Broadband cerium oxycarbonate hydrate microwave absorbent, preparation process and application thereof

A technology of microwave absorber and cerium oxycarbonate, which is applied in the preparation/treatment of rare earth metal compounds, rare earth metal carbonates, etc., can solve the problems of unchangeable equipment parameters, large concentration gradient, and few reports. Novel appearance, simple production equipment and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A preparation process of a broadband hydrated cerium oxycarbonate microwave absorber, specifically comprising the following steps:

[0054] 0.7816g Ce(NO) 3 ·6H 2 O, 0.2703g of urea was dissolved in 30mL of deionized water, and stirred magnetically at room temperature for 20min to form a colorless solution; then the solution was transferred to a Teflon-lined double-walled microwave digestion tank and placed in a microwave digestion apparatus (WX- 6000, Preekem), microwave radiation at 160°C for 20 minutes, naturally cooled to room temperature, alternately washed with absolute ethanol and deionized water, and dried in an oven at a constant temperature of 40°C to finally obtain the broadband hydrated cerium oxycarbonate microwave absorber.

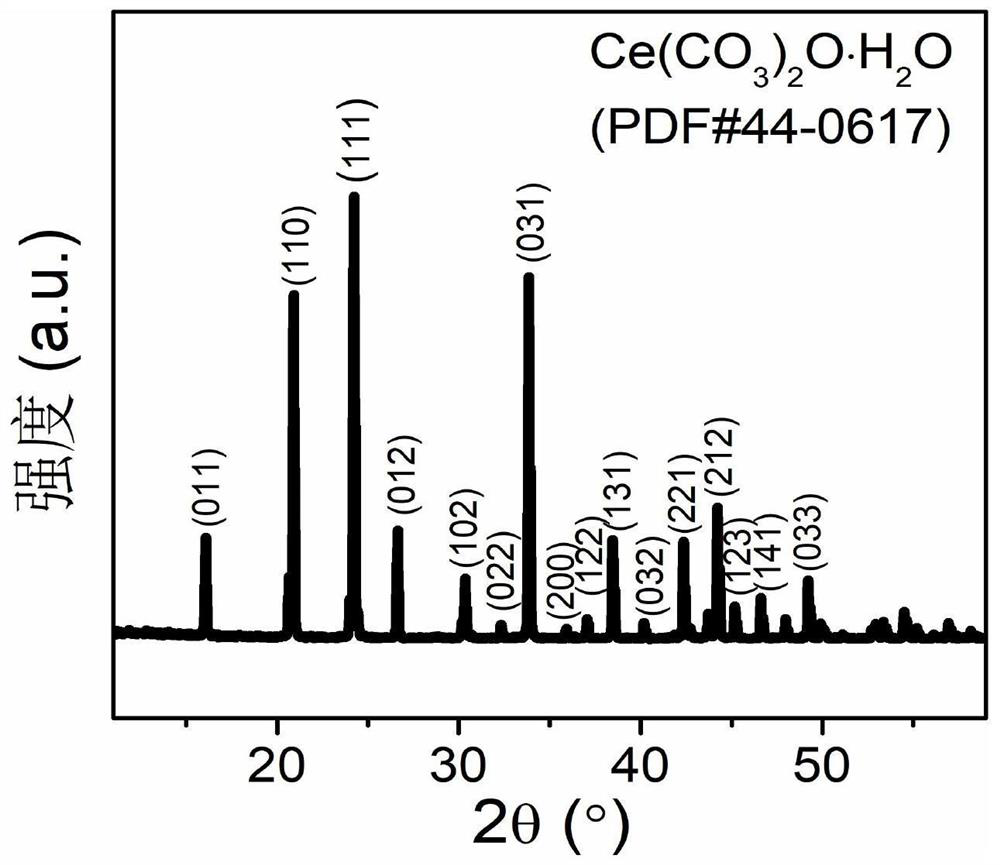

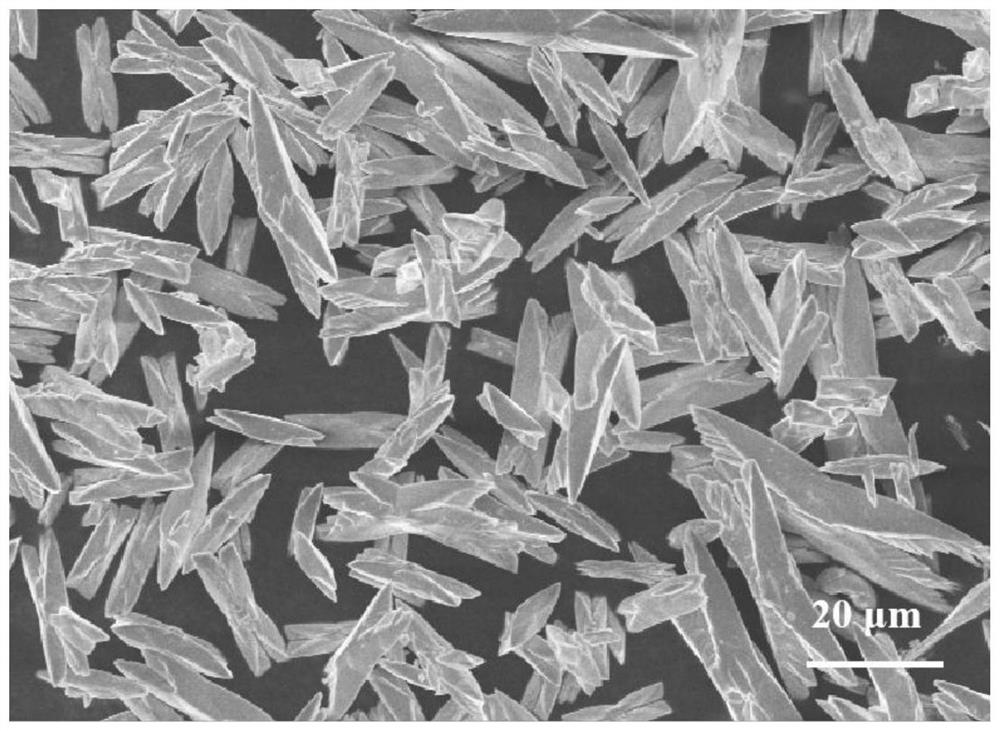

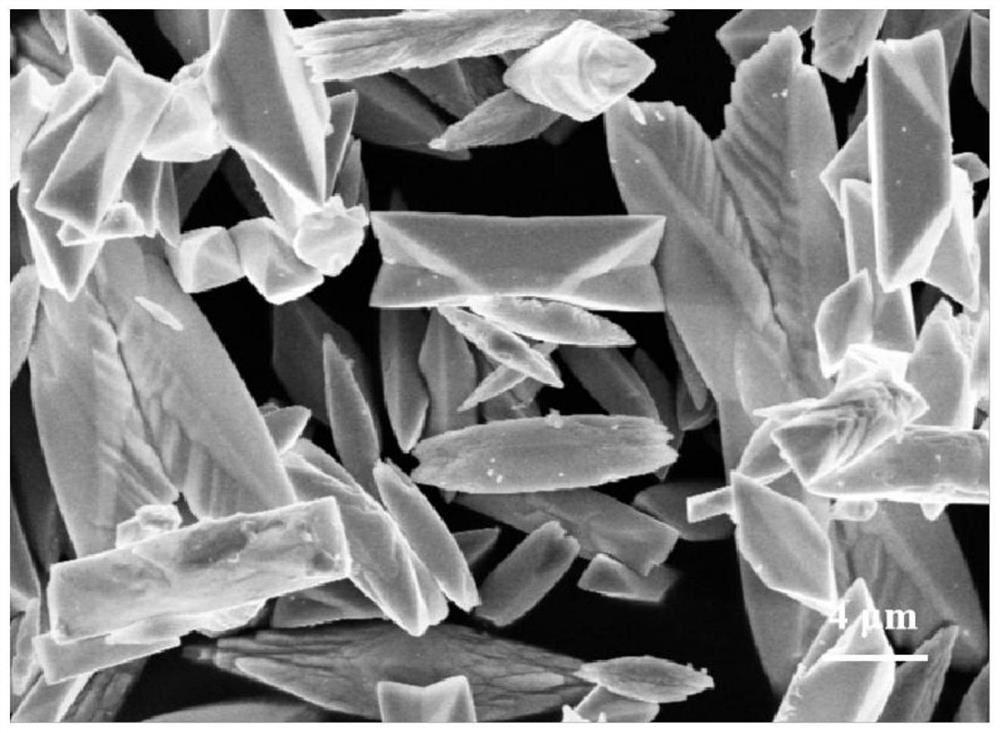

[0055] The phase and morphology of the obtained product measured under XRD and scanning electron microscope are as follows: Figure 1~2 shown. From the above analysis, it can be seen that the product is a uniform, monodisperse butt...

Embodiment 2

[0057] Compared with the preparation steps disclosed in Example 1, the only difference is that the temperature of microwave radiation is 140° C., and the rest of the preparation steps and process parameters are the same.

[0058] The morphologies of the obtained products measured under the scanning electron microscope are as follows: image 3 shown. The analysis shows that the product is hydrated cerium oxycarbonate mixed in rod shape and butterfly shape. Wherein, the long axis of the butterfly-shaped cerium oxycarbonate hydrate is about 9.79-25.41 μm, the widest part of the short axis is about 4.68-8.16 μm, and the thickness is about 3.76-7.68 μm.

[0059] The heterogeneous material was filled in the paraffin base with 60% mass fraction, and its reflectance was measured as Figure 4 As shown, the effective bandwidth range of reflectivity less than or equal to -10dB is 6.48-9.52GHz, and the maximum reflection loss is -47.35dB.

Embodiment 3

[0061] Compared with the preparation steps disclosed in Example 1, the only difference is that the temperature of microwave radiation is 180° C., and the rest of the preparation steps and process parameters are the same.

[0062] The morphology of the obtained product measured under the scanning electron microscope is as follows: Figure 5 shown. Analysis shows that the product is a uniform, monodisperse multi-level butterfly-shaped hydrated cerium oxycarbonate. Wherein, the butterfly-shaped cerium oxycarbonate hydrate has a long axis of about 11.65-31.66 μm, a short axis of the widest point of about 8.64-11.36 μm, and a thickness of about 4.07-8.46 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com