Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33 results about "F-test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An F-test is any statistical test in which the test statistic has an F-distribution under the null hypothesis. It is most often used when comparing statistical models that have been fitted to a data set, in order to identify the model that best fits the population from which the data were sampled. Exact "F-tests" mainly arise when the models have been fitted to the data using least squares. The name was coined by George W. Snedecor, in honour of Sir Ronald A. Fisher. Fisher initially developed the statistic as the variance ratio in the 1920s.

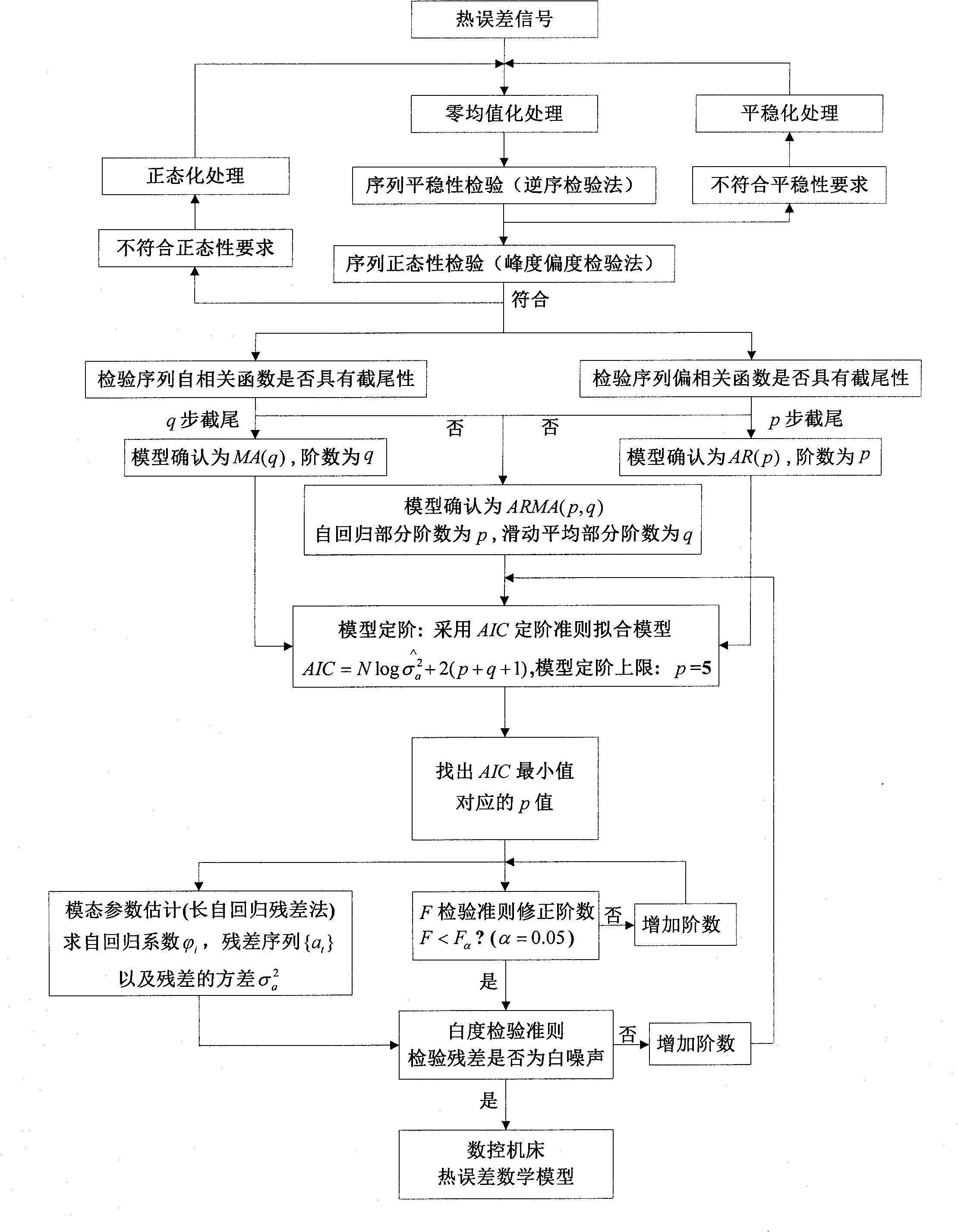

Numerical control machine tool thermal error real-time compensation modeling method based on time series algorithm

InactiveCN102736558AReduce hardware costsReduce complexityProgramme controlComputer controlNumerical controlMathematical model

The invention relates to a numerical control machine tool thermal error real-time compensation modeling method based on a time series algorithm, which belongs to the technical field of precision machining. The method comprises the steps of (1) carrying out data zero mean pretreatment, namely employing an inverted sequence test method and a kurtosis and skewness test method to judge the stationarity and the normality of the data; (2) using an autocorrelation function, a partial correlation function, and the censored results as judgment criteria to carry out the pattern recognition of a thermal error mathematical model; (3) employing a least square estimation method or a long autoregressive residual calculating method to realize the parameter estimation of the thermal error mathematical model; (4) determining the order of the thermal error mathematical model, namely employing a judgment method that combines an AIC order determination criterion, an F test order determination criterion, and a whiteness test order determination criterion to realize the order determination of the thermal error mathematical model; (5) and carrying out integration processing of synthesizing judgment conditions, namely constructing a complete forecasting mathematical model formula. The modeling method provided by the invention has the advantages that less hardware is required, the applicability is wide, and the established model has high prediction precision and reliability.

Owner:上海睿涛信息科技有限公司

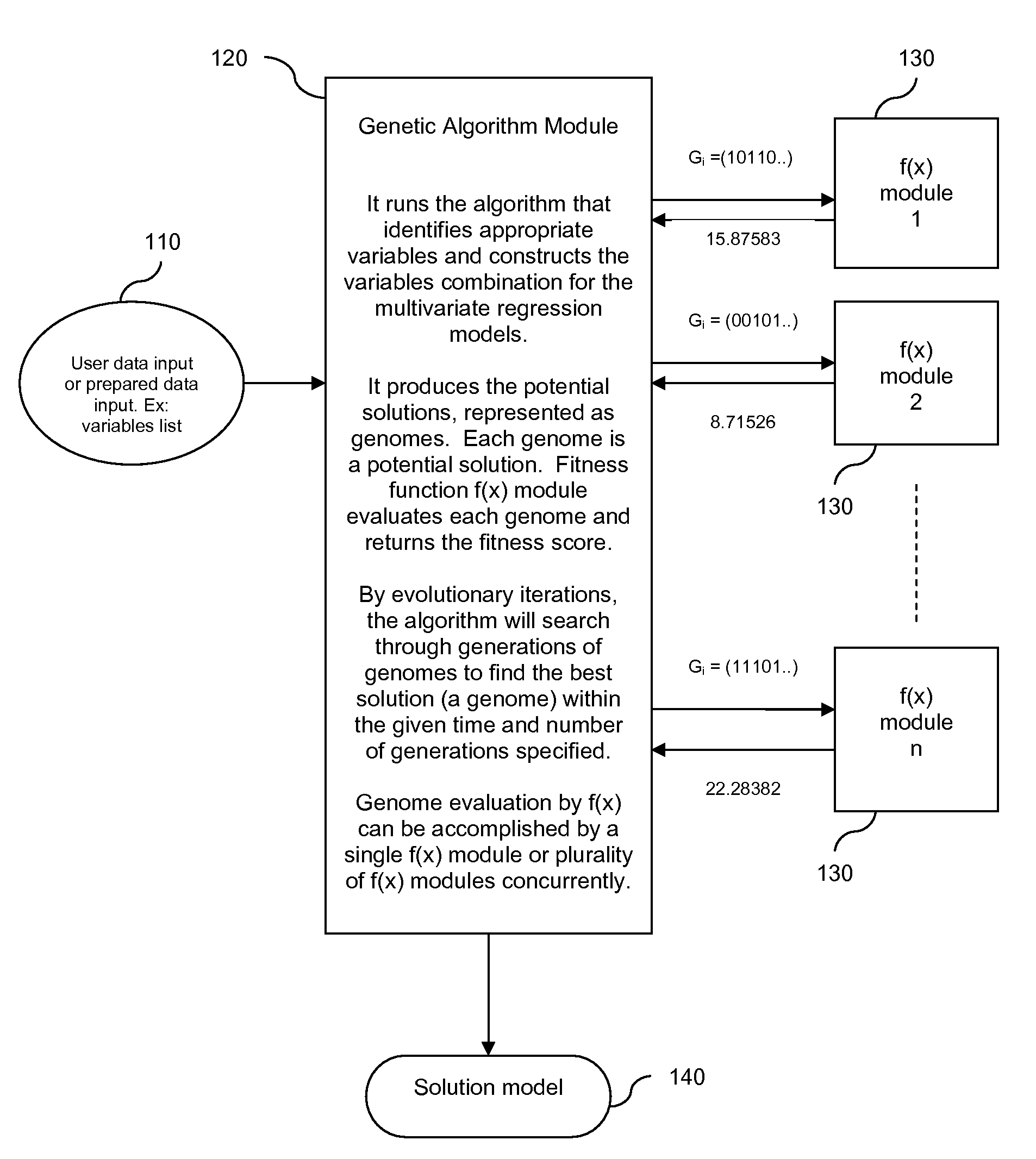

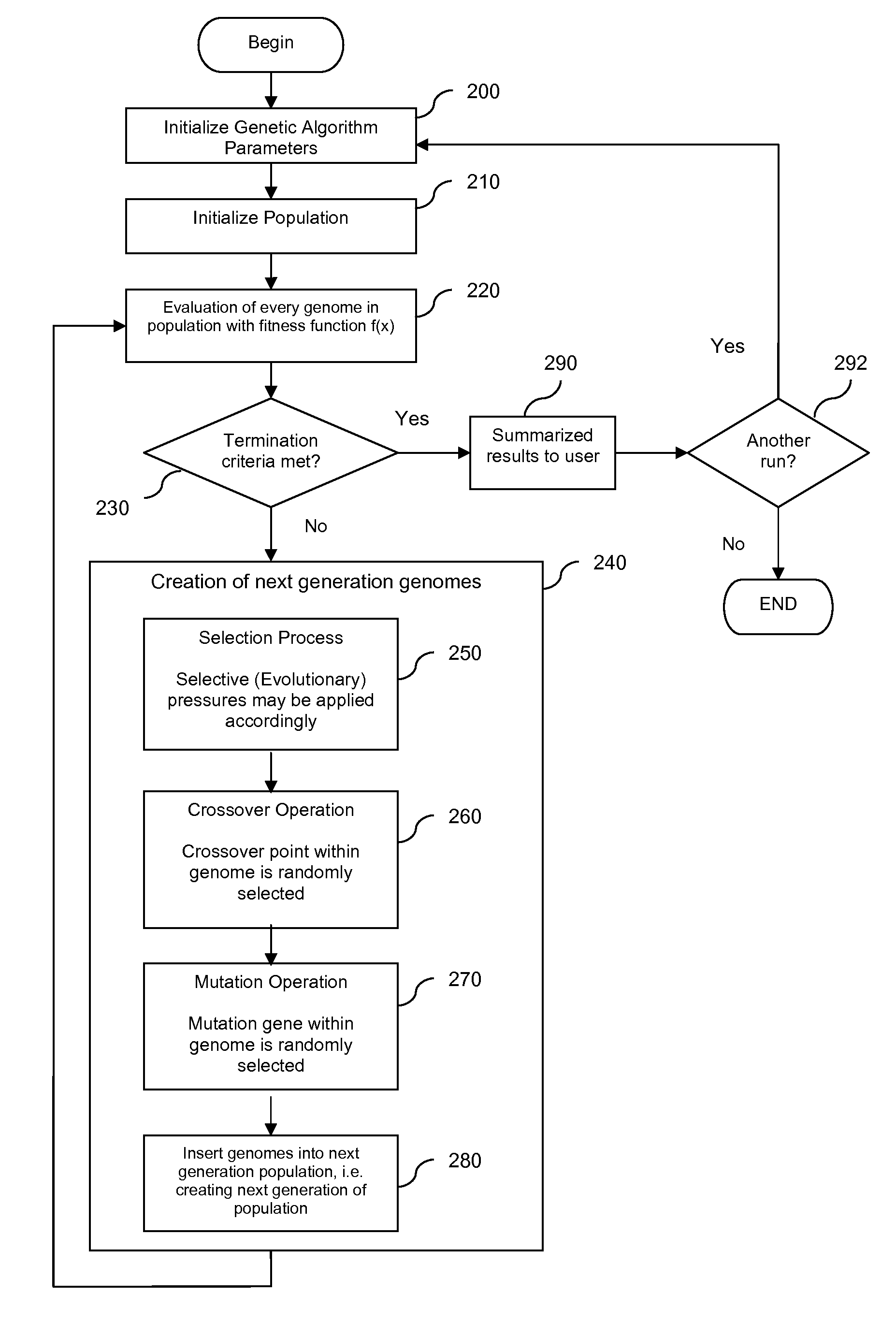

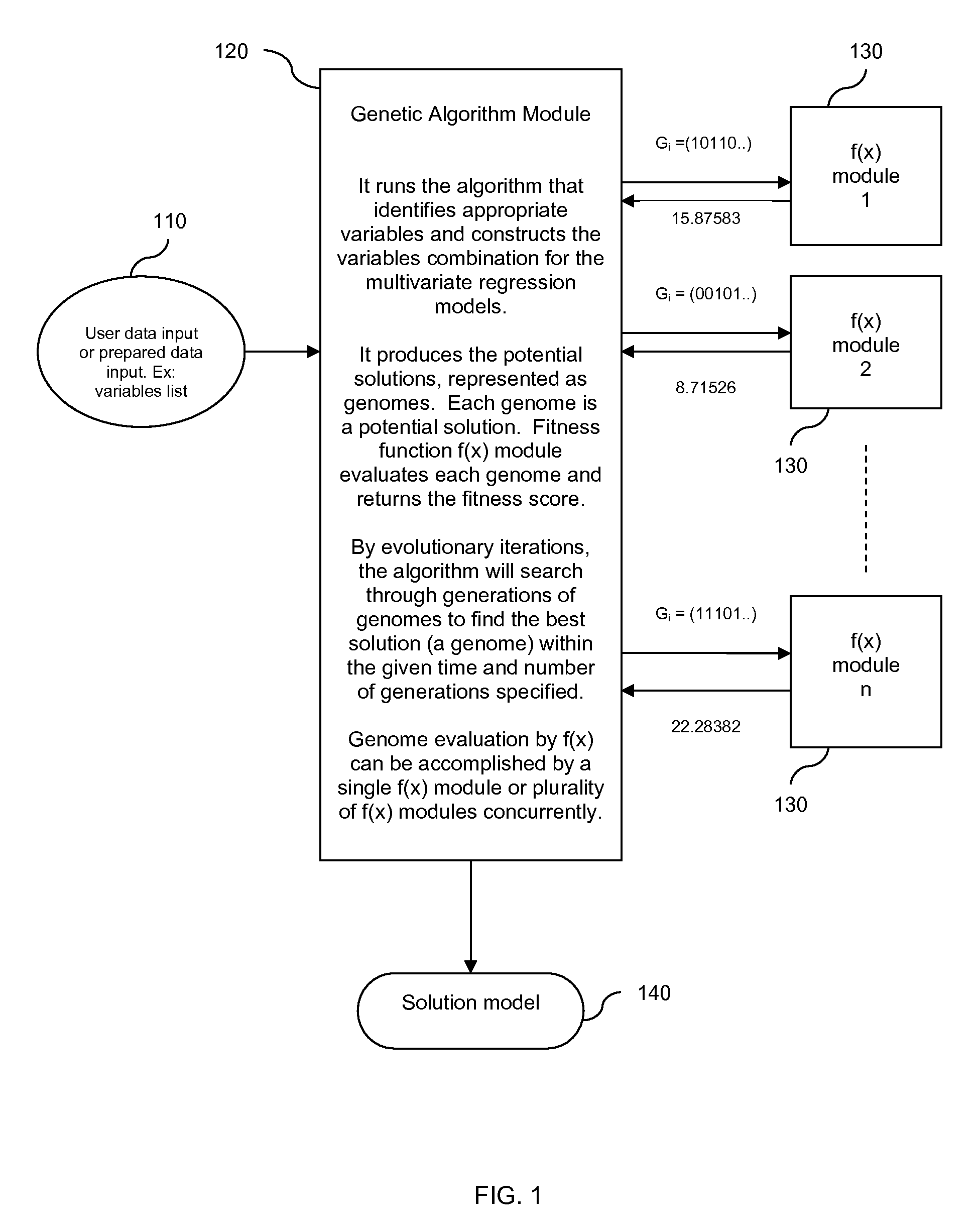

Adaptive Multivariate Model Construction

InactiveUS20080222061A1Increase powerImprove predictive performanceDigital computer detailsElectric digital data processingExplanatory powerMembership testing

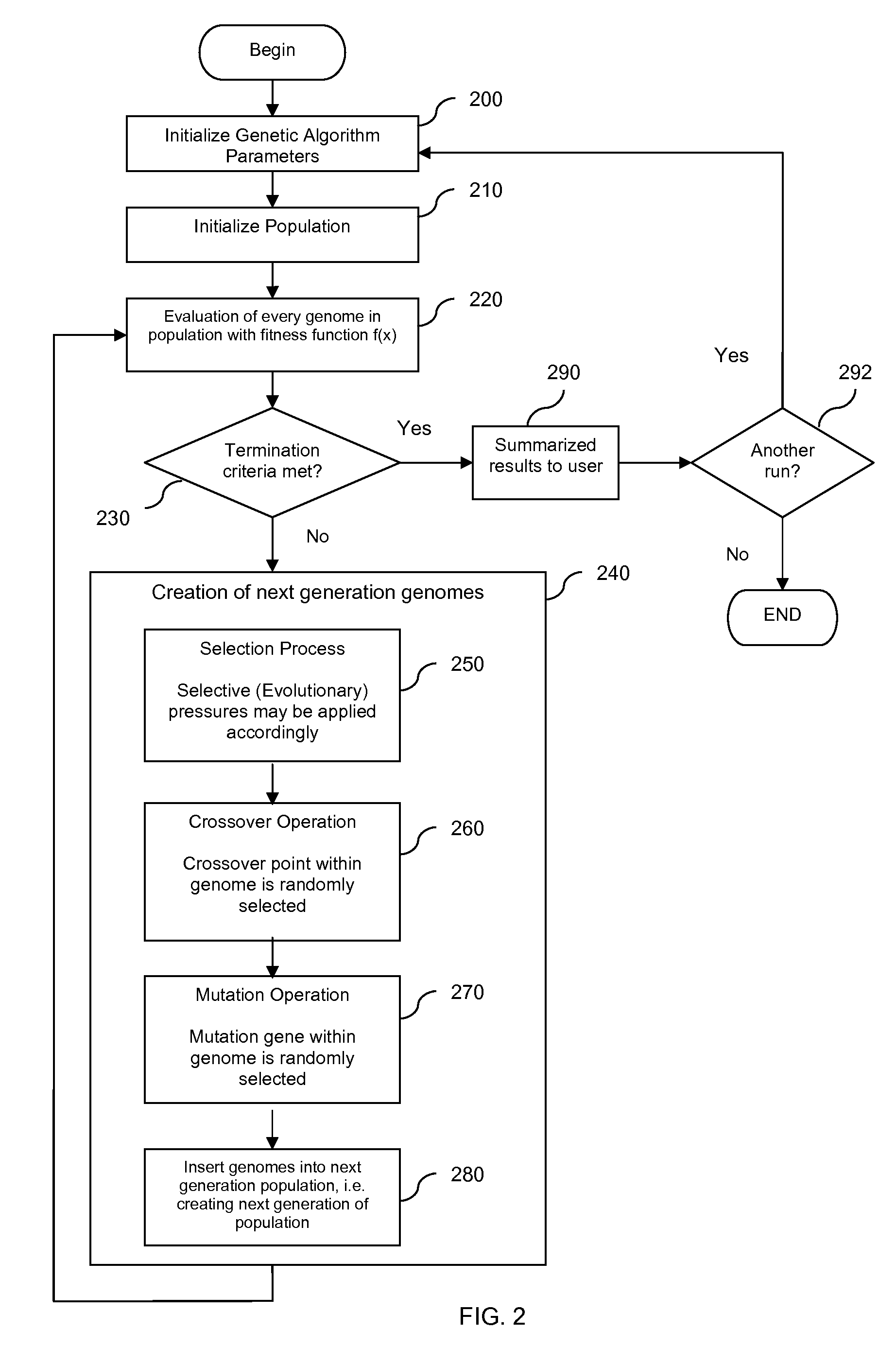

The present embodiment is able to find the optimal or near optimal variables composition of multivariate models by an evolutionary process within acceptable amount of time and resources that are less than using full variables permutation methodology. Subjected to any data, it adaptively identifies and constructs the most effective combination of the relevant variables to achieve one or more objectives. The objective could be for high explanatory power, high predictive power, response measure, or other objectives that the user defines. The present embodiment solves the sequential F-test problem by conducting non-sequential and non-linear search. The algorithm also solves partial F-test dilemma by evaluating all candidate variables membership intact, maintaining fidelity of full variables membership test throughout its permutation. Furthermore, the stochastic nature of the algorithm neutralizes the prejudices of manual decisions in variables identification and membership construction.

Owner:SOETJAHJA HENDRA

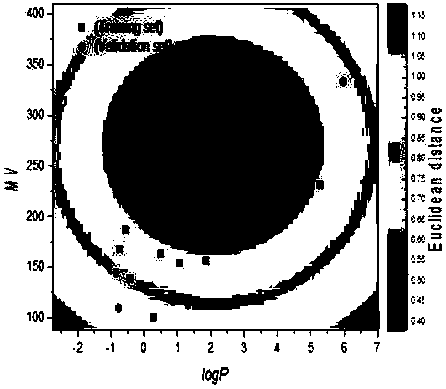

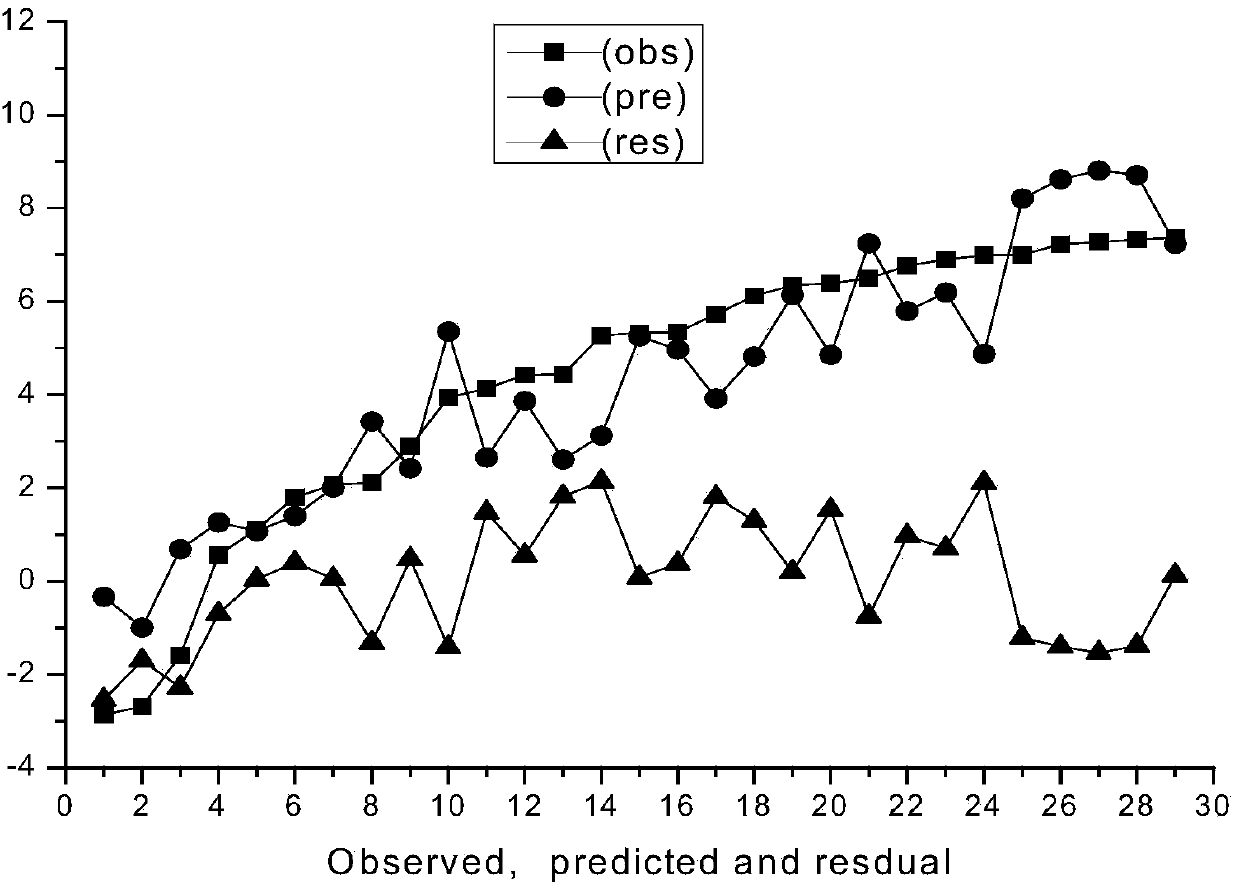

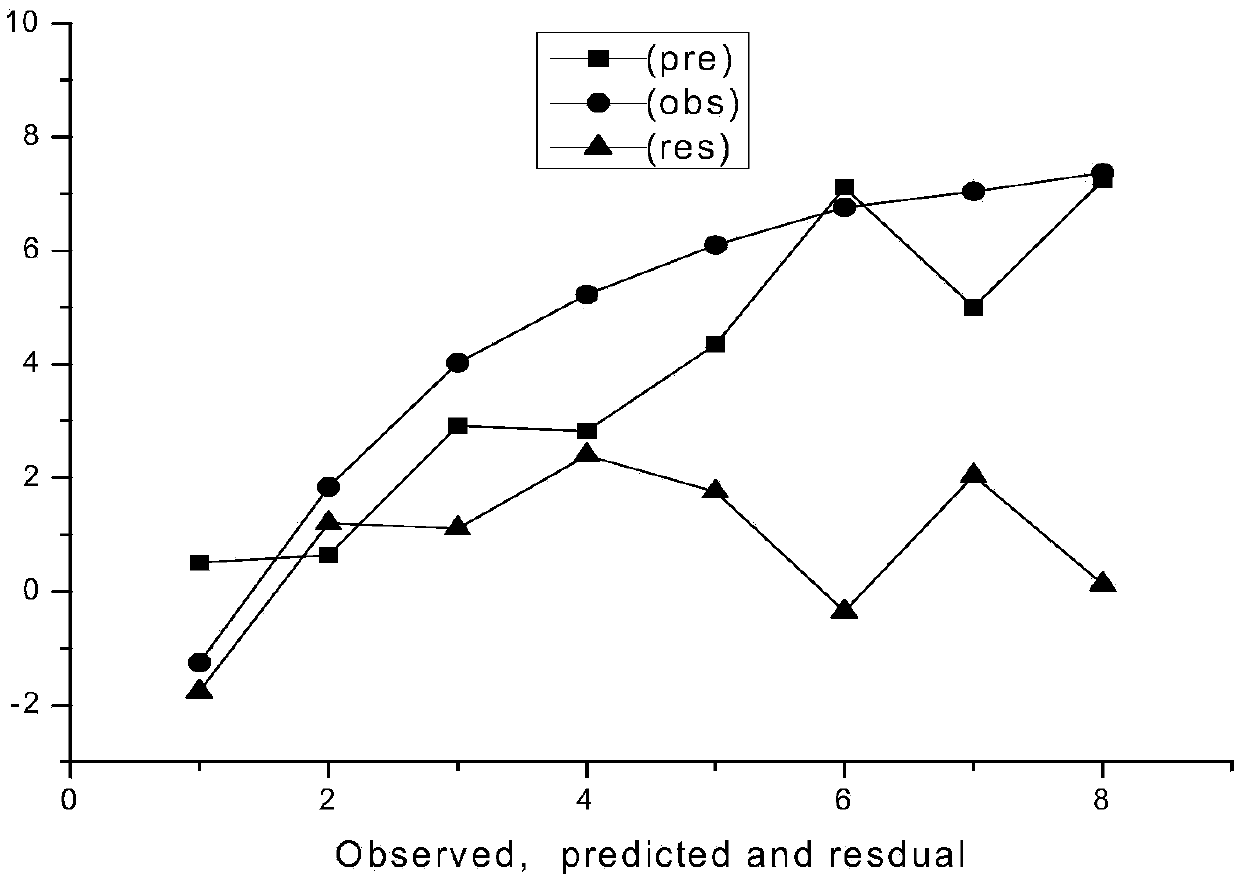

Method for forecasting acute toxicity of organic compounds by building quantitative structure-activity relationship model with quantum chemistry method

InactiveCN103646180APredict toxicityChemical property predictionSpecial data processing applicationsMolecular orbital energyAb initio quantum chemistry methods

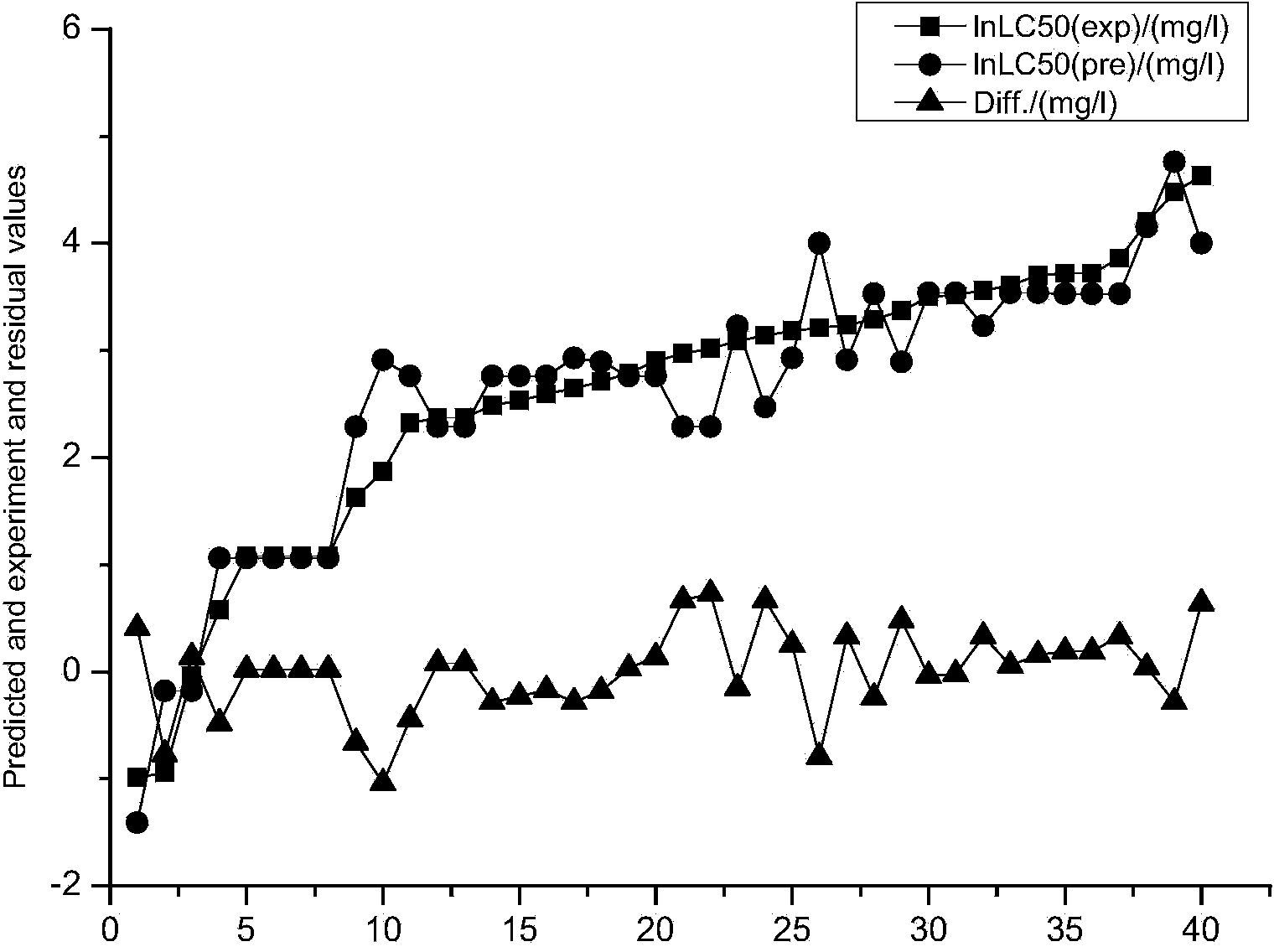

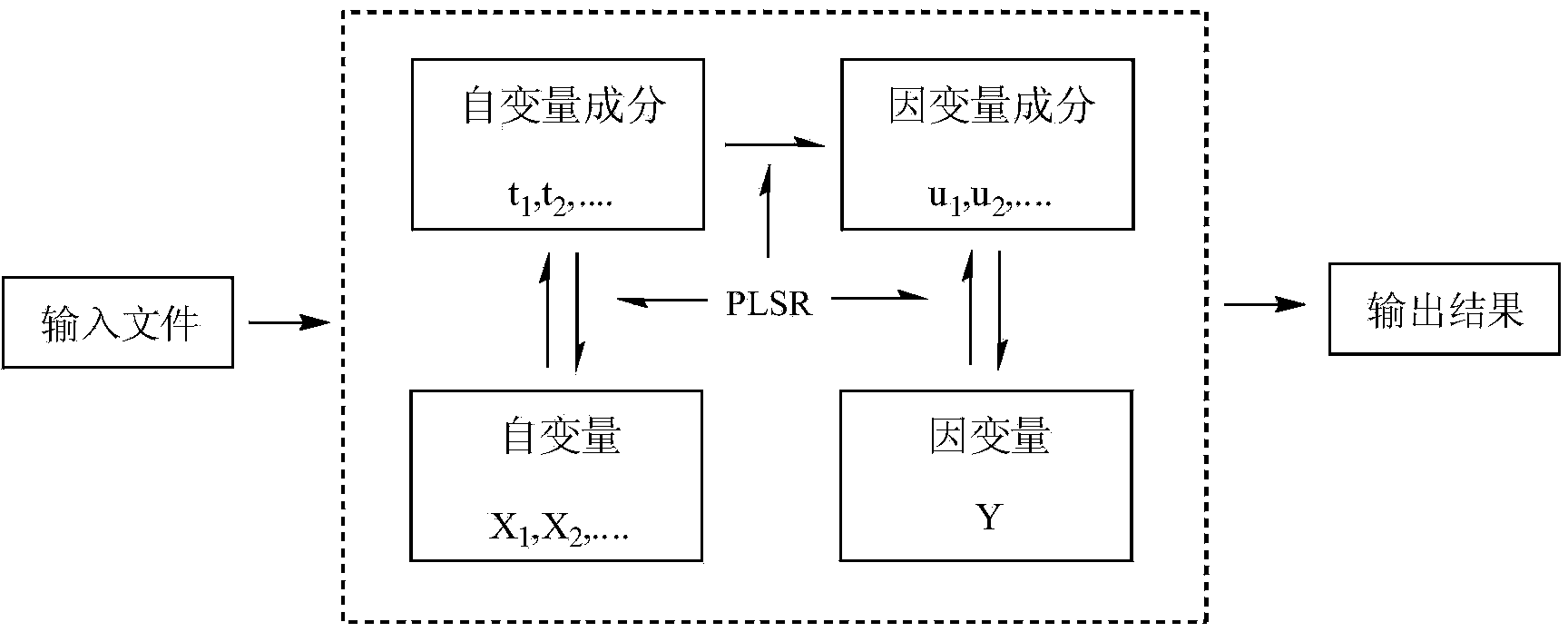

The invention discloses a method for forecasting the acute toxicity of organic compounds by building a quantitative structure-activity relationship model with a quantum chemistry method. The method fully geometrically optimizes compound structures by using a Gaussian procedure so as to obtain quantum chemistry parameters including molecular volume, relative molecular mass, highest occupied molecular orbital energy, lowest unoccupied molecular orbital energy, energy gaps of frontier molecular orbital, dipole moment, solvation energy, electron energy and the like; using the quantum chemistry parameters and a hydrophobicity parameter as structural descriptors; in combination with toxicity data, quantitative relationship equations between various structural descriptors and toxicity are established according to a written procedure based on partial least square stepwise linear regression to obtain the multiple correlation coefficient, F-test value and sum of squared residuals, and then the model is verified so as to guarantee the external predictive ability. Therefore, the method can quickly and effectively forecast the toxicity of organic compounds to be studied, and provide necessary basic data for risk assessment and supervision of chemicals.

Owner:SHANDONG UNIV

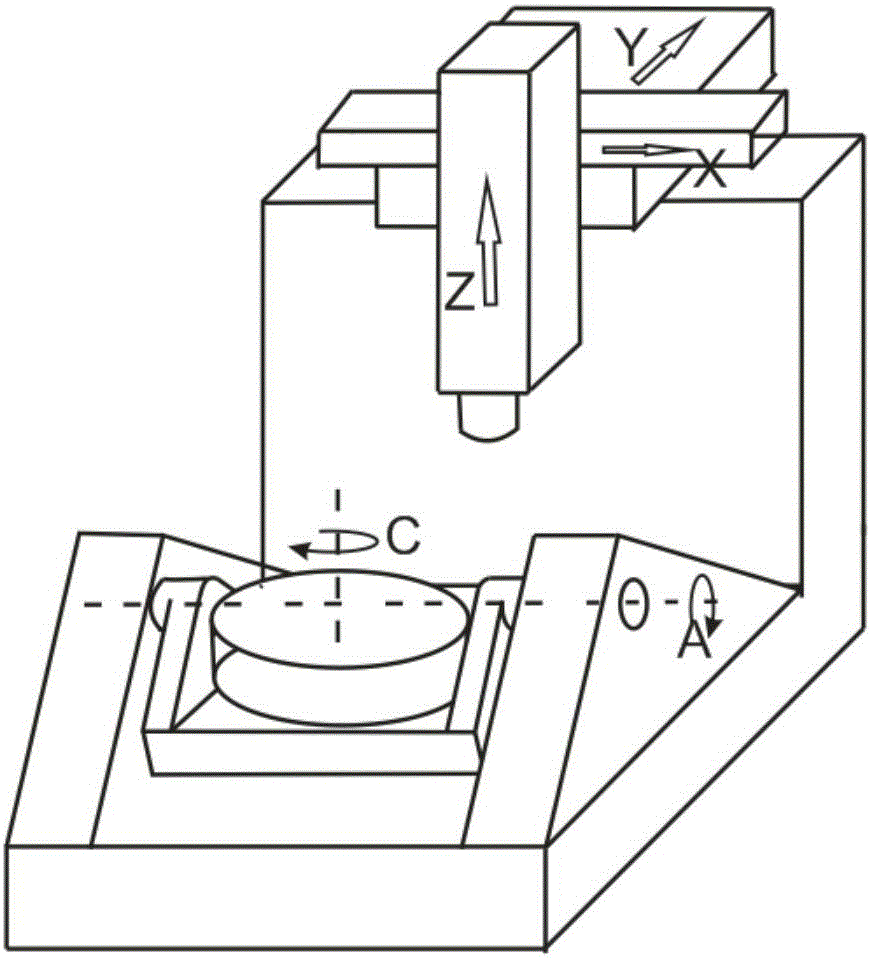

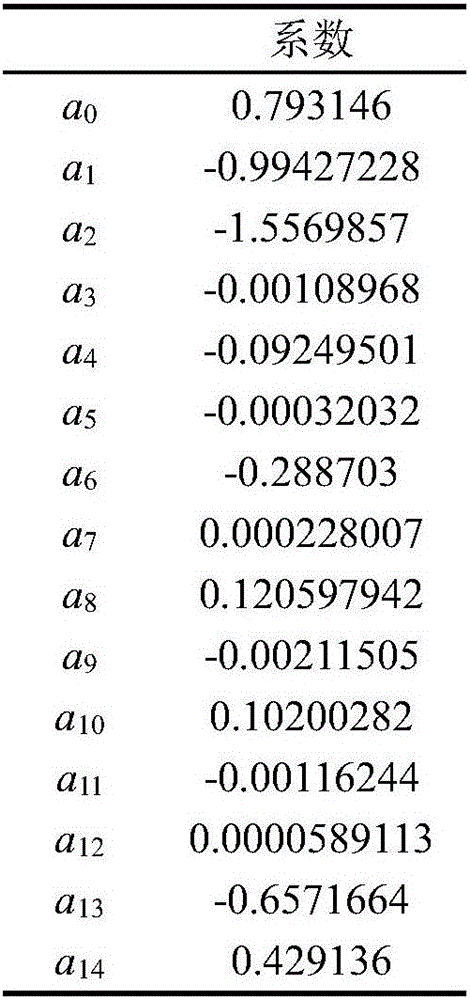

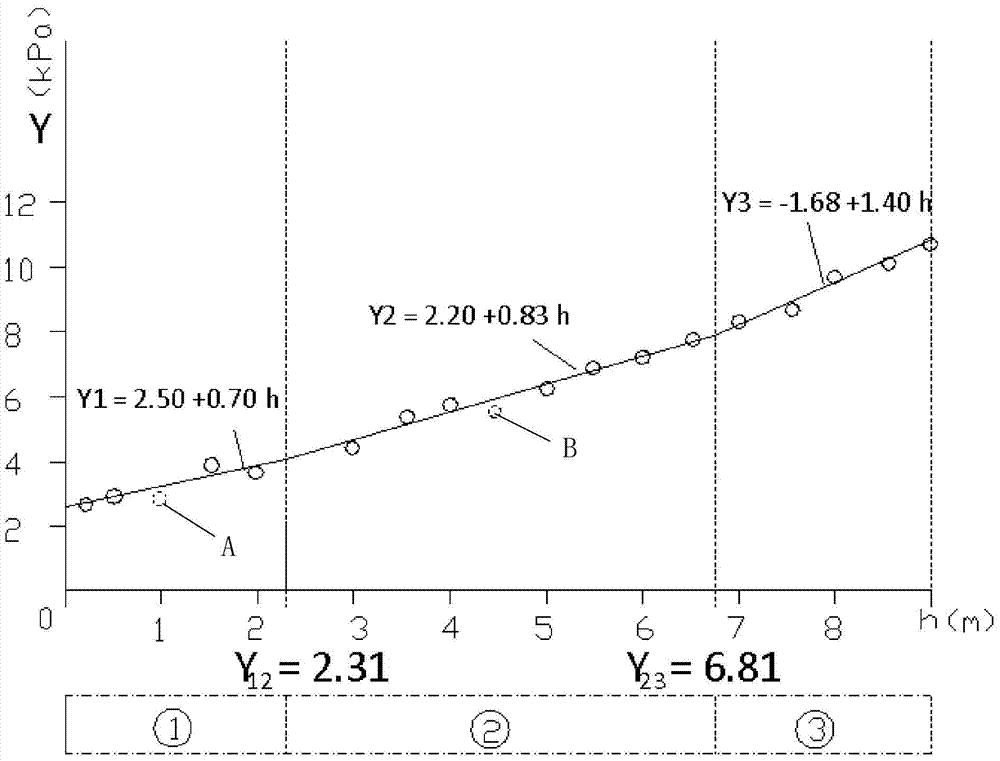

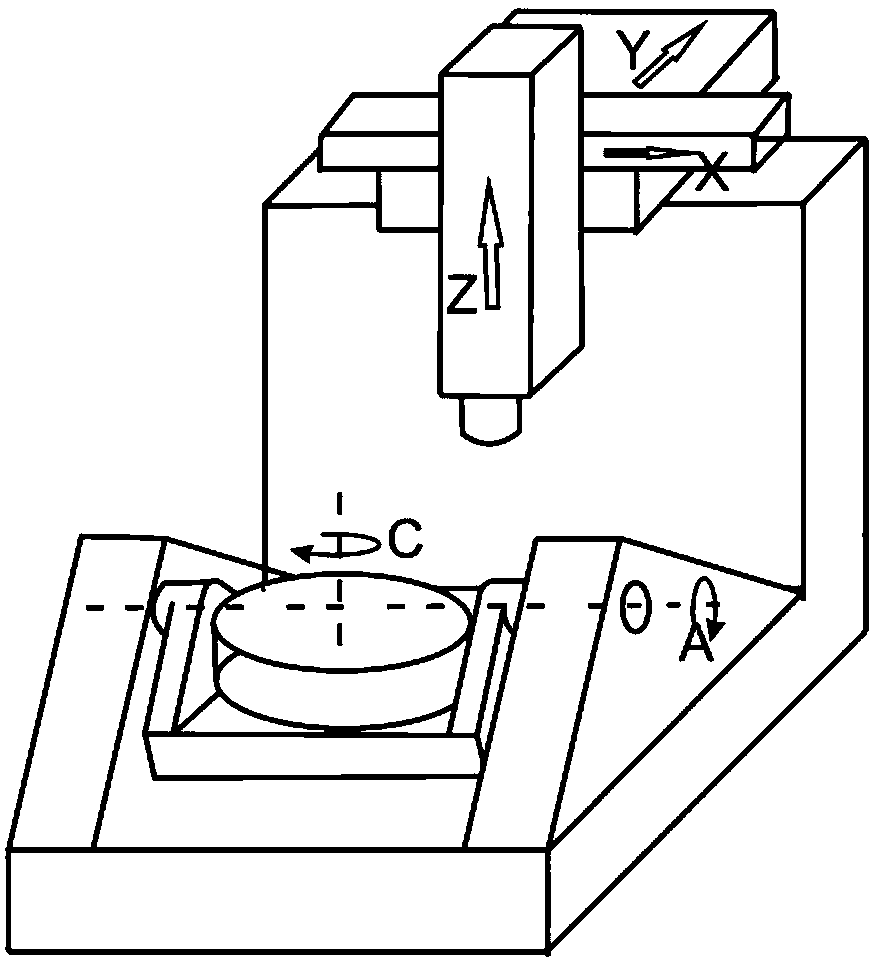

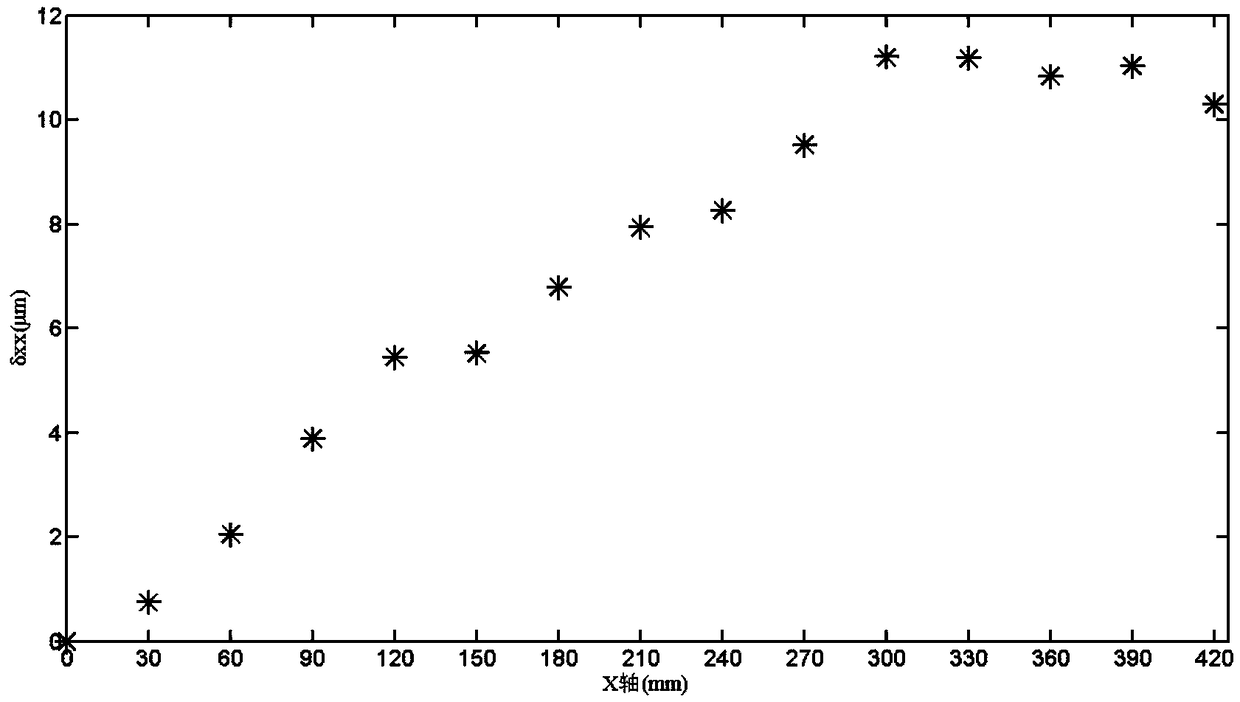

Method for modeling location-dependent geometric error item of numerical control machine tool

ActiveCN106774152AHigh precisionImprove robustnessProgramme controlComputer controlGeometric errorNumerical control

The invention discloses a method for modeling the location-dependent geometric error item of a numerical control machine tool, which belongs to the technical field of numerical control machine tool machining. The method comprises the following steps: determining the n-order polynomial form of the location-dependent geometric error item of a numerical control machine tool according to the property of the location-dependent geometric error item; according to the discrete data of the location-dependent geometric error item of the numerical control machine tool, getting an n-order polynomial coefficient calculation matrix M based on the principle of least square fitting, and calculating the coefficients of the n-order polynomial; calculating a series of polynomials from first-order to mth-order polynomials according to the discrete data of the location-dependent geometric error item of the numerical control machine tool, wherein the highest order m is set to half of the discrete data of the geometric error item; calculating the F values of first-order to m-order polynomials through a regression analysis F-test method; and finding out the maximum F value through comparison, and selecting the polynomial corresponding to the maximum F value as an optimized polynomial model of the location-dependent geometric error item of the numerical control machine tool. The method is mainly used to realize automated and programmed machine tool comprehensive error modeling.

Owner:SOUTHWEST JIAOTONG UNIV

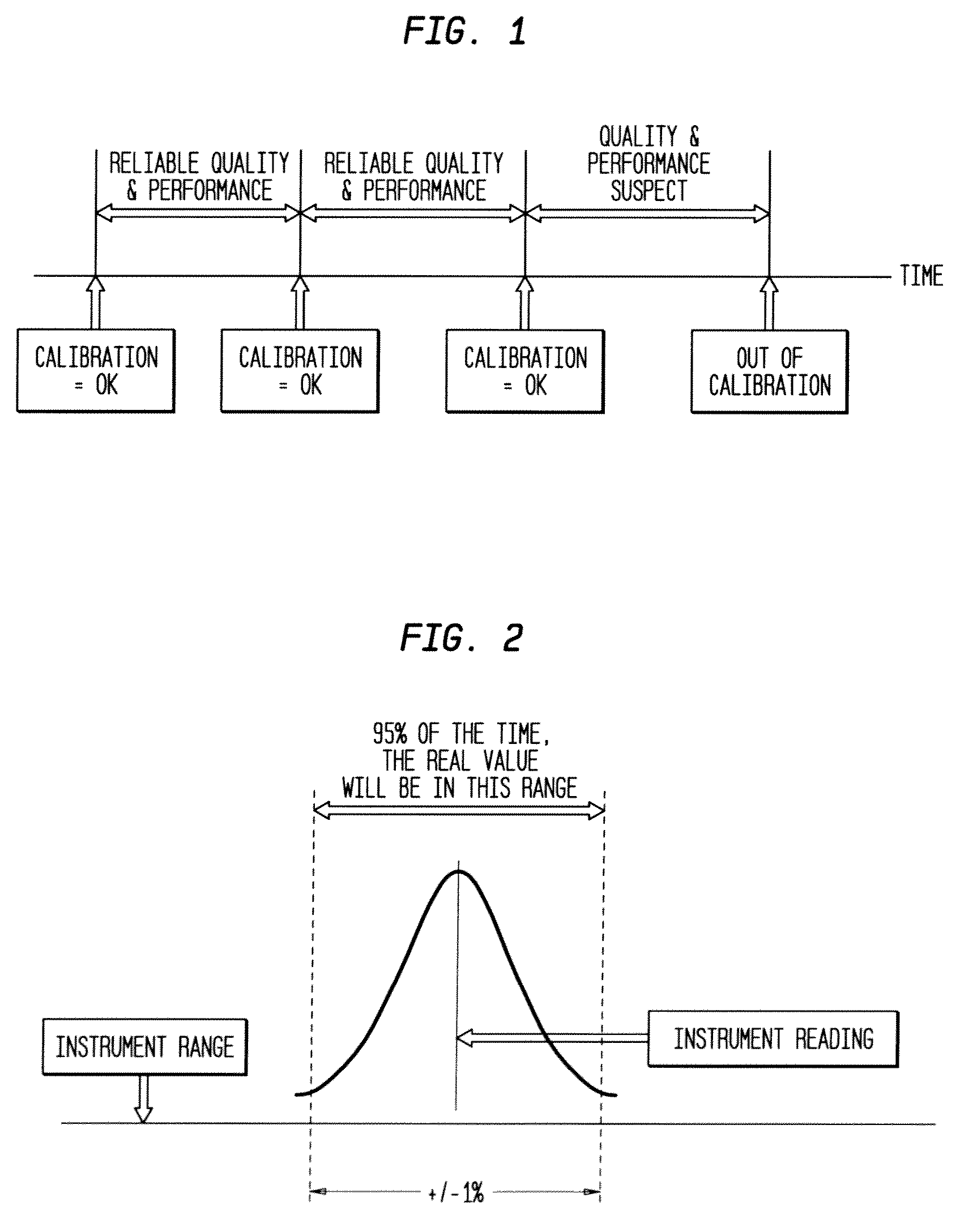

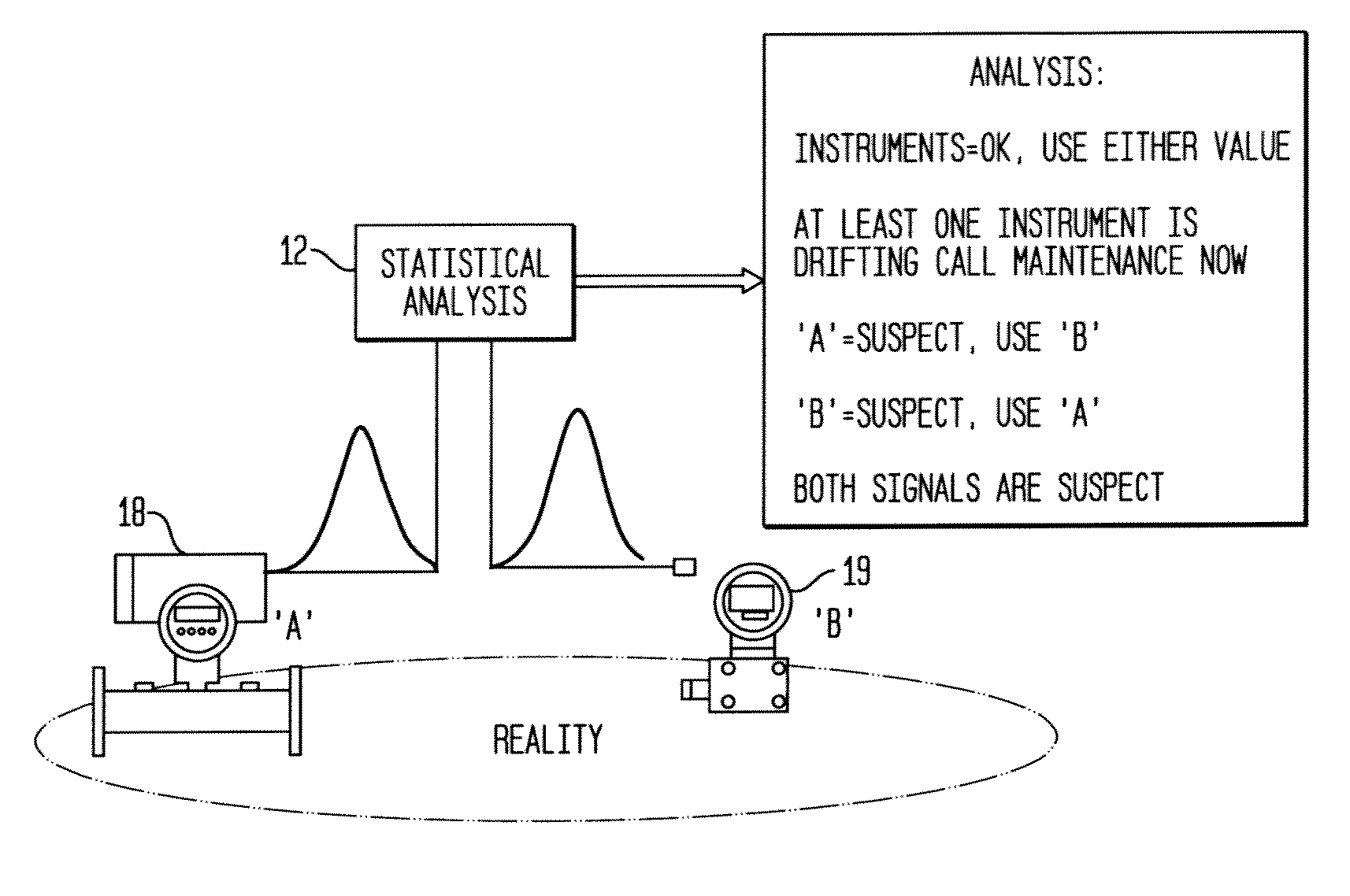

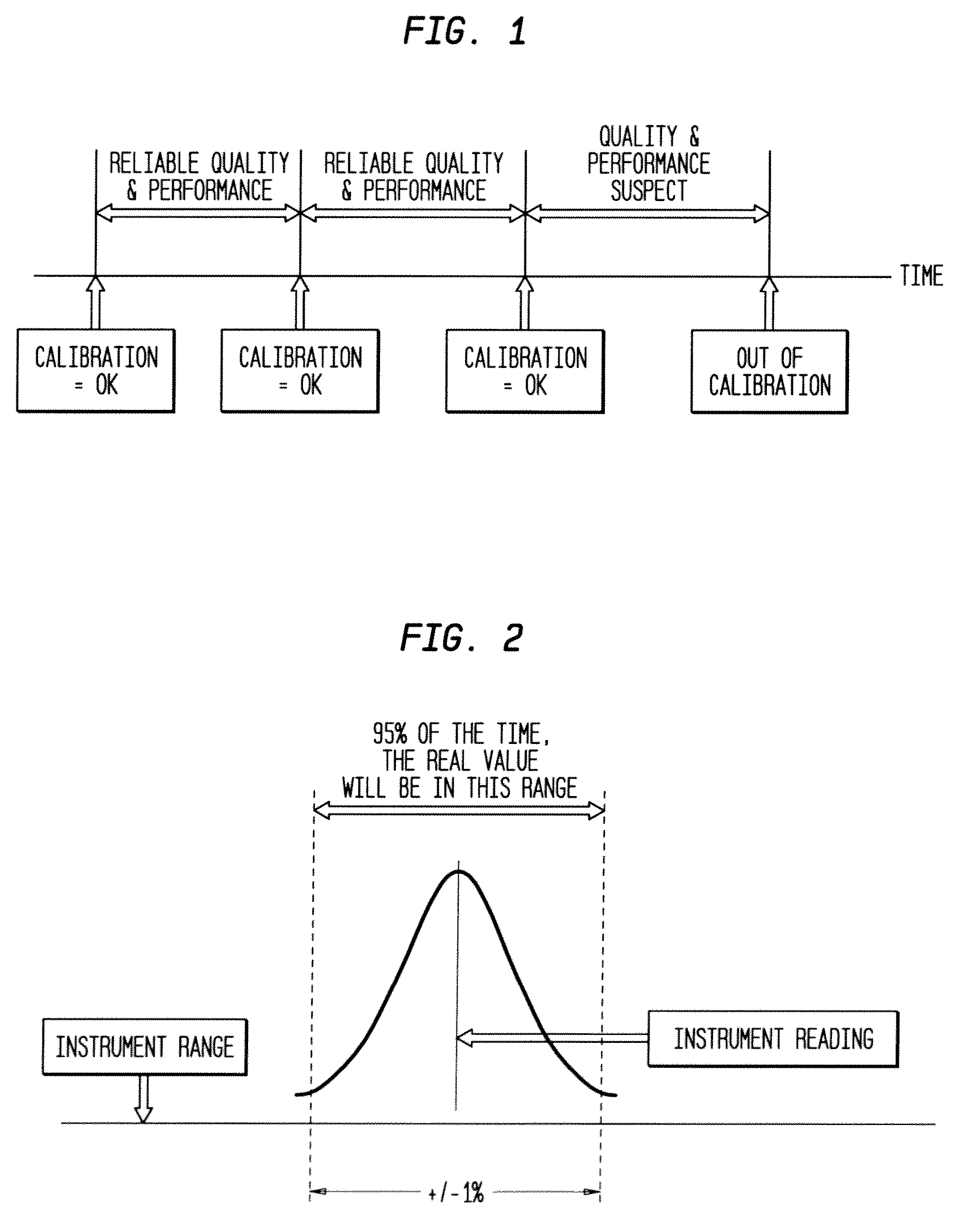

Use of statistics to determine calibration of instruments

The present invention relates generally to statistics and calibration of instruments. More particularly, the invention encompasses the use of statistics to determine calibration of instruments. The present invention is also directed to a remote system for determination of re-calibration of instruments. The present invention also teaches the use of multiple statistical tests to determine need for calibration. The invention also includes a novel use of tests, such as, the F-Test, the Z-Test, to determine need for calibration. Furthermore, this invention relates to an alternate instrument scheme consisting of the use of redundant sensors and statistical analysis to avoid unnecessary calibrations and to detect sensors that are starting to drift before they go out of calibration. With this invention reduced calibration cost, increased data integrity, and reduced off-spec uncertainty is achieved.

Owner:SIEMENS IND INC

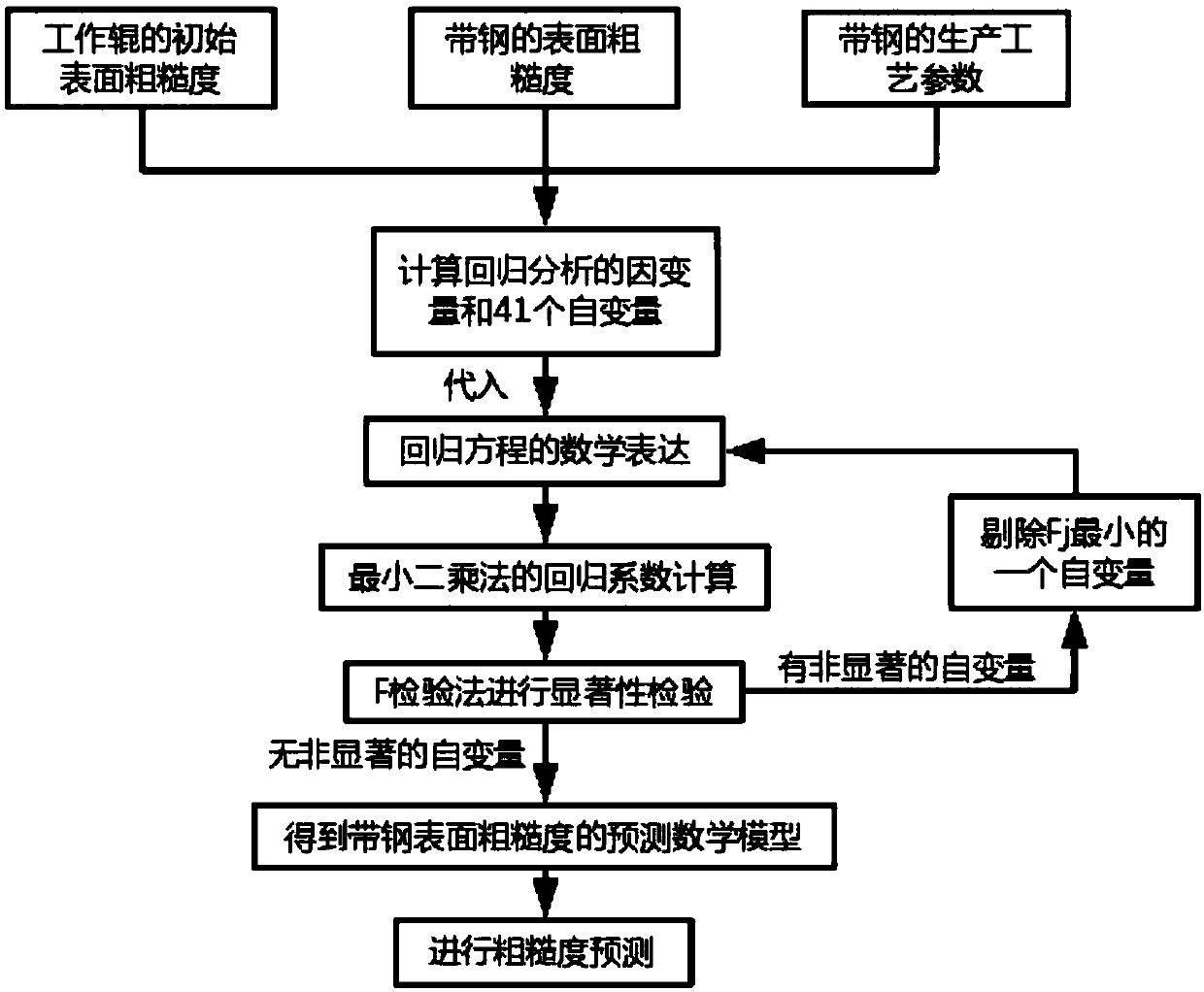

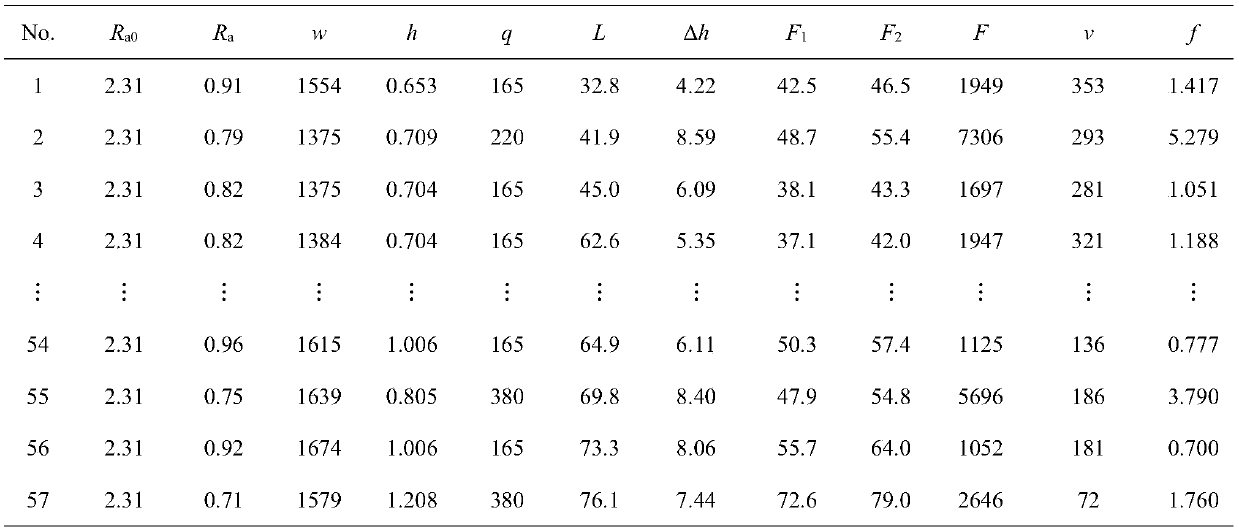

Forecasting method for surface roughness of strip steel in rolling process

ActiveCN106825068AThe principle is simpleEasy to calculateMeasuring devicesMetal rolling arrangementsPredictive methodsSurface roughness

The invention provides a forecasting method for the surface roughness of strip steel in the rolling process and belongs to the technical field of plate strip rolling. According to the method, on the basis of batch collection of industrial production site data, data of the initial surface roughness of a working roller, the surface roughness of the strip steel and production process parameters of the strip steel are obtained; by adopting a regression analysis method, the regression coefficient is calculated by utilizing a least square method; and independent variables with insignificant influence on dependent variables are eliminated one by one through a F test, and accordingly a forecasting model of the surface roughness of the strip steel is obtained. According to the forecasting method, considered process factors are more comprehensive, the principle is simple, the calculation process is convenient, and actual site process parameters can be fully utilized.

Owner:UNIV OF SCI & TECH BEIJING

Adaptive multivariate model construction

InactiveUS8073790B2Increase powerImprove predictive performanceDigital computer detailsElectric digital data processingExplanatory powerComputer science

The present embodiment is able to find the optimal or near optimal variables composition of multivariate models by an evolutionary process within acceptable amount of time and resources that are less than using full variables permutation methodology. Subjected to any data, it adaptively identifies and constructs the most effective combination of the relevant variables to achieve one or more objectives. The objective could be for high explanatory power, high predictive power, response measure, or other objectives that the user defines. The present embodiment solves the sequential F-test problem by conducting non-sequential and non-linear search. The algorithm also solves partial F-test dilemma by evaluating all candidate variables membership intact, maintaining fidelity of full variables membership test throughout its permutation. Furthermore, the stochastic nature of the algorithm neutralizes the prejudices of manual decisions in variables identification and membership construction.

Owner:SOETJAHJA HENDRA

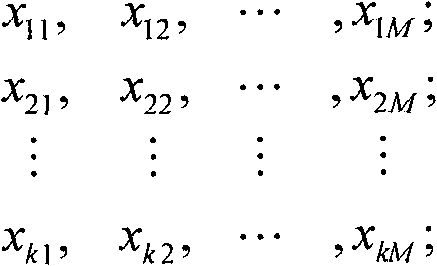

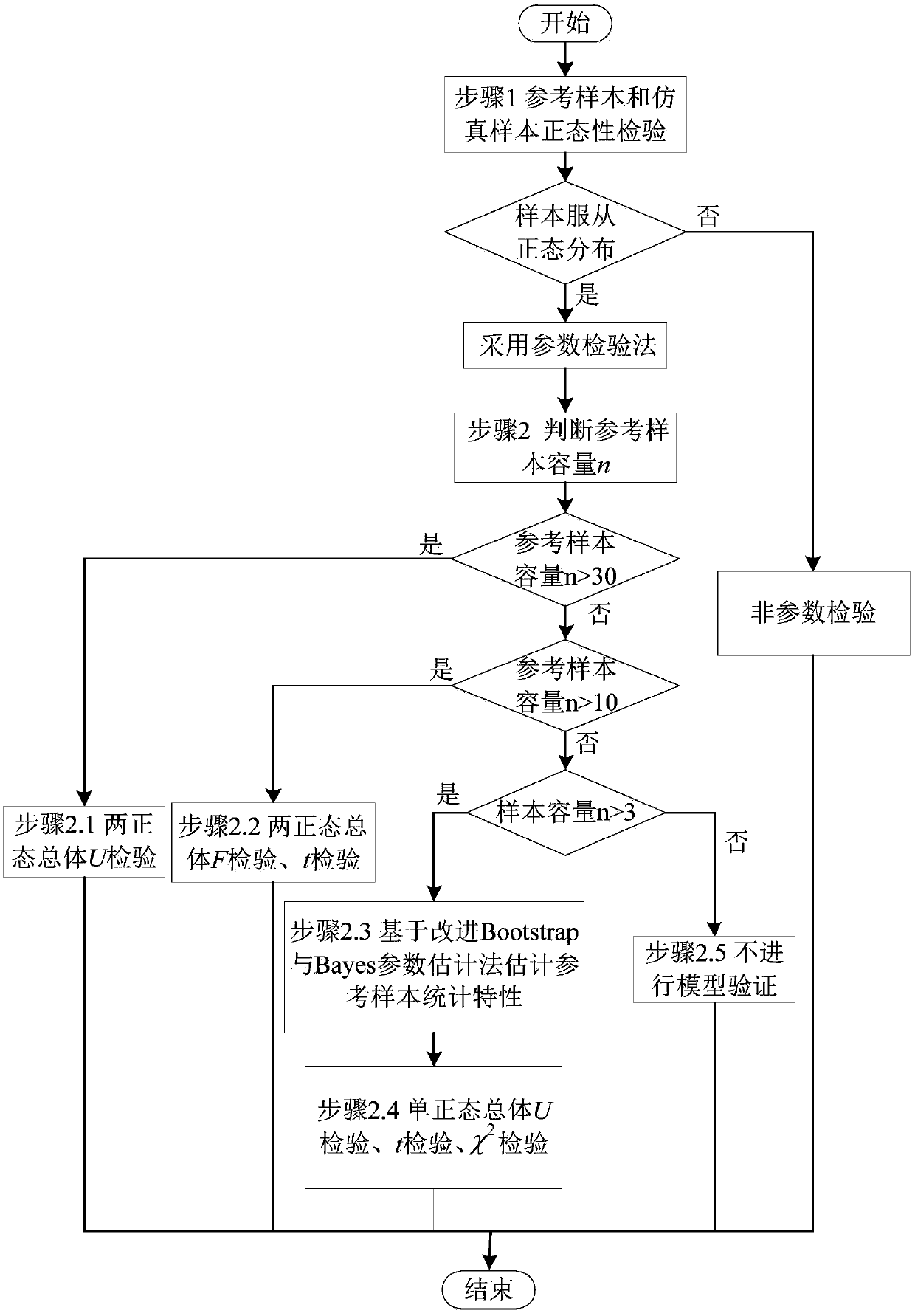

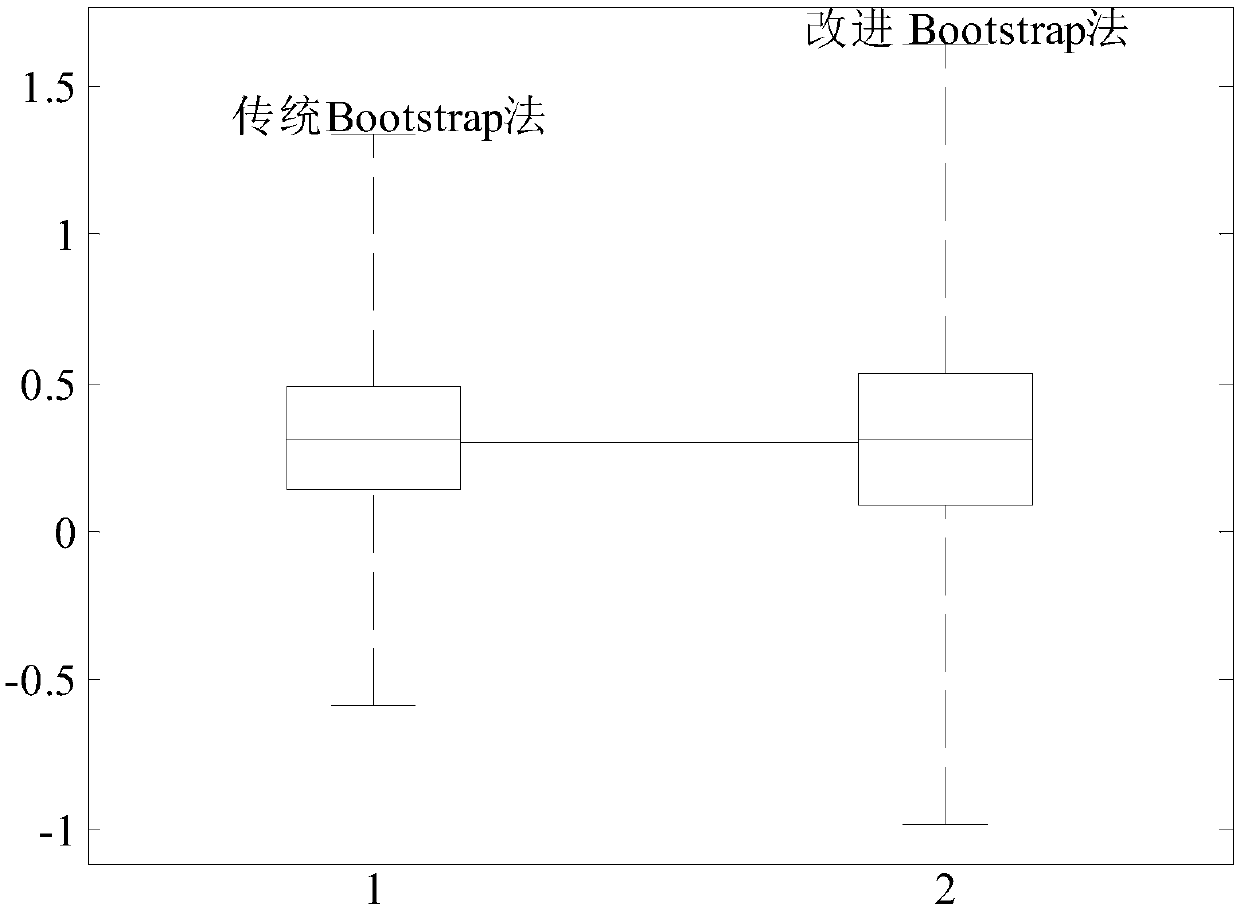

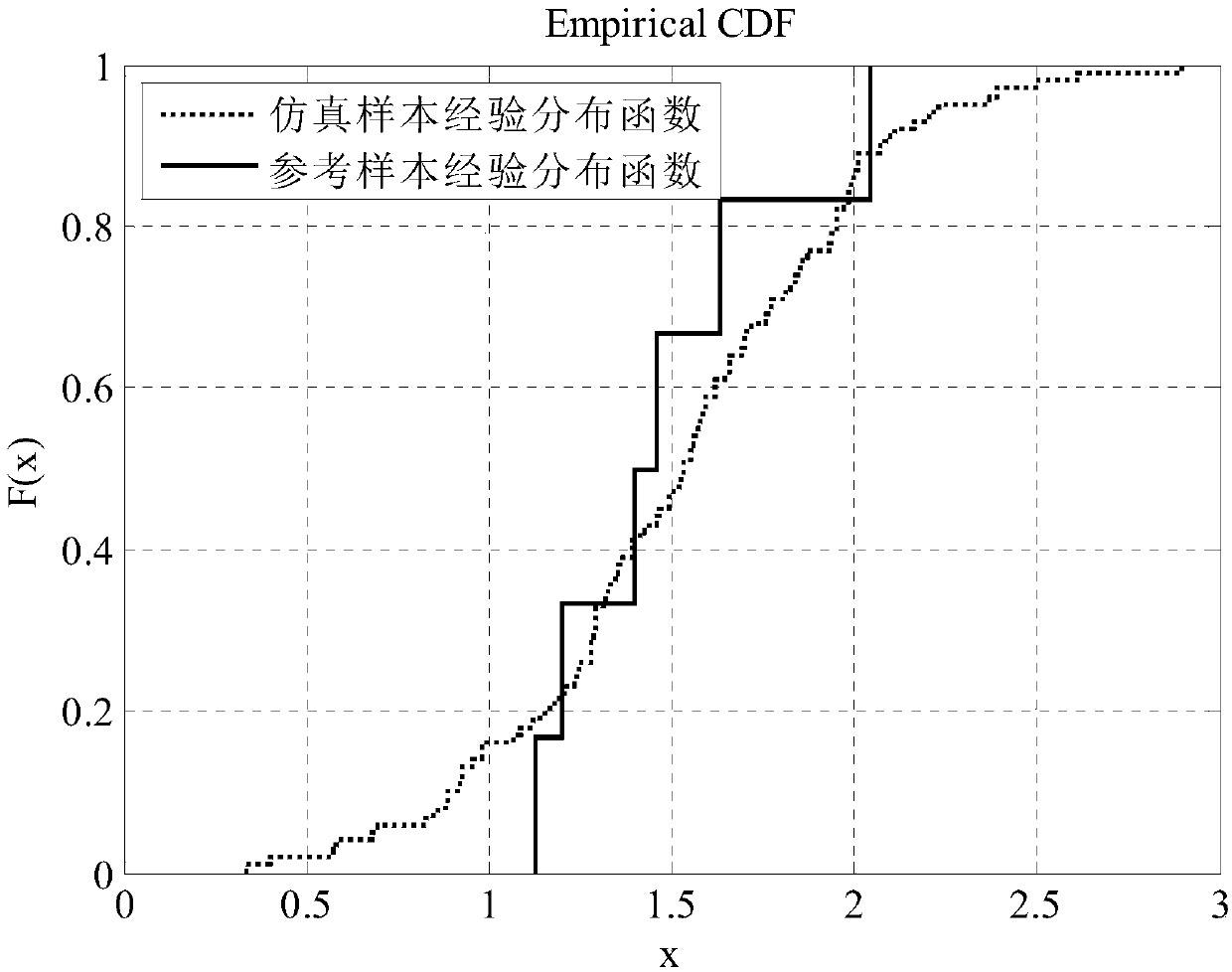

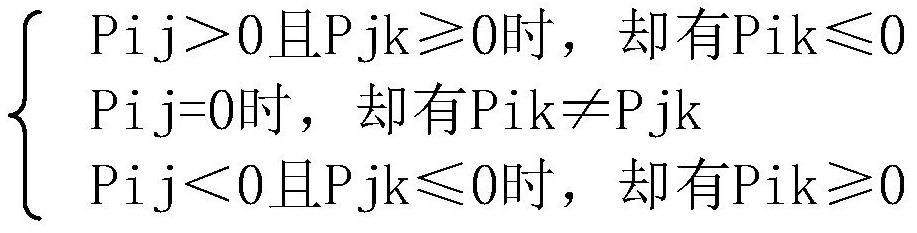

Small sample data model verification method based on statistical analysis

ActiveCN108763828ASolve problems such as easy deviation from the true distributionImprove accuracySustainable transportationDesign optimisation/simulationReference sampleSmall sample

The invention discloses a small sample data model verification method based on statistical analysis, relating to a small sample data model verification method. The invention aims to solve the problemsthat the scope of a conventional Bootstrap method for reproducing samples is limited to an original sample range, especially in the case of a small sample size, the distribution of the reproduced samples may deviate from the real distribution, the estimation results may be inaccurate, and certain risks exist. The method includes the following processes: step I, performing a normality test on a reference sample and a simulation sample, and if obeying the normal distribution, performing step II; and step II, when n is greater than or equal to 30, adopting a U test method; when n is greater than10 and less than 30, adopting a t or F test method; when n is greater than 3 and less than or equal to 10, adopting a formula 1 and a formula 2 (as shown in the original specification) to separatelyperform a single normal population parameter test on the simulation sample in the step I; determining whether the obtained mean value and variance of the reference sample and the simulation sample areconsistent; and when n is less than 3, not performing model verification. The scheme of the invention is applied to the field of simulation model verification.

Owner:HARBIN INST OF TECH

Use of statistics to determine calibration of instruments

The present invention relates generally to statistics and calibration of instruments. More particularly, the invention encompasses the use of statistics to determine calibration of instruments. The present invention is also directed to a remote system for determination of re-calibration of instruments. The present invention also teaches the use of multiple statistical tests to determine need for calibration. The invention also includes a novel use of tests, such as, the F-Test, the Z-Test, to determine need for calibration. Furthermore, this invention relates to an alternate instrument scheme consisting of the use of redundant sensors and statistical analysis to avoid unnecessary calibrations and to detect sensors that are starting to drift before they go out of calibration. With this invention reduced calibration cost, increased data integrity, and reduced off-spec uncertainty is achieved.

Owner:SIEMENS IND INC

Method for predicating acute toxicity of organophosphorus pesticide on aquatic organisms through quantitative structure activity relationship

InactiveCN103778483AForecast QuickPrediction is simpleChemical property predictionForecastingAcute toxicity testingChemical compound

The invention discloses a method for predicating the acute toxicity of organophosphorus pesticide on aquatic organisms through the quantitative structure activity relationship. On the basis that the structure of chemical compound is known, geometrical full optimization is performed on a Gaussian program to obtain the MV, the MW, the EHOMO, the ELUMO, the difference value delta E (hartree), the DM and the like to serve as structural descriptors, regression parameters of all parameters, the multiple correlation coefficient and an F-test value are obtained in combination with data of toxicity of the organophosphorus pesticide on aquatic organisms through the programmed partial least squares stepwise linear regression program, and quantitative relationships between the various structural descriptors and the toxicity. Thus, the toxicity of the organophosphorus pesticide on the aquatic organisms can be fast, conveniently and effectively predicted, and essential basic data are provided for risk assessment and supervision on the organophosphorus pesticide.

Owner:SHANDONG UNIV

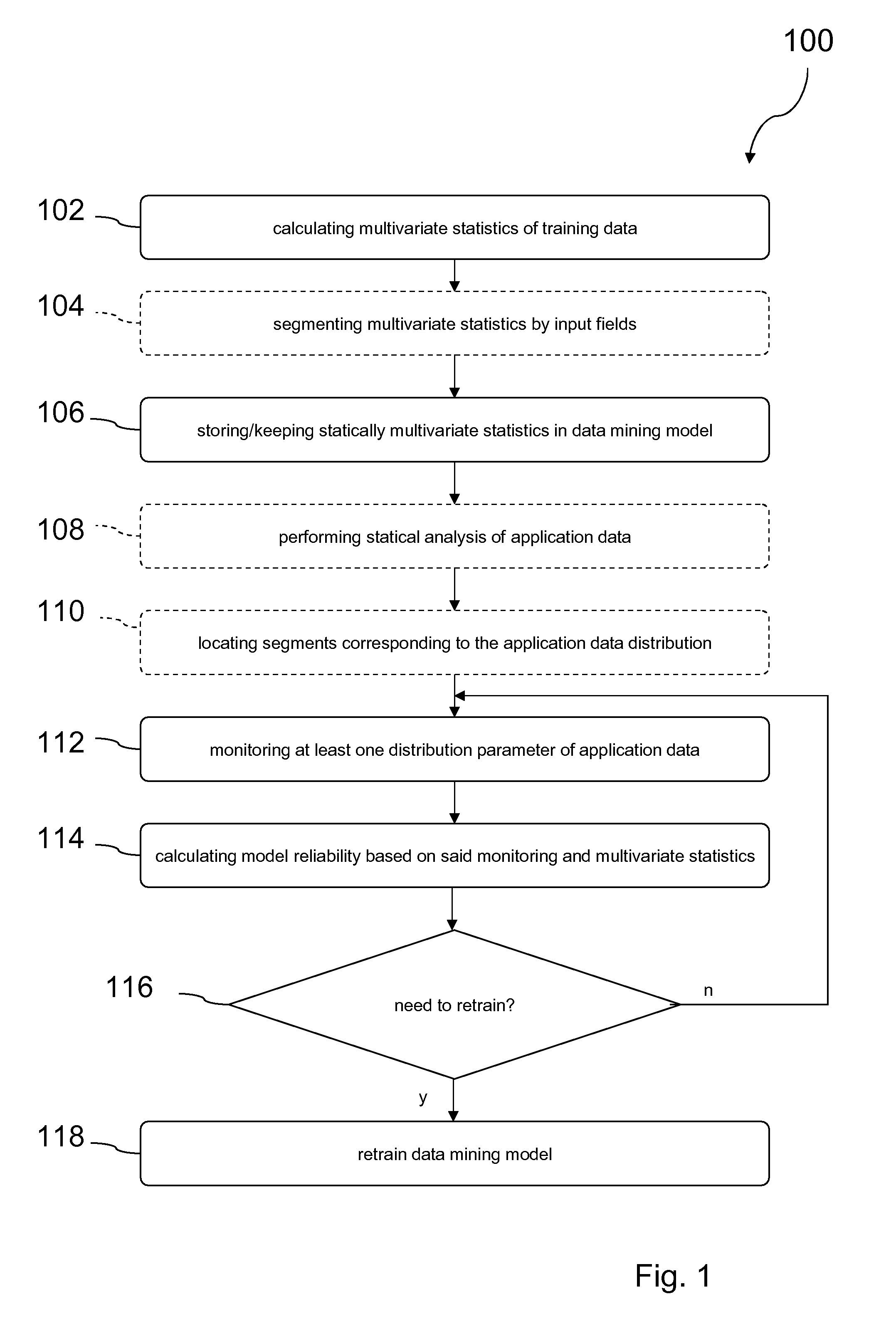

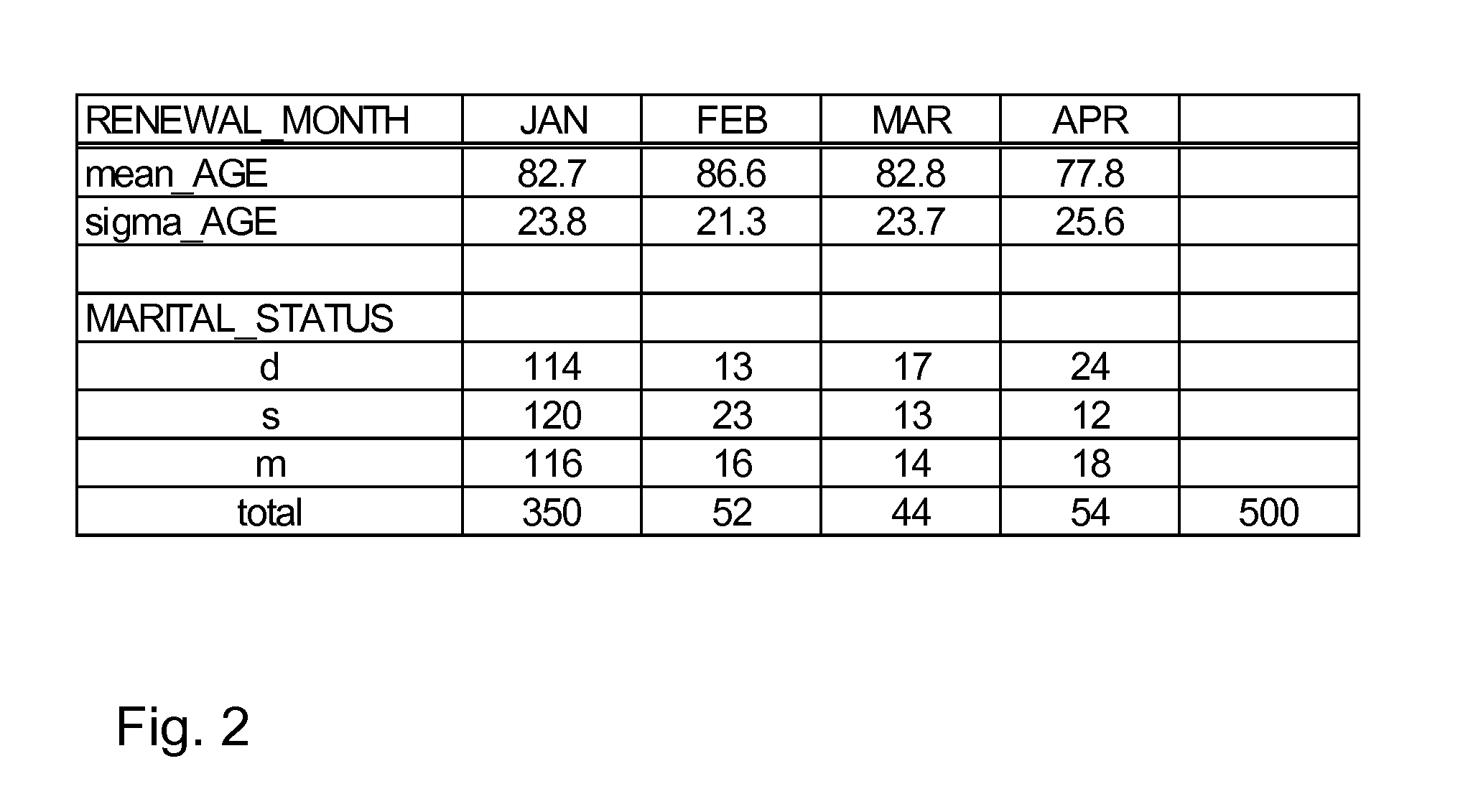

Method, system and program product for determining a time for retraining a data mining model

The invention relates to a method for determining a time for retraining a data mining model, including the steps of: calculating multivariate statistics of a training model during a training phase; storing the multivariate statistics in the data mining model; evaluating reliability of the data mining model based on the multivariate statistics and at least one distribution parameter, and deciding to retrain the data mining model based on an arbitrary measure of one or more statistical parameters including an F-test statistical analysis.

Owner:IBM CORP

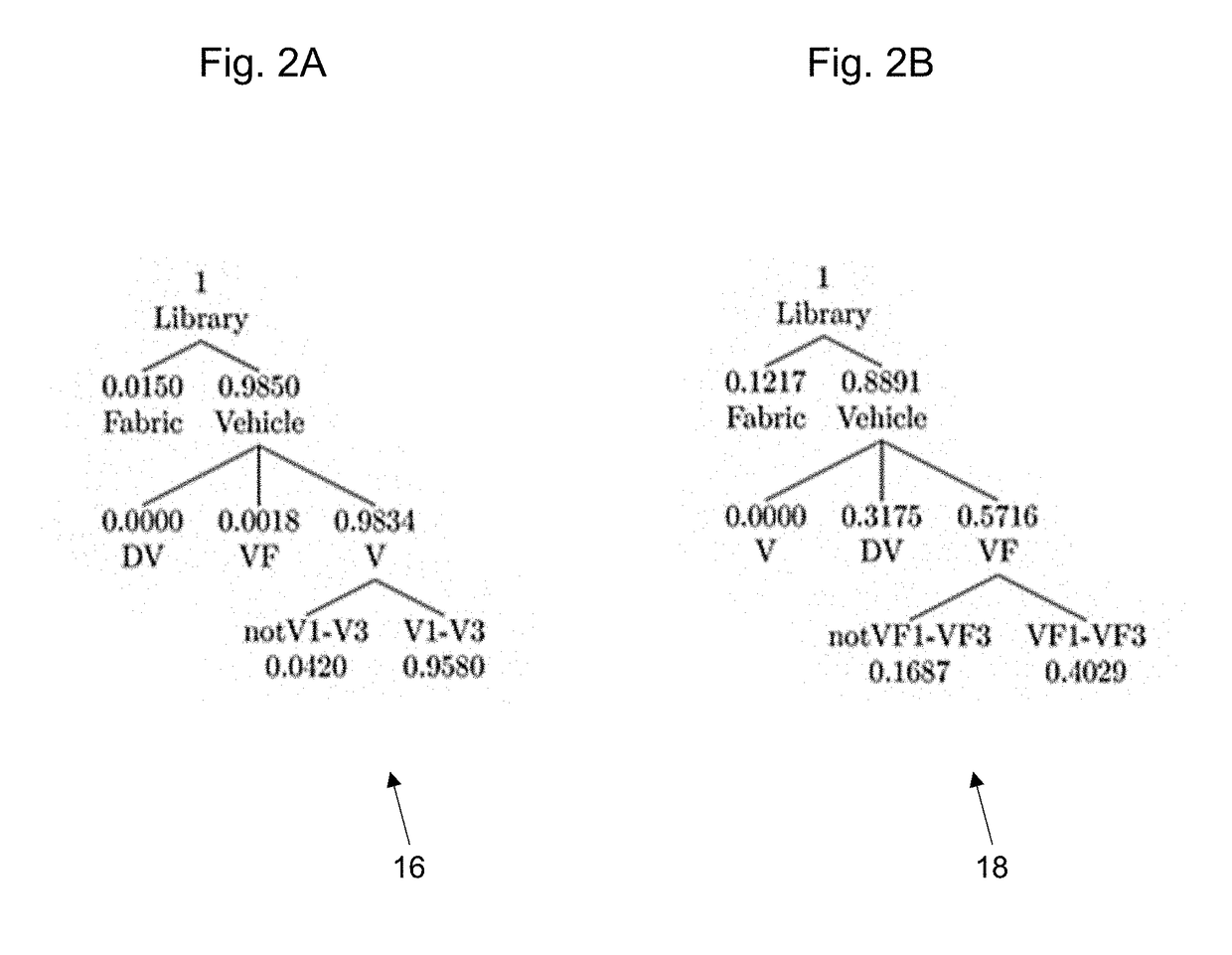

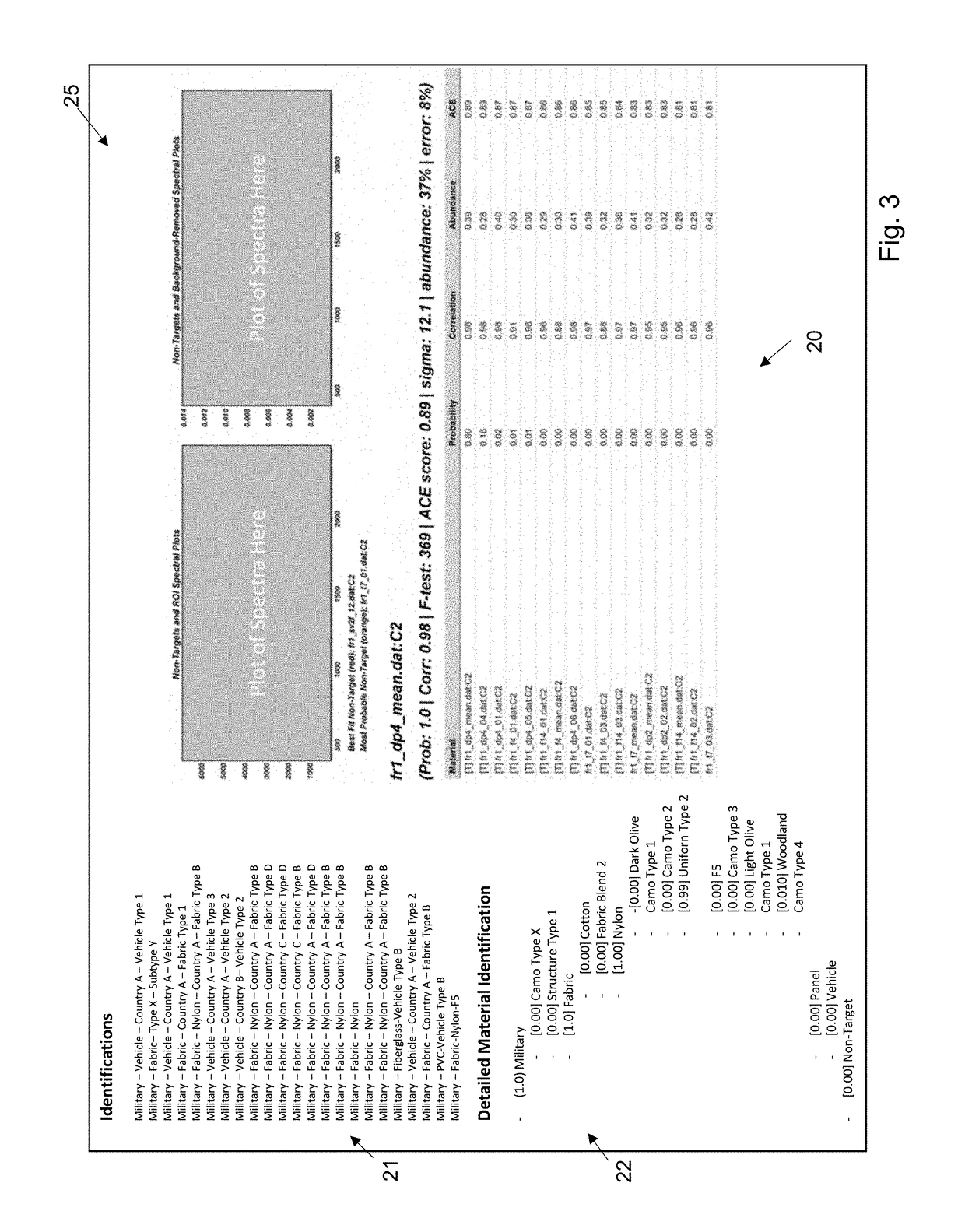

System, Apparatus and Method for Hierarchical Identification, Multi-Tier Target Library Processing, and Two-Stage Identification

ActiveUS20190065696A1Function increaseBroaden spectrumMolecular entity identificationSpectrum investigationImaging analysisPhases of clinical research

Embodiments of a system, method and apparatus incorporate two-stage identification of targets in hyperspectral image analysis. In various embodiments, unmixing is employed that integrates F-test and model averaging approaches. Further, a multi-tier target library process provides an improvement in the spectra that can be used to detect target materials and spectra that can be used for unmixing in identification. Additionally, the hierarchical identification of the present disclosure combines probabilities from model averaging to generate target identifications simultaneously at multiple levels of specificity.

Owner:GEOSPATIAL TECH ASSOC LLC

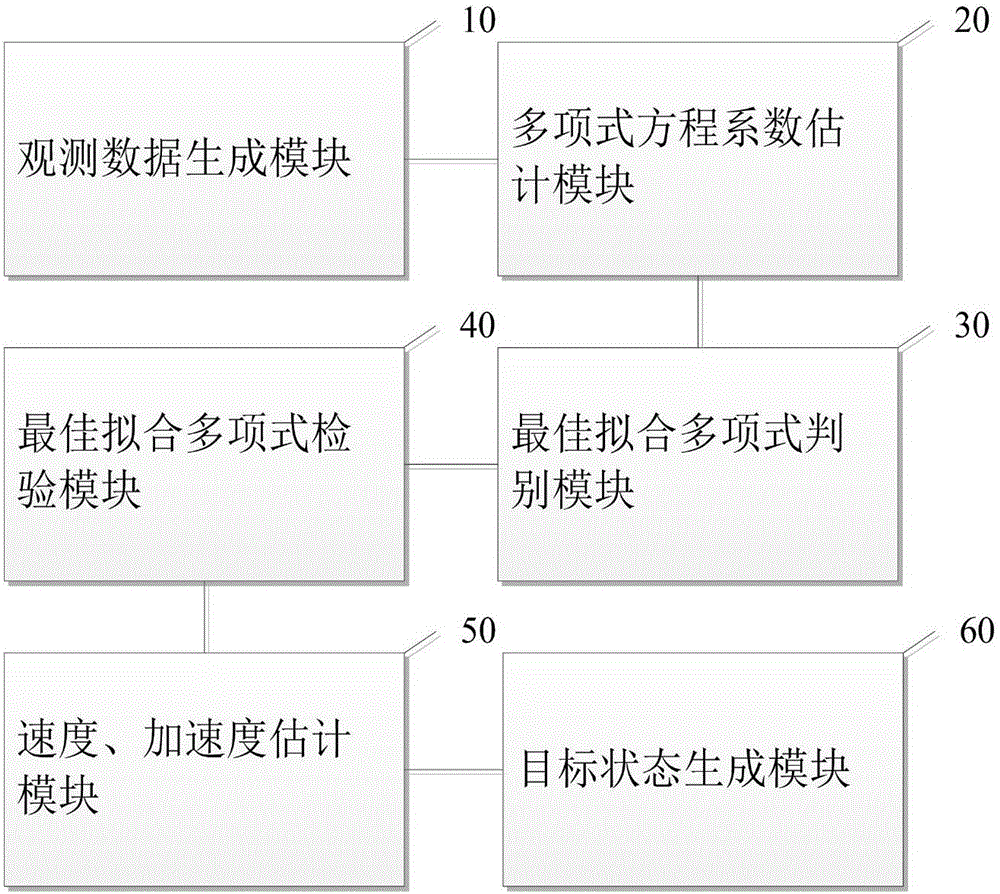

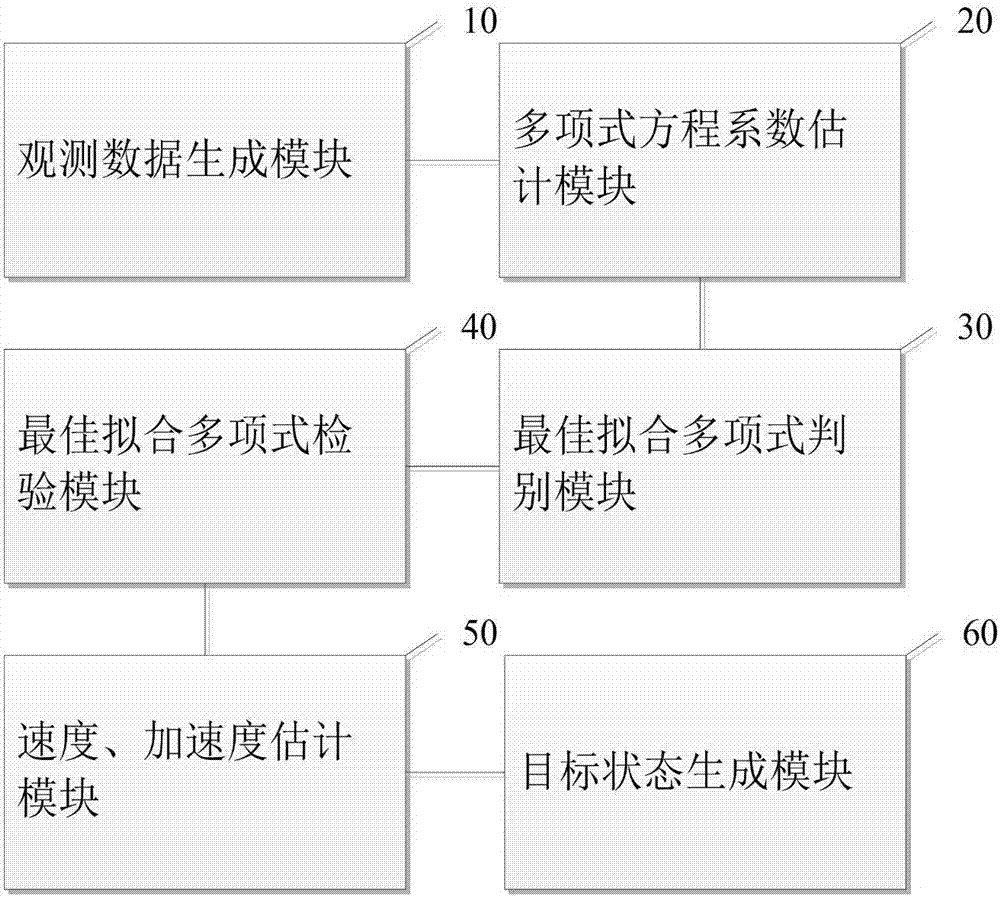

LS (Least square)-based multi- model adaptive state estimation method and system

ActiveCN105021199AOvercoming the need for prior informationOvercome stateNavigational calculation instrumentsEstimation methodsRectangular coordinates

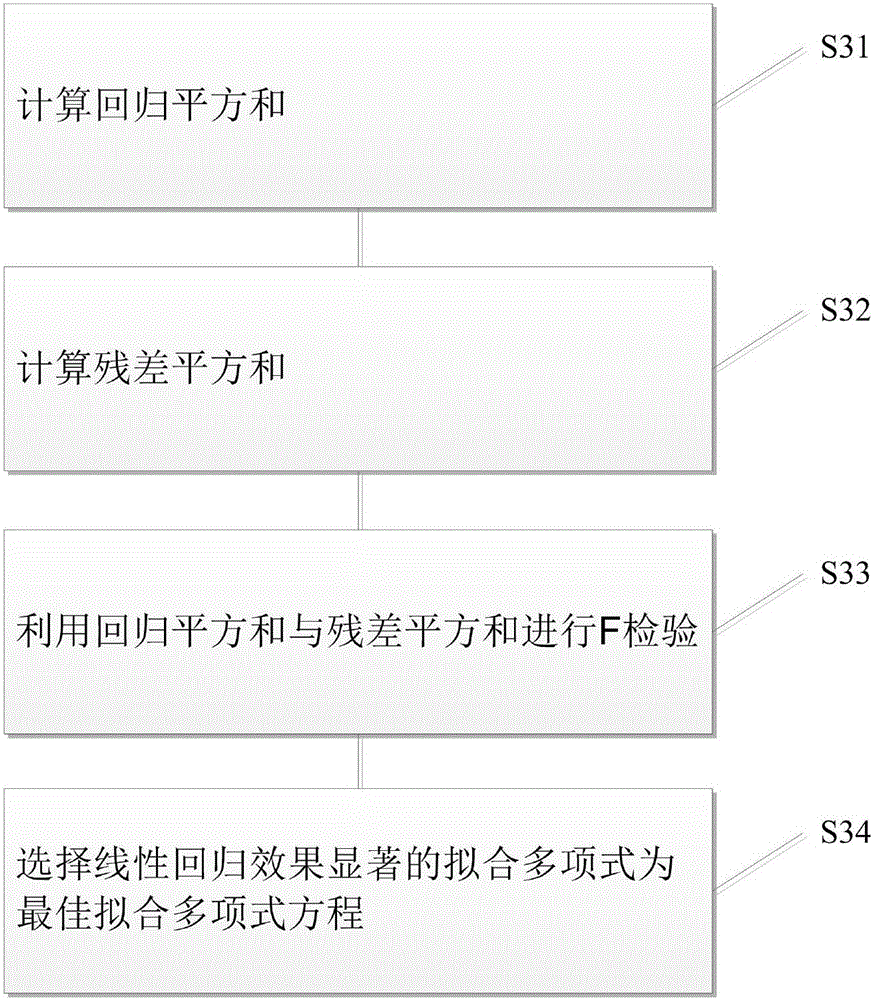

An LS (least square)-based multi- model adaptive state estimation method includes the following steps: S1, same moving object observation sequences of sensors are acquired to form moving object X, Y and Z direction observation sequences in the space rectangular coordinate system at different times; S2, the degrees and the number of time-variable polynomial equations are determined, and LS (least square)-based polynomial equation coefficient estimation of the moving object X, Y and Z direction observation sequences is performed respectively; S3, according to the polynomial equations in the step S2, regression sum of squares and residual sum of squares are respectively calculated for F-test to determine a best fit polynomial; S4, a corrected best fit polynomial is determined; S5, a first time partial derivative and a second time partial derivative are sought respectively to obtain moving object corresponding velocity and acceleration polynomials; and S6, object position state estimator coordinate conversion is performed to obtain corresponding position coordinates, and then by combining with velocity estimated values, object state estimation can be completed.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

Preparation method and application for electrochemiluminescence sensor based on protein activity protection

ActiveCN110441293AEasy transferHigh outputChemiluminescene/bioluminescenceMaterial electrochemical variablesPhosphateElectrochemiluminescence

Owner:UNIV OF JINAN

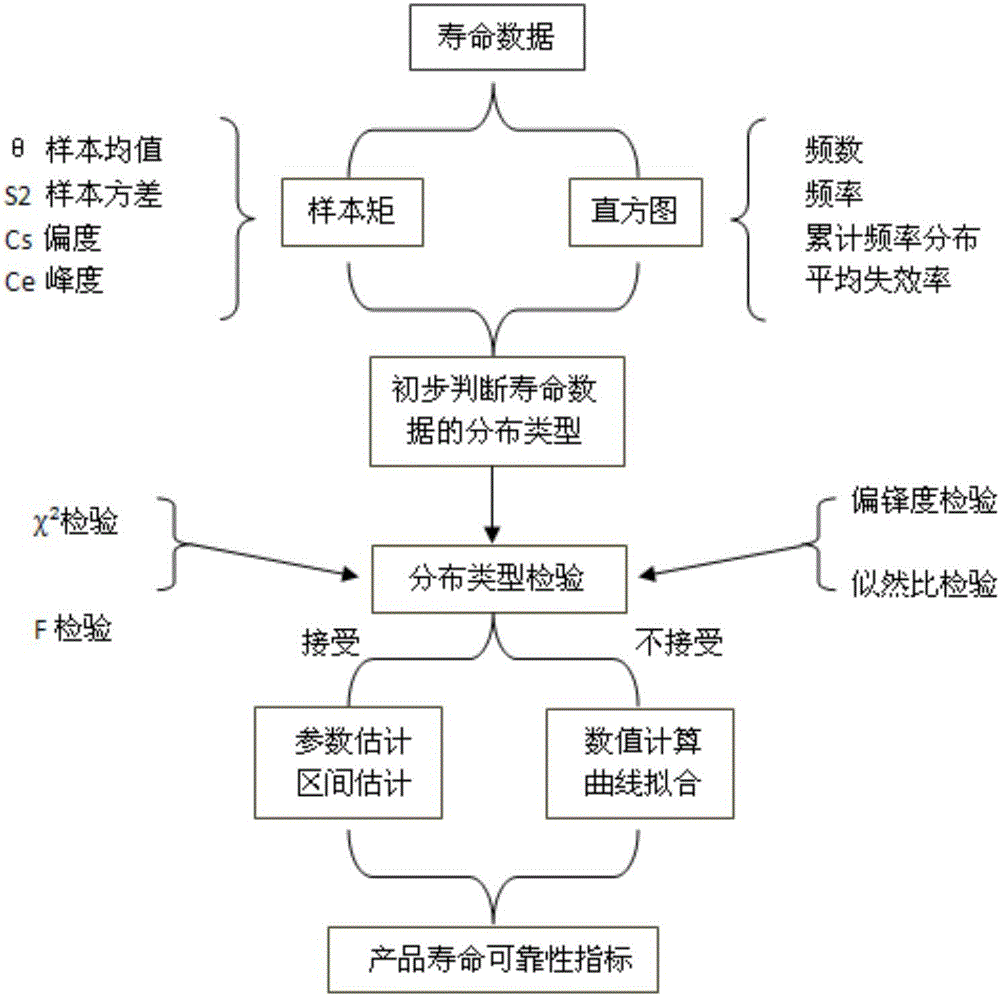

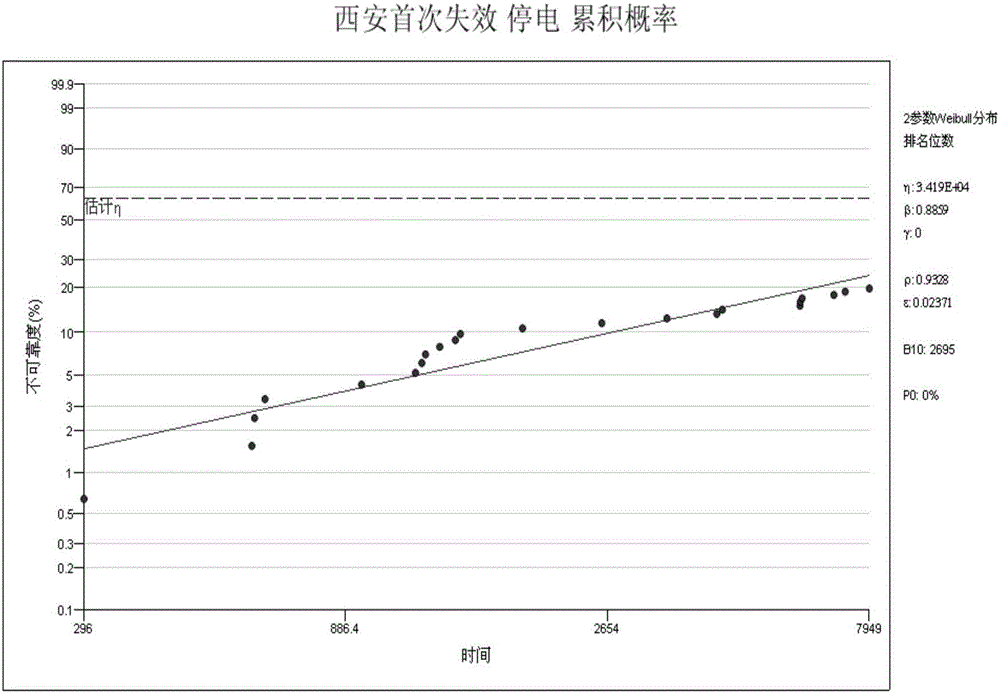

Method of predicting residual life of high-voltage switch product based on operation data

InactiveCN106777577AAccurate assessmentAccurate Reliability IndexDesign optimisation/simulationSpecial data processing applicationsProduct baseLife time

The invention discloses a method of predicting residual life of a high-voltage switch product based on operation data; the method comprises the steps of I, collecting basic data and operation data; II, sorting the operation data and establishing a database; classifying the collected data, and screening; III, testing distribution type of the classified data via one of slant test, likelihood ratio test, x<2> test and F test to determine an optimal distribution model; IV, performing parameter estimation and interval estimation for the distribution type selected in step III; V, drawing a reliability index curve for the high-voltage switch through the calculation results of step IV; predicting residual life of the high-voltage switch product according to the reliability index curve. The method allows the residual life of a high-voltage switch to be predicted accurately, and especially the reliability of electrical switch products can be analyzed according to different classes so as to guide the design, manufacture and usage processes of switch equipment.

Owner:CHINA XD ELECTRIC CO LTD

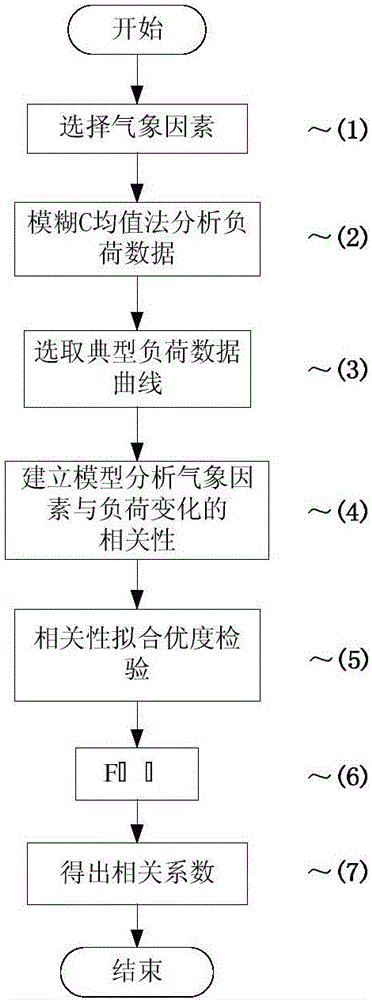

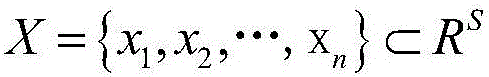

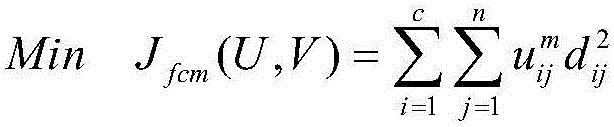

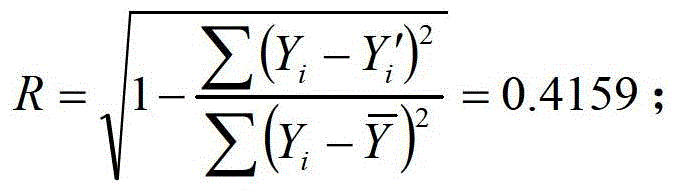

Method for analyzing influence correlation of multiple meteorological factors and load changes

InactiveCN105787259AImprove load characteristicsNo manual operationSpecial data processing applicationsInformaticsCorrelation coefficientGoodness of fit

The invention discloses a method for analyzing influence correlation of multiple meteorological factors and load changes.By means of the method, the influencing degree of the meteorological factors to a load can be accurately determined, therefore, the load characteristics are effectively improved, the contradiction between supply and demand is effectively relieved, manual operation is not needed basically, and the work efficiency is greatly improved.The method comprises the steps that 1, the meteorological factors are selected; 2, load data is analyzed by means of a fuzzy C-means method; 3, a typical load data curve is selected; 4, a model is built to analyze the correlation of the meteorological factors and the load changes; 5, a correlation goodness-of-fit test is conducted; 6, an F test is conducted; 7, a correlation coefficient of the meteorological factors and the load changes is obtained.

Owner:国网甘肃省电力公司武威供电公司 +1

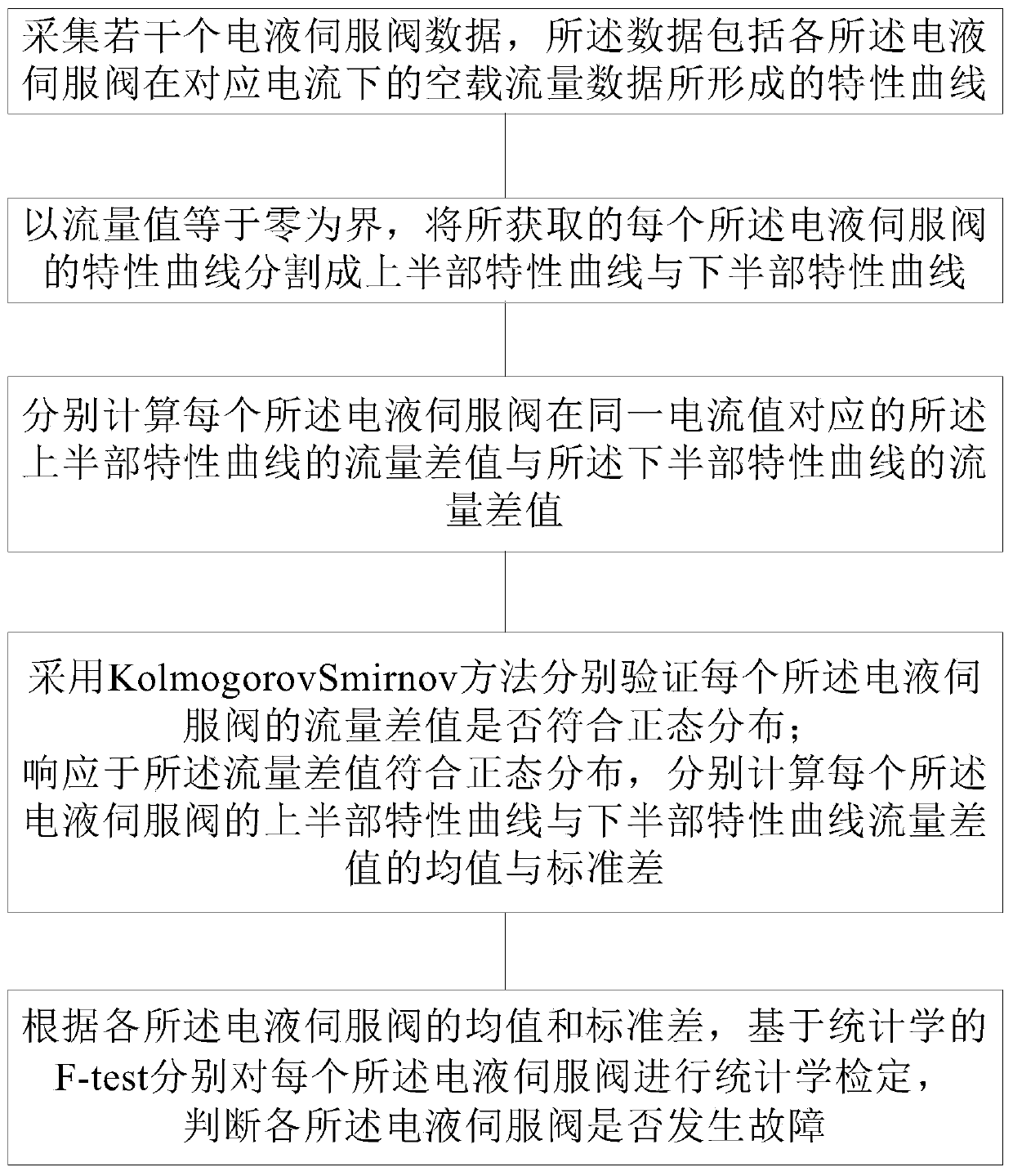

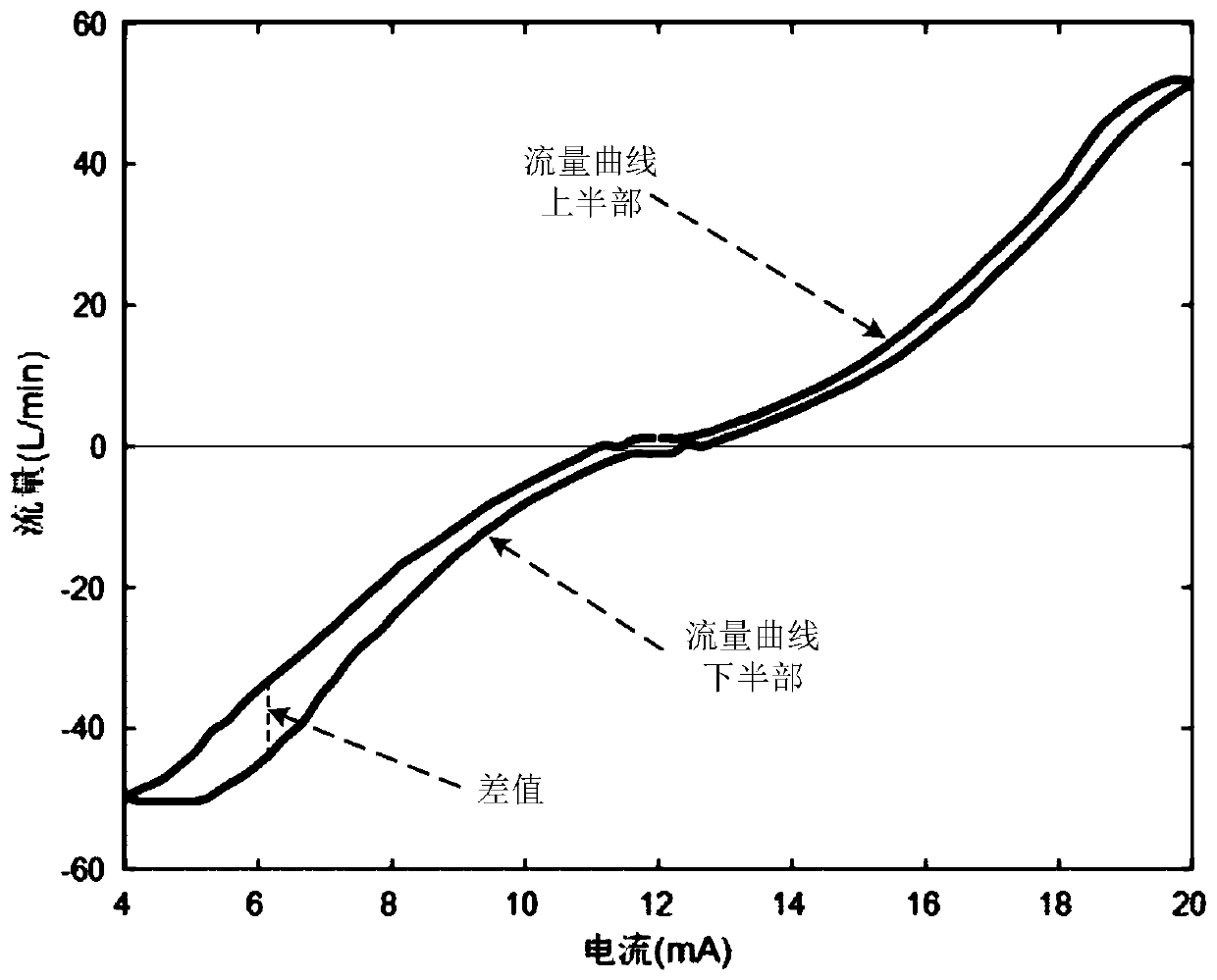

Fault diagnosis method and device for electro-hydraulic servo valve, storage medium and electronic equipment

ActiveCN110486350AEffective diagnosisAccurate diagnosisFluid-pressure actuator testingDiagnosis methodsElectro hydraulic

Owner:ZHENJIANG SILIAN MECHATRONIC TECH

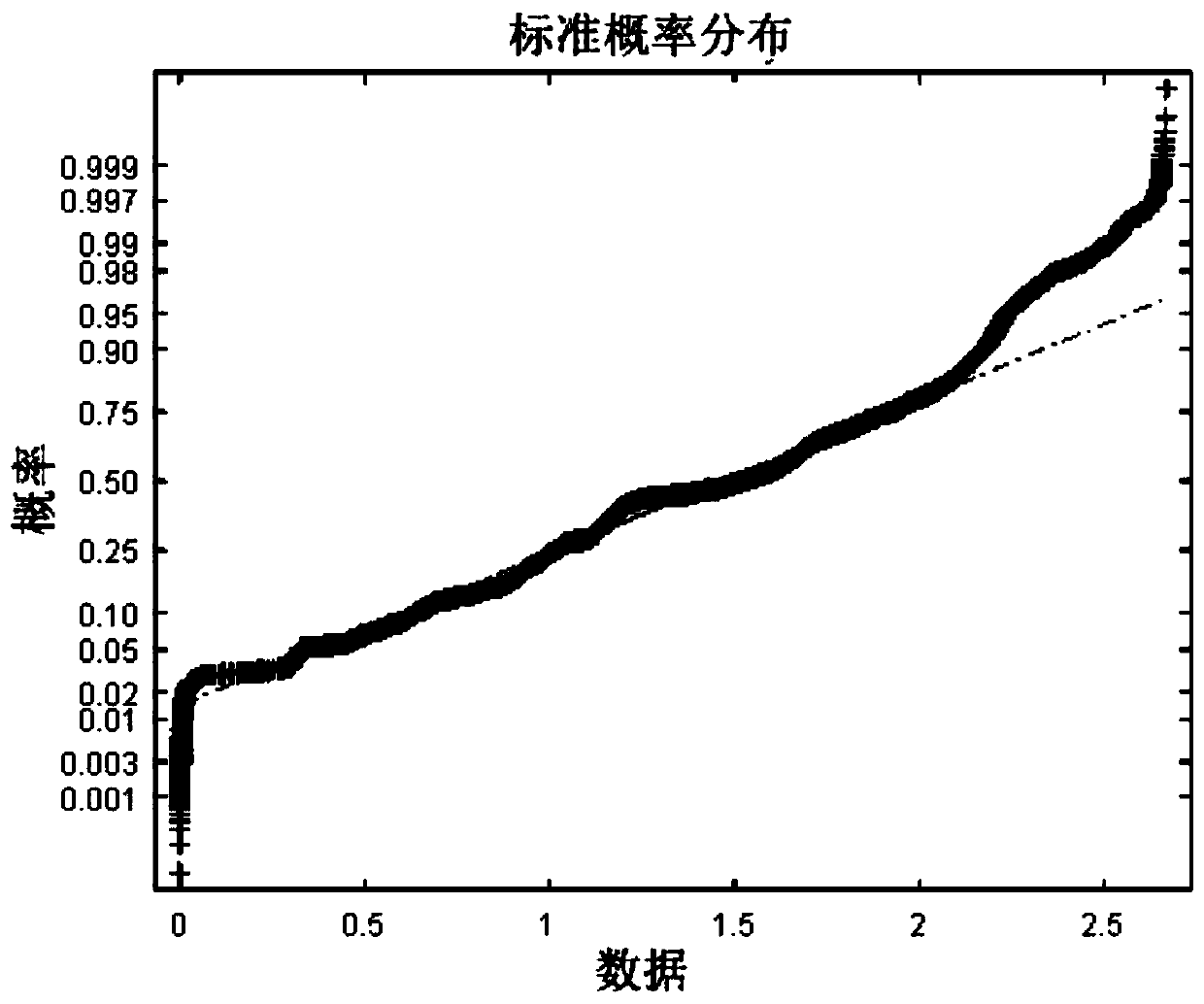

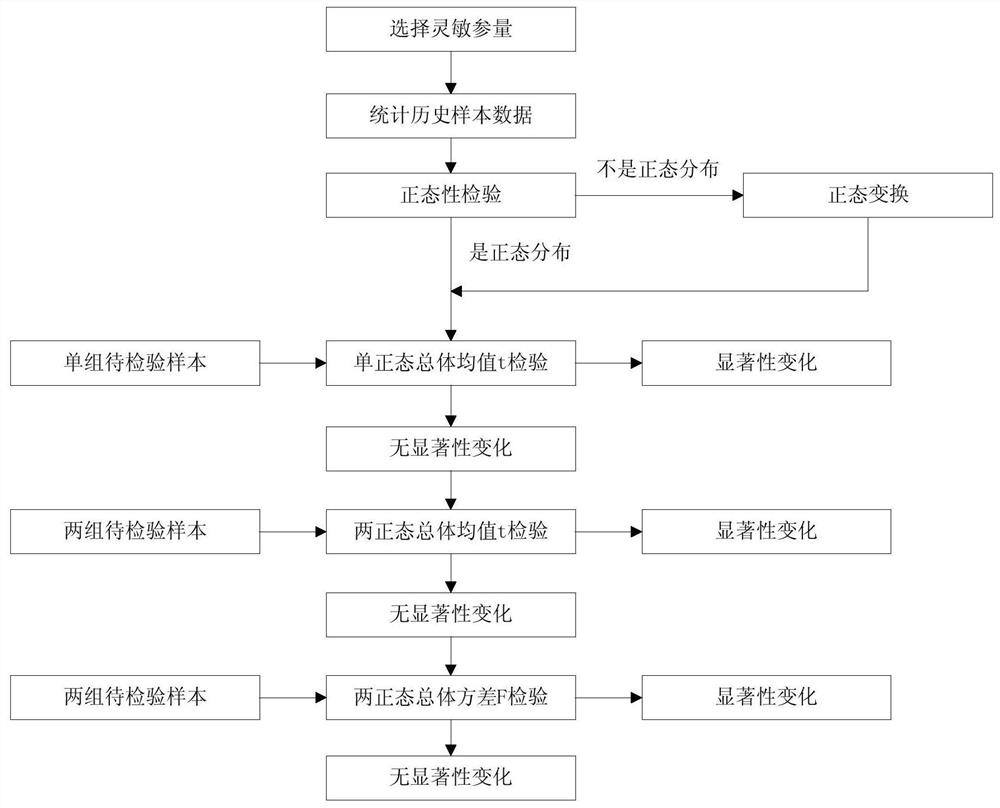

Hypothesis testing method for sensitive parameters of fire work system

ActiveCN112270063AImplementing the Significance Test Method for Sensitive ParametersMeet the needs of engineering applicationsDesign optimisation/simulationSpecial data processing applicationsTest sampleEngineering

The invention relates to a hypothesis testing method for sensitive parameters of a fire work system. The method comprises the following steps: (1) selecting the sensitive parameters of the fire work system; (2) counting historical sample data of sensitive parameters of the fire work system; (3) carrying out normality test and transformation on the historical sample data of the sensitive parametersof the initiating explosive system, so that the historical sample data of the sensitive parameters of the initiating explosive system and the to-be-tested sample data are in normal distribution; (4)when the number of historical sample data of the sensitive parameters of the fire work system is greater than or equal to a preset threshold, verifying significant changes by adopting a single normaltotal mean value t test method; and (5) when the historical sample data volume of the sensitive parameters of the fire work system is smaller than a preset threshold, verifying the significance changeby adopting a two-normal overall mean value t test method, and if the two groups of sensitive parameter samples do not have the significance change, verifying the significance change by adopting a two-normal overall variance F test method. According to the invention, more accurate inspection is realized.

Owner:CHUANNAN MACHINERY PLANT CHINA ASTRONAUTIC SCI &TECH GROUP CORP

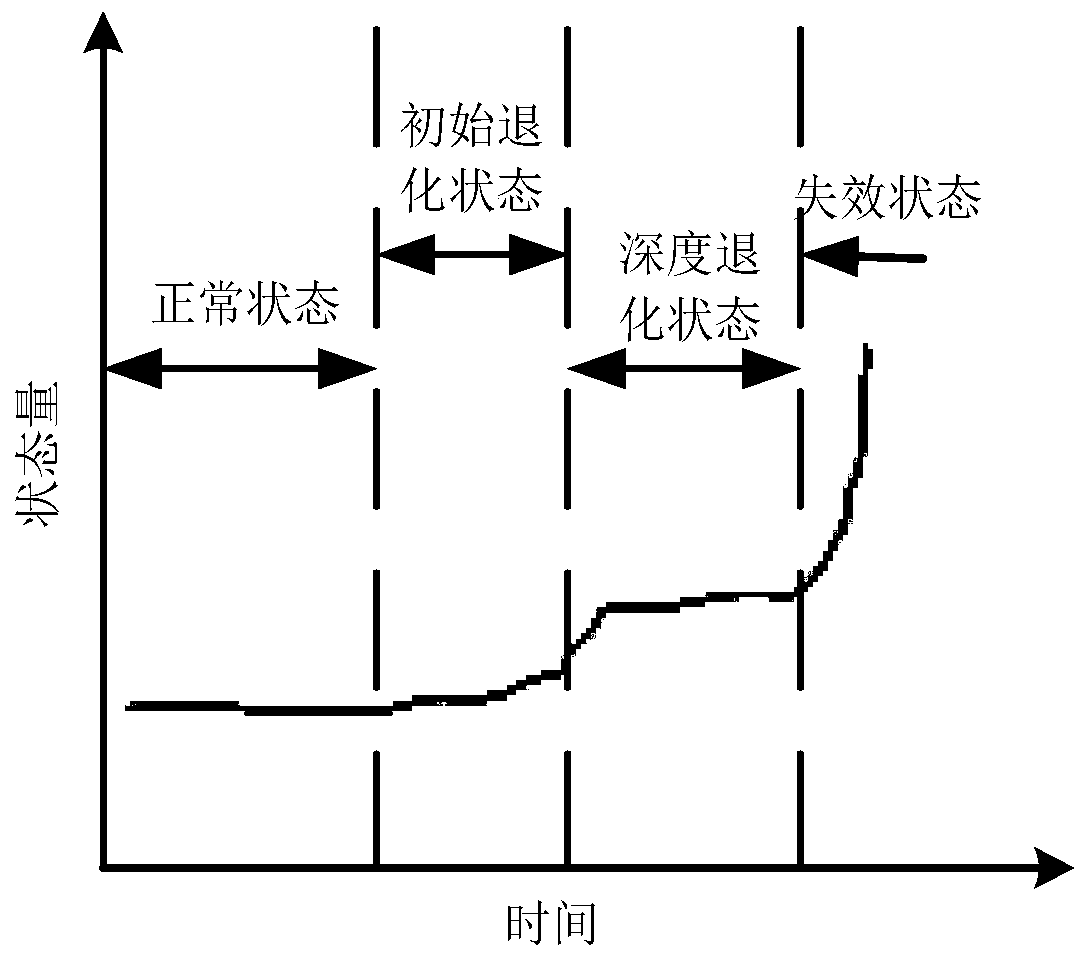

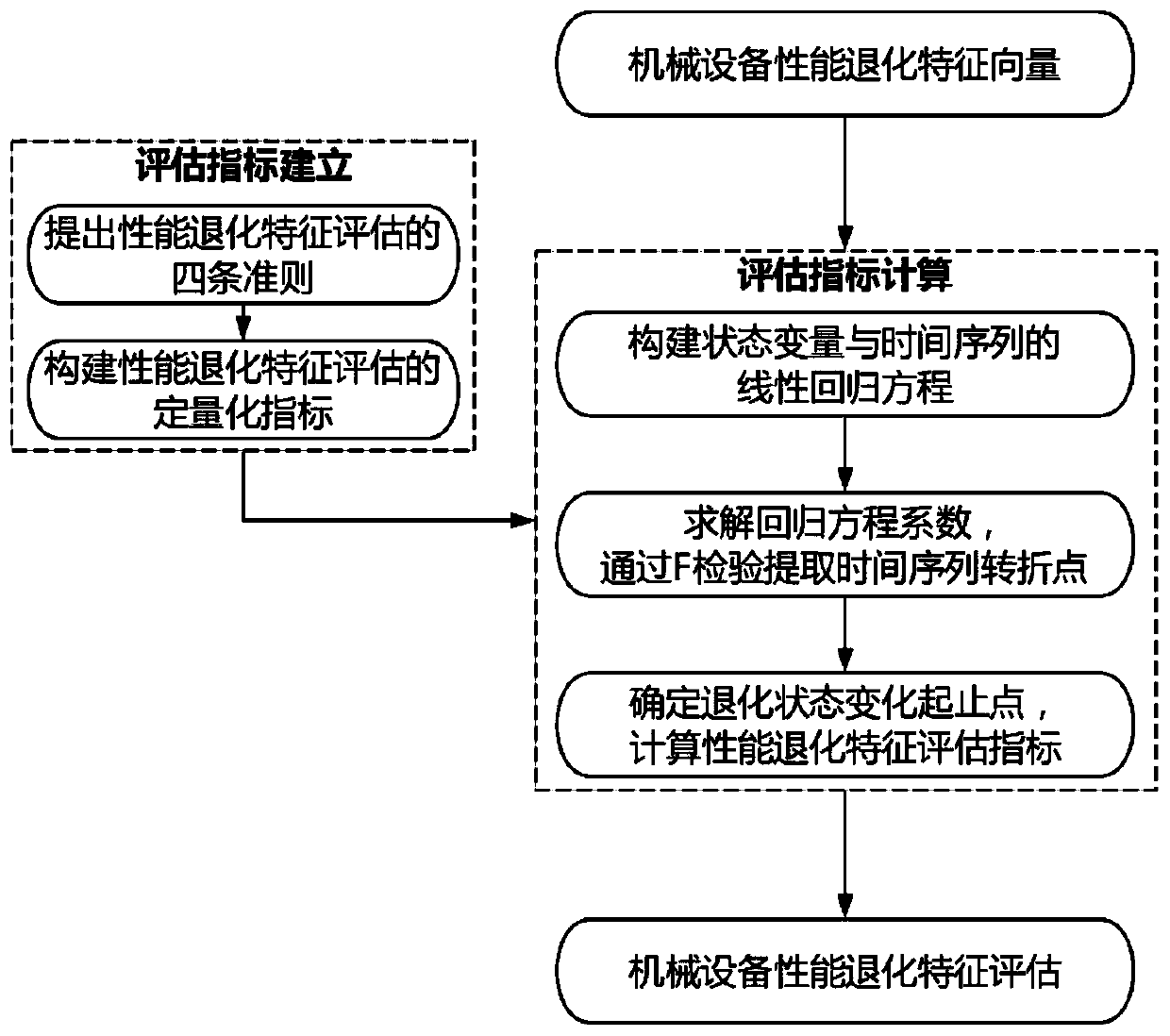

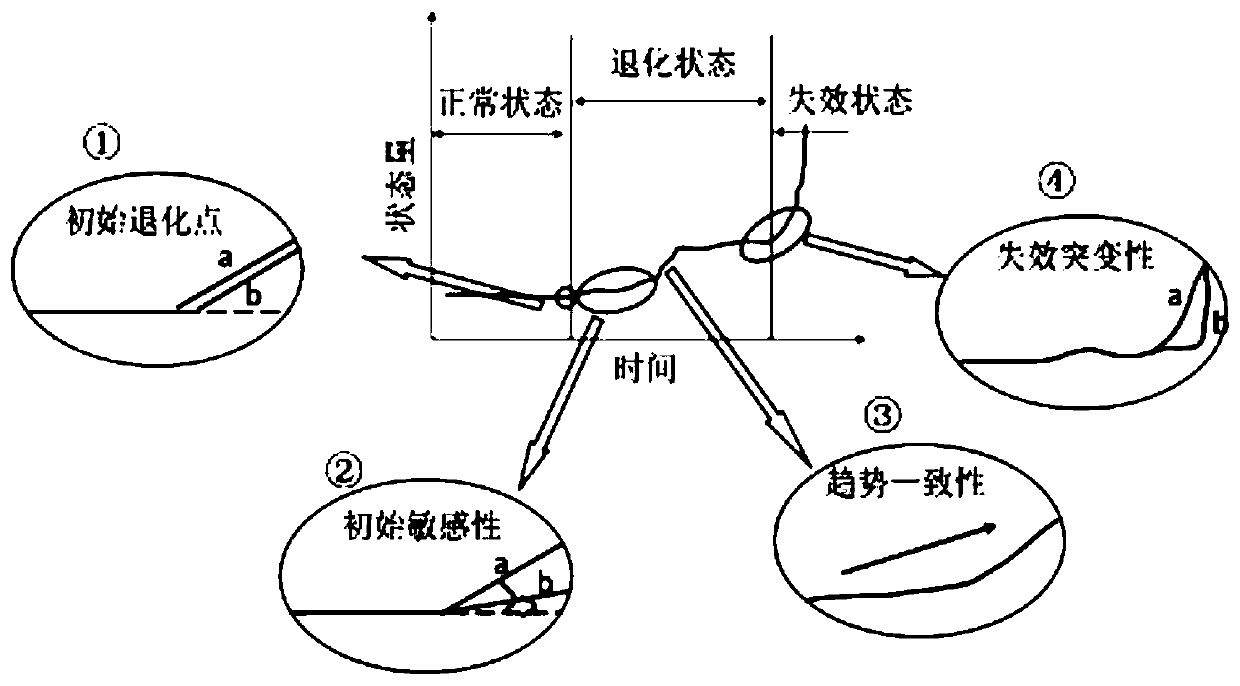

Performance degradation feature assessment method based on time series change mutation point detection

ActiveCN109828548AEffective evaluation systemReduce computational complexityElectric testing/monitoringComputation complexityEquation of state

A performance degradation feature assessment method based on time series change mutation point detection comprises the steps of: providing four performance degradation feature assessment criteria consisting of an initial degradation point, the initial sensitivity, the failure mutation and the trend consistency; for the four performance degradation feature assessment criteria, respectively constructing quantitative indexes; constructing a linear regression equation of state variables and time series; solving coefficients of the linear regression equation, and extracting time series turning points by employing the F test; determining starting and ending points of the degradation state change, and calculating performance degradation feature assessment indexes; and finally, comparing indexes of different performance degradation features to assess the performance degradation features. The performance degradation feature assessment method provides the performance degradation feature assessment criteria and the corresponding quantitative assessment indexes having guiding significance on the extraction of the performance degradation features, greatly reduces the computational complexity and is high in efficiency.

Owner:XI AN JIAOTONG UNIV

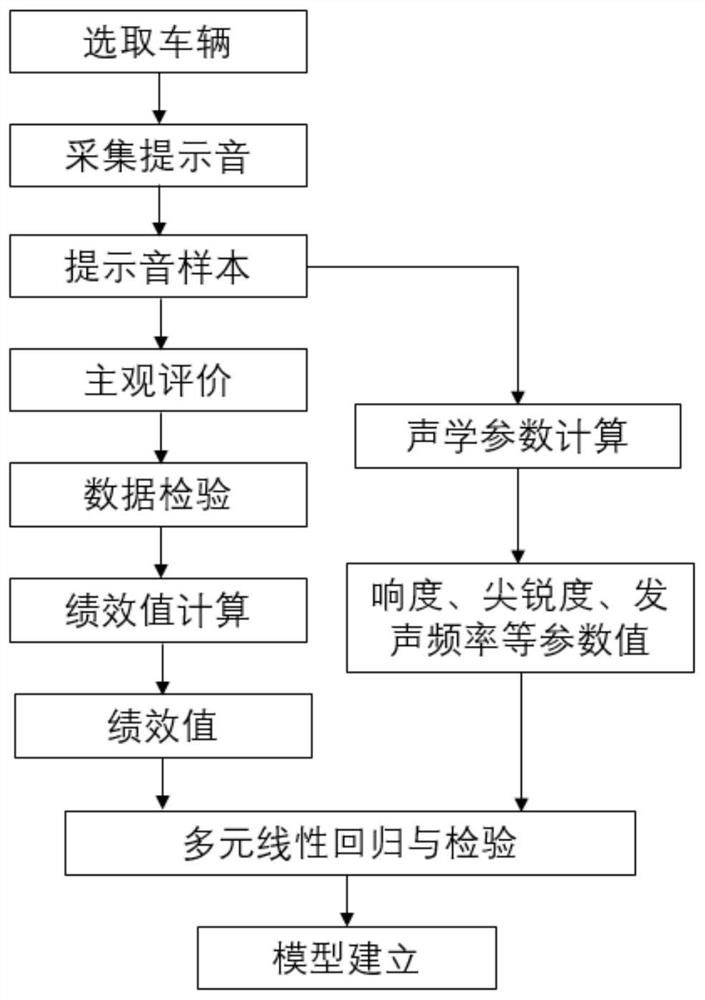

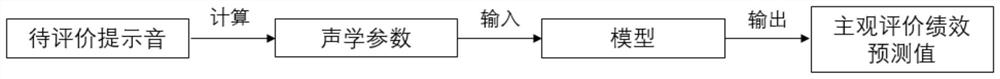

Objective quantification method for subjective evaluation of warning property of automobile warning tone

PendingCN113901576AReduce the impactSmall discreteGeometric CADDesign optimisation/simulationEvaluation resultAlgorithm

Owner:CHINA FIRST AUTOMOBILE

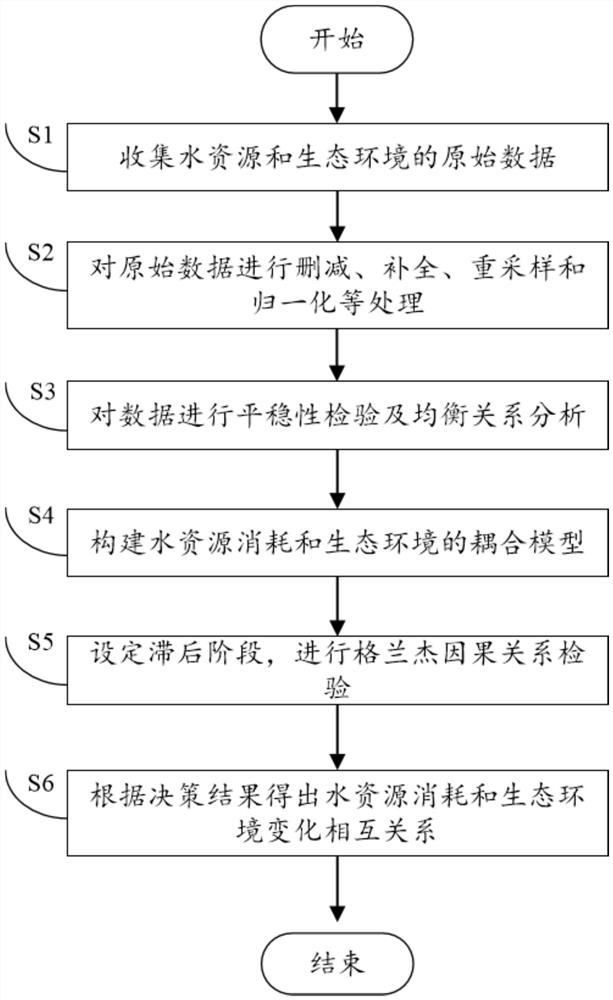

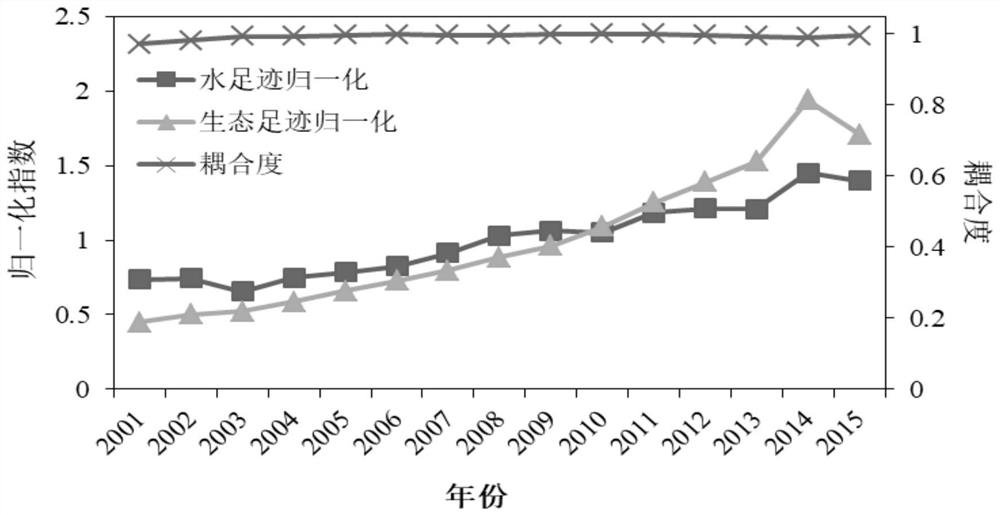

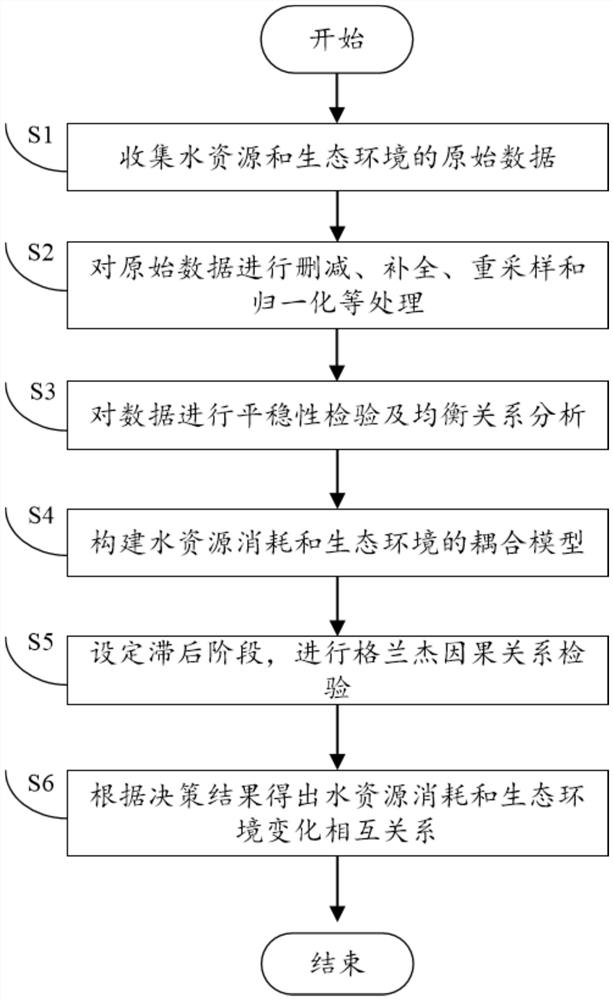

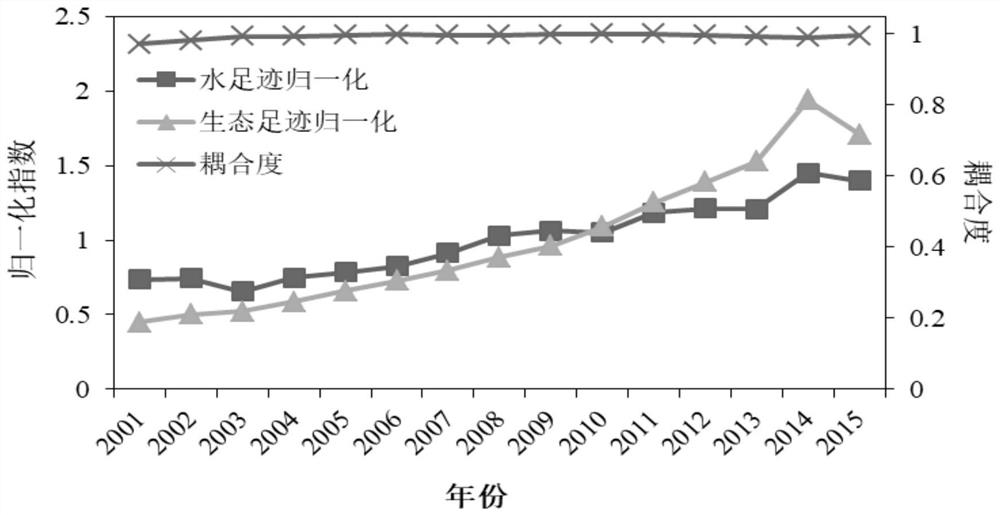

A method to determine the causal relationship between water resources and ecological environment based on Granger test

ActiveCN114202245BImprove accuracyGeneral water supply conservationResourcesWater useEcological environment

The invention discloses a method for determining the causal relationship between water resources and ecological environment based on Granger test. Test; S3: perform co-integration on the above two time series to determine whether there is an equilibrium relationship between the two; S4: establish a coupling model of water footprint and ecological footprint, and use the coupling model to calculate the coupling degree value of the above two time series; S5: Perform Granger causality verification on the water footprint time series and the ecological footprint time series; S6: Build a regression model, and use the regression model to calculate F statistics; S7: According to the F statistics, Combined with the F test critical table, determine the causal relationship between water resources and ecological environment. The present invention utilizes Granger causality check to establish the causal relationship between the data, the directivity is clear, the construction of the relationship conforms to reality, and the accuracy is improved compared with the existing scheme.

Owner:TIANJIN UNIV

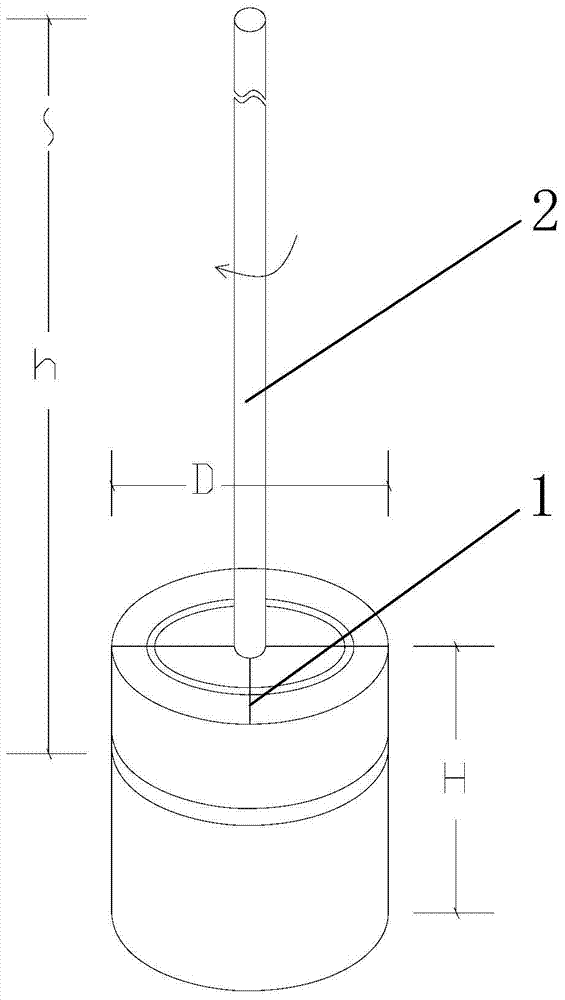

A Method for Determining the Flushing Temperature of Oil Well Hollow Rod

ActiveCN104213873BOvercoming the disadvantages of determining the hot washing temperature by experienceEnergy saving fuelCleaning apparatusInsulationCorrelation coefficientMathematical model

Owner:PETROCHINA CO LTD

Method of Stratification of Soft Soil According to Mechanical Properties

ActiveCN105158086BImprove sciencePromote stratificationMaterial strength using steady shearing forcesMechanical equationCorrelation analysis

Owner:CECEP WIND POWER

Multi-model self-adaptive state estimation method and system based on ls

A multi-model adaptive state estimation method based on LS, including: S1. Acquiring the observation sequence of each sensor on the same moving target, and forming the observation sequence of the moving target in the X, Y, and Z directions in the space Cartesian coordinate system at different times ; S2, determine the number and number of polynomial equations with time as a variable, and estimate the polynomial coefficients of the least squares LS to the observation sequence of the moving target in the X, Y, and Z directions respectively; S3, according to the polynomial equation in step S2, Calculate the regression sum of squares and the residual sum of squares respectively and perform F test to determine the best fitting polynomial; S4, determine the corrected best fitting polynomial; S5, calculate the first partial derivative and the second partial derivative for time respectively, and obtain the moving target Corresponding velocity and acceleration polynomials; S6. Carry out coordinate conversion on the target position state estimate, obtain the corresponding position coordinates, and then combine the velocity estimate value to complete the target state estimation.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

Method for determining causal relationship between water resource and ecological environment based on Granger test

ActiveCN114202245AResolve accuracySolved and lack of directionGeneral water supply conservationResourcesWater useEnvironmental resource management

The invention discloses a method for determining a causal relationship between a water resource and an ecological environment based on a Granger test. The method comprises the following steps: S1, obtaining a water footprint time sequence and an ecological footprint time sequence; s2, carrying out stationarity test on the two time sequences; s3, carrying out co-integration on the two time sequences, and judging whether the two time sequences have an equilibrium relationship or not; s4, establishing a coupling model of the water footprint and the ecological footprint, and calculating a coupling degree value of the two time sequences by using the coupling model; s5, performing Granger causal relationship verification on the water footprint time sequence and the ecological footprint time sequence; s6, constructing a regression model, and calculating an F statistic by using the regression model; and S7, determining the causal relationship between the water resource and the ecological environment according to the F statistic in combination with an F test critical table. According to the method, the causal relationship among the data is determined by utilizing Granger causal relationship verification, the directivity is clear, the constructed relationship accords with reality, and the accuracy is improved compared with the existing scheme.

Owner:TIANJIN UNIV

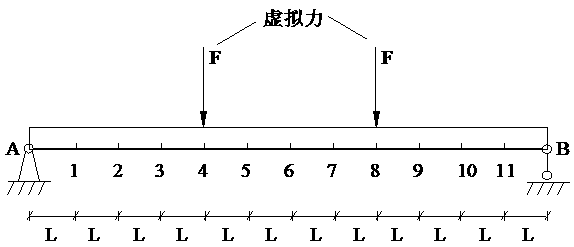

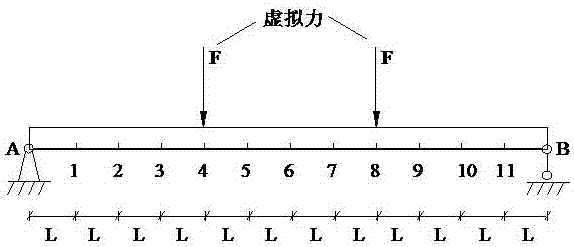

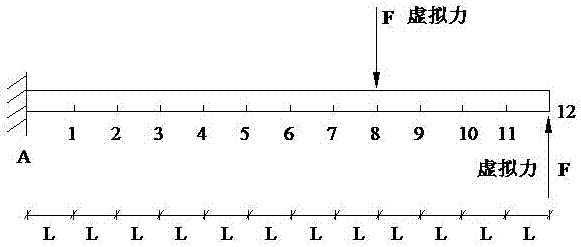

Elastic modulus test method based on virtual pure bending material

The invention relates to an elasticity modulus testing method based on a virtual pure bent material, and belongs to the technical field f test or analysis of materials by applying stable tension or pressure to test physical or chemical shapes such as strength character of the solid material. A long and thin component made of the material is used for carrying out a free vibration mode test, a corresponding virtual force vector is constructed according to support constraint conditions of components, a flexibility matrix of the component and the virtual force vector are multiplied to obtain a displacement parameter under a virtual pure bent state, then the curvature of the virtual pure bent section is calculated, and finally, the equation is listed according to balance conditions of the crosssection of the virtual pure bent section to obtain elasticity modulus. The elasticity modulus testing method based on the virtual pure bent material is applied to existing components which have various support constraint conditions and cross section types and have been used for a long time, and has the advantages of simplicity in operation, short time required for test, zero damage, zero limitation to an operation environment and the like.

Owner:SHAOXING UNIVERSITY

A Prediction Method of Strip Surface Roughness in Rolling Process

ActiveCN106825068BComprehensive process factorsThe principle is simpleMeasuring devicesMetal rolling arrangementsSurface roughnessStrip steel

Owner:UNIV OF SCI & TECH BEIJING

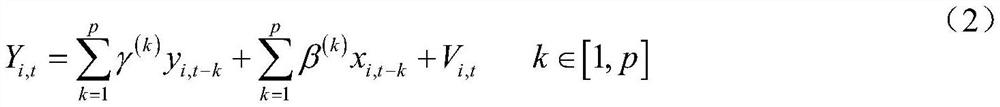

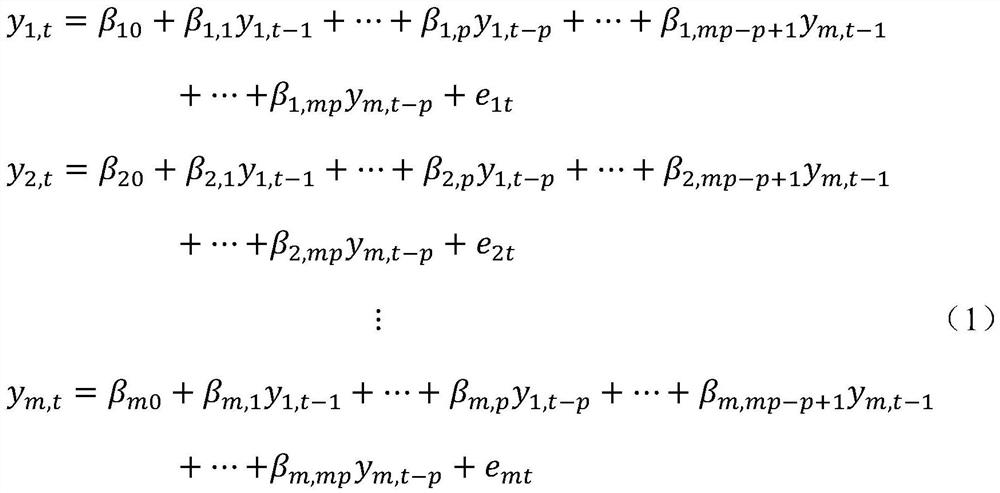

Electricity consumption and economic change analysis method based on time sequence

PendingCN114021951AGet rid of dependenceTechnology managementResourcesElectric consumptionPower usage

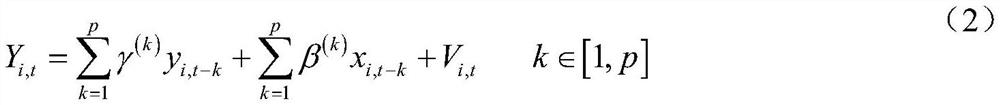

The invention relates to an electricity consumption and economic change analysis method based on a time sequence, and belongs to the technical field of power grids. The method comprises the following steps: 1) establishing a vector autoregression model in fusion multivariate time sequence analysis; 2) setting a model lag time length by taking a year as a period, and obtaining monthly data of cross-year electricity consumption and related economic indexes through a statistical yearbook disclosed by an electric power electricity consumption information acquisition system and a regional statistical bureau in which the electric power electricity consumption information acquisition system is located; 3) according to the sample data, obtaining an estimated value of consistency by using least square estimation; calculating a covariance matrix through samples of all observed values; and 4) performing causal test, and evaluating the relationship between each economic index and the electricity consumption by using F test. According to the method, electricity consumption and economic change conditions are regarded as multivariate time sequence variables, and a vector autoregression model is used for analyzing an endogenous mechanism of simultaneous mutual influence between the variables; the quantitative judgment method for determining the dynamic influence between the variables by using the sample data gets rid of dependence on correlation coefficients.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

A Modeling Method for Position-Dependent Geometric Error Term of CNC Machine Tool

ActiveCN106774152BHigh precisionImprove robustnessProgramme controlComputer controlNumerical controlGeometric error

The invention discloses a modeling method for position-related geometric error items of a numerical control machine tool, belonging to the technical field of numerical control machine tool processing. Including: according to the nature of the position-related geometric error term of the CNC machine tool, determine the n-degree polynomial form of the position-related geometric error term; according to the discrete data of the position-related geometric error term of the CNC machine tool, the n-degree polynomial coefficient calculation matrix M is obtained by using the least square method fitting principle, Calculate n-degree polynomial coefficients; combine the discrete data of CNC machine tool position-related geometric error items to calculate a series of polynomials from 1 to m-degree, the highest degree m is set to half the number of discrete data of geometric error items; calculate according to the regression analysis F test method The F value of a series of polynomials of degree 1 to m; compare and find the maximum F value, and select the polynomial corresponding to the maximum F value as the optimized polynomial model of the position-related geometric error item of the CNC machine tool. It is mainly used to realize the automation and programming of comprehensive error modeling of machine tools.

Owner:SOUTHWEST JIAOTONG UNIV

Elasticity modulus testing method based on virtual pure bent material

The invention relates to an elasticity modulus testing method based on a virtual pure bent material, and belongs to the technical field f test or analysis of materials by applying stable tension or pressure to test physical or chemical shapes such as strength character of the solid material. A long and thin component made of the material is used for carrying out a free vibration mode test, a corresponding virtual force vector is constructed according to support constraint conditions of components, a flexibility matrix of the component and the virtual force vector are multiplied to obtain a displacement parameter under a virtual pure bent state, then the curvature of the virtual pure bent section is calculated, and finally, the equation is listed according to balance conditions of the crosssection of the virtual pure bent section to obtain elasticity modulus. The elasticity modulus testing method based on the virtual pure bent material is applied to existing components which have various support constraint conditions and cross section types and have been used for a long time, and has the advantages of simplicity in operation, short time required for test, zero damage, zero limitation to an operation environment and the like.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com