Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

96results about "Fabrics trimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

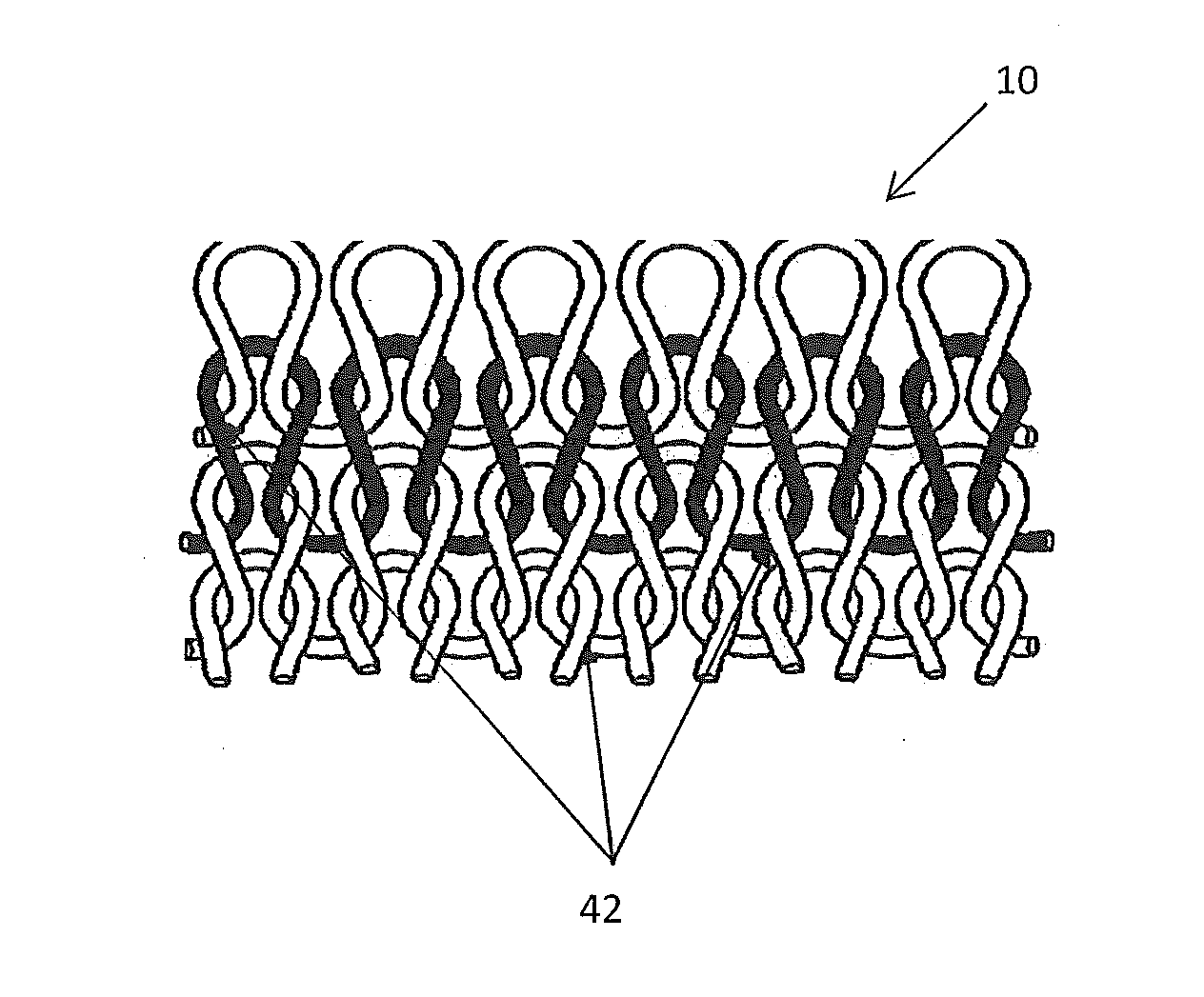

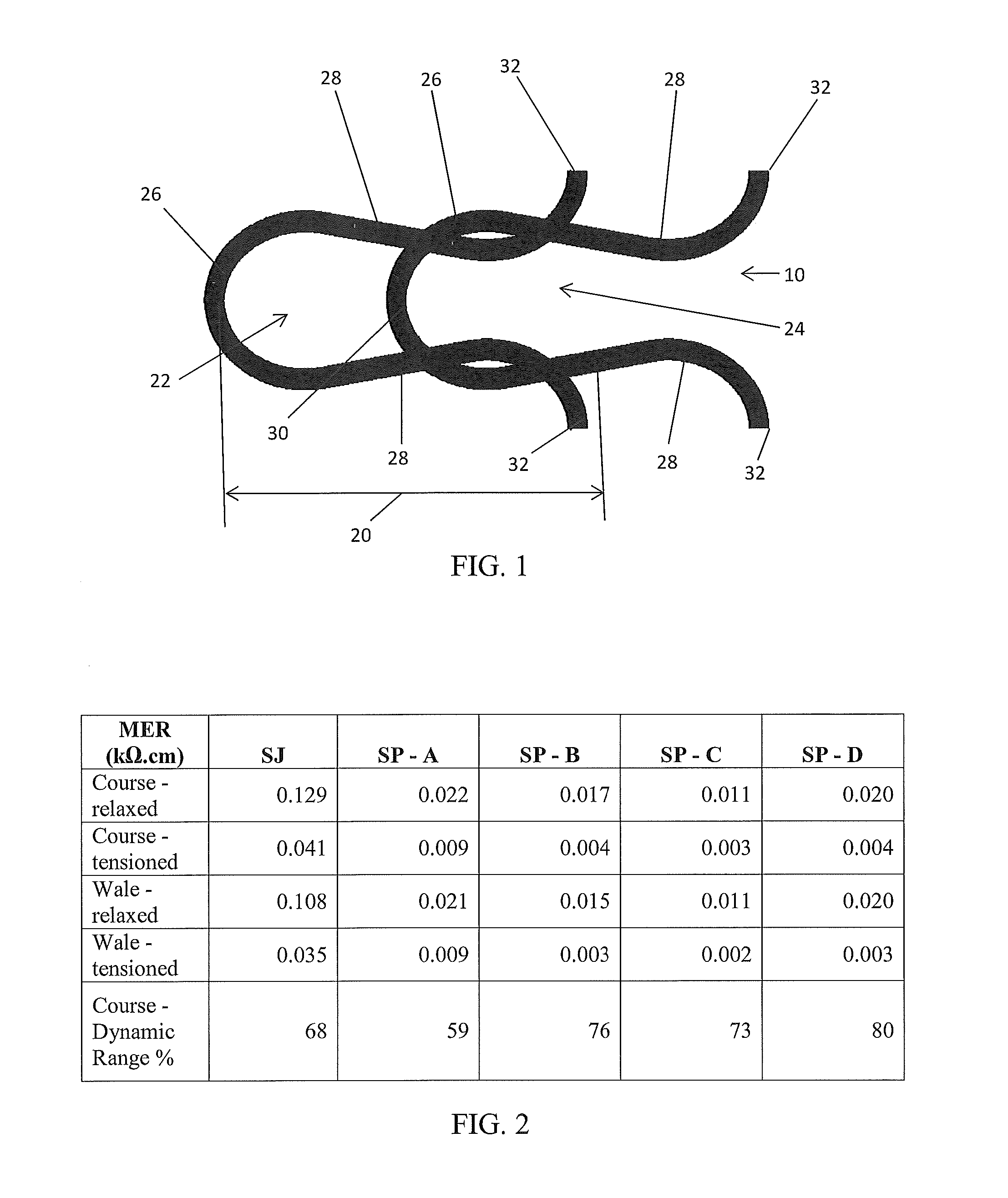

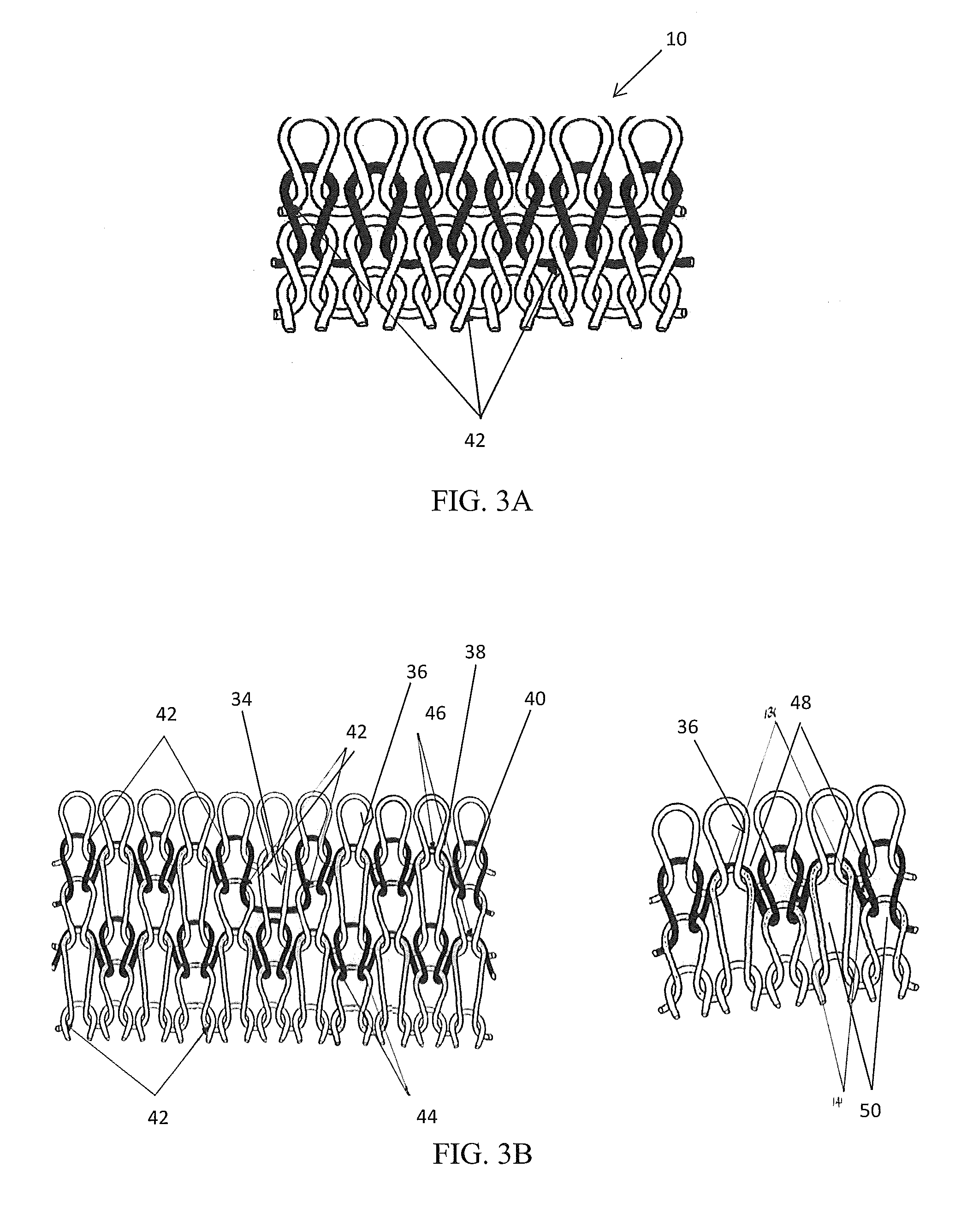

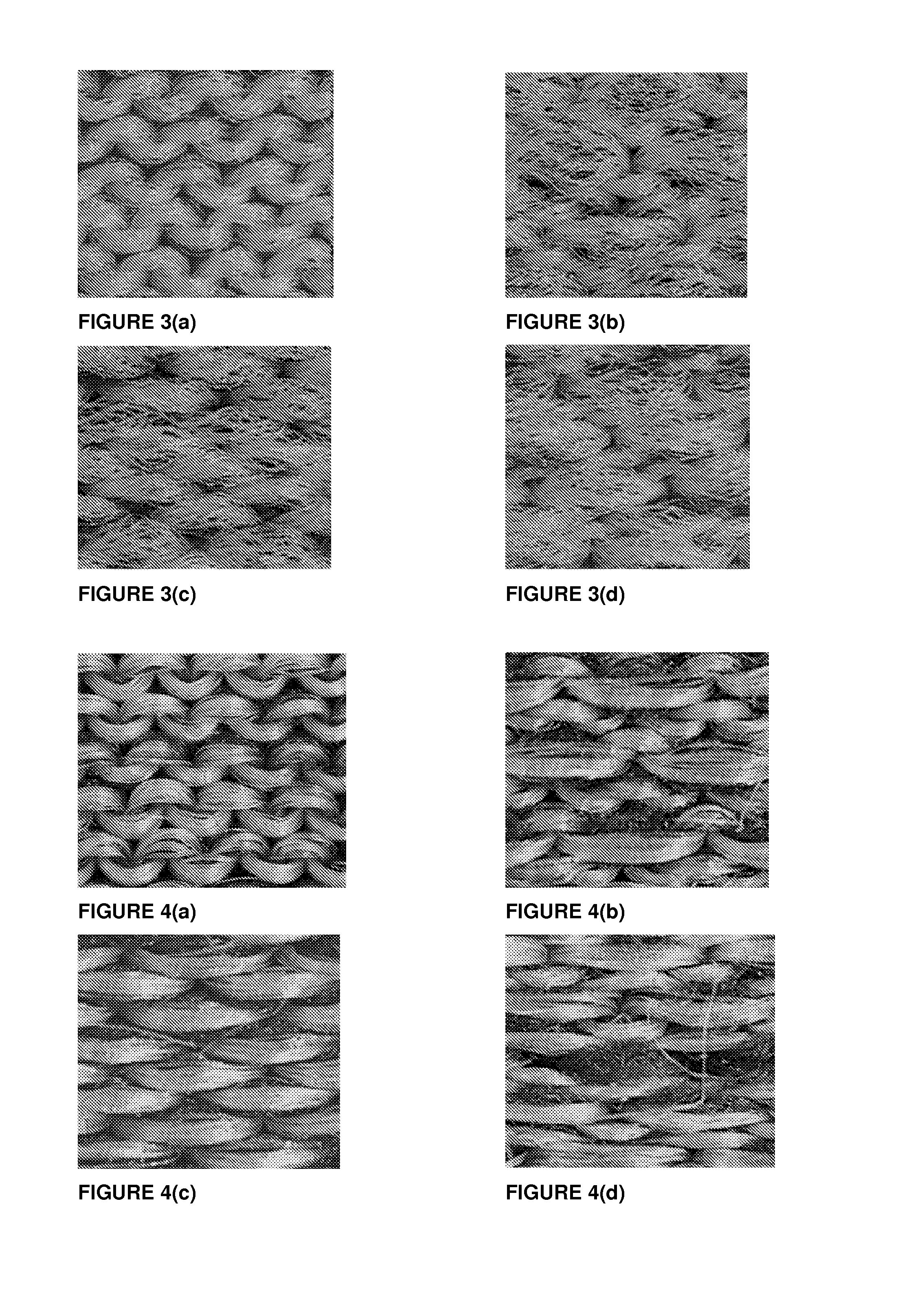

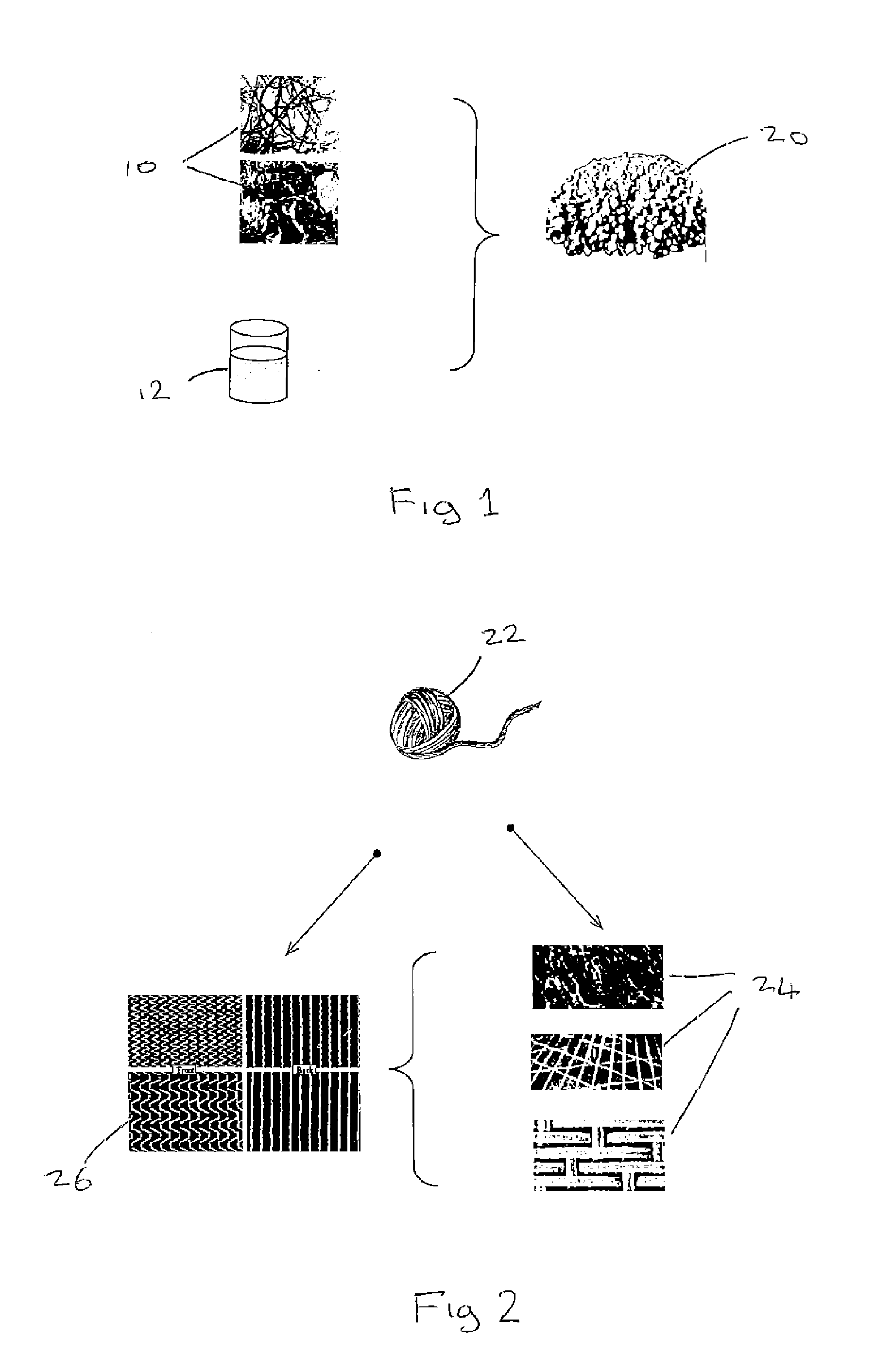

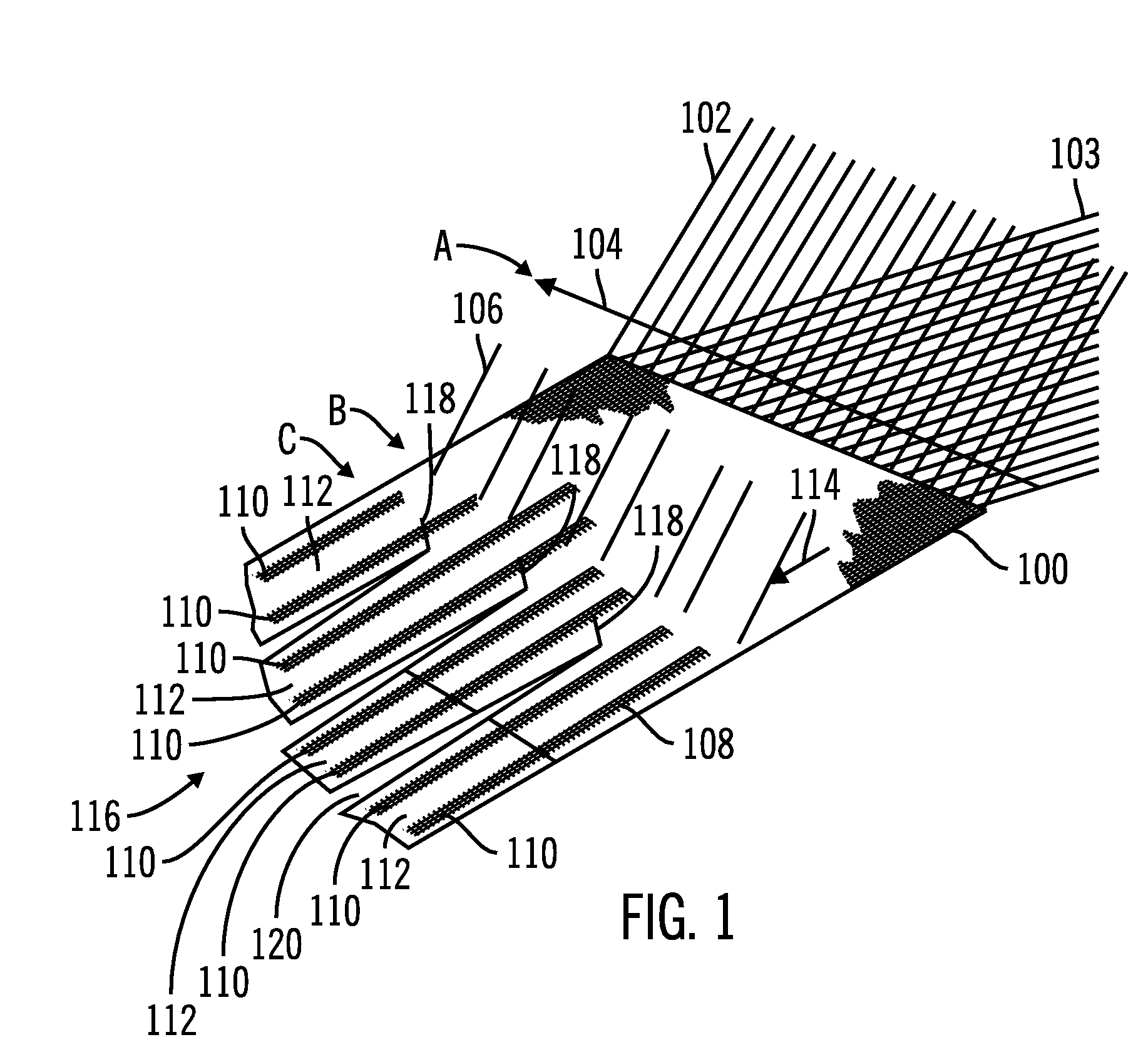

Method for making electrically conductive textiles and textile sensor

ActiveUS20160186366A1Automatically calibratingIncrease contact resistanceCrochetingOrnamental textile articlesYarnElectrical resistance and conductance

A method for making a textile sensor and a textile sensor can include selecting a combination of variables from the group consisting of yarn variables, stitch variables, and textile variables; and knitting an electrically conductive yarn in the textile sensor in accordance with the selected combination of variables, wherein the combination of variables is selected so as to provide a controlled amount of contact resistance in the textile sensor. The method and textile can further include a capacitive textile-sensor having at least two integrally knit capacitor plate elements and having a configuration adapted for a sensing activity. Resistance in the textile sensor can automatically calibrate to a stable baseline level after the textile sensor is applied to a body.

Owner:FOOTFALLS & HEARTBEATS (UK) LTD

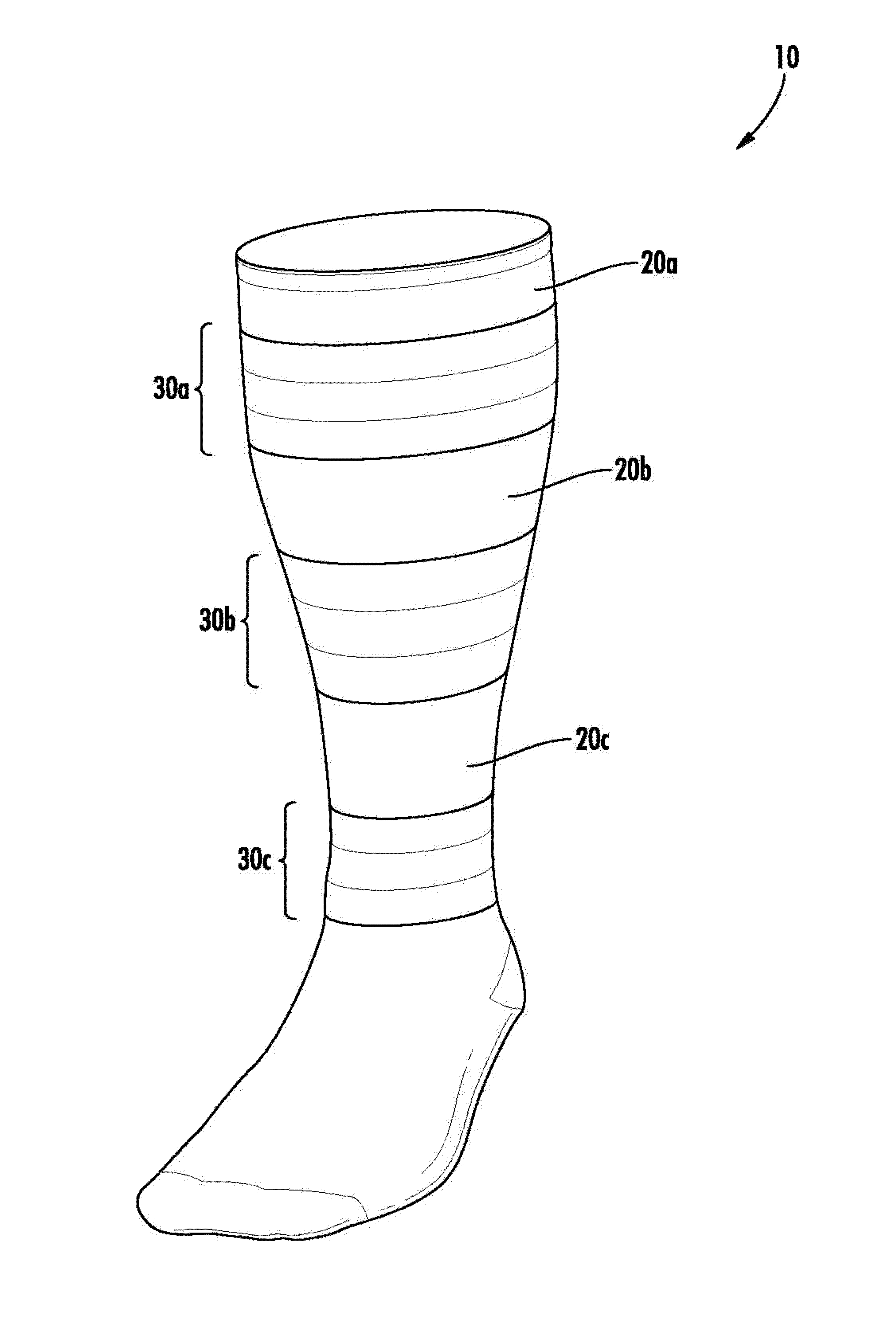

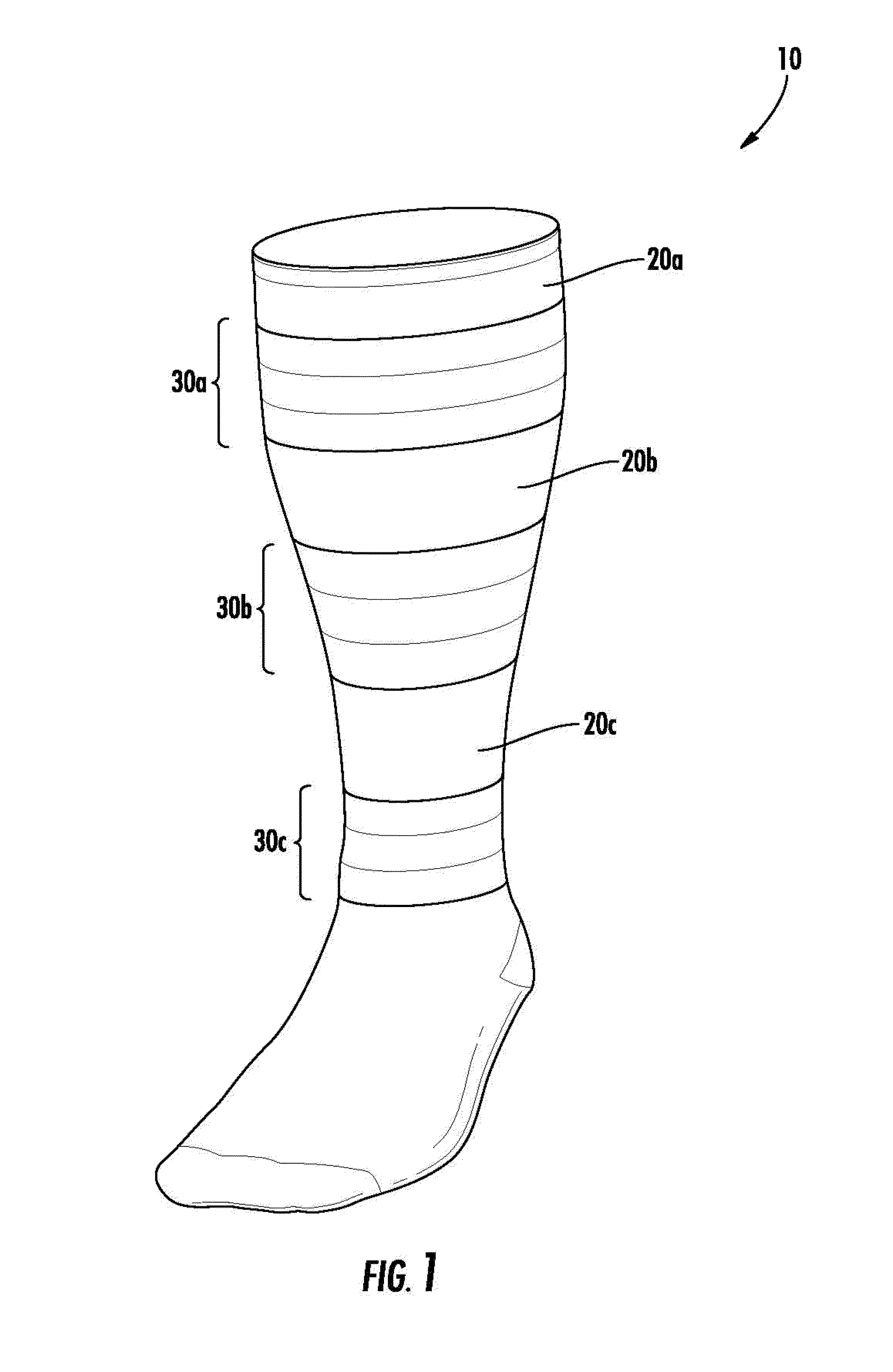

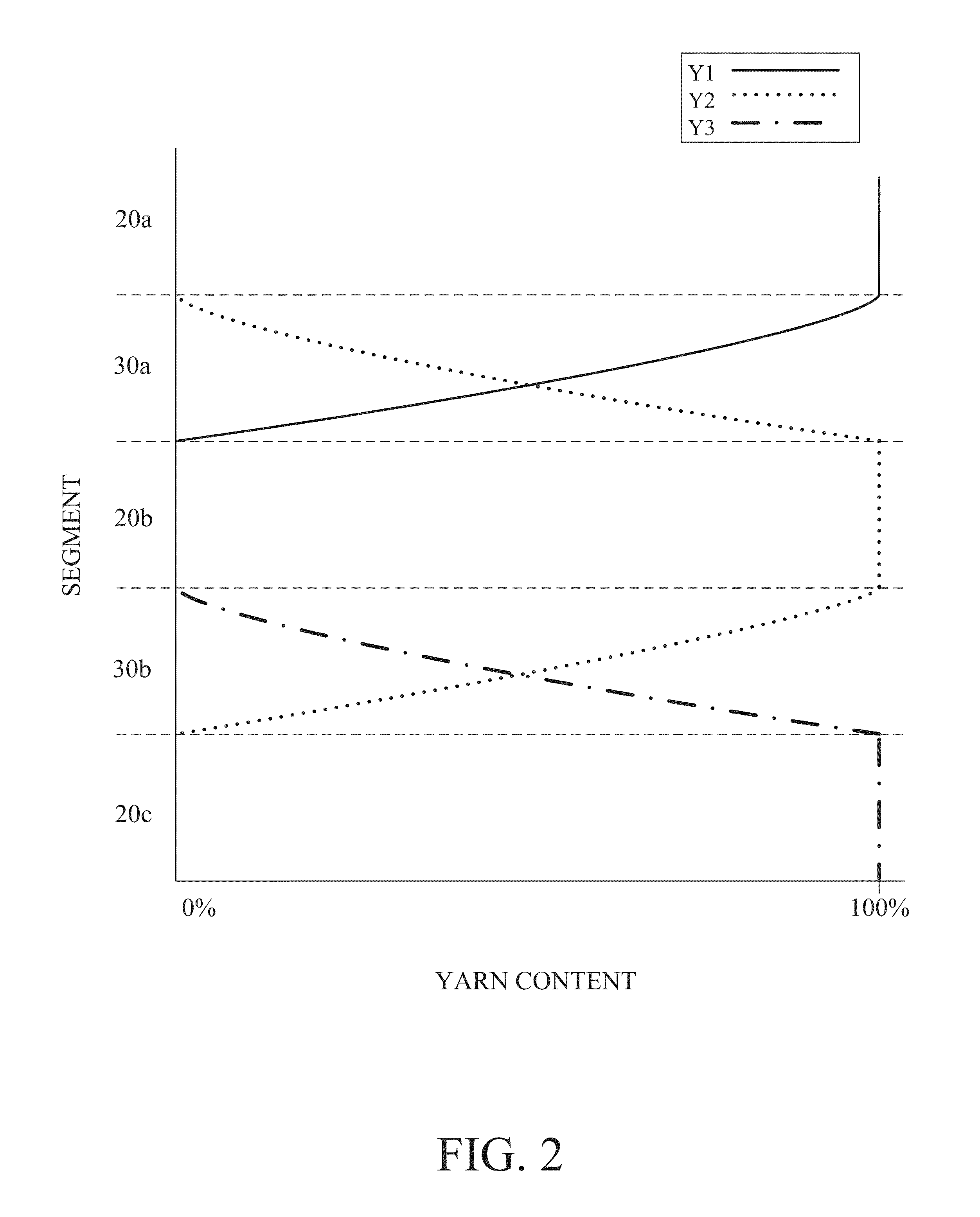

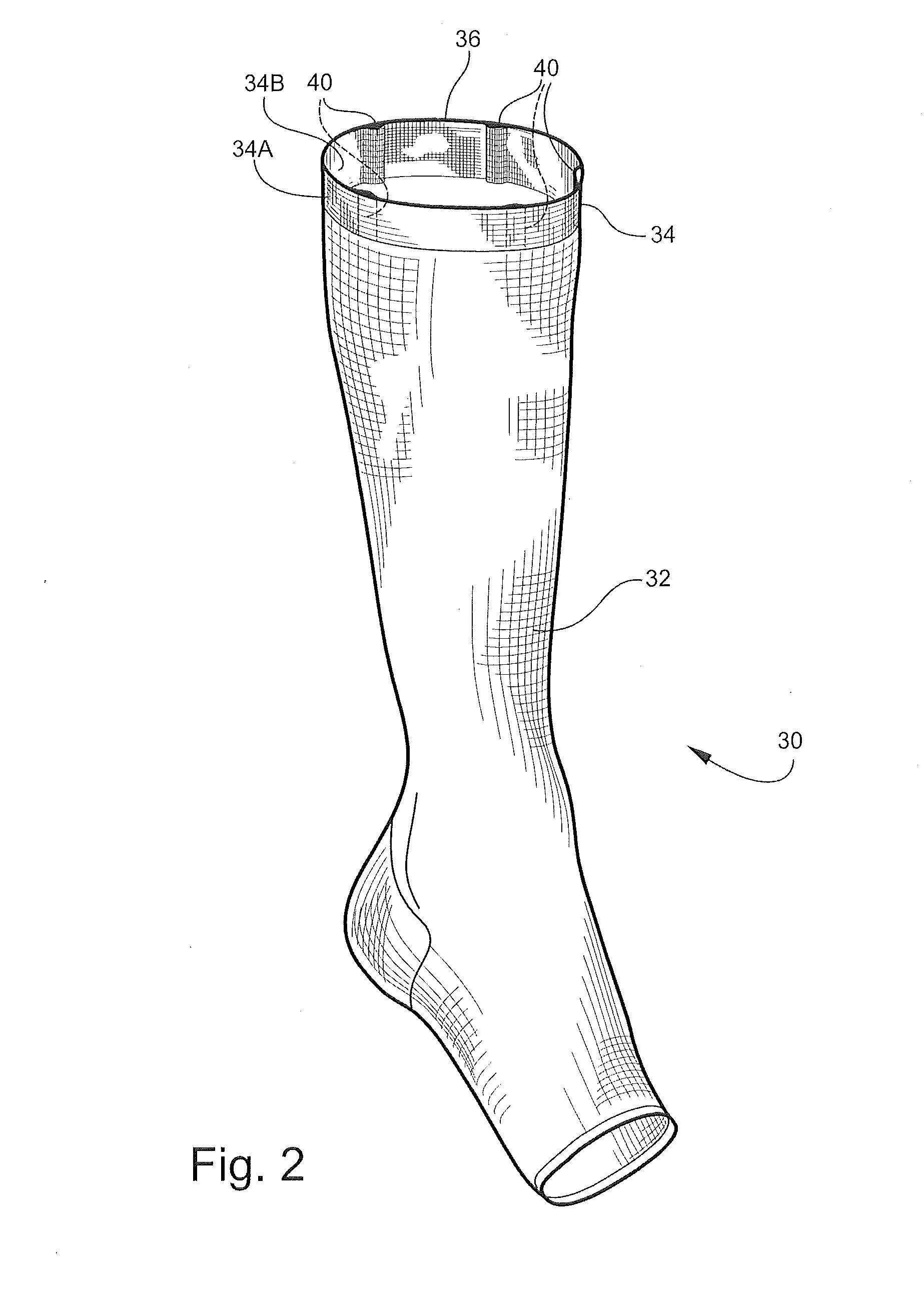

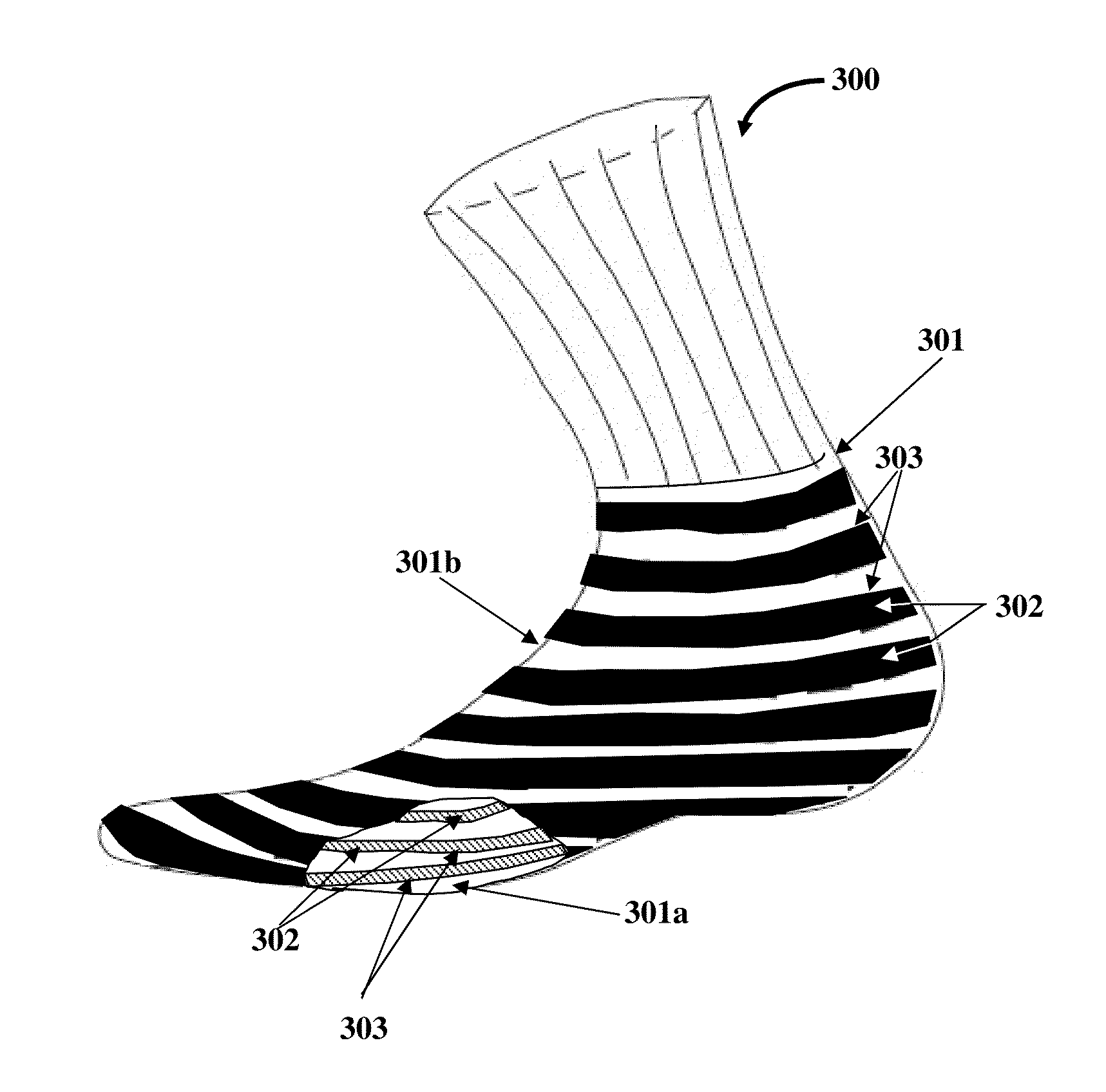

Compression fabrics with tailored comfort

Certain embodiments according to the invention provide compression articles suitable for a wide variety of uses (e.g., compression socks, athletic garments, etc.). In accordance with certain embodiments, the compression article includes at least two uniform compression regions, including a first uniform compression region having a first compression pressure and a second uniform compression region having a second compression pressure, and at least one transitioning compression region, including a first transitioning compression region positioned between the first and second uniform compression regions. The first transitioning compression region comprises a first end adjacent or proximate to the first uniform compression region and a second end adjacent or proximate to the second uniform compression region. The first transitioning compression region comprises a compression pressure gradient extending from the first end to the second end of the first transitioning compression region.

Owner:MYANT CAPITAL PARTNERS

Novel composite parts, methods and apparatus for manufacturing the same

Owner:UNIVERSITY OF OTTAWA

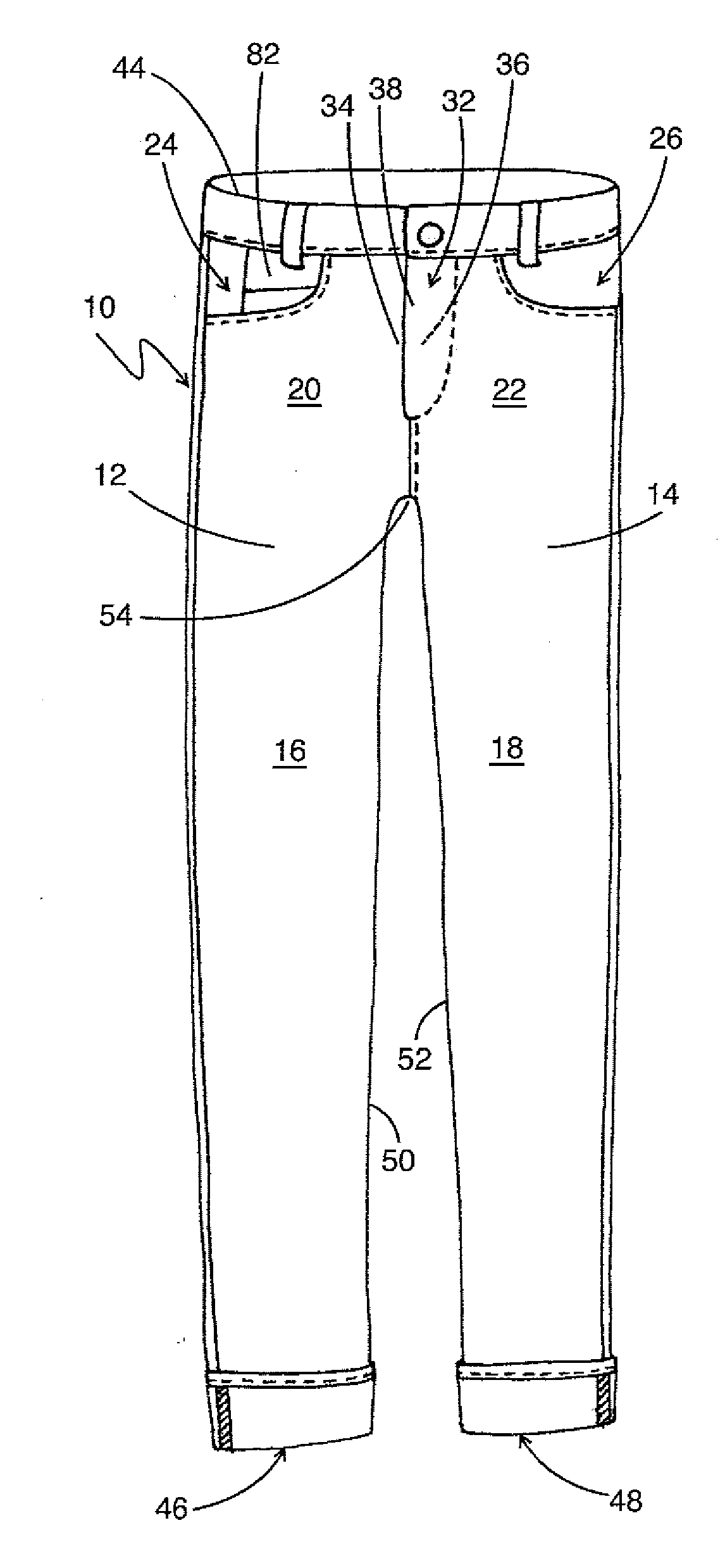

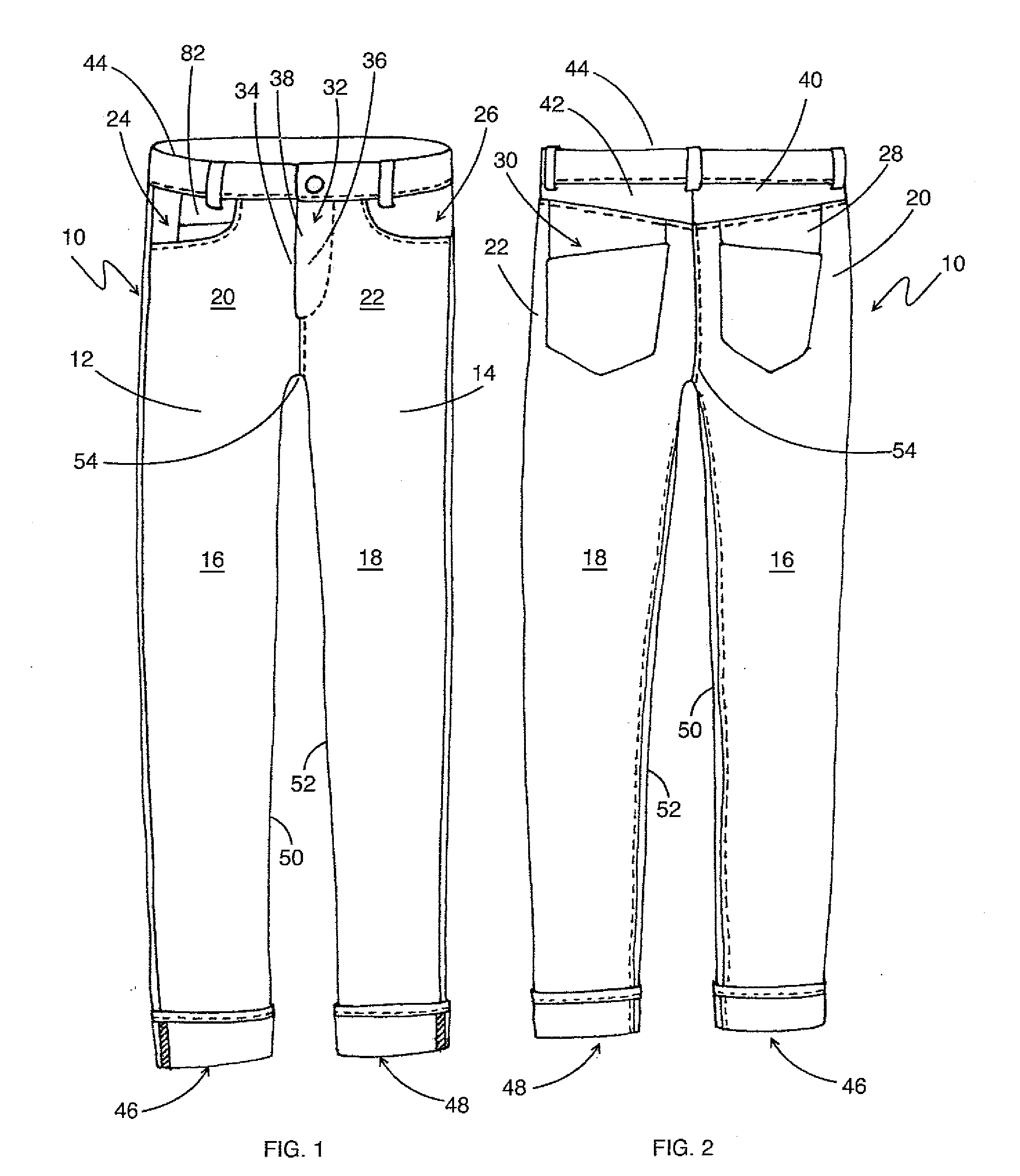

Methods for producing and merchandising a custom fit pant and custom fit pants

Methods for producing a pant, pants and methods for merchandising a pant. A pant is produced at a production facility by weaving right and left portions thereof using a multi-layer weaving process so as to produce an outer woven fly-cover layer and an inner woven left fly extension layer, or to form at least one pocket in at least one such portion, or both, and attaching the left portion of the pant to the right portion of the pant by stitching at least a portion of the crotch seam. The pant is then finished at a point of sale by stitching any remaining portion of the crotch seam and the inseams based on body dimensions and preferences of a purchaser to provide a custom fit. A pant produced at least in part by these steps is also presented.

Owner:CANDRIAN NATALIE A

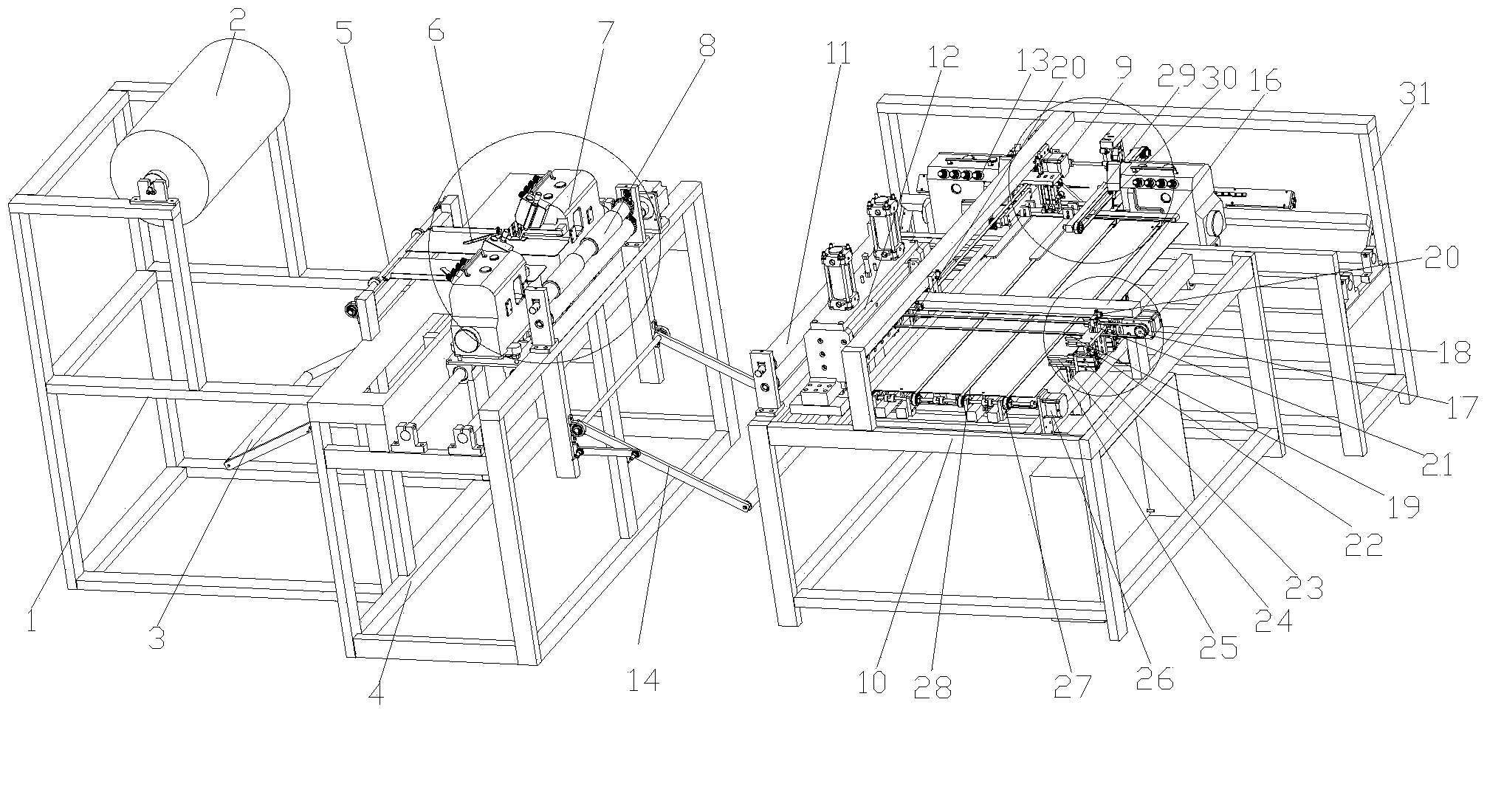

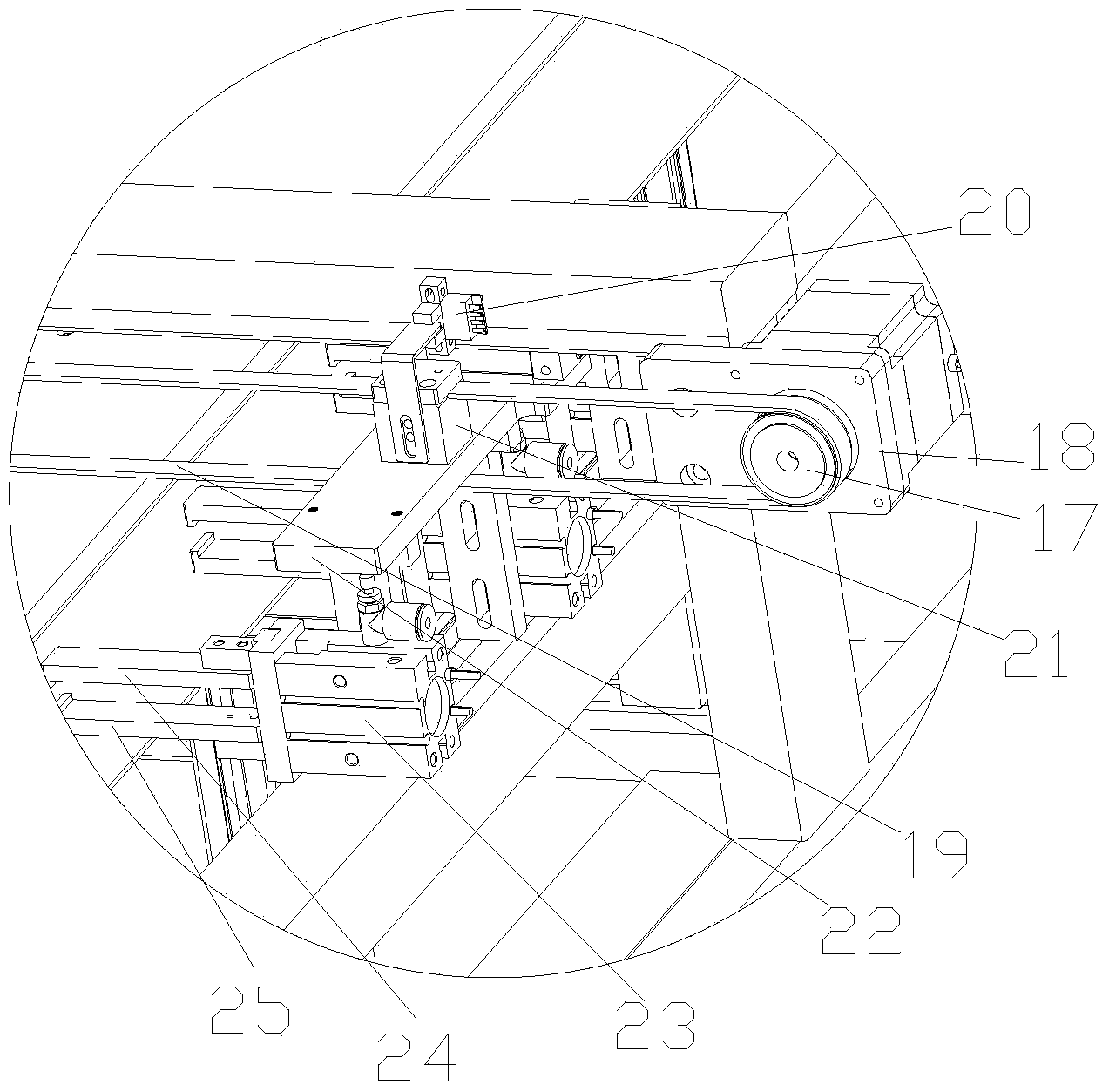

Towel machine with high product quality

ActiveCN103757827AReduce labor intensityReduce manufacturing costWork-feeding meansPressersUltimate tensile strengthAutomation

The invention discloses a towel machine with high product quality. The towel machine comprises a feeding device, a serging device, a manufacturing device and a hot melting device. The feeding device is fixedly connected with the serging device. The manufacturing device and the serging device are arranged in a relatively fixed mode. The hot melting device is arranged on the side face of the manufacturing device. Cloth is fed into the serging device by the feeding device. Primary double-side serging is carried out on the cloth fed by the feeding device by the serging device. Secondary double-side serging is carried out on the cloth by the manufacturing device after the cloth discharged out of the serging device is cut off. The hot melting device carries out hot melting on the cloth discharged out of the manufacturing device. According to the towel machine with the high product quality, mechanical automation replaces the original manual operation to produce towels, the labor intensity of workers is lowered, product production efficiency is stably improved, production cost is lowered, production can be effectively managed, and practical high production requirements are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Method of forming composite absorbent members

InactiveUS6932929B2High weight percentageSmall diameterCrochetingInspecting textilesFiberEngineering

A method for forming a composite absorbent member is provided that includes:a) extruding a first fibrous component through a first meltblowing die and intermingling pulp fibers with the first fibrous component to form a first admixture;b) extruding a second fibrous component through a second meltblowing die and intermingling pulp fibers with the second fibrous component to form a second admixture; andc) codepositing the first and second admixtures on a collecting surface so as to form a composite structure having at least a first layer and a second layer. The second layer has a higher weight percentage of pulp fibers than the first layer, and the average diameter of the pores within the second layer is smaller than the average diameter of the pores within the first layer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

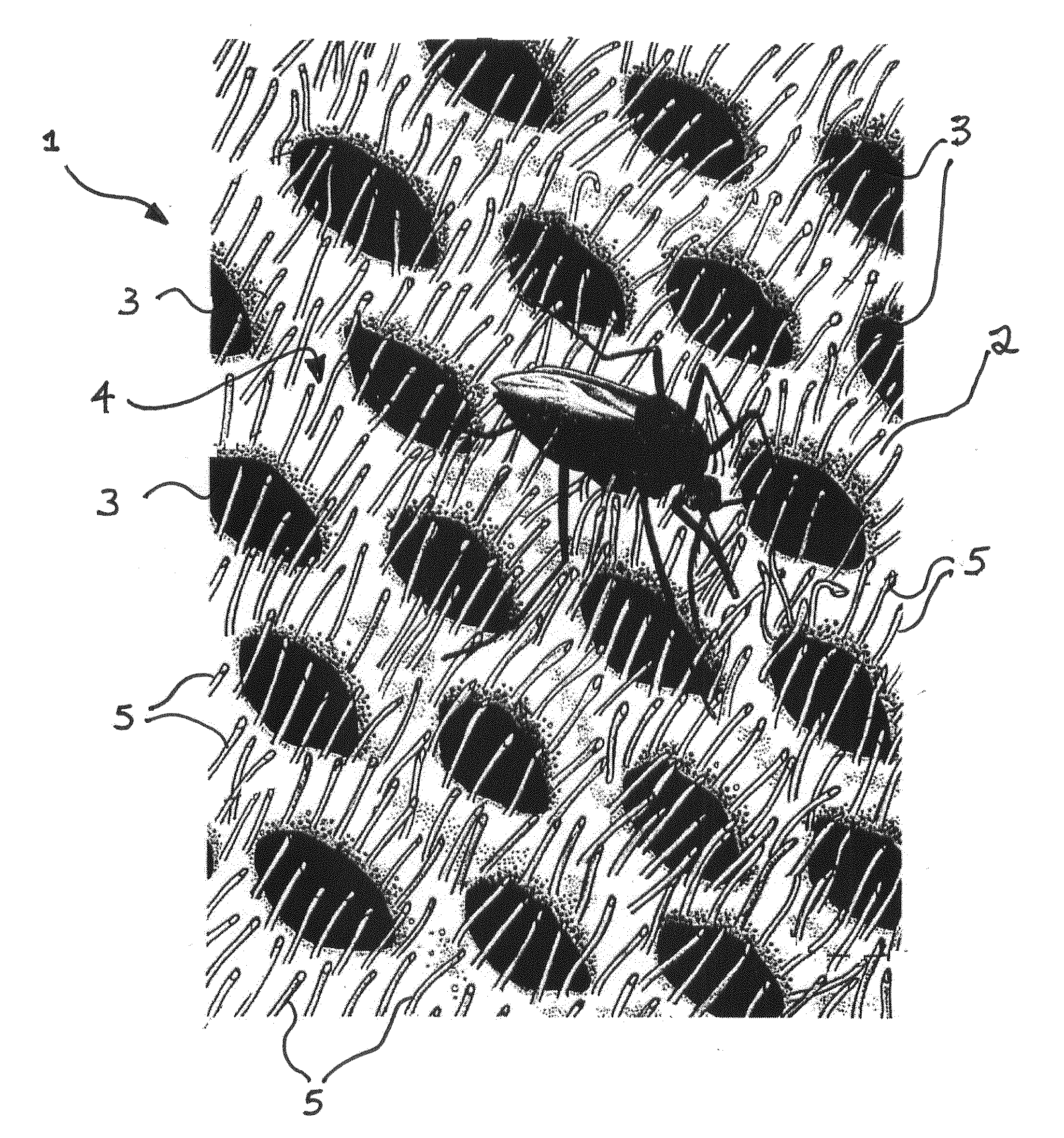

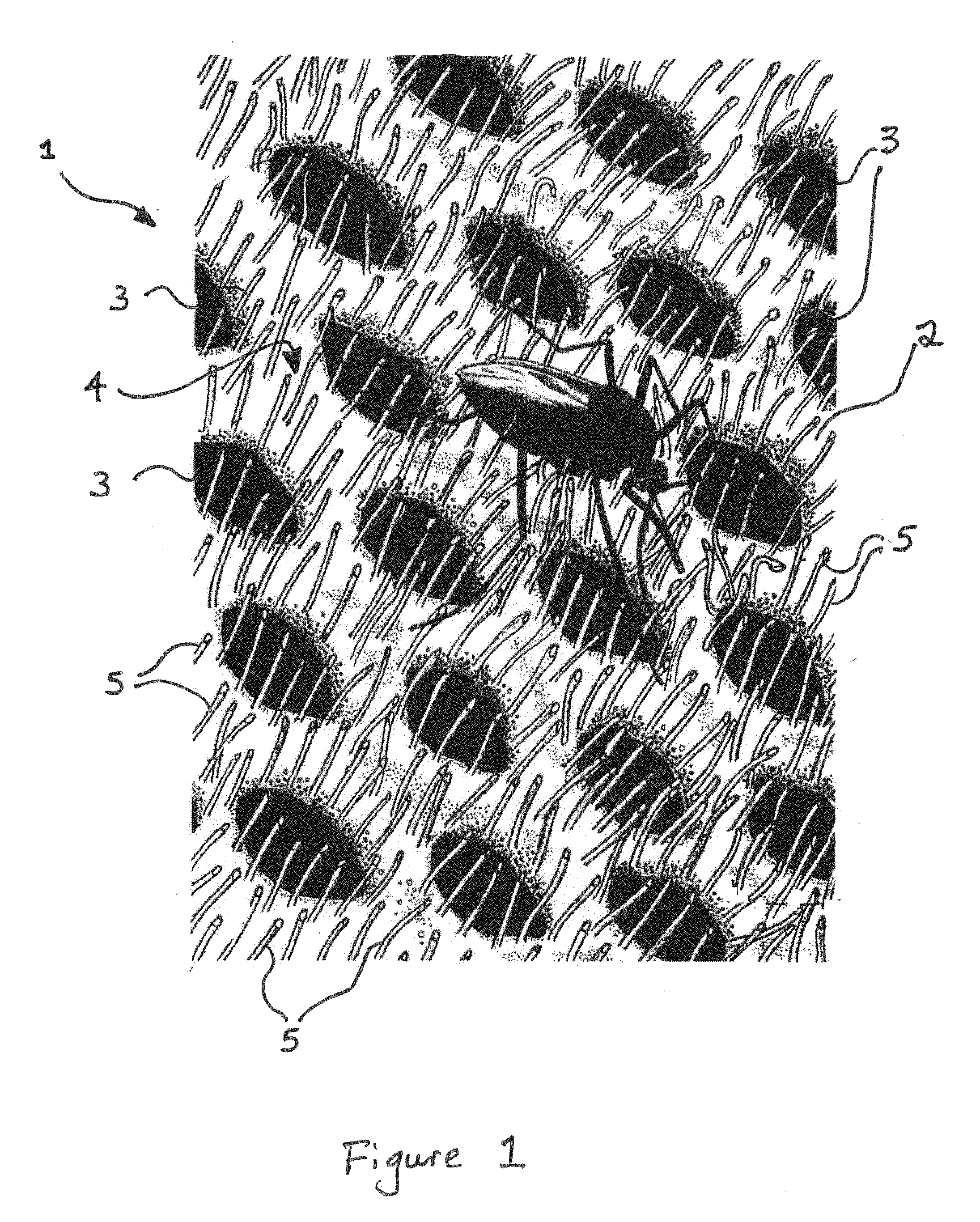

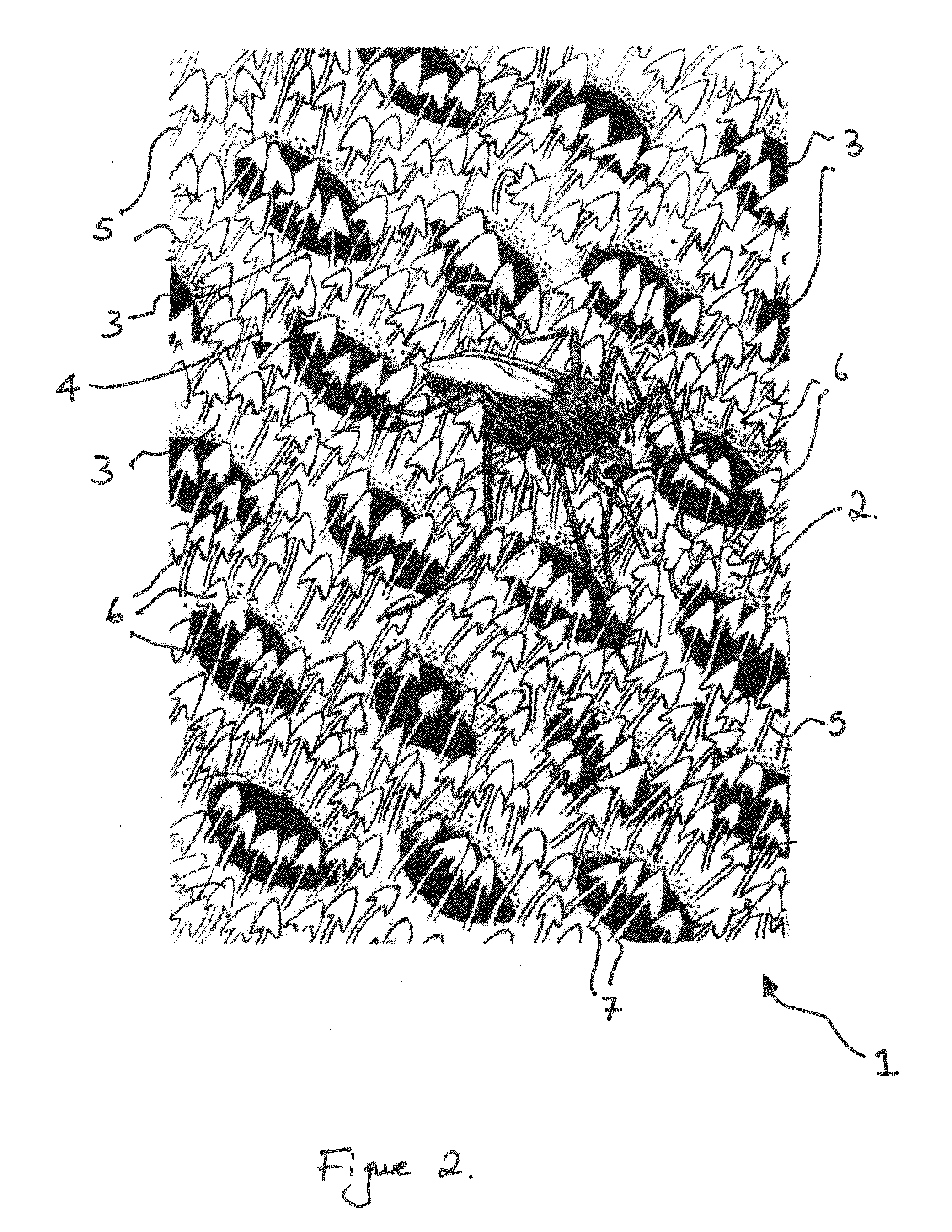

Pest control materials

InactiveUS20140041285A1Facilitate abrasionFacilitate mechanical interactionCrochetingTravelling sacksPaleontologyPest control

An open mesh insect control material is described which includes an insect contact surface, an internal surface, apertures communicating both surfaces and a plurality of filamentous projections protruding from the insect contact surface the projections at least partly occlude the apertures. The structure is suitable for use in pest control especially as a mosquito net.

Owner:INSECTSHIELD

Fabric system

ActiveUS20160017521A1Suitable for useReduce harmCrochetingOrnamental textile articlesMedicinePolyurethane

A composite yarn comprising one or more ultra-high molecular weight polyethylene fibres wrapped around one or more polyurethane-polyurea copolymer fibres.

Owner:GRT DEV PTY +1

Weaving method for producing a plurality of moisture sensors for a device for monitoring a patient access

ActiveUS20130075018A1Produced cost-effectivelyLow production costCrochetingLiquid/gas/vapor article treatmentBlood treatmentsElectrical conductor

A weaving method for producing a plurality of moisture sensors for a device for monitoring an access to a patient, in particular for monitoring the vascular access in an extracorporeal blood treatment, wherein the moisture sensors are woven. During the weaving of the moisture sensors, non-conductive warp threads, non-conductive weft threads, conductive warp threads and conductive weft threads are disposed in the textile two-dimensionally extending structure, such that spatially demarcatable structures of electrical strip conductors are created. The strip conductor structures can be produced by spatial separation or contacting of the conductive warp or weft threads. In order to be able to produce the moisture sensors cost effectively in large numbers, a plurality of individual moisture sensors are repeatedly woven each time beside one another normal to the production direction on a common woven fabric web as the web progressively advances, so that the width of the woven fabric web is occupied in the best possible way by as many moisture sensors as possible. The individual moisture sensors are separated from one another after weaving.

Owner:FRESENIUS MEDICAL CARE DEUTSCHLAND GMBH

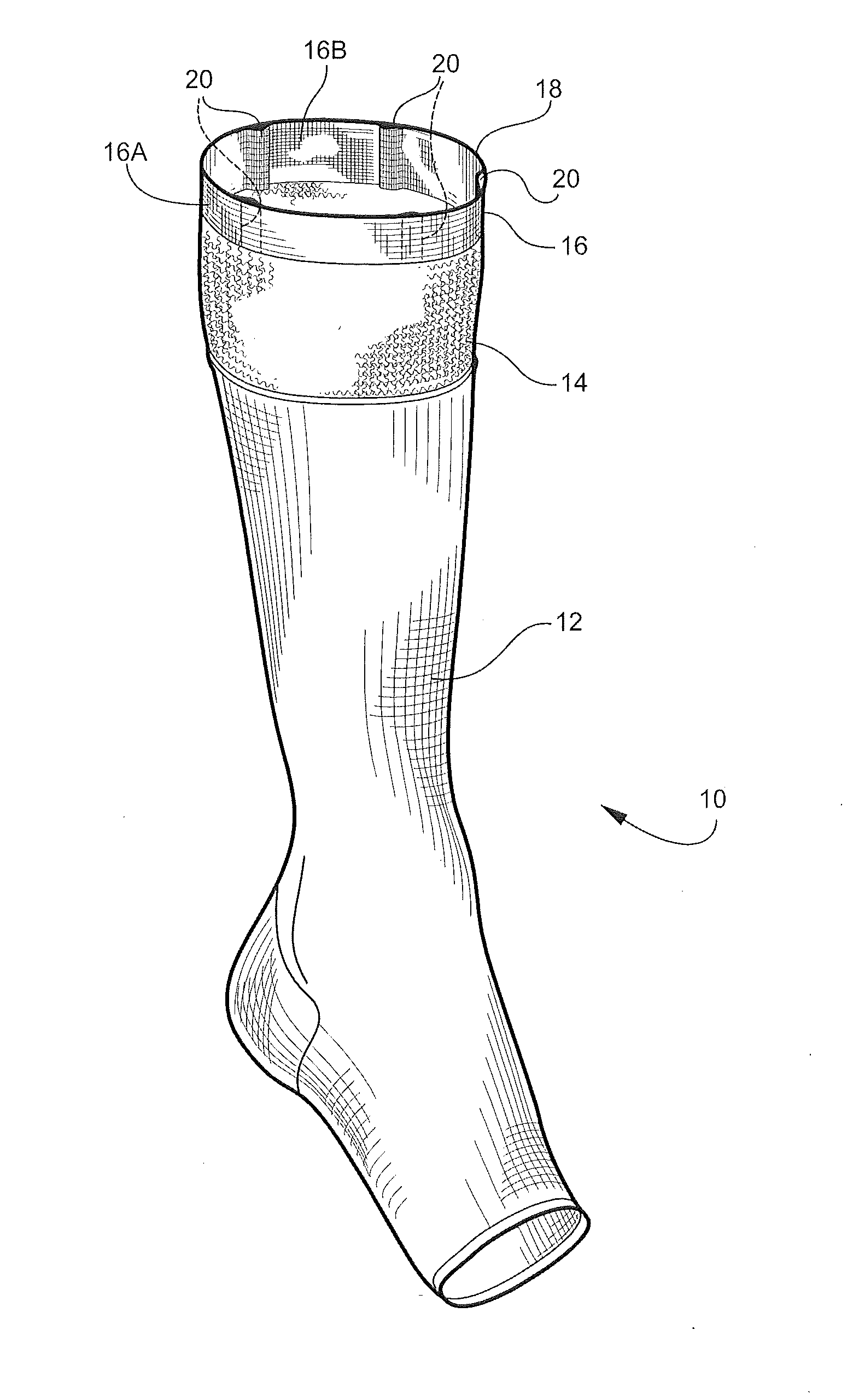

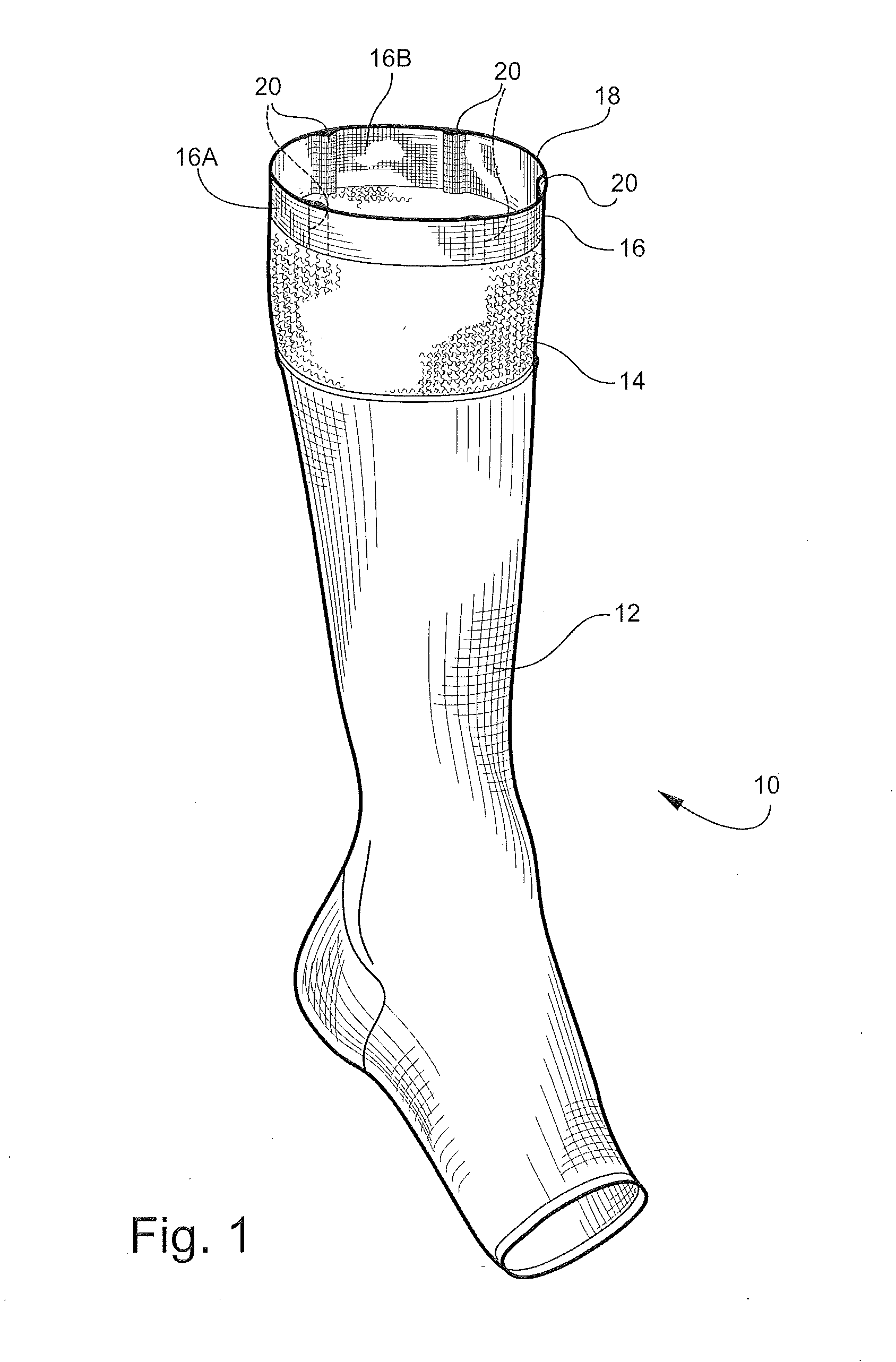

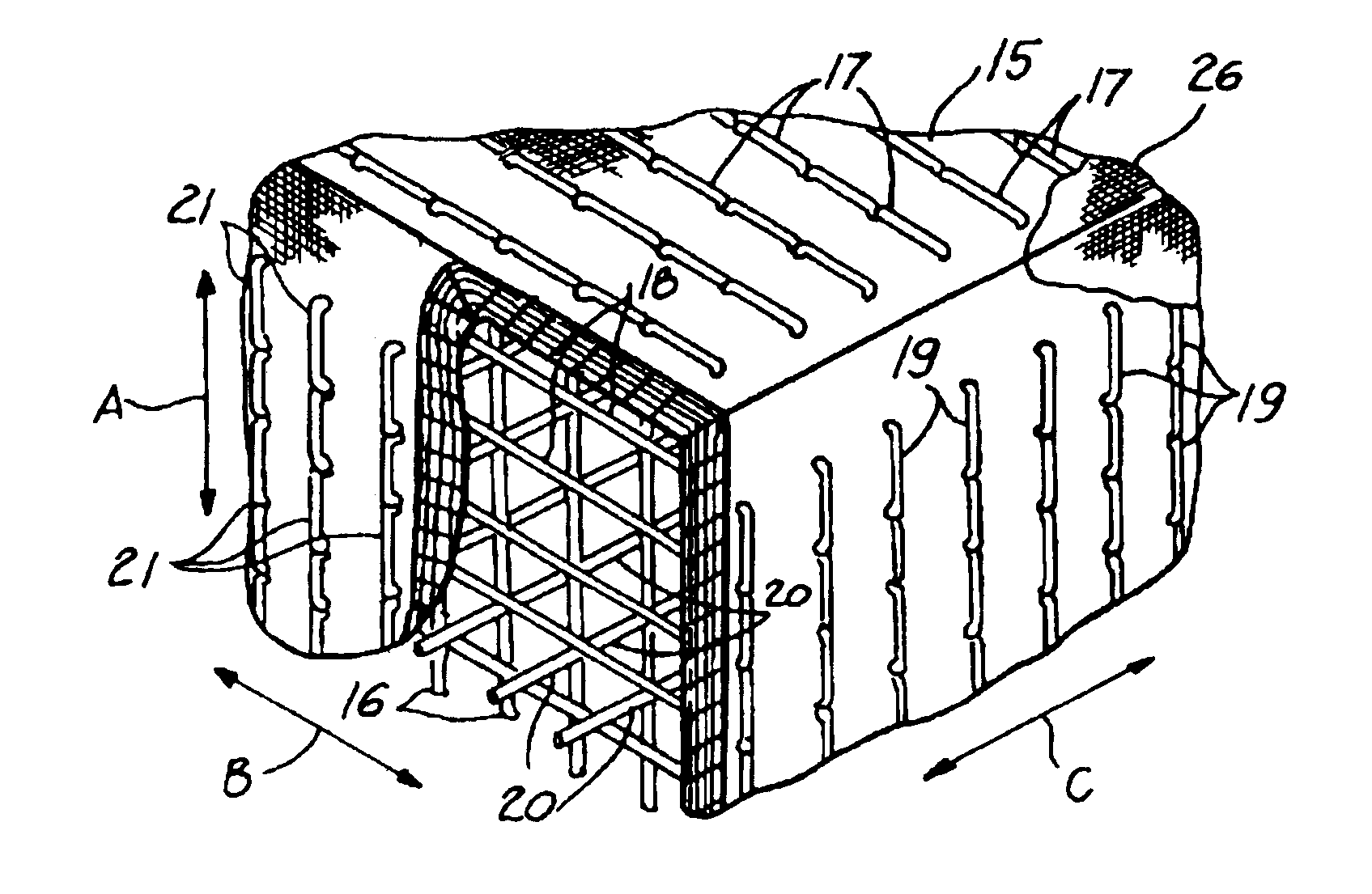

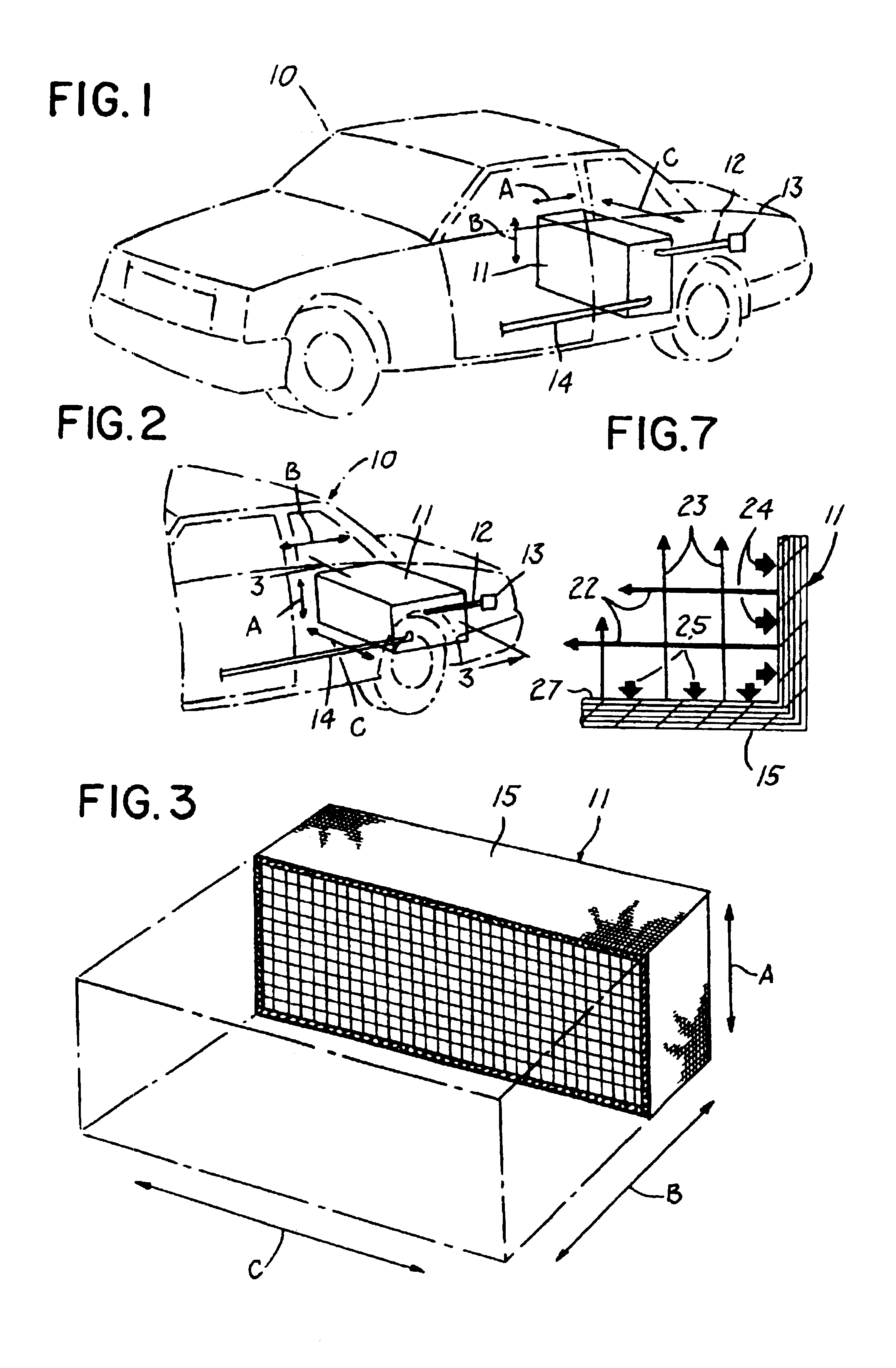

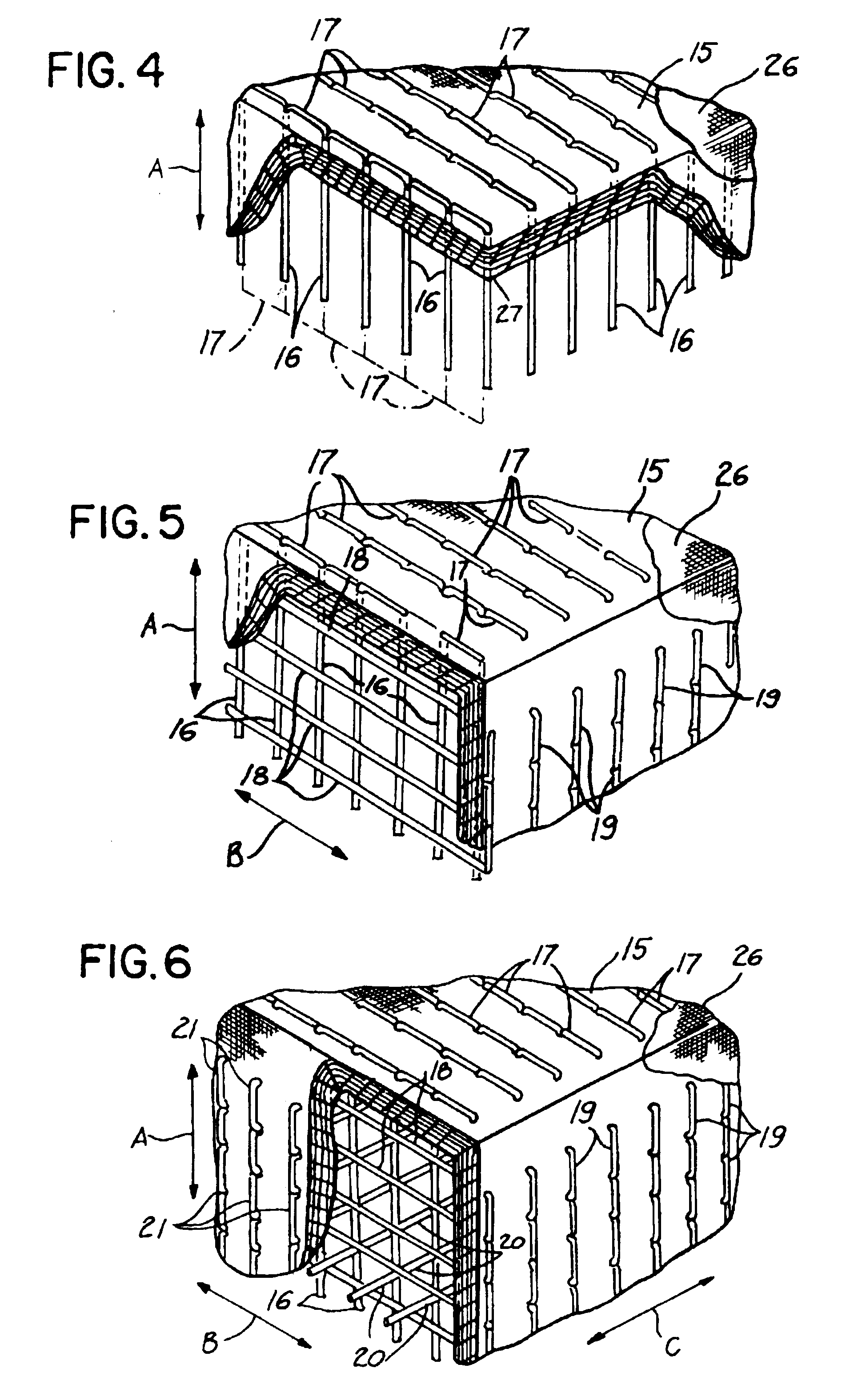

Therapeutic medical compression garment and method

ActiveUS20160038346A1Inhibit wearWelt becomes stableShrinkingNon-adhesive dressingsEngineeringBiomedical engineering

A therapeutic medical garment including a knitted welt proximate one end thereof with a surface adapted for residing against the wearer's skin. The garment includes a ground yarn and a plurality of raised, skin-engaging stabilizer elements, such as elongate bars extending in spaced-apart relation around an inner surface of the welt and along a longitudinal axis of the garment to reduce a tendency of the welt to roll over on itself.

Owner:BSN MEDICAL INC

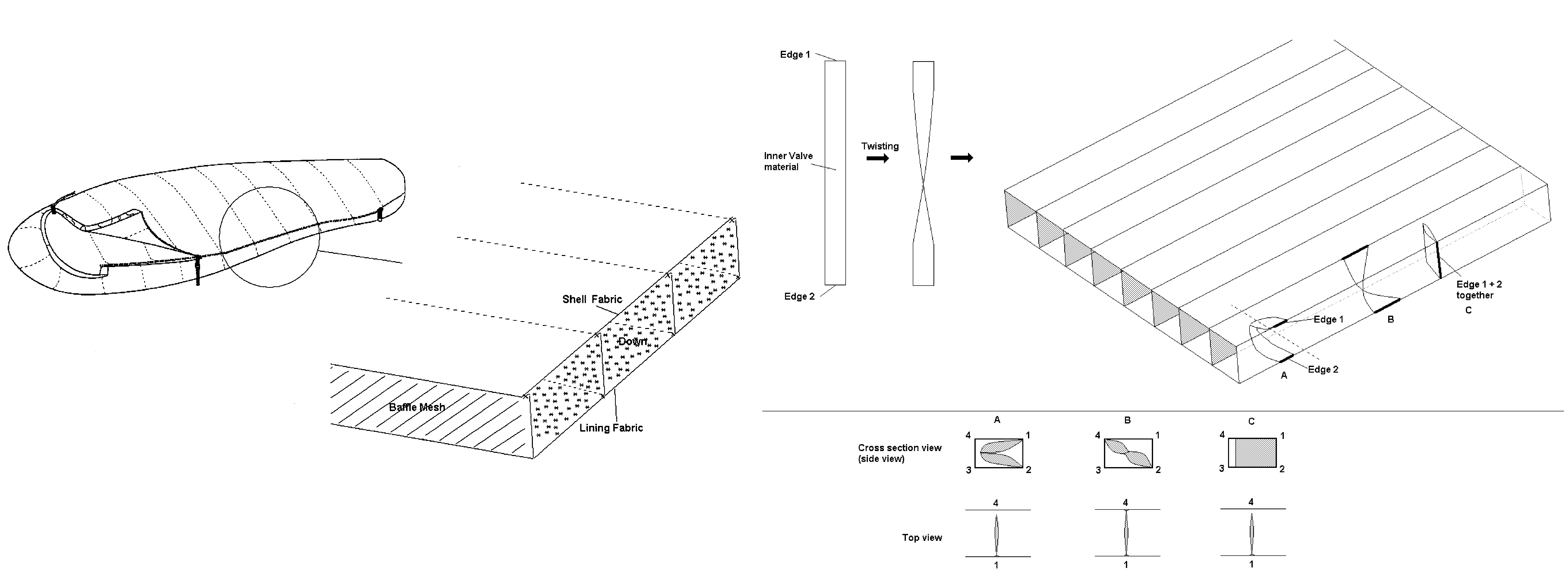

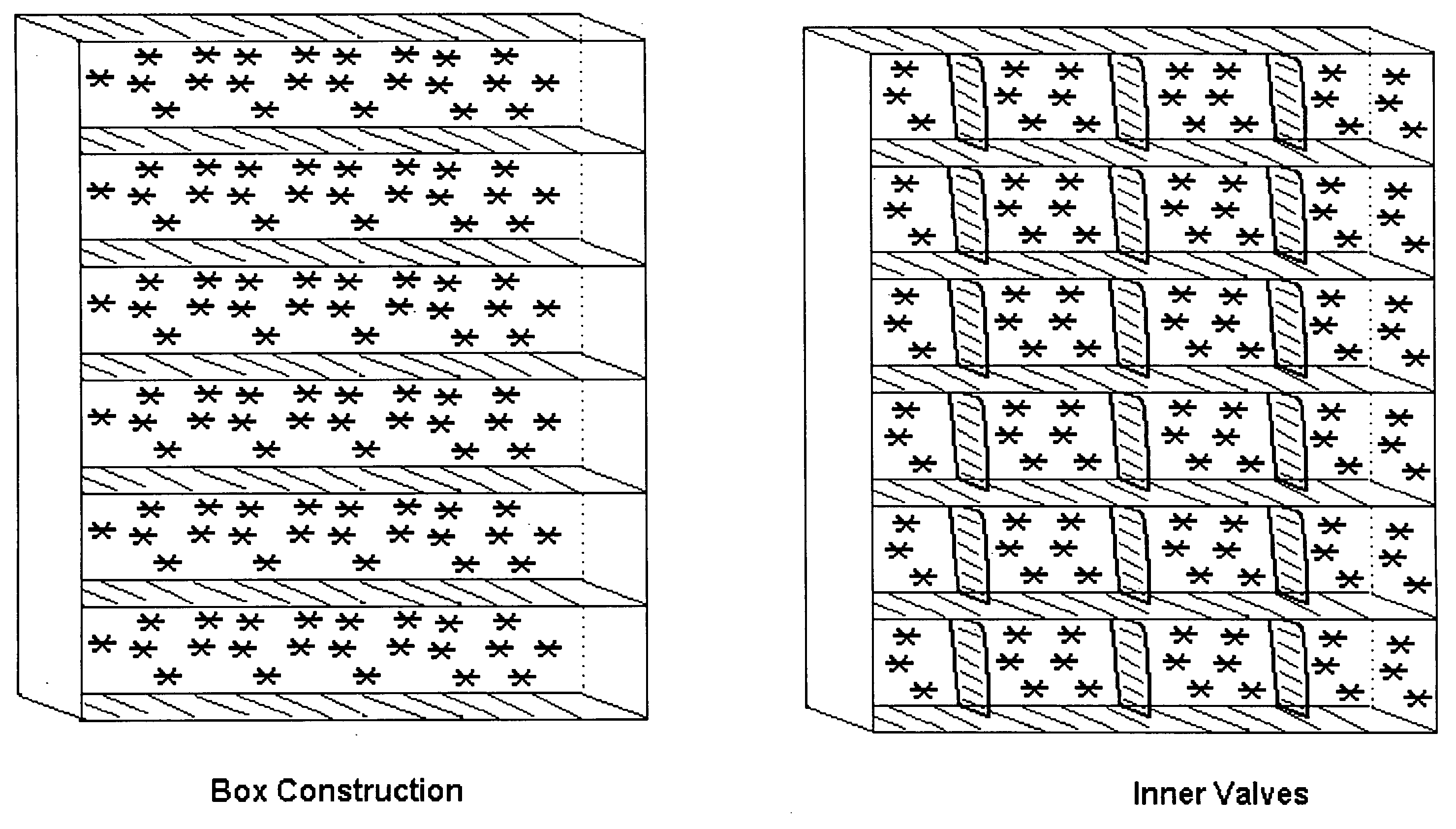

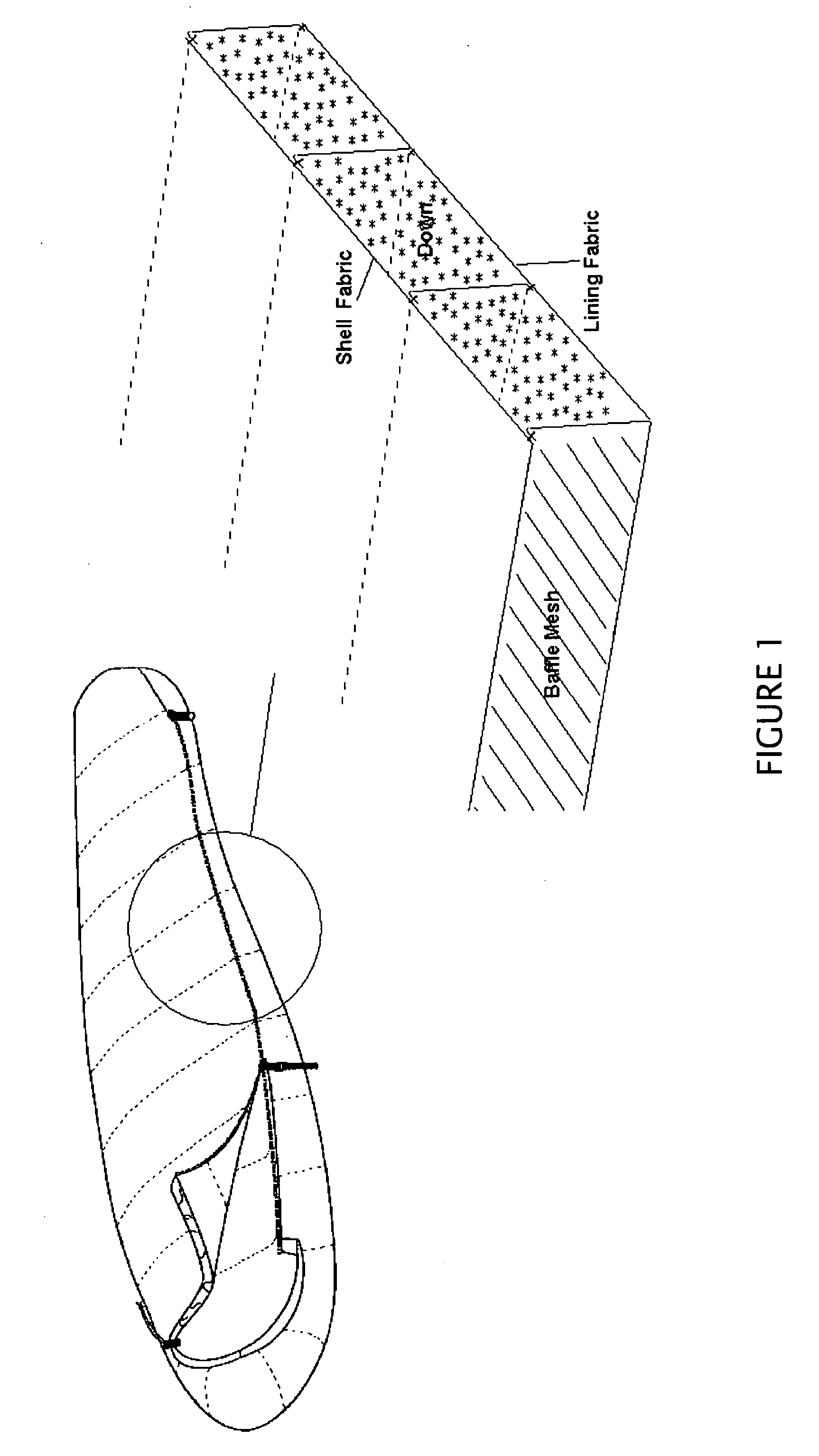

Insulated product

InactiveUS7818834B2More appearanceDesign moreCrochetingGarment special featuresEngineeringVALVE PORT

Owner:LI YICK LAP

Method of forming a composite material with added nanoparticles and carrier material containing nanoparticles

A method of forming a nanocomposite material that includes nanoparticles includes disposing in a forming apparatus a fiber material, a carrier material with nanoparticles dispersed therein, the carrier material having a releasing trigger to release the nanoparticles, the releasing trigger being at least one of a releasing temperature and a releasing pressure, and a resin having an infusion temperature, increasing the temperature within the forming apparatus to a temperature at least equal to the infusion temperature of the resin to allow the resin to impregnate the fiber material without triggering the releasing trigger of the carrier material, and triggering the releasing trigger of the carrier material in the forming apparatus by increasing at least one of the temperature and the pressure within the forming apparatus to cause dispersion of the nanoparticles.

Owner:SHORT BROTHERS

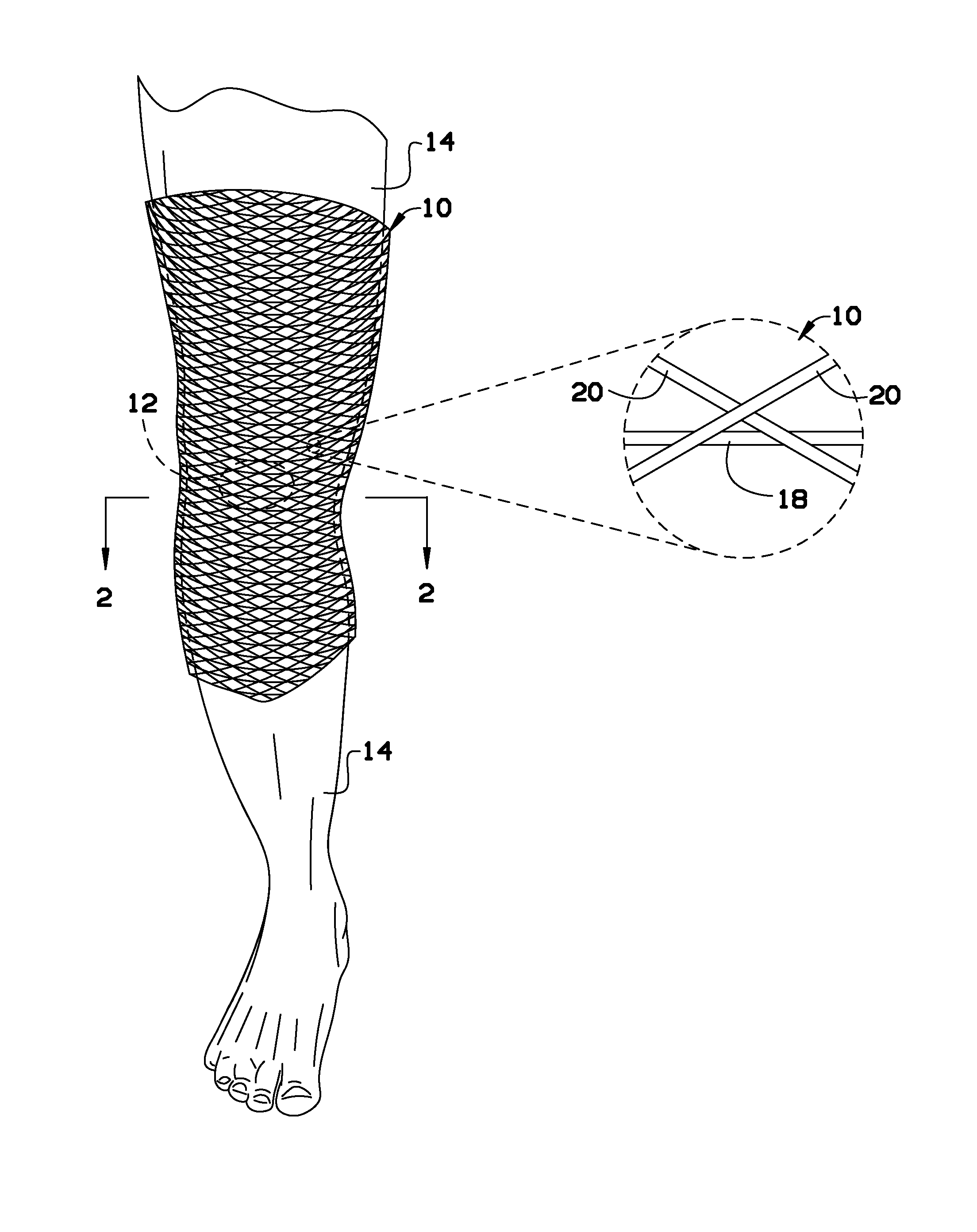

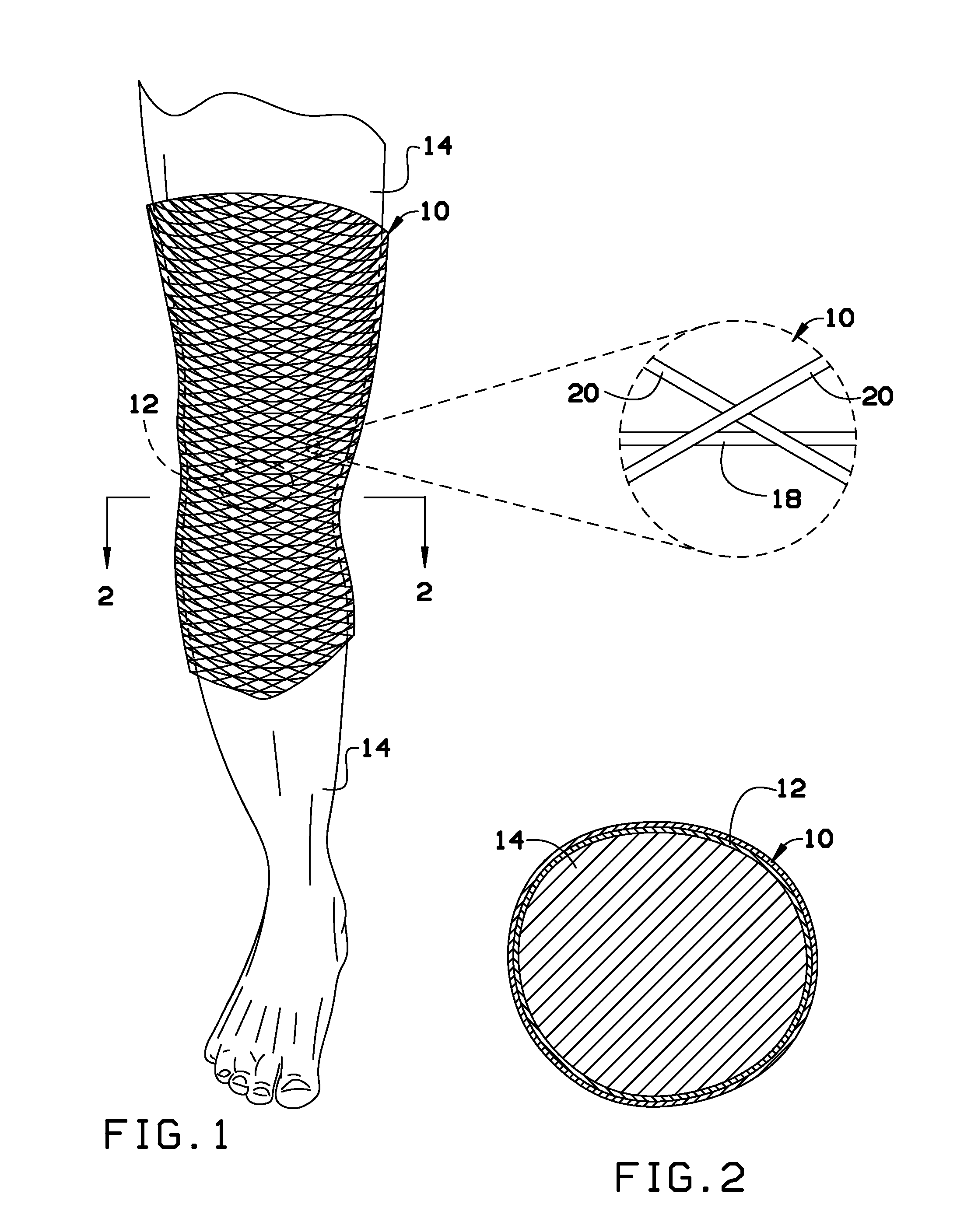

Joint support device

A joint support device is provided. The joint support device may include a first tubular layer and a second tubular layer both made of crisscrossing fibers. The crisscrossing fibers of the first tubular layer may be oriented in a spiral in a first direction and the crisscrossing fibers of the second tubular layer may be oriented in a spiral in an opposite direction of the first direction. The first and second tubular layers may be layered together and may be attached to an existing elastic knee brace.

Owner:CHANDLER JR FRANKLIN WOODROW

Three-dimensional surgical implant

Three-dimensional surgical implants include a grip-type knit mesh folded into a three-dimensional structure. Spiked naps provided on the mesh grip pores on the mesh to hold the implant in the three-dimensional structure.

Owner:TYCO HEALTHCARE GRP LP

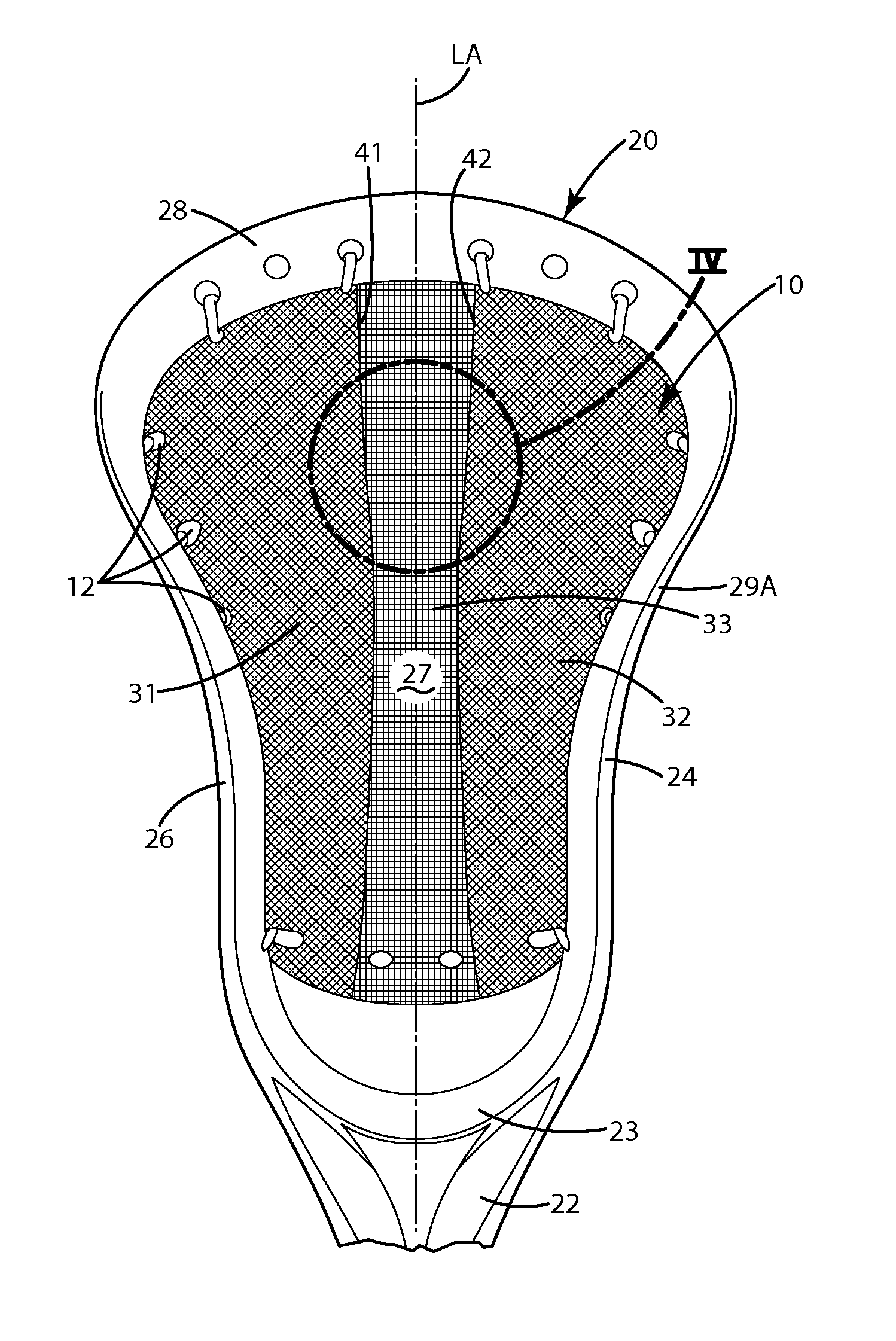

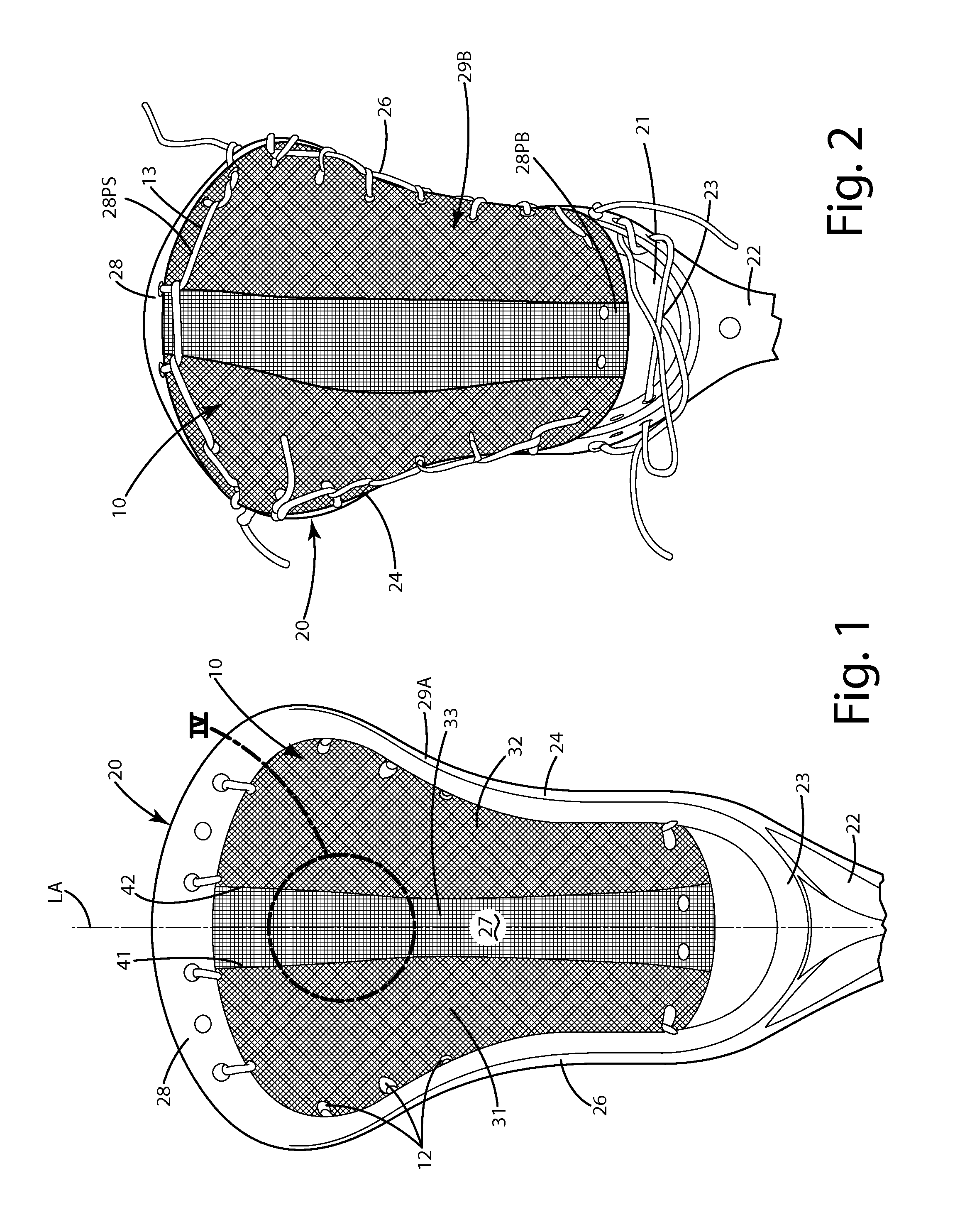

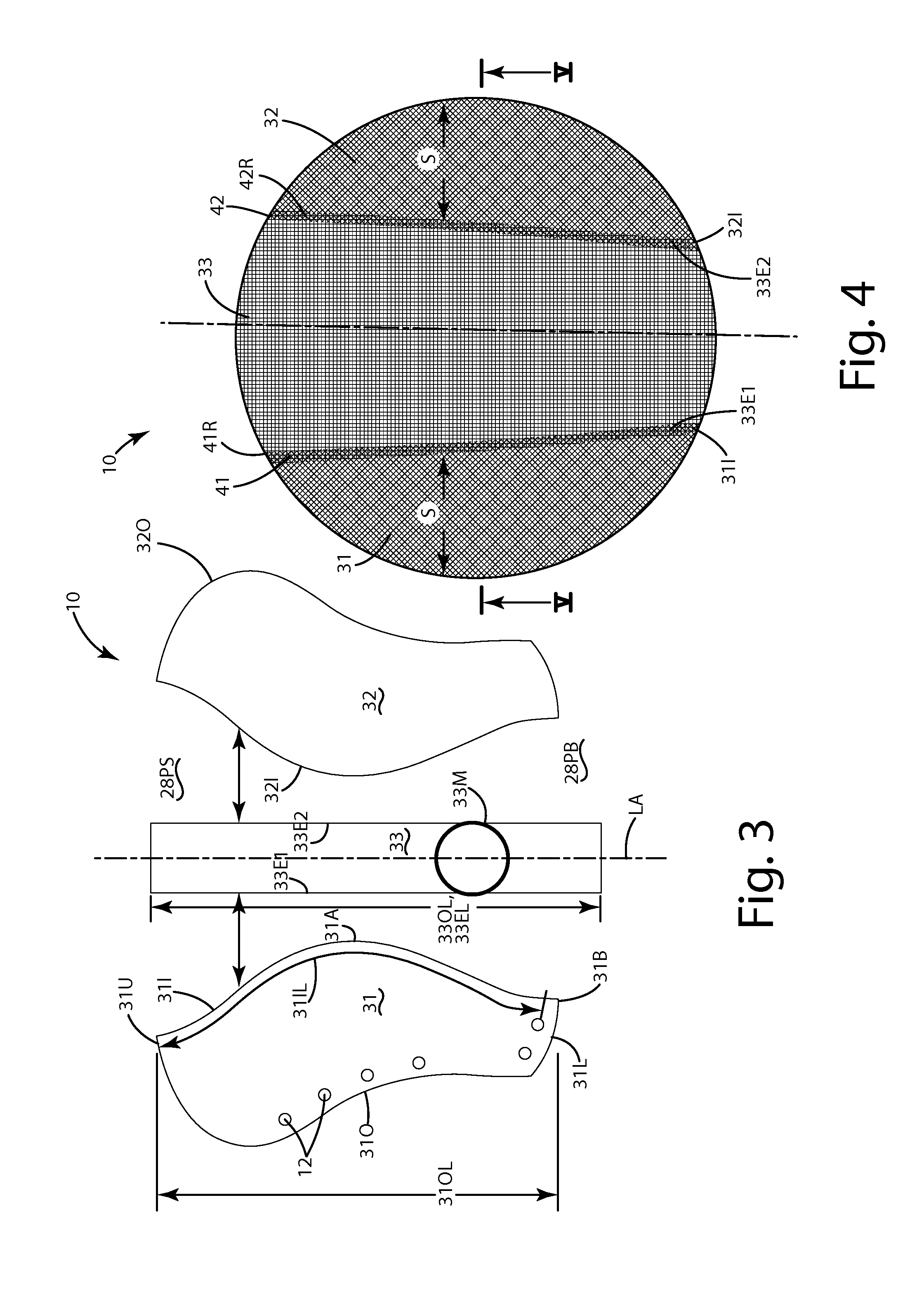

Lacrosse head pocket and related method of manufacture

ActiveUS20160038802A1Easy to manufactureEasy to replaceCrochetingOrnamental textile articlesEngineeringMechanical engineering

A lacrosse head pocket and a related method of manufacture are provided to facilitate consistent, repeatable and / or custom manufacture of lacrosse equipment. The pocket can be constructed from multiple different sections joined with one another, or can be knitted, weaved or otherwise assembled on an automated assembly machine from strands, and / or can be formed as a unitary textile material having regions / sections with different physical and / or mechanical properties. The pocket can be integrally molded within portions of a lacrosse head to eliminate manually constructed connections between the pocket and lacrosse head. The lacrosse head can be integrally molded with a lacrosse handle to provide a one-piece unitary lacrosse stick. Related methods of manufacturing also are provided.

Owner:WARRIOR SPORTS INC

Insulated product

InactiveUS20100024125A1More aesthetic appearanceMore appearance performanceCrochetingGarment special featuresEngineeringElectrical and Electronics engineering

Owner:LI YICK LAP

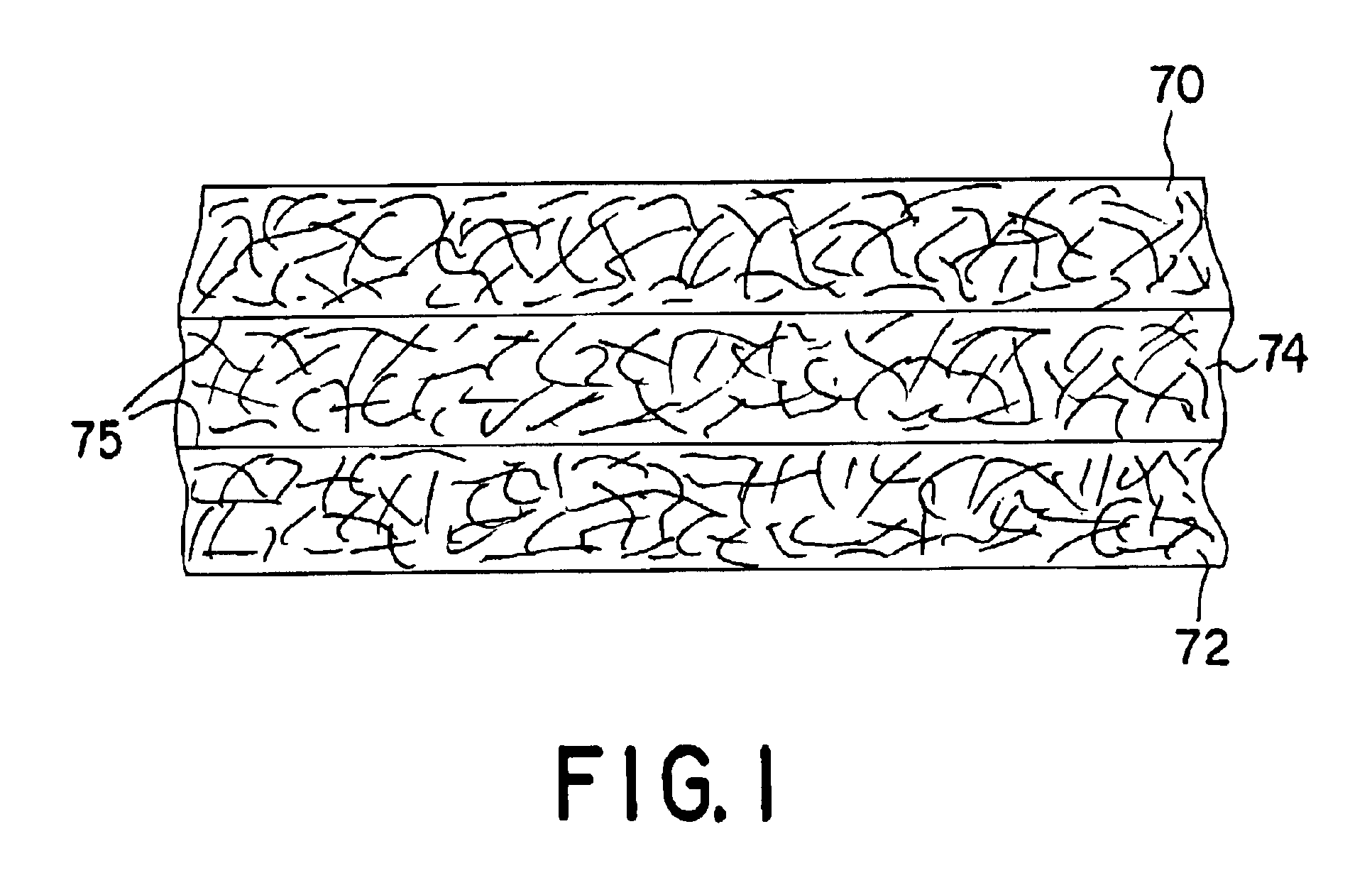

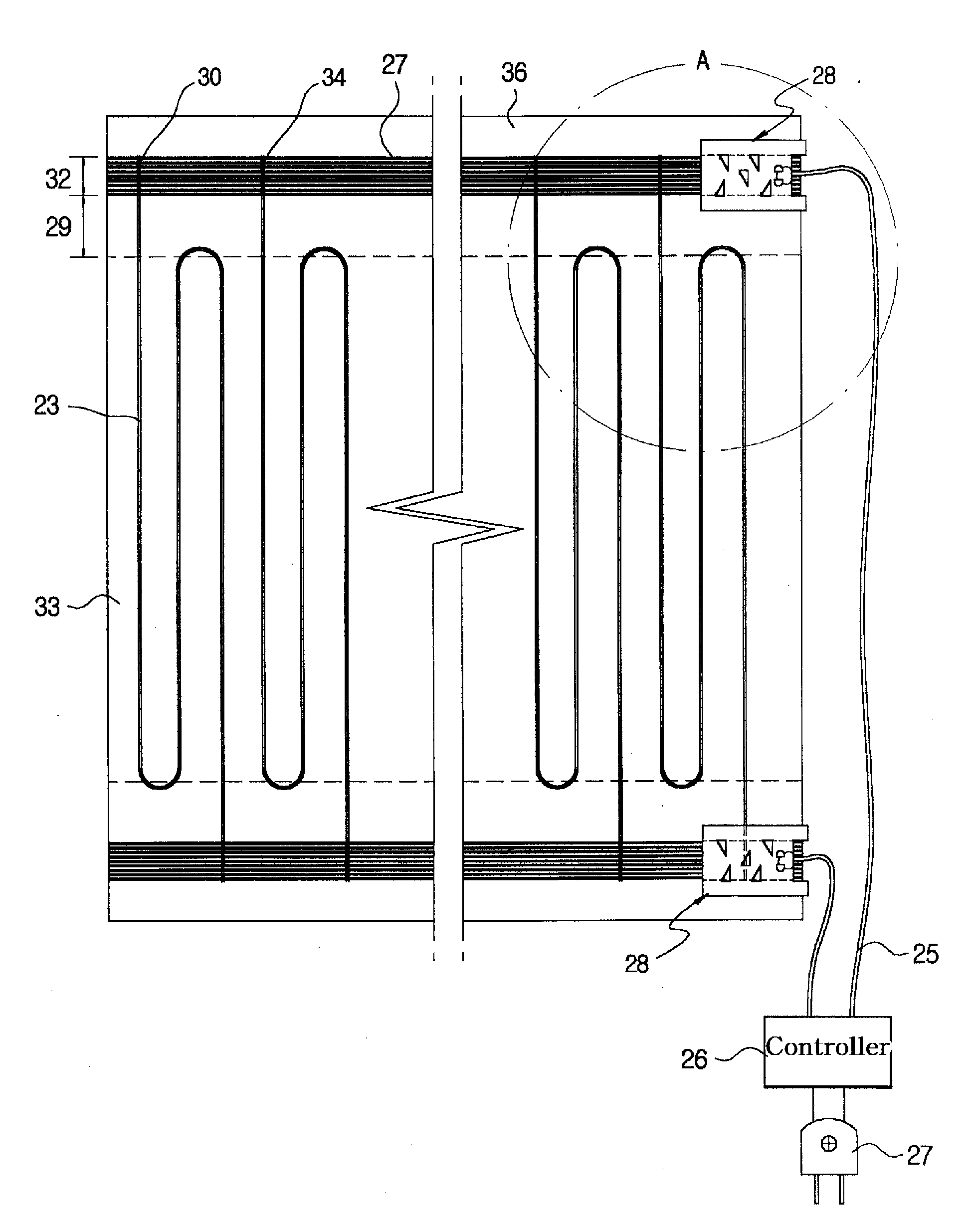

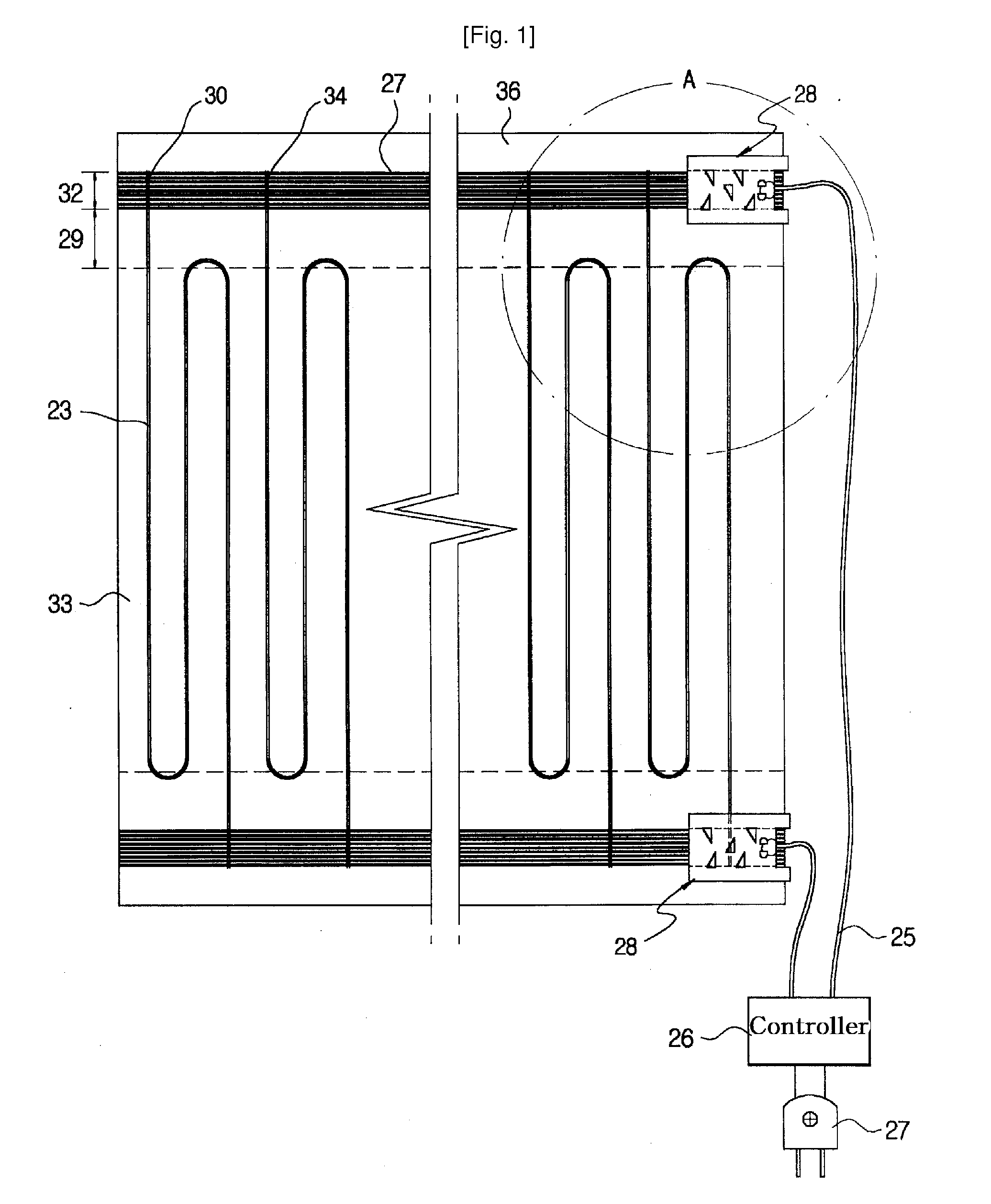

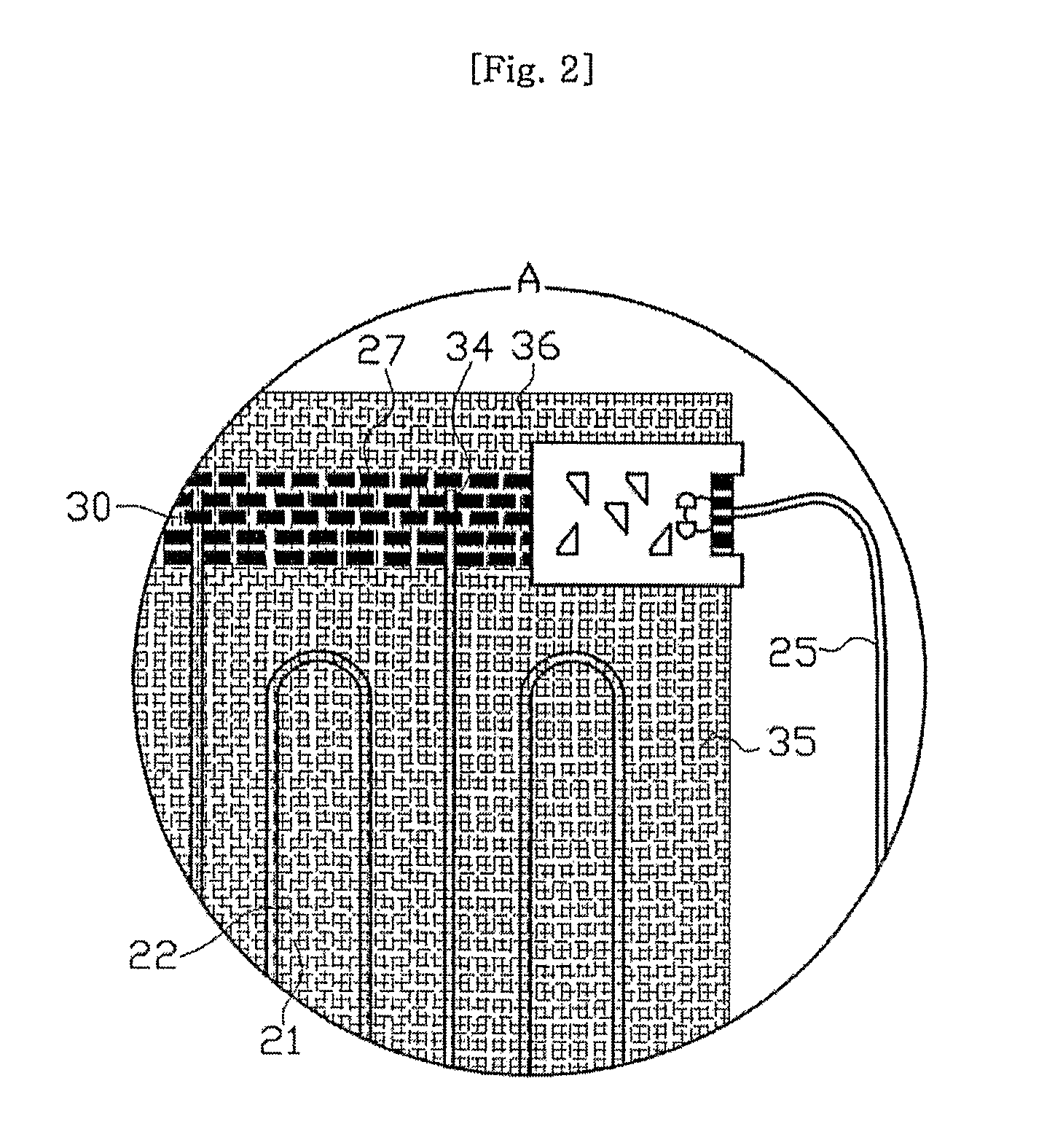

Heating Fabric and Manufacturing Method Thereof

InactiveUS20080135120A1Firmly connectedReduce product failureCrochetingOrnamental textile articlesFiberCarbon fibers

Disclosed is a heating fabric comprising a heating fabric element made by weaving woof fibers and warp fibers, a pair of conductive parts being a plain fabric made by a weaving method to extend from one side edge of the heating fabric element, for supplying electric power to the heating fabric element, wherein electrode fibers are woven in rows as warp threads in the conductive parts and a heating fiber is intermittently woven as woof threads at predetermined intervals so as to be conductive with the conductive parts, and wherein the heating fiber is woven in a zigzag pattern on the other side of the plain fabric of the conductive parts, in which one end of the heating fiber is woven into the conductive part, and a portion of the other end of the heating fiber is not woven into the conductive part, thereby forming a jumping portion having a length longer than a width of the conductive part, the jumping portion jumping over the conductive part so as not to be conductive with the conductive part. Due to the one-side arrangement of the conductive parts and the zigzag pattern of the carbon fibers, electromagnetic waves are reduced and offset. Accordingly, the heating fabric is advantageous for a user's health.

Owner:PACIFIC MEDICAL

Pet socks and manufacturing method thereof

InactiveUS20150053148A1Rational designSimple structureCrochetingFabrics trimmingEngineeringCompanion animal

Owner:ZHUJI LONGBOW KNITTING

Continuous Non-slip Layered Garment

InactiveUS20150275422A1Prevent slippingCrochetingOrnamental textile articlesBiomedical engineeringFabric structure

A method for making a continuous non-slip layered garment includes creating a fabric structure having inner and outer surfaces, which conforms to a body part, and creating continuous non-slip layers on the inner and outer surfaces of the fabric structure. The inner surface is proximal to a user contact surface and distal to an external contact surface. The outer surface is proximal to the external contact surface and distal to the user contact surface. The continuous non-slip layers are created by applying a non-slip material on selective continuous portions, selective non-continuous portions, whole portions, or an entirety of the inner surface and the outer surface of the fabric structure. The continuous non-slip layers provide simultaneous gripping contact between the inner surface of the fabric structure and the user contact surface, and between the outer surface of the fabric structure and the external contact surface.

Owner:TRUSOX LLC

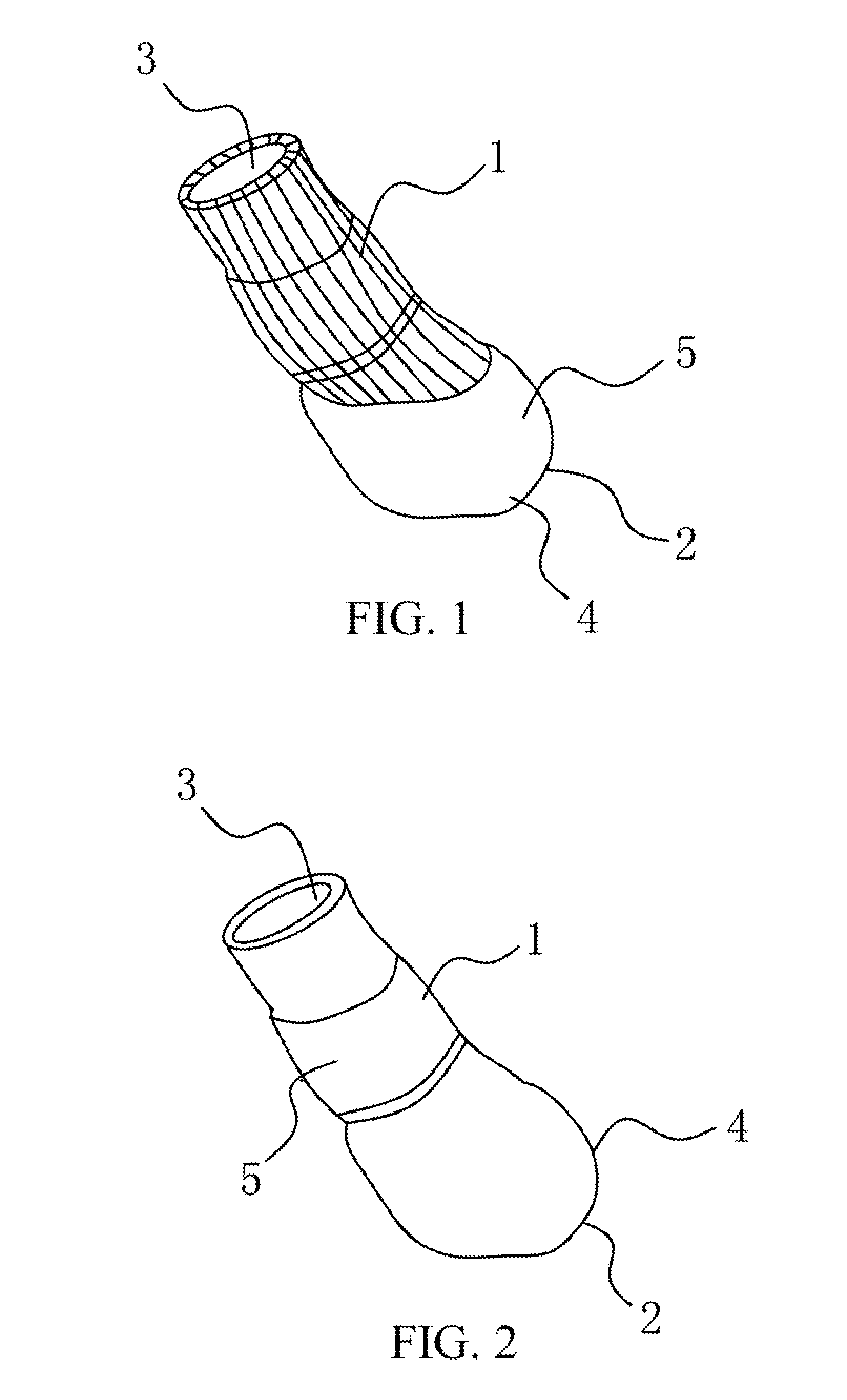

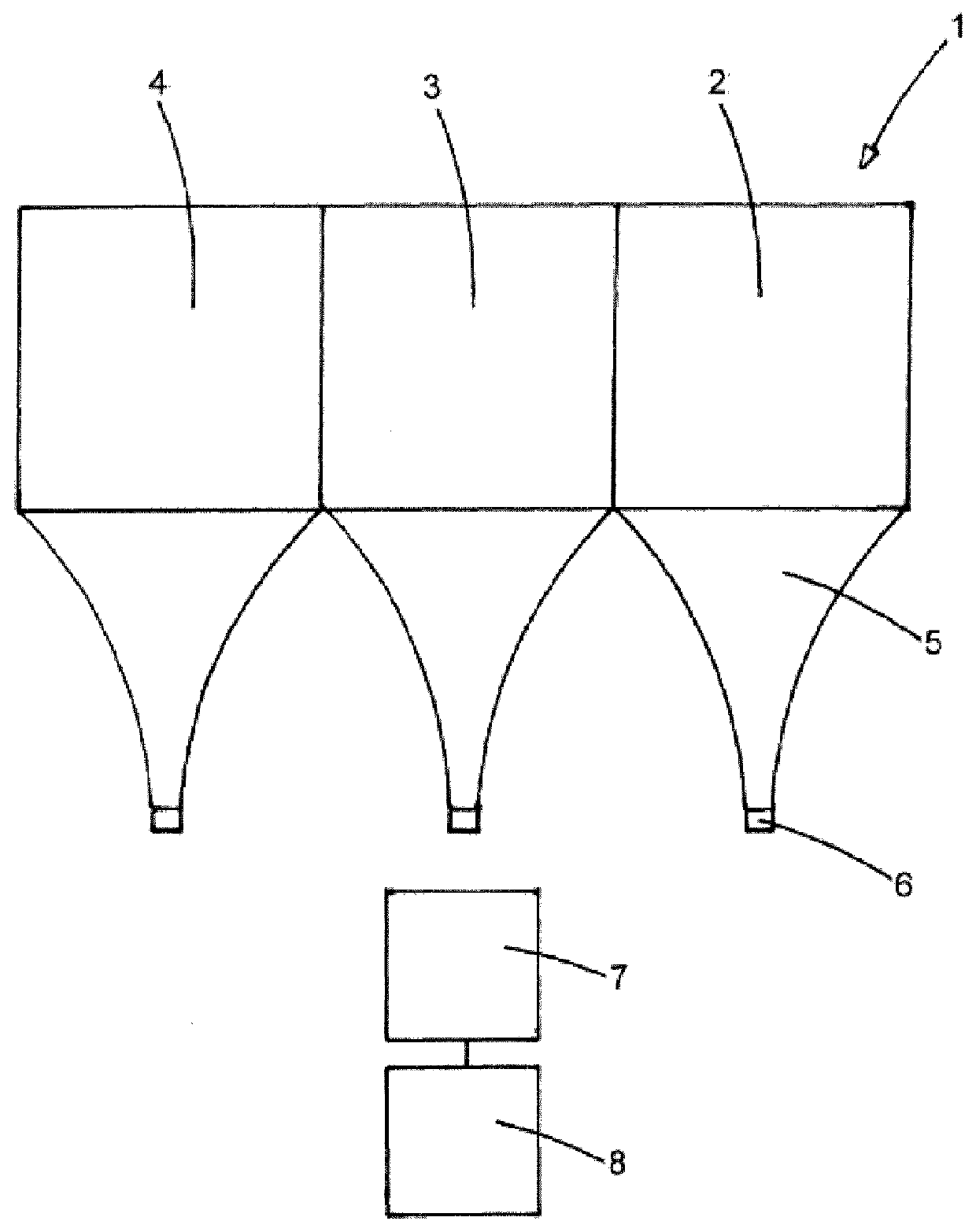

Medical Device, its Preparation Method and Applications Thereof

InactiveUS20160051832A1Facilitated DiffusionImprove homogeneityCrochetingElectrotherapyEngineeringLight emission

A medical device (1) comprising a flexible light source wherein said flexible light source comprises two or more individually manageable areas (2, 3, 4) of light emission and wherein each area (2, 3, 4) comprises a light diffuser textile comprising optical fibres (10) providing side diffusion of a light, method for its manufacture and medical uses.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +2

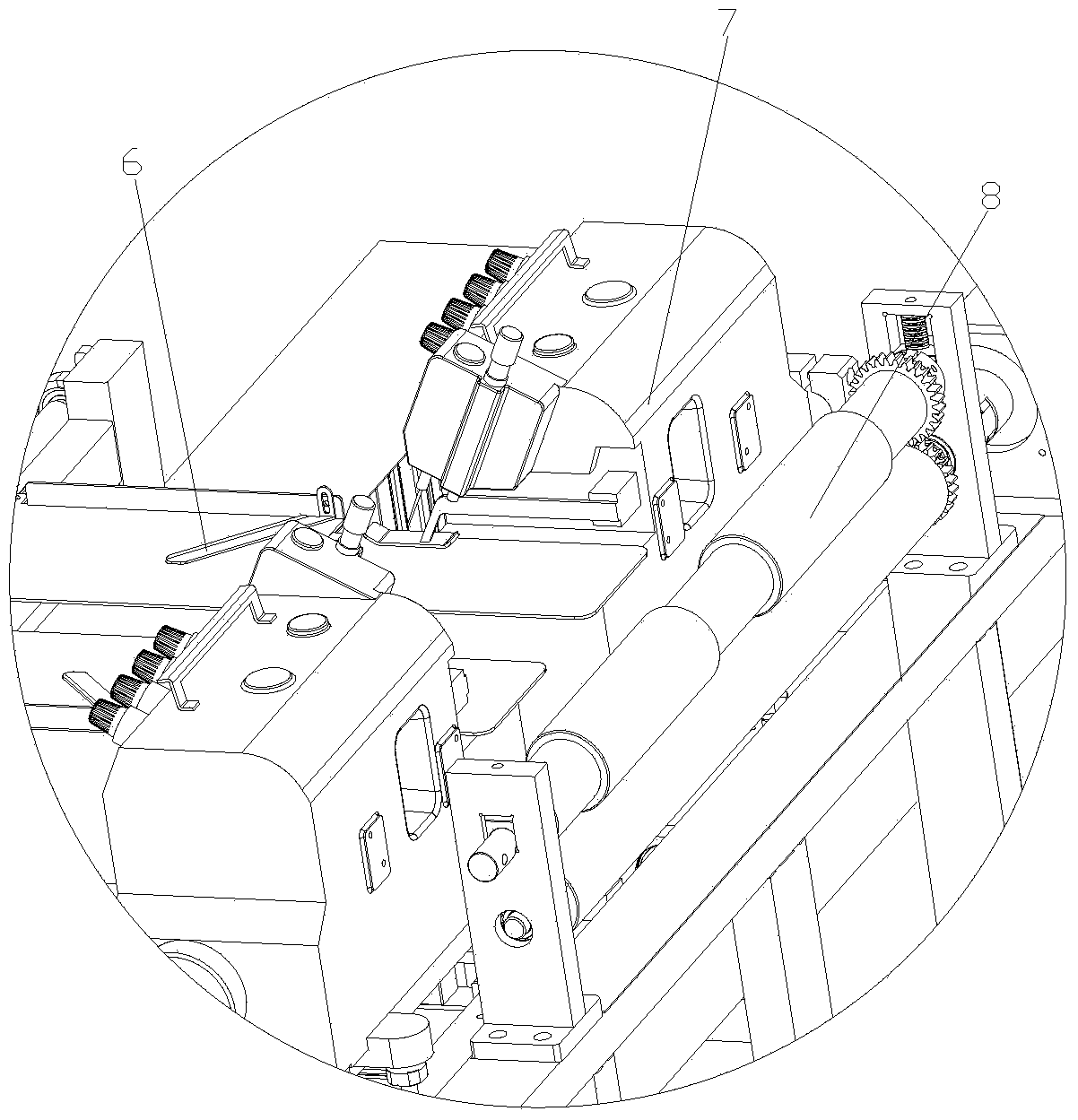

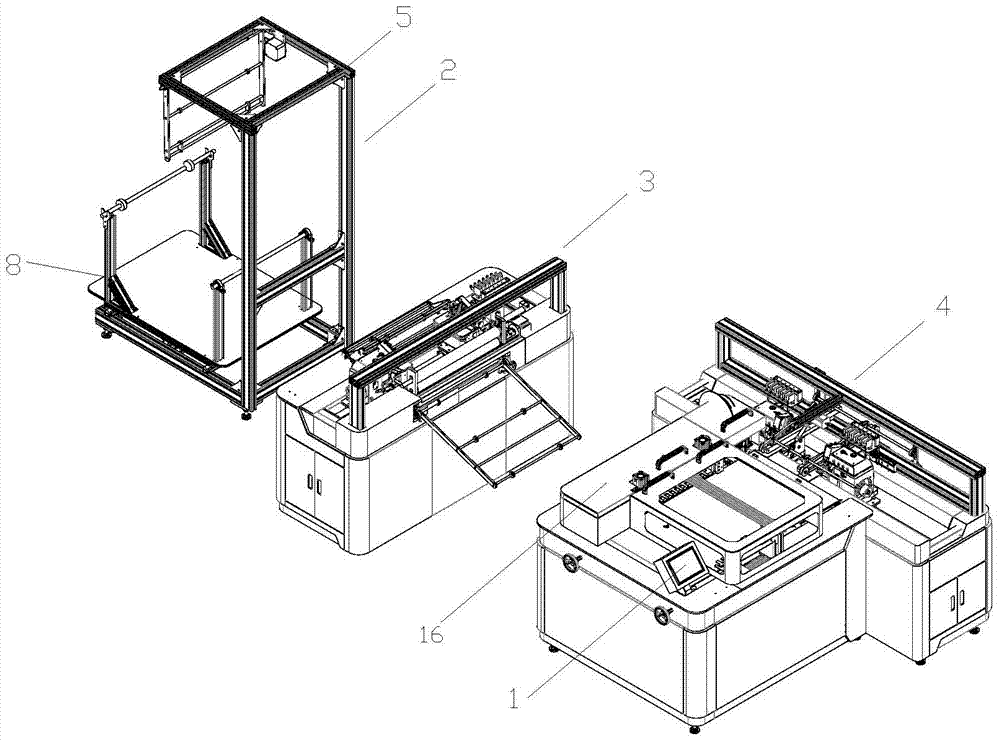

Novel towel machine

ActiveCN104514101AImprove processing efficiencyHigh precisionWorkpiece carriersWork-feeding meansEngineeringMechanical engineering

The invention discloses a novel towel machine. The machine comprises a control center, a feeding device, a first processing device and a second processing device, wherein the control center is used for intensively controlling the feeding device, the first processing device and the second processing device; the feeding device comprises a feeding frame, a sensor, a servo motor and an automatic adjusting frame; the feeding frame is provided with a guide rail vertical to a feeding direction; the servo motor is connected with an automatic adjusting frame and drives the automatic adjusting frame to slide on the guide rail; the sensor senses the size of a cloth and transmit the size data into the control center; the second processing device comprises a second cabinet, a belt transmission mechanism, a second synchronous roller, a cutting mechanism, a clamping mechanism, a sign folding and transmitting mechanism and a second twin-needles machine, wherein the belt transmission mechanism, the second synchronous roller, the cutting mechanism, the clamping mechanism, the sign folding and transmitting mechanism and the second twin-needles machine are arranged on the cabinet; the cutting mechanism is fixedly arranged between the second synchronous roller and the belt transmission mechanism; the clamping mechanism is used for clamping the cloth to the belt transmission mechanism; and a feeding outlet of the belt transmission mechanism is fixedly provided with the twin-needles machine.

Owner:SUZHOU TRANSPARENT TECH CO LTD

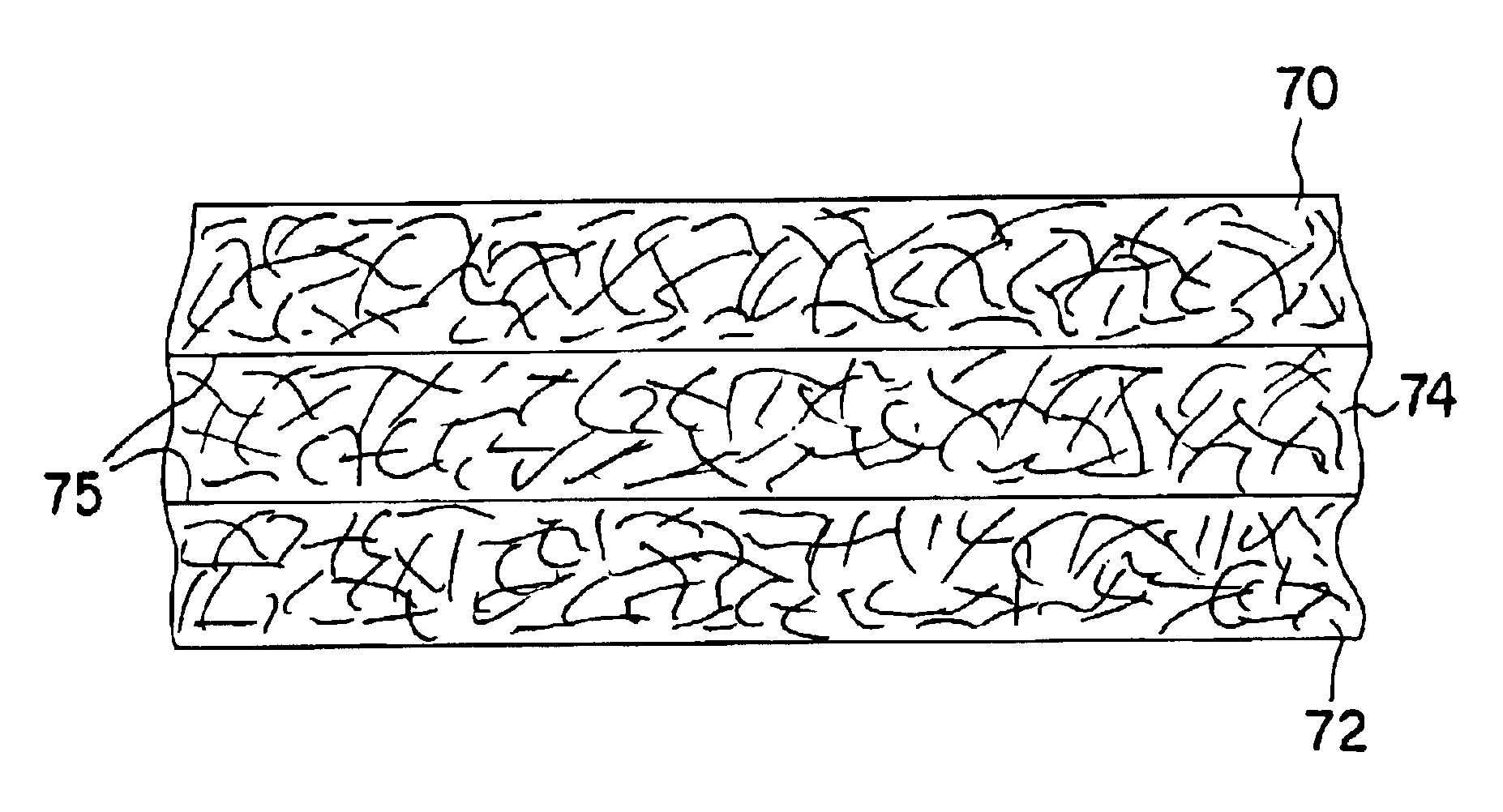

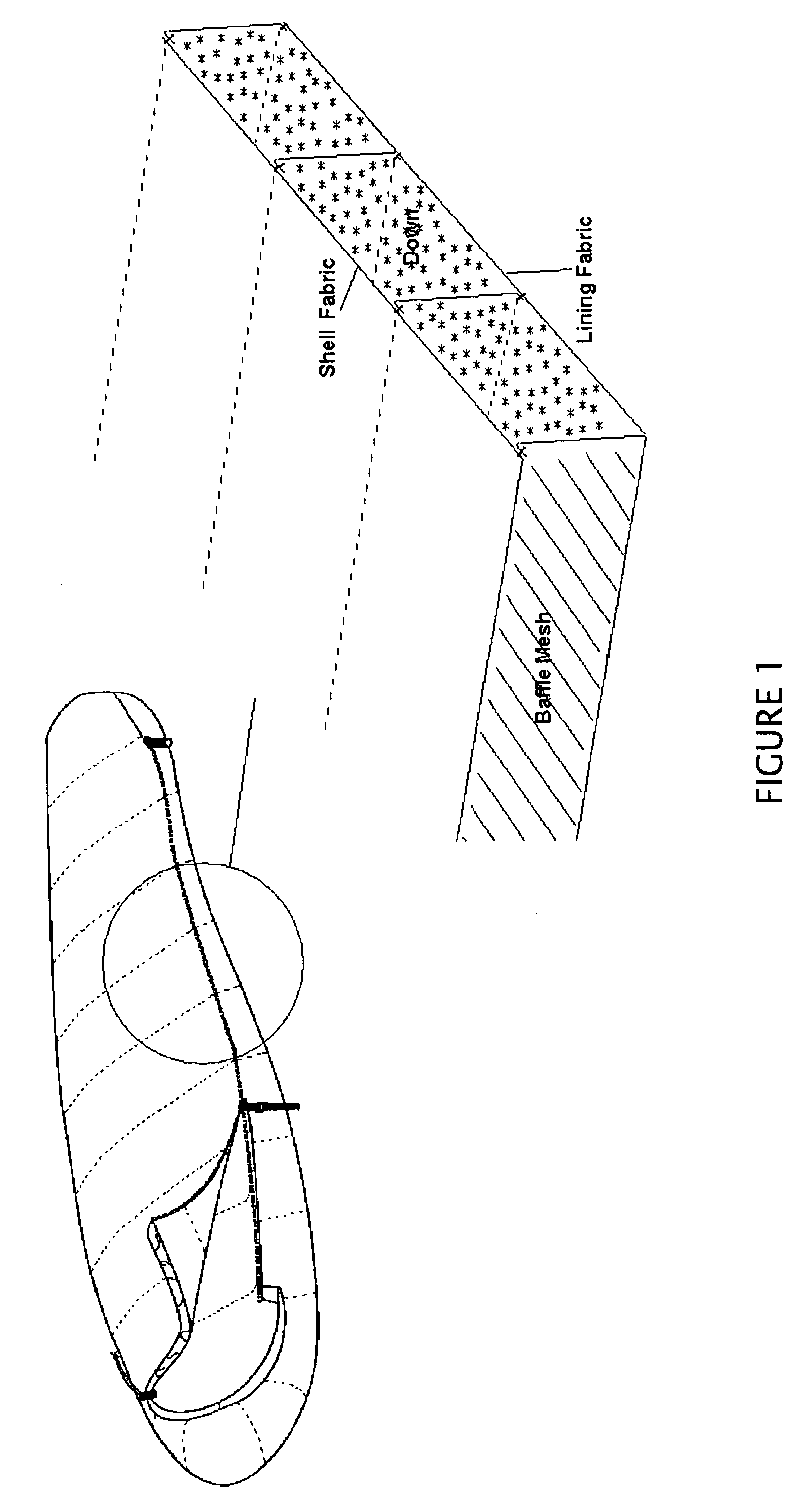

Manufacture process for composite heat insulation material

InactiveCN102337633ASolve non-spinnabilityAbundant resourcesFabrics trimmingNon-woven fabricsPolyesterCooking & baking

The invention relates to a manufacture process for a composite heat insulation material, which has the steps that: 1, feather is firstly washed by water, sterilized, dried and loosened, and then, feather stems and feather silks are separated; 2, meldable fibers and polyester staple fibers are loosened and are mixed according to a weight ratio of 16 to 19 / 10 to 15; 3, the processed feather silks and the fibers mixed in the second step are mixed and are uniformly mixed through a stirring machine, and in addition, some impurities are removed; 4, the feather silk mixed fibers are sewed into blocky materials by duck down threads via a patterning machine; 5, then, the sewed feather silk mixed fibers are processed into thin sheets with the thickness being 0.3mm to 0.5mm through a carding machine, and the impurities are removed for a second time; 6, the feather silk mixed fibers are overlapped and paved layer by layer by a net paving machine; and 7, the feather silk mixed fibers are baked by an infrared baking oven, the baking temperature is set to 100 DEG C to 140 DEG C, and in addition, the cutting treatment is carried out, so the initial product breadth maintains the constant value. The composite heat insulation material has good heat insulation performance, the environment is protected, the spinnability and the shearing performance are realized, the price is relatively low, the raw material resources are rich, and the market demand potential is huge.

Owner:河北兴瑞羽绒制品有限公司

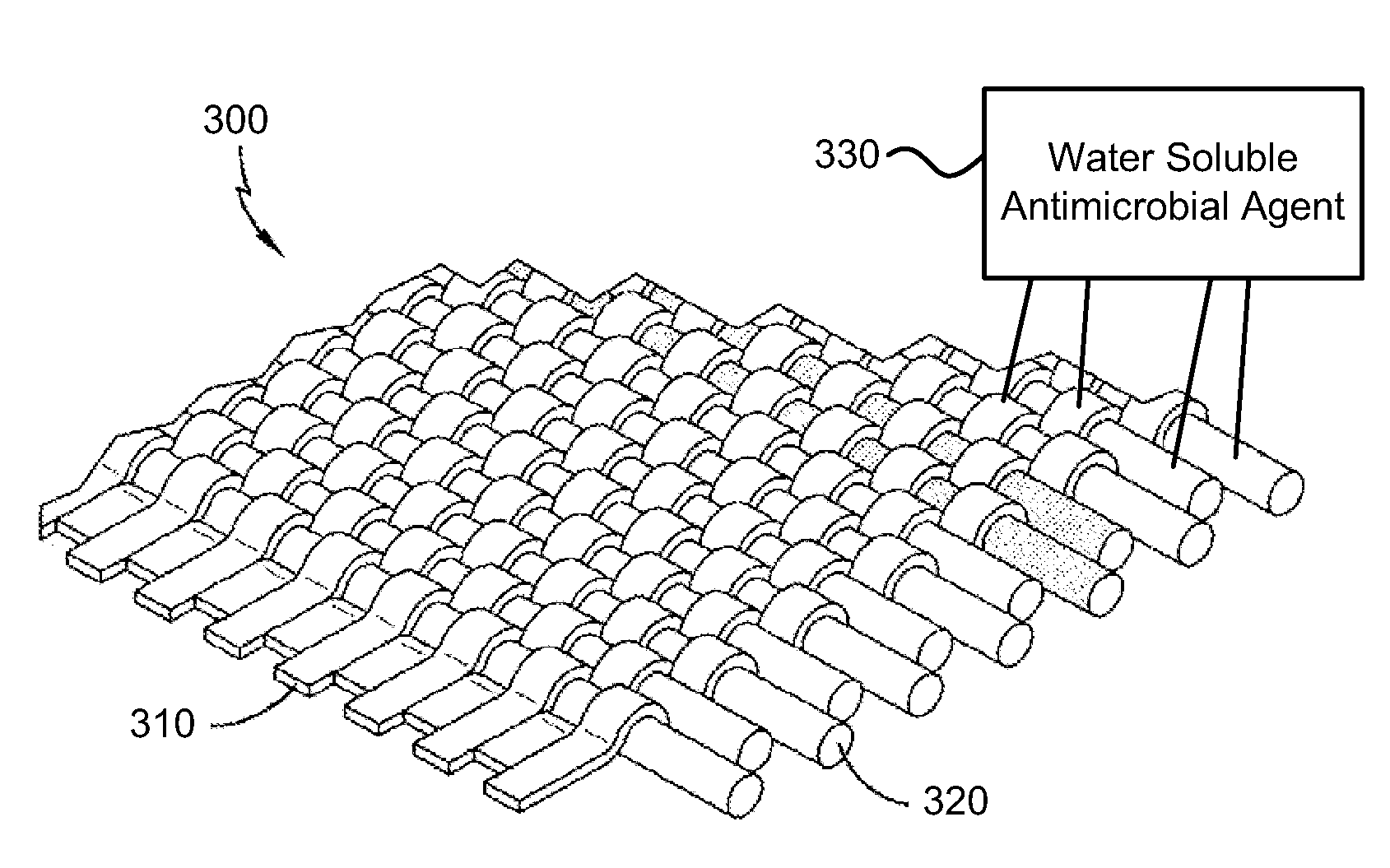

Pool Cover Fabric Containing Algaecide and/or Bactericide to Reduce Algae/Bacteria Growth

InactiveUS20080086808A1Reduce weightPrevent and reduce and algae growthCrochetingInspecting textilesYarnPolyolefin

A woven fabric pool cover has an antimicrobial agent that reduces / prevents the growth of microbes on the pool cover and in the water of a swimming pool covered by the cover. The fabric cover may be woven from polyolefin extruded monofilaments, and / or fibrillated tape yarns where the yarns have an antimicrobial agent added during the yarn extrusion process or added to fabric formed by the yarns. The fabric may be woven from traditional polyolefin extruded monofilaments, and / or fibrillated tape yarns before the resulting fabric is treated with a antimicrobial agent. Such treatment may involve spraying a solution onto the fabric or also dipping, soaking, or padding the fabric into the treating solution. The antimicrobial agent may form a zone of inhibition around the yarns and may seep out of the fabric to form zones of inhibition in the surrounding environment, like on the cover and / or in swimming pool water.

Owner:PROPEX OPERATING

Textile, Garment Including The Textile, And Methods For Manufacturing The Textile And The Garment

ActiveUS20160040325A1High elastic stretchabilityImprove adhesionCrochetingInspecting textilesEngineeringE-textiles

Owner:XEFCO PTY LTD

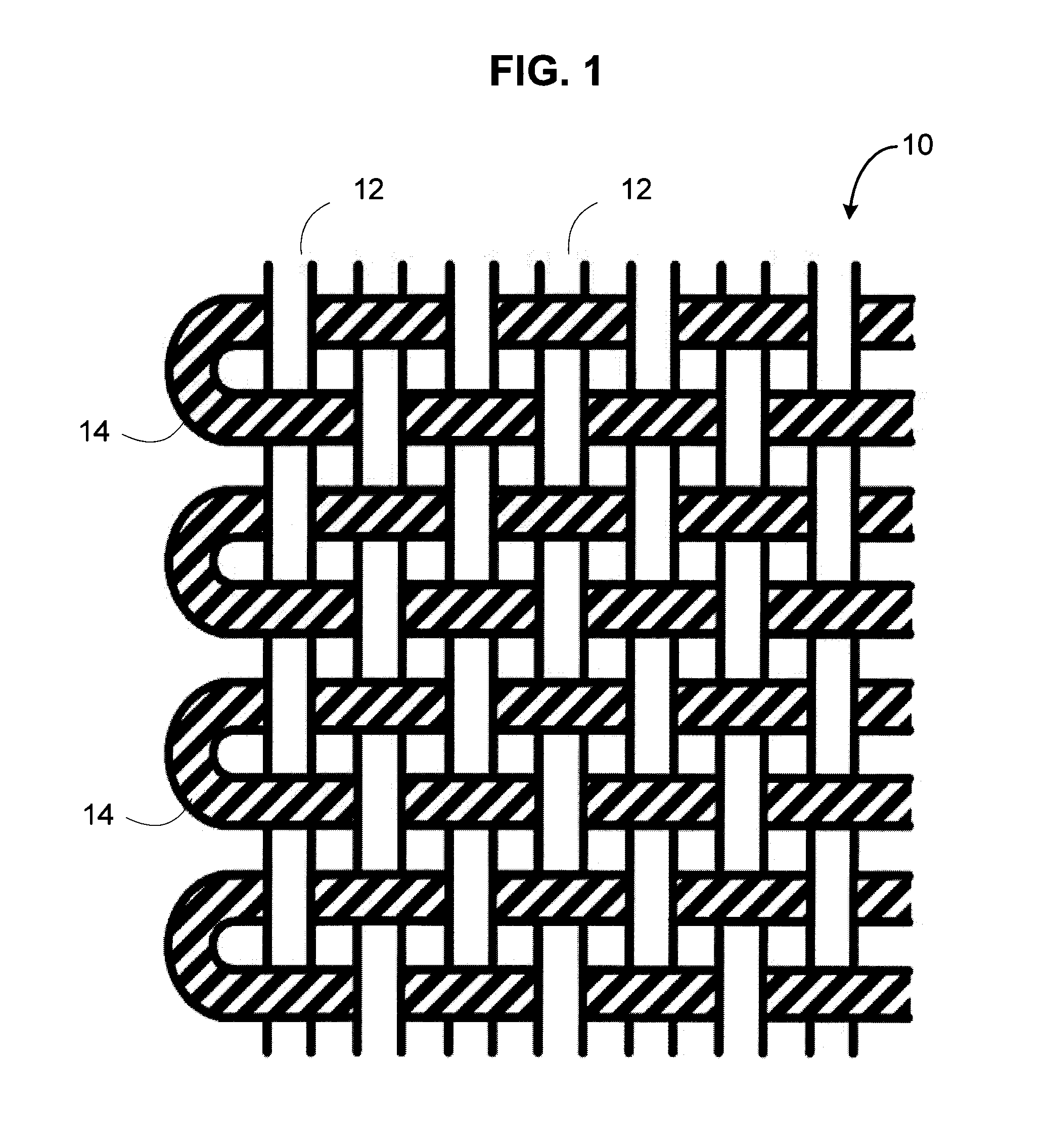

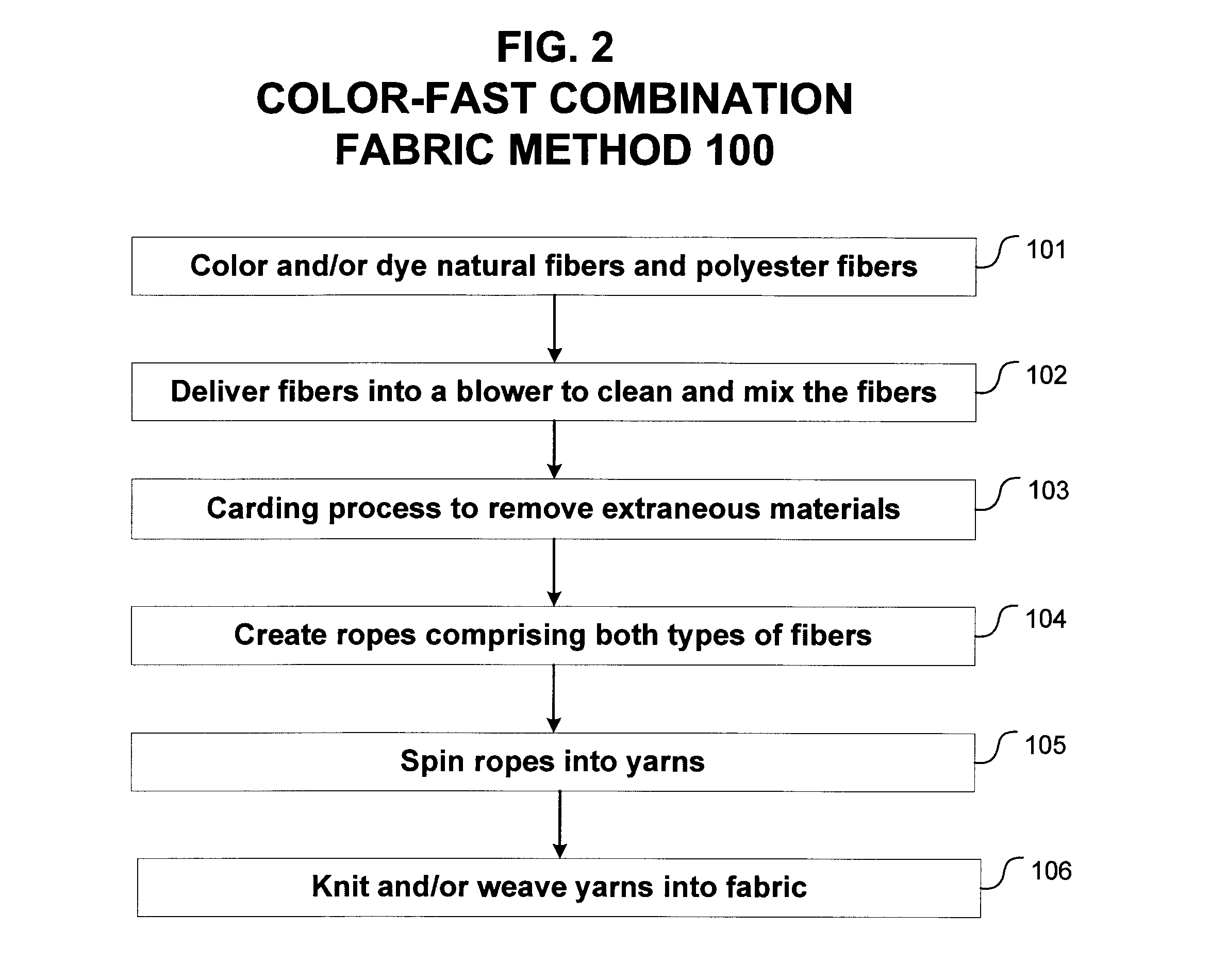

Color-fast and high-crocking combination fabric and method for making the same

A color-fast and high-crocking combination fabric and methods for making the same. The color-fast and high-crocking fabric consists of dyed natural fibers and dyed polyester fibers. The natural and polyester fibers are dyed and / or colored before being combined into yarns and fabrics. The color-fast and high-crocking combination fabric has very high color-fastness as measured by crocking standard, while maintaining a quality hand feel. The color fastness can withstand at least thirty regular cold-temperature home-wash laundries.

Owner:POON DOMINIC KIN MING

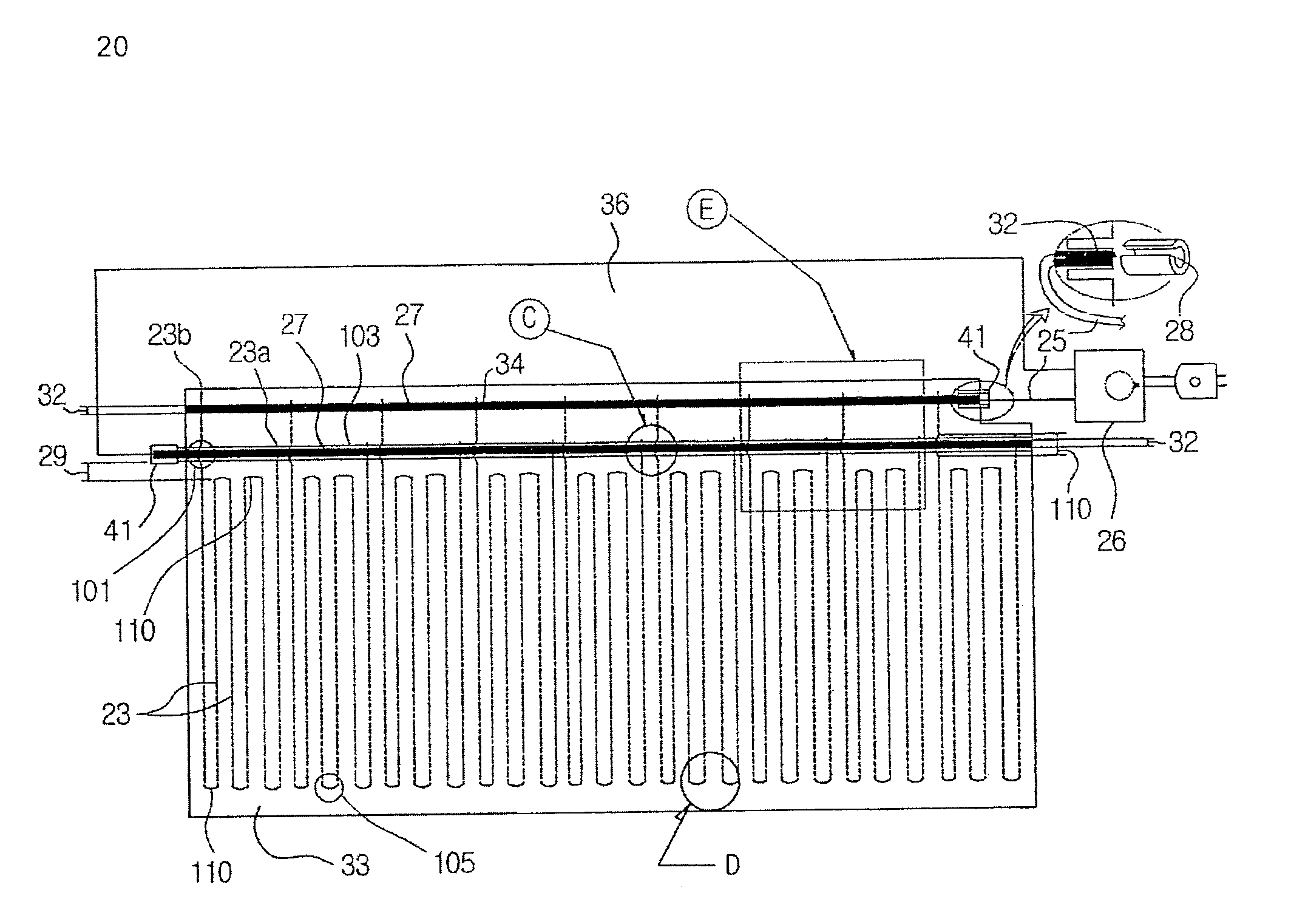

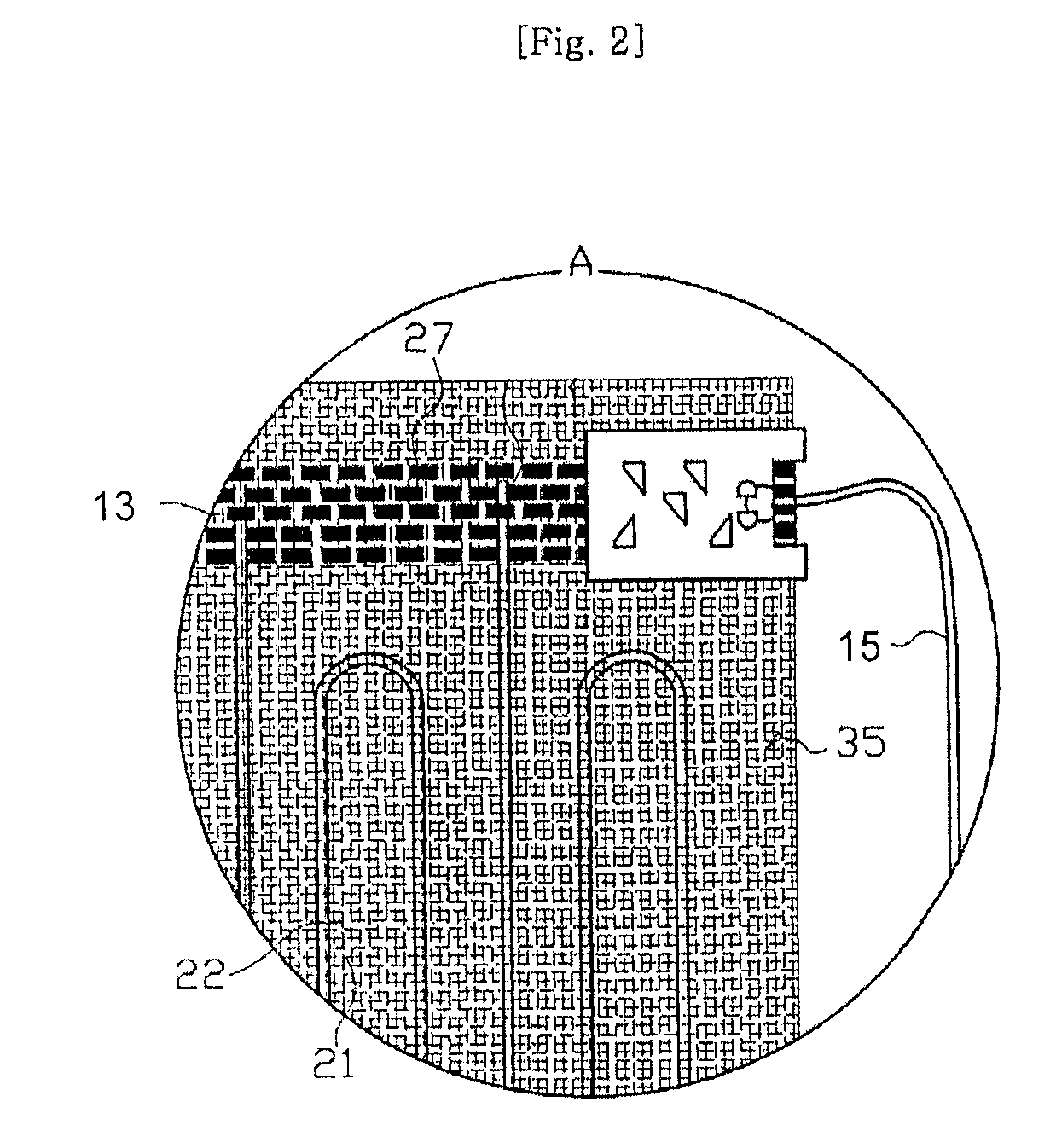

Heating fabric and manufacturing method thereof

InactiveUS7820945B2Firmly connectedImprove product reliabilityCrochetingOrnamental textile articlesFiberCarbon fibers

Disclosed is a heating fabric comprising a heating fabric element made by weaving woof fibers and warp fibers, a pair of conductive parts being a plain fabric made by a weaving method to extend from one side edge of the heating fabric element, for supplying electric power to the heating fabric element, wherein electrode fibers are woven in rows as warp threads in the conductive parts and a heating fiber is intermittently woven as woof threads at predetermined intervals so as to be conductive with the conductive parts, and wherein the heating fiber is woven in a zigzag pattern on the other side of the plain fabric of the conductive parts, in which one end of the heating fiber is woven into the conductive part, and a portion of the other end of the heating fiber is not woven into the conductive part, thereby forming a jumping portion having a length longer than a width of the conductive part, the jumping portion jumping over the conductive part so as not to be conductive with the conductive part. Due to the one-side arrangement of the conductive parts and the zigzag pattern of the carbon fibers, electromagnetic waves are reduced and offset. Accordingly, the heating fabric is advantageous for a user's health.

Owner:PACIFIC MEDICAL

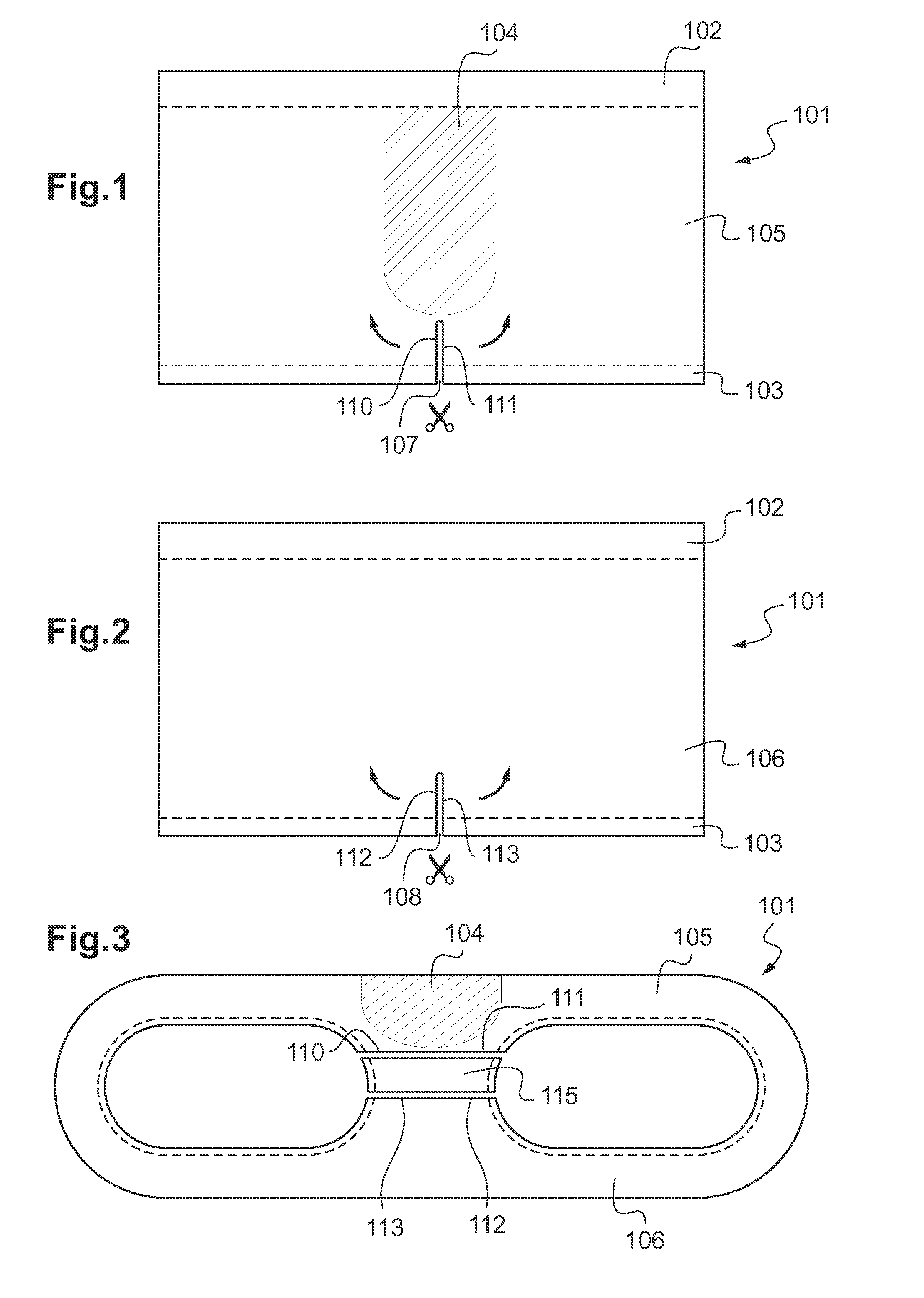

Method of Making Soft Edge Textile Labels to be Applied to Garments

A method of converting an elongated web of filamentary textile material into lengths; of coherent labels for application to garments includes placing a first row of selvage on the web at a first predefined distance from a first outer edge thereof, the first predefined distance being greater than zero, placing a second row of selvage on the web at a second predefined distance from a second outer edge thereof, the second predefined distance being greater than zero, and placing at least a third row and a fourth row of selvage on the web between the first and second rows, a portion of the filamentary material separating each of the rows from the other. A following step includes cutting the web along a line lying between the third and fourth rows of selvage and at a predefined distance away from each of the third and fourth rows of selvage, the predefined distance being greater than zero.

Owner:YIDI JR CARLOS

Method for preparing high-grade and casual fabric with special leather feel using biologically corn-based fibres

InactiveUS20130312236A1Improves fabric sizing processSpeed up the processCrochetingInspecting textilesPolyesterEngineering

A method for preparing high-grade and casual fabric with special leather feel using a corn-based fiber that comprises the steps of: 1) selecting 0.3-0.5 D / PF ultrafine corn-based SORONA fiber from DuPont (U.S.) and 0.2-0.4 D / PF long porous bright polyester yarns as raw materials; 2) compositing by air-jet texturing: having the above raw materials composited by low tension air-jet texturing in an air texturing machine, with the tension force controlled in the range of 4.5-6.0 cN, so as to form ATY yarns with a denier number of 120-180 D; 3) weaving, which includes yarn sizing, preliminary drying, oil applying and plain weaving; 4) dyeing and finishing, which include treating a fabric by pre-treating, presetting, splitting and alkali detaching, water washing and dehydrating, dyeing, water repellent treatment, instant ultrahigh temperature treatment, and one-sided lustering. The fabric prepared according to the present invention has the following advantages: it has smooth surface and soft feel, is waterproof, antifouling and antistatic, has excellent anti-wrinkle properties, has the luster and texture of natural leather material, and is good in breathability and moisture penetrability, it can be used for making both winter clothing and summer clothing, can be water-washed or dry cleaned, it has no need for ironing, is easy to care for, etc.

Owner:DANYANG DANQI YUYUE TEXTILE

Reinforced composite structure

A reinforced composite structure (29) is disclosed. The structure is formed by opposed layers of material extending over a core and continuous bundles stitched in a repeating pattern through the opposed layers (30, 32) and the intermediate core (29) to form the reinforced composite structural member (29).

Owner:SPECTRUM SOLUTIONS

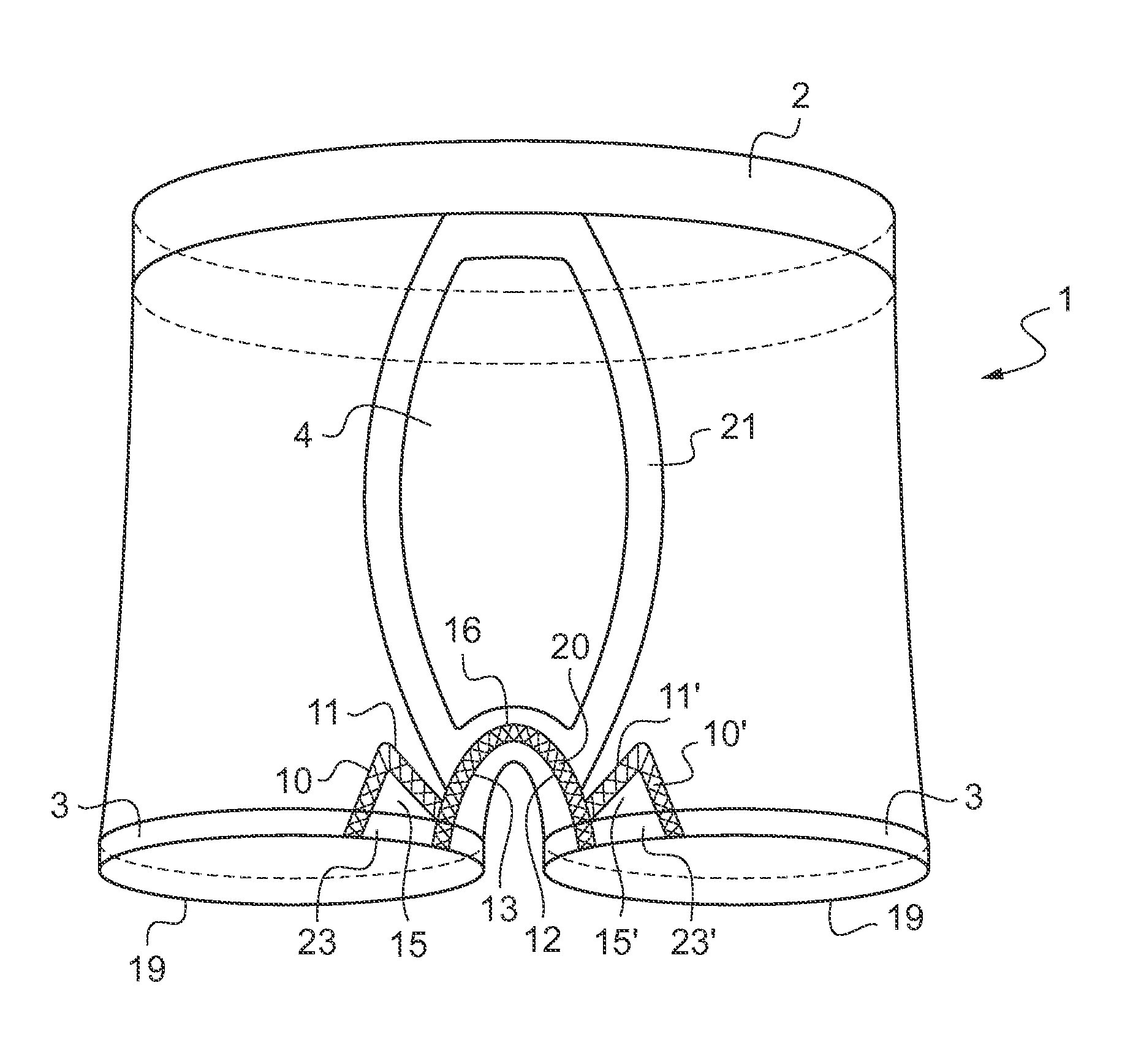

Knitted boxer short with improved crotch bottom and its confection method

InactiveUS20150296891A1Improve comfortWell formedCrochetingInspecting textilesEngineeringMechanical engineering

These comfortable boxer shorts are formed from a knitted main tube (1) comprising a front part (5) and a back part, the lower portions of which end in a first and second bottom line (10, 11, 16, 11′, 10; 13, 12) consisting of two front incisions and one rear incision. The first bottom line (10) (10, 11, 16, 11′, 10′) is composed of an edge (16) of a front flap (14) and of two bottom line side ends (10, 11; 11′, 10′) that rise higher than the edge (16) of the flap (14). Said edge (16) of the front flap (14) is sown to the middle of the second bottom line (13, 12), at the rear of the boxer shorts, and two separate crotch parts (15, 15′) (15) are sown between the ends (10, 11; 11′, 10′) of the first bottom line and the ends of the second bottom line (13, 12).

Owner:DBAPPL OPERATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com