Tape drive

A technology of driving device and supporting device, which is applied in the direction of inking device, carrier mechanical tension control, printing, etc., and can solve problems such as difficult to obtain performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

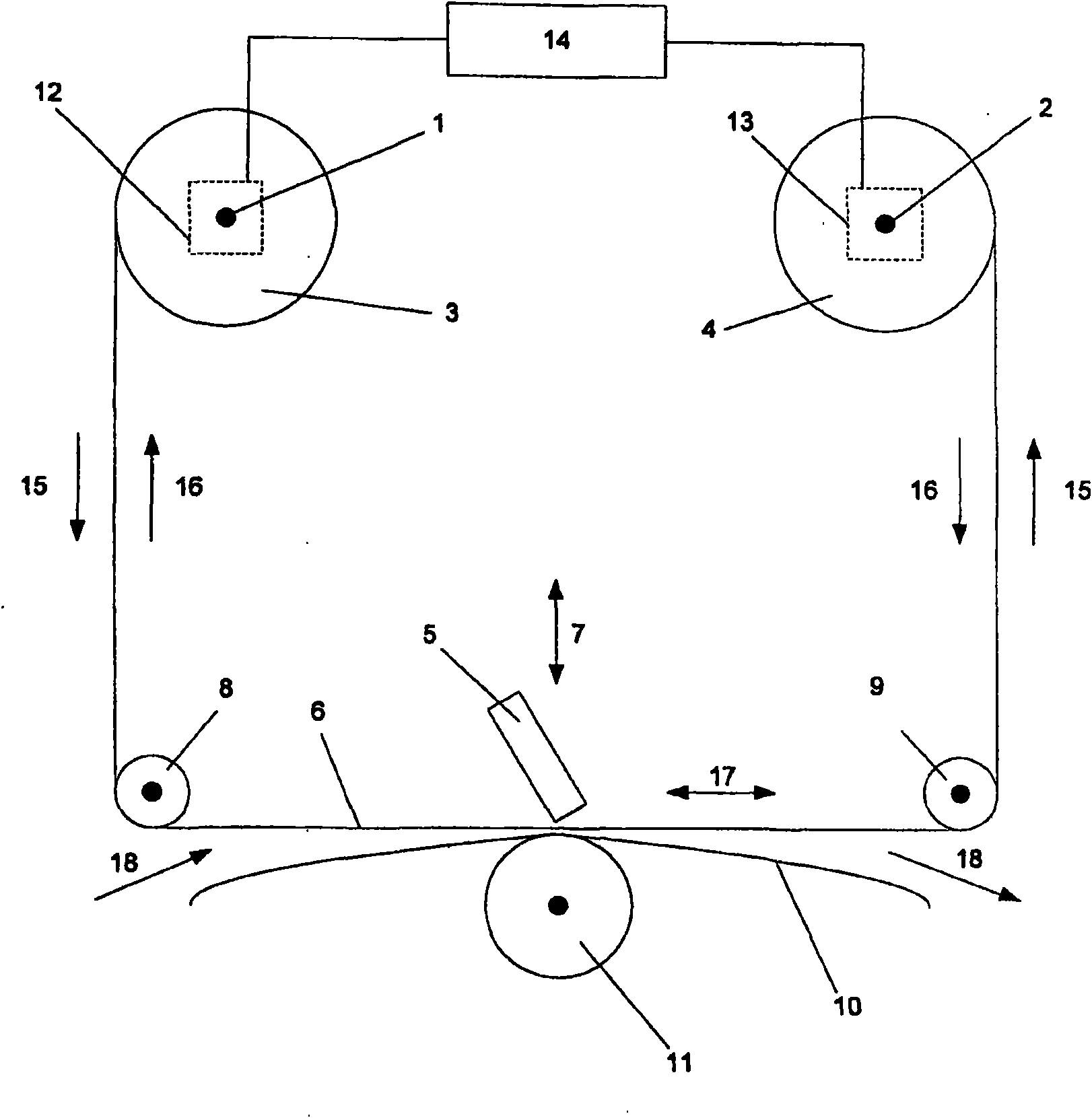

[0034] [34] Reference figure 1 , which schematically illustrates a belt drive suitable for use in a thermal transfer printer according to the present invention. The first shaft 1 and the second shaft 2 support a supply reel 3 and a take-up reel 4, respectively. The supply reel 3 is initially wound with a roll of unused tape, while the take-up reel 4 is initially not carrying any tape. As the tape is used, the used portion of the tape is transferred from the supply reel 3 to the take-up reel 4 . A movable print head 5 is provided which is movable relative to the belt 6 at least in a first direction indicated by arrow 7 . The belt 6 extends from a supply reel 3 around rollers 8 , 9 to a take-up reel 4 . The path followed by the belt 6 between the rollers 8 and 9 passes in front of the print head 5 . When printing starts, the substrate on which the printed pattern is deposited comes into contact with the belt 6 between the rollers 8 and 9 and the belt 6 is inserted between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com