Method of and apparatus for sticking tape on reel hub and method of and apparatus for winding tape on tape reel in tape cartridge

a technology of tape winding and tape end portion, which is applied in the direction of thin material processing, data recording, instruments, etc., can solve the problems of radial winding irregularity, possible excess of stick liquid applied quantitatively, and failure of sticking of tape end portion to the reel hub, etc., and achieves high yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is suitable for use on all types of tape cartridges and has particular application in the assembling of tape cartridges which are compliant with Linear Tape Open (LTO) standard. However, it should be appreciated that the invention has broader application and is not limited to this particular use.

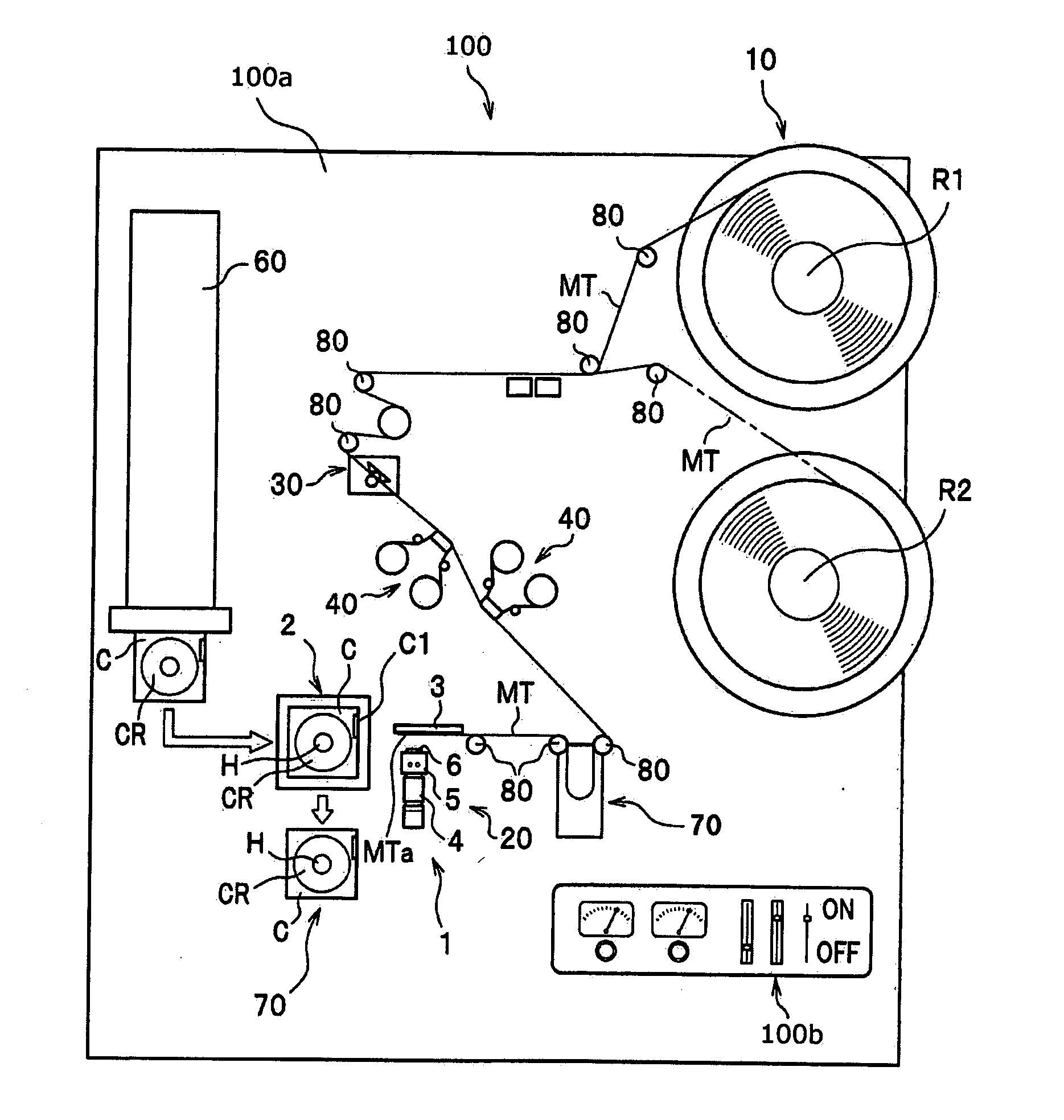

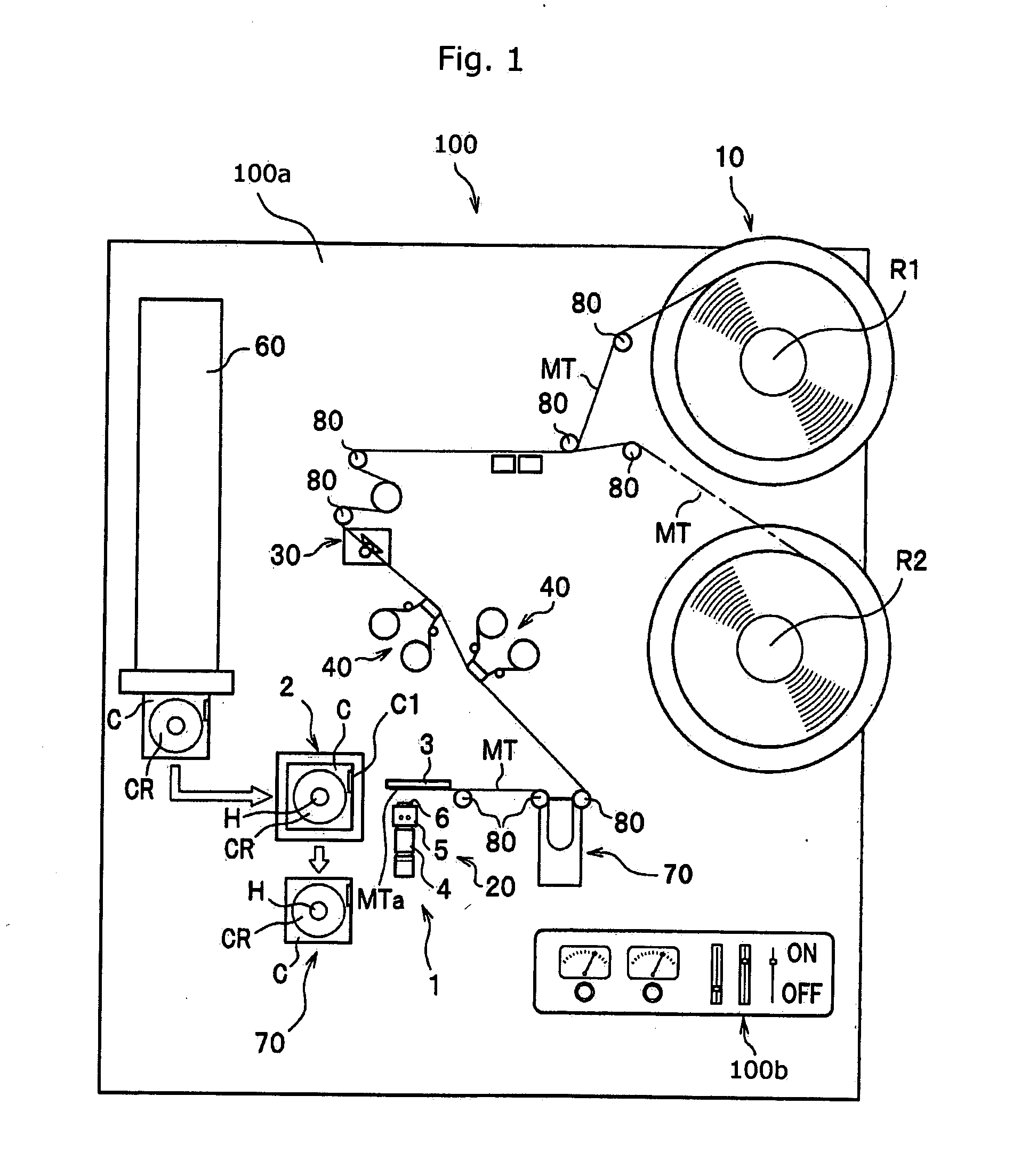

[0028] Referring now to the accompanying drawings in detail, FIG. 1 is a schematic view showing a tape winding apparatus 100 for winding a magnetic tape strip MT onto a reel hub H of a tape reel CR in an empty tape cartridge C. As shown in FIG. 1, the tape winding apparatus 100 winds a predetermined length of magnetic tape strip MT on the reel hub H installed in the cartridge case C. The predetermined length of magnetic tape strip MT is prepared by cutting a magnetic tape stock rolled in the shape like a pancake into rolls of magnetic tape strips MT, each roll having a given tape width, and by cutting the magnetic tape strip MT in a roll into the predetermined l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com