A Method for Determining the Flushing Temperature of Oil Well Hollow Rod

A certain method, hollow rod technology, applied in the direction of wellbore/well components, earthwork drilling, isolation devices, etc., to achieve the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A method for determining the flushing temperature of an oil well hollow rod, comprising the following steps;

[0034] Step 1. Determine the parameters of the thermally washed oil well with the hollow rod well washing device, and establish a mathematical model:

[0035] Y=a+bX

[0036] In the formula:

[0037] Y—oil outlet temperature at the wellhead of the oil well, °C;

[0038] X—hot car washing outlet (hollow rod inlet temperature), °C;

[0039] a—regression constant;

[0040] b—regression coefficient.

[0041] Step 2. Collect the actual values of the parameters of 30 oil wells using the hollow rod flushing device for hot flushing oil wells, as shown in Table 1.

[0042] Table 1

[0043]

[0044]

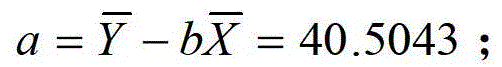

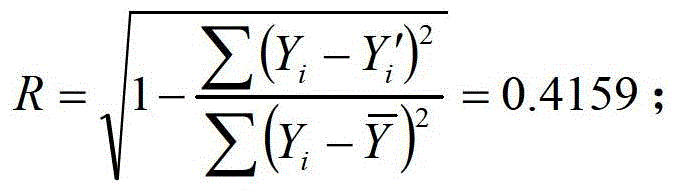

[0045] Step 3. Calculate the regression coefficient to obtain the regression equation.

[0046] b = Σ X i Y ...

Embodiment 2

[0067] Taking Jin 93-18 as an example, the application of the present invention will be described in detail.

[0068]In Well Jin 93-18, the freezing point of crude oil is 31°C, the wax content is 14.38%, the original wax point is 40°C, the hollow rod is lowered to a depth of 800m, and the oil output temperature at the hot-washed wellhead is 56°C according to the production requirements. According to the mathematical model, Y=40.5043+ 0.2315X is obtained, and the hot car washing outlet temperature X=67℃ can meet the hot washing requirements. During the on-site hot washing, the outlet temperature of the hot car washing is controlled between 66-69 °C, and the hot washing operation is successful.

Embodiment 3

[0069] Embodiment 3: Taking Jin 55 as an example, the application of the present invention is described in detail.

[0070] In Well Jin 55, the freezing point of crude oil is 34°C, the wax content is 17.19%, the original wax point is 43°C, and the hollow rod is lowered to a depth of 800m. According to the production requirements, the oil output temperature of the hot-washed wellhead is 58°C. According to the mathematical model, Y=40.5043+0.2315X It is obtained that the hot car washing outlet temperature X=75.6℃ can meet the hot washing requirements. During the on-site hot washing, the outlet temperature of the hot car washing is controlled between 75-78°C, and the hot washing operation is successful.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com