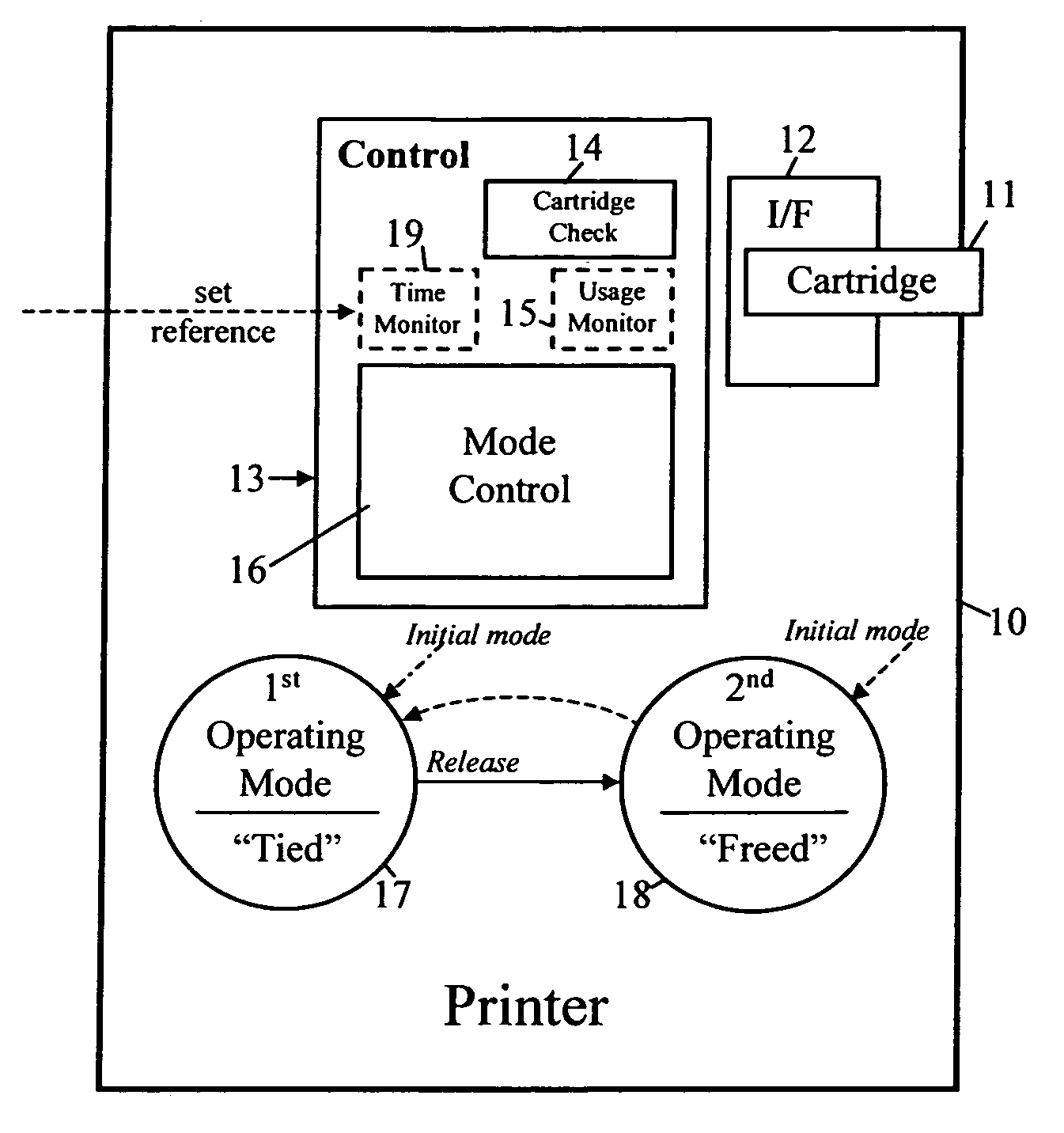

Apparatus that uses consumable items and a method of managing such apparatus

An apparatus is provided that uses a consumable item, of given type, requiring occasional renewal. The apparatus has a first operating mode in which it only works with a subset of consumable items of the given type; the apparatus also has a second operating mode in which it is not restricted to working with consumable items of the aforesaid subset. The apparatus is changed from its first mode to its second mode following a determination that the apparatus has reached a predetermined time or usage threshold for being in its first mode. The change to the second mode is preferably effected in response to a release code generated either by the apparatus itself or by a remote system following the determination that the predetermined time or usage threshold being reached. Advantageously, the consumable items can be used to pass usage data to a remote system.

Owner:HEWLETT PACKARD DEV CO LP

Electric power meter including a temperature sensor and controller

InactiveUS7068184B2Electric signal transmission systemsElectric devicesElectric power systemPower usage

An electric power meter (102) includes a temperature sensor (114) and a controller (112). The controller (112) is operable, based on the temperature reported from the temperature sensor (114), to generate alarm(s) when the temperature exceeds certain alarm threshold(s) (307, 507, 508) and to activate a power disconnect switch (104), thereby shutting off power to a customer premises, when the temperature exceeds a shut off threshold (309, 509). The controller (112) is operable to activate the power disconnect switch (104) for non-payment of electricity cost, subject to secondary criteria based on regulatory requirements. A customer terminal (103) may be used to notify a customer of an alarm condition, to provide information regarding electrical power usage or to provide information regarding disconnection of electrical power.

Owner:MOTOROLA SOLUTIONS INC

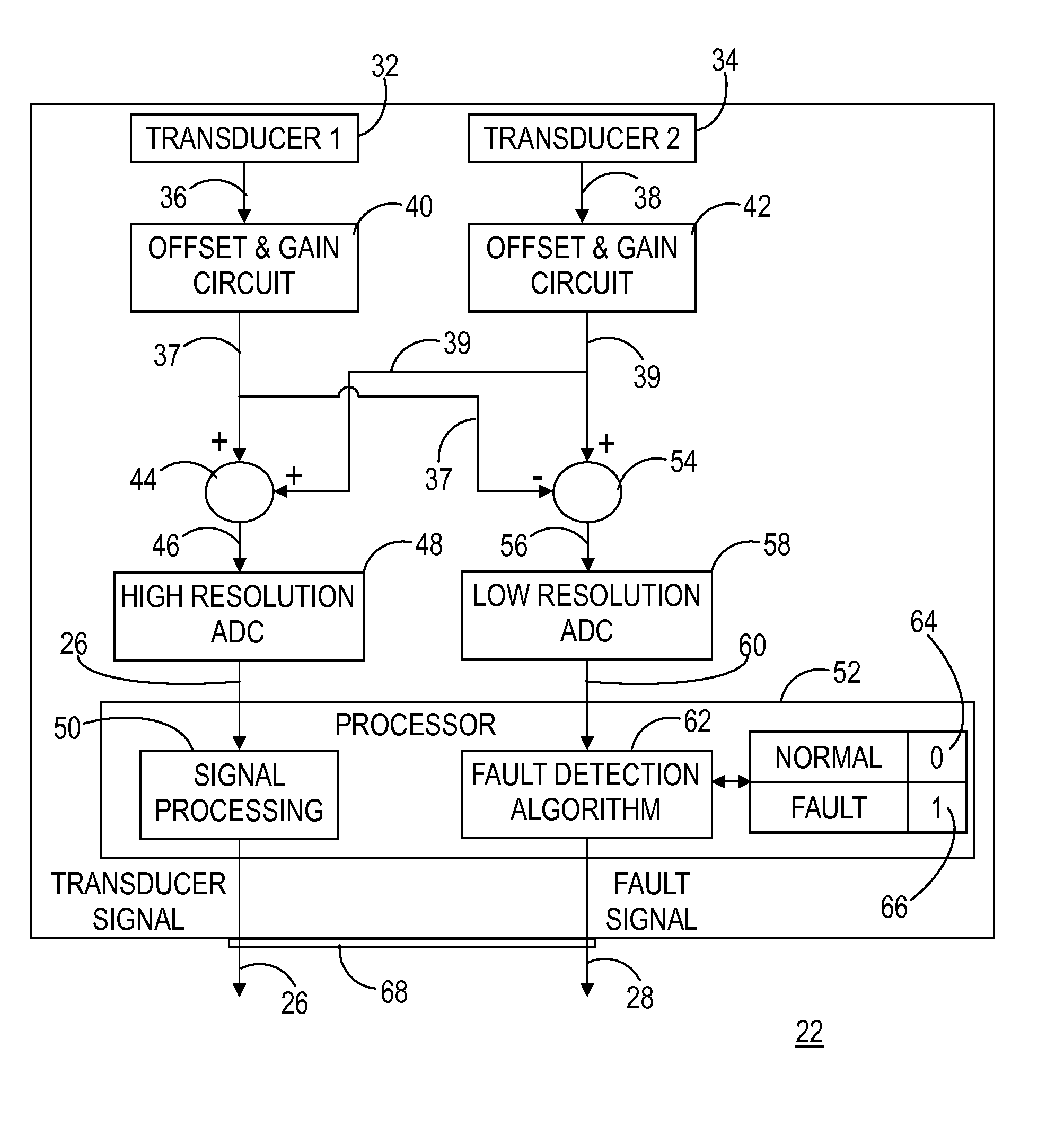

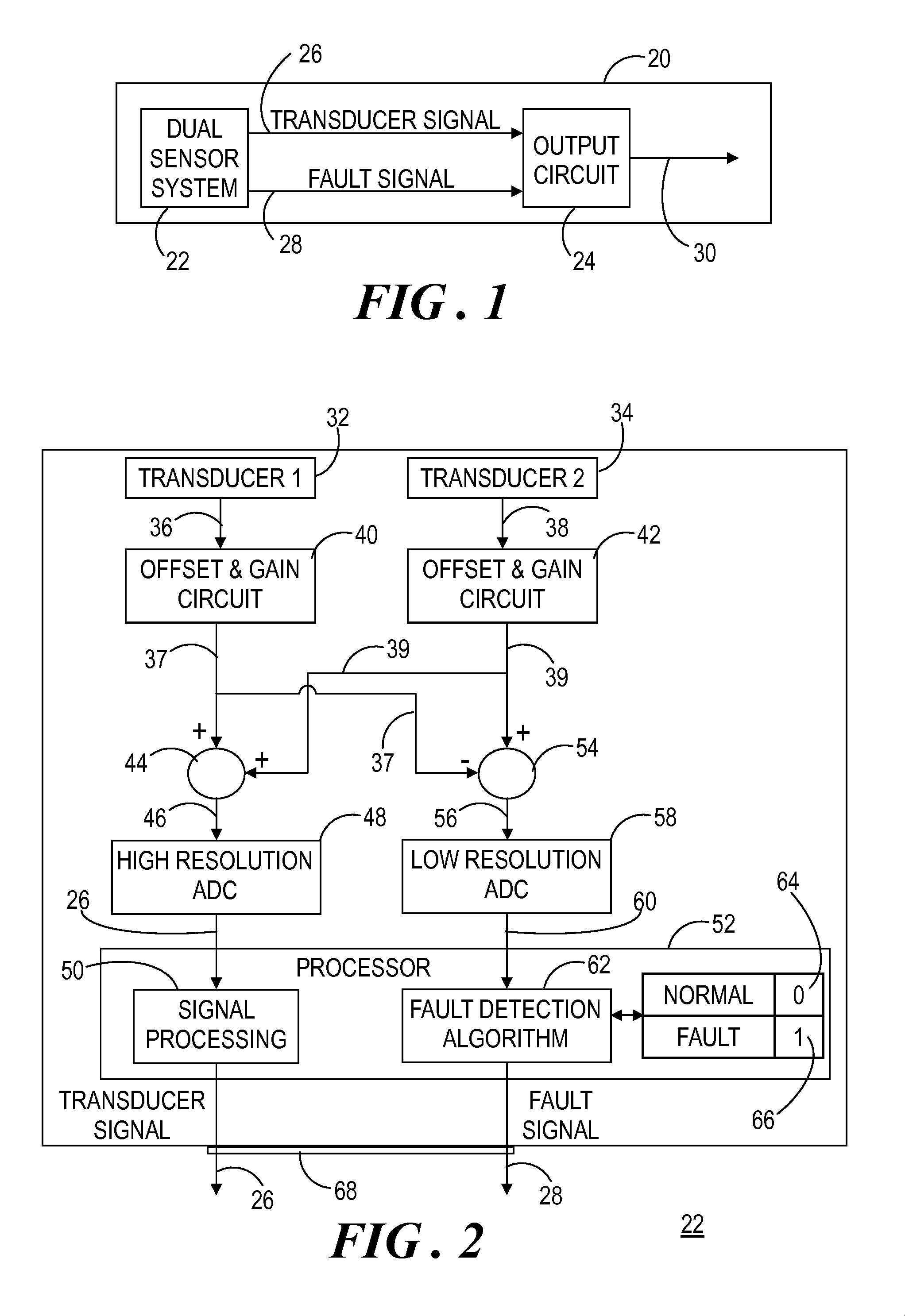

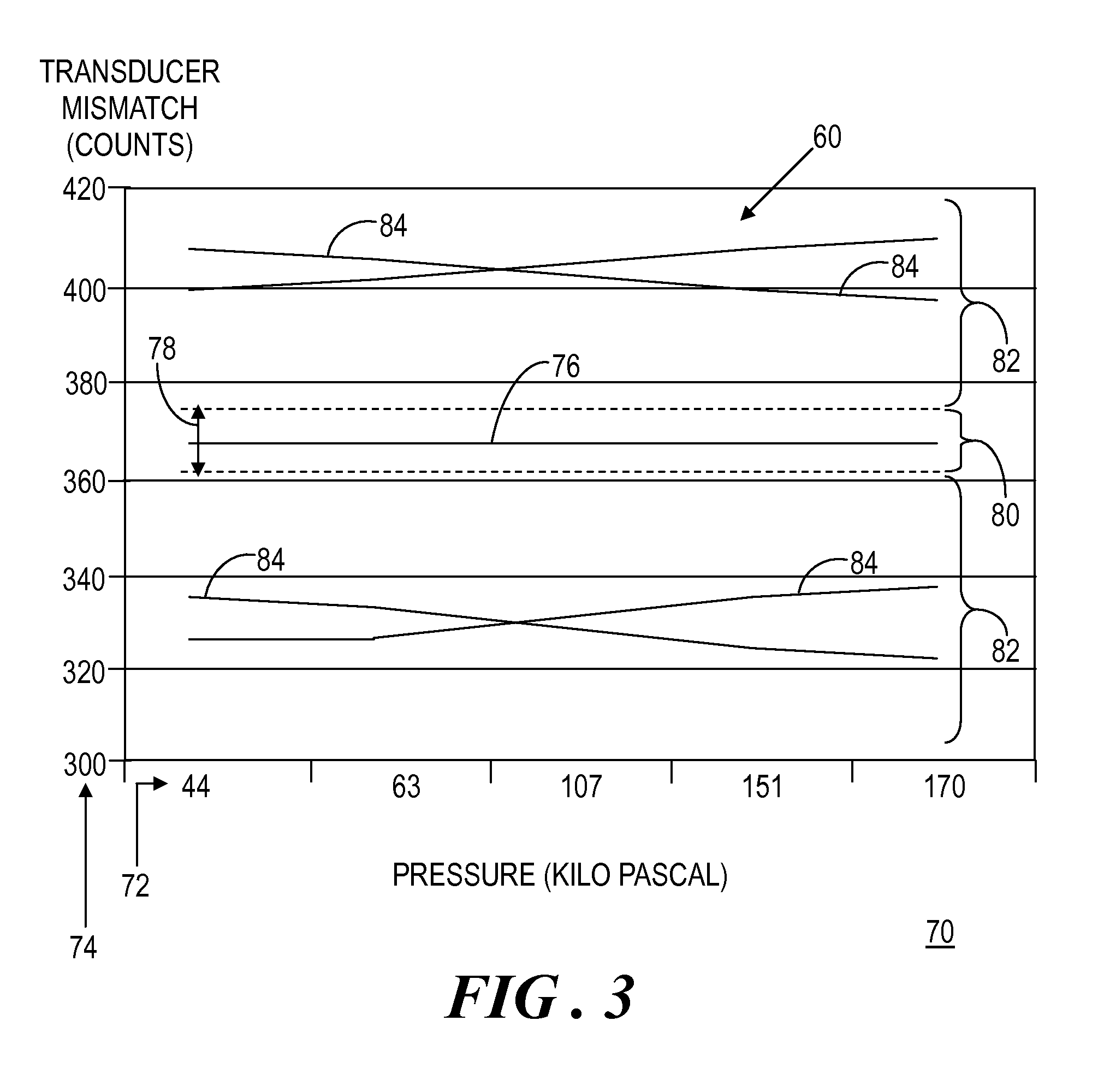

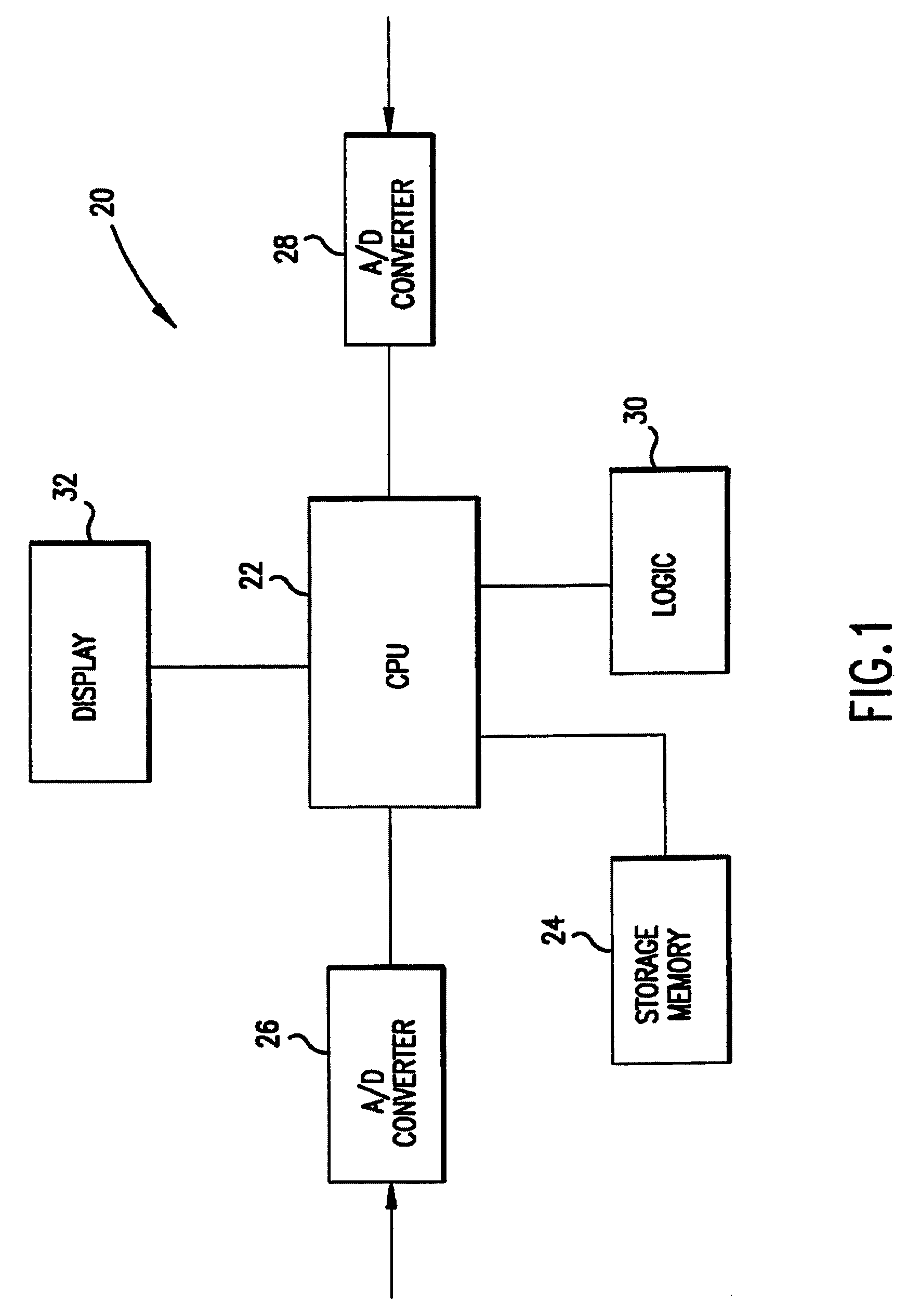

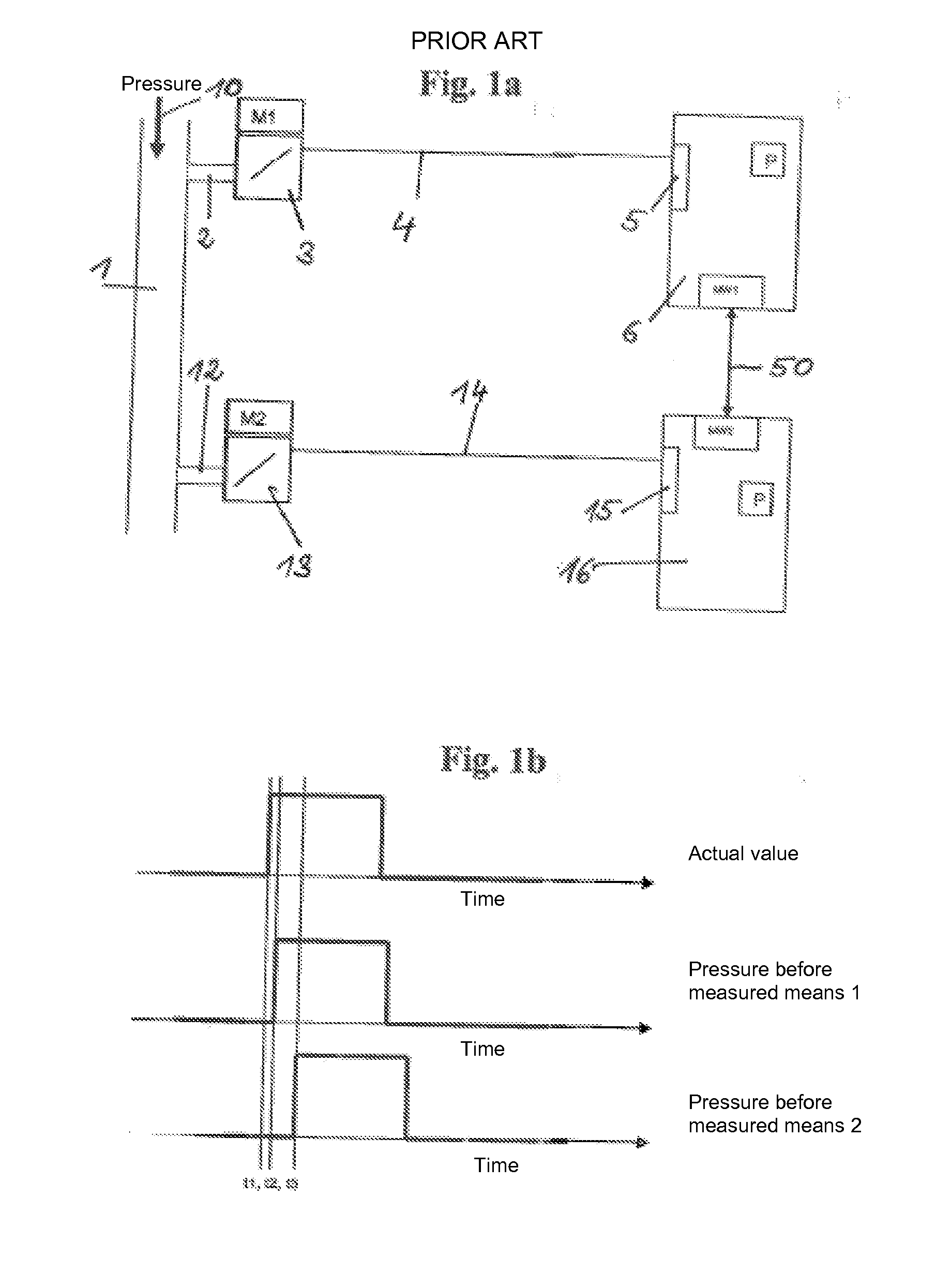

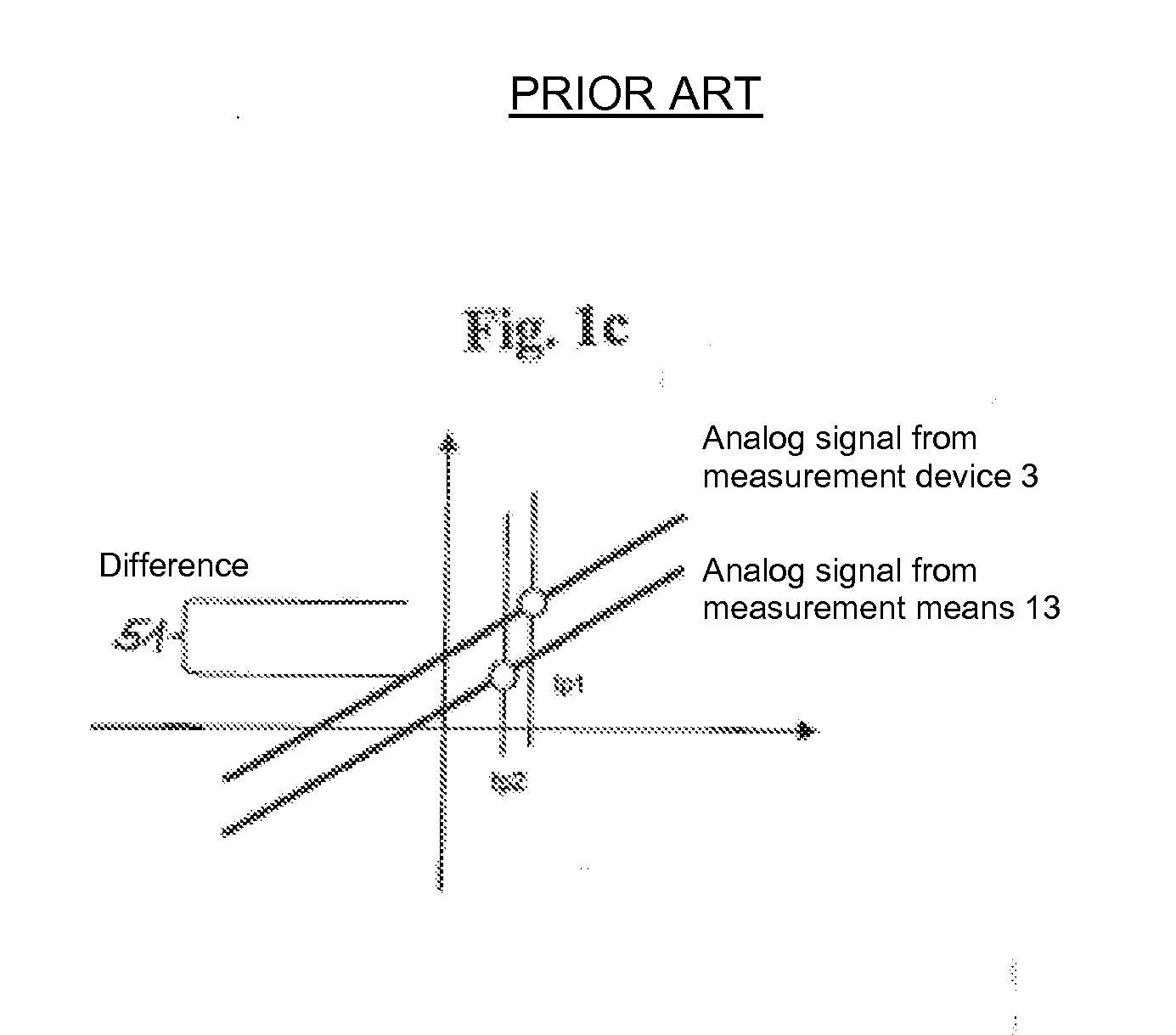

Dual sensor system having fault detection capability

A sensor system (20) includes transducers (32, 34) each yielding an analog signal (37, 39) representing a parameter independently sensed by each of the transducers (32, 34). The signals (37, 39) are summed and the resulting transducer signal (46) is converted to a digital transducer signal (26) by a high resolution analog-to-digital converter (ADC) (48). Concurrently, one of the signals (37, 39) is subtracted from the other. The resulting difference signal (56) is converted to a digital difference signal (60) by a low resolution ADC (58). When the digital difference signal (60) is within a threshold window (78), a fault signal (28) indicates a normal condition (80) of the transducers (32, 34). When the signal (60) falls outside of the threshold window (78), a fault signal (28) indicates a fault condition (82) of the transducers. The transducer and fault signals (26, 28) are concurrently output from the sensor system (20).

Owner:NXP USA INC

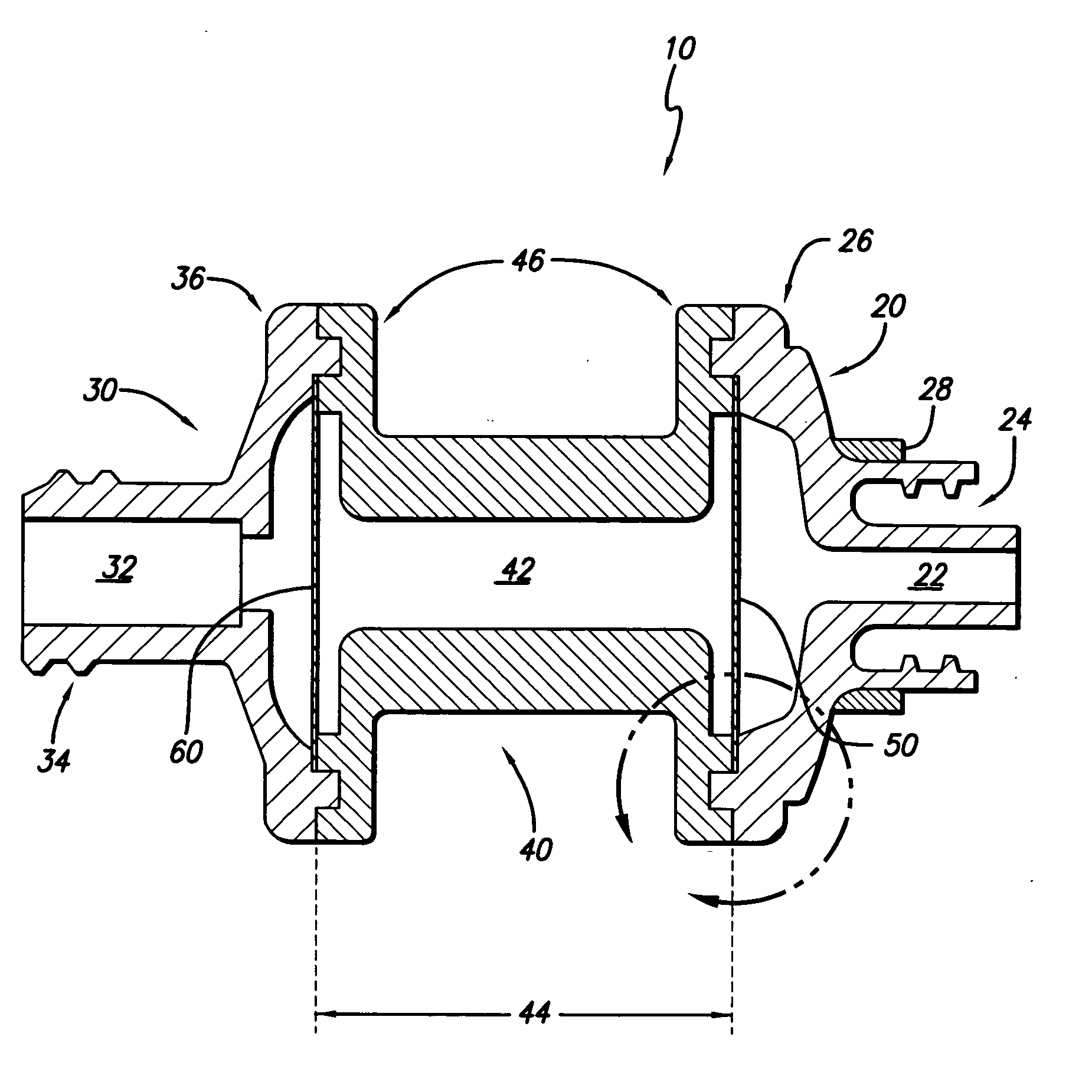

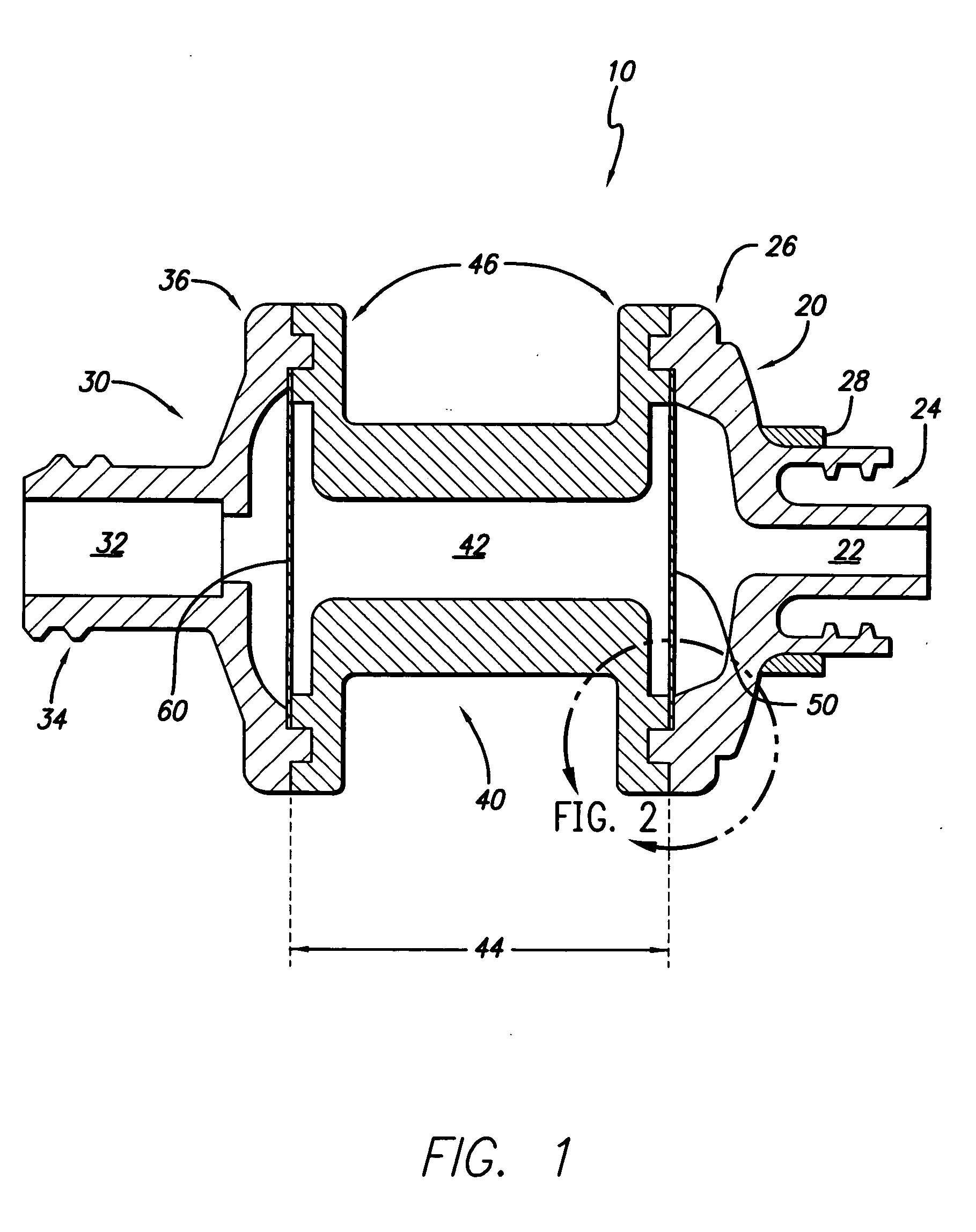

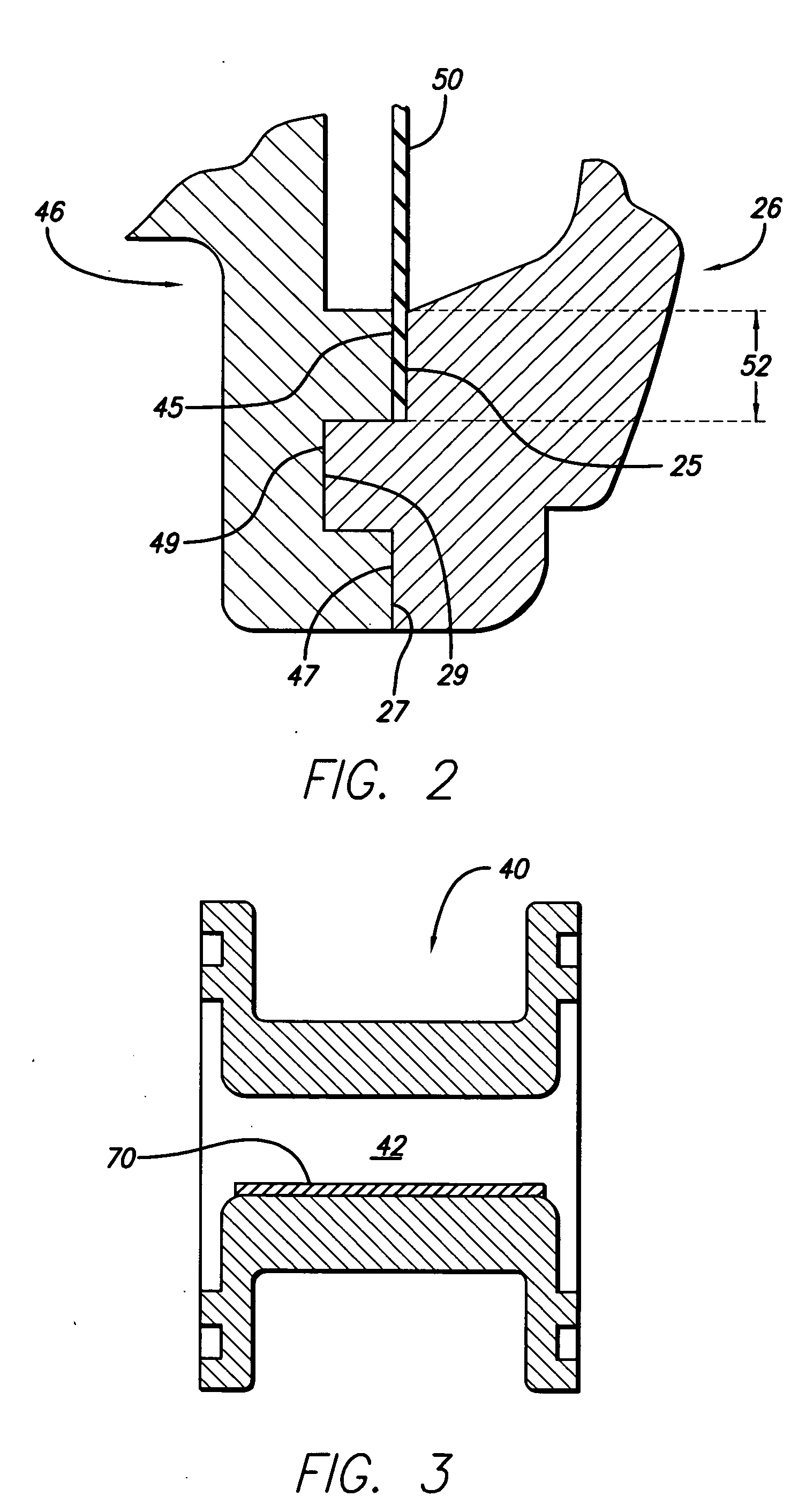

Double membrane transducer protector

InactiveUS20050132826A1Detection of fluid at leakage pointSemi-permeable membranesFiltration membraneTransducer

A transducer protector having at least two filter membranes. In one embodiment, the transducer protector includes a body between two tubular connectors, each of which has a lumen that may be axially aligned. The body lumen is separated from the lumen of each of the tubular connectors by a filter membrane. In one embodiment, the body is transparent and the body lumen has an indicator to alert a user that the filter membrane has been breached by a contaminant so that the user can take immediate steps to prevent further contamination of the system. The configuration of the transducer protector also facilitates the use of separate indicator devices, such as sensor clips.

Owner:JMS NORTH AMERICA

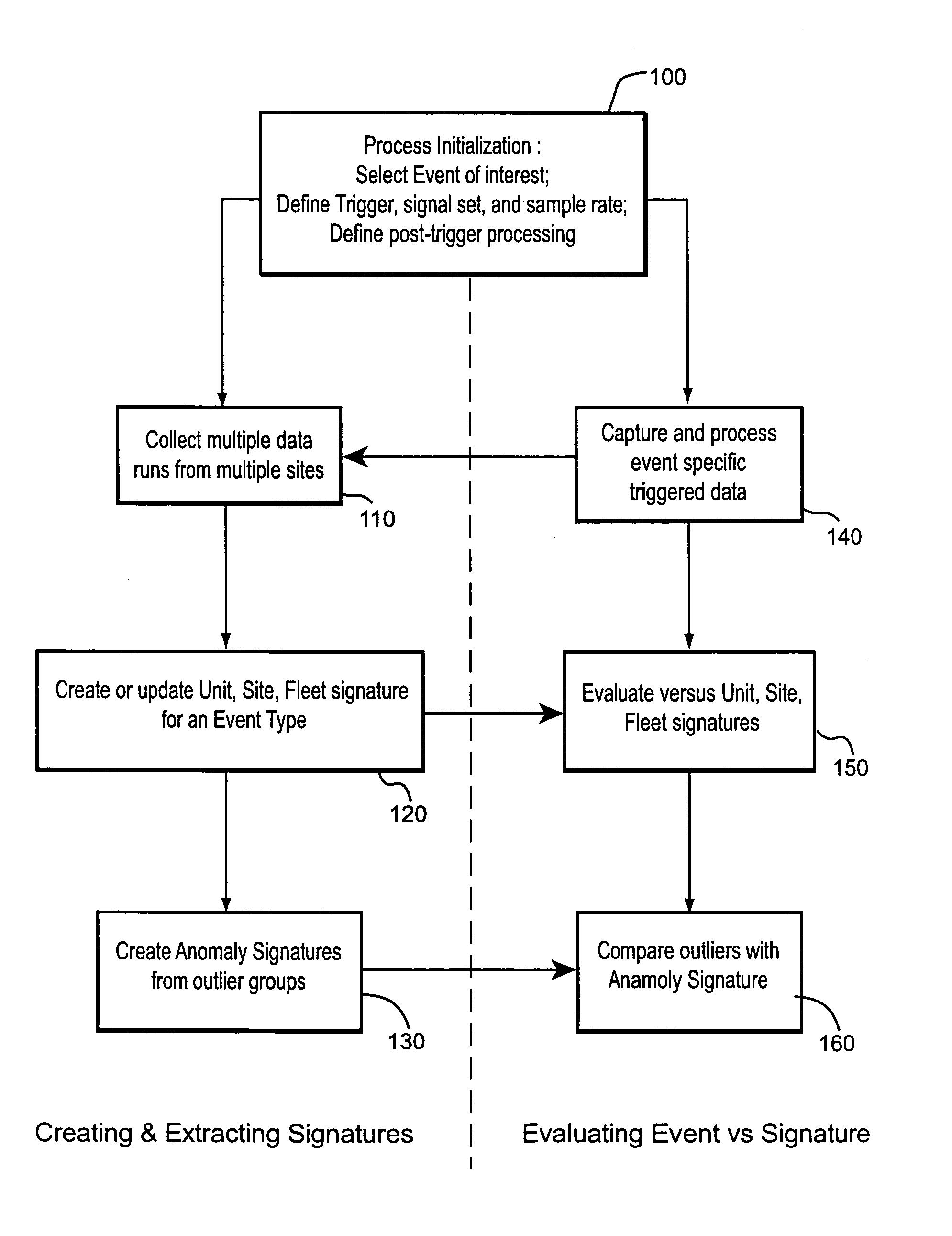

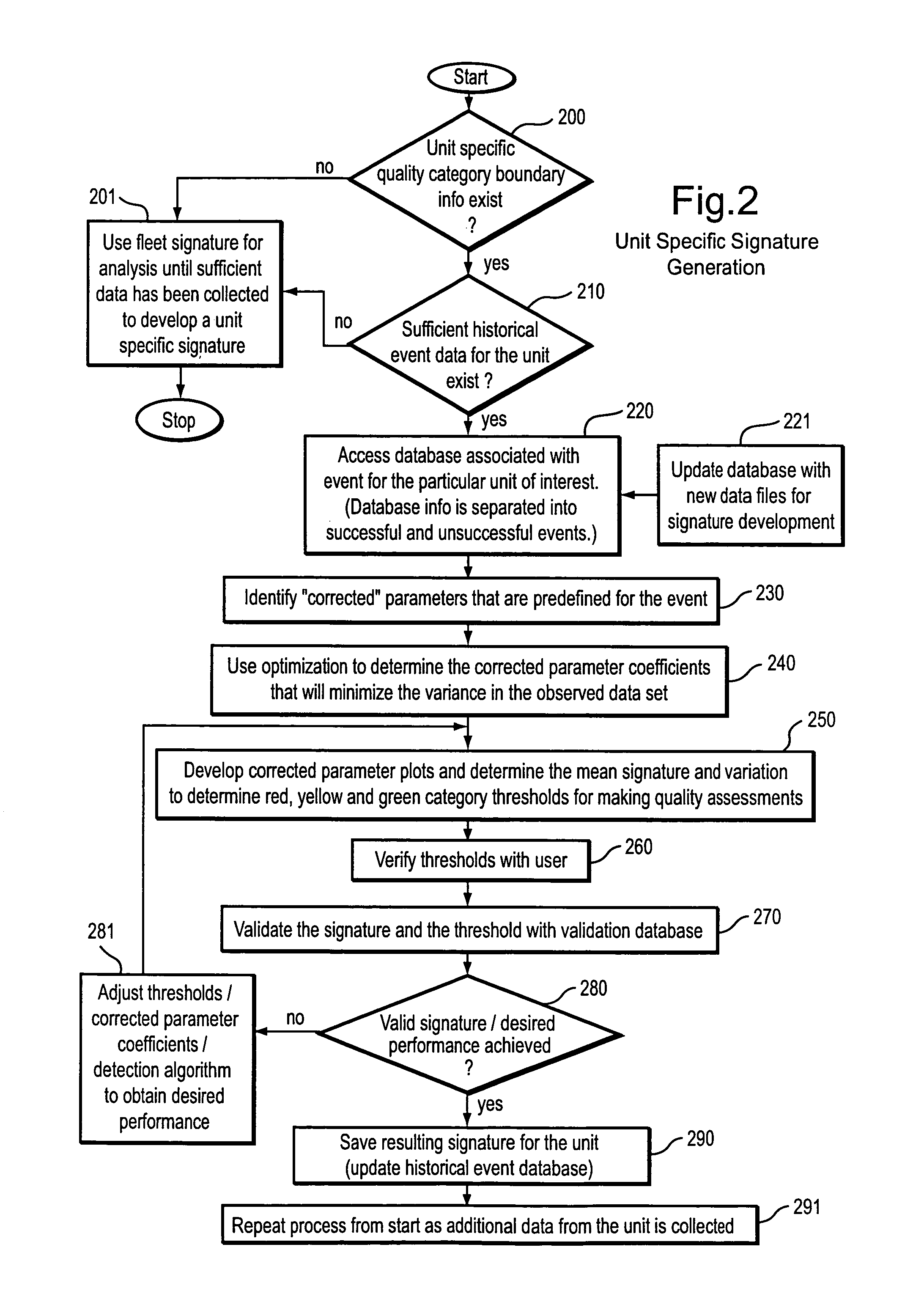

Method for developing a unified quality assessment and providing an automated fault diagnostic tool for turbine machine systems and the like

InactiveUS6973396B1Accurate analysisAccurate assessmentVibration measurement in solidsMachine part testingFuel qualityMachining system

A computer implemented process is provided for assessing and characterizing the degree of success or failure of an operational event of a machine system such as a fluid compressor machine or turbine machine or the like on a continuous numerical scale. The computer implemented process develops and tracks machine unit signatures, machine site signatures and machine fleet signatures to evaluate various operational events and provide fault detection. At least some sensor data acquired from the machine system during an operational event is transformed to correct or at least reduce variabilities in the data caused by ambient conditions and fuel quality. The transformed data is then analyzed using statistical methods to determine how closely the operational event conforms to an expected normal behavior and the information is used to develop a single comprehensive quality assessment of the event. By saving, tracking and updating operational event assessments over time, machine / component degradation may be recognized at any early stage and corrective action may be initiated in advance of a catastrophic failure.

Owner:GENERAL ELECTRIC CO

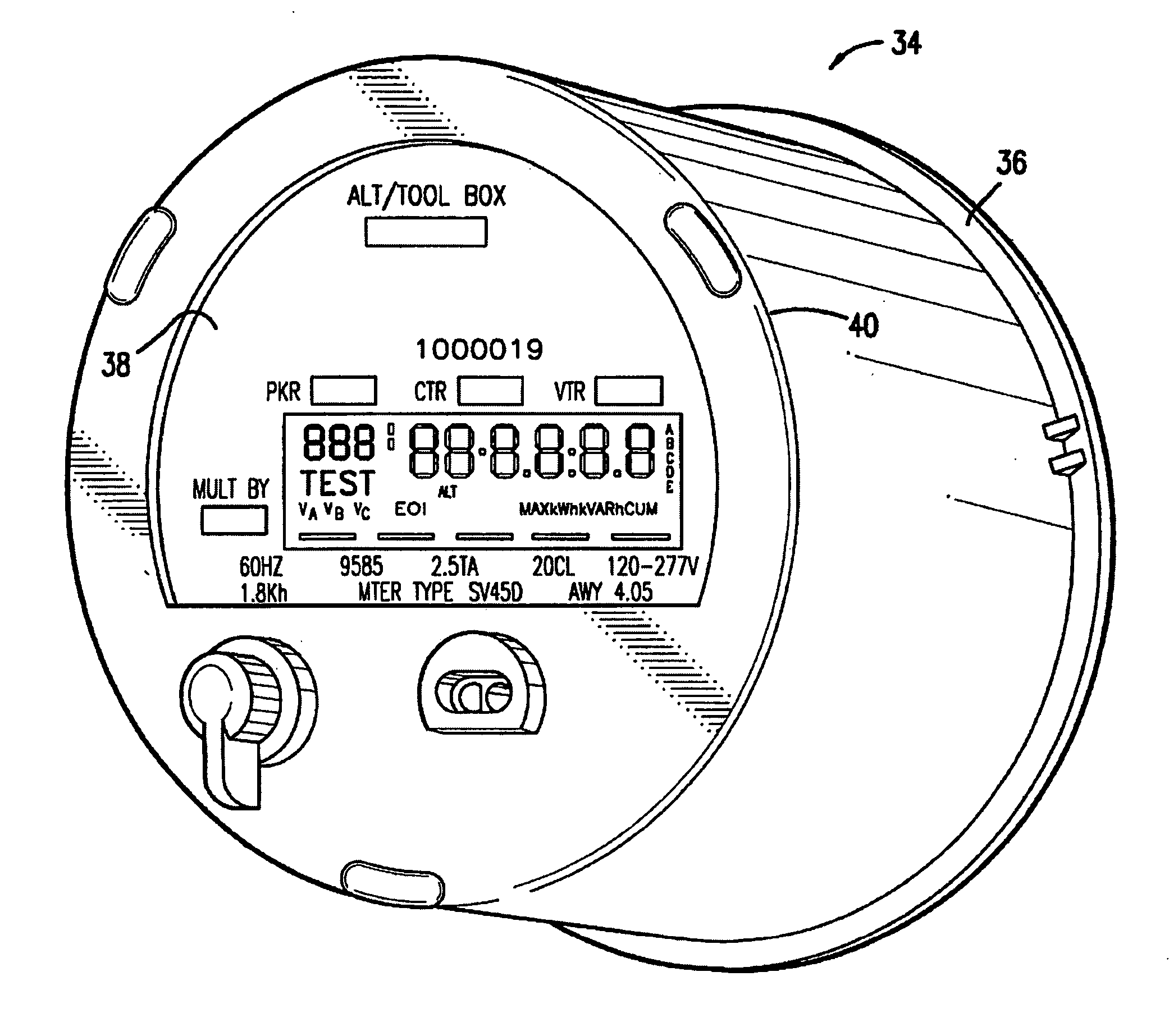

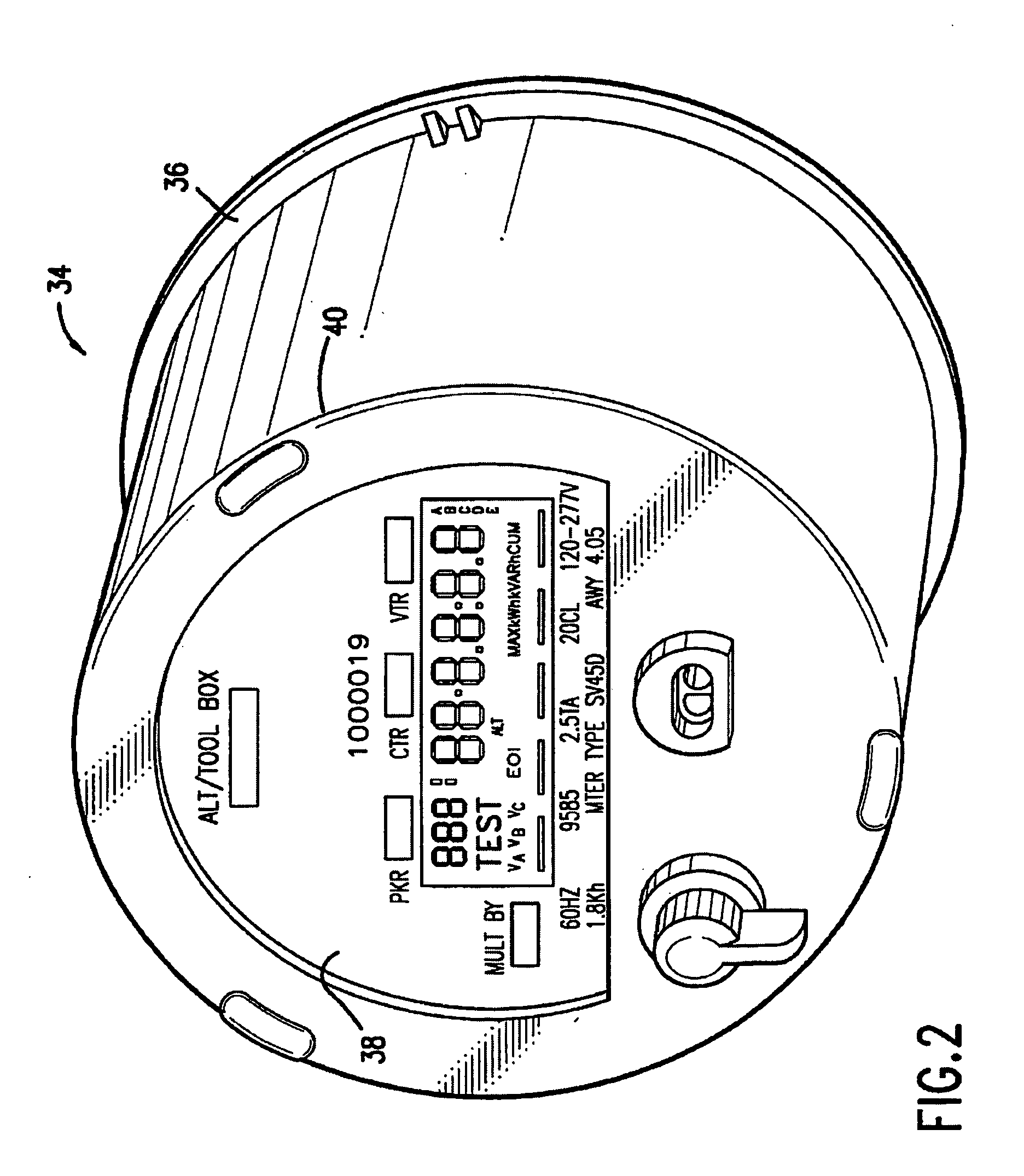

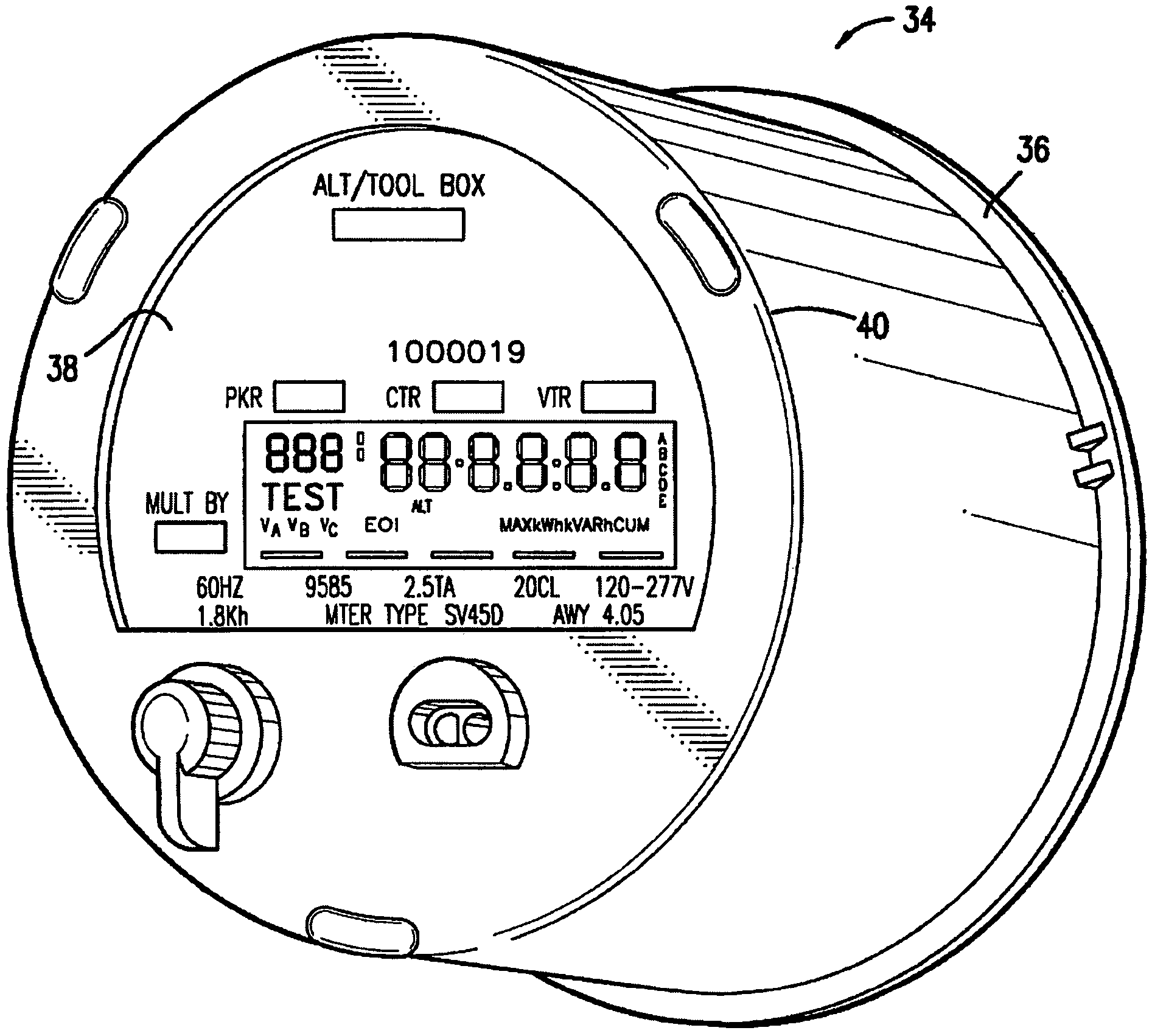

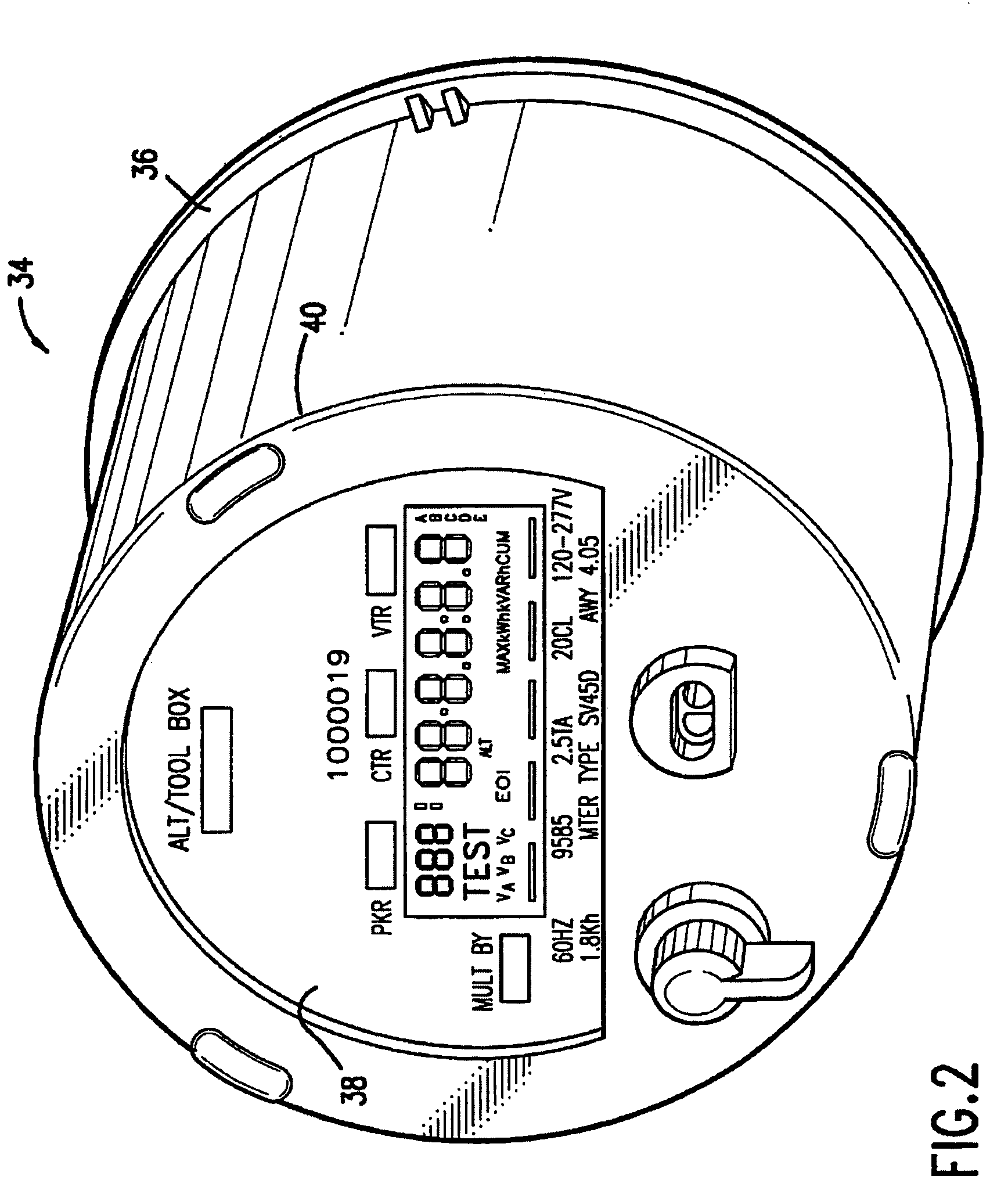

Electronic revenue meter with automatic service sensing

InactiveUS20050194962A1Data processing applicationsTariff metering apparatusElectricityDiagnostic data

An integral electronic revenue meter system diagnostics package including a microprocessor, storage memory, preselect series of system diagnostic tests, and recording any results which exceed predefined programmable thresholds, and display means for displaying error and / or diagnostic messages identifying selected diagnostic data and / or errors discovered in the meter tests during a predefined period is included as part of an electricity revenue meter of the type used for collecting metering data for a utility which uses such data for billing purposes. The system automatically senses the type of electrical service in which the revenue meter is installed when the revenue meter is installed in a socket at the customer's premises.

Owner:ITRON

Electronic revenue meter with automatic service sensing

An integral electronic revenue meter system diagnostics package including a microprocessor, storage memory, preselect series of system diagnostic tests, and recording any results which exceed predefined programmable thresholds, and display means for displaying error and / or diagnostic messages identifying selected diagnostic data and / or errors discovered in the meter tests during a predefined period is included as part of an electricity revenue meter of the type used for collecting metering data for a utility which uses such data for billing purposes. The system automatically senses the type of electrical service in which the revenue meter is installed when the revenue meter is installed in a socket at the customer's premises.

Owner:ITRON

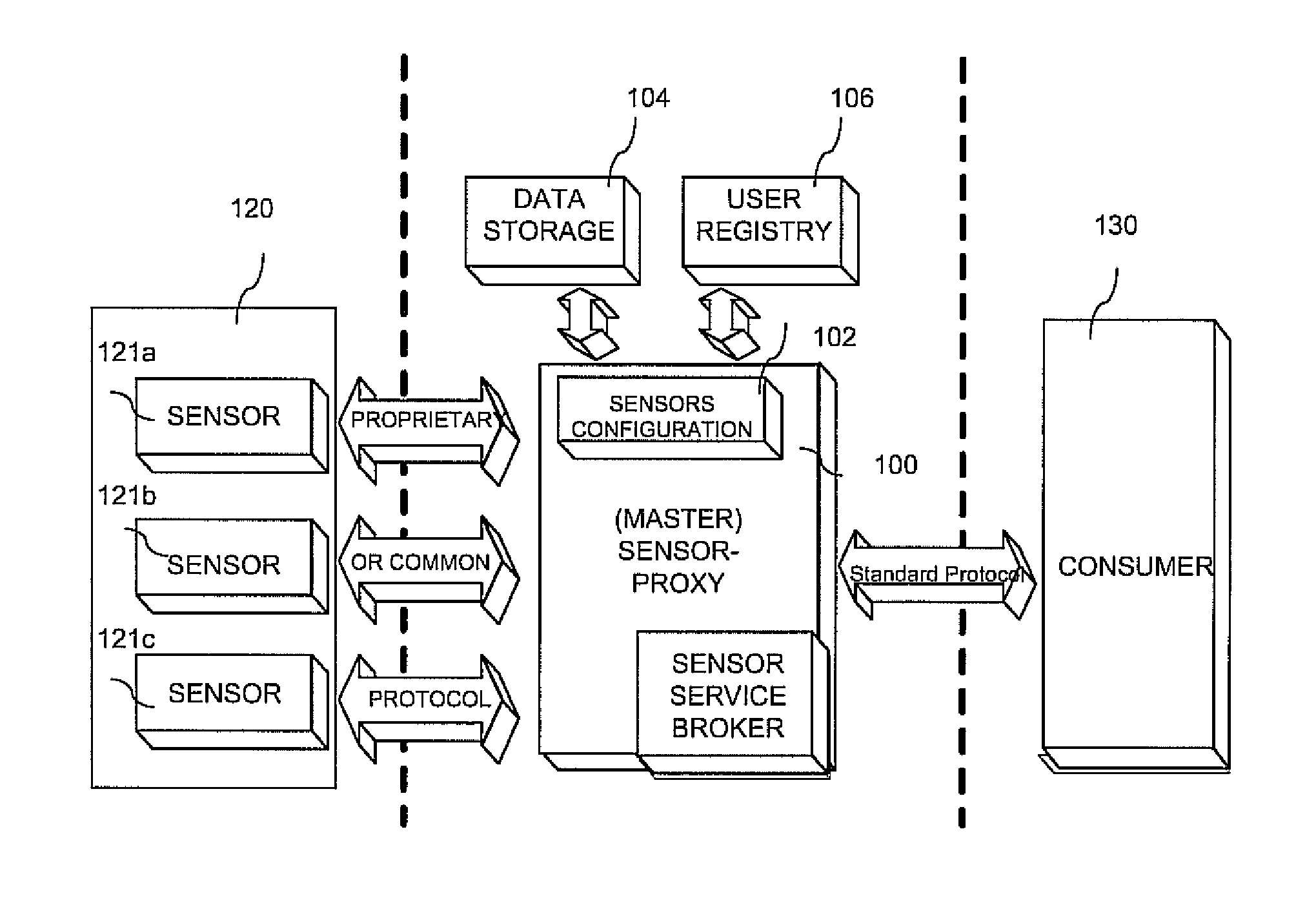

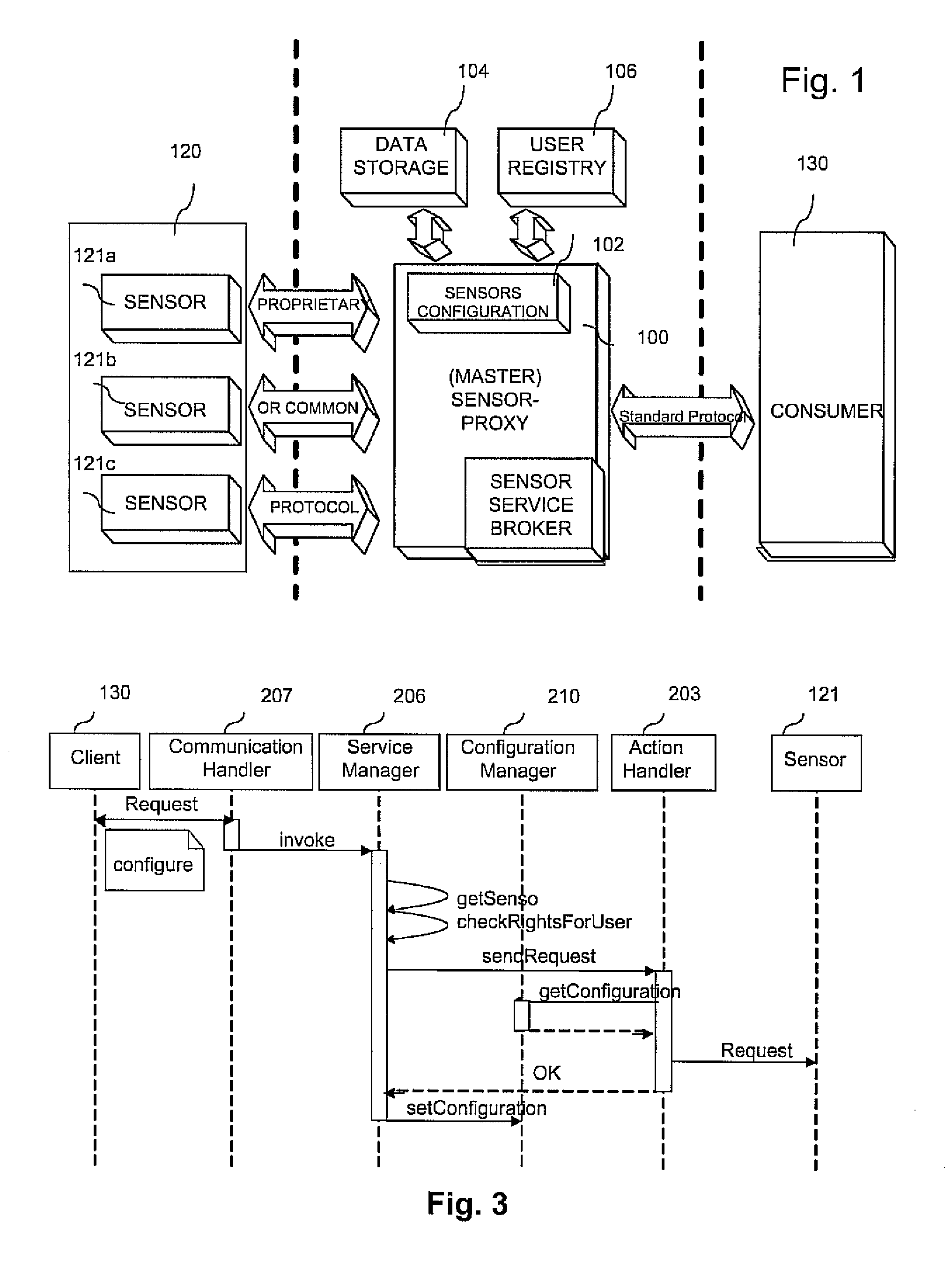

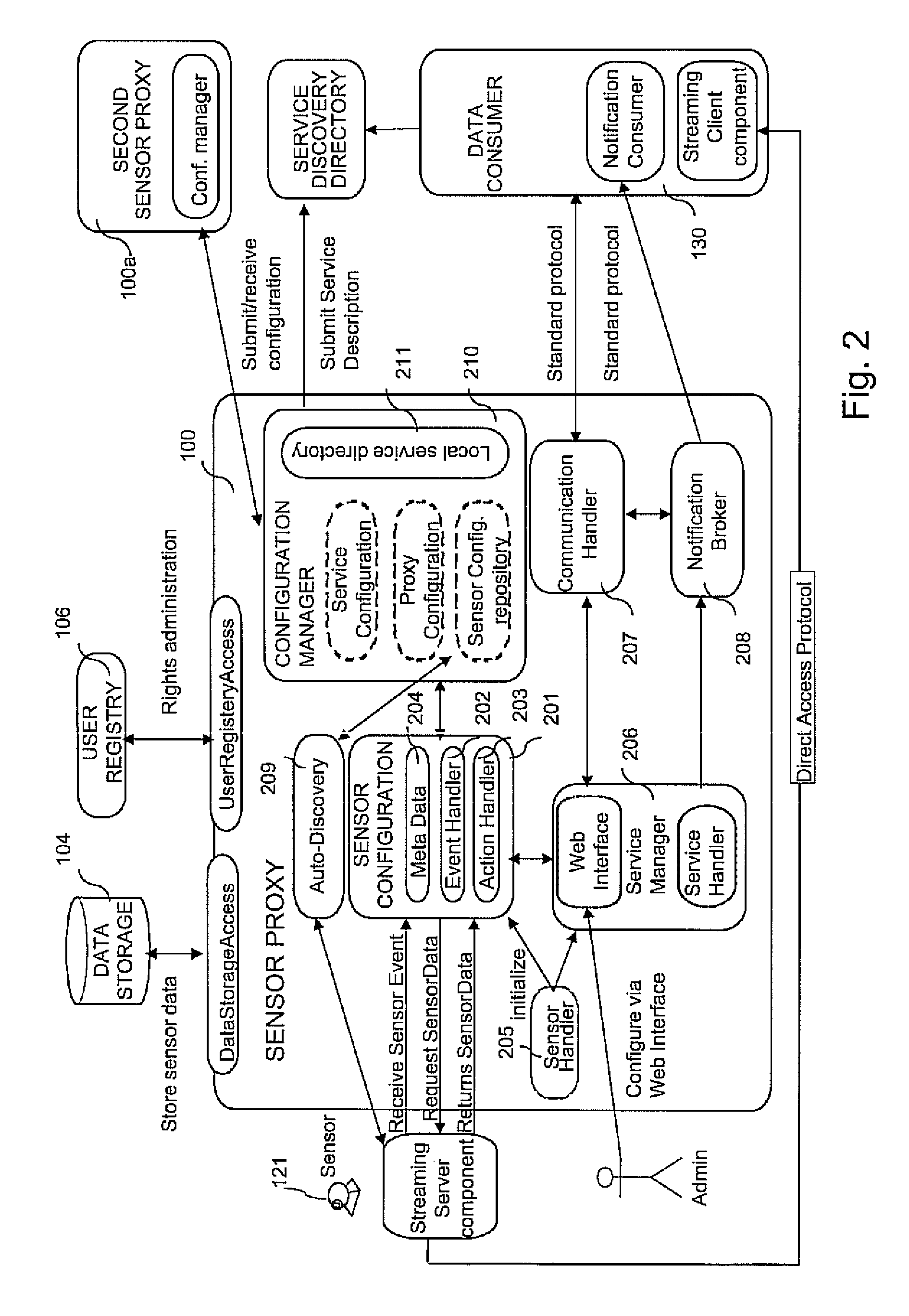

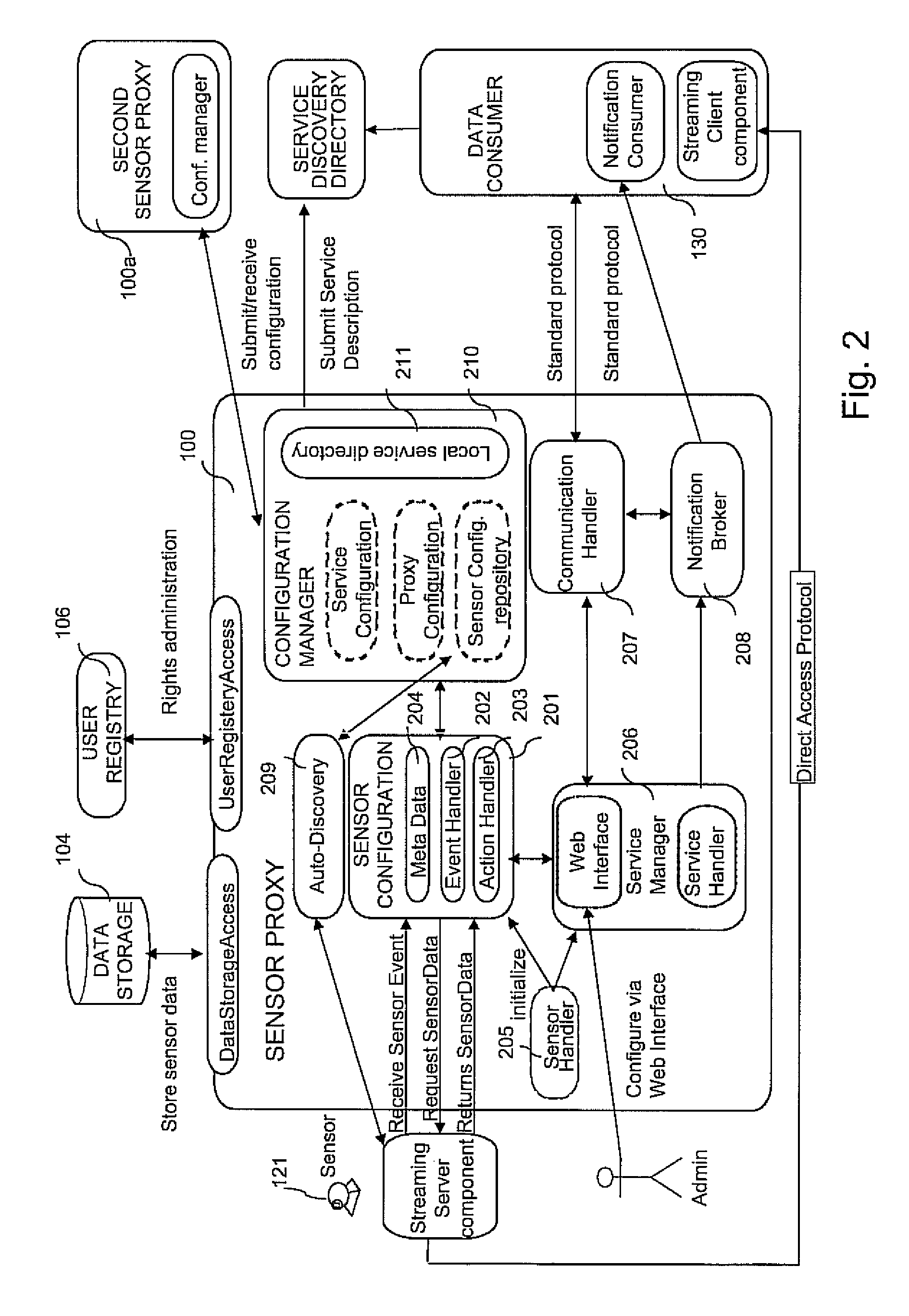

Sensor network controllers

A control element for a sensor network having a set of different sensors. In operation, the control element transfers connections between the control element and the set of different sensors, where the transfer connections are compliant with respective sensor-specific protocols. A sensor controller element is provided for each sensor, and establishes transfer connections between the control element and new sensors in runtime. Information obtained in a sensor-specific protocol format from the sensors is converted into a common format in the sensor controller elements. The common format information is processed by a set of common control components of the control element. The control element provides a service based on the information in the common format to at least one consumer, and updates the service in accordance with the sensors present in the sensor network.

Owner:INT BUSINESS MASCH CORP

Controller sensor networks

ActiveUS20080208367A1Electric controllersIgnition automatic controlEmbedded systemReliability engineering

A control element for a sensor network having a set of different sensors. In operation, the control element transfers connections between the control element and the set of different sensors, where the transfer connections are compliant with respective sensor-specific protocols. A sensor controller element is provided for each sensor, and establishes transfer connections between the control element and new sensors in runtime. Information obtained in a sensor-specific protocol format from the sensors is converted into a common format in the sensor controller elements. The common format information is processed by a set of common control components of the control element. The control element provides a service based on the information in the common format to at least one consumer, and updates the service in accordance with the sensors present in the sensor network.

Owner:IBM CORP

Sensor

ActiveUS20110153277A1Small tolerance limitSmall toleranceMeasurement apparatus componentsError detection/correctionElectrical and Electronics engineering

A sensor for measuring any desired variable, with the sensor having a sensor housing with a specimen feed and with at least two measured value pick-ups and at least two processing units being arranged redundantly respectively pairwise with respect to one another and / or diversely in the sensor housing.

Owner:LIEBHERR WERK EHINGEN

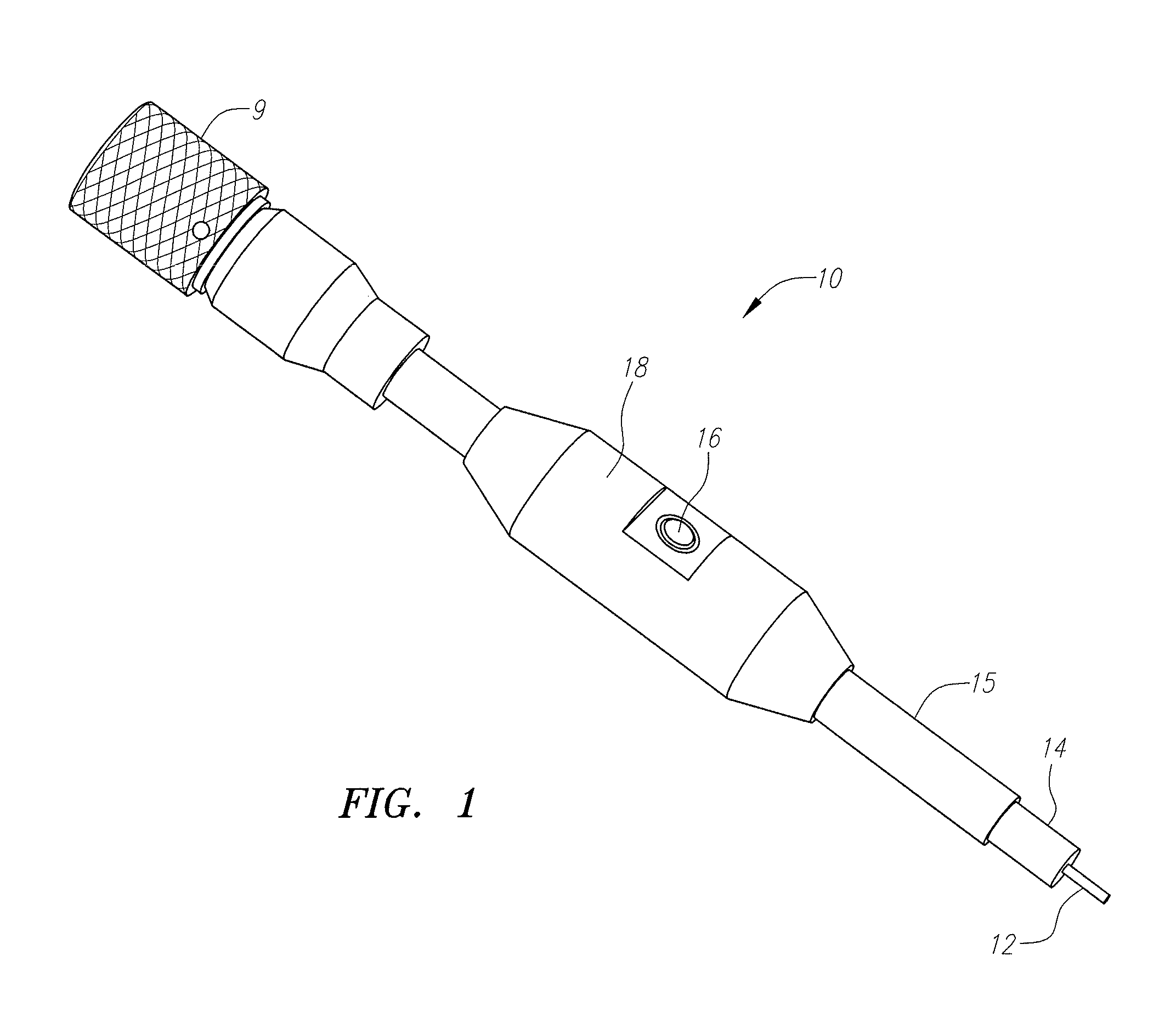

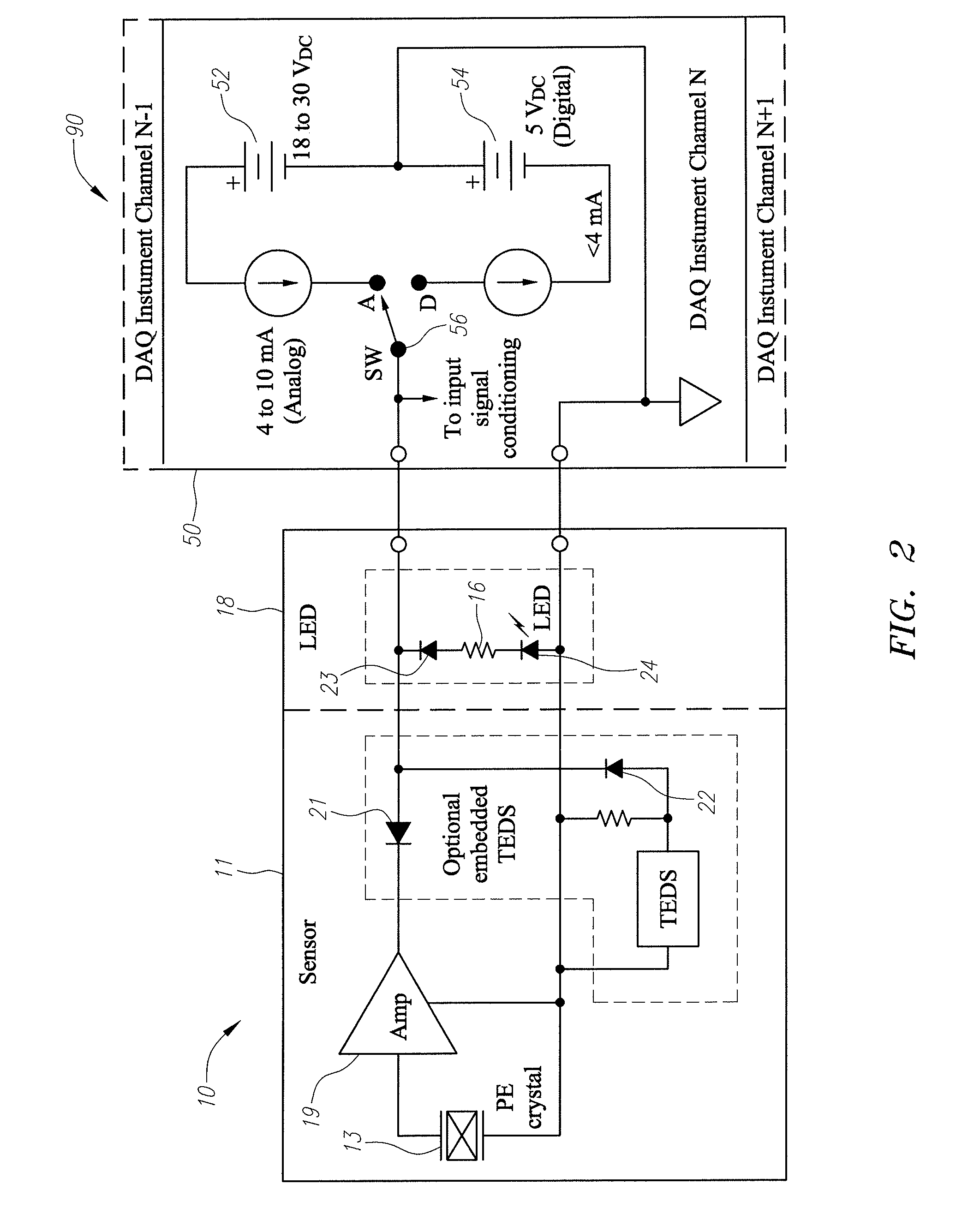

Cable with LED connection indicator and methods of using same

InactiveUS20140210631A1Ease interconnection verificationCurrent/voltage measurementCoupling device detailsElectricityEngineering

An interconnection verification means for sensors and a software implementation of interconnection verification between cabling and sensors in large, multi-channel test configurations are disclosed. In a preferred embodiment the sensor assembly comprises a sensor and an indicator electrically connected inline with the sensor. In a preferred embodiment the indicator is an LED. In an even more preferred embodiment, the sensor is an IEPE.

Owner:PCB PIEZOTRONICS OF NORTH CAROLINA

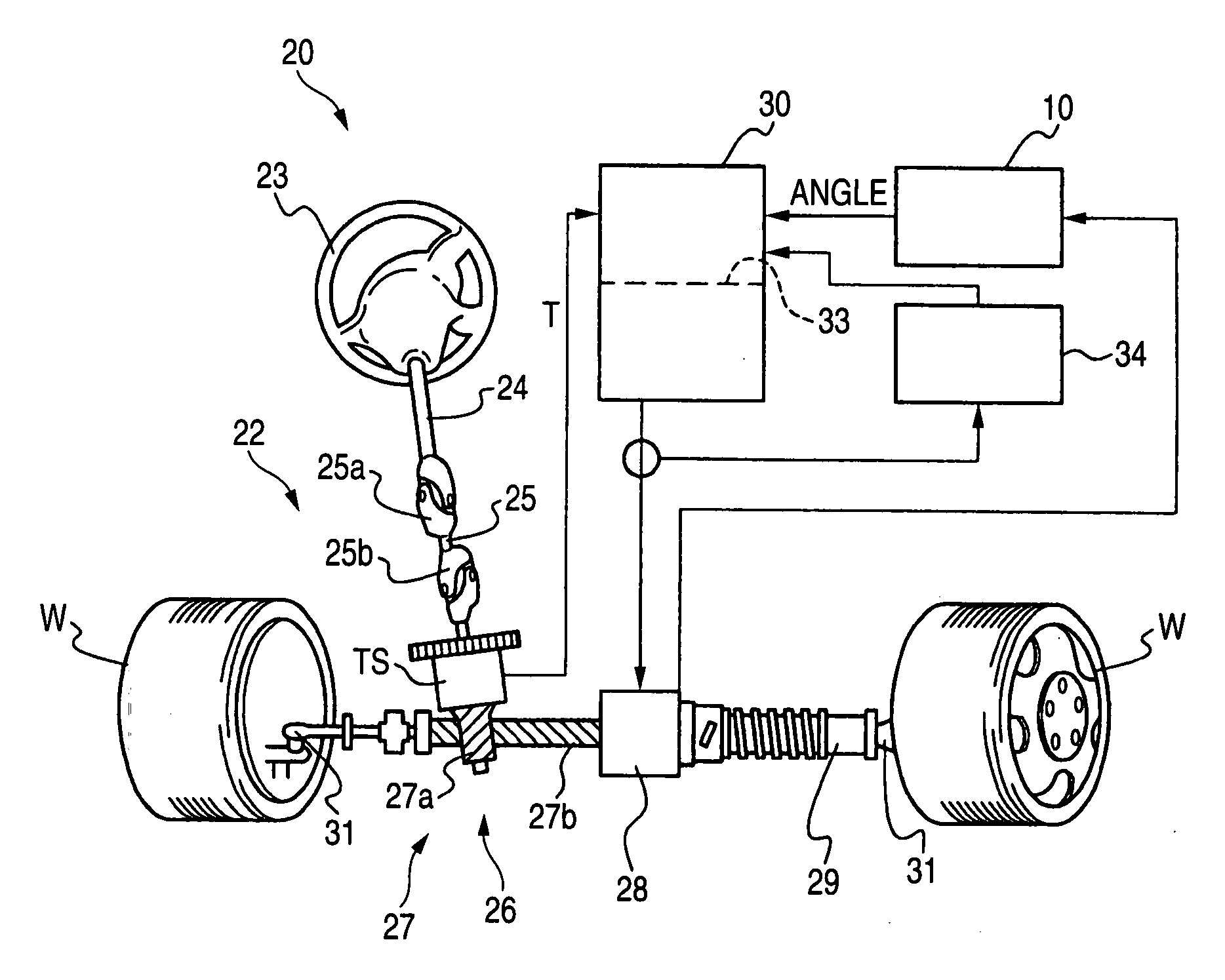

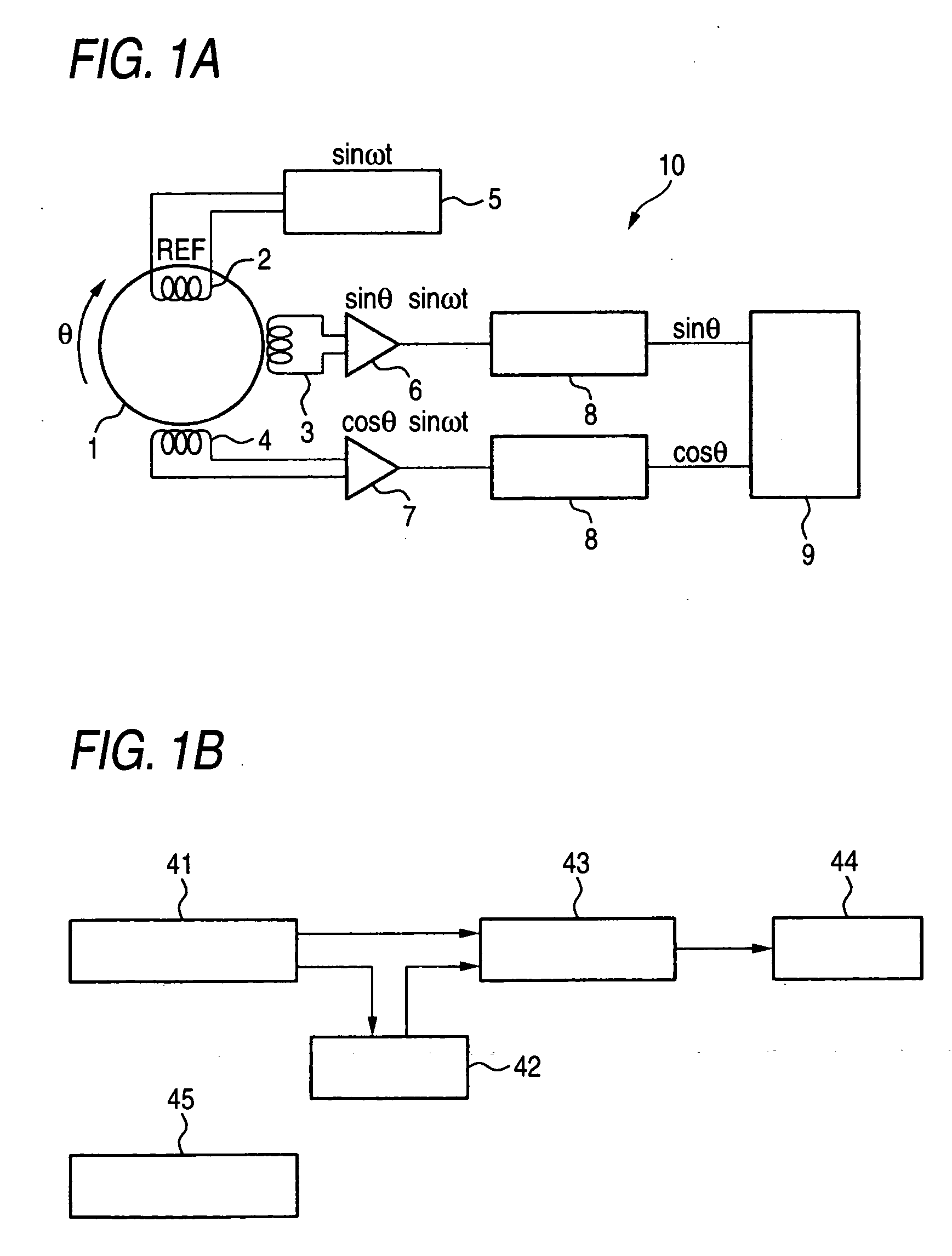

Rotation angle detection device and electric power steering apparatus employing the same

InactiveUS20060288800A1Enhance manual steering torqueReduce dependenceDC motor speed/torque controlAC motor controlElectric power steeringClassical mechanics

The rotation angle detection device detects the rotation angle of a rotary member by employing, at the least, either a sine wave signal or a cosine wave signal that is generated as the rotary member is rotated, and employs a change per unit time in the sine wave signal or cosine wave signal to determine whether an output abnormality has occurred in the rotation angle detection device. Further, this rotation angle device is employed to detect the motor angle of an electric power steering apparatus.

Owner:HONDA MOTOR CO LTD

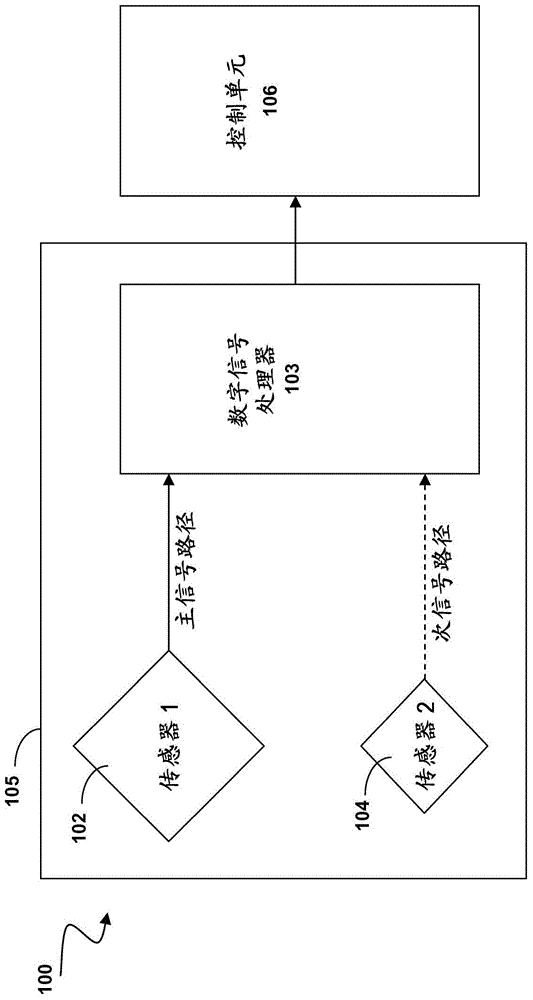

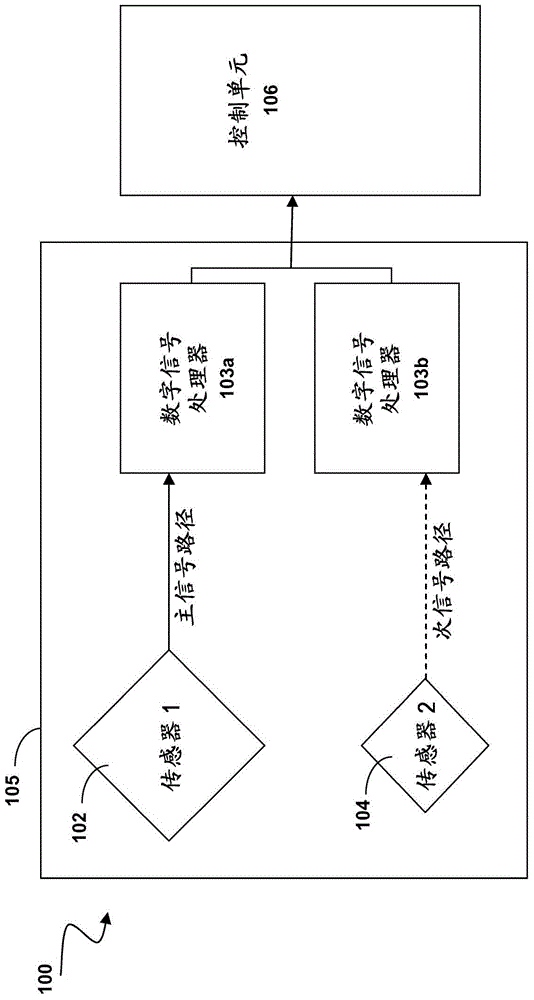

Sensor self-diagnosis using multiple signal paths

Embodiments relate to systems and methods for self-diagnosis and / or false detection using multiple signal paths in sensor and other systems. In one embodiment, a sensor system comprises at least two sensors such as magnetic field sensors, and separate signal paths which belong to each of the sensors. A first signal path can be coupled to a first sensor and a first digital signal processor (DSP), and a second signal path can be coupled to a second sensor and a second digital signal processor. A signal from the first digital signal processor can be compared with a signal from the second digital signal processor either on-chip or off-chip to detect defects, errors, and other information in connection with the operation of the sensor system. Embodiments of these systems and / or methods can be configured to satisfy or exceed relevant safety or other industry standards, such as safety integrity level (SIL) standards.

Owner:INFINEON TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com