Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

92results about "Magazine/cassette manufacturing apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

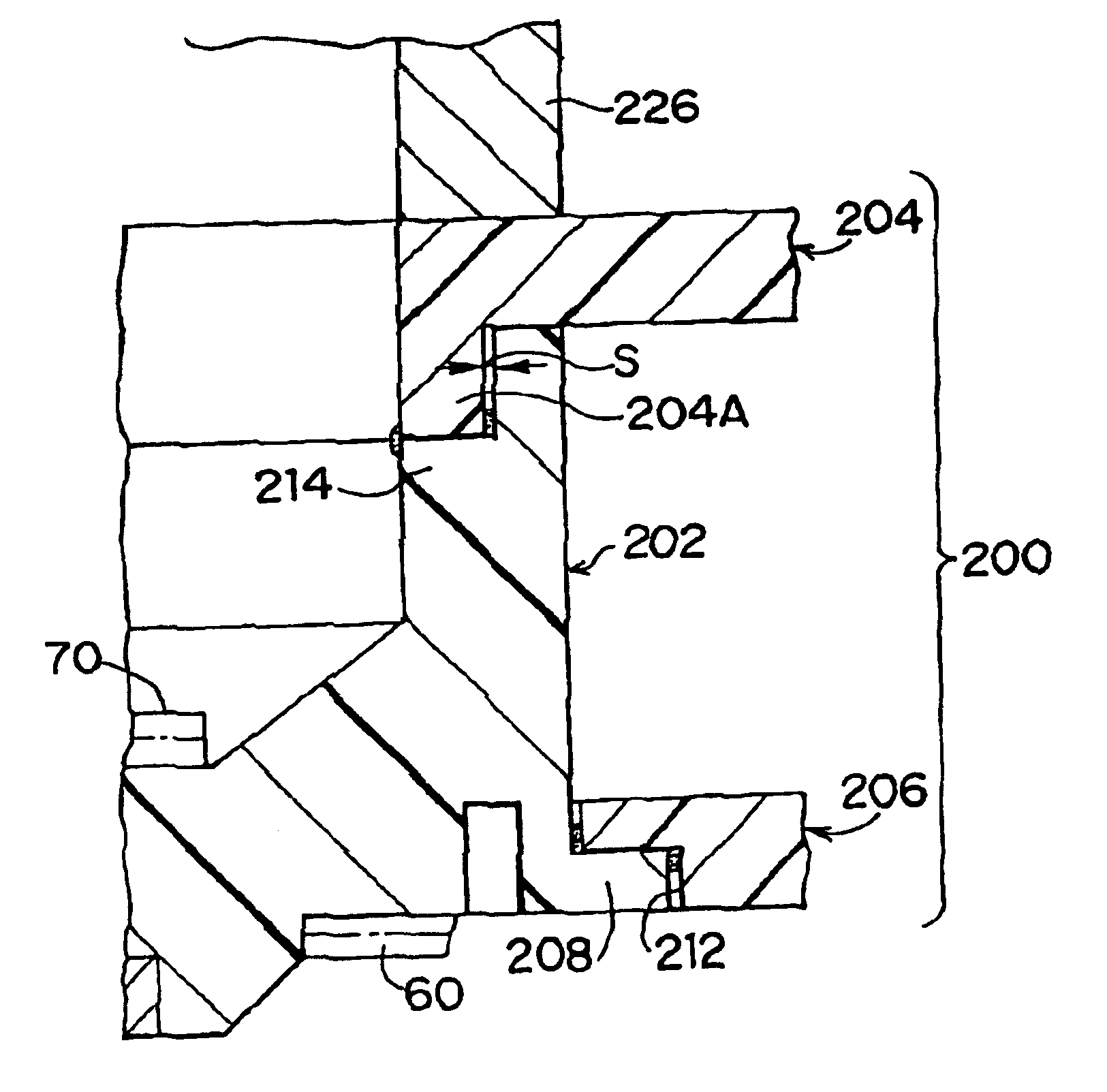

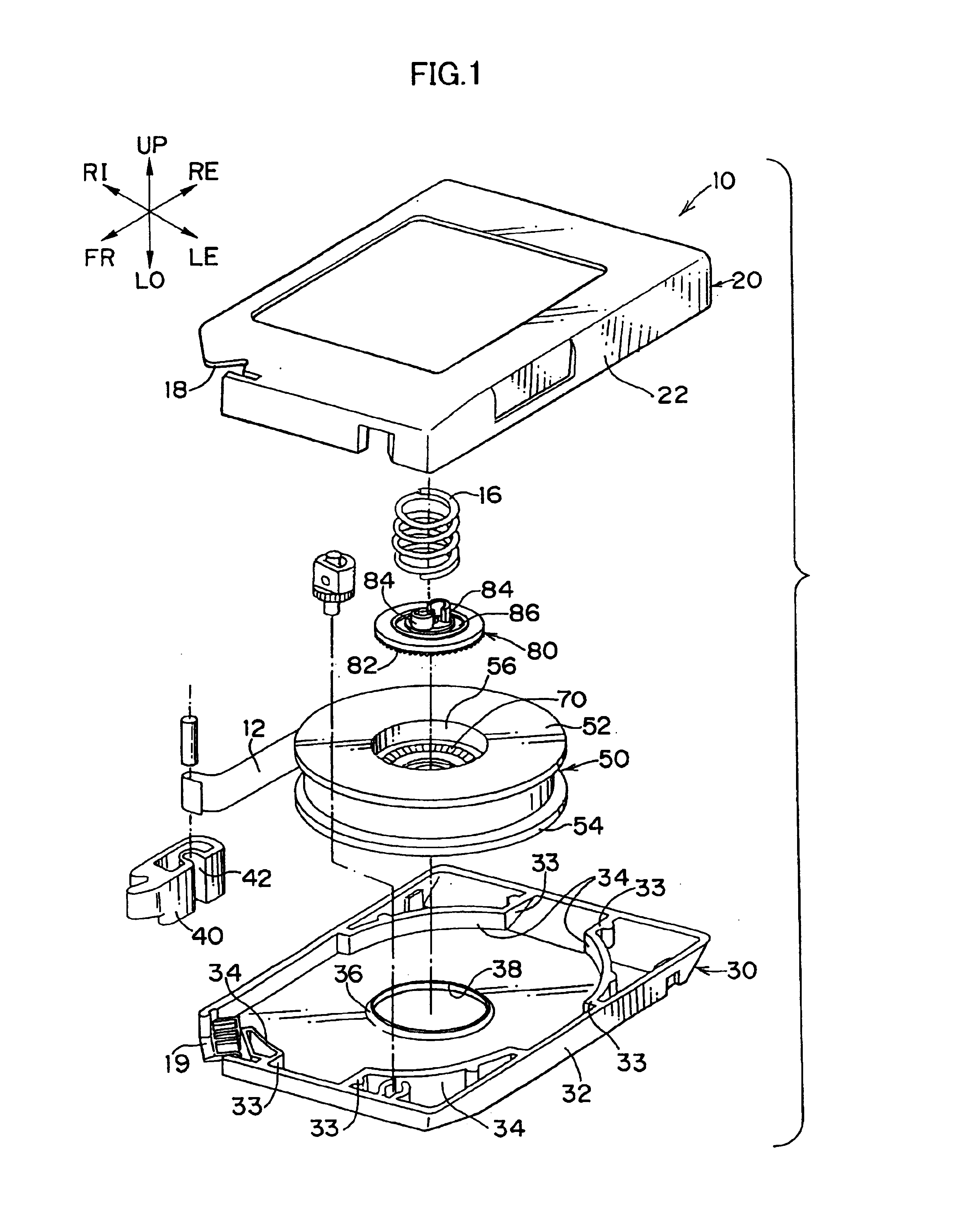

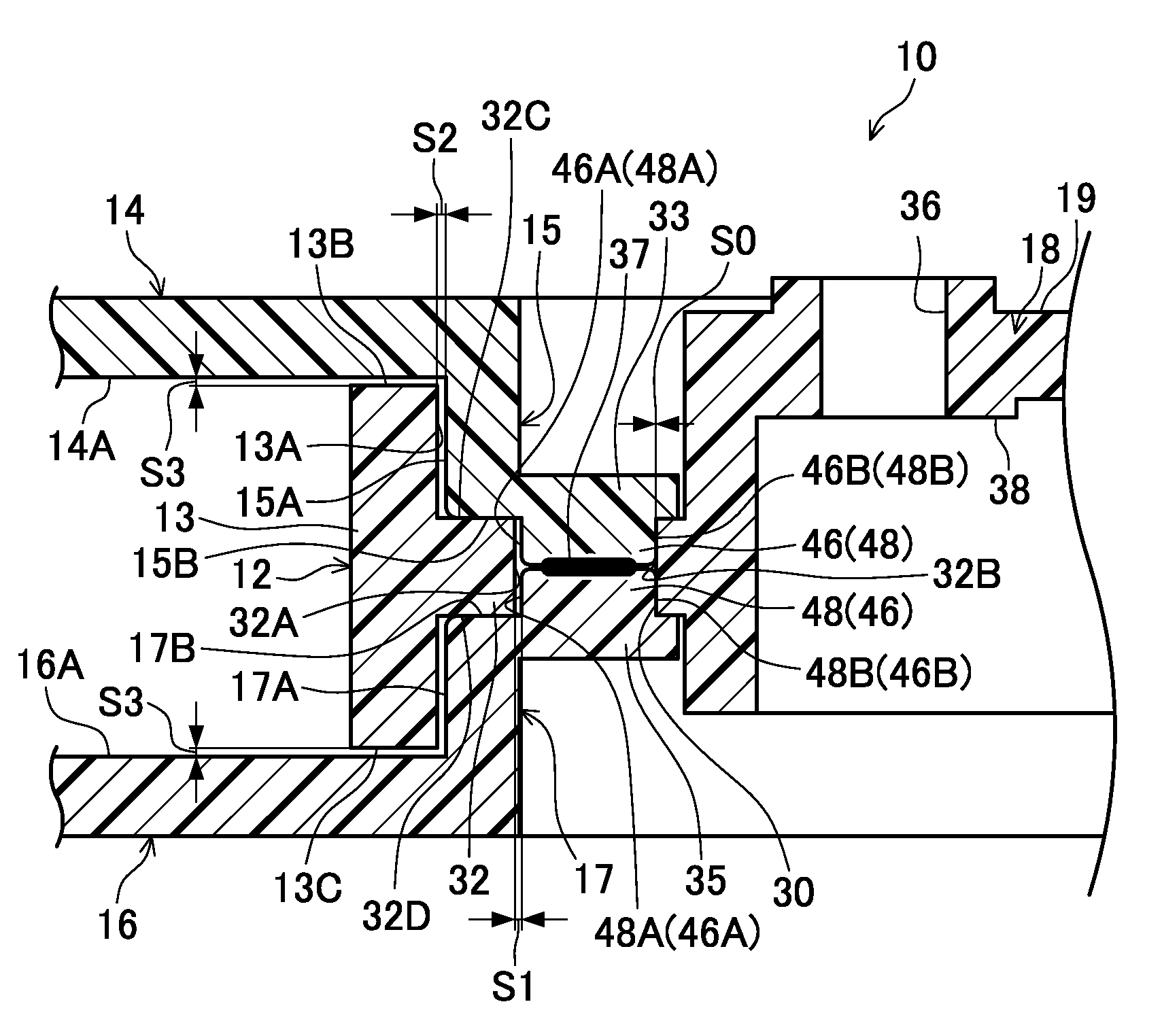

Recording tape cartridge

InactiveUS6913219B2Highly flat flangeImprove breaking capacityPicture changing apparatusRecord information storageEngineeringMetal mold

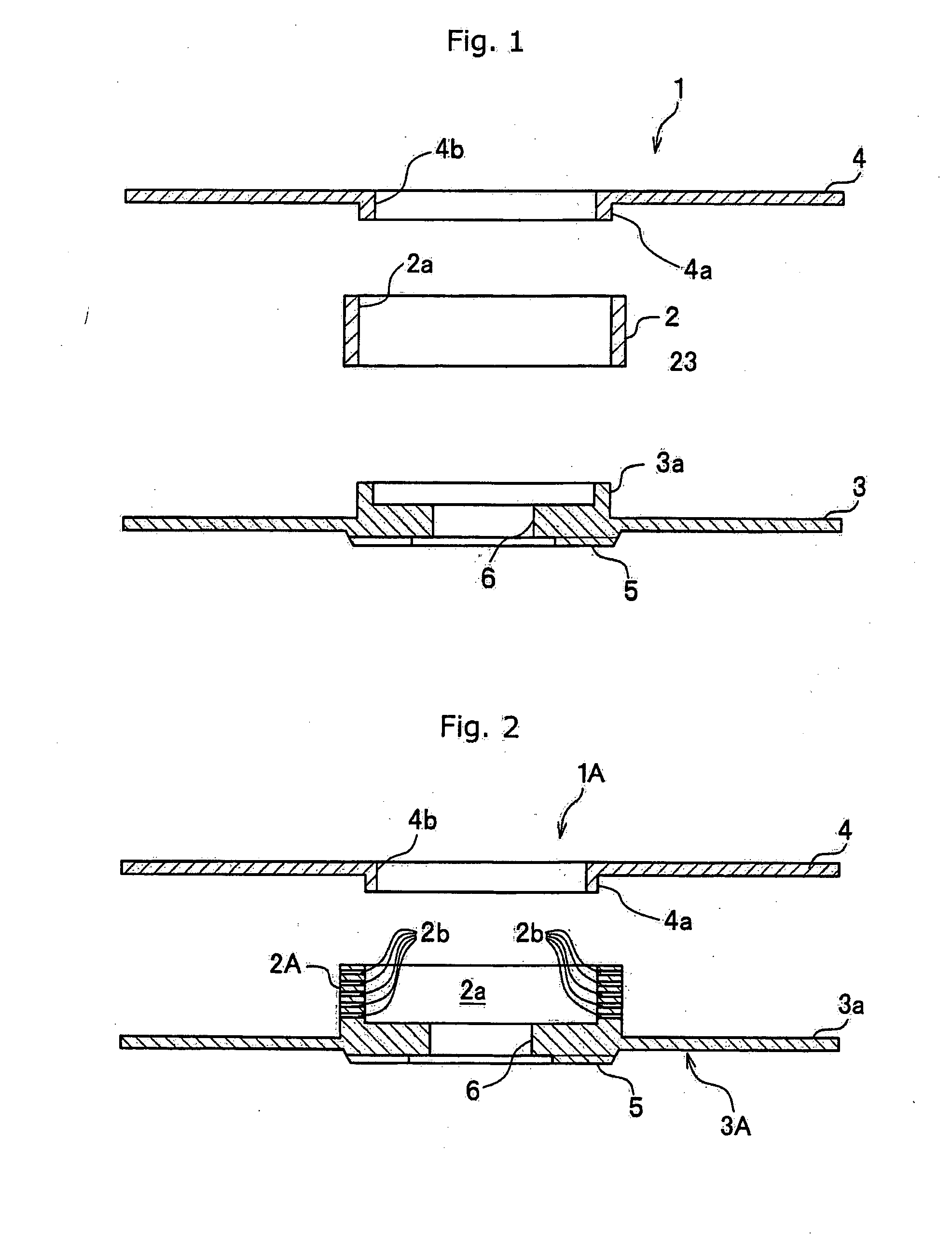

A metal plate of a recording tape cartridge is provided with a tapered portion at an outer circumference thereof. In a state in which the metal plate is attached at a fixed-side mold plate of a metal mold for molding a reel hub and a lower flange, a gap is formed between the tapered portion and the fixed-side mold plate. During molding, molding material flows into the gap. Because of this gap, an annular pawl portion is formed at the reel hub, which annular pawl portion integrally joins the metal plate with the reel hub by sandwiching the metal plate via the tapered portion.

Owner:FUJIFILM CORP

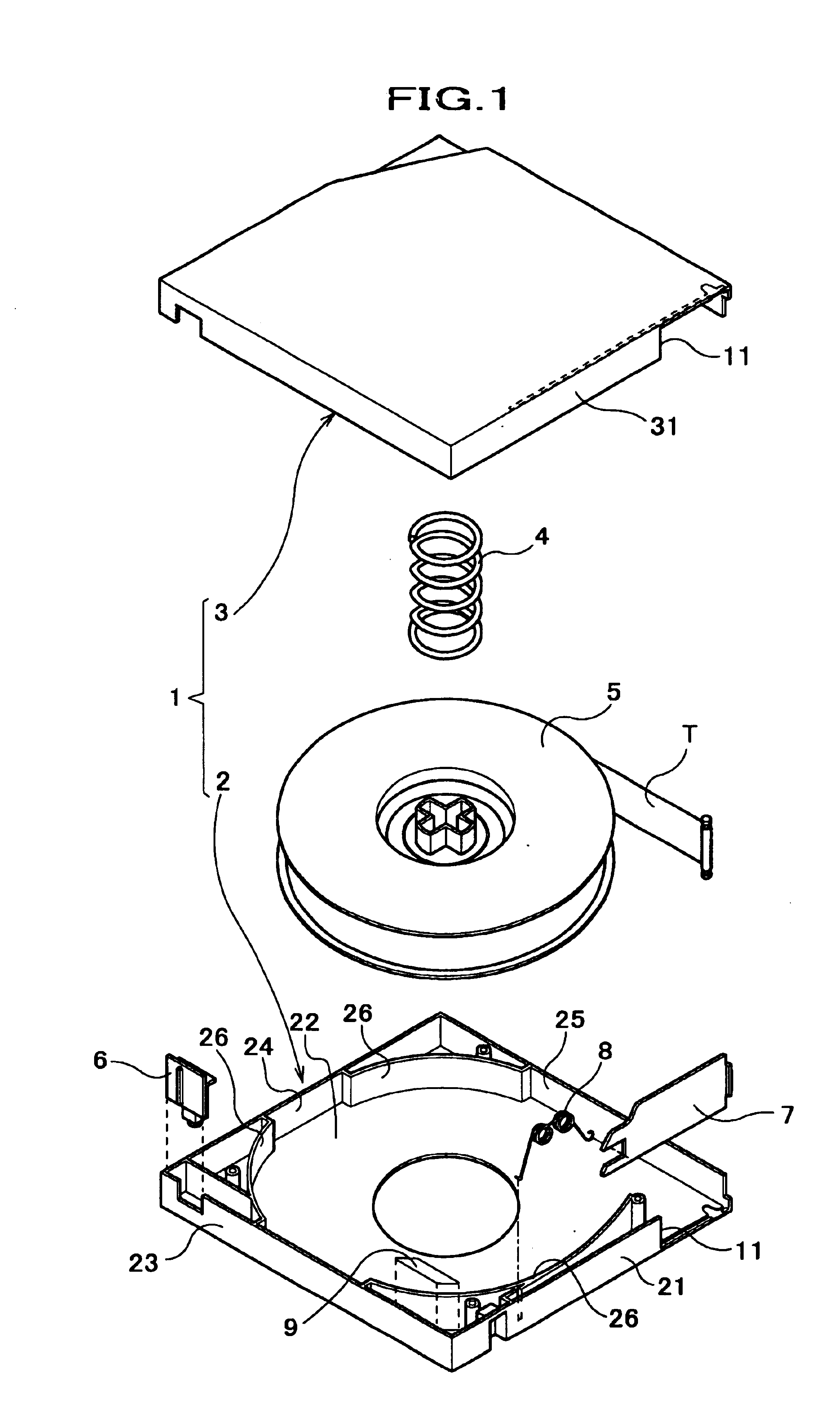

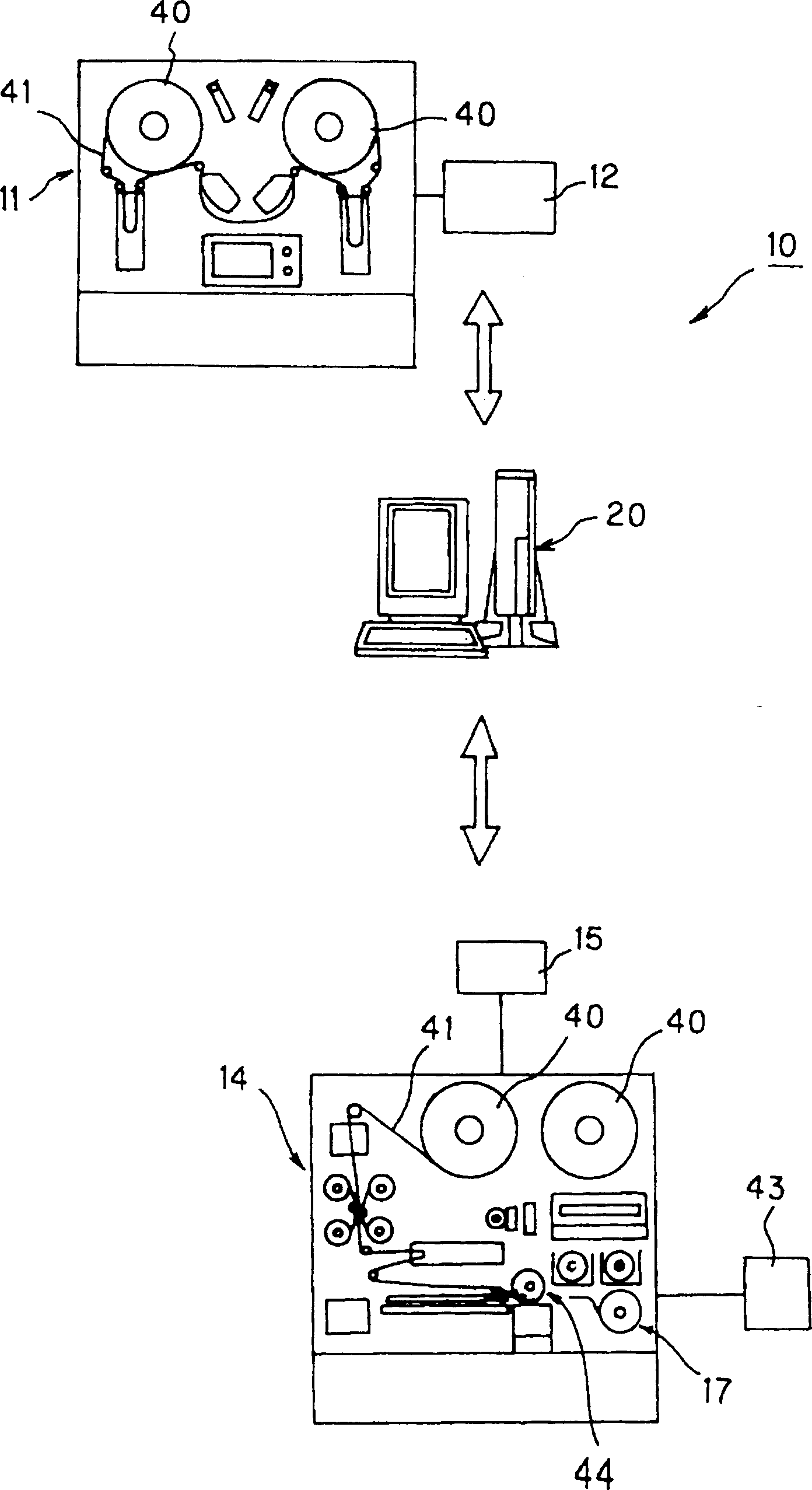

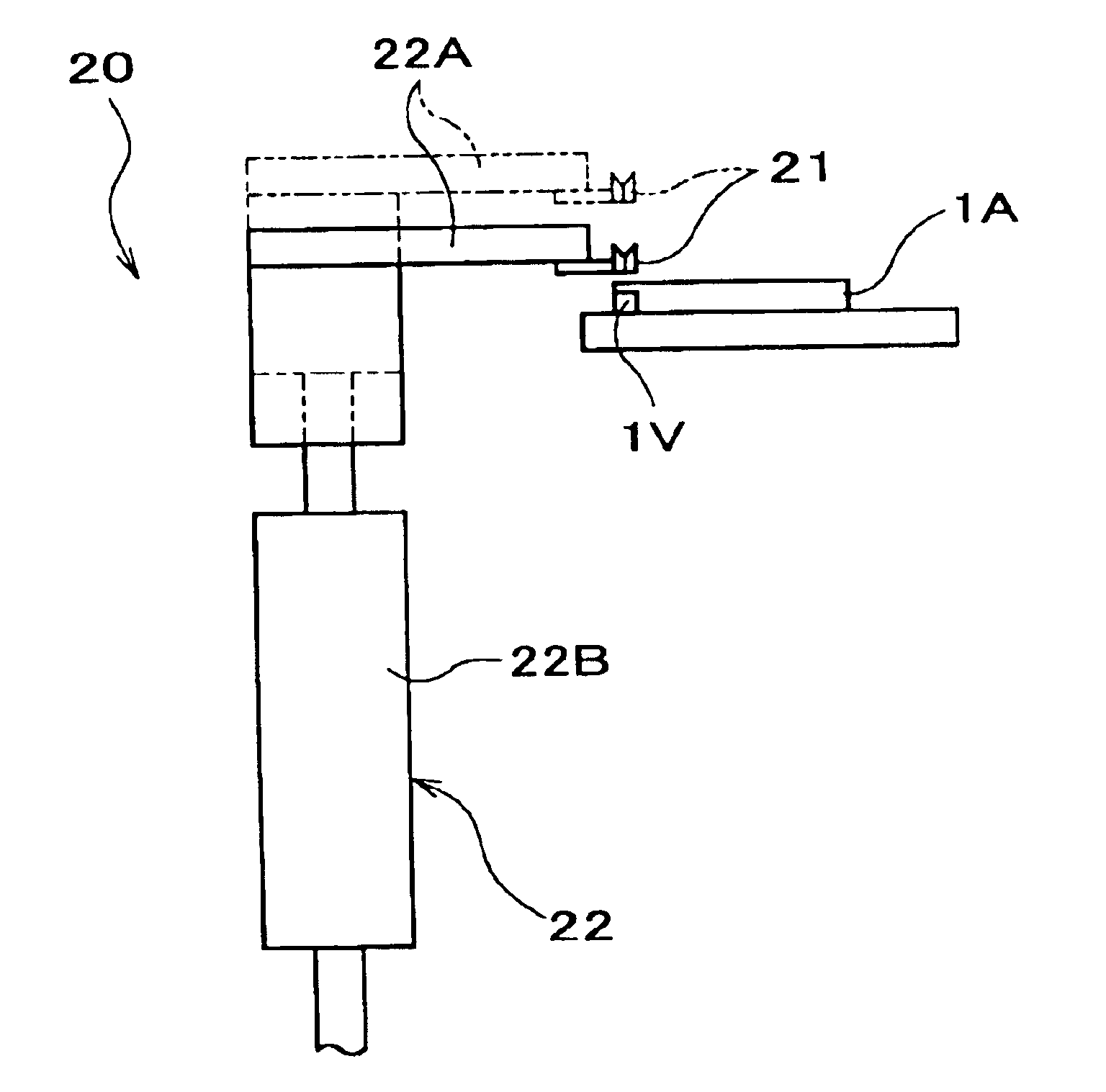

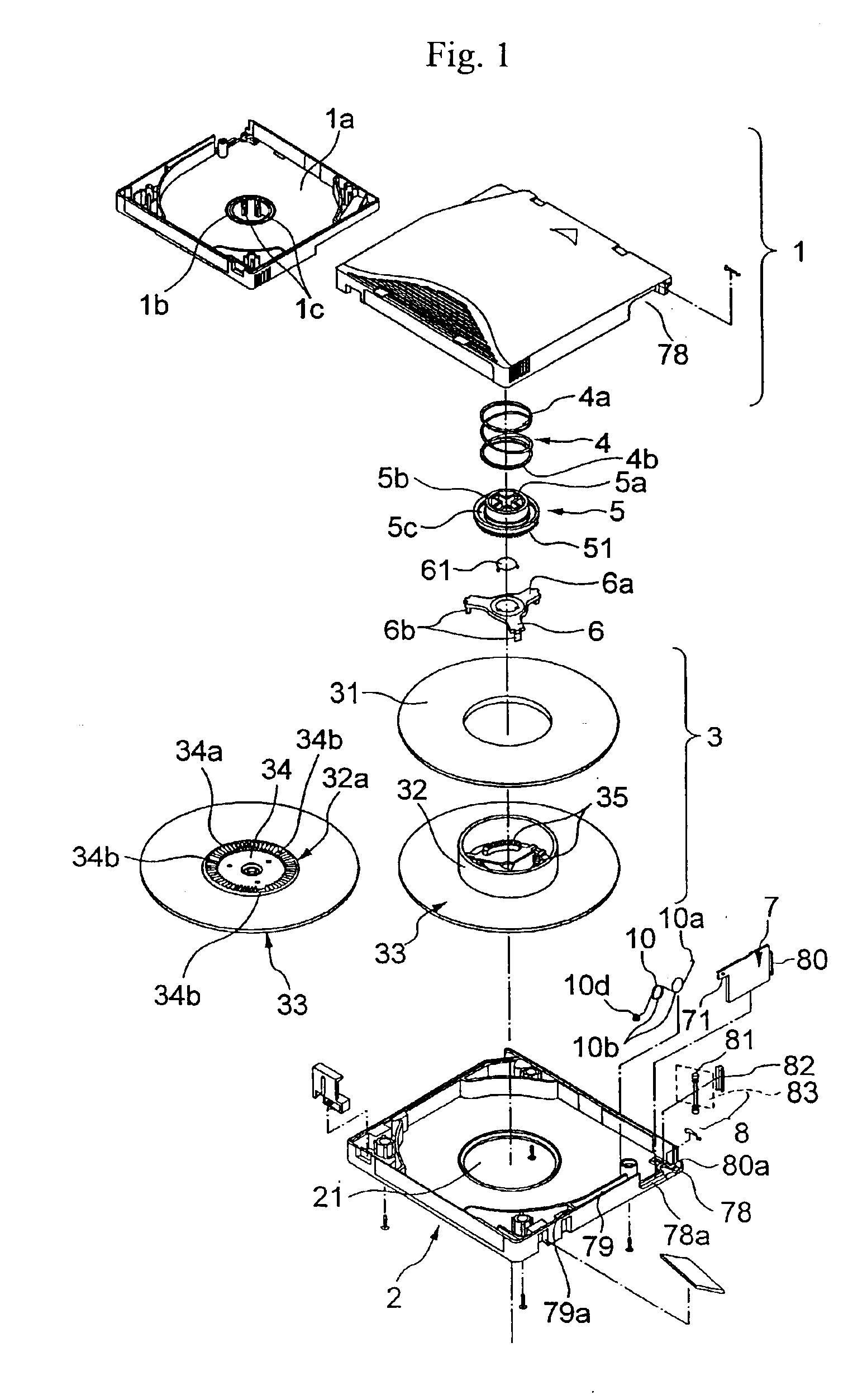

Method of and apparatus for sticking tape on reel hub and method of and apparatus for winding tape on tape reel in tape cartridge

InactiveUS20070262189A1High yield rateSufficiently spreadRecord information storageMagazine/cassette manufacturing apparatusEngineeringElectrical and Electronics engineering

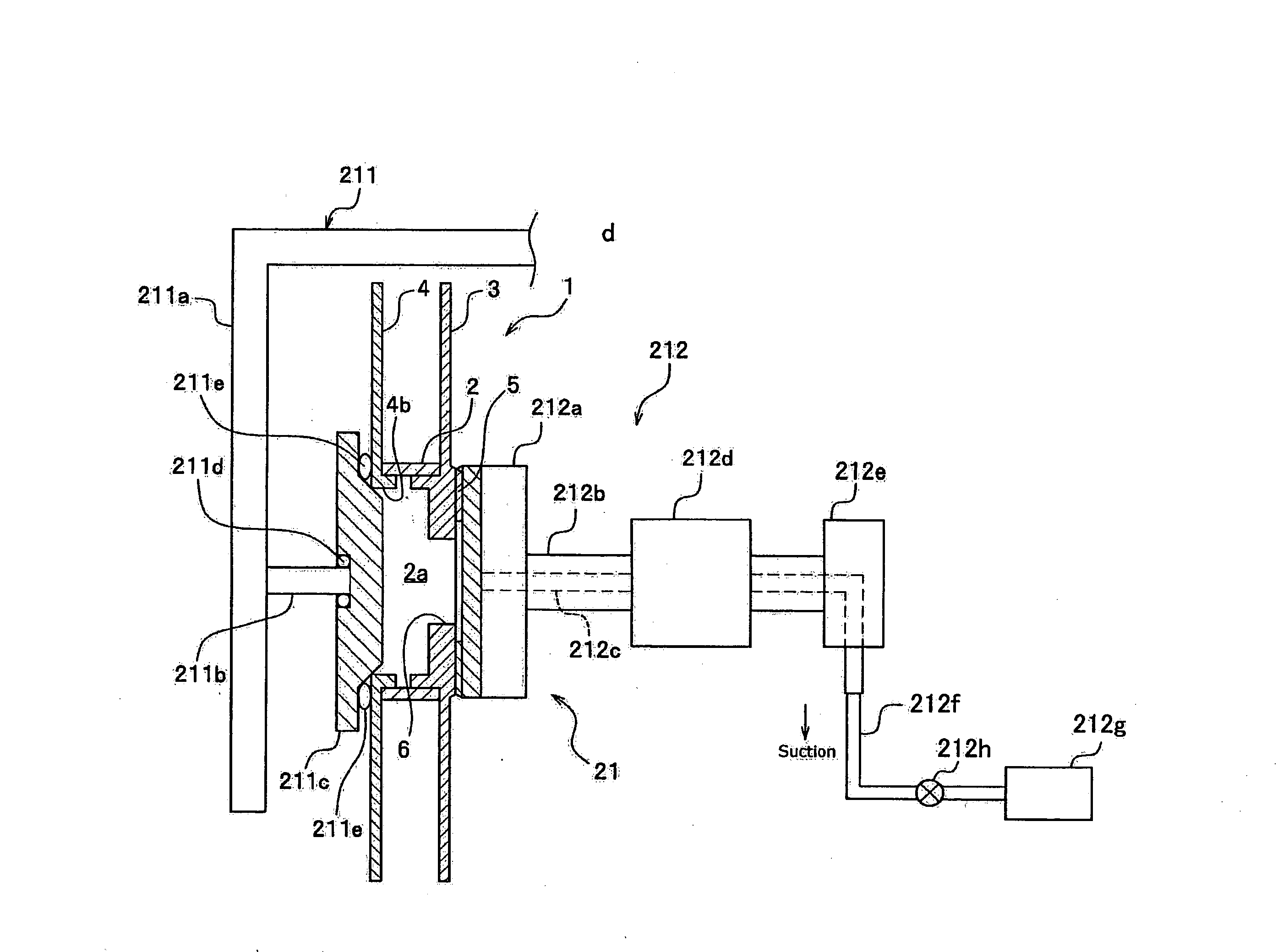

A tape end sticking apparatus sticking a tape end of a tape strip on a reel hub of a tape reel installed in a cartridge case having an egress / ingress opening before winding the tape strip onto the reel hub is described. The tape end sticking apparatus includes a tape carrier for grasping a tape end portion and bringing the tape end portion in close proximity to the reel hub which is movable into and out from a tape cartridge case through a cartridge opening and a liquid applying device for applying a sticking liquid to the reel hub and / or the tape end portion in a spread pattern having a width smaller at a remotest end than a foremost end thereof when the tape end sticking apparatus brings the tape end portion in close proximity to the reel hub.

Owner:FUJIFILM CORP

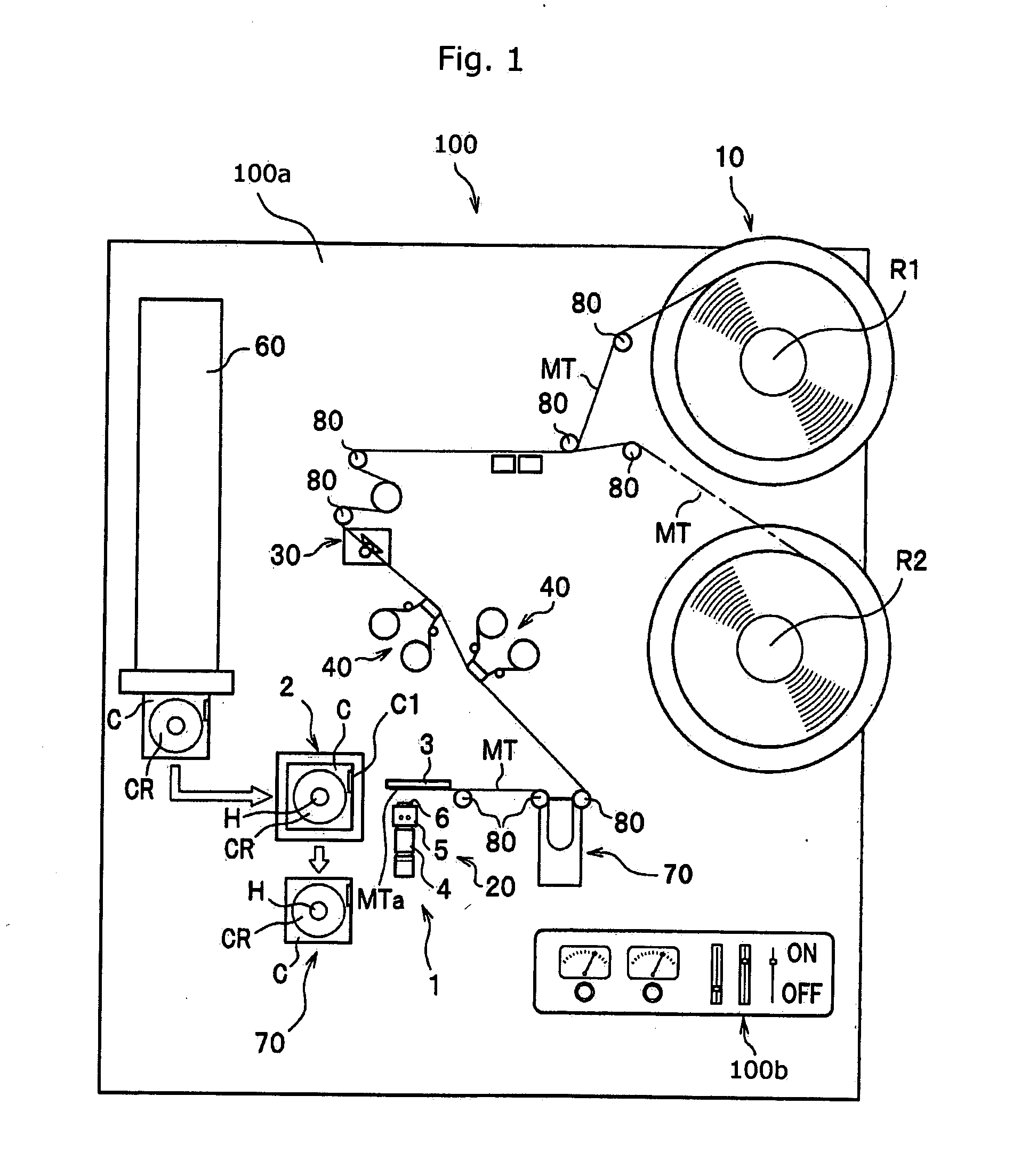

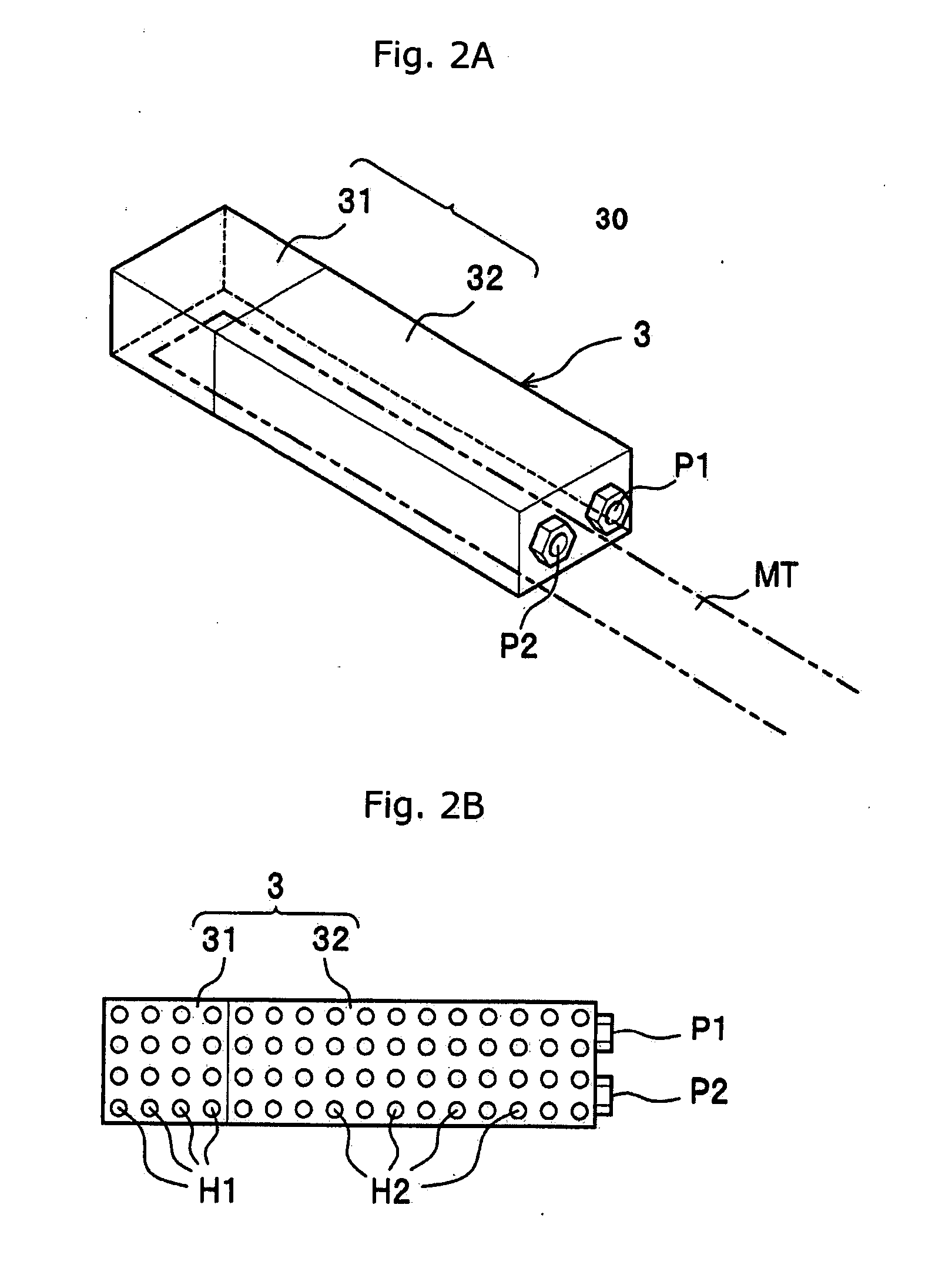

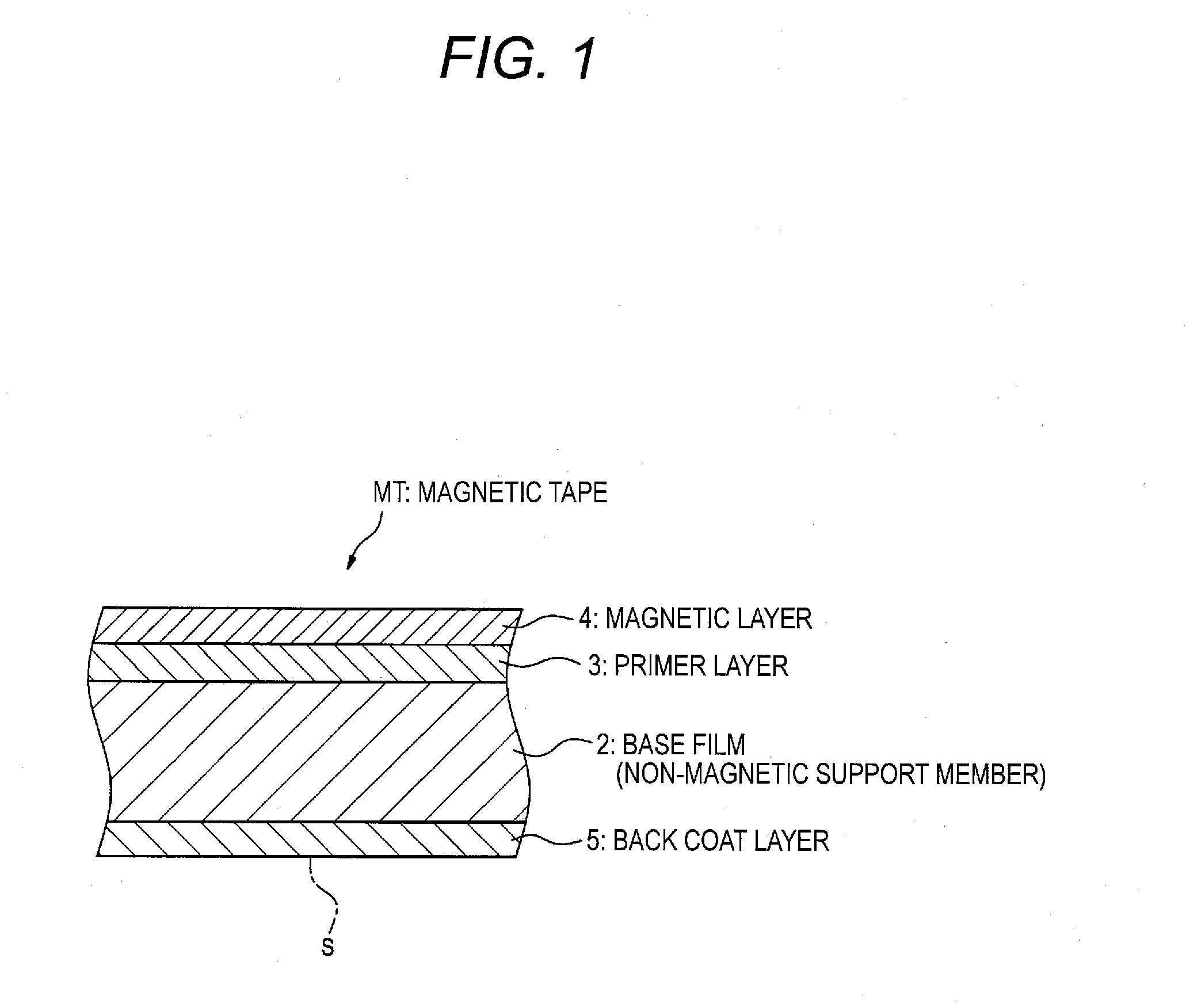

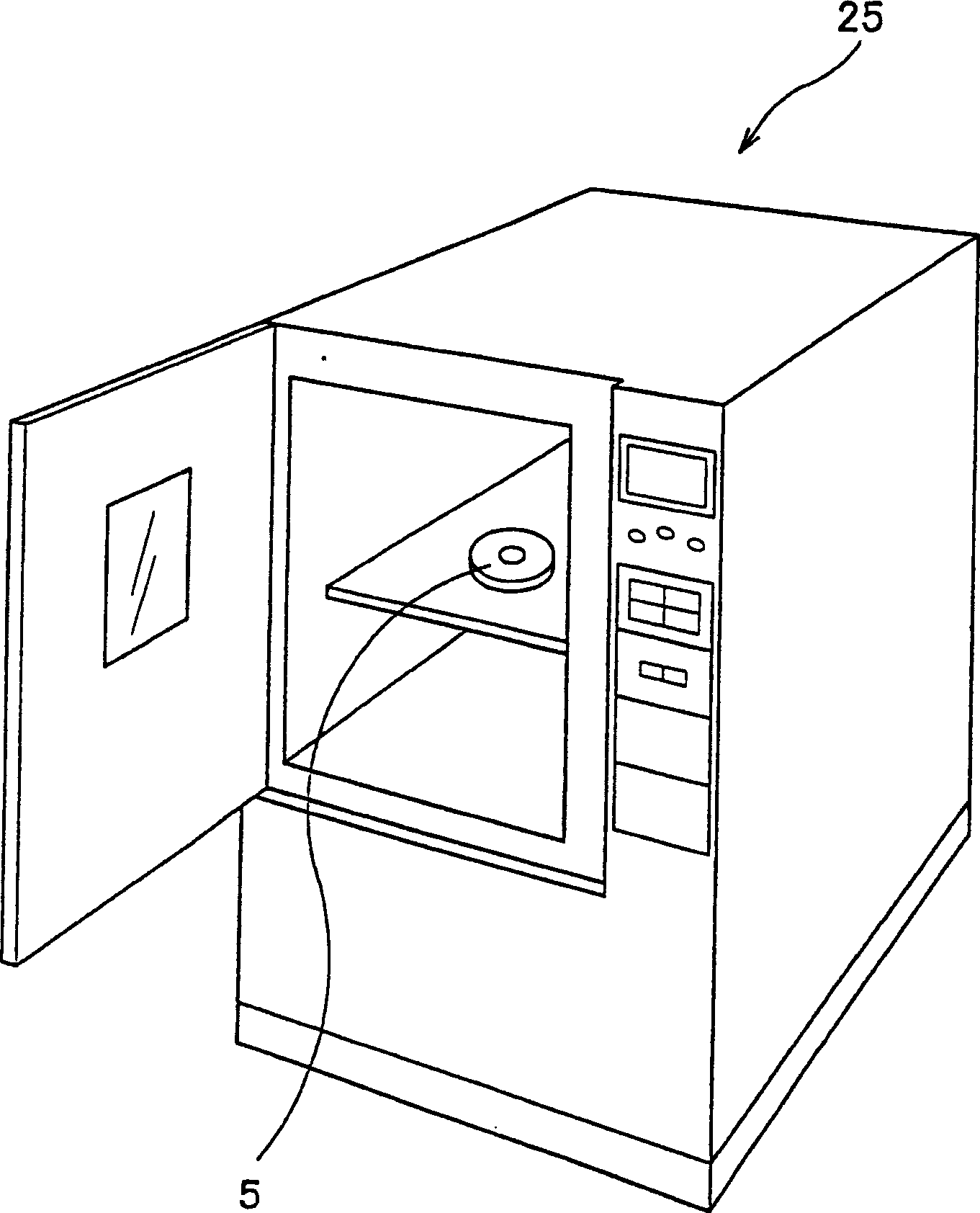

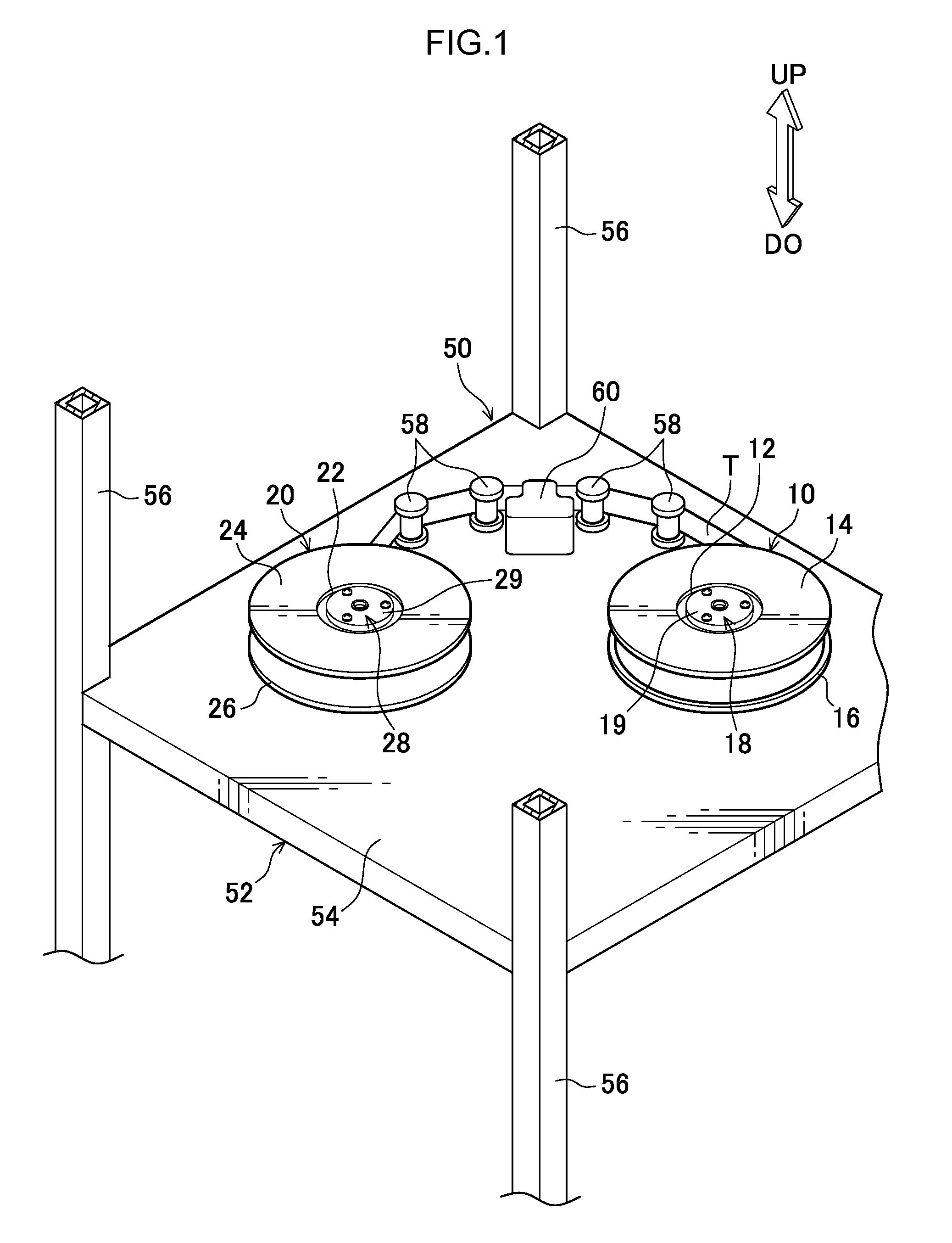

Magnetic tape winding-up method, magnetic tape winding-up apparatus, manufacturing method of magnetic tape cartridge, and magnetic tape cartridge

ActiveUS20120305692A1Increase capacityHigh densityPicture changing apparatusFilament handlingMagnetic tapeTension control

A winding-up method for winding up a magnetic tape, includes: winding up the magnetic tape around a takeup reel by laying turns one on top of another while causing the magnetic tape to run; and performing a tension control of maintaining tension exerted on a wound-up magnetic tape for a predetermined time.

Owner:FUJIFILM CORP

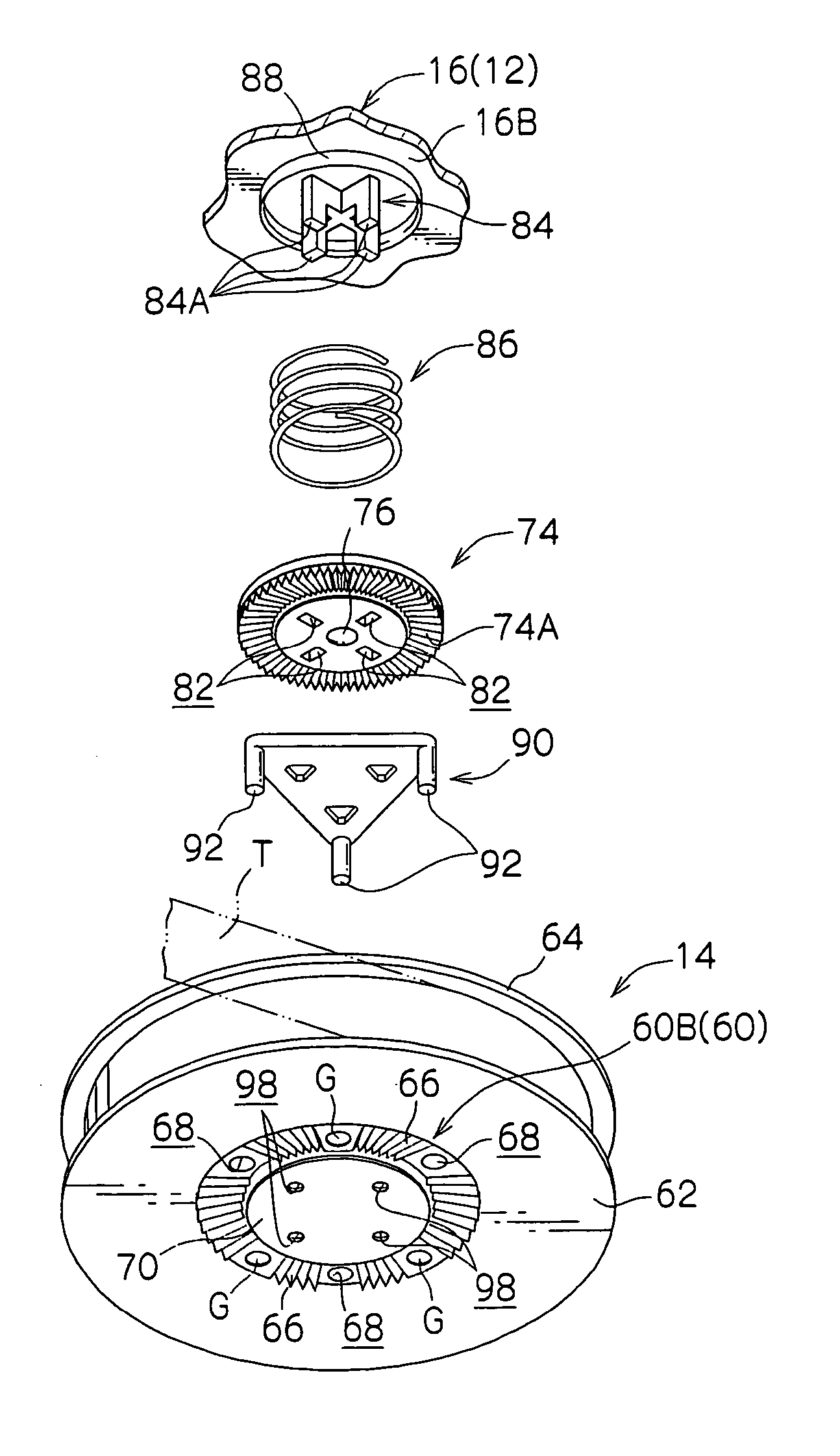

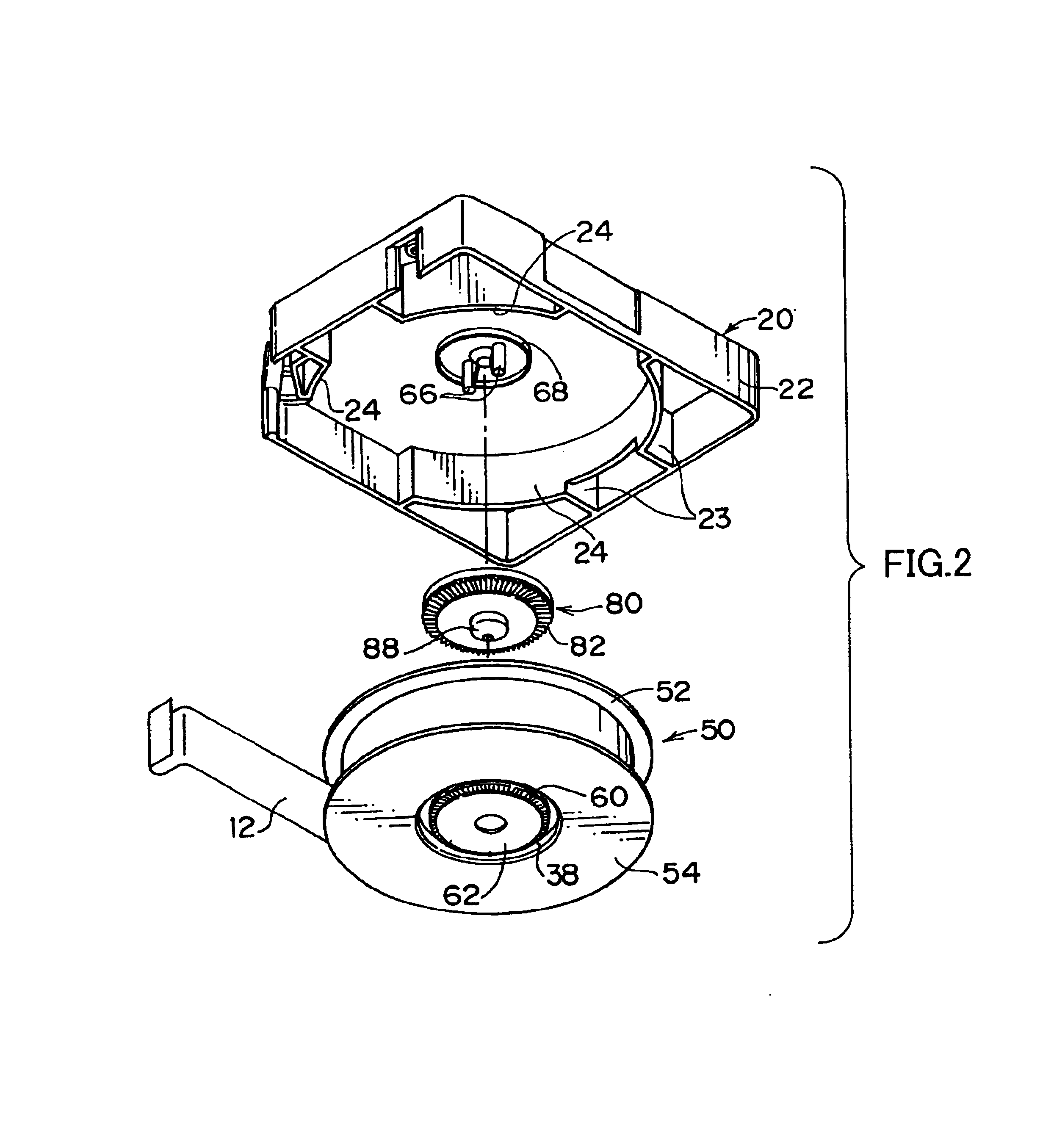

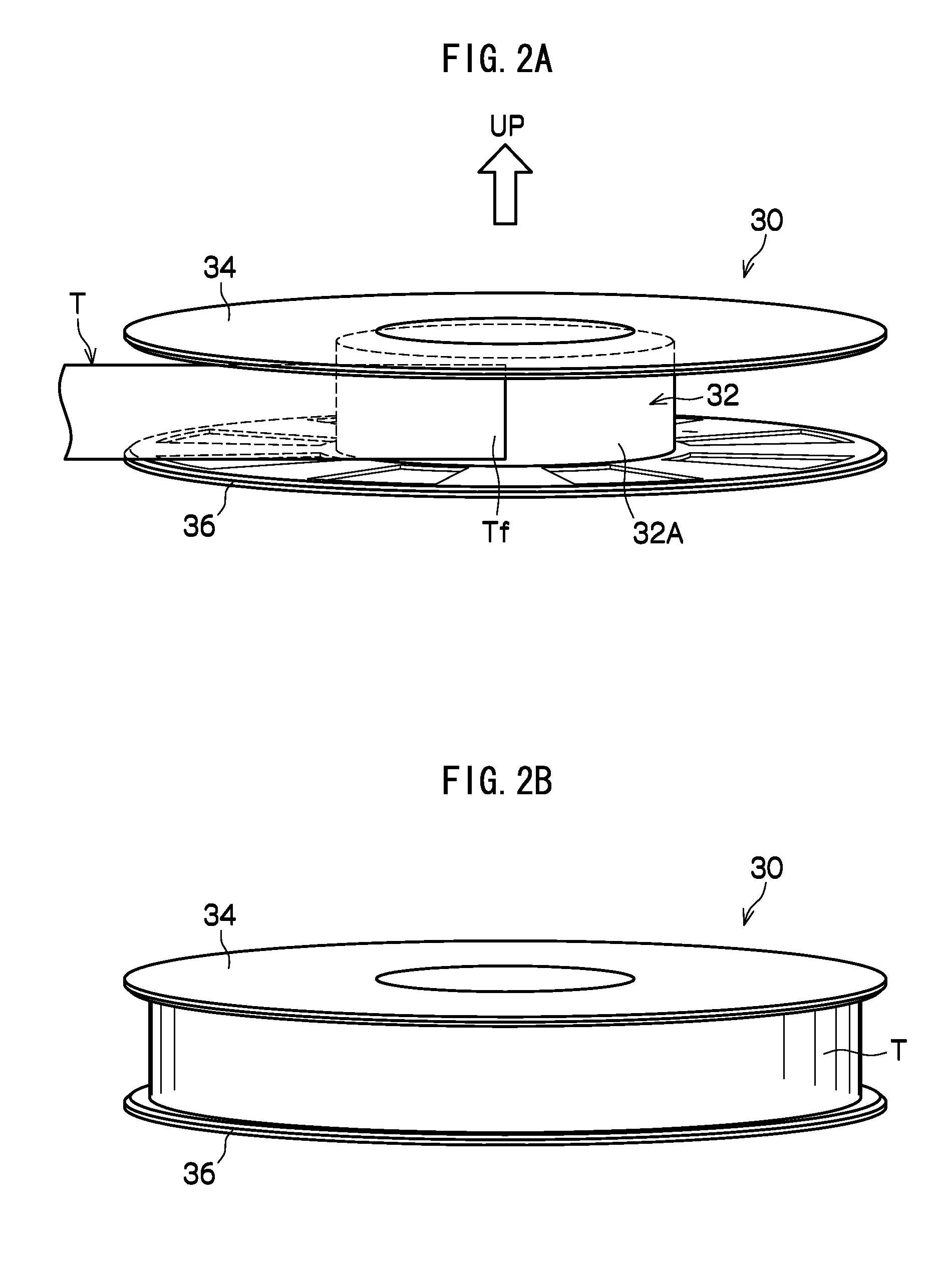

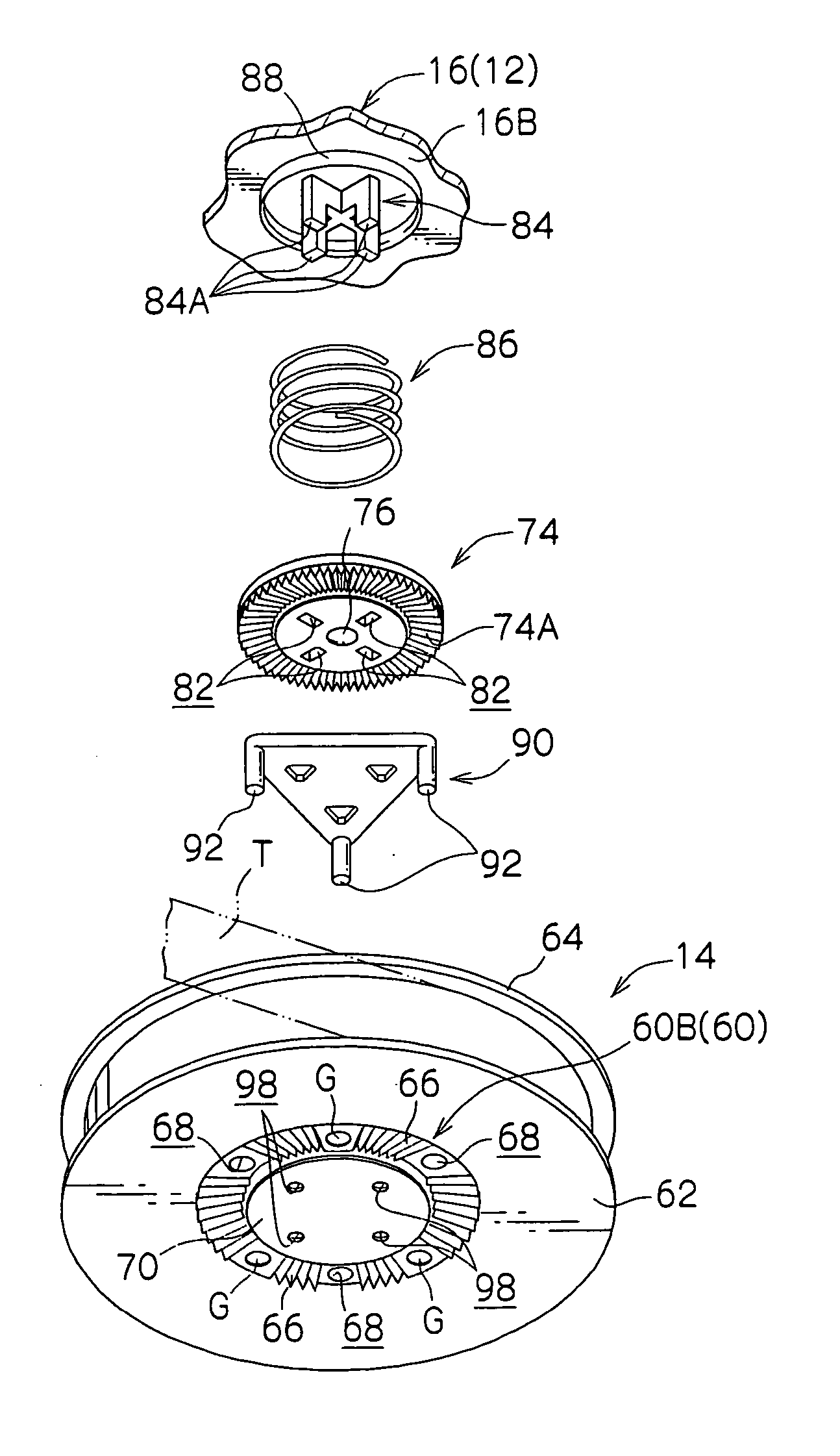

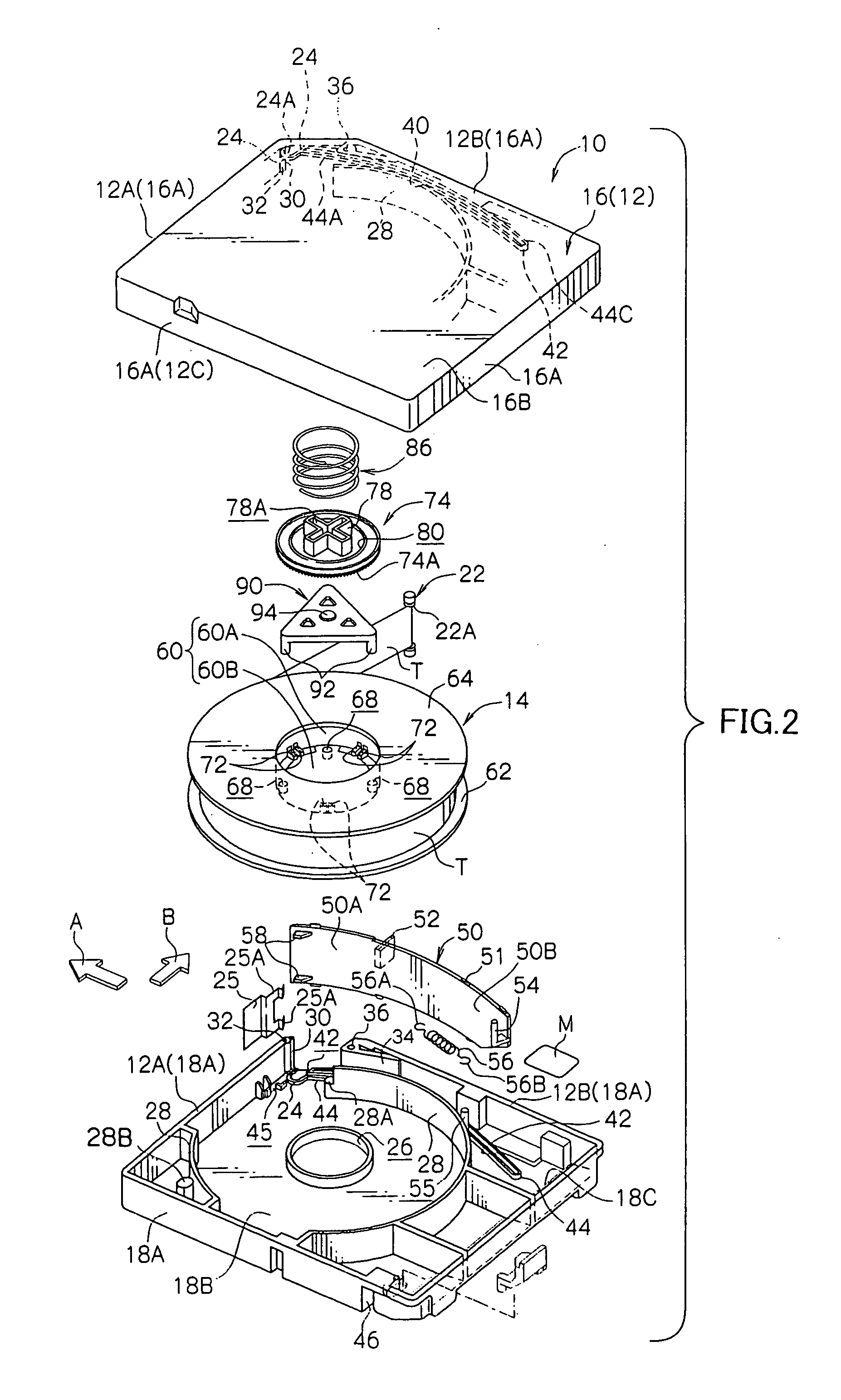

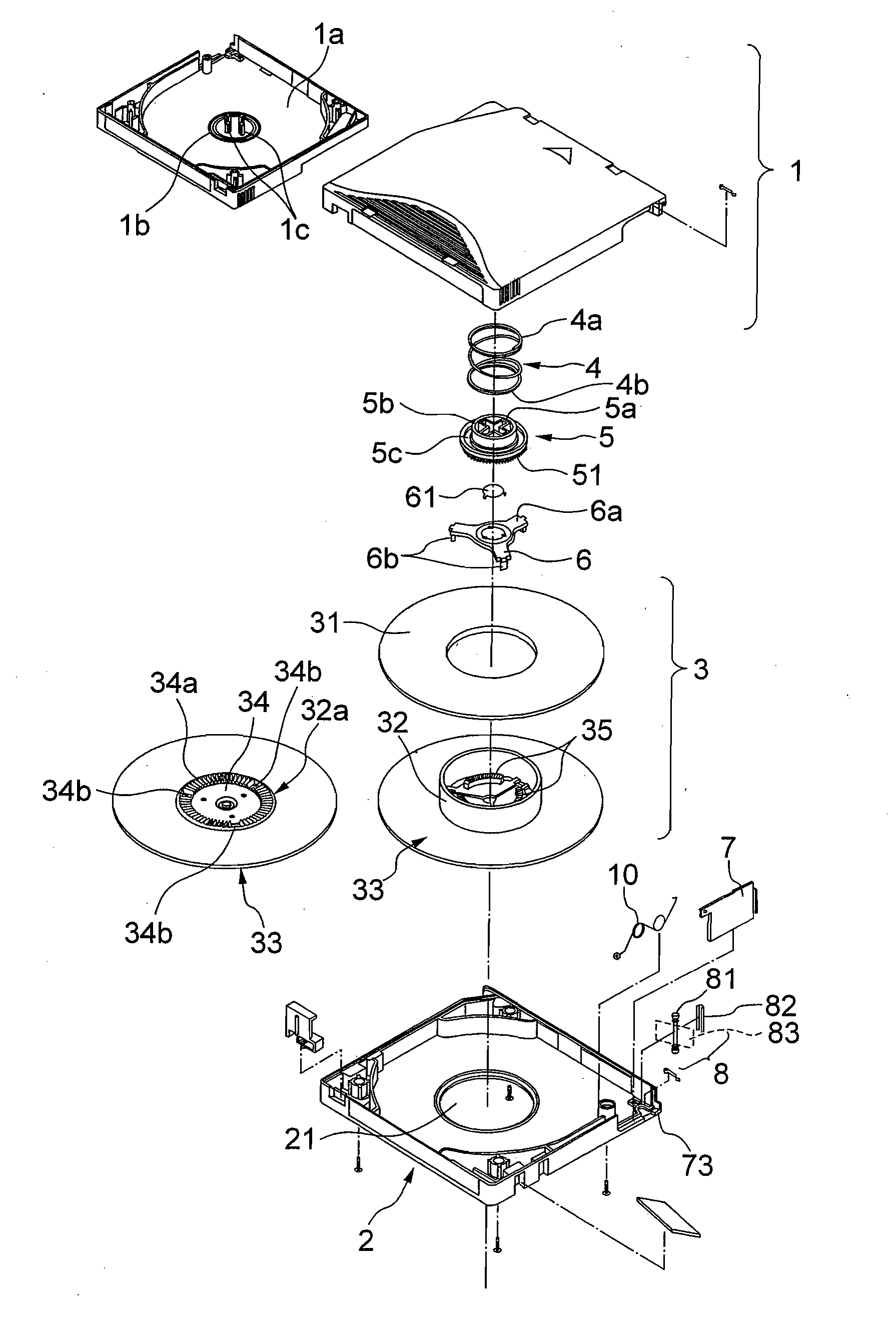

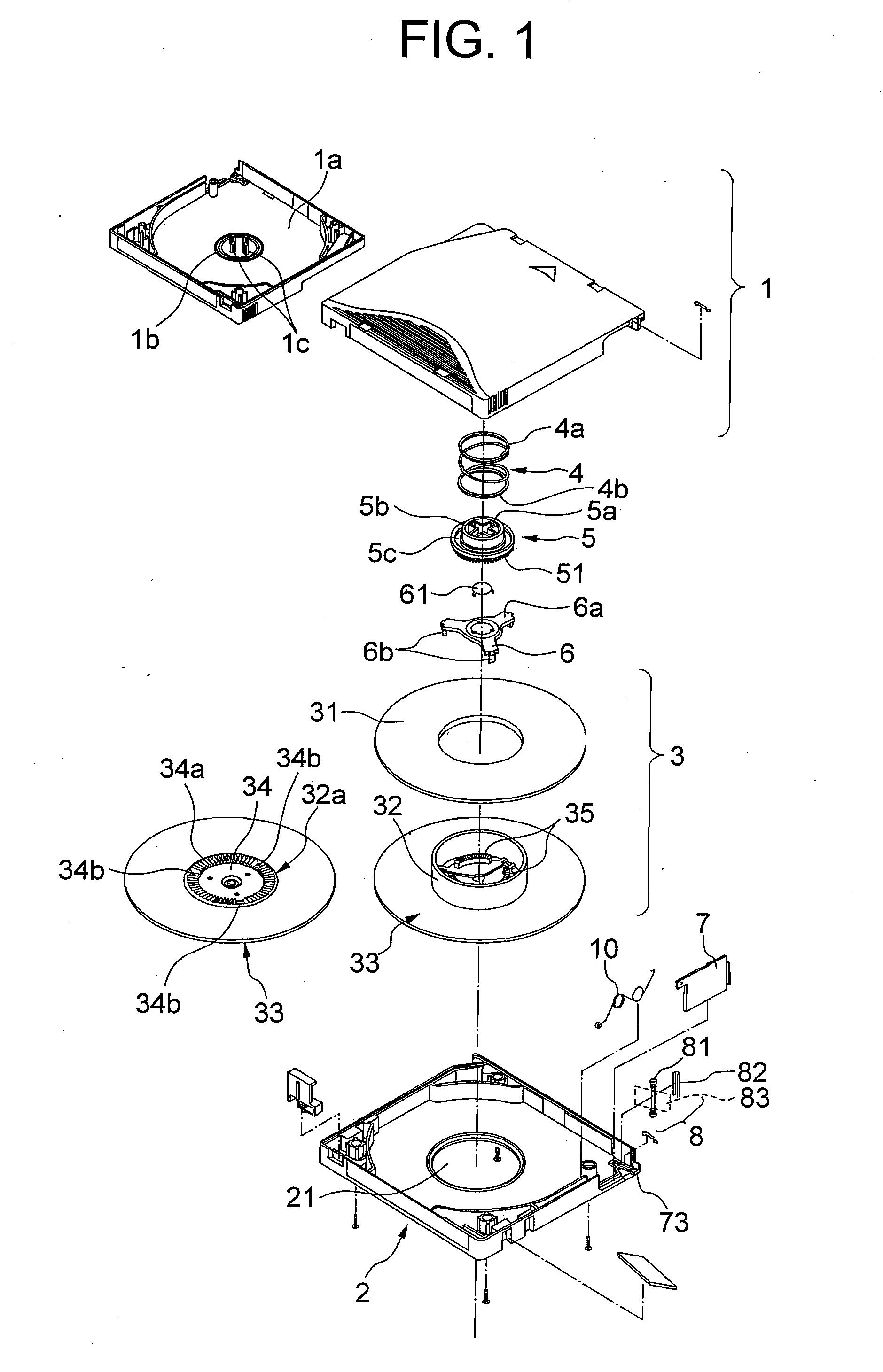

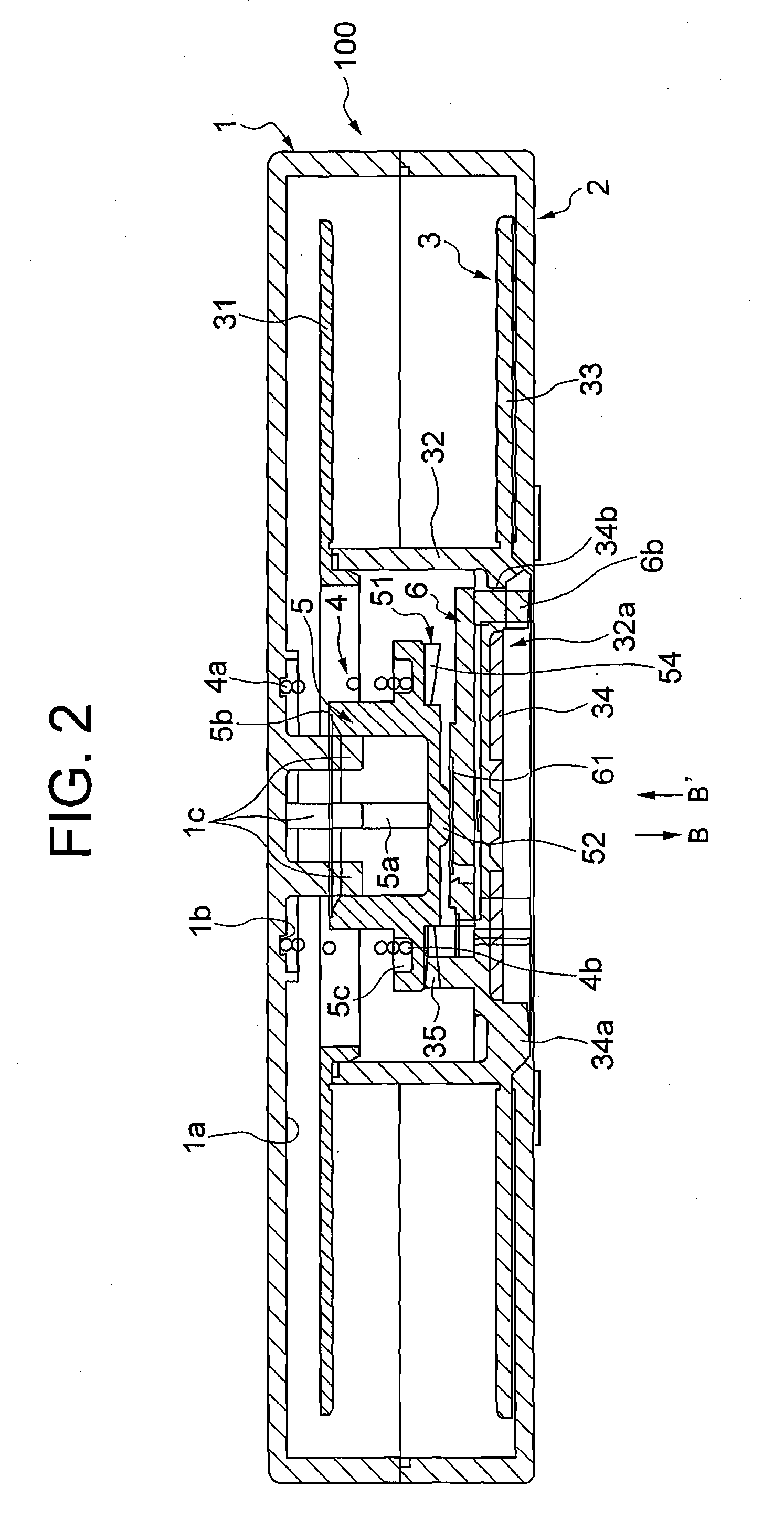

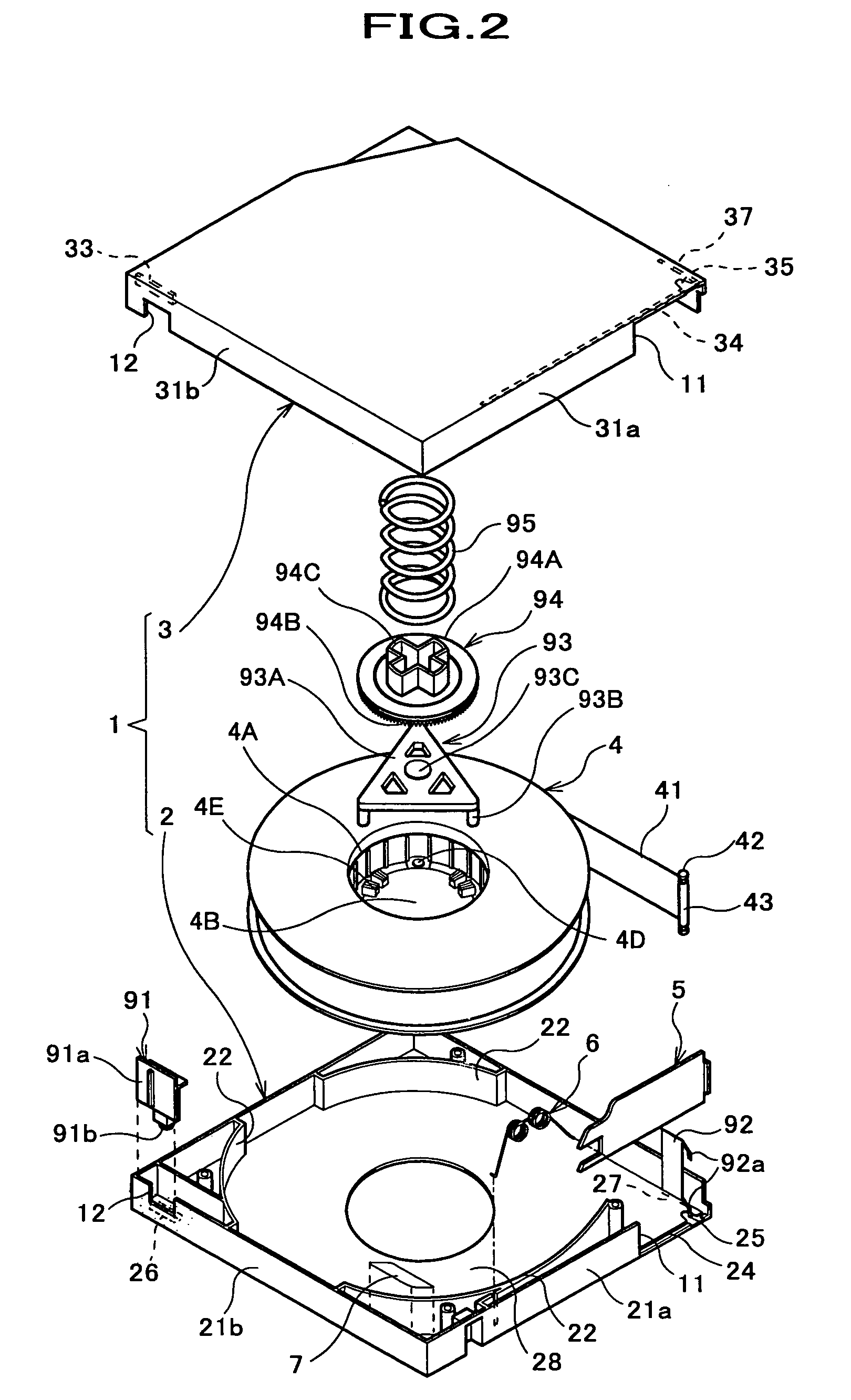

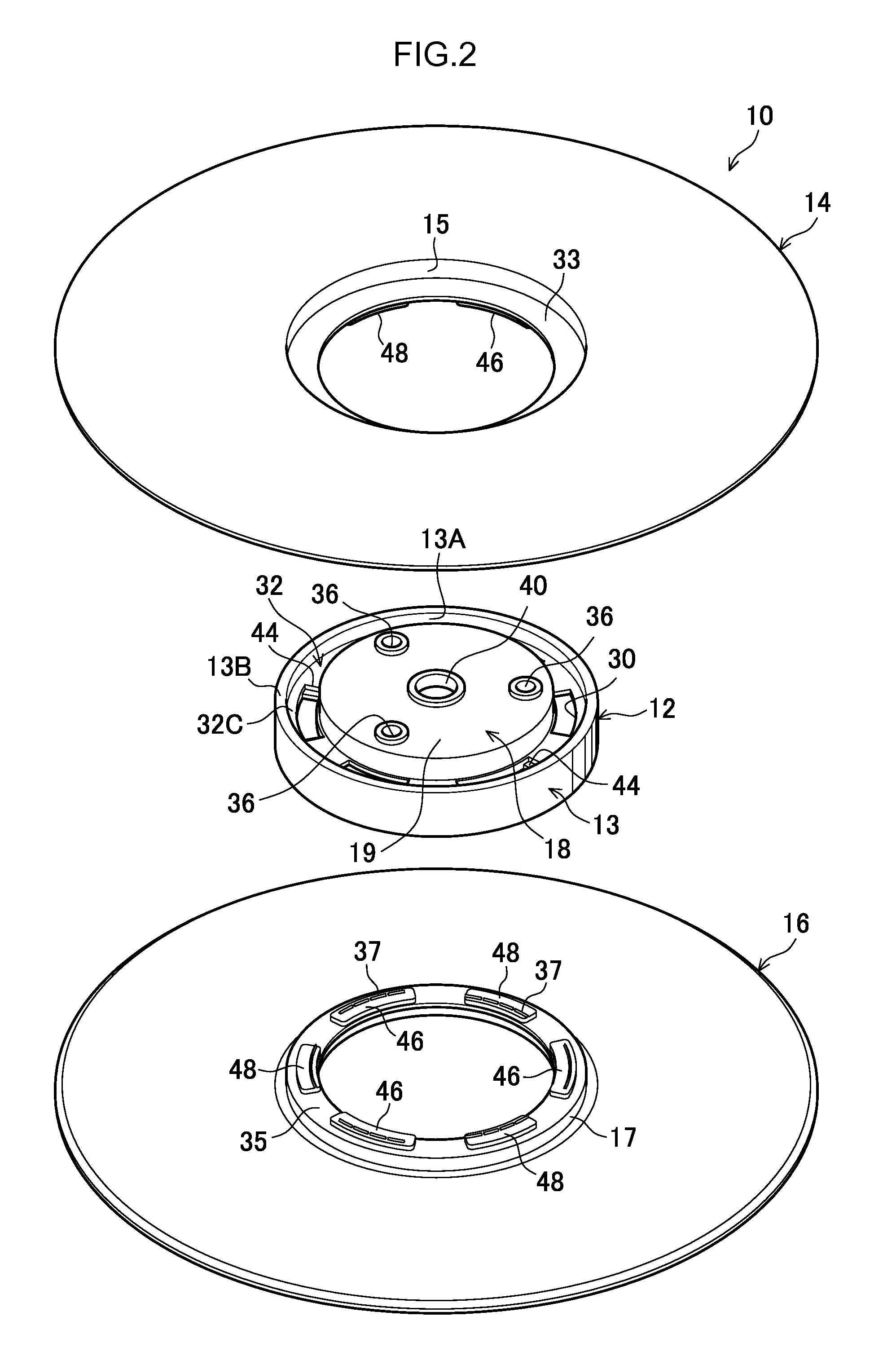

Reel, recording tape cartridge and method of manufacturing the reel

InactiveUS20050023397A1Simple designEasy Design ChangesPicture changing apparatusRecord information storageEngineeringMechanical engineering

A reel of a recording tape cartridge includes a reel hub formed in a bottomed cylindrical shape, an annular reel gear coaxially disposed at an outer surface of a bottom portion of the reel hub, and a through-hole the penetrates the axial center of the bottom portion and opens to an outer surface side of the bottom portion. The reel is resin-molded using a mold comprising a fixed mold, a movable mold and an insert. The reel gear and the through-hole are formed by a reel gear forming portion and a hole portion forming portion disposed in a single insert. As a result, the axial centers thereof are aligned with high precision.

Owner:FUJIFILM HLDG CORP +1

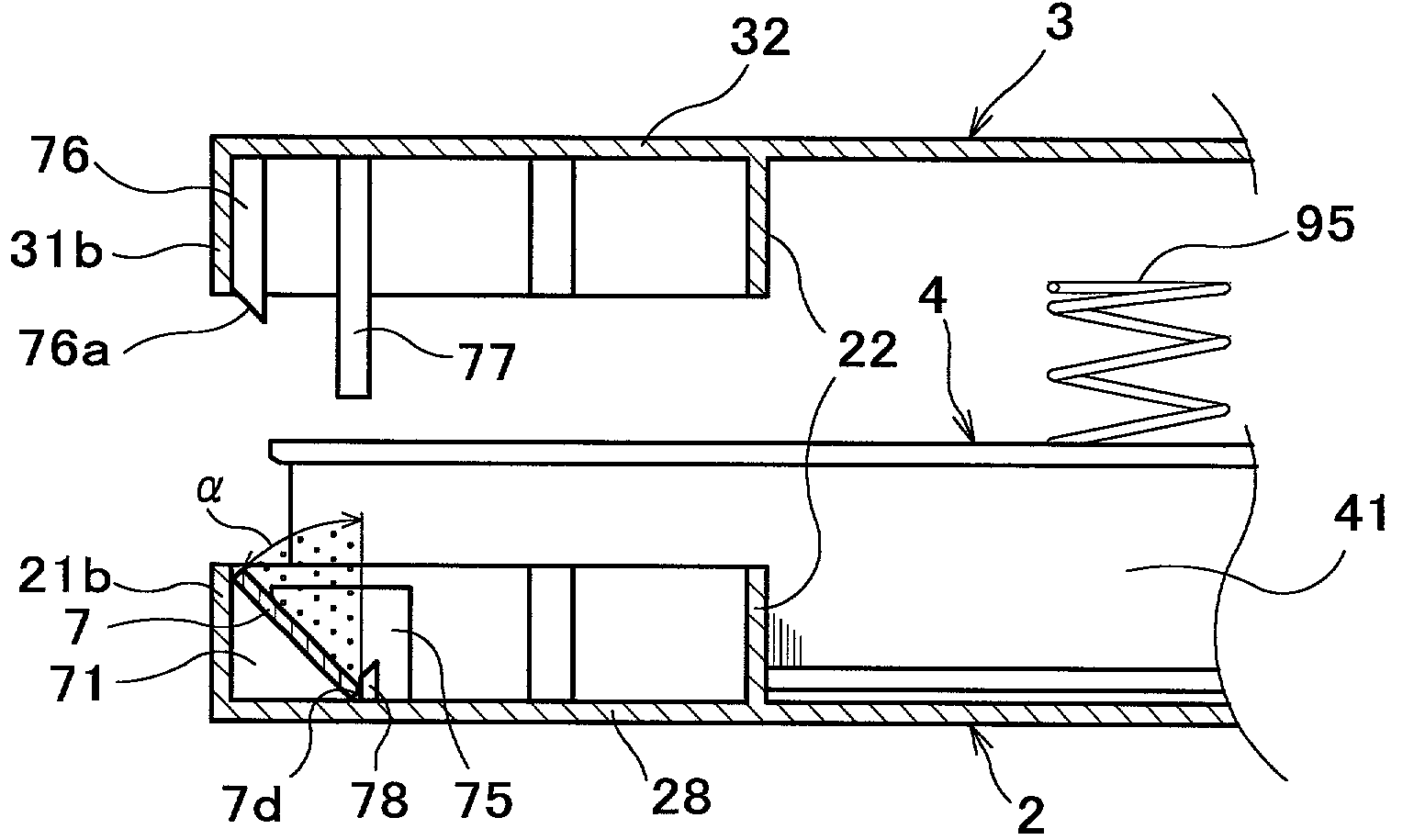

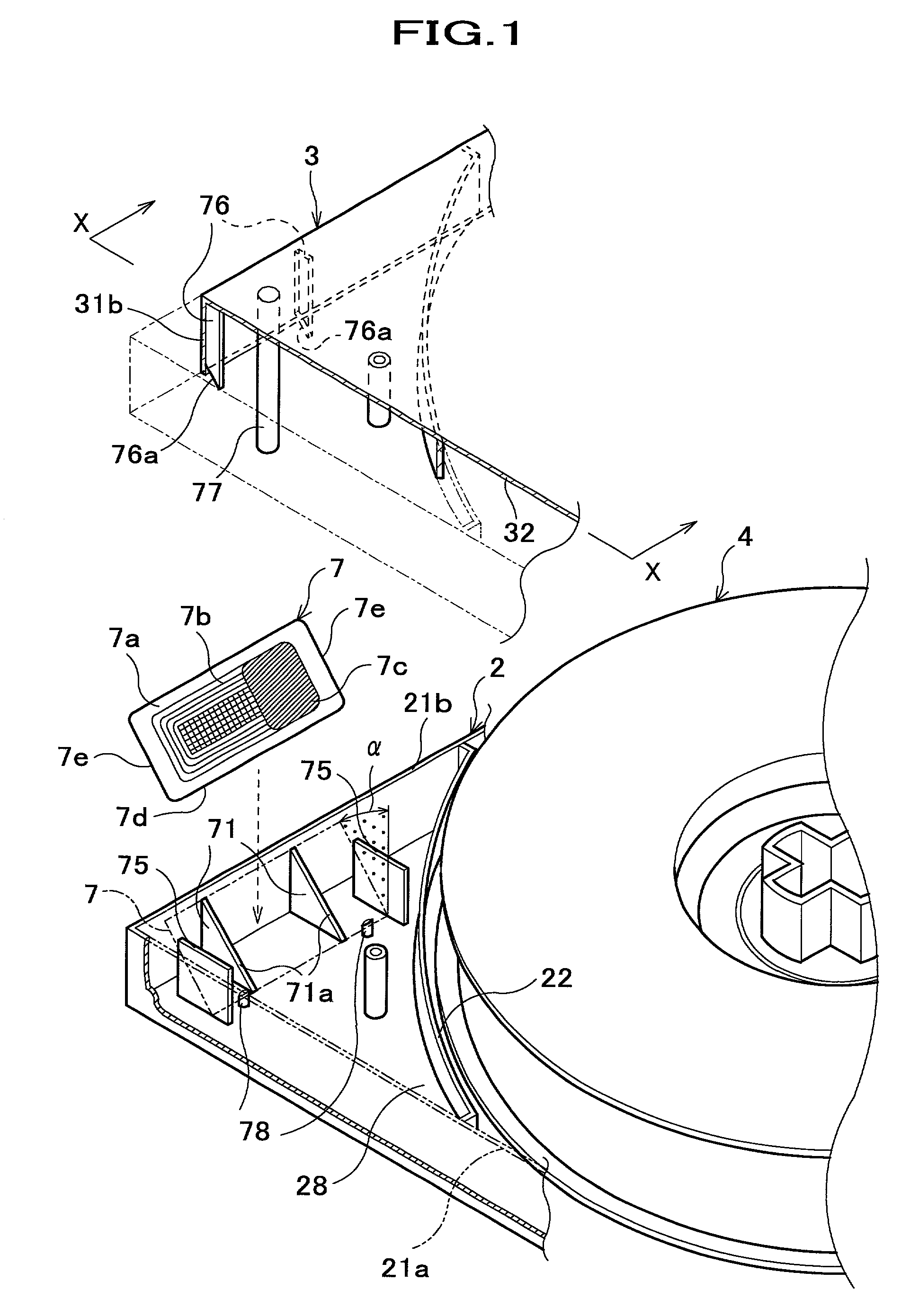

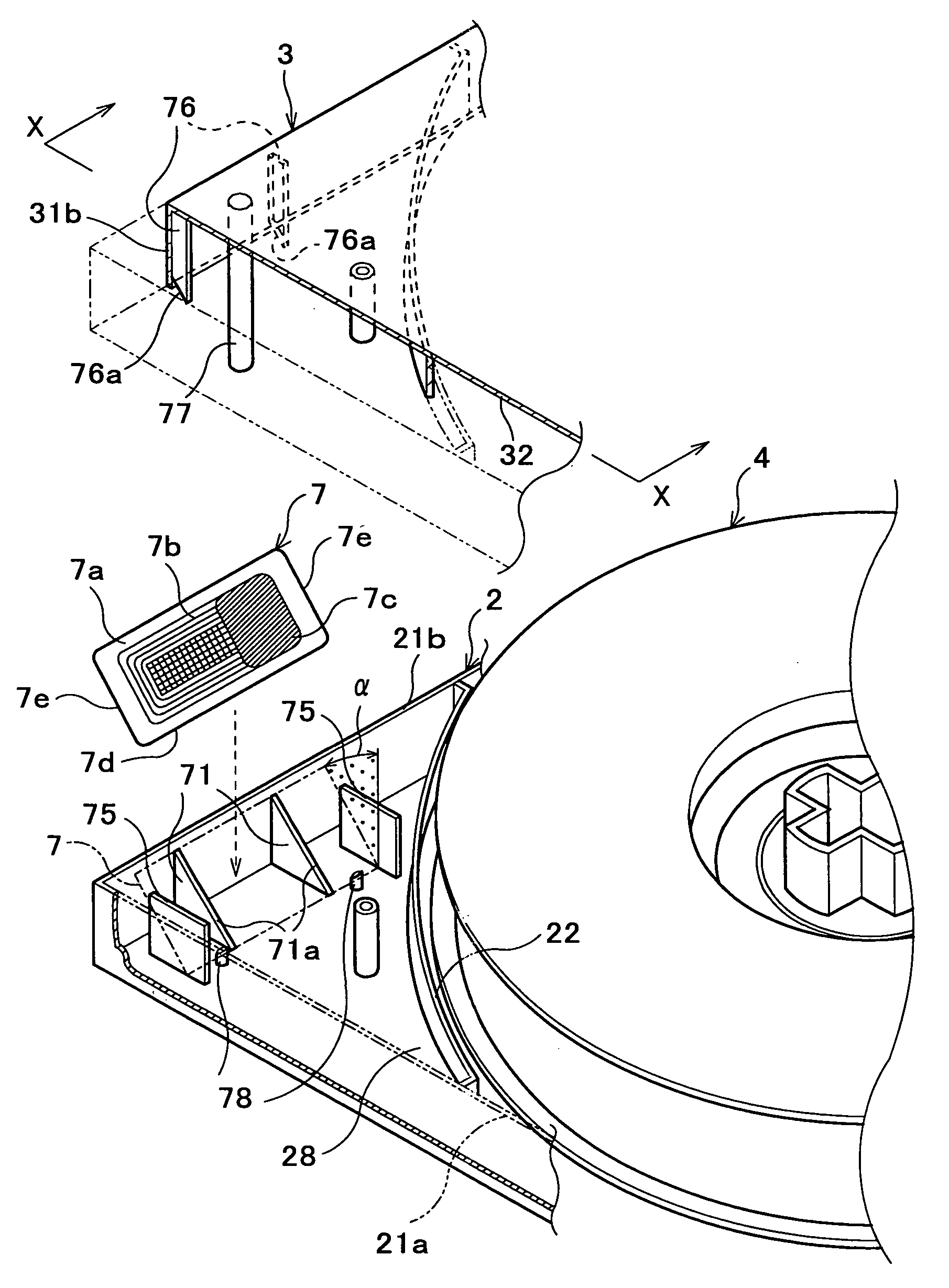

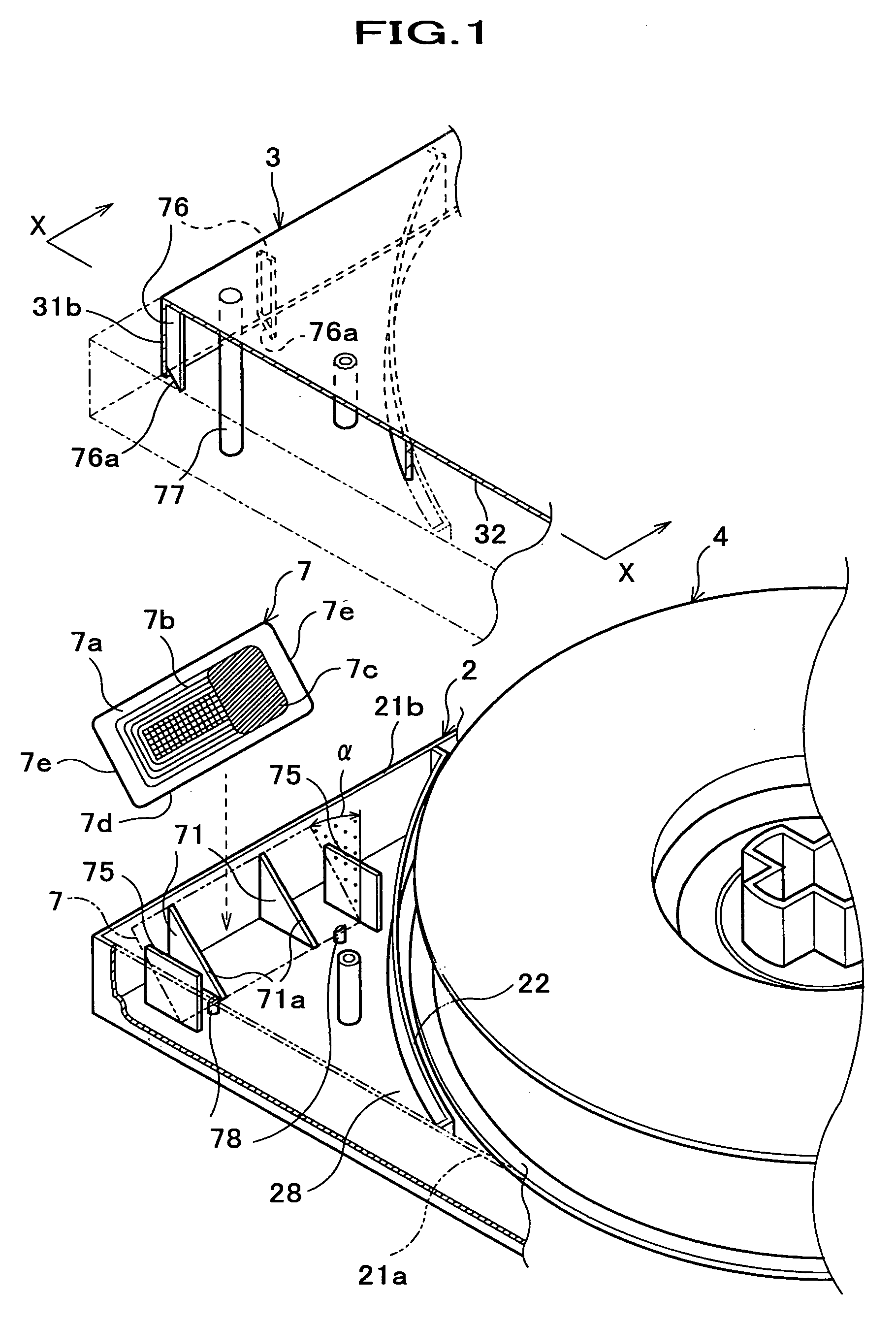

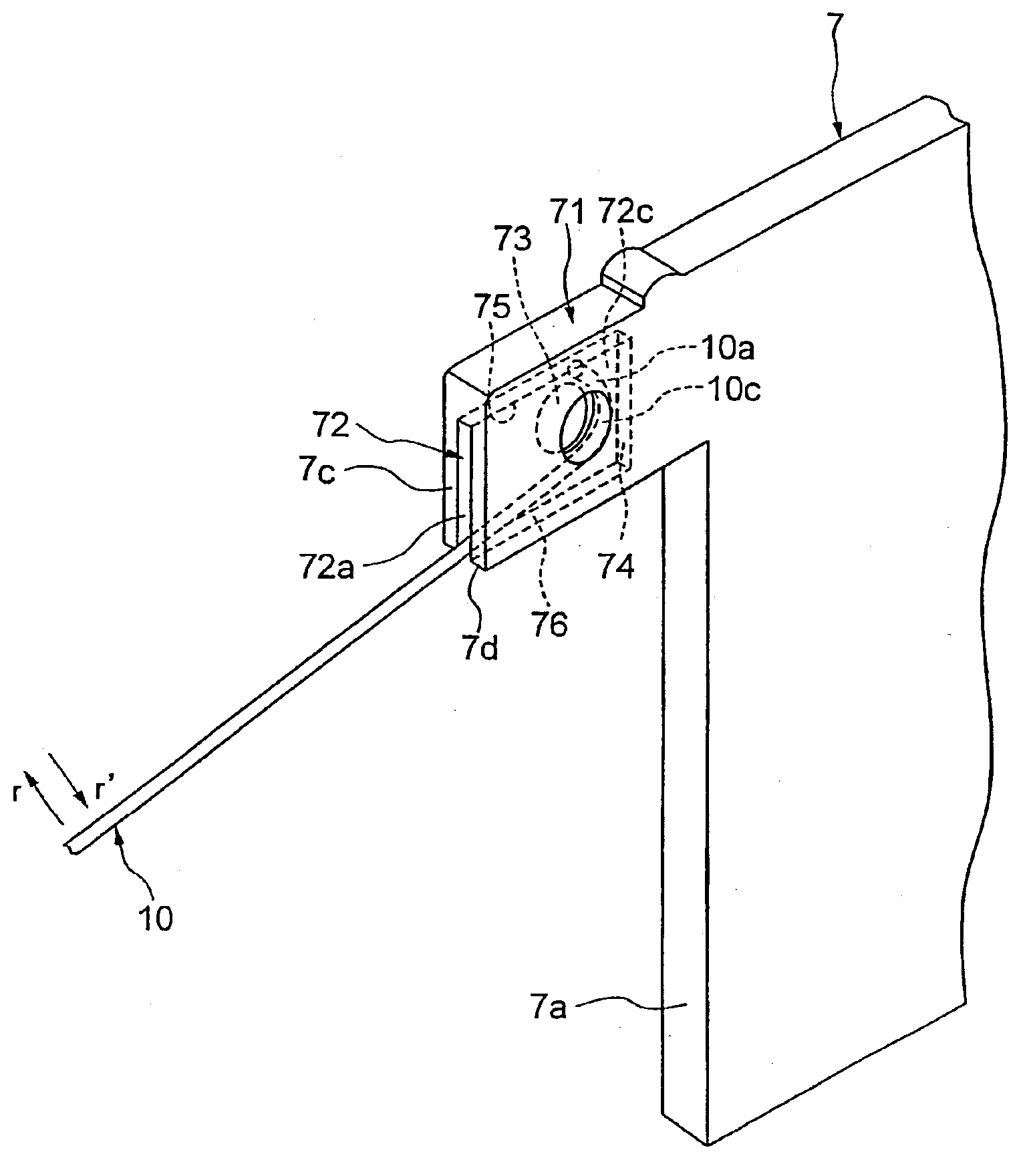

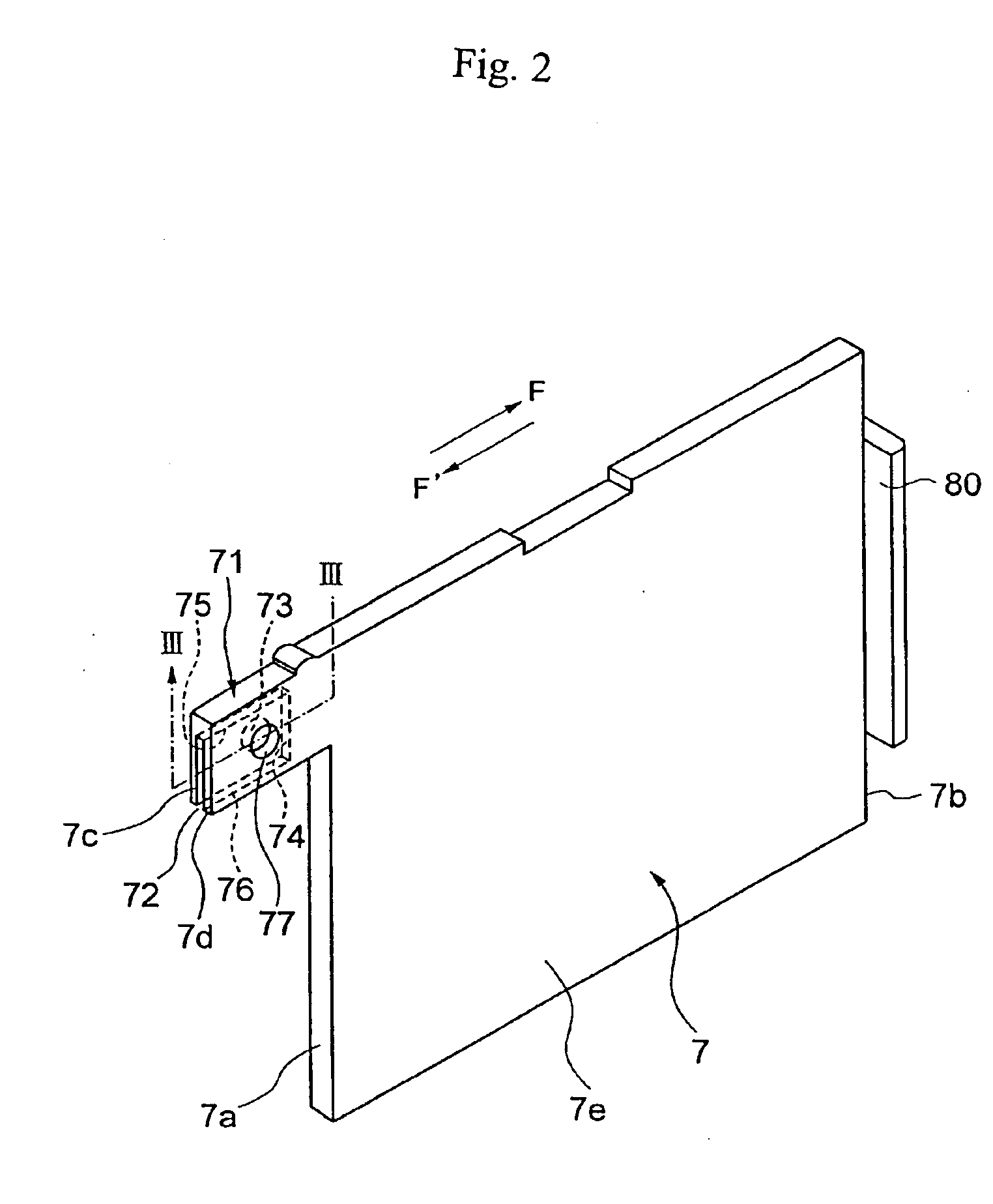

Cartridge case with chip retaining features

InactiveUS7064926B2Preventing defective assemblyRising of the cartridge memory isAccessories for auxillary signalsRecord information storageMagnetic tapeEngineering

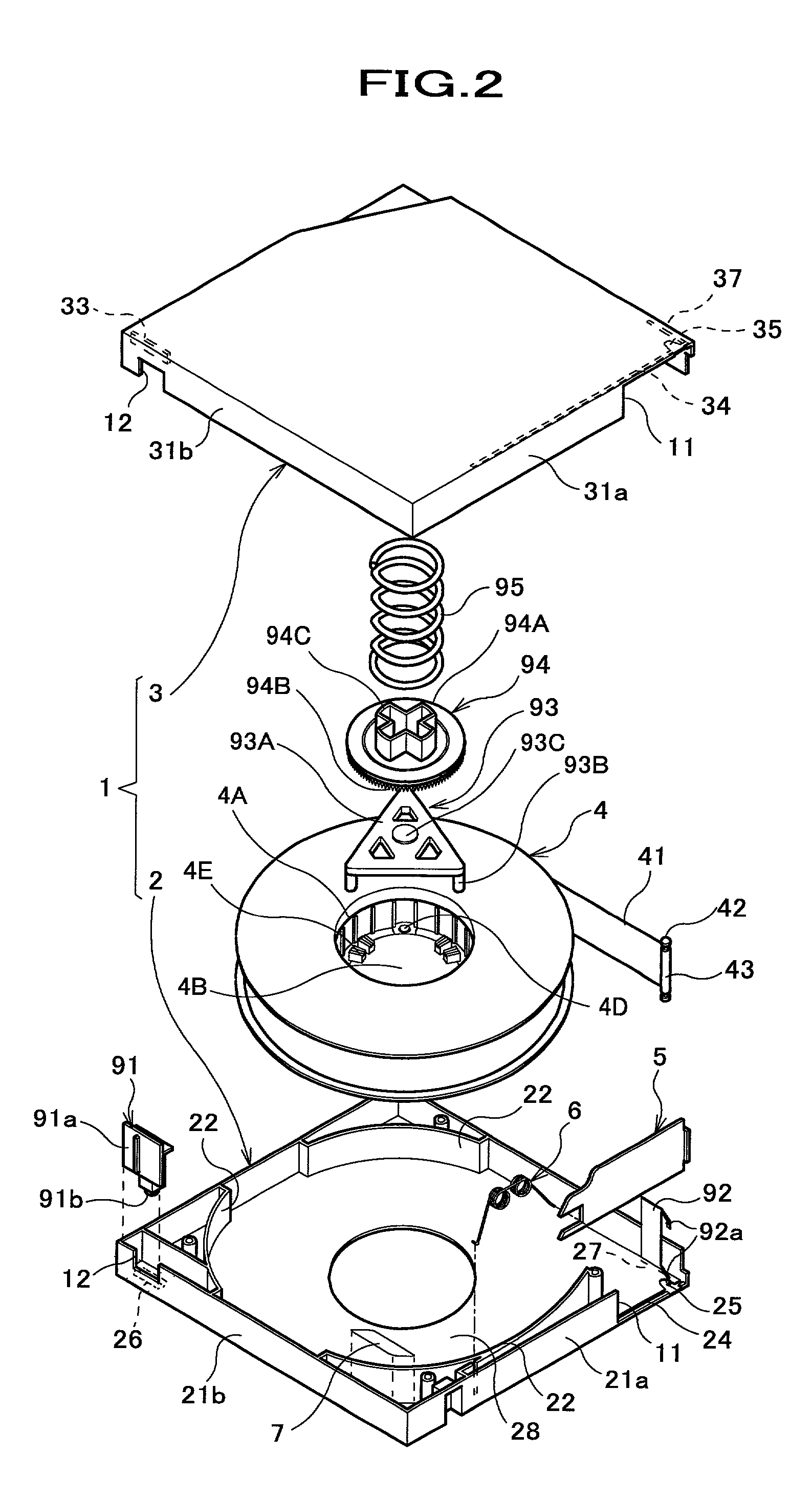

A cartridge case 1 for a magnetic tape cartridge comprises a cartridge case 1 consisting of a lower half 2 and an upper half 3. The lower half 2 is provided with retaining ribs 71 each having a retaining slanted surface 71a such that a plate-like cartridge memory 7 is positioned on the retaining slanted surfaces 71a with its one side 7d lowered and is obliquely supported with respect to a bottom plate 28 of the lower half 2. The upper half 3 is provided with supporting members for supporting various non-resilient constituent parts positioned on the lower half 2 and including the cartridge memory 7. The upper half 2 is provided with a stopper rod 77 such that when the upper half 3 is assembled with the lower half 2, the stopper rod 77 reaches a cartridge memory-rising region before the supporting members contact with the non-resilient constituent parts on the lower half 2.

Owner:FUJIFILM CORP +1

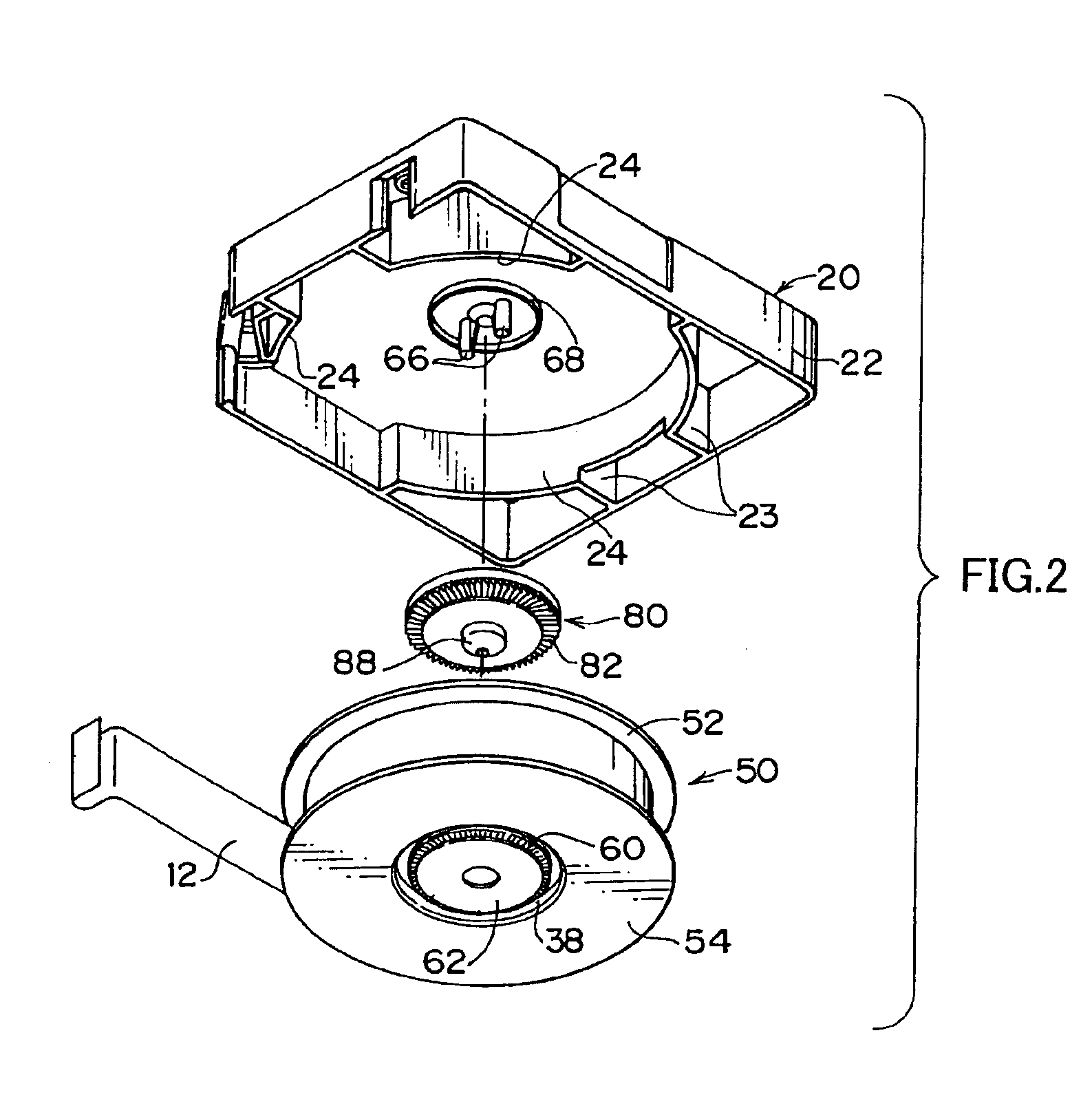

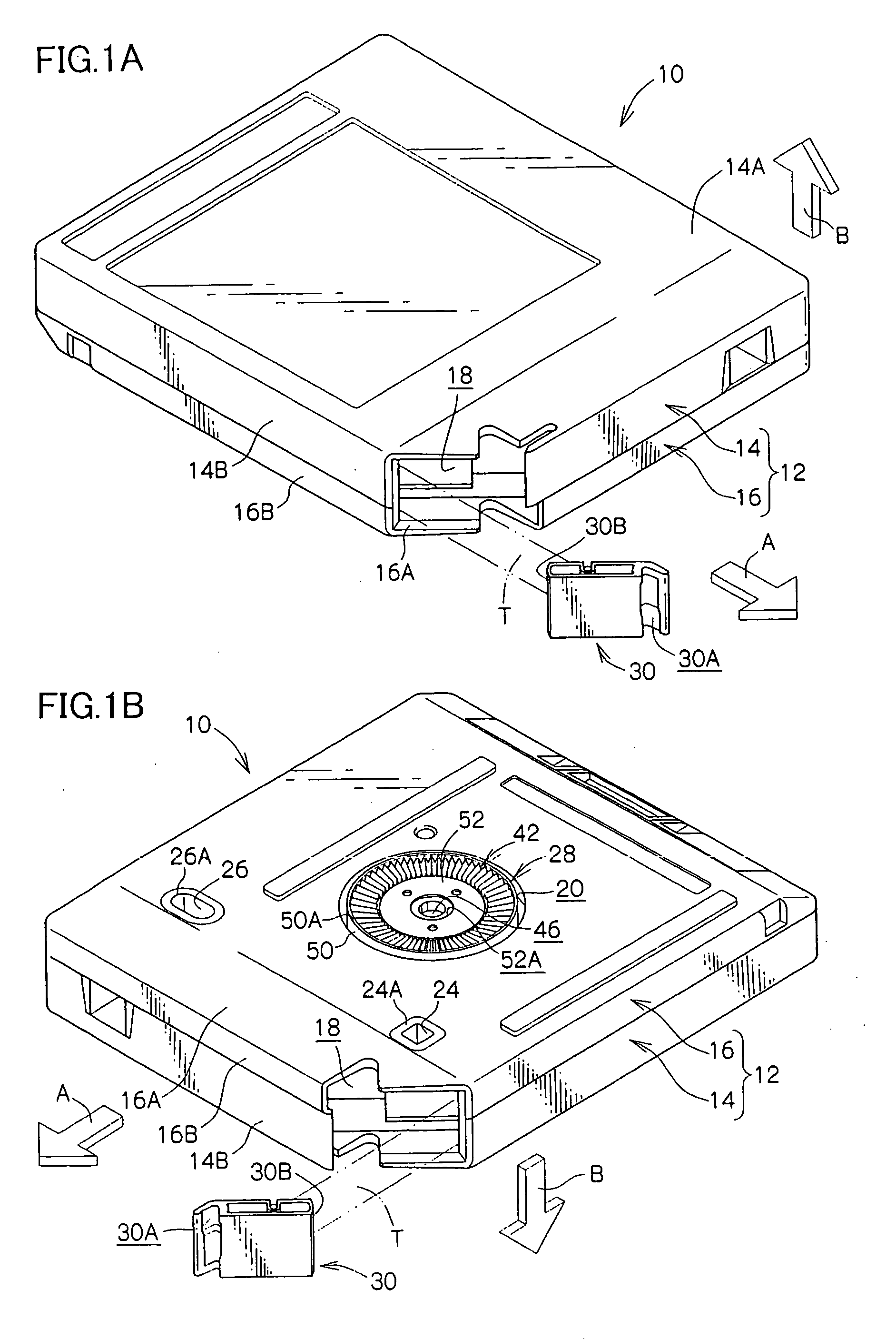

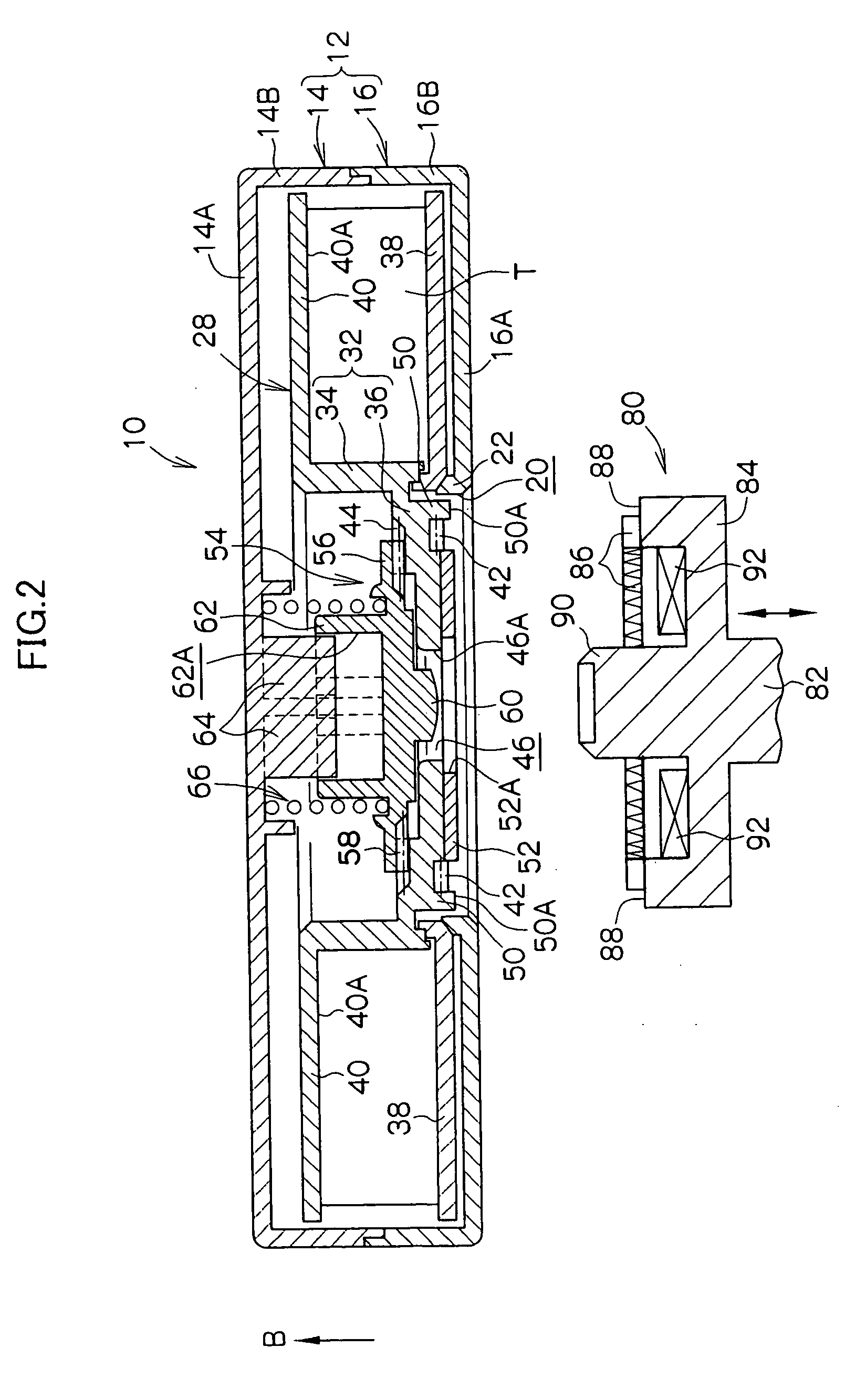

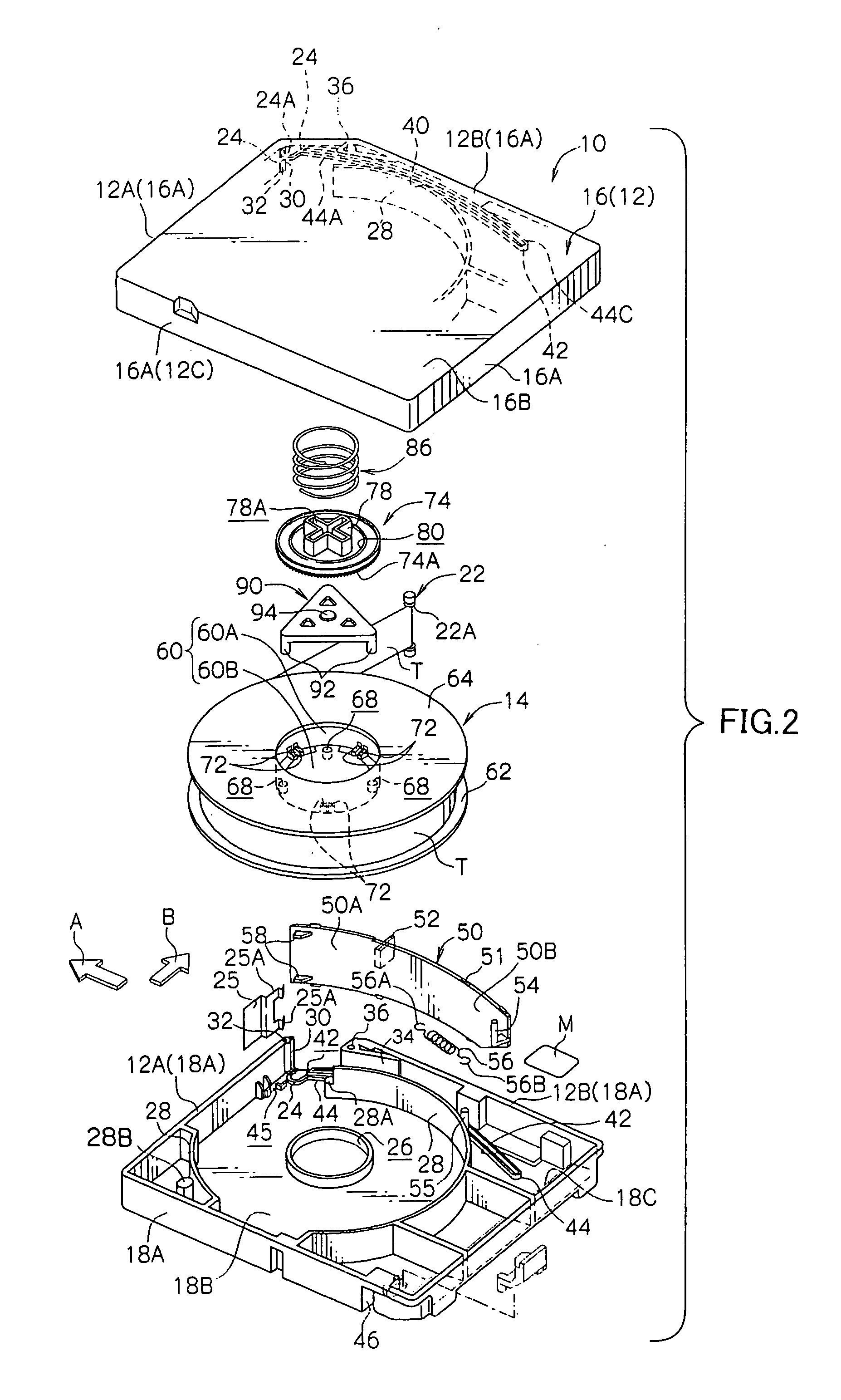

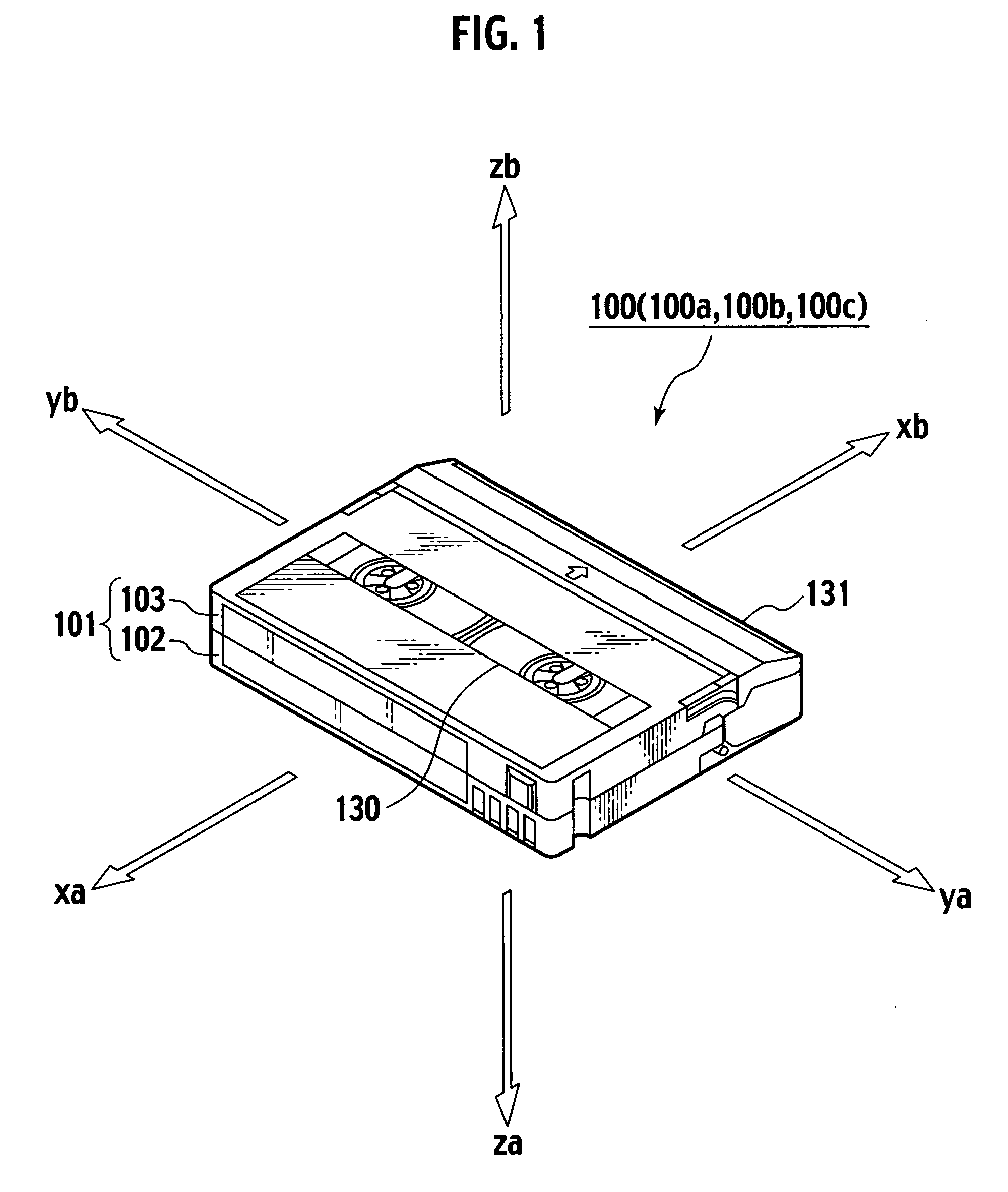

Recording tape cartridge

ActiveUS7252258B2Reduce areaImpairing mounting accuracyPicture changing apparatusRecord information storageEngineeringMechanical engineering

A recording tape cartridge which can be loaded into a drive device having a reel on which a recording tape is wound and which is rotatably accommodated in a case, the reel including: a resin-formed main portion which includes a reel hub formed in a tubular shape having a floor, the recording tape being wound around an outer peripheral surface of the reel hub; and a substantially disc-shaped metal plate attached firmly to an outer surface of a floor portion of the reel hub, wherein a gate portion, through which a resin material is introduced at the time of molding the main portion, is provided at a radial direction outer side of the metal plate.

Owner:FUJIFILM HLDG CORP +1

Recording tape cartridge

InactiveUS6857591B2Not always easyHighly flat flangesPicture changing apparatusRecord information storageEngineeringMetal mold

A metal plate of a recording tape cartridge is provided with a tapered portion at an outer circumference thereof. In a state in which the metal plate is attached at a fixed-side mold plate of a metal mold for molding a reel hub and a lower flange, a gap is formed between the tapered portion and the fixed-side mold plate. During molding, molding material flows into the gap. Because of this gap, an annular pawl portion is formed at the reel hub, which annular pawl portion integrally joins the metal plate with the reel hub by sandwiching the metal plate via the tapered portion.

Owner:FUJIFILM CORP

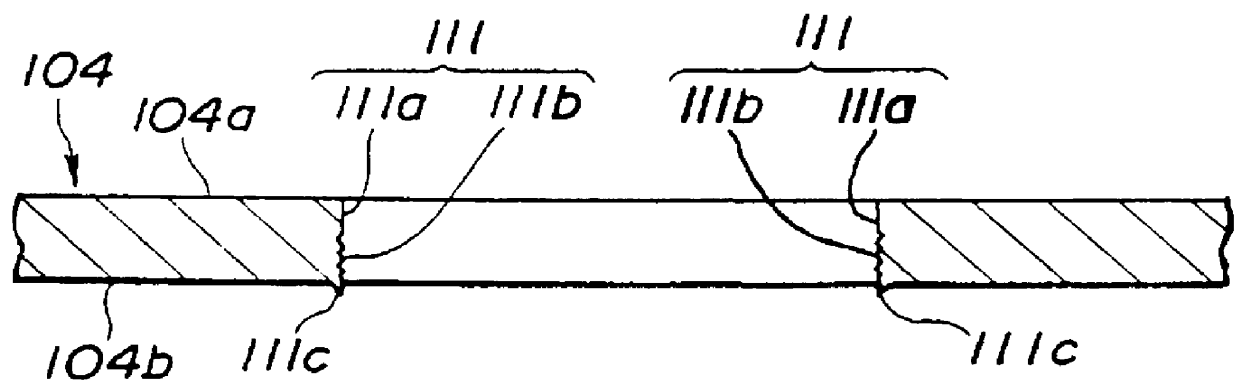

Method of punching template for forming a base plate of a tape cassette

InactiveUS6114016AInhibition formationPicture changing apparatusContainers for annular articlesEngineeringFracture plane

A method for punching a template is provided comprising the steps of partially punching the template by applying a first punch to a first surface of the template to form a recessed portion thereof and by applying a first die to a second surface of the template to form a projected portion thereof, so as to produce a first shear plane connected with the first surface on a peripheral surface of the recessed portion and a second shear plane connected with the second surface on a peripheral surface of said projected portion; returning the projected portion so as to be substantially aligned with the recessed portion by holding the first surface and the second surface between a second punch and a second die; and fully punching the template by applying a third punch to the second surface and a third die to the first surface to as to produce a third shear plane connected with the second surface on a peripheral surface of the recessed portion and a fracture plane connected between the third shear plane and the first shear plane thereby causing a portion of the template to fully punched therefrom.

Owner:SONY CORP

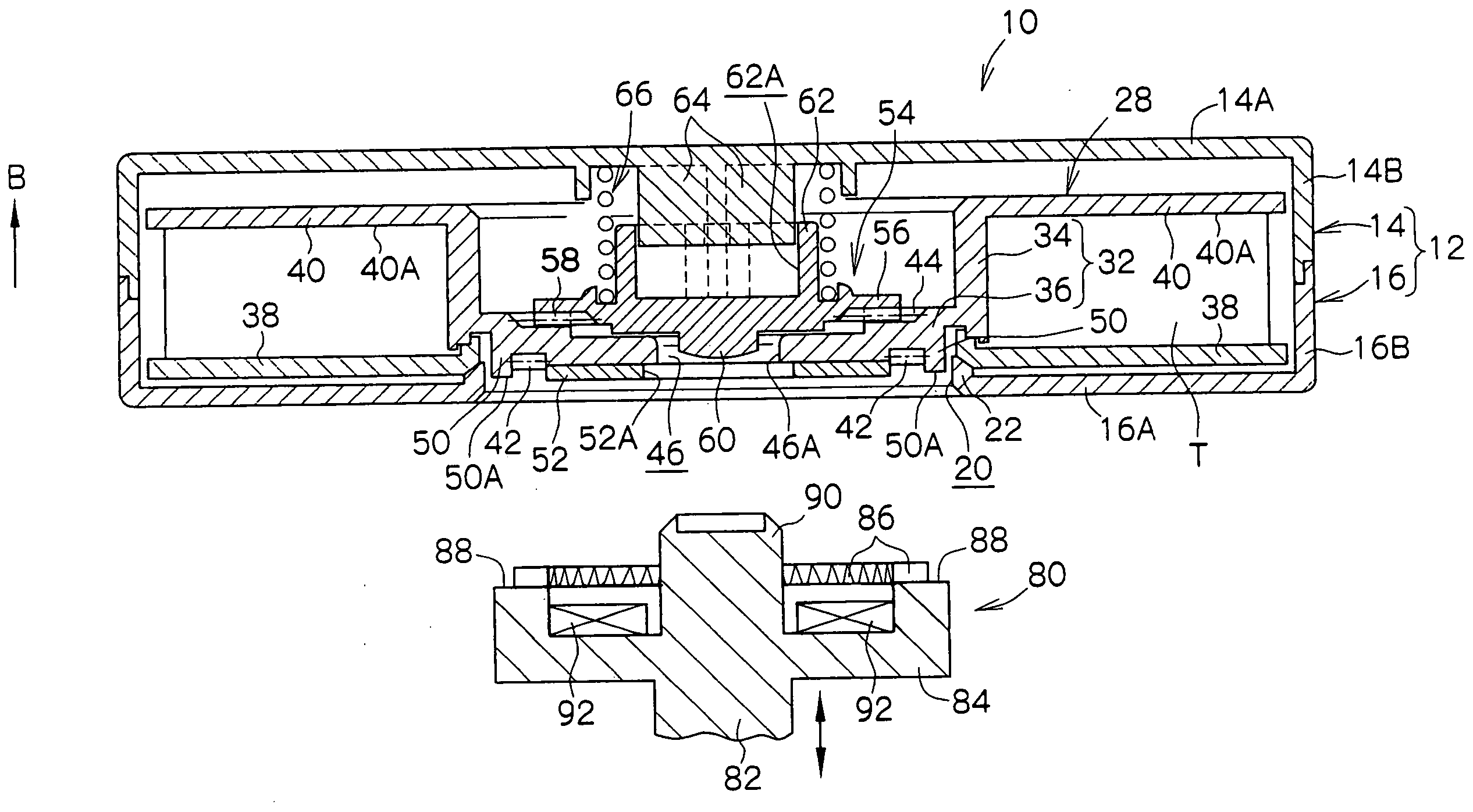

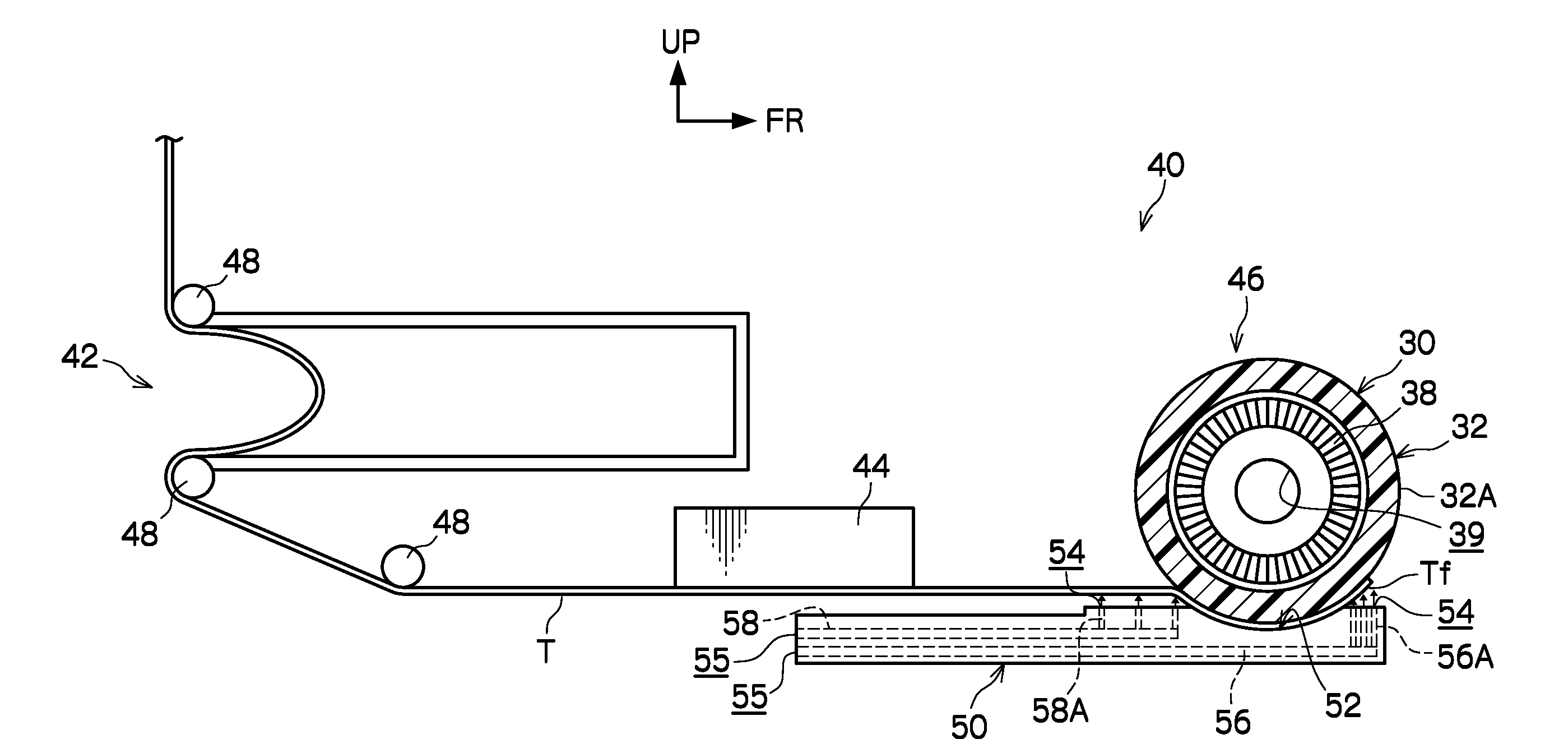

Recording tape attaching method and recording tape attaching apparatus

ActiveUS20090283621A1Accurate attachmentRecord carrier with multiple-tracksMagazine/cassette manufacturing apparatusEngineeringStatic electricity

The invention provides a recording tape attaching method and a recording tape attaching apparatus for accurately attaching a recording tape to a reel hub. In the method and the apparatus for winding a recording tape around a hub of a reel, a hub is contacted with a recording tape retained by suction by a retaining member and rotated, thereby generating static electricity, and the recording tape is attached to the hub by attracting the recording tape to the hub by the generated static electricity.

Owner:FUJIFILM CORP

Recording tape cartridge

ActiveUS20050145737A1Inhibition effectReduce areaPicture changing apparatusRecord information storageEngineeringMechanical engineering

A recording tape cartridge which can be loaded into a drive device having a reel on which a recording tape is wound and which is rotatably accommodated in a case, the reel including: a resin-formed main portion which includes a reel hub formed in a tubular shape having a floor, the recording tape being wound around an outer peripheral surface of the reel hub; and a substantially disc-shaped metal plate attached firmly to an outer surface of a floor portion of the reel hub, wherein a gate portion, through which a resin material is introduced at the time of molding the main portion, is provided at a radial direction outer side of the metal plate.

Owner:FUJIFILM HLDG CORP +1

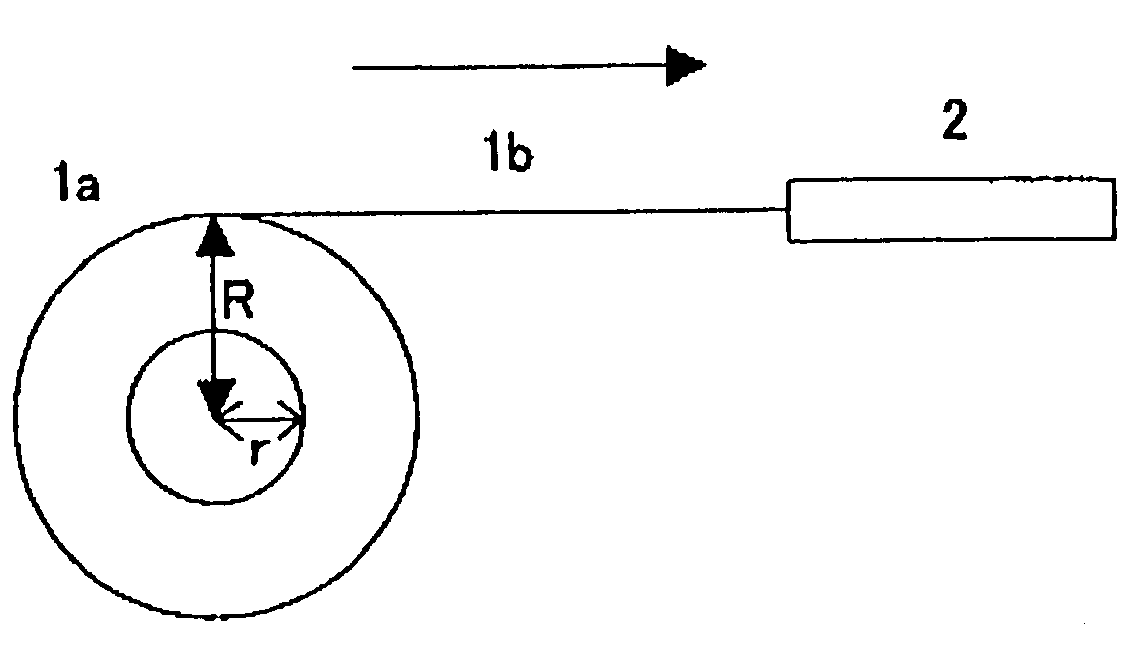

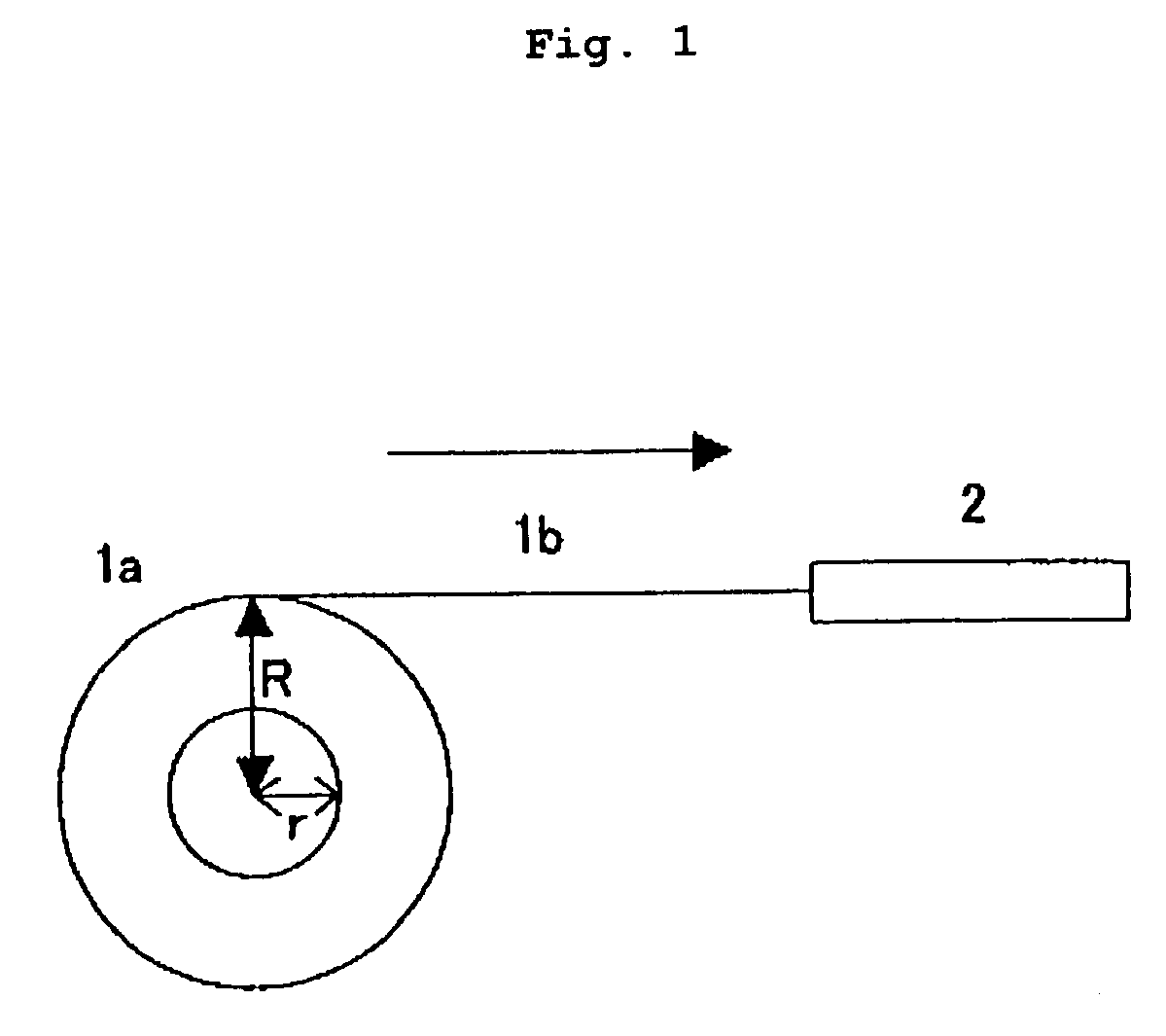

Tape reel

ActiveUS7072143B2Great winding ratioRaise the ratioTape carriersRecord information storageMagnetic tapeEngineering

A normal tape reel is disclosed, comprising a tape reel portion and a magnetic tape wound on the reel core of the tape reel portion, wherein the ratio of the winding radius R of the magnetic tape to the radius r of the reel core (R / r) is not smaller than 3.5 and the winding hardness of the magnetic tape is adjusted to a range of from 1.9 to 11.5 N.

Owner:FUJIFILM CORP +1

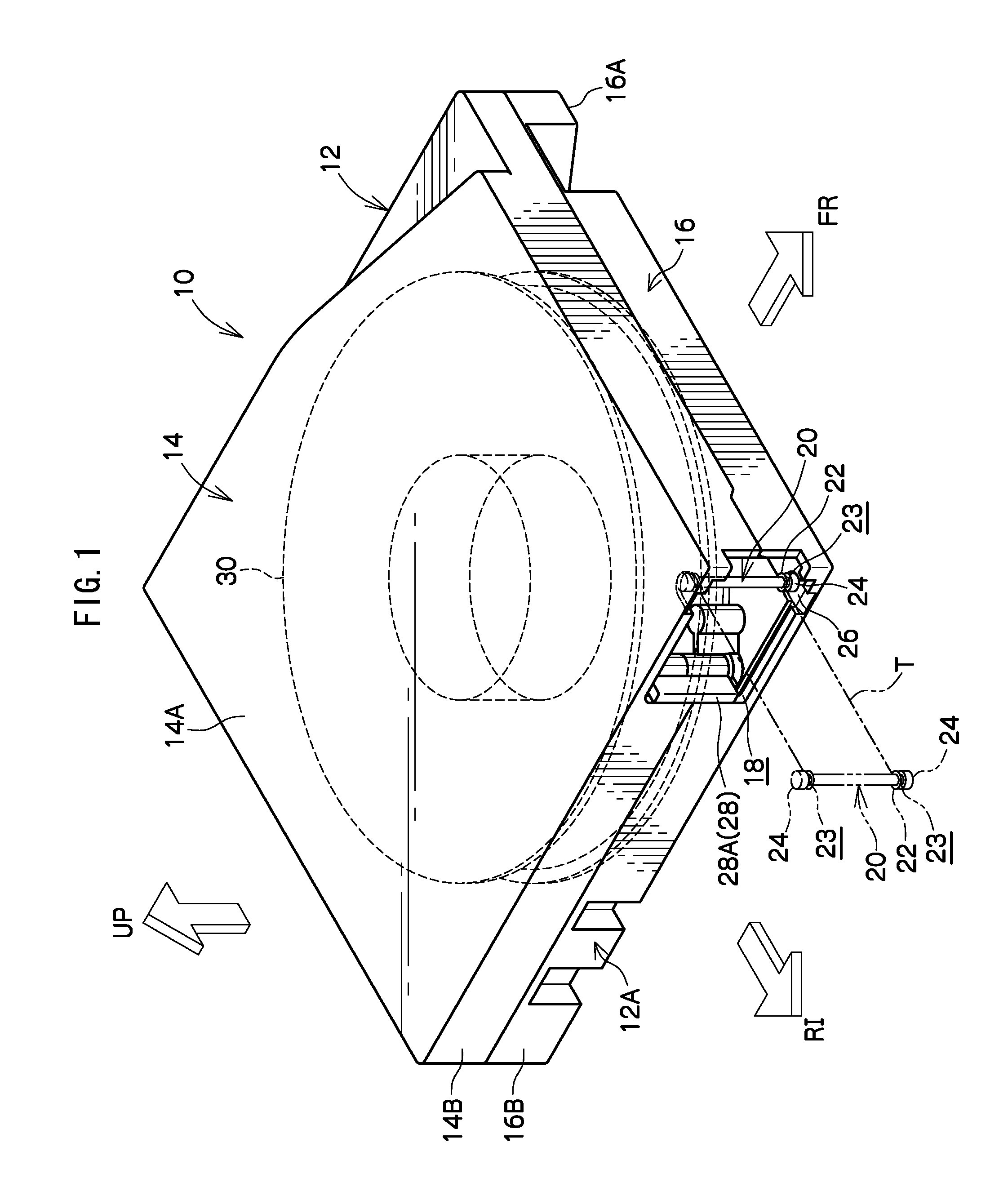

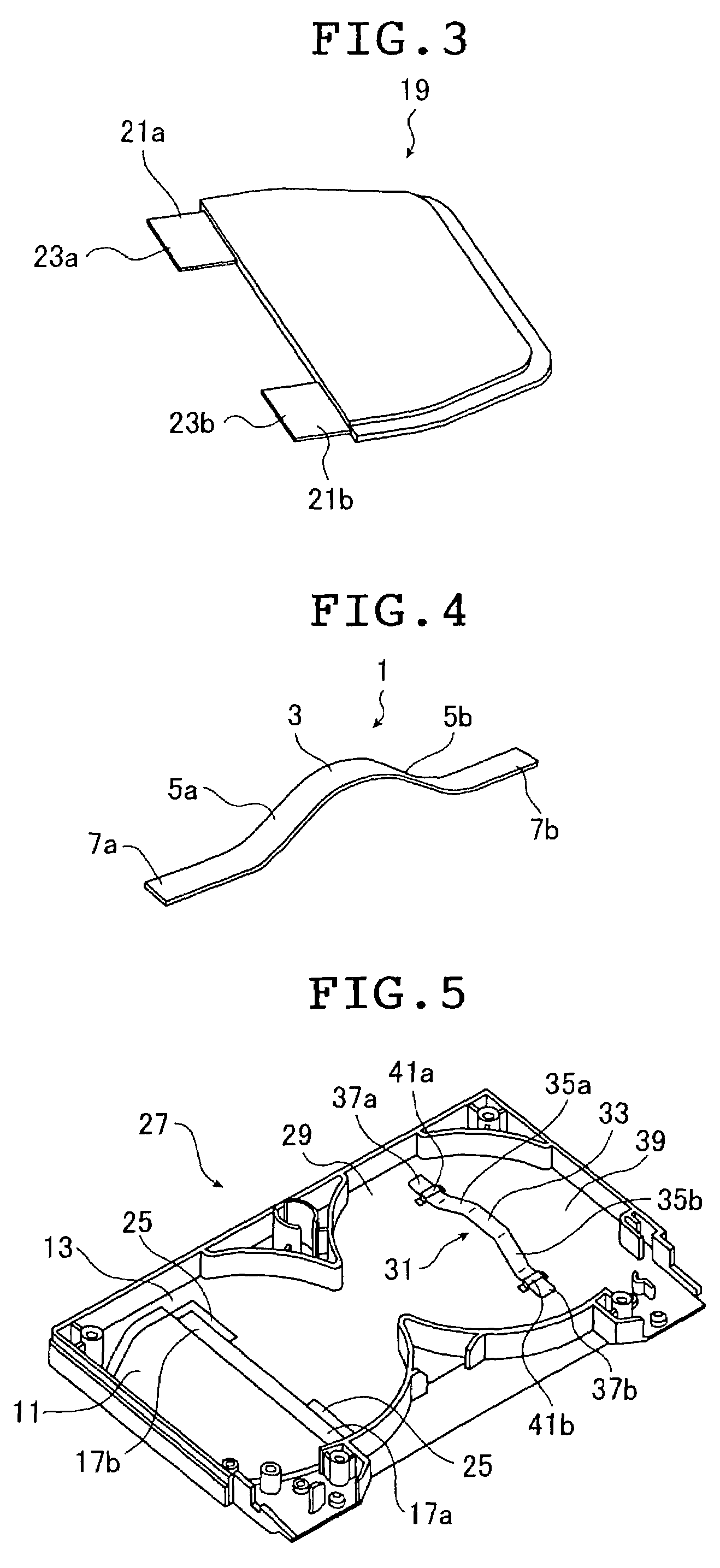

Tape reel, method of and apparatus for attaching tape to reel hub and method of and apparatus for winding tape on tape reel

InactiveUS20070262188A1Quality improvementImprove winding qualityPicture changing apparatusRecord information storageEngineeringFlange

Owner:FUJIFILM CORP

Method for manufacturing plastic component assembly and plastic component assembly, and plastic component-welded head and plastic component welding machine

InactiveCN101374649AImprove joint strengthImprove qualityRecord carriersRecord information storageMechanical engineeringMaterials science

Owner:VICTOR ADVANCED MEDIA CO LTD

Molding mold, molding method and tape cartridge

InactiveUS7270780B2Small sizeLarge heightOrganic active ingredientsTailstocks/centresMagnetic tapeEngineering

A molding mold and a molding method are disclosed, for molding a flange configuration in which a flange of a reel hub portion can be maintained in a predetermined configuration. Also a tape cartridge is disclosed, which can securely prevent a tape-shaped recording medium from touching at the flange while the tape cartridge is being used. In the molding mold for molding, a flange configuration is produced, which is provided with a reel hub portion having a flange and a hub arranged at a substantially center of the flange and an insert portion disposed at a substantially center of the reel hub portion at an opposite side of the hub, and which includes: an insert attaching portion; a flange forming portion for forming the flange; and a hub forming portion for forming the hub; wherein in a forming surface of at a side of the hub forming portion of the flange forming portion, a dimension of a circular area over from a root end of the hub forming portion to a substantially intermediate portion between the root end and a circumferential end of the flange forming portion, is corrected in view of deformation upon molding.

Owner:TDK CORPARATION

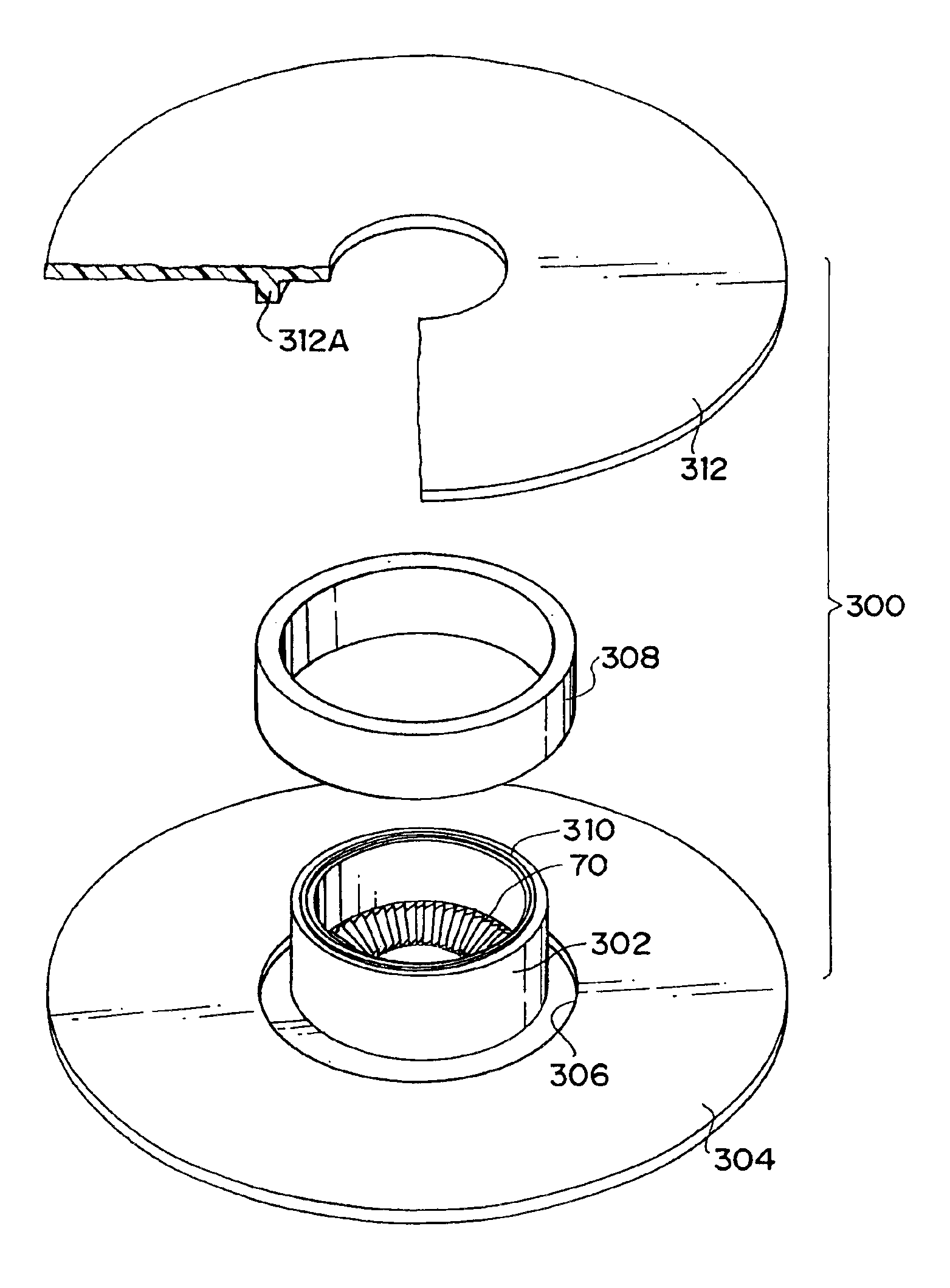

Manufacturing method of reel, reel, and recording tape cartridge

InactiveUS20110240786A1Flowability of the melted resin material in the metal moldLong processPicture changing apparatusRecord information storageMolding machineConductive materials

A manufacturing method of a reel including a substantially cylindrical hub, around an outer peripheral surface of which a recording tape is wound, and flanges provided at end portions of the hub, includes entering a pelletized resin material and a fibrous conductive material whose length is longer than a pellet length of the resin material into a molding machine to mold the hub and the flanges, thereby providing conductivity to the hub and the flanges.

Owner:FUJIFILM CORP

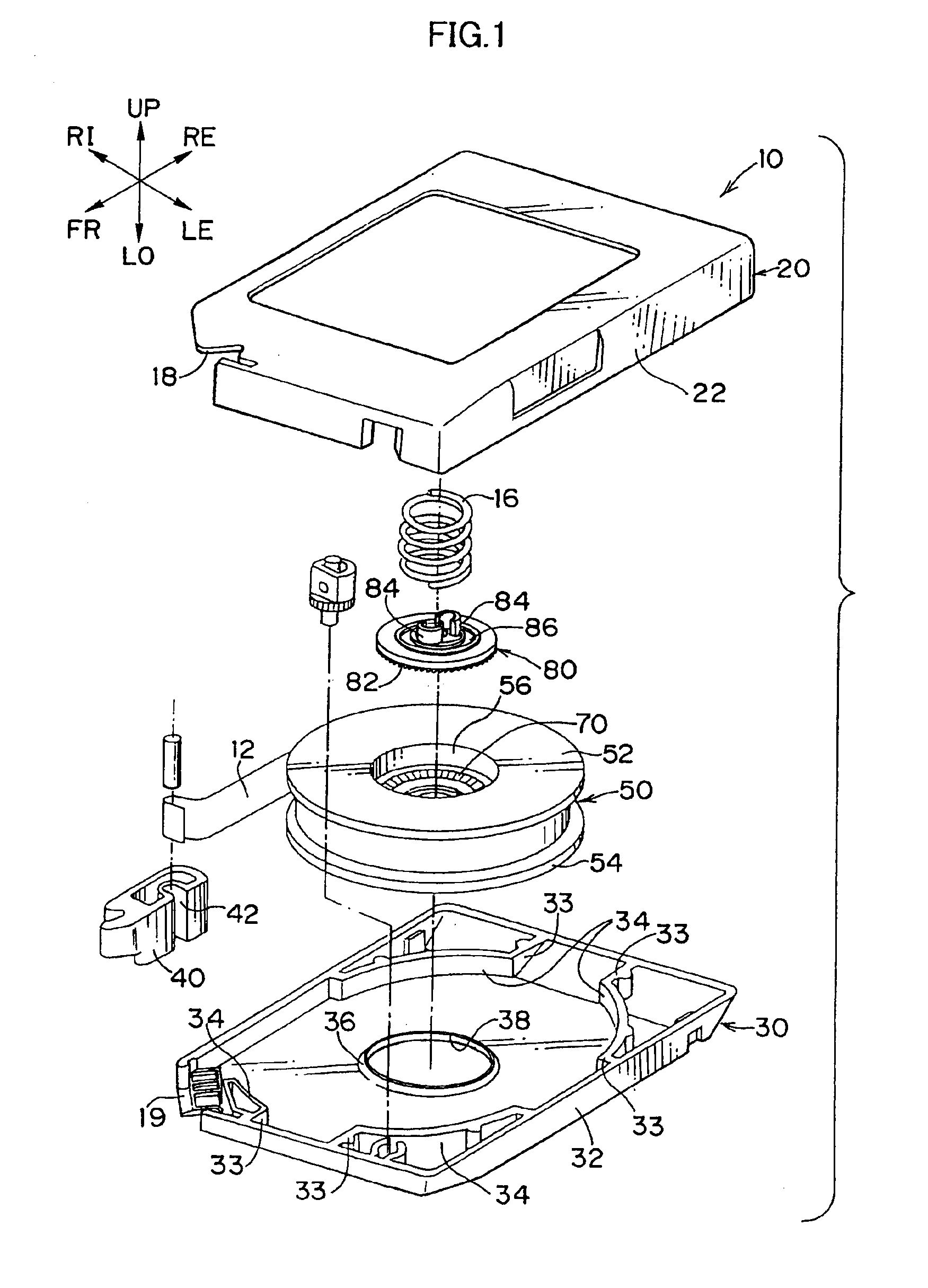

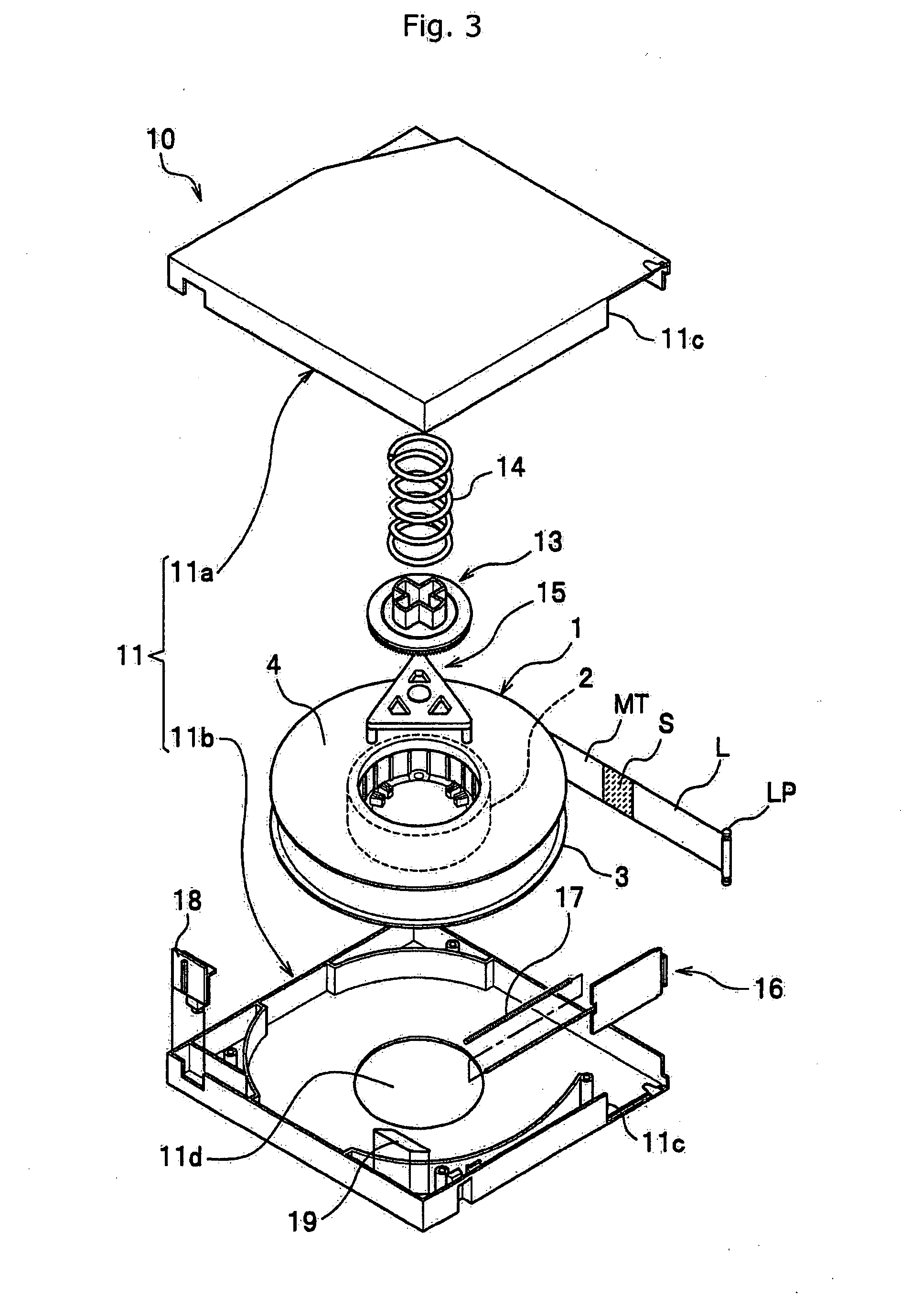

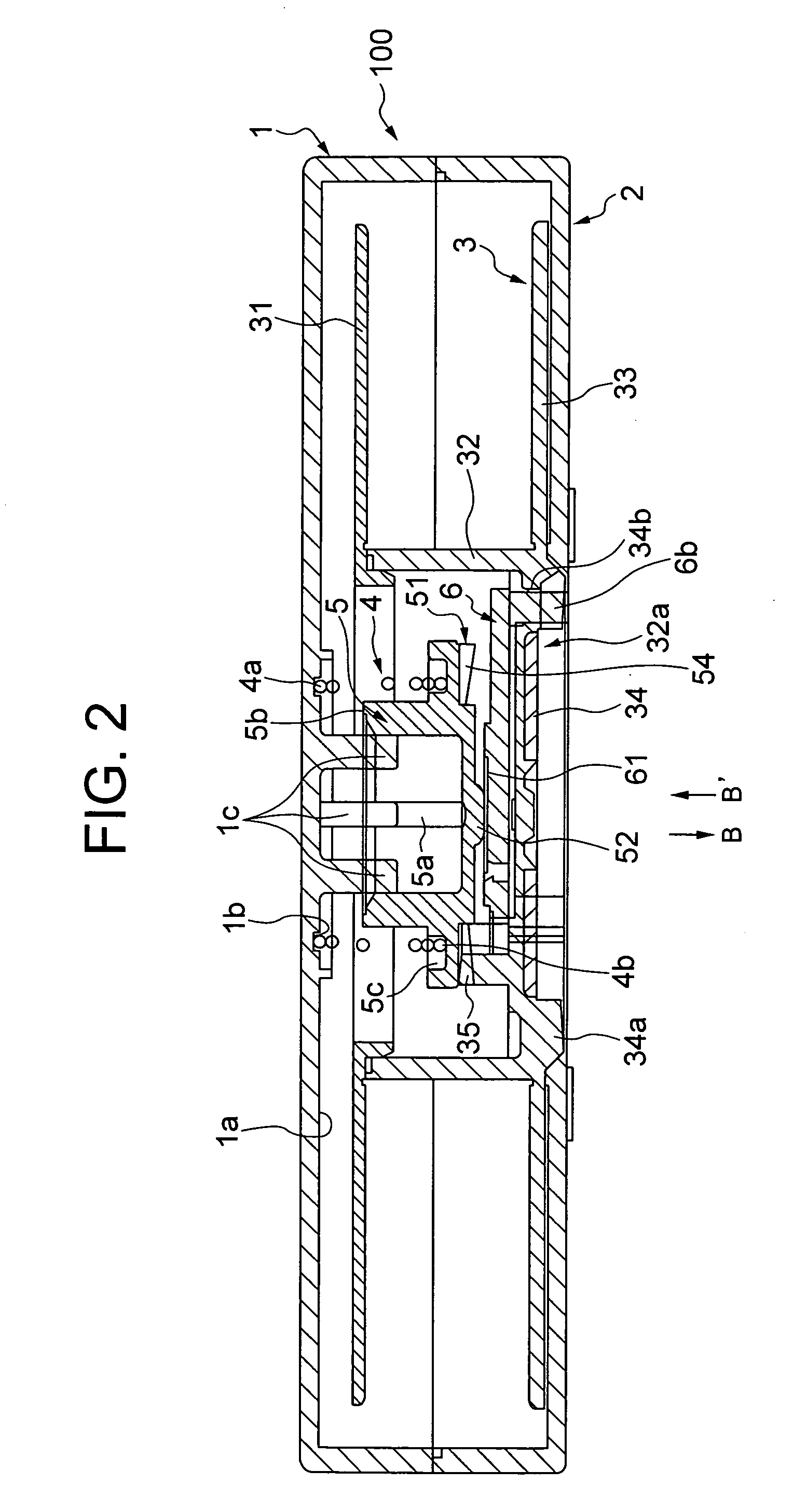

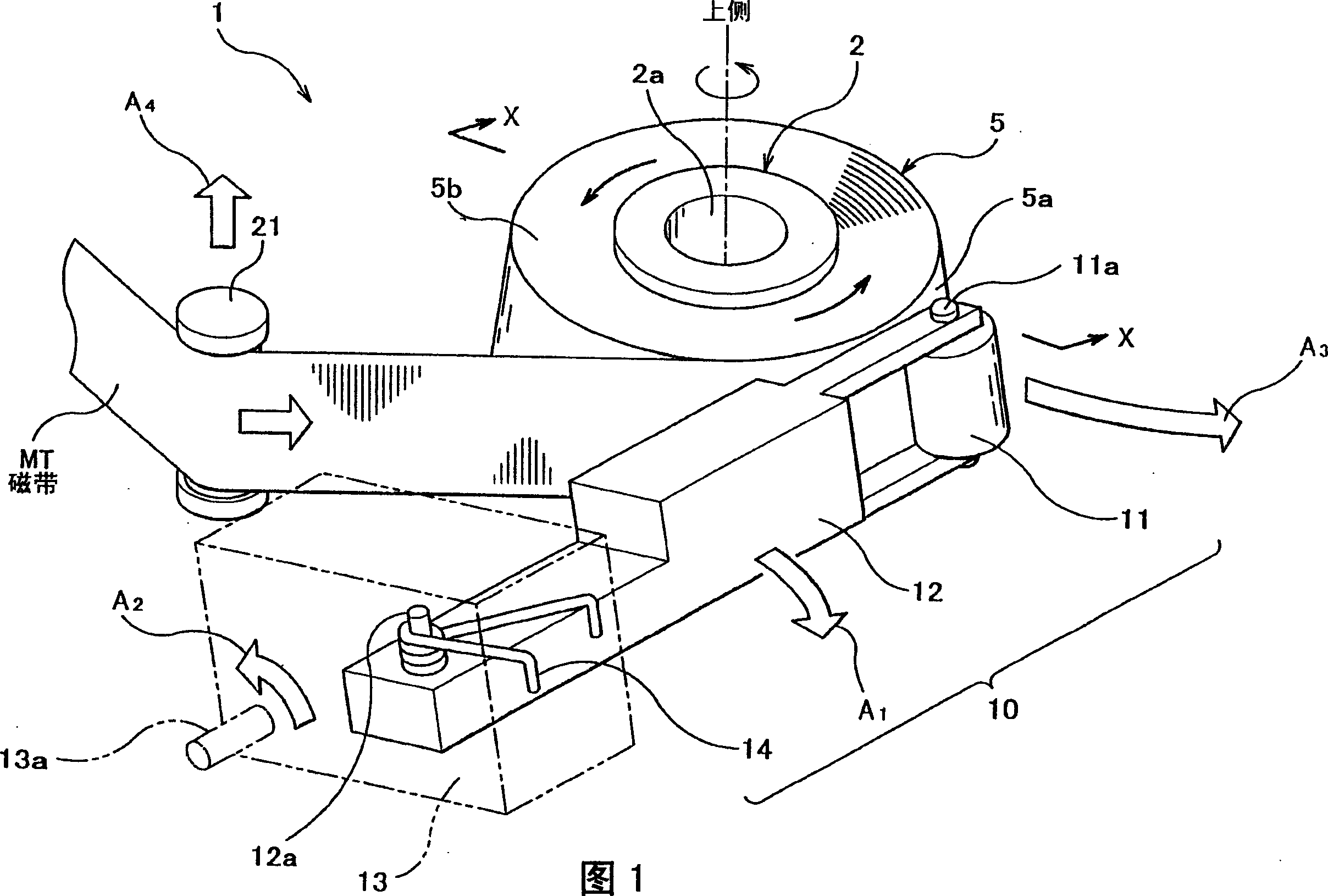

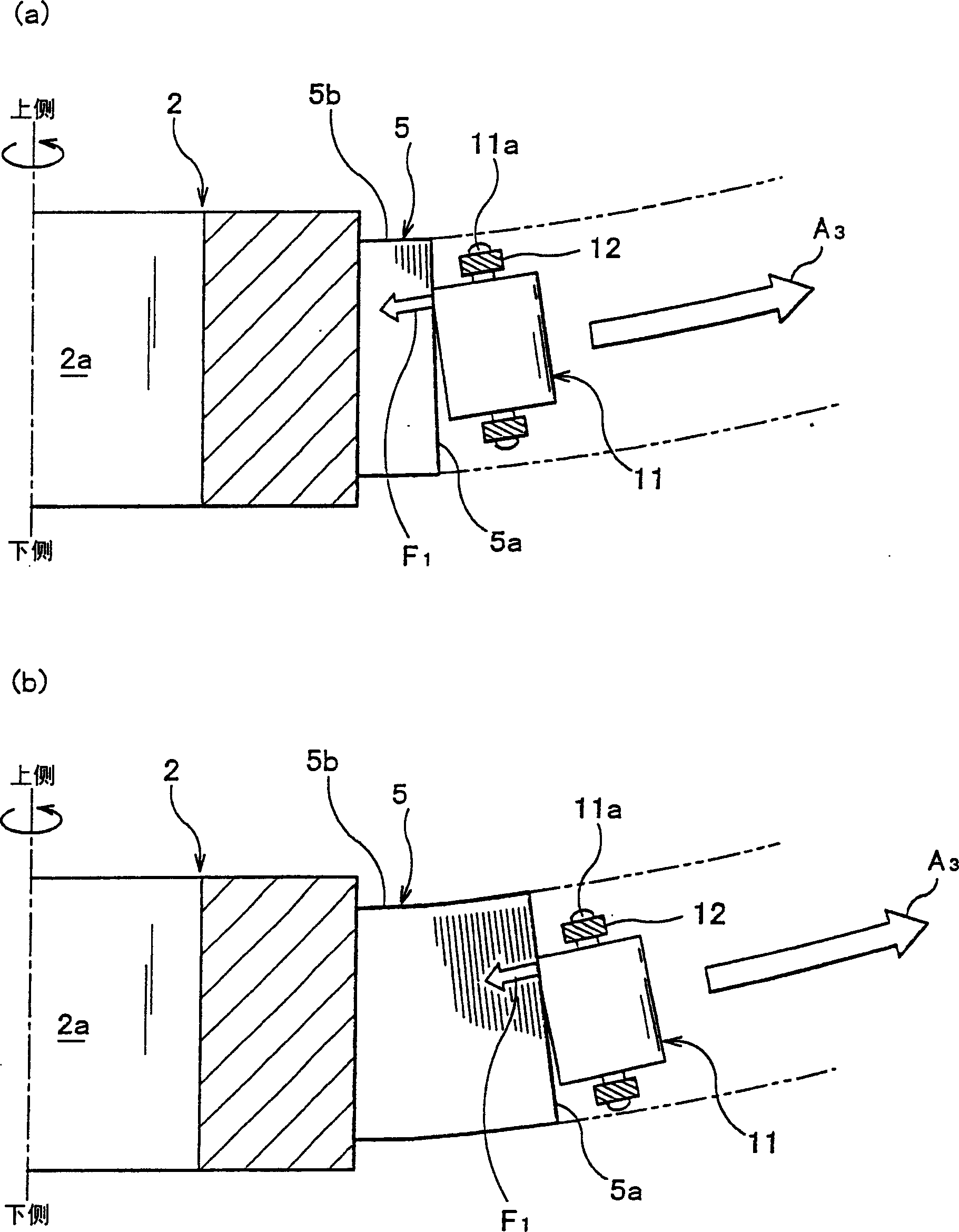

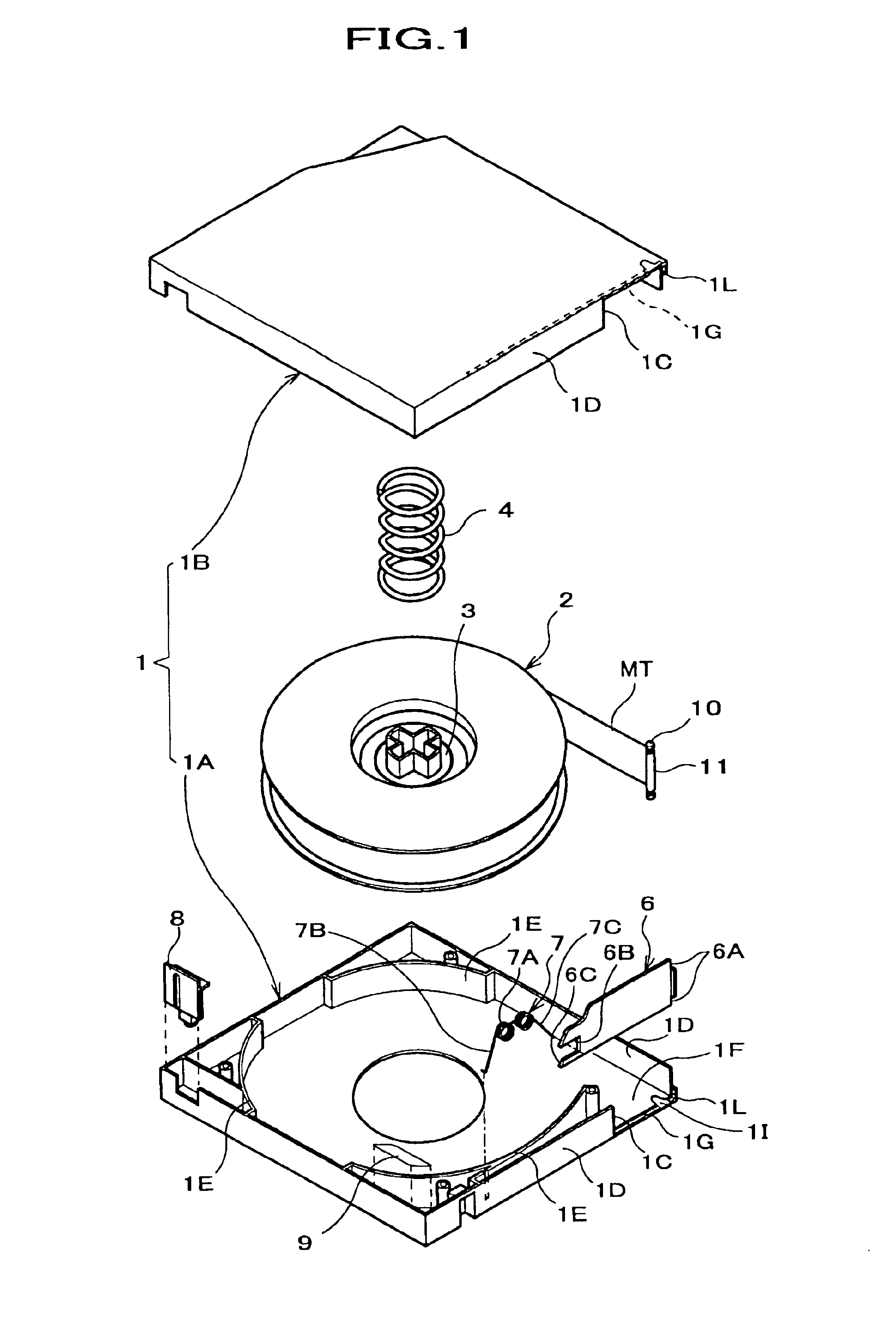

Magnetic tape cartridge

InactiveUS6954335B2Precise positioningDecrease the inclinationPicture changing apparatusRecord information storageMagnetic tapeEngineering

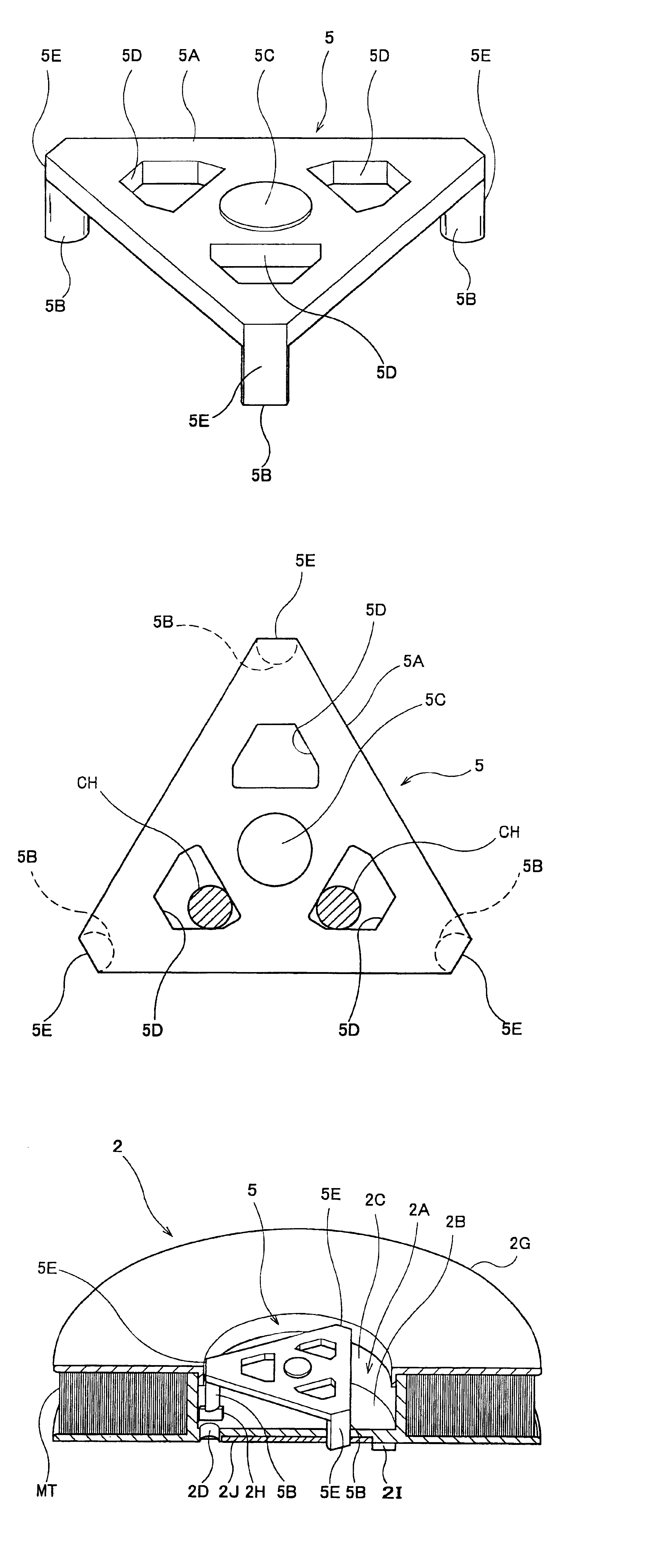

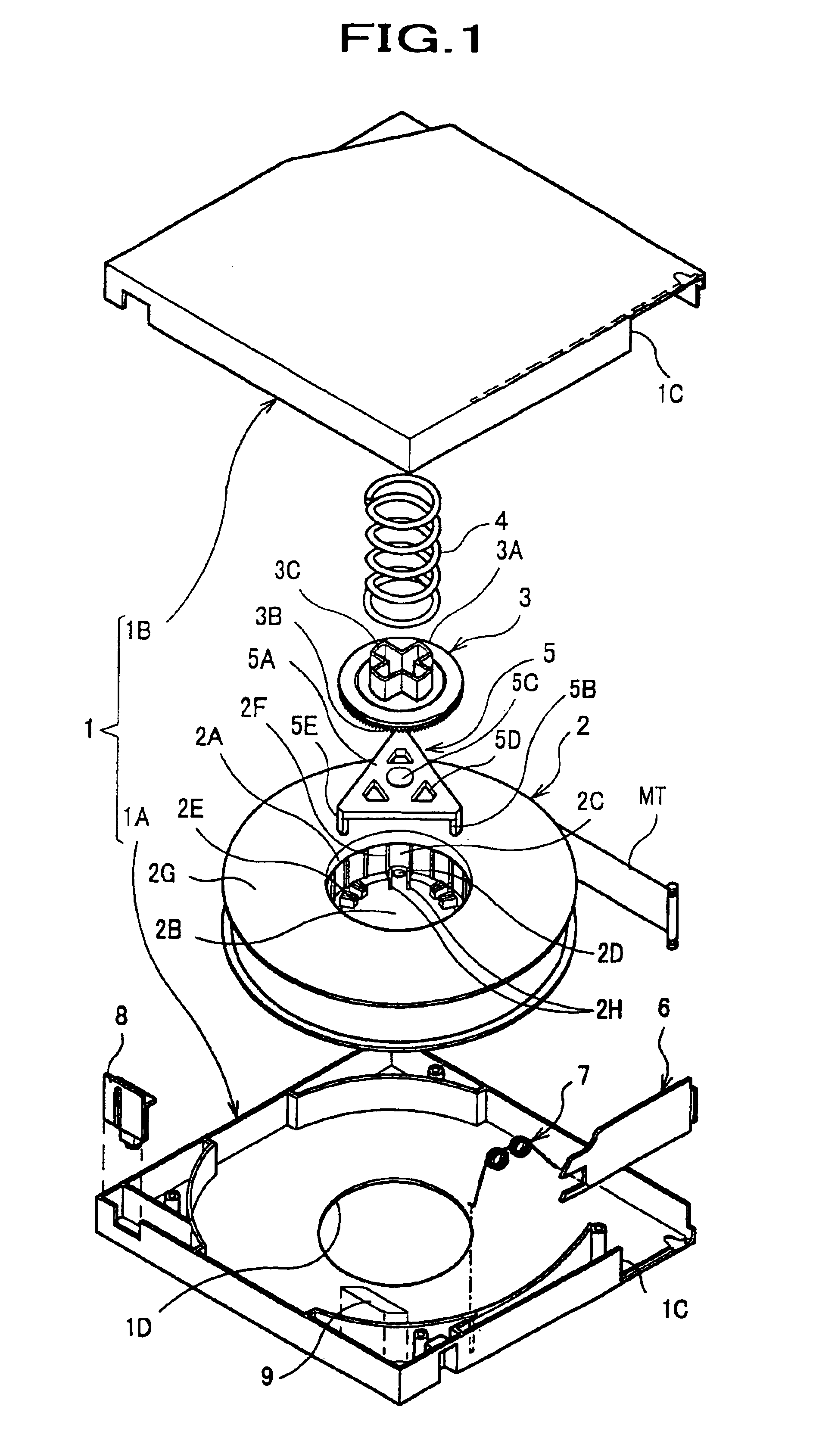

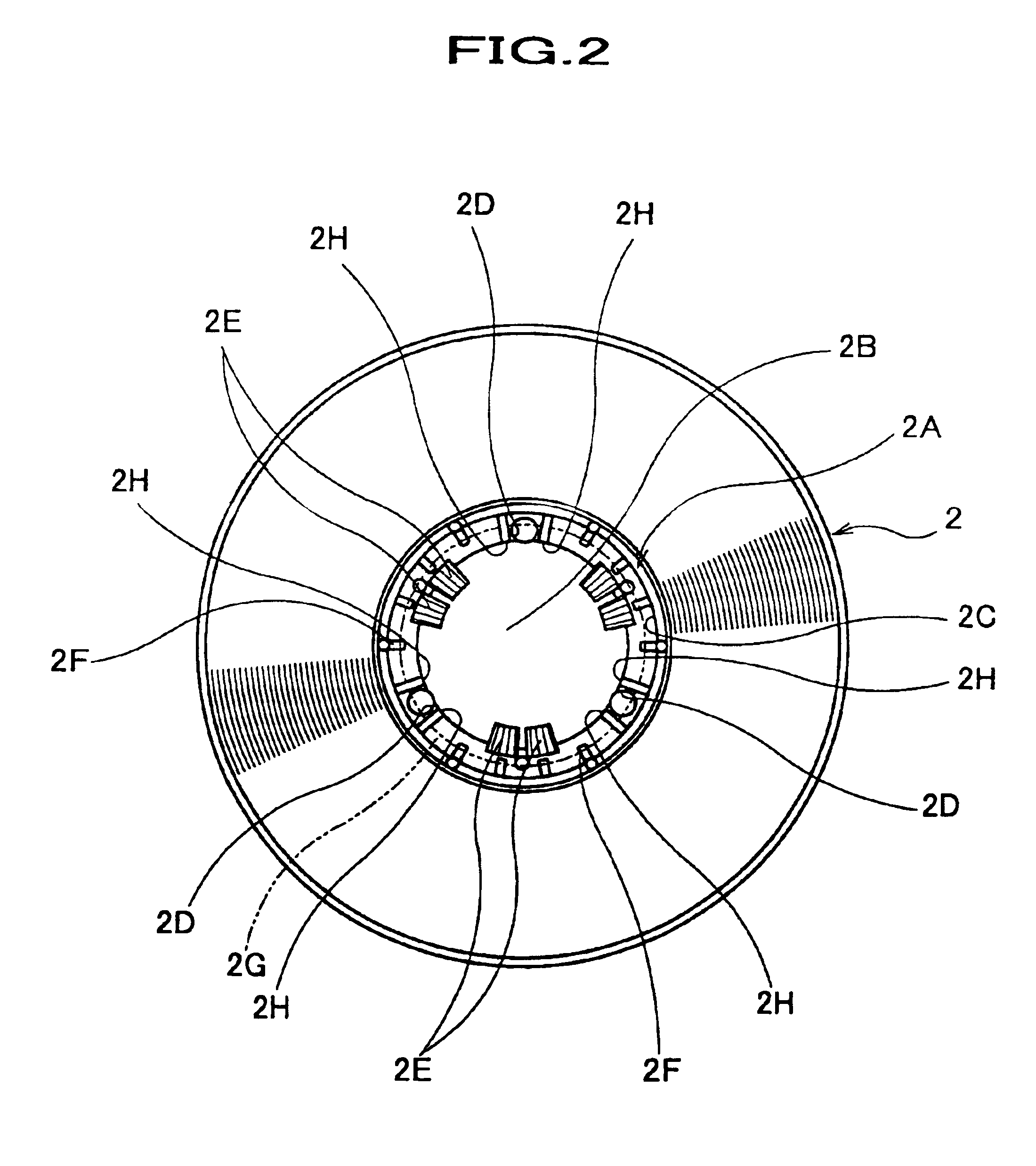

A magnetic tape cartridge comprises: a reel 2 around which a magnetic tape MT is wound; a cartridge case 1 for accommodating the reel 2 in a locked state; and a release pad 5 inserted into a cup-shaped hub 2A of the reel 2 in a locked state of the reel 2. The release pad 5 includes a pad body 5A having a plurality of corners to be faced proximately to the inner peripheral surface 2C of the cup-shaped hub 2A, and a plurality of lock releasing pins 5B projecting downwardly from a bottom surface of the pad body 5A at the respective corners and inserted through a bottom surface of the cup-shaped hub 2A. The release pad 5 is provided with a flank 5E extending from each corner downwardly through the respective lock release pin 5B so that an assembling clearance is formed with respect to an inner periphery of a flange 2G position in an open side of the cup-shaped hub 2A.

Owner:FUJIFILM CORP +1

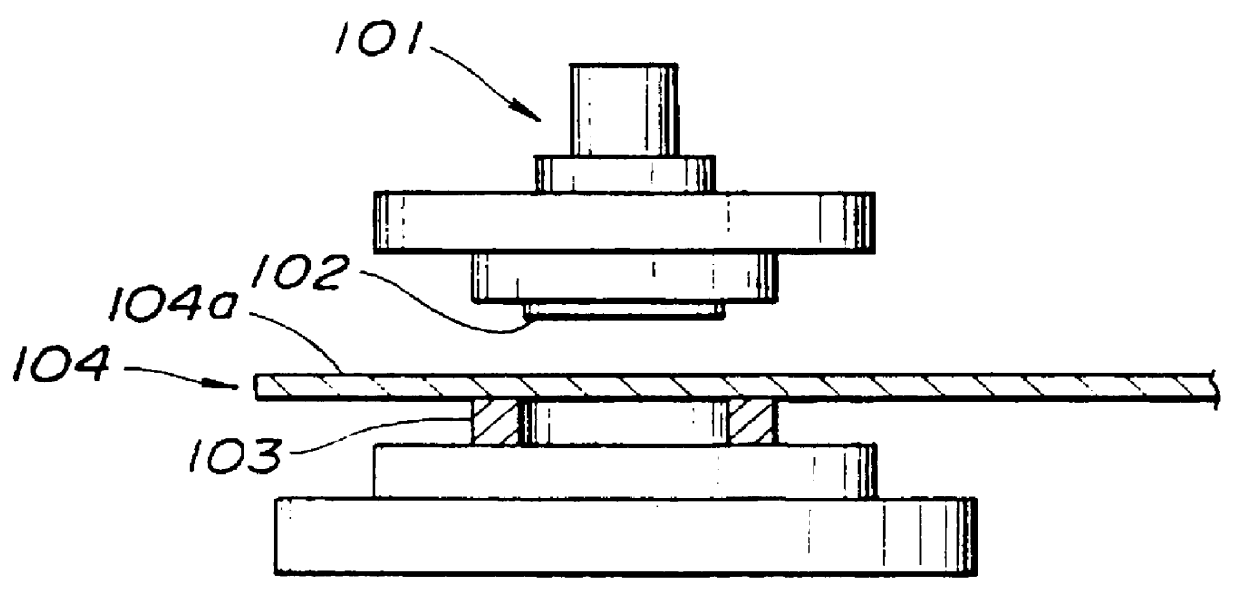

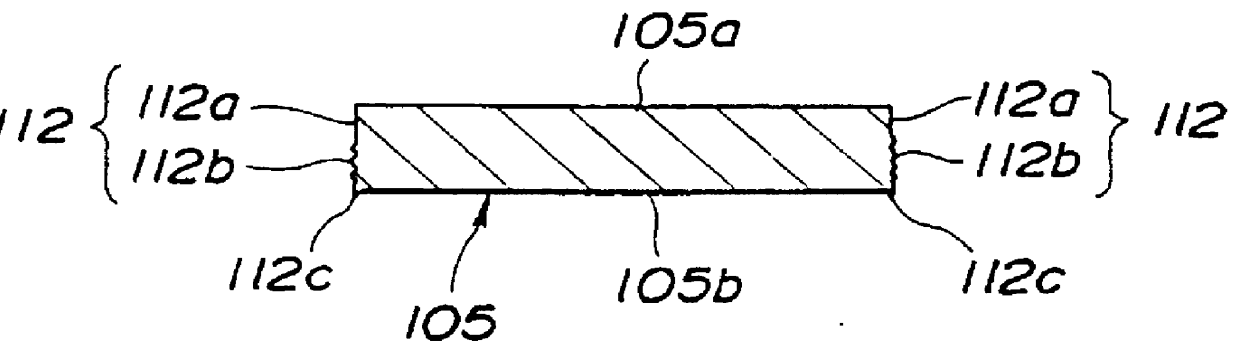

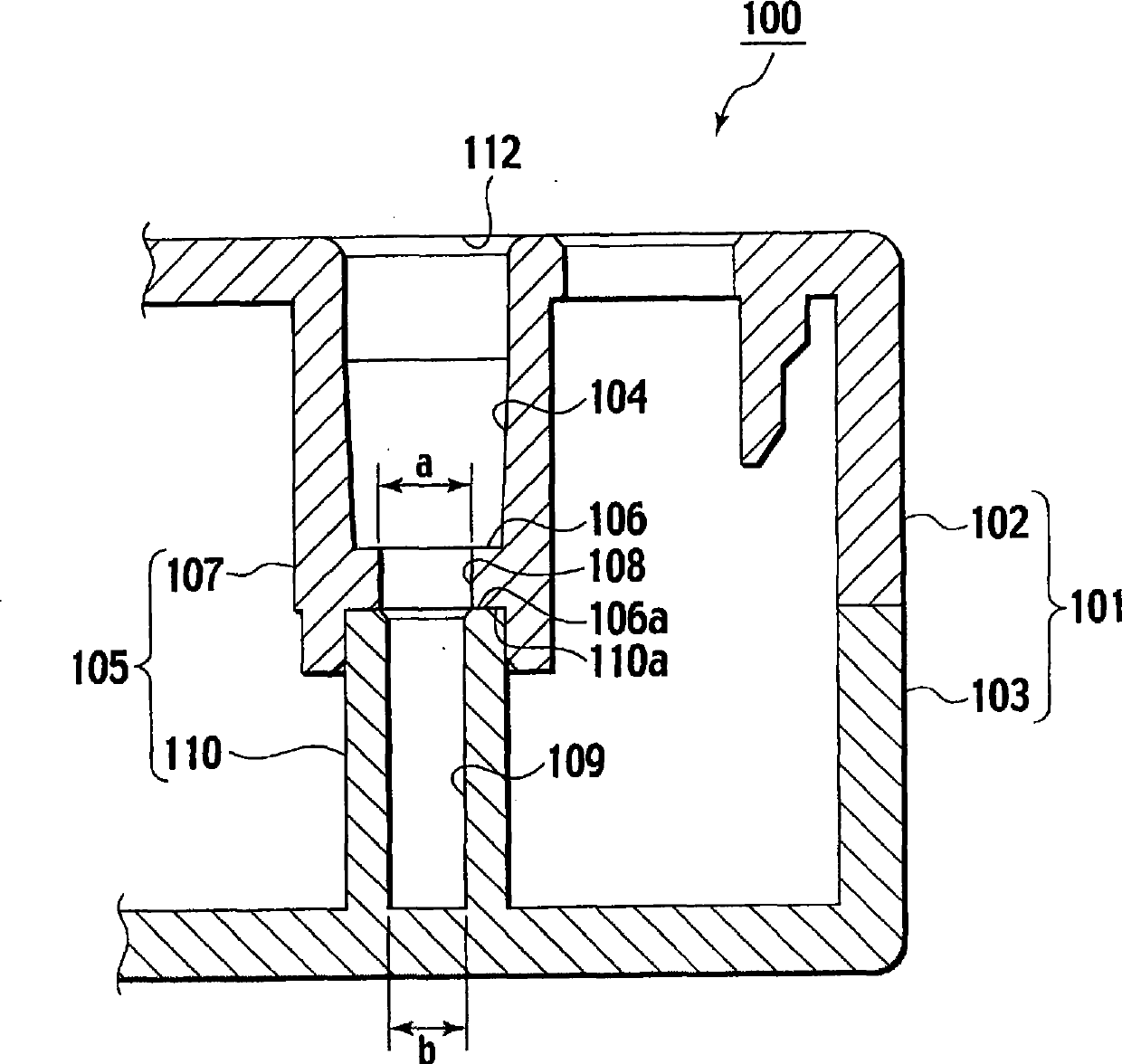

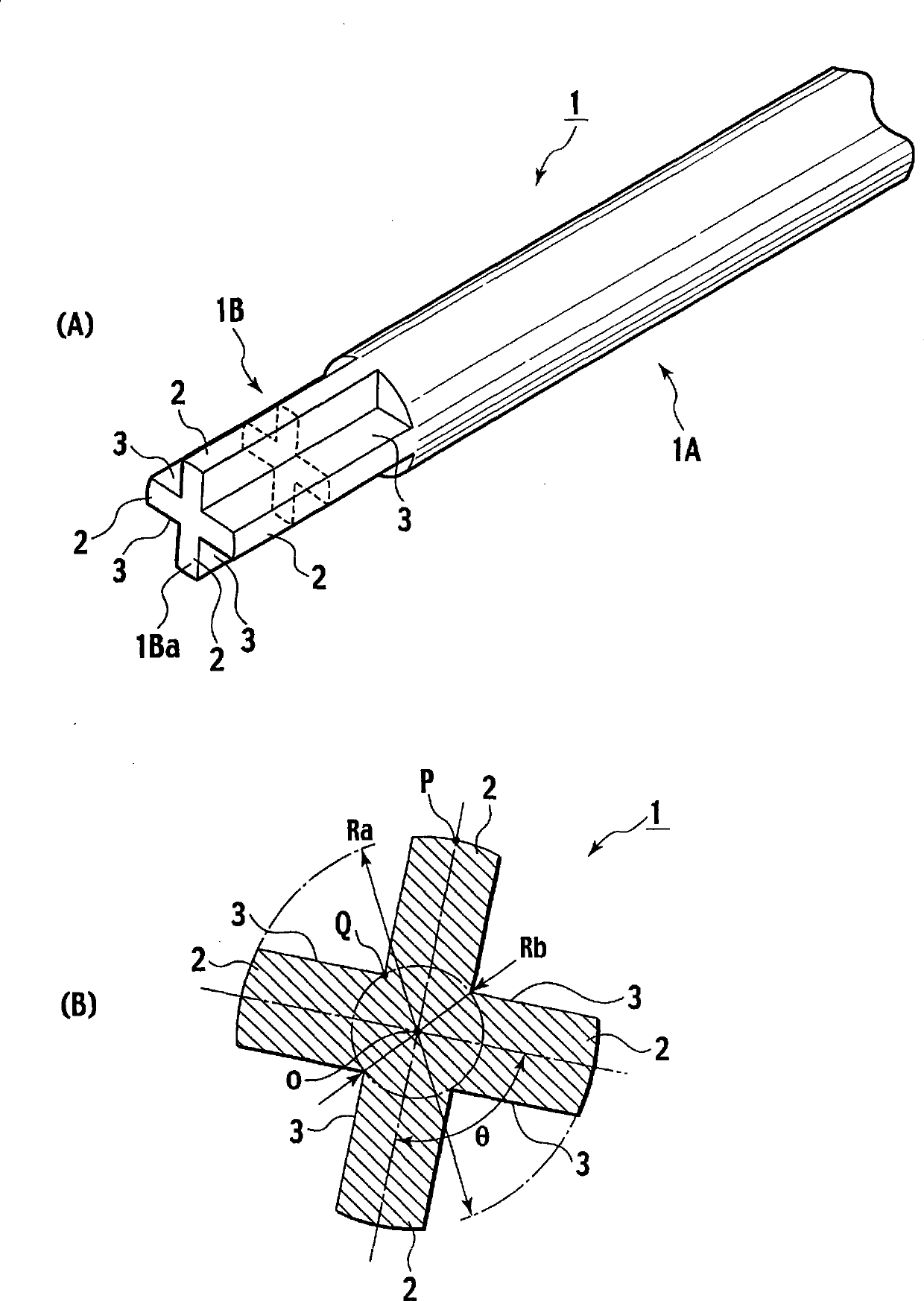

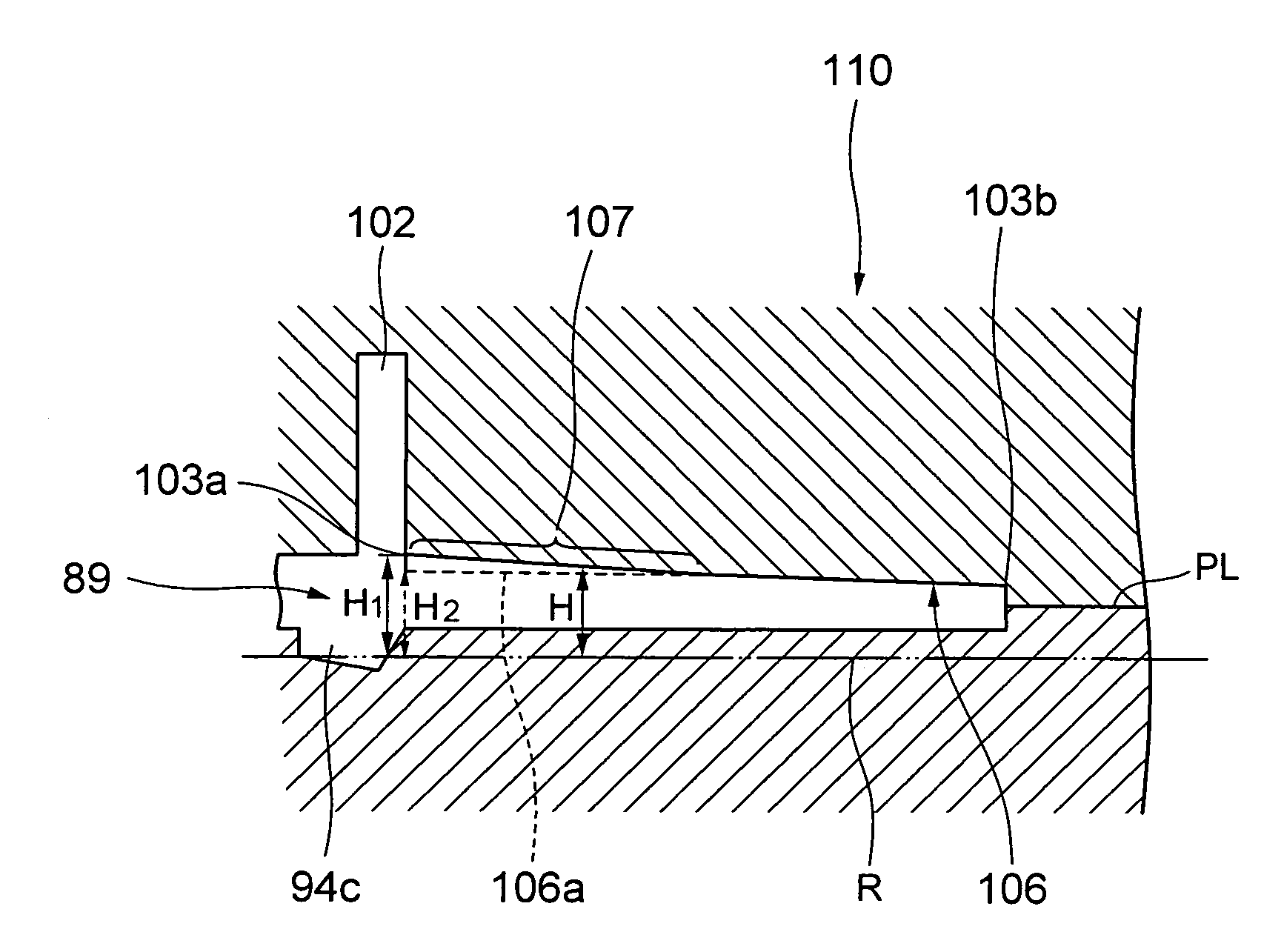

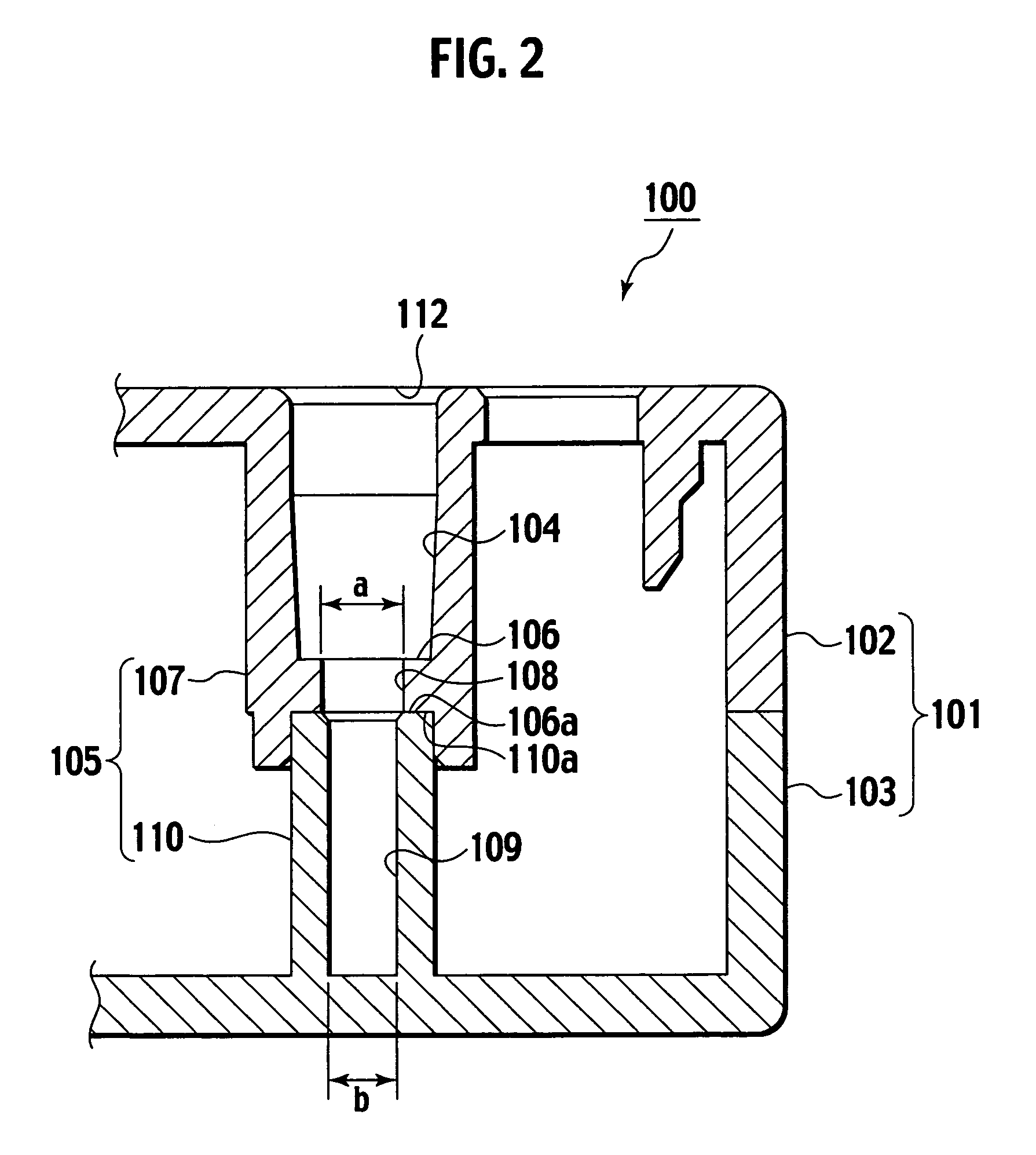

Method of Manufacturing Plastic Component Assembly and Plastic Component Assembly, and Plastic Component Welding Head and Plastic Component Welding Machine

InactiveUS20090011187A1Improve joint strengthQuality improvementMechanical working/deformationRecord carriersEngineeringMechanical engineering

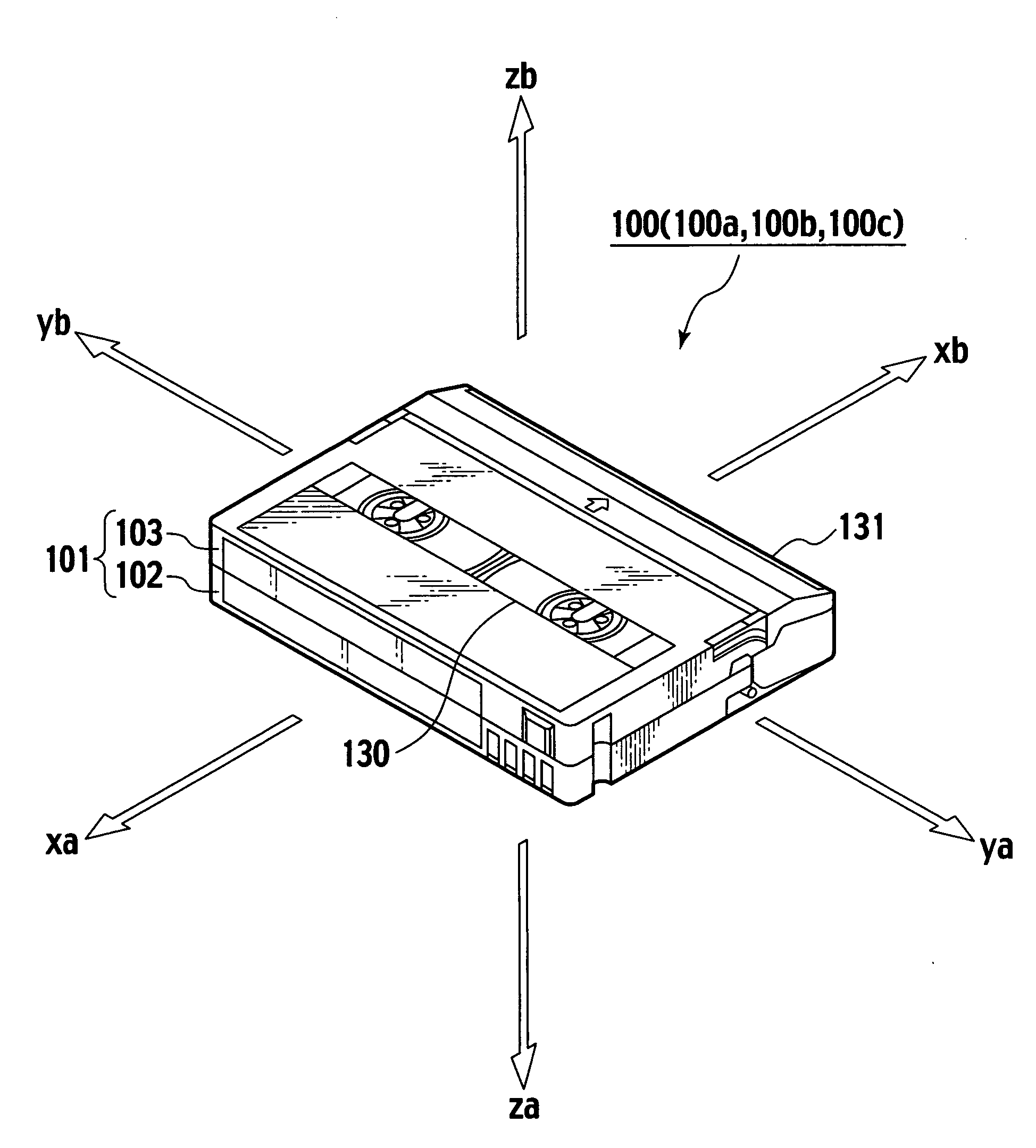

A lower half (102) and an upper half (103) are plastic components having thermoplasticity. A welding head (1) having a plurality of convex portions formed in a circumferential direction, the convex portions extending in a longitudinal direction within a range of a predetermined length, is inserted so as to span a lower boss (107) and an upper boss (110) in a joint portion (105). The plastic in the joint portion (105) is melted by means of the welding head (1). The lower half (102) and the upper half (103) are welded to and integrated with each other by solidifying the molten plastic.

Owner:VICTOR ADVANCED MEDIA CO LTD

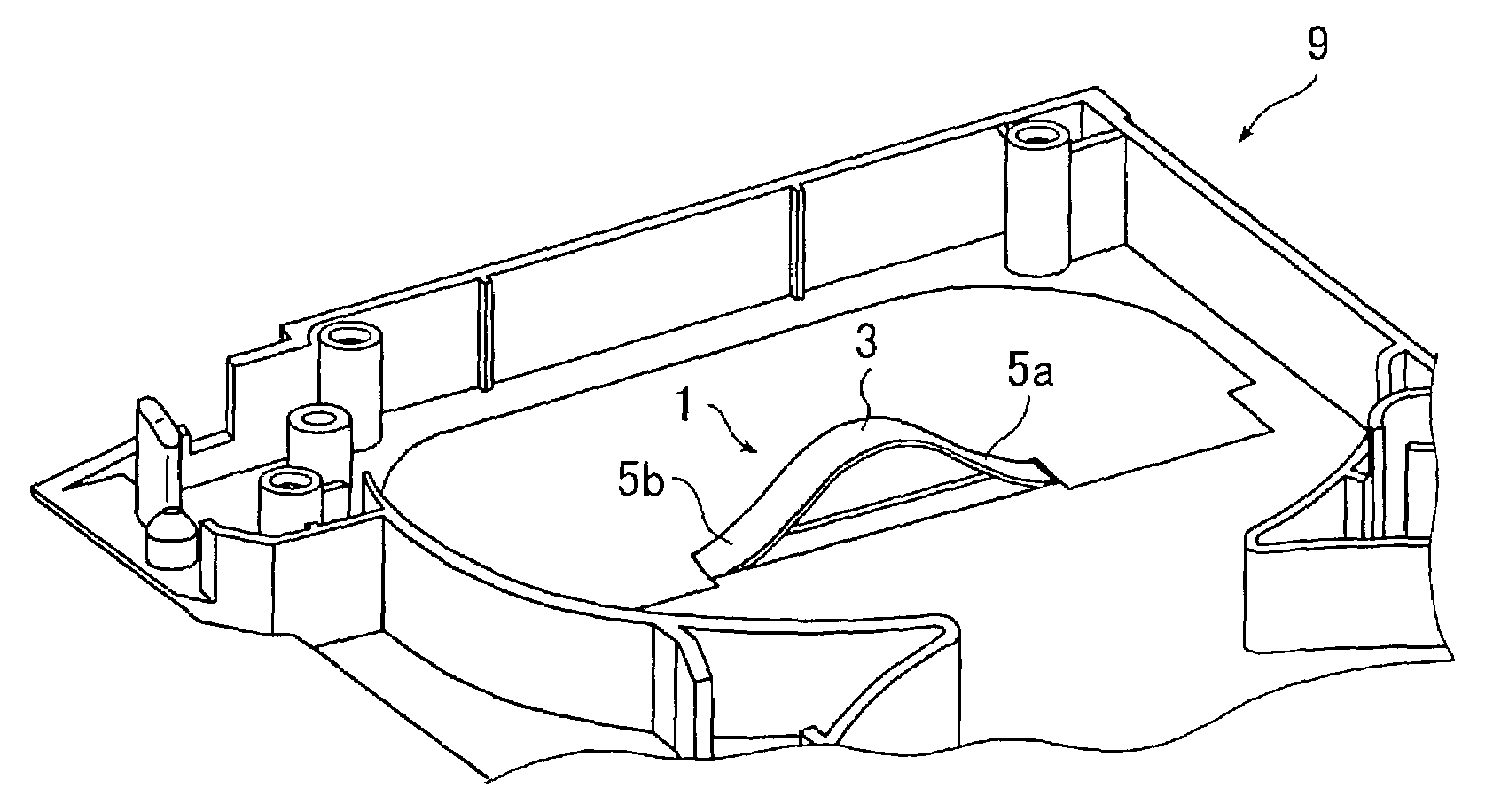

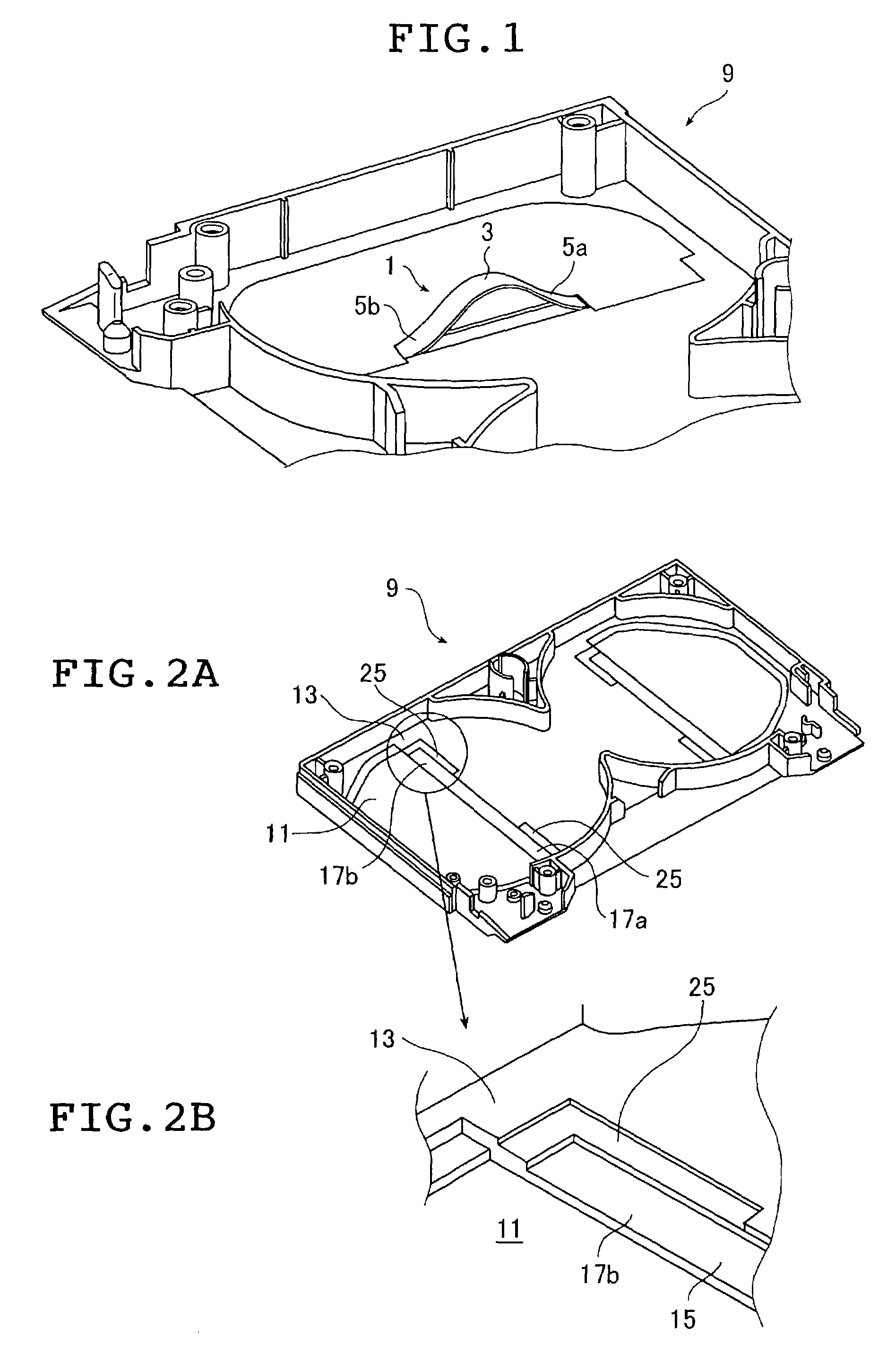

Magnetic tape cassettes, tape reels for use therewith, resinous leaf springs, and a process for producing them

InactiveUS7121493B2Easy to assembleReduce wastePicture changing apparatusLeaf springsMagnetic tapeMetallic materials

A magnetic tape cassette includes a case that is formed by joining an upper half and a lower half, one or more tape reels, a window and a reel urging member having a tape reel contacting portion which contacts an upper part of the tape reel(s), bent arms connected to opposite sides of the tape reel contacting portion and sliding end portions provided at distal ends of the bent arm. A slide groove is provided in an inner surface of a perimeter of a window opening in the upper half and a window member has hold-and-retain portions which hold the sliding end portions in cooperation with a bottom surface of the slide groove into which the sliding end portions have been fitted. A tape reel suitable for use with the magnetic tape cassette, a resinous leaf spring and its production process are also provided. Tape reels housed in a cassette case can be urged toward the lower half by a member whose structure is simple and permits easy fitting and removal. Assorted collection of constituent materials, particularly for assorted collection of resin materials and selective collection of resin materials as separate from metal materials are possible.

Owner:FUJIFILM HLDG CORP +1

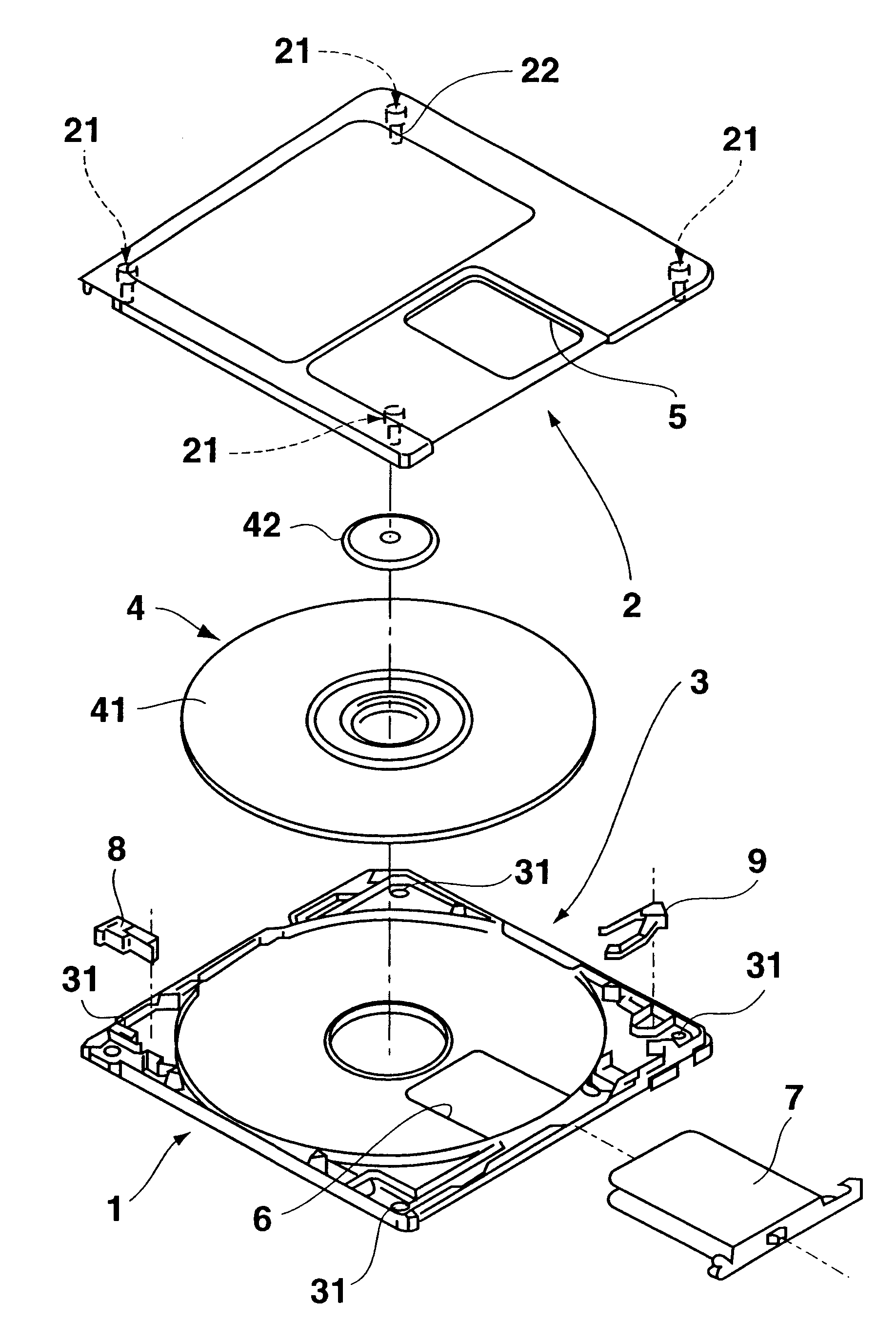

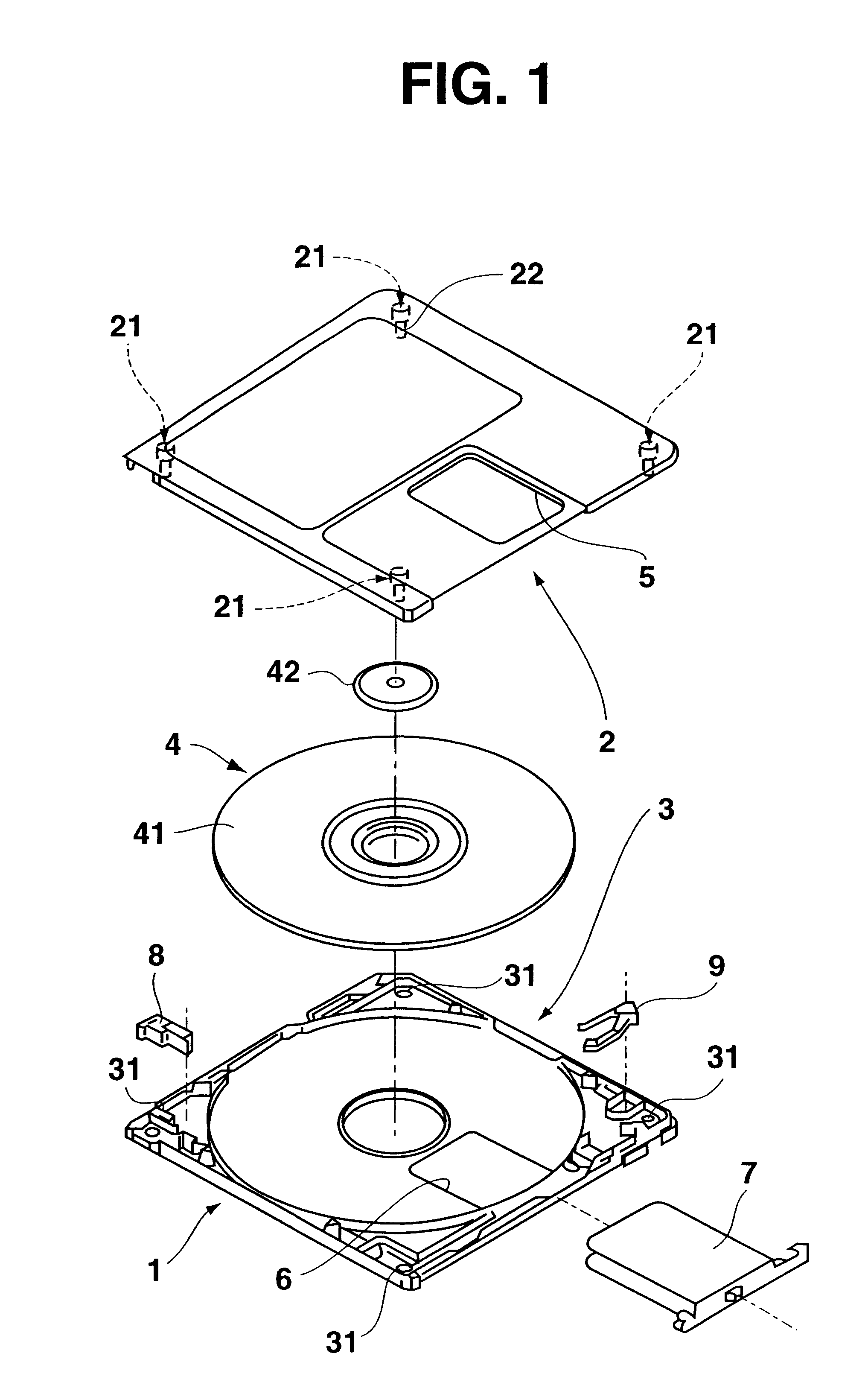

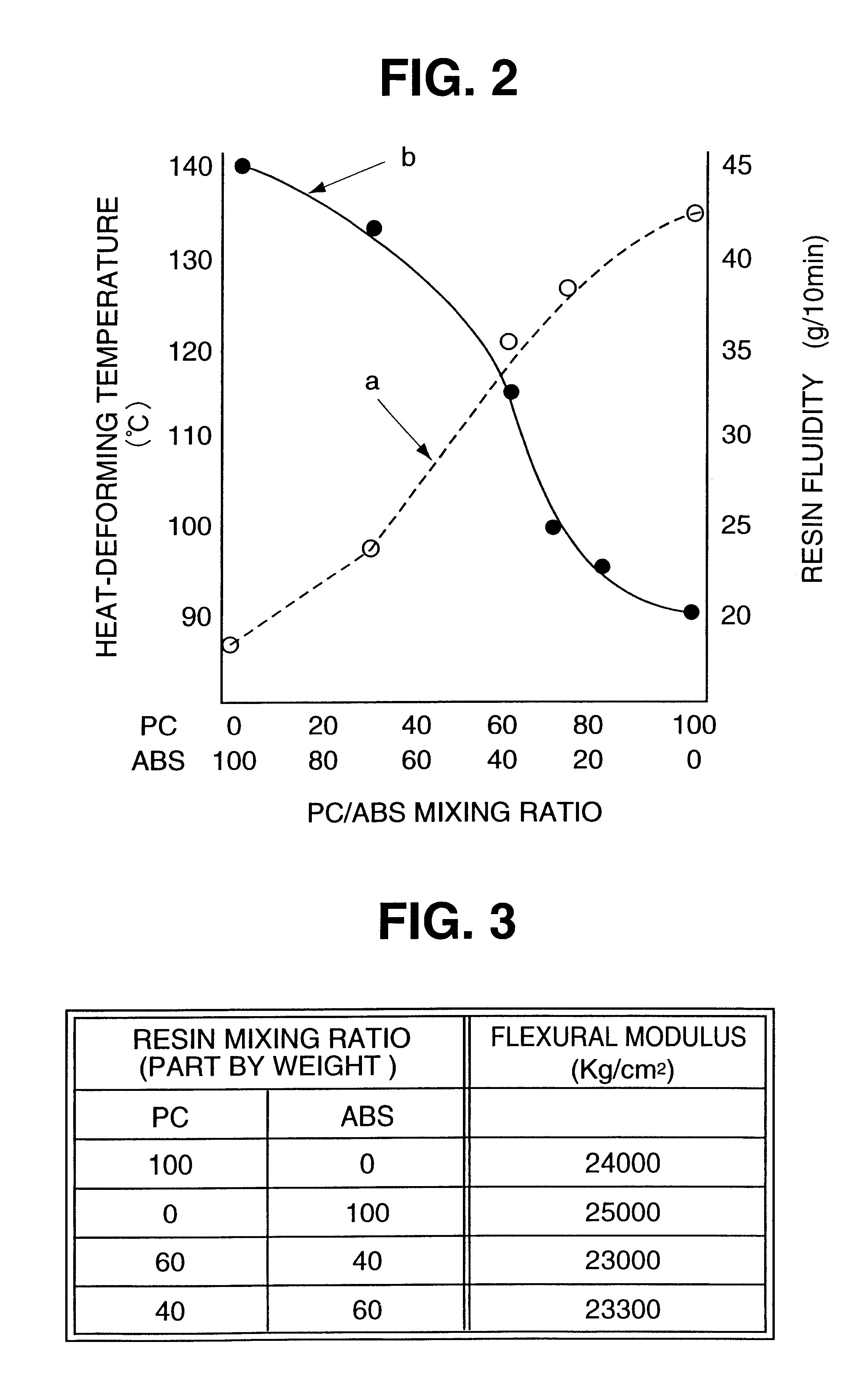

Disk cartridge and manufacturing method thereof

InactiveUS6952327B1High strengthRecord information storageFlat record carrier containersHeat deflection temperatureInjection moulding

A disk cartridge in which a disk is loaded is formed with composite synthetic resin including at least two types of thermoplastic resin, an anti-static polymer, and an inorganic filler, heat-deforming temperatures of at least two types of the thermoplastic resin mutually differing.The disk cartridge is provided by a method comprising the steps of mixing at least two types of thermoplastic resin to provide a mixture, heat-deforming temperatures of at least two types of the thermoplastic resin mutually differing, mixing an inorganic filler with a mixture of at least two types of the thermoplastic resin, mixing an anti-static polymer with the mixture of at least two types of the thermoplastic resin including the inorganic filler to provide a composite synthetic resin, injection molding the composite synthetic resin to provide component parts of the disk cartridge, and assembling the component parts to form the disk cartridge with the disk loaded therein.

Owner:SONY CORP

Molding mold, molding method and tape cartridge

InactiveUS20070284471A1Small sizeLarge heightProjector film strip handlingCamera film strip handlingMagnetic tapeEngineering

A molding mold and a molding method are disclosed, for molding a flange configuration in which a flange of a reel hub portion can be maintained in a predetermined configuration. Also a tape cartridge is disclosed, which can securely prevent a tape-shaped recording medium from touching at the flange while the tape cartridge is being used. In the molding mold for molding, a flange configuration is produced, which is provided with a reel hub portion having a flange and a hub arranged at a substantially center of the flange and an insert portion disposed at a substantially center of the reel hub portion at an opposite side of the hub, and which includes: an insert attaching portion; a flange forming portion for forming the flange; and a hub forming portion for forming the hub; wherein in a forming surface of at a side of the hub forming portion of the flange forming portion, a dimension of a circular area over from a root end of the hub forming portion to a substantially intermediate portion between the root end and a circumferential end of the flange forming portion, is corrected in view of deformation upon molding.

Owner:TDK CORPARATION

Tape winding method

InactiveCN1581303AImprove walking stabilityMagazine/cassette manufacturing apparatusRecord carrier guidanceMagnetic tapeEngineering

A tape winding method of the present invention comprises a winding process for winding tape on a periphery of a hub by rotating the hub so that one end surface of a wound roll, which consists of the tape having a base film and being wound, becomes concave; and a heating treatment process for performing a heating treatment for the wound roll within a predetermined temperature range just under a glass transition temperature of the base film.

Owner:FUJIFILM CORP

Magnetic tape cartridge

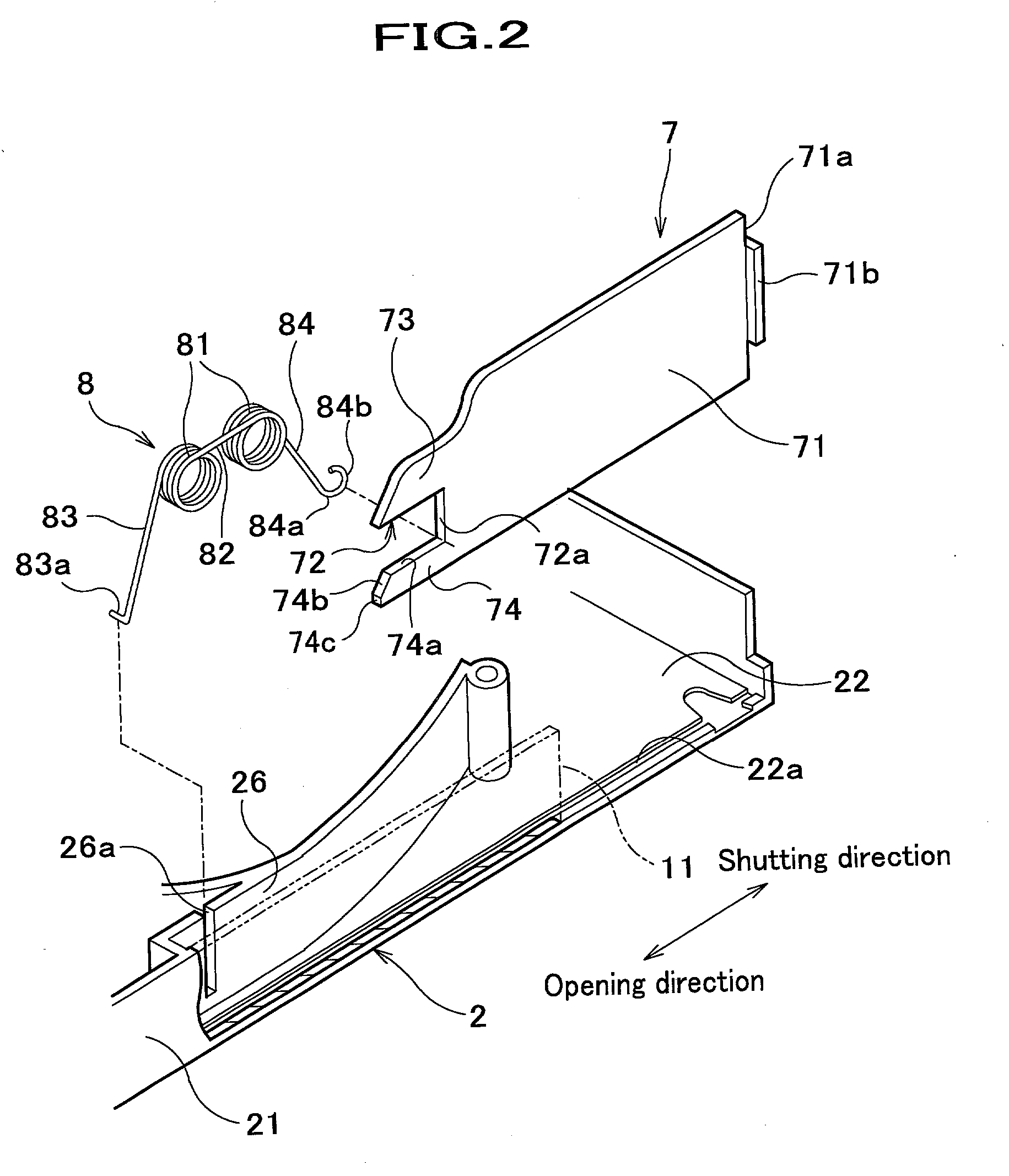

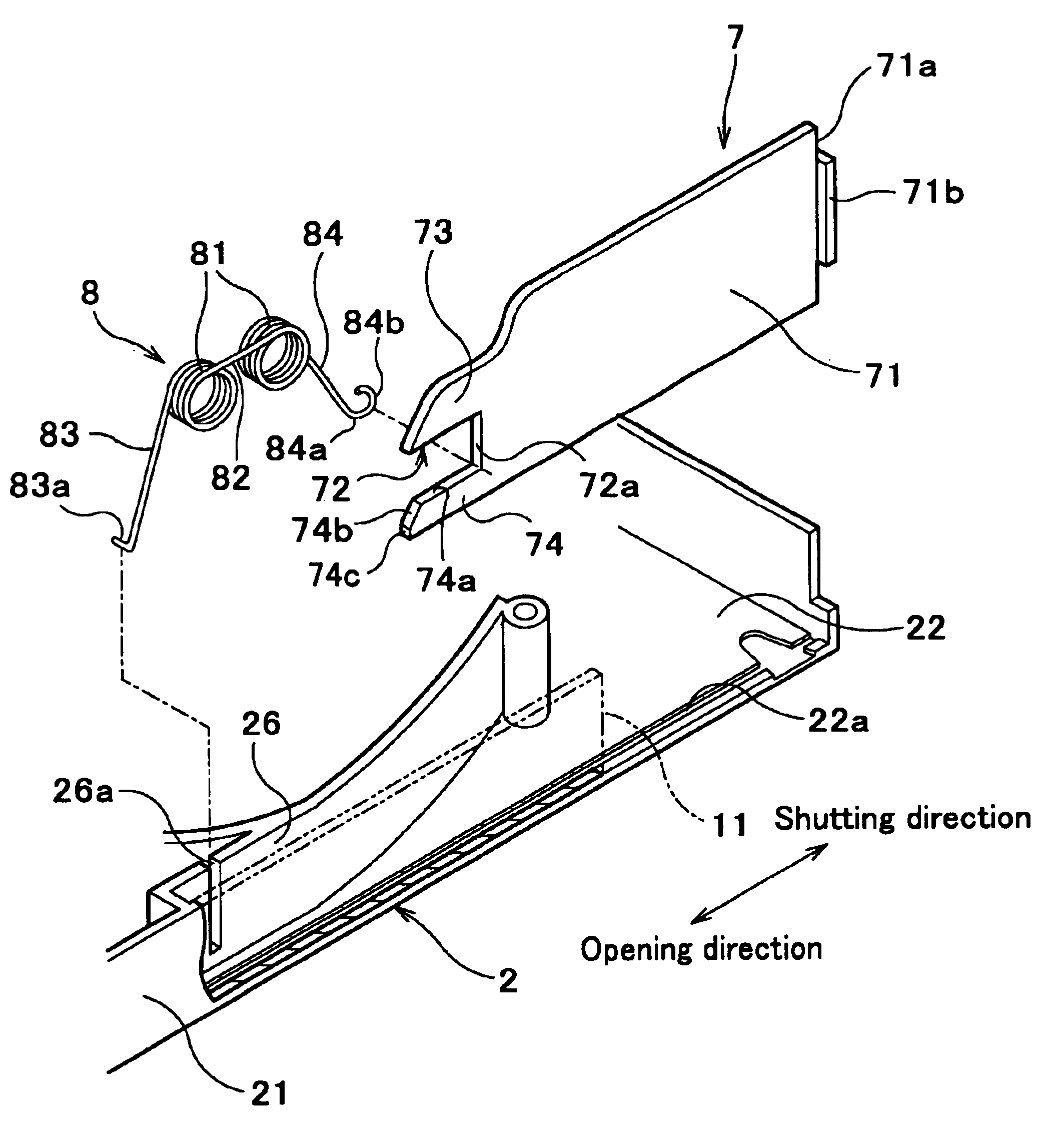

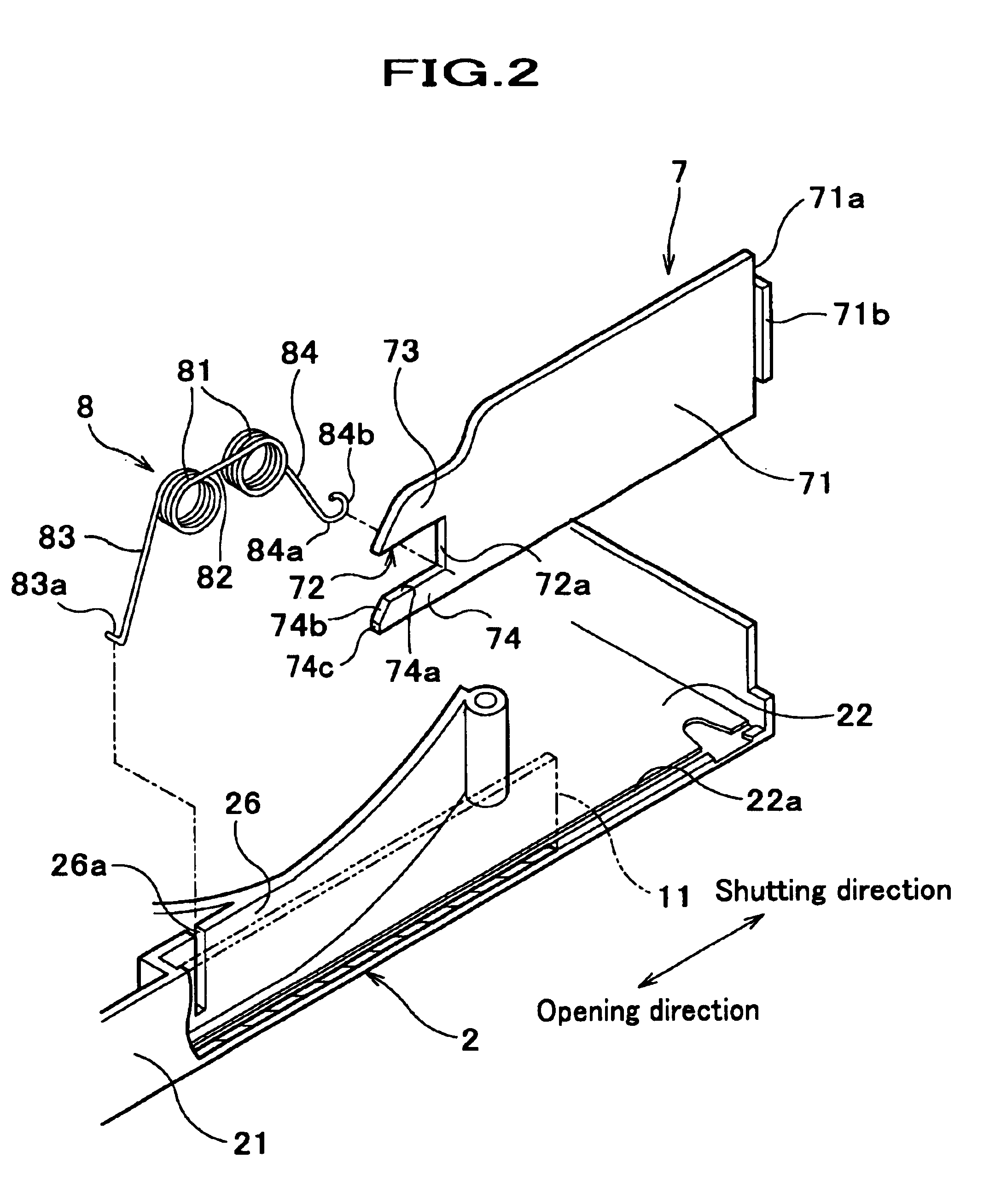

InactiveUS20020175240A1Picture changing apparatusRecord information storageProduction lineMagnetic tape

The present invention aim at providing a magnetic tape cartridge, which can be assembled using an automated products line by enabling the assembling operation of a spring member and a slide door with ease. For attaining these problems, there is provided a magnetic tape cartridge comprising a magnetic tape cartridge comprising; an opening provided on one side wall of a cartridge case, and is used for tape drawing; a slide door slidably supported by a guide part disposed along said one side wall, and said slide door is used for achieving the shutting-and-opening operation of said opening; a spring member for impelling said slide door to the shutting direction side, and is placed on said guide part; and a leading part for leading one end part of said spring member to a spring engaging part provided on said slide door, and is provided at one end part of said spring member.

Owner:FUJIFILM CORP +1

Magnetic tape cartridge

Owner:FUJIFILM CORP +1

Cartridge case

InactiveUS20060139804A1Preventing defective assemblyRising of the cartridge memory isAccessories for auxillary signalsRecord information storageMagnetic tapeEngineering

A cartridge case 1 for a magnetic tape cartridge comprises a cartridge case 1 consisting of a lower half 2 and an upper half 3. The lower half 2 is provided with retaining ribs 71 each having a retaining slanted surface 71a such that a plate-like cartridge memory 7 is positioned on the retaining slanted surfaces 71a with its one side 7d lowered and is obliquely supported with respect to a bottom plate 28 of the lower half 2. The upper half 3 is provided with supporting members for supporting various non-resilient constituent parts positioned on the lower half 2 and including the cartridge memory 7. The upper half 2 is provided with a stopper rod 77 such that when the upper half 3 is assembled with the lower half 2, the stopper rod 77 reaches a cartridge memory-rising region before the supporting members contact with the non-resilient constituent parts on the lower half 2.

Owner:FUJIFILM CORP

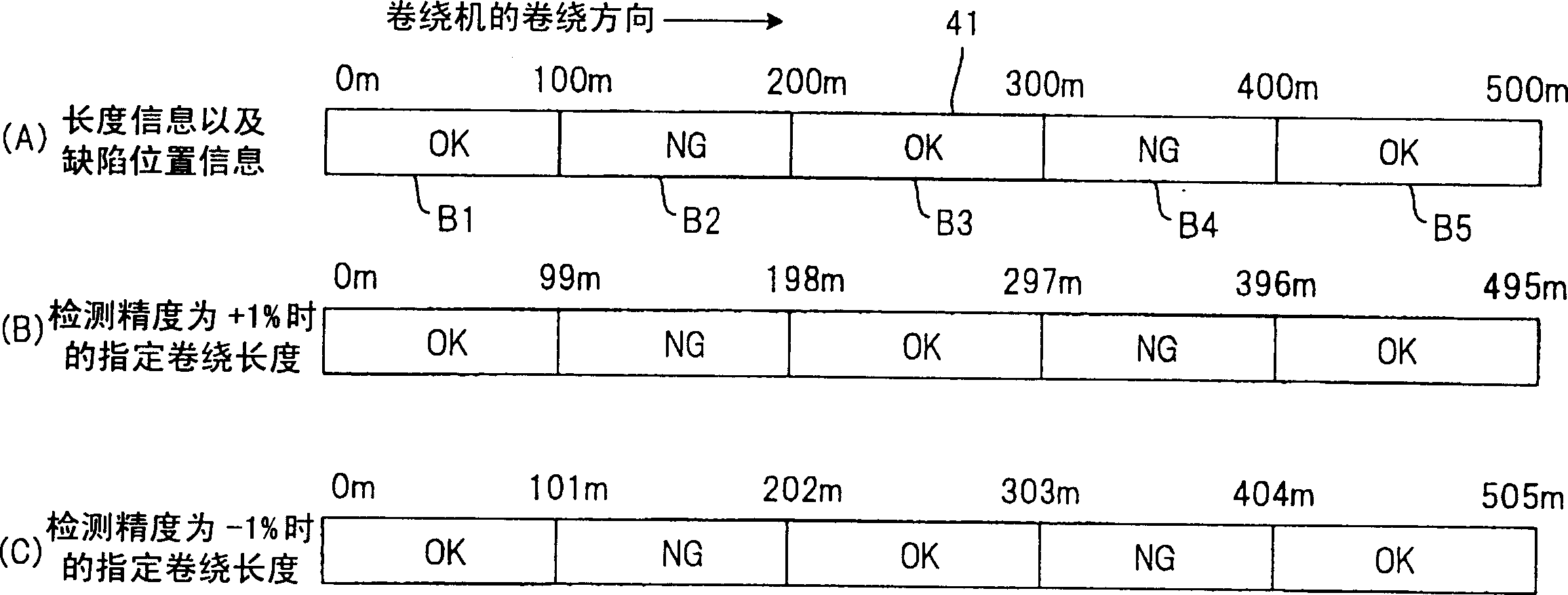

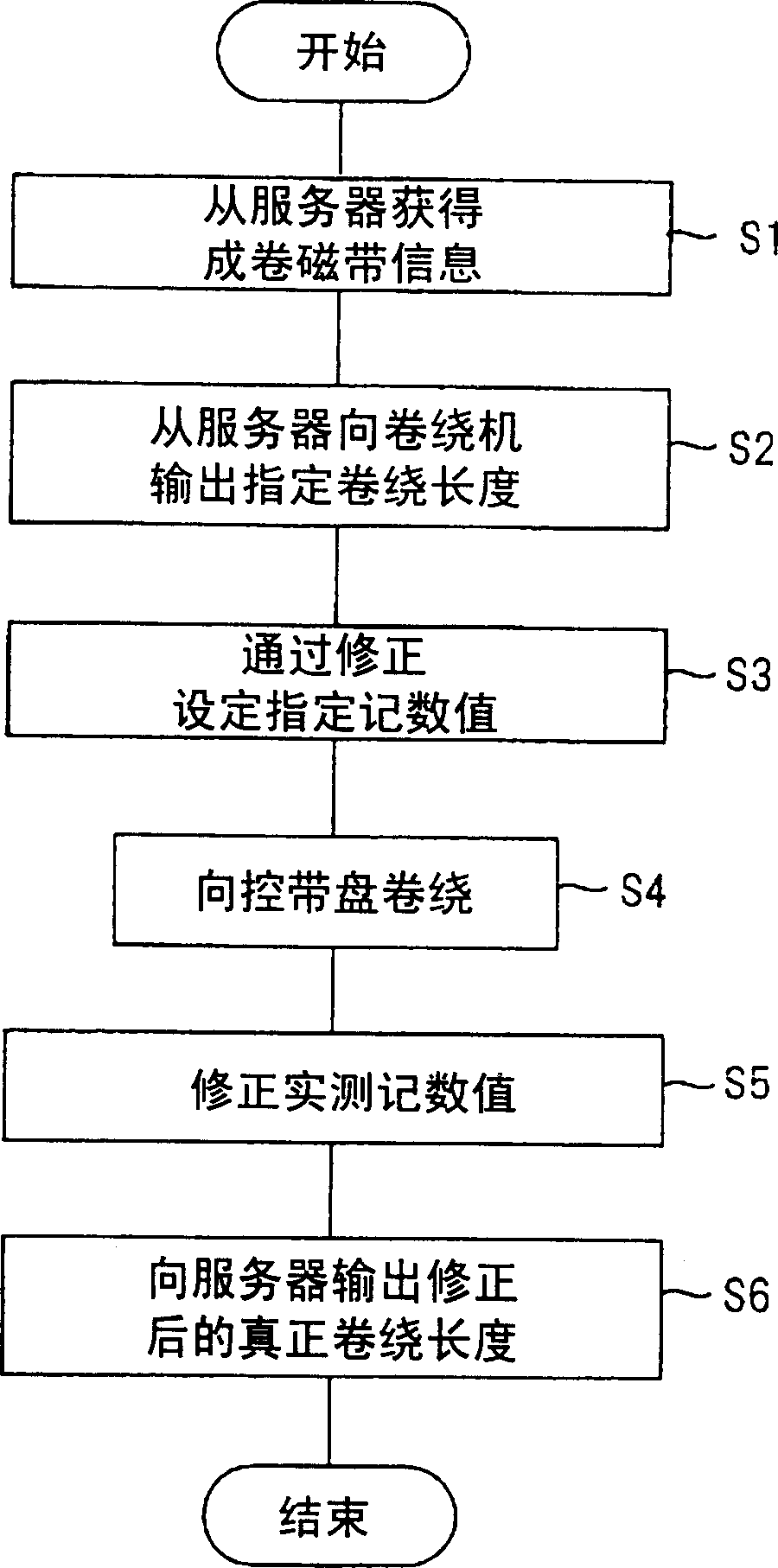

Magnetic tape separate winder

InactiveCN1408628ACorrect length managementRecord information storageMagazine/cassette manufacturing apparatusMagnetic tapeEngineering

The tape cut-out apparatus, having: a control unit for storing a defect positional information showing a position of a defective portion of magnetic tape and, for outputting a predetermined winding length in accordance with the defect positional information; a winding device for drawing out the magnetic tape by an input predetermined winding length, winding it onto a reel and cutting it, and detecting a winding length to the reel and outputting the winding length to the control unit; and, a correcting unit for correcting the input predetermined winding length according to an accuracy of detecting the winding length of the winding device, and correcting an actually measured winding length when the magnetic tape is wound according to an accuracy of detecting the winding length and for outputting the corrected value of the actually measured winding length to the control unit.

Owner:FUJIFILM CORP

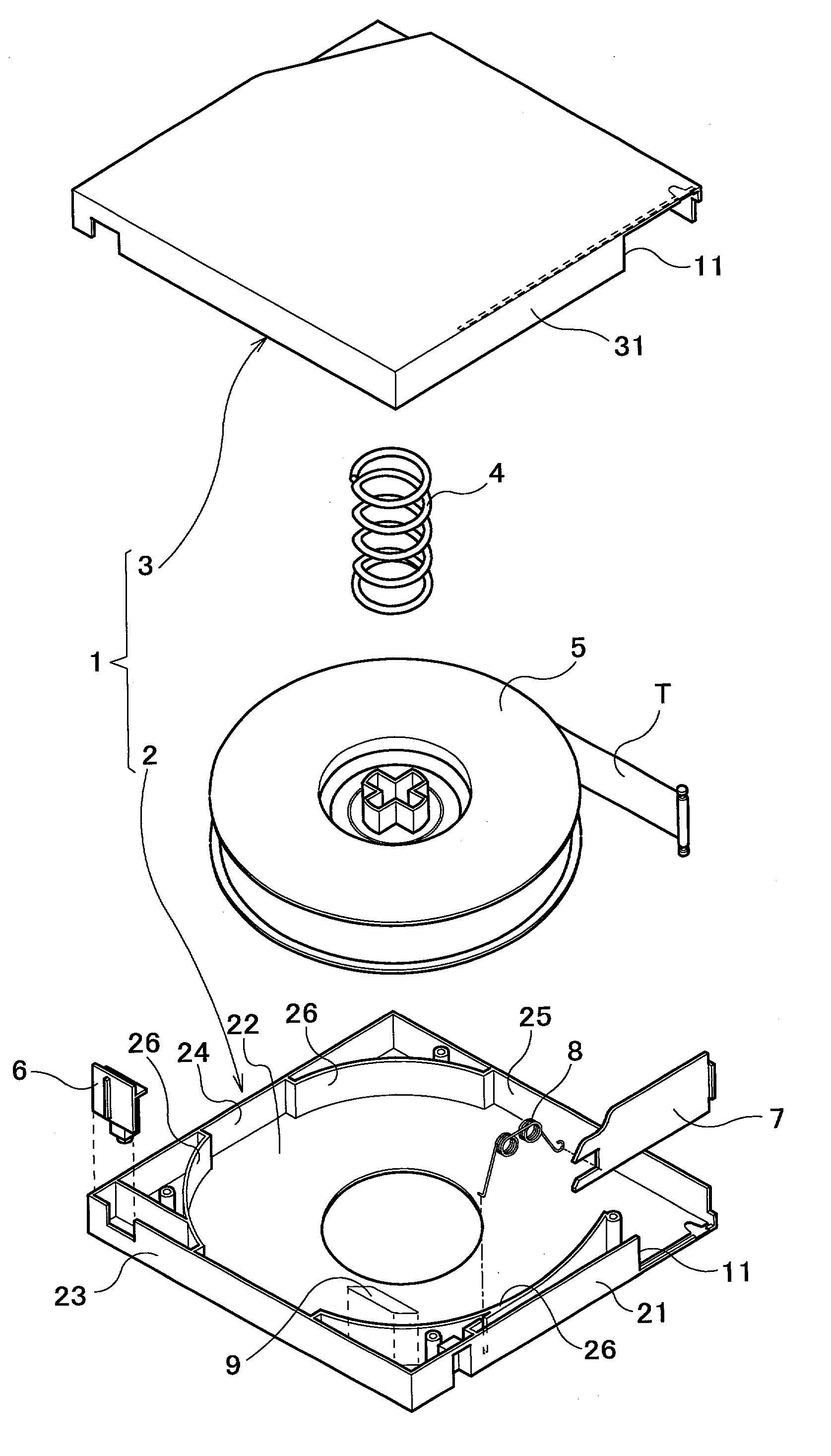

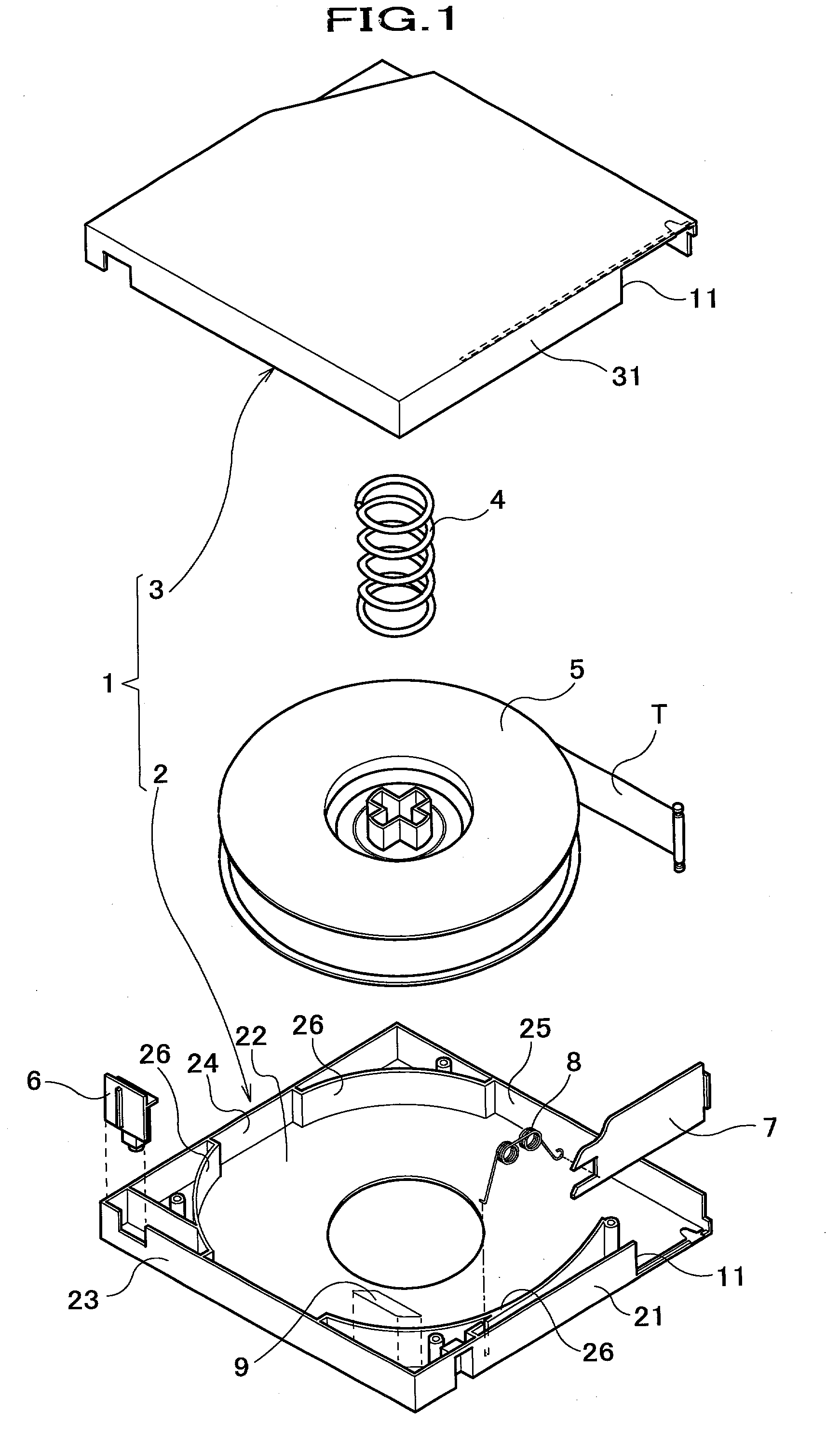

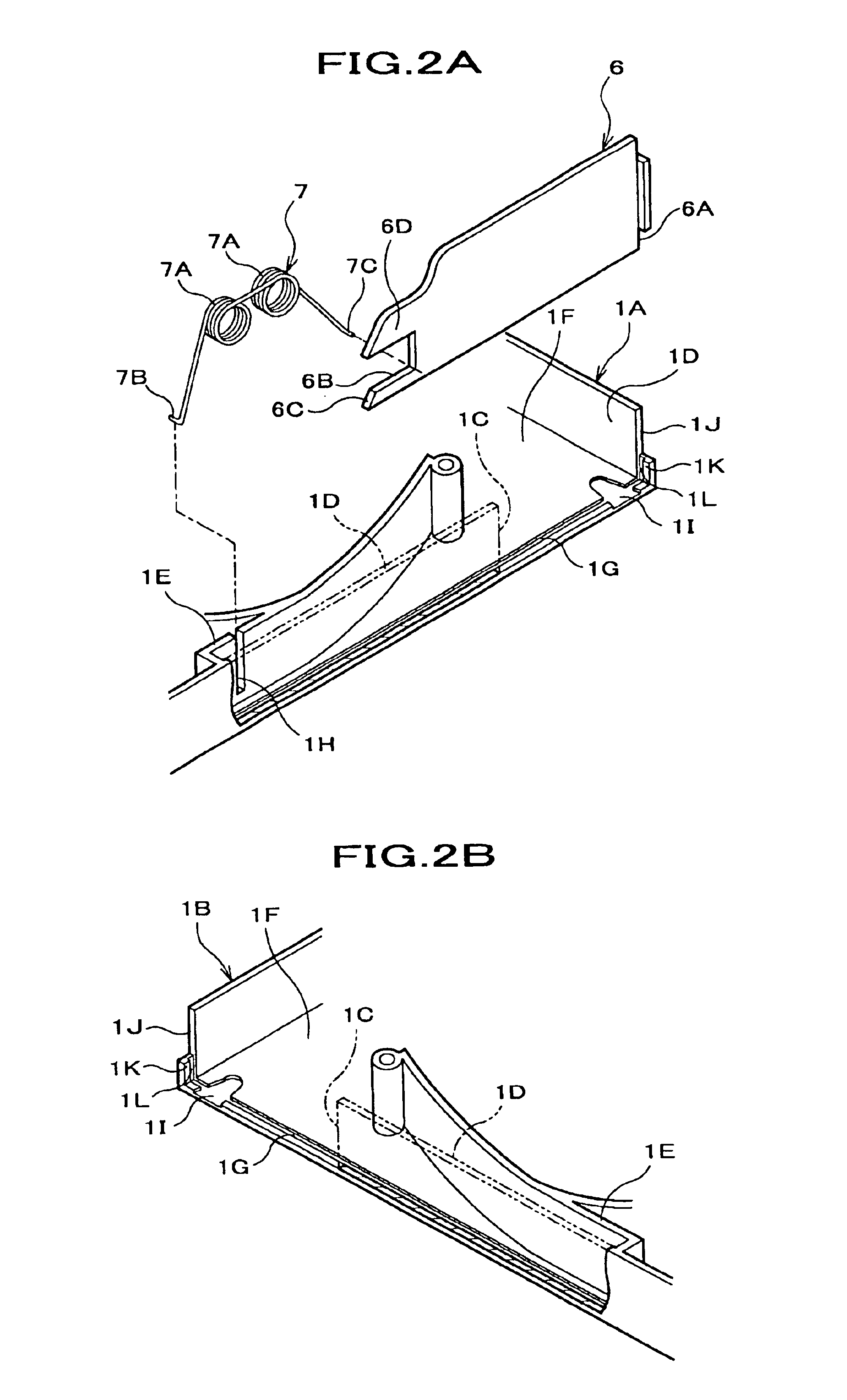

Assembly supporting device for magnetic tape cartridge

InactiveUS6898843B2Evenly combinedEasy to installPicture changing apparatusRecord information storageMagnetic tapeCoil spring

A magnetic tape cartridge includes an opening 1C through which a magnetic tape is drawn out, and a slide door 6 that slides along a sidewall 1D provided with the opening 1C to open and close the opening 1C. The cartridge having an assembly support device that guides a distal end of a spring support rod onto a support rod receiving block when the slide door is fitted in a lower half of the cartridge case. A proximal end of the spring support rod projects from the slide door, and a compression coil spring is wound around the spring support rod.

Owner:FUJIFILM CORP

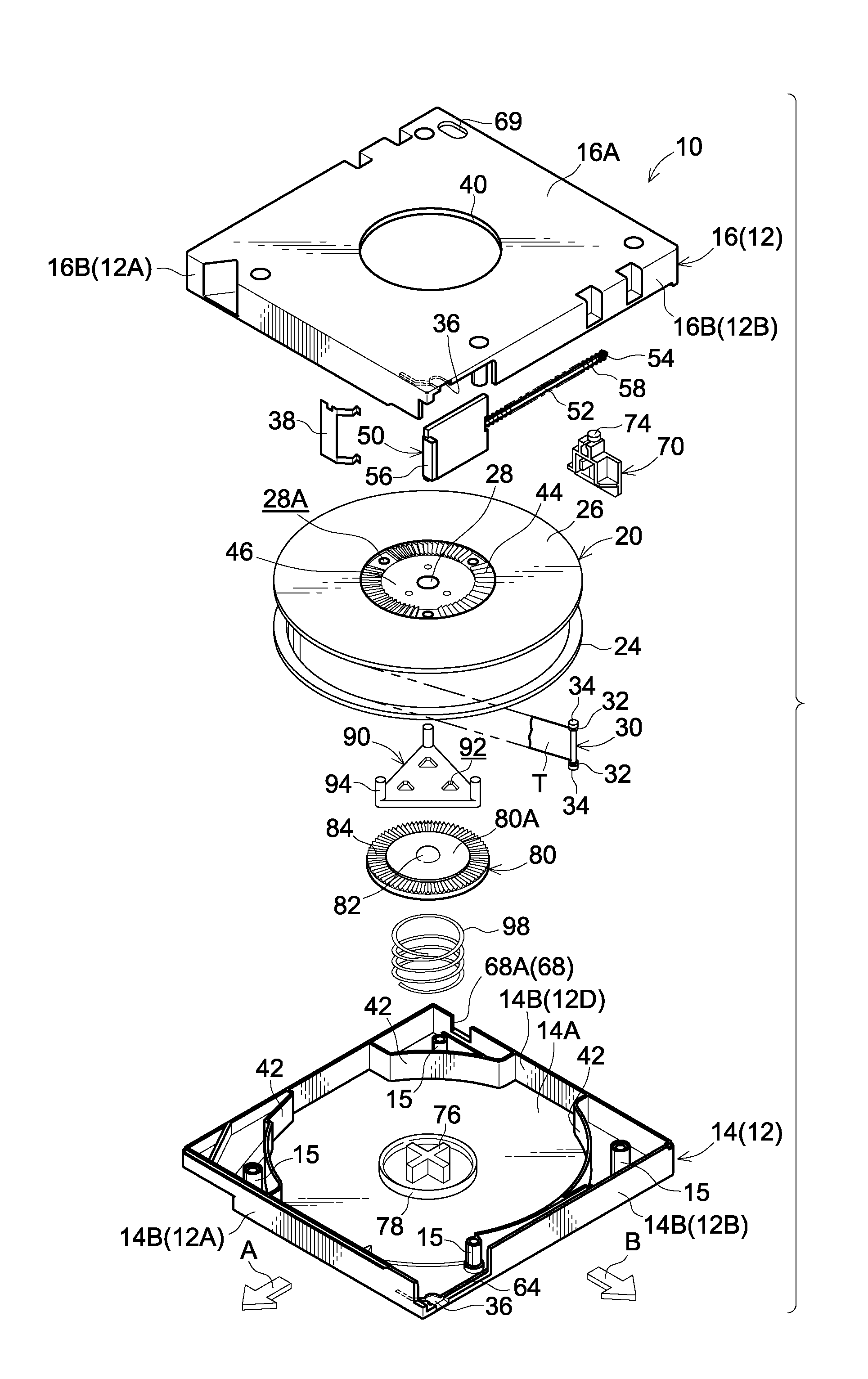

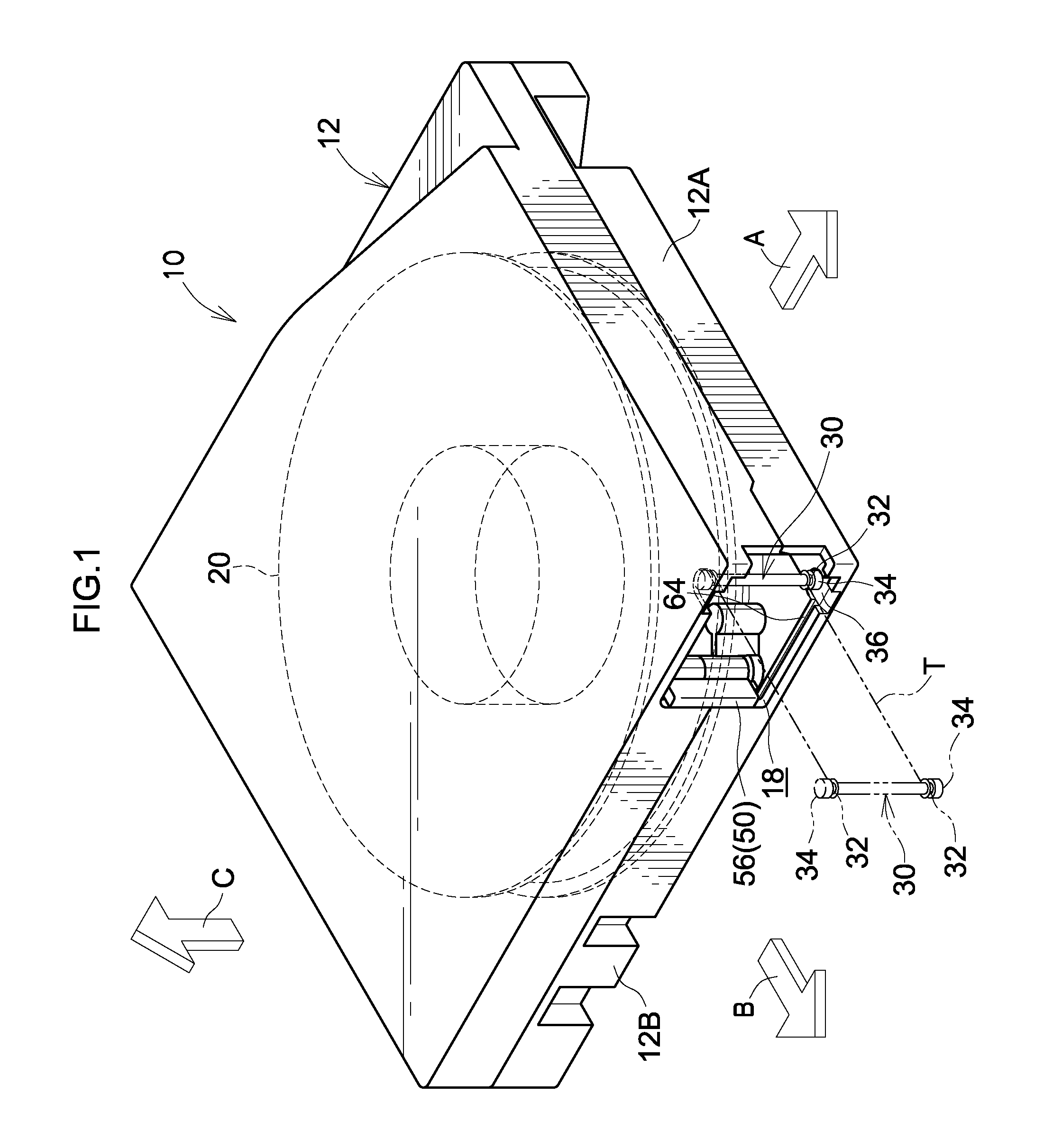

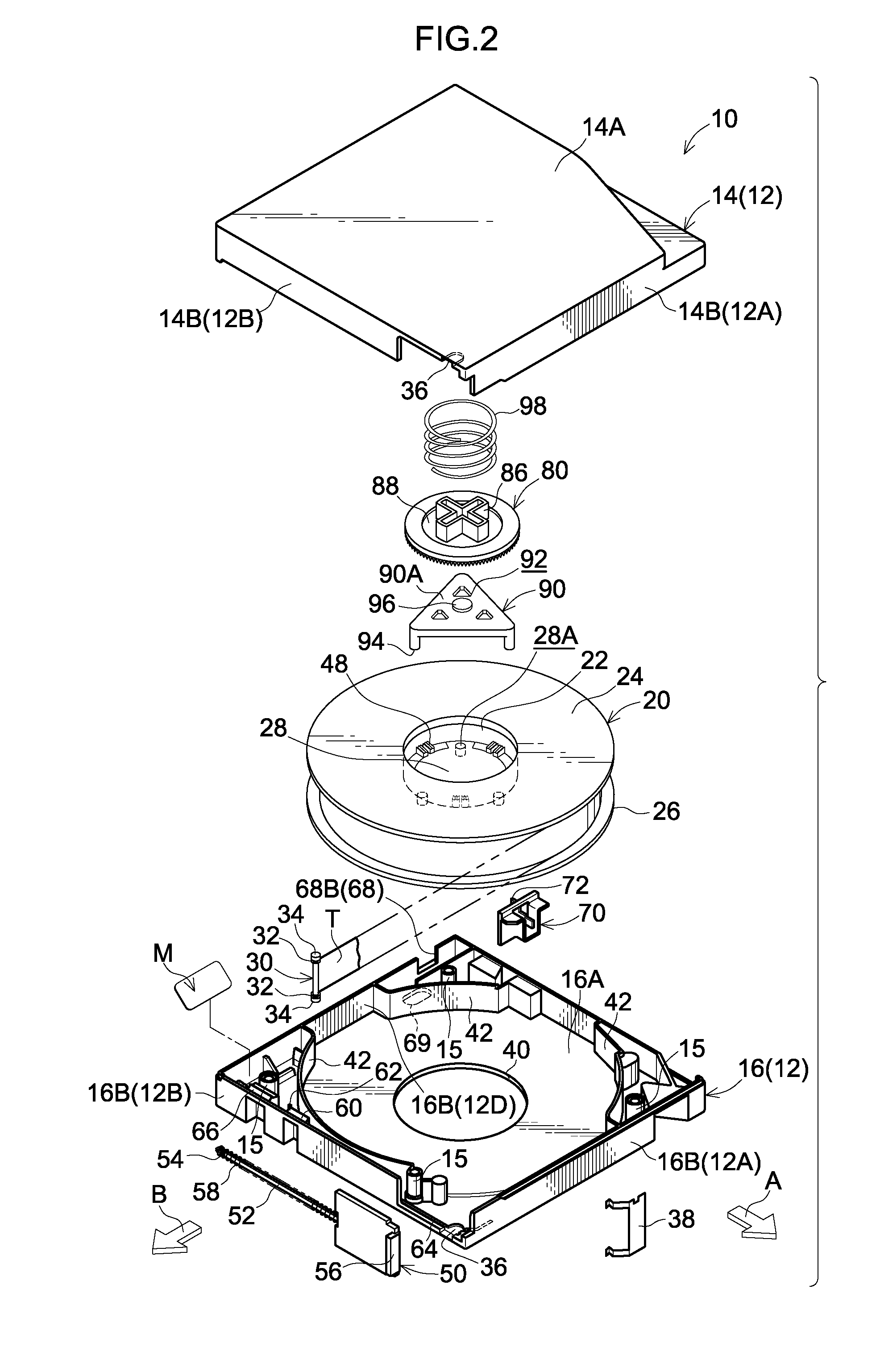

Media cartridge having reel suspension system and method of manufacture

ActiveUS20060151651A1Picture changing apparatusRecord information storageMechanical engineeringEngineering

In one example of one aspect of the invention, a data storage cartridge is provided. The data storage cartridge includes a housing having at least one opening, a reel rotatably disposed within the housing and accessible through the opening, the reel capable of translating axially, a biasing member for biasing the reel toward the opening, and an absorbing member disposed between the reel and a portion of the housing opposite the opening. In one example, the absorbing member includes a spring constant value of greater than 30 ounces per inch. The absorbing member may be disposed to engage and dampen the motion of the reel when the reel is displaced beyond a desired distance.

Owner:QUANTUM CORP

Tape cartridge and producing method thereof

InactiveUS6843440B2Readily and temporally assembledAssembly process can be substantially automatedPicture changing apparatusRecord information storageMagnetic tapeEngineering

This tape cartridge includes a tape reel on which a sheet-like recording medium is wound in the inside. A door member for opening and closing an opening in order to pull out the sheet-like recording medium from the tape reel to an outside is biased using a spring member so as to be closed upon non-using and opened upon using. The spring member is pushed in the concave fitting portion provided at the door member from the tip part and fitted therewith. When the tape cartridge is produced, the spring member can be temporally assembled, readily and securely. According to this tape cartridge, assembling performance of the spring member which biases the door member for opening and closing the opening and the door member can be enhanced, the assembly process can be automated, and there is no interference with sliding motion of the door member.

Owner:TDK CORPARATION

Reel

ActiveUS9352931B2High precisionAvoid changeRecord information storageMagazines/cassettes storageEngineeringFlange

Owner:FUJIFILM CORP

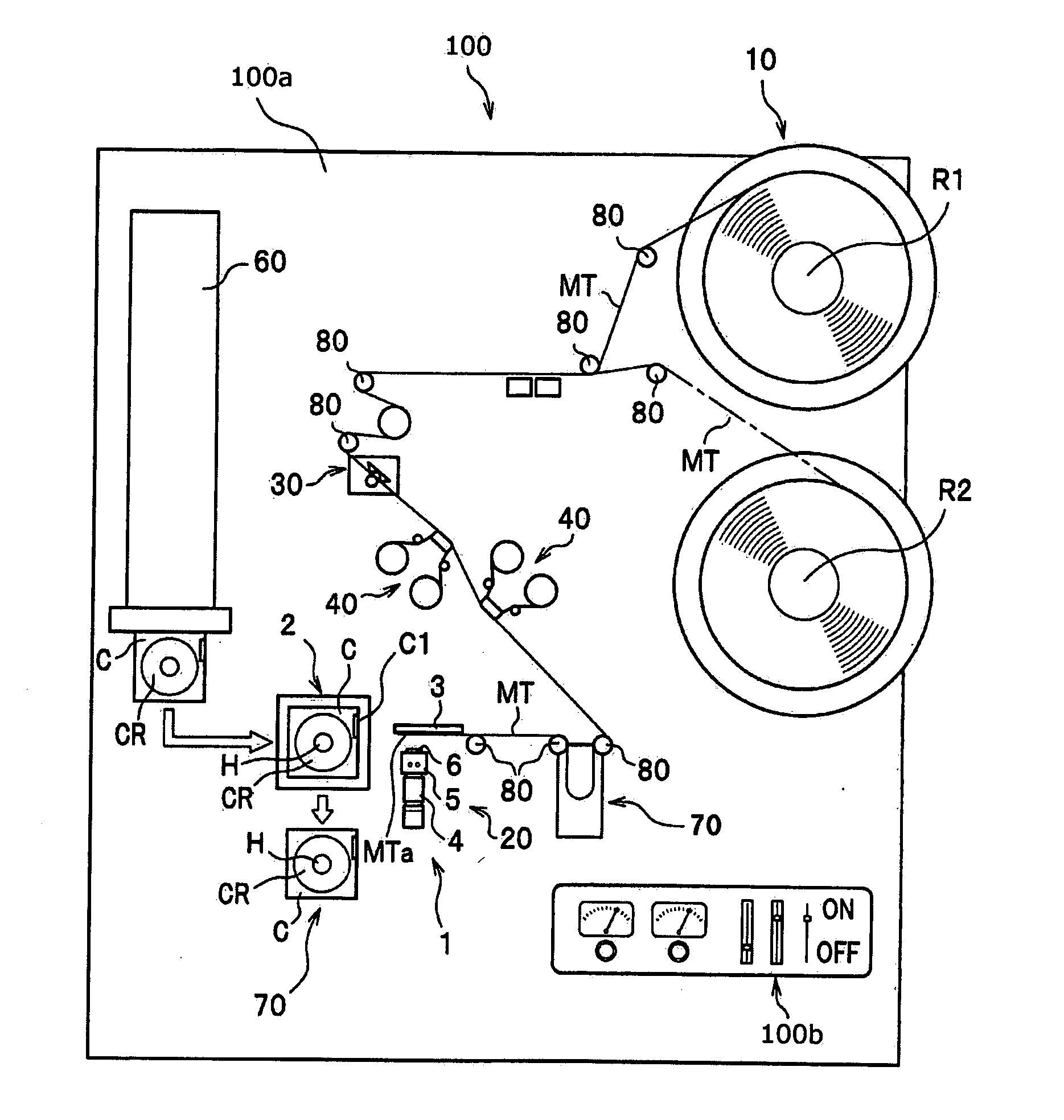

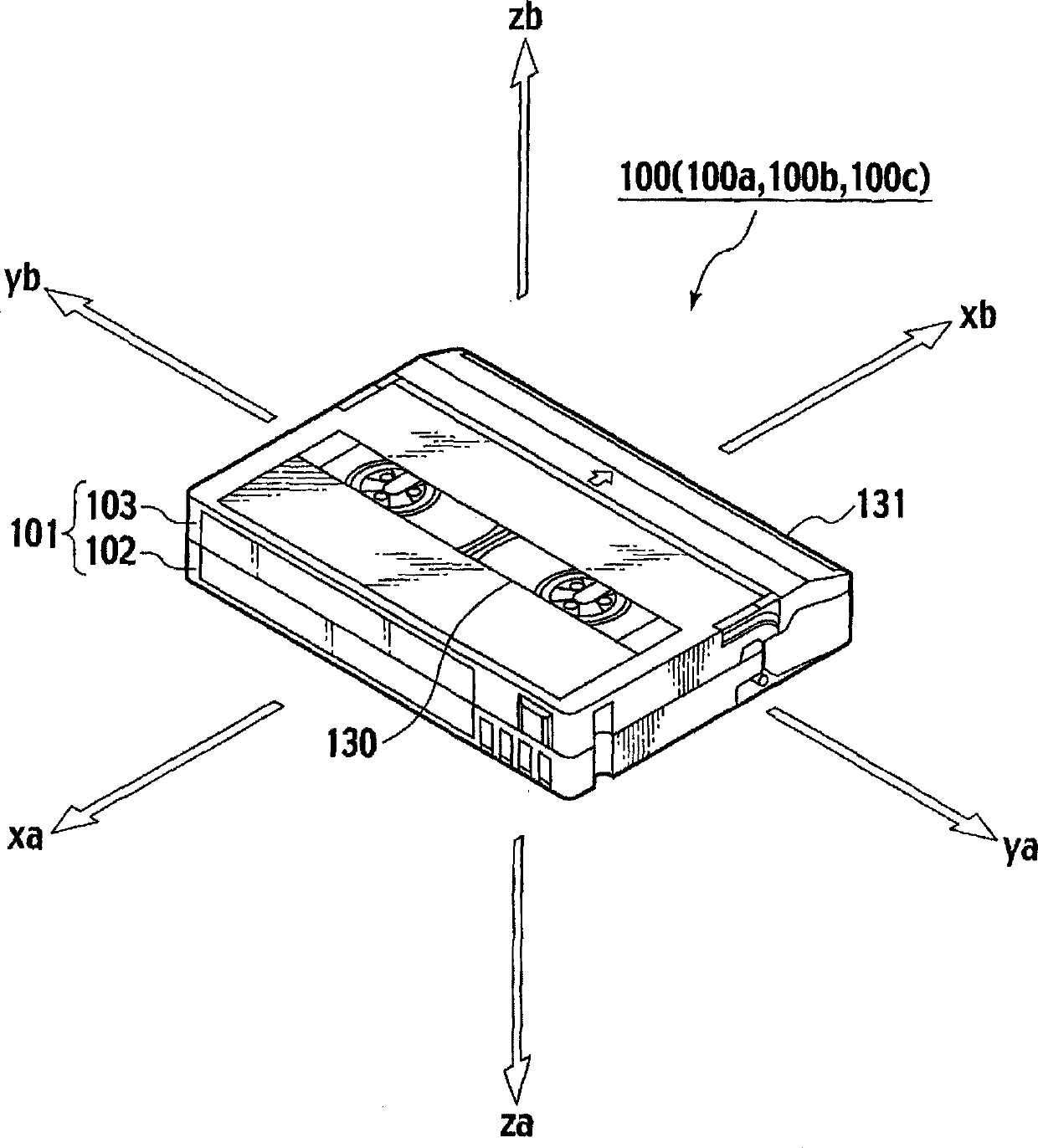

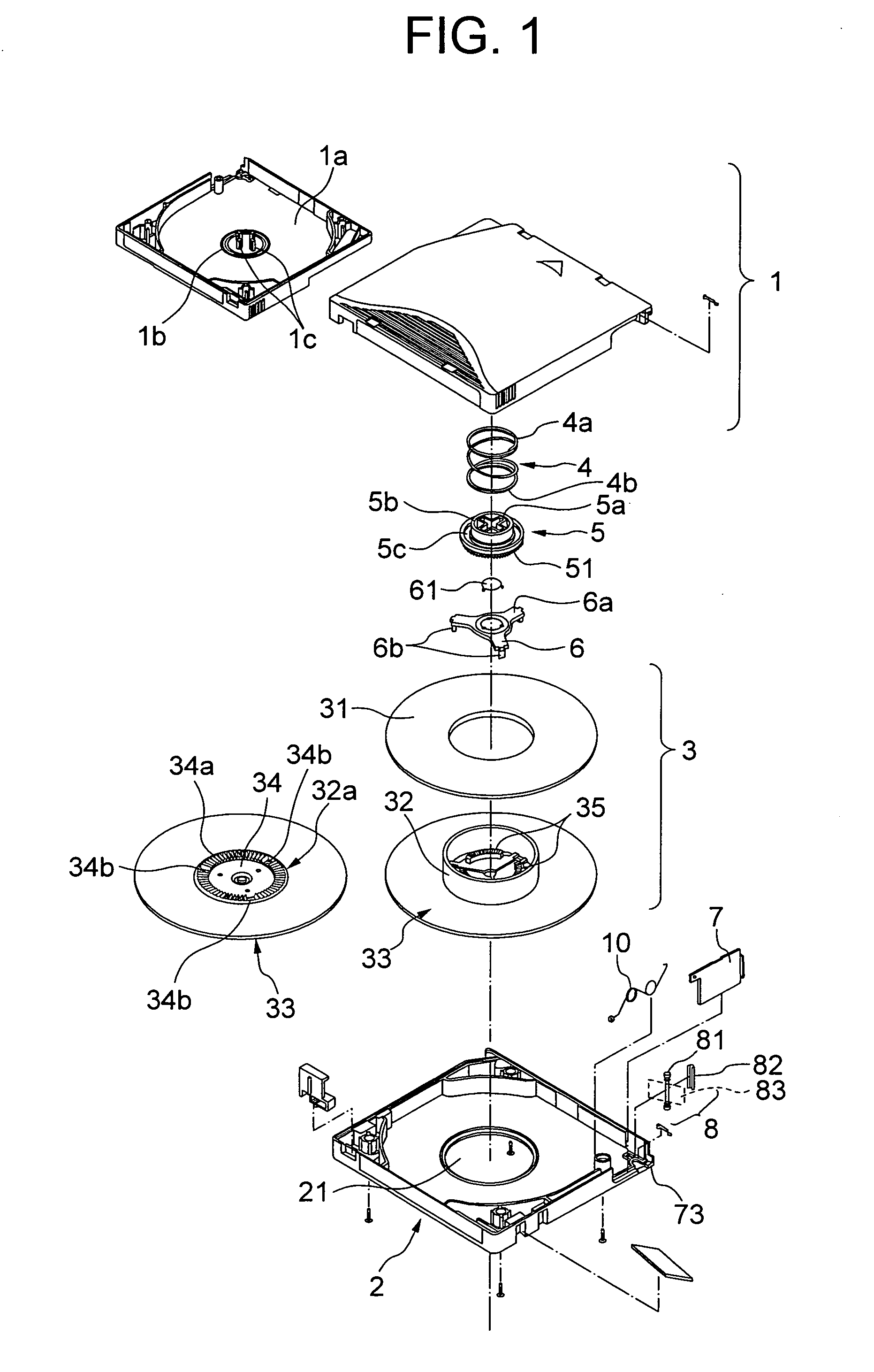

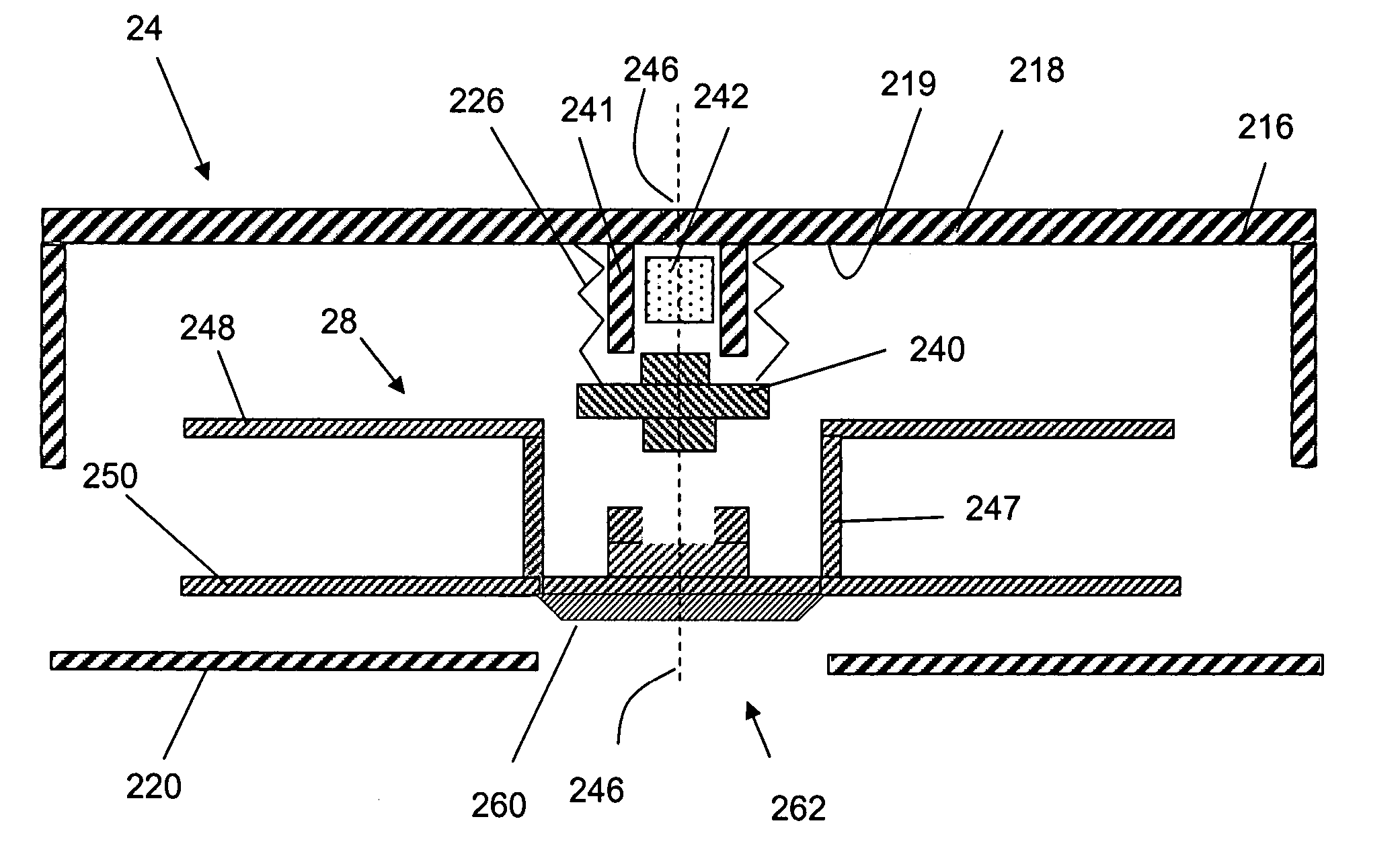

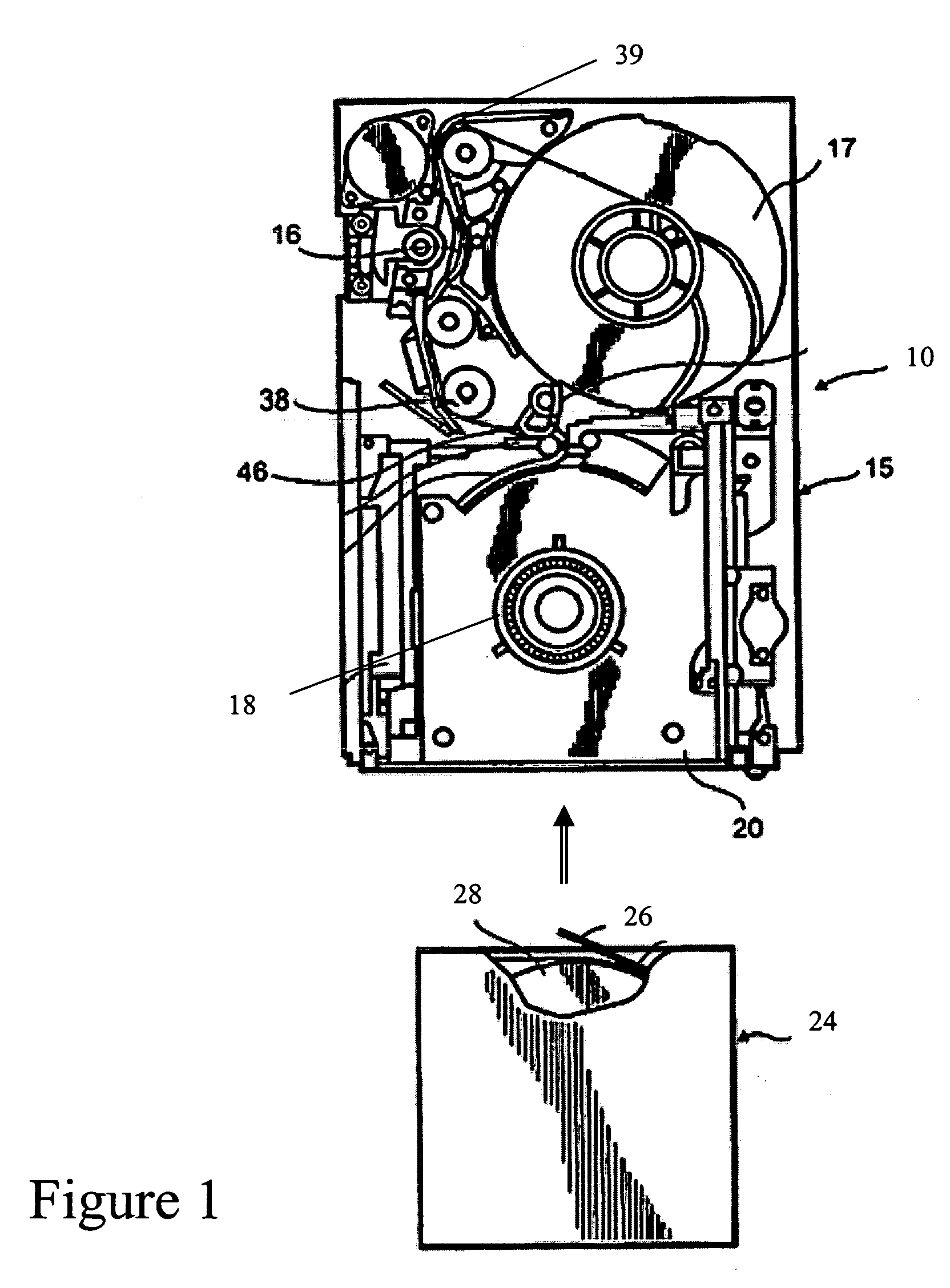

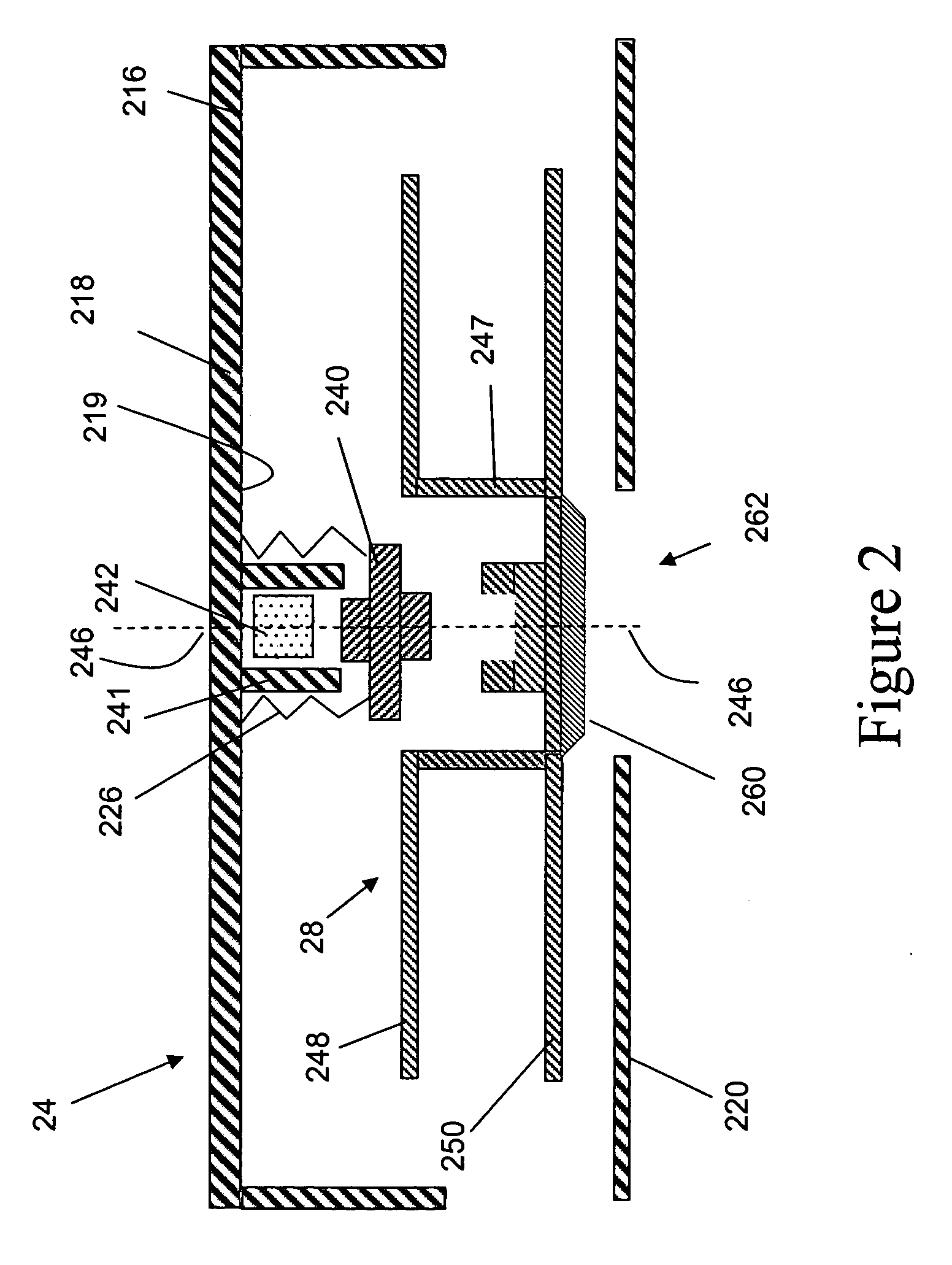

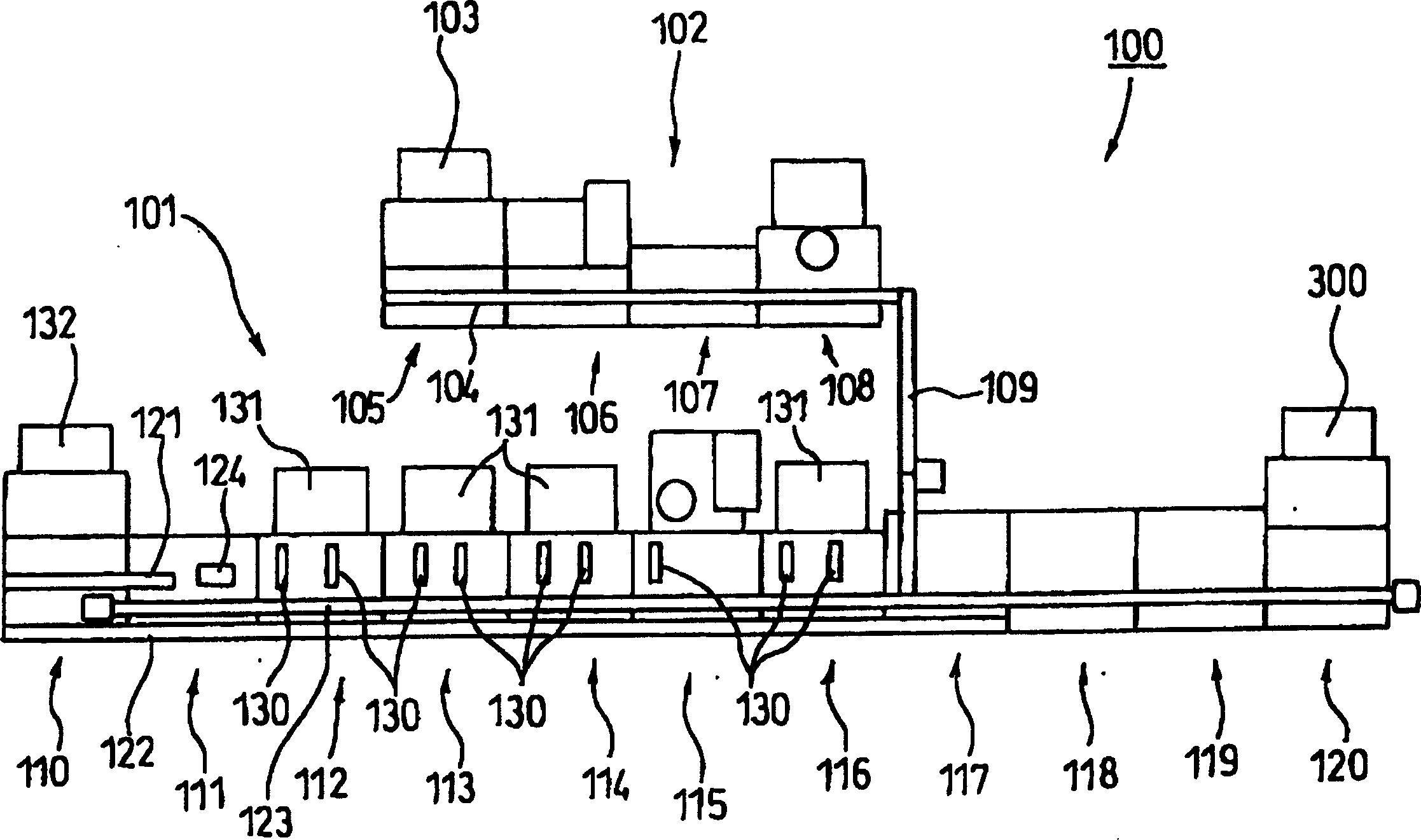

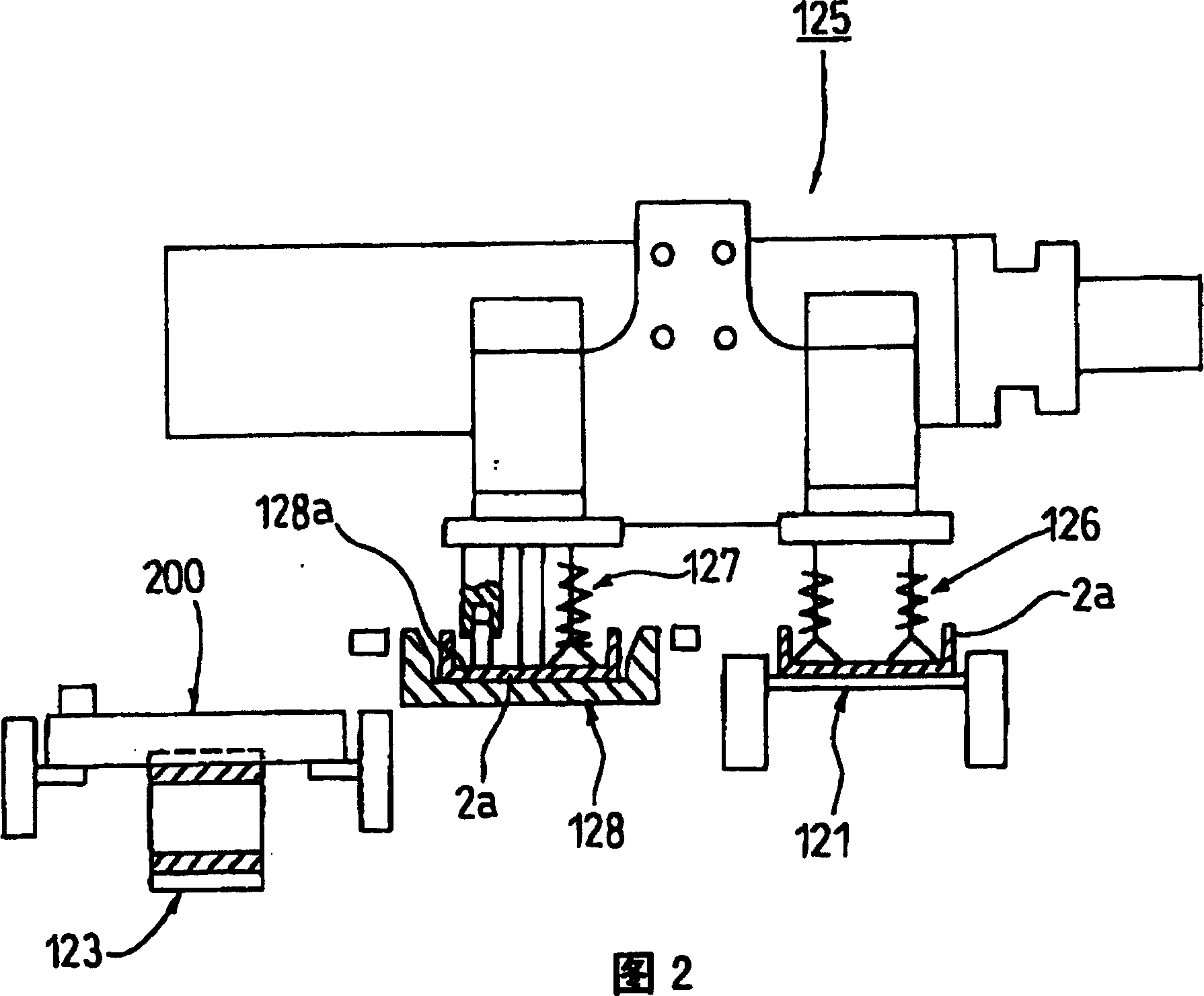

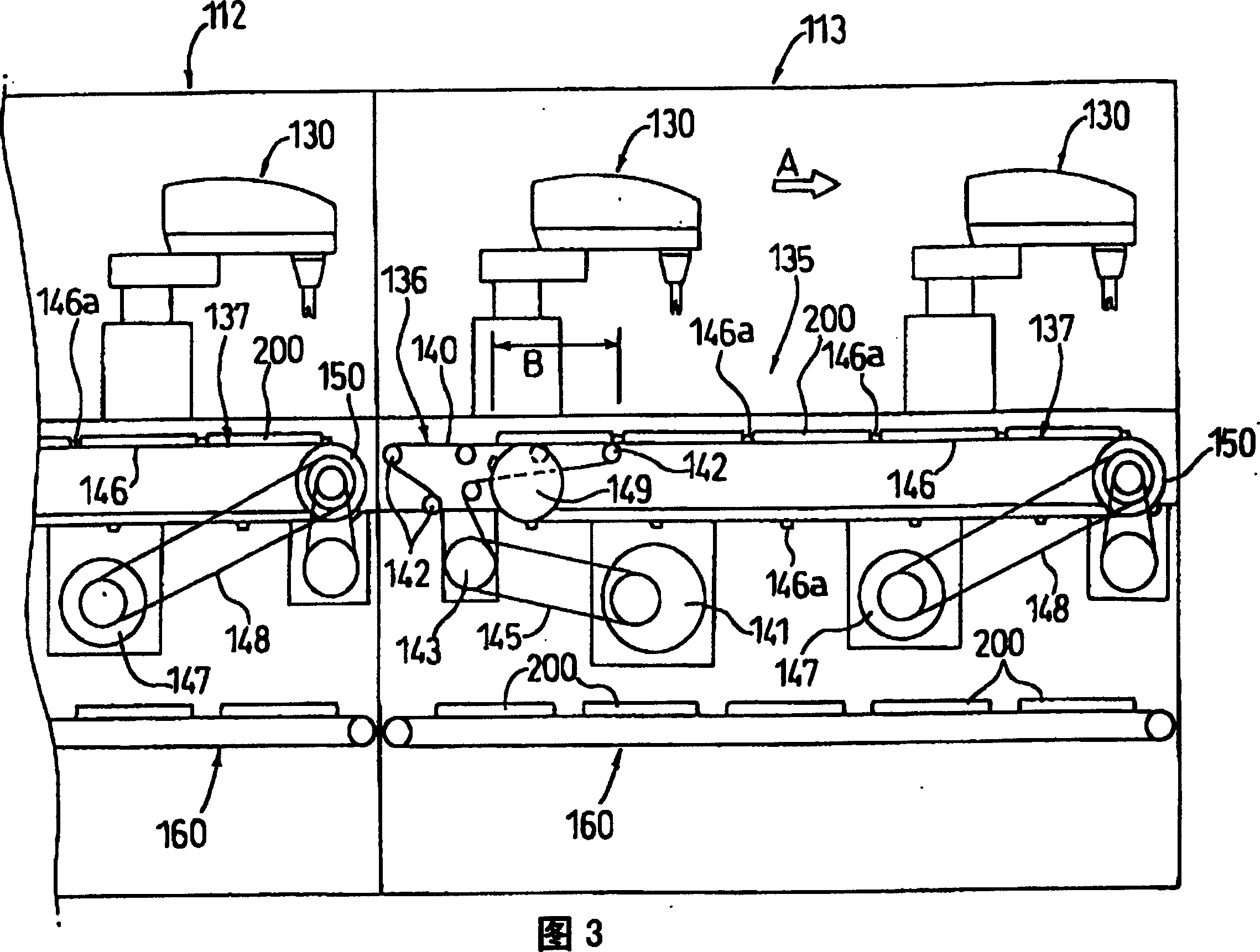

Method and apparatus for assembling magnetic tape cartridge

InactiveCN1179360CGood assembly precisionImprove productivityRecord information storageMagazine/cassette manufacturing apparatusProduction rateMagnetic tape

In the method and apparatus for assembling a magnetic tape cartridge, a plurality of assembling stations, each of which includes an assembling robot 130 for assembling the respective parts of a magnetic tape cartridge 1, respectively comprise pallet delivery mechanism 135 capable of delivering sequentially a pallet 200 on which an upper cases 2a can be placed. The pallet 200 comprises front and rear reel brake hold mechanism 210, 220 respectively capable of holding front and rear reel brakes 50, 51 against the energizing forces of brake springs 12, 13 in such a manner that the front and rear reel brakes 50, 51 retreat from the installation area of the reel 3, lid spring hold mechanism 230 capable of holding the lid engaging portion 15a of a lid spring 15 in such a manner that the lid engaging portion 15a is not in engagement with a lid 30, reel hold mechanism 240 capable of holding a reel 3 on the upper case 2a side against the energizing force of a reel spring 8, and lower case hold mechanism 250 capable of holding a lower case 2b on the upper case 2a side. Accordingly, it is possible to obtain a magnetic tape cartridge having an excellent assembling accuracy with high productivity.

Owner:FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com