Ion surface etching method for diamond-like coating before preparing

A technology of diamond coating and surface etching, applied in metal material coating process, coating, ion implantation plating, etc. The effect of reducing friction coefficient and wear rate, improving friction performance, and high film-base adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

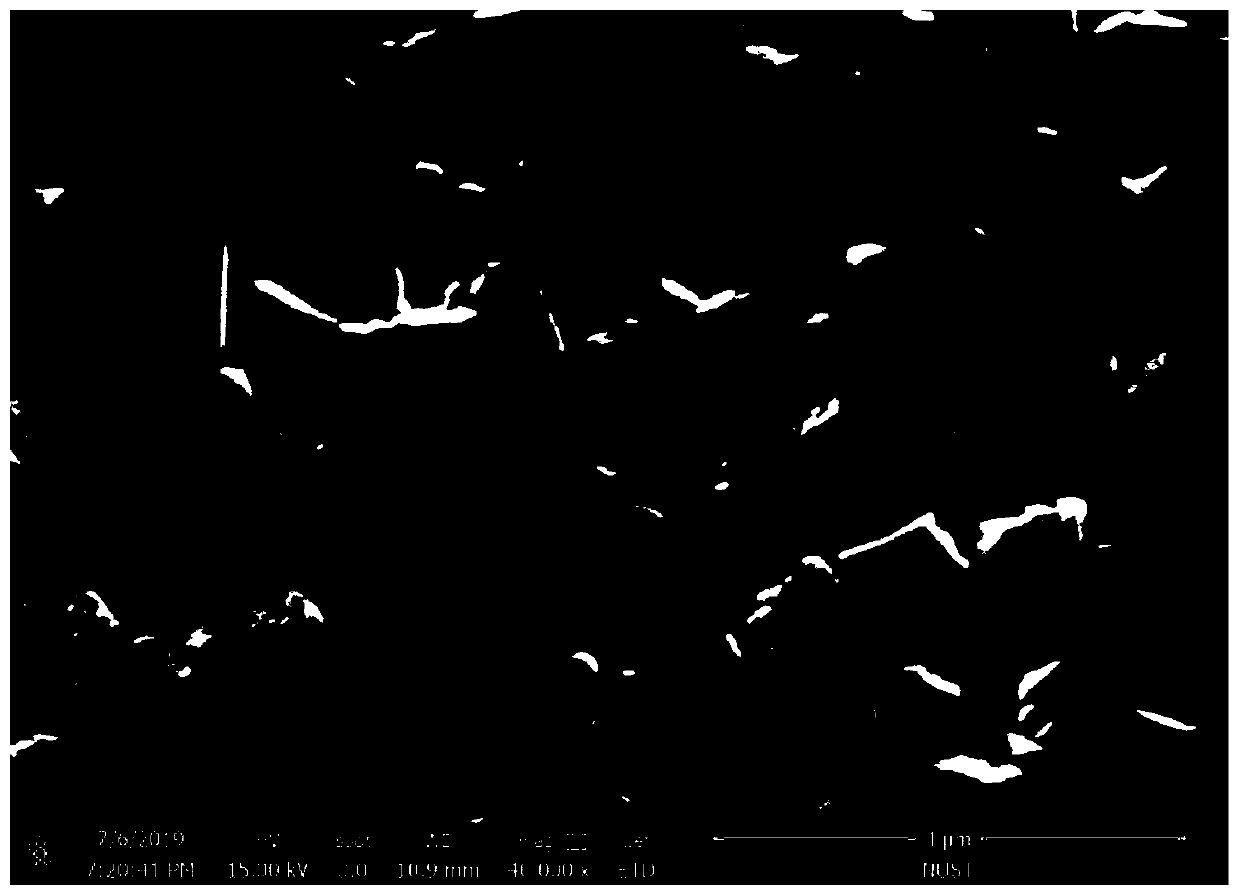

Image

Examples

Embodiment 1

[0032]A titanium ion surface etching method, specifically: polishing YG8 cemented carbide until the surface is bright without scratches, and ultrasonically cleaning in acetone, deionized water, and alcohol for 15 minutes in sequence. Put the cleaned YG8 cemented carbide into a vacuum chamber to evacuate, and heat the chamber to 100°C. After the vacuum degree of the chamber is 5E-3Pa, introduce Ar gas, the flow rate is 150ml / min, the chamber vacuum degree is set to 1.6Pa, turn on the bias power supply, the bias voltage is -1200V, the duty cycle is 60%, and the cleaning 15min. After the cleaning is completed, the Ar gas is introduced, the Ar gas flow rate is 80ml / min, and the vacuum degree of the chamber is set to 1.2Pa; the intermediate frequency power supply is turned on, and the current is 4.0A, and then the pulse bias power supply is turned on, the bias voltage is -1000V, and the duty cycle 60%, titanium ion etching treatment was performed on the surface for 30 minutes.

...

Embodiment 2

[0036] A titanium ion surface etching method, specifically: polishing YG8 cemented carbide until the surface is bright without scratches, and ultrasonically cleaning in acetone, deionized water, and alcohol for 15 minutes in sequence. Put the cleaned YG8 cemented carbide into a vacuum chamber to evacuate, and heat the chamber to 100°C. After the vacuum degree of the chamber is 5E-3Pa, introduce Ar gas, the flow rate is 150ml / min, the chamber vacuum degree is set to 1.6Pa, turn on the bias power supply, the bias voltage is -1200V, the duty cycle is 60%, and the cleaning 15min. After the cleaning is completed, Ar gas is introduced, the Ar gas flow rate is 80ml / min, and the vacuum degree of the chamber is set to 1.2Pa; the intermediate frequency power supply is turned on, and the current is 4.0A, and then the pulse bias power supply is turned on, the bias voltage is -1100V, and the duty cycle 60%, titanium ion etching treatment was performed on the surface for 30 minutes.

[00...

Embodiment 3

[0040] A titanium ion surface etching method, specifically: polishing YG8 cemented carbide until the surface is bright without scratches, and ultrasonically cleaning in acetone, deionized water, and alcohol for 15 minutes in sequence. Put the cleaned YG8 cemented carbide into a vacuum chamber to evacuate, and heat the chamber to 100°C. After the vacuum degree of the chamber is 5E-3Pa, introduce Ar gas, the flow rate is 150ml / min, the chamber vacuum degree is set to 1.6Pa, turn on the bias power supply, the bias voltage is -1200V, the duty cycle is 60%, and the cleaning 15min. After the cleaning is completed, the Ar gas is introduced, the Ar gas flow rate is 80ml / min, and the vacuum degree of the cavity is set to 1.2Pa; the intermediate frequency power supply is turned on, and the current is 4.0A, and then the pulse bias power supply is turned on, the bias voltage is -1200V, and the duty cycle 60%, titanium ion etching treatment was performed on the surface for 30 minutes.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com