Organic-inorganic antibacterial and antifouling interior wall paint and preparation method thereof

An inorganic antibacterial and interior wall coating technology, applied in the field of coatings, can solve the problems of inorganic coatings that do not have crack resistance and adhesion, and achieve super strong adhesion, not easy to pulverize, and good scrub resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

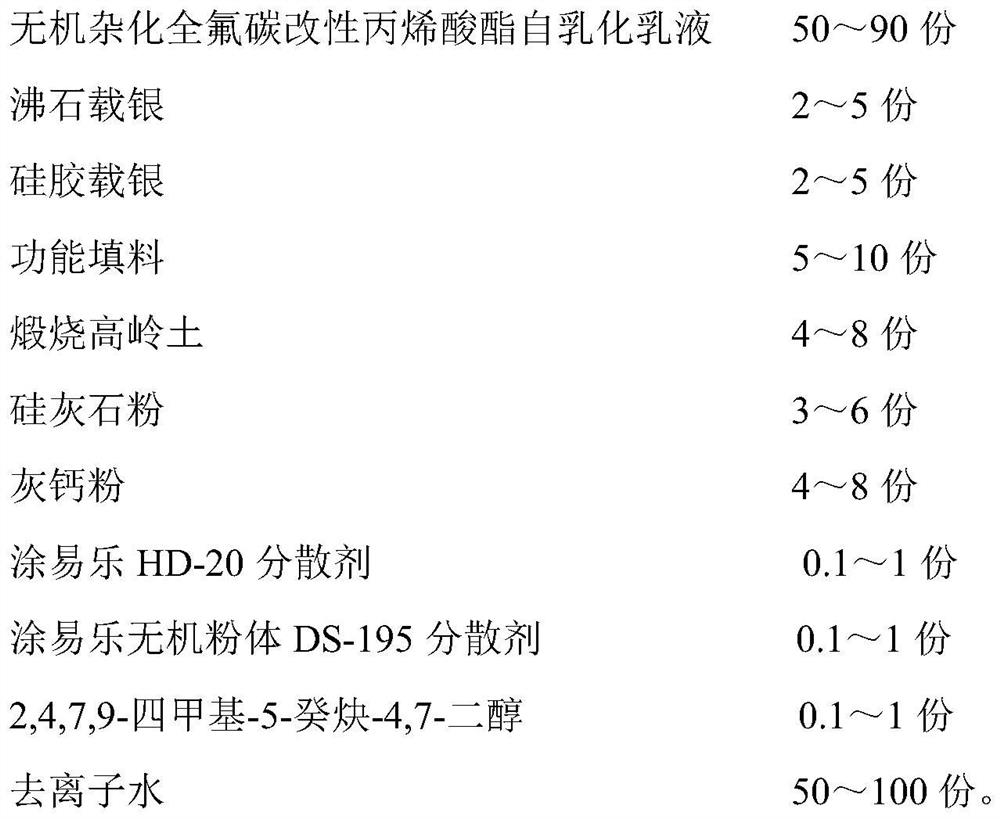

Method used

Image

Examples

Embodiment 1

[0040] Organic-inorganic antibacterial antifouling interior wall paint is prepared according to the following steps:

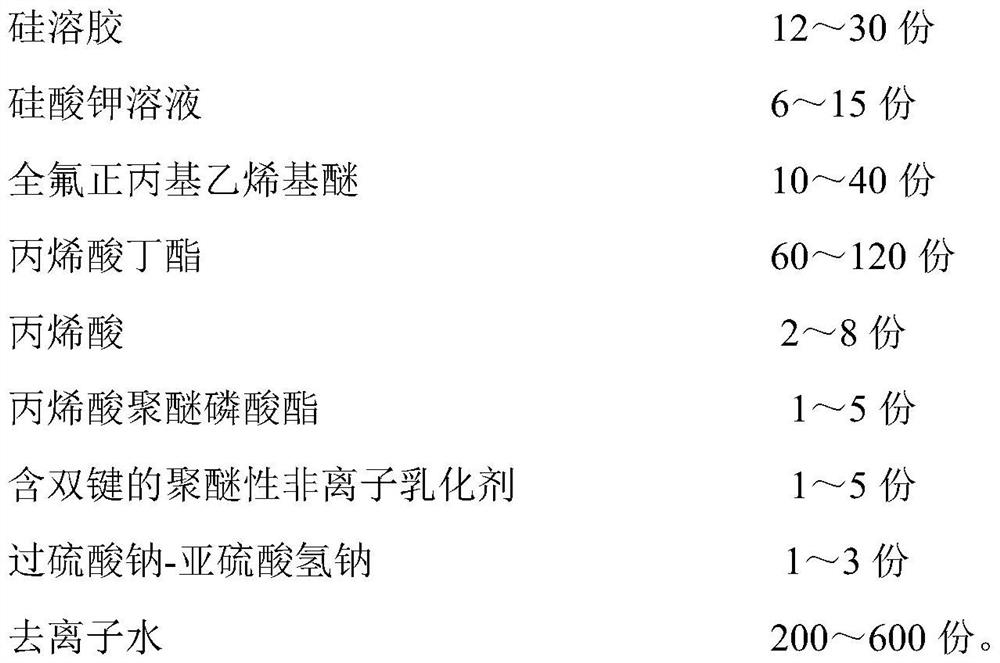

[0041] 1. Inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion, the number of parts by mass is 80 parts, and the preparation steps are as follows:

[0042] (1) Add 40 parts of perfluoro-n-propyl vinyl ether SF-000360, 80 parts of butyl acrylate, and 4 parts of acrylic acid into the reaction kettle, stir and mix to obtain a mixed monomer;

[0043] (2) Add 600 parts of deionized water, 3 parts of acrylic polyether phosphate APE-2005, 3 parts of polyether nonionic emulsifier ONIST AE-100 containing double bonds, and 3 parts of sodium persulfate-sodium bisulfite Into the reaction kettle, feed nitrogen, turn on the electric mixer to stir, pre-emulsify for 0.5 hours, and raise the temperature to 60°C to obtain a pre-emulsion;

[0044] (3) Keep the pre-emulsion at 60°C, add the mixed monomer obtained in step (1) dropwise to the pre-emulsion o...

Embodiment 2

[0060] Organic-inorganic antibacterial antifouling interior wall paint is prepared according to the following steps:

[0061] 1. Inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion, the number of parts by mass is 50 parts, and the preparation steps are as follows:

[0062] (1) Add 10 parts of perfluoro-n-propyl vinyl ether SF-000360, 60 parts of butyl acrylate, and 2 parts of acrylic acid into the reaction kettle, stir and mix to obtain a mixed monomer;

[0063] (2) Add 200 parts of deionized water, 1 part of acrylic polyether phosphate APE-2005, 1 part of polyether nonionic emulsifier ONIST AE-100 containing double bonds, and 1 part of sodium persulfate-sodium bisulfite Into the reaction kettle, feed nitrogen, turn on the electric mixer to stir, pre-emulsify for 0.5 hours, and raise the temperature to 40°C to obtain a pre-emulsion;

[0064] (3) Keep the pre-emulsion at 40°C, add the mixed monomer obtained in step (1) dropwise to the pre-emulsion obta...

Embodiment 3

[0080] Organic-inorganic antibacterial antifouling interior wall paint is prepared according to the following steps:

[0081] 1. Inorganic hybrid perfluorocarbon modified acrylate self-emulsifying emulsion, the number of parts by mass is 60 parts, and the preparation steps are as follows:

[0082] (1) Add 20 parts of perfluoro-n-propyl vinyl ether SF-000360, 60 parts of butyl acrylate, and 5 parts of acrylic acid into the reaction kettle, stir and mix to obtain a mixed monomer;

[0083] (2) Add 200 parts of deionized water, 1 part of acrylic polyether phosphate APE-2005, 2 parts of polyether nonionic emulsifier ONIST AE-100 containing double bonds, and 1 part of sodium persulfate-sodium bisulfite Into the reaction kettle, feed nitrogen, turn on the electric mixer to stir, pre-emulsify for 0.8 hours, and raise the temperature to 50°C to obtain a pre-emulsion;

[0084] (3) Keep the pre-emulsion at 50°C, add the mixed monomer obtained in step (1) dropwise to the pre-emulsion obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com