Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

105results about "Carrier mechanical tension control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

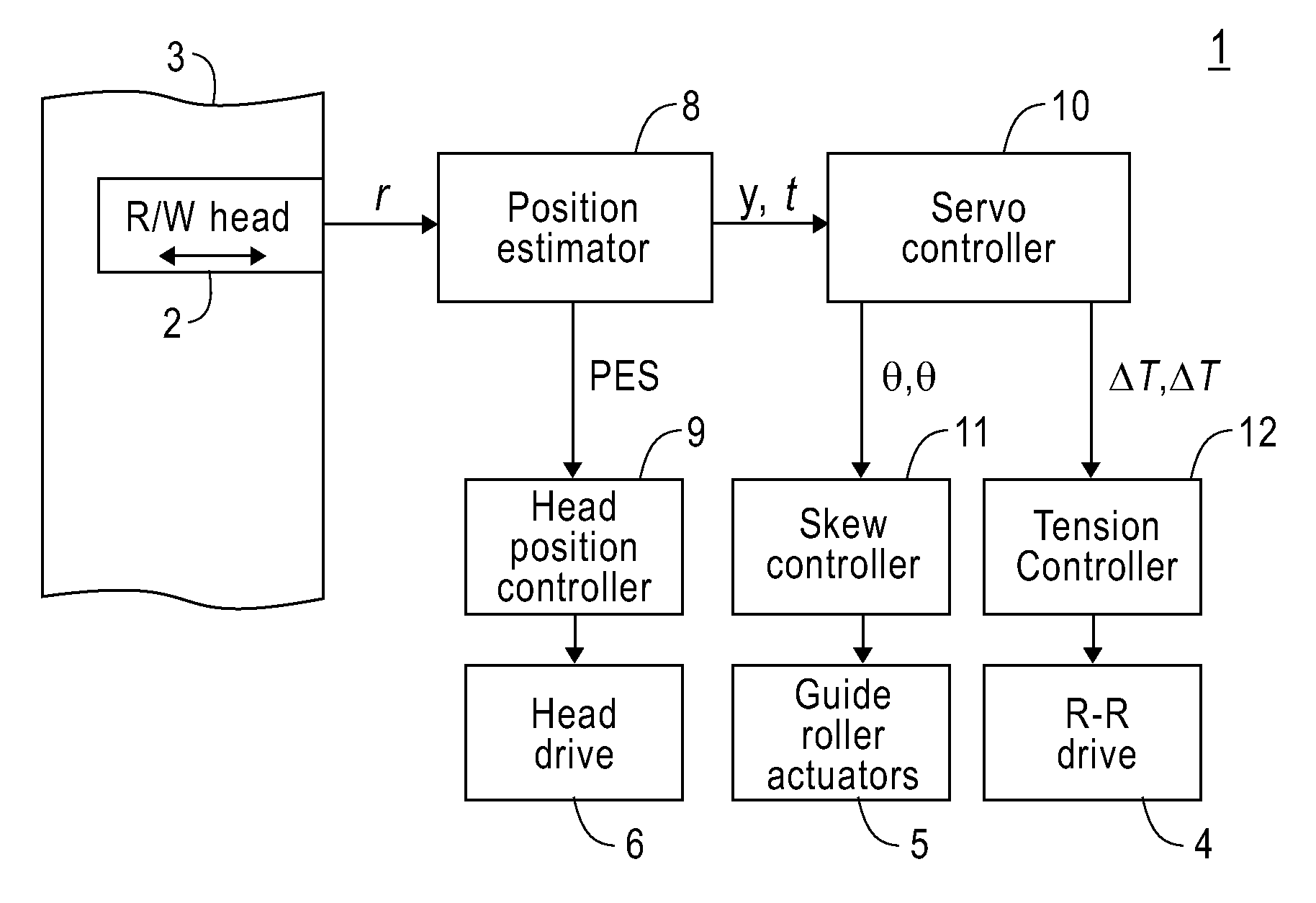

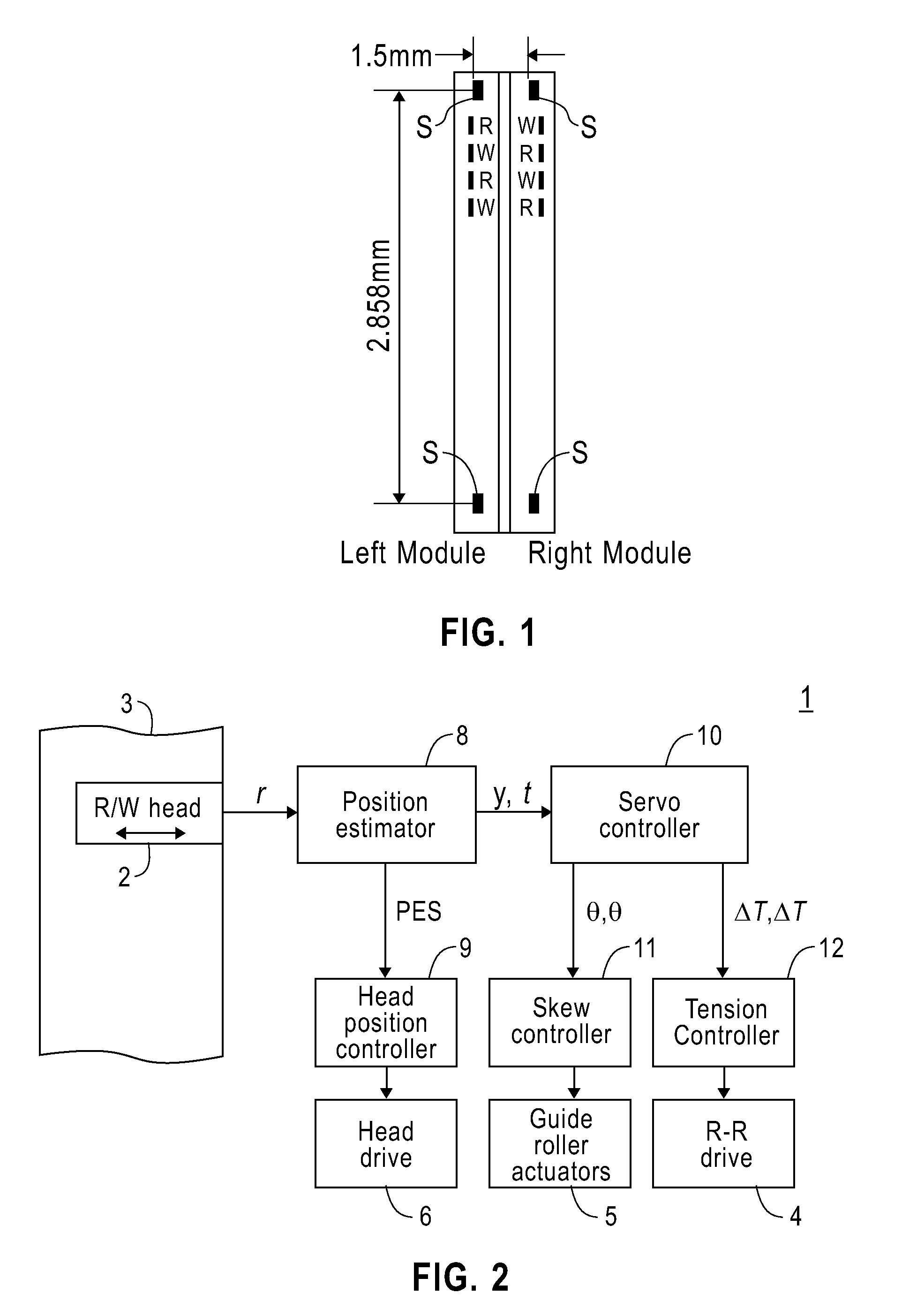

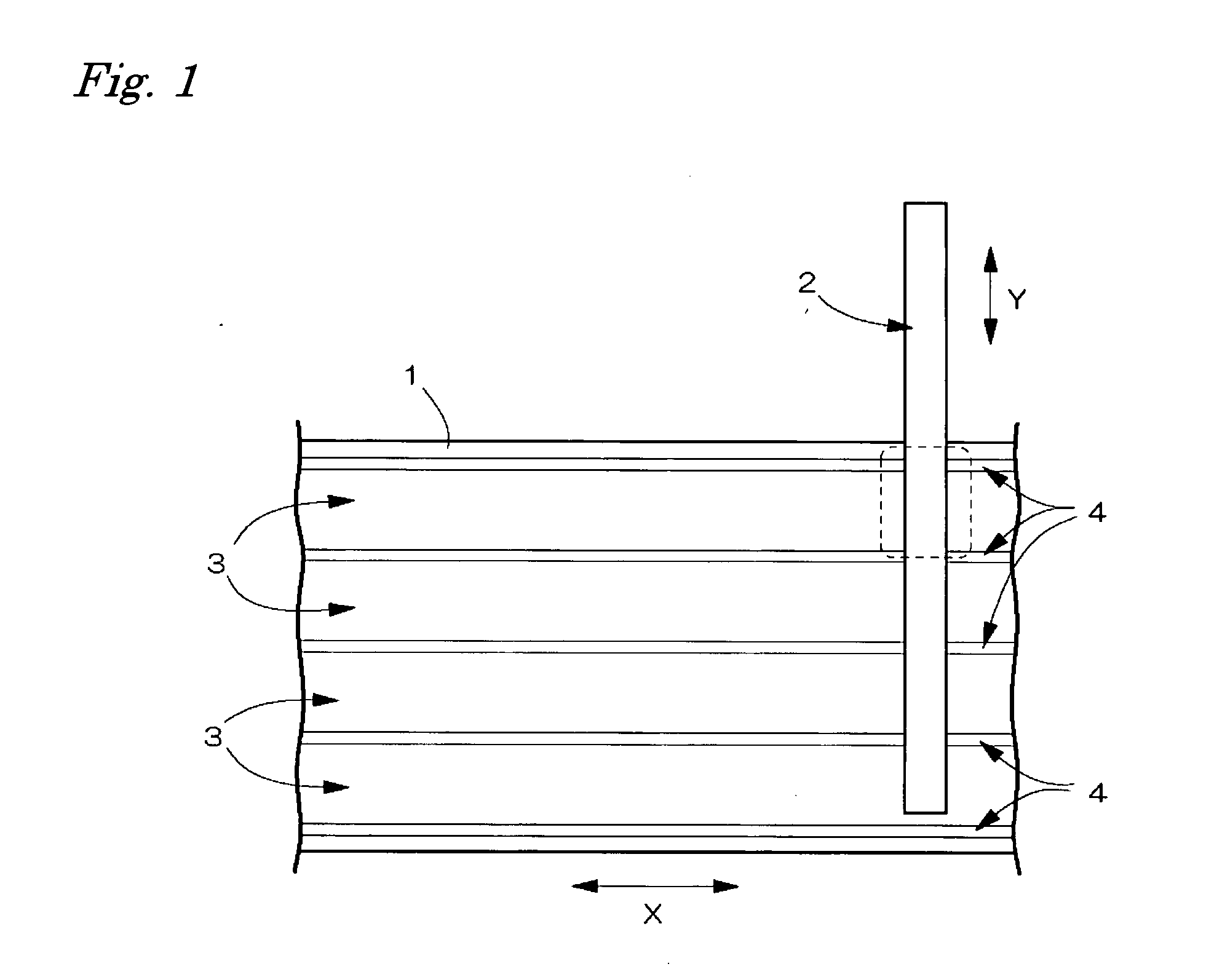

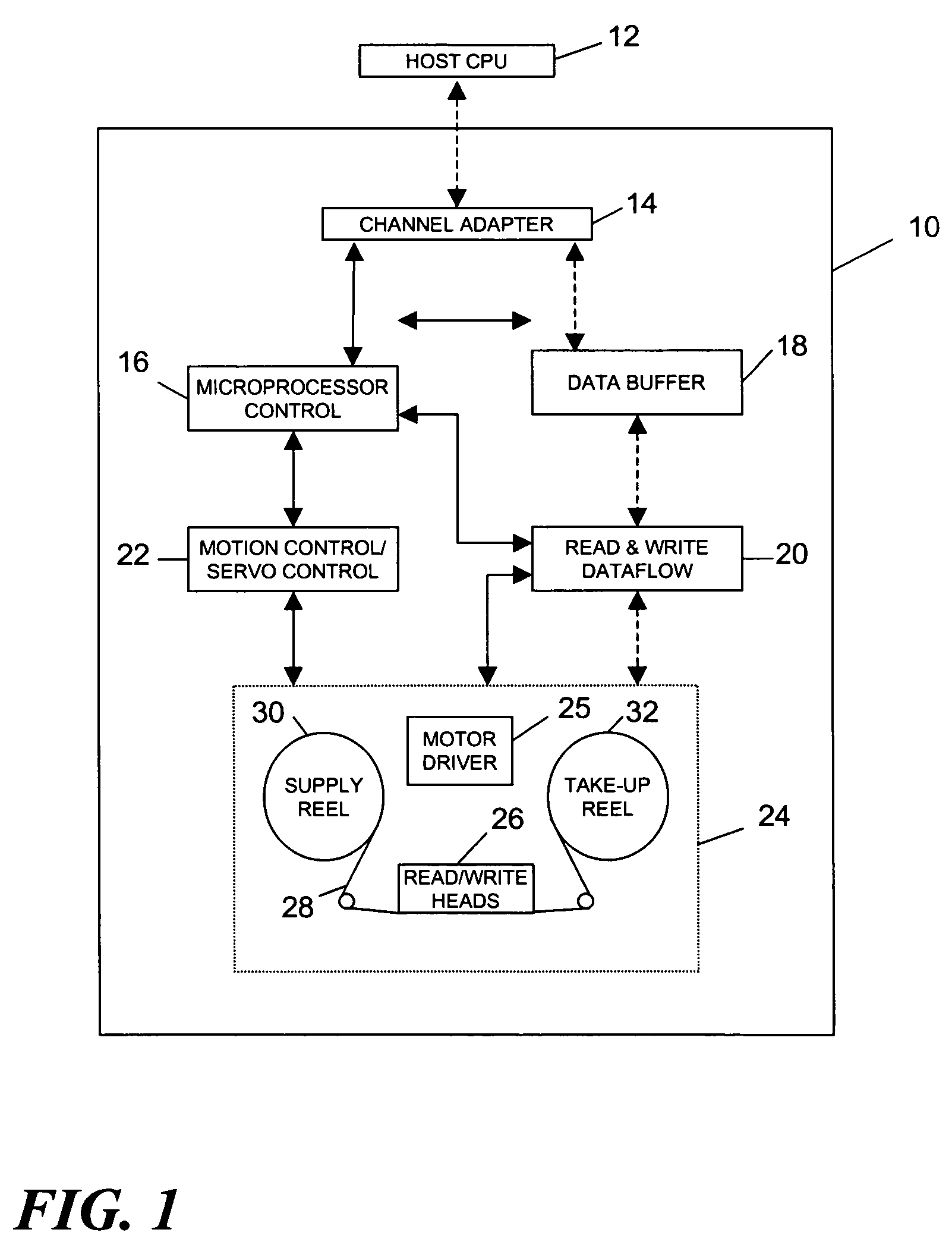

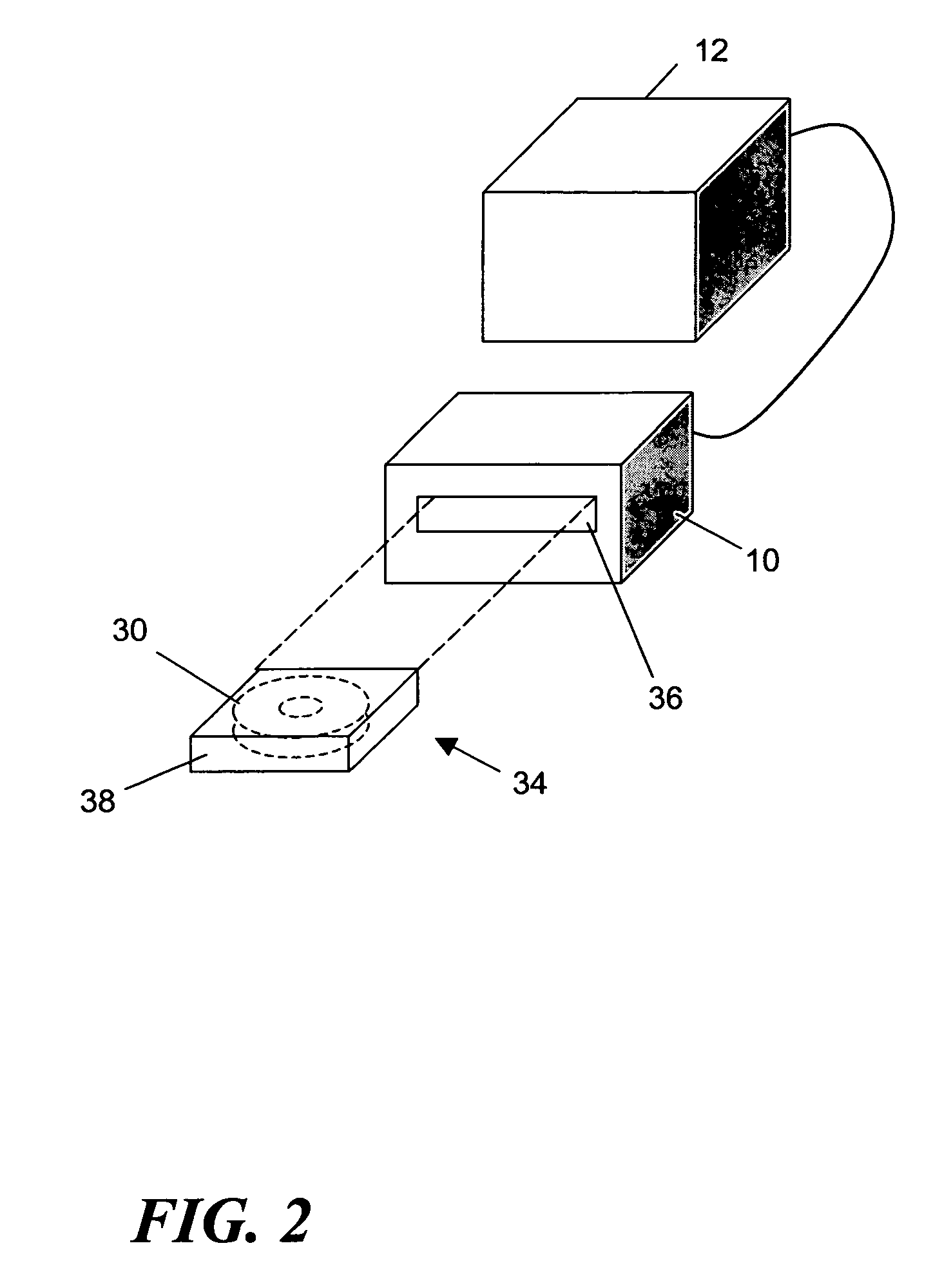

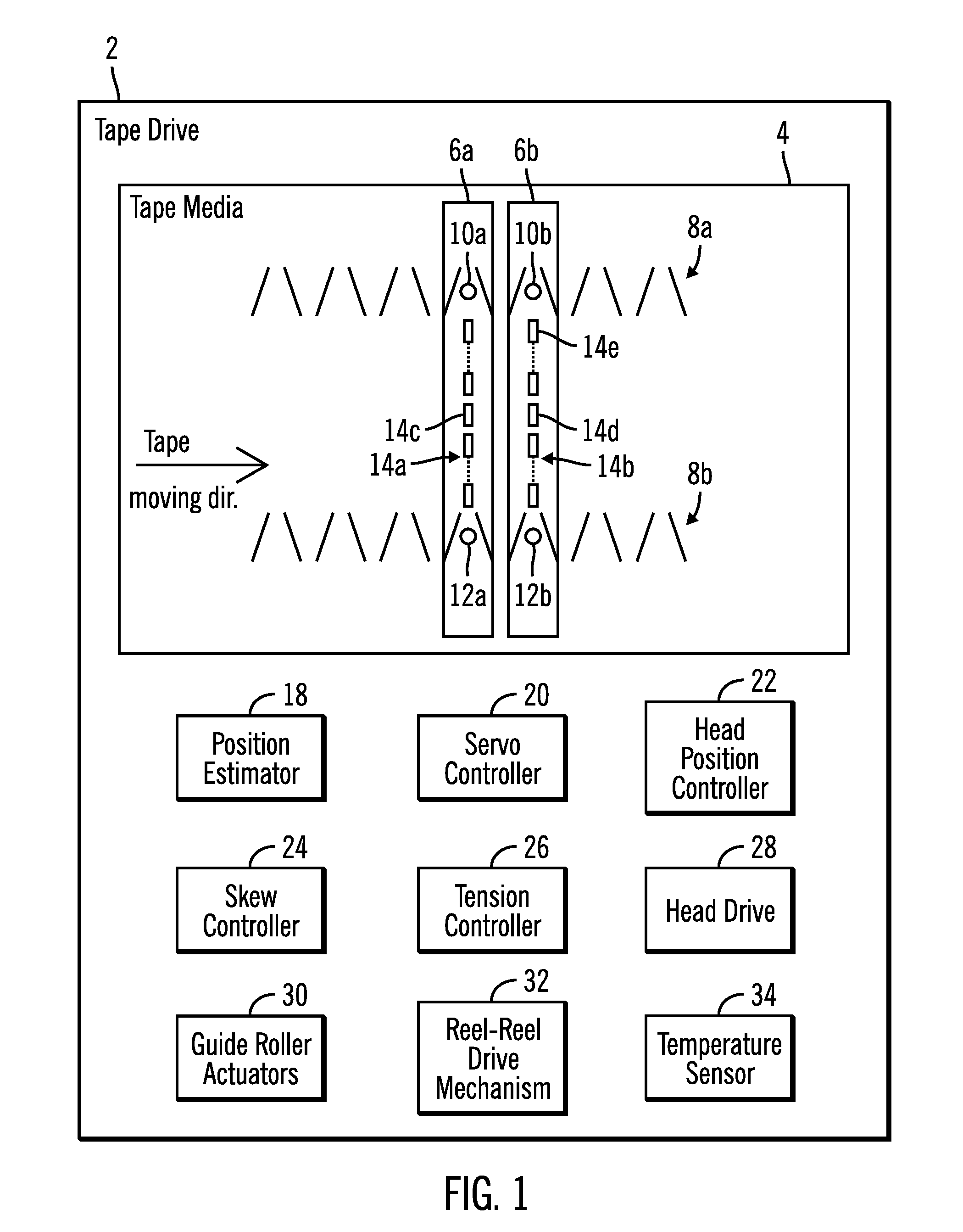

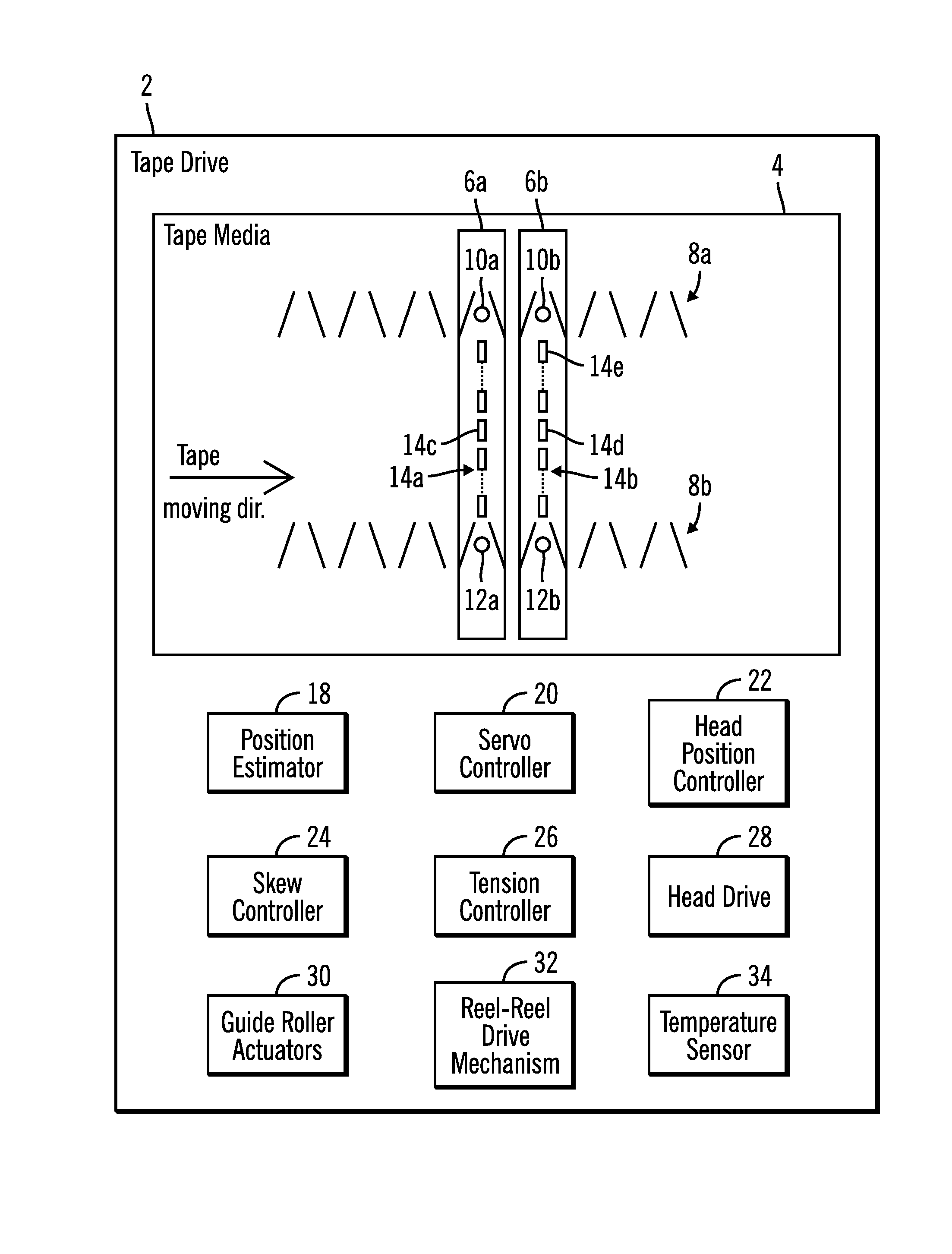

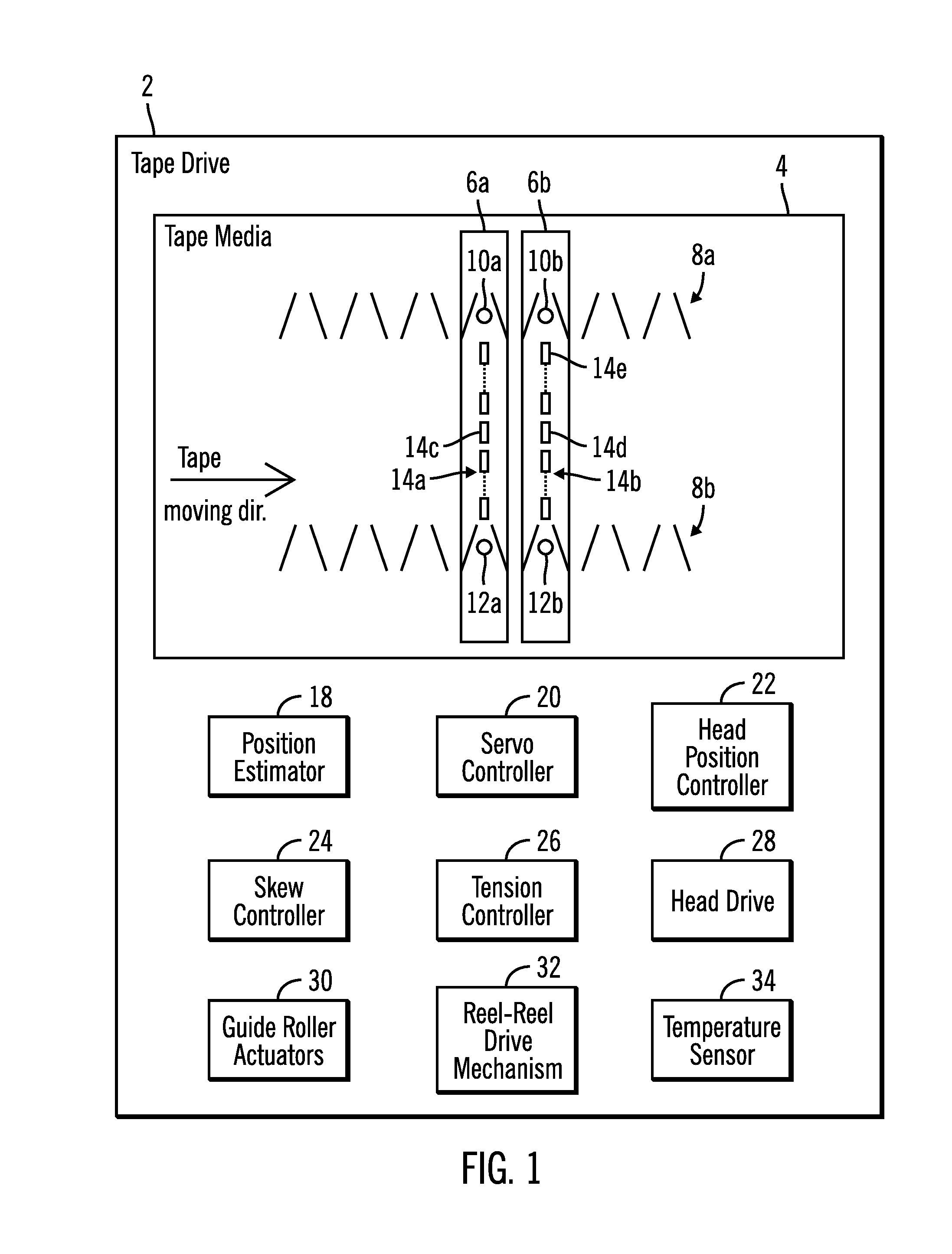

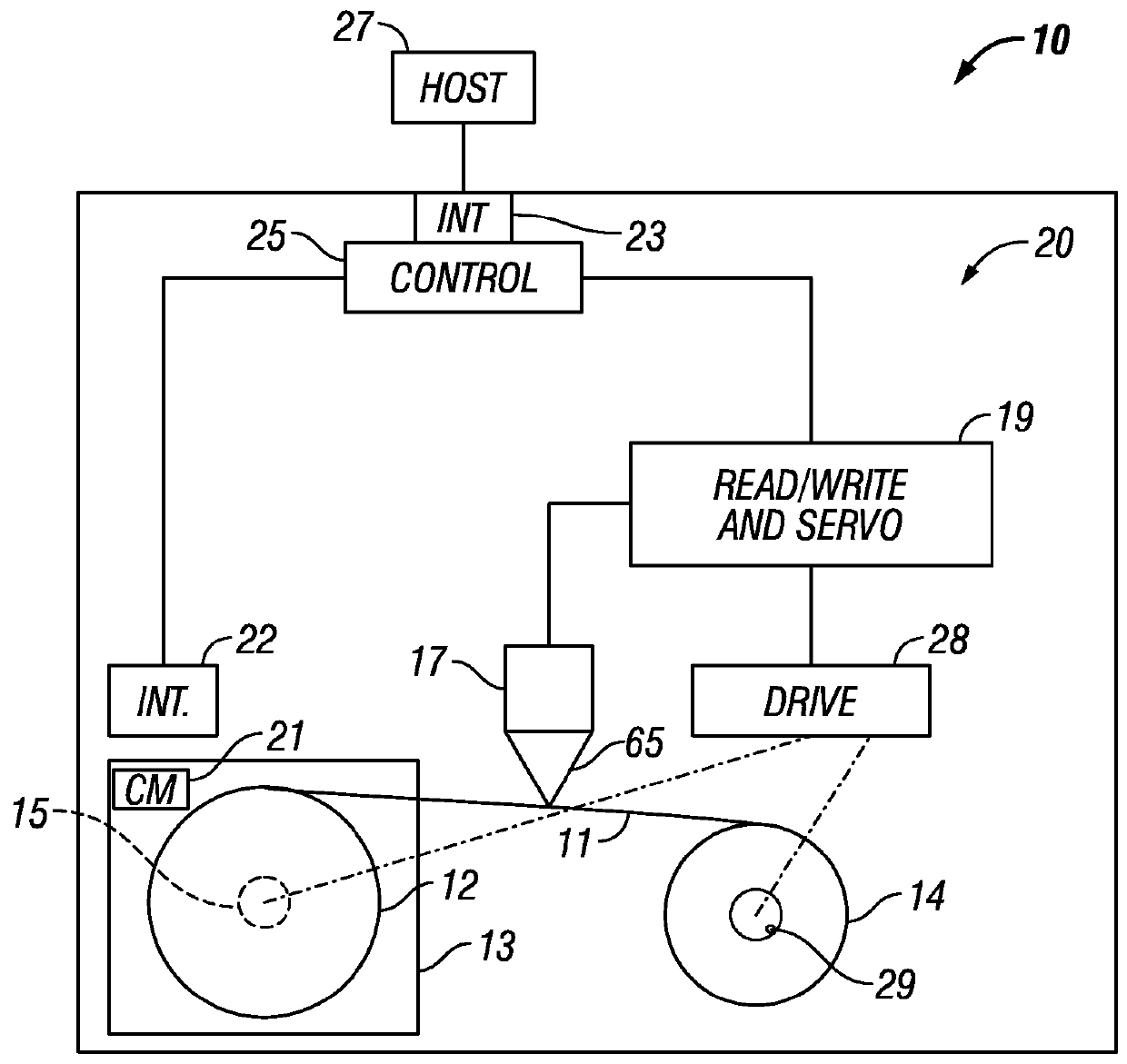

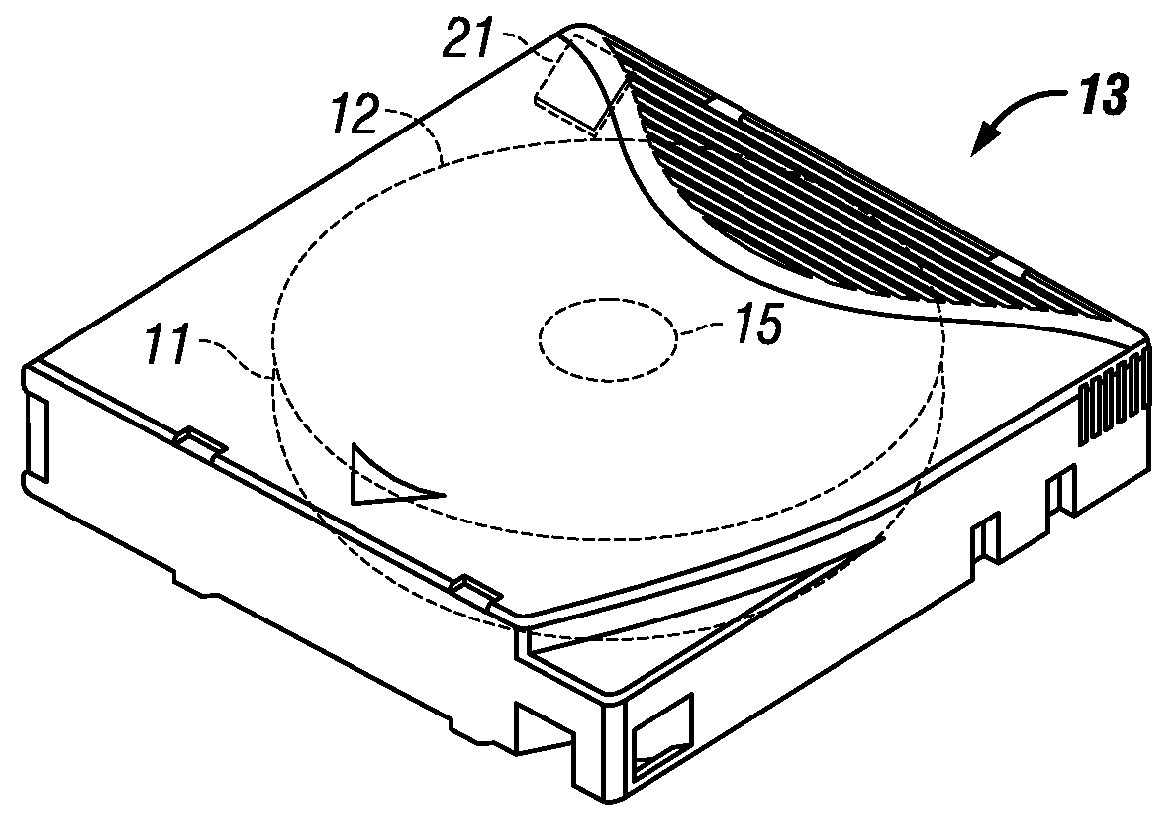

Servo control in tape drives

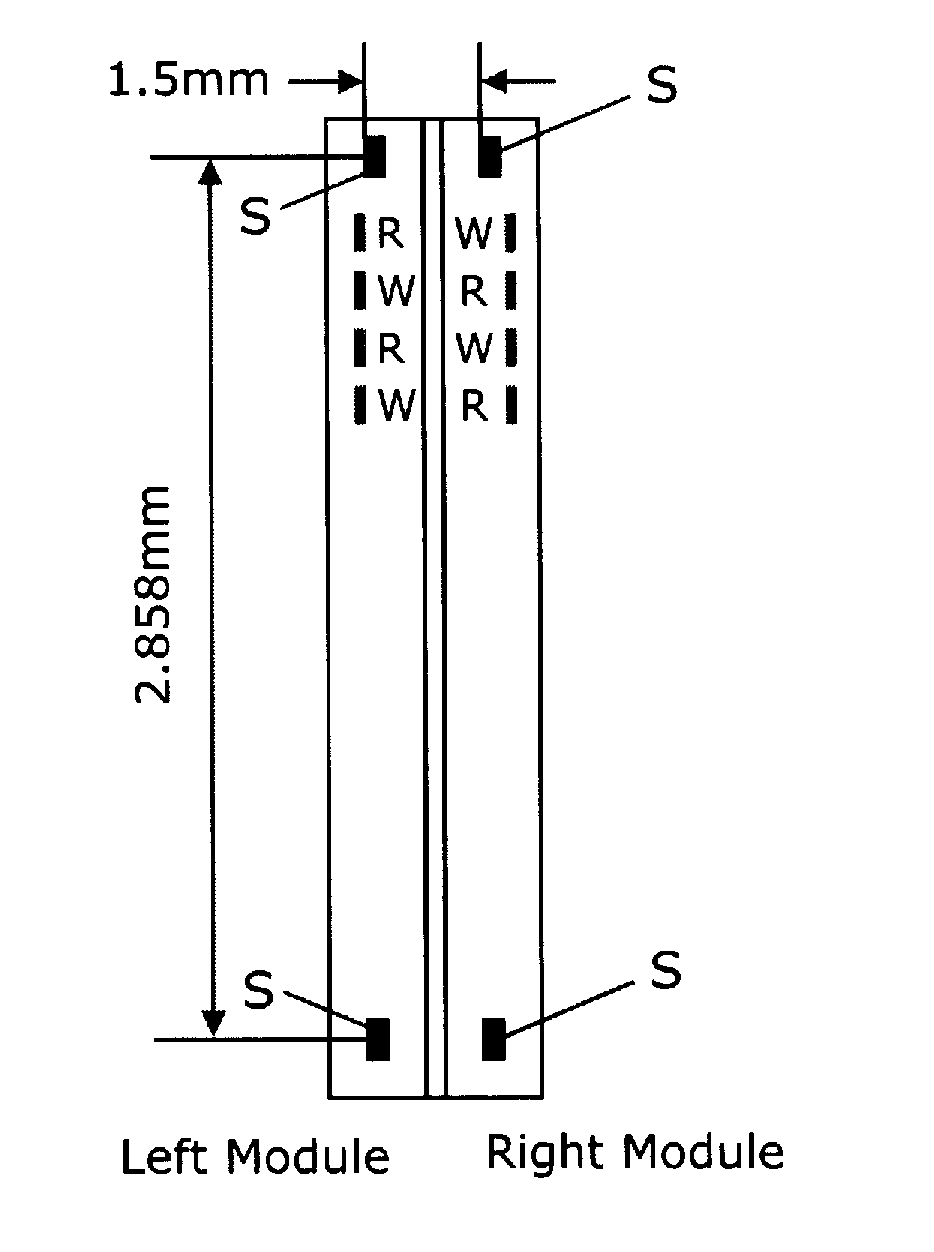

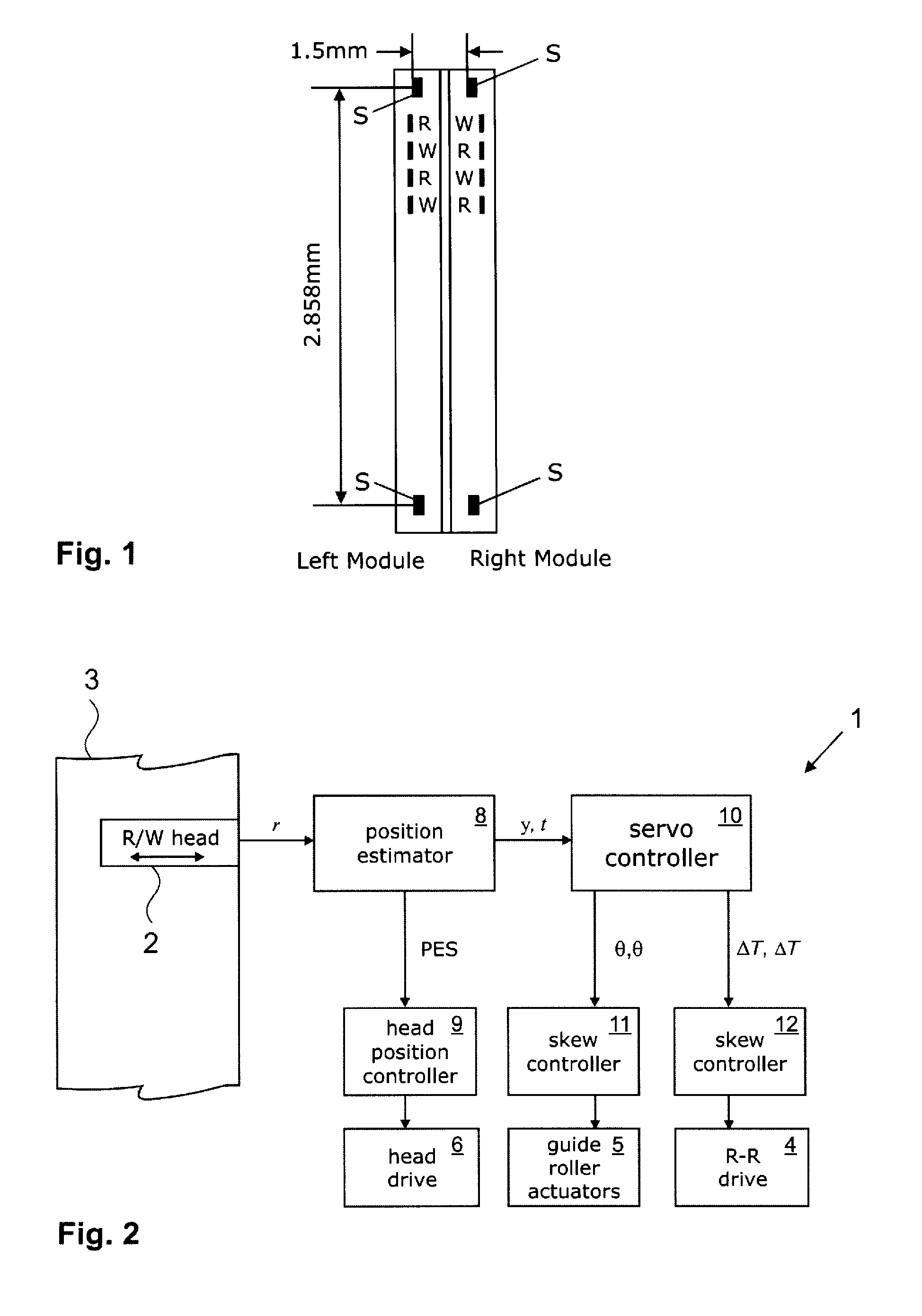

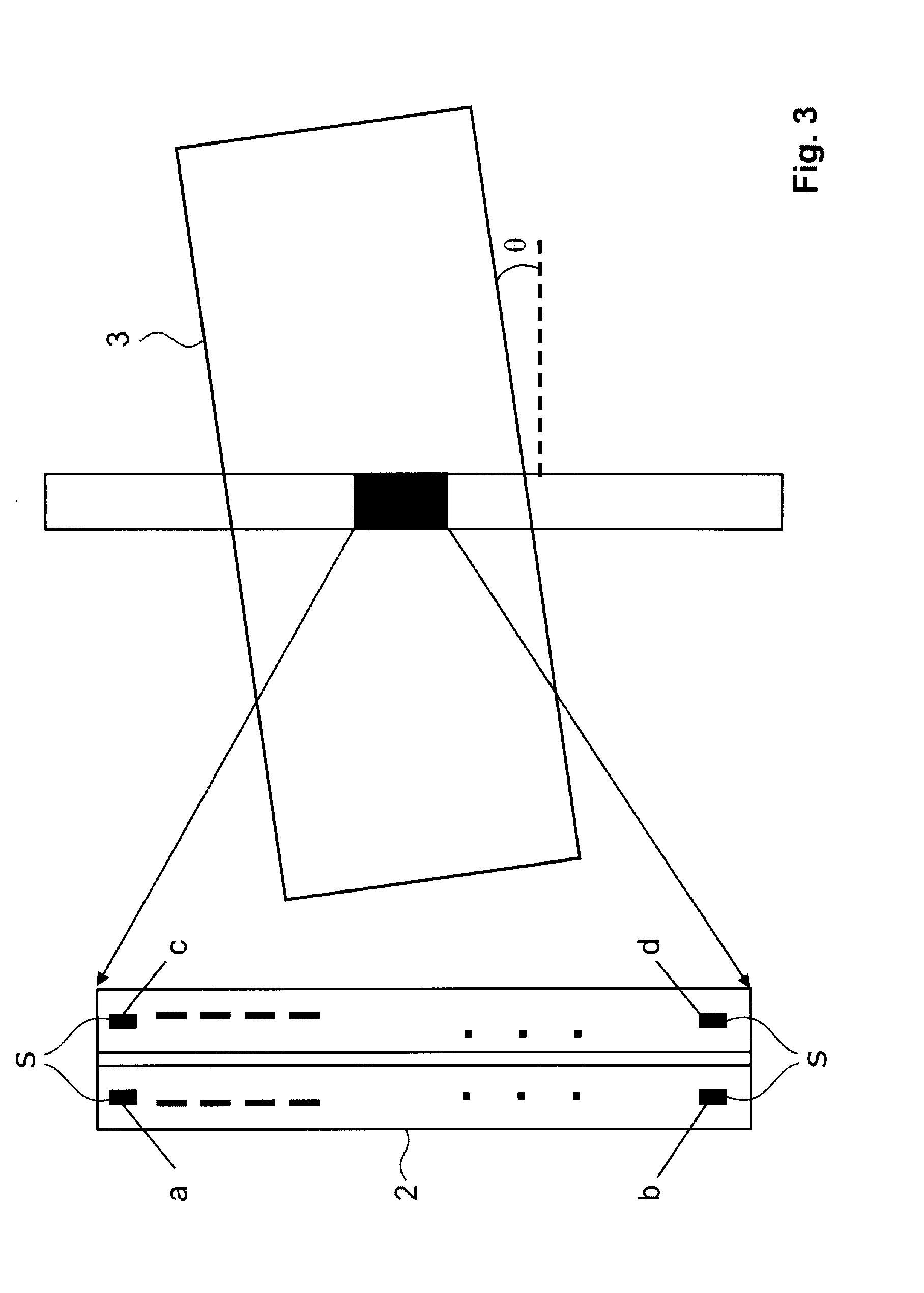

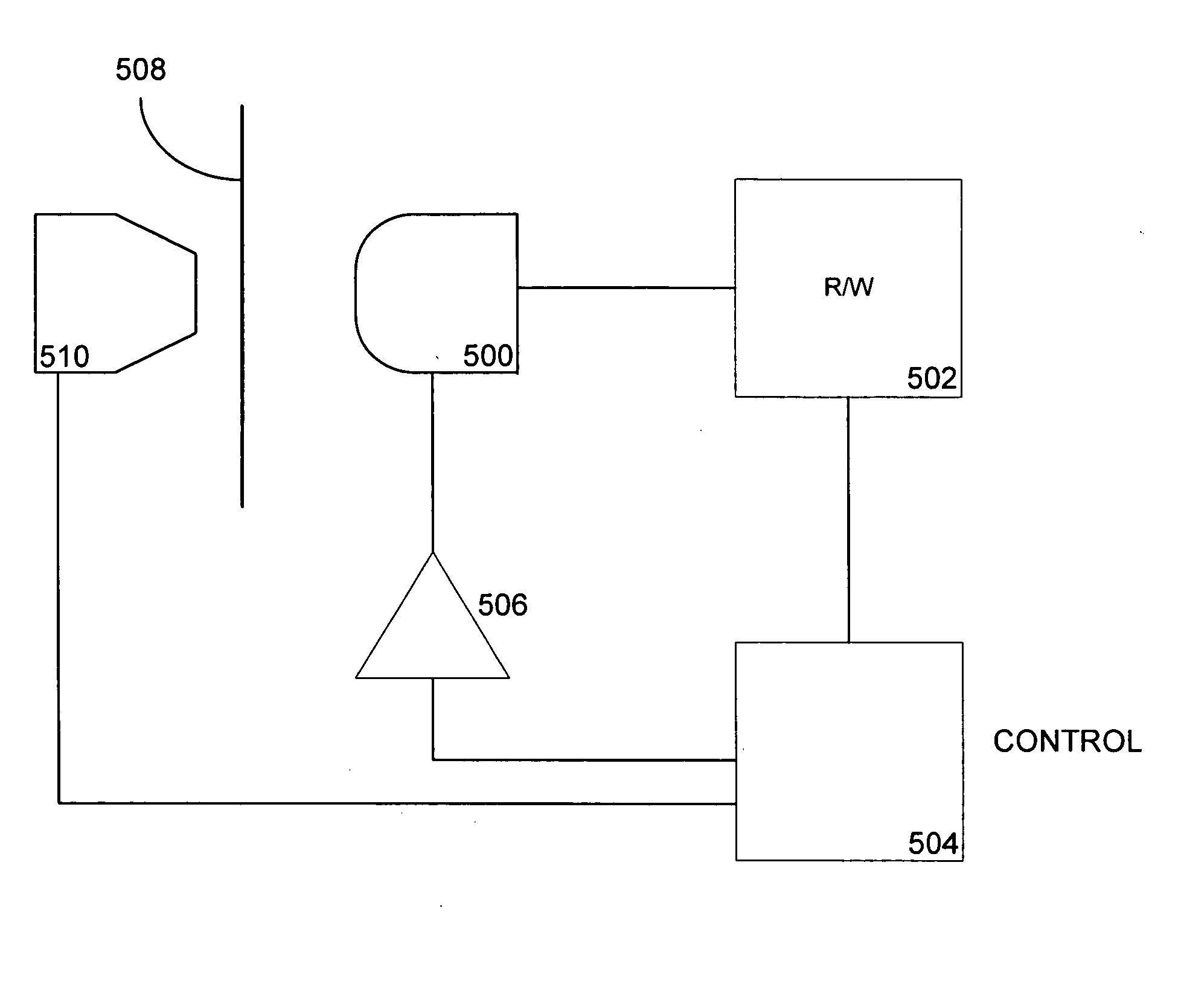

Servo control methods and apparatus for a tape drive. A read / write head reads and writes data on magnetic tape with at least one servo track providing transverse position information. At least two servo readers arranged for reading a servo track associated with the read / write head operate concurrently to generate servo read signals. A position estimator processes each servo read signal to generate a series of position values corresponding to respective time instants indicative of their transverse positions. A servo controller calculates a skew value indicative of tape skew relative to the read / write head and a tension variation value indicative of variation of tape tension. The servo controller is adapted to account for cross-coupling between tape skew and tension variation.

Owner:IBM CORP

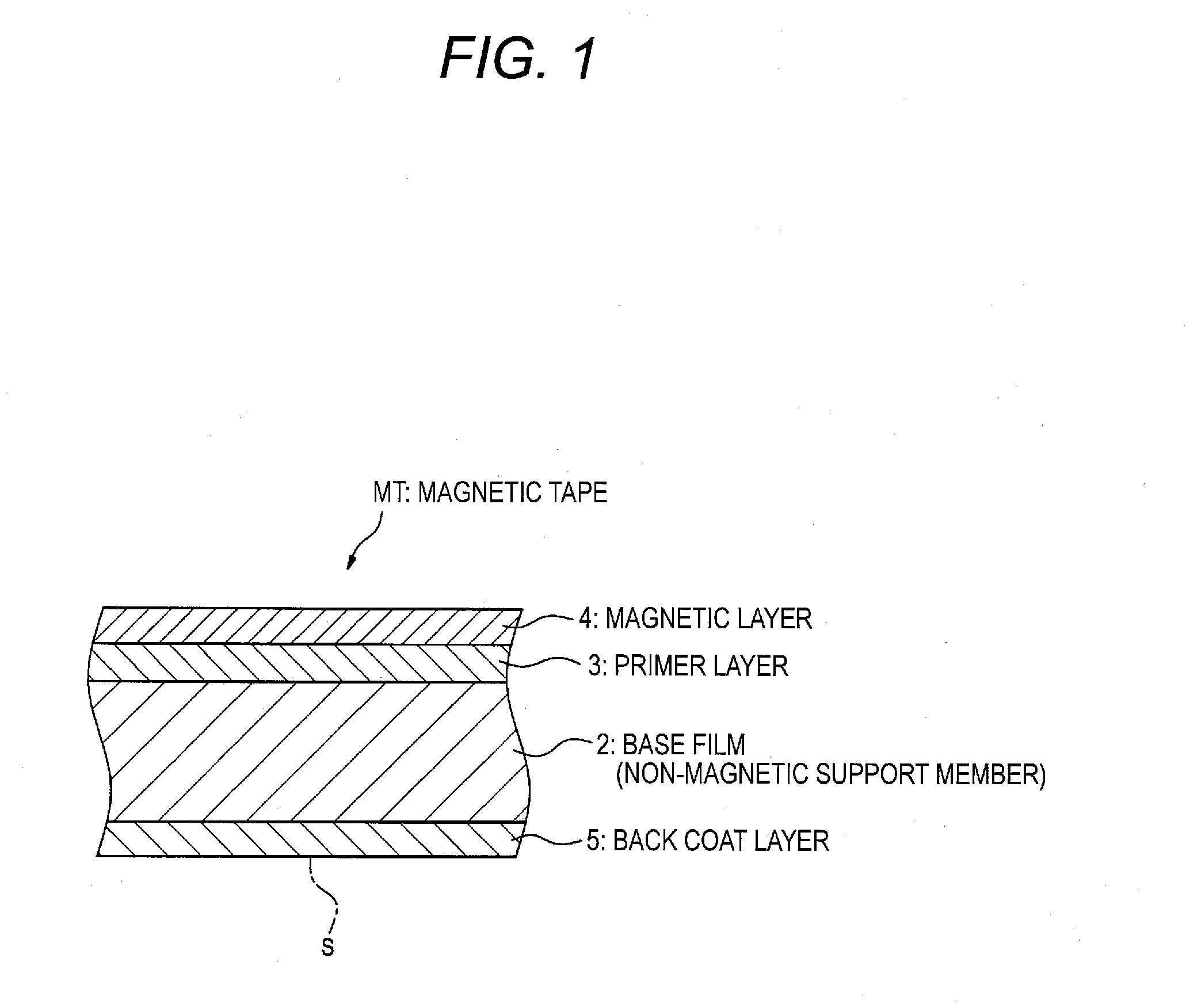

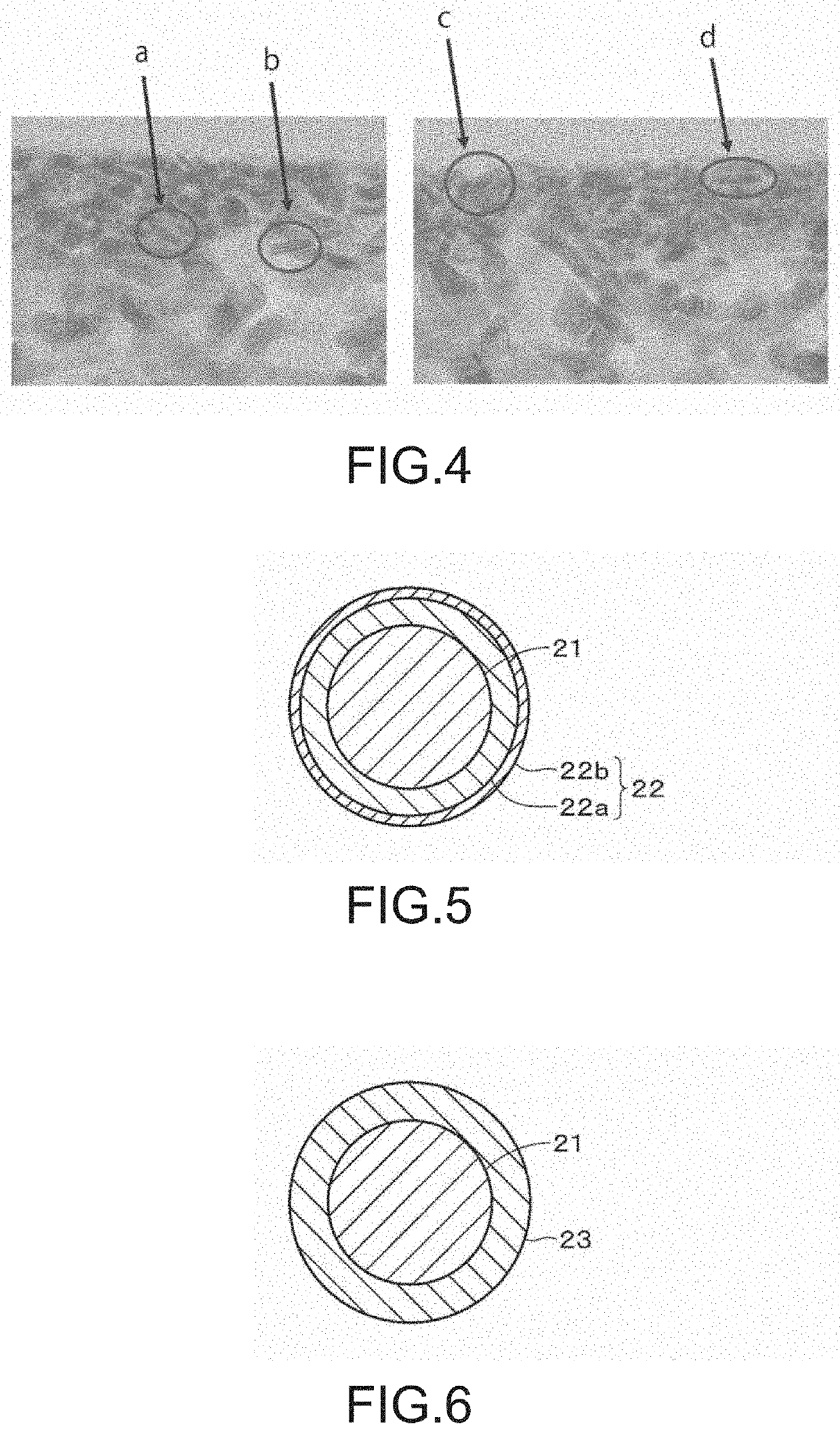

Resin film

ActiveUS20190180781A1High-density recordingAdjustmentDisposition/mounting of recording headsBase layers for recording layersYoung's modulusEngineering

To provide a resin film, of which dimensional stability required of an ultra-high density recording medium can be controlled easily by drive tension, and which has processability at high temperature in a processing step of the resin film into a magnetic recording medium. A resin film having a Young's modulus in the film longitudinal direction of 1 GPa or more and a film thickness of 1 μm or more, wherein the product of the Young's modulus in the longitudinal direction and the thickness is 5 GPa·μm or more and 20 GPa·μm or less and wherein a dimensional change in the film longitudinal direction is −2% or more and +2% or less when the film is heated at a rate of 5° C. / min under a load of 2 kg / mm2 applied in the longitudinal direction and the temperature has reached 110° C., the resin film satisfying at least either of the following (1) or (2): (1) the Young's modulus in the film longitudinal direction is 6 GPa or less and the film thickness is 4.5 μm or less; and (2) the Young's modulus in the film longitudinal direction is 4 GPa or less and the film thickness is 6 μm or less.

Owner:TOYOBO CO LTD

Servo control in tape drives

Servo control methods and apparatus for a tape drive. A read / write head reads and writes data on magnetic tape with at least one servo track providing transverse position information. At least two servo readers arranged for reading a servo track associated with the read / write head operate concurrently to generate servo read signals. A position estimator processes each servo read signal to generate a series of position values corresponding to respective time instants indicative of their transverse positions. A servo controller calculates a skew value indicative of tape skew relative to the read / write head and a tension variation value indicative of variation of tape tension. The servo controller is adapted to account for cross-coupling between tape skew and tension variation.

Owner:INT BUSINESS MASCH CORP

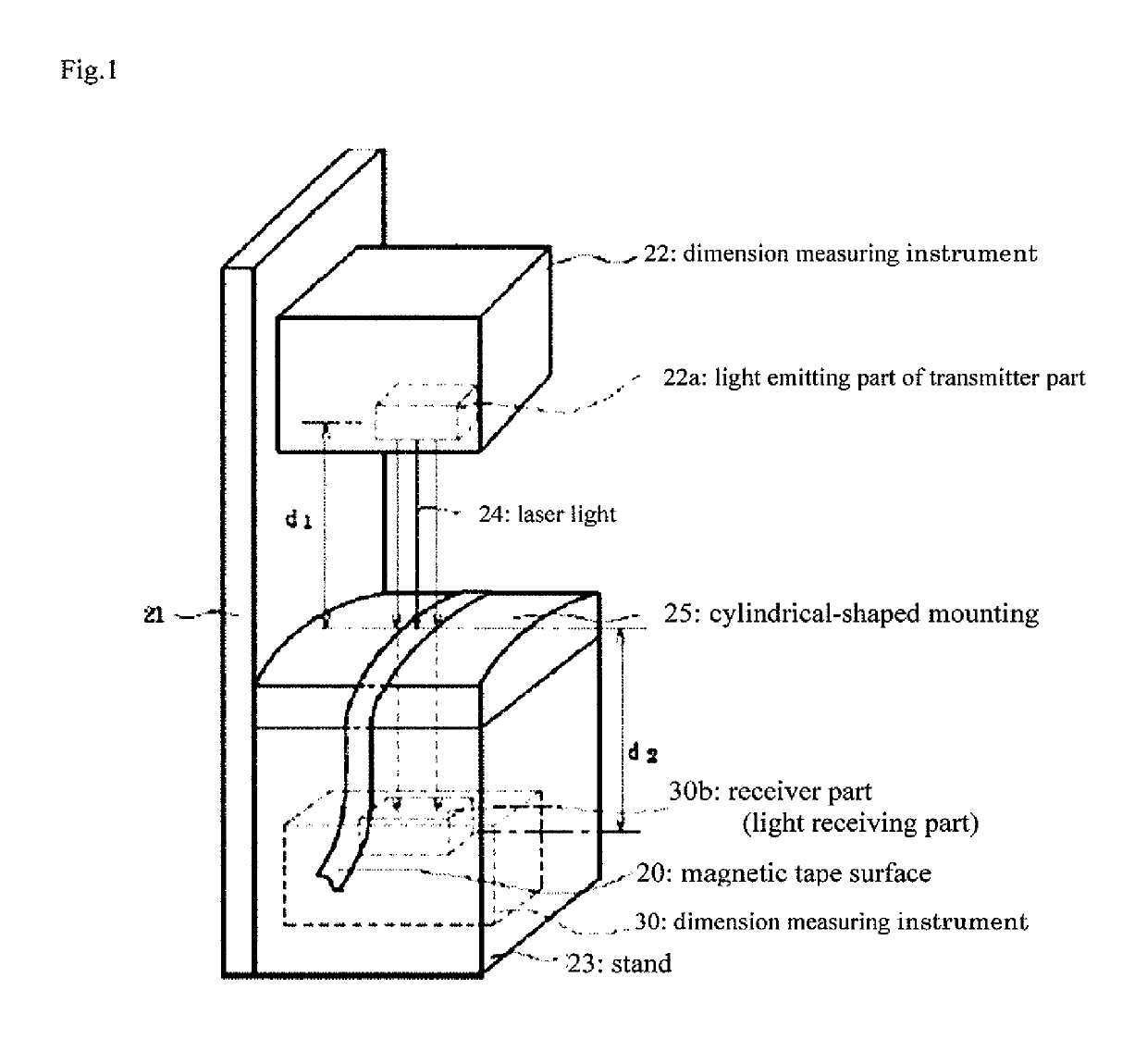

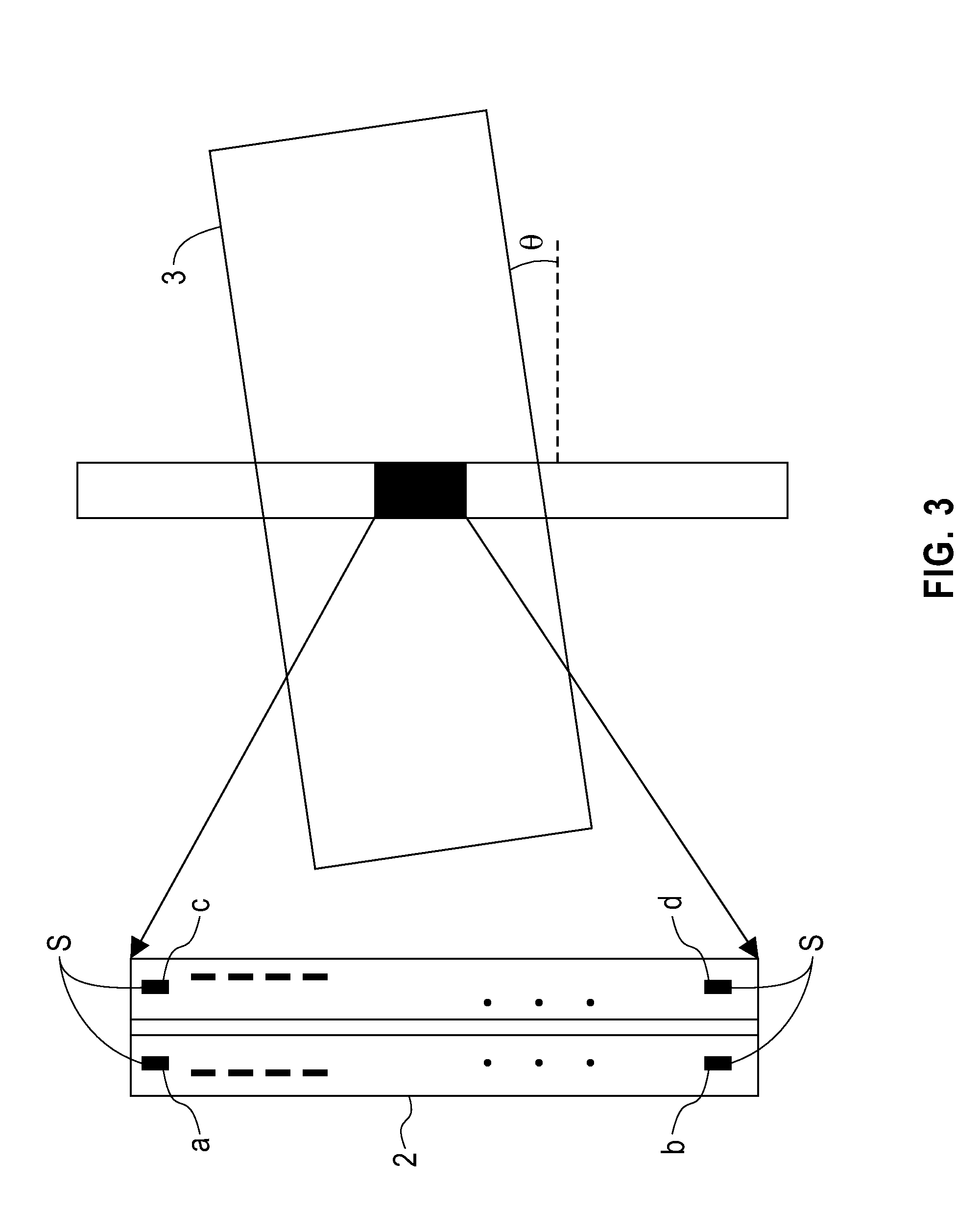

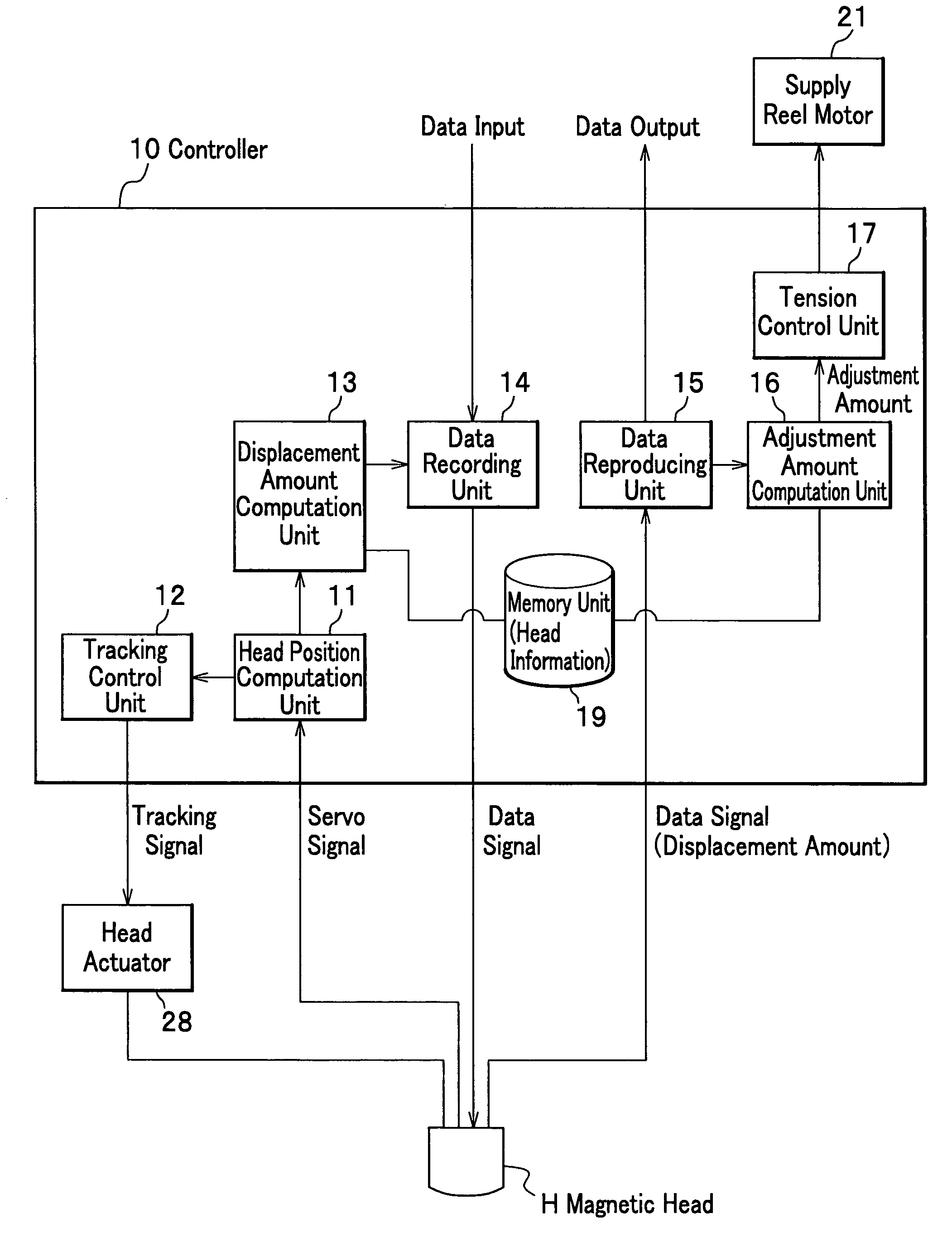

Method and a device for recording and reproducing data onto and from a magnetic tape

InactiveUS20060092547A1Minimizes valueAccurate readingAlignment for track following on tapesRecord information storageMagnetic tapeEngineering

A recording / reproducing method and a recording / reproducing device for magnetic tapes are less involved displacements between recording track and reproducing head even upon changes in the widthwise size of the magnetic tape, and capable of recording and reproducing data without causing errors, thus being ready for recording density enhancement of magnetic tapes. In both data recording and data reproduction, the tension of the magnetic tape is controlled so that absolute values of displacements between a pair of servo heads and a plurality of servo tracks corresponding to these servo heads are minimized.

Owner:HITACHT MAXELL LTD

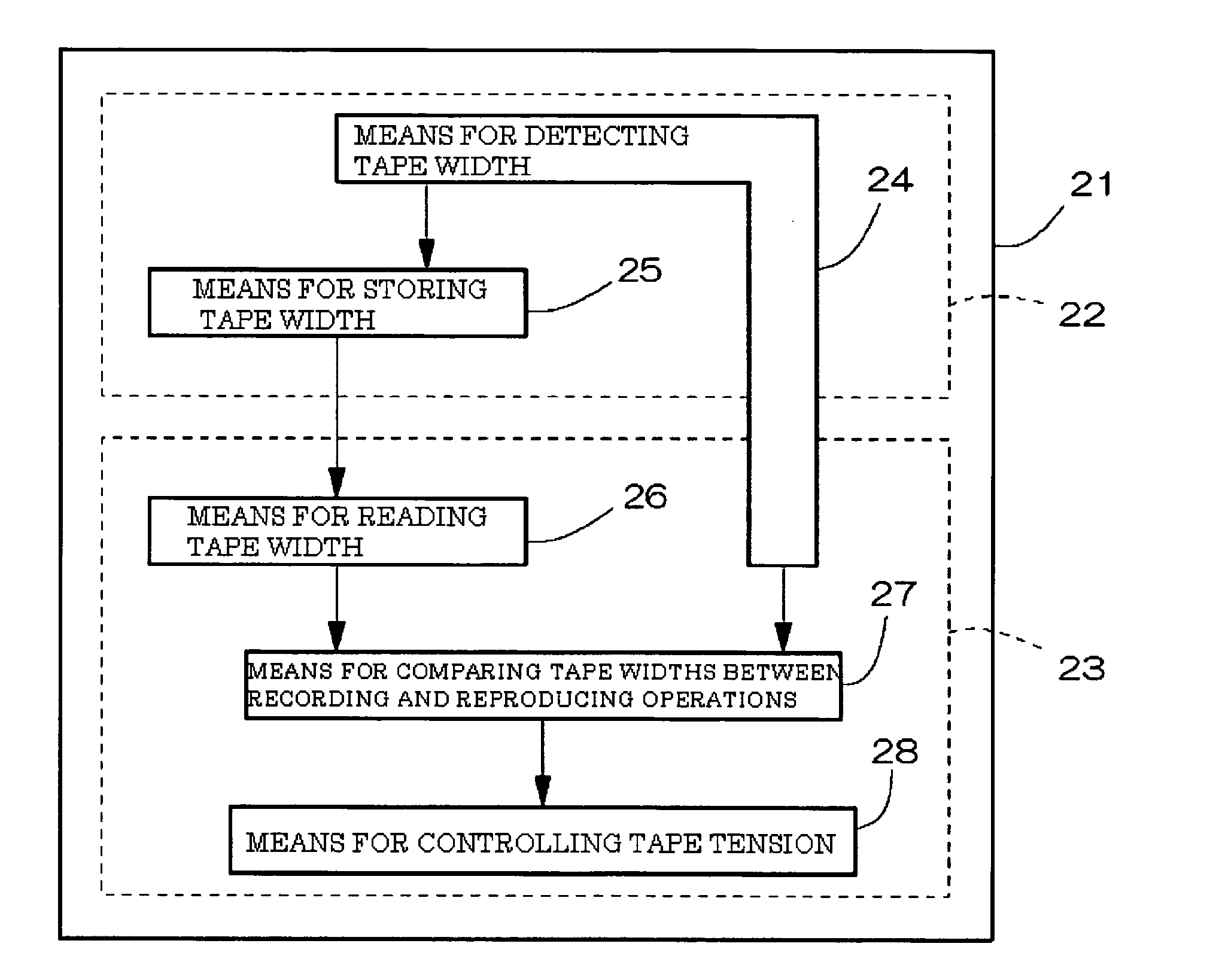

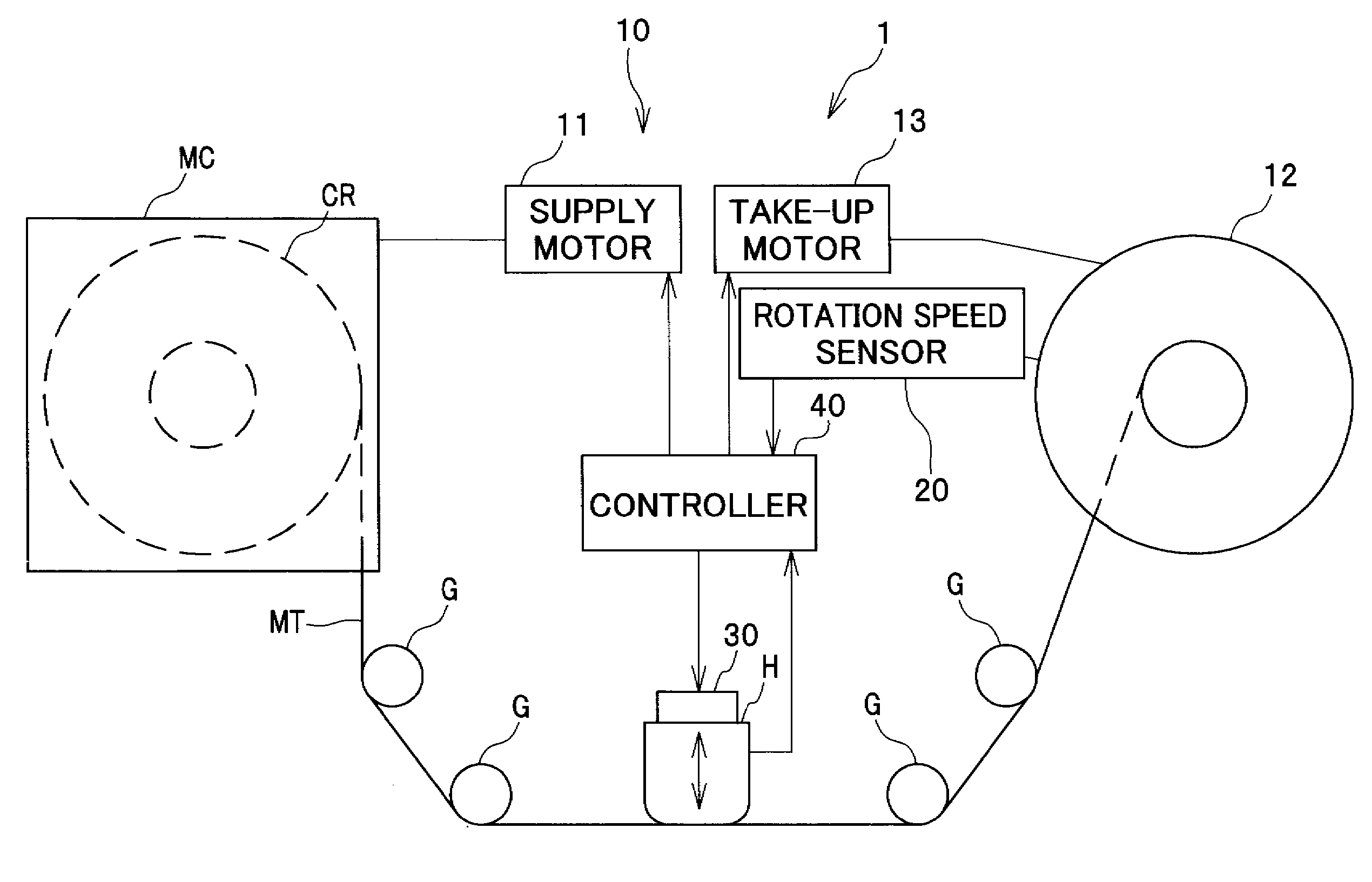

Recording/ reproducing method and recording/reproducing apparatus for magnetic tape

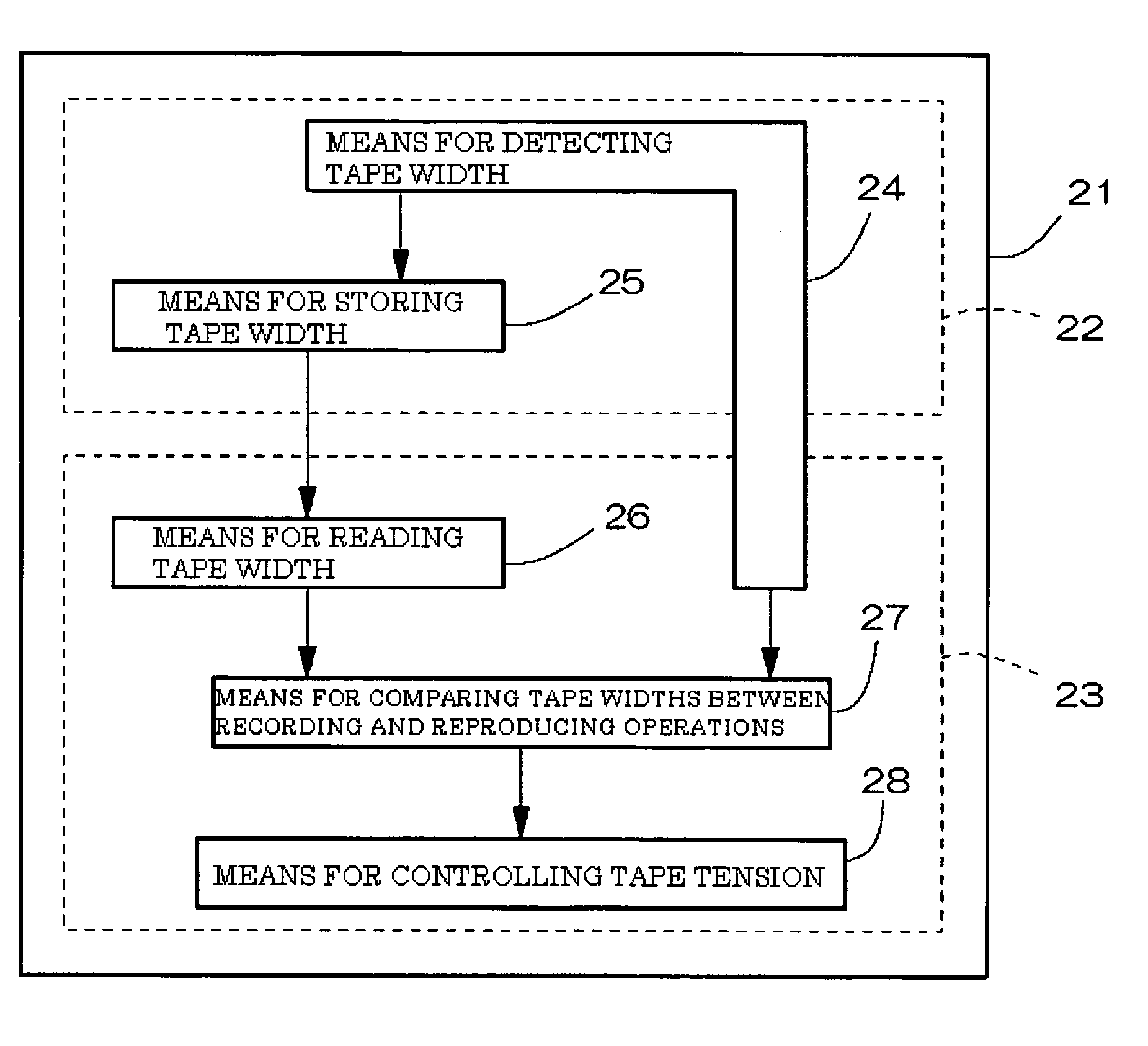

A recording / reproducing method and a recording / reproducing apparatus for magnetic tapes are provided as a recording / reproducing technique suitable for recording density enhancement of magnetic tapes. The method and apparatus are capable of correctly recording and reproducing data without causing errors even with occurrence of size changes in the widthwise direction of a magnetic tape. In the recording / reproducing method for magnetic tapes in which data tracks and servo tracks are provided, a tape width is detected and a value of the tape width is stored during data recording, and data reproduction is performed while tape tension is controlled so that the tape width during data reproduction is maintained equal to the tape width during data recording.

Owner:FUJIFILM CORP

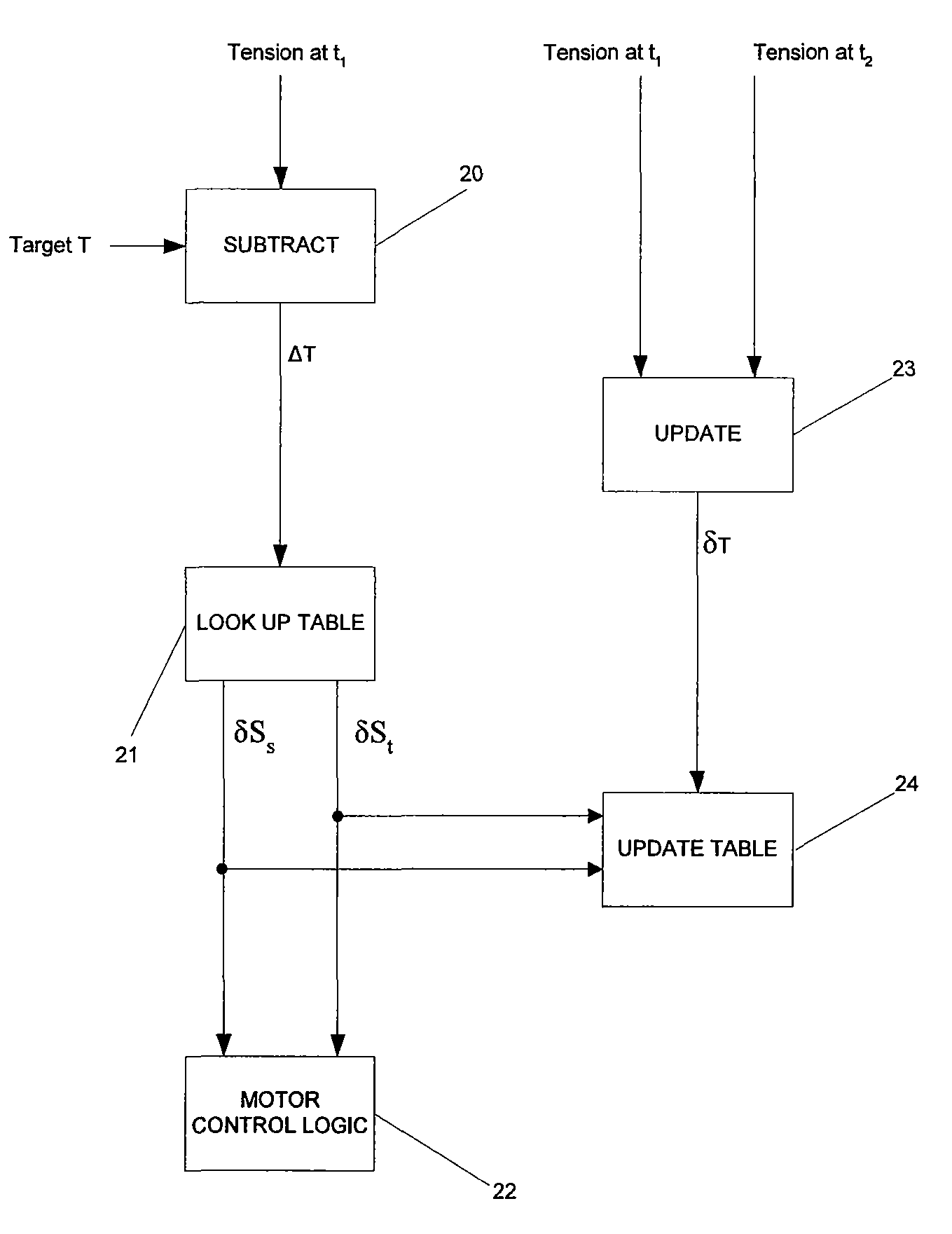

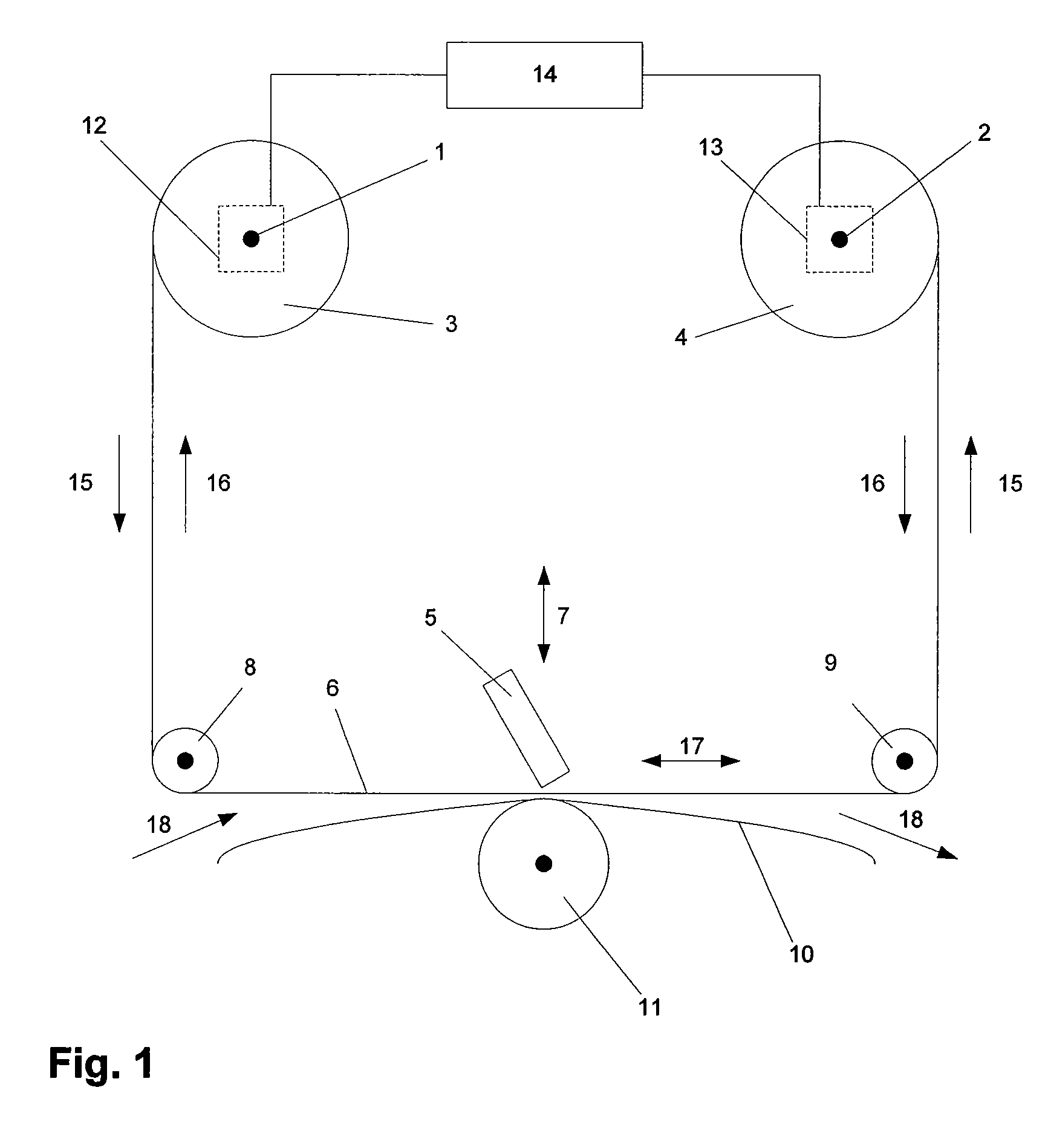

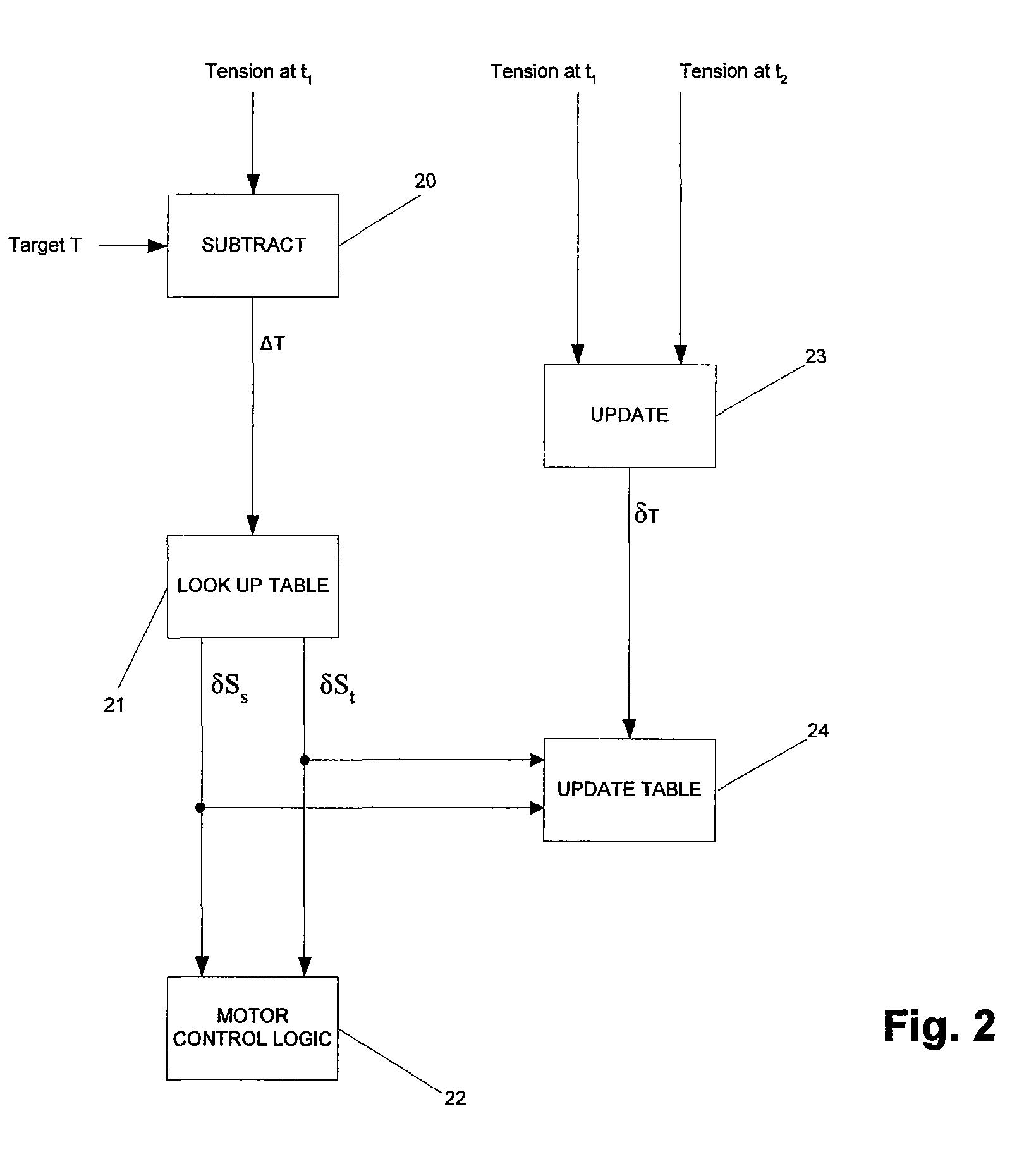

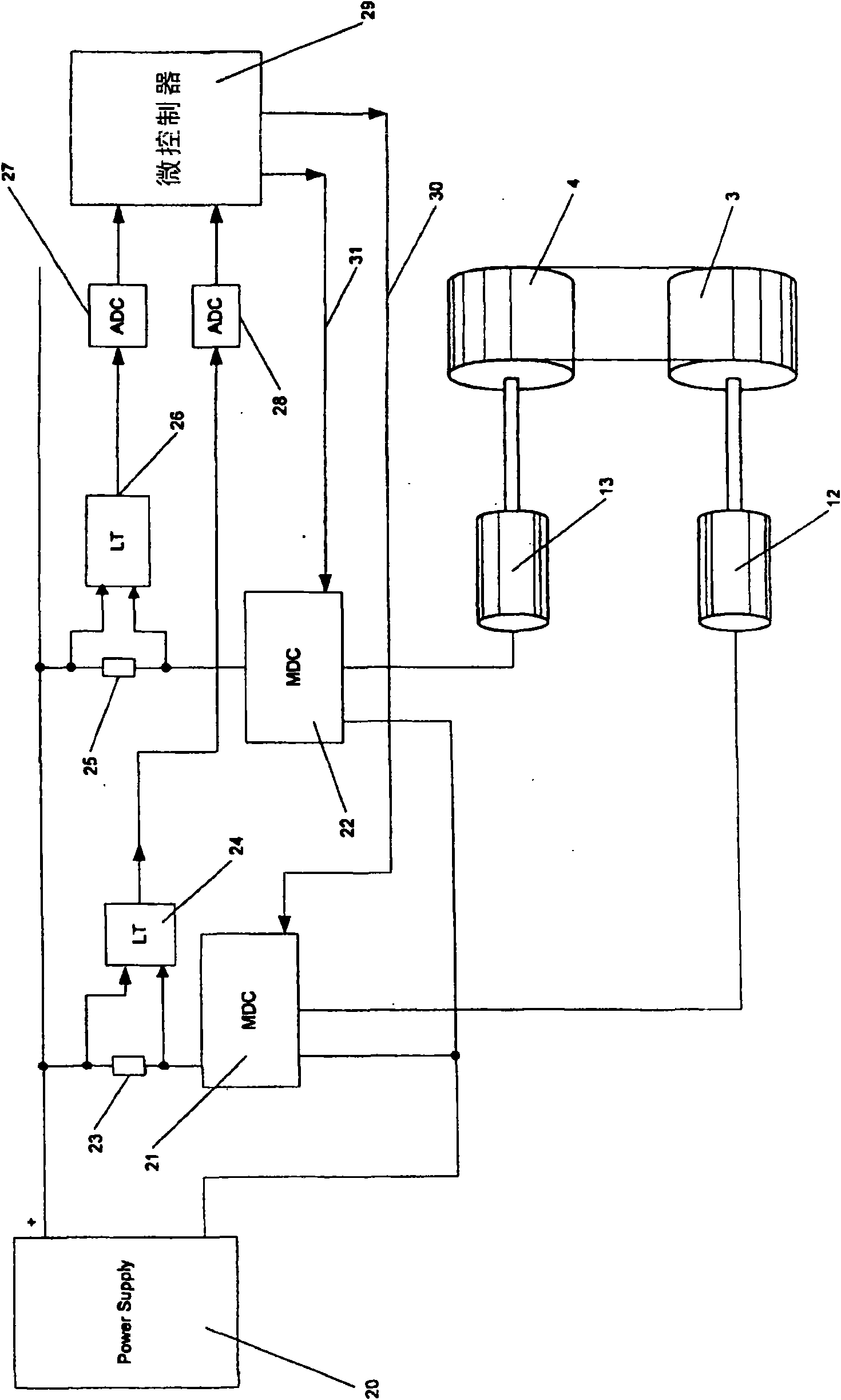

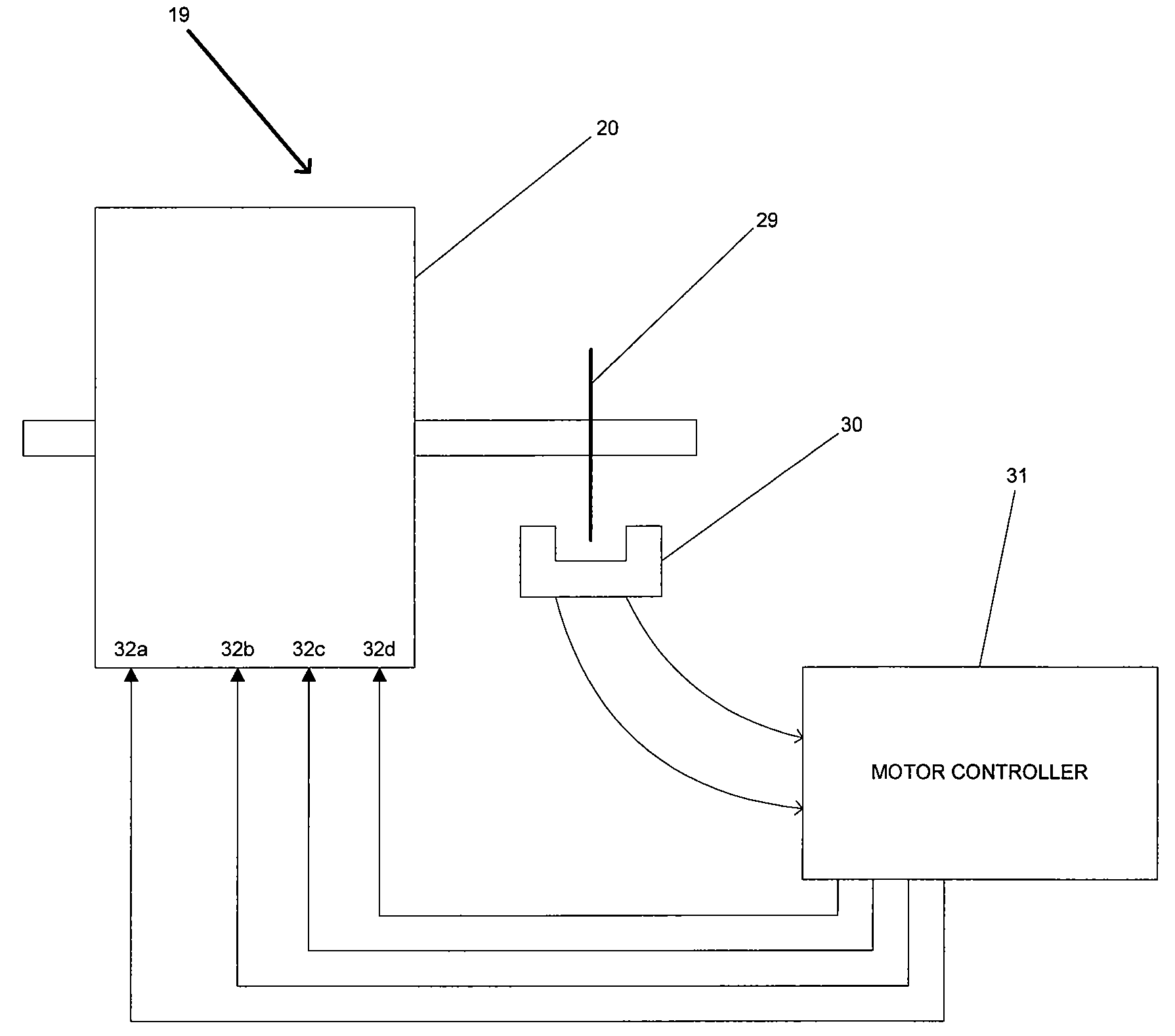

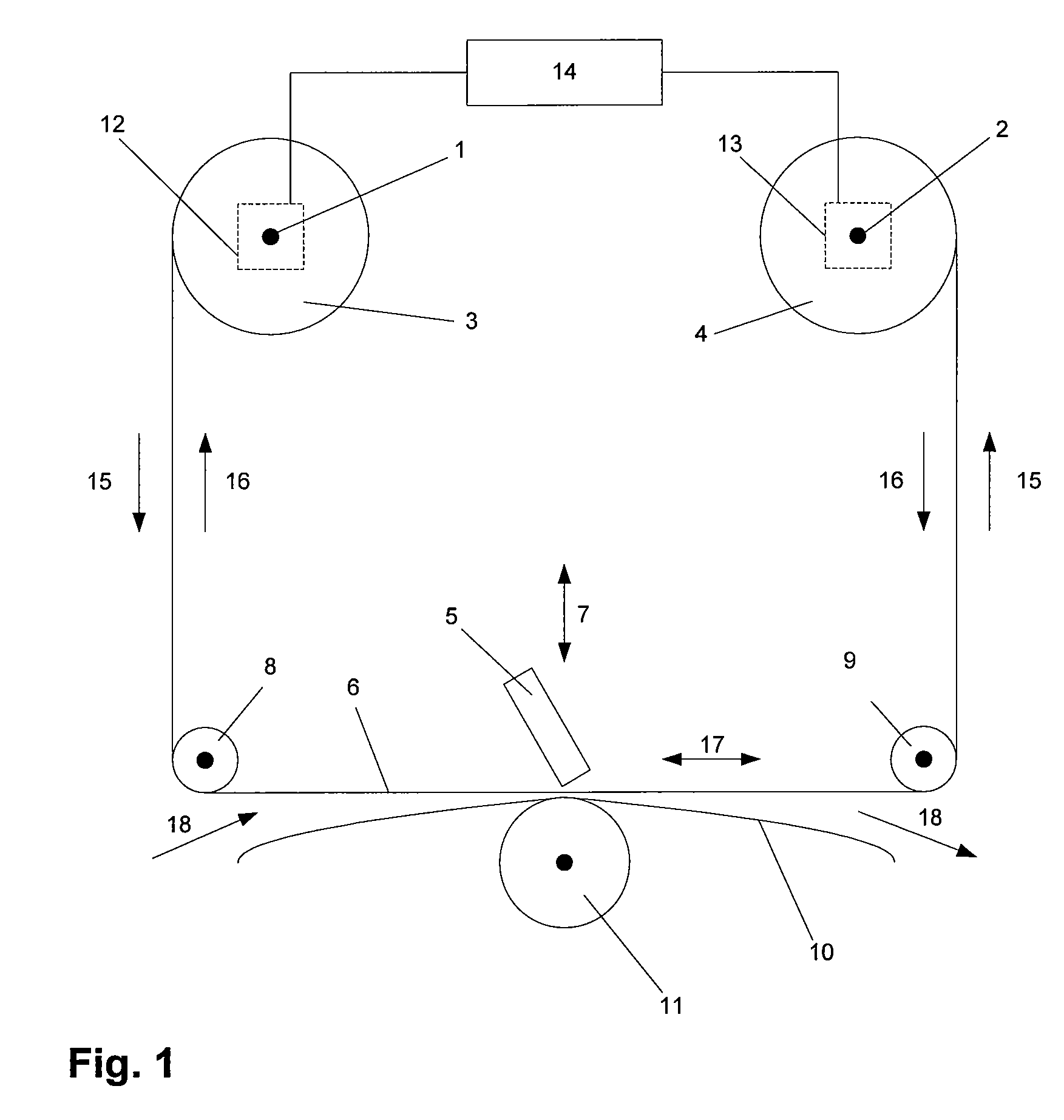

Tape drive

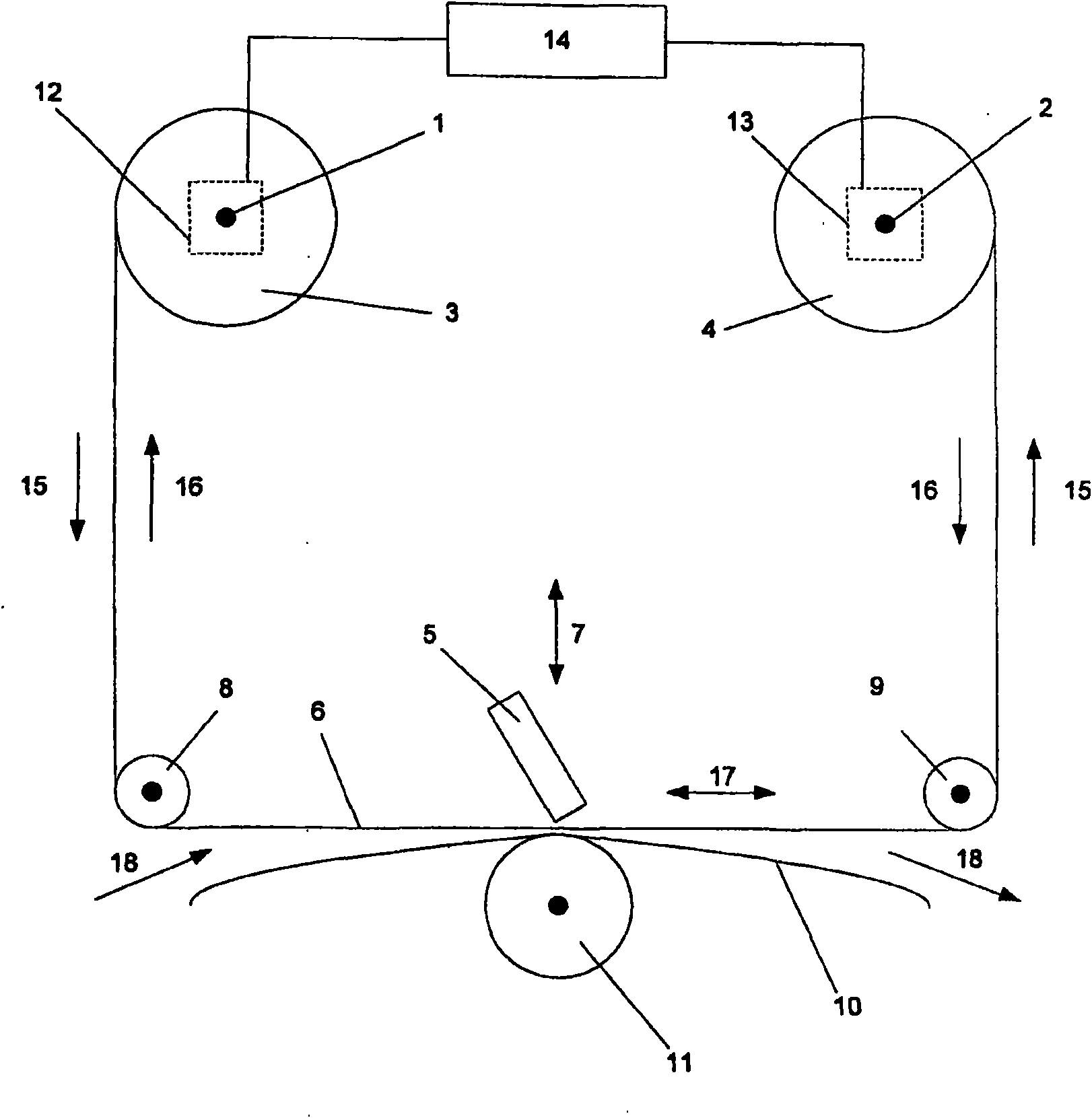

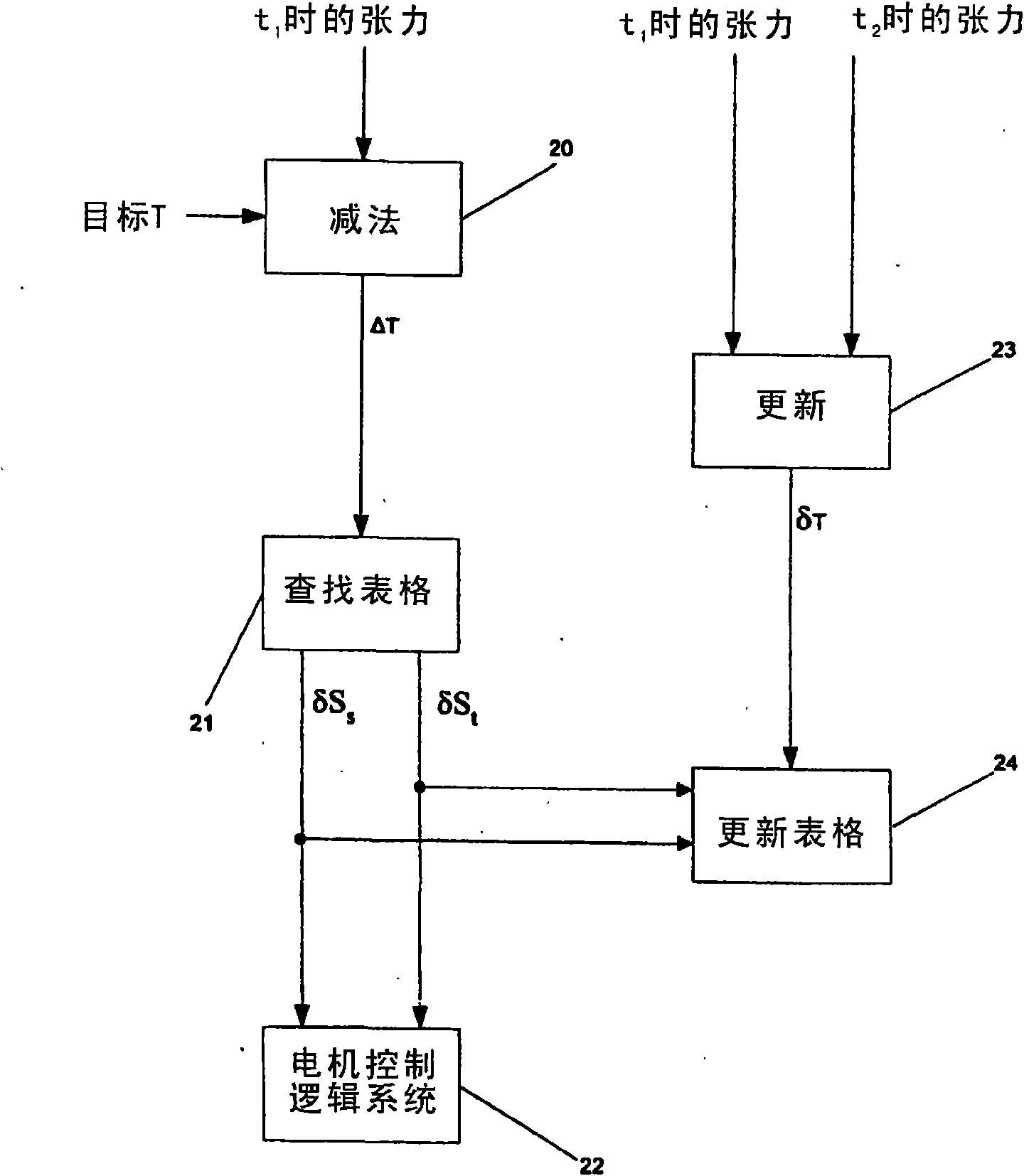

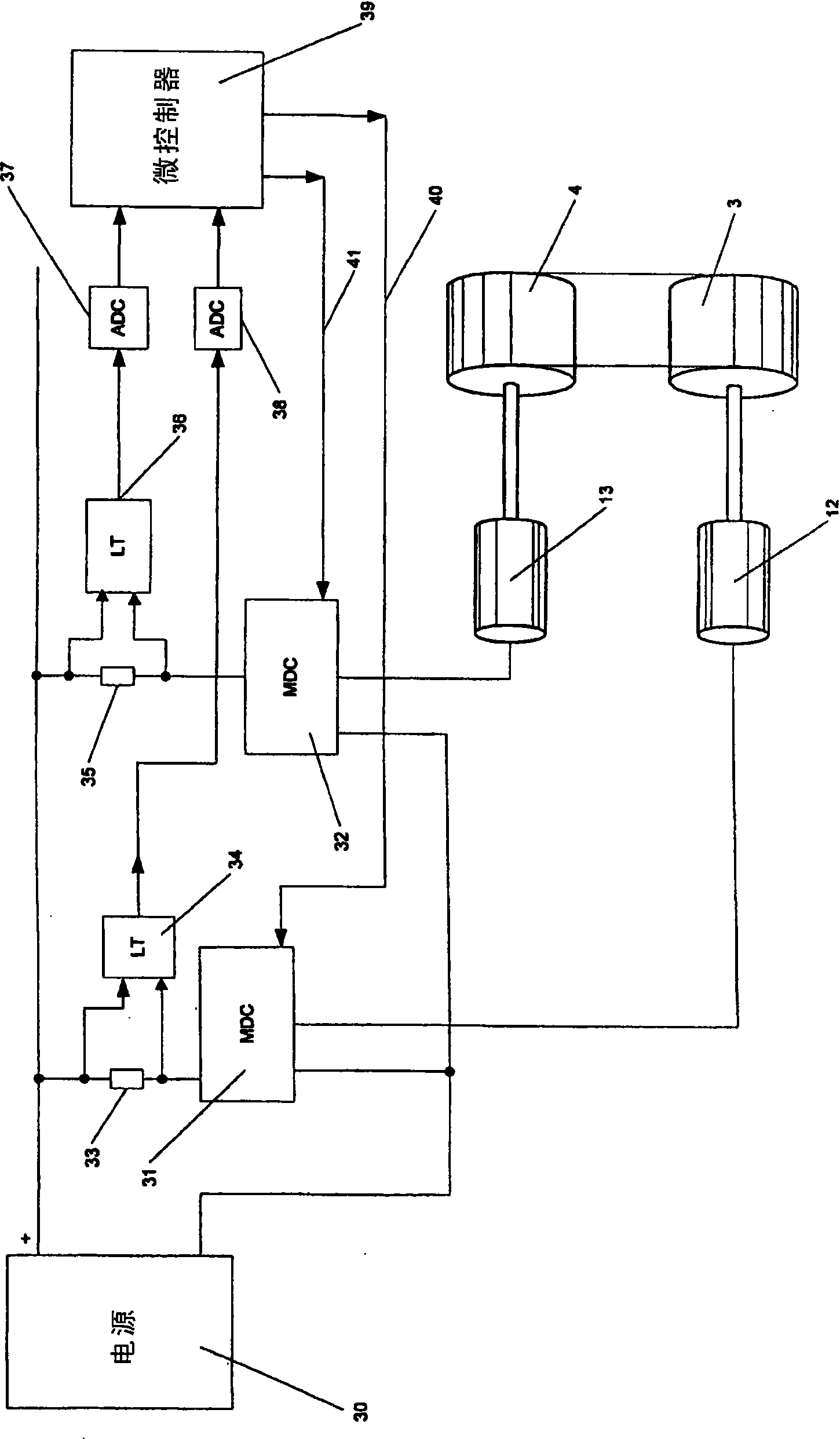

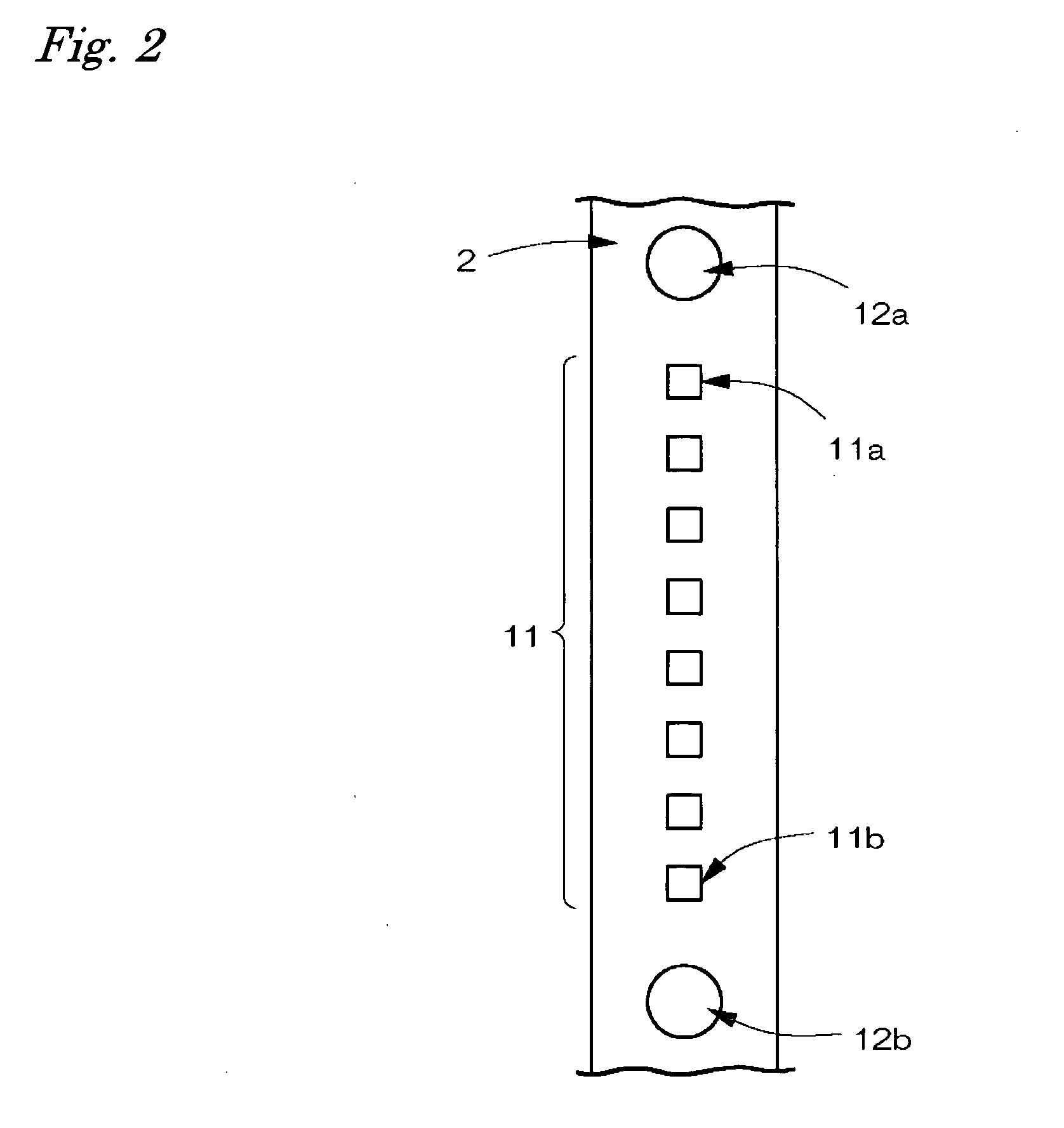

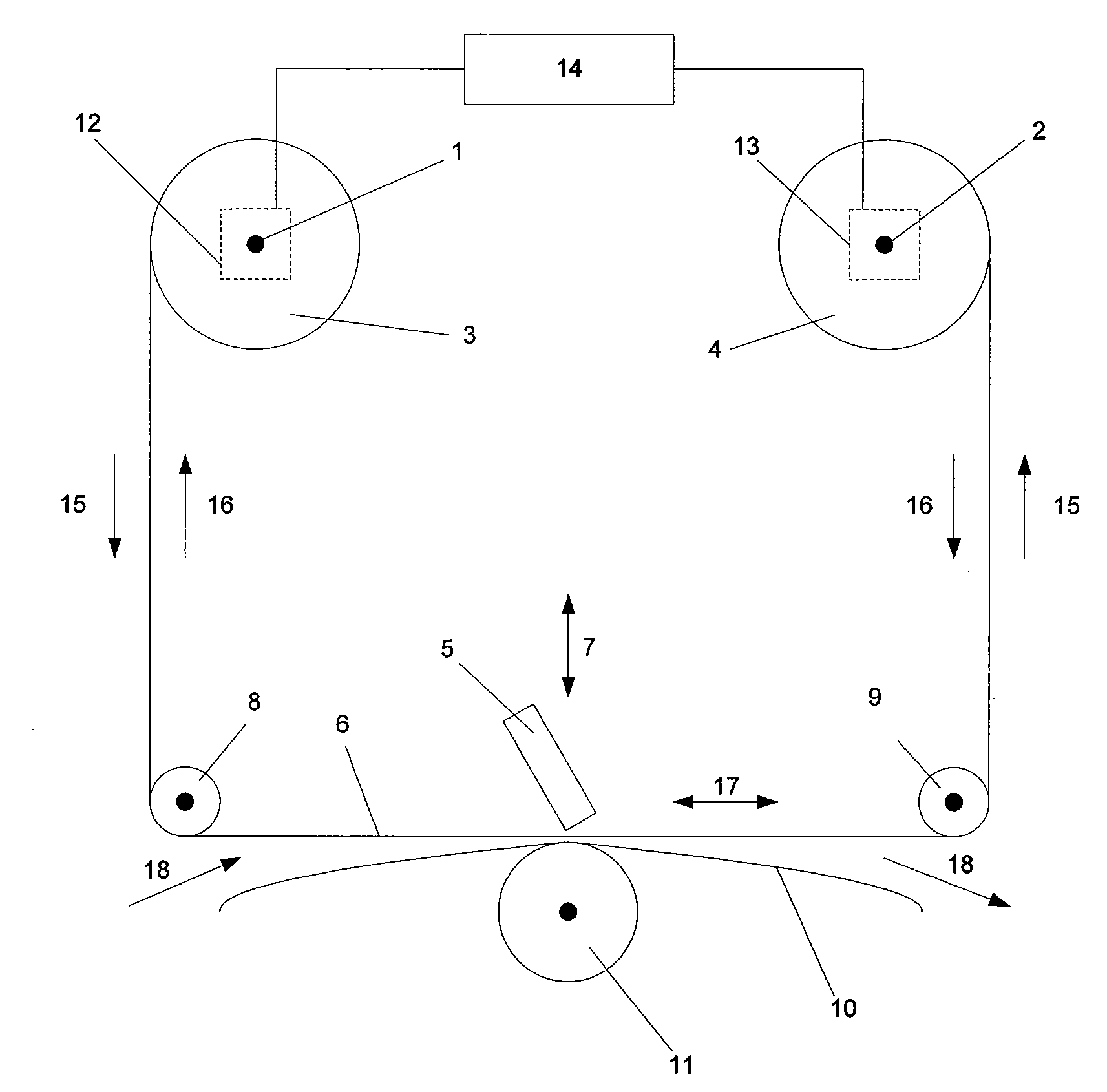

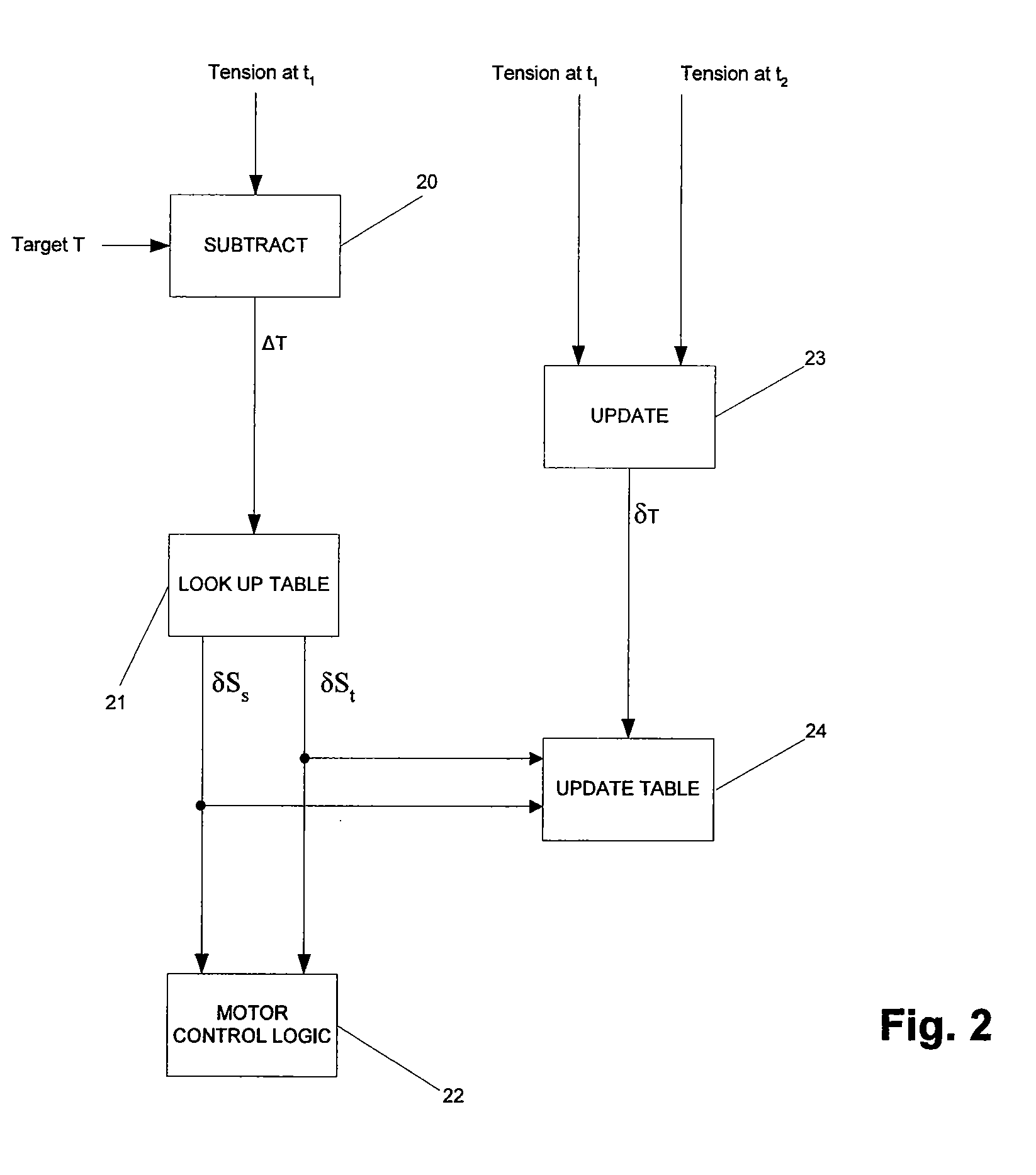

InactiveCN101663173AAvoid wastingInking apparatusCarrier mechanical tension controlMotor controlTape drive

A tape drive comprising two motors (12, 13), two tape spool supports on which, spools (3, 4) of tape may be mounted, each spool being drivable by a respective one of said motors, and a controller (14)for controlling the energisation of the motors such that the tape may be transported in at least one direction between spools mounted on the spool supports. The controller is configured to store a plurality of motor control data items, each data item being associated with a respective tension value. The controller is operative to monitor tension.in a tape being transported between spools mountedon the spool supports, read a motor control data item based upon said monitored tension, generate a motor control signal based upon said read motor control data item, and apply said motor control signal to at least one of the motors.

Owner:伟迪捷科技(诺丁汉)有限公司

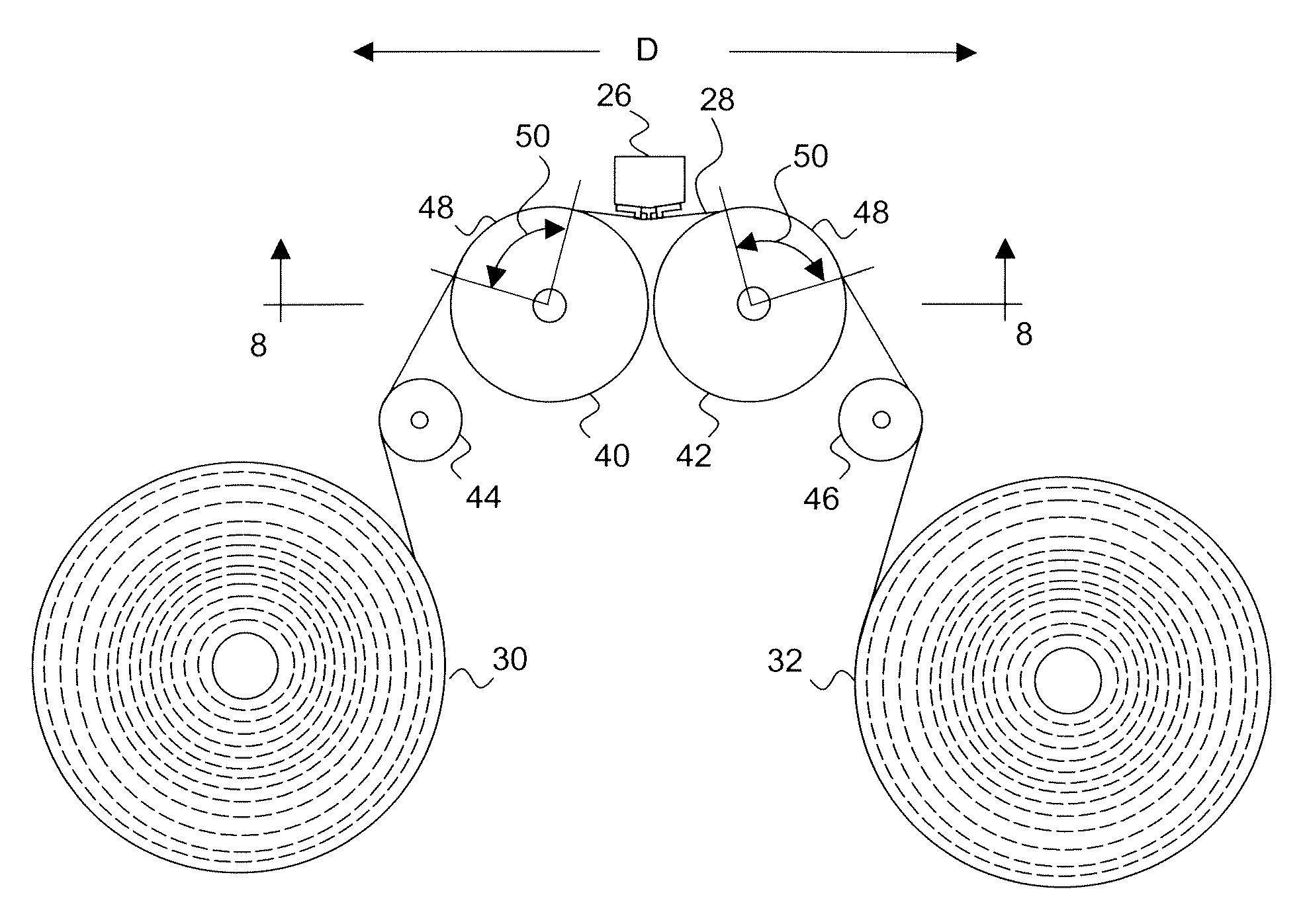

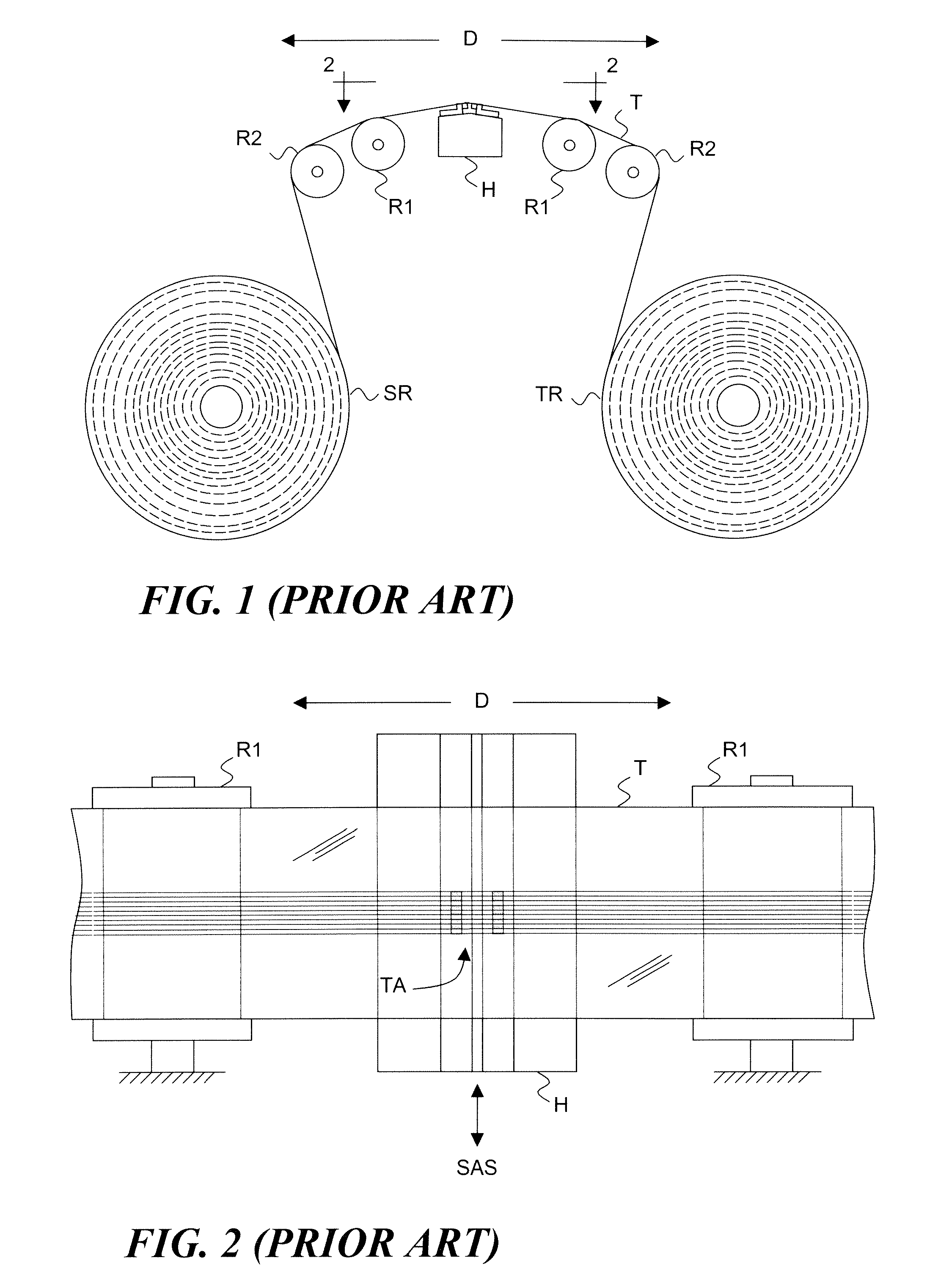

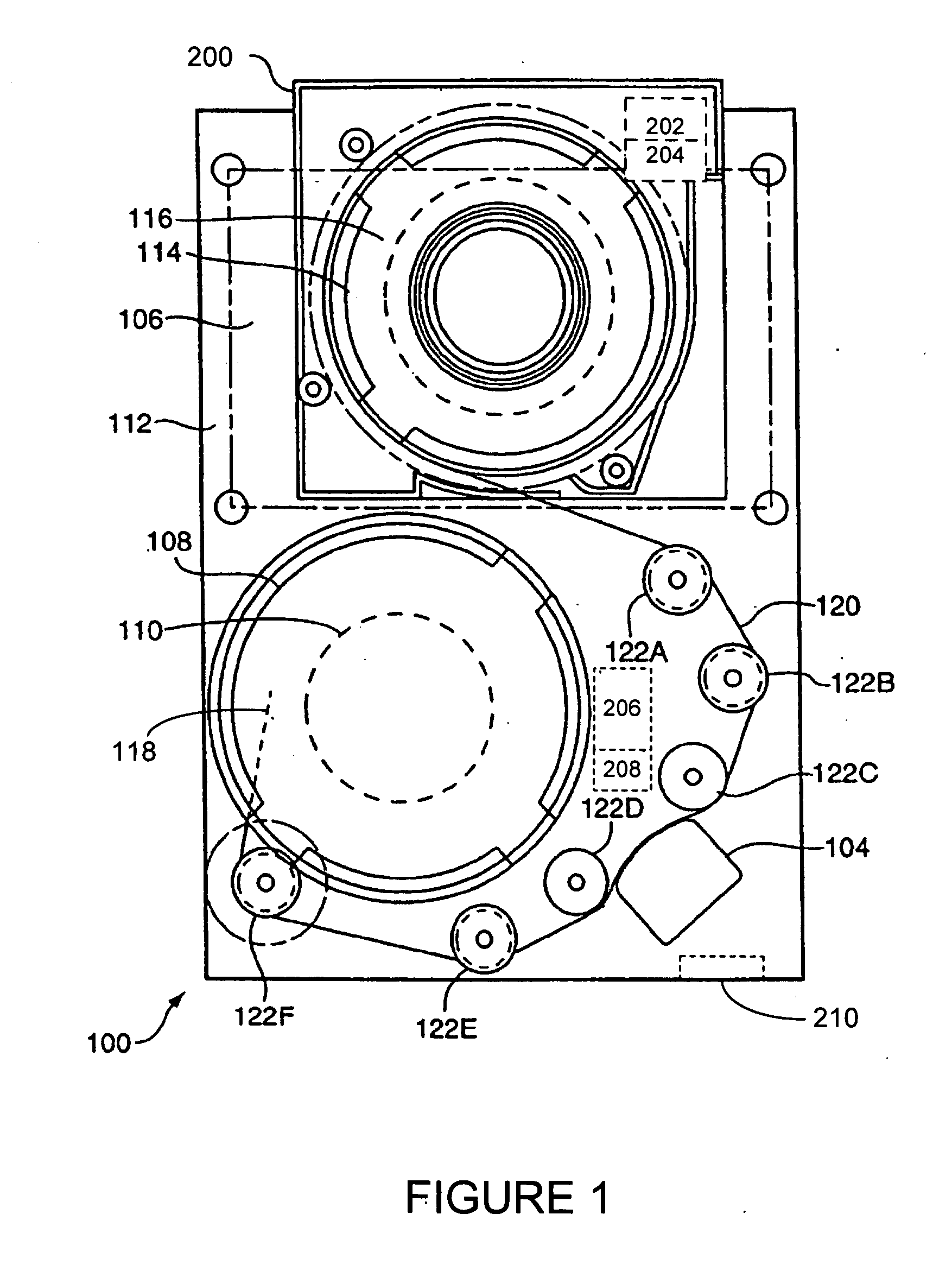

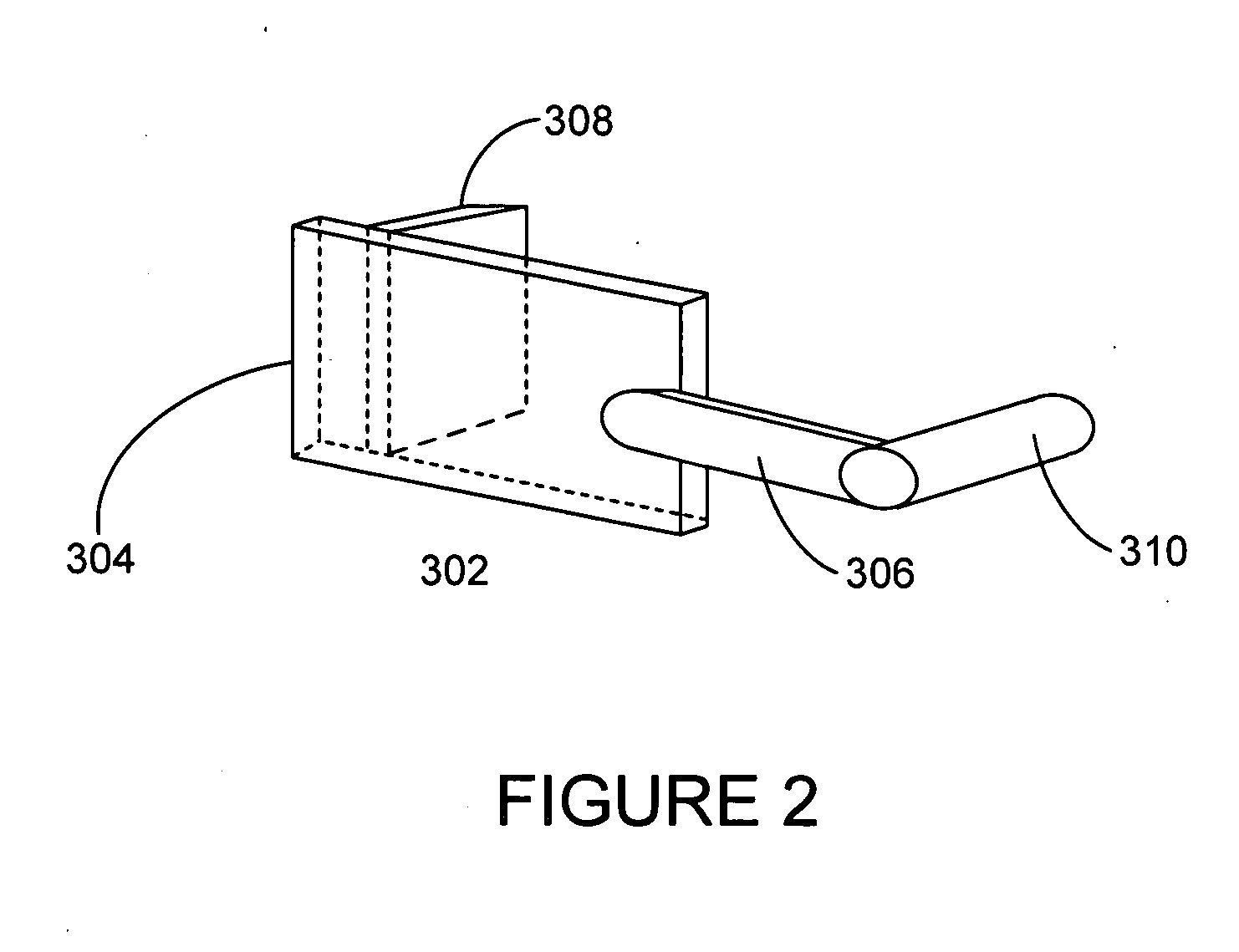

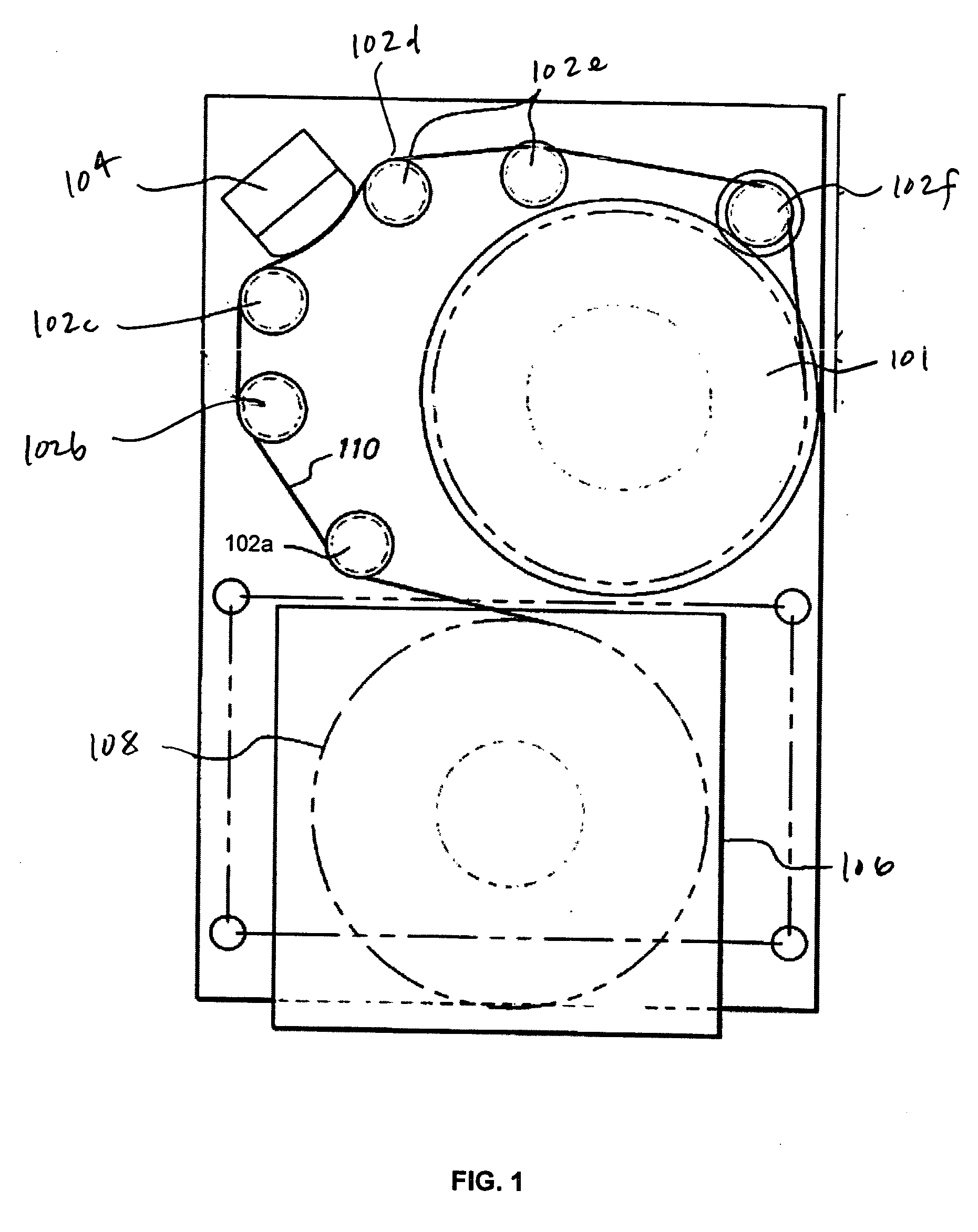

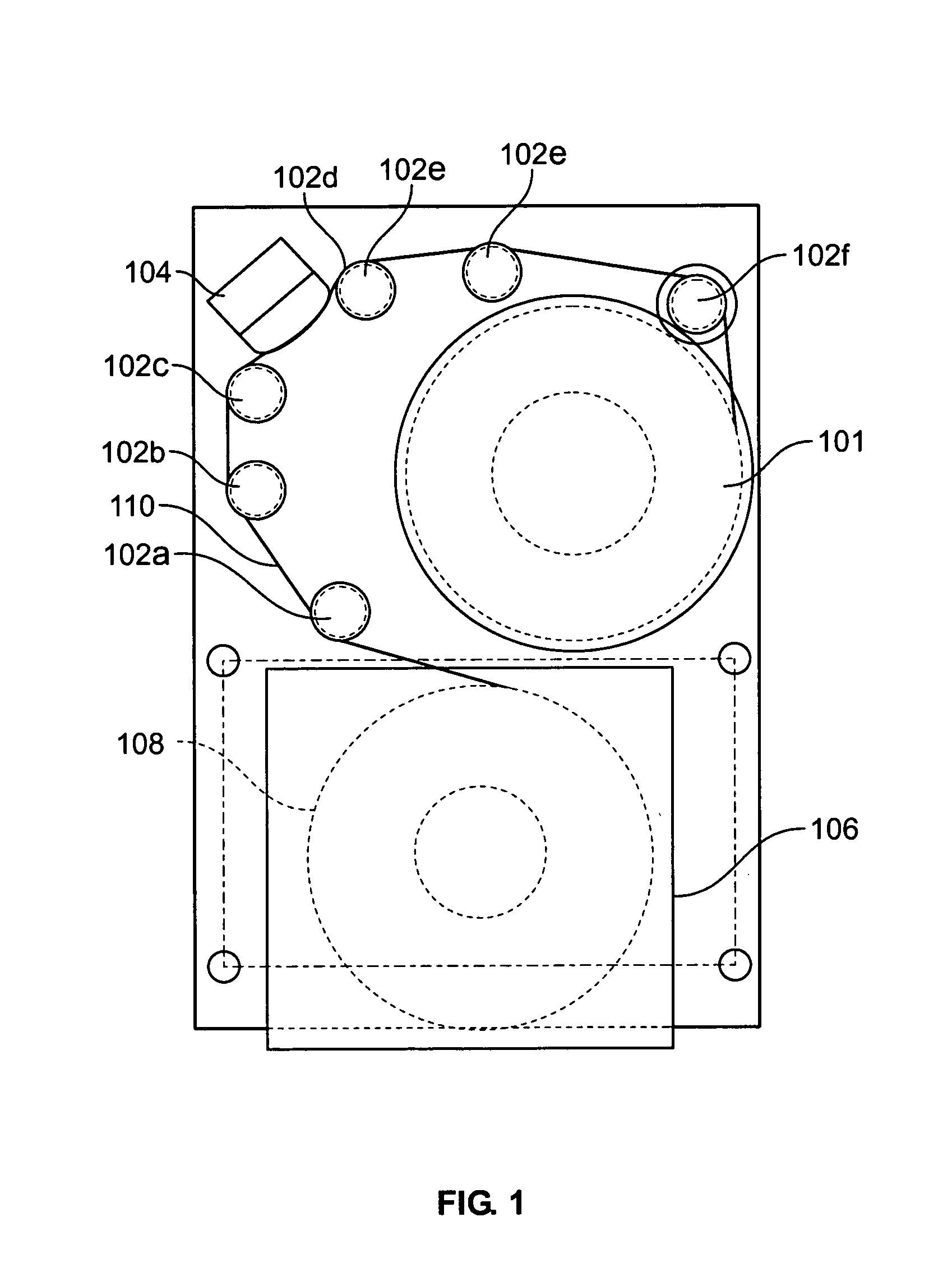

Tape Path Control System With Precision-Aligned Conjugated Rollers

InactiveUS20080068753A1Solve problemsAlignment for track following on tapesRecord information storageControl systemMagnetic tape

A tape path control system and related method for controlling the position of a tape medium in the tape drive. The tape path includes a first tape guide roller, a second tape guide roller spaced from the first roller, and a transducing head situated between the first and second rollers. The first and second rollers may be large and closely spaced, with the second tape guide roller being spaced from the first roller at a roller diameter / center-to-center spacing ratio of between approximately 1:1-1:2 while still accommodating the transducing head therebetween. The transducing head may be positioned to lie on an opposite side of the tape medium from the first and second guide rollers, or on the same side of the tape. A precision alignment system is associated with the second roller. When operable, the precision alignment system allows the second roller to be adjustably aligned relative to the first roller in order to control lateral tape movement when a tape medium streams across the rollers in operative engagement with the transducing head. The precision alignment system may include an axial adjustment control adapted to adjust a position of the second roller along an axis thereof. The precision alignment system may further include a tilt angle adjustment control adapted to adjust a tilt angle of the second roller.

Owner:IBM CORP

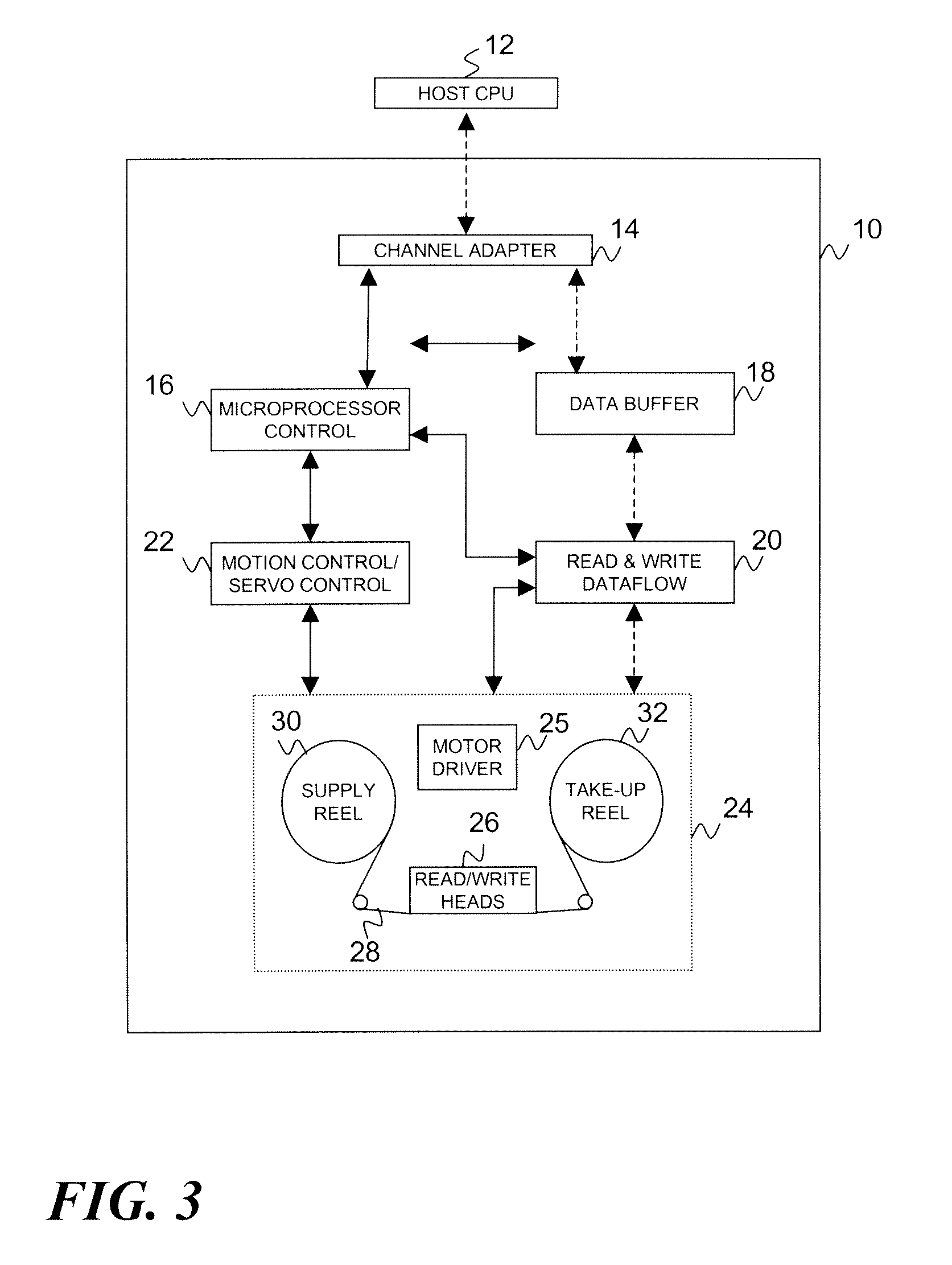

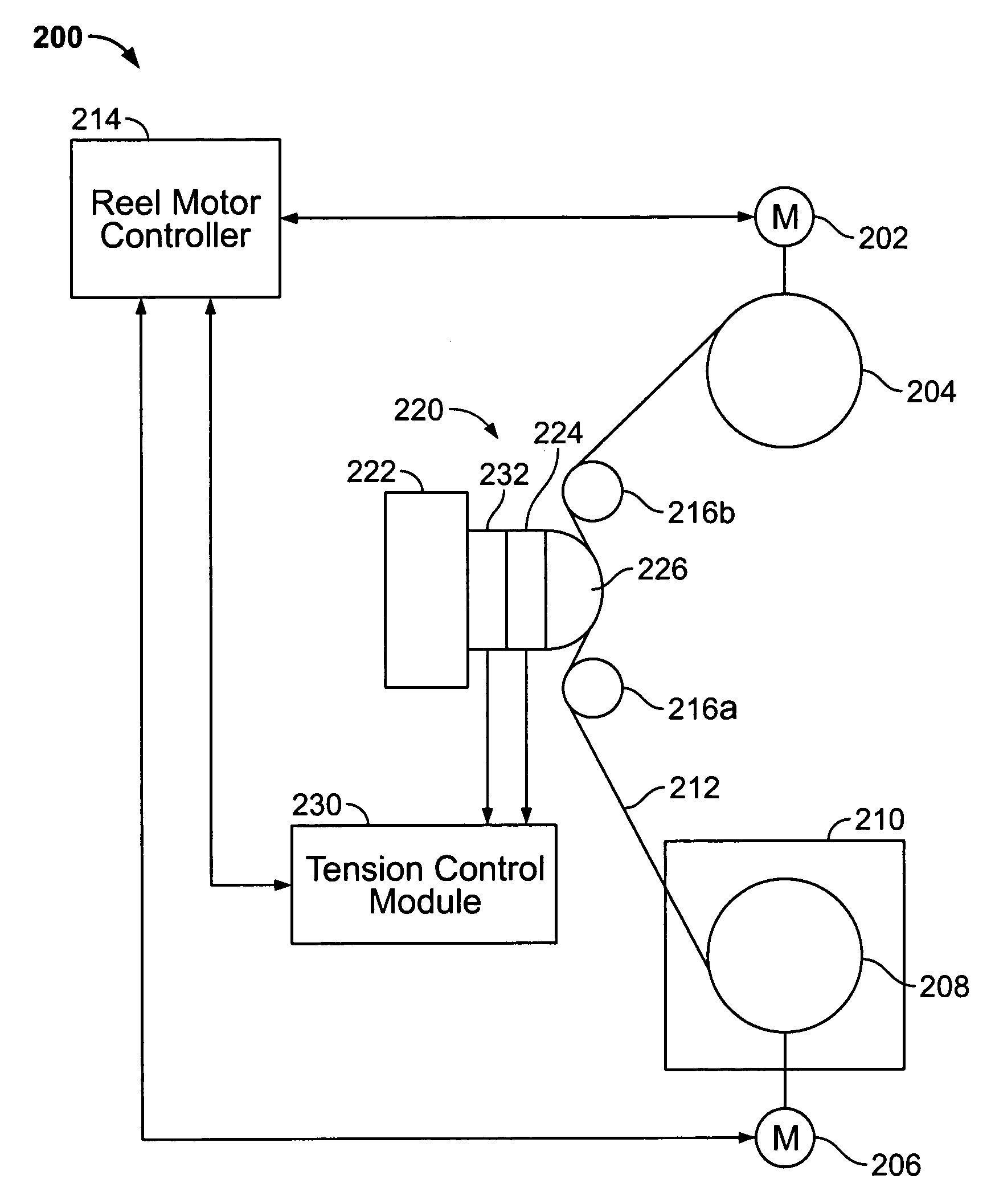

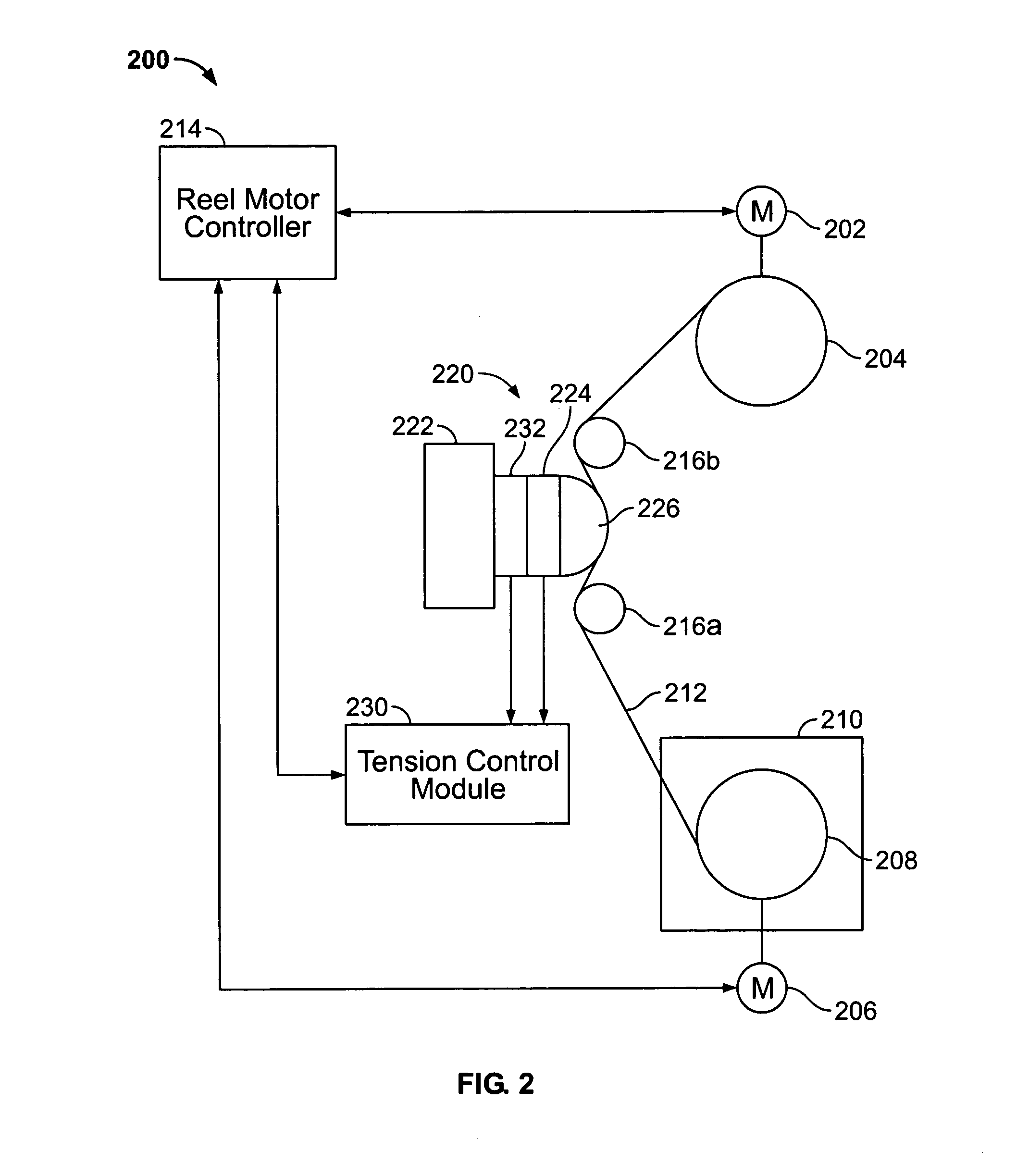

Tape drive tension control

ActiveUS8317421B2Improve performanceHigh of decelerationInking apparatusProjector film strip handlingMagnetic tapeTape drive

A tape drive comprising two motors, two tape spool supports on which spools of tape may be mounted, each spool being drivable by a respective one of the motors, and a controller. The controller controls the energization of the motors such that the tape may be transported in at least one direction between spools mounted on the spool supports. The controller is configured to store a plurality of motor control data items, each data item being associated with a respective tension value. The controller is operative to monitor tension in a tape being transported between spools mounted on the spool supports; read a motor control data item based upon the monitored tension; generate a motor control signal based upon the read motor control data item; and apply the motor control signal to at least one of the motors.

Owner:VIDEOJET TECH INC

Recording/ reproducing method and recording/reproducing apparatus for magnetic tape

A recording / reproducing method and a recording / reproducing apparatus for magnetic tapes are provided as a recording / reproducing technique suitable for recording density enhancement of magnetic tapes. The method and apparatus are capable of correctly recording and reproducing data without causing errors even with occurrence of size changes in the widthwise direction of a magnetic tape. In the recording / reproducing method for magnetic tapes in which data tracks and servo tracks are provided, a tape width is detected and a value of the tape width is stored during data recording, and data reproduction is performed while tape tension is controlled so that the tape width during data reproduction is maintained equal to the tape width during data recording.

Owner:FUJIFILM CORP

Tape drive

ActiveUS20080240830A1Improve performancePerformance requirementInking apparatusProjector film strip handlingMagnetic tapeElectric machinery

A tape drive comprising two motors, two tape spool supports on which spools of tape may be mounted, each spool being drivable by a respective one of the motors, and a controller. The controller controls the energization of the motors such that the tape may be transported in at least one direction between spools mounted on the spool supports. The controller is configured to store a plurality of motor control data items, each data item being associated with a respective tension value. The controller is operative to monitor tension in a tape being transported between spools mounted on the spool supports; read a motor control data item based upon the monitored tension; generate a motor control signal based upon the read motor control data item; and apply the motor control signal to at least one of the motors.

Owner:VIDEOJET TECH INC

Environmental watch device for magnetic storage

InactiveUS20060285240A1Alleviate the conditionLower performance requirementsReducing temperature influence on carrierRecord information storageMagnetic storageMagnetic tape

A tape media carrier has a tape medium for storing data, a rotatable element, such as a tape reel, bearing the tape medium, and a transducer within the tape media carrier. The transducer includes a sensor element and a detector for detecting at least one attribute of the sensor element that is responsive to ambient conditions within the tape carrier. The detector may be a strain gauge, in which case the measured attribute is strain. In another aspect, the sensor element may include marks disposed in at least one dimension. An optical detector in the media carrier may measure distance between the marks to represent the measured attribute of the sensor.

Owner:QUANTUM CORP

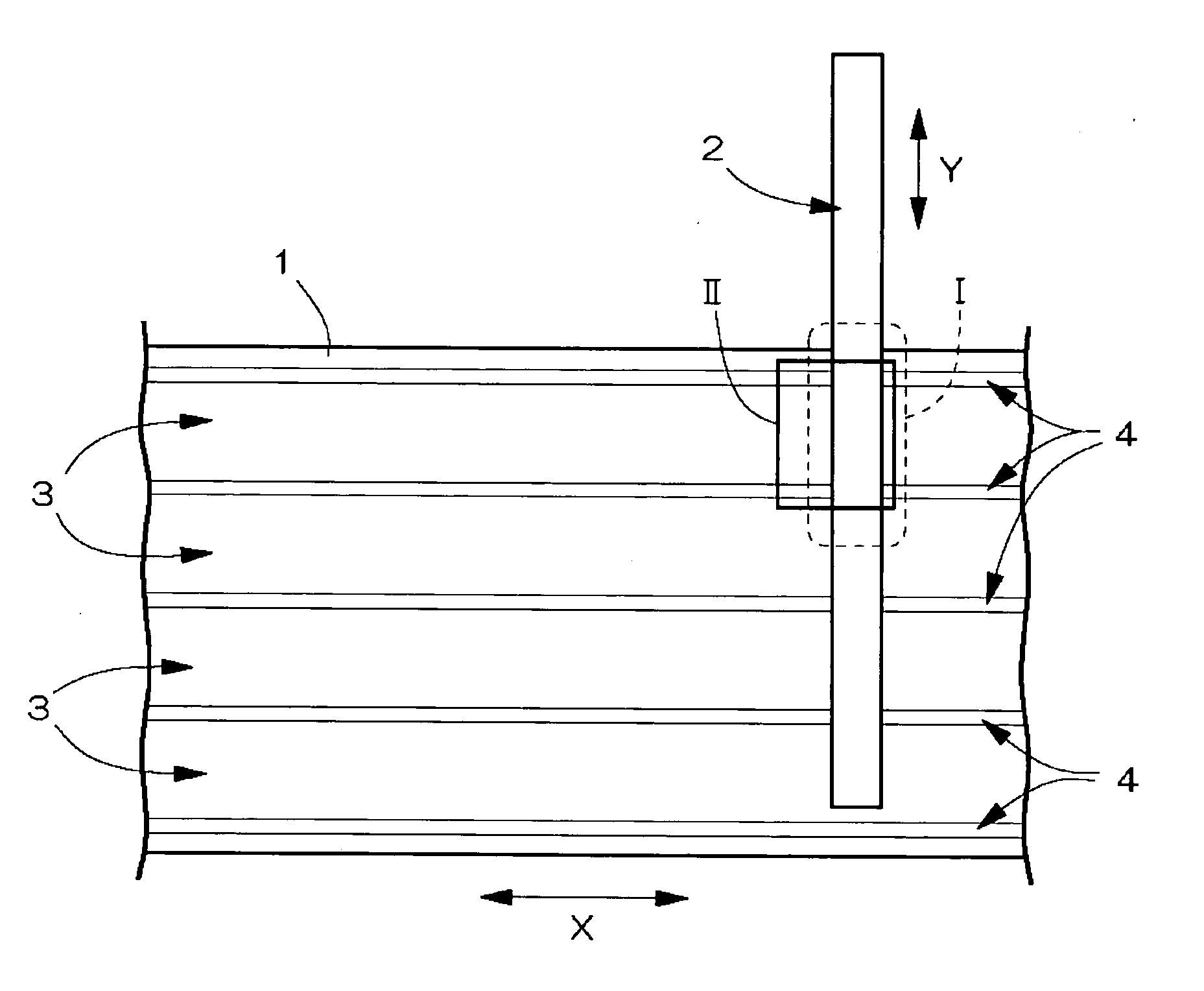

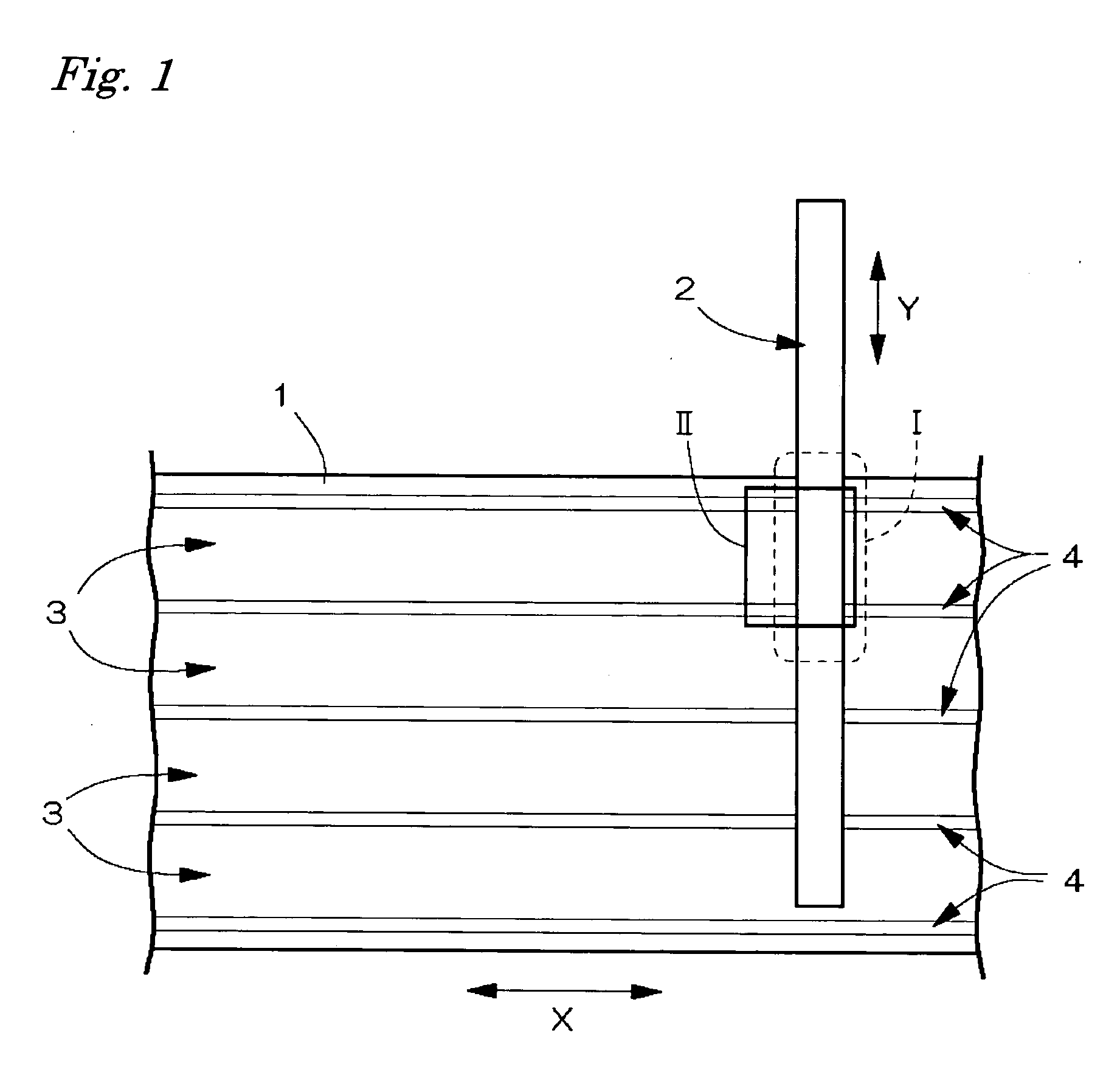

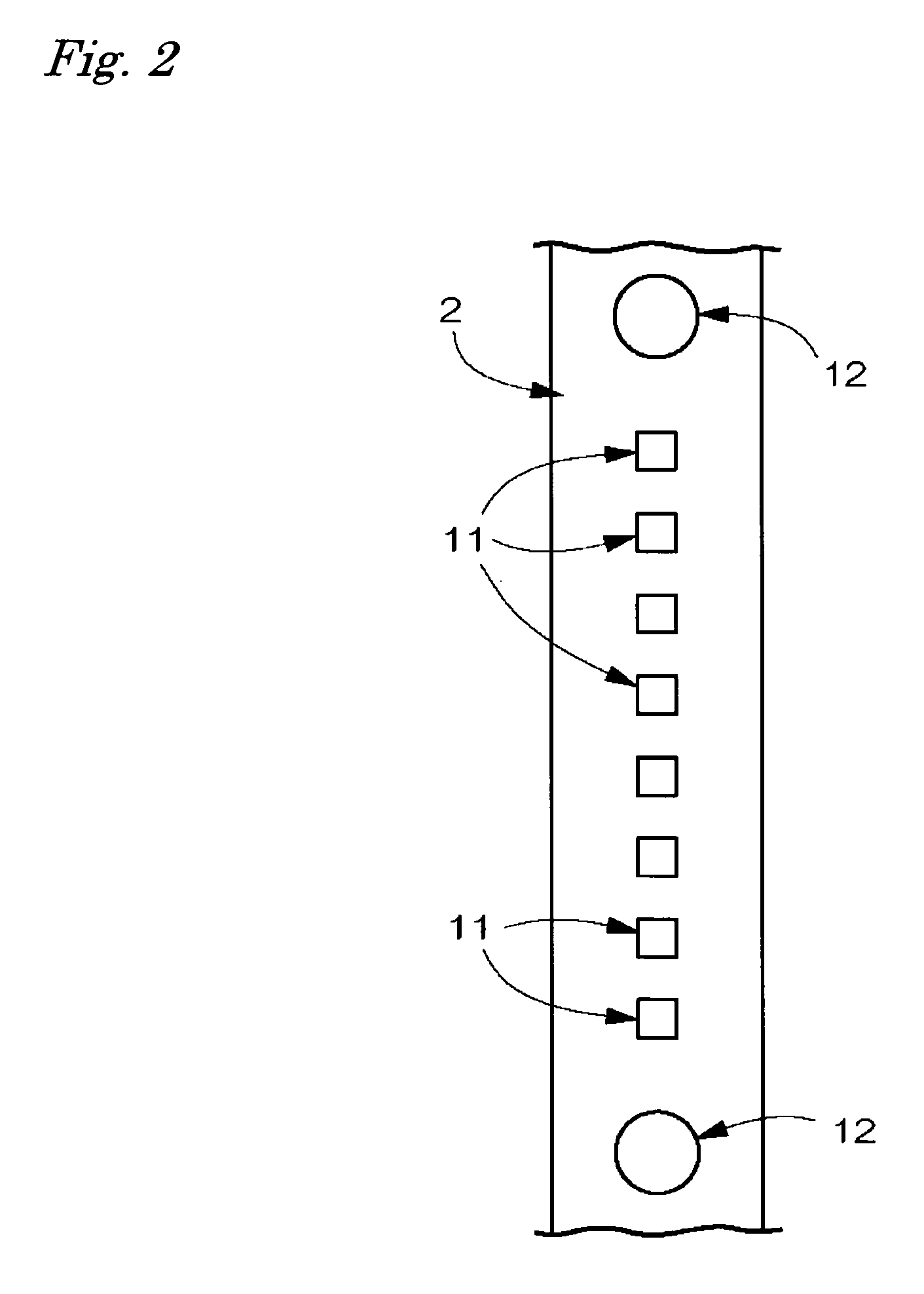

Tape drive

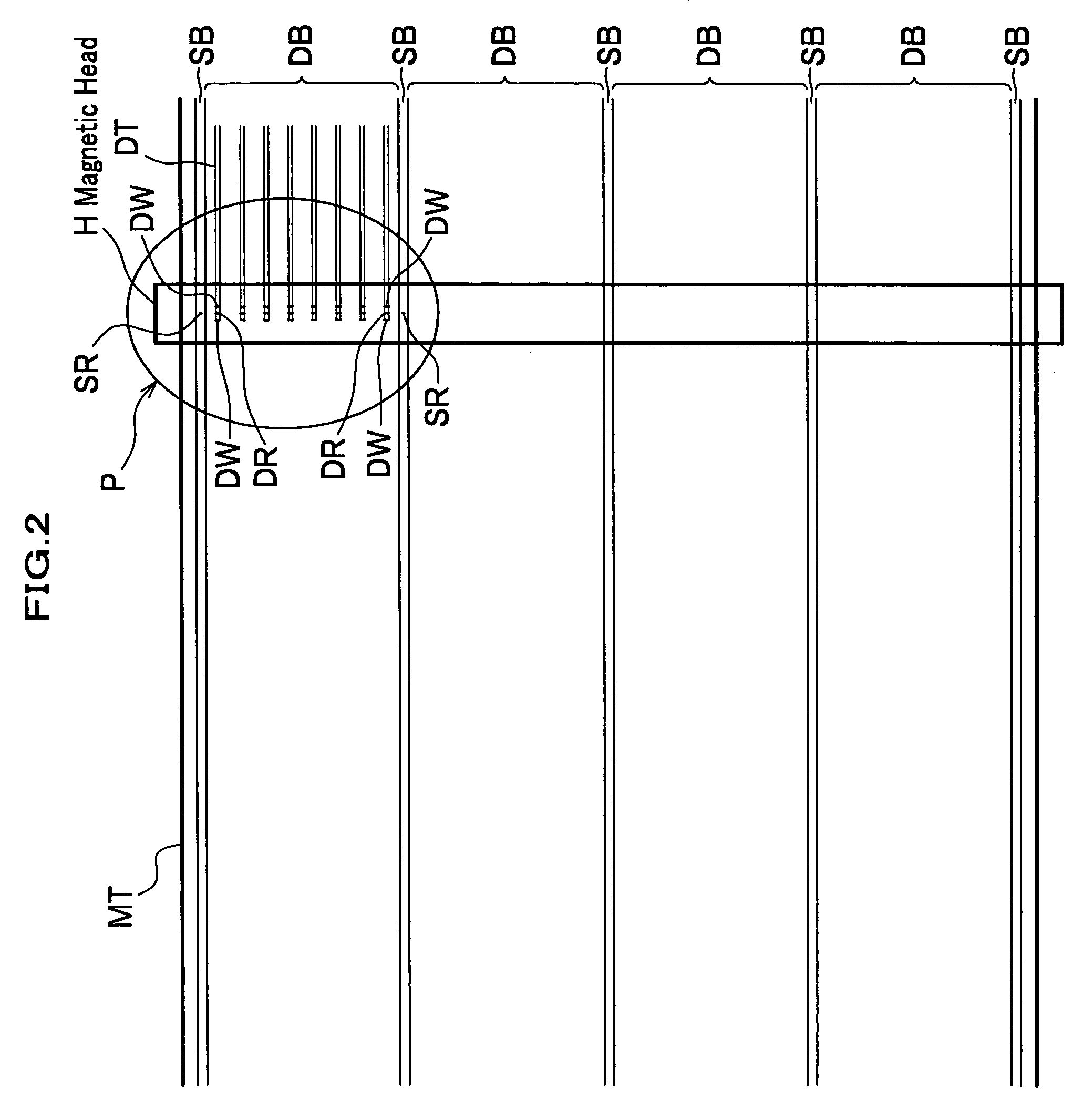

ActiveUS20050254161A1Precise positioningImprove matchAlignment for track following on tapesRecord information storageMagnetic tapeEngineering

A tape drive of the present invention records data on a tape having a plurality of servo bands, where a servo signal is recorded in advance along a longitudinal direction, and a data band containing a plurality of data tracks formed between each of the servo bands while tracking the tape, based on a servo signal: the tape drive comprises a tape running system for running the tape between two reels that can wind it; and a data recording head comprising a pair of servo read elements provided corresponding to the servo band, and data write elements provided plurally side by side between the pair of the servo read elements, wherein when recording the data, the tape drive writes a condition in recording, which is obtained by reading the servo signal with the servo read elements, in at least one of the data tracks with the data write elements.

Owner:FUJIFILM CORP +1

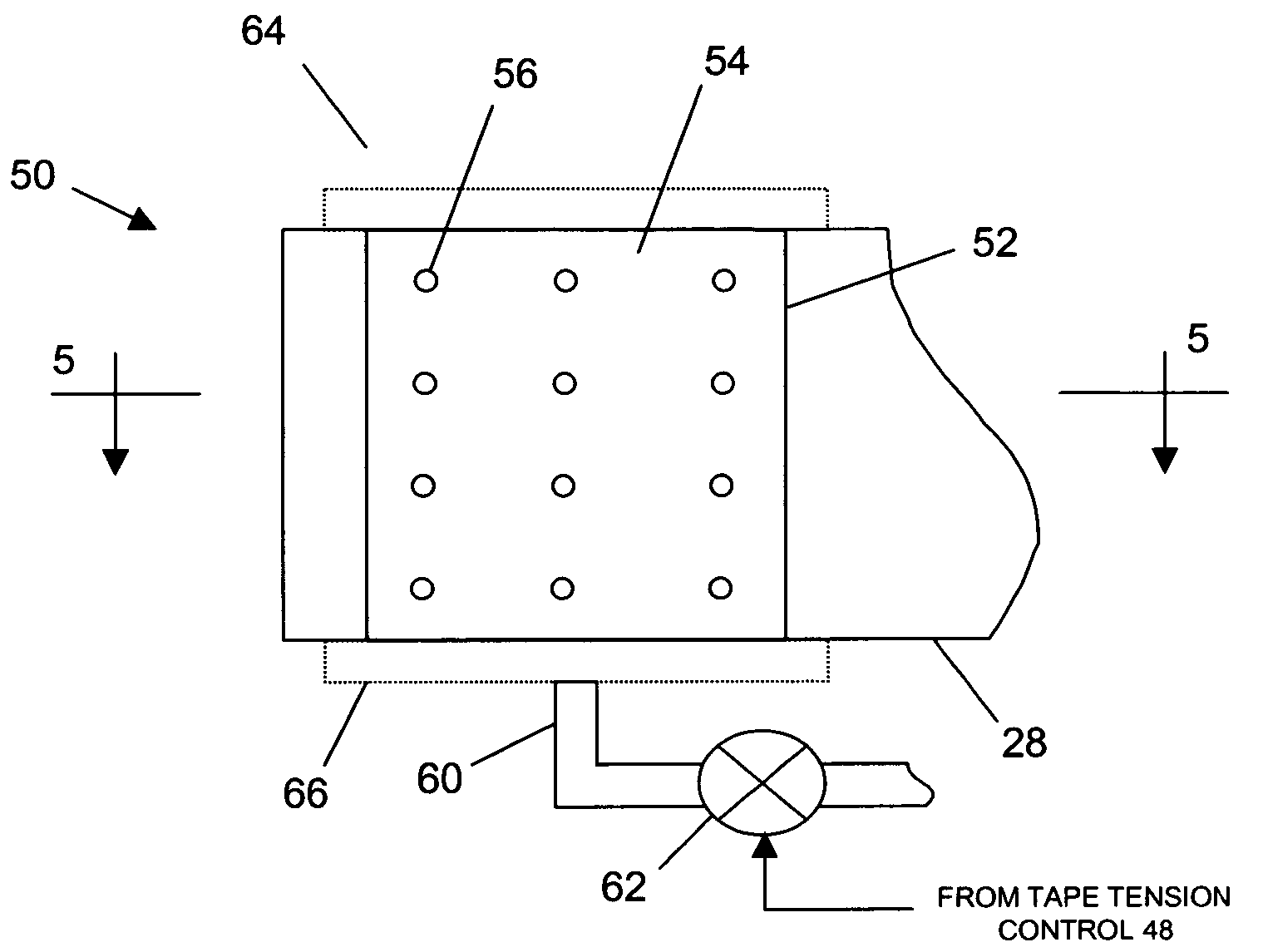

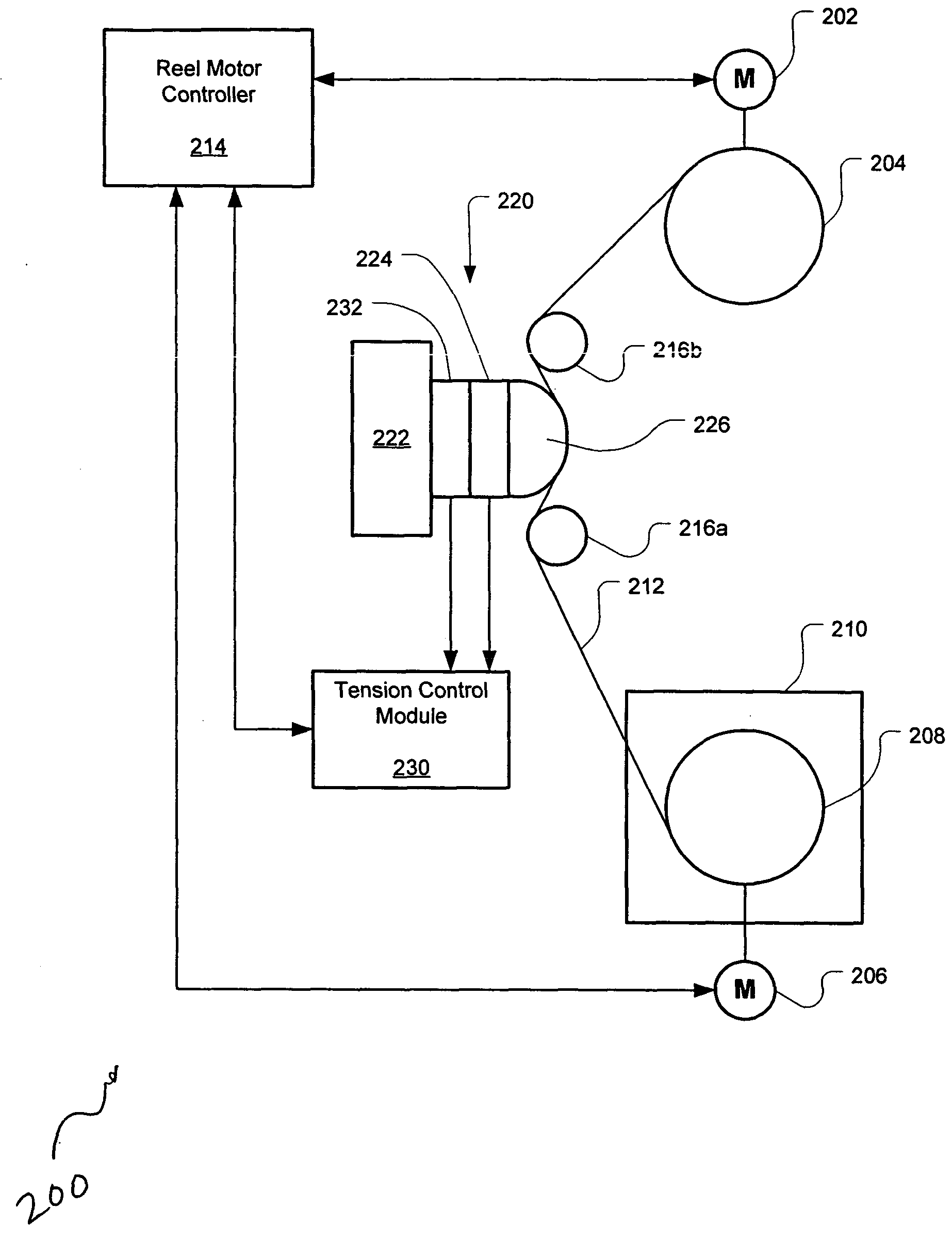

Tape tension modulation system and method

A system and method of modulating tape tension during operation of a tape drive data storage system in which a fixed position tape guide utilizes one or more drag elements to exert a control force on a tape medium that affects downstream tape tension. Drag elements that may be used include, but are not necessarily limited to, air ports that delivery positive or negative air pressure to the tape medium, skiving edge elements that are positionable into and out of engagement with the tape medium, and brakes or motors that engage the tape guide (if it is rotatably mounted) to control its rotational torque. A tension control circuit is used to vary the operation of the one or more drag elements. Signal inputs to the control circuit are provided by a tape tension sensor adjacent to or incorporated in the tape guide.

Owner:INT BUSINESS MASCH CORP

Tape tension modulation system and method

A system and method of modulating tape tension during operation of a tape drive data storage system in which a fixed position tape guide utilizes one or more drag elements to exert a control force on a tape medium that affects downstream tape tension. Drag elements that may be used include, but are not necessarily limited to, air ports that delivery positive or negative air pressure to the tape medium, skiving edge elements that are positionable into and out of engagement with the tape medium, and brakes or motors that engage the tape guide (if it is rotatably mounted) to control its rotational torque. A tension control circuit is used to vary the operation of the one or more drag elements. Signal inputs to the control circuit are provided by a tape tension sensor adjacent to or incorporated in the tape guide.

Owner:IBM CORP

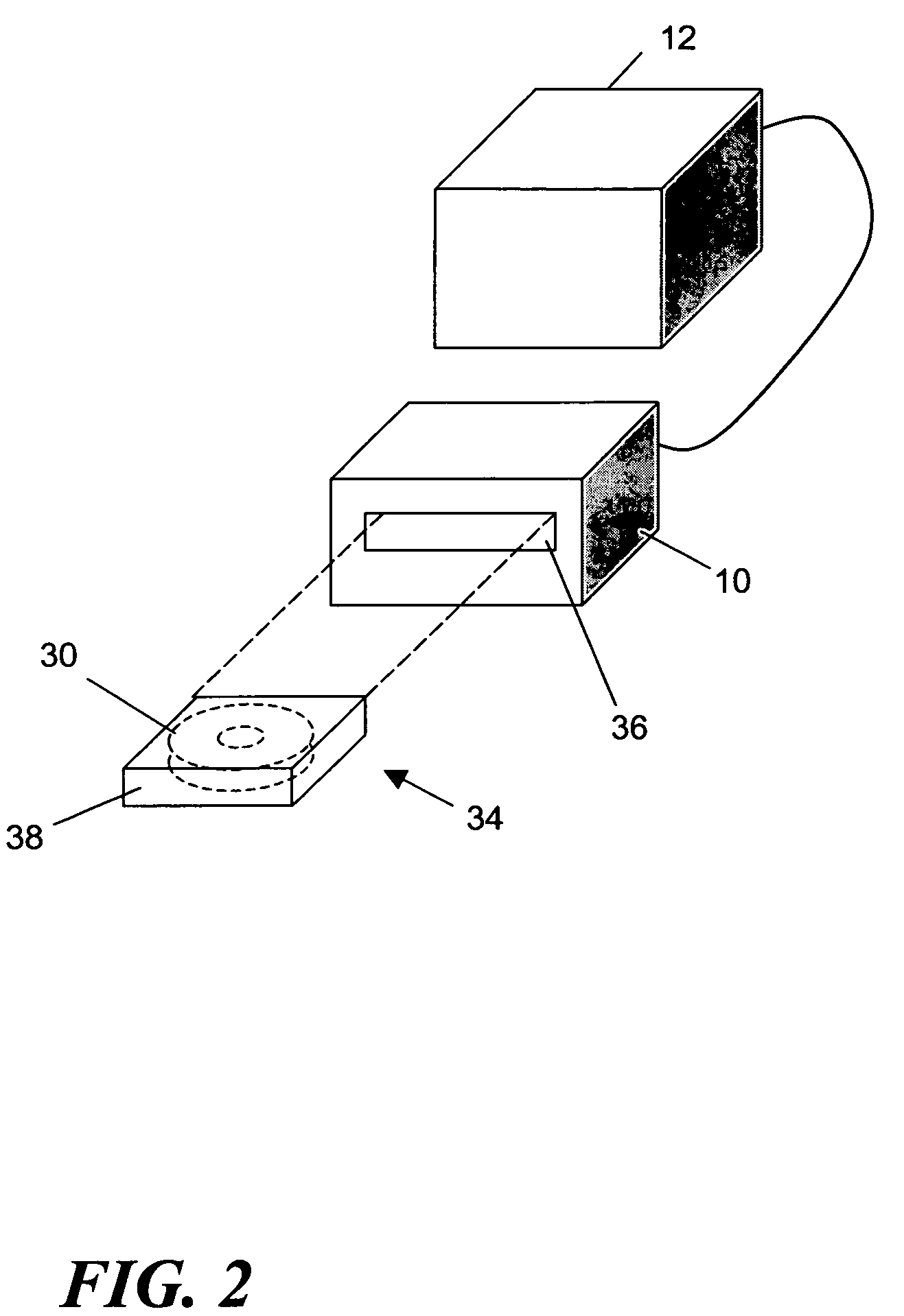

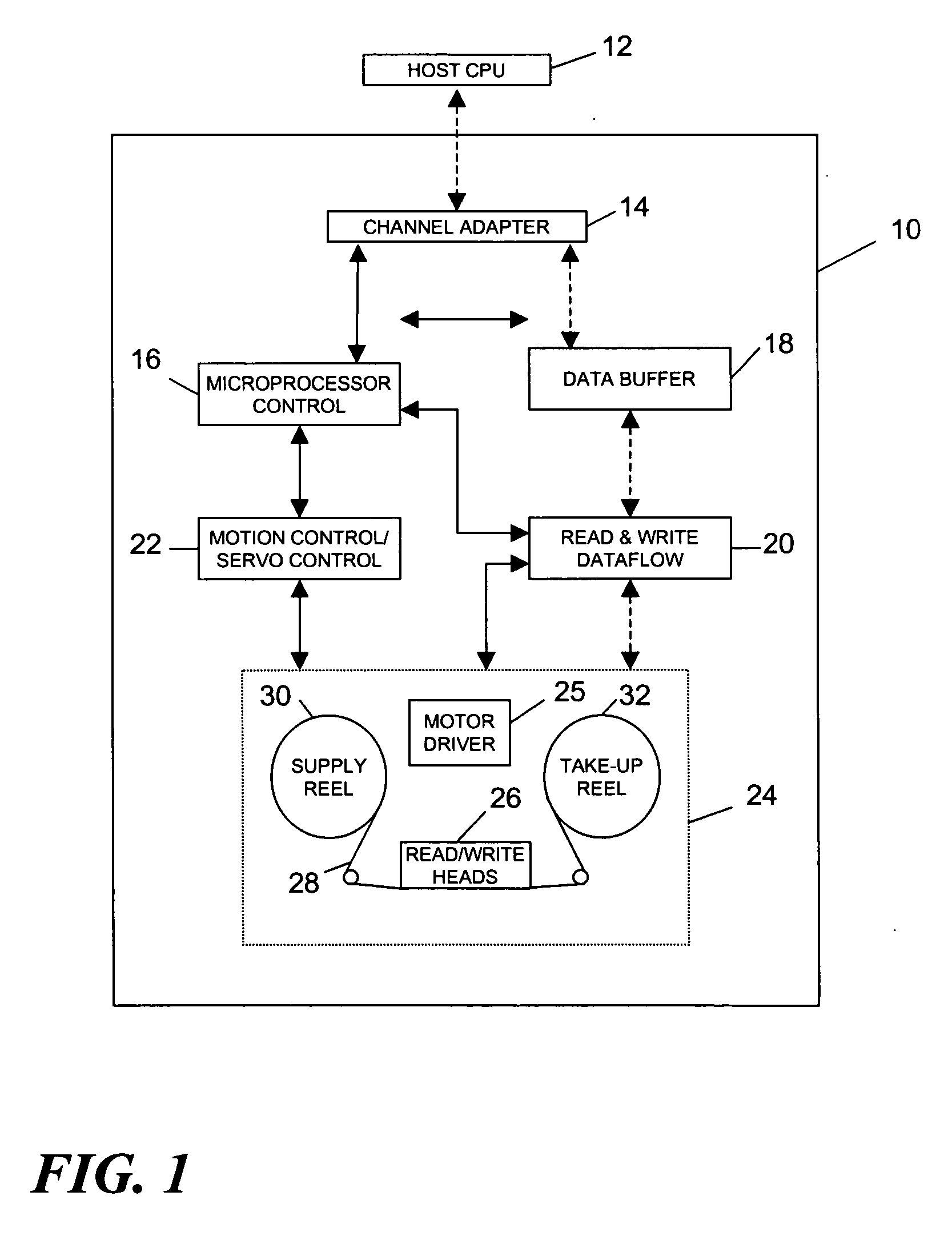

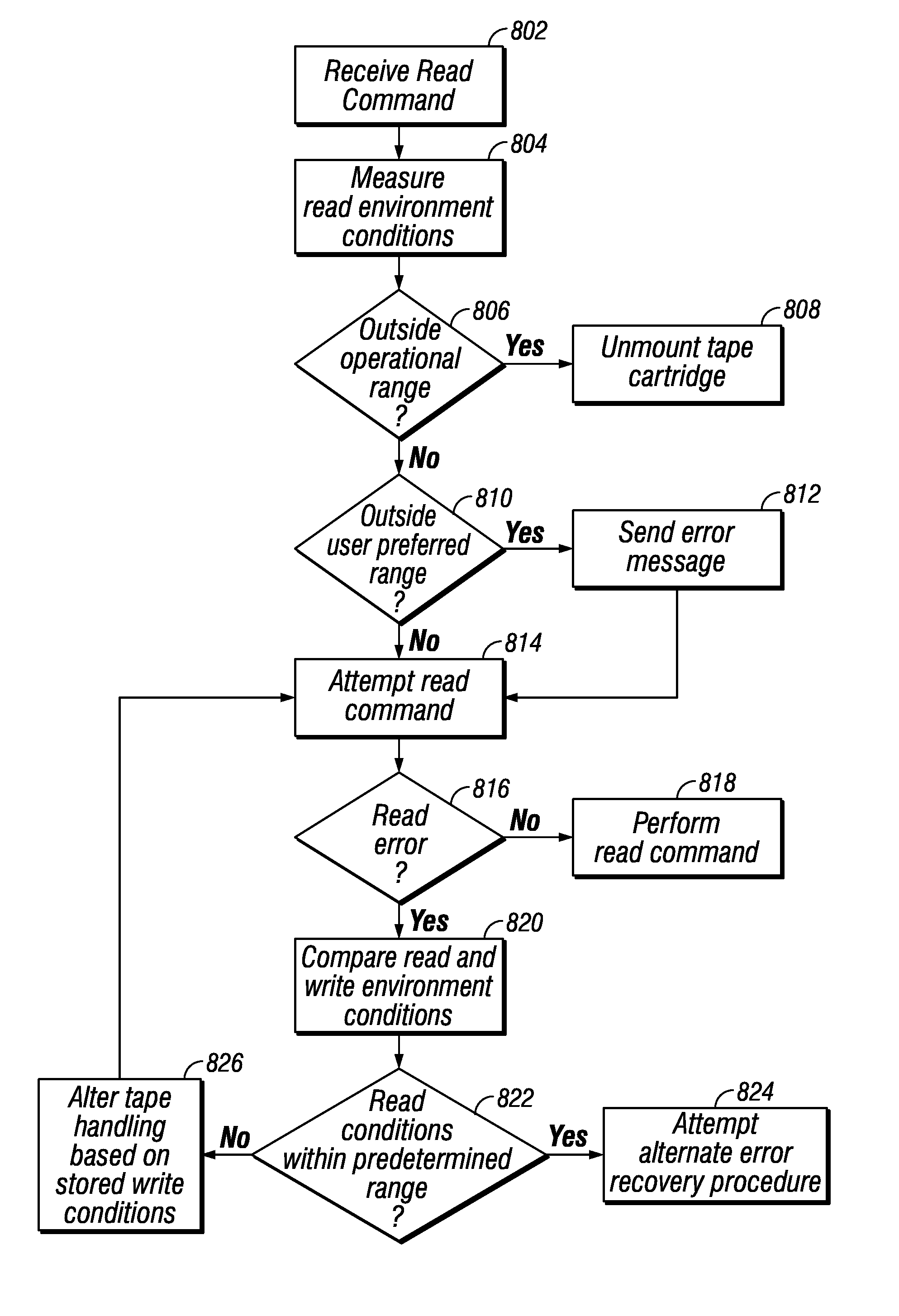

Utilizing stored write environment conditions for read error recovery

InactiveUS8941940B1Reduce tensionDriving/moving recording headsAlignment for track following on tapesTape driveWriting environment

Described herein are embodiments for utilizing stored write environment conditions for read error recovery. A tape drive measures read environment conditions as a result of receiving a read command to read data from a portion of tape and compares the read environment conditions to the write environment conditions stored for that portion of tape. If the read environment conditions are not within the predetermined range of the write environment conditions, then the handling of the tape is altered to improve read element placement on the tape by accounting for expansion and contraction of the tape based on the stored write environment conditions. The handling of the tape is altered by at least one of increasing or decreasing the tension of the tape, offsetting the tape head up or down laterally with respect to the tape, and slowing down the movement of tape across the tape head.

Owner:GLOBALFOUNDRIES INC

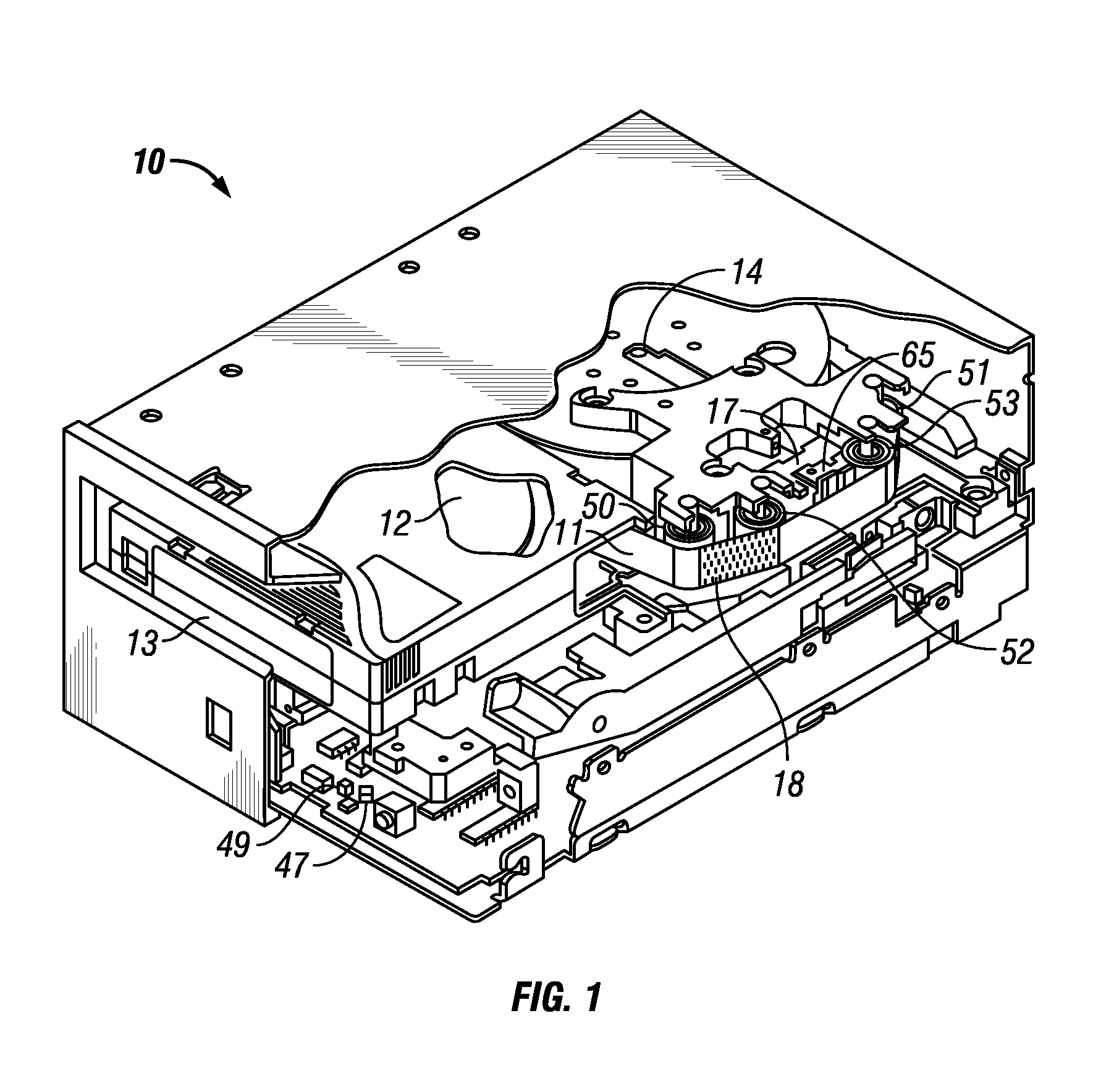

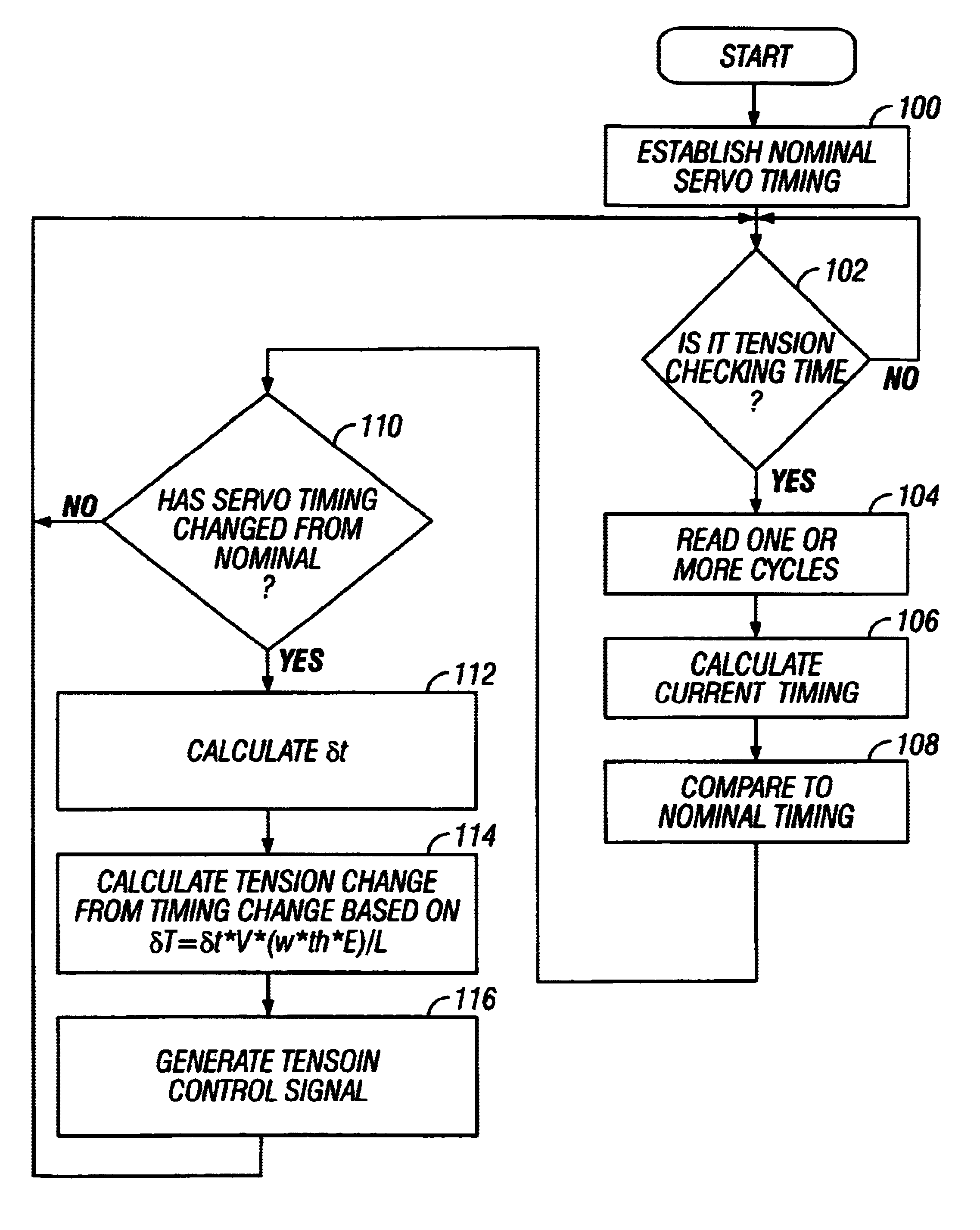

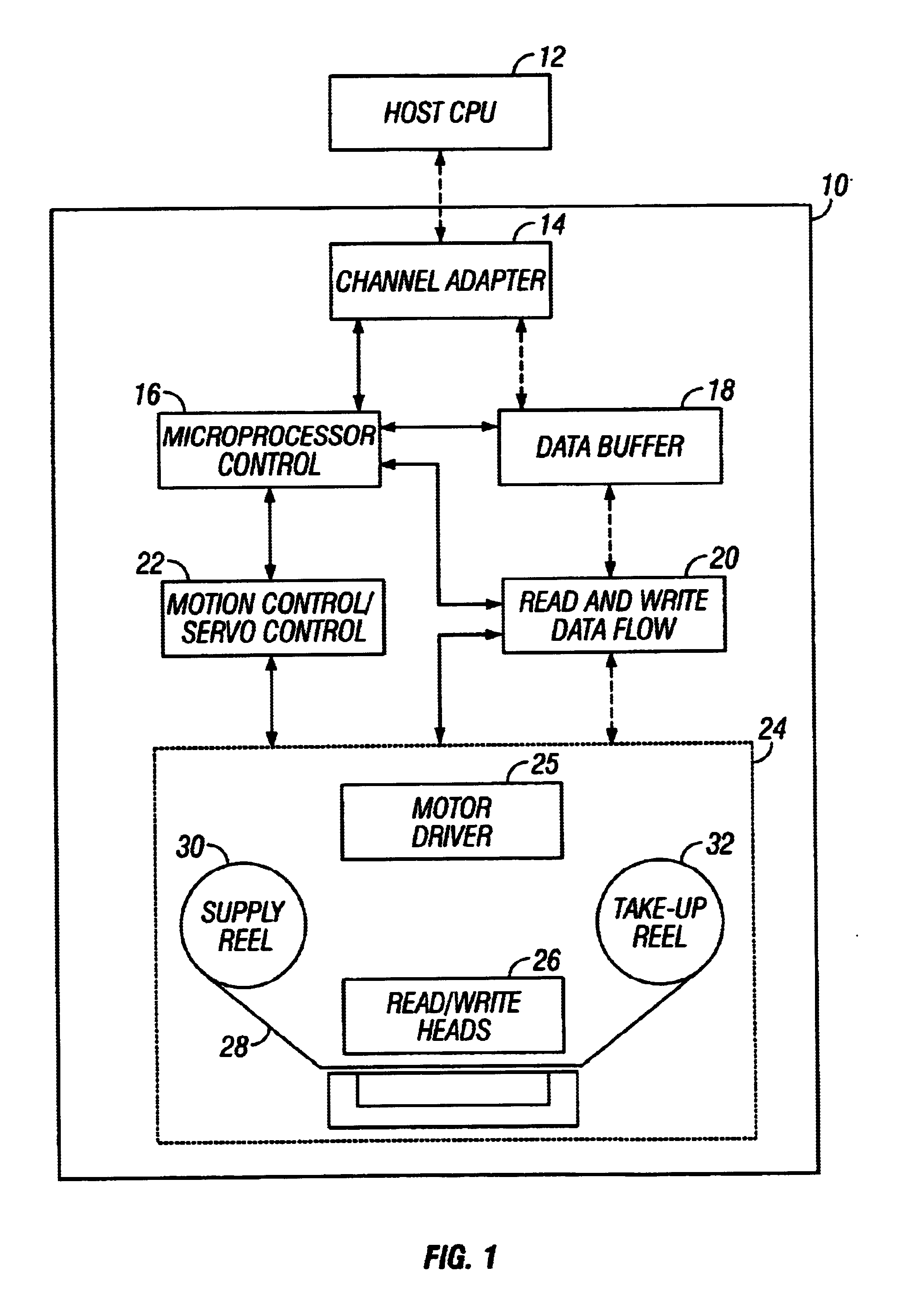

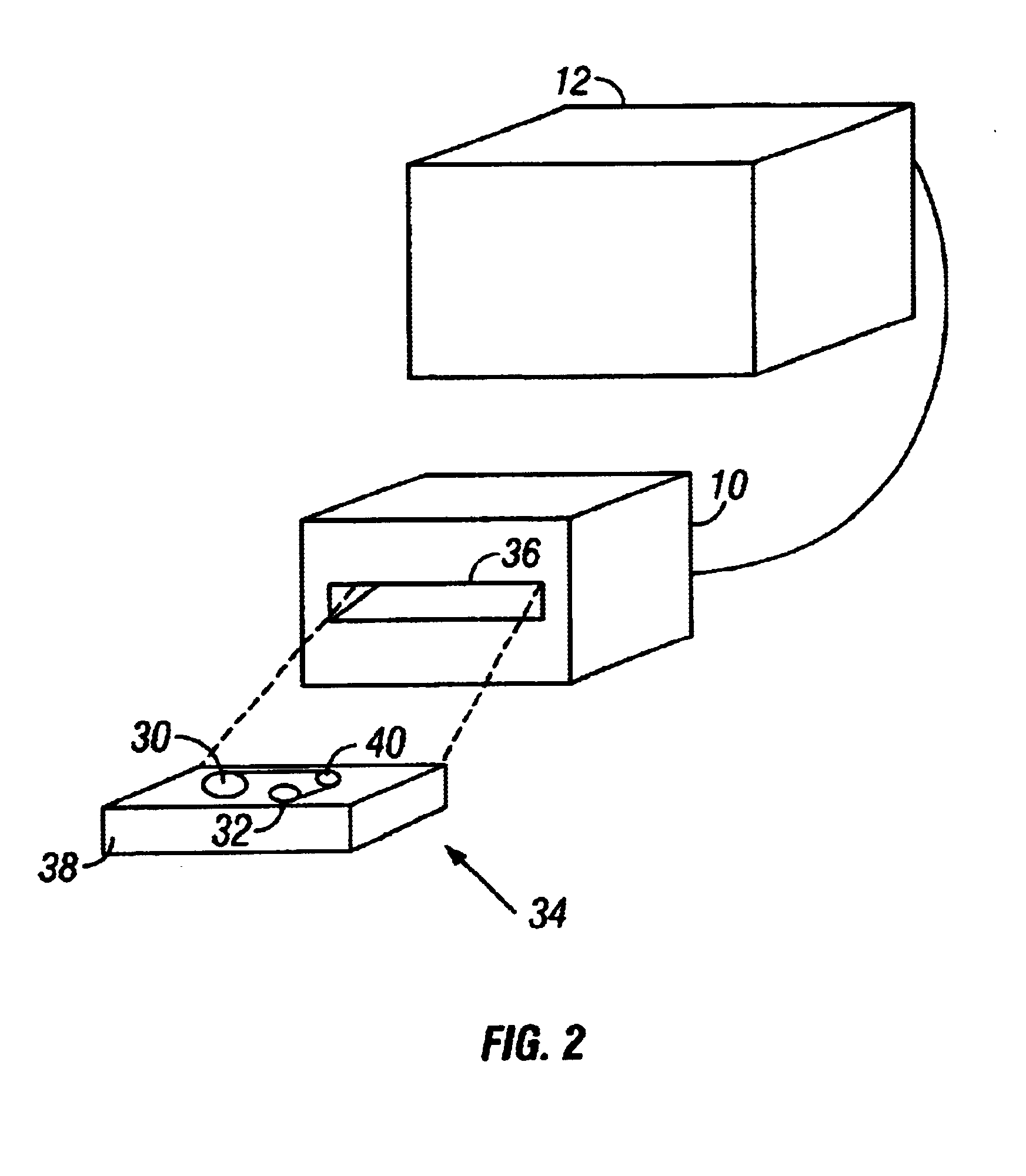

Servo pattern based tape tension control for tape drives

InactiveUS6934108B2Alignment for track following on tapesRecord information storageMagnetic tapeTape drive

A system and method of controlling tape tension during operation of a tape drive by making use of pre-existing timing based servo patterns formatted on the media. Changes in servo pattern timing are read at regular intervals and used to calculate changes in tension, with the torque of the tape reel motors being adjusted accordingly.

Owner:INTELLECTUAL DISCOVERY INC

Magnetic tape winding-up method, magnetic tape winding-up apparatus, manufacturing method of magnetic tape cartridge, and magnetic tape cartridge

ActiveUS20120305692A1Increase capacityHigh densityPicture changing apparatusFilament handlingMagnetic tapeTension control

A winding-up method for winding up a magnetic tape, includes: winding up the magnetic tape around a takeup reel by laying turns one on top of another while causing the magnetic tape to run; and performing a tension control of maintaining tension exerted on a wound-up magnetic tape for a predetermined time.

Owner:FUJIFILM CORP

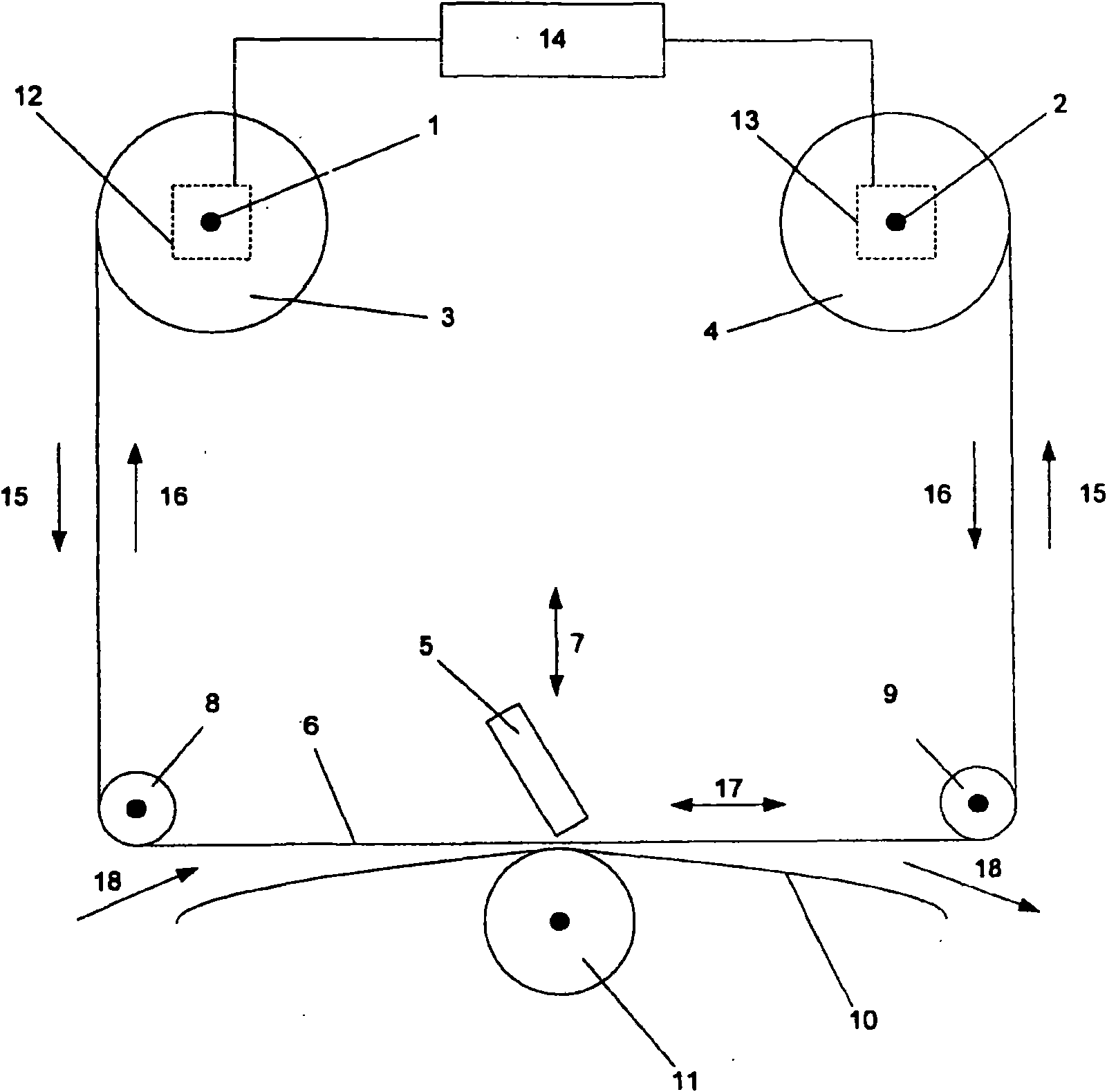

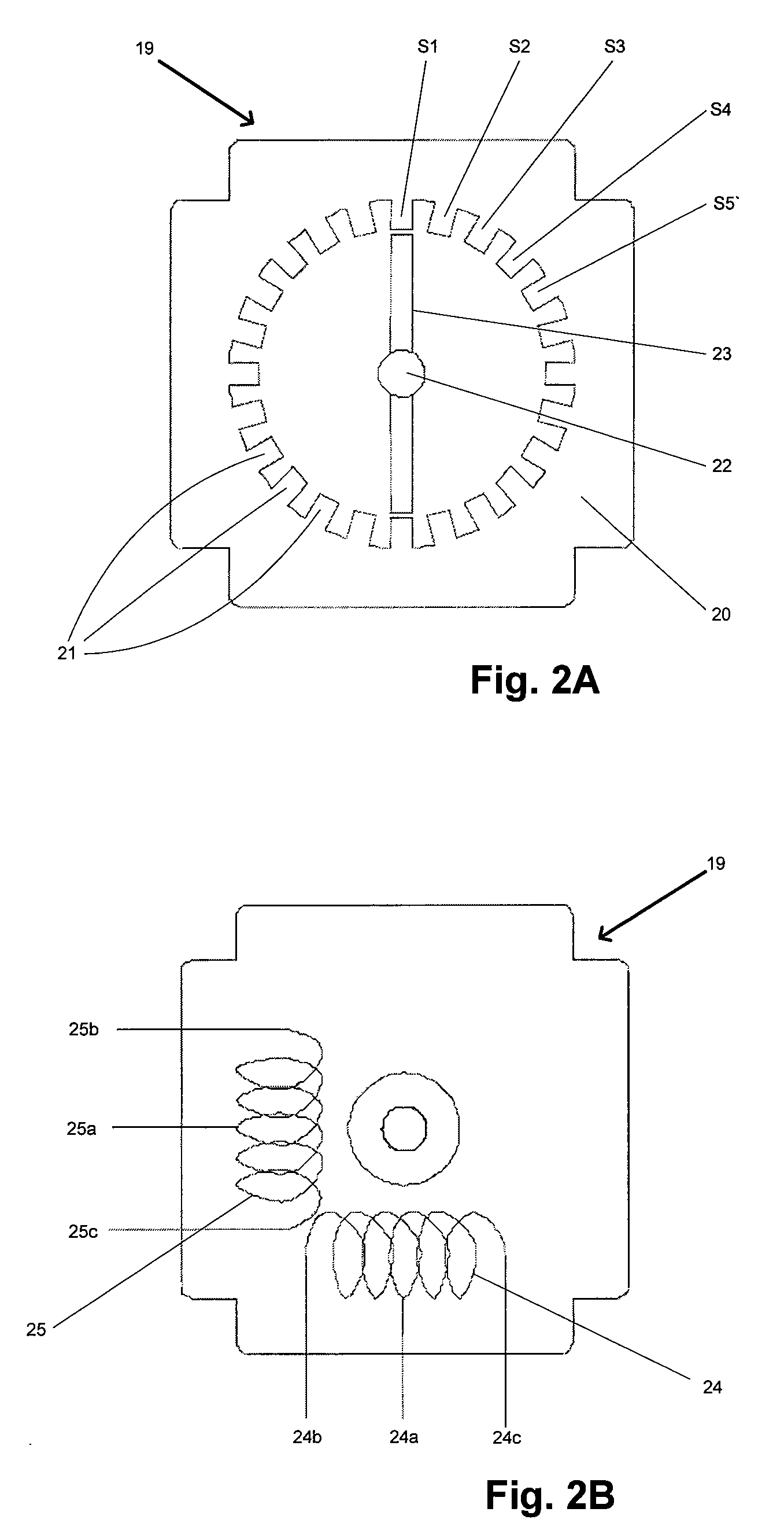

Tape drive

The invention relates to a tape drive comprising two position-controlled motors (12, 13), at least one of which is a closed-loop position-controlled motor, two tape spool supports on which spools (3, 4) of tape may be mounted, each spool being drivable by a respective one of said motors, and a controller (14) for controlling the energisation of the motors such that the tape may be transported in at least one direction between spools mounted on the spool supports. The controller is operative to energise both motors to drive the spools of tape in the direction of tape transport, to monitor tension in a tape being transported between spools mounted on the spool supports and to control the motors to maintain the monitored -tension between predetermined limits.

Owner:ZIPHER

Apparatus for recording or retrieving data on magnetic tape

ActiveUS20080253017A1Avoid stickingSuppression problemDriving/moving recording headsRecord information storageMagnetic tapeEngineering

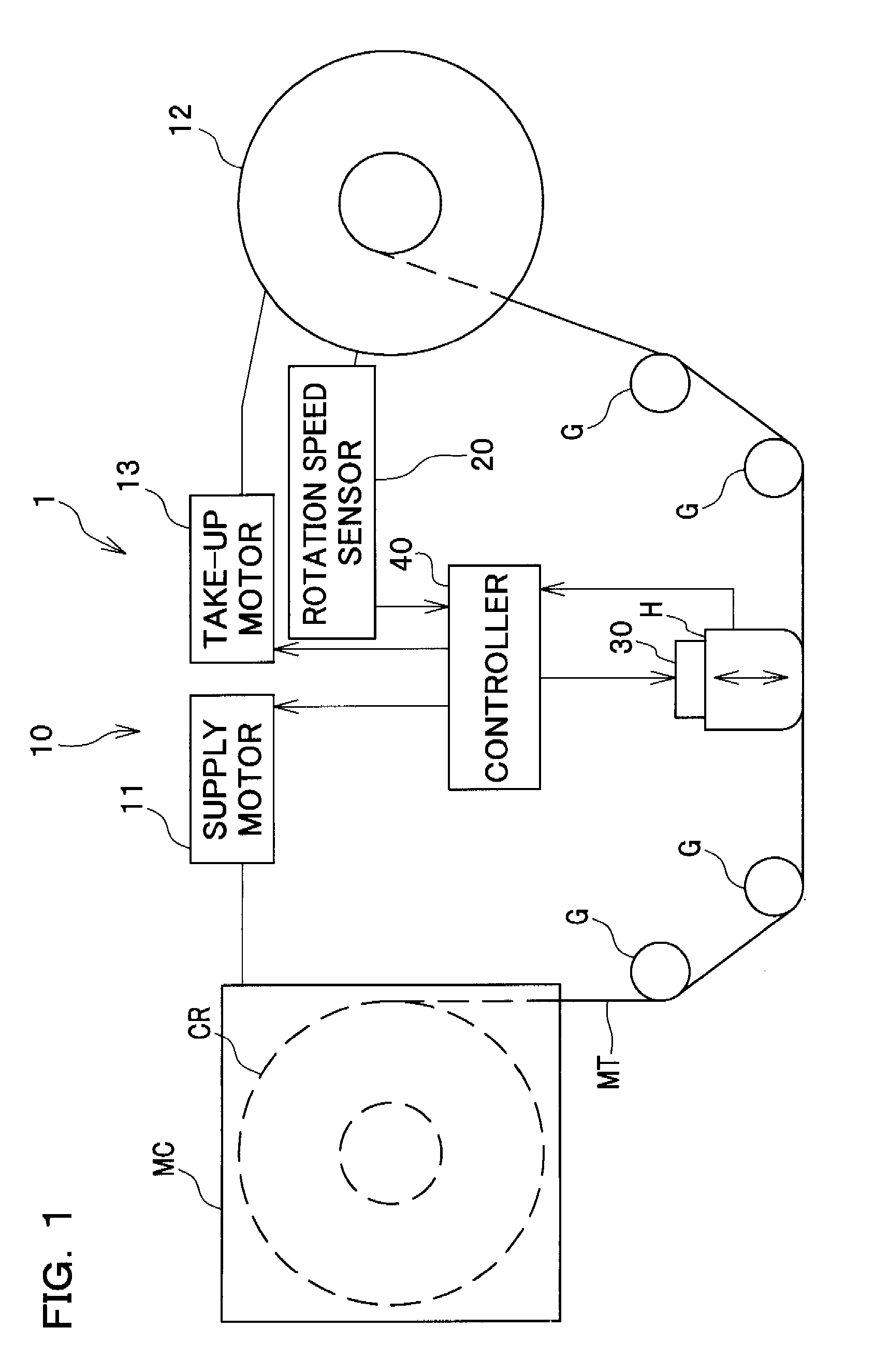

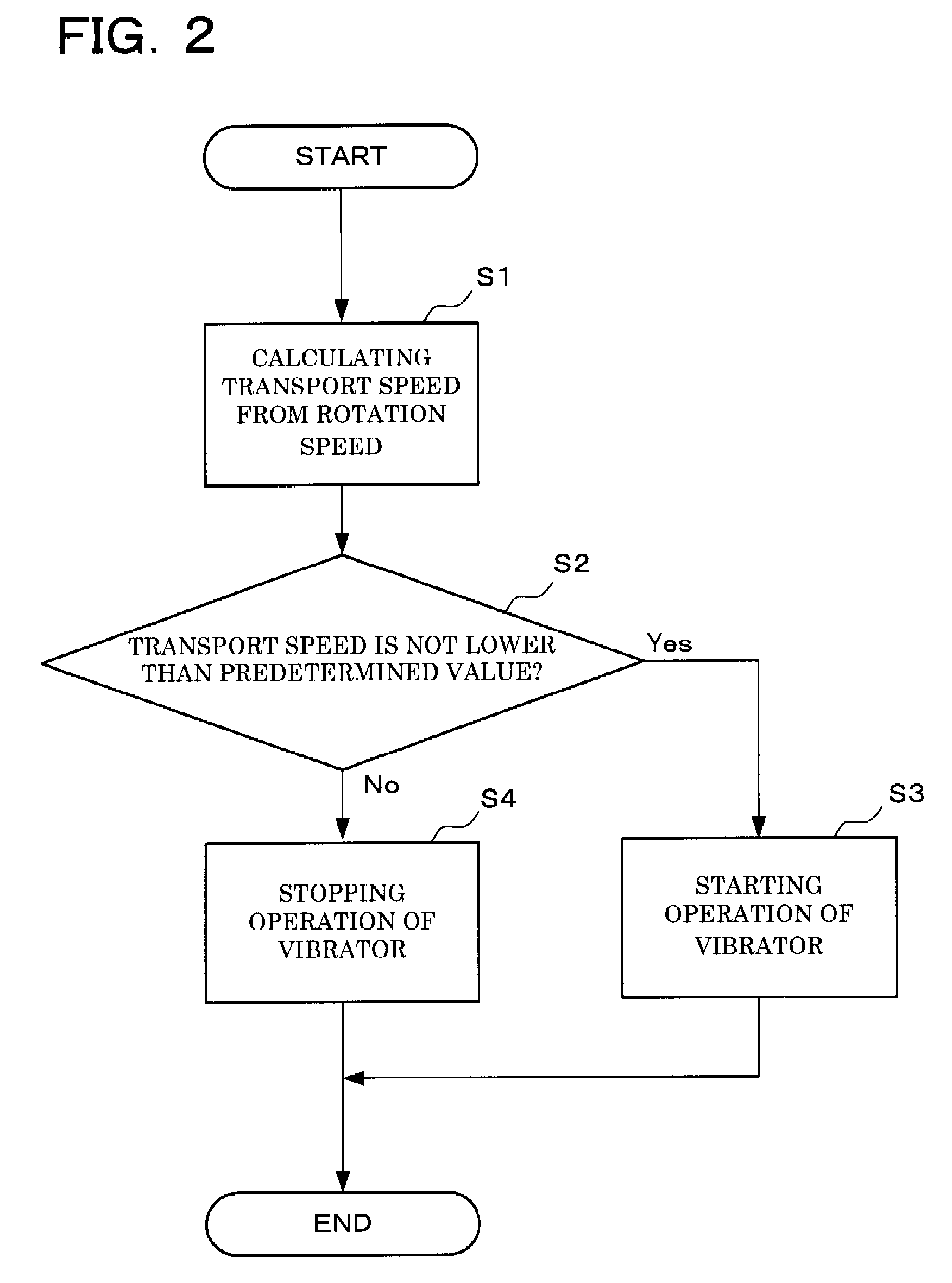

A magnetic tape drive includes a magnetic head configured to read or write data on a magnetic tape, a transport unit configured to drive the magnetic tape past the magnetic head, a speed detector configured to obtain speed information related to a transport speed of the magnetic tape, a vibrator configured to vibrate the magnetic head, and a controller configured to carry out control over the vibrator based upon the speed information obtained by the speed detector. The controller determines whether the transport speed of the magnetic tape is not lower than a predetermined value, based upon the speed information, starts operation of the vibrator in response to a determination that the transport speed is lower than the predetermined value, and stops the operation of the vibrator in response to a determination that the transport speed is not lower than the predetermined value.

Owner:FUJIFILM CORP

Tape drive

ActiveUS7142389B2Accurate recordPrecise positioningAlignment for track following on tapesRecord information storageMagnetic tapeData recording

A tape drive of the present invention records data on a tape having a plurality of servo bands, where a servo signal is recorded in advance along a longitudinal direction, and a data band containing a plurality of data tracks formed between each of the servo bands while tracking the tape, based on a servo signal: the tape drive comprises a tape running system for running the tape between two reels that can wind it; and a data recording head comprising a pair of servo read elements provided corresponding to the servo band, and data write elements provided plurally side by side between the pair of the servo read elements, wherein when recording the data, the tape drive writes a condition in recording, which is obtained by reading the servo signal with the servo read elements, in at least one of the data tracks with the data write elements.

Owner:FUJIFILM CORP +1

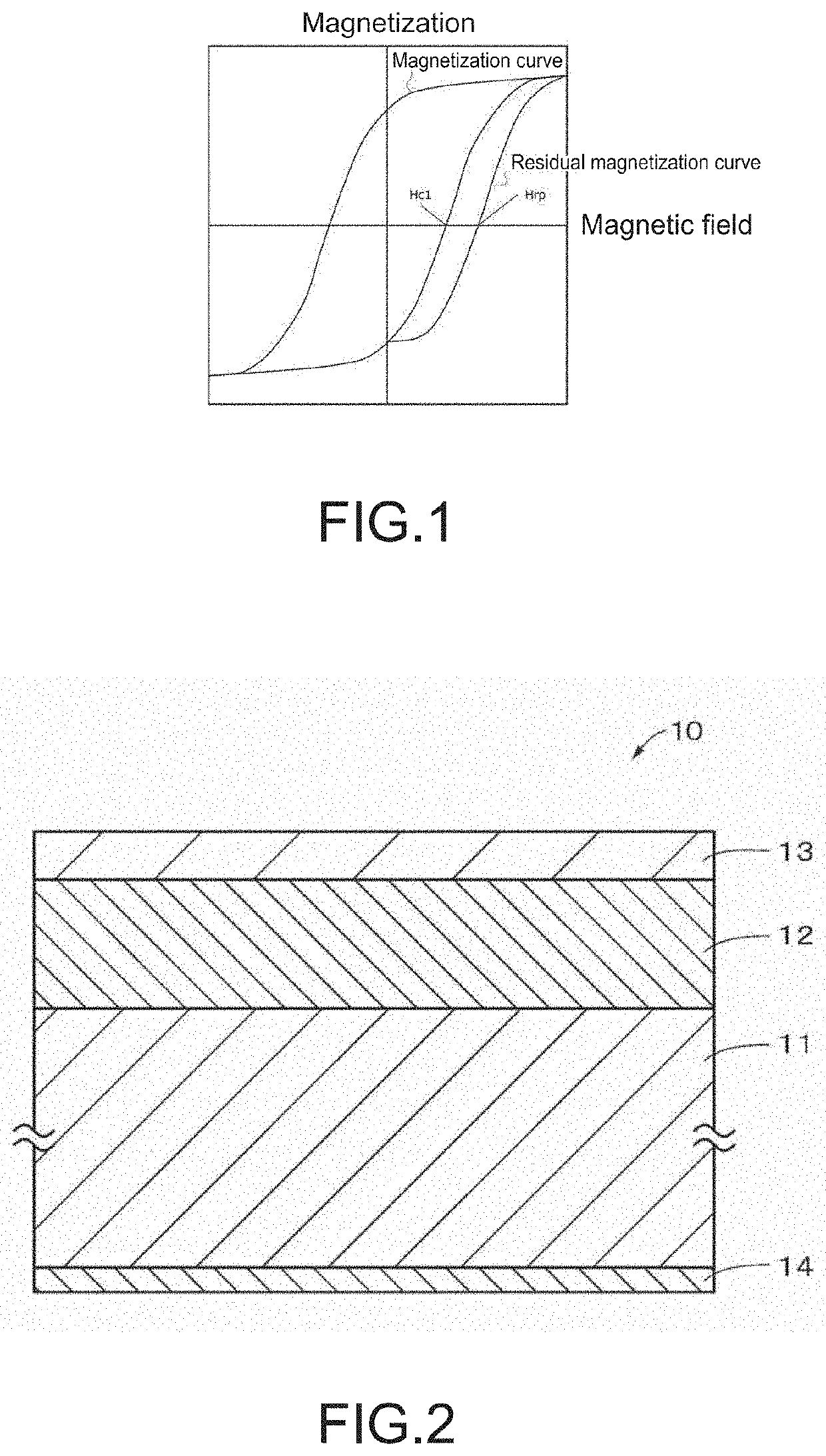

Magnetic recording medium

ActiveUS20210295868A1Improve recording densityReduce particle volumeMagnetic materials for record carriersAlignment for track following on tapesHeat stabilityMaterials science

It is an object of the present disclosure to improve preservation stability of a magnetic recording medium including a magnetic powder having a small average particle volume.The present disclosure provides a tape-shaped magnetic recording medium, including: a base; and a magnetic layer that is provided on the base and contains a magnetic powder, in which an average particle volume V of the magnetic powder is 2,000 nm3 or less, an average thickness of the magnetic recording medium is 5.3 μm or less, a thermal stability KuV / kBT of the magnetic recording medium is 60 or more, and a ratio Hrp / Hc1 of a residual coercive force Hrp of the magnetic recording medium measured using a pulsed magnetic field to a coercive force Hc1 of the magnetic recording medium in a perpendicular direction is 2.10 or less.

Owner:SONY CORP

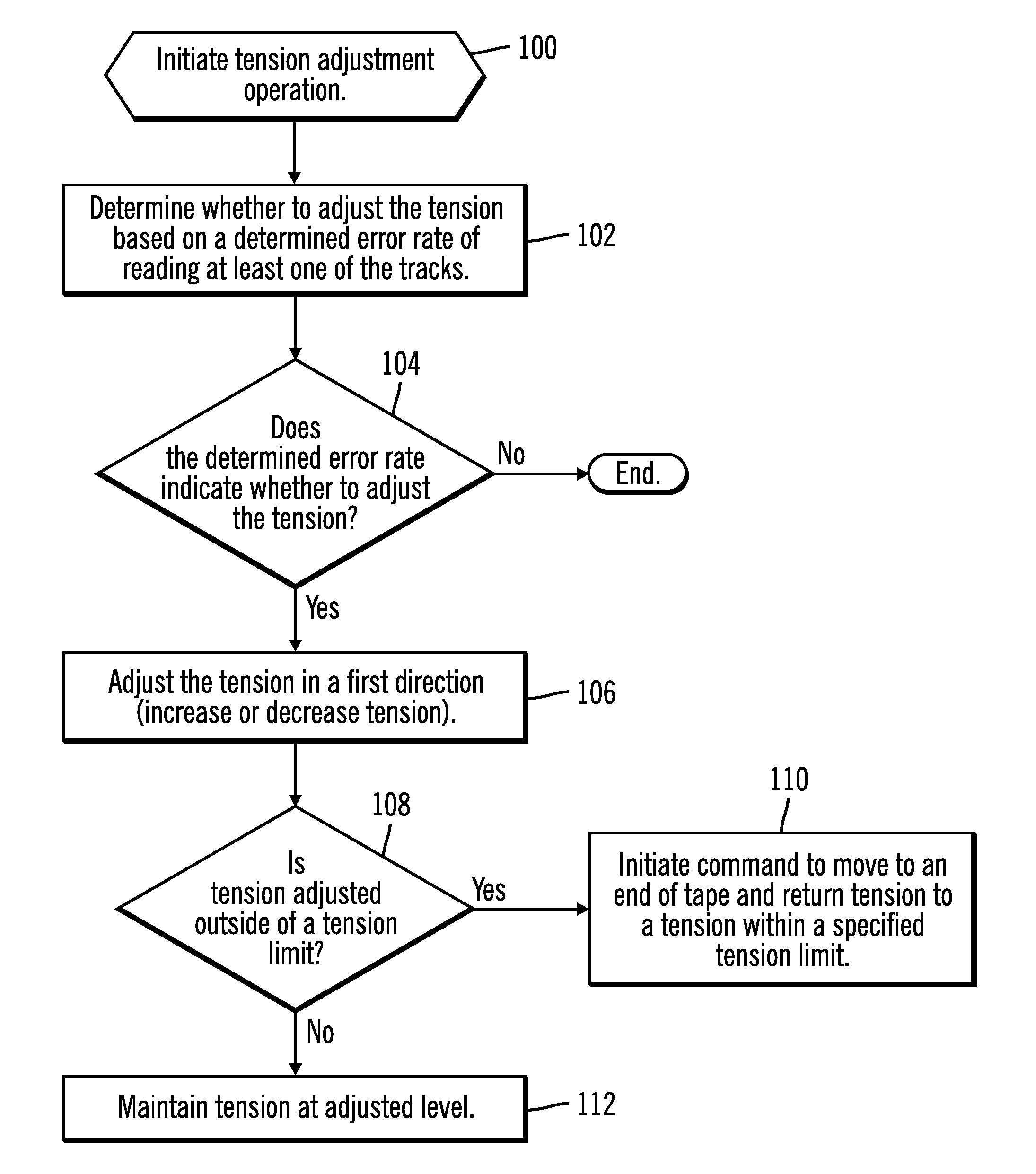

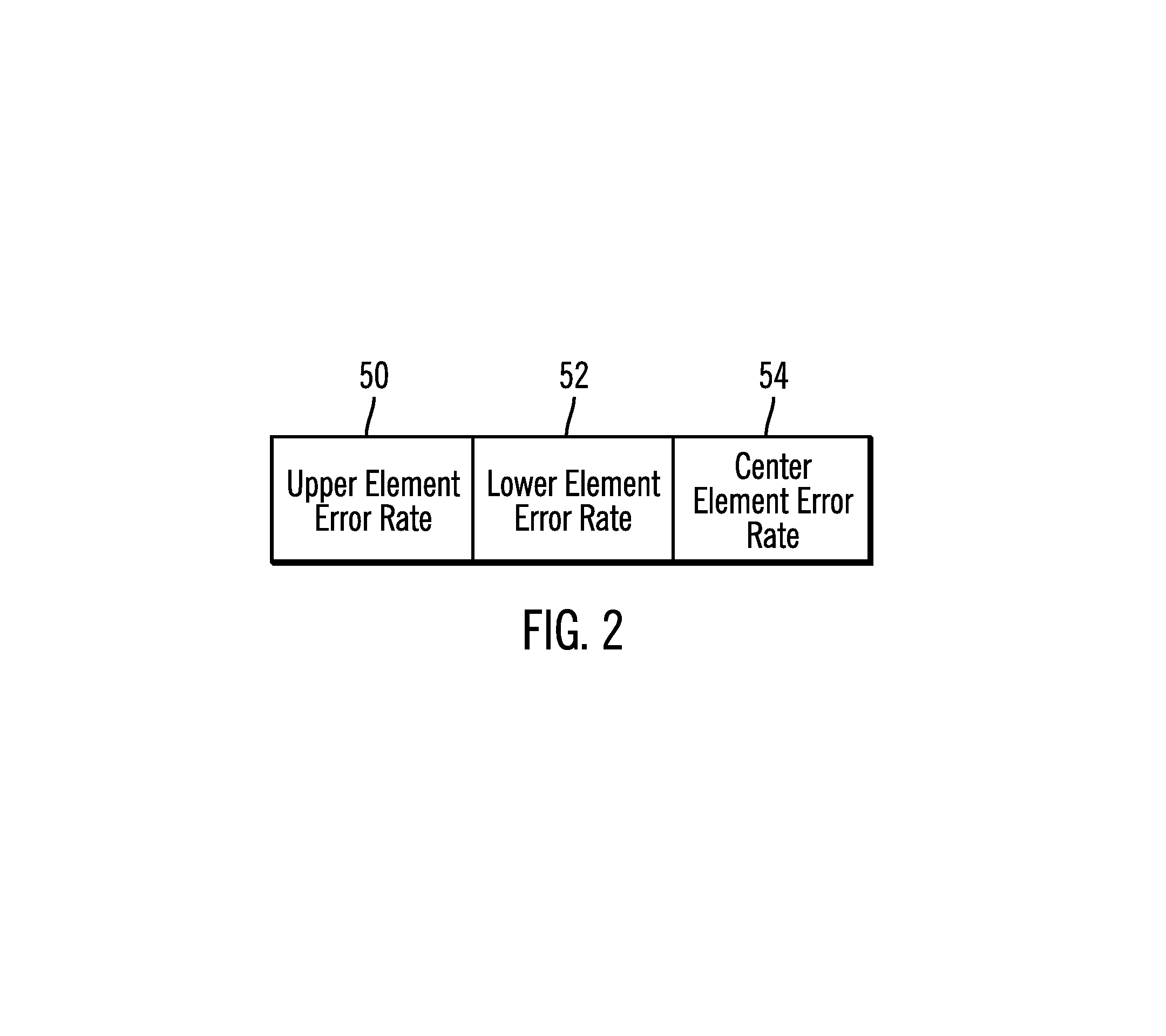

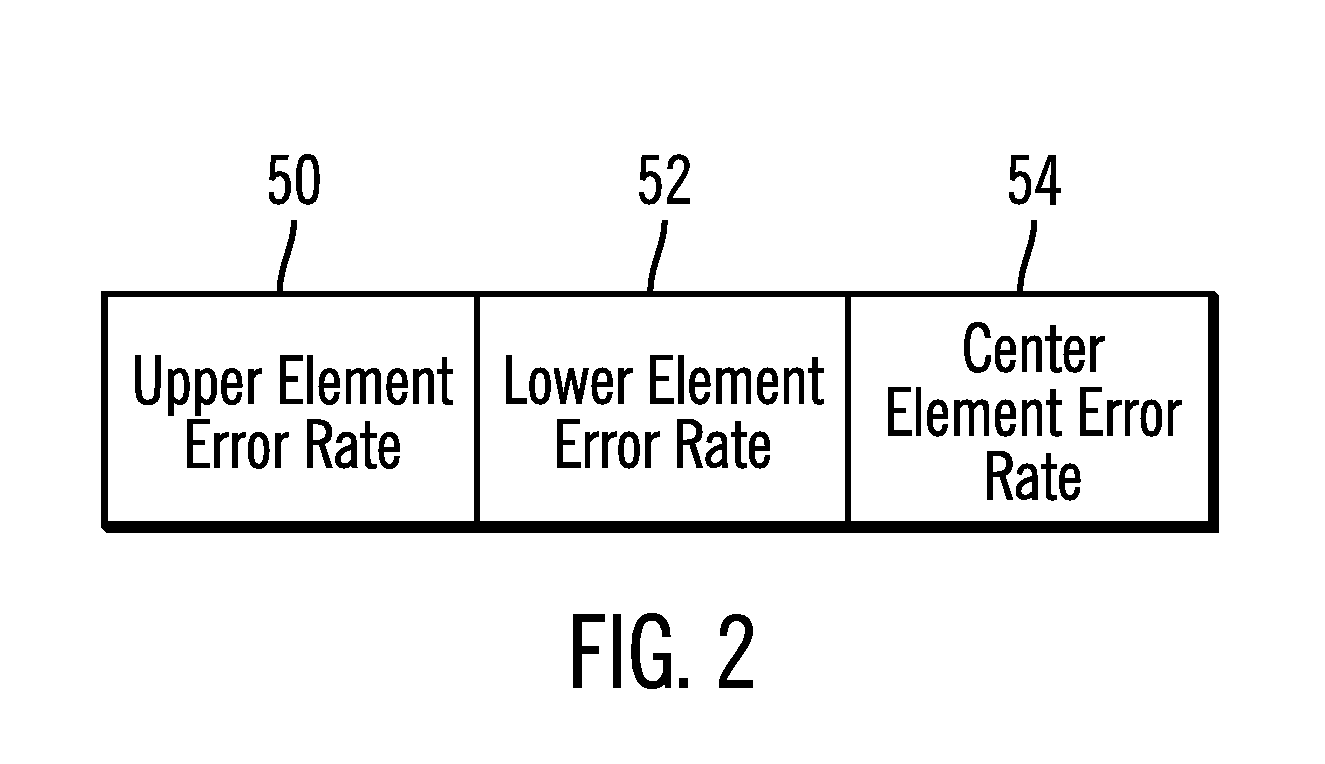

Adjusting tension in a tape media to counter tape dimensional stability (TDS) errors in a tape media

InactiveUS8982492B2Alignment for track following on tapesRecord information storageComputer hardwareMagnetic tape

Provided are a method, system, and program for adjusting tension in a tape media to counter tape dimensional stability (TDS) errors in a tape media. A determination is made of whether to adjust tension of the tape media based on a detected error rate of reading at least one of the tracks. The tension of the tape media is adjusted in response to determining to adjust the tension.

Owner:GLOBALFOUNDRIES INC

Tape drive

InactiveUS20080217454A1High of decelerationEasy mechanical assemblyInking apparatusProjector film strip handlingMagnetic tapeControl signal

A tape drive comprising two motors at least a first of which is an open loop position-controlled motor arranged to provide a controllable torque, two tape spool supports on which spools of tape may be mounted, each spool being drivable by a respective motor, and a controller for controlling the energization of the motors such that the tape may be transported in at least one direction between spools mounted on the spool supports. The controller is arranged to provide a control signal to the first motor to set the tape tension.

Owner:ZIPHER

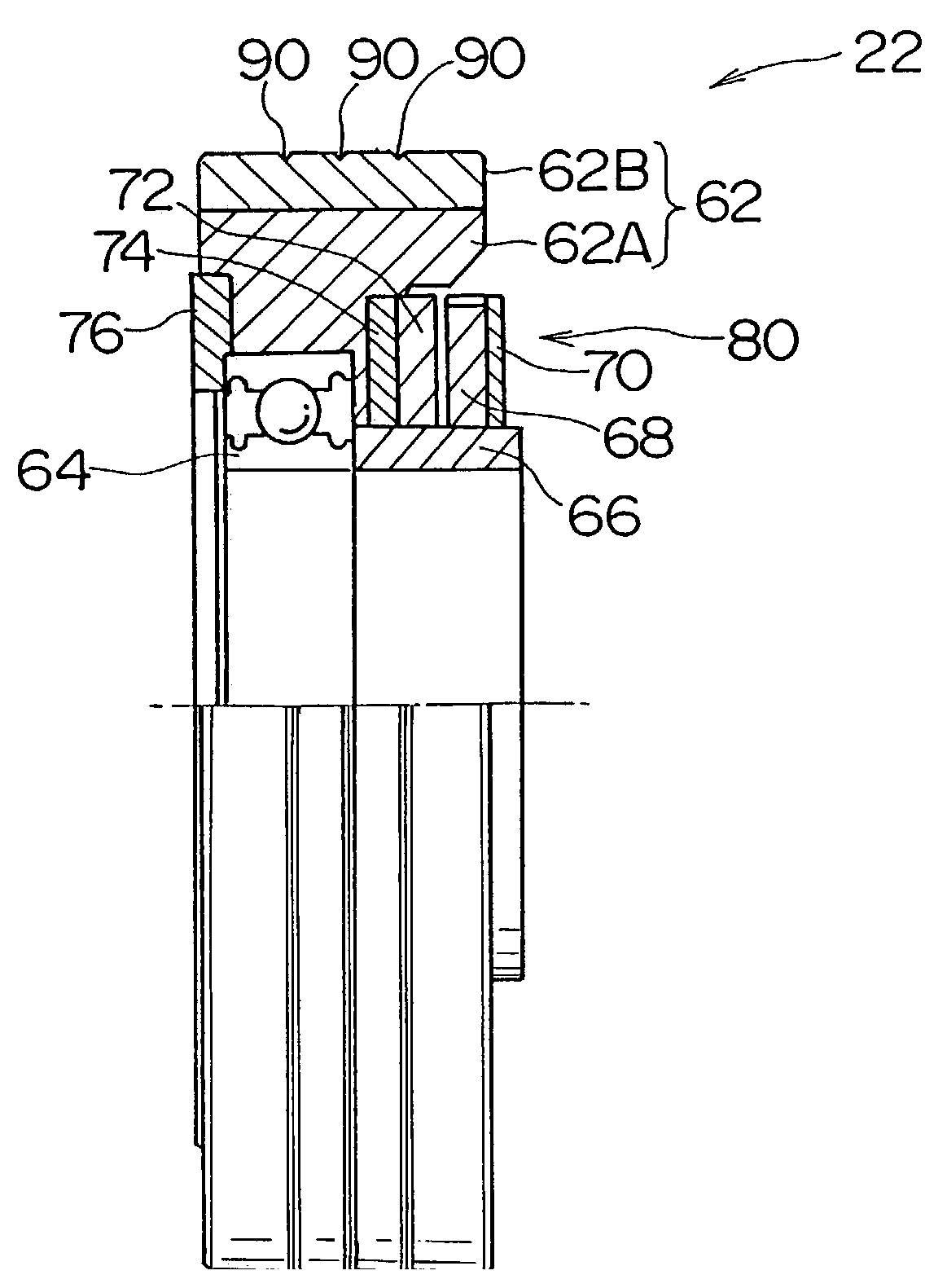

Tension feedback system for a tape drive

InactiveUS20050057843A1Driving/moving recording headsAlignment for track following on tapesAccelerometerMagnetic tape

Tape drive systems and methods for operating tape drive systems are provided. The system includes a head assembly having a head element for reading or writing data to a magnetic tape medium, and a pressure sensor coupled to the head element, the pressure sensor configured to generate a pressure signal representative of a pressure applied by the head element onto the pressure sensor. In some embodiments, an accelerometer is provided for sensing an acceleration of the head assembly and for generating a acceleration signal representative of an acceleration experienced by the head assembly. The method includes passing a tape medium between a take-up reel and a supply reel such that a tension in the tape medium causes the tape medium to apply a pressure onto a head element, and using a pressure sensor to detect a pressure applied by the head element onto the pressure sensor.

Owner:QUANTUM CORP

Tension feedback system for a tape drive

InactiveUS7016138B2Driving/moving recording headsAlignment for track following on tapesAccelerometerMagnetic tape

Tape drive systems and methods for operating tape drive systems are provided. The system includes a head assembly having a head element for reading or writing data to a magnetic tape medium, and a pressure sensor coupled to the head element, the pressure sensor configured to generate a pressure signal representative of a pressure applied by the head element onto the pressure sensor. In some embodiments, an accelerometer is provided for sensing an acceleration of the head assembly and for generating a acceleration signal representative of an acceleration experienced by the head assembly. The method includes passing a tape medium between a take-up reel and a supply reel such that a tension in the tape medium causes the tape medium to apply a pressure onto a head element, and using a pressure sensor to detect a pressure applied by the head element onto the pressure sensor.

Owner:QUANTUM CORP

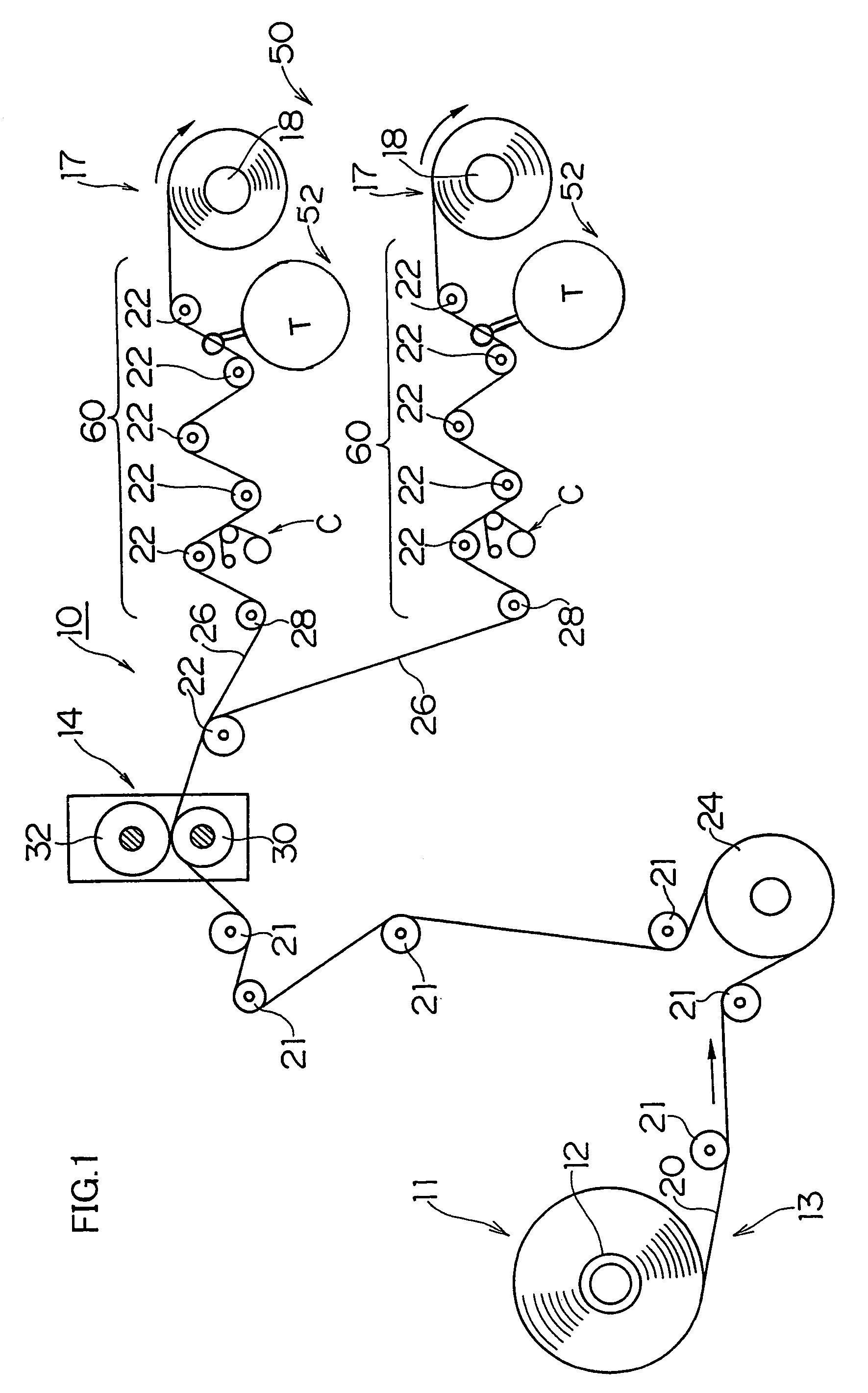

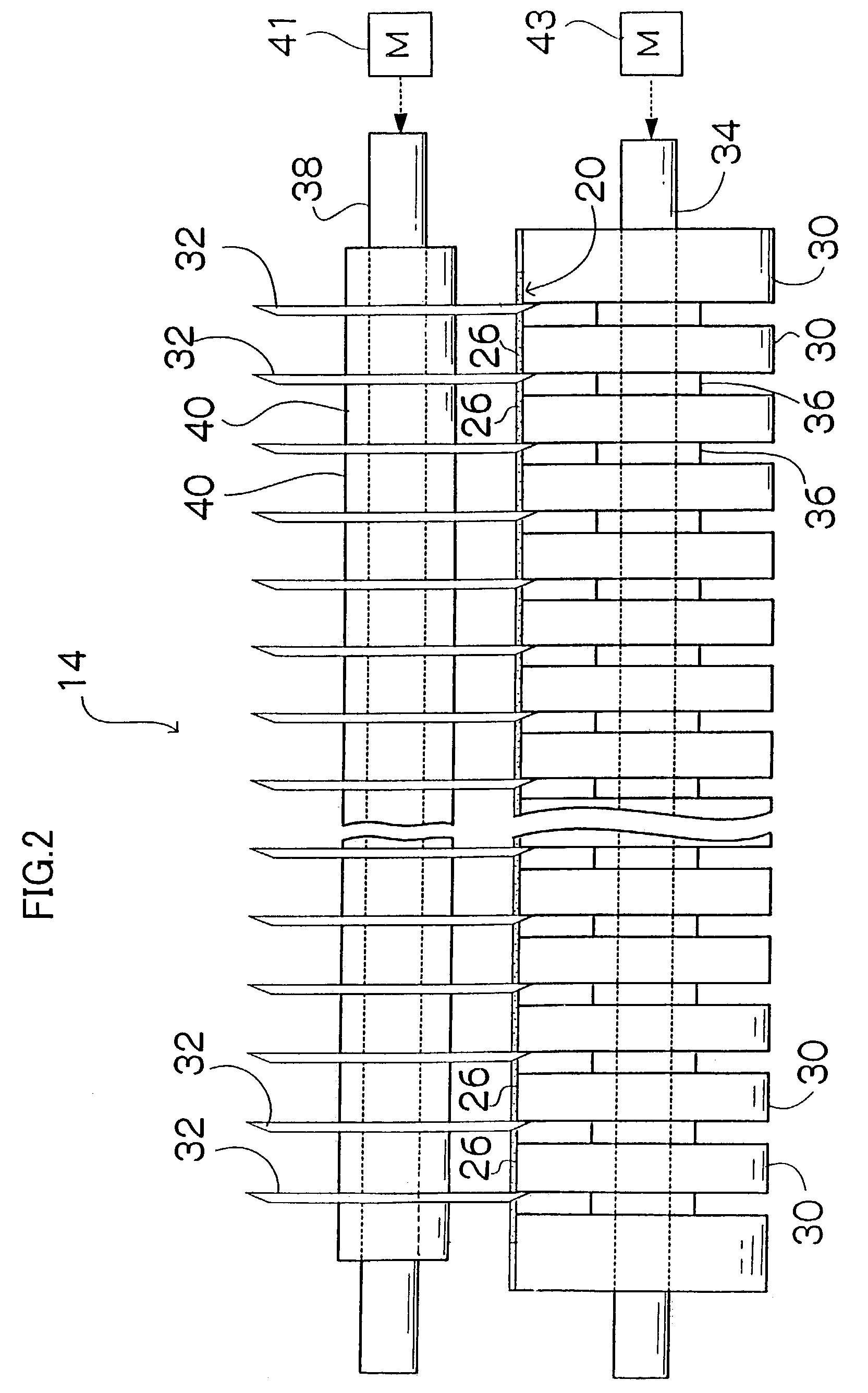

Magnetic tape manufacturing apparatus

InactiveUS6994290B2Increase productivityQuality improvementLiquid surface applicatorsFilament handlingProduction rateClutch control

The magnetic tape manufacturing apparatus draws out a wide web-like magnetic tape material wound in roll form from the delivery side, slits the magnetic tape material into a plurality of narrow magnetic tapes by use of a slitter while transporting the magnetic tape material, and winds the narrow magnetic tapes on cores on the winding side through a tape transporting device. In the tape transporting device, roller members supporting the narrow magnetic tapes are mounted on supporting shafts, respectively, and an eddy current type clutch is internally mounted on at least one of the supporting shafts so that the eddy current type clutch controls rotation of the one of supporting shafts to control tension of the narrow magnetic tape supported on the roller member mounted on the one of supporting shafts. Hence, by making the tension of the individual magnetic tapes uniform, productivity and product quality can be stabilized and improved and yield can also be improved.

Owner:FUJIFILM HLDG CORP +1

Adjusting tension in a tape media to counter tape dimensional stability (TDS) errors in a tape media

InactiveUS20140327985A1Alignment for track following on tapesRecord information storageComputer hardwareMagnetic tape

Provided are a method, system, and program for adjusting tension in a tape media to counter tape dimensional stability (TDS) errors in a tape media. A determination is made of whether to adjust tension of the tape media based on a detected error rate of reading at least one of the tracks. The tension of the tape media is adjusted in response to determining to adjust the tension.

Owner:GLOBALFOUNDRIES INC

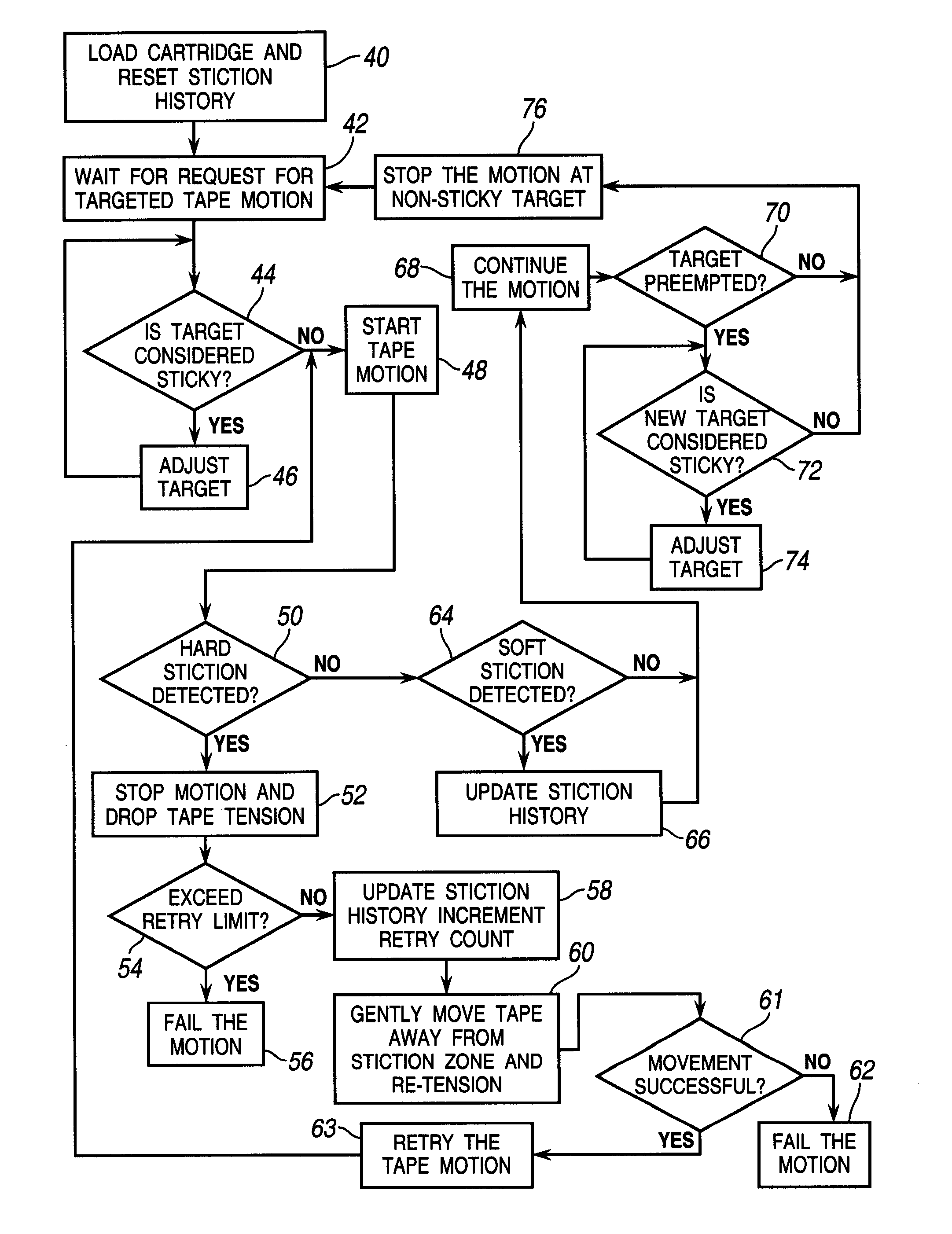

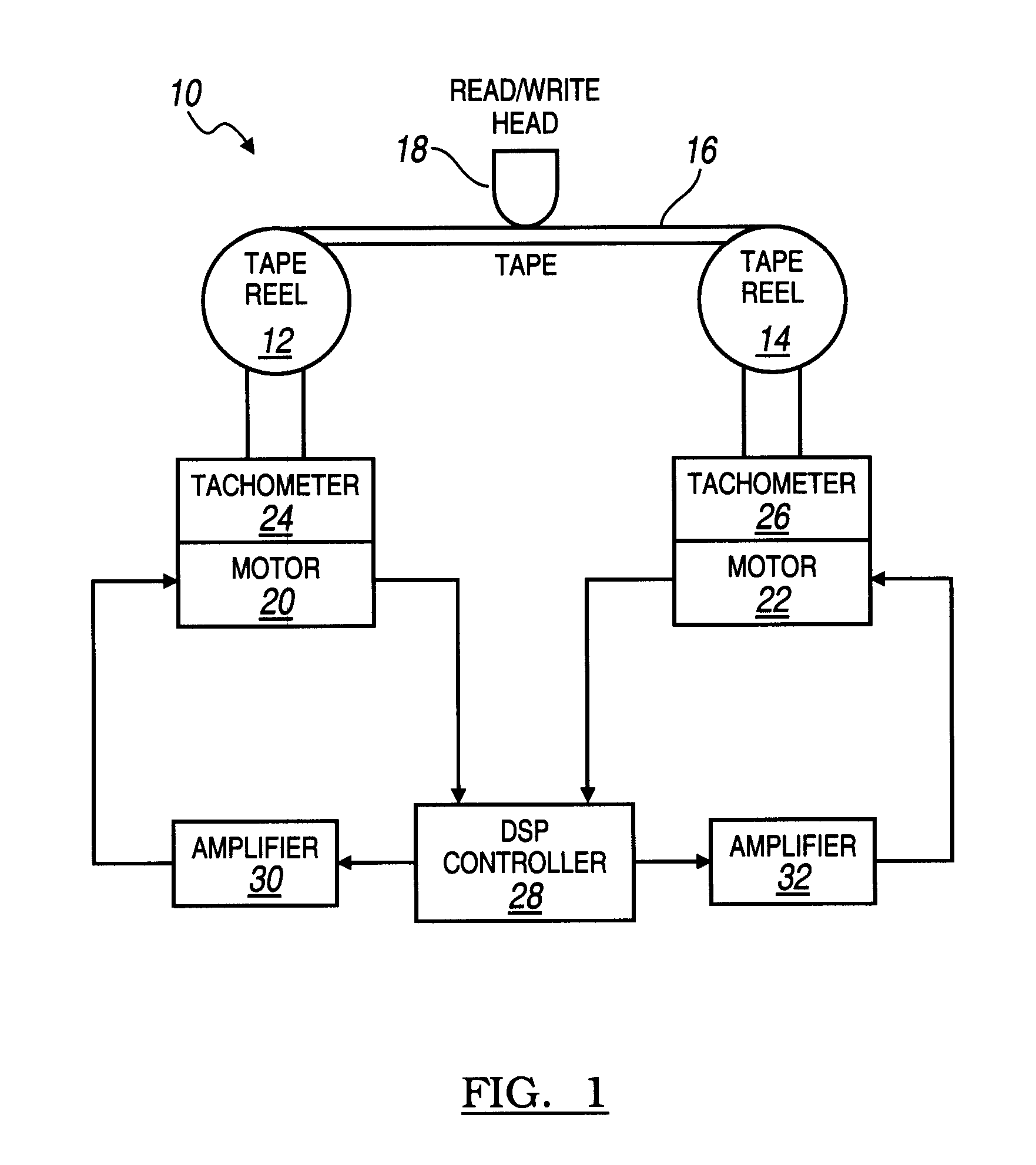

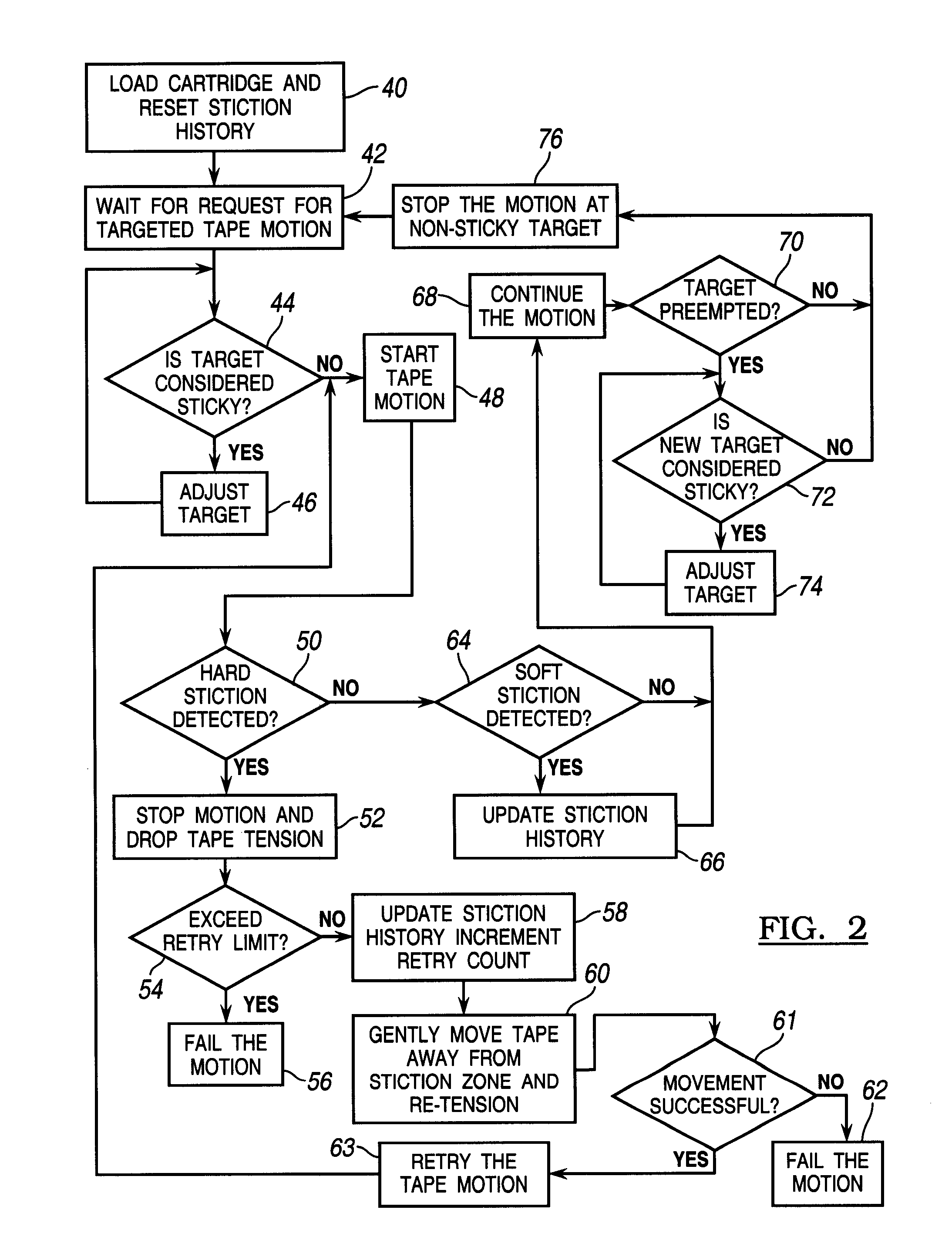

Tape drive for avoiding tape stiction

A method for avoiding tape stiction is provided with a tape drive with a pair of motors for driving a pair of tape reels for conveying data tape across one or more read / write heads. Tachometers measure rotation of the pair of tape reels. Motion of the tape is started and rotation of the tape reels is measured by the tachometers. The measurement of the rotation of the tape reels is compared to determine if there is enough slack associated with tape stiction. The location of tape stiction is stored and weighted. Another method stops motion of the tape at a location wherein excessive tape stiction has not been detected. A tape drive is provided for performing methods for avoiding tape stiction.

Owner:ORACLE INT CORP

Utilizing stored write environment conditions for read error recovery

InactiveUS9251826B1Reduce tensionDriving/moving recording headsAlignment for track following on tapesTape driveWriting environment

Owner:GLOBALFOUNDRIES INC

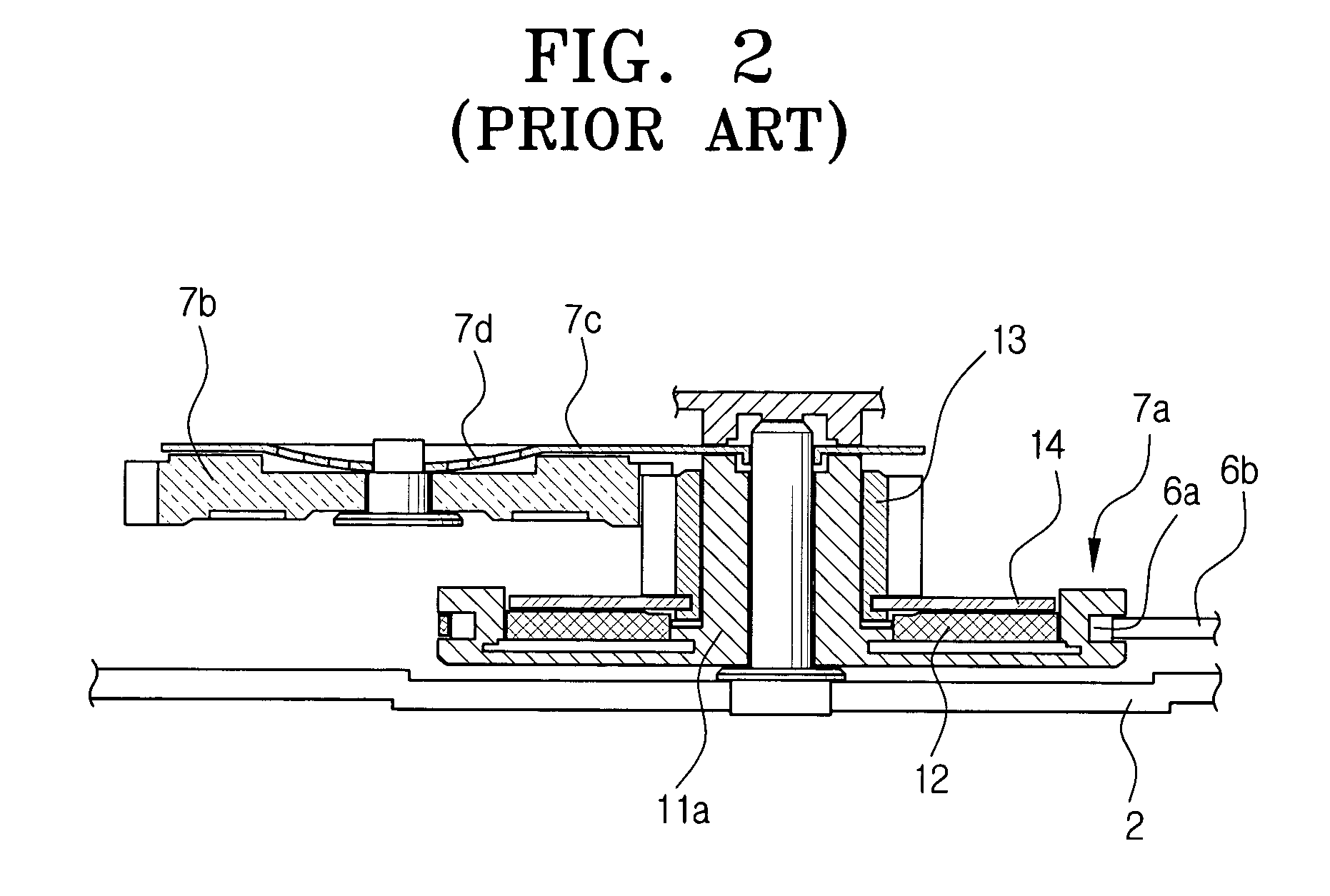

Reel clutch of a tape recorder

InactiveUS7048219B2Easy constructionCamera film strip handlingFilament handlingManufacturing cost reductionProduction rate

Owner:SAMSUNG ELECTRONICS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com