Method for covalently grafting biomolecules on the surface of metal materials and its products and uses

A biomolecule and metal material technology, applied in metal material coating process, drug delivery, tissue regeneration, etc., can solve the problems of human injury, cumbersome grafting process, chemical reagent residue, etc., and achieve the effect of avoiding injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The pure titanium (99.95%) with a length, width and height of 50mm×50mm×2mm was ground and polished, cleaned with a hydrofluoric acid mixture to remove surface dirt, then ultrasonically cleaned with deionized water, and dried for later use. Adopt acetylene gas plasma immersion ion implantation technology to construct diamond-like carbon film on the surface of titanium sheet. The specific process parameters are: substrate vacuum degree 0.3Pa, radio frequency power for generating plasma is 200W, implantation bias voltage -12kV, implantation pulse frequency 100Hz, pulse duration 50μs, a mixture of acetylene and argon is introduced, and the acetylene / argon gas flow ratio is 4:1sccm, and the treatment time is 120min.

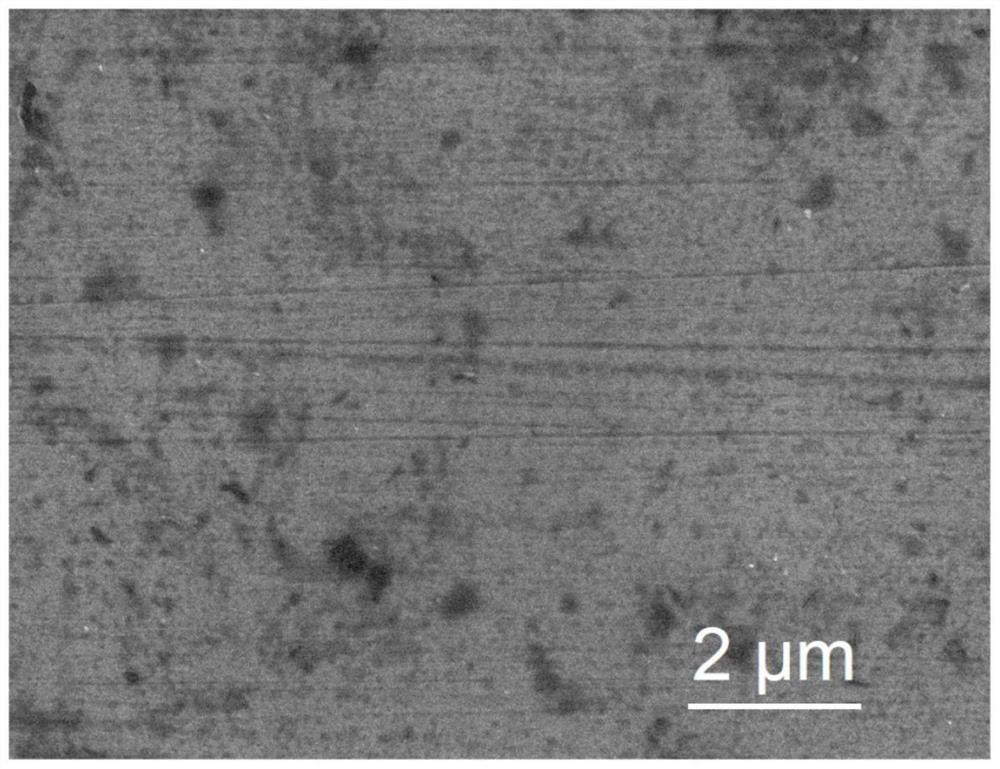

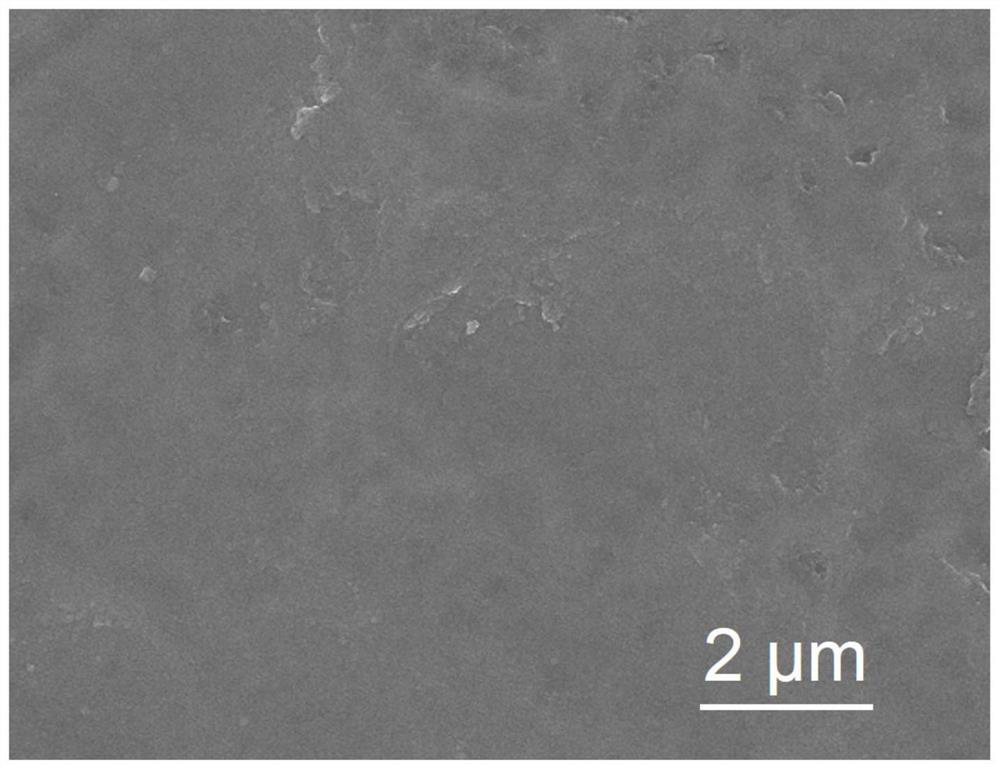

[0043] The surface of the pure titanium before and after the construction of the DLC was observed by a scanning electron microscope, and the surface micromorphology photos shown in Figure 1 were obtained. It can be seen from the figure that the construction of...

Embodiment 2

[0045] Continue to use the gas plasma immersion ion implantation technique to activate the diamond-like carbon film formed on the pure titanium surface in Example 1. The specific treatment process is: the gas used is nitrogen, and the background vacuum is 5×10 -3 Pa, the introduction flow rate of nitrogen gas is 30 sccm, the negative bias voltage applied to the sample plate is 15 kV, the injection pulse width is 20 microseconds, the injection pulse frequency is 500 Hz, and the radio frequency power for generating plasma is 1000 W. The injection treatment time was 180 minutes.

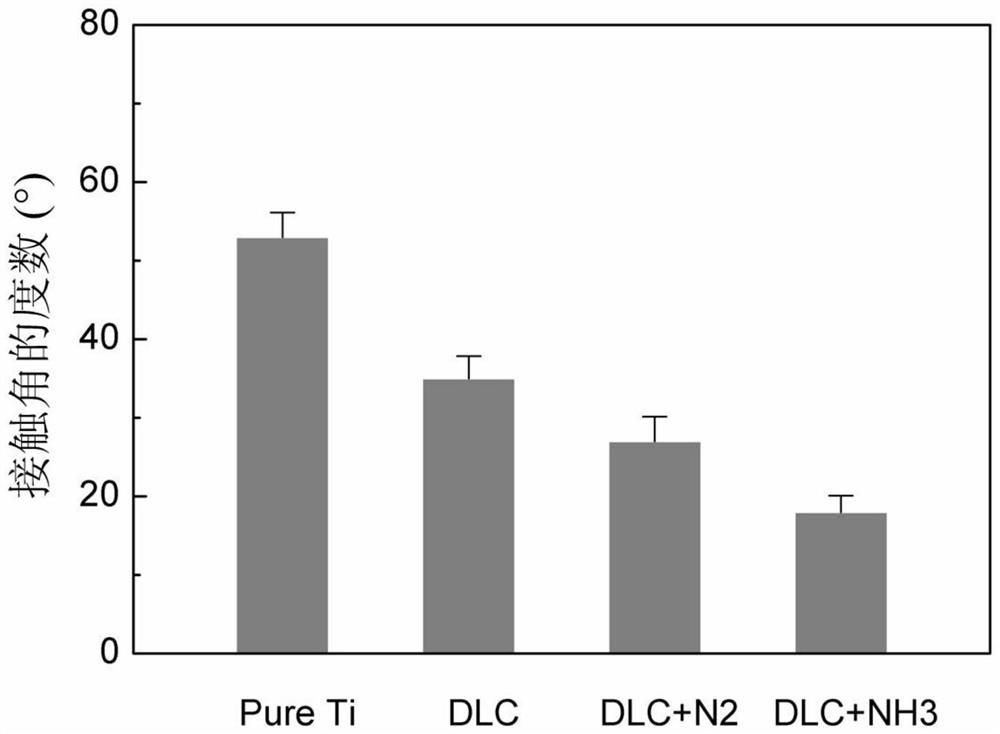

[0046] Meanwhile, other gases or parameters may be used for the activation treatment. The specific treatment process is: the gas used is ammonia, and the background vacuum is 5×10 -3 Pa, the ammonia gas introduction flow rate is 50 sccm, the negative bias applied to the sample plate is 20 kV, the injection pulse width is 50 microseconds, the injection pulse frequency is 200 Hz, the radio frequency pow...

Embodiment 3

[0051] Using horseradish peroxidase (Horseradish Peroxidase, referred to as HRP) easy color characteristics, we choose HRP as a representative to study the interaction between bioactive molecules and plasma immersion ion implantation activation treatment surface. The samples modified in Example 2 were immersed in a phosphate buffered solution (Phosphate Buffered Solution, PBS for short) containing HRP, and stored at 4°C for 12 hours. The concentration of HRP is 50 μg / mL. The sample was then removed from the solution and the sample was eluted with 2% sodium dodecyl sulfate (2% SDS) solution for 1 hour. Then put the eluted sample into a 24-well cell culture plate, add 500 microliters of 3,3',5,5'-tetramethylbenzidine solution to each well and incubate at room temperature for 3 minutes, then add 500 microliters L 2mol / L hydrochloric acid solution to terminate the reaction. Take 200 microliters from each well and put it into a 96-well culture plate, and measure the absorbance at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com