Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

246results about "Driving by direct/indirect member action" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

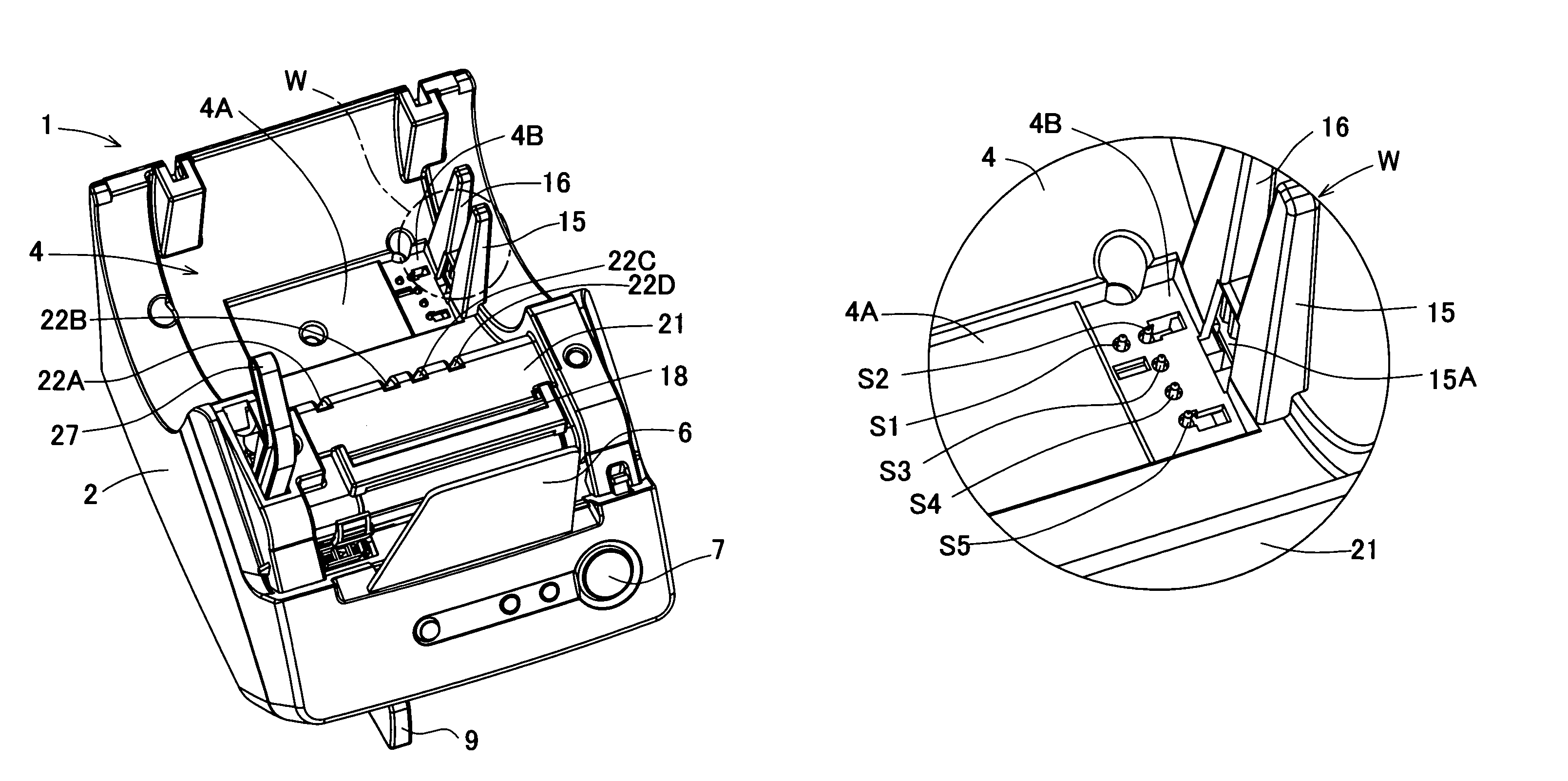

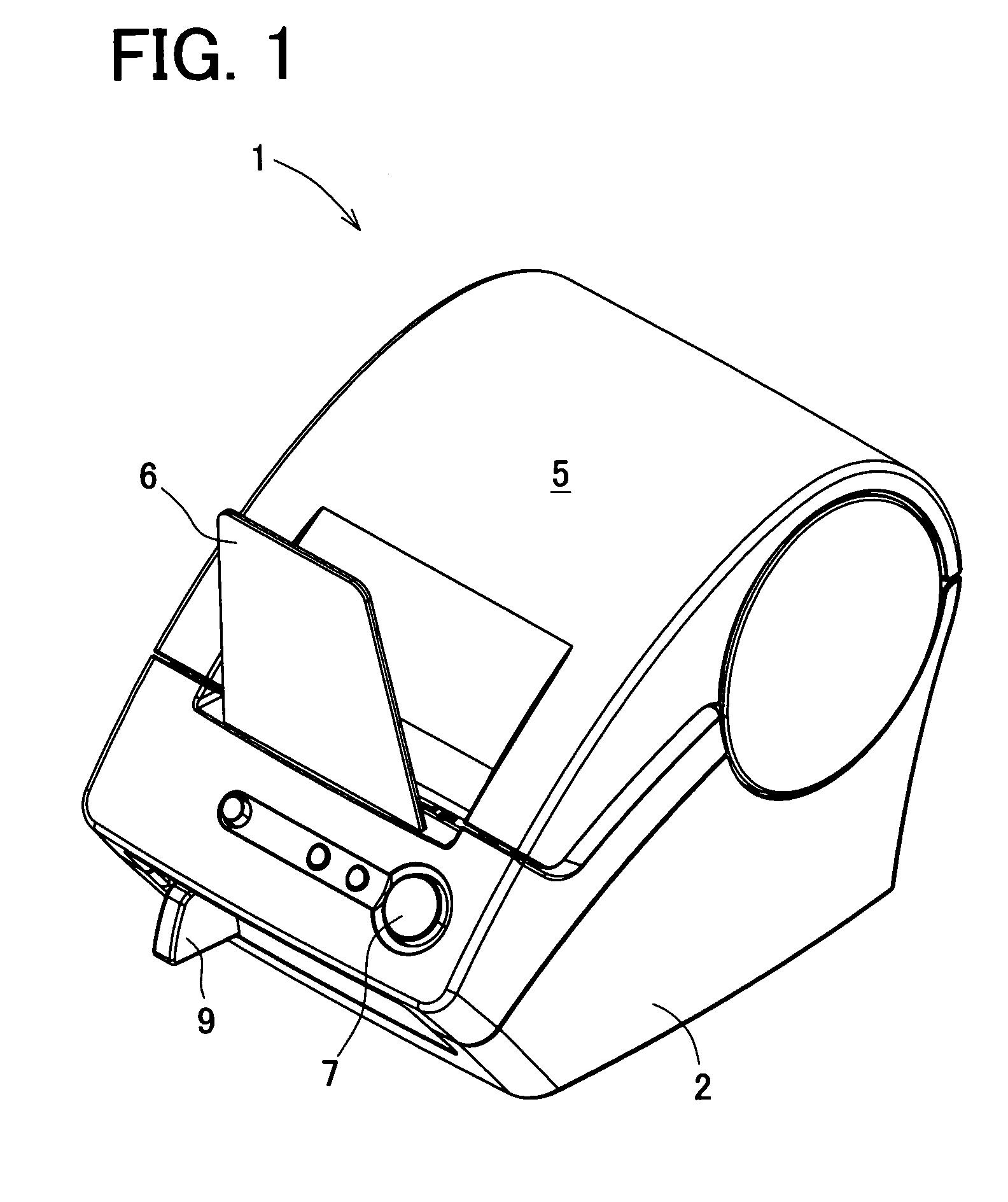

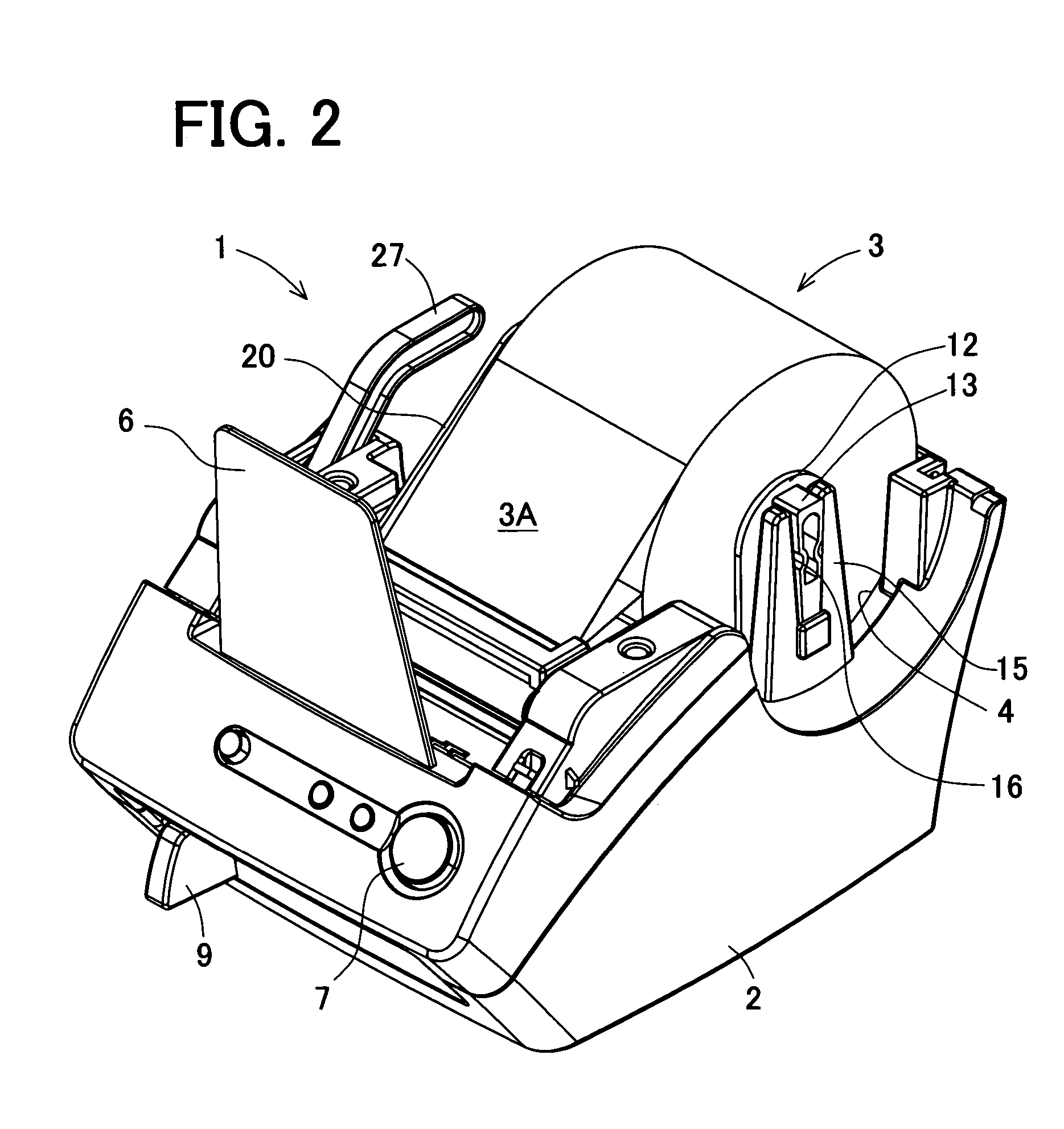

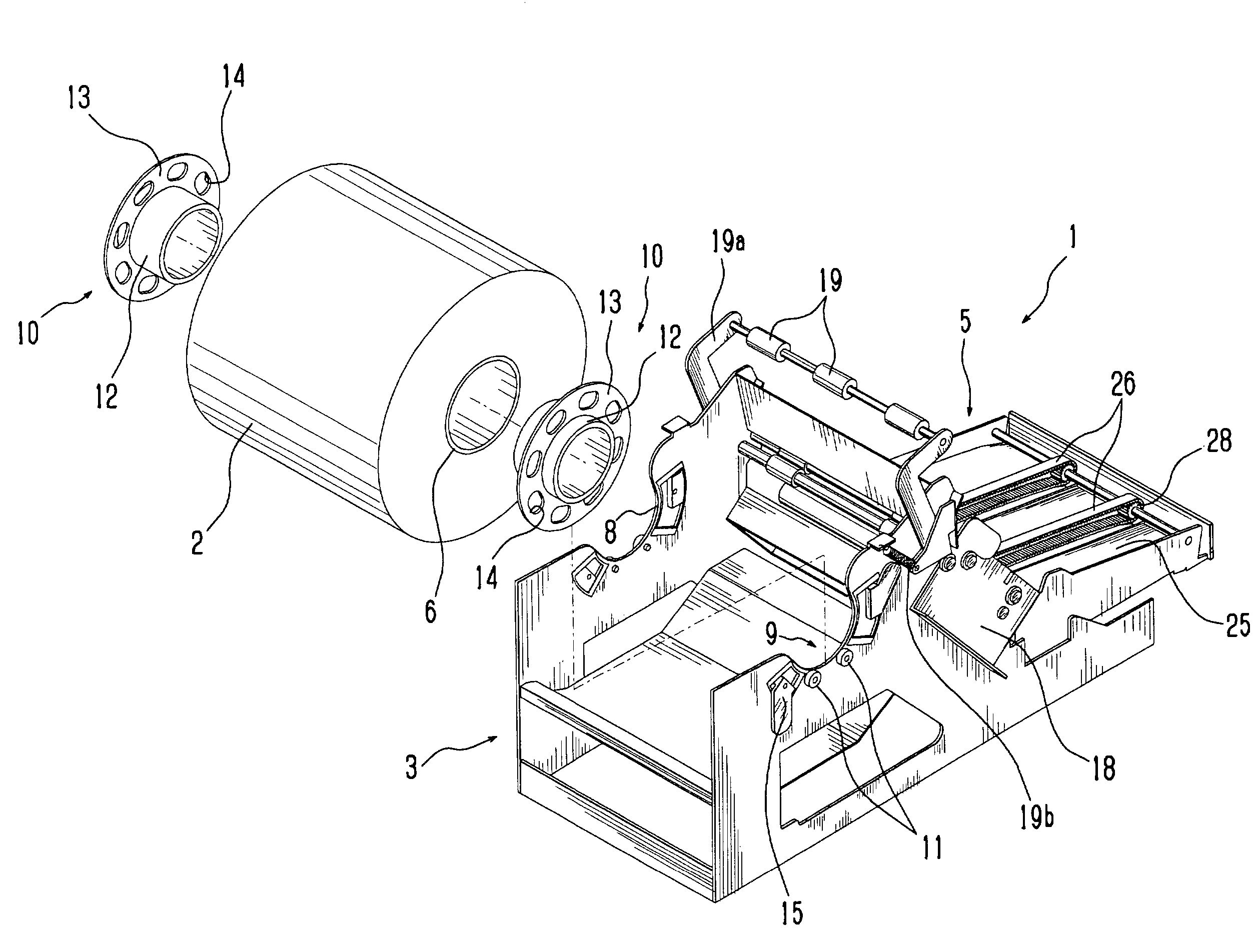

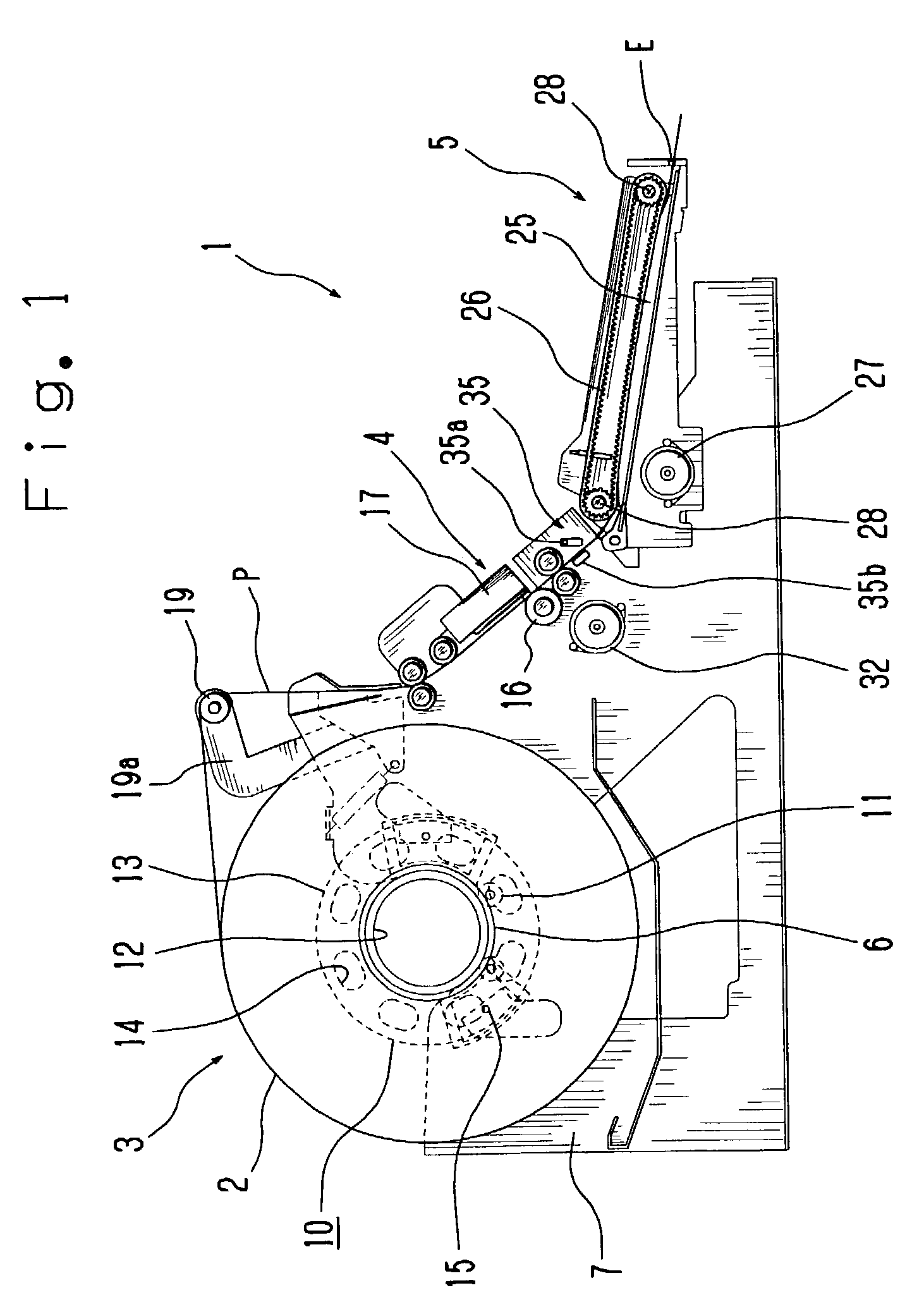

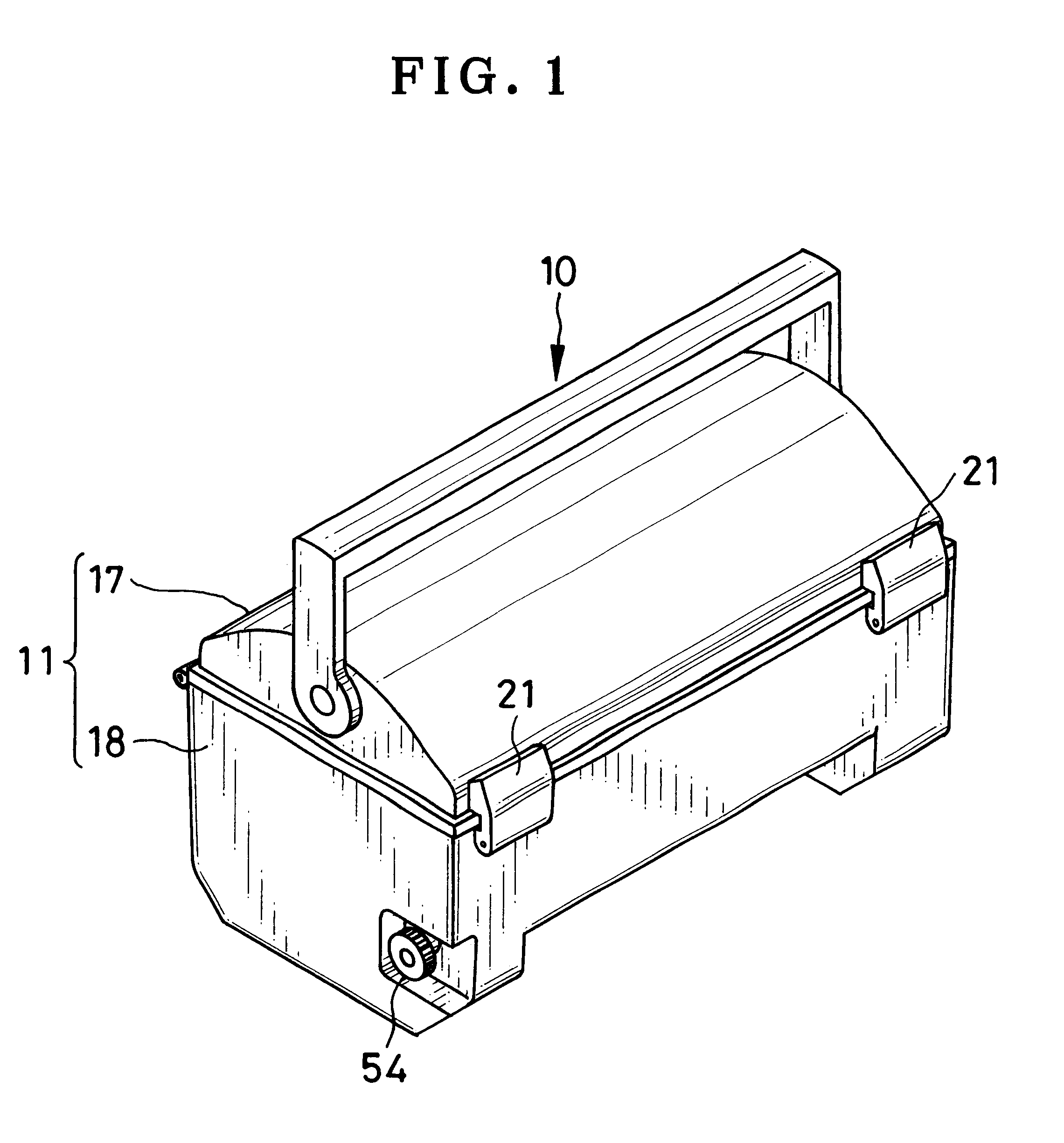

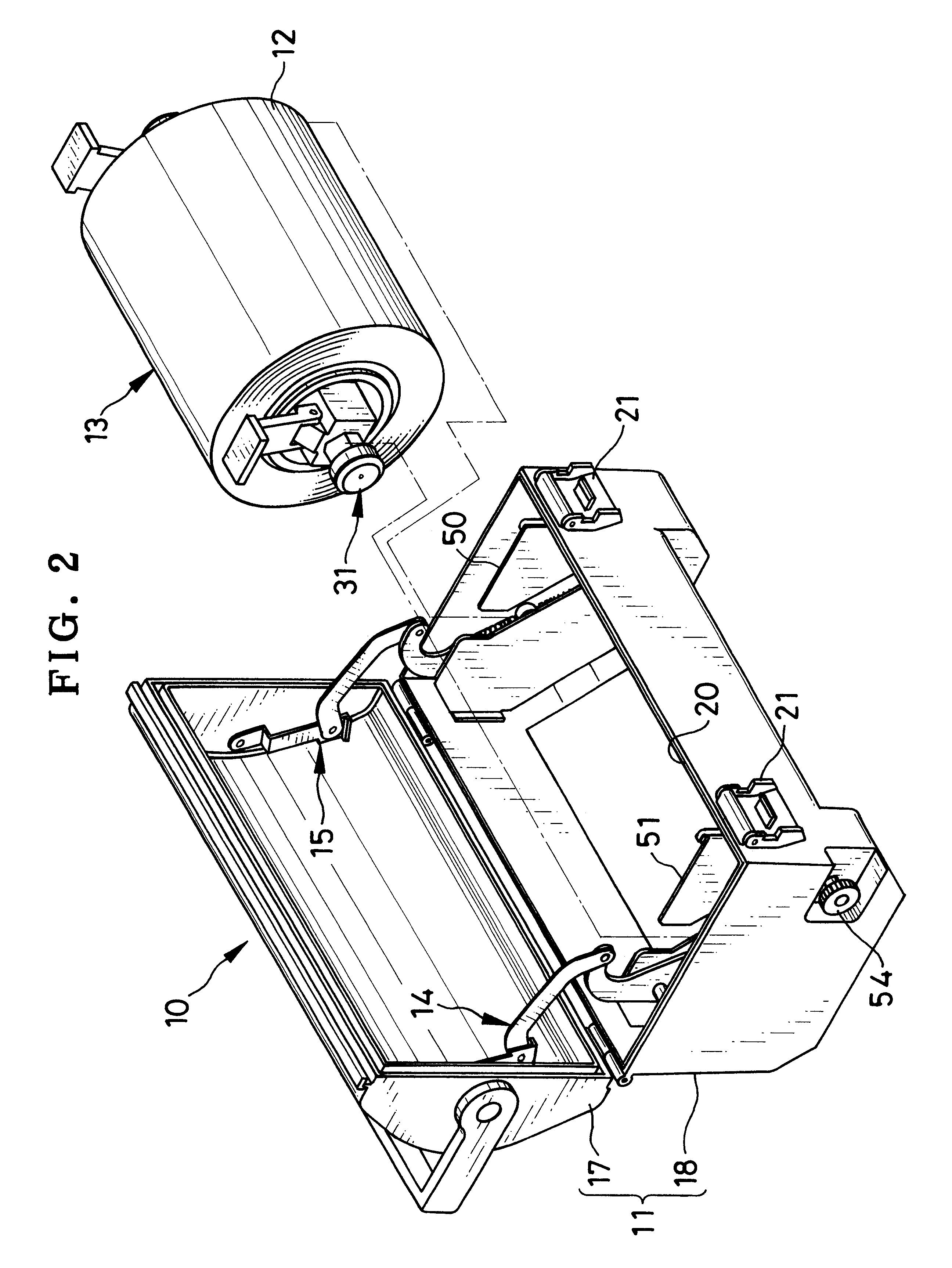

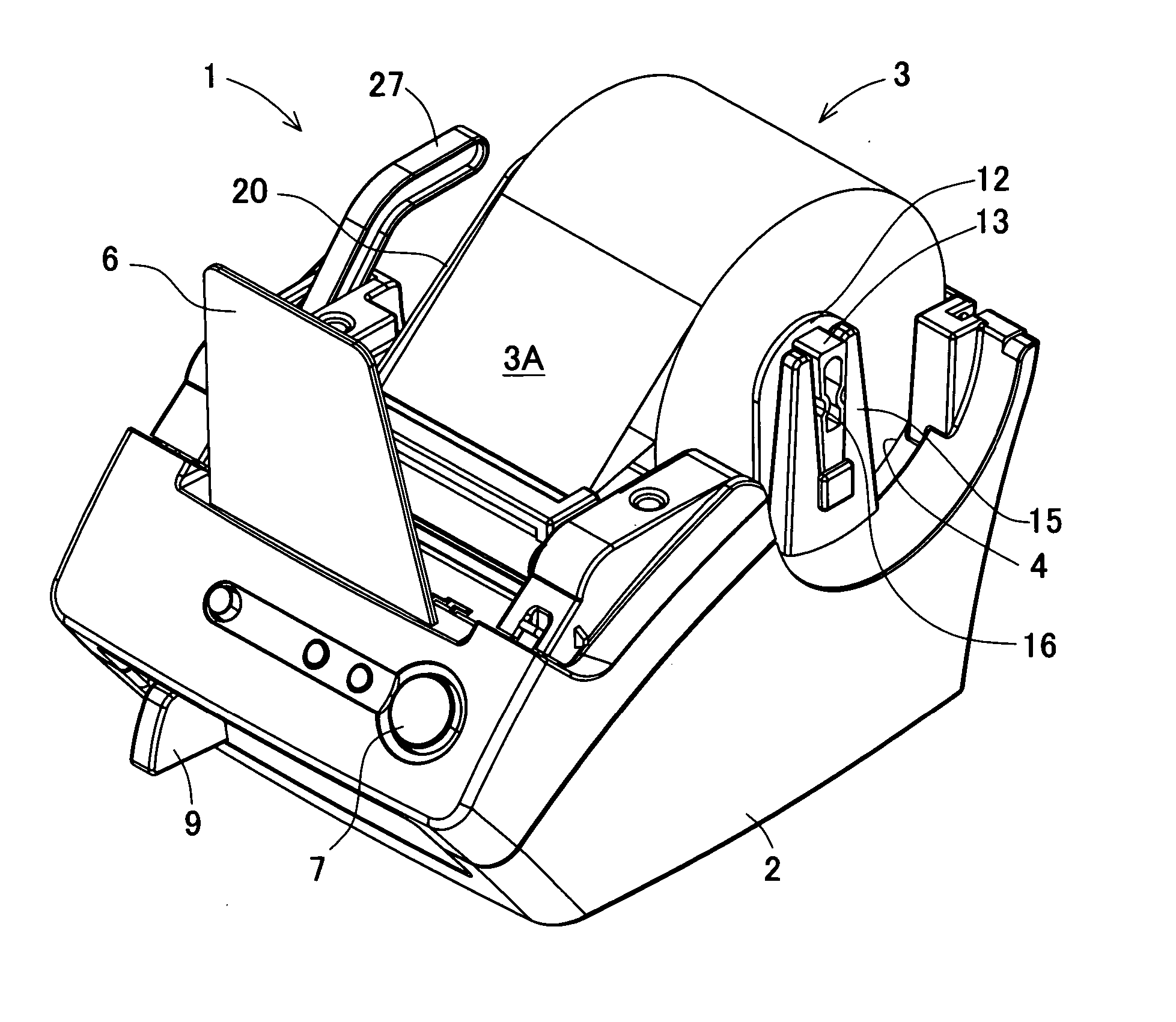

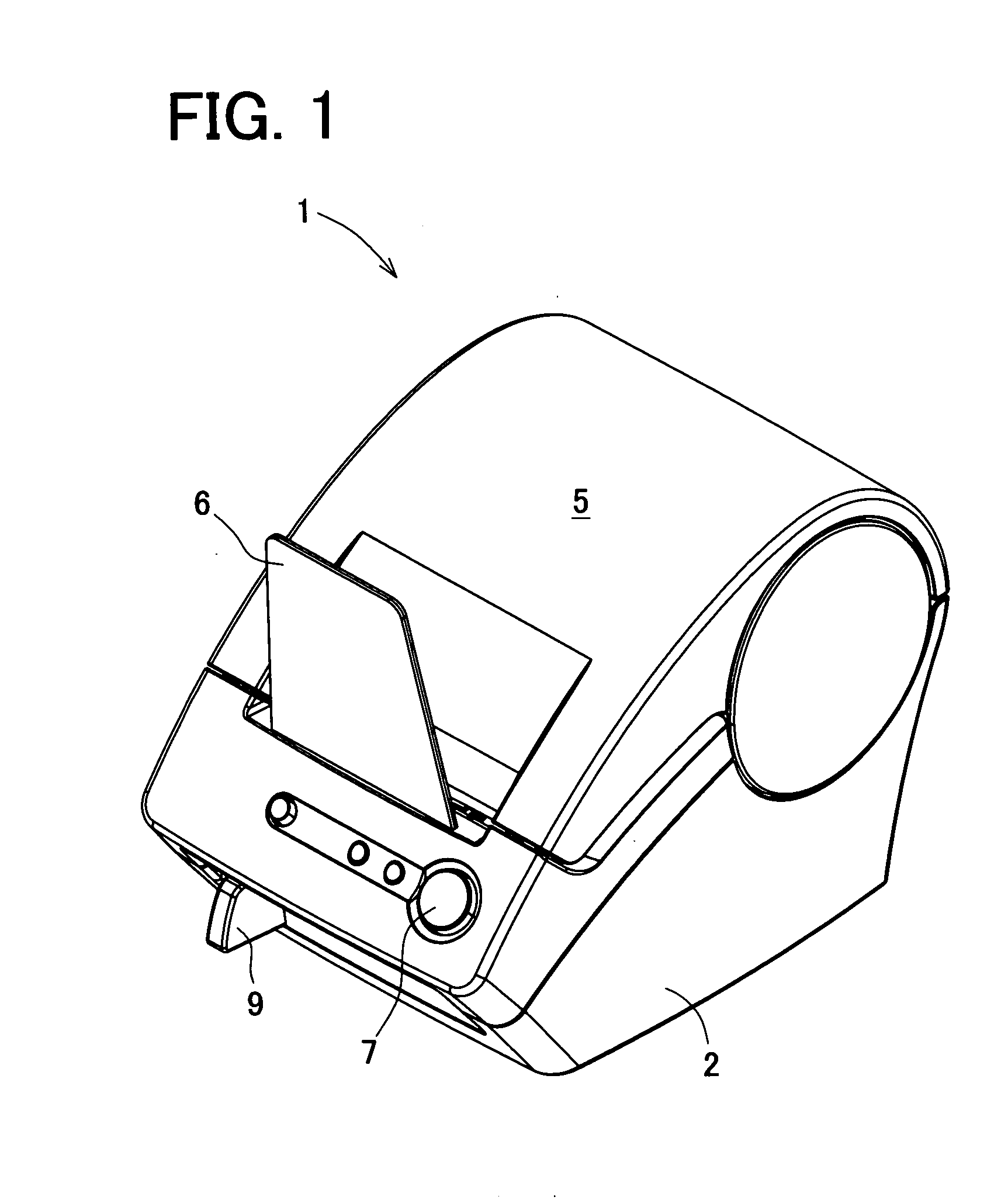

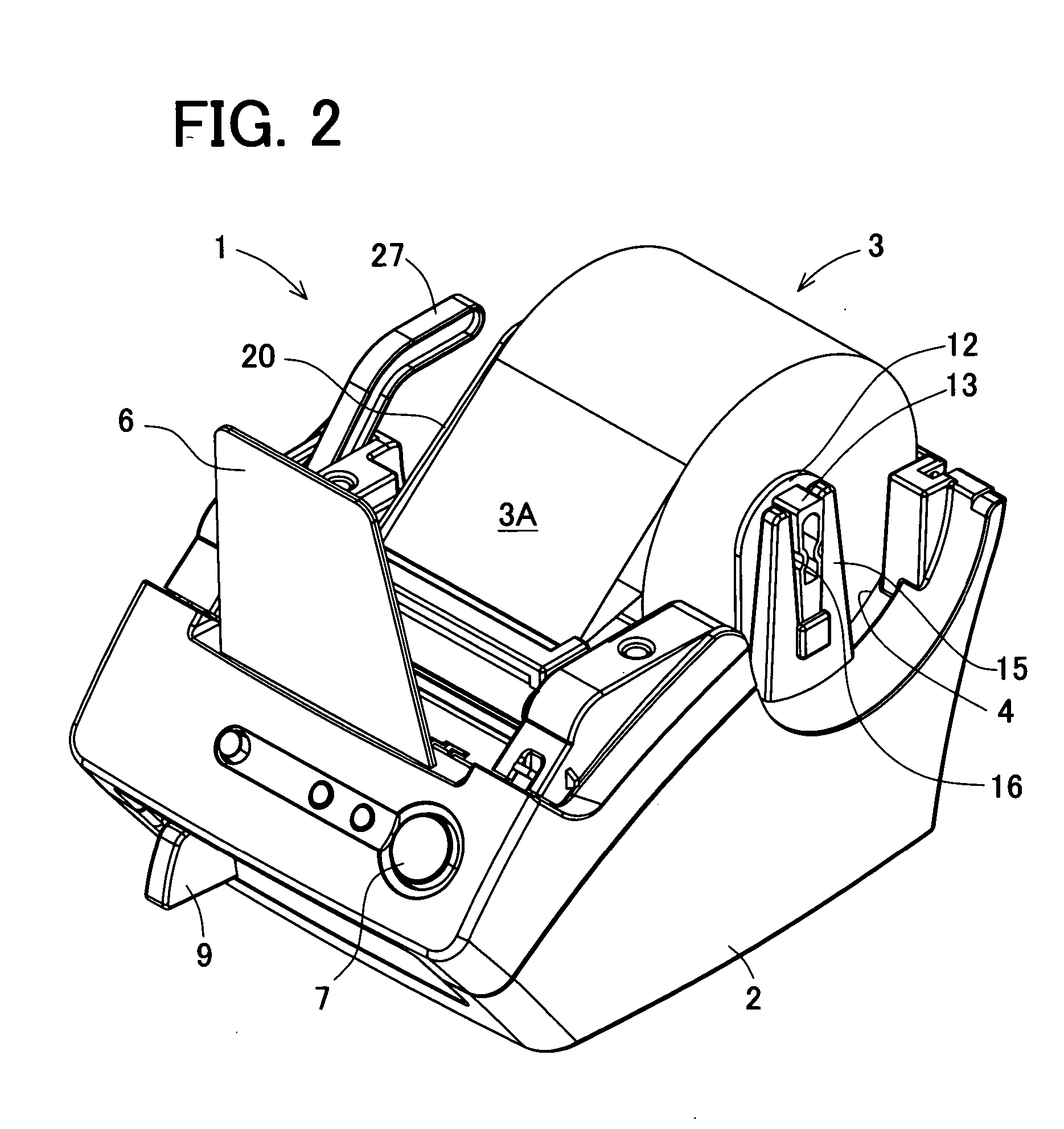

Roll sheet holder and tape printer

ActiveUS7070348B2Avoid partialImprove detection accuracyInking apparatusProjector film strip handlingRolling paperEngineering

Owner:BROTHER KOGYO KK

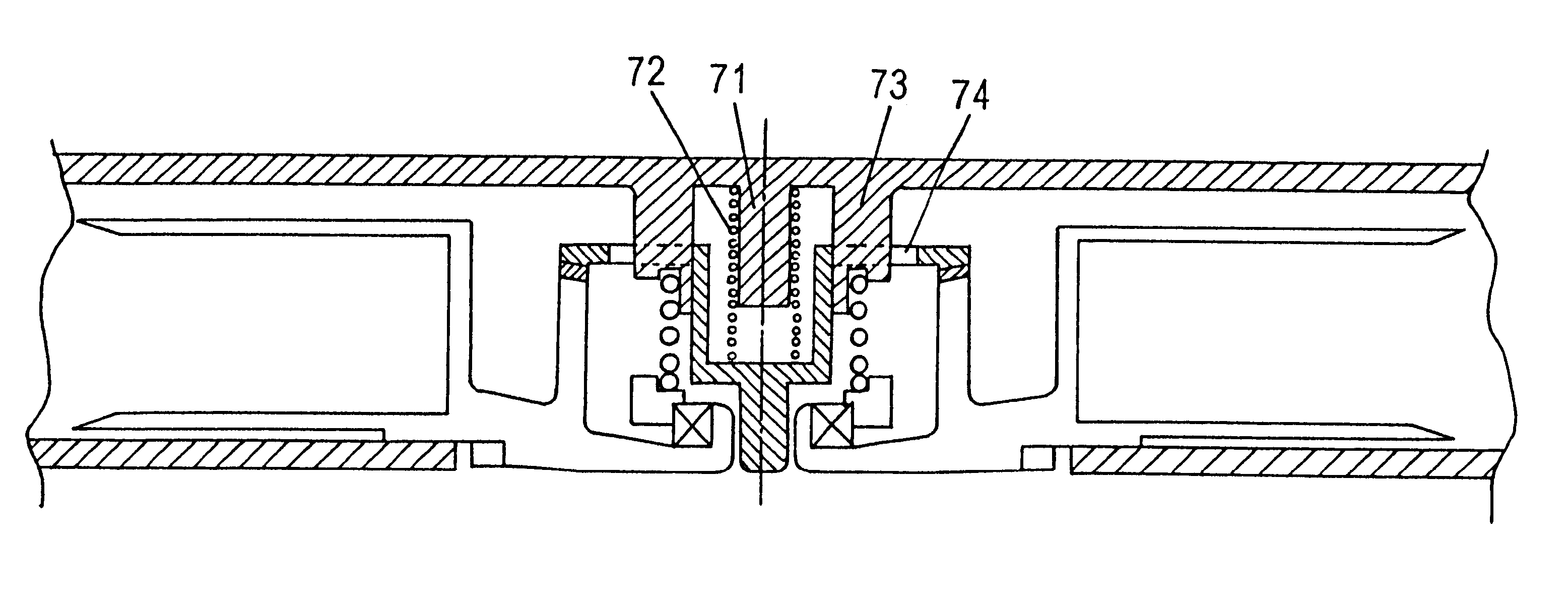

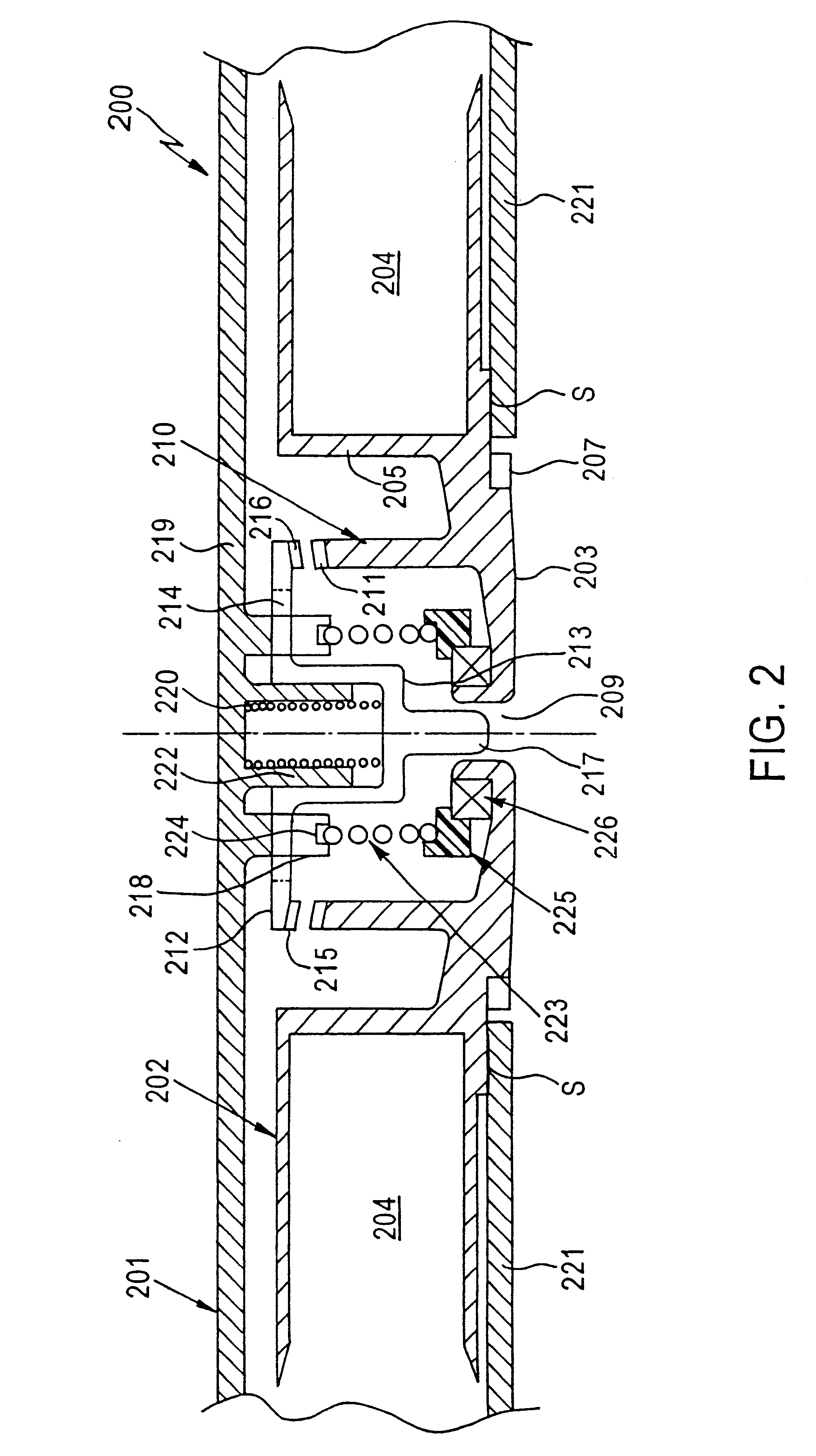

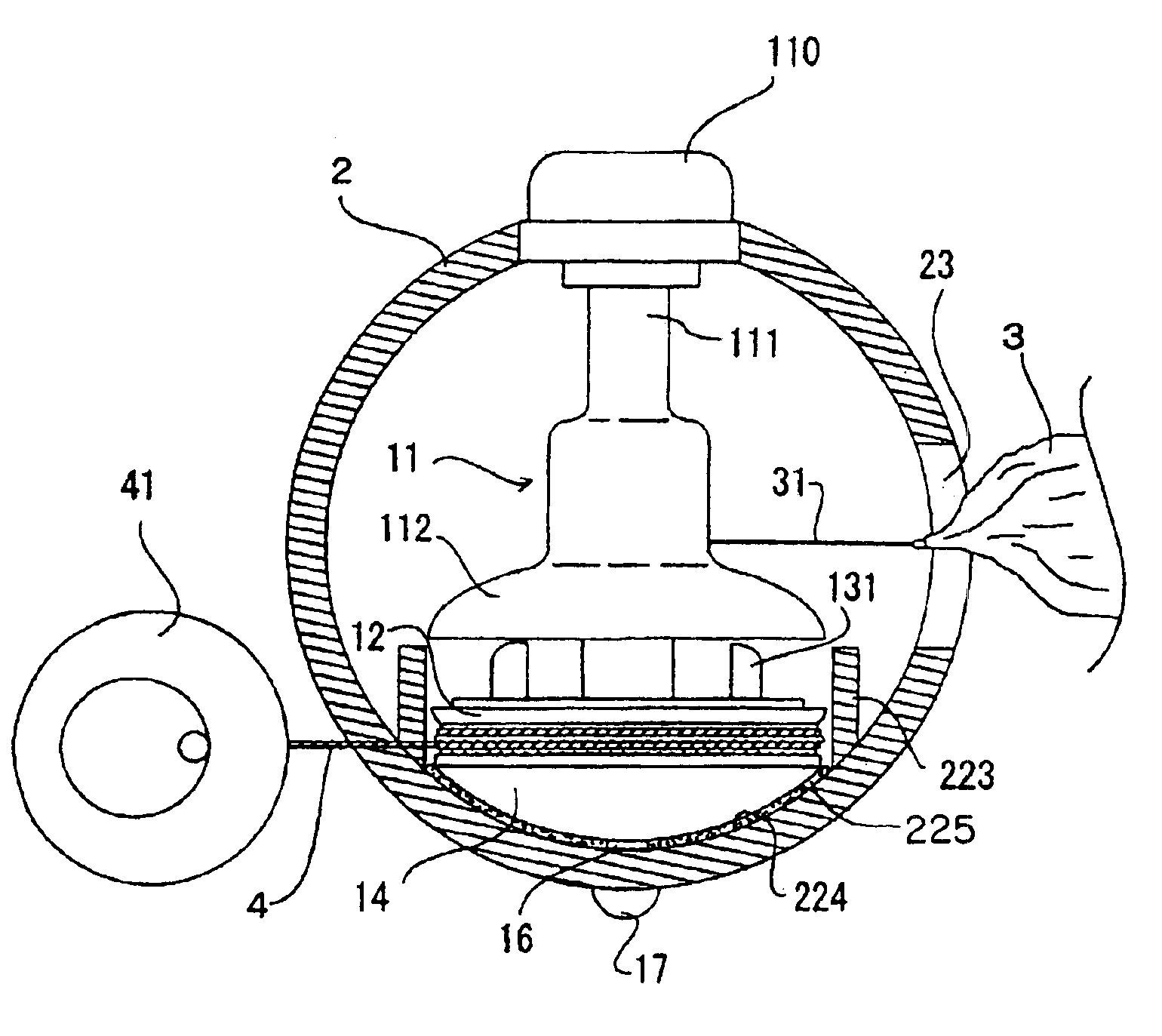

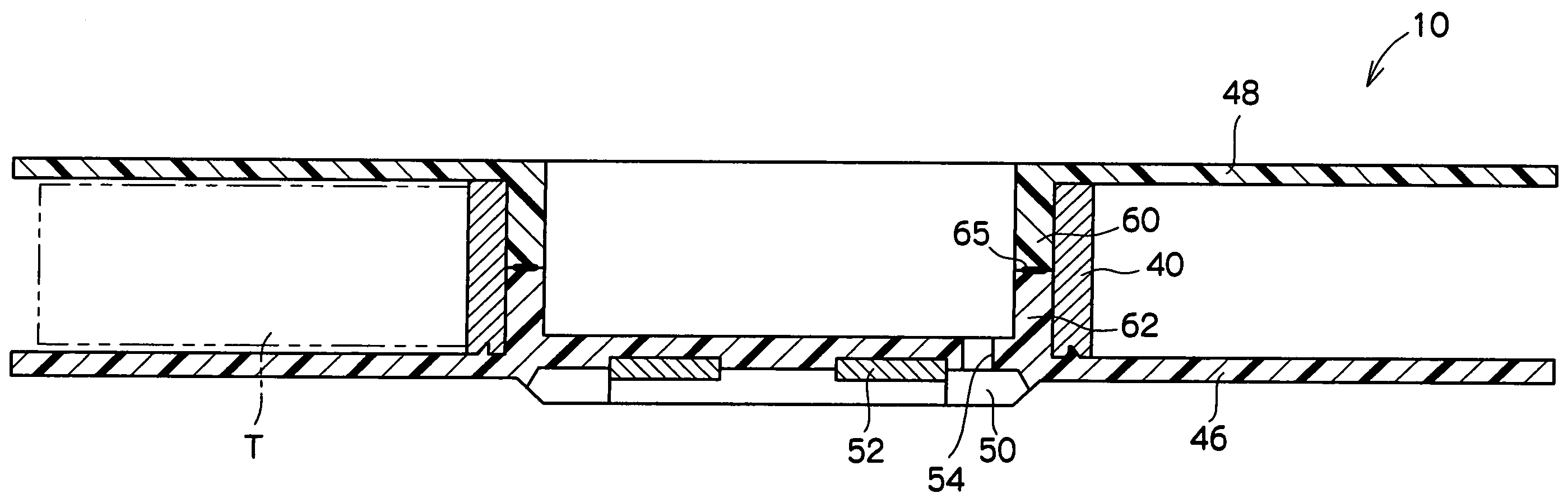

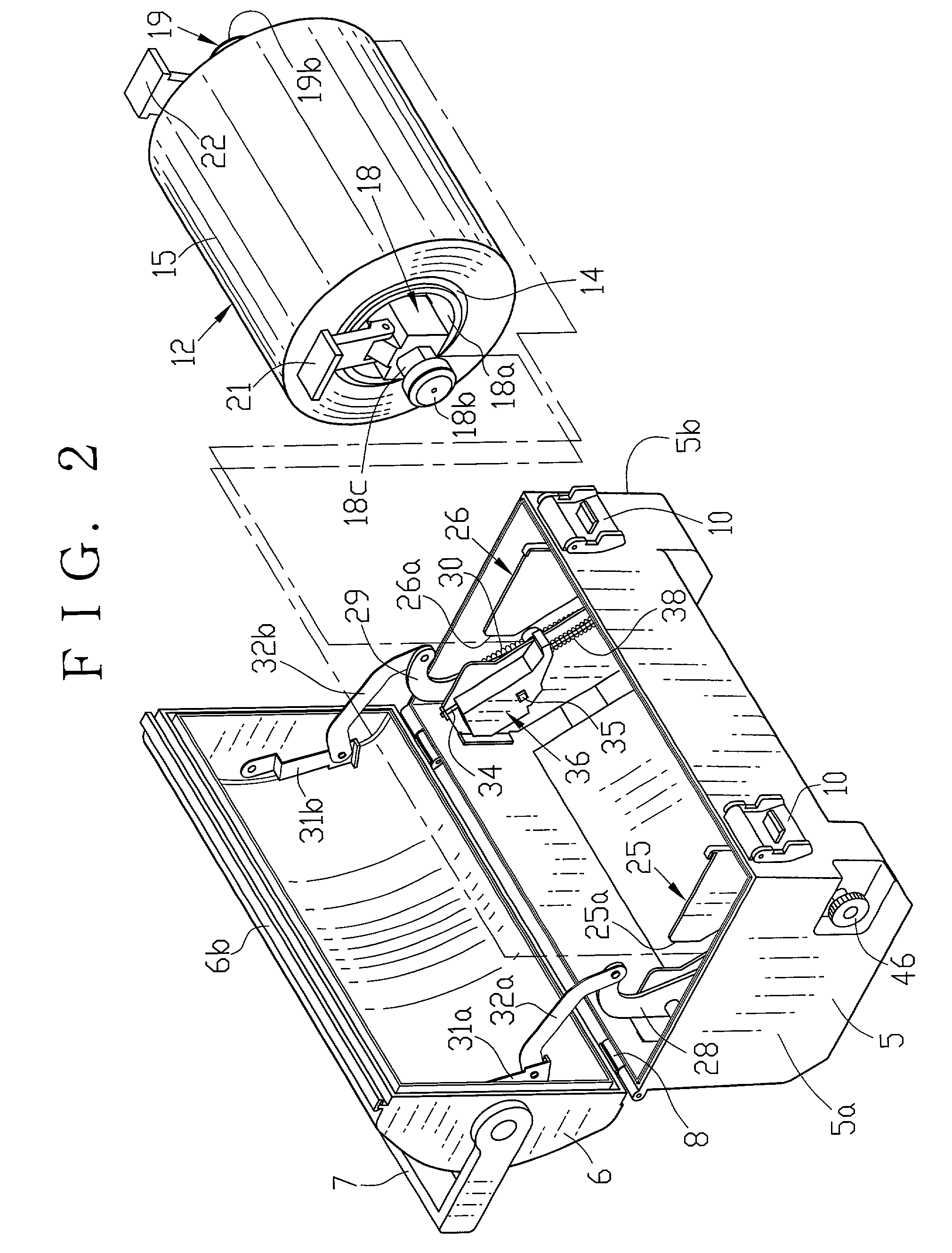

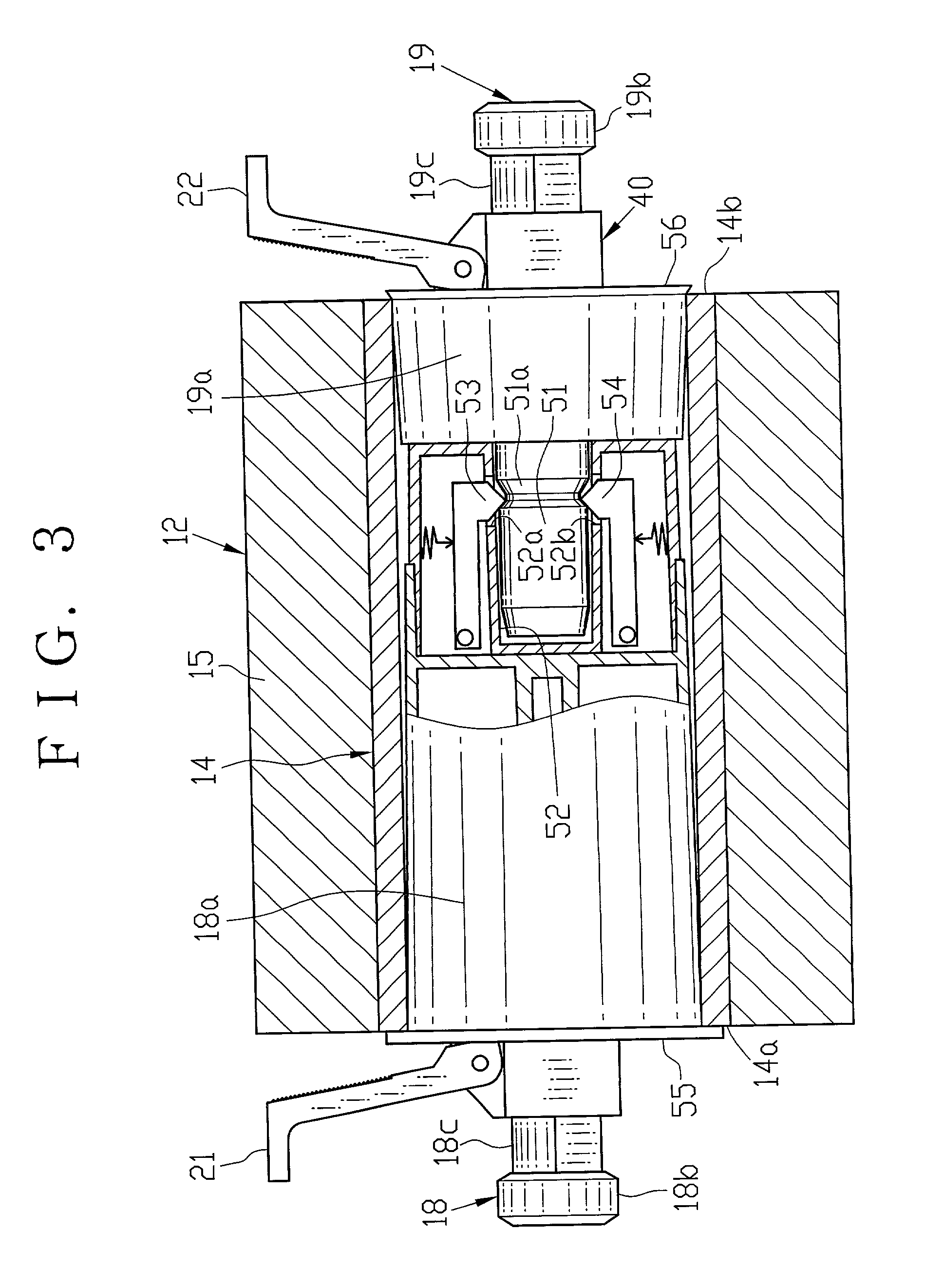

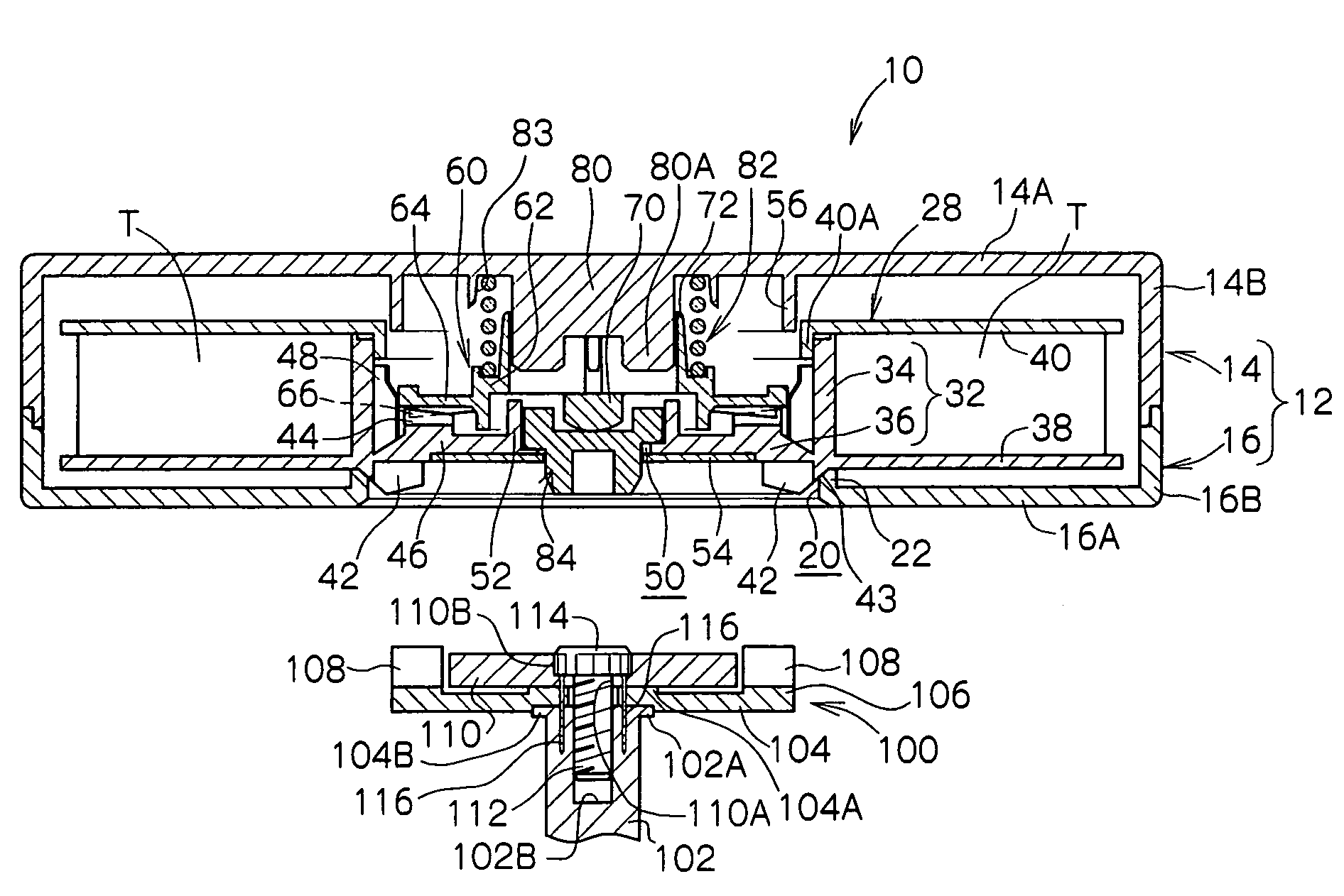

Reel lock and coupling engagement mechanisms for a cartridge

InactiveUS6318657B1Improve reliabilityShorten the timePicture changing apparatusRecord information storageCouplingMagnetic tape

A tape cartridge is provided with reliable reel lock and motor / reel coupling mechanisms whose functions are both accomplished during a single motion of the cartridge relative to the drive motor. The motor / reel coupling includes a circular set of gear teeth on the bottom of the tape reel which meshes with a complementary set of gear teeth on a motor coupling rotated by the motor when the cartridge is loaded into the tape drive and the cartridge and motor are moved towards each other. An engagement force to maintain the coupling is provided by an engagement spring in the cartridge which biases the reel towards the motor. Reel locking is accomplished by providing a second circular set of gear teeth on a top side of the tape reel which meshes with a complementary set of gear teeth provided on a slidably mounted locking bracket inside the tape cartridge. A lock spring normally biases the locking bracket towards the top of the tape reel, thus locking the reel when the cartridge is not engaged with the motor. When the cartridge and the drive motor are moved towards each other, the motor coupling engages the bottom of the tape reel, and a projection on the motor coupling extends into the tape cartridge to slide the locking bracket out of engagement with the teeth on the top of the tape reel, thereby unlocking the reel. Thus, reel unlocking and motor / reel coupling are accomplished with a single motion by reliable mechanisms.

Owner:QUANTUM CORP

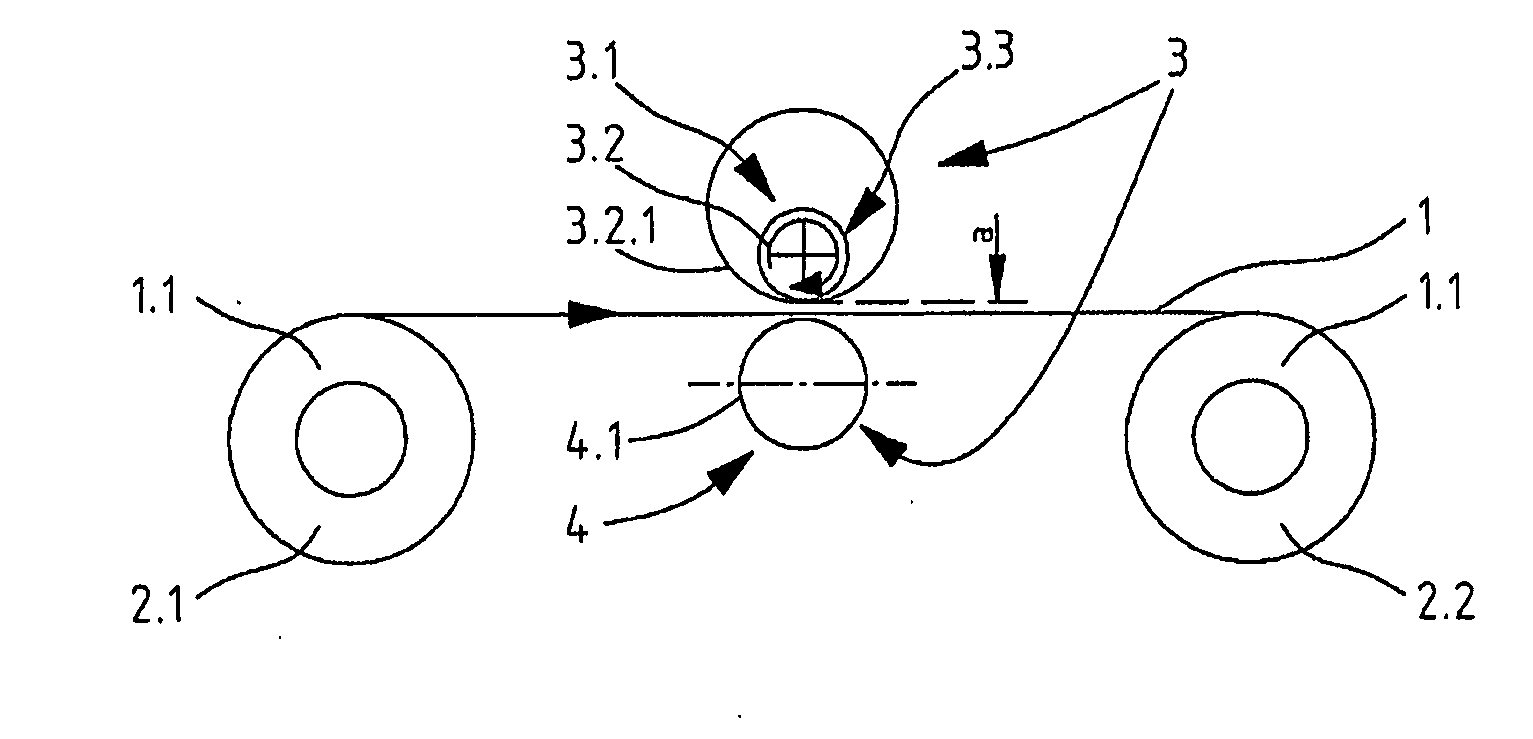

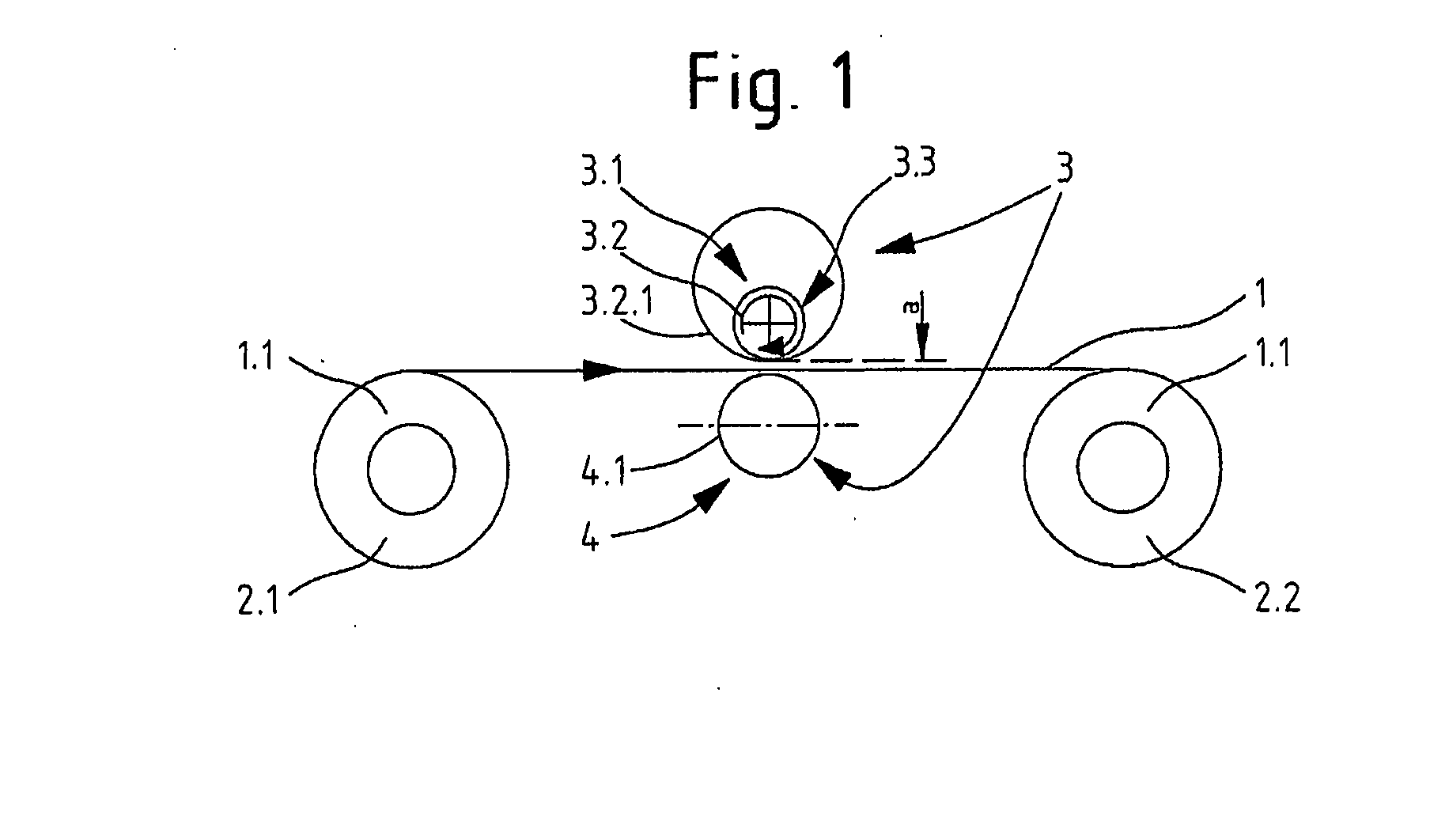

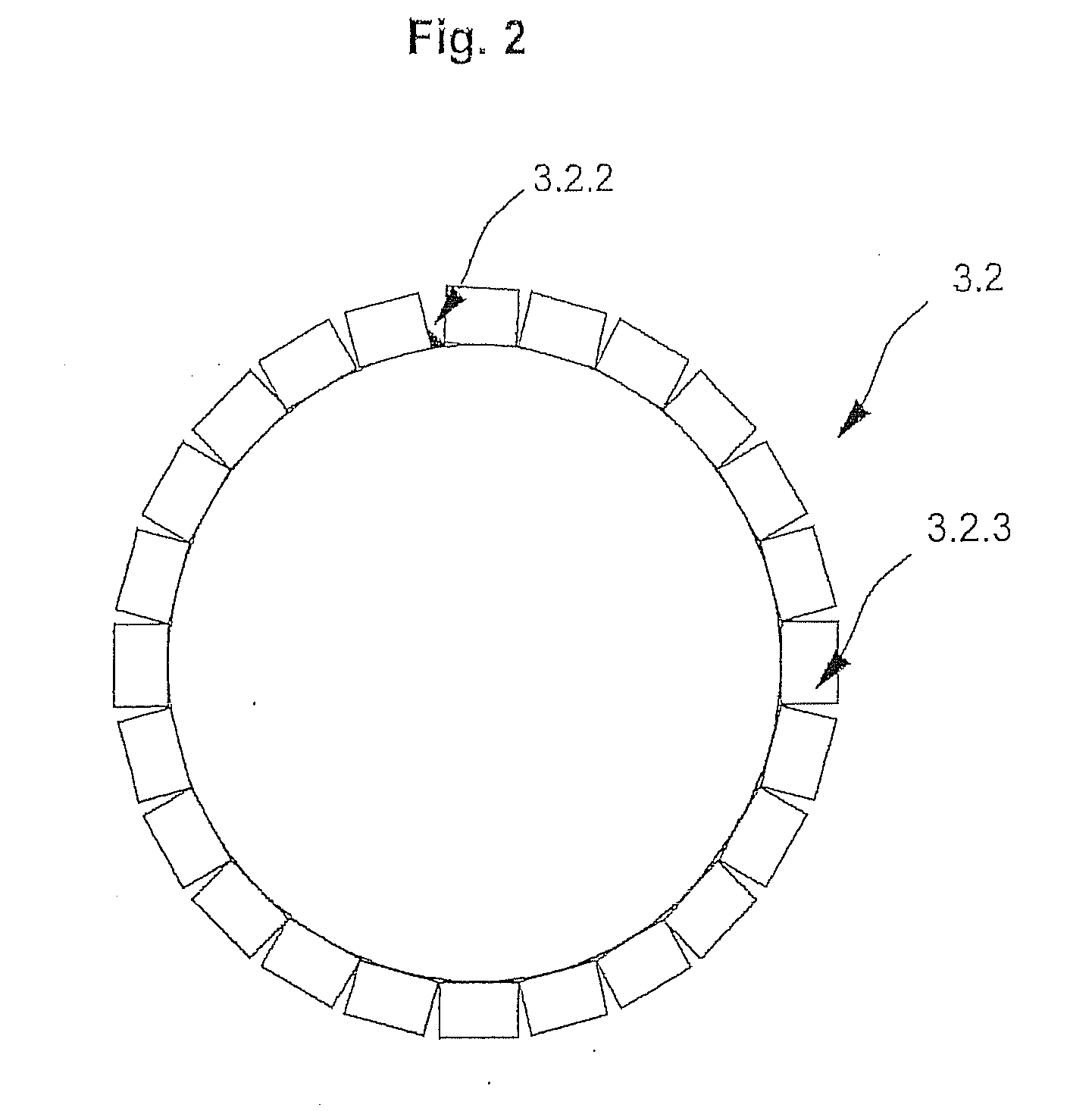

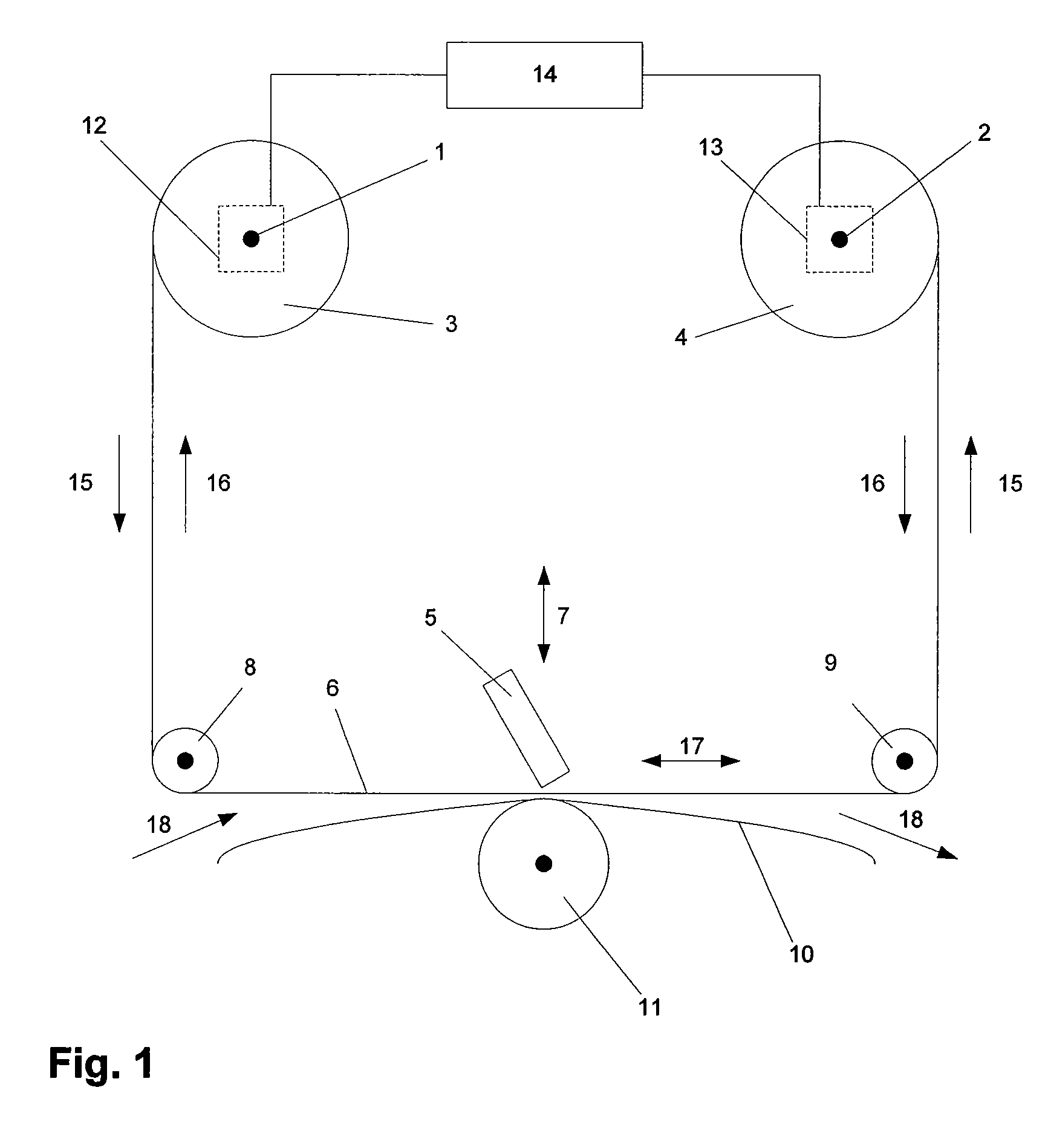

Method For Braking A Running Metal Strip And Unit For Carrying Out The Method

InactiveUS20090026303A1Simple designAC motor controlDigital data processing detailsEngineeringEddy current brake

The method and unit for braking a metal strip (1), running off a wind-out coiler (2.1) in the form of a coil (1.1) and running onto a wind-on coiler (2.2) again, are to guarantee that a surface of the metal strip remains undamaged and a full effective braking force is exerted on the metal strip (1) by means of an eddy current brake (3.1) with a rotating magnet system (3.2). The above is achieved, whereby the braking force is exerted on the metal strip (1) by means of an induced counter-torque against a support bearing (4) to one side in a non-contact manner, whereby the support bearing (4) may be embodied as a counter roller (4.1).

Owner:STEINERT ELEKTROMAGNETBAU

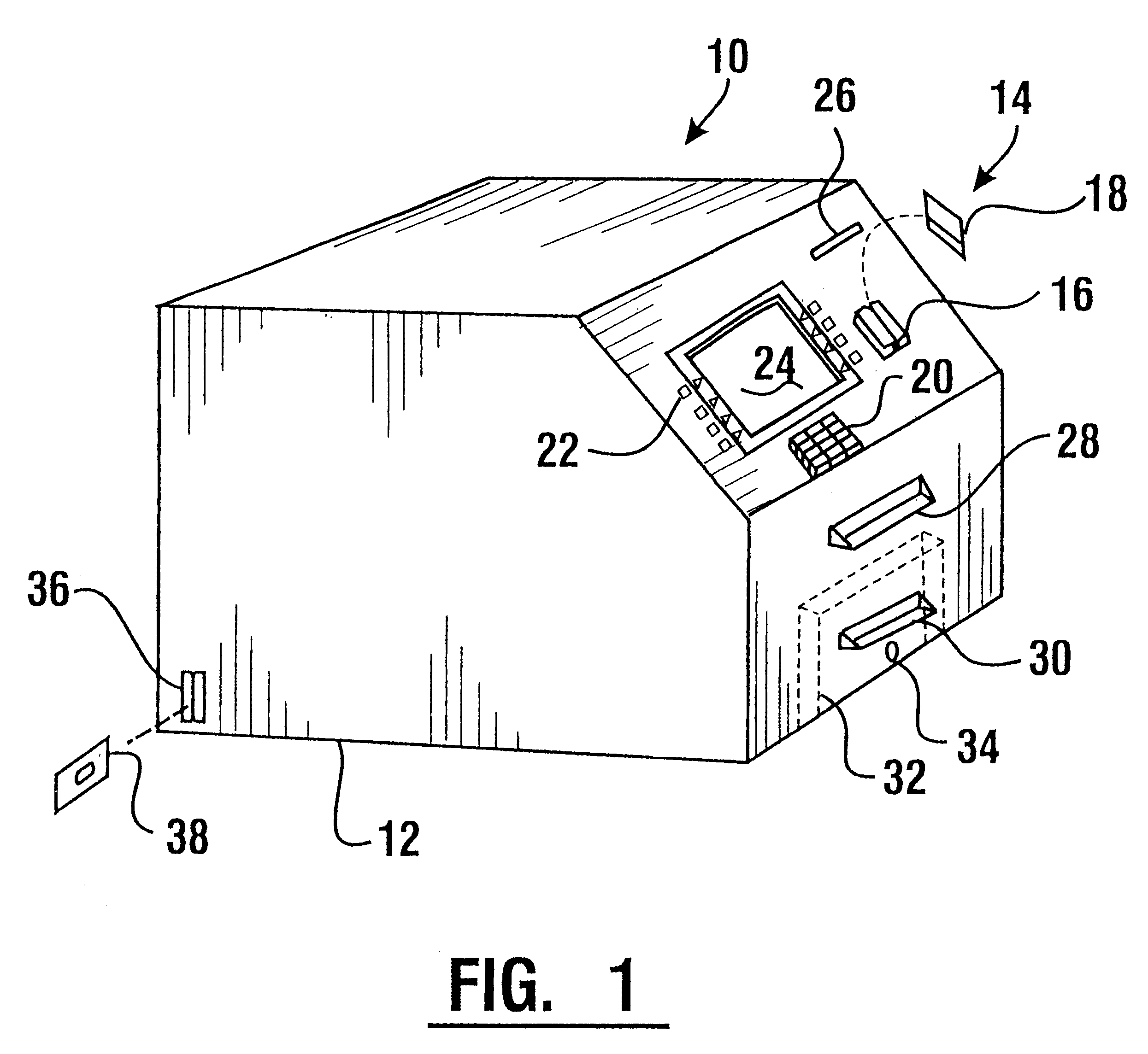

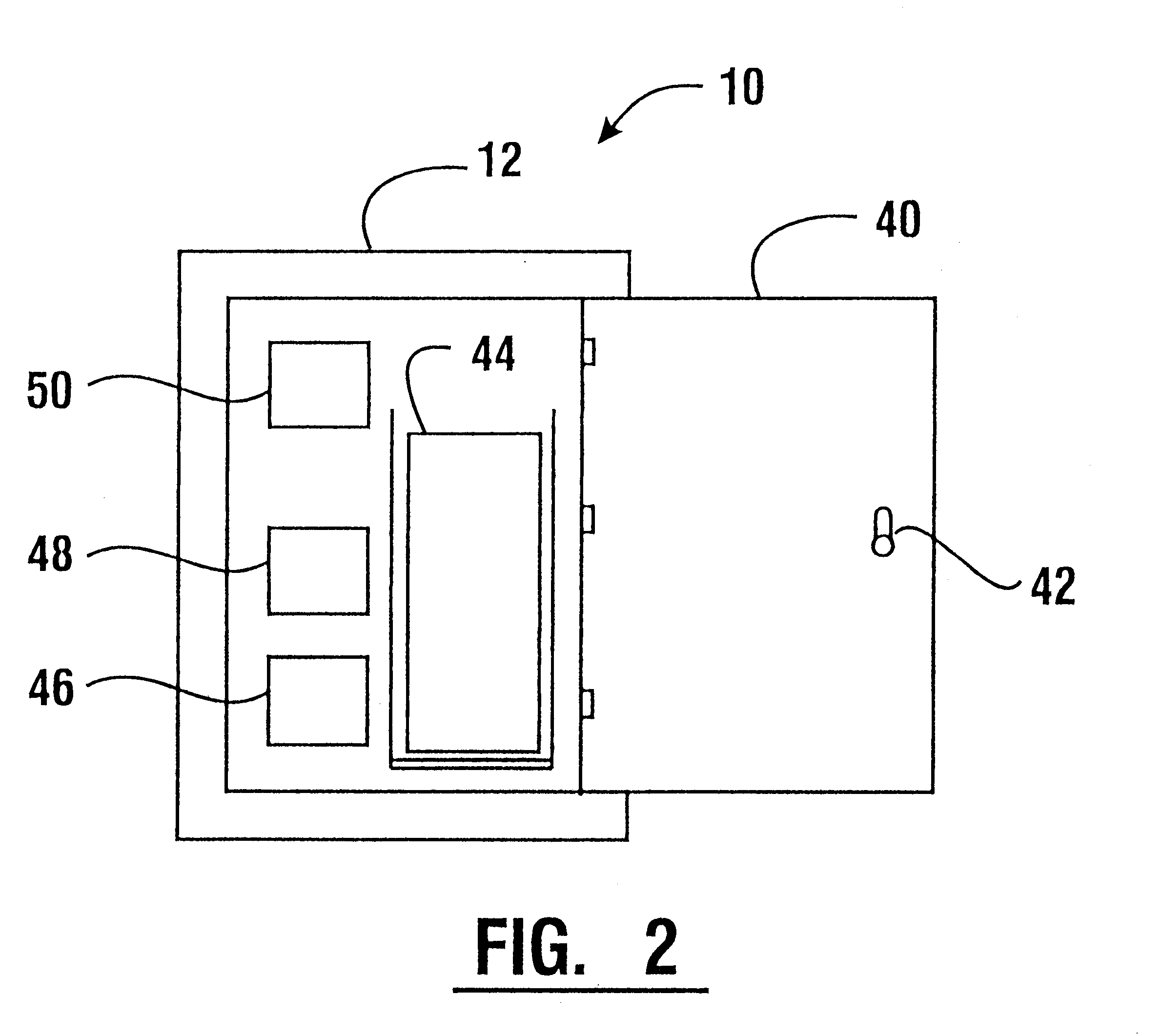

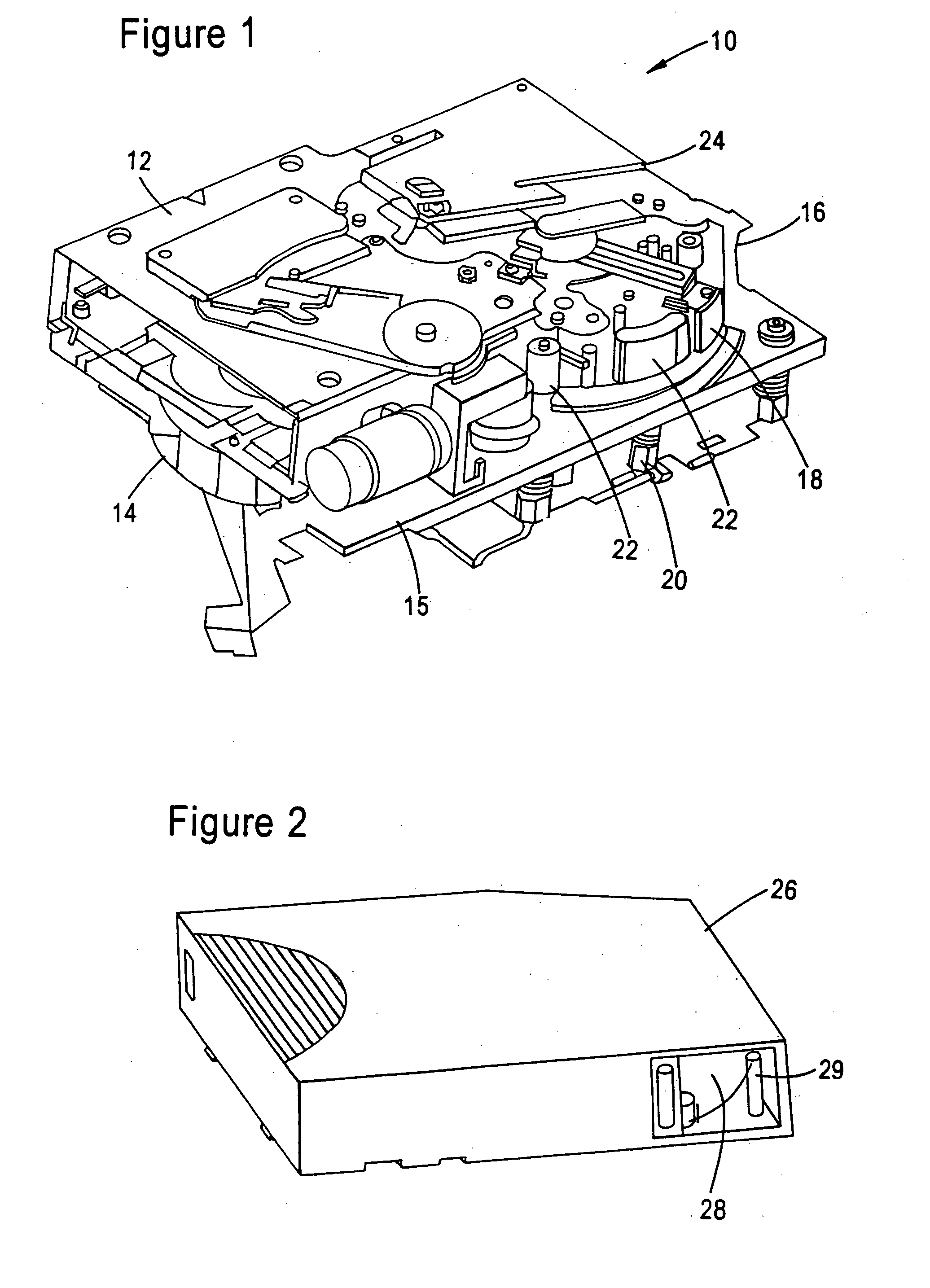

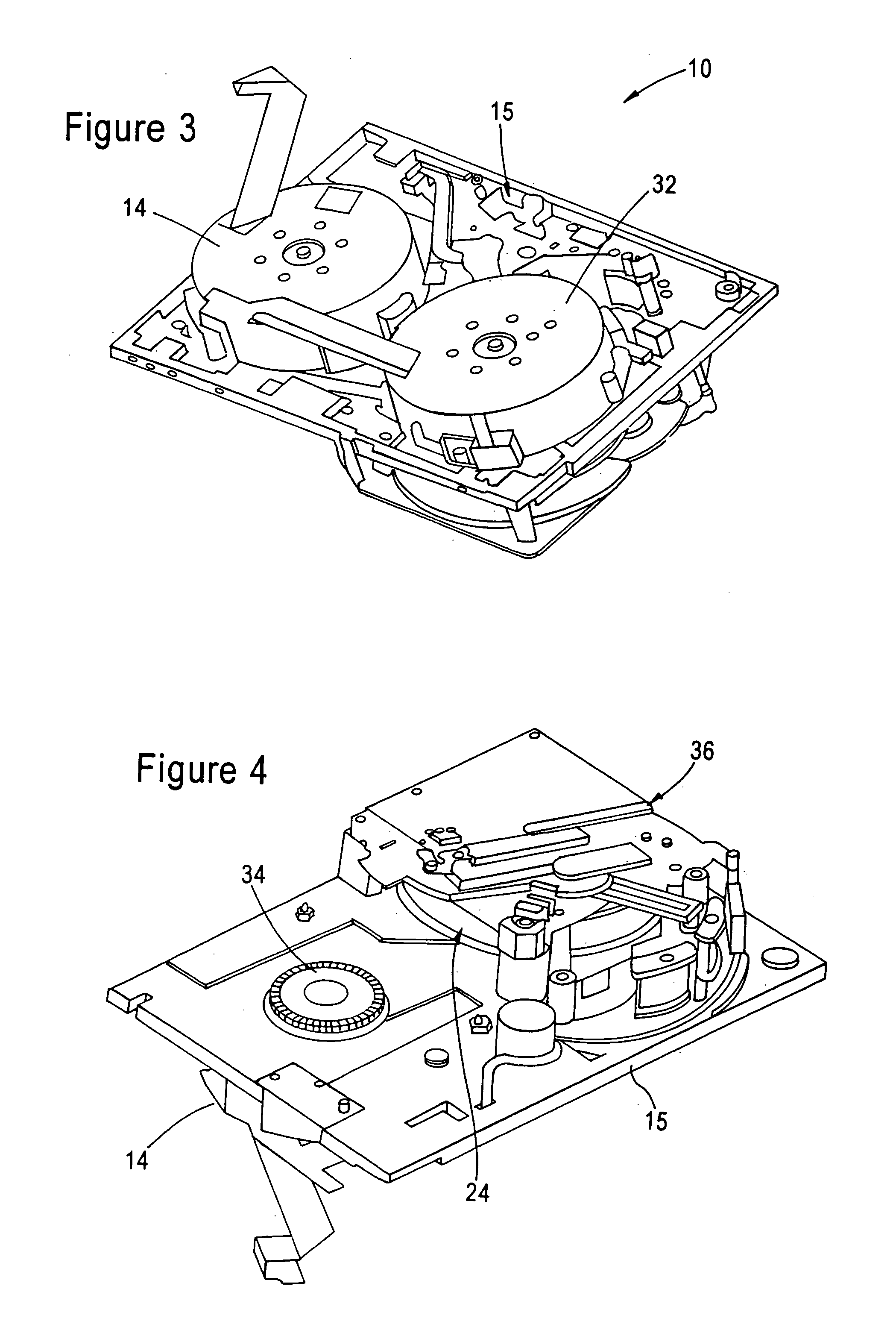

Automated transaction machine note storage and delivery mechanism

InactiveUS6227446B1Easy to installEasy to removeCamera film strip handlingRecord information storageEngineeringMechanical engineering

An automated transaction machine (10) includes a note receiving and dispensing mechanism (77). The mechanism includes a storage reel (66), a take-up reel (68) and a flexible web (70) extending between the reels. The note receiving and dispensing mechanism is housed within a note storage module (44). Notes are selectively passed into and out of the storage module to a passage area (92). The machine further includes a note inlet opening (30) and a note outlet opening (28). A note outlet transport (96) extends between the passage area and the note outlet opening. A note inlet transport (98) extends between the passage area and the note inlet opening. A note validator (58) extends adjacent to the note inlet transport for purposes of sensing the validity of notes inserted in the machine. The machine is selectively operative responsive to inputs to receive and deliver notes. The machine is further operative to enable replenishment of notes therein without accessing the interior of the housing.

Owner:DIEBOLD NIXDORF

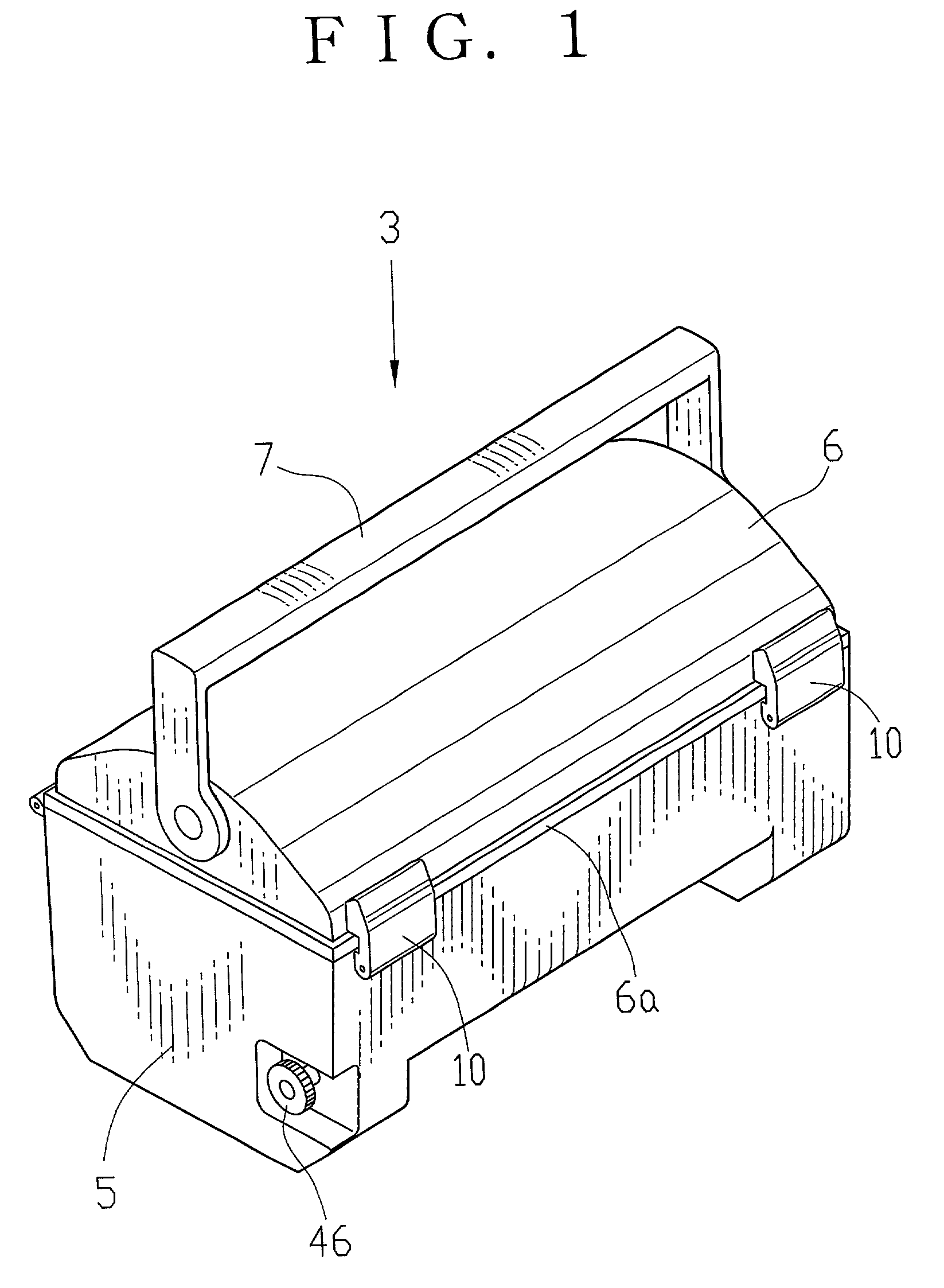

Supply magazine for recording material roll and having code reader

InactiveUS6412726B2Reliable readEasy accessPicture changing apparatusProjector film strip handlingCard readerMechanical engineering

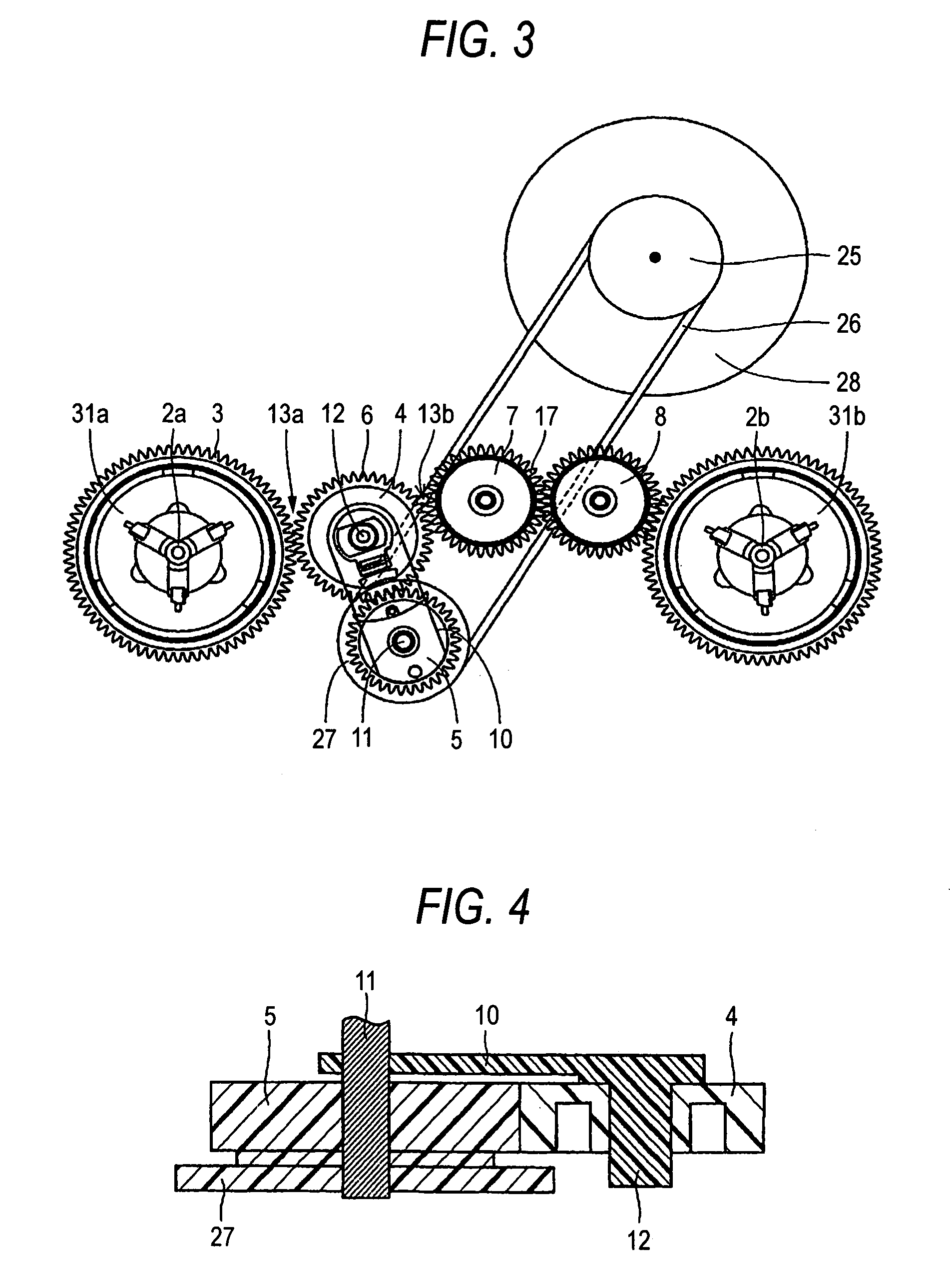

A recording paper roll includes a tubular spool shaft having first and second end faces. Thermosensitive recording paper is wound about the tubular spool shaft in a roll form. A code is formed in the first end face. For use with the recording paper roll, a supply magazine includes two roll holders secured to the spool shaft. First and second support plates are arranged in an axial direction of the roll holder, and support the roll holder in a rotatable manner. Guide cutouts are formed in the first and second support plates, receive first and second ends of the roll holder, and move the roll holder in a predetermined direction according to a decrease in a diameter of the recording material roll in use of the recording material. A code sensor reads the code from the first end face. A sensor shifter constituted by a depression portion moves the code sensor in the predetermined direction with the two roll holders.

Owner:FUJIFILM HLDG CORP +1

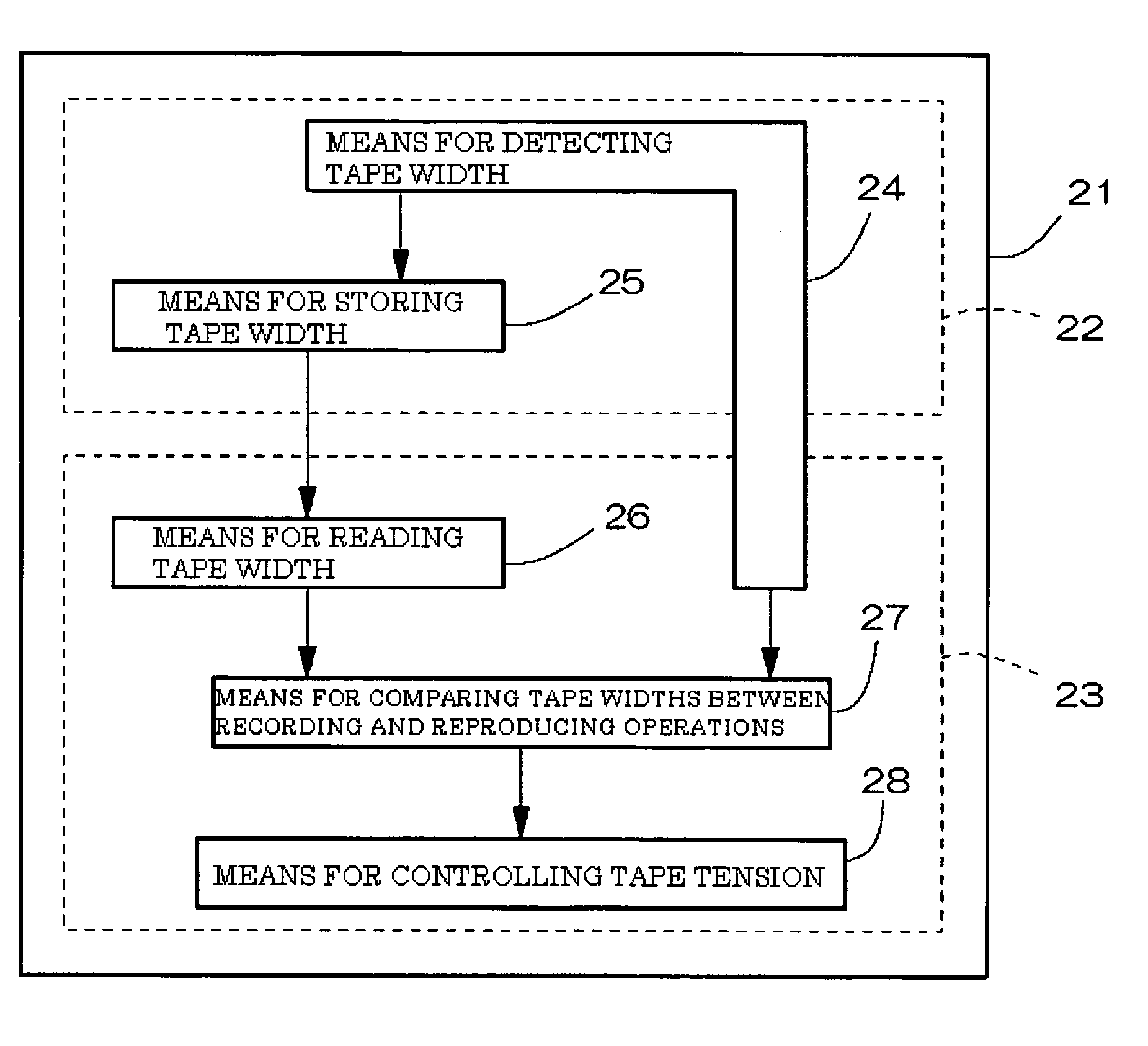

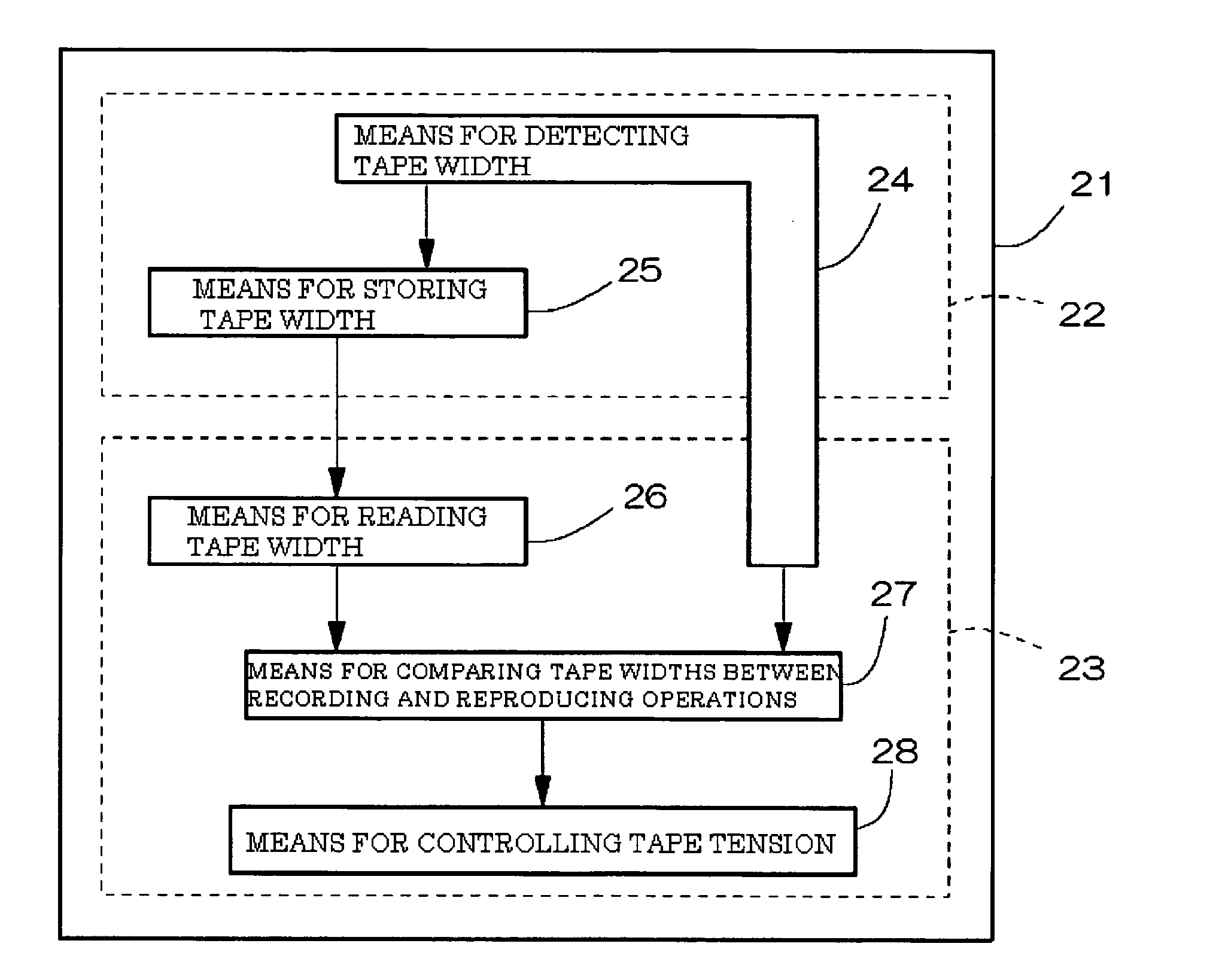

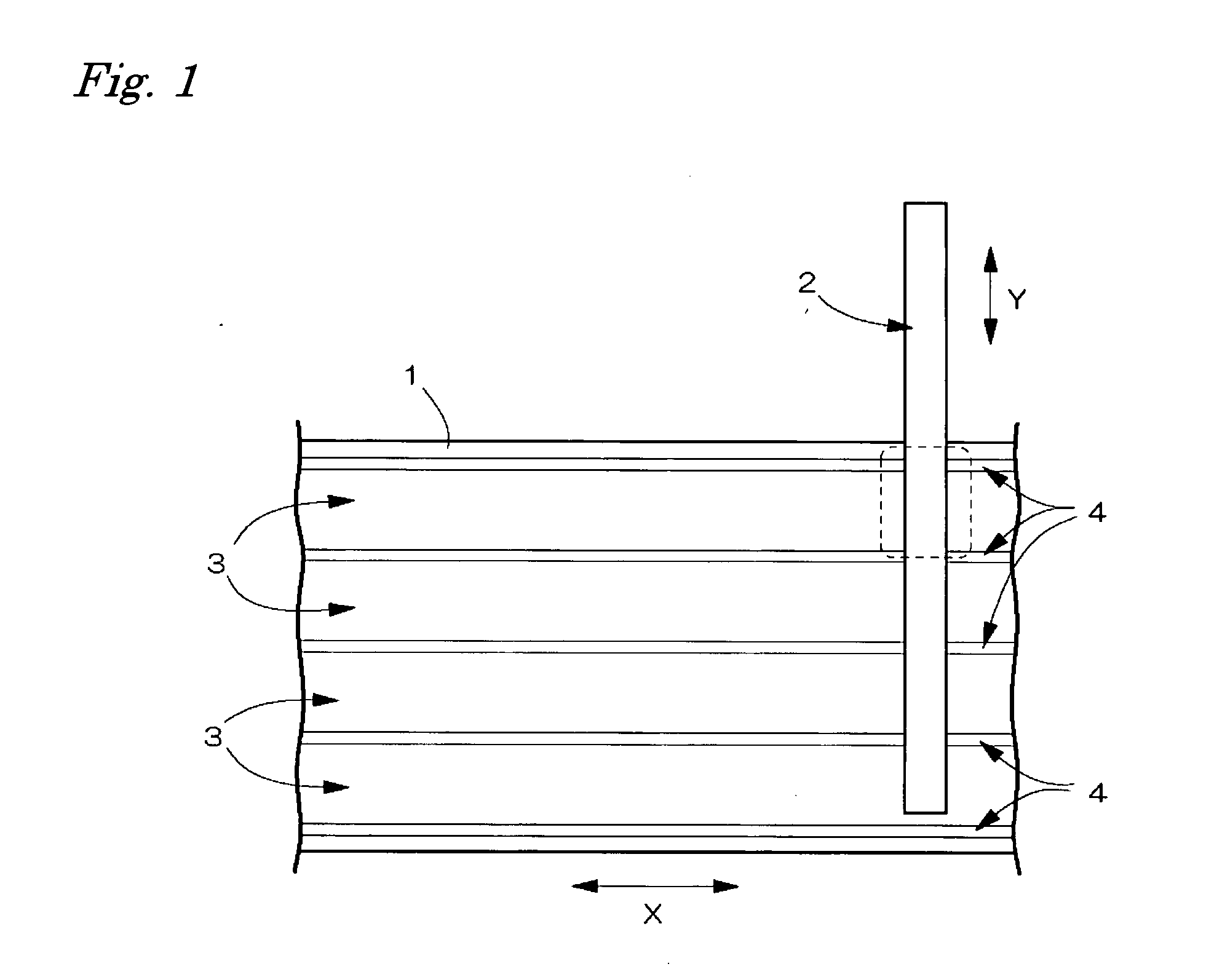

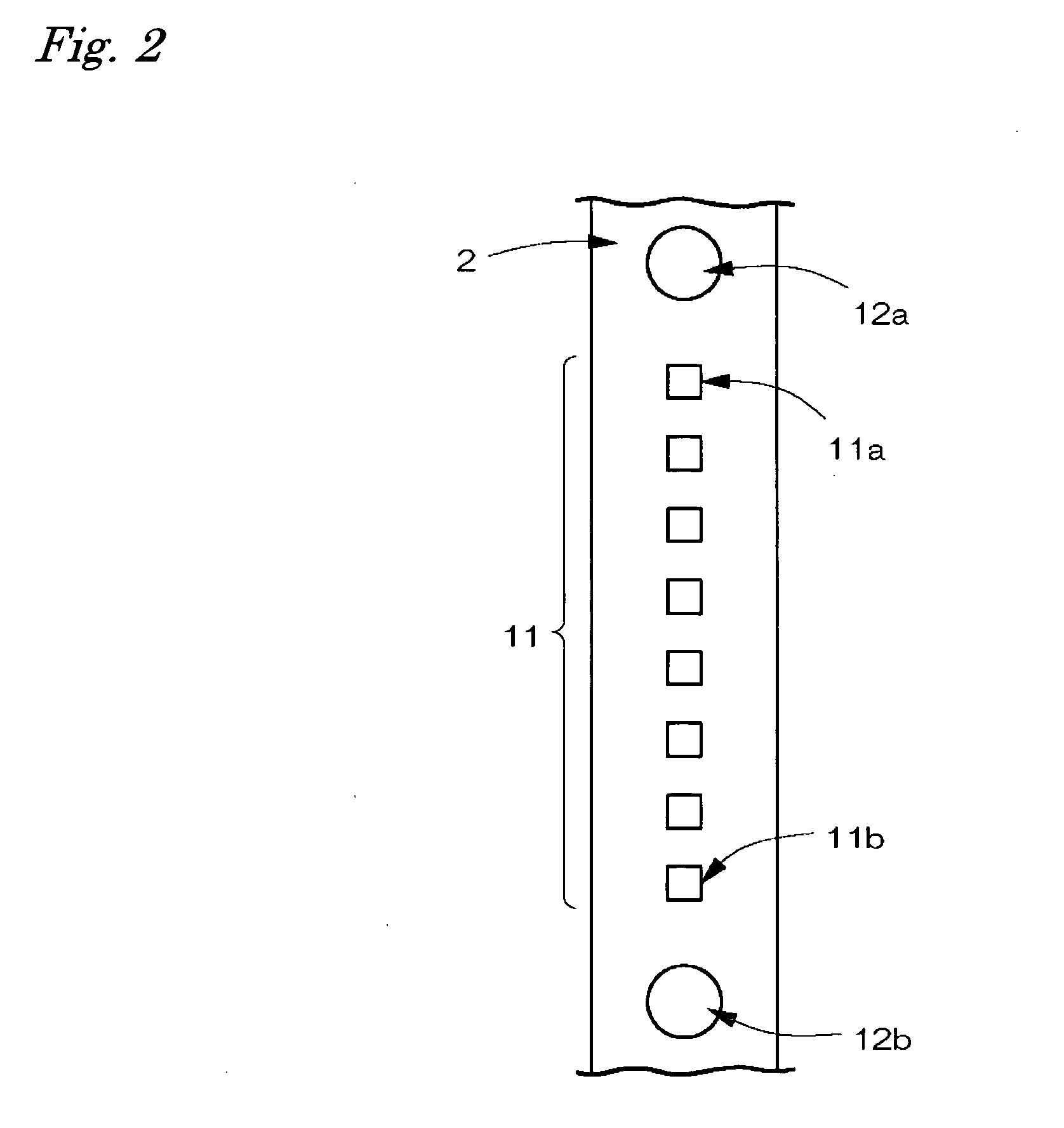

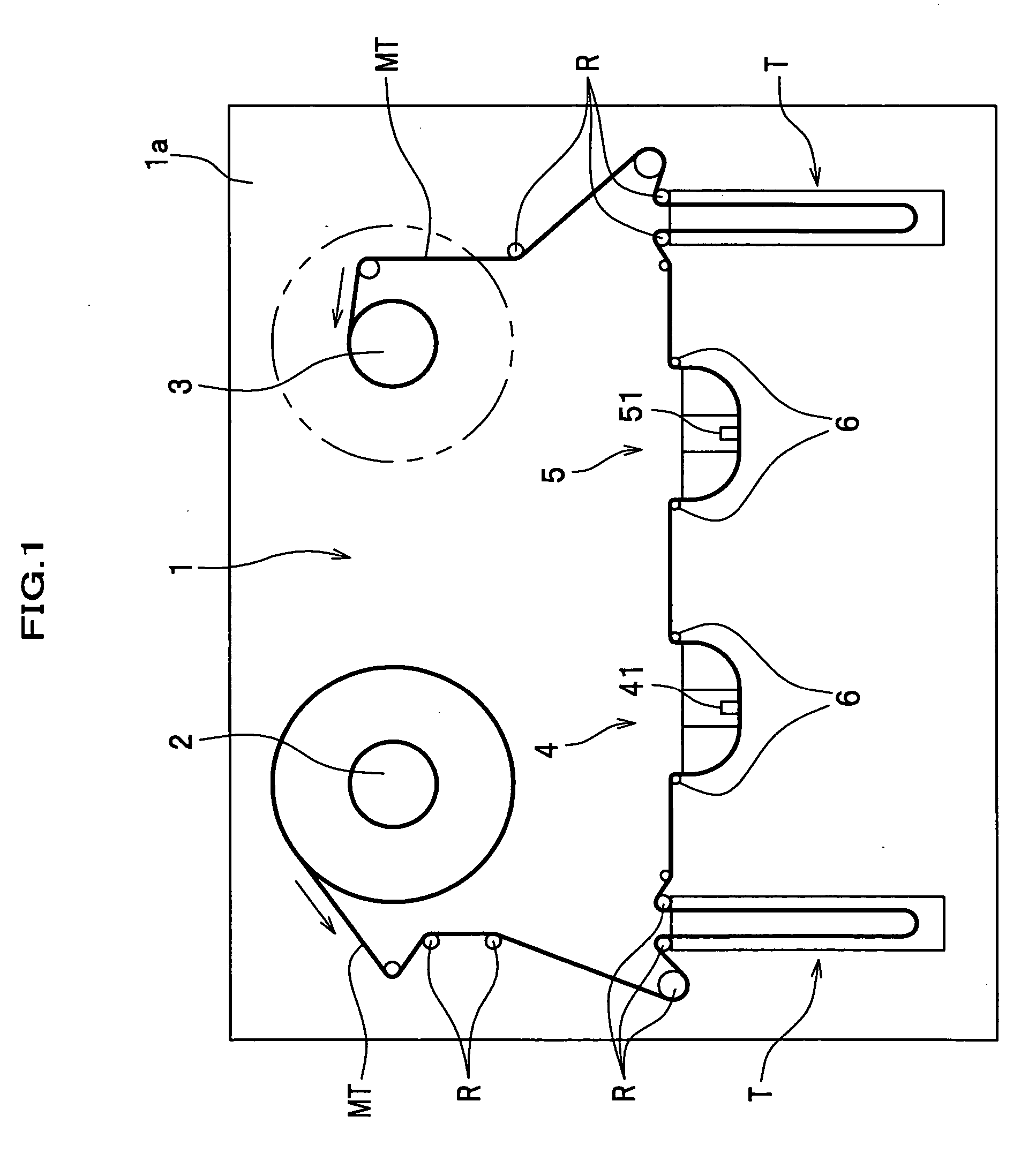

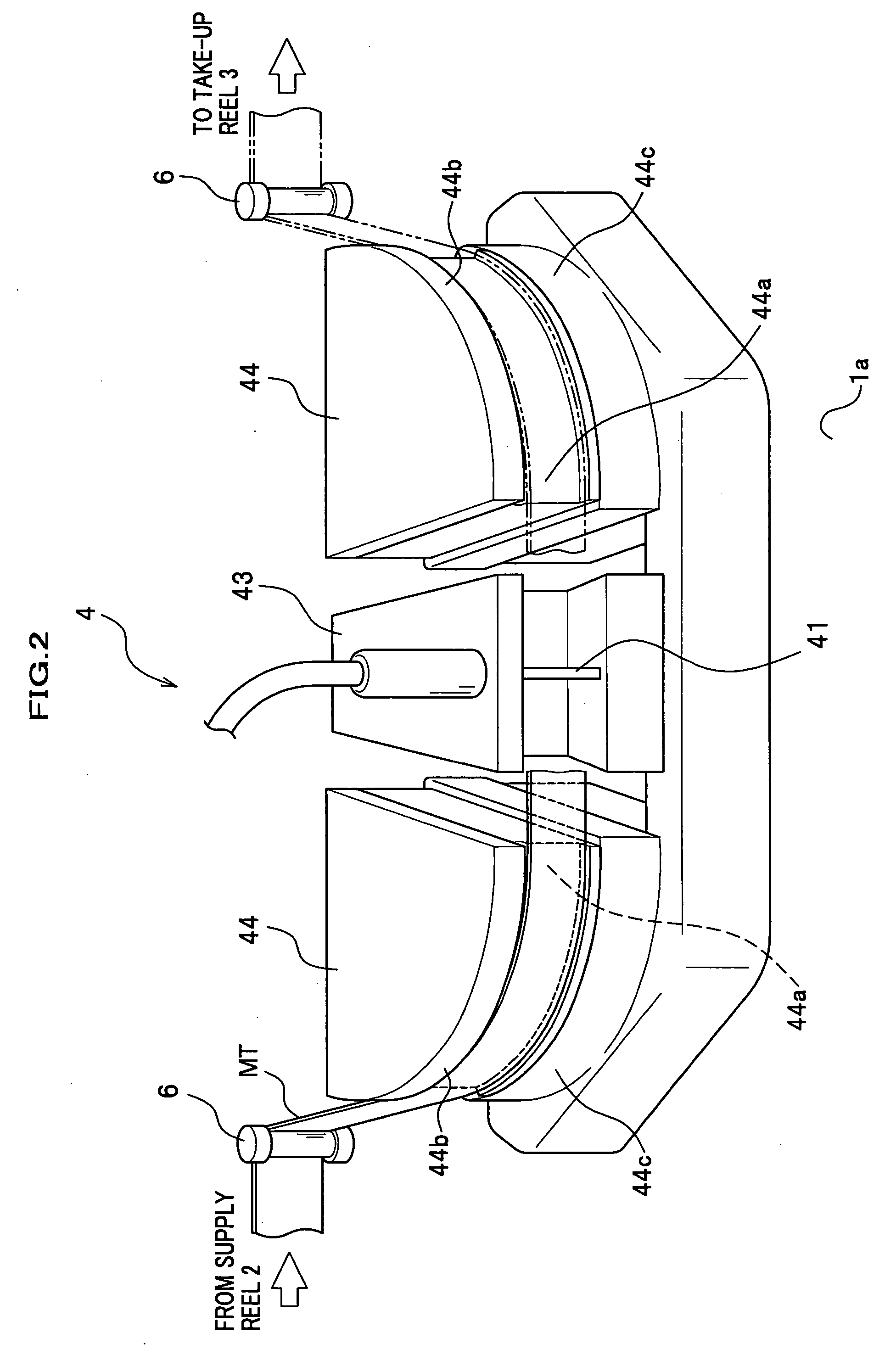

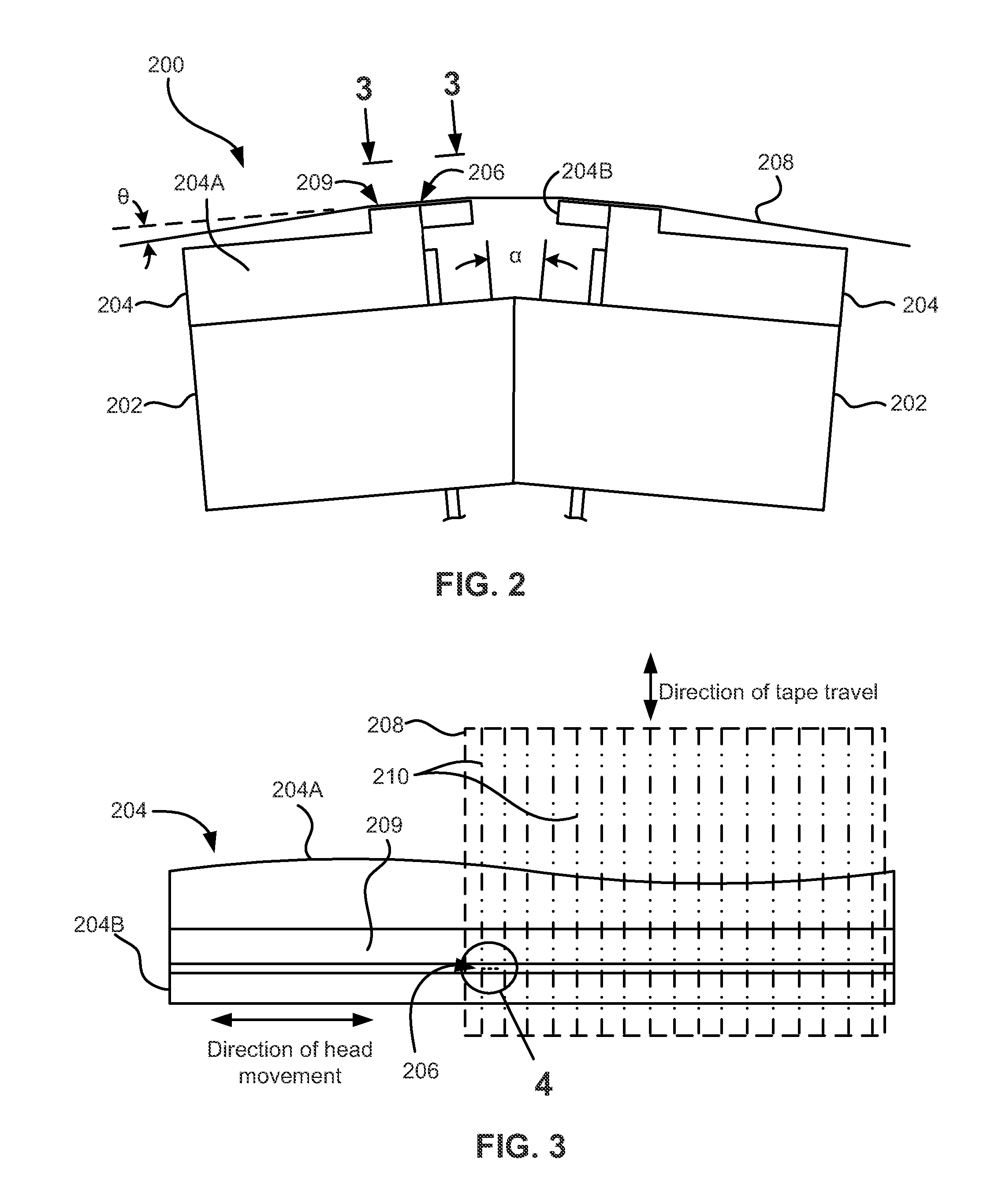

Recording/ reproducing method and recording/reproducing apparatus for magnetic tape

A recording / reproducing method and a recording / reproducing apparatus for magnetic tapes are provided as a recording / reproducing technique suitable for recording density enhancement of magnetic tapes. The method and apparatus are capable of correctly recording and reproducing data without causing errors even with occurrence of size changes in the widthwise direction of a magnetic tape. In the recording / reproducing method for magnetic tapes in which data tracks and servo tracks are provided, a tape width is detected and a value of the tape width is stored during data recording, and data reproduction is performed while tape tension is controlled so that the tape width during data reproduction is maintained equal to the tape width during data recording.

Owner:FUJIFILM CORP

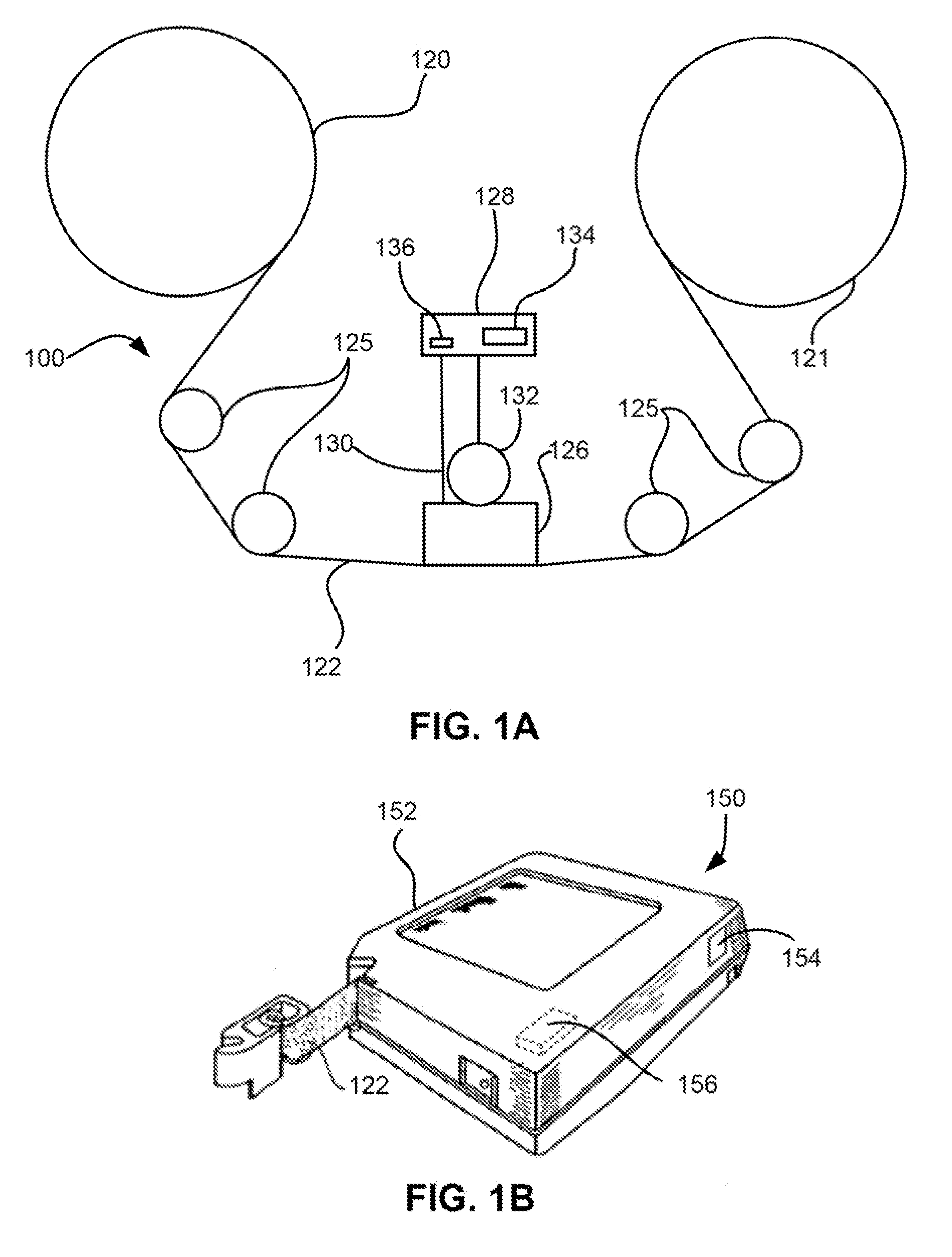

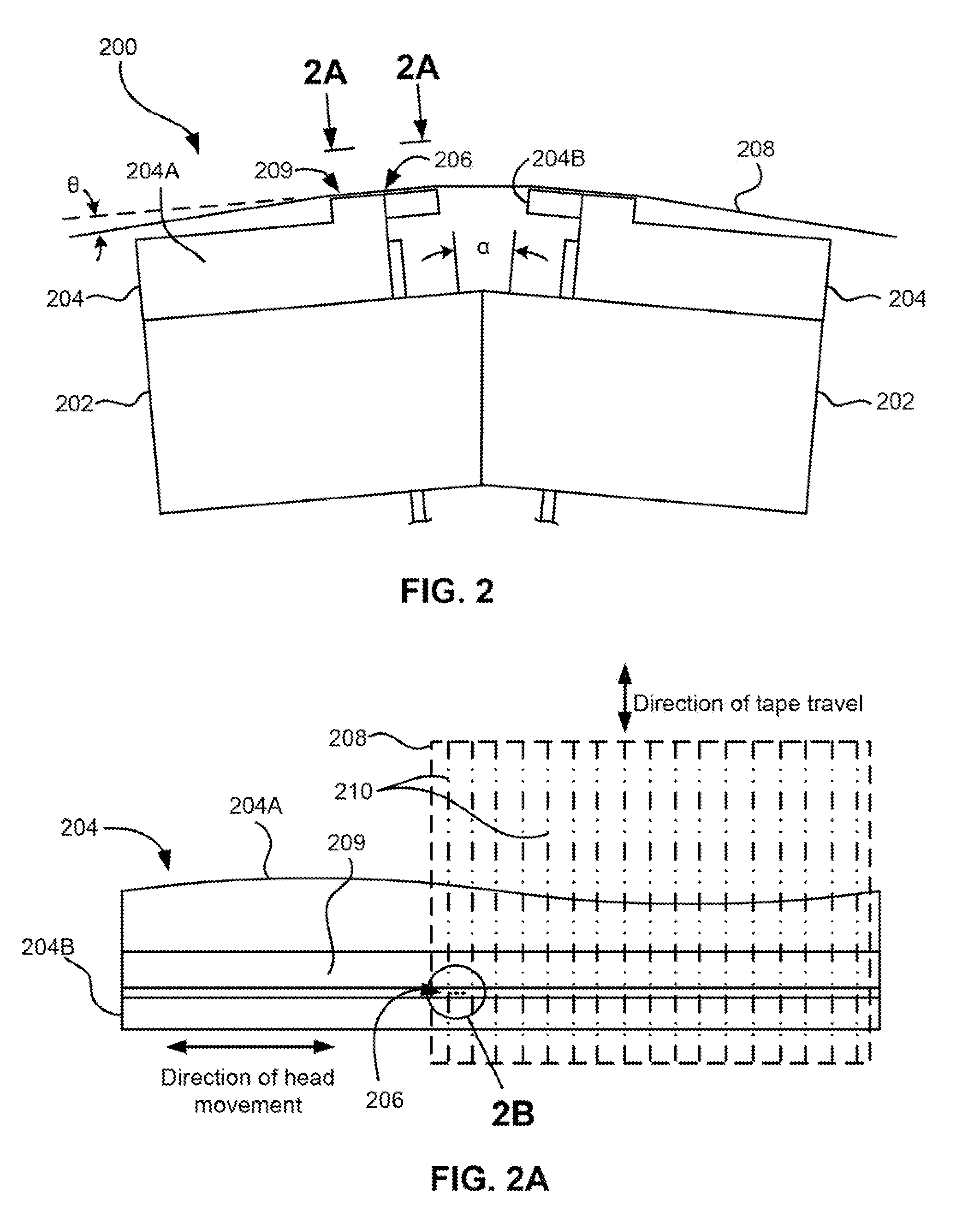

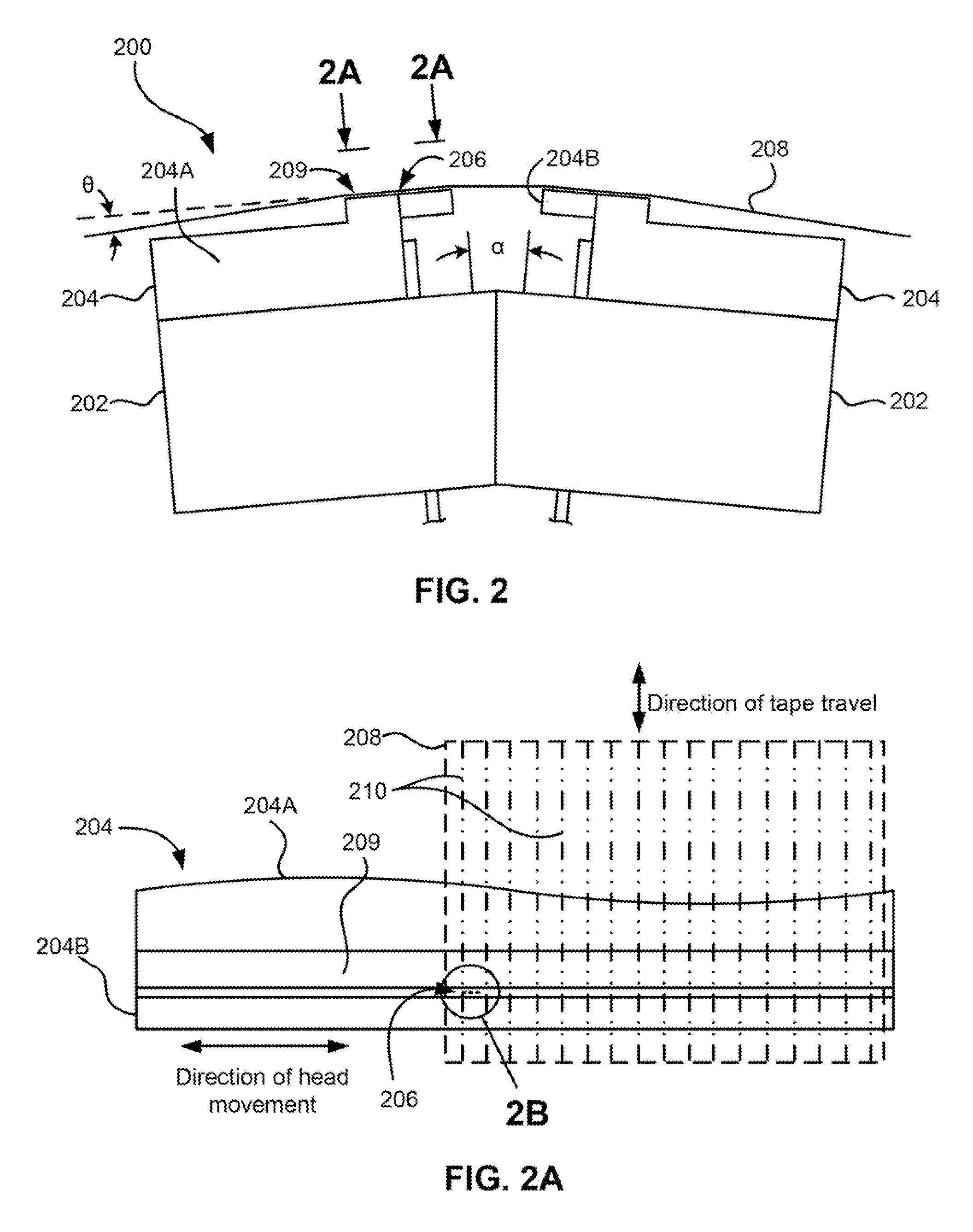

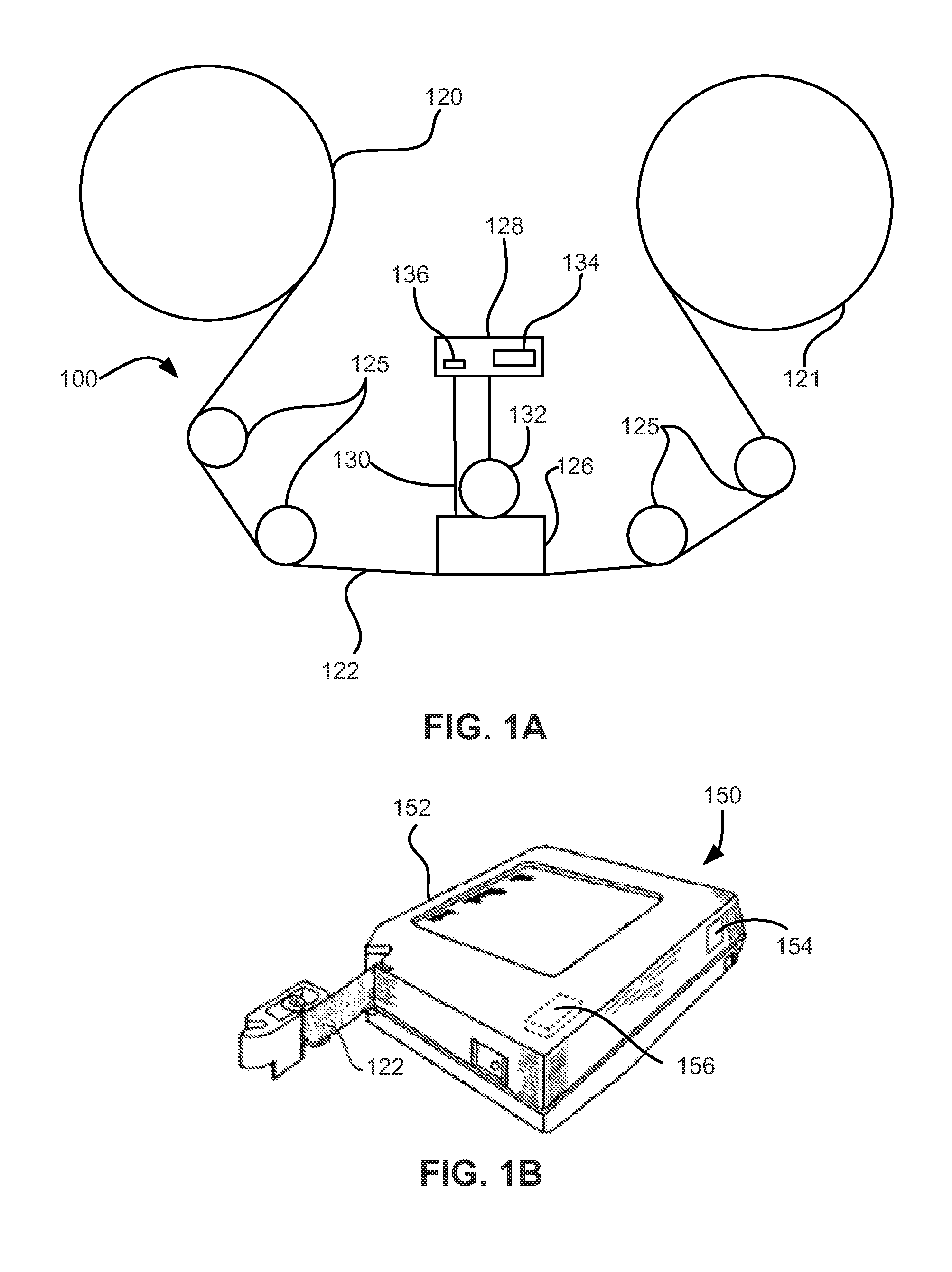

Quasi-statically tilted head having offset reader/writer transducer pairs

ActiveUS20150170691A1Driving/moving recording headsAlignment for track following on tapesInstabilityTransducer

Aspects of the present invention relates generally to apparatuses with transducer arrays having offset transducers. Various embodiments are particularly suited to tilting for tape dimensional instability compensation. Some embodiments include dual servo readers in a given array.

Owner:IBM CORP

Lockable chain winder

InactiveUS6093124AAssisted movementOvercome disadvantagesGearboxesProjector film strip handlingFree rotationSprocket

Owner:LOCKWOOD SECURITY PRODS

Windup type storage container

InactiveUS6921040B2Easy to operateEasily drawn outTravelling sacksTravelling carriersEngineeringConductor Coil

A wind-up type storage container is provided that can easily wind up and store a small or large item, such as a bag, a flag, a sheet, rainwear, etc. and from which such items can be easily pulled out. In order to pull in an item to be stored, a button is pressed to move a wind-up shaft downwardly. A pawl receiving portion is engaged with engaging pawls, and a reel portion is interlocked with a winding shaft. When a reel cord is pulled out, the reel portion is rotated, and the item to be stored is pulled to and wound around a winding shaft. When the button is released, the reel cord is rewound by a restoring force of a power spring. The reel cord is repetitively pulled until the item to be stored is completely stored in the main body capsule.

Owner:K I C KIKAKU

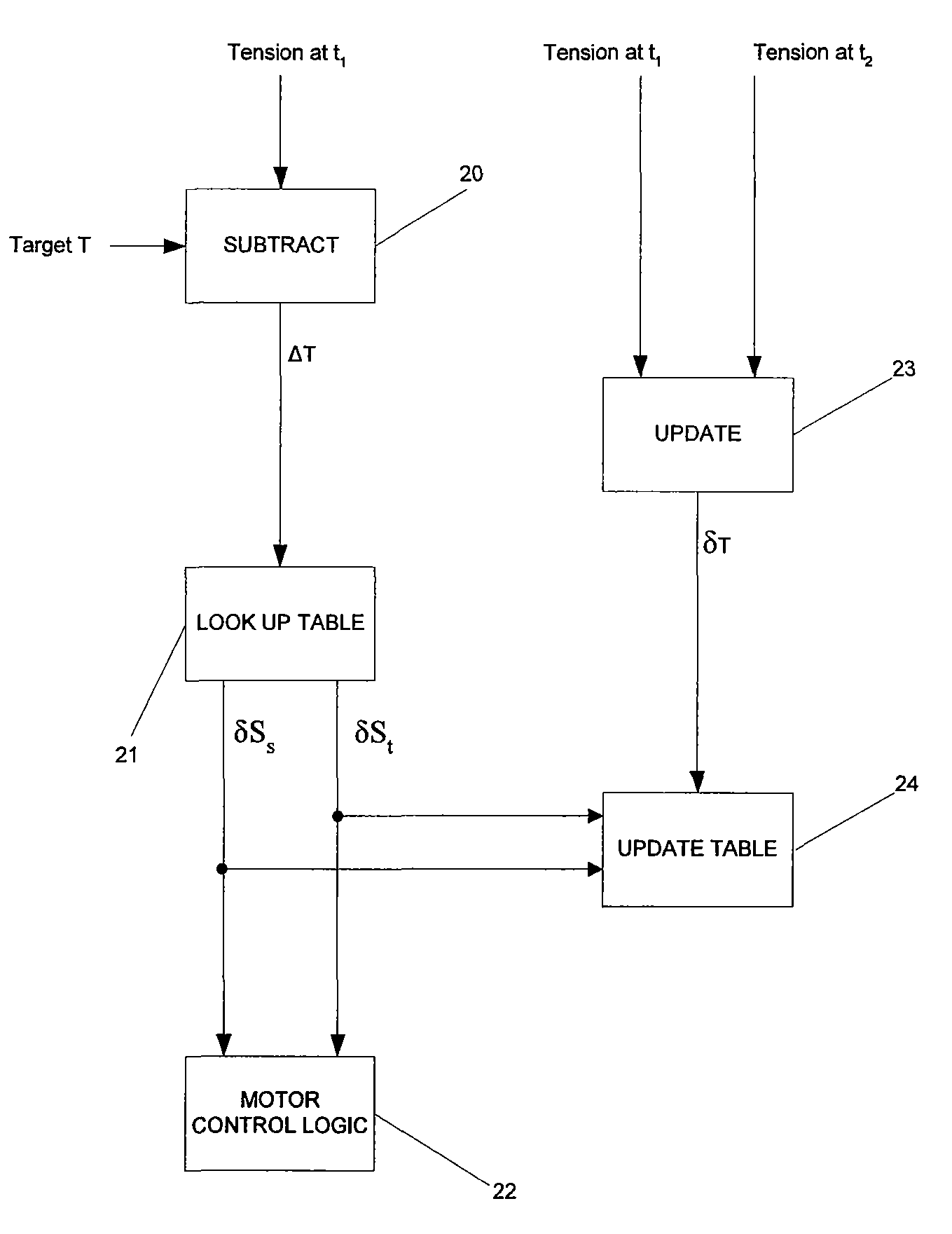

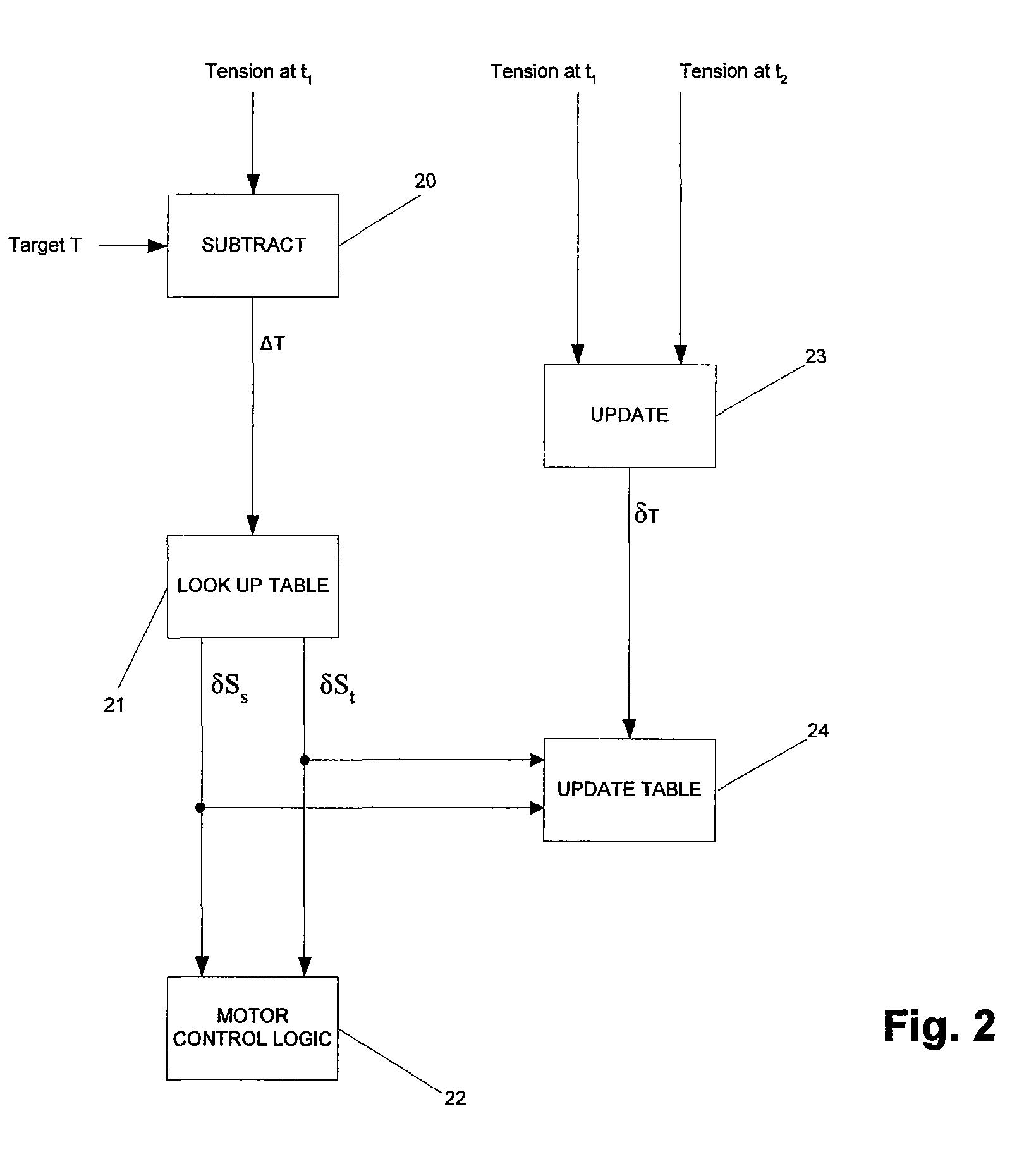

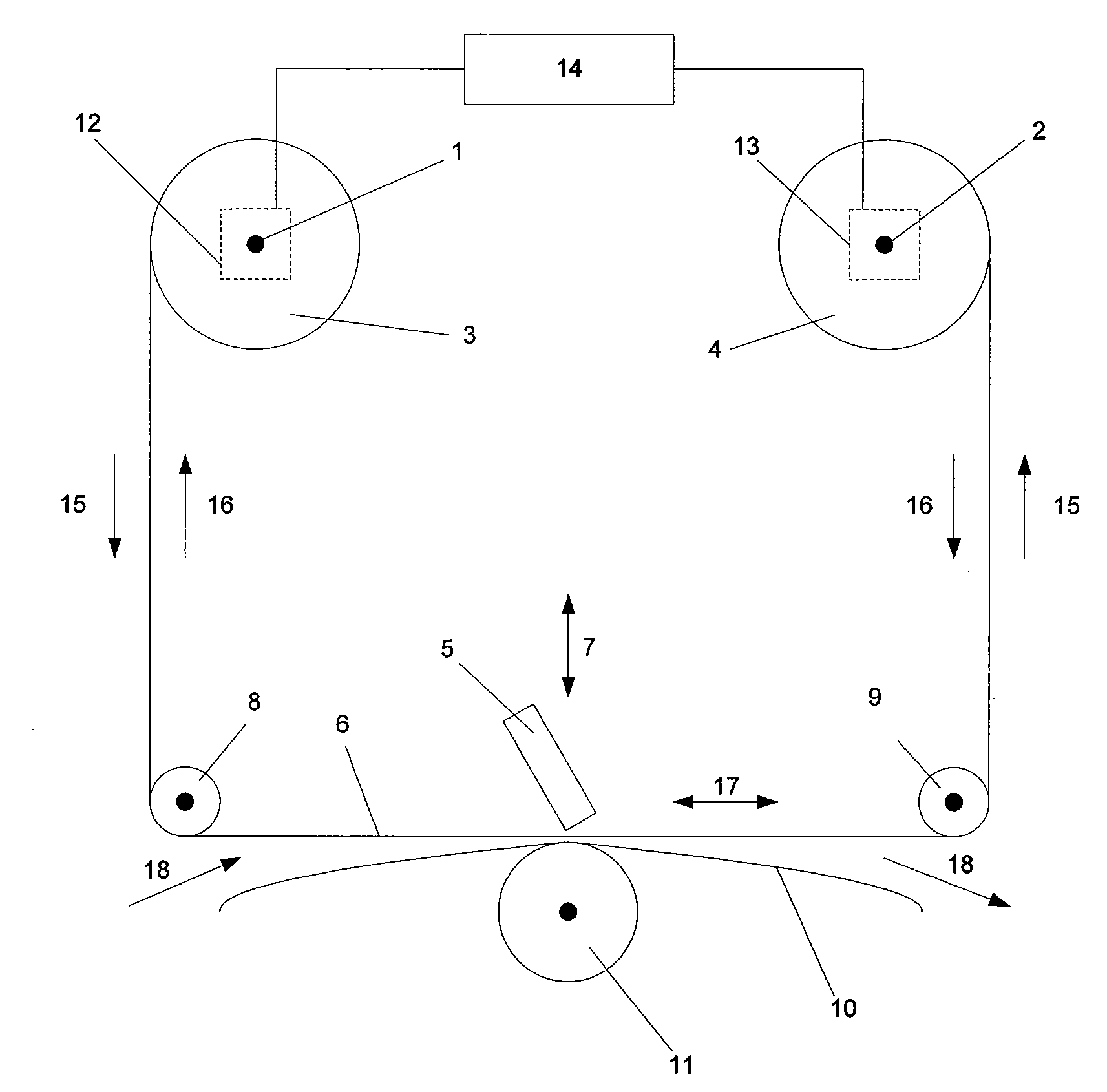

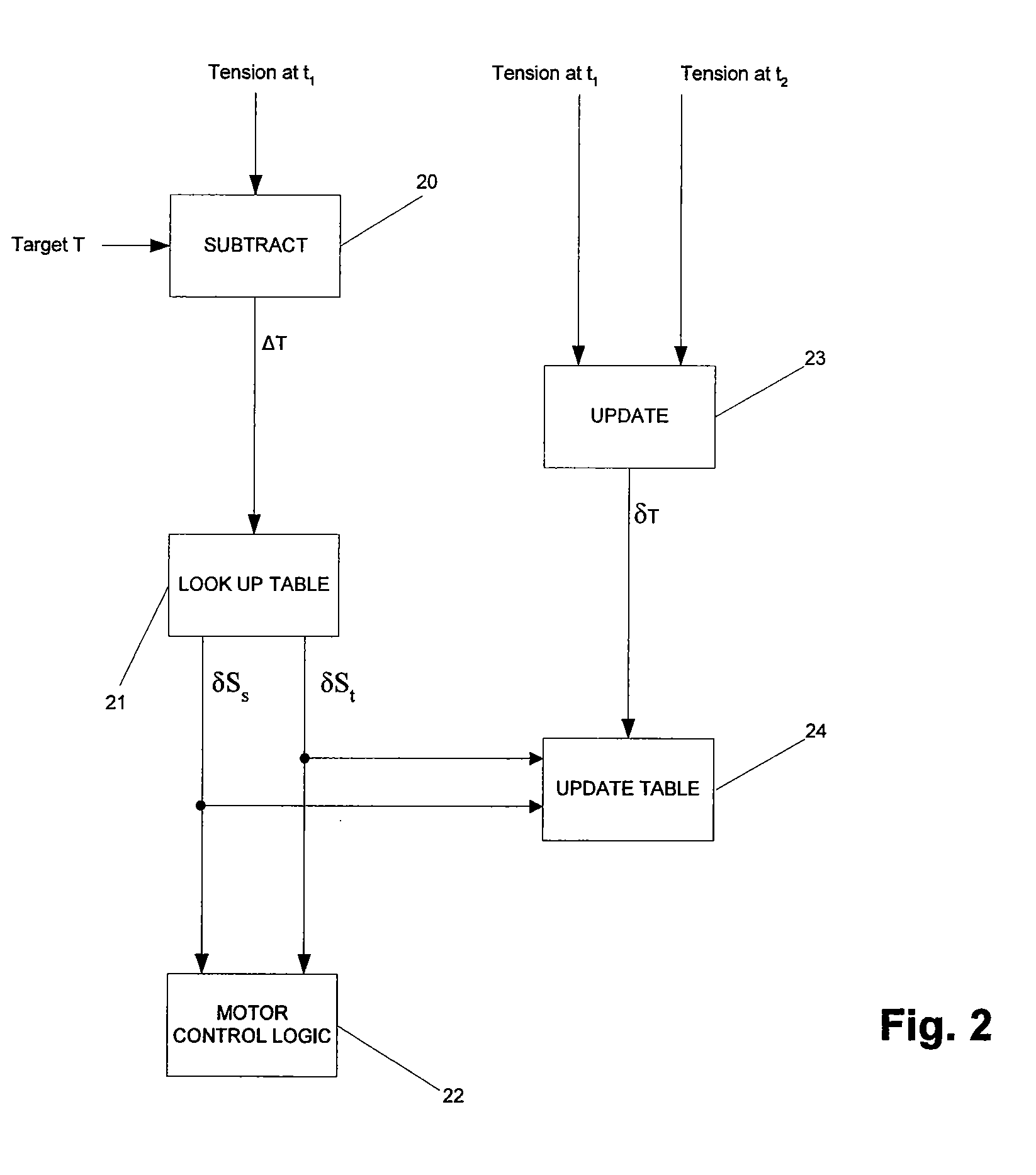

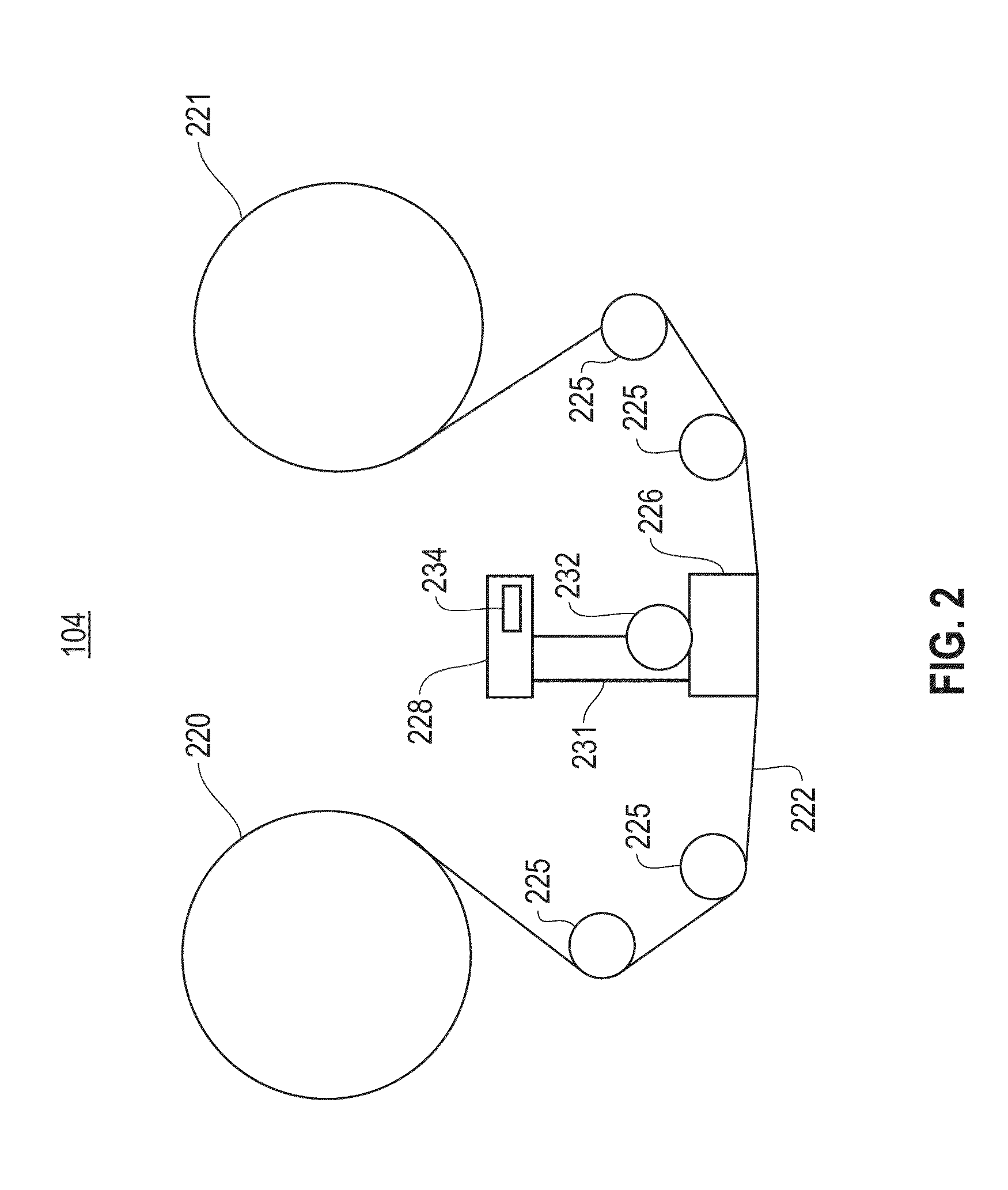

Tape drive tension control

ActiveUS8317421B2Improve performanceHigh of decelerationInking apparatusProjector film strip handlingMagnetic tapeTape drive

A tape drive comprising two motors, two tape spool supports on which spools of tape may be mounted, each spool being drivable by a respective one of the motors, and a controller. The controller controls the energization of the motors such that the tape may be transported in at least one direction between spools mounted on the spool supports. The controller is configured to store a plurality of motor control data items, each data item being associated with a respective tension value. The controller is operative to monitor tension in a tape being transported between spools mounted on the spool supports; read a motor control data item based upon the monitored tension; generate a motor control signal based upon the read motor control data item; and apply the motor control signal to at least one of the motors.

Owner:VIDEOJET TECH INC

Recording/ reproducing method and recording/reproducing apparatus for magnetic tape

A recording / reproducing method and a recording / reproducing apparatus for magnetic tapes are provided as a recording / reproducing technique suitable for recording density enhancement of magnetic tapes. The method and apparatus are capable of correctly recording and reproducing data without causing errors even with occurrence of size changes in the widthwise direction of a magnetic tape. In the recording / reproducing method for magnetic tapes in which data tracks and servo tracks are provided, a tape width is detected and a value of the tape width is stored during data recording, and data reproduction is performed while tape tension is controlled so that the tape width during data reproduction is maintained equal to the tape width during data recording.

Owner:FUJIFILM CORP

Apparatus for detecting an end portion of a recording medium

InactiveUS7011464B2Efficient use ofWithout complicating structureFilament handlingCamera film strip handlingPulp and paper industryExtremity Part

Owner:TOSHIBA TEC KK

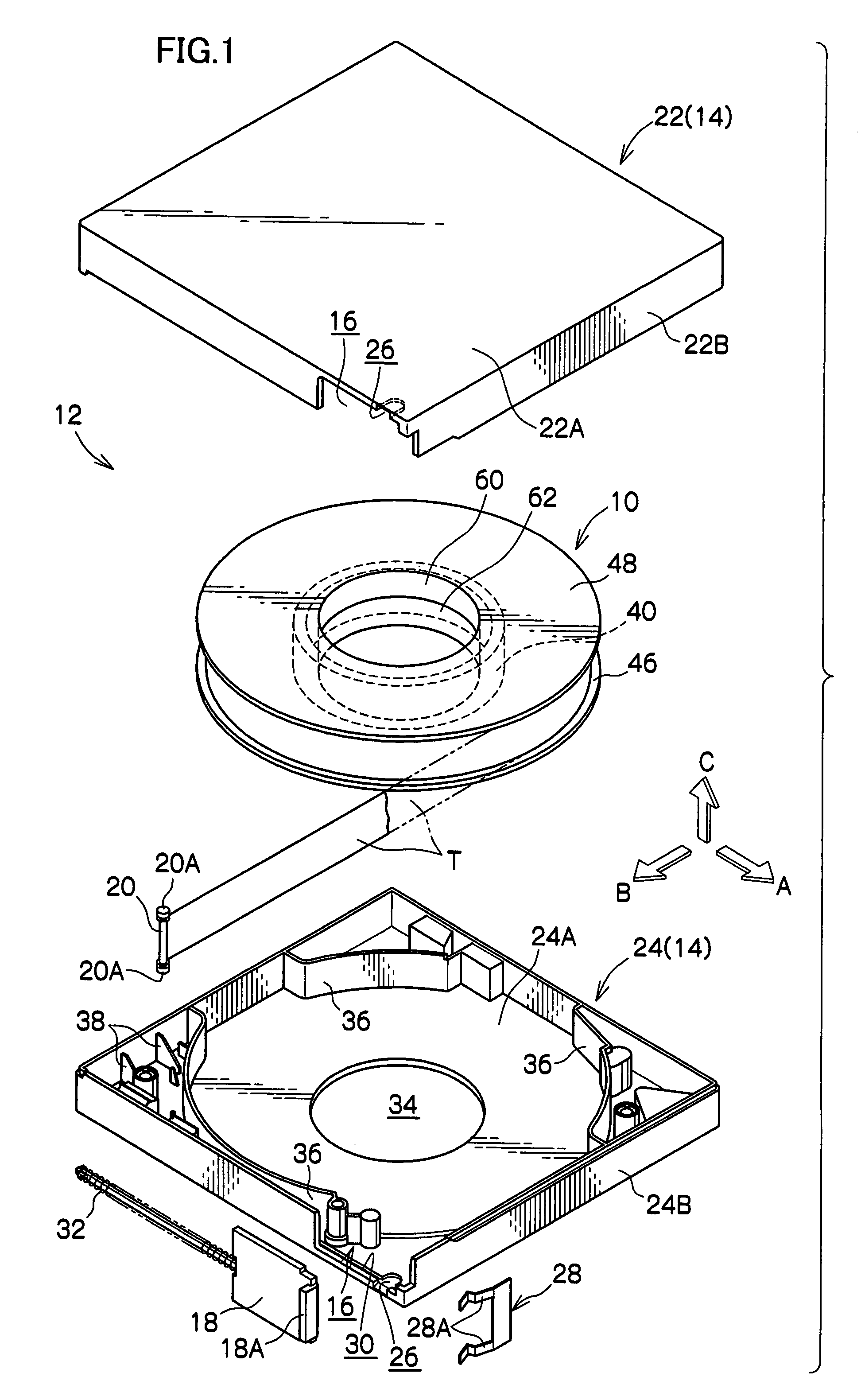

Reel and recording tape cartridge

A reel that includes: an upper flange and a lower flange that retain width direction edge portions of a recording tape; a lower circular cylinder portion disposed extending upward from an upper surface of the lower flange on the same circumference as the axial center of the lower flange; a hub that is fitted over the outside of the lower circular cylinder portion and around which the recording tape is wound; a rotational detent member that regulates movement of the hub in the circumferential direction with respect to the lower flange; and an upper circular cylinder portion that extends downward from an undersurface of the upper flange and is welded to an end surface of the lower circular cylinder portion such that the hub is interposed and held between the upper flange and the lower flange. A recording tape cartridge that includes this reel.

Owner:FUJIFILM CORP

Tape drive

ActiveUS20080240830A1Improve performancePerformance requirementInking apparatusProjector film strip handlingMagnetic tapeElectric machinery

A tape drive comprising two motors, two tape spool supports on which spools of tape may be mounted, each spool being drivable by a respective one of the motors, and a controller. The controller controls the energization of the motors such that the tape may be transported in at least one direction between spools mounted on the spool supports. The controller is configured to store a plurality of motor control data items, each data item being associated with a respective tension value. The controller is operative to monitor tension in a tape being transported between spools mounted on the spool supports; read a motor control data item based upon the monitored tension; generate a motor control signal based upon the read motor control data item; and apply the motor control signal to at least one of the motors.

Owner:VIDEOJET TECH INC

Quasi-statically tilted head having offset reader/writer transducer pairs

ActiveUS9218838B2Alignment for track following on tapesRecord information storageMagnetic tapeInstability

Aspects of the present invention relates generally to apparatuses with transducer arrays having offset transducers. Various embodiments are particularly suited to tilting for tape dimensional instability compensation. Some embodiments include dual servo readers in a given array.

Owner:IBM CORP

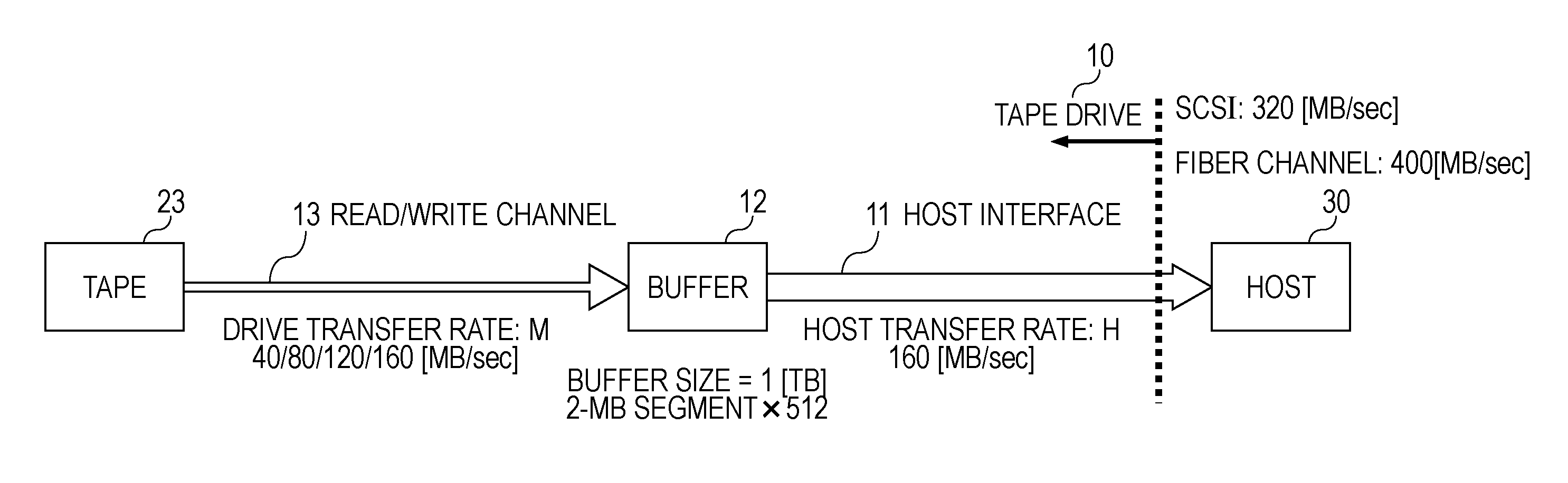

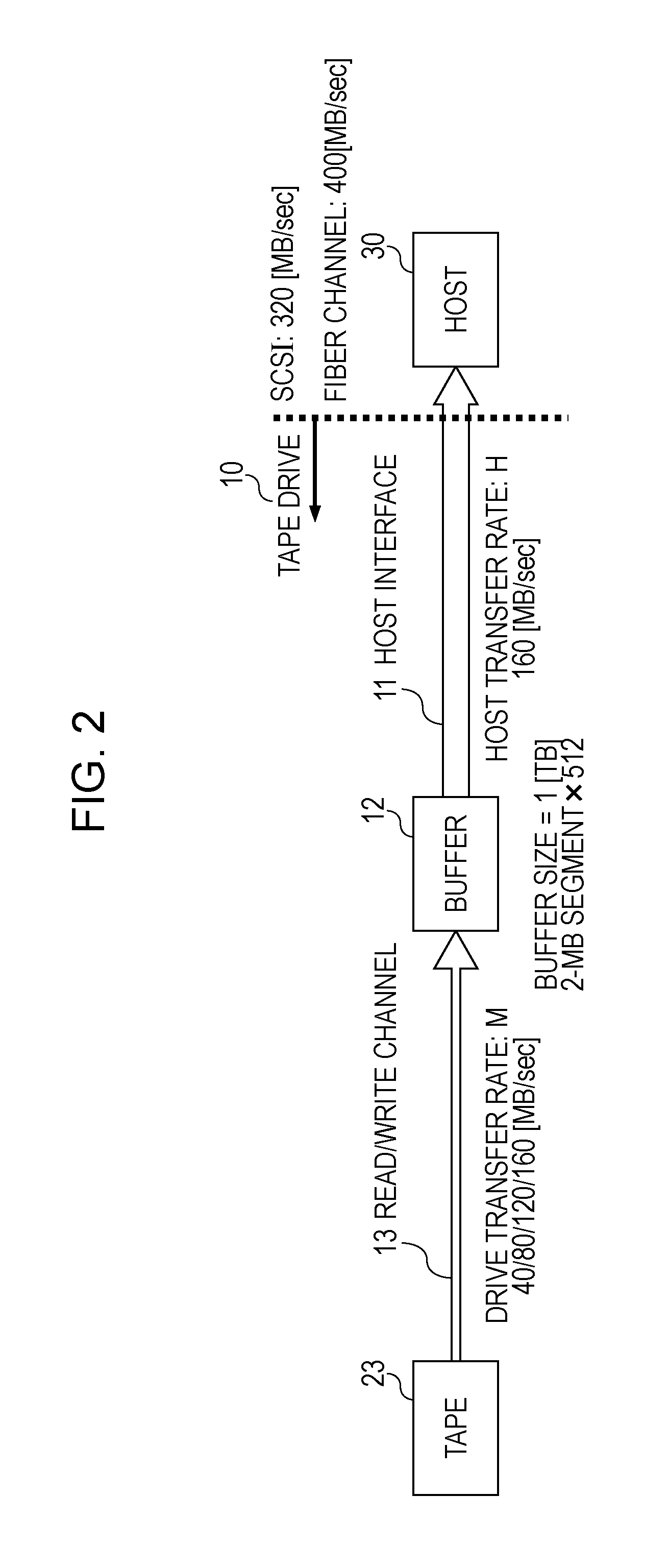

Tape drive, tape drive recording system, and method for selecting improved tape speed in response to intermittent read requests

ActiveUS20100095029A1Reduce negative impactIncrease speedCarrier speed control/regulation/indicationInput/output processes for data processingTape speedData transmission

A tape drive, tape drive recording system, and method are provided for improving tape speed selection during data transfer. The tape drive comprises a buffer, a tape for recording the data to be temporarily stored in the buffer, and a read head. The tape drive further comprises a reading controller that initially sets a tape speed such that a drive transfer rate matches a host transfer rate as closely as possible and that drives the tape at the tape speed. To address backhitching caused by one or more host transfer halts, the reading controller subsequently adjusts the tape speed such that the drive transfer rate is lower than the host transfer rate by recalculating the host transfer rate in consideration of the host transfer and the host transfer halt and setting the tape speed such that the drive transfer rate matches the recalculated host transfer rate as closely as possible.

Owner:LENOVO GLOBAL TECH INT LTD

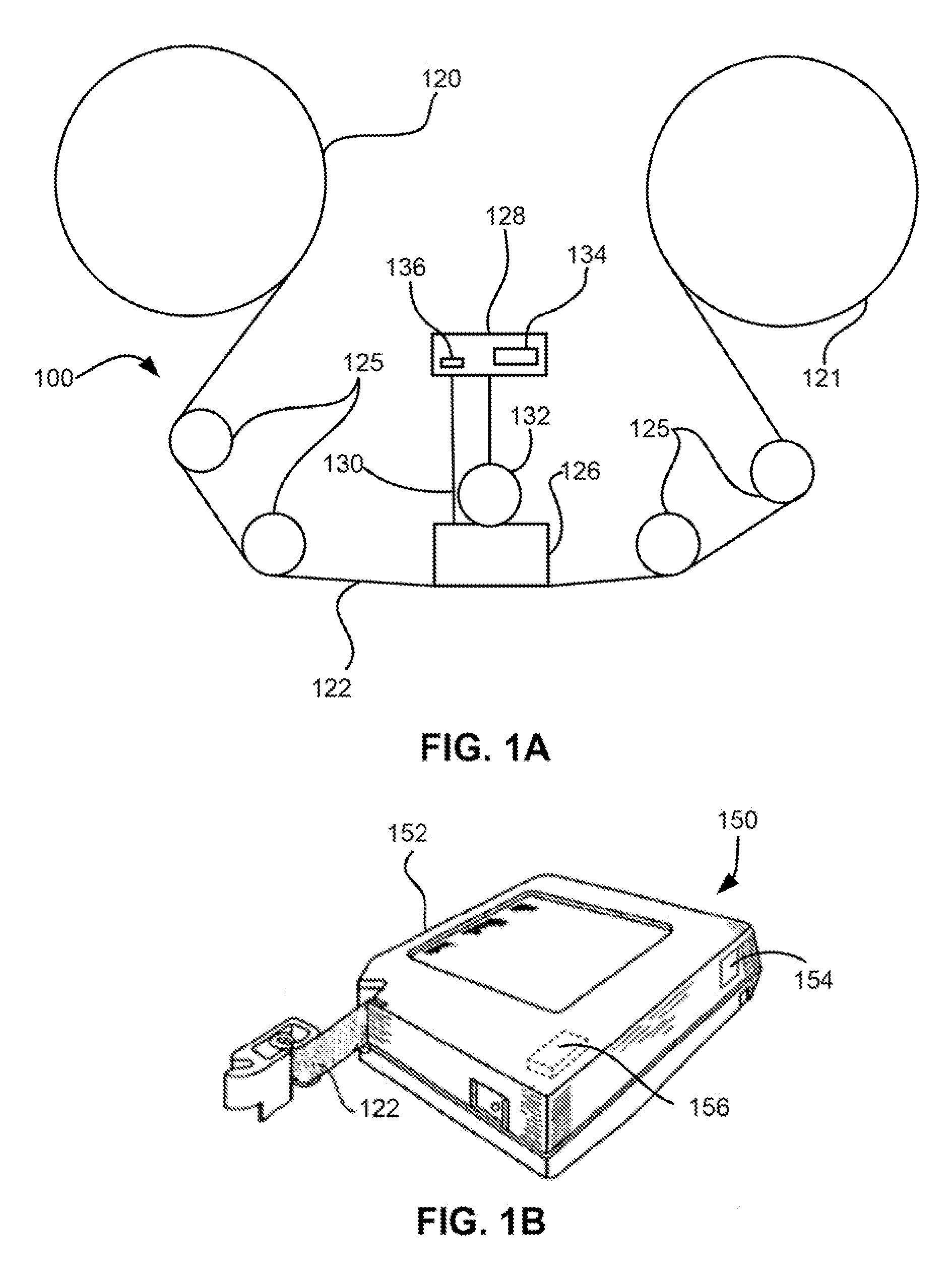

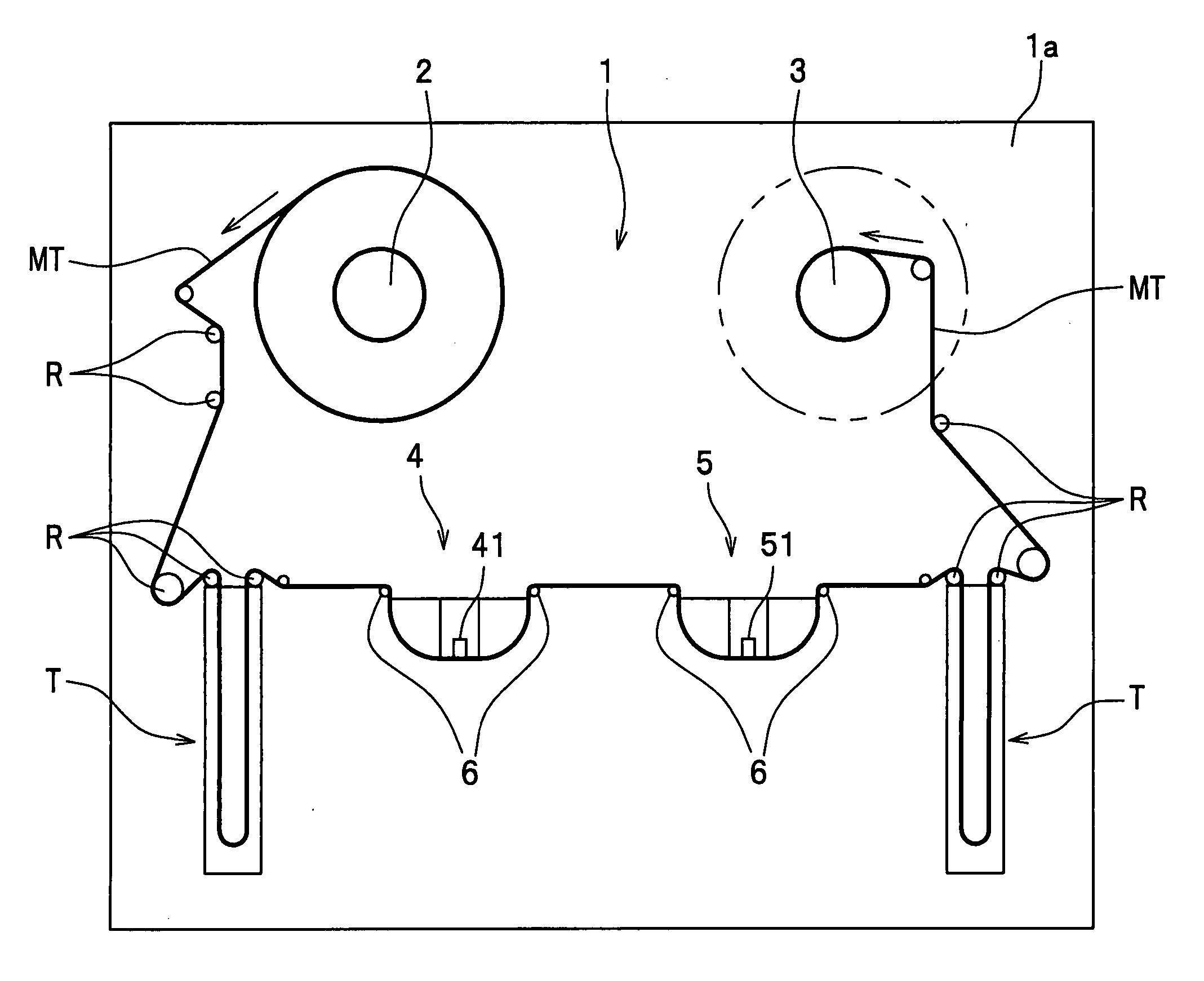

Servo writer and tape drive system

InactiveUS20060152846A1Control displacementImprove propertiesRecord information storageRecording on magnetic tapesAir bearingMagnetic tape

A head unit includes a head, and a head guide assembly disposed adjacent to the head to restrict a displacement of a tape (tape-like storage medium) in a tape width direction with respect to the head. A tape drive system includes a tape guide arrangement disposed to guide the tape supplied from a supply reel to the head unit, passed across the head unit and led to a take-up reel. The tape guide arrangement includes a guide disposed adjacent to the head unit, and the guide is supported with an air bearing. In one embodiment, the guide includes a motor for rotating a contact surface of the guide around which the tape is wrapped, in accordance with movement of the tape.

Owner:FUJIFILM HLDG CORP +1

Supply magazine for containing recording material roll

A supply magazine contains a recording paper roll constituted by continuous thermosensitive recording paper wound in a roll form. The recording paper is fed-by a supply roller. In the supply magazine, a magazine body receives the recording paper roll. A magazine lid closes the magazine body openably. Two retention levers are shiftable between retaining and releasing positions, press an outermost turn of the recording paper roll to the supply roller when in the retaining position, and release the recording paper roll from the supply roller when in the releasing position. A combination of two linking plates has first and second ends. The first end is connected with the magazine lid. The second end is connected with each of the retention levers. The linking plates shift each retention lever from the releasing position to the retaining position in response to closing of the magazine lid.

Owner:FUJIFILM HLDG CORP +1

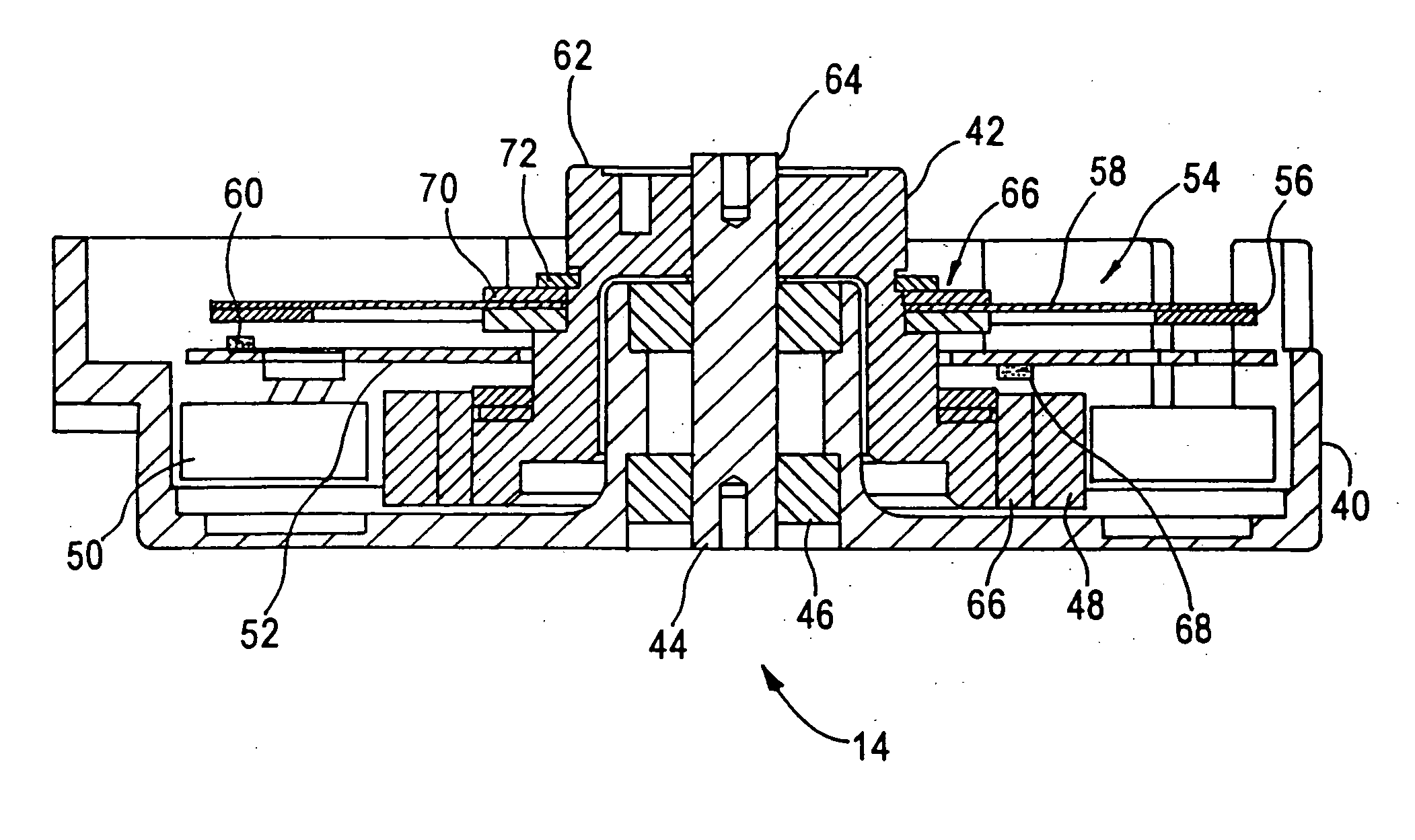

Motor/encoder assembly for tape drives

InactiveUS20060033388A1Compact designCurrent is limitedAssociation with control/drive circuitsMechanical energy handlingBrushless motorsEngineering

A magnetic / encoder assembly has a compact design and combines the features of motor, encoder and chuck locating feature within a single motor housing. The motor / encoder includes a DC brushless motor with an inner magnetic rotor. The motor windings and the commutation electronics are mounted towards the bottom side of a printed circuit board. The rotor of the motor is extended above the surface of the printed circuit board. The extended rotor provides a precision seat for the magnetic wheel with multiple poles. The top surface of the printed circuit board mounts the sensor for the encoder. The extension of the rotor provides the precision mounting surface of the cartridge driving chuck.

Owner:QUANTUM CORP

Supply magazine for recording material roll and having code reader

InactiveUS20010050320A1Reliable readEasy accessPicture changing apparatusProjector film strip handlingEngineeringCard reader

A recording paper roll includes a tubular spool shaft having first and second end faces. Thermosensitive recording paper is wound about the tubular spool shaft in a roll form. A code is formed in the first end face. For use with the recording paper roll, a supply magazine includes two roll holders secured to the spool shaft. First and second support plates are arranged in an axial direction of the roll holder, and support the roll holder in a rotatable manner. Guide cutouts are formed in the first and second support plates, receive first and second ends of the roll holder, and move the roll holder in a predetermined direction according to a decrease in a diameter of the recording material roll in use of the recording material. A code sensor reads the code from the first end face. A sensor shifter constituted by a depression portion moves the code sensor in the predetermined direction with the two roll holders.

Owner:FUJIFILM HLDG CORP +1

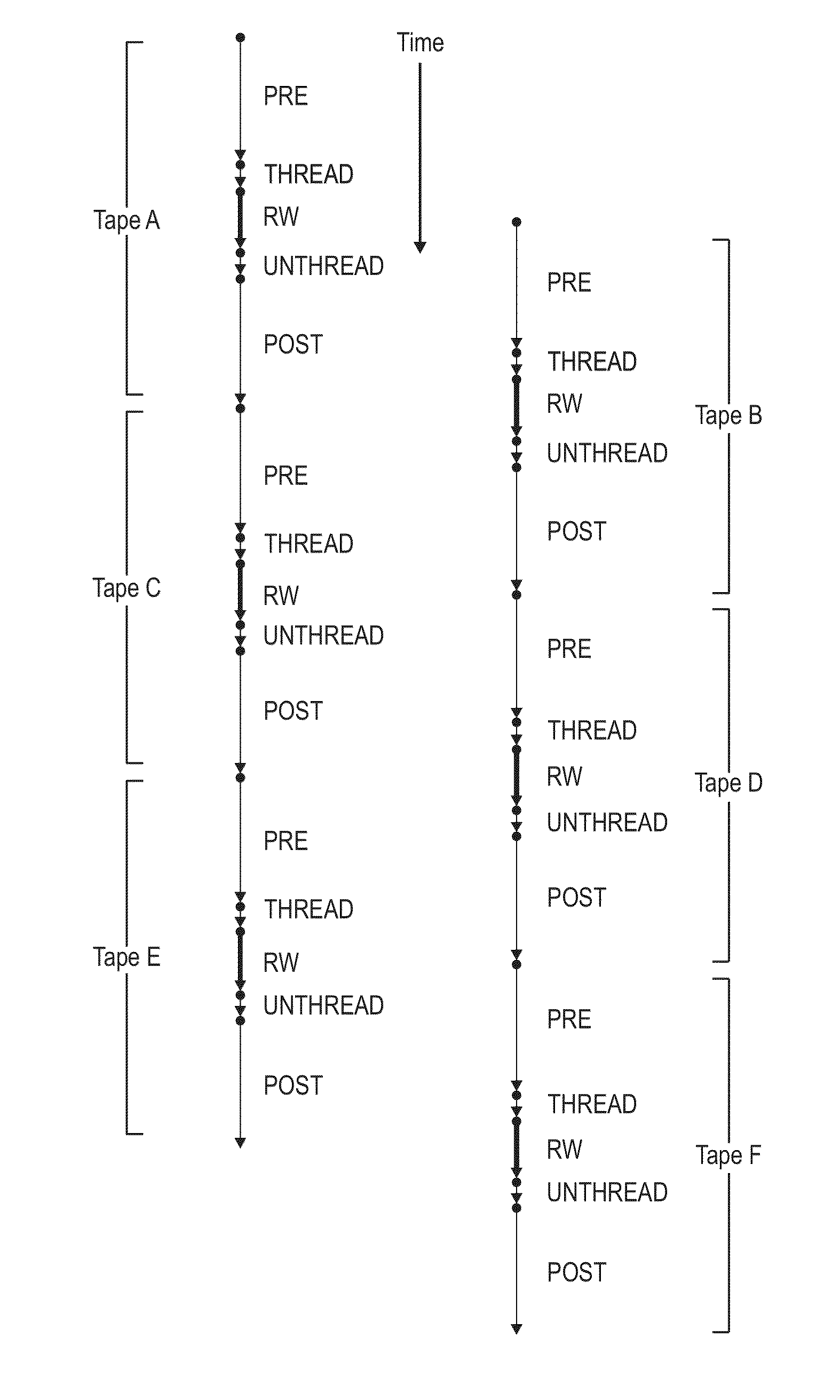

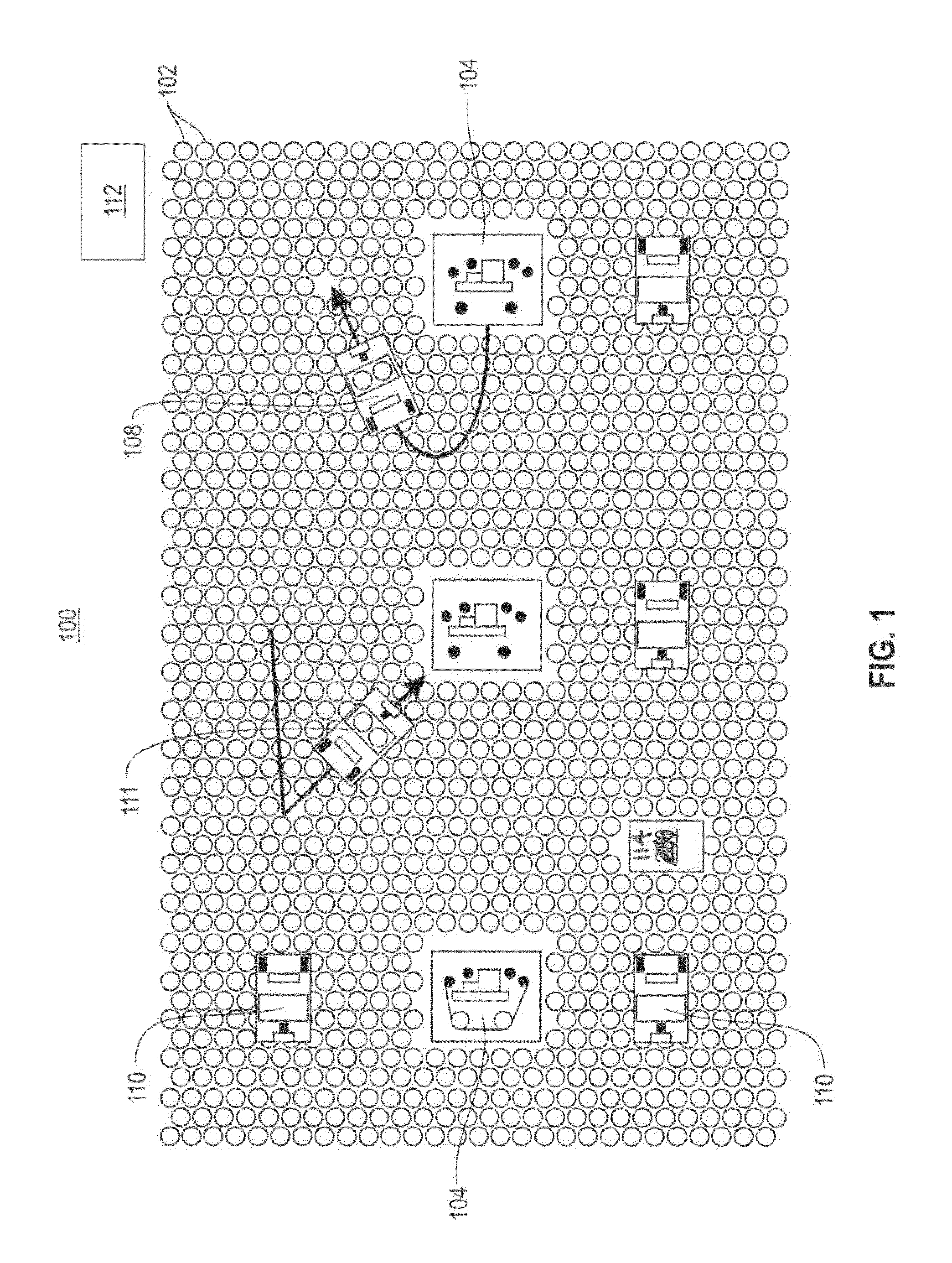

Tape drive with overlapped operations

ActiveUS20150002958A1Alignment for track following on tapesRecord information storageMagnetic tapeTape drive

Embodiments of the invention relate to tape drive systems having overlapped operations. In one aspect, a system includes a head for performing read and / or write operations, a first set of motors for performing positioning operations on a first tape, a second set of motors for performing positioning operations on a second tape, and a processor and logic integrated with and / or executable by the processor. The logic is configured to cause the first set of motors to pass the first tape over the head while causing the second set of motors to perform at least one of a coarse locate and a rewind operation on the second tape. Additional systems and methods are also disclosed.

Owner:IBM CORP

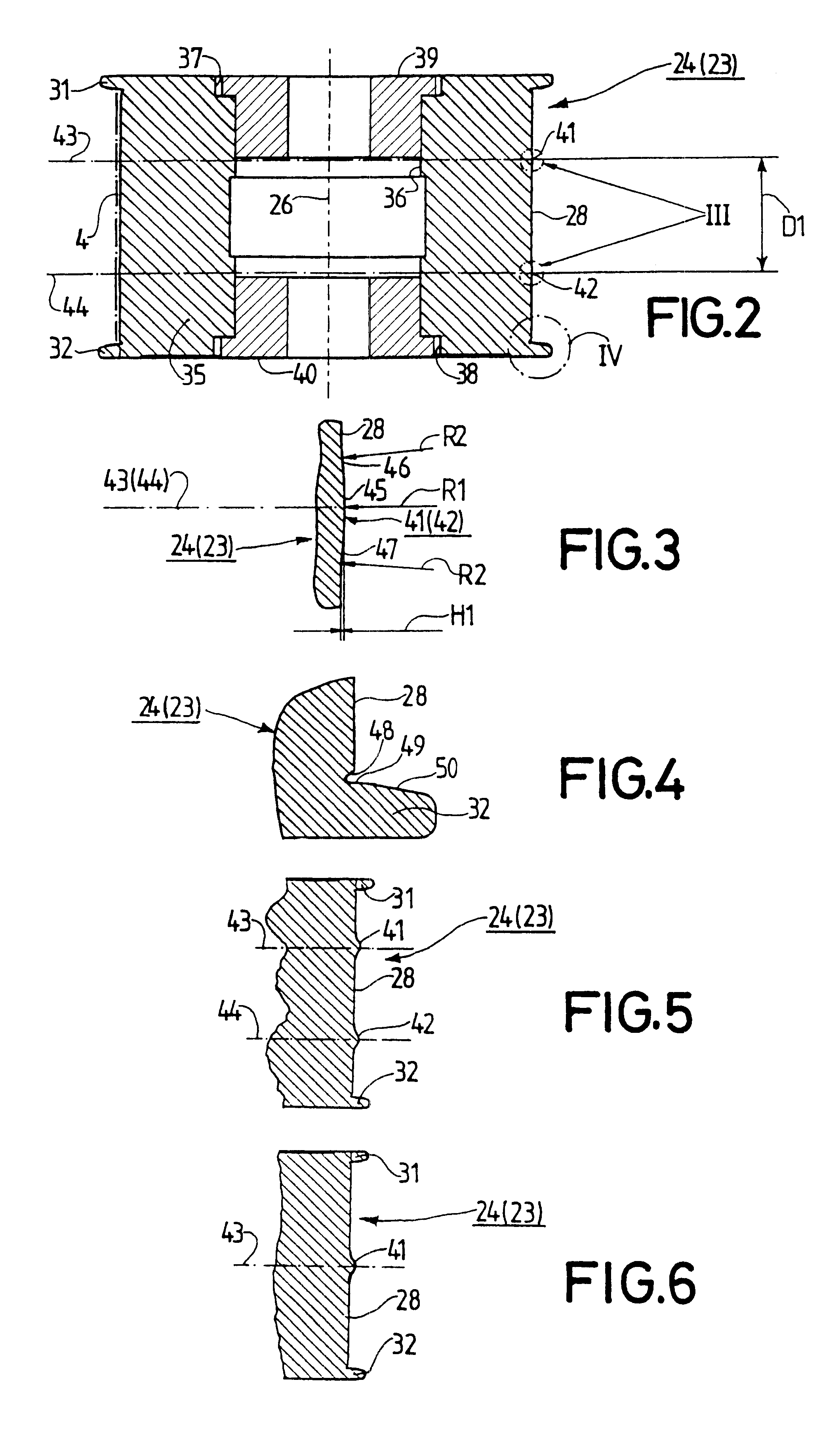

Recording and/or reproducing apparatus including at least one guide arrangement having at least one damping projection

InactiveUS6550658B2Easy to manufactureConvenient projectionPicture changing apparatusProjector film strip handlingRelative motionFlange

A recording and / or reproducing apparatus having at least one guide arrangement that facilitates recording and reproduction even when a tape edge comes into contact with an end flange of the guide arrangement. The guide arrangement structure preferable is in the form of a tape guide roller, for guiding a record carrier in the guide arrangement. There is at least one damping projection in the area of the guide surface. The damping projection extends in tangential directions of the guide surface and is adapted to damp axial relative movements of the record carrier with respect to the guide arrangement.

Owner:JABIL CIRCUIT CAYMAN

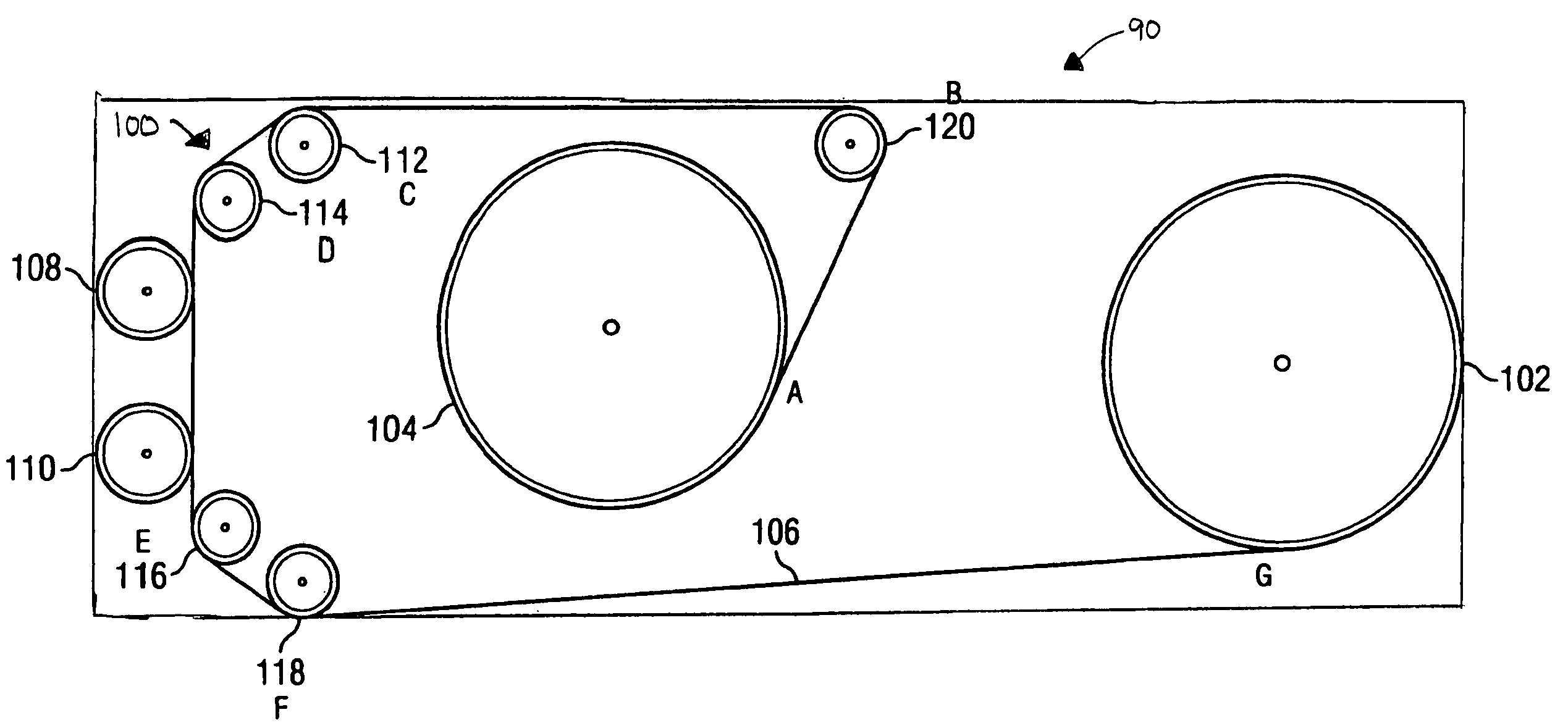

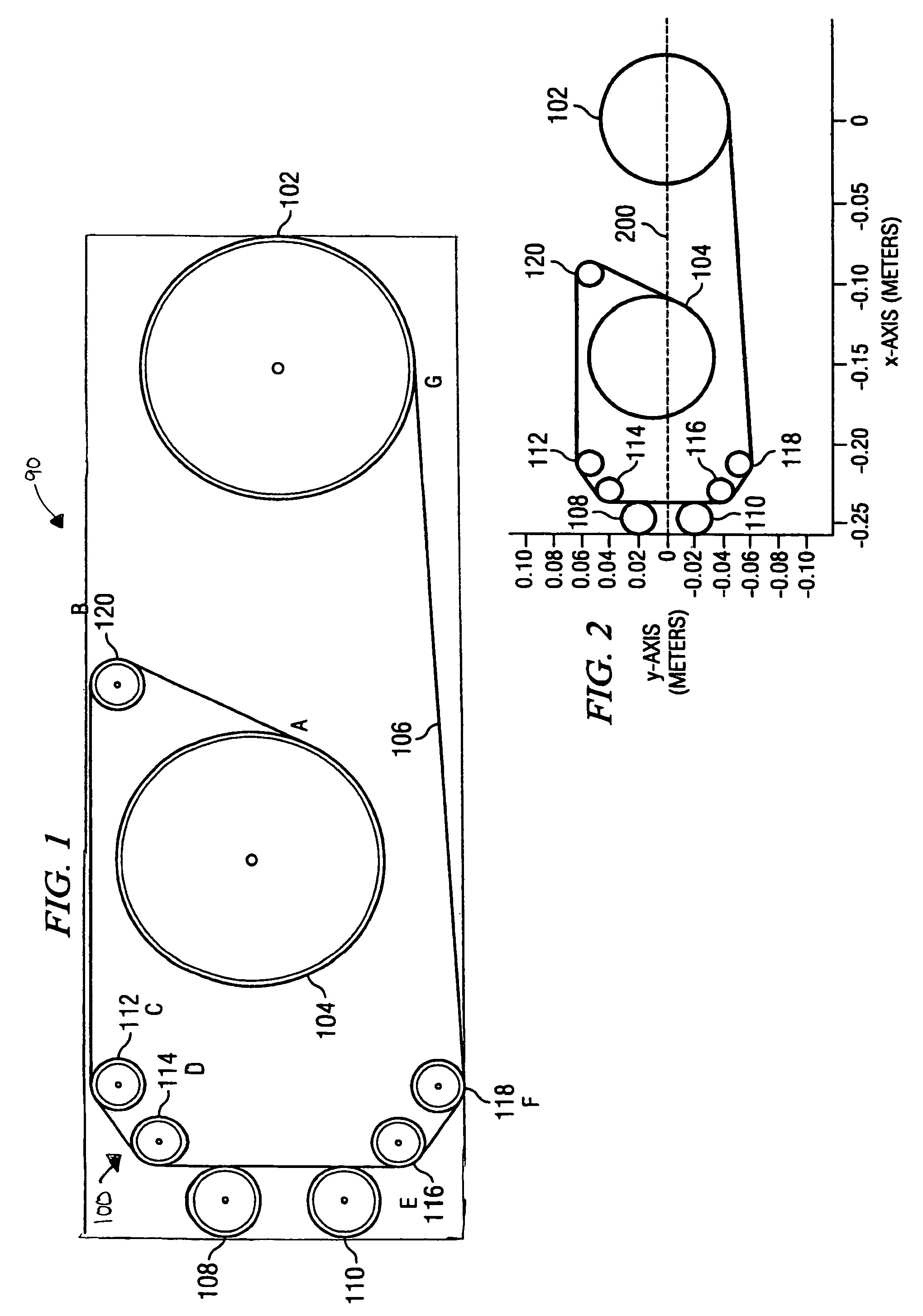

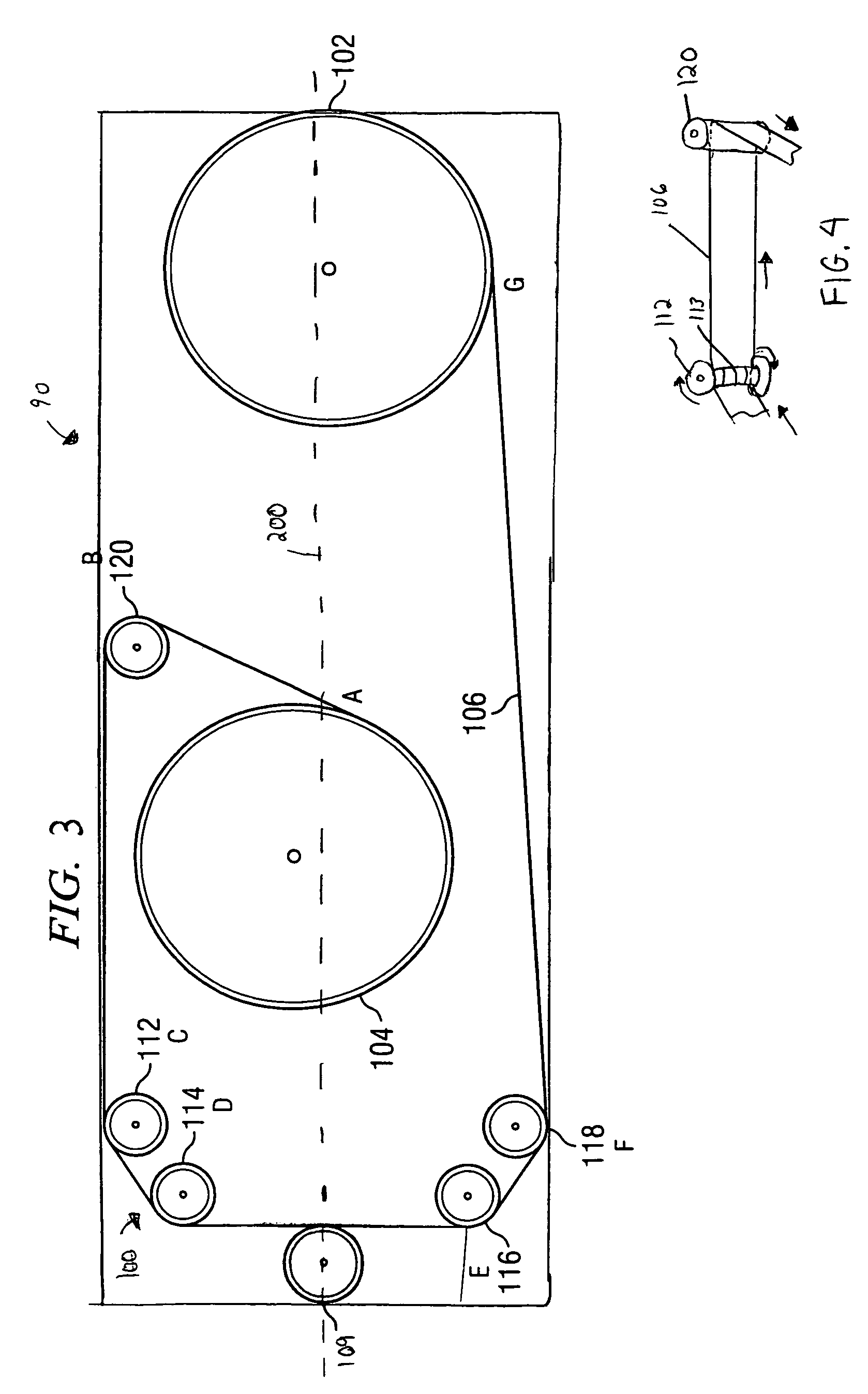

Roller guide tape path

ActiveUS7261250B1Increase the lengthPicture changing apparatusRecord information storagePath lengthAxis of symmetry

A tape guide mechanism in a storage device is disclosed for defining an improved roller guide tape path. A cartridge reel is provided for supplying tape to a take-up reel. Multiple flanged guides are provided located remotely from the cartridge and take-up reels. A non-flanged post guide is provided located proximate to the take-up reel for increasing a length of the tape path and for permitting the flanged guides to be located remotely from the cartridge and take-up reels so that the flanged guides are not located in proximity to the cartridge or take-up reels. An axis of symmetry exists longitudinally about one or two read / write heads. The tape path length is generally symmetrically disposed about this axis of symmetry.

Owner:ORACLE INT CORP

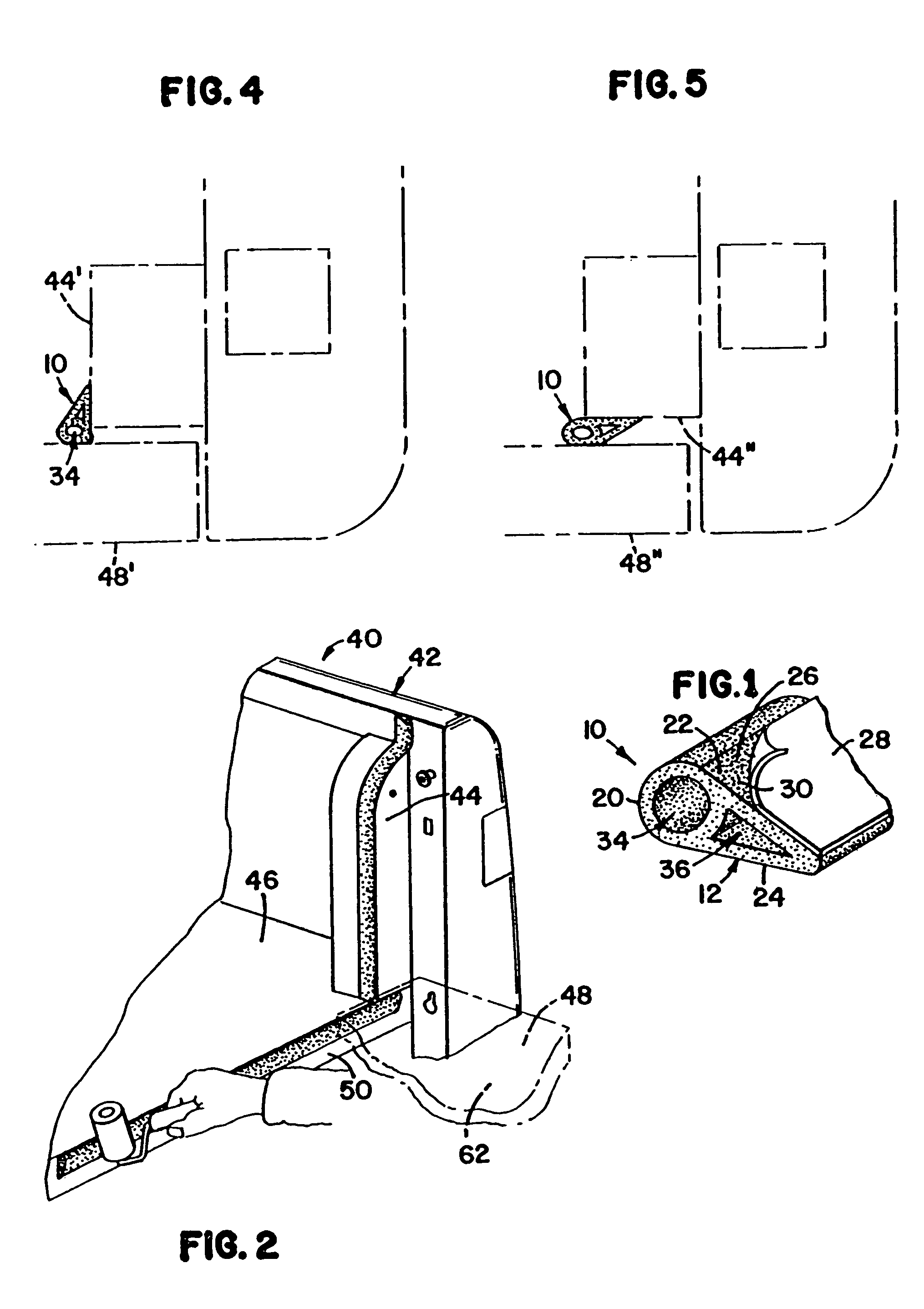

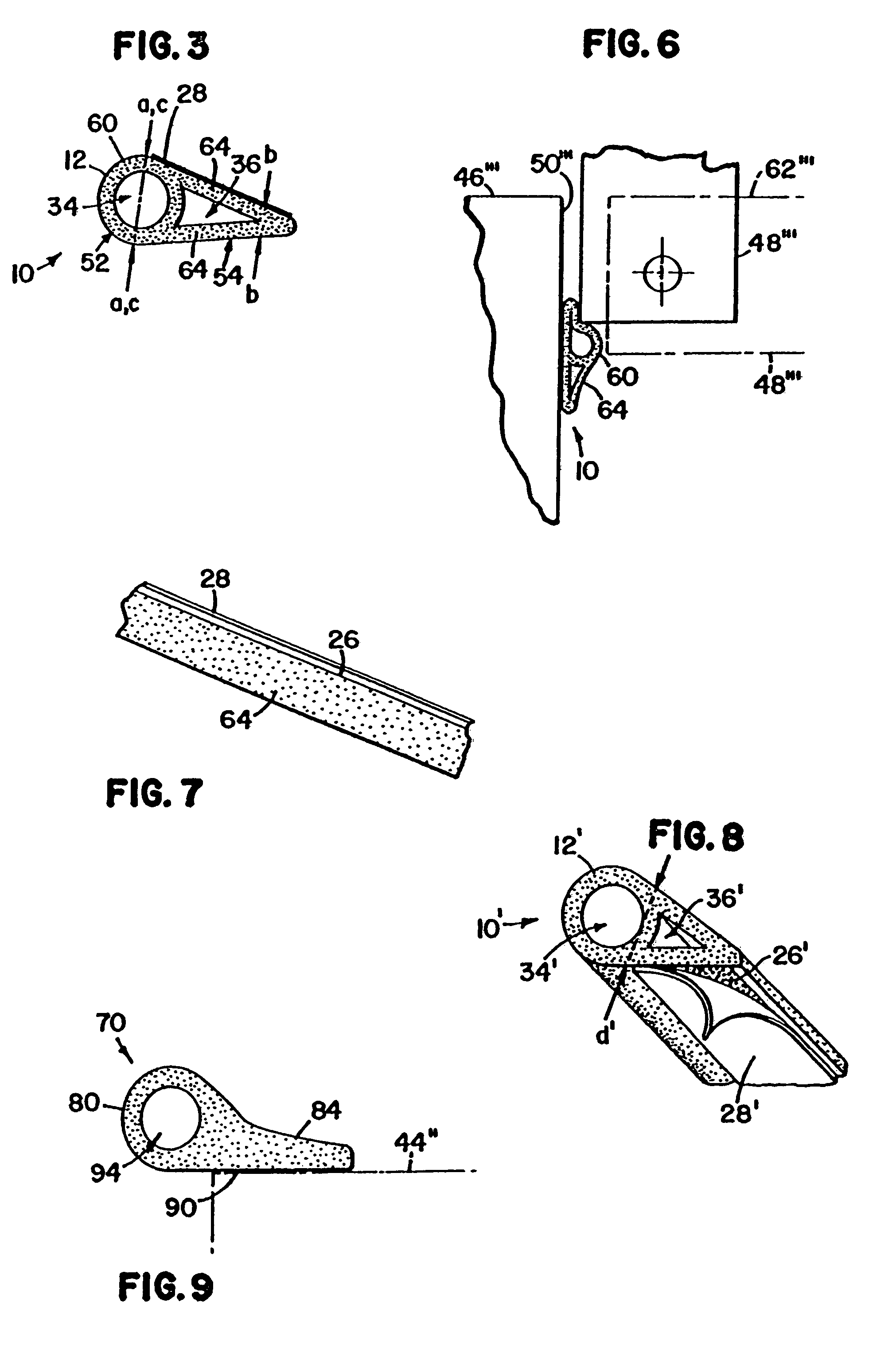

Tailgate sealing gasket

InactiveUS6959848B2Increase widthEfficient use ofRecord information storageSuperstructure subunitsPickup truckWater resistant

A sealing gasket for sealing gaps adjacent to a pickup truck is provided. In alternate embodiments a combination pickup truck and sealing gasket is also provided. The sealing gasket of the present invention comprises an elongated member made of a deformable and a somewhat resilient polymeric material. The polymeric material is preferably a closed cell sponge material made of one of a number of polymeric materials which are the somewhat flexible, resilient, water resistant and the like. The cross-section of the elongated member, if divided into two parts, includes a generally triangular portion and a generally semi-circular portion which come together to form a teardrop-like shape. The elongated member preferably has a first lumen which is generally circular in shape when the sealing gasket is undeformed, and preferably a second lumen which has two converging tear surfaces which converge to join at one end and join to an arcuate inner surface at the other end. This sealing gasket is uniquely designed to be both resilient and deformable in a manner which enables the sealing gasket to be used in a variety of different orientations and positions to seal gaps between a pickup truck tailgate and other portions of the pickup truck through which dust and moisture may pass if the gaps are not filled.

Owner:AGRI COVER

Recording tape cartridge

ActiveUS7059554B2Guaranteed functionReduce restrictionsPicture changing apparatusRecord information storageMagnetic tapeEngineering

A recording tape cartridge in which a reel includes a reel gear and an engaging gear. The reel gear is formed in an annular shape at an outer face of a base portion of a reel hub. The engaging gear is formed in an annular shape at an inner face of the base portion. Magnetic tape is wound onto an outer periphery of the reel hub. A braking member is engaged with the engaging gear by an urging force and prevents the reel from rotating. A clutch member opposes a gear aperture at a radial direction inner side relative to the reel gear. An operationally pushed surface of the clutch member is pushed by a releasing surface of a drive device and the brake member is lifted, whereby rotation of the reel is enabled.

Owner:FUJIFILM HLDG CORP +1

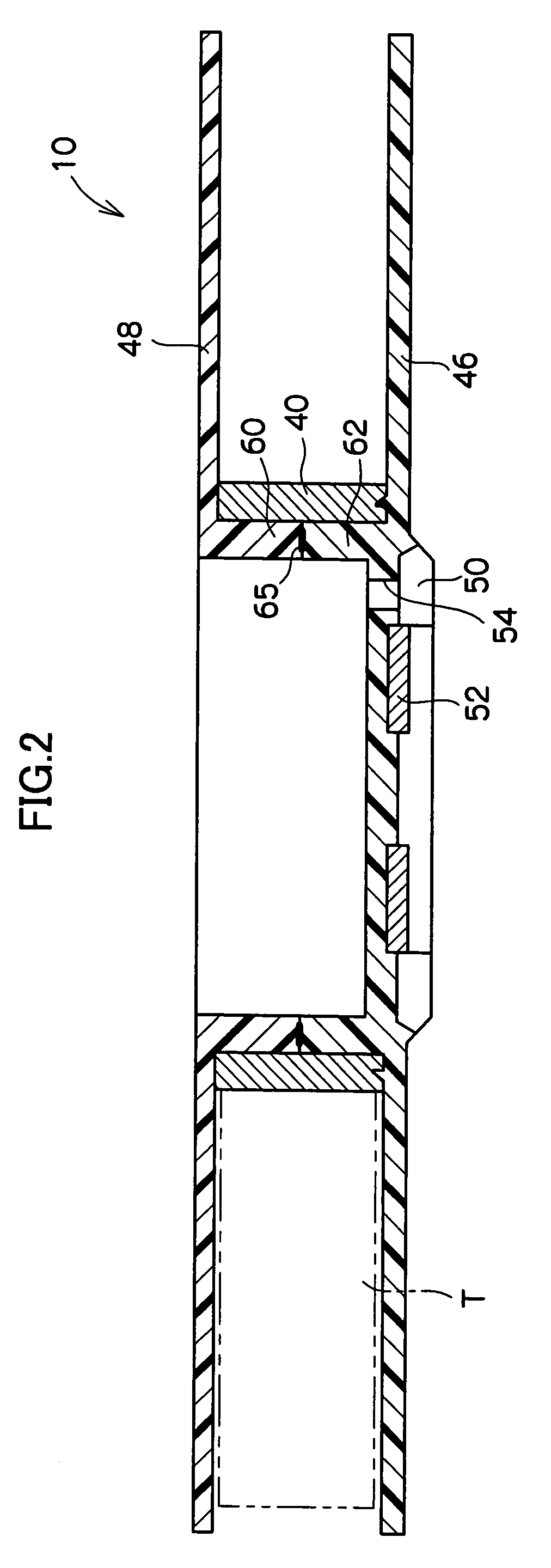

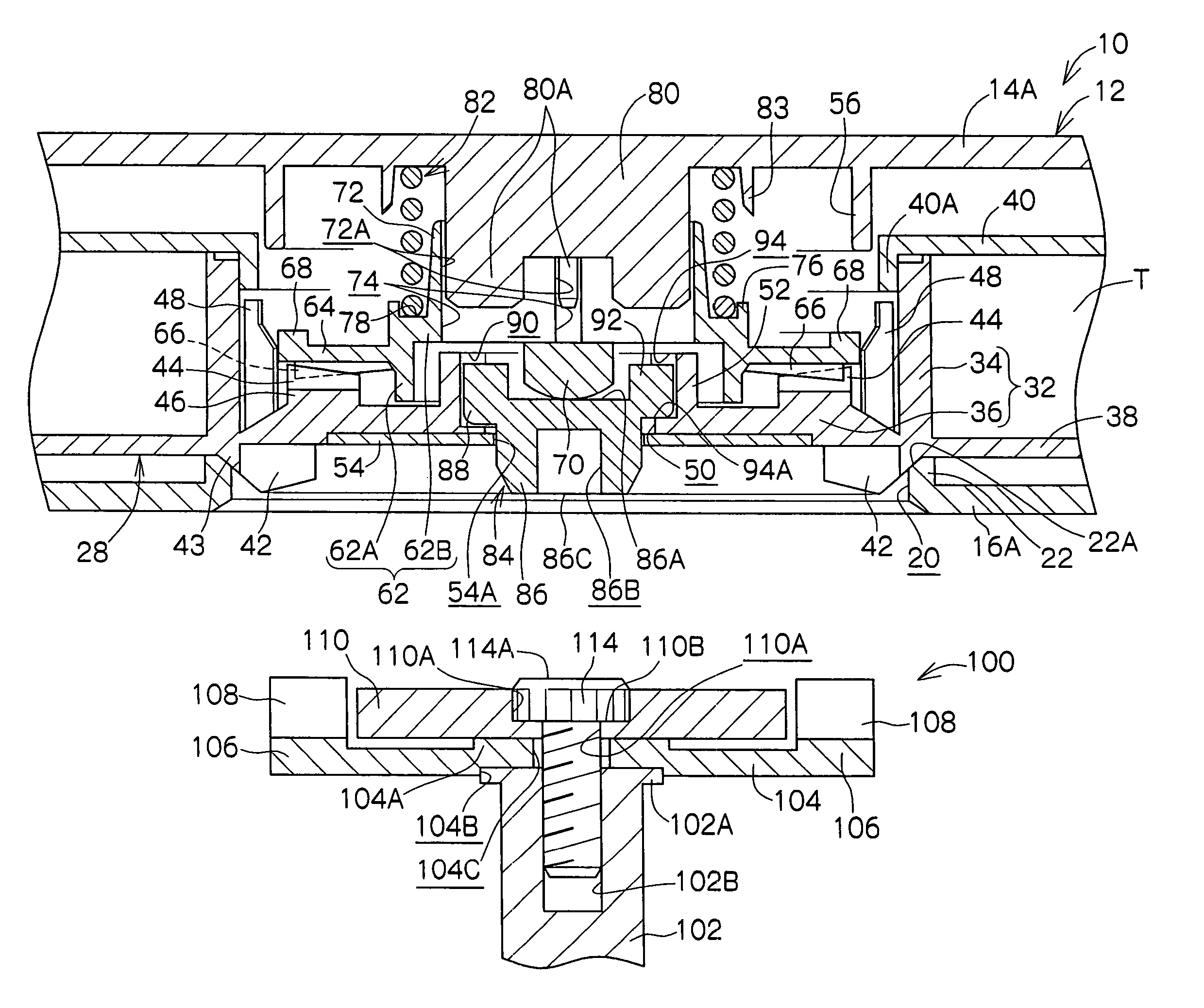

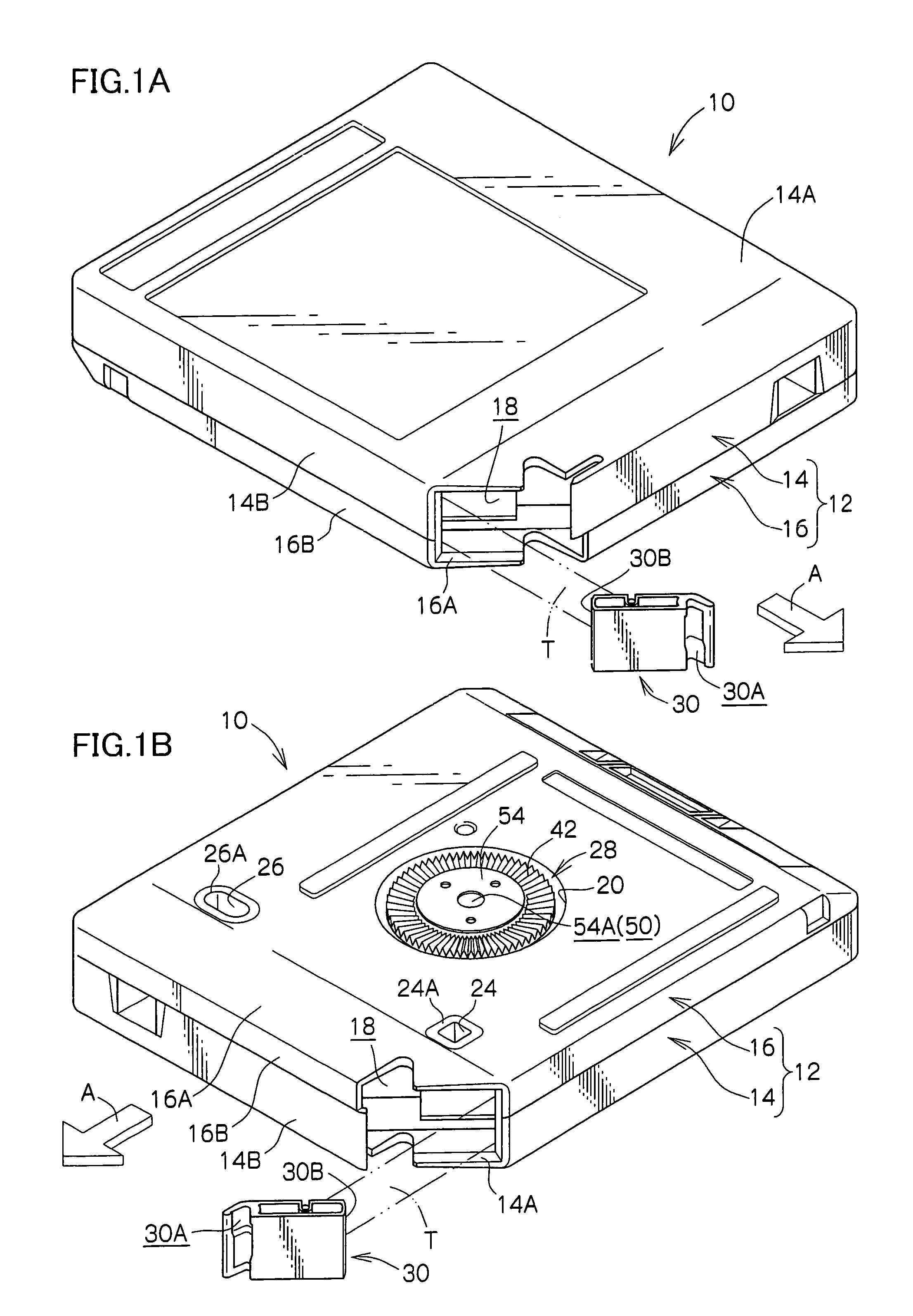

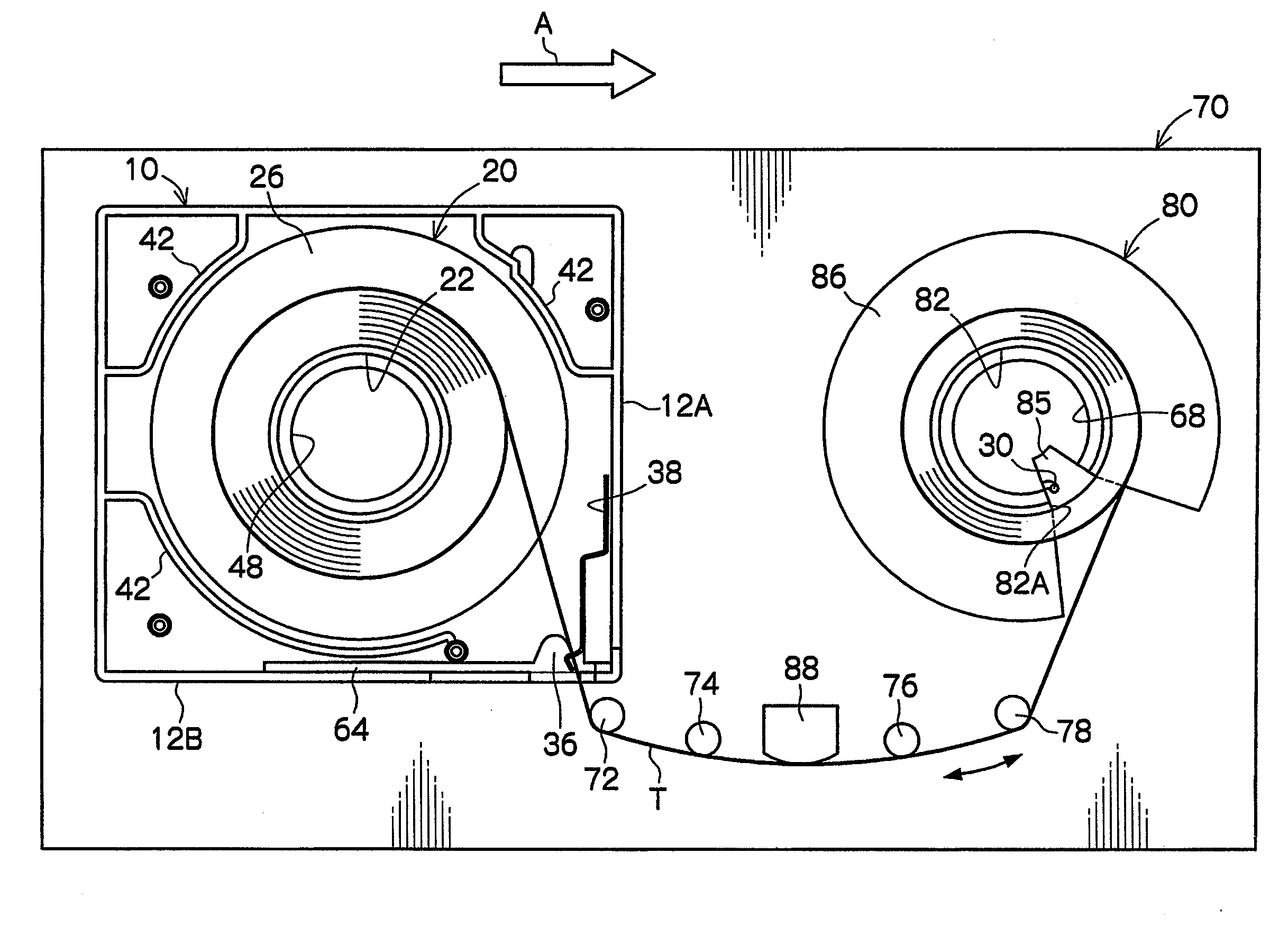

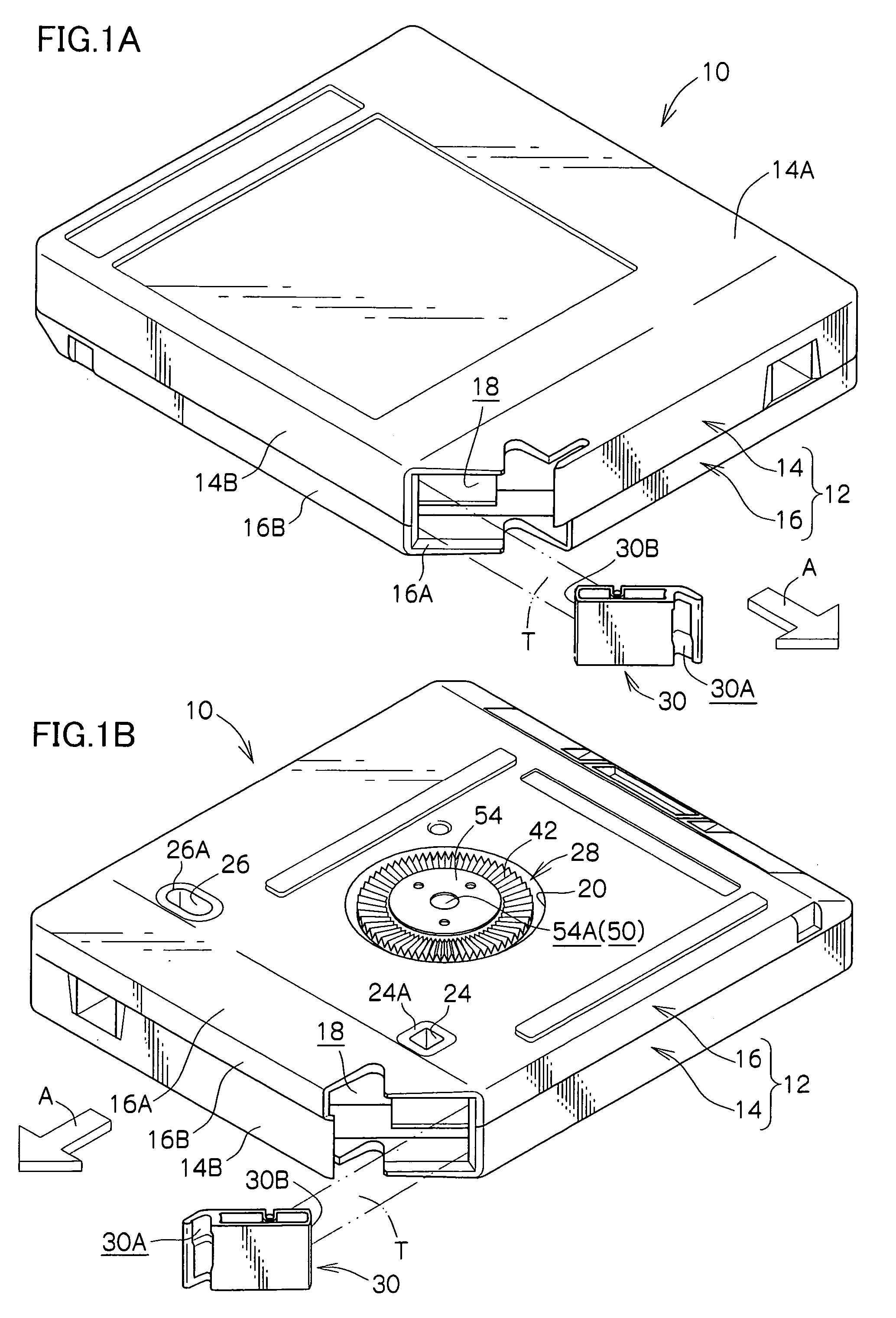

Tape reel, recording tape cartridge, take-up reel, and drive device

ActiveUS20080173749A1Picture changing apparatusProjector film strip handlingMechanical engineeringEngineering

There are provided a tape reel and a take-up reel at which it is possible to easily and inexpensively manufacture a hub having, at an outer peripheral surface thereof, a portion whose diameter is larger than diameters of each of the end portions of the hub, and a recording tape cartridge having the tape reel and a drive device having the take-up reel. At a tape reel 20 having a hub 22, which is made of resin on which a recording tape T is wound, and flanges 24, 26, which are provided at both end portions of the hub 22, a ring-shaped member 48, whose outer diameter is larger than an inner diameter of at least one portion of the hub 22, is press-fit in at an inner side of the hub 22. The tape reel 20 which has the hub 22 having, at least a portion of an outer peripheral surface, a portion whose diameter is larger than diameters of each of the end portions of the hub, is thereby easily formed.

Owner:FUJIFILM CORP

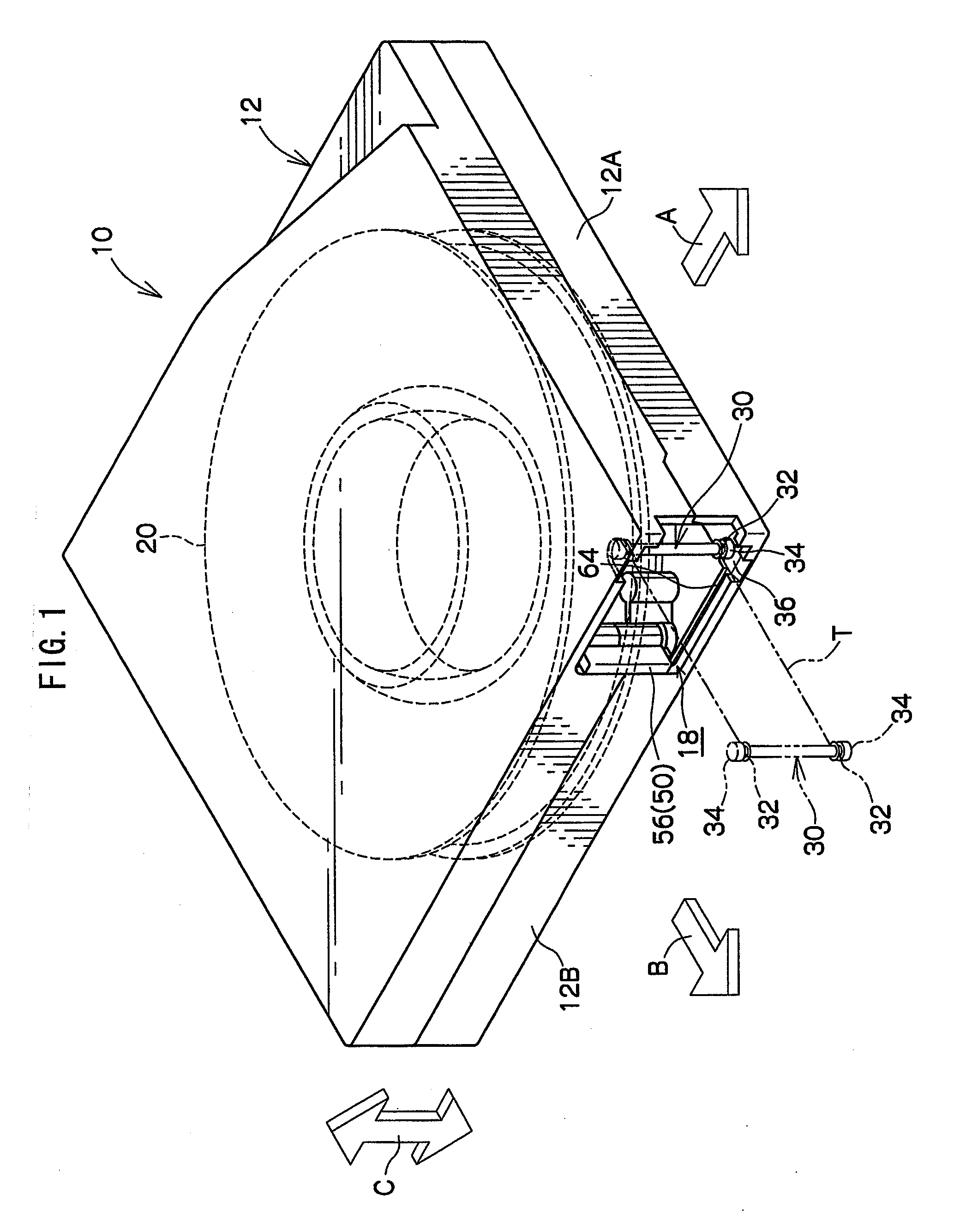

Drive device

ActiveUS7124973B2Prevent rotationPicture changing apparatusProjector film strip handlingPush upsEngineering

A drive device to which a recording tape cartridge is loaded, and which can record information in a recording tape and playback information recorded in the recording tape, the drive device includes: a rotating shaft having a drive gear which meshes with the reel gear of the cartridge and rotates the reel of the cartridge; an operating member which pushes up the brake member of the cartridge to the reel rotation permitted position; and an adjusting mechanism which adjusts a projecting height of the operating member.

Owner:FUJIFILM HLDG CORP +1

Reduced reel motor disturbances in a tape drive system

ActiveUS20150294683A1Magnetic circuit rotating partsDriving/moving recording headsElectric machineMotor disturbances

An apparatus according to one embodiment includes a motor having: a rotor, a magnet, and a damping layer positioned between the rotor and the magnet. The damping layer is constructed of a material characterized by converting kinetic energy into heat.

Owner:IBM CORP

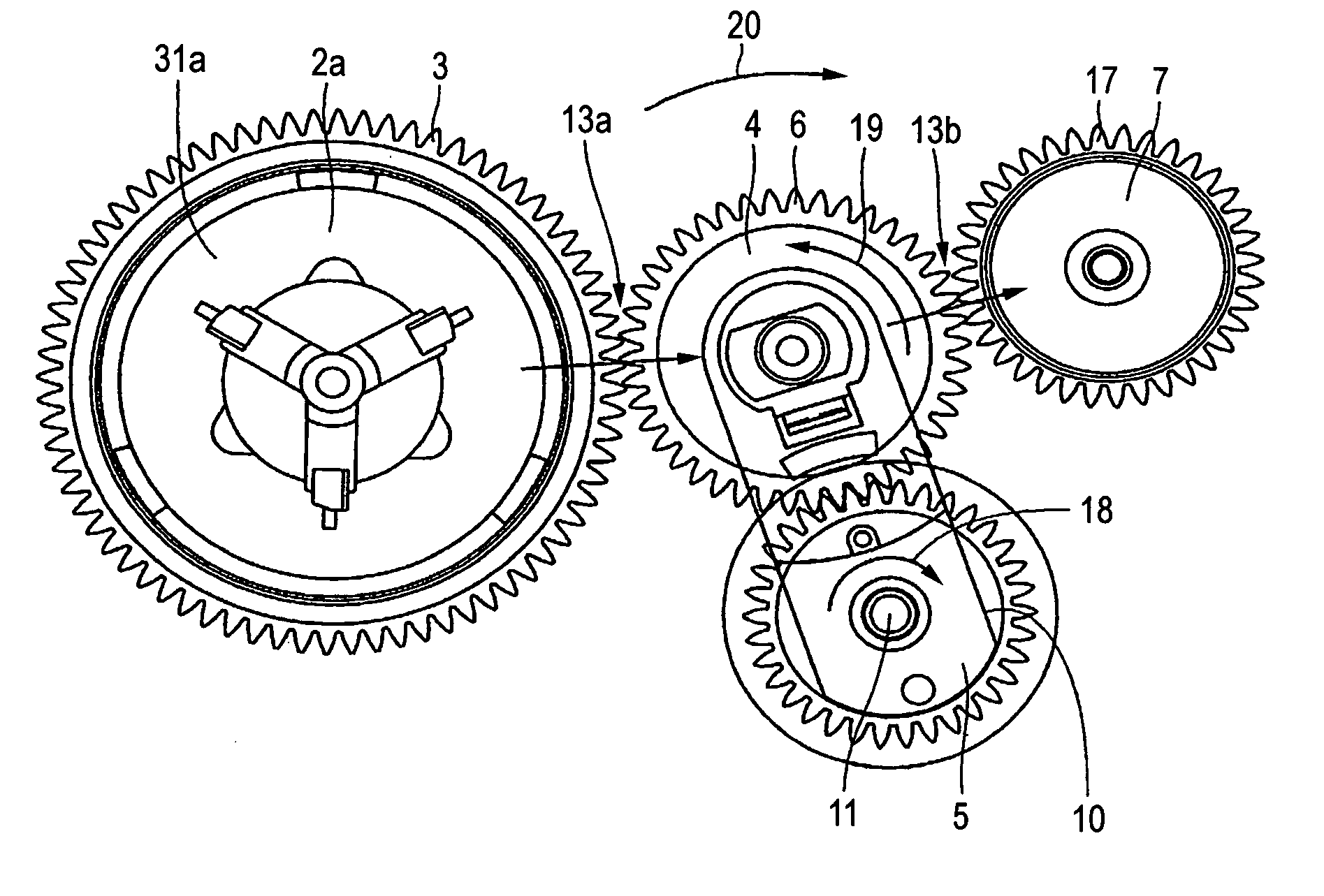

Magnetic recording/reproducing apparatus and electric apparatus

InactiveUS6978959B2Simple structureLow costProjector film strip handlingCamera film strip handlingGear wheelElectrical devices

Owner:FUNAI ELECTRIC CO LTD

Roll sheet holder and tape printer

ActiveUS20050147450A1Improve detection accuracyAvoid partialInking apparatusProjector film strip handlingRolling paperComputer printing

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com