High molecular material surface modification method and its product and application

A polymer material and surface modification technology, applied in the field of biomimetic modification, can solve the problems of cumbersome grafting process, complicated and cumbersome operation process, and difficult to achieve, and achieve the effect of improving the physical and chemical properties of the surface and eliminating the limitation of sight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A polytetrafluoroethylene sheet with a diameter of 15 mm and a thickness of 0.1 mm was ultrasonically cleaned with acetone, alcohol, and deionized water in sequence. This pretreated sample is called PTFE control.

[0056] The pretreated PTFE was treated by gas plasma immersion ion implantation technology. Use nitrogen injection, ammonia injection, or nitrogen injection followed by ammonia injection for treatment. The specific treatment process is: the background vacuum is 5×10 -3 Pa, the flow rate of the gas introduced is 30 sccm, the negative bias applied to the sample disk is 15 kV, the injection pulse width is 20 microseconds, the injection pulse frequency is 500 Hz, and the radio frequency power is 1000 W. Wherein, the injection time of nitrogen is 180 minutes, and the sample after this treatment is called N2PIII; The injection time of ammonia is 60 minutes, and the sample after this treatment is called NH3PIII; After injecting nitrogen 180 minutes, inject ammonia...

Embodiment 2

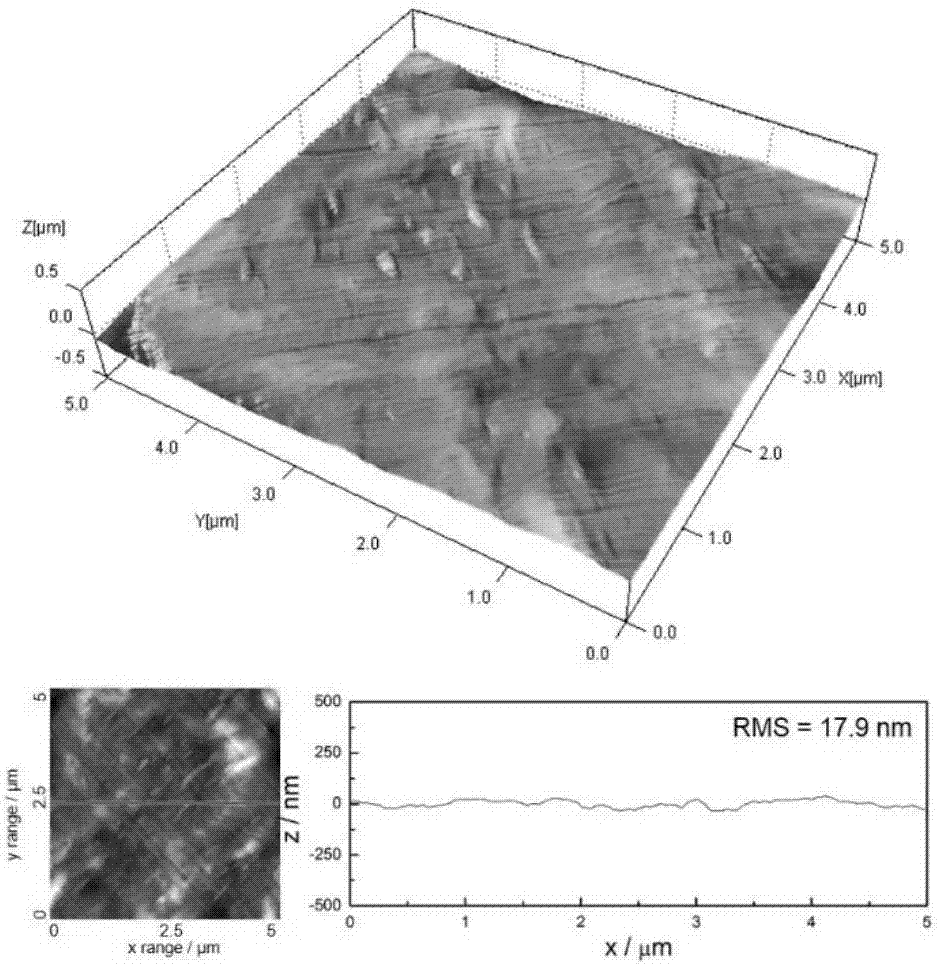

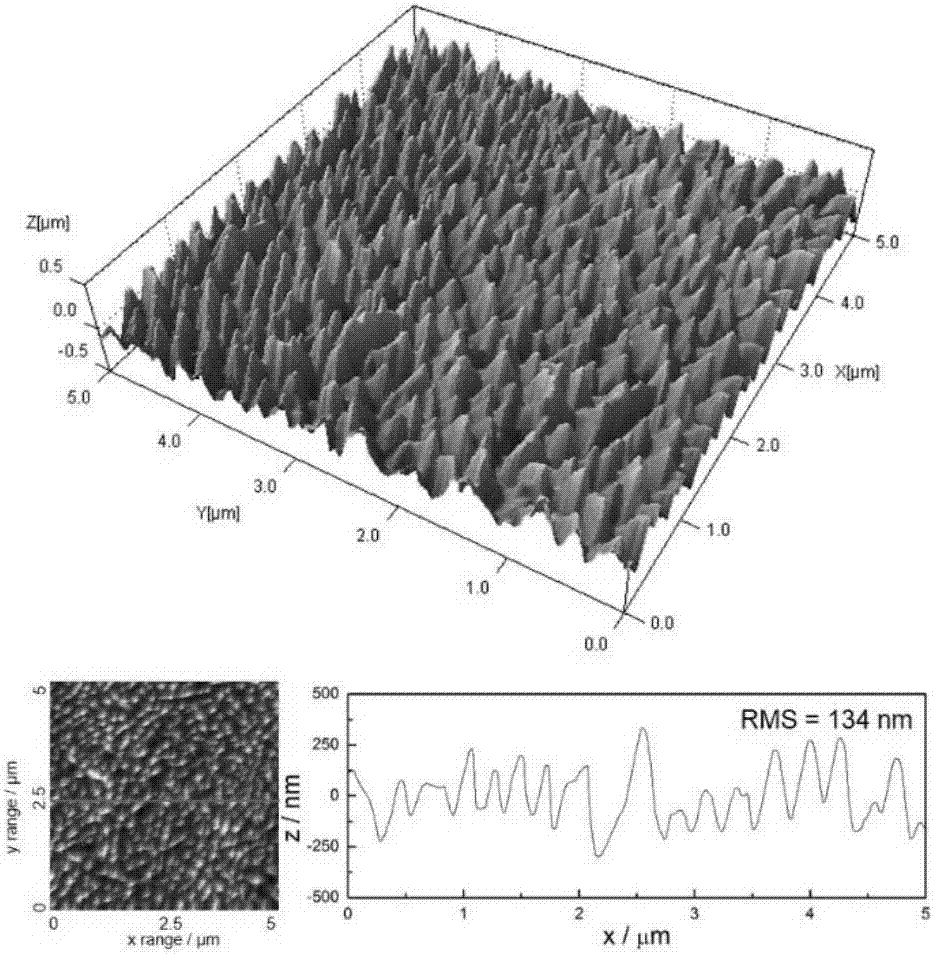

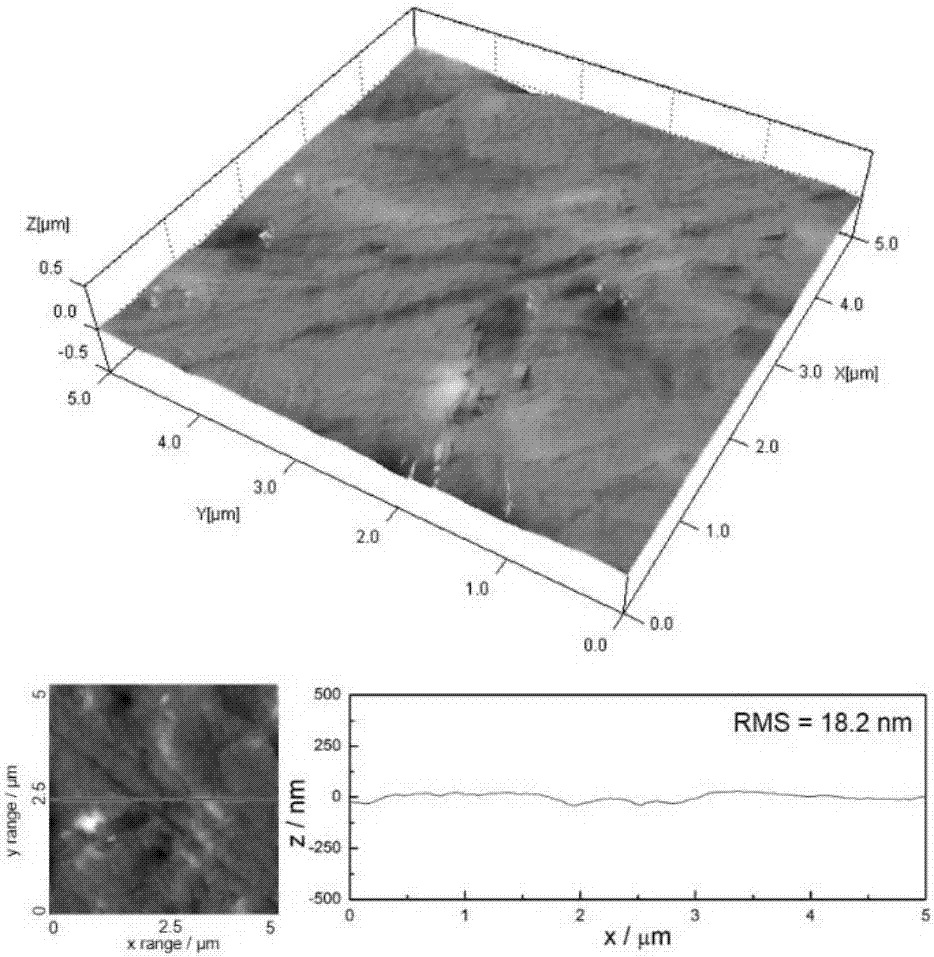

[0059] Using an atomic force microscope to characterize the surface roughness of the polytetrafluoroethylene sample processed in Example 1, the surface three-dimensional picture, section profile and corresponding mean square roughness (RMS) results shown in Figure 2 were obtained. From the three-dimensional image of the surface in Figure 2, it can be seen that the results obtained by the atomic force microscope are basically consistent with the surface morphology obtained by the scanning electron microscope in Example 1. Figure 2a The surface mean square roughness of the PTFE control shown is 17.9nm. Nitrogen plasma injection significantly increased the surface roughness of the sample to 134nm ( Figure 2b ). Ammonia plasma injection has basically no effect on the surface roughness, and the mean square roughness after treatment is 18.2nm ( Figure 2c ). The mean square roughness of the surface after nitrogen plasma injection and ammonia gas injection is basically the same ...

Embodiment 3

[0061] Carry out X-ray photoelectron energy spectrum (XPS) wide-field scanning to the polytetrafluoroethylene sample surface that processing obtains in embodiment 1, obtain image 3 The XPS full-spectrum spectrum is shown. The abscissa represents the binding energy, and the ordinate represents the peak intensity. By observing image 3 The peak heights of the C 1s peak, O 1s peak, N 1s peak and F 1s peak of each sample in the sample show that the nitrogen plasma immersion ion implantation treatment reduces the fluorine element content on the surface of PTFE to a certain extent, and in the material Oxygen was introduced into the surface; and ammonia plasma immersion ion implantation treatment significantly reduced the content of surface fluorine, and significantly increased the proportion of surface nitrogen and oxygen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com