Borosilicate glass and preparation method and application thereof

A borosilicate glass, boron oxide technology, applied in the field of lasers and optical fibers, can solve the problems of shortening the length of the gain fiber, devitrification, increasing the optical fiber, etc., to improve the mechanical properties and chemical stability, devitrification temperature and softening temperature. Large, central refractive index tunable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Alkali metal oxides play the role of breaking the network during the preparation of glass. Sodium oxide and potassium oxide have similar effects, which can reduce the melting temperature of glass. The higher the content, the worse the physical and chemical properties of the glass. An appropriate amount of lithium oxide has a good fluxing effect, and lithium oxide can also improve the chemical stability of the glass, but excessive introduction will easily lead to crystallization or phase separation. When containing two or more alkali metal oxides, the mixed alkali effect will occur in the glass, and the low melting point glass with high chemical stability and high resistivity can be prepared by using this effect.

[0046] The present invention adopts alkali metal oxide with a molar percentage of 10-35%, and further adopts lithium oxide with a molar percentage of 0-6%, sodium oxide with a molar percentage of 3-15%, and potassium oxide with a molar percentage of 3-15%. And...

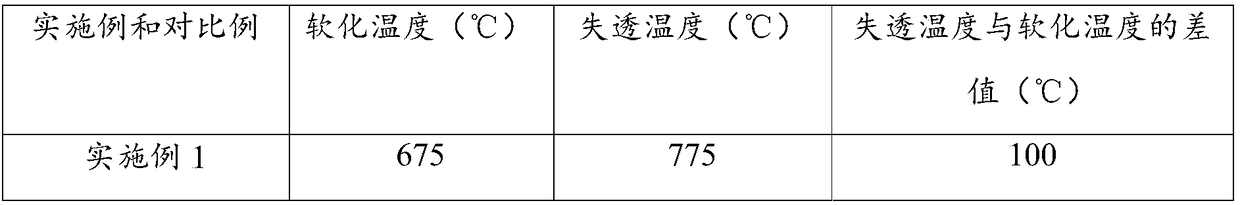

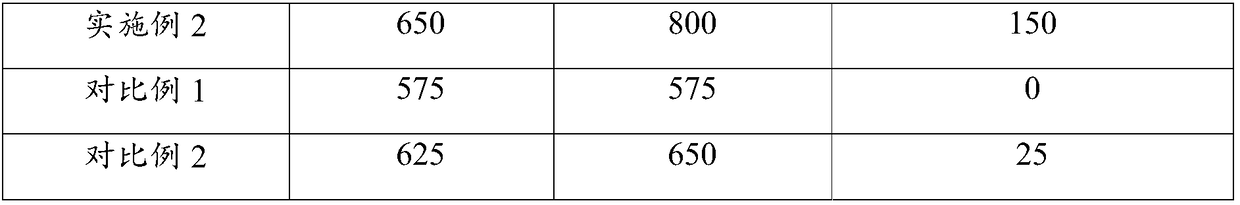

Embodiment 1

[0074] A borosilicate glass, which is mainly prepared from the following mole percentage raw materials:

[0075] Silicon dioxide 49.6%, boron oxide 7%, lithium oxide 6%, potassium oxide 9.8%, calcium oxide 8%, barium oxide 8%, zinc oxide 7%, aluminum oxide 3.8% and ytterbium oxide 0.8%.

[0076] The preparation method of the borosilicate glass comprises the following steps:

[0077] Calculate the content of each component. After weighing the glass raw materials with an electronic balance in a vacuum glove box, mix silicon dioxide, boron oxide, sodium oxide, calcium oxide, aluminum oxide and ytterbium oxide, and then pour them into a platinum crucible. Put it in a high-temperature furnace raised to 280°C to preheat for a period of time, and then raise the temperature of the furnace to 1600°C. After the glass raw materials are fully reacted, after homogenization and clarification, pour the molten glass into the preheated copper mold After the molten glass is solidified, it is p...

Embodiment 2

[0079] A borosilicate glass, which is mainly prepared from the following mole percentage raw materials:

[0080] Silicon dioxide 54.8%, boron oxide 3.4%, lithium oxide 6%, sodium oxide 11%, calcium oxide 6%, barium oxide 10%, zinc oxide 3.4%, aluminum oxide 5% and erbium oxide 0.4%.

[0081] The preparation method of the borosilicate glass comprises the following steps:

[0082] Calculate the content of each component. After weighing the glass raw materials with an electronic balance in a vacuum glove box, mix silicon dioxide, boron oxide, lithium oxide, barium oxide, zinc oxide and erbium oxide, then pour them into a platinum crucible, and place Preheat in a high-temperature furnace at 300°C for a period of time, and then raise the furnace temperature to 1600°C. After the glass raw materials are fully reacted, after homogenization and clarification, the molten glass is cast into a preheated copper mold. After the glass liquid is solidified, it is put into an annealing furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com