Method and apparatus for assembling magnetic tape cartridge

A cassette tape and equipment technology, applied in magazine/cassette tape manufacturing equipment, packaging, carrier storage devices, etc., can solve the problems of complex structure of assembly point and reduction of cassette tape production volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

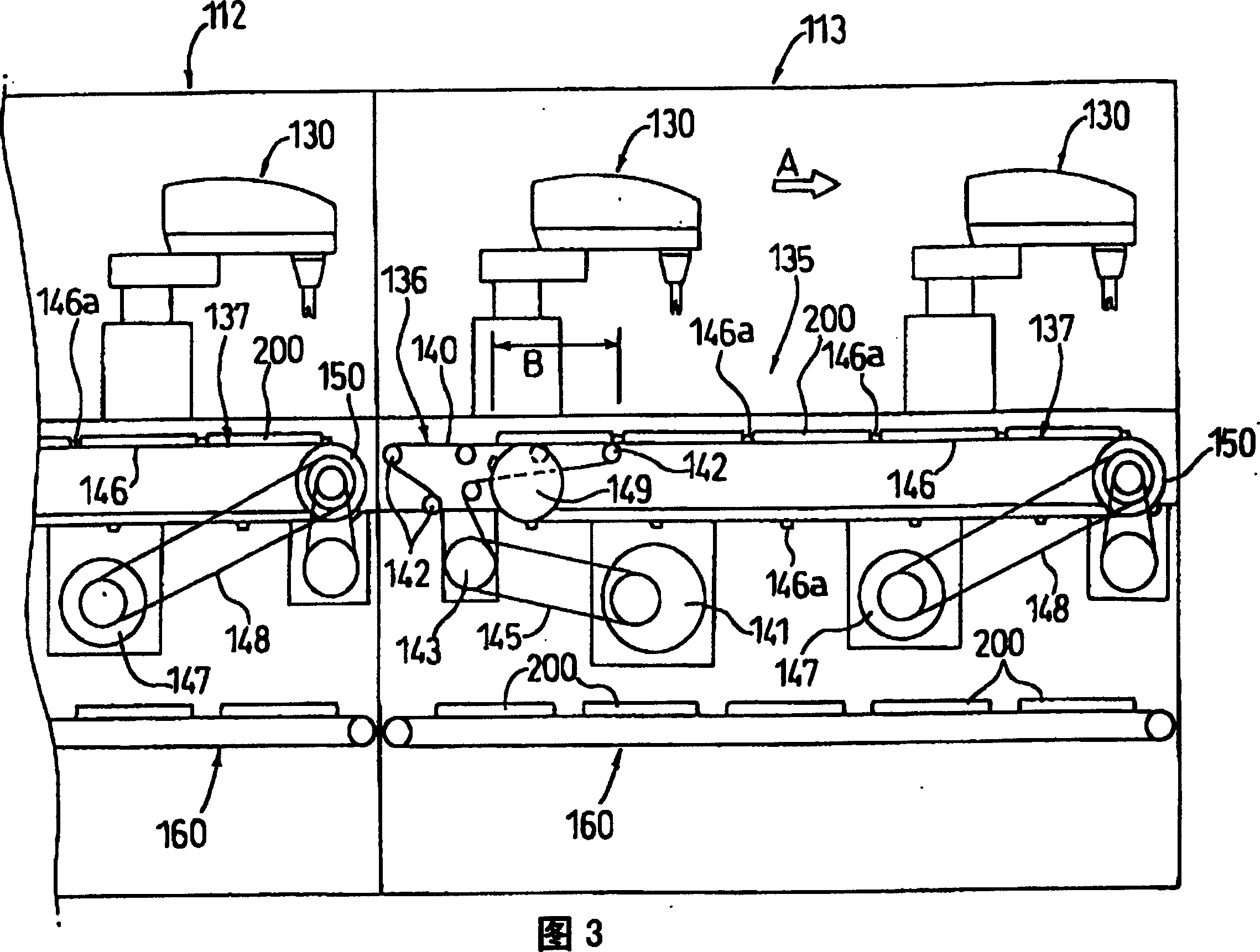

[0037] The method and apparatus for assembling a magnetic tape cassette of the present invention will be described in detail below based on the embodiments and with reference to the accompanying drawings. Incidentally, since the structure adopted by the cassette tape according to the embodiment of the present invention is similar to the above-mentioned conventional cassette tape 1, in the present embodiment, the reference numerals used for its parts are the same as Figure 13 The same reference numerals are used in , and their detailed descriptions are omitted here.

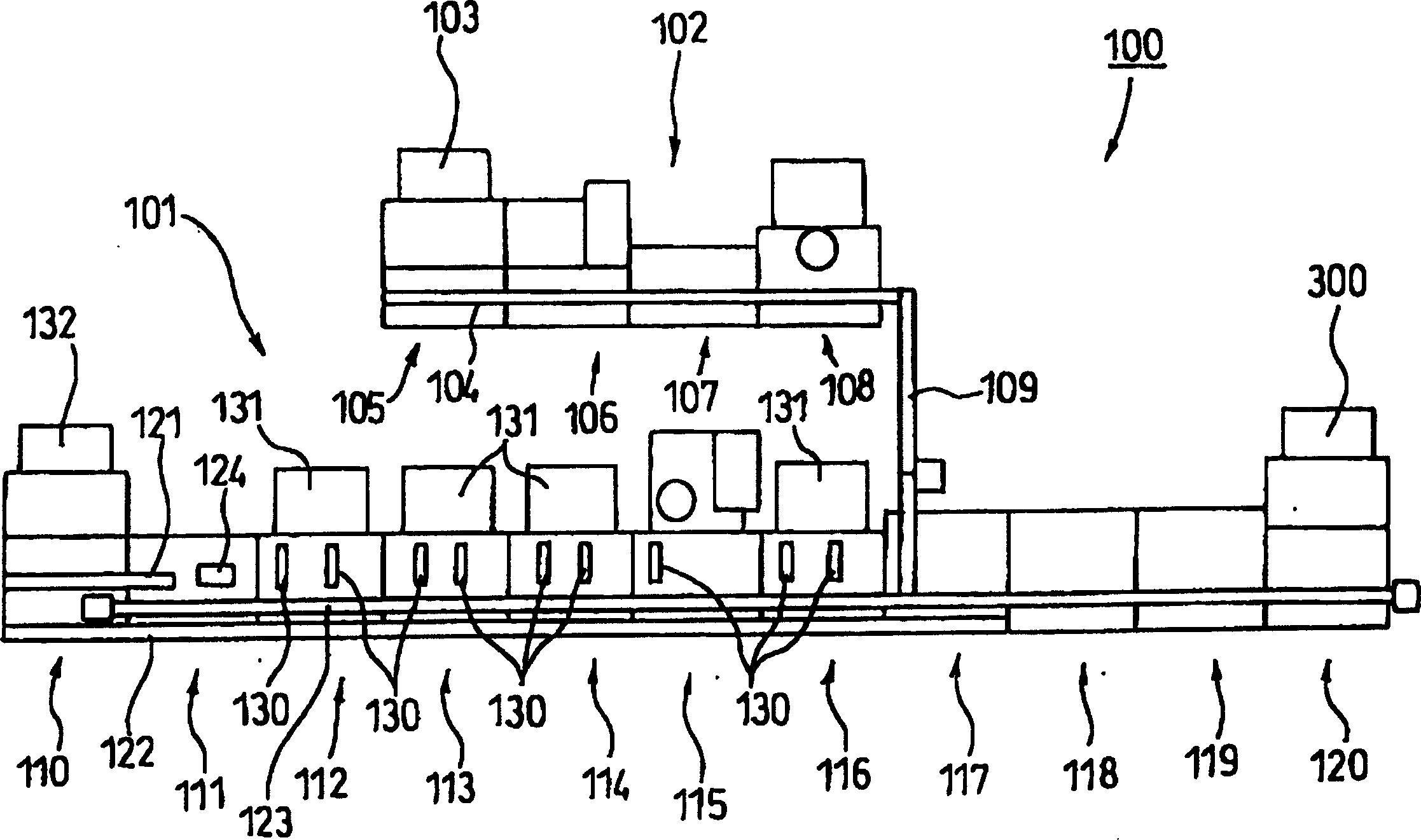

[0038] Such as figure 1 The illustrated cassette assembly apparatus 100 according to the present invention mainly includes a cassette assembly line 101 and a tape reel assembly line 102 .

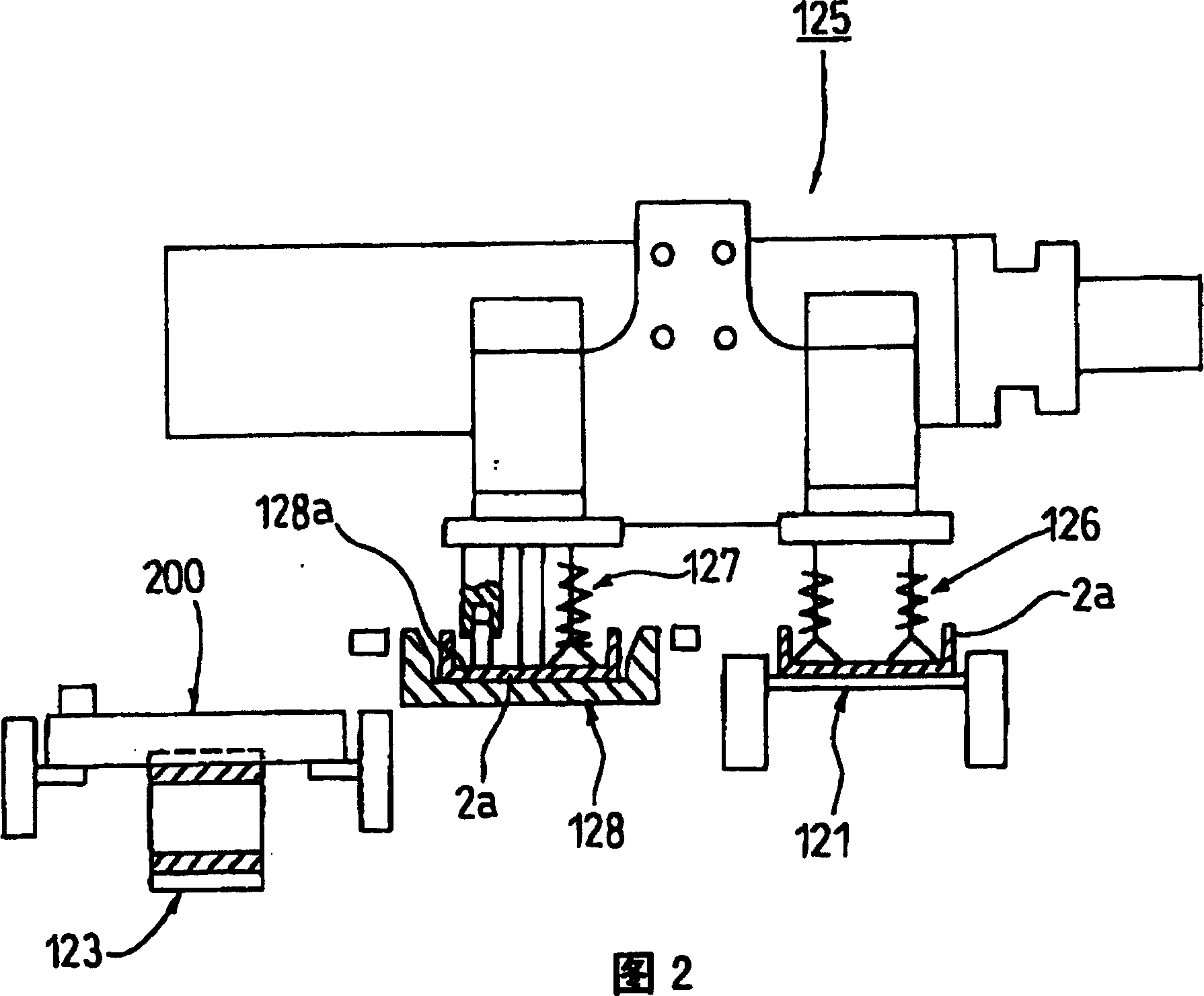

[0039] The reel assembly line 102 includes an upper reel feed point 105 for feeding the upper reel 4 from within the parts container 103 onto the belt conveyor 104, and a lower reel feed / welding point 106 for feeding the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com