Method for modeling location-dependent geometric error item of numerical control machine tool

A technology of geometric error and numerical control machine tools, applied in the field of polynomial modeling of position-related geometric error terms optimization of numerical control machine tools, to achieve the effects of improving versatility, realizing automation and programming, and strong robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

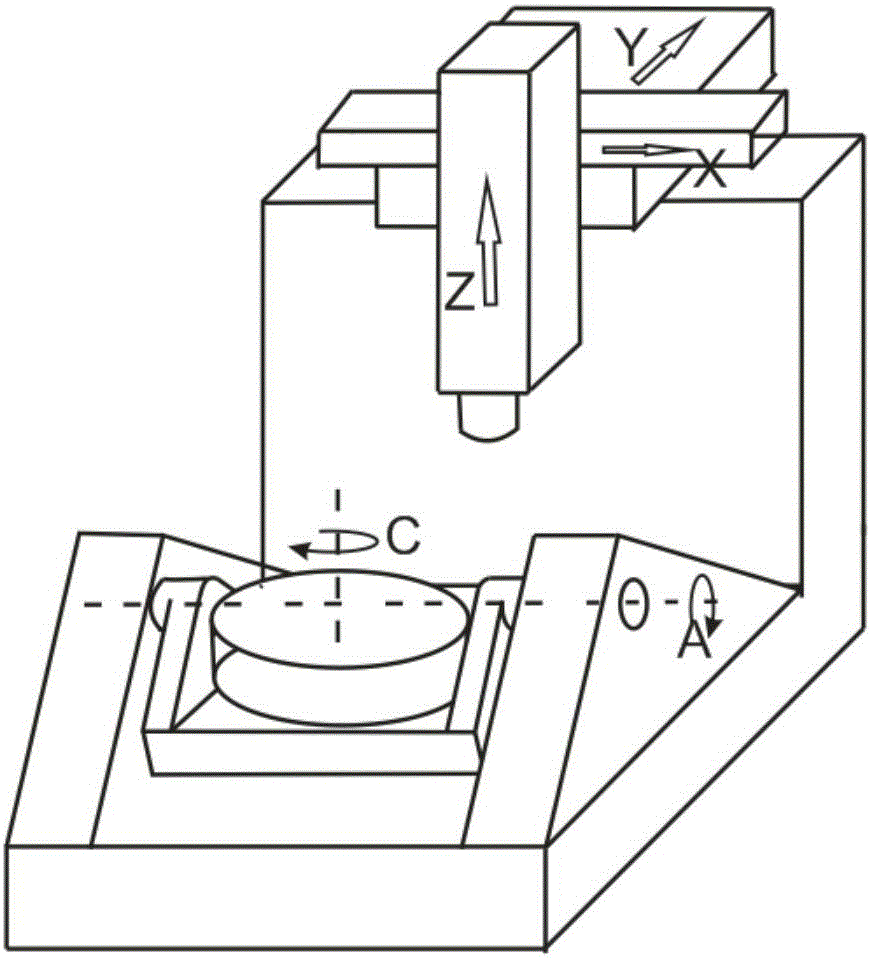

[0055] attached figure 1 Shown is the flow chart of the modeling method of the position-related geometric error item of the numerical control machine tool of the present invention. attached figure 2 Shown is a schematic diagram of the structure of a five-axis CNC machine tool, with image 3 Shown is the linear error δ in the x-axis direction of the X-axis xx The discrete data of figure 2 The linear geometric error δ of the X-axis of the machine tool in the x-direction xx An example is used to illustrate the modeling method of the position-related geometric error item of the numerical control machine tool of the present invention.

[0056] Step 1. According to the nature of the position-related geometric error term of the numerical control machine tool, determine the n-degree polynomial form of the position-related geometric error term of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com